Page 1

MODEL : GR-K24PS/GR-K243UG

CAUTION

PLEASE READ CAREFULLY THE SAFETY PRECAUTIONS OF THIS MANUAL

BEFORE CHECKING OR OPERATING THE REFRIGERATOR.

KIMCHI REFRIGERATOR

SERVICE MANUAL

http://biz.lgservice.com

Page 2

1. Safety warnings and cautions.......................................................................................................................3

2. Product specification .....................................................................................................................................6

3. Product installation method ..........................................................................................................................7

4. Circuit diagram ...............................................................................................................................................8

5. MICOM function and circuit description.......................................................................................................9

6. Freezing cycle and refrigerant.....................................................................................................................32

7. General details about the product ..............................................................................................................34

8. Characteristics of each part ........................................................................................................................36

9. Cautions for disassembling the product....................................................................................................41

10. Assembly diagram and service parts list.................................................................................................42

1. First check if there is any electric leakage in the refrigerator unit.

2. Always unplug the refrigerator before handling any electricity conducting parts.

3. When testing the refrigerator with the power on, use insulated gloves for safety.

4. When using measuring instruments, check the rated current, voltage and capacity.

5. Do not allow water or moisture to get into the mechanical or electrical parts of the refrigerator.

6. Remove all things on top of the refrigerator before tilting it during repairs to avoid spills.

Be especially careful for thin objects (glass sheet, book).

7. When the refrigerating cycle is damaged, always request service to the major repair service agency.

(This is to prevent the house from getting dirty from the gas within the cycle.)

8. Always double check for repairs related to safety to ensure customer safety.

Safety regulations

Contents

- 2 -

Page 3

Chapter 1. Safety warnings and cautions

u Always observe the 'Safety Warnings' and 'Cautions', which hare intended to ensure safety while repairing or operating

the product.

u Precautions are classified into 'Warning' and 'Caution', as explained below.

w Warning Warning means a dangerous condition which could result in significant damage, injury or death if

the instructions are not followed.

w Caution Caution means a condition which could result in damage or injury if instructions are not followed.

- 3 -

Safety warnings and cautions

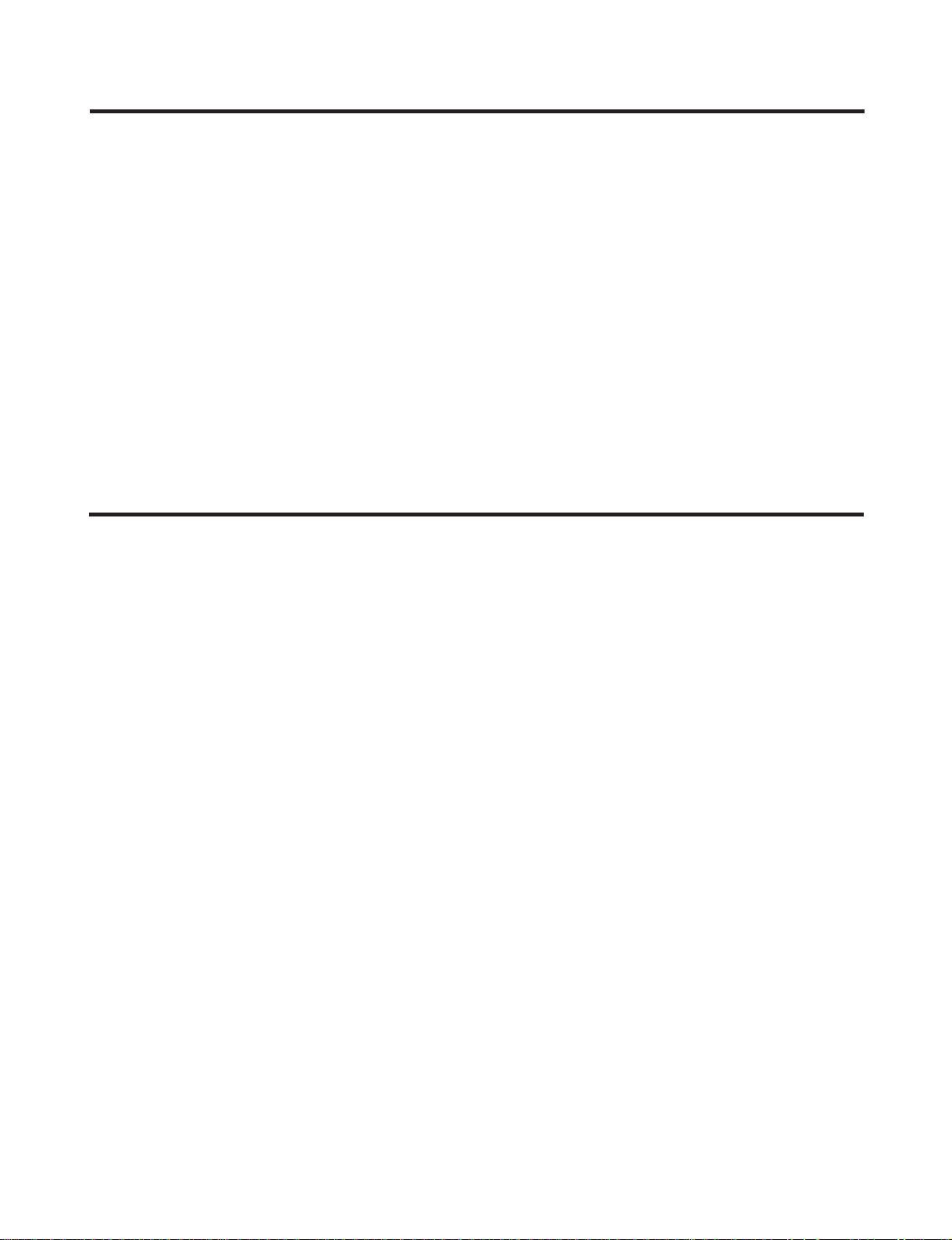

Use caution to prevent electric shock

The control panel (main

PCB) uses 310V. When

replacing PCB parts, wait at

least 3 minutes after

unplugging. Always unplug

the refrigerator before

repairing.

Make sure that the power plug is not

pressed by the back of the refrigerator

Power plug may be

damaged and cause a fire

or electric shock.

Use a dedicated circuit.

Overloading circuits or outlets

could cause a fire.

Do not allow the consumer to repair ,

disassemble or modify the refrigerator .

Damaged power plug can

cause fire or electric

shock.

w Warning

Page 4

Safety warnings and cautions

- 4 -

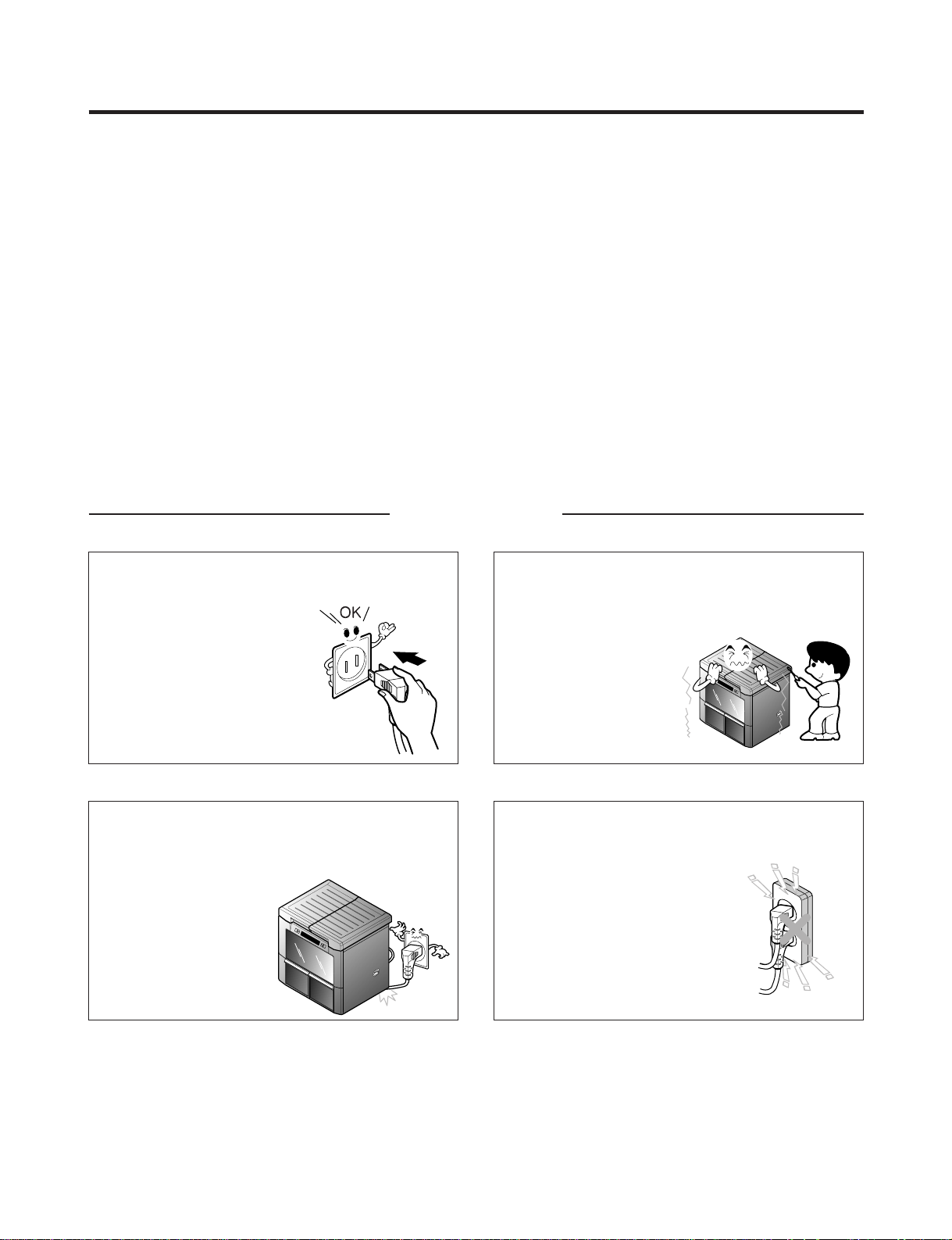

This product should always be

grounded, when needed.

If you think that there is a possibility of electricity

leakage by water or moisture, always ground the unit.

Do not store flammable liquid or gas in

the refrigerator such as ether , benzene,

alcohol, medicine, LP gas etc.

It can cause an explosion or a fire.

Do not store medicine or academic

material etc. in the refrigerator .

Store an object that

requires precise

temperature control

can cause deterioration

in quality or

unexpected reaction to

cause a dangerous

situation.

Do not set items, particularly flower

vase, cup, cosmetic or medicine on top

of the refrigerator .

It can cause fire and

electric shock or cause an

injury from dropping.

Do not stack items or carelessly store

food on the refrigerator .

Items stored on the

refrigerator could fall

and cause injury.

When disposing the refrigerator ,

remove the rubber packing on the door

and do not leave it where children play.

