LG FB915BU Service Manual

Service Guide Specification

Service Guide Specification

Model Description

1.

MODEL

SUFFIX

2.

F920BJ

ALEUQ

BRAND

Product Name

Printing Specification

1. Trim Size (Format) : 215mm x 280 mm

2. Printing Colors

• Cover : LG COLORS

• Inside : Black

3. Stock (Paper)

• Cover : Snow White 150 g/

• Inside : Snow White 100 g/

4. Printing Method :

5. Bindery : Saddle stitch

6. Language : English

7. Number of pages : 52 ( Including blank 3page)

LG

FLATRON F920B

Part No.

3828TSL087F

Special Instructions3.

(1) Origin Notification

* LGEDI : Printed in Indonesia * LGEWA : Printed in U.K.

* LGESP : Printed in Brazil * LGEMX : Printed in Mexico

* LGENT : Printed in China * LGEIL : Printed in India

4.

Changes

8

7

6

5

4

3

2

1

REV.

MM/DD/YY

NO.

CHANGE NO.

CHANGE CONTENTS

Pagination sheet

Pagination sheet

Cover

English

2

English

44

English

3

Blank

English

4

Blank

English

5

2 2

45 34

English

….

English

…..

English

PCB 2

47 48

English

42

43

Rear

Cover

Inside

Blank

Rear

Cover

COLOR MONIT OR

SER VICE MANUAL

Website:http://biz.LGservice.com

E-mail:http://www.LGEservice.com/techsup.html

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MODEL: F920B (F920BJ-AL**Q)

CHASSIS NO. : CA-130

( ) **Same model for Service

1. PICTURE TUBE

Size : 19 inch (Flat Slot Mask)

DefIection Angle : 90°

Neck Diameter : 29.1 mm

Strip Pitch : 0.24 mm

Diagonal Size : 457.5 mm

View Size : 366.0 x 274.5 mm

Face Treatment : AR-ASC (Anti-Reflective and

Anti-Static Coating)

2. SIGNAL

2-1. Horizontal & Vertical Sync

1) Input Voltage Level: Low= ≤0.8V, High= ≥2.1V

2) Sync Polarity : Positive or Negative

2-2. Video Input Signal

1) Voltage Level : 0~0.7 Vp-p

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.7 Vp-p

2) Input Impedance : 75 Ω

3) Video Color : R, G, B Analog

4) Signal Format : Refer to the Timing Chart

2-3. Signal Connector

15 Pin D-Sub Connector

2-4. Scanning Frequency

Horizontal : 30~98 kHz

Vertical : 50~160 Hz

3. POWER SUPPLY

3-1. Power Range

AC 100-240V~50/60HZ, 2.5A Max

AC 200-240V~50Hz, 1.5A Max.(PFC version)

3-2. Power Consumption

4. DISPLAY AREA

4-1. Active Video Area :

• Max Image Size - 366.0 x 274.5mm (14.40" x 10.80")

• Preset Image Size - 350 x 262 mm (13.78" x 10.31")

4-2. Display Color : Full Colors

4-3. Display Resolution : 1600 Dots x 1200Lines/75Hz

4-4. Video Bandwidth : 203MHz

5. ENVIRONMENT

5-1. Operating Temperature: 0°C~40°C (32°F~103°F)

(Ambient)

5-2. Relative Humidity : 10%~90%

(Non-condensing)

5-3. Altitude : 10,000 ft

6. DIMENSIONS (with TILT/SWIVEL)

Width : 466.6 mm (18.37")

Depth : 472.5 mm (18.60")

Height : 474 mm (18.66")

7. WEIGHT (with TILT/SWIVEL)

Net Weight : 23.2 kg (51.82 lbs)

Gross Weight : 26.6 kg (59.52 lbs)

8. USB Specifications

USB Standard :

Rev. 1.0 complied self-powered hub

Downstream power supply

: 500mA for each (MAX)

Communication speed : 12 Mbps (Full), 1.5 Mbps (Low)

USB port : 1 Upstream port

2 Downstream ports

CONTENTS

SPECIFICATIONS

- 2 -

SPECIFICATIONS ................................................... 2

SAFETY PRECAUTIONS ........................................ 3

SERVICE PRECAUTIONS ...................................... 4

TIMING CHART ....................................................... 7

DISASSEMBLY ....................................................... 8

ADJUSTMENT ........................................................ 9

WIRING DIAGRAM ............................................... 15

BLOCK DIAGRAM ................................................. 16

DESCRIPTION OF BLOCK DIAGRAM...................17

TROUBLESHOOTING GUIDE .............................. 19

EXPLODED VIEW.................................................. 36

REPLACEMENT PARTS LIST ...............................38

SCHEMATIC DIAGRAM......................................... 45

POWER CONSUMPTION

less than 120W

less than 8W

less than 8W

less than 3W

less than 1W

LED COLOR

GREEN

AMBER

AMBER

AMBER

-

MODE

MAX

STAND-BY

SUSPEND

DPM OFF

POWER SWITCH

OFF

VIDEO

Yes

No

No

No

-

SAFETY PRECAUTIONS

- 3 -

SAFETY-RELATED COMPONENT WARNING!

There are special components used in this color monitor

which are important for safety. These parts are marked

on the schematic diagram and the replacement

parts list. It is essential that these critical parts should be

replaced with the manufacturer's specified parts to prevent

X-radiation, shock, fire, or other hazards. Do not modify

the original design without obtaining written permission

from manufacturer or you will void the original parts and

labor guarantee.

CAUTION:

No modification of any circuit should be

attempted.

Service work should be performed only after

you are thoroughly familiar with all of the

following safety checks and servicing

guidelines.

SAFETY CHECK

Care should be taken while servicing this color monitor

because of the high voltage used in the deflection circuits.

These voltages are exposed in such areas as the

associated flyback and yoke circuits.

FIRE & SHOCK HAZARD

An isolation transformer must be inserted between the

color monitor and AC power line before servicing the

chassis.

• In servicing, attention must be paid to the original lead

dress specially in the high voltage circuit. If a short

circuit is found, replace all parts which have been

overheated as a result of the short circuit.

• All the protective devices must be reinstalled per the

original design.

• Soldering must be inspected for the cold solder joints,

frayed leads, damaged insulation, solder splashes, or

the sharp points. Be sure to remove all foreign

materials.

IMPLOSION PROTECTION

All used display tubes are equipped with an integral

implosion protection system, but care should be taken to

avoid damage and scratching during installation. Use only

same type display tubes.

X-RADIATION

The only potential source of X-radiation is the picture tube.

However, when the high voltage circuitry is operating

properly there is no possibility of an X-radiation problem.

The basic precaution which must be exercised is keep the

high voltage at the factory recommended level; the normal

high voltage is about 27kV. The following steps describe

how to measure the high voltage and how to prevent Xradiation.

Note : It is important to use an accurate high voltage

meter calibrated periodically.

• To measure the high voltage, use a high impedance

high voltage meter, connect (–) to chassis and (+) to

the CDT anode cap.

• Set the brightness control to maximum point at full

white pattern.

• Measure the high voltage. The high voltage meter

should be indicated at the factory recommended level.

• If the meter indication exceeds the maximum level,

immediate service is required to prevent the possibility

of premature component failure.

• To prevent X-radiation possibility, it is essential to use

the specified picture tube.

Leakage Current Hot Check Circuit

CAUTION:

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

- 4 -

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this

service manual and its supplements and addenda, read

and follow the SAFETY PRECAUTIONS on page 3 of this

publication.

NOTE: If unforeseen circumstances create conflict

between the following servicing precautions and any of the

safety precautions on page 3 of this publication, always

follow the safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC

power source before;

a. Removing or reinstalling any component, circuit

board module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical

plug or other electrical connection.

c. Connecting a test substitute in parallel with an

electrolytic capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may

result in an explosion hazard.

d. Discharging the picture tube anode.

