LG LB-H1860PH, LB-H2460RU, LB-H1860FH, LB-H2460RH, LB-H2460PH Service Manual

...

Ceiling Duct Type

Air Conditioner

SERVICE MANUAL

MODELS: LB-H1860RH/RU/PH/FH

LB-H2460RH/RU/PH/FH

LB-G3660RH/RU/PH/FH

LB-G3680RH/FH

LB-E4880RH/FH

LB-E6080RH/FH

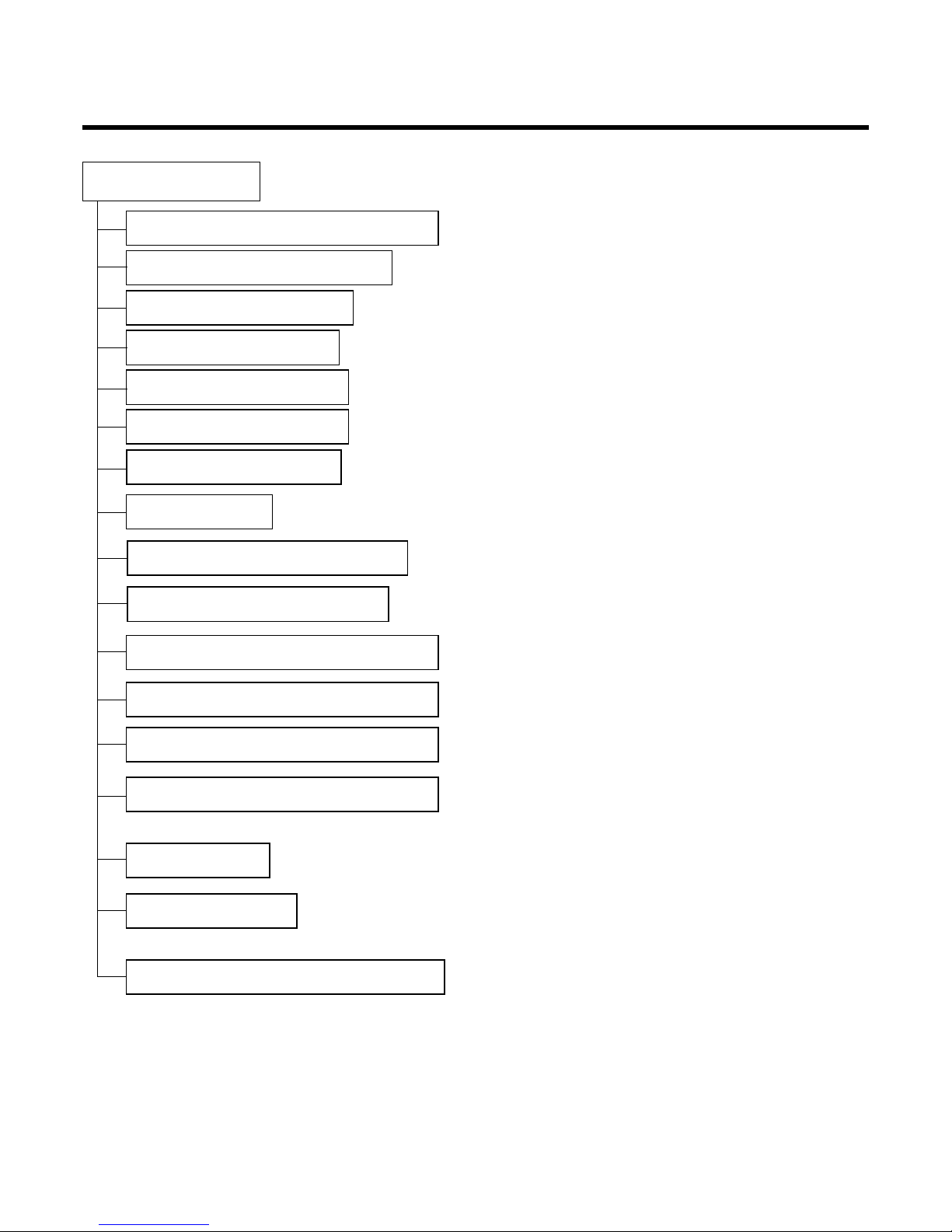

Contents

Functions .................................................................................................................................3

Product Specifications (Cooling & Heating)..........................................................................5

Dimensions ............................................................................................................................11

Refrigeration Cycle Diagram ................................................................................................13

Wiring Diagram ......................................................................................................................15

Operation Details ...................................................................................................................21

Installation of Indoor, Outdoor Unit .....................................................................................24

Test Running...........................................................................................................................35

Optional Operation.................................................................................................................37

E.S.P(External Static Pressure) Setting ...............................................................................39

How to set E.S.P ?..................................................................................................................40

Cycle........................................................................................................................................42

Cycle Troubleshooting Guide ...............................................................................................45

Electronic Parts Troubleshooting Guide .............................................................................46

Electronic Control Device .....................................................................................................49

Exploded View and Replacement Parts List .......................................................................50

Plasma Air cleaner .................................................................................................................66

–2–

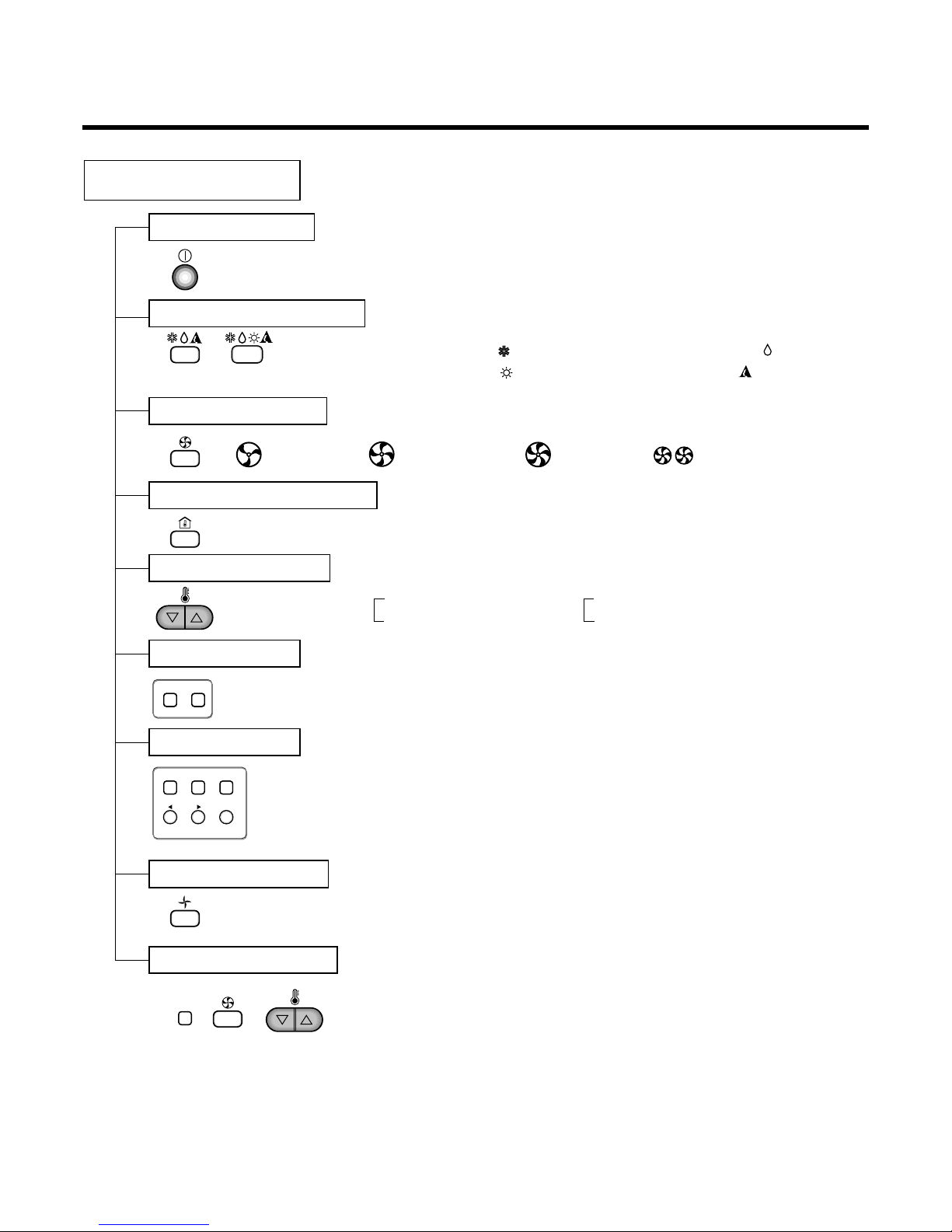

Functions

Indoor Unit

Operation ON/OFF by Remote controller

Sensing the Room Temperature

Room temperature control

Starting Current Control

Time Delay Safety Control

Indoor Fan Speed Control

Soft Dry Operation Mode

Auto Operation(Auto Change Over)

Deice (defrost) control (Heating)

Auto Restart

–3–

Hot-start Control (Heating)

• The indoor fan stops until the evaporator piping temperature will be reached at 28°C.

High head height Drain pump(Optional)

• A standard drain-head height of up to 700mm is possible.

Central Control(Optional)

•

It is operating individually or totally by central control function.

Group Control(Optional Wiring)

Phase Control

PLASMA (Optional)

Telephone Control Operation (Optional)

•

Each controller can control 16 units and 8 controllers can connect.

•

It operates maximum 16 units by only one wired remote controller and each unit starts random to prevent overcurrent.

• Room temperature sensor. (Thermistor)

•

Maintains the room temperature in accordance with the Setting Temp.

• Indoor fan is delayed for 5 seconds at the starting.

• Restarting is inhibited for approx. 3 minutes.

• High, Med, Low

• Intermittent operation of fan at low speed.

• Although the air-conditioner is turned off by a power failure, it is restarted automatically previous operation mode after power supply.

• Fan speed is varied according to the state of dampers by micom.

• Calling from outside, you can start the air conditioner to

keep the room comfortable.

• Even though you went out with the air conditioner on, you

can turn it off using the phone outside.

• The function will be operated while in any operation mode wigh selecting the

function.

• The function is to be stopped while it is operating with selecting the function.

• The setting temperature and desired operation mode are automatically set by fuzzy rule.

• Both the indoor and outdoor fan stops during defrosting.

• Hot start after defrost ends.

