LG FB790G-UL Service manual

COLOR MONIT OR

SER VICE MANUAL

Website:http://biz.LGservice.com

E-mail:http://www.LGEservice.com/techsup.html

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

MODEL: F700P (FB790G-UL)

CHASSIS NO. : CA-1 14

F ACTORY MODEL: FB790G

*( ) ID LABEL Model No.

1. PICTURE TUBE

Size : 17 inch (Flat Slot Mask)

DefIection Angle : 90°

Neck Diameter : 29.1 mm

Phosphor : P22

Slot Pitch : 0.24 mm

Face Treatment : W-ARASC (Anti-Reflective and

Anti-Static Coating),

Internal Anti-Glare

2. SIGNAL

2-1. Horizontal & Vertical Sync

1) Input Voltage Level: Low= ≤0.8V, High= ≥2.1V

2) Sync Polarity : Positive or Negative

2-2. Video Input Signal

1) Voltage Level : 0~0.7 Vp-p

a) Color 0, 0 : 0 Vp-p

b) Color 7, 0 : 0.467 Vp-p

c) Color 15, 0 : 0.7 Vp-p

2) Input Impedance : 75 Ω

3) Video Color : R, G, B Analog

4) Signal Format : Refer to the Timing Chart

2-3. Signal Connector

15 Pin D-Sub Connector

2-4. Scanning Frequency

Horizontal : 30~96 kHz

Vertical : 50~160 Hz

3. POWER SUPPLY

AC 100~240V, 50/60HZ, 2.5A Max

AC 200~240V, 50Hz, 1.5A Max.(PFC version)

3-2. Power Consumption

4. DISPLAY AREA

4-1. Active Video Area :

• Max Image Size - 325.4 x 244.1mm (12.91" x 9.61")

• Preset Image Size - 310 x 230 mm (12.20" x 9.06")

4-2. Display Color : Full Colors

4-3. Display Resolution : 1600 Dots x 1200Lines

4-4. Video Bandwidth : 203MHz

5. ENVIRONMENT

5-1. Operating Temperature: 0°C~40°C (32°F~103°F)

(Ambient)

5-2. Relative Humidity : 10%~90%

(Non-condensing)

5-3. Altitude : 10,000 ft

6. DIMENSIONS (with TILT/SWIVEL)

Width : 415.0 mm (16.34")

Depth : 432.0 mm (17.00")

Height : 413.0 mm (16.25")

7. WEIGHT (with TILT/SWIVEL)

Net Weight : 18 kg (39.68 lbs)

Gross Weight : 20.5 kg (45.20 lbs)

8. USB Specifications

USB Standard :

Rev. 1.0 complied self-powered hub

Downstream power supply

: 500mA for each (MAX)

Communication speed : 12 Mbps (Full), 1.5 Mbps (Low)