2. Test high voltage only by measuring it with an

appropriate high voltage meter or other voltage

measuring device (DVM, FETVOM, etc) equipped with

a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Discharge the picture tube anode only by (a) first

connecting one end of an insulated clip lead to the

degaussing or kine aquadag grounding system shield

at the point where the picture tube socket ground lead

is connected, and then (b) touch the other end of the

insulated clip lead to the picture tube anode button,

using an insulating handle to avoid personal contact

with high voltage.

4. Do not spray chemicals on or near this receiver or any

of its assemblies.

5. Unless specified otherwise in this service manual,

clean electrical contacts only by applying the following

mixture to the contacts with a pipe cleaner, cottontipped stick or comparable non-abrasive applicator;

10% (by volume) Acetone and 90% (by volume)

isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual,

lubrication of contacts in not required.

6. Do not defeat any plug/socket B+ voltage interlocks

with which receivers covered by this service manual

might be equipped.

7. Do not apply AC power to this instrument and/or any of

its electrical assemblies unless all solid-state device

heat sinks are correctly installed.

8. Always connect the test receiver ground lead to the

receiver chassis ground before connecting the test

receiver positive lead.

Always remove the test receiver ground lead last.

9. Use with this receiver only the test fixtures specified in

this service manual.

CAUTION: Do not connect the test fixture ground strap

to any heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be

damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive (ES)

Devices. Examples of typical ES devices are integrated

circuits and some field-effect transistors and

semiconductor "chip" components. The following

techniques should be used to help reduce the incidence of

component damage caused by static by static electricity.

1. Immediately before handling any semiconductor

component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a

known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device,

which should be removed to prevent potential shock

reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with

ES devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic

charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or

unsolder ES devices.

4. Use only an anti-static type solder removal device.

Some solder removal devices not classified as "antistatic" can generate electrical charges sufficient to

damage ES devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charges sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its

protective package until immediately before you are

ready to install it. (Most replacement ES devices are

packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable

conductive material).

7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly

into which the device will be installed.

CAUTION: Be sure no power is applied to the chassis

or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an ES

device.)

- 5 -

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and

appropriate tip size and shape that will maintain tip

temperature within the range or 500¡£F to 600¡£F.

2. Use an appropriate gauge of RMA resin-core solder

composed of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a

mall wire-bristle (0.5 inch, or 1.25cm) brush with a

metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal

temperature.

(500¡£F to 600¡£F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static,

suction-type solder removal device or with solder

braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal

temperature (500¡£F to 600¡£F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of

the component lead and the printed circuit foil, and

hold it there only until the solder flows onto and

around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the

circuit board printed foil.

d. Closely inspect the solder area and remove any

excess or splashed solder with a small wire-bristle

brush.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong)

through which the IC leads are inserted and then bent flat

against the circuit foil. When holes are the slotted type,

the following technique should be used to remove and

replace the IC. When working with boards using the

familiar round hole, use the standard technique as

outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation

by gently prying up on the lead with the soldering iron

tip as the solder melts.

2. Draw away the melted solder with an anti-static

suction-type solder removal device (or with solder

braid) before removing the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad

and solder it.

3. Clean the soldered areas with a small wire-bristle

brush. (It is not necessary to reapply acrylic coating to

the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as

close as possible to the component body.

2. Bend into a "U" shape the end of each of three leads

remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the

corresponding leads extending from the circuit board

and crimp the "U" with long nose pliers to insure metal

to metal contact then solder each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor

leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the

circuit board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close

as possible to diode body.

2. Bend the two remaining leads perpendicular y to the

circuit board.

3. Observing diode polarity, wrap each lead of the new

diode around the corresponding lead on the circuit

board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder

joints of the two "original" leads. If they are not shiny,

reheat them and if necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board

hollow stake.

2. Securely crimp the leads of replacement component

around notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the

replaced component and adjacent components and the

circuit board to prevent excessive component

temperatures.

- 6 -

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed

circuit board will weaken the adhesive that bonds the foil

to the circuit board causing the foil to separate from or

"lift-off" the board. The following guidelines and

procedures should be followed whenever this condition is

encountered.

At IC Connections

To repair a defective copper pattern at IC connections use

the following procedure to install a jumper wire on the

copper pattern side of the circuit board. (Use this

technique only on IC connections).

1. Carefully remove the damaged copper pattern with a

sharp knife. (Remove only as much copper as

absolutely necessary).

2. carefully scratch away the solder resist and acrylic

coating (if used) from the end of the remaining copper

pattern.

3. Bend a small "U" in one end of a small gauge jumper

wire and carefully crimp it around the IC pin. Solder the

IC connection.

4. Route the jumper wire along the path of the out-away

copper pattern and let it overlap the previously scraped

end of the good copper pattern. Solder the overlapped

area and clip off any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper

pattern at connections other than IC Pins. This technique

involves the installation of a jumper wire on the

component side of the circuit board.

1. Remove the defective copper pattern with a sharp

knife.

Remove at least 1/4 inch of copper, to ensure that a

hazardous condition will not exist if the jumper wire

opens.

2. Trace along the copper pattern from both sides of the

pattern break and locate the nearest component that is

directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead

of the nearest component on one side of the pattern

break to the lead of the nearest component on the

other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is

dressed so the it does not touch components or sharp

edges.

