Page 1

3

INTRODUCTION

FEATURES

1. General

1) Enhanced IDE interface.

2) Internal 5.25 inch, halfheight CD-R/RW Drive.

3) 8 Mbytes buffer memory.

4) Audio CD like tray loading of a disc without using a caddy.

5) Power loading and power ejecting of a disc. The disc can also be ejected manually.

6) Supports Power saving mode and Sleep mode.

7) Vertical and Horizontal operation.

8) ExacLink Function.

2. Supported disc formats

1) Reads and writes data in each CD-ROM, CD-ROMXA, CD-I FMV, Video CD, and CD-EXTRA

2) Reads data in Photo CD (Single and Multi session).

3) Reads and writes standard CD-DA.

4) Reads and writes CD-R discs conforming to “Orange Book Part 2”.

5) Reads and writes CD-RW discs conforming to “Orange Book Parts 3”.

3. Supported write method

1) Disc at once (DAO), Session at once (SAO), Track at once (TAO), Variable packet, Fixed packet, and

Multi-session.

4. Performance

1) Random 110 ms average access time.

2) CD-R Record speed : 8X, 12X, 16X, 16-24X Z CLV.

3) CD-RW Record speed : 2X, 4X, 10X.

4) CD-ROM : Max 6,000 KB/s(Max 40x) Sustained Transfer rate.

5) Supports real time error correction and real time layered error correction at each speed.

6) PIO Mode 4, Multi DMA Mode 2 .

7) Multimedia MPC-3 Spec compliant.

8) Support CD-TEXT read/write.

5. Audio

1) Output 16 bit digital data over ATA interface.

2) 8 Times Digital Filter for CD Audio

3) Software Volume Control

4) Equipped with audio line output and headphone jack for audio CD playback.

5) Front panel Volume Control for Headphone Output.

This service manual provides a variety of service

information.

It contains the mechanical structure of the CDR/RW Drive and the electronic circuits in

schematic form. This CD-R/RW Drive was

manufactured and assembled under our strict

quality control standards and meets or exceeds

industry specifications and standards.

This CD-R/RW drive is an internal drive unit

designed for use with IBM PC, HP Vectra, or

compatible computer. It can write as much as 700

Mbytes of digital data into CD-R/RW disc, and can

read as much as 650 Mbytes of digital data stored

in a CD-ROM, CD-R and CD-RW disc.

This CD-R/RW Drive can easily meet the

upcoming MPC level 3 specification, and its

Enhanced Intelligent Device Electronics (E-IDE)

and ATAPI interface allows Plug and play

integration in the majority of today’s PCs without

the need of an additional interface card.

Page 2

4

SPECIFICATIONS

1. SYSTEM REQUIREMENTS

-CPU: IBM Compatible Pentium 350MHZ (or faster)

(For 24X Write speed, 500MHz or faster recommended.)

-64MB Memory or greater

2. SUPPORTING OPERATING SYSTEM

3. GENERAL

1) Host Interface.......................................................................................................................ATAPI compliant

2) Read Function

• Acceptable discs ...............................................................CD-ROM Mode1 (basic format), CD-ROM XA

CD-Audio

Mixed Mode (Audio and Data Combined)

Photo-CD (Single and Multi-Session)

CD-I FMV, Video CD

CD-Plus/CD-Extra,

CD-R (Conforming to “Orange Book Part2”)

CD-RW (Conforming to “Orange Book Part3”)

3) Write function

• Applied Format..................................................................CD-ROM Mode-1

CD-ROM XA

CD-Audio

Mixed Mode (Audio and Data Combined)

Video CD, CD-I FMV

CD-Plus/CD-Extra

• Writing Method..................................................................Disc at once(DAO)

Session at once(SAO)

Track at once(TAO)

Variable packet writing

Fixed packet writing

Multi-session

4) Cache memory (R/W) .........................................................8 Mbyte

5) Disc diameter ......................................................................12 cm /8 cm

6) Data capacity (Yellow-Book)

• User Data/Block ................................................................2,048 bytes/block (Mode 1 & Mode 2 Form 1)

2,336 bytes/block (Mode 2)

2,328 bytes/block (Mode 2 Form 2)

2,352 bytes/block (CD-DA)

7) Rotational Speed

CD-Audio.............................................................................8x~24x(CAV) Approx.3,600 r/min

DAE speed ..........................................................................18x~40x(CAV) Approx.8,400 r/min

CD-RW data ........................................................................14x~32x(CAV) Approx.6,500 r/min

CD-ROM/CD-R data............................................................18x~40x(CAV) Approx.8,400 r/min

8) MTBF

• 125,000 POH at an operating duty of 10% at room temperature.

• DOS 3.1 or Higher

• Windows 95/98/2000/ME/XP

• OS/2 Warp (Ver 3.0)

• Solaris Ver 2.4 or higher

• Linux Slackware Ver 2.3

• Windows NT 4.0 or later

Page 3

5

4. DRIVE PERFORMANCE

1) Data Transfer Rate

* Sustained Data Transfer Rate ..........................................300 Kbytes/s (2x)

600 Kbytes/s (4x)

1,200 Kbytes/s (8x)

1,800Kbytes/s(12x)

2,400Kbytes/s(16x)

3,600 Kbytes/s(24X)

2,700 to 6,000 Kbytes/s 18 to 40x CAV

* Burst Data Transfer Rate (ATAPI) ....................................16.67 Mbytes/s (PIO Mode 4)

16.67 Mbytes/s (MULTI-DMA Mode 2)

2) Average Access Time

Random Access ..................................................................110 ms Typical (Max.40X) : INCLUDING LATENCY

3) Data Buffer Capacity ...........................................................8 Mbytes

5. POWER REQUIREMENTS

1) Voltage

+5 V DC with +5% tolerance, less than 100 mVp-p Ripple voltage

+12 V DC with +5% tolerance, less than 100 mVp-p Ripple voltage

2) Current

• Hold Track State ...............................................................+5V DC 1.4A, +12V DC 0.5A (Typical)

• Seeking & Spin up ............................................................+5V DC 1.4A, +12V DC 0.9A (Typical)

6. AUDIO PERFORMANCE

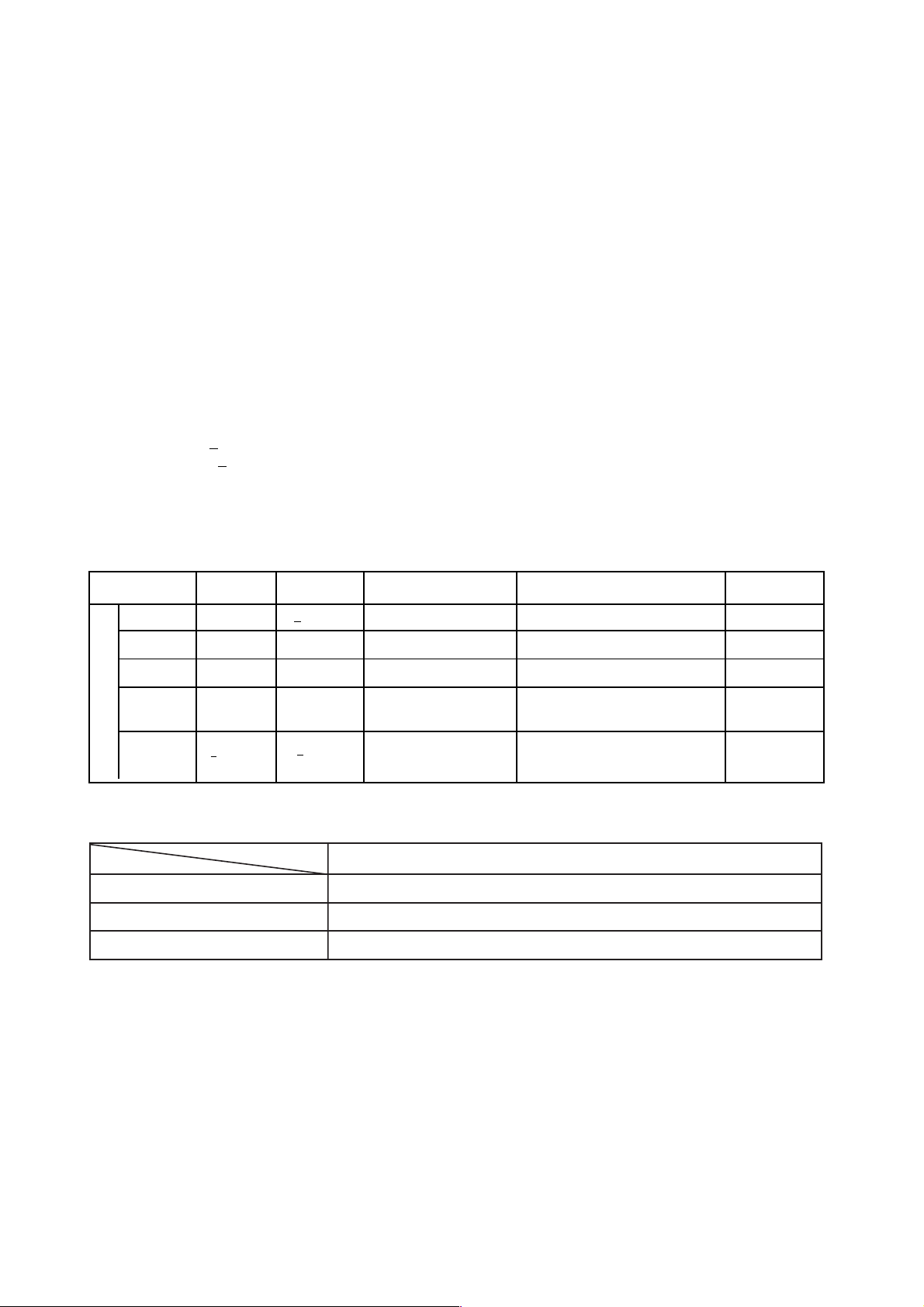

* GCE-8240B FUNCTION TABLE

Item Typical Limit Test Signal Test Condition Note

Output Level

0.7 Vrms

+

10 % 1KHz 0 dB No Filter at 47 kΩ

S/N 85 dB 75 dB 1KHz 0 dB with IHF-A + 20KHz LPF at 47kΩ

THD 0.08 % 0.1 % 1KHz 0 dB with IHF-A + 20KHz LPF at 47kΩ

Channel

65 dB 60 dB 1KHz 0 dB with IHF-A + 20KHz LPF at 47kΩ

Separation

Frequency +

2dB

Response

AUDIO OUT

+

3 dB 20Hz~20KHz 0 dB No Filter at 47 kΩ

Funtion GCE-8240B

• CD-R Writing speed 8x/12x/16x/16x-24x ZCLV Data writing

• CD-RW Writing speed 2x/4x/10x Data writing

• CD-ROM Reading speed 40x Data transfer

MODEL

Page 4

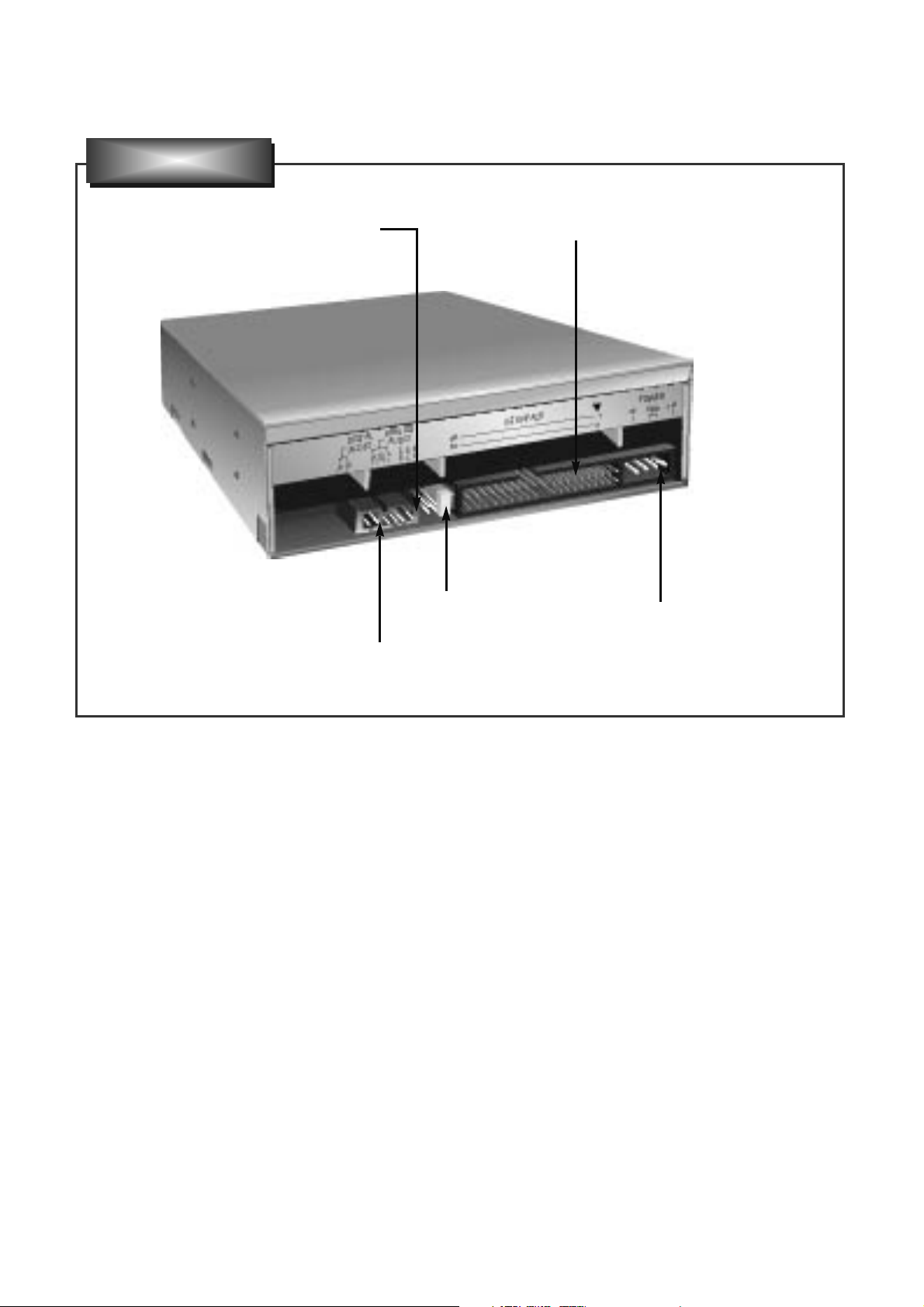

LOCATION OF CUSTOMER CONTROLS

6

1. Disc tray

This is the tray for the disc. Place the disc on the

ejected disc tray, then lightly push the tray (or

push the eject button) and the CD will be loaded.

NOTE: Don’t pull out or push in the disc tray

forcibly. This might cause damage to the loading

section of the drive.

2. Stop/Eject button

This button is pressed to open the CD tray.

This button works only when power is supplied to

the drive.

If an Audio CD is playing, pressing this button will

stop it, and pressing it again will open the tray.

3. Emergency Eject Hole

Insert a paper clip here to eject the Disc tray

manually or when there is no power.

4. Volume control

This is used to adjust the output volume of the

headphone jack. It can’t be used to adjust the

output volume for the audio output connectors on

the rear panel.

NOTE : Turn the volume down before turning on

the power. Sudden loud noises can damage your

hearing.

5. Headphone jack

This jack is for connecting headphones or minispeakers.

6. Drive activity indicators

Two colored LEDs are used to indicate the

operation of CD-R/RW Drive.

(1) Read

The orange color is displayed when the spindle

motor begins the Spin up operation: accessing

data, reading data, playing Audio, and up loading

tray.

(2) Write

The green color is flashed during disc writing

sessions.

READ

READ

WRITE

WRITE

Headphone Jack

Volume

Control

Drive Activity Indicators

Stop/Eject Button

Disc Tray

Emergency Eject Hole

Front Panel

Page 5

7

1. Power Connector

Connects to the power supply (5-and 12-V DC) of

the host computer.

NOTE : Be careful to connect with the proper

polarity. Connecting the wrong way may damage

the system (and is not guaranteed). Usually this

connector can only be attached one-way.

2. IDE Interface Connector

Connect to the IDE (Integrated Device

Electronics) Interface using a 40-pin flat IDE

cable.

NOTE : Do not connect or disconnect the cable

when the power is on, as this could cause a short

circuit and damage the system. Always turn the

power OFF when connecting or disconnecting the

cable.

3. Jumper Connector

This jumper determines whether the drive is

configured as a master or slave. Changing the

master-slave configuration takes effect after

power-on reset.

4. Analog Audio Output Connector

Provides output to a sound card (analog signal).

