LG DVP-7772, DP-8800 Service manual

1-1

CONTENTS

SECTION 1 . . . . SUMMARY

SECTION 2 . . . . EXPLODED VIEWS

SECTION 3 . . . . ELECTRICAL

SECTION 4 . . . . REPLACEMENT PARTS LIST

1-2

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS ............. 1-3

SERVICING PRECAUTIONS ................................................................................................... 1-4

SPECIFICATIONS ...................................................................................................................... 1-5

1-3

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

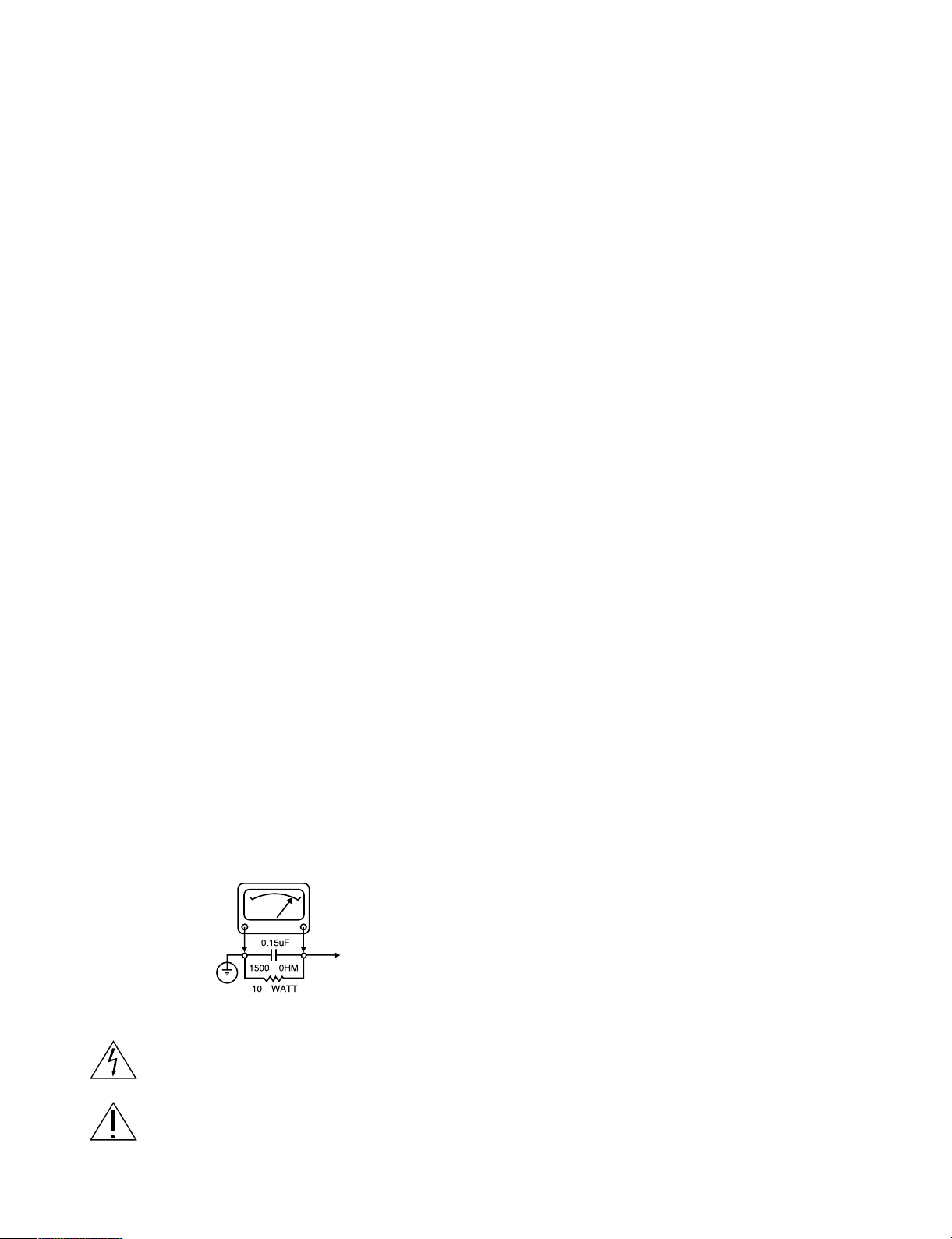

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER’S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V.’S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

1-4

SERVICING PRECAUTIONS

CAUTION : Before servicing the PORTABLE DVD covered

by this service data and its supplements and addends, read

and follow the

SAFETY PRECAUTIONS. NOTE : if unforeseen circumstances create conflict between the following

servicing precautions and any of the safety precautions in

this publications, always follow the safety precautions.

