LG GA-B499YAQZ User guide

SERVICE MANUAL

REFRIGERATOR

Before servicing the unit, read the SAFETY PRECAUTIONS in this manual.

MODELS

GA-B499Y**Z

http://gsfs-eu.lge.com

CONTENTS

SAFETY PRECAUTIONS .......................................................................................................................................................................................

SERVICING PRECAUTIONS ...................................................................................................................................................................... 5

SPECIFICATIONS ....................................................................................................................................................................................................

PARTS IDENTIFICATION .......................................................................................................................................................................................

INSTRUCTIONS FOR REVERSING DOOR SWING .......................................................................................................................................... 9-10

DISASSEMBLY .........................................................................................................................................................................................................

DOOR .................................................................................................................................................................................................................. 10

REFRIGERATOR ROOM LAMP

FAN AND FAN MOTOR ..................................................................................................................................................................................

DEFROST CONTROL ASSEMBLY ................................................................................................................................................................. 11

HEATER, SHEATH ............................................................................................................................................................................................. 11

DISPLAY REMOVE ............................................................................................................................................................................................. 11

BACKLIGHT LED IN THE DOOR .................................................................................................................................................................... 11

ADJUSTMENT .......................................................................................................................................................................................................... 12

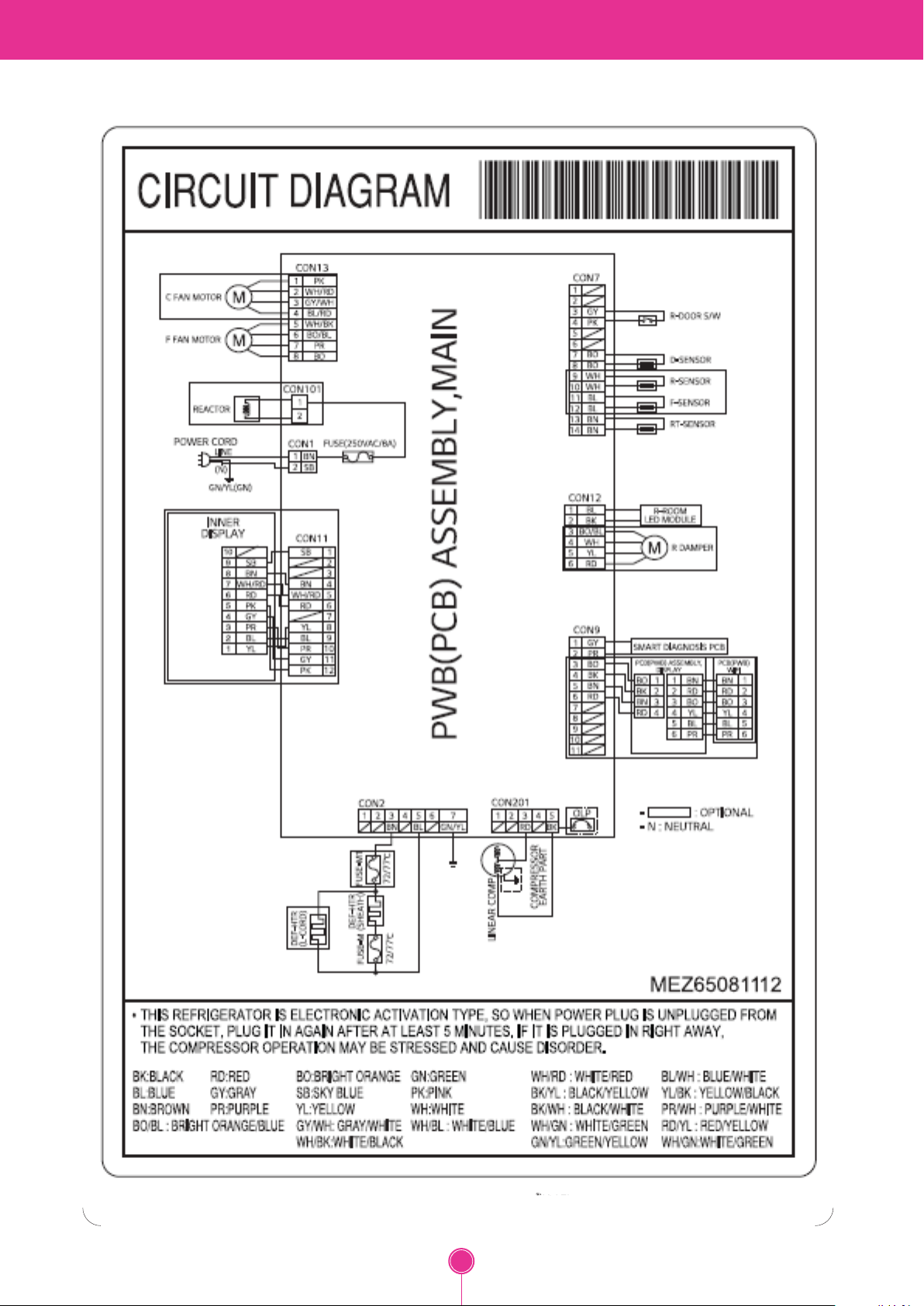

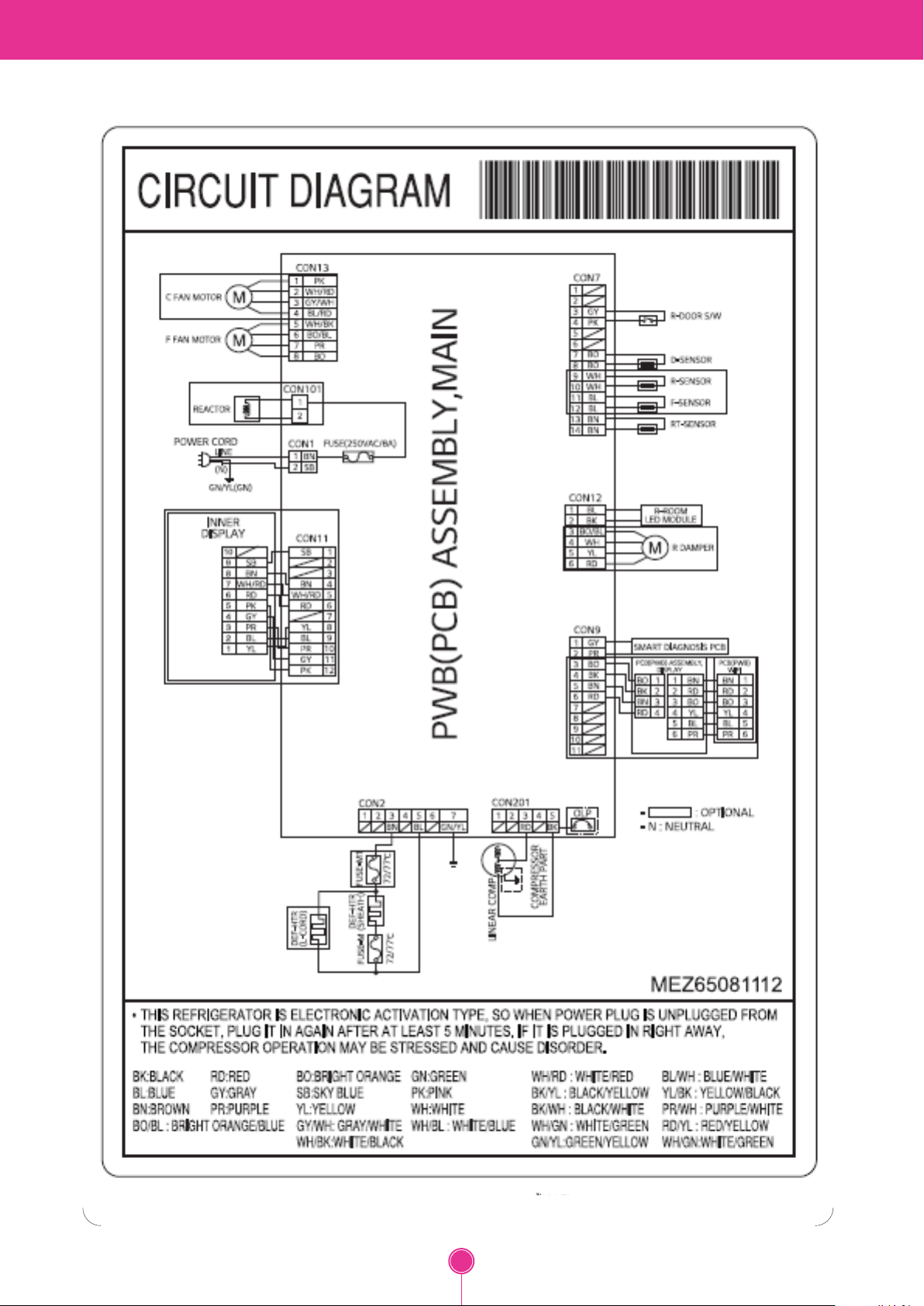

CIRCUIT DIAGRAM ................................................................................................................................................................................................... 13

COMPRESSOR ......................................................................................................................................................................................................... 14-21

TROUBLESHOOTING WITH ERROR DISPLAY ...............................................................................................................................................

TROUBLESHOOTING WITHOUT ERROR DISPLAY .......................................................................................................................................

TROUBLESHOOTING (MECHANICAl PART) ..................................................................................................................................................

ANOTHER ELECTRIC COMPONENTS .......................................................................................................................................................... 50

SERVICE DIAGNOSIS CHART ......................................................................................................................................................................... 51

REFRIGERATING CYCLE .................................................................................................................................................................................. 52-53

HEAVY REPAIR METHOD OF REFRIGERATOR BY APPLICATION OF REFRIGERANT ................................................................... 54-58

MICOM FUNCTION & PCB CIRCUIT EXPLANATION ...................................................................................................................................

MICOM ERROR CODE ...........................................................................................................................................................................................

PCB PICTURE ..........................................................................................................................................................................................................

EXPLODED VIEW &REPLACEMENT PARTS LIST ........................................................................................................................................... 74-78

.......................................................................................................................................................................

4

6

7-8

10-11

10

11

22-39

40-49

50-59

60-71

72

72-73

3

SAFETY PRECAUTIONS

SAFETY PRECAUTIONS

Please read the following instructions before servicing your refrigerator.

1. Check the set for electric losses.

2. Unplug prior to servicing to prevent electric shock.

3. Whenever testing with power on, wear rubber gloves to prevent electric shock.

4. If you use any kind of appliance, check regular current, voltage and capacity.

5. Don't touch metal products in the freezer with wet hands. This may cause frostbite.

6. Prevent water from following onto electric elements in the mechanical parts.

7. When standing up after having checked the lower section of the refrigerator with the upper door open, move with care

to avoid hitting the upper door.

