LG DLEV833W Owner’s Manual

1-800-243-0000

24 HOURS A DAY, 7 DAYS A WEEK FOR LG CUSTOMER SERVICE

buying an LG Dryer.

manual carefully, as it provides

Installation, Use, and Maintenance.

Numbers,

,rfuture reference.

our website at

PiNo.:3828EL3006G

O Ultra Big Capacity Drum

The LG Dryer has a large capacity.

Reduced d_ing time

@

Drying time is shortened by efficient air flow mechanism and

optimized heater.

Innovative Noise Reduction

Noise is reduced by optimized design

vibration reduction technology.

of air flow system and

Ease of Use

Large LED display and electronic control.

Your dryer pr_wides sensor drying and manual drying programs,

Sensor Dry Dryer de_ tronk_a[Jy senses laundry moisture [evd and it automatically determines operation time

based on the dryness of the load and the _[ect___d program. At times,you (an see sudden in(tease or

decrease of operation time. it happens because a sensor will detect laundry humidity with a certain period,

Sudden change of operation time is not a malfunction.

_nual Dry Manual Dry allows you to set operation time manualiy to complete drying. Or use Manual Dry if

clothes are still damp after sensor dry (ycle is finished. Manual Dry is more effective (or heavyweight and bulky

ilems such as king-size bed shc_ts and thick work clothes,

ontents

Safety Instructions 3

Installation Instructions .....................................................................................5

Electrical Requirement For Electric Dryers ........................ 11

Exhaust RequiremenLs And Maintenance ............................................15

Appearance And Design .......................................................... 17

Operating Your Dryer .....................................................................................18

Additional Functions ...................................................................................21

Caring [:or Your Dryer ............................................................ 22

Additional Tips For Smart Use ........................................................................25

Troubleshooting Guide .......................................................................27

Technical Data .................................................... 31

Warranty 32

afety Instructions

IMPORTANT SAFETY INSTRUCTIONS

precautions, including the following:

1) Read allinstructions before using the applian_.

2) Do not dry articles that have come into contact with

gasoline, dry-cleaning solvents, or other flammable

or explosive substances, as they give off vapors

that could ignite or explode.

3) Do not allow chitdren to play on or in the appliance.

Close supervision of children is necessary when

using the appliance.

4) Before the appliance is removed from service or

discarded, remove the door to the drying

compartment.

5)Do not reach into the appliance ifthe drum is

rotating.

6) Do not installor storethis appliance where it will be

exposed to the weather.

7) Do not tamper the with the controls.

SAVE THESE INSTRUCTIONS

GROUNDING INSTRUCTIONS

This appliance must begrounded. In the event of

malfunction or breakdown, grounding will reduce the

risk of electric shock by providing apath of least

resistance for electric current. This appliance is

equipped with a cord having anequipment-grounding

conductor and a grounding plug, The plug must be

plugg_ into an appropriate outlet that is properly

installed and grounded in accordance with all i_a[

_es and ordinances.

8) Do not repair or replace any part of the appliance or

attempt any servicing unless specifically

recommended in the user-maintenance instructions.

9) Do not use heat:to dry articles containing foam

rubber or similarly textured rubber-like materials.

10)Clean lint screen before or after each load.

11) Keep area around the exhaust opening and

adjacent surrounding areas free from the

accumulationof tint,dust, and dirt.

12)The interior of the appliance and exhaust dud

should becleaned periodically by qualifi_ _rvice

personnel

13)Do not place items exposed to cooking oils inyour

dryer, Items contaminated with o¢_king oils may

contribute to a chemical reaction that could cause

a toadto catch fire,

14)Do not use fabric softners or products _ eliminate

static unless recommended by the manufacturer of

the fabric s,oftner or product,

Do not modi_ the plug provided with the appliance: if

itwill not fit the outlet, have a proper outlet installed by

a qualified eiecthcian

This appliance must be connected to a grounded

metal, permanent wiring system or an equipment-

grounding conductor must be runwith the circuit

conductors and connected to the equipment-

grounding terminal or lead on the appliance.

WARNING - Improper connection of the equipment_

grounding conductor can result ina riskof electric

shock. Check with a qualified electrician or service

person if you are in doubt as to whether the appliance

is properly grounded.

To reduce the risk of fire or explosion, electric

shock, property damage, personal injury, or death

when using this appliance, please follow all

instructions and information, including those in

this manual and instructions provided by your

gas suppliel:

*Do not store or use any gasoline, dry_cleaning

solvents any other flammable vapors or

liquids in the area surrounding this appliance.

• Do not dl?! anything that has ever had anything

flammable on it, even after washing.

• No washer can cornpletely remove oil. Do not

dry any mlicIes that have ever had any kind of

oil on them, including cooking oil.

• Articles containing foam, rubber, rubber-like

materials, plastic or similar materials should be

air dried.

*Failure to follow these insla'uctions can result in

fire, death or serious injm2y.

• Keep flammable materials and vapors, such

as gasoline, away from dryer.

- Place dryer at least 18 inches above the floor

for a garage installation.

- Failure to do so can result in death,

explosion or fire ....

° A qualified selwice person or company must

_fform installation and service of this

appliance.

nstallation

The following instructions will help guide you through the initial steps of setting up your dl2cer for use.

Please note that evei_' section of this manual provides important info_Tnation regarding the preparation

and use of your dryer, and it is impol_ant that you review this entire manual before proceeding with any

installation or use Morn detailed instructions concerning electrical connections, gas connections, and

exhaust requirements are provided in other parts of this manual.

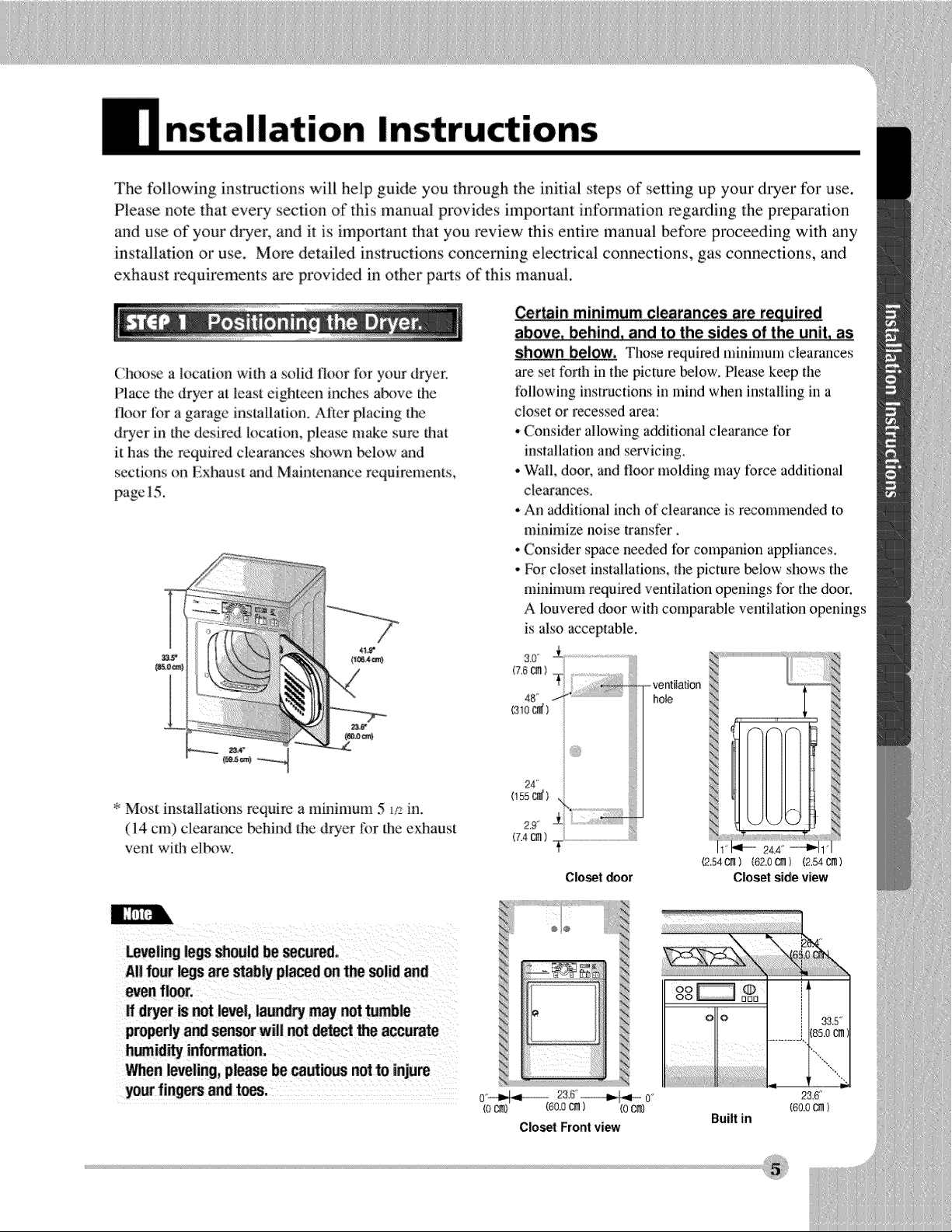

Certain minimum _!earan_s are rea uir_

above, behind, and to the sides of the unit, as

shown below, Those required minimmn clearances

Choose a location with a solid floor for your dryer.

Place the dryer at least eigNeen inches above the

floor for a garage installation. After placing the

dryer in the desired location, please make sure that

it has the required clearances shown N_low and

sections on Exhaust and Maintenance requirements,

page 15.

aa_

_a_.oera)

i

are set fo_h in the picture below. Please keep {he

following instructions in mind when installing in a

closet or recessed area:

• Consider allowing additional clearance tor

installation and servicing.

• Wall, door, and floor molding may lorce additional

cleaances.

°An additional inch of clearance is recommended to

minimize noise transfer.

Consider space needed tor companion appliances.

• For closet installations, the picture _low shows the

minimum required ventilation openings for the door.

A Iouvered door with comparable ventilation openings

is also acceptable.

(7,6_ )

48" i" hole

/3_o_ }

_ventilaflen

_ gK4"

* Most installations require a minimmn 5 1/'2in.

(14 cm) clearance behind the dryer liar the exhaust

vent with elN)w.

Levelinglegs shouldbe secured,

All four legsare stably placed on the solidand

evenfloor.

If dryer isnot level, laundrymay not tumble

properlyand sensorwill notdet_ the accurate

humidly information.

When leveling,please becautious notto injure

yourfingers and toes.

nstallat

WARNING!

• Use a heavy metal vent.

- Do not use plastic or thin foil duct.

. Failure to follow these instructions can

result in death or fire.

• Clean old ducts before installing this dryer

improper taping and unstable installation ofvent

will _use und_irable d_ing performance,

In Mdifion to the following warnings, please refer to

manual section on Exhaust Requirements aM

Maintenance, page 15.

IMPORTANT: To reduce the risk of fire, combustion,

and gas accumulation, the dryer must be vented to the

ou:tdoo_. Please follow the instructions (arid all

others in this manual) very carefully.

Du6ng' !mns_on s!de_p canco_.__t _gid!y.

