Page 1

Before beginning installation, read these

C

E

R

T

I

F

I

E

D

D

E

S

I

G

N

instructions carefully. This will simplify installation

and ensure that the dryer is installed correctly and

safely. Leave these instructions near the dryer

after installation for future reference.

To contact LG Electronics, 24 hours a day,

7 days a week:

1-800-243-0000

Or visit us on the Web at: us.lge.com

Número telefónico de LG Electronics, las 24

horas del día, 7 días a la semana:

1-800-243-0000

O visítenos en la Web en: us.lge.com

Antes de comenzar la instalación, lea atentamente

estas instrucciones. Esto simplificará la instalación

y asegurará que la secadora está instalada

en forma correcta y segura. Conserve estas

instrucciones cerca de la secadora luego de la

instalación para futuras consultas.

DLEX3001W

DLEX3001R

DLEX3001P

DLGX3002W

DLGX3002R

DLGX3002P

Protocol P154

Sanitization Performance of Residetial

Clothes dryer

Protocolo P154

Ejecucion de Saneamiento en la zona

residencial Secadoras

P/No. 3828EL3010N

Page 2

ImPORTANT SAFETY INSTRUCTIONS

Basic Safety Precautions .......................................3

What to Do if You Smell Gas

California safe drinking water and toxic

enforcement act

Grounding Instructions

Safety Instructions for Installation

Safety Instructions for Steam Functions

Safety Instructions for Connecting Electricity

.................................................... 4

.................................. 4

........................................... 5

...................... 5, 6

................6

.......7

THANK YOU!

Congratulations on your purchase

and welcome to the LG family. Your

PARTS AND FEATURES

Special Features ..................................................... 8

Key Parts and Components

................................... 9

INSTALLATION INSTRUCTIONS

IMPORTANT: Read all installation instructions

completely before installing and operating your

dryer!

................................................................... 10

Choose the Proper Location

Clearances

Installation With Optional

Pedestal Base or Stacking Kit

Optional Accessories

Leveling the Dryer

Reversing the Door Swing

Changing the Dryer Vent Location

Venting the Dryer

Connecting Gas Dryers

Connecting Electric Dryers

Special Requirements for Manufactured

or Mobile Homes

Final Installation Check

Flow Check (Duct condition test)

........................................................... 10

................................................ 12

............................................ 14, 15

.................................................. 23

................................10

.............................. 11

......................................... 11

.................................... 12

....................... 13

.................................. 16, 17

............................. 18–22

.......................................23

......................... 24

HOW TO USE

Sorting Loads ....................................................... 25

Loading the Dryer

Check the Lint Filter Before Every Load

Control Panel Features

Cycle Guide

The LCD Display

Operating the Dryer

Cycle Setting Buttons

Cycle Option Buttons

Special Functions

Custom Program

Steam Functions

Steam Cycle Guide

................................................. 25

............... 25

......................................... 26

.......................................................... 27

............................................. 28, 29

.............................................. 30

.......................................... 30

.......................................... 31

................................................. 32

.................................................. 33

............................................ 33–35

.............................................. 35

new LG Dryer combines the most

advanced drying sensor technology

with simple operation and high

efficiency. By following the

operating and care instructions

in this manual, your dryer will

provide you with many years of

reliable service.

OPTIONAL ACCESSORIES/

SPECIFICATIONS

Optional Accessories ........................................... 40

Pedestal Installation

Stacking Kit Installation

Key Dimensions and Specifications

....................................... 41, 42

.................................. 43, 44

..................... 44

WARRANTY ................................................... 45

USER mAINTENANCE INSTRUCTIONS

Regular Cleaning .................................................. 36

TROUBLESHOOTING

Before Calling for Service ............................... 37–39

2

Page 3

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

Your Safety and the safety of others is very important.

We have provided many important safety messages in this manual and on your appliance. Always read

and obey all safety messages.

This is the safety alert symbol.

This symbol alerts you to potential hazards that can kill or hurt you and others.

All safety messages will follow the safety alert symbol and either the word DANGER or WARNING.

These words mean:

wDANGER: You can be killed or seriously injured if you don’t immediately follow instructions.

wWARNING: You can be killed or seriously injured if you don’t follow instructions.

All safety messages will tell you what the potential hazard is, tell you how to reduce the chance of

injury, and tell you what can happen if the instructions are not followed.

BASIC SAFETY PRECAUTIONS

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Read all instructions before using the dryer.

• Before use, the dryer must be properly installed

as described in this manual.

• Do not place items exposed to cooking oils in

your dryer. Items contaminated with cooking

oils may contribute to a chemical reaction that

could cause a load to catch fire.

• Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted

with gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they give

off vapors that could ignite or explode.

• Do not reach into the dryer if the drum or any

other part is moving.

• Do not repair or replace any part of the dryer

or attempt any servicing unless specifically

recommended in this Use and Care Guide or

in published user-repair instructions that you

understand and have the skills to carry out.

• Do not tamper with controls.

• Before the dryer is removed from service or

discarded, remove the door to the drying

compartment.

• Do not allow children to play on or in the dryer.

Close supervision of children is necessary when

the dryer is used near children.

• Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

• Do not use heat to dry articles containing

foam rubber or similarly textured rubber-like

materials.

• Keep area around the exhaust opening and

adjacent surrounding areas free from the

accumulation of lint, dust, and dirt.

• The interior of the dryer and exhaust vent

should be cleaned periodically by qualified

service personnel.

• Do not install or store the dryer where it will be

exposed to the weather.

• Always check the inside of the dryer for foreign

objects.

• Clean lint screen before or after each load.

3

Page 4

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

• Do not store or use gasoline or other

flammable vapors and liquids in the

vicinity of this appliance or any other

appliances.

• Installation and service must be

performed by a qualified installer,

service agency, or the gas supplier.

WHAT TO DO IF YOU SMELL GAS:

1. Do not try to light a match or cigarette,

or turn on any gas or electrical

appliance.

2. Do not touch any electrical switches.

Do not use any phone in your building.

3. Clear the room, building, or area of all

occupants.

CALIFORNIA SAFE DRINKING WATER AND TOXIC ENFORCEMENT ACT

This act requires the governor of California to publish a list of substances known to the state to cause

cancer, birth defects, or other reproductive harm and requires businesses to warn customers of potential

exposure to such substances.

Gas appliances can cause minor exposure to four of these substances, namely benzene, carbon monoxide,

formaldehyde, and soot, caused primarily by the incomplete combustion of natural gas or LP fuels.

4. Immediately call your gas supplier

from a neighbor’s phone. Follow the

gas supplier’s instructions carefully.

5. If you cannot reach your gas

supplier, call the fire department.

Properly adjusted dryers will minimize incomplete combustion. Exposure to these substances can be

minimized further by properly venting the dryer to the outdoors.

4

Page 5

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

GROUNDING INSTRUCTIONS

This appliance must be grounded. In the event

of malfunction or breakdown, grounding will

reduce the risk of electric shock by providing

a path of least resistance for electric current.

This appliance must be equipped with a cord

having an equipment-grounding conductor and

a grounding plug. The plug must be plugged into

an appropriate outlet that is properly installed and

grounded in accordance with all local codes and

ordinances.

Do not modify the plug provided with the

appliance. If it will not fit the outlet, have a proper

outlet installed by a qualified electrician.

This appliance must be connected to a grounded

metal, permanent wiring system or an equipmentgrounding conductor must be run with the circuit

conductors and connected to the equipmentgrounding terminal or lead on the appliance.

Electrical shock can result if the dryer is not

properly grounded.

wWARNING — Improper

connection of the equipment-grounding

conductor can result in a risk of electric shock.

Check with a qualified electrician or service

person if you are in doubt as to whether the

appliance is properly grounded.

SAFETY INSTRUCTIONS FOR INSTALLATION

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Properly ground dryer to conform with all

governing codes and ordinances. Follow

details in the installation instructions. Electrical

shock can result if the dryer is not properly

grounded.

• Before use, the dryer must be properly

installed as described in this manual.

Electrical shock can result if the dryer is not

properly grounded.

• Install and store the dryer where it will not be

exposed to temperatures below freezing or

exposed to the weather.

• All repairs and servicing must be performed

by an authorized servicer unless specifically

recommended in this Owner’s Guide. Use

only authorized factory parts. Failure to follow

this warning can cause serious injury, fire,

electrical shock, or death.

• To reduce the risk of electric shock, do not

install the dryer in humid spaces. Failure to

follow this warning can cause serious injury, fire,

electrical shock, or death.

• Connect to a properly rated, protected,

and sized power circuit to avoid electrical

overload. Improper power circuit can melt,

creating electrical shock and/or fire hazard.

• Remove all packing items and dispose of all

shipping materials properly. Failure to do so

can result in death, explosion, fire, or burns.

• Place dryer at least 18 in. above the floor

for a garage installation. Failure to do so can

result in death, explosion, fire, or burns.

• Keep all packaging from children. Packaging

material can be dangerous for children. There is

a risk of suffocation.

• Do not install nearby heat item. Such as

stove, cooking oven. Failure to do so can cause

deform, smoke and fire.

• Do not place candle and cigarettes on top of

the product. Failure to do so can cause deform,

smoke and fire.

• Remove all protective vinyl film from the

product. Failure to do so can cause deform,

smoke and fire.

5

Page 6

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

SAFETY INSTRUCTIONS FOR INSTALLATION

Exhaust/Ducting:

• Gas dryers MUST be exhausted to the

outside. Failure to follow these instructions

can result in fire or death.

• The dryer exhaust system must be exhausted

to the outside of the dwelling. If the dryer is

not exhausted outdoors, some fine lint and

large amounts of moisture will be expelled

into the laundry area. An accumulation of

lint in any area of the home can create a health

and fire hazard.

• Use only rigid metal or flexible metal 4-in.

diameter ductwork inside the dryer cabinet

or for exhausting to the outside. Use of

plastic or other combustible ductwork can

cause a fire. Punctured ductwork can cause

a fire if it collapses or becomes otherwise

restricted in use or during installation.

• Ductwork is not provided with the dryer, and

you should obtain the necessary ductwork

locally. The end cap should have hinged

dampers to prevent backdraft when the dryer

is not in use. Failure to follow these instructions

can result in fire or death.

• The exhaust duct must be 4 in. (10 cm) in

diameter with no obstructions. The exhaust

duct should be kept as short as possible.

Make sure to clean any old ducts before

installing your new dryer. Failure to follow

these instructions can result in fire or death.

• Rigid or semi rigid metal ducting is

recommended for use between the

dryer and the wall. In special installations

when it is impossible to make a connection

with the above recommendations, a ULlisted flexible metal transition duct may be

used between the dryer and wall connection

only. The use of this ducting will affect drying

time. Failure to follow these instructions can

result in fire or death.

• DO NOT use sheet metal screws or other

fasteners which extend into the duct that

could catch lint and reduce the efficiency

of the exhaust system. Secure all joints with

duct tape. For complete details, follow the

Installation Instructions. Failure to follow these

instructions can result in fire or death.

SAFETY INSTRUCTIONS FOR STEAM FUNCTIONS

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Do not open the dryer door during steam

cycles. Failure to follow these instructions can

result in a burn hazard.

• Do not dry articles that have been previously

cleaned in, washed in, soaked in, or spotted

with gasoline, dry-cleaning solvents, or other

flammable or explosive substances as they

give off vapors that could ignite or explode.

Failure to follow these instructions can result in

fire or death.

6

• Do not fill the steam feeder with gasoline,

dry-cleaning solvents, or other flammable or

explosive substances. Failure to follow these

instructions can result in fire or death.

• Do not touch the steam nozzle in the drum

during or after the steam cycle. Failure to

follow these instructions can result in a burn

hazard.

• Do not fill the steam feeder with hot water

(over 86°F/30°C). Failure to follow these

instructions can result in a burn hazard.

Page 7

READ ALL INSTRUCTIONS BEFORE USE

wWARNING For your safety, the information in this manual must be

followed to minimize the risk of fire or explosion, electric shock, or to prevent

property damage, personal injury, or loss of life.

SAFETY INSTRUCTIONS FOR CONNECTING ELECTRICITY

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Do not, under any circumstances, cut or

remove the ground prong from the power

cord. To prevent personal injury or damage to

the dryer, the electrical power cord must be

plugged into a properly grounded outlet.

• For personal safety, this dryer must be

properly grounded. Failure to do so can result

in electrical shock or injury.

• Refer to the installation instructions in this

manual for specific electrical requirements

for your model. Failure to follow these

instructions can create an electrical shock

hazard and/or a fire hazard.

• This dryer must be plugged into a properly

grounded outlet. Electrical shock can result if

the dryer is not properly grounded. Have the

wall outlet and circuit checked by a qualified

electrician to make sure the outlet is properly

grounded. Failure to follow these instructions

can create an electrical shock hazard and/or a

fire hazard.

• The dryer should always be plugged into

its own individual electrical outlet which

has a voltage rating that matches the rating

plate. This provides the best performance

and also prevents overloading house wiring

circuits which could cause a fire hazard from

overheated wires.

• Never unplug your dryer by pulling on the

power cord. Always grip plug firmly and pull

straight out from the outlet. The power cord

can be damaged, resulting in a risk of fire and

electrical shock.

• Repair or replace immediately all power

cords that have become frayed or otherwise

damaged. Do not use a cord that shows

cracks or abrasion damage along its length

or at either end. The power cord can melt,

creating electrical shock and/or fire hazard.

• When installing or moving the dryer, be

careful not to pinch, crush, or damage

the power cord. This will prevent injury and

prevent damage to the dryer from fire and

electrical shock.