USB port : 1 Upstream port

4 Downstream ports

CONTENTS

SPECIFICATIONS

- 2 -

SPECIFICATIONS ................................................... 2

SAFETY PRECAUTIONS ........................................ 3

TIMING CHART ....................................................... 4

OPERATING INSTRUCTIONS ................................ 5

CONTROL LOCATIONS ......................................... 7

WIRING DIAGRAM ................................................. 8

DISASSEMBLY ....................................................... 9

BLOCK DIAGRAM ................................................. 10

DESCRIPTION OF BLOCK DIAGRAM................... 11

ADJUSTMENT ...................................................... 13

TROUBLESHOOTING GUIDE .............................. 15

EXPLODED VIEW.................................................. 22

REPLACEMENT PARTS LIST .............................. 24

PIN CONFIGURATION .......................................... 31

SCHEMATIC DIAGRAM......................................... 32

PRINTED CIRCUIT BOARD................................... 34

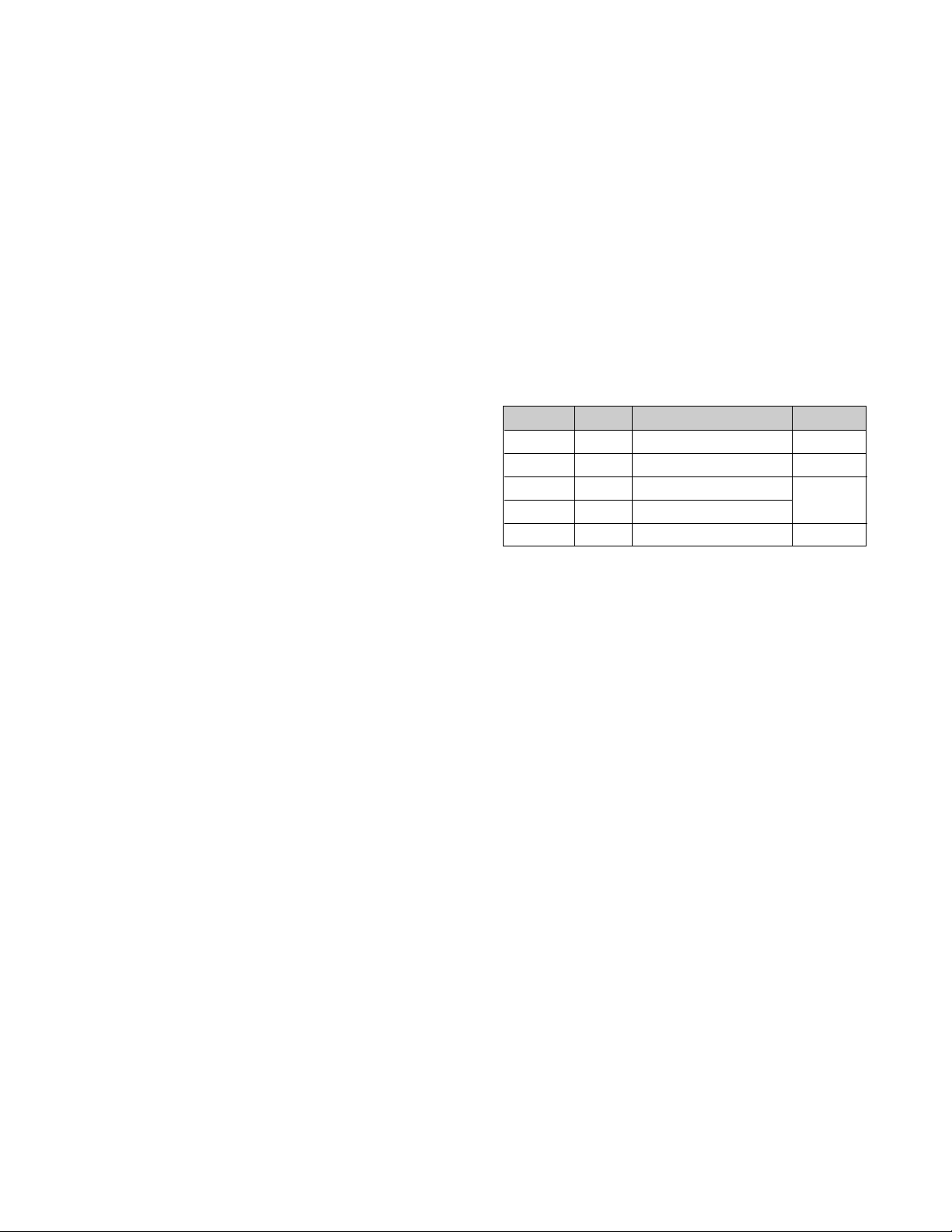

MODE

MAX

NORMAL (ON)

STAND-BY

SUSPEND

OFF

H/V SYNC

ON/ON

OFF/ON

ON/OFF

OFF/OFF

POWER CONSUMPTION (USB)

less than 110W (130W)

less than 83W (104W)

less than 8W (30W)

less than 8W (30W)

less than 1W (20W)