–4–

Remote Controller

Operation ON/OFF

Operation Mode Selection

Fan Speed Selection

Room Temperature Display

Temperature Setting

Setting the Timer

Weekly Program

(Cooling

model only)

(Heating

model only)

(Low) (Med) (High)

Cooling Operation Mode ( )

Heating Operation Mode ( ) Auto Operation Mode ( )

Soft Dry Operation Mode ( )

Fan Operation Mode

Phase Control Setting

HI AUTOMEDLO

Program Holiday

SET/CLR

MinHour

Week

Timer CancelTimer Cancel

Timer

: High:39°C ↔ LOW:11°C

: Fan Operates without cooling & heating

Cooling Heating

Down to 18°C

Up to 30°C

Down to 16°C

Up to 30°C

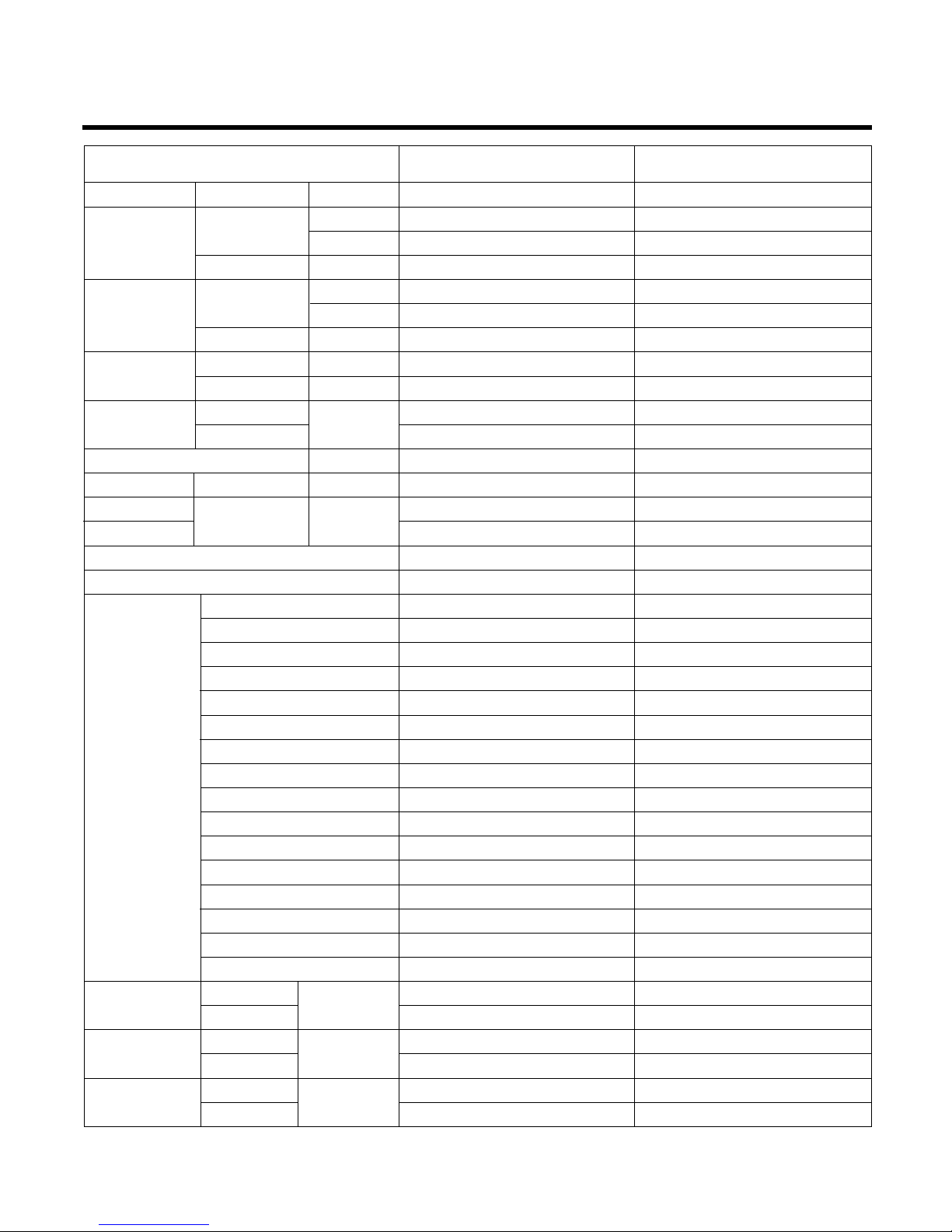

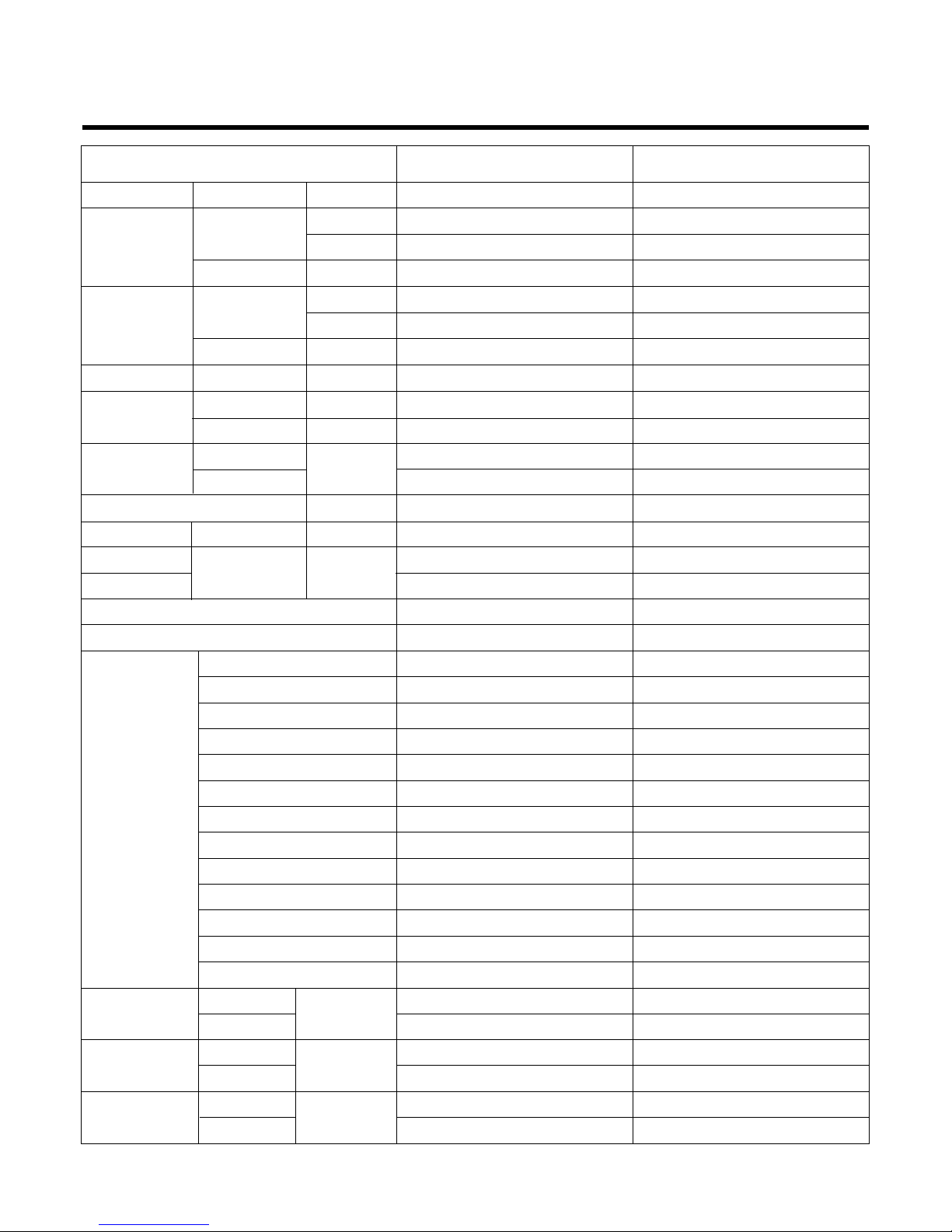

Product Specifications (Cooling & Heating)

–5–

Power Source Ø, V, Hz"

Cooling Capacity kcal/h(BTU/h)

W

Input W

Heating Capacity kcal/h(BTU/h)

W

Input W

Rated Load Amp. Cooling A

Heating A

Air Volumn Cooling(H/M/L)

CMM(m

3

/min)

Heating(H/M/L)

Refrigerant(R-407) g

Drain Hose In. Dia mm

Main Cable

No. X mm

2

Connecting Cable

Remote Control Type

Refigerant Control Type

Fuction Soft Dry

Timer

Self Diagnosis

Deice Operation

Hot Start

Zone Control(Optional)

Central Control(Optional)

Group Control(Optional wiring)

Weekly Programning

Thermistor

Drain Pump

Auto changeover(Auto Operation: CL)

Stand-by Consumption 0

Phase Control

Tele Control(Optional)

PLASMA(Optional)

Connecting Pipe Liquid Inch

Gas (mm)

Dimension Indoor mm

Outdoor (WxDxH)

Net Indoor Kg

Weight

Outdoor

1, 220-240, 50 1, 220-240, 50

4,536(18,000) 4,536(18,000)

5,275 5,275

2,000 2,000

4,546(18,000) -

5,275 2,000 -

10 10

10 -

16.5/14.5/13 16.5/14.5/13

16.5/14.5/13 1,250 1,250

22.6 22.6

3*2.5 3*2.5

5*0.75 4*0.75

L.C.D Wired L.C.D Wired

Capillary type Capillary type

Yes -

24 Hours On/Off 24 Hours On/Off

Yes Yes

Yes -

Yes Optional Optional

Optional Optional

Yes Yes

Yes Yes

Yes Yes

Optional Optional

Yes Yes

Yes Yes

Yes Yes

Optional Optional

Optional Optional

1/4(6.35) 1/4(6.35)

5/8(15.88) 5/8(15.88)

880*450*260 880*450*260

870*320*655 870*320*655

34 34

57 57

Model

LB-H1860RH LB-H1860FH

–6–

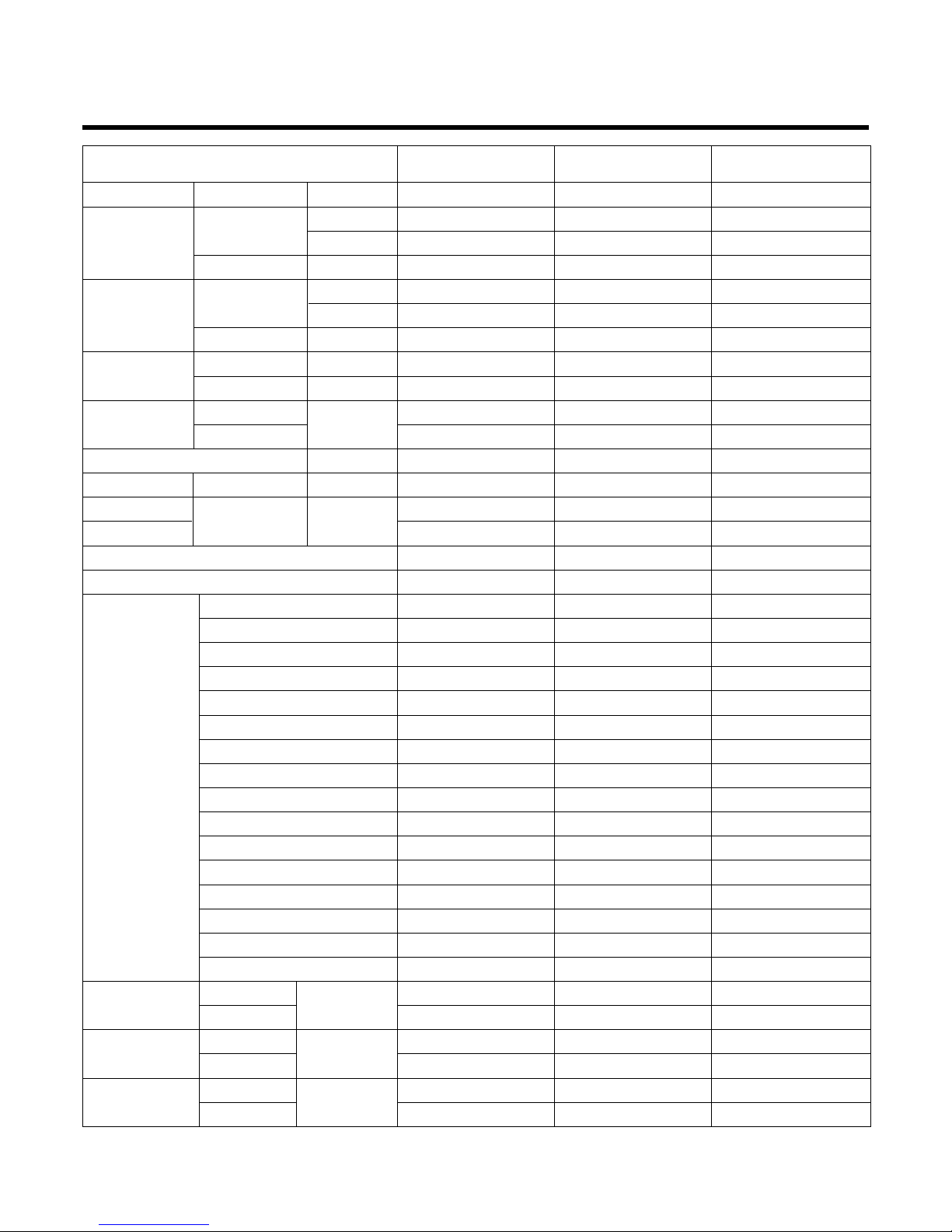

Power Source Ø, V, Hz"