!flhatiss?, _sh and _ it !ot'neF_ _ prevent

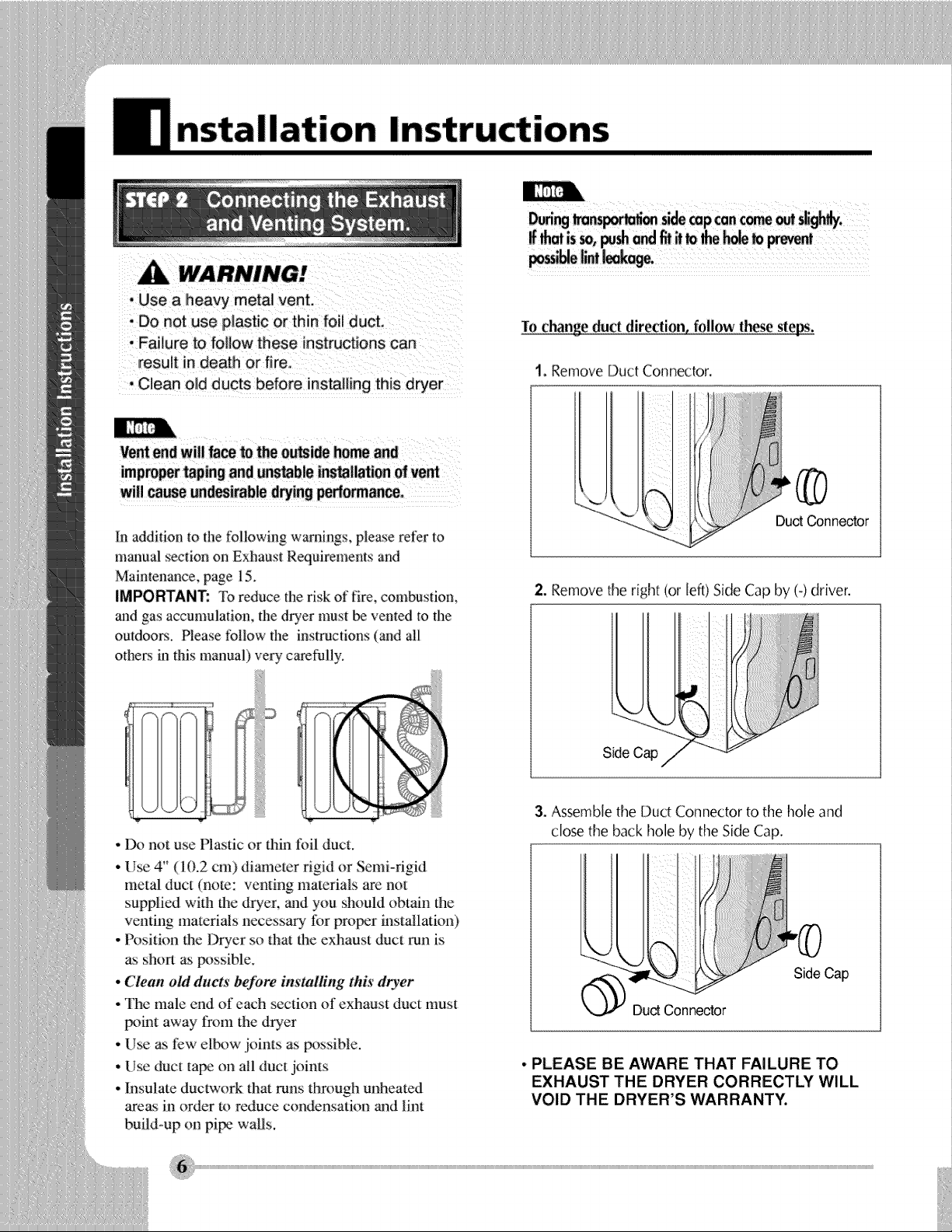

To change duct direction, follow these ste_,

, Remove Duct Conn_tor.

DuctConnector

2. Remove the right (or left) Side Cap by (4 driver,

÷ +

• Do not use Plastic or thin loil duct.

° Use 4" (10.2 cm) diameter rigid or Semi-rigid

metN duct (note: venting materials am not

supplied with the dryer, and you should obtain the

venting rnaterials necessary for proFmr installation)

° Positkm the Dryer so that the exhaust duct run is

as short as possible.

• Clean oM ducts bejore installing this dryer

. The male end of each section of exhaust duct must

point away from the dryer

• Use as li:w elbow joints as possible.

o[lse duct ta_ on all duct joints

° Insulate ductwoN that runs through unheamd

areas in order m reduce condensation and lint

build-up on piw walls.

Side Cap

3, Assemble the Duct Connector to the hole and

dose the back hole by the Side Cap.

• PLEASE BE AWARE THAT FAILURE TO

EXHAUST THE DRYER CORRECTLY WILL

VOID THE DRYER'S WARRANTY.

/

Side Cap

nstal Instructions

Following are several warnings mid inslructions

concerning ma_ng the electrical connectkm fi_r electric

dryers. More detailed intk_rlnatkm concerning the

electrical connection is provided in tile manual secli(m

entitled Electrical Requirements liar Electric Drvel:

It is imporlant _hat you thoroughly review that section

_d the remainder of this manual, b_fore taking any

s_eps to install or use riffs dryer.

1. Use only a new U.L. listed No. 10 (copper wire only)

three c_mductor power supply cord kit rated 2_)

Volts (minimum) 30 Amperes and labmled as suitable

for use in a clothes dryer.

2. Fourowire cord is required _i_rmanufactured (mobile)

home installations and where local c(_es do not

allow grounding of this appliance thrcmgh neutral.

3, Electrical Plug Cormections.

4. For addifi(mal inslruction on connecting the dryer to

an eleclrical [_)wer source, please refi_r m this

manual's section on Electrical Requirements and

Electric Dryer.

WARNING!

- Use a new UL approved 30 amp power supply

cord or 10 gauge solid copper wire

• Use a UL approved strain relieL

, Disconnect power before making electrical

connections.

- Connect neutral wire(white or center wire) to

center terminal

- Ground wire(green or bare ware)must be

connected to green ground connector.

- Securely tighten all electricN connections

- See installation instructions for complete

nstruct_ons,

- Failure to do so can result in fire or electrical

shock.

Prior to the first use of riffs appliance, use all-

purpose cleanfl_g products or a solution of detergent

and water, with damp clotll to remove from the

inside of the duer drungdrying compamnent any

dust or dirt that may have accunmlated inside the

dryer. Plug-in your dryer after reviewing the

lk_llowing parts on your dryer's Electrical

Requirements.

eleva_onbecau_ A,G.A_rtifi_ _iS drier wiRnot

haveany problemwi_ the BoT.Urating atthis aRRude.

If your houseisabove10,_0 feet, youaret_uired

raSng i_icated onthemodel/serial raUngplate,

Close the d_r to the dryer drum/drsdng

compartment and, after completing all steps in this

manual for pro_r installation of this dryer, start the

dryer on a heat setting, asdescribed more fully in

the o_rating instructions that accompany the dryer.

The exhaust air or the exhaust pipe should be warm

after the dryer has been o_rating for three minutes.

nstallat

The fo[[ow+ng instructions are applicable to

instaltations of the dryer in a manufactured or mobile

home+tf you are uncertain whether your propo_d

insia[[ation will comp]y wkh these standards, please

contact a _rvice and installation professional for

assistance.

The following instructions apply to any installation

of the dryer in a manufactured or mobile home:

1) Electric dryers may be vent_ to the outside

using the back, left, or right+

2) The dryer exhaust duct must be affixal securely

to the manufactured or mobile home structure,

and the exhaust duct must be made of amaterial

that will resistfire and combustion, and it is

recommend_J that you u_ a rigid or flexible

metal pi_,

3)

Make sure the dryer has adequate accessto

outside fresh air to ensure profit of_ration. The

o_ning for outside fresh air must _ at [east25 in_

(163c_)

4)

It is imf_rtant that the clearance of the dud from

any combustible construction _ at [east2 inches

(5 cm), and, when venthlg the dryer to the

outdoors, the dryer can _ insta[[_ with a

clearances of 1 inch (2.5 crn) at the sides and back

of the dryer.

5)

DO NOT connect the exhaust duct with any other

duct, vent, chimney, or other exhaust duct.

6)

Make sure the dryer has adequate accessto ouBide

fresh air to ensure pro_r operation. The o_rling

for outside fresh air must be at [east25 in_(163cr_).

7)

It is important that the clearance of die duct from

any combustible construction be at least 2 inches

(5 cm), and, when venting the dryer to the

outdoors, the dryer can be installed with a

clearance of 1 inch at the sides _d back of the

dryer.

8)

Please_ aware that venting materials am not

supplied with the dryer. You should obtain the

venting materials n_:essary for prof_,r insta[iation.

metal screwsor fasteners that extend

DO NOT vent the exhaust duct under the

manufactured or mobile home.

nstallation Instructions

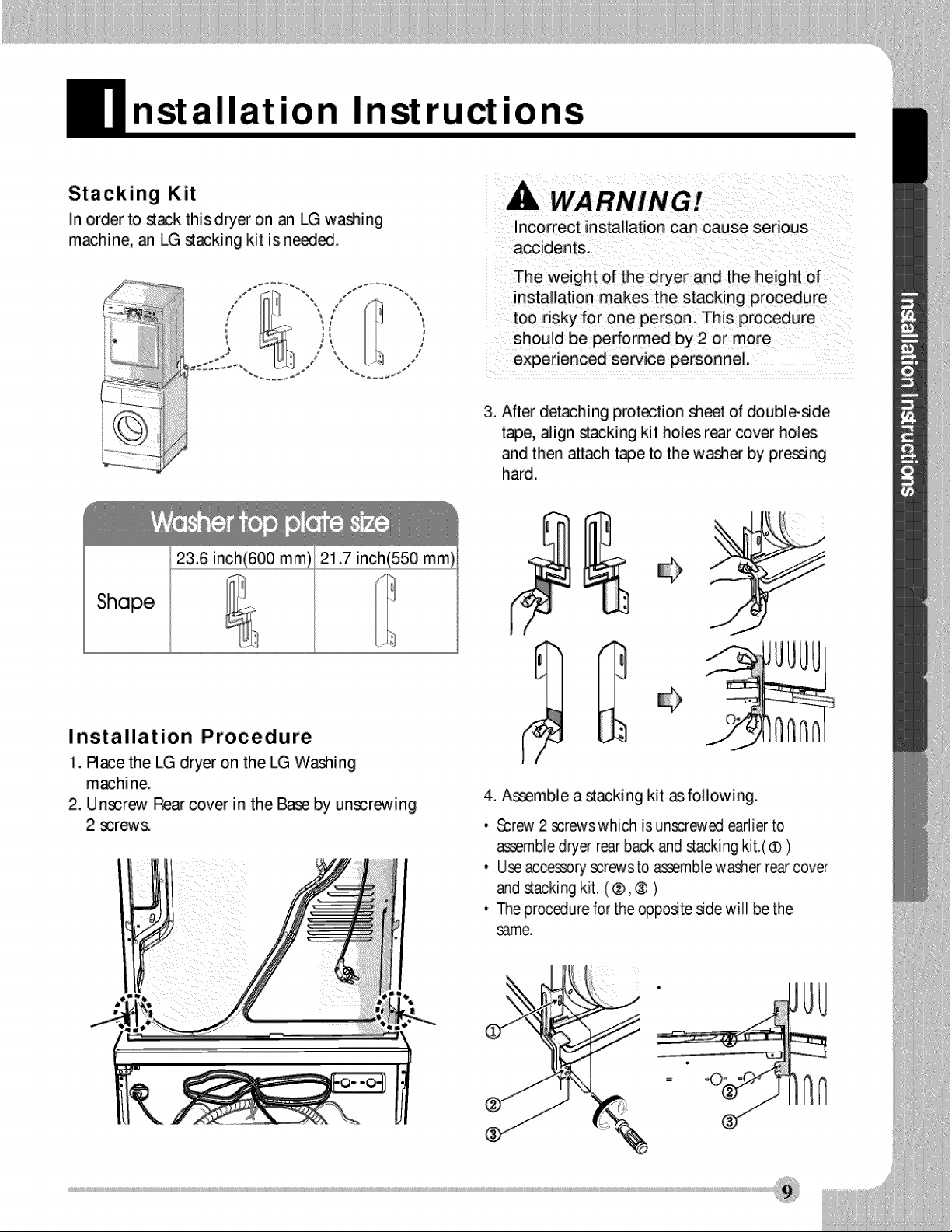

Stacking Kit

in order to stack thisdryer on _ LG washing

machine, an LG stacking kit is needed.

