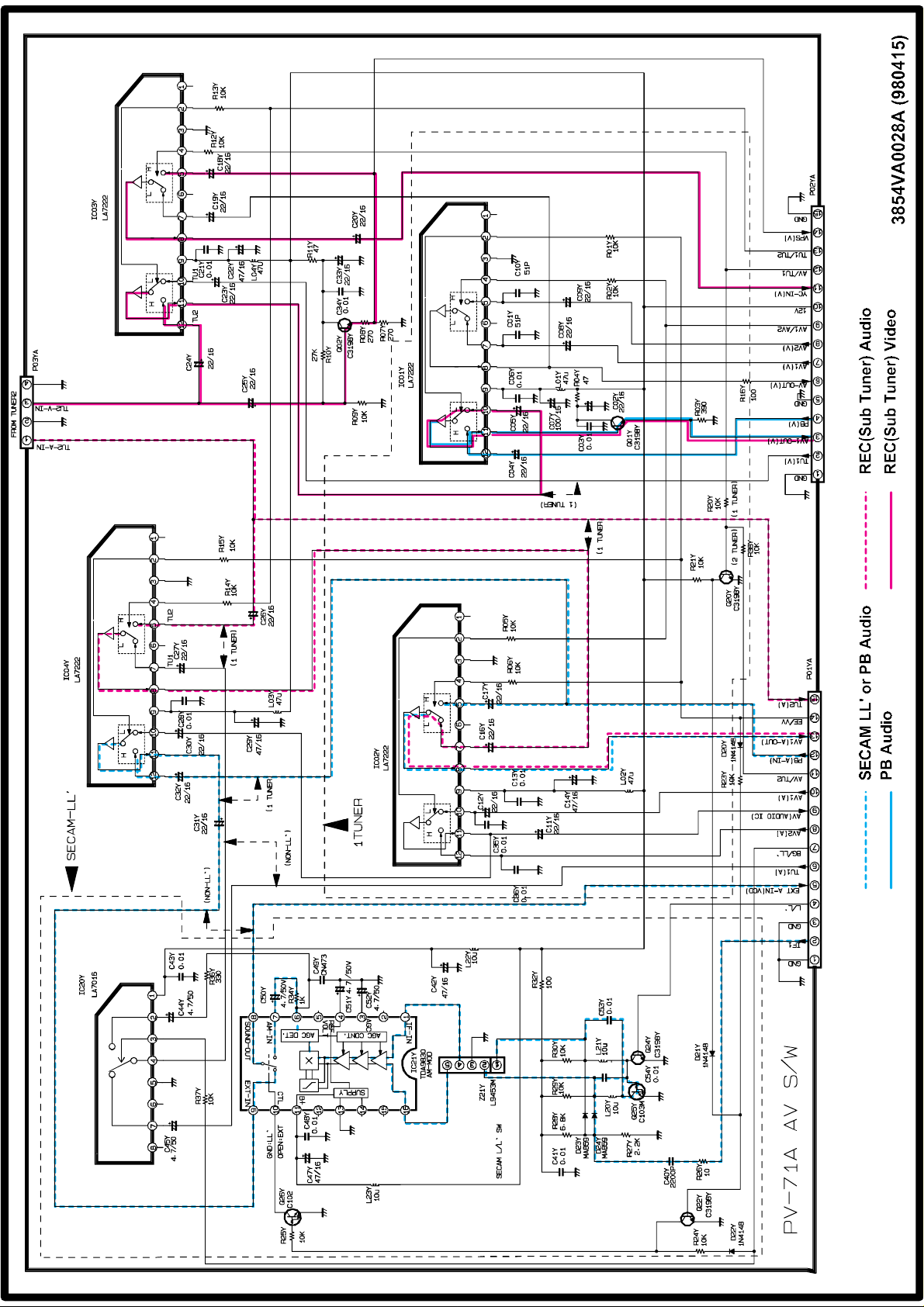

LG KI-14U71, KI-20U71, KI-20U72 Schematic

Model

FACTORY.

Buyer

EFFECTIVE DATE

Subject

SERVICE BULLETIN

KI-14U71

KI-14U71X

KI-20U71

KI-20U72X

GB000001

31/05/1998

Improvement of the reliability

EFFECTIVE FROM(SERIAL NO.)

No. : VSB-85030

Date : 08/06/1998

From the shipment

on June 1998

No. LOC NO.

Before Change After Change

PART NO. DESC./SPEC. PART NO. DESC./SPEC.

1 4814V00016A

SHIELD

BUTTOM

4814V00016B

SHIELD

MAIN 1 SBHG-1 . BOTTOM

Reason Of Change

Symptom : "HUM" in sound when playing a tape recorded in SET.

Countermeasure : Add a silicon shield plate to SHIELD BOTTOM.

** FILE THIS SERVICE BULLETIN WITH YOUR SERVICE MANUAL

NOTE(**) : INTERCHANGEABILITY CODE KEY-WORD CODE

Parts Set

Original

A

New

Original

B

New

Original

C

New

Original

D

New

Original or new parts may be used in early or

Early

late production sets.

Late

Use original parts until exhausted, then stock

new parts.

Original parts may be used in early production

sets only.

Early

New parts may be used in early or late production

sets.

Late

Use original parts where possible, then stock new

parts.

New parts only may be used in early or late

Early

production sets.

Late

Stock new parts.

Original parts only may be used in early

Early

production sets.

New parts may be used in late production sets

Late

only.

Stock original and new parts.