LED COLOR

GREEN

GREEN

ORANGE

ORANGE

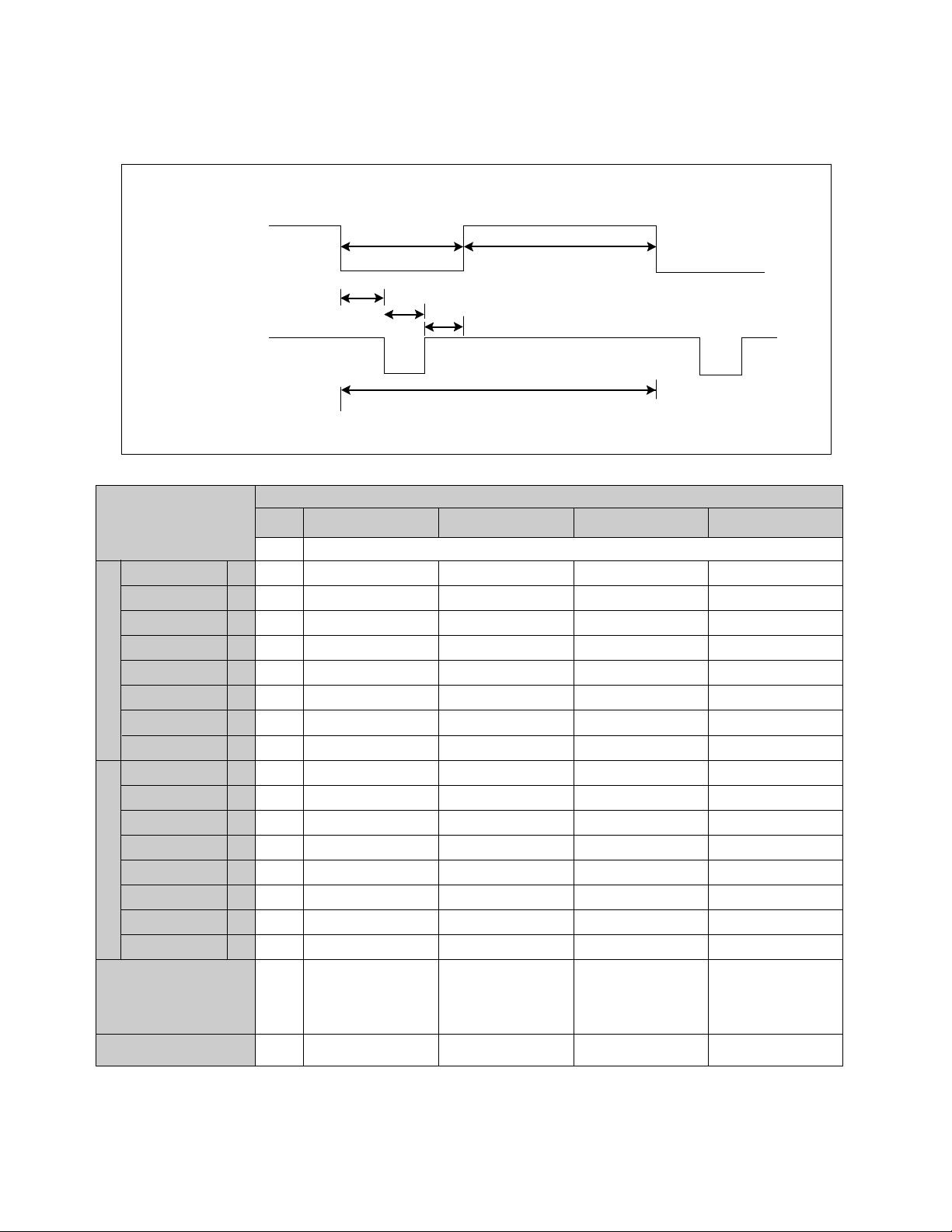

TIMING CHART

- 4 -

VIDEO

SYNC

D

A

E

F

BC

kHz

µs

µs

µs

µs

µs

µs

Hz

ms

ms

ms

ms

ms

ms

MODE 1

–

43.269

23.112

17.778

5.334

1.556

1.556

2.222

–

85.008

11.763

11.093

0.670

0.023

0.069

0.578

640

X

480

85Hz

Yes

MODE 2

+

53.674

18.631

14.222

4.409

0.569

1.138

2.702

+

85.061

11.756

11.178

0.578

0.019

0.056

0.503

800

X

600

85Hz

Yes

MODE 3

+

68.677

14.561

10.836

3.725

0.508

1.016

2.201

+

84.997

11.765

11.183

0.582

0.015

0.044

0.523

1024

X

768

85Hz

Yes

MODE 4

+

91.146

10.971

8.127

2.844

0.406

1.016

1.422

+

85.024

11.762

11.235

0.527

0.011

0.033

0.483

1280

X

1024

85Hz

Yes

MARK

A

B

C

D

E

F

A

B

C

D

E

F

MODE

FACTORY PRESET MODE

Resolution

Recall

H

O

R

I

Z

O

N

T

A

L

V

E

R

T

I

C

A

L

Sync Polarity

Frequency

Total Period

Video Active Time

Blanking Time

Front Porch

Sync Duration

Back Porch

Sync Polarity

Frequency

Total Period

Video Active Time

Blanking Time

Front Porch

Sync Duration

Back Porch

VESA

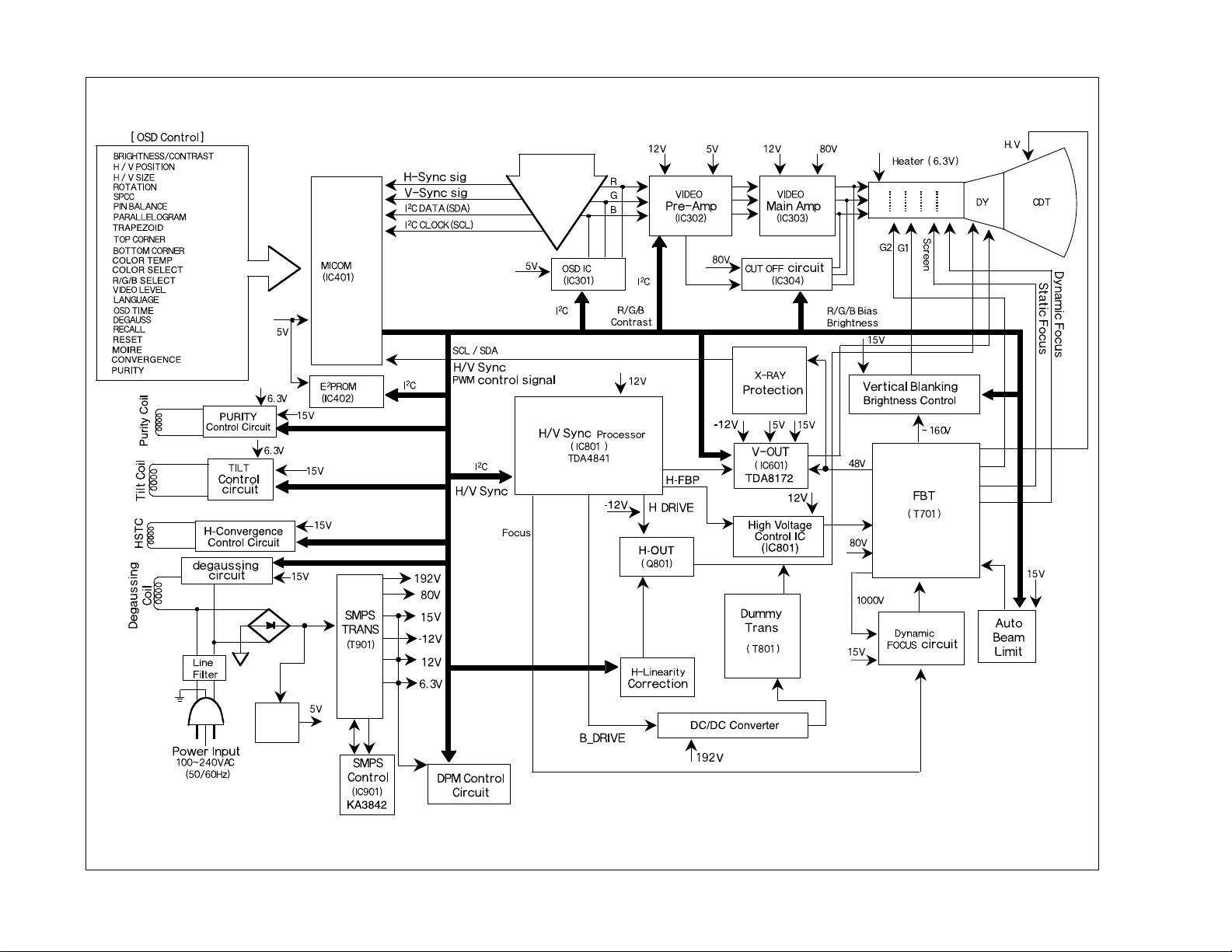

BLOCK DIAGRAM

- 10 -

SIGNAL

INPUT

SUB

TRANS

(T903)

DESCRIPTION OF BLOCK DIAGRAM

- 11 -

1. Line Filter & Associated Circuit.

