Page 1

Please read this manual carefully before operating

your set and retain it for future reference.

Original instruction

[Representative] LG Electronics Inc. EU Representative : LG Electronics European Shared

Service Center B.V. Krijgsman 1, 1186 DM Amstelveen, The Netherlands

[Manufacturer] LG Electronics Inc. Changwon 2nd factory 84, Wanam-ro, Seongsan-gu,

Changwon-si, Gyeongsangnam-do, KOREA

OWNER’S MANUAL

AIR-TO-WATER

HEAT PUMP

www.lg.com

MFL68680905

Rev.05_082019

Copyright © 2017 - 2019 LG Electronics Inc. All Rights Reserved.

PORTUGUÊS

ENGLISH ITALIANO

MAGYAR

БЪЛГАРСКИ

ESPAÑOL

FRANÇAIS DEUTSCH

SRPSKI

HRVATSKI

SLOVENŠČINA

ΕΛΛΗΝΙΚΆ

УКРАÏНСЬКА

ČEŠTINA

NEDERLANDS

POLSKI

LIMBA ROMÂNĂ

Page 2

INTRODUCTION

2

ENGLISH

INTRODUCTION

What is AWHP(Air to Water Heat Pump)?

• Air to Water Heat Pump system can be used as various heating solution from floor heating to

hot water supply with multiple heat sources. It is 4 times more energy efficient than

conventional system.

• High efficiency with conventional boiler functions.

Why is AWHP(Air to Water Heat Pump)?

• Various regulations are implemented in Europe to reduce energy use of building heating.

• Also, AWHP-related subsidy programs are implemented by country.

Read this manual

Inside you will find many helpful hints on how to use and maintain your AWHP properly. Just a

little preventive care on your part can save you a great deal of time and money over the life of

your product.

You'll find many answers to common problems in the chart of troubleshooting tips. If you review

our chart of Troubleshooting Tips first, you may not need to call for service at all.