1. To improve performance

2. To improve productivity

3. To improve reliability

4. Change of material or

dimension

5. Addtion

6. Deletion

7. Correction

Note

K-

CODE

B 3

Remark

CHIEF ENGINEER ,

1

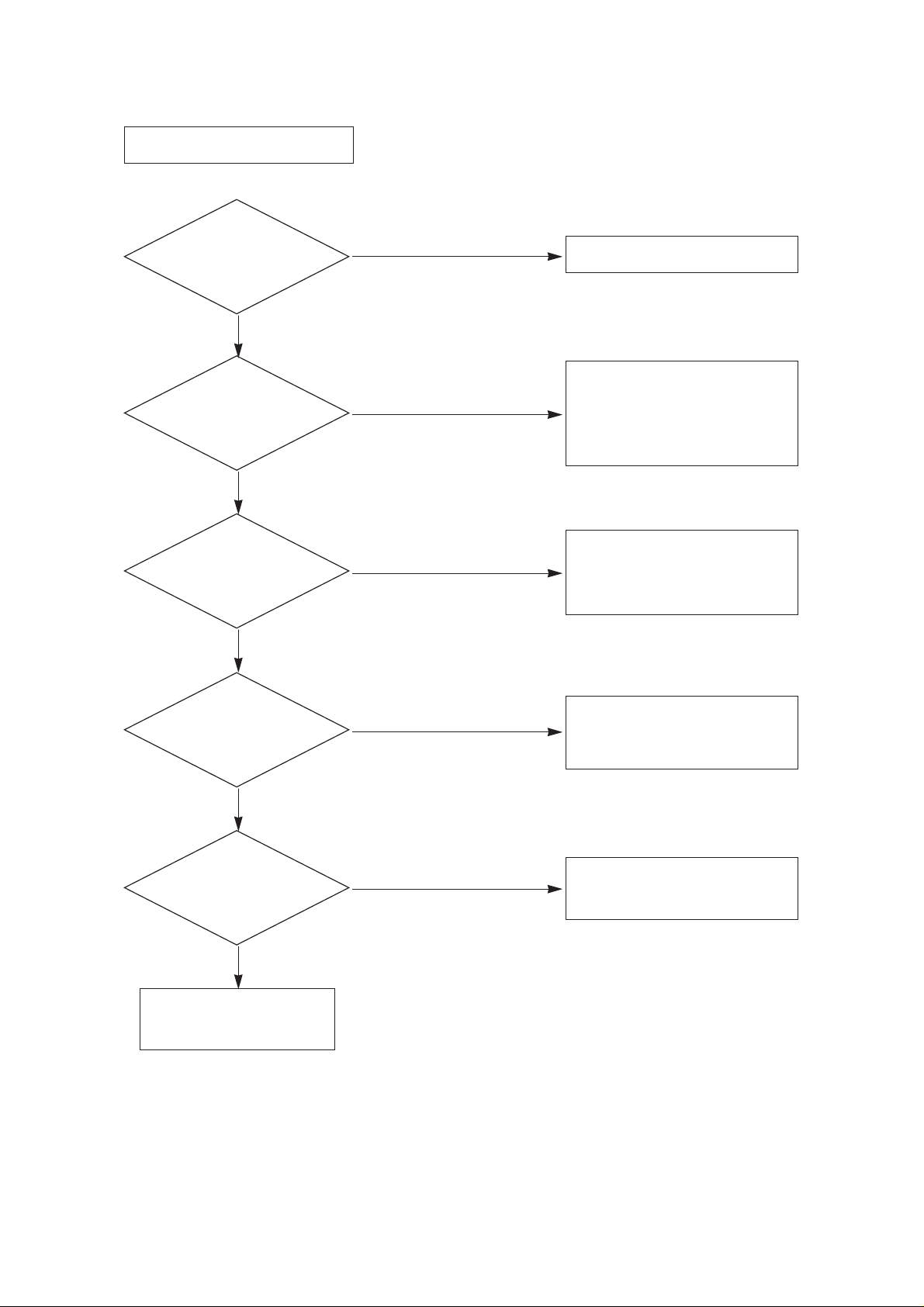

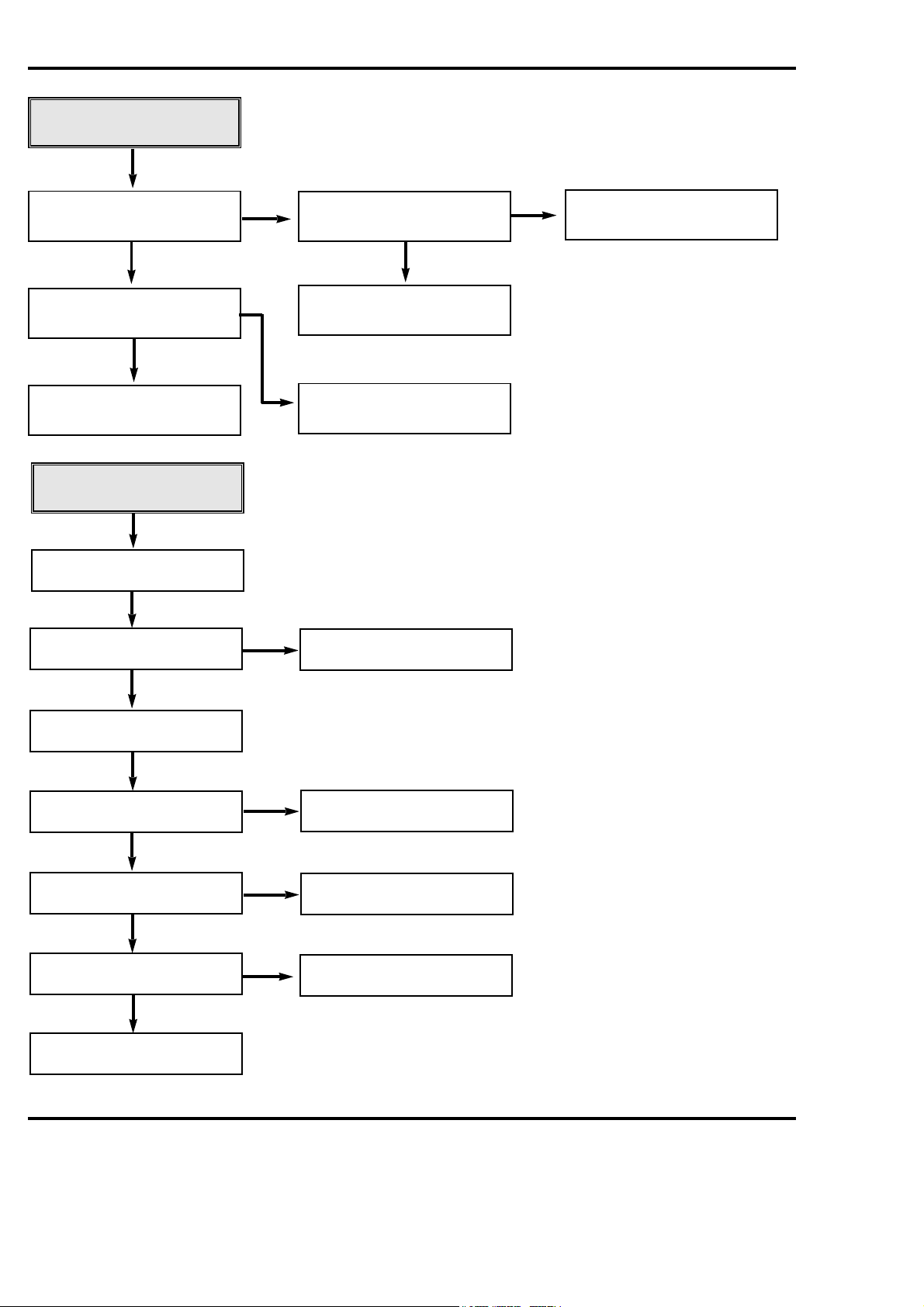

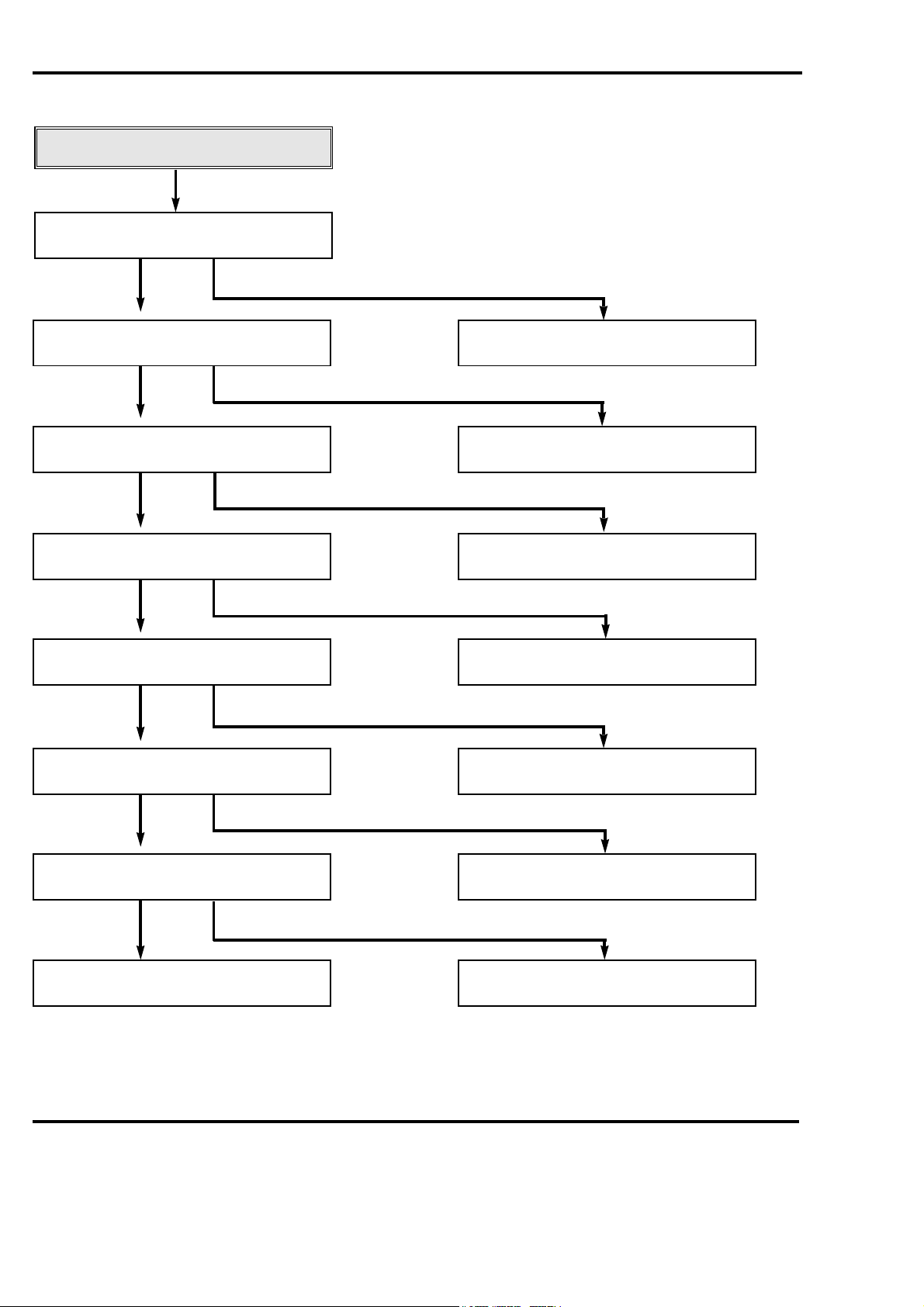

Is there about 6V

at pin 9 of P804?

YES

Is there about 11V

at '+' terminal

of C856?

YES

Is there about 6.1V

at pin 9 of IC801?

YES

Is there voltage at

pin 9 of T801?

YES

NO POWER : NO STAND-BY

Replace the Fuse

Check the 6V Line

of MAIN 1 BOARD

Check if the

Fuse is O.K.?

YES

NO

Check/Replace

D801, D802, 803, 804, R801, C807.

NO

Check/Replace

D806, Q801, R807, ZD801, C814,

IC801.

NO

¡ Check/Replace FR851, D852,

C856, Q860, Q861, Q862,

ZD860, ZD861, R874.

¡ Check the pin 11 of P804 :

'LOW"

