LG GCE-8481B Service Manual

3

INTRODUCTION

FEATURES

1. General

1) Enhanced IDE interface.

2) Internal 5.25 inch, halfheight CD-R/RW Drive.

3) 2Mbytes buffer memory.

4) Audio CD like tray loading of a disc without using a caddy.

5) Power loading and power ejecting of a disc. The disc can also be ejected manually.

6) Supports Power saving mode and Sleep mode.

7) Vertical and Horizontal operation.

8) SuperLink Function.

2. Supported disc formats

1) Reads and writes data in each CD-ROM, CD-ROMXA, CD-I FMV, Video CD, and CD-EXTRA

2) Reads data in Photo CD (Single and Multi session).

3) Reads and writes standard CD-DA.

4) Reads and writes CD-R discs conforming to “Orange Book Part 2”.

5) Reads and writes CD-RW discs conforming to “Orange Book Parts 3”.

3. Supported write method

1) Disc at once (DAO), Session at once (SAO), Track at once (TAO), Variable packet, Fixed packet, and

Multi-session.

4. Performance

1) Random 100 ms average access time.

2) CD-R Record speed : 8X, 12X, 16X, 22X~40X (PCAV), 48X CAV.

3) CD-RW Record speed : 4X, 10X, 12X, 16X, X24(PCAV).

4) CD-ROM : Max 7,200 KB/s(Max 48x) Sustained Transfer rate.

5) Supports real time error correction and real time layered error correction at each speed.

6) PIO Mode 4, Multi DMA Mode 2, UDMA Mode 2.

7) Multimedia MPC-3 Spec compliant.

8) Support CD-TEXT read/write.

5. Audio

1) Output 16 bit digital data over ATA interface.

2) 8 Times Digital Filter for CD Audio

3) Software Volume Control

4) Equipped with audio line output and headphone jack for audio CD playback.

5) Front panel Volume Control for Headphone Output.

This service manual provides a variety of service

information.

It contains the mechanical structure of the CDR/RW Drive and the electronic circuits in

schematic form. This CD-R/RW Drive was

manufactured and assembled under our strict

quality control standards and meets or exceeds

industry specifications and standards.

This CD-R/RW drive is an internal drive unit

designed for use with IBM PC, HP Vectra, or

compatible computer. It can write as much as 700

Mbytes of digital data into CD-R/RW disc, and can

read as much as 650 Mbytes of digital data stored

in a CD-ROM, CD-R and CD-RW disc.

This CD-R/RW Drive can easily meet the

upcoming MPC level 3 specification, and its

Enhanced Intelligent Device Electronics (E-IDE)

and ATAPI interface allows Plug and play

integration in the majority of today’s PCs without

the need of an additional interface card.

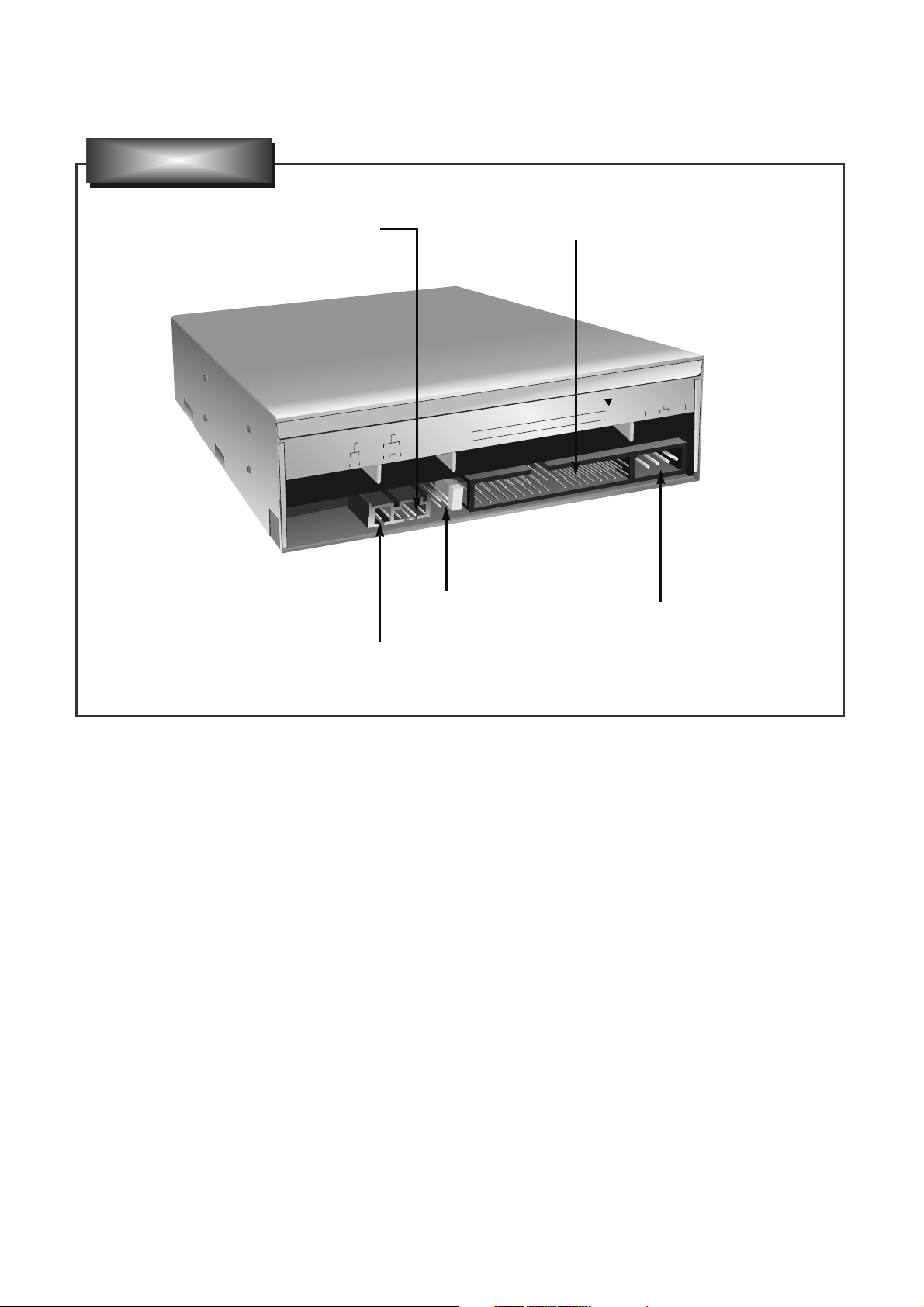

LOCATION OF CUSTOMER CONTROLS

6

1. Disc tray

This is the tray for the disc. Place the disc on the

ejected disc tray, then lightly push the tray (or

push the eject button) and the CD will be loaded.

NOTE: Don’t pull out or push in the disc tray

forcibly. This might cause damage to the loading

section of the drive.

2. Stop/Eject button

This button is pressed to open the CD tray.

This button works only when power is supplied to

the drive.

If an Audio CD is playing, pressing this button will

stop it, and pressing it again will open the tray.

3. Emergency Eject Hole

Insert a paper clip here to eject the Disc tray

manually or when there is no power.

4. Volume control

This is used to adjust the output volume of the

headphone jack. It can’t be used to adjust the

output volume for the audio output connectors on

the rear panel.

NOTE : Turn the volume down before turning on

the power. Sudden loud noises can damage your

hearing.

5. Headphone jack

This jack is for connecting headphones or minispeakers.

6. Drive activity indicator(Read/Write)

Two colored LED is used to indicate the operation

of CD-R/RW Drive.

Headphone Jack

Volume

Control

Drive Activity Indicator

Stop/Eject Button

Disc Tray

Emergency Eject Hole

Front Panel

7

1. Power Connector

Connects to the power supply (5-and 12-V DC) of

the host computer.

NOTE : Be careful to connect with the proper

polarity. Connecting the wrong way may damage

the system (and is not guaranteed). Usually this

connector can only be attached one-way.

2. IDE Interface Connector

Connect to the IDE (Integrated Device

Electronics) Interface using a 40-pin flat IDE

cable.

NOTE : Do not connect or disconnect the cable

when the power is on, as this could cause a short

circuit and damage the system. Always turn the

power OFF when connecting or disconnecting the

cable.

3. Jumper Connector

This jumper determines whether the drive is

configured as a master or slave. Changing the

master-slave configuration takes effect after

power-on reset.

4. Analog Audio Output Connector

Provides output to a sound card (analog signal).

Generally you need this to play a regular audio

CD.

5. Digital Audio Output Connector

Provides output to a sound card (digital signal).