8. When tilting the set, remove any materials on the set, especially the thin plates (ex. Glass shelf or books).

9. When servicing the evaporator, wear cotton gloves. This is to prevent injuries from the sharp evaporator ns.

10. Leave the disassembly of the refrigerating cycle to a specialized service center. The gas inside the circuit may pollute

the environment.

11. When you discharge the refrigerant, wear the protective safety glasses or goggle for eye safety.

12. When you repair the cycle system in refrigerator, the work area is well ventilated.

Especially if the refrigerant is R600a, there are no re or heat sources. (No smoking)

4

SERVICING PRECAUTIONS

Features of Refrigerant (R600a)

• Achromatic and odor less gas;

• Flammable gas and the ignition (explosion) at 494°C.

• Upper/lower explosion limit: 1.8%~8.4%/Vol. Features of

the R600a refrigerator;

• Charging of 60% refrigerant compared with a R134a model;

• The suction pressure is below 1bar (abs) during the operation;

• Because of its low suction pressure, the external air may ow

in the cycle system when the refrigerant leak, and it causes

malfunction in the compressor;

• The displacement of compressor using R600a must be at

least 1.7 times larger than that of R134a;

• Any type of dryer is applicable (XH-5, 7, 9);

• The EVAPORATOR or any other cycle part that has welding

joint is hidden in the foam. (If not hidden inside, the whole

electric parts must be tested with the LEAKAGE TEST

according to the IEC Standard);

• The compressor has label of the refrigerant R600a;

• Only the SVC man must have an access to the system.

Installation Place

• Must be well ventilated.

• Must be 20 m3 or larger.

• Must be no-smoking area.

• No ignitable factors must be present.

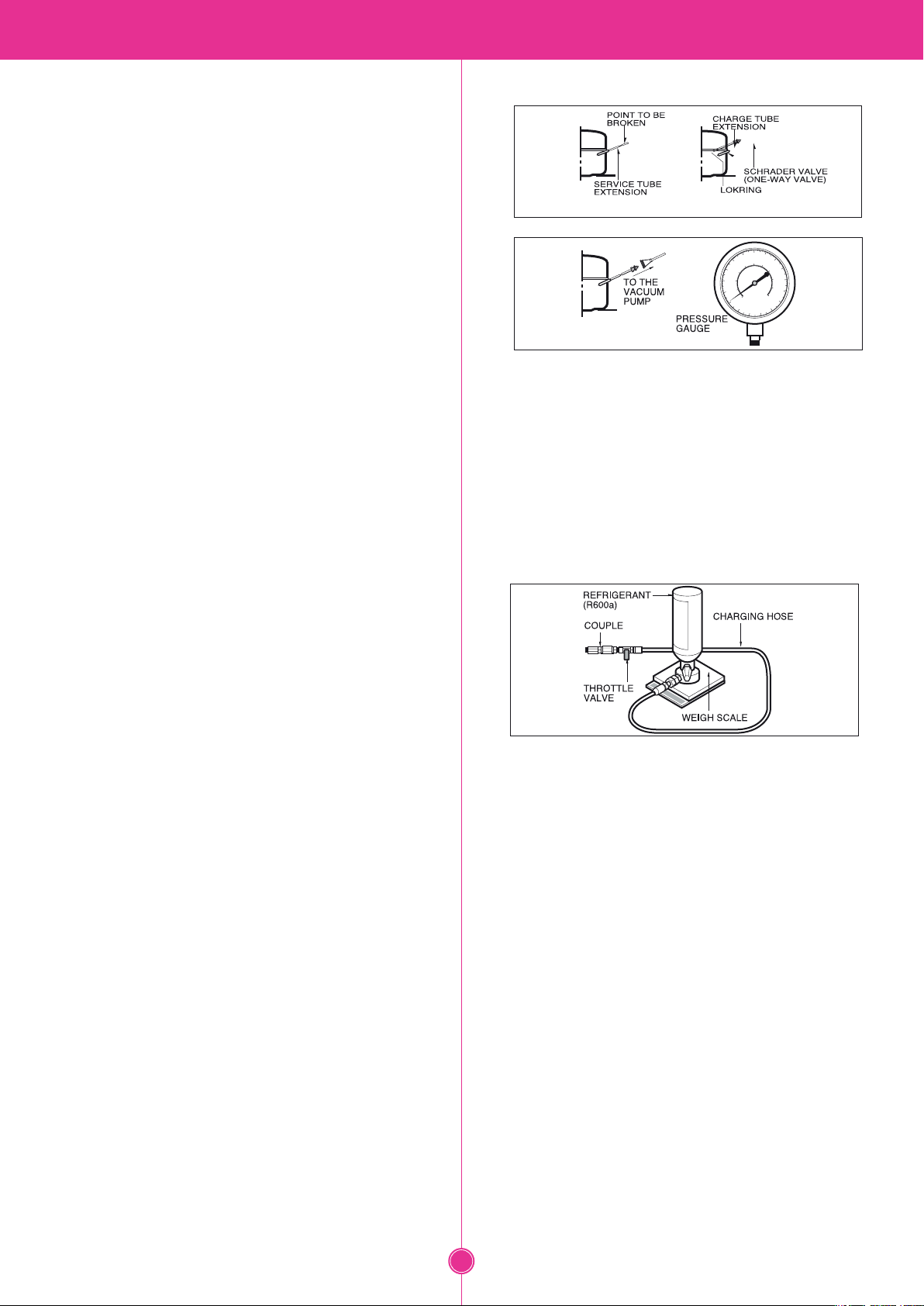

Figure 1 Figure 2

Figure 3

After the refrigerant (R600a) is completely discharged, repair any

defective parts and replace the dryer. At any case you must use the

LOKRING for connecting or replacing any part in the cycle (No Fire,

No Welding). Connect the Schrader valve to pump with the coupler.

And then turn the pump on for vacuum state (Figure 3). Let the

pump run until the low-pressure gauge indicates the vacuum

(gauge pressure 0, absolute pressure -1atm or -760mmHg).

Recommended vacuum time is 30 min. Charge the N2 gas in

order to check for leakage from welding points and the LOKRING.

If leakages are found, repair the defects and repeat the vacuum

process.

Utility

• Refrigerant cylinder (MAX NET 300g);

• Manometer;

• Vacuum pump (600^/min);

• Piercing Clamp;

• Quick coupler;

• Hoses (5m-1EA, 1m-3EA);

• LOKRING;

• Portable Leakage detector (3g/yearl);

• Nitrogen cylinder (for leakage test);

• Concentration gauge.

Make Sure before Serving

• Refrigerant Conrm the refrigerant by checking Name Plate and

the label on the compressor, after opening the COVER ASSEMBLY,

BACK-M/C.

• If the refrigerant is R600a, you must not weld or apply

a heat source.

Air Recharging in Compressor

Before relling the refrigerant, you must perform the test

according to Chapter 5 (TROUBLESHOOTING CHART). When the

defects

are found, you must discharge the residual refrigerant (R600a) in

the outdoor. For discharging the refrigerant R600a, break the

narrow portion of tube extension by hand or with a pipe cutter as

shown in Figure 1. Leave it for 3O min in outside to stabilize the

pressure with ambient. Then, check the pressure by piercing the

dryer part with piercing pliers. If the refrigerant is not completely

discharged, let the refrigerator alone for more 3O min in outside.

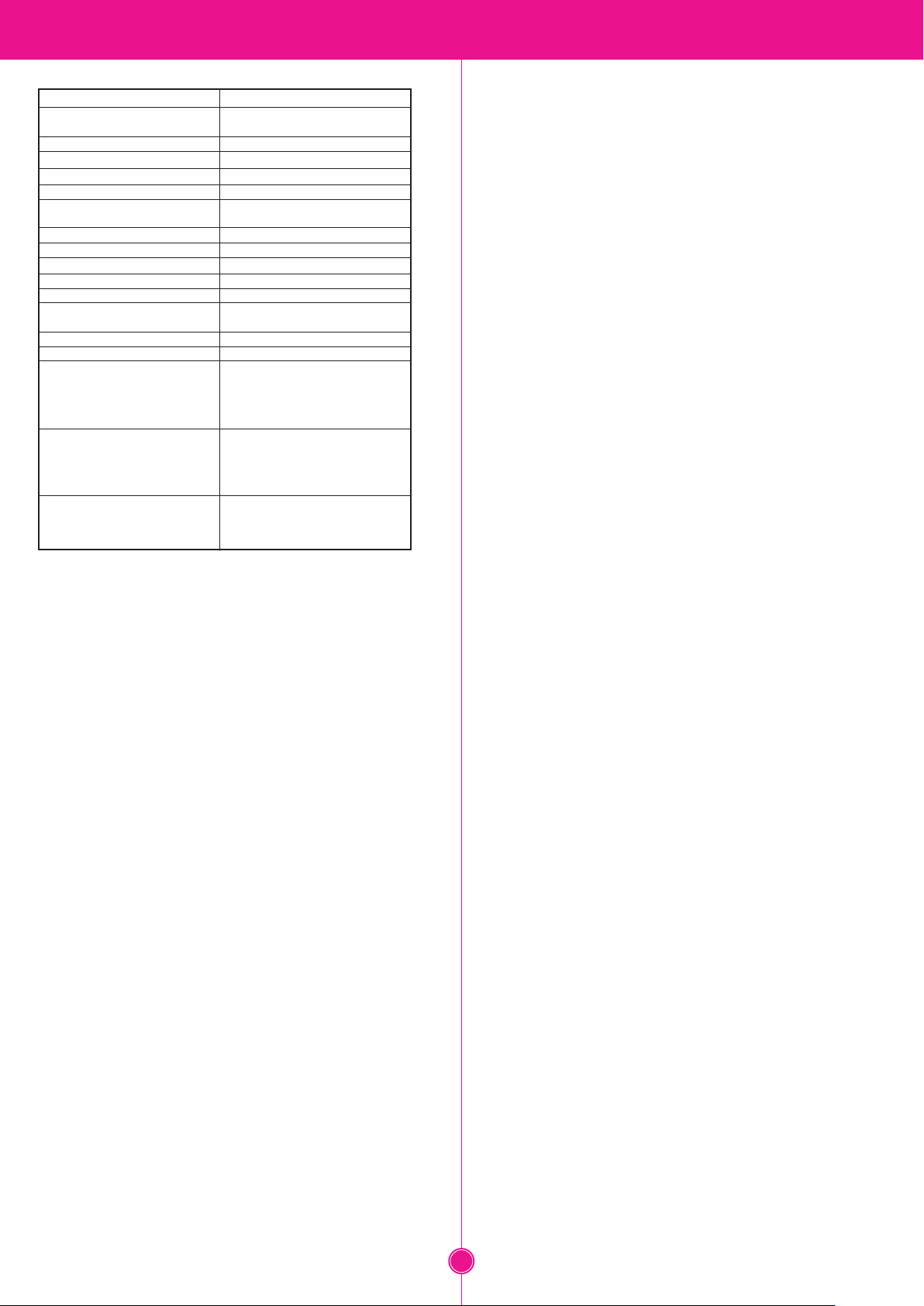

Figure 4

After the system is completely vacuumed, ll it with the refrigerant

R600a up to what has been specied at your refrigerator Name

Plate. The amount of refrigerant (R600a) must be precisely

measured within the error of ±2g by an electron scale (Figure 4).

