Page 1

website : http://biz.lgservice.com

e-mail : http://LGEservice.com/techsup.html

WASHING MACHINE

SERVICE MANUAL

CAUTION

READ THIS MANUAL CAREFULLY TO DIAGNOSE PROBLEMS

CORRECTLY BEFORE OFFERING SERVICE.

BEFORE SERVICING THE WASHING MACHINE, UNPLUG THE POWER

CORD TO AVOID THE RISK OF AN ELECTRIC SHOCK.

WHEN SERVICING INTERNAL PARTS ,

USE ONL

AFTER SERVICING THE ELECTRIC WIRE, INSURE THAT INSULATION

Y SE RVICE PARTS SUPPLIED FROM LG.

TAPE IS APPLIED TO PREVENT AN ELECTRICAL SHORT.

MODEL :

F*V7*CP(0~9)

Page 2

CONTENTS

SPECIFICATIONS ............................................................................................................................. 3

1.

2. FEATURES & TECHNICAL EXPLANATION ..................................................................................... 4

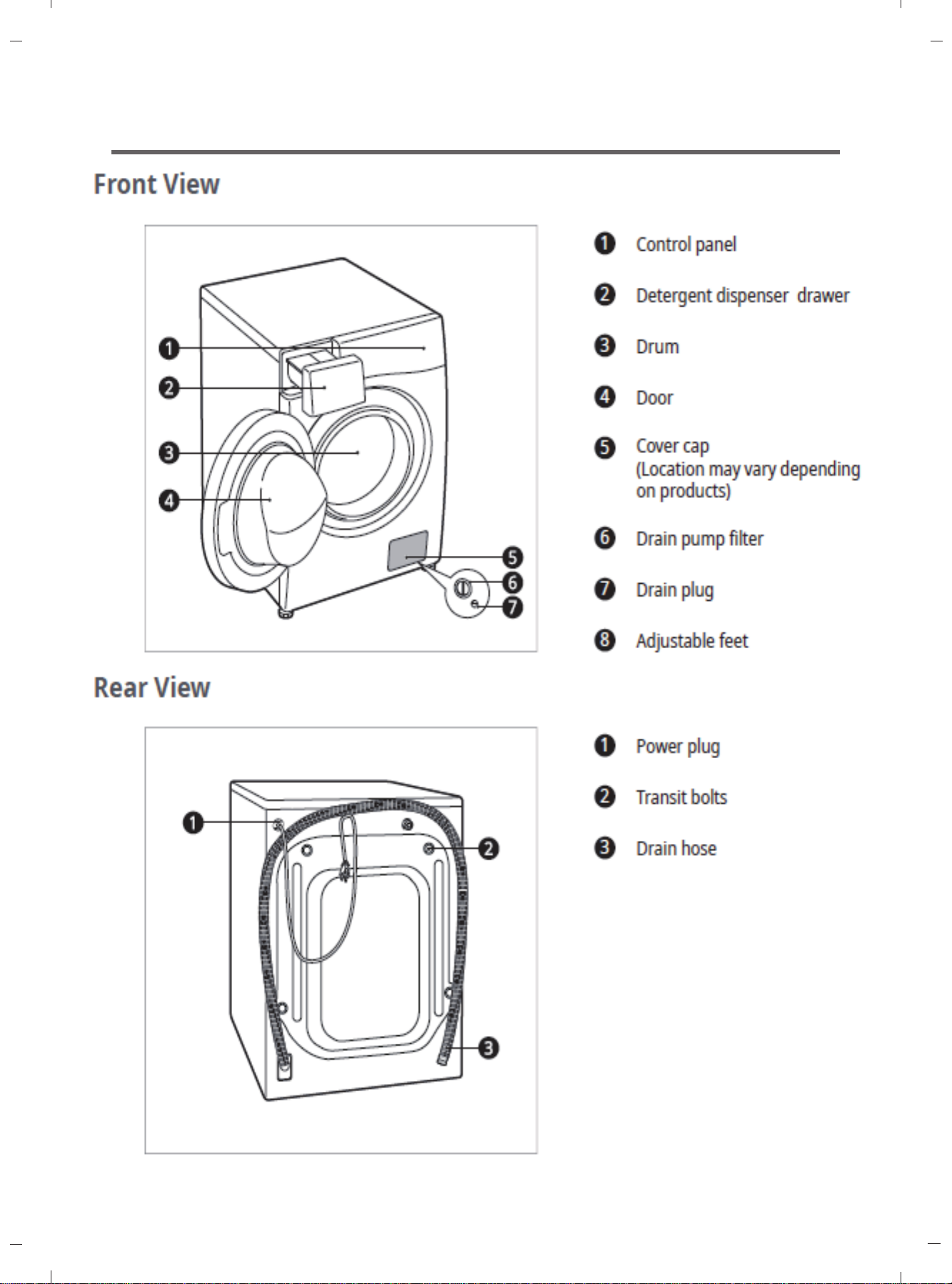

3. PARTS IDENTIFICATION ................................................................................................................. 6

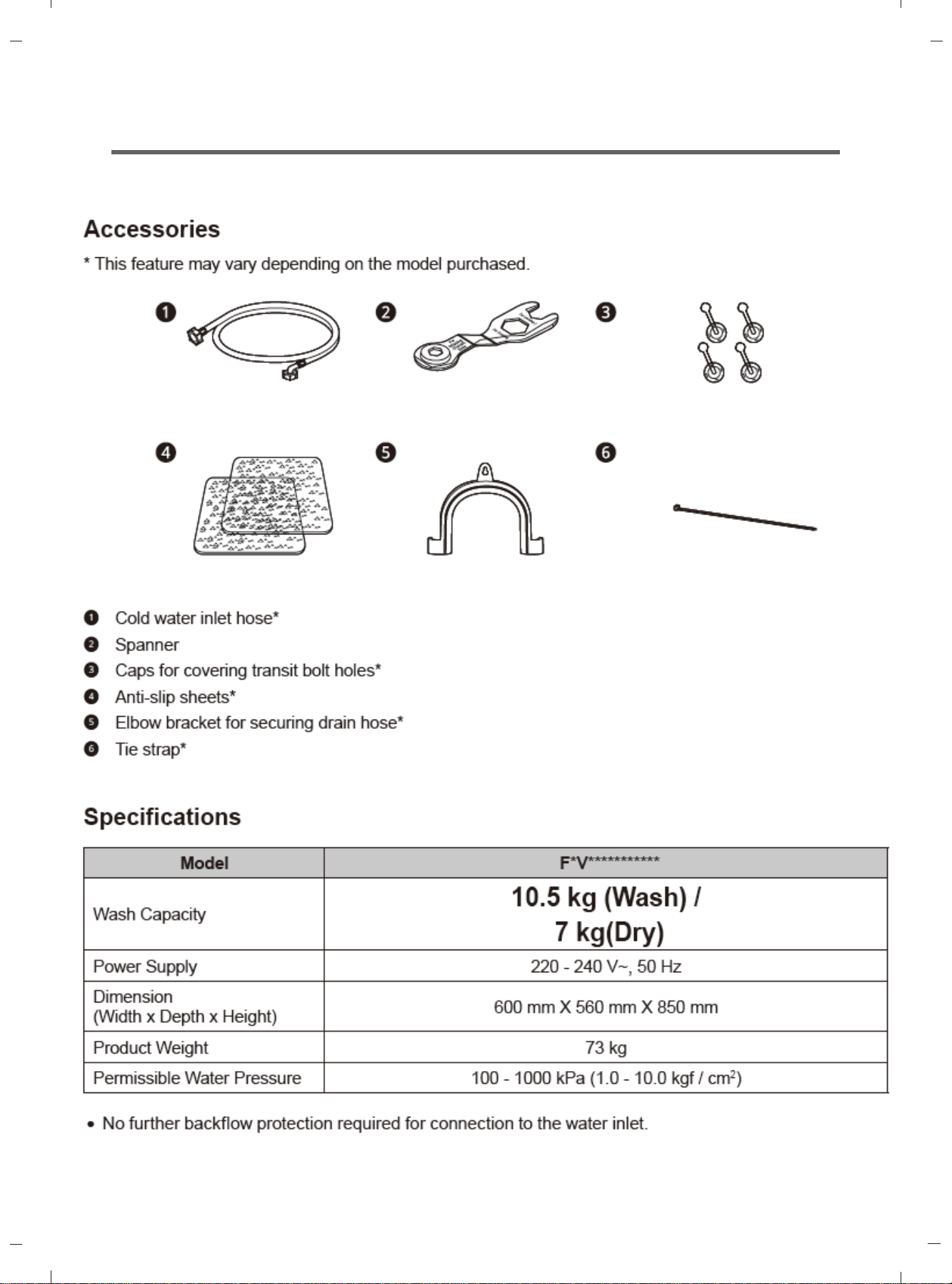

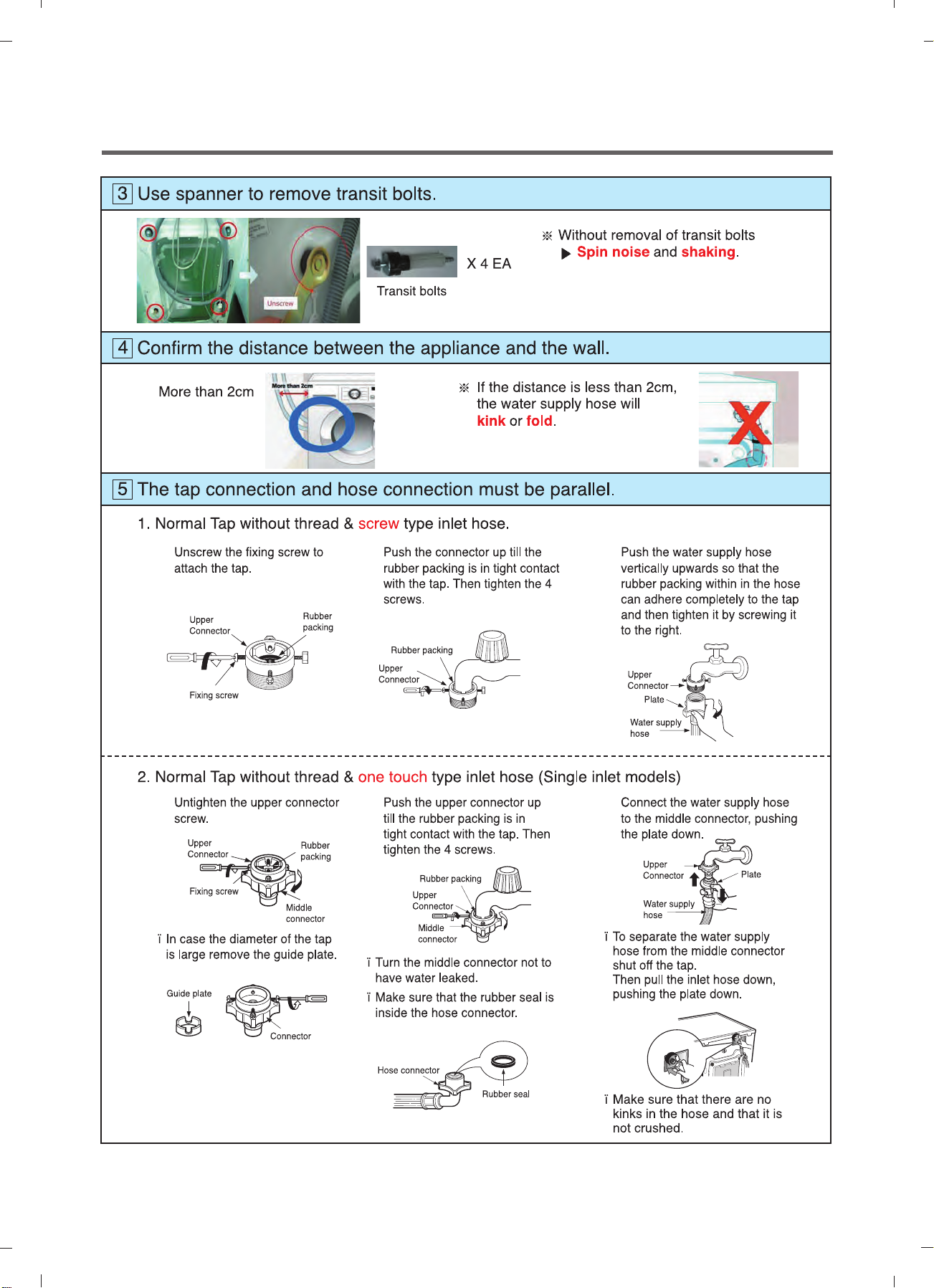

4. INSTALLATION.................................................................................................................................. 7

5. OPERATION ...................................................................................................................................12

6. WIRING DIAGRAM / PCB LAYOUT ................................................................................................17

7. TROUBLESHOOTING......................................................................................................................19

7-1.BEFORE PERFORMING SERVICE .........................................................................................19

7-2.LOAD TEST MODE .................................................................................................................. 19

7-3.HOW TO CHECK THE WATER LEVEL FREQUENCY ............................................................ 20

7-4.ERROR DISPLAY ..................................................................................................................... 21

7-5.TROUBLESHOOTING WITH ERROR .....................................................................................23

• IE (Water Inlet Error) .............................................................................................................. 24

• UE (Unbalanced Error) ........................................................................................................... 25

• OE (Water Outlet Error) .......................................................................................................... 26

• FE (Over Flow Error) .............................................................................................................. 28

• PE (Pressure Sensor S/W Error) ............................................................................................ 29

• dE2 (Door open Error) .............................................................................................................. 31

• dE1 (Door switch Error) .............................................................................................................. 31