A child can be

dangerously entrapped in

the refrigerator.

w Warning

Grounding screw

Grounding line

Copper plateCopper plate

More than 75cm

Academic

material

Medicine

Ether

Benzene

gas

Page 5

Safety warnings and cautions

- 5 -

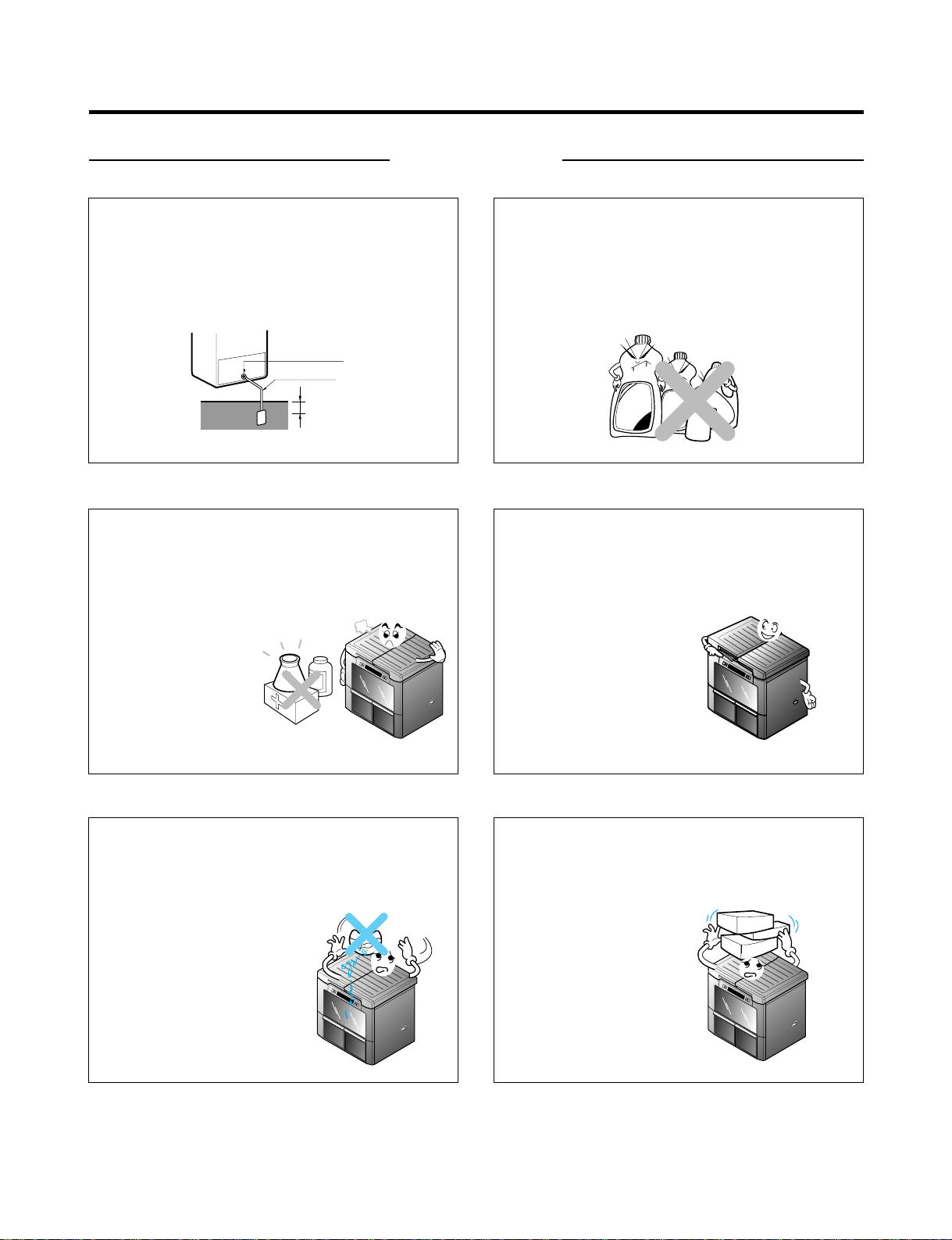

When using the refrigerator for low

temperature in freezer or refrigerator ,

do not store bottles.

Bottles can freeze and cause the bottles to crack,

which can cause an injury.

During repairs, be sure all connectors

are tight and wires are properly routed.

Make sure the connectors of the housing part are

properly connected.

During repairs, remove all dust and

foreign material from the housing part,

connector part and check part.

It can prevent problems such as tracking or short

circuit.

Always use exact replacement parts.

Make sure that the model name, voltage, current and

temperature ratings are correct for the electric part.

Do not bend, modify , bend, pull or twist

the power cord.

It can cause fire or electric shock.

Allow at least 5 minutes for resetting if

you unplug the refrigerator .

If can cause an

overload to the

condenser operation

and cause problems.

w Caution

Rated parts

After

After

After

minutesminutes

minutes

Page 6

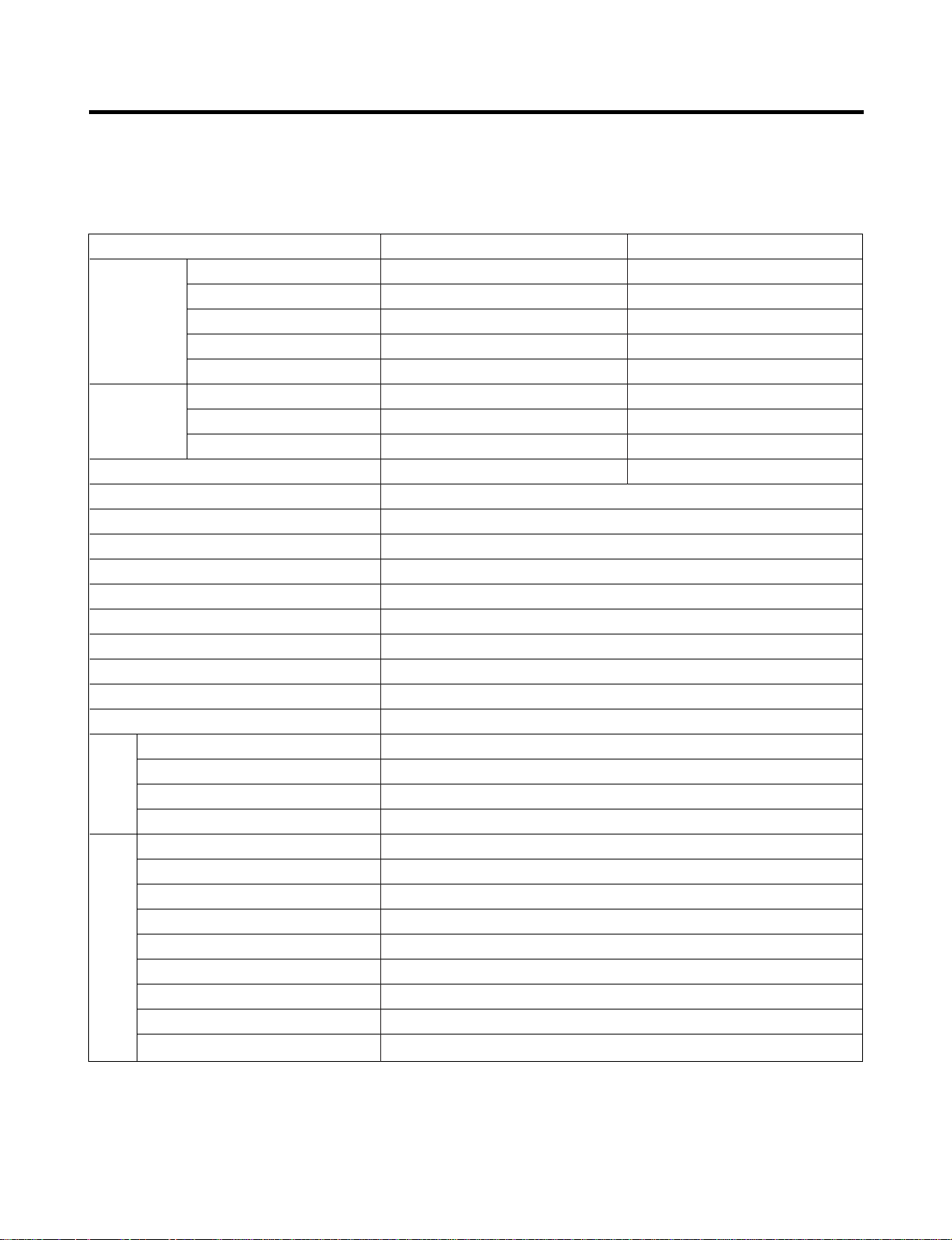

Chapter 2. Product specification

2-1. GR-K24PS/GR-K243UG

Product specification

- 6 -

Item GR-K24PS GR-K243UG

238Li 242.6Li

92Li 94.3Li

92Li 94.3Li

27Li 27Li

27Li 27Li

922mm 922mm

712mm 699mm

975mm 975mm

88kg 87kg

108W

Direct cooling

Electronic

Manual start, manual end

CYCLO PENTANE

1pc

8pcs

1pc

1pc

2pcs

MA57LAQF

PIPE ON SHEET

R134a(165g)

Freol 10G (220cc)

P6R8MA

4TM412RFBYY

ø110, 3blades attached

115V / 80W (Resistance: 165Ω)

115V / 80W (Resistance: 165Ω)

115V / 8W (Resistance: 1,653Ω)

115V / 6W (Resistance: 2,204Ω)

115V / 8W (Resistance: 1,653Ω)

CS: 160 VAC 100

µF

Volume

External

dimensions

Usable volume

Top left compartment

Top right compartment

Bottom left compartment

Bottom right compartment

Width

Depth

Height

Total weight

Motor power consumption

Cooling method

Store/Season

Icing removing method

Insulation material

Fresh vegetable basket

Kimchi storage container

Drawer storage container

Chungukjang fermenting container

Low temperature catalytic deodorizing system

Compressor

Evaporator

Refrigerant

Oil

PTC

Overload protection device

Fan motor for compressor cooling

Lid left compartment Kimchi seasoning heater

Lid right compartment Kimchi seasoning heater

Drawer left compartment Kimchi seasoning heater

Drawer left compartment Chungukjang seasoning heater

Drawer right compartment rice storage heater

Capacitor

Freeze cycle

Electrical part rating

Page 7

Chapter 3. Product installation method

3-1. Method to adjust height of refrigerator

■ First adjust the level of the refrigerator.

(If the floor is uneven, the refrigerator may vibrate or cause noise.)

u Adjust the front to be leveled by turning the height adjustment screws under the front corners in the arrow direction.

3-2. Grounding method

1. In the following cases, you must always ground the refrigerator.

1) When using the refrigerator in the 110V region

2) When using the refrigerator in the 220V region where the power

outlet is not grounded to the side.

2. You must install a circuit breaker (rated current 15mA, rated

non-operating current 7.5mA) if it is difficult to ground the

refrigerator. For the circuit breaker, you can purchase and use the

one with plug and outlet.

