Page 1

4

SERVICING PRECAUTIONS

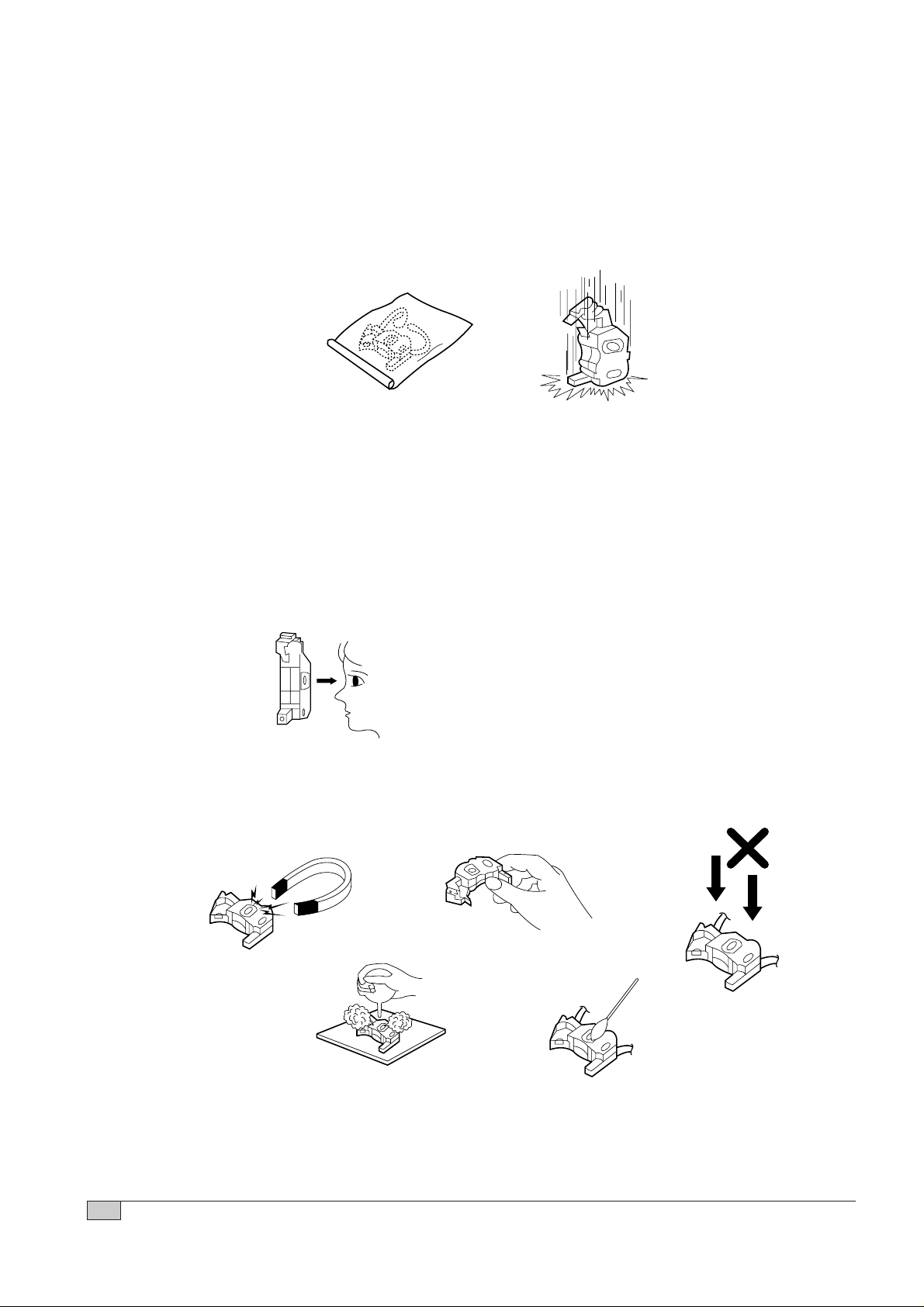

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a

cotton swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do

not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much of

this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don

¡˙t let

contact fingers or other exposed skin.

Magnet

How to hold the pick-up

Pressure

Pressure

Cotton swab

Conductive Sheet

Page 2

5

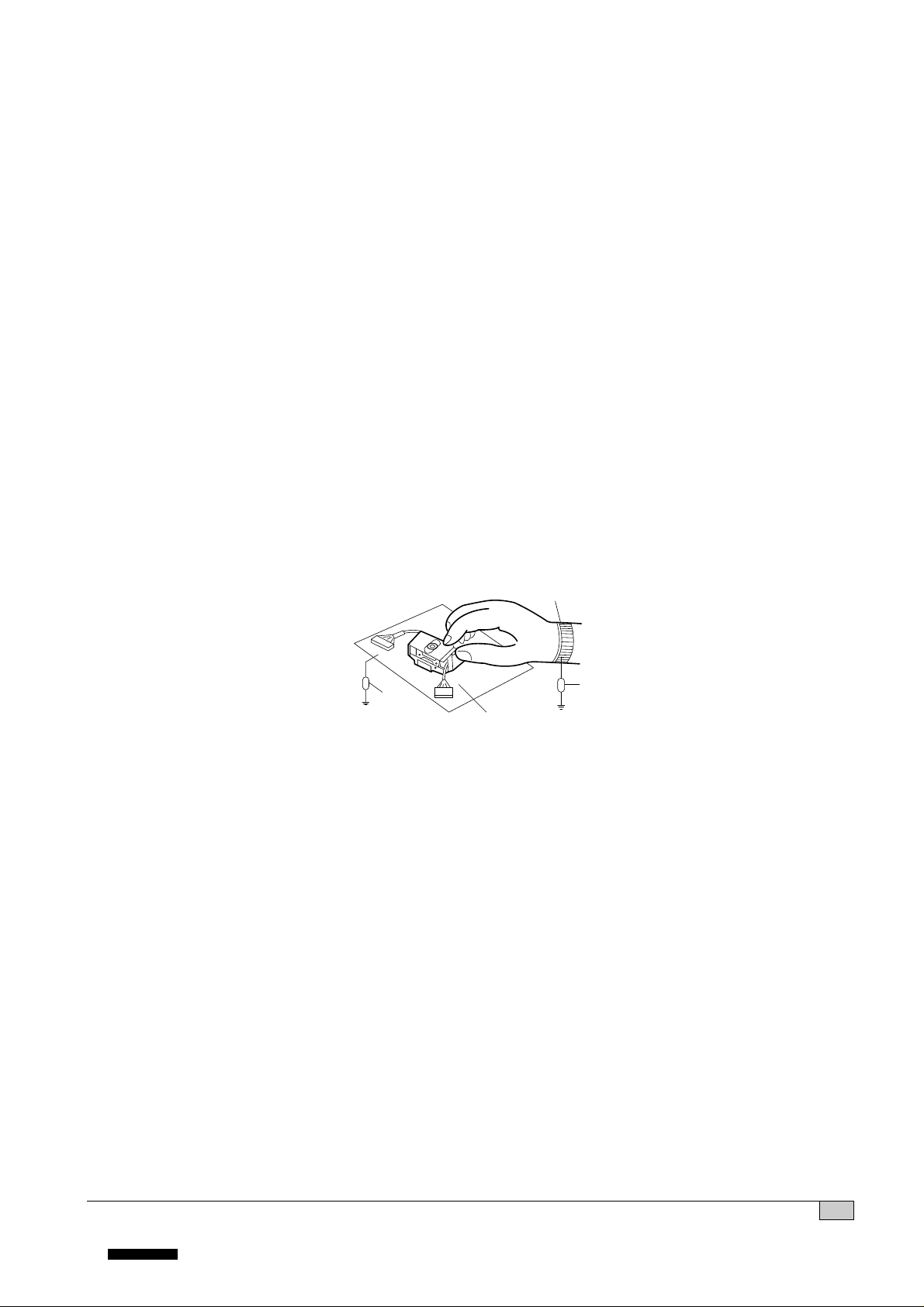

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These

components are sensitive to, and easily affected by, static electricity. If such static electricity is high

voltage, components can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must

be taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong

magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Armband

Conductive

Sheet

Resistor

(1 Mohm)

Resistor

(1 Mohm)

Page 3

6

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an ESD device).

Page 4

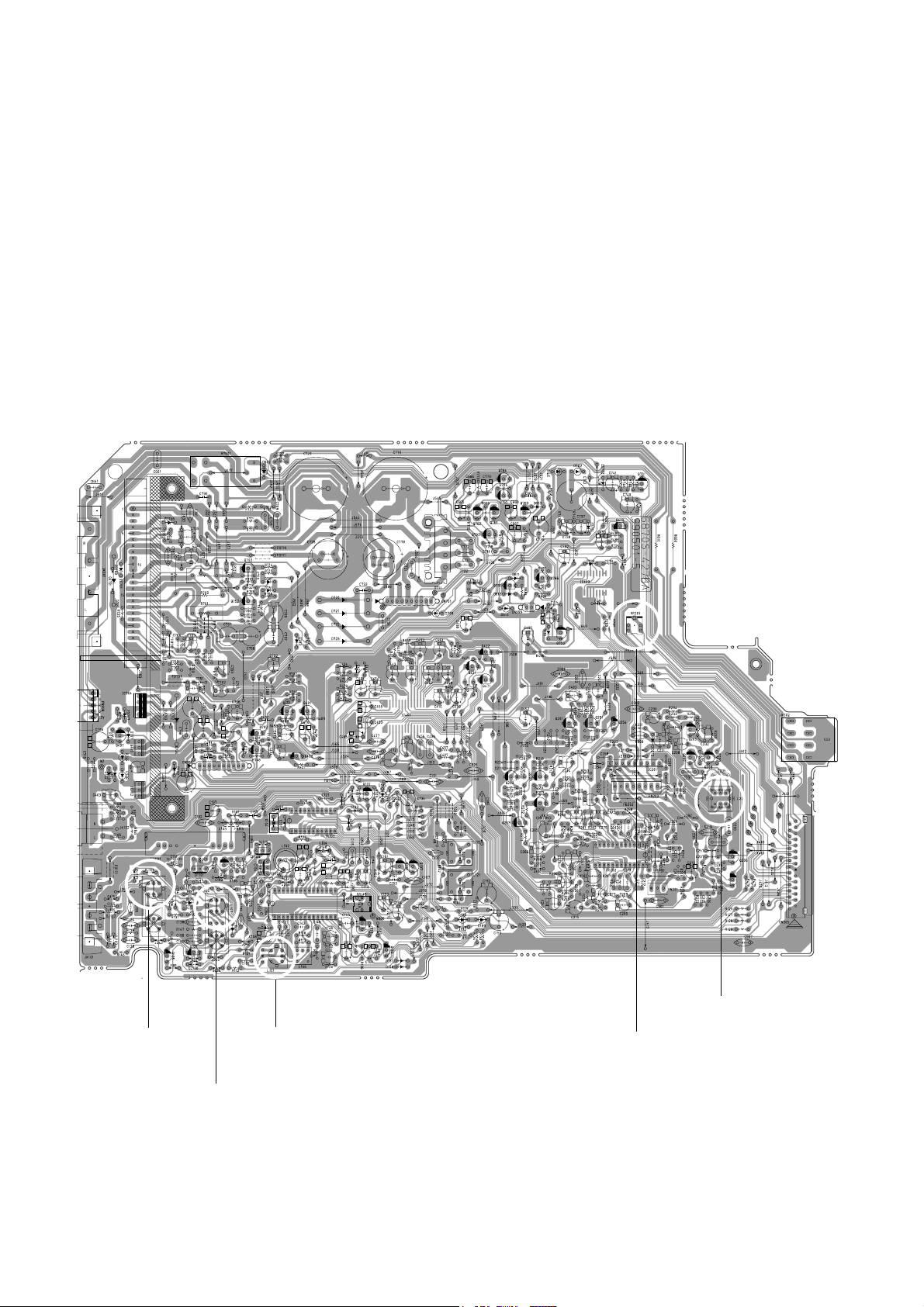

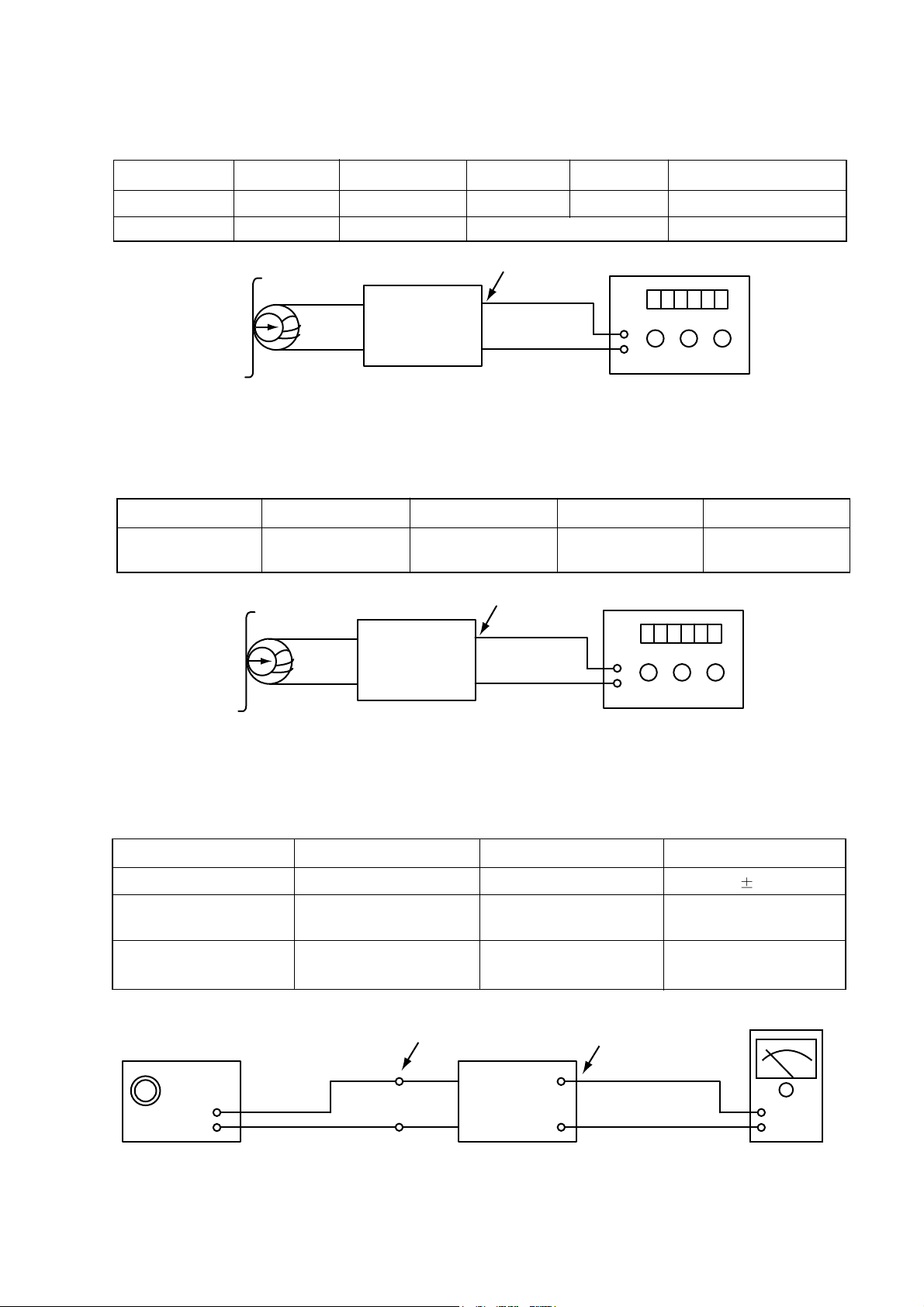

ADJUSTMENTS

This set has been aligned at the factory and normally will not require further adjustment. As a result, it is not

recommended that any attempt is made to modificate any circuit. If any parts are replaced or if anyone tampers

with the adjustment, realignment may be necessary.

