Page 1

DRYERS

USER'SGUIDE&

INSTALLATIONINSTRUCTIONS

Before beginning installation, read these

instructions carefully. This wli simplify installation

and ensure that the dryer is installed correctly and

safely. Leave these instructions near the dryer

after installation for future reference.

SECADORAS

GU|ADELUSUARIOE

INSTRUCCiONESDEINSTALACION

Antes de comenzar la instalacion, lea atentamente

estas instrucciones. Esto simplificara la instalacion

y asegurara que la secadora esta instalada

en forma correcta y segura. Conserve estas

instrucciones cerca de la secadora luego de la

instalacion para futuras consultas.

TOcontact LG Electronics, 24 hours a day,

7 days a week:

1=800=243=0000

Or visit us on the Web at: usJge.com

Pour contacter LG Electronics, 24 heures

par jour, 7 jours par semaine :

1-800-243-0000

ou visitez notre site Web a radresse :

us. Ige. tom

To contact LG Electronics, 24 hours a day,

7 days a week:

1=888=LGCANADA

Or visit us on the Web at: caJge.com

Pour contacter LG Electronics, 24 heures

par jour, 7 jours par semaine :

1=888=LGCANADA

Ou visitez notre site Web a I'adresse

ca. Ige. tom

GUIDEDEL'UTILISATEURET

DIRECTIVESD'INSTALLATiON

Avant de commencer a installer votre s¢cheuse, Iisez

attentivement ces instructions. Cela simplifiera votre

installation et assurera que la s¢cheuse est installce

correctement et en route securite. Conservez ces

instructions a proximite de las¢cheuse apr¢s son

installation, pour reference future.

Models/Modelos/Modeles

Electric/Eledrica/l_lec[rique

DLE2150W DLE2050W DLE2020W

DLE2150R DLE2050R DLE2020R

DLE2150S DLE2050S DLE2020S

DLE2150L DLE2050L DLE2020L

SECttEUSES

Cas/Cas/A_az

DLG2151W DLG2051W DLG2021CW

DLG2151R DLG2051R DLG2021CR

DLG2151S DLG2051S DLG2021CS

DLG2151L DLG2051L DLG2021CL

P/No. MFL62512801

Page 2

INT ODUCflON

IMPORTANT SAFETY INSTRUCTIONS

What to Do if You Smell Gas .................................. 3

Basic Safety Precautions ....................................... 4

California safe drinking water and toxic

enforcement act ..................................................... 4

Grounding Instructions ........................................... 5

Safety Instructions for Installation ...................... 5, 6

Safety Instructions for Connecting Electricity ....... 7

f_

THANK YOU!

Congratulations on your purchase

PARTS AND FEATURES

Special Features ..................................................... 8

Key Parts and Components ................................... 9

INSTALLATION INSTRUCTIONS

IMPORTANT: Read all installation instructions

completely before installing and operating your

dryer! .................................................................... 10

Choose the Proper Location ................................ 10

Clearances ........................................................... 10

Installation With Optional

Pedestal Base or Stacking Kit.............................. 11

Leveling the Dryer ................................................ 12

Reversing the Door Swing .................................... 12

Changing the Dryer Vent Location ....................... 13

Venting the Dryer ............................................ 14, 15

Connecting Gas Dryers .................................. 16, 17

Connecting Electric Dryers .............................. 18-22

Special Requirements for Manufactured

or Mobile Homes .................................................. 23

Final Installation Check ....................................... 23

Duct Condition Testing ......................................... 24

NOW TO USE

Sorting Loads ....................................................... 25

Loading the Dryer ................................................. 25

Check the Lint Filter Before Every Load ............... 25

Control Panel Features ......................................... 26

Cycle Guide .................................................... 27, 28

The Time and Status Display ............................... 29

Operating the Dryer .............................................. 30

Cycle Setting Buttons .......................................... 31

Cycle Option Buttons .......................................... 32

Special Functions ................................................. 33

Custom Program .................................................. 33

and welcome to the LG family. Your

new LG Dryer combines the most

advanced drying sensor technology

with simple operation and high

efficiency. By following the

operating and care instructions

in this manual, your dryer will

provide you with many years of

reliable service.

CARE AND CLEANING

Regular Cleaning .................................................. 34

TROUBLESHOOTING

Before Calling for Service ............................... 35-37

SPECIFICATIONS/OPTIONAL

ACCESSORIES

Optional Accessories ........................................... 37

Pedestal Installation ....................................... 38, 39

Stacking Kit Installation .................................. 40, 41

Key Dimensions and Specifications ..................... 41

WARRANTY

Product Information Registration ................... 42.43

2

Page 3

iMPORTANTSAFETYiNSTRUCTiONS

READ ALL iNSTRUCTiONS BSFORE USE

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

Your Safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

This isthe safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word DANGER or WARNING.

These words mean:

_:)A_G_::_." You can be killed or seriously injured if you don't immediately follow instructions.

_WARN|NG: You can be killed or seriously injured if you don't follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of

injury, and tell you what can happen if the instructions are not followed.

Do not install a clothes dryer with

flexible plastic venting materials. If

flexible metal (foil type) duct is in-

stalled, it must be of a specific type

identified by the appliance manufac=

turer as suitable for use with clothes

dryers. Flexible venting materials are

known to collapse, be easily crushed,

and trap lint. These conditions will

obstruct clothes dryer airflow and

increase the risk of fire.

• Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this appliance or any other

appliances.

• Installation and service must be

performed by a qualified installer,

service agency, or the gas supplier.

,, Install the clothes dryer according to

the manufacturer's instructions and

local codes.

= Save these instructions.

WHAT TO DO IF YOU SMELL GAS:

1. Do not try to light a match or cigarette,

or turn on any gas or electrical

appliance.

2. Do not touch any electrical switches.

Do not use any phone in your building.

3. Clear the room, building, or area of all

occupants.

4. Immediately call your gas supplier

from a neighbor's phone. Follow the

gas supplier's instructions carefully.

5. If you cannot reach your gas

supplier, call the fire department.

5

Page 4

I PORTANTSAFETYINSTRUcTiONS

R :AD ALL iNSTRUCTiONS BEFORE USS

WARNING For your safety,the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

BASICSAFETY PRECAUTIONS

WARNING:

appliance, follow basic precautions, including the following:

• Read all instructions before using the dryer.

• Before use, the dryer must be properly installed

as described in this manual.

• Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking

oils may contribute to a chemical reaction that

could cause a load to catch fire.

Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted

with gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

• DO not reach into the dryer if the drum or any

other part is moving.

Do not repair or replace any part of the dryer

or attempt any servicing unless specifically

recommended in this Use and Care Guide or

in published user-repair instructions that you

understand and have the skills to carry out.

• DO not tamper with controls.

Before the dryer is removed from service or

discarded, remove the door to the drying

compartment.

TOreduce the risk of fire, electric shock, or injury to persons when using this

DO not allow children to play on or in the dryer.

Close supervision of children is necessary when

the dryer is used near children.

Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

Do not use heat to dry articles containing

foam rubber or similarly textured rubber-like

materials.

Keep area around the exhaust opening and

adjacent surrounding areas free from the

accumulation of lint, dust, and dirt.

The interior of the dryer and exhaust vent

should be cleaned periodically by qualified

service personnel.

Do not install or store the dryer where it will be

exposed to the weather.

Always check the inside of the dryer for foreign

objects.

Clean lint screen before or after each load.

CALIFORNIA SAFE DRINKING WATER AND TOXIC ENFORCEMENT ACT

This act requires the governor of California to publish a list of substances known to the state to cause

cancer, birth defects, or other reproductive harm and requires businesses to warn customers of potential

exposure to such substances.

Gas appliances can cause minor exposure to four of these substances, namely benzene, carbon monoxide,

formaldehyde, and soot, caused primarily by the incomplete combustion of natural gas or LP fuels.

Properly adjusted dryers will minimize incomplete combustion. Exposure to these substances can be

minimized further by properly venting the dryer to the outdoors.

4

Page 5

iMPORTANTSAFETYiNSTRUCTiONS

READ ALL iNSTRUCTiONS BSFORE USE

,WARNING For your safety,the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

GROUNDING iNSTRUCTiONS

This appliance must be grounded. In the event

of malfunction or breakdown, grounding will

reduce the risk of electric shock by providing

a path of least resistance for electric current.

This appliance must be equipped with a cord

having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into

an appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided with the

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

This appliance must be connected to a grounded

metal, permanent wiring system or an equipment-

grounding conductor must be run with the circuit

conductors and connected to the equipment-

grounding terminal or lead on the appliance.

Electrical shock can result if the dryer is not

properly grounded.

WARNING-Improper

connection of the equipment=grounding

conductor can result in a risk of electric shock.

Check with a qualified electrician or service

person if you are in doubt as to whether the

appliance is properly grounded.

SAFETY iNSTRUCTiONS FOR iNSTALLATiON

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Properly ground dryer to conform with all

governing codes and ordinances. Follow

details in the installation instructions. Electrical

shock can result if the dryer is not properly

grounded.

• Before use, the dryer must be properly

installed as described in this manual.

Electrical shock can result if the dryer is not .

properly grounded.

• install and store the dryer where it will not be

exposed to temperatures below freezing or

exposed to the weather.

, All repairs and servicing must be performed

by an authorized servicer unless specifically ,

recommended in this Owner's Guide. Use

only authorized factory parts. Failure to follow

this warning can cause serious injury, fire,

electrical shock, or death.

• To reduce the risk of electric shock, do not

install the dryer in humid spaces. Failure to

follow this warning can cause serious injury, fire,

electrical shock, or death.

Connect to a properly rated, protected,

and sized power circuit to avoid electrical

overload, improper power circuit can melt,

creating electrical shock and/or fire hazard.

Remove all packing items and dispose of all

shipping materials properly. Failure to do so

can result in death, explosion, fire, or burns.

Place dryer at least 18 in. above the floor

for a garage installation. Failure to do so can

result in death, explosion, fire, or burns.

Keep all packaging from children. Packaging

material can be dangerous for children. There is

a risk of suffocation.

Do not install nearby heat item. Such as

stove, cooking oven. Failure to do so can cause

deform, smoke and fire.

Do not place candle and cigarettes on top of

the product. Failure to do so can cause deform,

smoke and fire.

Remove all protective vinyl film from the

product. Failure to do so can cause deform,

smoke and fire.

5

Page 6

I PORTANTSAFETYiNSTRUcTiONS

R :AD ALL iNSTRUCTiONS BI=FORI: USS

WARNING For your safety,the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

SAFETY iNSTRUCTiONS FOR iNSTALLATiON

Exhaust/Ducting:

• Gas dryers MUST be exhausted to the

outside. Failure to follow these instructions

can result in fire or death.

• The dryer exhaust system must be exhausted

to the outside of the dwelling, if the dryer is

not exhausted outdoors, some fine lint and

large amounts of moisture will be expelled

into the laundry area. An accumulation of

lint inany area of the home can create a health

and fire hazard.

• Use only rigid metal or flexible metal 4=in.

diameter ductwork inside the dryer cabinet

or for exhausting to the outside. Use of

plastic or other combustible ductwork can

cause a fire. Punctured ductwork can cause

a fire if itcollapses or becomes otherwise

restricted inuse or during installation.

• Ductwork is not provided with the dryer, and

you should obtain the necessary ductwork

locally. The end cap should have hinged

dampers to prevent backdraft when the dryer

is not in use. Failure to follow these instructions

can result in fire or death.

• The exhaust duct must be 4 in. (10.2 cm) in

diameter with no obstructions. The exhaust

duct should be kept as short as possible.

Make sure to clean any old ducts before

installing your new dryer. Failure to follow

these instructions can result in fire or death.

• Rigid or semi rigid metal ducting is

recommended for use between the

dryer and the wall. in special installations

when it is impossible to make a connection

with the above recommendations, a UL-

listed flexible metal transition duct may be

used between the dryer and wall connection

only. The use of this ducting will affect drying

time. Failure to follow these instructions can

result in fire or death.

• DO NOT use sheet metal screws or other

fasteners which extend into the duct that

could catch lint and reduce the efficiency

of the exhaust system. Secure all joints with

duct tape. For complete details, follow the

installation Instructions. Failure to follow these

instructions can result in fire or death.

6

Page 7

iMPORTANTSAFETYiNSTRUCTiONS

READ ALL INSTRUCTIONS BEFORE USE

WARNING For your safety,the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

SAFETY iNSTRUCTiONS FOR CONNECTING ELECTRiCiTY

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

, Do not, under any circumstances, cut or

remove the ground prong from the power

cord. To prevent personal injury or damage to

the dryer, the electrical power cord must be

plugged into a properly grounded outlet.

, For personal safety, this dryer must be

properly grounded. Failure to do so can result

in electrical shock or injury.

• Refer to the installation instructions in this

manual for specific electrical requirements

for your model. Failure to follow these

instructions can create an electrical shock

hazard and/or a fire hazard.

• This dryer must be plugged into a properly

grounded outlet. Electrical shock can result if

the dryer is not properly grounded. Have the

wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly

grounded. Failure to follow these instructions

can create an electrical shock hazard and/or a

fire hazard.

• The dryer should always be plugged into

its own individual electrical outlet which

has a voltage rating that matches the rating

plate. This provides the best performance

and also prevents overloading house wiring

circuits which could cause a fire hazard from

overheated wires.

, Never unplug your dryer by pulling on the

power cord. Always grip plug firmly and pull

straight out from the outlet. The power cord

can be damaged, resulting in a risk of fire and

electrical shock.

• Repair or replace immediately all power

cords that have become frayed or otherwise

damaged. Do not use a cord that shows

cracks or abrasion damage along its length

or at either end. The power cord can melt,

creating electrical shock and/or fire hazard.

• When installing or moving the dryer, be

careful not to pinch, crush, or damage

the power cord. This will prevent injury and

prevent damage to the dryer from fire and

electrical shock.

SAVE THESE INSTRUCTIONS

7

Page 8

PARTSAND FEATU ES

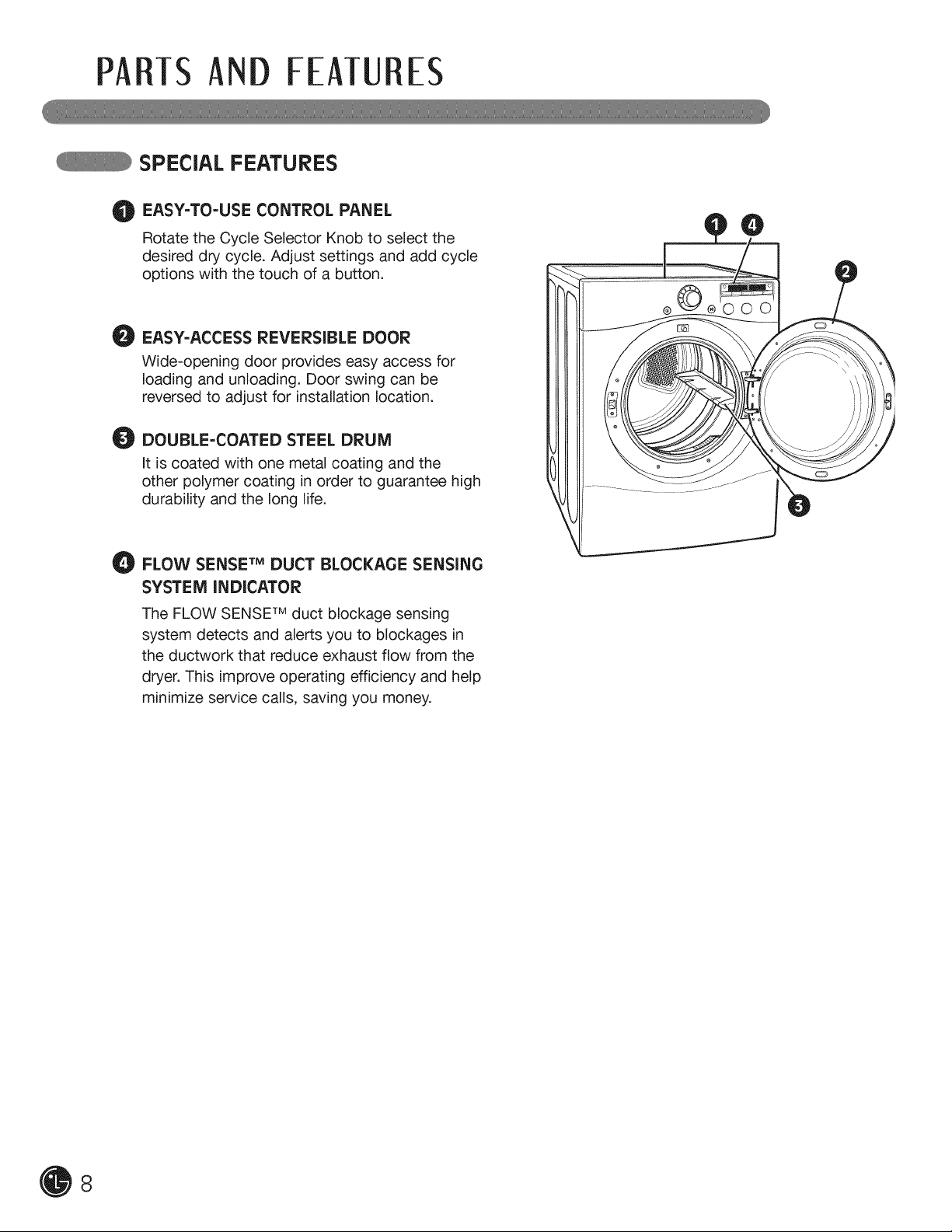

SPECIAL FEATURES

O EASY-TO-USE CONTROL PANEL

Rotate the Cycle Selector Knob to select the

desired dry cycle. Adjust settings and add cycle

options with the touch of a button.

