LG FBNC608RSA0 Owner’s Manual

CEILING DUCT TYPE AIR CONDITIONERS

INSTALLATION INSTRUCTIONS

(Refrigerant : R407C)

• This unit is charged with new refrigerant, R407C.

• Be sure to use proper tools for R407C, when installing the unit.

• Please read this instruction sheet completely before installing the product.

• When the power cord is damaged, replacement work shall be performed by authorized

personnel only.

• Installation work must be performed in accordance with the national wiring standards by

authorized personnel only.

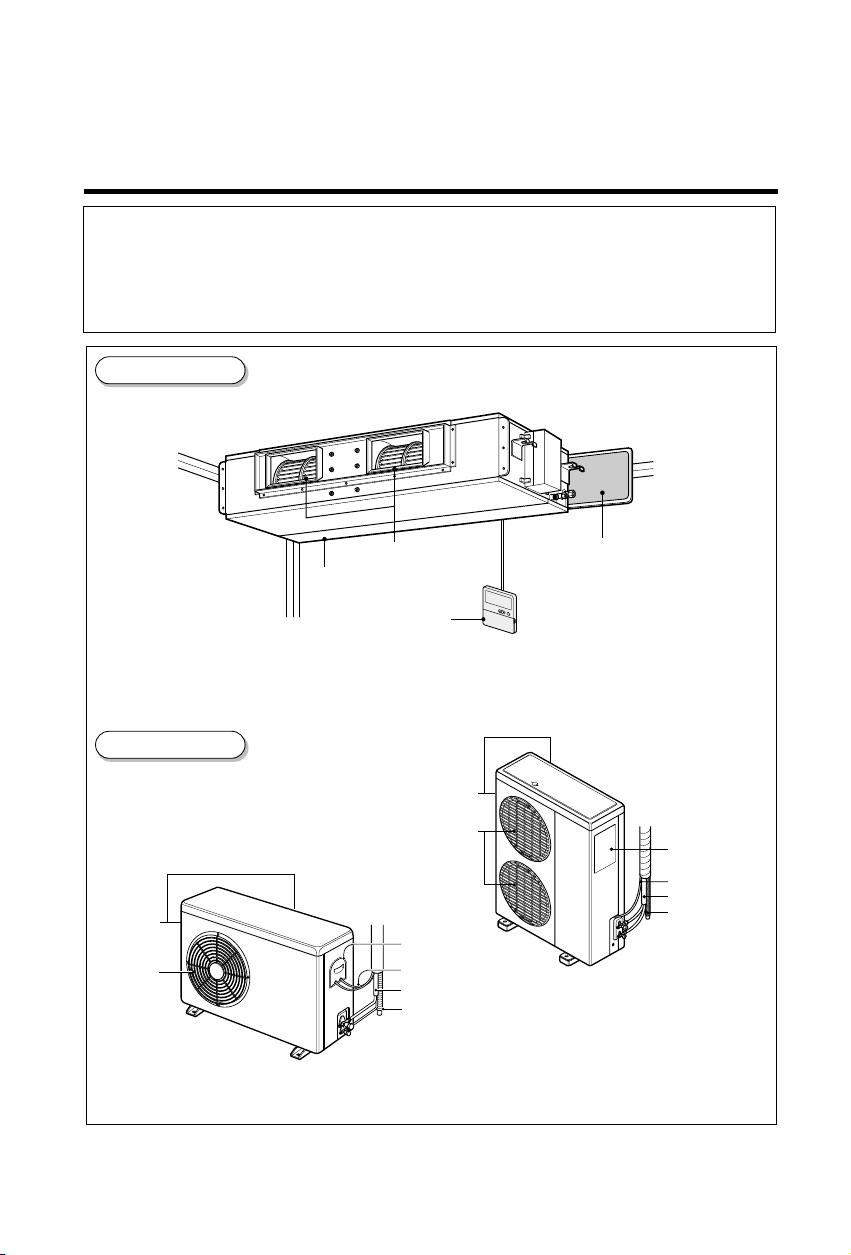

Indoor Unit

Outdoor Unit

(Side)

Air intake

vents

Air outlet

vents

Air outlet vents

Air intake vents

Remote Controller

(Rear)

(Side)

Air intake vents

Air outlet vents

Control Cover

Connecting Wire

Connection Pipe

Drain Hose

Air filters

(Rear)

Control cover

Connecting wire

Piping

Drain hose

P/No.:

MFL65000405

OUT-LINE OF INSTALLATION

1. The following should be always observed for safety ..............................3

Installation works Installation Parts Required tools

2. Installation of Indoor, Outdoor unit

1)

Selection of the best

............................4

location

2) Indoor unit installation....5

3. Connecting Pipes to the Indoor Unit

1) Preparation of Piping...14

4. Connecting Pipes to the Outdoor Unit

1) Connecting the pipes to

the Outdoor Unit ..........16

5. Checking the Drainage..............................................................................16

•

Four Type “A” screws

•

Connecting cable

•

Pipes: Gas side ..... / ", / "

Liquid side .............