SAVE THESE INSTRUCTIONS

7

Page 8

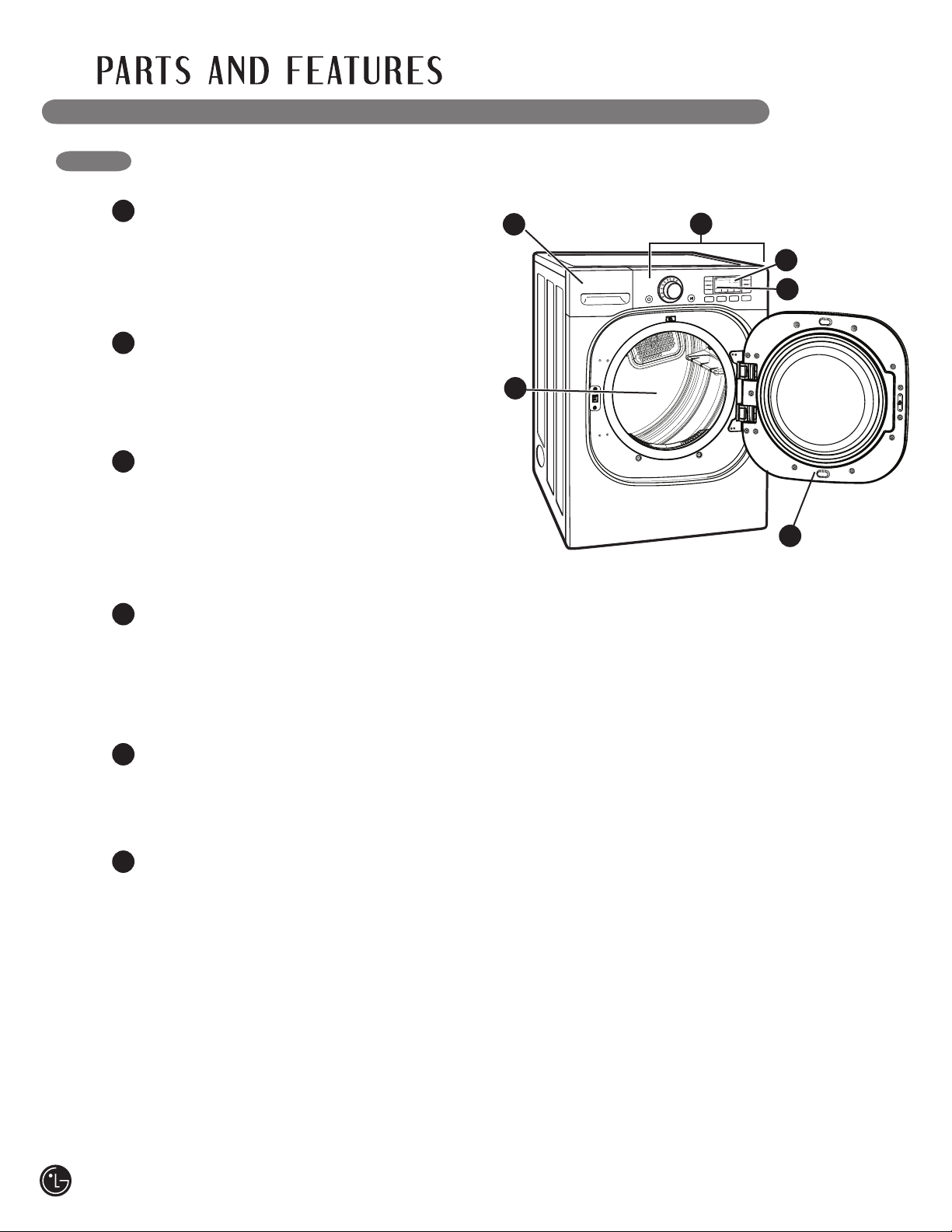

SPECIAL FEATURES

EASY-TO-USE CONTROL PANEL

1

Rotate the Cycle Selector Knob to select the

desired dry cycle. Add cycle options or adjust

settings with the touch of a button.

EASY-ACCESS REVERSIBLE DOOR

2

Wide-opening door provides easy access for

loading and unloading. Door swing can be

reversed to adjust for installation location.

ULTRA-CAPACITY STAINLESS STEEL DRUM

3

WITH DRUM LIGHT

The ultra-large stainless steel drum offers

superior durability. The drum is equipped with a

yellow light that illuminates when the dryer door

is open and turns off when the door is closed.

4

HELPFUL STEAM FUNCTIONS

LG’s new steam technology allows you to inject

fabrics with a swirling jet of hot steam to refresh

clothes, reduce static, and make ironing easier.

Simply select the STEAMFRESH™ cycle, or you

can add a Steam option to selected cycles.

4

3

1

5

6

2

5

LCD DISPLAY SCREEN

The easy-to-read LCD screen shows cycle

options and information and provides status

messages during operation.

6

FLOWSENSE™ DUCT/FILTER BLOCKAGE

SENSING SYSTEM

The FLOWSENSE™ duct/filter blockage sensing

system detects and alerts you to blockages in the

filter and ductwork that reduce exhaust flow from

the dryer. This improves operating efficiency and

help minimize service calls, saving you money.

8

Page 9

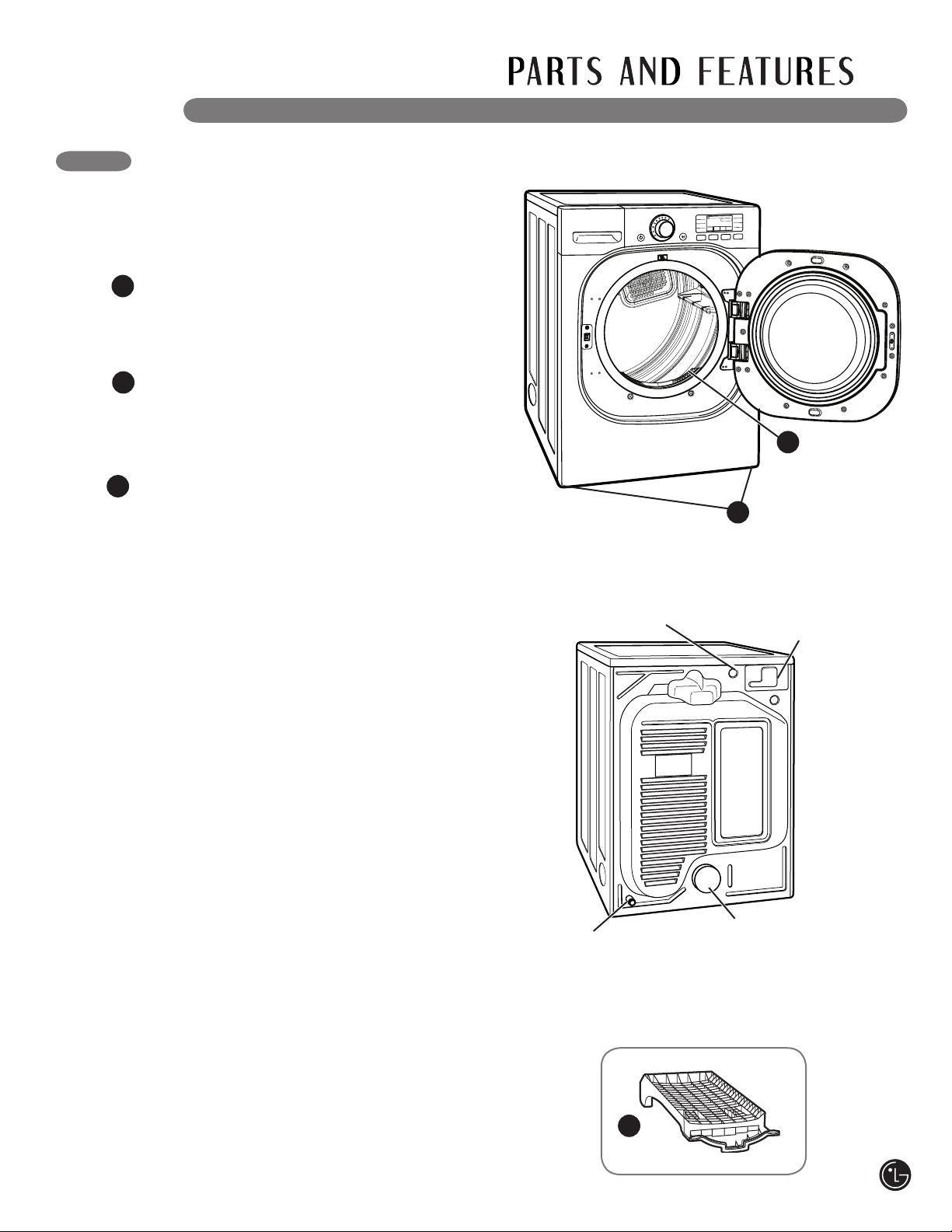

KEY PARTS AND COMPONENTS

In addition to the special features and components outlined in

the Special Features section, there are several other important

components that are referenced in this manual.

FRONT-MOUNT LINT FILTER

1

Front-mounted lint filter allows for easy access

and cleaning after every load.

2

LEVELING FEET

Four leveling feet (two in the front, and two in the back)

adjust to improve dryer stability on uneven floors.

DRYING RACK

3

Use the drying rack with the RACK DRY cycle option. The

drying rack allows items, such as sweaters, delicates, and

gym shoes, to be placed in a flat position for drying.

1

2

Power Cord Location

(Gas Models)

Gas

Connection

Location

(Gas Models)

Terminal Block

Access Panel

(Electric Models)

Exhaust Duct

Outlet

Rear of Dryer

Included Accessories

3

Drying Rack

9

Page 10

(129.7mm)

(56.8 mm)

22.4

IMPORTANT: Read all installation instructions completely before

installing and operating your dryer!

It is important that you review this entire manual before installing and using your dryer. Detailed instructions

concerning electrical connections, gas connections, and exhaust requirements are provided on the

following pages.

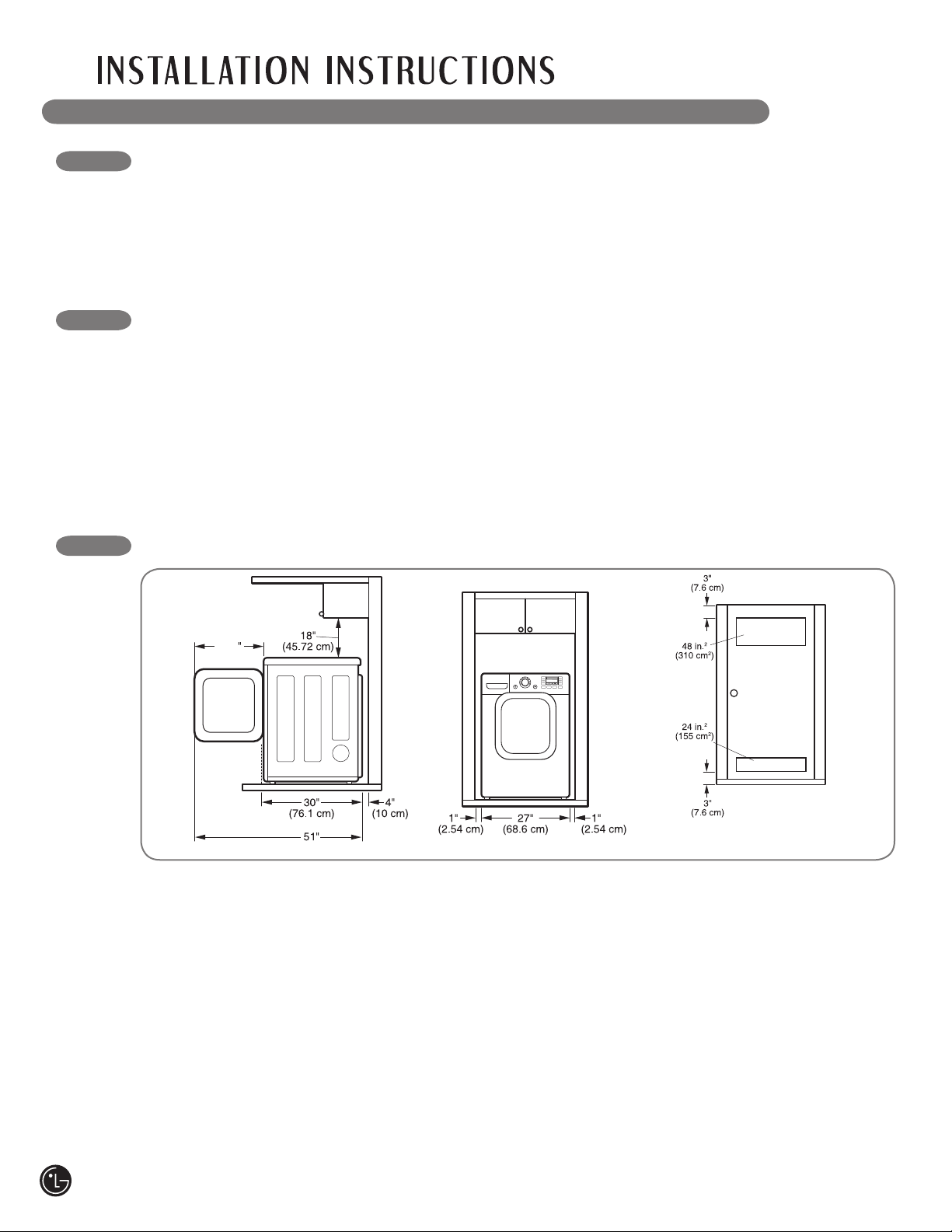

CHOOSE THE PROPER LOCATION

• Store and install the dryer where it will not be

exposed to temperatures below freezing or

exposed to outdoor weather conditions.

• Choose a location with a solid, level floor.

• If the dryer is being installed in a garage,

place the dryer at least 18 in. (46 cm) above

the floor.

CLEARANCES

• Properly ground dryer to conform with all

governing codes and ordinances.

• To reduce the risk of electric shock, do not

install the dryer in damp or wet locations.

• If you are installing your dryer in a manufactured

or mobile home, please refer to the section

Special Requirements for Manufactured or

Mobile Homes.

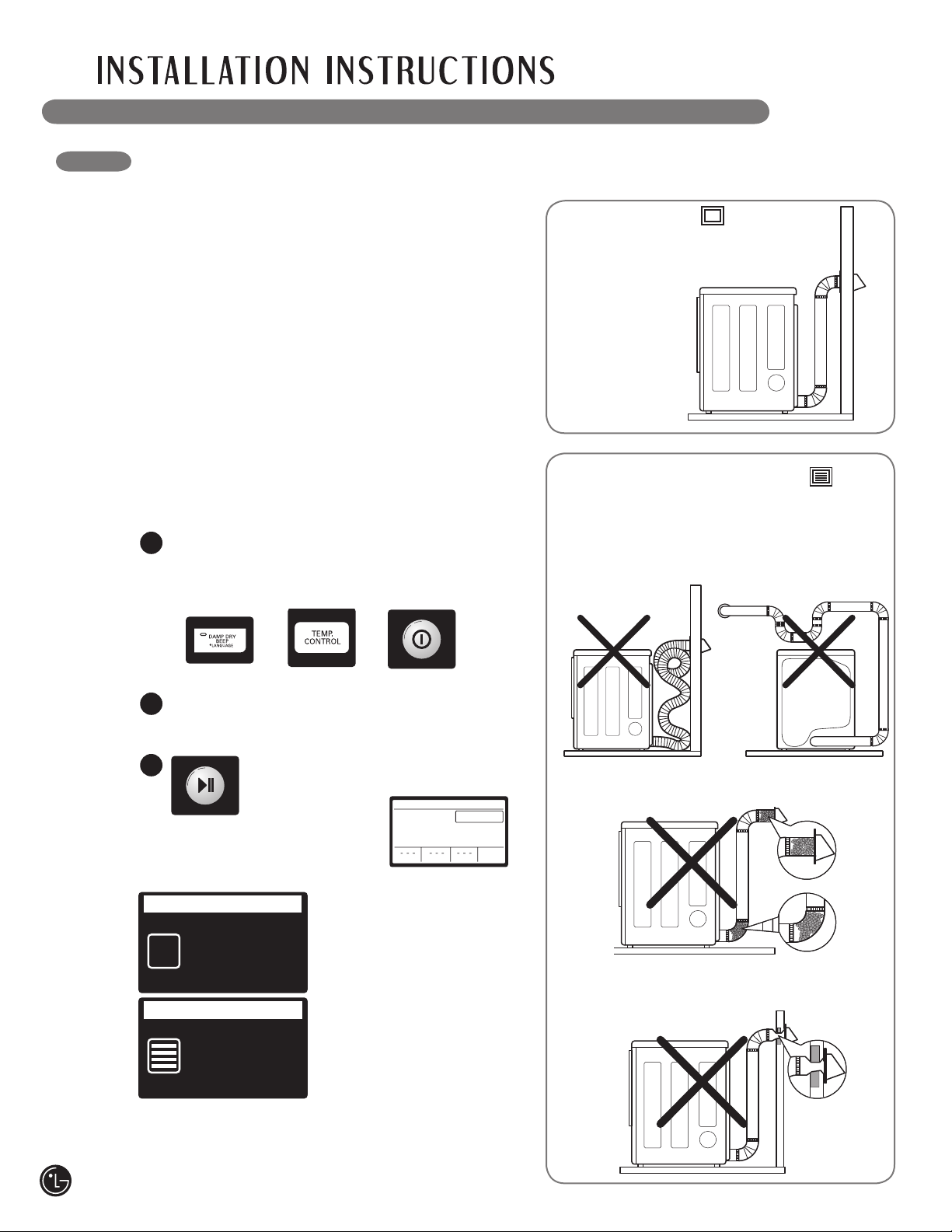

Closet Door Vent

Requirements

10

• Most installations require a minimum 5½ in.