EASY=ACCESS REVERSIBLE DOOR

O

Wide-opening door provides easy access for

loading and unloading. Door swing can be

reversed to adjust for installation location.

DOUBLE=COATED STEEL DRUM

O

It is coated with one metal coating and the

other polymer coating in order to guarantee high

durability and the long life.

x

\\

]

FLOW SENSE TM DUCT BLOCKAGE SENSING

O

SYSTEM iNDiCATOR

The FLOW SENSE TM duct blockage sensing

system detects and alerts you to blockages in

the ductwork that reduce exhaust flow from the

dryer. This improve operating efficiency and help

minimize service calls, saving you money.

8

Page 9

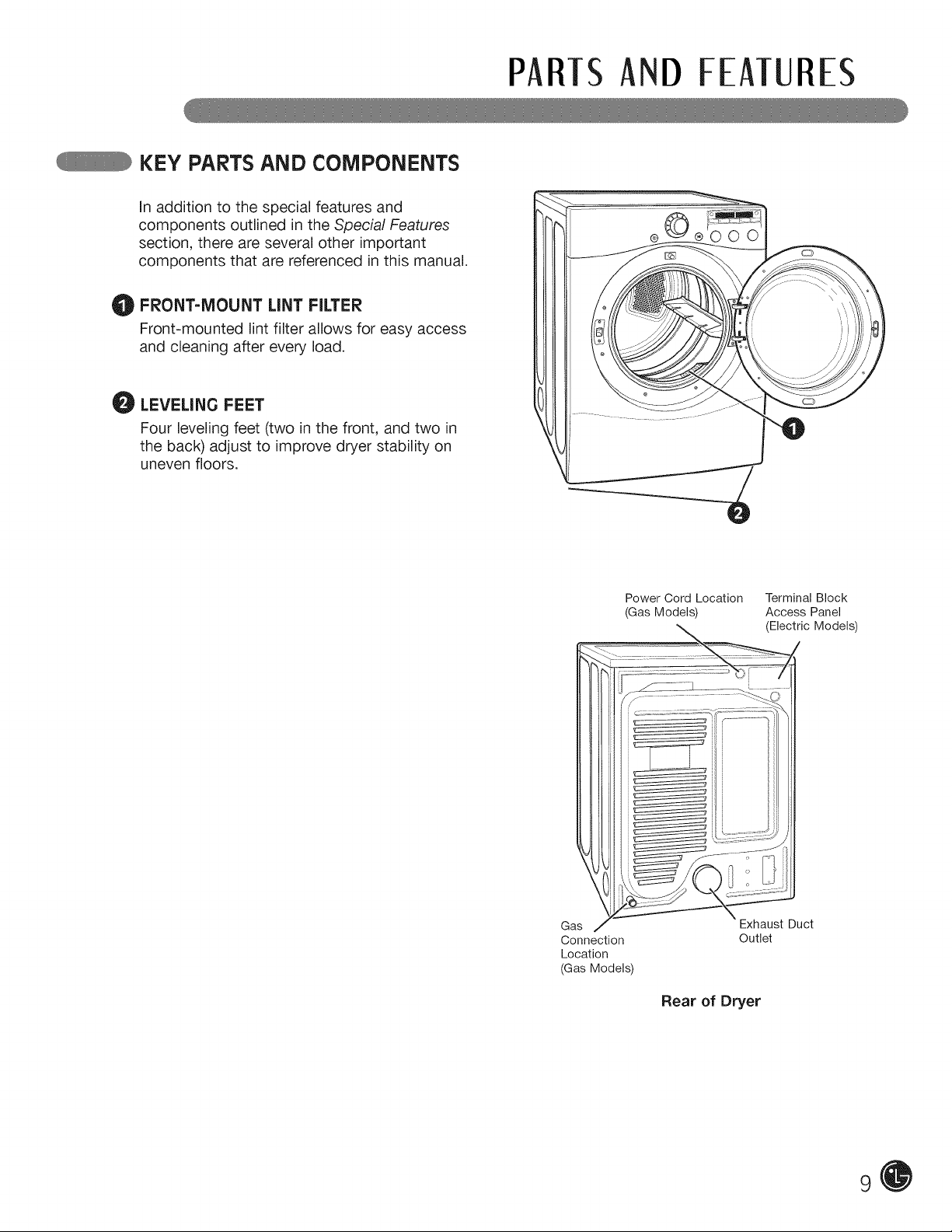

KEY PARTS AND COMPONENTS

In addition to the special features and

components outlined in the Special Features

section, there are several other important

components that are referenced in this manual.

FRONT-MOUNT LINT FILTER

0

Front-mounted lint filter allows for easy access

and cleaning after every load.

LEVELING FEET

Four leveling feet (two in the front, and two in

the back) adjust to improve dryer stability on

uneven floors.

PARTSAND FEATURES

®

Gas

Connection

Location

(Gas Models)

Power Cord Location Terminal Block

(Gas Models) Access Panel

(Electric Models)

Exhaust Duct

Outlet

Rear of Dryer

9

Page 10

INSTALLATIONINST UcTIONS

IMPORTANT: Read all installation instructions completely before

installing and operating your dryer!

It is important that you review this entire manual before installing and using your dryer. Detailed instructions

concerning electrical connections, gas connections, and exhaust requirements are provided on the

following pages.

CHOOSE THE PROPER LOCATION

• Store and install the dryer where it will not be

exposed to temperatures below freezing or

exposed to outdoor weather conditions.

• Choose a location with a solid, level floor.

If the dryer is being installed in a garage,

place the dryer at least 18 in. (46 cm) above

the floor.

• Properly ground dryer to conform with all

governing codes and ordinances.

To reduce the risk of electric shock, do not

install the dryer in damp or wet locations.

if you are installing your dryer in a manufactured

or mobile home, please refer to the section

Special Requirements for Manufactured or

Mobile Homes.

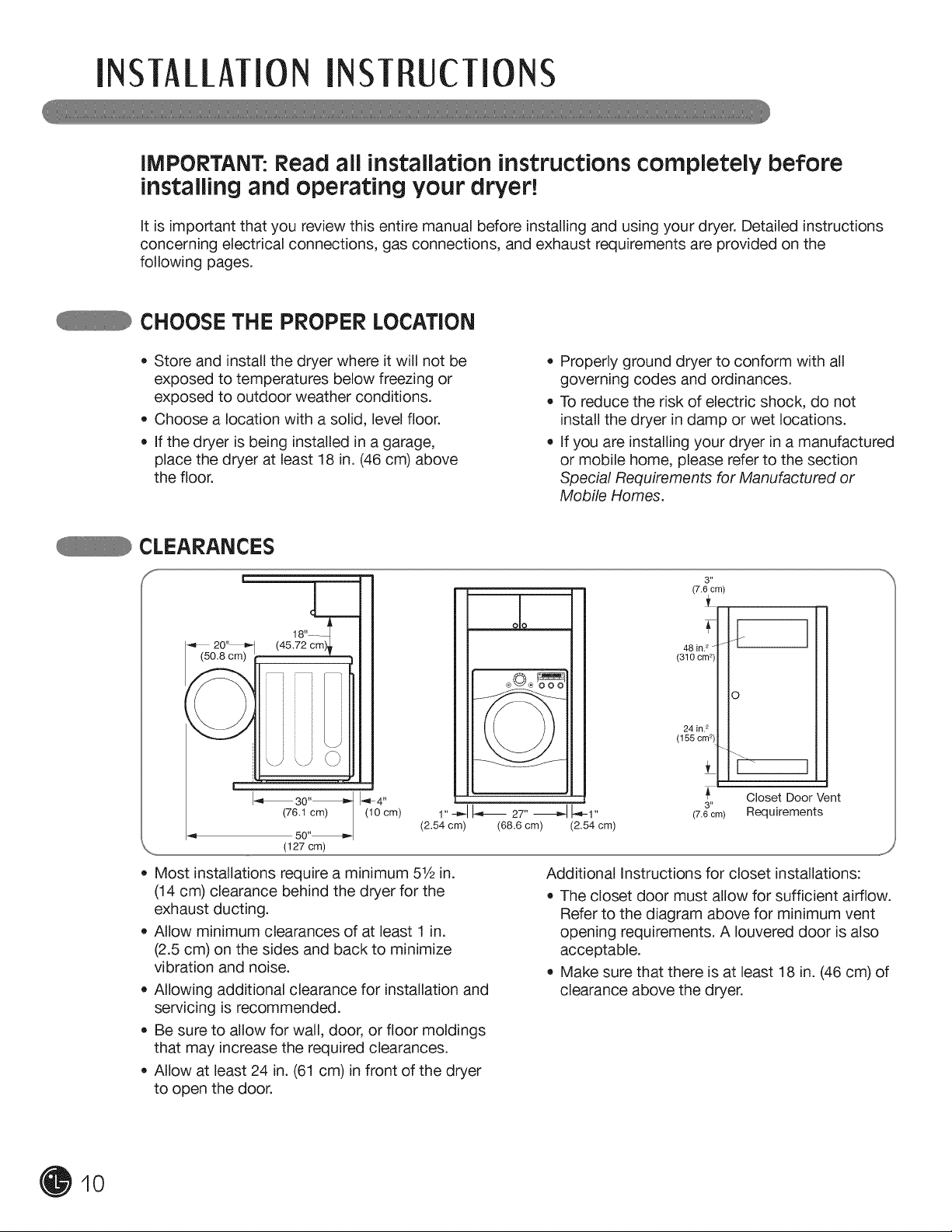

CLEARANCES

3"

(7.6 cm)

(50.8cm)

I_ 30_

(76.1 cm)

50_'_

,o_ (127 cm) ....

1_4" _ Closet Door Vent

(10 cm) (7.6cm) Requirements

1"-_11-_ 27"-_1 _1"

(2.54 cm) (68.6 cm) (2.54 cm)

Most installations require a minimum 51/2in.

(14 cm) clearance behind the dryer for the

exhaust ducting.

Allow minimum clearances of at least 1 in.

(2.5 cm) on the sides and back to minimize

vibration and noise.

Allowing additional clearance for installation and

olo

Additional instructions for closet installations:

The closet door must allow for sufficient airflow.

Refer to the diagram above for minimum vent

opening requirements. A Iouvered door is also

acceptable.

Make sure that there is at least 18 in. (46 cm) of

clearance above the dryer.

servicing is recommended.

Be sure to allow for wall, door, or floor moldings

that may increase the required clearances.

Allow at least 24 in. (61 cm) in front of the dryer

to open the door.

48 in.2 -_

(310 cm 2)

24 in.2

(155 cm 2)

3"

10

Page 11

INSTAllATION INSTRUCTIONS

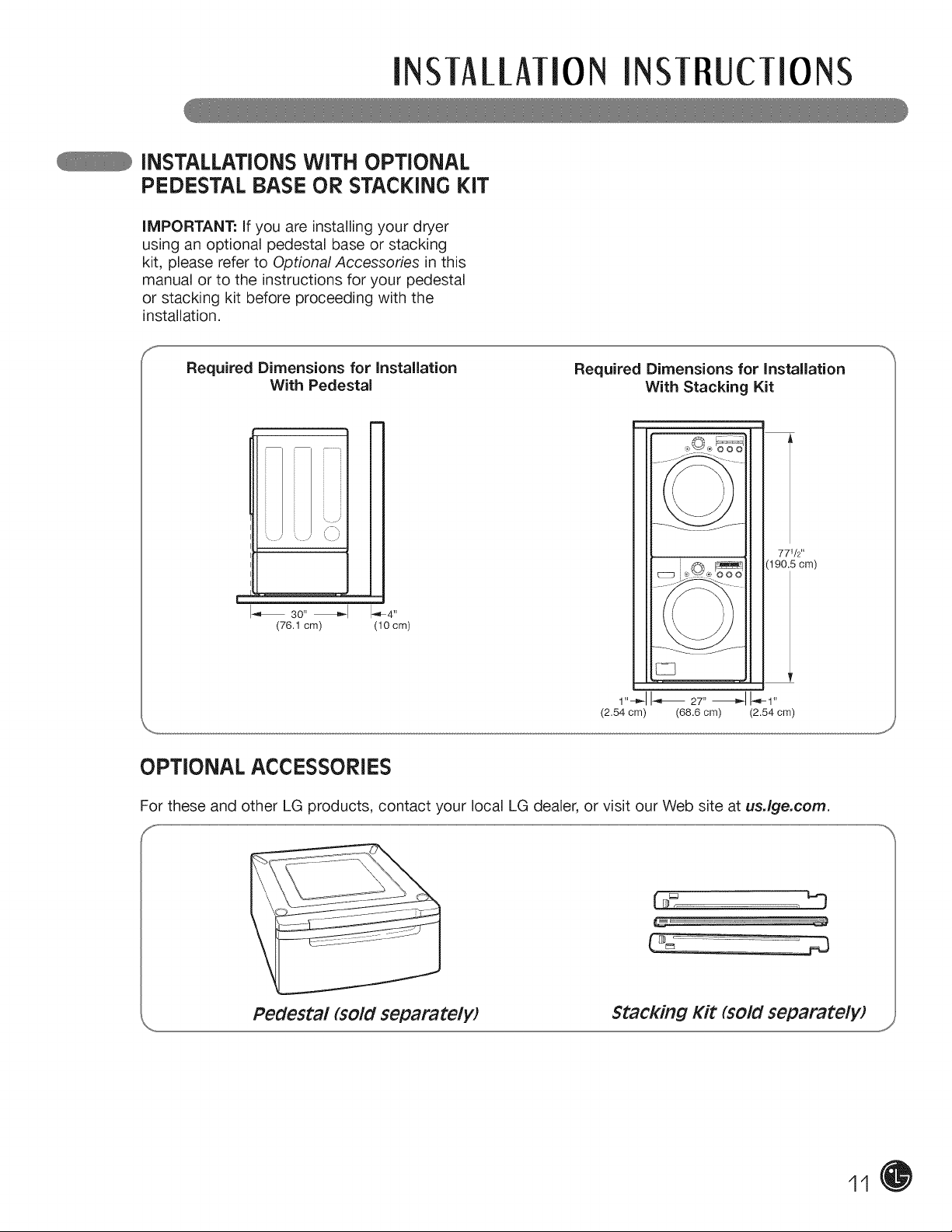

iNSTALLATiONS WITH OPTIONAL

PEDESTAL BASE OR STACKING KIT

iMPORTANT: If you are installingyour dryer

using an optional pedestal base or stacking

kit, please refer to Optional Accessories in this

manual or to the instructions for your pedestal

or stacking kit before proceeding with the

installation.

Required Dimensions for Installation

With Pedestal

'\ /' '\ J _ /

/ \,

Required Dimensions for Installation

With Stacking Kit

L

i

771/2 '`

(190.5 cm)

I_ 30"_1 1_4"

(76.1 cm) (10 cm)

{Z

1"-_1I_ 27" _ I_a-1 ''

(2.54 cm) (68.6 cm) (2.54 cm)

OPTIONAL ACCESSORIES

For these and other LG products, contact your local LG dealer, or visit our Web site at us.lge.com.

