Page 1

P/No.: MFL61988408

For U.K. Customer

CUSTOMER SERVICES Tel. : +44-(0) 844 847 LGLG(5454)

Fax. : +44-(0) 844 847 1413

LGEUK SERVICE WEB-SITE : http://www.lge.co.uk

Page 2

Washing Machine

OWNER’S MANUAL

F8056QD(1~9)/WD-8069(1~9)TDK

F1056QD(1~9)/WD-1069(1~9)TDK/WD-1039(1~9)TDK/F1056QDW(1~9)/

WF-7705WQD(1~9)

F1256QD(1~9)/WD-1239(1~9)TDK/WF-7704WQD(1~9)

F1456QD(1~9)/WD-1439(1~9)TDK

Thank you for buying a

LG Fully Automatic Washing machine.

Please read your owner’s manual carefully, it provides

instructions on safe installation, use and maintenance.

Retain it for future reference.

Record the model and serial numbers of your washing machine.

Page 3

2

roduct Features

P

ontents

C

Warnings....................................................................................3

Specifications.............................................................................4

Installation..................................................................................5

Care before washing................................................................11

Adding detergent .....................................................................12

Function ...................................................................................14

How to use washer ..................................................................15

Maintenance ............................................................................22

Troubleshooting guide .............................................................26

Terms of Warranty ...................................................................29

ˆ¡…–¯ˆ¿„

Direct Drive System

The advanced Brushless DC motor directly drives the drum without

belt and pulley.

Low noise speed control system

By sensing the amount of load and balance, it evenly distributes

load to minimize the spinning noise level.

Child Lock

The Child lock prevents children from pressing any button to

change the settings during operation.

More economical by Intelligent Wash System

Intelligent Wash System detects the amount of load and water

temperature, and then determines the optimum water level and

washing time to minimize energy and water consumption.

Built-in heater

Internal heater automatically heats the water to the best

temperature on selected cycles.

Protection against creases

With the alternate rotation of the drum, creasing in the laundry is

minimized.

Page 4

3

arnings

W

For your safety, the information in this manual must be followed to minimize

the risk of fire or explosion, electric shock, or to prevent property damage,

personal injury, or loss of life.

READ ALL INSTRUCTIONS AND EXPLANATION OF THE INSTALLATION BEFORE USE

WARNING!

❊ Do not push down the door excessively, when washer door open.

This could topple over the washer.

• Before installation, check exterior damages. If it has,

do not install.

• Do not install or store the washer where it will

be exposed to the weather.

• Do not tamper with controls.

• Do not repair or replace any part of the washer

or attempt any servicing unless specifically

recommended in the user-maintenance instructions

or published user-repair instructions that you

understand and have the skills to carry out.

• Keep the area underneath and around your

appliances free of combustible materials such as

lint, paper, rags, chemicals, etc.

• Close supervision is necessary if this appliance is

used by or near children. Do not allow children to

play on, with, or inside this or any other appliance.

• Keep small animals away from the appliance.

• Do not leave the washer door open.

An open door could entice children to hang on the

door or crawl inside the washer.

• Never reach into washer while it is moving. Wait

until the drum has completely stopped.

• The laundry process can reduce the flame retardant

of fabrics.

• To avoid such a result, carefully follow the garment

manufacturer’s wash and care instructions.

• Do not wash or dry articles that have been cleaned

in, washed in, soaked in, or spotted with

combustible or explosive substances (such as wax,

oil, paint, gasoline, degreasers, dry-cleaning

solvents, kerosene, etc.) which may ignite or

explode. Oil may remain in the tub after a whole

cycle resulting in fire during drying. So, do not load

oiled clothes.

• Do not slam the washer door closed or try to force

the door open when locked. This could result in

damage to the washer.

• When the machine runs high temperature, the front

door may be very hot. Don’t touch it.

• To minimize the possibility of electric shock, unplug

this appliance from the power supply or disconnect

the washer at the household distribution panel by

removing the fuse or switching off the circuit breaker

before attempting any maintenance or cleaning.

• When unplugging power cord, do not pull out by

grasping the cord. Otherwise, the power cord may

be damaged.

• Never attempt to operate this appliance if it is

damaged, malfunctioning, partially disassembled, or

has missing or broken parts, including a damaged

cord or plug.

• Before discarding an old machine unplug it. Render

the plug useless. Cut off the cable directly behind

the appliance to prevent misuse.

• When a product was under water, Please call

service center. The risk of electric shock and fire.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk of electric shock by providing a path

of least resistance for electric current. This appliance is equipped with a cord having an equipment-grounding conductor and grounding plug.

The plug must be plugged into an appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinance.

• Do not use an adapter or otherwise defeat the grounding plug.

• If you don’t have the proper outlet, consult an electrician.

IMPORTANT SAFETY INSTRUCTIONS

WARNING : To reduce the risk of fire, electric shock, or injury to persons when using

the washer, follow basic precautions, including the following:

SAVE THESE INSTRUCTIONS

WARNING :

Improper connection of the equipment-grounding conductor can result in risk of electric shock. Check with

a qualified electrician or serviceman if you are in doubt as to whether the appliance is properly grounded. Do not modify

the plug provided with the appliance - if it does not fit the outlet, have a proper outlet installed by a qualified electrician.

Page 5

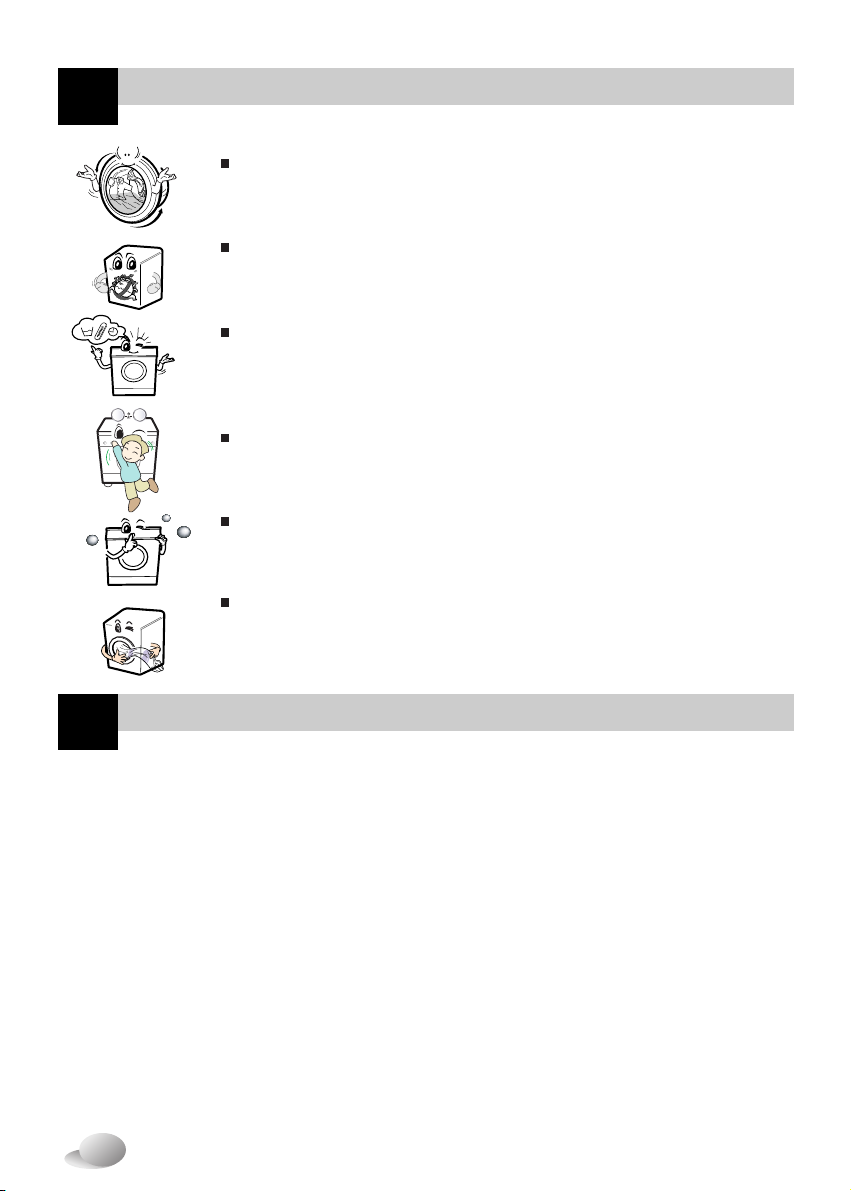

■ Name : Front loading washing machine

■ Power supply : 220-240V~,50Hz

■ Size : 600mm(W)

550mm(D) 850mm(H)

■ Weight/Max.Watt : 61kg / 2100W

■ Wash capacity : Refer to the Rating Label

■ Water consumption : 49 (7 /kg)

■ Permissible water pressure : 0.3-10kgf/cm

2

(30-1000kPa)

■ Spin speed :

No Spin/400/600/800 [F8056QD(1~9)/WD-8069(1~9)TDK]

No Spin/400/800/1000 [F1056QD(1~9)/WD-1069(1~9)TDK/

WD-1039(1~9)TDK/F1056QDW(1~9)/

WF-7705WQD(1~9)]

No Spin/400/800/1200 [F1256QD(1~9)/WD-1239(1~9)TDK/

WF-7704WQD(1~9)]

No Spin/400/800/1400 [F1456QD(1~9)/WD-1439(1~9)TDK]

The appearance and specifications may be varied without notice to raise the units quality.

