Page 1

Website:http://biz.LGservice.com

(AxxKEP : INL 8ms, AxxBEP : CPT 8ms, AxxJEP : INI

E-mail:http://www.LGEservice.com/techsup.html

COLOR MONITOR

SERVICE MANUAL

CHASSIS NO. :

MODEL: L1718S

(L1718S-SNQ/L1718S-BNQ.Axx*EP)

xx* means sales region and module type

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

*To apply the MSTAR Chip.

Page 2

SPECIFICATIONS ................................................... 2

PRECAUTIONS ....................................................... 3

TIMING CHART ....................................................... 7

DISASSEMBLY ........................................................ 8

BLOCK DIAGRAM...................................................10

DISCRIPTION OF BLOCK DIAGRAM ................... 11

ADJUSTMENT ...................................................... 13

SPECIFICATIONS

1. LCD CHARACTERISTICS

Type

Active Display Area : 17 inch

Pixel Pitch

Color Depth

Size

Electrical Interface : LVDS

Surface Treatment : Hard-coating(3H), Haze=25%

Operating Mode

Backlight Unit

2. OPTICAL CHARACTERISTICS

2-1. Viewing Angle by Contrast Ratio ≥ 10

(a) For

(b)

2-2. Luminance

(a) For

(b)

2-3. Contrast Ratio

(a) For

(b) For

3. SIGNAL (Refer to the Timing Chart)

3-1. Sync Signal Type :

Separate Sync, Composite, SOG (Sync On Green)

InnoLux MT170EN01 V.7(8ms),V9(5ms) panel

Left 75°(85°)/Right75°(85°);Top 75°(85°)

/Bottom60°(70°) at type CR≥10 (CR≥5)

For

CLAA170EA07QG(8ms) ,CLAA170EA07P(5ms)

panel: Left 70°(85°)/Right70°(85°);Top

63°(85°)/Bottom67°(85°) at type CR≥10(CR≥5)

300cd/m

For

CLAA170EA07QG & 07P panel: 280cd/m2 (Typ.)

250cd/m

For

InnoLux MT170EN01 V.7 & V.9 panel:

2

(Typ.) 250cd/m2 (Min.) (6500k);

200 cd/m

2

(Min.) (6500k);200 cd/m2 (Min.)(9300k)

InnoLux MT170EN01 V.7 & V.9 700:1 Typical

CLAA170EA07QG panel: 500:1 Typical

CLAA170EA07P panel: 700:1 Typical

3-2. Video Input Signal

1) Type

2) Voltage Level

a) Color 0, 0

b) Color 7, 0

Color 15, 0

3) Input Impedance : 75 Ω

3-3. Operating Frequency

Horizontal

Vertical

4

. Max. Resolution

D-sub Analog

: TFT Color LCD Module

: 0.264 (H) x 0.264 (V)

: 16.2M colors

: 358.5 (H) x 296.5 (V) x 17.5(D)

: Normally White, Transmissive mode

: Top/Bottom edge side 4-CCFL

(Cold Cathode Fluorescent Lamp)

: R, G, B Analog

: 0~0.71 V

: 0 Vp-p

: 0.467 Vp-p c)

: 0.714 Vp-p

: 30 ~ 83kHz

: 56 ~ 775Hz

: 1280 x 1024@75Hz

Anti-Glare treatment

2

(Min.)(9300k)

CONTENTS

SERVICE OSD ............................................... .........14

TROUBLESHOOTING GUIDE .............................. 15

WIRING DIAGRAM ............................................... 22

EXPLODED VIEW ................................................... 24

REPLACEMENT PARTS LIST ............................... 25

SCHEMATIC DIAGRAM ......................................... 48

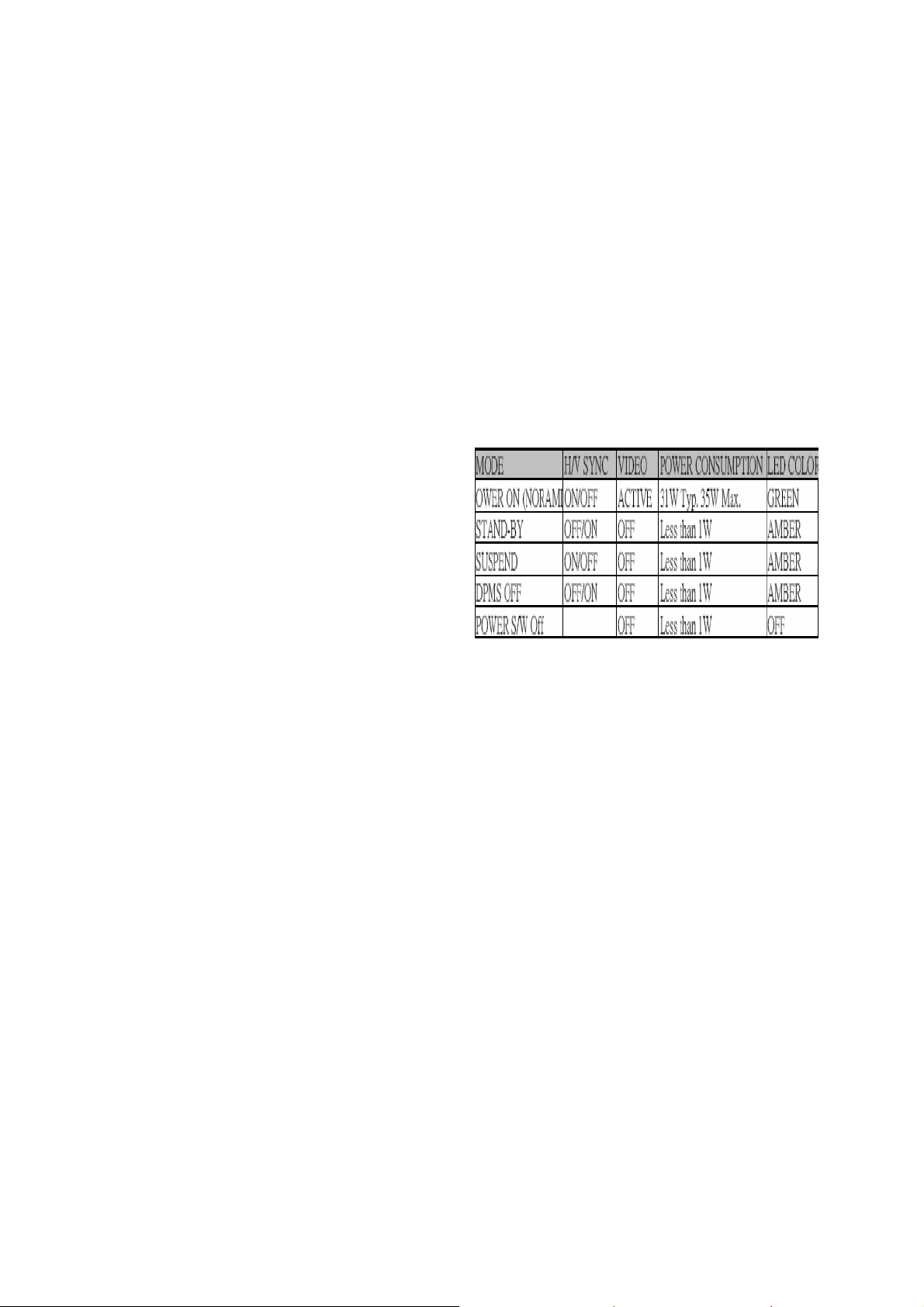

5. POWER SUPPLY

5-1. Power

5-2. Power Consumption

6. ENVIRONMENT

6-1. Operating Temperature : 10°C~35°C (50°F~95°F)

6-2. Relative Humidity

6-3. MTBF

7. DIMENSIONS (with TILT/SWIVEL)

Width

Depth

Height

8. WEIGHT (with T I LT/SWIVEL)

Net. Weight

Gross Weight

2

: AC 90~264V, 47.5~63Hz , <0.8A

(Ambient)

: 10%~80%

(Non-condensing)

Lamp Life

: 50,000 HRS with 90% Confidence

: 50,000 Hours(Min)

: 308.4 mm

: 180.1 mm

: 380.7 mm

: 3.7 +/- 0.3 kg

: 4.8 +/-0.4 kg

Page 3

PRECAUTION

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD

monitor that are important for safety. These parts are

marked on the schematic diagram and

t he replacement parts list. It is essential that these

critical parts should be replaced with the

manufacturer’s specified parts to prevent electric

shock, fire or other hazard.

• Do not modify original design without obtaining written

permission from manufacturer or you will void the

original parts and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE

WITH BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged

in four corners.

• Do not press on the panel, edge of the frame strongly

or electric shock as this will result in damage to the

screen.

• Do not scratch or press on the panel with any sharp

objects, such as pencil or pen as this may result in

damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

• Make certain that treatment person’s body are

grounded through wrist band.

• Do not leave the module in high temperature and in

areas of high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within

the module.

• If the surface of panel become dirty, please wipe it off

with a softmaterial. (Cleaning with a dirty or rough cloth

may damage the panel.)

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL)

or inverter circuit, must disconnect the AC

adapter because high voltage appears at inverter

circuit about

650Vrms.

• Handle with care wires or connectors of the

inverter circuit. If the wires are pressed cause short

and may burn or take fire.

• Be careful while tilting and rotating the monitor to

avoid pinching hand(s)

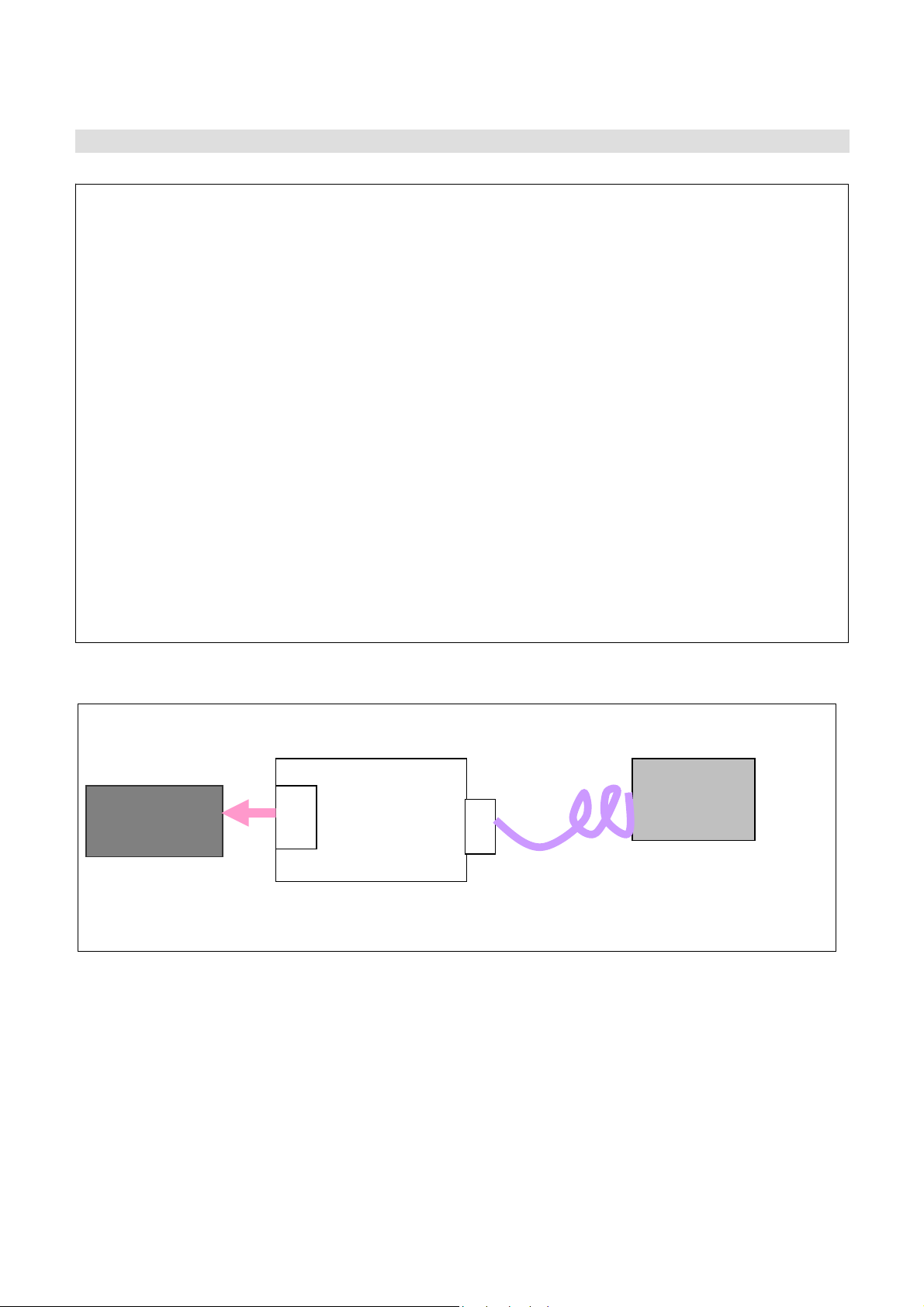

Leakage Current Hot Check Circuit

AC Volt-meter

To Instrument's

exposed METALLIC

PARTS

1.5 Kohm/10W

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

3

Page 4

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this

service manual and its supplements and addenda, read

and follow the SAFETY PRECAUTIONS on page 3 of this

publication.

NOTE:

between the following servicing precautions and any of the

safety precautions on page 3 of this publication, always

follow the safety precautions. Remember: Safety First.

General Servicing Precaution s

1. Always unplug the receiver AC power cord from the AC

2. Test high voltage only by measuring it with an

3. Discharge the picture tube anode only by (a) first

4. Do not spray chemicals on or near this receiver or any of

5. Unless specified otherwise in this service manual,

6. Do not defeat any plug/socket B+ voltage interlocks

7. Do not apply AC power to this instrument and/or any of

8. Always connect the test receiver ground lead to the

If unforeseen circumstances create conflict

power source before;

a. Removing or reinstalling any component, circuit

board module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical

plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may

result in an explosion hazard.

d. Discharging the picture tube anode.

appropriate high voltage meter or other voltage

measuring device (DVM, FETVOM, etc) equipped with a

suitable high voltage probe.

Do not test high voltage by "drawing an arc".

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield

at the point where the picture tube socket ground lead is

connected, and then (b) touch the other end of the

insulated clip lead to the picture tube anode button,

using an insulating handle to avoid personal contact

with high voltage.

its assemblies.

clean electrical contacts only by applying the following

mixture to the contacts with a pipe cleaner, cottontipped stick or comparable non-abrasive applicator;

10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual,

lubrication of contacts in not required.

with which receivers covered by this service manual

might be equipped.

its electrical assemblies unless all solid-state device

heat sinks are correctly installed.

receiver chassis ground before connecting the test

receiver positive lead.

Always remove the test receiver ground lead last.

9. Use with this receiver only the test fixtures specified in

this service manual.

CAUTION: Do not connect the test fixture ground strap

to any heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be

damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES)

Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors

and semiconductor "chip" components. The

fol l o wing techniques should be used to help reduce the

incidence of component damage caused by static by static

electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed to prevent potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with

ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static type solder removal device.

Some solder removal devices not classified as "antistatic" can generate electrical charges sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor

can generate static electricity sufficient to damage an

ES device.)

4

Page 5

General Soldering Guidelin es

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range or 500。F to 600。F.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

mall wire-bristle (0.5 inch, or 1.25cm) brush with a

metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal

temperature.