Pedestal (sold separatelW Stacking Kit (sold separately)

11

Page 12

INSTALLATIONINST UcTIONS

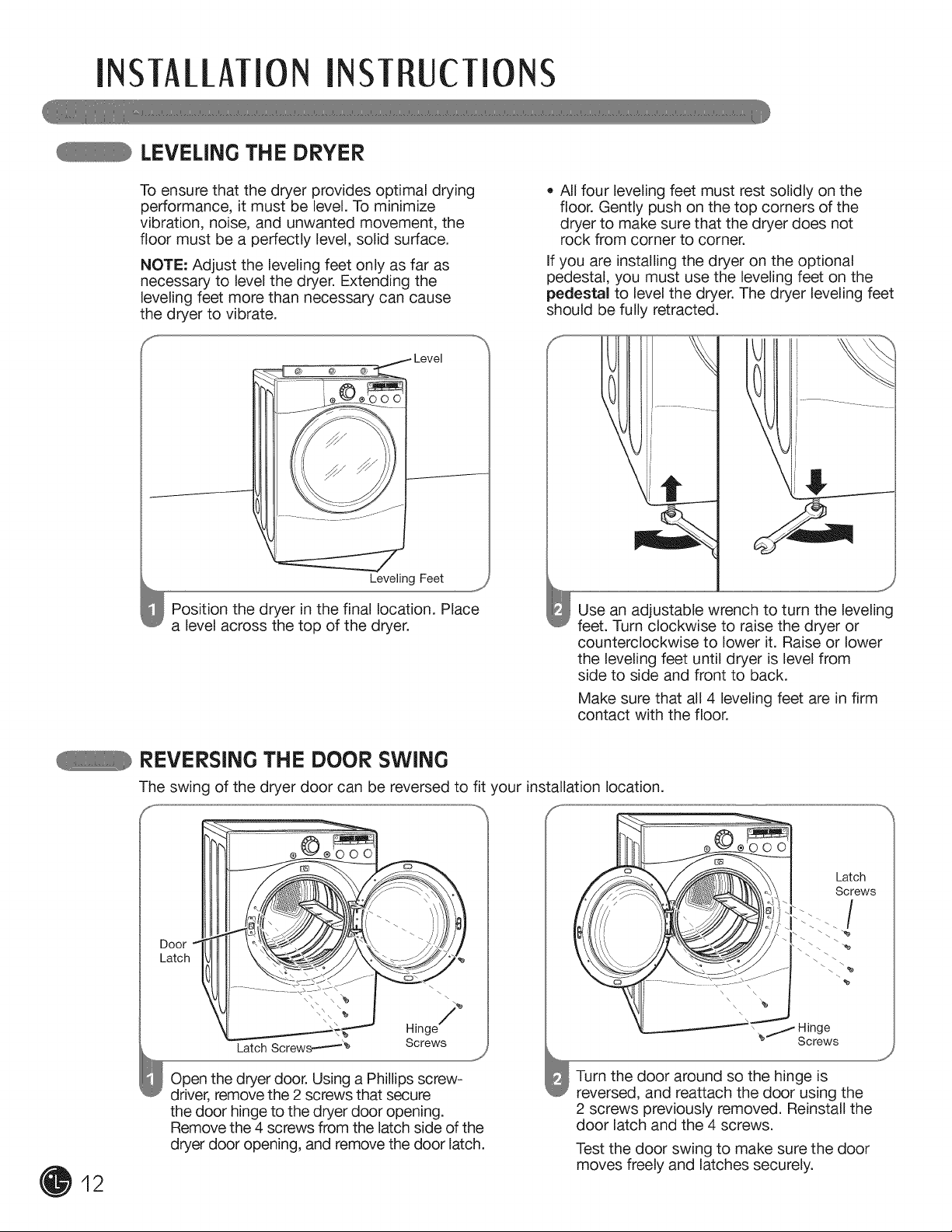

LEVELING THE DRYER

TOensure that the dryer provides optimal drying

performance, it must be level. TOminimize

vibration, noise, and unwanted movement, the

floor must be a perfectly level, solid surface.

NOTE: Adjust the leveling feet only as far as

necessary to level the dryer. Extending the

leveling feet more than necessary can cause

the dryer to vibrate.

Level

Leveling Feet

Position the dryer in the final location. Place

a level across the top of the dryer.

• All four leveling feet must rest solidly on the

floor. Gently push on the top corners of the

dryer to make sure that the dryer does not

rock from corner to corner.

If you are installing the dryer on the optional

pedestal, you must use the leveling feet on the

pedestal to level the dryer. The dryer leveling feet

should be fully retracted.

J

Use an adjustable wrench to turn the leveling

feet. Turn clockwise to raise the dryer or

counterclockwise to lower it. Raise or lower

the leveling feet until dryer is level from

side to side and front to back.

Make sure that all 4 leveling feet are in firm

contact with the floor.

12

REVERSING THE DOOR SWING

The swing of the dryer door can be reversed to fit your installation location.

\

Hinge

Screws

Open the dryer door. Using a Phillips screw-

driver, remove the 2 screws that secure

the door hinge to the dryer door opening.

Remove the 4 screws from the latch side of the

dryer door opening, and remove the door latch.

Turn the door around so the hinge is

reversed, and reattach the door using the

2 screws previously removed. Reinstall the

door latch and the 4 screws.

Test the door swing to make sure the door

moves freely and latches securely.

Latch

Screws

-. /

"'\\\%

\

\

oJ

Page 13

INSTALLATIONINSTRUCTIONS

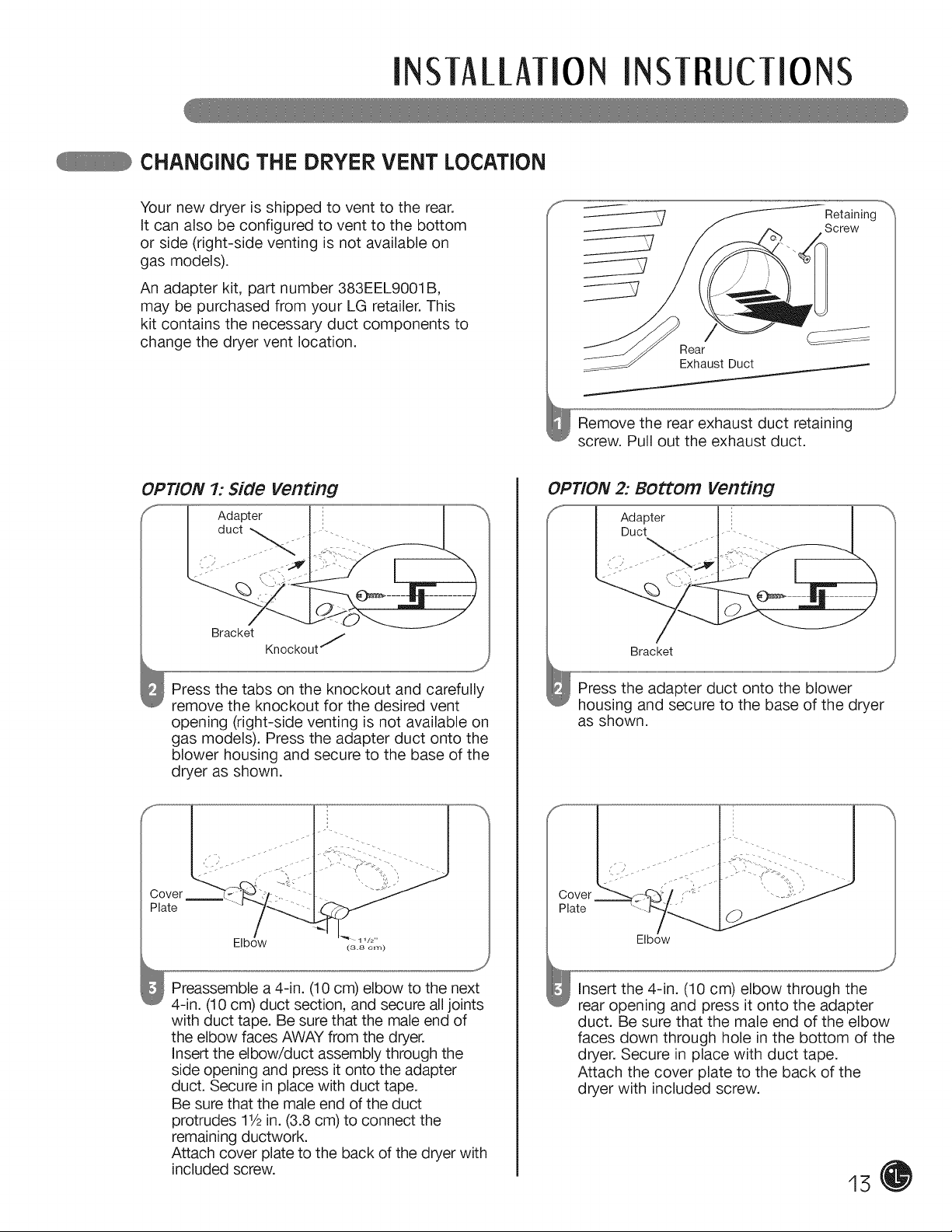

CHANGING THE DRYER VENT LOCATION

Your new dryer is shipped to vent to the rear.

It can also be configured to vent to the bottom

or side (right-side venting is not available on

gas models).

An adapter kit, part number 383EEL9001B,

may be purchased from your LG retailer. This

kit contains the necessary duct components to

change the dryer vent location.

f

Rear

Exhaust Duct

Remove the rear exhaust duct retaining

screw. Pull out the exhaust duct.

OPTION 2: Bottom venting

Adapter

Duct - .

Bracket

Retaining

Screw

_J

Press the tabs on the knockout and carefully

remove the knockout for the desired vent

opening (right-side venting is not available on

gas models). Press the adapter duct onto the

blower housing and secure to the base of the

dryer as shown.

f ....

Cover

Plate

Elbow

(3.8 ore)

Preassemble a 4-in. (10 cm) elbow to the next

4-in. (10 cm) duct section, and secure all joints

with duct tape. Be sure that the male end of

the elbow faces AWAY from the dryer.

Insert the elbow/duct assembly through the

side opening and press it onto the adapter

duct. Secure in place with duct tape.

Be sure that the male end of the duct

protrudes 11/2in. (3.8 cm) to connect the

remaining ductwork.

Attach cover plate to the back of the dryer with

included screw.

Press the adapter duct onto the blower

housing and secure to the base of the dryer

as shown.

Cover

Plate

Elbow

J

insert the 4-in. (10 cm) elbow through the

rear opening and press it onto the adapter

duct. Be sure that the male end of the elbow

faces down through hole in the bottom of the

dryer. Secure in place with duct tape.

Attach the cover plate to the back of the

dryer with included screw.

15

Page 14

INSTAllATIONINST UCTIONS

VENTING THE DRYER

WARN|NG: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Do not crush or collapse ductwork. Failure

to follow these instructions can result in fire

or death.

• Do not allow ductwork to rest on or

contact sharp objects. Failure to follow these

instructions can result in fire or death.

• if connecting to existing ductwork, make

sure it is suitable and clean before installing

the dryer. Failure to follow these instructions

can result in fire or death.

• Venting must conform to local building

codes. Failure to follow these instructions can

result in fire or death.

• Gas dryers MUST exhaust to the outdoors.

Failure to follow these instructions can result

in fire or death.

• Use only 4-in. (10.2 cm) rigid or flexible

metal ductwork inside the dryer cabinet and

for venting outside. Failure to follow these

instructions can result in fire or death.

• To reduce the risk of fire, combustion, or

accumulation of combustible gases, DO

NOT exhaust dryer air into an enclosed and

unventilated area, such as an attic, wall,

ceiling, crawl space, chimney, gas vent, or

concealed space of a building. Failure to

follow these instructions can result in fire

or death.

• To reduce the risk of fire, DO NOT exhaust

the dryer with plastic or thin foil ducting.

Failure to follow these instructions can result

in fire or death.

• The exhaust duct must be 4 in. (10.2 cm} in

diameter with no obstructions. The exhaust

duct should be kept as short as possible.

Make sure to clean any old ducts before

installing your new dryer. Failure to follow

these instructions can result in fire or death.

• Rigid or semirigid metal ducting is

recommended for use between the dryer

and the wall. in special installations when

it is impossible to make a connection with

the above recommendations, a UL-listed

flexible metal transition duct may be used

between the dryer and wall connection only.

The use of this ducting will affect drying

time. Failure to follow these instructions can

result in fire or death.

• DO NOT use sheet metal screws or other

fasteners which extend into the duct that

could catch lint and reduce the efficiency

of the exhaust system. Secure all joints

with duct tape. Failure to follow these

instructions can result in fire or death.

• TOmaximize operating results, please

observe the duct length limitations noted in

the chart on page 15. Failure to follow these

instructions can result in fire or death.

• Ductwork is not provided with the dryer.

You should obtain the necessary ductwork

locally. The end cap should have hinged

dampers to prevent backdraft when the

dryer is not in use. Failure to follow these

instructions can result in fire or death.

•The Total length of flexible metal duct shall

not exceed 8 ft.(2.4m)

• in Canada, that only those foil-type flexible

ducts, if any, specifically identified for use

with the appliance by the manufacturer

shall be used. in the United States, that only

those foil-type flexible ducts, if any, specifically

identified for use with the appliance by the

manufacturer and that comply with the Outline

for Clothes Dryer Transition Duct, Subject

2158A, shall be used.

14

Page 15

INSTALLATIONINSTRU€TIONS

VENTING THE DRYER (cont.)

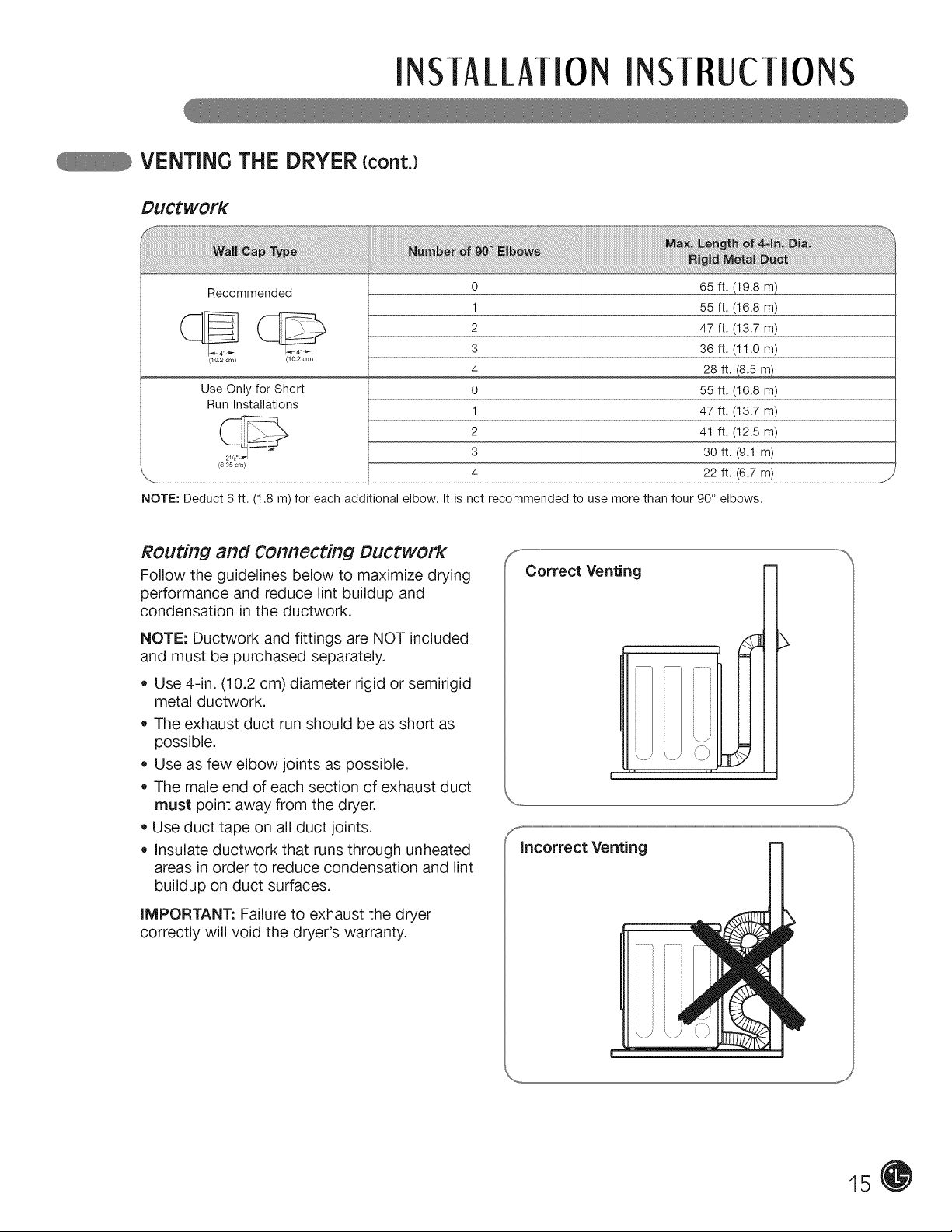

DuCtwOrk

Recommended

(10.2 cm) (10.2 cm)

Use Only for Short

Run Installations

(6.35 era)

NOTE: Deduct 6 ft. (1.8 m) for each additional elbow. It is not recommended to use more than four 90° elbows.