Generally you need this to play a regular audio

CD.

5. Digital Audio Output Connector

Provides output to a sound card (digital signal).

Digital Audio Output

Connector

Jumper Connector

Analog Audio Output Connector

IDE Interface Connector

Power Connector

Rear Panel

Page 6

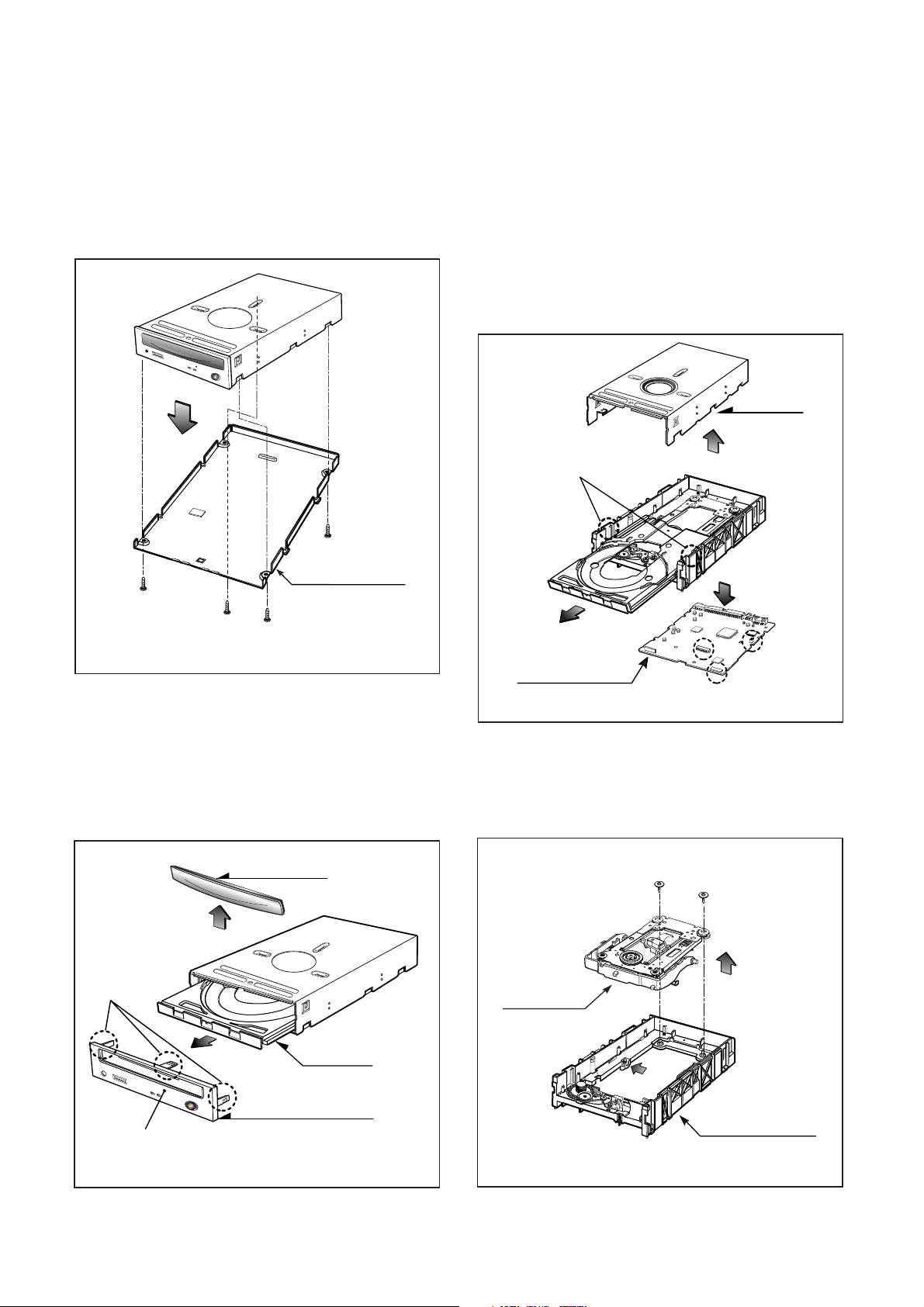

1. CABINET and CIRCUIT BOARD

DISASSEMBLY

1-1. Bottom Chassis

A. Release 4 screws (A) and remove the Bottom Chassis

in the direction of arrow (1). (See Fig.1-1)

1-2. Front Bezel Assy

A. Insert and press a rod in the Emergency Eject

Hole and then the CD Tray will open in the direction

of arrow (2).

B. Remove the Tray Door in the direction of arrow

(3) by pushing the stoppers forward.

C. Release 3 stoppers and remove the Front Bezel Assy.

1-3. Cabinet and Main Circuit Board

A. Remove the Cabinet in the direction of arrow (4).

(See Fig. 1-3)

B. Release 2 hooks (a) and remove the CD Tray

drawing forward.

C. Remove the Main Circuit Board in the direction of

arrow (5).

D. At this time, be careful not to damage the 4

connectors, are positioned at right side, of the Main

Circuit Board.

2. MECHANISM ASSY DISASSEMBLY

2-1. Pick-up Unit

A. Release screws (B).

B. Separate the Pick-up Unit in the direction of arrow (6).

(4)

(5)

Main

Circuit Board

Hooks (a)

Cabinet

(A)

(A)

(A)

(A)

(1)

Bottom Chassis

Fig. 1-1

Fig. 1-2

DISASSEMBLY

8

Fig. 1-3

Mechanism Assy

Pick-up Unit

(B)

(B)

(6)

Fig. 2-1

(3)

Stoppers

Emergency Eject Hole

(2)

Tray Door

Front Bezel Assy

CD Tray

Page 7

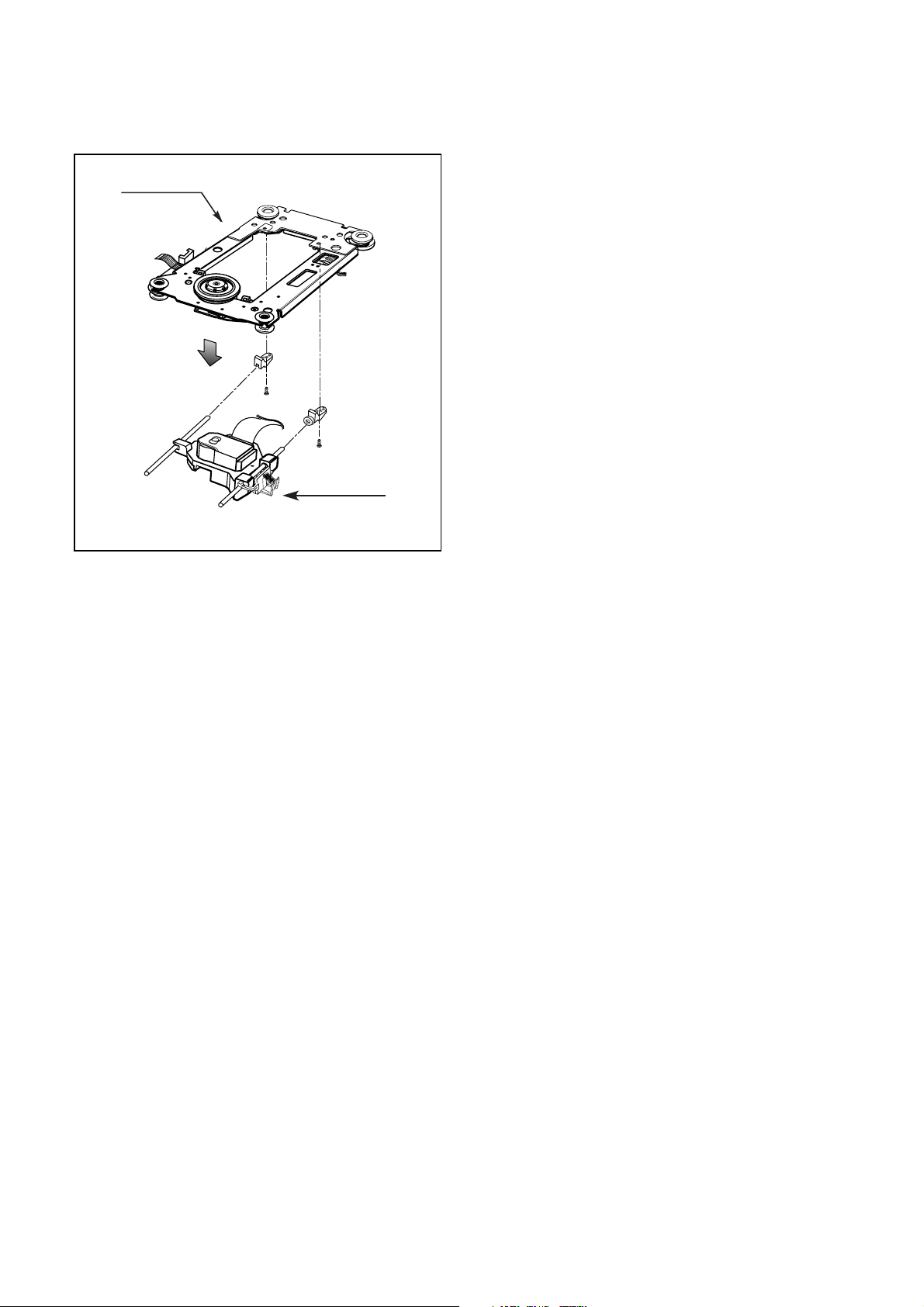

2-2. Pick-up

A. Release 2 screws (C) and remove the Pick-up.

Pick-up Unit

Pick-up

(C)

(C)

Fig. 2-2

9

Page 8

ATIP Absolute Time in Pre-groove. With an additional modulation of the “Wobble”, the “Groove” contains a time

code information.

Wobble The pre-groove in the Disc is not a perfect spiral but is wobbled.

With : – A typical amplitude of 30 nm

– A spatial peried of 54~64 µm

CW Continuous Wave. The laser light output is at a constant level.

DOW Direct Over-Write. The action in which new information is recored over previously recorded information in

CD-RW disc.

Overwrite

The action in which new information is recorded over previously recorded information.

(Pre-)Groove

The guidance track in which clocking and time code information is stored by means of an FM

modulated wobble.

Land Land is characterized in the following way:

When radial signals are concerned,land is defined as the area between the grooves.

When HF signal are concerned,land is defined as the area between the marks(pits) in tangential

direction.

Hybrid Disc A Multisession disc of which the first Session is mastered. On a hybrid disc, recorded and

mastered information may co-exist.

Mastered Information,stored as pits on the disc during the manufacturing process of the disc.

Information (when making the master)

OPC Optimum Power Control. Procedure is determined optimum recording power according to CD-

R/RW Media in recording start step.

ROPC Running OPC. The purpose is to continuously adjust the writing power to the optimum power

that is required.

When the optimum power may change because of changed conditions of disc and change in

operating temperature.

Jitter The 16 value of the time variation between leading and trailing edges of a specific (I3 … I11) pit

or land as measured by Time Interval Analysis.

Deviation The difference between a fixed value of Pit length and Land length.

TOC Table Of Contents : in the Lead-in Area the subcode Q-channel contains information about the

Tracks on the disc.

Packet A method of writing data on a CD in small increments.

Writing Two kinds of packets can be written : Fixed-length and Variable-length.

Write The shape of the HF write signal used to modulate the power of the laser.

Strategy The Write Strategy must be used for recordings necessary for disc measurements.

Information Wobble, ATIP, Disc Identification, Write Power, Speed Range OPC Parameters, etc are

Area recorded in the Information area of CD-RW Disc

Finalization The action in which (partially) unrecorded or logically erased tracks are finished and the Lead-in

and/or Lead-out areas are recorded or overwritten with the appropriate TOC subcode.

Logical Erase

A method to remove information from a disc area by overwriting it with an EFM signal containing

mode 0 subcode

A logically erased area is equivalent to an unrecorded

Physical Erase

The action in which previously recorded information is erased by overwriting with a CW laser

output.

After a Physical Erase action, the erased area on the CD-RW disc is in the unrecorded state

again.

Session

An area on the disc consisting of a Lead-in area, a Program area, a lead-out area.

Multi session

A session that contains or can contain more than one session composed Lead-in and Lead-out

