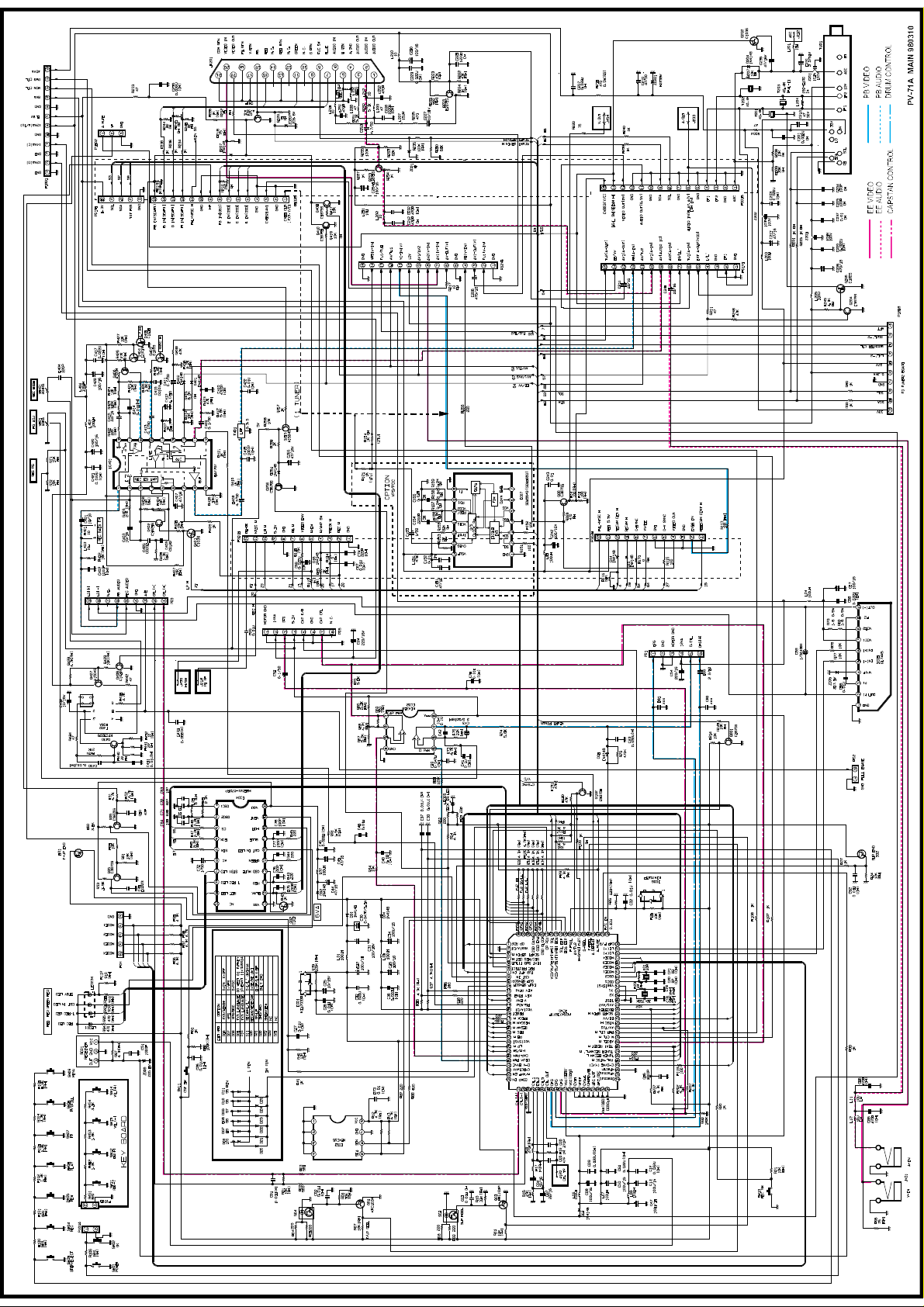

Page 1

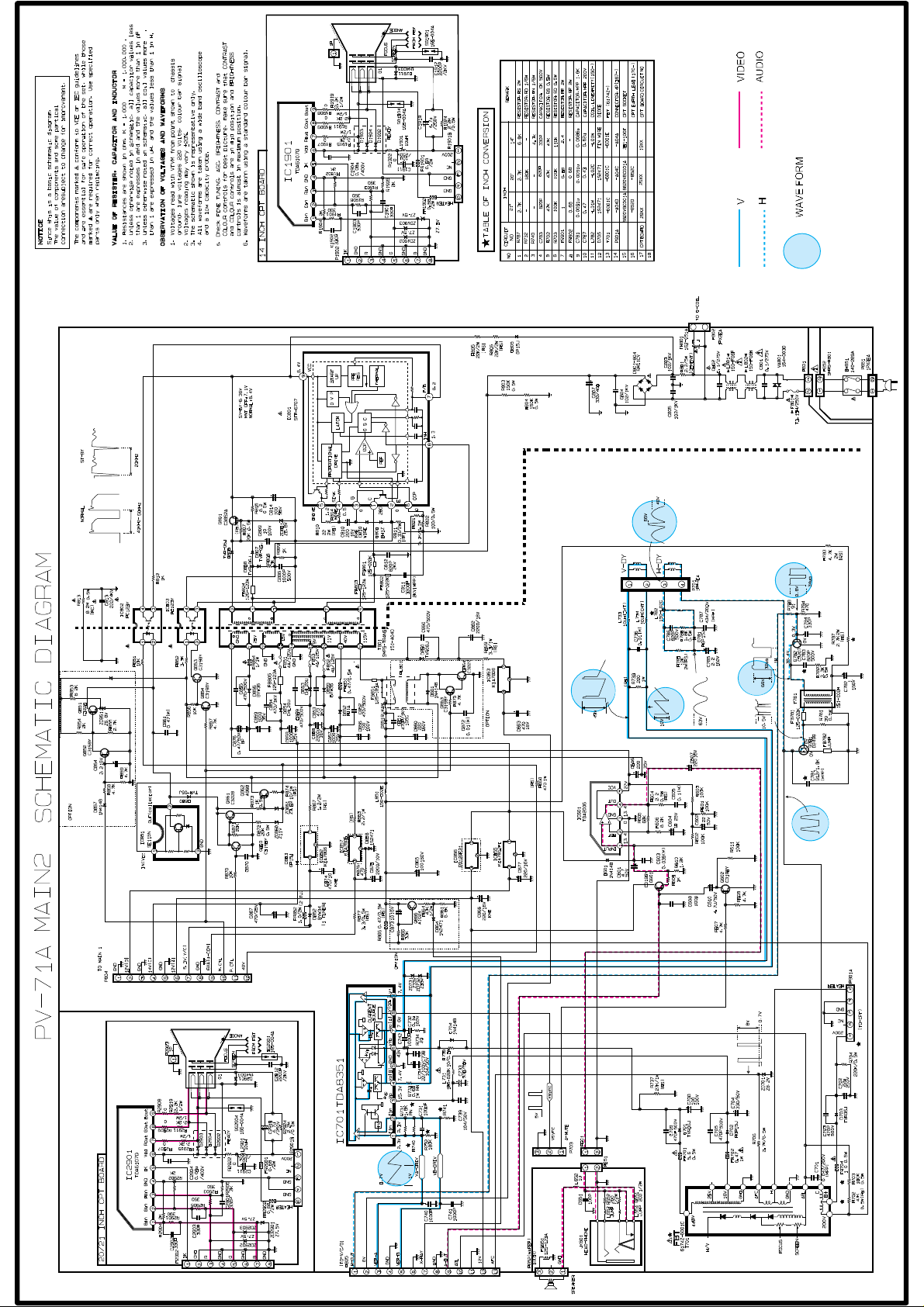

Page 2

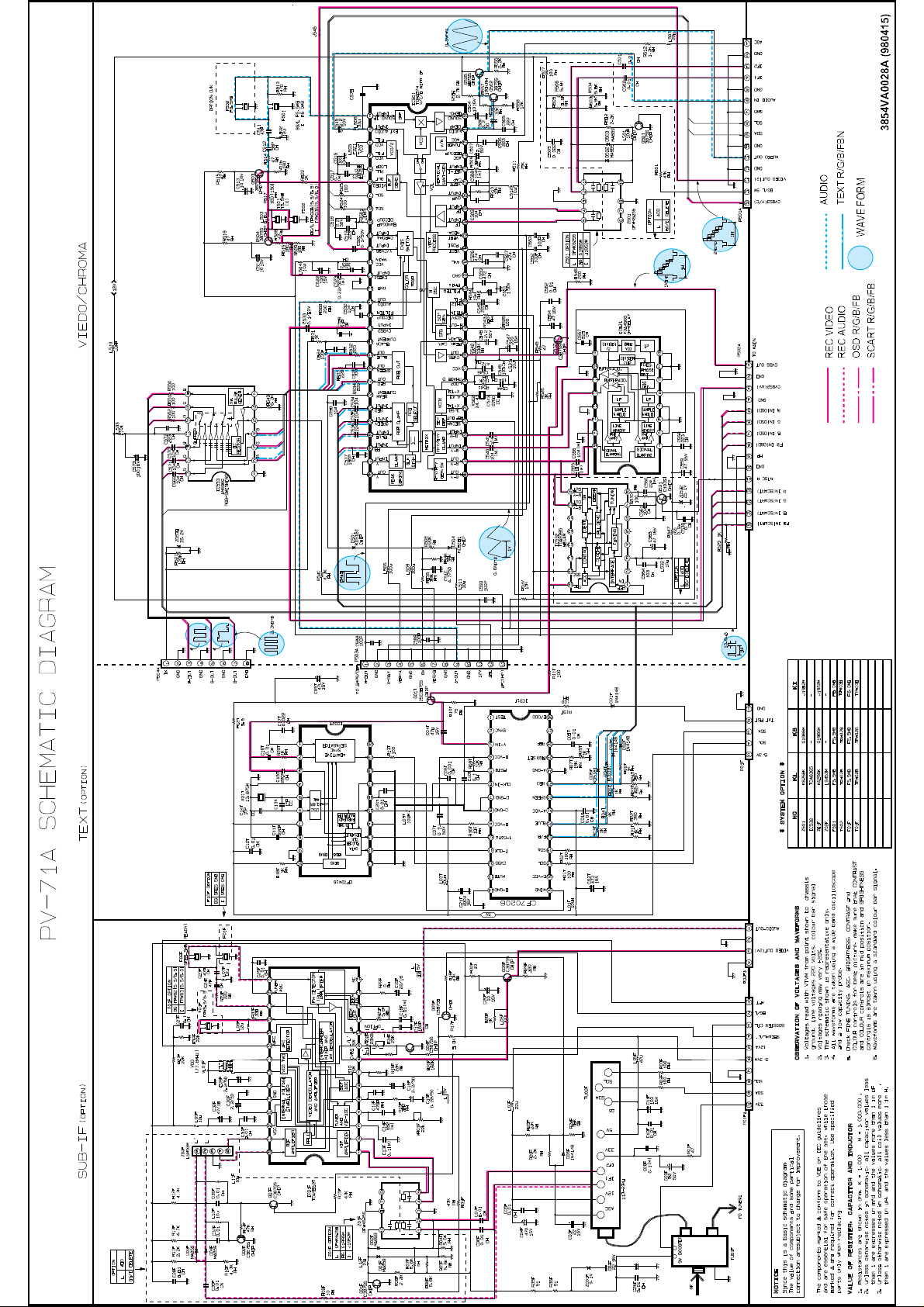

Page 3

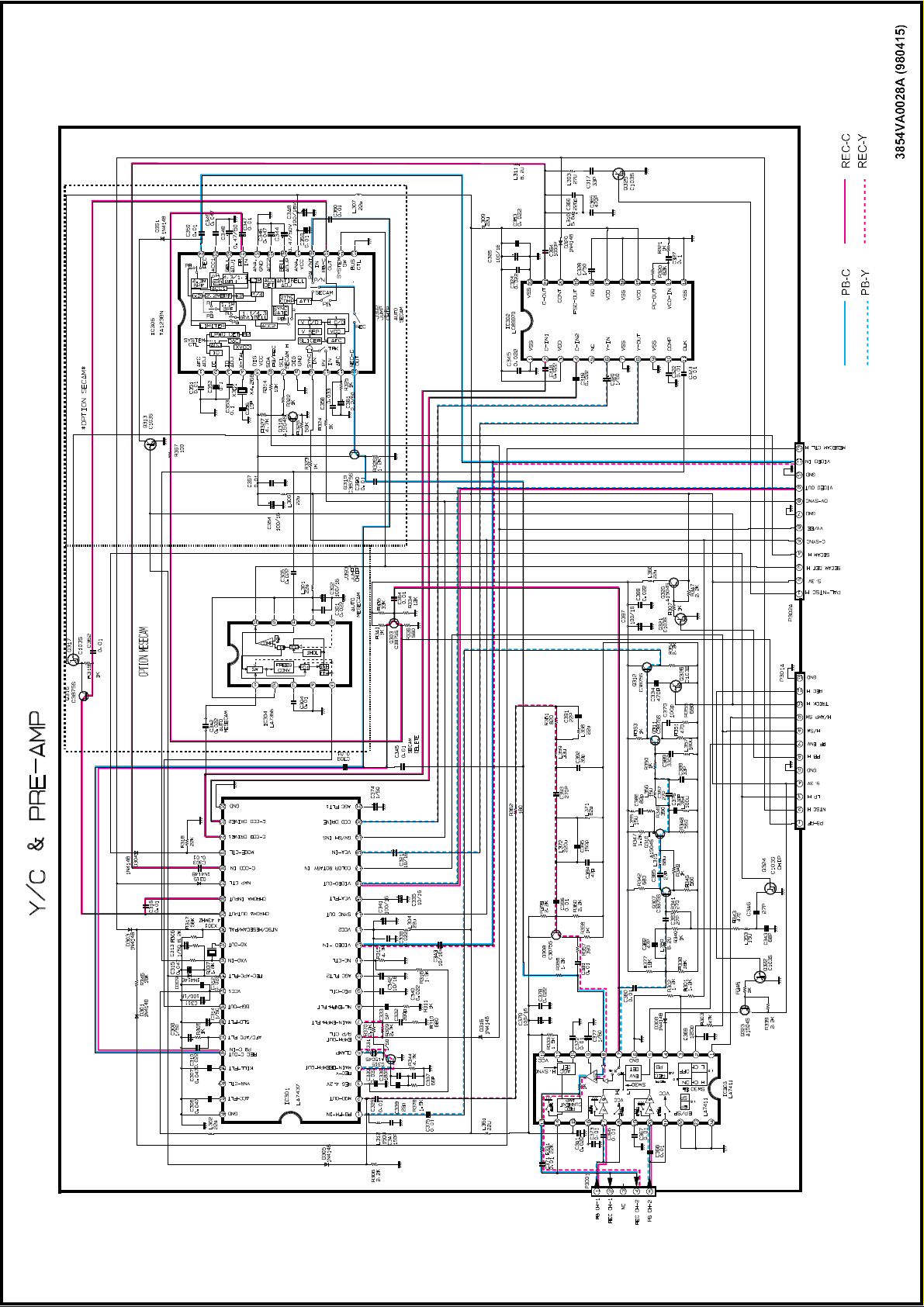

Page 4

Page 5

Page 6

Model

FACTORY.

Buyer

EFFECTIVE DATE

Subject

SERVICE BULLETIN

KI-14U71

KI-14U71X

KI-20U71

KI-20U72X

GB000001

31/05/1998

Improvement of the reliability

EFFECTIVE FROM(SERIAL NO.)

No. : VSB-85030

Date : 08/06/1998

From the shipment

on June 1998

No. LOC NO.

Before Change After Change

PART NO. DESC./SPEC. PART NO. DESC./SPEC.

1 4814V00016A

SHIELD

BUTTOM

4814V00016B

SHIELD

MAIN 1 SBHG-1 . BOTTOM

Reason Of Change

Symptom : "HUM" in sound when playing a tape recorded in SET.

Countermeasure : Add a silicon shield plate to SHIELD BOTTOM.

** FILE THIS SERVICE BULLETIN WITH YOUR SERVICE MANUAL

NOTE(**) : INTERCHANGEABILITY CODE KEY-WORD CODE

Parts Set

Original

A

New

Original

B

New

Original

C

New

Original

D

New

Original or new parts may be used in early or

Early

late production sets.

Late

Use original parts until exhausted, then stock

new parts.

Original parts may be used in early production

sets only.

Early

New parts may be used in early or late production

sets.

Late

Use original parts where possible, then stock new

parts.

New parts only may be used in early or late

Early

production sets.

Late

Stock new parts.

Original parts only may be used in early

Early

production sets.

New parts may be used in late production sets

Late

only.

Stock original and new parts.