IMPORTANT

1. Check Power-source voltage.

2. Set the function switch to band being aligned.

3. Turn volume control to minimum unless otherwise noted.

4. Connect low side of signal source and output indicator to chassis ground unless otherwise specified.

5. Keep the signal input as low as possible to avoid AGC and AC action.

TEST & ADJUSTMENT POINT

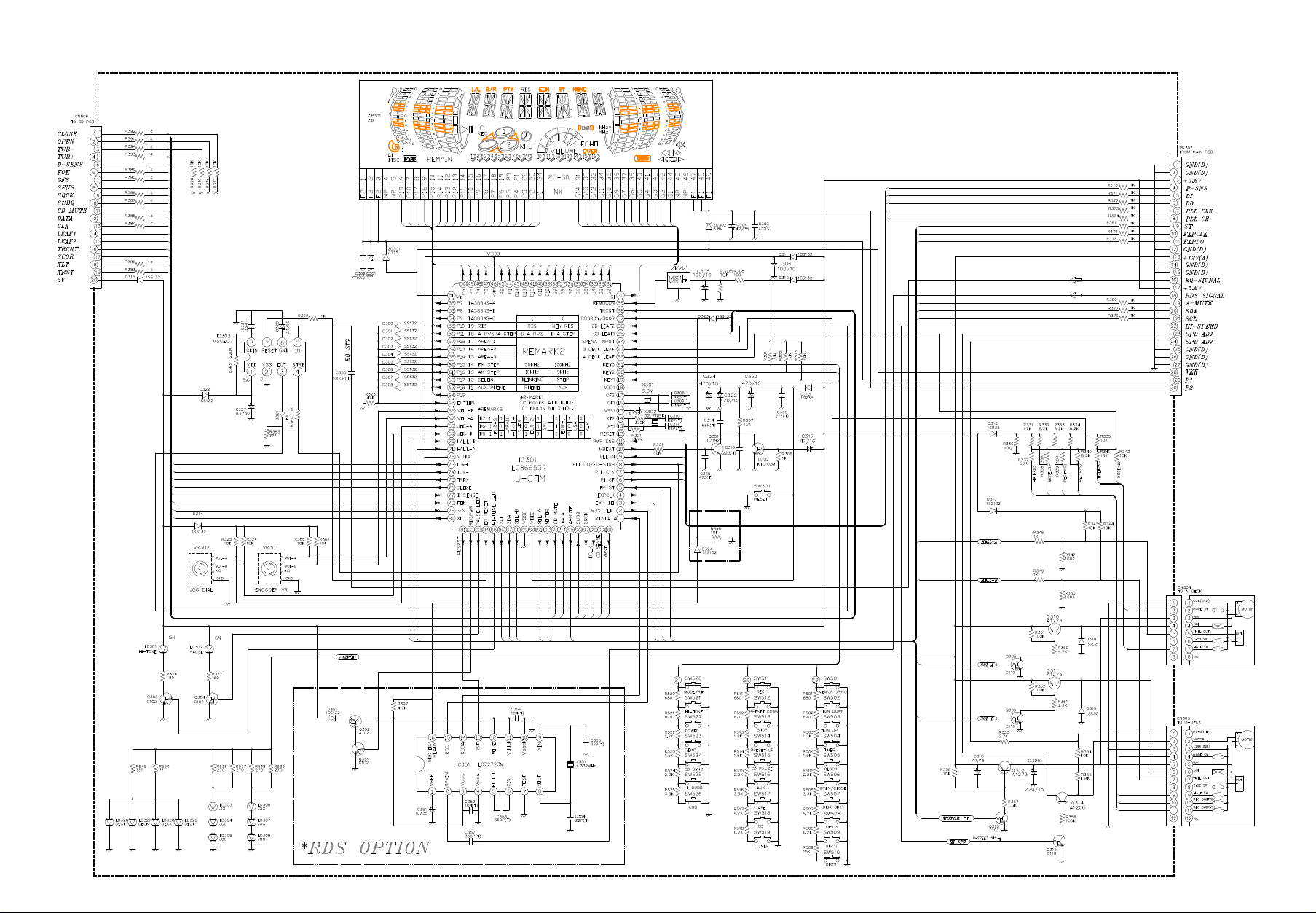

Figure 1. Main P.C. Board(FFH-717)

- 8 -

VR201

(Adjustment Point)

L203

(Rec Bias)

L105

(LW/SW USABLE

SENSITIVITY)

L016

(DC VOLTAGE)

L017

(MW USABLE

SENSITIVITY)

Page 5

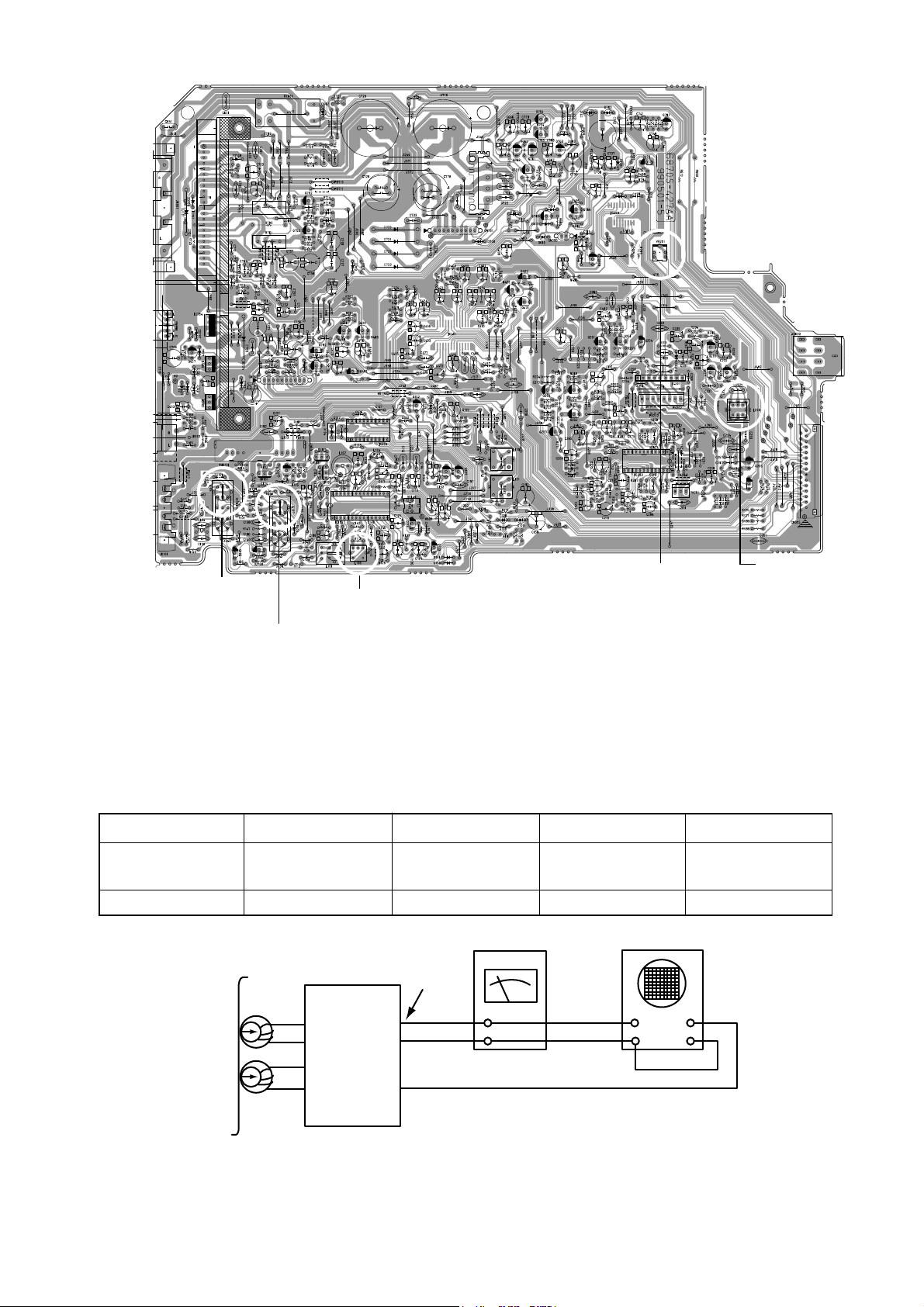

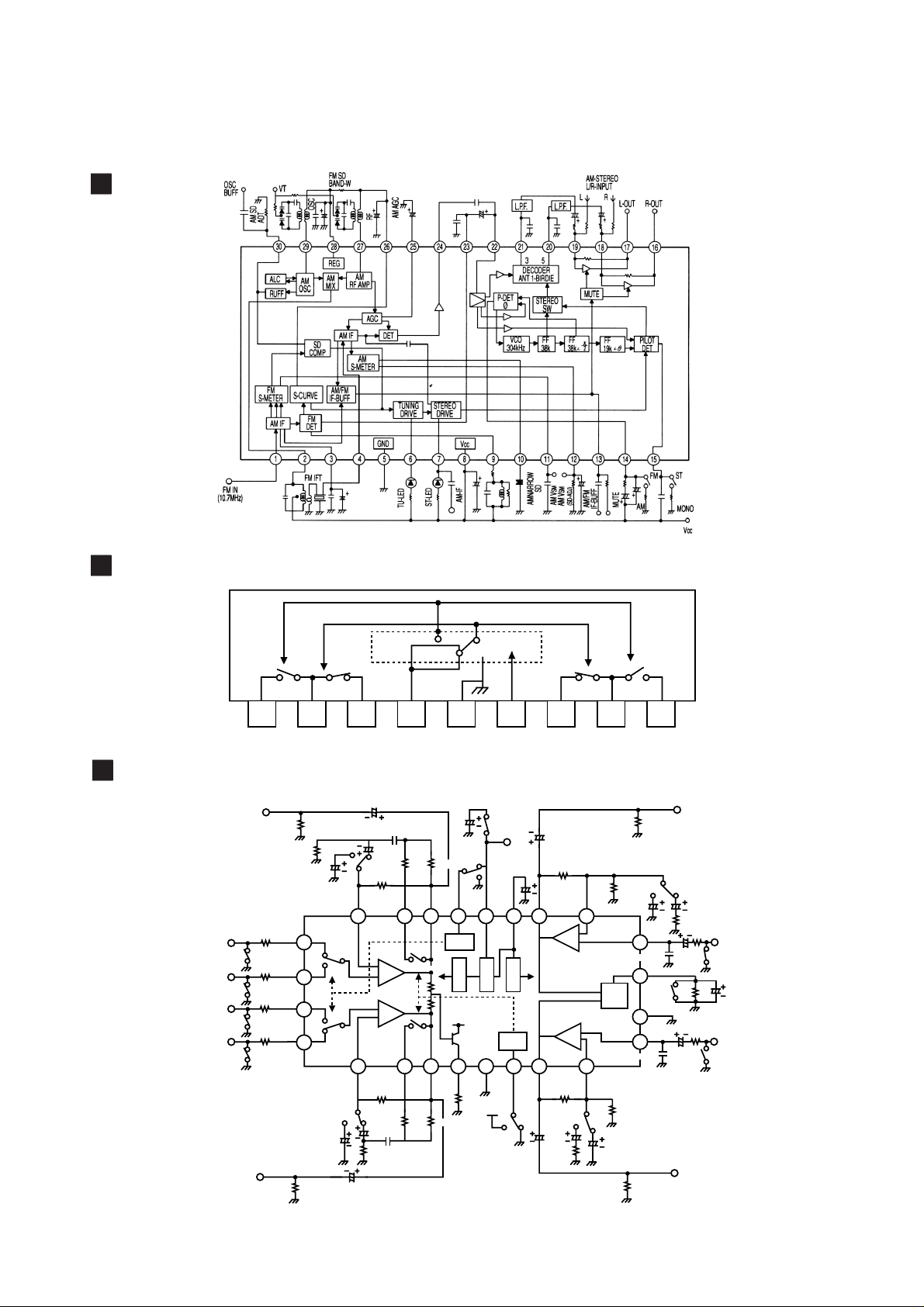

TAPE DECK ADJUSTMENT

1. AZIMUTH ADJUSTMENT

Figure 3. Azimuth Adjustment Connection Diagram

CH1 CH2

Speaker Out

Playback Mode

Head

Test Tape

MTT-114

L ch

R ch

GND

Dual-trace

synchroscope

Electronic

Voltmeter

L out

R out

Unit

Figure 2. Main P.C. Board(FFH-818)

Deck Mode Test Tape Test Point Adjustment Adjust for

A Deck Playback MTT-114 Speaker Out

DECK Screw

Maximum

Azimuth Screw

B Deck Playback MTT-114 Speaker Out Azimuth Screw Maximum

VR201

(Adjustment Point)

L203

(Rec Bias)

L105

(LW/SW USABLE

SENSITIVITY)

L016

(DC VOLTAGE)

L017

(MW USABLE SENSITIVITY)

- 9 -

Page 6

- 10 -

3. RECORD BIAS ADJUSTMENT

Head

Unit

PN202

GND

Record/Playback

head

Test Tape

MTT-5511

Record/Playback

and Pause Mode

Frequency Counter

Deck Mode Test Tape Test Point Adjustment Adjust for

Rec/Pause MTT-5511

ERASE HEAD

L203 85kHz±5kHz

WIRE(PN202)