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

Page 3

TABLE OF CONTENTS

2 INTRODUCTION

5 SAFETY INSTRUCTIONS

11 PRODUCT INTRODUCTION

11 Typical installation scene

12 Remote controller

13 DESCRIPTION OF THE OPERATION

13 Main screen

13 Menu screen

14 Setting screen

14 Popup screen

15 Monitoring

15 Returning to the screen

16 OPERATION SETTING

16 On / Off

16 Operation mode

17 Cooling operation

18 Heating operation

19 AI / Auto operation

TABLE OF CONTENTS

3

ENGLISH

20 TEMPERATURE SETTING

20 Controlling desired temperature

21 Select Temperature Sensor

22 DHW heating operation

22 Quick DHW tank heating

23 View temperature

25 LOCK SETTING

25 How to enter Lock setting

25 Lock setting – all, on/off, mode, DHW lock

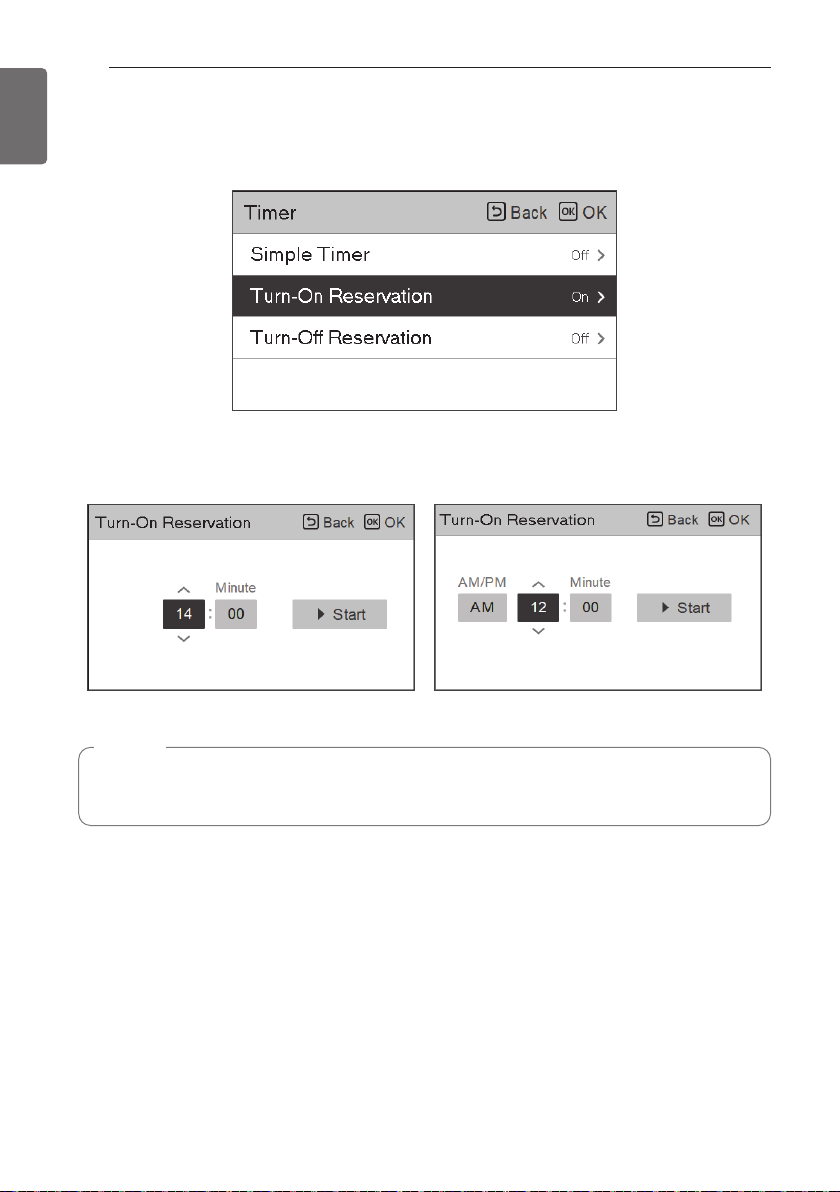

26 TIMER SETTING

26 Timer entrance and setting method

27 Simple Timer

28 Turn-On Reservation

29 Turn-Off Reservation

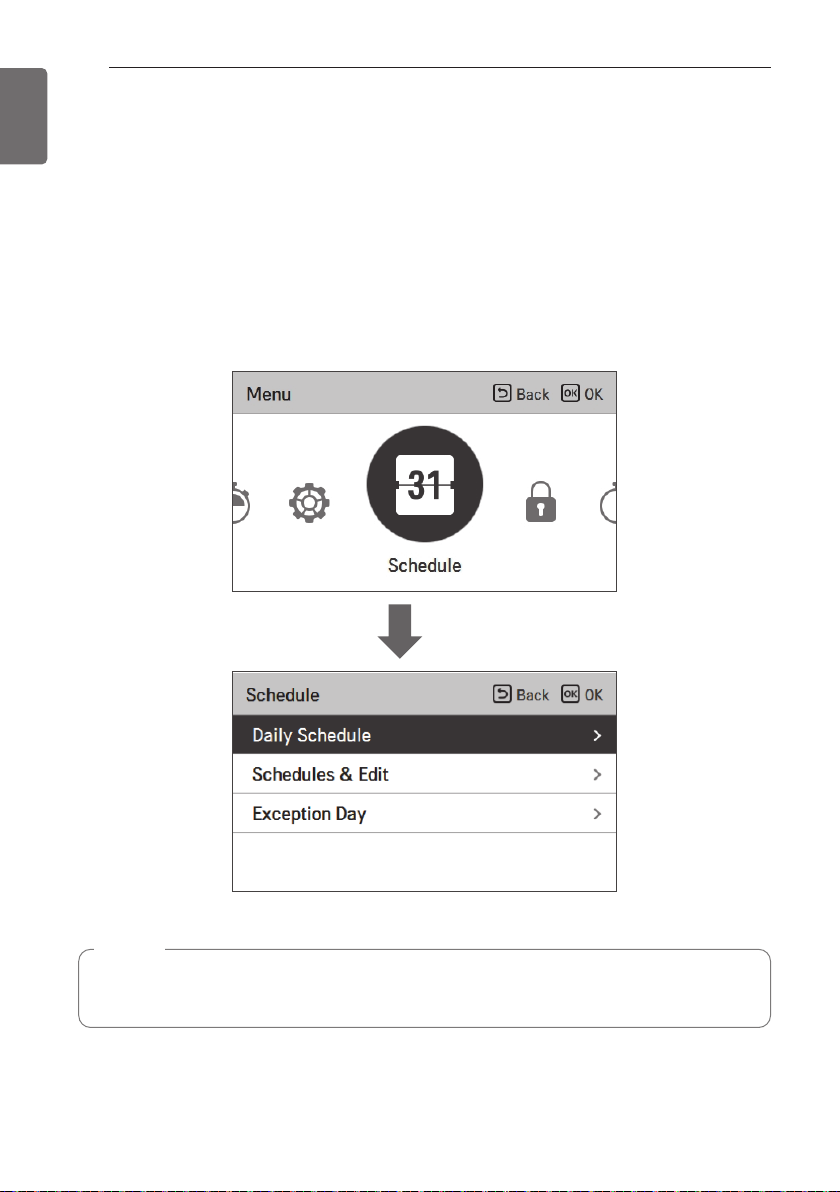

30 SCHEDULE SETTING

30 How to enter schedule

31 Daily schedule

32 Schedules & Edit

33 Schedules & Edit – Add schedule

34 Exception Day

Page 4

TABLE OF CONTENTS

4

ENGLISH

35 METER INTERFACE SETTING

35 Connection path of meter interface

36 Information of meter interface

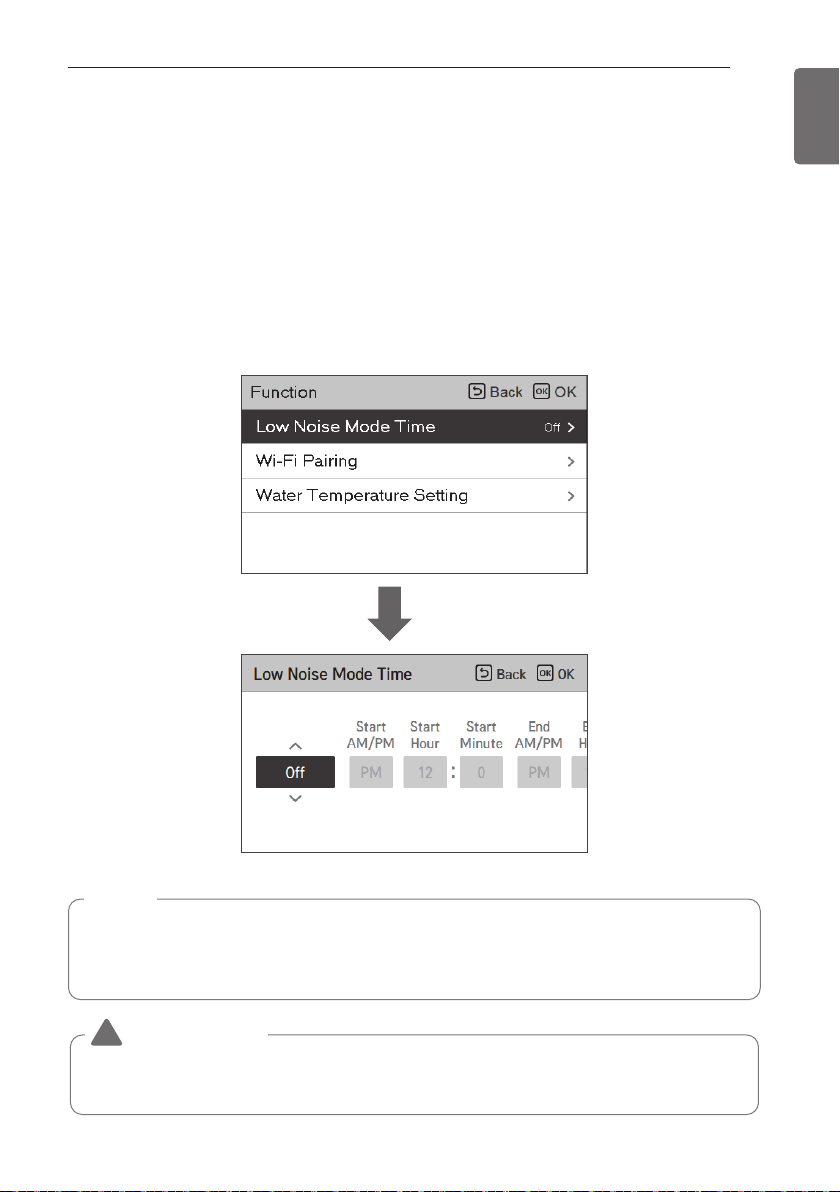

37 FUNCTION SETTING

37 How to enter function setting

38 Function setting

39 Low Noise Mode Time

40 Wi-Fi Pairing

41 Water Temperature Setting

42 3rdParty Boiler

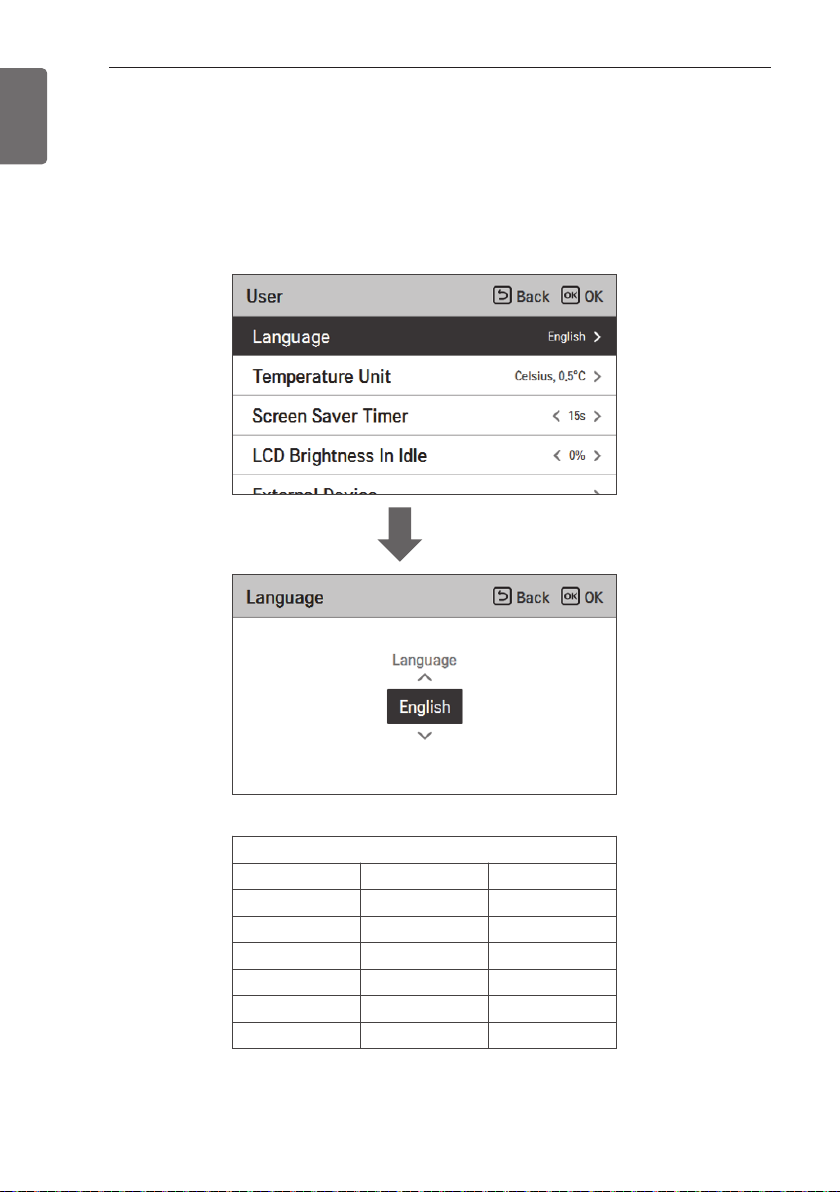

43 USER SETTING

43 How to enter user setting

43 User Setting

44 Language

45 Temperature Unit

46 Screen Saver Timer

46 LCD Brightness In Idle

47 Date

48 Time

49 Summer Time

50 Password

51 Schedule Initialization

52 Theme

52 System Reboot

53 OVERVIEW OWNER’S SETTINGS

53 Menu structure

55 USING THERMOSTAT

55 How to use thermostat

56 EMERGENCY OPERATION

58 MAINTENANCE AND SERVICE

58 Maintenance activities

58 When the unit is not going....

58 Call the service immediately in the following situations

Page 5

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS

5

ENGLISH

Read the precautions in this manual

carefully before operating the unit.

This symbol indicates that the

Operation Manual should be read

carefully.

This appliance is filled with

flammable refrigerant (R32)

This symbol indicates that a service

personnel should be handling this

equipment with reference to the

Installation Manual.

The following safety guidelines are intended to prevent

unforeseen risks or damage from unsafe or incorrect operation

of the appliance.

The guidelines are separated into ‘WARNING’ and ‘CAUTION’ as

described below.

This symbol is displayed to indicate matters and operations

!

that can cause risk.

Read the part with this symbol carefully and follow the

instructions in order to avoid risk.

WARNING

!

This indicates that the failure to follow the instructions can cause

serious injury or death.

CAUTION

!

This indicates that the failure to follow the instructions can cause

the minor injury or damage to the product.

WARNING

!

• Always ground the product.

- There is a risk of electric shock.

• Do not use a defective or underrated circuit breaker. Use the correctly

rated breaker and fuse.

- There is risk of fire or electric shock.

• Do not use a multi outlet. Always use this appliance on a dedicated circuit

and breaker.

- There is risk of fire or electric shock.

Page 6

SAFETY INSTRUCTIONS

6

ENGLISH

• For electrical work, contact the dealer, seller, a qualified electrician, or an

Authorized Service Center. Do not disassemble or repair the product by

yourself.

- There is risk of fire or electric shock.

• Always ground the product as per the wiring diagram. Do not connect the

ground wire to gas or water pipes lightning rod or telephone ground wire.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock due to dust, water etc.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable. If the power cable or cord has

scratches or skin peeled off or deteriorated then it must be replaced.

- There is risk of fire or electric shock.

• For installation, removal or reinstall , always contact the dealer or an

Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install the product on a defective installation stand. Be sure that the

installation area does not deteriorate with age.

- It may cause product to fall.

• Never install the unit on a moving base or a place from where it can fall

