LG DLGX3876, DLEX3875, DLEX3885 Service Manual

U.S.A. Website: http://us.lgservice.com

Canadian Website: http://lg.ca

ELECTRIC & GAS DRYER

SERVICE MANUAL

CAUTION

READ THIS MANUAL CAREFULLY IN ORDER TO

PROPERLY DIAGNOSE PROBLEMS AND TO SAFELY

PROVIDE QUALITY SERVICE ON THESE DRYERS.

MODEL : Electric Gas

DLEX3885* DLGX3886*

DLEX3875* DLGX3876*

JAN. 2010 PRINTED IN KOREA

P/No.: MFL62119907

2

To avoid personal injury, disconnect power before servicing this product. If electrical power is required

for diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

!

WARNING !

WHAT TO DO IF YOU SMELL GAS:

IMPORTANT SAFETY NOTICE

The information in this service guide is intended for use by individuals possessing skill and experience in

electrical, electronic, and mechanical appliance repair. Any attempt to repair a major appliance may result

in personal injury and property damage. The manufacturer or seller cannot be responsible for the

interpretation of this information, nor can it assume any liability in connection with its use.

RECONNECT ALL GROUNDING DEVICES

If grounding wires, screws, straps, clips, nuts, or washers used to complete a path to ground are

removed for service, they must be returned to their original position and properly fastened.

IMPORTANT

Electrostatic Discharge (ESD)

Sensitive Electronics

ESD problems are present everywhere. ESD may damage or weaken the electronic

control assembly. The new control assembly may appear to work well after repair is

finished, but failure may occur at a later date due to ESD stress.

■

Use an anti-static wrist strap. Connect wrist strap to green ground connection point or unpainted

metal in the appliance.

- OR -

Touch your finger repeatedly to a green ground connection point or unpainted metal

in the appliance.

■

Before removing the part from its package, touch the anti-static bag to a green ground connection

point or unpainted metal in the appliance.

■

Avoid touching electronic parts or terminal contacts; handle electronic control assembly by edges only.

■

When repackaging failed electronic control assembly in anti-static bag, observe above instructions.

■ Do not try to light a match, or cigarette, or turn on

any gas or electrical appliance.

■ Do not touch any electrical switches. Do not use

any phone in your building.

■ Clear the room, building or area of all occupants.

■ Immediately call your gas supplier from a

neighbor’s phone. Follow the gas supplier’s

instructions carefully.

■ If you cannot reach your gas supplier, call the fire

department.

CONTENTS

1. SPECIFICATIONS ............................................................................................................... 4

2. FEATURES AND BENEFITS ............................................................................................... 6

3. INSTALLATION INSTRUCTIONS ........................................................................................ 6

4. DRYER CYCLE PROCESS ................................................................................................ 13

5. COMPONENT TESTING INFORMATION ......................................................................... 14

6. MOTOR DIAGRAM AND SCHEMATIC ............................................................................. 17

7. WIRING DIAGRAM ............................................................................................................ 18

8. STEAM FUNCTION ............................................................................................................ 19

8-1. STEAM CYCLE GUIDE ............................................................................................ 19

8-2. TROUBLESHOOTING FOR STEAM DRYER .......................................................... 20

8-3. DISPLAY FAULT/ERROR CODES FOR STEAM DRYER ........................................ 21

9. FLOW SENSOR FUNCTION ............................................................................................. 22

9-1. FLOW SENSOR ....................................................................................................... 22

9-2. INSTALLATION CHECK .......................................................................................... 23

9-3. TROUBLESHOOTING FOR FLOW SENSOR DRYER ............................................ 24

10. DIAGNOSTIC TEST ........................................................................................................ 25

10-1. TEST 1 120V AC ELECTRICAL SUPPLY ............................................................ 26

10-2. TEST 2 THERMISTOR TEST - MEZSURE WITH POWER OFF ......................... 29

10-3. TEST 3 MOTOR TEST ......................................................................................... 30

10-4. TEST 4 MOISTURE SENSOR .............................................................................. 31

10-5. TEST 5 DOOR SWITCH TEST ............................................................................. 32

10-6. TEST 6 HEATER SWITCH TEST - ELECTRIC TYPE .......................................... 33

10-7. TEST 7 GAS VALVE TEST - GAS TYPE .............................................................. 34

10-8. TEST 8 SEMI-CONDUCTOR ............................................................................... 35

10-9. TEST 9 MOTOR ASSEMBLY, DC, PUMP ............................................................ 35

10-10. TEST 10 GENERATOR ASSEMBLY .................................................................. 36

11. CHANGE GAS SETTING (NATURAL GAS, PROPANE GAS) ....................................... 37

12. DISASSEMBLY INSTRUCTIONS .................................................................................... 39

13. EXPLODED VIEW ............................................................................................................ 49

13-1-1. Control Panel and Plate Assembly (Touch LCD type) ......................................... 49