4

pecifications

S

Spanner

Option : Hot/Cold(2EA)Inlet hose(1EA)

■

Accessories

Page 6

5

nstallation

I

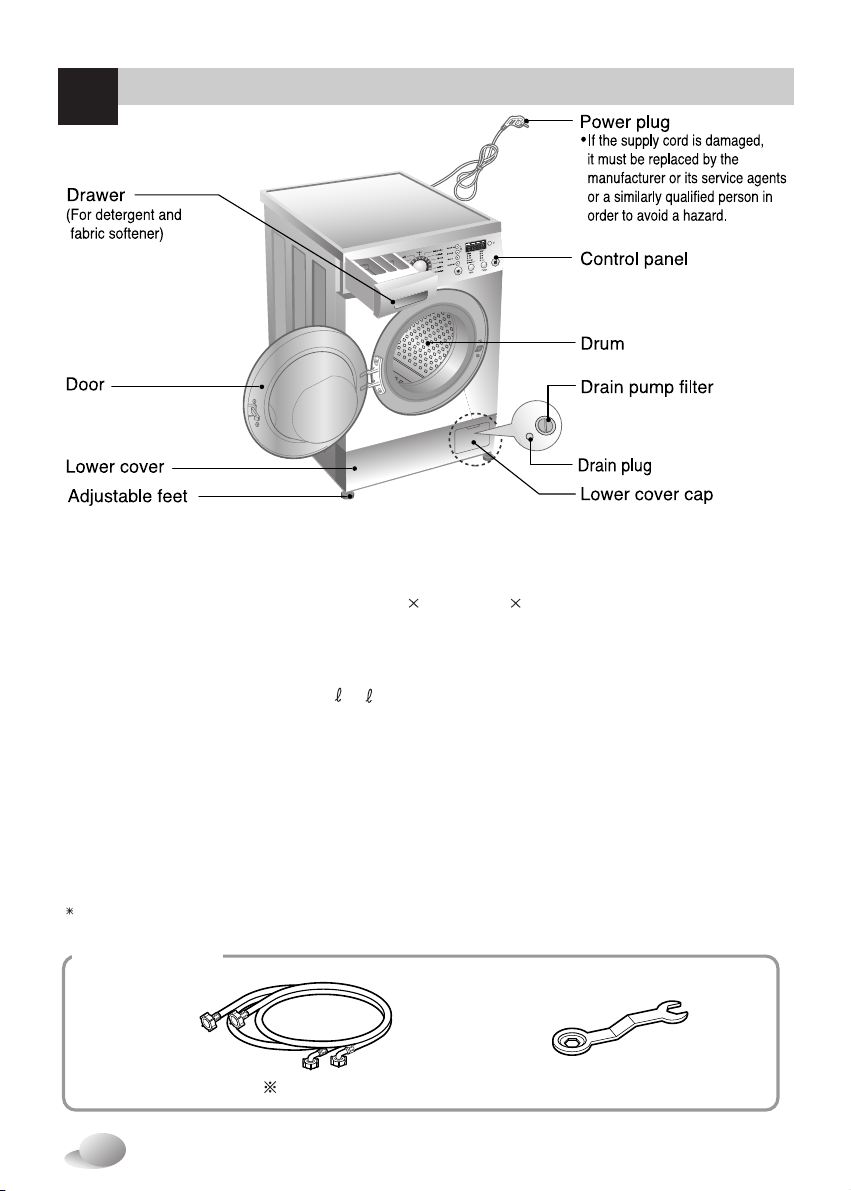

1. To prevent internal damage during

transport, the special 4 bolts are

locked. Before operating the washer,

remove

the bolts along with the rubber bungs.

• If they are not removed, it may cause

heavy vibration, noise and malfunction.

3. Take out the 4 bolts along with the

rubber bungs by slightly twisting the

bung. Keep the 4 bolts and the

spanner for future use.

• Whenever the appliance is transported,

the transit bolts must be refitted.

The appliance is fitted with transit bolts to prevent internal damage during transport.

• Packing and all transit bolts must be removed

before using the washer.

When unpacking the base, be sure to remove

the additional packing support in the middle

of the base packing.

2. Unscrew the 4 bolts with

the spanner supplied.

4. Close the holes with the caps supplied.

Transit bolts

Install or store where it will not be exposed to temperatures below freezing or exposed to the weather.

Properly ground washer to conform with all governing codes and ordinances.

The base opening must not be obstructed by carpeting when the washing machine is installed on a

carpeted floor.

In countries where there are areas which may be subject to infestation by cockroaches or other vermin,

pay particular attention to keeping the appliance and its surroundings in clean condition at all times.

Any damage which may be cause by cockroaches or other vermin will not be covered by the appliance

guarantee.