Remembers Safety First:

General Servicing Precautions

1. Always unplug the PORTABLE DVD AC power cord from

the AC power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this PORTABLE DVD

or any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this PORTABLE DVD and/or

any of its electrical assemblies unless all solid-state

device heat sinks are cerrectly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grouned-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a “anti-static” can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

1-5

SPECIFICATIONS

[DVD player]

Power supply DC 9.8 V (AC adapter terminal), DC 7.4 V (Battery)

Power consumption 25 W with battery

Weight 12.6 lbs (0.66 kg) (without battery pack)

External dimensions (W X D X H) 7.3 x 5.9 x 1.0 inches (186 x 150 x 25 mm)

Signal system PAL

Laser Semiconductor laser, wavelength 650 nm (DVD),

780 nm (CD)

Frequency range (audio) DVD linear sound: 48kHz sampling 4 Hz to 20 kHz

96kHz sampling 4 Hz to 44 kHz

Signal-to-noise ratio (audio) More than 95 dB

Dynamic range (audio) More than 95 dB

Harmonic distortion (audio) 0.08 %

Operating conditions Temperature: 41°F to 95°F, Operation status: Horizontal

[Connectors]

Video input/output (VIDEO In/Out) 1.0 V (p-p), 75 Ω, negative sync., ø3.5mm mini jack x 1

Audio output (optical audio) Optical connector (ø3.5mm) x 1

Audio input/output 2.0 Vrms(1 KHz, 0 dB), ø3.5mm mini jack x 1

(AUDIO In/Out, analog audio)

Earphone terminal ø3.5mm stereo mini jack x 1

[Liquid Crystal Display]

Panel size 7 inches (16:9)

Projection system TN color transmission

Driving system TFT active matrix

Resolution 800 x 480 (effective pixel rate: more than 99.99%)

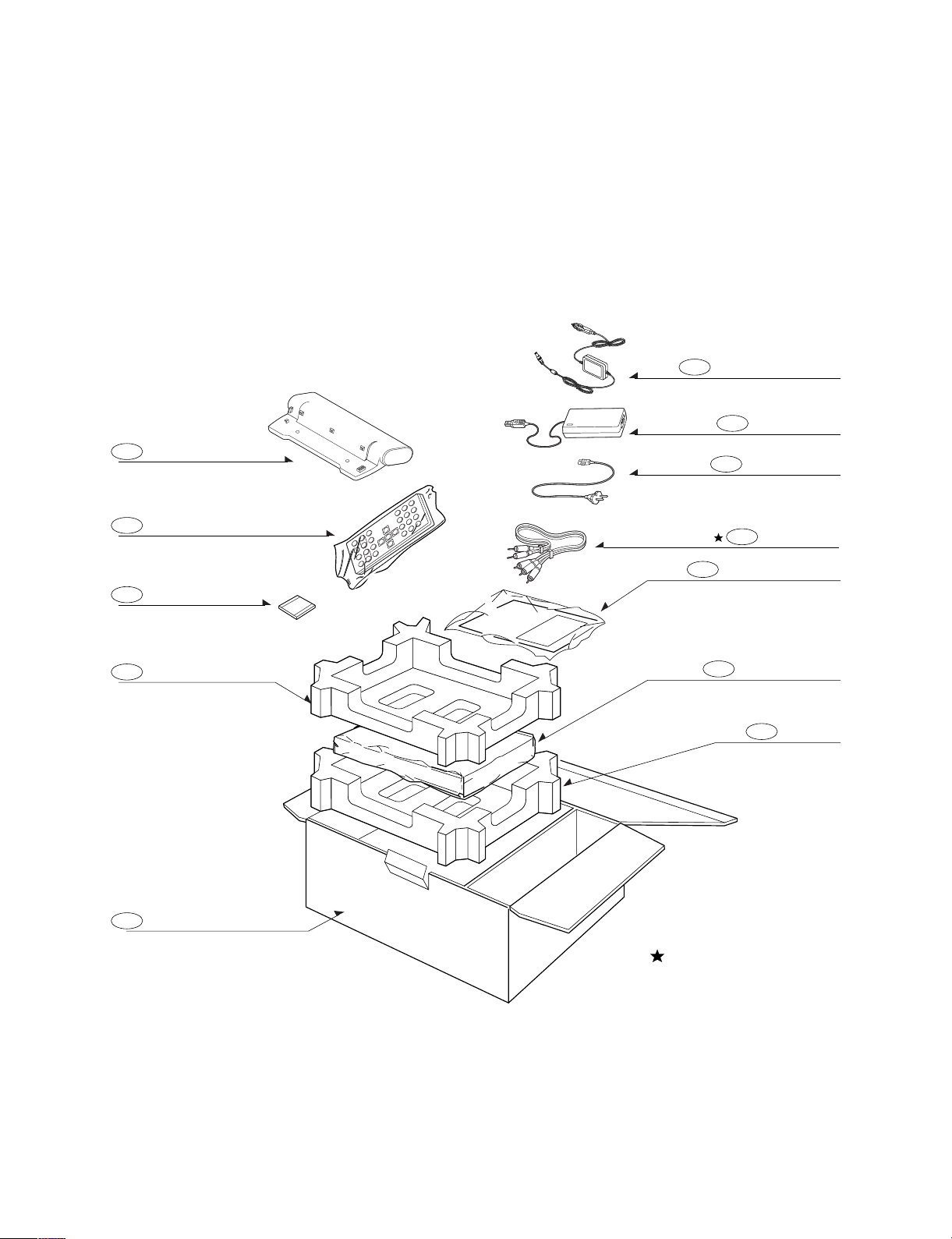

[Supplied Accessories]