DIGITAL

AUDIO

ANALOG

AUDIO

INTERFACE

POWER

D G

39

40

1

+5

GND

+12

2

C S M

S L A

R G L

Digital Audio Output

Connector

Jumper Connector

Analog Audio Output Connector

IDE Interface Connector

Power Connector

Rear Panel

TROUBLESHOOTING GUIDE

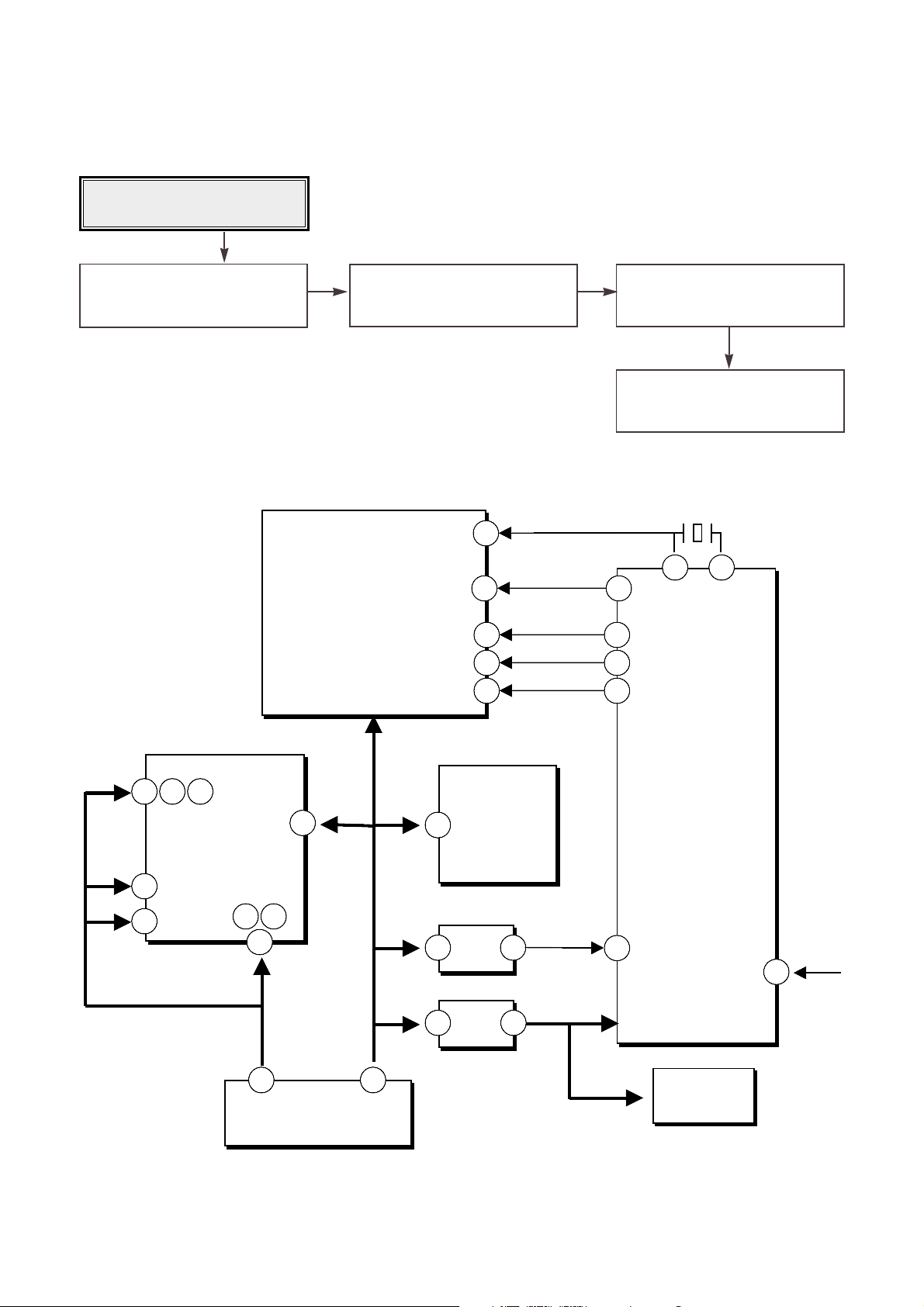

Power check

(Malfunction of LED and Tray).

52

Check the connection of 5V, 12V.

Check the Reset (Pin 170, 122 of

IC101, pin2 of IC401).

Check the input of oscillation (pin

109 of IC401).

Check SCLK, SDATA, XLAT

(pin 122, 123, 124 of IC401).

1. Connect only the power cable

BD7907FS

6Ch Servo DRIVE

MT1516

RF Amp

Wobble

ALPC

General port use

EEPROM access

MT1508

DSP

Decoder

Encoder

ATIP Demodulator

Write Strategy

Write S/H Signal

I / F

Micro Processor

33.868 8MHz

IC 101

IC 501

IC 103

IC 401

IC 102

3.3 V

Reset

12V 5V

AT49F002N

512KB

Flash ROM

IC 502

41

109

44

2

54

31

3

32

10 19 20

31

32

30

44 51

IC 202

2 170

PRST

‘ L ’

122

/ HRST

‘ H ’

74 75

MCLK

55

‘ H ’

/XRST

SDRAM

123

124

122

63

62

65

SCLK

SDATA

XLAT

CN 100

MT1518

AT49F040

53

Check the Reference voltage

(+/- 10%).

Check VC (1.4V) of Drive IC

(pin27 of IC501).

Check voltage of VREF(1.4V)

(pin 53 of IC101, pin 27 of IC501).

Check voltage of 2VREF(2.8V)

(pin 52 of IC101).

Check HAVC/PDVC(2.0V)

(pin 34 of IC401, pin 13 of CN201).

Check FVREF/FPDVC (2.8V)

(pin 52 of IC401, pin22 of CN201).

Check FPDO(2.8V)

(pin 54, 65 of IC401).

CN 201

Optical

Pick-up

KRS-340B

FPDVC

FPDO

LD

Drive

FPDVcc

20

5 V

PDVC

13

22

19

6Ch Servo DRIVE

2.0 V

2.8 V

2.8V

IC 501

BD7907FS

75

VHAVC

34

HAVC

74

VFVREF

52

FVREF

General port use

EEPROM access

54

FPDO

65

FPDOLP

27

VC

IC 401

MT1516

RF Amp

Wobble

ALPC

IC 506

1.4 V

1

2

NJM

3414

V28

V14

IC 101

2.8 V

76

1.4 V

76

52

53

2VREF

VREF

MT1518

DSP

Decoder

Encoder

ATIP Demodulator

Write Strategy

Write S/H Signal

I / F

3

Micro Processor

3.3 V

2.5 V

IC 503

32

17 28 76 134 18 0

54

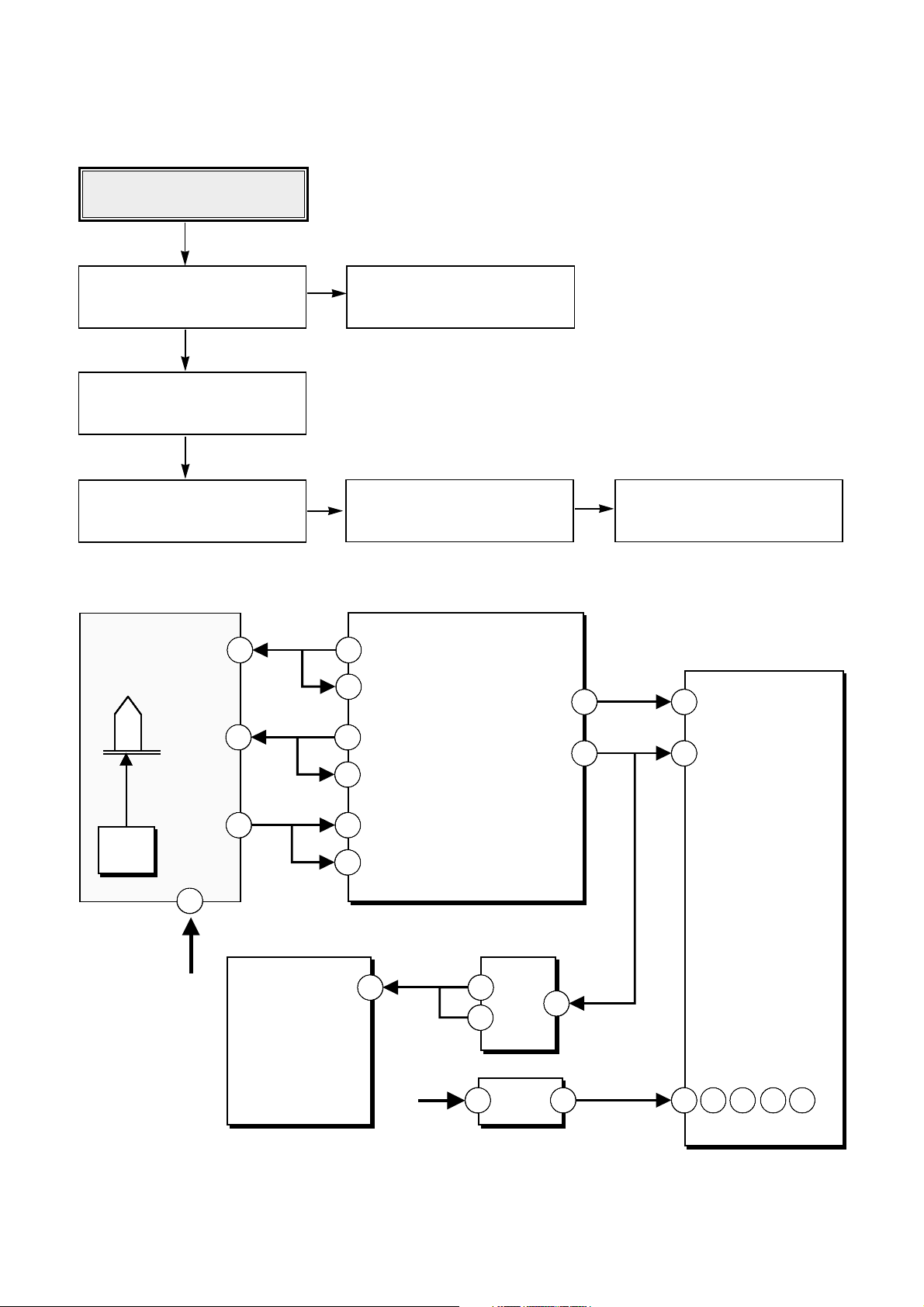

Check the initial operation

(Power-on state)

• Check the operating signal of Sled

(pin 28, 29 of IC501 : SLIN1, 2).

• Check the output signal of Sled

(pin 34, 35, 36, 37 of IC501).

• Check /SLEDIN_SW.

(pin 104 of IC401).

• Check the control signal of Driver

IC(pin 22, 23 of IC501).

• Check the power of DRIVE IC

and VC.

Check SCLK, SDATA, XLAT

(pin 122, 123, 124 of IC401).

Sled move to inside.

Spindle motor rotate.

Laser On.

Check the Laser.

•

Check the Spindle signal

(pin 24 of IC501 : SPIN).

•

Check FG input

(pin 20 of IC101).

•

Check the Hall signal

(pin 1, 2, 3, 4, 5, 6 of IC501).

Check the operation of Focus

Focus up / Down.

Laser Off / Spindle Stop.

2 times iteration

Spindle

Motor

Optical

Pick-up

KRS-340B

STEP Motor

(From pin 1 of CN402)