23.6 inch(600 mm)

inch(550 mm)

21.7 I

WARNING!

Incorrect installation can cause serious

accidents.

The weight of the dryer and the height of

installation makes the stacking procedure

too risky for one person. This procedure

should be performed by 2 or more

experienced service personnel.

3. After detaching prot_tion sheet of double-side

tape, align stacking kit holes r_r cover holes

and then attach tape to the washer by pressing

hard.

Installation Procedure

1. Place the LG dryer on the LG Washing

machine.

2. Unscrew Pea,-cover in the Ba_ by unscrewing

2 _rews

4. A_mble a stacking kit as following.

• _rew 2 _rews which is un_re, ved earlier to

_mbie dry_ rear back and stacking kit.(® )

• Useaccessory screws to assemblewasher rearcover

and stacking kit. ( @, ® )

• The proc_ure for the opposite dde will be the

_me.

nstallat

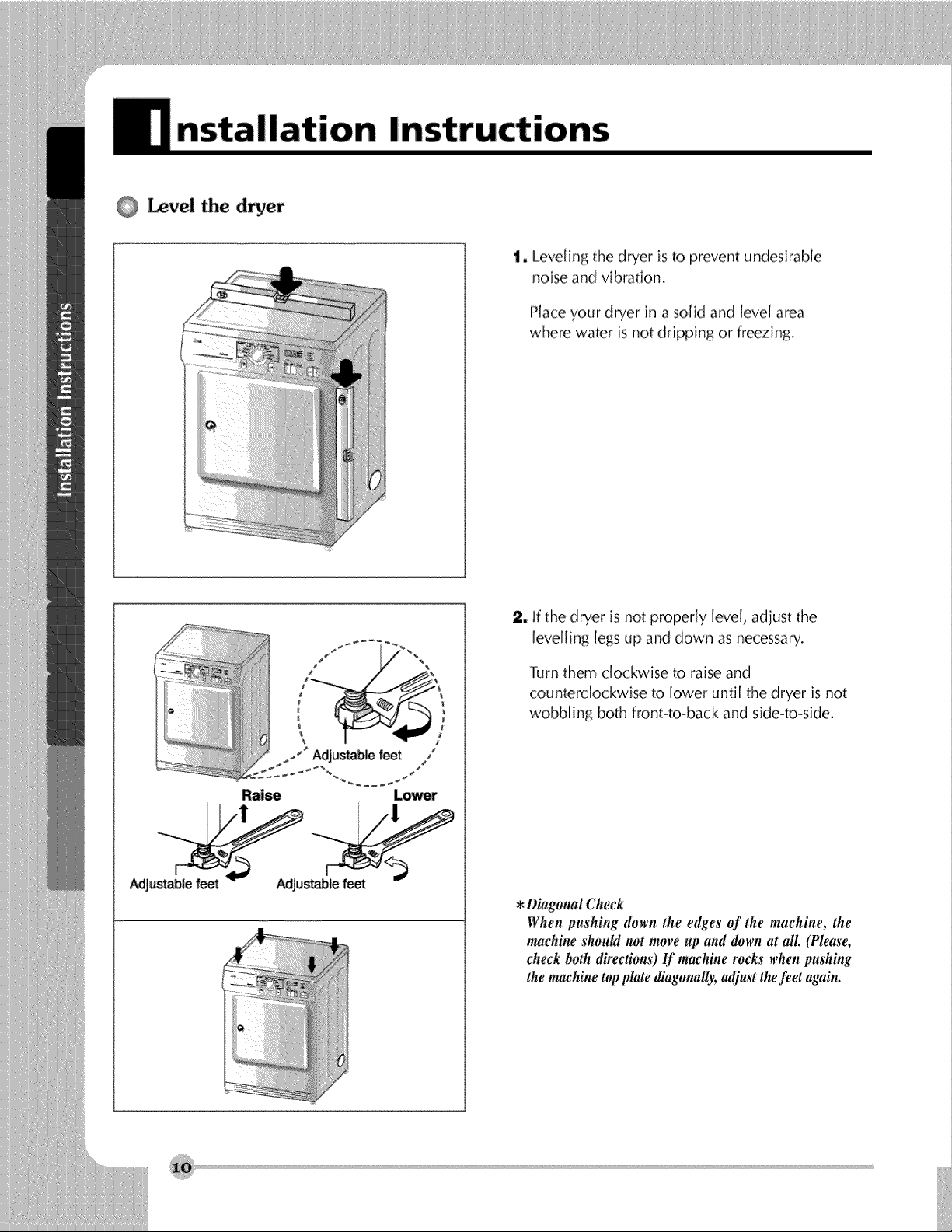

vel the dryer

t, Leveling the dr_er is to prevent undesirable

noise and vibration.

Place your dryer in a solid and [eve[ area

where water is not dripping or fr_zing,

Raise Lower

2. if the dryer is not properly Jeve[, adjust the

JeveJ[ing legs up and down as necessary,

°lurn them clockwise to raise and

counterclockwise to lower until the dryer is not

wobbling both front4ooback and sideoto-side.

* Diagonal Check

When pushing down the edges of the machine, the

_:_ehine shoakl not move up aad down at all. (Please,

check bot_ direetion_9If nulchine rocks when pushing

the machine topplate diagonally,adjust thefeet again_

lectrical Requirement For El

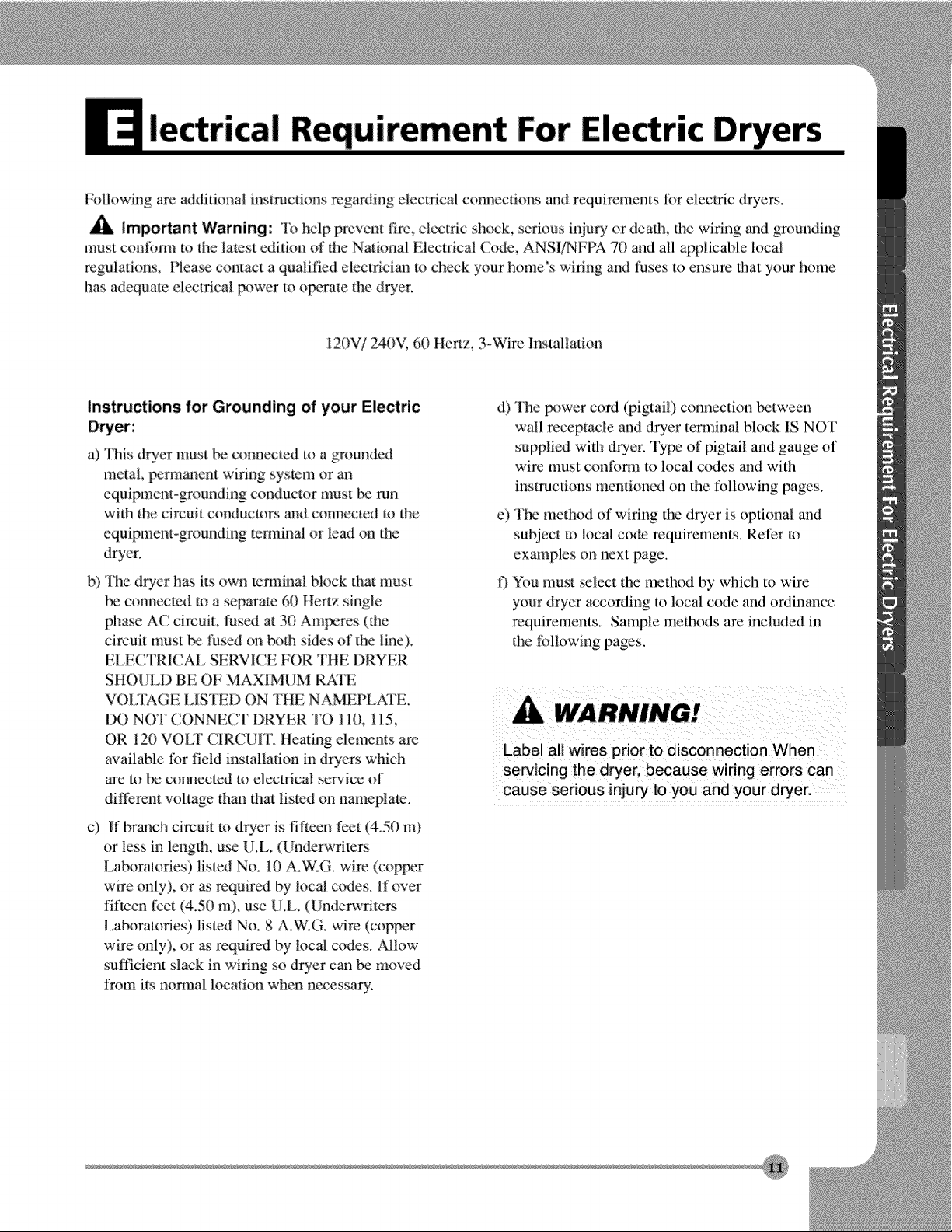

Following are additional instructions regarding electrical connections and requirements li}r electric dryer_.

Impor_nt Warning: To help prevent fire, dectric shock, serious injury or death, the wiring and groundhlg

nmst contbrm to the latest edition of the National Electrical Code, ANS//NFPA 70 and all applicable local

regulations. Please contact a qualified electrician to check your home's wiring and luses to ensure that your home

has adequate electrical power to operate the dryer.