Figure 5. Record Bias Adjustment Connection Diagram

4. TUNER ADJUSTMENT

Figure 6. Tuner(S curve) Adjustment Connection Diagram

Unit

Signal Generator

GND

Electronic

OSCILLOSCOPE

FM Antenna

Terminal

Speake

Item Test Point Adjustment Adjust for

DC Voltage Checker Pin L106 0V

50mV

MW Usable

Speaker Out L107 Maximum

Sensitivity

LW/SW Usable

Speaker Out L105 Maximum

Sensitivity

2. MOTOR SPEED ADJUSTMENT

Figure 4. Motor Speed Adjustment Connection Diagram

Head

Playback Mode

Unit

Speaker Out

GND

L out

R out

Record/Playback

head

Test Tape

MTT-111

Frequency Counter

Deck Mode Test Tape Test Point Adjustment Adjust for Remark

Normal Speed MTT-111 Speaker Out VR201 3kHz ± 1% A Deck

HI-Speed MTT-111 Speaker Out more than 5.4kHz HI-Speed Dubbing Mode

Page 7

Page 8

Page 9

- 41 -

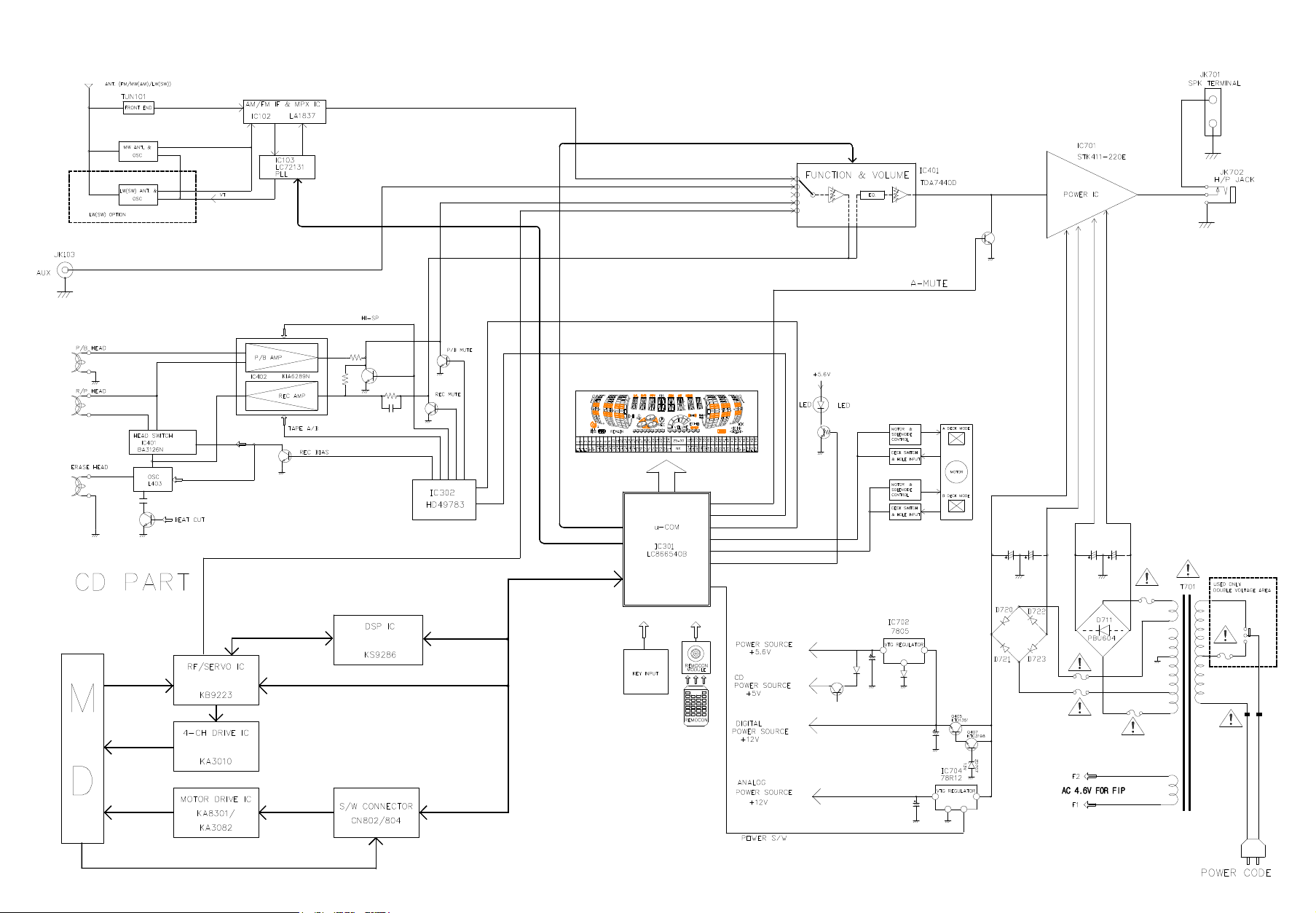

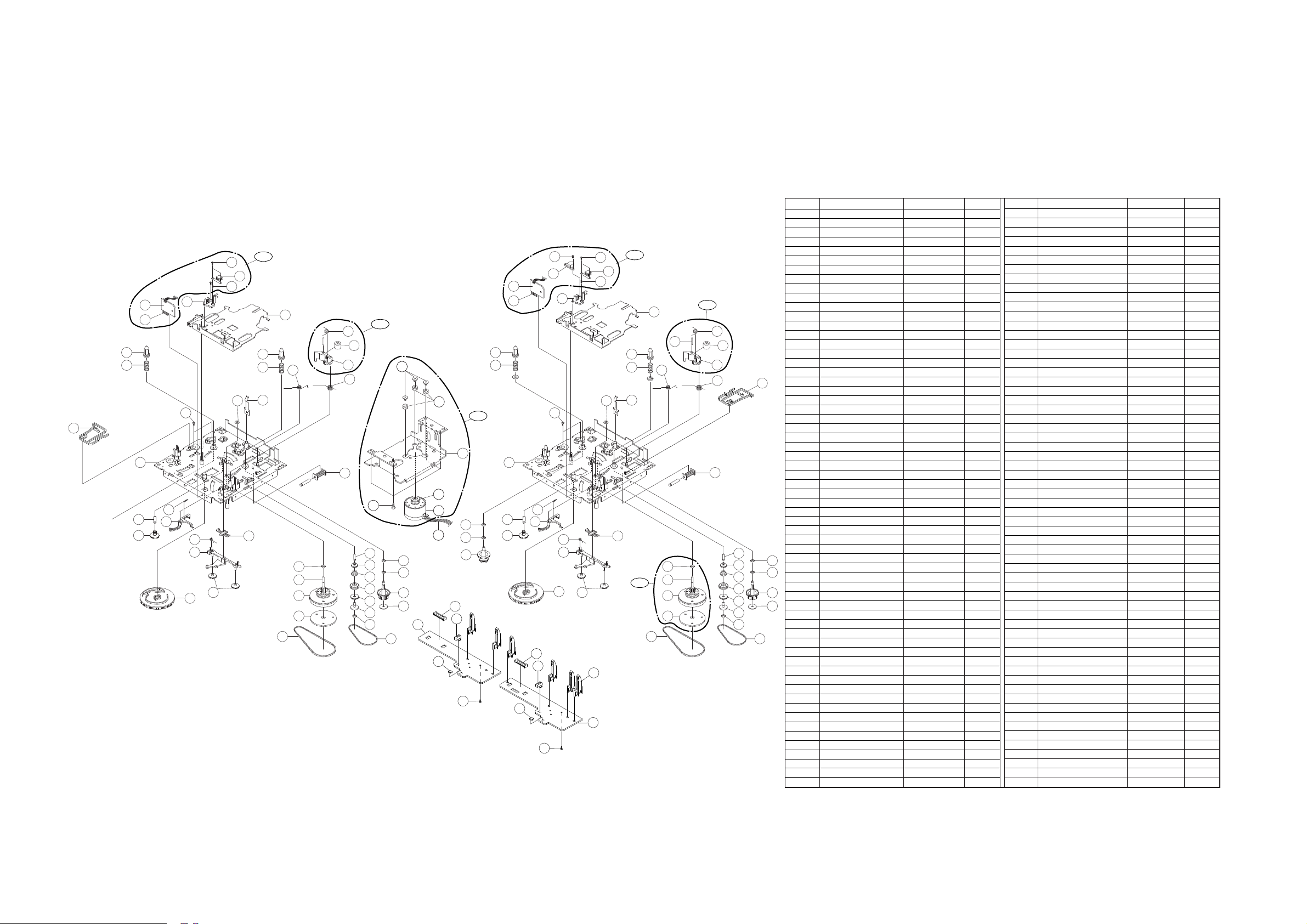

EXPLODED VIEW/PARTS LIST

CABINET

A05

A16

A14

A10

A11

A02

A03

A25

A01

A33

A17

A36

A19

A31

A23

A37

A04

A12

A13

A32

A20

A22

A39

A18

A34

A27

A26

A09

A08

A06

A21

A15

A07

A38

A35

A01 3720SCM038A(*) PANEL FRONT HZ

A02 3580SCA346A DOOR CST LEFT HZ

A01 3720SCM038A PANEL FRONT HZ

A02 3580SCA346A DOOR CST HZ

A03 3580SCA347A DOOR CST RIGHT HZ

A04 3580SCC878B DOOR CD HZ

A05 3550SC0008C COVER FRONT HZ

A06 4940SC0053A KNOB JOG HZ

A07 3680SC0004A LENS JOG HZ

A08 3790SCM056C( *) WINDOW CST-L(FOR FFH-717) HZ

3790SCM056E(*) WINDOW CST-L(FOR FFH-818) HZ

A09 3790SCM057A WINDOW CST-R HZ

A10 3790SCM058A WINDOW AMP HZ

A11 3790SCM059A WIMDOW CD HZ

A12 4940SC0051A KNOB TUNING HZ

A13 4940SC0052B KNOB PLAY & FUNC HZ

A14 4940SC0055A KNOB VOL HZ

A15 3680SC0005A LENS SET HZ

A16 3508SB0001A DECORATION HI-TONE

A17 4901SK0001C DAMPER ASSY HZ

A18 3140S-P907A CHASSIS MAIN HZ

A19 3720S-0036D PANEL SIDE HZ

A20 3090S-0003F CABINET TOP HZ

A21 447-938K CUSHION CUSHION RUBBER(MTR-400/50) HZ

A22 3720SCM409A(*) PANEL BACK(FOR FFH-717) HZ

3720SCM043A(*) PANEL BACK(FOR FFH-818) HZ

A23 6410SCE200A POWER CORD CE-503PLUG CHAUS CE 2000M HZ

A24 632N218E COIL, ANTENNA KS951212-01 KWANGSUNG HZ

A25 442-577B SPRING SPRING CST-PACK(H=7.5)

A26 442-085A SPRING SPRING-DOOR

A27 384-535A GUIDE EJECT AY

A28 4930S-0536A HOLDER HOLDER GUIDE

A29 442-780A SPRING

A30 384-014A GUIDE EJECTOR

A31 265-013B FOOT RUBBER(NBR)

A32 246-444K DECORATION PLATE FFHKL588V SILVER HZ

A33 353-025T SCREW TAPTITE 3X10.5 FZMY HZ

A34 353-025C SCREW TAPTITE 3X10 FBK HZ

A35 1TRL0402418 BRAIZER HEAD TA D 4.0 L 8.0 MSWR3/FZY HZ

A36 6730S-G005B DECK MECHANISM ADR2400FF SAMSUNG HZ

A37 4405SCE002A MECHANISM ASSY CDM-H1303 SHIN HEUNG CD HZ

A38 4920S-E007A HEAT SINK MAIN HZ

A39 4810S-0901A BRACKET IC HZ

SS LL OOCCAA ..NNOO.. PPAARRTT NNOO..((GGSS)) DDEESSCCRRIIPPTTIIOONN SSPP EECCIIFFIICCAATT IIOONN VV CC

ƒUVC Shows the origin of local ports(HZ:LGEHZ)

ƒU* : Refer to the SPPL (Service Parts Price List).

Page 10

- 42 -

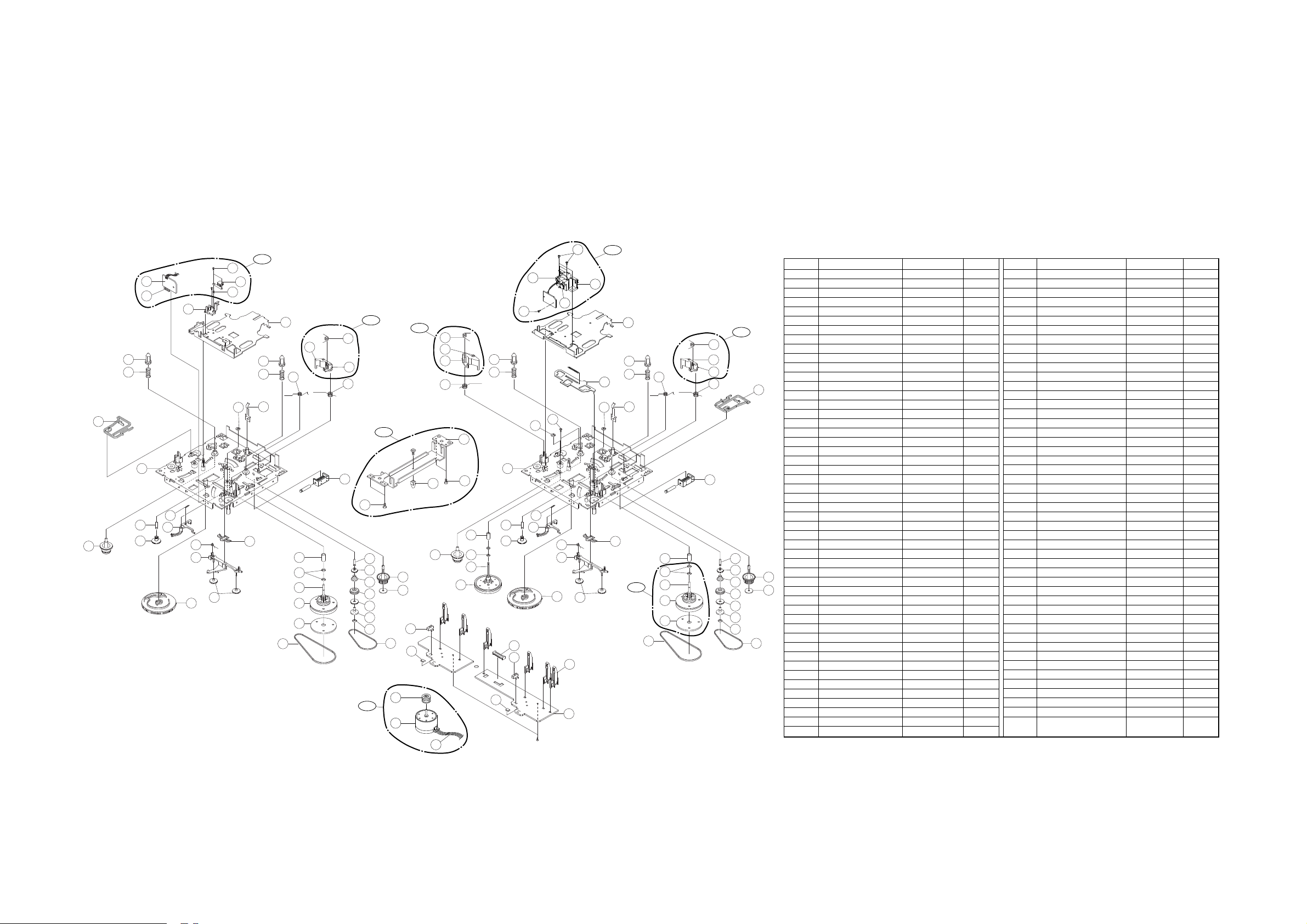

TAPE DECK MECHANISM:AUTO STOP DECK(OPTIONAL)

9

8

1

47

34

4

8

46

40

58

56

84

45

27

55

41

12

25

13

53

26

21

69

16

7

33

43

54

15

66

14

23

82

49

62

28

38

67

8

1

29

47

34

4

8

46

58

56

84

45

27

55

41

39

36

12

25

13

53

26

21

68

16

7

33

43

54

15

66

14

23

82

49

62

28

38

67

9

36

39

72

61

59

93

3

31

61

59

93

3

31

64

108

109

110

112

61

20

81

94

29

113

74

90

89

88

61

115

90

88

61

74

9

36

39

85

117

80

117

79

B

D

E

A

D

C

REF.NO. PART NAME PART NO. Q'TY

- DECK MECHANISM 6730S-G005B

1 CHASSIS MAIN NSP 2

2 BASE HEAD C NSP 0

3 BASE HEAD D NSP 2

4 PLATE SPRING NSP 2

5 BARK MOTOR 110 NSP 0

6 BARK MOTOR 128 NSP 0

7 PLATE PLYWHEEL F NSP 2

8 CHIP REEL NSP 4

9 BASE REEL NSP 4

10 BRACKET HEAD NSP 0

11 GEAR HEAD C NSP 0

12 GEAR CAM NSP 2

13 GEAR IDLER NSP 2

14 BUSH C NSP 2

15 PULLEY C NSP 2

16 PULLEY F/W F NSP 2

17 PULLER F/W R NSP 0

18 BRKT HEAD B NSP 0

19 GEAR HEAD B NSP 0

20 PULLEY M/T YDW NSP 1

21 LEVER BRAKE NSP 2

22 GEAR DIR NSP 0

23 ARM PINCH F 6768SCAS03A 2

24 ARM PINCH R NSP 0

25 ARM CAM LOCK NSP 2

26 ARM RF NSP 2

27 GEAR RF NSP 4

28 CAP C NSP 2

29 LEVER EJECT 6768SCDS03A 2

30 GUIDE MOTOR NSP 0

31 TAPE GUIDE NSP 2

32 LEVER AC NSP 0

33 W/S(2.3ƒN3.5ƒN0.25) NSP 2

34 W.S(1.8ƒN4ƒN0.5) NSP 2

35 W/S(1.6ƒN3.5ƒN0.5) NSP 0

36 W/S(3.6ƒN6ƒN0.5) NSP 4

37 W/S(6ƒN11ƒN0.25) NSP 0

38 W/S(1.2ƒN3.2ƒN0.25) NSP 2

39 W/S(4.6ƒN71ƒN0.13) NSP 4

40 SHAFT PINCH NSP 2

41 SHAFT IDLER NSP 2

42 PIN AZIMUTH NSP 0

43 SHAFT RF NSP 2

44 SHAFT F/W R NSP 0

45 SHAFT F/W F NSP 2

46 S/P B.T(F) NSP 2

47 S/P B.T(R) NSP 2

48 S/P LEVER AC NSP 0

49 S/P BASE HEAD NSP 2

50 S/P DIR NSP 0

51 S/P PINCH(F) 6768SCSS02A 0

52 S/P PINCH(R) NSP 0

53 S/P ARM CAM LOCK NSP 2

54 S/P C NSP 2

55 S/P ARM RF NSP 2

56 S/P P/R(F) NSP 2

57 S/P P/R(R) NSP 0

58 S/P PINCH 1-WAY NSP 2

59 S/P AZIMUTH NSP 2

60 (HEAD)PH M1 6ƒN8 NSP 0

61 (NORMAL)BH M2ƒN4 NSP 6

REF.NO. PART NAME PART NO. Q'TY

62 (MOTOR)PH M2 6ƒN5 NSP 0

63 (BAKT)Tapping M26ƒN4 NSP 0

64 S/C AZIMUTH(M2ƒN8) NSP 2

65 (AZIMUTH)M2ƒN5.7 NSP 0

66 FELT C NSP 2

67 BELT SUB(34.7) NSP 2

68 BELT 110 ¢¤“ 54.3 6768SCBS03B 1

69 BELT 110˘¤ “ 76.2 6768SCBS03C 1

70 BELT 128 ¢¤“ 54.3 NSP 0

71 BELT 128˘¤ “ 80.8 NSP 0

72 BELT SR ¢¤“ 66.3 NSP 0

73 BELT TR ¢¤“ 66.3 NSP 0

74 PCB CTRL SINGLE NSP 2

75 PCB CTRL DOUBLE NSP 0

76 CONN R/P(16P) NSP 0

77 CONN R/P(13P) NSP 0

78 CONN PB(10P) NSP 0

79 CONN HEAD(6P) NSP 1

80 CONN HEAD(3P) NSP 1

81 WIRE MOTOR(4P-80) NSP 1

82 ROLLER PINCH 6768SCRS01A 2

83 WEDGE NSP 2

84 SOLENOID(24) 6768SCVS02A 2

85 REFLECTOR NSP 2

86 METAL FG F(CAPS) NSP 2

87 METAL FG R(CAPS) NSP 0

88 PHOTO SENSOR NSP 2

89 SETECT(MXS00220) NSP 5

90 SWITCH MODE 6768SCTS01B 2

91 HEAD R/P NSP 0

92 HEAD P/B NSP 0

93 HEAD 1-WAY 6768SCHS01A 2

94 MOTOR(YD2BH) 6768SCQS01A 1

95 WIRE HEAD(BRN) NSP 0

96 WIRE HEAD(BLU) NSP 0

97 WIRE HEAD(GRN0 NSP 0

98 WIRE HEAD(ORA) NSP 0

99 WIRE HEAD(RED) NSP 0

100 WIRE HEAD(WHT) NSP 0

101 WIRE HEAD(YEL) NSP 0

102

103

104 DIODE NSP 2

105 RESISTOR NSP 2

106 SHAFT SUB NSP 0

107 M/T GUIDE NSP 0

108 HEAD ERASE 6768SCHS03A 1

109 (M/T)MACH M2.6 4 NSP 3

110 CUSHION MOTOR NSP 3

111 BRKT MOTOR D2 NSP 0

112 BRKT MOTOR D1 NSP 1

113 CONN R/P(12P) NSP 1

114 CONN R/P(11P) NSP 0

115 CONN PB(8P) NSP 1

116 PH M2 9(E-HEAD) NSP 1

117 PCB HEAD NSP 2

£ HEAD ASSY RP5 6768SCES03A

£ HEAD ASSY RP6 6768SCES03B

£ Pulley F/W F ASSY 6268SCJS02A

£ ARM Pinch F ASSY 6768SCAS01B

£ MOTOR ASSY 6768SCOS01A

NSP: Not Serviceable Part

Page 11

- 43 -

TAPE DECK MECHANISM:AUTO REVERSE DECK(OPTIONAL)