Cooling Capacity kcal/h(BTU/h)

W

Input W

Heating Capacity kcal/h(BTU/h)

W

Input W

Rated Load Amp. Cooling A

Heating A

Air Volumn Cooling(H/M/L)

CMM(m

3

/min)

Heating(H/M/L)

Refrigerant(R-407) g

Drain Hose In. Dia mm

Main Cable

No. X mm

2

Connecting Cable

Remote Control Type

Refigerant Control Type

Fuction Soft Dry

Timer

Self Diagnosis

Deice Operation

Hot Start

Zone Control(Optional)

Central Control(Optional)

Group Control(Optional wiring)

Weekly Programning

Thermistor

Drain Pump

Auto changeover(Auto Operation: CL)

Stand-by Consumption 0

Phase Control

Tele Control(Optional)

PLASMA(Optional)

Connecting Pipe Liquid Inch

Gas (mm)

Dimension Indoor mm

Outdoor (WxDxH)

Net Indoor Kg

Weight

Outdoor

1, 220-240, 50 1, 220-240, 50

6,048(24,000) 6,048(24,000)

7,034 7,034

2,950 2,950

6,048(24,000) -

--

2,650 -

13 13

12 18/16.5/14 18/16.5/14

18/16.5/14 -

1,700 1,250

22.6 22.6

3*2.5 3*2.5

6*0.75 4*0.75

L.C.D Wired L.C.D Wired

Capillary type Capillary type

Yes -

24 Hours On/Off 24 Hours On/Off

Yes Yes

Yes -

Yes Optional Optional

Optional Optional

Yes Yes

Yes Yes

Yes Yes

Optional Optional

Yes Yes

Yes Yes

Yes Yes

Optional Optional

Optional Optional

1/4(6.35) 1/4(6.35)

5/8(15.88) 5/8(15.88)

880*450*260 880*450*260

870*320*655 870*320*655

33 35

60 60

Model

LB-H2460RH LB-H2460FH

–7–

Power Source Ø, V, Hz"

Cooling Capacity kcal/h(BTU/h)

W

Input W

Heating Capacity kcal/h(BTU/h)

W

Input W

Rated Load Amp. Cooling A

Heating A

Air Volumn Cooling(H/M/L)

CMM(m

3

/min)

Heating(H/M/L)

Refrigerant(R-407) g

Drain Hose In. Dia mm

Main Cable

No. X mm

2

Connecting Cable

Remote Control Type

Refigerant Control Type

Fuction Soft Dry

Timer

Self Diagnosis

Deice Operation

Hot Start

Zone Control(Optional)

Central Control(Optional)

Group Control(Optional wiring)

Weekly Programning

Thermistor

Drain Pump

Auto changeover(Auto Operation: CL)

Stand-by Consumption 0

Phase Control

Tele Control(Optional)

PLASMA(Optional)

Connecting Pipe Liquid Inch

Gas (mm)

Dimension Indoor mm

Outdoor (WxDxH)

Net Indoor Kg

Weight

Outdoor

3, 380-415, 50 3, 380-415, 50

8,820(3,500) 8,820(3,500)

10,257 10,257

4,050 4,050

9,072(36,000) -

14,067 -

3,470 -

6.6 6.6

5.9 32/29/26.5 32/29/26.5

32/29/26.5 -

1,900 1,900

22.6 22.6

4*2.5 4*2.5

5*0.75 4*0.75

L.C.D Wired L.C.D Wired

Capillary type Capillary type

Yes -

24 Hours On/Off 24 Hours On/Off

Yes Yes

Yes -

Yes Optional Optional

Optional Optional

Yes Yes

Yes Yes

Yes Yes

Optional Optional

Yes Yes

Yes Yes

Yes Yes

Optional Optional

Optional Optional

1/4(6.35) 1/4(6.35)

5/8(15.88) 5/8(15.88)

1,180*450*298 1,180*450*298

870*320*800 870*320*800

38 38

72 72

Model

LB-G3680RH LB-G3680FH

–8–

Power Source Ø, V, Hz"

Cooling Capacity kcal/h(BTU/h)

W

Input W

Heating Capacity kcal/h(BTU/h)

W

Input W

Rated Load Amp. Cooling A

Heating A

Air Volumn Cooling(H/M/L)

CMM(m

3

/min)

Heating(H/M/L)

Refrigerant(R-407) g

Drain Hose In. Dia mm

Main Cable

No. X mm

2

Connecting Cable

Remote Control Type

Refigerant Control Type

Fuction Soft Dry

Timer

Self Diagnosis

Deice Operation

Hot Start

Zone Control(Optional)

Central Control(Optional)

Group Control(Optional wiring)

Weekly Programning

Thermistor

Drain Pump

Auto changeover(Auto Operation: CL)

Stand-by Consumption 0

Phase Control

Tele Control(Optional)

PLASMA(Optional)

Connecting Pipe Liquid Inch

Gas (mm)

Dimension Indoor mm

Outdoor (WxDxH)

Net Indoor Kg

Weight

Outdoor

1, 220-240, 50 1, 220-240, 50 1, 220-240, 50

8,820(3,500) 8,820(3,500) 8,820(3,500)

10,257 10,257 10,257

4,270 4,270 4,100

9,072(36,000) 9,072(36,000) -

14,067 14,067 -

3,600 3,600 -

20 20 19

17 17 32/29/26.5 32/29/26.5 32/29/26.5

32/29/26.5 32/29/26.5 -

1,950 1,950 1,900

22.6 22.6 22.6

4*2.5 4*2.5 4*2.5

5*0.75 5*0.75 4*0.75

L.C.D Wired L.C.D Wired L.C.D Wired

Capillary type Capillary type Capillary type

Yes Yes -

24 Hours On/Off 24 Hours On/Off 24 Hours On/Off

Yes Yes Yes

Yes Yes -

Yes Yes Optional Optional Optional

Optional Optional Optional

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Optional Optional Optional

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Optional Optional Optional

Optional Optional Optional

1/4(6.35) 1/4(6.35) 1/4(6.35)

5/8(15.88) 5/8(15.88) 5/8(15.88)

1,180*450*298 1,180*450*298 1,180*450*298

870*320*800 870*320*800 870*320*800

38 38 38

72 72 72

Model

LB-G3660RH LB-G3660PH LB-G3660FH

–9–

Power Source Ø, V, Hz"

Cooling Capacity kcal/h(BTU/h)

W

Input W

Heating Capacity kcal/h(BTU/h)

W

Input W

Electhic Heater Capacity Kw

Rated Load Amp. Cooling A

Heating A

Air Volumn Cooling(H/M/L)

CMM(m

3

/min)

Heating(H/M/L)

Refrigerant(R-407C) g

Drain Hose In. Dia mm

Main Cable

No. X mm

2

Connecting Cable

Remote Control Type

Refigerant Control Type

Fuction Soft Dry

Timer

Self Diagnosis

Deice Operation

Hot Start

Zone Control(Optional)

Central Control(Optional)

Group Control(Optional wiring)

Weekly Programning

Thermistor

Drain Pump(Optional)

Auto changeover(Auto Operation: CL)

Stand-by Consumption 0

Connecting Pipe Liquid Inch

Gas (mm)

Dimension Indoor mm

Outdoor (WxDxH)

Net Indoor Kg

Weight

Outdoor

3, 380-415, 50 3, 380-415, 50

12,096(48,000) 12,096(48,000)

14,066 14,066

5,250 5,250

12,096(48,000) -

14,066 -

4,700 -

--

8.5 8.5

8-

40/35/30 40/35/30

40/35/30 -

4,900 4,900

22.6 22.6

4*3.5 4*3.5

5*1.25 4*1.25

L.C.D Wired L.C.D Wired

Capillary type Capillary type

Yes -

24 Hours On/Off 24 Hours On/Off

Yes Yes

Yes -

Yes Optional Optional

Optional Optional

Yes Yes

Yes Yes

Yes Yes

Optional Optional

Yes Yes

Yes Yes

3/8(9.52) 3/8(9.52)

3/4(19.05) 3/4(19.05)

1,230*680*370 1,230*680*370

900*370*1,220 900*370*1,220

70 70

95 90

Model

LB-E4880RH LB-E4880FH

–10–

Power Source Ø, V, Hz"

Cooling Capacity kcal/h(BTU/h)

W

Input W

Heating Capacity kcal/h(BTU/h)

W

Input W

Electhic Heater Capacity Kw

Rated Load Amp. Cooling A

Heating A

Air Volumn Cooling(H/M/L)

CMM(m

3

/min)

Heating(H/M/L)

Refrigerant(R-407C) g

Drain Hose In. Dia mm

Main Cable

No. X mm

2

Connecting Cable

Remote Control Type

Refigerant Control Type

Fuction Soft Dry

Timer

Self Diagnosis

Deice Operation

Hot Start

Zone Control(Optional)

Central Control(Optional)

Group Control(Optional wiring)

Weekly Programning

Thermistor

Drain Pump(Optional)

Auto changeover(Auto Operation: CL)

Stand-by Consumption 0

Connecting Pipe Liquid Inch

Gas (mm)

Dimension Indoor mm

Outdoor (WxDxH)

Net Indoor Kg

Weight

Outdoor

3, 380-415, 50 3, 380-415, 50

14,111(56,000) 14,111(56,000)

16,412 16,412

6,150 6,150

15,120(60,000) -

17,584 -

5,200 -

--

10 10

8.5 49/45/40/35 49/45/40/35

49/45/40/35 -

6,200 6,200

22.6 22.6

4*3.5 4*3.5

5*1.25 4*1.25

L.C.D Wired L.C.D Wired

Capillary type Capillary type

Yes -

24 Hours On/Off 24 Hours On/Off

Yes Yes

Yes -

Yes Optional Optional

Optional Optional

Yes Yes

Yes Yes

Yes Yes

Optional Optional

Yes Yes

Yes Yes

1/2(12.7) 1/2(12.7)

3/4(19.05) 3/4(19.05)