REFRIGERANT (R600a) COUPLE CHARGING HOSE If you use the

manifold connected with both the refrigerant (R600a) cylinder and

the vacuum pump simultaneously, make sure the pump valve

is closed.

Connect the charging hose (that is connected to the refrigerant

(R600a) cylinder) to the Schrader valve installed on the service tube.

Then, charge the refrigerant (R600a) by controlling the Throttle valve.

When you do so, do not fully open the Throttle valve because it may

make damage to the compressor. Gradually charge the refrigerant

(R600a) by changing open and close the Throttle Valve (5g at each

time). The charging hose must use a one-way valve to prevent the

refrigerant reuence. Close the Schrader valve cap after the

refrigerant (R600a) is completely recharged.

After you completely recharge the refrigerant (R600a), perform the

leakage test by using a portable leakage detector or soapy water.

Test the low pressure (suction) parts in compressor o time and

high pressure parts in compressor on time. If the leakages are found,

restart from the refrigerant (R600a) discharging process and repairs

defects of leaks.

After the leakage test, check the temperature of each parts of the

cycle. Check with hands if the CONDENSER and the case (HOT-LINE

pipe) that is contacted to the door gasket are warm. Conrm that

frost is uniform distributed on the surface of the EVAPORATOR.

5

1. Ref. No: GA-B499Y*QZ

ITEMS SPECIFICATION

DIMENSIONS (mm)

NET WEIGHT (kg)

COOLING SYSTEM

TEMPERATURE CONTROL

DEFROSTING SYSTEM

DOOR FINISH

OUT CASE

INNER CASE ABS

INSULATION Polyurethane Foam

DEFROSTING DEVICE Heater, Sheath

REFRIGERANT

LUBRICATION OIL

COMPRESSOR Liner Type

EVAPORATOR Fin Tube Type

CONDENSER Wire Condenser

REFRIGERATOR

COMPARTMENT

DOOR BASKET

FREEZER COMPARTMENT

595(W)X668(D)X2000(H)

81/87

Fan Cooling

Micom Control

Full Automatic

Pre-Coated Metal or

Vinyl Coated Metal

Painted Steel Sheet

R600a (62g)

Mineral S5HFP (120㎤)

Transparent Shelf (3EA)

Folding Shelf (1EA)

Fresh Balanser(1EA)

Vegetable Container (1EA)

Fresh Converter (1EA)

Dairy Corner (1EA)

Basket (2EA)

Egg Tray (2EA)

2 ℓ Bottle Basket (1EA)

Bottle Guide (1EA)

Tray Drawer (3EA)

Shallow Drawer (1EA)

Shelf Net (2EA)

Tray Ice (1EA)

SPECIFICATIONS

6

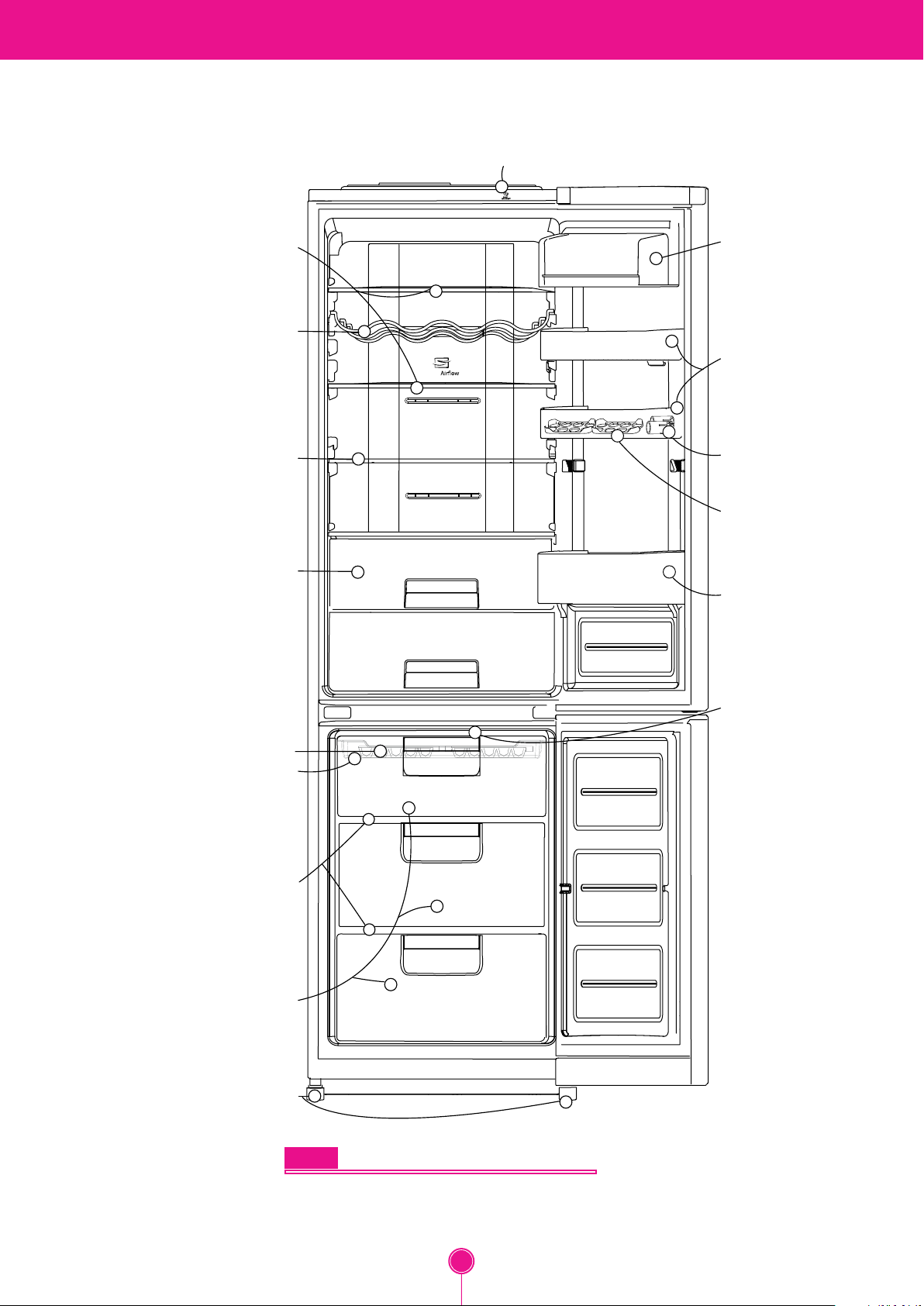

PARTS IDENTIFICATION

7

2. Ref. No: GA-B499Y*QZ

PARTS IDENTIFICATION

Removable

Glass Shelf

Bottle Rack

Folding

Glass Shelf

Tray Vegetable

SmartDiagnosis

Multi

TM

.

Dairy Corner

Basket Door

Stopper

Egg Tray

Basket Door

Tray Ice

Shallow Drawer

Wire Shelf

Freezer

Compartment

Leveling Screw

LED backlight

NOTE

This is a basic model. The shape of refrigerator is subject to change.

8

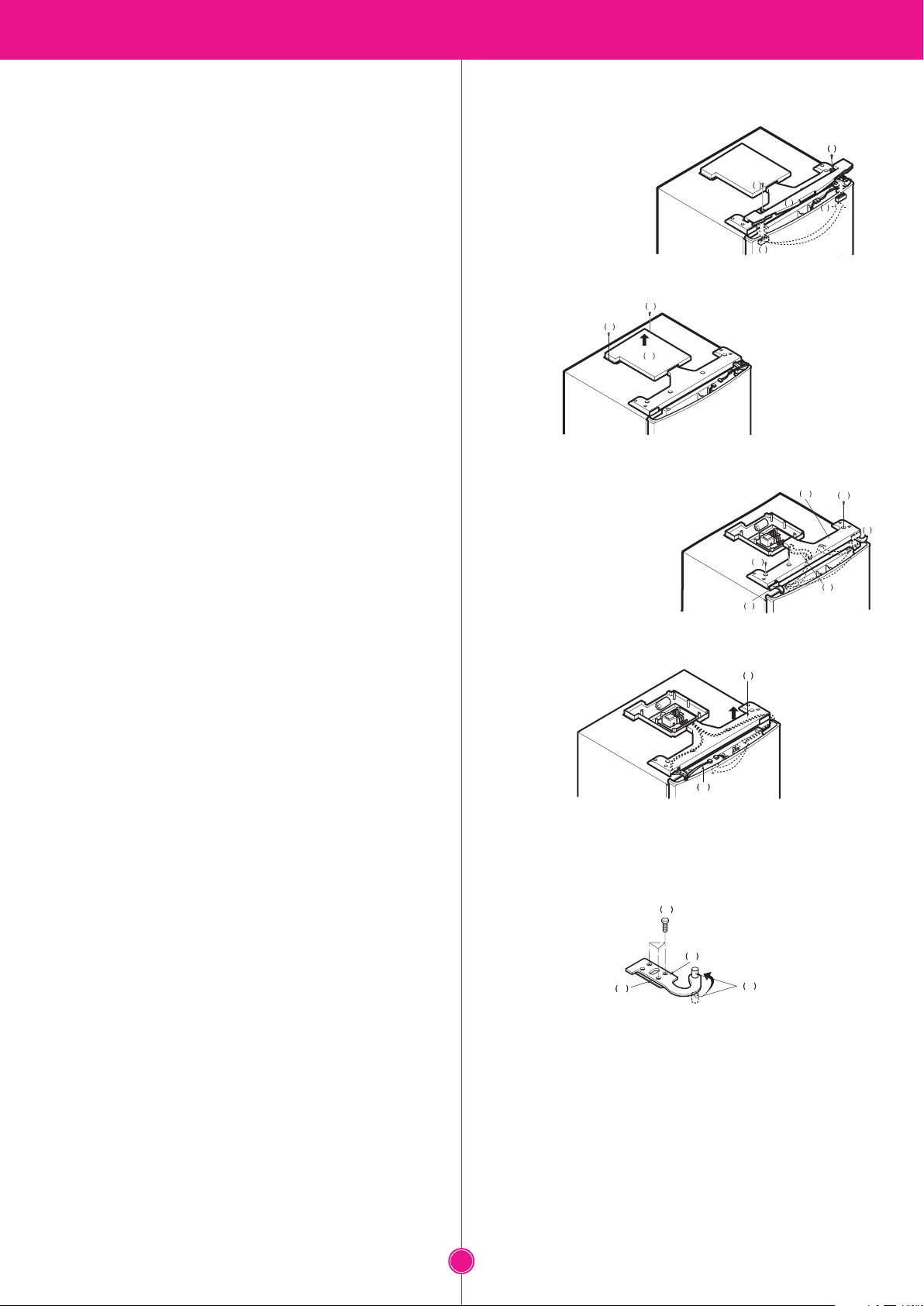

INSTRUCTIONS FOR REVERSING DOOR SWING

INSTRUCTIONS FOR

REVERSING DOOR SWING

This refrigerator allows the owner to change the door swing if

desired. The hinging of the doors can be changed to the opposite

side anytime you wish. A Warning Electric Shock Hazard

Disconnect electrical supply to refrigerator before in stalling.

