Page 1

SERVICE MANUAL

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Internal Use Only

Website http://biz.lgservice.com

JULY, 2015

MODEL: DP547

MODEL: DP547

DVD Player

P/NO : AFN76412152

Page 2

CONTENTS

SECTION 1 ........ SUMMARY

SECTION 2 ........ CABINET & MAIN CHASSIS

SECTION 3 ........ ELECTRICAL

SECTION 4 ........ REPLACEMENT PARTS LIST

1-1

Page 3

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR DVD PRODUCTS .................................................. 1-3

SERVICING PRECAUTIONS .......................................................................................................................... 1-4

• GENERAL SERVICING PRECAUTIONS

• INSULATION CHECKING PRODEDURE

• ELECTROSTATICALLY SENSITIVE (ES) DEVICES

THE PROCESS OF USB DOWNLOAD ......................................................................................................... 1-5

SPECIFICATIONS ............................................................................................................................................ 1-8

1-2

Page 4

PRODUCT SAFETY SERVICING GUIDELINES FOR DVD PRODUCTS

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-video service

technicians.

When servicing this product, under no circumstances should the original design be

modified or altered without permission from LG Corporation. All components should

be replaced only with types identical to those in the original circuit and their physical

location, wiring and lead dress must conform to original layout upon completion of

repairs.

Special components are also used to prevent x-radiation, shock and fire hazard.

These components are indicated by the letter “x” included in their component designators and are required to maintain safe performance. No deviations are allowed

without prior approval by LG Corporation.

Circuit diagrams may occasionally differ from the actual circuit used. This way,

implementation of the latest safety and performance improvement changes into the

set are not delayed until the new service literature is printed.

CAUTION: Do not attempt to modify this product in any way. Never perform cus-

tomized installations without manufacturer’s approval. Unauthorized modifications

will not only void the warranty, but may lead to property damage or user injury.

Service work should be performed only after you are thoroughly familiar with these

safety checks and servicing guidelines.

GRAPHIC SYMBOLS

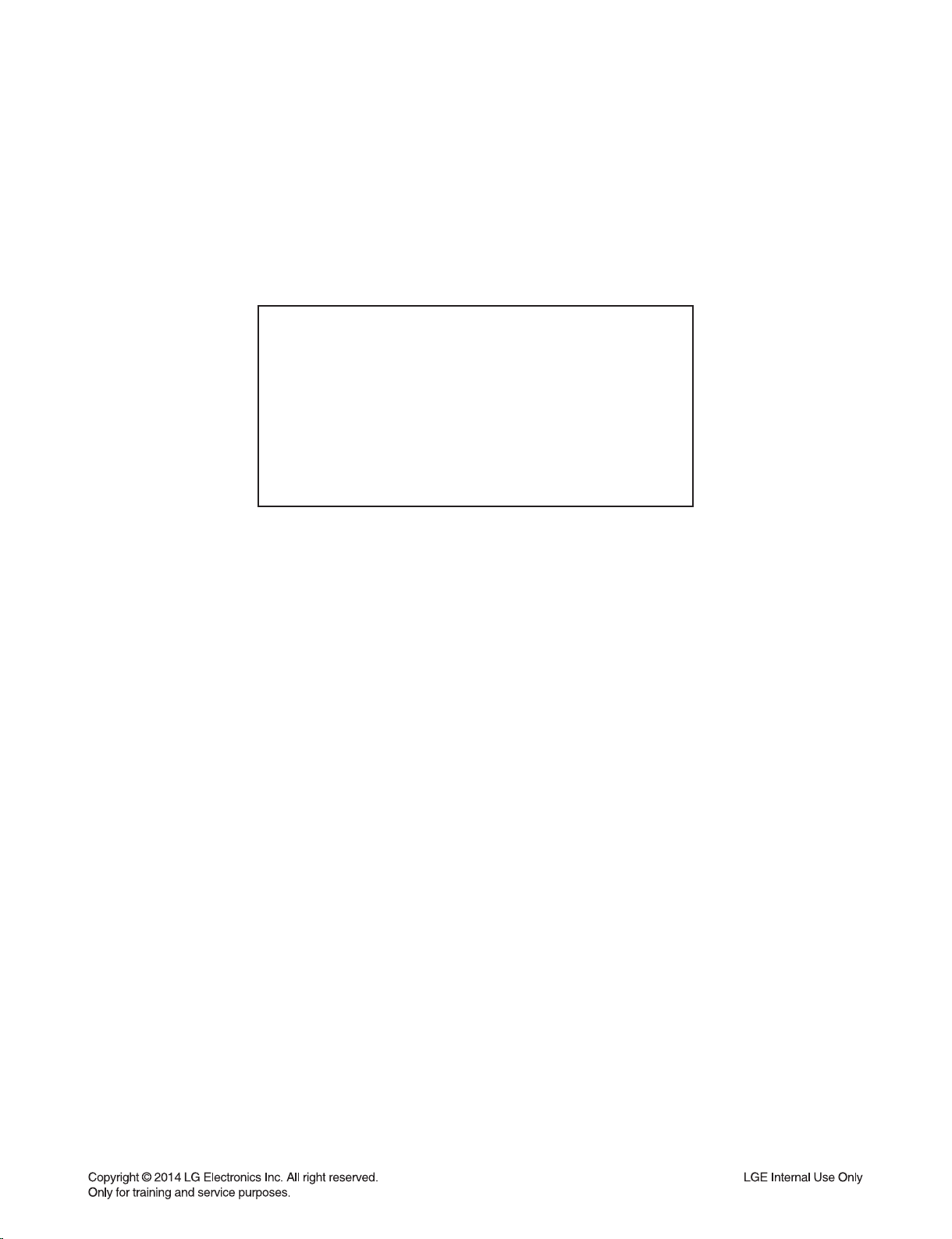

The exclamation point within an equilateral triangle is intended to

alert the service personnel to important safety information in the

service literature.

The lightning flash with arrowhead symbol within an equilateral

triangle is intended to alert the service personnel to the presence of

noninsulated “dangerous voltage” that may be of sufficient magnitude

to constitute a risk of electric shock.

The pictorial representation of a fuse and its rating within an equilateral triangle is intended to convey to the service personnel the

following fuse replacement caution notice:

CAUTION: FOR CONTINUED PROTECTION AGAINST RISK

OF FIRE, REPLACE ALL FUSES WITH THE SAME TYPE AND

RATING AS MARKED NEAR EACH FUSE.

SERVICE INFORMATION

While servicing, use an isolation transformer for protection from AC line shock. After

the original service problem has been corrected, make a check of the following:

FIRE AND SHOCK HAZARD

1. Be sure that all components are positioned to avoid a possibility of adjacent

component shorts. This is especially important on items trans-ported to and from

the repair shop.

2. Verify that all protective devices such as insulators, barriers, covers, shields,

strain reliefs, power supply cords, and other hardware have been reinstalled per

the original design. Be sure that the safety purpose of the polarized line plug has

not been defeated.

3. Soldering must be inspected to discover possible cold solder joints, solder

splashes, or sharp solder points. Be certain to remove all loose foreign particles.

4. Check for physical evidence of damage or deterioration to parts and components, for frayed leads or damaged insulation (including the AC cord), and

replace if necessary.

5. No lead or component should touch a high current device or a resistor rated at 1

watt or more. Lead tension around protruding metal surfaces must be avoided.

6. After reassembly of the set, always perform an AC leakage test on all exposed

metallic parts of the cabinet (the channel selector knobs, antenna terminals,

handle and screws) to be sure that set is safe to operate without danger of

electrical shock. DO NOT USE A LINE ISOLATION TRANSFORMER DURING

THIS TEST. Use an AC voltmeter having 5000 ohms per volt or more sensitivity

in the following manner: Connect a 1500 ohm, 10 watt resistor, paralleled by a

.15 mfd 150V AC type capacitor between a known good earth ground water pipe,

conduit, etc.) and the exposed metallic parts, one at a time. Measure the AC voltage across the combination of 1500 ohm resistor and .15 mfd capacitor. Reverse

the AC plug by using a non-polarized adaptor and repeat AC voltage measurements for each exposed metallic part. Voltage measured must not exceed 0.75

volts RMS. This corresponds to 0.5 milliamp AC. Any value exceeding this limit

constitutes a potential shock hazard and must be corrected immediately.

TIPS ON PROPER INSTALLATION

1. Never install any receiver in a closed-in recess, cubbyhole, or closely fitting shelf

space over, or close to, a heat duct, or in the path of heated air flow.

2. Avoid conditions of high humidity such as: outdoor patio installations where dew

is a factor, near steam radiators where steam leakage is a factor, etc.

3. Avoid placement where draperies may obstruct venting. The customer should

also avoid the use of decorative scarves or other coverings that might obstruct

ventilation.

4. Wall- and shelf-mounted installations using a commercial mounting kit must

follow the factory-approved mounting instructions. A product mounted to a shelf

or platform must retain its original feet (or the equivalent thickness in spacers) to

provide adequate air flow across the bottom. Bolts or screws used for fasteners

must not touch any parts or wiring. Perform leakage tests on customized installations.

5. Caution customers against mounting a product on a sloping shelf or in a tilted

position, unless the receiver is properly secured.

6. A product on a roll-about cart should be stable in its mounting to the cart.

Caution the customer on the hazards of trying to roll a cart with small casters

across thresholds or deep pile carpets.

7. Caution customers against using extension cords. Explain that a forest of extensions, sprouting from a single outlet, can lead to disastrous consequences to

home and family.

1-3

Page 5

SERVICING PRECAUTIONS

CAUTION: Before servicing the DVD covered by this service

data and its supplements and addends, read and follow the

SAFETY PRECAUTIONS. NOTE: if unforeseen circumstances create conflict between the following servicing precautions

and any of the safety precautions in this publication, always

follow the safety precautions.

Remember Safety First :

General Servicing Precautions

1. Always unplug the DVD AC power cord from the AC power

source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an electro-

lytic capacitor.

Caution: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Do not spray chemicals on or near this DVD or any of its

assemblies.

3. Unless specified otherwise in this service data, clean electrical contacts by applying an appropriate contact cleaning

solution to the contacts with a pipe cleaner, cotton-tipped

swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5. Do not apply AC power to this DVD and / or any of its electrical assemblies unless all solid state device heat sinks are

correctly installed.

6. Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and

turn the power on. Connect an insulation resistance meter

(500V)

to the blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1Mohm.

Note 1: Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples

of typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which should

be removed for potential shock reasons prior to applying

power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

an electrical charge sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install