down.

- The falling unit can cause damage or injury or even death of a person.

• When the product is soaked (flooded or submerged) in water, contact an

Authorized Service Center for repair before using it again.

- There is risk of fire or electric shock.

• Be sure to check the refrigerant to be used. Please read the label on the

product.

- Incorrect refrigerant can prevent the normal operation of the unit.

• Don't use a power cord, a plug or a loose socket which is damaged.

- Otherwise it may cause a fire or electrical shock.

• Do not touch , operate, or repair the product with wet hands.

- There is risk of electric shock or fire.

• Do not place a heater or other heating appliances near the power cable.

- There is risk of fire and electric shock.

• Do not allow water to run into electric parts. Install the unit away from

water sources.

- There is risk of fire, failure of the product, or electric shock.

• Do not store or use or even allow flammable gas or combustibles near the

product.

- There is risk of fire.

Page 7

SAFETY INSTRUCTIONS

7

ENGLISH

• Wiring connections must be secured tightly and the cable should be

routed properly so that there is no force pulling the cable from the

connection terminals.

- Improper or loose connections can cause heat generation or fire.

• Safely dispose off the packing materials. Like screws, nails, batteries,

broken things etc after installation or service and then tear away and throw

away the plastic packaging bags.

- Children may play with them and cause injury.

• Make sure to check that the power device is not dirty, loose or broken and

then turn on the power.

- Dirty, loose or broken power device can cause electric shock or fire.

• In unit the step-up capacitor supplies high voltage electricity to the

electrical components. Be sure to discharge the capacitor completely

before conducting the repair work.

- An charged capacitor can cause electrical shock.

• When installing the unit, use the installation kit provided with the product.

- Otherwise the unit may fall and cause severe injury.

• Be sure to use only those parts which are listed in the service parts list.

Never attempt to modify the equipment.

- The use of inappropriate parts can cause an electrical shock, excessive

heat generation or fire.

• Do not use the product in a tightly closed space for a long time. Perform

ventilation regularly.

- Oxygen deficiency could occur and hence harm your health.

• Do not open the front cover or grille of the product during operation.

(Do not touch the electrostatic filter, if the unit is so equipped.)

- There is risk of physical injury, electric shock, or product failure.

• If strange sounds, smell or smoke comes from product, immediately turn

the breaker off or disconnect the power supply cable.

- There is risk of electric shock or fire.

• Ventilate the product room from time to time when operating it together

with a stove, or heating element etc.

- Oxygen deficiency can occur and hence harm your health.

• Turn the main power off when cleaning or repairing the product.

- There is risk of electric shock.

• Take care to ensure that nobody especially kids could step on or fall onto

the unit.

- This could result in personal injury and product damage.

• Take care to ensure that power cable could not be pulled out or damaged

during operation.

- There is risk of fire or electric shock.

Page 8

SAFETY INSTRUCTIONS

8

ENGLISH

• Do not touch any electric part with wet hands. you should be cut power

before touching electric part.

- There is risk of electric shock or fire.

• Do not touch refrigerant pipe and water pipe or any internal parts while the

unit is operating or immediately after operation.

- There is risk of burns or frostbite, personal injury.

• If you touch the pipe or internal parts, you should be wear protection or

wait time to return to normal temperature.

- Otherwise , it may cause burns or frostbite, personal injury.

• Do not touch leaked refrigerant directly.

- There is risk of frostbite.

• Make sure to install mixing valve (field supply). The mixing valve is setting

the water temperature. The hot water temperature maximum values shall

be selected according to the applicable legislation.

• Do not heated to a temperature of more than provided by the product.

- Otherwise, it may cause fire or damage of product.