•

Insulated drain hose

•

Insulation materials

•

Additional Drain hose

(Inner Dia...............25mm)

583

1

43812

/ ", / ", / "

•

Level

•

Screw driver

•

Electric drill

•

Hole core drill (ø70mm)

4

•

Flaring Tools set

6. Connecting Cables between Indoor Unit and Outdoor Unit

1) Connecting cables to the

Indoor Unit ...................17

2) Clamping of cables ......17

3) Connecting cables to the

Outdoor Unit ................18

4) Form the pipings..........19

•

Screw driver

7. Air Purging of the Connecting Pipes and the Indoor Unit ....................20

•

Hexagonal Wrench (4mm/5mm)

•

Gas-leak Detector

8. Group Control ............................................................................................21

9. Two Thermistor System ............................................................................21

1 . E.S.P (External Static Pressure) Setting................................................2

0 2

1 . How to Set E.S.P...................................................................................... 20 3

2

1. The following should be always observed for safety

• Please report to or take consent by the supply authority before connecting to the system.

• Be sure to read "THE FOLLOWING SHOULD BE ALWAYS OBSERVED FOR SAFETY" before

installing the air conditioner.

• Be sure to observe the cautions specified here as they include important items related to safety.

• The indications and meanings are as follows.

WARNING

CAUTION

Could lead to death, serious injury, etc.

Could lead to serious injury in particular environments when operated incorrectly.

• After reading this manual, be sure to keep it together with the owner's manual in an accessible

place.

WARNING

Do not install it yourself (customer).

• Incomplete installation could cause injury due to fire, electric shock,

the unit falling or a leakage of water. Consult the dealer from whom

you purchased the unit or special installer.

Install the unit securely in a place which can bear the

weight of the unit.

• When installed in an insufficient strong place, the unit could fall

causing injured.

Use the specified wires to connect the indoor and the

outdoor units securely and attach the wires firmly to

the terminal board connecting sections so the stress

of the wires is not applied to the sections.

• Incomplete connecting and fixing could cause fire.

Check that the refrigerant gas do not leak after

installation is completed.

Perform the installation securely referring to the

installation manual.

• Incomplete installation could cause a personal injury due to

fire, electric shock, the unit falling or a leakage of water.

Perform electrical work according to the installation

manual and be sure to use an exclusive circuit.

• If the capacity of the power circuit is insufficient or there is

incomplete electrical work, it could result in a fire or an electric

shock.

Attach the electrical part cover to the indoor unit and

the service panel to the outdoor unit securely.

• If the electrical par t cover if the indoor unit and/or the service

panel if the outdoor unit are not attached securely, it could result

in a fire or electric shock due to dust, water, etc.

Be sure to use the part provided or specified parts for

the installation work.

• The use of defective parts could cause an injury or leakage of

water due to a fire, electric shock, the unit falling, etc.

Perform the drainage/piping work securely

according to the installation manual.

• If there is a defect in the drainage/piping work, water

could drop from the unit and household goods could be

wet and damaged.

Do not install the electric heater

• Electric heater may cause deformation or fire of blower

and housing which were made of plastic.

CAUTION

Do not install the unit in a place where an

inflammable gas leaks.

• If gas leaks and accumulates in the area surrounding the unit, it

could cause an explosion.