(500。F to 600。F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder

braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500。F to 600。F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

IC Remove/Replacemen t

Some chassis circuit boards have slotted holes (oblong)

through which the IC leads are inserted and then bent flat

against the circuit foil. When holes are the slotted type,

the following technique should be used to remove and

replace the IC. When working with boards using the

familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation

by gently prying up on the lead with the soldering iron

tip as the solder melts.

2. Draw away the melted solder with an anti-static

suction-type solder removal device (or with solder

braid) before removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle

brush. (It is not necessary to reapply acrylic coating to

the areas).

"Small-Signal" Discrete Transi stor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board

and crimp the "U" with long nose pliers to insure metal

to metal contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close

as possible to diode body.

2. Bend the two remaining leads perpendicular y to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit

board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the

solder joints of the two "original" leads. If they are not

shiny, reheat them and if necessary, apply additional

solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component

around notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent components and the

circuit board to prevent excessive

component temperatures.

5

Page 6

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil to

the circuit board causing the foil to separate from or

"lift-off" the board. The following guidelines and

procedures should be followed whenever this condition is

encountered.

At IC Connections

To repair a defective copper pattern at IC connections use

the following procedure to install a jumper wire on the

copper pattern side of the circuit board. (Use this

technique only on IC connections).

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as

absolutely necessary).

2. carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

3. Bend a small "U" in one end of a small gauge jumper

wire and carefully crimp it around the IC pin. Solder the

IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area and clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the

component side of the circuit board.

1. Remove the defective copper pattern with a sharp

knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire

opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead

of the nearest component on one side of the pattern

break to the lead of the nearest component on the

other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire

is dressed so the it does not touch components or

sharp edges.

6

Page 7

distingis

hment

Polo

rity

VIDEO

SYNC

DOT

CLOCK

[MHz]

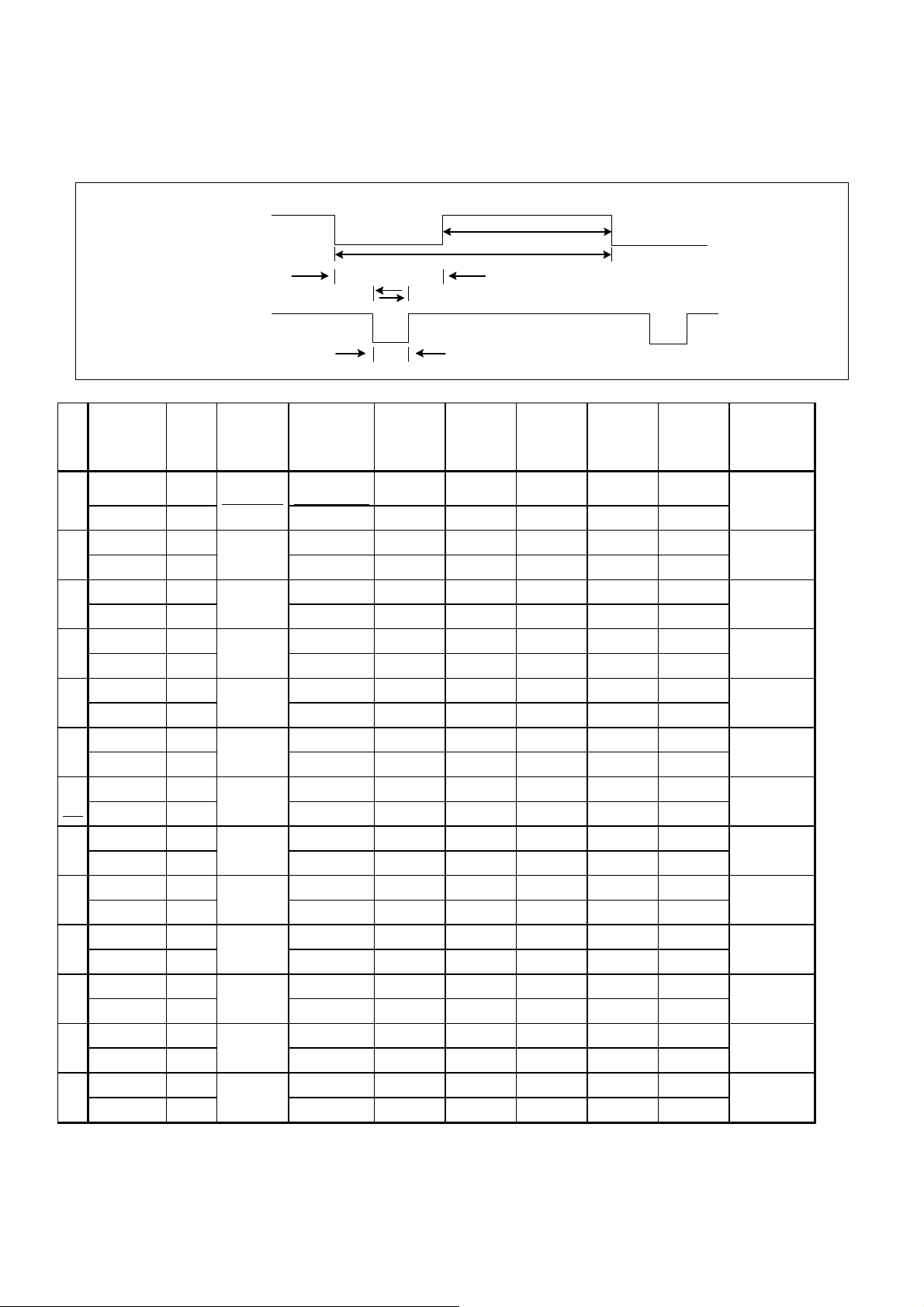

TIMING CHART

D B

C

M

Frequency

[kHz]/ [Hz]

Total period

Display

(E)

A

E

(A)

Front

Porch

(D)

Sync.

(C)

Back

Porch

(B)