/SLEDIN_SW

IC 401

MT1516

104

ALPC

General port use

DRV-MUTE2

SCLK

122

SDATA

123

XLA T

124

102101

DRV-MUTE1

65

63

62

IC 101

MT1518

DSP

I / F

HB

HU+ , HU-

HV+ , HV-

HW+ , HW-

23

U

9

V

11

W

18

7

34

B+ A- A+

B-

373635

IC 501

BD7907FS

1

2

,

4

3

,

65

,

6Ch Servo

DRIVE

22

CTL1

CTL2

SLIN1

SLIN2

SPIN

FG

VC

28

29

27

1.4 V

Micro

Processor

26

FMO

27

FMO2

2524

DMO

2021

FG

55

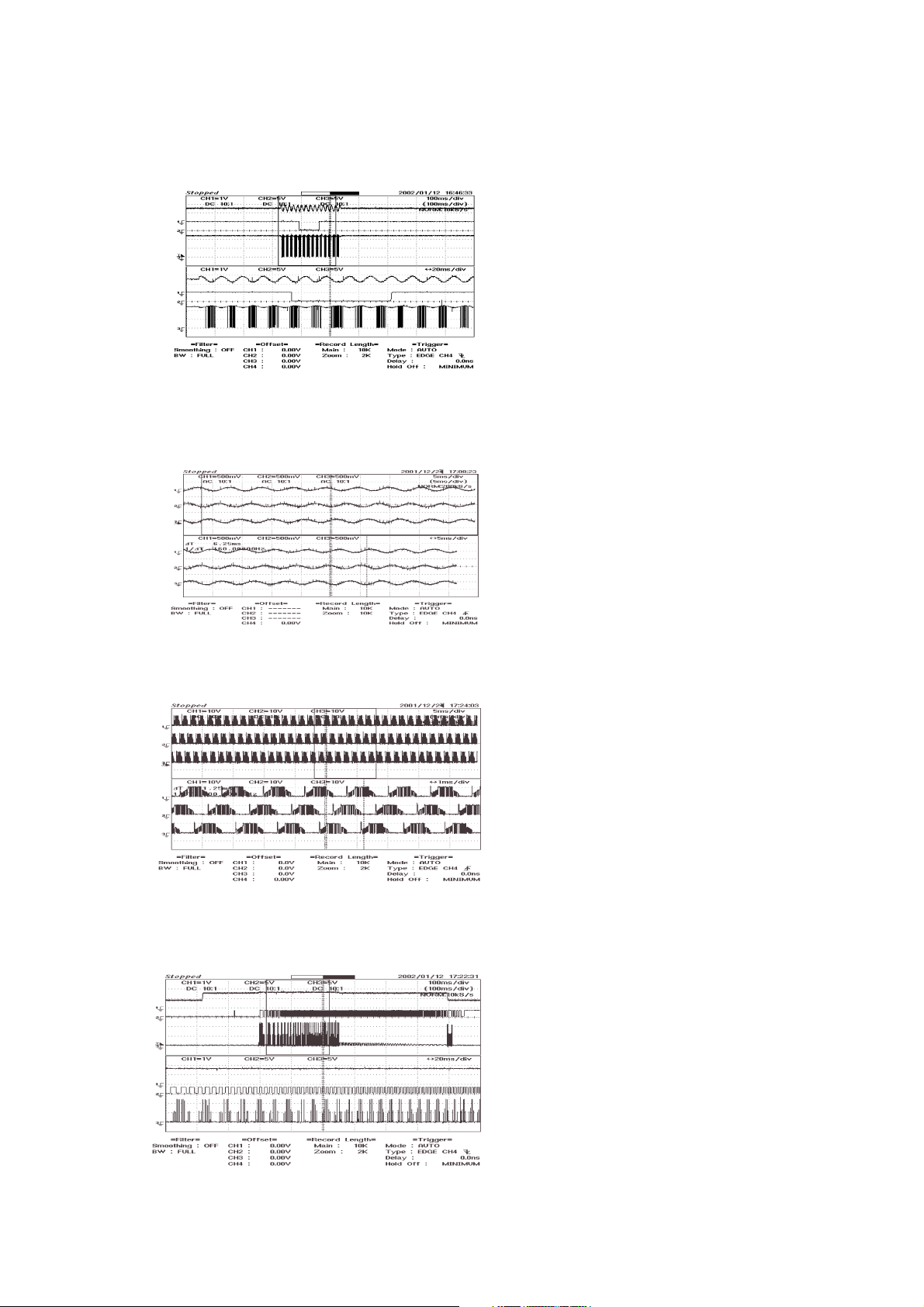

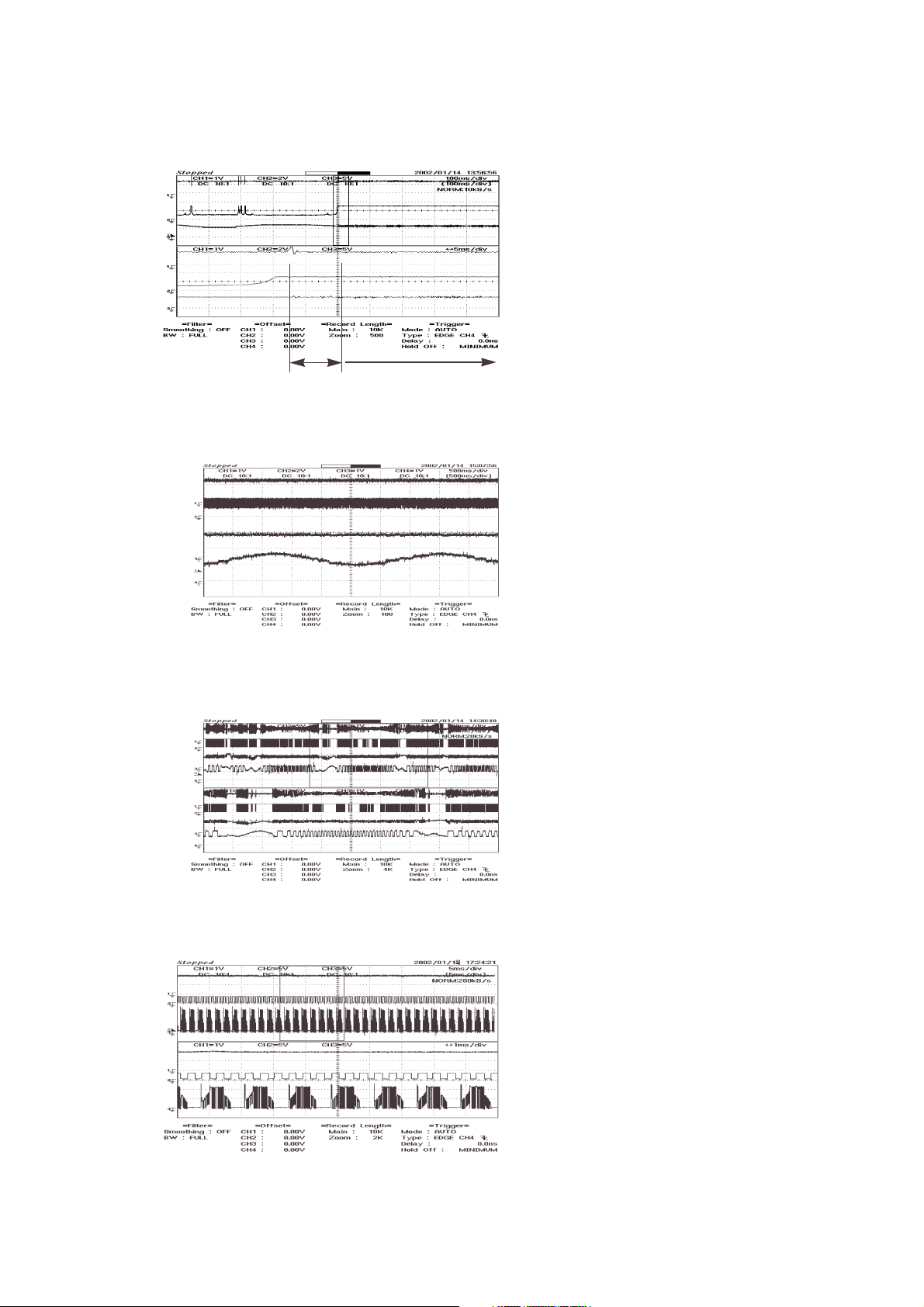

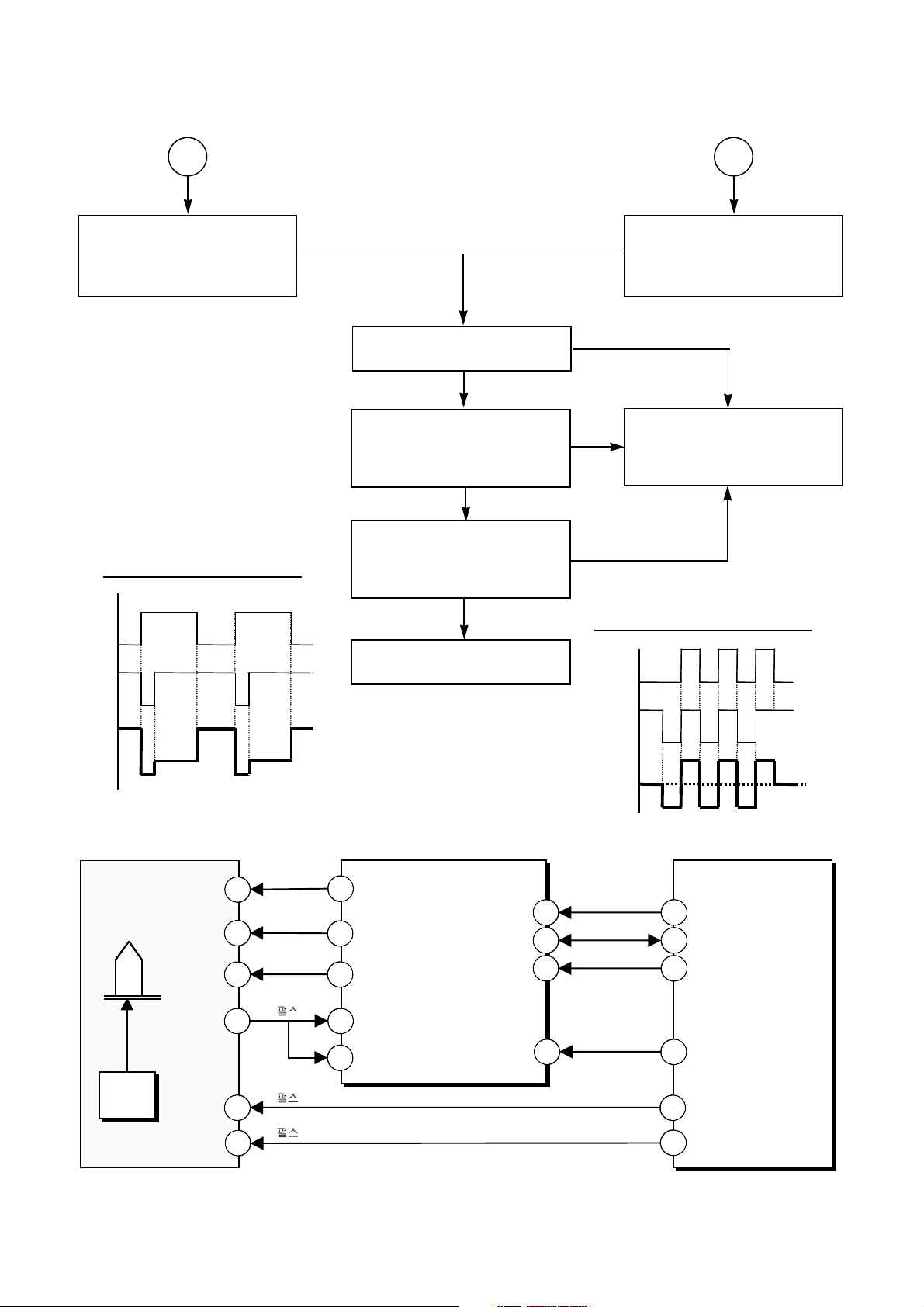

1. Waveform when Sled moves to inside

SLIN1

/SLEDINSW

A+

2. Waveform of Spindle rotation

HU+

HV+

HW+

3. Waveform of Spindle Kick

SPIN

FG

U

Zoom in

wave

Zoom in

wave

Zoom in

wave

Zoom in

wave

When the sled moves to the inner position,

the sine wave(refer to Fig1) inputs to

SLIN1/SLIN2 (the input pins of drive IC).

When Pick-Up unit approached to innermost

position, the /SLEDINSW signal(CN402 pin 1)

becomes 0 V.