1. To improve performance

2. To improve productivity

3. To improve reliability

4. Change of material or

dimension

5. Addtion

6. Deletion

7. Correction

Note

K-

CODE

B 3

Remark

CHIEF ENGINEER ,

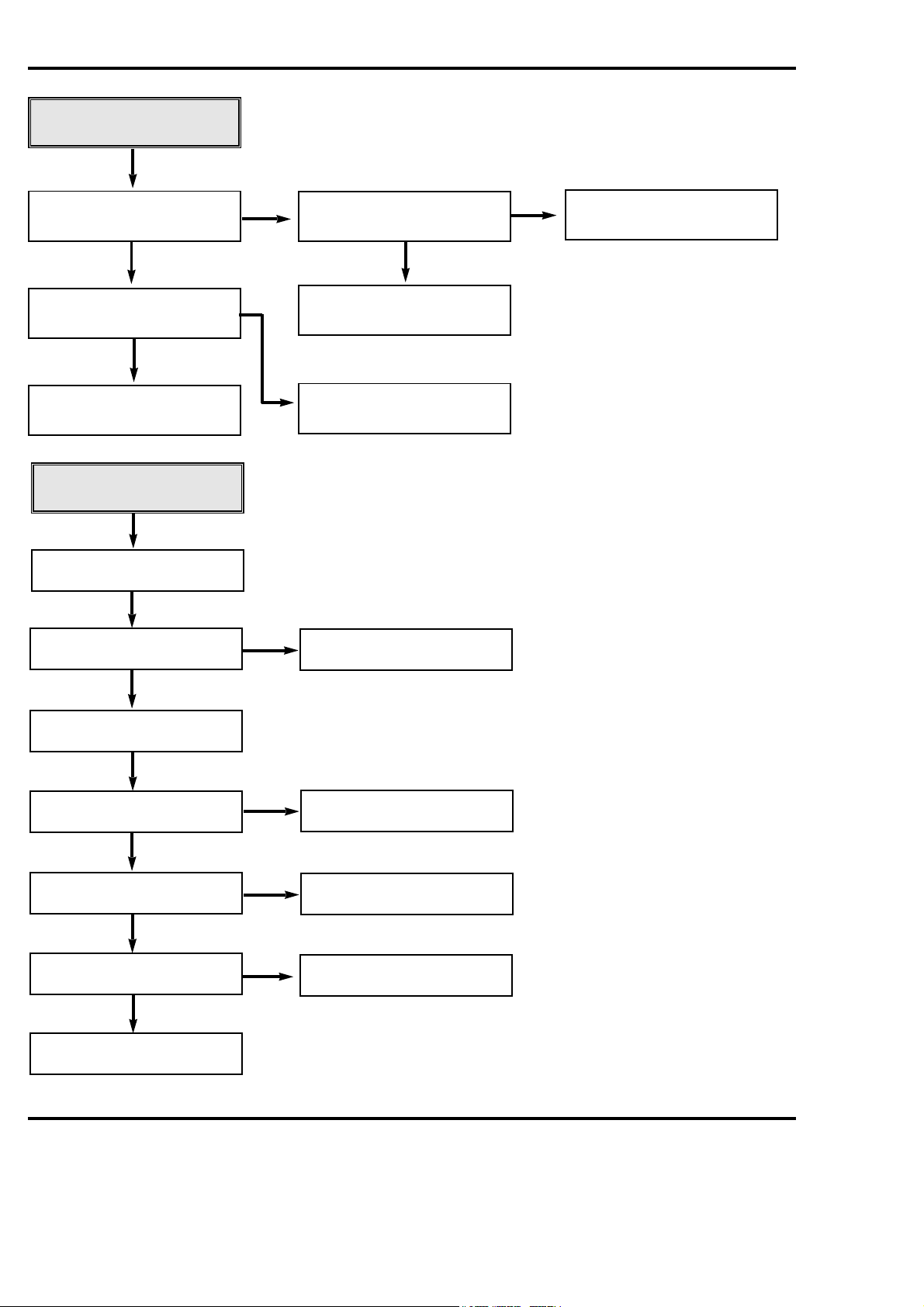

Page 7

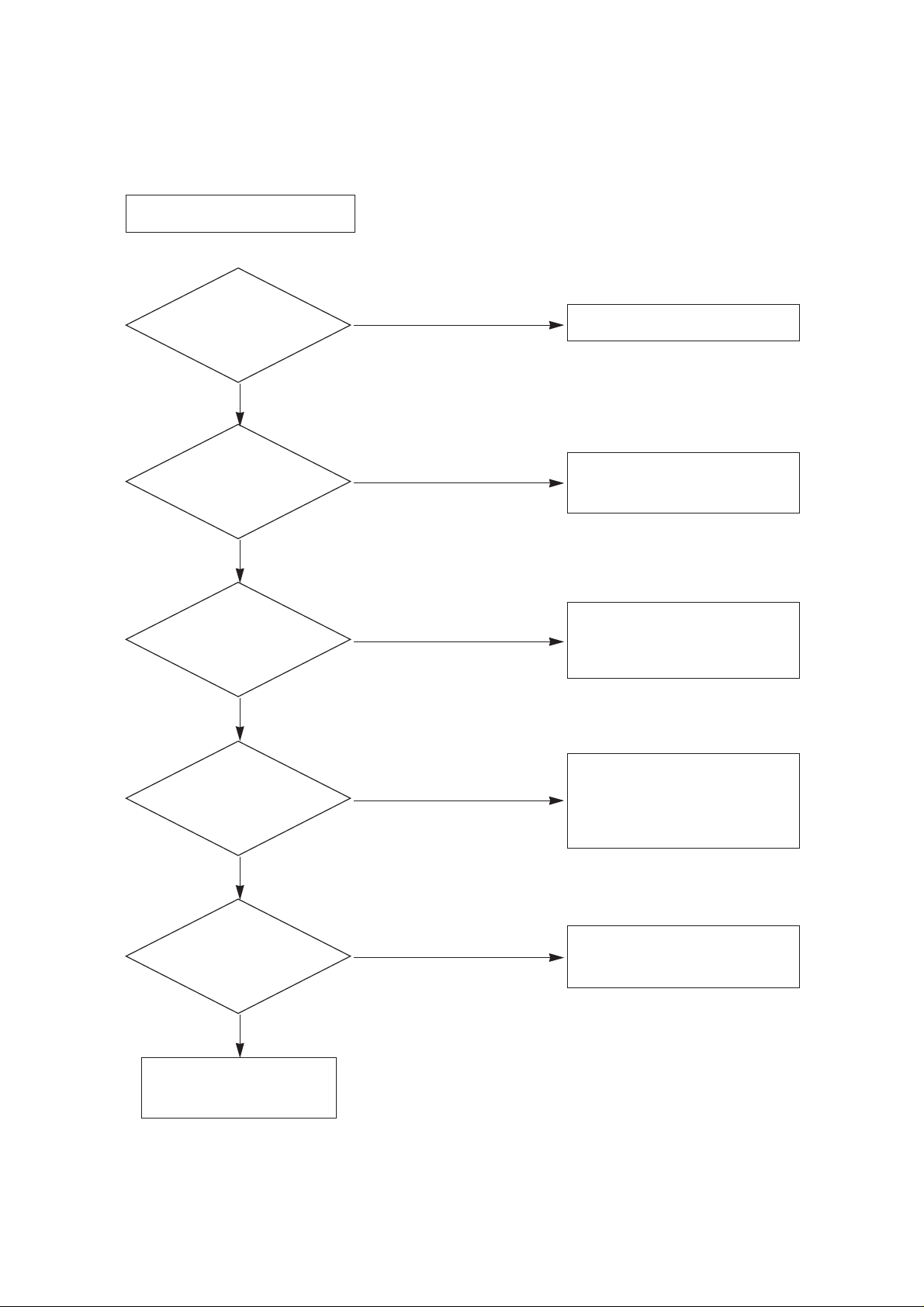

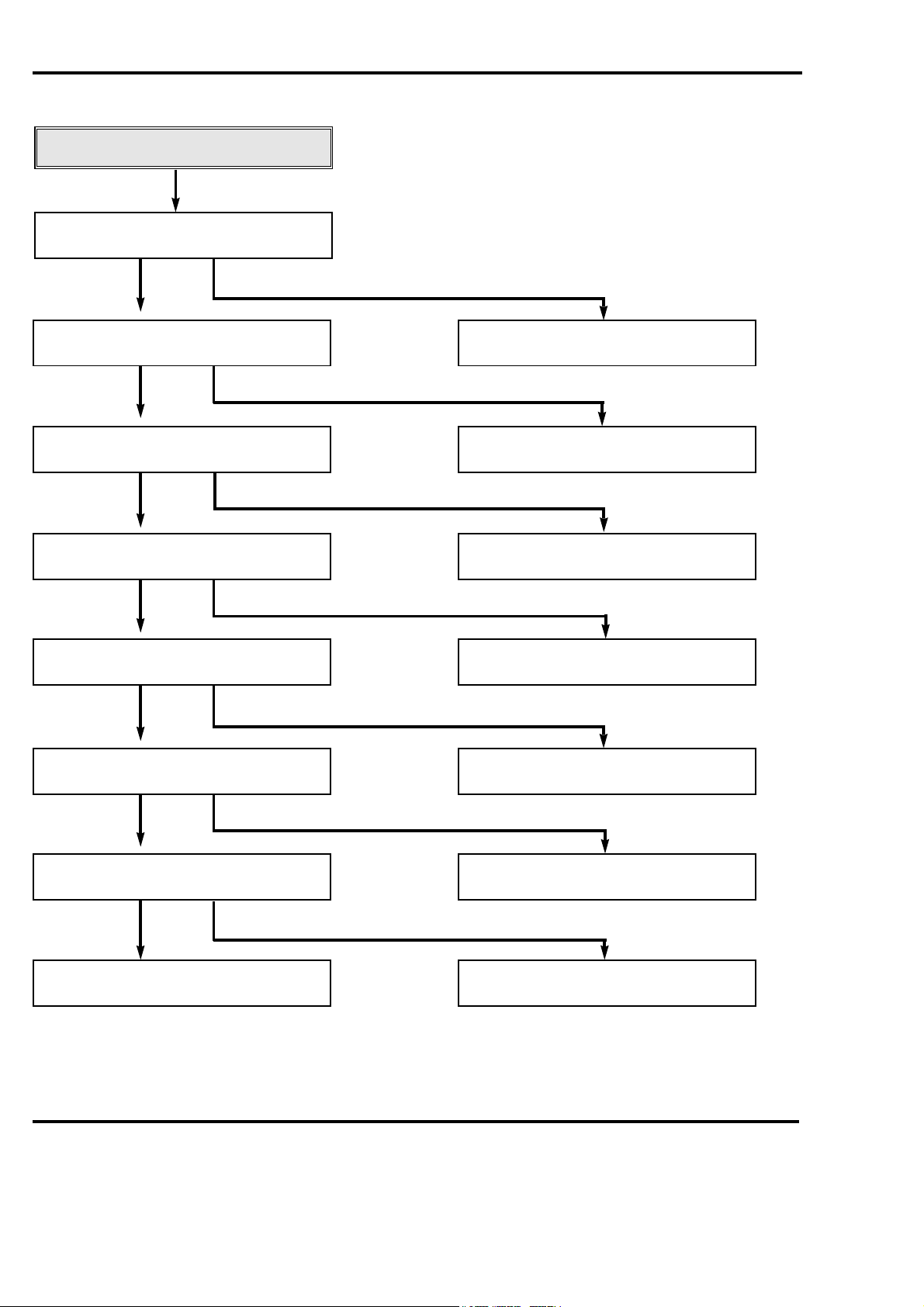

1

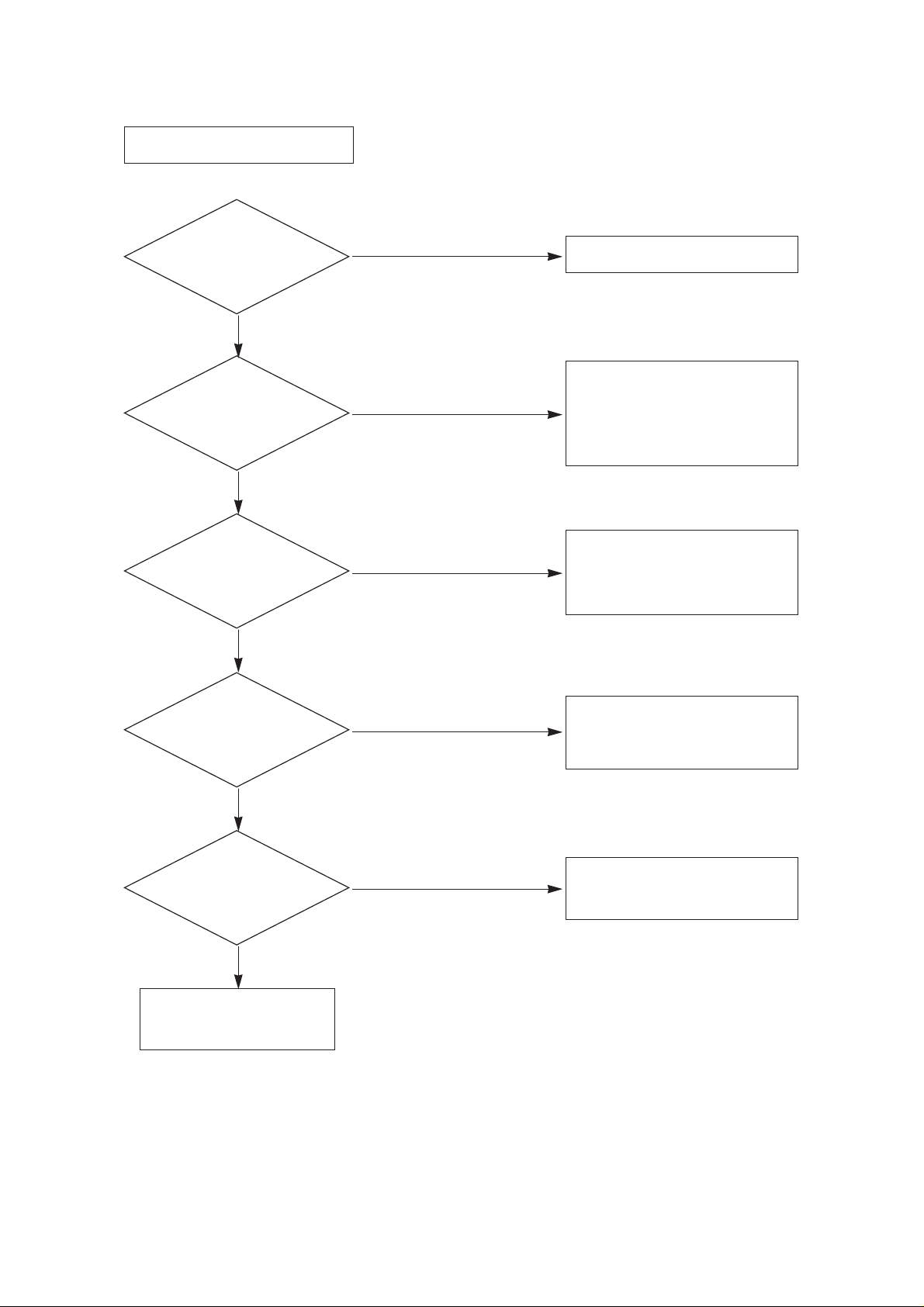

Is there about 6V

at pin 9 of P804?

YES

Is there about 11V

at '+' terminal

of C856?

YES

Is there about 6.1V

at pin 9 of IC801?

YES

Is there voltage at

pin 9 of T801?

YES

NO POWER : NO STAND-BY

Replace the Fuse

Check the 6V Line

of MAIN 1 BOARD

Check if the

Fuse is O.K.?

YES

NO

Check/Replace

D801, D802, 803, 804, R801, C807.

NO

Check/Replace

D806, Q801, R807, ZD801, C814,

IC801.

NO

¡ Check/Replace FR851, D852,

C856, Q860, Q861, Q862,

ZD860, ZD861, R874.

¡ Check the pin 11 of P804 :

'LOW"