1,230*680*370 1,230*680*370

900*370*1,220 900*370*1,220

79 79

95 90

Model

LB-E6080RH LB-E6080FH

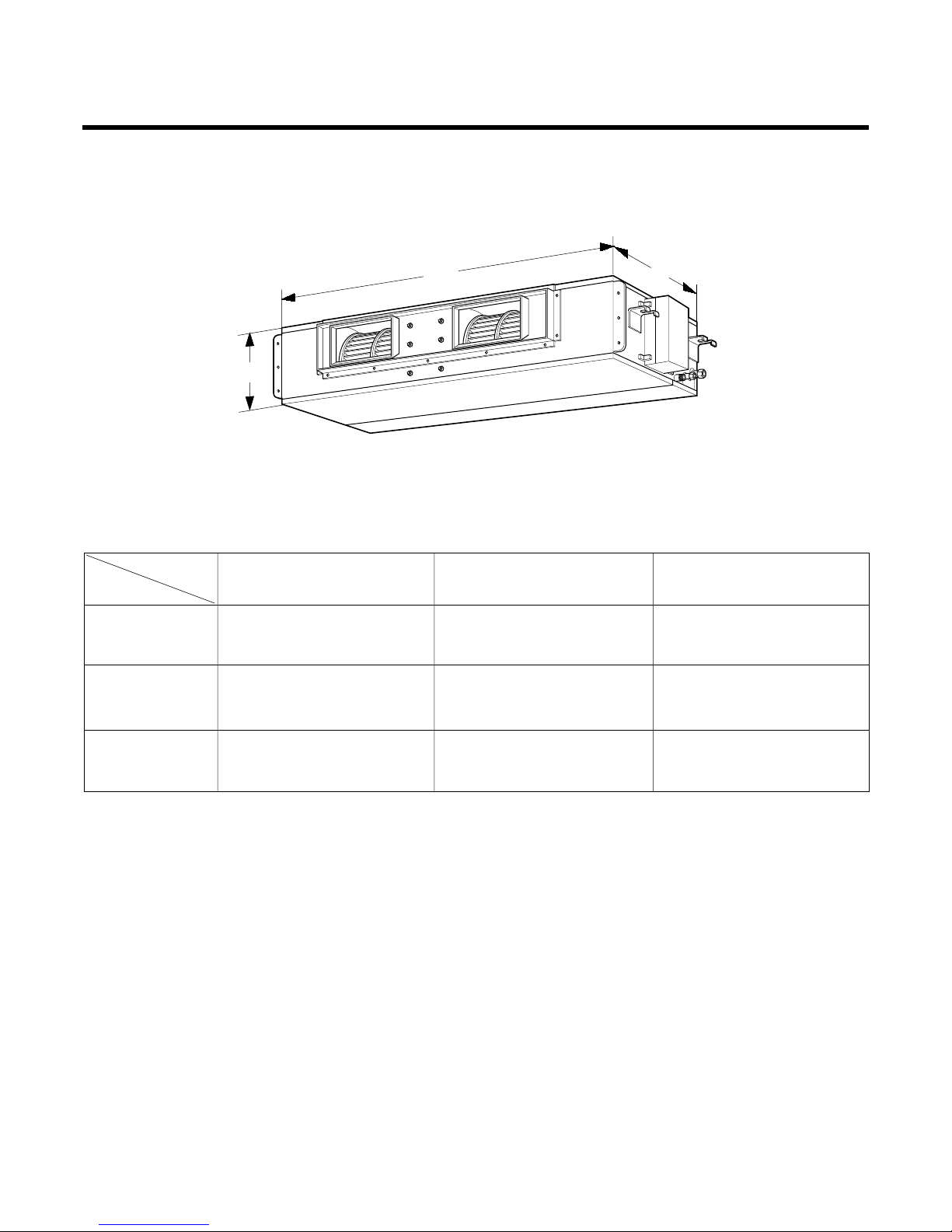

Dimensions

–11–

W

H

D

(1) Indoor Unit

DIM

MODEL

LB-H1860RH/FH

880 260 450

LB-H2460RH/FH

LB-G3660RH/PH/FH

1,180 298 450

LB-G3680RH/FH

LB-E4880RH/FH

1,230 370 680

LB-E6080RH/FH

W(mm) H(mm) D(mm)

(2) Outdoor Unit

–12–

H

W

D

W

H

D

DIM

MODEL

LB-H1860RH/FH

870 655 320

LB-H2460RH/FH

LB-G3660RH/PH/FH

870 800 320

LB-G3680RH/FH

LB-E4880RH/FH

900 1,220 370

LB-E6080RH/FH

W(mm) H(mm) D(mm)

(18K/24K/36K) (48K/60K)

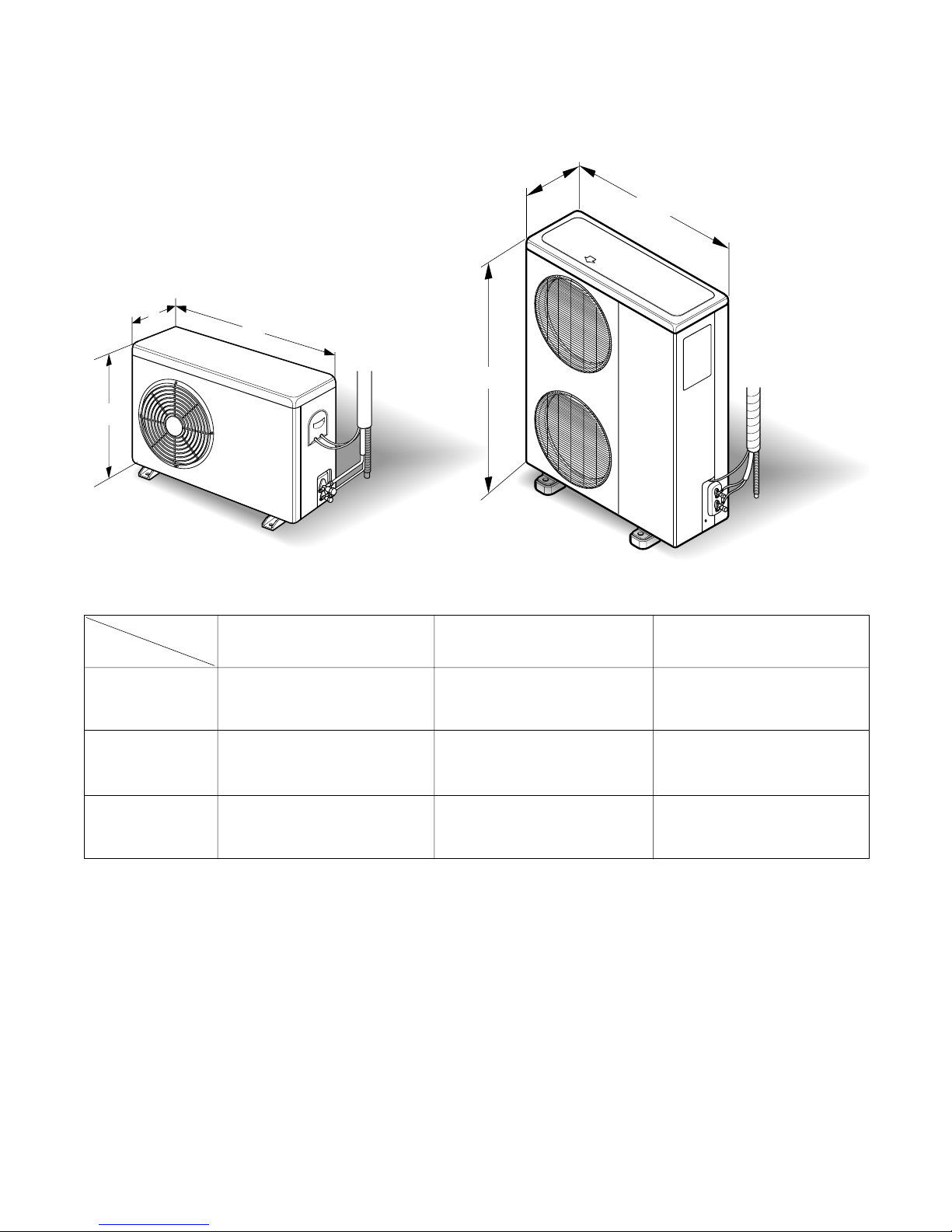

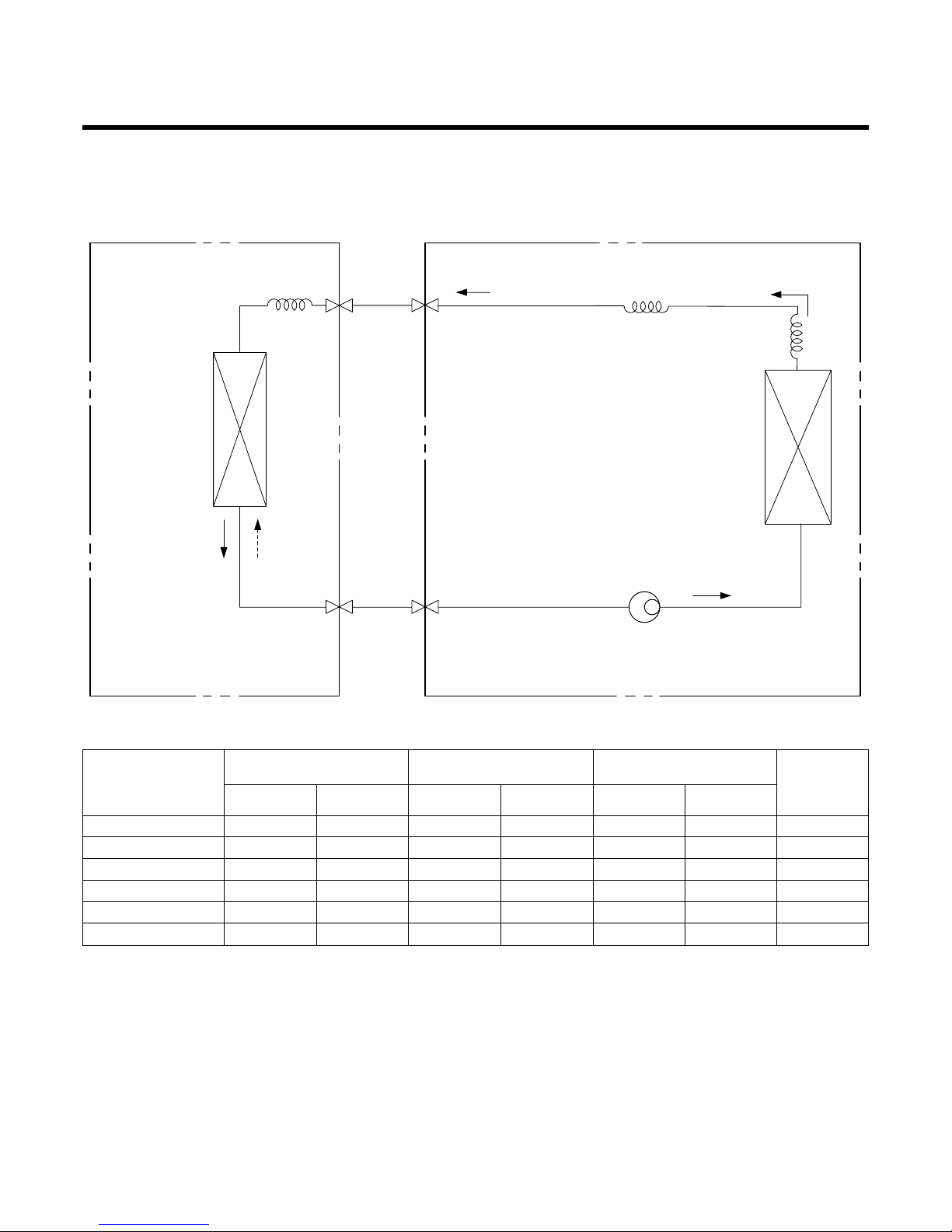

Refrigeration Cycle Diagram

•

HEAT PUMP (LB-H1860RH/LB-H2460RH/LB-G3680RH/LB-G3660RH/

LB-G3660PH/LB-E4880RH/LB-E6080RH)

–13–

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGER

HEAT

EXCHANGER

COMPRESSOR

GAS SIDE

LIQUID SIDE

COOLING

HEATING

REVERSING

VALVE

CAPILLARY TUBE

• Rated performance for refrigerant line length of: 7.5m

• If 18K Model is installed at a distance of 15m, 255g of refrigerant should be added (15-7.5)x30g=225g

LB-H1860RH 5/8" 1/4" 7.5 50 5 30 30

LB-H2460RH 5/8" 1/4" 7.5 50 5 30 30

LB-G3660RH/PH 5/8" 1/4" 7.5 50 5 30 40

LB-G3680RH 5/8" 1/4" 7.5 50 5 30 40

LB-E4880RH 3/4" 3/8" 7.5 50 5 30 40

LB-E6080RH 3/4" 1/2" 7.5 50 5 30 80

Pipe size(Diameter: ø) Piping length(m) Elevation(m)

MODEL

Gas Liquid Rated Max. Rated Max.