7

1

43

47

37

21

52

31

4

7

42

46

51

73

41

24

50

38

74

30

8

40

14

9

22

10

48

23

18

64

13

6

30

39

49

12

61

11

20

37

44

32

57

25

35

62

8

72

7

1

26

43

31

4

7

42

53

51

71

73

40

24

50

38

8

9

22

10

48

23

18

63

13

6

30

39

49

12

61

11

20

37

44

25

35

62

8

72

66

65

77

77

76

75

75

59

54

79

2

28

71

26

17

80

68

29

19

60

15

56

16

3

58

58

5

27

88

89

A

D

C

F

E

G

D

B

REF.NO. PART NAME PART NO. Q'TY

- DECK MECHANISM 6730S-G005A

1 CHASSIS MAIN NSP 2

2 BASE HEAD C NSP 1

3 BASE HEAD D NSP 1

4 PLATE SPRING NSP 2

5 BRKT MOTOR 110 NSP 1

6 PLATE FLYWHEEL F NSP 2

7 CHIP REEL NSP 4

8 BASE REEL NSP 4

9 GEAR CAM NSP 2

10 GEAR IDLER NSP 2

11 BUSH C NSP 2

12 PULLEY C NSP 2

13 PULLEY F/W F NSP 2

14 PULLEY F/W R NSP 1

15 BRKT HEAD B NSP 1

16 GEAR HEAD B NSP 1

17 PULLEY M/T TDW NSP 1

18 LEVER BRAKE NSP 2

19 GEAR DIR NSP 1

20 ARM PINCH F 6768SCAS03A 2

21 ARM PINCH R 6768SCAS04A 1

22 ARM CAMLOCK NSP 2

23 ARM RF NSP 2

24 GEAR RF NSP 4

25 CAP C NSP 1

26 LEVER EJECT 6768SCDS03A 2

27 GUIDE MOTOR NSP 1

28 TAPE GUIDE NSP 1

29 LEVER AC NSP 1

30 W/S(2.3*3.5*0.25) NSP 3

31 W/S(1.8*4*0.5) NSP 2

32 W/S(1.6*3.5*0.5) NSP 1

33 W/S(3.6*6*0.5) NSP 4

34 W/S(6*11*0.25) NSP 4

35 W/S(1.2*3.2*0.25) NSP 2

36 W/S(4.6*7.1*0.13) NSP 4

37 SHAFT PINCH NSP 3

38 SHAFT IDLER NSP 2

39 SHAFT RF NSP 2

40 SHAFT F/W R NSP 1

41 SHAFT F/W F NSP 2

42 SPRING B/T(F) NSP 2

43 SPRING B/T(R) NSP 2

44 SPRING BASE HEAD NSP 2

44-1 SPRING LEVER AC NSP 1

45 SPRING DIR NSP 1

46 SPRING PINCH(F) 6768SCSS02A 1

47 SPRING PINCH(R) 6768SCSS03A 1

48 S/P ARM CAM LOCK NSP 2

REF.NO. PART NAME PART NO. Q'TY

49 SPRING C NSP 2

50 SPRING ARM RF NSP 2

51 SPRING P/RETURE(F) NSP 2

52 SPRING P/RETURN(R) NSP 1

53 SPRING PINCH 1-WAY NSP 1

54 SPRING AZIMUTH NSP 1

55 PH M1.6*8 NSP 2

56 BH M2*4 NSP 4

57 PH M2.6*5 NSP 2

58 TAPPING M2.6*4 NSP 4

59 AZIMUTH S/C 1-WAY NSP 1

60 AZIMUTH S/C M2*5.7 NSP 2

61 FELT C NSP 2

62 BELT SUB(PI33.1) NSP 2

63 BELT 110 ¢ NSP 1

64 BELT 110 ˘ NSP 1

65 PCB CONTROL DOUBL NSP 1

66 CONNECTOR(16P) NSP 1

67 CONNECTOR(6P) NSP 1

68 WIRE MOTOR(4P-80) NSP 1

69 ROLLER PINCH 6768SCRS01A 3

70 WEDGE( ”˛`˘ ) NSP 1

71 SOLENOID(24 OHM) 6768SCVS02A 2

72 REFLECTOR NSP 2

73 METAL FG F(CAPSTAN) NSP 2

74 METAL FG R(CAPSTAN) NSP 1

75 PHOTO SENSOR NSP 2

76 SWITCH DETECT NSP 6

77 SWITCH MODE 6768SCTS01B 2

78 HEAD R/P NSP 1

79 HEAD 1-WAY NSP 1

80 MOTOR(YD2BH) 6768SCQS01A 1

81 WIRE HEAD(BRN) NSP 1

82 WIRE HEAD(BLU) NSP 1

83 WIRE HEAD(GRN) NSP 1

84 WIRE HEAD(ORA) NSP 1

85 WIRE HEAD(RED) NSP 1

86 WIRE HEAD(WHT) NSP 1

87 WIRE HEAD(YEL) NSP 1

88 Head PCB NSP 1

89 CONN Head(3P) NSP 1

£ HEAD ASSY RP6 6768SCES03B

£ BRK HEAD ASSY RP1 6768SCES04A

£ ARM Pinch R ASSY 6768SCAS01A

£ ARM Pinch F ASSY 6768SCAS01B

£ Pulley F/W F ASSY 6268SCJS02A

£ MOTOR BRKT ASSY 6768SCPS01A

£ MOTOR ASSY 6768SCOS03A

NSP: Not Serviceable Part

Page 12

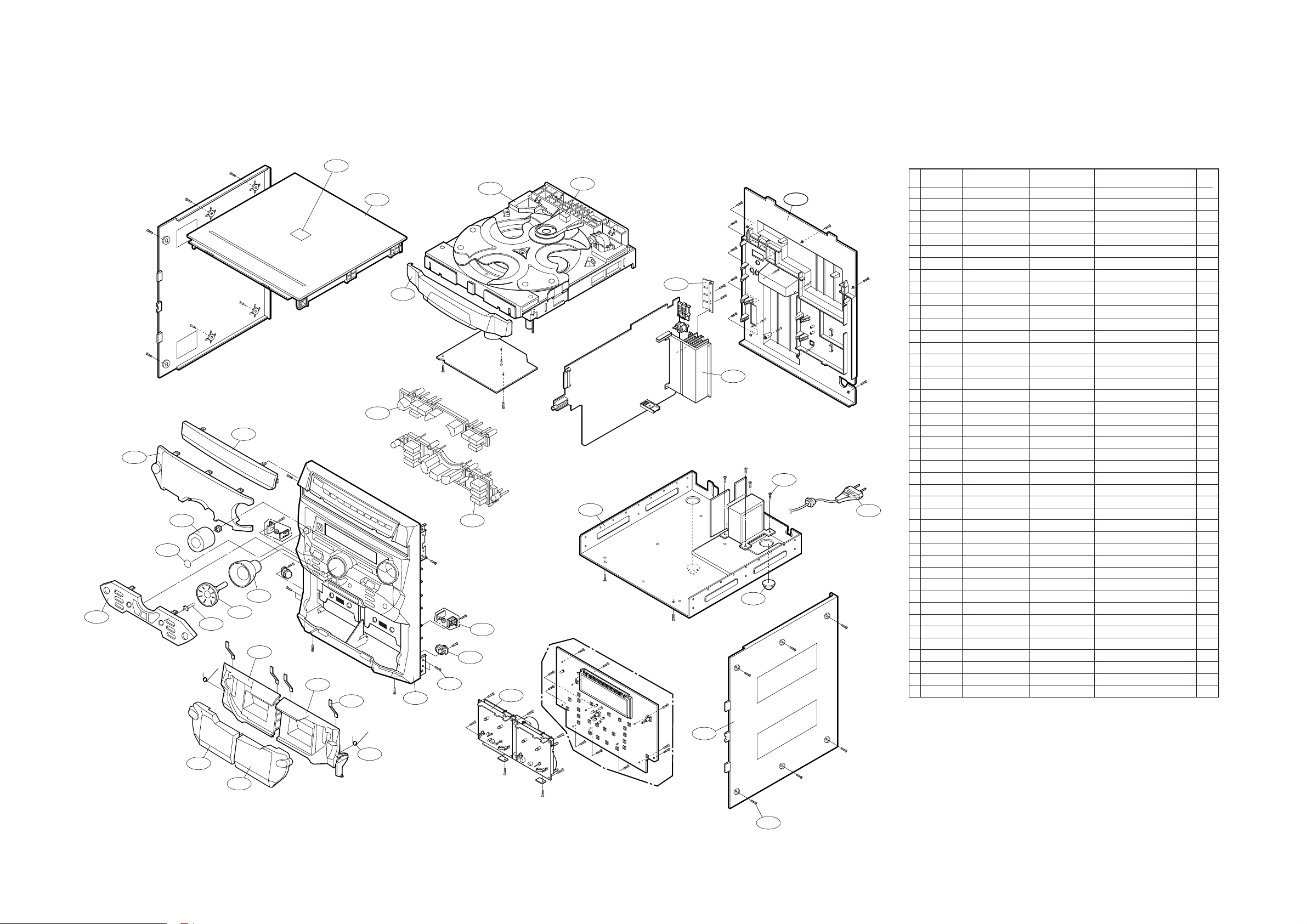

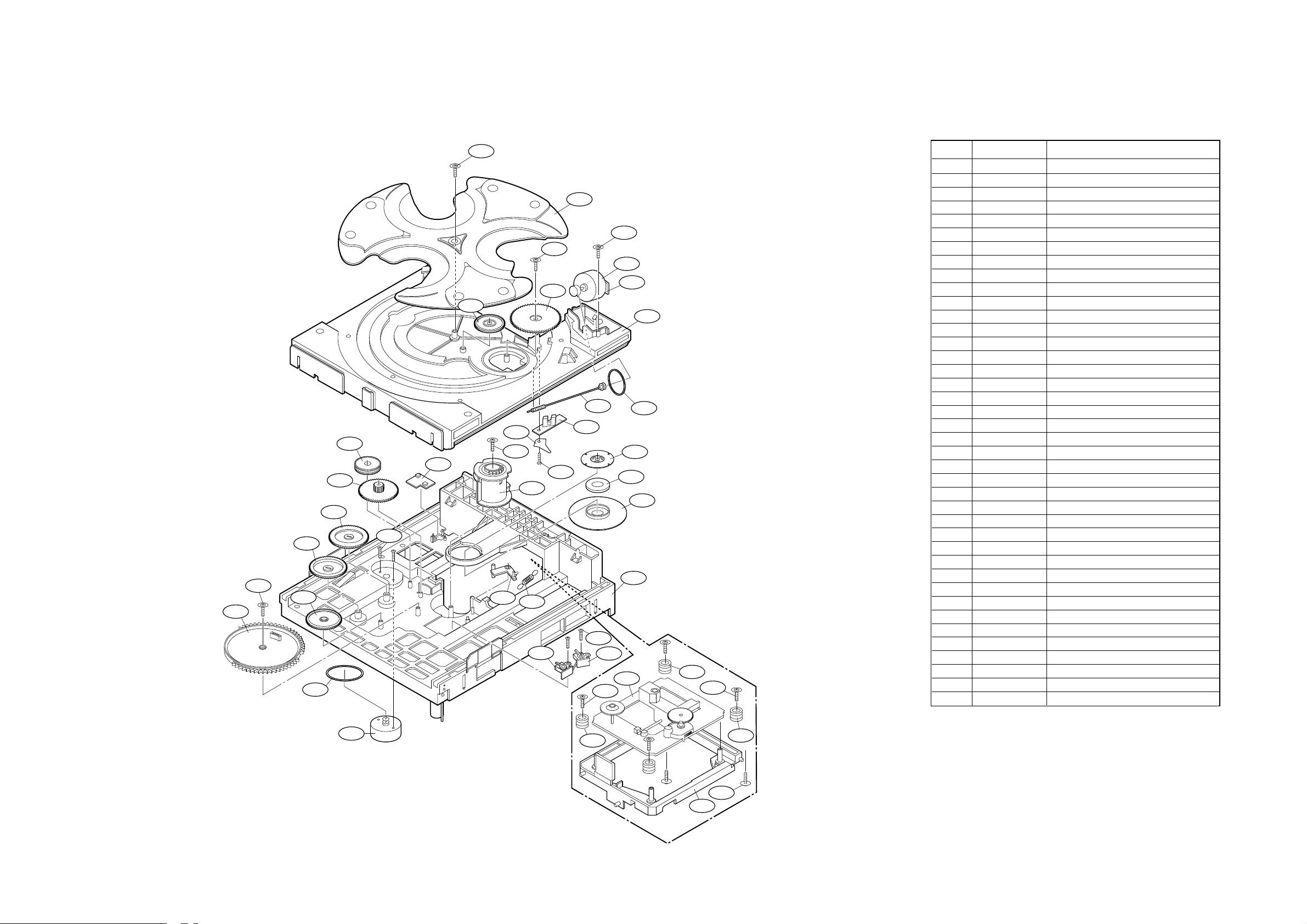

- 44 -

EXPLODED VIEW/PARTS LIST

CD MECHANISM

4

36

38

35

34

25

24

20

20

21

20

18

19

19

28

23

22

22

37

33

32

31

30

27

29

4

26

10

9

8

7

6

3

5

2

1

12

13

14

15

16

17

22

11

REF.NO. PART NO. DESCRIPTION

- 4405SCE002A CD MECHANISM ASSÕY(CDM-H1303)

1 4680SBP001A MOTOR PULLEY ASSÕY

2 4400SB0001A BELT MAIN

3 4470SB0005A GEAR MAIN

4 88H-0004 SCREW(3X12X12)

5 4470SB0007A GEAR PU UP-A

6 4470SB0008A GEAR PU UP-B

7 4470SB0006A GEAR PU DOWN

8 4470SB0004A GEAR LOADING

9 4470SB0003A GEAR PULLEY

10 6871SB21RAD PCB ASSÕY CLOSE

11 353S353F SCREW D2.6 L4.0

12 4974SB0001A GUIDE CAM

13 4970SBN002A SPRING CAM

14 6871SC21RAD PCB ASSÕY OPEN

15 6871SD21RAD PCB ASSÕY CAM

16 88H-0004 SCREW(3X12X12)

17 3040SB0002A BASE MAIN

18 4405SCB001A MECHANISM ASSÕY(KSM-213CCM)

19 6756SBX001A SCREW(2.6X10X10)

20 4900SB0001A DAMPER RUBBER

21 3040SB0003A BASE PU(CDM-H1303)

22 88H-0002 SCREW(3X9X12)

23+24+25 4860SB0002A CLAMP ASSÕY

23 4860SB0001A CLAMP DISC

24 524-012A COVER CLAMP MAGNET

25 3550SB0001A COVER MAGNET

26 4471SB0001A GEAR CAM ASSÕY

27 353-025B SCREW D3.0 L8.0

28 88H-0003A SCREW(3X12X10)

29 4974SB0003A GUIDE WORM

30 6871SF21RAD PCB ASSÕY SENSOR

31 4371SB0002A SHAFT ASSÕY TRAY

32 4400SB0001B BELT TRAY

33 3390SB0001A TRAY LOADING

34 6870SE21RAB PCB ASSÕY TRAY

35 4680SBP002A MOTOR ASSÕY TRAY

36 3390SB0002A TRAY DISC

37 4470SB0010A GEAR TRAY A

38 4470SB0011A GEAR TRAY B

Page 13

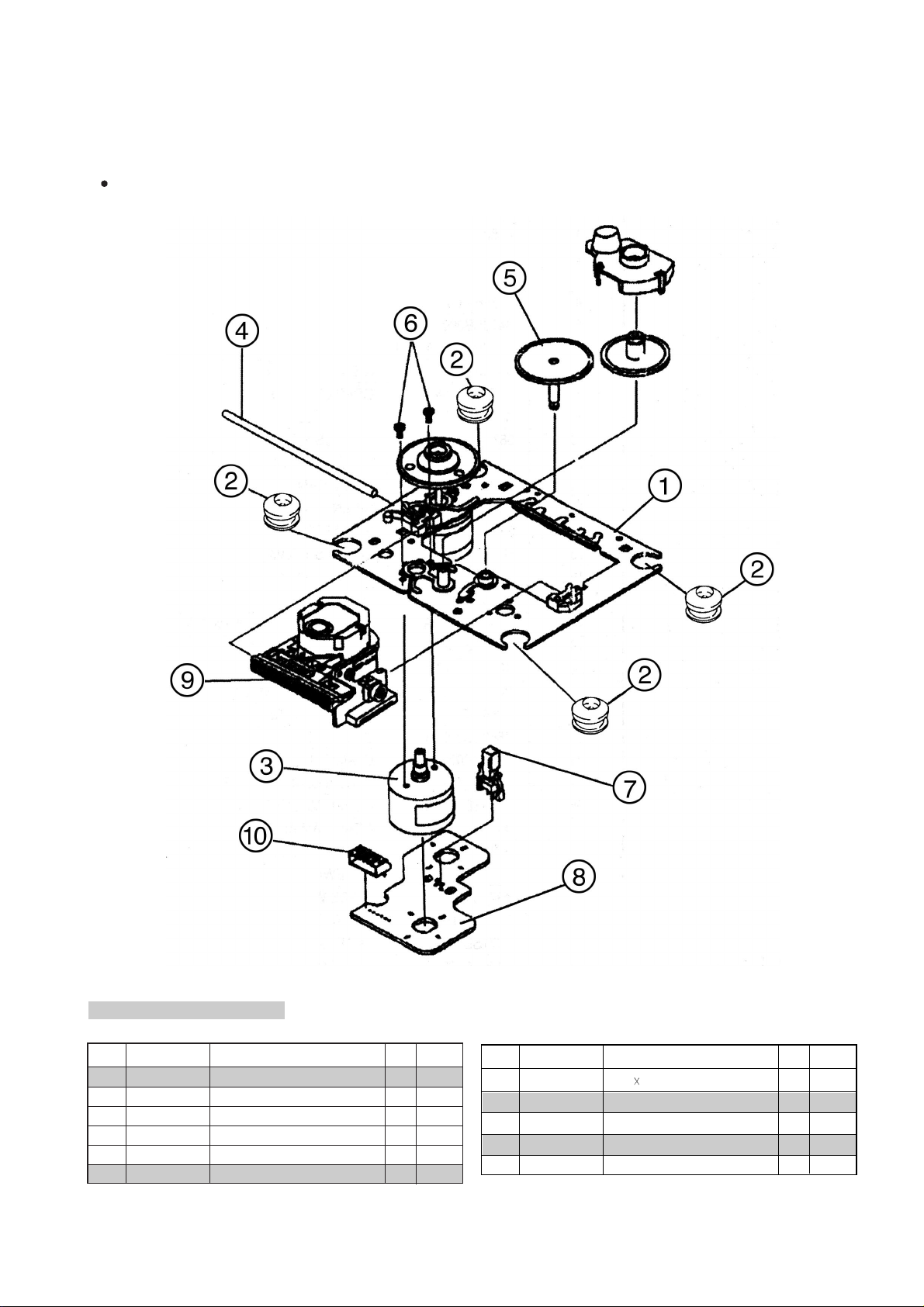

- 45 -

EXPLODED VIEW/PARTS LIST

OPTICAL PICK-UP CARRIAGE

REF.NO. PART NO DESCRIPTION Q'TY REMARK

4405SCB001A MECHANISM ASSEMBLY, KSM-213CCM 1 SP

1 88S-0099 TT CHASSIS ASSÕY 1 NSP

2 88S-0089 INSULATOR(S) 4 NSP

3 6756S-O001A MOTOR 1 NSP

4 88S-0088 SLIDE SHAFE(S) 1 NSP

5 6756S-G001A GEAR 1 SP

NSP: Not Serviceable Part

SP: Serviceable Part

REF.NO. PART NO DESCRIPTION Q'TY REMARK

6 88S-0101 +P 2 3 2 NSP

7 6756S-T001A SWITCH 1 SP

8 88S-0098 MOTOR BASE(6P) 1 NSP

9 6756S-X001A PICK-UP, KSS-213C 1 SP

10 88S-0100 CONNECTOR 6P 1 NSP

Page 14

Page 15

- 30 -

Pre Out

Ch2

3.3µF

3.3µF

3.3µF

3.3µF

3.3µF

1000µF

1000µF

47µF

47µF

47µF

0.018µF

1000µF

3.3µF

47µF

1.2µF

100

µF

R . R

Vcc

1000

µF

47µF

0.018µF

10kΩ

10kΩ

150kΩ

150kΩ

1MΩ

2.2kΩ

2.2kΩ

Rec IN

Ch2

Rec

IN

Rec IN

Ch1

ALC

Rec Out

Ch2

180kΩ

180kΩ

Gv

Gvo

180kΩ

180kΩ

1kΩ

1kΩ

1kΩ

1kΩ

100kΩ

100Ω

10kΩ

10kΩ

10Ω

300kΩ

9.1kΩ

100Ω

Pre IN

Ch2/B

(Play Rec)

Pre IN

Ch2/A

(Play only)

Pre IN

Ch1/B

(Play Rec)