Failure to do so could result in death or serious injury.

When reversing the door swing :

• Read the in structions all the way through be fore starting.

• Handle parts carefully to avoid scratching paint.

• Set screws/bol ts d own by their related pa rts to avoid using

them in the wrong places.

• Provide a non - scratching work surface for the doors.

IMPORTANT

Once you begin, do not move the cabinet until door-swing

reversal is completed. These in structions are for changing the

hinges from the right side to the left side, if you ever want to

change the hinges back to the right side, follow these same in

structions and reverse all references to left and right. Before

Removing the Doors, empty and Remove all the Door Baskets of

both Refrigerator/ Freezer Doors, including the Bank Dairy. Close

both doors before removing hinge pins.

CAUTION!

• After unscrewing the screws (1)

take o top (2) of refrigerator

door. Move the cap (3)

to the opposite side

1

2

the top cover (2).

Disconnect the cabel (4).

3

• Unscrew the screws (5) and take off the cover (6).

5

5

6

• Unscrew the screws (7) and take off the cover (8). Remove

the cabel holder (9) and x it (9) in central part

8

of the cover (8). Install the cap (11)

opposite side the cover (8). Take o

the cabel holder (10) from

central part of the cover (8)

7

and install it (10) in reversing side.

11

1

4

7

9

10

1. Prior to hanging the door to the opposite side, rst of all remove

all food products and loose accessories – shelves and trays –from

the refrigerator.

2. Make use of a torque wrench or box wrench 10 mm to tigh ten

and remove the bolts.

3. Do not place the refrigerator on the Door.

4. Be careful not to drop the door while assembling and

disassembling.

• Move the rope of cabel (12) to opposite side the cover (8).

8

12

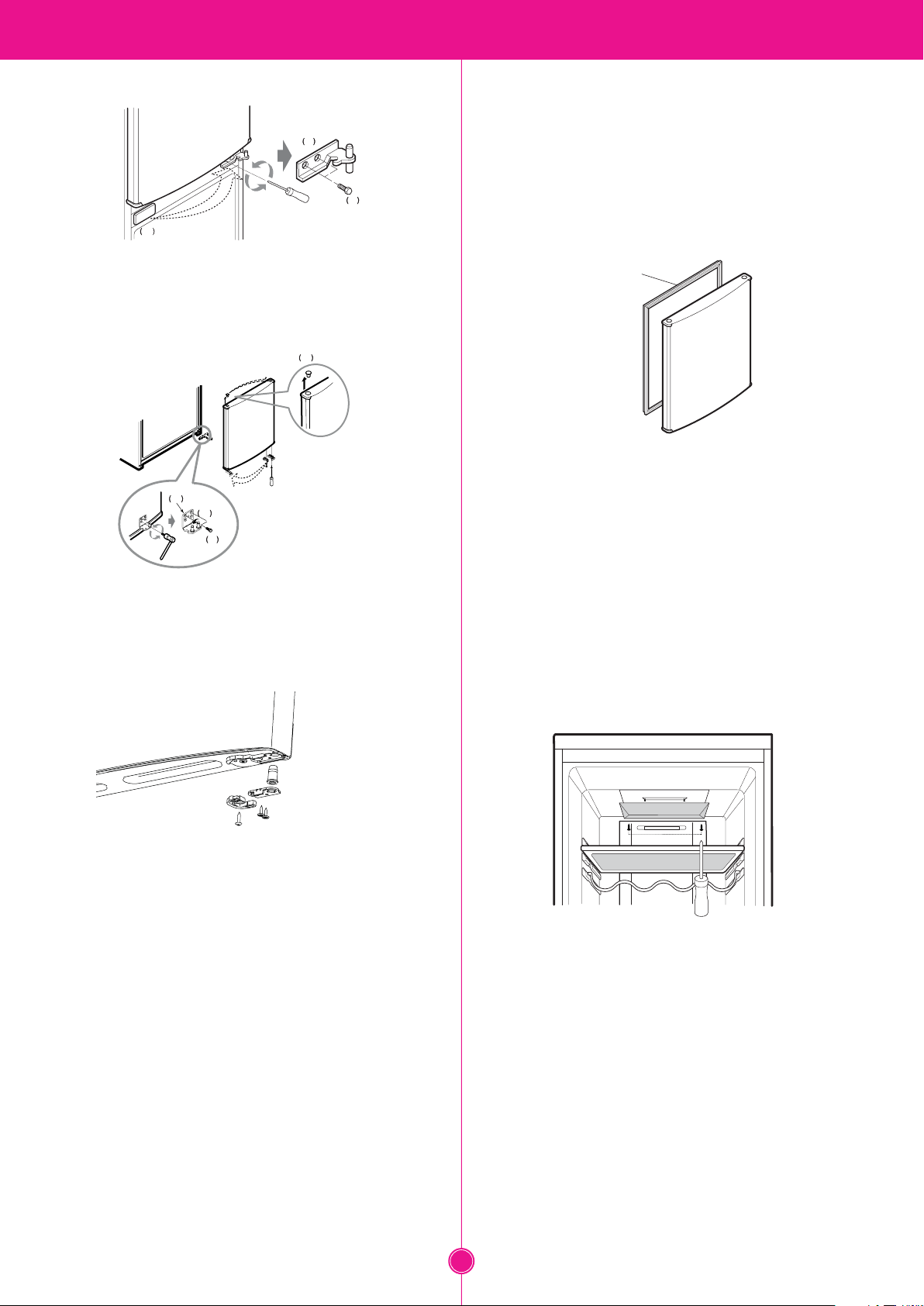

• Remove the upper hinge (14) by unscrew the bolts (13). Remove

the door of refrigerating compartment. Unscrew the rod (15) and

screw it on opposite side of the hinge (14). Fix the gasket (16) on

opposite side of the hinge (14).

13

14

16

15

• Remove the central hinge (18) by unscrew the bolts (17) with

hexahedron of 5 mm. Remove the door of freezing compartment.

Move the cap (19) to opposite side the refrigerator.

9

INSTRUCTIONS FOR REVERSING DOOR SWING

DISASSEMBLY

18

17

19

• Take off the lower hinge (21) by unscrew the screws (20). After

unscrew the rod (22) install it (22) to opposite side of the lower

hinge (21) using key of 6 mm. Remove the cap (23) from upper

part the door of freezing compartment and install it (23) to

opposite side.

21

22

20

23

DISASSEMBLY

1.DOOR

• Freezer Door

1. Refer to previous chapter "Instruction for Reversing Door Swing".

2. Pull out the Door Gasket to remove from the Door Foam Assembly,

Freezer.

GASKET

• Refrigerator Door

1. Refer to previous chapter "Instruction for Reversing Door Swing".

2. Pull out the Door Gasket to remove from the Door Foam Assembly,

Refrigerator.

2. REFRIGERATOR ROOM LAMP

• Remove the limiter (24), the sleeve (25) and the closer (26) from

lower part of the door of refrigerating compartment by unscrew

the screws (27). After install and screw it (24,25,26) to opposite

side. Repeat this doing with the door of freezing compartment.

(25)

(26)

(27)

(24)

• Install the lower hinge (21) of freezing compartment, then

install the door of freezing compartment, then install the central

hinge (18) and the door of refrigerating compartment, then

install the upper hinge (14), connect the cabel (4) and install the

covers (8,6) and the top cover (2).

1. Unplug the power cord from the outlet.

2. Turn out 2 screw and remove cover lamp assembly.

3. Turn out 2 screw to remove LED PCB assembly if needed.

4. Assemble in reverse order of disassembly.

Replacement must be the same specication as original.