120V/240_,_ 60 Hertz, 3-Wire Installatkm

Instructions for Grounding of your Electric

a) 'Ibis dryer must _ connected m a grounded

metal, permanent wiring system or an

equipment=grounding conductor must be run

with the circuit conductors and connected to the

equipment-grounding terminal or lead on the

&yer.

b) The dryer has its own tenuh_al block fl_at must

be connected l_,}a separate 60 tlertz single

phase AC circuit, lused at 3(i)Amperes (the

circuit must _ fused on both sides of the line).

EI._ECTR/CA/_ SERVICE FOR THE DRYER

SItOULD BE Ol: MAXIMUM RATE

VOHAGE LISTED ON THE NAMEPL_I E.

DO NOT CONNECT 1)RYER TO 110_ 115,

OR 120 VOEF CIRCUIT. Heating elements are

available R_rfield installation in dryers which

are to _ colmecmd to electrical service of

different voltage lhan that listed on nameplate.

c) If branch circuit to dryer is fifteen l)et (4.50 m)

or less in length, use U.L, (Underwriters

Laboratories) lismd No. 10 A.W.G. wire (copper

wire only), or as required by local codes. If over

fifteen feet (4,50 m), use U.L. (Undepa, ritcrs

Laboratories) listed No. 8 A.W.G. wire (copper

wire only), or as required by local codes, Allow

sufficient slack in wiring so dryer can be moved

from its normal location when necessa U.

The _wer cord (pigtail) connection N_twem'_

wahl receptacle and dryer terminal Nock iS NOT

supplied with dryer. "13_peof pigtail and gauge of

wire must contiml_ to local codes and with

instructions mentioned on the ibllowing pages.

e)

The n]ethod of wiring the dryer is optional and

subject m local code requirements. Refer m

examples on next page,

You must _,elect the method by which to wire

your dryer according to local code and ordinance

requirements. Sample methods are included in

the following pages,

Label all wires prior to disconnection When

servicing the dryer, because wiring errors can

cause serious injury to you and your dryer.

irement For

¢

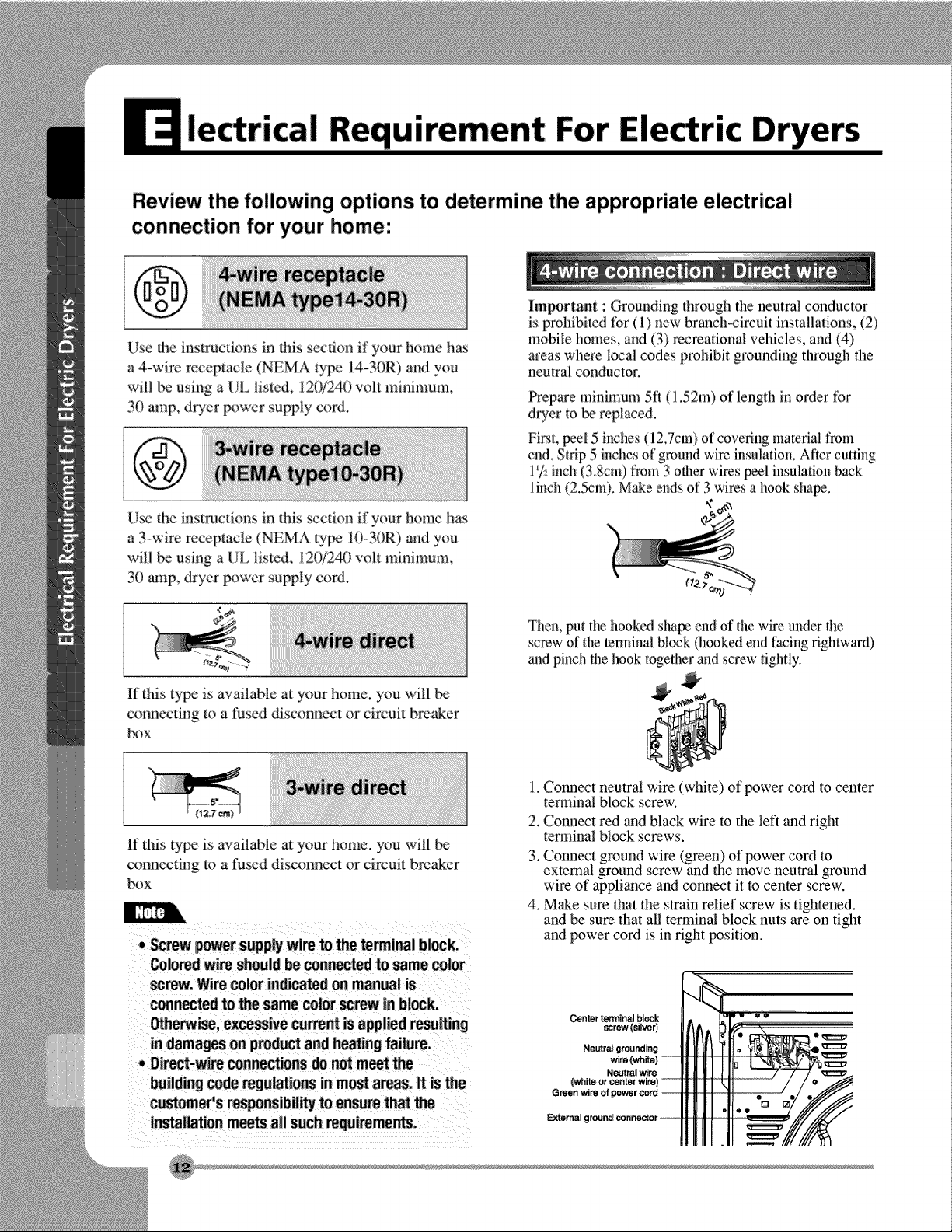

Review the following options to determine the appropriate electrical

connection for your home:

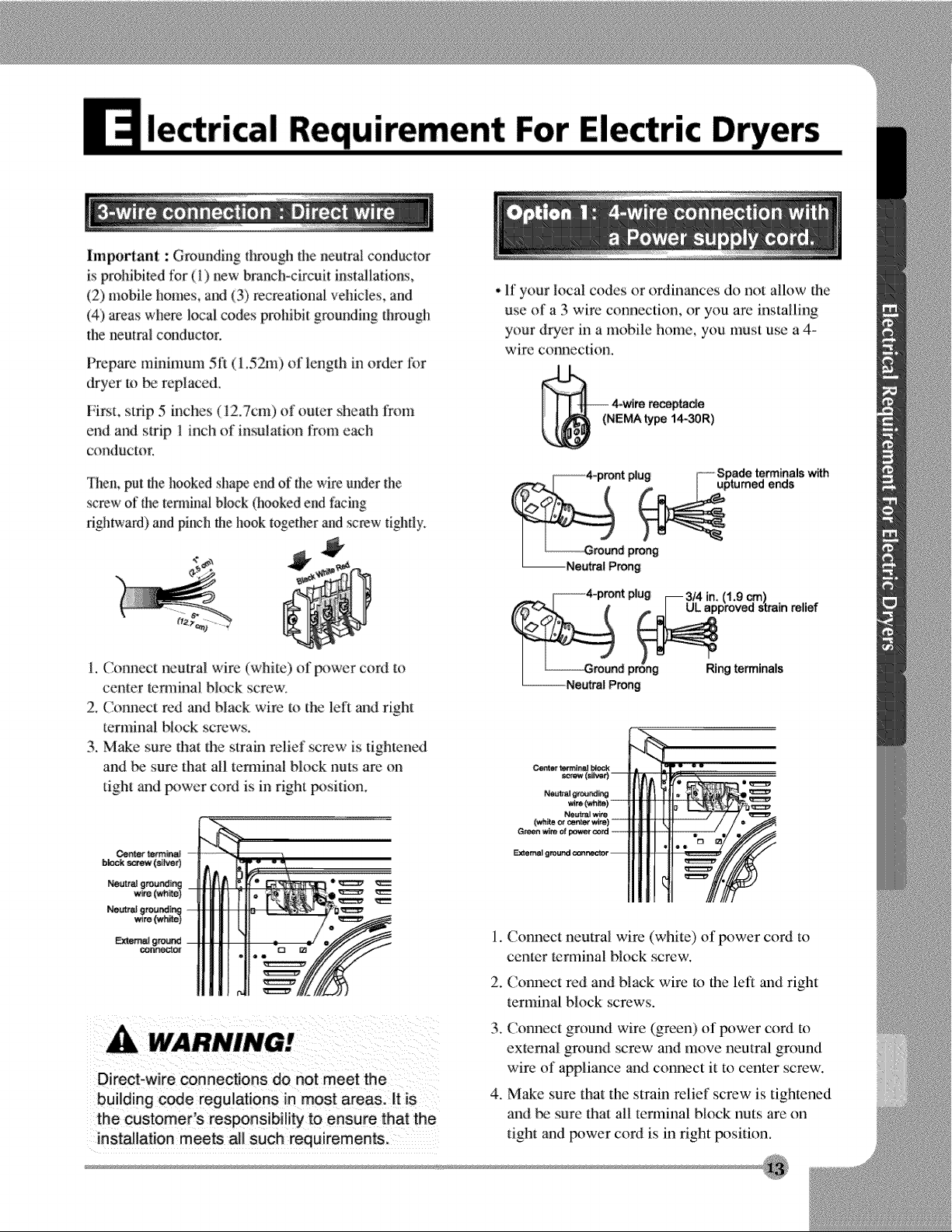

Important : Grounding fhrough the neutral conductor

is prohibited tor (1) new branch-*circt|it installations, (2)

Use the instructions in this section if your home has

a 4-wire :receptacle (NEMA tyl_e 14_30R) and you

will b.e using a UL misted, I20/240 volt mimmum,

30 amp_ duer F_)wer supply cord.

Use the instructions in this section if your home has

a 3-wire receptacle (NEMA type 10-30R) and you

will be using a UI_ lismd, 120,/2da3volt mininmm,

30 amp, &yet _wer supply cord.

mobile homes, and (3) recreational vehicles, and (4)

areas where l_al codes prohibit grounding tls-ough tile

neutral conductor.

Prepare minimum 5fi (1.52m) of length in order tbr

duer to be replace_.

First, wee 5 inches (12.7cm) of coveting material from

eM. Strip 5 hlches of ground wire htsulation. After cutting

1_£inch (3.8cm) front 3 olher wires peel insulatim| back

1hlch (2.5cm). Make ends of 3 wires a hook shape.

,¢

If this type is available at your home. you will be

connecting to a lused disconnect or circuit breaker

box

If this tyw is available at your home. you will be

connecting to a :fused disconnect or circuit b:reaker

box

• Screw power supplywire to the terminal block.

Coloredwire shouldbe connectedto _me color

screw. Wire color indicatedon manual is

connectedto the same color screw in block.

Otherwise, exce_ive cu_nt isapplied resulting

in damageson productand heatingfailure.

- Direct-wire connectionsdonot m_ the

buildingcode regulations in mostareas. It isthe

customer's responsibilit-ytoensurethat the

installation meets all such requirements.

Then, put the hooked shatT_end of the wke under the

screw of the temlinal block (hooked end facing rightward)

and pinch tile hook together and screw tightly.

1. Connect neutral write (white) of _wer cord m center

terminal block screw.