(14 cm) clearance behind the dryer for the

exhaust ducting.

• Allow minimum clearances of at least 1 in.

(2.5 cm) on the sides and back to minimize

vibration and noise.

• Allowing additional clearance for installation and

servicing is recommended.

• Be sure to allow for wall, door, or floor moldings

that may increase the required clearances.

• Allow at least 24 in. (61 cm) in front of the dryer

to open the door.

Additional Instructions for closet installations:

• The closet door must allow for sufficient airflow.

Refer to the diagram above for minimum vent

opening requirements. A louvered door is also

acceptable.

• Make sure that there is at least 18 in. (46 cm) of

clearance above the dryer.

Page 11

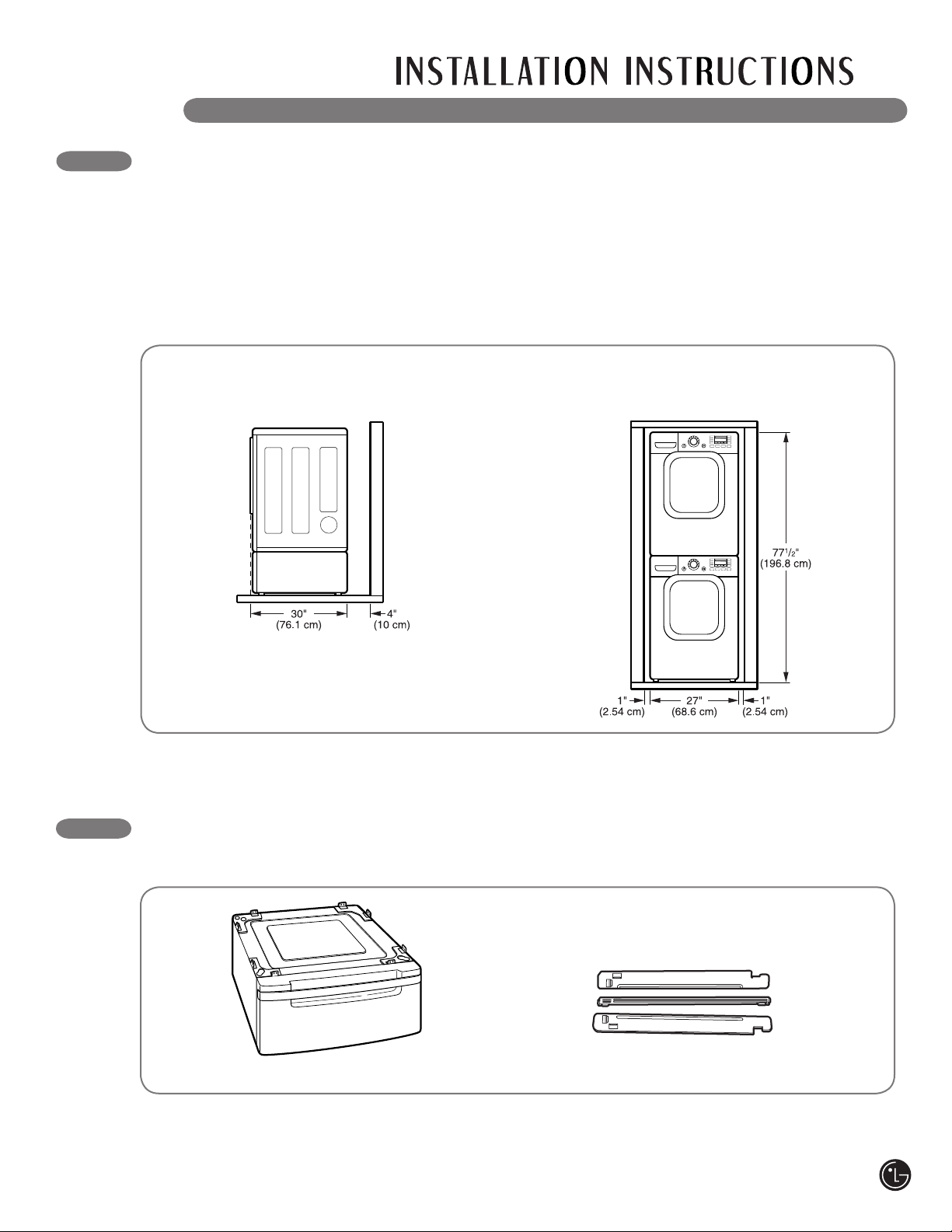

INSTALLATION WITH OPTIONAL

PEDESTAL BASE OR STACKING KIT

IMPORTANT: If you are installing your dryer

using an optional pedestal base or stacking

kit, please refer to Optional Accessories in this

manual or to the instructions for your pedestal

or stacking kit before proceeding with the

installation.

Required Dimensions for Installation

With Pedestal

Required Dimensions for Installation

With Stacking Kit

OPTIONAL ACCESSORIES

For these and other LG products, contact your local LG dealer, or visit our Web site at us.lge.com.

Pedestal (sold separately)

Stacking Kit (sold separately)

11

Page 12

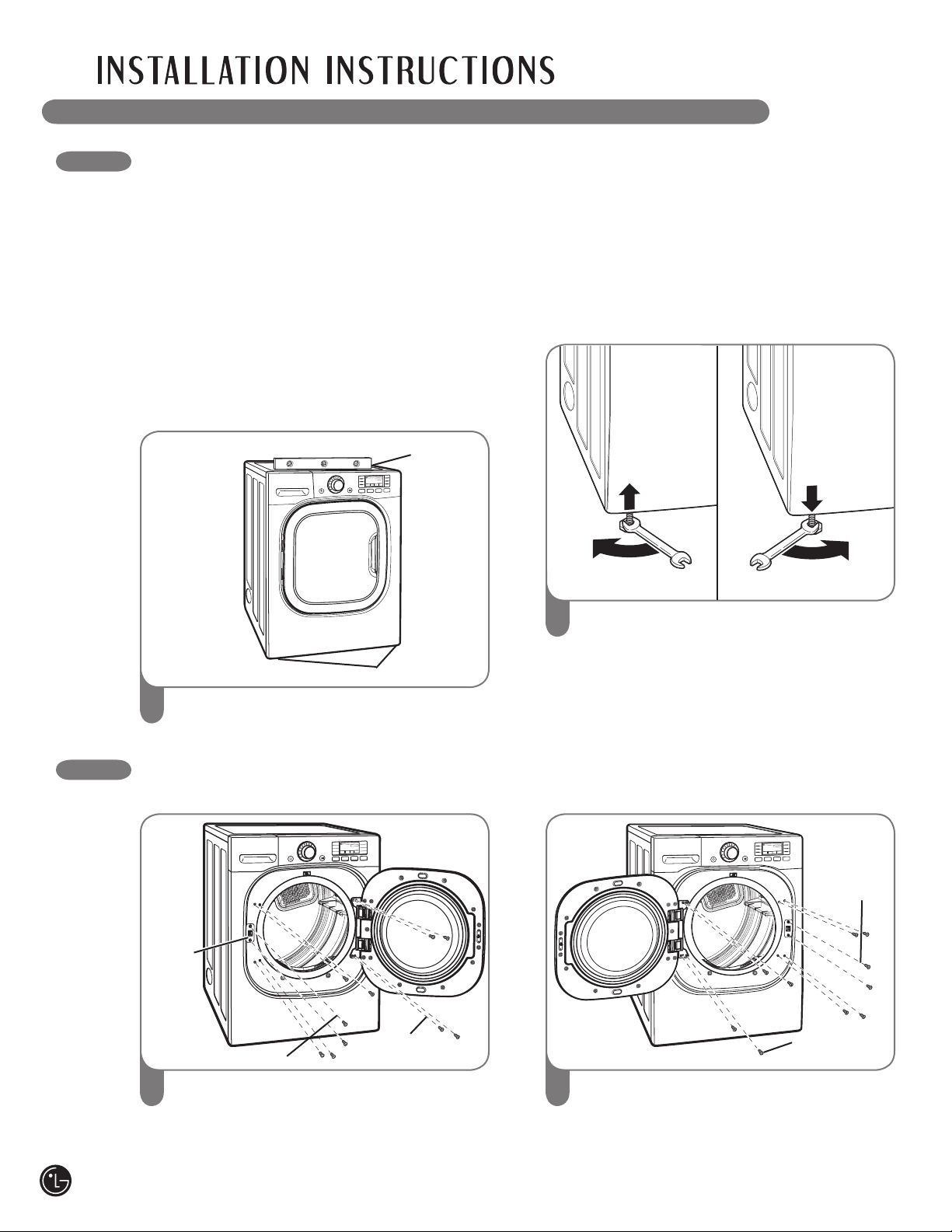

LEVELING THE DRYER

WARNING

w

• Wear gloves during installation.

• Failure to follow these instructions can result in injury.

To ensure that the dryer provides optimal drying

performance, it must be level. To minimize

vibration, noise, and unwanted movement, the

floor must be a perfectly level, solid surface.

NOTE: Adjust the leveling feet only as far as

necessary to level the dryer. Extending the

leveling feet more than necessary can cause

the dryer to vibrate.

Level

Leveling Feet

1

Position the dryer in the final location. Place

a level across the top of the dryer.

• All four leveling feet must rest solidly on the

floor. Gently push on the top corners of the

dryer to make sure that the dryer does not

rock from corner to corner.

If you are installing the dryer on the optional

pedestal, you must use the leveling feet on the

pedestal to level the dryer. The dryer leveling feet

should be fully retracted.

2

Use an adjustable wrench to turn the leveling

feet. Turn clockwise to raise the dryer or

counterclockwise to lower it. Raise or lower

the leveling feet until dryer is level from

side to side and front to back.

Make sure that all 4 leveling feet are in firm

contact with the floor.

12

REVERSING THE DOOR SWING

The swing of the dryer door can be reversed to fit your installation location.

Door

Latch

Hinge

Latch Screws

Open the dryer door. Using a Phillips

1 2

screwdriver, remove the 4 screws that secure

the door hinge to the dryer door opening.

Remove the 6 screws from the latch side of the

dryer door opening, and remove the door latch.

Screws

Turn the door around so the hinge is

reversed, and reattach the door using the

4 screws previously removed. Reinstall the

door latch and the 6 screws.

Test the door swing to make sure the door

moves freely and latches securely.

Latch

Screws

Hinge

Screws

Page 13

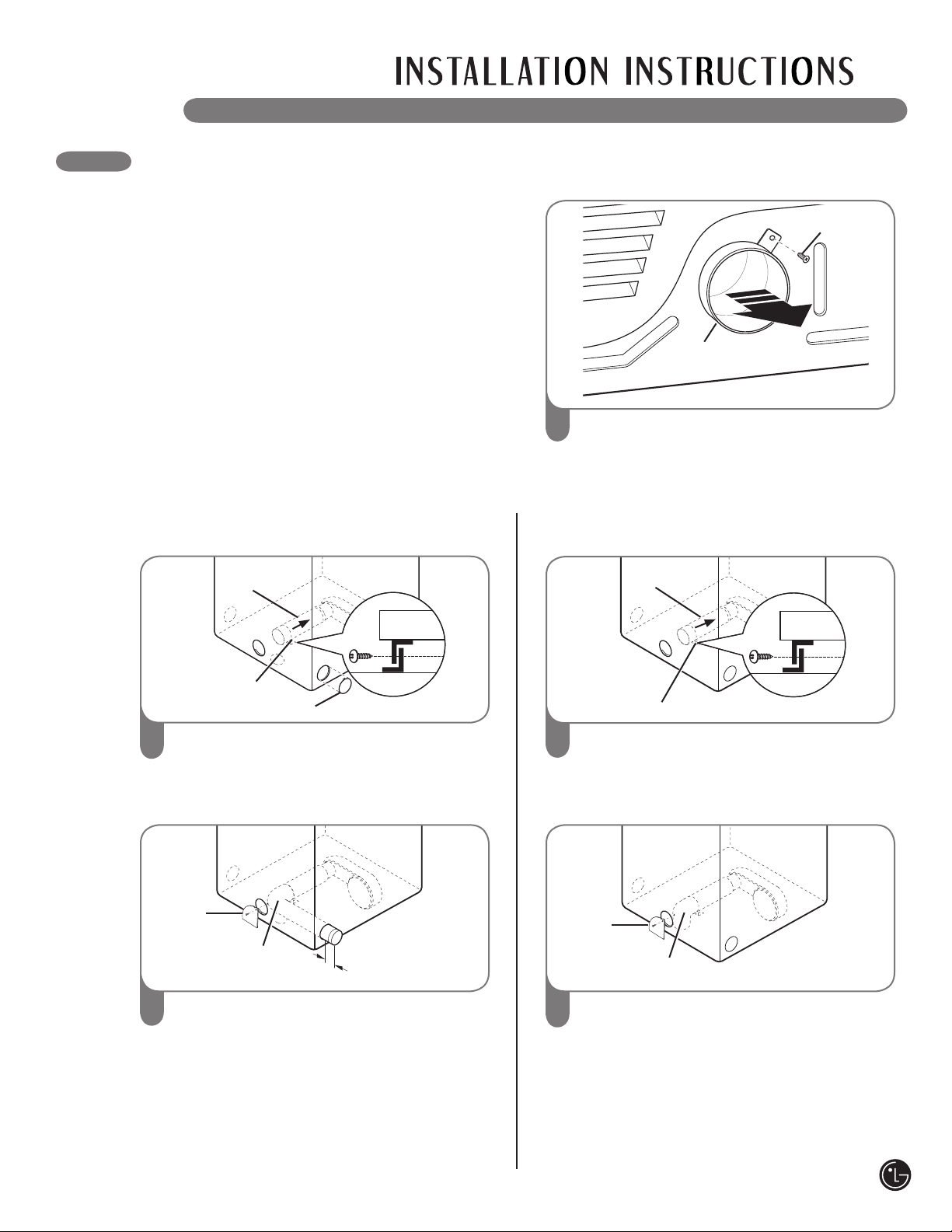

CHANGING THE DRYER VENT LOCATION

11/2"

(3.8 cm)

WARNING

w

• Use a heavy metal vent.

• Do not use plastic or thin foil duct.

• Clean old ducts before installing this dryer.

• Wear gloves during installation.

• Failure to follow these instructions can result in death

or fire.

Your new dryer is shipped to vent to the rear.

It can also be configured to vent to the bottom

or side (right-side venting is not available on

gas models).