• This appliance is intended to be used by expert or trained users in shops, in

light industry and on farms, or for commercial use by lay persons.

• Do not step on the unit and do not put anything on it.

It may cause an injury through dropping of the unit or falling down.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air

purge. Do not compress air or Oxygen and Do not use Flammable gases.

Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

• The appliance shall be stored in a well-ventilated area where the room size

corresponds to the room area as specified for operation.

• The appliance shall be stored in a room without continuously operating

open flames (for example an operating gas appliance) and ignition sources

(for example an operating electric heater).

• The appliance shall be stored so as to prevent mechanical damage from

occurring.(for R32)

• Any person who is involved with working on or breaking into a refrigerant

circuit should hold a current valid certificate from an industry-accredited

assessment authority, which authorises their competence to handle

refrigerants safely in accordance with an industry recognised assessment

specification.(for R32)

• Keep any required ventilation openings clear of obstruction.(for R32)

• Servicing shall only be performed as recommended by the equipment

manufacturer. Maintenance and repair requiring the assistance of other

skilled personnel shall be carried out under the supervision of the person

competent in the use of flammable refrigerants. (for R32)

Page 9

SAFETY INSTRUCTIONS

9

ENGLISH

• The appliance shall be stored in a well-ventilated area where the room size

corresponds to the room area as specified for operation. (for R32)

• The appliance shall be stored in a room without continuously operating

open flames (for example an operating gas appliance) and ignition sources

(for example an operating electric heater). (for R32)

CAUTION

!

• Two or more people must lift and transport the product.

- Avoid personal injury.

• Do not install the product where it will be exposed to sea wind (salt spray)

directly.

- It may cause corrosion on the product.

• Keep level even when installing the product.

- To avoid vibration or noise.

• Do not install the product where the noise or hot air from the unit could

damage or disturb the neighborhoods.

- It may cause a problem for your neighbors and hence dispute.

• Always check for gas (refrigerant) leakage after installation or repair of

product.

- Low refrigerant levels may cause failure of product.

• Do not use the product for special purposes, such as preserving foods,

works of art, etc. It is a consumer AWHP, not a precision refrigeration

system.

- There is risk of damage or loss of property.

• Do not block the inlet or outlet of air flow.

- It may cause product failure.

• Use a soft cloth to clean. Do not use harsh detergents, solvents or

splashing water etc.

- There is risk of fire, electric shock, or damage to the plastic parts of the

product.

• Do not step on or put anything on the product.

- There is risk of personal injury and failure of product.

• Do not insert hands or other objects through the air inlet or outlet while the

product is operating.

- There are sharp and moving parts that could cause personal injury.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury.

• If the refrigerant gas leaks during the repair, do not touch the leaking

refrigerant gas.

- The refrigerant gas can cause frostbite (cold burn).

Page 10

SAFETY INSTRUCTIONS

10

ENGLISH

• Do not tilt the unit when removing or uninstalling it.

- The condensed water inside can spill.

Do not mix air or gas other than the specified refrigerant used in the system.

•

- If air enters the refrigerant system, an excessively high pressure results,

causing equipment damage or injury.

• If the refrigerant gas leaks during the installation, ventilate the area

immediately.

- Otherwise it can be harmful for your health.

• Dismantling the unit, treatment of the refrigerant oil and eventual parts

should be done in accordance with local and national standards.

• Do not expose your skin or kids or plants to the cool or hot air draft.

- This could harm to your health.

• Use a firm stool or ladder when cleaning, maintaining or repairing the

product at an height.

- Be careful and avoid personal injury.

• The hot water may not be available immediately, during disinfection

operation or depending on the amount of hot water.

• During floor heating operation it is important to limit the

minimum/maximum water temperature.

• If anyone other than a licensed Professional installs, repairs, or alters LG

Electronics Air Conditioning Products, the warranty is voided.

- All costs associated with repair are then the full responsibility of the

owner.

This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities or lack of experience and

knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the

appliance.

This appliance can be used by children aged from 8 years and above and

persons with reduced physical, sensory or mental capabilities or lack of

experience and knowledge if they have been given supervision or

instruction concerning use of the appliance in a safe way and understand

the hazards involved. Children shall not play with the appliance. Cleaning

and user maintenance shall not be made by children without supervision.

Page 11

PRODUCT INTRODUCTION

4

3

Water

Out

Water

In

1

6

2

5

Typical installation scene

PRODUCT INTRODUCTION

11

ENGLISH

1. Indoor unit

2. Outdoor unit

3. Refrigerant pipe and connecting cable

4. Water pipe

5. Ground wire to ground outdoor unit to prevent electrical shocks.

6. Remote controller

*The shape of products can be changed according to the model capacity and type.

Page 12

PRODUCT INTRODUCTION

12

ENGLISH

Remote controller

Operation display

window

Back button

Up/Down/Left/Right

OK

On/Off button

OK button

button

Operation display window

Back button

Up/down/left/right button

OK button

On/Off button

Operation and Settings status display

When you move to the previous stage from the menu’s

setting stage

When you change the menu’s setting value

When you save the menu’s setting value

When you turn ON/OFF the AWHP

NOTE

• Some functions may not be operated and displayed depending on the product type.

• The actual product can be different from above contents depending upon model type.

• When using simultaneous operation system, whenever press remote controller button,

system will approximately operate after 1~2 minutes.

Page 13

DESCRIPTION OF THE OPERATION

DESCRIPTION OF THE OPERATION

Main screen

In the main screen, press [<, >(left/right)] button to select the category to set, and you can

control by pressing [∧,∨ (up/down)] button.

Menu screen

In the main screen, press [<, >(left/right)] button to select the menu and press [OK] button to

move to menu screen.

13

ENGLISH

In the menu screen, press [<, >(left/right)] button to select the category to set, and press [OK]

button to move to the detail screen.

Page 14

DESCRIPTION OF THE OPERATION

14

ENGLISH

Setting screen

Select the category to set using [∧,∨(up/down)] button.

In each detail screen of the menu, as in the box in the left figure,

when “<,>” icons are displayed at the same time, you can

immediately apply the setting value by pressing [<, >(left/right)]

button.

※ For the values that can be set in each category, refer to the

detail manual for each function.

In each detail screen of the menu, as in the box in the left figure,

if only “>” icon is displayed, you can move to the detail setting

screen by pressing [>(right) or OK] button.

※ For the values that can be set in each category, refer to the

detail manual for each function.

Popup screen

The toast message is the message displayed at the bottom of the screen when an operation is

turned On/Off or if a function is set / canceled.

The popup message is mainly displayed when an error occurred in the product.

< Toast message > < Popup message >

Page 15

DESCRIPTION OF THE OPERATION

Monitoring

In the main screen, you can enter the monitoring screen by pressing [Back] button

In the monitoring screen, you can check the following information,

- The room temperature

- The water inlet / outlet temperature

- The water pump operation

15

ENGLISH

Returning to the screen

In the main screen, after moving to the category by pressing [<, >(left/right)] button, if there is no

remote controller operation, after 10 seconds, it returns to the main screen basic position. (basic

position: indoor temperature display part)

In the screens except the main screen, if there is no remote controller operation for 1 minute, it

moves to the main screen.

Page 16

OPERATION SETTING

16

ENGLISH

OPERATION SETTING

On / Off

will be turned on or off.

Press the remote controller’s (On/Off) button.

- If the product is in operation, On/Off button will be illuminated.

If the product is in off, On/Off button backlight will be off.

Operation mode

You can easily control the desired operation mode.