3. For the grounding connector on back of the refrigerator, use a connecting line with a diameter of 1.6mm or longer or a

single core cord line with a nominal cross section area of 1.25mm or bigger. After soldering, bury the copper plate 75cm

or deeper from the ground.

u Size of copper plate: Thickness (0.7mm or more), area (90cm or more)

Do not ground the circuit in one of the following places:

1. Water pipe: If there is a plastic piping within the system, the ground may not be valid.

2. Gas pipe: There is a danger of fire or exposition.

3. Phone line or lightning rod: If lightening strikes, dangerous voltage may be induced in the circuit.

Product installation method

- 7 -

Horizontal adjustment leg

(lower handle part)

Caution

GR-K24PS

Page 8

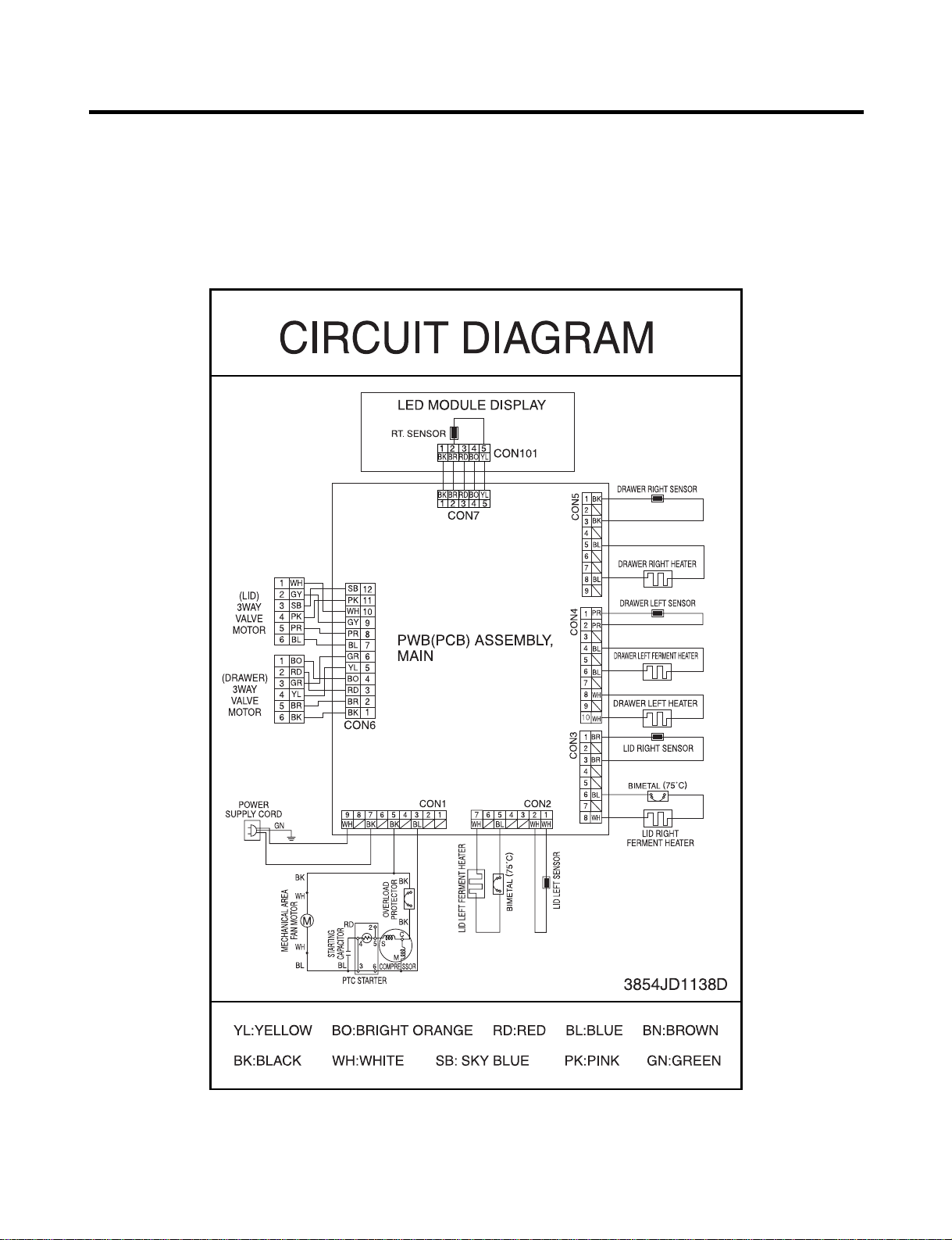

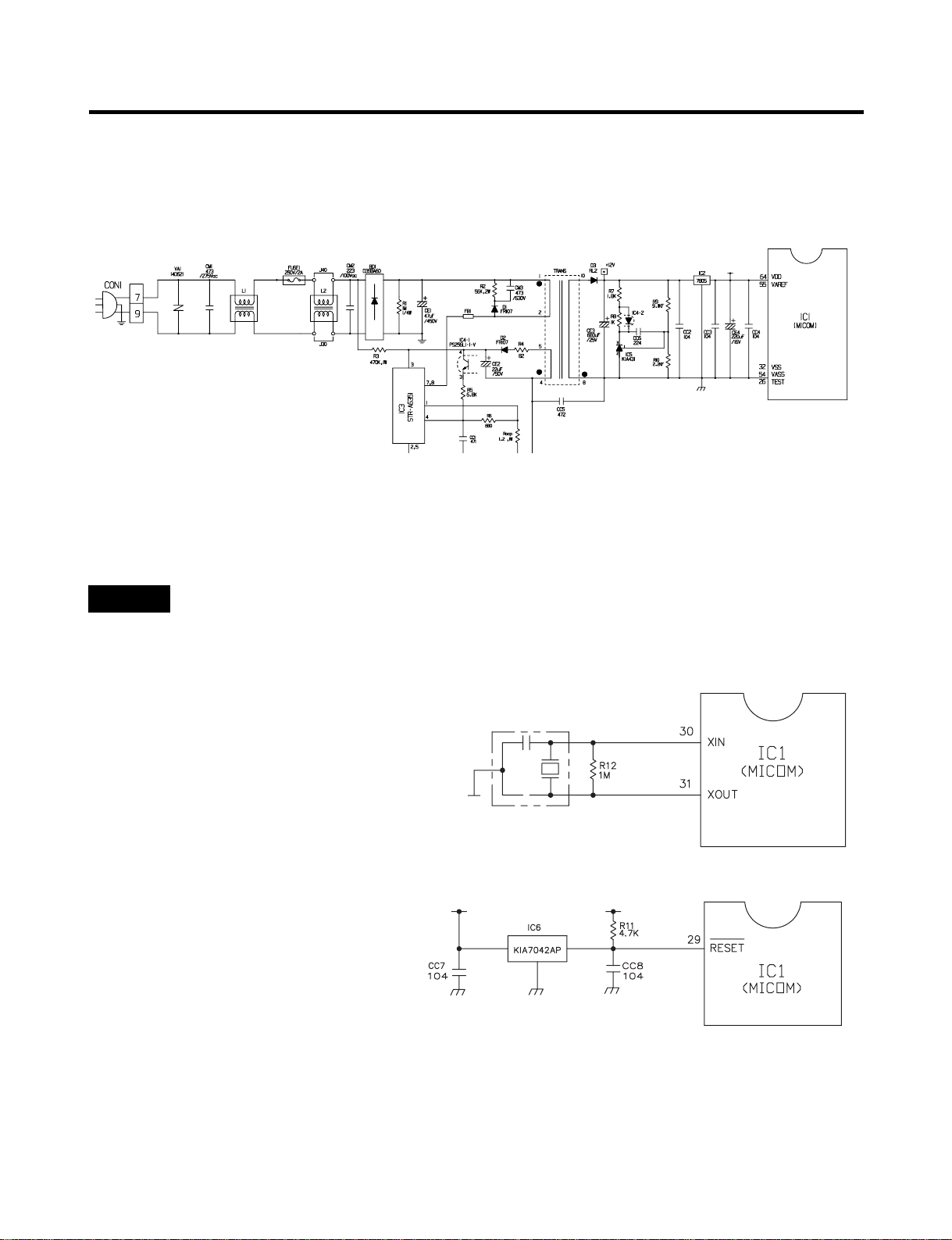

Chapter 4. Circuit diagram

Circuit diagram

- 8 -

Page 9

Chapter 5. MICOM function and circuit description

5-1. Function description

5-1-1. Display part

1. When the power is connected for the first time, it is set to “Lock”, “Left compartment-Cabbage Kimchi-Mid” and “Right

compartment-Cabbage Kimchi-Mid”.

2. During a power shut-down or when the power is reconnected, the refrigerator maintains the prior display. But in case of a

power-shut down or power reconnection during rhythm fermenting, the temperature returns to “Mid” for the applicable

food type.

3. In “Lock” status, you will not hear a buzzer even when you press the buttons and the functions will not work.

But even in the Lock status, if you press the “Compartment selection” button, it will operate in the order of “Lid left

compartment” ’ “Lid right compartment” ’ “Drawer right compartment” ’ “Drawer left compartment” to show you the

selected display.

MICOM function and circuit description

- 9 -

NOTCH

Cabbage/Radish/Mul Kimchi Vegetable/Fruit Light freezing Freezing food Rice Chungukjang

Min Mid Max Min Mid Max Min Mid Max Min Mid Max Min Mid Max Min Mid Max

Temperature 0°C -1.0°C -2.0°C 3.5°C 2.5°C 1.5°C -4.0°C -5.0°C -6.0°C -15°C -18°C -21°C 10.5°C 10°C 9.5°C 2.0°C 1.0°C 0°C

1) GR-K24PS

2) GR-K243UG

Page 10

5-1-2. Food storage/seasoning function

(1) When selecting food type and storing temperature

1. Press the “Lock/Unlock” button for more than 2 seconds to switch to “Unlock” status.

2. Press the “Compartment selection” button to select the compartment to use.

3. Press the “Store” button to change the storing temperature to “Mid” ’ “Max” ’ “Min” ’ “Mid”. The food type changes as

follows. (“Cabbage Kimchi” ’ “Radish Kimchi” ’ “Mul Kimchi” ’ “Vegetable/Fruit” ’ “Light Freeze” ’ “Freeze” ’ “Old

Kimchi” ’ “Chungukjang” ’ “Rice”.) But the selected food type differs by the “Compartment selection”.

4. Press the “Lock/Unlock” button to complete the selection of food type and storing temperature. At this time, if a minute

passes without pressing the “Lock/Unlock” button, it will automatically switch to Lock status and end the food type and

storing temperature selection mode.

(2) When selecting food type and rhythm fermenting (seasoning)

1. Press the “Lock/Unlock” button for more than 2 seconds to switch to “Unlock” status.

2. Press the “Compartment selection” button to select the compartment to use.

3. Press the “Ferment” button to change the seasoning stage to “Seasoning” ’ “Seasoning+>” ’ “Mature seasoning” ’

“Underground fermenting” ’ “Fresh seasoning” ’ “Fresh seasoning+>” ’ “Seasoning”. The food type changes as follows

as the seasoning degree changes from “Fresh seasoning+>” ’ “Seasoning”. (“Cabbage Kimchi” ’ Radish Kimchi” ’ Mul

Kimchi” ’ “Old Kimchi” ’ ”Chungukjang”.). But the seasoning stage for old Kimchi and Chungukjang changes from

“Seasoning” ’ “Mature seasoning” ’ “Fresh seasoning” ’ “Seasoning”, and the underground fermenting only works for

the cabbage Kimchi in the lid right compartment. Also selected food type differs by the “Compartment selection”.