13-1-2. Control Panel and Plate Assembly 50

13-2. PANEL DRAWER ASSEMBLY and GUIDE ASSEMBLY ......................................... 51

13-3-1. CABINET and DOOR ASSEMBLY: ELECTRIC TYPE ........................................ 52

13-3-2. CABINET and DOOR ASSEMBLY: GAS TYPE .................................................. 53

13-4-1. DRUM and MOTOR ASSEMBLY: ELECTRIC TYPE ........................................... 54

13-4-2. DRUM and MOTOR ASSEMBLY: GAS TYPE ..................................................... 55

3

1

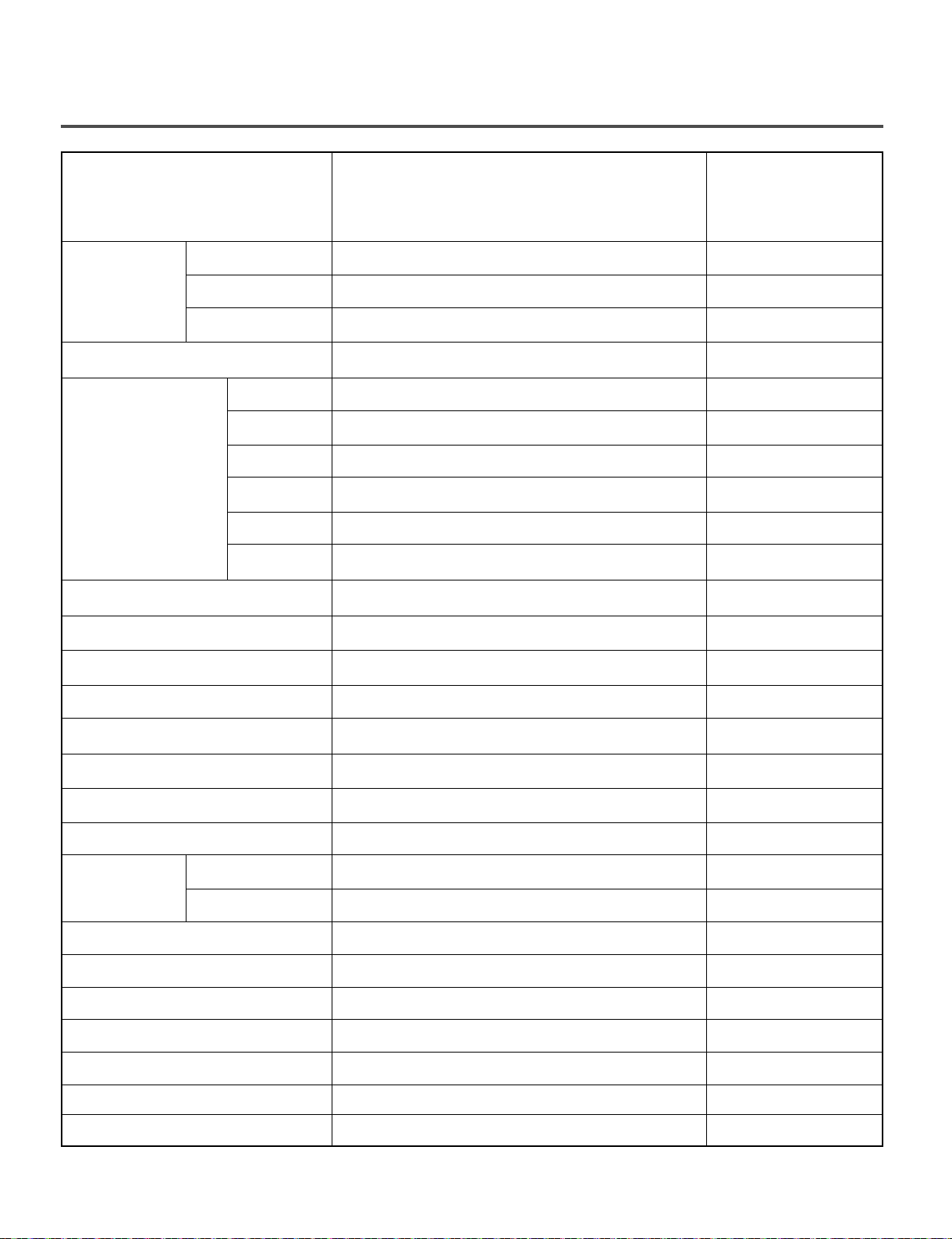

SPECIFICATIONS

Name: Electric and Gas Dryer

Power supply: Please refer to the rating label regarding detailed

Size : 27 X 30 X 38.7 (inch)

Dryer capacity: IEC 7.4 cu.ft.

Weight: 136(lbs)

Specifications are subject to change by manufacturer.

ACCESSORIES

Dryer rack (1 each)

information.

Stacking kit (1 each)

Purchased Separately

Pedestal (1 each)

Purchased Separately

See page 6

See page 7 See page 8

4

ITEM

DLEX3885* DLGX3886*

DLEX3875* DLGX3876*

REMARK

Color

Material &

Finish

Top Plate

Door Trim

POWER SUPPLY

MOTOR

ELECTRICITY

HEATER

CONSUMPTION

GAS VALVE

AG HEATER

DC, PUMP

CONTROL TYPE

DRUM CAPACITY

Weight (lbs) - Net/Gross

No. of Programs

LAMP

Blue White / Stainless Silver / Vintage Gold

Porcelain

Chromate

120V/240V 60Hz (26A)

250W (4.5A)

5400W (22.5A)

15 W (0.2A)

13 W (0.11A) x 2

1100W (9.2A)

2.4W (0.15A)

Electronic

7.4 cu.ft.