The output pins A+ ,A-, B+, B- of the drive IC is

PWM waveform and drives the Stepping Motor.

The output signal of Hall(HU+, HU-, HV+, HV,

HW+, HW-) comes from a Hall sensor of spindle

motor and they were inputted to pin 1, 2, 3, 4, 5, 6

of drive IC(BD7907FS) via CN402. When spindle

motor rotate, HU+, HW+, HV+ signals are

generated in a regular order with 120

0

phase delay

each other.(Refer Fig 2)

If waveforms of HU+, HU-, HV+, HV-, HW+, HWdifferent from Fig 2, check the pin 7(HB signal) of

drive IC. The HB signal must be about 5V.

Wave of U,V,W assigned to pin 9,11,18 of Drive

IC is a PWM waveform and they drive Spindle

motor.

When spindle motor rotate, U/W/V signals are

generated in a regular order with 120

0

phase delay

each other. (Refer Fig 3)

If waveforms different from Fig 3, check pin

27(VC), pin 51(VCC), pin22(CTL1), pin23 (CTL2),

R514, R512, R510, R511.

When spindle kick, refer to Fig 4.

Fig.1

Fig.2

Fig.3

Fig.4

56

Check Tray operation.

Check /EJECT KEY

(pin 11 of IC101).

Check the output signal of tray

(pin 49, 50 of IC501).

Check the LED.

Check operating signal of tray

(pin 26 of IC501).

• Check the control singal of Drive IC

(pin 22, 23 of IC501).

• Check the power of DRIVE IC and

VC.

Check operating signal of LED (pin

96, 98 of IC401).

Check SCLK, SDATA, XLAT (pin

122, 123, 124 of IC401).

Check operation S/W of tray

(/OPEN SW:pin 94 of IC401

/LOAD SW : pin 95 of IC401).

MT1518

LED102

LED101

Q802

Q801

SW103

DETECTOR

-TRAY

2

1

LED1

96

IC 401

LED2

98

MT1516

RF Amp

/OPEN_SW

/LOAD_SW

General port use

94

95

101

102

122

123

124

SCLK

SDATA

XLA T

65

63

62

IC 101

MT1508

FRONT

SW102

EJECT

-SW

Tray Motor

M

TRAY -

TRAY +

DRV-MUTE2 DRV-MUTE1

23

22

49

CTL1

CTL2

LDIN

BD7907FS

6Ch Servo DRIVE

27

50

IC 501

VC

/EJECT_KEY

PWMOUT

1.4 V

2426

Processor

11

DSP

Decoder

Encoder

I / F

Micro

57

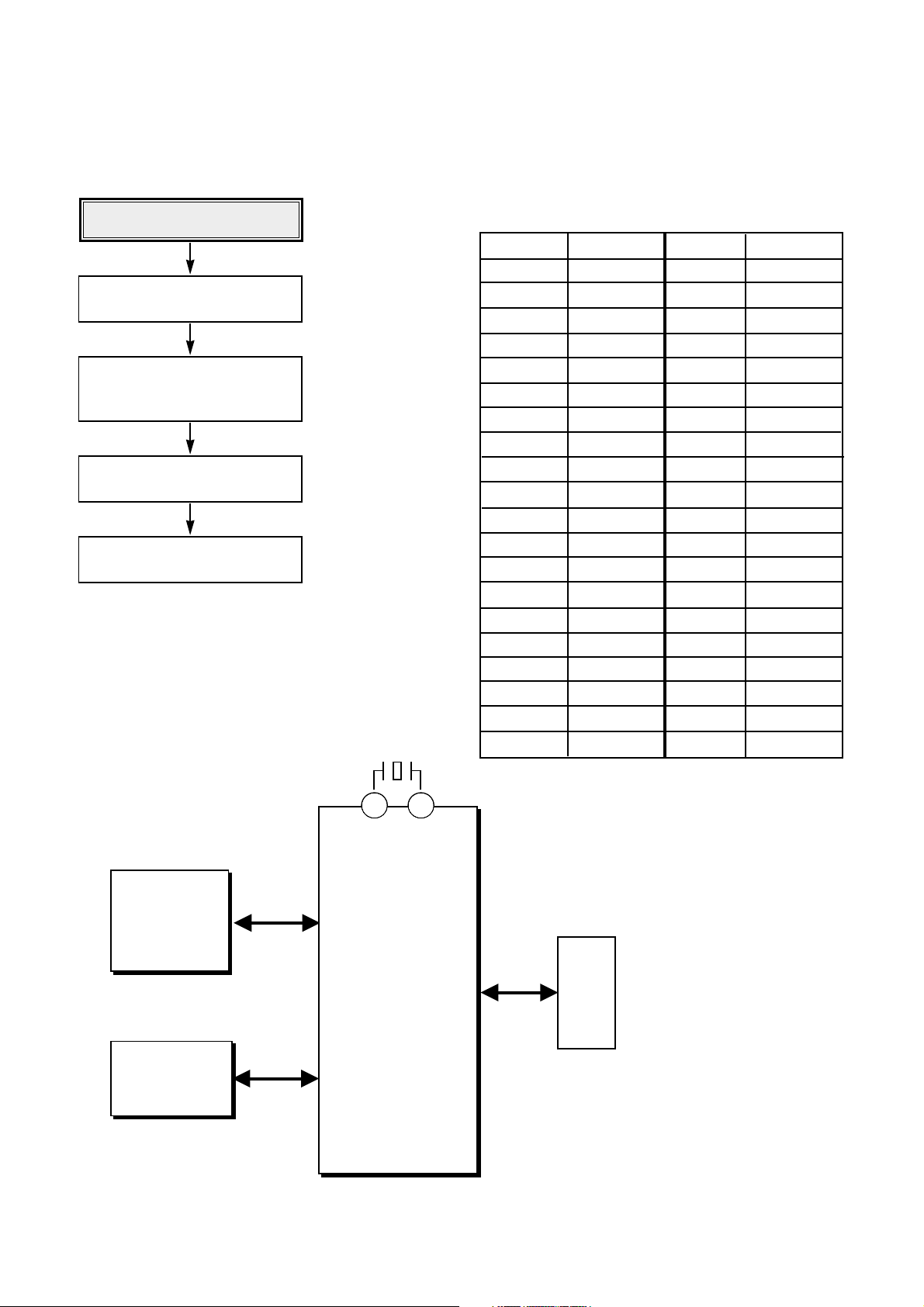

Check identification of Drive.

Check the connection of ATAPI

cable.

Check the communication between

PC and MT1518 (IC101).

Check SDRAM.

(IC102)

Check Flash ROM

(IC103).

2. Connection of Power and ATAPI cable

MT1508

DSP

Decoder

Encoder

ATIP Demodulator

Write Strategy

Write S/H Signal

I / F

Micro Processor

H

O

S

T

8MB

SDRAM

I/F

cable

Address

Data

IC 101

IC 103

IC 102

AT49F002N

512KB

Flash ROM

33.868 8MHz

74 75

Address

Data

Pin no. Pin name Pin no. Pin name

39 DASP GND 40

37 CS1 CS3 38

35 DA0 DA2 36

33 DA1 PDIAG 34

31 INTRQ IO16 32

29 DMACK GND 30

27 IORDY CSEL 28

25 IOR GND 26

23 IOW GND 24

21 DMARQ GND 22

19 GND KEY 20

17 HD0 HD15 18

15 HD1 HD14 16

13 HD2 HD13 14

11 HD3 HD12 12

9 HD4 HD11 10

7 HD5 HD10 8

5 HD6 HD9 6

3 HD7 HD8 4

1 /HRST GND 2

CN101(ATAPI)

SDRAM

MT1518

AT49F040

58

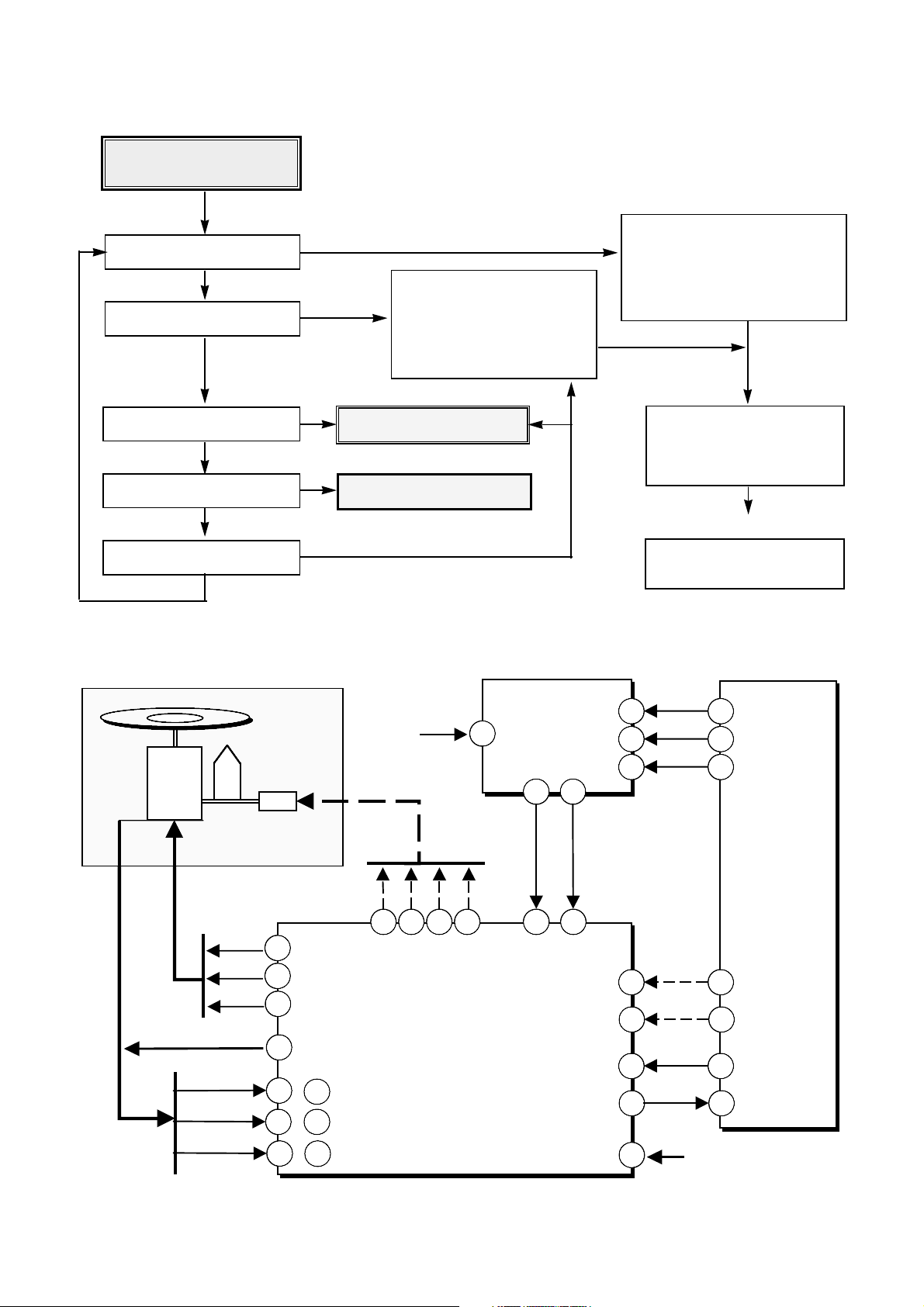

Check the identification of CD-

ROM Disc (insert Disc).