Removing transit bolts

Base Packing

Washer

Page 7

6

nstallation

I

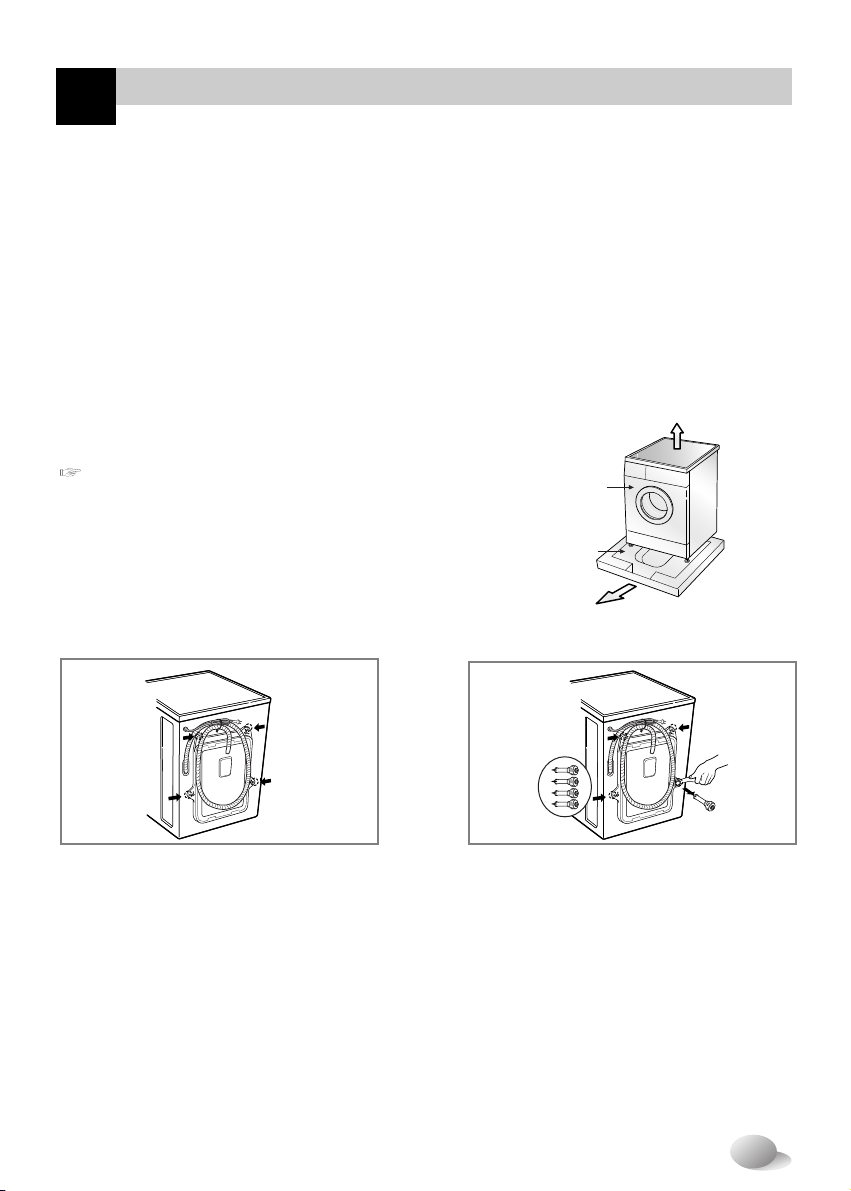

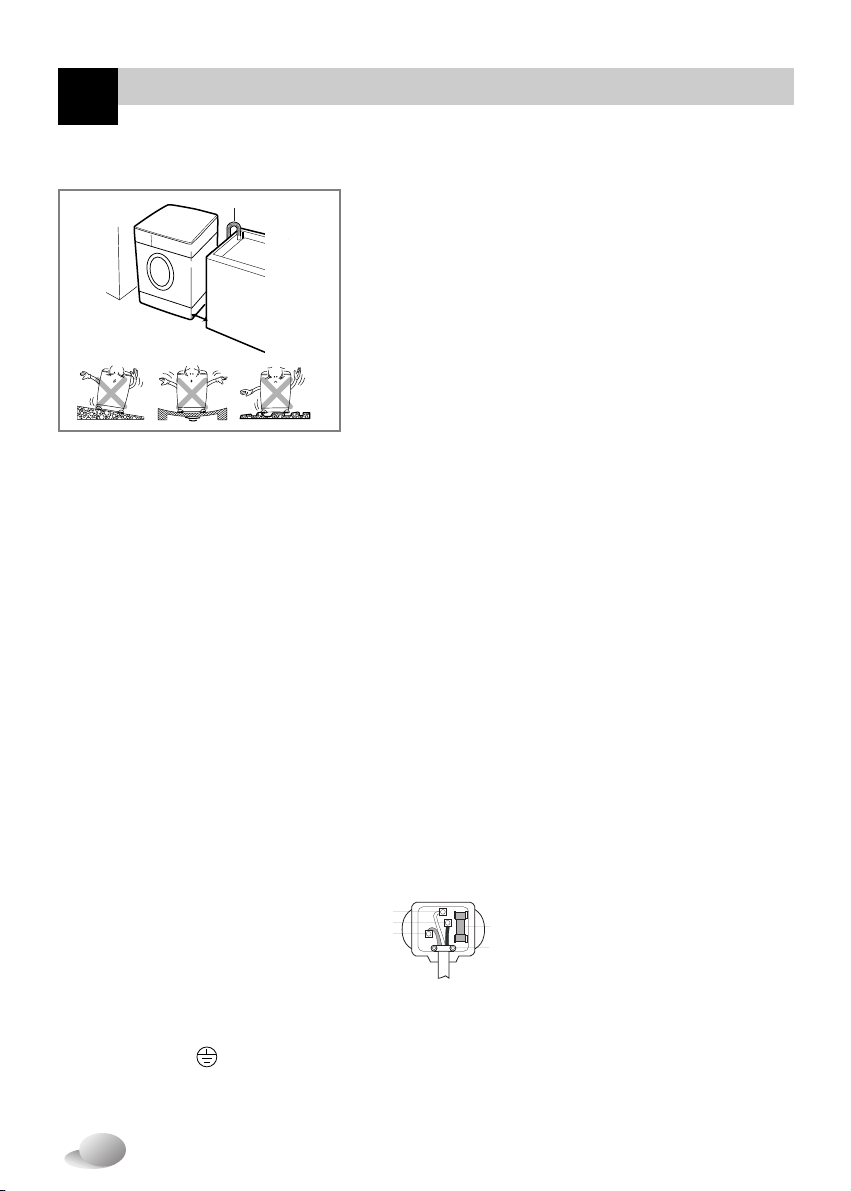

Laundry

Tub

Washer

approx.

2cm

Drain Hose

Level floor :

Allowable slope under entire washer is 1˚

Power outlet :

Must be within 1.5 meters of either side of location of

washer. Do not overload the outlet with more than one

appliance.

Additional Clearance :

For wall, door and floor modeling is required.

(10cm : rear /2cm:right & left side)

Do not place or store laundry products on top of washer at

any times.

They can damage the finish or controls.

Installation place requirement

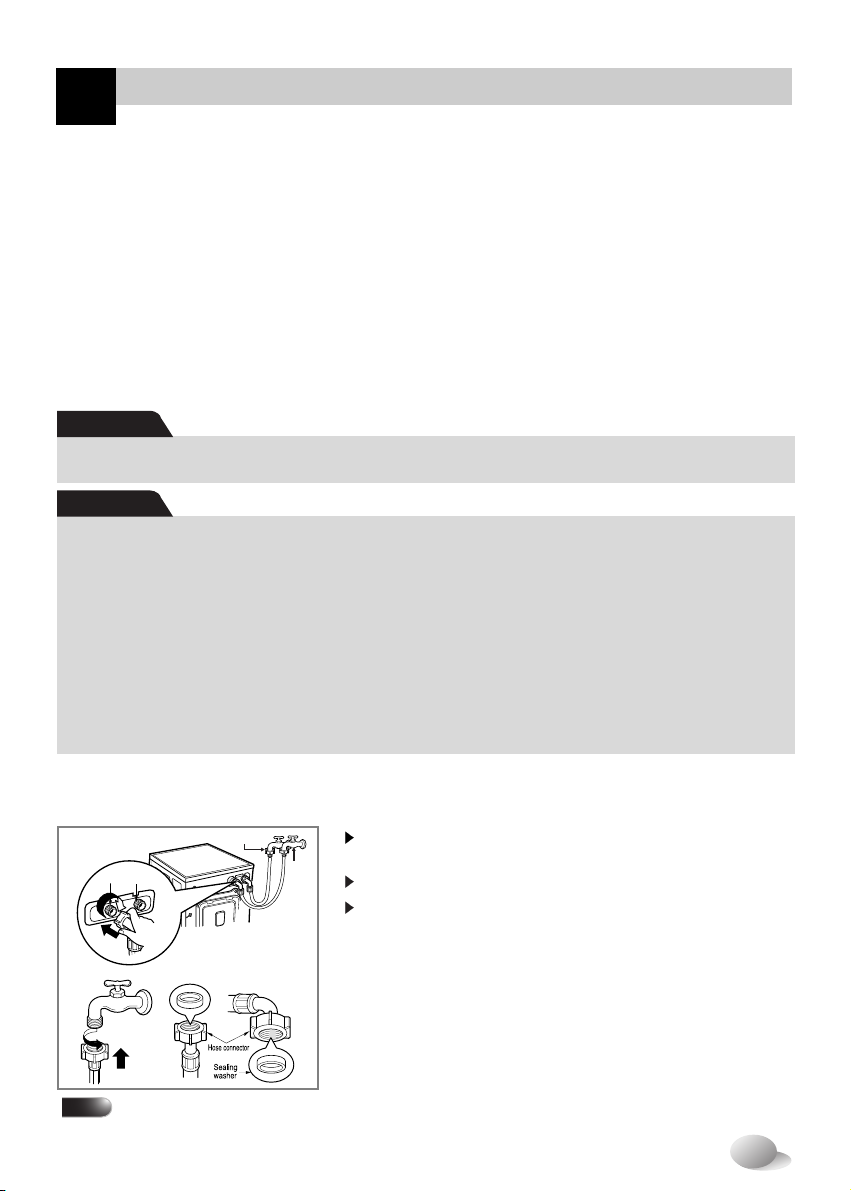

BS Plug Safety Details (For U.K. User)

IMPORTANT

THE WIRES IN THIS MAINS LEAD ARE COLOURED IN

ACCORDANCE WITH THE FOLLOWING CODE:

GREEN AND YELLOW: EARTH

BLUE: NEUTRAL

BROWN: LIVE

This appliance must be earthed

As the colours of the wires in the mains lead of this apparatus may not correspond with the coloured markings identifying

the terminals in your plug, proceed as follows:

The wire which is coloured Green and Yellow must be connected to the terminal in the plug which is marked with the letter E

or by the earth symbol or coloured Green or Green and Yellow.