• RCAAudio/Video cable . . . . . . . . . . . . . . . . . . . .1

• AC Adapter (AD-DP40) . . . . . . . . . . . . . . . . . . . .1

• Power Cord . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

• Battery Pack (DP-BT50) . . . . . . . . . . . . . . . . . . .1

• Remote control . . . . . . . . . . . . . . . . . . . . . . . . . .1

• Battery for Remote control (Lithium) . . . . . . . . . . .1

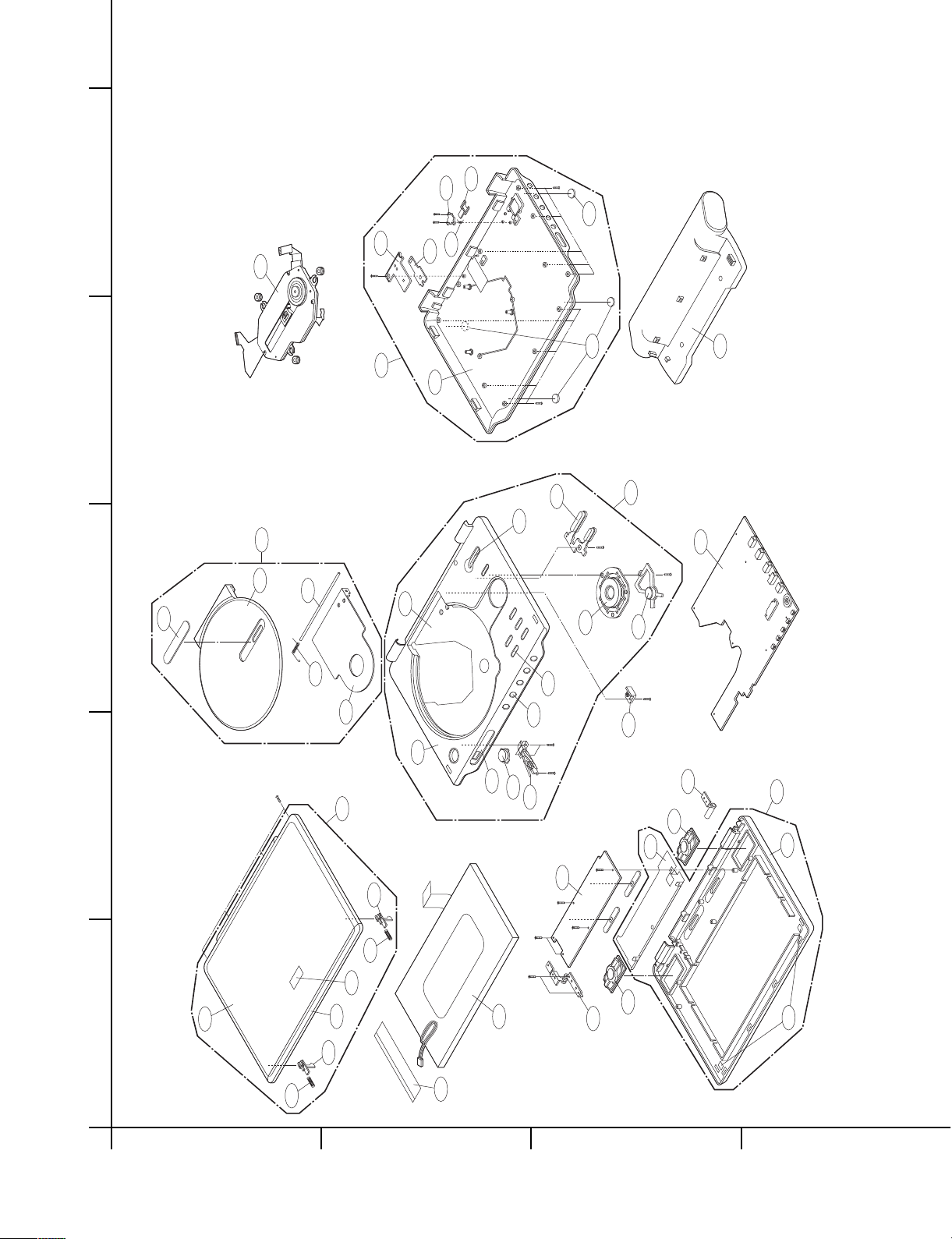

2-1

SECTION 2

EXPLODED VIEWS

CONTENTS

EXPLODED VIEWS .....................................................................................................................2-2

Cabinet and Main Frame Section ..............................................................................................2-2

Deck Mechanism Section ...........................................................................................................2-3

Packing Accessory Section .......................................................................................................2-4