GLOSSARY

14

Page 9

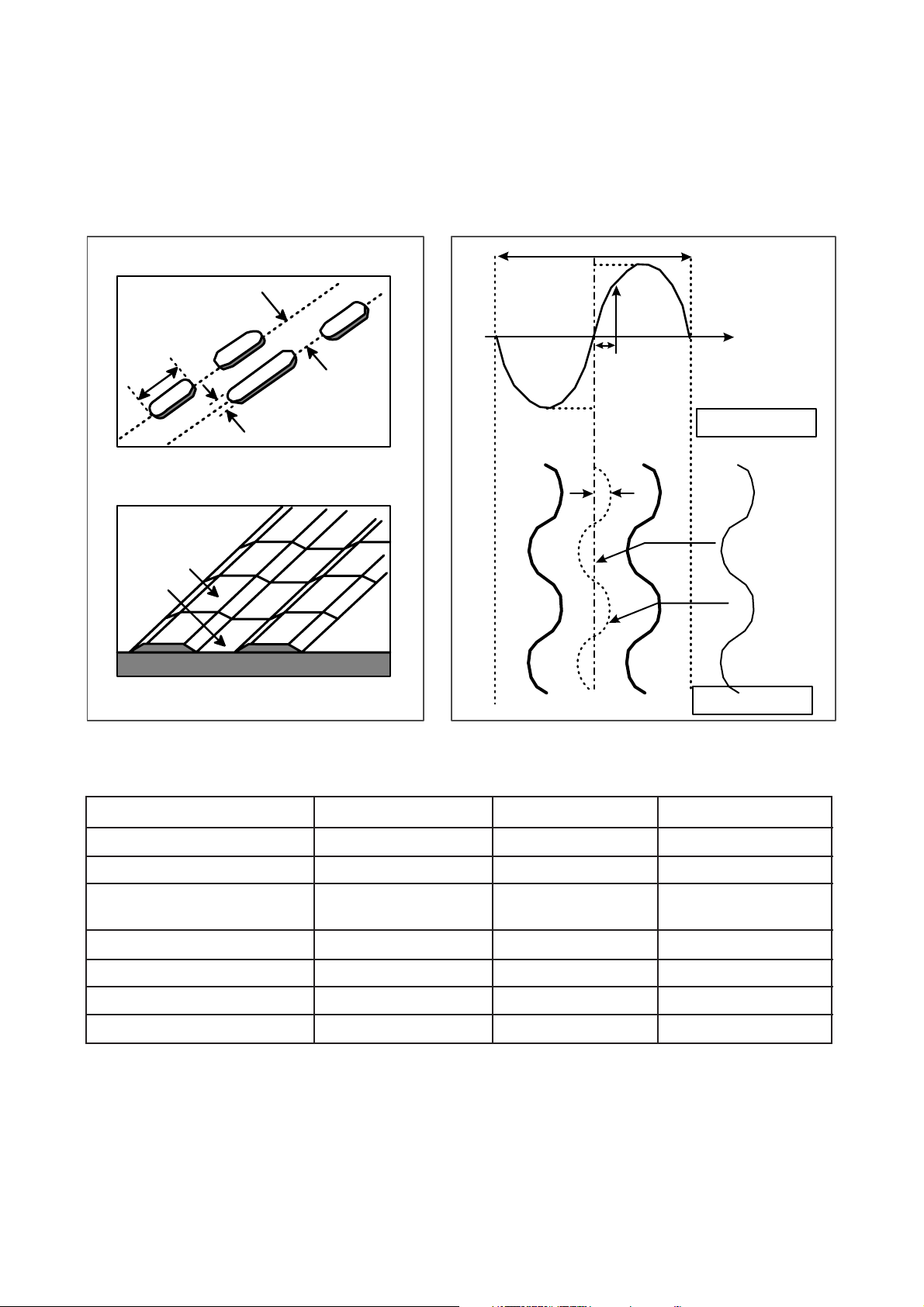

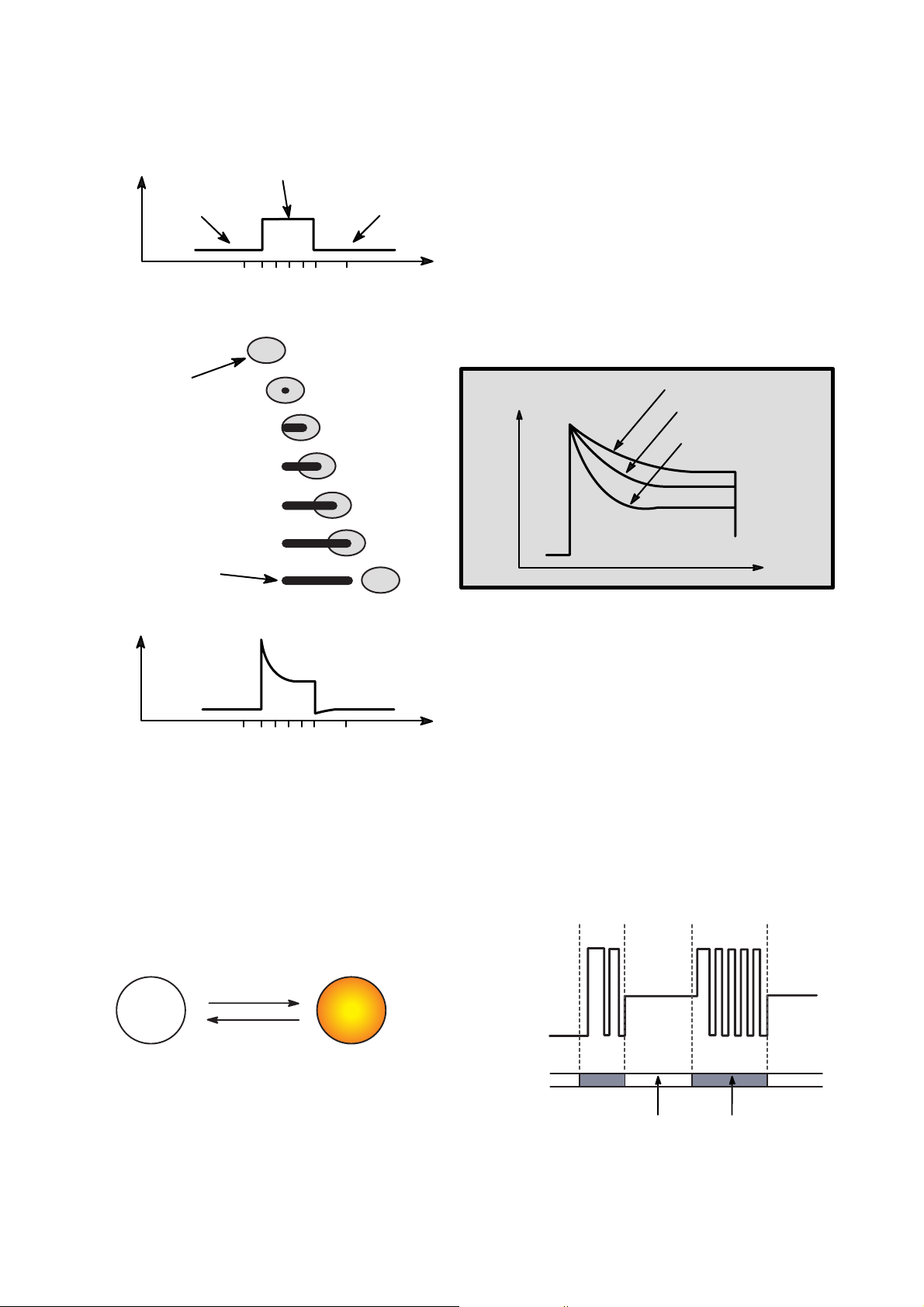

The differences of CD-R/CD-RW discs and General CD-ROM

1. Recording Layer

Recordable CD has a wobbled pre-groove on the surface of disc for laser beam to follow track.

2. Disc Specification

Read-only Disc

CD-R and CD-RW Disc

3~11T

1.6um

0.4~0.5 um

(Pit)Groove

Land

Track pitch(p)

Radial Direction

Iw

A

O

a

a

Groove

Land

Radial Error Signal

The Groove wobble

Average center

Actual center

CD-ROM CD-R CD-RW

Standard Yellow Book Orange Book II Orange Book III

Record Not available Write once Re-writable

I 11/Itop

> 0.6 > 0.6 0.55 > M11> 0.70

(HF Modulation)

Write Laser Power(mW) 10-30 mW 6-25 mW

Read Laser Power(mW) < 0.5 mW < 0.7 mW < 1.0 mW

Jitter < 35 nsec < 35 nsec < 35 nsec

Reflectivity (R

top) 70 % 65 % 15 % ~ 25 %

15

CD-ROM (READ-ONLY DISC)

a=30nm

Page 10

16

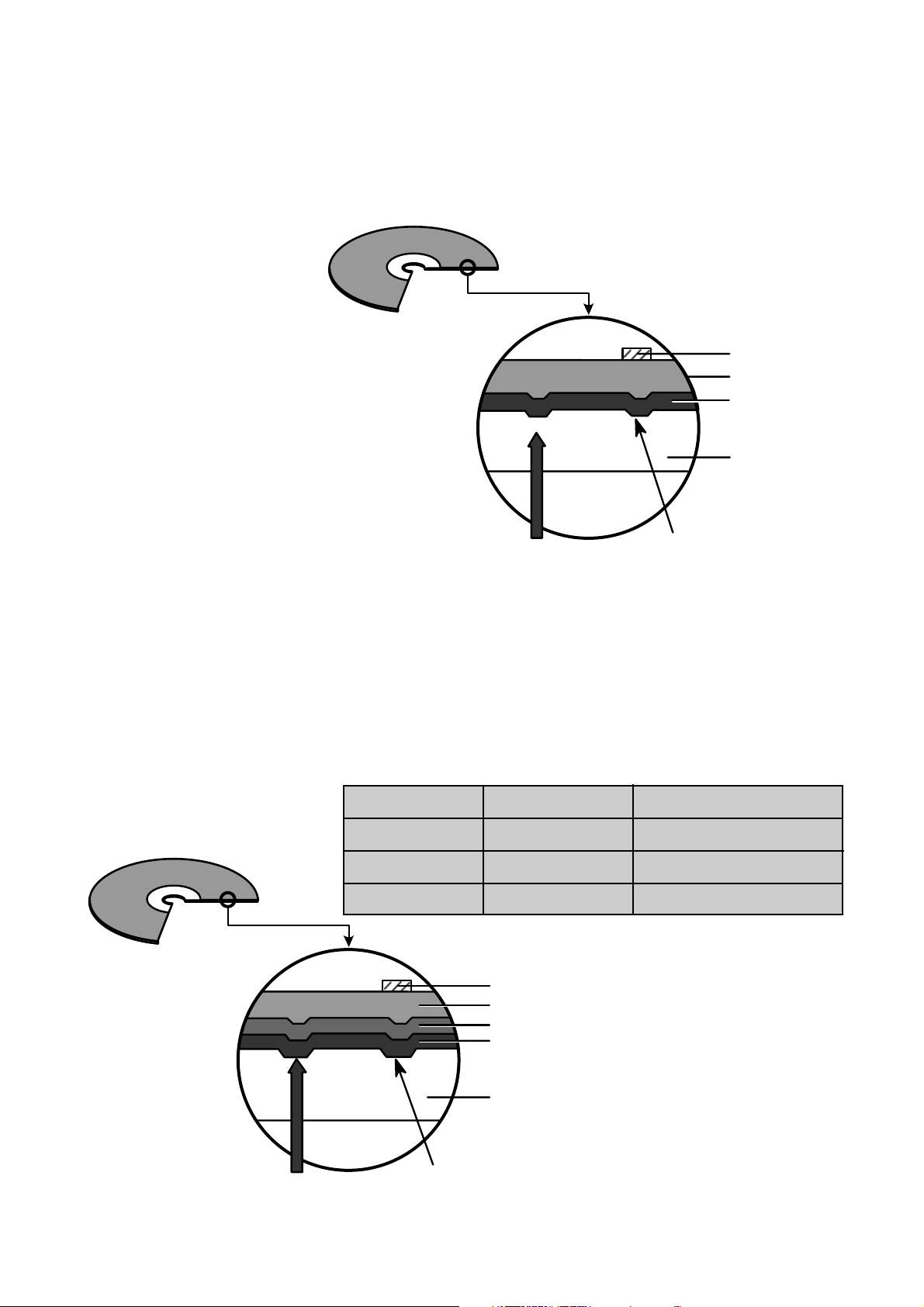

3. Disc Materials

1) CD-ROM disc

Laser Beam

Groove

Substrate

(Polycarbonate)

Organic Dye Layer

Reflective Layer

Protective Layer

Label Printing

2) CD-R disc

Pigment Reflective Layer Color

Phtalocyanine Gold/Silver Yellow/White

Cyanine Gold/Silver Dark Green/Bright Green

Azo Gold/Silver Dark Blue

• It is composed of Silver _ colored aluminum plate and Reflective layer.

• Groove (Pit) of aluminum plate make a track.

• Laser wavelength : 780 nm, Laser Power (Read): 0.5mW

• Signal is detected by the

difference of reflective beam

intensity between “pit” and

“Land” on the disc.

• It is so-called WORM (Write Once Read Many) CD.

• It is composed of polycarbonate layer, Organic dye layer, Reflective layer, and Protective

layer.Gold/Silver Reflective layer is used to enhance the reflectivity

• According to the kinds of Organic dye layer, it is divided by Green CD, Gold CD, Blue CD.

• Laser Wavelength : 780 nm, Laser Power (read) : 1.2 mW

• Recording Power : 8x(9~30mW), 12x(12~38mW), 16x(14~44mW), 24x(18~50mW)

• When some part of dye layer is exposed to laser heat, it’s color changs black.Therefore, writing and

reading is enabled by the difference of reflectivity between changed part and unchanged part.

• Polycarbonate layer has Pre_Groove which make a Track.

Laser Beam

Pit

Substrate

(Polycarbonate)

Reflective Layer

Protective Layer

Label Printing

Page 11

17

3) CD-RW Disc

4.

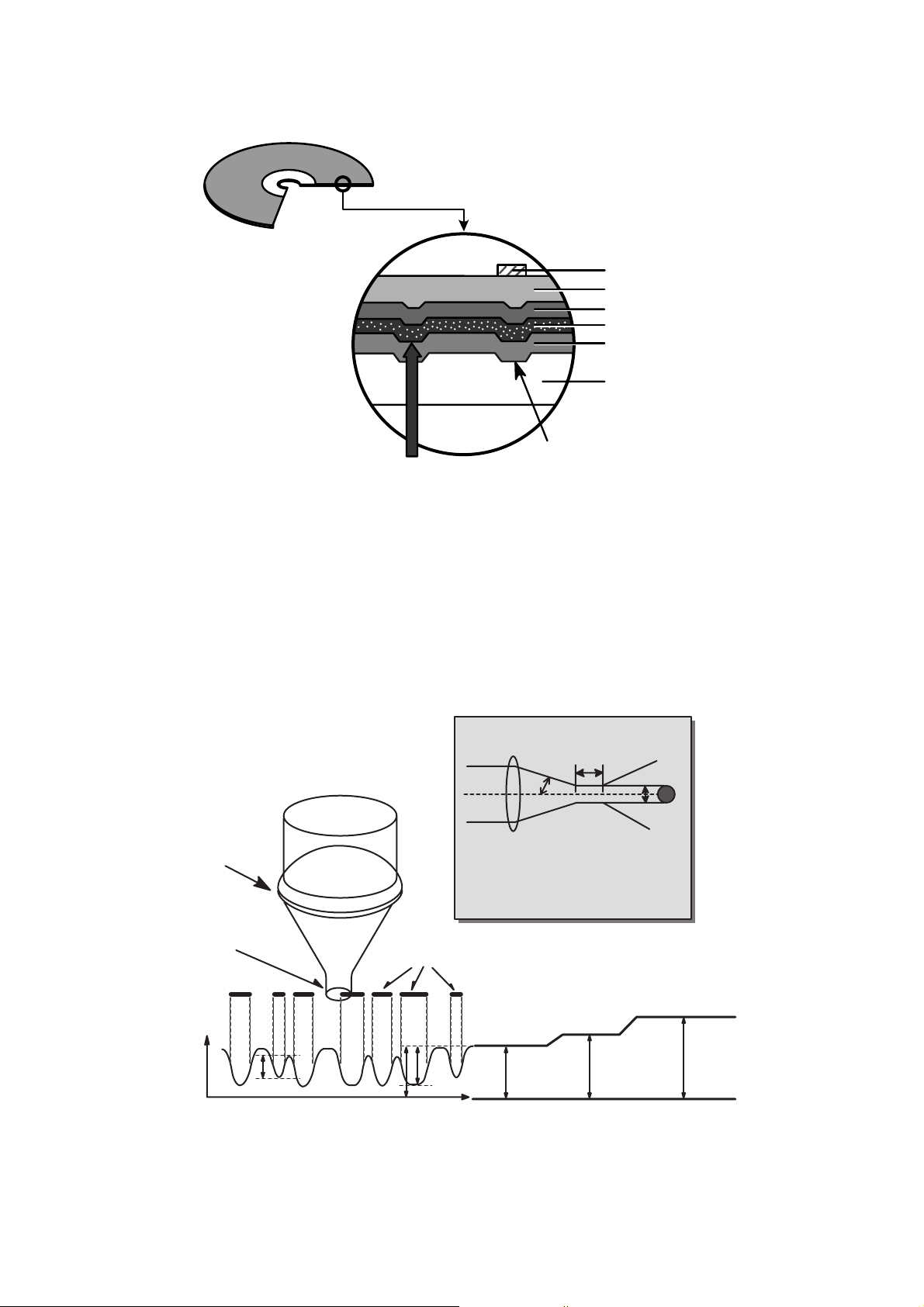

Reading process of Optical Disc

Laser Beam

Groove

Substrate

(Polycarbonate)

Reflective Layer

Dielectric Layer(TL)

Dielectric Layer(UL)

Protective Layer

Label Printing

• It is composed of polycarbonate layer, alloy(silver, arsenic) layer, aluminum reflectivity layer, protective layer.

• An crystalized alloy layer is transformed into noncrystalized by the laser heat. Therefore, writing and reading

is enabled by the difference of reflectivity.

• It is possible to overwrite about 1000 times.

• Laser Wavelength : 780 nm, Laser Power (Read) : 1.0mW

• Recording Power : Erase (4~18mW), Write (15~40mW)

• When disc rewriting, new data is overwritten previously recorded data.

• Polycarbonate layer has a Pre-Groove which make a track.

Lens

H

D

Beam

Spot

Focusing

Lens

Laser Spot

at Constant

Read Intensity

Reflected

Light

Signal

Laser Spot

Position

(Time)

Previously Recorded Marks

Groove Land Mirror

I

3

I

top

I

11

I

G

I

L

I

0

Numerical aperture: NA=nsinθ,

n: Refractive index

Focus depth : H =

λ

/NA

laser spot diameter : D =

λ

/NA

2

θ

Page 12

18

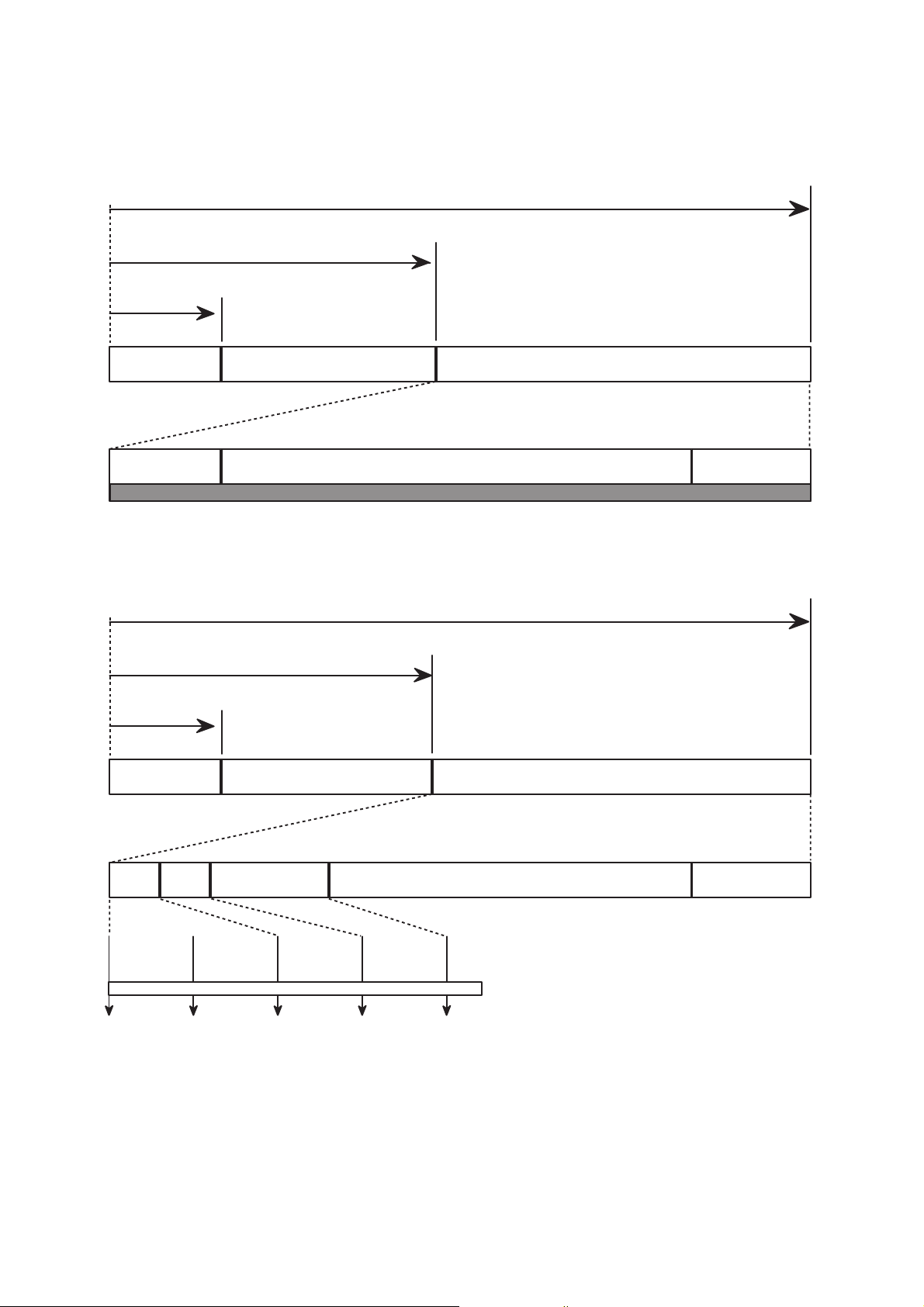

5. Writing Process of CD-R Disc

a b c d e f g

a

b

c

d

e

f

g

Incident

Laser

Powe r

(Read)