ROuting and Connecting Ductwork

Follow the guidelines below to maximize drying

0

1

2

3

4

0

1

2

3

4

f_

Correct Venting

65 ft. (19.8 m)

55 ft. (16.8 m)

47 ft. (13.7 m)

36 ft. (11.0 m)

28ft._

55 ft. (16.8 m)

47 ft. (13.7 m)

41 ft. (12.5 m)

30 ft. (9.1 m)

22 ft. (6.7 m)

performance and reduce lint buildup and

condensation in the ductwork.

NOTE: Ductwork and fittings are NOT included

and must be purchased separately.

• Use 4-in. (10.2 cm) diameter rigid or semirigid

metal ductwork.

• The exhaust duct run should be as short as

possible.

• Use as few elbow joints as possible.

i _\ ./'

f= \

I; I?'

R,

• The male end of each section of exhaust duct

must point away from the dryer.

• Use duct tape on all duct joints.

• Insulate ductwork that runs through unheated

incorrect Venting

areas in order to reduce condensation and lint

buildup on duct surfaces.

iMPORTANT: Failure to exhaust the dryer

correctly will void the dryer's warranty.

15

Page 16

INSTALLATIONINST UcTIONS

CONNECTING GAS DRYERS

_I_WARN|_I_G: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Gas supply requirements:

As shipped from the factory, this dryer

is configured for use with natural gas.

it can be converted for use with LP (Liquefied

Propane) gas. Gas pressure

must not exceed 13 in. water column.

• A qualified service or gas company technician

must connect the dryer to the gas service.

Failure to do so can result in fire, explosion, or

death.

• isolate the dryer from the gas supply system

by closing its individual manual shutoff valve

during any pressure testing of the gas supply.

Failure to do so can result in fire, explosion, or

death.

• Supply line requirements:

Your laundry room must have a rigid gas

supply line to your dryer, in the United States,

an individual manual shutoff valve MUST be

installed within at least 6 ft. (1.8 m) of the

dryer, in accordance with the National Fuel

Gas Code ANSi Z223.1. A 1/8=in. NPT pipe

plug must be installed. Failure to do so can

result in fire, explosion, or death.

• if using a rigid pipe, the rigid pipe should be

1/2-in. IPS. if acceptable under local codes

and ordinances and when acceptable to your

gas supplier, 3/8-in. approved tubing may be

used where lengths are less than 20 ft. (6.1

m). Larger tubing should be used for lengths

in excess of 20 ft. (6.1 m). Failure to do so can

result in fire, explosion, or death.

• Connect the dryer to the type of gas shown

on the nameplate. Failure to do so can result in

fire, explosion, or death.

• To prevent contamination of the gas valve,

purge the gas supply of air and sediment

before connecting the gas supply to the dryer.

Before tightening the connection between the

gas supply and the dryer, purge remaining air

until the odor of gas is detected. Failure to do

so can result infire, explosion, or death.

• DO NOT use an open flame to inspect for

gas leaks. Use a noncorrosive leak=detection

fluid. Failure to do so can result infire, explosion,

or death.

• Use only a new AGA- or CSA=certified gas

supply line with flexible stainless steel

connectors. Failure to do so can result in fire,

explosion, or death.

• Securely tighten all gas connections. Failure to

do so can result infire, explosion, or death.

• Use Teflon®tape or a pipe-joint compound

that is insoluble in Liquefied Petroleum (LP)

gas on all pipe threads. Failure to do so can

result in fire, explosion, or death.

• DO NOT attempt any disassembly of the

dryer; any disassembly requires the attention

and tools of an authorized and qualified

service person or company. Failure to do so

can result infire, explosion, or death.

16

Electrical Requirements for Gas MOdelS Only

• Do not, under any circumstances, cut or

remove the third (ground) prong from the

power cord. Failure to follow this warning can

result infire, explosion, or death.

• For personal safety, this dryer must be

properly grounded. Failure to follow this warning

can result in fire, explosion, or death.

• The power cord of this dryer is equipped with

a 3-prong (grounding) plug which mates with

a standard 3-prong (grounding) wall outlet

to minimize the possibility of electric shock

hazard from this appliance. Failure to follow

this warning can result infire, explosion,

or death.

• This dryer must be plugged into a

120-VAC, 60=Hz. grounded outlet protected by

a 15-ampere fuse or circuit breaker. Failure to

follow this warning can result in fire, explosion, or

death.

• Where a standard 2-prong wall outlet is

encountered, it is your personal responsibility

and obligation to have it replaced with a

properly grounded 3-prong wall outlet. Failure

to follow this warning can result in fire, explosion,

or death.

Page 17

INSTALLATIONINSTRUCTIONS

CONNECTING GAS DRYERS (cont.)

WARNING:

appliance, follow basic precautions, including the following:

• installation and service must be performed

by a qualified installer, service agency, or the

gas supplier. Failure to do so can result in fire,

explosion, or death.

• Use only a new stainless steel flexible

connector and a new AGA=certified

connector. Failure to do so can result in fire,

explosion, or death.

• A gas shutoff valve must be installed within

6 ft. (1.8 m) of the dryer. Failure to do so can

result in fire, explosion, or death.

• The dryer is configured for Natural Gas when

shipped from the factory. Make sure that the

dryer is equipped with the correct burner

nozzle for the type of gas being used (Natural

Gas or Liquefied Petroleum). Failure to do so

can result in fire, explosion, or death.

To reduce the risk of fire, electric shock, or injury to persons when using this

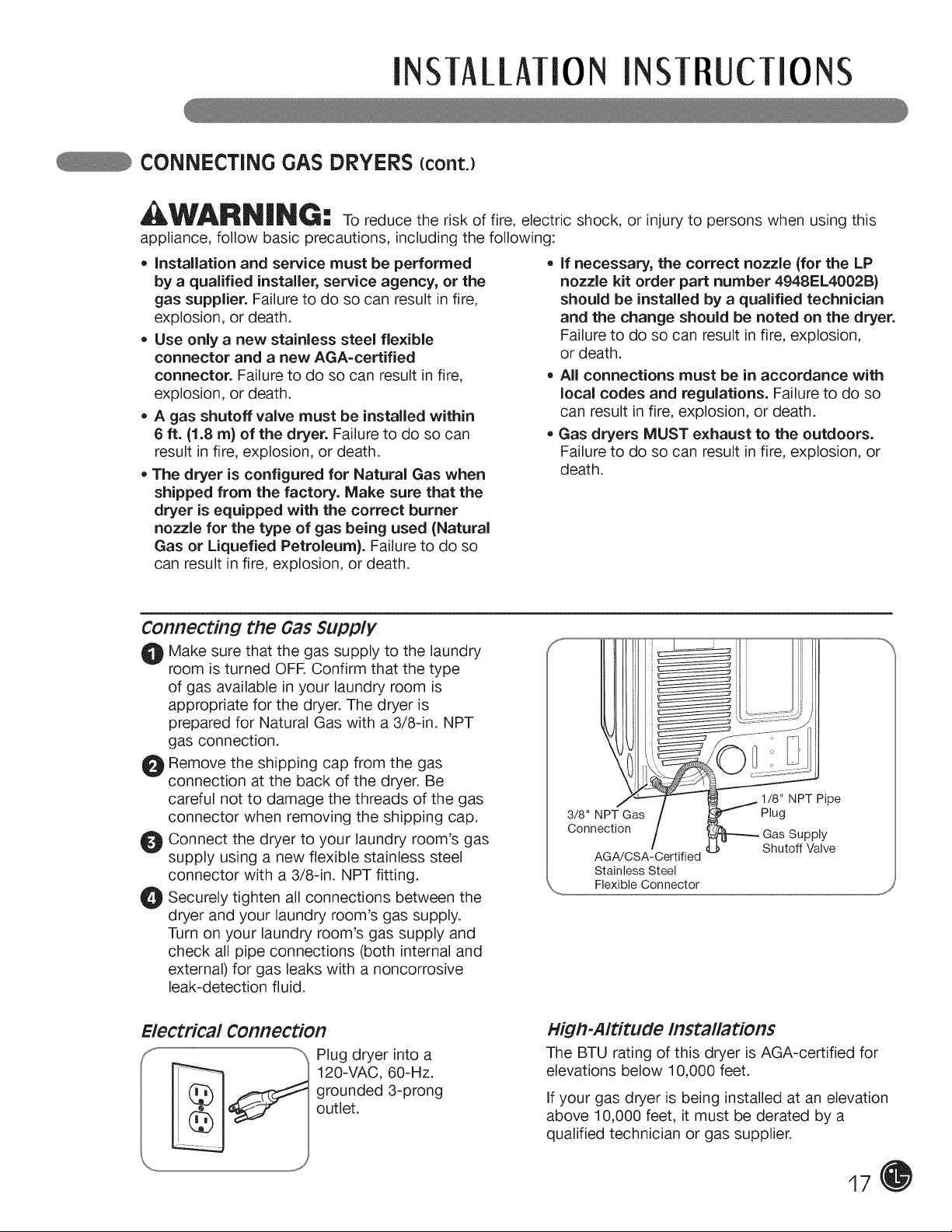

Connecting the Gas Supply

O Make sure that the gas supply to the laundry

room is turned OrE Confirm that the type

of gas available in your laundry room is

appropriate for the dryer. The dryer is

prepared for Natural Gas with a 3/8-in. NPT

gas connection.

O Remove the shipping cap from the gas

connection at the back of the dryer. Be

careful not to damage the threads of the gas

connector when removing the shipping cap.

Connect the dryer to your laundry room's gas

supply using a new flexible stainless steel

connector with a 3/8-in. NPT fitting.

O Securely all connections between thetighten

dryer and your laundry room's gas supply.

Turn on your laundry room's gas supply and

check all pipe connections (both internal and

external) for gas leaks with a noncorrosive

leak-detection fluid.

If necessary, the correct nozzle (for the LP

nozzle kit order part number 4948EL4002B)

should be installed by a qualified technician

and the change should be noted on the dryer.

Failure to do so can result in fire, explosion,

or death.

All connections must be in accordance with

local codes and regulations. Failure to do so

can result in fire, explosion, or death.

Gas dryers MUST exhaust to the outdoors.

Failure to do so can result in fire, explosion, or

death.

Stainless Steel

Flexible Connector

,,J

Electrical Connection

Plug dryer into a

120-VAC, 60-Hz.

grounded 3-prong

outlet.

High-Altitude Installations

The BTU rating of this dryer is AGA-certified for

elevations below 10,000 feet.

If your gas dryer is being installed at an elevation

above 10,000 feet, it must be derated by a

qualified technician or gas supplier.

17

Page 18

INSTALLATIONINST UcTIONS

cONNEcTiNG ELEcTRic DRYERS

• I_WARN|_II!_G -= To help prevent fire, electdc shock, serious injuryor death, the wiring and

grounding must conform to the latest edition of the National Electrical Code, ANSVNFPA 70 and all

applicable local regulations. Please contact a qualified electrician to check your home's wiring and

fuses to ensure that your home has adequate electrical power to operate the dryer.

Electrical Requirements for Electric MOdelS Only

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

This dryer must be connected to a grounded

metal, permanent wiring system, or an

equipment- rounding conductor must be run

with the circuit conductors and connected

to the equipment-grounding terminal or lead

on the dryer. Failure to do so can result in fire,

explosion, or death.

The dryer has its own terminal block that

must be connected to a separate 240 VAC,

60=Hertz, single-phase circuit, fused at 30

amperes (the circuit must be fused on both

sides of the line). ELECTRICAL SERVICE

FOR THE DRYER SHOULD BE OF THE

MAXIMUM RATE VOLTAGE LISTED ON THE

NAMEPLATE. DO NOT CONNECT DRYER TO

110=, 115-, OR 120-VOLT CIRCUIT. Heating

elements are available for field installation

in dryers which are to be connected to an

electrical service of a different voltage than

that listed on the rating plate. Failure to follow

these instructions can result infire, explosion,

or death.

• If branch circuit to dryer is 15 ft. (4.5 m)

or less in length, use UL (Underwriters

Laboratories) listed No.-10 AWG wire

(copper wire only}, or as required by local

codes, if over 15 ft. (4.50 m), use UL-listed

No.-8 AWG wire (copper wire only), or as

required by local codes. Allow sufficient

slack in wiring so dryer can be moved from

its normal location when necessary. Failure

to do so can result infire, explosion, or death.

• The power cord (pigtail} connection between

wall receptacle and dryer terminal block

IS NOT supplied with dryer. Type of pigtail

and gauge of wire must conform to local

codes and with instructions on the following

pages. Failure to follow these instructions can

result in fire, explosion, or death.

A 4-wire connection is required for all mobile

and manufactured home installations, as

well as all new construction after January

1, 1996. A 4-wire connection must be used

where local codes do not permit grounding

through the neutral wire. Failure to do so can

result in fire, explosion, or death.

18

Special Electrical Requirements for Mobile or Manufactured Homes

_I_WAR_!_|_I_G ==To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Any installation in a manufactured or mobile

home must comply with the Manufactured

Home Construction and Safety Standards

Title 24 CFR, Part 32-80 or Standard CAN/

CSAOZ240 MH and local codes and ordinances.

• A 4-wire connection is required for all mobile

and manufactured home installations, as well

as all new construction after January 1, 1996.

Failure to do so can result infire, explosion, or

death.

Page 19

INSTALLATIONINSTRUCTIONS

CONNECTING ELECTRIC DRYERS

WARHiHG:

* Connect the power cord to the terminal block. Each colored wire should be connected to

same color screw. Wire color indicated on manual is connected to the same color screw

in block. Failure to follow these instructions may result in a short or overload.

* Grounding through the neutral conductor is prohibited for: (1) new branch-circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductor.

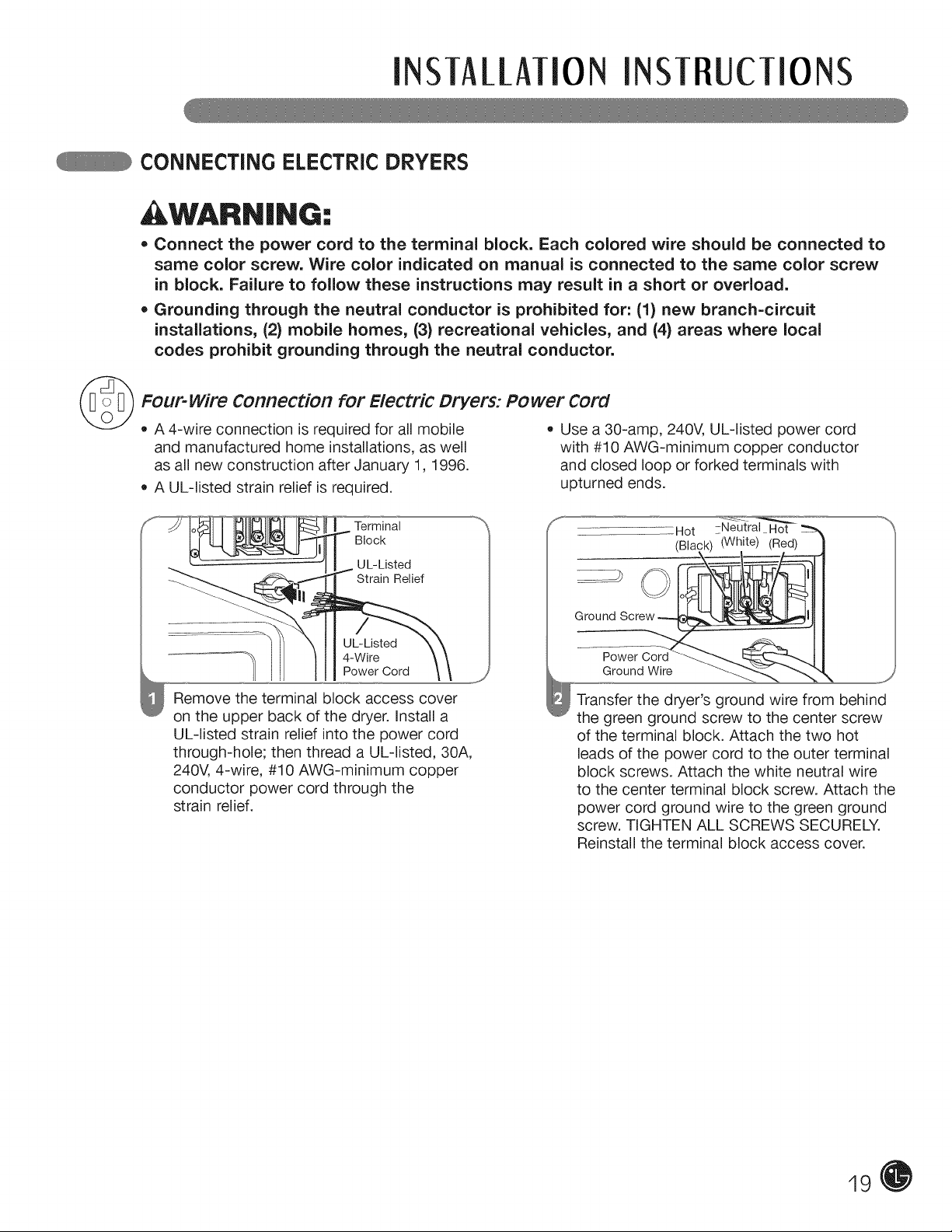

Four-wire Connection for Electric Dryers: Power Cord

• A 4-wire connection is required for all mobile

and manufactured home installations, as well

as all new construction after January 1, 1996.