Pre Out

Ch1

Pre IN

Ch1/A

Ch1/B

NF

Ch2/A

Ch1/A

Ch1/B

Gvo

Gv

Gvo

Gv

Vcc

M

N

NF

NF

Ch1

Ch1

Ch2

Gvc

GV

Ch2

ALC

GND

Rec

15

14

13

12

11

23

24

1

2

161718192122

IN

Vref1

Vref

Vref2

A/B

Metal

Out

Pre

Out

REC

Out

Rec Out

Ch1

Mix

Out

GND1 M/N

6.8kΩ

A

B

1000pF

1000pF

6.8kΩ

9.1kΩ

20

10 9876435

M/N

REC SW REC SWGND P/B SW P/B SWCONT GND GNDV

CC

123456789

KA3082

KIA6289N

- 30 -

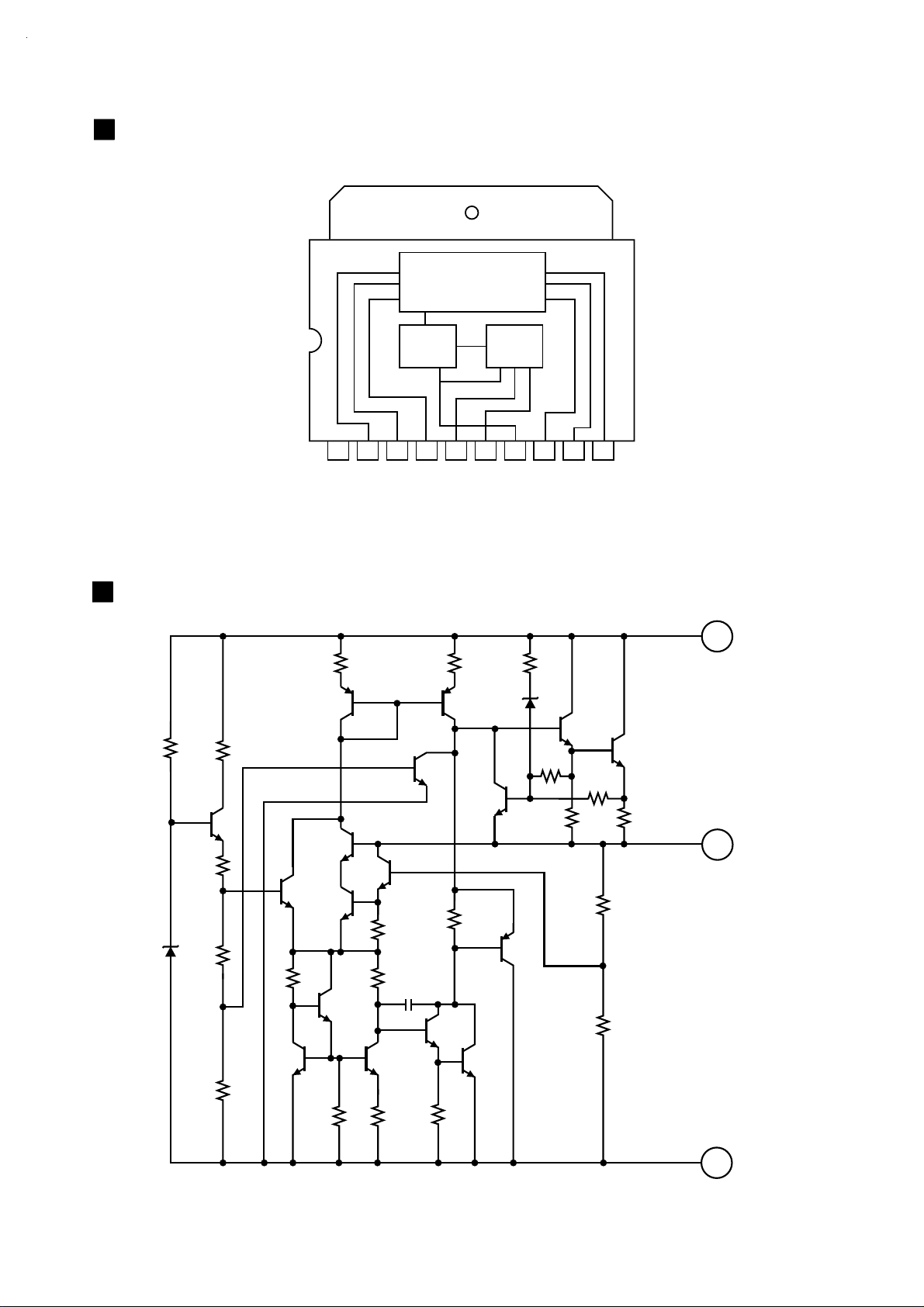

INTERNAL BLOCK DIAGRAM OF ICs

LA1837

Page 16

- 31 -

KA8301

KIA7805 P/PI ~ KIA7824P/PI

DRIVER

PRE

LOGIC

2 3 4 5 6 7 8 9 101

GND

Vout1

Vz1VrFin

Rin

Vcc1

Vcc2

Vz2

Vout2

3

1

2

4

R

12

R

1

C

21

R

12

Q

1

Q

7

Q

13

Q

10

Q

6

Q

5

Q

4

Q

3

Q

11

Q

15

Q

14

Q

9

Q

8

Q

16

Q

17

Q

INPUT

OUTPUT

GND

2

Q

1

Z

18

R

8

R

9

R

13

R

11

R

17

R

5

R

6

R

1

R

2

R R

16

R

20

R

19

R

14

R

10

R

7

R

Page 17

- 32 -

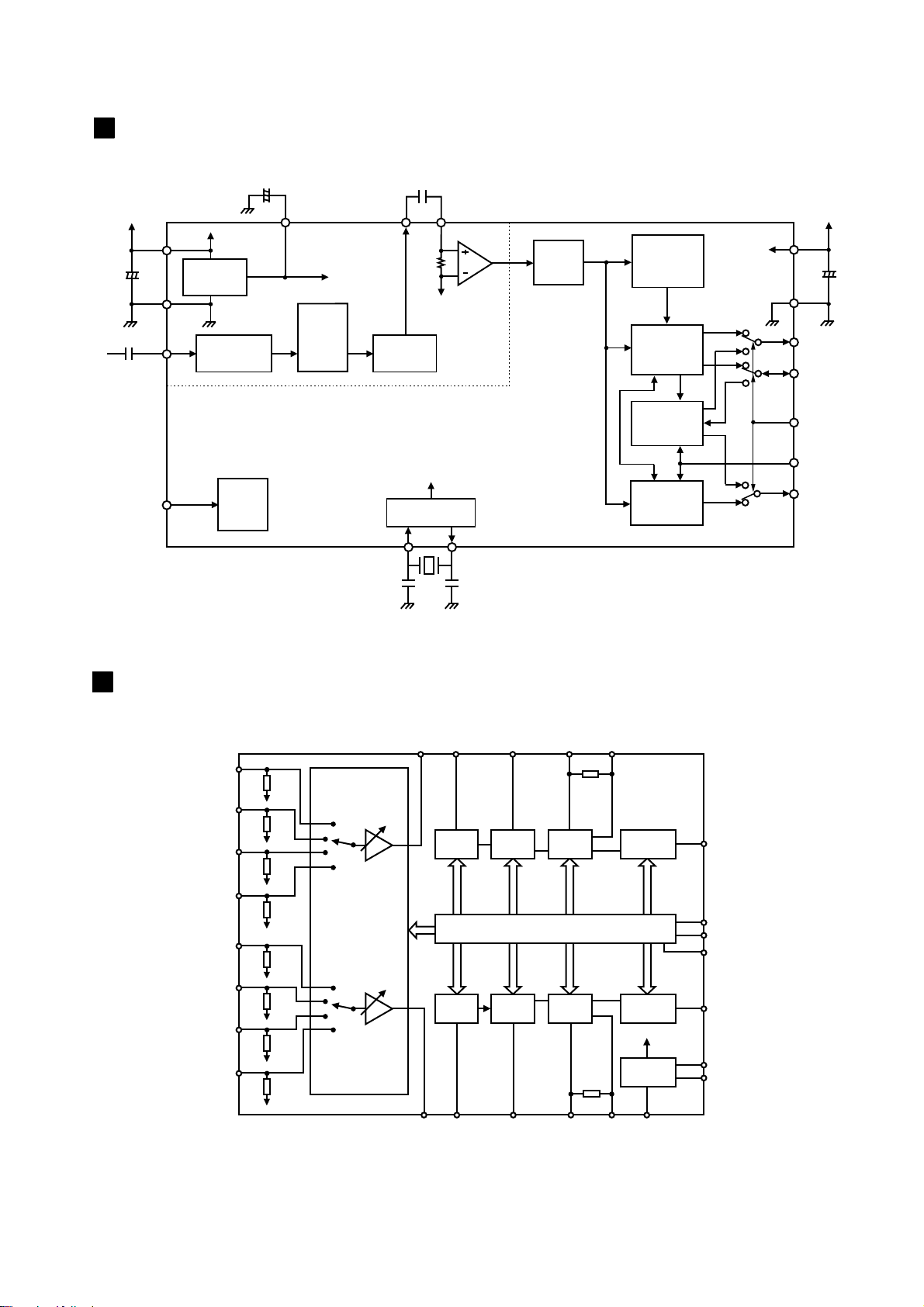

LC7273M

TDA7440D

+5V

+5V

VREF

CINFLOUTVREF

Vdda

Vssa

MPXIN

TEST

XIN XOUT

Vssd

Vddd

RDCL

RDDA

MODE

RST

RDS-ID

READY

CLK(4.332MHz)

SMOOTHING

FILTER

OSC

PLL

(57kHz)

DATA

DECODER

RAM

(128bit)

RDS-ID

DETECT

CLOCK

RECOVERY

(1187.5Hz)

ANTIALIASING

FILTER

REFERENCE

VOLTAGE

57kHz

BPF

(SCF)

TEST

L-IN1

100K

100K

100K

100K

100K

100K

100K

100K

4 8 9 18

27

21

22

20

26

24

25

LOUT

SCL

SDA

DIG_GND

ROUT

V

S

AGND

R

B

R

B

14 15

10 11 19 12 13 23

5

G

G

6

7

3

2

INPUT MULTIPLEXER

+GAIN

MUXOUTR INR TREBLE(R) BIN(R) BOUT(R) CREF D98AU883

0/30dB

2dB STEP

MUXOUTL

VOLUME TREBLE

I CBUS DECODER + LATCHES

BASS

SPKR ATT

LEFT

VOLUME TREBLE BASS

SUPPLY

V

REF

SPKR ATT

RIGHT

INL TREBLE(L) BOUT(L)BIN(L)

1

28

L-IN2

L-IN3

L-IN4

R-IN1

R-IN2

R-IN3

R-IN4

2

Page 18

- 33 -

STK411-220E

Page 19

- 34 -

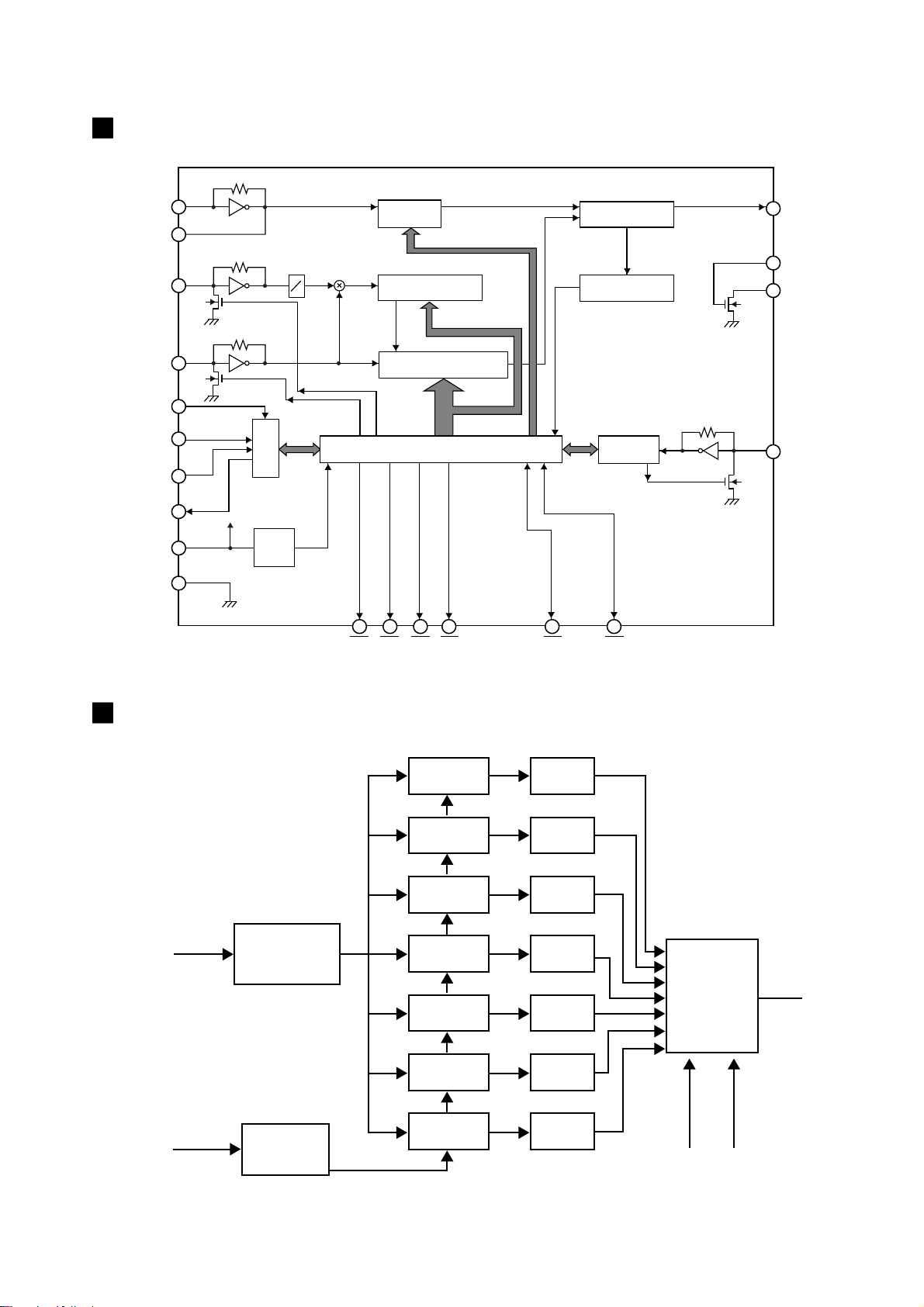

MSGEQ7

Audio

In

Anti-Alias

Filter

Clock

Oscillator

Output

Multiplexor

CKIN

Reset

63Hz

Bandpass

160Hz

Bandpass

400Hz

Bandpass

1kHz

Bandpass

2.5kHz

Bandpass

6.25kHz

Bandpass

16kHz

Bandpass

Peak

Detector

Peak

Detector

Peak

Detector

Peak

Detector

Peak

Detector

Peak

Detector

Peak

Detector

Strobe

DC Out

LC72131, 72131M

B01 B02 B03 B04 I01 I02

XIN

PD

AIN

AOUT

IFIN

XOUT

FMIN

AMIN

CE

DI

CL

D0

VDD

VSS

REFERENCE

DIVIDER

PHASE DETECTOR

CHARGE PUMP

UNLOCK

DETECTOR

UNIVERSAL

COUNTER

DATA SHIFT REGISTER

LATCH

12bits PROGRAMMABLE

DIVIDER

SWALLOW COUNTER

1/16. 1/17 4bits

POWER

ON

RESET

CCB

I/F

1

2

Page 20

- 35 -

KA3010

PIN DESCRIPTION

28 27

26 25 24 23 22

T S D

REGULATOR

MUTE

LEVEL

SHIFT

LEVEL

SHIFT

100K

50K

50K

10K

10K

10K 10K

10K

BUY

BUY

BUY

LEVEL

SHIFT

LEVEL

SHIFT

1 2 3 4 5 6 7

8 9 10 11 12 13 14

21 20 19 18 17 16 15

Pin No. Symbol I/O Description

1 DO1.1 O DRIVE OUTPUT

2 DO1.2 O DRIVE OUTPUT

3 DI1.1 I DRIVE INPUT

4 DI1.2 I DRIVE INPUT

5 REG REGULATOR

6 REO O REGULATOR OUTPUT

7 MUTE MUTE

8 GND1 GROUND

9 DI2.1 I DRIVE INPUT

10 DI2.2 I DRIVE INPUT

11 DO2.1 O DRIVE OUTPUT

12 DO2.2 O DRIVE OUTPUT

13 GND2 GROUND

14 OPOUT O OPAMP OUTPUT

15 OPIN (-) I OPAMP OUTPUT (-)

16 OPIN (+) I OPAMP INPUT (+)

17 DO3.1 O DRIVE OUTPUT

18 DO3.2 O DRIVE OUTPUT

19 DI3.1 I DRIVE INPUT

20 DI3.2 I DRIVE INPUT

21 VCC1 SUPPLY VOLTAGE

22 VCC2 SUPPLY VOLTAGE

23 VREF 2.5V BIAS VOLTAGE

24 DI4.1 I DRIVE INPUT

25 DI4.2 I DRIVE INPUT

26 DO4.1 O DRIVE OUTPUT

27 DO4.2 O DRIVE OUTPUT

28 GND3 GROUND

Page 21

- 36 -

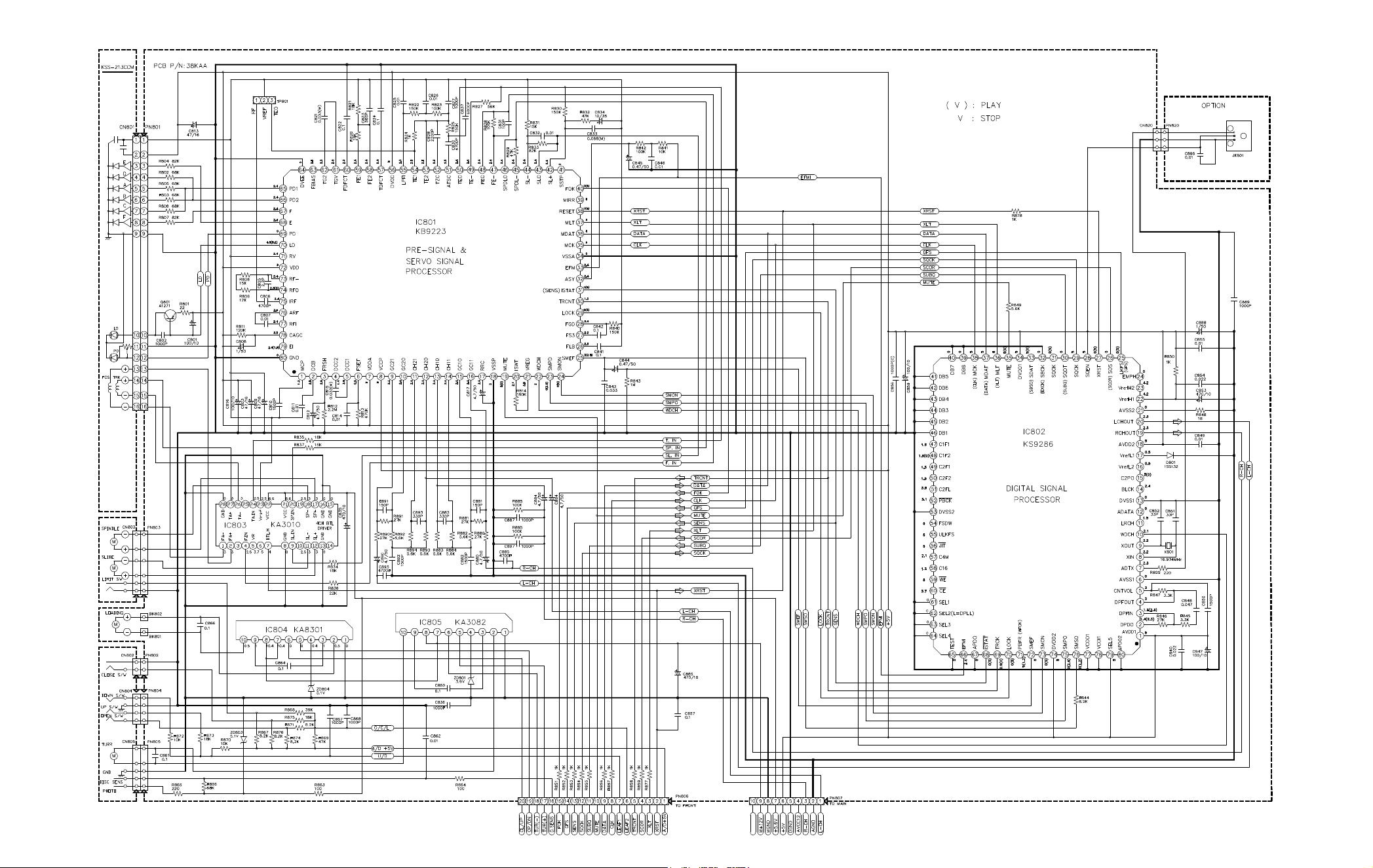

KB9223

MICOM TO SERVO CONTROL

AUTO SEQUENCER

FOK DETECTION

CIRCUIT

MIRROR DETECTION

CIRCUIT

Spindle Servo LPF

(Double Speed)

Sled Servo Amplifier

& Sled Kick GEN.