3

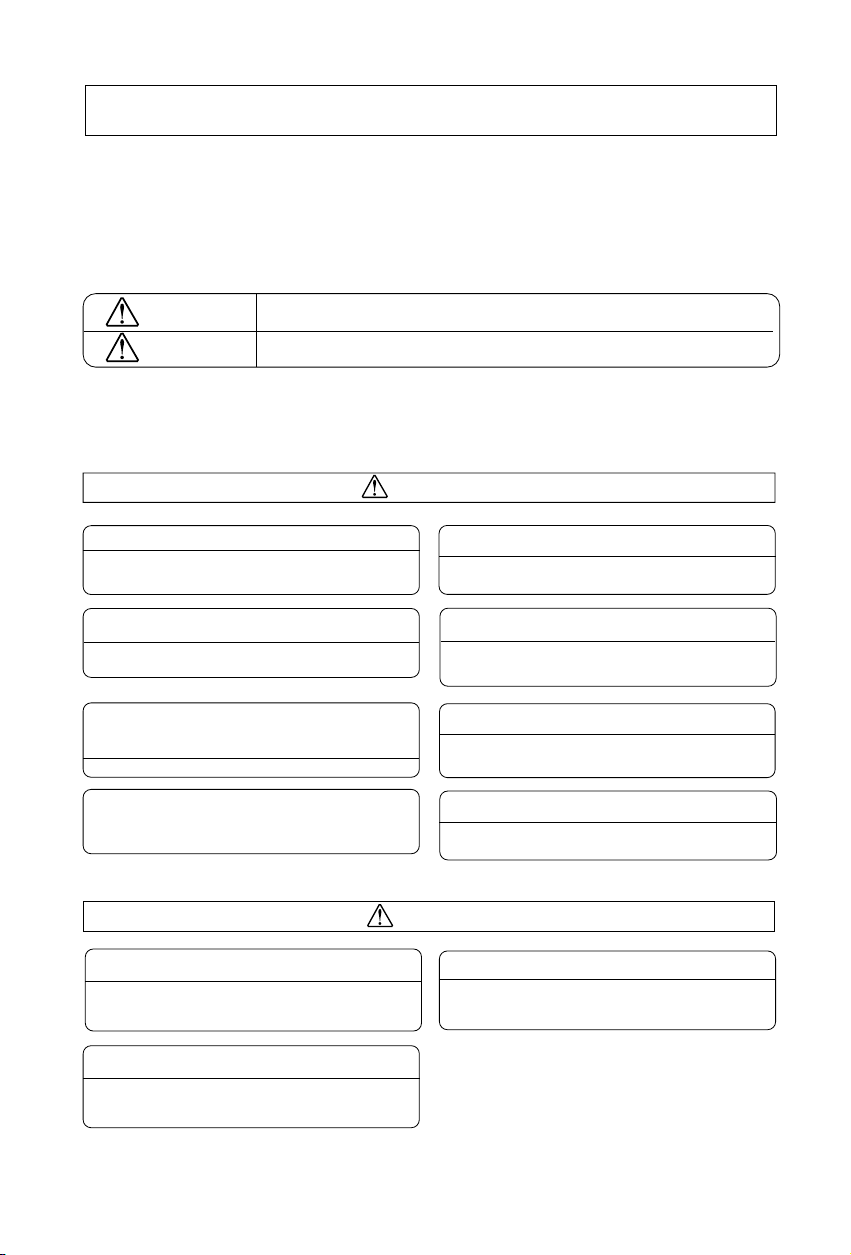

2. Installation of Indoor, Outdoor Unit

1. Selection of the best location

1) Indoor unit

Top view

(unit: mm)

Select location

Install the air conditioner in the location that

satisfies the following conditions.

• The place shall easily bear a load exceeding

four times the indoor unit’s weight.

• The place shall be able to inspect the unit as

the figure.

Front view

• The place where the unit shall be leveled.

• The place shall allow easy water

drainage.(Suitable dimension “H” is necessary

to get a slope to drain as figure.)

• The place shall easily connect with the

outdoor unit.

• The place where the unit is not affected by an

More than

30cm

electrical noise.

• The place where air circulation in the room will

be good .

• There should not be any heat source or steam

Fence or

obstacles

near the unit

2) Outdoor unit

• If an awning is built over the unit to prevent

direct sunlight or rain exposure, be careful

that heat radiation from the condenser is not

restricted.

• There should not be any animals or plants

More than

30cm

which could be affected by hot air

discharged.

• Ensure the spaces indicated by arrows from

the wall, ceiling, fence or other obstacles.