In the main screen, press [<,>(left/right)] button to select the operation mode or home leave or

hold category, and press [∧,∨(up/down)] button to set the operation mode.

※Some products may not support some operation modes.

Mode Description

Cool the room to the desired temperature.

Cool

Heat Heats the room to the desired room temperature.

AI / Auto

Activated when No. 4 ON of indoor unit PCB DIP SW 2. (Refer to

installer setting.)

The product automatically provides the appropriate fan speed based on

the temperature of the room.

Page 17

OPERATION SETTING

Cooling operation

Cooling operation’s minimum setting temperature is 5 °C.

• The desired temperature can be controlled in the units of 1 °C.

- Set the desired temperature lower than the water temperature.

- water temperature is displayed on the default screen of the remote controller.

- If the setpoint is set higher than the water temperature, then the unit will remain in the cool

mode but will not begin to cool the water temperature exceeds the setpoint.

- If your unit is operating in cooling mode and you press the [On/Off] button the cooling operation

will shut off.

NOTE

17

ENGLISH

Activated when No. 4 ON of indoor unit PCB DIP SW 2 (Refer to installer setting)

What is 3 minutes delay function?

After the cooling stops, when the product is started right away, the reason that the cold

water does not come out is that it is the function to protect the compressor.

The compressor starts after 3 minutes and the cold water comes out.

NOTE

The compressor starts after 3 minutes and the cold water comes out.

In the cooling operation, you can select the desired temperature in the range of 5 °C~27 °C.

The favorable temperature difference between the water inlet temperature and outlet

temperature is 5 °C.

Page 18

OPERATION SETTING

18

ENGLISH

Heating operation

The heating operation’s minimum setting temperature is 15 °C.

• The desired temperature can be controlled in the units of 1 °C.

- Set the desired temperature higher than the water temperature.

- Water temperature is displayed on the default screen of the remote controller.

- When the desired temperature is set lower than the water temperature, warm water doesn't

come out.

- If your unit is operating in heating mode and you press the [On/Off] button the heating operation

will shut off.

NOTE

In the heating operation, you can select the desired temperature in the range of 15 °C~65 °C.

Page 19

OPERATION SETTING

AI / Auto operation

In order to save energy and to give highest comfort, setting temperature will follow outside

temperature. If outdoor temperature decreases, heating capacity for the house will increase

automatically in order to keep same room temperature. All parameters will be set by installer

during start-up procedure and will be adapted to the site characteristic.

1. Select AI / Auto mode.

2. Select the desired temperature category

19

ENGLISH

3. Adjust the desired temperature level by press [∧,∨(up/down)] button.

NOTE

Decreasing temperature profile by 3 °C (based on room air temperature)

<Temperature adjust step (unit : °C)>

-5, -4, -3, -2, -1, 0, 1, 2, 3, 4, 5

Cold Hot

Page 20

TEMPERATURE SETTING

20

ENGLISH

TEMPERATURE SETTING

Controlling desired temperature

You can easily control to the desired temperature.

• In the main screen, press [<, > (left/right)] button to select the desired temperature category,

and press [∧,∨(up/down)] button to set the desired temperature.

- In the cooling, heating, and AI/auto mode, the desired temperature control is possible.

Mode Description

Room

temperature

Room1 &

Room2

temperature

Leaving water

temperature

DHW tank

temperature

Water inlet

temperature

Room

temperature +

Leaving water

temperature

Room temperature setting is available when remote room air sensor (sold

separately) is installed

Temperature of Room 1 and Room 2 can be set respectively, when 2nd

circuit option is activated in installer mode.

If the desired temperature is lower than the water temperature, the heating

is not performed.

Set the desired temperature higher than the water temperature.

DHW tank temperature setting is available when DHW tank is installed.

This operation is changed to the temperature sensor only, the inlet

temperature sensor, and temperature control logic is the same as the leaving

water temperature operation.

Room temperature setting is available when remote room air sensor (sold

separately) is installed. If the desired temperature is lower than the water

temperature, the heating is not performed. Set the desired temperature

higher than the water temperature.

NOTE

The function can be activated according to the installer setting.

Page 21

TEMPERATURE SETTING

Select Temperature Sensor

There are 3 sensor options, air only, leaving water only, and air+water in installer mode.

Sensor Locations are not available on all models.

<For R410A> <For R32>

21

ENGLISH

Page 22

TEMPERATURE SETTING

22

ENGLISH

DHW heating operation

Function to set whether or not to use a installed DHW tank

NOTE

• This function is not used when the DHW tank is not installed.

• If you want to know more information, refer function on installation information section.

Quick DHW tank heating

If there is urgent DHW heating demand, Quick DHW Tank Heating mode can be used to reduce

the time to reach target DHW tank temperature by forcibly turning on DHW tank heater.

After reaching target DHW tank temperature or by user’s input to stop, Quick DHW Tank Heating

mode will be finished.

1. Press down [Back] button for a second focused on DHW Heating Operation.

Page 23

TEMPERATURE SETTING

View temperature

General mode

You can check the current temperature.

• In the main screen, you can enter the monitoring screen by pressing [Back] button.

23

ENGLISH

Mode Description

Room

temperature

Inlet

temperature

Outlet

temperature

DHW

temperature

Solar heat

temperature

View room temperature

View inlet temperature

View outlet temperature

View DHW temperature

(Only displayed when DHW heating mode)

View solar power temperature

(Only displayed when DHW water heating mode)

Page 24

24

ENGLISH

2ndcircuit mode

TEMPERATURE SETTING

Mode Description

Room 1

temperature

Room 2

temperature

Inlet

temperature

Outlet

temperature

DHW

temperature

Solar heat

temperature

View room 1 temperature

View room 2 temperature

View inlet temperature

View outlet temperature

View DHW temperature

(Only displayed when DHW heating mode)

View solar power temperature

(Only displayed when DHW water heating mode)

Page 25

LOCK SETTING

LOCK SETTING

How to enter Lock setting

• In the menu screen, press [<,>(left/right)] button to select “lock setting” category, and press

[OK] button to move to the lock setting list screen.

• In the lock setting list, if you press [∧ ,∨(up/down)] button, you can turn on/off the

corresponding lock function.

OK

25

ENGLISH

Lock setting – all, on/off, mode, DHW lock

• It is the function to lock the button operation of the remote controller so that children or other

persons cannot use it without permission.

•

It is the function to limit the desired temperature range that can be set in the wired remote controller.

Mode Description

All Lock It locks all button operation of the remote controller.

On/Off Lock It locks the On/Off button operation of the remote controller.

Mode Lock lock It locks the operation mode button operation of the remote controller

DHW Lock lock It locks the DHW On/Off button operation of the remote controller.

NOTE

• DHW lock is not used when the DHW tank is not installed.

• If you want to know more information, refer function on installation information section.

NOTE

In the central controller, when the central control temperature range lock is set, the wired

remote controller’s temperature lock setting is cleared.

The temperature change by external equipment is reflected regardless of the remote

controller temperature range lock.

Page 26

TIMER SETTING

26

ENGLISH

TIMER SETTING

Timer entrance and setting method

• In the menu screen, press [<,>(left/right)] button to select the timer category, and press [OK]

button to move to the timer setting list screen.

• In the timer setting list screen, press [∧,∨(up/down)] button to select the timer to set, and

press [OK] button to move to the detail screen.

• After setting the value, when you press [OK] button, the timer is activated.

• After setting the value, if you press [Back] button, the changed value will not be applied.