An adapter kit, part number 383EEL9001B,

may be purchased from your LG retailer. This

kit contains the necessary duct components

to change the dryer vent location.

OPTION 1: Side Venting

Adapter

Duct

Rear

Exhaust Duct

1

Remove the rear exhaust duct retaining

1

screw. Pull out the exhaust duct.

OPTION 2: Bottom Venting

Adapter

Duct

Retaining

Screw

Bracket

Knockout

2

Press the tabs on the knockout and carefully remove the

knockout for the desired vent opening (right-side venting

is not available on gas models). Press the adapter duct

onto the blower housing and secure to the base of the

dryer as shown.

Cover

Plate

Elbow

3

Preassemble a 4-in. (10 cm) elbow to the next 4-in. (10 cm)

duct section, and secure all joints with duct tape. Be sure

that the male end of the elbow faces AWAY from the dryer.

Insert the elbow/duct assembly through the side opening

and press it onto the adapter duct. Secure in place with

duct tape.

Be sure that the male end of the duct protrudes 1½ in. (3.8

cm) to connect the remaining ductwork.

Attach cover plate to the back of the dryer with included

screw.

Bracket

2

Press the adapter duct onto the blower

housing and secure to the base of the dryer

as shown.

Cover

Plate

Elbow

3

Insert the 4-in. (10 cm) elbow through the

rear opening and press it onto the adapter

duct. Be sure that the male end of the elbow

faces down through hole in the bottom of the

dryer. Secure in place with duct tape.

Attach the cover plate to the back of the

dryer with included screw.

13

Page 14

VENTING THE DRYER

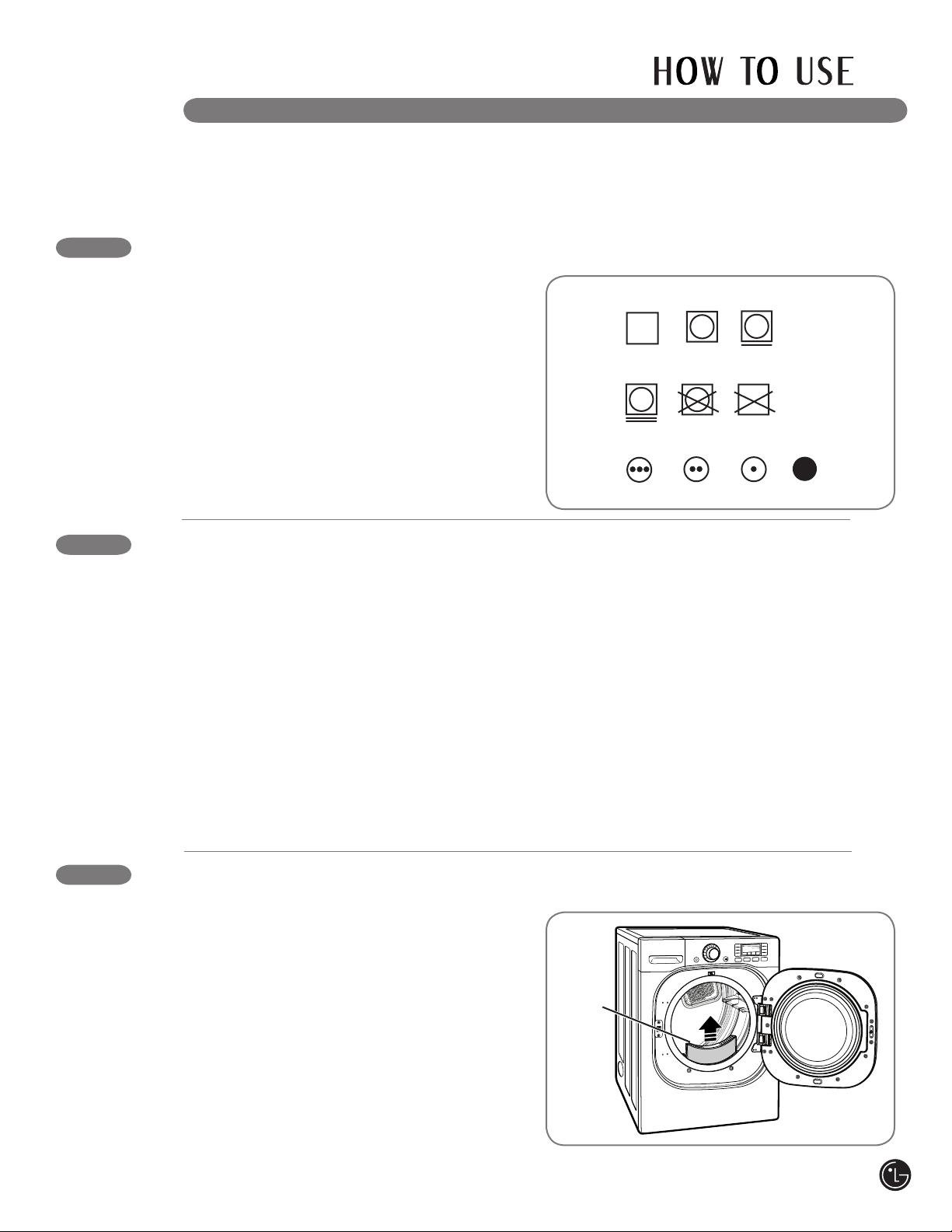

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Do not crush or collapse ductwork. Failure

to follow these instructions can result in fire

or death.

• Do not allow ductwork to rest on or

contact sharp objects. Failure to follow these

instructions can result in fire or death.

• If connecting to existing ductwork, make

sure it is suitable and clean before installing

the dryer. Failure to follow these instructions

can result in fire or death.

• Venting must conform to local building

codes. Failure to follow these instructions can

result in fire or death.

• Gas dryers MUST exhaust to the outdoors.

Failure to follow these instructions can result

in fire or death.

• Use only 4-in. (10 cm) rigid or flexible metal

ductwork inside the dryer cabinet and

for venting outside. Failure to follow these

instructions can result in fire or death.

• To reduce the risk of fire, combustion, or

accumulation of combustible gases, DO

NOT exhaust dryer air into an enclosed and

unventilated area, such as an attic, wall,

ceiling, crawl space, chimney, gas vent, or

concealed space of a building. Failure to

follow these instructions can result in fire

or death.

• To reduce the risk of fire, DO NOT exhaust

the dryer with plastic or thin foil ducting.

Failure to follow these instructions can result

in fire or death.

• The exhaust duct must be 4 in. (10 cm) in

diameter with no obstructions. The exhaust

duct should be kept as short as possible.

Make sure to clean any old ducts before

installing your new dryer. Failure to follow

these instructions can result in fire or death.

• Rigid or semirigid metal ducting is

recommended for use between the dryer

and the wall. In special installations when

it is impossible to make a connection with

the above recommendations, a UL-listed

flexible metal transition duct may be used

between the dryer and wall connection only.

The use of this ducting will affect drying

time. Failure to follow these instructions can

result in fire or death.

• DO NOT use sheet metal screws or other

fasteners which extend into the duct that

could catch lint and reduce the efficiency

of the exhaust system. Secure all joints

with duct tape. Failure to follow these

instructions can result in fire or death.

• To maximize operating results, please

observe the duct length limitations noted in

the chart on page 15. Failure to follow these

instructions can result in fire or death.

• Ductwork is not provided with the dryer.

You should obtain the necessary ductwork

locally. The end cap should have hinged

dampers to prevent backdraft when the

dryer is not in use. Failure to follow these

instructions can result in fire or death.

14

Page 15

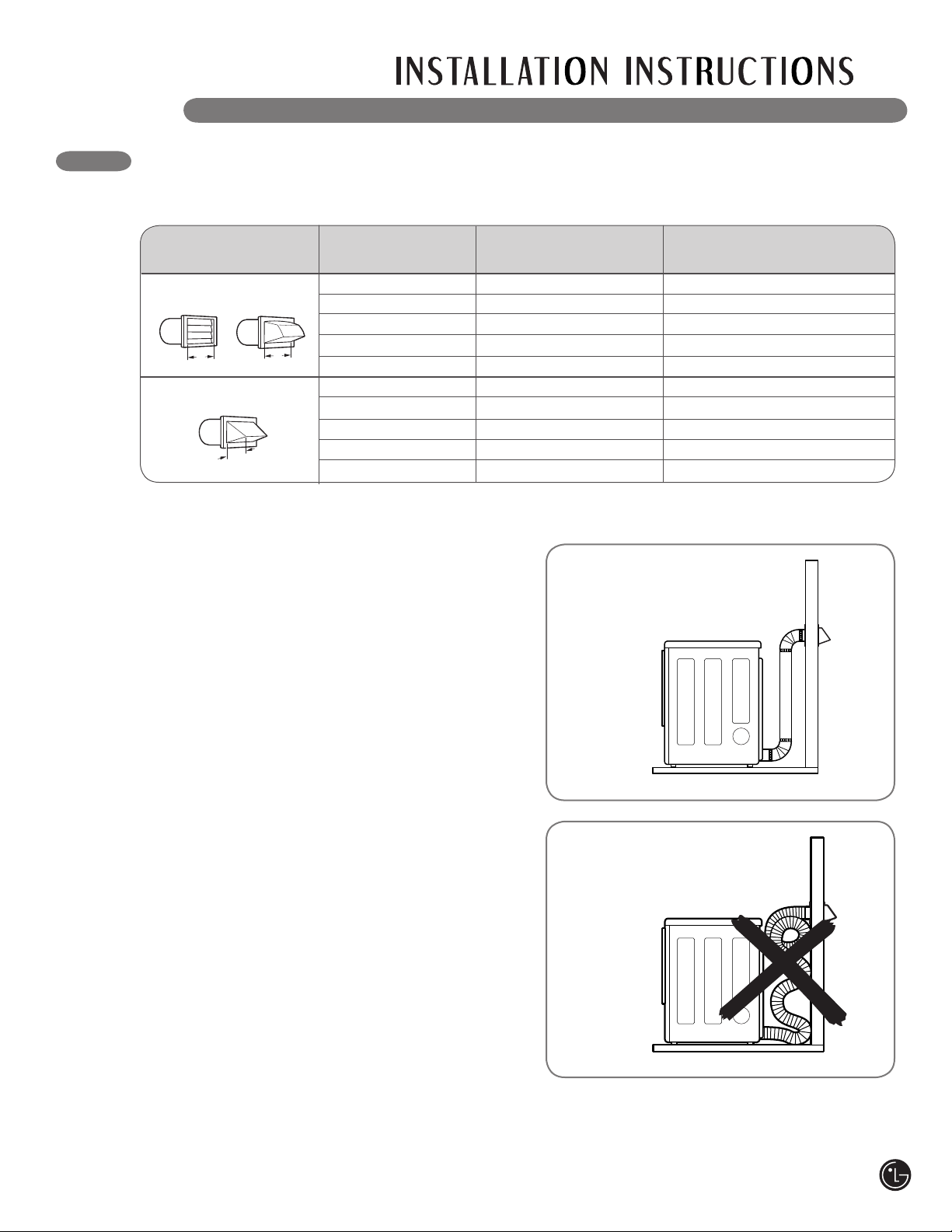

VENTING THE DRYER (cont.)

4"

(10.2 cm)

21/2"

(6.35 cm)

4"

(10.2 cm)

Ductwork

Number of Max. Length of 4-In. Dia. Max. Length of 4-In. Dia.

Wall Cap Type 90° Elbows Rigid Metal Duct Flexible Metal Duct

0 65 ft. (19.8 m) 45 ft. (13.7 m)

Recommended

1 55 ft. (16.8 m) 35 ft. (10.7 m)

2 47 ft. (13.7 m) 30 ft. (9.1 m)

3 36 ft. (11.0 m) 25 ft. (7.6 m)

4 28 ft. (8.5 m) 20 ft. (6.1 m)

0 55 ft. (16.8 m) 35 ft. (10.7 m)

Use Only for Short

2 41 ft. (12.5 m) 21 ft. (6.4 m)

3 30 ft. (9.1 m) 17 ft. (5.2 m)

4 22 ft. (6.7 m) 15 ft. (4.5 m)

NOTE: Deduct 6 ft. (1.8 m) for each additional elbow. It is not recommended to use more than four 90° elbows.

Run Installations

1 47 ft. (13.7 m) 27 ft. (8.1 m)

Routing and Connecting Ductwork

Follow the guidelines below to maximize drying

performance and reduce lint buildup and

condensation in the ductwork.

NOTE: Ductwork and fittings are NOT included

and must be purchased separately.

• Use 4-in. (10 cm) diameter rigid or semirigid

metal ductwork.

• The exhaust duct run should be as short as

possible.

• Use as few elbow joints as possible.

• The male end of each section of exhaust duct

must point away from the dryer.

• Use duct tape on all duct joints.

• Insulate ductwork that runs through unheated

areas in order to reduce condensation and lint

buildup on duct surfaces.

IMPORTANT: Failure to exhaust the dryer

correctly will void the dryer’s warranty.

Correct Venting

Incorrect Venting

15

Page 16

CONNECTING GAS DRYERS

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Gas supply requirements:

As shipped from the factory, this dryer is

configured for use with natural gas. It can be

converted for use with LP (Liquefied Propane)

gas. Gas pressure must not exceed 13 in.

water column.

• A qualified service or gas company technician

must connect the dryer to the gas service.

Failure to do so can result in fire, explosion,

or death.

• Isolate the dryer from the gas supply system

by closing its individual manual shutoff valve

during any pressure testing of the gas supply.

Failure to do so can result in fire, explosion,

or death.

• Supply line requirements:

Your laundry room must have a rigid gas

supply line to your dryer. In the United States,

an individual manual shutoff valve MUST be

installed within at least 6 ft. (1.8 m) of the dryer,

in accordance with the National Fuel Gas Code

ANSI Z223.1 or Canadian gas installation code

CSA B149.1. A 1/8-in. NPT pipe plug must

be installed. Failure to do so can result in fire,

explosion, or death.

• If using a rigid pipe, the rigid pipe should be

1/2-in. IPS. If acceptable under local codes

and ordinances and when acceptable to your

gas supplier, 3/8-in. approved tubing may be

used where lengths are less than 20 ft. (6.1

m). Larger tubing should be used for lengths

in excess of 20 ft. (6.1 m). Failure to do so can

result in fire, explosion, or death.

• Connect the dryer to the type of gas shown on

the nameplate. Failure to do so can result in fire,

explosion, or death.

• To prevent contamination of the gas valve,

purge the gas supply of air and sediment

before connecting the gas supply to the dryer.

Before tightening the connection between the

gas supply and the dryer, purge remaining air

until the odor of gas is detected. Failure to do

so can result in fire, explosion, or death.

• DO NOT use an open flame to inspect for gas

leaks. Use a noncorrosive leak-detection fluid.

Failure to do so can result in fire, explosion, or

death.

• Use only a new AGA- or CSA-certified gas

supply line with flexible stainless steel

connectors. Failure to do so can result in fire,

explosion, or death.

• Securely tighten all gas connections. Failure

to do so can result in fire, explosion, or death.

• Use Teflon® tape or a pipe-joint compound that

is insoluble in Liquefied Petroleum (LP) gas on

all pipe threads. Failure to do so can result in fire,

explosion, or death.