• tE (Thermistor (Heating) Error) ............................................................................................... 33

• LE (Motor Lock Error) ............................................................................................................. 36

8. TROUBLESHOOTING WITHOUT ERROR CODES ...................................................................... 38

• Power Failure or no power .................................................................................................... 38

• Vibration & Noise during spin ................................................................................................. 39

• Detergent & Softener does not flow in .................................................................................... 40

• Water Leak ............................................................................................................................. 41

• Before using the Tag On function .......................................................................................... 43

9. PART INSPECTION ........................................................................................................................ 45

9-1.FILTER ASSEMBLY (LINE FILTER) ......................................................................................... 45

9-2.DOOR LOCK SWITCH ASSEMBLY ......................................................................................... 46

9-3.STATOR ASSEMBLY ............................................................................................................... 48

10. DISASSEMBLY INSTRUCTIONS .................................................................................................. 49

11. EXPLODED VIEW AND PART LIST .............................................................................................. 57

Page 3

1. SPECIFICATION

ITEM

POWER SUPPLY

PRODUCT WEIGHT

WASHING

SPIN

ELECTRICITY

CONSUMPTION

REVOLUTION

SPEED

OPERATION WATER PRESSURE

CONTROL TYPE

WASH & DRY CAPACITY

DRAIN MOTOR

WASH HEATER

DRY HEATER 1350 W

WASH

SPIN

DIMENSION

Refer to 1 page

220 V - 240 V ~,50Hz/60Hz

73kg

155 W

490 W

20 W

2200 W

46 rpm

F4V******* : No Spin / 400 / 800 / 1000 / 1200 / 1400

F2V******* : No Spin / 400 / 800 / 1000 / 1100 / 1200

0.1 ~ 1.0 MPa (1.0 kgf / cm2~ 10.0 kgf / cm2)

Electronic

Refer to the Rating Label

600mm x 560mm x 850mm

WASH PROGRAM

RINSE

DOOR SWITCH TYPE

WATER LEVEL

RESERVATION

SENSING LAUNDRY AMOUNT

FUZZY LOGIC

DISPLAY REMAINING TIME

ERROR DIAGNOSIS

POWER AUTO OFF

CHILD LOCK

AUTO RESTART

TIME SAVE

SMART

Cotton , Cotton+, Turbo Wash 39, Mixed Fabric, Easy Care,

Steam Refresh

Speed 14, Wash+Dry, Tub Clean, Download Cycle

, Allergy Care, Delicate, Hand/Wool, Dry Only,

+

Rinse

PTC+Sol

by Pressure Sensor S/W

From 3 hours to 19 hours

Wi-fi (Smart ThinQ 3.0)

enoid

Adapted

Adapted

Adapted

13 items

Adapted

Adapted

Adapted

Adapted

WARNING

To reduce the risk of personal injury, adhere to all industry recommended safety procedures including

the use of long sleeved gloves and safety glasses.

Failure to follow all of the safety warnings in this

injury or death.

manual could result in property damage, personal

Page 4

2. FEATURES & TECHNICAL EXPLANATION

2-1.

Product Features

Inverter Direct Drive system

The advanced Brushless DC motor directly drives the drum without

belt and pulley.

6 Motion

Washer is able to perform various drum actions or a combination of

different actions depending on the wash program selected.

Combined with a controlled spin speed and the ability of the drum to

rotate both left and right, the wash performance of the machine is greatly

improved, giving you perfect results every time.

Turbo Wash

Wash the laundries in 1 hour with energy and water saving.

Smart ThinQ (Wi-Fi feature)

This feature lets you use various functions of the product, e.g., remote

control, smart alert, mode download, and smart self-diagnosis via the

smartphone app.

More economical with Intelligent Wash system

Intelligent Wash System detects the size of load and water temperature,

and then determines the optimum water level and washing time to

minimize energy and water consumption.

Child Lock

The Child Lock prevents children from pressing any button to change

the settings during operation.

Low noise speed control system

By sensing the amount of load and balance, it evenly distributes load

to minimize the spinning noise level.

Auto Restart

Auto Restart allows the program to restart all by itself in case of power

failure. It does from the stage where it stopped.

SmartDiagnosis™

Should you experience any technical difficulty with your washing

machine, it has the capability of transmitting data by phone to the

Customer Information Center. The call center agent records the data

transmitted from your machine and uses it to analyze the issue,

providing a fast and effective diagnosis.

Page 5

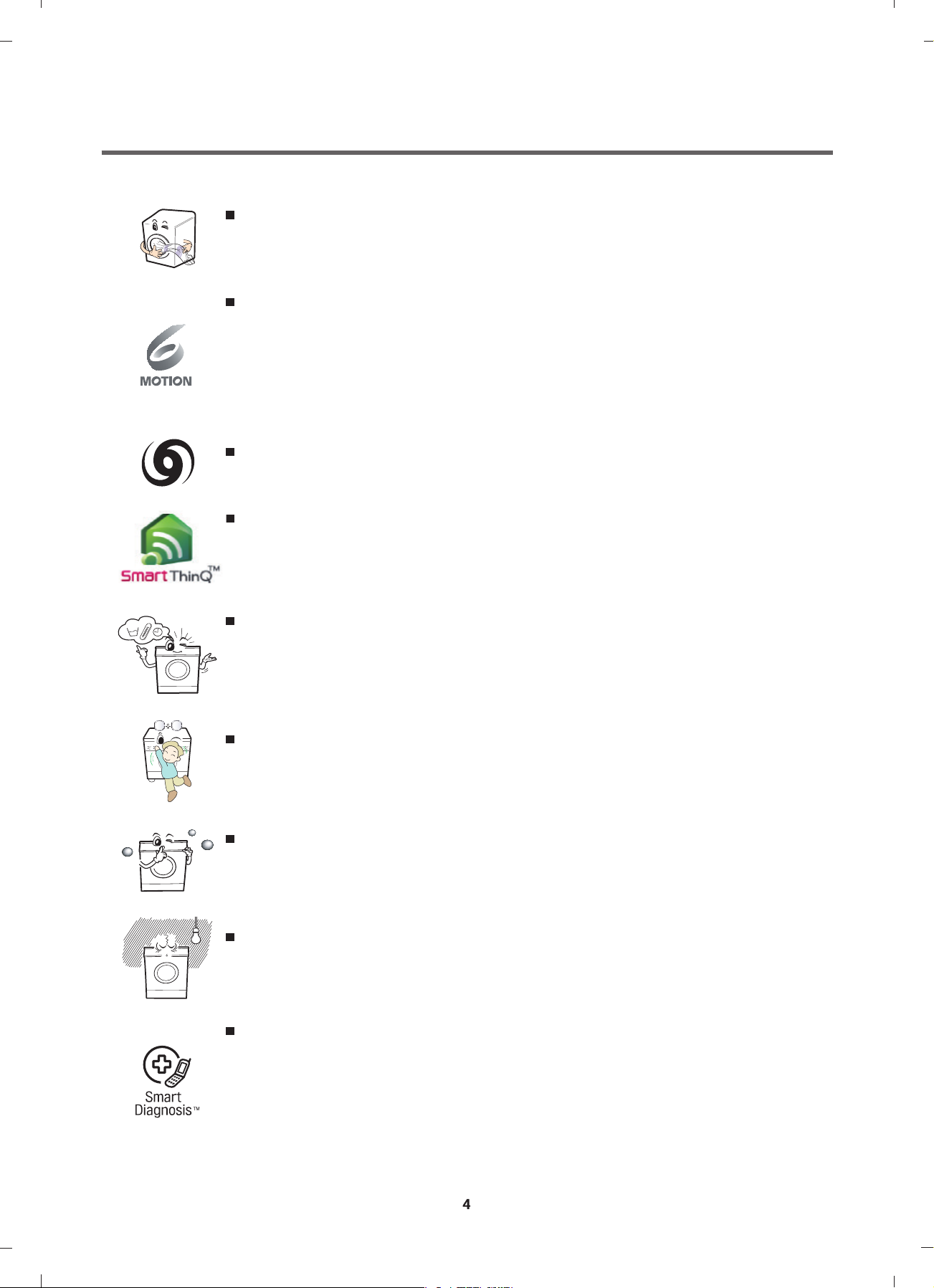

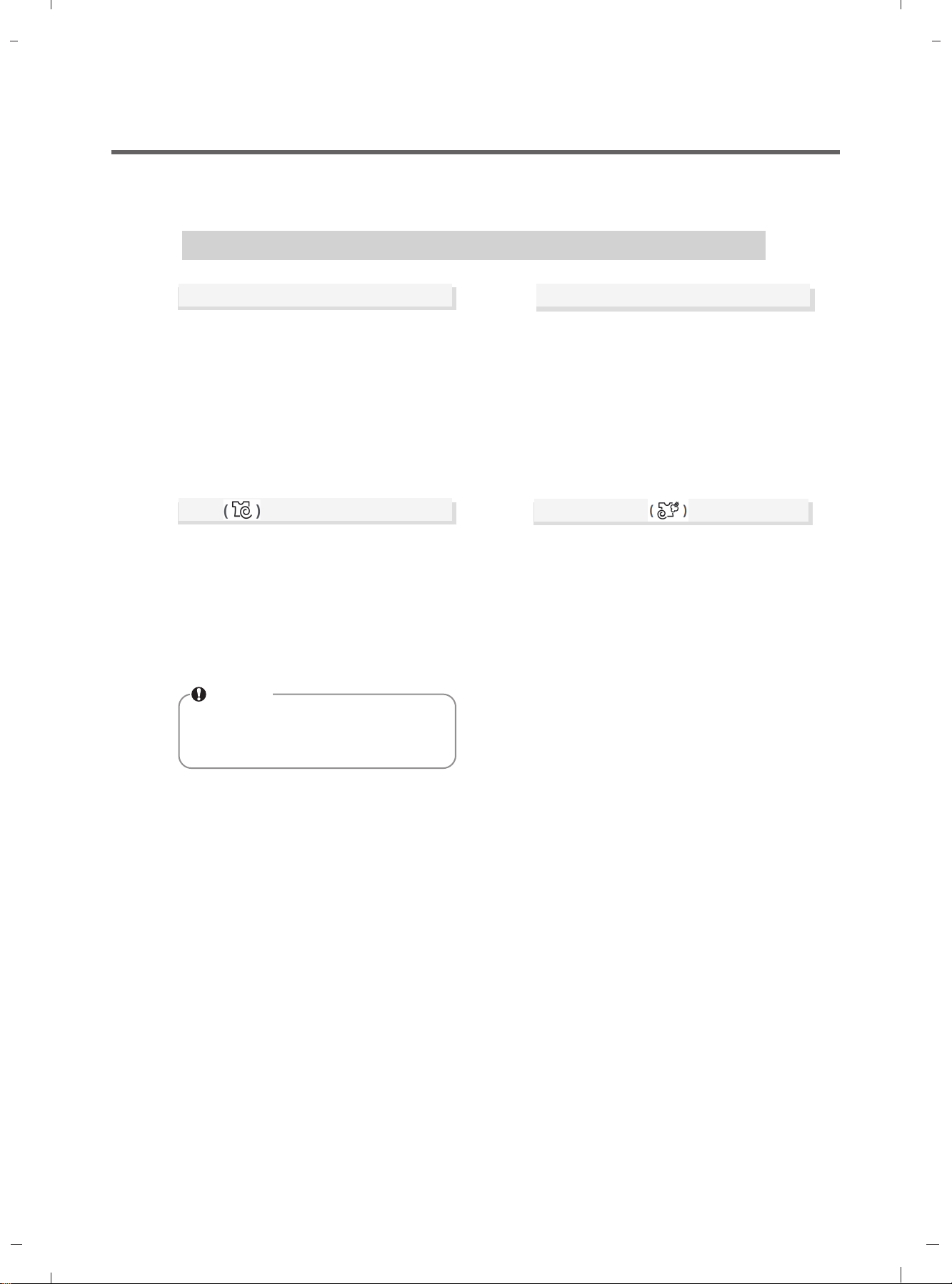

2-2. DETERMINE WASHING TIME BY FUZZY LOGIC

To get the best washing performance optimal time is determined by sensing the water

temperature, selected washing temperature and laundry amount.

water

temperature

washing time

selected

washing

temperature

SENSING

laundry

amount

PROCESSING

FUZZY

LOGIC

rinse time

spin rhythm, time

DET ERMINATION

the best

washing

performance

EFFECT

2-3. WATER LEVEL CONTROL

This model adopts a pressure sensor which can sense the water level in the tub.

Water supply is stopped when the water level reach the preset level, then washing program proceeds.

Spinning does not proceed until the water in the tub reduces to a certain level.

2-4. THE DOOR CAN NOT BE OPENED

While program is operating.

While Door Lock light is on.