2-2

EXPLODED VIEWS

• Cabinet and Main Frame Section

A

5

4

3

2

1

BCD

282

283

286

284

A00

A44

281

280

285

286

809

269

A45

A46

270

268

261

A43

293

294

295

296

264

267

292

260

250

254

A48

253

254

251

252

253

A41

262

290

265

263

266

A42

275

291

277

273

277

276

A49

272

274

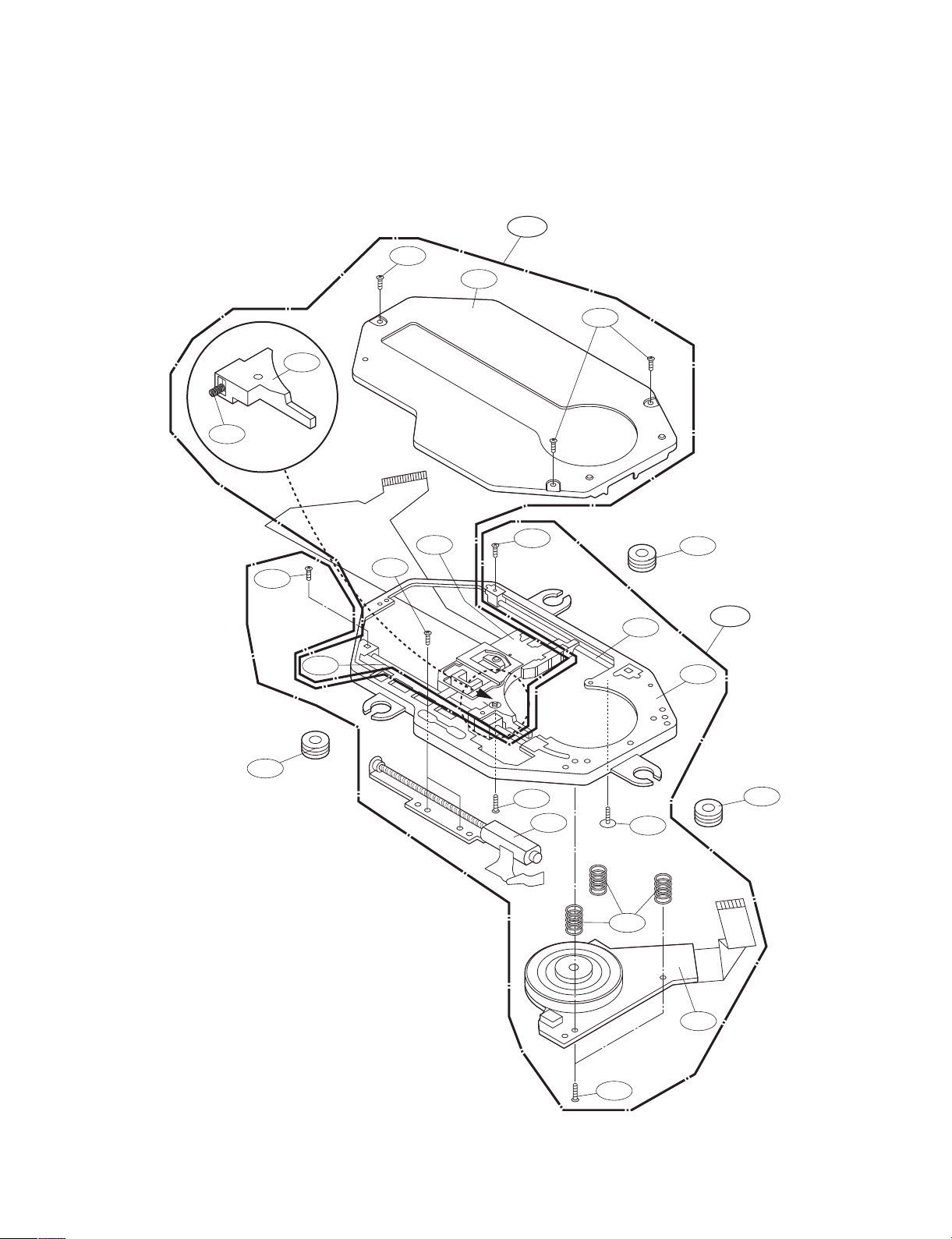

2-3

• Deck Mechanism Section

004

003

A01

430

001

430

433

021

002

431

005

433

433

014

015

012

434

021

A02

011

021

013

432

2-4

• Packing Accessory Section

PACKING SHEET

804

PACKING

OPTIONAL PARTS

803

OWNER’S MANUAL

801

REMOCON

900

R/C BATTERY

808

BOX CARTONX

802

PACKING

803

300

POWER CORD

830

AC ADAPTER

831

ADAPTER DC DC 12

814

PLUG ASS’Y

BATTERY

809

3-1

SECTION 3

ELECTRICAL

CONTENTS

LCD PART ................................................................................................................3-2

ELECTRICAL TROUBLE SHOOTING GUIDE ......................................................3-16

BLCOK DIAGRAMS ..............................................................................................3-25

CIRCUIT DIAGRAM ................................................................................................3-28

PRINTED CIRCUIT DIAGRAMS ............................................................................3-58

1) Power measuring

Measure each power after power supply.

CE809(+): -10V, CE812(+): +15V, C828: +7.5V, CE8F6: +5V, CE8H1: +9.8V

2) VCO frequency adjustment

Change the VR805 when there is no signal (video signal off) and adjust to 29.1MHz(error: +/-

0.03MHz) with a frequency counter.

Check the LCD operates at 29.68MHz when applying video signal with a frequency counter.