• DO NOT attempt any disassembly of the dryer;

any disassembly requires the attention and

tools of an authorized and qualified service

person or company. Failure to do so can result

in fire, explosion, or death.

16

Electrical Requirements for Gas Models Only

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Do not, under any circumstances, cut or

remove the third (ground) prong from the power

cord. Failure to follow this warning can result in

fire, explosion, or death.

• For personal safety, this dryer must be properly

grounded. Failure to follow this warning can result

in fire, explosion, or death.

• The power cord of this dryer is equipped with

a 3-prong (grounding) plug which mates with

a standard 3-prong (grounding) wall outlet

to minimize the possibility of electric shock

hazard from this appliance. Failure to follow this

warning can result in fire, explosion, or death.

• This dryer must be plugged into a

120-VAC, 60-Hz. grounded outlet protected by

a 15-ampere fuse or circuit breaker. Failure to

follow this warning can result in fire, explosion,

or death.

• Where a standard 2-prong wall outlet is

encountered, it is your personal responsibility

and obligation to have it replaced with a

properly grounded 3-prong wall outlet. Failure

to follow this warning can result in fire, explosion,

or death.

Page 17

CONNECTING GAS DRYERS (cont.)

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Installation and service must be performed

by a qualified installer, service agency, or the

gas supplier. Failure to do so can result in fire,

explosion, or death.

• Use only a new stainless steel flexible

connector and a new AGA-certified

connector. Failure to do so can result in fire,

explosion, or death.

• A gas shutoff valve must be installed within

6 ft. (1.8 m) of the dryer. Failure to do so can

result in fire, explosion, or death.

• The dryer is configured for Natural Gas when

shipped from the factory. Make sure that the

dryer is equipped with the correct burner

nozzle for the type of gas being used (Natural

Gas or Liquefied Petroleum). Failure to do so

can result in fire, explosion, or death.

• If necessary, the correct nozzle (for the LP

nozzle kit order part number 4948EL4002B)

should be installed by a qualified technician

and the change should be noted on the dryer.

Failure to do so can result in fire, explosion,

or death.

• All connections must be in accordance with

local codes and regulations. Failure to do so

can result in fire, explosion, or death.

• Gas dryers MUST exhaust to the outdoors.

Failure to do so can result in fire, explosion,

or death.

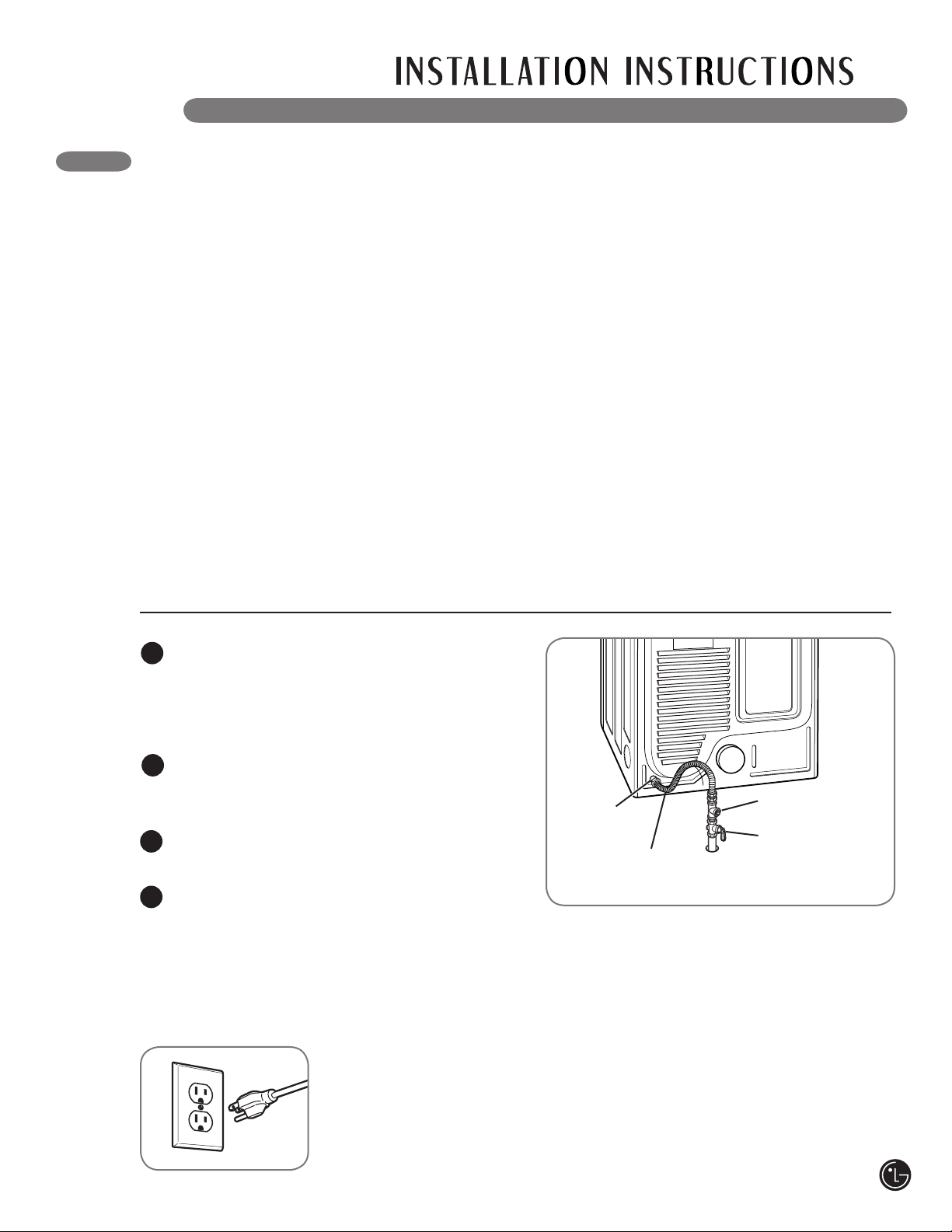

Connecting the Gas Supply

Make sure that the gas supply to the laundry

1

room is turned OFF. Confirm that the type

of gas available in your laundry room is

appropriate for the dryer. The dryer is

prepared for Natural Gas with a 3/8-in. NPT

gas connection.

Remove the shipping cap from the gas

2

connection at the back of the dryer. Be

careful not to damage the threads of the gas

connector when removing the shipping cap.

Connect the dryer to your laundry room’s gas

3

supply using a new flexible stainless steel

connector with a 3/8-in. NPT fitting.

Securely tighten all connections between the

4

dryer and your laundry room’s gas supply.

Turn on your laundry room’s gas supply and

check all pipe connections (both internal and

external) for gas leaks with a noncorrosive

leak-detection fluid.

Electrical Connection

Plug dryer into a

120-VAC, 60-Hz.

grounded 3-prong

outlet.

1/8" NPT Pipe

3/8" NPT Gas

Connection

AGA/CSA-Certified

Stainless Steel

Flexible Connector

Plug

Gas Supply

Shutoff Valve

High-Altitude Installations

The BTU rating of this dryer is AGA-certified for

elevations below 10,000 feet.

If your gas dryer is being installed at an elevation

above 10,000 feet, it must be derated by a

qualified technician or gas supplier.

17

Page 18

CONNECTING ELECTRIC DRYERS

wWARNING: To help prevent fire, electric shock, serious injury, or death, the wiring and

grounding must conform to the latest edition of the National Electrical Code, ANSI/NFPA 70 and all

applicable local regulations. Please contact a qualified electrician to check your home’s wiring and

fuses to ensure that your home has adequate electrical power to operate the dryer.

Electrical Requirements for Electric Models Only

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• This dryer must be connected to a grounded

metal, permanent wiring system, or an

equipment-grounding conductor must

be run with the circuit conductors and

connected to the equipment-grounding

terminal or lead on the dryer. Failure to do

so can result in fire, explosion, or death.

• The dryer has its own terminal block that

must be connected to a separate 240 VAC,

60-Hertz, single-phase circuit, fused at 30

amperes (the circuit must be fused on both

sides of the line). ELECTRICAL SERVICE

FOR THE DRYER SHOULD BE OF THE

MAXIMUM RATE VOLTAGE LISTED ON THE

NAMEPLATE. DO NOT CONNECT DRYER TO

110-, 115-, OR 120-VOLT CIRCUIT. Heating

elements are available for field installation

in dryers which are to be connected to an

electrical service of a different voltage than

that listed on the rating plate. Failure to follow

these instructions can result in fire, explosion,

or death.

• If branch circuit to dryer is 15 ft. (4.5 m)

or less in length, use UL (Underwriters

Laboratories) listed No.-10 AWG wire

(copper wire only), or as required by local

codes. If over 15 ft. (4.50 m), use UL-listed

No.-8 AWG wire (copper wire only), or as

required by local codes. Allow sufficient

slack in wiring so dryer can be moved from

its normal location when necessary. Failure

to do so can result in fire, explosion, or death.

• The power cord (pigtail) connection between

wall receptacle and dryer terminal block

IS NOT supplied with dryer. Type of pigtail

and gauge of wire must conform to local

codes and with instructions on the following

pages. Failure to follow these instructions can

result in fire, explosion, or death.

• A 4-wire connection is required for all mobile

and manufactured home installations, as

well as all new construction after January

1, 1996. A 4-wire connection must be used

where local codes do not permit grounding

through the neutral wire. Failure to do so can

result in fire, explosion, or death.

18

wWARNING:

appliance, follow basic precautions, including the following:

• Do not modify the plug and internal wire

provided with the dryer.

• The dryer should be connected to 4-hole outlet.

To reduce the risk of fire, electric shock, or injury to persons when using this

• If it does not fit the outlet, a proper outlet will

need to be installed by a qualified electrician.

Special Electrical Requirements for Mobile or Manufactured Homes

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Any installation in a manufactured or mobile

home must comply with the Manufactured

Home Construction and Safety Standards

Title 24 CFR, Part 32-80 or Standard CAN/

CSA0Z240 MH and local codes and ordinances.

• A 4-wire connection is required for all mobile

and manufactured home installations, as well

as all new construction after January 1, 1996.

Failure to do so can result in fire, explosion,

or death.

Page 19

CONNECTING ELECTRIC DRYERS (cont.)

USA ONLY

wWARNING:

• Connect the power cord to the terminal block. Each colored wire should be connected

to same color screw. Wire color indicated on manual is connected to the same color

screw in block. Failure to follow these instructions may result in a short or overload.

• Grounding through the neutral conductor is prohibited for: (1) new branch-circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductor.

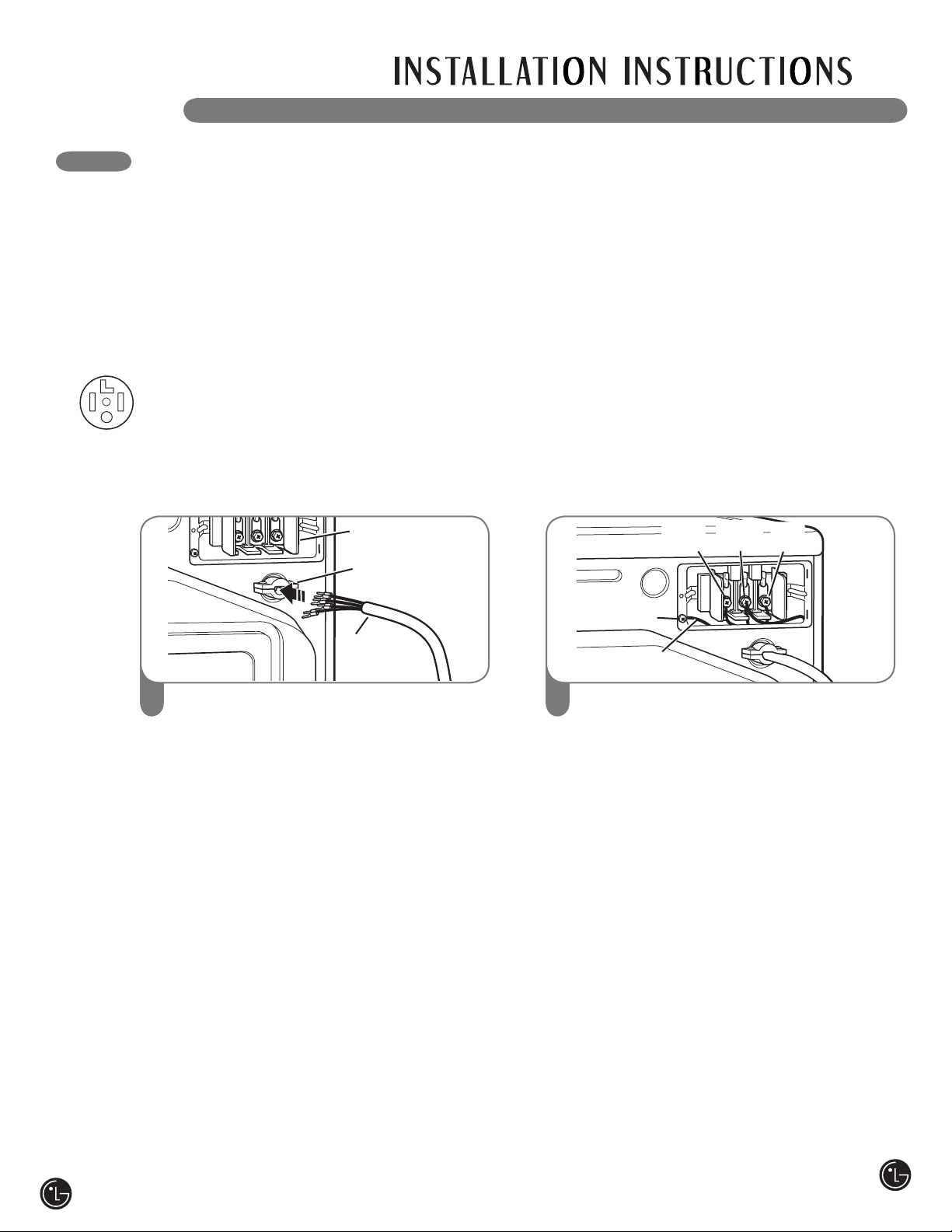

Four-Wire Connection for Electric Dryers: Power Cord

• A 4-wire connection is required for all mobile

and manufactured home installations, as well

as all new construction after January 1, 1996.

• A UL-listed strain relief is required.

Terminal

Block

UL-Listed

Strain Relief

UL-Listed

4-Wire

Power Cord

1

Remove the terminal block access cover

on the upper back of the dryer. Install a

UL-listed strain relief into the power cord

through-hole; then thread a UL-listed, 30A,

240V, 4-wire, #10 AWG-minimum copper

conductor power cord through the

strain relief.

• Use a 30-amp, 240V, UL-listed power cord

with #10 AWG-minimum copper conductor

and closed loop or forked terminals with

upturned ends.

Hot

(Black)

Ground Screw

Power Cord

Ground Wire

2

Transfer the dryer’s ground wire from behind

Neutral

(White)

Hot

(Red)

the green ground screw to the center screw

of the terminal block. Attach the two hot

leads of the power cord to the outer terminal

block screws. Attach the white neutral wire

to the center terminal block screw. Attach the

power cord ground wire to the green ground

screw. TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access cover.