The wire which is coloured Blue must be connected to the terminal which is marked with the letter N or coloured Black.

The wire which is coloured Brown must be connected to the terminal which is marked with the letter L or coloured Red.

If a 13 amp (BS 1363) plug is used, fit a 13 amp BS 1362 fuse.

Green and Yellow(Earth)

Brown(Live)

Blue(Neutral)

Cord

grip

Fuse

E

L

N

Positioning

Install the washer on a flat hard floor.

Make sure that air circulation around the washer is not impeded by carpets,rug etc.

• Never try to correct any unevenness in the floor with pieces of wood, cardboard or similar materials

under the washer.

• If it is impossible to avoid positioning the washer next to a gas cooker or coal burning stove,an

insulating(85x60cm) covered with aluminum foil on the side facing the cooker or stove,must be

inserted between the two appliance.

• The washer must not be installed in rooms where the temperature can drop below 0°C.

• Please ensure that when the washer is installed, it is easily accessible for the engineer in the event of

a breakdown.

• With the washer installed adjust all four feet using the transit bolt spanner provided ensuring the

appliance is stable, and a clearance of approximately 20mm is left between the top of the washer and

the underside of the work-top.

Page 8

7

nstallation

I

Hot water tap

Cold

Hot(option)

Cold

water

tap

Water supply pressure must be between 30kPa and 1000kPa

(0.3~10kgf/cm

2

)

Don’t strip or crossthread when connecting Inlet hose to the valve.

If the water supply pressure is more than 1000kPa, a decompression device

should be installed.

• Two rubber seals are supplied with the water inlet hoses. They are

used for preventing water leaks.

• Make sure the connection to taps is tight enough.

• Periodically check the condition of the hose and replace the hose if

necessary.

• Make sure that there is no kink on the hose and that it is not crushed.

■ Washing Machine is to be connected to the water mains using new hose-sets and old hose-sets

should not be used.

■ Connecting water supply hose

1. Do not use an extension cord or double adapter.

2. If the supply cord is damaged, it must be replaced by the manufacturer or its service agents or similarly

qualified person in order to avoid a hazard.

3. Always unplug the machine and turn off the water supply after use.

4. Connect the machine to an earthed socket in accordance with current wiring regulations.

5. The appliance must be positioned so that the plug is easily accessible.

• Repairs to the washing machine must only be carried out by qualified personnel. Repairs carried out by

inexperienced persons may cause injury or serious malfunctioning. Contact your local service center

• Do not install your washing machine in rooms where temperature below freezing may occur. Frozen hoses may burst

under pressure. The reliability of the electronic control unit may be impaired at temperatures below freezing point.

• If the appliance is delivered in the winter months and temperatures are below freezing : Place the washing

machine at room temperature for a few hours before putting it into operation.

■ Electrical connection

CAUTION concerning the Power Cord

Most appliances recommend they be placed upon a dedicated circuit; that is, a single outlet circuit

which powers only that appliance and has no additional outlets or branch circuits. Check the

specification page of this owner's manual to be certain.

Do not overload wall outlets. Overloaded wall outlets, loose or damaged wall outlets, extension cords,

frayed power cords, or damaged or cracked wire insulation are dangerous. Any of these conditions

could result in electric shock or fire. Periodically examine the cord of your appliance, and if its

appearance indicates damage or deterioration, unplug it, discontinue use of the appliance, and have

the cord replaced with an exact replacement part by an authorized servicer.

Protect the power cord from physical or mechanical abuse, such as being twisted, kinked, pinched,

closed in a door, or walked upon. Pay particular attention to plugs, wall outlets, and the point where

the cord exits the appliance.

CAUTION

NOTE

After completing connection, if water leaks from the hose, repeat the same steps. Use the most conventional type

of faucet for water supply. In case the faucet is square or too big, remove the spacing ring before inserting the

faucet into the adaptor.

The appliance is not intended for use by young children or infirm persons without supervision.

Young children should be supervised to ensure that they do not play with appliance.

CAUTION

Page 9

8

nstallation

I

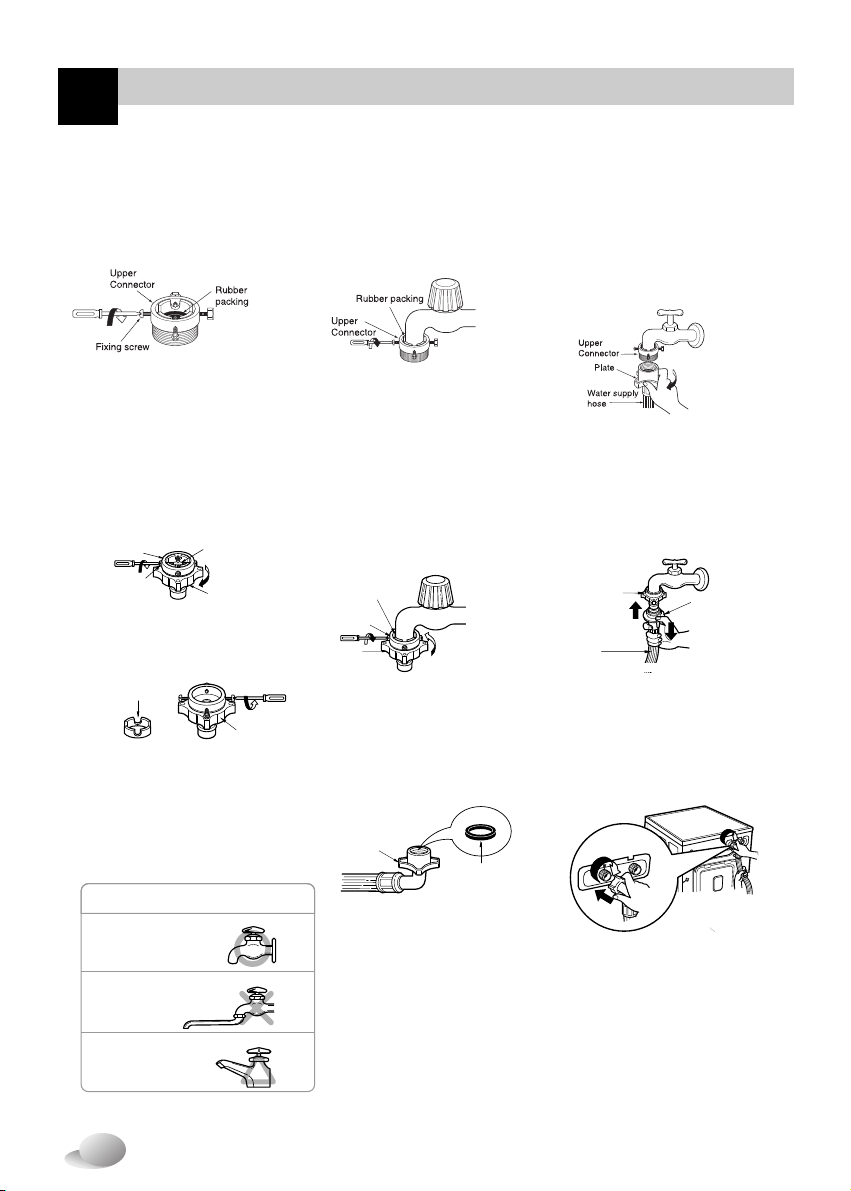

Normal Tap without thread & screw type inlet hose

Normal Tap without thread & one touch type inlet hose (Single inlet models)

1. Unscrew the fixing screw to

attach the tap.

2. Push the connector up till the

rubber packing is in tight contact

with the tap. Then tighten the 4

screws.

3. Push the water supply hose

vertically upwards so that the

rubber packing within in the

hose can adhere completely to

the tap and then tighten it by

screwing it to the right.

1. Untighten the upper connector

screw.

2. Push the upper connector up till

the rubber packing is in tight

contact with the tap. Then

tighten the 4 screws.

3. Connect the water supply hose

to the middle connector,

pushing the plate down.

• Make sure that there are no

kinks in the hose and that it is

not crushed.

• Make sure that the rubber seal

is inside the hose connector.

Upper

Connector

Rubber

packing

Middle

connector

Fixing screw

Guide plate

Connector

Rubber seal

Hose connector

Used the horizontal tap

Horizontal tap

Extension tap

Square tap

Rubber packing

Upper

Connector

Middle

connector

Plate

Upper

Connector

Water supply

hose

• In case the diameter of the tap is

large remove the guide plate.