Tracking Phase

Compensation Block

& Jump Pulse GEN.

Focus Phase

Compensation

& Offset cancel circuit

Micom Data

Interface Logic

RF Amp

73

74

65

66

63

67

68

79

69

70

71

78

76

75

32

33

77

2

4

RF-

RFO

PD1

PD2

F

E

EI

PD

LD

VR

ARF

IRF

ASY

EFM

RFI

DCB

DCC1

GC1O

MLT

TZC

FE2

FLB

FGD

FS3

TE1

FE1

GC1I

CH1O

CH1I

MUTEI

RRC

CH2O

CH2I

GC2I

GC2O

5

15 16 13 14 19 17 12 11 9 10

40

1

39

6

25

24

23

45

46

42

44

43

61

62

55

53

50

49

57

48

47

60

FOK

MCP

MIRROR

FSET

SMEF

SMON

FS1 to

FS4

TM1 to

TM6

BAL1 to

BAL5

PS1 to

PS4

GA1 to

GA5

SMPD

SPDL-

SPDLO

SL+

SL-

SLO

TGU

TG2

LPFT

TE2

TEO

TE-

TDFCT

FEO

FE-

FDFCT

327282658525135363738312930225459

APC Amp

Center Voltage Amp.

Focus Error Amp

FE-BIAS Adjustment

Tracking Error Amp

E/F Balance & Gain

Control

RF Level AGC

&

Equalizer

EFM

Comparator

Defect Detection

CircuitT

ADJUSTMENT-FREE CONTROL

Built-in Post Filter Amp(L&R)

LDON

PIN DESCRIPTION

Pin No. System Description

1 MCP Capacitor connection pin for mirror hold

2 DCB Capacitor connection pin for defect Bottom hold

3 FRSH. Capacitor connection pin for time constant to generate focus search waveform

4 DCC2 The input pin through capacitor of defect bottom hold output

5 DCC1 The output pin of defect bottom hold

6 FSET The peak frequency setting pin for focus, tracking servo and cut off frequency of CLV LPF

7 VDDA Analog VCC for servo part

8 VCCP VCC for post filter

9 GC2I Amplifier negative input pin for gain and low pass filtering of DAC output CH2

10 GC2O Amplifier output pin for gain and low pass filtering of DAC output CH2

11 CH2I The input pin for post filter channel2

12 CH2O The output pin for post filter channel2

13 CH1O The output pin for post filter channl1

14 CH1I The input pin for post filter channel1

15 GC1O Amplifier output pin for gain and low pass filtering of DAC output CH1

Page 22

- 37 -

Pin No. System Description

16 GC1I Amplifier negative input pin for gain and low pass filtering of DAC output CH1

17 RRC The pin for noise reduction of post filter bias

18 VSSP VSS for post filter

19 MUTEI The input pin for post filter muting control

20 ISET The input pin for current setting of focus search, track jump and sled kick voltage

21 VREG The output pin of regulator

22 WDCK The clock input pin for auto sequence

23 SMDP The input pin of CLV control output pin SMDP of DSP

24 SMON The input pin for spindle servo ON through SMON of DSP

25 SMEF The input pin of provide for an external LPF time constant

26 FLB Capacitor connection pin to perform rising low bandwidth of focus loop

27 FS3 The pin for high frequency gain change of focus loop with internal FS3 switch

28 FGD Reducing high freqency gain with capacitor between FS3 pin

29 LOCK Sled runaway prevention pin

30 TRCNT Track count output pin

31 ISTAT Internal status output pin

32 ASY The input pin for asymmetry control

33 EFM EFM comparator output pin

34 VSSA Analog VSS for servo part

35 MCK Micom clock input pin

36 MDATA Micom data input pin

37 MLT Micom data latch input pin

38 RESET Reset input pin

39 MIRROR The mirror output for test

40 FOK The output pin of focus OK comparator

41 SSTOP The pin for detection whether pick_up position is innermost or not

42 SL+ The noninverting input pin of sled servo amplifier

43 SLO The output pin of sled servo amplifier

44 SL- The inverting input pin of sled servo amplifier

45 SPDL- The noninverting input pin of spindle servo amplifier

46 SPDLO The output pin of spindle servo amplifier

47 FE- The inverting input pin of focus servo amplifier

48 FEO The output pin of focus servo amplifier

49 TE- The inverting input pin of tracking servo amplifier

50 TEO The output pin of tracking servo amplifier

51 ATSC The input pin for Anti-shock detection

52 TZC The comaparator input pin for tracking zero crossing detection

53 TE2 Tracking servo input pin

54 TE1 Tracking error amplifier output pin

55 LPFT The input pin of tracking error low pass filtering signal

56 DVDD The power supply pin for logic circuit

57 TDFCT The capacitor connection pin for tracking defect compensation

58 FE2 Focus servo input pin

59 FE1 Focus error amplifier output pin

60 FDFCT The capacitor connection pin for focus defect compensation

61 TGU The capacitor connection pin for high frequency tracking gain switch

62 TG2 The pin for high frequency gain change of tracking servo loop with internal TG2 switch

63 FEBIAS Focus error bias voltage control pin

64 DVEE The DVEE pin for logic circuit

65 PD1 The negative input pin of RF I/V amplifier1 (A+C signal)

66 PD2 The negative input pin of RF I/V amplifier2 (B+D signal)

67 F The negative input pin of F I/V amplifier (F signal)

68 E The negative input pin of E I/V amplifier (E signal)

69 PD The input pin for APC

70 LD The output pin for APC

71 VR The output pin of (AVEE+AVCC)/2 voltage

72 VCC VCC for RF part

73 RF- RF summing amplifier inverting input pin

74 RFO RF summing amplifier output pin

75 IRF The input pin for AGC

76 ARF The output pin for AGC

77 RFI The input pin for EFM comparating

78 CAGC The capacitor connection pin for AGC

79 EI Feedback input pin of E I/V amplifier for EF Balance control

80 GND GND for RF part

Page 23

- 38 -

KS9286

SUBCODE

SYNC

DETECTOR

SUBCODE

OUTPUT

EFM

DEMODULATOR

8BIT DATA BUS

ADDRESS

GENERATOR

EFM

PHASE

DETECTOR

DIGITAL

PLL

DIGITAL

CLV

SERVO

CPU

INTERFACE

MODE

SELECTOR

DIGITAL

OUTPUT

D/A

CONVERTER

DIGITAL

FILTER

& DE-EMPH

INTERPOLATOR

ECC

16K

SRAM

TRACK

COUNTER

23BIT

SHIFT

REGISTER

FRAME SYNC

DETECTOR

PROTECTOR

INSERTOR

X-TAL

TIMING

GENERATOR

SUBCODE-Q

REGISTER

SQDT

30

29

11

66

5

3

4

2

72

73

75

76

70

9

8

37

38

36

616263

65

7

19

20

33

32

26

69

68

12

14

77

67

60

24

17

22

SDAT

SBCK

S0S1

LRCHO

ADATAO

BCKO

BCKI

ADATAI

LRCHI

EMPH

VREFL1

VREFH1

EFMI

CNTVOL

DPFIN

DPFOUT

DPDO

SMEF

SMON

SMDP

SMSD

LOCK

XOUT

LCHOUT

RCHOUT

DATX

TEST1

TEST0

XTALSEL

CDROM

XIN

MDAT

MCK

MLT

TRCNT

/ISTAT

SQCK

PIN DESCRIPTION

Pin No. Symbol IO Description

1 AVDD1 - Analog VCC1

2 DPDO O Charge pump output for Digital PLL

3 DPFIN I Filter input for Digital PLL

4 DPFOUT O Filter output for Digital PLL

5 CNTVOL I VCO control voltage for Digital PLL

6 AVSS1 - Analog Ground1

7 DATX O Digital Audio output data

8 XIN I X tal oscillator input

9 XOUT O X tal oscillator output

10 WDCHO O Word clock output of 48bit/Slot (88.2KHz)

11 LRCHO O Channel clock output of 48 bit/Slot (44.1KHz), 88.2KHz when ESP ON

12 ADATAO O Serial audio data output of 48 bit/Slot (MSB first), double speed output when ESP ON

13 DVSS1 - Digital Ground1

14 BCKO O Audio data bit clock output of 48 bit/Slot (2.1168MHz), 4.2336MHz when ESP ON

15 C2PO O C2 Pointer for output audio data

16 VREFL2 I Input terminal2 of reference voltage

L (Floating)

Page 24

- 39 -

Pin No. Symbol IO Description

17 VREFL1 I Input terminal1 of reference voltage L (GND connection)

18 AVDD2 - Analog VCC2

19 RCHOUT O Right-Channel audio output through D/A converter

20 LCHOUT O Left-Channel audio output through D/A converter

21 AVSS2 - Analog ground2

22 VREFH1 I Input terminal1 of reference voltage H (VDD connection)

23 VREFH2 I Input terminal2 of reference voltage H (Floating)

24 EMPH O Emphasis/Non-Emphasis output, H: Emphasis ON, L: Emphasis OFF

25 LKFS O The Lock Status output of frame sync

26 S0S1 O Output of subcode sync signal (S0+S1)

27 RESET I System reset at L

28 /ESP I ESP function ON/OFF control ( L : ESP function ON, H : ESP function OFF)

29 SQCK I Clock for output Subcode-Q data

30 SQDT O Serial output of Subcode-Q data

31 SQOK O The CRC (Cycle Redundancy Check) check result signal output of Subcode-Q

32 SBCK I Clock for output subcode data

33 SDAT O Subcode serial data output

34 DVDD1 - Digital VDD1

35 MUTE I Mute control input ( H : Mute ON)

36 MLT I Latch Signal Input from Micom (Scmit Trigger)

37 MDAT I Signal data input from Micom (Scmit Trigger)

38 MCK I Signal clock Input from Micom (Scmit Trigger)

39 DB8 I/O SRAM data I/O port 8 (MSB)

40 DB7 I/O SRAM data I/O port 7

41 DB6 I/O SRAM data I/O port 6

42 DB5 I/O SRAM data I/O port 5

43 DB4 I/O SRAM data I/O port 4

44 DB3 I/O SRAM data I/O port 3

45 DB2 I/O SRAM data I/O port 2

46 DB1 I/O SRAM data I/O port 1 (LSB)

47 C1F1 I/O Monitoring output for C1 error correction (RA1)

48 C1F2 I/O Monitoring output for C1 error correction (RA2)

49 C2F1 I/O Monitoring output for C2 error correction (RA3)

50 C2F2 I/O Monitoring output for C2 error correction (RA4)

51 C2FL I/O C2 decoder flag (RA5, H : When one processing C2 code is impossible correction status.)

52 /PBCK I/O Output of VCO/2 (4.3218MHz) (RA6)

53 DVSS2 I/O Digital ground 2

54 FSDW I/O Window or unprotected frame sync (RA7)

55 ULKFS I/O Frame sync protection state (RA8)

56 /JIT I/O Display of either RAM overflow onncerflow for ±4 frame jitter margin (RA9)

57 C4M I/O Only monitoring signal (4.2336M .. RA10)

58 C16M I/O 16.9344MHz signal output (RA11)

59 /WE I/O Terminal for test

60 /CS I/O Terminal for test

61 XTALSEL I Mode Selection1 (H: 33.8688MHz, L: 16.9344MHz)

62 TEST0 I TEST input terminal (GND connection)

63 CDROM I Mode Selection2 (H: CD-ROM, L: CDP)

64 SRAM I TEST input terminal (GND connection)

65 TEST1 I TEST input terminal (GND connection)

66 EFMI I EFM signal input

67 ADATAI I Serial audio data input of 48 bit/Slot (MSB first)

68 /ISTAT O The internal status output

69 TRCNT I Tracking counter input signal

70 LOCK O Output signal of LKFS condition sampled PBFR/16 (if LKFS is

H , LOCK is H , if LKFS is sampled

L at least 8 times by PBFR/16, LOCK is L .)

71 PBFR O Write frame clock (Lock: 7.35KHz)

72 SMEF O LPF time constant control of the spindle servo error signal

73 SMON O ON/OFF control signal for spindle servo

74 DVDD2 - Digital VDD2

75 SMDP O Spindle Motor drive (Rough control in the SPEED mode, Phase control in the PHASE mode)

76 SMSD O Spindle Motor drive (Velocity control in the PHASE mode)

77 BCKI I Audio data bit clock input of 48 bit/Slot (2.1168MHz)

78 TESTV I TEST input terminal (GND connection)

79 DSPEED I TEST input terminal (VDD connection)

80 LRCHI I Channel clock input of 48 bit/Slot (44.1KHz)

Page 25

Page 26

- 11 -

TROUBLESHOOTING

Turn power on.

Is power on?

Does initial read work?

Does it play?

Does it output audio?

Check power supply circuit.

(Check PN 807)

Check laser circuit.

Check focus circuit.

Check disc.

Check tracking servo circuit.

Check audio circuit.

OK

YES

YES

YES

YES

NO

NO

NO

NO

Page 27

1.3V

A

B

- 12 -

Fails to initial read

YES

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO NO NONO

NO

NO

NO

NO

Does laser light?

Disc motor turns.

Does RF

waveform

appear?

TP 801(RF)

Does tracking

servo work?

Lower envelope

of TP801(RF)

waveform is flat.

Does signal

appear at

TP801(TEO)?

Does signal appear at IC 803

Pin and Pin ?

Does GFS (IC802 pin )

show as below?

Is rotation normal?

Is there no dropout of RF

signal?

Does TE2 signal

appear at pin

of IC801?

Defective IC

801, pick up

and/or open

wire.

Detective pattern.

Defective IC 801

and/or IC 803

Defective pick-up

and/or connector.

Defective IC 801.

Scratch in disc

initial read area.

Defective pick-up

adjustment focus offset.

Page 28

A

- 13 -

NO

NO

NO

NO

NO

NO

Laser does not light.

Is Ò3.5VÓ applied to pin of IC 801?

Is power supplied to laser Q801?

(Q 801 collector: about 1.8V)

Does laser current flow?

1.0V across R801

Is data transferred from

MICOM IC ?

Does voltage appear at IC

803 pin , ?

Defective MICOM.

Defective MICOM.

Defective connector.

Defective IC 801, 803

Defective slide motor and/or

connector.

Defective LMT SW and/or

connector.

Defective Q 801 and/or laser.

Defective laser and/or

connector.

Did pickup return to

innermost circular?

Does it stop at inner pick

circular after shift?

Is defect output from LM

SW applied to pin of

PN803?

R801 1.0V

R801 1.0V

YES

YES

YES

YES

OPEN

CLOSE

YES

YES

YES

YES

YES

YES

Page 29

B

C

- 14 -

Does lens move up/down?

Does IC 801 out focus

search signal?

IC 801 pin (FEO)

Is focus search signal

applied to pin , of

CN801?

Laser lights.

Confirm

initial

read with

disc

Defective IC801

Defective IC803

Defective IC 801.

Open activator and/or

connector.

Open connector and/or

defective IC 801.

Incorrect turntable height.

Degraded laser diode.

Does TP 801 RF signal appear even in

low level?

Is laser output adjustment correct?

Does FOK(focus ok) signal appear?

YES

YES

YES

YES

YES

YES

TP801

(RF)

IC801 pin

(FOK)

NO

NO

NO

NO

NO

NO

Page 30

FER

ISTAT(SENSE)

C

Start mode

- 15 -

Does FE1 signal appear? IC 801 pin

Does FZC signal (focus zero cross signal)

appear at pin of IC 801, ISTAT (SENSE)

terminal?

Does SMON signal appear

at pin of IC 802?

Does SMPO signal appear

at pin of IC 802?

Is drive voltage applied to disk motor?

Defective IC 801.

Open pick diode

Defective IC 801.

Defective Pattern between IC 801 and

IC 802.

Defective IC 801, 803 and/or

peripheral circuit.

Defective disk motor and/or insulation.

(Focus servo turns

ON by FZC signal

of FOK mod.)