(Read)

(Write)

Laser Spot

Position

(Time)

a b c d e f g

Laser Spot

Position

(Time)

Laser

Spot

Recorded

Mark

Reflected

Light

Signal

Reflected

Light

Signal

Below "ORP"– Mark Too Short

At Optimum Record Power ("ORP")

Above "ORP" – Mark Too Long

Time

6. Writing process of CD-RW Disc

Write Power

Erase Power

Read Power

Groove

Crystal

Amorphous

Amorphous

Recorded state

(lower reflectivity)

Melting/

quenching

Heating/

gradual cooling

Crystal phase

Erased state

(higher reflectivity)

Page 13

7. Organization of the PCA, PMA and Lead-in Area

1) Layout of CD-ROM disc

19

Center hole Clamping and Label Area Information Area

Lead-in Area

Lead-in Area

Diameter 15 mm

Diameter 46 mm

Diameter 120 mm

Program Area

Read Only Disc

Lead-out Area

Program Area Lead-out Area

Center hole

Clamping and Label Area

Information Area

PCA PMA

Test Area Count Area

Diameter 15 mm

Diameter 45 mm

Diameter 120 mm

Unrecorded Disc

Tsl-00:35:65 Tsl-00:15:05

Tsl-00:13:25

Tsl

99:59:74

00:00:00

in out

Test Area : for performing OPC procedures.

Count Area : to find the usable area immediately in T.A

Tsl : start time of the Lead-in Area, as encoded in ATIP

PMA : Program Memory Area

Disc Center

Disc Center

2) Layout of CD-R/RW disc

Page 14

20

8. Function of PCA and PMA area

1) PCA (Power Calibration Area)

• PCA area is used to determine the correct Laser Power for a disc.

– Method 1 : PCA area is divided by a track.

– Method 2 : The previous Calibration value is referred.

– Method 3 : ROPC is used to determine Laser Power value automatically in data writing.

• CD-R Disc can write maximum 99 Tracks but CD-RW Disc can write unlimited tracks because it has a rewritable

function.

2) PMA (Program Memory Area)

• It has a track information (track No, track Start/End time) of every track before writing completed.

– PMA area has the last written point and the next writable point of a disc.

– In case of CD to CD copy, some writer may not write PMA area.

* When Disc is Finalized,

PMA information is transferred to the Lead_In area so that general Driver can read it.

* Because PCA and PMA area exist before Lead-In area, General CD Player or CD-ROM Drive can’t read

these areas.

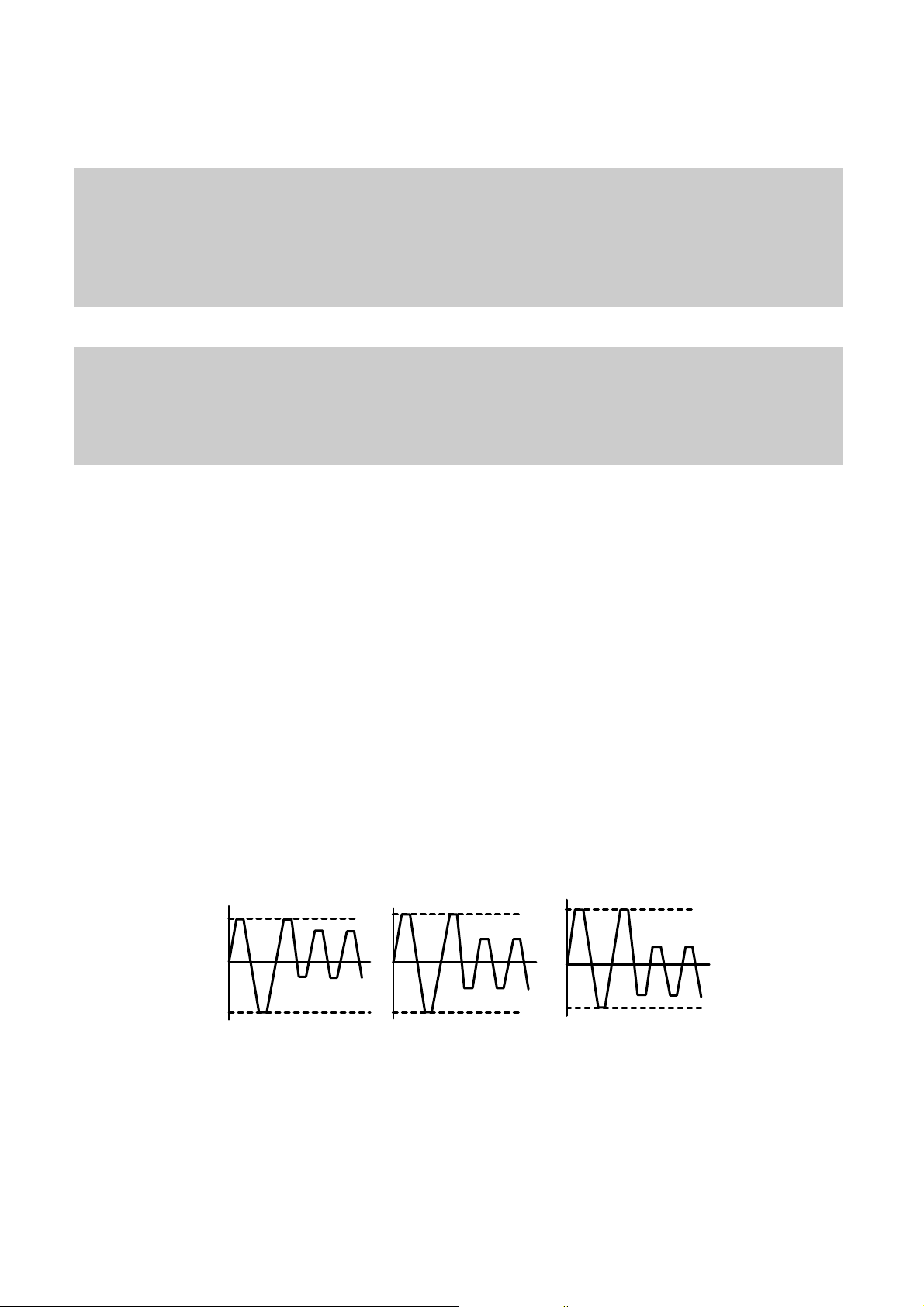

9. OPC and ROPC

1) OPC (Optimum Power Control)

• This is the first step of writing process, because CD writer has its own laser power value and media have different

writing characteristics,

– This is determined by the Writing characteristic, speed, temperature, and humidity.

– Laser wavelength is determined by the environmental temperature (775~795nm) and Optical Laser Power is

determined by the test and retry.

• Asymmetry and optimum writing Power

– EFM signal Asymmetry is determined by the writing power.

Therefore, Optical Power which has the same value to the preset power value can be estimated by measuring

HF signal Asymmetry on the PCA area.

• Measurement of Asymmetry

* Parameter setting (Beta) : Using AC coupled HF signal before equalization

Beta = (A1+A2)/(A1-A2)

Time

P << Po

Time

P = Po

HF Signal

A1

0

A2

Time

P >> Po

Page 15

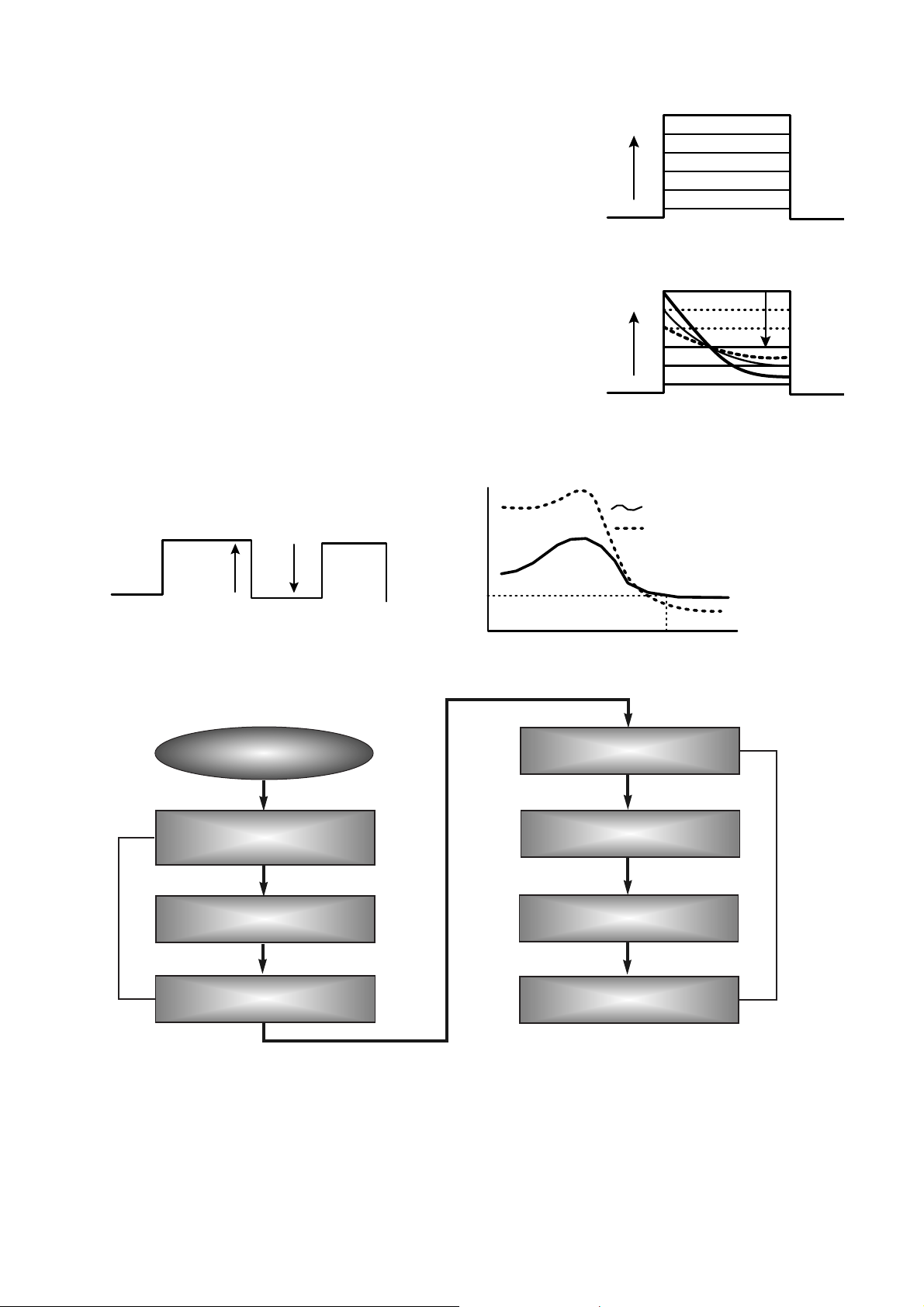

2) ROPC (Running Optimum Power Control)

• Variable primary factor of Optimum Power

– Change of Power sensitivity on the Disc. (limited to 0.05 *Po)

– Wavelength shift of the laser diode due to the operating temperature change.

– Change of the Spot aberration due to the Disc skew,

Substrate thickness, Defocus.

– Change of Disc or Optics conditions due to the long term OPC

==> It is necessary to adjust continuously to obtain the Optimum Power.

• Principle of Running OPC

– To meet the factors mentioned above,

a horizontal _ direction movement of a curve is uesd.

– Beta = f(B-level) = constant on the Recorded Disc

– Procedure of ROPC

a. Reference B-level is determined during OPC Procedure.

b. During Recording, B-level value is controlled to have a close

Reference B-level value.

c. Normalization of B-level is used to eliminate the effect of reflectivity fluctuation.

==> The reflected B-level value is normalized by the disc reflectivity itself.

21

CD-R/RW Media

Write Strategy

Determination

PCA Test Area

Program Area

PMA Area

Lead-In Area

Lead-out Area

OPC

PCA Count Area

ROPC

* Recording Capacity of CD-R/RW (74Minute Recording media)

• (2048 Byte/Sector) X (75 Sector/Second) X (60 Second/Minute) X 74 Minute

= 681,984,000 Bytes = 682 Mbytes

• But the actual recording capacity is about 650 Mbytes. (according to the ISO 9660 standard, approximately

30 Mbytes are used to make directory structure and volume names.)

Incident recording pulse

Reflected recording pulse

Sampled timing B

11T

Sample B-level (Write Power)

Level B

Sampled at timing B

Pwo decided by OPC

Recording Power

Level B with Pwo

normalized to recording power

Sample Disc Reflectivity

(Read power)