19

Page 20

CONNECTING ELECTRIC DRYERS (cont.)

USA ONLY

wWARNING:

• Connect the power cord to the terminal block. Each colored wire should be connected

to same color screw. Wire color indicated on manual is connected to the same color

screw in block. Failure to follow these instructions may result in a short or overload.

• Grounding through the neutral conductor is prohibited for: (1) new branch-circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductor.

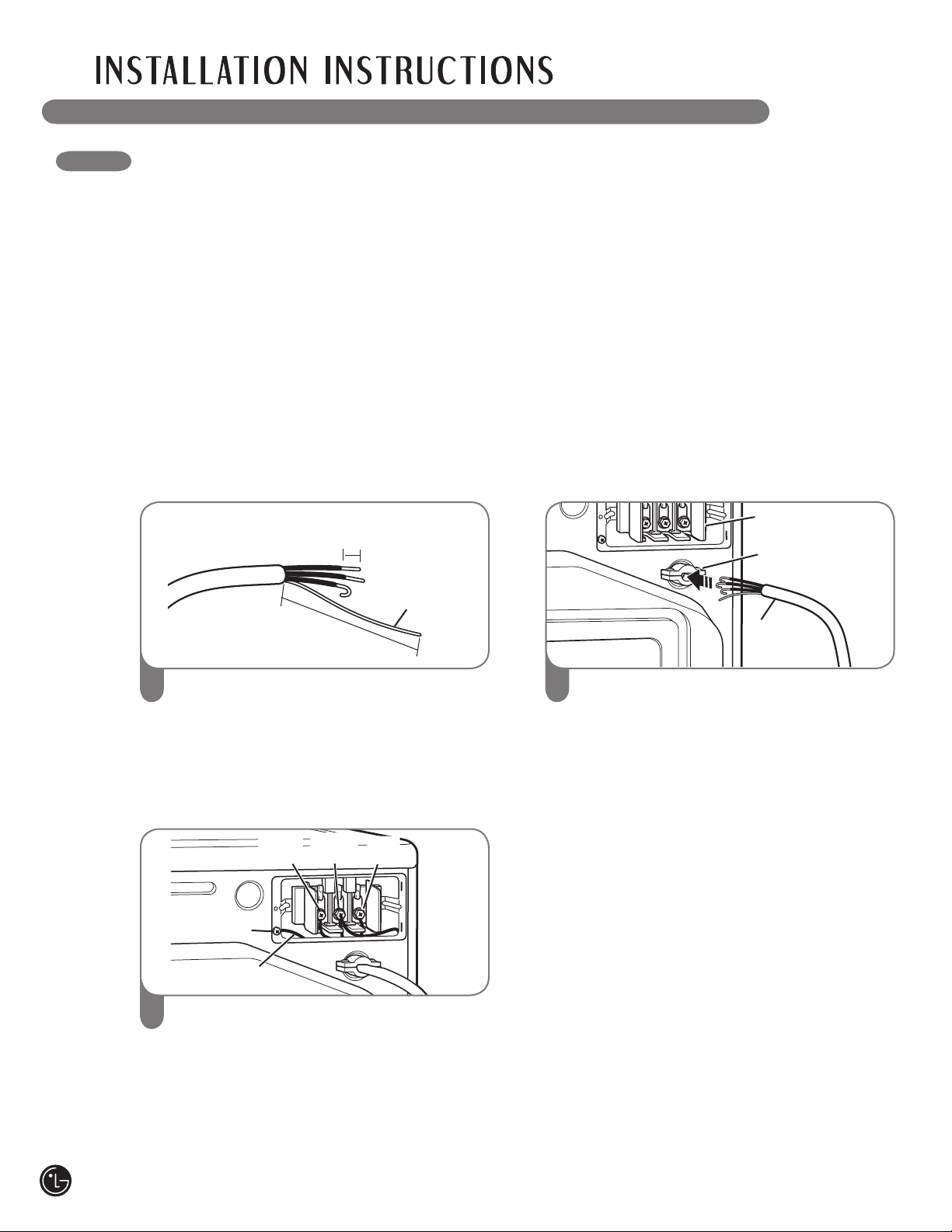

Four-Wire Connection for Electric Dryers: Direct Wire

• A 4-wire connection is required for all mobile

and manufactured home installations, as well

as all new construction after January 1, 1996.

• A UL-listed strain relief is required.

1" (2.5 cm)

Ground Wire

• Use UL-listed 4-wire #10 AWG-minimum

copper conductor cable.

• Allow at least 5 ft (1.5 m) length to allow for

removal and reinstallation of the dryer.

Terminal

Block

UL-Listed

Strain Relief

5"

(12.7 cm)

1

Remove 5 inches (12.7 cm) of the outer

covering from the wire. Remove 5 inches

of insulation from the ground wire. Cut off

approximately 11⁄2 inches (3.8 cm) from the

other three wires and strip 1 inch (2.5 cm)

insulation from each wire. Bend the ends of

the three shorter wires into a hook shape.

Hot

(Black)

Ground Screw

Ground Wire

3

Transfer the dryer’s ground wire from behind

Neutral

(White)

Hot

(Red)

the green ground screw to the center screw

of the terminal block. Attach the two hot

leads of the power cable to the outer terminal

block screws. Attach the white neutral wire

to the center terminal block screw. Attach the

power cable ground wire to the green ground

screw. TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access cover.

UL-Listed

4-Wire

Power Cord

2

Remove the terminal block access cover

on the upper back of the dryer. Install a

UL-listed strain relief into the power cord

through-hole; then thread the power cable

prepared in Step 1 through the strain relief.

20

Page 21

CONNECTING ELECTRIC DRYERS (cont.)

USA ONLY

wWARNING:

• Connect the power cord to the terminal block. Each colored wire should be connected

to same color screw. Wire color indicated on manual is connected to the same color

screw in block. Failure to follow these instructions may result in a short or overload.

• Grounding through the neutral conductor is prohibited for: (1) new branch-circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductor.

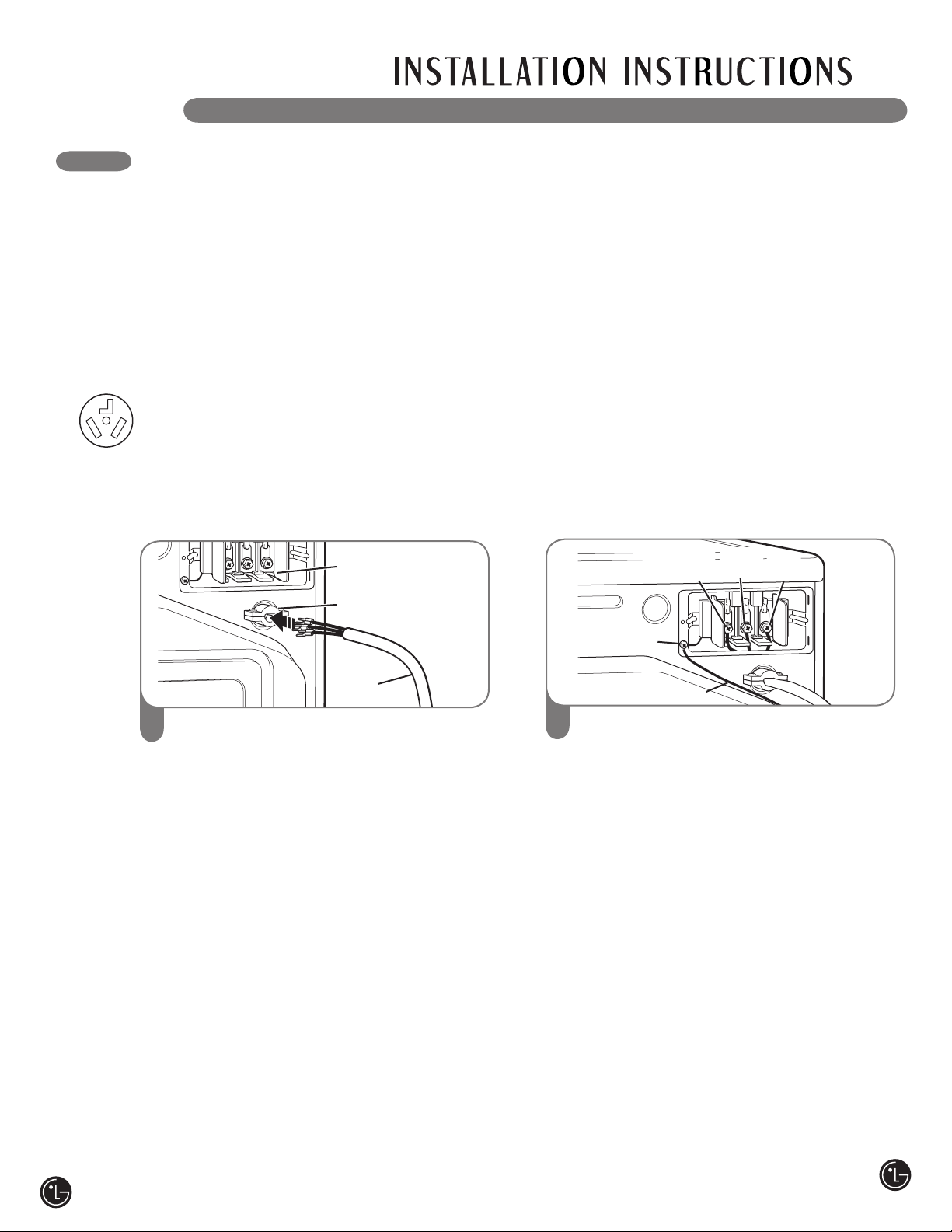

Three-Wire Connection for Electric Dryers: Power Cord

• A 3-wire connection is NOT permitted on new

construction after January 1, 1996.

• A UL-listed strain relief is required.

Terminal

Block

UL-Listed

Strain Relief

UL-Listed

3-Wire

Power Cord

1

Remove the terminal block access cover

on the upper back of the dryer. Install a

UL-listed strain relief into the power cord

through-hole; then thread a UL-listed, 30A,

240V, 3-wire, #10 AWG-minimum copper

conductor power cord through the strain

relief.

• Use a 30-amp, 240V, UL-listed power cord

with #10 AWG-minimum copper conductor

and closed loop or forked terminal s with

upturned ends.

Hot

(Black)

Ground Screw

Ground Wire

2

Attach the two hot leads of the power cord

Neutral

(White)

Hot

(Red)

to the outer terminal block screws. Attach

the neutral wire to the center terminal block

screw. Connect the external ground (if

required by local codes) to the green ground

screw. TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access cover.

21

Page 22

CONNECTING ELECTRIC DRYERS (cont.)

USA ONLY

wWARNING:

• Connect the power cord to the terminal block. Each colored wire should be connected

to same color screw. Wire color indicated on manual is connected to the same color

screw in block. Failure to follow these instructions may result in a short or overload.

• Grounding through the neutral conductor is prohibited for: (1) new branch-circuit

installations, (2) mobile homes, (3) recreational vehicles, and (4) areas where local

codes prohibit grounding through the neutral conductor.

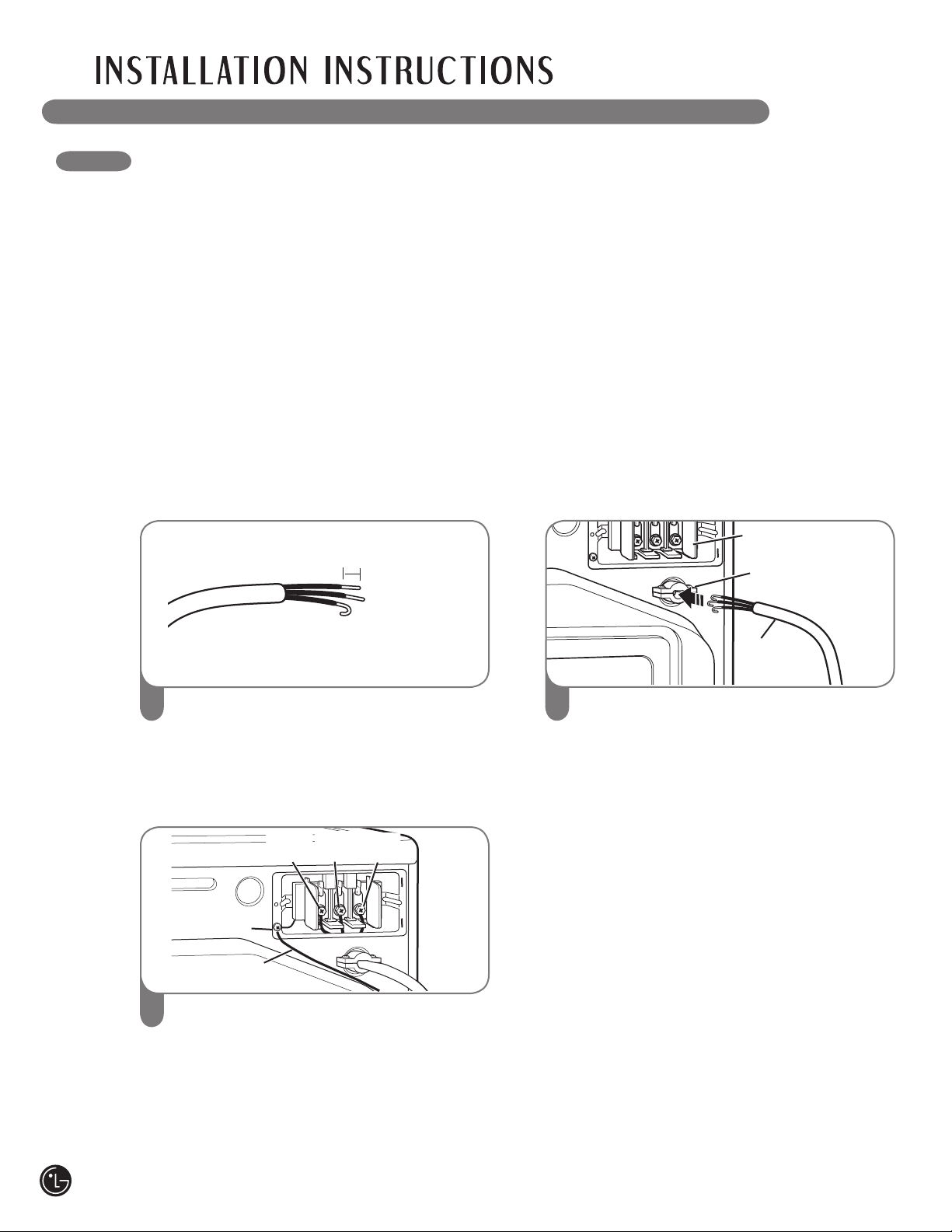

Three-Wire Connection for Electric Dryers: Direct Wire

• A 3-wire connection is NOT permitted on new

construction after January 1, 1996.

• A UL-listed strain relief is required.

1" (2.5 cm)

1

Remove 31⁄2 inches (8.9 cm) of the outer

covering from the wire. Strip 1 inch (2.5 cm)

insulation from each wire. Bend the ends of

the three wires into a hook shape.

Hot

Black)

Neutral

(White)

Hot

(Red)

• Use UL-listed 3-wire #10 AWG-minimum

copper conductor cable.