10

10

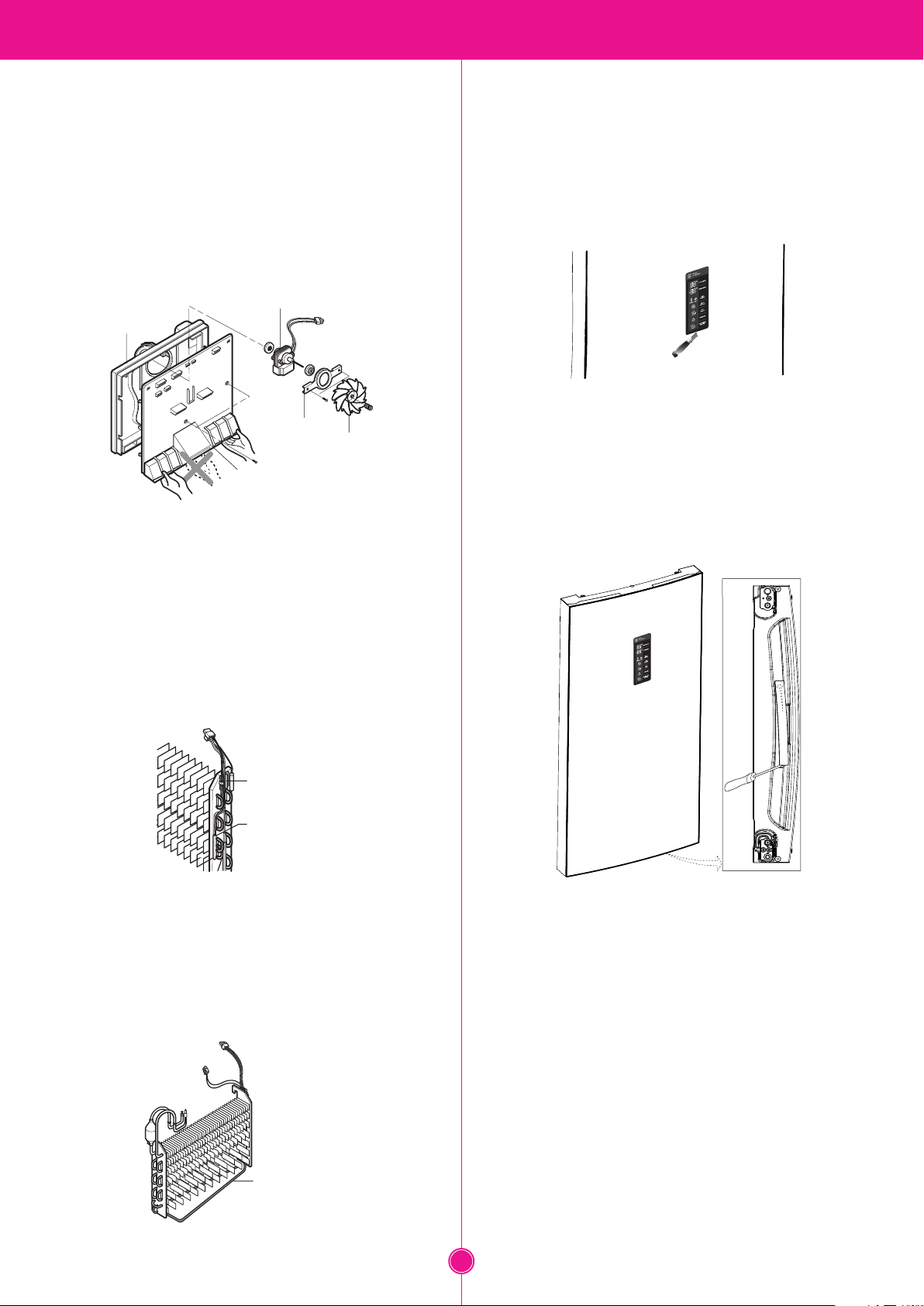

DISASSEMBLY

3. FAN AND FAN MOTOR

1. Remove freezer drawers.

2. Remove two cap, screws and loosen two screws in Grille Fan.

3. Pull out the Grille Fan and Shroud, F.

4. Disconnect the housing of lead wire.

5. Separate the Fan Assembly.

6. Losse 2 screw xed to the Bracket.

7. Pull out Shroud, F remove the Fan Motor Assembly.

8. Separate the Motor Bracket and Rubber.

4. DEFROST CONTROL ASSEMBLY

Defrost Control Assembly consists of Thermistor and Fuse,

Melting. Thermistor functions to defrost automatically and it is

attached to metal side of the Evaporator and senses temperature.

Fuse, Melting is a kind of safety device for preventing overheating

of the Heater when defrosting. At the temperature of 77°C, it

stops the emission of heat from the Heater.

1. Pull out the Shroud, F after removing the Grille.

2. Separate the connector connected with the Defrost

Control Assembly and replace new one.

6. DISPLAY REMOVE

1. Insert the blade of a knife in the middle bottom of the

screen carefully.

2. Tilt the knife down until the display while latches do not come

out of the grooves.

3. Remove the display.

7. BACKLIGHT LED IN THE DOOR

1. To remove LED move cover LED to the left side for 2 mm in the

lower part of the door. Than insert at screwdriver in the gap and

extract LED cover.

2. Disconnect the connector and remove LED.

Thermister

Fuse, Melting

5. HEATER, SHEATH

In this refrigerator, Heater, Sheath is used for defrosting heater.

During heating, the temperature of heater rises about 300 ~ 350.

Therefore, be careful not to burn while servicing.

1. After removing the Grille and Shroud, separate the Heater,

Sheath by disconnecting the connectors.

2. Exchanged Heater, Sheath and connected the housing.

Heater, Sheath

11

GA-B499Y**Z

CIRCUIT DIAGRAM

12

GA-B499Z**Z

CIRCUIT DIAGRAM

13

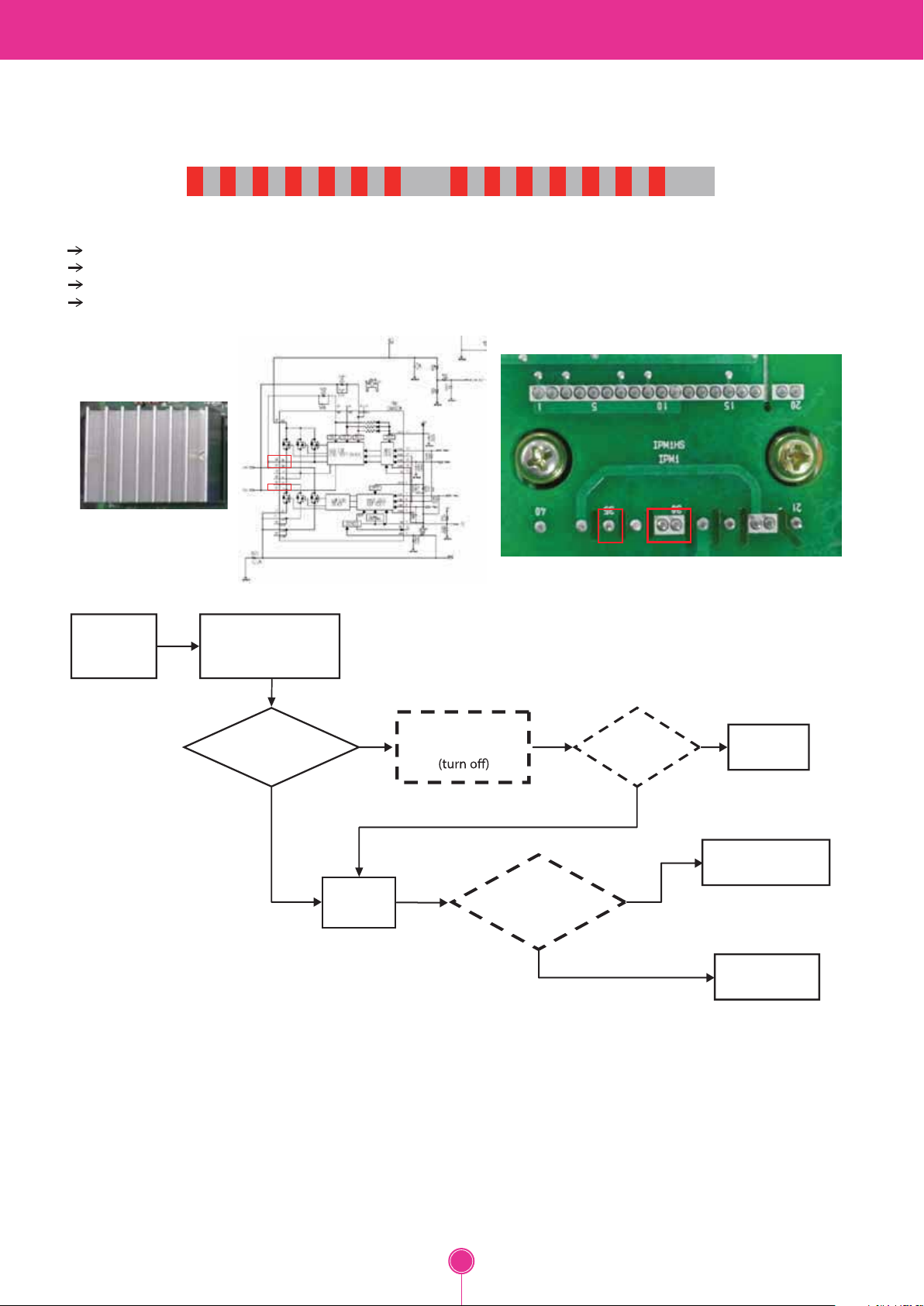

COMPRESSOR

1. Inverter Linear Compressor

Check for defect of the inverter linear compressor in following orders:

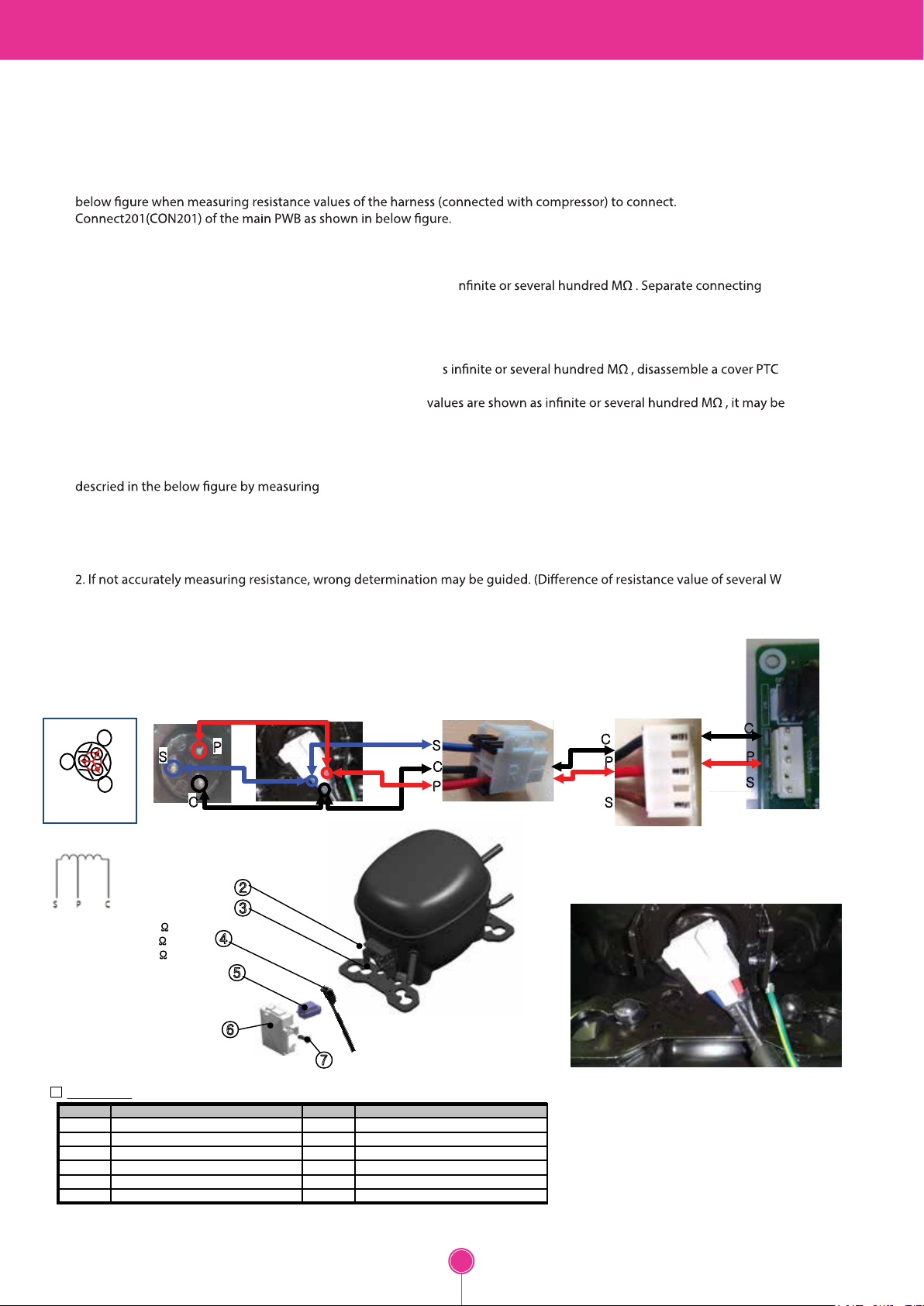

1) Method to Measure Compressor Winding Resistance

Normal Determination Criteria.