Resolutio

n

H(Pixels) +

1

V(Lines) H(Pixels) - 31.468 900 720 18 108 54

2

V(Lines) +

H(Pixels) - 31.469 800 640 16 96 48

3

V(Lines) H(Pixels) - 37.5 840 640 16 64 120

4

V(Lines) H(Pixels) + 37.879 1056 800 40 128 88

5

V(Lines) +

H(Pixels) + 46.875 1056 800 16 80 160

6

V(Lines) +

H(Pixels) +/- 49.725 1152 832 32 64 224

7

V(Lines) +/H(Pixels) - 48.363 1344 1024 24 136 160

8

V(Lines) H(Pixels) - 60.123 1312 1024 16 96 176

9

V(Lines) H(Pixels) +/- 68.681 1456 1152 32 128 144

10

V(Lines) +/H(Pixels) +/- 61.805 1504 1152 18 134 200

11

V(Lines) +/H(Pixels) + 63.981 1688 1280 48 112 248

12

V(Lines) +

H(Pixels) + 79.976 1688 1280 16 144 248

13

V(Lines) +

25.175

28.321

25.175

31.5

40.0

49.5

57.283

65.0

78.75

100.0

92.978

108.0

135.0

31.469

70.08 449 350 37 2 60

70.09 449 400 12 2 35

59.94 525 480 10 2 33

75 500 480 1 3 16

60.317 628 600 1 4 23

75.0 625 600 1 3 21

74.55 667 624 1 3 39

60.0 806 768 3 6 29

75.029 800 768 1 3 28

75.062 915 870 3 3 39

65.96 937 900 2 4 31

60.02 1066 1024 1 3 38

75.035 1066 1024 1 3 38

800 640 16 96 48

640 x 350

720 X 400

640 x 480

640 x 480

800 x 600

800 x 600

832 x 624

1024 x 768

1024 x 768

1152 x 870

1152 x 900

1280 x 1024

1280 x 1024

7

Page 8

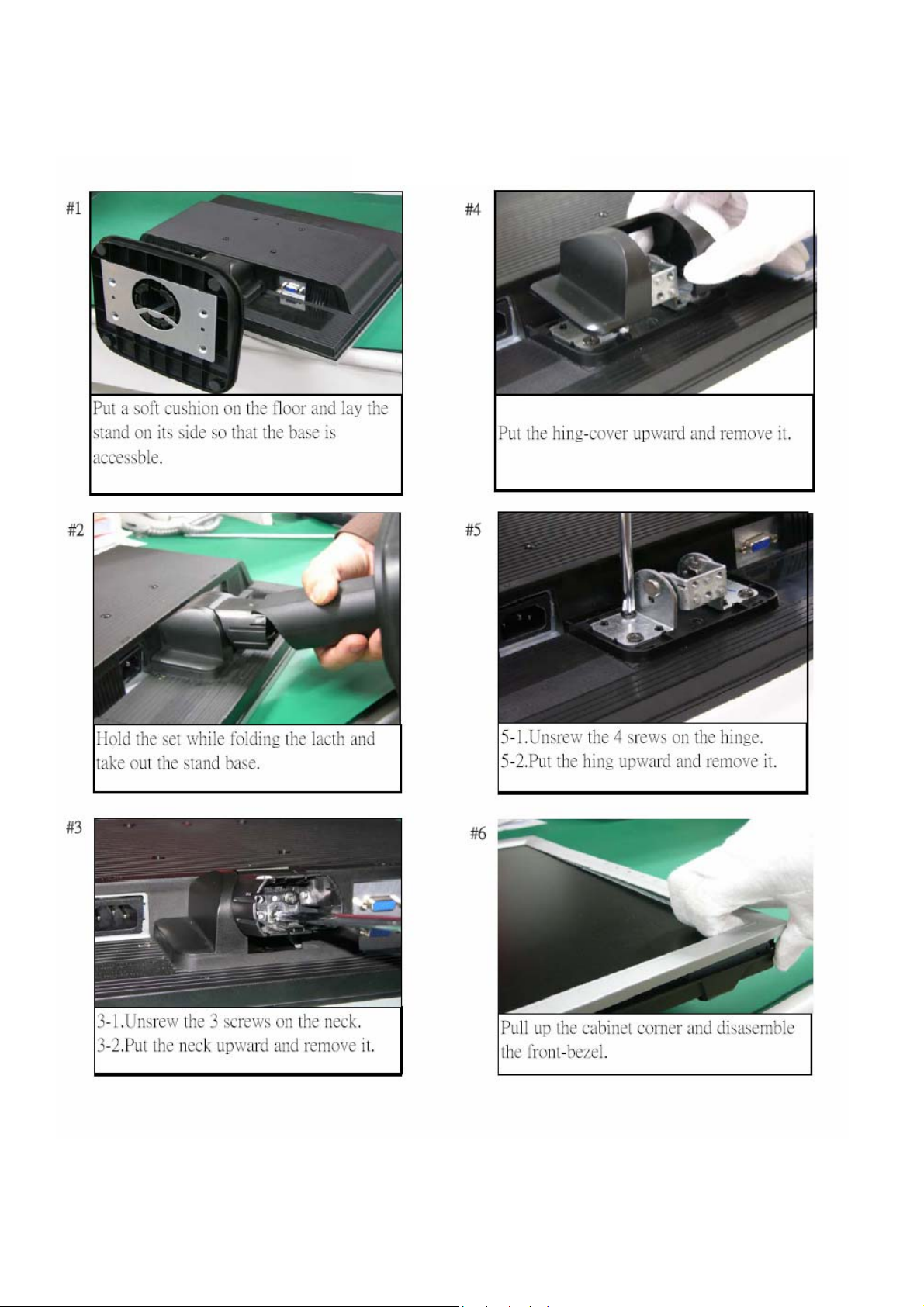

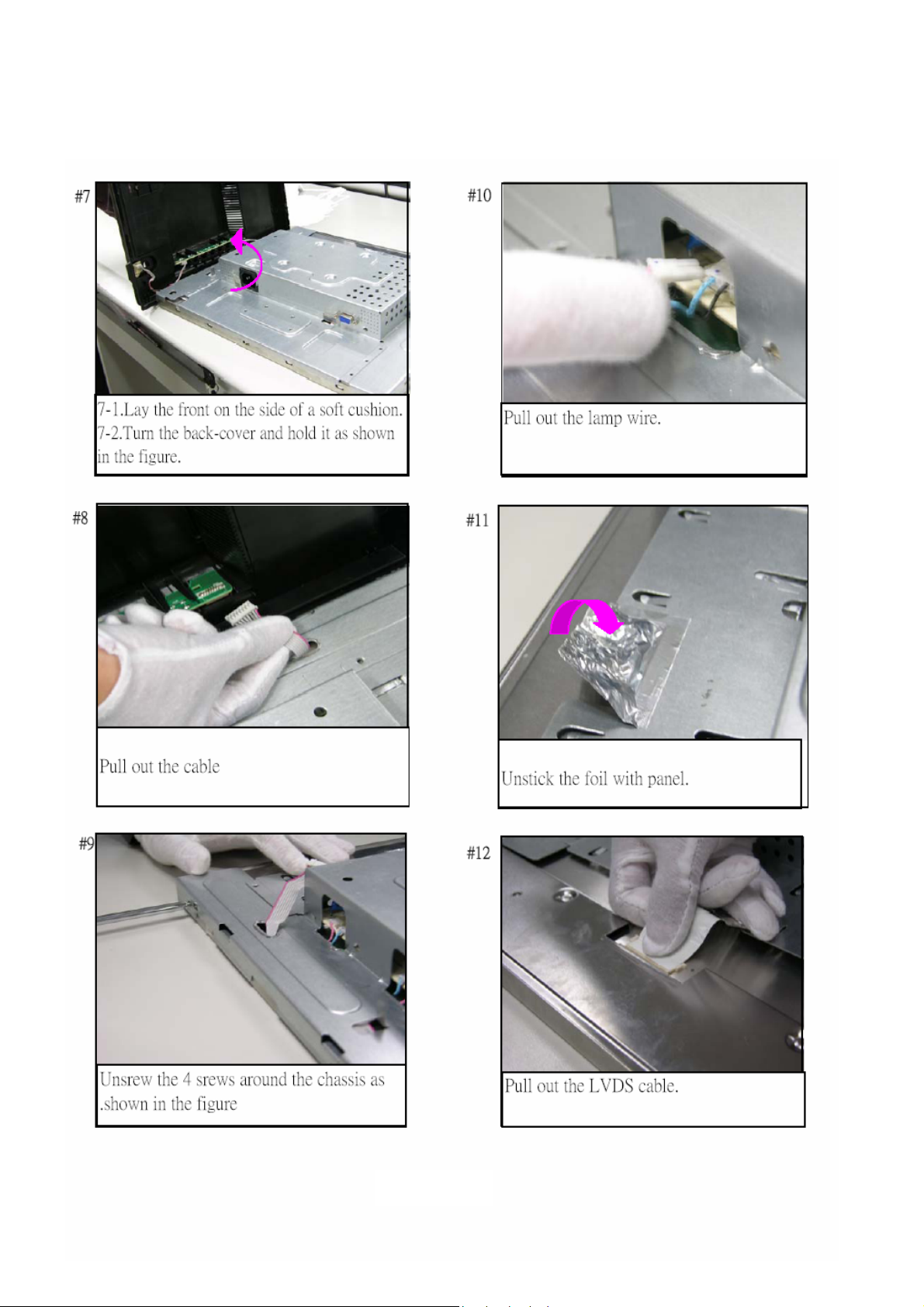

DISASSEMBLY

8

Page 9

9

Page 10

x

A

p

A

r

A

p

r

y

p

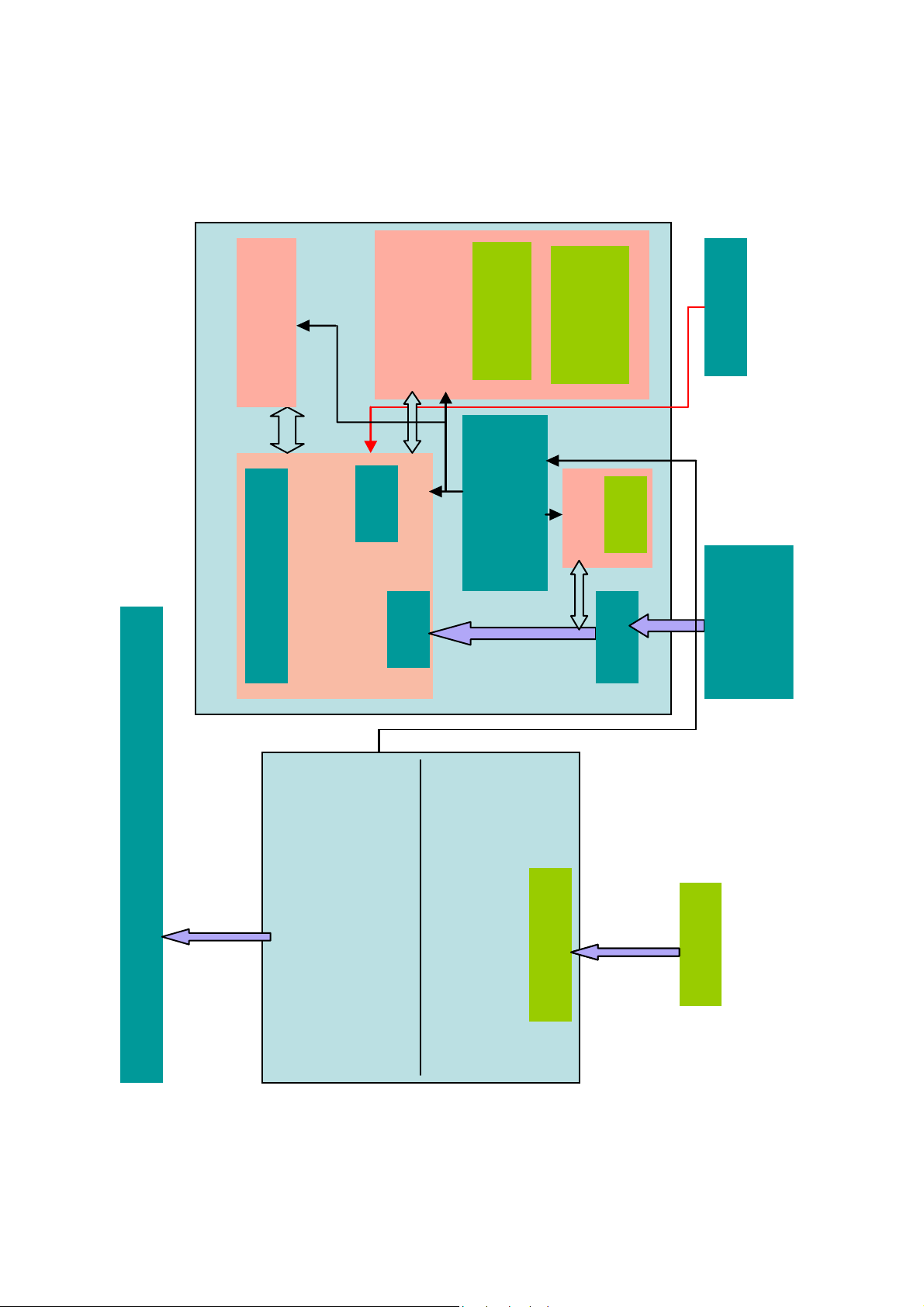

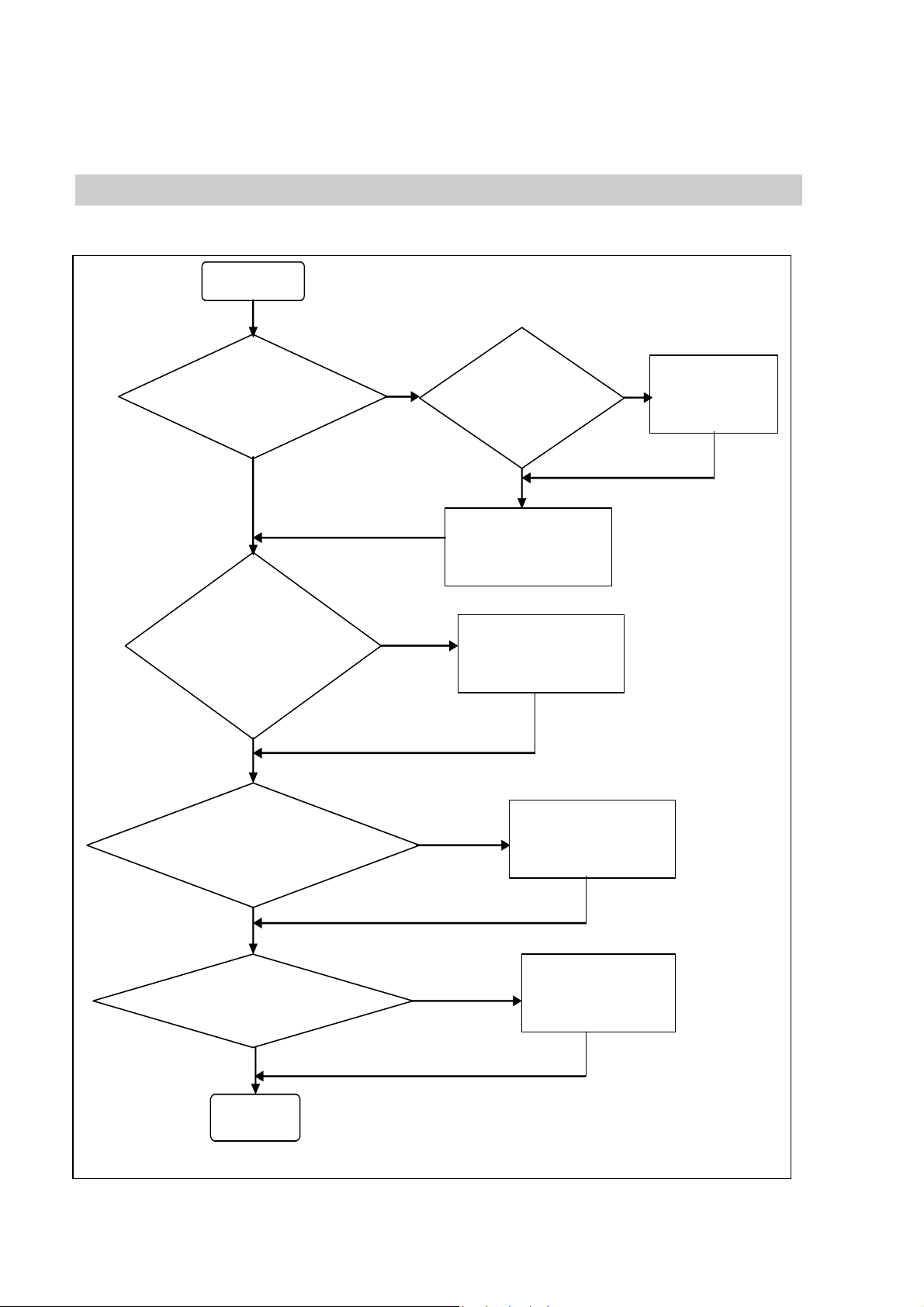

BLOCK DIAGRAM

TFT-LCD Module with 4FFCLs

InnoLu

128KB Flash RO M

LVDS Transmitte

Inverter +

MCU

TSUM16AL-LF

24C04

EEPROM

DC

DC12V to DC5V

OSD parameter

3.3V and

1.8V regulator

C Socket

Timing

aramete

24C02

D-sub

DDC

ad

Ke

Analog

RGB Signal

ut

C In

10

Page 11

DESCRIPTION OF BLOCK DIAGRAM

1. Video Controller Part.

This part amplifies the level of video signal for the digital conversion and converts from the analog video signal to the

digital video signal using a pixel clock.

The pixel clock for each mode is generated by the PLL.

The range of the pixel clock is from 25MHz to 135MHz.

This part consists of the Scaler, ADC convertor and LVDS transmitter.

The Scaler gets the video signal converted analog to digital, interpolates input to 1280 X 1024 resolution signal and

outputs 8-bit R, G, B signal to transmitter.

2. Power Part.

This part consists of the one 3.3V, and one 1.8V regulators to convert power which is provided 5V in Power board.

12V is provided for inverter, 12V is provided for LCD panel and 5V for micom.

Also, 5V is converted 3.3V and 1.8V by regulator. Converted power is provided for IC in the main board.

The inverter converts from DC12V to AC 700Vrms and operates back-light lamps of module.

3. MICOM Part.

This part is include video controller part. And this part consists of EEPROM IC which stores control data, and the

Micom which imbedded in scaler IC.

The Micom distinguishes polarity and frequency of the H/V sync are supplied from signal cable.

The controlled data of each modes is stored in EEPROM.

11

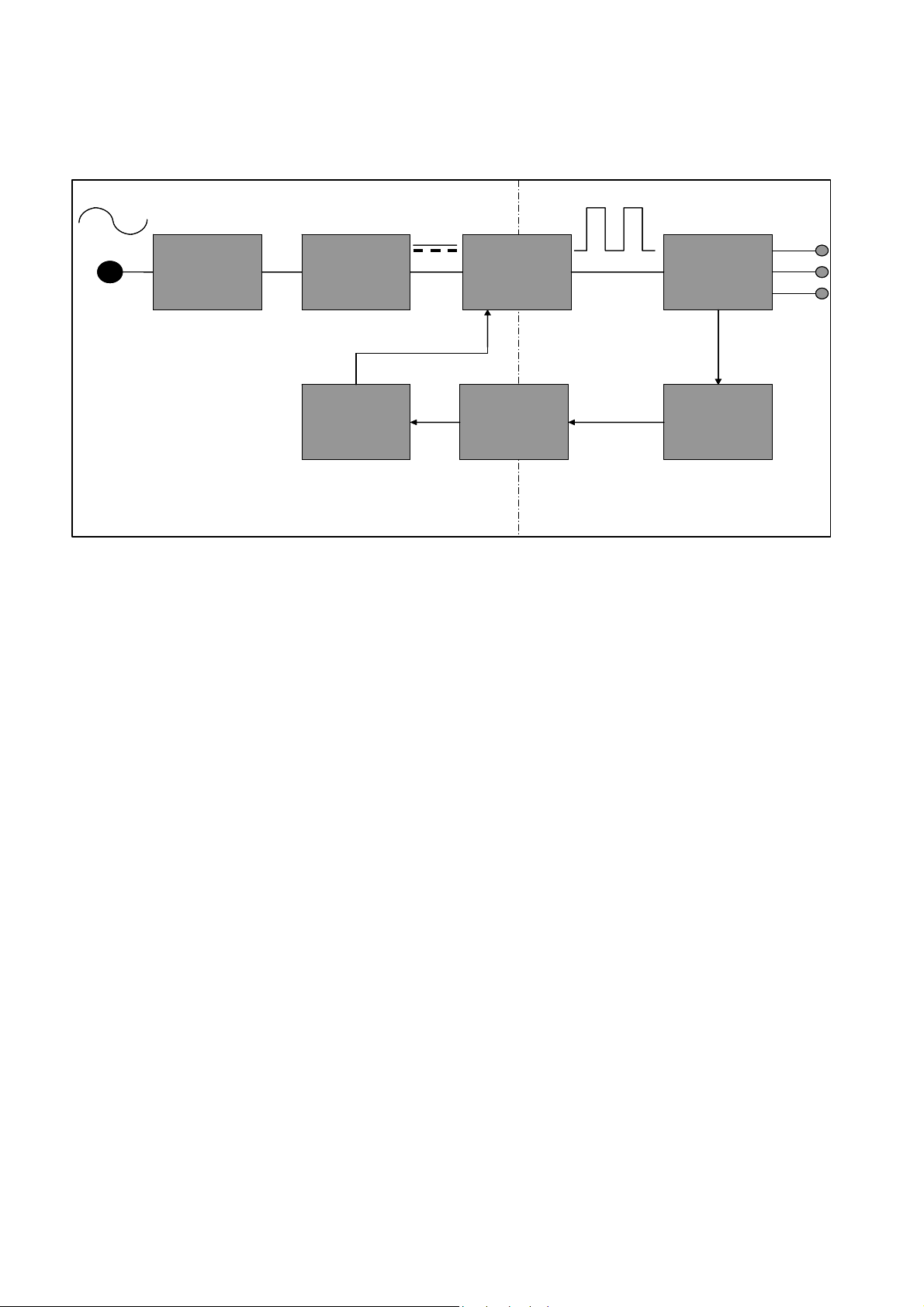

Page 12

50~60Hz

LINE

LINE

100~240V

100~240V

EMI

EMI

COMPONENTS

COMPONENTS

LIPS Board Block Diagram

INPUT REXTIFIER

INPUT REXTIFIER

AND FILTER

AND FILTER

PWM

PWM

COMTROL

COMTROL

CIRCUIT

CIRCUIT

PRIMARY

PRIMARY

ENERGY

ENERGY

TRANSFER

TRANSFER

PHOTO-COUPLER

PHOTO-COUPLER

ISOLATION

ISOLATION

SECONDARY

SECONDARY

12V

12V

5V

66KHzHVDC

66KHzHVDC

OUTPUT RECTIFIER

OUTPUT RECTIFIER

AND FILTER

AND FILTER

SIGNAL

SIGNAL

COLLENTION

COLLENTION

5V

GND

GND

Operation description_LIPS

1. EMI components.

This part contains of EMI components to comply with global marketing EMI standards like FCC, VCCI CISPR, the

circuit included a line-filter, across line capacitor and of course the primary protection fuse.

2. Input rectifier and filter.

This part function is for transfer the input AC voltage to a DC voltage through a bridge rectifier and a bulk capacitor.

3. Energy Transfer .

This part function is transfer the primary energy to secondary through a power transformer.

4. Output rectifier and filter .

This part function is to make a pulse width modulation control and to provide the driver signal to power switch, to

adjust the duty cycle during different AC input and output loading condition to achive the dc output stablize, and also

the over power protection is also monitor by this part.

5. Photo-Coupler isolation.

This part function is to feed back the dc output changing status through a photo transistor to primary controller to

achieve the stabilized dc output voltage.

6. Signal collection.

This part function is to collect the any change from the dc output and feed back to the primary through photo

transistor.