Fence or

obstacles

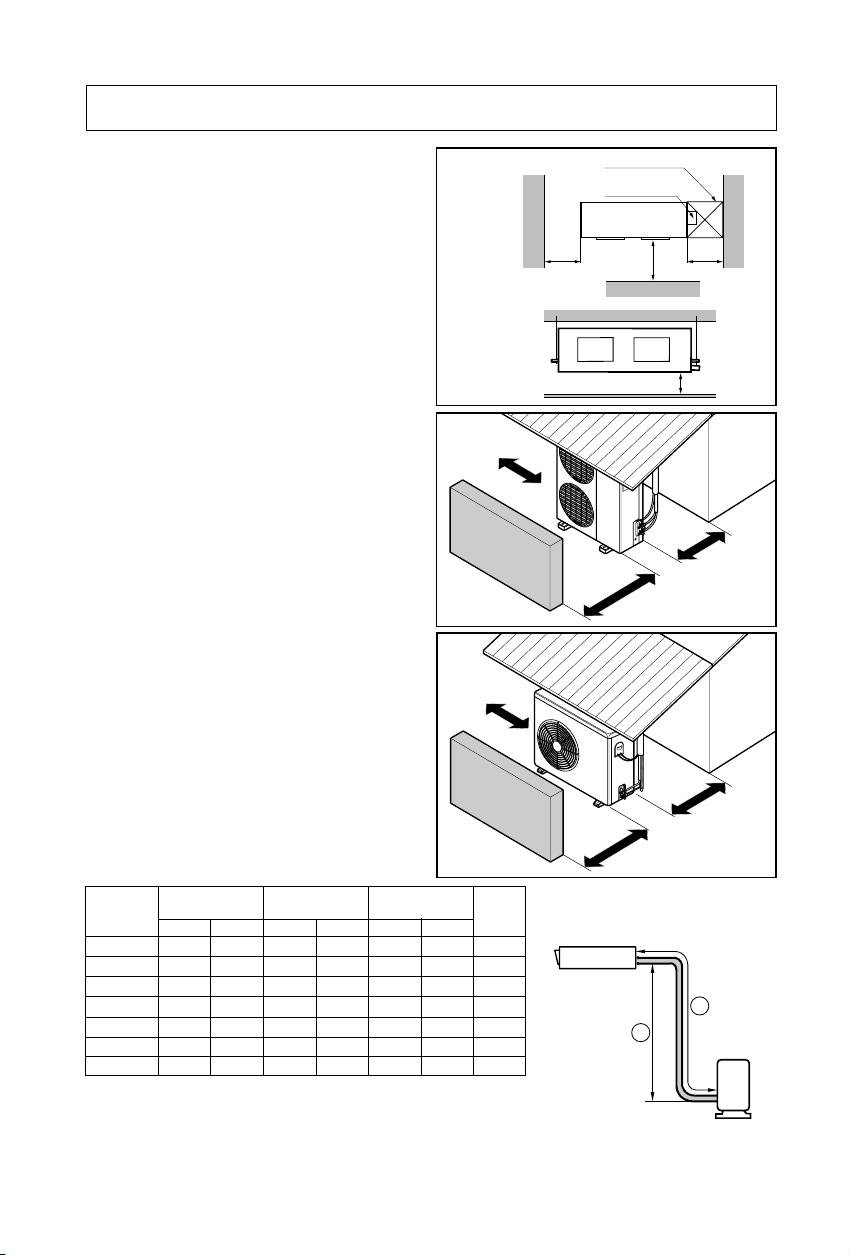

3) Piping length and the elevation

Capacity

18K BTU/h

24K BTU/h

30K BTU/h

36K BTU/h

42K BTU/h

48K BTU/h

60K BTU/h

Pipe Size

(Diameter: Ø)

Gas Liquid

5/8"

5/8"

5/8"

5/8"

5/8"

5/8"

3/4"

Length A(m)

Standard StandardMax. Max.

1/4"

7.5

1/4"

7.5

1/4"

7.5

3/8"

7.5

3/8"

7.5

3/8"

7.5

1/2"

7.5

• If 18K Model is installed at a distance of 15m, g of

refrigerant should be added (15-7.5) x 15g = 112.5g

• Capacity is based on standard length and maximun allowance

length is on the basis of reliability.

• Improper refrigerant charge may result in abnormal cycle.

30

30

30

30

30

30

30

Elevation B(m)

15

5

5

15

15

5

15

5

5

15

5

15

15

5

112.5

4

*Additional

refrigerant

(g/m)

15

25

35

30

0

3

45

75

Sun

Sun

Inspection hole

(600X600)