NO

Check/Replace

R863, IC857, D858, R877, C875

NO

TROUBLE SHOOTING

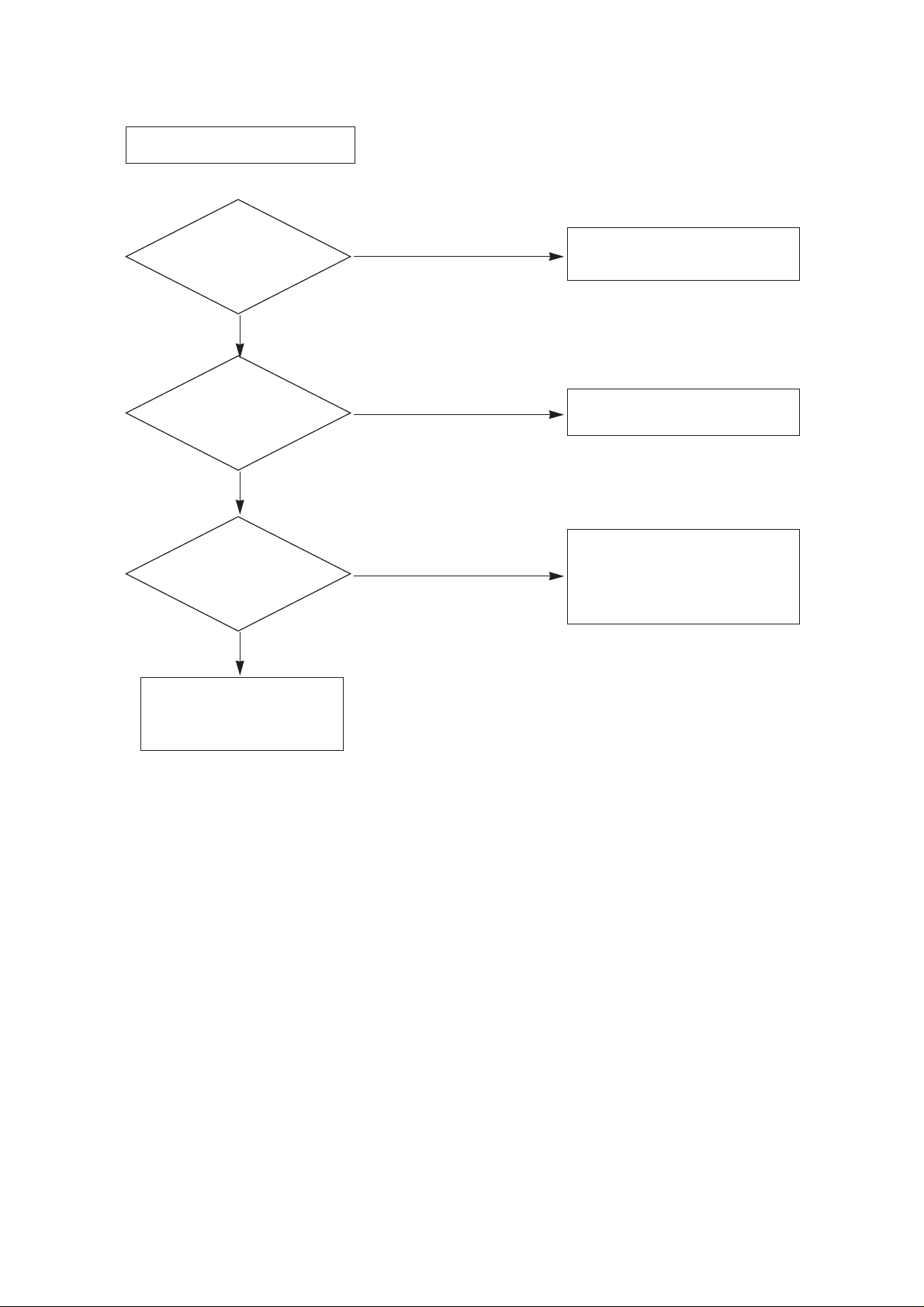

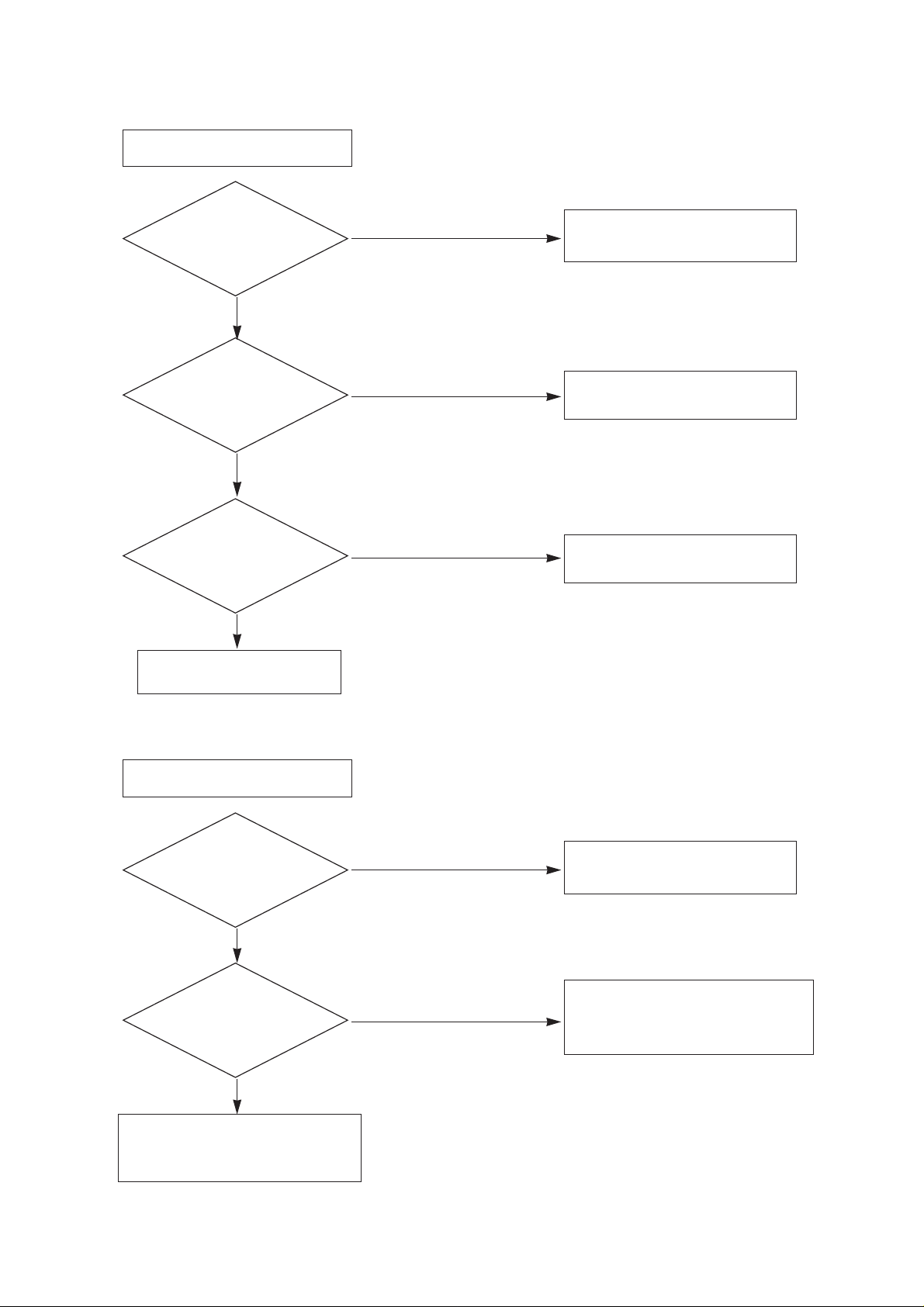

2

Is there about 115V

at '+' terminal of C865?

YES

Is there about

6V at pin 9 of P804?

YES

NO POWER : NO MONITOR ON

Go to NO POWER (NO ST-BY)

BLOCK

Go to NO RASTER BLOCK

Check T701, Q781 and go to

NO RASTER BLOCK

Check the

NO POWER(NO ST-BY)

BLOCK

YES

NO

Check the pin 10 of P804 ; "HIGH"

NO

¡ Check/Replace D851, L851,

C860, IC851.

¡ Check the pin 10 of P804 :

'HIGH"

NO

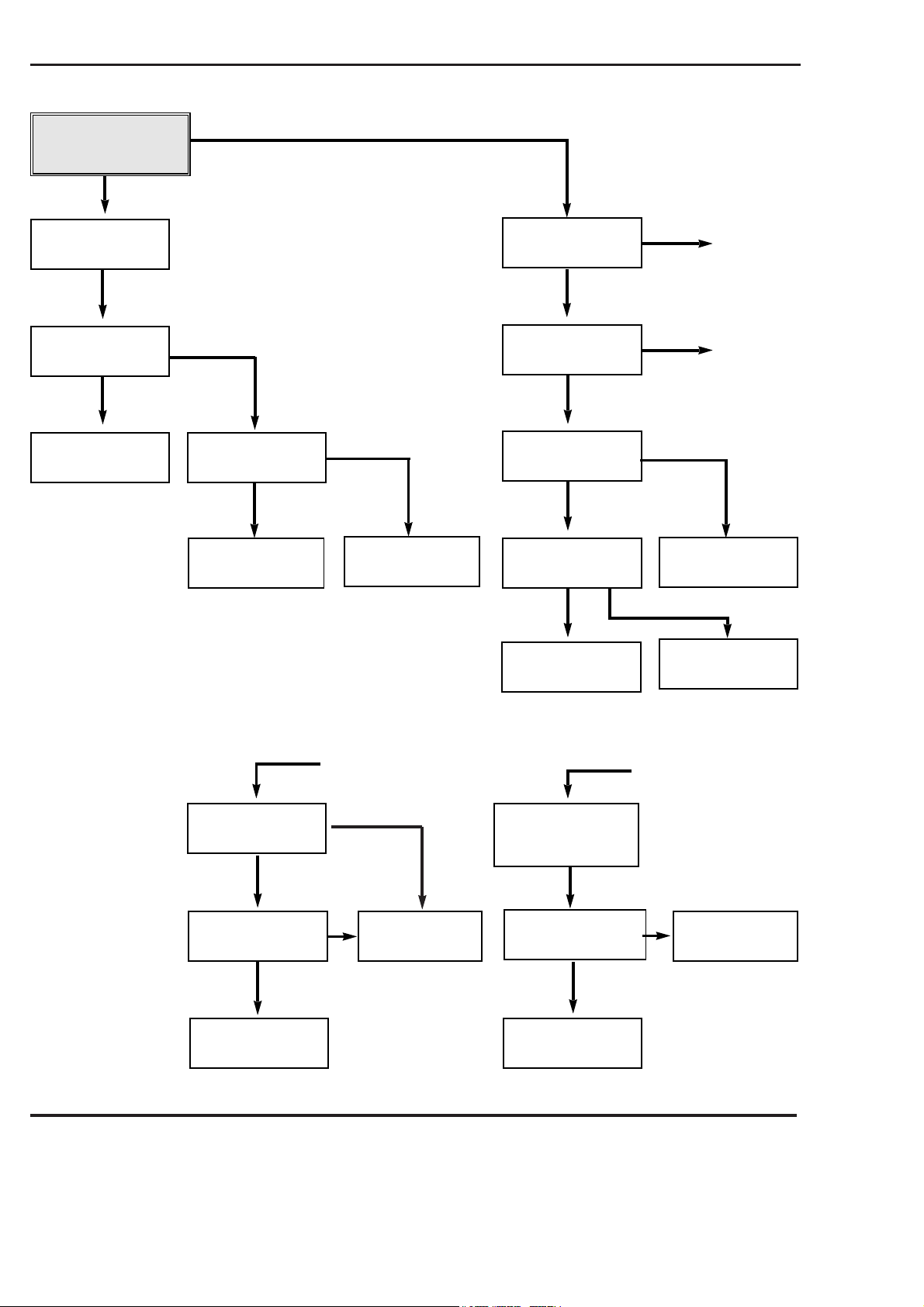

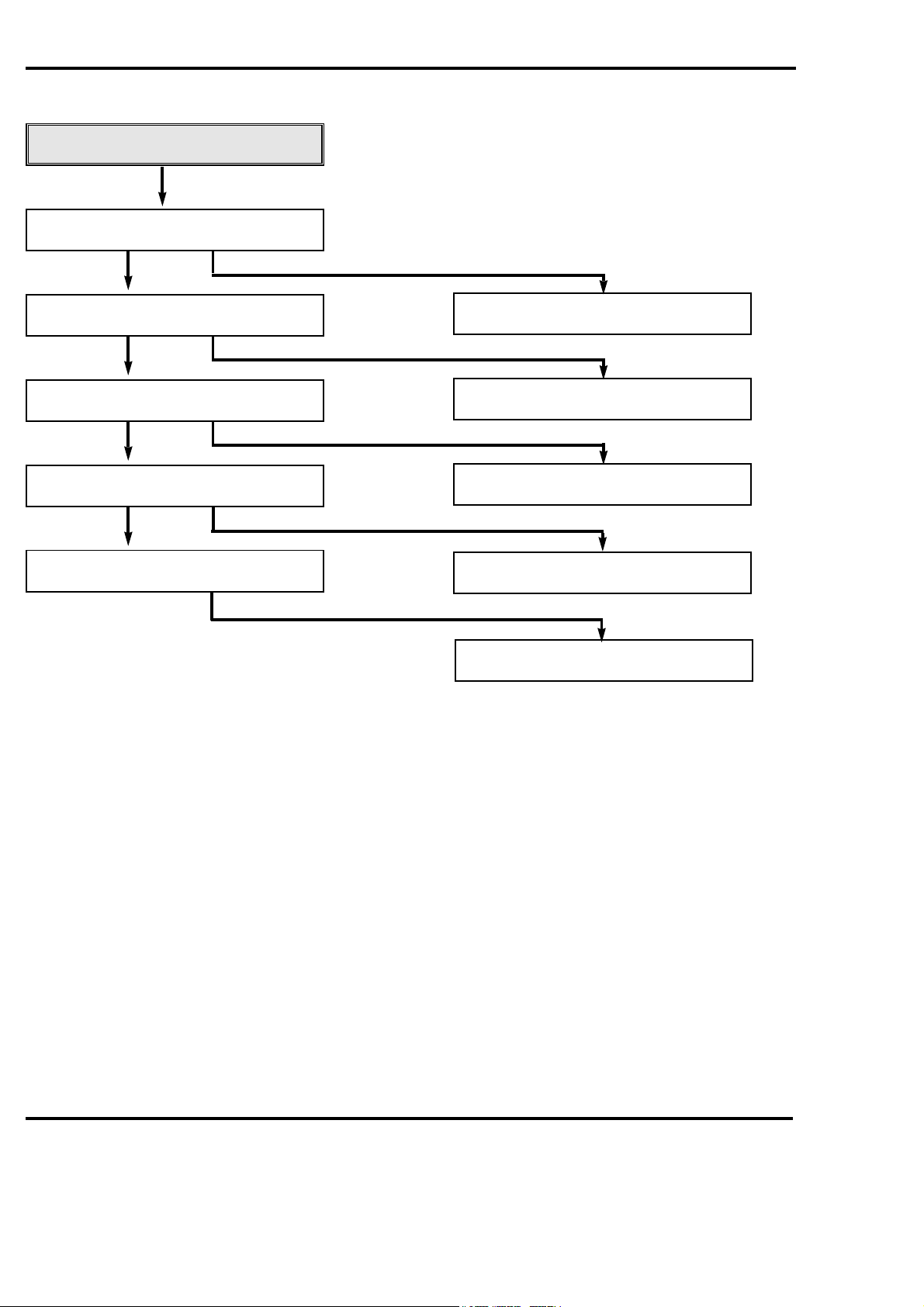

3

Is there about

6.3VAC at HEATER of CPT

SOCKET?