*Additional

refrigerant

(g/m)

–14–

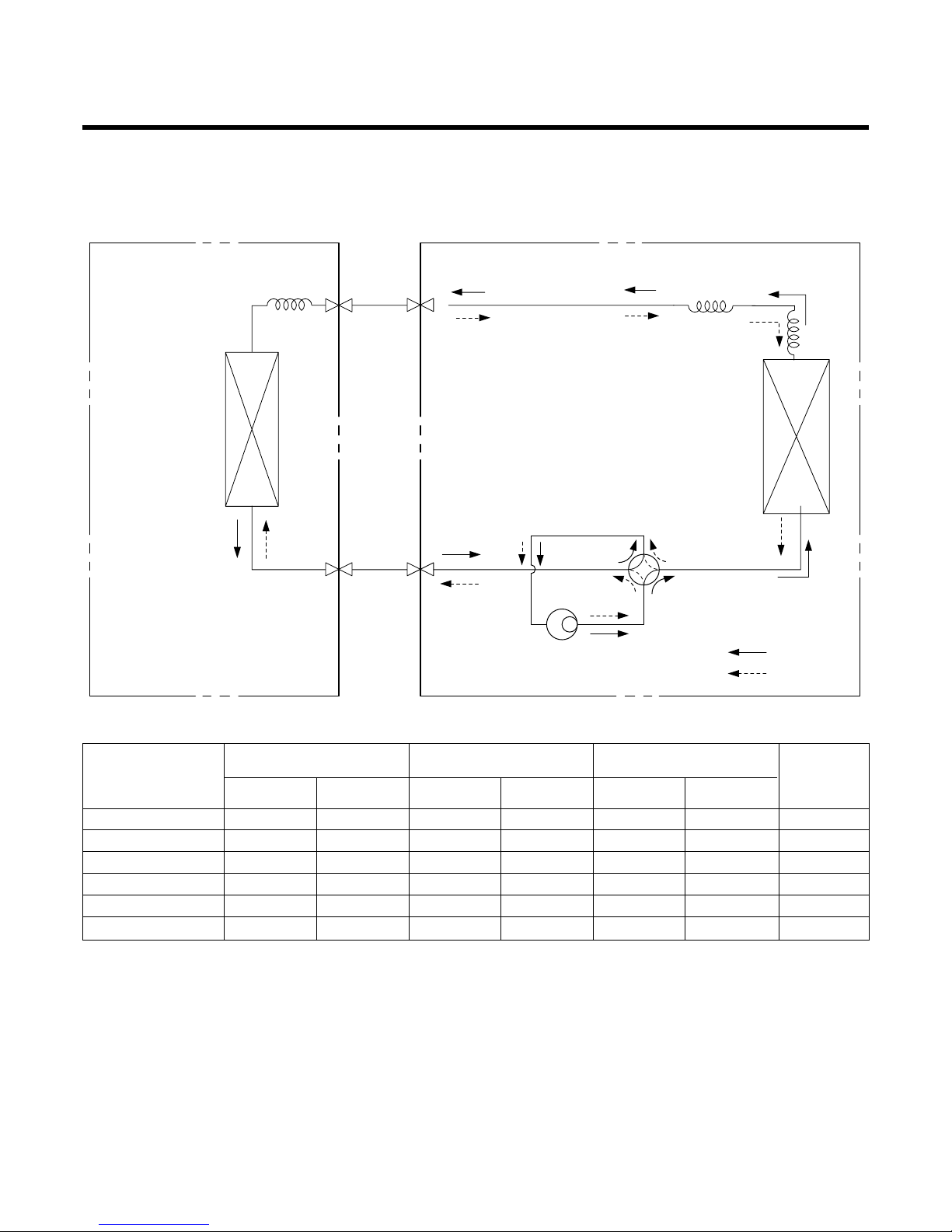

• COOLING ONLY (LB-H1860FH/LB-H2460FH/LB-G3660FH/LB-G3680FH/

LB-E4880FH/LB-E6080FH)

INDOOR UNIT OUTDOOR UNIT

HEAT

EXCHANGER

(CONDENSER)

HEAT

EXCHANGER

(CONDENSER)

COMPRESSOR

GAS SIDE

LIQUID SIDE

CAPILLARY TUBE

• Rated performance for refrigerant line length of: .7.5m

• If 18K Model is installed at a distance of 15m, 225g of refrigerant should be added (15-7.5)x30g=225g

LB-H1860FH 5/8" 1/4" 7.5 50 5 30 30

LB-H2460FH 5/8" 1/4" 7.5 50 5 30 30

LB-G3660FH 5/8" 1/4" 7.5 50 5 30 40

LB-G3680FH 5/8" 1/4" 7.5 50 5 30 40

LB-E4880FH 3/4" 3/8" 7.5 50 5 30 40

LB-E6080FH 3/4" 1/2" 7.5 50 5 30 80

*Additional

refrigerant

(g/m)

Pipe size(Diameter: ø) Piping length(m) Elevation(m)

MODEL

Gas Liquid Rated Max. Rated Max.

–15–

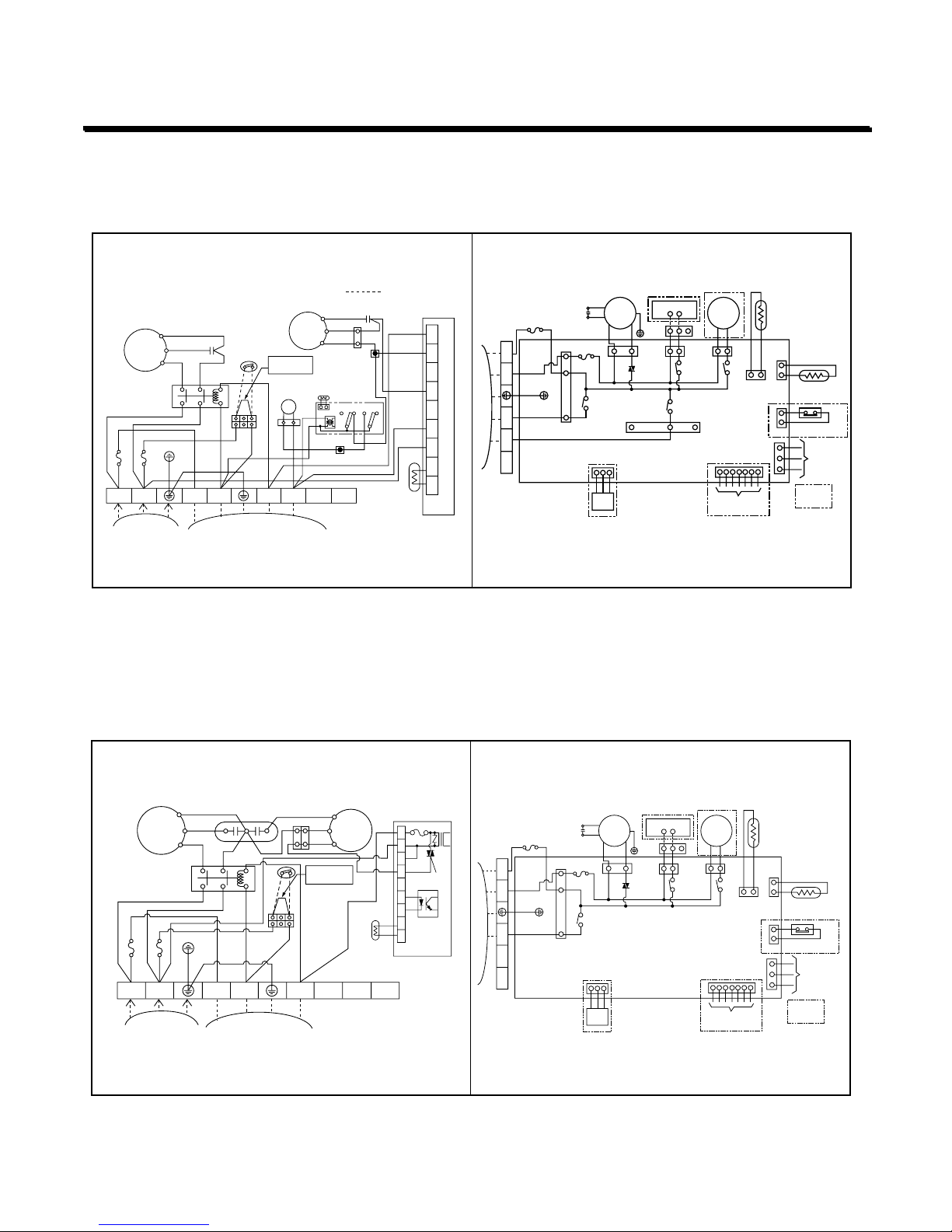

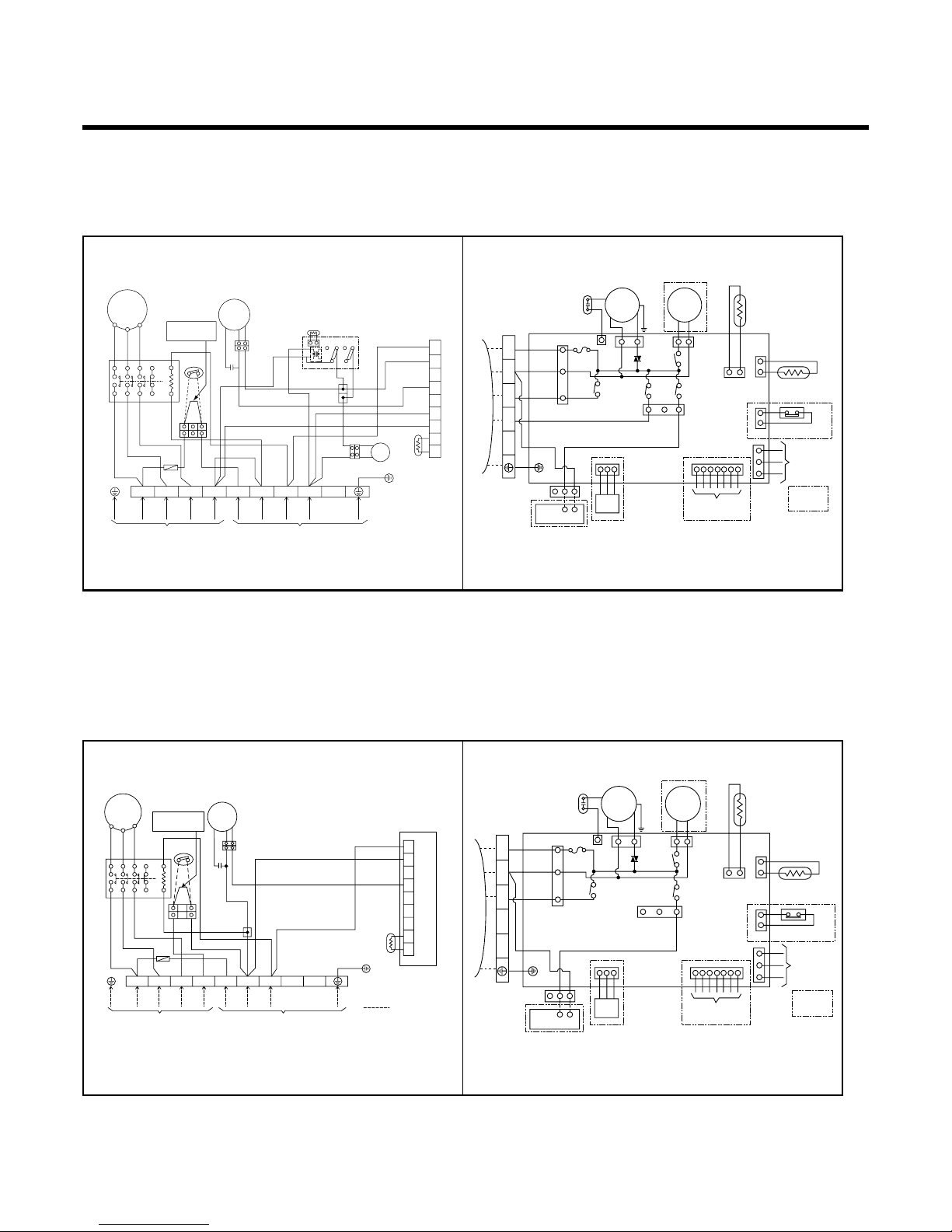

Wiring Diagram

HEAT PUMP

Model : LB-H1860RH

COOLING ONLY

Model : LB-H1860FH

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

BL

BK BK

BK

RD

BL

BR

GN/YL

YL

OR

BL

BL

BK

GN/YL

COMP

4 WAY

VENT

FUSE

250V 3.15A

TEMP.