12

Page 13

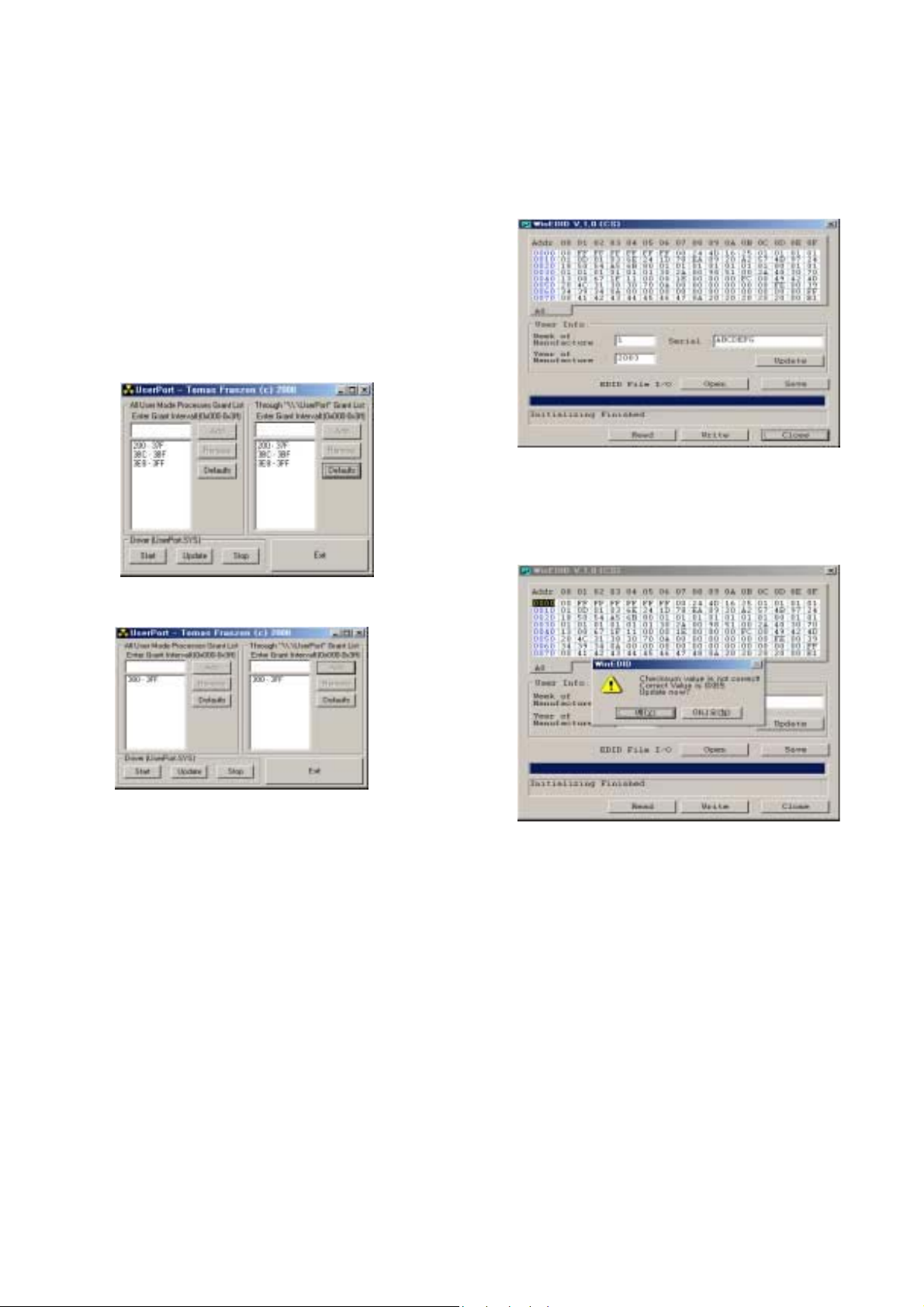

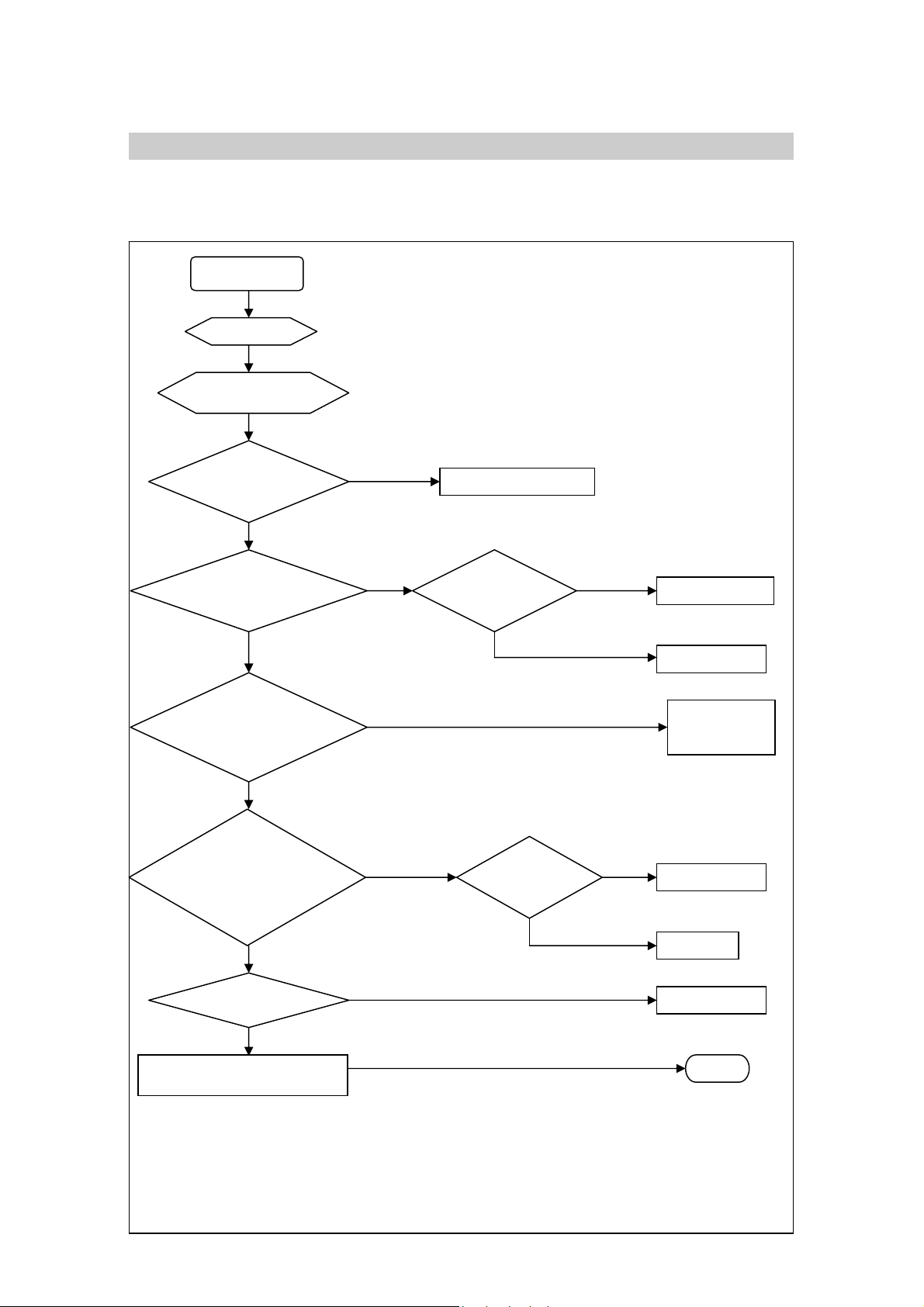

Windows EDID V1.0 User Manual

Operating System: MS Windows 98, 2000, XP

Port Setup: Windows 98 => Don’t need setup

Windows 2000, XP => Need to Port Setup.

This program is available to LCD Monitor only.

1. Port Setup

a) Copy “UserPort.sys” file to

“c:\WINNT\system32\drivers” folder b)

Run Userport.exe

ADJUSTMENT

2. EDID Read & Write

1) Run WinEDID.exe

c) Remove all default number d)

Add 300-3FF

e) Click Start button. f)

Click Exit button.

2) Edit Week of Manufacture, Year of Manufacture,

Serial Number

a) Input User Info Data

b) Click “Update” button

c) Click “ Write” button

13

Page 14

o

SERVICE OSD

1) Turn off the power switch at the front side of the display.

2) Wait for about 5 seconds and press MENU, POWER switch with 1 second interval.

3) The SVC OSD menu contains additional menus that the User OSD menu as described below.

a) Auto Color : W/B balance and Automatically sets the gain and offset value.

b) NVRAM INIT : EEPROM initialize.(24C04)

c) CLEAR ETI : To initialize using time.

d) AGING : Select Aging mode(on/off).

e) R/G/B-9300K : Allows you to set the R/G/B-9300K value manually.

f) R/G/B-6500K : Allows you to set the R/G/B-6500K value manually.

g) R/G/B-Offset : Allows you to set the R/G/B-Offset value manually.(Analog Only)

h) R/G/B-Gain : Allows you to set the R/G/B-Gain value manually.(Analog Only)

i) MODULE : Show Current module Type

j)RS232: Enable/Disable Debug Mode(on/off)

Insert to

Parallel Port

n PC

Port

ISP Board

Parallel

D-SUB

15PIN

Figure 1.Cable Connection For ISP

14

LCD

Monitor DSub

Page 15

g

g

TROUBLESHOOTING GUIDE

1. No Power & Power LED Off

No power

Check primary

rectifier volta

e

Check pin3 of

IC802 voltage

about 1V

Check pin2 of IC802

e about 2V

volta

Check circuit

if short

Check F801, P801,

D801

Check R801, R805,

R822, R823, R817

Check R803, R807,

R824, R825

Check IC802,

C805, T801

Check R812, R816,

Check pin1 of IC802

C818

END

15

Page 16

- 15 -

2. Backlight can’t be turned on

No raster?

Ye s

LED Green?

Ye s

Backlight can’t be

turned on.

Ye s

Is there 5Vdc voltage on

pin2 of IC501?

Ye s

No

Check power supply

Is there high-level

voltage on pin10 of IC501?

No

Is Ok R526?

No

Ye s

Ye s

Check I/F board

R526 open

Are connected rightly CN501,

CN502, CN503 and CN504?

No

Connecting the

output

connector

Ye s

Is there instantaneously pulse

wave on pin1, pin3, pin15 of IC501

at the moment of restart?

No

Is Ok IC501?

Ye s

U501, U502 fail

Is ok T501, T502?

Ye s

No

No

IC501 fail

T501, T502 fail

Check feedback circuit

END

Isen,Vsen.(D503,D504,D501,D50

Ye s

16

Page 17

3. DC output voltage is unstable

Output Voltage Unstable

Check Vbe of

Q801 below 0.3V

Check reference

voltage

Check feedback

circuit

END

Check circuit if

short

Check Q801, Q802

Check Pin R of

IC803 voltage

Check R810, R811

Check Vpin3-4 of

IC801 about 6V

Check Vpin1-2 of

IC801 about 1V

Check R809,

R814

17

Check ZD801,

ZD802, ZD803,

D803, D805

Check R809,

R814, IC801,

R818

Check C815,

D806, R812

Page 18

4.Output power is unstable

Unstable power

Check sampling

Circuit

Check the R pin

voltage of IC803

about 2.5V

Check pin1 of

IC802 voltage

is 5.8V

Check pin3 of

IC802 voltage

about 1V

END

Check R810,

R811, R818

Check the C

pin voltage

of IC803 if

Check R809, R808,

R814, D809

Check D806, C815 if

Change R801, R805,

R822, R823, R817

18

Change

R810, R811,

Change

IC803

3V

short

Change

D806, C815

Page 19

K

K

f

A

A

KOKOK

Black Screen

Check power supply:

Pin1, 2 of CN101

Check pin34, 51, 66, and 82

Of U105

Check pin32, 49, 56, and 75

Of U105

Check Reset (pin84)

Of U105

Check Crystal: Pin96,

Pin97

Of U105

Check CCFL- Enable

(pin85) of U105

MCU Fail

5.Black Screen and backlight turn on

NG

Power Fail

O

NG

Check FB103

nd U102

O

NG

Check FB106

nd U101

NG

Check C144, R172

NG

Check: X101,

C153, C154

O

OK OK

NG

Check pin5 o

CN101

NG

Inverter Fail

Check R167, Q106

R108, R110

19

Page 20

White Screen

LVDS Cab le

Reinsert

Change LVDS

Cable

Check VLCD

Is 5V?

Check Panel

Of U105 (pin48) is High?

Check R168, R105

Q103, Q101

END

NG

NG

NG

Enable

-

6.White Screen

OK

OK

OK

OK

Check LVDS

Signals

NG

Check the HW Reset

Of U105 pin84

NG

OK

Check the pins

Of U105

Workmanship

LVDS Cable NG

Panel Fail

NG

Check C144

R172

20

Page 21

7. BAD SCREEN

Bad Screen

OK

WorkmanshipLVDS Cable Reinsert

NG

OK

Change LVDS Cable

NG

Check Crystal:Pin96,97

Of U105

OK

Check the communication

Of U105 and U106

OK

OK

NG

LVDS Cable NG

Check :X101,

C153,C154

Check: SDO,SCZ,

SCK,SDI, Reset

Check the pins of

U105 and U106

21

Page 22

22

WIRING DIAGRAM

Page 23

- 23 -

EXPLODED VIEW

130 140

100

120

110

040

020

050

090

080

030

070

010

060

Page 24

EXPLODED VIEW PARTS LIST

Related to Models: L1718S-SNQ/BNQ.AxxJEP for 5ms InnoLux module and

L1718S-SNQ/BNQ.AxxAEP for 5ms CPT Module

Ref.No. LGE Part No. INL Part No. Description

010

020

030

040

050

060

070

080

090

100

110

120

130

140

MCK30281901 501010205300R

MCK30284501 501010205310R

EBU38047801 631102072411R

EBU38048701 631102072384R

EBU38048201 790621300610R

EBU38049101 790621300010R

AGU30210301 701000001300R

AGU30211601 701000001310R

ACQ30210201 714050005200R

MFB30282101 501120103100R

EBU30459001 790621400600R

AGU30210601 502060002000R

MCK30283101 501260202000R

ACQ30211201 714020005200R

ACQ30211001 714010005200R

MCK30282901 501020207300R

EBU30458901 430303000410R

EBU30459301 453010100210R

Related to Models : L1718S-SNQ/BNQ.AxxKEP for 8ms Innolux module and

L1718S-SNQ/BNQ.AxxBEP for 8ms CPT module

Ref.No. LGE Part No. INL Part No. Description

010

020

030

040

050

060

070

080

090

100

110

120

130

140

MCK30281901 501010205300R

MCK30284501 501010205310R

EBU30459201 631102071430R

EBU30460301 631102072020R

EBU30458301 790621300600R

EBU30460201 790621300000R

AGU30210301 701000001300R

AGU30211601 701000001310R

ACQ30210201 714050005200R

MFB30282101 501120103100R

EBU30459001 790621400600R

AGU30210601 502060002000R

MCK30283101 501260202000R

ACQ30211201 714020005200R

ACQ30211001 714010005200R

MCK30282901 501020207300R

EBU30458901 430303000410R

EBU30459301 453010100210R

BEZEL,FRONT(Black),LE1730

BEZEL,FRONT(Silver),LE1730

LCD Panel 17" MT170EN01-V9(INNOLUX)

LCD Panel 17" CLAA170EA07P-040(CPT) RoHS

PCBA,I/F BOARD(MT170EN01-V9),LE1730-6E0 ROHS

PCBA,IF BOARD,for CPT CLAA170EA07P-040 LE1730-0E0

ASSY,CHASSIS, Metal frame(for InnoLux 5ms/8ms),LE1730

ASSY,CHASSIS, Metal frame (for CPT 5ms/8ms)