136 / 155.7

9

AC 120V

AC 240V (ELECTRIC MODEL)

AC 120V

AC 120V (GAS MODEL)

AC 120V (STEAM MODEL)

DC 9V (STEAM MODEL)

AC 240V (ELECTRIC MODEL)

No. of Dry Options

No. of Temperature Controls

No. of Dry Levels

Sound levels

Moisture

Sensor

Temperature

Reversible Door

Drum

Dryer Rack

Child Lock

Interior Light

Product (WxHxD)

Packing (WxHxD)

5

5

5

5

Available

Available

Available

Stainless Steel

Available

Available

Available

27" x 42 3/4" x 28 1/3"

29 1/2" x 44 3/4" x 30 3/4"

5

Electrode sensor, Dual Sensor

Thermistor, Dual Sensor

2

FEATURES AND BENEFITS

3

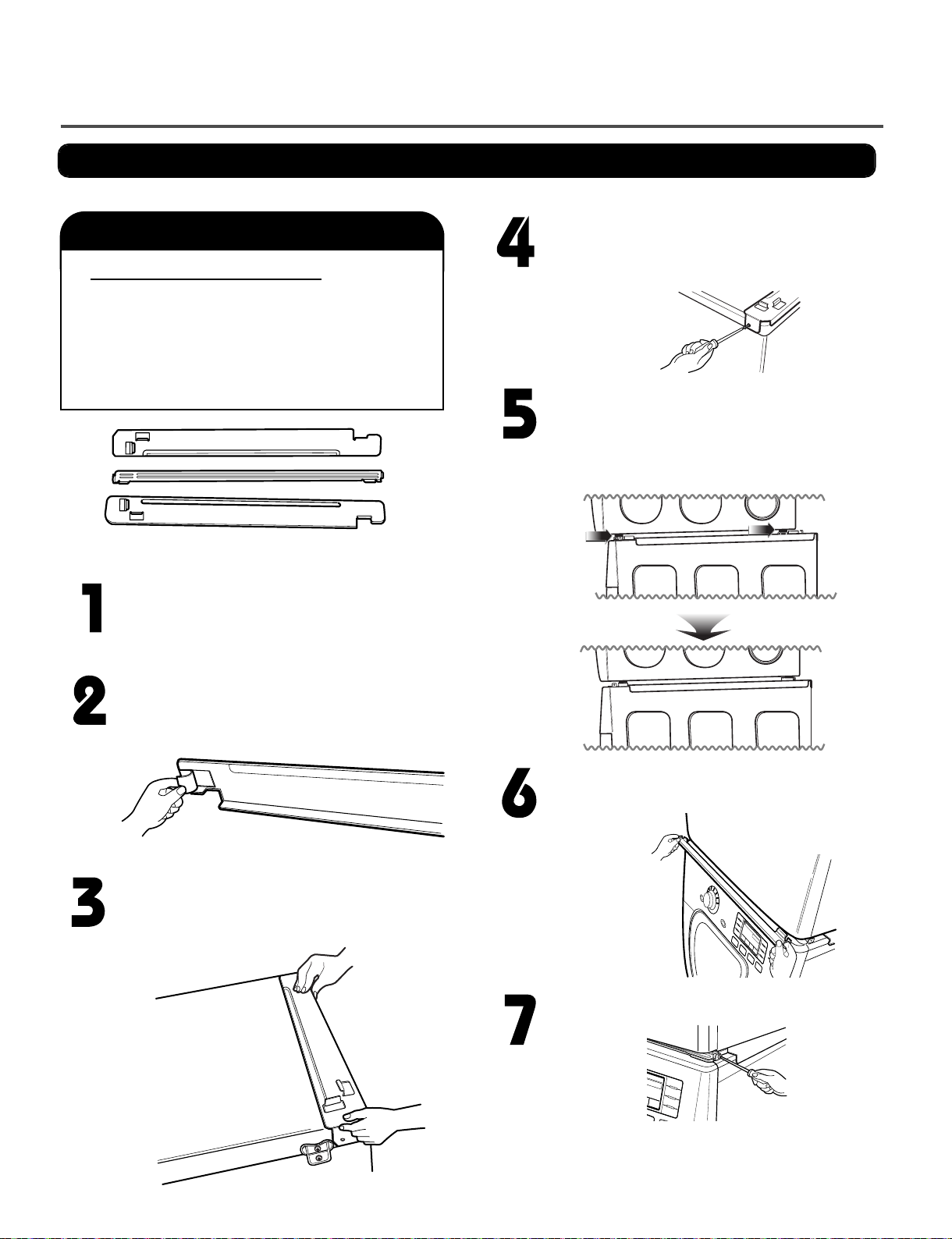

Dryer Rack Installation Instructions

INSTALLATION INSTRUCTIONS

Open the door.

Hold the dryer rack

with both hands.

Put the dryer rack into

the drum

Check and be sure that the

front of the rack is properly

seated behind the lint filter.

6

Stacking Kit Installation Instructions

To ensure safe and secure installation, please observe the instructions below.

WWAARRNNIINN GG

Do not attempt this alone!

At least two people are required to lift and

position the dryer on top of a washing

machine!

Failure to heed this warning can result in

serious physical injury and damage to the

appliance.

Stacking kit

Place the washer firmly on a stable, even

and solid floor as product installation

instructions describe in the owner’s

manual.

Secure the side bracket to the washer with

a screw on the back of the bracket. Repeat

Steps 2, 3, and 4 for the other side.

Place the dryer on top of the washer by

placing the legs as shown. Be careful not to

pinch fingers between the washer and dryer.

Slide the dryer back against the stop on the

side rail.

Peel the protective paper from the tape on

the side bracket.

Fit the side bracket firmly to the side of the

top plate by attaching the double-faced tape

to the top plate as picture shown.

Insert the front rail of the stacking kit. Push

the front rail back against the stops on the

side brackets.

Attach the front bracket to the side rails with

a screw on each side.

• Do not use a stacking kit with a gas dryer in

7

potentially unstable conditions like a mobile

home.

Pedestal Installation Instructions

The pedestal accessory includes:

Drawer divider (1)

•

Screws (18) †

•

† Dryer installation only uses 8 screws

†† For dryer only

Wrench (1)

•

T-clips (4) ††

•

Tools Needed for Installation:

Phillips-head screwdriver

•

Wrench (supplied)

•

To ensure safe and secure installation, please

thoroughly follow the instructions below.

WARNING

• Incorrect installation can cause serious accidents.