Page 6

3. PARTS IDENTIFCATION

6

Page 7

3.PARTS IDENTIFCATION

7

Page 8

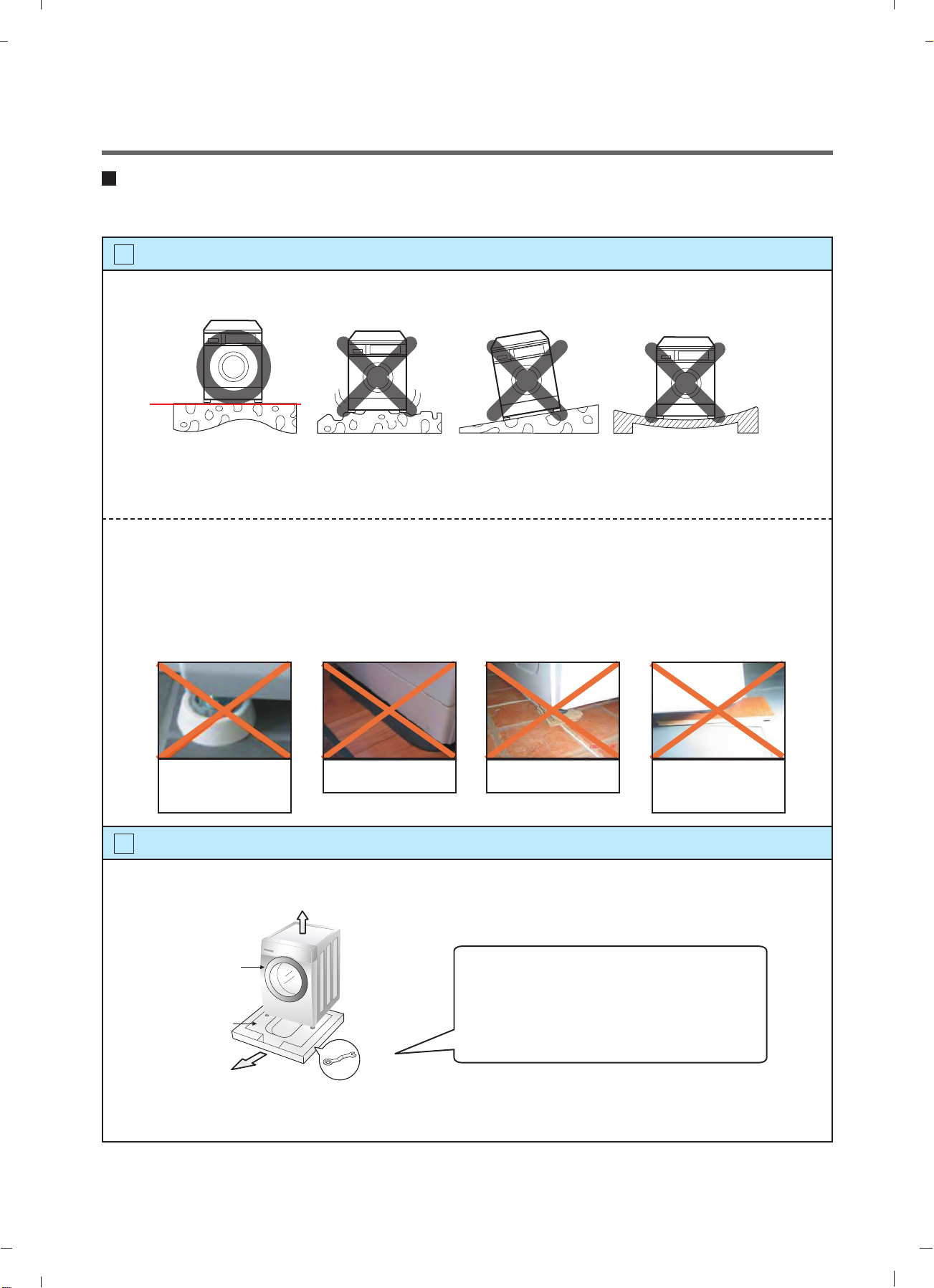

4. INSTALLATION

INSTALLATION

The appliance should be installed as follows.

1

Check the conditions of installation area.

1. Check level ground.

horizontal

On raised foundations or upper level homes, the vibrations can be caused by the type of flooring.

It may be necessary to move the machine to a different area in the home or have the floor

reinforced to properly support the operation of the unit.

2. Check for humidity or any foreign objects under the feet.

Clean the floor, there should be no foreign objects under the feet.

If the unit has foreign objects underneath the feet, this will prevent the unit from being leveled properly

and will cause vibrations and slipping.

Remove any foreign objects, if any from underneath the machine and level unit properly.

See below for examples of foreign objects.

Purchased

stopper

2

Open the box and check appliance condition.

Washer

Carpet Paper Laminated

paper

This leveling (or spanner) wrench must

be used to remove the shipping bolts

Base Packing

and level the unit. This should be kept

for future use.

Spanner

8

Page 9

1. 2. 3.

1. 2. 3.

9

Page 10

6

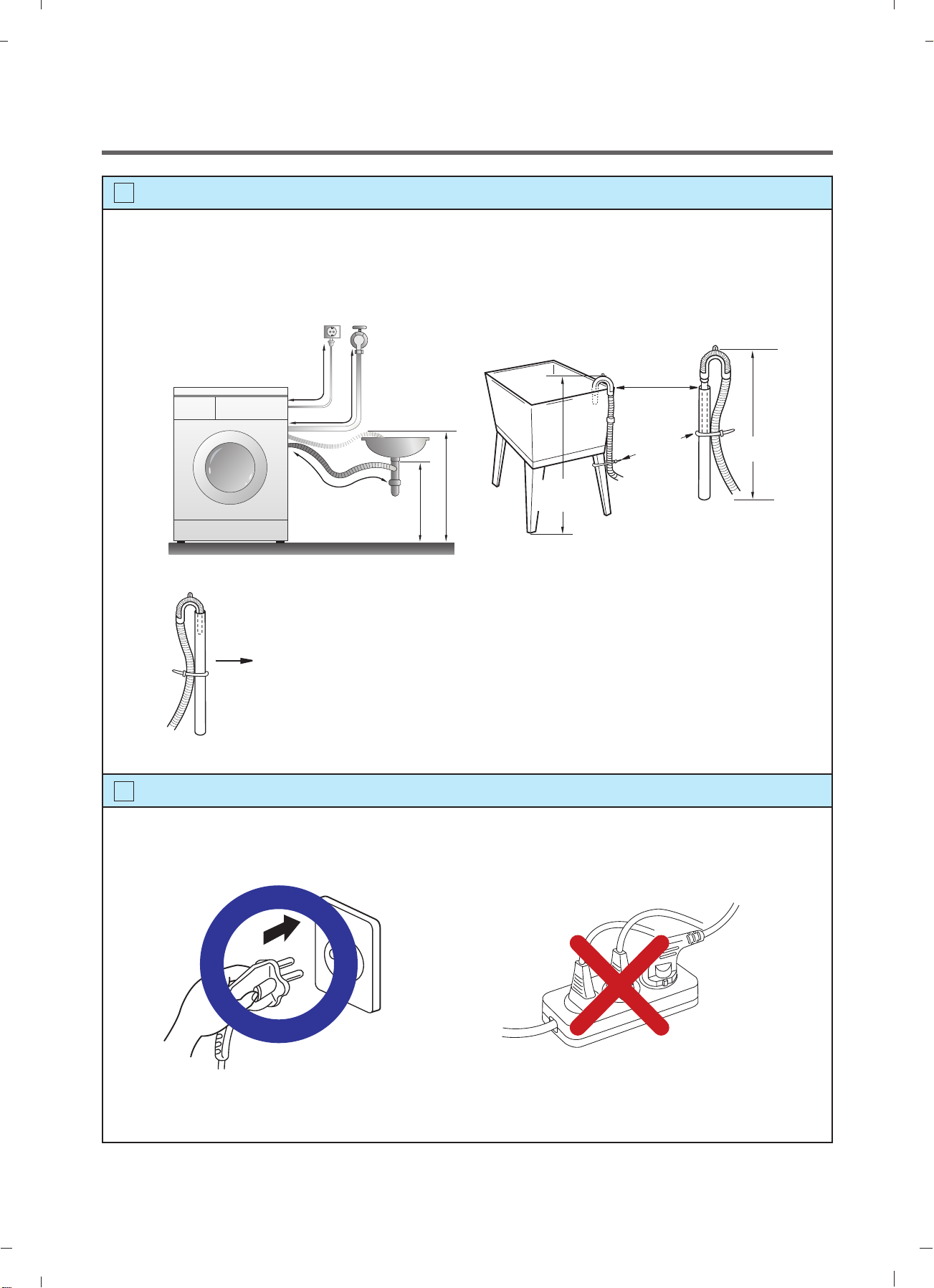

Connect Drain Hose.

If the drain hose is not installed properly, the unit will not drain properly.

This allows water to back flow into the unit which can cause odors.

Refer to Owner Manual for proper drain hose installation.

The odor could also be coming from the home’s drain to which the drain hose is attached.

Laundry tub

about 100 cm

about 145 cm

about 105 cm

max. 100 cm

min. 60 cm

Max. 100cm

min. 60cm

Hose

Retainer

Tie

strap

Max. 100cm

min. 60cm

In this type of drain hose installation, the odor could be coming from the standpipe.

This odor can come up the drain hose and into the unit.

Pour a cup or two of bleach or vinegar down the home drain

and let it sit for 24 hours before running another cycle.

This will help eliminate odor from the home drain.

If a cycle is started too soon after doing this, it will not help the issue.

7

Connect power plug.

Connect the power plug to the wall outlet. Avoid connecting several electric devices,

it may be the cause of a fire.

10

Page 11

8

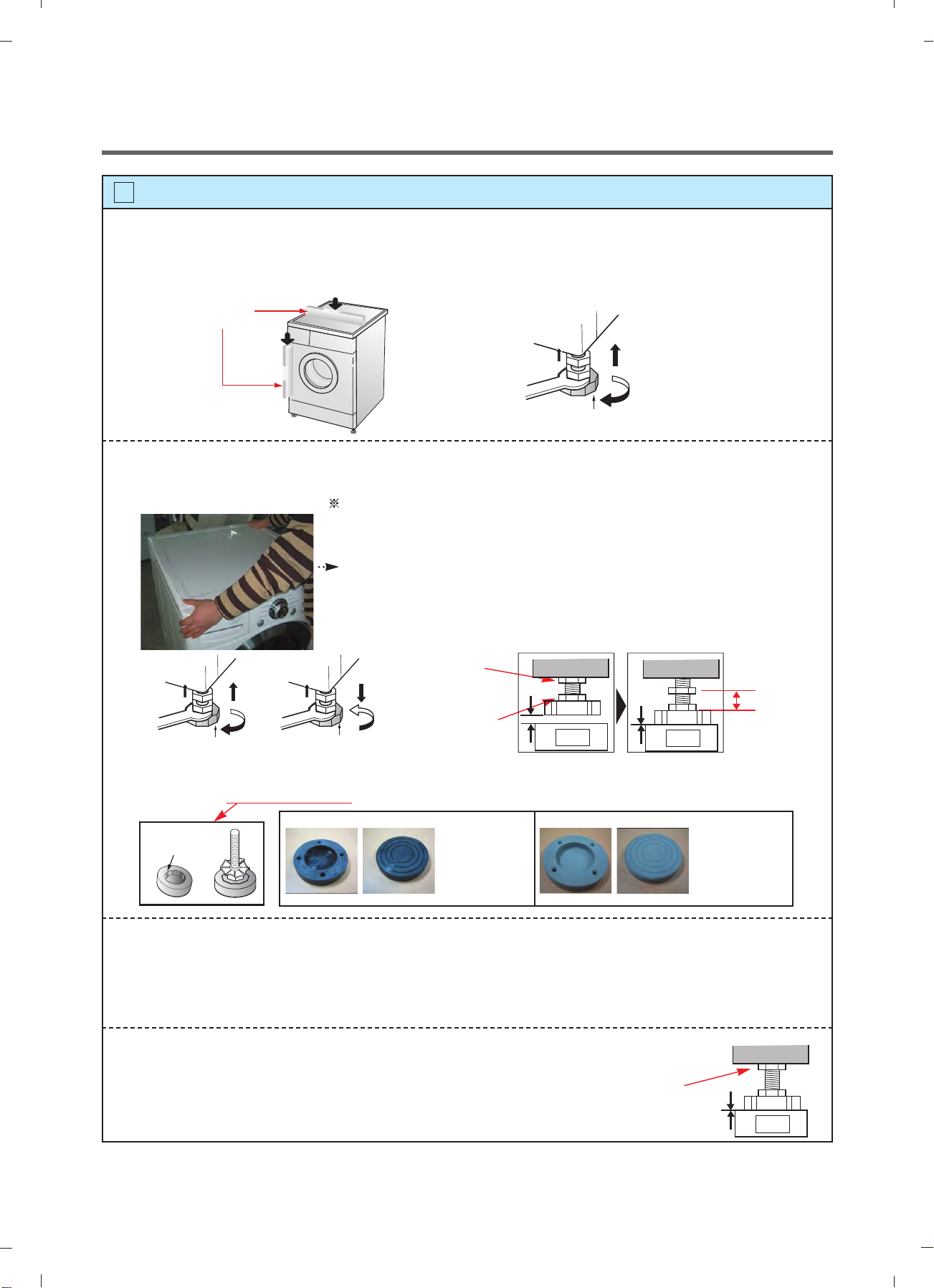

Check the horizontality with a level (Gage).

Step 1

If washing machine legs are loose or not Screwed in, then tighten with the spanner wrench.

Using the level, level the washing machine from front to back and side to side.

A level

Higher

Tighten

Adjustable feet

Step 2

Use the spanner wrench to adjust Legs until level and try the Diagonal test.

Diagonal test

How to perform a diagonal test:

Place your right hand on the back, right corner and your left hand on the front,

left corner of the unit, then attempt to rock the unit from corner to corner.

Then, move your right hand to the front, right side and your left hand to the

back, left corner and attempt to rock the unit from corner to corner.

If the unit is level, it will not rock. However, if the unit is not level, it will rock.

If the unit rocks, it will be necessary to adjust the leveling feet of the unit.

Adjust the foot under the hand that is on the front of the machine.

Lock nut

Adjustabl

e bolt

Gap

Floor

No Gap

Floor

Tighten

Higher

Adjustable feet

Lower

Tighten

Adjustable feet

Lower the foot until there is no gap between floor and foot.

