Page 1

www.LGEservice.com

DISCOVERY DRYER

TRAINING MANUAL

CAUTION!

READ THIS MANUAL CAREFULLY

BEFORE DIAGNOSING OR SERVICING THIS PRODUCT.

Page 2

Customer Service (and Part Sales) (800) 243-0000

Technical Support (and Part Sales) (800) 847-7597

USA Website us.lgservice.com

Customer Service Website us.lgservice.com

B2B Service Website biz.lgservice.com

LG CS Academy lgcsacademy.com

Published April 2006 by LG Technical Support and Training

Page 3

DRYER

IMPORTANT SAFETY NOTICE

The information in this training manual is intended for use by persons possessing an adequate background

in electrical equipment, electronic devices, and mechanical systems. In any attempt to repair a major

appliance, personal injury and property damage can result. The manufacturer or seller maintains no liability

for the interpretation of this information, nor can it assume any liability in conjunction with its use. When

servicing this product, under no circumstances should the original design be modified or altered without

permission from LG Electronics. Unauthorized modifications will not only void the warranty, but may lead to

property damage or user injury. If wires, screws, clips, straps, nuts, or washers used to complete a ground

path are removed for service, they must be returned to their original positions and properly fastened.

CAUTION

To avoid personal injury, disconnect the power before servicing this product. If electrical power is required

for diagnosis or test purposes, disconnect the power immediately after performing the necessary checks.

Also be aware that many household appliances present a weight hazard. At least two people should be

involved in the installation or servicing of such devices. Failure to consider the weight of an appliance could

result in physical injury.

ESD NOTICE

Some of the electronic components in appliances are electrostatic discharge (ESD) sensitive. ESD can

weaken or damage the electronics in these appliances in a manner that renders them inoperative or reduces

the time until their next failure. Connect an ESD wrist strap to a ground connection point or unpainted metal

in the appliance. Alternatively, you can touch your finger repeatedly to a ground connection point or

unpainted metal in the appliance. Before removing a replacement part from its package, touch the anti-static

bag to a ground connection point or unpainted metal in the appliance. Handle the electronic control

assembly by its edges only. When repackaging a failed electronic control assembly in an anti-static bag,

observe these same precautions.

REGULATORY INFORMATION

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to

Part 15 if the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference when the equipment is operated in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy, and, if not installed and used in accordance with the instruction

manual, may cause harmful interference to radio communications. However, there is no guarantee that

interference will not occur in a particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the equipment off and on, the user is

encouraged to try to correct the interference by one or more of the following measures: Reorient or relocate

the receiving antenna; Increase the separation between the equipment and the receiver; Connect the

equipment to an outlet on a different circuit than that to which the receiver is connected; or consult the

dealer or an experienced radio/TV technician for help.

COMPLIANCE

The responsible party for this device’s compliance is LG Electronics Alabama, Inc.; 201 James Record Road,

Huntsville, AL, 35824.

DLE8377xM/DLG8388xM

DLE7177WM/DLG7188WM Page 3 of 60 TRAINING MANUAL

Page 4

DRYER

Contents

Regulatory Notices 3

Contents 4

Introduction 6

Sensor Dry 7

Manual Dry 7

Gas Safety Page 8

Specifications 9

Accessories 10

Installation (of accessories) 10

Rack 10

Stacking Kit 11

Pedestal 13

Modem and Monitor 15

Electric Dryer 16

Pigtail 16

4-wire Connection 16

3-wire Connection 17

Gas Dryer 19

Piping 19

Dryer Cycle Chart 20

Component Test Procedures 21

Motor Diagram and Schematic 22

Safety Switches 25

Control and PCB Layout 26

Wiring Diagram 28

Diagnostic Test 29

Test 1 – 120 V AC Electrical Supply 30

Test 2 – Thermistor Test (Power Off) 33

Test 3 – Motor Test 34

Test 4 – Moisture Sensor Test 35

Test 5 – Door Switch Test 36

Test 6 – Heater Switch Test (Electric Dryer) 37

Test 7 – Gas Valve Test (Gas Dryer) 38

Test 8 – Semiconductor Test 39

Gas Conversion (Natural to Propane) 40

Safety Warning 40

Orifice 41

Gas Valve Operation 42

Flow Chart 42

Ignition Sequence 42

continued on next page Æ

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 4 of 60 TRAINING MANUAL

Page 5

DRYER

Contents, continued

Disassembly/Repair 43

Top Cover 43

Control Panel 44

Front Cover and Door 45

Door Reversal 45

Tub Front 46

Drum Assembly and Belt 46

Lamp 47

Filter Assembly and Moisture Sensor 49

Back Cover 49

Air Duct 50

Rollers 51

Blower and Housing 52

Exploded Views 53

Top Cover and Control Panel 53

Cabinet and Door 54

Drum and Motor (Electric Dryer) 55

Drum and Motor (Gas Dryer) 56

Parts List 57

Vent Replacement (Rear to side exhaust) 48

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 5 of 60 TRAINING MANUAL

Page 6

DRYER

INTRODUCTION

The DISCOVERY dryer is very similar to other LG dryers with the exception of

the LCD display on the control panel. The LCD display shows all the information

formerly indicated by LEDs but also allows for scrolling instruction.