4. Press the “Lock/Unlock” button to complete the rhythm fermenting. At this time, if a minute passes without pressing the

“Lock/Unlock” button, it will automatically switch to Lock status and end the rhythm ferment (seasoning) selection mode.

5. When the rhythm fermenting selection is completed, the remaining time is indicated and when seasoning is done, the

remaining time will be “0 hours”. And the storing temperature will automatically be set to “Mid”.

(3) When selecting flavor keeping

1. Press the “Lock/Unlock” button for more than 2 seconds to switch to “Unlock” status.

2. Press the “Compartment selection” button to select the compartment to use.

3. At this time, press the “Flavor keeping” button to select or cancel the flavor keeping function. (But the flavor keeping

function only applies to the Cabbage Kimchi, Radish Kimchi and Mul Kimchi in the lid left and right compartment.)

4. Press the “Lock/Unlock” button to end the flavor keeping selection mode. At this time, if a minute passes without pressing

the “Lock/Unlock” button, it will automatically switch to Lock status and end the flavor keeping selection mode.

5. If you select flavor keeping during seasoning process, it will immediately end the seasoning and switch to flavor keeping.

At this time the storing temperature will automatically be set to “Mid”.

6. If you select the flavor keeping function, the refrigerator will lower the temperature to maintain the current Kimchi flavor.

(-1 degrees for “Min”, -0.5 degrees for “Mid” and -0 degrees for “Max”.)

7. During flavor keeping operation, a cold shock operation is done every 12 hours.

8. If you select rhythm fermenting during flavor keeping, the flavor keeping function will be canceled.

MICOM function and circuit description

- 10 -

Page 11

5-1-3. When selecting power on/off function

1. Press the “Lock/Unlock” button for more than 2 seconds to switch to “Unlock” status.

2. Press the “Compartment selection” button to select the compartment.

3. At this time, press the “Power” button for more than 2 seconds to turn the power off.

4. At this time, all the LEDs in the display will be turned off with the power off LED turning on.

5. If you press the “Power” button when the power is off, it will turn on the power and recover to “Cabbage Kimchi” and

“Mid”.

6. When the power is turned off, the heater of the applicable compartment is turned off and the valve will be closed.

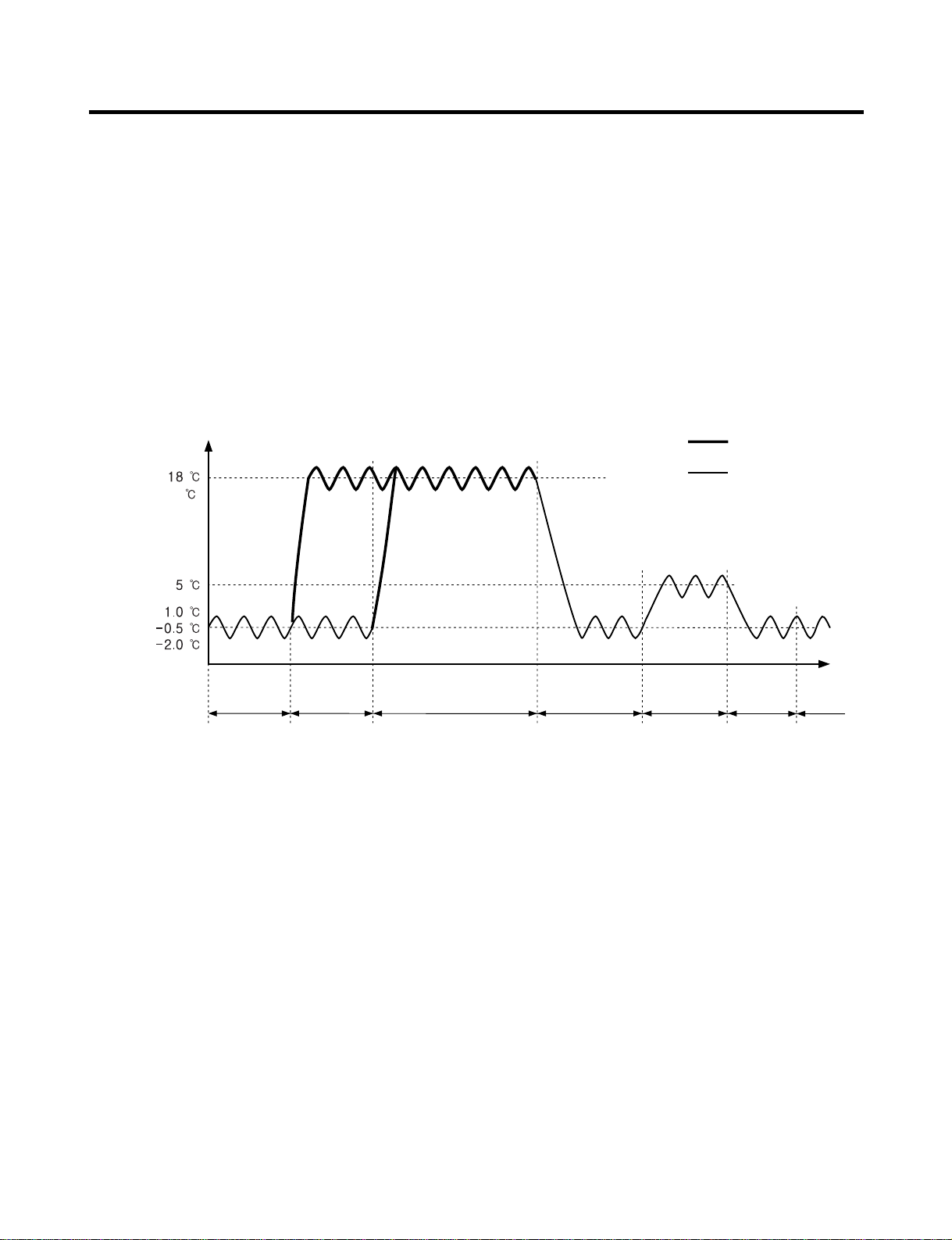

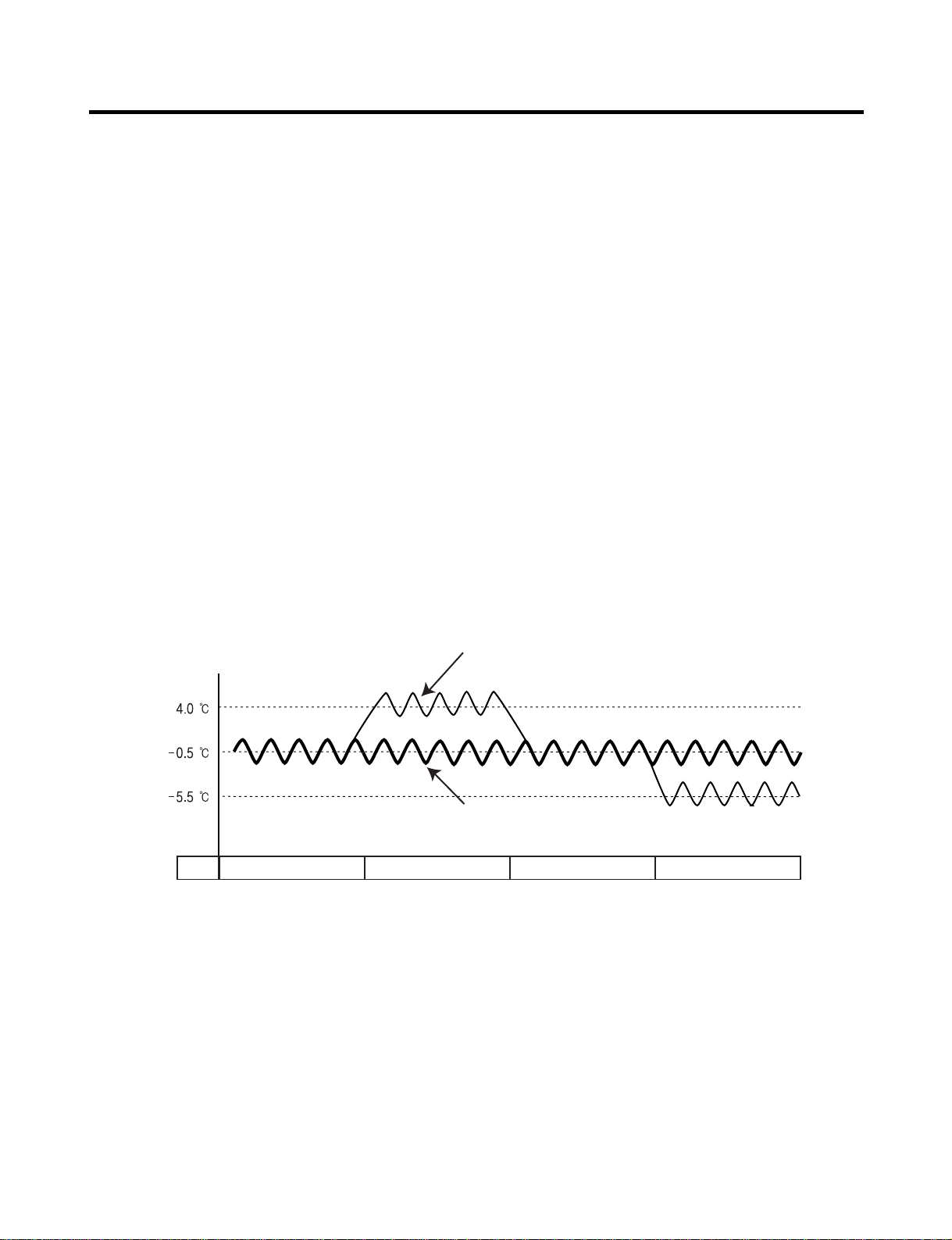

5-1-4. Rhythm fermenting control pattern diagram

1. The fermenting control pattern varies, depending on the temperature of the Kimchi when it is placed into the storage, the

type of Kimchi being made and the degree of the seasoning selected.

2. In the 1st seasoning cycle, if the Kimchi is at room temperature, the cold control operates.

3. During the seasoning cycle, if the Kimchi is cold, the seasoning heater is turned on and if the Kimchi is warm, the

seasoning heater is turned off.

4. If a failure occurs, such as a sensor error during seasoning, the storage will default to Cabbage Kimchi storage status.

MICOM function and circuit description

- 11 -

: Seasoning heater ON/OFF

: Seasoning heater OFF

Time

Seasoning completeSeasoning start

Kimchi sensor temperature

Mul Kimchi (10 )

Storage operation

When the Kimchi placed

in the refrigerator is cool

When the Kimchi placed

in the refrigerator is

at room temperature

1st seasoning 5th seasoning2nd seasoning 3rd seasoning 4th seasoning

Page 12

5-1-5. Temperature contr ol method

1. The compressor runs or stops and the 3-way valve opens or closes depending on the temperature sensed by each

sensor.

2. If the temperature in either compartment is unsatisfactory, the compressor is turned on and the 3-way value is opened to

the affected compartment.