10. Writing Process of DISC

Page 16

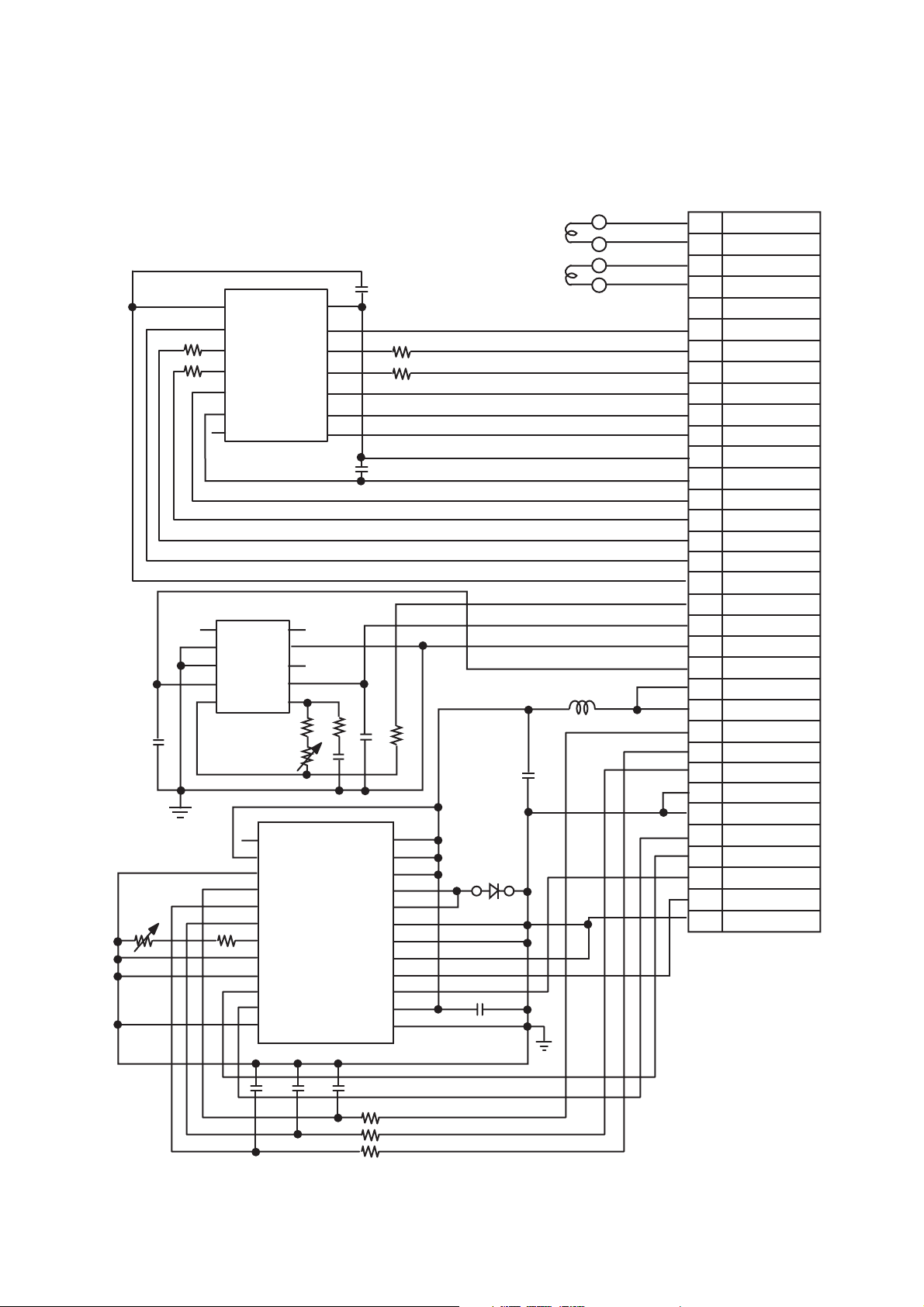

INTERNAL STRUCTURE OF THE PICK-UP

1. KRS-310B Circuit Diagram

22

1

2

3

4

5

6

7

1

2

3

4

5

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

14

13

12

11

10

9

8

10

9

8

7

6

R3

VR1

VR2

R2

C5

C3

C6

LD

A

11

C

C4

R4

R1

L1

R6

R7

C7

R8

C10 C9 C8

Vcc

2 Axis Actuator

IC1

PDIC

IC2 FPDIC

C1

R9

R11

R12

R10

C2

GND

G

D

C

E

RF

SW

GND

H

A

B

F

Vc

NC

GND

GNDGND

VccVc

BinOUT

PDIN

VOUT

VCC

VREF

VCC

GND

IOUT

IINR

IOUT

IIN2

GND

IIN3

GND

RFREQ

RAMP

GND

ENABLE

GND

OSCEN

WEN3

VCC

WEN2

GND

GND

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

6

5

4

3

2

1

FCS +

FCS -

TRK +

TRK -

G

D

C

E

RF SUM

SW

PDGND

PDVC

F

B

A

H

PDVCC

FPDO

FPDVCC

FPDGND

FPDVC

LDVCC

LDVCC

VRDC

VWDC1

VWDC2

LDGND

LDGND

WE1

WE2

OSCEN

33

34

ENBL

MODAMP

IC3

LD

Driver

Page 17

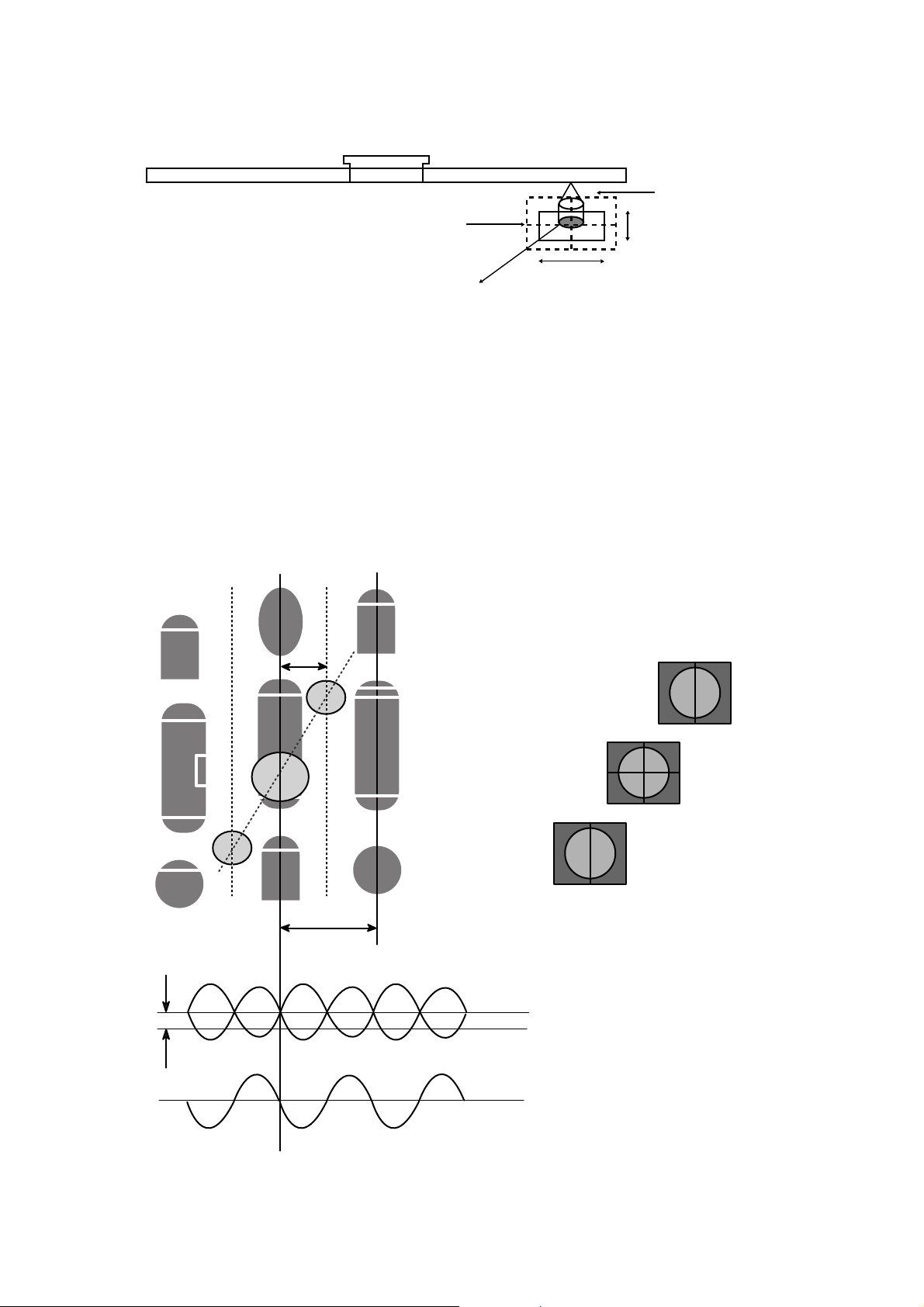

2. Signal detection of the P/U

1) Focus Error Signal ==> (A+C)-(B+D)

This signal is generated in RF IC (IC401 : CXA2638R) and controls the pick-up’s up and down to focus on

Disc.

2) Tracking Error Signal (DPP Method) ==> {(A+D)-(B+C)}- kx {(F+H)-(E+G)}

This signal is generated in RF IC (IC401 : CXA2638R) and controls the pick-up’s left and right shift to find

to track on Disc.

3) RF Signal ==> (A+B+C+D)

This signal is converted to DATA signal in DSP IC (IC201 : OTI-9797).

23

Pick-Up module

Photo Diode

Tracking

Focusing

Infrared Iaser

k[(F+H) - (E+G)]

(A+D) - (B+C)

(A+D) - (B+C) - k[(F+H) - (E+G)]

Offset

TE

Tp

Sub2

Main

Tp/2

Sub1

Track Center

F, E

D,C

A,B

H,G

Page 18

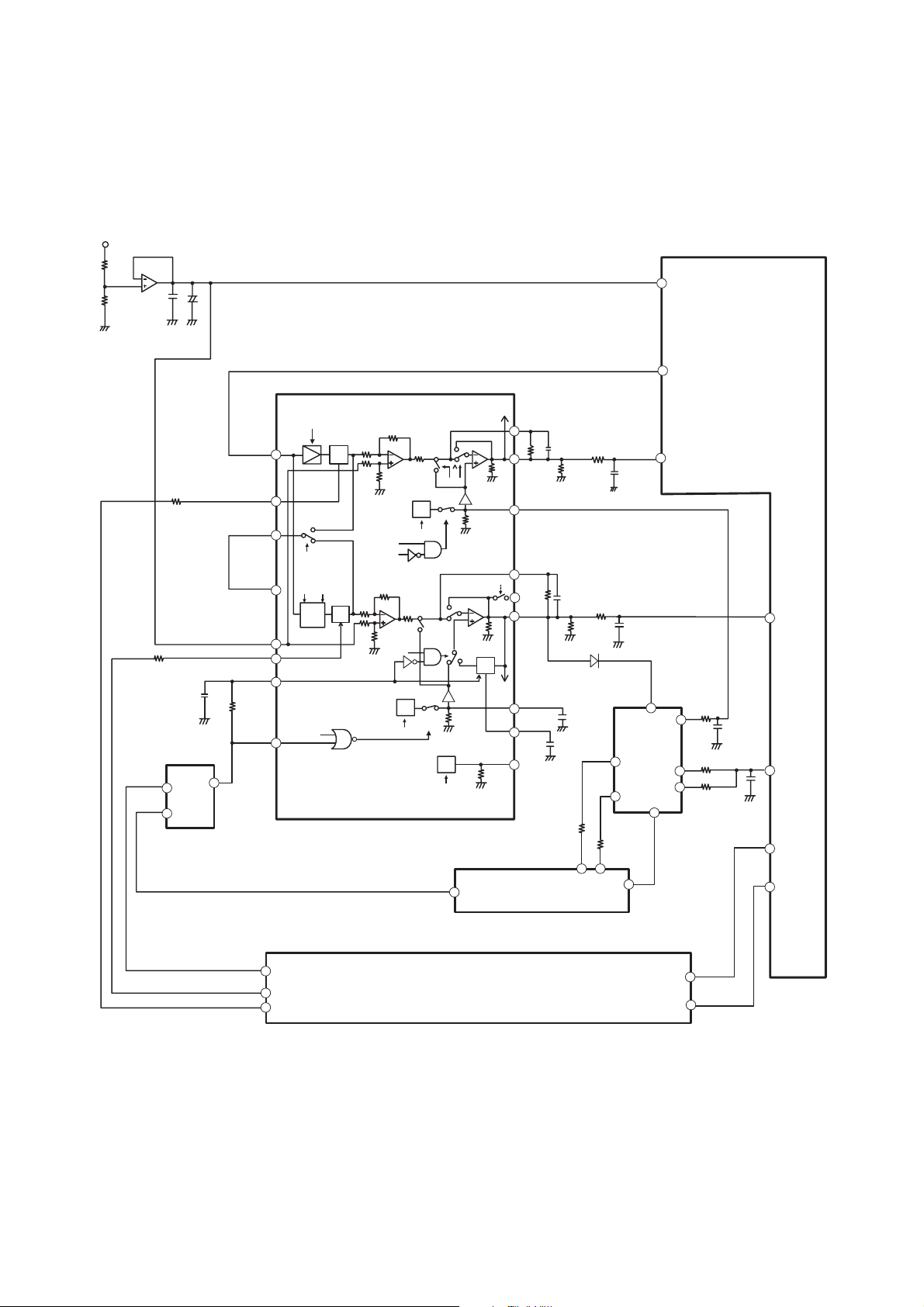

DESCRIPTION OF CIRCUIT

1. ALPC (Automatic Laser Power Control) Circuit

1-1. ALPC Loop Circuit

24

RFPDG

FPDO

AUX

FVREF

WFPDSH

HOLDSW

WLDON

WR/RE

WGATE

WR/RE

WGATE

EFM1

EFM2

R321

C4

R322

R427

R426

C454

C443

R447

D401

GND

R19

VWDC

WREF

HOLDTC

ODREF

APCCSW

R18

R408

C432

VWDCN

APCCSW

WREFSE

S3.

B

B

R14

25.8K

R15

25.8K

GND

GND

A

A

R12

R10

5K

R6

20K

R3

R4

20K

20K

R8

20K

10K

GND

GND

C3

SCLK

DACS

WREFSE

C445

R252

R247

R429

SHOUT

RFPDSH

20dB/26dB

3.3V

R422

R423

IC403

IC205

IC301 MICOM

IC201

OTI-9797

C456

C455

MPXOUT

(testmode)

MPXOUT

(testmode)

VRDCN

VRDC

VRDC

R16

R17

R410

C433

R11

10K

GND

GND

RREFSE

R9

5K

R1

20K

R2

20K

A:OFF

B:ON

A:OFF

L:B.HOLD

H:A.SAMPLE

B:ON

RREF

WREF

ODREF

SHOUT

WRITEG WFPDG

DAC

DAC

DAC

GNDTyp.

10mV/step

sbit

GND

GND

Typ.

10mV/step

8 bit

Typ.

10mV/step

7 bit

H:RREF

R13

R5

R7

20K

(Read)

(Write)

20K

25.8K

GND

L:OPEN

H:OPEN

L:WREF

RLDON

ERCNT

8

GND

C1

96

94

97

98

25

19

22

100

32

99

62

1

31

45

48

3

5

6

7

166

188

180

183

184

60

6564

24

92

90

91

17

16

15

5

4

18

13

95

PN401

P/U

TC7W08FV

IC401 CXA2638R

FPDVC

FPDO

VRDC

26

VWDC

27

VWDC2

30

WE1

31

WE2

x1

S/H

S/H

Gain

adj.

IC402

DAC

x1

S/H

Page 19

1-2. ALPC(Automatic Laser Power Control) Circuit Operation

This circuit consists of Feedback Loop to maintain light output of the Laser Diode(FPDO).

Feedback signal, output voltage from PD(Photo Detector) of P/U, is used monitor the light power of

Laser Diode.

1) Read Loop

RREF(Read Reference Voltage) of IC401(CXA2638R) Pin 96, which is from DAC(IC403) Pin 18, is the

reference level of the Read Loop part of this ALPC Circuit.

• When Playback

VRDC(Pin 97) signal of IC401(CXA2638R) is output to P/U through Gain Control S/W and drives

Laser Diode during play back.

This S/W Ciruit is designed to reduce transition time from CD-RW writing mode to playback mode.

• When writing mode

- CD-R

Three Laser Power Levels, Read, Write, and Overwrite, are used to write on CD-R disc, and Read

Level is used to monitor the output laser power.

For stabilizing read loop, the S/H signal(RFPDSH), which sample and hold the Read Level of laser

power in the CD-R writing mode, is input through Pin 32 of IC401(CXA2638R).

- CD-RW

Three Laser Power Levels, Read, Erase and Write, are used to write on CD-RW disc, and Erase

Level is used, during CD-RW writing, to monitor output laser power.

It is not VRDC but VWDC that is the output signal of the control loop performed by Erase level.

2) Write Loop

For stabilizing write Loop, the S/H signal(WFPDSH), which sample and hold the Erase Level of laser

power in the CD-RW writing mode, is input through Pin 31 of IC401(CXA2638R).

Output voltage of Write Loop, VWDC(Pin 93 of IC401(CXA2638R)), is protected by the high limit diode

applied to P/U.