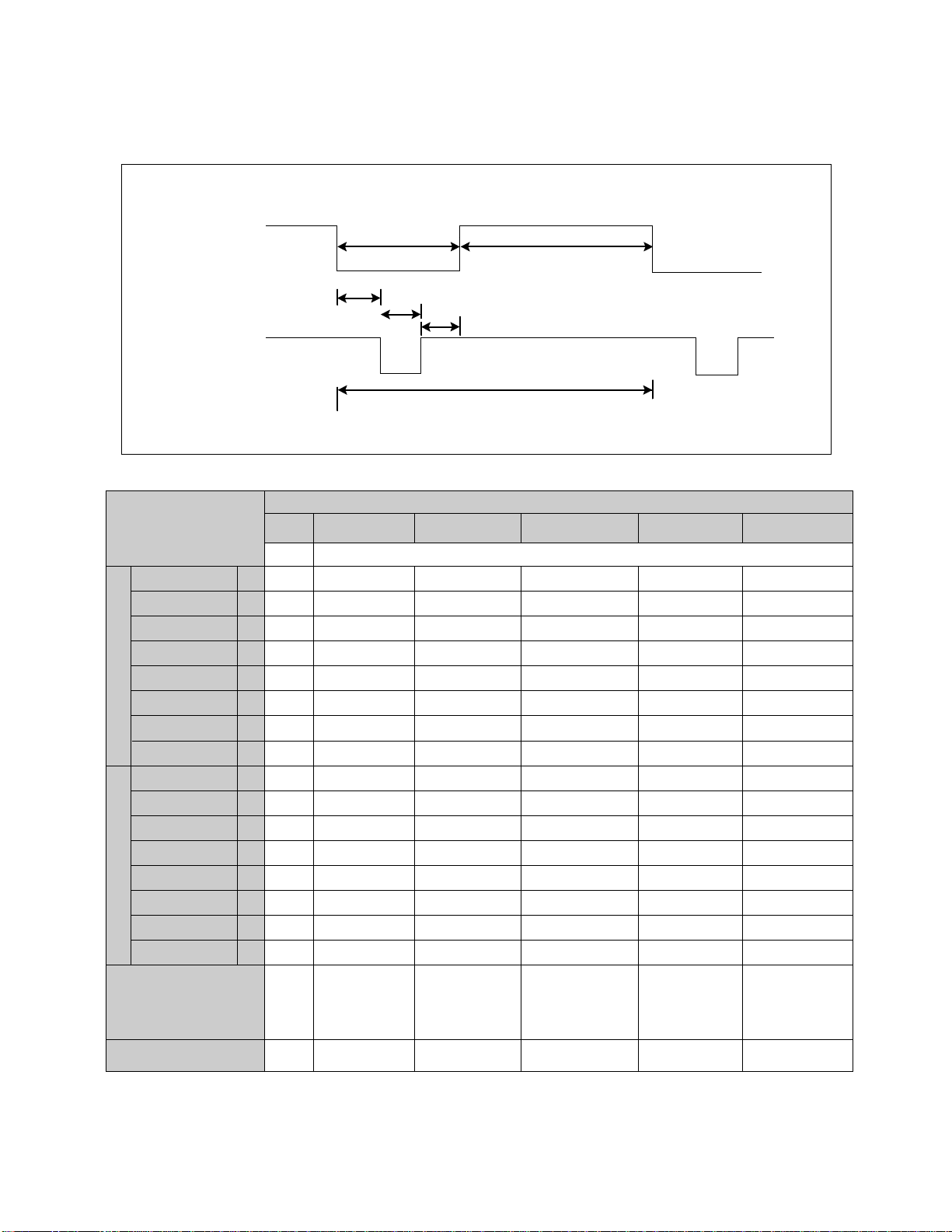

TIMING CHART

- 7 -

VIDEO

kHz

µs

µs

µs

µs

µs

µs

Hz

ms

ms

ms

ms

ms

ms

MODE 1

–

43.269

23.112

17.778

5.334

1.556

1.556

2.222

–

85.008

11.763

11.093

0.670

0.023

0.069

0.578

640

X

480

85Hz

Yes

MODE 2

+

53.674

18.631

14.222

4.409

0.569

1.138

2.702

+

85.061

11.756

11.178

0.578

0.019

0.056

0.503

800

X

600

85Hz

Yes

MODE 3

+

68.677

14.561

10.836

3.725

0.508

1.016

2.201

+

84.997

11.765

11.183

0.582

0.015

0.044

0.523

1024

X

768

85Hz

Yes

MODE 4

+

91.146

10.971

8.127

2.844

0.406

1.016

1.422

+

85.024

11.762

11.235

0.527

0.011

0.033

0.483

1280

X

1024

85Hz

Yes

MODE 5

+

93.750

10.666

7.901

2.765

0.316

0.948

1.501

+

75.000

13.333

12.800

0.533

0.011

0.032

0.490

1600

X

1200

75Hz

MARK

A

B

C

D

E

F

A

B

C

D

E

F

MODE

FACTORY PRESET MODE

Resolution

Recall

H

O

R

I

Z

O

N

T

A

L

V

E

R

T

I

C

A

L

Sync Polarity

Frequency

Total Period

Video Active Time

Blanking Time

Front Porch

Sync Duration

Back Porch

Sync Polarity

Frequency

Total Period

Video Active Time

Blanking Time

Front Porch

Sync Duration

Back Porch

VESA

BC

SYNC

D

F

E

A

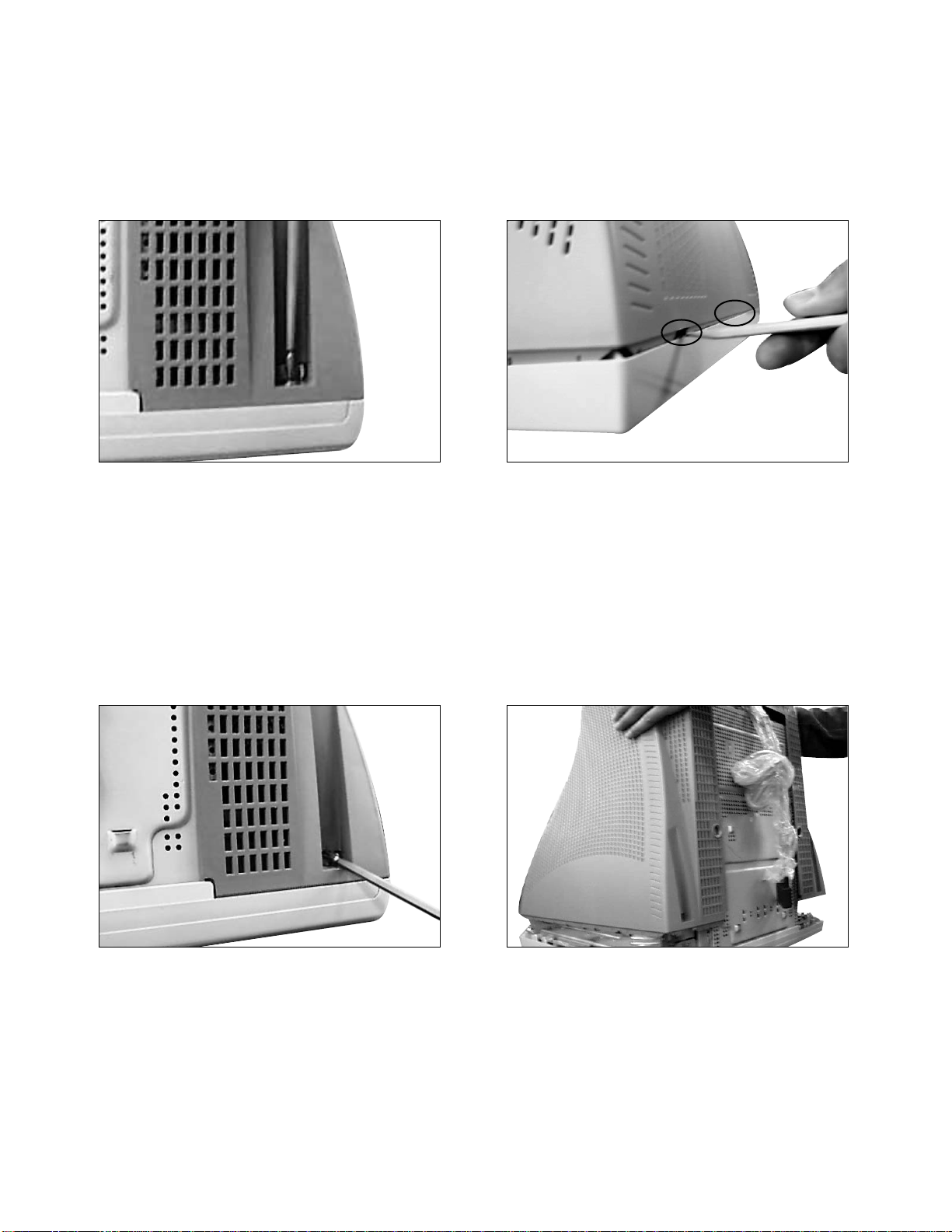

DISASSEMBLY

- 8 -

1. Carefully place the monitor on a soft cushion

and stand it upright with the cabinet facing

downward.

2. Remove the two screws from the back cover.

4. Separate the back cover from the latch at the

bottom of the cabinet using the jig as shown in

the figure.

(Insert the jig into the latch and lift slightly.)

3. Separate the back cover from the latch on top

of the cabinet using a screwdriver as shown in

the figure.

(Insert the screwdriver and gently press the

latch.)

5. Lift up the back cover to separate from cabinet

assembly.

1. Preparation for Service Adjustment

GENERAL INFORMATION

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several adjustments may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

• Alignment appliances and tools.

- IBM compatible PC.

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- EPROM or EEPROM with saved each mode data.

- Alignment Adaptor and Software.

- Digital Voltmeter.

- White Balance Meter.

- Luminance Meter.

- High-voltage Meter.