Control box

r

oof

r

oof

Indoor unit

1000

Front

More than

70cm

More than

70cm

B

600600

H

More than

30cm

More than

30cm

A

Outdoor unit

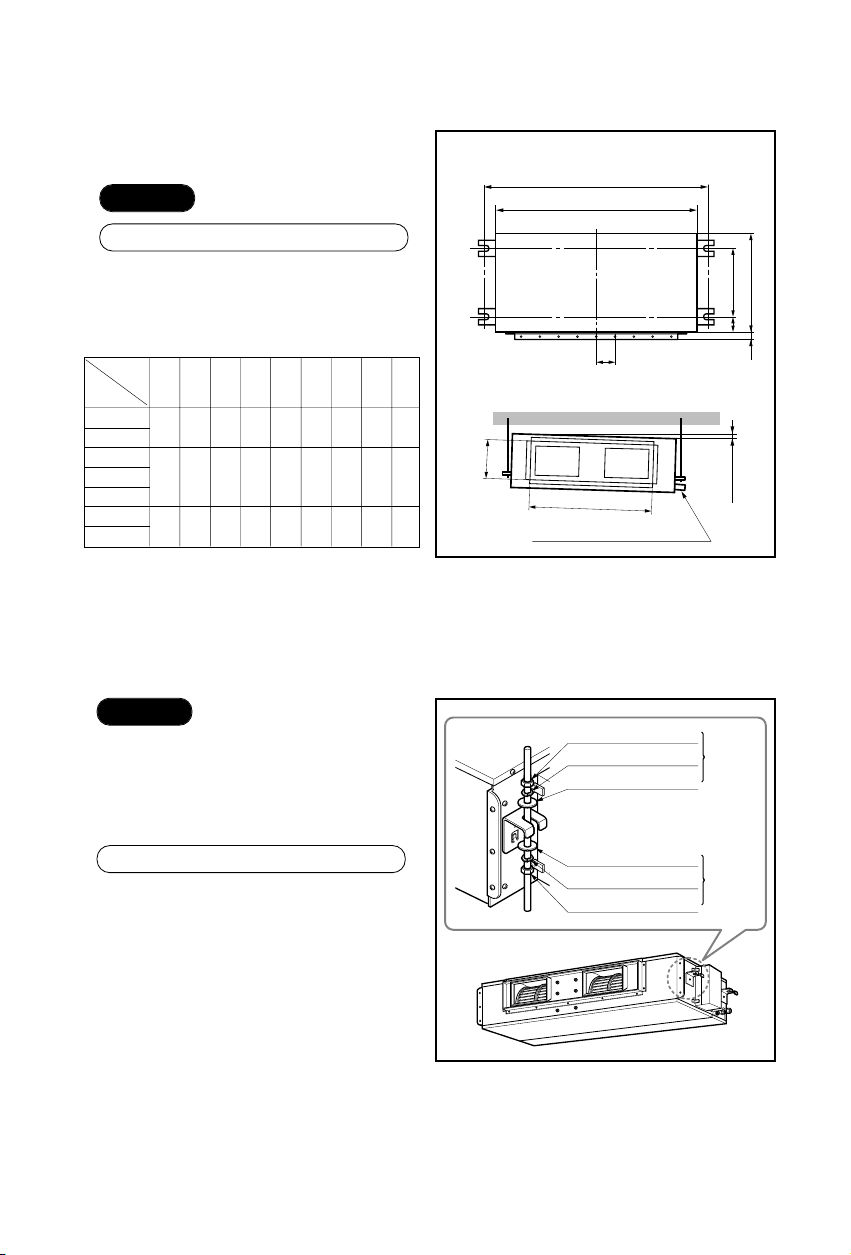

2. Indoor unit installation

■Installation of Unit

Install the unit above the ceiling correctly.

CASE 1

POSITION OF SUSPENSION BOLT

• Apply a joint-canvas between the unit and

duct to absorb unnecessary vibration.

• Apply a filter Accessory at air return hole.

(Unit:mm)

Dimension

Capacity

18K BTU/h

24K BTU/h

30K BTU/h

36K BTU/h 1180 355 45.5 450 30 87 830 184

42K BTU/h

48K BTU/h

60K BTU/h

A B C D E F (G) H I

932

880

355 45.5 450 30 87 750 16

1233

1281

1230 477 56 590 30 120 1004 294

A

B

E

CD

(G)

0

F

I

H

Drainage hole

1~3mm

CASE 2

• Install the unit leaning to a drainage hole

side as a figure for easy water drainage.

POSITION OF CONSOLE BOLT

• A place where the unit will be leveled and

that can support the weight of the unit.

• A place where the unit can withstand its

vibration.

• A place where service can be easily

performed.