YES

Does the waveform

appear at the collector

of Q781?

YES

Does the square

waveform appear at pin 1 of

P805?

YES

Is there about 8V

at pin 6 of P805?

YES

NO RASTER

Go to NO POWER BLOCK

Go to NO PICTURE BLOCK

Is there about 115V

at pin 3 of T701?

YES

NO

¡ Check/Replace F852, D850,

C857, R899, IC853, C863.

¡ Check the 8V LINE of VCD

BOARD

NO

¡ Check the H-OUT LINE of VCD

BOARD.

¡ Check/Replace IC501 of VCD

BOARD.

NO

Check/Replace Q782, T781, R783,

R787, Q781.

NO

Check/Replace T701, 5PIN

CONNECTOR, FR2901, FR2902

(14" : FR1901)

NO

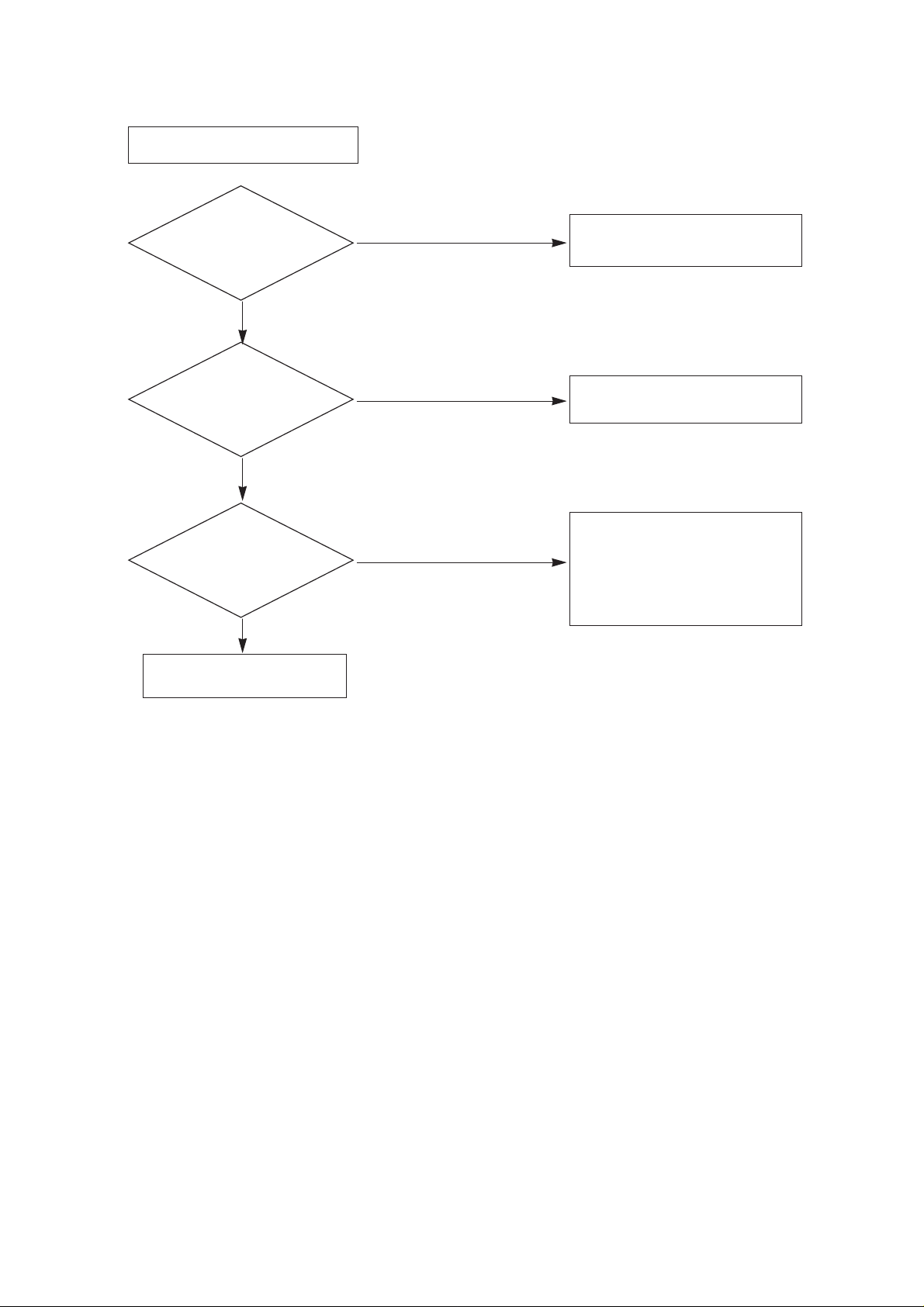

4

Is there about

44V at pin 6 of IC701?

YES

Is there about

15V at pin 3 of

IC701?

YES

V. Deflection ERROR

Check the vertical part of VCD

BOARD

Check/Replace IC701

Does the V-A, V-B

signal appear at pin 4, 7

of P805?

YES

NO

Check/Replace FR702, D702, C704,

L731

Check;/Replace FR701, D701, C708,

L732, C734.

NO

Is there about

200V at pin 1 of P2901B?

(14" : P1901B)

YES

NO PICTURE

Check the CVBS line of VCD BOARD

(Refer to VCD BLOCK DIAGRAM)

¡ Check/Replace IC2901.

(14" : IC1901)

¡ Check screen voltage

Does the RGB signal

appear at pin 3, 5, 7 of

P2902? (14" : P1902)

YES

NO

Check/Replace FR704, D703, C702,

T701, 5PIN CONNECTOR, L2901,

R2924 (14" : L1901, R1924)

NO

NO

5

Does the sound

signal appear at pin 4

of IC601?

YES

Does the sound

signal appear at pin 9

of P805?

YES

NO SOUND

Check/Replace FR854, D855, IC601.

Check/Replace speaker,

speaker connector.

Is there about

25V at pin 5

of IC601?

YES

NO

Check the Audio source line of

VCD BOARD

¡ Check the voltage at collector of

Q601.

¡ Check/Replace IC601, external

components of IC601.