AUTOMATIC AND MANUAL DEGAUSSING

The degaussing coil is mounted around the CDT so that

automatic degaussing when turn on the monitor. But a

monitor is moved or faced in a different direction, become

poor color purity cause of CDT magnetized, then press

DEGAUSSING on the OSD menu.

ADJUSTMENT PROCEDURE & METHOD

- Install the cable for adjustment such as Figure 1and run

the alignment program on the DOS for IBM

compatible PC.

- Set external Brightness and Contrast volume to max

position.

1. Adjustment for B+ Voltage.

1) Display cross hatch pattern at Mode 4.

2) Adjust C905 (+) voltage to 190V ±0.5V with VR901.

2. Adjustment for High-Voltage.

1) Display cross hatch pattern at Mode 4.

2) Adjust CDT Anode voltage to 27kV ± 0.2kV with

VR801.

3. Adjustment for Horizontal Raster Center.

1) Display cross hatch pattern at Mode 4.

2) Adjust the Back Raster should be center of the

screen with SW801.

2. Adjustment by Service Hot key

How to enter SVC HOT KEY

1. Press Menu and OSD window will appear.

2. While OSD window is displayed,

is seen on the

left bottom of OSD window.

3. Press

+ simultaneously and the screen will

immediately refresh.

4. Press Menu and make sure that

is changed to

1 2.

5. Follow the menu on the left of OSD window to find 12

and OSD will change as shown in the figure.

6. Select Degauss in the above figure and then press

Select and

to change the screen as shown in the

figure. (Back Raster for Pattern)