3. If the temperatures in several compartments are unsatisfactory, the compressor is turned on and runs until both

compartments become satisfactory. The 3-way valve is opened and closed for each compartment until the temperature is

satisfactory.

4. During the seasoning cycle, if the temperature is low, the heater is turned on and if the temperature is high, the

compressor is turned on and the 3-way value is opened.

5-1-6. Buzzer sound

When you press a button on the front display, you will hear “ding dong” sound. (Refer to 5-2-4. (2) Buzzer operating circuit).

5-1-7 Power failure compensation function

1. When the power is restored after an outage, the refrigerator performs the setting originally programmed except for Error

status and Test mode.

2. If the power fails during the seasoning process, there is not power outage compensation function and the storage defaults

to previously set Kimchi type and temperature of “Mid”. (to protect excessive seasoning)

5-1-8. Operation in response to ambient temperature

The storage senses the ambient temperature and adjusts the temperature in the compartments accordingly. This keeps the

storage from being too cold or too warm because of seasonal variations and maintains exact temperatures in the

compartments.

MICOM function and circuit description

- 12 -

Storage

temperature

Operation in response to the ambient temperature

In general operation

Season Spring Summer Autumn Winter

Page 13

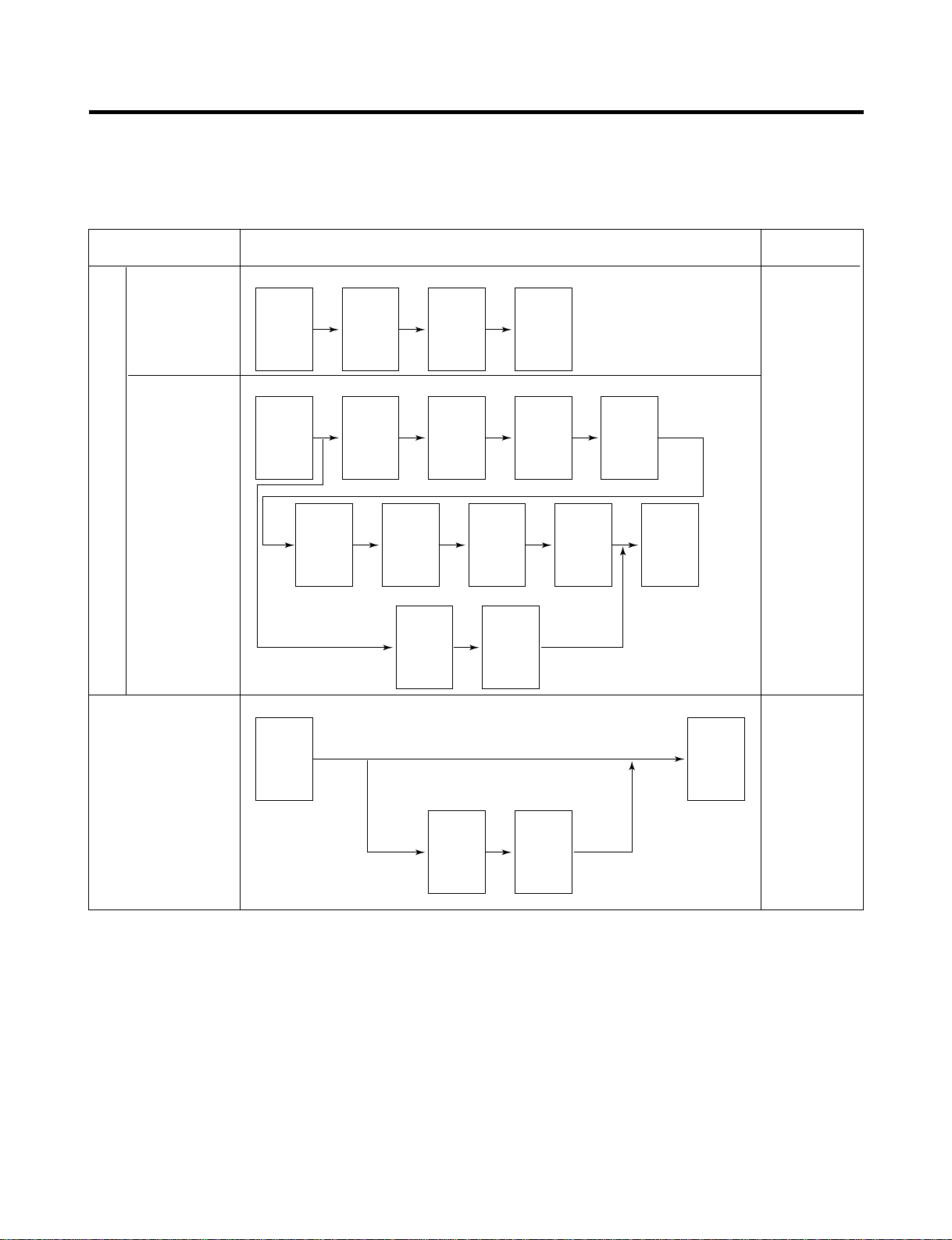

5-1-9. Sequential operation of components

Components (compressor, 3-way valve, lid left compartment seasoning heater, lid right compartment seasoning heater,

drawer left compartment heater and drawer right compartment heater) are operated in a specific order to prevent damage

and noise caused by simultaneous operation of all parts when the unit is started and after completing the self-test routine.

g Operation order may slightly vary depending on temperature setting.

MICOM function and circuit description

- 13 -

Operation status Operating order Remarks

Initial power-up

Temperature of

the left of right

sensor is >10°C

Temperature of

the left of right

sensor is <10°C

When returning to

normal status in test

mode

Power

on

3-way

valve

open

3-way

valve

left

open

Compressor

on

Immediately 3 min 10 sec

Power

on

Compressor

on

Lid left

compartment

seasoning

heater on

Lid left

compartment

seasoning

heater off

3-way

valve

open

All

loads

off

Compressor

on

3-way

valve

open

3-way

valve left

open

3-way

valve lid right

compartment

open

Lid right

compartment

seasoning

heater on

Lid right

compartment

seasoning

heater off

Drawer left

compartment

seasoning

heater on

Drawer left

compartment

seasoning

heater off

Drawer right

compartment

seasoning

heater on

Drawer right

compartment

seasoning

heater off

Immediately 0.5 sec 5 sec 0.5 sec

0.5 sec 0.5 sec 0.5 sec 0.5 sec

0.3 sec 3 min 10 sec

0.3 sec 3 min

7 min

The 3-way valve is

opened to both

compartments for

3 minutes; then it is

opened to lid

left/right

compartment or

drawer left/right

compartment.

Page 14

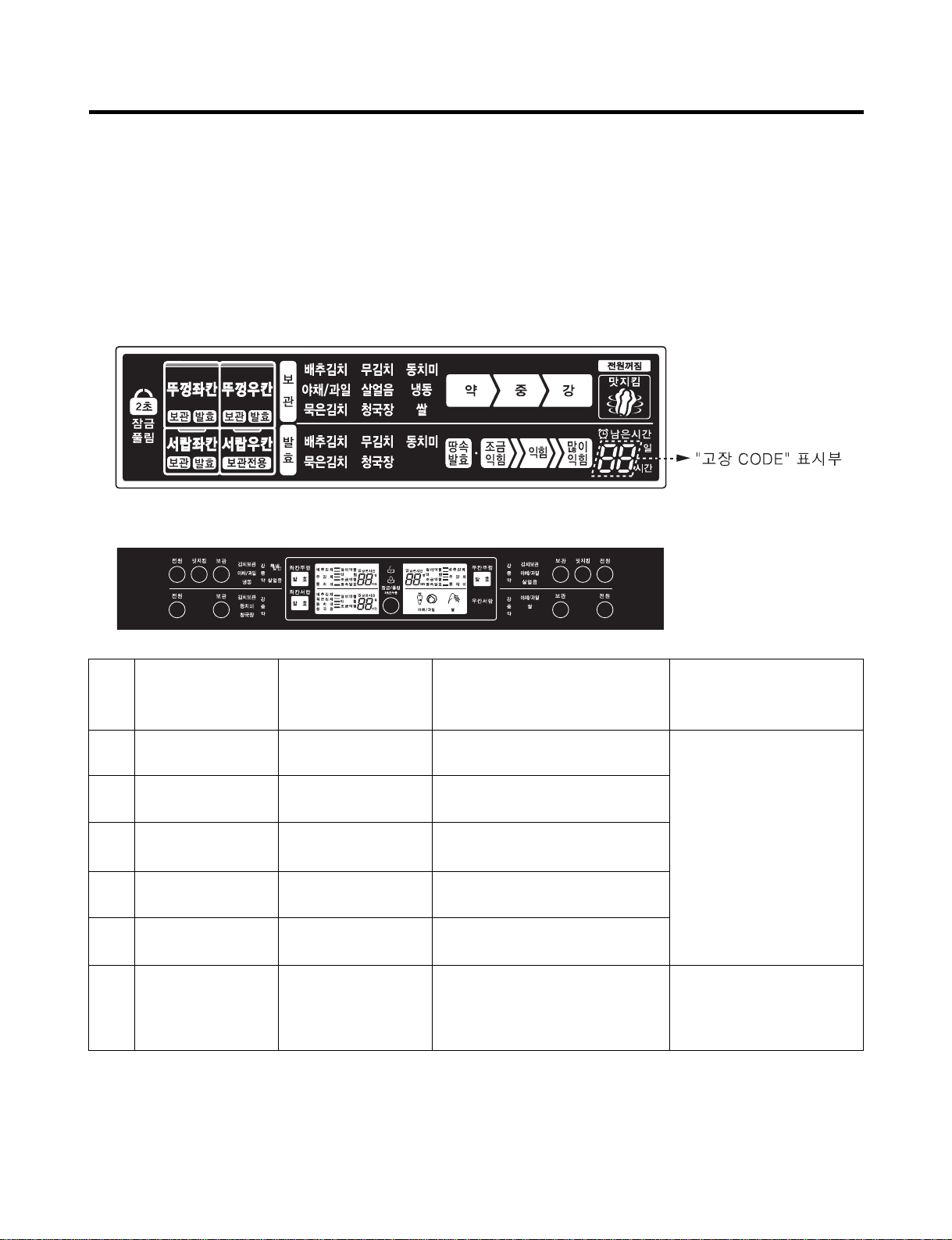

5-1-10. Error diagnosis function

1. The error diagnosis function is the function to support SVC in case of an error that can affect the performance of the

product.

2. If an error occurs, the control panel button will not work.

3. If an error occurs and is resolved, the refrigerator will default to the normal status. (The unit is reset.)

4. The error codes are shown in segment for the remaining seasoning time display of the right compartment, and all LEDs,

except for failure code, are turned off.

Note 1) A. For display 1) ,press the “compartment selection” and “store” button simultaneously, all LED’s will turn on except the

remaining fermentation time displaying LED’s.

B. For display 2) , press the left lid compartment store button and right lid compartment store button together all LED’s will turn

on except right lid compartment remaining fermentation time display LED’s.