M10 Nut

M10 SP. washer

M10 washer

M10 washer

M10 SP. washer

M10 Nut

X 4

X 4

X 4

X 4

X 4

X 4

(Local

supply)

(Local

supply)

5

6

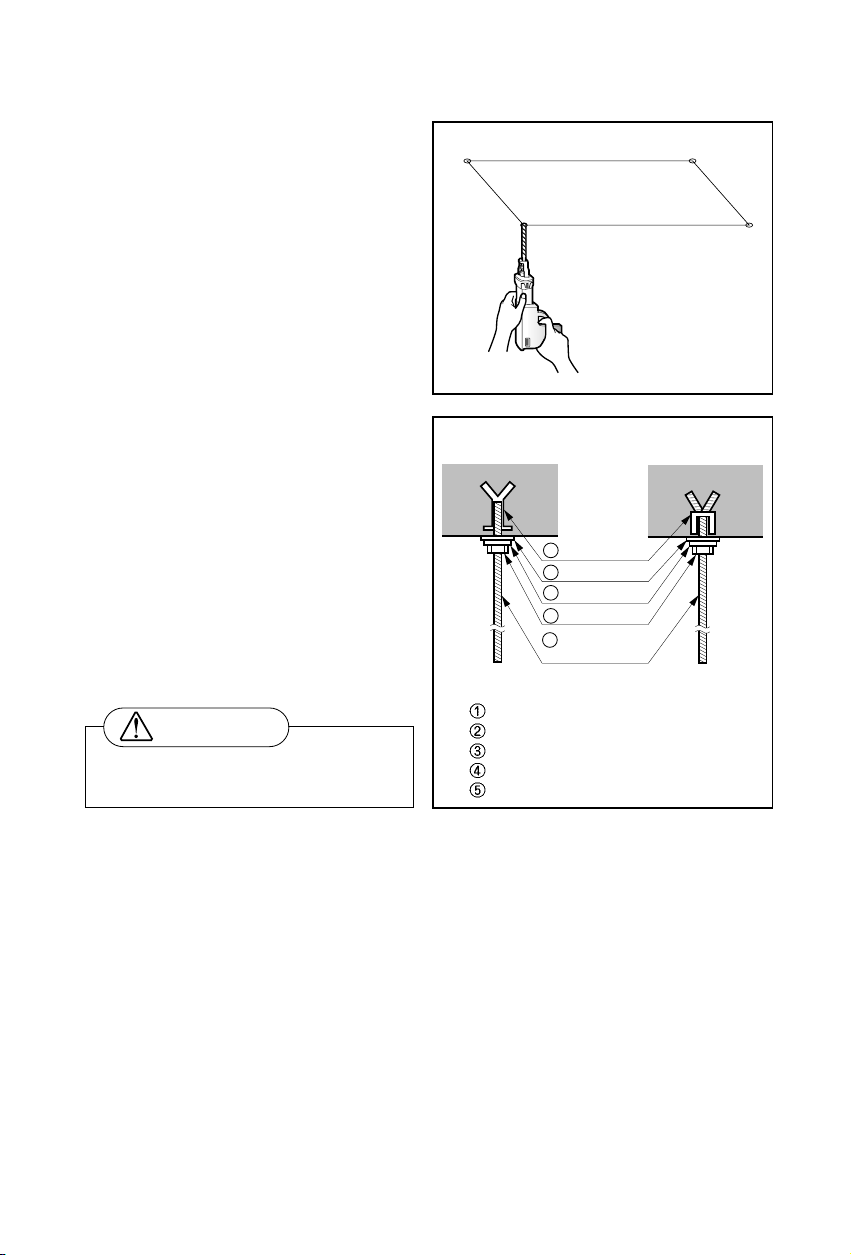

• Select and mark the position for fixing

bolts.

• Drill the hole for set anchor on the face

of ceiling.

• Insert the set anchor and washer onto

the suspension bolts for locking the

suspension bolts on the ceiling.

• Mount the suspension bolts to the set

anchor firmly.

• Secure the installation plates onto the

suspension bolts (adjust level roughly)

using nuts, washers and spring

washers.