THERMISTOR

PIPE

THERMISTOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20166Z

FUSE

250V 5A

3(L) 4(N) 5 6 7

TRIAC

A/CL

UNIT

OPTION

VENTILATOR

T/B

COMP

R

S

42861

0

BL

BL

WH

WH

BR

BR

BL

BL

BL

RD

BL

BL

BR

GN/YL

GN/YL

CAPACITOR

CAPACITOR

REVERSING

VALVE

RD

BR

RD

WIRING OF FIELD

BK

OR

TB1

OR

YL

BKORBK

WH

BK

C

POWER

RELAY

FAN

MOTOR

FUSE 5A

FUSE 5A

POWER

INPUT

TO INDOOR UNIT

TERMINAL

BLOCK

3854A20128L

1(L)2(N

)

3(L)4(N

)

5

6

7

8

1

2

3

4

5

6

7

8

9

Low Ambient PCB

PIPE TH

TNS

NO

L1

L2

L3 L4

D.P

NC NO NC

pipe TH

TB2

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

BL

BK BK

RD

BL

BR

GN/YL

YL

OR

BL

BL

BK

GN/YL

COMP

VENT

FUSE

250V 3.15A

TEMP.

THERMISTOR

PIPE

THERMISTOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

TERMINAL

BLOCK

TO OUTDOOR UNIT

FUSE

250V 5A

3(L) 4(N) 5 6 7

TRIAC

A/CL

UNIT

OPTION

VENTILATOR

T/B

3854A20166M3854A30079G

8

COMP

R

S

H

42861

0

CF

BL

BL

YL

OR

OR

BK

BR

BR

BL

BR

BR

BL

BL

BL

BL

GN/YL

GN/YL

BK

BK

BK

BK

RD

CAPACITOR

RD

C

POWER

RELAY

FAN

MOTOR

FUSE 5A

FUSE 5A

POWER

INPUT

TO INDOOR UNIT

TERMINAL

BLOCK

1(L)2(N

)

3(L)4(N

)

5

6

7

8

WH

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

1

2

3

4

5

6

7

8

9

Low Ambient PCB

OUTDOOR TH

FUSE T3.15A

TRIAC

–16–

HEAT PUMP

Model : LB-H2460RH

COOLING ONLY

Model : LB-H2460FH

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

BL

BK BK

BK

RD

BL

BR

GN/YL

YL

OR

BL

BL

BK

GN/YL

COMP

4 WAY

VENT

FUSE

250V 3.15A

TEMP.

THERMISTOR

PIPE

THERMISTOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

TERMINAL

BLOCK

TO OUTDOOR UNIT

3854A20166Z

FUSE

250V 5A

3(L) 4(N) 5 6 7

TRIAC

A/CL

UNIT

OPTION

VENTILATOR

T/B

3854A20126S

COMP

R

S

42861

0

BL

BL

WH

WH

BR

BR

BL

BL

BL

RD

BL

BL

BR

GN/YL

GN/YL

CAPACITOR

CAPACITOR

REVERSING

VALVE

RD

BR

RD

BK

OR

TB1

OR

YL

BK

WH

BK

C

POWER

RELAY

FAN

MOTOR

FUSE 5A

FUSE 5A

POWER

INPUT

TO INDOOR UNIT

TERMINAL

BLOCK

1(L)2(N

)

3(L)4(N

)

5

6

7

8

1

2

3

4

5

6

7

8

9

Low Ambient PCB

PIPE TH

TNS

NO

L1

L2

L3 L4

D.P

NC NO NC

pipe TH

TB2

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

BL

BK BK

RD

BL

BR

GN/YL

YL

OR

BL

BL

BK

GN/YL

COMP

VENT

FUSE

250V 3.15A

TEMP.

THERMISTOR

PIPE

THERMISTOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

TERMINAL

BLOCK

TO OUTDOOR UNIT

FUSE

250V 5A

3(L) 4(N) 5 6 7

TRIAC

A/CL

UNIT

OPTION

VENTILATOR

T/B

3854A20166M3854A30079G

8

COMP

R

S

H

42861

0

CF

BL

BL

YL

OR

OR

BK

BR

BR

BL

BR

BR

BL

BL

BL

BL

GN/YL

GN/YL

BK

BK

BK

BK

RD

CAPACITOR

RD

C

POWER

RELAY

FAN

MOTOR

FUSE 5A

FUSE 5A

POWER

INPUT

TO INDOOR UNIT

TERMINAL

BLOCK

1(L)2(N

)

3(L)4(N

)

5

6

7

8

WH

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

1

2

3

4

5

6

7

8

9

Low Ambient PCB

OUTDOOR TH

FUSE T3.15A

TRIAC

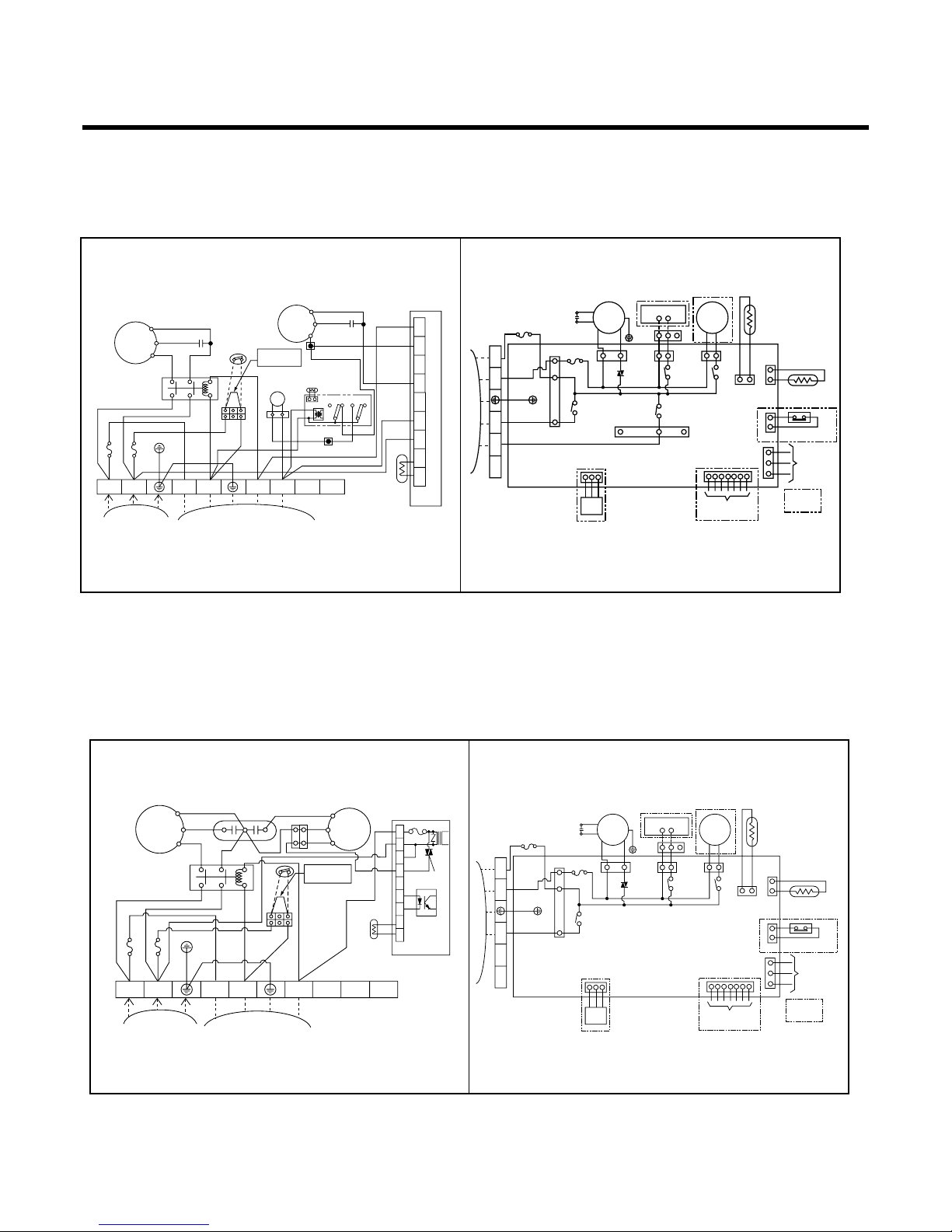

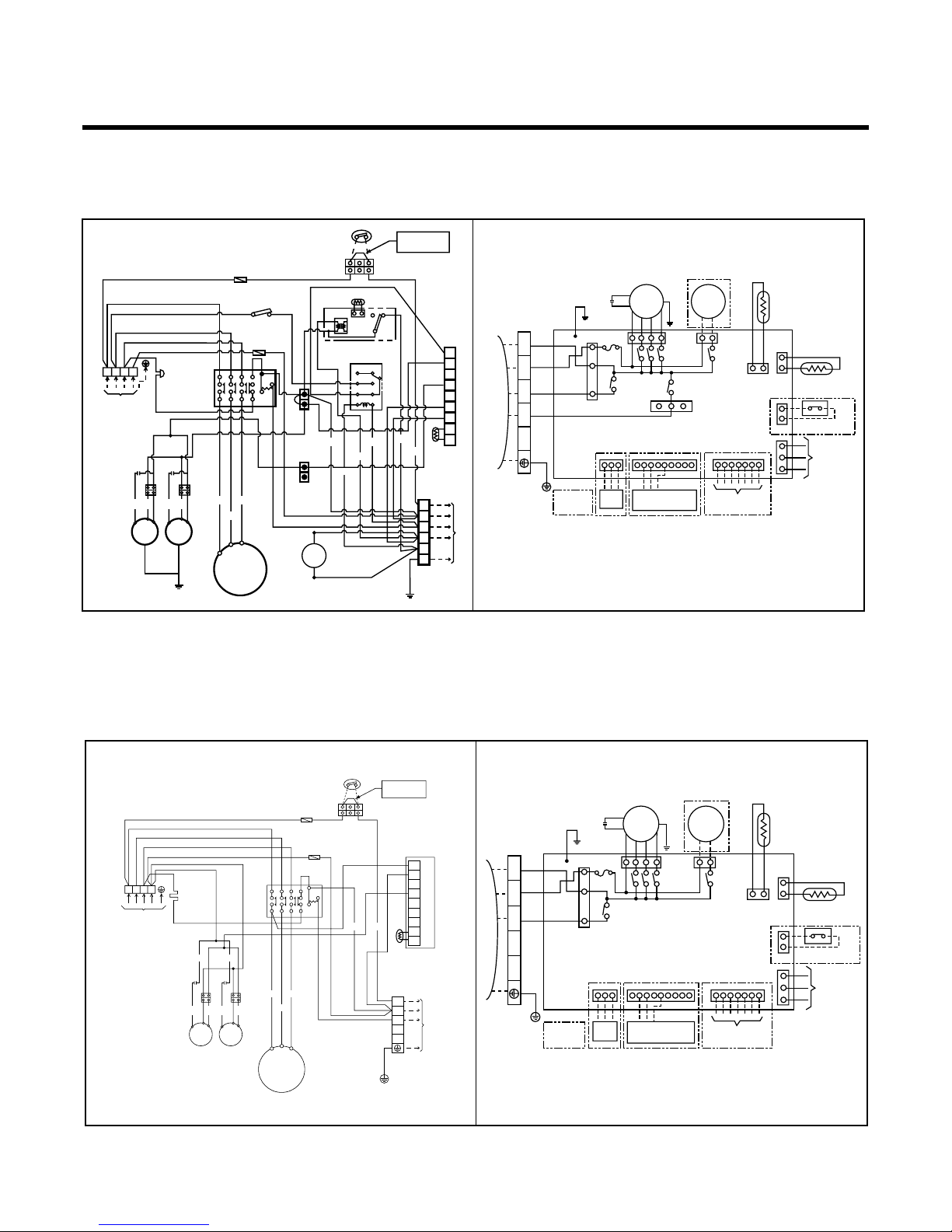

HEAT PUMP

Model : LB-G3660RH/PH

COOLING ONLY

–17–

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

3854A20166A

3854A20126H

INDOOR

MOTOR

DRAIN

PUMP

YL

BR

OR

BR

BK

BL

RD

BK

BL BR

BL

BL

GN/YL

GN/YL

COMP

4 WAY

FUSE

250V 8A

TEMP.