2. Comlect red and black wire to the left and right

terminal Nock screws.

3. Connect ground wire (green) of F_wer cord to

external ground screw and the move neutral ground

wire of a_pplianceand connect it to center scow.

4. M_:e sure that the strain relief screw is tightened.

and _ sure that all terminal Nock nuts are on tight

and power cord is in right _sitio_.

Requirement For E

Important : Grounding dlrough the neutral conductor

is prohibited for (I) new branch,-circuit installations,

(2) mobile homes, and (3) recreational vehicles, and

(4) areas where local codes prohibit grounding |hmugh

the neutral conductor.

Prepare minimum 5ft (1.52m) of length in order for

dryer to be replaced.

First, strip 5 inches (12.7cm) of outer sheath from

end and strip 1 inch of insulation l}om each

conductor.

Then, put the hooked shape end of file wire under the

screw of die terminal block (hooked end facing

rig!ltward) aJldpinch the hook together and screw tightly.

• It' your Iocal codes or ordinances do not allow the

use of a 3 wire connection, or you are installing

your dryer in a mobile home, you must use a 4=

wire connection.

4-_re r_tade

EMA type 14-30 R)

,..............4-pront plug r _o-Spade t_inals with

i uptumea ends

1. Connect neutral wire (white) of power cord to

center mrminal bh_'k screw:

2. Connect red and black wire to the left and right

terminal Nock screws.

3. Make sure that the strain mlie:f screw is tighmned

and be sure that all terminM block nuts are on

tight and _r,_a_'r cord is in right Ix_sition.

Ceme* t_mMal

b_k screw(silver)

NeutraJ grounding

w_ (white)

N_v=_=ral grounding

rare (w_.e)

[] []

Direct-wire connections do not meet the

building code regulations in most areas. It is

the customer's responsibility to ensure that the

installation meets all such requirements.

g Ringterminals

I.

Connect neural wire (white) of _)wer cord to

center terminal block screw.

2_

Connect red and black wire to the lel_ and right

termi:nal block screws.

3. Connect ground wire (green) of power cord m

external ground screw and move neutral ground

wire of appliance mid connect it to center screw.

4. Make sure that tile strain relief screw is tightened

mid be sure that all terminal block nuts are on

tight and f-_)wer cord is in right position.

lectrical Requirement For E

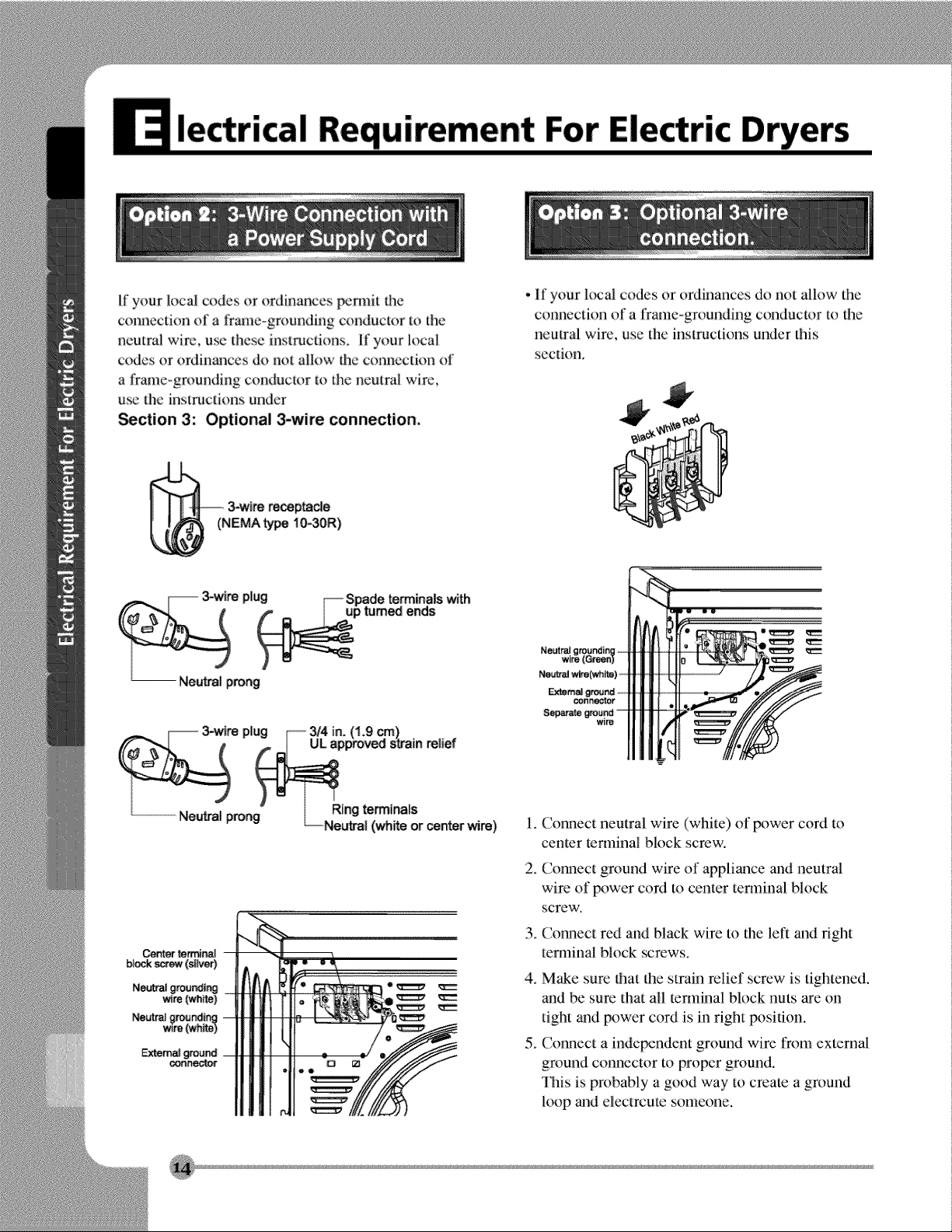

Ifyour local codes or ordinances permit the

connection of a tYame-grounding conductor to the

neutral wire, use these instructions. If your local

codes or ordinalces do not allow tile connection of

a frame+grounding conductor to the neutral wire,

use tl_e insm_ctions under

_ction 3: Optional 3+wire connection.

,3-wire recepNcle

NEMAtype 10-30R)

I Neutral prong

• If your kraal codes or ordinances do not allow the

connection of a frame+grounding conductor to the

neutral wire, use the instructions under this

section.

Neutral

Center termir_

b_k screw (silver)

Neutralgrou_i_

wire(white)

Neutralgrounding

wl;m(whffe)

1.

C{ nnect neutral wire (white) of _wer cord to

center terminal block screw.

+

Cormect ground w_e of appliance and neutral

wire of _}wer cord to center terminal block

screw.

.

Com]ect red and black wke to the left and fight

terminal block screws.

4. Make sure that the strain relief screw is tightened.

and be sure that all terminal block nuts are on

tight mid power cord is in right position.

5+Colmect a independent ground wire from exmrnal

ground conrlector to proper ground.

This is probably a good way to cream a ground

loop and electrcute someone.

uirements And Ma

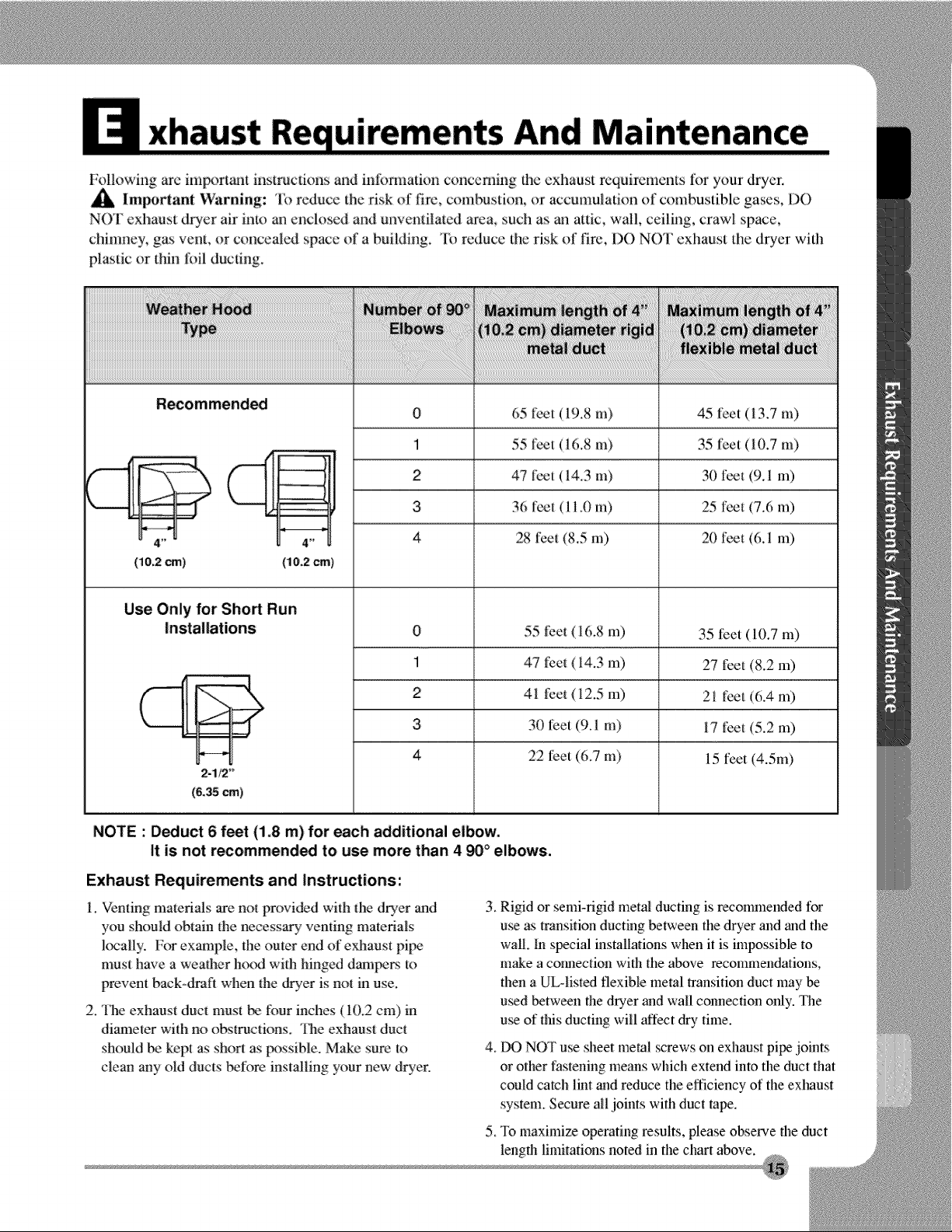

l-:ollowing are important instructions and infonnation concerning the exhaust requirements tor your dryer.

Important Warning:: To reduce the :risk of fire, combustion, or accumulation of combustible gases, DO

NOT exhaust dryer air into an enclosed and mwentilated area, such as an attic, wall, ceiling, crawl space,

chimney, gas vent, or concealed space of a building. "lb reduce the risk of fire, DO NOT' exhaust the dQcer with

plastic or thin foil ducting.