OK

Page 27

Simple Timer

You can easily set the timer in the range of 1~7 hours in the units of 1 hour.

OK

TIMER SETTING

27

ENGLISH

NOTE

If the product operation is On, the easy timer turns off the operation after the corresponding

time.

If the product operation is Off, the easy timer turns on the operation after the corresponding

time.

If the easy timer operation is turned On/Off before the timer operation, the set timer will be

cleared.

Page 28

TIMER SETTING

28

ENGLISH

Turn-On Reservation

The product is automatically turned On at the set timer time.

It provides 2 Time formats, 12Hours(AM/PM) or 24Hours reference.

NOTE

Even if the Turn-on Reseravation operation is turned On/Off after the setting and before the

timer operation, the set timer is not cleared.

Page 29

Turn-Off Reservation

The product is automatically turned Off at the set timer time.

It provides 2 Time formats, 12 Hours(AM/PM) or 24 Hours reference.

TIMER SETTING

29

ENGLISH

NOTE

Even if the Turn-off Reservation operation is turned On/Off after the setting and before the

timer operation, the set timer is not cleared.

Page 30

SCHEDULE SETTING

30

ENGLISH

SCHEDULE SETTING

How to enter schedule

• In the menu screen, press [<,>(left/right)] button so select the schedule category, and press

[OK] button to move to the schedule setting list screen.

• In the schedule setting list screen, press [∧,∨(up/down)] button to select the menu to set, and

press [OK] button to move to the detail screen.

• There are 3 options in schedule formula ,depending on product function.

- Room

- Hot water

- Heater of hot water tank

OK

NOTE

Even though there is a heater of hot water tank schedule option, It cannot be activated in

case of sterilization operation.

Page 31

SCHEDULE SETTING

Daily schedule

It is the function that can check the status of the timer (schedule) saved in the remote controller.

• In the schedule list, select the daily schedule status category, and press [OK] button to move to

the detail daily schedule status screen.

• You can use the remote controller’s [<,>(left/right)] button to check the timer information of

other dates.

• You can use the remote controller’s [∧,∨(up/down)] button to check the corresponding date’s

other timer information.

31

ENGLISH

• Select the timer information, and press [OK] button to move to the corresponding timer’s edit

screen.

NOTE

In the daily schedule status screen, even if the timer (schedule) is set, if the corresponding

date is designated as an exception date, the schedule will not be performed.

Less than 5 schedules per day is recommended.

Page 32

SCHEDULE SETTING

32

ENGLISH

Schedules & Edit

It is the function that can check the status of the timer (schedule) saved in the remote controller.

• In the schedule list, select the daily schedule status category, and press [OK] button to move to

the daily schedule status detail screen.

• You can use the remote controller’s [<,>(left/right)] button to check other date’s timer

information.

You can check the set

timer’s operation

information (operation

On/Off, operation

mode, desired

temperature), timer

time, period, and day of

week.

• You can edit the saved schedule’s timer information.

- Select the schedule to edit using [∧,∨(up/down)] button, and press [OK] button to move to

the edit screen.

• Select the timer information, and press [OK] button to move to the corresponding timer’s edit

screen.

< If schedule is changed > < If schedule is deleted >

Page 33

Schedules & Edit – Add schedule

Description of each stage in Add schedule

Stage 1. Period setting Stage 2. Day of week setting

Stage 3. Time setting Stage 4. Operation setting

SCHEDULE SETTING

33

ENGLISH

Add schedule is completed

In ‘Stage 1’, it sets the period to perform the timer.

In ‘Stage 2’, it sets the day of week to perform the timer.

- You can select ‘Everyday / Weekend / Weekdays / Individual selection’.

In ‘Stage 3’, it sets the start time for the timer.

In ‘Stage 4’, it sets the timer operation information.

- If ‘Stop’ is selected, you cannot set the mode / temperature.

When stages 1~4 are completed, along with the message of ‘schedule is added’, it moves to

View and edit schedule screen.

Page 34

SCHEDULE SETTING

34

ENGLISH

Exception Day

It is the function to automatically stop the operation on the set timer day.

• In the schedule list, select the exception day category, and press [OK] button to move to the

Exception day designation detail screen.

• In the exception day, you can check, and add/change/delete the exception day information

saved in the remote controller.

- To add an exception day, in the Exception day registration detail screen, designate

year/month/day, and press [OK] button to save the Exception day.

- Select the Exception day to edit using [∧,∨(up/down)] button, and press [OK] button to move

to the edit screen.

- In the exception day edit screen, you can check, delete/change the corresponding exception

day’s setting contents.

- When you change the exception day information, you need to save it after the change.

Page 35

METER INTERFACE SETTING

METER INTERFACE SETTING

Connection path of meter interface

It is the function that can check the status of energy and power on screen. It collects and

calculates power or calorie data to create data for energy monitoring and energy warning alarm

pop-ups. This function can be activated in installer mode.

OK

35

ENGLISH

There are 2 options, modbus address and unit, in this function. Activating the modbus address

option, you choose one address(B0 or B1) or don’t use. Then, you set the port and specification

in range of 0000.0~9999.9[pulse/kW] as shown in the figure below.

Page 36

METER INTERFACE SETTING

36

ENGLISH

Information of meter interface

It provides useful information on the mount of energy and power during the week/month/year.

Opening “Energy “option , these are presented on screen.

Instantaneous Power

Power/Calorie

The information includes instantaneous power as well as power/calorie usage and up to annual

trend .

Energy Setting

In addition, various energy settings are possible as shown below.

Current value reaches to defined target value, It alerts to you on display

Page 37

FUNCTION SETTING

FUNCTION SETTING

How to enter function setting

To enter the menu displayed at the bottom, you need to enter the function setting menu as

follows.

• In the menu screen, press [<,>(left/right)] button to select the setting category, and press [OK]

button to move to the setting list.

• In the setting list, select the function setting category, and press [OK] button to move to the

function setting list.

OK

37

ENGLISH

Page 38

FUNCTION SETTING

38

ENGLISH

Function setting

Menu Description

Low Noise Mode Time

Wi-Fi Pairing It is the function to control remotely through network with indoor unit.

Water Temperature

Setting

3rdParty Boiler

It is the function to set the start and end time of the outdoor unit’s

low noise mode operation.

If you choose (Leaving/Inlet) water temperature control way, This

option is activated on screen. It is the function to set target water

temperature.

It is the function to linkage the boiler of other companies. (this

function can be activated, after setting every value in installer mode.)

Page 39

FUNCTION SETTING

Low Noise Mode Time

It is the function to set the start and end time of the outdoor unit’s low noise mode operation.

• In the function setting list, select the Low Noise Mode Time category, and press [OK] button to

move to the detail screen.

- After setting the start time and the end time, press [OK] button to move to the upper level

list.

- If the start time and the current time are the same, it enters the outdoor unit low noise

operation mode, and in the monitoring screen, ‘in outdoor unit low noise operation mode’

message is displayed.

- If the end time and the current time are the same, the outdoor unit low noise operation mode

is cleared.

OK

39

ENGLISH

NOTE

Low noise mode time setting function can be set only when the installer setting’s outdoor

unit function M/S setting is set to “Master”.

Low noise mode time setting function is only available in some products.

CAUTION

!

If the function is not used, please set it to Off.

When you enter the low noise operation, the cooling capacity may be degraded.

Page 40

FUNCTION SETTING

40

ENGLISH

Wi-Fi Pairing

It is the function to control remotely through network with indoor unit.