This is used for suppressing noise of power input line

flowing into the monitor and/or some noise generated

in this monitor flowing out through the power input

line.

That is to say, this circuit prevents interference

between the monitor and other electric appliances.

2. Degauss Circuit & Coil.

The degauss circuit consists of the degaussing coil,

the PTC (Positive Temperature Coefficient) thermistor

(TH901), and the relay (RL901). This circuit eliminates

abnormal color of the screen automatically by

degaussing the slot mask in the CDT when turn on the

power switch.

When you need to degauss while using the monitor,

select DEGAUSS on the OSD menu.

3. SMPS (Switching Mode Power Supply).

This circuit works with power of 100~240V or

200~240V (50/60Hz) specially for PFC version.

The operation procedure is as follows:

1) AC input voltage is rectified and smoothed by

the bridge diode (D901) and the capacitor (C905).

2) The rectified voltage (DC voltage) is applied to the

primary coil of the transformer (T901).

3) The control IC (IC901) generates switching pulse

to turn on and off the primary coil of the

transformer (T901) repeatedly.

4) Depending on the turn ratio of the transformer, the

secondary voltages appear at the secondary coil of

the transformer (T901).

5) These secondary voltages are rectified by each

diode (D924, D926, D923, D922, D921, D920) and

operate the other circuits. (Deflection, Video

Amplifier, etc.)

4. Display Power Management Circuit.

This circuit control power consumption of the monitor

by detecting H and V sync signal. There are stand-by

and suspend mode. When no horizontal or vertical

sync signal input, the circuit consists of Q913, Q915

and IC401 control signal becomes stand-by and

suspend mode. It’s power consumption is below 8W.

When no horizontal and vertical sync signal input, it’s

power consumption is below 1W.

5. X-ray Protection.

This circuit detects the rectified DC voltage comes

from the FBT pin 4. If the high voltage of the FBT

reaches up to about 30kV (abnormal state), H.V

control (IC802) detects. It stops B+voltage supplied to

the FBT (T701), and high voltage is not be generated,

(In the normal state, the high voltage is about 26kV.)

6. Micom(Microprocessor) Circuit.

The operating procedure of Micom (Microprocessor)

and its associated circuit is as follows:

1) H and V sync signal is supplied from Signal Cable t o t he

Micom (IC401).

2) The Micom (IC401) distinguishes polarity and

frequency of H and V sync.

3) The Micom controls each OSD function signals.

(H-size, H-position, V-size, etc.)

4) The controlled data of each mode is stored in IC402.