And only use adjustment rubber when difference at the leg adjustment is more than 10mm.

Rubber Cup

Rubber Cup

4620ER4002A

(Black)

for Tile floors

4620ER4002B

(Gray)

for Wooden floors

10mm

Step 3

Perform a Rinse and Spin with some clothing in the machine.

To do this, put 2~3kg of clothing in the unit, turn on the unit, Select the Rinse+Spin

and then start. When the unit reaches the spin cycle, watch for vibrations.

If the unit is vibrating, make small adjustments to the leg until they subside. (Repeat step 2)

Step 4

Tighten the lock nut against the base of the machine to lock the position leg.

Tighen the lock nut

11

No Gap

Floor

Page 12

9

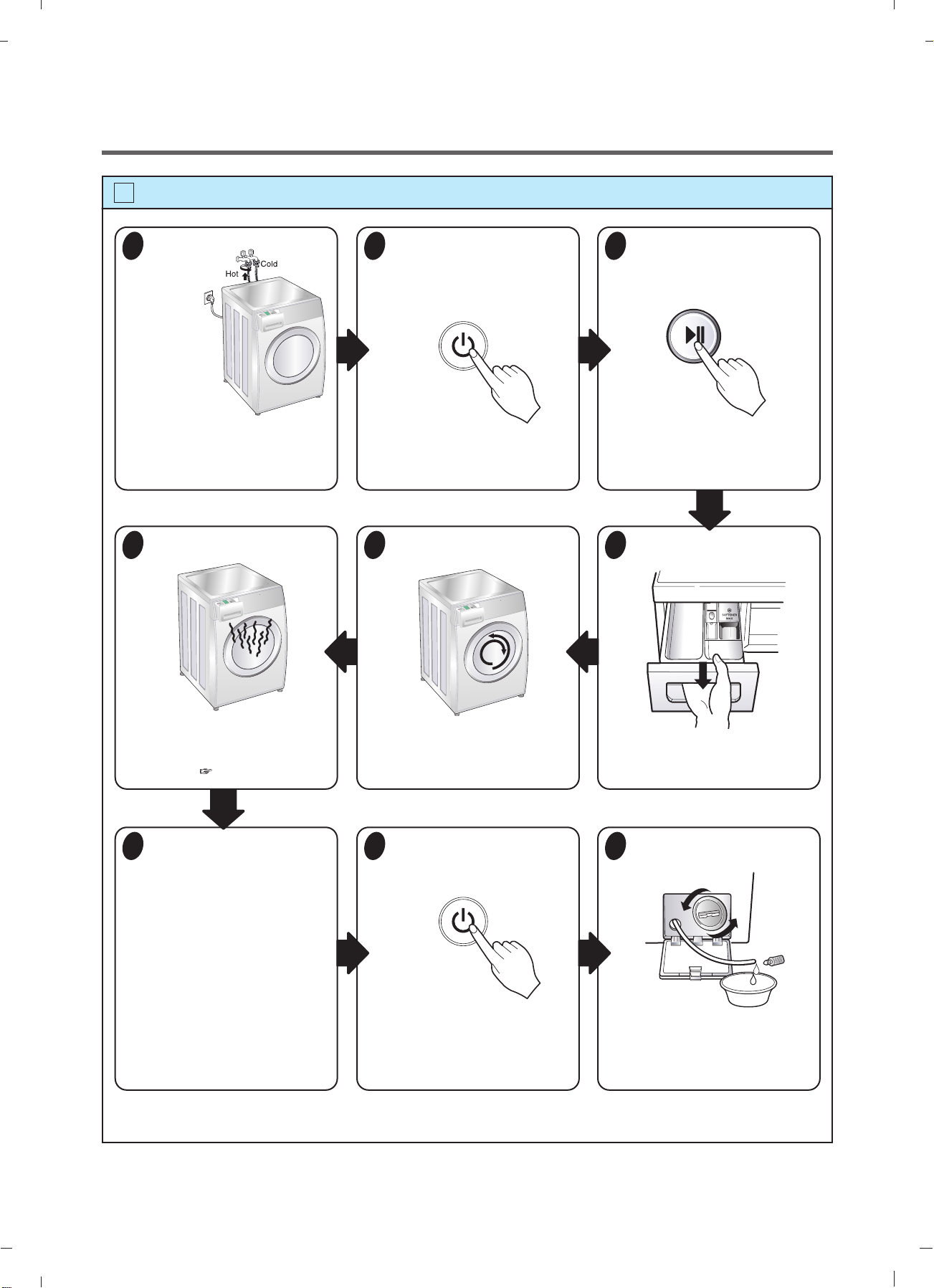

Test operation

Preparation

1

for

washing.

· Connect the power plug to the

outlet.

· Connect the inlet hose.

Check the water heating.

6

Press the power button.

2

Check automatic reverse turn.

5

Press the START/PAUSE

3

button.

· In case of Coloreds program.

Check the water supply.

4

· Touch the Temp and Medic

Rinse button simultaneously and

the present temperature will be

displayed.

Check the drain and spin

7

functions.

· Turn power off and then power on.

· Select the spin rpm

· Press the START PAUSE button.

· Check the spin and drain

functions.

Page 20

· Check if the drum rotates

clockwise and counterclockwise.

Turn power off and open

8

the door.

· Turn power off and then power on.

· Listen for a click to determine if the

door is unlocking.

· Check if water is supplied through

the detergent dispenser.

Water removal.

9

· If SVC is needed during check,

remove the remaining water by

pulling out the hose cap.