• The appliances are heavy. Two or more people are

required when installing the pedestal. There is a

risk of serious back injury or other injuries.

• Do not allow children to play in or on the drawer.

There is a risk of suffocation or injury.

• Do not step on the handle. There is a risk of serious injury.

• If appliances are already installed, disconnect them

from all power, water, or gas lines and from draining or

venting connections. Failure to do so can result in

electrical shock, fire, explosion, or death.

• When installing, gloves must be put on.

Place the dryer on the

pedestal. Make sure

the front and back feet

are in the correct

positions. The dryer

feet will fit into the

innermost positions as

shown.

Make sure the screws on the pedestal align with the

holes in the retainers, then install 4 screws on each

side to securely attach the appliance to the pedestal.

NOTE: If the screws are not installed properly, noise

and vibration may result.

Move the appliance to the desired location.

Loosen the locknuts on all 4 leveling feet of the

pedestal until you can turn them with the wrench.

Turn clockwise to raise or counterclockwise to lower

until the pedestal is level and all 4 feet are solidly

against the floor.

For dryer

For washer/combo

Make sure the leveling feet of the dryer are

fully retracted.

NOTE: The appliance and pedestal assembly

must be placed on a solid, sturdy, level floor

for proper operation.

Retract fully

Insert the T-clip of the 4 retainers into the dryer

base as shown. Press up on the back of the

clip and pull outward to lock into place.

T-clip

Retainer

Raise

Securely tighten all locknuts by hand.

NOTE: Noise and vibration may result if locknuts are not

tightened.

Be sure to connect the appliances to all water, power,

or gas lines and draining or venting connections before

operation.

If there is excessive vibration during the first operation

after installation, slightly adjust the leveling feet.

8

Locknut

Lower

9

Use the instructions under option 2 or 3 if your

home has a 3-wire receptacle (NEMA type 10-30R).

Use option 2 if local codes and ordinances permit

the connection of a chassis ground to the neutral

connector. If this is not permitted, use option 3.

Review the following options to determine the appropriate electrical connection for your home:

Electric Dryer Only

If this type is available at your home. you will be

connecting to a fused disconnect or circuit breaker

box

Important :Grounding through the neutral conductor

is prohibited for (1) new branch-circuit installations,

(2) mobile homes, and (3) recreational vehicles, and

(4) areas where local codes prohibit grounding through

the neutral conductor.

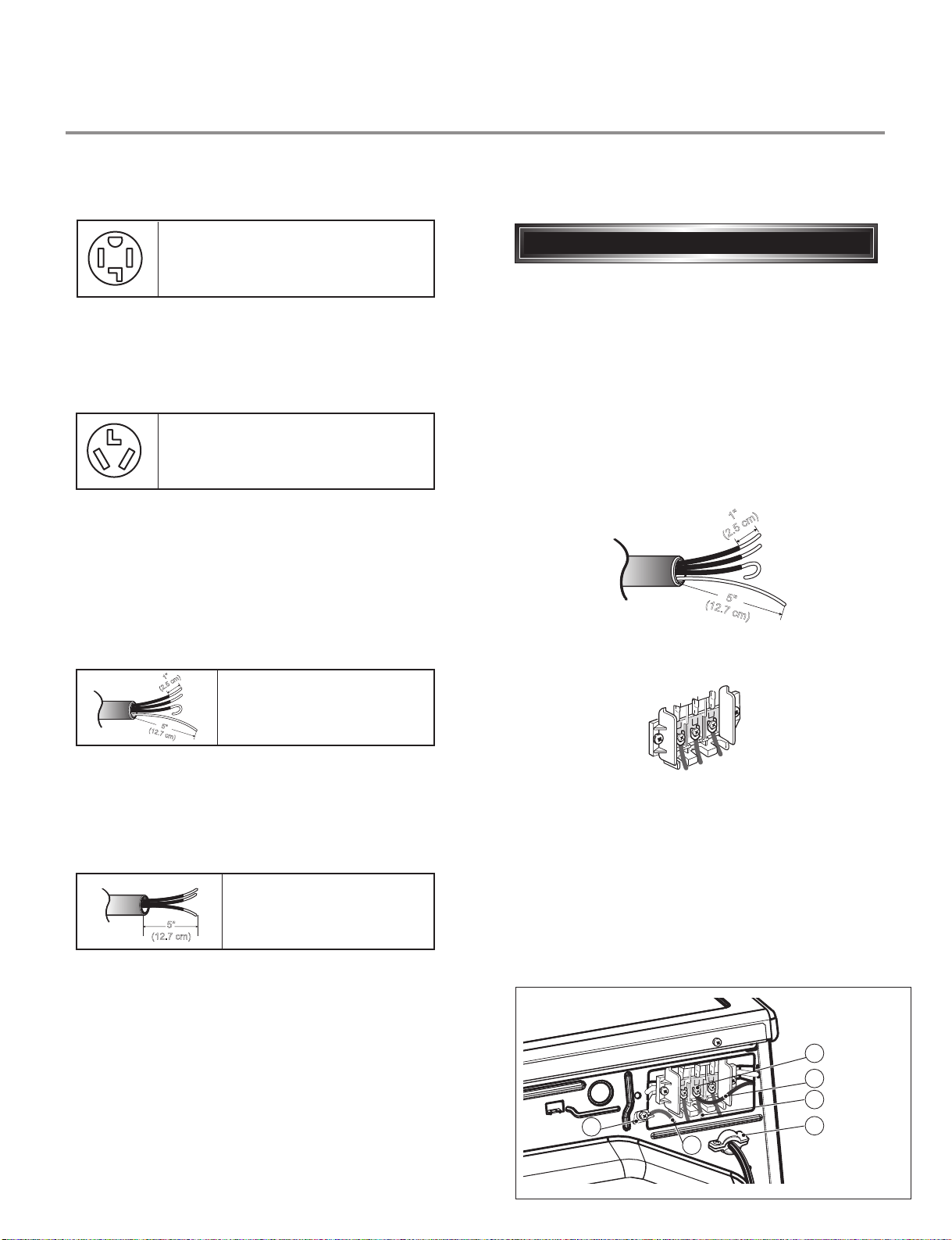

Prepare minimum 5ft(1.52m) of length in order for

dryer to be replaced.