• Turn the middle connector not

to have water leaked.

• To separate the water supply

hose from the middle connector

shut off the tap. Then pull the

inlet hose down, pushing the

plate down.

Page 10

9

nstallation

I

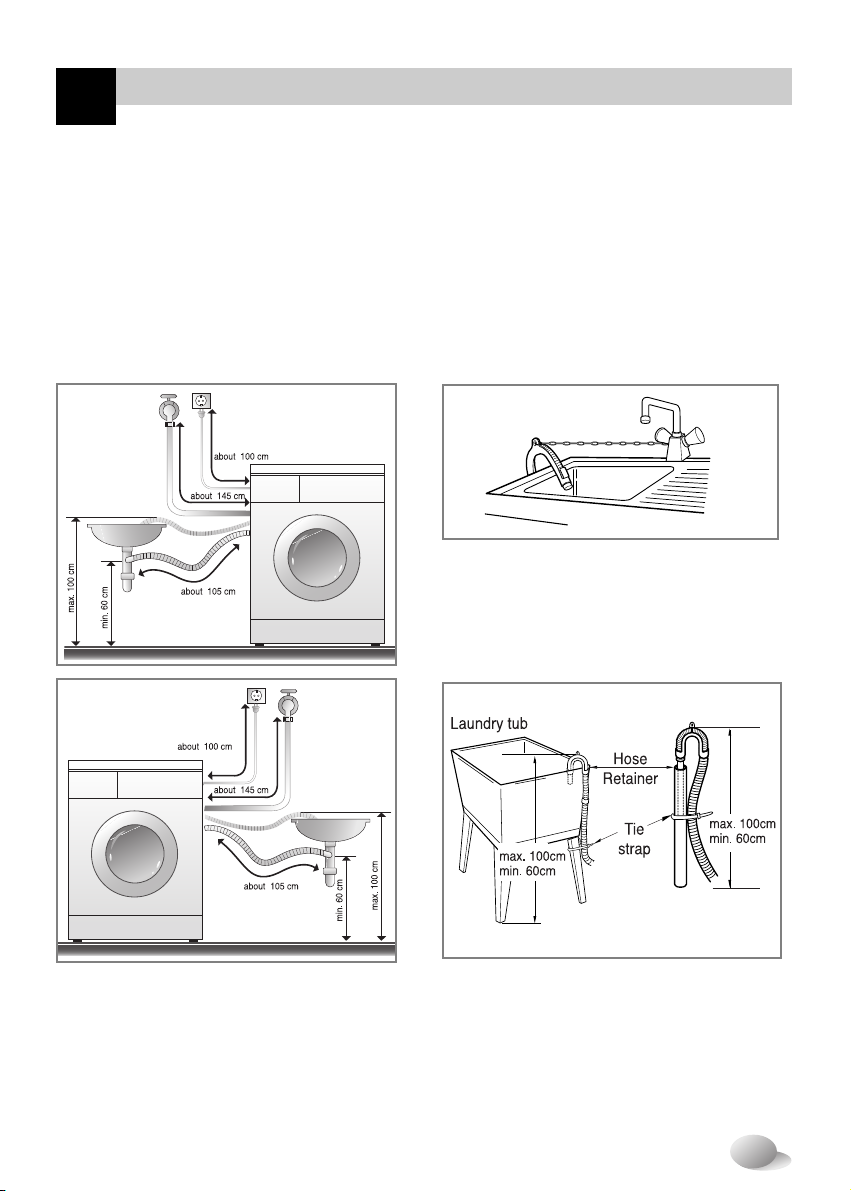

Installation of drain hose

• The drain hose should not be placed

higher than 100 cm above the floor.

• Proper securing of the drain hose will

protect the floor from damage due to

water leakage.

• When the drain hose is too long, do

not force back into the washer. This

will cause abnormal noise.

• When installing the drain hose sink,

secure it tightly with a string.

• Proper securing of the drain hose will

protect the floor from damage due to

water leakage.

This equipment is not designed for maritime use or for use mobile installations such as

caravans, aircraft etc.

Turn off the stopcock if the machine is to be left for any length of time (e.g. holiday),

especially if there is no floor drain(gully) in the immediate vicinity.

When disposing of the appliance, cut off the mains cable, and destroy the plug Disable the

door lock to prevent young children being trapped inside.

Packaging material (e.g. Films, Styrofoam) can be dangerous for children. There is a risk

of suffocation !

Keep all packaging well away from children

Page 11

10

nstallation

I

Level adjustment

Concrete floors

Wooden floors (Suspended floors)

1. Adjusting the washing machine level properly prevents excessive

noise and vibration.

Install the appliance on a solid and level floor surface, preferably in a

corner of the room.

2. If the floor is uneven, adjust the adjustable feet as required. (do not

insert pieces of wood etc. under the feet)

Make sure that all four feet are stable and resting on the floor and

then check that the appliance is perfectly level. (use a spirit level)

❊ Diagonal Check

When pushing down the edges of the washing machine top plate diagonally, the machine

should not move up and down at all. (Please, check both of two directions)

If machine rocks when pushing the machine top plate diagonally, adjust the feet again.

• The installation surface must be clean, dry and level.

• Install washer on a flat hard floor.

Tile floors (Slippery floors)

• Position each foot on the Tread Mate and level the machine to suit. (Cut Tread Mate into 70x70 mm

sections and stick the pieces on to the dry tile where machine is to be placed.)

Tread Mate is a self adhesive material used on ladders & steps that prevents slipping.

•

Wooden floors are particularly susceptible to vibration.

•

To prevent vibration we recommend you place rubber cups under each foot,

at least 15mm thick under the washer, secured to at least 2 floor beams with screws.

•

If possible install the washer in one of the corners of the room, where the floor is more stable.

Insert the rubber cups to reduce vibration.

You can obtain the rubber cups (p/no.4620ER4002B) from the LG spares dept.

Important!

•

Proper placement and levelling of the washer ensure long,regular and reliable operation.

•

The washer must be absolutely horizontal and stand firmly in position.

•

It must not “Seesaw” across corners under load.

•

The installation surface must be clean, free from floor wax and other lubricant coatings.

•

Do not let the feet of the washer get wet. If feet of the washer get wet, slipping may occur.

Rubber Cup

NOTE

Timber or suspended type flooring may contribute to

excessive vibration and unblance errors.

NOTE

In the case that the washing machine is installed on a raised

platform, it must be securely fastened in order

to eliminate the risk that it might fall off.

After the washer is level, tighten the lock nuts up towards of the base of

the washer. All lock nuts must be tightened.

Page 12

11

are before washing

C

1. Care Labels

Look for a care label on your clothes. This will tell you about the fabric content of your garment and

how it should be washed.

2. Sorting

To get the best results, Sort clothes into loads that can be washed with the same wash cycle.

Water temperature and spin speed and different fabrics need to be washed in different ways.

Always sort dark colors from pale colors and whites. Wash separately as dye and lint transfer can

occur causing discoloration of white etc. If possible, do not wash heavily soiled items with lightly

soiled one.

Soil (Heavy, Normal, Light) Separate clothes according to amount of soil.

Color (White, Lights, Darks) Separate white fabrics from colored fabrics.

Lint (Lint producers, Collectors) Wash lint producers and lint collectors

separately.

3. Caring before loading

Caring before washing

Before the first washing

Combine large and small items in a load. Load large items first. Large items should not be more than half

the total wash load.

Do not wash single items. This may cause an out-of-balance load. Add one or two similar items.

• Check all pockets to make sure that they

are empty. Items such as nails, hair clip,

matches, pens, coins and keys can damage

both your washer and your clothes.

• Close zippers, hooks and strings to

make sure that these items don’t

snag on other clothes.

• Pre treat dirt and stains by brushing a little

detergent dissolved in water onto stains like

collars and cuffs to help shift dirt.

Select a cycle (COTTON 60°C, add a half load of detergent) allow the unit to wash

without clothing. This will remove residues and water from the drum that may have been left

during manufacturing.

• Check the folds of the flexible gasket (gray) and

remove any small articles,if any.

• Check inside of the drum and remove any left

items in it for next wash cycle.

• Remove any clothing or items on the flexible

gasket to prevent clothing and the gasket

damages.