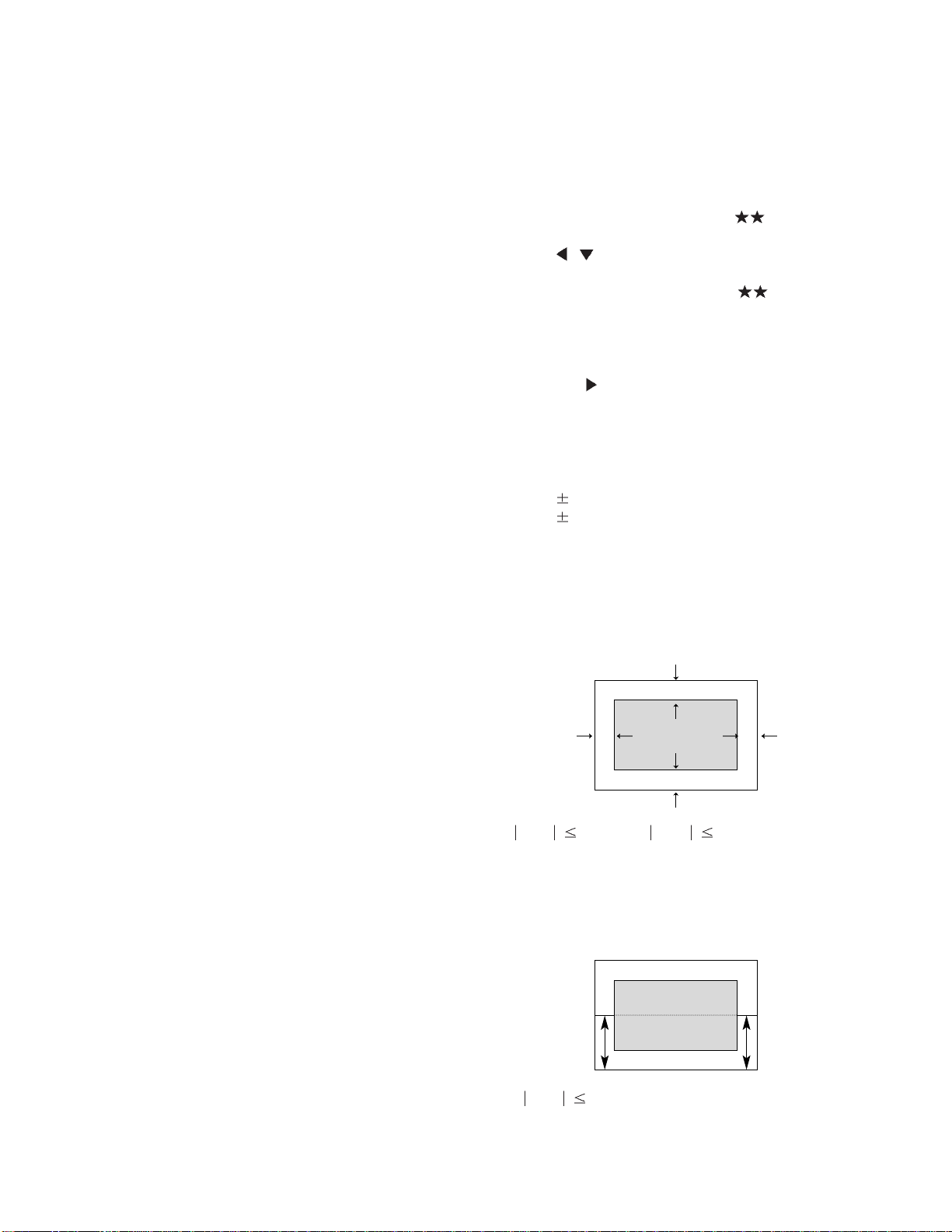

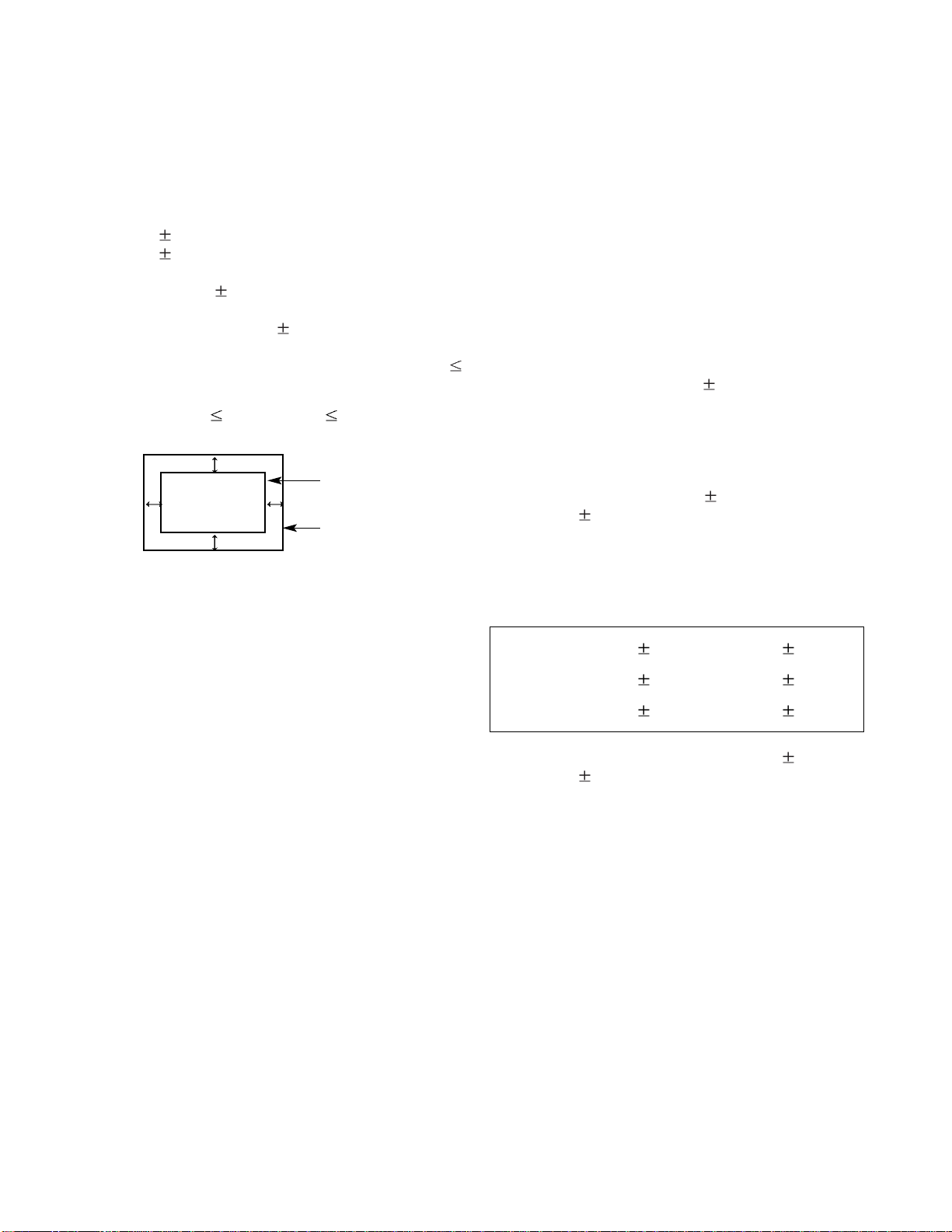

FOS SPEC

1. Size

H : 350

4mm

V : 262

4mm

Scanning frequency : All Mode (Mode 1~5)

Display image : Crosshatch pattern

2. Centering

Scanning frequency : All Mode (Mode 1~5)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

H :

L-R 4mm, V : U-D 4mm

3. Tilt

Scanning frequency : All Mode (Mode 1~5)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

Tilt :

E-F 2.0mm

- 9 -

ADJUSTMENT

U

D

L

R

EF

- 10 -

4. Distortion

Scanning frequency : All Mode (Mode 1~5)

Display image : Crosshatch pattern

Horizontal : 10 Row

Vertical : 8 Row

A-B 2.5mm, C-D 2.5mm

E-F 2.0mm, G-H 2.0mm

5. Displa Size drift

4mm : 25 Standard, 10 35

0.5mm : 180V ~ 264V

6. Linearity

Formula :

(Max - Min) / Max x 100(%)

Criteria : H - 10% Max. (Upper 40kHz)

12% Max. (Less 40kHz)

V - 8% Max.

7. Regulation

Luminance

1mm

Dynamic(lode) 1mm

Scanning frequency : All Mode (Mode 1~5)

8. Trapezoid

9. Pin Balance

10.Parallelogram

11. Adjustment of white balance (Adjustment of

chromaticity diagram)

*(Adjustment of white balance must be made after

entering Hot Key Mode and DEGAUSS.)

CONDITIONS

Signal: 91 kHz / 85 Hz

Display image: Back raster (Color 0,0)

Contrast: Maximum

Brightness: Maximum

Color temperature: 9300K

11-1. Adjustment of cut off (Adjustment of back raster)

11-1(a). Before adjustment, press Menu and Degauss

to remove.

=> Enter hot key mode.

Adjust Brightness and Contrast to Max in OSD

window.

(1)Adjust cut off (back raster) first. Enter DEGAUSS in

the Menu and modify the following data.

Modify RCUT to Min ( 1 ) ,

Modify GCUT To Min ( 1 ) ,

Adjust to BCUT Data = 70 (46 (h)) ,

Adjust to SBRT Data = 90 ( 5A (h)).

(2)Turn FBT screen volume on "CRT COLOR

ANALYZER CA-100" equipment to adjust

Brightness to 0.15

0.05FL.

(3)Adjust RCUT, GCUT, and SBRT to set chromaticity

diagram at :

x: 0.283

0.003

y: 0.298 0.003

Y: 0.40

0.05FL

* If color values would not be matched desirable values,

repeat sequence 1 and 2 after readjusting “GREEN

CUTOFF” control a little different.

U

D

D

U

U-D

< 4mm

L1 R1

2.0mm

L1

R1 L1

R1

Y1

Y2

Y3

Y4

X1 X2 X3 X4

4mm

A B

DC

EG

FH

11-2. Adjustment of White Balance

After finishing adjustment of cut off (back raster),

approve "Color(15.0) Full white pattern".

Adjust to BDRV Data = 94.

Adjust RDRV and GDRV to set chromaticity diagram at :

x: 0.283 0.003

y: 0.298 0.003

Approve "Window pattern (70x70mm)" to adjust

S-CON to Y : 40

1FL.

Approve "Color (15.0) Full white pattern" again and

adjust ABL Data to Y : 30 1FL

Adjust the horizontal position and vertical position to

4.0 mm of the center point of the screen.

*

SIZE adjustment should be made in ALL Mode.

12. Focus Adjustment

CONDITIONS

Scanning frequency : All Mode (Mode 1~5)

Display image: “H” character pattern

Brightness: Cut off point

Contrast: Maximum

PROCEDURE

1. Adjust the Focus VR on the FBT to display the

sharpest image possible.

2. Use Locktite to seal the Focus VR in position.

14. Color Purity Adjustment

Color purity is the absence of undesired color.

Conspicuous mislanding (unexpected color in a uniform

field) within the display area shall not be visible at a

distance of 50 cm from the CRT surface.

CONDITIONS

Orientation: Monitor facing east

Scanning Frequency: 1208 x 1024@85Hz(91kHz/85Hz)

Display image: White flat field

Luminance: Cut off point at the center of the

display area

Note: Color purity adjustments should only be

attempted by qualified personnel.

PROCEDURE

For trained and experienced service technicians only.

Use the following procedure to correct minor color

purity problems:

1. Make sure the display is not affected by external

magnetic fields.

2. Very carefully break the glue seal between the 2-pole

purity convergence magnets (PCM), the band and

the spacer.

3. Make sure the spacing between the PCM assembly

and the CRT stem is 29 mm

1 mm.

4. Display a green pattern over the entire display area.

5. Adjust the purity magnet rings on the PCM assembly

to display a pure green pattern.

(Optimum setting: x = 0.295

0.015,

y = 0.594 0.015)

6. Repeat steps 4 and 5 using a red pattern and then

again, using a blue pattern.