First, peel 5 inch (12.7cm) of covering material from

end. Make a 5 inch of ground wire bared. After cutting

1

1

/2 inch (3.8cm) from 3 other wires. peel insulation

back 1inch (2.5cm). Make ends of 3 wires a hook

shape.

Then, put the hooked shape end of the wire under the

screw of the terminal block(hooked end facing rightward)

and pinch the hook together and screw tightly.

Use the instructions under option 1 if your home

homehas a 4-wire receptacle (NEMA type 14-30R).

If this type is available at your home. you will be

connecting to a fused disconnect or circuit breaker

box

1. Connect neutral wire(white) of power cord to center

terminal block screw.

2. Connect red and black wire to the left and right

terminal block screws.

3. Connect ground wire(green) of power cord to external

ground screw and move neutral ground wire of

appliance and connect it to center screw.

4. Make sure that the strain relief screw is tightened.

and be sure that all terminal block nuts are on tight and

power cord is in right position.

1"

(2.5 cm)

5

"

(12.7 cm)

3-wire direct

4-wire receptacle

(NEMA type14-30R)

3-wire receptacle

(NEMA type10-30R)

4-wire direct

5"

(12.7 cm)

4-wire connection : Direct wire

1"

(2.5 cm)

5

"

(12.7 cm)

D

E

F

a

C

b

10

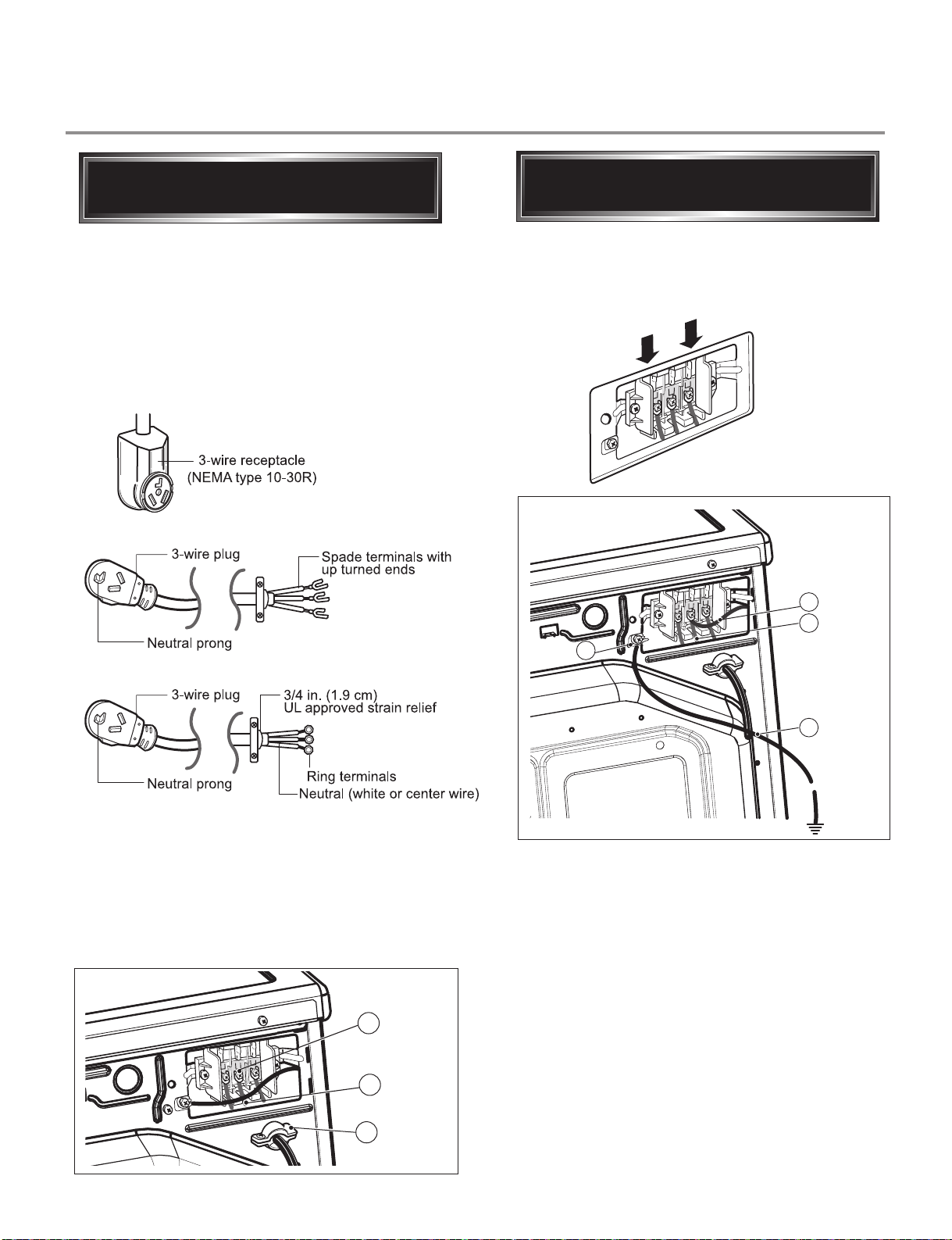

Important : Grounding through the neutral conductor

is prohibited for (1) new branch-circuit installations,

(2) mobile homes, and (3) recreational vehicles, and

(4) areas where local codes prohibit grounding through

the neutral conductor.