0 65 feet (19.8 m) 45 feet (I3.7 m)

1 55 I)et (16.8 m) 35 feet (10.7 m)

2 47 feet (14.3 m) 30 feet (9.1 m)

3 36 feet (11.0 m) 25 feet (7.6 m)

4 28 feet (8.5 m) 20 t)et (6. I m)

Use Only for Short Run

Installations

0

1

2

3

4

{6,35 cm)

NOTE : Deduct 6 feet (1_8 m)for each additional elbow.

It is not recommended to use more than 4 _° elbows.

Exhaust Requirements and Instructions:

1. Vendng materials are not provided with the dwcr aud

you should obtain the necess_y venting materials

locally. For ex:ample, the outer end of exhaust pipe

must have a weaher hood with hinged dampe_ m

prewent back_drafl when the @er is not in use.

2. The exhaust duct must be four inches (10.2 cm) in

diameter with no obslrucfions. The exhaust duct

should be kept as shor! as possible. Make sure to

clean any old ducts before instNling your new dryer.

55 fce_ (i 6.8 m)

47 fret (14.3 m)

41 fL'et(12.5 m)

30 feet (9.1 m)

22 feet (6.7 m)

3. Rigid or semi-rigid metal ducting is rc,conm_ended tor

u_ as transition ducth_g between the dryer and and fl_e

wal!. h_ s_ial installations when it is impossible m

make a coimecdon with the above recommendations,

then a UL-lisled flexible metal transition duct may

u_d betwee_ fl_e dryer and wall conneclion only. The

u_ of this ducting will affect dry time.

35 l?eet(10.7 m)

27 feet (18.2m)

21 l_et (6.4 m)

17 feet (5.2 m)

15 feet (4.5m)

4. DO NO]" u_ sheet metal screws on exhaust pi_ joints

or other thstening means which ex_end into the duct that

could catch lint and reduce the efficiency of the exlmust

system. Secure all joints with duct rope.

5. To maximize operating results, please observe the duct

length limitations noted in the chart above.

irements And

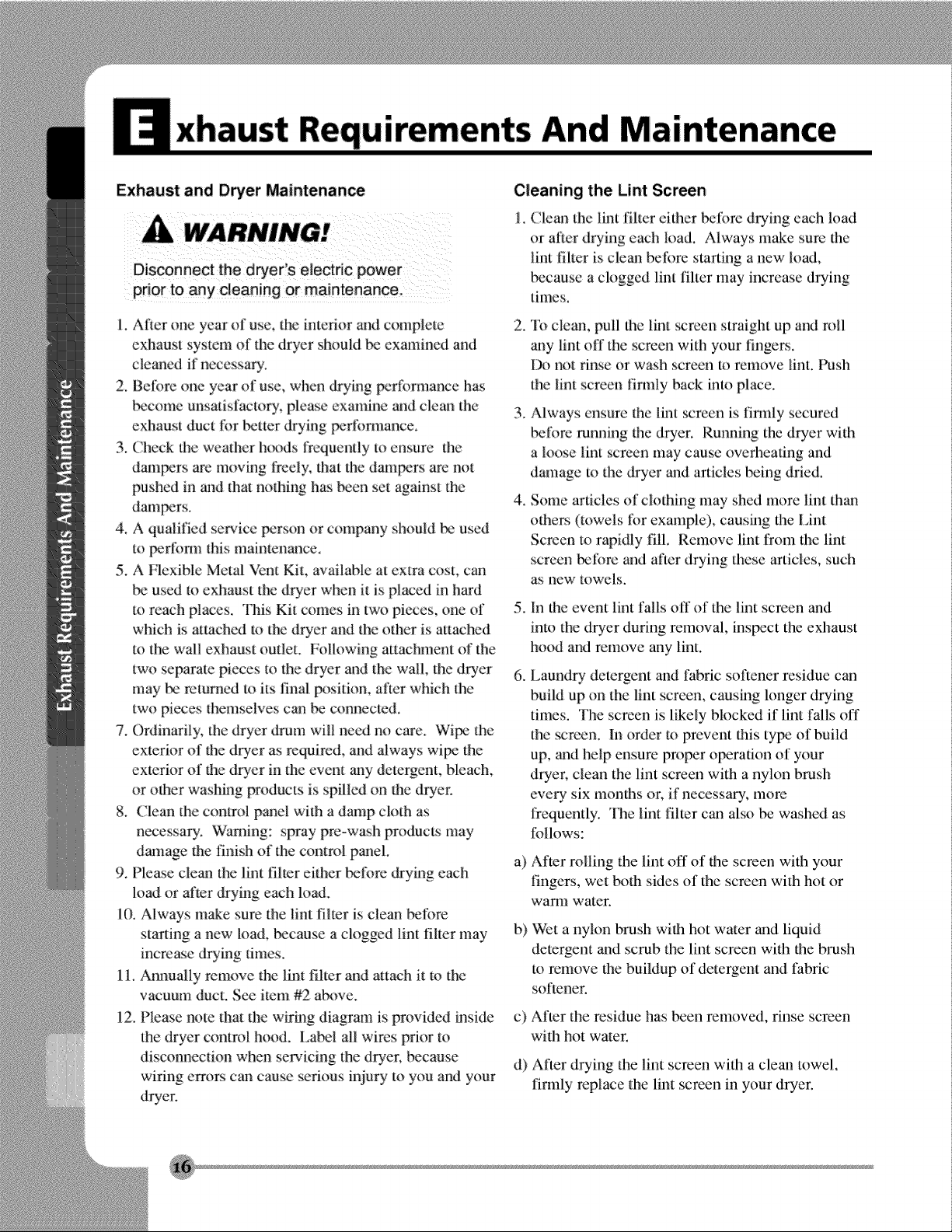

Exhaust and Dryer Maintenan_

1. Alter one year of use, the interior and complete

exhaust system of the dryer Should be examined and

cleaned if necessary.

2. Before one year of use, when drying performance has

become unsatisfactory, please exanfine and clean the

exhaust duct for t'mtmr &ying performance.

3. Check the weather h_ds frequently m ensure the

damwrs are moving freely, that the dampers are not

pushed in and that nothing has been set against the

damwrs.

4. A qualified service person or company shoukt be used

to perform this maintenance.

5. A Flexible Metal Vent Kit, available at extra cost, can

be used to exhaust the dryer when it is placed in hard

to :reach places. This Kit comes in two pieces, one of

which is attached m the dryer and file other is attached

to the wNl exhaust outlet. Following attachment of the

two separate pieces to the dryer and the wall, the @er

may be returned m its finn _silion_ after which the

two pieces themselves can be connected.

7. Ordinarily, the dryer drum will need no care. Wipe the

exterior of the dryer as required, and Mways wi_ the

exterior of the dryer in the event any deterg)2nt, Neach,

or other washing products is spilled on the d_er.

8. (]ean the control panel with a damp cloth as

necessary. Warning: spray pro-wash products may

damage the finish of the control pmlel.

9. Please clean the lint :filmr either I7_li}re drying each

load or after drying each load.

10. Always make sum the lint filmr is clean before

starting a new load, N_'cause a clogged lint filmr may

increase @rag times.

11. Annually :remove the lint t'ilter and attach it m the

vacumn duct. See imm #2 aN_ve.

12. Please nora that the wirh_g diagram is provided inside

the &yet control hood. Label all wires prior to

discormection when servicing the dryer, because

wiring errors can cause serious injury to you and your

&yeJ:

Cleaning the Lint Screen

I.

Clean the lint filter either befl}re drying each load

or alter drying each load. Always make sure the

lint filter is clean beti}re starting a new load,

because a ck)gged lint filter may increase drying

times.

2_

"lb clean, pull the lint screen straight up and roll

m_y lint off tile screen with your fingers.

INanot rinse or wash screen to remove lint. Push

the lint screen :firefly back into place.

3_

Always ensure the lint screen is finnly secured

N£o:re :running _le dlTyer. Running the dryer with

a loose lint screen may cause overheating and

damage m the dryer mid articles being dried.

.

Some articles of clothing may shed more lint than

others (towels tier example), causing the Lint

Screen m rapidly fill. Remove lint from the lint

screen before and after drying these articles, such

as new towels.

In the event lint falls off of the lint screen and

.

into the dryer during removal, inspect the exhaust

hood and. remove any lint.

.

Laundry detergent a:nd fabric softener residue c_

build up on the lint screen, causing longer duing

times. The screen is likely blocked if lint falls off

the screen. In order to prevent this type of build

up, alld help ensure proper o_ration of your

dryer, clean the lint screen with a nylon brush

every six months or, if necessary, more

l?equently. The lint filter can alsx}I_e washed as

follows:

a) After rolling the lint off of the scroen with your

lingers, wet both sides of the screen with hot or

warm water.

b) ",Weta nylon brush with hot water and liquid

detergent and scrub the lint screen with the brush

to remove the buildup of detergent and fabric

softener.

c) After the residue has been removed, rinse screen

with hot water.

d) After drying the lint screen with a clean towel,

firmly replace the lint screen in your dryer.