NO

Check/Replace

R863, IC857, D858, R877, C875

NO

TROUBLE SHOOTING

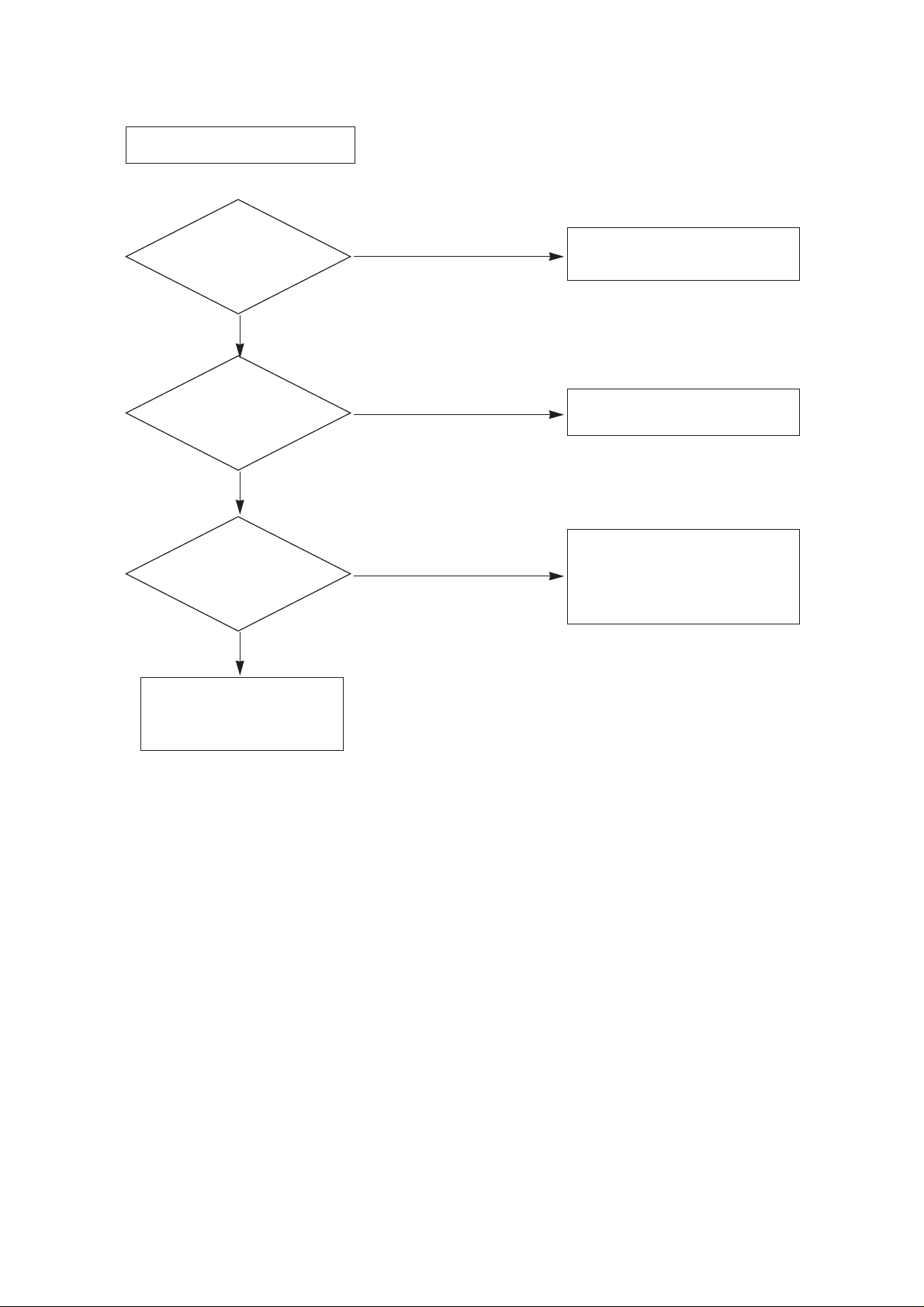

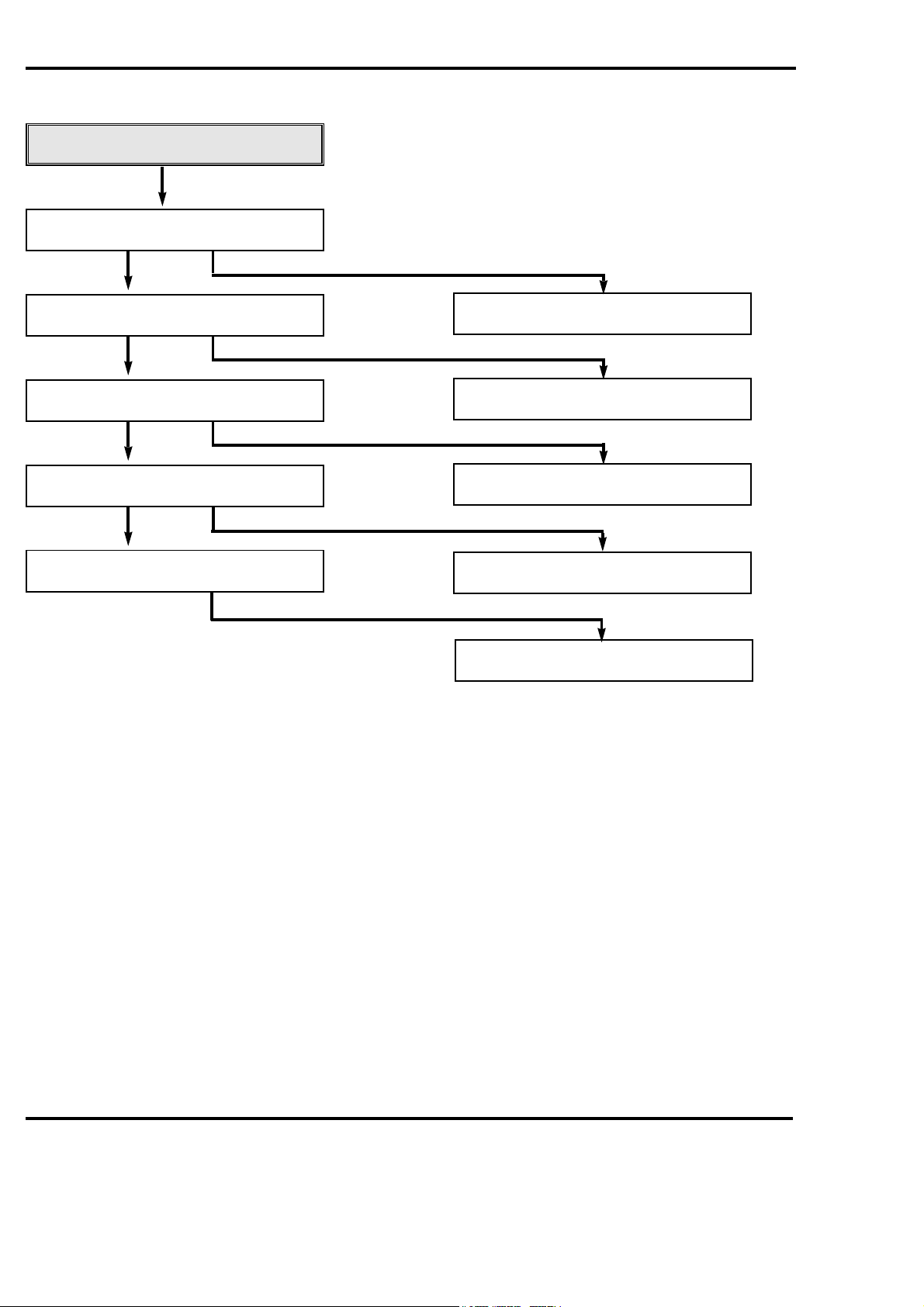

Page 8

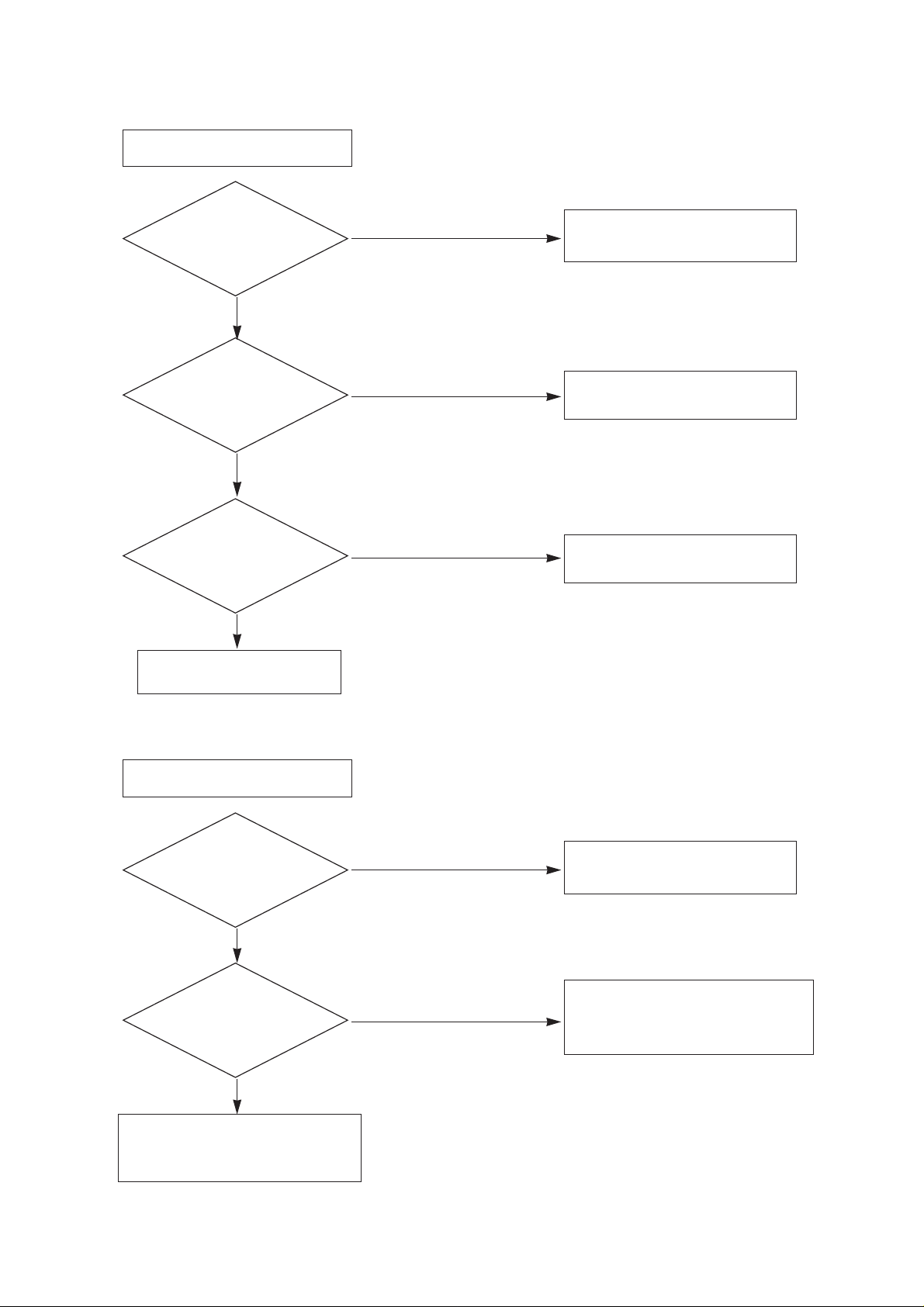

2

Is there about 115V

at '+' terminal of C865?

YES

Is there about

6V at pin 9 of P804?

YES

NO POWER : NO MONITOR ON

Go to NO POWER (NO ST-BY)

BLOCK

Go to NO RASTER BLOCK

Check T701, Q781 and go to

NO RASTER BLOCK

Check the

NO POWER(NO ST-BY)

BLOCK

YES

NO

Check the pin 10 of P804 ; "HIGH"

NO

¡ Check/Replace D851, L851,

C860, IC851.

¡ Check the pin 10 of P804 :

'HIGH"

NO

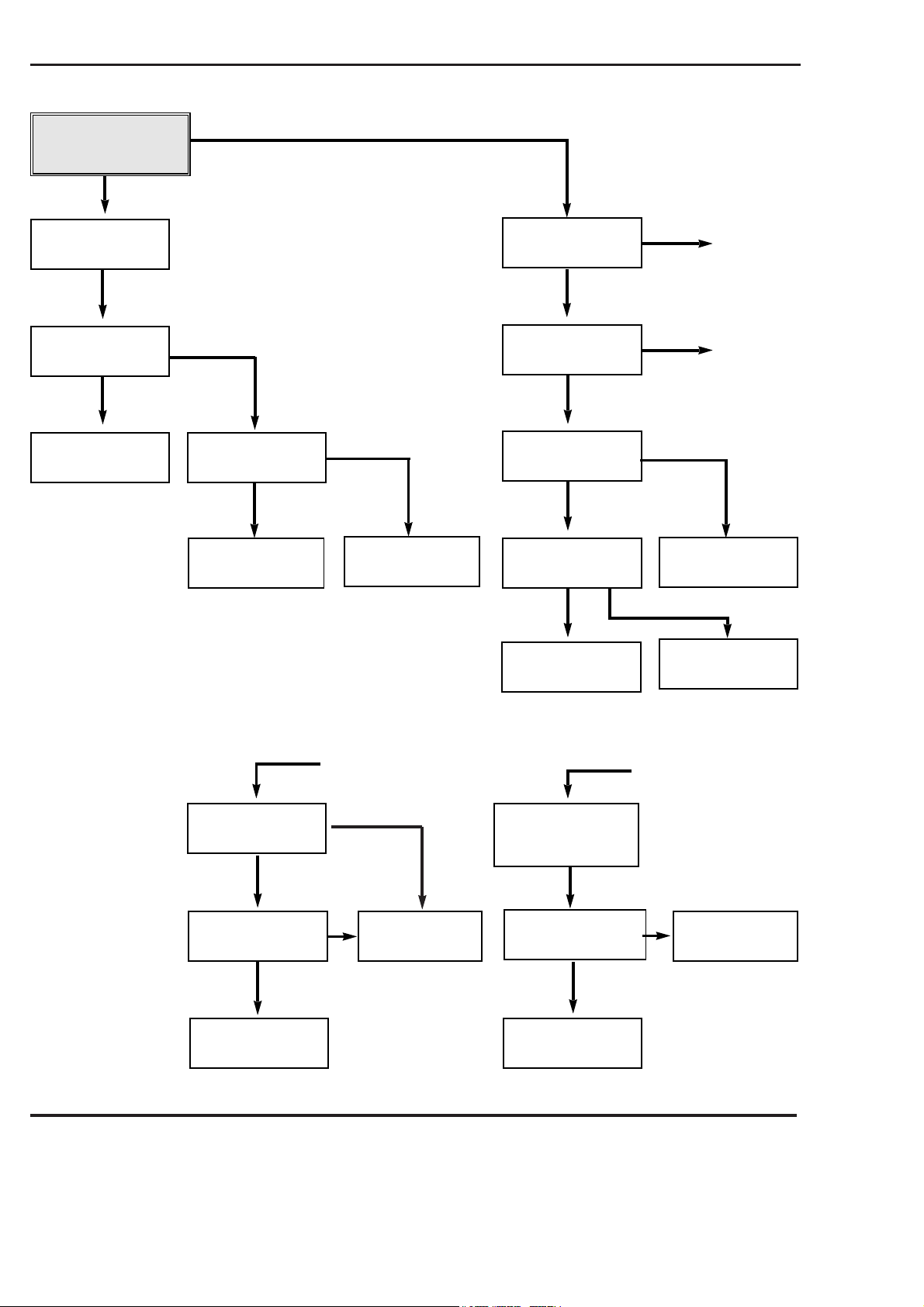

Page 9

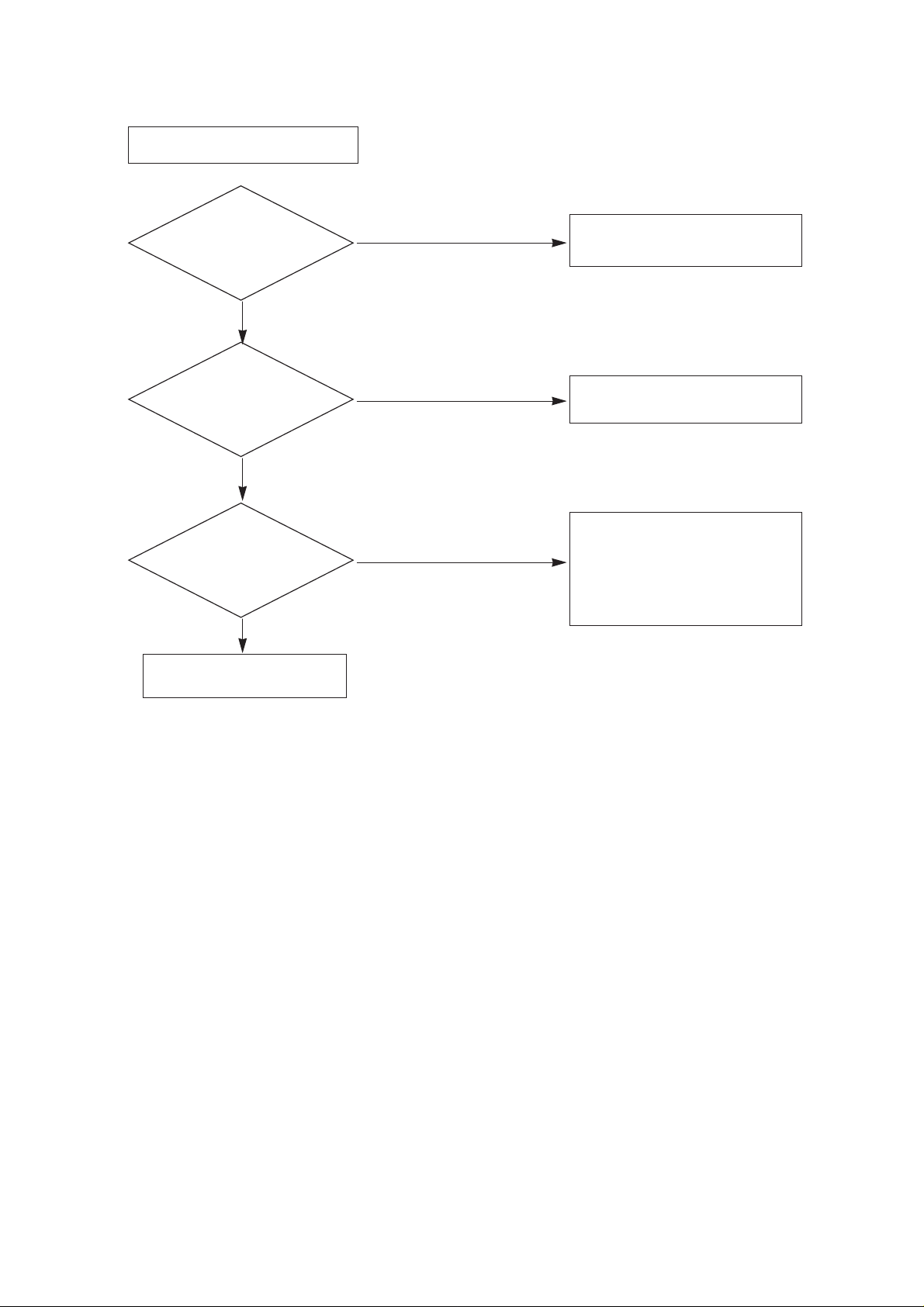

3

Is there about

6.3VAC at HEATER of CPT

SOCKET?

YES

Does the waveform

appear at the collector

of Q781?

YES

Does the square

waveform appear at pin 1 of

P805?

YES

Is there about 8V

at pin 6 of P805?

YES

NO RASTER

Go to NO POWER BLOCK

Go to NO PICTURE BLOCK

Is there about 115V

at pin 3 of T701?

YES

NO

¡ Check/Replace F852, D850,

C857, R899, IC853, C863.

¡ Check the 8V LINE of VCD

BOARD

NO

¡ Check the H-OUT LINE of VCD

BOARD.

¡ Check/Replace IC501 of VCD

BOARD.

NO

Check/Replace Q782, T781, R783,

R787, Q781.

NO

Check/Replace T701, 5PIN

CONNECTOR, FR2901, FR2902

(14" : FR1901)

NO

Page 10

4

Is there about

44V at pin 6 of IC701?

YES

Is there about

15V at pin 3 of

IC701?

YES

V. Deflection ERROR

Check the vertical part of VCD

BOARD

Check/Replace IC701

Does the V-A, V-B

signal appear at pin 4, 7

of P805?

YES

NO

Check/Replace FR702, D702, C704,

L731

Check;/Replace FR701, D701, C708,

L732, C734.

NO

Is there about

200V at pin 1 of P2901B?

(14" : P1901B)

YES

NO PICTURE

Check the CVBS line of VCD BOARD

(Refer to VCD BLOCK DIAGRAM)

¡ Check/Replace IC2901.

(14" : IC1901)

¡ Check screen voltage

Does the RGB signal

appear at pin 3, 5, 7 of

P2902? (14" : P1902)

YES

NO

Check/Replace FR704, D703, C702,

T701, 5PIN CONNECTOR, L2901,

R2924 (14" : L1901, R1924)

NO

NO

Page 11

5

Does the sound

signal appear at pin 4

of IC601?

YES

Does the sound

signal appear at pin 9

of P805?

YES

NO SOUND

Check/Replace FR854, D855, IC601.

Check/Replace speaker,

speaker connector.

Is there about

25V at pin 5

of IC601?

YES

NO

Check the Audio source line of

VCD BOARD

¡ Check the voltage at collector of

Q601.

¡ Check/Replace IC601, external

components of IC601.