12

Page 13

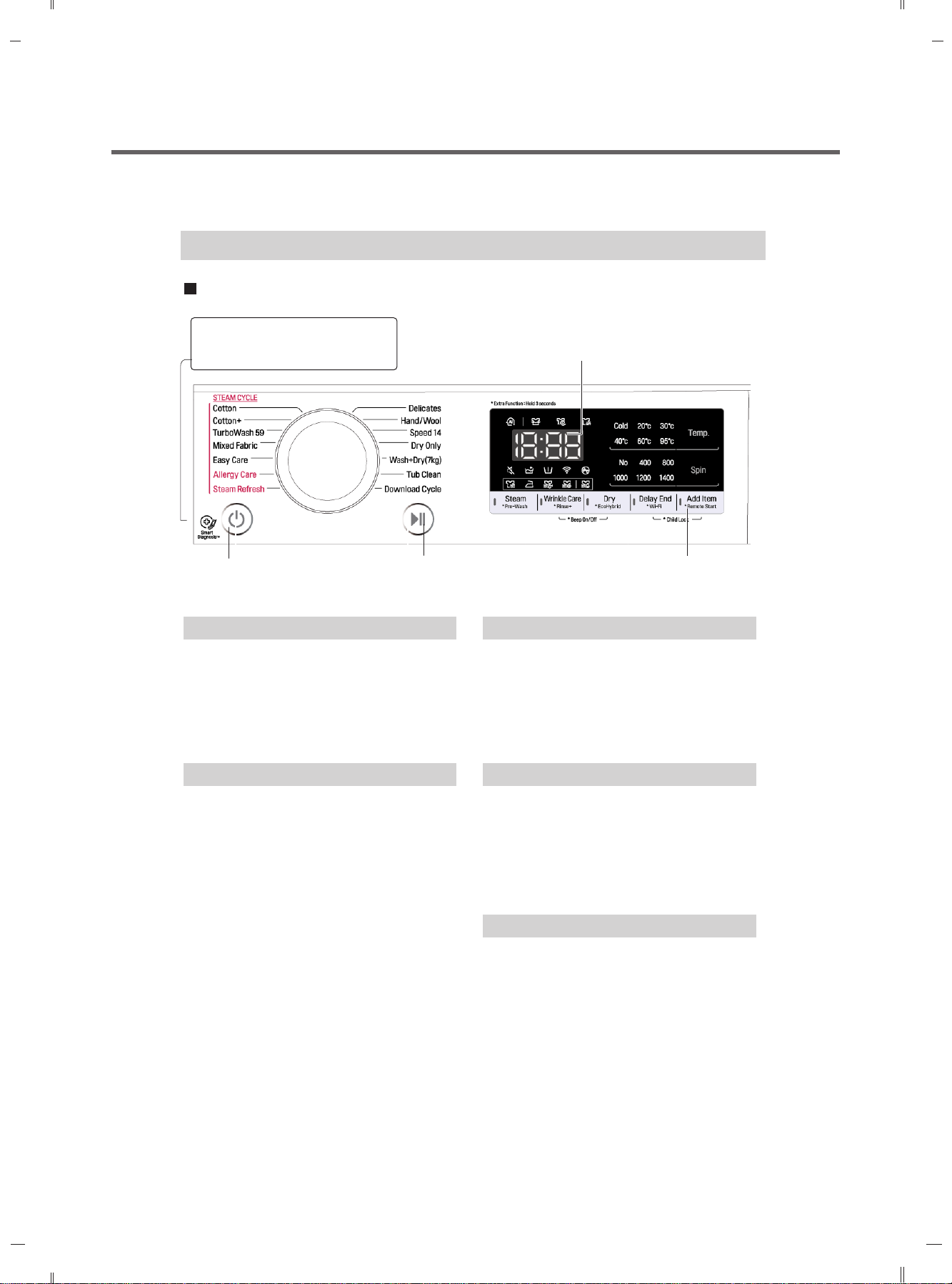

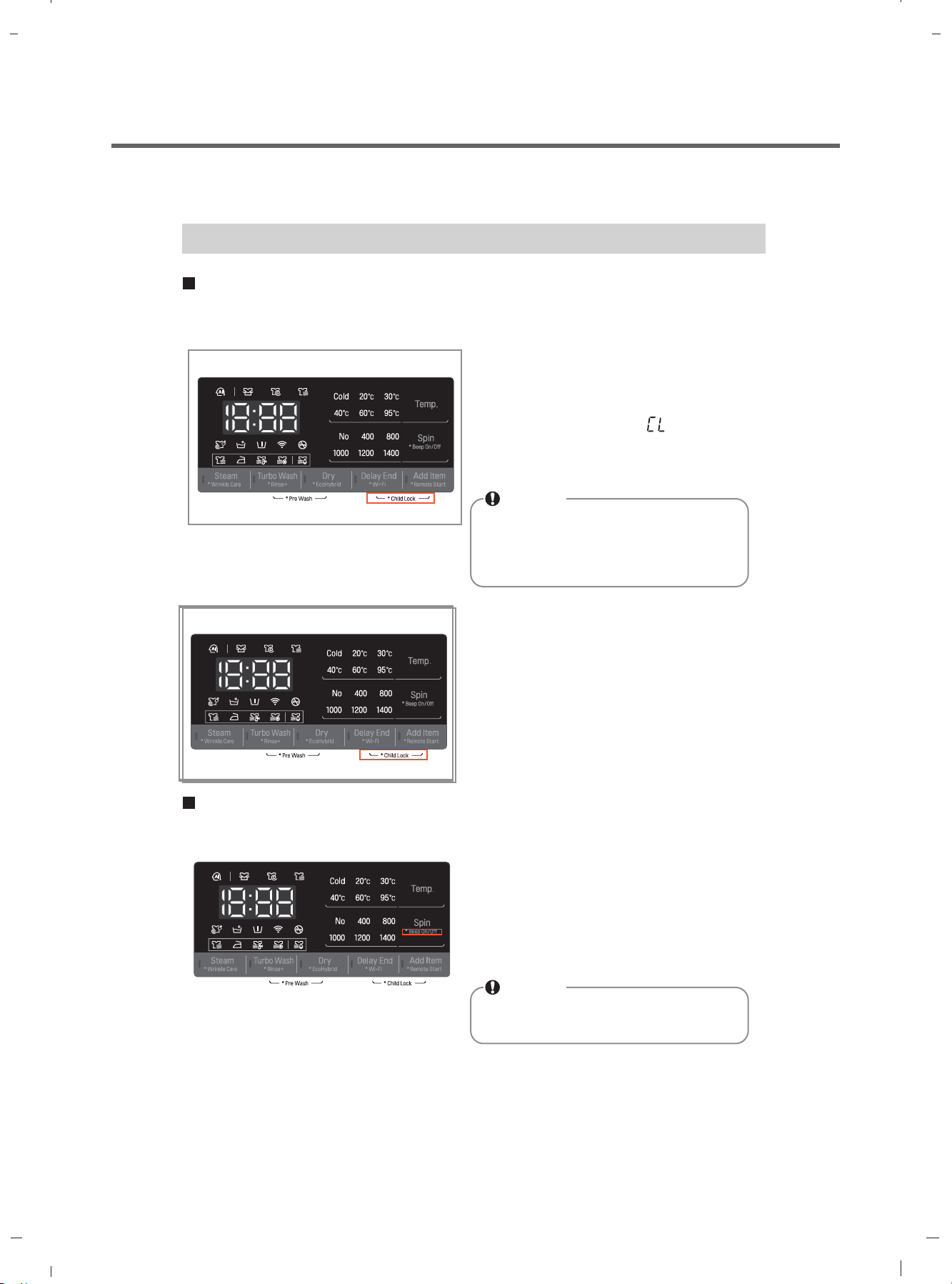

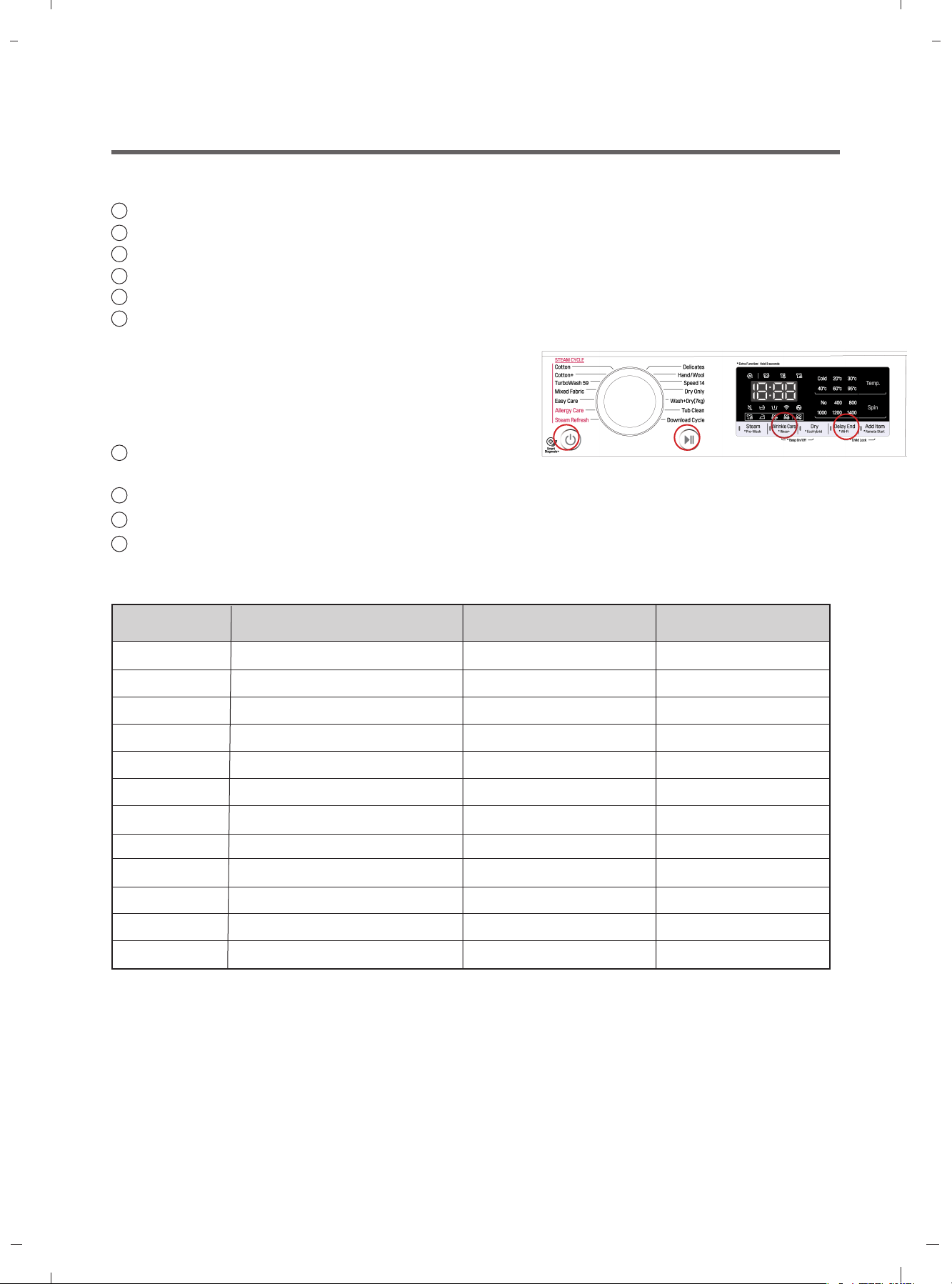

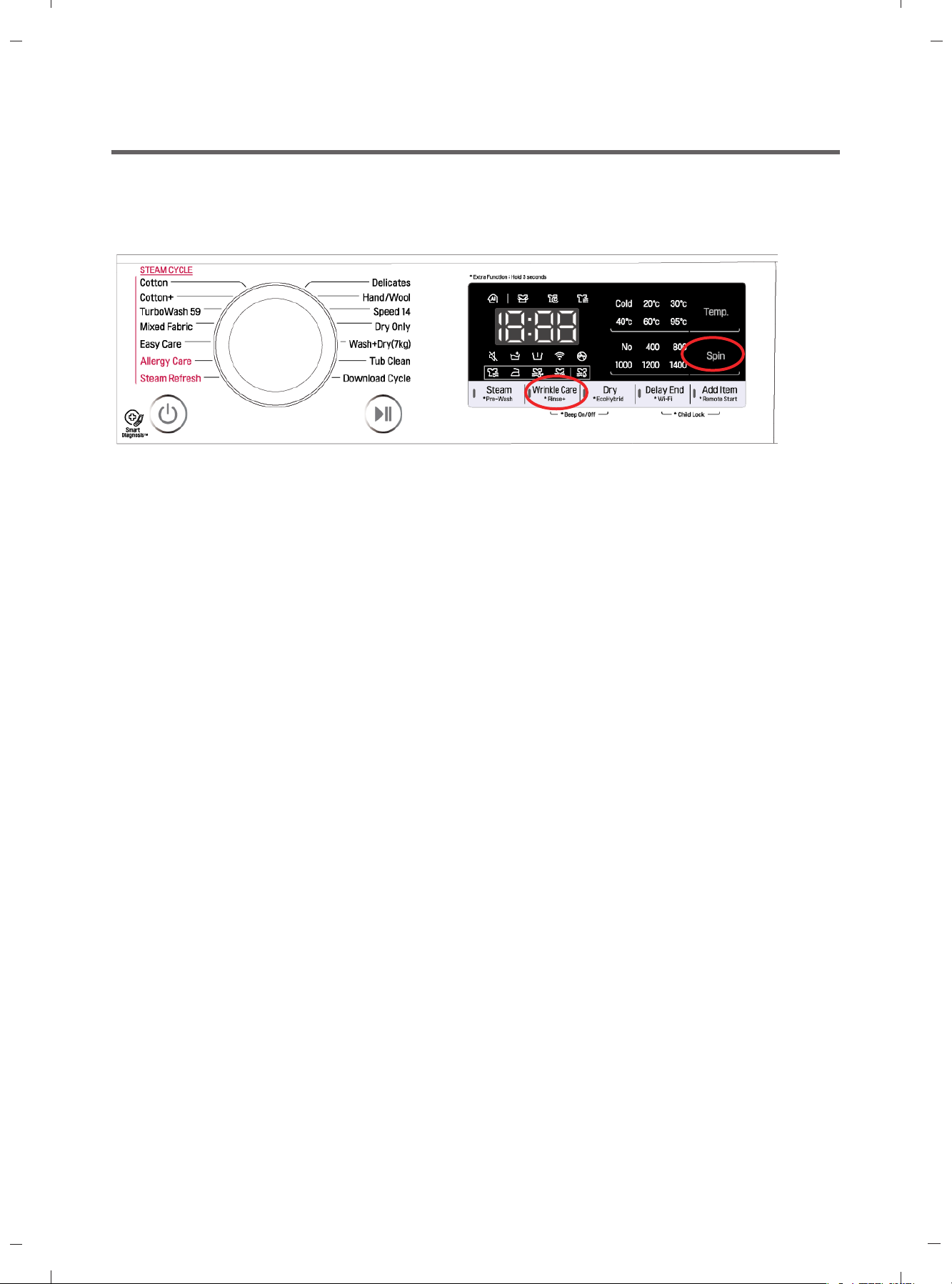

5. OPERATION

How to use washer

Control panel

SmartDiagnosis™ function is

available only for the products with

a SmartDiagnosis™ mark.

LED display

Power Button

Program dial

Start/Pause

Button

Power

Press the Power button to turn power on

and off.

To cancel the Time Delay function, the

power button should pressed.

Start/Pause

This Start/Pause button is used to start

wash cycle or pause the wash cycle.

If temporary stop of wash cycle is

needed, touch the Start/Pause button.

When in Pause, the power is turned off

automatically after 4 minutes.

Options

Program Dial

Programs are available according to the

laundry type.

Lamp will light up to indicate selected

program.

LED display

The display shows the settings, estimated

time remaining, options, and status

messages for your washer.

The display will remain on through the

cycle.

Options

This allows you to select an additional

cycle and will light when selected.

Use thise buttons to select the desired

cycle options for the selected cycle.

13

Page 14

How to use washer

Options

Steam: This option is featured with the

enhanced washing performance. This

option consumes low energy.

Rinse + ( ) : Add rinse once.

Dealy End :

You can set a time delay so that the washing

machine will start automatically and finish

after a specifed time interval.

NOTE

The delay time is the time to the end of the

programme, not the start. The actual running

time may vary due to water temperature, wash

load and other factors.

To cancel the function, the power button

should be pressed.

Avoid using liquid detergent for this option.

1. Touch the Power button.

2. Select a washing programme.

3. Touch the Time Delay button and set time

required.

4. Touch the Start/Pause button.

14

Page 15

How to use washer

Temp.

By touching the Temp. button the water

temperature can be selected.

- Cold

- 20°C, 30°C, 40°C, 60°C, 95°C

Water temperature can be selected

according to the program.

Spin

yb detceles eb nac level deepS nipS

touching 'Spin' button repeatedly.

ylnO nipS

1. Touch the Power button.

2. Touch the Spin button to select RPM.

3. Touch the Start/Pause.

NOTE

When you select , it will still rotate for a

short time to drain quickly.

Pre Wash

If the laundry is heavily soiled, “Pre Wash”

course is effective.

1. Touch the Power button.

2. Select a cycle.

3. Touch the Pre Wash button.

4. Touch the Start/Pause button.

Wrinkle Care

This washing programme reduces wrinkles by

steaming after spin.

1. Press the Power button.

2. Select a washing programme.

3. Press the Wrinkle Care button for 3 seconds.

4. Press the Start/Pause button.

15

Page 16

How to use washer

Child Lock

Select this function to lock the buttons on the control assembly to prevent tampering.

"Child Lock" can be set only during the washing cycle.

Locking the control panel

1. Touch and hold the Child Lock button for

3 seconds.

2. A beeper will sound, and ' ' will appear on

the LED display.

When the child lock is set, all buttons are

locked except the Power button.

NOTE

Turning off the power will not reset the

child lock function. You must deactivate

child lock before you can access any

other functions.

Unlocking the control panel

1. Touch and hold the Child Lock button for

3 seconds.

2. A beeper will sound and the remaining time

for the current programme will reappear on

the LED display.

Beep On / Off

The Beep on/off function can be set only during the washing cycle.

1. Touch the Power button.

2. Touch the Start/Pause button.

3.

Touch and hold the Spin button

three seconds to set Beep on/off function.

Once the Beep on/off function is set, the setting

is memorized even after the power is turned off.

NOTE

If you want to turn the Beeper off,

simply repeat this process.

16

Page 17

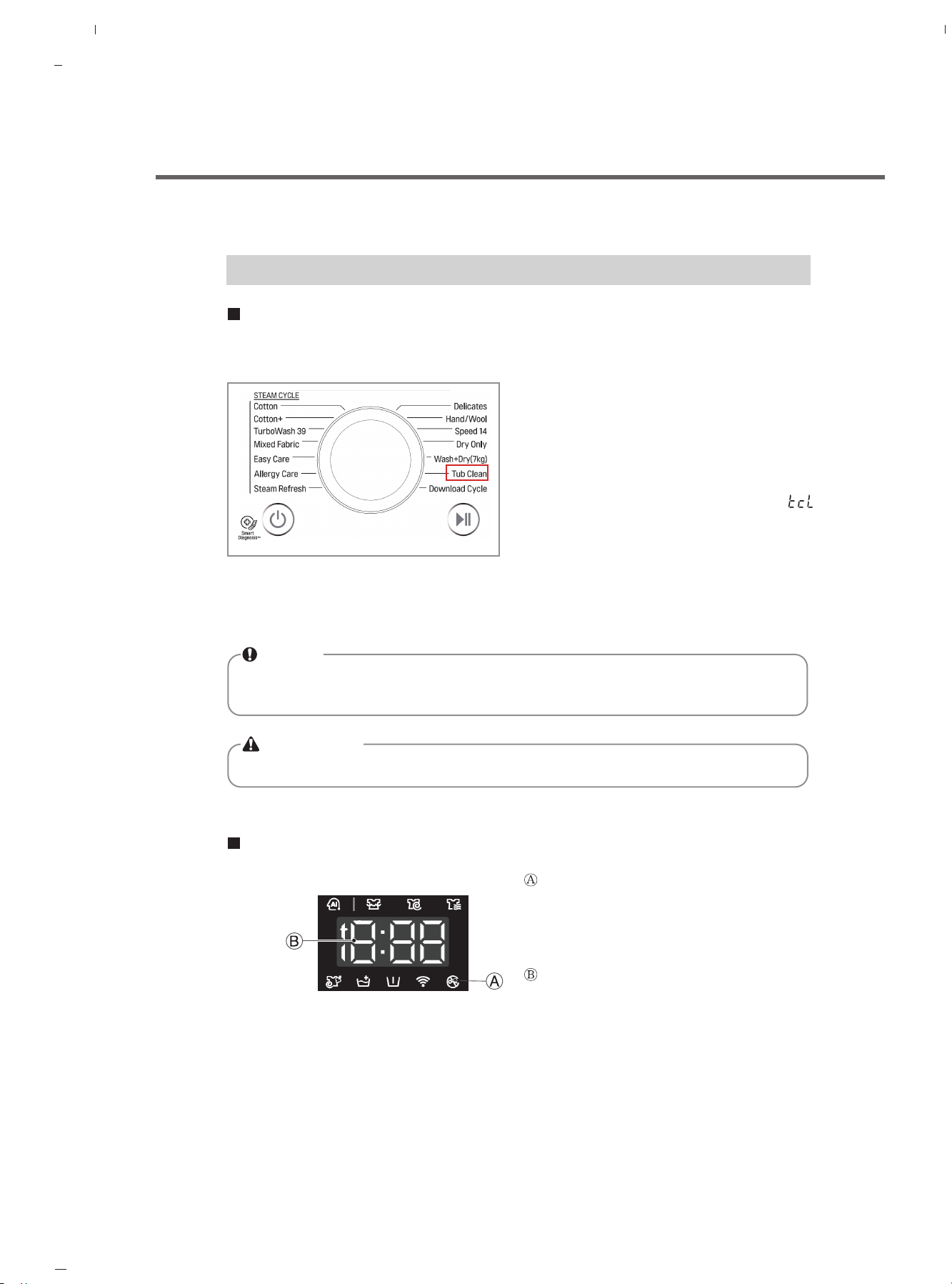

How to use washer

Tub Clean

Tub Clean is a special cycle to clean the inside of the washing machine.