it. (Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

1-4

Page 6

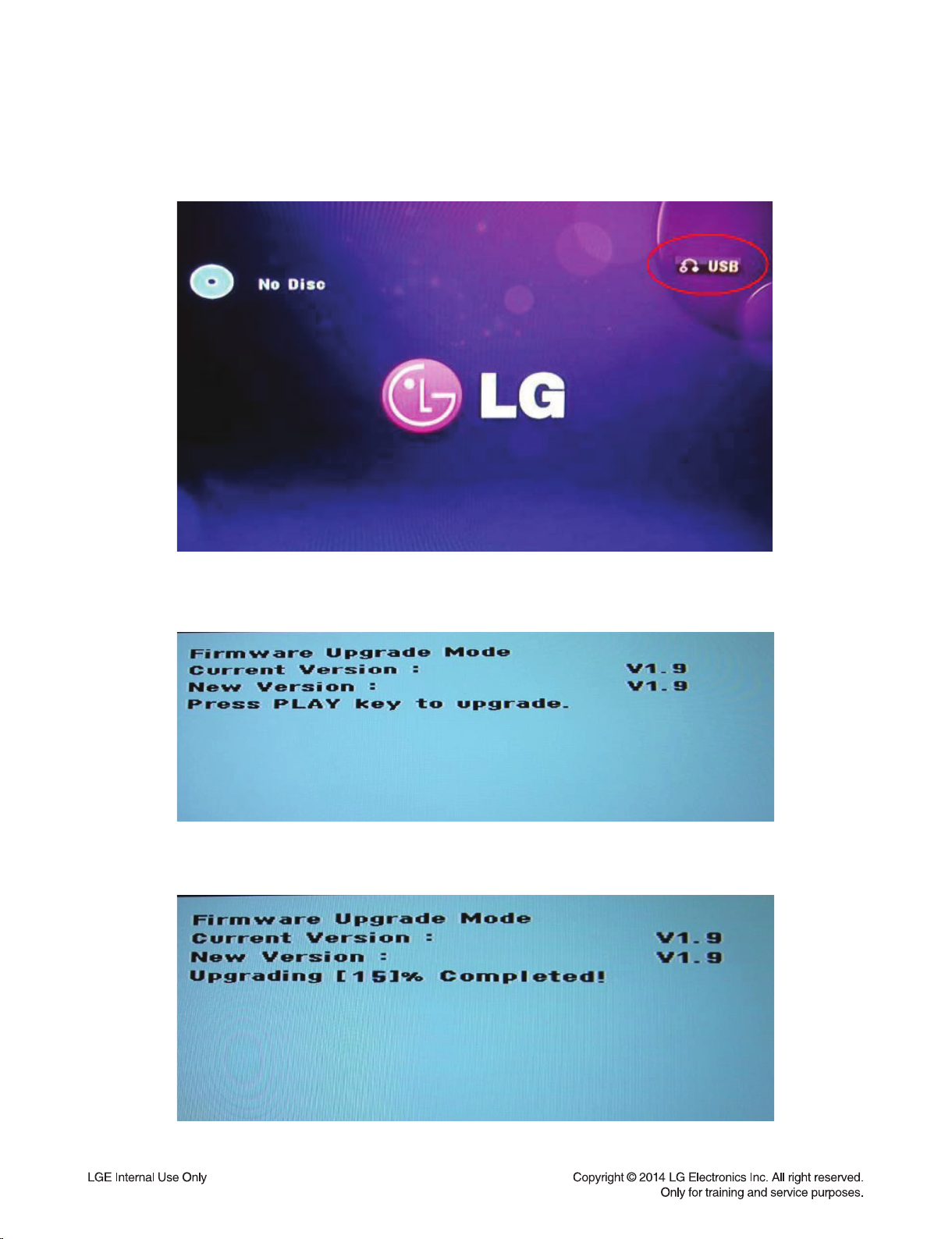

THE PROCESS OF USB DOWNLOAD

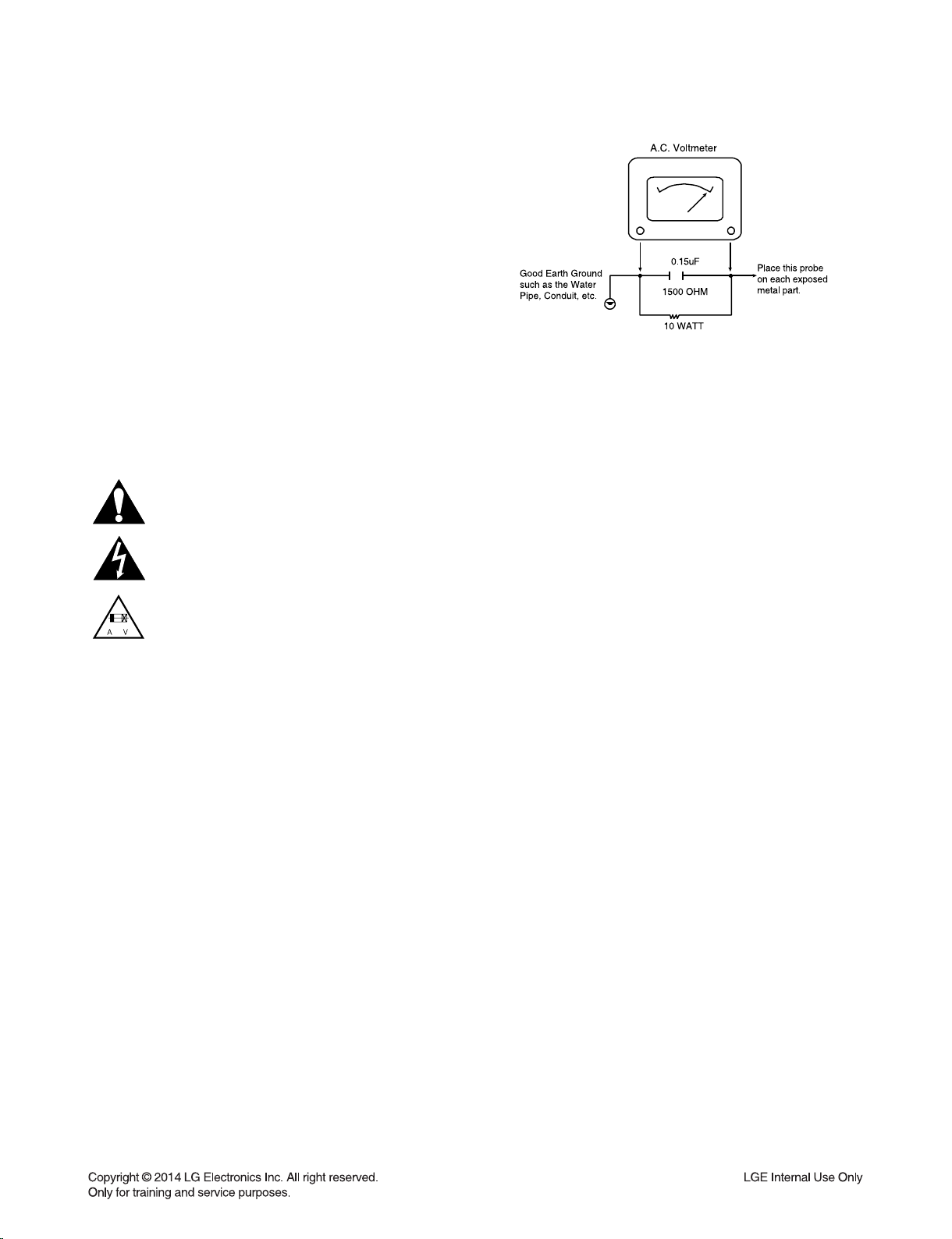

Please follow the below process to download a program with disc

1. Turn on the DVD-player.

Note: Be sure that there is no disc in DVD-player.

2. Press “SETUP” button on Remote control.

3. Choose a “DISPLAY” menu by using the cursor button and then choose a “TV Aspect” menu.

And choose “16:9” menu.

4. Press the 1 --> 3 --> 9 --> 7 --> 1 --> 3 --> 9(Numerical button) --> Enter key on remote control

to confi rm the system information.

5. Remember or write the model.

6. Change the program fi le name of new version to the model.

Example:

New ver. program fi le: LG_DV_LVB00B70000EHS_V1.9.ROT

Model: LG_DV_LVB00B70008EHS.ROT

Change New ver. program fi le like this LG_DV_LVB00B70008EHS.ROT

If you don’t change the fi le name like that,disc download isn’t be worked.

7. Copy the changed fi le to a USB memory stick or burn it to CD-R/RW.

1-5

Page 7

8. Insert the copied USB memory stick or Disc to DVD-player.

9. Press the RETURN button on the DVD Player. (USB only)

10. If the below picture appears on the screen. Press “PLAY” button on Remote controller.

While this menu appears, please don’t eject disc or take out USB.

11. After the below picture appears on the screen. New DVD program will download from USB

Memory stick or Disc automatically. Do not eject or take out the USB memory stick.

1-6

Page 8

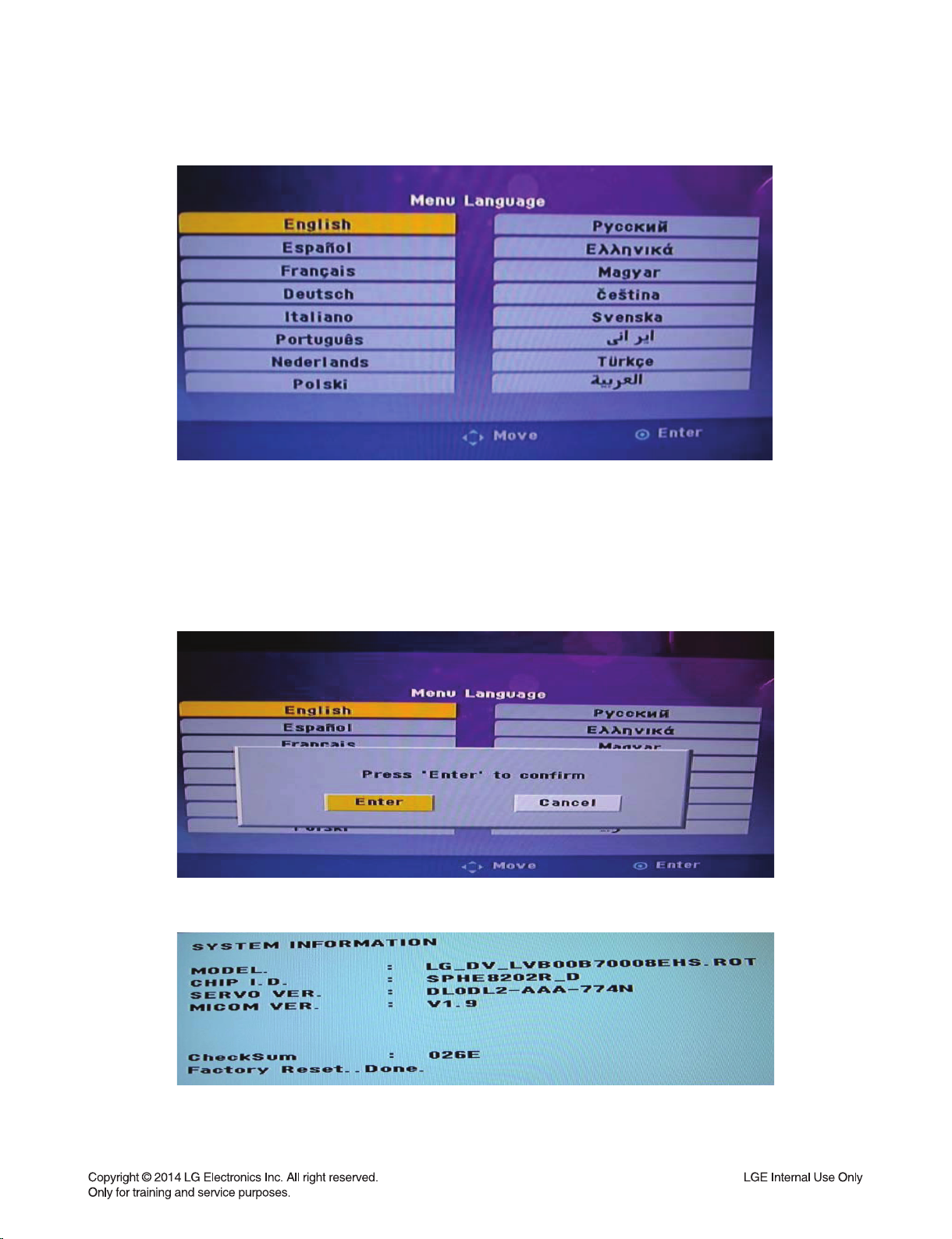

12. After USB download is completed, DVD-player displays below picture automatically.

13. Do power off of DVD-Player.

14. Remove the Disc or USB memory stick.

15. Turn on the DVD-player.

Select the initial Language and Press “Enter” button.

Then, Select “Enter” and Press “Enter” button.

16. Do it again the process 1, 2, 3, 4 to confi rm the version.

17. Do power off of DVD-Player again.

1-7

Page 9

SPECIFICATIONS

Power requirements AC 110 - 240 V, 50 / 60 Hz

Power consumption 9 W

Dimensions (W x H x D) (360 x 39.5 x 200) mm

Net Weight (Approx.) 1.14 kg

Operating temperature 0 °C - 40 °C

Operating humidity 5 % - 90 %

Laser Semiconductor laser

Signal system PAL / NTSC

Bus Power Supply (USB) DC 5 V 200 mA

VIDEO OUT 1.0 V (p-p), 75 Ω, sync negative, RCA jack x 1

COMPONENT VIDEO OUT (Y) 1.0 V (p-p), 75 Ω, sync negative, RCA jack x 1,

(Pb)/(Pr) 0.7 V (p-p), 75 Ω, RCA jack x 2

ANALOG AUDIO OUT 2.0 Vrms (1 kHz, 0 dB), 600 Ω, RCA jack (L, R) x 1

DIGITAL AUDIO OUT (COAXIAL) 0.5 V (p-p), 75 Ω, RCA jack x 1

Note : Design and specifications are subject to change without prior notice.