Prepare minimum 5ft(1.52m) of length in order for

dryer to be replaced.

First, peel 3

1

/2 inch (8.9cm) of covering material

from end and bare 1 inch from the ends.

1. Connect neutral wire(white) of power cord to

center terminal block screw.

2. Connect red and black wire to the left and right

terminal block screws.

3. Make sure that the strain relief screw is tightened

and be sure that all terminal block nuts are on

tight and power cord is in right position.

Then, put the hooked shape end of the wire under

the screw of the terminal block(hooked end facing

rightward) and pinch the hook together and screw

tightly.

1

"

(

2

.

5

c

m

)

3V

2

"

(8.9 cm)

3-wire connection : Direct wire

1. Connect the neutral wire (white) of the power

cord to the center terminal block screw.

2. Connect the red and black wires to the left and

right terminal block screws.

3. Connect the ground wire (green) of the power

cord to the external ground screw. Remove the

neutral ground wire of appliance and connect it to

center screw.

4. Make sure that the strain relief screw is tightened

and that all terminal block nuts are tight and the

power cord is in the right position.

F

a

b

E

D

C

• lf your local codes or ordinances do not allow the

use of a 3 wire connection, or you are installing

your dryer in a mobile home, you must use a

4-wire connection.

Option 1: 4-wire connection with

a Power supply cord.

C

B

D

a

E

11

1. Remove the appliance ground wire (D) (green)

fromthe external ground connector screw and

reconnect it, together with the center, white,

neutral wire (E) to the center, silver colored,

terminal block screw.

2. Connect the other two power cord wires (red and

black) to the left and right terminal block screws

and tighten securely.

3. Tighten the strain relief screws securely.

4. Connect an independent ground wire (F) from the

external ground connector screw to a proper

ground. (The ground wire must be long enough to

allow the appliance to be moved, if necessary, for

service or cleaning.)

C

B

A

lf your local codes or ordinances permit the

connection of a frame-grounding conductor to the

neutral wire, use these instructions. If your local

codes or ordinances do not allow the connection of

a frame-grounding conductor to the neutral wire,

use the instructions under Option 3: Optional

3-wire connection.

1. Connect the neutral (white or center) wire (B) to

the center, silver colored, screw (A) and tighten

securely.

2. Connect the other two power cord wires (red and

black) to the left and right terminal block screws

and tighten securely.

3. Tighten the strain relief screws (C) securely.

Option 2: 3-Wire Connection with

a Power Supply Cord

• If your local codes or ordinances do not allow the

connection of a frame-grounding conductor to the

neutral wire, use the instructions under this

section.

E

A

D

F

Option 3: Optional 3-wire

connection.

12

3-2. Connect Gas Supply Pipe (Gas Dryer ONLY)

2

3

5

1

4

1. Make certain your dryer is equipped for use with the

type of gas in your laundry room. Dryer is equipped

at the factory for Natural Gas with a

3

/8” NP T gas

connection.

2. Remove the shipping cap from the gas connection

at the rear of the dryer. Make sure you do not

damage the pipe thread when removing the cap.

3. Connect to gas supply pipe using a new flexible

stainless steel connector.

4. Tighten all connections securely. Turn on gas and

check all pipe connections (internal and external) for

gas leaks with a non-corrosive leak detection fluid.

5. For LP (Liquefied Petroleum) gas connection, refer

to section on Gas Requirements.

For further assistance, refer to section on Gas Requirements.

1 New Stainless Steel Flexible Connector - Use

only if allowed by local codes (Use Design

A.G.A. Certified Connector)

2

1

/8” NPT Pipe Plug

(for checking inlet gas pressure)

3 Equipment Shut-Off Valve-Installed within 6’

(1.8 m) of dryer

4 Black Iron Pipe

Shorter than 20’ (6.1 m) - Use

3

/8” pipe

Longer than 20’ (6.1 m) - Use

1

/2” pipe

5

3

/8” NPT Gas Connection

4

Cycle

Default

Conditions of operation and termination

Tem p-

erature

Dry

Level

Display

time

Sensor

Dry *

Manual

Dry **

STEAM FRESH

TM

ANTIBACTERIAL

BULKY /

LARGE

HEAVY DUTY

PERM PRESS

CASUAL

COTTON /

NORMAL

DELICATES

TOWELS

SMALL LOAD

SPORTS

WEAR

STEAM

SAINTARY

TM

SPEED DRY

AIR DRY

FRESHEN UP

HIGH

MEDIUM

MEDIUM

Off

Off

Off

Off

Off

Ver y

Dry

HIGH

HIGH

HIGH

LOW

HIGH

NO

HEAT

20min

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

Saturation

66±4˚C 45 ±5˚C

45 ±5˚C

45 ±5˚C

45 ±5˚C

45 ±5˚C

38 ±5˚C

(47 ±5˚C)

45 ±5˚C

45 ±5˚C

45 ±5˚C

68±4˚C

68±4˚C

68±4˚C

60±4˚C

52±3˚C

66±4˚C

68±4˚C

60±4˚C

(68±5˚C)

(66±5˚C)

5min

5min

5min

5min

5min

5min

5min

5min

5min

5min

5min

39min

70min

Normal

Adjustable

LOW

Saturation

45 ±5˚C

52±3˚C

5min

32min

54min

41min

28min

55min

30min

27min

15min

30min

25min

Drying Cooling

Wrinkle care

Time

Electro-

sensor

Te mp-

Control

Default

time

Temp-

Control**

3Hr

3Hr

Load

Motor

Heater

Temperature Control for each cycl e

Off Time: 6min

On Time: 10sec

*Sensor dry : Dry Level is set by users.