User can adjust screen condition by each OSD

function. The data of the adjust screen condition is

stored automatically.

7. Horizontal and Vertical Synchronous Processor.

This circuit generates the horizontal drive pulse and

the vertical drive pulse by taking sync-signal from

Signal Cable. This circuit consists of the

TDA4841(IC801) and the associated circuit.

8. Oscillating Circuit for D/D Converter.

This circuit generates the pulse wave which has the

horizontal period by taking the output of the

TDA4841(IC801).

9. D/D (DC to DC) Converter.

This circuit supplies DC voltage to the horizontal

deflection output circuit by decreasing DC 192V which

is the secondary voltage of the SMPS in accordance

with the input horizontal sync signal.

10. D/D Drive & Convert Circuit.

This circuit is used for supplying B+voltage to

horizontal deflection output transistor (Q801).

11. Horizontal Deflection Output Circuit.

This circuit makes the horizontal deflection by

supplying the saw-tooth current to the horizontal

deflection yoke.

- 12 -

12. High Voltage Output & FBT (Flyback Transformer).

The high voltage output circuit is used for generating

pulse wave to the primary coil of the FBT (Flyback

Transformer (T701)). A boosted voltage (about 26kV)

appears at the secondary of the FBT and it is supplied

to the anode of the CDT.

And there are another output voltages such as the

dynamic focus voltage.

13. H-Linearity Correction Circuit.

This circuit corrects the horizontal linearity for each

horizontal sync frequency.

14. Vertical Output Circuit.

This circuit takes the vertical wave from the

TDA4841(IC801) and performs the vertical deflection

by supplying the saw-tooth wave current from the

TDA8172 (IC601) to the vertical deflection yoke.

15. Dynamic Focus Output Circuit.

This circuit takes H and V parabola wave from the

TDA4841(IC801), and amplifies these waves to offer

to the FBT (T701).

16. H & V Blanking and Brightness Control.

This circuit eliminates the retrace line by supplying a

negative pulse to the G1 of the CDT.

17. Image Rotation (Tilt) Circuit.

This circuit corrects the tilt of the screen by supplying

the image rotation signal to the tilt coil which is

attached to the CDT near the deflection.

18. Static Convergence Control Circuit.

This circuit corrects the convergence of the screen by

supplying the convergence signal to the 4H (STC) coil

which is attached to the CDT near the deflection.

19. Moire Reduction Circuit

This circuit reduce interference between the periodical

display pattern and the CDT's slot (or dot).

The positions of every other one dot video signal

beams (red, green, and blue beam) are shifted finely,

thus reducing interference.

20. OSD Circuit.

This circuit is used for performing the OSD (OnScreen- Display) function.

When a user selects the OSD Select/Adjustment

control, the adjustment status displays on the screen.

21. Video Pre-Amp Circuit.

This circuit amplifies the analog video signal from 0-

0.7V to 0-4V. This circuit is operated by taking the

clamp, R, G, B drives, and contrast signals from the

Micom (IC401).

22. Video Output Amp Circuit.

This circuit amplifies the video signal which comes

from the video pre-amp circuit and amplified video

signal is applied to the CDT cathode.

ADJUSTMENT

- 13 -

GENERAL INFORMATION

All adjustment are thoroughly checked and corrected

when the monitor leaves the factory, but sometimes

several adjustments may be required.

Adjustment should be following procedure and after

warming up for a minimum of 30 minutes.

• Alignment appliances and tools.

- IBM compatible PC.

- Programmable Signal Generator.

(eg. VG-819 made by Astrodesign Co.)

- EPROM or EEPROM with saved each mode data.

- Alignment Adaptor and Software.

- Digital Voltmeter.

- White Balance Meter.

- Luminance Meter.

- High-voltage Meter.

AUTOMATIC AND MANUAL DEGAUSSING

The degaussing coil is mounted around the CDT so that

automatic degaussing when turn on the monitor. But a

monitor is moved or faced in a different direction, become

poor color purity cause of CDT magnetized, then press

DEGAUSSING on the OSD menu.