NO

NO

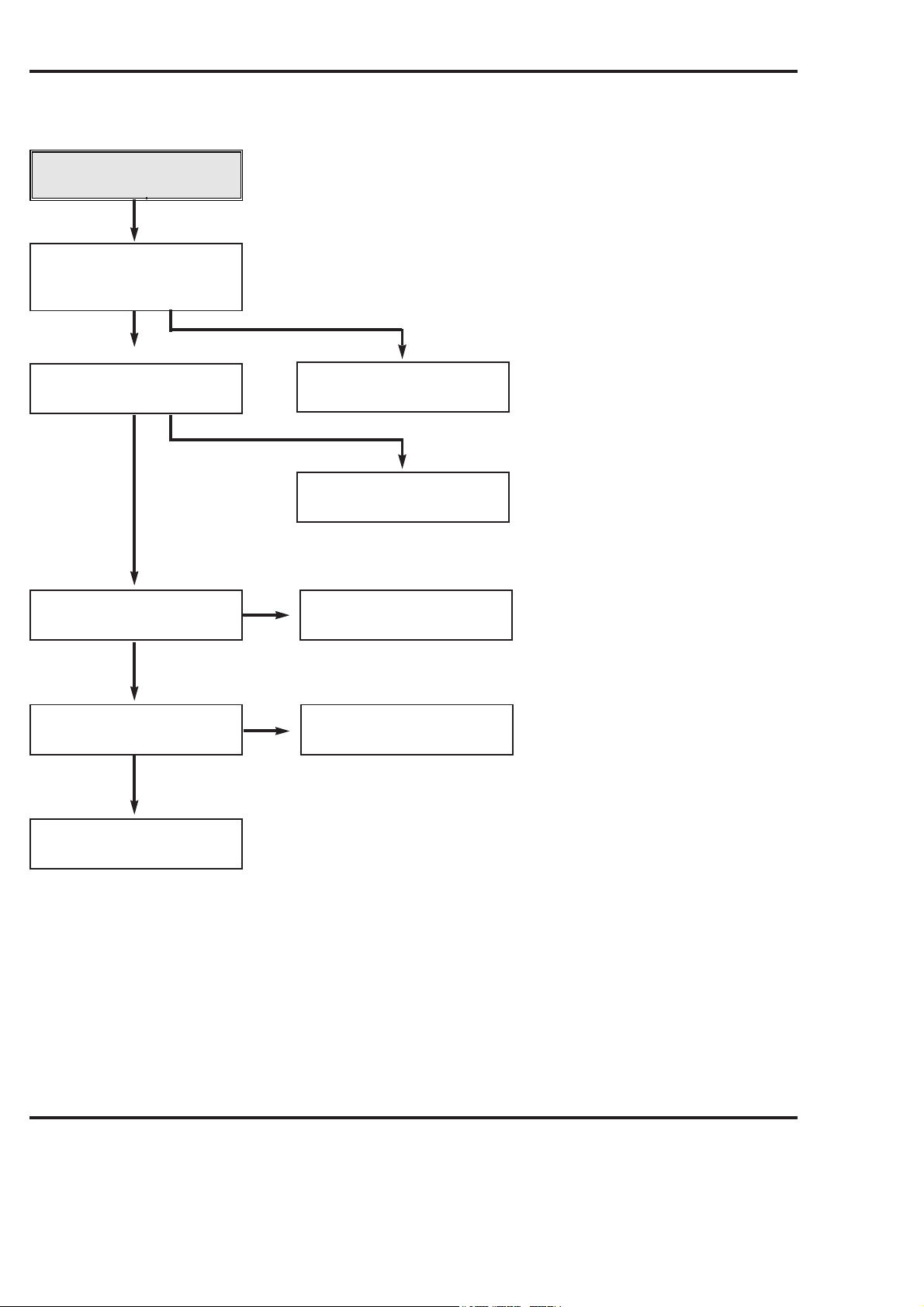

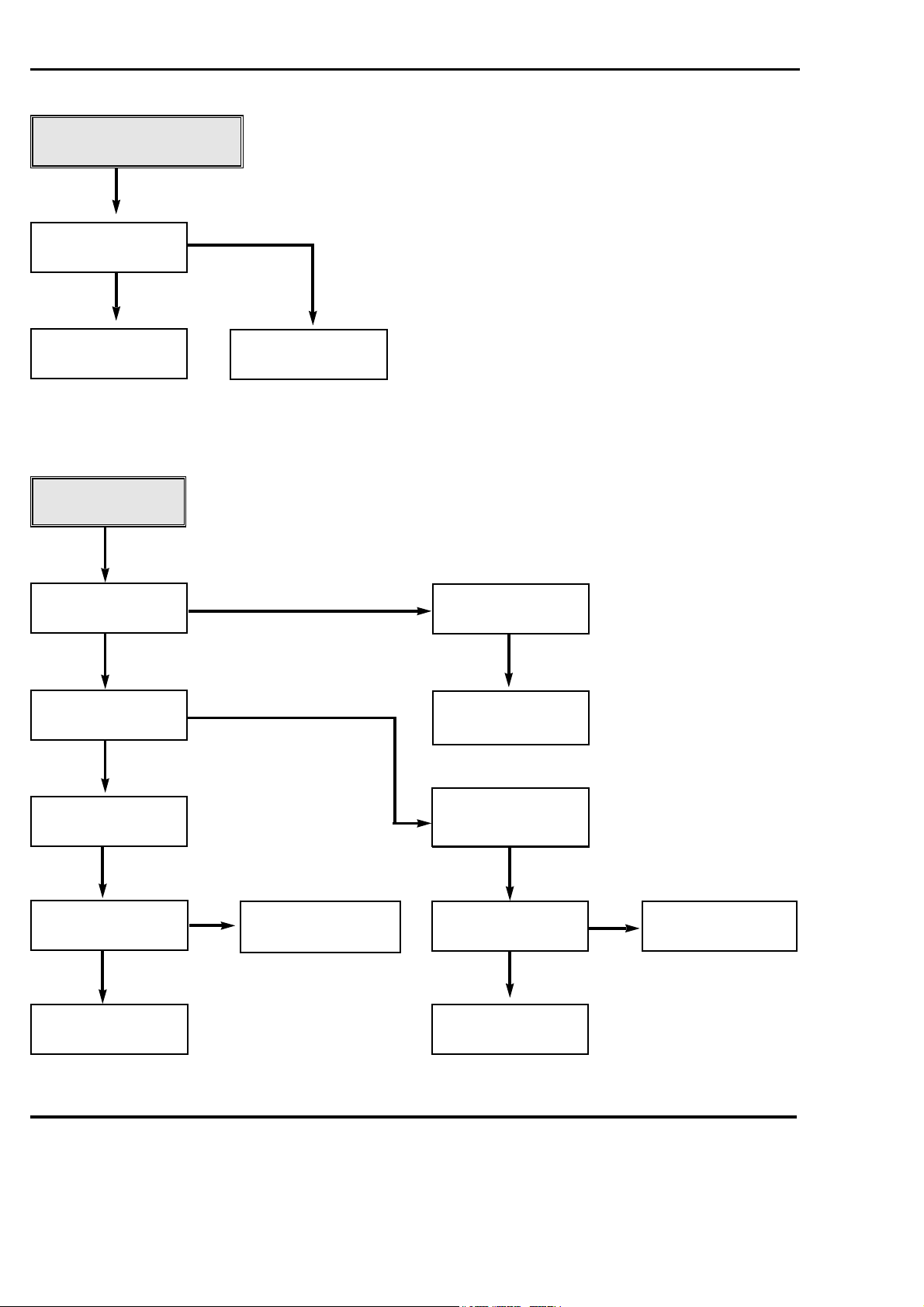

MECHANISM TROUBLESHOOTING GUIDE

1.Deck Mechanism

A.

Auto REW doesn't work.

YES

Is the output of END senser

of supply side "L"?

Is the supply end sensor less than

3.5V ("L")

YES

NO

Is the voltage drop across IR LED

between 0.8

~1.5V?

NO

Is LED-Prism OK?

YES

NO

Check the system (u-com).

Replace LED.

Check the 5VA supply, replace

LED Prism.

YES

Is the Prism housing damaged? Replace Prism.

NO

YES

Replace Photo Tr.

NOTES:

1)Auto REW takes place when the supply end sensor is "H" high.

2)"H"=voltage greater than 3.5V, "L"=voltage between 0.7~1.0V.

4-27

MECHANISM TROUBLESHOOTING GUIDE

AUTO STOP.

YES

In auto stop is the pinch roller in

contact with the capstan shaft.

YES

Are there T/up and supply reel

pulses.

YES

Check the Syscon, u-COM.

No cassette loading.

YES

Insert the cassette.

YES

Does the cassette door lever S/W

work normally.

NO

NO

NO

Is the output of DFG, DPG OK?

YES

Check Servo, Syscon.

Replace Reel Sensor.

Check Housing Assembly.

NO

Replace Drum Motor.

YES

Is the output of F/L S/W"H"?

YES

Is the mode SW in the ULC

position. (tape unloaded)

NO

Does Capstan Motor turn?

YES

Did the H1 lever change position.

YES

Check Housing Ass'y.

YES

NO

NO

Refer to 1. Mechanism and Mode

Switch Alignment check (Page 4-16)

Check Capstan Motor.

Refer to Page 4-8 item 11.

4-28

MECHANISM TROUBLESHOOTING GUIDE

D.

In PB mode Tape

Presence not sensed.

YES

Is the Pinch Roller

attached to the

Capstan Motor Shaft?

YES

Does the T/Up

Reel turn?

YES

Check the clutch and

the Idler Assembly.

NO

NO

Is the Belt OK?

YES

Check T/up Reel

and replace.

NO

Replace the Belt.

Does the Capstan

Motor turn?

YES

Does the Drum

Motor turn?

YES

Are there DPG,

DFG Pulses?

YES

Are the T/Up Supply

Reel SensorsOK?

NO

¨Í

NO

¨Î

NO

Replace Drum

Motor.

¨Î

Is the Vcc voltage of the

Drum Motor normal?

YES

Is the terminal voltage

of the Drum Motor

more than 2V?

YES

Replace the

Drum Motor.

NO

NO

NO

Check Servo.

YES

Check Servo, Syscon.

NO

¨Í

Is the voltage supplied

to the Capstan Motor

Vcc1, Vcc2 each?

YES

Does terminal voltage of

Capstan Motor supplied

more than 4V?

YES

Replace the

Capstan Motor.

Replace Reel

Sensor.

NO

Check Servo,

Power.

4-29

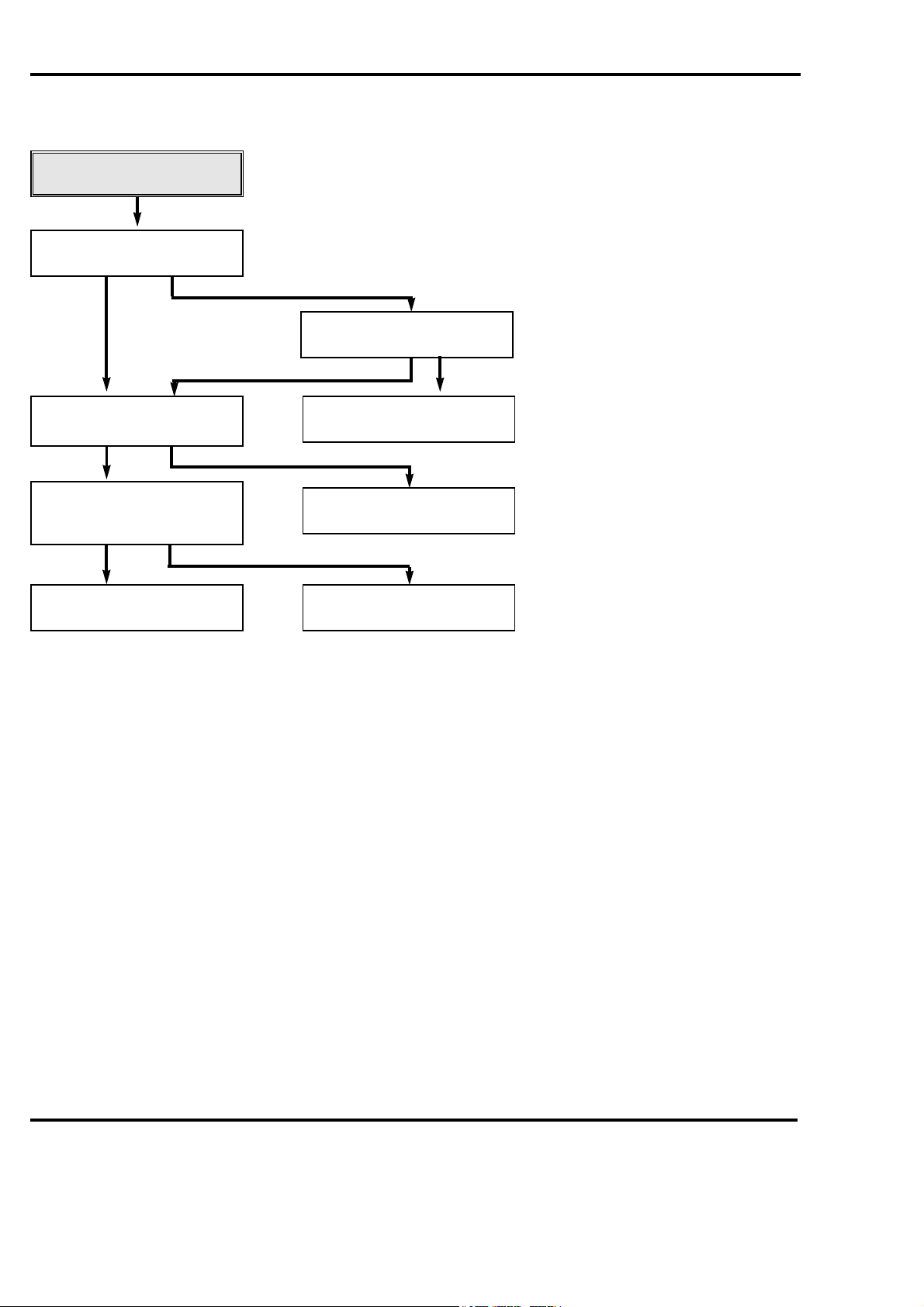

YES

MECHANISM TROUBLESHOOTING GUIDE

In Eject mode, the Tape

will not eject.

Are the T/Up and Supply

End Sensors OK?

Replace the F/L S/W.

Replace End Sensor.

No F/R modes.

Does the Capstan Motor

rotate?

Do the T/Up, Supply

Reel rotate?

Replace Reel Sensor.

Capstan motor stopped

due to jammed

mechanism?

Is the normal voltage

supplied to the Capstan

Motor Vcc1, Vcc2.?

Eject Key-in.

Is the mode SW

assembled correctly

(refer to Pages 4-16.)

Does terminal voltage of

Capstan Motor supply

side more than 4V?

Replace the

Capstan Motor.

Check Servo, Power.

Check the clutch, Lever

Ass'y F/R and Idler Ass'y.

Is the present mode,

F/R Mode?

NO

NO

NO

NO

YES

YES

YES

YES

NO

YES

YES

YES

YES

YES

4-30

E.

MECHANISM TROUBLESHOOTING GUIDE

2. Front Loading Mechanism

A.

Cassette cannot be inserted.

Does the Lever Switch work?

YES

Is 5V applied to the ¥-COM

Vcc port.

YES

Is 5V applied to CST switch port of

u-COM

YES

Check the syscon Part.