• A UL-Iisted strain relief is required.

Terminal

Block

UL-Listed

Strain Relief

UL-Listed

Power Cord

4-Wire

Remove the terminal block access cover

on the upper back of the dryer. Install a

UL-listed strain relief into the power cord

through-hole; then thread a UL-listed, 30A,

240V, 4-wire, #10 AWG-minimum copper

conductor power cord through the

strain relief.

• Use a 30-amp, 240V, UL-Iisted power cord

with #10 AWG-minimum copper conductor

and closed loop or forked terminals with

upturned ends.

.................................Hot -Neutral Hot

Ground Screw

Power Cord

Ground Wire

Transfer the dryer's ground wire from behind

the green ground screw to the center screw

of the terminal block. Attach the two hot

leads of the power cord to the outer terminal

block screws. Attach the white neutral wire

to the center terminal block screw. Attach the

power cord ground wire to the green ground

screw. TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access cover.

_,_

(White) (Red)

19

Page 20

INSTAllATION INST UcTIONS

cONNEcTiNG ELEcTRic DRYERS (cont.)

,AWARN|NG:

. Connect the power cord to the terminal block. Each colored wire should be connected to

same color screw. Wire color indicated on manual is connected to the same color screw

in block. Failure to follow these instructions may result in a short or overload.

. Grounding through the neutral conductor is prohibited for: (1) new branch=circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductor.

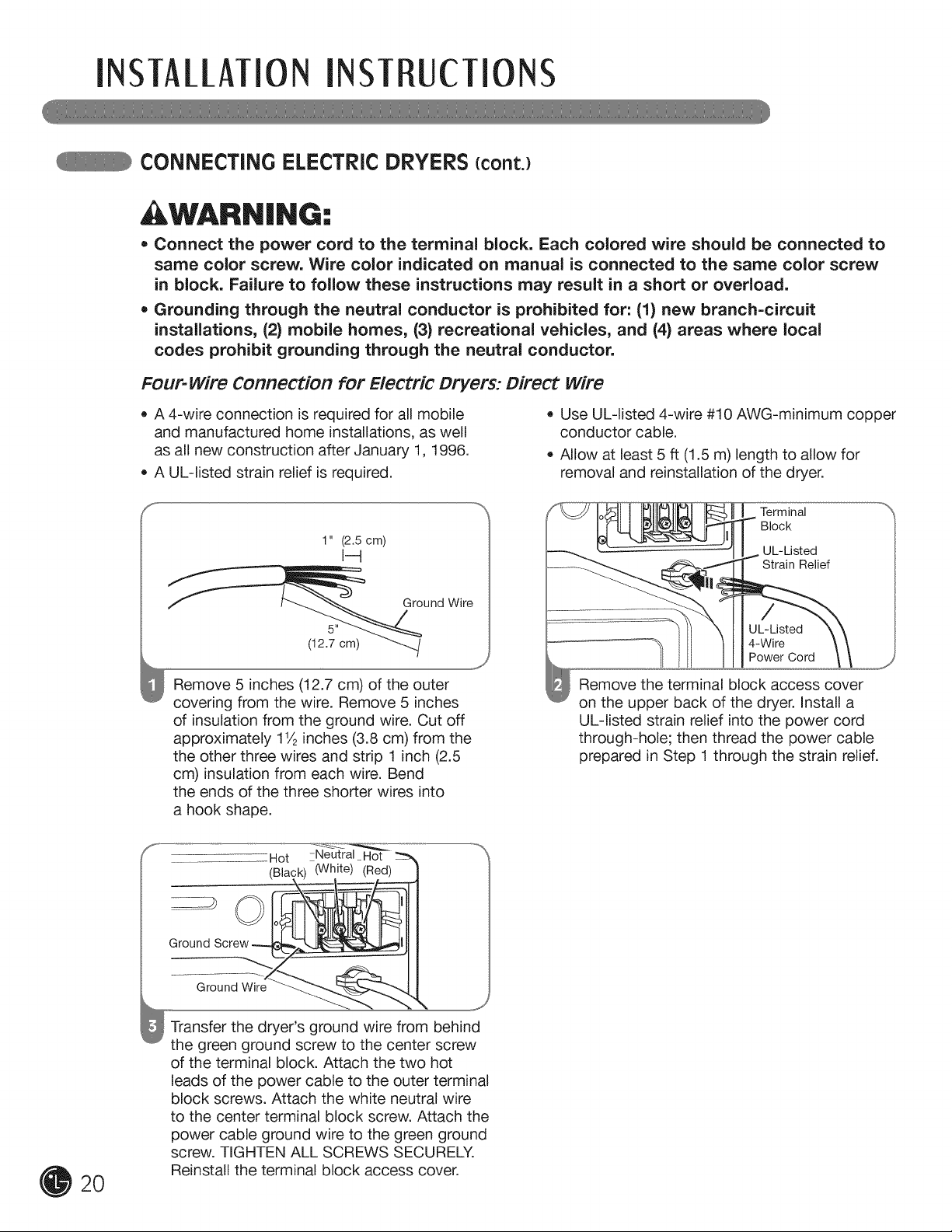

FOur-Wire Connection for Electric Dryers: Direct wire

• A 4-wire connection is required for all mobile

and manufactured home installations, as well

as all new construction after January 1, 1996.

• A UL-listed strain relief is required.

1" (2.5 cm)

I-4

Remove 5 inches (12.7 cm) of the outer

covering from the wire. Remove 5 inches

of insulation from the ground wire. Cut off

approximately 11/2inches (3.8 cm) from the

the other three wires and strip 1 inch (2.5

cm) insulation from each wire. Bend

the ends of the three shorter wires into

a hook shape.

:Neutral _Hot

Hot

(White) (Red)

• Use UL-listed 4-wire #10 AWG-minimum copper

conductor cable.

Allow at least 5 ft (1.5 m) length to allow for

removal and reinstallation of the dryer.

Terminal

Block

UL-Listed

Strain Relief

UL-Listed

Power Cord

s

Remove the terminal block access cover

on the upper back of the dryer. Install a

UL-listed strain relief into the power cord

through-hole; then thread the power cable

prepared in Step 1 through the strain relief.

4-Wire

20

Ground Wire

Transfer the dryer's ground wire from behind

the green ground screw to the center screw

of the terminal block. Attach the two hot

leads of the power cable to the outer terminal

block screws. Attach the white neutral wire

to the center terminal block screw. Attach the

power cable ground wire to the green ground

screw. TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access cover.

Page 21

INSTALLATIONINSTRUCTIONS

CONNECTING ELECTRIC DRYERS {cont.)

WARH|HG:

• Connect the power cord to the terminal block. Each colored wire should be connected to

same color screw. Wire color indicated on manual is connected to the same color screw

in block. Failure to follow these instructions may result in a short or overload.

= Grounding through the neutral conductor is prohibited for: (1) new branch-circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductor.

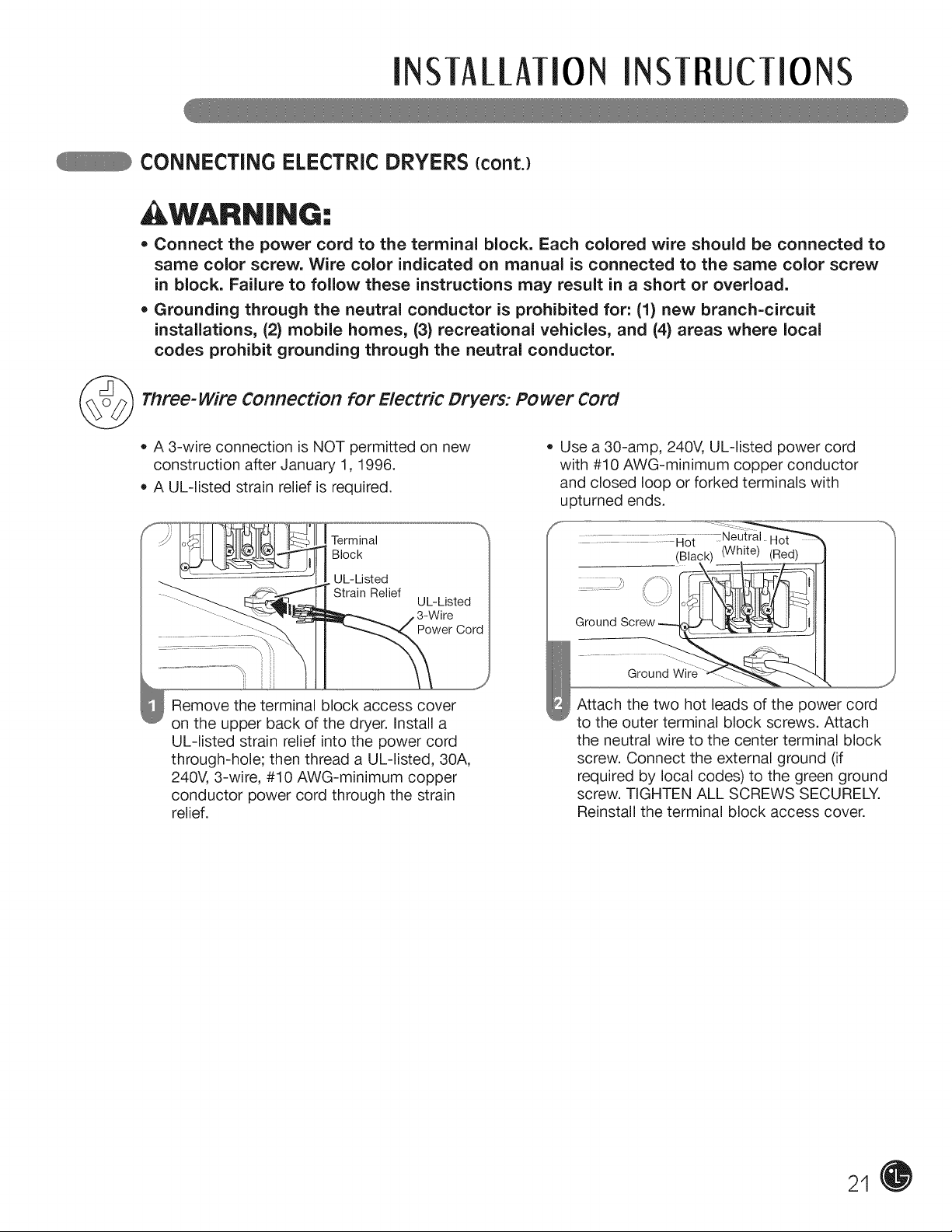

_ Three-wire Connection for Electric Dryers: Power Cord

• A 3-wire connection is NOT permitted on new

construction after January 1, 1996.

• A UL-listed strain relief is required.

Terminal

Block

, UL-Listed

Strain Relief

Remove the terminal block access cover

on the upper back of the dryer. Install a

UL-listed strain relief into the power cord

through-hole; then thread a UL-listed, 30A,

240V, 3-wire, #10 AWG-minimum copper

conductor power cord through the strain

relief.

UL-Listed

Power Cord

• Use a 30-amp, 240V, UL-listed power cord

with #10 AWG-minimum copper conductor

and closed loop or forked terminals with

upturned ends.

(Black) (W____hite)(Red)

Ground Screw i /,

_J

Attach the two hot leads of the power cord

to the outer terminal block screws. Attach

the neutral wire to the center terminal block

screw. Connect the external ground (if

required by local codes) to the green ground

screw. TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access cover.

21

Page 22

INSTALLATIONINST UCTIONS

cONNEcTiNG ELEcTRic DRYERS (cont.)

,&WARN|NG:

. Connect the power cord to the terminal block. Each colored wire should be connected to

same color screw. Wire color indicated on manual is connected to the same color screw

in block. Failure to follow these instructions may result in a short or overload.

. Grounding through the neutral conductor is prohibited for: (1) new branch=circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductor.

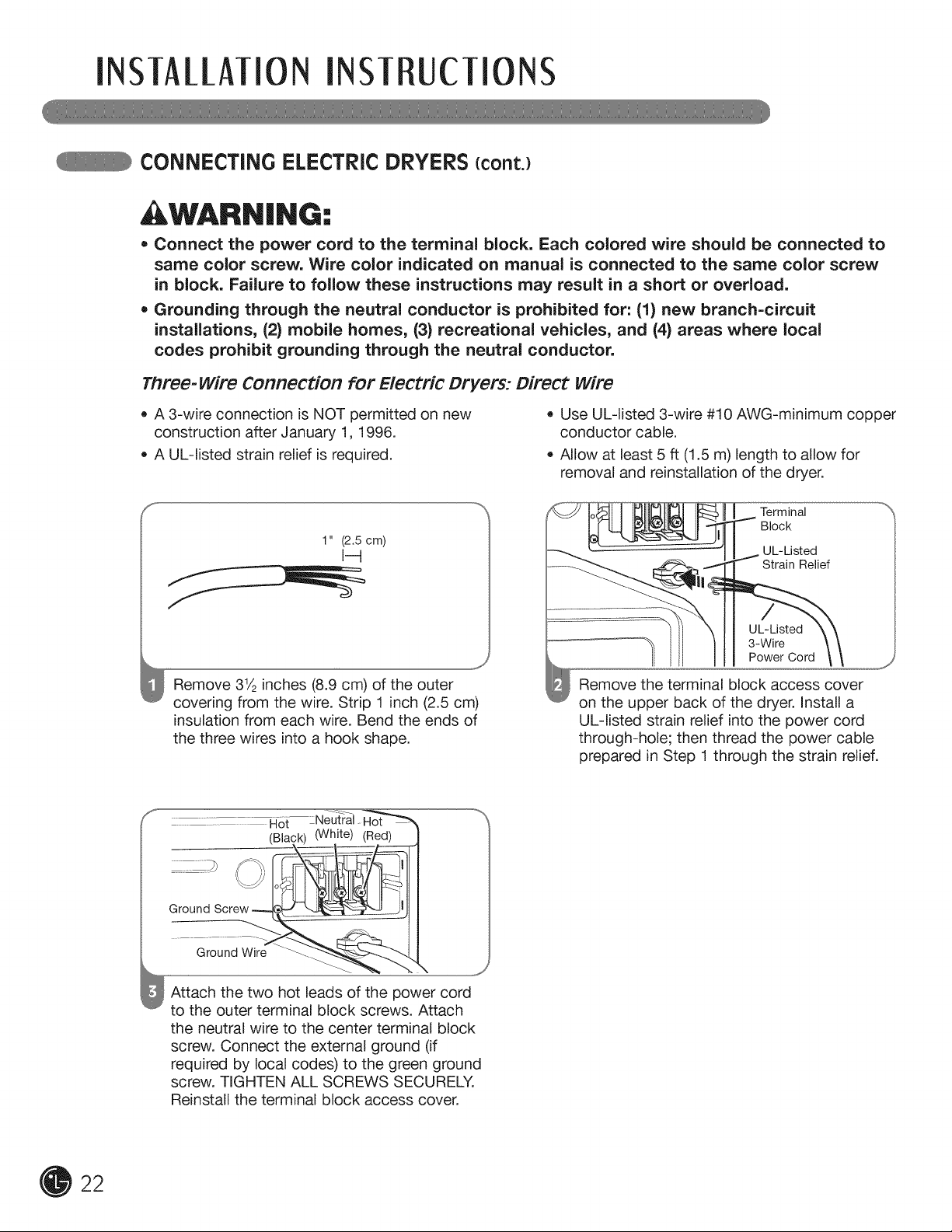

Three-wire Connection for Electric Dryers: Direct wire

• A 3-wire connection is NOT permitted on new

construction after January 1, 1996.

• A UL-listed strain relief is required.

1" (2.5 cm)

I--4

Remove 31/2inches (8.9 cm) of the outer

covering from the wire. Strip 1 inch (2.5 cm)

insulation from each wire. Bend the ends of

the three wires into a hook shape.

• Use UL-listed 3-wire #10 AWG-minimum copper

conductor cable.