NO

NO

NO

NO

YES

YES

YES

YES

YES

Page 31

Page 32

Page 33

No. Sales Model C/Part No Description Spec

1 FFH-818A

246-444K

DECORATION PLATE FFHKL588V SILVER

2 FFH-818A

246-444K

DECORATION PLATE FFHKL588V SILVER

3 FFH-818A

255-717A

HEAT SINK DIODE(GSA-PA10/FA-5000)

4 FFH-818A

255-717A

HEAT SINK DIODE(GSA-PA10/FA-5000)

5 FFH-818A

265-013B

FOOT FOOT RUBBER(NBR) MC-10

6 FFH-818A

265-013B

FOOT FOOT RUBBER(NBR) MC-10

7 FFH-818A

3040SB0002A

BASE MAIN(CDM-H1303)

8 FFH-818A

3040SB0002A

BASE MAIN(CDM-H1303)

9 FFH-818A

3040SB0003A

BASE PU(CDM-H1303)

10 FFH-818A

3040SB0003A

BASE PU(CDM-H1303)

11 FFH-818A

3040SB0004B

BASE PU ASSY(CDM-H1313)

12 FFH-818A

3090S-0003F

CABINET TOP(FFHK680V/390V,SILVER)

13 FFH-818A

3090S-0003F

CABINET TOP(FFHK680V/390V,SILVER)

14 FFH-818A

3140S-P907A

CHASSIS MAIN (FFH-585)

15 FFH-818A

3140S-P907A

CHASSIS MAIN (FFH-585)

16 FFH-818A

328-190B

BAND NYLON BAND TIE

17 FFH-818A

328-190B

BAND NYLON BAND TIE

18 FFH-818A

3390SB0001A

TRAY LOADING (CDM-H1303)

19 FFH-818A

3390SB0001A

TRAY LOADING (CDM-H1303)

20 FFH-818A

3390SB0002A

TRAY DISC (CDM-H1303)

21 FFH-818A

3390SB0002A

TRAY DISC (CDM-H1303)

22 FFH-818A

3508SB0001A

DECORATION MDSS (FFH-313/315/513/515/717/

23 FFH-818A

3508SB0001A

DECORATION MDSS (FFH-313/315/513/515/717/

24 FFH-818A

353-025C

SCREW SPECIAL 3X10 FBK

25 FFH-818A

353-025C

SCREW SPECIAL 3X10 FBK

26 FFH-818A

353-025G

SCREW TAPTITE 3X10 FZMY

27 FFH-818A

353-025G

SCREW TAPTITE 3X10 FZMY

28 FFH-818A

353-025HAAA

SCREW TAPTITE 3X16 FZMY

29 FFH-818A

353-025HAAA

SCREW TAPTITE 3X16 FZMY

30 FFH-818A

3550SC0008C

COVER FRONT(DEMO F-717/818)

31 FFH-818A

3550SC0008C

COVER FRONT(DEMO F-717/818)

32 FFH-818A

3580SCA346A

DOOR CST

33 FFH-818A

3580SCA346A

DOOR CST

34 FFH-818A

3580SCA347A

DOOR CST RIGHT

35 FFH-818A

3580SCA347A

DOOR CST RIGHT

36 FFH-818A

3580SCC878B

DOOR CD(FFH-515/717)

37 FFH-818A

3580SCC878B

DOOR CD(FFH-515/717)

38 FFH-818A

3680SC0004A

LENS JOG(FFH-717)

39 FFH-818A

3680SC0004A

LENS JOG(FFH-717)

40 FFH-818A

3680SC0005A

LENS SET(FFH-717)

41 FFH-818A

3680SC0005A

LENS SET(FFH-717)

42 FFH-818A

3720S-0036D

PANEL SIDE(FFHK588VABL2-Z,SILVER)

43 FFH-818A

3720S-0036D

PANEL SIDE(FFHK588VABL2-Z,SILVER)

44 FFH-818A

3720SCM038A

PANEL FRONT FFH-313

45 FFH-818A

3720SCM038A

PANEL FRONT FFH-313

46 FFH-818A

3720SCM043A

PANEL BACK FFHK818AAL3 LGEMS

47 FFH-818A

3790SCM056E

WINDOW CST-L(FFH-818)

48 FFH-818A

3790SCM056E

WINDOW CST-L(FFH-818)

49 FFH-818A

3790SCM057A

WINDOW CST-R FFH-313

50 FFH-818A

3790SCM057A

WINDOW CST-R FFH-313

51 FFH-818A

3790SCM058A

WINDOW AMP FFH-313

52 FFH-818A

3790SCM058A

WINDOW AMP FFH-313

53 FFH-818A

3790SCM059B

WINDOW CD (LG RED BADGE HOLE)

54 FFH-818A

3790SCM059B

WINDOW CD (LG RED BADGE HOLE)

55 FFH-818A

3828SXD018U

MANUAL,CHINA F-515/717/818 ENG/SPA (9908) L

56 FFH-818A

384-535A

GUIDE EJECT AY(FK-535 BD1)DUAL

57 FFH-818A

384-535A

GUIDE EJECT AY(FK-535 BD1)DUAL

58 FFH-818A

3846S-0205A

MARK BADGE LG (RED+SILVER)

59 FFH-818A

3846S-0205A

MARK BADGE LG (RED+SILVER)

60 FFH-818A

3850SCN025N

LABEL,STREAMER CST-L "MDSS" (FFH-8800/5500)

61 FFH-818A

3850SCN025N

LABEL,STREAMER CST-L "MDSS" (FFH-8800/5500)

62 FFH-818A

3850SCN042B

LABEL FFH-717 RIGHT DOOR

63 FFH-818A

3850SCN042B

LABEL FFH-717 RIGHT DOOR

64 FFH-818A

3890SCC010D

BOX FFH-818A LGEMS LG

65 FFH-818A

4370SB0019A

SHAFT TRAY (CDM-H1303)

66 FFH-818A

4370SB0019A

SHAFT TRAY (CDM-H1303)

67 FFH-818A

4371SB0002A

SHAFT ASSY TRAY (CDM-H1303)

68 FFH-818A

4371SB0002A

SHAFT ASSY TRAY (CDM-H1303)

Page 34

69 FFH-818A

4400SB0001A

BELT MAIN(CDM-H1303)

70 FFH-818A

4400SB0001A

BELT MAIN(CDM-H1303)

71 FFH-818A

4400SB0001B

BELT TRAY(CDM-H1303)

72 FFH-818A

4400SB0001B

BELT TRAY(CDM-H1303)

73 FFH-818A

4404SBA001B

MECHANISM CDM-H1313 SHIN HEUNG

74 FFH-818A

4404SBA002A

MECHANISM MECHANISM TRAY(CDMH1303)

75 FFH-818A

4404SBA002A

MECHANISM MECHANISM TRAY(CDMH1303)

76 FFH-818A

4405SBE001B

MECHANISM ASSY CDM-H1313 SHIN HEUNG

77 FFH-818A

4405SCE003A

MECHANISM ASSY CDM-H1313 SHIN HEUNG

78 FFH-818A

4405SCE003A

MECHANISM ASSY CDM-H1313 SHIN HEUNG

79 FFH-818A

442-085E

SPRING SPRING-DOOR (F-101)50D L=35

80 FFH-818A

442-085E

SPRING SPRING-DOOR (F-101)50D L=35

81 FFH-818A

442-577B

SPRING SPRING CST-PACK(H=7.5)

82 FFH-818A

442-577B

SPRING SPRING CST-PACK(H=7.5)

83 FFH-818A

447-938K

CUSHION CUSHION RUBBER(MTR-400/500)

84 FFH-818A

447-938K

CUSHION CUSHION RUBBER(MTR-400/500)

85 FFH-818A

447-938K

CUSHION CUSHION RUBBER(MTR-400/500)

86 FFH-818A

4470SB0003A

GEAR PULLEY (CDM-H1303)

87 FFH-818A

4470SB0003A

GEAR PULLEY (CDM-H1303)

88 FFH-818A

4470SB0004A

GEAR LOADING (CDM-H1303)

89 FFH-818A

4470SB0004A

GEAR LOADING (CDM-H1303)

90 FFH-818A

4470SB0005A

GEAR MAIN (CDM-H1303)

91 FFH-818A

4470SB0005A

GEAR MAIN (CDM-H1303)

92 FFH-818A

4470SB0005A

GEAR MAIN (CDM-H1303)

93 FFH-818A

4470SB0006A

GEAR PU DOWN (CDM-H1303)

94 FFH-818A

4470SB0006A

GEAR PU DOWN (CDM-H1303)

95 FFH-818A

4470SB0007A

GEAR PU UP-A (CDM-H1303)

96 FFH-818A

4470SB0007A

GEAR PU UP-A (CDM-H1303)

97 FFH-818A

4470SB0008A

GEAR PU UP-B (CDM-H1303)

98 FFH-818A

4470SB0008A

GEAR PU UP-B (CDM-H1303)

99 FFH-818A

4470SB0009A

GEAR WORM (CDM-H1303)

100 FFH-818A

4470SB0009A

GEAR WORM (CDM-H1303)

101 FFH-818A

4470SB0010A

GEAR TRAY A (CDM-H1303)

102 FFH-818A

4470SB0010A

GEAR TRAY A (CDM-H1303)

103 FFH-818A

4470SB0011A

GEAR TRAY B (CDM-H1303)

104 FFH-818A

4470SB0011A

GEAR TRAY B (CDM-H1303)

105 FFH-818A

4471SB0001A

GEAR ASSY GEAR CAM ASSY

106 FFH-818A

4471SB0001A

GEAR ASSY GEAR CAM ASSY

107 FFH-818A

4560SB0001A

PULLEY MOTOR (CDM-H1303)

108 FFH-818A

4560SB0001A

PULLEY MOTOR (CDM-H1303)

109 FFH-818A

4560SB0001A

PULLEY MOTOR (CDM-H1303)

110 FFH-818A

4560SB0001A

PULLEY MOTOR (CDM-H1303)

111 FFH-818A

4560SB0002A

PULLEY TRAY (CDM-H1303)

112 FFH-818A

4560SB0002A

PULLEY TRAY (CDM-H1303)

113 FFH-818A

4680SBP001A

MOTOR(MECH) PULLEY ASSY (CDM-H1303)

114 FFH-818A

4680SBP001A

MOTOR(MECH) PULLEY ASSY (CDM-H1303)

115 FFH-818A

4680SBP001A

MOTOR(MECH) PULLEY ASSY (CDM-H1303)

116 FFH-818A

4680SBP002A

MOTOR(MECH) ASSY TRAY

117 FFH-818A

4680SBP002A

MOTOR(MECH) ASSY TRAY

118 FFH-818A

4810S-0901A

BRACKET IC(FM-95M)

119 FFH-818A

4810S-0901A

BRACKET IC(FM-95M)

120 FFH-818A

4860SB0002A

CLAMP CLAMP ASSY

121 FFH-818A

4860SB0002A

CLAMP CLAMP ASSY

122 FFH-818A

4900SB0001A

DAMPER DAMPER RUBBER

123 FFH-818A

4900SB0001A

DAMPER DAMPER RUBBER

124 FFH-818A

4901SK0001C

DAMPER ASSY GEAR DAMPER AY(WH+WH;G331)

125 FFH-818A

4901SK0001C

DAMPER ASSY GEAR DAMPER AY(WH+WH;G331)

126 FFH-818A

4920S-E007A

HEAT SINK MAIN(F-680V/390V)

127 FFH-818A

4920S-E007A

HEAT SINK MAIN(F-680V/390V)

128 FFH-818A

4930SCM007A

HOLDER FIP(N1V/N2V)

129 FFH-818A

4930SCM007A

HOLDER FIP(N1V/N2V)

130 FFH-818A

4940SC0051A

KNOB TUNING (FFH-717)

131 FFH-818A

4940SC0051A

KNOB TUNING (FFH-717)

132 FFH-818A

4940SC0052B

KNOB PLAY&FUNC(NON AUTO REVERSE F-7

133 FFH-818A

4940SC0052B

KNOB PLAY&FUNC(NON AUTO REVERSE F-7

134 FFH-818A

4940SC0053A

SDGZKNOB JOG(FFH-717)

135 FFH-818A

4940SC0053A

SDGZKNOB JOG(FFH-717)

136 FFH-818A

4940SC0055A

KNOB VOL (F-313/515/717)

137 FFH-818A

4940SC0055A

KNOB VOL (F-313/515/717)

138 FFH-818A

4970SBN002A

SPRING CAM (CDM-H1303)

Page 35

139 FFH-818A

4970SBN002A

SPRING CAM (CDM-H1303)

140 FFH-818A

4974SB0001A

GUIDE CAM (CDM-H1303)

141 FFH-818A

4974SB0001A

GUIDE CAM (CDM-H1303)

142 FFH-818A

4974SB0003A

GUIDE WORM (CDM-H1303)

143 FFH-818A

4974SB0003A

GUIDE WORM (CDM-H1303)

144 FFH-818A

5010SCT001A

ANTENNA FM T , 533-010K LGEHZ LOCAL

145 FFH-818A

5010SCT001A

ANTENNA FM T , 533-010K LGEHZ LOCAL

146 FFH-818A

563-801D

CONNECTOR ASSY C,AY GSIL-S06X2 157/#28 250(S)

147 FFH-818A

563-801D

CONNECTOR ASSY C,AY GSIL-S06X2 157/#28 250(S)

148 FFH-818A

563-935E

CONNECTOR ASSY C,AY GS IL-G03X2 (I) 250

149 FFH-818A

563-935E

CONNECTOR ASSY C,AY GS IL-G03X2 (I) 250

150 FFH-818A

563-935I

CONNECTOR ASSY C,AY GS IL-G08/06 (I,G) 240

151 FFH-818A

563-935I

CONNECTOR ASSY C,AY GS IL-G08/06 (I,G) 240

152 FFH-818A

632N218E

COIL,ANTENNA AM LOOP LGEHZ LOCAL (=218E)

153 FFH-818A

632N218E

COIL,ANTENNA AM LOOP LGEHZ LOCAL (=218E)

154 FFH-818A

6631SBE001A

CONNECTOR ASSY P=2.0 , GIL-S02/S02 UL1571

155 FFH-818A

6631SBE001A

CONNECTOR ASSY P=2.0 , GIL-S02/S02 UL1571

156 FFH-818A

6631SBE001B

CONNECTOR ASSY P=2.0 ,GIL-S04/S04 UL 1571

157 FFH-818A

6631SBE001B

CONNECTOR ASSY P=2.0 ,GIL-S04/S04 UL 1571

158 FFH-818A

6631SBE001C

CONNECTOR ASSY P=2.0 ,GIL-S05/S05 UL1571

159 FFH-818A

6631SBE001C

CONNECTOR ASSY P=2.0 ,GIL-S05/S05 UL1571

160 FFH-818A

6710SCDC21A

REMOTE CONTROLLER 25KEY DONGDO FFH-515/717 AUTO

161 FFH-818A

6710SCDC21A

REMOTE CONTROLLER 25KEY DONGDO FFH-515/717 AUTO

162 FFH-818A

6716R-A001A

PICK UP KSS-880 PICK UP OF K

163 FFH-818A

6716R-A001B

PICK UP X-2646-550-(1) SL MO

164 FFH-818A

6716R-A001C

PICK UP 1-564-722-(11) CONNE

165 FFH-818A

6716R-A001D

PICK UP 1-674-388-(11) MOTOR

166 FFH-818A

6716R-A001E

PICK UP 1-771-642-(11) LEAF

167 FFH-818A

6716R-A001F

PICK UP 2-647-407-(01) GEAR

168 FFH-818A

6716R-A001G

PICK UP 2-647-408-(02) GEAR

169 FFH-818A

6716R-A001H

PICK UP 2-647-415-(01) SHUTT

170 FFH-818A

6716R-A001J

PICK UP 2-647-732-(01) NS SL

171 FFH-818A

6716R-A001K

PICK UP 2-647-742-(01) SPRIN

172 FFH-818A

6716R-A001L

PICK UP 3-321-813-(11) POLIW

173 FFH-818A

6716R-A001M

PICK UP 2-647-416-(02) SPRIN

174 FFH-818A

6716R-A001N

PICK UP 7-621-255-(15) SCREW

175 FFH-818A

672-001AAAA

WIREW SHIELD TIN WIRE

176 FFH-818A

672-001AAAA

WIREW SHIELD TIN WIRE

177 FFH-818A

6756SBX001A

CD MECHANISM PARTS SCREW 2.6X10X10XFZMY CDM-H813

178 FFH-818A

6756SBX001A

CD MECHANISM PARTS SCREW 2.6X10X10XFZMY CDM-H813

179 FFH-818A

6768SCAS01B

DECK MECHANISM PARTS MT90-21010J ARM ASSY S/S

180 FFH-818A

6768SCAS01B

DECK MECHANISM PARTS MT90-21010J ARM ASSY S/S

181 FFH-818A

6768SCAS03A

DECK MECHANISM PARTS MT72-00022A ARM S/S PINCH-F AD

182 FFH-818A

6768SCAS03A

DECK MECHANISM PARTS MT72-00022A ARM S/S PINCH-F AD

183 FFH-818A

6768SCBS03B

DECK MECHANISM PARTS 6602-001013 BELT/FELT S/S MAIN

184 FFH-818A

6768SCBS03C

DECK MECHANISM PARTS 6602-1038 BELT/FELT S/S MAIN A

185 FFH-818A

6768SCDS03A

DECK MECHANISM PARTS MT72-00069A LEVER S/S EJECT AD

186 FFH-818A

6768SCES03A

DECK MECHANISM PARTS MT91-04012G HEAD ASSY S/S ADR2

187 FFH-818A

6768SCES03B

DECK MECHANISM PARTS MT91-04012F HEAD ASSY S/S ADR2

188 FFH-818A

6768SCES03B

DECK MECHANISM PARTS MT91-04012F HEAD ASSY S/S ADR2

189 FFH-818A

6768SCHS01A

DECK MECHANISM PARTS MT59-00044A(TC881CB) HEAD S/S

190 FFH-818A

6768SCHS03A

DECK MECHANISM PARTS MT59-00043A(TC2132) HEAD S/S H

191 FFH-818A

6768SCJS02A

DECK MECHANISM PARTS MT91-01011P PULLEY/FLYWHEEL AS

192 FFH-818A

6768SCOS01A

DECK MECHANISM PARTS MT91-15012M MOTOR ASSY S/S

193 FFH-818A

6768SCOS01A

DECK MECHANISM PARTS MT91-15012M MOTOR ASSY S/S

194 FFH-818A

6768SCQS01A

DECK MECHANISM PARTS 3101-000174 MOTOR S/S YD2BH AD

195 FFH-818A

6768SCQS01A

DECK MECHANISM PARTS 3101-000174 MOTOR S/S YD2BH AD

196 FFH-818A

6768SCRS01A

DECK MECHANISM PARTS MT73-00010A ROLLER S/S PINCH A

197 FFH-818A

6768SCSS02A

DECK MECHANISM PARTS 6107-000353 SPRING S/S PINCH-F

198 FFH-818A

6768SCTS01B

DECK MECHANISM PARTS 3404-000306 SWITCH S/S

199 FFH-818A

6768SCTS01B

DECK MECHANISM PARTS 3404-000306 SWITCH S/S

200 FFH-818A

6768SCVS02A

DECK MECHANISM PARTS MT75-00049A SOLENOID S/S ADR24

201 FFH-818A

6850SCHT24A

CABLE,FLAT P=1.25 FFC UL2896 20 240 A TYP

202 FFH-818A

6850SCHT24A

CABLE,FLAT P=1.25 FFC UL2896 20 240 A TYP

203 FFH-818A

6871S-38KAC

PWB(PCB) ASSY,TOTAL F-313/515/717 SONY D

204 FFH-818A

6871S-40WDC

PWB(PCB) ASSY,TOTAL FFH-818 NEW MD FRONT

205 FFH-818A

6871S-427AC

PWB(PCB) ASSY,TOTAL FFH-818 MAIN+POWER

206 FFH-818A

6871SA427AC

PWB(PCB) ASSY,AMP FFH-818 MAIN

207 FFH-818A

6871SA427AC

PWB(PCB) ASSY,AMP FFH-818 MAIN

208 FFH-818A

6871SB21RAD

PWB(PCB) ASSY 3CH M/D U/D/O/C PWB ASSY

Page 36

209 FFH-818A

6871SB21RAD

PWB(PCB) ASSY 3CH M/D U/D/O/C PWB ASSY

210 FFH-818A

6871SC21RAD

PWB(PCB) ASSY 3CH M/D OPEN PWB ASSY

211 FFH-818A

6871SC21RAD

PWB(PCB) ASSY 3CH M/D OPEN PWB ASSY

212 FFH-818A

6871SD21RAD

PWB(PCB) ASSY 3CH M/D CAM PWB ASSY

213 FFH-818A

6871SD21RAD

PWB(PCB) ASSY 3CH M/D CAM PWB ASSY

214 FFH-818A

6871SF21RAD

PWB(PCB) ASSY 3CH M/D SENSOR PWB ASSY

215 FFH-818A

6871SF21RAD

PWB(PCB) ASSY 3CH M/D SENSOR PWB ASSY

216 FFH-818A

6871SP427AC

PWB(PCB) ASSY,POWER FFH-818 POWER

217 FFH-818A

796-003B

MICA MICA(20X24)