NO

NO

?

NO

Is the Cassette Lever/Spring

Switch damaged or omitted?

NO

Replace or add the Lever/Spring

Switch.

Check the Power Part.

Replace the Cassette Switch.

YES

4-31

Cassette will not load.

Does the CST insert?

Does the lid opener work?

Does the Gear Cam F/L work?

Does the lid opener work?

Does the Arm Assembly F/L work?

Does the Capstan Motor work?

Does the Holder Assembly Cassette move

the Arm Assembly F/L?

Replace the Front Loading

Mechanism Assembly.

Check the Gear H1 position on the Deck.

Replace the lid opener.

Is the (R) side gear train and bracket

assembled correctly?

Is the lid opener assembled correctly.

Replace the Arm Assembly F/L.

Check the power of Capstan Motor.

Check the Holder Assembly Cassette.

YES

YES

NO

NO

NO

NO

NO

YES

NO

YES

YES

YES

YES

YES

NO

MECHANISM TROUBLESHOOTING GUIDE

4-32

(Tape does not thread around the drum.)

B.

Cassette will not eject.

Is the Gear H1 position correct on the deck?

Does the Capstan Motor shaft rotate?

Does the Lever Switch work?

Does the Gear Cam F/L work?

Does the Opener Door work?

Check the Gear H1.

Check the Capstan Motor.

Replace the Lever/Spring Switch.

Check the Gear Train of Bracket Side (R).

Replace the Opener Door.

NO

NO

NO

NO

NO

YES

YES

YES

YES

MECHANISM TROUBLESHOOTING GUIDE

C.

4-33

ADJUSTMENT INSTRUCTIONS

Notes;

(Adjustments must be performed by the following procedures)

1. It is recommended that an isolation transformer be used

when servicing this chassis to prevent electric shock and

damage to test equipment.

2. The ac line voltage must be maintained at 230 vac, +- 10%,

50/60 hz.

3. Prior to making any adjustments, the receiver must be

operated for 10 minutes.

1. DECK ADJUSTMENT

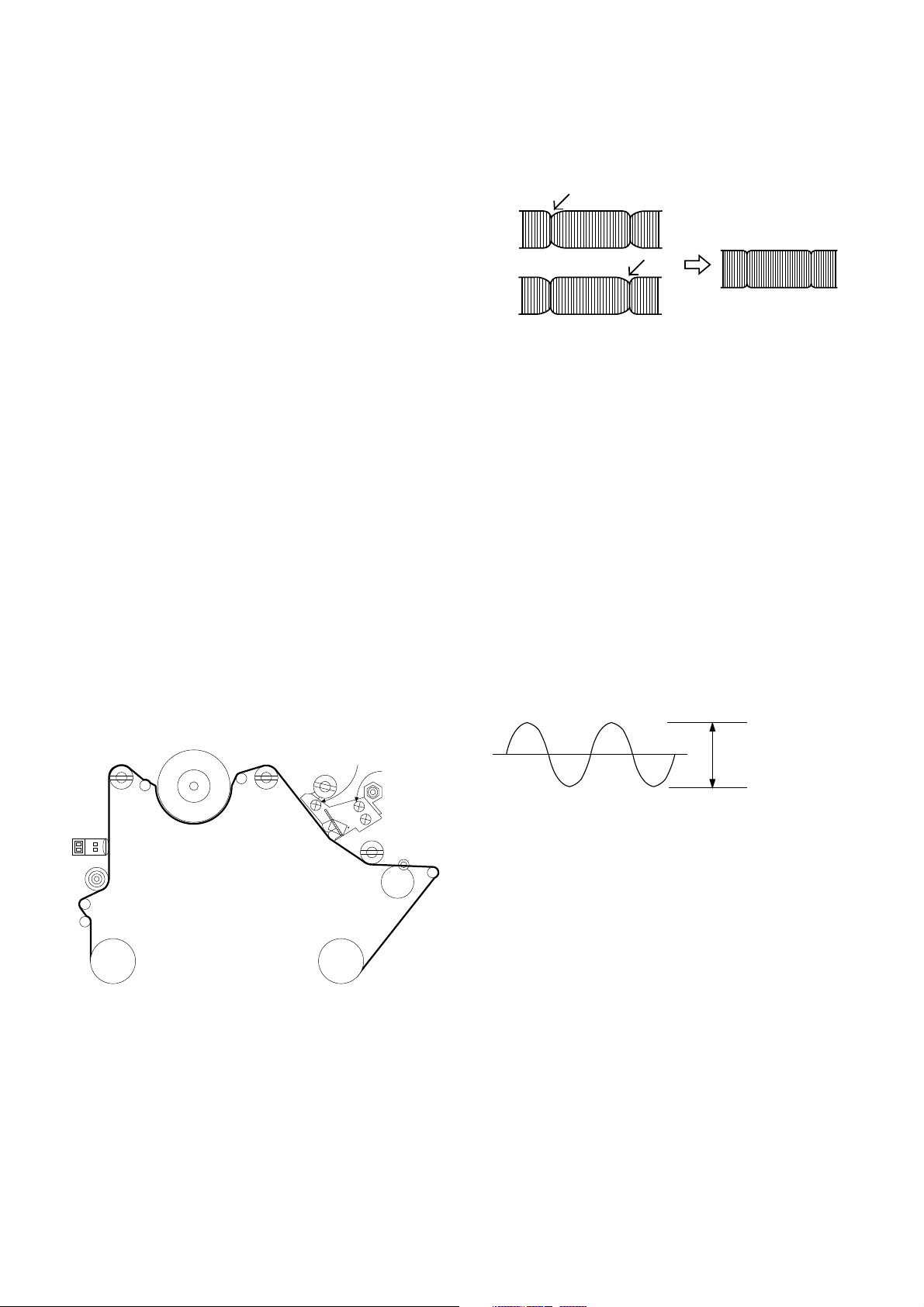

1. Deck Transit System Adjustment

1-1. Necessary Instruments

1)TAPE for SP (4HD), Normal (2HD)

2)Oscilloscope

3)10:1 Probes 2EA

4)Adjustment Driver

(P2, P3, X-distance (NUT), Audio (NUT) control)

5)RMS Meter (Audio Level Meter)

1-2.Preliminary Steps

1)

Connect CH 1 of the oscilloscope to J439 (H/SW) on the

main PCB. Trigger on this channel.

2)Connect CH 2 of the oscilloscope to J218 (RF) on the main

PCB. Monitor this waveform when preceding with step 4.

3)Play an alignment tape.

4)When the "auto Trk" caption appears on screen, press the

TRK up (+) button on the RCU to initialize the manual

tracking feature.

5) If manual tracking differs from auto tracking, precede with

steps 1-3 (RF Linearity) and 1-4 (X-Distance Adj.).

P2

P2 POST ADJUST

P3 POST ADJUST

P3

<Adjustment waveform>

1-4. X-Distance Adjustment

1)Turn the Cone Screw of the DECK left or right so that the

RF waveform is maximum.

2)Check if the RF waveform satisfies the linearity by

pressing TRK UP(+) and DOWN(-) button one step.

CAUTION:If the RF waveform becomes maximum with

the Cone Screw more than 2 turns, its out of adjustment.

(2 turns; 720)

1-5. Audio Level Check and Adjustment

1)Connect "+" terminal of RMS Meter (Audio Level Meter)

to J233 on MAIN PCB AUDIO OUT and "-" terminal to

GND, respectively.

2)Play the 1khz and 7khz segments on the alignment tape

and confirm if the spec is meet in item #3. If not adjust

the azimuth screw to meet this spec.

3)Audio Level Spec: 1KHz ; 0.5

6KHz ; 1K

+_0.1Vrms

+_1.5dB

FE HEAD

P1

P0

ARM

TENSION

SUPPLY

REEL

P2

DRUM

P3

X-DISTANCE

ADJUST SCREW

A/C

HEAD

AZIMUTH

SCREW

TAKE-UP

REEL

PINCH

ROLLER

CONE POINT

SCREW

A/C HEAD

HEIGHT ADJUST NUT

P4

<Adjust Parts Location>

1-3. RF linearity check and adjustment

1)Adjust P2 & P3 so that the RF ENVELOPE waveform is

maximum and stabilized .

2)Check if the ENVELOPE waveform is at its maximum size

by pressing TRK UP(+) and DOWN(-) button one step.

CAPSTAN

TAPE

<Adjustment Waveform>

2. CIRCUIT ADJUSTMENT

T/UP

ARM

1. PG Adjustment

1-1. Necessary Instruments

1)Alignment tape SP

2)Oscilloscope

3)10 : 1 Probe

1-2.Adjustment

1)PLAY exclusive use of SP tape. (2HD: NORMAL TAPE)

2)Connect CH 1 of the Oscilloscope to J439 (H/SW) on the

MAIN PCB and VOL/DIV to 1V Range and Trigger the

Oscilloscope.

3)Connect CH 2 of the oscilloscope to J454 (Video Out) on

the main PCB and set the VOL/DIV to 500mV Range.

4)Set TIME/DIV of oscilloscope to 50

5) Adjust VR01 so that V-sync Falling Edge of Video signal

become 412

usec+_20usec.

Adjust waveform

us Range.

3-5

Adjust Period

<Adjust Waveform>

* CAUTION:Set the trigger mode of Oscilloscope to DC.

2. Normal REC Bias Level Adjustment

2-1. Necessary Instruments

1) Blank tape for Recording

2)RMS Meter

2-2. Adjustment

1) Set the TV/VCR to A/V input mode.

2)Insert a tape and press REC button.

3)Connect RMS Meter's (+), (-) to R401 on MAIN PCB.

4)Adjust VR401 so that the RMS Meter's indicator become

within 2.6mV

+_0.05mV.

3. Focus Voltage Adjustment

1)Receive the cross hatch pattern.

2)Press the PICTURE button to set the Standard ON

condition.

3)Adjust Focus control knob so that the focus of center &

circumference to be best.

4. Screen Adjustment

1)Press TV/AV button and select AV mode.

2)Adjust SCREEN control until the retrace line is visible and

return until the retrace line is invisible.

*HHHHoooowwww ttttoooo ggggeeeetttt iiiinnnnttttoooo SSSSVVVVCCCC mmmmooooddddeeee wwwwhhhheeeennnn yyyyoooouuuu ddddoooonnnn''''tttt hhhhaaaavvvveeee SSSSVVVVCC

RRRReeeemmmmooootttteeee CCCCoooonnnnttttrrrroooolllllllleeeerrrr..

PPPPuuuusssshhhh tttthhhheeee """"OOOOKKKK"""" KKKKeeeeyyyy oooonnnn tttthhhheeee uuuusssseeeerrrr''''ssss RRRReeeemmmmooootttteeee CCCCoooonnnnttttrrrroooolllllllleeeerrrr aaaannnndddd llllooooccccaaaall

""""OOOOKKKK"""" bbbbuuuuttttttttoooonnnn aaaatttt tttthhhheeee ssssaaaammmmeeee ttttiiiimmmmeeee..

..

..

5. VCO Adjustment

1)Select channel 0.

2) Input PAL Digital pattern (175.25MHz).