1-8

Page 10

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

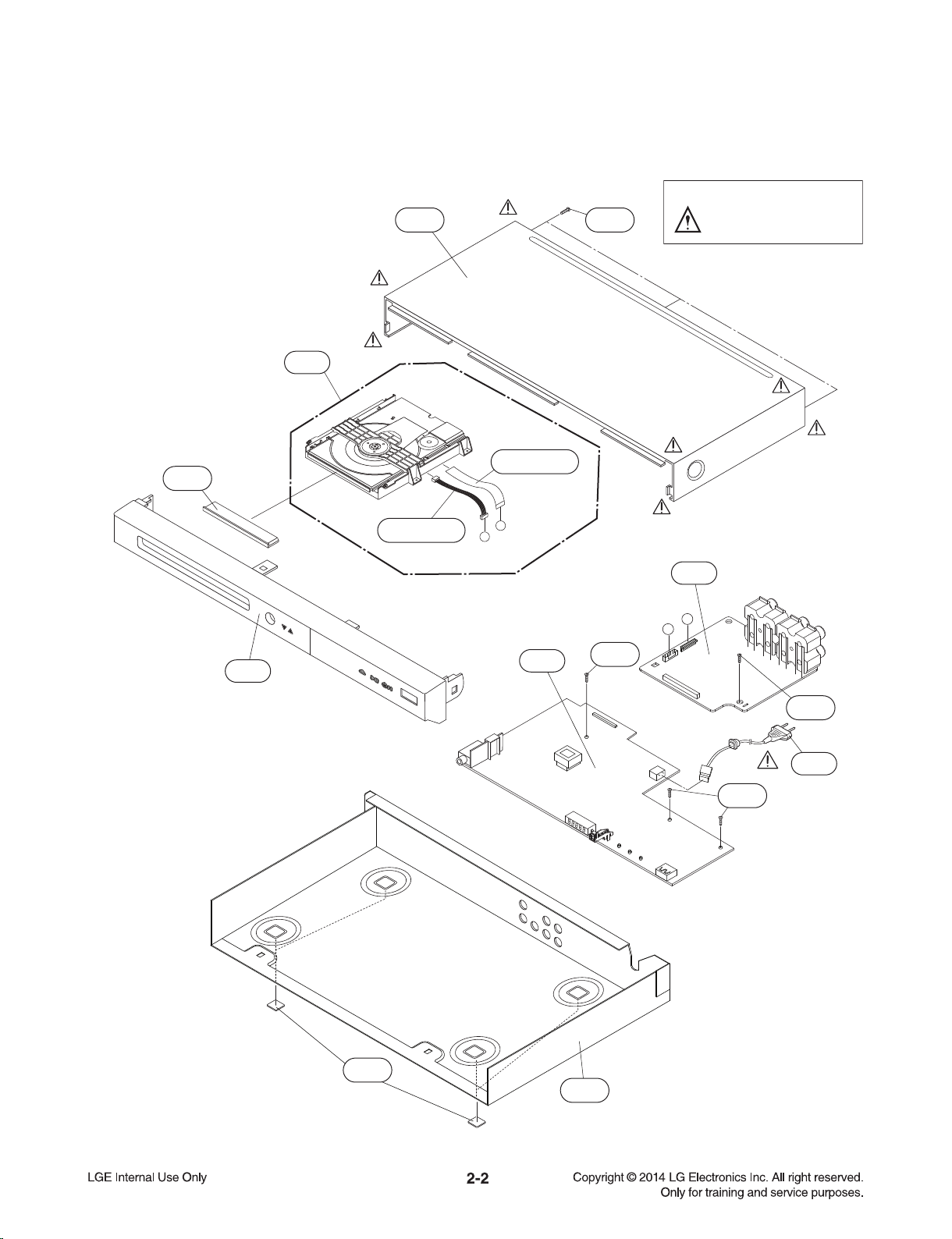

EXPLODED VIEWS ......................................................................................................................................... 2-2

1. CABINET AND MAIN FRAME SECTION ................................................................................................. 2-2

2. PACKING ACCESSORY SECTION ......................................................................................................... 2-3

2-1

Page 11

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

A26

CABLE1

283

NOTES) THE EXCLAMATION POINT WITHIN AN

EQUILATERAL TRIANGLE IS INTENDED

TO ALERT THE SERVICE PERSONNEL

455250

TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION IN SERVICE

LITERATURE.

A43

CABLE2

A

B

A47

KARAOKE & MIC BOARD

SMPS & FRONT

BOARD

455

B

A46

A

MAIN

BOARD

455

300

455

261

260

Page 12

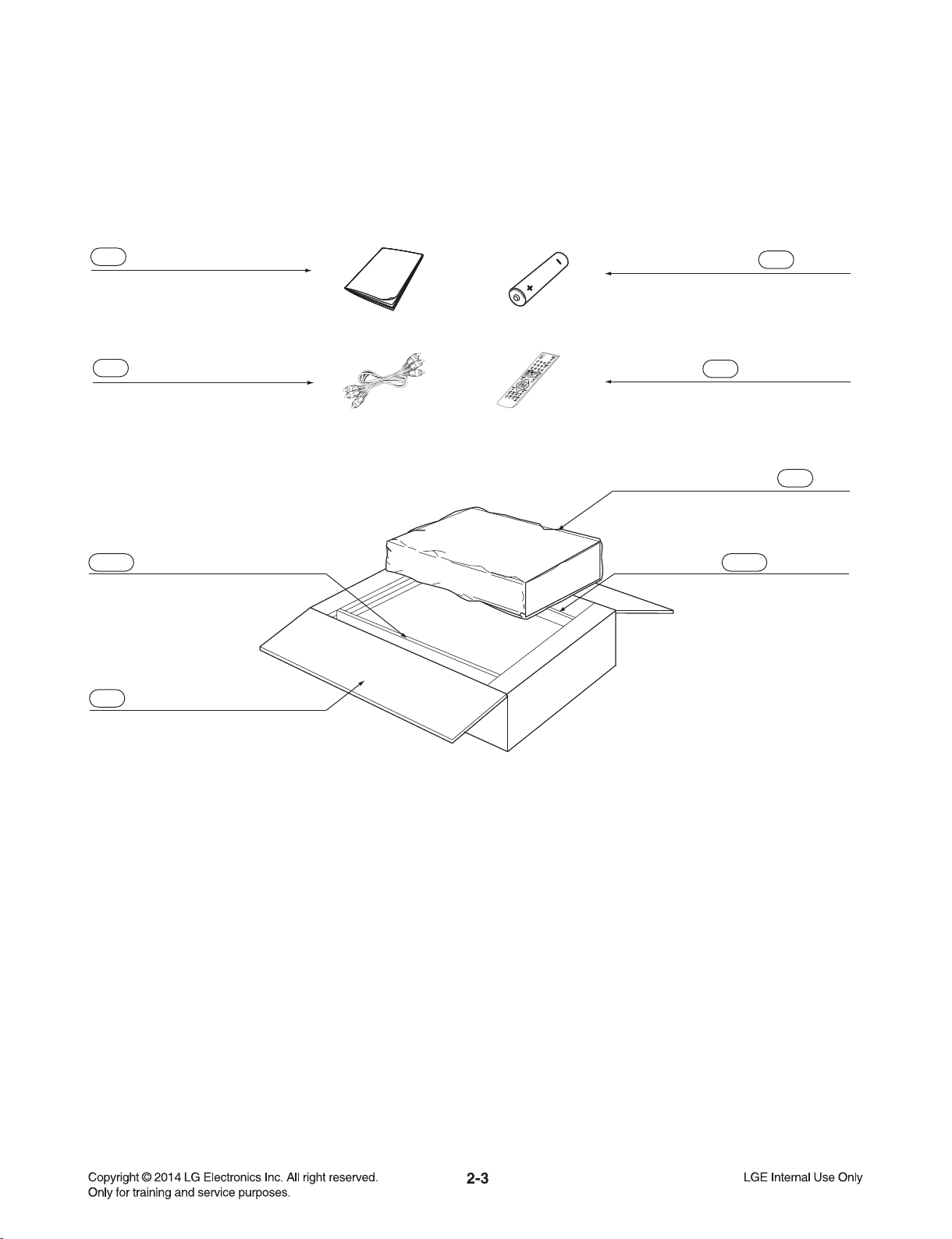

2. PACKING ACCESSORY SECTION

801 Owner’s manual

813 RCA Video/Audio cable

802A Pad (Front) 802B Pad (Rear)

802 Box

900 Remote control

808 Battery

804 Bag

Page 13

MEMO

2-4

Page 14

SECTION 3

ELECTRICAL

CONTENTS

ONE POINT REPAIR GUIDE ...............................................................................................3-2

1. NO BOOTING WHEN YOU TURN THE UNIT ON ................................................................................. 3-2

2. NO VIDEO OUTPUT WHEN YOU TURN THE UNIT ON ...................................................................... 3-7

3. NO AUDIO OUTPUT WHEN YOU TURN THE UNIT ON ...................................................................... 3-8

ELECTRICAL TROUBLESHOOTING GUIDE ......................................................................3-9

1. SMPS TROUBLESHOOTING FLOW ..................................................................................................... 3-9

2. POWER CHECK FLOW ....................................................................................................................... 3-10

3. SYSTEM OPERATION FLOW .............................................................................................................. 3-11

4. SYSTEM TEST FLOW .......................................................................................................................... 3-12

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING ..........................3-18

1. SYSTEM 27 MHz CLOCK, RESET, FLASH R/W SIGNAL .................................................................. 3-18

2. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION) .......................................................... 3-20

3. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION) .......................................................... 3-20

4. LASER POWER CONTROL RELATED SIGNAL ................................................................................. 3-21

5. SPINDLE CONTROL WAVEFORM ...................................................................................................... 3-22

6. FOCUS ON WAVEFORM ..................................................................................................................... 3-22

7. TRACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING) ................................................... 3-23

8. SPHE8202RQ-D AUDIO COAXIAL OUTPUT (SPDIF) ........................................................................ 3-24

9. SPHE8202RQ-D VIDEO OUTPUT WAVEFORM ................................................................................. 3-24

10. AUDIO OUTPUT FROM SPHE8202RQ-D/128 .................................................................................... 3-25

WIRING DIAGRAM .............................................................................................................3-26

CIRCUIT DIAGRAMS .........................................................................................................3-27

1. SMPS & FRONT - SMPS CIRCUIT DIAGRAM .................................................................................... 3-27

2. SMPS & FRONT - FRONT CONTROL CIRCUIT DIAGRAM ............................................................... 3-29

3. SMPS & FRONT - MIC CIRCUIT DIAGRAM (OPTIONAL PART) ....................................................... 3-31

4. MAIN - POWER SUPPLY/ OPU CIRCUIT DIAGRAM.......................................................................... 3-33

5. MAIN - SPHE8202RQ-D/ FLASH/ SDRAM CIRCUIT DIAGRAM ........................................................ 3-35

6. MAIN - AUDIO AMPLIFIER/ AUDIO OUTPUT/ MUTE/ VIDEO BUFFER/

VIDEO OUTPUT CIRCUIT DIAGRAM ..................................................................................... 3-37

CIRCUIT VOLTAGE CHART ..............................................................................................3-39

1. MPEG & SDRAM .................................................................................................................................. 3-39

2. IC ........................................................................................................................................................... 3-40

3. TR ......................................................................................................................................................... 3-41

4. CAPACITOR ......................................................................................................................................... 3-41

5. CONNECTOR ....................................................................................................................................... 3-42

PRINTED CIRCUIT BOARD DIAGRAMS ..........................................................................3-43

1. SMPS & FRONT P.C.BOARD .............................................................................................................. 3-43

2. MAIN P.C.BOARD ................................................................................................................................ 3-47

3-1

Page 15

ONE POINT REPAIR GUIDE

1. NO BOOTING WHEN YOU TURN THE UNIT ON

When you plug power cord and turn the unit on, LED light won’t turn red, the unit won’t

read disc normally.

1-1. Please check every output voltage.