Check the operation of Focus.

Check the operation of Tracking.

Check the Jump action.

• Check the drive signal of FCS-/+

(pin 1, 2 of CN201).

• Check drive input signal of Focus

(pin 53 of IC501 : FCIN).

• Check the input signal of FE

(pin 42 of IC101 : FEI).

• Check the input signal of SBAD

(pin 38 of IC101).

• Check the input signal of CSI (pin

41 of IC401).

• Check the input signal of RFZC (pin

60 of IC101 : HRFZC).

• Check the drive signal of TRK+/(pin 3, 4 of CN201).

• Check the signal of Tracking

(pin 52 of IC501 : TKIN).

• Check the signal of SLED

(pin 28, 29 of IC501 : SLIN1, 2).

• Check control signal of Drive IC

(pin 22, 23 of IC501: CTL1,2).

• Check power and VC of DRIVE IC.

Check signal of A~H (pin 39, 38, 37,

36, 30, 31, 32, 33 of IC401).

Check the input signal of TE

(pin 40 of IC101 : TEI).

In case of Focus Up/Down

MT1516

RF Amp

General port use

IC 401

123

124

122

SCLK

SDATA

XLA T

MT1518

DSP

Decoder

Encoder

I / F

Micro Processor

IC 101

63

62

65

BD7907FS

6Ch Servo

DRIVE

IC 501

DRV-MUTE2

DRV-MUTE1

CTL2

CTL1

27

1.4 V

VC

45

TEO

40

43

CSI

41

49

SBAD

38

NJM

3404

7

IC 505

1

52

53

6

2

23

22

Optical

Pick-up

KRS-340B

45 46

1 2

47 48

3 4

FCS-

FCS+

TRK+

TRK-

22

23

101

102

FCIN

TKIN

FOO

TRO

FOSO

TRSO

A ~ D

E ~ H

CN 201

TEI

CSI

SBAD

42

FEO

42

FEI

FMO

29

SLI N2

28

SLI N1

27

26

FMO2

126

RFZC

60

HRFZC

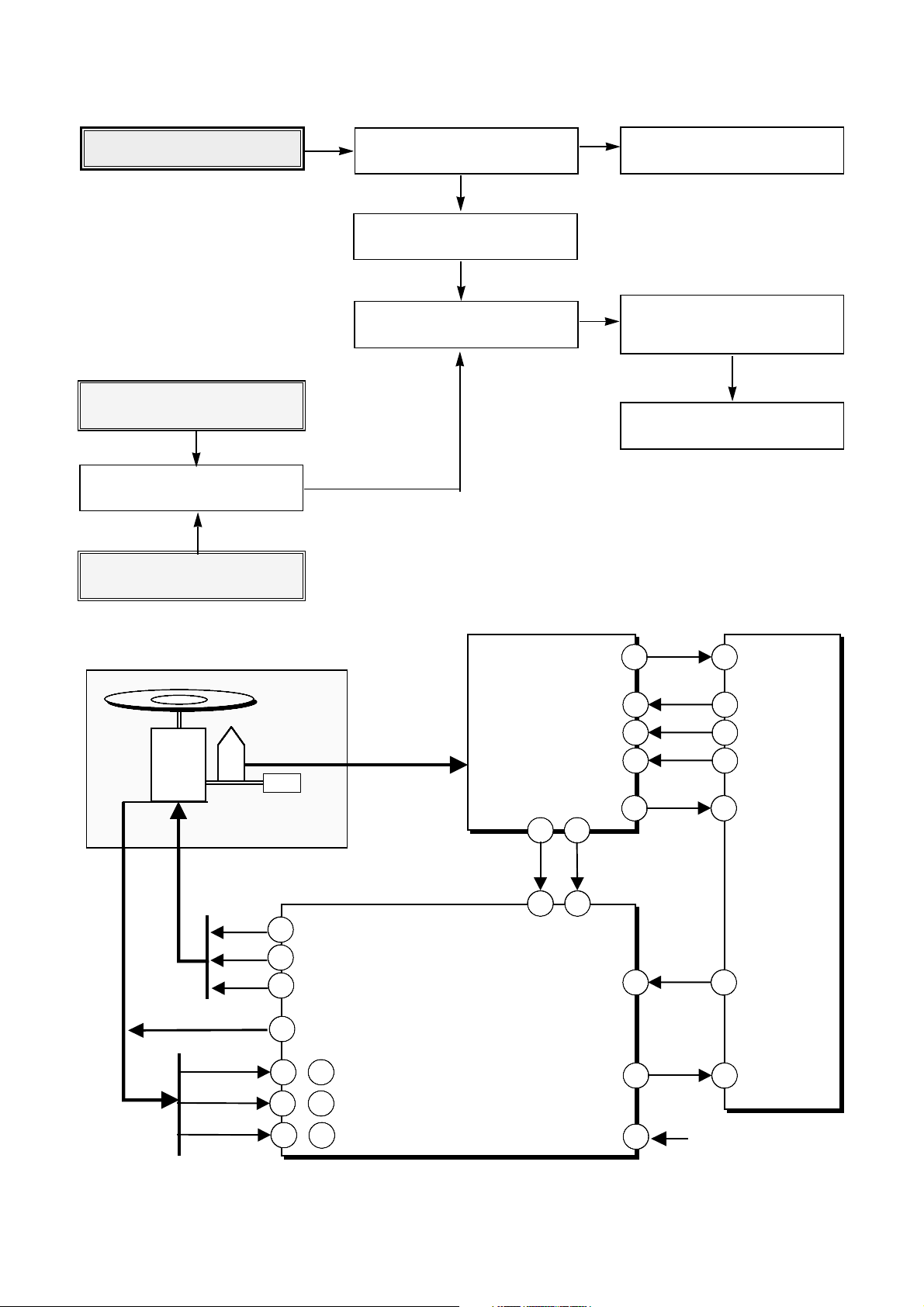

59

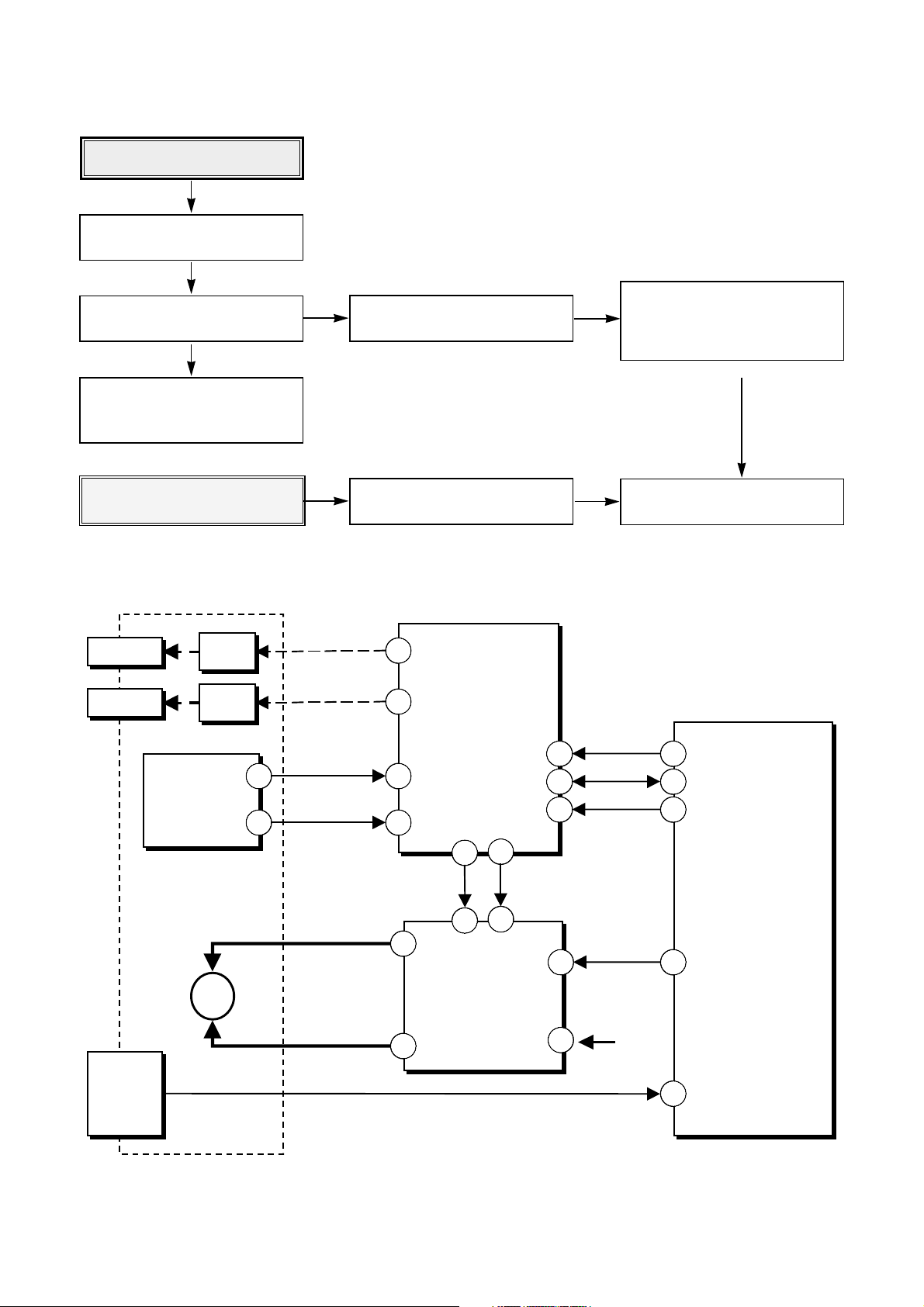

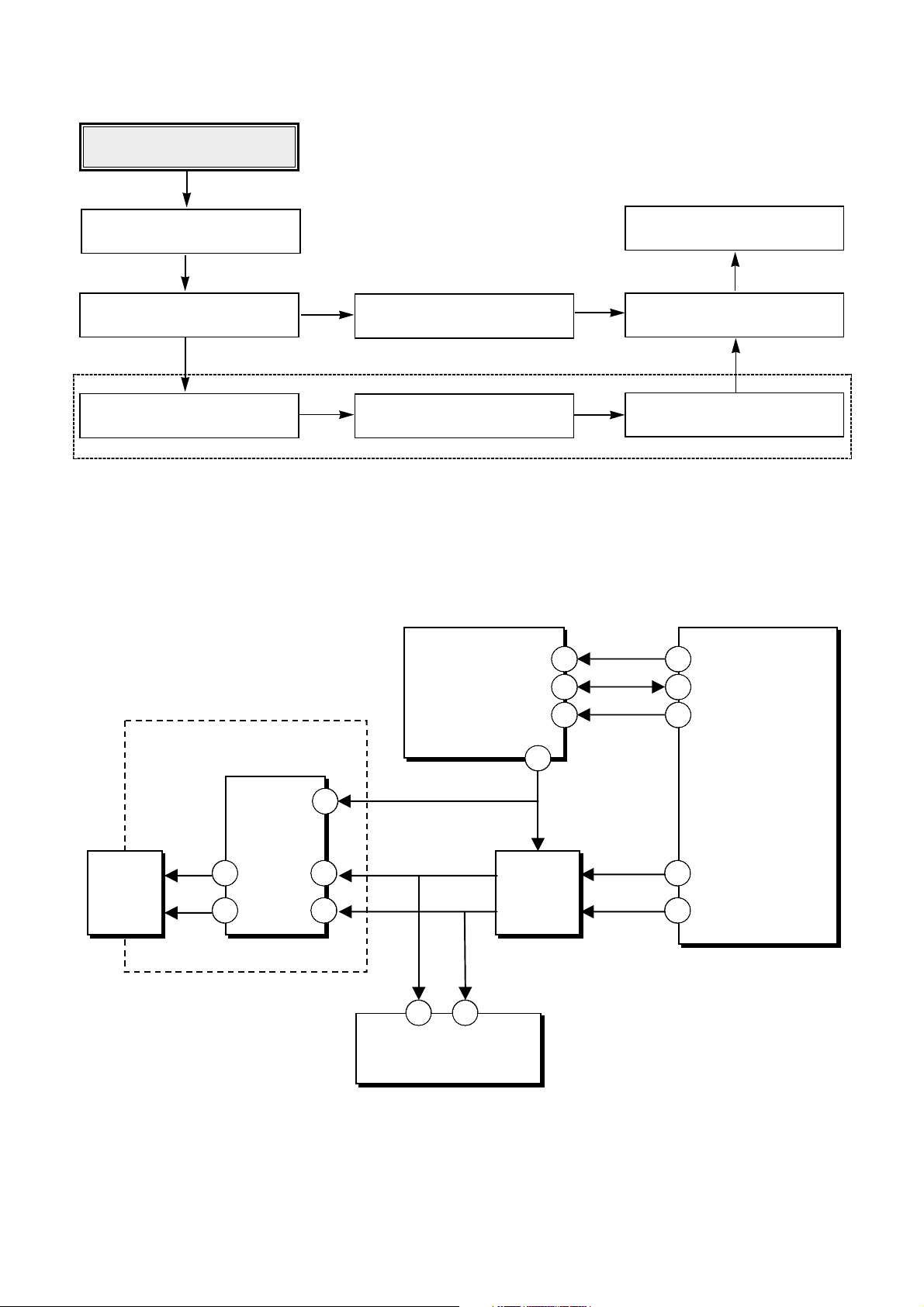

4. Operation of Focus Up/Down

FE

SBAD

FCS+

5. Waveform of Track Following