Allow at least 5 ft (1.5 m) length to allow for

removal and reinstallation of the dryer.

Terminal

Block

UL-Listed

Strain Relief

UL-Listed

3-Wire

_J

Remove the terminal block access cover

on the upper back of the dryer. Install a

UL-listed strain relief into the power cord

through-hole; then thread the power cable

prepared in Step 1 through the strain relief.

Power Cord

22

Attach the two hot leads of the power cord

to the outer terminal block screws. Attach

the neutral wire to the center terminal block

screw. Connect the external ground (if

required by local codes) to the green ground

screw. TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access cover.

Page 23

INSTALLATIONINSTRUCTIONS

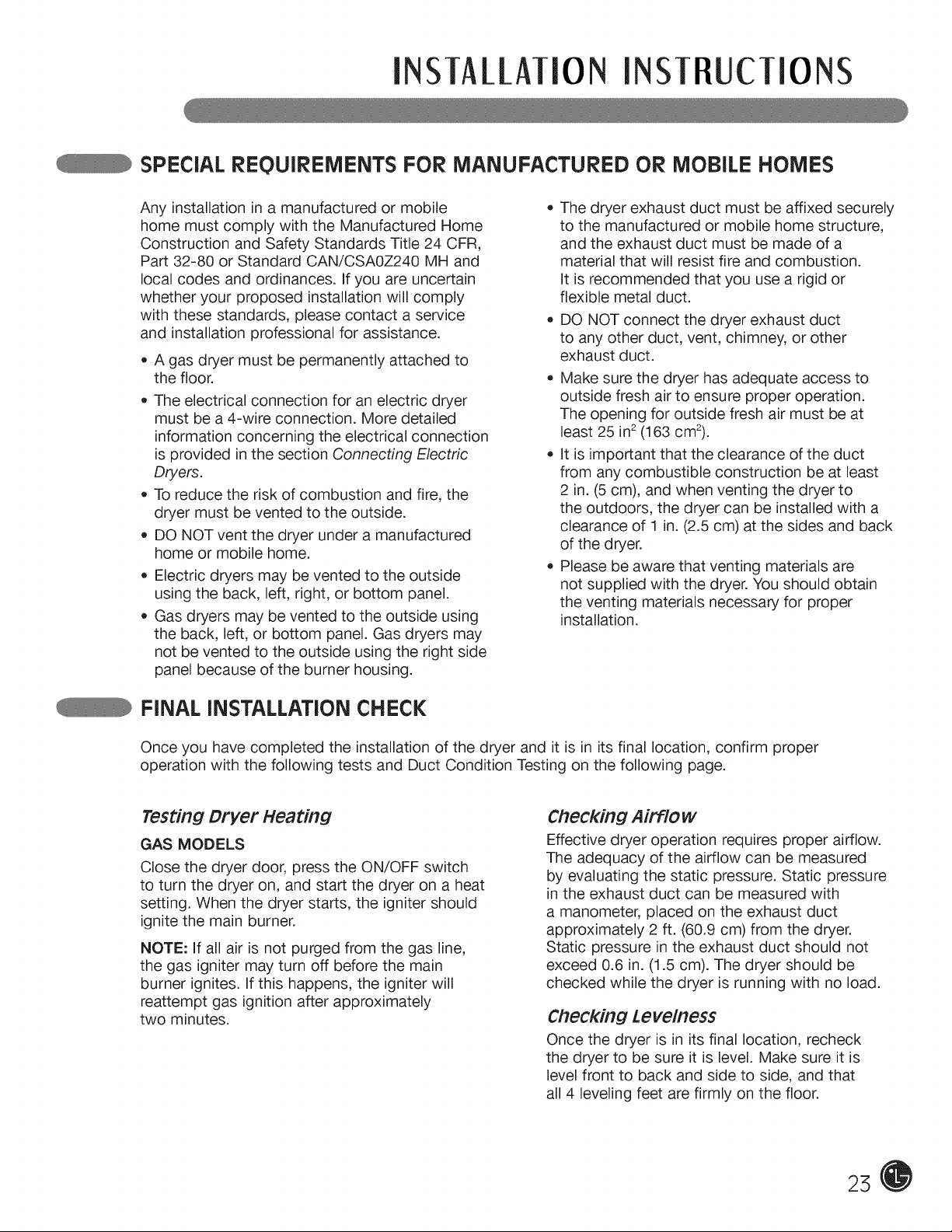

SPEciAL REQUIREMENTS FOR MANUFACTURED OR MOBILE HOMES

Any installation in a manufactured or mobile

home must comply with the Manufactured Home

Construction and Safety Standards Title 24 CFR,

Part 32-80 or Standard CAN/CSA0Z240 MH and

local codes and ordinances. If you are uncertain

whether your proposed installation will comply

with these standards, please contact a sewice

and installation professional for assistance.

• A gas dryer must be permanently attached to

the floor.

The electrical connection for an electric dryer

must be a 4-wire connection. More detailed

information concerning the electrical connection

is provided in the section Connecting Electric

Dryers.

To reduce the risk of combustion and fire, the

dryer must be vented to the outside.

DO NOT vent the dryer under a manufactured

home or mobile home.

Electric dryers may be vented to the outside

using the back, left, right, or bottom panel.

• Gas dryers may be vented to the outside using

the back, left, or bottom panel. Gas dryers may

not be vented to the outside using the right side

panel because of the burner housing.

The dryer exhaust duct must be affixed securely

to the manufactured or mobile home structure,

and the exhaust duct must be made of a

material that will resist fire and combustion.

It is recommended that you use a rigid or

flexible metal duct.

DO NOT connect the dryer exhaust duct

to any other duct, vent, chimney, or other

exhaust duct.

Make sure the dryer has adequate access to

outside fresh air to ensure proper operation.

The opening for outside fresh air must be at

least 25 in2 (163 cm2).

It is important that the clearance of the duct

from any combustible construction be at least

2 in. (5 cm), and when venting the dryer to

the outdoors, the dryer can be installed with a

clearance of 1 in. (2.5 cm) at the sides and back

of the dryer.

Please be aware that venting materials are

not supplied with the dryer. You should obtain

the venting materials necessary for proper

installation.

FINAL INSTALLATION CHECK

Once you have completed the installation of the dryer and it is in its final location, confirm proper

operation with the following tests and Duct Condition Testing on the following page.

Testing Dryer Heating

GAS MODELS

Close the dryer door, press the ON/OFF switch

to turn the dryer on, and start the dryer on a heat

setting. When the dryer starts, the igniter should

ignite the main burner.

NOTE: If all air is not purged from the gas line,

the gas igniter may turn off before the main

burner ignites. If this happens, the igniter will

reattempt gas ignition after approximately

two minutes.

Checking Airflow

Effective dryer operation requires proper airflow.

The adequacy of the airflow can be measured

by evaluating the static pressure. Static pressure

in the exhaust duct can be measured with

a manometer, placed on the exhaust duct

approximately 2 ft. (60.9 cm) from the dryer.

Static pressure in the exhaust duct should not

exceed 0.6 in. (1.5 cm). The dryer should be

checked while the dryer is running with no load.

Checking Levelness

Once the dryer is in its final location, recheck

the dryer to be sure it is level. Make sure it is

level front to back and side to side, and that

all 4 leveling feet are firmly on the floor.

25

Page 24

INSTALLATIONINST UCTIONS

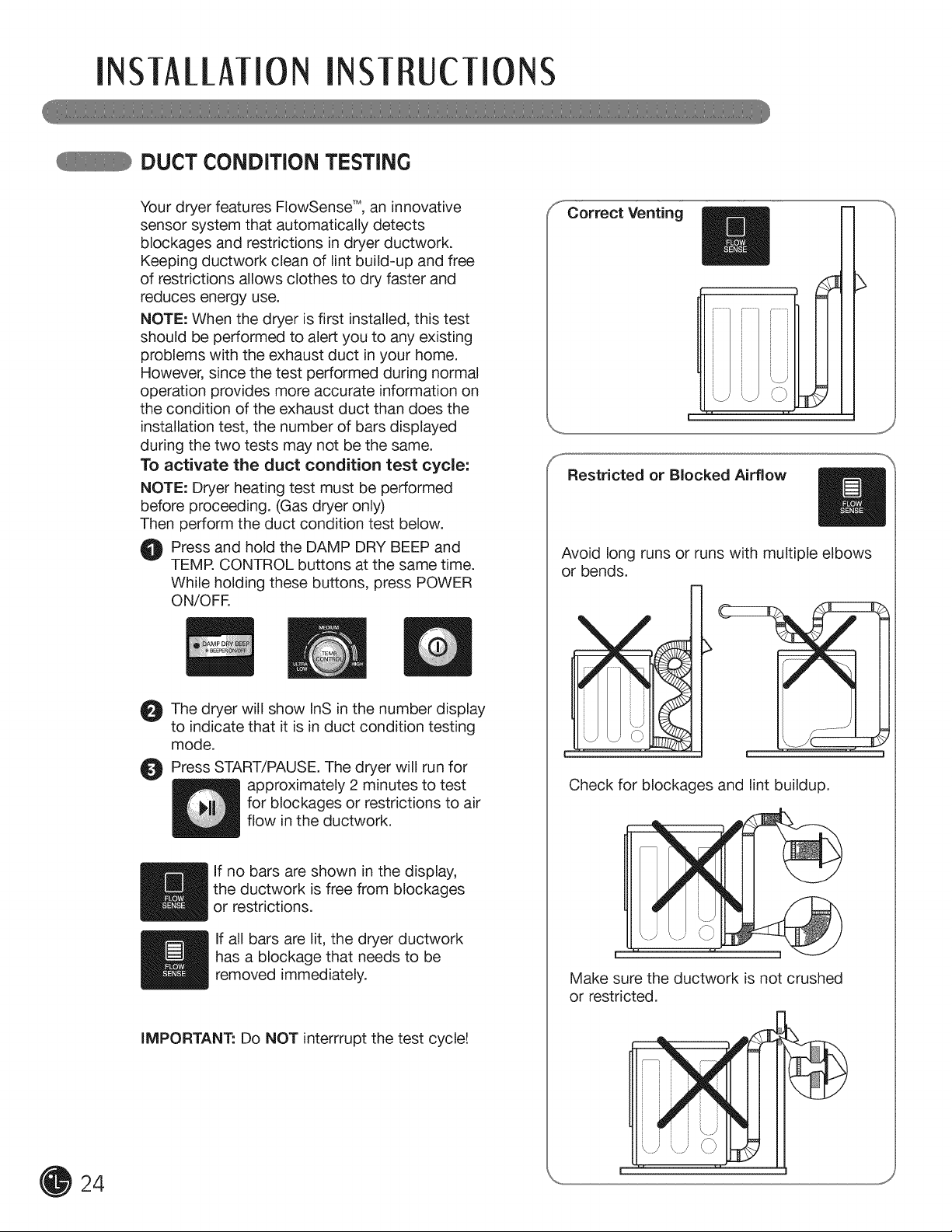

DUCT CONDiTiON TESTING

Your dryer features FlowSense TM, an innovative

sensor system that automatically detects

blockages and restrictions in dryer ductwork.

Keeping ductwork clean of lint build-up and free

of restrictions allows clothes to dry faster and

reduces energy use.

NOTE: When the dryer isfirst installed, this test

should be performed to alert you to any existing

problems with the exhaust duct in your home.

However, since the test performed during normal

operation provides more accurate information on

the condition of the exhaust duct than does the

installation test, the number of bars displayed

during the two tests may not be the same.

To activate the duct condition test cycle:

NOTE: Dryer heating test must be performed

before proceeding. (Gas dryer only)

Then perform the duct condition test below.

O Press and hold the DAMP DRY BEEP and

TEMP. CONTROL buttons at the same time.

While holding these buttons, press POWER

ON/OFF.

f

Correct Venting

I i, ,'r r

Restricted or Blocked Airflow

Avoid long runs or runs with multiple elbows

or bends.

I

i....... i

_lThe dryer will show InS in the number display

to indicate that it is in duct condition testing

mode.

O Press START/PAUSF.. The dryer will run for

approximately 2 minutes to test

for blockages or restrictions to air

flow in the ductwork.

the ductwork is free from blockages

lf no bars are shown in the display,

or restrictions.

has a blockage that needs to be

lf all bars are lit, the dryer ductwork

removed immediately.

IMPORTANT: Do NOT interrrupt the test cycle!

i

Check for blockages and lint buildup.

Make sure the ductwork is not crushed

or restricted.

24

Page 25

HOWTO USE

Following are instructions for starting and using your new dryer. Please refer to specific sections of this

manual for more detailed information, important Warning: To reduce the risk of fire, electric shock,

or injury to persons, read this entire manual, including the important Safety instructions, before

operating this dryer.

SORTING LOADS

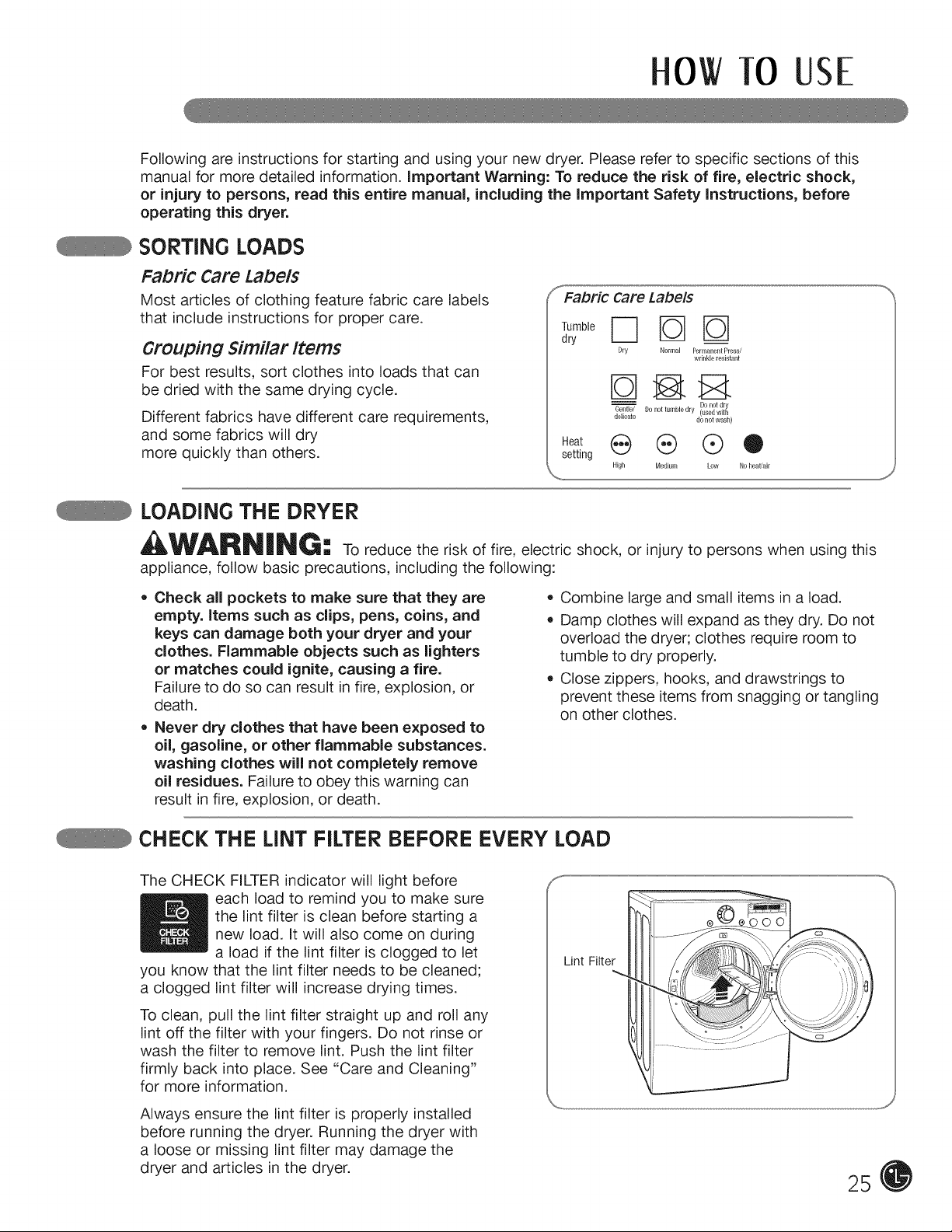

Fabric Care Labels

Most articles of clothing feature fabric care labels

that include instructions for proper care.

Grouping Similar Items

For best results, sort clothes into loads that can

be dried with the same drying cycle.

Different fabrics have different care requirements,

and some fabrics will dry

more quickly than others.