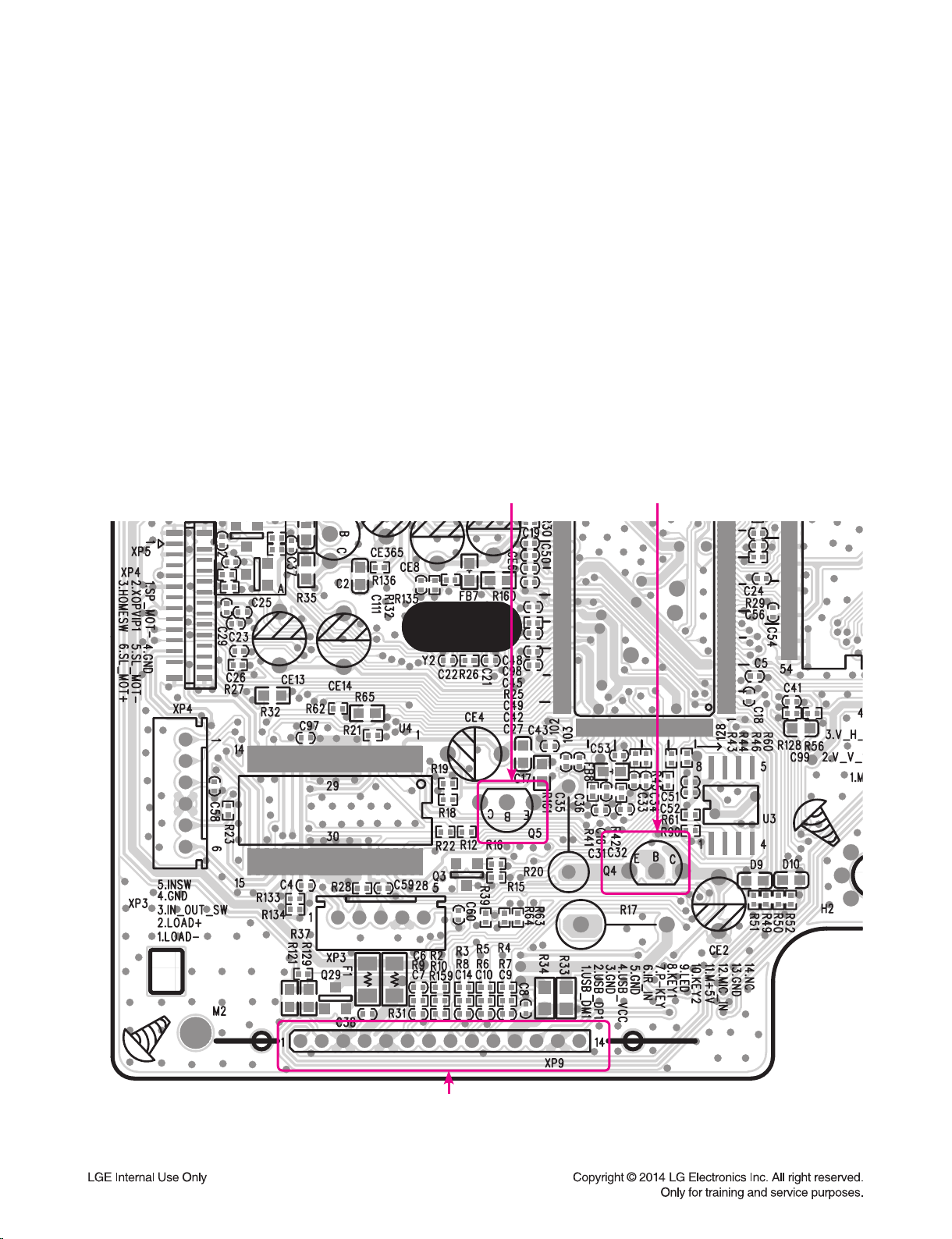

1-1-1. Please check if output voltage 3.3 V from main board Q4 C polarity is normal.

If output voltage 3.3 V is not normal, please check the working status of SMPS board.

1-1-2. Please check if output voltage 5 V from main board XP9 pin11 is normal.

If output voltage 5 V is not normal, please check the working status of SMPS board.

1-1-3. Please check if output voltage 1.2 V from main board Q5 C polarity is normal.

If output voltage 1.2 V is not normal, please check the working status of main board Q5.

Q5 Q4

XP9

< Main board top view >

3-2

Page 16

ONE POINT REPAIR GUIDE

When you plug power cord and turn the unit on, LED light won’t turn red, the unit won’t

read disc normally

1-2. Please check main board IC U1 signal and its peripheral circuit.

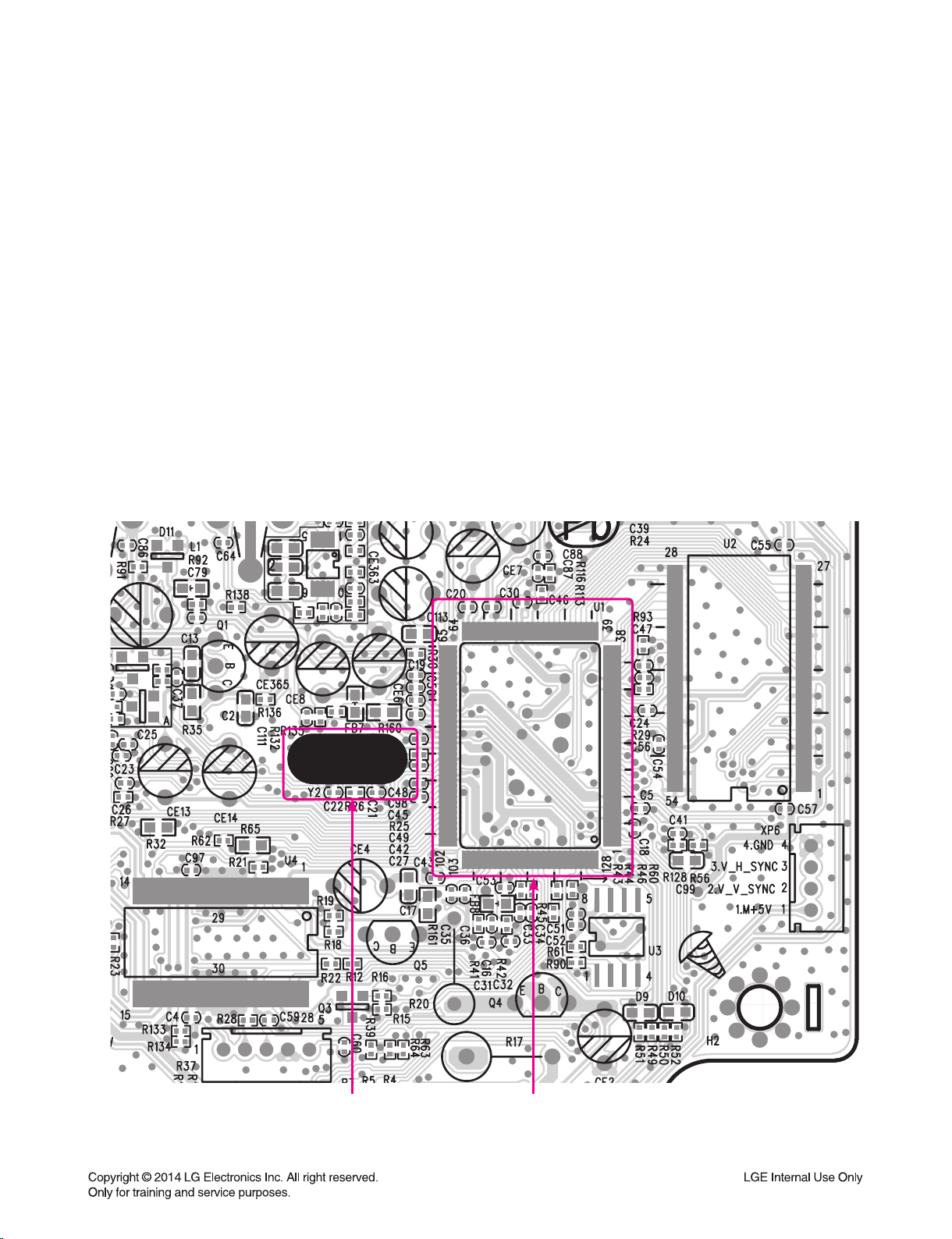

1-2-1. Please check if output voltage 3.3 V from U1 pin4, pin32, pin78, pin83 is normal.

If output voltage 3.3 V is not normal, please check 3.3 V power circuit of main board.

1-2-2. Please check if output voltage 1.2 V from U1 pin10, pin77, pin86 is normal.

If output voltage 1.2 V is not normal, please check 1.2 V power circuit of main board.

1-2-3. Please check if oscillating frequency 27 MHz of main board Y2 crystal is normal.

If oscillating frequency 27 MHz is not normal, please check if Y2 and its peripheral circuit is in failure.

1-2-4. Please check if frequency 135 MHz of U1 pin31 RAM_CLK is normal.

If oscillating frequency 135 MHz is not normal, please check if U1 is in failure.

.

Y2 U1

< Main board top view >

3-3

Page 17

ONE POINT REPAIR GUIDE

When you plug power cord and turn the unit on, LED light won’t turn red, the unit won’t

read disc normally.

1-3. Please check main board IC U2 signal and its peripheral circuit.

1-3-1. Please check if output voltage 3.3 V from IC U2 pin1, 3, 9, 14, 27, 43, 49 is normal.

If output voltage 3.3 V is not normal, please check 3.3 V power circuit of main board.

1-3-2. Please check every signal connected between IC U2 and IC U1, especially including DATA and

ADDRESS signal.

If DATA and ADDRESS signal is not normally output, please check if U2 is in failure.

U1 U2

< Main board top view >

3-4

Page 18

ONE POINT REPAIR GUIDE

When you plug power cord and turn the unit on, LED light won’t turn red, the unit won’t

read disc normally.

1-4. Please check main board IC U3 signal and its peripheral circuit.

1-4-1. Please check if output voltage 3.3 V from IC U3 pin8 is normal.

If output voltage 3.3 V is not normal, please check 3.3 V power circuit of main board.

1-4-2. Please check every signal connected between IC U3 and IC U1, especially including CE, DATA

and CLK signal.

If CE, DATA and CLK signal is not normally output, please check if U3 is in failure.

U1 U3

< Main board top view >

3-5

Page 19

ONE POINT REPAIR GUIDE

When you plug power cord and turn the unit on, LED light won’t turn red, the unit won’t

read disc normally.

1-5. Please check main board IC U4 signal and its peripheral circuit.

1-5-1. Please check if output voltage 5 V from U4 pin8, pin19 is normal.

If output voltage 5 V is not normal, please check 5 V power circuit of main board.

1-5-2. Please check every signal connected between IC U4 and IC U1, especially including F+, F-,

T+, T-, SP+, SP-, SL+, SL- signal to drive MD.

If F+, F-, T+, T-, SP+, SP-, SL+, SL- signal is not normally output, please check if U4 is in failure.

< Main board top view >

3-6

U1U4

Page 20

ONE POINT REPAIR GUIDE

2. NO VIDEO OUTPUT WHEN YOU TURN THE UNIT ON

When you plug power cord and turn the unit on, LED light will turn red, the unit will read

disc normally, but it won’t have video output.

2-1. Please check the solder joint status of main board connector P2.

2-2. Please check CVBS signal of main board IC U1 pin69.

If CVBS signal is not normally output, please check if U1 is in failure.

P2

U1

< Main board top view >

3-7

Page 21

ONE POINT REPAIR GUIDE

3. NO AUDIO OUTPUT WHEN YOU TURN THE UNIT ON

When you plug power cord and turn the unit on, LED light will turn red, the unit will read

disc normally, but it won’t have audio output.

3-1. Please check the solder joint status of main board connector P2.

If P2 has cold solder joint, P2 pins should be oxidated, and please replace P2.

3-2. Please check the working status of main board IC U927.

If output voltage 5 V from U927 pin7 is not normal, please check 5 V power circuit of main board.

If AL and AR signal from U927 pin1, pin2, pin9, pin10 is not normally output, please check if U927

is in failure.

3-3. Please check the working status of main board IC U1.

If AL and AR signal from U1 pin65, pin66 is not normally output, please check if U1 is in failure.

P2U927

U1

< Main board top view >

3-8

Page 22

ELECTRICAL TROUBLESHOOTING GUIDE

1. SMPS TROUBLESHOOTING FLOW

No +5 V

YES

Is the F501(T2AL) normal?

YES

Is the D501/ D502/ D503/ D504

normal?

YES

Is the U501(TNY176) normal?

YES

Is the D508 normal?

YES

Is there about 2.5 V

at the U503 Pin1?

NO

NO

NO

NO

NO

Replace the F501.

(Use the same ICW)

Replace the D501/ D502/ D503/ D504.

Replace the U501.

Replace the D508.

Replace the U503.

YES

Is the U502 normal?

YES

Power line of main PCB(DVD) is short.

NO

Replace the U502.

3-9

Page 23

ELECTRICAL TROUBLESHOOTING GUIDE

2. POWER CHECK FLOW

No 3.3 V No 1.2 V

Is M5V

supplied to Q4

emitter?

YES

Check or replace Q4.

NO

Replace the R17(1.8R/2W).

Replace the R20(5.6R/1W).

NO

NO

Is M5V

supplied to Q5

emitter?

YES

Is M5V

supplied to Q5

collector?

YES

Check or replace Q5.