NO

NO

Page 12

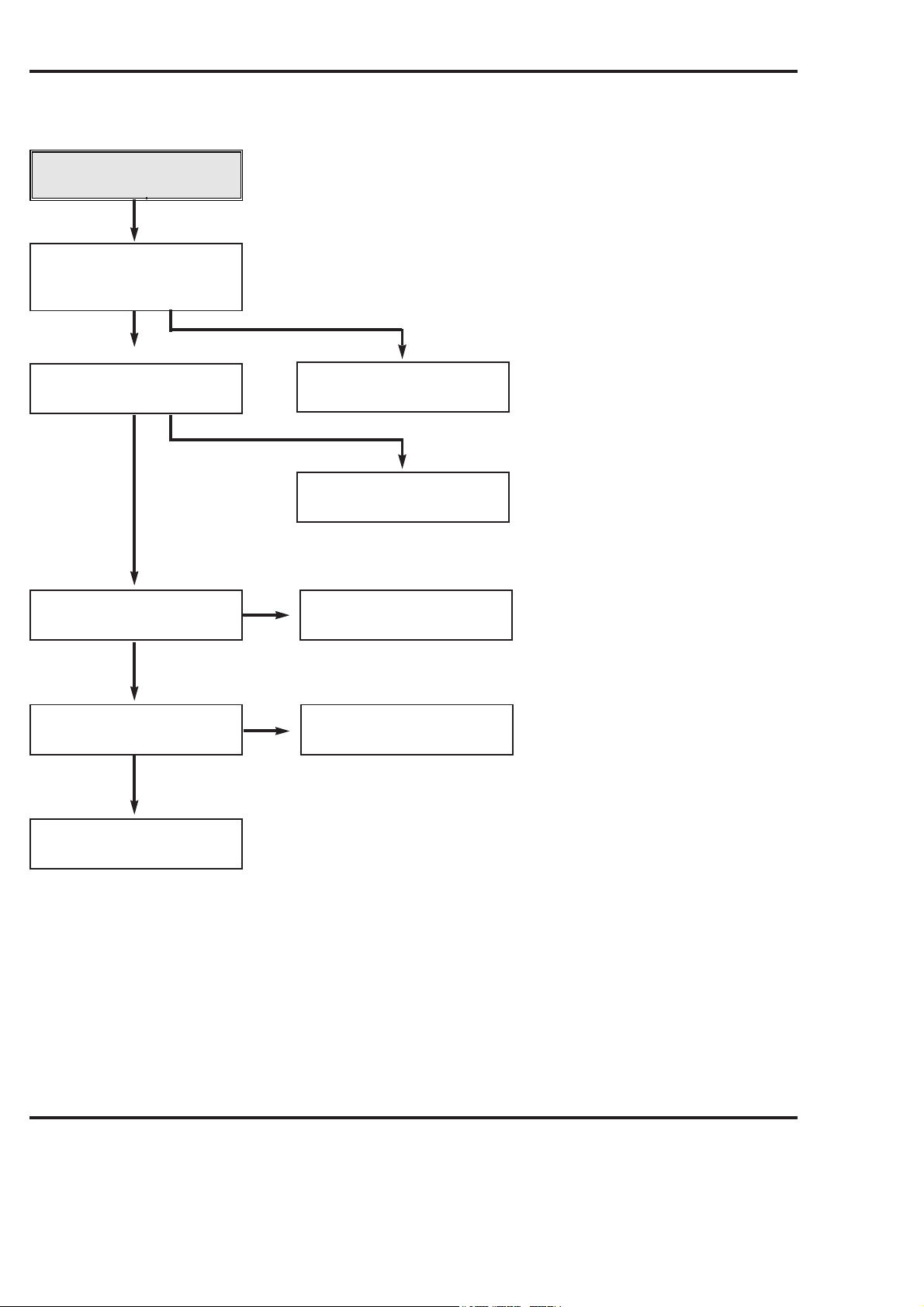

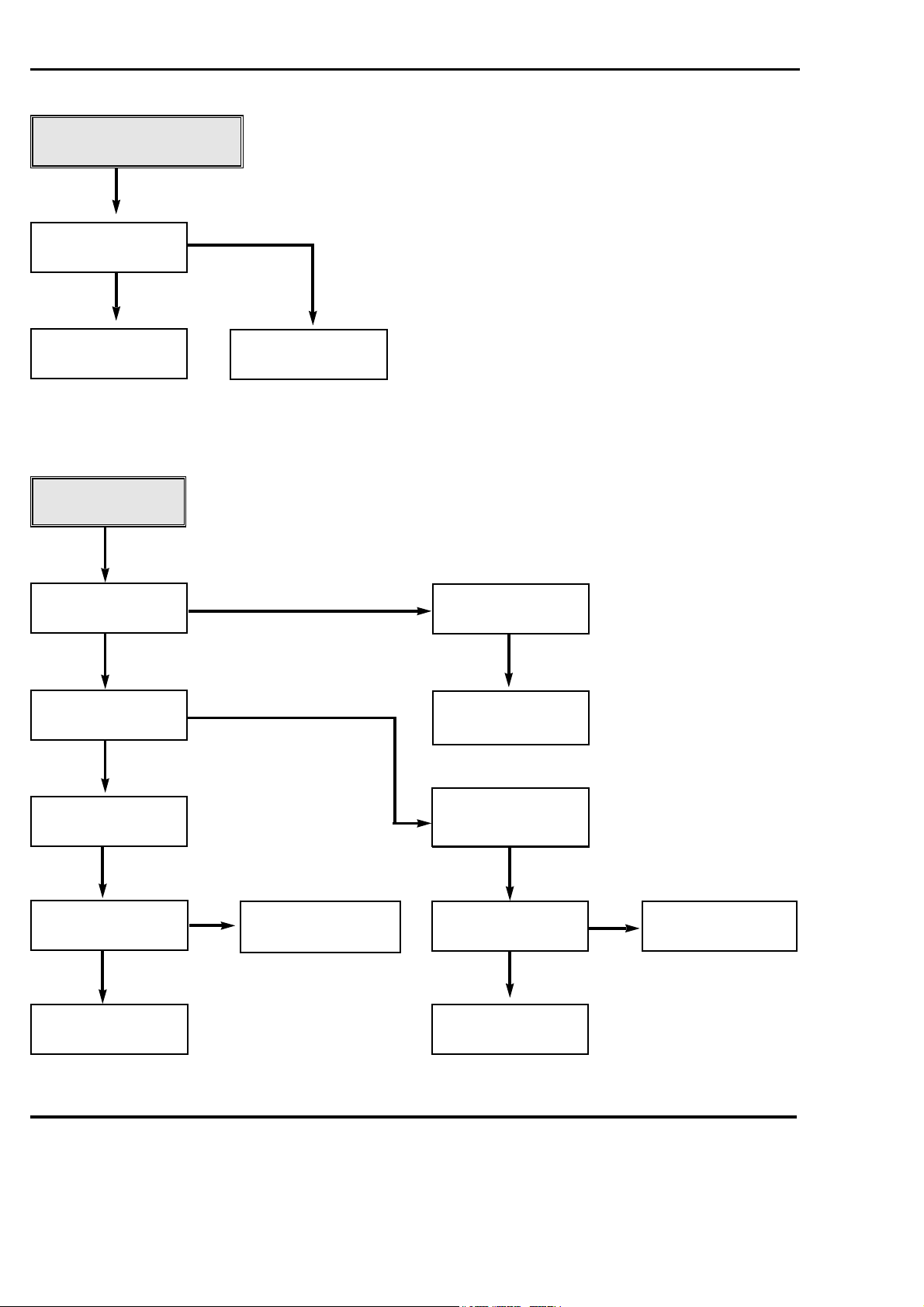

MECHANISM TROUBLESHOOTING GUIDE

1.Deck Mechanism

A.

Auto REW doesn't work.

YES

Is the output of END senser

of supply side "L"?

Is the supply end sensor less than

3.5V ("L")

YES

NO

Is the voltage drop across IR LED

between 0.8

~1.5V?

NO

Is LED-Prism OK?

YES

NO

Check the system (u-com).

Replace LED.

Check the 5VA supply, replace

LED Prism.

YES

Is the Prism housing damaged? Replace Prism.

NO

YES

Replace Photo Tr.

NOTES:

1)Auto REW takes place when the supply end sensor is "H" high.

2)"H"=voltage greater than 3.5V, "L"=voltage between 0.7~1.0V.

4-27

Page 13

MECHANISM TROUBLESHOOTING GUIDE

AUTO STOP.

YES

In auto stop is the pinch roller in

contact with the capstan shaft.

YES

Are there T/up and supply reel

pulses.

YES

Check the Syscon, u-COM.

No cassette loading.

YES

Insert the cassette.

YES

Does the cassette door lever S/W

work normally.

NO

NO

NO

Is the output of DFG, DPG OK?

YES

Check Servo, Syscon.

Replace Reel Sensor.

Check Housing Assembly.

NO

Replace Drum Motor.

YES

Is the output of F/L S/W"H"?

YES

Is the mode SW in the ULC

position. (tape unloaded)

NO

Does Capstan Motor turn?

YES

Did the H1 lever change position.

YES

Check Housing Ass'y.

YES

NO

NO

Refer to 1. Mechanism and Mode

Switch Alignment check (Page 4-16)

Check Capstan Motor.

Refer to Page 4-8 item 11.

4-28

Page 14

MECHANISM TROUBLESHOOTING GUIDE

D.

In PB mode Tape

Presence not sensed.

YES

Is the Pinch Roller

attached to the

Capstan Motor Shaft?

YES

Does the T/Up

Reel turn?

YES

Check the clutch and

the Idler Assembly.

NO

NO

Is the Belt OK?

YES

Check T/up Reel

and replace.

NO

Replace the Belt.

Does the Capstan

Motor turn?

YES

Does the Drum

Motor turn?

YES

Are there DPG,

DFG Pulses?

YES

Are the T/Up Supply

Reel SensorsOK?

NO

¨Í

NO

¨Î

NO

Replace Drum

Motor.

¨Î

Is the Vcc voltage of the

Drum Motor normal?

YES

Is the terminal voltage

of the Drum Motor

more than 2V?

YES

Replace the

Drum Motor.

NO

NO

NO

Check Servo.

YES

Check Servo, Syscon.

NO

¨Í

Is the voltage supplied

to the Capstan Motor

Vcc1, Vcc2 each?

YES

Does terminal voltage of

Capstan Motor supplied

more than 4V?

YES

Replace the

Capstan Motor.

Replace Reel

Sensor.

NO

Check Servo,

Power.

4-29

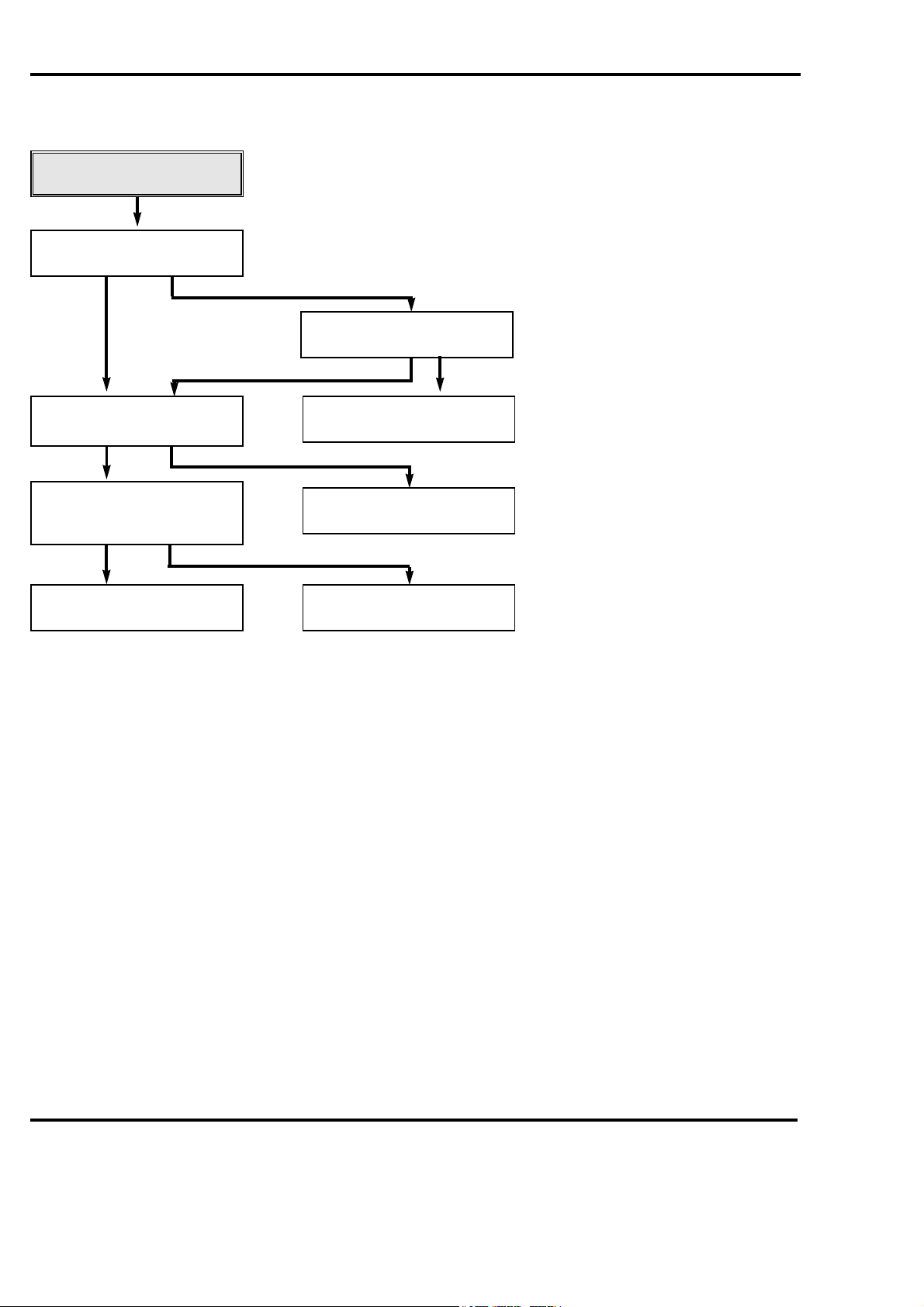

Page 15

YES

MECHANISM TROUBLESHOOTING GUIDE

In Eject mode, the Tape

will not eject.

Are the T/Up and Supply

End Sensors OK?

Replace the F/L S/W.

Replace End Sensor.

No F/R modes.

Does the Capstan Motor

rotate?

Do the T/Up, Supply

Reel rotate?

Replace Reel Sensor.

Capstan motor stopped

due to jammed

mechanism?

Is the normal voltage

supplied to the Capstan

Motor Vcc1, Vcc2.?

Eject Key-in.

Is the mode SW

assembled correctly

(refer to Pages 4-16.)

Does terminal voltage of

Capstan Motor supply

side more than 4V?

Replace the

Capstan Motor.

Check Servo, Power.

Check the clutch, Lever

Ass'y F/R and Idler Ass'y.

Is the present mode,

F/R Mode?

NO

NO

NO

NO

YES

YES

YES

YES

NO

YES

YES

YES

YES

YES

4-30

E.

Page 16

MECHANISM TROUBLESHOOTING GUIDE

2. Front Loading Mechanism

A.

Cassette cannot be inserted.

Does the Lever Switch work?

YES

Is 5V applied to the ¥-COM

Vcc port.

YES

Is 5V applied to CST switch port of

u-COM

YES

Check the syscon Part.

NO

NO

?

NO

Is the Cassette Lever/Spring

Switch damaged or omitted?

NO

Replace or add the Lever/Spring

Switch.

Check the Power Part.

Replace the Cassette Switch.

YES

4-31

Page 17

Cassette will not load.

Does the CST insert?

Does the lid opener work?

Does the Gear Cam F/L work?

Does the lid opener work?

Does the Arm Assembly F/L work?

Does the Capstan Motor work?

Does the Holder Assembly Cassette move

the Arm Assembly F/L?

Replace the Front Loading

Mechanism Assembly.

Check the Gear H1 position on the Deck.

Replace the lid opener.

Is the (R) side gear train and bracket

assembled correctly?

Is the lid opener assembled correctly.

Replace the Arm Assembly F/L.

Check the power of Capstan Motor.

Check the Holder Assembly Cassette.

YES

YES

NO

NO

NO

NO

NO

YES

NO

YES

YES

YES

YES

YES

NO

MECHANISM TROUBLESHOOTING GUIDE

4-32

(Tape does not thread around the drum.)

B.

Page 18

Cassette will not eject.

Is the Gear H1 position correct on the deck?

Does the Capstan Motor shaft rotate?

Does the Lever Switch work?

Does the Gear Cam F/L work?

Does the Opener Door work?

Check the Gear H1.

Check the Capstan Motor.

Replace the Lever/Spring Switch.

Check the Gear Train of Bracket Side (R).

Replace the Opener Door.

NO

NO

NO

NO

NO

YES

YES

YES

YES

MECHANISM TROUBLESHOOTING GUIDE

C.

4-33

Page 19

ADJUSTMENT INSTRUCTIONS

Notes;

(Adjustments must be performed by the following procedures)

1. It is recommended that an isolation transformer be used

when servicing this chassis to prevent electric shock and

damage to test equipment.

2. The ac line voltage must be maintained at 230 vac, +- 10%,

50/60 hz.

3. Prior to making any adjustments, the receiver must be

operated for 10 minutes.

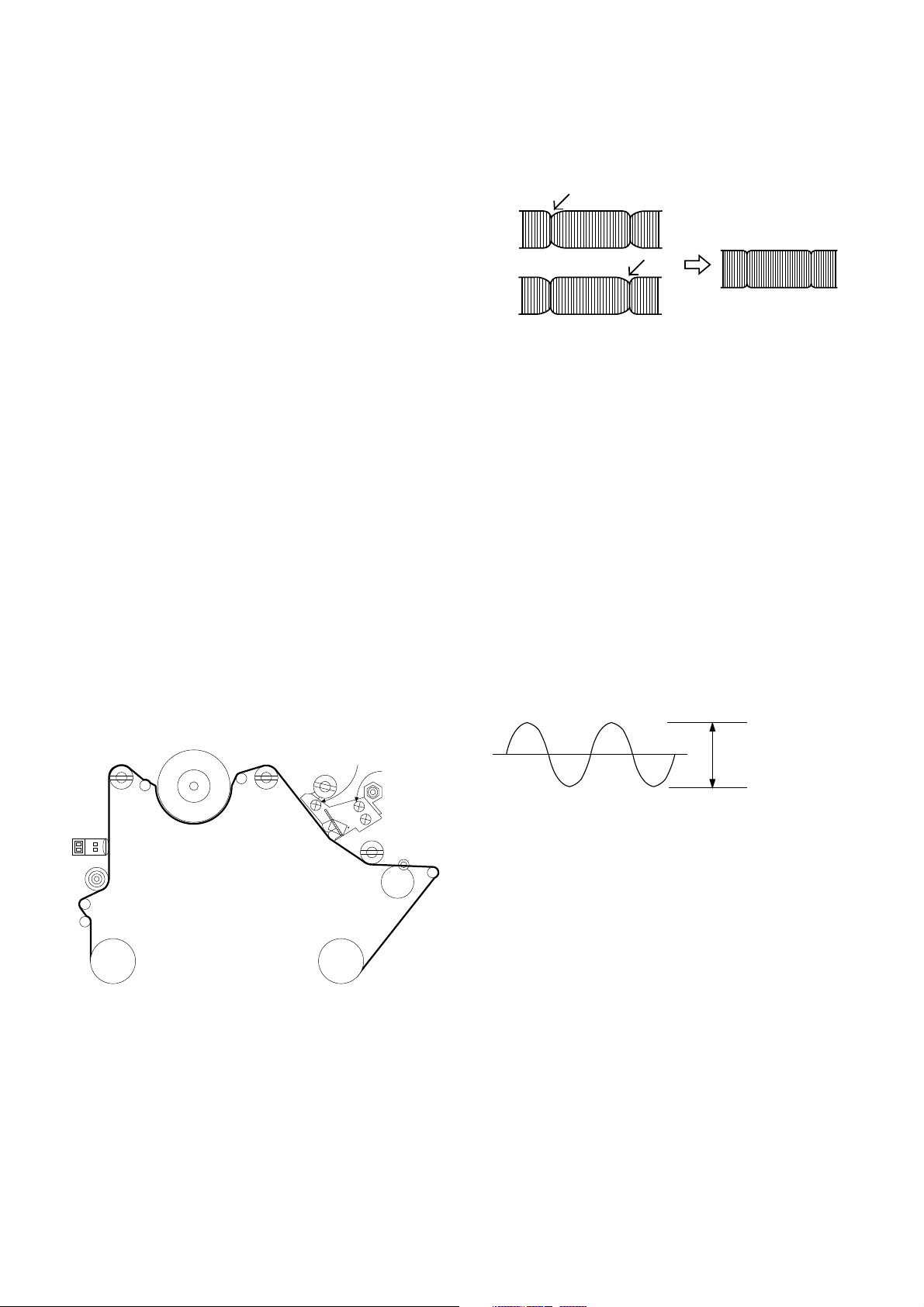

1. DECK ADJUSTMENT

1. Deck Transit System Adjustment

1-1. Necessary Instruments

1)TAPE for SP (4HD), Normal (2HD)

2)Oscilloscope

3)10:1 Probes 2EA

4)Adjustment Driver

(P2, P3, X-distance (NUT), Audio (NUT) control)

5)RMS Meter (Audio Level Meter)

1-2.Preliminary Steps

1)

Connect CH 1 of the oscilloscope to J439 (H/SW) on the

main PCB. Trigger on this channel.