THERMISTOR

PIPE

THERMISTOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

A/CL

UNIT

VENTILATOR

T/B

TERMINAL

BLOCK

1

(

L

)

2

(

N

)

4 3

5

TO OUTDOOR UNIT

TRIAC

VENT

OPTION

1TM

220-240V

1Ø, 50Hz

POWER SUPPLY

BK

L1 L2

T1 T2

A2

A1

BK

WH

WH

OR

RD

BK

TNS

NO

C TH

PIPE TH

NCNO NC

D.P

52C

LOW AMBIENT KIT.

WH

WH

WH

WH

F1

BK

Co

BKBKOR

OR

YL

FMo

20SV

RDOR

WH

BK

BK

BK

BL

T/B

BK BK

BK BK

GN/YL

Tmo

To the indoor unit

GN/YL

23

LN

1

2

3

4

5

6

BKWHRD

R

C

S

CM

Cr

PTCR

1

2

3

4

5

6

7

8

9

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

BK

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

3854A20166C

3854A20126G

INDOOR

MOTOR

DRAIN

PUMP

YL

BR

OR

BR

BK

BL

RD

BL BR

BL

BL

GN/YL

GN/YL

COMP

FUSE

250V 8A

TEMP.

THERMISTOR

PIPE

THERMISTOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

A/CL

UNIT

OPTION

TERMINAL

BLOCK

1

(

L

)

2

(

N

)

4 3

5

TO OUTDOOR UNIT

TRIAC

VENTILATOR

T/B

VENT

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

BK

BK

1TM

220-240V

1Ø, 50Hz

POWER SUPPLY

BK

52C

L1 L2

T1 T2

A2

A1

BK

WH

F1

BK

WH

WH

Co

BKBKOR

OR

YL

FMo

WH

RD

WH

WH

WH

RD

GN/YL

Tmo

To the indoor unit

WH

GN/YL

23

LN

543

2(N) 1(L)

BKWHRD

R

C

S

CM

Cr

PTCR

1

2

3

4

5

6

7

8

9

LOW AMBIENT KIT

PIPE. TH

–18–

HEAT PUMP

Model : LB-G3680RH

COOLING ONLY

Model : LB-G3680FH

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

3854A20166A

3854A20126X

CM

52C

T1

2143632

A

B

31

5

T2

T3

BL

BL

BL

BL

BK

BK

WH

PIPE. TH

BKBK

BK

BK

GN/YL

20SV

TMo

C TH

TNS

NO NONC NC

T/B1

T/B2

D.P

BK

OR

Co

OR

OR

OR

BK

BK

R

3Ø, 50Hz

380-415V

POWER SUPPLY

To the indoor unit

STN

1(L) 2(N) 3 4 5

BKBK

BL

BK

WH

WH

WH

WH

WH

WH

RD

YL

RD

RD

1

2

3

4

LOW AMBIENT CIRKIT

5

6

7

8

9

RD

FMo

WH

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

INDOOR

MOTOR

DRAIN

PUMP

YL

BR

OR

BR

BK

BL

RD

BK

BL BR

BL

BL

GN/YL

GN/YL

COMP

4 WAY

FUSE

250V 8A

TEMP.

THERMISTOR

PIPE

THERMISTOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

A/CL

UNIT

VENTILATOR

T/B

TERMINAL

BLOCK

1

(

L

)

2

(

N

)

4 3

5

TO OUTDOOR UNIT

TRIAC

VENT

OPTION

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

3854A20166C

3854A20126U

CM

OR BK

OR

Co

RD

1

2

3

4

5

6

7

8

9

WH

BK

BL

LOW AMBIENT KIT

PIPE. TH

WH

T3

T2

T1

214632

A

B

31

35

52C

FUSE

R S T N 1(L) 3 4 5

GN/YL

To the indoor unit

3Ø, 50Hz

380-415V

POWER SUPPLY

WIRING OF FIELD

(CONNECTING WIRE)

TMo

TB

2(N)

BK

BKBK

BK

BL

BL

RD

RD

YL

WH

WH

WH

WH

FMo

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

WH

INDOOR

MOTOR

DRAIN

PUMP

YL

BR

OR

BR

BK

BL

RD

BL BR

BL

BL

GN/YL

GN/YL

COMP

FUSE

250V 8A

TEMP.

THERMISTOR

PIPE

THERMISTOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

A/CL

UNIT

OPTION

TERMINAL

BLOCK

1

(

L

)

2

(

N

)

4 3

5

TO OUTDOOR UNIT

TRIAC

VENTILATOR

T/B

VENT

–19–

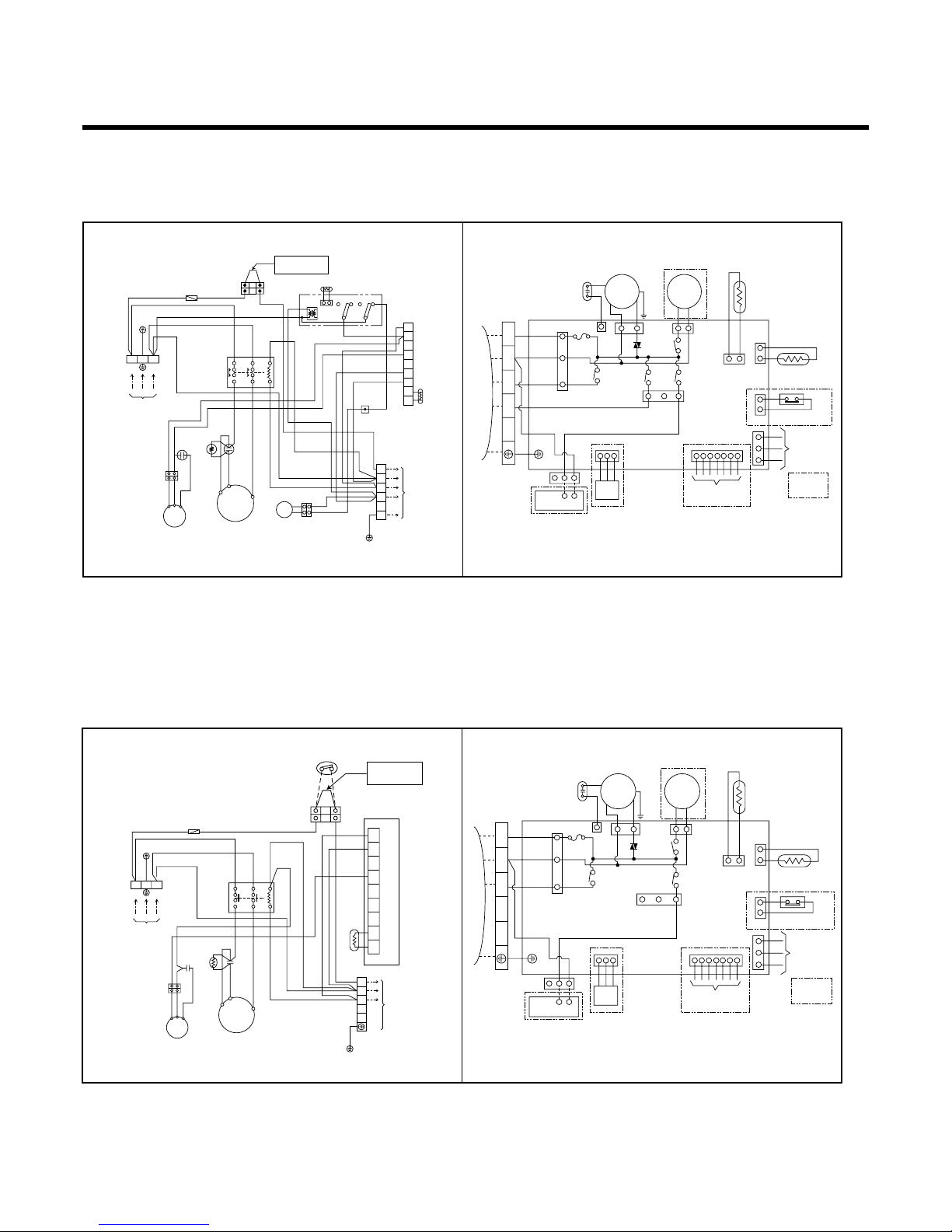

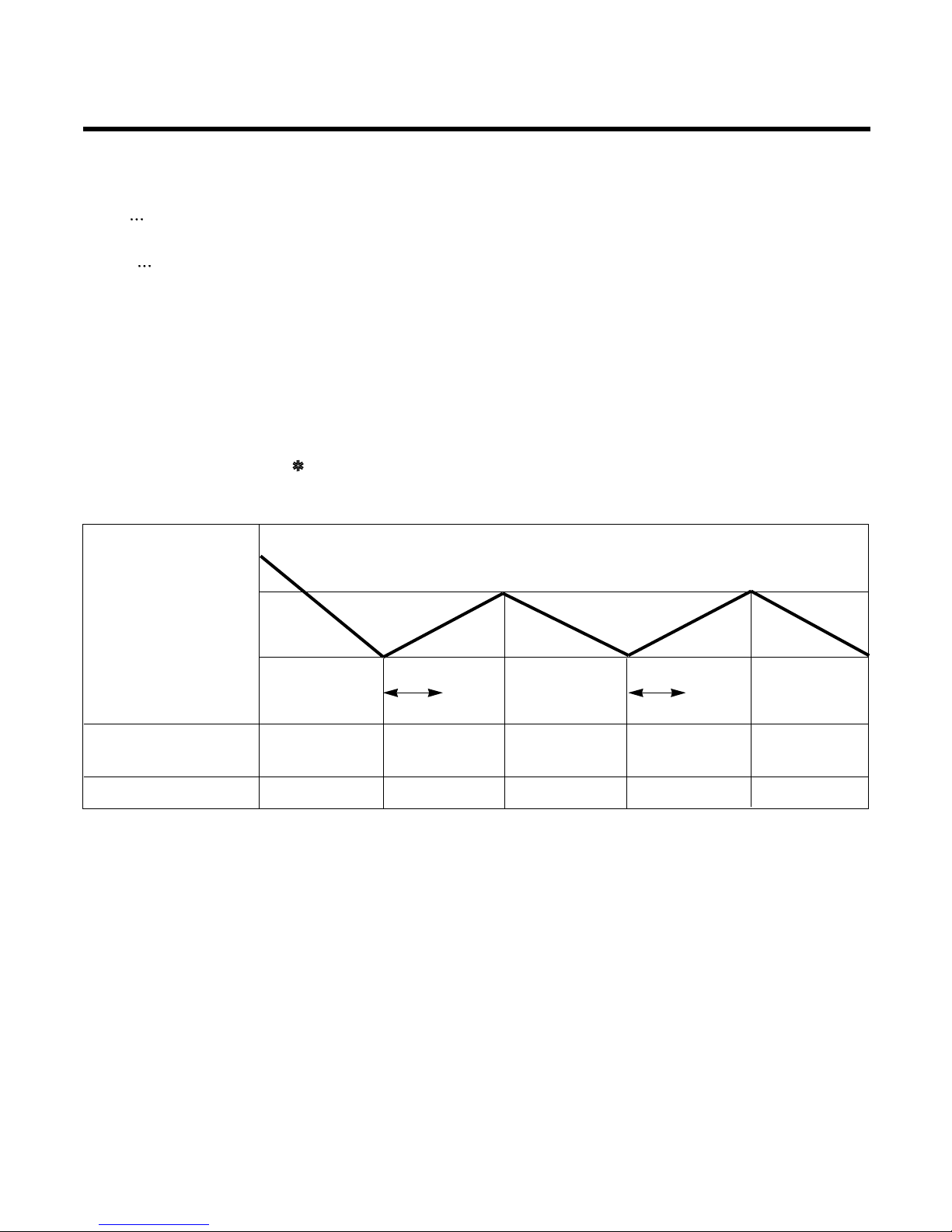

HEAT PUMP

Model : LB-E4880RH

COOLING ONLY

Model : LB-E4880RH

INDOOR

MOTOR

DRAIN

PUMP

BR

BR

YL

ORRDBL

BL

RD

BK

GN/YL

BL

BL

BK

GN/YL

COMP

4WAY

FUSE

250V10A

ROOM

SENSOR

PIPE

SENSOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTION

TERMINAL

BLOCK

1

(

L

)

2

(

N

)

4 3

5

TO OUTDOOR UNIT

3854A20166K3854A20235A

TELECONTROL/

CENTRAL CONTROL

A/CL

UNIT

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

R

POWER SUPPLY

MAGNETIC

CONTACTER

CRANK-CASE

HEATER

STN

BK

BK

BK

BK

BK

WH

WH

WH

WH

RD

BK

BL

WH

D.P

TNS

NONO

pipe TH

NCNC

WH

OR

WH

BK

BK

OR

BK

BK

BK

WH

POWER

RELAY

12345631

T/B3

T/B2

T/B1

32

B

A

FAN

MOTOR

FAN

MOTOR

YL BK

OR

BK

T3

T2

T1

RD

BK

WH

COMP.