3-10

Page 24

ELECTRICAL TROUBLESHOOTING GUIDE

3. SYSTEM OPERATION FLOW

Power on

1. MCU initializes SERVO, DSP & RISC registers.

2. Write RISC code to SDRAM.

3. Reset RISC.

Show “HELLO”

YES

Tray closed?

NO

Tray close to closed position.

SLED at inner side?

NO

SLED moves to inner position.

1. Judge whether have disc and disc type.

2. Jump to related disc reading procedure.

Recieve OPEN/ CLOSE key?

YES

YES

NO

NO

1. Execute pressed Key & IR key.

2. System operation routine loop.

1. Stop playback & open tray.

2. Display tray open message & LOGO.

Receive CLOSE key?

3-11

YES

Page 25

ELECTRICAL TROUBLESHOOTING GUIDE

4. SYSTEM TEST FLOW

TEST

Check the AC

voltage power PCBA.

YES

Make sure the main PCBA don’t short.

Power PCBA connected to AC voltage.

Is the DC

voltage outputs OK?

(5 V)

YES

Is 3.3 V

and 1.2 V DC outputs normal

on main PCBA?

YES

NO

Replace power PCBA.

NO

Repair or replace main PCBA.

NO

Repair or replace power PCBA.

NO

Check or replace Q4 or Q5.

Connect to PC RS232 cable and

update the FLASH memory code.

Update FLASH

successfully?

YES

A

NO

3-12

1. Check 27 MHz system clock.

2. Check system reset circuit.

3.

Check FLASH R/W enable signal WR, HOLD.

4. Check RS232 signals.

5. Check flash memory related circuit.

Page 26

ELECTRICAL TROUBLESHOOTING GUIDE

A

RESET or power on.

Show “SET”?

YES

Set language.

YES

NO NO

connection to TV set.

Flash

memory operates

properly?

YES

SPHE8202RQ-D

VIDEO outputs

properly?

YES

Have TV

signal output?

YES

Check AV cable

NO

NO

Check connection lines

between FLASH &

SPHE8202RQ-D and the

FLASH access time whether is

suitable or not.

Check the related circuit

of SPHE8202RQ-D.

Check the filtering and

amp circuit of TV signal.

Does

tray move inside

when it is not at closed

position?

YES

B

NO

OPEN_SW & CLOSE_

Normal

SW signals?

YES

Normal

OPEN & CLOSE

signal?

YES

Normal

FAN_TRAY+ & FAN_

TRAY- signal?

YES

Check the cable connection

between main PCBA and loader.

3-13

NO

NO

NO

Check the load

OPEN & CLOSE switch.

Check the tray control IO pins

on SPHE8202RQ-D & AM5890S.

Check the tray control

amplifying circuit on motor driver.

Page 27

ELECTRICAL TROUBLESHOOTING GUIDE

B

Does

the SLED move

to inner side when it is

at outter position?

YES

Do not put in disc

and tray close.

Motor

driver DMEA

Pin is High?

YES

Is SPDCO

DC Level Higher

than 1.65 V?

YES

SP+

& SP- output

properly?

YES

Check the cable

connection with mechanism.

NONO

NO

NO

Check the connection

line of DMEA signal.

Check the related circuit

of SCO.

Check the amp circuit

on motor driver.

Optical Lens

has movements for

searching

focus?

YES

C

Proper

FCO outputs to

motor driver?

YES

Proper

FOC+ & FOC-

outputs?

YES

Check cable connect on

with pick-up head.

3-14

NONO

NO

Check FCO connection

on SPHE8202RQ-D

and motor driver.

Check the amp circuit

on motor driver.

Page 28

ELECTRICAL TROUBLESHOOTING GUIDE

C

Laser

turns on when

reading disc?

YES

Put disc in?

YES

Disc ID

is correct?

NO NO

NO

NO

DVDLDO,

CDLDO output

properly?

YES

Collector

voltage of power

transistor is OK?

YES

Check cable connection

between transistor ouput

and pick-up head.

Laser off.

Proper PUHRF

signal on OPU.

YES

NO

NO

Check the laser power circuit

on SPHE8202RQ-D and

connedting to power transistor.

Check the related circuit

on laser power transistor.

Check the related circuit

on PUHRF signal.

YES

Does

spindle rotate?

YES

D

Check DVDLDO &

CDLDO signal.

NO NO

between spindle and main PCBA.

Proper SCO signal

on SPHE8202RQ-D.

YES

SLED+

& SLED- output

properly?

YES

Check the cable connection

NO

3-15

Check SCO related circuit

on SPHE8202RQ-D.

Check the spindle control

amp circuit of motor driver.

Page 29

ELECTRICAL TROUBLESHOOTING GUIDE

D

Focus on OK?

YES

Track on OK?

NO NO

signals on A, B, C, D of

Check cable connection

NO NO

Proper

SPHE8202RQ-D.

YES

Check FCO signal

on SPHE8202RQ-D.

YES

FOC+ & FOC-

output properly?

YES

on pick-up head.

Properly TCO signal

on SPHE8202RQ-D?

YES

NO

NO

Check connections

between SPHE8202RQ-D

and pick-up head.

Check the FCO connection

on SPHE8202RQ-D

and motor driver.

Check the focus control

amp circuit on motor driver

Check the TCO connection

on SPHE8202RQ-D

and motor driver.

YES

Disc is play?

YES

E

NO

RAD+ & RAD-

output properly?

YES

Check cable connection

on pick-up head.

Check PUHRF

signal waveform.

3-16

NO

Check the tracking control

amp circuit on motor driver.

Page 30

ELECTRICAL TROUBLESHOOTING GUIDE

E

Normal

audio output when

disc playback?

YES

Normal

IR.VFD & front panel key

functions?

YES

NO

NO NO

AMP received correct

between IR.VFD front panel key

Audio

data stream?

YES

Normal

audio AMP out?

YES

Check audio filter,

amplify, mute circuit.

Communications

& SPHE8202RQ-D is

normally?

YES

NO

NO

Check connection between

SPHE8202RQ-D & audio AMP.

Check the related

circuit of audio AMP.

Check communication lines

on SPHE8202RQ-D.

Test end.

Check the cable connection

on front panel.

3-17

Page 31

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING

1. SYSTEM 27 MHz CLOCK, RESET, FLASH R/W SIGNAL

1) SPHE8202RQ-D main clock is at 27 MHz (Y2)

1

2) SPHE8202RQ-D reset is active high.

FIG 1-1

3.3V

1

CLKOUT CLKIN

R25 75R25 75

Y2

Y2

R26 100KR26 100K

C21

C21

33pF/50V/NP0

33pF/50V/NP0

GND

27MHz/30PPM

27MHz/30PPM

C22

C22

33pF/50V/NP0

33pF/50V/NP0

RESET

R56

R56

27K

27K

DVCC3

GND

R128 1KR128 1K

C99

C99

2.2uF/10V/Y5V

2.2uF/10V/Y5V

TP17TP17

C41

C41

0.1uF/25V/Y5V

0.1uF/25V/Y5V

4

RESET1

3

PCON/LED

TP71TP71

R16 4.7KR16 4.7K

R15

R15

4.7K

4.7K

Q3

Q3

NPN_3DG3904M

NPN_3DG3904M

GND

2

2

POCN

RESET

3

4

FIG 1-2

3-18

Page 32

3) RS232 waveform during procedure (Downloading)

5

6

TXD

RXD

FIG 1-3

4) Flash CE# enable signal and SCK signal during Downloading

M+5V

Debug Port

V_V_SYNC

V_H_SYNC

GND

TP47TP47

TP48TP48

5 6

TP46TP46

TP45TP45

XP6

XP6

1

1

2

2

3

3

4

4

4PIN/2.0mm

4PIN/2.0mm

7

8

CS

SCK

DVCC3 DVCC3

R90 10KR90 10K

R61 10KR61 10K

C52

C52

0.1uF/25V/Y5V

0.1uF/25V/Y5V

GND

7 8

U3

U3

1

SPI_CE

2

SPI_D0

3

4

GND GND

8

CE#

VDD

7

SO

HOLD#

6

WP#

SCK

5

VSS

SI

SPI_16Mb_EN25T160

SPI_16Mb_EN25T160

SPI_CLK

SPI_D1

C51

C51

0.1uF/25V/Y5V

0.1uF/25V/Y5V

FIG 1-4

3-19

Page 33

2. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)

U4

1

9

10

11

12

FIG 2-1

M+5V

GND

C97

C97

0.1uF/25V/Y5V

0.1uF/25V/Y5V

SP_MOT+

XOPVIP1

XOPVIN1

FOCUS_S

TR_B1

REGO2

SPDL_S TR_B2

10

REGO1

11

LOAD-

9

SP_MOT-

R65 1R65 1

VINFC

2

TR_B1

3

REGO2

4

VINSL

5

REGO1

6

SL-

FWD

7

SL+

REV

29

GND

8

VCC1

9

VOTR-

10

VOTR+

11

VOSL+

12

VOSL-

13

FACT-

VOFC-

14

FACT+

VOFC+

AM5890SU4AM5890S

MUTE

BIAS

VINTK

TR_B2

RESET

VINLD

GND

GND

VCTL

VCCD

VCC2

VOLD-

VOLD+

VOTK-

VOTK+

12

28

27

26

25

24

23

22

30

21

20

19

18

17

16

15

TP50TP50

DRVSB

DRVSB

VREF2

TRACK_S

RESET

SLED_S

GNDGND

SL_MOT+

SL_MOT-

TACT-

TACT+

3. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION)

FOCUS_S

TR_B1

13

14

15

FIG 3-1

M+5V

GND

C97

C97

0.1uF/25V/Y5V

0.1uF/25V/Y5V

SP_MOT+

XOPVIP1

XOPVIN1

REGO2

SPDL_S TR_B2

REGO1

SL-

SL+

LOAD-

SP_MOT-

R65 1R65 1

FACT-

FACT+

1415

13

TP50TP50

U4

1

VINFC

2

TR_B1

3

REGO2

4

VINSL

5

REGO1

6

FWD

7

REV

29

GND

8

VCC1

9

VOTR-

10

VOTR+

11

VOSL+

12

VOSL-

13

VOFC-

14

VOFC+

AM5890SU4AM5890S

MUTE

BIAS

VINTK

TR_B2

RESET

VINLD

GND

GND

VCTL

VCCD

VCC2

VOLD-

VOLD+

VOTK-

VOTK+

28

DRVSB

DRVSB

27

VREF2

26

TRACK_S

25

24

RESET

23

SLED_S

22

30

21

GNDGND

20

19

18

SL_MOT+

17

SL_MOT-

16

TACT-

15

TACT+

3-20

Page 34

4. LASER POWER CONTROL RELATED SIGNAL

7

7

16

17

18

GND

XP5

XP5

27

28

24PIN/0.5mm

24PIN/0.5mm

24

23

22

FIG 4-1 (NO DISC CONDITION)

16

17

18

21

20

19

18

17

16

15

14

13

12

TOP

TOP

11

10

9

8

7

6

5

4

3

2

1

25

26

TP20TP20

GND

TP44TP44

FACTFACT+

TACT+

TACT-

TP43TP43

TP42TP42

C

D

TP56TP56

TP63TP63

TP57TP57 C37

TP65TP65

TP66TP66

TP62TP62

TP67TP67

PUHRF

A

B

F

TP61TP61

TP55TP55

TP58TP58

GND

TP64TP64

TP59TP59

VREF1

E

CDVR#

DVDVR#

PUH_CDLD

DVDMDI

PUH_DVDLD

C29

C29

0.1uF/25V/Y5V

0.1uF/25V/Y5V

0.1uF/25V/Y5V

0.1uF/25V/Y5V

P+5V

R27

R27

10K

10K

TP5TP5

P+5V

C23 0.1uF/25V/Y5VC23 0.1uF/25V/Y5V

C25 0.1uF/25V/Y5VC25 0.1uF/25V/Y5V

R36 100R36 100

R38 100R38 100

16

GND

C37

GND

CDLDO

PNP_MMBT8550CLT1

PNP_MMBT8550CLT1

TP8TP8

LDSW

TRAY-

C11

C11

1000pF/50V/X7R

1000pF/50V/X7R

GND

TP9TP9

RF3.3V

CE13

CE13

+

+

47uF/16V

47uF/16V

CDVR

DVDVR

DVDMDI

CDMDI

C12

C12

1000pF/50V/X

1000pF/50V/X

GND

R47

R47

5.1

5.1

Q9

Q9

GND

16

17

18

FIG 4-2 (CD)

FIG 4-3 (DVD)