2)Connect CH 2 of the oscilloscope to J218 (RF) on the main

PCB. Monitor this waveform when preceding with step 4.

3)Play an alignment tape.

4)When the "auto Trk" caption appears on screen, press the

TRK up (+) button on the RCU to initialize the manual

tracking feature.

5) If manual tracking differs from auto tracking, precede with

steps 1-3 (RF Linearity) and 1-4 (X-Distance Adj.).

P2

P2 POST ADJUST

P3 POST ADJUST

P3

<Adjustment waveform>

1-4. X-Distance Adjustment

1)Turn the Cone Screw of the DECK left or right so that the

RF waveform is maximum.

2)Check if the RF waveform satisfies the linearity by

pressing TRK UP(+) and DOWN(-) button one step.

CAUTION:If the RF waveform becomes maximum with

the Cone Screw more than 2 turns, its out of adjustment.

(2 turns; 720)

1-5. Audio Level Check and Adjustment

1)Connect "+" terminal of RMS Meter (Audio Level Meter)

to J233 on MAIN PCB AUDIO OUT and "-" terminal to

GND, respectively.

2)Play the 1khz and 7khz segments on the alignment tape

and confirm if the spec is meet in item #3. If not adjust

the azimuth screw to meet this spec.

3)Audio Level Spec: 1KHz ; 0.5

6KHz ; 1K

+_0.1Vrms

+_1.5dB

FE HEAD

P1

P0

ARM

TENSION

SUPPLY

REEL

P2

DRUM

P3

X-DISTANCE

ADJUST SCREW

A/C

HEAD

AZIMUTH

SCREW

TAKE-UP

REEL

PINCH

ROLLER

CONE POINT

SCREW

A/C HEAD

HEIGHT ADJUST NUT

P4

<Adjust Parts Location>

1-3. RF linearity check and adjustment

1)Adjust P2 & P3 so that the RF ENVELOPE waveform is

maximum and stabilized .

2)Check if the ENVELOPE waveform is at its maximum size

by pressing TRK UP(+) and DOWN(-) button one step.

CAPSTAN

TAPE

<Adjustment Waveform>

2. CIRCUIT ADJUSTMENT

T/UP

ARM

1. PG Adjustment

1-1. Necessary Instruments

1)Alignment tape SP

2)Oscilloscope

3)10 : 1 Probe

1-2.Adjustment

1)PLAY exclusive use of SP tape. (2HD: NORMAL TAPE)

2)Connect CH 1 of the Oscilloscope to J439 (H/SW) on the

MAIN PCB and VOL/DIV to 1V Range and Trigger the

Oscilloscope.

3)Connect CH 2 of the oscilloscope to J454 (Video Out) on

the main PCB and set the VOL/DIV to 500mV Range.

4)Set TIME/DIV of oscilloscope to 50

5) Adjust VR01 so that V-sync Falling Edge of Video signal

become 412

usec+_20usec.

Adjust waveform

us Range.

3-5

Page 20

Adjust Period

<Adjust Waveform>

* CAUTION:Set the trigger mode of Oscilloscope to DC.

2. Normal REC Bias Level Adjustment

2-1. Necessary Instruments

1) Blank tape for Recording

2)RMS Meter

2-2. Adjustment

1) Set the TV/VCR to A/V input mode.

2)Insert a tape and press REC button.

3)Connect RMS Meter's (+), (-) to R401 on MAIN PCB.

4)Adjust VR401 so that the RMS Meter's indicator become

within 2.6mV

+_0.05mV.

3. Focus Voltage Adjustment

1)Receive the cross hatch pattern.

2)Press the PICTURE button to set the Standard ON

condition.

3)Adjust Focus control knob so that the focus of center &

circumference to be best.

4. Screen Adjustment

1)Press TV/AV button and select AV mode.

2)Adjust SCREEN control until the retrace line is visible and

return until the retrace line is invisible.

*HHHHoooowwww ttttoooo ggggeeeetttt iiiinnnnttttoooo SSSSVVVVCCCC mmmmooooddddeeee wwwwhhhheeeennnn yyyyoooouuuu ddddoooonnnn''''tttt hhhhaaaavvvveeee SSSSVVVVCC

RRRReeeemmmmooootttteeee CCCCoooonnnnttttrrrroooolllllllleeeerrrr..

PPPPuuuusssshhhh tttthhhheeee """"OOOOKKKK"""" KKKKeeeeyyyy oooonnnn tttthhhheeee uuuusssseeeerrrr''''ssss RRRReeeemmmmooootttteeee CCCCoooonnnnttttrrrroooolllllllleeeerrrr aaaannnndddd llllooooccccaaaall

""""OOOOKKKK"""" bbbbuuuuttttttttoooonnnn aaaatttt tttthhhheeee ssssaaaammmmeeee ttttiiiimmmmeeee..

..

..

5. VCO Adjustment

1)Select channel 0.

2) Input PAL Digital pattern (175.25MHz).

3)Press SVC Key on the Service Remote Controller to get

into SVC mode and press PR +/- Key to select VCO.

4)Press VOL +/- Key until OK is displayed on the screen.

7. RF AGC Adjustment

1)Input PAL DIGITAL PATTERN.

2)Connect DMM to AGC(J232) test point on the Main PCB.

3)Press SVC Key on the Service Remote Controller to get

into SVC mode and press PR +/- Key to select AGC.

4) Press VOL +/- Key until DMM reads the data on the table

below.

MODEL

2 TUNER

1 TUNER

NNNNooootttteeee ::::When adjusting 2 TUNER Model, select BOOSTER OFF

Electric fields strength

AGC Voltage

Electric fields strength

AGC Voltage

from MENU.

KL/KB/KI

70dBu 1dBu

5.5 0.1Vdc

65dBu 1dBu

5.6 0.1Vdc

8. White Balance Adjustment

1)Input a signal which lower half is black and upper half is

white.

2) Set the picture at standard on.

3)Press SVC Key on the Service Remote Controller to get

into Service mode.

4)Press PR +/- Key to select BG, RG.

Press VOL +/- Key until X=281

*GG is fixed data at 32 so, do not adjust GG data.

+_3, Y=288+_3.

9. Deflection Data Adjustment

1)Input PAL Digital Pattern.

2)Press SVC Key on the Service Remote Controller and

select LINE SERVICE 2 mode.

3)Press PR +/- Key to select an adjustment mode.

4) Press VOL +/- Key to adjust data.

5) Vertical SLOPE adjustment

a) Select V-SLP mode with PR +/- Key.

b) Press VOL +/- Key until the horizontal center line of

CC

ll

the large circle coincides with Blanking Line.

6) Vertical amplitude adjustment

a) Select V-AMP mode with PR +/- Key.

b) Press VOL +/- Key until the upper and lower end of the

large circle reach 5 mm inside from the effective area

of CPT.

7) Vertical Shift Adjustment

a) Select V-SFT mode with PR +/- Key.

b) Press VOL +/- Key until the horizontal center coincides

with the vertical sign slot mark of CPT.

6. LCO Adjustment

1)Select channel 99.

2) Input SECAM-L' pattern (55.75MHz).

3)Press SVC Key on the Service Remote Controller to get

into SVC mode and Press PR +/- Key to select LCO.

4)Press VOL +/- Key until OK is displayed on the screen.

3-6

8) Horizontal Shift Adjustment

a) Select H-SFT mode with PR +/- Key.

b) Press VOL +/- Key until the vertical center coincides

with the horizontal sign slot mark of CPT.

9) Vertical S-Correction Adjustment

a) Select S-COL mode with PR +/- Key.

b) Press VOL +/- Key until the grid of Cross Hatch

Pattern is even all over the screen.

Page 21

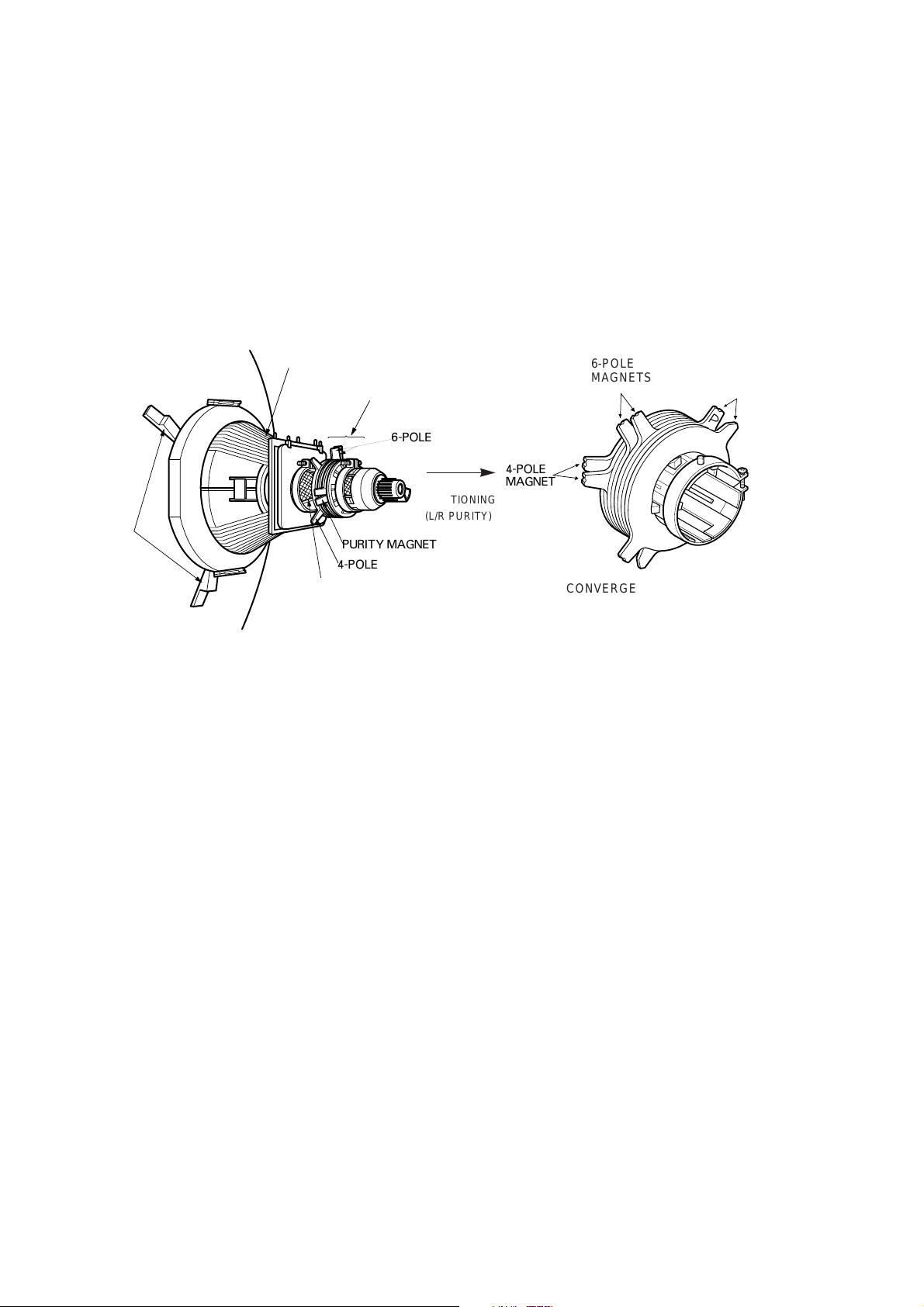

PURITY & CONVERGENCE ADJUSTMENT

Caution:

Convergence and Purity have been factory aligned. Do not

attempt to tamper with these alignments.

However, the effects of adjacent receiver components, or

replacement of picture tube or deflection yoke may require the

need to readjust purity any convergence.

DEFLECTION YOKE

PURITY &CONVERGENCE

MAGNET ASSEMBLY

6-POLE

,,,

RUBBER

WEDGES

,,

,,

,,,

PURITY MAGNET

4-POLE

GLASS CLOTH TAPE

X-AXIS YOKE

POSITIONING

(L/R PURITY)

5.Reconnect the internal degaussing coil.

6. Position the beam bender locking rings at the 9 o'clock

position and the other three pairs of tabs (2,4 and 6 pole

magnets) at the 12 o'clock position.

6-POLE

6-POLE

MAGNETS

4-POLE

MAGNET

MAGNES

CONVERGENCE MAGNET ASSEMBLY

CONVERGENCE MAGNET ASSEMBLY

PURITY MAGNET(2-POLE)

* Purity Adjustment

This procedure DOES NOT apply to bonded yoke and picture

tube assemblies.

The instrument should be at room temperature (60 degrees F or

above) for six (6) hours and be operating at low beam current

(dark background) for approximately 20 to 30 minutes before

performing purity adjustments.

CAUTION:Do not remove any trim magnets that may be

attached to the bell of the picture tube.

1. Remove the AC power and disconnect the internal

degaussing coil.

2. Remove the yoke from the neck of the picture tube.

3. If the yoke has the tape version beam bender, remove it and

replace it with a adjustable type beam bender (follow the

instructions provided with the new beam bender)

4. Replace the yoke on the picture tube neck, temporarily

remove the three (3) rubber wedges from the bell of the

picture tube and then slide the yoke completely forward.

7. Perform the following steps, in the order given, to prepare the

receiver for the purity adjustment procedure.

a. Face the receiver in the "magnetic north" direction.

b. Externally degauss the receiver screen with the television

power turned off.

c. Turn the television on for approximately 10 seconds to

perform internal degaussing and then turn the TV off.

d. Unplug the internal degaussing coil. This allows the

thermistor to cool down while you are performing the purity

adjustment. DO NOT MOVE THE RECEIVER FROM ITS

"MAGNETIC NORTH" POSITION.

e. Turn the receiver on and obtain a red raster by increasing

the red bias control (CW) and decreasing the bias controls

for the remaining two colors (CCW).

f. Attach two round magnets on the picture tube screen at 3

o'clock and 9 o'clock positions, approximately one (1) inch

from the edge of the mask (use double-sided tape).

3-2

Page 22

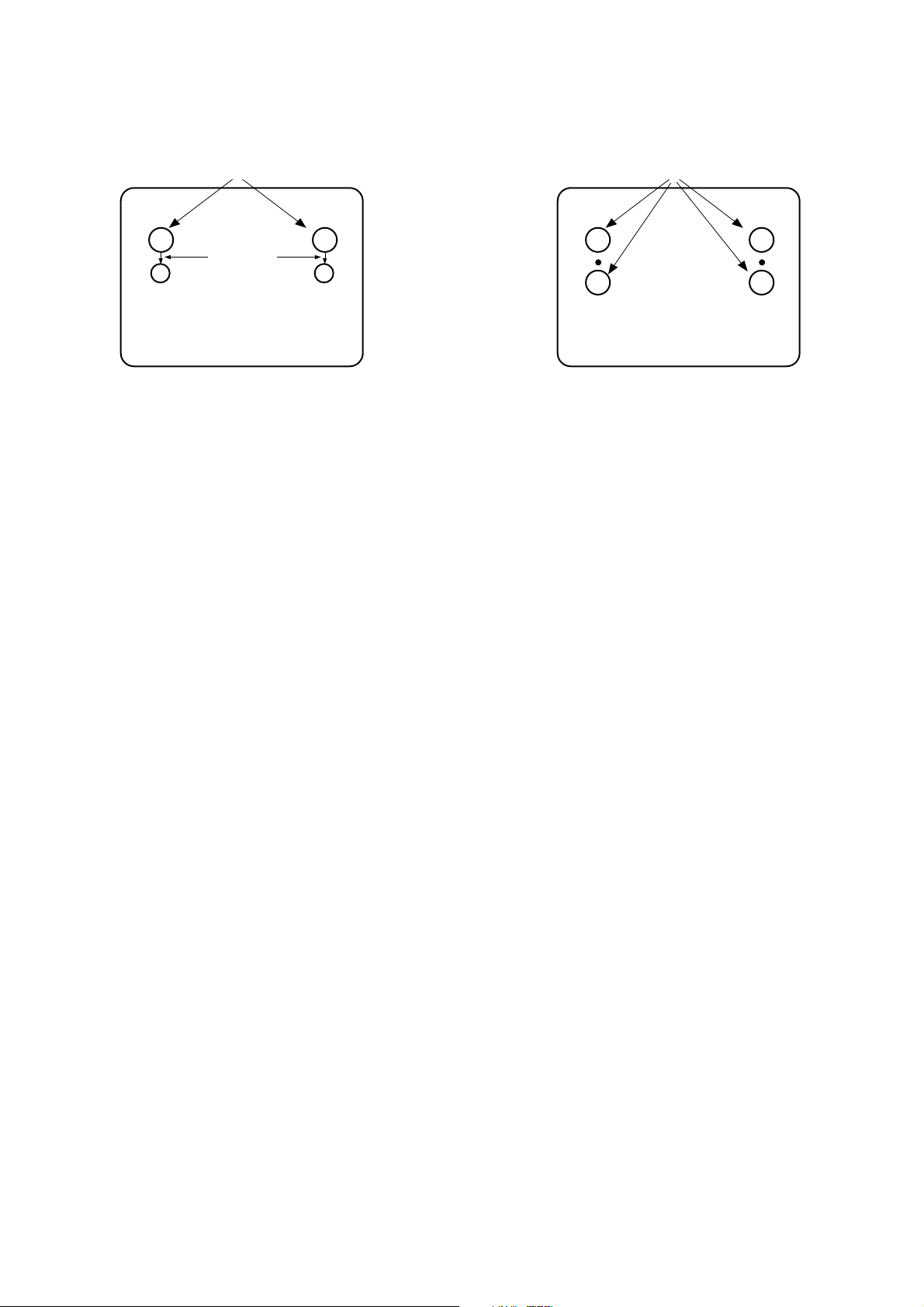

1.ADJUST YOKE Z-AXIS FIRST

TO GET EQUAL BLUE

COLOR CIRCLES

MAGNETS

RED RED

2 .ADJUST BEAM BENDER 2 POLE

MAGNET TO GET FOUR EQUAL

COLOR CIRCLES

8. Referring to above, perform the following two steps:

a. Adjust the yoke Z-axis to obtain equal blue circles.

b. Adjust the appropriate beam bender tabs to obtain correct

purity (four equal circles).