12

34

56

78

YL BK

OR

OR

BK

BK

BL

BL

BK

WH

CAPACITOR CAPACITOR

REVERSING

VALVE

BR

BL

BR

BL

GN/YL

GN/YL

TERMINAL BLOCK

To the indoor unit

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

BK

WHWH

BL

Fuse

(250V 5A)

Fuse

(250V 5A)

BK

BK

BK

PIPE TH

Low Ambient PCB

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

FUSE T3.15A

TRIAC

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

INDOOR

MOTOR

DRAIN

PUMP

BR

BR

YL

ORRDBL

BL

RD

BL

BL

BK

GN/YL

COMP

FUSE

250V10A

ROOM

SENSOR

PIPE

SENSOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTION

TERMINAL

BLOCK

1

(

L

)

2

(

N

)

4 3

5

TO OUTDOOR UNIT

3854A20166L3854A20078C

TELECONTROL/

CENTRAL CONTROL

A/CL

UNIT

GN/YL

GN/YL

TMo

To the indoor unit

Low Ambient PCB

2(N)

1(L)

3

4

5

F1

F1

RTM

POWER SUPPLY

STN

BK

BK

BK

BK

WH

RD

WH

WH

52C

12345631

32

B

A

FMo

49FMo

FMo

49FMo

BK

T3

T2

T1

RD

WH BK

BK

BK

WH

BL

WH

CM

YL BK

OR

Co Co

YLORBK

BR

OR

OR

BR

1

2

3

4

5

6

7

8

9

PIPE TH

BK

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

CRANK-CASE

HEATER

HEAT PUMP

Model : LB-E6080RH

COOLING ONLY

Model : LB-E6080FH

–20–

3854A20166N

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

R

POWER SUPPLY

MAGNETIC

CONTACTER

STN

BK

BK

BK

WH

WH WH

WH

WH

RD

BK

HIGH PRESSURE S/W

WH

Deice PCB

CTH

TNS

NO

NC

WH

OR

WH

BK

BK

BK

BK

WH

POWER

RELAY

12345631

T/B1

T/B2

T/B3

32

B

A

FAN

MOTOR

FAN

MOTOR

YL BK

OR

BK

T3

T2

T1

RD

WH

COMP.

12

34

56

78

YL BK

OR

OR

BK

BK

BL

BL

BK

WH

CAPACITOR CAPACITOR

REVERSING

VALVE

BR

BL

BR

BL

GN/YL

GN/YL

TERMINAL BLOCK

To the indoor unit

1

2

3

4

5

6

1

2

3

4

5

6

7

8

9

BK

WHWH

YL

RD

Fuse

(250V 5A)

Fuse

(250V 5A)

BK

3854A20284A

BK

BK

PIPE TH

Low Ambient PCB

BK

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

CRANK-CASE

HEATER

INDOOR

MOTOR

DRAIN

PUMP

BR

BR

YL

ORBLBK

BL

RD

BK

GN/YL

BL

BL

YL

GN/YL

COMP

4WAY

FUSE

250V10A

ROOM

SENSOR

PIPE

SENSOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTION

TERMINAL

BLOCK

1

(

L

)

2

(

N

)

4 3

5

TO OUTDOOR UNIT

TELECONTROL/

CENTRAL CONTROL

A/CL

UNIT

OUTDOOR WIRING DIAGRAM INDOOR WIRING DIAGRAM

3854A20078C

GN/YL

TMo

To the indoor unit

Low Ambient PCB

2(N)

1(L)

3

4

5

F1

F1

RTM

POWER SUPPLY

STN

BK

BK

BK

BK

WH

RD

WH

WH

52C

12345631

32

B

A

FMo

49FMo

FMo

49FMo

BK

T3

T2

T1

RD

WH BK

BK

BK

WH

BL

WH

CM

YL BK

OR

Co Co

YLORBK

BR

OR

OR

BR

1

2

3

4

5

6

7

8

9

PIPE TH

BK

REMOVE JUMP WIRE

WHEN CONNECTING

FIRE ALARM SYSTEM

CRANK-CASE

HEATER

INDOOR

MOTOR

DRAIN

PUMP

BR

BR

YL

ORBLBK

BL

RD

BL

BL

YL

GN/YL

COMP

FUSE

250V10A

ROOM

SENSOR

PIPE

SENSOR

FLOAT S/W

REMOTE

CONTROL

ZONE

CONTROL

OPTION

TERMINAL

BLOCK

1

(

L

)

2

(

N

)

4 3

5

TO OUTDOOR UNIT

3854A20166P

TELECONTROL/

CENTRAL CONTROL

A/CL

UNIT

GN/YL

–21–

Operation Details

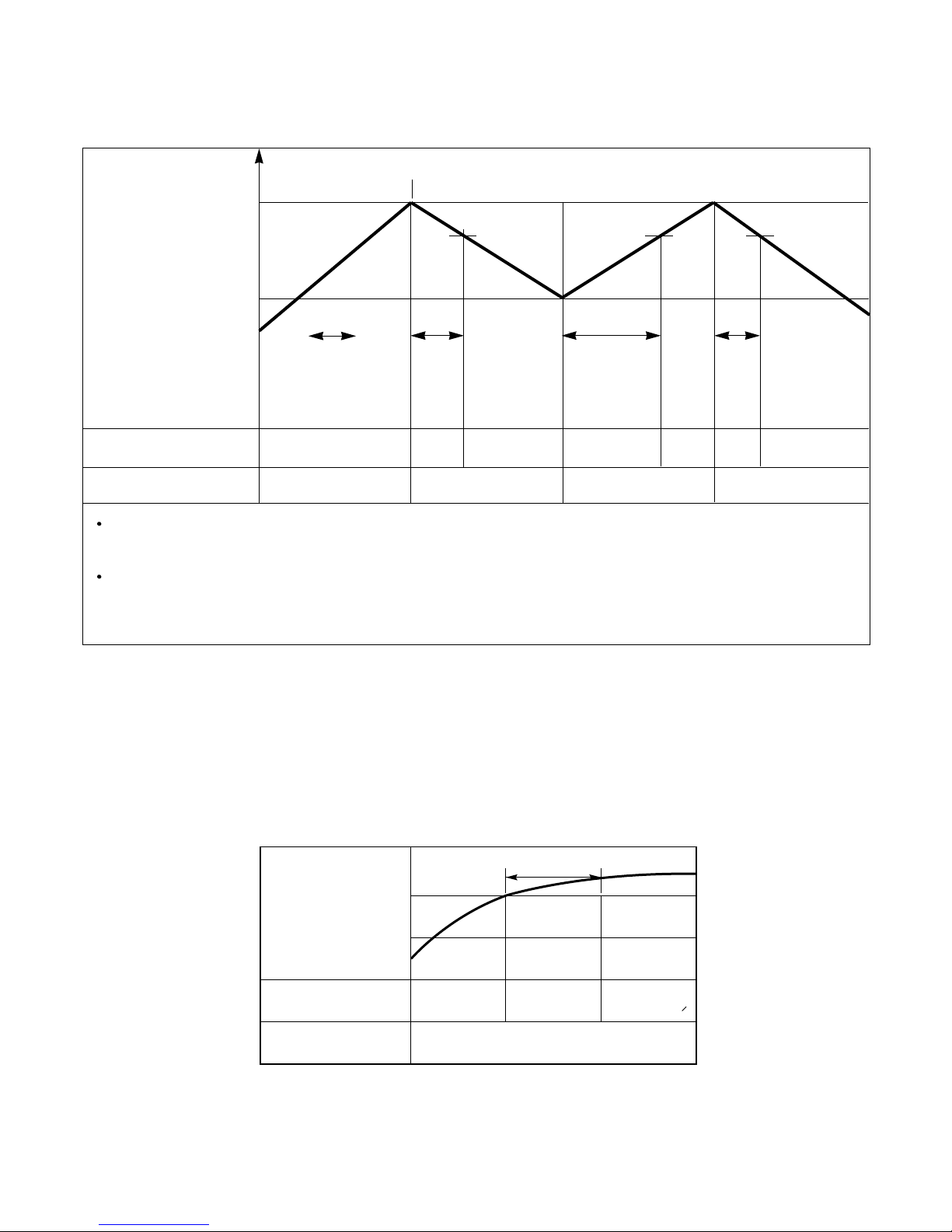

(1) The function of main control

1. Time Delay Safety Control

• 3min The compressor is ceased for 3minutes to balance the pressure in the refrigeration cycle.

(Protection of compressor)

• 30sec The 4-way valve is ceased for 30sec. to prevent abnormal noise when the Heating operation is OFF or

switched to the other operation mode while compress is off.

While compressor is running, it takes 3~5 seconds to switch.

2. Soft-Dry Operation

• The indoor fan speed is automatically set to the low, and fan speed control is not available because of already

being set to the best speed for Dry Operation by Micom Control.

3. Cooling Mode Operation

• When selecting the Cooling( ) Mode Operation, the unit will operate according to the setting by the remote con-

troller and the operation diagram is as follows.

Intake Air temp.

SET TEMP.+0.5°C

(COMP. ON)

SET TEMP

SET TEMP. -0.5°C

(COMP. OFF)

Selected Selected Selected

fan speed fan speed fan speed

COMPRESSOR ON OFF ON OFF ON

INDOOR FAN Low Low

More than

3 minutes

More than

3 minutes

–22–

4. Heating Mode Operation (Except Cooling Model)

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

5. Hot-Start Control

• The indoor fan stops until the evaporator piping temperature will be reached to 25°C.

• The operation diagram is as following.

PIPING

TEMPERATURE

1min

COMPRESSOR

INDOOR FAN

ON

OFF LOW

Selected

fan speed

22°C

25°C

Intake Air temp.

Setting temp.+3°C

(Compressor OFF)

Setting temp.

(Compressor ON)

INDOOR FAN

COMPRESSOR ON OFF ON OFF

A point; While the indoor Heat-Exchanger temperature is higher than 40°C fan operates at low speed, when

it becomes lower than 40˚C fan stops.

B point; When the indoor Heat-Exchanger temperature is higher than 51(42)°C, fan operates at selected fan

speed, when it becomes lower than 48(39)°C, the fan operates at low speed.

Selecting fan

speed

minimum

10sec.

1min

A

A

minimum

1min.

minimum

10sec.

B

Loading...

Loading...