A higher water level is used in this cycle at higher spin speed . Perform this cycle regularly.

1. Remove any clothing or items from the

washer and close the door.

2. Open the dispenser drawer and add Anti

limescale(e.g. Calgon) to the main wash

compartment.

3. Close the dispenser drawer slowly.

Power On and select the Tub

4.

displayed on the display.

5

. Touch the Start/Pause button to start.

6. After the cycle is complete, leave the door

open to allow the washer door opening,

flexible gasket and door glass to dry.

NOTE

Do not add any detergent to the detergent compartments.

Excessive suds may generate and leak from the washer.

Clean .Then will be

CAUTION

If there is a child, be careful not to leave the door open for too long.

Door Lock & Detecting

“Door Lock” - For safety reasons, the

door will lock while machine is in use and the

“Door Lock” icon will light up. You can safely

open the door after the “Door Lock” icon

turns off.

While "Detecting" is shown on the

display the washing machine rotates slowly

and detects how much laundry is loaded in

the drum.

It will take a short time.

17

Page 18

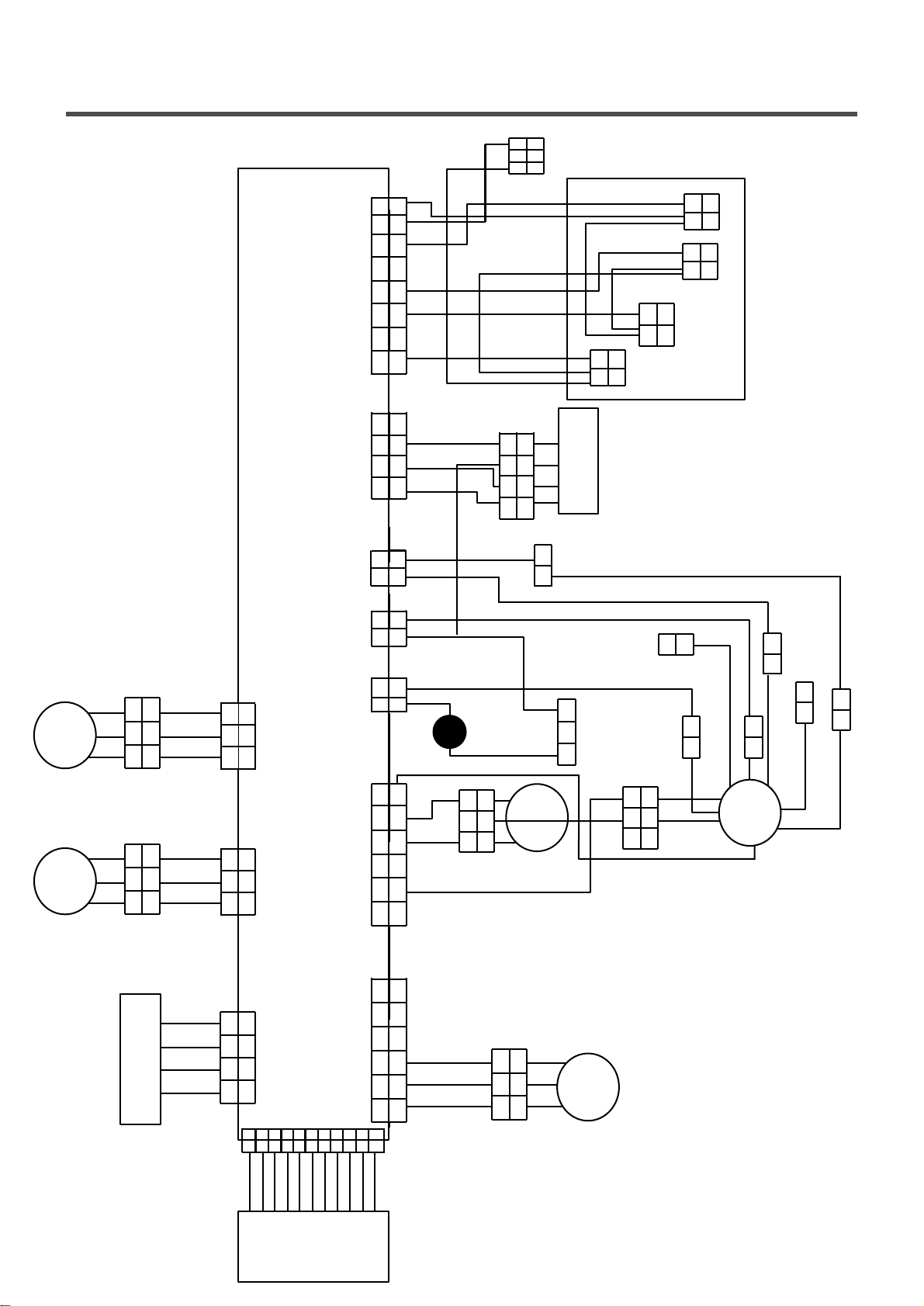

6. WIRING DIAGRAM/PCB LAYOUT

YL

BK

8

8

7

7

YL BK

BL

NA8NA4

PL

WH

123 456

123 456

GY

BKRD

1 2 3

1 2 3

Flow meter

BL

1 2

BK BK

GY

1 2

BL

BK

BK

BK BK

1 2

1 2

Pre

1 2

Filter Clean

WH

BK

1 2

1 2

BK

1 2

Steam

Main

Inlet V/V

1 234

1 234

YL/RD BL BK

GR

NA

1 2

1 2

BK

YL

BK

WH

YL

BK

WH

RD BL YL

YL3

123

123

BL6

Main PCBA

GY3

123

123

YL

BK

123

Fan Motor

Motor

123

BL YL

123

123

RD

RD

1 2

1 2

BR

1 2

1 2

BL YL

OR PL WHLBDR BS

123 456

123 456

BL

1 2 3 4

1 2 3 4

YL/RD

123

OR WH PL

Pressure

123

Door S/W

1 1

1

1

Earth

BLBR

Earth

3 2 1

Noise Filter

WH

Switch

WH SB

YL

1 1

2 312 3

1

1 1

BK

Earth

RD

1 1

RD

1 1

TH

Heater

1 1

NA5

GY6

1 234

Vibration Sensor

1 234

RD BL BK YL

1 101

10 11

CN11

1 2 3

1 2 3456

1 2 3456

YL BK OR

1 2 3 4 5 6 7 8 9

1 2 3 4 5 6 7 8 9

1 2 3

YL BK OR

Drain

Pump

Display PCBA

18

Page 19

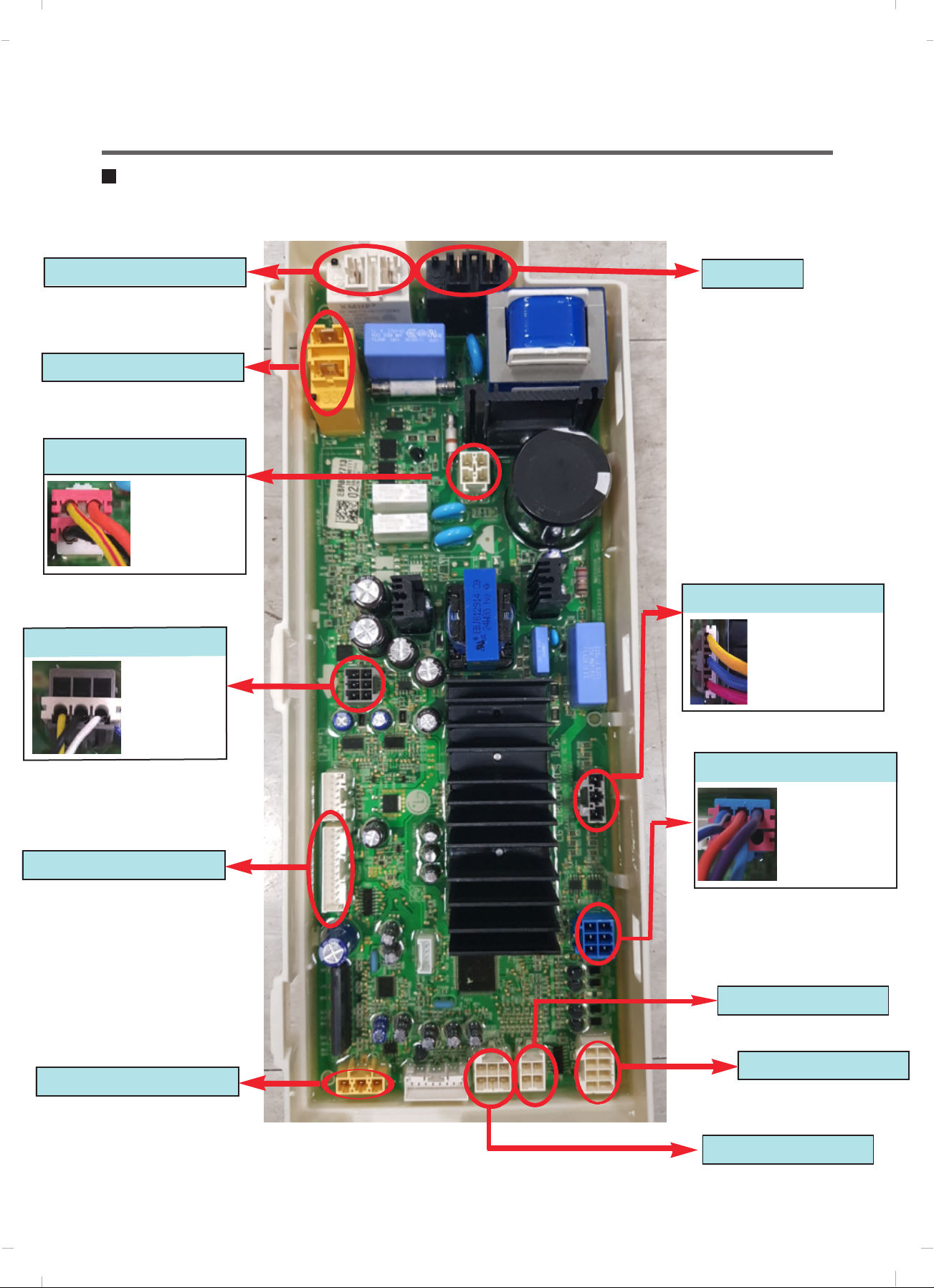

PCB Layout (Main)

Dry Heater

PCB POWER

Door Switch

yellow&red:door switch

black:door switch

orange:door switch

Drain motor

BLDC pump

white:U

black:V

yellow:W

Heater

Moter Stator Control

V-U/U-W

/W-V

→R:8~11Ω

Display

Dry Fan motor

Water sensor

blue&white:thermister

blue:common

violet:pressure switch

orange:pressure switch

Vibration Sensor

DC Valve

Thermistor

19

Page 20

7. TROUBLESHOOTING

7-1. CHECK BEFORE SERVICE

1

Before servicing ask the customer what the trouble is.

2

Check the adjustments. (Power supply :220-240V~, Removal of transit bolts etc..)

Check the troubles referring to the troubleshooting.

3

Decide service steps referring to disassembly instructions.

4

Then, service and repair.

5

After servicing, operate the appliance to see whether it works OK or NOT.

6

7-2. LOAD TEST MODE

1

Turn on, and touch ‘Wrinkle Care’ and ‘Delay End’

at the same time in 1 second.

2

The washer must be empty and the controls must be in the off state.

Press Power with above two buttons pressed and then buzzer will sound.

3

Press the Start/Pause button repeatedly to cycle through the test modes

4

0

1

2

3

4

5

6

7

8

9

10

11

Turns on all light and locks the door.

Tumble clockwise

Low speed spin

High speed spin

Inlet valve for prewash turns on.

Inlet valve for main wash turns on.

Inlet valve for hot water turns on.

Inlet valve for atomizing turn on.

Tumble counterclockwise

Heater turns on for 3 sec.

Drain pump turns on.

Off

Display StatusNumbers Check Point Remark

PGM Version Information

rpm(42~50)

rpm (60)

rpm (130~140)

Water level frequency

Water level frequency

Water level frequency

Water level frequency

rpm

Water temperature

Water level frequency

-

For Hot&Cold Model

20

Page 21

7-3. HOW TO CHECK THE WATER LEVEL FREQUENCY

Touch the Spin

Keeping touch, the digits indicate the water level frequency.

and Wrinkle Care button simultaneously.

21

Page 22

7-4. ERROR DISPLAY

If you press the Start/Pause button in error condition, any error except will disappear and the

machine will change into the pause status.

In case of

error is not resolved within 4 min., the power will turn off automatically and the error only will blink.

But in the case of

, , if the error is not resolved within 20 sec., and in case of all other errors, if the

, the power will not turn off.