**Manual dry : Temperature control is set by users.

Default settings can be adjusted by users.

HIGH

HIGH

MEDIUM

Mid High

Normal

Adjustable

MEDIUM

Saturatio

n

45 ±5˚C

60±4˚C

5min

55min

Normal

Adjustable

Normal

Adjustable

Normal

Adjustable

Normal

Adjustable

Normal

Adjustable

(66±5˚C)

5min

(45 ± 5˚C)

DRYER CYCLE PROCESS

13

14

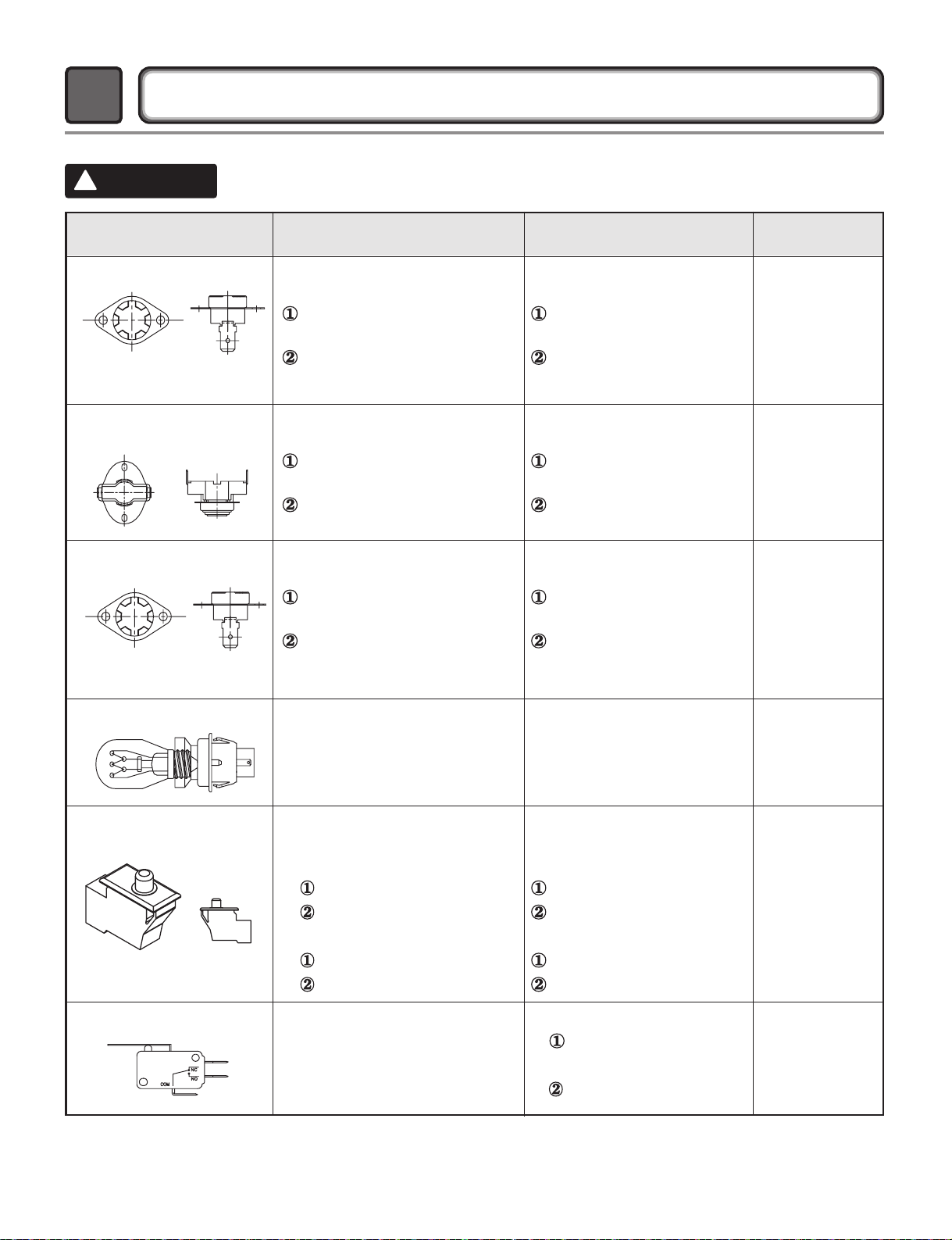

When checking the component, be sure to turn the power off, and do voltage discharge sufficiently.

COMPONENT TESTING INFORMATION

5

!

CAUTION

Component Test Procedure Check result Remark

1. Thermal cut off

• Check Top Marking:

N130

Measure resistance of terminal

to terminal

Open at 266±12°F

(130±7°C)

Auto reset 31°F (35°C)

Same shape as Outlet Thermostat.

If thermal fuse is open must

be replaced

Resistance value ≒∞

Continuity (250°F ↓) < 1Ω

• Heater caseSafety

• Electric type

2. Hi limit Thermostat

(Auto reset)

Measure resistance of terminal

to terminal

Open at 257±9°F

(125±5°C)

Close at 221±9°F

(105±5°C)

Resistance value ≒∞

Resistance value < 5Ω

• Heater case Hi limit

• Electric type

3. Outlet Thermostat

( Auto reset)

• Check Top Marking:

N85

Measure resistance of terminal

to terminal

Open at 185±9°F

(85±5°C)

Close at 149±9°F

(65±5°C)

Same shape as Thermal cut off.