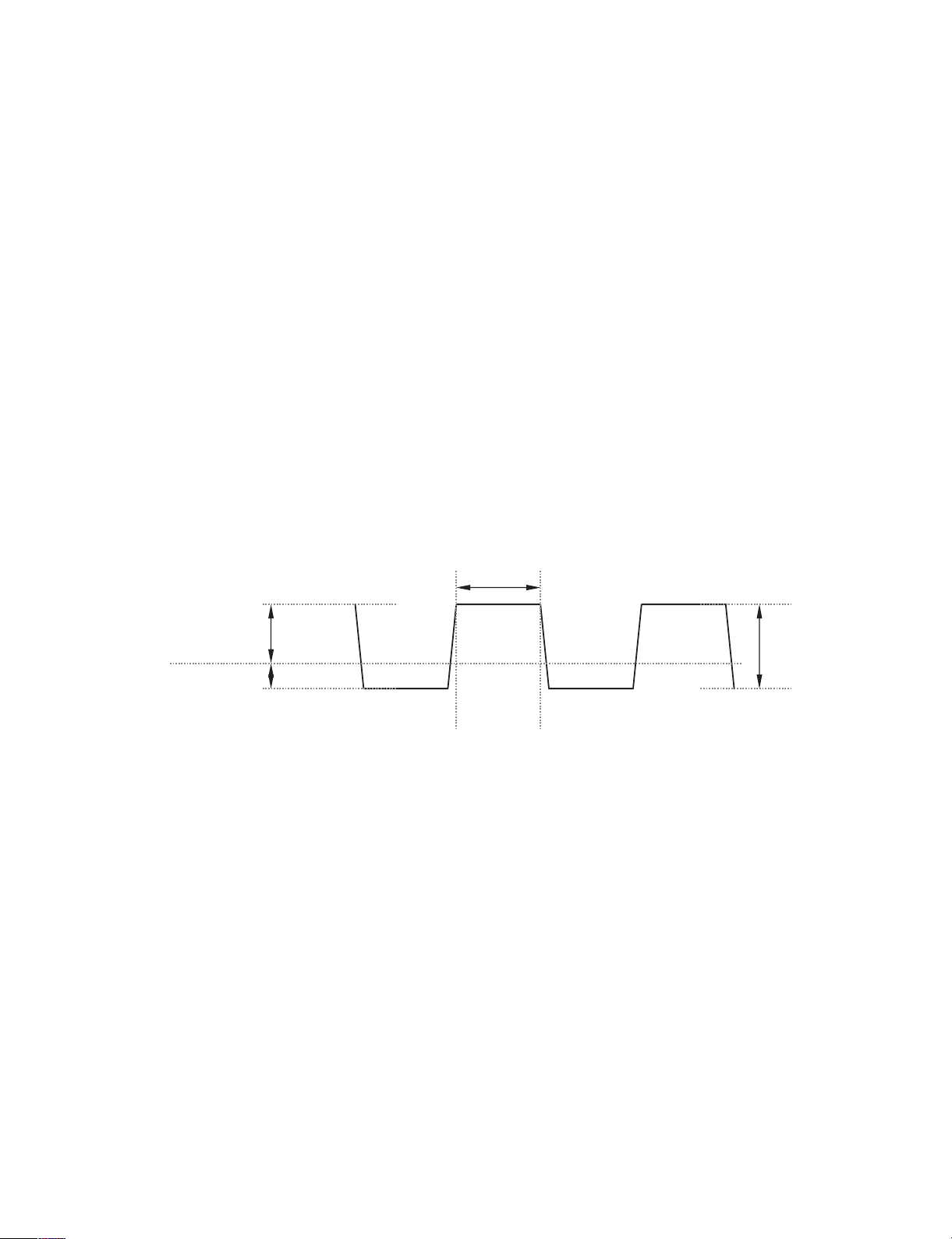

3) VCOM waveform adjustment

Adjust the VCOM level while changing the VR801 as below waveform by using the scope in the

CE814.

3-2

Vcom Waveform

63.5

3Vp-p

GND

LCD PART

GND

4.6V

0.7V

63.5

µs

5.5.3Vp-p

4) Adjustment of screen center position

Change and adjust the VR802 so that the middle vertical line between Green and magenta is

located at the center of the LCD Panel on the Full color bar screen.

5) Removal of horizontal line noise

Remove a thick horizontal line noise while changing the VR803 and monitoring the logo screen.

Remove a thin horizontal line noise while viewing the logo screen after removing a thick horizontal line noise via the VR803.