The compressor winding resistance can be determined as normal if resistance values show the values as described in

Defect Determination Criteria

• Check connection status of the Compressor Connection Harness-P(Lead Wire) which is located at the M/C room where

resistance values measured at the CON201 Housing are shown as i

wires of the M/C room (A-point in Figure) and then measure resistance values at the connecting wires again. The

compressor can be determined as normal if resistance values are shown as standard resistance value. Check connection

status of a harness.

Defect at M/C room connection contact or CON201 Housing contact, short-circuit of harness)

• Where resistance values measured at A-point are also shown a

of the compressor terminal and check the terminal connecting status at the B-point in Figure.

• Where there is no failure in the wiring status and resistance

determined as defect of compressor.

• Since if there is no failure in resistance values of the compressor, it may be defective Main PWB, replace the Main PCB

and check for normal operation of the compressor.

• When determining any defect through resistance measuring, it can be determined as normal if resistance values show as

① power and ③ common terminal or ② full power and ③ common terminal.

However, resistance values are measured when measuring ① power and ② full but measuring is meaningless since they

cannot become criteria for determining defect (measuring not required).

Caution

1. Be sure to powering o the refrigerator and measure after several minutes has passed.

or so may occur.)

Connect harness to linear compressor FMC088NAMA

P : Power Line

S : Save Line

C : Common Line

S

TERMINAL Part

Ex) S – C : 803 turn (17.4Ω 23℃)

S – P : 192 turn ( 5.3Ω

P – C : 611 turn (12.1Ω

Herametic terminal

(Comp. side)

P

S

C

23℃)

23℃)

Wafer

( Drive side )

Harness : 3 pin

( Comp. side )

P

Harness : 4 pin

( Case side )

S

C

P

C

②

Harness : 5 pin

( Drive side )

C

P

C

P

S

S

The correct position connect

Harness to compressor

③

④

⑤

⑥

⑦

■ Parts List

Ref. Description Ref. Description

1 Compressor 7 Cover Screw

2 Bracket Terminal

3 Hermetic Terminal

4 Harness (Compressor Cable)

5 OLP (Overload protector)

6 Cover PTC

Fig. 1 Linear Controller exploded view

14

COMPRESSOR

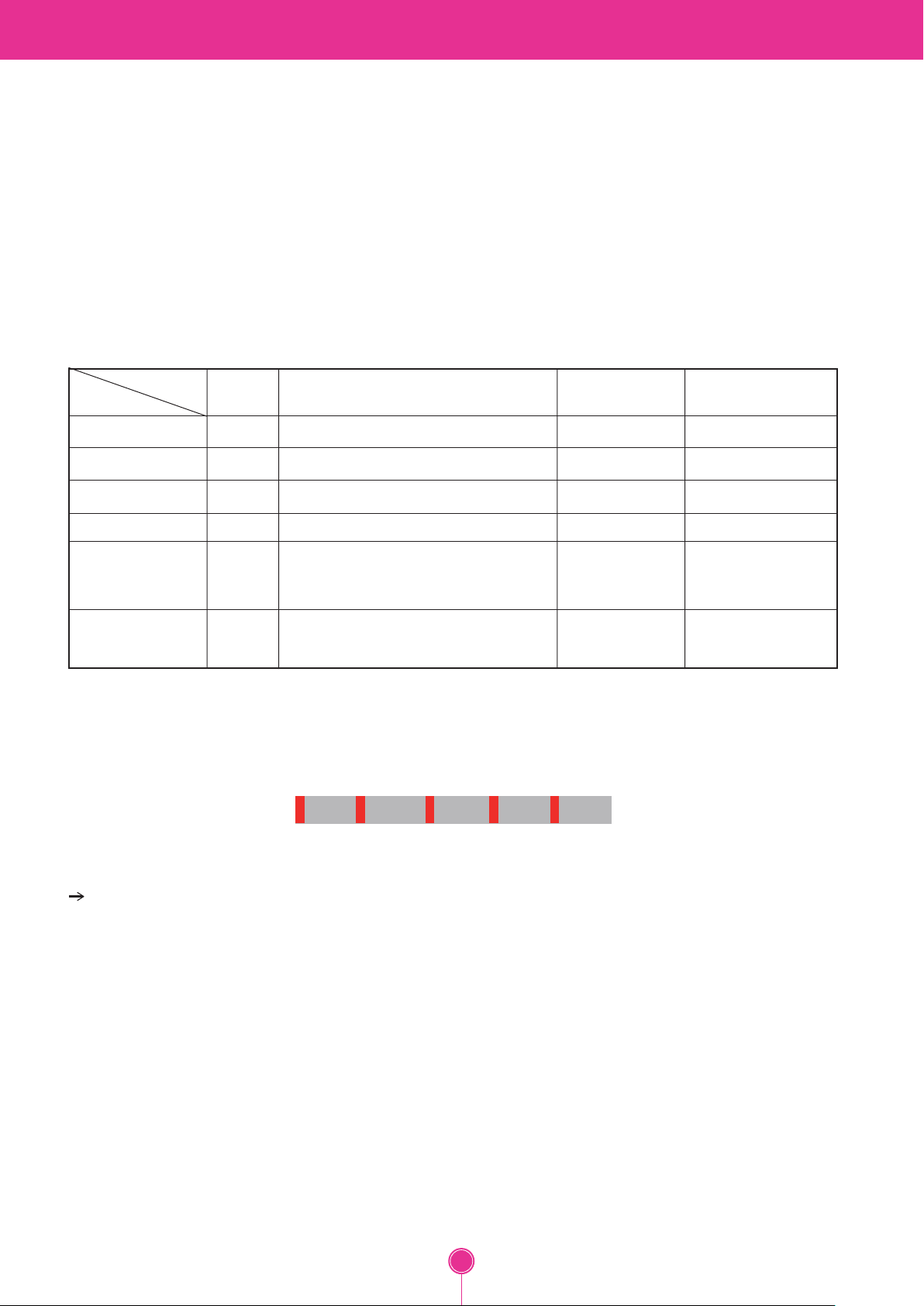

2) Method to Determine Defect of Inverter Linear Drive

Determination of Comp Operation

Separate the back cover at the rear of refrigerator and determine for possible operation while touching the compressor with

the hands with insulation gloves worn.

Comp Operation

- Determine possible trip by checking operation status if cold air comes out after opening the doors of the R-Room.

Protective Logic (Trip)

- To protect the compressor from abnormal operation, this logic is used to temporally stop the refrigerator when abnormal

operation occurs and to re-operate it after abnormal signal disappears.

Compressor protection Logic Table

App.

FCT0 Trip

Stroke Trip

Locked Piston Trip

Current Trip

IPM Fault

Communication

Error

* If LED of PCB is blinking, Refer to next page.

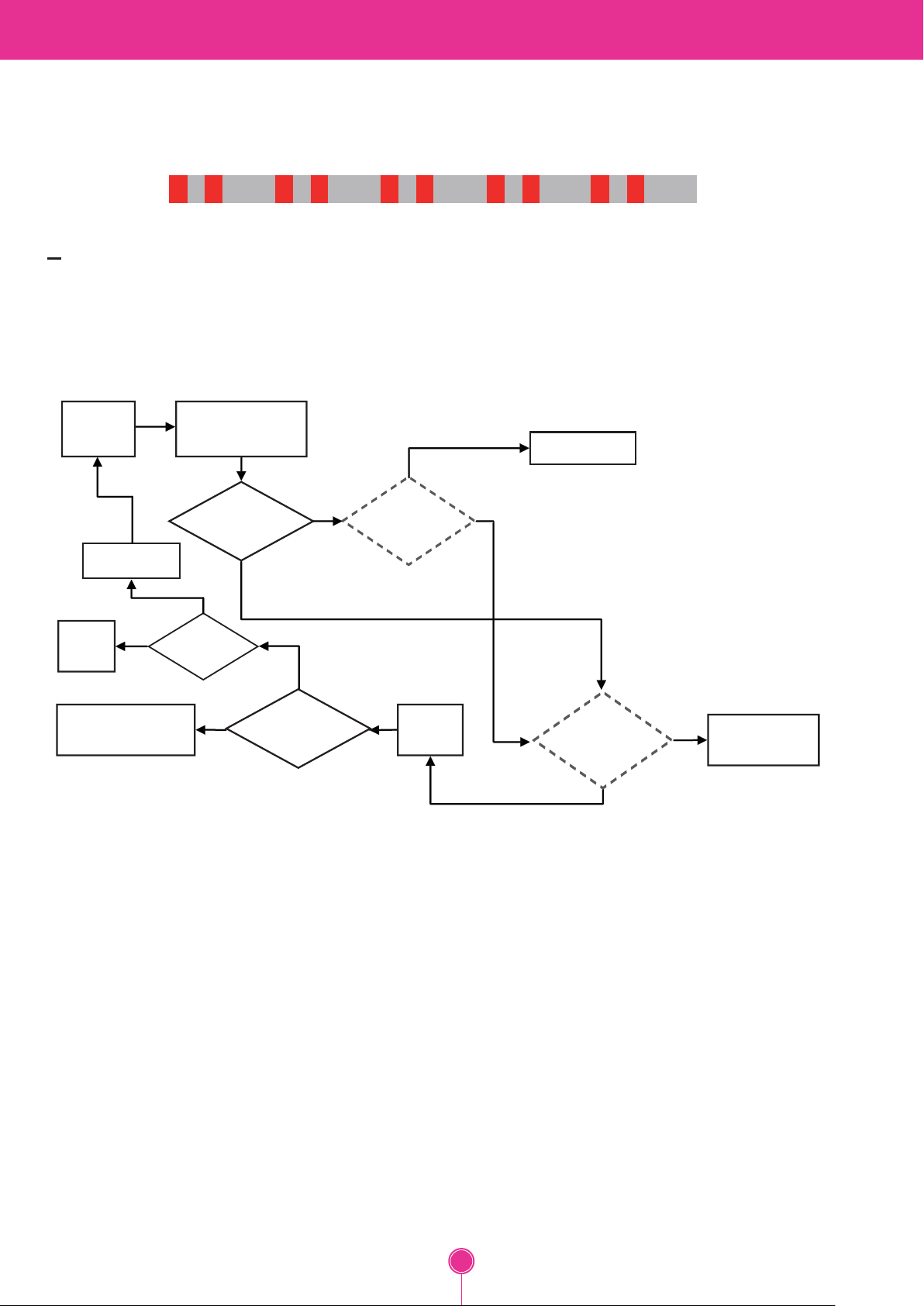

3) LED blinks one time, then repeats (FCTO Trip)

A-Inv.