ADJUSTMENT PROCEDURE & METHOD

-Install the cable for adjustment such as Figure 1and run

the alignment program on the DOS for IBM compatible PC.

-Set external Brightness and Contrast volume to max position.

1. Adjustment for B+ Voltage.

1) Display cross hatch pattern at Mode 4.

2) Adjust C921 (+) voltage to 192V ± 0.2V with VR901.

2. Adjustment for High-Voltage.

1) Display cross hatch pattern at Mode 4.

2) Adjust CDT Anode voltage to 26kV ± 0.2kV with

VR801.

3. Adjustment for Horizontal Raster Center.

1) Display cross hatch pattern at Mode 4.

2) Adjust the Back Raster should be center of the

screen with SW801.

4. Adjustment for Factory Mode (Preset Mode).

1) Display cross hatch pattern at Mode 1~4.

2) Run alignment program for FB790G on the IBM

compatible PC.

3) EEPROM → ALL CLEAR → Y(Yes) command.

<Caution> Do not run this procedure unless the

EEPROM is changed. All data in EEPROM (mode

data and color data) will be erased.

4) COMMAND → PRESET START → Y(Yes)

command.

5) DIST. ADJ. → FOS. ADJ command.

6) Adjust H-POSITION as arrow keys to center of the

screen.

7) Adjust H-SIZE as arrow keys to 310 ± 2mm.

8) Adjust V-POSITION as arrow keys to center of the

screen.

9) Adjust V-SIZE as arrow keys to 230 ± 2mm.

10) Adjust TRAPEZOID as arrow keys to be the best

condition.

11) Adjust TILT as arrow keys to be the best condition.

12) Display cross hatch pattern at Mode 4.

13) DIST. ADJ. → BALANCE DATA command.

14) Adjust balance of Pin-Balance as arrow keys to be

the best condition.

15) Adjust parallelogram as arrow keys to be the best

condition.

16) Save of the Mode.

17) Save of the System.

18) Display from Mode 4 and repeat above from

number 6) to 15).

19) COMMAND → PRESET EXIT → Y (Yes) command.

5. Adjustment for White Balance and Luminance.

1) Set the White Balance Meter.

2) Press the DEGAUSSING on the OSD menu for

demagnetization of the CDT.

3) Display color 0,0 pattern at Mode 4.

4) COMMAND → PRESET START → Y(Yes)

command.

5) Set Bightness and Contrast to max position.

6) COLOR ADJ. → LUMINANCE command of the

alignment program.

7) COLOR ADJ. → BIAS ADJ. command of the

alignment program.

8) Check whether blue color or not at R-BIAS and GBIAS to min position, Sub-Brightness to 90 position,

B-BIAS to 75 position. If it's not blue color, the

monitor must repair.

9) Adjust Screen control on the FBT to 0.15 ± 0.02FL

of the raster luminance.

10)Adjust R-BIAS and G-BIAS command to x=0.283 ±

0.006 and y=0.298 ± 0.006 on the White Balance

Meter with PC arrow keys.

- 14 -

11) Display color 15,0 box pattern(70x70mm) at mode 4.

12)DRIVE ADJ command.

13) Set B-DRIVE to 100 at DRIVE of the alignment

program.

14) Adjust R-DRIVE and G-DRIVE command to white

balance x=0.283 ± 0.003 and y=0.298 ± 0.003 on

the White Balance Meter with PC arrow keys.

15) Adjust SUB-CONTRAST command to 47±1FL of

the raster luminance.

15)Display color 15,0 full white patten at Mode 4.

16)COLOR ADJ. → LUMINANCE → ABL command.

17) Adjust ABL to 32 ± 1FL of the luminance.

18) Exit from the program.

6. Adjustment for Focus.

1)

Display H character in full screen at Mode 4.

2)

Adjust two Focus control on the FBT that focus

should be the best condition.

Loading...

Loading...