6. Waveform of Track Jump

TE

EQRF

CE

SLIN1

7. Waveform of Spindle Servo On

SPIN

FG

U

Zoom in

wave

Focus Search

Focus Servo On

Zoom in

wave

Zoom in

wave

Waveform of Focus Search refer to Fig 5.

In Focus Search, FE signal and SBAD signal are

used to Focus Servo On.

Therefore, in case of Focusing Fail, check the FE

signal and SBAD signal.

Waveform of Track Following(Sequential Read)

refer to Fig 6.

By Sled Servo, SLIN1, SLIN2 (pin 28, 29 of Drive

IC) drive the Sled Motor(Stepping Motor) for

locating the lens on the center axis of Pick-up.

Waveform of Track Jump refer to Fig 7.

Center level of TE,CE is 1.4V.

SLIN1, SLIN2 signal (pin 28, 29 of Drive IC)

assume the form of Pulse. And they drive the Sled

Motor(Stepping Motor).

RFZC(RF Ripple Zero Cross) signal is Pulse form

and it lags behind TE signal 90

0

.

To maintain constant rpm(CAV) or linear

velocity(CLV), the drives control spindle motor.

The Fig 8 shows the waveforms when spindle

servo is on.

TE

RFZC

CE

SLIN1

Fig.5

Fig.6

Fig.7

Fig.8

60

Check RF and Spindle

(Insert CD-ROM Disc).

Check the identification of

CD-R Disc(Insert Blank CD-R).

Check the identification of CD-RW

Disc (Insert Blank CD-R).

Check EQRF input signal

(pin 45 of IC101)

Check the signal of A~H (pin 39, 38,

37, 36, 30, 31, 32, 33, of IC401)

Check the operation signal of Spindle

(pin 24 of IC501).

Check SCLK, SDATA, XLAT

(pin 122, 123, 124 of IC401).

Check FG input

(pin 20 of IC101).

Check the input signal of ATFG

(pin 69 of IC101).

• Check the control signal of Drive IC

(pin 22, 23, of IC501).

• Check power/VC of DRIVE IC.