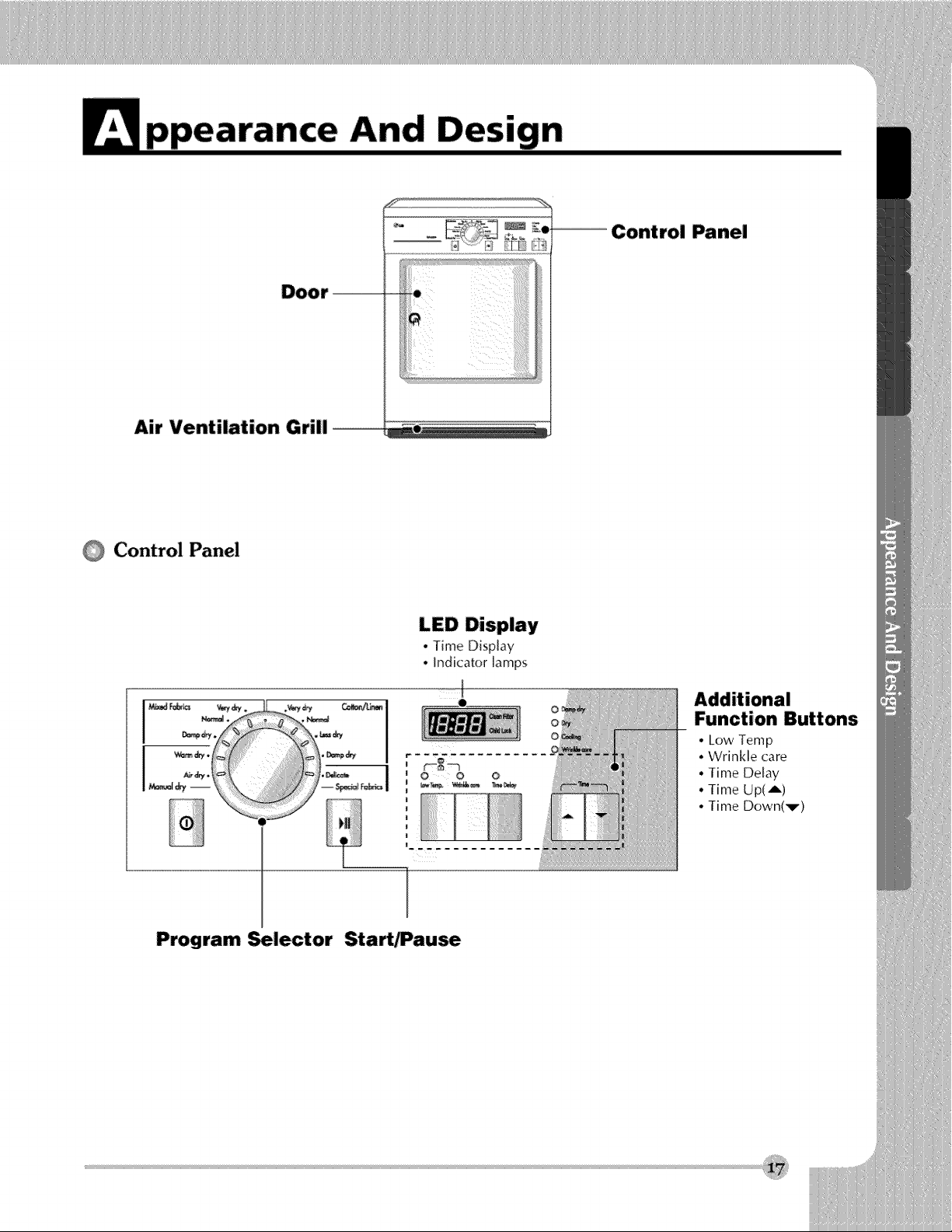

Air Ventilation Grill

@ Control Panel

And Design

-- Control Panel

Program Selector Start/Pau_

LED Display

• Time Display

• Indicator lamps

0 0 0

Function Buttons

• Low Temp

• Wrinkle care

• Time Delay

• Time Up(A)

• Time Down(_)

Your

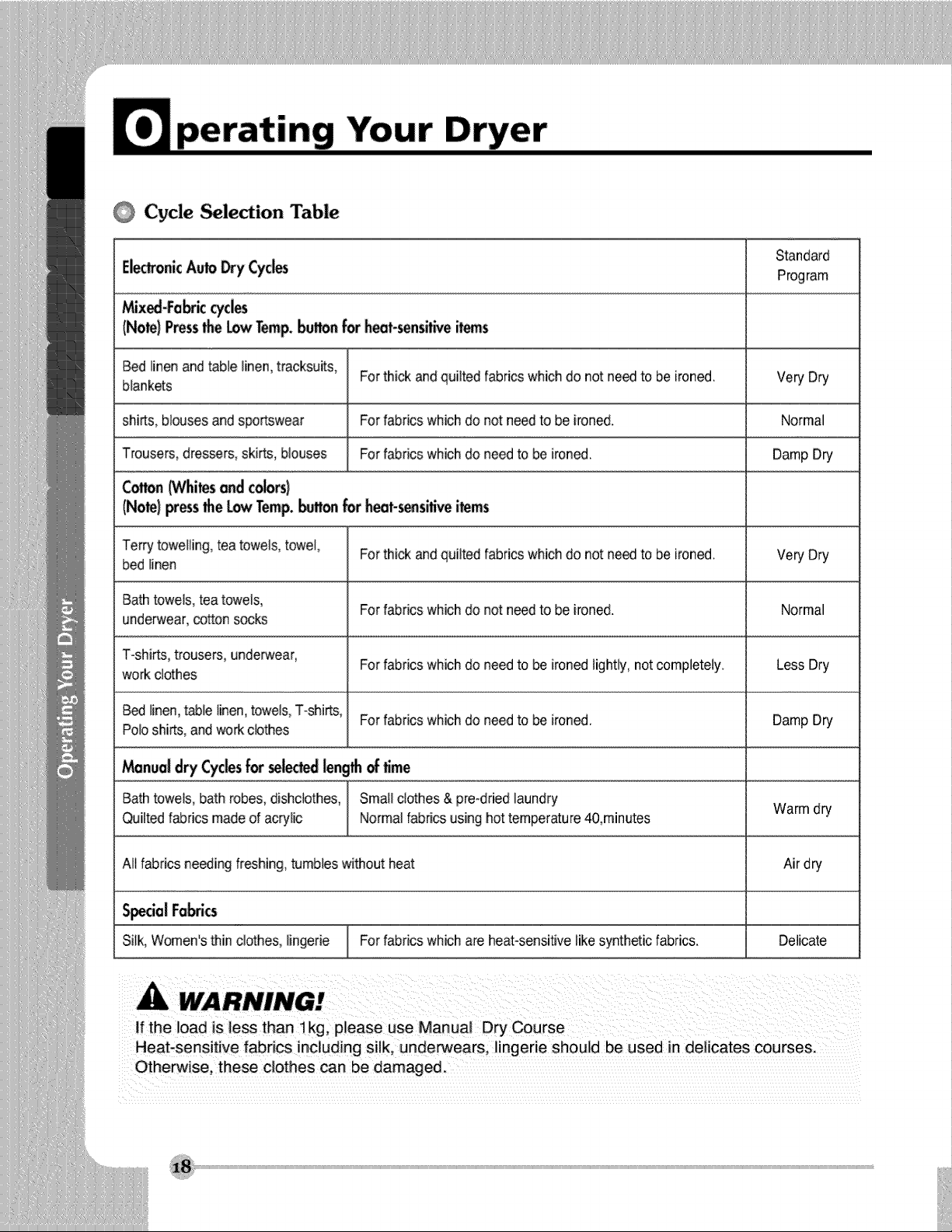

@ Cycle _lection Table

Eie_onic Auto Dry Cycles

Mixed-Fa_ic cycles

(Note) PresstheLowTemp.buttonfor h_t-sensitive items

Standard

Program

Bed linenandtable linen,tracksuits,

blankets

shirts, blousesand sportswear

Trousers,dres_rs, skirts,blouses

Cotton(Whitesand colors)

(Note) pressthe LowTemp._tton for

Terry towelling,tea towels, towel,

bed linen

BathtoweFs,tea towels,

underwear,cottonsocks

T-shirts,trousers,underwear,

workclothes

Bed linen,table linen,towels,T-shirts,

Poloshirts,andwork clothes

Manual dry Cyclesfor selectedlength _ time

Bathtowe_s,bathrobes, dishclothes, Smallclothes & prettified laundry

Quiltedfabrics madeof acrylic Normalfabricsusing hottemperature40,minutes

Forthick andquiltedfabricswhichdo notneedto be ironed.

Forfabrics which do notneedto be ironed.

Forfabrics which do needto be ironed.

Forthick andquiltedfabricswhichdo notneedto be ironed.

Forfabrics which do notneedto be ironed.

Forfabrics which do needto be ironed lightly,notcompletely.

Forfabrics which do needto be ironed.

VeryDry

Normal

DampDry

Very Dry

Normal

Less Dry

DampDry

Warmdry

NI fabricsneedingfleshing,tumbles without heat Air dry

SpecialFobrics

Silk, Women'sthinclothes, lingerie Forfabrics which are heatosensitivelikesyntheticfabrics. Delicate

If the load is Jess than I kg, please use Manual Dry Course

Heat-sensitive fabrics including silk, underwears, lingerie should be used in delicates courses.

Otherwise. these clothes can be damaged.

perating Your Dryer

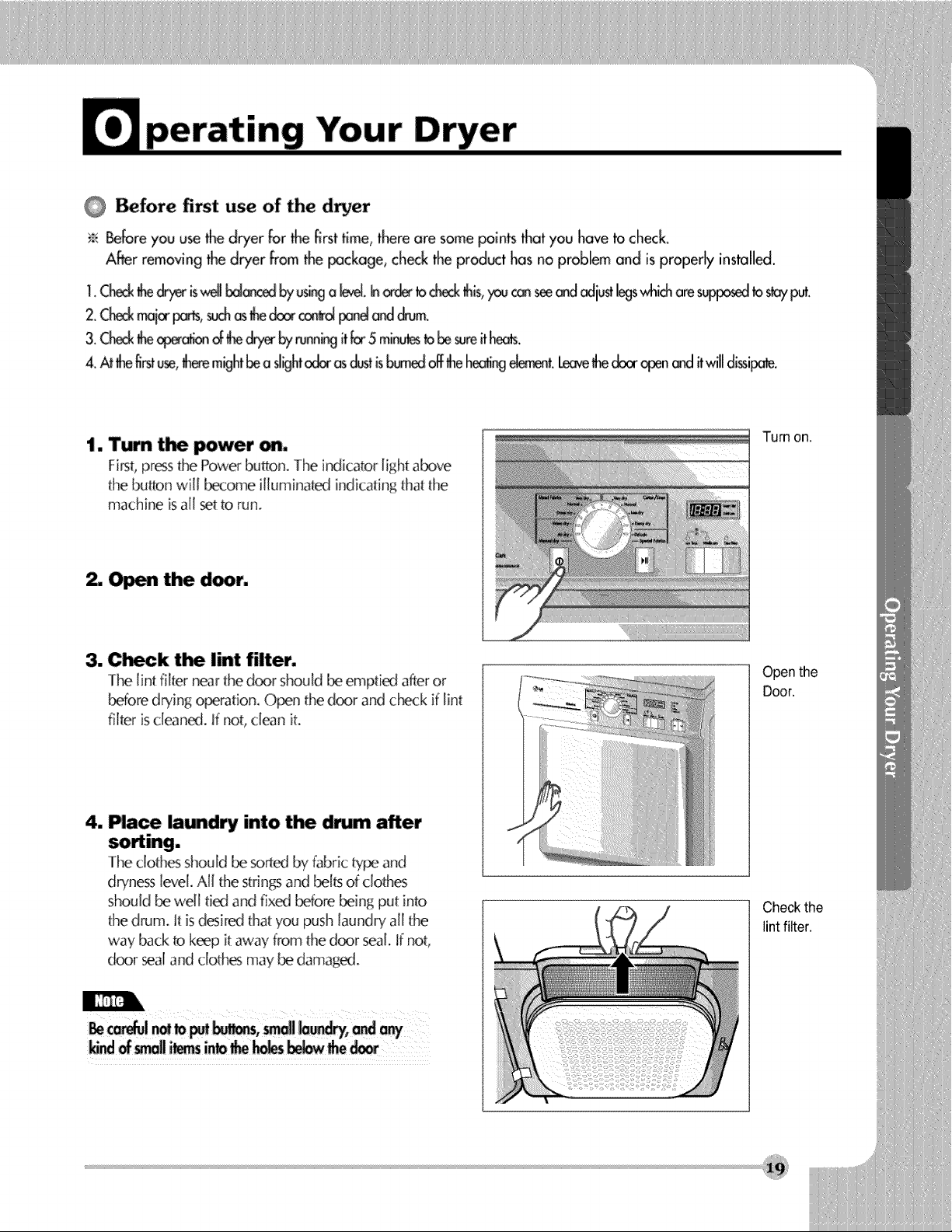

0 Before first use of the dryer

÷ Beforeyou use the dryer for the first time, there are some points that you have to check.