A-Inv.

A-Inv.

A-Inv.

A-Inv.

A-Inv.

Initial, Motor sensing Voltage > 2.5V+20%

Piston overruns the designed range.

Piston is locked.

Current overruns the designed range

IPM pin 14 output voltage = low (IPM Short,

High current input, or low voltage input)

Checksum error

Requirement Waiting Time

30”

1’00”

2’30”

6’00”

20”

-

The number of LED

blinking

1

2

5

6

7

8

Blink BlinkOFF OFF

• FCT0 : When same trip occurs after power reset, change PCB.

Because it is occurred by overvoltage (more than 2.5V) at voltage and

current sensing parts, PCB has to be changed.

15

COMPRESSOR

4) LED blinks two times, then repeats (Stroke Trip)

Blink Blink OffBlink Blink Off

Purpose: Prevent abnormally long piston strokes.

Case 1. If compressor doesn’t work and LED blinks

- Cause: Possibly harness from compressor to PCB might be defective.

Case 2. If compressor works intermittently and LED blinks

- Cause: Condenser Fan or Freezer Fan is not running. Sealed system problem such as moisture restriction, restriction at

capillary tube or refrigerant leak.

Logic: Compressor is forced to o� and then tries to restart after 1 minute.

Protection

logic

Check B

Replace

Driver PCB

OK

Fix

Cycle

Check Procedure

NG

Repeat

Blink 2 times

(Stroke Trip)

Check B2

Compressor

Doesn ’ t work

Cycle

Check E

N

N

Y

Stroke Trip

Occur?

N

Y

Harness

Connecting

Check C

Reset

Power

Y

Fix Harness

Compressor

Damage

Check C

Y

N

Replace

Compressor

16

COMPRESSOR

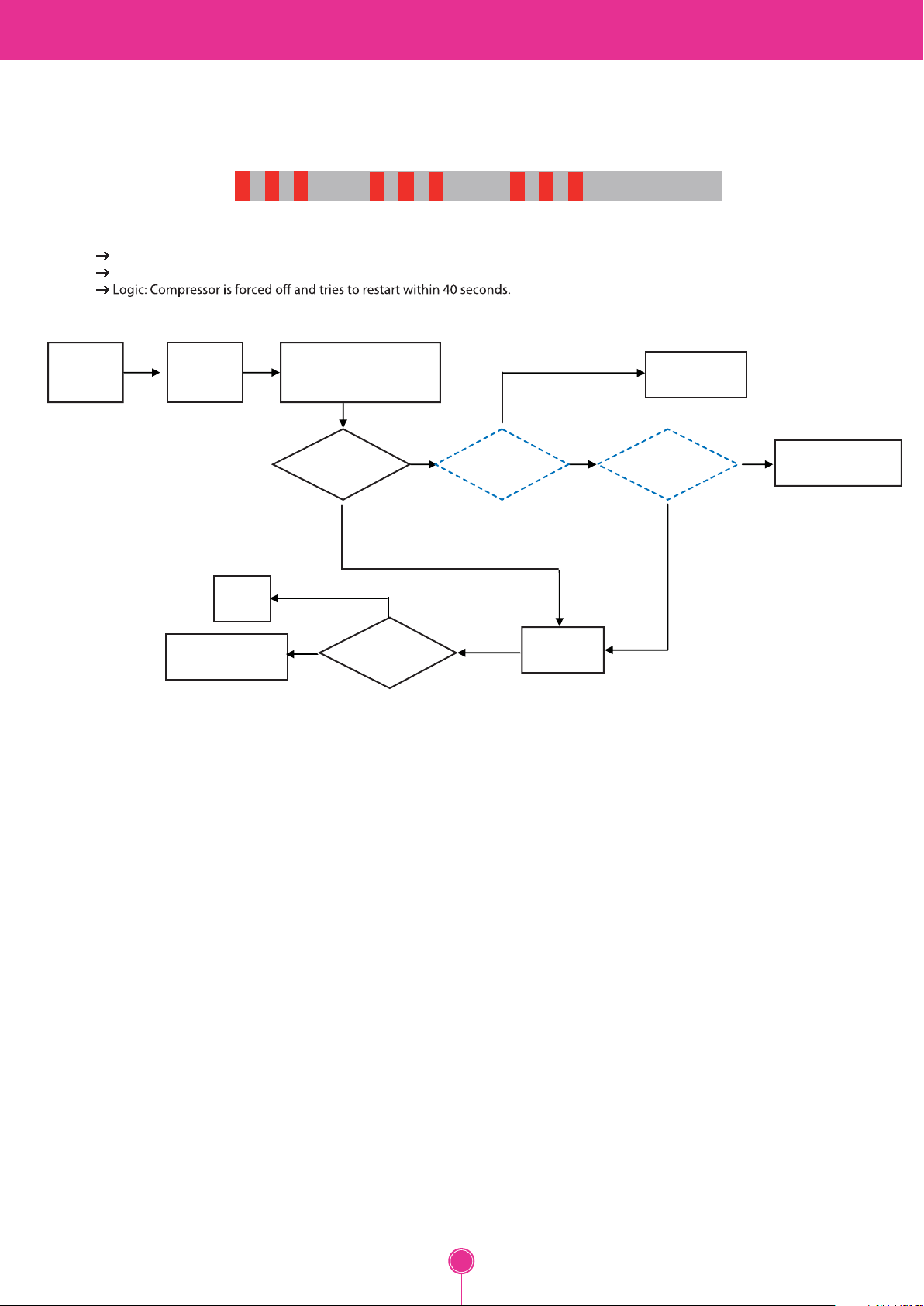

5) No Connect Trip, LED blinks 3 times

Blink Blink Blink OFF Blink Blink Blink OFF

Purpose: Check for Connecting error. Prevent Over Current, Over Voltage.

Cause: Harness Error between PCB and Compressor, Insulation Defect.

Protection

logic

Check

Rec

ord

Replace

PCB

Repeat

Check Procedure

No Connect or

Blink 3 times

(No Connect Trip) Check

Compressor

Doesn’t work

N

Y

N

Stroke Trip

Occur?

N

Y

Harness

Connecting

Check

Reset

Power

Y

Compressor

Damage Check

Y

Fix

Harness

N

Replace

Compressor

17

COMPRESSOR

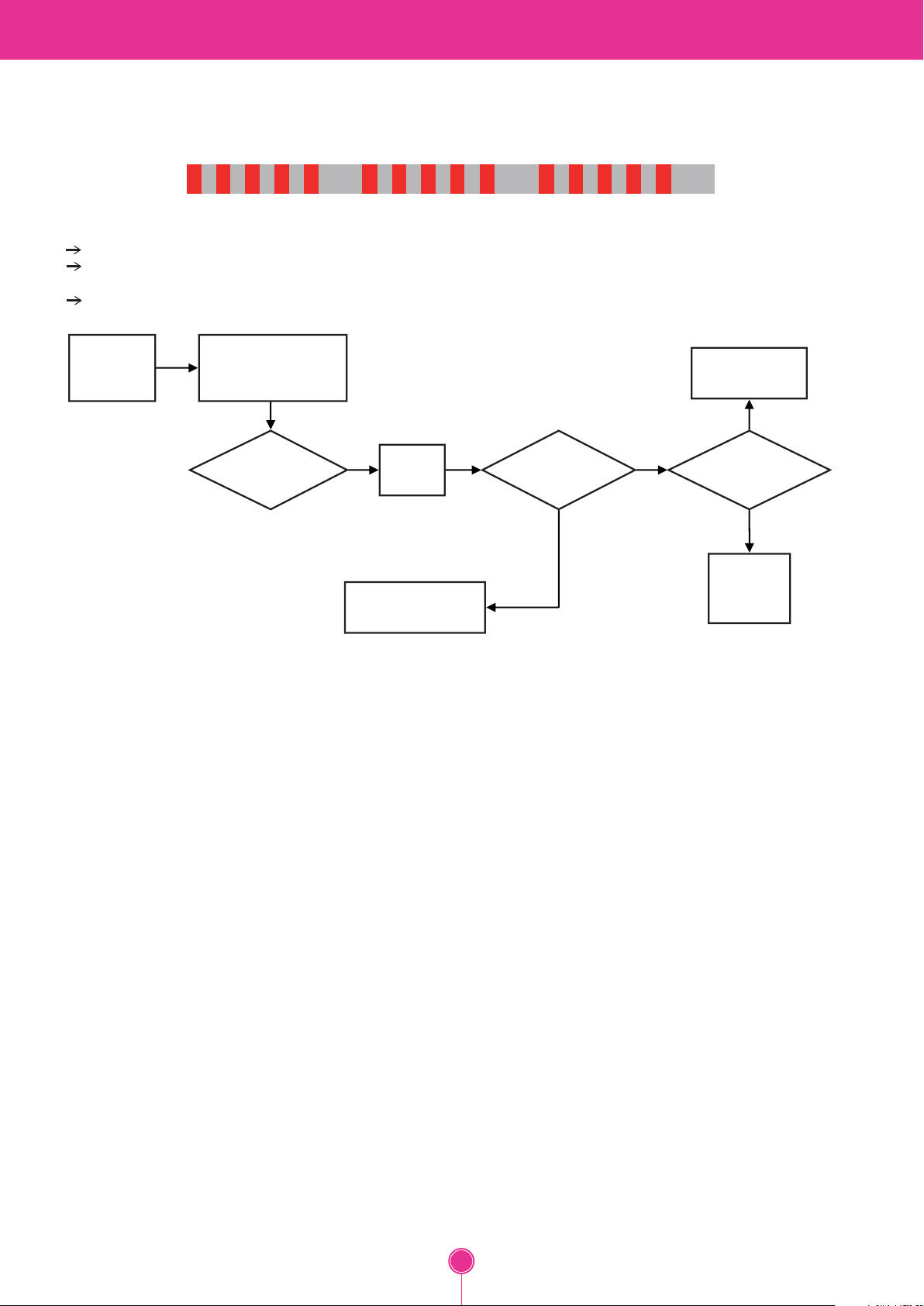

6) LED blinks ve times, then repeats (Locked Piston)

Blink Blink Blink Blink Blink OFF

Purpose: To detect locked piston

Cause: Lack of oil to the cylinder, cylinder or piston damaged and or restricted discharge.