3-21

17

0.1uF/25V/Y5V

0.1uF/25V/Y5V

5V

C37

C37

GND

PNP_MMBT8550CLT1

PNP_MMBT8550CLT1

TP8TP8

TP9TP9

RF3.3V

CE13

CE13

+

+

47uF/16V

47uF/16V

Q9

Q9

R47

R47

5.1

5.1

RF3.3V

R48

R48

+

+

5.1

5.1

Q10

Q10

PNP_MMBT8550CLT1

PNP_MMBT8550CLT1

TP6TP6

CE14

CE14

47uF/16V

47uF/16V

TP7TP7

DVDLDOCDLDO

18

Page 35

5. SPINDLE CONTROL WAVEFORM

19

20

21

6. FOCUS ON WAVEFORM

FIG 5-1

M+5V

GND

C97

C97

0.1uF/25V/Y5V

0.1uF/25V/Y5V

SP_MOT+

XOPVIP1

XOPVIN1

FOCUS_S

TR_B1

REGO2

SPDL_S TR_B2

19

REGO1

20

LOAD-

21

SP_MOT-

R65 1R65 1

VINFC

2

TR_B1

3

REGO2

4

VINSL

5

REGO1

6

SL-

FWD

7

SL+

REV

29

GND

8

VCC1

9

VOTR-

10

VOTR+

11

VOSL+

12

VOSL-

13

FACT-

VOFC-

14

FACT+

VOFC+

AM5890SU4AM5890S

U4

1

MUTE

VINTK

TR_B2

RESET

VINLD

VCTL

VCCD

VCC2

VOLD-

VOLD+

VOTK-

VOTK+

BIAS

GND

GND

TP50TP50

28

DRVSB

DRVSB

27

VREF2

26

TRACK_S

25

24

RESET

23

SLED_S

22

30

21

GNDGND

20

19

18

SL_MOT+

17

SL_MOT-

16

TACT-

15

TACT+

22

23

24

22

23

24

FIG 6-1 (CD)

M+5V

GND

C97

C97

0.1uF/25V/Y5V

0.1uF/25V/Y5V

SP_MOT+

XOPVIP1

XOPVIN1

22

U4

1

FOCUS_S

TR_B1

REGO2

SPDL_S TR_B2

REGO1

LOAD-

SP_MOT-

R65 1R65 1

VINFC

2

TR_B1

3

REGO2

4

VINSL

5

REGO1

6

SL-

FWD

7

SL+

REV

29

GND

8

VCC1

9

VOTR-

10

VOTR+

11

VOSL+

12

VOSL-

13

FACT-

VOFC-

14

FACT+

VOFC+

AM5890SU4AM5890S

2423

MUTE

BIAS

VINTK

TR_B2

RESET

VINLD

GND

GND

VCTL

VCCD

VCC2

VOLD-

VOLD+

VOTK-

VOTK+

TP50TP50

28

DRVSB

DRVSB

27

VREF2

26

TRACK_S

25

24

RESET

23

SLED_S

22

30

21

GNDGND

20

19

18

SL_MOT+

17

SL_MOT-

16

TACT-

15

TACT+

FIG 6-2 (DVD)

3-22

Page 36

7. TRACKING CONTROL RELATED SIGNAL (SYSTEM CHECKING)

25

26

27

TP50TP50

MUTE

BIAS

VINTK

TR_B2

RESET

VINLD

GND

GND

VCTL

VCCD

VCC2

VOLD-

VOLD+

VOTK-

VOTK+

25

28

DRVSB

DRVSB

27

VREF2

26

TRACK_S

25

TR_B2

24

RESET

23

SLED_S

22

30

21

GND

20

19

18

SL_MOT+

17

SL_MOT-

16

TACT-

15

TACT+

26 27

C4 0.1uF/25V/Y5VC4 0.1uF/25V/Y5V

R22 0R22 0

R23 0R23 0

GND

SL-

SL+

25

FIG 7-1 (CD)

U4

1

VINFC

2

TR_B1

3

REGO2

4

VINSL

5

REGO1

6

FWD

7

REV

29

GND

8

VCC1

9

VOTR-

10

VOTR+

11

VOSL+

12

VOSL-

13

VOFC-

14

VOFC+

AM5890SU4AM5890S

RESET CIRCUIT

M+5V

R1331KR133

1K

R1343KR134

3K

GND

26

27

FIG 7-2 (DVD)

3-23

Page 37

8. SPHE8202RQ-D AUDIO COAXIAL OUTPUT (SPDIF)

TP68TP68

SPDIF_OUT

R113

R113

28

200

200

C87

C87

R116

R116

0.1uF/25V/Y5V

0.1uF/25V/Y5V

100

28

FIG 8-1

100

GND

SPDIF Circuit

FB9 500/800mAFB9 500/800mA

C88

C88

10pF/50V/NP0

10pF/50V/NP0

COAX

C114

C114

47pF/50V/NP0

47pF/50V/NP0

9. SPHE8202RQ-D VIDEO OUTPUT WAVEFORM

1) 100% COLOR BAR

FIG 9-1

3-24

Page 38

10. AUDIO OUTPUT FROM SPHE8202RQ-D/128

FIG 10-1

3-25

Page 39

WIRING DIAGRAM

DVD LOADER

TDL-5 LOADER+Doree TDT-DM00

SPSP+

HOMESW

GND

SLSL+

INSW

GND

1

24

1

6

1

XP3 XP4 XP5

2

6PIN*2.0 24PIN*0.5

2PIN*2.0

P1

AUDIO & VIDEO

MOTER

DRIVER

AM5890S

COAXFR

CVBS

FL

AMP&LPF

SPHE8202RQ-D

14PIN*2.0

XP2

1

Pb Pr

Y

M12L64164A

12

64M

16M SPI

FLASH

EN25T1

SDRAM

MAIN BOARD

USB_DP

USB_DM

GND

USB_5V

GND

IR

powerKEY

DATA

CLOCK

STB

M5V

MIC

12 1

XS301

12PIN*2.0

KEY+USB+MIC+LED

PI176

3-26

Page 40

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

AC INPUT

GND1

HV1 HV2

GND2

HV1

GND1

GND2

HV2

GND_POWER

<IREF>

+5V

<IREF>

+12V

<IREF>

F501

10ohm/2W

F501

10ohm/2W

ZD501

BZX79C11

ZD501

BZX79C11

R501 10KR501 10K

T501

36-TRF325-XX0-M

T501

36-TRF325-XX0-M

10

11

1

4

6

8

2

9

7

+

470uF/16V

CE507

+

470uF/16V

CE507

L501

680uH/300mA

L501

680uH/300mA

+

C505

NC 47uF/25V

+

C505

NC 47uF/25V

D501

1N4007/1A/1000V

D501

1N4007/1A/1000V

D506

FR104/1A/400V

D506

FR104/1A/400V

D505

1N4007/1A/1000V

D505

1N4007/1A/1000V

R510 10KR510 10K

C502 0.1uF/63VC502 0.1uF/63V

+

10uF/50V

CE503

+

10uF/50V

CE503

FB501

FB80@100MHz

FB501

FB80@100MHz

U502

LTV-817S-B

U502

LTV-817S-B

12

43

C501

1500pF/1KV

C501

1500pF/1KV

CY501 1000pF/250VACCY501 1000pF/250VAC

+

15uF/450V

CE502

+

15uF/450V

CE502

R504

NC 10k

R504

NC 10k

R502

150K

R502

150K

+

10uF/50V

CE504

+

10uF/50V

CE504

R503

150K

R503

150K

U501

TNY177

U501

TNY177

S

8

EN/UV

1

S5S

6

Drain

4

S

7

NC

3

BP/M

2

+

1000uF/16V

CE506

+

1000uF/16V

CE506

L502 6.8uHL502 6.8uH

U503U503

3

1

2

R511

100K

R511

100K

R505

12K/1%

R505

12K/1%

D507

NC

FR104/1A/400V

D507

NC

FR104/1A/400V

D508

SR360/3A/60V

D508

SR360/3A/60V

R507

11.3K/1%

R507

11.3K/1%

CN501

2PIN/7.92mm

CN501

2PIN/7.92mm

1

1

2

2

R5081KR508

1K

LF501

NC/20mH

LF501

NC/20mH

R509 100R509 100

D502

1N4007/1A/1000V

D502

1N4007/1A/1000V

+

15uF/500V

CE501

+

15uF/500V

CE501

D504

1N4007/1A/1000V

D504

1N4007/1A/1000V

D503

1N4007/1A/1000V

D503

1N4007/1A/1000V

ZD502NCZD502

NC

Warning

Parts that are shaded are critical with

respect to risk of fire or electrical shock.

3-27 3-28

CIRCUIT DIAGRAMS

1. SMPS & FRONT - SMPS CIRCUIT DIAGRAM

WHEN SERVICING THIS CHASSIS, UNDER NO

CIRCUMSTANCES SHOULD THE ORIGINAL

DESIGN BE MODIFIED OR ALTERED WITHOUT

PERMISSION FROM THE LG CORPORATION. ALL

COMPONENTS SHOULD BE REPLACED ONLY WITH

TYPES IDENTICAL TO THOSE IN THE ORIGINAL

CIRCUIT. SPECIAL COMPONENTS ARE SHADED

ON THE SCHEMATIC FOR EASY IDENTIFICATION.

THIS CIRCUIT DIAGRAM MAY OCCASIONALLY

DIFFER FROM THE ACTUAL CIRCUIT USED. THIS

WAY, IMPLEMENTATION OF THE LATEST SAFETY

AND PERFORMANCE IMPROVEMENT CHANGES

INTO THE SET IS NOT DELAYED UNTIL THE NEW

SERVICE LITERATURE IS PRINTED.

1. Shaded( ) parts are critical for safety. Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmeter

during Play mode.

IMPORTANT SAFETY

NOTE :

Page 41

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

CLOSE ET6207

TO MAIN BORAD

Power

Open/Close

Play/Pause

Volumn Down

Volumn Up

KS4

KS3

SG3

KS2

KS1

SG5

SG6

SG7

SG8

GR5

GR4

GR3

GR2

GR1

KS5

KS6

KS3

KS5

KS6

KEY2

GR[1:5]

GR1

SG8

GR5

SG2

SG7

SG6

SG3

SG1

SG4

M5VL

VSDA

SG1

SG2

SG4

IR

VCC_USB

VSCK

VSTB

KEY1

osc

SG[1:8]

KS[1:6]

KS1

GND

GR4

GND_POWER

GND_POWER

KS2

MIC

+5V

VSDA

IR

GND

VCC_USB

GND_POWER

USB_DP

USB_DM

GR3

GR2

SG5

USB_DM

USB_DP

VSTB

VSCK

INSW

INSW

+5V

+5V

+5V

MIC

+5V

GND_POWER

+12V

<IREF>

+5V

R1421KR142

1K

USB

P301

USB

USB

P301

USB

1

2

3

4

5

6

7

8

XS3

14PIN/2.0mm

XS3

14PIN/2.0mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

+

47uF/16V

CE135

+

47uF/16V

CE135

S135

TAC041

S135

TAC041

R1 0R1 0

R139

4.7K

R139

4.7K

R135 1KR135 1K

S140

TAC041

S140

TAC041

R145 1KR145 1K

C167

1uF/10V/Y5V

C167

1uF/10V/Y5V

S136

TAC041

S136

TAC041

C306

NC/100pF/50V/NP0

C306

NC/100pF/50V/NP0

R144 10KR144 10K

R141 1KR141 1K

C137

100pF/50V/NP0

C137

100pF/50V/NP0C136

100pF/50V/NP0

C136

100pF/50V/NP0

S137

TAC041

S137

TAC041

R2 0R2 0

R143 51KR143 51K

R140

4.7K

R140

4.7K

R137 1KR137 1K

XS2

14PIN/2.0mm

XS2

14PIN/2.0mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

XP1

NC

2PIN/2.0mm

XP1

NC

2PIN/2.0mm

1

1

2

2

C307

NC/100pF/50V/NP0

C307

NC/100pF/50V/NP0

R138

4.7K

R138

4.7K

R167 470R167 470

R166

470

R166

470

LED1

LED_2501AHG1

LED1

LED_2501AHG1

GRID5

13

GRID4

12

GRID3

11

GRID2

10

GRID1

9

SEG8

8

SEG7

7

SEG6

6

SEG5

5

SEG4

4

SEG3

3

SEG2

2

SEG1

1

IR1

IRM_8.3mm

IR1

IRM_8.3mm

IR

1

GND

2

VCC

3

C135

100pF/50V/NP0

C135

100pF/50V/NP0

U135

DRIVER_LED_ETK6207

U135

DRIVER_LED_ETK6207

OSC

1

DI/O

2

CLK

3

STB

4

KEY2

5

VDD

6

SG1/KS1

7

SG2/KS2

8

SG3/KS3

9

SG4/KS4

10

GR2

19

GND

18

GR3

17

GR4

16

SG14/GR5

15

SG13/GR6

14

SG12/GR7

13

GR1

20

SG6/KS6

12

SG5/KS5

11

C166

47pF/50V/NP0

C166

47pF/50V/NP0

R136 1KR136 1K

S139

TAC041

S139

TAC041

C138

0.1uF/50V/Y5V

C138

0.1uF/50V/Y5V

3-29 3-30

2. SMPS & FRONT - FRONT CONTROL CIRCUIT DIAGRAM

Page 42

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

3-31 3-32

3. SMPS & FRONT - MIC CIRCUIT DIAGRAM (OPTIONAL PART)

Page 43

9

21

1120

1019

12

25

26 27

14

24

15

23

2

16

18

17

3

: WAVEFORM NUMBER

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

13

22

GND

GND

SP-

STANDBY:40mA

Imax: 570mA

SP+

STANDBY:25mA

Imax: 368mA

STANDBY:15mA

Imax: 202mA

HOMESW

INSW

SLEDSLED+

8202 kernel +1.2V

Servo analog +5V

RESET CIRCUIT

M+5V

+12V: +12V(+-10%)