218 FFH-818A

796-003B

MICA MICA(20X24)

219 FFH-818A

88H-0002

CD MECHA PARTS 3X9X12FZMY

220 FFH-818A

88H-0002

CD MECHA PARTS 3X9X12FZMY

221 FFH-818A

L82+H12S

LEAD SET FLAT UL2877#26-08 120 S/G-G

222 FFH-818A

L82+H12S

LEAD SET FLAT UL2877#26-08 120 S/G-G

223 FFH-818A

L82+J18S

LEAD SET FLAT UL2878#26-10 180 S/G-G

224 FFH-818A

L82+J18S

LEAD SET FLAT UL2878#26-10 180 S/G-G

225 FFH-818A

L82+J30S

LEAD SET FLAT UL2878#26-10 300 S/G-G

226 FFH-818A

L82+J30S

LEAD SET FLAT UL2878#26-10 300 S/G-G

227 FFH-818A

L82+L12S

LEAD SET P=2.0 UL2877#26 SA-SC 12 120 S

228 FFH-818A

L82+L12S

LEAD SET P=2.0 UL2877#26 SA-SC 12 120 S

229 FFH-818A

88H-0002

CD MECHA PARTS 3X9X12FZMY

230 FFH-818A

88H-0002

CD MECHA PARTS 3X9X12FZMY

231 FFH-818A

353-025C

SCREW SPECIAL 3X10 FBK

232 FFH-818A

353-025C

SCREW SPECIAL 3X10 FBK

233 FFH-818A

353-025TAAA

SCREW TAPTITE 3X10.5 FZMY

234 FFH-818A

353-025TAAA

SCREW TAPTITE 3X10.5 FZMY

235 FFH-818A

353-025C

SCREW SPECIAL 3X10 FBK

236 FFH-818A

353-025C

SCREW SPECIAL 3X10 FBK

237 FFH-818A

353-025TAAA

SCREW TAPTITE 3X10.5 FZMY

238 FFH-818A

353-025TAAA

SCREW TAPTITE 3X10.5 FZMY

239 FFH-818A

4810S-7829A

BRACKET CD MOTOR(0.3T)NEW-MD

240 FFH-818A

4810S-7829A

BRACKET CD MOTOR(0.3T)NEW-MD

241 FFH-818A

4810S-7829A

BRACKET CD MOTOR(0.3T)NEW-MD

242 FFH-818A

4810S-7829A

BRACKET CD MOTOR(0.3T)NEW-MD

243 FFH-818A

353-025C

SCREW SPECIAL 3X10 FBK

244 FFH-818A

353-025C

SCREW SPECIAL 3X10 FBK

245 FFH-818A

353-025TAAA

SCREW TAPTITE 3X10.5 FZMY

246 FFH-818A

353-025TAAA

SCREW TAPTITE 3X10.5 FZMY

247 FFH-818A

0CN1040K949

CAPACITOR TUBULA(HIGH DIELE) 0.1M 50V Z F TA52

248 FFH-818A

0CN1040K949

CAPACITOR TUBULA(HIGH DIELE) 0.1M 50V Z F TA52

249 FFH-818A

0CK1040K945

CAPACITOR,CERAMIC(HIGH DIELE) 0.1M 50V Z F TS

250 FFH-818A

0CK1040K945

CAPACITOR,CERAMIC(HIGH DIELE) 0.1M 50V Z F TS

251 FFH-818A

0CN1030F679

CAPACITOR TUBULA(HIGH DIELE) 0.01MF 16V M Y TA52

252 FFH-818A

0CN1030F679

CAPACITOR TUBULA(HIGH DIELE) 0.01MF 16V M Y TA52

253 FFH-818A

0CK2230K945

CAPACITOR CERAMIC(HIGH DIELE) 0.022M 50V Z F TS

254 FFH-818A

0CK2230K945

CAPACITOR CERAMIC(HIGH DIELE) 0.022M 50V Z F TS

255 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

256 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

257 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

258 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

259 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

260 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

261 FFH-818A

0CE1056K618

CAPACITOR,ELECTROLYTIC 1.0M SMS 50V M FL TP(5)

262 FFH-818A

0CE1056K618

CAPACITOR,ELECTROLYTIC 1.0M SMS 50V M FL TP(5)

263 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

264 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

265 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

266 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

267 FFH-818A

0CQ3331N409

CAPACITOR POLYESTER(MYLAR) 0.033U 100V J POLY TP

268 FFH-818A

0CQ3331N409

CAPACITOR POLYESTER(MYLAR) 0.033U 100V J POLY TP

269 FFH-818A

0CQ3331N409

CAPACITOR POLYESTER(MYLAR) 0.033U 100V J POLY TP

270 FFH-818A

0CQ3331N409

CAPACITOR POLYESTER(MYLAR) 0.033U 100V J POLY TP

271 FFH-818A

0CE1056K618

CAPACITOR,ELECTROLYTIC 1.0M SMS 50V M FL TP(5)

272 FFH-818A

0CE1056K618

CAPACITOR,ELECTROLYTIC 1.0M SMS 50V M FL TP(5)

273 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

274 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

275 FFH-818A

0CN1040K949

CAPACITOR TUBULA(HIGH DIELE) 0.1M 50V Z F TA52

276 FFH-818A

0CN1040K949

CAPACITOR TUBULA(HIGH DIELE) 0.1M 50V Z F TA52

277 FFH-818A

0CE3356K618

CAPACITOR,ELECTROLYTIC 3.3M SMS 50V M FL TP(5)

278 FFH-818A

0CE3356K618

CAPACITOR,ELECTROLYTIC 3.3M SMS 50V M FL TP(5)

Page 37

279 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

280 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

281 FFH-818A

0CX2000K419

CAPACITOR TUBULA(T.C) 20P 50V J C TA52

282 FFH-818A

0CX2000K419

CAPACITOR TUBULA(T.C) 20P 50V J C TA52

283 FFH-818A

0CE3366F618

CAPACITOR,ELECTROLYTIC 33M SMS 16V M FL TP(5)

284 FFH-818A

0CE3366F618

CAPACITOR,ELECTROLYTIC 33M SMS 16V M FL TP(5)

285 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

286 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

287 FFH-818A

0CK4730K945

CAPACITOR CERAMIC(HIGH DIELE) 0.047U 50V Z F TS

288 FFH-818A

0CK4730K945

CAPACITOR CERAMIC(HIGH DIELE) 0.047U 50V Z F TS

289 FFH-818A

0CN1020K519

CAPACITOR TUBULA(HIGH DIELE) 1000P 50V K B TA52

290 FFH-818A

0CN1020K519

CAPACITOR TUBULA(HIGH DIELE) 1000P 50V K B TA52

291 FFH-818A

0CN2220F669

CAPACITOR TUBULA(HIGH DIELE) 2200P 16V M X TA52

292 FFH-818A

0CN2220F669

CAPACITOR TUBULA(HIGH DIELE) 2200P 16V M X TA52

293 FFH-818A

0CK4730K945

CAPACITOR CERAMIC(HIGH DIELE) 0.047U 50V Z F TS

294 FFH-818A

0CK4730K945

CAPACITOR CERAMIC(HIGH DIELE) 0.047U 50V Z F TS

295 FFH-818A

0CX3000K409

CAPACITOR TUBULA(T.C) 30P 50V J SL TA52

296 FFH-818A

0CX3000K409

CAPACITOR TUBULA(T.C) 30P 50V J SL TA52

297 FFH-818A

0CX3000K409

CAPACITOR TUBULA(T.C) 30P 50V J SL TA52

298 FFH-818A

0CX3000K409

CAPACITOR TUBULA(T.C) 30P 50V J SL TA52

299 FFH-818A

0CN1020K519

CAPACITOR TUBULA(HIGH DIELE) 1000P 50V K B TA52

300 FFH-818A

0CN1020K519

CAPACITOR TUBULA(HIGH DIELE) 1000P 50V K B TA52

301 FFH-818A

0CE2276F618

CAPACITOR,ELECTROLYTIC 220M SMS 16V M FM5 TP(5)

302 FFH-818A

0CE2276F618

CAPACITOR,ELECTROLYTIC 220M SMS 16V M FM5 TP(5)

303 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

304 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

305 FFH-818A

0CK4730K945

CAPACITOR CERAMIC(HIGH DIELE) 0.047U 50V Z F TS

306 FFH-818A

0CK4730K945

CAPACITOR CERAMIC(HIGH DIELE) 0.047U 50V Z F TS

307 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

308 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

309 FFH-818A

0CC1000K015

CAPACITOR,CERAMIC(TEMP COMP) 10P 50V C NP0 TS

310 FFH-818A

0CC1000K015

CAPACITOR,CERAMIC(TEMP COMP) 10P 50V C NP0 TS

311 FFH-818A

0CN4730K949

CAPACITOR TUBULA(HIGH DIELE) 0.047M 50V Z F TA52

312 FFH-818A

0CN4730K949

CAPACITOR TUBULA(HIGH DIELE) 0.047M 50V Z F TA52

313 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

314 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

315 FFH-818A

0CE4746K618

CAPACITOR,ELECTROLYTIC 0.47M SMS 50V M FL TP(5)

316 FFH-818A

0CE4746K618

CAPACITOR,ELECTROLYTIC 0.47M SMS 50V M FL TP(5)

317 FFH-818A

0CE4746K618

CAPACITOR,ELECTROLYTIC 0.47M SMS 50V M FL TP(5)

318 FFH-818A

0CE4746K618

CAPACITOR,ELECTROLYTIC 0.47M SMS 50V M FL TP(5)

319 FFH-818A

0CE3356K618

CAPACITOR,ELECTROLYTIC 3.3M SMS 50V M FL TP(5)

320 FFH-818A

0CE3356K618

CAPACITOR,ELECTROLYTIC 3.3M SMS 50V M FL TP(5)

321 FFH-818A

0CQ4731N409

CAPACITOR POLYESTER(MYLAR) 0.047U 100V J POLY TP

322 FFH-818A

0CQ4731N409

CAPACITOR POLYESTER(MYLAR) 0.047U 100V J POLY TP

323 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

324 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

325 FFH-818A

0CE1056K618

CAPACITOR,ELECTROLYTIC 1.0M SMS 50V M FL TP(5)

326 FFH-818A

0CE1056K618

CAPACITOR,ELECTROLYTIC 1.0M SMS 50V M FL TP(5)

327 FFH-818A

0CN2220F669

CAPACITOR TUBULA(HIGH DIELE) 2200P 16V M X TA52

328 FFH-818A

0CN2220F669

CAPACITOR TUBULA(HIGH DIELE) 2200P 16V M X TA52

329 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

330 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

331 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

332 FFH-818A

0CE1066K618

CAPACITOR,ELECTROLYTIC 10M SMS 50V M FM5 TP(5)

333 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

334 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

335 FFH-818A

0CN1010K519

CAPACITOR TUBULA(HIGH DIELE) 100P 50V K B TA52

336 FFH-818A

0CN1010K519

CAPACITOR TUBULA(HIGH DIELE) 100P 50V K B TA52

337 FFH-818A

0CN1030F679

CAPACITOR TUBULA(HIGH DIELE) 0.01MF 16V M Y TA52

338 FFH-818A

0CN1030F679

CAPACITOR TUBULA(HIGH DIELE) 0.01MF 16V M Y TA52

339 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

340 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

341 FFH-818A

0CN2210K519

CAPACITOR TUBULA(HIGH DIELE) 220P 50V K B TA52

342 FFH-818A

0CN2210K519

CAPACITOR TUBULA(HIGH DIELE) 220P 50V K B TA52

343 FFH-818A

0CN2210K519

CAPACITOR TUBULA(HIGH DIELE) 220P 50V K B TA52

344 FFH-818A

0CN2210K519

CAPACITOR TUBULA(HIGH DIELE) 220P 50V K B TA52

345 FFH-818A

0CE2276F618

CAPACITOR,ELECTROLYTIC 220M SMS 16V M FM5 TP(5)

346 FFH-818A

0CE2276F618

CAPACITOR,ELECTROLYTIC 220M SMS 16V M FM5 TP(5)

347 FFH-818A

0CX8R20K519

CAPACITOR TUBULA(T.C) 8.2P 50V K C TA52

348 FFH-818A

0CX8R20K519

CAPACITOR TUBULA(T.C) 8.2P 50V K C TA52

Page 38

349 FFH-818A

0CE1066J618

CAPACITOR,ELECTROLYTIC 10M SMS 35V M FL TP(5)

350 FFH-818A

0CE1066J618

CAPACITOR,ELECTROLYTIC 10M SMS 35V M FL TP(5)

351 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

352 FFH-818A

0CN2230H949

CAPACITOR TUBULA(HIGH DIELE) 22000P 25V Z FTA52

353 FFH-818A

0CN6810K519

CAPACITOR TUBULA(HIGH DIELE) 680P 50V K B TA52

354 FFH-818A

0CN6810K519

CAPACITOR TUBULA(HIGH DIELE) 680P 50V K B TA52

355 FFH-818A

0CN6810K519

CAPACITOR TUBULA(HIGH DIELE) 680P 50V K B TA52

356 FFH-818A

0CN6810K519

CAPACITOR TUBULA(HIGH DIELE) 680P 50V K B TA52

357 FFH-818A

0RD1002F609

RESISTOR,FIXED CARBON FILM 10K 1/6W 5 TA52

358 FFH-818A

0RD1002F609

RESISTOR,FIXED CARBON FILM 10K 1/6W 5 TA52

359 FFH-818A

0CN1820F669

CAPACITOR TUBULA(HIGH DIELE) 1800P 16V M X TA52

360 FFH-818A

0CN1820F669

CAPACITOR TUBULA(HIGH DIELE) 1800P 16V M X TA52

361 FFH-818A

0CN3320F669

CAPACITOR,TUBULAR(HIGH DIELEC) 3300PF 16V M X TA52

362 FFH-818A

0CN3320F669

CAPACITOR,TUBULAR(HIGH DIELEC) 3300PF 16V M X TA52

363 FFH-818A

0CE2256K618

CAPACITOR,ELECTROLYTIC 2.2M SMS 50V M FL TP(5)

364 FFH-818A

0CE2256K618

CAPACITOR,ELECTROLYTIC 2.2M SMS 50V M FL TP(5)

365 FFH-818A

0CN2210K519

CAPACITOR TUBULA(HIGH DIELE) 220P 50V K B TA52

366 FFH-818A

0CN2210K519

CAPACITOR TUBULA(HIGH DIELE) 220P 50V K B TA52

367 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

368 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

369 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

370 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

371 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

372 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

373 FFH-818A

0CQ1031N409

CAPACITOR POLYESTER(MYLAR) 0.01U 100V J POLY TP

374 FFH-818A

0CQ1031N409

CAPACITOR POLYESTER(MYLAR) 0.01U 100V J POLY TP

375 FFH-818A

0CE4756K618

CAPACITOR,ELECTROLYTIC 4.7M SMS 50V M FL TP(5)

376 FFH-818A

0CE4756K618

CAPACITOR,ELECTROLYTIC 4.7M SMS 50V M FL TP(5)

377 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

378 FFH-818A

0CE4766F618

CAPACITOR,ELECTROLYTIC 47M SMS 16V M FL TP(5)

379 FFH-818A

0CE1066J618

CAPACITOR,ELECTROLYTIC 10M SMS 35V M FL TP(5)

380 FFH-818A

0CE1066J618

CAPACITOR,ELECTROLYTIC 10M SMS 35V M FL TP(5)

381 FFH-818A

0CN5620F669

CAPACITOR TUBULA(HIGH DIELE) 5600P 16V M X TA(52)

382 FFH-818A

0CN5620F669

CAPACITOR TUBULA(HIGH DIELE) 5600P 16V M X TA(52)

383 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

384 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

385 FFH-818A

0CN1020K519

CAPACITOR TUBULA(HIGH DIELE) 1000P 50V K B TA52

386 FFH-818A

0CN1020K519

CAPACITOR TUBULA(HIGH DIELE) 1000P 50V K B TA52

387 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

388 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

389 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

390 FFH-818A

0CN3310K519

CAPACITOR TUBULA(HIGH DIELE) 330P 50V K B TA52

391 FFH-818A

0CE1076F618

CAPACITOR,ELECTROLYTIC 100M SMS 16V M FM5 TP(5)

392 FFH-818A

0CE1076F618

CAPACITOR,ELECTROLYTIC 100M SMS 16V M FM5 TP(5)

393 FFH-818A

0CE4756K618