BACK COVER ,ASSEMBLY,LE1730

LENS,LE1730

PCBA,PWR&INV./B,LE1730-6E0

HINGE,ASSEMBLY,LE1730

STAND,NECK,LE1730

BASE,ASSEMBLY,LE1730

STAND, ASSEMBLY,LE1730

COVER,HINGE,LE1730

HRN LVDS,FFC 30P 281MM ROHS

CABLE,D-SUB,15P MALE 1850MM BLACK/BLUE,R

BEZEL,FRONT(Black),LE1730

BEZEL,FRONT(Silver),LE1730

LCD PANEL 17" MT170EN01-V7(INNOLUX)

LCD PANEL 17" CPT CLAA170EA07QG

PCBA,IF BOARD for MT170EN01-V7(INL) , LE1730-6E0

PCBA,IF BOARD, for CPT CLAA170EA07QG LE1730-0E0

ASSY,CHASSIS, Metal frame(for InnoLux 5ms/8ms),LE1730

ASSY,CHASSIS, Metal frame (for CPT 5ms/8ms)

BACK COVER ,ASSEMBLY,LE1730

LENS,LE1730

PCBA,PWR&INV./B,LE1730-6E0

HINGE,ASSEMBLY,LE1730

STAND,NECK,LE1730

BASE,ASSEMBLY,LE1730

STAND, ASSEMBLY,LE1730

COVER,HINGE,LE1730

HRN LVDS,FFC 30P 281MM ROHS

CABLE,D-SUB,15P MALE 1850MM BLACK/BLUE,R

24

Page 25

Related to Models: L1718S-SNQ/BNQ.AxxJEP for 5ms InnoLux module and

L1718S-SNQ/BNQ.AxxAEP for 5ms CPT Module

IF BOARD

1. FOR INL

ITEM Location P/N Description

790621300610R PCBA,I/F BOARD(V9),LE1730-6E0 ROHS

10 790621320600R PCBA,IF BOARD,OTHRS,LE1730-6E0

20 790621340600R PCBA,IF BOARD,SMD, LE1730-6E0

30 629030006501R PROGRAM(V9),LE1730-6E0 ROHS

50 511130001201R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5(SAC305 VAC

50 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

70 506440003800R LABEL,BLANK,YELLOW,10x4mm

ITEM Location P/N Description

790621320600R PCBA,IF BOARD,OTHRS,LE1730-6E0

10 C111,C144, 420431000260R

20 C101,C102, 420431010461R

C130,C133,C142,C145,

30

C105,

40 C108, 420432210460R

50 CN101, 430631060020R WAFER 2.0mm 6P 180°,RoHS

60 CN105, 430631080130R WAFER 2x4P 2.0mm,200PHD-2*4ST RoHS

70 X101, 432008010370R XTAL 14.31818MHz 16pF HC-49US 30PPM,DIP,

80 CN103, 440819015030R CON D-SUB FEM.15P RA W/O SCREW DZ11AA1-H

ITEM Location P/N Description

790621340600R PCBA,IF BOARD,SMD, LE1730-6E0

10 Q103,Q106, 410500045210R XSTR PMBT3904 NPN 200MA,40V SOT23(PHILIP

10 410500045130R XSTR MMBT3904 NPN SOT-23(INFIN EON)RoHS

10 410500045140R XSTR MMBT3904LT1G NPN 200MA 40V SOT23(ON

20 Q102,Q105, 410500046210R XSTR PMBT3906 PNP 200MA,40V SOT23(PHILIP

20 410500046130R XSTR MMBT3906 PNP SOT-23(INFIN EON)RoHS

20 410500046180R XSTR MMBT3906LT1G PNP 200mA 40V SOT23(ON

420432200460R

CAP EC 10uF 25V M,105℃ ST 5x11 RoHS

CAP EC 100uF 16V M,105℃ ST 5x11(SK) RoH

CAP EC 22uF 16V M,105℃ ST, 5x11,RoHS

CAP EC 220uF 16V M,105℃ ST 6.3x11 RoHS

25

Page 26

30 Q101, 410500068290R XSTR AP2305GN P-CH SOT23(APEC) RoHS

30 410500044270R XSTR AO3401L P-CH(ALPHA-OMEGA) SOT23 RoH

30 410500075270R XSTR AO3415 P-CH,SOT23(AOS) RoHS

40 Q107, 410500050210R XSTR 2N7002,N-CH FET SOT-23 (PHILIPS)RoH

40 410500050130R XSTR SN7002N N-CH SOT-23(INFINEON),RoHS

40 410500050090R XSTR 2N7002 N-CH SOT-23(PANJIT)RoHS

TVS101,TVS102,TVS1

50

03,TVS104,

50 411020026020R DIO BAV99-LF 350mW 70V SOT-23 (FEC)RoHS

50 411020026390R DIO BAV99,SOT-23(INFINEON)RoHS

50 411020026090R DIO BAV99 350mW 75V SOT-23(PEC RoHS

60 D103, 411020047210R DIO BAV70 85V SOT23 (PHILIPS) RoHS

60 411020047020R DIO BAV70-LF, 70V SOT-23(FEC) ROHS

ZD101,ZD105,ZD106,Z

70

D107,ZD108,

70 411101156950R ZENER BZV55-C5V6 SOD80C(PHILIP S) RoHS

70 411150356950R ZENER 5.6V MTZS05-5.6-G,SOD-12 3(MMC)RoH

80 U108, 412000279480R IC AT24C04N-10SU-2.7 SOP8 4K(A TMEL)RoHS

80 412000279280R IC M24C04-WMN6TP4K SOP8 (ST) RoHS

80 412000479990R IC CAT24C04WI-TE13 SOIC-8(CATALYST)RoHS

90 U102, 412000330830R IC AS1117L-1.8/TR-LF,SOT223(A1 SEMI)RoHS

90 412000330020R IC LD1117AL-1.8V-A SOT223(UTC) RoHS

100 U101, 412000372830R IC AS1117L-3.3TR-LF,SOT223(A1S EMI)RoHS

100 412000372020R IC LD1117AL-3.3V-A SOT-223(UTC RoHS

110 U103, 412000435480R IC AT24C02BN-10SU-1.8 SOIC8 2K (ATMEL)Ro

110 412000480990R IC CAT24C02WI-TE13 SOIC-8(CATALYST)RoHS

110 412000480280R IC M24C02-RMN6TP SO8(ST)RoHS

120 U105, 412000436190R IC TSUM16AL-LF PQFP100(MSTAR)R oHS

130 U106, 412000373190R IC SST25VF010A-33-4C-SAE,SOIC- 8(SST)RoH

130 412000486310R IC PM25LV010A-100SCE SOIC8(PMC)RoHS

130 412000486190R IC PS25LV010A-100SCE SOIC8(MSTAR)RoHS

411020026210R DIO BAV99 350mW 70V SOT-23(PHI RoHS

411100656951R ZENER 5.6V ZMM5232B-LF DO213AA (FRONTIER

140 R190,R170,R171,R103, 414916000050R RES SMD (0603) 0Ω J,RT RoHS

150 R186,R187, 414916010050R RES SMD (0603) 10Ω J,RT RoHS

R130,R129,R114,R117,

R120,R124,R125,R127,

160

R131,R132,R101,R167,

R168,R178,R179,

R157,R158,R159,R160,

170

R161,R162,R163,

414916010150R RES SMD (0603) 100Ω J,RT RoHS REV:A

414916010250R RES SMD (0603) 1KΩ J,RT RoHS REV:A

26

Page 27

180 R106,R172,R180,R181, 414916010350R RES SMD (0603) 10KΩ J,RT RoHS

190 R102, 414916010450R RES SMD (0603) 100KΩ J,RT REV:A RoHS

200 R105, 414916020350R RES SMD (0603) 20KΩ J,RT RoHS REV:A

210 R136,R137, 414916022250R RES SMD (0603) 2.2KΩ J,RT RoHS

220 R121, 414916047150R RES SMD (0603) 470Ω J,RT RoHS REV:A

R108,R110,R122,R149,

R150,R154,R155,R173,

230

R174,R166,R182,R183,

R184,R185,R109,

240 R169, 414916390010R RES SMD (0603) 390Ω F,RT RoHS

250 R133,R134,R135, 414916750910R RES SMD (0603) 75Ω F,RT RoHS REV:A

260 RP102, 415751035080R RP(0612)10KΩx4 1/16W J 8P4R RoHS

C158,C159,C160,C161,

270

C162,C163,C164,

280 C153,C154, 419302200560R C SMD(0603) NPO 22PF/50V J RoHS

290 C126, 419302210560R C SMD(0603) NPO 220PF/50V J RoHS

300 C125, 419303300560R C SMD(0603) NPO 33PF/50V J RoHS

414916047250R RES SMD (0603) 4.7KΩ J,RT RoHS

419301010560R C SMD(0603) NPO 100PF/50V J RoHS

C103,C104,C106,C107,

C109,C129,C156,C131,

C132,C134,C135,C136,

310

C137,C139,C141,C143,

C147,C148,C149,C150,

C151,C152,C166,

320 C140, 419311054070R C SMD(0805) X7R 1uF/16V K RoHS REV:A

C112,C113,C114,C115,

330

C116,C117,C118,

340 FB101, 432002312111R BEAD CORE SMD(0805)120Ω 300mA RoHS

FB102,FB103,FB105,F

350

B106,

360 CN104, 444099030030R CON, SMD 1.0mm 30PIN RoHS AL2309-A0G1Z

370 506140005700R

380 490621300100R PCB,INTERFACE, LE1730-XE0

390 R107, 414916022150R RES SMD (0603) 220Ω J,RT RoHS REV:A

400 R113,R116,R119, 414916560910R RES SMD (0603) 56Ω F,RT RoHS REV:A

410 FB107,FB108,FB109, 432002360140R BEAD CORE SMD(0603)60Ω 600mA, GBK160808

420 511130002203R SOLDER PASTE,Sn96.5/Ag3.0/Cu0.5(SAC305 O

420 511130002200R SOLDER PASTE,Sn96.5-Ag3.0-Cu0.5 ROHS

420 511130002201R SOLDER PASTE,Sn96.5%Ag3.0%Cu0.5%

419311040060R C SMD(0603) X7R 0.1uF/50V K RoHS

419314730060R C SMD (0603) X7R 0.047uF 50V,K RoHS

432002360012R BEAD CORE SMD(0805)60Ω 800mA GBK201209T

LABEL,BARCODE,BLANK,33x7mm, ROHS,FOR

PCB

27

Page 28

2.For CPT

ITEM Location P/N Description

790621300010R PCBA,I/F BOARD(040),LE1730-0E0 ROHS

10 790621320600R PCBA,IF BOARD,OTHRS,LE1730-6E0

20 790621340600R PCBA,IF BOARD,SMD, LE1730-6E0

30 629030006521R PROGRAM(040),LE1730-0E0 ROHS

50 511130001201R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5(SAC305 VAC