3-3

Full color bar screen

3-4

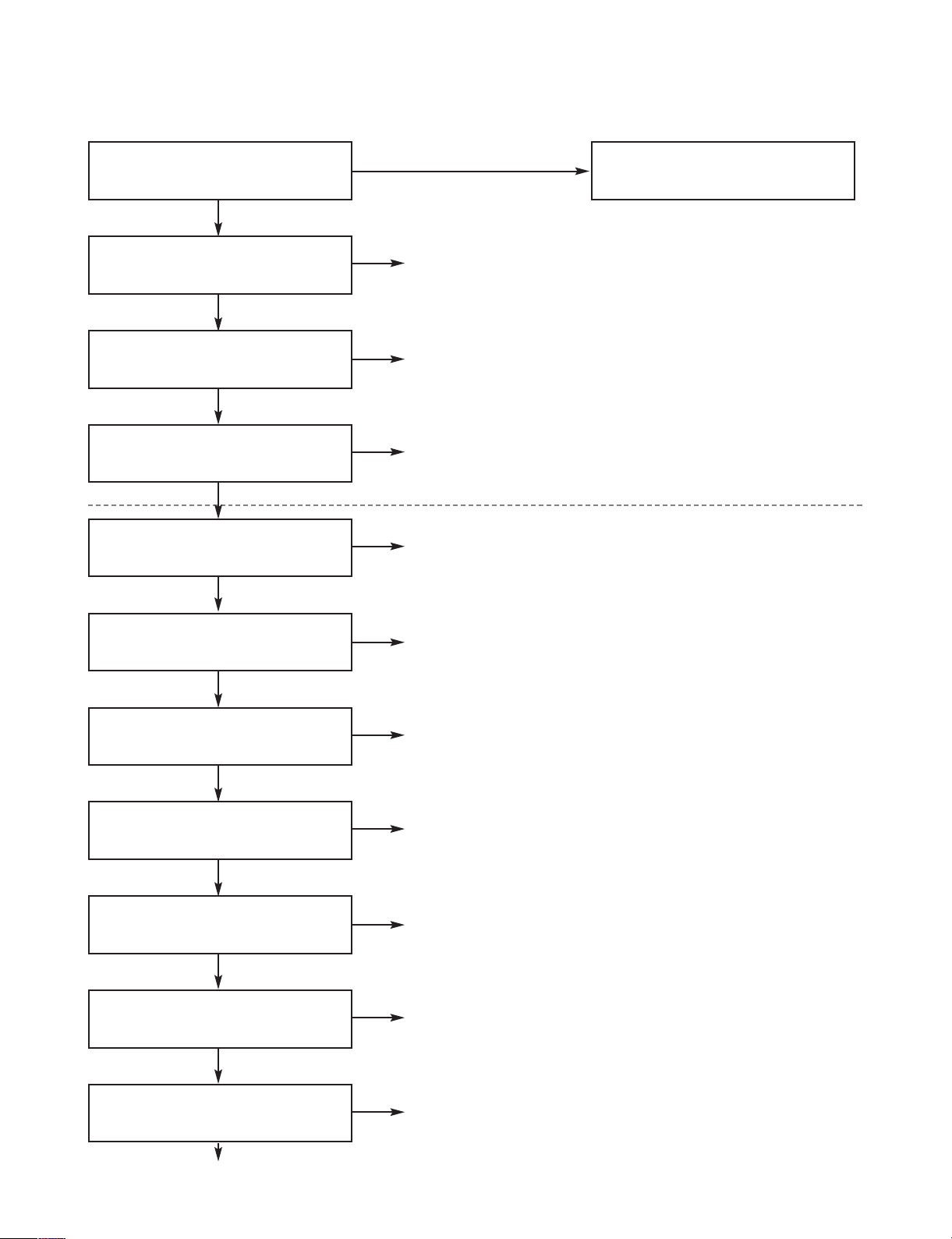

DESPLAY CONDITION? INVERTOR ABNORMAL

appear shadow form interference

in black background

There is only bright light.(LCD B/D abnormal)

FUSE Replace

IC8F1, IC8F2 Check and Replace

T801, D8F1, D8F2, D8F3 Check

Main B/D on located

IC8F3 Check and Replace

A/V IN S/W Check

X801, C832 Replace

IC801, IC803 Check and Replace

IC805 Check and Replace

D801, L819, IC804 VCO Check and Replace

Q810 Check and Replace

FUSE(F801)Normal?

Q8F1 Normal operate?

7.5V, 15V, -10V Normal?

+5V Normal?

Y/C Display signal?

X801 operate?

R.G.B signal output?

VCOM signal?(6.5Vpp)

VCO Normal operate?

H/V SYNC?

YES

YES

NO

NO

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

LCD TROUBLE SHOOTING GUIDE(1/2)