+5V: +5V(+-2.5%)

TO FRONT PANEL

FROM POWER BOARD

GND

IR

KEY2(STB)

KEY1(DATA)

LED (CLOCK)

USB_DM

USB_DP

USB_VCC(protect)

Use INSW and GND for DOREE LAODER

GND

MIC

powerkey

SPDL_S TR_B2

TR_B1

REGO2

LDSW

HOMESW

INSW

IN_OUT_SW

SP_MOT+

REGO2

REGO1

TR_B2TR_B1

SL_MOT-

SL_MOT+

SP_MOT-

DVDMDI

PUHRF

DVDVR

CDVR

VREF1

CDMDI

DVDMDI

E

DVDVR#

TRAY-

DVDLDO

CDMDI

USB_POWER

PCON/LED

VREF1

IR_IN

F

E

DVDMDI

RESET

USB_POWER

CDLDO

DVDLDO

RESET

FACT+

FOCUS_S

XOPVIN1

XOPVIP1

SL_MOT-

SP_MOT+

SL_MOT+

LDSW

XOPVIP1

XOPVIN1

VREF2

A

B

IN_OUT_SW

C

HOMESW

SLED_S

FOCUS_S

INSW

DRVSB

SPDL_S

TRACK_S

FACT-

VREF2

TACT-

TRACK_S

D

REGO1

SLED_S

DRVSB

SP_MOT-

TACT+

LOAD-

USB_DM1

USB_DP1

USB_VCC

PCON/LED

USB_DM1

USB_VCC

VFD_CLK

VFD_DATA

VFD_STB

IR_IN

USB_DP1

CDVR#

DVDVR

CDVR

VFD_DATA

VFD_STB

VFD_CLK

SL-

SL-

LOAD-

SL+

SL+

CDLDO

FACTFACT+

TACT+

TACT-

C

D

PUHRF

A

B

F

PUH_CDLD

PUH_DVDLD

M+5V

MIC_IN

MIC_IN

M+5V

P+5V

POWERKEY

POWER_KEY

POWER_KEY

M+5V

DRVSB

M+5V

INSW

GND

GND

GND

GND

GND

DVCC3

GND

GND

M+5V

DVCC3

P+5V

GND

GND

GND

GND

GND

P+5V

GND

RF3.3V

RF3.3V

P+5V

GND

GND

GND

M+5V

GND

GND

GND

M+5V

DVCC3

GNDGND

M+5V

GND

GND

VCC1.2

CDVR

4

DVDVR

4

DVDMDI

4

PUHRF

4

CDMDI

4

VREF1

4

F

4

E

4

RESET

4

CDLDO

4

DVDLDO

4

USB_POWER

4

LDSW

4

SPDL_S

4

SLED_S

4

TRACK_S

4

FOCUS_S

4

XOPVIP1

4

HOMESW

4

XOPVIN1

4

A

4

IN_OUT_SW

4

VREF2

4

D

4

INSW

4

B

4

C

4

DRVSB

4

PCON/LED

4

VFD_CLK

4

VFD_DATA

4

VFD_STB

4

IR_IN

4

USB_DM1

4

USB_DP1

4

USB_VCC

4

MIC_IN

4

M+5V

5

P+5V

5

POWER_KEY

5

M+5V

4

R47

5.1

R47

5.1

C14

100pF/50V/NP0

C14

100pF/50V/NP0

TP65TP65

R10

4.7K

R10

4.7K

R16 4.7KR16 4.7K

TP34TP34

TP25TP25

TP64TP64

TP29TP29

TP43TP43

TP20TP20

TP66TP66

Q4

PNP_3CA8550C

Q4

PNP_3CA8550C

R8 220R8 220

TP5TP5

TP26TP26

C3

0.1uF/50V/Y5V

C3

0.1uF/50V/Y5V

TP42TP42

R17

1.8/2W

R17

1.8/2W

C25 0.1uF/25V/Y5VC25 0.1uF/25V/Y5V

R27

10K

R27

10K

C7

100pF/50V/NP0C7100pF/50V/NP0

TP62TP62

R18

20K/1%

R18

20K/1%

TP27TP27

R2

4.7KR24.7K

R48

5.1

R48

5.1

TP67TP67

R7 220R7 220

C29

0.1uF/25V/Y5V

C29

0.1uF/25V/Y5V

TP61TP61

Q10

PNP_MMBT8550CLT1

Q10

PNP_MMBT8550CLT1

TP21TP21

R37

3.3K

R37

3.3K

C58

1000pF/50V/X7R

C58

1000pF/50V/X7R

C6

100pF/50V/NP0

C6

100pF/50V/NP0

TP50TP50

TP35TP35

Q1

PNP_3CA8550D

Q1

PNP_3CA8550D

R35 0R35 0

C59

1000pF/50V/X7R

C59

1000pF/50V/X7R

R340R34

0

TP36TP36

R20 5.6/1WR20 5.6/1W

U4

AM5890SU4AM5890S

VINFC

1

VOTR-

9

VOTR+

10

VOSL-

12

REGO2

3

TR_B1

2

VOTK+

15

REV

7

VOFC+

14

VOFC-

13

VCTL

21

VCC2

19

VCCD

20

RESET

24

BIAS

27

FWD

6

VINSL

4

REGO1

5

MUTE

28

VCC1

8

VOSL+

11

VOLD+

17

VOLD-

18

VOTK-

16

VINLD

23

GND

22

TR_B2

25

VINTK

26

GND

29

GND

30

C17

0.1uF/50V/Y5V

C17

0.1uF/50V/Y5V

TP8TP8

XP4

6PIN/2.0mm

XP4

6PIN/2.0mm

1

1

2

2

3

3

4

4

5

5

6

6

R6 220R6 220

C12

1000pF/50V/X7R

C12

1000pF/50V/X7R

C60

1000pF/50V/X7R

C60

1000pF/50V/X7R

R62

4.7K

R62

4.7K

TP37TP37

TP40TP40

TP9TP9

R3

NC/4.7KR3NC/4.7K

TP18TP18

XP10

2PIN/2.0mm

XP10

2PIN/2.0mm

1

1

2

2

TP57TP57

R19

12K/1%

R19

12K/1%

C9

100pF/50V/NP0C9100pF/50V/NP0

TP6TP6

R65 1R65 1

C13

0.1uF/50V/Y5V

C13

0.1uF/50V/Y5V

R1591KR159

1K

TP70TP70

C37

0.1uF/25V/Y5V

C37

0.1uF/25V/Y5V

C10

100pF/50V/NP0

C10

100pF/50V/NP0

TP19TP19

R5

NC/4.7KR5NC/4.7K

+

47uF/16V

CE13

+

47uF/16V

CE13

TP63TP63

R933R9

33

TP7TP7

TP30TP30

R33 0R33 0

R4

NC/4.7KR4NC/4.7K

C4 0.1uF/25V/Y5VC4 0.1uF/25V/Y5V

R36 100R36 100

Q5

PNP_3CA8550C

Q5

PNP_3CA8550C

TP28TP28

Q9

PNP_MMBT8550CLT1

Q9

PNP_MMBT8550CLT1

R631KR63

1K

XP9

14PIN/2.0mm

XP9

14PIN/2.0mm

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

13

13

14

14

TOP

XP5

24PIN/0.5mm

TOP

XP5

24PIN/0.5mm

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

25

26

27

28

R22 0R22 0

TP69TP69

R1331KR133

1K

TP31TP31

R39 0R39 0

TP56TP56

R28 10KR28 10K

+

47uF/16V

CE14

+

47uF/16V

CE14

TP55TP55

C2

0.1uF/50V/Y5V

C2

0.1uF/50V/Y5V

TP32TP32

R23 0R23 0

R38 100R38 100

C8

0.1uF/25V/Y5VC80.1uF/25V/Y5V

+

100uF/16V

CE2

+

100uF/16V

CE2

R641KR64

1K

C97

0.1uF/25V/Y5V

C97

0.1uF/25V/Y5V

TP58TP58

R15

4.7K

R15

4.7K

TP41TP41

TP33TP33

R1343KR134

3K

+

100uF/16V

CE4

+

100uF/16V

CE4

TP59TP59

C11

1000pF/50V/X7R

C11

1000pF/50V/X7R

Q3

NPN_3DG3904M

Q3

NPN_3DG3904M

TP71TP71

TP44TP44

C23 0.1uF/25V/Y5VC23 0.1uF/25V/Y5V

3-33 3-34

4. MAIN - POWER SUPPLY/ OPU CIRCUIT DIAGRAM

Page 44

4

1

5 6

7 8

: WAVEFORM NUMBER

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

RF +3.3V

Video DAC +3.3V

SDRAM +3.3V

Internal DA +3.3V

Internal AD +3.3V

TO USB READER BORAD

Close to 8202R

Close to SDRAM

NC(3PIN/2.0mm)