LOADING THE DRYER

FFabri¢ Care Labels

Tumble r--] [o7 _

dry

Heat (_ (_ Q O

setting

%..... J

Dry Normal PermanentPress/

Gentle/ Donottumbledry (usedwigl

delicate do not wash)

High Medium Low No heaVair

wrinkle resisblnt

Do notdry

WARN|NG: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

, Check all pockets to make sure that they are

empty. Items such as clips, pens, coins, and

keys can damage both your dryer and your

clothes. Flammable objects such as lighters

or matches could ignite, causing a fire.

Failure to do so can result in fire, explosion, or

death.

• Never dry clothes that have been exposed to

oil, gasoline, or other flammable substances.

washing clothes will not completely remove

oil residues. Failure to obey this warning can

result in fire, explosion, or death.

CHECK THE LINT FILTER BEFORE EVERY LOAD

The CHECK FILTER indicator will light before

each load to remind you to make sure

the lint filter is clean before starting a

new load. it will also come on during

a load ifthe lint filter is clogged to let

you know that the lint filter needs to be cleaned;

a clogged lint filter will increase drying times.

• Combine large and small items in a load.

Damp clothes will expand as they dry. Do not

overload the dryer; clothes require room to

tumble to dry properly.

Close zippers, hooks, and drawstrings to

prevent these items from snagging or tangling

on other clothes.

Lint Filter

To clean, pull the lint filter straight up and roll any

lint off the filter with your fingers. Do not rinse or

wash the filter to remove lint. Push the lint filter

firmly back into place. See "Care and Cleaning"

for more information.

Always ensure the lint filter is properly installed

before running the dryer. Running the dryer with

a loose or missing lint filter may damage the

dryer and articles in the dryer.

25

Page 26

HOWTO USE

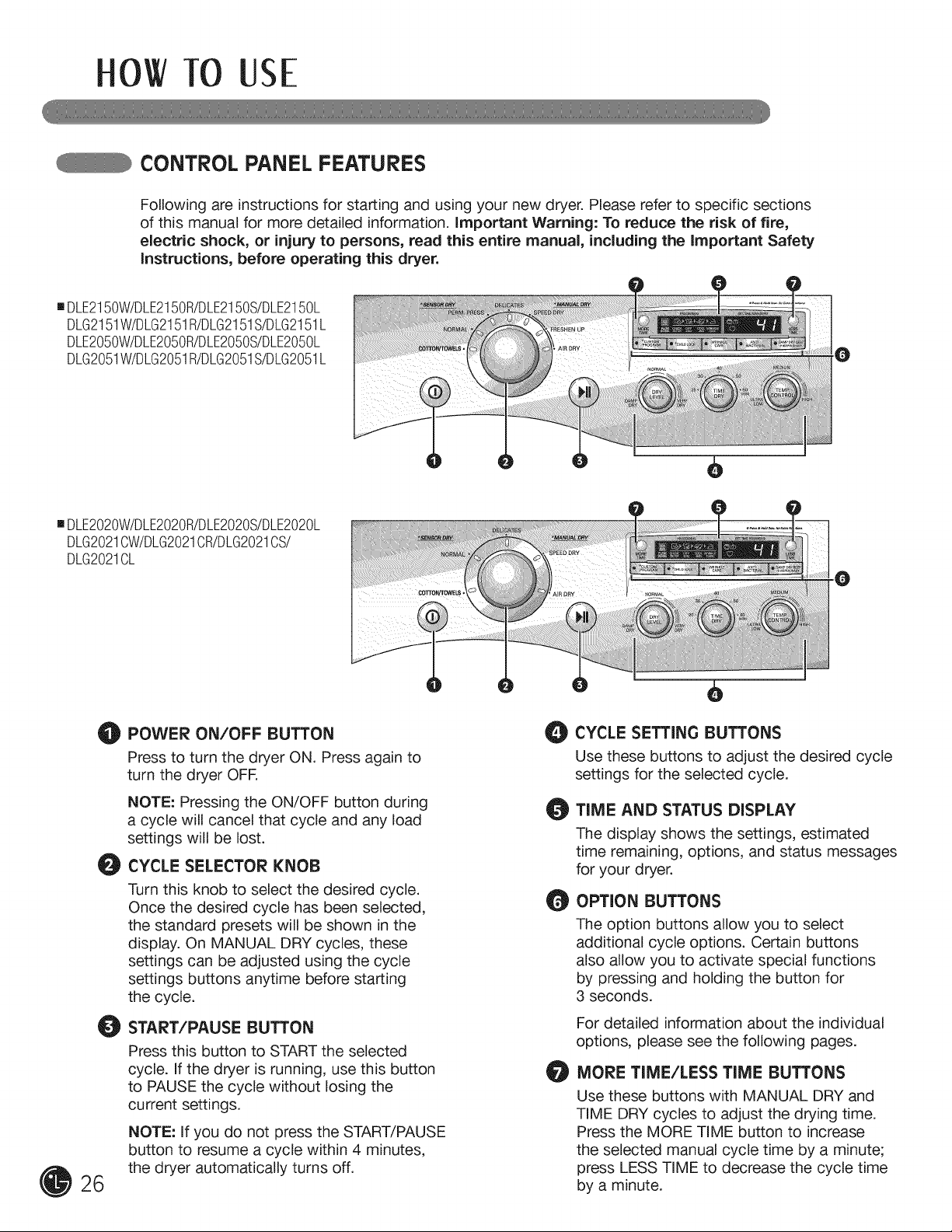

CONTROL PANEL FEATURES

Following are instructions for starting and using your new dryer. Please refer to specific sections

of this manual for more detailed information, important Warning: To reduce the risk of fire,

electric shock, or injury to persons, read this entire manual, including the important Safety

instructions, before operating this dryer.

[] DLE2150W/DLE2150R/DLE2150S/DLE2150L

DLG2151W/DLG2151R/DLG2151S/DLG2151L

DLE2050W/DLE2050R/DLE2050S/DLE2050L

DLG2051W/DLG2051R/DLG2051S/DLG2051L

[] DLE2020W/DLE2020R/DLE2020S/DLE2020L

DLG2021CW/DLG2021CR/DLG2021CS/

DLG2021CL

O

O

POWER ON/OFF BUTTON

O

Press to turn the dryer ON. Press again to

turn the dryer OFR

NOTE: Pressing the ON/OFF button during

a cycle will cancel that cycle and any load

settings will be lost.

CYCLE SELECTOR KNOB

O

Turn this knob to select the desired cycle.

Once the desired cycle has been selected,

the standard presets will be shown in the

display. On MANUAL DRY cycles, these

settings can be adjusted using the cycle

settings buttons anytime before starting

the cycle.

START/PAUSE BUTTON

O

Press this button to START the selected

cycle. If the dryer is running, use this button

to PAUSE the cycle without losing the

current settings.

NOTE: If you do not press the START/PAUSE

button to resume a cycle within 4 minutes,

the dryer automatically turns off.

26

CYCLE SETTING BUTTONS

O

Use these buttons to adjust the desired cycle

settings for the selected cycle.

TIME AND STATUS DISPLAY

O

The display shows the settings, estimated

time remaining, options, and status messages

for your dryer.

OPTION BUTTONS

O

The option buttons allow you to select

additional cycle options. Certain buttons

also allow you to activate special functions

by pressing and holding the button for

3 seconds.

For detailed information about the individual

options, please see the following pages.

MORE TIME/LESS TIME BUTTONS

O

Use these buttons with MANUAL DRY and

TIME DRY cycles to adjust the drying time.

Press the MORE TIME button to increase

the selected manual cycle time by a minute;

press LESS TIME to decrease the cycle time

by a minute.

Page 27

HOWTO USE

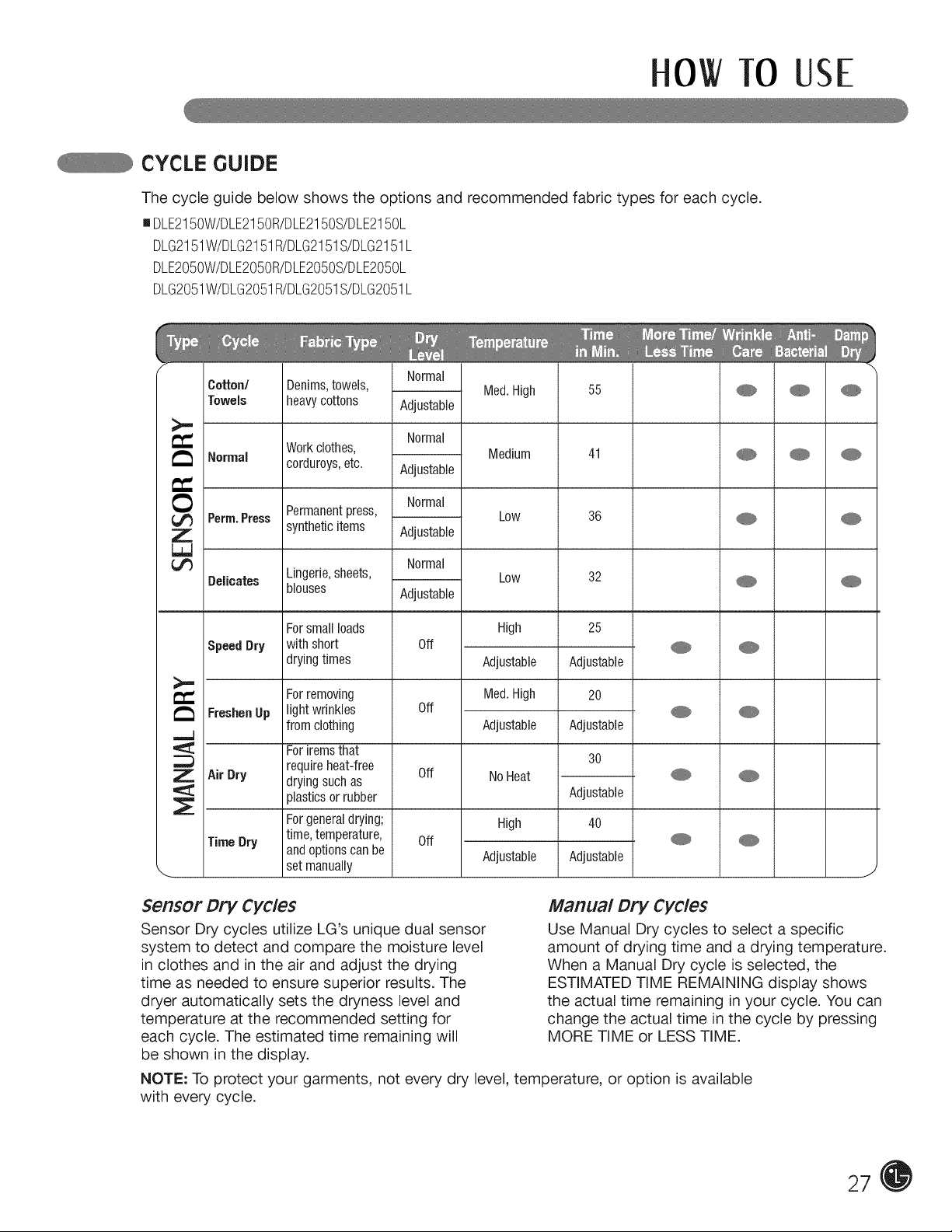

CYCLE GUIDE

The cycle guide below shows the options and recommended fabric types for each cycle.

[]DLE2150W/DLE2150R/DLE2150S/DLE2150L

DLG2151W/DLG2151R/DLG2151S/DLG2151L

DLE2050W/DLE2050R/DLE2050S/DLE2050L

DLG2051W/DLG2051R/DLG2051S/DLG2051L

Cotton/ Denims,towels, Med.High 55 _ @ @

Normal

Towels heavycottons Adjustable

Workclothes,

Normal corduroys,etc.

Perm.Press

Delieates Lingerie,sheets,

Speed Dry with short Off

FreshenUp

Air Dry

TimeDry

Permanentpress,

syntheticitems Adjustable

blouses Adjustable

Forsmallloads

dryingtimes

Forremoving

lightwrinkles

from clothing

Foriremsthat

requireheat-free

dryingsuchas

plasticsor rubber

Forgeneraldrying;

time,temperature, Off

andoptions canbe

setmanually

Normal

Adjustable

Normal

Normal

Off

Off

Medium

Low

Low

High

Adjustable

Med.High

Adjustable

NoHeat

High

Adjustable

41 _ _

36 _

32

25

Adjustable

2O

Adjustable

3O

Adjustable

4O

Adjustable

,J

Sensor Dry Cycles

Sensor Dry cycles utilize LG's unique dual sensor

system to detect and compare the moisture level

in clothes and in the air and adjust the drying

time as needed to ensure superior results. The

dryer automatically sets the dryness level and

temperature at the recommended setting for

each cycle. The estimated time remaining will

Manual Dry Cycles

Use Manual Dry cycles to select a specific

amount of drying time and a drying temperature.

When a Manual Dry cycle is selected, the

ESTIMATED TIME REMAINING display shows

the actual time remaining in your cycle. You can

change the actual time in the cycle by pressing

MORE TIME or LESS TIME.

be shown in the display.

NOTE: To protect your garments, not every dry level, temperature, or option is available

with every cycle.

27

Page 28

HOWTO USE

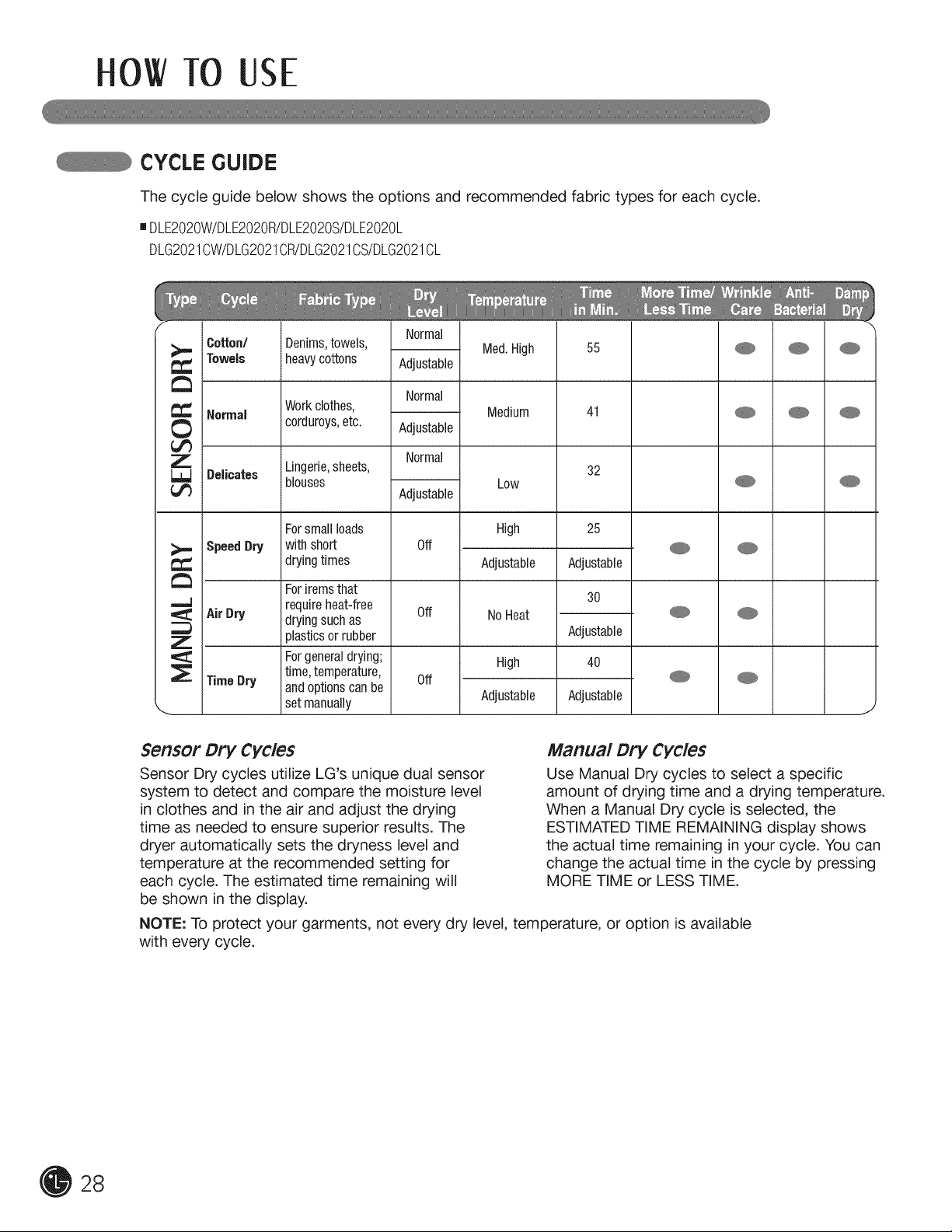

CYCLEGUIDE

The cycle guide below shows the options and recommended fabric types for each cycle.

mDLE202OW/DLE202OR/DLE202OS/DLE2020L

DLG2021CW/DLG2021CR/DLG2021CS/DLG2021CL

Cotton/

Towels

Normal

Z

L_L=JDelicates

_=, SpeedDry

,.=J

,=_ AirDry

Z

TimeDry

Denims,towels,

heavycottons

Workclothes,

corduroys,etc.