After removing the drier from the _ckage, check the prod_t has no problem and is properly installed.

1.Checkt_ d_ is,,_l Wm,cedby usingalevel,h _ to_=k this,,,,ou_ see_d adjust_s whichares,_pr..._:Jtostayput.

2. C_ _ior _, sud_as_ _ contro!panga_ drum.

3. C_ _ _atbn of _ dryerbyrunningitI:c_5 minukesto_ sureit heals.

4. At thefirstuse,lh_ mightbea slight_ asdustisbum_ offthehealingelement.Leavethedooropen_ itwilldissipa_.

1. Turn the power on.

First,pressthe Power button. The indicator light above

the button will become illuminated indicathlg that the

machine isall _t to run.

2. O_ the donr.

3. C_k the lint filter.

The lint filter near the door should L_ emptic_:Jafteror

_fore drying o_ration. O_n the door and c_,:k if lint

filter iscleaned. If not, dean it.

4. Mace _ondry into t_ drum after

The clofll_ should De.,sorl_J by fabric type and

dryn_s level. AI[ the stringsand t_[ts d clothes

should _ well tied and fixed b_fore L-_ingput:into

the drurn. It is desired that you push laundry a[[ the

way back to keep it away from thedoor seal, If not,

door sealand c[oth_ may be damaged.

Turnon.

Openthe

Door.

Checkthe

lintfilter.

careMn_ _t _J_s, small_u_ry, a_d a_y

_nd of_al! i_s in_ _ h_ _k_, the

Your

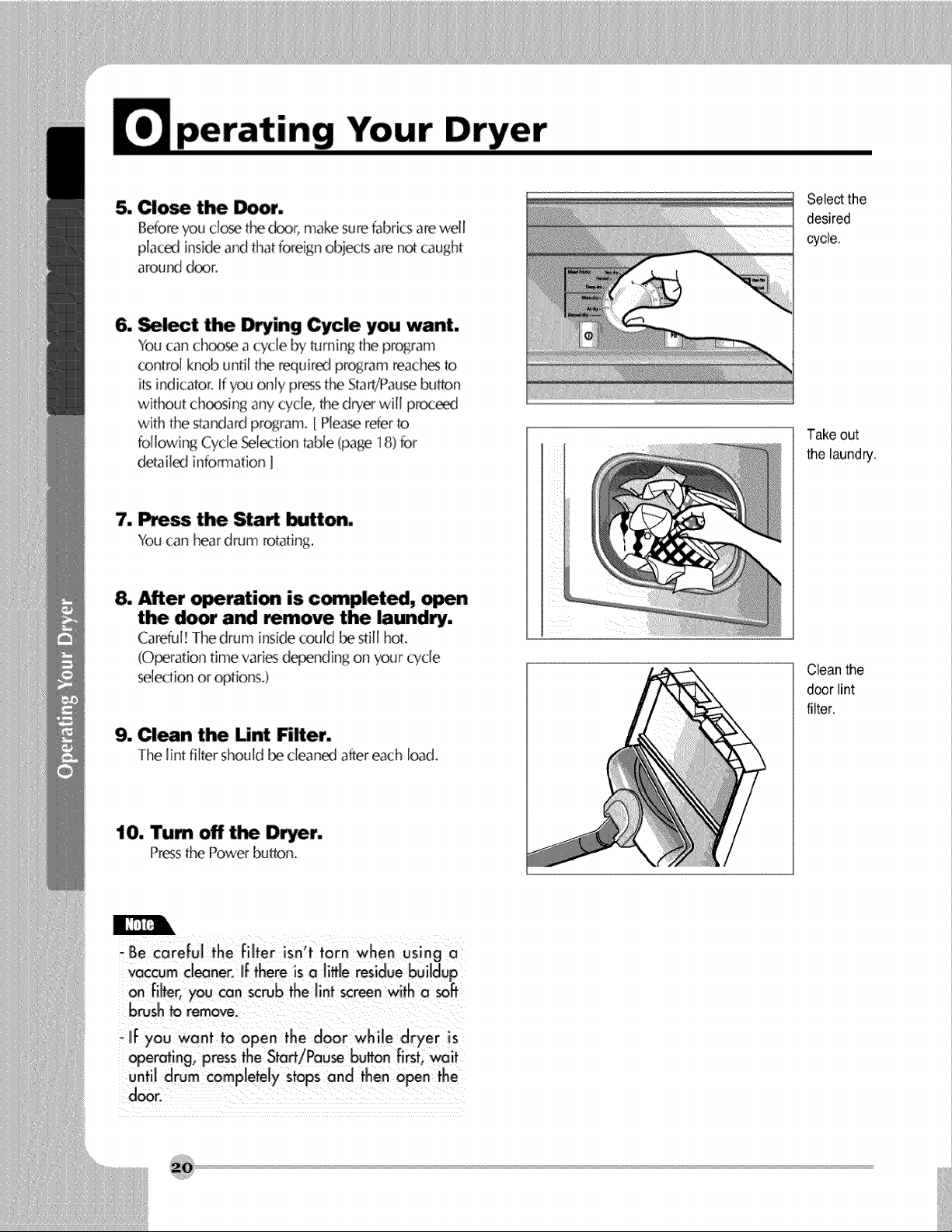

5. CIo_ the _or.

Beforeyou do_ the d_r, make sure fabricsare'well

p[acc_ inside and that foreign objects are not caught

arour,ddoor.

_t ti'_ Drying Cycle you want.

You can ch_se acycle by turning the pr_4ram

control knob until the required program reach_ to

its indicator, if you only pressthe Start/Pau_ button

without chasing any cycle, the d_/er will proc_d

with the standardprc_4ram.[ Pleaserefer to

following Cycie Se[_tion ubie (page 18) for

detailed information ]

7. Press the Sta_ button.

You can heardrum rotating.

After o_rati_ is comp_ted, open

the _or and remove t_ laundry.

Careful! The drum inside could be still hot.

(O_ration time vari_ de_nding on your cycle

selection or options.)

9. Clean the Unt Fiker.

The lint filter should I_ cleanod a_er each load.

Selectthe

desired

cycle

Take out

the laundry.

Cleanthe

d_r lint

filter.

10. Tum off t_ Dryer.

Pros the Power bu_:on.

on filter, you can scrub the lint screen with a soft

brush to remove.

-if you wont to open the door while dryer is

erating, press the Start/Pause button first, wait

til drum completely stops and then open the

door.

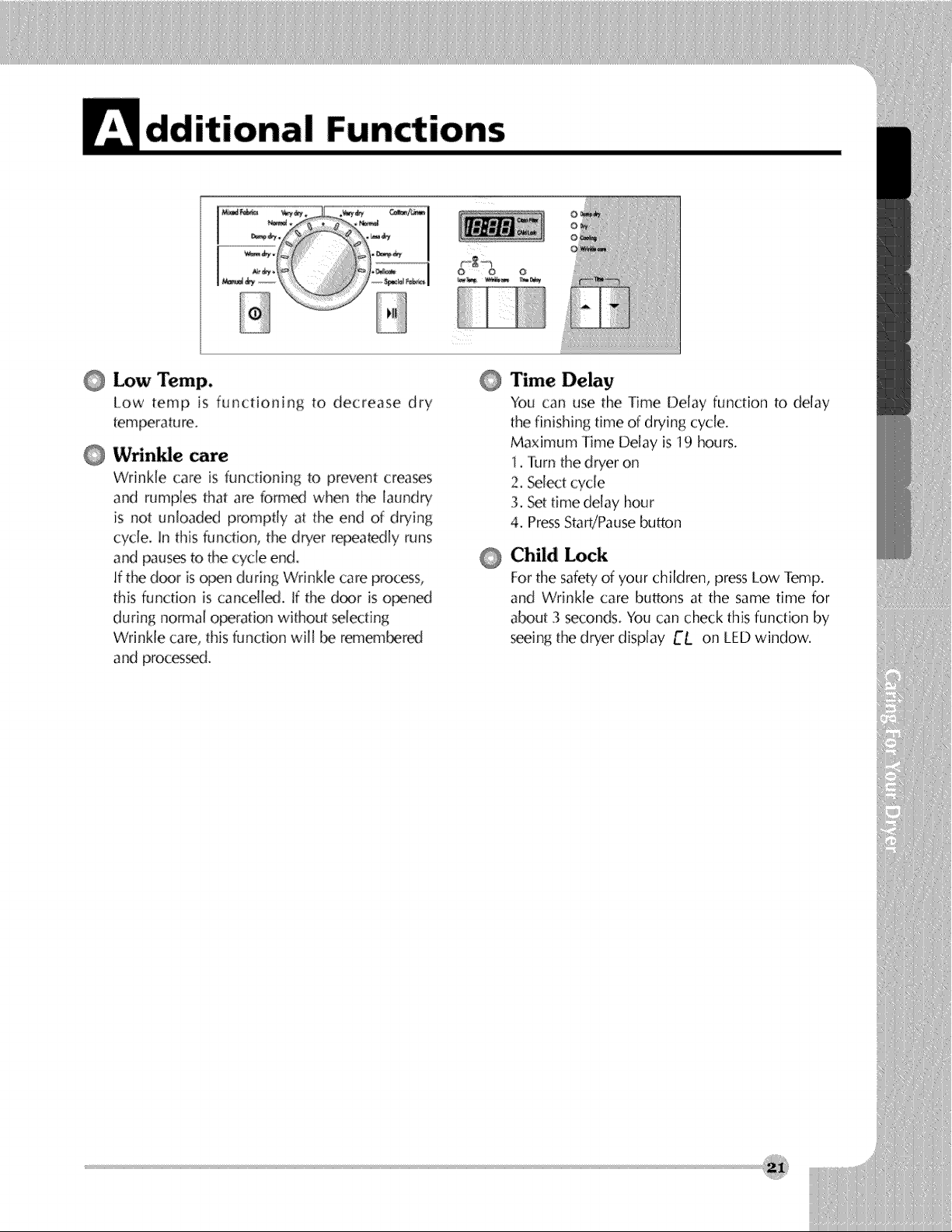

I Functions

0 Low Temp.

Low temp is functioning to decrease dry

ternperatu re.

Wrin_e care

Wrinkle (:are is functioning to prevent creases

and rumples that are formed when the laundry

is not unloaded promptly at the end of drying

cycle, in this l_mction, the dryer repeatedly runs

and pauses to the cycle end,

if the de_r is o_n du ring Wrinkle care process,

this function is cancelled, if the d_r is o_ned

during normal op,elgtion without selecting

Wrinkle care, this function will be remem_red

and proces_d.

Time Delay

©

You can use the Time Delay function to delay

the finishing time of drying cycle.

Maximum Time Delay is 19 hours.

1. Turn the dryer on

2. Sdect cycle

3. Settime delay hour

4. PressSta_tPause button

Child Lock

@

For the safety of your children, press Low Temp.

and Wrinkle care buttons at the same time for

about 3 seconds, You can check this function by

seeing the dryer display CL on LED window,

Loading...

Loading...