3-5

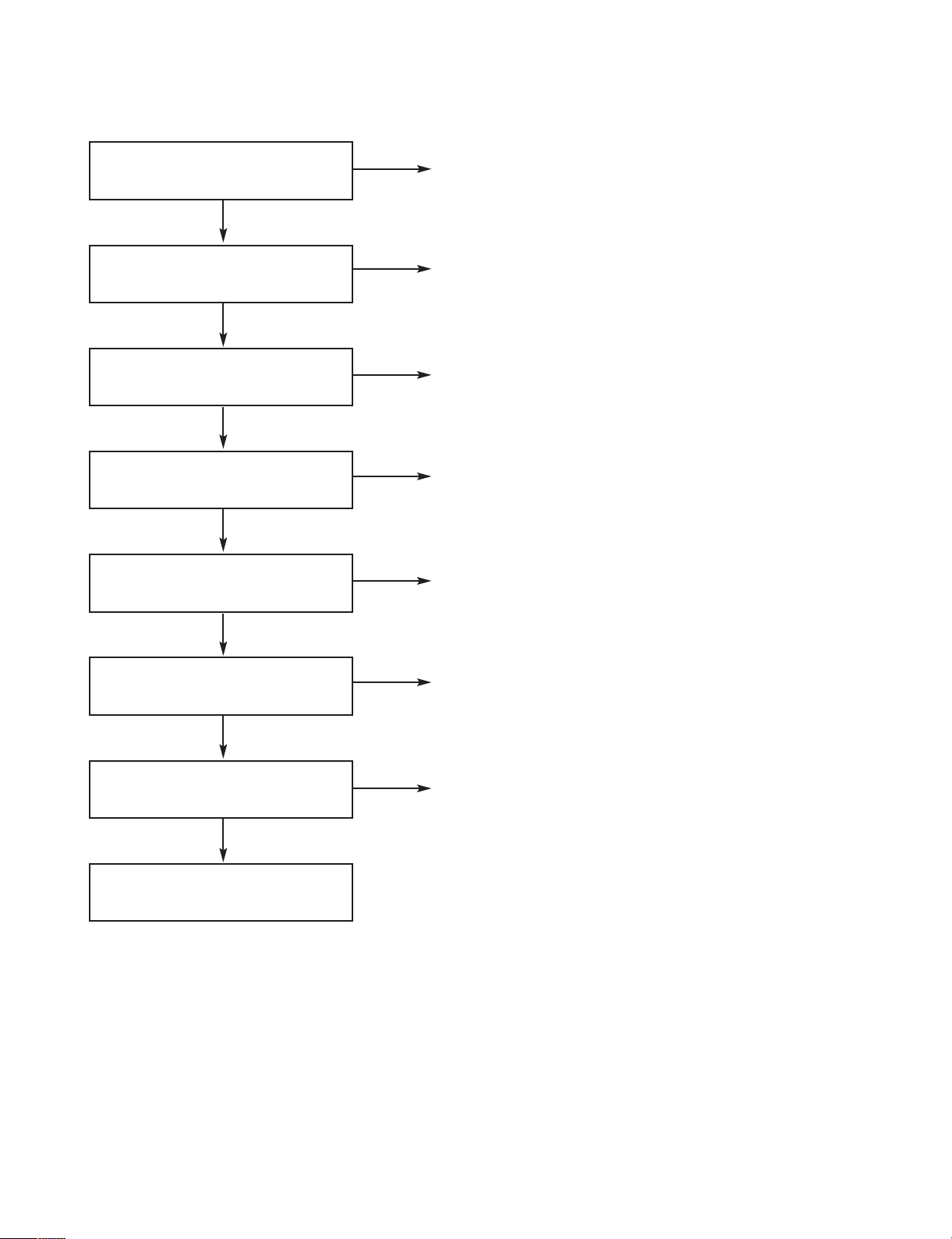

IC802’s CLK and CONT signal?

IC802 Replace

MAIN B/D Check

LCD MODE CONT signal?

ALL “LOW”(NORMAL condition)

TFT LCD pressure voltage?

+15V, -10V, +5V

Power source and D803, D804 Check

TFT LCD Normal?

Replace

Color Adjusting Normal?

Readjust as adjustement standard.

Each CONNECTOR?

Replace and Reassemble

INVERTOR Normal?

Replace

END

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

LCD TROUBLE SHOOTING GUIDE(2/2)

3-6

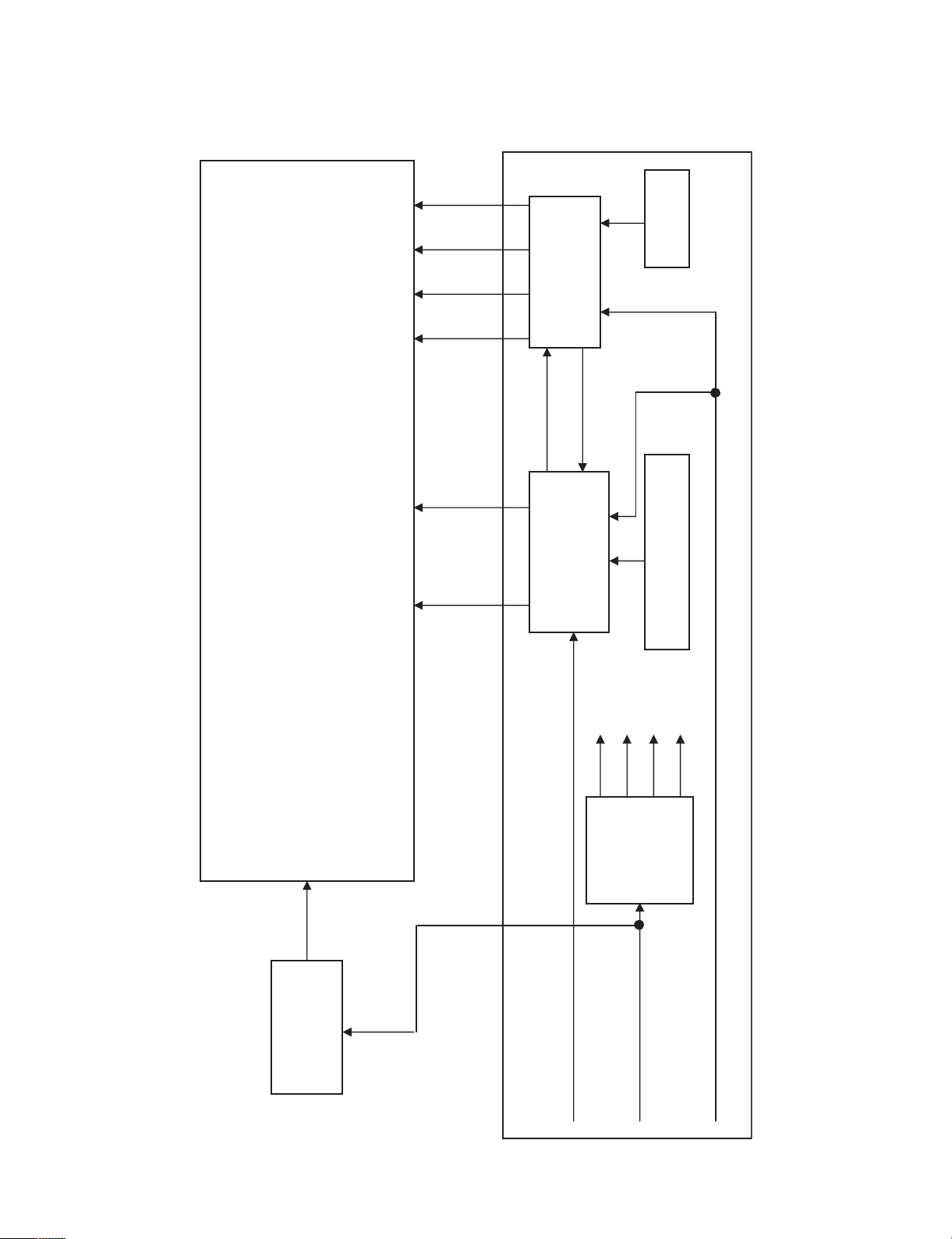

LCD BLOCK DIAGRAM

OEV

(480X3X234)