3)Press SVC Key on the Service Remote Controller to get

into SVC mode and press PR +/- Key to select VCO.

4)Press VOL +/- Key until OK is displayed on the screen.

7. RF AGC Adjustment

1)Input PAL DIGITAL PATTERN.

2)Connect DMM to AGC(J232) test point on the Main PCB.

3)Press SVC Key on the Service Remote Controller to get

into SVC mode and press PR +/- Key to select AGC.

4) Press VOL +/- Key until DMM reads the data on the table

below.

MODEL

2 TUNER

1 TUNER

NNNNooootttteeee ::::When adjusting 2 TUNER Model, select BOOSTER OFF

Electric fields strength

AGC Voltage

Electric fields strength

AGC Voltage

from MENU.

KL/KB/KI

70dBu 1dBu

5.5 0.1Vdc

65dBu 1dBu

5.6 0.1Vdc

8. White Balance Adjustment

1)Input a signal which lower half is black and upper half is

white.

2) Set the picture at standard on.

3)Press SVC Key on the Service Remote Controller to get

into Service mode.

4)Press PR +/- Key to select BG, RG.

Press VOL +/- Key until X=281

*GG is fixed data at 32 so, do not adjust GG data.

+_3, Y=288+_3.

9. Deflection Data Adjustment

1)Input PAL Digital Pattern.

2)Press SVC Key on the Service Remote Controller and

select LINE SERVICE 2 mode.

3)Press PR +/- Key to select an adjustment mode.

4) Press VOL +/- Key to adjust data.

5) Vertical SLOPE adjustment

a) Select V-SLP mode with PR +/- Key.

b) Press VOL +/- Key until the horizontal center line of

CC

ll

the large circle coincides with Blanking Line.

6) Vertical amplitude adjustment

a) Select V-AMP mode with PR +/- Key.

b) Press VOL +/- Key until the upper and lower end of the

large circle reach 5 mm inside from the effective area

of CPT.

7) Vertical Shift Adjustment

a) Select V-SFT mode with PR +/- Key.

b) Press VOL +/- Key until the horizontal center coincides

with the vertical sign slot mark of CPT.

6. LCO Adjustment

1)Select channel 99.

2) Input SECAM-L' pattern (55.75MHz).

3)Press SVC Key on the Service Remote Controller to get

into SVC mode and Press PR +/- Key to select LCO.

4)Press VOL +/- Key until OK is displayed on the screen.

3-6

8) Horizontal Shift Adjustment

a) Select H-SFT mode with PR +/- Key.

b) Press VOL +/- Key until the vertical center coincides

with the horizontal sign slot mark of CPT.

9) Vertical S-Correction Adjustment

a) Select S-COL mode with PR +/- Key.

b) Press VOL +/- Key until the grid of Cross Hatch

Pattern is even all over the screen.

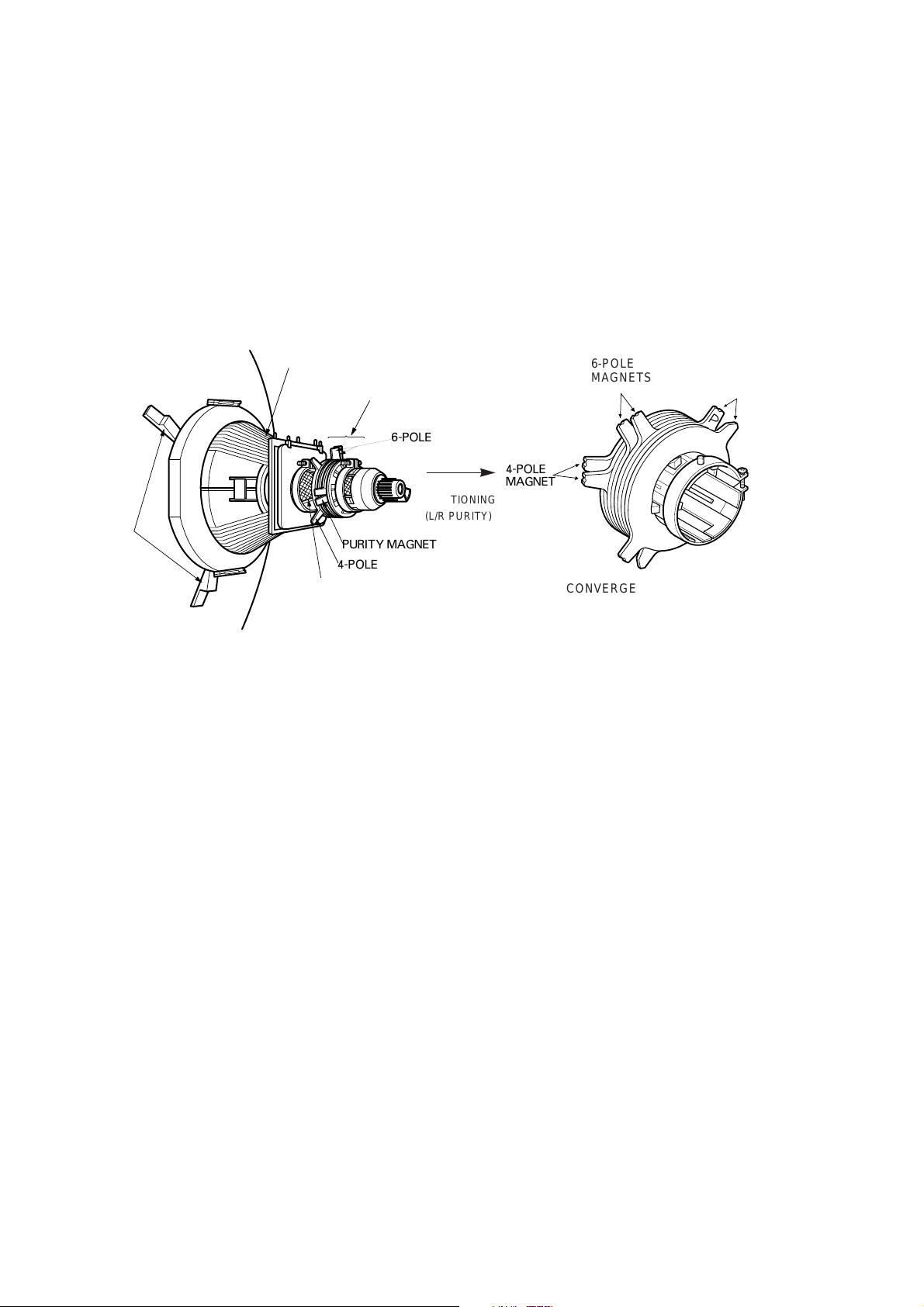

PURITY & CONVERGENCE ADJUSTMENT

Caution:

Convergence and Purity have been factory aligned. Do not

attempt to tamper with these alignments.

However, the effects of adjacent receiver components, or

replacement of picture tube or deflection yoke may require the

need to readjust purity any convergence.

DEFLECTION YOKE

PURITY &CONVERGENCE

MAGNET ASSEMBLY

6-POLE

,,,

RUBBER

WEDGES

,,

,,

,,,

PURITY MAGNET

4-POLE

GLASS CLOTH TAPE

X-AXIS YOKE

POSITIONING

(L/R PURITY)

5.Reconnect the internal degaussing coil.

6. Position the beam bender locking rings at the 9 o'clock

position and the other three pairs of tabs (2,4 and 6 pole

magnets) at the 12 o'clock position.

6-POLE

6-POLE

MAGNETS

4-POLE

MAGNET

MAGNES

CONVERGENCE MAGNET ASSEMBLY

CONVERGENCE MAGNET ASSEMBLY

PURITY MAGNET(2-POLE)

* Purity Adjustment

This procedure DOES NOT apply to bonded yoke and picture

tube assemblies.

The instrument should be at room temperature (60 degrees F or

above) for six (6) hours and be operating at low beam current

(dark background) for approximately 20 to 30 minutes before

performing purity adjustments.

CAUTION:Do not remove any trim magnets that may be

attached to the bell of the picture tube.

1. Remove the AC power and disconnect the internal

degaussing coil.

2. Remove the yoke from the neck of the picture tube.

3. If the yoke has the tape version beam bender, remove it and

replace it with a adjustable type beam bender (follow the

instructions provided with the new beam bender)

4. Replace the yoke on the picture tube neck, temporarily

remove the three (3) rubber wedges from the bell of the

picture tube and then slide the yoke completely forward.

7. Perform the following steps, in the order given, to prepare the

receiver for the purity adjustment procedure.

a. Face the receiver in the "magnetic north" direction.

b. Externally degauss the receiver screen with the television

power turned off.

c. Turn the television on for approximately 10 seconds to

perform internal degaussing and then turn the TV off.

d. Unplug the internal degaussing coil. This allows the

thermistor to cool down while you are performing the purity

adjustment. DO NOT MOVE THE RECEIVER FROM ITS

"MAGNETIC NORTH" POSITION.

e. Turn the receiver on and obtain a red raster by increasing

the red bias control (CW) and decreasing the bias controls

for the remaining two colors (CCW).

f. Attach two round magnets on the picture tube screen at 3

o'clock and 9 o'clock positions, approximately one (1) inch

from the edge of the mask (use double-sided tape).