9. After correct purity is set, tighten the yoke clamp screw and

remove the two screen magnets.

10.Remove the AC power and rotate the receiver 180 degrees

(facing "magnetic south").

11. Reconnect the internal degaussing coil.

12. Turn the receiver on for 10 seconds (make sure the receiver

came on) to perform internal degaussing, and then turn the

receiver off.

13. Unplug the internal degaussing coil.

14. Turn on the receiver and check the purity by holding one (1)

round magnet at the 3 o'clock and a second round magnet at

9 o'clock position. If purity is not satisfactory, repeat steps 8

through 14.

15. Turn off the receiver and reconnect the internal degaussing

coil.

* Convergence Adjustment

Caution:This procedure DOES NOT apply to bonded yoke and

picture tube assemblies.

Do not use screen magnets during this adjustment

procedure. Use of screen magnets will cause an

incorrect display.

1. Remove AC power and disconnect the internal degaussing

coil.

2. Apply AC Power and set the brightness to the Picture Reset

condition. Set the Color control to minimum.

3. Apply 8V to the pin.

6. Reconnect the internal degaussing coil and apply AC power.

7. Turn the receiver on for 10 seconds to perform internal

degaussing and then turn the receiver off again.

8. Unplug the internal degaussing-coil.

9. Turn on the receiver, connect a signal generator to the VHF

antenna terminal and apply a crosshatch signal.

Caution:During the convergence adjustment procedure, be

very careful not to disturb the purity adjustment tabs

are accidentally move, purity should be confirmed

before proceeding with the convergence adjustments.

Note:

Make sure the focus is set correctly on this instrument

before proceeding with the following adjustment.

10. Converge the red and blue vertical lines to the green vertical

line at the center of the screen by performing the following

steps (below TABLE).

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in opposite directions from the 12 o'clock

position to converge the red and blue vertical lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in opposite directions form the 12 o'clock

position to converge the red and blue (now purple)

vertical lines with the green vertical line.

11. Converge the red and blue horizontal with the green line at

the center of the screen by performing the following steps.

(below TABLE)

a. Carefully rotate both tabs of the 4-pole ring magnet

simultaneously in the same direction (keep the spacing

between the two tabs the same) to converge the red and

blue horizontal lines.

b. Carefully rotate both tabs of the 6-pole ring magnet

simultaneously in same direction (keep the spacing

between the two tabs the same) to converge the red and

blue (now purple) horizontal lines with the green

horizontal line.

c. Secure the tabs previsouly adjusted by locking them in

place with the locking tabs on the beam bender.

4. Adjust the Red, Green and Blue Bias controls to get a dim

white line.

5. Remove the AC power and 8V from the pin.

3-3

Page 23

3-4

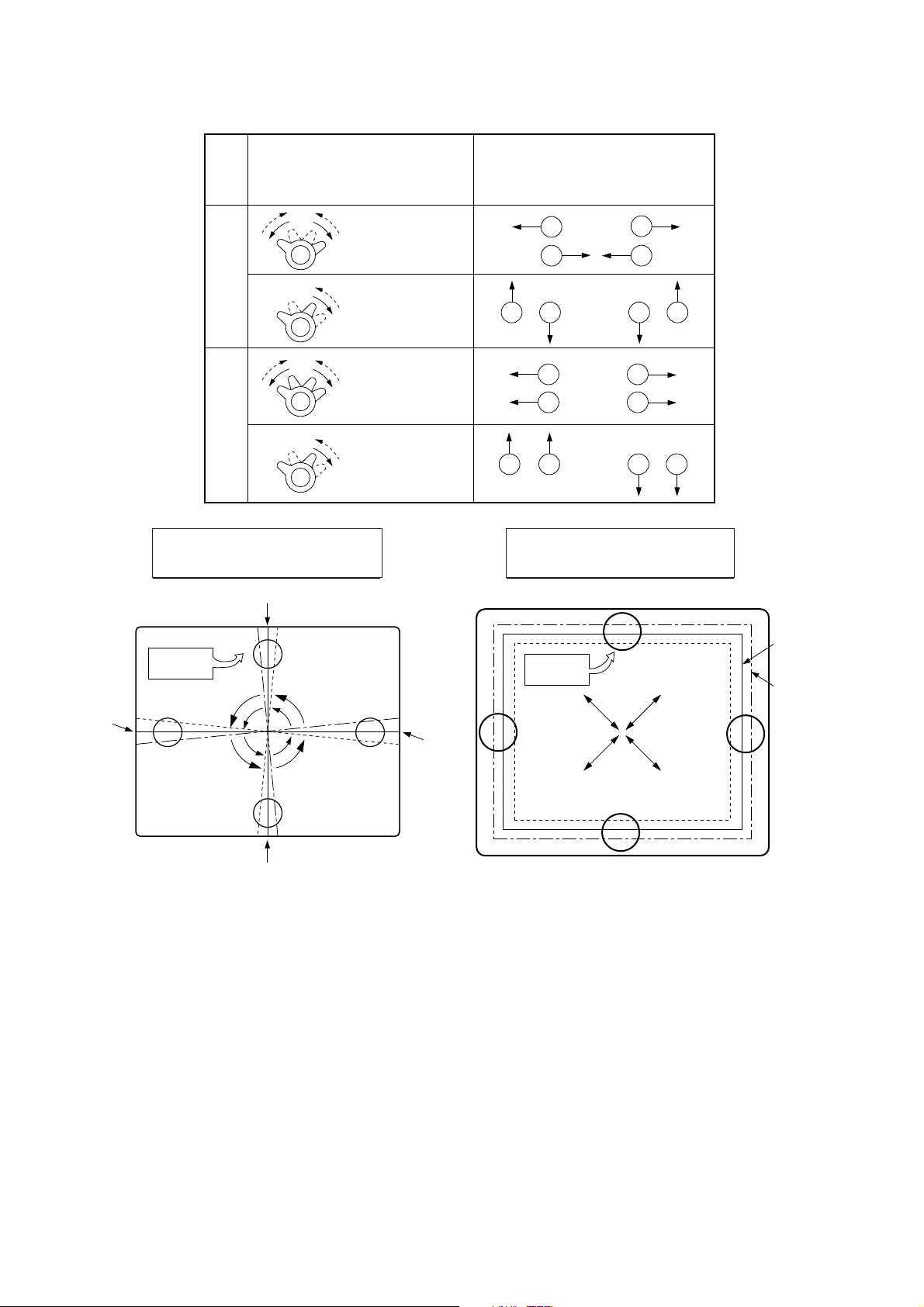

RING

PAIRS

4

POLE

ROTATION DIRECTION

OF BOTH TABS

OPPOSITE

SAME

OPPOSITE

SAME

MOVEMENT OF RED

AND BLUE BEAMS

B B

RR

OR

OR

B R B R

OR

B

R

B

R

B R

OR

B

R

6

POLE

12. While watching the 6 o'clock positions on the screen, rock the

front of the yoke in a vertical (up/down) direction to converge

the red and blue vertical lines. (Fig upper left)

13. Temporarily place a rubber wedge at the 12 o'clock position

to hold the vertical position or the yoke.

14.

Check the 3 o'clock and 9 o'clock areas to confirm that the red

and blue horizontal lines are converged.

If the lines are not converged, slightly offset the vertical tilt of the

yoke (move the rubber wedge if necessary) to equally balance the

convergence error of the horizontal lines at 3 o'clock and 9 o'clock

and the vertical lines at 6 o'clock and 12 o'clock.

15. Place a 1.5 inch piece of glass tape over the rubber foot at

the rear of the 12 o'clock wedge.

16. While watching the 6 o'clock and 12 o'clock areas of the

screen, rock the front of the yoke in the horizontal (left to

right) motion to converge the red and blue horizontal lines.

(Fig. upper right)

17. Temporarily place a rubber wedge at the 5 o'clock and 7

o'clock positions to hold the horizontal position of the yoke.

18. Check the 3 o'clock and 9 o'clock areas to confirm that the

red and blue vertical lines are converged. If the lines are not

converged, slightly offset the horizontal tilt of the yoke (move

the temporary rubber wedges if necessary) to equally

balance the convergence error of the horizontal lines at 6

o'clock and 12 o'clock and the vertical lines at 3 o'clock and 9

o'clock.

19. Using a round magnet confirm purity at the center, right and

left sides and corners. See Purity Adjustment Procedure.

20. Reconfirm convergence and apply a 1.5 inch piece of glass

tape over the rubber foot at the rear of the 5 o'clock and the 7

o'clock wedges.

RED

BLUE

RED BLUE

BLUE

RED

GREEN

GREEN

BLUE RED

GREEN

GREEN

ADJUSTMENT

VIEWING

AREA

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

ADJUSTMENT

VIEWING

AREA

RED

RED

GREEN

TV

SCREEN

LEET/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF

THE RED AND BLUE RASTERS

UP/DOWN ROCKING OF THE YOKE

CAUSES OPPOSITE ROTATION OF RED

AND BLUE RASTERS

LEFT/RIGHT ROCKING OF THE YOKE

CAUSES OPPOSITE SIZE CHANGE OF THE

RED AND BLUE RASTERS

Page 24

4-1

FRONT LOADING MECHANISM DISASSEMBLY

¡¡

‹

Front Loading Mechanism Assembly, Parts Location

¡¡

ÿ

Component list below will be discribed as

if the top and bottom covers, front panel

and deck mechanism assembly have

already been removed.

1. Guide Cassette

2. Bracket Assembly Side (R)

3. Top Plate

4. Holder Assembly Cassette

5. Arm Assembly F/L

6. Plate Reflector

7. Opener Door

8. Plate Ground(R)

9. Plate Ground(L)

6. Plate Reflector

3. Top Plate

8. Plate Ground (R)

9. Plate Ground (L)

6. Plate

Reflector

1. Guide Cassette

4. Holder

Assembly

Cassette

2. Bracket Assembly

Side(R)

7. Opener Door

5. Arm Assembly F/L

Page 25

FRONT LOADING MECHANISM DISASSEMBLY

1.Front Loading Mechanism Assembly

(Fig. A-1)

1)Remove the Top and Bottom Covers and Front Panel.

2) Remove two screws(A).

3)Lift up the Front Loading Mechanism Assembly in the

direction of arrow(B).

NOTE

When disassembling and reassembling:

a.Give special attention to removal and to reassembly

because two tabs(L), (R) are engaged.

(A)

(B)

(L)

(R)

Fig. A-1 Front Loading Mechanism

3. Bracket Assembly Side (R)

1)Push the tabs(L), (R) of Bracket Assembly Side(R) to

disengage with the Top Plate and remove it in the

direction of arrow(A).

Top Plate

(A)

(L)

(Fig. A-3)

Plate Ground

(A)

(R)

Bracket Assembly

Side(R)

Fig. A-3 Bracket Assembly Side(R)

4.Bracket Side(L)/Top Plate (Fig. A-4)

1)Remove the screw(B).

2)Remove the plate Ground(L), in the direction of

arrow(A).

3)Push the locking tab(L1) and then remove the Bracket

Side(L) in the direction of arrow(B).

4)The Top Plate can be removed by Separating the

Bracket Side(L).

2. Guide Cassette (Fig. A-2)

1)Push tab(R) of the Cassette Guide and disengage with

Bracket Side(R) and push tab(L) of the cassette Guide

which is engaged with Bracket Side(L) and remove it in

the direction of arrow (B).

(L)

(B)

Cassette Guide

Fig. A-2 Guide Cassette

(B)

(R)

(B)

(A)

(C)

Brackdt Side(L)

Plate Ground(L)

Hook(L)

(B)

(L1)

Top Plate

Fig. A-4 Bracket Side(L)/Top Plate

4-2

Page 26

FRONT LOADING MECHANISM DISASSEMBLY

5.Holder Assembly Cassette (Fig. A-5)

1)Separate the Bracket Assembly Side(R).

2)Push the two lever tabs(L), (R) down and separate the

Holder Assembly Cassette and the Arm Assembly F/L

from the Top Plate.

Holder

Assembly Cassette

Fig. A-5 Holder Assembly Cassette

6.Arm Assembly F/L (Fig. A-6)

1) Remove by pulling the Arm F/L(R) from the Bracket

Holder(R) Boss in the direction of arrow(A).

2)Separate the Arm Assembly F/L from Cassette Holder

Boss in the direction of arrow(B).

7.Spring Stopper (Fig. A-7)

1)Remove the Spring Stopper which is connected to the

tabs(A), (B) of the Lever Stopper(R) and the Bracket

Holder(R).

Lever Stopper(R)

Spring Stopper

(A)

(B)

Bracket Holder(R)

Fig. A-7

Spring Stopper

8.Plate Reflector (Fig. A-8)

1)Detach the Plate Reflector(L) from the Bracket Side(L)

by using a knife.

2)Detach the Plate Reflector(R) from the Bracket

Assembly Side(R) by using a knife.

NOTE

When disassembling and reassembling:

a. Be sure to remove the Arm F/L(R) first. If not the Arm

Assembly F/L can be damaged.

(B)

(A)

Arm Assembly F/L

Fig. A-6 Arm Assembly F/L

Bracket Side(L)

Bracket

Assembly Side(R)

Plate Reflector

(L), (R)

Fig. A-8 Plate Reflector

4-3

Page 27

DECK MECHANISM DISASSEMBLY

*

‹

Deck Mechanism Parts Location

TOP VIEW

Auto Head Cleaner Assembly

Drum Brush

A/C Head Assembly

Bracket Assembly

L/D Motor

FE Head

Drum Assembly

Base Assembly

P2/P3

Tension Arm

Assembly

Supply Reel

Assembly (S27)

TAB Lever

BOTTOM VIEW

Capstan Motor

Assembly

Holder

Assembly Pinch

Arm Assembly T/up

Gear Pinch Cam

Plate Up

Take-up Reel

Assembly (T27)

Mode Switch

Slider Plate

Gear Pulley

H1 Lever

Gear H2/H1

Clutch Assembly

T27

Bracket Cam

Clutch Assembly

S27

Arm Assembly

Idler

4-4

Page 28

DECK MECHANISM DISASSEMBLY

1.Auto Head Cleaner Assembly (Fig. B-1)

(Optional Item)

1)Push the tab(A) of Auto Head Cleaner and remove the

Cleaner Arm Assembly.

NOTES:

When disassembling and reassembling:

a. Do not allow fingers or tools to touch the outside of the

Drum.

b. Be careful not to get any foreign substance on the

Roller.

Cleaner Arm Assembly

(A)

Drum

Assembly

Drum

Base

(A)

7(A)

(B)

Fig. B

-2 Drum and Base Assembly

Drum

Brush

(A)

Fig. B

-1 Auto head cleaner Assembly

2.Drum and Base Assembly (Fig. B-2)

1)Remove the Auto Head Cleaner Assembly. (option)

2)Remove three screws(A) and separate the Drum

Assembly, Drum Base and the Drum Brush from the

Deck Mechanism Assembly.

3) Remove three screws(B) on the back side and remove

the Drum Assembly from the Drum Base.

NOTES:

When disassembling and reassembling:

a. Do not touch the video tips with fingers or tools.

Give special attention to disassembling and

reassembling of Auto Head Cleaner Assembly.

b. After assembling, adjust the tape transport system and

Servo PG.

3.Drum Sub Assembly and Motor

Assembly (Fig. B-3-1)

1)Remove the Drum Base from the Deck Mechanism

Assembly.

2)Separate the Drum Assembly from the Drum Base.

3)Remove two screws(A) and then remove the rotor.

4)Remove three screws(B) and then remove the stator.

NOTE

When disassembling and reassembling:

a. Do not touch the video tips with fingers or tools.

Drum

Sub Assembly

stator

Motor

Assembly

(B)

rotor

4-5

(A)

Fig. B

-3-1 Drum Sub and Motor Assembly

Page 29

DECK MECHANISM DISASSEMBLY

4.A/C (Audio/Control) Head Assembly

(Fig. B-4)

1)Unplug the A/C connector from the Loading Motor

P.C.B.

2)Remove two screws(A) and remove the A/C Head

Assembly from the Deck Mechanism Assembly.

NOTES:

When disassembling and reassembling:

a. When assembling, the 3mm hole of the Base A/C

should coincide to 3mm hole in the Chassis.

b. Do not touch the A/C Head Tips with fingers or tools.

c. After reinstalling the Audio Control Head Assembly,

adjust the Tilt, Azimuth and Height of A/C Head.

(A)

5.FE (Full Erase) Head Assembly (Fig. B-5)

(Optional Item)

1)Push two tabs(A) and remove the FE Head.

NOTE

When disassembling and reassembling:

a. Be careful not to get any foreign substance on the FE

Head.

(A)

Fig. B-4 A/C Head Assembly

Fig. B-5 FE Head Assembly

4-6

Page 30

DECK MECHANISM DISASSEMBLY

6.Plate Up/Supply Main Brake/T ake up Main

Brake/Body Prism Led Assembly (Fig. B-6)

1)Plate Up

a. Remove three screws(A) and remove the Plate Up.

2)Supply Main Brake

a. Remove the Spring MB.

b. Lift up the Supply Main Brake.

3)Take-Up Main Brake

a. Lift up the Take-Up Main Brake.

4)Body Prism Led

a. Remove the Body Prism Led.

SMB

(A)

Body

Prism Led

(A)

Plate Up

(A)

TMB

Spring

MB

NOTES:

When disassembling and reassembling:

a. (D) is engaged to the cam groove of the Gear Cam L/D

and two tabs(C) are engaged in the chassis. (care must

be taken not to damage the two tabs when

disassembling and reassembling)

b. When disassembling, turn to the counterclockwise and

lift up so that grease which may be on (D) is not

transfered to the Reel Brake Drum.

c. When assembling, the 2.5mm hole of the Lever

Assembly Tension should be aligned with the 2.5mm

hole in the chassis.

d. After reassembling, adjust the Tension.

Spring Tension

Tension Arm

Tension shaft

(C)

(B)

(C)

(D)

Holder Band (A)

Holder Band (C)

Holder Band (B)

Lever Ass'y Tension

Fig. B-6 Plate up/SMB/TMB/BPL

7.Tension Arm/Lever Assembly T ension

(Fig. B-7)

1)Remove the Spring Tension.