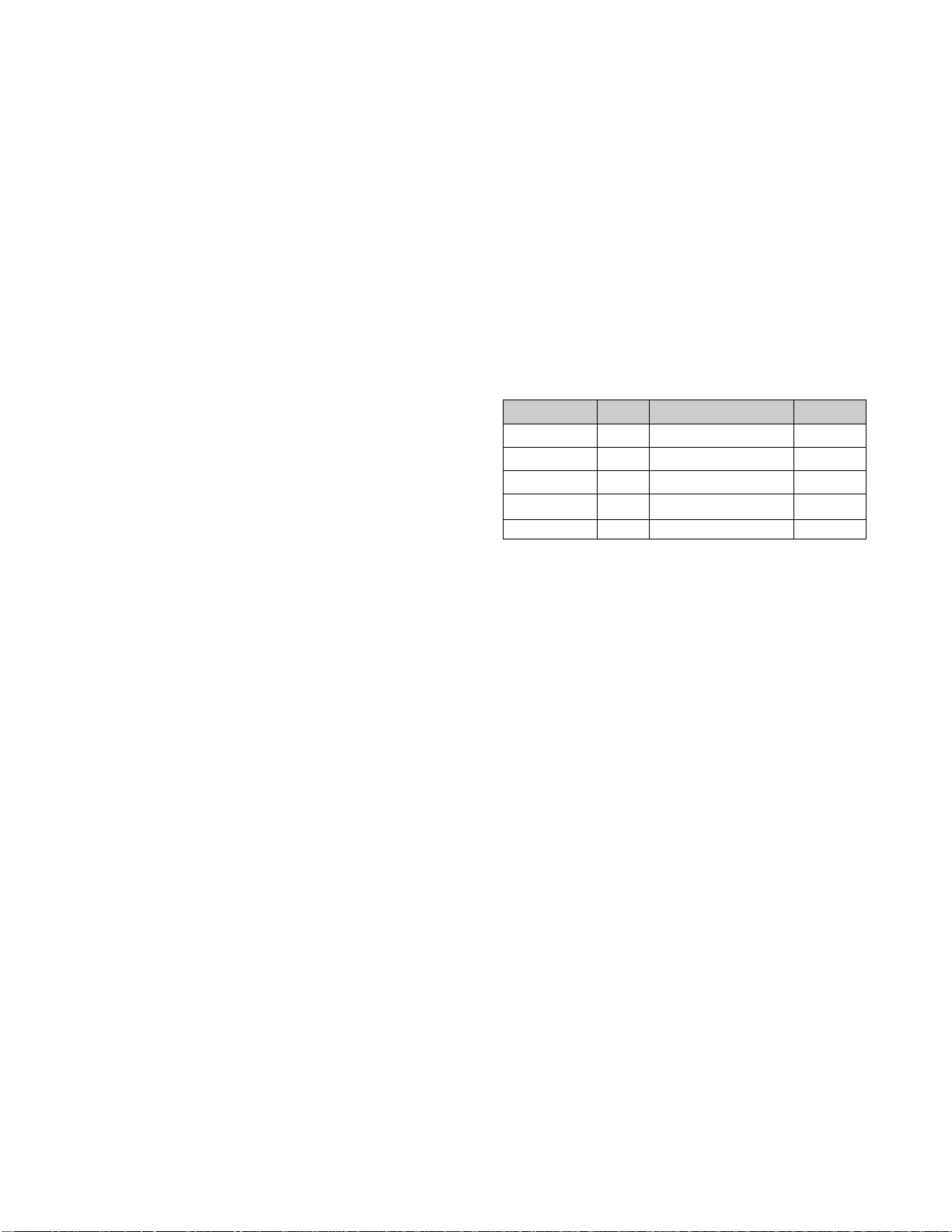

Table 4-6. Color Purity Tolerances

(For 9300K color adjustment: x = 0.283 0.02,

y = 0.298

0.02)

7. When you have the PCMs properly adjusted,

carefully glue them together to prevent their

movement during shipping.

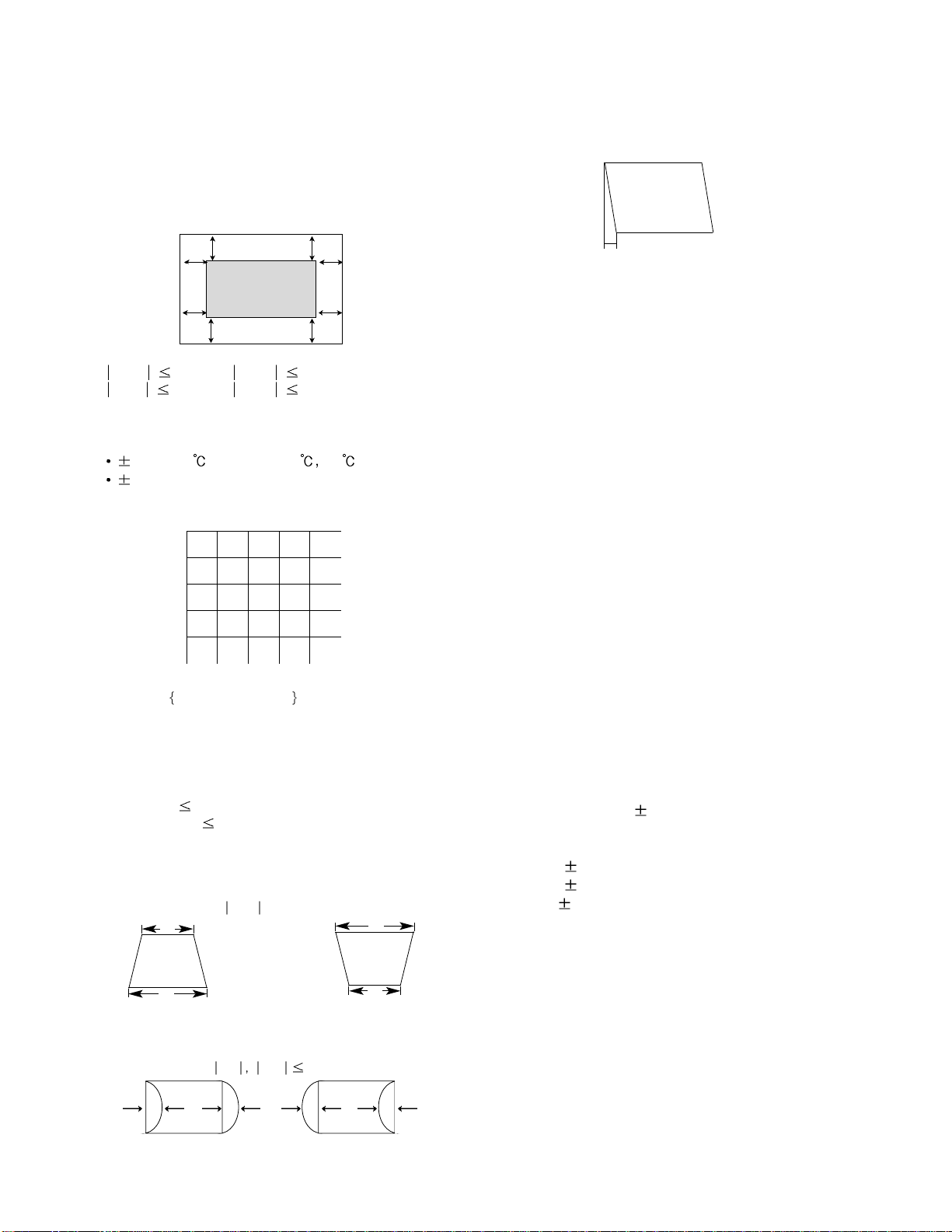

- 11 -

U

DISPLAY AREA

EDGE OF BEZEL

D

LR

|L-R| 4.0 mm. |U-D| 4.0 mm.

Red: x=0.620

0.015 y=0.334 0.015

Green: x=0.620

0.015 y=0.334 0.015

Blue: x=0.620 0.015 y=0.334 0.015

- 12 -

3. Adjustment Using Service software Program

(Adjustment Program)

1. Adjustment for Factory Mode (Preset Mode).

1) Display cross hatch pattern at Mode All.

2) Run alignment program for F900BJ on the IBM

compatible PC.

3) EEPROM → ALL CLEAR → Y(Yes) command.

<Caution> Do not run this procedure unless the

EEPROM is changed. All data in EEPROM (mode

data and color data) will be erased.

4) COMMAND → PRESET START → Y(Yes)

command.

5) DIST. ADJ. → FOS. ADJ command.

6) Adjust H-POSITION as arrow keys to center of the

screen.

7) Adjust H-SIZE as arrow keys to 350 ± 2mm.

8) Adjust V-POSITION as arrow keys to center of the

screen.

9) Adjust V-SIZE as arrow keys to 262 ± 2mm.

10) Adjust TRAPEZOID as arrow keys to be the best

condition.

11) Adjust SIDE PINCUSHON as arrow keys to be the

best condition.

12) Adjust TILT as arrow keys to be the best condition.

13) Display cross hatch pattern at Mode 4.

14) DIST. ADJ. → BALANCE DATA command.

15) Adjust balance of Pin-Balance as arrow keys to be

the best condition.

16) Adjust parallelogram as arrow keys to be the best

condition.

17) Save of the Mode.

18) Save of the System.

19) Display from Mode 4 and repeat above from number

6) to 16).

20) COMMAND → PRESET EXIT → Y (Yes) command.