Page 13

12

dding detergent

A

• Main wash only

➔

• Pre Wash + Main Wash

➔

• Do not exceed the maximum fill line.

Close the dispenser drawer slowly.

Overfilling can cause early dispensing

of the fabric softener which could stain

clothes.

• Do not leave the fabric softener in the

detergent drawer for more than 2 days.

(Fabric softener could harden)

• Softener will automatically be added

during the last rinse cycle.

• Do not open the drawer when water is

supplied.

• Solvents(benzene, etc) are not

allowable.

1. The Dispenser Drawer

2. Adding Fabric Softener

Adding detergent and fabric softener

Do not pour fabric softener

directly on the cloths

NOTE

MAX

max

Page 14

13

dding detergent

A

• The detergent should be used according to the

instruction of the detergent manufacture.

• If too much detergent is used, too many suds

can occur and this will decrease the washing

result or cause heavy load to the motor.

• Use powder detergent only for the front

loading washer.

❇

If suds occur too much, pleas reduce the

detergent amount.

• Detergent usage may need to be adjusted

for water temperature, water hardness,

size and soil level of the load. For best

results, avoid oversudsing.

4. Water softener

• A water softener, such as Anti limescale

(Clagon) can be used to cut down on the

use of detergent in extremely hard water

areas. Dispense according to the amount

specified on the packaging.

First add detergent and then the water

softener.

• Use the quantity of detergent as for soft

water.

❋

Tips

Full load : according to

manufacturer’s recommendation.

Part load : 3/4 of the normal

amount.

Minimum load : 1/2 of full load.

• Detergent is flushed from the dispenser

at the beginning of the cycle.

1) Open the door and Tablets into the

drum.

3. Detergent dosage

5. Using the Tablets

MAX

max

2) Load the laundry into the drum.

3) Close the door.

Page 15

14

unction

F

The wool wash cycle of this machine has been approved by Woolmark for the washing of machine

washable Woolmark products provided that the products are washed according to the instructions

on the garment label and those issued by the manufacturer of this washing machine M0806.

Notes : Neutral detergent is recommended. The wool cycle features gentle tumbling and low-speed spin for

garment care.

Recommended courses according to the laundry type

Cotton Quick

Synthetic

Quick 30

Hand Wash /

Wool

Delicate

Blanket

Bio Care

Baby Care

White

Bulky

Cotton which is lightly soiled

Polyamide, Acryic, Polyester

Colored Laundry which is lightly

soiled fast.

“Hand Wash” marked laundry or

machine washable woolens

Delicate laundry easily

damaged (silk, curtains...)

Cotton bedding with filling, duvet,

pillow, blanket, sofa cover with

light filling.

For elimination of protein

stains

Laundry for infant

For elimination of remnant

detergent after boliling wash.

Thick laundry absorbing

much water(Jumper)

30˚C

(Cold, 40°C )

30˚C

(Cold, 40°C )

30˚C

(Cold, 40°C )

40˚C

(Cold, 30˚C, 60°C)

60˚C

(Cold, 30˚C, 40°C)

60˚C

(95°C)

60˚C

(95°C)

95˚C

(60°C)

95˚C

30˚C

(Cold)

Medic Rinse

Intensive

Pre Wash

Crease Care

Intensive

-

Rating

Rating

Rating

Less than

6.0 kg

Rating

Less than

2.0 kg

Rating

Less than

2.0 kg

Less than

3.0 kg

Less than

2.0 kg

Medic Rinse

Intensive

Crease Care

Program

Fabric Type

Proper Temp.

Option

Maximum Load

Cotton

Color fast gaments (shirts, night

dresses, pajamas...) and lightly

soiled white cotton(underwear...)

60˚C

(Cold, 30˚C,

40°C,95°C)

Medic Rinse

Intensive

Pre Wash

Crease Care

Rating

Water Temperature : Select the water temperature to the wash cycles.

Always follow garment manufacture’s care label or instructions when laundering.

Medic Rinse : For high effectiveness or more purity in rinse operation you can choose Medic Rinse option.

Pre Wash : If the laundry is heavily soiled, “Pre Wash” Course is recommended.

Intensive : When washing heavily soiled laundry you can increase effectiveness by choosing “Intensive” option.

Program setting with “Cotton

60˚C+

Intensive” option for test in accordance or in conformity with IEC60456 and

EN60456 .

Crease Care : If you want to prevent crease, select Crease Care button.

Page 16

15

ow to use washer

H

• Press the Power button to start.

• Press the Start/Pause button.

• Initial conditions

- Wash : main wash

- Rinse : 3 times

- Spin :

•

800 rpm

[F8056QD(1~9)/WD-8069

(1~9)

TDK]

•

1000 rpm

[F1056QD(1~9)/WD-1069(1~9)TDK/

WD-1039(1~9)TDK/F1056QDW(1~9)/

WF-7705WQD(1~9)]

•

1200 rpm

[F1256QD(1~9)/WD-1239(1~9)TDK/

WF-7704WQD(1~9)]

•

1400 rpm

[F1456QD(1~9)/WD-1439(1~9)TDK]

- Water temperature : 60˚C

- Program : Cotton

• Press the Power button to start.

• Select the conditions which you want to use,

by turning the program dial and pressing

each button.

For selecting the each conditions, please refer to

the page16~page21

• Press the Start/Pause button.

1. Cotton automatically selected

upon power on.

2. Manual Selecting

Page 17

16

ow to use washer

H

(1) Dial : Program

(2) Button : Start / Pause

(3) Button : Spin

(4) Button : Temperature

(5) Button : Power

(6) Button : Medic Rinse

(7) Button : Pre Wash

(8) Button : Intensive

(9) Button : Crease Care

(10) Child Lock

(11) Button : Time Delay

1. Power

2. Initial Program

Power

• Press the Power button to turn power on and off.

• To cancel the Time Delay function, the power

button should be pressed.

• When the Power button is pressed, the

washer is ready for Cotton program. And

the other initial conditions as follows.

• So, if you want to advance into the ashing

cycle without changing the program, just

press the Start/Pause button and then the

washer will proceed.

■

Initial program

•

[F8056QD(1~9)/WD-8069(1~9)TDK]

- Cotton Program / Main wash /

Normal Rinse / 800 rpm / 60˚C

•

[F1056QD(1~9)/WD-1069

(1~9)

TDK/

WD-1039(1~9)TDK/F1056QDW(1~9)/

WF-7705WQD(1~9)]

- Cotton Program / Main wash /

Normal Rinse / 1000 rpm / 60˚C

•

[F1256QD(1~9)/WD-1239(1~9)TDK/WF-7704WQD(1~9)]

- Cotton Program / Main wash /

Normal Rinse / 1200 rpm / 60˚C

•

[F1456QD(1~9)/WD-1439(1~9)TDK

]

- Cotton Program / Main wash /

Normal Rinse / 1400 rpm / 60˚C

• 13 programs are available according to

the laundry type.

• Lamp will light up to indicate selected

program.

• When Start/Pause button is pressed, the

Cotton program is automatically selected.

- By turning the Program dial, the program

is selected in order of

“ Cotton – Cotton Quick – Synthetic –

Blanket – Bulky – Quick 30 –

Rinse+Spin – Spin – Delicate – Hand

Wash/Wool – Bio Care – White – Baby

Care”.

Regarding to the laundry type for each

program Please refer to the page14.

Program

Page 18

17

ow to use washer

H

Option

• By pressing the

Option button, all

Option functions

may be selected.

4. Crease Care

• If you want to prevent crease, select this

button with spin speed.

The required lamp will light up for identification.

3. Intensive

• If the laundry is heavily soiled “Intensive”

option is effective.

• By selecting the Intensive option, the wash

time may be extended, depending on the

program selected.

2. Pre Wash

• If the laundry is heavily soiled, “Pre

Wash” course is effective.

1. Medic Rinse

• For high effectiveness or more purity in

rinse operation you can choose Medic

Rinse option.

Start/Pause

Detecting

• This Start/Pause button is used to start

wash cycle or pause the wash cycle.

• If temporary stop of wash cycle is

needed, press the Start/Pause button.

• When in Pause, the power is turned off

automatically after 4 minutes.

• NB. The door will not open before 1 to 2

minutes when Pause is selected,

or at the end of the wash cycle.

1. Start

2. Pause

• While the "Detecting" is shown in the display

the machine rotates slowly and detects how

many laundries are loaded in the drum. It will

take a few seconds.

• Available in Cotton and Synthetic.