50 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

70 506440003800R LABEL,BLANK,YELLOW,10x4mm

ITEM Location P/N Description

790621320600R PCBA,IF BOARD,OTHRS,LE1730-6E0

10 C111,C144, 420431000260R

20 C101,C102, 420431010461R

C130,C133,C142,C

30

145,C105,

420432200460R

CAP EC 10uF 25V M,105℃ ST 5x11 RoHS

CAP EC 100uF 16V M,105℃ ST 5x11(SK) RoH

CAP EC 22uF 16V M,105℃ ST, 5x11,RoHS

40 C108, 420432210460R

50 CN101, 430631060020R WAFER 2.0mm 6P 180°,RoHS

60 CN105, 430631080130R WAFER 2x4P 2.0mm,200PHD-2*4ST RoHS

70 X101, 432008010370R XTAL 14.31818MHz 16pF HC-49US 30PPM,DIP,

80 CN103, 440819015030R CON D-SUB FEM.15P RA W/O SCREW DZ11AA1-H

ITEM Location P/N Description

790621340600R PCBA,IF BOARD,SMD, LE1730-6E0

10 Q103,Q106, 410500045210R XSTR PMBT3904 NPN 200MA,40V SOT23(PHILIP

10 410500045130R XSTR MMBT3904 NPN SOT-23(INFIN EON)RoHS

10 410500045140R XSTR MMBT3904LT1G NPN 200MA 40V SOT23(ON

20 Q102,Q105, 410500046210R XSTR PMBT3906 PNP 200MA,40V SOT23(PHILIP

20 410500046130R XSTR MMBT3906 PNP SOT-23(INFIN EON)RoHS

20 410500046180R XSTR MMBT3906LT1G PNP 200mA 40V SOT23(ON

30 Q101, 410500068290R XSTR AP2305GN P-CH SOT23(APEC) RoHS

30 410500044270R XSTR AO3401L P-CH(ALPHA-OMEGA) SOT23 RoH

30 410500075270R XSTR AO3415 P-CH,SOT23(AOS) RoHS

40 Q107, 410500050210R XSTR 2N7002,N-CH FET SOT-23 (PHILIPS)RoH

40 410500050130R XSTR SN7002N N-CH SOT-23(INFINEON),RoHS

40 410500050090R XSTR 2N7002 N-CH SOT-23(PANJIT)RoHS

CAP EC 220uF 16V M,105℃ ST 6.3x11 RoHS

TVS101,TVS102,TV

50

S103,TVS104,

411020026210R DIO BAV99 350mW 70V SOT-23(PHI RoHS

28

Page 29

50 411020026020R DIO BAV99-LF 350mW 70V SOT-23 (FEC)RoHS

50 411020026390R DIO BAV99,SOT-23(INFINEON)RoHS

50 411020026090R DIO BAV99 350mW 75V SOT-23(PEC RoHS

60 D103, 411020047210R DIO BAV70 85V SOT23 (PHILIPS) RoHS

60 411020047020R DIO BAV70-LF, 70V SOT-23(FEC) ROHS

ZD101,ZD105,ZD10

70

6,ZD107,ZD108,

70 411101156950R ZENER BZV55-C5V6 SOD80C(PHILIP S) RoHS

70 411150356950R ZENER 5.6V MTZS05-5.6-G,SOD-12 3(MMC)RoH

80 U108, 412000279480R IC AT24C04N-10SU-2.7 SOP8 4K(A TMEL)RoHS

80 412000279280R IC M24C04-WMN6TP4K SOP8 (ST) RoHS

80 412000479990R IC CAT24C04WI-TE13 SOIC-8(CATALYST)RoHS

90 U102, 412000330830R IC AS1117L-1.8/TR-LF,SOT223(A1 SEMI)RoHS

90 412000330020R IC LD1117AL-1.8V-A SOT223(UTC) RoHS

100 U101, 412000372830R IC AS1117L-3.3TR-LF,SOT223(A1S EMI)RoHS

100 412000372020R IC LD1117AL-3.3V-A SOT-223(UTC RoHS

110 U103, 412000435480R IC AT24C02BN-10SU-1.8 SOIC8 2K (ATMEL)Ro

110 412000480990R IC CAT24C02WI-TE13 SOIC-8(CATALYST)RoHS

110 412000480280R IC M24C02-RMN6TP SO8(ST)RoHS

120 U105, 412000436190R IC TSUM16AL-LF PQFP100(MSTAR)R oHS

130 U106, 412000373190R IC SST25VF010A-33-4C-SAE,SOIC- 8(SST)RoH

130 412000486310R IC PM25LV010A-100SCE SOIC8(PMC)RoHS

130 412000486190R IC PS25LV010A-100SCE SOIC8(MSTAR)RoHS

411100656951R ZENER 5.6V ZMM5232B-LF DO213AA (FRONTIER

R190,R170,R171,R

140

103,

150 R186,R187, 414916010050R RES SMD (0603) 10Ω J,RT RoHS

R130,R129,R114,R

117,R120,R124,R12

160

5,R127,R131,R132,

R101,R167,R168,R

178,R179,

R157,R158,R159,R

160,R161,R162,R16

170

3,

R106,R172,R180,R

180

181,

190 R102, 414916010450R RES SMD (0603) 100KΩ J,RT REV:A RoHS

200 R105, 414916020350R RES SMD (0603) 20KΩ J,RT RoHS REV:A

210 R136,R137, 414916022250R RES SMD (0603) 2.2KΩ J,RT RoHS

220 R121, 414916047150R RES SMD (0603) 470Ω J,RT RoHS REV:A

414916000050R RES SMD (0603) 0Ω J,RT RoHS

414916010150R RES SMD (0603) 100Ω J,RT RoHS REV:A

414916010250R RES SMD (0603) 1KΩ J,RT RoHS REV:A

414916010350R RES SMD (0603) 10KΩ J,RT RoHS

29

Page 30

R108,R110,R122,R

149,R150,R154,R15

230

5,R173,R174,R166,

R182,R183,R184,R

185,R109,

240 R169, 414916390010R RES SMD (0603) 390Ω F,RT RoHS

250 R133,R134,R135, 414916750910R RES SMD (0603) 75Ω F,RT RoHS REV:A

260 RP102, 415751035080R RP(0612)10KΩx4 1/16W J 8P4R RoHS

C158,C159,C160,C

161,C162,C163,C16

270

4,

280 C153,C154, 419302200560R C SMD(0603) NPO 22PF/50V J RoHS

290 C126, 419302210560R C SMD(0603) NPO 220PF/50V J RoHS

300 C125, 419303300560R C SMD(0603) NPO 33PF/50V J RoHS

C103,C104,C106,C

107,C109,C129,C15

6,C131,C132,C134,

C135,C136,C137,C

310

139,C141,C143,C14

7,C148,C149,C150,

C151,C152,C166,

414916047250R RES SMD (0603) 4.7KΩ J,RT RoHS

419301010560R C SMD(0603) NPO 100PF/50V J RoHS

419311040060R C SMD(0603) X7R 0.1uF/50V K RoHS

320 C140, 419311054070R C SMD(0805) X7R 1uF/16V K RoHS REV:A

C112,C113,C114,C

115,C116,C117,C11

330

8,

340 FB101, 432002312111R BEAD CORE SMD(0805)120Ω 300mA RoHS

FB102,FB103,FB10

350

5,FB106,

360 CN104, 444099030030R CON, SMD 1.0mm 30PIN RoHS AL2309-A0G1Z

370 506140005700R LABEL,BARCODE,BLANK,33x7mm, ROHS,FOR PCB

380 490621300100R PCB,INTERFACE, LE1730-XE0

390 R107, 414916022150R RES SMD (0603) 220Ω J,RT RoHS REV:A

400 R113,R116,R119, 414916560910R RES SMD (0603) 56Ω F,RT RoHS REV:A

FB107,FB108,FB10

410

9,

420 511130002203R SOLDER PASTE,Sn96.5/Ag3.0/Cu0.5(SAC305 O

420 511130002200R SOLDER PASTE,Sn96.5-Ag3.0-Cu0.5 ROHS

420 511130002201R SOLDER PASTE,Sn96.5%Ag3.0%Cu0.5%

419314730060R C SMD (0603) X7R 0.047uF 50V,K RoHS

432002360012R BEAD CORE SMD(0805)60Ω 800mA GBK201209T

432002360140R BEAD CORE SMD(0603)60Ω 600mA, GBK160808

30

Page 31

Power and Inverter Board

ITEM Location P/N Description

790621400600R PCBA,PWR&INV./B, LE1730-6E0

10 IC801, 412140002380R IC LTV817M-PR VDE (LITE-ON) P=10mm RoHS

10 412140001390R IC EL817M-B(EVERLIGHT)RoHS

20 D801, 411050005020R DIO BRDG BL4-06-BF52-LF 600V/4A(FRONTIER

20 411050007010R DIO BRDG KBL405G 600V/4A(TSC) RoHS

20 411050005090R DIO BRDG FL406 600V/4A(PEC)RoH S

30 C804, 416194743011R CAP MEX 0.47uF 275V K X2,F15 RoHS

40 C820,C801,C806, 416202224610R CAP MEY 2200pF 400V M Y,F10mm RoHS

60 C812,C809, 420421020110R

70 C808, 420421020211R

80 C805, 420431014582R

90 C824, 416204724610R CAP MEY 4700pF 400V M Y,F10mm RoHS

100 L802,L803, 425000010530R COIL CHK 5uH 7.8X10 CHK-053 0 181085R0L

110 L801, 426000050070R CHOKE L-FILTER 12mH LIN-007 ET-20,RoHS

120 T801, 426000090470R XFMR 750u@1K,+-8%,3m,113m,SPW- 047,DIP-1

130 RT801, 432009400701R NTC 5Ω 4A 10ψ P=5mm, F RoHS

140 F801, 430613125210R FUSE SLOW 2.5A/250V,U/C/V,AT,3.6x10,RoHS

150 P801, 440149000220R SKT AC 10A/250V U/C/V,G/Y=45mm TU-301-SP

160 CN801, 430300600120R HRN ASS'Y 6P 110mm UL1007#24,RoHS

180 C803, 418247233020R CAP CD X7R 4700pF 1KV K,W/O FO RMING,RoH

CN501,CN502,CN503,CN504

190

,

200 T501,T502, 426000090670R XFMR SW,105uH EEL19M DIP SPW-067,RoHS

210 C525,C527, 418105058010R CAP CD SL 5pF 3KV K,F7.5 RoHS

220 C524,C526, 418110058510R CAP CD SL 10pF 3KV J,F7.5 RoHS CC45SL3FD

230 U501,U502, 410500071290R XSTR AP9971GD,N-CH,PDIP-8(APEC RoHS

230 410050062330R XSTR AF4971NN N-CH PDIP8(ANACH IP)RoHS

240 735100007400R ASSY,H/S,UFF80-005CT/UFF80-015CT,LE1730

250 735100005100R ASSY,H/S TOP245Y, LE1704/05 ROHS

260 790621440600R PCBA,PWR&INV./B,SMD,LE1730-6E0

270 H501, 502040604500R SHIELD EMI LE1915 ROHS

280 511130001201R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5(SAC305 VAC

280 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

300 511110000101R HOT-MELT ADHESIVES (#526)

320 511110000501R SILICONE RTV RUBBER,UB-511(EURO)