TFT LCD 7" WIDE

STV

STH

CLK

VCOM

RGB

(UPS017)

CONTROL

C_SYNC

H/V SYNC

(IR3Y29B)

CHROMA IC

VCO

COLOR

CONTROL

INVERTER

15V

-10V

CONV

DC-DC

Y/C OR CVBS

DC9.8V OR BAT7.2V

5V

7.5V

LCD MODE

AV I/O CON

3-16

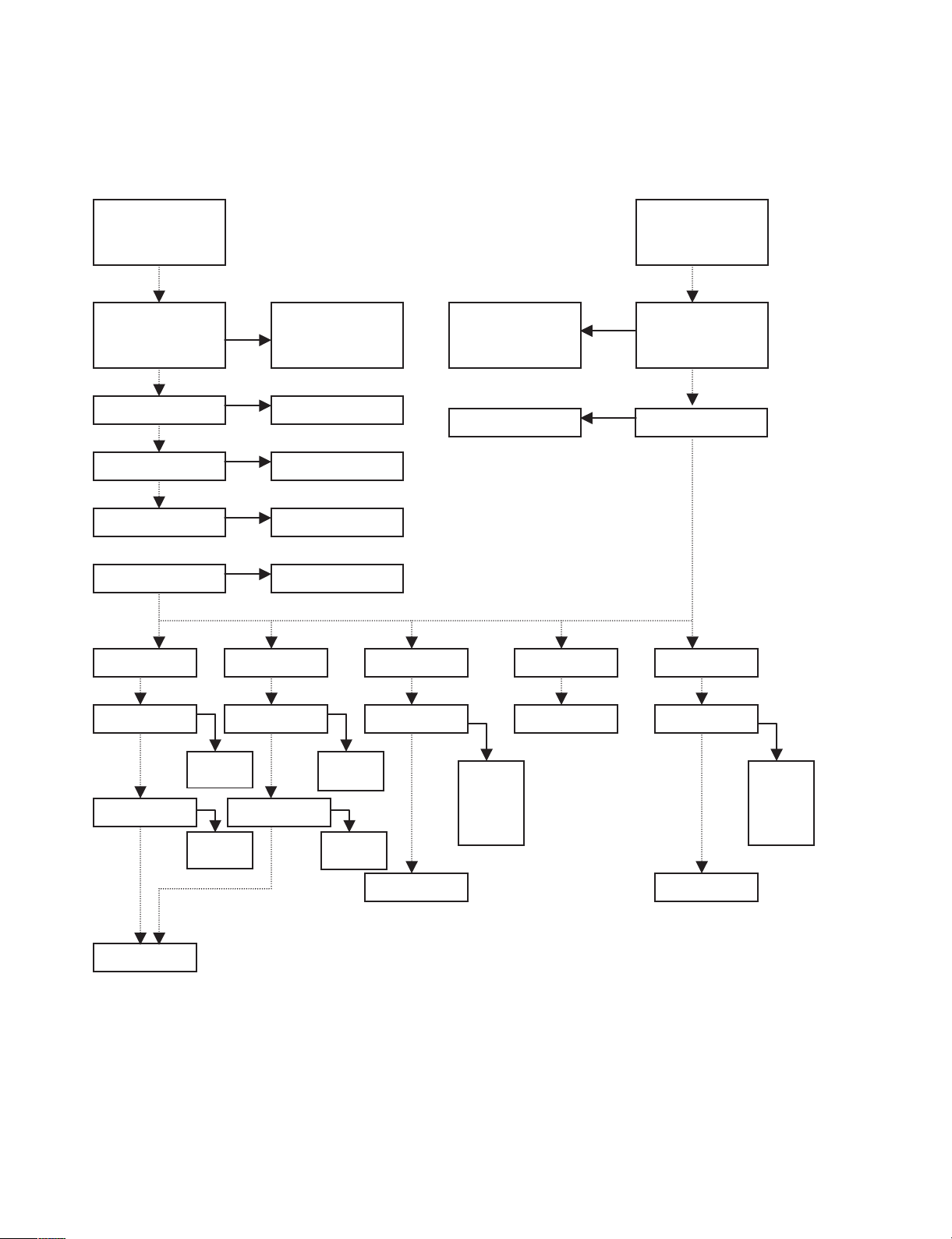

ELECTRICAL TROUBLE SHOOTING GUIDE

1. Power (DC-DC Converter) Circuit

A.

NO POWER ON

by ADAPTO

R

Is ADAPTOR

9.8V?

OUT

YES

Is F101 OK?

Is LF101 OK

Is

D105 OK?

?

Is F102 OK?

NO +1.8V

NO

Replace ADAPTOR

Replace F101

Replace LF101

Replace D105

Replac F102

NO +3.3V

Replace BATTERY

Replace Q

102

NO -5VNO + 5V

NO POWER ON

by BATTERY

NO

Is BATTERY

Is Q102 OK

NO LCD POWER

YES

OK?

?

Is Q104 OK?

Is Q105 OK?

Replace IC108

Is Q104 OK?

Replace

Q104

Is Q105 OK?

Replace

Q105

Replace

Q104

Replace

Q105

Replace IC104

Is E+5V OK?

Replace

Q103

Replace IC103

Is Q102 OK

Replace L437

?

Replace

Q102

Loading...

Loading...