25

Page 20

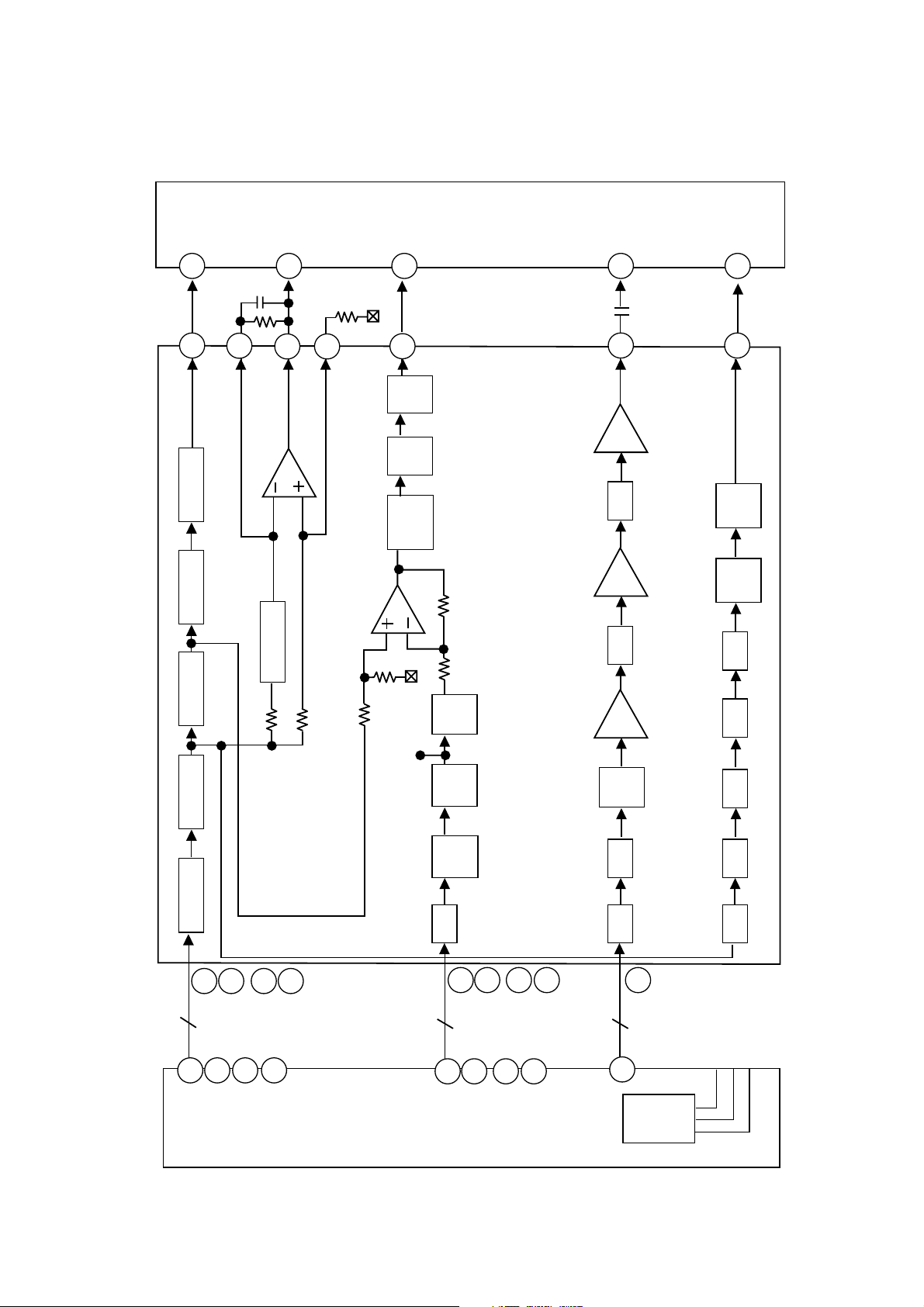

2. RF Amplifier Circuit

Block Diagram

26

FE

FE

A,B,C,D

E,F,G,H

RFSUM

PDIC

VC

GND

Vcc

CXA2638R (IC401)

IC201

OTI9797

Pick up

KRS-310B

Gain Amp

16

15

8

7

9

14

6

17

10

7

59 197

8

9

10

87

2

3

4

5

Offset adj

R1

R2

R3

R4

R6R5

R403

C417

R404

Vref

Main S/H Gain adj Offset adj

CEM

CEO

CEP

TE

CE

198

204

TE

58

EQRFP

C223

EFM

163

ATFG

WOBBLE

132

Limit

Gain

Amp.

Side

S/H

SPPO

4((F+H)-(E+G))

MPP 2(A+D)-(B+C))

DVC

Gain

adj

Gain

adj

Offset

adj

LPF

(40KHz)

Gain

adj

offset

adj

Limit

GCA HPF

HPF AGC BPF AGC

Slice

circuit

HPF

EQ HPF

636567

x0.25 x5 x3.2

71

38

Page 21

3. Focus/Tracking/Sled Servo Circuit

3-1. Focus, Tracking & Sled Servo Process

27

Focus, Tracking Servo

C

B

D

A

E

F

G

H

Pick- up

A,B,C,D,E,F,G,H

A,B,C,D

Focus Error

Detector

Detector

Track Error

A,B,C,D

E,F,G,H

IC401 CXA2638R

FE

TE

TE FE

A/D

Low freq Gain Filter

Ditital EQ

DAC

Sled Control

Signal

A/D

IC201

Servo Control

OTI9797

LEVEL SHIFT

LEVEL SHIFT

Tracking Focusing

Actuator

FAO

TAO

SLO

F+

F-

T+

T-

Sled Control

M

SLED MOTOR

LEVEL SHIFT

SM_A-

IC501

BD7902C

SM_A+

SM_B+

SM_B-

IC501 BD7902C

IC402

BU2500FV

(DAC)

Page 22

3-2. Focus Servo

The aim of Focus Servo is to maintain the distance between object lens of P/U and disc surface, so that

the detected RF signals (A, B, C, D) can be maximized.

Focus Servo is based on focus error (FE) signal which is generated from focus error detection block in

CXA2638R(IC401) using Astigmatism Method. Focus gain and path can be changed at the CXA2638R

according to the disc, and the resulting output (FE) is input to Servo IC (IC201, OTI9797).

FE signal after first amplification in OTI9797 is A/D converted and input to Digital Equalizer Block, most

important part at the Focus Servo. At the Digital Equalizer, adjustments for Focus Bias and Loop Gain are

performed.

After D/A converted, Focus servo signal is output through FOO port (OTI9797, Pin207) and drive Focus

Actuator through the Focus Drive IC (IC501, BD7902C).

3-3. Tracking Servo

The aim of Tracking Servo is to make laser beam trace the data track on disc. Tracking Error (TE) signal

is generated from tracking error detection block in CXA2638R (IC401) using DPP (Differential Push-Pull)

Method. DPP method uses not only main beam (A, B, C, D) but side beams (E,F and G, H) for correcting

DC offset generated in Push-Pull method.

The remaining procedures of TE signal processing in CXA2638R is similar to Focus Servo.

After D/A converted, Tracking servo signal is output through TRO port (OTI9797, Pin208) and drive

Tracking Actuator through the Tracking Drive IC (IC501, BD7902C).

3-4. Sled Servo

The working distance of tracking actuator is too short to cover whole disc radius. Sled Servo make PU

move by little and little so that the laser beam keep tracing the data track on disc continuously when

tracking actuator reaches the working limit.

Another function of Sled Servo is to seek a target point on disc, following user commands.

Sled control signal, STEP-CTRL0,1 from BU2500FV is generated in µ-com, STEP-CTRL0,1 are output to

sled motor via IC501(BD7902C).

28

Page 23

4. Spindle Servo Circuit

4-1. Spindle Servo Process

4-2. Spindle Servo

Spindle servo is as followings;

1) Wobble CLV x2, x4, x8, x10, x12, x16, 24x : Blank area in CD-R, CD-RW.

2) CD 8x-20x CAV: Eccentric CD-R/RW.

3) CD 14x-30x CAV: Video CD, CD-DA in CD-ROM/R

4) CD 32x CAV: Recorded area in CD-RW.

5) CD 40x CAV: CD-ROM. Recorded area in CD-R.

– Spindle Servo is controlled by IC401 (CXA2638R), IC201(OTI9797) and servo signal is output via

DMO ( pin2, OTI-9797).

29

Pick- up

IC401 CXA2638R

Wobble Signal

Generator

RF

SRF

EQRFP

ATFG

Decode PLL

Frequency

Controller

CD-DSP/SERVO

LOCK

DEFS

MOTOR SPEED

CONTROLLER

FILTER

TON

DMO

ATIP CLV, FG

Level Shif t

Hall Sensor

M

Spindle Motor

IC 301

u-COM

MUTE

SPNFG

IC201 OTI9797

CD EFM CL V

CAV x32

6

8

E

CB

DA

F

G

H

IC501 BD7902C

Page 24

MAJOR IC INTERNAL BLOCK DIAGRAM AND PIN DESCRIPTION

IC401 (CXA2638R) : CD-R/RW Analog Signal Processor

Block Diagram

30

RFEQ

PH/BH

CE

RFRP

REGISTER

ATIP

S/H MATRIX

BIAS

APC

VC

MPX

SPP

SADBC

EFGH

FEO

SPPO

ADO

BCO

RFO

SADO

SBCO

FE TE

BETA

RECD

96

RREF

97

VRDC

98

VRDCN

99

SHOUT

100

FPDO

95

APCCSW

94

VWDCN

93

VWDC

92

WREF

91

ODREF

90

HOLDTC

89

VTIREF

88

GND

87

RFIN

86

Vcc

85

RRF

84

RRFIN

83

BHC2

82

PHC2

81

BHO2

80

PHO2

79

BETAOUT

78

BHC3

77

BHC1

76

75

PHC1

BHO174PHO173RECD1C72EQRFN71EQRFP70SRFO69RFRP68RFCT67CEP66GND65CEM64Vcc63CEO62AUX61MPXOUT60MPP59FE58TE57TEIN56TOK1C55TOK2C54RFCTC153RFCTC252XTOK

51

50

XTOR

XTAND

49

CS

48

WLDON

47

TFGCNT

46

AGCON

45

HOLDSW

44

ERGCNT

43

SCLK

42

SDATA

41

XLAT

40

Vcc

39

DVcc

38

ATFG

37

RECD

36

GND

35

ROPCSH

34

M/SPDSH

33

WBLSH

32

RFPDSH

31

WFPDSH

30

DSPVcc

29

VC

28

DVC

27

HDVC

26

25

VCT1

VCT2

24

CAVC3

23

CAVC2

22

CAVC1

21

CAV_CNT

20

ATFM

19

AGC3C

18

AGC3C

17

AGC1C

16

BGIREF

15

SBADO

14

Vcc

13

WRF

12

GND

11

SWRF

10

HIN

9

GIN

8

FIN

7

EIN

6

HAVC

5

DIN

4

CIN

3

BIN

2

AIN

1

FVREF

Page 25

31

• Pin Assignment

Pin no Symbol I/O Description

1 FVREF I Reference voltage of APC input signal

2 AIN I Input of Main beam signal(A)

3 BIN I Input of Main beam signal(B)

4 CIN I Input of Main beam signal(C)

5 DIN I Input of Main beam signal(D)

6 HAVC I Reference Voltage of Main and Side beams

7 EIN I Input of Side beam signal (E)

8 FIN I Input of Side beam signal (F)

9 GIN I Input of Side beam signal (G)

10 HIN I Input of Side beam signal (H)

11 SWRF O Output of Write RF sample signal

12, 36, 66, 88 GND * Ground

13 WRF O Output of Write RF signal

14, 40, 64, 86 VCC * Analog Power

15 SBADO O Output of SRFO and EFGH Balance signal

16 BGIREF * Reference Voltage of Resister

17 AGC1C * External Capacitor connection for AGC1 Detection Time Constant

18 AGC2C * External Capacitor connection for AGC2 Detection Time Constant

19 AGC3C * External Capacitor connection for AGC3 Detection Time Constant

20 ATFM O Output of Wobble signal

21 CAV_CNT I Input of BPF control voltage for CAV mode

22 CAVC1 * External Capacitor connection for Peak Hold Detection Time Constant

23 CAVC2 * External Capacitor connection for Peak Hold Detection Time Constant

24 CAVC3 * External Capacitor connection for BPF control voltage smoothing

25 VCT2 * Decoupling of VC

26 VCT1 * Decoupling of DVC

27 HDVC O Output of DVC/2 Voltage

28 DVC O Output of DSPVCC/2 Voltage

29 VC O Output of VCC/2 Voltage

30 DSPVCC * DSP Power

31 WFPDSH I Sample Pulse for Write APC Mode (H: Sample, L: Hold)

32 RFPDSH I Sample Pulse for Read APC Mode (H: Sample, L: Hold)

33 WBLSH I Sample Pulse for Wobble signal (H: Sample, L: Hold)

34 M/SPDSH I Sample Pulse for Main and Side Beams signal (H: Sample, L: Hold)

35 ROPCSH I Sample Pulse for Running OPC (H: Sample, L: Hold)

41 XLAT I Latch input

42 SDATA I Serial Data input

43 SCLK I Clock input for Serial Data transmission

45 HOLDSW I VWDC Hold control (H : Sample, L: Hold)

46 AGCON I AGC ON/OFF control (H:AGC ON, L: AGC RESET)

47 TFGCNT I Gain transmission control for TE and FE signal (H: 0 dB, L: -4dB)

48 WLDON I Transmission control for Write (H: LD ON, L: LD OFF)

37 RECD O Output of Recorded Area Detection signal

38 ATFG O ATIPFG output

44 ERGCNT O Output of Erase gain transmission control

50 XTAND O Output of Out-of -Track Detection signal (AND)

51 XTOR O Output of Track Amplitude Detection signal (OR)

Page 26

32

Pin no Symbol I/O Description

52 XTOK O Output of Out-of -Track Amplitude Detection signal

39 DVCC * Digital power

49 CS I Chip power save control (H: power ON, L: Power OFF)

53 RFCTC2 * External Capacitor connection of Peak Hold Time Constant for RFRP signal

54 RFCTC1 * External Capacitor connection of Bottom Hold Time Constant for RFRP signal

55 TOK2C * External Capacitor connection for Retriggerable mono multi Time Constant

56 TOK1C * External Capacitor connection for Retriggerable mono multi Time Constant

57 TEIN I Input of Tracking error signal

58 TE O Output of Tracking error signal

59 FE O Output of Focus error signal

60 MPP O Output of Main Push- Pull signal

61 MPXOUT O Multiplexer Output for Signal monitoring

62 AUX I Auxiliary input for Signal monitoring

63 CEO O Output of Center error AMP

65 CEP * Input of Center error AMP

67 CEM * Reverse Input of Center error AMP

68 RFCT O Output of RFRP Slice level

69 RFRP O Output of Radial contrast signal

70 SRFO O Output of RF Sample signal

71 EQRFP O Output of RF Equalizer

72 EQRFN O Output of RF Equalizer

73 RECD1C * External Capacitor connection for Retriggerable mono multi Time Constant

74 PHO1 O Output of Pick Hold

75 BHO1 O Output of Bottom Hold

76 PHC1 * External Capacitor connection for Peck Hold Time Constant

77 BHC1 * External Capacitor connection for Bottom Hold Time Constant

78 BHC3 * External Capacitor connection for Bottom Hold Time Constant

79 BETAOUT O Output of Beta Value

80 PHO2 O Output of Pick Hold

81 BHO2 O Output of Bottom Hold

82 PHC2 * External Capacitor connection for Pick Hold Time Constant

83 BHC2 * External Capacitor connection for Bottom Hold Time Constant

84 RRFIN I External Capacitor connection for RRF(85 Pin)

85 RRF O Output of Read RF signal

87 RFIN I Input of Main beam composite signal

89 VTIREF * Reference Voltage of Resister

90 HOLDTC * External Capacitor connection for VWDC Hold

91 TDREF O Output of Reference Voltage for Overdrive power

92 WREF O Output of Write Power Reference Voltage level control

96 RREF O Output of Read Power Reference Voltage level control

93 VWDC O Output of APC for Write

94 VWDCN * Reverse Output of APC Amp for Write

98 VRDCN * Reverse Output of APC Amp for Read

95 APCCSW * External Capacitor connection of APC time constant for Write

97 VRDC O Output of APC for Read

99 SHOUT O Sample hold output for signal monitoring

100 FPDO I Input of Laser Power Monitor Voltage

Page 27

IC201(OTI-9797) : CD-R/RW Encoder/Decoder/Write Strategy Chip

Block Diagram

33

Page 28

34

2.4.2 CD-ENCODER INTERFACE

Pin Name Pin # Type Description

XIN 137

X

IN

Crystal In: System clock

XOUT 136

X

OUT

Crystal Out: System Clock

AT I P C K /

WBLCLK

138 O ATIP Clock Out

ENCLK 6 I Encoder Clock Input

CLKOUT /

ARST#

65 O

General Purpose Clock Output

Pin Name Pin # Type Description

PA N I C I N 168

I

S

Panic Input

WBLIN 132

I

S

Wobble In: Wobble input digital signal

HFSW 167 O High Frequency Modulation Switch

WGATE /

NRZWGATE

166 O

Write Gate /

EFM NRZ Write Gate

EFM1 183 O EFM1: EFM output

EFM2 184 O EFM2: EFM output

EFM3 185 O EFM3: EFM output

EFMNT1 /

EFMNT1

/

ELPBS1

169 O

EFMNT1: EFM pit pattern length indicator /

EFMN : Non-Delayed EFM Pit Pattern Length Indicator /

ELPBS1: External Low Pass Filter Band Switch

CLOCK

CD-ENCODER INTERFACE

Page 29

35

EFMNT2 /

EFMNT2’ /

ELPBS2

170 O

EFMNT2: EFM pit pattern length indicator /

EFMN

: Non-Delayed EFM Pit Pattern Length Indicator /

ELPBS2: External Low Pass Filter Band Switch

EFMNT3 /

EFMNT3’ /

ELPBS3

171 O

EFMNT3: EFM pit pattern length indicator /

EFMN : Non-Delayed EFM Pit Pattern Length Indicator /

ELPBS3: External Low Pass Filter Band Switch

EFMNT4 /

EFMNT4’ /

ELPBS4 /

RWSW

172 O

EFMNT4: EFM pit pattern length indicator /

EFMN

: Non-Delayed EFM Pit Pattern Length Indicator /

ELPBS4: External Low Pass Filter Band Switch /

RWSW: CD-RW Write Gate Switch

E11TP /

EFMSY

175 O EFM11T Pit Pattern: EFM11T pit pattern indicator

E11TS /

MONIT /

SVSY

176 O EFM11T Space Pattern: EFM11T space pattern indicator

EFCK 177 O EFM Bit Clock: EFM bit clock generated from internal clock in CD encoder

SMP3 /

SYEQ

180 O SMP3: Sample and Hold Signal 3

SMP1 /

MONIT

181 O SMP1: Sample and Hold Signal 1

SMP2 /

ASYEQ

182 O SMP2: Sample and Hold Signal 2

SMP4 /

TLDLD

186 O SMP4: Sample and Hold Signal 4

SMP5 /

TPDLD

187 O SMP5: Sample and Hold Signal 5

SMP6 /

OPC11T /

RWS WI

188 O

SMP6: Sample and Hold Signal 6 /

RWSWI : CD-RW Write Gate Switch Inverted

Pin Name Pin # Type Description

Page 30

36

2.4.4 CD-SERVO INTERFACE

Pin Name Pin # Type Description

REVDET 4

I

S

Reverse Detect Motor Drive: Indicates spindle motor is rotating in reverse

direction

FG 5

I

S

FG IN: HG (tachometer) pulse input

MON 7 O Motor Drive On: Enables spindle motor drive

SBRK 8 O

Short Brake: Stops spindle motor by applying a short pulse to the motor

winding

AT I P C K /

WBLCLK

138 O Wobble Clock

EEFS /

LSRPREP

179 O EFM Frame Sync

ESFS /

EFMNRZ

178 O Encoder Subcode Frame Sync

Pin Name Pin # Type Description

DMO 2

O

A

Spindle Motor Servo Output

SLO 3

O

A

Sled Servo Output

FOO 207

O

A

Focus Servo Output: Focus servo feedback signal.