1 Set anchor

Old building New building

2 Plate washer

3 Spring washer

4 Nut

5 Suspension

bolts

Tighten the nut and bolt to prevent

unit falling

CAUTION

• Local supply

Set anchor

Plate washer - M10

Spring washer - M10

Nut - W3/8 or M10

Suspension bolt - W3/8 or M10

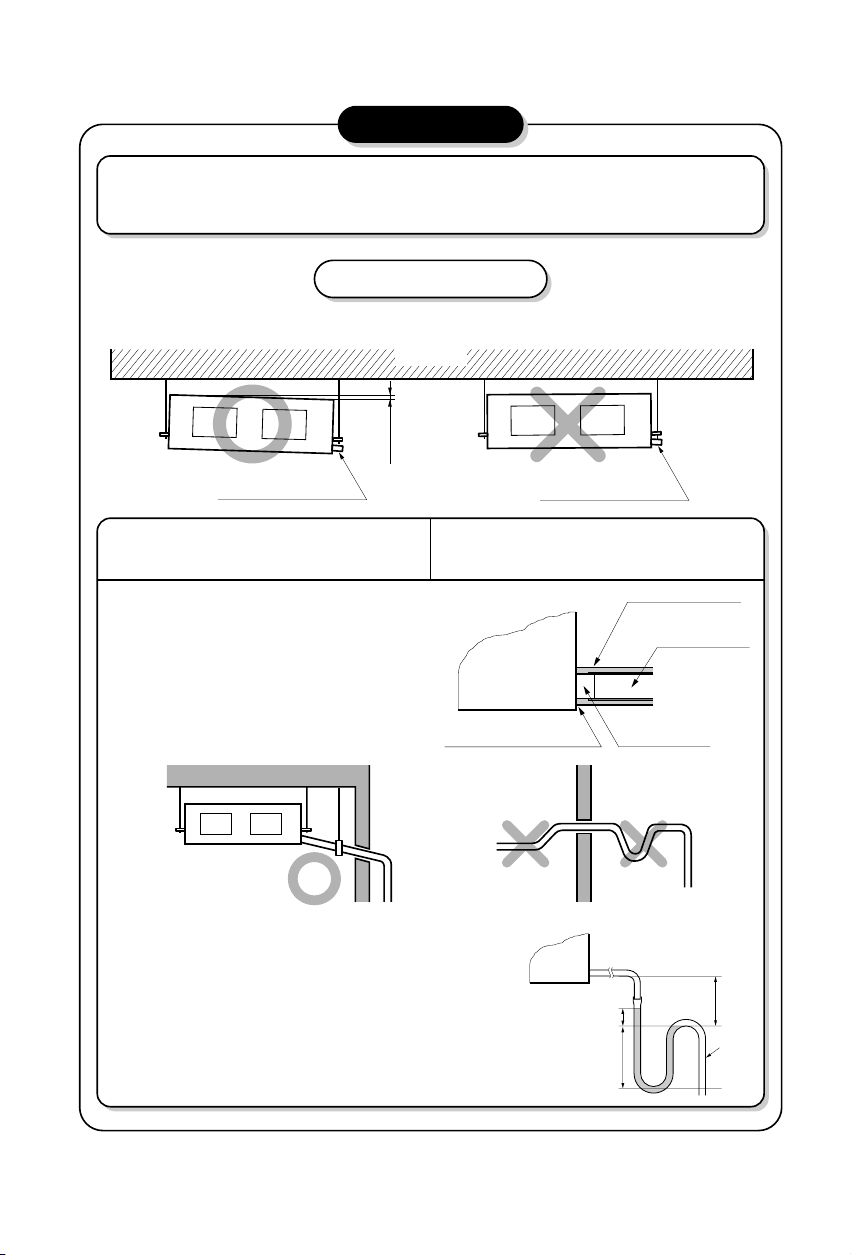

CAUTION

1. Install declination of the indoor unit is very important for the drain of the duct type air

conditioner.

2. Minimum thickness of the insulation for the connecting pipe shall be 5mm.

Front of view

• The unit must be horizontal or declined to the drain hose connected when finished

installation.

CORRECT

Drainage hole

Ceiling

1~3mm

INCORRECT

Drainage hole

CAUTION FOR GRADIENT OF

UNIT AND DRAIN PIPING

• Always lay the drain with downward

inclination (1/50 to 1/100).

Prevent any upward flow or reverse flow

in any part.

• 5mm or thicker formed thermal insulator

shall always be provided for the drain

pipe.

• Upward routing not

CORRECT

• Install the P-Trap (or U-Trap) to prevent

a water leakage caused by the blocking

of intake air filter.

Lay the drain hose with a downward

inclination so water will drain out.

Thermal insulator

Unit

Make sure to be closed.

allowed

INCORRECT

Applied U-Trap Dimension

A ≥ 70mm

B ≥ 2C

C ≥ 2 x SP

SP = External Pressure

(mmAq)

Ex) External Pressure

= 10mmAq

A ≥ 70mm

B ≥ 40mm

C ≥ 20mm

Drainage hole

C

A

(Local supply)

Drainage pipe

(Local supply)