Spindle

Motor

Optical

Pick-up

KRS-340B

STEP Motor

A ~ D

E ~ H

DRV-MUTE2 DRV-MUTE1

IC 401

MT1516

RF Amp

Wobble

General port use

102101

EQRF

21

122

123

124

SCLK

SDATA

XLA T

45

65

63

62

IC 101

MT1518

ATFG

116 69

DSP

Decoder

Encoder

I / F

HB

HU+ , HU-

HV+ , HV-

HW+ , HW-

23

U

9

V

11

W

18

IC 501

22

CTL1

CTL2

SPIN

2524

ATIP

Demodulator

DMO

Micro

7

Processor

BD7907FS

21

,

4

3

,

65

,

6Ch Servo

DRIVE

FG

VC

27

1.4 V

2021

FG

61

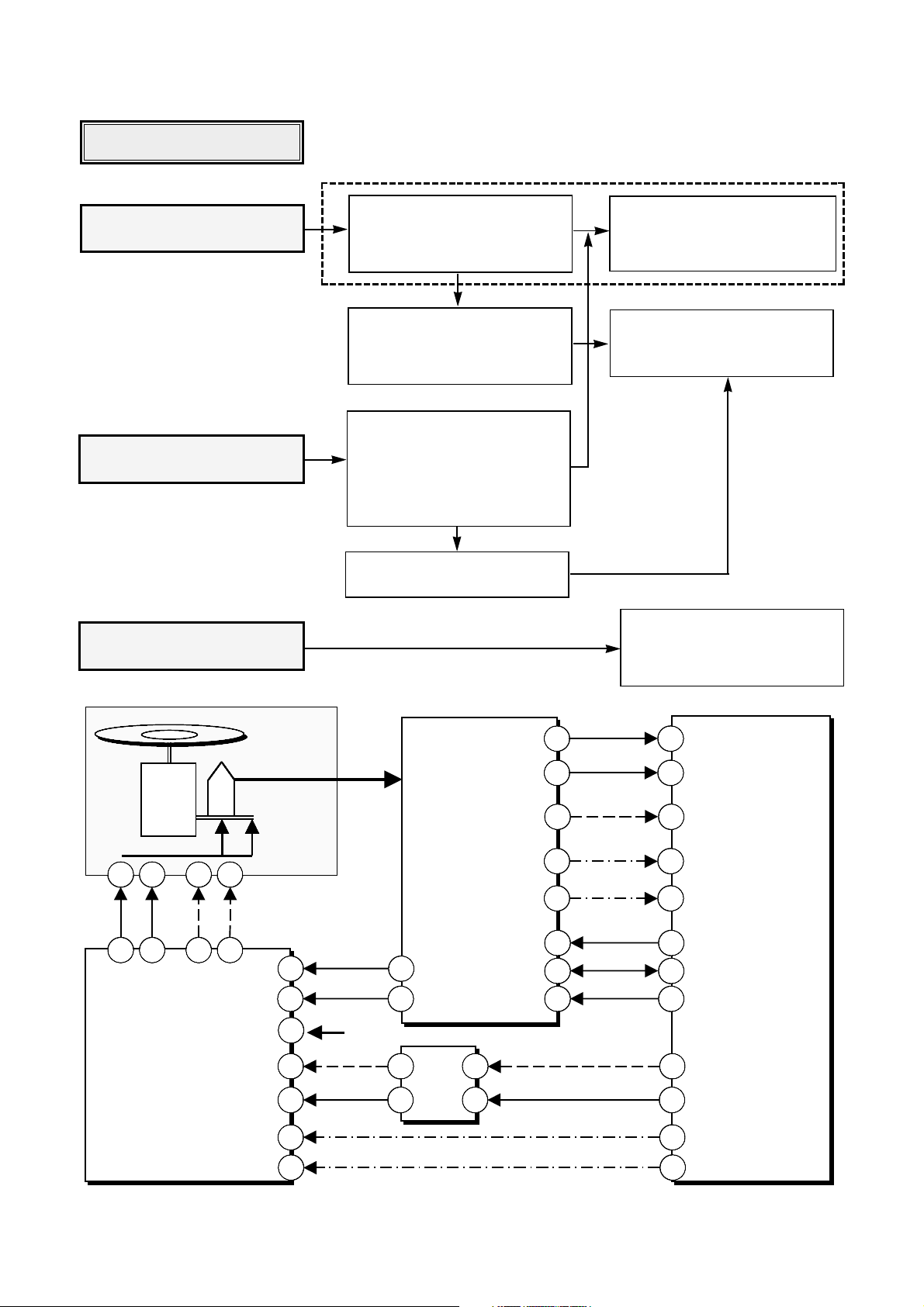

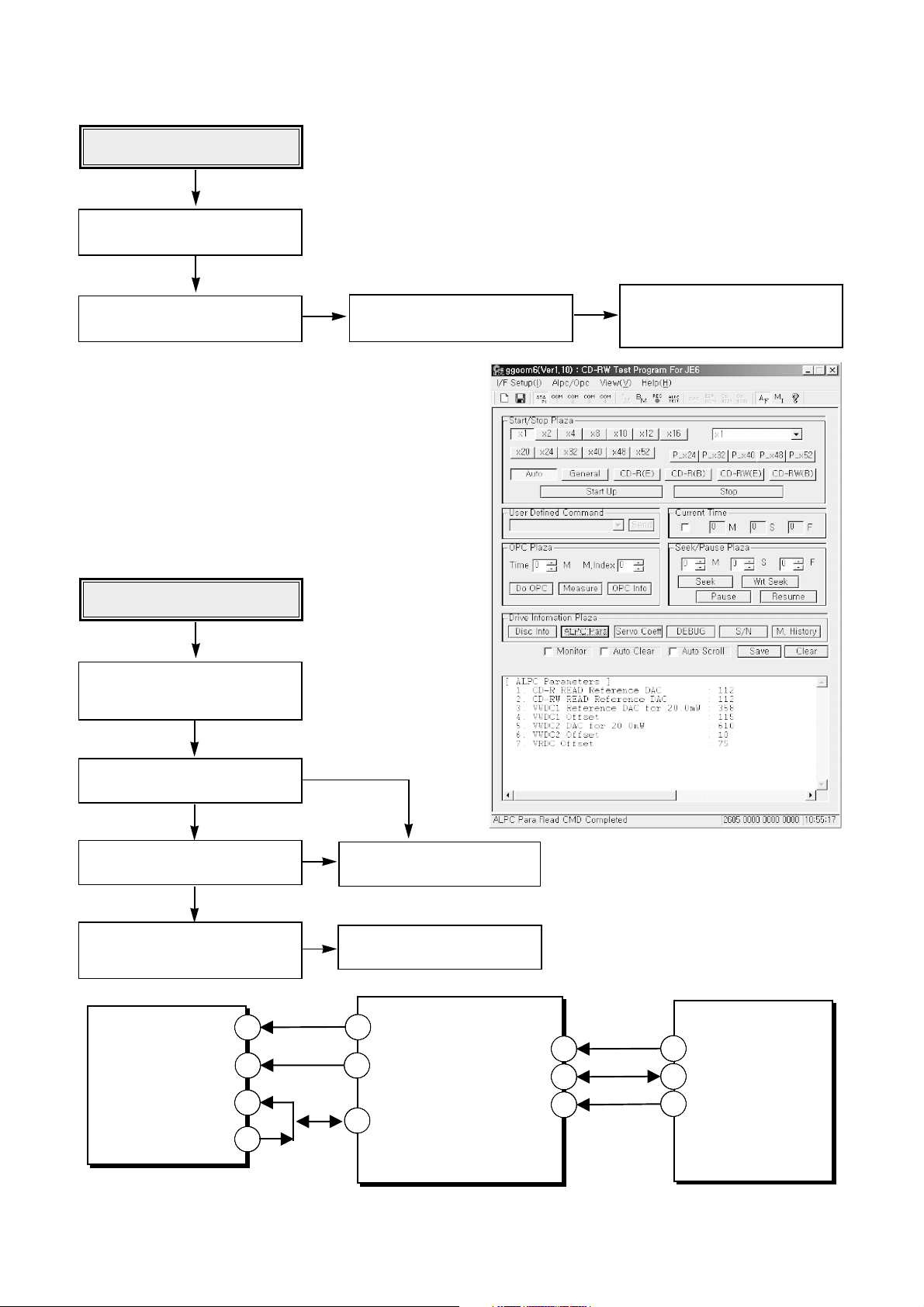

Check point of Writing

Check the compatibility between

Drive and Tool.

Check Disc state (Fingerprint,

Scratch, Dust...).

Check whether or not additional

writing is allowed.

(Given in the Disc Info of writing tool)

Check whether or not Disc is

writeable (CD-R/CD-RW).

(ALPC initial value before ‘Laser Power Setting’)

MT1518

Check Laser 1

(Check EEPROM)

Activate ‘Addition Func.’ window in

Test Tool(GGOOM6).

Execute ‘S/N’ (Identify Serial

Number).

Execute ‘ALPC Parameters’

(Identify ALPC Parameters).

Check the communication line

of EEPROM.

Execute ‘C. Laser Power

setting’ in Test Tool(GGOOM6).

Check whether or not ‘ALPC

Parameters is initial value.

CS

IC 203

SLK

AT93C86

2KB

EEPROM

DI

DO

1

2

3

4

110

108

107

EEP-SDATA

EEP-CS

EEP-CL K

MT1516

IC 401

ALPC

EEPROM access

IC 101

MT1508

Decoder

Encoder

122

123

124

SCLK

SDATA

XLA T

65

63

62

Micro

Processor

NG

NG

OK

62

Check Laser 2 (No disc).

Execute ‘E.ALPC Test for AS’ in

Test Tool (GGOOM6) (select

‘VRDC Loop’, and ‘Trigger’).

E

E

Check Read Laser

Initial value of FPDO : 2.8V +/- 10%.

OFF LEVEL.

VRDC LEVEL FPD.

Execute ‘D. Laser Inspection’ in

Test Tool (GGOOM6).

Check the input of ENBL

(pin 33 of CN201 : ‘H’).

Check the input of VRDC

(pin 25 of CN201 : 0.4~0.8V).

Check the input of FPDO (pin 54,

65 of IC401 : FPDO~0.1V).

• Check the input of RLDON

(pin 128 of IC401 : ‘H’).

• Check SCLK, SDATA, XLAT

(pin 122, 123, 124 of IC401).

Check Reference voltage.

NG

F

NG

G

VWDC1 LEVEL FPD.

VWDC2 FPD.

MT1516

ALPC

MT1518

Decoder

Encoder

Write Strategy

Write S/H Signal

Micro

Processor

IC 101CN 201

5

ENBL

IC 401

Optical

Pick-up

KRS-340B

LD

Drive

33

0.4~0.8 V

19FPDO 54

65

FPDO

FPDOLP

ENBL

FPDO-0.1V

123

124

122

63

62

65

SCLK

SDATA

XLAT

6325

VRDCO

VRDC

128 57

RLDON

H

H

63

Execute ‘E.ALPC Test for AS’ in

Test Tool(GGOOM6) (Select

‘CD-R Rec Mode’, and ‘Trigger’)

F

Inspection of CD-R Recording Laser

Execute ‘E. ALPC Test for AS’ in

Test Tool (GGOOM6) (Select

‘CD-RW Rec Mode’, and

‘Trigger’)

G

Inspection of CD-RW writing Laser

Chect input of ENBL

(pin 33 of CN201 : ‘H’).

• Check input of VWDC1

(pin 26 of CN201 : 0.4~1.0V).

• Check input of VWDC2

(pin 27 of CN201 : 0.1~0.5V).

• Check input of WLDON

(pin 27 of IC401 : ‘H‘)

• Check SCLK, SDATA, XLAT

(pin 122, 123, 124 of IC401)

• Check input of WXR

(pin 30 of CN201 : Pulse)

• Check input of ODON

(pin 31 of CN201 : Pulse)

Check input of FPDO

(pin 54, 65 of IC401 : Pulse).

Initial value of FPDO :

2.8V/-10%)

CD-R Recording Pulse

WXR

CD-RW Recording Pulse

ODON

FPDO

Optical

Pick-up

KRS-340B

Drive

CN 201

LD

ENBL

VWDC1

VWDC2

WXR

33

26

19FPDO 54

H

0.4~1.0 V

62

0.1~0.5 V

6127

65

5

ENBL

VWDC1O

VWDC2O

IC 401

MT1516

ALPC

FPDO

FPDOLP

WLDON

WXR

ODON

FPDO

122

123

124

127 58

SCLK

SDATA

XLAT

H

65

63

62

1330

IC 101

MT1518

Decoder

Encoder

Write Strategy

Write S/H Signal

Micro

Processor

WXR

ODON

31

15

ODON

64

Check Audio signal

(Insert Audio Disc).

Identify playback of Audio Disc

(Play Mode).

Check Output signal of AUIO L/R

(pin 51, 54 of CN100).

Check Output signal of AUDIO

L/R (pin 165, 167 of IC101).

Check Output signal of

/AUD-MUTE (pin 103 of IC401).

Check SCLK, SDATA, XLAT

(pin 122, 123, 124 of IC401).

Check Output signal of AUDIO

L/R (pin 1, 7 of IC801).

Check Input signal of AUDIO L/R

(pin 3, 5 of IC801).

Check Input signal of

/AUD-MUTE (pin 3 of IC801).