2. Adjustment for White Balance and Luminance.

1) Set the White Balance Meter.

2) Press the DEGAUSSING on the OSD menu for

demagnetization of the CDT.

3) Display color 0,0 pattern at Mode 4.

4) COMMAND → PRESET START → Y(Yes)

command.

5) Set Bightness and Contrast to max position.

6) COLOR ADJ. → LUMINANCE command of the

alignment program.

7) COLOR ADJ. → BIAS ADJ. command of the

alignment program.

8) Check whether blue color or not at R-BIAS and GBIAS to min position, Sub-Brightness to 90

(5A(h))position, B-Bias to 70(46(h))position. If it's not

blue color, the monitor must repair.

9) Adjust Screen control on the FBT to 0.15 ± 0.05FL

of the raster luminance.

10) Adjust R-BIAS and G-BIAS command to x=0.283 ±

0.006 and y=0.298 ± 0.006 on the White Balance

Meter with PC arrow keys.

11)Display color 15,0 Full White(70x70mm) at mode 4.

12)DRIVE ADJ command.

13)Set B-DRIVE to 94(5E(h)) at DRIVE of the alignment

program.

14) Adjust R-DRIVE and G-DRIVE command to white

balance x=0.283 ± 0.003 and y=0.298 ± 0.003 on

the White Balance Meter with PC arrow keys.

15)Adjust SUB-CONTRAST command to 40±1FL of the

raster luminance.

15)Display color 15,0 full white patten at Mode 4.

16)COLOR ADJ. → LUMINANCE → ABL command.

17) Adjust ABL to 30 ± 1FL of the luminance.

18) Exit from the program.

- 13 -

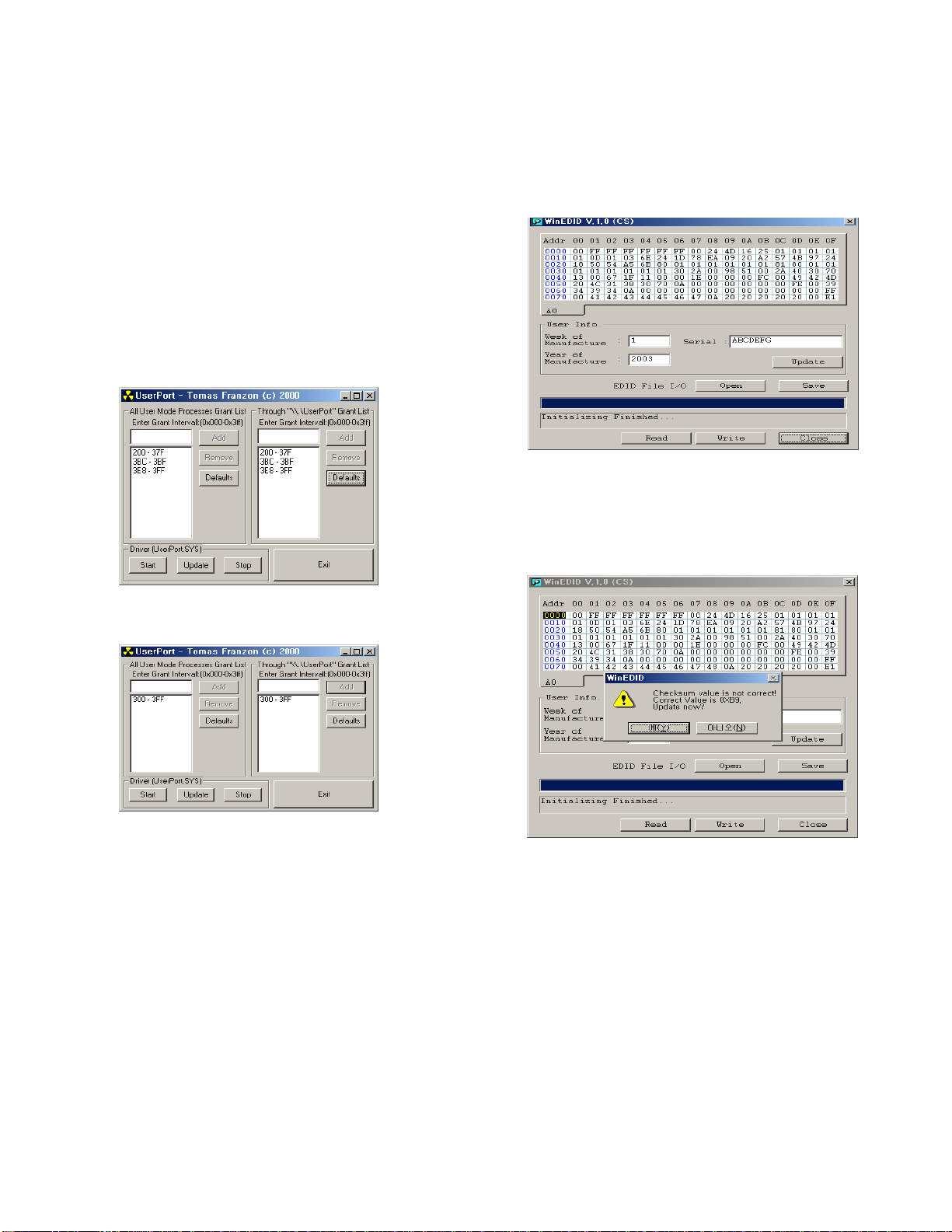

Windows EDID V1.0 User Manual

Operating System: MS Windows 98, 2000, XP

Port Setup: Windows 98 => Don’t need setup

Windows 2000, XP => Need to Port Setup.

This program is available to LCD Monitor only.

1. Port Setup

a) Copy “UserPort.sys” file to

“c:\WINNT\system32\drivers” folder

b) Run Userport.exe

c) Remove all default number

d) Add 300-3FF

e) Click Start button.

f) Click Exit button.