OK

Page 41

FUNCTION SETTING

Water Temperature Setting

NOTE

This function is not default.

It can be activated, after setting value in installer mode.

If you choose air+water temperature control way, This option is listed-up on function setting

display. It is the function to set target water temperature.

41

ENGLISH

Page 42

FUNCTION SETTING

42

ENGLISH

3rdParty Boiler

NOTE

This function is not default.

It can be activated, after setting value in installer mode.

Function to set whether or not to use a installed 3rd Party function.

If the mode of this function is set to “Manual”, you can set temperature of the boiler and

hysteresis, respectively.

AS shown above, After every setting is completed in installer mode, 3rd party boiler option is

activated in function list.

On/off mode of this option are opened by pushing "<" or ">" button simply and easily.

Page 43

USER SETTING

USER SETTING

How to enter user setting

To enter the menu displayed at the bottom, you need to enter the user setting menu as follows.

• Select the setting category, and press [OK] button to move to the setting list.

• Select the user setting category, and press [OK] button to move to the user setting list.

OK

43

ENGLISH

User Setting

• You can set the product user functions.

• Some functions may not be available in some product types.

Menu Description

Language Set the language to be displayed on the remote controller.

Temperature Unit Set the temperature unit displayed on the remote controller.

Screen Saver Timer Adjust the screen Off time of the remote controller.

LCD Brightness In Idle Adjust the remote controller’s screen brightness.

Date Set the date displayed on the remote controller.

Time Set the time displayed on the remote controller.

Summer Time Set the summer time in the remote controller.

Password

Schedule Initialization Initialize all timer settings in the remote controller.

Theme Set the theme of the remote controller screen.

System Reboot Restart the remote controller.

Set the password to prevent unauthorized change to remote controller settings.

Page 44

USER SETTING

44

ENGLISH

Language

Set the language to be displayed on the remote controller.

• In the user setting list, select the language category, and press [OK] button to move to the

detail screen.

• After the setting, if you press [OK] button, the setting is saved and moves to the previous

screen.

OK

Language

한국어

Deutsche Italiano Español

Русский Polski Português

中国

Nederlands

Magyar Български Srpski

Hrvatski Slovenščina

English Français

Čeština Türk

Românesc ελληνικά

Page 45

USER SETTING

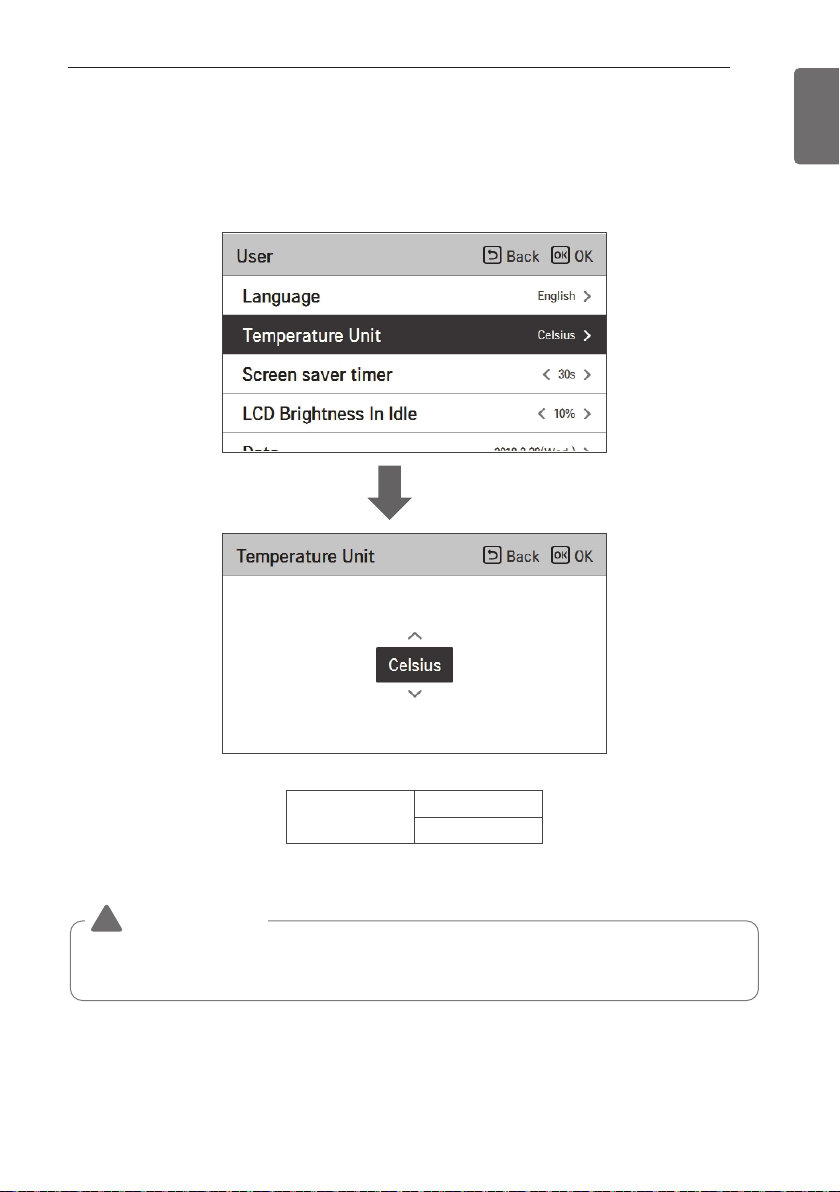

Temperature Unit

Set the temperature unit displayed on the remote controller.

• In the user setting list, select the temperature unit setting category, and press [OK] button to

move to the detail screen.

OK

45

ENGLISH

Value

CAUTION

!

The temperature unit function may not work or work differently in some products.

You cannot set the temperature unit in the slave wired remote controller.

Celsius

Fahrenheit

Page 46

USER SETTING

46

ENGLISH

Screen Saver Timer

Adjust the screen Off time of the remote controller.

• Select the following setting values using [<,>(left/right)] button.

Value

15 seconds 30 seconds (default) 1 minute

CAUTION

!

Selecting longer stand by screen will decrease LCD lifespan.

LCD Brightness In Idle

Adjust the remote controller’s screen brightness.

• Select the following setting values using [<,>(left/right)] button.

Value

0 %

CAUTION

!

Selecting brighter stand by screen will decrease LCD lifespan.

10 %

(default)

20 % 30 %

Page 47

USER SETTING

Date

Set the date displayed on the remote controller.

• In the user setting list, select the date category, and press [OK] button to move to the detail

screen.

• After the setting, if you press [OK] button, the setting is saved and moves to the previous

screen.

OK

47

ENGLISH

Page 48

USER SETTING

48

ENGLISH

Time

Set the time displayed on the remote controller.

• In the user setting list, select the time category, and press [OK] button to move to the detail

screen.

• After the setting, if you press [OK] button, the setting is saved and moves to the previous

screen.

• In the screen, Time display can be presented in the form of AM / PM or 24 hours standard.

OK

Page 49

USER SETTING

Summer Time

Set the daylight savings time dates in the remote controller.

• In the user setting list, select the summer time setting category, and press [OK] button to

move to the detail screen.

- Summer time: The system to advance the time by 1 hour from the spring when the day is

longer and return back in the fall when the day gets shorter.

- When it becomes AM 02:00 on the DST start date, the current time changes to AM 03:00,

and when it becomes AM 02:00 of the DST end date, the current time changes to AM 01:00.