• Allow at least 5 ft (1.5 m) length to allow for

removal and reinstallation of the dryer.

Terminal

Block

UL-Listed

Strain Relief

UL-Listed

3-Wire

Power Cord

2

Remove the terminal block access cover

on the upper back of the dryer. Install a

UL-listed strain relief into the power cord

through-hole; then thread the power cable

prepared in Step 1 through the strain relief.

22

Ground Screw

Ground Wire

3

Attach the two hot leads of the power cord

to the outer terminal block screws. Attach

the neutral wire to the center terminal block

screw. Connect the external ground (if

required by local codes) to the green ground

screw. TIGHTEN ALL SCREWS SECURELY.

Reinstall the terminal block access cover.

Page 23

SPECIAL REQUIREMENTS FOR MANUFACTURED OR MOBILE HOMES

Any installation in a manufactured or mobile

home must comply with the Manufactured Home

Construction and Safety Standards Title 24 CFR,

Part 32-80 or Standard CAN/CSA0Z240 MH and

local codes and ordinances. If you are uncertain

whether your proposed installation will comply

with these standards, please contact a service

and installation professional for assistance.

• A gas dryer must be permanently attached to

the floor.

• The electrical connection for an electric dryer

must be a 4-wire connection. More detailed

information concerning the electrical connection

is provided in the section Connecting Electric

Dryers.

• To reduce the risk of combustion and fire, the

dryer must be vented to the outside.

• DO NOT vent the dryer under a manufactured

home or mobile home.

• Electric dryers may be vented to the outside

using the back, left, right, or bottom panel.

• Gas dryers may be vented to the outside using

the back, left, or bottom panel. Gas dryers may

not be vented to the outside using the right side

panel because of the burner housing.

• The dryer exhaust duct must be affixed securely

to the manufactured or mobile home structure,

and the exhaust duct must be made of a

material that will resist fire and combustion.

It is recommended that you use a rigid or

flexible metal duct.

• DO NOT connect the dryer exhaust duct

to any other duct, vent, chimney, or other

exhaust duct.

• Make sure the dryer has adequate access to

outside fresh air to ensure proper operation.

The opening for outside fresh air must be at

least 25 in2 (163 cm2).

• It is important that the clearance of the duct

from any combustible construction be at least

2 in. (5 cm), and when venting the dryer to

the outdoors, the dryer can be installed with a

clearance of 1 in. (2.5 cm) at the sides and back

of the dryer.

• Please be aware that venting materials are

not supplied with the dryer. You should obtain

the venting materials necessary for proper

installation.

FINAL INSTALLATION CHECK

Once you have completed the installation of the dryer and it is in its final location, confirm proper operation

with the following tests and Duct Condition Testing on the following page.

Testing Dryer Heating

GAS MODELS

Close the dryer door, press the ON/OFF switch

to turn the dryer on, and start the dryer on a heat

setting. When the dryer starts, the igniter should

ignite the main burner.

NOTE: If all air is not purged from the gas line,

the gas igniter may turn off before the main

burner ignites. If this happens, the igniter will

reattempt gas ignition after approximately

two minutes.

ELECTRIC MODELS

Close the dryer door, press the ON/OFF switch

to turn the dryer on, and start the dryer on a heat

setting. The exhaust air should be warm after the

dryer has been operating for 3 minutes.

Checking Airflow

Effective dryer operation requires proper airflow.

The adequacy of the airflow can be measured

by evaluating the static pressure. Static pressure

in the exhaust duct can be measured with

a manometer, placed on the exhaust duct

approximately 2 ft. (60.9 cm) from the dryer.

Static pressure in the exhaust duct should not

exceed 0.6 in. (1.5 cm). The dryer should be

checked while the dryer is running with no load.

Checking Levelness

Once the dryer is in its final location, recheck

the dryer to be sure it is level. Make sure it is

level front to back and side to side, and that

all 4 leveling feet are firmly on the floor.

23

Page 24

FLOW CHECK (DUCT CONDITION TEST)

THE DUCTWORK IS FREE

FROM BLOCKAGES OR

RESTRICTIONS.

COMPLETED FLOW CHECK

THE DUCTWORK HAS

A BLOCKAGE THAT NEEDS

TO BE REMOVED

IMMEDIATELY.

NEED FLOW CHECK

FLOW CHECK

0:02

EST. TIME

REMAINING

HIGH

Your dryer features FlowSense

TM

, an innovative

sensing system that automatically detects blockages

and restrictions in dryer ductwork. Keeping ductwork

clean of lint buildup and free of restrictions allows

clothes to dry faster and reduces energy use.

NOTE: When the dryer is first installed, this test

should be performed to alert you to any existing

problems with the exhaust duct in your home.

However, since the test performed during normal

operation provides more accurate information on

the condition of the exhaust duct than does the

installation test, the number of bars displayed during

the two tests may not be the same.

To activate the flow check (Duct condition test) :

NOTE: Dryer heating test must be performed before

proceeding. Then perform the duct condition test

below:

Press and hold the DAMP DRY BEEP and

1

TEMP. CONTROL buttons at the same time.

While holding these buttons, press POWER

ON/OFF.

Correct Venting

Restricted or Blocked Airflow

Avoid long runs or runs with multiple elbows

or bends.

2

The display will show the FLOW CHECK start

screen.

3

Press START/PAUSE. The dryer

will run for approximately 2

minutes to test

for blockages

or restrictions

to air flow in the

ductwork.

If no bars are shown in

the display, the ductwork

is free from blockages

or restrictions.

If all bars are lit, the

dryer ductwork has a

blockage that needs to

be removed immediately.

IMPORTANT: Do NOT interrupt the test cycle!

Check for blockages and lint buildup.

Make sure the ductwork is not crushed

or restricted.

24

Page 25

Tumble

dry

Dry

Normal

Permanent Press

/

wrinkle resistant

Gentle/

delicate

Do not tumble dry

Do not dry

(used with

do not wash)

Heat

setting

High

Medium

Low

No heat/air

Following are instructions for starting and using your new dryer. Please refer to specific sections of this

manual for more detailed information. Important Warning: To reduce the risk of fire, electric shock,

or injury to persons, read this entire manual, including the Important Safety Instructions, before

operating this dryer.

SORTING LOADS

Fabric Care Labels

Fabric Care Labels

Most articles of clothing feature fabric care labels

that include instructions for proper care.

Grouping Similar Items

For best results, sort clothes into loads that can

be dried with the same drying cycle.

Different fabrics have different care

requirements, and some fabrics will dry

more quickly than others.

LOADING THE DRYER

wWARNING: To reduce the risk of fire, electric shock, or injury to persons when using this

appliance, follow basic precautions, including the following:

• Check all pockets to make sure that they are

empty. Items such as clips, pens, coins, and

keys can damage both your dryer and your

clothes. Flammable objects such as lighters

or matches could ignite, causing a fire.

Failure to do so can result in fire, explosion,

or death.

• Never dry clothes that have been exposed to

oil, gasoline, or other flammable substances.

Washing clothes will not completely remove

oil residues. Failure to obey this warning can

result in fire, explosion, or death.

• Combine large and small items in a load.

• Damp clothes will expand as they dry. Do not

overload the dryer; clothes require room to

tumble dry properly.

• Close zippers, hooks, and drawstrings to

prevent these items from snagging or tangling

on other clothes.

CHECK THE LINT FILTER BEFORE EVERY LOAD

Always make sure the lint filter is clean before

starting a new load; a clogged lint filter will

increase drying times.

To clean, pull the lint filter straight up and roll any

lint off the filter with your fingers. Do not rinse or

wash the filter to remove lint. Push the lint filter

firmly back into place. See “Care and Cleaning”

for more information.

Always ensure the lint filter is properly installed

before running the dryer. Running the dryer with

a loose or missing lint filter may damage the

dryer and articles in the dryer.

Lint Filter

25

Page 26

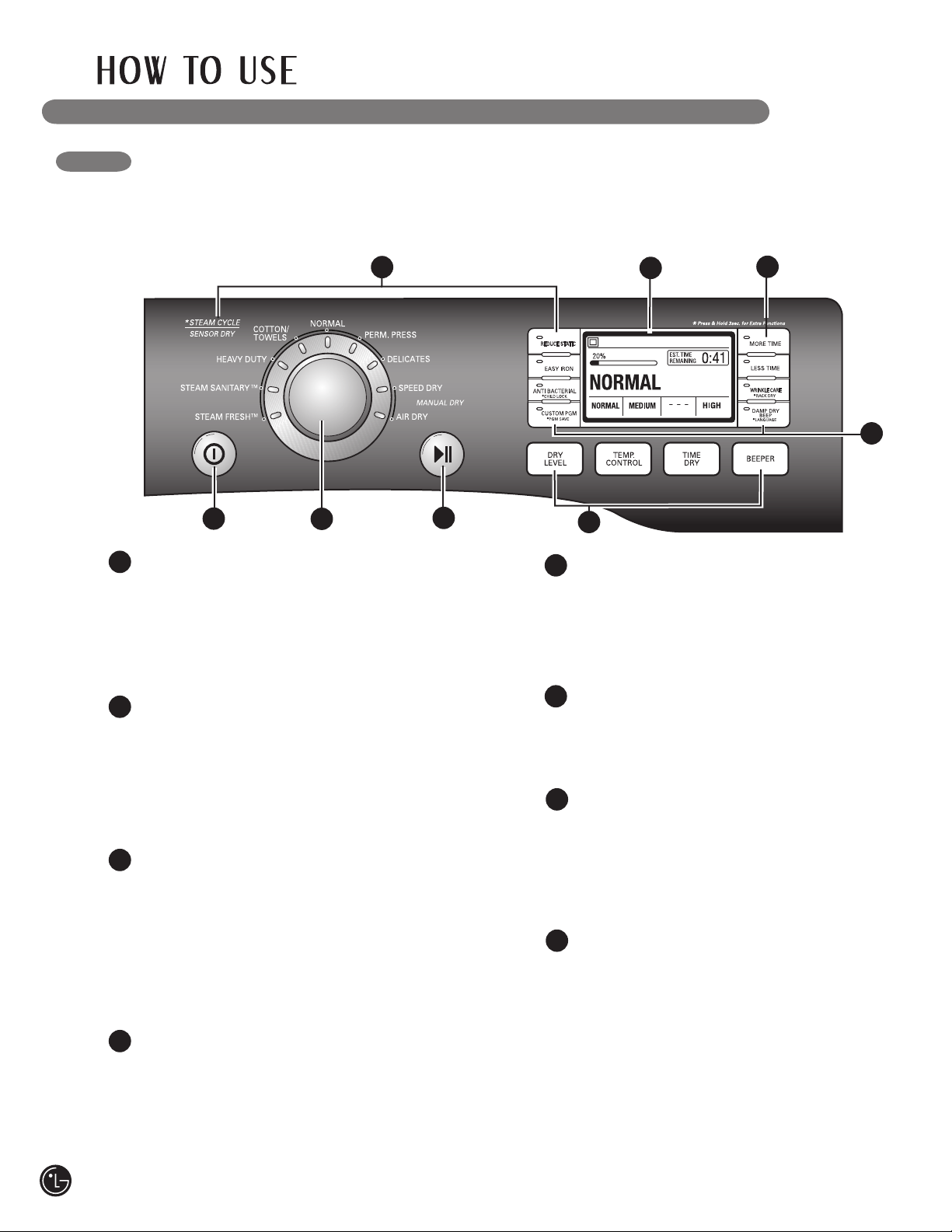

CONTROL PANEL FEATURES

Following are instructions for starting and using your new dryer. Please refer to specific sections

of this manual for more detailed information. Important Warning: To reduce the risk of fire,

electric shock, or injury to persons, read this entire manual, including the Important Safety

Instructions, before operating this dryer.

8

6

4

7

26

1

1

POWER ON/OFF BUTTON

Press to turn the dryer ON. Press again to

turn the dryer OFF.

NOTE: Pressing the ON/OFF button during

a cycle will cancel that cycle and any load

settings will be lost.

2

CYCLE SELECTOR KNOB

Turn this knob to select the desired cycle.

Once the desired cycle has been selected, the

standard presets will be shown in the display.

On MANUAL DRY cycles, these settings can

be adjusted using the cycle settings buttons

anytime before starting the cycle.

3

START/PAUSE BUTTON

Press this button to START the selected

cycle. If the dryer is running, use this button

to PAUSE the cycle without losing the

current settings.

NOTE: If you do not press the START/PAUSE

button to resume a cycle within 4 minutes,

the dryer automatically turns off.

4

MORE TIME/LESS TIME BUTTONS

To adjust the drying time, use these buttons with

MANUAL DRY, TIME DRY, and STEAMFRESH™

cycles, as well as the REDUCE STATIC and

EASY IRON options. Press the MORE TIME

button to increase the selected manual cycle

time by a minute; press LESS TIME to decrease

the cycle time by a minute.

2

3

5

5

CYCLE SETTING BUTTONS

Use these buttons to select the desired cycle

settings for the selected cycle. The current

settings are shown in the display. Press the

button for that option to view and select

other settings.

6

LCD DISPLAY

The display shows the settings, estimated

time remaining, options, and status

messages for your dryer.

OPTION BUTTONS

7

The OPTION buttons allow you to select

additional cycle options. Certain buttons

feature a special function (see the following

pages for details) that can be activated by

pressing and holding that option button.

HELPFUL STEAM FUNCTIONS

8

LG’s new steam technology allows you

to inject fabrics with a swirling jet of hot

steam to refresh clothes, reduce static,

and make ironing easier. Simply select the

STEAMFRESH™ cycle, or you can add a

STEAM option to selected cycles.

For detailed information about the individual

options, please see the following pages.