Output of Headphone

MT1516

RF Amp

General p

ort use

MT1508

DSP

Decoder

Encoder

I / F

Micro Processor

IC 101

BH3544F

AUDIO

AMP

IC 801

103

IC 401

LO

165

RO

167

AUDIO Line Out

51 54

CN 100

JK101

H-JACK

SB

3

5

3

Audio

Mute

Circuit

1

7

123

124

122

63

62

65

SCLK

SDATA

XLAT

L-CH R-CH

ROUT

LOUT

ROUT

LOUT

/AUD-MUTE

ROUT

LOUT

MUTE

FRONT

MT1518

65

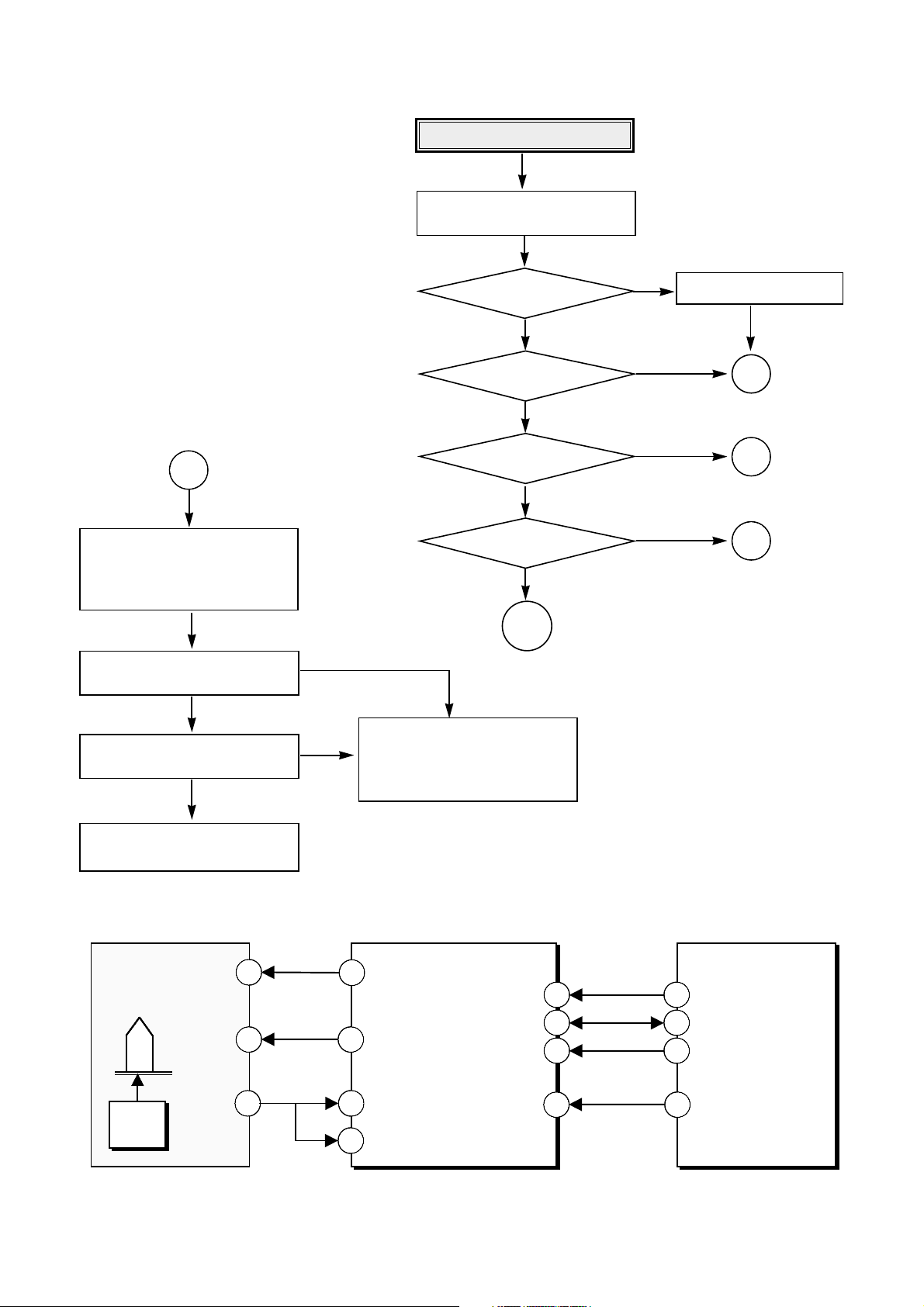

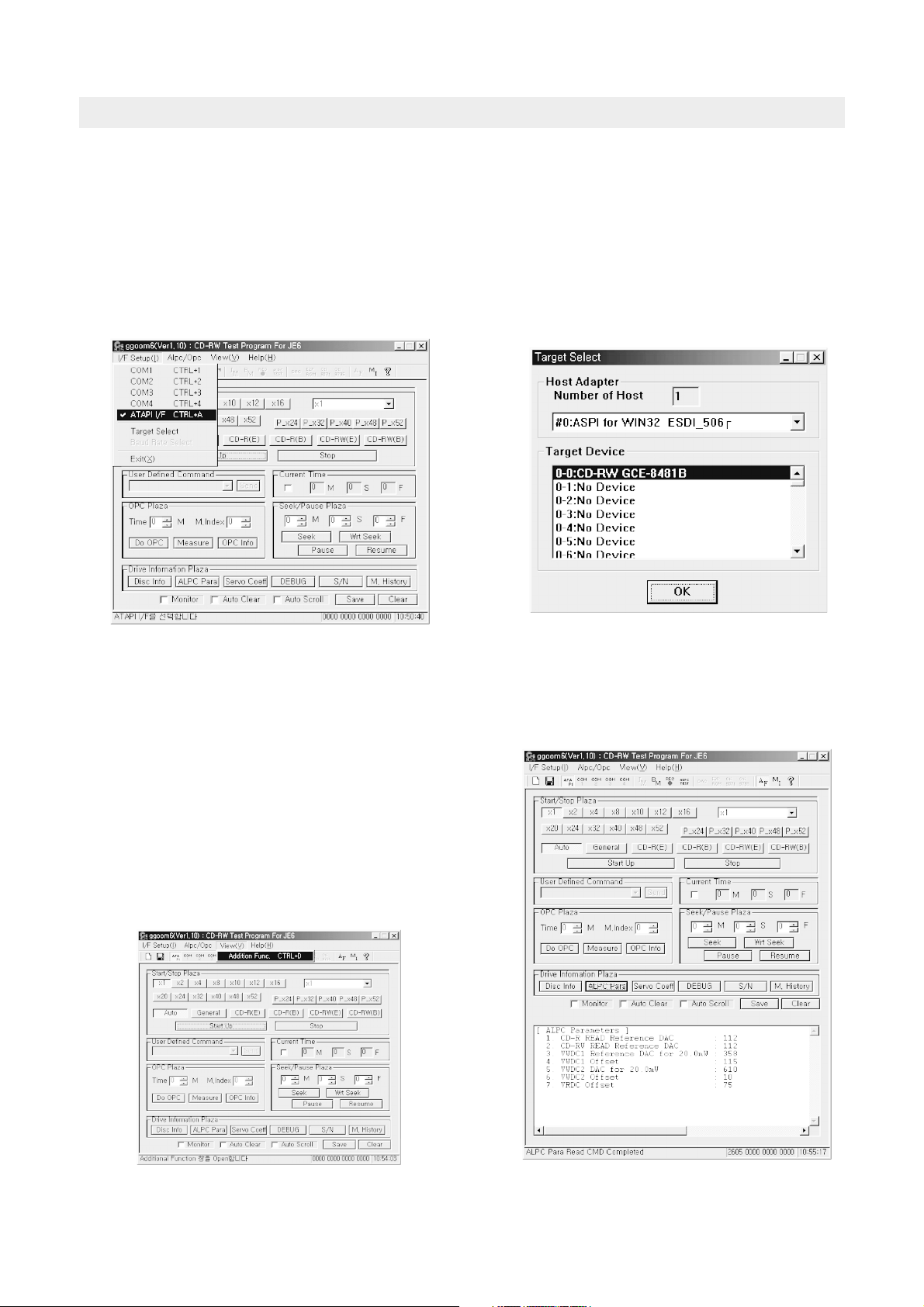

A. Start

1. Install GCE-8481B -> PC Power ON -> Execute Windows.

2. Execute GGOOM6.exe on Windows (GGOOM6.exe & GGOOM6.cfg should be on the same Directory).

3. If you use GCE-8481B, “GGOOM6(Ver x.xx)” will be displayed on the Window Frame.

4. Select I/F Setup on the menu bar.

5. Select ATAPI I/F and then Click OK.

6. Select Target Select on the menu bar.

7. Select Number of Host(#0 or #1) appropriately, then “GCE-8481B” displays on Target Device.

8. Select “GCE-8481B” on Target Device, and then Click OK.

B. Check ALPC Parameters

1. Select VIEW on the menu bar.

2. Click Addition Func. on VIEW window -> New frame will be displayed.

3. Click ALPC Para tab.

[ALPC Parameters]

1) CD-R READ Reference DAC : 60 ~185

2) CD-RW READ Reference DAC : 60 ~185

3) VWDC1 : 200 ~ 296

4) VWDC1 Offset : 30 ~ 175

5) VWDC2 : 499 ~787

6) VWDC2 Offset : -55 ~ 75

4. Close Calibration window.

• How to use Test Tool (GGOOM6)

[I/F Setup Menu]

[Target Select window]

[ALPC Parameters Menu]

[Additional Function Menu]

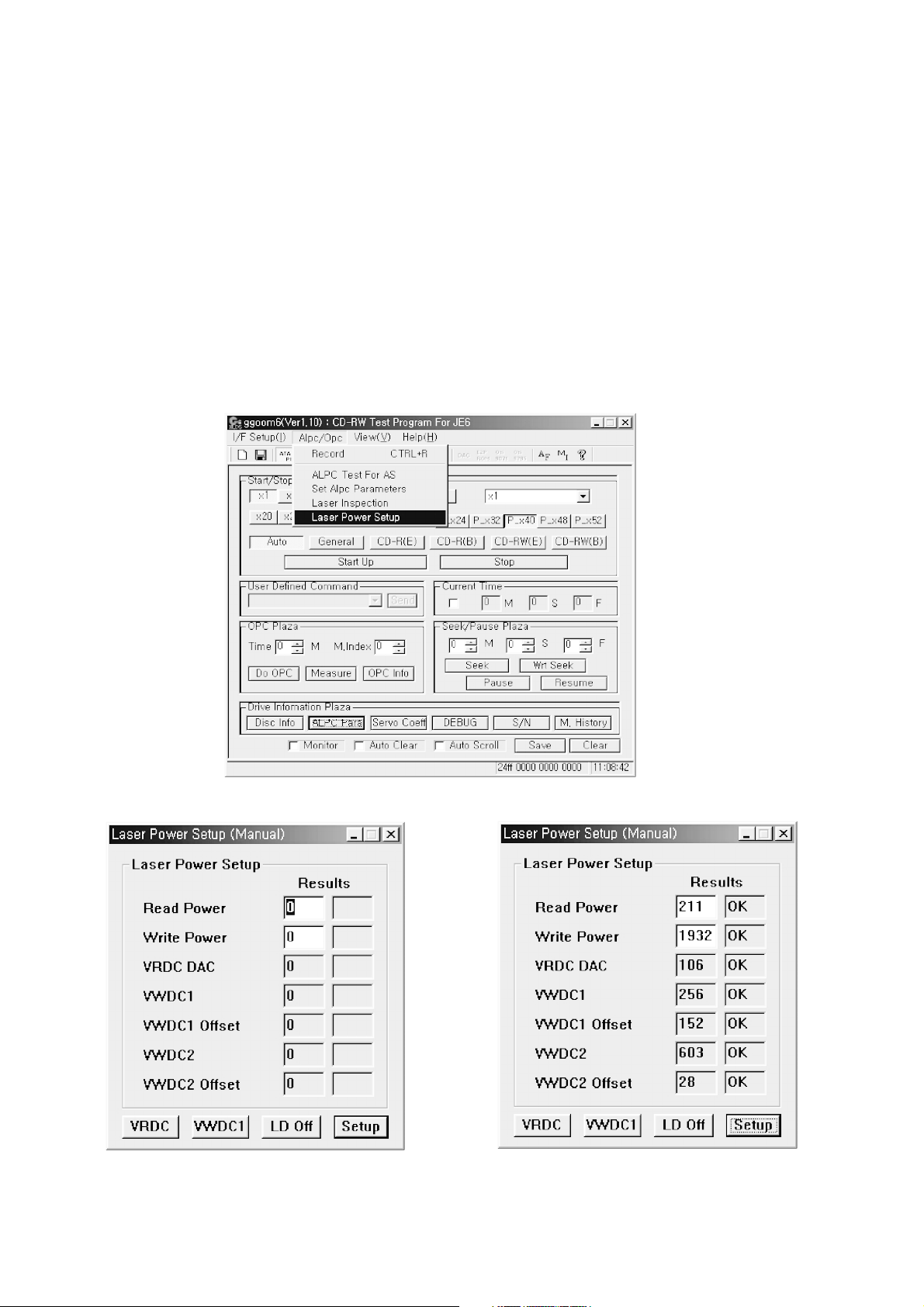

C. Laser Power Setup (VWDC / VWDC 1, 2 re-setup)

1. Remove disc on the tray.

2. Select ALPC/OPC on the menu bar, and then select Laser Power Setup menu.

3. Setup LD Power meter (Frequency :780nm, Measure Range : 0.01mW unit).

4. Click VRDC button on the Laser Power Setup window. Laser beam will be emitted from LD.

5. Measure LD Power with LD Power meter. Type the result in the blank(Read Power box).

[Ex] 2.11mW ->211

6. Click VWDC1 button and follow above step 5. But VWDC1 result should be filled in the Write Power box.

[Ex] 19.32mW ->1932

7. Click Setup button, and result will be displayed with OK or NG.

8. Close Laser Power Setup window.

66

[Laser Power Setup window]

[Laser Power Setup Frame]

[Laser Power Setup Result]

Loading...

Loading...