OK

49

ENGLISH

Page 50

USER SETTING

50

ENGLISH

Password

Set the password to prevent unauthorized change to remote controller settings.

• Select the user password setting category, and press [OK] button to move to the detail screen.

- If the password is set, when you enter “menu – setting”, you need to input password to

enter the setting list.

- When you forgot the password, you can initialize the password using the installer setting’s

“password initialization”.

The initialized password is “0000”.

OK

Page 51

USER SETTING

Schedule Initialization

Initialize all timer settings in the remote controller.

• In the user setting list, select the schedule initialization setting category, and press [OK] button

to move to the detail screen.

- Press the check button to initialize the sleep/simple timer, on/off timer, schedule and

exception date in the remote controller.

OK

51

ENGLISH

Page 52

USER SETTING

52

ENGLISH

Theme

Set the theme of the remote controller screen.

• Select either white or black using [<,>(left/right)] button.

System Reboot

Restart the remote controller.

• In the user setting list, select the system restart setting category, and press [OK] button to

move to the detail screen.

- In the detail screen, when you press [OK] button, a popup message is displayed, press the

check button, to restart the system.

- For forced reset, press down [On/Off + Back] button for 5 seconds to restart the system.

OK

Page 53

OVERVIEW OWNER’S SETTINGS

OVERVIEW OWNER’S SETTINGS

Menu structure

Menu

Lock

All Lock

On/Off Lock

Mode Lock

Timer

Simple Timer

Turn-On Reservation

Turn-Off Reservation

Schedule

Daily Schedule

Schedules & Edit

Exception Day

........................................................................25

........................................................................25

........................................................................25

........................................................................27

........................................................................28

........................................................................29

........................................................................31

........................................................................32

........................................................................34

53

ENGLISH

Energy

Setting

Connection path of meter interface

Information of meter interface

Instantaneous Power

Power/Calorie

Energy Setting

Function

Low Noise Mode Time

Wi-Fi Pairing

Water Temperature Setting

3rdParty Boiler

....................................................35

....................................................36

.........................36

.........................36

.........................36

.........................39

.........................40

.........................41

.........................42

Page 54

54

ENGLISH

OVERVIEW OWNER’S SETTINGS

User

Language

Temperature Unit

Screen Saver Timer

LCD Brightness In Idle

Date

Time

Summer Time

Password

Schedule Initialization

Theme

System Reboot

.........................44

.........................45

.........................46

.........................46

.........................47

.........................48

.........................49

.........................50

.........................51

.........................52

.........................52

Page 55

USING THERMOSTAT

USING THERMOSTAT

The term "thermostat", which is widely used in this chapter, is a kind of 3rd party accessory.

LG Electronics does not supply thermostat and it should be supplied 3rd party manufacturers.

Room thermostat can be used for easy and convenience control. To utilize thermostat more

efficiently and correctly, this chapter presents information about using thermostat.

When thermostat is interlocked, the subject of Thermo On / Off is limited to the thermostat

CAUTION

!

• Some electro-mechanical type thermostat has internal delay time to protect compressor. In that

case, mode change can takes time more than user's expectation. Please read thermostat

manual carefully if the product does not response quickly.

• Setting temperature range by thermostat can be different with that of the product. The heating

or cooling set temperature should be chosen within the setting temperature range of the

product.

How to use thermostat

To find how to turn on and off, how to set target temperature, how to change operating mode,

etc, please refer thermostat operating manual provided by thermostat manufacturer.

55

ENGLISH

Page 56

EMERGENCY OPERATION

56

ENGLISH

EMERGENCY OPERATION

• Definition of terms

- Trouble : a problem which can stop system operation, and can be resumed temporally under

limited operation without certificated professional's assist.

- Error : problem which can stop system operation, and can be resumed only after certificated

professional's check.

- Emergency mode : temporary heating operation while system met trouble.

• Objective of introducing 'Trouble'

- Not like airconditioning product, Air-to-Water heat pump is generally operation in whole winter

season without any system stopping.

- If system found some problem, which is not critical to system operating for yielding heating

energy, the system can temporarily continue in emergency mode operation with end user's

decision.

• Classified trouble

- Trouble is classified two levels according to the seriousness of the problem. : Slight trouble and

Heavy trouble

- Slight trouble : Sensor trouble. In most case, this trouble is concerned with sensor problems.

The unit is operating under emergency mode operation(level 1).

- Heavy trouble : Compressor cycle trouble. Emergency mode operation(level 2) is performed by

optional electric heater.

- Option trouble : a problem is found for option operation such as water tank heating. In this

trouble, the troubled option is assumed as if it is not installed at the system.

• Emergency operation level

When the AWHP has any trouble,

(1) If there is not a function to judge possibility of operation : Once an error occurs mainly in

indoor unit, AWHP stops. On the other hand, Remocon allows the product to activate On / Off

operation.(On : emergency operation)

- Slight / Heavy trouble : Heating Operable only

- Critical trouble : Full stop

- Treatment priority : Critical > Heavy > Slight

(2) If there is a function to judge possibility of operation : Depending on the status of slight /

heavy / critical trouble, pop-up phrase is guided separately on display.

- Slight trouble : Heating / Cooling Operable

- Heavy trouble : Heating Operable only

- Critical trouble : Service center request

- AWHP operates when user pressed OK button on pop-up window.

Page 57

EMERGENCY OPERATION

• Duplicated trouble : Option trouble with slight or heavy trouble

- If option trouble is occurred with slight (or heavy) trouble at the same time, the system puts

higher priority to slight (or heavy) trouble and operates as if slight (or heavy) trouble is occurred.

- Therefore, sometimes sanitary water heating can be impossible in emergency operation mode.

When sanitary water is not warming up while emergency operation, please check if sanitary

water sensor and related wiring are all Ok.

• Emergency operation is not automatically restarted after main electricity

power is reset.

- In normal condition, the product operating information is restored and automatically restarted

after main electricity power is reset.

- But in emergency operation, automatic re-start is prohibited to protect the product.

- Therefore, user must restart the product after power reset when emergency operation has

been running.

57

ENGLISH

Page 58

MAINTENANCE AND SERVICE

58

ENGLISH

MAINTENANCE AND SERVICE

Maintenance activities

In order to ensure optimal availability of the unit, a number of checks and inspections on the unit

and the field wiring have to be carried out at regular intervals, preferably yearly. This maintenance

should be carried out by your local agreed technician.

When the unit is not going....

CAUTION

!

• If the product is not used for long time, we strongly

recommend not to switch off the power supply to the product.

• When the power is applied for the first time, operate the

product after preheating for 2 hours. To protect the unit by

increasing the oil temperature of the compressor.

• If power is not supplied, some special product-protecting

actions (such as water pump anti-locking) will not performed.

Call the service immediately in the following situations

• Anything abnormal such as burning smell, loud noise etc. happen. Stop the unit and turn the

breaker off. Never try to repair by yourself or restart the system in such cases.

• Main power cord is too hot or damaged.

• Error code is generated by self diagnosis.

• Water leaks from unit.

• Any switch, breaker (safety, earth) or fuse fails to work properly.

User must carry routine checkup & cleaning to avoid unit’s poor performance.

In case of special situation, the job must be carried out by the only service person.

CAUTION

!

• In the case of water with added brine, the drain valve of shut-off valve must be connected to a

recovery container.

• Do not touch the water stirred with the brine.

• When the brine in the pipe is leaked, do not operate the unit and contact dealer, seller or an

authorized service center.

Page 59

Loading...

Loading...