2. EDID Read & Write

1) Run WinEDID.exe

2) Edit Week of Manufacture, Year of Manufacture,

Serial Number

a) Input User Info Data

b) Click “Update” button

c) Click “ Write” button

- Adjustment and EDID Data Down in GCSC

- 14 -

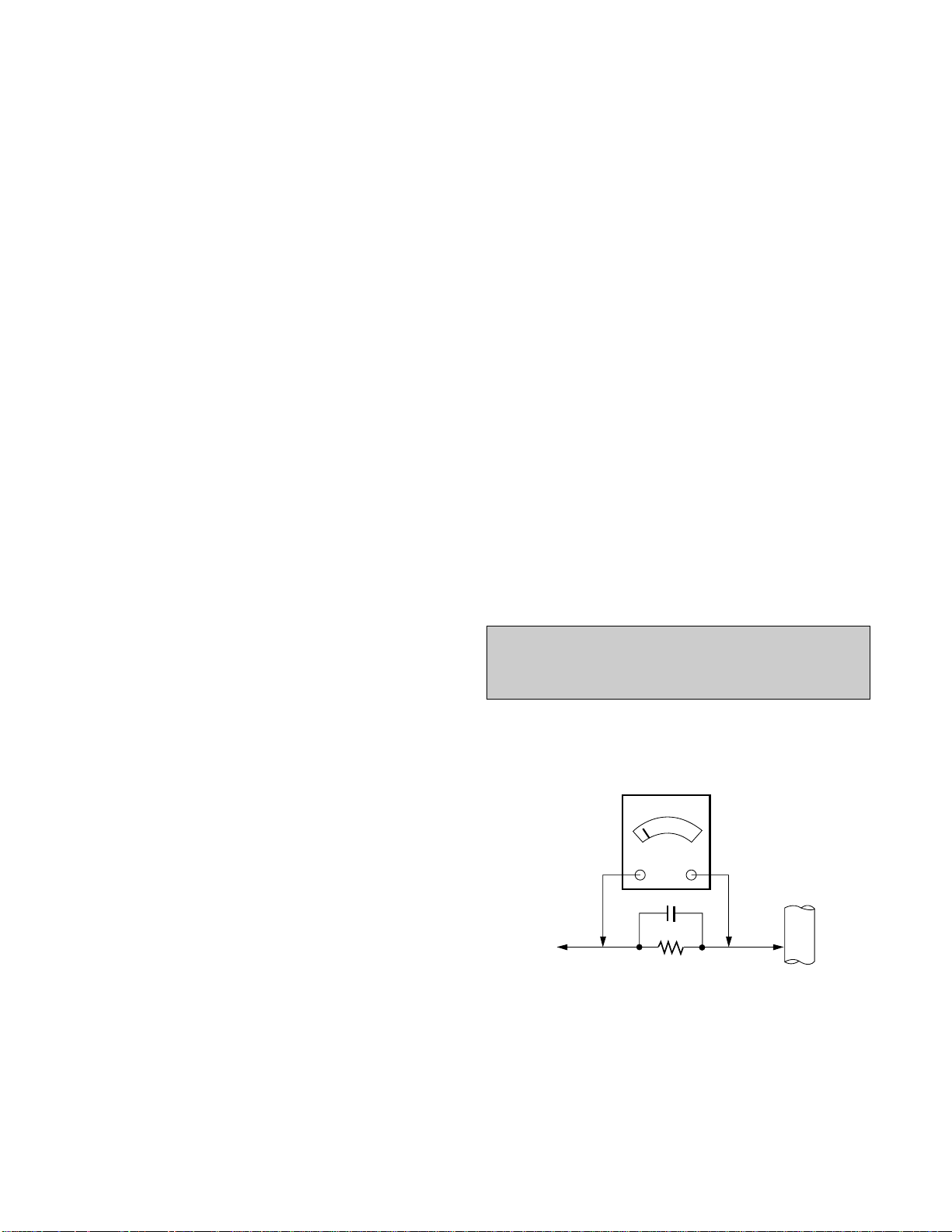

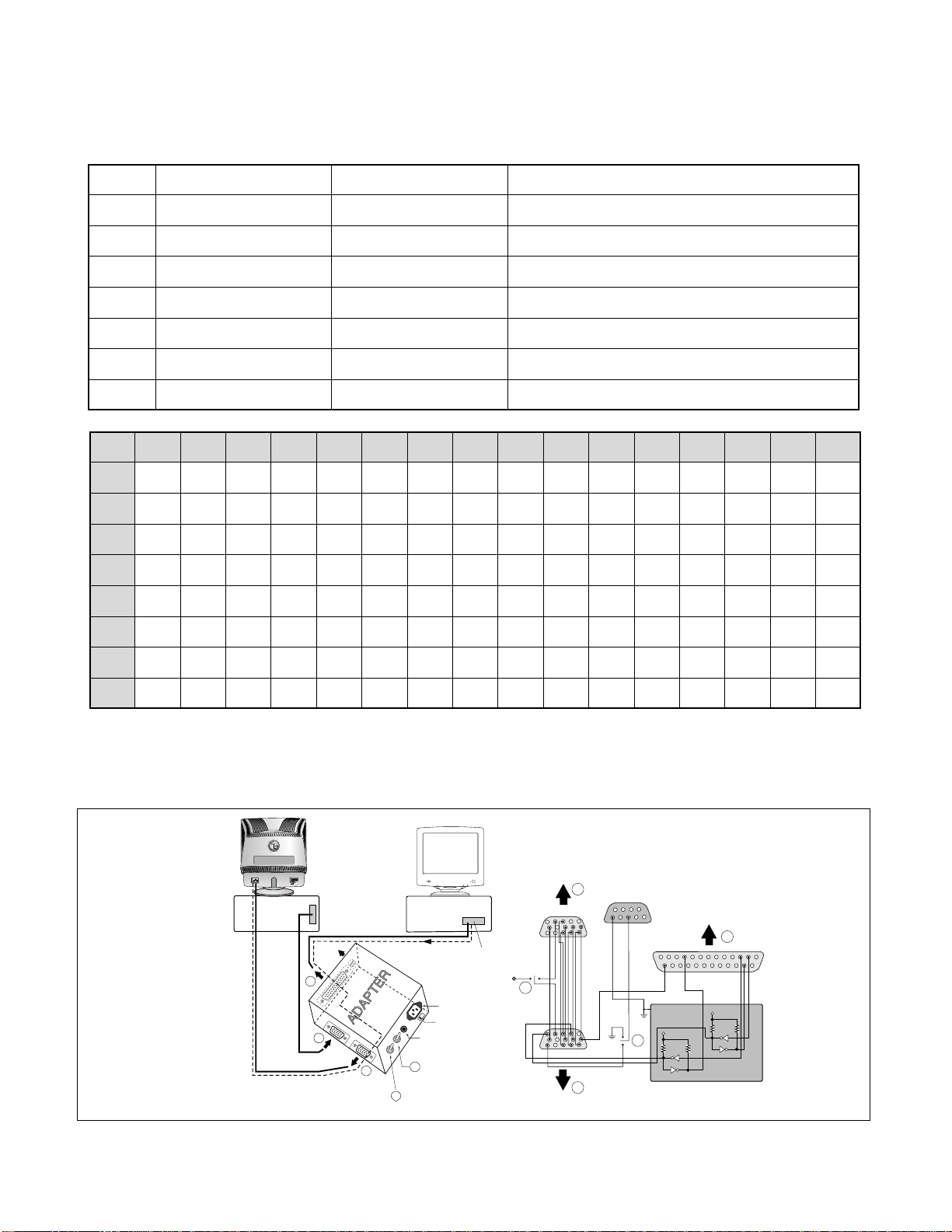

Figure 1. Cable Connection

220

IBM

Compatible PC

PARALLEL PORT

Power inlet (required)

Power LED

ST Switch

Power Select Switch

(110V/220V)

Control Line

Not used

RS232C

PARALLEL

V-SYNC

POWER

ST

VGS

MONITOR

E

V-Sync On/Off Switch

(Switch must be ON.)

F

A

B

C

E

F

A

B

C

15

10

5

5

69

1

1

1

14

13

25

6

5V

5V

5V

4.7K

4.7K

4.7K

74LS06

74LS06

OFF ON

OFF

ON

11

VIDEO

SIGNAL

GENERATOR

EDID DATA EDIT

- Changeable Data

* : Serial No : Controlled / Data : 01

** : Week : Not Controlled / Data : 00

*** : Year : Controlled

No Item Content Hexadecimal

1 Manufacturer ID GSM 1E6D

2 Product ID 19093 4A95

3 Year 2004 0E

4 Version 1 01

5 Revision 3 03

6 Model name F920BJ 7 Special

0x00 0x01 0x02 0x03 0x04 0x05 0x06 0x07 0x08 0x09 0x0A 0x0B 0x0C 0x0D 0x0E 0x0F

0x00 00 FF FF FF FF FF FF 00 1E 6D 95 4A 01

* 00* 00* 00*

0x01 01** 0E*** 01 03 7C 24 1B BF E8 9A D9 A1 54 4B 99 24

0x02 12 48 4C FF FF 80 31 59 45 59 61 59 81 80 A9 40

0x03 E1 40 A9 4A A9 4F 86 3D 00 C0 51 00 30 40 40 A0

0x04 13 00 5E 06 11 00 00 1E 00 00 00 FD 00 32 A0 1E

0x05 62 1B 00 0A 20 20 20 20 20 20 00 00 00 FC 00 46

0x06 39 32 30 42 0A 20 20 20 20 20 20 20 00 00 00 FC

0x07 00 0A 20 20 20 20 20 20 20 20 20 20 20 20 00 2D

Loading...

Loading...