Page 27

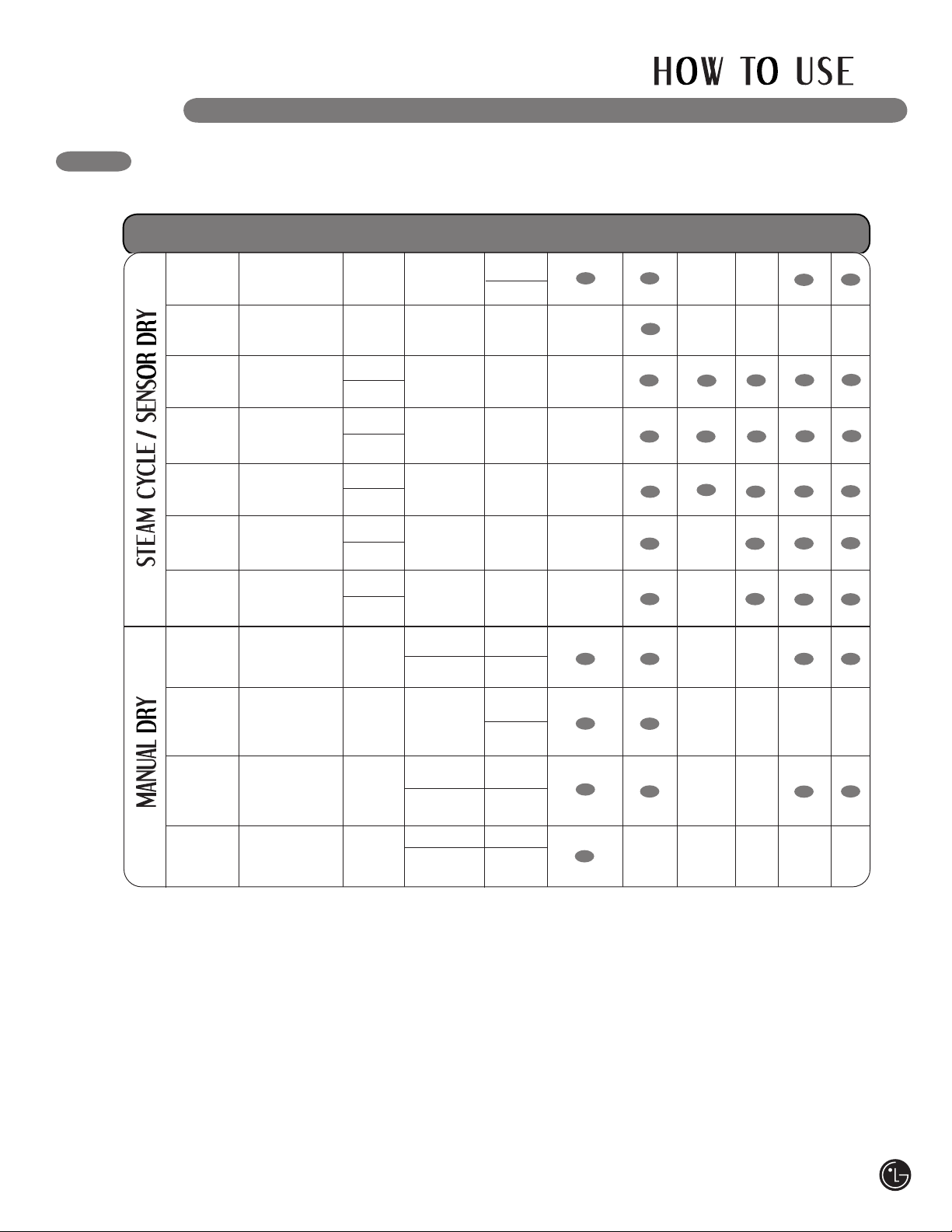

CYCLE GUIDE

The cycle guide below shows the options and recommended fabric types for each cycle.

Type

Cycle

STEAM

TM

FRESH

STEAM

SANITARY

HEAVY DUTY

COTTON/

TOWELS

NORMAL

PERM. PRESS

DELICATES

SPEED DRY

AIR DRY

TIME DRY

RACK DRY

TM

Fabric Type

Comforter, Shirts,

Trousers

especially delicate fabrics)

Comforter, Bedding,

children’s clothing

Jeans,

heavyweight items

Denims, towels,

heavy cottons

Work clothes,

corduroys, etc.

Permanent press,

synthetic items

Lingerie, sheets,

blouses

For small loads

with short

drying times

For irems that

require heat-free

drying such as

plastics or rubber

For general drying;

time, temperature,

and options can be

set manually

Wool sweaters,

silk, lingerie

(

except

Dry

Level

Off

Off

Normal

Adjustable

Normal

Adjustable

Normal

Adjustable

Normal

Adjustable

Normal

Adjustable

Off

Off

Off

Off

Temperature

MID HIGH

HIGH

HIGH

MID HIGH

MEDIUM

LOW

LOW

HIGH

Adjustable

No Heat

HIGH

Adjustable

Off

ULTRA LOW

LOW

Time

in Min.

20

Adjustable

39

54

55

41

36

32

25

Adjustable

30

Adjustable

40

Adjustable

50

Adjustable

More Time/

Less Time

Wrinkle

Care

Anti-

Bacterial

Damp

Dry

Reduce

Static

Easy

Iron

Sensor Dry Cycles

Sensor Dry cycles utilize LG’s unique dual sensor

system to detect and compare the moisture level

in clothes and in the air and adjust the drying

time as needed to ensure superior results. The

dryer automatically sets the dryness level and

temperature at the recommended setting for

each cycle. The estimated time remaining will

Manual Dry Cycles

Use Manual Dry cycles to select a specific

amount of drying time and a drying temperature.

When a Manual Dry cycle is selected, the

ESTIMATED TIME REMAINING display shows

the actual time remaining in your cycle. You can

change the actual time in the cycle by pressing

MORE TIME or LESS TIME.

be shown in the display.

NOTE: To protect your garments, not every dry level, temperature, or option is available

with every cycle.

27

Page 28

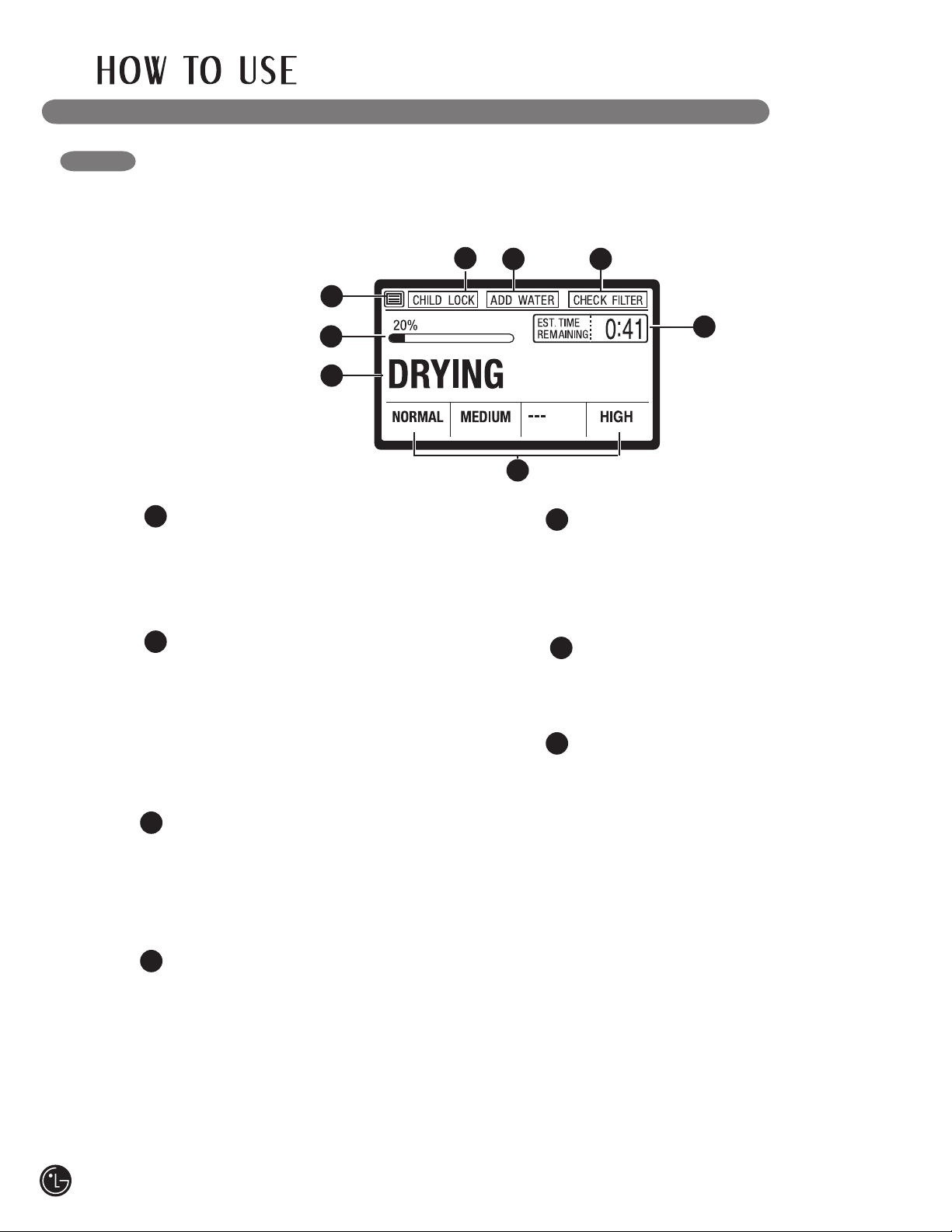

THE LCD DISPLAY

The display shows the settings, estimated time remaining, options, and status messages for your

dryer. When the dryer is turned on, the light in the display will illuminate.

8

4

1

1

STATUS/CYCLE DISPLAY

This portion of the display shows the

selected cycle, operating status, and special

messages. If a cycle has special instructions,

they will also be displayed in this area.

ESTIMATED TIME REMAINING

2

When the START/PAUSE button is pressed,

the dryer will display the estimated (SENSOR

DRY) or set time (TIME DRY) remaining, and

begin tumbling.

NOTE: The cycle time on SENSOR

DRY cycles may fluctuate as the dryer

recalculates drying time for optimal results.

3

CYCLE SETTING INDICATORS

These indicators show the current cycle

settings for DRY LEVEL, TEMP. CONTROL,

TIME DRY, and BEEPER. To change these

settings, press the appropriate settings

button.

5

6

3

7

2

5

CHILD LOCK INDICATOR

When CHILD LOCK is set, the Child Lock

indicator will appear and all buttons are

disabled except the ON/OFF button. This

prevents children from changing settings

while the dryer is operating.

6

ADD WATER INDICATOR

If the steam feeder is lack for water, this

error may be displayed. Fill the feeder and

restart the cycle.

7

LINT FILTER INDICATOR

The dryer automatically detects reduced

air flow caused by a full lint filter. The LINT

FILTER indicator will light before each load

as a reminder to check the lint filter before

starting each load. If the lint filter becomes

clogged during a load, the indicator will

come on to let you know that the filter

should be cleaned immediately for maximum

efficiency. Always clean the lint filter before

every cycle.

28

4

CYCLE COMPLETION INDICATOR

Shows how much of the current drying cycle

has been completed.

Page 29

THE LCD DISPLAY (cont.)

THE DUCTWORK HAS

A BLOCKAGE THAT NEEDS

TO BE REMOVED

IMMEDIATELY.

NEED FLOW CHECK

END OF CYCLE

8

FLOW SENSE™ DUCT BLOCKAGE

SENSING SYSTEM INDICATOR

The FLOW SENSE™ duct blockage sensing

system detects and alerts you to blockages

in the ductwork that reduce exhaust flow

from the dryer. This improves operating

efficiency and helps minimize service calls,

saving you money.

If no bars are shown in the

display, the ductwork is free from

blockages.

If two bars in the display are

lighted, examine the dryer

exhaust system for lint build up

or other restrictions, including

damage, excess length, foreign

objects, etc. See note below.

If all bars are lit, the dryer

ductwork has a blockage

that needs to be removed

immediately.

NOTE: If the duct has been checked and

cleaned and two bars are still displayed after

several cycles, then there is some restriction

in the duct due to length, condition, etc. In

this case, no further action is necessary and

the dryer can be used normally. However,

drying times may be increased and there may

be some reduction in operating efficiency

• 2 bars are displayed In the LCD screen.

1. Possible causes

• Ductwork is slightly too long or has too

many turns/restrictions.

• Partial blockage of the

buildup.

ductwork due to lint

2. Solutions

• Install a shorter or straighter duct run. See

the Installation Instructions.

• Ductwork should be checked/cleaned soon.

Dryer can be used in this condition, but

drying times may be longer.

• If “END OF CYCLE” is displayed after the

end of cycle, it will be off in 4 minutes. If

POWER button is pressed or the door is

opened, power will be off immediately.

• 4 bars are displayed In the LCD screen.

1. Possible causes

• Ductwork is too long or has too many turns/

restrictions.

• Significant blockage of the ductwork due to

lint buildup or debris.

2. Solutions

• Install a shorter or straighter duct run. See

the Installation Instructions.

• Ductwork should be checked/cleaned soon.

Dryer can be used in this condition, but

drying times may be longer.

• If “NEED FLOW CHECK” is displayed after

the end of cycle, it will be off in 2 hours. If

POWER button is pressed or the door is

opened, power will be off immediately.

29

Page 30

OPERATING THE DRYER

CYCLE SETTING BUTTONS

Once you have loaded the dryer:

Press the ON/OFF button to turn on the

1

dryer. The lights around the cycle

selector knob will illuminate.

Turn the cycle selector knob to the desired

2

cycle. The display will show

the preset Dry Level,

Temperature, Time, and

Option settings for that cycle.

3

If you would like to change the settings

for that cycle, press the option button(s)

to display additional settings for that option. Press

the button again to cycle through the settings until

the desired setting is highlighted.

NOTE: To protect your garments, not every dry level,

temperature, or option is available with every cycle.

Select any additional cycle options, such as ANTI-

4

BACTERIAL, DAMP DRY BEEP,

WRINKLE CARE, or RACK DRY

by pressing the button for that

option.

Press the START/PAUSE button to begin the

5

cycle. The display will change,

and the dryer will display the

estimated (SENSOR DRY) or set

time (MANUAL DRY) remaining

and start tumbling. To pause the cycle at

any time, press PAUSE. To resume the cycle

where it was stopped, press START/PAUSE

again.

SENSOR DRY cycles have preset settings

that are selected automatically. MANUAL DRY

cycles have default settings, but you may also

customize the settings using the cycle setting

buttons. Press the button for that option to

view and select other settings.

NOTE: To protect your garments, not every

dryness level, temperature, or option is

available with every cycle. See the Cycle

Guide for details.

DRY LEVEL

Selects the level of dryness for

the cycle. Press the DRY LEVEL

button repeatedly to scroll through

available settings.

• This option is only available with SENSOR

DRY cycles.

• The dryer will automatically adjust the cycle

time. Selecting VERY DRY or MORE DRY

will increase the cycle time, while LESS

DRY or DAMP DRY will decrease the cycle

time.

• Use a LESS DRY or DAMP DRY setting for

items that you wish to iron.

TEMP. CONTROL

Adjusts the temperature setting

from ULTRA LOW to HIGH. This

allows precise care of your fabrics

and garments. Press the TEMP.

CONTROL button repeatedly to scroll through

available settings.

30

NOTE: If the dryer has been stopped for

more than 8 minutes, the dryer will turn

off automatically.

When the load is finished, the beeper (if

6

set) will sound. If you have set the WRINKLE

CARE option, the dryer will tumble the load

periodically for up to 3 hours.

To prevent wrinkling, remove items from the

dryer immediately after the end of the cycle.

Always clean the lint filter after every cycle.

7

To clean, pull the lint filter straight up and

roll any lint off the filter with your fingers.

Do not rinse or wash the filter to remove lint.

Push the lint filter firmly back into place.

TIME DRY

Allows you to manually select the

drying time, from 20 to 60 minutes,

in 10-minute increments. Use

this for small loads or to remove

wrinkles. Use the MORE TIME/LESS TIME

buttons to add or reduce the drying time in 1minute increments.

BEEPER

Adjusts the volume of the end-

of-cycle beeper, or turns off the

beeper.

Page 31

CYCLE OPTION BUTTONSCYCLE SETTING BUTTONS

Your dryer features several additional cycle

options to customize cycles to meet your

individual needs. Certain option buttons also

feature a special function (see the following page

for details) that can be activated by pressing and

holding that option button for 3 seconds.

To Add Cycle Options to a Cycle:

Turn on the dryer and turn the cycle selector

1

knob to select the desired cycle.

Use the cycle settings buttons to adjust the

2

settings for that cycle.