Door Lock

• Lights whenever the door of the washer is

locked.

• The door can be unlocked by pressing the

Start/Pause button to stop the washer.

• The door can be opened after a short delay.

Page 19

18

ow to use washer

H

Child Lock

If you choose to lock the buttons on the control

assembly to prevent tampering this function

may be selected.

• Child Lock can be set by pressing the Medic

Rinse button and Pre Wash button

simultaneously. (About three seconds)

•

To deactivate Child Lock system, press

Medic Rinse

and Pre Wash buttons

simultaneously again. (About three seconds)

• To change to the desired program, whilst in

child lock mode.

1. Press both

Medic Rinse

and Pre Wash

together once again. (About three seconds)

2. Press the Start/Pause button.

3. Select the desired program and press the

Start/Pause button again.

• The child lock can be set at any time and it

can be deactivated only by using child lock

cancel process. Turning the power off and

operational errors will not affect child lock.

Change

the desired

program

Page 20

19

ow to use washer

H

Spin

• After selecting the spin

course, the spin speed

can be chosen by

pressing the spin button.

[F1256QD(1~9)/

WD-1239(1~9)TDK/

WF-7704WQD(1~9)]

[F1056QD(1~9)/

WD-1069(1~9)TDK/

WD-1039(1~9)TDK/

F1056QDW(1~9)/

WF-7705WQD(1~9)]

[F8056QD(1~9)/

WD-8069(1~9)TDK]

2. No spin

3. Rinse Hold

• Rinse Hold is selected by pressing the

spin button repeatedly this function

leaves clothes in the machine;

suspended in the water after a rinse

without entering into spin.

• To proceed through to a drain or spin,

once the rinse hold function is completed

using to Program dial and Spin button to

the required program.

(Spin)

The required lamp will light up for

identification.

• If No spin is selected, the washer stops

after draining water.

1. Spin selection

• Spin Speed is available according to

the program as follows.

F8056QD(1~9)/WD-8069(1~9)TDK

- Cotton, Rinse+Spin, Quick 30, Bio Care,

Bulky

Rinse Hold - No Spin - 400 - 600 - 800

- Delicate, Blanket, Baby Care, White, Cotton

Quick, Synthetic, Hand Wash/Wool

Rinse Hold - No Spin - 400 - 600

- Spin

No Spin - 400 - 600 - 800

F1056QD(1~9)/WD-1069

(1~9)

TDK/WD-1039(1~9)TDK/

F1056QDW(1~9)/WF-7705WQD(1~9)

- Cotton, Rinse+Spin, Quick 30, Bio Care,

Bulky

Rinse Hold - No Spin - 400 - 800 - 1000

- Delicate, Blanket, Baby Care, White, Cotton

Quick, Synthetic, Hand Wash/Wool

Rinse Hold - No Spin - 400 - 800

- Spin

No Spin - 400 - 800 - 1000

F1256QD(1~9)/WD-1239(1~9)TDK/WF-7704WQD(1~9)

- Cotton, Rinse+Spin, Quick 30, Bio Care,

Bulky

Rinse Hold - No Spin - 400 - 800 - 1200

- Delicate, Blanket, Baby Care, White, Cotton

Quick, Synthetic, Hand Wash/Wool

Rinse Hold - No Spin - 400 - 800

- Spin

No Spin - 400 - 800 - 1200

[F1456QD(1~9)/

WD-1439(1~9)TDK]

F1456QD(1~9)/WD-1439(1~9)TDK

- Cotton, Rinse+Spin, Quick 30, Bio Care,

Bulky

Rinse Hold - No Spin - 400 - 800 - 1400

- Delicate, Blanket, Baby Care, White, Cotton

Quick, Synthetic, Hand Wash/Wool

Rinse Hold - No Spin - 400 - 800

- Spin

No Spin - 400 - 800 - 1400

Page 21

20

ow to use washer

H

Water Temp.

• By pressing the Temp.

button, the water

temperature can be

selected.

- Cold

- 30˚C / 40˚C / 60˚C / 95˚C

• Water temperature can be selected

according to the program.

The required temperature lamp will light up

for identification.

For the more detailed information, please

refer to the page14.

Time Delay

Preparing washing before starting

“Time Delay”

- Turn on the water tap.

- Load laundry and close the door.

- Place the detergent and fabric softener in

the drawer.

• How to set “Time Delay”

- Press Power button.

- Turn the Program dial to select

the program you require.

- Press Time Delay button and set the

desired time.

- Press the Start/Pause button.

(“:” blinks.)

• If Time Delay button is pressed, “3:00” is

displayed. The maximum delayed time is

19 hours and the minimum time is 3 hours.

• Each pressing of the button advances on

time delay by one hour.

• To cancel the time delay, press the Power

button.

• Time Delay is ‘expected time’ from the

present to the completion of washing cycle

or selected process (Wash, Rinse, Spin).

• According to the condition of water supply

and temperature, the delayed time and the

actual washing time may vary.

Page 22

21

• If the machine encounters a fault during

operation, the associated fault will be

displayed.

“ ” : Water pressure sensing error

“ ” : Problem of overfilling water

“ ” : Door is not closed

“ ” : Over load in motor

“ ” : Over load in motor

“ ” : Water inlet trouble

“ ” : Drainage trouble

“ ” : Unbalanced load

“ ” : Water temperature trouble

“ ” : The washer experienced a

power failure.

If these error letters are displayed, please

refer to the troubleshooting page26 and

follow the guide.

Display

• When child lock is selected, the

“ ” is displayed.

• When time delay is selected, it shows

the remaining time to finish the selected

program.

• When washing cycle is completed,

“ ” is displayed on the “Multi

display”.

• During washing cycle, the remaining washing

time is displayed.

• Recommended program by manufacturer.

( ) : F1456QD(1~9)/WD-1439(1~9)TDK

- Cotton : around 1 hour and 50(55) minutes

- Synthetic :

around 1 hour and 15 minutes

- Cotton Quick : around 1 hour and 35 minutes

- Delicate : around 51 minutes

- Hand Wash/Wool : around 49 minutes

- Quick 30 : around 30 minutes

- Rinse+ Spin : around 18(23) minutes

- Baby Care : around 2 hours and 24 minutes

- Bio Care : around 2 hours and 22(27) minutes

- Bulky : around 59 minutes

- Blanket : around 1 hour and 40 minutes

- White : around 2 hours and 17 minutes

- Spin : around 13(18) minutes

• The washing time may vary by the amount of

laundry, water pressure, water temperature and

other washing conditions.

• If an unbalanced load is detected or if the suds

removing program operates, the wash time may

be extended.

(Max. increasing time is 45 minutes.)

1. Special function display

3. Completion of washing

4. Time left

2. Self diagnosis display

ow to use washer

H

Page 23

22

aintenance

M

The water inlet filter

- " " error message will blink on the control panel when water does not enter the

detergent drawer.

- If water is very hard or contains traces of lime deposit, the water inlet filter may

become clogged.

It is therefore a good idea to clean it from time to time.

❋ Before cleaning the washer interior, unplug the electrical power cord to avoid electrical

shock to avoid electrical shock hazards.

❋ When disposing of the appliance, cut off the mains cable, and destroy the plug Disable

the door lock to prevent young children being trapped inside.

1. Turn off the water tap.

2. Unscrew the water inlet hose.

3. Clean the filter using a hard bristle

brush.

4. Tighten up the inlet hose.

Page 24

23

aintenance

M

3

2

3

2

1

100

The drain pump filter

❋ The drain filter collects threads and small objects left in the laundry.

Check regularly that the filter is clean to ensure smooth running of your machine.

CAUTION First drain using the drain hose and then open the pump filter to

remove whatever any threads or objects.

Be careful when draining if the water is hot.

❋ Allow the water to cool down before cleaning the drain pump, carrying out

emergency emptying or opening the door in an emergency.

1. Open the lower cover cap ( ) by using

a coin.

Drain plug (

) to pull out the hose.

2. Unplug the drain plug ( ), allowing the

water to flow out. At this time use a

vessel to prevent water flowing on to the

floor. When water does not flow any

more, turn the pump filter (

) open to

the left.

3. Remove out any foreign material from

the pump filter (

).

4. After cleaning, turn the pump filter ( )

clockwise and insert the drain plug (

)to

the original place. close the lower cover

cap.

Page 25

24

aintenance

M

■

Dispenser drawer

❋ After a while detergents and fabric softeners leave a deposit in the drawer.