KARAOKE Circuit

KARAOKA INPUT

Close to 8202R

Debug Port

Close to 8202R

USB Protect Circuit

Close to 8202R

Close to 8202R

try 0 ohm

IN_OUT_SW

USB_POWER

INSW

USB_DM1

CDVR

A

HOMESW

XOPVIP1

IR_IN

VFD_DATA

VFD_STB

VFD_CLK

PCON/LED

DVDLDO

PCON/LED

M_A10

VREF1

M_A2

M_A1

SPDIF_OUT

M_RAS

M_CAS

M_A0

M_A4

M_DQM0

CDLDO

SLED_S

AOUT_FL

CLKOUT

B

USB_POWER

RAM_CLK

AUDIO_MUTE_CTL

C

AOUT_FR

CLKIN

SPI_CE

RESET

XOPVIP1

XOPVIN1

D

VFD_DATA

M_CLK

V_FSADJ

M_BA0

M_WE

E

RESET

RESET1

SLED_S

SPDL_S

M_BA1

F

DVDMDI

VREF2

VREF1

PUHRF

VREF2

TRACK_S

FOCUS_S

V_COMP

M_A3

DVDMDI

DRVSB

AIN_R

CDMDI

AUDIO_MUTE_CTL

RESET1

USB_DM

CDMDI

IR_IN

M_D3

V_H_SYNC

V_V_SYNC

SPDL_S

M_D7

VFD_STB

VFD_CLK

M_D6

M_D0

M_D1

M_D4

M_D11

M_D14

M_D5

M_D12

M_D2

M_D9

M_D13

M_D10

M_D15

M_A9

M_A8

M_D8

M_A6

M_A5

M_A7

CLKIN

PUHRF

SPI_CE

CDLDO

SPI_D0

DRVSB

SPI_CLK

SPI_D1

INSW

IN_OUT_SW

DVDVR

CDVR

CLKOUT

USB_DP

USB_DM

SPDIF_OUT

CVBS

CVBS

A

DAC_VREF

BDC

F

XOPVIN1

E

DVDLDO

AOUT_FR

AOUT_FL

SPI_D1

SD_CKE

SPI_CLK

SPI_D0

LDSW

LDSW

M_DQM1

DVDVR

M_A11

USB_DP1

USB_DM1

USB_VCC

USB_DP1

MIC_IN

M_A9

M_A7

M_A5

M_A6

M_A4

M_A8

M_A11

M_DQM0

M_DQM1

M_WE

M_RAS

M_CAS

SD_CKE

RAM_CLK

M_A2

M_A1

M_A3

M_A0

M_A10

M_BA0

M_BA1

M_D0

M_D1

M_D2

M_D3

M_D4

M_D5

M_D6

M_D7

M_D8

M_D9

M_D10

M_D11

M_D12

M_D13

M_D14

M_D15

HOMESW

TRACK_S

FOCUS_S

USB_DP

AIN_R

V_V_SYNC

V_H_SYNC

MIC_IN

POWER_KEY

POWER_KEY

M+5V

USB_VCC

G/Y

B/U

R/V

G/Y

B/U

R/V

GND

VVCC3

RF3.3V

GND

SD_VCC3

AD_VCC3

GND

AVCC3

DVCC3

GND

GND

GND

GND

GND

RF3.3V

GND

GND

GND

GND

GND

M+5V

DVCC3

GND

GND

VCC1.2

GND

GND

GND

DVCC3

GND

GND

AD_VCC3

AVCC3

GND

GND

VVCC3

GND

GND

VCC1.2

GND

DVCC3

DVCC3

GND

GND

RF3.3V

RF3.3V

M+5V

GND

DVCC3

GND

VVCC3

GND

VCC1.2

VVCC3

GND

DVCC3

VCC1.2

RF3.3V

GND GND

DVCC3 DVCC3

SD_VCC3

GND

SD_VCC3

SD_VCC3

SD_VCC3

SD_VCC3

SD_VCC3

SD_VCC3

SD_VCC3

GND

GND

GND

GND

GND

GND

GND

IN_OUT_SW

3

INSW

3

VREF1

3

HOMESW

3

IR_IN 3

VFD_CLK

3

VFD_STB

3

VFD_DATA 3

PCON/LED

3

PUHRF

3

CDMDI

3

DVDMDI

3

RESET

3

AUDIO_MUTE_CTL

5

XOPVIN1

3

XOPVIP1

3

SPDL_S

3

SLED_S

3

VREF2

3

FOCUS_S

3

TRACK_S

3

DRVSB

3

CVBS

5

USB_POWER

3

SPDIF_OUT

5

DVDVR

3

CDVR

3

CDLDO

3

DVDLDO

3

AOUT_FL

5

AOUT_FR

5

A3

D

3

C

3

B3

E

3

F

3

LDSW

3

USB_DP1 3

USB_VCC

3

USB_DM1 3

MIC_IN

3

POWER_KEY

3

M+5V

3

B/U 5

R/V 5

G/Y 5

C99

2.2uF/10V/Y5V

C99

2.2uF/10V/Y5V

C36 0.1uF/25V/Y5VC36 0.1uF/25V/Y5V

D9

33pF/50V/NP0

D9

33pF/50V/NP0

U2

SDRAM_64Mb_M12L64164A-75H

U2

SDRAM_64Mb_M12L64164A-75H

VDD

1

DQ0

2

VDDQ

3

DQ1

4

DQ2

5

VSSQ

6

DQ3

7

DQ4

8

VDDQ

9

DQ5

10

DQ6

11

VSSQ

12

DQ7

13

VDD

14

LDQM

15

WE

16

CAS

17

RAS

18

CS

19

BA0

20

A11

35

NC

36

CKE

37

CLK

38

NC

40

VSS

41

DQ8

42

VDDQ

43

DQ9

44

DQ10

45

VSSQ

46

DQ11

47

DQ12

48

VDDQ

49

DQ13

50

DQ14

51

VSSQ

52

DQ15

53

VSS

54

BA1

21

A10/AP

22

A0

23

A1

24

A2

25

A5

30

A6

31

A7

32

A8

33

A9

34

A3

26

VDD

27

VSS

28

A4

29

UDQM

39

C56

0.1uF/25V/Y5V

C56

0.1uF/25V/Y5V

TP47TP47

Y2

27MHz/30PPM

Y2

27MHz/30PPM

C54

0.1uF/25V/Y5V

C54

0.1uF/25V/Y5V

U1

SPHE8202RQ-D

U1

SPHE8202RQ-D

DVDLDO

102

APC_AVSS

101

OPVIN

100

OPVIP

99

CDE

98

CDF

97

DVDA96DVDB

95

DVDC94DVDD

93

RFIS

92

AGCCAP

91

AD_AVDD

90

AD_AVSS

89

LDSW/GPIO40

88

HOME/GPIO39

87

VDD_18

86

CLKOUT

85

CLKIN

84

PLL_VDD

83

PLL_VSS

82

USB_AVSS

81

USB_DM

80

USB_DP

79

CDLDO

103

DVDMDI

104

CDMDI

105

SRV_AVDD

106

V21

107

V165

108

DA_AVSS

109

DA_TEO

110

DA_FEO

111

DA_AVDD

112

SPDC_OUT

113

SC_OUT

114

DVDVR

115

DMEA

116

SD_D1/GPIO4

117

SD_D0/GPIO5

118

SD_CLK/GPIO6

119

TRAYIN/SD_SMD/GPIO7

120

TRAYOUT/SD_D3/GPIO8

121

SD_D2/GPIO9

122

CDVR

123

SPI_CE

124

SPI_D0

125

SPI_CLK

126

SPI_D1

127

ADAC_AVSS

64

VREF

61

ADAC_AVDD

62

AOUT_RS

59

AOUT_LS

60

ADAC_AVSS

58

AOUT_SUBW

57

AOUT_CENTER

56

AD_AVSS

53

AD_AVDD

54

AIN_R

55

SPDIF_OUT

51

M_A3

50

M_A2

49

M_A1

48

M_A0

47

M_A10

46

M_BA1/GPIO27

45

M_BA0

44

M_RAS

43

M_CAS

42

M_DQM0

40

M_WE

41

AOUT_L

65

USB_AVDD

78

VDD_18

77

TV_AVSS76TV_DAC375TV_DAC274TV_DAC1

73

TV_AVDD

72

TV_AVSS

71

TV_AVDD

70

TV_DAC0

69

V_FSADJ

68

V_COMP

67

AOUT_R

66

ADAC_AVDD

63

TRAY+

128

VFD_CLK/GPIO16

1

VFD_STB/GPIO17

2

VFD_DATA/GPIO183VDD_18

10

RESET_B5M_DQM2/GPIO22

11

M_DQM3/GPIO23

12

M_D013M_D114M_D215M_D316M_D417M_D518M_D619M_D720M_D1521M_D1422M_D1323M_D1224M_D1125M_D1026M_D927M_D828M_DQM129VSS30M_CLK31VDD_3332M_A11/GPIO25

33

M_A934M_A835M_A736M_A637M_A5

38

M_A4

39

VDD_334VSS6IR/GPIO197GPIO208GPIO21

9

GPIO29

52

C39 1uF/16V/Y5VC39 1uF/16V/Y5V

C35 0.1uF/25V/Y5VC35 0.1uF/25V/Y5V

TP48TP48

C50

0.1uF/25V/Y5V

C50

0.1uF/25V/Y5V

TP17TP17

TP22TP22

C38

0.1uF/25V/Y5V

C38

0.1uF/25V/Y5V

TP1TP1

R45 2.2KR45 2.2K

U3

SPI_16Mb_EN25T160

U3

SPI_16Mb_EN25T160

CE#

1

SO

2

WP#

3

VSS

4

SI

5

SCK

6

HOLD#

7

VDD

8

C20

0.1uF/25V/Y5V

C20

0.1uF/25V/Y5V

R128 1KR128 1K

C33 0.1uF/25V/Y5VC33 0.1uF/25V/Y5V

C42

0.1uF/25V/Y5V

C42

0.1uF/25V/Y5V

FB7 500/200mAFB7 500/200mA

TP2TP2

R46 1KR46 1K

R40 NCR40 NC

C34 0.1uF/25V/Y5VC34 0.1uF/25V/Y5V

C43

0.1uF/25V/Y5V

C43

0.1uF/25V/Y5V

F1 PTC/1.5A/6VF1 PTC/1.5A/6V

R301KR30

1K

R32

4.7K

R32

4.7K

R61 10KR61 10K

C31 680pF/50V/NP0C31 680pF/50V/NP0

R93 4.7KR93 4.7K

TP3TP3

R42 20KR42 20K

R2933R29

33

C45

0.1uF/25V/Y5V

C45

0.1uF/25V/Y5V

R56

27K

R56

27K

C52

0.1uF/25V/Y5V

C52

0.1uF/25V/Y5V

C30

0.1uF/25V/Y5V

C30

0.1uF/25V/Y5V

TP4TP4

TP12TP12

TP23TP23

R43 2.2KR43 2.2K

C32 1000pF/50V/X7RC32 1000pF/50V/X7R

C5

0.1uF/25V/Y5VC50.1uF/25V/Y5V

C46

0.1uF/25V/Y5V

C46

0.1uF/25V/Y5V

R25 75R25 75

XP6

4PIN/2.0mm

XP6

4PIN/2.0mm

1

1

2

2

3

3

4

4

C27 0.1uF/25V/Y5VC27 0.1uF/25V/Y5V

TP16TP16

R41 91KR41 91K

C24

10pF/50V/NP0

C24

10pF/50V/NP0

C48

0.1uF/25V/Y5V

C48

0.1uF/25V/Y5V

R31 0R31 0

+

47uF/16V

CE6

+

47uF/16V

CE6

C41

0.1uF/25V/Y5V

C41

0.1uF/25V/Y5V

C18

0.1uF/25V/Y5V

C18

0.1uF/25V/Y5V

D10

33pF/50V/NP0

D10

33pF/50V/NP0

R51

15K

R51

15K

C49

0.1uF/25V/Y5V

C49

0.1uF/25V/Y5V

C98 0.1uF/25V/Y5VC98 0.1uF/25V/Y5V

R121 180R121 180

TP49TP49

TP24TP24

R44 2.2KR44 2.2K

R52

15K

R52

15K

C26 1uF/10V/Y5VC26 1uF/10V/Y5V

C47

0.1uF/25V/Y5V

C47

0.1uF/25V/Y5V

R129 180R129 180

R160 2.2R160 2.2

C19

0.1uF/25V/Y5V

C19

0.1uF/25V/Y5V

R90 10KR90 10K

C22

33pF/50V/NP0

C22

33pF/50V/NP0

+

10uF/16V

CE10

+

10uF/16V

CE10

C57

0.1uF/25V/Y5V

C57

0.1uF/25V/Y5V

R26 100KR26 100K

C51

0.1uF/25V/Y5V

C51

0.1uF/25V/Y5V

+

47uF/16V

CE8

+

47uF/16V

CE8

TP10TP10

TP45TP45

C53 0.1uF/25V/Y5VC53 0.1uF/25V/Y5V

C16

0.1uF/25V/Y5V

C16

0.1uF/25V/Y5V

C40

1000pF/50V/X7R

C40

1000pF/50V/X7R

TP11TP11

+

100uF/16V

CE7

+

100uF/16V

CE7

C55

0.1uF/25V/Y5V

C55

0.1uF/25V/Y5V

C21

33pF/50V/NP0

C21

33pF/50V/NP0

Q29

PNP_PBSS5320T

Q29

PNP_PBSS5320T

FB8 500/200mAFB8 500/200mA

R24 5.6R24 5.6

TP46TP46

3-35 3-36

5. MAIN - SPHE8202RQ-D/ FLASH/ SDRAM CIRCUIT DIAGRAM

Page 45

28

: WAVEFORM NUMBER

A

1

2

3

4

5

6

7

8

9

10

11

12

B C D E F G H I J K L M N O P Q R ST

SPDIF Circuit

VIDEO OUT

AOUT_FR

AOUT_FL

SPDIF_OUT

COAX

SPDIF_OUT

AUDIO_MUTE_CTL

CVBS

P+5V

M+5V

AOUT_FR

AUDIO_MUTE_CTLAUDIO_MUTEAUDIO_MUTEAUDIO_MUTE

P+5V

RCH

LCH

AOUT_FL

R/V

B/U

G/Y

G/Y1

B/U1

R/V1

B/U

G/Y

R/V

CVBS

U_OUT

Y_OUT

CVBS_O

G/Y1

R/V1

B/U1

V_OUT

V_OUT

Y_OUT

COAX

CVBS_O

V_OUT

U_OUT U_OUT

LCH

RCH

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

GND

SPDIF_OUT

4

AUDIO_MUTE_CTL

4

AOUT_FL

4

AOUT_FR

4

CVBS

4

P+5V

3

M+5V

3

B/U 4

R/V 4

G/Y 4

TP15TP15

C81

100pF/50V/NP0

C81

100pF/50V/NP0

R127 100R127 100

R116

100

R116

100