430637020030R WFR. 2P P=3.5mm 90°W/LOCK,RoHS

CAP SD 1000uF/10V M,105℃ F,10x16,RoHS

CAP SD 1000uF 25V M,105℃ F 13x20 RoHS

CAP SEK 100uF/450V M,105℃ CF,18x35,RoHS

31

Page 32

ITEM Location P/N Description

735100005100R ASSY,H/S TOP245Y, LE1704/05 ROHS

10 IC802, 412000342270R IC TOP245YN,TO-220-7C,RoHS (POWER INTEGR

20 507200003700R HEATSINK,46x20xt10mm LE1704/05

30 509112306100R SCREW,P,CROSS,T.T-3*6,ZnROHS

ITEM Location P/N Description

735100007400R ASSY,H/S,UFF80-005CT/UFF80-015CT,LE1730

10 D805, 411090015020R SCHTKY SRF5-04CT-LF ITO-220AB (FEC) RoHS

10 411090024040R SCHTKY SRF1040CM 40V/10A ITO22 OAB(MOSPE

10 411090025040R SCHTKY SRF1045CM 45V/10A ITO22 OAB(MOSPE

20 D803, 411020065020R DIO UFF80-015CT-LF 150V/8A, ITO-220AC(FR

20 411030058040R DIO URF1020 200V/10A ITO220(MO SPEC)RoHS

30 507200003800R HEATSINK,56x20xt10mm LE1904/05

40 509112306100R SCREW,P,CROSS,T.T-3*6,ZnROHS

ITEM Location P/N Description

790621440600R PCBA,PWR&INV./B,SMD,LE1730-6E0

10 Q801, 410500045210R XSTR PMBT3904 NPN 200MA,40V SOT23(PHILIP

10 410500045140R XSTR MMBT3904LT1G NPN 200MA 40V SOT23(ON

10 410500045130R XSTR MMBT3904 NPN SOT-23(INFIN EON)RoHS

20 ZD803, 411150356950R ZENER 5.6V MTZS05-5.6-G,SOD-12 3(MMC)RoH

20 411100956920R ZENER 5.6V MMSZ5232A SOD123(PE C)RoHS

20 411131556920R ZENER 5.6V 0.5W DDZ5V6B-F,SOD1 23(DIODES

30 ZD801, 411150375950R ZENER 7.5V MTZS05-7.5-G, SOD-123(MMC)RoH

30 411100975920R ZENER 7.5V MMSZ5236A SOD123(PE C)RoHS

30 411131575952R ZENER 7.5V 0.5W DDZ7V5C-F,SOD1 23(DIODES

40 ZD804, 411100915020R ZENER 15V MMSZ5245A SOD123(PEC RoHS

40 411150315050R ZENER 15V MTZS05-15-G,SOD-123 (MMC) RoHS

40 411131515052R ZENER 15V 0.5W DDZ15-F,SOD123(DIODES)RoH

50 R809, 414904100010R RES SMD (1206) 100Ω F,RT RoHS

60 R808,R819,R827, 414908010350R RES SMD (0805) 10KΩ J,RT RoHS REV:A

70 R801,R805,R822,R823, 414908024550R RES SMD (0805) 2.4MΩ J,RT RoHS

80 R813,R814,R815, 414908010250R RES SMD (0805) 1KΩ J,RT RoHS REV:A

90 R825, 414908047450R RES SMD (0805) 470KΩ J,RT RoHS

32

Page 33

100 R510,R511, 414916000050R RES SMD (0603) 0Ω J,RT RoHS

110 R803,R807,R824, 414908051450R RES SMD (0805) 510KΩ J,RT RoHS

120 R818,R502,R504,R517,R520, 414908330110R RES SMD (0805) 3.3KΩ F,RT RoHS REV:A

130 R816, 414908068950R RES SMD (0805) 6.8Ω J RT RoHS

140 R811, 414908430210R RES SMD (0805) 43KΩ F,RT,RoHS

150 R817, 414908820110R RES SMD (0805) 8.2KΩ F,RT RoHS

160 R802,R806, 414904010050R RES SMD (1206) 10Ω J,RT RoHS

170 R829, 414908020150R RES SMD (0805) 200Ω J,RT RoHS

180 R810, 414908510110R RES SMD (0805) 5.1KΩ F,RT RoHS

190 R522, 414916390210R RES SMD (0603) 39KΩ F,RT RoHS

200 R518,R519, 414908100310R RES SMD (0805) 100KΩ F,RT,RoHS

210 R514, 414916010450R RES SMD (0603) 100KΩ J,RT REV:A RoHS

220 R527, 414916330410R RES SMD (0603) 3.3M F RT RoHS

240 R512,R526, 414916010350R RES SMD (0603) 10KΩ J,RT RoHS

250 R538, 414916604310R RES SMD (0603) 604KΩ F,RT RoHS

260 R513,R529,R530, 414916010550R RES SMD (0603) 1MΩ J,RT RoHS REV:A

270 R523, 414916330210R RES SMD (0603) 33KΩ F,RT RoHS

290 R524, 414916220210R RES SMD (0603) 22KΩ F,RT RoHS

300 R515,R516, 414908220210R RES SMD (0805) 22KΩ F,RT,RoHS

310 C507,C511, 419342254670R C SMD(0805) Y5V 2.2uF/16V Z RoHS

320 C821, 419311040060R C SMD(0603) X7R 0.1uF/50V K RoHS

330 C510, 419316830060R C SMD (0603) X7R 0.068uF 50V,K RoHS

340 C523,C530, 419316810070R C SMD(0805) X7R 680PF/50V K,RoHS

350 C529, 419304710560R C SMD(0603) NPO 470PF/50V,J,RoHS

360 C504, 419311020060R C SMD(0603) X7R 1000PF/50V K RoHS

370 C506, 419314720060R C SMD(0603) X7R 4700PF/50V K RoHS

380 C501,C502,C513,C514, 419312220060R C SMD(0603) X7R 2200PF/50V K RoHS

390 C505, 419311030060R C SMD(0603) X7R 0.01uF/50V K RoHS

400 D506, 411023004021R DIO SN4148-LF 75V/0.15A SMD 1206 (FEC)Ro

400 411020046090R DIO 1N4148W 75V/0.15A(PEC)RoHS SOD-123

410 D501,D502, 411020026210R DIO BAV99 350mW 70V SOT-23(PHI RoHS

410 411020026020R DIO BAV99-LF 350mW 70V SOT-23 (FEC)RoHS

410 411020026390R DIO BAV99,SOT-23(INFINEON)RoHS

410 411020026090R DIO BAV99 350mW 75V SOT-23(PEC RoHS

33

Page 34

420 D503,D504, 411020047210R DIO BAV70 85V SOT23 (PHILIPS) RoHS

420 411020047020R DIO BAV70-LF, 70V SOT-23(FEC) ROHS

430 D505, 411020068210R DIO BAW56 85V SOT-23(PHILIPS)RoHS

430 411020068020R DIO BAW56 70V SOT-23(FRONTIER)RoHS

430 411020068090R DIO BAW56 75V SOT-23(PANJIT)RoHS

440 IC501, 412000455630R IC OZ9938GN SOIC16(O2 MICRO)RoHS

450 C516,C512, 419313330060R C SMD(0603) X7R 0.033uF/50V K ROHS

460 790621410600R PCBA,PWR&INV./B,AI,LE1730-6E0

470 R509, 414916200010R RES SMD (0603) 200Ω F,RT RoHS

480 R534, 414916100210R RES SMD (0603) 10KΩ F,RT RoHS

500 C508, 419312230060R C SMD(0603) X7R 0.022uF/50V K RoHS

510 506140005700R

520 ZD805, 411100991920R ZENER 9.1V MMSZ5239A SOD123(PE C)RoHS

520 411131591952R ZENER 9.1V 0.5W DDZ9V1C-F,SOD1 23(DIODES

520 411150391950R ZENER 9.1V MTZS05-9.1-G SOD-123 (MITSUBI

ITEM Location P/N Description

790621410600R PCBA,PWR&INV./B,AI,LE1730-6E0

10 790621450600R PCBA,PWR&INV./B,AI/A, LE1730-6E0

30 790621460600R PCBA,PWR&INV./B,AI/R, LE1730-6E0

ITEM Location P/N Description

790621450600R PCBA,PWR&INV./B,AI/A, LE1730-6E0

10 R804, 415130680540R RES CF 1/2W 68Ω J,AT RoHS REV:A

20 R828, 415340101540R RES MOF 1W 100Ω J,AT MINI RoHS

30 D806, 411020052020R DIO A02-LF 200V/1A R1(FEC)RoHS

30 411030003040R DIO FR103 200V/1A DO-41(MOSPEC RoHS

40 D809, 411022003210R DIO 1N4148 75V/0.2A AT (PHIL) RoHS

40 411022003020R DIO 1N4148-LF 75V/0.15A AT (FEC)RoHS

40 411020048090R DIO 1N4148-35 75V/0.15A,DO35(P EC)RoHS

50 D804, 411020053090R DIO PS1010R 1000V/1A DO-41(PAN JIT)RoHS

50 411032006020R DIO FR10-10-LF 1000V/1A AT(FRO NTIER)RoH

60 ZD802, 411020050090R DIO P6KE150A,DO-15,AT(PANJIT)RoHS

60 411020050020R DIO P6KE150A-LF AT(FRONTIER) RoHS

60 411020050010R DIO P6KE150A,DO-15AT,(TSC)RoHS

70 B801, 432002200160R BEAD CORE BF30TA-3.5x9x0.8 AT

80 R820,R821, 415030105540R RES CF 1/2W 1MΩ J,AT MINI RoHS

LABEL,BARCODE,BLANK,33x7mm, ROHS,FOR

PCB

34

Page 35

90 R506,R508,R532,R533, 414030330540R RES FSM 1/2W 33Ω J,AT MINI,RoHS

100 R501,R503, 414870305540R RES MG HV 1/2Ws 3MΩ 3KV J,AT RoHS

J502,J507,J510,J516,J804,J8

110

05,J809,

110 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 7.5mm

J503,J505,J514,J801,J803,J8

120

08,

120 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 10mm

130 J508,J513,J515,J810, 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 12.5mm

130 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 12.5mm

140 J501,J512,J802,J511, 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 15mm

140 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 15mm

150 J506,J509, 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 17.5mm

150 430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 17.5mm

160 700000000100R ASSY,PCB&RIVENT,LE1730

170 R521, 415020330540R RES CF 1/4W 33Ω J,AT MINI RoHS

180 R812, 414020689540R RES FSM 1/4W 6.8Ω J AT MINI,RoHS

ITEM Location P/N Description

790621460600R PCBA,PWR&INV./B,AI/R, LE1730-6E0

10 C813, 418147038530R CAP CD NPO 47pF 1KV J,VT RoHS

20 C802,C811, 418210227030R CAP CD X7R 1000pF 500V K VT RoHS

30 C817,C822, 419111040030R CAP MTL X7R 0.1uF 50V K,VT, RoHS

430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 7.5mm

430405000000R JMPR ROLL/KG D=0.6mm,AT,RoHS 10mm

40 C814,C815,C818,C819, 420264700230R

50 Q802, 410072013210R XSTR 2PC1815GR*I VT (PHILIPS) RoHS REV:

50 410072013370R XSTR 2SC1815-GR (T2SPF.T) VT (TOSHIBA)Ro

50 410072013150R XSTR UTC2SC1815L-GR NPN TO92 (UTC)RoHS

60 IC803, 412022002840R IC TL431ACLPG TO-92 1%,VT(ON)RoHS

60 412022002240R IC KA431AZ 1%,VT (FAIRCHILD) RoHS

60 412022002300R IC AP431VL TO-92 1% VT (ATC) RoHS

60 412022002830R IC AS431 TO-92 VT(A1SEMI)RoHS

70 C816, 416231041530R CAP MEB 0.1uF 100V J,(RSB),VT RSBEC3100D

70 416141041531R CAP MKT 0.1uF 100V J,VT(ARCO) RoHS,R82EC

CAP SH 47uF 25V M,125℃,VT, 6.3x11,RoHS

35

Page 36

80 C810, 420424710260R

90 C509,C522, 420421510330R

ITEM Location P/N Description

700000000100R ASSY,PCB&RIVENT,LE1730

10 490621400100R PCB,PWR&INV./B, LE1730-XE0

20 M3,M4,M5,M6,M7,M8, 512006000500R RIVET,Φ3.0xΦ1.6x3.0mm

30 M1,M2, 512006000600R RIVET,Φ4.1xΦ2.2x3.0mm

CAP SD 470uF/25V M 105℃ ST 10x16,RoHS

CAP SD 150uF 35V M,105℃ VT 8x12 RoHS

Related to Models : L1718S-SNQ/BNQ.AxxKEP for 8ms Innolux module and

L1718S-SNQ/BNQ.AxxBEP for 8ms CPT module

IF Board

1. For INL

ITEM Location P/N Description

790621300600R PCBA,IF BOARD, LE1730-6E0

10 790621320600R PCBA,IF BOARD,OTHRS,LE1730-6E0

20 790621340600R PCBA,IF BOARD,SMD, LE1730-6E0

30 629030006500R PROGRAM, LE1730-6E0

50 511130001201R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5(SAC305 VAC

50 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

70 506440003800R LABEL,BLANK,YELLOW,10x4mm

ITEM Location P/N Description

790621320600R PCBA,IF BOARD,OTHRS,LE1730-6E0

10 C111,C144, 420431000260R

20 C101,C102, 420431010461R

C130,C133,

30

C142,C145,

C105,

40 C108, 420432210460R

50 CN101, 430631060020R WAFER 2.0mm 6P 180°,RoHS

60 CN105, 430631080130R WAFER 2x4P 2.0mm,200PHD-2*4ST RoHS

70 X101, 432008010370R XTAL 14.31818MHz 16pF HC-49US 30PPM,DIP,

80 CN103, 440819015030R CON D-SUB FEM.15P RA W/O SCREW DZ11AA1-H

ITEM Location P/N Description

790621340600R PCBA,IF BOARD,SMD, LE1730-6E0

10 Q103,Q106, 410500045210R XSTR PMBT3904 NPN 200MA,40V SOT23(PHILIP

10 410500045130R XSTR MMBT3904 NPN SOT-23(INFIN EON)RoHS

420432200460R

CAP EC 10uF 25V M,105℃ ST 5x11 RoHS

CAP EC 100uF 16V M,105℃ ST 5x11(SK) RoH

CAP EC 22uF 16V M,105℃ ST, 5x11,RoHS

CAP EC 220uF 16V M,105℃ ST 6.3x11 RoHS

36

Page 37

10 410500045140R XSTR MMBT3904LT1G NPN 200MA 40V SOT23(ON

20 Q102,Q105, 410500046210R XSTR PMBT3906 PNP 200MA,40V SOT23(PHILIP

20 410500046130R XSTR MMBT3906 PNP SOT-23(INFIN EON)RoHS

20 410500046180R XSTR MMBT3906LT1G PNP 200mA 40V SOT23(ON

30 Q101, 410500068290R XSTR AP2305GN P-CH SOT23(APEC) RoHS

30 410500044270R XSTR AO3401L P-CH(ALPHA-OMEGA) SOT23 RoH

30 410500075270R XSTR AO3415 P-CH,SOT23(AOS) RoHS

40 Q107, 410500050210R XSTR 2N7002,N-CH FET SOT-23 (PHILIPS)RoH

40 410500050130R XSTR SN7002N N-CH SOT-23(INFINEON),RoHS

40 410500050090R XSTR 2N7002 N-CH SOT-23(PANJIT)RoHS

TVS101,TVS

102,TVS103,

50

TVS104,

50 411020026020R DIO BAV99-LF 350mW 70V SOT-23 (FEC)RoHS

50 411020026390R DIO BAV99,SOT-23(INFINEON)RoHS

50 411020026090R DIO BAV99 350mW 75V SOT-23(PEC RoHS

60 D103, 411020047210R DIO BAV70 85V SOT23 (PHILIPS) RoHS

60 411020047020R DIO BAV70-LF, 70V SOT-23(FEC) ROHS

ZD101,ZD10

5,ZD106,ZD

70

107,ZD108,

70 411101156950R ZENER BZV55-C5V6 SOD80C(PHILIP S) RoHS

70 411150356950R ZENER 5.6V MTZS05-5.6-G,SOD-12 3(MMC)RoH

80 U108, 412000279480R IC AT24C04N-10SU-2.7 SOP8 4K(A TMEL)RoHS

80 412000279280R IC M24C04-WMN6TP4K SOP8 (ST) RoHS

80 412000479990R IC CAT24C04WI-TE13 SOIC-8(CATALYST)RoHS

90 U102, 412000330830R IC AS1117L-1.8/TR-LF,SOT223(A1 SEMI)RoHS

90 412000330020R IC LD1117AL-1.8V-A SOT223(UTC) RoHS

100 U101, 412000372830R IC AS1117L-3.3TR-LF,SOT223(A1S EMI)RoHS

100 412000372020R IC LD1117AL-3.3V-A SOT-223(UTC RoHS

110 U103, 412000435480R IC AT24C02BN-10SU-1.8 SOIC8 2K (ATMEL)Ro

110 412000480990R IC CAT24C02WI-TE13 SOIC-8(CATALYST)RoHS

110 412000480280R IC M24C02-RMN6TP SO8(ST)RoHS

120 U105, 412000436190R IC TSUM16AL-LF PQFP100(MSTAR)R oHS

130 U106, 412000373190R IC SST25VF010A-33-4C-SAE,SOIC- 8(SST)RoH

130 412000486310R IC PM25LV010A-100SCE SOIC8(PMC)RoHS

130 412000486190R IC PS25LV010A-100SCE SOIC8(MSTAR)RoHS

R190,R170,

140

R171,R103,

150 R186,R187, 414916010050R RES SMD (0603) 10Ω J,RT RoHS

411020026210R DIO BAV99 350mW 70V SOT-23(PHI RoHS

411100656951R ZENER 5.6V ZMM5232B-LF DO213AA (FRONTIER

414916000050R RES SMD (0603) 0Ω J,RT RoHS

37

Page 38

R130,R129,

R114,R117,

R120,R124,

R125,R127,

160

R131,R132,

R101,R167,

R168,R178,

R179,

R157,R158,

R159,R160,

170

R161,R162,

R163,

R106,R172,

180

R180,R181,

190 R102, 414916010450R RES SMD (0603) 100KΩ J,RT REV:A RoHS

200 R105, 414916020350R RES SMD (0603) 20KΩ J,RT RoHS REV:A

210 R136,R137, 414916022250R RES SMD (0603) 2.2KΩ J,RT RoHS

220 R121, 414916047150R RES SMD (0603) 470Ω J,RT RoHS REV:A

R108,R110,

R122,R149,

R150,R154,

R155,R173,

230

R174,R166,

R182,R183,

R184,R185,

R109,

240 R169, 414916390010R RES SMD (0603) 390Ω F,RT RoHS

R133,R134,

250

R135,

260 RP102, 415751035080R RP(0612)10KΩx4 1/16W J 8P4R RoHS

C158,C159,

C160,C161,

270

C162,C163,

C164,

280 C153,C154, 419302200560R C SMD(0603) NPO 22PF/50V J RoHS

290 C126, 419302210560R C SMD(0603) NPO 220PF/50V J RoHS

300 C125, 419303300560R C SMD(0603) NPO 33PF/50V J RoHS

C103,C104,

C106,C107,

C109,C129,

C156,C131,

C132,C134,

C135,C136,

310

C137,C139,

C141,C143,

C147,C148,

C149,C150,

C151,C152,

C166,

320 C140, 419311054070R C SMD(0805) X7R 1uF/16V K RoHS REV:A

C112,C113,

C114,C115,

330

C116,C117,

C118,

340 FB101, 432002312111R BEAD CORE SMD(0805)120Ω 300mA RoHS

414916010150R RES SMD (0603) 100Ω J,RT RoHS REV:A

414916010250R RES SMD (0603) 1KΩ J,RT RoHS REV:A

414916010350R RES SMD (0603) 10KΩ J,RT RoHS

414916047250R RES SMD (0603) 4.7KΩ J,RT RoHS

414916750910R RES SMD (0603) 75Ω F,RT RoHS REV:A

419301010560R C SMD(0603) NPO 100PF/50V J RoHS

419311040060R C SMD(0603) X7R 0.1uF/50V K RoHS

419314730060R C SMD (0603) X7R 0.047uF 50V,K RoHS

38

Page 39

FB102,FB10

350

3,FB105,FB1

06,

360 CN104, 444099030030R CON, SMD 1.0mm 30PIN RoHS AL2309-A0G1Z

370 506140005700R LABEL,BARCODE,BLANK,33x7mm, ROHS,FOR PCB

380 490621300100R PCB,INTERFACE, LE1730-XE0

390 R107, 414916022150R RES SMD (0603) 220Ω J,RT RoHS REV:A

R113,R116,

400

R119,

FB107,FB10

410

8,FB109,

420 511130002203R SOLDER PASTE,Sn96.5/Ag3.0/Cu0.5(SAC305 O

420 511130002200R SOLDER PASTE,Sn96.5-Ag3.0-Cu0.5 ROHS

420 511130002201R SOLDER PASTE,Sn96.5%Ag3.0%Cu0.5%

432002360012R BEAD CORE SMD(0805)60Ω 800mA GBK201209T

414916560910R RES SMD (0603) 56Ω F,RT RoHS REV:A

432002360140R BEAD CORE SMD(0603)60Ω 600mA, GBK160808

2. For CPT

ITEM Location P/N Description

790621300000R PCBA,IF BOARD, LE1730-0E0

10 790621320600R PCBA,IF BOARD,OTHRS,LE1730-6E0

20 790621340600R PCBA,IF BOARD,SMD, LE1730-6E0

30 629030006520R PROGRAM, LE1730-0E0

50 511130001201R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5(SAC305 VAC