Resistance value ≒∞

Resistance value < 5Ω

• Blow housing Safety

• Electric type

4. Lamp holder Measure resistance of terminal

to terminal

Resistance value:

80Ω ~ 100Ω

6. Idler switch Measure resistance of the

following terminal:

COM - NC

1. lever open

Resistance value < 1Ω

2. Lever push (close)

Resistance value ≒∞

5. Door switch Measure resistance of the

following terminal

1) Door switch knob: open

Terminal: COM - NC (1-3)

Terminal: COM - NO (1-2)

2) Door switch push: push

Terminal: COM - NC (1-3)

Terminal: COM - NO (1-2)

Resistance value < 1Ω

Resistance value ≒∞

Resistance value ≒∞

Resistance value < 1Ω

The state that

Knob is

pressed is

opposite to

Open

condition.

15

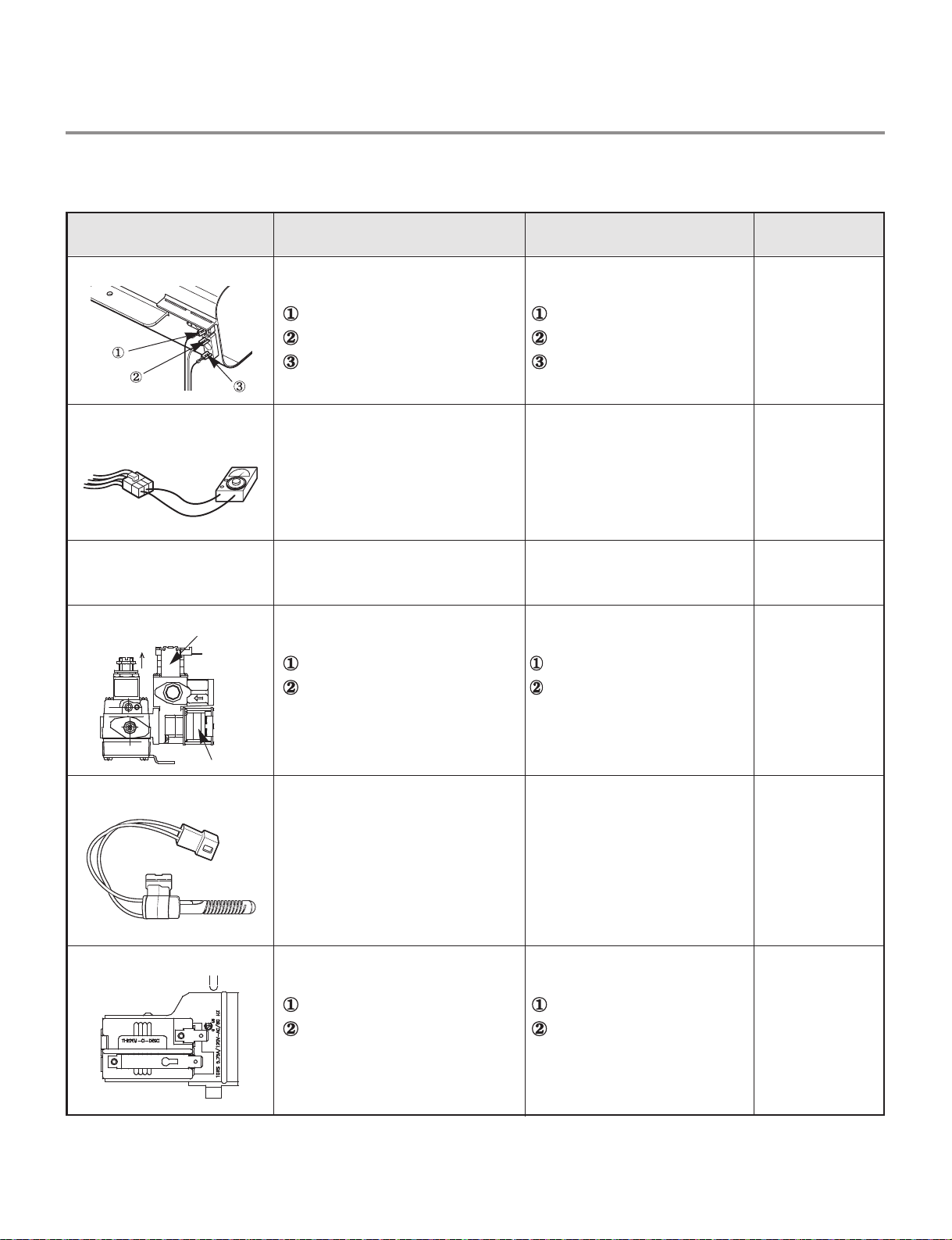

Component Test Procedure Check result Remark

7. Heater Measure resistance of the

following terminal

Terminal: 1 (COM) - 2

Terminal: 1 (COM) - 3

Terminal: 2 - 3

Resistance value: 10Ω

Resistance value: 10Ω

Resistance value: 20Ω

• Electric type

8. Thermistor Measure resistance of terminal

to terminal

Temperature condition:

58°F ~ (10~40°C)

58°F ~ 104F (10~40°C)

Resistance value: 10Ω • Heater case -

Hi limit

• Electric type

9. Motor • See Page 13

10. Gas valve

valve 1

valve 2

Measure resistance of the

following terminal

Valve 1 terminal

Valve 2 terminal

Resistance value: > 1.5 kΩ

Resistance value: >

1.5~2.5 kΩ

• Gas type

11. Igniter Measure resistance of terminal

to terminal

Resistance value: 100~800Ω • Gas type

12. Flame Detect Measure resistance of terminal

to terminal

Open at 370°F ((Maximum)

Close at 320°F

Resistance value ≒∞

Resistance value < 1Ω

• Gas type

Loading...

Loading...