2)Push the tab(A) of the Base Tension on the back cover

of the Deck Mechanism Assembly outward and remove

the Tension Arm Assembly.

3)Push the tab(B) on the back side of the Holder Band(A)

and remove the Tension Arm Assembly.

4)Push two tabs(C) on the bottom side of the Lever

Tension and Lift up the Lever Assembly Tension.

Chassis

Hole (2.5mm)

(A)

Fig. B-7 Tension Arm/Lever Assembly Tension

8. TAB Lever (Fig. B-8)

(Optional Item)

1)Remove the Lever Ass'y Tension.

2)Remove the Spring TAB.

3)Push the tab(A) on the bottom side of TAB Lever and

remove the TAB Lever.

Spring TAB

(A)

TAB Lever

4-7

Fig. B-8 TAB Lever

Page 31

DECK MECHANISM DISASSEMBLY

9.Supply Reel/T ake Up Reel Assembly

(Fig. B-9)

1)Lift up Reel(S), (T) after removing the Plate Up and

Band Assembly.

NOTES:

a. Be sure not to interchange the Take-up Reel and the

Supply Reel.

b. Do not allow the Brake Drum to come in contact with

grease.

Supply Reel(S27)

(White)

Take-up Reel(T27)

(Black)

11.Gear H1, H2/Lever H1 (Fig. B-11)

1)Push and lift up the hook(B) of Lever H1.

2)Remove the washer(A) and then lift up the Gear H1.

3)Lift up the Spring H1.

4)Push and lift up the hook(B) of the Gear H2.

(B)

Lever H1

(B)

Gear H2

(C)

Washer(A)

Gear H1

Spring H1

Fig. B-9 Supply Reel/Take-up Reel Assembly

10. Gear Pulley/Belt Capstan (Fig. B-10)

1)Turnover the Deck Mechanism Assembly.

2)Remove the Belt Capstan.

3)Remove the washer(A) and then lift up the Gear Pulley.

Belt Capstan

Washer(A)

Gear Pulley

Fig. B-11 Gear H1,H2/Lever H1

12.Arm Assembly Idler (Fig. B-12)

1)Lift up the Gear Pulley after removing the washer(A).

2)Lift up the Spring Up/D after removing the washer(B).

3)Lift up the Arm Assembly Idler.

Washer(A)

Washer(B)

Spring Up/D

Arm Ass'y Idler

Fig. B-10 Gear Pulle y/Belt Capstan

Fig. B-12 Arm Assembly Idler

4-8

Page 32

DECK MECHANISM DISASSEMBLY

13.Mode S/W (Fig. B-13)

1)Lift up the Lever H1.

2)Remove the screw(A) and lift up the Mode S/W.

NOTE

a. When assembling mode, the groove of Gear ( ) and Body

( o) of the Mode Switch should be aligned.

Lever H1

(A)

Groove (o), ( )

U

U

Mode S/W

15.CAM Bracket Assembly

1)Remove three screws(A).

2)Remove the CAM Bracket Assembly.

(Fig. B-15)

NOTE

a. The (Tension Shaft Holder) fixes the Tension Shaft on Fig

B-7. therefore when the CAM Bracket Assembly is removed,

First remove the Tension Arm on Fig B-7.

(A)

CAM Bracket

(A)

(A)

(Tension shaft Holder)

Fig. B-15 CAM Bracket Assembly

Fig. B-13 Mode S/W

14.Capstan Motor Assembly (Fig. B-14)

1)Remove three Screws(A) on the top side and remove

the Capstan Motor Assembly.

Capstan Motor

(A)

(A)

(A)

Fig. B-14 Capstan Motor Assembly

16. Cam Bracket/Lever Jog/Gear Jog (Fig. B-16)

(Optional Item)

1)Remove the Cam Bracket Assembly.

2)Remove the Spring Jog.

3)Push the tab(A) and remove the Lever Jog.

4)Push the tab(B) and remove the Gear Jog.

NOTE

a. The tab(B) on the Gear Jog should be in groove of the

Lever Jog.

CAM Bracket

(A)

Gear Jog

(B)

Fig. B-16 Cam Bracket/Lever Jog/Gear Jog

Lever Jog

Spring Jog

4-9

Page 33

DECK MECHANISM DISASSEMBLY

17.Gear Cam L/D (Fig. B-17)

1)Remove the Cam Bracket Assembly.

2)Remove the Gear Cam L/D.

NOTE

1)When assembling the Gear Cam L/D, the groove

( ) of Plate Slider should coincide with to the groove

( ) on the Gear Cam L/D.

CAM Bracket

Gear CAML/D

19.Gear Assembly P2/P3 (Fig. B-19)

1)Remove the Plate Slider.

2)Remove by pushing one hook(B) on the top side of Gear

Assembly P3.

3)Remove by pushing one hook(A) on the top side of Gear

Assembly P2.

NOTES:

When disassembling and reassembling:

a. The P2 and P3 Gear Assembly should not be

interchanged.

b. The groove( ) of Gear P2 should be aligned to

the groove( ) of Gear P3.

c. Set the hole of Lever to the Boss of P2 and P3 Base

Assembly.

(When assembling make sure that the Lever is not

bent.)

GEAR P3

GEAR P2

Fig. B-17 Gear Cam L/D

18.Gear PS/Plate Slider

1)Remove two washers(C).

2)Remove the Plate Slider.

3)Remove the Gear PS.

(Fig. B-18)

NOTE

1)When the hole(A) of the Gear PS is aligned to the

hole(B) of the chassis, the groove( ) of the Plate Slider

should be aligned to the groove( ) of the Gear PS.

(C)

(C)

(A)

Gear PS

Plate Slider

(A)

Lever

BOSS

BOSS

Fig. B-19 Gear Assembly P2/P3

20.Base Assembly P2/P3 (Fig. B-20)

1)Remove the P2/P3 Gear Assembly.

2)Remove the P2/P3 Base Assembly.

BASE P2

(B)

BASE P3

(B)

Fig. B-18 Gear PS/Plate Slider

Fig. B-20 Base Assembly P2/P3

4-10

Page 34

DECK MECHANISM DISASSEMBLY

21.Guide Roller Assembly (Fig. B-21)

1)Remove two screws(A).

2)Remove the Guide Roller From the Base P2/P3 by

turningit.

NOTE

When disassembling and reassembling:

a. The P2 and P3 Base should not be interchanged.

Guide Roller

(A)

BASE P2

Guide Roller

(A)

BASE P3

23.Clutch Assembly T27 (Fig. B-23)

1)Remove the Gear H1 and Arm Assembly Idler.

2)Remove the washer(A).

3)Remove the Clutch Assembly T27.

Washer (A)

Clutch T27

Fig. B-23 Clutch Assembly T27

Fig. B-21

Guide Roller Assembly

22.Clutch Assembly S27 (Fig. B-22)

1)Remove the Gear Cam L/D and the Arm Assembly Idler.

2)Remove the washer(A).

3)Remove the Clutch Assembly S27.

Washer (A)

Clutch S27

24.Lever F/R & Arm F/R (Fig. B-24)

1)Remove the Plate Slider.

2)Remove the washer(A).

3)Remove the Lever F/R.

4)Remove the Arm Assembly Idler.

5)Remove the Arm F/R.

NOTE

1)When disassembling the Arm F/R should be horizontal.

Washer (A)

Lever F/R

ARM F/R

4-11

Fig. B-22

Clutch Assembly S27

Fig. B-24

Lever F/R&Arm F/R

Page 35

DECK MECHANISM DISASSEMBLY

25.Holder Pinch Assembly (Fig. B-25)

1)Separate the Holder Pinch Assembly by pushing tab(A)

on the L/D Motor Bracket in the direction of arrow (B).

Holder Pinch

B

(A)

27.L/D Motor Bracket Assembly (Fig. B-27)

1)Remove three Screws(A).

2)Push the tabs(A) and remove the L/D Motor Bracket

Assembly.

NOTES:

When assembling and disassembling:

a. Make sure Grease from the Gear Pinch does not come in

contact with the wing of the L/D Motor Bracket.

(A)

Chassis

L/D Motor

Bracket

(A)

(A)

(A)

Fig. B-25

Holder Pinch Assembly

26.Pinch Arm Assembly (Fig. B-26)

1)Remove the Spring Pinch.

2)Remove the Pinch Arm Assembly by turning it

counterclockwise.

Spring Pinch

Pinch Arm

Pinch Roller

Fig. B-27 L/D Motor Bracket Assembly

28.Worm Wheel (Fig. B-28)

1)Remove the L/D Motor Bracket Assembly.

2)Push two Tabs(A) on the L/D Motor Bracket and then

remove it.

Worm Wheel

(A)

Fig. B-26

Pinch Arm Assembly

Fig. B-28

Worm Wheel

4-12

Page 36

29. L/D Motor Assembly & Worm L/D Motor &

L/D Motor Bracket (Fig. B-29)

1) Remove the L/D Motor Bracket Assembly.

2) Push the L/D Motor Assembly in lower direction and

then remove.

3) Remove the Worm L/D Motor from the L/D Motor

Assembly in the direction of arrow (A).

4) Remove the L/D Motor Assembly and the Worm L/D

Motor and then L/D Motor Bracket is removed.

30 . Gear CNT (Fig. B-30)

1) Remove the L/D Motor Bracket Assembly.

2) Remove the Pinch Arm Assembly.

3) Remove the Gear CNT.

31. Gear Pinch (Fig. B-31)

1) Remove the Pinch Arm Assembly.

2) Remove the Gear CNT.

3) Remove the Gear Pinch.

4) When reassembling, make sure that the two teeth, Gear

pinch CAM(£ ) and Gear pinch(£ ), with timing marks

line up with the arrow at two o'clock on the Pinch Cam

Gear. (See Fig on B-30)

32. T/Up Arm Assembly (Fig. B-32)

1) Remove the L/D Motor Bracket Assembly.

2) Turn over the T/Up spring and separate the T/Up Arm

Assembly.

3) Remove the spring.

4-13

Fig. B

-29

L/D Motor Assembly/ Worm

L/D Motor/ L/D Motor Bracket

Gear CNT

Gear Pinch CAM

Gear Pinch

A

B

Fig. B-30

Gear CNT

Fig. B-31

Gear Pinch

L/D Motor Ass'y

L/D Motor

Bracket

(A)

Worm L/D Motor

Gear Pinch

Gear Pinch CAM

DECK MECHANISM DISASSEMBLY

T/Up Arm

T/Up Spring

Fig. B-32

T/up Arm Assembly

Page 37

DECK MECHANISM DISASSEMBLY

33.Gear Pinch Cam (Fig. B-33)

1)Remove the T/Up Arm Assembly.

2)Remove by pushing one tab(A) on the bottom side of the

Gear Pinch Cam.

NOTE

When disassembling and reassembling:

a. The small hole on the Gear Pinch Cam and hole of

chassis should be aligned.

Gear Pinch CAM

(A)

Fig. B-33

Gear Pinch Cam

4-14

Page 38

MECHANISM ADJUSTMENT

¡¡

‹

Tools and Fixtures for Deck

1. Cassette Torque meter

Parts No: D00-D006

300

S

-

T

250

H

V

-

200

K

R

150

S

SRK

VIDEO

CASSETTE

H

V

T

-

-

K

T

R

0

S

TORQUE

50

0

METER

VHT-303

50

100

150

200

250

300

4. Torque gauge adaptor

Parts No: D09-R001

2. Alignment tape

Parts No NTSC: DTN-0001

PAL: DTN-0002

5. Post height adjusting driver

Parts No: DTL-0005

3. Torque gauge

Parts No: D00-D002

6. + Type driver (¿5)

Obtain locally

4-15

Page 39

MECHANISM ADJUSTMENT

1. Mechanism and Mode Switch Alignment Check

Purpose:To determine if the mode switch and mechanism are in the correct position, when a

tape is ejected from the loading mechanism.

Test Equipment /Fixture Test Conditions VCR (VCP) State Check Point

*

Eject Mode (with cassette ejected)

*

Blank tape

1)Turn power on and eject the cassette by pressing the

eject button.

2)Remove the top and bottom covers.

3)Visually check the alignment of the Pinch Cam gear

and PS gear holes, line up with holes in the chassis

(figure C-2).

4)If the gears in step 3 do not align as indicated, then

rotate the shaft of the loading motor to either the

clockwise or counterclockwise direction until alignment

does occur.

CHECK DIAGRAM

*

Mechanism and Mode Switch Position

5)Turn the unit over and remove the main P.C.B thus

exposing the bottom side of the deck mechanism.

6)Check the alignment of the mode switch as illustrated

in figure C-1, (A).

7)If the alignment is incorrect then remove the mode

switch and align as shown in figure C-1 with out

changing the position of the Pinch Cam gear and PS

gear.

8)Remount the mode switch and main P.C.B assembly

and check operation.

Mode S/W

(A)

BOTTOM VIEW

TOP VIEW

Gear ( ) and Body (¡Û) groove alignment

Fig. C-1

Gear

Pinch Cam

Hole

Gear

PS

Hole

Fig. C-2

4-16

Page 40

MECHANISM ADJUSTMENT

2.Preparation for Adjustment (T o set VCR

(VCP) to the loading state without inserting

a cassette.)

1)Unplug the Power Cord from the AC outlet.

2)Separate the Top Cover and Front Loading Mechanism.

3)Plug the Power Cord into the AC outlet.

4)Turn the VCR on and push the tact switch in the P.C.B.

Assembly.

The VCR can accept inputs for each mode in this case.

However the rewind and review operation cannot be

performed for more than a few seconds because the

take-up reel table is in the stop state and reel pulses

cannot be detected.

NOTES:

Always return the VCR(VCP) to the Front Loading Mechanism Assembly State in the following order after the above

operations have been performed.

1)Press the Eject button after turning the power ON.

2)Wait for about 10 seconds until searching out the

assembly position.

3)Assemble the Front Loading Mechanism and connect

the Front Loading Mechanism Connector.

4)Refer to the "Front Loading Mechanism Disassembly"

Section.

NOTE

Cover the holes in the end sensors with black tape to

prevent a light leak.

3.Tension Post Position and Tension Adjustment

Purpose:To insure uniform tape contact with the video head by maintaining constant tape

tension.

Test Equipment /Fixture

*

Cassette Torque Meter

(For play 100g/cm)

Test Conditions VCR(VCP) State

*

Position Adjustment: Play without a

cassette

*

Tension Check: Play

Adjustment Point

*

Holder Band B and C

Position Adjustment

1)Remove cassette.

2)Adjust the position of tension post in accordance

with figure C-3.

NOTE

Align the Tension Post (2mm) to the hole in the Chassis

(2.5mm).

Post P1

Tension Arm

Chassis Hole (2.5mm)

¡¡

Tolerance

æ

0.3mm with in

Post Tension

Post P0

Tension Adjustment

1)Turn on VCR and load the cassette torque meter.

2)Press the play button and observe the torque tension

on the supply reel (spec. 37g/cm+5g/cm).

3)If torque is out of spec. then use a Phillips screw

driver and move the screw head located in the center

of the B and C band hold; to either the right or left

until correct torque is indicated.

Lever Tension

Hold Band(B)

Hold Band(C)

4-17

Fig. C

-3

Page 41

MECHANISM ADJUSTMENT

4. Checking Torque

Purpose:To insure smooth transport of the tape during each mode of operation. If tape

transport is abnormal, then check the torque as indicated by the chart below .

Test Equipment /Fixture

*

Torque Gauge(600 g/cm ATG)

*

Torque Gauge Adaptor

*

Cassette Torque Meter

VNTSC: 16.67msec

PAL: 20msec

Item

Slack Removal Torque

Fast Forward Torque

Rewind Torque

Play Take-Up Torque

Review Torque

Mode

Unloading

Fast Forward

Rewind

Play

Review

Cassette Torque Meter

Cassette Torque Gauge

Cassette Torque Gauge

Cassette Torque Meter

Cassette Torque Meter

Checking Method:

The Values are measured by using a torque gauge and

torque gauge adaptor with the torque gauge affixed.

NOTE

The torque reading to measure occurs when the tape

abruptly changes direction from fast forward or rewind

mode, when quick braking is applied to both reels.

*

Set the VCR to each operating mode without

Test Equipment

Test Conditions VCR(VCP) State

inserting a cassette. (See '2. Preparation for

Adjustment'. Page 4-17)

Measurement Reel

Supply Reel

Take-Up Reel

Supply Reel

Take-Up Reel

Supply Reel

Measurement Values

More than 150~270g/cm

More than 500g/cm

More than 500g/cm

55~95g/cm

170~250g/cm

Torque Gauge

T

H

V

-

K

R

S

300

S

-

250

50

0

Fig. C-5

200

150

VHT-303

SRK

VIDEO

CASSETTE

TORQUE

METER

Torque Gauge

Adaptor

H

V

T

-

-

K

T

R

0

S

50

100

150

200

250

300

Reel Table

Fig. C-4

4-18

Page 42

MECHANISM ADJUSTMENT

5. Guide Roller Height Adjustment

Purpose:To regulate the height of the tape so that the bottom of the tape runs along the

tape guide line on the lower drum.

A. Preliminary Adjustment

Test Equipment /Fixture

*

Post Height Adjusting Driver

*

Hexagonal Wrench or Allen

Wrench Phillips screw driver

Test Conditions VCR(VCP) State

*

Allows a good tape to play

normally in spite of a damaged

guide roller.

Adjustment Procedure

1)Perform the precise adjustment(See below B).

2)If the Guide Roller is damaged, loosen the Guide Roller

retaining screw and replace the Guide Roller.

3)Adjust the height of P2, P3 so that TAPE is adjacent to

the guide line.

B. Precise Adjustment

Test Equipment /Fixture

*

Oscilloscope

*

Alignment Tape

*

Post Height Adjusting

Driver

Test Equipment Connection Points

*

CH-1: PB RF Envelope

*

CH-2: NTSC: SW 30Hz

*

*

PAL : SW 25Hz

Head Switching Output

Point

RF Envelope Output

Point

*

Guide Roller Height Adjustment

screws on the Supply and Take-Up

Guide Rollers.

ADJUSTMENT DIAGRAM

Fig. C-5-1

Test Conditions VCR(VCP) State

*

Play an alignment tape

Waveform Diagrams

P2 POST

ADJUSTMENT

Adjustment Point

GUIDE ROLLER HEIGHT

ADJUSTMENT SCREW

UPPER FLANGE

GUIDE ROLLER

RETAINING SCREW

Adjustment Point

*

Guide Roller Height

Adjustment Screws.

Adjustment Procedure

1)Play an alignment tape after connecting the probe of

the oscilloscope to the RF Envelope Output Test Point

and Head Switching Output Test Point.