ERROR SYMPTOM CAUSE

1

2

3

4

5

6

WATER INLET

ERROR

WATER OUTLET

ERROR

OVERFLOW

ERROR

PRESSURE SENSOR

S/W ERROR

DOOR OPEN

ERROR

UNBALANCE

ERROR

Not reached the water level(248) within 10 minutes

after water supplied or not reached to the preset

water level within 25 minutes.

Not fully drained within 10 minutes.

Water is overflowing (under 21.3kHz).

If " " is displayed, the drain pump operates

to drain the water automatically.

The pressure sensor switch is out of order.

In case of operating the reservation function or the

other function with door opened. Close the door,

then the error display is resolved.

The door switch is out of order.

The appliance is tilted.

Laundry is gatherd to one side.

Page 24

Page 26

Page 28

Page 29

Page 31

Page 25

THERMISTOR(HEATING)

7

ERROR

The THERMISTOR is out of order.

22

Page 33

Page 23

ERROR SYMPTOM CAUSE

8

9

10

11

MOTOR

FROZEN FAILURE

VIBRATION SENSOR

ERROR

LOCKED

ERROR

POWER

FAILURE

The connector in the LEAD WIRE ASSEMBLY is

not connected to the connector of STATOR

ASSEMBLY.

Reconnect or repair the connector.

Page 36

The washer experienced a power failure

Press the start/pause button

Supply warm water into the drum and unfreeze drain

hose and drain pump. Wet a towel in warm and

apply to supply hose.

Malfunction of vibration sensor

12

DRY HEATER

ERROR

• The Dry Heater is out of orde

• The Connector of the Dry Heater is not connecte

properly to the connector in the

Main PWB ASSEMBLY

• The Dry fan motor is out of orde

23

Page 24

7-5. TROUBLESHOOTING WITH ERROR

Symptom Check Point

1.INLET VALVE

ERROR

Steam&Condensate

Pre wash

1.Check Electric Wiring.

2.Check Inlet valve’s Resistance.

3.Check Inlet valve clogged.

4.Voltage of the inlet valve’s connector.

- LQC mode : Valve running with 13.6V ± 10%

- In normal cycle : Valve running with 7V±10%

Need to check 2s later from valve start to running

Filter Cleaan

Main wash

24

Page 25

Water Inlet Error (IE)

[Note] Environmental safety check list

1. No water tap leakage or freeze 4. No entanglement of water supply hose.

2. No water shortage. 5. No water supply hose leakage

3. The inlet filter is not cloggeed.

Is the water tap closed ?

YES

NO

When there is water in the tub,

is the water level frequency

over 26.0khz ?

YES

NO

Is the Connector connected correctly to the

and the Inlet Valve ? is the Harness alright ?

YES

Check the Water tap and open it fully.

Check the Air Chamber and the Tube (clogged)

Check the water level frequency again,

if it is over 26.2KHz, replace the Pressure switch.

Main PCB

NO

Reconnect or repair the Connector .

Or replace the Harness .

Is the resistance of each lnlet valve within 3.5 ~4.5 k ?

1

Pre Valve

1

1

Main Valve

2

2

YES

When the washing machine is started, is the inlet valve

operating?

NO

NO

Replace the Inlet Valve .

Replace the Main PCB .

25

Page 26

Unbalanced Error (UE)

Does the load lean toward one

side, or is the load a few items?

NO

Is the laundry mixed?

NO

YES

YES

The few items of clothing will clump together

and their weight will be in one place on the drum,

throwing the weight off during spin mode.

So add some laundry to overcome UE error.

And rearrange load to allow proper spinning.

Try rearranging the laundry in drum

Or the laundry is separated by size, type, and color.

Separate by size,

type and color

Is the washing machine installed

at an angle?

YES

Adjust the height of washing

machine to be kept horizontally.

( Page 7)

26

Page 27

Water Outlet Error (OE)

Is the drain hose kinked ?

YES

NO

Is the Pump filter clogged ?

YES

NO

Next Page

* How to disassemble and clean pump filter

Open the Cover by coin or

finger(only new model)

Drain water by removing the

hose cap.

Check drain hose for kink and straighten the Hose.

Drain Hose

Check & Clean Pump Filter.

This kind of accumulation on the drain filter not only

prevents proper drainage, but also will promote

bacteria growth and cause odors.

This drain filter should be cleaned once a month.

Disassemble the pump

filter by turning the filter

cap counterclockwise.

Pump Filter

Cover

Filter Cap

Filter clogged by foreign objectsAssemble & close cap

filter CapHose Cap

Clean the filter

27

Page 28

Is the Standpipe Height greater

than1.0 m above the floor?

NO

YES

Observe Standpipe Height requirements

of 1.0m maximum.

- Your washer will not be able to drain out

water adequately, if the standpipe exceeds 1.0 m.

In this case, water may flow back into the washer.

When there is no water in the

pump casing, is the water level

frequencyover 26.0khz ?

YES

Is the Connector connected correctly to

the Main PCB and the Pump Motor ?

Or is the Harness alright ?

YES

Or is the Impeller operating normally?

Binding

NO

NO

Check the Air Chamber and the Tube (clogged).

Check the water level frequency again, if it is over

25.5KHz, replace the If it is clogged, Pressure

switch.

Reconnect or repair the Connector .

Or replace the Harness .

YES

Replace the Pump Motor.

NO

Does the Pump motor start, when the spin mode

starts?

YES

If the drain hose blocked?

28

NO

YES

Replace the Main PCB .

Clean the drain hose.

Page 29

FE (Overflow Error)

Power off for 10sec. Then power on.

Is the water level over reference line and is the water level f requency under 21.3kHz?

* Water level frequency

- Touch and Hold 'Spin' & 'Turbo Wash'

simultaneously.

NO

Is water continuously

coming into the drawer?

YES

Replace the Main PCB.

Replace the Inlet Valve assembly.

NO

YES

Drain out the water and then

check the Air Chamber and the Tube (clogged).

If FE is displayed again,

then replace the Pressure Switch .

If FE is displayed again,

then replace the Main PCB .

29

Page 30

Pressure Sensor S/W Error (PE)

Is the Connector connected correctly to

the Main PCB and the Pressure Switch ?

Is the Harness alright ?

YES

Is the resistance of the Pressure Switch

out of range?

[Pin1 ~ Pin3]

21~23 )

NO

YES

Reconnect or repair the Connector .

Or replace the Harness .

Replace the Pressure Switch .

NO

Is the air chamber and the tube clogged?

NO

Replace the Main PCB .

YES

Check air chamber and remove foreign material.

30

Page 31

Symptom Check Point

1.PRESSURE

SENSORERROR(PE)

1.Check Electric Wiring.

2.Check Pressure sensor’s Resistance.

3.Check Air Chamber and Tubeclogged.

Pressure Sensor

(3)

(2)

(1)

BL6

31

Page 32

Door Open Error (dE2)

Is the door closed?

YES

Is the Door assembly in line with door switch ?

Scratch by Latch Hook

or

Touching

YES

NO

Does the Spring of Latch Hook actuate?

YES

NO

NO

Close the door fully.

Lift up & Close the door.

If the dE is displayed, Replace the Door Bracket.

Replace the Spring

Does the Door Switch operate as follows?

* Door Locking time : 1~8 sec.

1

Check the time between from

input the power to parts

move up, then Door locked.

*

Door Releasing time : 25~100 sec.

Check the time between from off the

power to parts

move down, then Door released.

1

1

Door Switch Error (dE1)

Is the Connector connected correctly to

the Main PCB and the Door Switch?

Is the Harness alright ?

YES

NO

NO

Replace the Door switch.

Reconnect or repair the Connector.

Or replace the Harness.

Is there clicking sound once or twice when the

START/PAUSE button is pressed to start the

cycle? No

Replace the MAIN PWB ASSEMBLY.

32

Page 33

Symptom Check Point

1. DOOR OPEN

ERROR(dE)

1.Check Electric Wiring.

2.Check latch hook sping.(Cracked)

3.Check Door switch’s Resistance.

4.Check Voltage of Door switch’s connector.

(5) (3)

(4) (2)

13.1V

33

Page 34

Thermistor (Heating) Error (tE)

Is the Connector connected correctly to

the Main PCB and the Thermistor and the Heater?

Is the Harness alright ?

Heater for Washing

NO

Is the resistance of the Thermistor out of range 44 ~

53 K at 25°C? (Page 17)

NO

YES

YES

Reconnect or repair the Connector .

Or replace the Harness .

Replace the Thermistor .

Is the resistance of the Heater out of range 24.5 ~

28.5 (for Washing) ? (Page 19)

NO

Replace the Main PCB .

[Note] Thermistor Spec

S

P

E

C

Temp

30 °C

40 °C

60 °C

70 °C

95 °C

105 °C

Resistance (k )

MIN

36.35 39.45 42.72

24.20 26.05 27.97

11.43 12.12 12.82

8.088 8.514 8.940

3.544 3.791 4.045

2.617 2.816 3.023

STD MAX

YES

Replace the Heater.

34

Page 35

Symptom Check Point

1.HEA TING ERROR(tE) 1.Check Electric Wiring.

2.Check Heater’s Resistance.

3.Check Thermistor’s Resistance.

4.Water Leaked into the Thermistor’s Connector.

Wash Heater

Heater

Wash Heater

(1) ~ (2)

Main

PWB

BK 3

YL 3

th

WH

BK

Resistance

[ ]

~

th

12 ~ 18

35

Page 36

Wash Thermistor

WH6

Thermistor

Wash

Thermistor

(1) ~ (2)

Main

PWB

NA3 4

NA3 5

th

~

th

Resistance

[k ]

39.5 86(30)

26.1 104(40)

12.1 140(60)

8.5 158(70)

3.8 203(95)

2.8 221(105)

Remarks

(℃)

℉

36

Page 37

Motor Locked Error (LE)

[Pre Check]

Gentle wash cycles, such as Perm Press, Delicates, Hand Wash, and Wool/Silk should only be used for smaller loads.

Because these cycles are more gentle in tumbling and spinning, putting too much in the drum can register an issue

with the motor. Remove items, reset unit and test with a Rinse/Spin cycle.

Press the Power button & Start / Pause button.

Does the Drum stop when the start/pause button is pr essed to start the cycle ?

Or Sometimes does the Drum rotateweakly (under 15rpm)?

YES

Is the Connector connected correctly to

the Main PCB and the Motor?

Is the Harness alright ?

YES

Disassemble the Rotor .

Is the Magnet of rotor cracked or broken?

NO

Is the resistance the same

betweenStator points?

V~U / U~W / W~V : 8~11

V U W

Magnet

V U W

NO

YES

NO

Reconnect or repair the Connector .

Or replace the Harness .

Replace the Rotor .

Replace the Stator.

Replace the Main PCB .

YES

37

Page 38

Symptom Check Point

1. NO POWER 1.Check Electric Wiring.

2.Check the Customer’s outlet.

3.Check Noise Filter.

4.Check LED on in Main PWB

Noi se Fi lter

(3)

Noise Filter

WH1

(1)

(3)

(1)

Resistance

[Ω]

(2)

(1)

(3)

(3)

(1)

RD1

WH1 (1) ~ RD1 (3) 0

WH1 (3) ~ RD1 (1) 0

38

Page 39

8.TROUBLESHOOTING WITHOUT ERROR CODES

PF (Power Failure or no power)

Is the Power Plug connected

firmly to the power outlet?

And is the supply voltage

220~240V AC?

YES

Is Multi-plug socket used ?

NO

Is the Connector connected correctly to

the Main PCB and the Noise Filter ?

Is the Harness alright ?

NO

YES

NO

Reconnect Power Plug firmly.

Check the fuse or

reset the circuit breaker.

Don’t use Multi-plug socket.

Use Single Plug socket for

washing machine.

Reconnect or repair the Connector .

Or replace the Harness .

Noise Filter PCB

YES

Is Red LED ON while power supplied ?

YES

Is the connectors connected

Correctly to the Display

PCB?

Main PCB

NO

YES

Check and replace Main PCB .

Check connectors otherwise.

Replace Display PCB .

39

Page 40

Vibration & Noise During Spin

Have all the Transit Bolts been removed?

Washer

Packing Support

NO

Remove the Transit Bolts

YES

Refer to INSTALLATION . (Page 7)

40

Page 41

Detergent & Softener does not flow in

Is water supplied?

YES

YES

Is detergent & softener put in

the correct compartment of the drawer?

Main Wash

(Powder)

Pre Wash

(Powder)

YES

Only

softener

NO

NO

Reference (Amount of Detergent & Softener)

Detergent

Refer to [Water Inlet Error (IE) ]

(page 23)

Put it in the Correct Position .

Softener

Is the Detergent caked or hardened ?

YES

Clean the drawer and dispenser.

NO!!

OK!!

Check point

41

Page 42

Water Leak

1. Water Leak from Dispenser

Is the Dispenser Tray Damaged or warped?

NO

Is detergent & softener put in

the correct compartment of the drawer?

Only

softener

YES

NO

Reference (Amount of Detergent & Softener)

Replace the Dispenser Tray .

Put it in the Correct Position .

Main Wash

(Powder)

YES

Is the Detergent caked or hardened ?

YES

Clean the drawer and dispenser.

Pre Wash

(Powder)

Detergent

Softener

NO!!

OK!!

Check point

42

Page 43

2. Water Leak from Dispenser

Are the gasket (seal)

and door cleaned regularly?

YES

Is the door or gasket damaged?

3. Unknown – Water on Floor

Are the inlet hoses loose or cracked/split?

Check!!

NO

YES

YES

Clean the periphery of Gasket and Door regularly.

Replace the damaged parts.

Replace the Inlet Hoses .

NO

Is the washer horizontal ?

YES

Are the drain filter and manual

drain hose open?