MICOM function and circuit description

- 14 -

NO Item

Error code display

Error contents Remarks

Failure of lid left

compartment sensor

Failure of lid right

compartment sensor

Failure of drawer left

compartment sensor

Failure of drawer right

compartment sensor

Failure of outside

temperature sensor

Communications error

Lid left compartment sensor disconnected

or short circuited

Lid right compartment sensor disconnected

or short circuited

Drawer left compartment sensor

disconnected or short circuited

Drawer right compartment sensor

disconnected or short circuited

Outside temperature sensor disconnected

or short circuited

When communication is not working

continuously for 30 sec

* Check the connection

of each sensor

The connector could be pulled out.

Poor TR in communications part

1

2

3

4

5

6

E1

E2

E3

E4

CO

Note 1)

1) GR-K24PS

2) GR-K243UG

Page 15

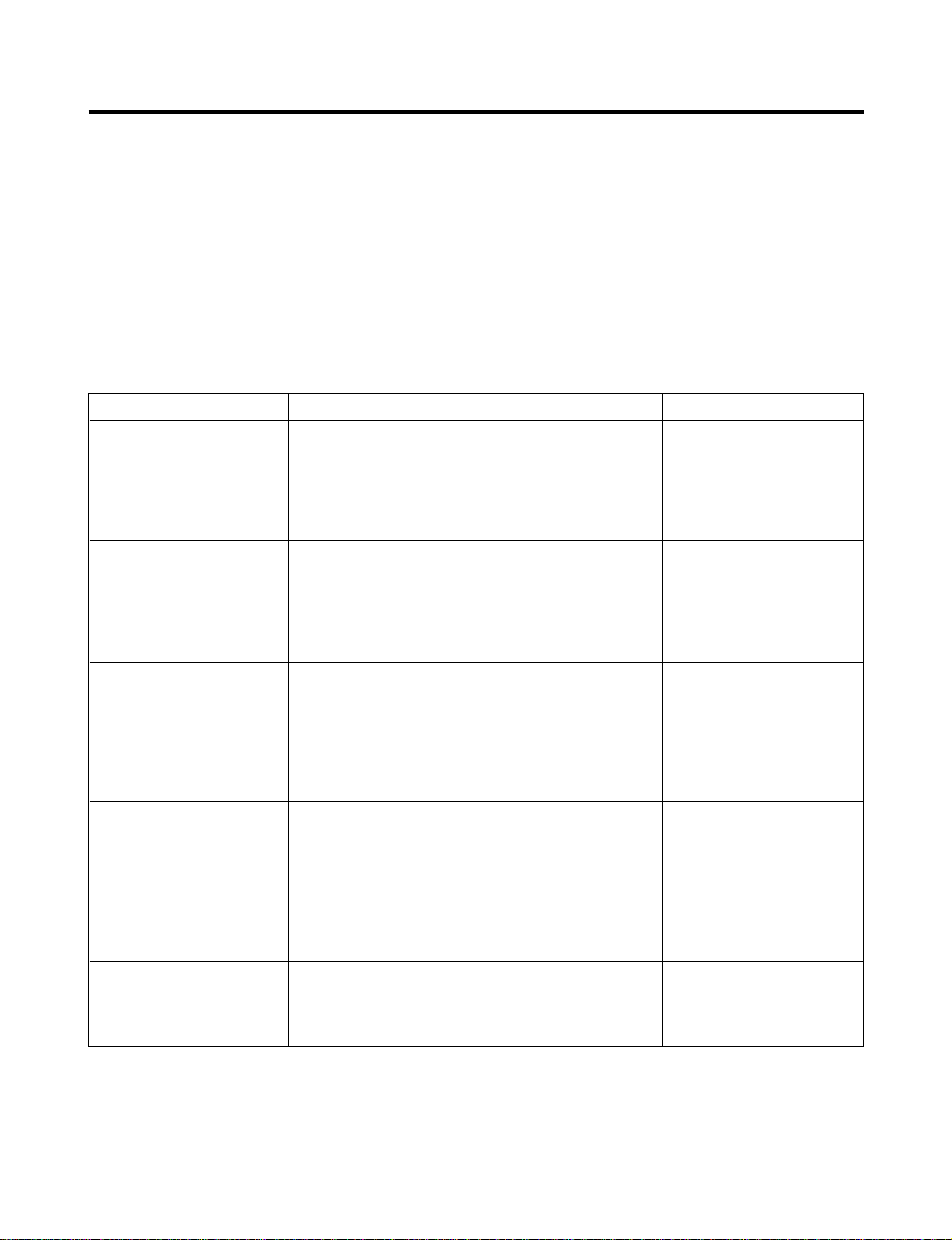

5-1-11. Test function

1. The test function checks the functions of the PCB and the refrigerator, searching for errors in parts.

2. The test switch on the PCB operates the test mode. The refrigerator reverts to the normal mode after 2 hours if you forget

to end it manually.

3. When the test mode is active, the buttons on the control panel are disabled but the buzzer still sounds a ding if one is

pressed.

4. When the test mode is completed, unplug the refrigerator briefly and plug it in again to reset it and allow normal

operation.

5. If a sensor failure or other failure is detected during the test mode, release the test mode to display the failure code.

6. During the display of the error code, test mode does not work even if you press the Test switch.

MICOM function and circuit description

- 15 -

Mode Operation Contents Remarks

Test 1

(lid left

compartment

cooling

power

mode)

Test 2 (lid

right

compartment

cooling

power

mode)

Test 3

(drawer

left

compartment

cooling

power

mode)

Test 4

(drawer

right

compartm

ent cooling

power

mode)

Normal

recovery

Press the test

switch once

Press the test

switch once when

Test 1 indicates it is

completed.

Press the test

switch once when

Test 2 indicates it is

completed.

Press the test

switch once when

Test 3 indicates it is

completed.

Press the test

switch once when

Test 4 indicates it is

completed.

1) Compressor ON.

2) 3-way valve open

3) Heater all off

4) Display “11”

1) Compressor ON.

2) 3-way valve open

3) Heater all off

4) Display “22”

1) Compressor ON.

2) 3-way valve open

3) Heater all off

4) Display “33”

1) Compressor ON.

2) 3-way valve open

3) Heater all off

4) Display “44”

Returns to initial status (COMP 7 min delay)

g The system recovers to

the initial status after a

maximum of 2 hours.

g The system recovers to

the initial status after a

maximum of 2 hours.

g The system recovers to

the initial status after a

maximum of 2 hours.

g The system recovers to

the initial status after a

maximum of 2 hours.

Page 16

5-2. Circuit description

5-2-1. Power circuit

The power circuit consists of the noise attenuation part and the SMPS (Switch Mode Power Supply) part. The SMPS

consists of the rectifier (BD1 & CE1) to convert AC voltage to DC voltage, switching part (IC3) to switch the converted DC

voltage, transformer to transmit energy of the first side of the switching end to the second side, the secondary power to

supply power to MICOM and IC, and the feedback part (IC4) to feedback the secondary voltage to the first side of the

transformer in order to maintain the secondary voltage constant.

: High voltage (DC 310V) is maintained in this circuit. Wait at least 3 minutes after unplugging to allow the

current to dissipate. There is a danger of electric shock.

5-2-2. Oscillation circuit

The oscillation circuit provides the clock signal for

synchronization and calculation of time in relation

to the logic elements of microprocessor IC1

(MICOM). OSC1 must always use the original

rated parts, because if the specification changes,

the timing generated will not be correct, causing

erratic functioning of the microprocessor.

5-2-3. Reset circuit

The reset circuit allows the entire process to be

started from the initial status by resetting the

various elements within the MICOM (IC1), such as

RAM, whenever power is applied to the unit. Low

voltage is applied to the reset terminal for 10ms at

the beginning of the power input. The reset

terminal has a voltage of 5 V during general

operation. (If the reset operation fails, the

microprocessor will not operate.)

MICOM function and circuit description

- 16 -

Caution

OSC1

CSTLS4M00G53

Page 17

5-2-4. Load/Buzzer driving circuit

(1) Load driving circuit

(2) Buzzer driving circuit (located on display PCB)

MICOM function and circuit description

- 17 -

“Ding-Dong” sound(Ding-)(Dong-) “Ding” sound(Ding-) Off

IC101 (Pin 3/61)

5V

IC101 (Pin 2/62)

0V

Measuring

point

Status

45ms

1046.5Hz 1174.7Hz 1318.5Hz

45ms 45ms45ms 70ms 750ms

5V

0V

5V

0V

45ms

1568.0Hz 1318.5Hz 1046.5Hz

45ms 45ms45ms 70ms 750ms

Type of load

Measuring point(IC7)

10 11 12 13 14 15

Status

ON Within 1V

OFF 12~13V

COMP. fan motor

Lid left compartment

seasoning heater

Lid right compartment

seasoning heater

Drawer left compartment

seasoning heater

Drawer right

compartment rice heater

Drawer left compartment

Chungukjang heater

LLEEDD MMOODDUULLEE TTYYPPEE

Page 18

5-2-5. Switch input circuit

The following circuit is the input circuit to detect the test switch signal to check the refrigerator.

5-2-6. Temperature sensor circuit

The following temperature sensor circuit consists of a sensor to detect the outside (ambient) temperature, sensors in the lid

left and right compartment, sensor in the drawer left and right compartment for storing and seasoning Kimchi. The status of

each sensor, whether open or shorted, is shown below.

MICOM function and circuit description

- 18 -

RAR2

10K

CON5

CON4

CON3

CON2

Sensor Check point Normal

(-30°C~50°C)

Shorted Open

Drawer right compartment sensor

POINT Voltage

Drawer left compartment sensor

POINT Voltage

Lid right compartment sensor

POINT Voltage 0.5V~4.5V 0V 5V

Lid left compartment sensor POINT Voltage

Outside sensor POINT Voltage

A

B

C

D

E

Page 19

5-2-7. Stepping motor operation circuit (3-way valve)

u The motor is operated by sending out “High” and “Low” signals as many as the designated number of steps through

MICOM Pin 44, 43, 46, 45 (lid part) and 48, 47, 50, 49 (drawer part) to rotate the motor through the magnetic field formed

by the motor and the coil wrapped around each stator.

5-2-8. Power failure compensation circuit (located on display PCB)

uThe power failure compensation circuit recalls the temperature range of the right and left compartment for lid and drawer,

and maintains these levels if power if interrupted briefly.

The IC for power failure compensation (EEPROM) delivers to and maintains the information in MICOM through the serial

interface.

MICOM function and circuit description

- 19 -

LLEEDD MMOODDUULLEE TTYYPPEE

Page 20

5-2-9. Storing temperature compensation and over-cool/under-cool cut compensation circuit

(1) Storing temperature compensation

u This is the circuit to input the temperature compensation level required for adjusting storage temperature at the left or

right compartment of the lid or drawer.

u Temperature compensation table by adjustment of resistance value (difference against current temperature)

Ex) If you change the resistance of compensation at the lid left compartment (RCL) from 10KΩ (current resistance) to

18KΩ (adjusted resistance), the storage temperature in the lid left compartment will be increased by 1°C .