50 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

70 506440003800R LABEL,BLANK,YELLOW,10x4mm

ITEM Location P/N Description

790621320600R PCBA,IF BOARD,OTHRS,LE1730-6E0

C111,C1

10

44,

C101,C1

20

02,

C130,C1

33,C142

30

,C145,C

105,

40 C108, 420432210460R

50 CN101, 430631060020R WAFER 2.0mm 6P 180°,RoHS

60 CN105, 430631080130R WAFER 2x4P 2.0mm,200PHD-2*4ST RoHS

70 X101, 432008010370R XTAL 14.31818MHz 16pF HC-49US 30PPM,DIP,

80 CN103, 440819015030R CON D-SUB FEM.15P RA W/O SCREW DZ11AA1-H

ITEM Location P/N Description

790621340600R PCBA,IF BOARD,SMD, LE1730-6E0

Q103,Q1

10

06,

420431000260R

420431010461R

420432200460R

410500045210R XSTR PMBT3904 NPN 200MA,40V SOT23(PHILIP

CAP EC 10uF 25V M,105℃ ST 5x11 RoHS

CAP EC 100uF 16V M,105℃ ST 5x11(SK) RoH

CAP EC 22uF 16V M,105℃ ST, 5x11,RoHS

CAP EC 220uF 16V M,105℃ ST 6.3x11 RoHS

39

Page 40

10 410500045130R XSTR MMBT3904 NPN SOT-23(INFIN EON)RoHS

10 410500045140R XSTR MMBT3904LT1G NPN 200MA 40V SOT23(ON

Q102,Q1

20

05,

20 410500046130R XSTR MMBT3906 PNP SOT-23(INFIN EON)RoHS

20 410500046180R XSTR MMBT3906LT1G PNP 200mA 40V SOT23(ON

30 Q101, 410500068290R XSTR AP2305GN P-CH SOT23(APEC) RoHS

30 410500044270R XSTR AO3401L P-CH(ALPHA-OMEGA) SOT23 RoH

30 410500075270R XSTR AO3415 P-CH,SOT23(AOS) RoHS

40 Q107, 410500050210R XSTR 2N7002,N-CH FET SOT-23 (PHILIPS)RoH

40 410500050130R XSTR SN7002N N-CH SOT-23(INFINEON),RoHS

40 410500050090R XSTR 2N7002 N-CH SOT-23(PANJIT)RoHS

TVS101,

TVS102,

50

TVS103,

TVS104,

50 411020026020R DIO BAV99-LF 350mW 70V SOT-23 (FEC)RoHS

50 411020026390R DIO BAV99,SOT-23(INFINEON)RoHS

50 411020026090R DIO BAV99 350mW 75V SOT-23(PEC RoHS

60 D103, 411020047210R DIO BAV70 85V SOT23 (PHILIPS) RoHS

60 411020047020R DIO BAV70-LF, 70V SOT-23(FEC) ROHS

ZD101,Z

D105,ZD

70

106,ZD10

7,ZD108,

70 411101156950R ZENER BZV55-C5V6 SOD80C(PHILIP S) RoHS

70 411150356950R ZENER 5.6V MTZS05-5.6-G,SOD-12 3(MMC)RoH

80 U108, 412000279480R IC AT24C04N-10SU-2.7 SOP8 4K(A TMEL)RoHS

80 412000279280R IC M24C04-WMN6TP4K SOP8 (ST) RoHS

80 412000479990R IC CAT24C04WI-TE13 SOIC-8(CATALYST)RoHS

90 U102, 412000330830R IC AS1117L-1.8/TR-LF,SOT223(A1 SEMI)RoHS

90 412000330020R IC LD1117AL-1.8V-A SOT223(UTC) RoHS

100 U101, 412000372830R IC AS1117L-3.3TR-LF,SOT223(A1S EMI)RoHS

100 412000372020R IC LD1117AL-3.3V-A SOT-223(UTC RoHS

110 U103, 412000435480R IC AT24C02BN-10SU-1.8 SOIC8 2K (ATMEL)Ro

110 412000480990R IC CAT24C02WI-TE13 SOIC-8(CATALYST)RoHS

110 412000480280R IC M24C02-RMN6TP SO8(ST)RoHS

120 U105, 412000436190R IC TSUM16AL-LF PQFP100(MSTAR)R oHS

130 U106, 412000373190R IC SST25VF010A-33-4C-SAE,SOIC- 8(SST)RoH

130 412000486310R IC PM25LV010A-100SCE SOIC8(PMC)RoHS

130 412000486190R IC PS25LV010A-100SCE SOIC8(MSTAR)RoHS

R190,R1

140

70,R171,

410500046210R XSTR PMBT3906 PNP 200MA,40V SOT23(PHILIP

411020026210R DIO BAV99 350mW 70V SOT-23(PHI RoHS

411100656951R ZENER 5.6V ZMM5232B-LF DO213AA (FRONTIER

414916000050R RES SMD (0603) 0Ω J,RT RoHS

40

Page 41

R103,

R186,R1

150

87,

R130,R1

29,R114,

R117,R1

20,R124,

R125,R1

160

27,R131,

R132,R1

01,R167,

R168,R1

78,R179,

R157,R1

58,R159,

170

R160,R1

61,R162,

R163,

R106,R1

180

72,R180,

R181,

190 R102, 414916010450R RES SMD (0603) 100KΩ J,RT REV:A RoHS

200 R105, 414916020350R RES SMD (0603) 20KΩ J,RT RoHS REV:A

R136,R1

210

37,

220 R121, 414916047150R RES SMD (0603) 470Ω J,RT RoHS REV:A

R108,R1

10,R122,

R149,R1

50,R154,

R155,R1

230

73,R174,

R166,R1

82,R183,

R184,R1

85,R109,

240 R169, 414916390010R RES SMD (0603) 390Ω F,RT RoHS

R133,R1

250

34,R135,

260 RP102, 415751035080R RP(0612)10KΩx4 1/16W J 8P4R RoHS

C158,C1

59,C160,

270

C161,C1

62,C163,

C164,

C153,C1

280

54,

290 C126, 419302210560R C SMD(0603) NPO 220PF/50V J RoHS

300 C125, 419303300560R C SMD(0603) NPO 33PF/50V J RoHS

414916010050R RES SMD (0603) 10Ω J,RT RoHS

414916010150R RES SMD (0603) 100Ω J,RT RoHS REV:A

414916010250R RES SMD (0603) 1KΩ J,RT RoHS REV:A

414916010350R RES SMD (0603) 10KΩ J,RT RoHS

414916022250R RES SMD (0603) 2.2KΩ J,RT RoHS

414916047250R RES SMD (0603) 4.7KΩ J,RT RoHS

414916750910R RES SMD (0603) 75Ω F,RT RoHS REV:A

419301010560R C SMD(0603) NPO 100PF/50V J RoHS

419302200560R C SMD(0603) NPO 22PF/50V J RoHS

41

Page 42

C103,C1

04,C106,

C107,C1

09,C129,

C156,C1

31,C132,

C134,C1

35,C136,

310

C137,C1

39,C141,

C143,C1

47,C148,

C149,C1

50,C151,

C152,C1

66,

320 C140, 419311054070R C SMD(0805) X7R 1uF/16V K RoHS REV:A

C112,C1

13,C114,

330

C115,C1

16,C117,

C118,

340 FB101, 432002312111R BEAD CORE SMD(0805)120Ω 300mA RoHS

FB102,F

B103,FB

350

105,FB10

6,

360 CN104, 444099030030R CON, SMD 1.0mm 30PIN RoHS AL2309-A0G1Z

370 506140005700R LABEL,BARCODE,BLANK,33x7mm, ROHS,FOR PCB

380 490621300100R PCB,INTERFACE, LE1730-XE0

390 R107, 414916022150R RES SMD (0603) 220Ω J,RT RoHS REV:A

R113,R1

400

16,R119,

FB107,F

410

B108,FB

109,

420 511130002203R SOLDER PASTE,Sn96.5/Ag3.0/Cu0.5(SAC305 O

420 511130002200R SOLDER PASTE,Sn96.5-Ag3.0-Cu0.5 ROHS

420 511130002201R SOLDER PASTE,Sn96.5%Ag3.0%Cu0.5%

419311040060R C SMD(0603) X7R 0.1uF/50V K RoHS

419314730060R C SMD (0603) X7R 0.047uF 50V,K RoHS

432002360012R BEAD CORE SMD(0805)60Ω 800mA GBK201209T

414916560910R RES SMD (0603) 56Ω F,RT RoHS REV:A

432002360140R BEAD CORE SMD(0603)60Ω 600mA, GBK160808

Power and Inverter Board

ITEM Location P/N Description

790621400600R PCBA,PWR&INV./B, LE1730-6E0

10 IC801, 412140002380R IC LTV817M-PR VDE (LITE-ON) P=10mm RoHS

10 412140001390R IC EL817M-B(EVERLIGHT)RoHS

20 D801, 411050005020R DIO BRDG BL4-06-BF52-LF 600V/4A(FRONTIER

20 411050007010R DIO BRDG KBL405G 600V/4A(TSC) RoHS

20 411050005090R DIO BRDG FL406 600V/4A(PEC)RoH S

30 C804, 416194743011R CAP MEX 0.47uF 275V K X2,F15 RoHS

42

Page 43

C820,C8

40

01,C806,

C812,C8

60

09,

70 C808, 420421020211R

80 C805, 420431014582R

90 C824, 416204724610R CAP MEY 4700pF 400V M Y,F10mm RoHS

L802,L8

100

03,

110 L801, 426000050070R CHOKE L-FILTER 12mH LIN-007 ET-20,RoHS

120 T801, 426000090470R XFMR 750u@1K,+-8%,3m,113m,SPW- 047,DIP-1

130 RT801, 432009400701R NTC 5Ω 4A 10ψ P=5mm, F RoHS

140 F801, 430613125210R FUSE SLOW 2.5A/250V,U/C/V,AT,3.6x10,RoHS

150 P801, 440149000220R SKT AC 10A/250V U/C/V,G/Y=45mm TU-301-SP

160 CN801, 430300600120R HRN ASS'Y 6P 110mm UL1007#24,RoHS

180 C803, 418247233020R CAP CD X7R 4700pF 1KV K,W/O FO RMING,RoH

CN501,C

N502,CN

190

503,CN5

04,

T501,T5

200

02,

C525,C5

210

27,

C524,C5

220

26,

U501,U5

230

02,

230 410050062330R XSTR AF4971NN N-CH PDIP8(ANACH IP)RoHS

240 735100007400R ASSY,H/S,UFF80-005CT/UFF80-015CT,LE1730

250 735100005100R ASSY,H/S TOP245Y, LE1704/05 ROHS

260 790621440600R PCBA,PWR&INV./B,SMD,LE1730-6E0

270 H501, 502040604500R SHIELD EMI LE1915 ROHS

280 511130001201R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5(SAC305 VAC

280 511130001200R SOLDER BAR,Sn96.5/Ag3.0/Cu0.5/Ni0.06/Ge0

300 511110000101R HOT-MELT ADHESIVES (#526)

320 511110000501R SILICONE RTV RUBBER,UB-511(EURO)

ITEM Location P/N Description

735100005100R ASSY,H/S TOP245Y, LE1704/05 ROHS

10 IC802, 412000342270R IC TOP245YN,TO-220-7C,RoHS (POWER INTEGR

20 507200003700R HEATSINK,46x20xt10mm LE1704/05

30 509112306100R SCREW,P,CROSS,T.T-3*6,ZnROHS

416202224610R CAP MEY 2200pF 400V M Y,F10mm RoHS

420421020110R

425000010530R COIL CHK 5uH 7.8X10 CHK-053 0 181085R0L

430637020030R WFR. 2P P=3.5mm 90°W/LOCK,RoHS

426000090670R XFMR SW,105uH EEL19M DIP SPW-067,RoHS

418105058010R CAP CD SL 5pF 3KV K,F7.5 RoHS

418110058510R CAP CD SL 10pF 3KV J,F7.5 RoHS CC45SL3FD

410500071290R XSTR AP9971GD,N-CH,PDIP-8(APEC RoHS

CAP SD 1000uF/10V M,105℃ F,10x16,RoHS

CAP SD 1000uF 25V M,105℃ F 13x20 RoHS

CAP SEK 100uF/450V M,105℃ CF,18x35,RoHS

43

Page 44

ITEM Location P/N Description

735100007400R ASSY,H/S,UFF80-005CT/UFF80-015CT,LE1730

10 D805, 411090015020R SCHTKY SRF5-04CT-LF ITO-220AB (FEC) RoHS

10 411090024040R SCHTKY SRF1040CM 40V/10A ITO22 OAB(MOSPE

10 411090025040R SCHTKY SRF1045CM 45V/10A ITO22 OAB(MOSPE

20 D803, 411020065020R DIO UFF80-015CT-LF 150V/8A, ITO-220AC(FR

20 411030058040R DIO URF1020 200V/10A ITO220(MO SPEC)RoHS

30 507200003800R HEATSINK,56x20xt10mm LE1904/05

40 509112306100R SCREW,P,CROSS,T.T-3*6,ZnROHS

ITEM Location P/N Description

790621440600R PCBA,PWR&INV./B,SMD,LE1730-6E0

10 Q801, 410500045210R XSTR PMBT3904 NPN 200MA,40V SOT23(PHILIP

10 410500045140R XSTR MMBT3904LT1G NPN 200MA 40V SOT23(ON

10 410500045130R XSTR MMBT3904 NPN SOT-23(INFIN EON)RoHS

20 ZD803, 411150356950R ZENER 5.6V MTZS05-5.6-G,SOD-12 3(MMC)RoH

20 411100956920R ZENER 5.6V MMSZ5232A SOD123(PE C)RoHS

20 411131556920R ZENER 5.6V 0.5W DDZ5V6B-F,SOD1 23(DIODES

30 ZD801, 411150375950R ZENER 7.5V MTZS05-7.5-G, SOD-123(MMC)RoH

30 411100975920R ZENER 7.5V MMSZ5236A SOD123(PE C)RoHS

30 411131575952R ZENER 7.5V 0.5W DDZ7V5C-F,SOD1 23(DIODES

40 ZD804, 411100915020R ZENER 15V MMSZ5245A SOD123(PEC RoHS

40 411150315050R ZENER 15V MTZS05-15-G,SOD-123 (MMC) RoHS

40 411131515052R ZENER 15V 0.5W DDZ15-F,SOD123(DIODES)RoH

50 R809, 414904100010R RES SMD (1206) 100Ω F,RT RoHS

R808,R8

60

19,R827,

R801,R8

05,R822,

70

R823,

R813,R8

80

14,R815,

90 R825, 414908047450R RES SMD (0805) 470KΩ J,RT RoHS

R510,R5

100

11,

R803,R8

110

07,R824,

R818,R5

02,R504,

120

R517,R5

20,

130 R816, 414908068950R RES SMD (0805) 6.8Ω J RT RoHS

414908010350R RES SMD (0805) 10KΩ J,RT RoHS REV:A

414908024550R RES SMD (0805) 2.4MΩ J,RT RoHS

414908010250R RES SMD (0805) 1KΩ J,RT RoHS REV:A

414916000050R RES SMD (0603) 0Ω J,RT RoHS

414908051450R RES SMD (0805) 510KΩ J,RT RoHS

414908330110R RES SMD (0805) 3.3KΩ F,RT RoHS REV:A

44

Page 45

140 R811, 414908430210R RES SMD (0805) 43KΩ F,RT,RoHS

150 R817, 414908820110R RES SMD (0805) 8.2KΩ F,RT RoHS

R802,R8

160

06,

170 R829, 414908020150R RES SMD (0805) 200Ω J,RT RoHS

180 R810, 414908510110R RES SMD (0805) 5.1KΩ F,RT RoHS

190 R522, 414916390210R RES SMD (0603) 39KΩ F,RT RoHS

R518,R5

200

19,

210 R514, 414916010450R RES SMD (0603) 100KΩ J,RT REV:A RoHS

220 R527, 414916330410R RES SMD (0603) 3.3M F RT RoHS

R512,R5

240

26,

250 R538, 414916604310R RES SMD (0603) 604KΩ F,RT RoHS

R513,R5

260

29,R530,

270 R523, 414916330210R RES SMD (0603) 33KΩ F,RT RoHS

290 R524, 414916220210R RES SMD (0603) 22KΩ F,RT RoHS

R515,R5

300

16,

C507,C5

310

11,

320 C821, 419311040060R C SMD(0603) X7R 0.1uF/50V K RoHS

330 C510, 419316830060R C SMD (0603) X7R 0.068uF 50V,K RoHS

C523,C5

340

30,

350 C529, 419304710560R C SMD(0603) NPO 470PF/50V,J,RoHS

360 C504, 419311020060R C SMD(0603) X7R 1000PF/50V K RoHS

370 C506, 419314720060R C SMD(0603) X7R 4700PF/50V K RoHS

C501,C5

02,C513,

380

C514,

390 C505, 419311030060R C SMD(0603) X7R 0.01uF/50V K RoHS

400 D506, 411023004021R DIO SN4148-LF 75V/0.15A SMD 1206 (FEC)Ro

400 411020046090R DIO 1N4148W 75V/0.15A(PEC)RoHS SOD-123

D501,D5

410

02,

410 411020026020R DIO BAV99-LF 350mW 70V SOT-23 (FEC)RoHS

410 411020026390R DIO BAV99,SOT-23(INFINEON)RoHS

410 411020026090R DIO BAV99 350mW 75V SOT-23(PEC RoHS

D503,D5

420

04,

420 411020047020R DIO BAV70-LF, 70V SOT-23(FEC) ROHS

430 D505, 411020068210R DIO BAW56 85V SOT-23(PHILIPS)RoHS

430 411020068020R DIO BAW56 70V SOT-23(FRONTIER)RoHS

430 411020068090R DIO BAW56 75V SOT-23(PANJIT)RoHS