TRO 208

O

A

Tracking Servo Output: Tracking servo feedback signal.

TEBC 194

O

A

Tracking Error Balance Control

FE 197

I

A

Focus Error

TE 198

I

A

Tracking Error

BS 201

I

A

Beam Strength

RPBC 202

O

A

Ripple Balance Control

RP 203

I

A

Ripple of RF

WOBBLE MOTOR INTERFACE

CD-SERVO INTERFACE

Page 31

37

2.4.5 CD-DSP INTERFACE

RX 191

I

S

RP Zero Crossing: Used for fine search.

TX 192

I

S

TE Zero Crossing: Track crossing signal input used in conjunction with RX

to

perform fine searches.

CE 204

I

A

Center Position Error

LDON /

NDIVOUT

141 O

Laser Diode On / CAV Write N Divider: MUXing of this pin is controlled by bit

ATIPN (18Fh.7). - Not used.

TC 193

I

S

Track Count Input: High-frequency track crossing signal input used to

perform

rough searches and to increment the internal track counter.

FLAGA 142 O

Servo Monitor Flag A: FLAGA is used to output one of four internal servo

signals. FLAGA can also be used as a general output port.

FLAGB 145 O

Servo Monitor Flag B: FLAGB is used to output one of four internal servo

signals. FLAGB can also be used as a general output port.

FLAGC 146 O

Servo Monitor Flag C: FLAGC is used to output one of four internal servo

signals. FLAGC can also be used as a general output port.

FLAGD 149 O

Servo Monitor Flag D: FLAGD is used to output one of three internal servo

signals. FLAGD can also be used as a general output port.

Pin Name Pin # Typ e Description

EFM 163

I

A

EFM Analog Data

ASY 162

O

A

Asymmetry DAC Output

EFMR1 159

I

A

EFM Analog Data Bias 1

EFMR2 160

I

A

EFM Analog Data Bias 2

EFMR3 161

I

A

EFM Analog Data Bias 3

MONIT /

PLCK

133 O

CD-DSP Monitor Output: MONIT is used to output several internal CD-DSP

signals.

Pin Name Pin # Type Description

CD-DSP INTERFACE

Page 32

38

Pin Name Pin # T ype Description

MIO0 /

L–

143 I/O

Multiple I/O 0: MIO0 is used to output several internal test signals.

DEFAULT

Serial Data: This signal is for 16-bit PCM serial audio data.

It can

be used to send audio data to an external or internal OTI-9797 DAC.

Audio

data is in 24-bit slot format for input and output.

Differential Audio Output

MIO1 /

L+

144 O

Multiple I/O 1: MIO1 is used to output several internal test signals.

DEFAULT

Audio Left/R ight Clock: Indicates the start of the 24-bit value

on

SDATA. High indicates the start of the left channel.

L+: Differential Audio Output

MIO2 /

R+

147 O

Multiple I/O 2: MIO2 is used to output several internal test signals.

DEFAULT

Audio Bit Clock:This is the data bit clock output for SDATA.

There are 24 cycles of bit clock for each 16-bit audio word.

R+: Differential Audio Output

MIO3 /

R–

148 O

Multiple I/O 3: MIO3 is used to output several internal test signals.

DEFAULT De-Emphasis Control

: Differential Audio Output

DOUT 139 O

Digital Audio Output: Bi-phase serial audio output that follows the IEC 60958

standard.

L151

O

A

Left Channel Audio Output

R154

O

A

Right Channel Audio Output

AUDIO INTERFACES

Page 33

39

Pin Name Pin # Type Description

HD15

HD14

HD13

HD12

HD11

HD10

HD9

HD8

HD7

HD6

HD5

HD4

HD3

HD2

HD1

HD0

76

78

80

82

86

88

90

94

95

91

89

87

85

81

79

77

HD7=I/O

Host Data Bus (ATAPI & SCSI DMA Modes)

HWR#/

STOP/

DBWR#

72

I

PU

ATA Write Strobe (ATAPI Mode): During PIO and DMA transfers, the host

uses this signal to write data to the device.

ATA Stop Ultra DMA Burst (ATAPI Mode): During Ultra DMA transfers,

the host uses this signal to halt a burst transfer. Bit SUDMA (0C3h.7)

enables UDMA mode.

O

SCSI DMA Write Strobe (SCSI DMA Mode): The SCSI protocol controller

latches data from the OTI-9797 on the rising edge of DBWR#, which is

driven by the OTI-9797 and derives its timing from the SCSICLK signal.

HRD# /

HDMARDY# /

HSTROBE /

DBRD#

71

I

PU

ATA Read Strobe (ATAPI Mode): During PIO and DMA transfers, the host

uses this signal to read data from the device.

ATA Ultra DMA Host Ready / Host Data Strobe (ATAPI Mode): The h ost

uses this signal to indicate it is ready to begin an Ultra DMA read data

transfer. During an Ultra DMA write transfer, the host uses this signal to

strobe data to the device.

O

SCSI DMA Read Strobe (SCSI DMA Mode

):

The OTI-9797 latches data

from the SCSI protocol controller on the rising edge of DBRD#, which is

driven by the OTI-9797 and derives its timing from the SCSICLK signal.

ATAPI/SCSI PASS-THROUGH HOST INTERFECE

Page 34

40

HA2 /

HA1

61

64

I

S

ATA Address (ATAPI Mode): The host uses the 3-bit ATA address to

select an ATAPI control command block register or data port.

HA0 /

48M

62

I

S

ATA Address 0 (ATAPI Mode): The host uses the 3-bit ATA address to

select

an ATAPI control command block register or data port.

48MHz USB Reference Clock (USB Mode): If bit USBCKSEL (0A9h.2) = 1,

48M is used as the USB reference clock input, and a 48MHz clock signal

must be input to 48M. If USBCKSEL = 0, the internal system clock

(controlled by bits PLLCO1

[2FEh

2FDh]) is used, and 48M must be

grounded.

IOCS16# 66

O

OD

ATA I/O Chip Select 16 (ATAPI Mode): For PIO transfer, IOCS16#

indicates to the host system that the 16-bit data port has been addressed

and the chip is prepared to send or receive a 16-bit data word.

CS1FX# /

USBD–

59

I

S

ATA Chip Select 1 (ATAPI Mode): The host uses this signal to select the

ATAPI command block registers for access.

USB Differential Serial Data

Negative (USB Mode)

CS3FX# /

SCSICLK /

USBD

+

58

I

S

ATA Chip Select 3 (ATAPI Mode): The host uses this signal to select the

ATAPI control block registers for access.

SCSI Reference Clock (SCSI DMA Mode): If bit SCSICLKS (07Bh.6) = 0,

this signal is used as the SCSI DMA reference clock (40MHz is

recommended). If SCSICLKS = 1, the internal CD-Decoder system clock

(controlled by bits PLLCO1

[2FEh 2FDh]) is used, and this signal must

be grounded.

USB Differential Serial Data

Positive (USB Mode)

HDRQ /

DREQ

73

O

TS

ATA DMA Request (ATAPI Mode): This signal will be asserted for DMA

data transfer when the chip is ready to transfer data to or from the host.

This signal is used in a handshake manner with DMACK#.

I

SCSI DMA Request (SCSI DMA Mode): The SCSI protocol controller uses

DREQ to request data transfer with the OTI-9797.

DMACK# /

DA CK #

69

I

PU

ATA DMA Acknowledge (ATAPI Mode): This signal is used by the host to

respond to HDRQ.

O

SCSI DMA Acknowledge (SCSI DMA Mode): The OTI-9797 uses DACK#

to acknowledge it is ready for data transfer.

Pin Name Pin # Type Description

Page 35

41

HIRQ /

SIRQ#

67

O

TS

ATA Interrupt Request (ATAPI Mode): This signal is used to interrupt the

host system. HIRQ is controlled by bit HINTRQ (02Eh.3).

I

SCSI Interrupt (SCSI DMA Mode): This signal is asserted by the SCSI

Protocol Controller to interrupt the system controller. DTE(0E3h.2) is set to

1 when SIRQ# is asserted.

IORDY /

DDMARDY# /

DSTROBE

70

O

TS

ATA IO Ready (ATAPI Mode): When PIO mode is active, the device deasserts this signal to extend any host read data access cycle when the

host

FIFO is empty or EDAC throttling is enabled.

ATA Ultra DMA Device Ready / Data Strobe (ATAPI Mode): The device

uses this signal to indicate it is ready to begin an Ultra DMA write data

transfer. During a read transfer, the device uses this signal to strobe data

to

the host.

HDASP# 56

I

PU/OD

ATA D rive Active/Drive 1 Pre sent (ATAPI M ode): This is a timemultiplexed signal that indicates if a drive is active or Drive 1 is present.

HDASP# is controlled by bit DASPEN (020h.5). Firmware can read the

state of HDASP# from bit DASPb (02Eh.0).

HPDIAG# 63

I

PU/OD

ATA Passed Diagnostics(ATAPI Mode): This signal is asserted by Drive 1 to

indicate to Drive 0 that it has completed diagnostics. HPDIAG# is

controlled by bit PDIAGEN (020h.6). Firmware can read the state of

HPDIAG# from bit PDIAGb (02Eh.1).

HRST# 55

I

S

Host Reset: The host uses this signal to reset the OTI-9797.

RD15 /

DJ

17 I/O

Drive Jumper Input: When HRST# (if bit DJRSTb [019h.5] = 0) or PRST# is

asserted, the inverted state of DJ is used to set bit DRV1b (02Eh.4) to set

the device as an IDE master or slave. DJ is used as RD15 (RAM Data

Bus

bit 15) after reset.

RD12 /

IFSEL

20 I/O

Host Interface Select: When HRST# or PRST# is asserted, IPSEL selects

whether the ATAPI (if IFSEL is high) or SCSI pass-through (if IFSEL is

low)

host interface is enabled. Bit SCSIEN (07Bh.0) also selects between

SCSI

a

nd ATAPI Modes. After reset this signal is used as RD12 for the

buffer

interface.

Pin Name Pin # Type Descrip

tion

Page 36

42

Pin Name Pin # Type Description

UA15

UA14

UA13

UA12

UA11

UA10

UA9

UA8

116

117

118

119

120

121

122

123

I

System Controller Address 15

8 Bus: This bus is the upper 8-bits of the 16-

bit system controller address. In register access mode (UCS0# asserted),

UA15

are not decoded.

UA7

UA6

UA5

UA4

UA3

UA2

UA1

UA0

124

125

126

127

128

129

130

131

I

System Controller Address 7

0 Bus: This bus is the lower 8-bits of the 16-

bit system controller address when non-multiplexed mode is enabled (see

UALE description). In Non-Multiplexed Mode, U

ust be grounded.

UAD7

UAD6

UAD5

UAD4

UAD3

UAD2

UAD1

UAD0

104

103

102

101

100

99

98

97

I/O

System Controller Address 7

0/Data Bus: This bi-directional bus transfers

8-bit data. When multiplexed mode is enabled (see UALE description),

UAD7

0 also functions as the lower 8-bits of the system controller address

bus. UAD7

0 is high-impedance when not used to transfer data or

addresses.

URD# /

UR/W#

105

I

S

Microcontroller Read Strobe: In X86 Mode, URD# is the read data strobe.

Read or Write Status: In Motorola Mode, UR/W# high indicates that a read

is occurring when UDS# is asserted. UR/W# low indicates that a write is

occurring when UDS# is asserted.

UWR# /

UDS#

106

I

S

Microcontroller Write Strobe: In X86 Mode, UWR# is the write data

strobe.

Data Strobe: In Motorola Mode, UDS# is the data strobe. Signal UR/W#

determines whether a read or write is occurring when UDS# is asserted.

SYSTEM CONTROLLER INTERFACE

Page 37

43

URDY 111

O

PU/TS

System Controller-RAM Transfer Ready: This signal is asserted low to

extend a system controller-RAM access until the RAM data is ready to be

read or written. If direct-RAM access is used (UCS1# asserted), a system

controller with a wait-state insertion input must be used. For RAMRD/

RAMWR (01Eh) accesses (UCS0# asserted), URDY can also be used to

extend accesses of the RAMRD and RAMWR registers if bit URDY0E

(0D5h.4) = 1. Bit URDYZb (0C8h.5) controls whether URDY is Hi-Z when

UCS1# and UCS0# are de-asserted. URDY is default Hi-Z when neither

chip select is asserted, therefore a pull-up resistor must be used with

URDY.

Bit URDYMOD (0C8h.4) controls whether URDY is high or low when the

data strobes are inactive.

UCS0# 107

I

S

System Controller Chip Select 0: When UCS0# is asserted, the system

controller can address the internal registers.

UCS1# 110

I

S

System Controller Chip Select 1: When UCS1# is asserted, the system

controller can address the RAM directly.

SDINT# 114

O

PU

CD-DSP / CD-Servo Interrupt Request

CLKOUT /

ARST#

65

O

OD

ATAPI Reset Interrupt Request or Output: OTI-9797 asserts ARST# whe

n

the host has written the ATAPI Soft Reset Command (08h). ARST#

(enabled

when bit ARSTEN (02Fh.3) = 1) can be used as an interrupt

request output

(if ARSTS (02Fh.2) = 1) or a reset output pulse. ARST# is

cleared for

interrupt operation by writing to register ARSTACK (030h).

UINT0# 112

O

PU

CD-Decoder/Encoder Interrupt Request 0

UINT1# 113

O

PU

CD-Decoder/Encoder Interrupt Request 1

UALE

115

I

S

Address Latch Enable: In multiplexed mode, UALE indicates that UAD7 0

contains a valid address. UALE must be grounded to enable nonmultiplexed mode.

PRST# 96

I

S

Powe r- on R ese t: Forcing this input low resets the device.

RD13 /

CPUTYPE

19

I/O

PU

CPU Type Select: When HRST# or PRST# is asserted, this signal selects

whether the System Controller Interface is configured for Motorola (if

CPUTYPE is low) or x86 Mode (if CPUTYPE is high). After reset this

signal

is used as RD13 for the buffer interface.

Pin Name Pin # Type Description

Page 38

44

Pin Name Pin # Type Description

RCLK 36 O

SDRAM System Clock: RCLK clocks data and commands to/from the

SDRAM.

RCLKE 38 O

SDRAM Clock Enable: RCLKE is asserted high to enable the SDRAM clock.

RCS# 37 O SDRAM Chip Select: RCS# is asserted low to select the SDRAM.

RAD13 /

RBA2

39

O

DRAM Row Address 13: Row address 13 in EDO DRAM Mode

SDRAM Bank Address 2: When RRCF (0CCh

selects 12 row address

signals, this signal is used as bank address bit 1

up to 4

banks are

supported.