NO

NO

Adjust the height of washing machine to be kept

horizontally. (Page 7)

Turn the filter cap clockwise to close.

43

Page 44

Application Installation

Using the Wi-Fi Function

Search for the LG Smart ThinQ application

from the Google Play Store on a smart phone.

Follow instructions to download and install the

application.

Product Registration

Run the LG Smart ThinQ application on a

1

smart phone.

Create an account and sign in.

2

Select Register.

3

Select Front Load Washer.

4

Follow the instruction on the smart phone.

5

Communicate with the appliance from a smart

phone using the convenient smart features.

Using the Application

Select the appliance in the application.

1

Select the menu on the upper right side to

2

access settings and features.

Washer Cycle

Set or download any perferred cycle and operate

by remote control.

Tub Clean Coach

Check the appropriate Tub Clean period by

washing frequency.

NOTE

• To verify the Wi-Fi connection, check the Wi-Fi

icon(

• LG Smart

network connection problems or any faults,

malfunctions, or errors caused by network

connection.

•

The machine supports 2.4 GHz Wi-Fi networks

only

If the appliance is having trouble connecting

•

to the Wi-Fi network, it may be too far from

the router.Purchase a Wi-Fi repeater (range

extender) to improve the Wi-Fi signal strength.

•

The Wi-Fi connection may not connect or may

be interrupted because of the home network

environment.

•

The network connection may not work properly

depending on the internet service provide

•

The surrounding wireless environment can

make the wireless network service run slowly

The application is subject to change for

•

appliance improvement purposes without

notice to users.

) on the control panel is lit.

ThinQ is not responsible for any

.

r.

.

Energy Monitoring

Check the energy consupmtion of the recently

used cycles and monthly average.

Smart Diagnosis

This function provides useful information for

diagnosing and solving issues with the appliance

based on the pattern of use.

Settings

Various functions are available.

Push Alert

Turn on the Push Alerts to receive appliance

triggered even if the LG Smart ThinQ application

is off.

44

Page 45

Open Source Software Notice

Information

To obtain the source code under GPL, LGPL,

MPL, and other open source licenses, that is

contained in this product, please visit http://

opensource.lge.com.

In addition to the source code, all referred

license terms, warranty disclaimers and

copyright notices are available for download.

LG Electronics will also provide open source

code to you on CD-ROM for a charge covering

the cost of performing such distribution (such as

the cost of media, shipping, and handling) upon

email request to opensource@lge.com. This

offer is valid for three (3) years from the date on

which you purchased the product.

Declaration of Conformity

Hereby, LG Electronics European Shared

Service Center B.V., declares that this Washing

machine is compliant with the essential

requirements and other relevant provisions of

Directive 1999/5/EC. The complete Declaration

of Conformity may be requested through the

following postal address:

LG Electronics European Shared Service Center

B.V.

Krijgsman 1

1186 DM Amstelveen

The Netherlands

or can be requested at our dedicated DoC

website: http://www.lg.com/global/support/cedoc/

cedoc#

This device is a 2.4 GHz wideband transmission

system, intended for use in all EU member

states and EFTA countries.

For consideration of the user, this device should

be installed and operated with a minimum

distance of 20 cm between the device and the

body.

Wireless LAN Module

Model LCW-004

Frequency

Range

Output Power

(Max.)

45

IEEE 802.11 b : 17.82 dBm

IEEE 802.11 g : 17.72 dBm

IEEE 802.11 n : 16.61 dBm

2412~2472 MHz

Page 46

Using the Smart Diagnosis™

Function

Smart Diagnosis™ Through the

Customer Information Centre

Should you experience any problems with the

appliance, it has the capability of transmitting

data to a smart phone using the LG Smart ThinQ

application or via the phone to the LG Customer

Information Centre.

Smart Diagnosis™ can not be activated unless

the appliance is turned on by pressing the

Power button. If the appliance is unable to turn

on, then troubleshooting must be done without

using Smart Diagnosis™.

Smart Diagnosis™ Using a Smart

Phone

Open the LG Smart ThinQ application on the

1

smart phone.

Select the appliance and then the menu on

2

upper right side.

Select the Smart Diagnosis, then press

3

Start Smart Diagnosis button.

NOTE

• If the diagnosis fails several times, use the

following instructions.

Press the Power button to turn on the

1

washing machine. Do not press any other

buttons or turn the programme knob.

When instructed to do so by the call center,

2

place the mouthpiece of your phone close to

the Power button.

Max.

10 mm

Press and hold the Temp. button for 3

3

seconds, while holding the phone mouthpiece

to the icon or Power button.

Keep the phone in place until the tone

4

data transfer is displayed.

• For best results, do not move the phone

while the tones are being transmitted.

• If the call centre agent is not able to get an

accurate recording of the data, you may be

asked to try again.

Select the Try Again or Audible Diagnosis.

4

Follow the instructions on the smart phone.

5

Keep the phone in place until the tone

6

on the phone.

Once the countdown is over and the tones

5

have stopped, resume your conversation with

the call centre agent, who will then be able to

assist you using the information transmitted

for analysis.

NOTE

• The Smart Diagnosis™ function depends on

the local call quality.

• The communication performance will improve

and you can receive better service if you use

the home phone.

• If the Smart Diagnosis™ data transfer is poor

due to poor call quality, you may not receive

the best Smart Diagnosis™ service.

46

Page 47

WARNING

• Unplug the washing machine before cleaning

to avoid the risk of electric shock. Failure to

follow this warning may result in serious injury,

• Never use harsh chemicals, abrasive cleaners,

or solvents to clean the washing machine.

Cleaning Your Washing

Machine

Care After Wash

•

the inside of the door seal to remove any

moisture.

• Leave the door open to dry the drum interior.

• Wipe the body of the washing machine with a

dry cloth to remove any moisture.

Cleaning the Interior

• Use a towel or soft cloth to wipe around the

washing machine door opening and door glass.

• Always remove items from the washing

machine as soon as the cycle is complete.

Leaving damp items in the washing machine

can cause wrinkling, colour transfer, and odour.

• Run the Tub Clean programme once a month

(or more often if needed) to remove detergent

buildup and other residue

Cleaning the Water Inlet Filter

• Turn off the supply taps to the machine if the

washing machine is to be left for any length of

drain (gully) in the immediate vicinity.

•

icon will be displayed on the control panel

when water is not entering the detergent

drawer.

• If water is very hard or contains traces of lime

Cleaning the Exterior

Proper care of your washing machine can

extend its life.

Door:

• Wash with a damp cloth on the outside and

inside and then dry with a soft cloth.

Exterior:

• Immediately wipe off any spills.

• Wipe with a damp cloth.

• Do not press the surface or the display with

sharp objects.

clogged. It is therefore a good idea to clean it

occasionally.

Turn off the water tap and unscrew the water

1

supply hose.

2

47

Page 48

9. Par t i nspect i on

48

Page 49

49

Page 50

50

Page 51

51

Page 52

I

I

I

I

I

I

I

I

II II I

II II I

I I

II

I

I

I

I

I

52

Page 53

10. DISASSEMBLY INSTRUCTIONS

Remove the power cord from the outlet before disassembling or repairing the unit.

CONTROL PANEL ASSEMBLY

Screws

1

Unfasten the screws from the parts displayed

in the fig.

2

Disassemble the top plate assembly by sliding

it back and then lifting it up.

3

Pull the drawer panel assembly out.

4

Unfasten the screws from the parts displayed

in the fig.

5

Unfasten the screws from the parts displayed

in the fig.

6

Disconnect the wiring connectors between the

multi harness and the control panel assembly.

Disassemble the control panel assembly.

7

8

Disassemble the display PCB assembly from

the control panel assembly by unfastening the

screws.

*When re-assemble should fasten by screw

(4EA)

9

53

10

Disconnect the wiring connector between the

Display PCB assembly and the NFC

PCB assembly.

Page 54

PWB ASSEMBLY(MAIN)

1

Unscrew four screws.

2

Disassembly back cover assembly.

3

Unscrew the screw.

4

Pull the PWB assembly in direction of red

arrow.

DISPENSER ASSEMBLY

5

Disassembly PWB like the picture.

1

The plate assembly(Top) are disassembled.

2

Pull the drawer to arrow direction.

3

Two screws are unscrewed.

4

Clamp

5

Cutting cable ties and the ventillation hose

are disassembly on the dispenser

54

Page 55

INLET VALVE

1

Disconnect the wiring connector.

2

Remove the valve by two screws of the valve

holder.

When reconnecting the connector

1

VALVE (

Main Wash)

White/Black

DOOR

VALVE

VALVE (

VALVE

Rating : 12V

Resistant : 3.5~4.5 k

1

Open the door completely.

2

Remove the three screws from the hinge.

When removing the Door Assembly, it is

necessary to hold the Bracket that is inner of

the Cabinet Cover.

Removing method of remained water

2

(Steam)

Pre Wash)

3

4

(Filter Clean)

Purple/Black

Gray/Black

Blue/Black

Pull it out from hose.

First, prepare a bucket to put in the remained

water.

CAP(REMAING HOSE)

55

Page 56

CABINET COVER

1

The plate assembly(Top) is disassembled.

2

Pull out the drawer and unscrew 2 screws.

3

Lift the side the Control Panel Assembly and

pull it out

1

Two screws are unscrewed.

2

Push the hook( , ) below.

3

Unscrew the screws from the lower cover .

2

Disassembly cap cover and pump case.

3

Unscrew the screw from the CABINET COVER.

Remove gasket clamp and release gasket from

④

cabinet cover.

2

1

retfa LORTNOC ,YLBMESSA LENAP tuo hsuP

56

Page 57

4

Lift and separate the cabinet cover.

1

2

SWITCH ASSY, DOOR LOCK

NOTE :

When assembling the CABINET

COVER, connect the Door S/W connector.

1

Two screws are unscrewed and disassembly

cabinet cover.

2

The Door Lock S/W is disconnected form the

wiring connector and the strap.

57

Just check cut-off.

Check the operating time.

1

* Door Locking time : 1~8 sec.

Check the time between from

input the power to parts

move up, then Door locked.

*

Door Releasing time : 25~100 sec.

Check the time between from off

the power to parts

move down, then Door released.

1

1

Page 58

ROTOR ASSEMBLY, STATOR ASSEMBLY, FRICTION DAMPER

1

Remove the back cover.

2

After loosening the bolt, Rotor, pull out the

rotor.

1

Remove the 6 bolts from the stator.

2

Disconnect the 2 connectors.

Motor Stator

V ~ U (8~11 )

U ~ W (8~11 )

W ~ V (8~11 )

1

Remove the hinges (Damper) at the Tub.

2

The Hinge(Damper) at the base is pulled off by

pressing on the snaps at the sharp end.

3

The hinge at the base is pulled off.

(In directions of the arrow)

U V W

58

Page 59

Bellows

Pump

Hose

PUMP

1

Disassembly Top Plate, Control Panel,

Drawer Panel Assembly, Cabinet Cover

Assembly, Lower Cover Assembly

4

Remove pump outlet hose.

5

Remove tub pump bellows.

6

Remove cap(Remaining Hose).

7

Disconnect the wiring.

8

Three screws are unscrewed from the cabinet.

Remaining

Hose

HEATER

9

Remove the pump to arrow direction.

Rating : 26V

Resistant : 3.46~3.98

1

Loosen the nut.

2

Remove washing heater by pulling out.

< Heater for Washing>

Rating : 230V 2000W

Resistant : 24.5~28.5

CAUTION

When assembling the washing heater, insert

the heater to heater clip on the bottom of tub

and check the position of wire color.

59

Page 60

WHEN FOREIGN OBJECT STUCK BETWEEN DRUM AND TUB

1

Remove washing heater.

2

Remove the foreign object(wire,coin,etc) by

inserting long bar in the hole.

60

Page 61

How to disassemble Vibration sensor (Only for Vivace 550 model)

1

Open the top plate by removing 2ea screws.r.

2

Cut cable ties from tub cover.

3

Remove the vibration sensor housing from the Harness

4

Remove the vibration sensor from tub cover.

61

Page 62

How to disassemble Pressure sensor(for Vivace 460, 550 model)

1

Open the top plate by removing 2ea screws.r.

2

Remove the EPDM hose and connector from the pressure sensor.

3

Turn the pressure sensor 90 degrees counterclockwise. And remove it

※If there is no separate hole, the hook shape of pressure sensor

should be broken and separated.(Replace with new one)

※When assembling, the embossed shape of the hook

should be aligned in the circular hole.(For horizontal fixing)

62

Page 63

EXPLODE VIEW AND PART LIST

THE PART LIST OF CABINET ASSEMBLY

A154

A134

A103

A102

A104

A106

A150

A133

A440

A130

A151

A141

F120

A140

A152

A310

A110

A101

A100

A430

A410

A200

A135

A303

A276

A220

A485

A201

COLD (BLUE)

A450

Page 64

THE EXPLODED VIEW OF CONTROL ANEL &

DISPENSER ASSEMBLY

F300

F310

F225

F433

F462

F321

F160

F432

F430

F220

F441

F110

F210

Page 65

THE EXPLODED VIEW OF

F140

K411

K410

K655

DRUM & TUB ASSEMBLY

K350 K360 K143

K123

K122K121

K125

K320

K140

K510

K444

K141

K110

K111

K130

K150

K115

K320

K105

K410

K135

K610

K611

K349

K344

K340

K131

F468

K151

F461

K520 K540

F467

K530

K571

K570

K550

K572

Page 66

11-4. THE EXPLODED VIEW OF DRYER

M100

M110

M120

65

Page 67

59

P/No.: MFL69882928

Loading...

Loading...