MICOM function and circuit description

- 20 -

470 Ω 2 KΩ 3.3 KΩ 5.6 KΩ 8.2 KΩ 10 KΩ 12 KΩ 18 KΩ 33 KΩ 56 KΩ 180 KΩ

470KΩ

No change

0.5°C UP 1°C UP 1.5°C UP 2°C UP 2.5°C UP 3°C UP 3.5°C UP 4°C UP 4.5°C UP 5°C UP

2 KΩ 0.5°C DOWN

No change

0.5°C UP 1°C UP 1.5°C UP 2°C UP 2.5°C UP 3°C UP 3.5°C UP 4°C UP 4.5°C UP

3.3 KΩ 1°C DOWN 0.5°C DOWN

No change

0.5°C UP 1°C UP 1.5°C UP 2°C UP 2.5°C UP 3°C UP 3.5°C UP 4°C UP

5.6 KΩ 1.5°C DOWN 1°C DOWN 0.5°C DOWN

No change

0.5°C UP 1°C UP 1.5°C UP 2°C UP 2.5°C UP 3°C UP 3.5°C UP

8.2 KΩ 2°C DOWN 1.5°C DOWN 1°C DOWN 0.5°C DOWN

No change

0.5°C UP 1°C UP 1.5°C UP 2°C UP 2.5°C UP 3°C UP

10 KΩ 2.5°C DOWN 2°C DOWN 1.5°C DOWN 1°C DOWN 0.5°C DOWN

No change

0.5°C UP 1°C UP 1.5°C UP 2°C UP 2.5°C UP

12 KΩ 3°C DOWN 2.5°C DOWN 2°C DOWN 1.5°C DOWN 1°C DOWN 0.5°C DOWN

No change

0.5°C UP 1°C UP 1.5°C UP 2°C UP

18 KΩ 3.5°C DOWN 3°C DOWN 2.5°C DOWN 2°C DOWN 1.5°C DOWN 1°C DOWN 0.5°C DOWN

No change

0.5°C UP 1°C UP 1.5°C UP

33 KΩ 4°C DOWN 3.5°C DOWN 3°C DOWN 2.5°C DOWN 2°C DOWN 1.5°C DOWN 1°C DOWN 0.5°C DOWN

No change

0.5°C UP 1°C UP

56 KΩ 4.5°C DOWN 4°C DOWN 3.5°C DOWN 3°C DOWN 2.5°C DOWN 2°C DOWN 1.5°C DOWN 1°C DOWN 0.5°C DOWN

No change

0.5°C UP

180 KΩ 5°C DOWN 4.5°C DOWN 4°C DOWN 3.5°C DOWN 3°C DOWN 2.5°C DOWN 2°C DOWN 1.5°C DOWN 1°C DOWN 0.5°C DOWN

No change

Lid left

compartment

(RCUL)

Lid right

compartment

(RCUR)

Drawer left

compartment

(RCBL)

Drawer right

compartment

(RCBR)

Modified

resistance

Classification

Current

resistance

Lid left compartment Lid right compartment Drawer left compartment Drawer right compartment

Temperature

Remarks

(RCUL) (RCUR) (RCBL) (RCBR)

compensation value

180

KΩ

+2.5 ˚C

Warmer

56

KΩ

+2.0 ˚C

33

KΩ

+1.5 ˚C

18

KΩ

+1.0 ˚C

12

KΩ

+0.5 ˚C

10

KΩ

0 ˚C

Standard temperature

8.2

KΩ

-0.5 ˚C

5.6

KΩ

-1.0 ˚C

3.3

KΩ

-1.5 ˚C

2

KΩ

-2.0 ˚C

Cooler

470

Ω

-2.5 ˚C

Page 21

(2) Over-cool/Under-cool cut compensation

u The cut compensation circuit compensates the storing temperature of the left or right compartment of the lid or drawer by

simply cutting it out of service for a brief period.

MICOM function and circuit description

- 21 -

JCUL1 JCUL2 JCUR1 JCUR2 JCBL1 JCBL2 JCBR1 JCBR2

CUT +1

°C

CUT +1

°C

CUT +1

°C

CUT +1

°C

CUT -1

°C

CUT -1

°C

CUT -1

°C

CUT -1

°C

CUT CUT 0

°C

CUT CUT 0

°C

CUT CUT 0

°C

CUT CUT 0

°C

Lid left compartment cut

compensation

Lid left

compartment

storing

temperature

compensation

0¡

(Factory default)

0¡

(Factory default)

0¡

(Factory default)

0¡

(Factory default)

Lid right

compartment

storing

temperature

compensation

Drawer left

compartment

storing

temperature

compensation

Drawer right

compartment

storing

temperature

compensation

Lid right compartment cut

compensation

Drawer left compartment cut

compensation

Drawer left compartment storing

temperature compensation

Over-cool

compensation

Under-cool

compensation

Over-cool

compensation

Under-cool

compensation

Over-cool

compensation

Under-cool

compensation

Over-cool

compensation

Under-cool

compensation

Page 22

5-2-10. Communication circuit between main PCB and display PCB

This circuit provides communications between the MICOM on the main PCB and the MICOM of the display PCB.

If there is no communication between these boards for 30 seconds, a communication error occurs.

MICOM function and circuit description

- 22 -

MICOM for

LED/LCD control

Receive (Notch status)

Send (Error status)

PWB(PCB) ASSEMBLY, MAIN PWB(PCB) ASSEMBLY, DISPLAY

Page 23

5-2-11. Button input and display part illumination cir cuit

This circuit determines which buttons are pressed and drives the LED display, whose driving method is a scan method.

MICOM function and circuit description

- 23 -

D110

IN4004X6

D111

D112

D113

D114

D115

PPRREEMMIIUUMM//SSTTAANNDDAARRDD//FFIIGGHHTTIINNGG ((LLEEDD MMOODDUULLEE TTYYPPEE))

Page 24

- 24 -

MICOM function and circuit description

D110

PPRREEMMIIUUMM MMOODDEERRNN CCOOLLOORR ((LLEEDD MMOODDUULLEE TTYYPPEE))

Page 25

5-3. Sensor resistance characteristics table

u The tolerance of the sensor resistance is °±3%.

u Measure the resistance value of the sensor after leaving it for more than 3 minutes (delay is required due to sensing

speed.)

u Always use a digital tester. Analog testers have a higher margin of error.

u For left and right sensor of lid and drawer, measure both sensor ends of the connector after separating the connectors of

CON 2, 3, 4, 5, CON101 of PWB (PCB) assembly and main part. For the outside sensor, measure end of 2 and 5 of

CON101.

MICOM function and circuit description

- 25 -

Measuring temperature (°C)

-20°C 77 KΩ

-15°C 60 KΩ

-10°C 47.3 KΩ

-5°C 38.4 KΩ

0°C 30 KΩ

+5°C 24.1 KΩ

+10°C 19.5 KΩ

+15°C 15.9 KΩ

+20°C 13 KΩ

+25°C 11 KΩ

+30°C 8.9 KΩ

+40°C 6.2 KΩ

+50°C 4.3 KΩ

Lid left compartment, lid right compartment, drawer left

compartment, drawer right compartment, outside sensor

CON5

CON4

CON3

CON2

Page 26

5-4. PCB parts diagram and parts list

5-4-1. PWB (PCB) assembly and main parts diagram

MICOM function and circuit description

- 26 -

Page 27

5-4-2. PWB (PCB) assembly and main parts list

g The parts list can slightly change according to the situation.

MICOM function and circuit description

- 27 -

ATHENA1-PJT

G

Z

YW396-10AV(10P-1,2,4,6,8,10)BLUE

YW396-09AV(9P-1,3,5,8)YELLOW

DH12D1-O-Q

GBL06

Page 28

- 28 -

MICOM function and circuit description

Page 29

5-4-3. PWB (PCB) assembly and display parts diagram and parts list (6871JB1395_)

g The parts diagram and parts list can slightly change according to the situation.

MICOM function and circuit description

- 29 -

Page 30

- 30 -

MICOM function and circuit description

Page 31

5-4-3. PWB (PCB) assembly, sub parts diagram and parts list (common for 6871JB2073A/B left and right)

g The parts diagram and parts list can slightly change according to the situation.

MICOM function and circuit description

- 31 -

Page 32

5-5. PCB circuit diagram

5-5-1. PWB (PCB) assembly and main circuit diagram (6871JB1246)

g PCB circuit diagram can slightly change according to the situation.

MICOM function and circuit description

- 32 -

Page 33

MICOM function and circuit description

- 33 -

PWB(PCB) ASSEMBLY, DISPLAY

:6871JB1395, 6871JB1463

LED

Module

Page 34

5-5-2. PWB (PCB) assembly and display circuit diagram (6871JB1395_)

g The circuit diagram can slightly change according to the situation.

g This includes the PWB (PCB) assembly and sub circuit diagram.

MICOM function and circuit description

- 34 -

D110

IN4004X6

D111

D112

D113

D114

D115

Page 35

- 35 -

MICOM function and circuit description

Page 36

Chapter 6. Freezing cycle and refrigerant

6-1. Freezing cycle (Freezing principle/Refrigerant gas circulation diagram)

6-1-1. Freezing principle

Freezing is an operation of maintaining a lower temperature (generally 0°…) than the natural temperature (usually ambient

temperature surrounding us). This requires an insulated space, refrigerant (R134a) to absorb the heat and the circulation

circuit (compressor, condenser, evaporator etc.) to operate the phase change of the refrigerant.

6-1-2. Refrigerant gas circulation diagram

1. Compressor

2. Wire condenser

3. Drier

4. 3-way valve (2 EA)

5. Capillary tube (lid left)

6. Capillary tube (lid right)

7. Capillary tube (drawer left)

8. Capillary tube (drawer right)

9. Evaporator (lid left)

10. Evaporator (lid right)

11. Evaporator (drawer left)

12. Evaporator (drawer right)

13. Suction pipe

14. Cooling fan

Freezing cycle and refrigerant

- 36 -

1

2

3

4

4

7

8

6

9

10

11

12

14

13

5

Page 37

6-1-3. Operation description of each circulation circuit

u Because the outlet of the capillary tube is where the high pressure refrigerant changes from high to low

pressure, the low pressure refrigerant quickly diffuses to the evaporator, making flash sounds. (shik shik

sound)

u When the low pressure liquid refrigerant evaporates from the evaporator, it is done throughout the whole

pipe from inlet to outlet, making a sound of liquid refrigerant flowing. This can happen depending on the

load condition of the refrigerator and on the evaporation, but it is not a problem.

6-2. Refrigerant

g ODP: Ozone Depleting Potential (Relative index with CFC11 as 1.0)

GWP: Global Warming Potential (Relative index with CO2 as 1.0)

Freezing cycle and refrigerant

- 37 -

No.

Parts name Operation details

Refrigerant gas condition (input and output)

1

2

3

4

5

6

Compressor

Condenser

Drier

Capillary tube

Evaporator

Suction pipe

Compress the refrigerant from low pressure

to high pressure.

High pressure gas refrigerant exhausts heat

and becomes liquid refrigerant.

There is an absorbent that absorbs the

moisture within the circulation circuit.

(Moisture absorption device)

This is the long narrow pipe where high

pressure refrigerant passes to reduce the

pressure.

Low pressure liquid refrigerant absorbs heat

to change to low pressure gas refrigerant.