RAD12 /

RBA1

40

O RAM Row/Column Address 12: Row and column address 12

O

SDRAM Bank Address 1: When RRCF (0CCh

selects 12 row address

signals, this signal is used as bank address bit 0

up to 4 banks are

supported.

RAD11 /

RBA0

41 O

RAM Row/Column Address 11: Row and column address 11

SDRAM Bank Address 0: When RRCF (0CCh

selects 11 row address

signals, this signal is the only bank address signa l

to 2 banks are

supported.

RAD10 /

RAP

42

O RAM Row/Column Address 10: This signal is row and column address 10.

O

SDRAM Auto-Precharge:In SDRAM Mode during the read/write command,

this signal is used as auto-precharge and is asserted low to disable autoprecharge.

RAD9

RAD8

RAD7

RAD6

RAD5

RAD4

RAD3

RAD2

RAD1

RAD0

43

44

45

48

49

50

51

52

53

54

O

RAM Row/Column Address

0: These signals are row and column

address

bits

0.

BUFFER MEMORY INTERFACE

Page 39

45

RD15 /

DJ

17 I/O

RAM Data 15 / Drive Jumper: RD15 is bit 15 of the RAM data bus. It is

also

used as the DJ for the host interface.

RD14 18 I/O RAM Data 14: RD14 is bit 14 of the RAM data bus.

RD13 /

CPUTYPE

19

I/O

PU

RAM Data Bus 13/CPU Type: RD13 is bit 13 of the RAM Data Bus. It is also

used as CPUTYPE for the system controller interface. (1 = Intel & 0 =

Motorola)

RD12 /

IFSEL

20 I/O

RAM Data Bus 12 / Interface Select: RD12 is bit 12 of the RAM data bus

and also used as IFSEL for the host interface. (1 = IDE & 0 = SCSI)

RD11

RD10

RD9

RD8

RD7

RD6

RD5

RD4

RD3

RD2

RD1

RD0

21

24

25

28

11

12

13

14

15

16

29

26

I/O

PU

RAM Data

Bus 0: RD 0 are bits 11–0 of the RAM data bus.

RRAS# 33 O

RAM Row Address Strobe: In DRAM Mode, RRAS# indicates that RAD13

0

contains a row address. In SDRAM Mode, RRAS# is asserted to send the

row

active command.

RWE# /

RWEL#

30 O

RAM Write Enable Low: In dual-CAS# DRAM Mode, RWE# is indicates that

RD

0 is write data. For dual WE# DRAM mode, this signal enable writing

of the lower data byte (RD7

). In SDRAM mode, RWE# is asserted to

generate the write command.

ROE# /

LDQM

32 O

DRAM Output Enable: In DRAM Mode, ROE# is asserted low to enable data

output.

SDRAM Data Mask Low: In SDRAM Mode, LDQM is driven high to disable

RAM data output or block write data for RD7

0.

RCAS# /

RCASL#

31 O

RAM Column Address Strobe Low: In DRAM Mode, RCAS# indicates that

RAD7

contains a column address. For dual-CAS# DRAM Mode, this

signal

is the column address strobe for the low data byte (R

In SDRAM

Mode, RCAS# is asserted to generate the read/write command

and

output

the column address.

Pin Name Pin # Type Description

Page 40

46

2.4.10 POWER SUPPLY

RCASH# /

RWEH# /

UDQM

27

O

DRAM Column Address Strobe High: For dual-CAS# DRAM Mode,

RCASH#

is the column address strobe for the upper data byte (R .

O

DRAM Write Enable High: For dual-WE# DRAM mode, RWEH# enables

writing of the upper data byte (RD

8).

O

SDRAM Data Mask High: In SDRAM Mode, UDQM is driven high to disable

RAM data output or block write data for RD15

8.

Pin Name Pin # Description

VDD 22, 83, 108, 189 Digital Power 2.5 Volts

IOVDD 9, 34, 46, 57, 74, 92, 134, 173 I/O Power 3.3 Volts

VSS 10, 23, 35, 47, 60, 68, 75, 84, 93, 109, 135, 174, 190 Digital Ground

AVDD 152, 153, 157, 158, 199, 206 Analog Power 3.3 Volts

AVSS 1, 150, 155, 156, 165, 195, 200 Analog Ground

VREF 164, 196 Reference voltage 1.65 Volts

2VREF 205 Reference voltage 3.3 Volts

Pin Name Pin # Type Description

POWER SUPPLY

Page 41

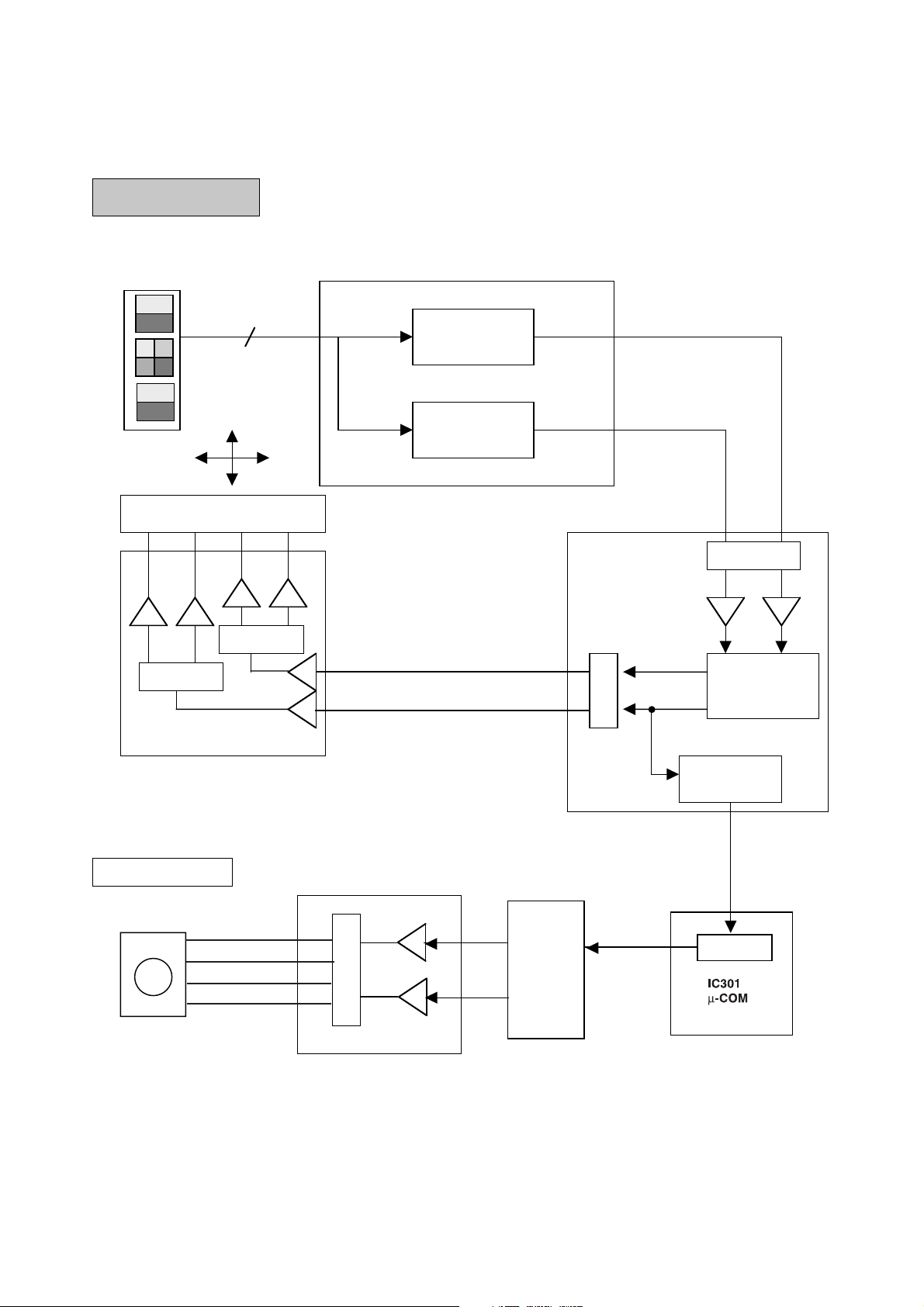

IC301 (MB90F482) : Micom

Block Diagram

47

X0, X1, RST,

X0A, X1A

MD2, 1, 0

8

CPU

FMC16X series

Prescaler

UART

A/D converter

(10 bits)

I/O expansion

serial

interface x 2ch

SIN1, 2

SOT1, 2

SCK1, 2

AVCC

AVRH

AVSS

ADTG

AN0-7

Interrupt controller

8-/16-bit PPG

PPG0, 1

PPG2, 3

PPG4, 5

8-/16-bits U/D counter

16-bit reload timer

TIN0

TOT0

External interrupts

IRQ0 to 7

8

I/O port

P00 P10 P20 P30 P40 P50 P60 P70 P80 P90 PA0

P07 P17 P27 P37 P47 P57 P67 P77 P87 P97 PA3

888 88 88 88 8 8

AIN0, 1

BIN0, 1

ZIN0, 1

2

Clock control

circuit

RAM

ROM

SIN0

SOT0

SCK0

IN0, 1

OUT0, 1,

I/O timers

16-bit input capture x 2

16-bit output conveyer x 6

16-bit free-run timer

Chip selects

CS0, 1, 2, 3

to to to to to to to to to to to

2, 3, 4, 5

* P00 to P07 (8pin) : Incorporates a pull-up resistor setting register (for input)

* P10 to P17 (8pin) : Incorporates a pull-up resistor setting register (for input)

* P40 to P47 (8pin) : Incorporates and open-drain setting register (for input)

* P70 to P77 (8pin) : Incorporates and open-drain setting register (for input)

Page 42

48

•Pin Description

LQFP QFP Pin Name

Circuit Type

Function

80 82 X0 A Oscillator pin

81 83 X1 A Oscillator pin

78 80 X0A A 32 kHz Oscillator pin

77 79 X1A A 32 kHz Oscillator pin

75 77 RSTX B Reset input pin

P00 to P07

General-purpose I/O ports

A pull-up resistor can be attached using the pull-up resistor setting

register (RDR0) (RD07 to RD00 = 1). (Invalid when set to output)

AD00 to

AD07

In the multiplex mode, the pins function as external address/data bus

lower I/O pins.

83 to 90 85 to 92

D00 to D07

C

(CMOS)

In the non-multiplex mode, they function as external data bus lower

output pins.

P10 to P17

General-purpose I/O ports

A pull-up resistor can be attached using the pull-up resistor setting

register (RDR1) (RD17 to RD10 = 1). (Invalid when set to output)

AD08 to

AD15

In the multiplex mode, the pins function as external address/data bus

upper I/O pins.

91 to 98

93 to

100

D08 to D15

C

(CMOS)

In the non-multiplex mode, they function as external data upper output

pins.

P20 to P23

General-purpose I/O ports

When the corresponding bit of the HACR register is 0, the pins function

as address upper output pins (A20 to A23).

A16 to A19

When the multiplex mode is enabled and the corresponding bit of the

HACR register is 1, the pins function as general-perpose I/O port.

99

100

1 and 2

1 to 4

A16 to A19

E

(CMOS/H)

In the non-multiplex mode, they function as external address upper

output pins.

P24 to P27

General-purpose I/O ports

When the corresponding bit of the HACR register is 0, the pins function

as address upper output pins (A20 to A23).

A20 to A23

When the multiplex mode is enabled and the corresponding bit of the

HACR register is 1, the pins function as general-perpose I/O port.

A20 to A23

In the non-multiplex mode, they function as external address upper

output pins.

3 to 6 5 to 8

PPG0 to 3

E

(CMOS/H)

The pins function as PPG timer output pin.

Page 43

49

LQFP QFP Pin Name Circuit Type Function

P30 General-purpose I/O ports

A00 In the external bus mode, the pin functions as an external address pin.79

AIN0

E

(CMOS/H)

The pin is an 8-/16-bit up-and-down timer input pin (ch0).

P31 General-purpose I/O port

A01

In the non-multiplex bus mode, the pin functions as an external address

pin.

810

BIN1

E

(CMOS/H)

The pin is the 8-/16-bit up-and-down timer input pin (ch0).

P32 General-purpose I/O port

A02

In the non-multiplex bus mode, the pin functions as an external address

pin.

10 12

ZIN0

E

(CMOS/H)

The pin is an 8-/16-bit up-and-down timer input pin (ch0).

P33 General-purpose I/O port

A03

In the non-multiplex bus mode, the pin functions as an external address

pin.

11 13

AIN1

E

(CMOS/H)

The pin is an 8-/16-bit up-and-down timer input pin (ch1).

P34 General-purpose I/O port

A04

In the non-multiplex bus mode, the pin functions as an external address

pin.

12 14

BIN1

E

(CMOS/H)

The pin is an 8-/16-bit up-and-down timer input pin (ch1).

P35 General-purpose I/O port

A05

In the non-multiplex bus mode, the pin functions as an external address

pin.

13 15

ZIN1

E

(CMOS/H)

The pin is an 8-/16-bit up-and-down timer input pin (ch1).

P36, P37 General-purpose I/O port

A06, A07 In the non-multiplex bus mode, the pins function as external address pins.

14 and 15

16 and

17

PWC0,

PWC1

E

(CMOS/H)

This pin functions as PWC input pin.

P40 General-purpose I/O port

A08

In the non-multiplex bus mode, the pin functions as an external address

pin.

16 18

SIN2

G

(CMOS/H)

Simple serial I/O input pin

P41 General-purpose I/O port

A09

In the non-multiplex bus mode, the pin functions as an external address

pin.

17

19

SOT2

F

(CMOS/H)

SCI Output pin

P42 General-purpose I/O port

A10

In the non-multiplex bus mode, the pin functions as an external address

pin.

18 20

SCK2

G

(CMOS)

SCI Clock I/O pin

P43, P44 General-purpose I/O port

A11, A12 In the non multiplex bus mode, the pins function as external address pins.

19 and 20

21 and

22

MT00,

MT01

F

(CMOS)

µ

PG Output pins

P45 General-purpose I/O port

A13

In the non-multiplex bus mode, the pin functions as an external address

pin.

22 24

EXTC

G

(CMOS)

µ

PG Input pin

P46,P47 General-purpose I/O ports

A14, A15 In the non-multiplex bus mode, the pins function as external address pins.

23 and 24

25 and

26

OUT4/

OUT5

D

(CMOS)

The pins function as output-compare event output pins.

Page 44

50

LQFP QFP Pin Name Circuit Type Function

P50

General-purpose I/O port

In the external bus mode, the pin functions as ALE pin.

68 70

ALE

D

(CMOS)

In the external bus mode, the pin functions as an address capture

enable signal (ALE) pin.

P51

General-purpose I/O port

In the external bus mode, the pin functions as the RDX pin.

69 71

RDX

D

(CMOS)

When the external bus mode is enabled, the pin functions as the read

strobe output (RDX) pin.

P52

General-purpose I/O port

When the external bus mode is enabled and the WRE bit of the EPCR

register is 1, the pin functions as the WRLX pin

70 72

WRLX

D

(CMOS)

When the external bus mode is enabled, the pin functions as the lowerorder side data write strobe output (WRLX) pin. When the WRE bit of

the EPCR register is 0, the pin functions as a general-purpose I/O port.

P53

General-purpose I/O port

When the external bus mode is enabled (the bus is 16-bits long) and

the WRE bit of the EPCR register is 1, the pin functions as the WRHX

pin.

71 73

WRHX

D

(CMOS)

When the external bus mode is enabled (the bus is 16-bits long), the

pin functions as the higher-order side data write strobe output (WRHX)

pin. When the WRE bit of the EPCR register is 0, the pin functions as

a general-purpose I/O port.

P54

General-purpose I/O port

When the external bus mode is enabled and the HDE bit of the EPCR

register is 1, the pin functions as the HRQ pin.

72 74

HRQ

D

(CMOS)

When the external bus mode is enabled, the pin functions as the hold

request input (HRQ) pin. When the HDE bit of the EPCR register is 0,

the pin functions as a general-purpose I/O port.

P55

General-purpose I/O port

When the external bus mode is enabled and the HDE bit of the EPCR

register is 1, the pin functions as the HAKX pin.

73 75

HAKX

D

(CMOS)

When the external bus mode is enabled, the pin functions as the hold

acknowledge output (HAKX) pin. When the HDE bit of the EPCR

register is 0, the pin functions as a general-purpose I/O port.

P56

General-purpose I/O port When the external bus mode is enabled and

the RYE bit of the EPCR register is 1, the pin functions as the RDY pin.

74 76

RDY

D

(CMOS)

When the external bus mode is enabled, the pin functions as the

external ready input (RDY) pin. When the RYE bit of the EPCR