3-2

1.ADJUST YOKE Z-AXIS FIRST

TO GET EQUAL BLUE

COLOR CIRCLES

MAGNETS

RED RED

2 .ADJUST BEAM BENDER 2 POLE

MAGNET TO GET FOUR EQUAL

COLOR CIRCLES

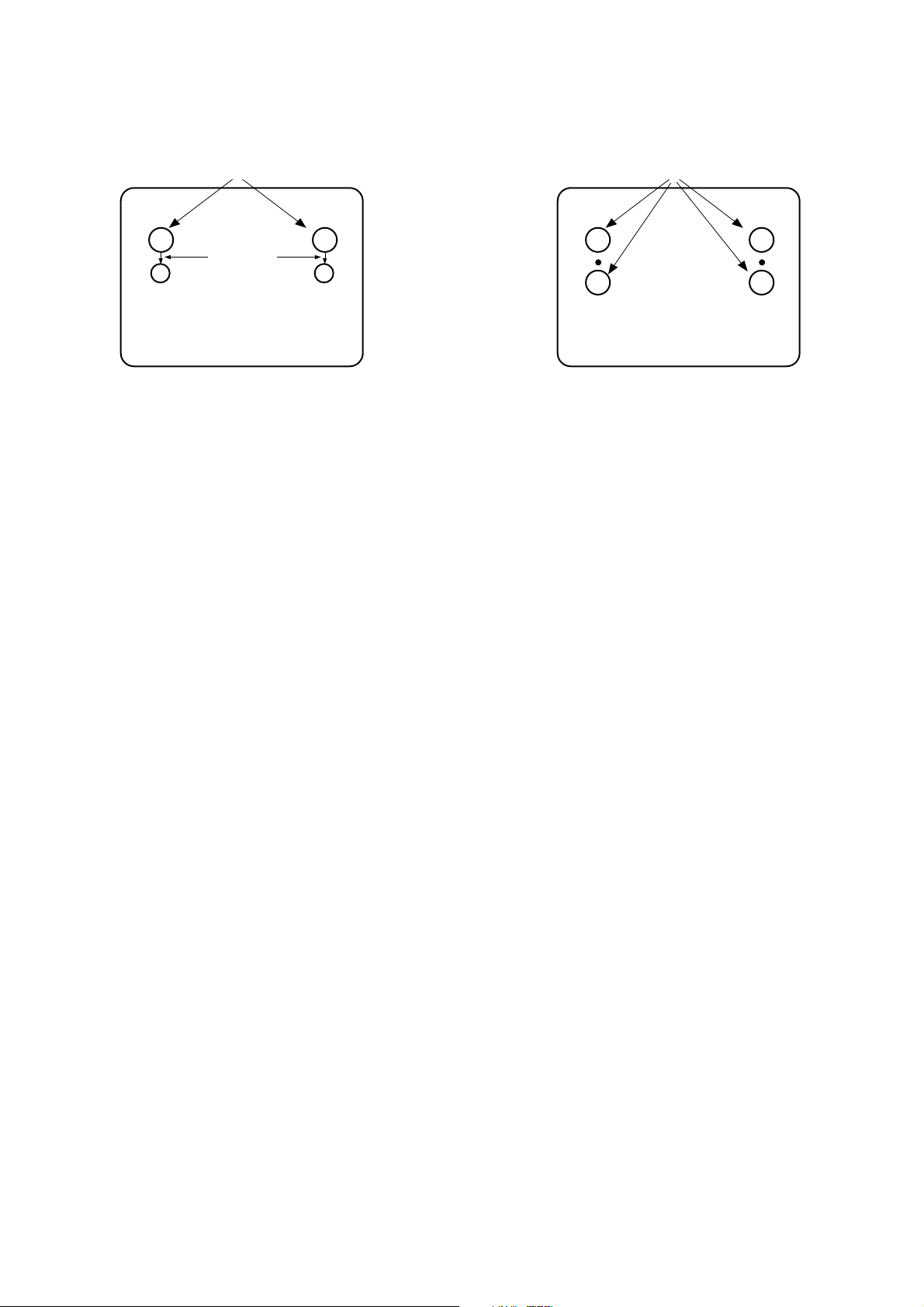

8. Referring to above, perform the following two steps:

a. Adjust the yoke Z-axis to obtain equal blue circles.

b. Adjust the appropriate beam bender tabs to obtain correct

purity (four equal circles).

9. After correct purity is set, tighten the yoke clamp screw and

remove the two screen magnets.

10.Remove the AC power and rotate the receiver 180 degrees

(facing "magnetic south").

11. Reconnect the internal degaussing coil.

12. Turn the receiver on for 10 seconds (make sure the receiver

came on) to perform internal degaussing, and then turn the

receiver off.

13. Unplug the internal degaussing coil.

14. Turn on the receiver and check the purity by holding one (1)

round magnet at the 3 o'clock and a second round magnet at

9 o'clock position. If purity is not satisfactory, repeat steps 8

through 14.

15. Turn off the receiver and reconnect the internal degaussing

coil.

* Convergence Adjustment

Caution:This procedure DOES NOT apply to bonded yoke and

picture tube assemblies.

Do not use screen magnets during this adjustment

procedure. Use of screen magnets will cause an

incorrect display.

1. Remove AC power and disconnect the internal degaussing

coil.

2. Apply AC Power and set the brightness to the Picture Reset

condition. Set the Color control to minimum.

3. Apply 8V to the pin.

6. Reconnect the internal degaussing coil and apply AC power.

7. Turn the receiver on for 10 seconds to perform internal

degaussing and then turn the receiver off again.

8. Unplug the internal degaussing-coil.

9. Turn on the receiver, connect a signal generator to the VHF

antenna terminal and apply a crosshatch signal.

Caution:During the convergence adjustment procedure, be

very careful not to disturb the purity adjustment tabs

are accidentally move, purity should be confirmed

before proceeding with the convergence adjustments.

Note:

Make sure the focus is set correctly on this instrument

before proceeding with the following adjustment.

10. Converge the red and blue vertical lines to the green vertical

line at the center of the screen by performing the following

steps (below TABLE).

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in opposite directions from the 12 o'clock

position to converge the red and blue vertical lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in opposite directions form the 12 o'clock

position to converge the red and blue (now purple)

vertical lines with the green vertical line.

11. Converge the red and blue horizontal with the green line at

the center of the screen by performing the following steps.

(below TABLE)

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in the same direction (keep the spacing

between the two tabs the same) to converge the red and

blue horizontal lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in same direction (keep the spacing

between the two tabs the same) to converge the red and

blue (now purple) horizontal lines with the green

horizontal line.

c. Secure the tabs previsouly adjusted by locking them in

place with the locking tabs on the beam bender.

4. Adjust the Red, Green and Blue Bias controls to get a dim

white line.

5. Remove the AC power and 8V from the pin.

3-3

3-4

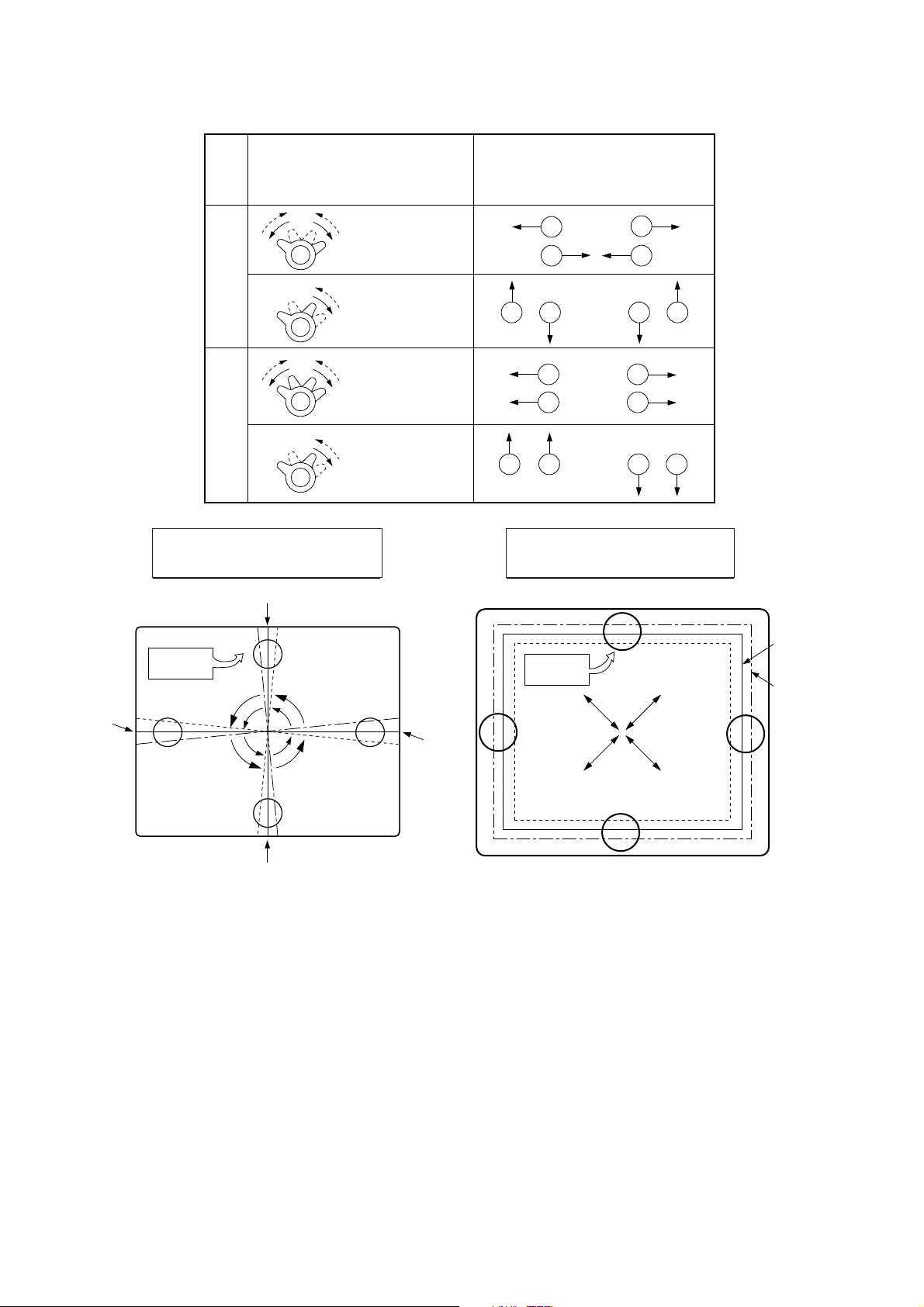

RING

PAIRS

4

POLE

ROTATION DIRECTION

OF BOTH TABS

OPPOSITE

SAME

OPPOSITE

SAME

MOVEMENT OF RED

AND BLUE BEAMS

B B

RR

OR

OR

B R B R

OR

B

R

B

R

B R

OR

B

R

6

POLE

12. While watching the 6 o'clock positions on the screen, rock the

front of the yoke in a vertical (up/down) direction to converge

the red and blue vertical lines. (Fig upper left)

13. Temporarily place a rubber wedge at the 12 o'clock position

to hold the vertical position or the yoke.

14.

Check the 3 o'clock and 9 o'clock areas to confirm that the red

and blue horizontal lines are converged.

If the lines are not converged, slightly offset the vertical tilt of the

yoke (move the rubber wedge if necessary) to equally balance the

convergence error of the horizontal lines at 3 o'clock and 9 o'clock

and the vertical lines at 6 o'clock and 12 o'clock.

15. Place a 1.5 inch piece of glass tape over the rubber foot at

the rear of the 12 o'clock wedge.

16. While watching the 6 o'clock and 12 o'clock areas of the

screen, rock the front of the yoke in the horizontal (left to

right) motion to converge the red and blue horizontal lines.

(Fig. upper right)

17. Temporarily place a rubber wedge at the 5 o'clock and 7

o'clock positions to hold the horizontal position of the yoke.

18. Check the 3 o'clock and 9 o'clock areas to confirm that the

red and blue vertical lines are converged. If the lines are not

converged, slightly offset the horizontal tilt of the yoke (move

the temporary rubber wedges if necessary) to equally

balance the convergence error of the horizontal lines at 6

o'clock and 12 o'clock and the vertical lines at 3 o'clock and 9

o'clock.

19. Using a round magnet confirm purity at the center, right and

left sides and corners. See Purity Adjustment Procedure.

20. Reconfirm convergence and apply a 1.5 inch piece of glass

tape over the rubber foot at the rear of the 5 o'clock and the 7

o'clock wedges.

RED

BLUE

RED BLUE

BLUE

RED

GREEN

GREEN

BLUE RED

GREEN

GREEN

ADJUSTMENT

VIEWING

AREA

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

ADJUSTMENT

VIEWING

AREA

RED

RED

GREEN

TV

SCREEN

LEET/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF

THE RED AND BLUE RASTERS

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

LEFT/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF THE

RED AND BLUE RASTERS

Loading...

Loading...