This connects the evaporator and the

compressor.

Low pressure gas¡High pressure gas

Temperature(30

°C)¡ (80~120°C)

High pressure gas¡High pressure liquid

Temperature(80~120

°C)¡ (40~60°C)

High pressure liquid¡Low pressure liquid

Temperature(40~60

°C)¡ (-27°C)

Low pressure liquid¡Low pressure gas

Temperature(-27

°C)

Low pressure gas¡Low pressure gas

Temperature(-27

°C)¡ (30°C)

Caution

Refrigerant

name

Characteristics

ODP GWP

Remarks

R134a

(ISO butane)

Refrigerant

12000

R134a is highly explosive (ISO butane) and need extra

special care during refrigerator manufacturing and

servicing. As an environmental friendly refrigerant, the ODP

and GWP is respectively 0.

Page 38

Chapter 7. General details about the product

7-1. Refrigerator noise

The structure of the freezing room and mechanical room, which are the sources of Kimchi refrigerator noise, is as follows.

Here you can see that the main source of noise during refrigerator operation is the compressor, the condenser and the fan

motor that cools the compressor in the mechanical room.

7-1-1. SVC method for noise claim

(1) Basic method of noise reduction

• Block: This method blocks the noise from the source so that it does not reach the ears by blocking the transmission path

of the sound with high density sound blocker. (This is effective in high frequency area)

• Using sound absorber: This method is similar to the blocking method but uses Styrofoam and glass wool in the

transmission path to absorb the sound. (This is effective in low frequency area)

• Vibration reduction: This method blocks the mechanical vibration from the operating part so that it does not reach other

parts. (using vibration reduction rubber etc.)

• Dynamic balance maintenance: This method minimizes the dynamic imbalance of the rotating object.

• Fixing the vibrating part: This method firmly fixes the vibrating part depending on the situation.

• Removing contact: Separate the two parts or firmly fix the object that periodically make sound by hitting each other.

General details about the product

- 38 -

(Fig. Diagram of Kimchi refrigerator noise source)

•

Page 39

(2) Service method for major noise claim item for Kimchi refrigerator

7-2. Details on power consumption

The power consumption of the refrigerator is

measured within the chamber where constant

temperature and humidity is maintained. In the

right figure, maintain the chamber to 30°C…

and 75% humidity with no load to the

refrigerator and set the temperature of the left

and right compartment to 3°C… to measure the

power consumption. The power consumption is

calculated as follows.

Monthly power consumption (kWh/month) = Measured value (kWh/day) x 365 days / 12 months

The actual power consumption and the one indicated on the refrigerator can differ due to the using condition.

General details about the product

- 39 -

Noise claim Noise generation Service method Remarks

Noise from poor

installation

Parts vibration

Compressor

resonance sound

Compressor noise

Operating device

noise

Wire condenser

noise (vibration

noise)

u The installation floor surface is

not hard enough

u The refrigerator is not leveled

u “Wing” sound

u “Woong Woong” sound

u Poor balance of the compressor

u Contacting sound of the

surrounding pipe of the

compressor part

u Contact sound from the OLP

contact point during compressor

operation

u “Woong Woong” sound

u “Ching” sound

• Reinforce the floor hardness

• Move the installation location

• Use the adjustment screw in

front of the refrigerator to level

the refrigerator

• Insert firmly all the parts of the

refrigerator in the right location

• Reduce the noise by adjusting

the pipe and seat rubber

• Adjust the surrounding pipe and

seat rubber to maintain the

level of the compressor

• Remove contact

• Exchange OLP

• Recheck the screws

• Remove the welding part of the

heat plate (wire) and remove

the heat plate

u Mainly within the

refrigerating

compartment

u “Tak Tak”

Caution

Page 40

8-1. Refrigerant valve

(1) Function

This switches the refrigerant that went through the compressor to the lid left/right or drawer left/right evaporator.

g When connecting the 3-way valve and capillary tube, they must be welded by matching the same color as shown below. If

not matched, it can cause a problem to the refrigerator.

(2) Operating structure

Characteristics of each part

- 40 -

Operating coil

Pipe (inlet)

Pipe (outlet)

Valve body

(External structure)

(Operating circuit)

(Internal structure)

Valve coil

Page 41

(3) Operating principle

Controlling the rotating angle of the stepping motor will open/close the outlet pipe entrance by changing the shape of the

valve connected to the bottom of the rotor.

(4) Operating characteristics

Characteristics of each part

- 41 -

Left/Right compartment open

Right compartment open

(STEP : 54)

Left/Right compartment open

(STEP : 36)

Left compartment open

(STEP : 18)

Closed area

Valve

Left side outlet

Right side outlet

Page 42

8-2. Motor (mechanical room)

(1) Function

• Motor cooling (mechanical room)

This is the part used for circulating the air within the mechanical room and applies to the wire condenser type. This

operates when the compressor operates and the heated refrigerant from the compressor lowers the temperature when

passing through the wire condenser and also reduces the temperature of the compressor to improve the performance.

(2) Operating principle and characteristic

• Characteristic

The motor applied to the refrigerator is the shading pole motor of the inductive motors. As shown below, it is a 2 pole

device with one pole composed of 2 parts. On the small pole called the shading pole, wire is connected (shorted) called

the shading coil. In accordance with the characteristics of the AC motor, the motor switches between + and - to operate but

because in the 2 pole device, the N and S pole changes within both poles without left and right rotation, the device cannot

rotate without help from an external device. Therefore the shading pole and coil creates the rotating direction for operation.

The shading pole motor cannot rotate in reverse direction. Therefore the rotating direction must be set during assembly to

rotate in the desired direction.

Characteristics of each part

- 42 -

Shading

Pole

Shading

Coil

Page 43

• Operating principle

When the AD power is connected to the coil of the shading pole

motor, the central axis of the magnetic field shifts in the bold

arrow direction of <Fig. 2>. As the central axis moves, the rotor

moves in the same direction to turn the motor.

Why does the central axis of the magnetic field shift?

<Fig. 1> shows a diagram of AC current changing as time

changes. If you look at changes of magnetic velocity in “a” zone

where the current abruptly increases, the velocity increases as

the current increases in the main pole. But in the shading pole,

the negative effect of the velocity increase is generated from the

shading coil to reduce the velocity shifting the center of the

magnetic field to the main pole. In “b” zone, the change in

current is minimal and the negative effect of shading coil is

minimal to have the center of the magnetic field in the middle as

shown in <Fig. 2>. In “c” zone, the velocity of the main pole

decreases but with the negative effect increasing the velocity

from the shading pole side, the center shifts to the shading pole

side. As shown, the center of the magnetic field shifts from the

main pole to the shading pole to rotate the rotor.

Characteristics of each part

- 43 -

Shading

Pole

ab c

<Fig. 1> Change of AC current

Current

Time

Main pole

"a"

zone

"b"

zone

"c"

zone

Removal of magnetic velocity on the pole surface

<Fig. 2> Change in magnetic velocity by changes in current

Page 44

8-3 Heater

(1) Introduction

When using the refrigerator, several heaters are applied to season the Kimchi or store the rice.

(2) Heater type and role

g The resistance value can differ by the model.

■ Heater assembly (ferment/rice storage)

Characteristics of each part

- 44 -

Classification Applied part Function Resistance value Remarks

Problem (parts) Symptom Check method Resolution

1. Heat wire

disconnected/connecting

wire disconnected

2. Poor terminal contact

Kimchi not

seasoned

1. Measure the resistance of both

ends of the heater with a tester to

see if it is →∞

Ω

.

2. Measure the resistance of both

ends of the heater with a tester to

see if it fluctuates.

1. Exchange the product

2. Properly insert the

connector

Heater assembly

Heater assembly

Heater plate

External surface of inner case

(Lid-compartment)

Floor of inner case

(Drawer-compartment)

Left side of inner case (Left

drawer-compartment)

For Kimchi seasoning

For Kimchi seasoning

/ rice storage

For Chungukjang seasoning

165Ω/EA

1,653Ω/EA

2,204Ω/EA

80W × 2

EA

8W × 2

EA

6W × 2

EA

Page 45

Chapter 9. Cautions for disassembling the product

1. Main PWB assembly

• When disassembling the main PWB assembly, located

in the mechanical room, be careful so that the lead

wires do not touch the edge part.

• If the lead wire coating is disconnected or the coating is

damaged, it can cause a short circuit.

2. Frame assembly , display

• Using the - driver, open the slot between the frame

display and the case-U to disassemble the unit. At this

time, be careful not to apply too much pressure to

damage the PWB assembly, display or make scratches

on frame display and case-U.

g Depending on the mode, the service slot is on the top

left/right side or bottom left/right side.

Cautions for disassembling the product

- 45 -

Case-U

Frame Display

Case-U

Deco, Case

Frame Display

GR-K24PS

GR-K243UG

Page 46

10-3. Assembly diagram

uu

GR-K24PS

Assembly diagram and service parts list

- 46 -

203A

501A

502B

323B

323C

319A

307A

314A

309A

310A

308A

312A

315C

619A

411

319C

329C

315A

315B

304A

618B

318A

310B

420A

327A

243A

243A

410H

203A

243A

243A

281B

281C

221A

233A

233A

230A

230B

281D

281E

221A

233A

233A

200A

200B

604A

420B

604B

604D

604C

604A

420B

604B

604D

604C

618A

327B

Page 47

uu

GR-K24PS

Assembly diagram and service parts list

- 47 -

248D

147C

249G

249D

248A

104A

249B

147A

248F

147C

147B

212D

270A

155B

236B

248D

248D

248D

248F

248F

155A

236A

206C

104A

248D

248D

207C

212G

Page 48

uu

GR-K24PS

Assembly diagram and service parts list

- 48 -

248D

241A

241A

125C

241B

145B

125D

248B

249A

250A

231A

231B

248B

248B

203B

248G

248C

248G

248C

203B

155C

206F

212A

236C

201B

236D

212B

155C

207D

207D

206G

201A

Page 49

- 49 -

uu

GR-K243UG

Assembly diagram and service parts list

203A

500A

502B

323B

323C

319A

307A

314A

309A

310A

308A

312A

315C

619A

411A

319C

329C

315A

315B

304A

618B

318A

310B

420A

327C

243A

243A

410H

203A

243A

243A

281B

281C

222A

233A

233A

230A

230B

281D

281E

222A

233A

233A

200A

200B

618A

327B

604B

604A

420B

604B

604A

420B

Page 50

- 50 -

uu

GR-K243UG

Assembly diagram and service parts list

248D

147C

249G

249D

248A

104A

249B

147A

248E

147C

147B

242D

270A

155B

236B

248D

248D

248D

248E

248E

155A

236A

206C

104A

248D

248D

207A

212G

234B

234A

204A

Page 51

- 51 -

uu

GR-K243UG

Assembly diagram and service parts list

248D

241A

241A

248B

249A

250A

231A

231B

248B

248B

203B

248G

248C

248G

248C

203B

155C

206F

212A

236C

201B

236D

212B

155C

207B

207C

206G

201A

148B

242C

242B

125C

242A

242B

Page 52

P/No. MFL31842101 MAR.,2008 Printed in Korea

Loading...

Loading...