2)Tracking Control (in PB mode): Center position (When

this adjustment is performed after the drum assembly

has been replaced, set the tracking control so that the

RF output is maximum.)

3)Height adjustment screw: Flatten the RF waveform.

(Fig. C-5-2)

4)Turn (Move) the tracking control (in the Playback

mode) clockwise and counterclockwise. (Fig. C-5-3))

5)Check that any drop of RF output is uniform at the start

and end of the waveform.

CAUTION

If the adjustment is excessive or insufficient the tape will

jam or fold.

4-19

P3 POST

ADJUSTMENT

Fig. C-5-2

Tracking control at center

Fig. C-5-3

Connection Diagram

RF ENVELOPE OUTPUT TEST POINT

HEAD SWITCHING OUTPUT TEST

POINT

Turn the Roller Guide Height

Adjustment Screw slightly

to flatten the waveform.

Turn (Move) the tracking

control to both directions.

OSCILLOSCOPE

CH-1 CH-2

Page 43

MECHANISM ADJUSTMENT

6. Audio/Control (A/C) Head Adjustment

Purpose:To insure that the tape passes accurately over the audio and control tracks in

exact alignment in both the record and playback modes.

A.Preliminary Adjustment (Height and tilt adjustment)

Perform the Preliminary adjustment, when there is no Audio Output signal with a blank tape.

Test Equipment /Fixture

*

Blank Tape

*

Screw Driver(+) Type 5mm

Test Conditions VCR(VCP) State

*

Play the blank tape (CTL Tape)

Adjustment Procedure /Diagrams

1)Initially adjust the A/C head assembly as shown in

figure C-6-1, by using the height adjustment screw(B).

2)Play a blank tape and observe if the tape passes

accurately over the A/C head without tape curling or

folding.

3)If folding or curling does occur then adjust the Tilt

adjusting screw(C) while the tape is running to

resemble figure C-6-3.

4)Confirm that the tape passes over the A/C head

assembly as indicated by proper audio reproduction

and proper tape counter performance.

NOTE

Ideal A/C head height occurs, when the tape runs

between 0.2~0.25mm above the bottom edge of the A/C

head core.

Adjustment Points

*

Tilt Adjustment Screw(C)

*

Height Adjustment Screw(B)

*

Azimuth Adjustment Screw(A)

¡¡

æ

11.1

0.05mm

Tilt

Adjustment

Screw(C)

Height Adjustment

Screw(B)

Fig. C-6-1 A/C Head Base

X value

Adjustment

Screw(X)

Azimuth Adjustment

Screw(A)

Turning

Center

Fix

Fig. C-6-2 A/C Head Assembly

A/C Head

Tape

P4

Tape

0.2~0.25 mm

Fig. C-6-3

4-20

Page 44

MECHANISM ADJUSTMENT

B. Confirm that the tape passes smoothly between

the T/UP guide and the Pinch Roller (Using a

mirror or the naked eye).

1)After completing step A. (Preliminary Adjustment), check

that the tape passes around the T/UP post without folding

at the top or bottom.

If folding is observed, due the following:

a. If folding is observed at the lower part of the T/UP

post, then slowly turn the tilt adjustment in the

clockwise direction to eliminate tape the curling.

b. If folding is observed at the upper part of the T/UP

D. Precise Adjustment (Azimuth adjustment)

Test Equipment /Fixture

*

Oscilloscope

*

Alignment tapes

*

Screw Driver(+) Type 5mm

Test Equipment

Connection Point

*

Audio output jack

Adjustment Procedure

1)Connect the probe of oscilloscope to Audio Output Jack.

2)Alternately adjust the Azimuth adjustment screw(A) and

the Tilt adjustment screw(C) for maximum output of the

1KHz and 7KHz segments, while maintaining the flattest

envelope differential between the two frequencies.

post, then slowly turn the tilt adjustment in the

counterclockwise direction to eliminate the tape

curling.

C. RF Fine Adjustment (only if the RF waveform

differs from figure C-5-3).

1)Check the RF Envelope after confirming smooth tape

transport path at the T/UP Guide/Pinch Roller.

Test Conditions

VCR (VCP) State

*

Play an alignment tape

1KHz, 7KHz sections.

1KHZ

A: Maximum

Adjustment Points

*

Azimuth Adjustment Screw(A)

*

Tilt Adjustment Screw(C)

7KHZ

B: Maximum

Fig. C-6-4

7. X-Value Adjustment

Purpose:To obtain compatibility with other VCR(VCP).

Test Equipment /Fixture

*

Oscilloscope

*

Alignment tapes

*

Screw Driver(+) Type 5mm

*

Post Height Adjusting

Driver

Adjustment Procedure

1)Loosen the fixed mounting and X Value adjustment

screw.

2)Allow the mechanism to run long enough for auto

tracking to complete it's cycle.

3)Move the A/C base laterally in the direction as shown

in the diagram to find the center of the peak that

allows for the maximum waveform envelope. This

method should allow the 30um head to be centrally

located over the 60um tape track.

4)Tighten the A/C head assembly mounting screws.

Test Equipment

Connection Point

*

CH-1: PB RF Envelope

*

CH-2: NTSC: SW 30Hz

PAL : SW 25Hz

*

Head Switching Output

Test Point

*

RF Envelope Output Test

Point

*

Adjustment Diagram

Tilt

Adjustment

Screw(C)

Height

Adjustment

Screw(B)

Connection Diagram

Test Conditions

VCR (VCP) State

Play an alignment tape

Left

Right

Fig. C-7

Adjustment diagrams

Groove at the

Base A/C

3mm Hole

X value Adjustment

Screw(X)

Azimuth

Adjustment

Screw(A)

Turning

Center

Fixed

OSCILLOSCOPE

4-21

RF ENVELOPE OUTPUT TEST POINT

HEAD SWITCHING OUTPUT TEST

POINT

CH-1

CH-2

Page 45

MECHANISM ADJUSTMENT

8. Adjustment after Replacing Drum Assembly (V ideo Heads)

Purpose: To correct for shift in the roller guide and X value after replacing the drum.

Test Equipment /Fixture

*

Oscilloscope

*

Alignment tape

*

Blank Tape

*

Post Height Adjusting

Driver

*

Screw Driver(+) Type

5mm

Test Equipment

Connection Points

*

CH-1: PB RF Envelope

*

CH-2: NTSC: SW 30Hz

PAL: SW 25Hz

*

Head Switching Output Test

Point

*

RF Envelope Output Test

Point

Checking/Adjustment Procedure

Play a blank tape and check for tape curling or creasing

around the roller guide. If there is a problem then follow the

procedure 5. "Guide Roller Height" and 6. "Audio

Control(A/C) Head Adjustment".

Waveform

V1

V

V2

Test Conditions

VCR(VCP) State

*

*

Play the blank tape

*

Play an alignment tape

*

*

*

Connection Diagram

RF ENVELOPE OUTPUT TEST POINT

HEAD SWITCHING OUTPUT TEST

POINT

V1/V MAX

V2/V MAX

RF ENVELOPE OUTPUT POINT

Adjustment Points

Guide Roller Precise

Adjustment

Switching Point

Tracking Preset

X-Value

OSCILLOSCOPE

CH-1 CH-2

§§[[

0.7

§§[[

0.8

Fig. C-8

9. Check the Tape Travel after Reassembling Deck Assembly .

9-1. Check Audio and RF Locking Time during playback and after CUE or REV (FF/REW)

Test Equipment /Fixture

*

Oscilloscope

*

Alignment tape (with 6H

3kHz Color Bar Signal)

*

Stop Watch

Specification

*

RF Locking Time: Less

than 5 sec.

*

Audio Locking Time: Less

than 10 sec.

Checking Procedure

Play an alignment tape then change the operating mode to

CUE or REV and confirm if the unit meets the above listed

specifications.

Test Equipment

Connection Points

*

CH-1: PB RF Envelope

*

CH-2: Audio Output

*

RF Envelope Output

Point

*

Audio Output Jack

NOTES:

1)CUE is fast forward mode (FF)

2)REV is the rewind mode (REW)

3)Referenced to the Play mode

Test Conditions

VCR(VCP) State

*

Play an alignment tape

(with 6H 3kHz Color Bar

Signal)

4-22

Page 46

MECHANISM ADJUSTMENT

9-2. Check the condition between the Audio and Video Sync. (Lip Sync.)

Test Equipment /Fixture

*

Oscilloscope

*

Alignment Tape

Specification

*

Less than¡¾V

Checking Procedure

1)Confirm that the period ¨Í in Fig. C-9-1 is within

¡¾ V.

2)If the result is abnormal, repeat adjustment #7.

(X-Value adjustment)

NTSC: 16.67msec

V

PAL: 20msec

9-3. Check for tape curling or jamming

Test Equipment /Fixture

*

T-160 Tape

*

T-120 Tape

*

Be sure there is no tape jamming or

curling at the begining, middle or

end of a T-160 tape.

Specification

Test Equipment

Connection Points

*

CH-1: PB RF Envelope

*

CH-2: Audio Output

*

RF Envelope Output

Point

*

Audio Output Jack

Test Conditions

VCR(VCP) State

*

Play an alignment tape

V

V

¨Í

RF SIGNAL

AUDIO SIGNAL

¡¡

æ

¤V

Fig. C-9-1

VCR(VCP) State

*

Run the CUE, REV play mode at

the beginning and the end of the

tape.

Checking Procedure

1)Confirm that the tape runs smoothly around the roller

guides, drum and A/C head assemblies while abruptly

changing operating modes from Play to CUE or REV.

This is to be checked at the begining, middle and end

sections of the cassette.

2)Confirm that the tape passes over the A/C head

assembly as indicated by proper audio reproduction and

proper tape counter performance.

4-23

Page 47

MECHANISM ADJUSTMENT

10. Maintenance/Inspection Procedure

1) Required Maintenance

The recording density of a VCR(VCP) is much higher than

that of an audio tape recorder. VCR(VCP) components

must be very precise, at tolerances of 1/1000mm, to ensure

compatiblity with other VCRs. If any of these components

are worn or dirty, the symptoms will be the same as if the

part is defective. To ensure a good picture, periodic

inspection and maintenance, including replacement of worn

out parts and lubrication, is necessary.

2) Scheduled Maintenance

Schedules for maintenance and inspection are not fixed

because they vary greatly according to the way in which the

customer uses the VCR(VCP), and the environment in

which the VCR(VCP) is used.

But, in general home use, a good picture will be maintained

if inspection and maintenance is made every 1,000 hours.

The table below shows the relation between time used and

inspection period.

Table 1

When

inspection is

necessary

Average

hours used

per day

One hour

Two hours

Three hours

3)Check before starting repairs

The following faults can be remedied by cleaning and oiling.

Check the needed lubrication and the conditions of

cleanliness in the unit.

Check with the customer to find out how often the unit is

used, and then determine that the unit is ready for in

spection and maintenance. Check the following parts.

About 1

year

¡å

¡å

About 18

months

¡å

About 3

years

Tabel 2

Phenomenon

Poor S/N, no color

Tape does not run or tape is

slack

Vertical jitter, horizontal jitter

Color beats

Low volume or distorted audio

No Fast forward or rewind or

rotation is slow

Dirt on video head or worn

video head

Dirt on pinch roller, belt or

flywheel belt

Dirt on video head or in tape

transport system

Dirt on full-erase head

Dirt on audio/control head

Dirt on belt

Inspection

4)Supplies Required for Inspection and Maintenance

(1)Grease Kanto G-311G or equivalent

(2)Isopropyl Alcohol or equivalent

(3)Cleaning Patches

5) Maintenance Procedure

5-1) Cleaning

(1)Cleaning video head

First use a cleaning tape. If the dirt on the head is too

stubborn to remove by tape, use the cleaning patch.

Coat the cleaning patch with Isopropyl Alcohol. Touch

the cleaning patch to the head tip and gently turn the

head(rotating cylinder) right and left.

(Do not move the cleaning patch vertically. Make sure

that only the buckskin on the cleaning patch comes into

contact with the head. Otherwise, the head may be

damaged.)

Thoroughly dry the head. Then run the test tape. If

lsopropyl Alcohol remains on the video head, the tape

may be damaged when it comes into contact with the

head surface.

(2)Clean the tape transport system and drive system, etc,

by wiping with a cleaning patch wetted with Isporopyl

Alcohol.

NOTES:

a. It is the tape transport system which comes into

contact with the running tape. The drive system

consists of those parts which moves the tape.

b. Make sure that during cleaning you do not touch

the tape transport system with the tip of a screw

driver and no that force is that would cause

deforming or damage applied to the system.

4-24

Page 48

4-25

(1) Greasing guidelines

Apply grease, with a cleaning patch. Do not use excess

grease. It may come into contact with the tape transport

or drive system. Wipe any excess and clean with

cleaning patch wetted in Isopropyl Alcohol.

(2) Periodic greasing

Grease specified locations every 5,000 hours.

Fig. C-10-1

Video Head

(rotating cylinder)

Coat With Isopropyl Alcohol

Head Tip

Touch this section of cleaning

patch to the head tip and gently

turn the head

5-2) Greasing

MECHANISM ADJUSTMENT

Fig. C-10-2 Tape Transport System

P1 POST

P0 POST

P4 POST

POST T/UP

TENSION POST

GUIDE ROLLER

AUDIO CONTROL HEAD

TAPE

DRUM ASSEMBLY

FULL ERASE HEAD

Page 49

MECHANISM ADJUSTMENT

Phenomenon Inspection

Color beats Dirt on full-erase head ¡Û

Poor S/N no color Dirt on video head

Vertical jitter

Low volume

Sound distorted

Tape does not run.

Tape is slack.

Phenomenon Inspection

Dirt on video head

Dirt on tape transport system

Dirt on audio/control head

Dirt on pinch roller

Replacement

¡Û

¡Û

¡Û

¡Û

Replacement

¨ç

¨è

¨é

¨ê

¨ë

¨è

¨ç

¨é

¨ê

¨ë

Fig. C-10-3 Top VIEW

*

No fast forward

or rewind, or

rotation is slow

*

Tape does not run

*

Slack tape

In Review and

Unloading (off mode),

the Tape is rolled up

loosely.

Dirt on reel belt

Clutch Ass'y S27

Torque reduced

Cleaning Drum and

transport system

¡Û

¡Û

Note

If locations marked with do not operate normally

after cleaning, check for wear and replace.

See the EXPLODED VIEWS at the end of this manual as

well as the above illustrations for the sections to be

lubricated and greased.

¡Û

¨ì

¨í

¨ì

¨í

Fig. C-10-4 BOTTOM VIEW

4-26

Page 50

1

MAIN2 BLOCK DIAGRAM

D/G COIL

TH801

AC-IN

D801

IC801

STR6707

9

8

7

1

2 4 6 7 9 10 11 12

IC802

PC123Y

IC803

PC123Y

40V

P.CTL

M.CTL

6VA

5.3V

12V(A)

14V(C)

12V(D)

1 3 7 6 9 11 13

H-SYNC

12V

A-OUT

8V

V-B

V-A

H-OUT

A-MUTE

V-SYNC

25V

25V

P805

(TO VCD)

P804

(TO MAIN1)

IC855

KIA7812

IC857

KIA7806

IC852

KIA7806

POWER

CONTROL

CIRCUIT

. ST-BY

. MONITOR

ON/OFF

IC701

TDA8351

V.OUT

IC601

TDA2006

AUDIO AMP

FBT

ANODE

VOLTAGE

B+

(115V)

IC856

PQ12RF21

IC853

KIA7808

Q781

D2499

(14V) (44V)

AFC

25V

SPEAKER

CPT

1

5

1

1 3 5 7

5

HEATER

CPT BOARD

P901A

FROM VCD

IK

(P1901B)

P2901B

R

VIDEO AMP

TDA6107Q

GB

200V

15V

11V

115V

40V

9V

2 1

P703

(TO MAIN1)

P2902

(14":P1902)

Q862

A968

P.CTL

Page 51

VCD BLOCK DIAGRAM

2

IC501

TDA8374A

V/C/D WITH IF

4746454443424140 55 56545352515049483938373635343332313029

B-Y

OUT

B-Y

INPUT

R-Y

INPUT

SECAM

REF OUT

3.58

X-TAL

4.43

X-TAL

LOOP

PHASE

CVBS

OUT

BLACK

PEAK CAP.

SCP/

FB IN

PHI2

FIL

PHI1

FILTER

VERT

POSI

VERT

NEGA.

IF

INPUT

IF

INPUT

0VP

INPUT

VERT

CAP

REF-I

INPUT

TUNER

AGC

AUDIO

DEMP

SOUND

DEMO.

E-W

DRIVE

AGC

DECOUP

VCC

H-OUT

GND

R-Y

OUT

12345678910111213141516171819202122232425262728

SOUND IF

INPUT

EXIT AUDIO

INPUT

VCO

FIL

VCO

FIL

VIDEO

OUT

CHROMA

INPUT

Y/CVBS

INPUT

AUDIO

OUT

DECOUP

FILTER

CVBS1

INPUT

CVBS2

INPUT

BLACK

CURRENT

BEAM

CURRENT

BLUE

OUT

GREEN

OUT

RED

OUT

RED

INPUT

GREEN

INPUT

BLUE

INPUT

FB

INPUT

Y

INPUT

Y

OUT

SCL

SDA

GND

PLL

LOOP

VCC

MAIN

BANDGAP

DECOUP

BPF

VCO/2

VERTICAL

SAWT-GEM

BUF

DEMO

CVBS

SWITCH

VCO

VOL

V/R

VERT

PROCESS

H

OSC

STB

R-Y/B-Y

CLAMP

SE-

REF

METRIX

SCP

GEN.

VCOX

R-Y/B-Y

DEM.SW

COLOR

TRAP

RGB OUT

RGB

SELECT

RGB CLAMP

CLAMP

BLK

STR-

PEAK

CORING

14 13 12 11 10 9 8

1 2 3 4 5 6 7

IC533

AN5860

(RGB-SWITCHING)

IC02T

CF72416

IC01T

CF70206

BUFFER

DC

RESTOR

SW.

PULSE

GENER

RRGGB

RGB FB

B

IK

GNDRGNDGGNDBGND

1234567

8

P504A

TO CPT

H-OUT

GND

X-RAY

V-A

GND

8V

V-B

GND

A-OUT

GND

12V

ABL

HP

P503A

FROM MAIN2

TO MAIN1

CVBS OUT

GND

CVBS2(AV)

GND

R(OSD)

G(OSD)

B(OSD)

FB(OSD)

HP

GND

NTSC H

R(EXT)

G(EXT)

B(EXT)

FB(EXT)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

P502A

GND

TXT PST

SDA

SCL

5.3V

1

2

3

4

5

P01T

AGC

GND

IF 2

IF 1

GND

A-IN

GND

SCL

SDA

GND

A-OUT

GND

VIDEO OUT(2V)