Lingerie,sheets,

blouses

Forsmallloads

with short Off

dryingtimes

Foriremsthat

requireheat-free

dryingsuchas

plasticsor rubber

Forgeneraldrying;

time,temperature, Off

andoptionscanbe

setmanually

Sensor Dry Cycles

Sensor Dry cycles utilize LG's unique dual sensor

system to detect and compare the moisture level

in clothes and in the air and adjust the drying

time as needed to ensure superior results. The

dryer automatically sets the dryness level and

temperature at the recommended setting for

each cycle. The estimated time remaining will

Normal

Adjustable

Normal

Adjustable

Normal

Adjustable

Off

Med.High

Medium

Low

High

Adjustable

No Heat

High

Adjustable

55

41

32

25

Adjustable

3O

Adjustable

4O

Adjustable

Manual Dry Cycles

Use Manual Dry cycles to select a specific

amount of drying time and a drying temperature.

When a Manual Dry cycle is selected, the

ESTIMATED TIME REMAINING display shows

the actual time remaining inyour cycle. You can

change the actual time in the cycle by pressing

MORE TIME or LESS TIME.

be shown in the display.

NOTE: To protect your garments, not every dry level, temperature, or option is available

with every cycle.

J

28

Page 29

HOWTO USE

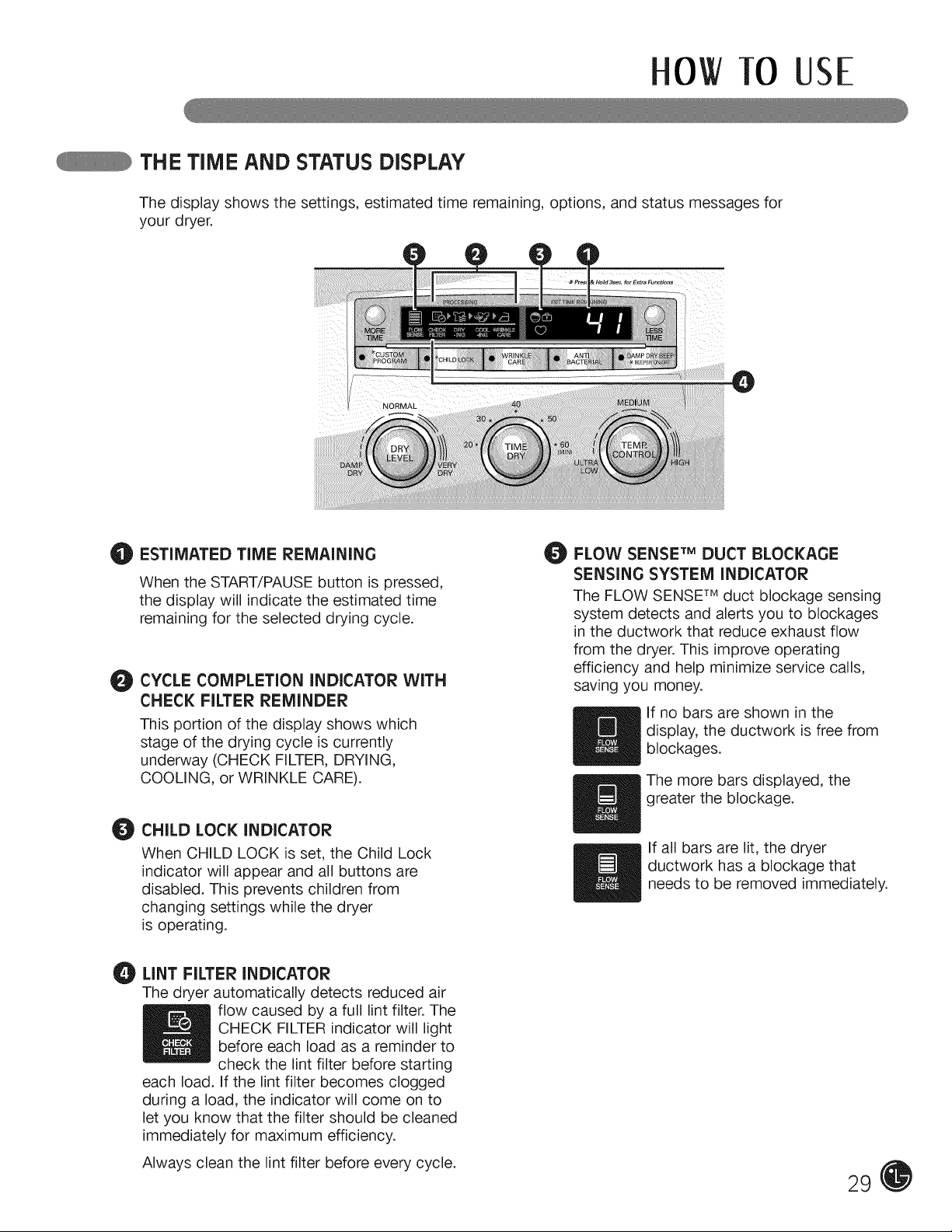

THE TiME AND STATUS DISPLAY

The display shows the settings, estimated time remaining, options, and status messages for

your dryer.

O

O ESTIMATED TIME REMAINING

When the START/PAUSE button is pressed,

the display will indicate the estimated time

remaining for the selected drying cycle.

CYCLE COMPLETION INDICATOR WITH

CHECK FILTER REMINDER

This portion of the display shows which

stage of the drying cycle is currently

underway (CHECK FILTER, DRYING,

COOLING, or WRINKLE CARE).

CHILD LOCK INDICATOR

O

When CHILD LOCK is set, the Child Lock

indicator will appear and all buttons are

disabled. This prevents children from

changing settings while the dryer

is operating.

LiNT FILTER iNDICATOR

O

The dryer automatically detects reduced air

flow caused by a full lint filter. The

CHECK FILTER indicator will light

before each load as a reminder to

check the lint filter before starting

each load. If the lint filter becomes clogged

during a load, the indicator will come on to

let you know that the filter should be cleaned

immediately for maximum efficiency.

FLOW SENSE TM DUCT BLOCKAGE

O

SENSING SYSTEM INDICATOR

The FLOW SENSE TM duct blockage sensing

system detects and alerts you to blockages

in the ductwork that reduce exhaust flow

from the dryer. This improve operating

efficiency and help minimize service calls,

saving you money.

If no bars are shown in the

display, the ductwork is free from

m

blockages.

The more bars displayed, the

greater the blockage.

m

If all bars are lit, the dryer

ductwork has a blockage that

m

needs to be removed immediately.

Always clean the lint filter before every cycle.

29

Page 30

flOW TO USE

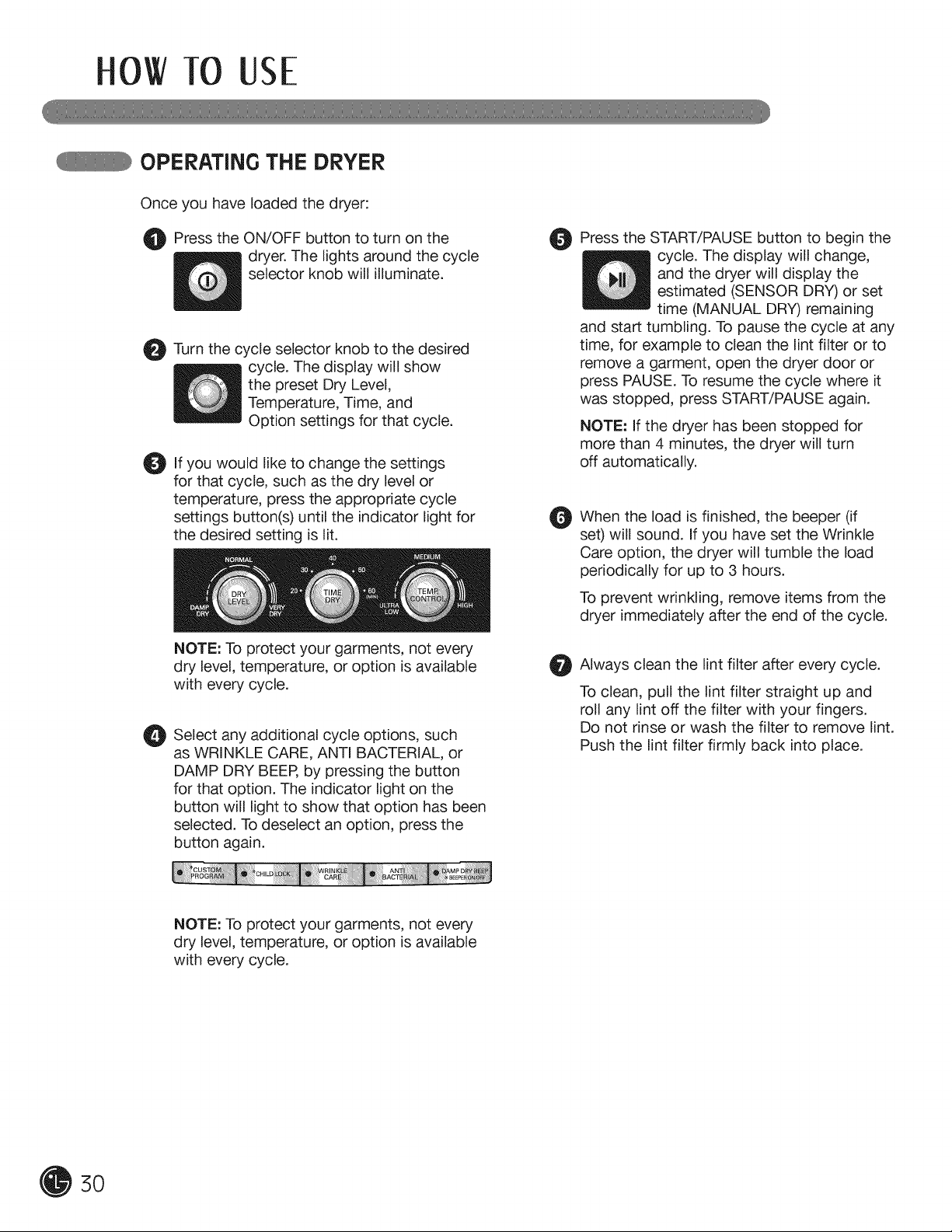

OPERATING THE DRYER

once you have loaded the dryer:

O Press the ON/OFF button to turn on the

dryer. The lights around the cycle

selector knob will illuminate.

O Turn the selector knob to the desired

_lf you to change settings

for that cycle, such as the dry level or

temperature, press the appropriate cycle

settings button(s) until the indicator light for

the desired setting is lit.

NOTE: To protect your garments, not every

dry level, temperature, or option is available

with every cycle.

Select any additional cycle options,

as WRINKLE CARE, ANTI BACTERIAL, or

DAMP DRY BEER by pressing the button

for that option. The indicator light on the

button will light to show that option has been

selected. To deselect an option, press the

button again.

cycle

cycle. The display will show

the preset Dry Level,

Temperature, Time, and

Option settings for that cycle.

would like the

such

Press the START/PAUSE button to begin the

cycle. The display will change,

and the dryer will display the

estimated (SENSOR DRY) or set

time (MANUAL DRY) remaining

and start tumbling. To pause the cycle at any

time, for example to clean the lint filter or to

remove a garment, open the dryer door or

press PAUSE. To resume the cycle where it

was stopped, press START/PAUSE again.

NOTE: Ifthe dryer has been stopped for

more than 4 minutes, the dryer will turn

off automatically.

When the load is finished, the beeper (if

O

set) will sound, if you have set the Wrinkle

Care option, the dryer will tumble the load

periodically for up to 3 hours.

To prevent wrinkling, remove items from the

dryer immediately after the end of the cycle.

Always clean the lint filter after every cycle.

O

To clean, pull the lint filter straight up and

roll any lint off the filter with your fingers.

Do not rinse or wash the filter to remove lint.

Push the lint filter firmly back into place.

50

NOTE: To protect your garments, not every

dry level, temperature, or option is available

with every cycle.

Page 31

CYCLE SETTING BUTTONS

HOWTO USE

Sensor Dry cycles have preset settings that are

selected automatically and cannot be changed.

Manual Dry cycles have default settings, but you

may also customize the settings using the cycle

setting buttons. Press the button for that setting

until the indicator light for the desired value is lit.

DRY LEVEL

Selects the level of

dryness for the cycle.

Press the DRY LEVEL

button until the indicator

light for the desired

setting is lit.

• This option is only available with SENSOR DRY

cycles.

The dryer will automatically adjust the cycle

time. Selecting VERY DRY or MORE DRY will

increase the cycle time, while LESS DRY or

DAMP DRY will decrease the cycle time.

Use a LESS DRY or DAMP DRY setting for

items that you wish to iron.

NOTE: To protect your garments, not every

dryness level, temperature, or option is available

with every cycle. See the Cycle Guide for details.

TIME DRY

Allows you to manually

select the drying time,

from 20 to 60 minutes, in

10- minute increments.

Use this for small loads

or to remove wrinkles.

Press the TIME DRY

button until the indicator light for the desired

drying time is lit. Use the MORE TIME/

LESS TIME buttons to add or reduce the

drying time in 1-minute increments.

TEMP. CONTROL

Adjusts the temperature

setting from ULTRA LOW

to HIGH. This allows

precise care of your

fabrics and garments.

Press the TEMR

CONTROL button until

the indicator light for the desired setting is lit.

3t

Page 32

HOWTO USE

CYCLE OPTION BUTTONS

Your dryer features several additional cycle

options to customize cycles to meet your

individual needs. Certain option buttons also

feature a special function (see the following page

for details) that can be activated by pressing and

holding that option button for 3 seconds.

TOAdd Cycle Options to a Cycle:

O Turn on the dryer and turn the cycle selector

knob to select the desired cycle.

_tUse cycle settings to adjust

0) Press the cycle option button(s) for the

O Press the START/PAUSE button start the

the buttons the

settings for that cycle.

option you would like to add. A confirmation

message will be shown in the display.

to

cycle. The dryer will start automatically.

WRINKLE CARE

Selecting this option will tumble the

load periodically for up to 3 hours after

the selected cycle, or until the door is

opened. This is helpful in preventing

wrinkles when you are unable to immediately

remove items from the dryer.

A NTI BACTERIA L

This option will add a high heat setting

to reduce bacteria. It can only be

used with the CO-FI-ON/TOWELS, and

NORMAL cycles.

NOTE: Do not use this cycle with

delicate fabrics.

DAMP DRY BEEP

With this option, the dryer will beep

when the load is approximately 80%

dry. This allows you to remove

faster- drying lightweight items or

items that you would like to iron or hang while still

slightly damp.

52

Page 33

SPECIAL FUNCTIONS

The option buttons also activate special

functions, including CHILD LOCK and

BEEPER ON/OFR Press and hold the option

button marked with the special function

for 3 seconds to activate.

HOWTO USE

CHILD LOCK

Use this option to prevent unwanted

use of the dryer or to keep cycle

settings from being changed while the

dryer is operating. Press and hold the

CHILD LOCK button for 3 seconds to activate or

deactivate CHILD LOCK.

The lock icon will be shown in the display, and all

controls are disabled.

CUSTOM PROGRAM

If you have a special combination of

settings that you use frequently, you

can save these settings as a CUSTOM

PROGRAM.

BEEPER ON/OFF

To turn the beeper off, press and hold

DAMP DRY BEEP for 3 seconds. Press

and hold again for 3 seconds to turn

the beeper back on.

:_ TO Save a Custom Program:

_i_ Turn on the dryer and turn the cycle selector

knob to select the desired cycle.

Use the cycle setting knobs to adjust the

settings for that cycle.

O Press the cycle option button(s) for the

option(s) you would like to add.

O Press and hold the

button for 3 seconds.

NOTE: You may only save one custom

program at a time. Pressing and holding the

CUSTOM PROGRAM button will overwrite

any previously saved custom program.

CUSTOM PROGRAM

TO Recall a Custom Program:

O Turn on the dryer.

O Press the CUSTOM PROGRAM button.

O Press the START/PAUSE button to start

the cycle.

55

Page 34

CA E AND clEANING

REGULAR CLEANING

__R_|_G: TOreduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Unplug the dryer before cleaning to avoid the risk of electric shock. Failure to follow this warning can