A Locked Piston can also be caused by foreign materials inside the compressor.

Logic: Compressor is forced o� and tries to restart within 2.5 minutes.

Protection

logic

Check B

Blink 5 times

(Lock Piston Trip)

Check B3

Compressor

Doesn’t work

Reset

Power

Repeat

Check Procedure

Compressor

Doesn’t work

N

Replace

Compressor

N

Y

Hi side

restriction

Y

Sealed

system

Repair

18

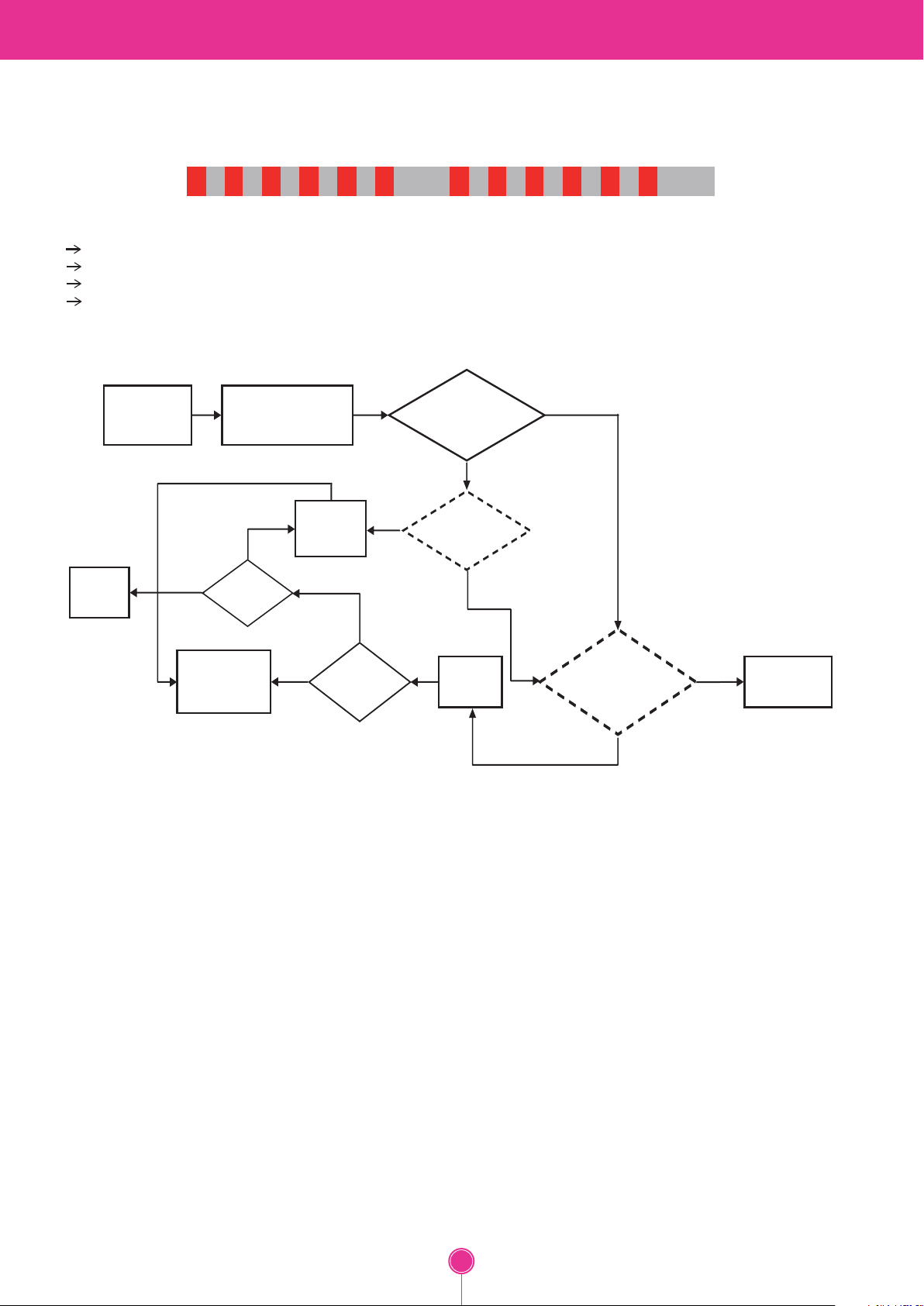

7) LED blinks six times, then repeats (Current Trip)

COMPRESSOR

Blink Blink Blink Blink Blink Blink

Purpose: Prevent over-current (overload protect)

Cause: Ambient temperature is high (over 43°C) and/or refrigerator’s condenser air movement is restricted.

Condenser Fan is stopped, restricted discharge line, compressor is damaged, or IPM device is defective.

Logic: Compressor is forced o� and tries to restart after 6 min.

Protection

logic

Check B

Fix

Cycle

Blink 6 time

(Current Trip)

Check B4

Y

Cycle

Check E

Replace

Driver

PCB

Y

NG

OFF

Compressor

Intermittently

works

IPM

Check B5

Y

N

Y

Repeat

Check

Procedure

N

Current trip

Occur?

Reset

Power

Compressor

Damage

Check C3

Y

NG

Replace

Compressor

19

COPMRESSOR

8) LED blinks seven times, then repeats (IPM Fault)

Purpose: Prevent high current due to IPM Short

Cause: Damaged IPM (Dead Short)

Test for a dead short at Point Awith a VOM.

Logic: Compressor is forced o and tries to restart after 20 sec.

OFFBlink Blink Blink Blink Blink Blink Blink

Protection

logic

Check B

Blink 7 times

(Lock Piston Trip)

Check B5

Compressor

Doesn’t work

N

Y

Power

Reset

Check IPM

visual inspection

Compressor

Damage

Check C3

NG

Short

Test

Point A

Y

Y

N

Replace

Drive PCB

Repeat

Check Procedure

Replace

Compressor

20

COMPRESSOR

9) LED blinks eight times, then repeats (Communication Error)

Blink

Blink

• Communication Error : When same trip occurs after power reset,

change PCB.

Because Program is not matching in MICOM, program has to be

rewritten or PCB has to be changed.

Blink

Blink

Blink

Blink OFF

Blink

Blink

21

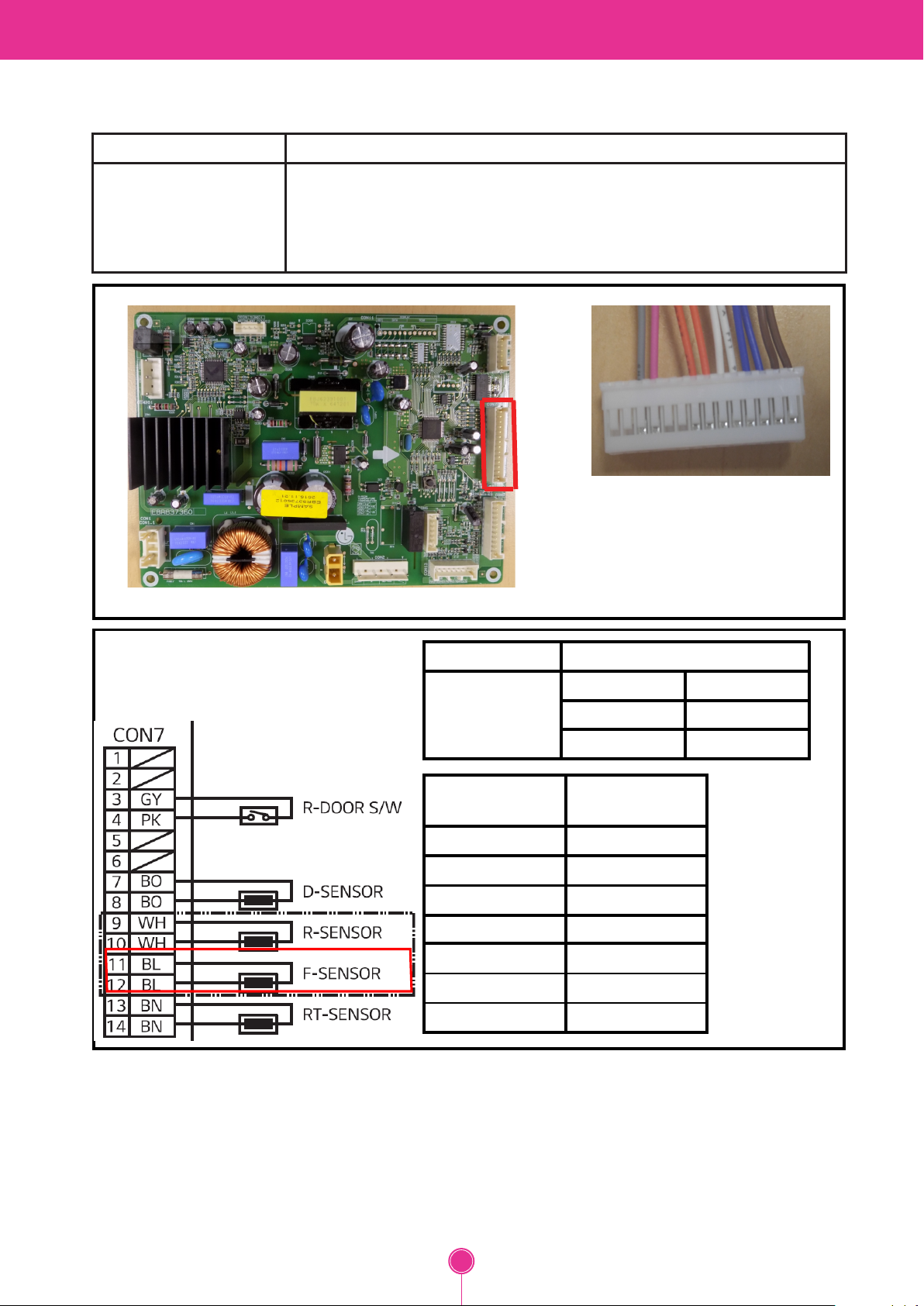

TROUBLESHOOTING WITH ERROR DISPLAY

1. Freezer Sensor Error (FS E)

Symptom Check Point

1. FS E 1. Check for a loose connection

2. Check Sensor Resistance

C

ON7

CON7

11

th

pin ~ 12

th

pin

CON7

11

th

-22

-13

14

pin ~ 12

o

o

o

-4

o

5

o

23

32

th

pin

F / -30oC 40k

F / -25oC 30k

F / -20oC 23k

F / -15oC 17k

F / -10oC 13k

o

F / -5oC 10k

o

F / 0oC 8k

Resistance [Ω]

Short 0

Open OFF

Other Normal

Resistance [Ω]

22

Loading...

Loading...