• It should be cleaned from time to time with a jet of running water.

• If necessary it can be removed completely from the machine by pressing the catch

downwards and by pulling it out.

• To facilitate cleaning, the upper part of the fabric softener compartment can be removed.

■

The drawer recess

❋ Detergent can also accumulate inside the recess which should

be cleaned occasionally with an old toothbrush.

• Once you have finished cleaning, replace the drawer and run a

rinse cycle without laundry.

■

The washing drum

• If you live in a hard water area, limescale may continuously build up in places where it cannot be

seen and thus not easily removed.

Over time the build up of scale clogs appliances, and if it is not kept in check these may have to

be replaced.

• Although the washing drum is made of Stainless steel, specks of rust can be caused by small

metal articles (paper clips, safety pins) which have been left in the drum.

• The washing drum should be cleaned from time to time.

• If you use descaling agents, dyes or bleaches, make sure they are suitable for washing machine

use.

❋ Descaler may contain chemicals that may damage part of your washing machine.

❋ Remove any spots with a stainless steel cleaning agent.

❋ Never use steel wool.

MAX

max

MAX

max

Page 26

25

aintenance

M

■

Cleaning your washer

1. Exterior

Proper care of your washer can extend its life.

The outside of the machine can be cleaned with warm water and a neutral non abrasive

household detergent.

Immediately wipe off any spills. Wipe with damp cloth.

Try not to hit surface with sharp objects.

❋

IMPORTANT: Do not use methylated spirits, diluents or similar products.

2. Interior

Dry around the washer door opening, flexible gasket and door glass.

Run washer through a complete cycle using hot water.

Repeat process if necessary.

■

Cold condition

If the washer is stored in an area where freezing may occur or moved in freezing

temperatures, follow these instructions to prevent damage to the washer:

1. Turn off water supply tap.

2. Disconnect hoses from water supply and drain water from hoses.

3. Plug electrical cord into a properly grounded electrical outlet.

4. Add 1gallon(3.8L) of nontoxic recreational vehicle(RV) antifreeze into an empty wash drum.

Close the door.

5. Set spin cycle and let washer spin for 1minute to drain out all water.

Not all of the RV antifreeze will be expelled.

6. Unplug electrical power cord, dry the drum interior, and close the door.

7. Remove dispenser drawer drain and dry excessive water from the compartments.

8. Store washer in an uprignt position.

9. To remove antifreeze from washer after storage, run empty washer

through a complete cycle using detergent. Do not add wash load.

NOTE

Remove hard water deposits using only cleaners labeled as washer safe.

Page 27

26

roubleshooting guide

❋ This washing machine is equipped with automatic safety functions which detect and diagnose faults at an

early stage and react appropriately

When the machine does not function properly or does not function at all, check the following points before

you contact your service provider.

Symptom Possible Cause Solution

Rattling and

clanking noise

Thumping sound

Vibrating noise

Water leaks.

Oversudsing

Water does not enter

washer or it enters

slowly

Water in the washer

does not drain or

drains slowly.

• Foreign objects such as coins or

safety pins maybe in drum or

pump.

• Heavy wash loads may produce

a thumping sound. This is usually

normal.

• Have all the transit bolts and

packing been removed?

• Are all the feet resting firmly on

the ground?

• Fill hoses or drain hose are loose

at tap or washer.

• House drain pipes are clogged.

• Water supply is not adequate in

area.

• Water supply tap is not

completely open.

• Water inlet hose(s) are kinked.

• The filter of the inlet hose(s)

clogged.

• Drain hose is kinked or clogged.

• The drain filter is clogged.

Stop washer and check drum

and drain filter.

If noise continues after washer

is restarted, call your authorised

service centre.

If sound continues, washer is

probably out of balance. Stop and

redistribute wash load.

If not removed during

installation. Refer to Installation guide

for removing transit bolts.

Wash load may be unevenly

distributed in drum. Stop washer and

rearrange wash load.

Check and tighten hose connections.

Unclog drain pipe. Contact plumber

if necessary.

Too much detergent or unsuitable

detergent may cause excessive

foaming which may result in water

leaks.

Check another tap in the house.

Fully open tap.

Straighten hose.

Check the filter of the inlet hose.

Clean and straighten the drain hose.

Clean the drain filter

T

Page 28

27

Washer does not start

Washer will not spin

Door does not open

Wash cycle time

delayed

• Electrical power cord may not

be plugged in or connection

may be loose.

• House fuse blown, circuit

breaker tripped,or a power

outage has occurred.

• Water supply tap is not turned

on.

❋ Check that the door is firmly

shut.

Make sure plug fits tightly in wall

outlet.

Reset circuit breaker or replace fuse.

Do not increase fuse capacity.

If problem is a circuit overload, have

it corrected by a qualified electrician.

Turn on water supply tap.

Close the door and press the

Start/Pause button. After pressing

the Start/Pause button, it may take

a few moments before the clothes

washer begins to spin. The door

must lock before spin can be

achieved.

Once started, the door can not be

opened for safety reasons.

Wait one or two minutes before

opening the door to give the electric

locking mechanism time to release.

The washing time may vary by the

amount of laundry, water

pressure, water temperature and

other usage conditions.

If the imbalance is detected or if the

suds removing program works, the

wash time shall be increased.

Symptom Possible Cause Solution

roubleshooting guide

T

Page 29

28

roubleshooting guide

Symptom Possible Cause Solution

T

• Water supply is not adequate in area.

• Water supply taps are not completely open.

• Water inlet hose(s) are kinked.

• The filter of the inlet hose(s) are clogged.

• Drain hose is kinked or clogged.

• The drain filter is clogged.

• Load is too small.

• Load is out of balance.

• The appliance has an imbalance detection

and correction system. If individual heavy

articles are loaded (ex. bath mat, bath robe,

etc.) this system may stop spinning or even

interrupt the spin cycle altogether.

• If the laundry is still too wet at the end of the

cycle, add smaller articles of laundry to

balance the load and repeat the spin cycle.

• Is the door opened?

• Water overfills due to the faulty water valve.

• Water level sensor has malfunctioned.

• Over load in motor.

• Over load in motor.

• The washer experienced a power failure.

Check another tap in the house.

Fully open tap.

Straighten hose(s).

Check the filter of the inlet hose.

Clean and straighten the drain hose.

Clean the drain filter.

Add 1 or 2 similar items to help

balance the load.

Rearrange load to allow proper

spinning

Close the door.

❋ If “ ” is not released, call for

service.

Unplug the power plug and call for

service.

Close the water tap.

Unplug the power plug.

Call for service.

Restart the cycle.

Page 30

29

erms of Warranty

T

What Is Not Covered:

• Service trips to your home to teach you how to use the product.

• If the product is connected to any voltage other than that shown on the rating plate.

• If the fault is caused by accident, neglect, misuse or Act of God.

• If the fault is caused by factors other than normal domestic use or use in accordance

with the owner's manual.

• Provide instruction on use of product or change the set-up of the product.

• If the fault is caused by pests for example, rats or cockroaches etc..

• Noise or vibration that is considered normal for example water drain sound, spin

sound, or warming beeps.

• Correcting the installation for example, levelling the product, adjustment of drain.

• Normal maintenance which recommended by the owner's manual.

• Removal of foreign objects / substances from the machine, including the pump and

inlet hose filter for example, grit, nails, bra wires, buttons etc.

• Replace fuses in or correct house wiring or correct house plumbing.

• Correction of unauthorized repairs.

• Incidental or consequential damage to personal property caused by possible defects

with this appliance.

• If this product is used for commercial purpose, it is not warranted.

(Example : Public places such as public bathroom, lodging house, training

center, dormitory)

If the product is installed outside the normal service area, any cost of

transportation involved in the repair of the product, or the replacement of a

defective part, shall be borne by the owner.

Disposal of your old appliance

1. When this crossed-out wheeled bin symbol is attached to a

product it means the product is covered by the European

Directive 2002/96/EC.

2. All electrical and electronic products should be disposed of

separately from the municipal waste stream via designated

collection facilities appointed by the government or the local

authorities.

3. The correct disposal of your old appliance will help prevent

potential negative consequences for the environment and

human health.

4. For more detailed information about disposal of your old

appliance, please contact your city office, waste disposal

service or the shop where you purchased the product.

Page 31

30

emo

M

Page 32

Loading...

Loading...