B

U-Trap

7

8

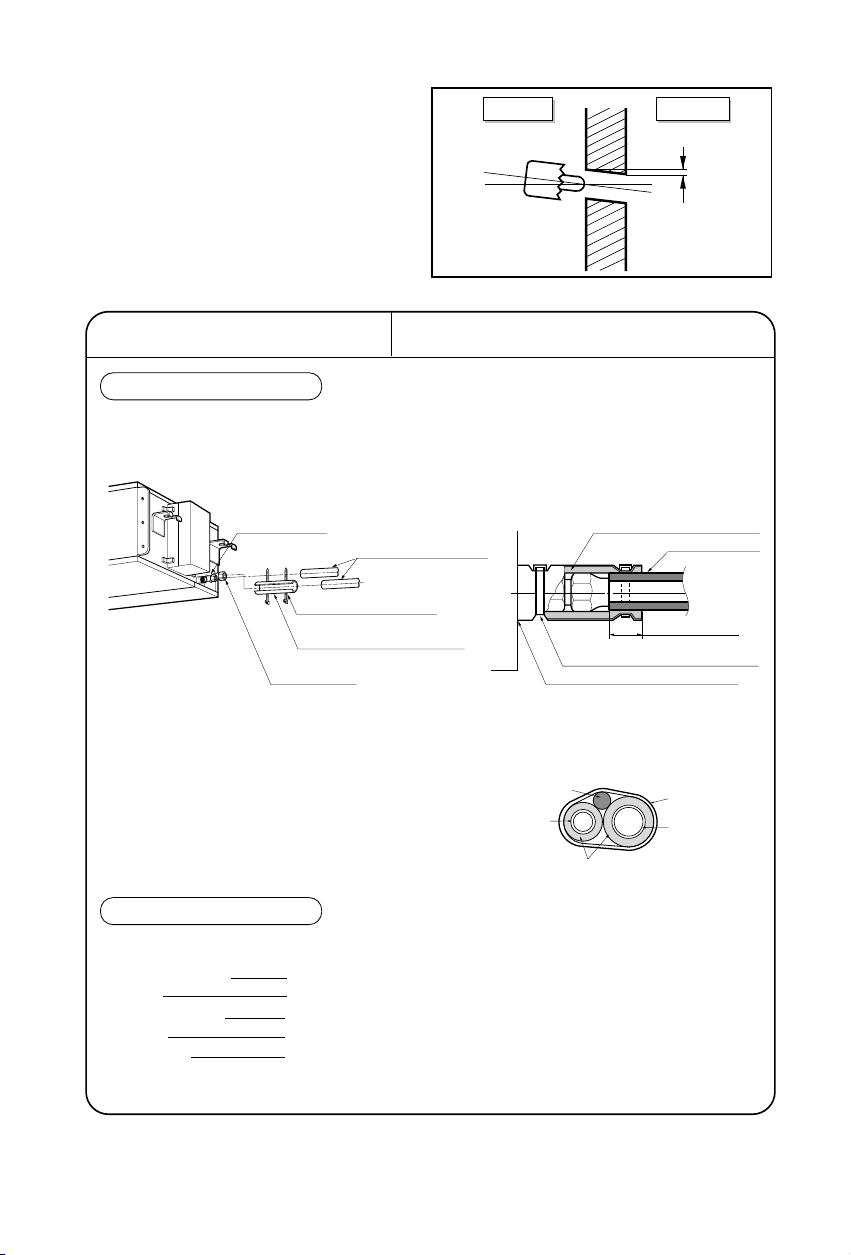

• Drill the piping hole with 70mm dia, hole

core drill.

• Piping hole should be slightly slant to the

outdoor side.

INSULATION, OTHERS

Insulate the joint and tubes completely.

All thermal insulation must comply with local requirement.

INDOOR UNIT

REFRIGERANT PIPE

• Insulate and tape both the gas piping and

liquid piping.

■ After all workings are finished, check the working and operation.

• Air distribution Is the air circulation good?

• Drain Is the drainage smoothly and no sweating?

• Gas leakage Is the piping connection correctly?

• Wiring Is the wiring connection correctly?

• Lock-bolt Is the lock-bolt of compressor loosened?

THERMAL INSULATION

TEST AND CHECK

Make sure that there is no clearance here.

Overlap with thermal

insulator for piping.

Thermal insulator for refrigerant pipe

(Local supply)

Thermal insulator for

piping(Local supply)

Hose clip for thermal insulator(Local supply)

Union for liquid pipe

Refrigerant pipe and thermal

insulator(Local supply)

Union for gas pipe

Thermal insulator for refrigerant pipe

(Local supply)

Hose clip for thermal insulator

(Local supply)

Power cable

Liquid pipe

Thermal insulator

Gas pipe

Tape

Indoor Outdoor

WALL

5~7mm

Loading...

Loading...