When a cycle is selected, the

options are preset. They can be

overridden by changing them using

the option buttons.

Pressing the buttons cycles through

the available options. If an option is

not available for a particular cycle, it

is grayed out or not available for

selection. For example, the EXTRA

HOT wash is not available for the

DELICATE cycle.

The interior components remain the same: motor, belt, drum, and heat source

(gas or electric). The gas model can be refitted with an orifice to allow the use of

propane instead of natural gas. All such conversions and adjustments should be

performed by a licensed and certified gasfitter.

The DISCOVERY model also has an additional sensor in the exhaust stream to

detect the moisture level more accurately for better drying results.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 6 of 60 TRAINING MANUAL

Page 7

DRYER

Models DLE7177WM and DLG7188WM use the LED indicator panel instead of

the newer LCD. The only difference is the type of display. The dryers function

identically. The main and display PCB (Printed Circuit Board) will carry a different

part number depending upon the type of display. Always order parts by model

number and serial number to ensure receiving the correct parts.

The drying cycle is shown

in the left window and the

time remaining is show in

the right. Feature

selections like DRY

LEVEL and BEEPER

volume are indicated by

LEDs on the panel.

The DISCOVERY line of dryers feature enhanced sensor drying. In addition to

the drying sensor in the tub near the filter, there is an additional sensor in the

exhaust stream to ensure the correct level of dryness is determined, from damp

dry to very dry. The dryer can also be set manually to dry at a particular heat

level and for a specified time.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 7 of 60 TRAINING MANUAL

Page 8

DRYER

SAFETY

Check the local laws and regulations concerning the installation and connection

of gas. In most localities, it is illegal to connect gas piping, re-jet or adjust burners,

or repair gas-fired equipment unless you are licensed and certified so to do. It is

the servicer’s responsibility to comply with all such regulation.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 8 of 60 TRAINING MANUAL

Page 9

DRYER

SPECIFICATIONS

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 9 of 60 TRAINING MANUAL

Page 10

DRYER

ACCESSORIES

DRYING RACK STACKING KIT PEDESTAL

The DRYING RACK is used to dry items that should not be tumbled, like

sweaters, tennis shoes, etc. It should be removed and stored when not in use.

The rack is included with the dryer. (See installation procedure, page xx.)

The STACKING KIT is used to stack a dryer on top of a matching washer.

(NEVER put a washer on top of a dryer!) The stacking kit should not be used in

situation where there is the possibility of excessive vibration and movement of

the washer, such as in a mobile home or an upper floor of a frame structure. The

stacking kit is available as an optional purchase. (See installation procedure,

page 11.)

The PEDESTAL can be used under either the washer or the dryer. It is possible

to stack a washer and dryer on a pedestal, but the dryer controls may be difficult

to reach and the possibility of vibration and movement is greater. The pedestal is

available as an optional purchase. (See installation procedure, page 13.)

Pedestals are available in heights of 7¼” and 13”.

INSTALLATION (RACK)

It’s simple!

Open the dryer door.

Put the rack in place.

Select RACK DRY (2

Press START.

Be sure the front of the rack is properly

situated in the notches on either side

of the filter. The back should rest on

the drum and allow the drum to rotate.

nd

button on right)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 10 of 60 TRAINING MANUAL

Page 11

DRYER

INSTALLATION (Stacking Kit)

WARNING! Do not attempt this alone! At least two people are required to lift the

dryer and place it properly on top of the washer. Failure to observe this warning

could result in serious physical injury and damage to the appliances.

1. Place the washer on a solid,

even floor. If you plan to use a

pedestal, install it now before

going any further.

2. Peel the protective paper from

the adhesive tape on the side

bracket.

3. Fit the side bracket firmly to the

top plate using the adhesive

tape, as shown in the drawing.

4. Secure the bracket to the top

plate using a screw, as shown.

Repeat steps 2, 3, and 4 for the

other side.

5. Level the dryer on a firm solid

floor and lock down the

adjusters before placing it on top

of the washer. (See page xx.)

Lift the dryer on top of the

washer it toward the front of the

washer, as shown.

Slide the dryer all the way back

to the stop on the rail.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 11 of 60 TRAINING MANUAL

Page 12

DRYER

INSTALLATION (Stacking Kit) continued

6. Install the front rail of the

stacking kit. Push the front rail

back against the stops on the

side brackets.

7. Insert a screw to attach the front

rail to the side bracket.

Repeat step 7 for the other side.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 12 of 60 TRAINING MANUAL

Page 13

DRYER

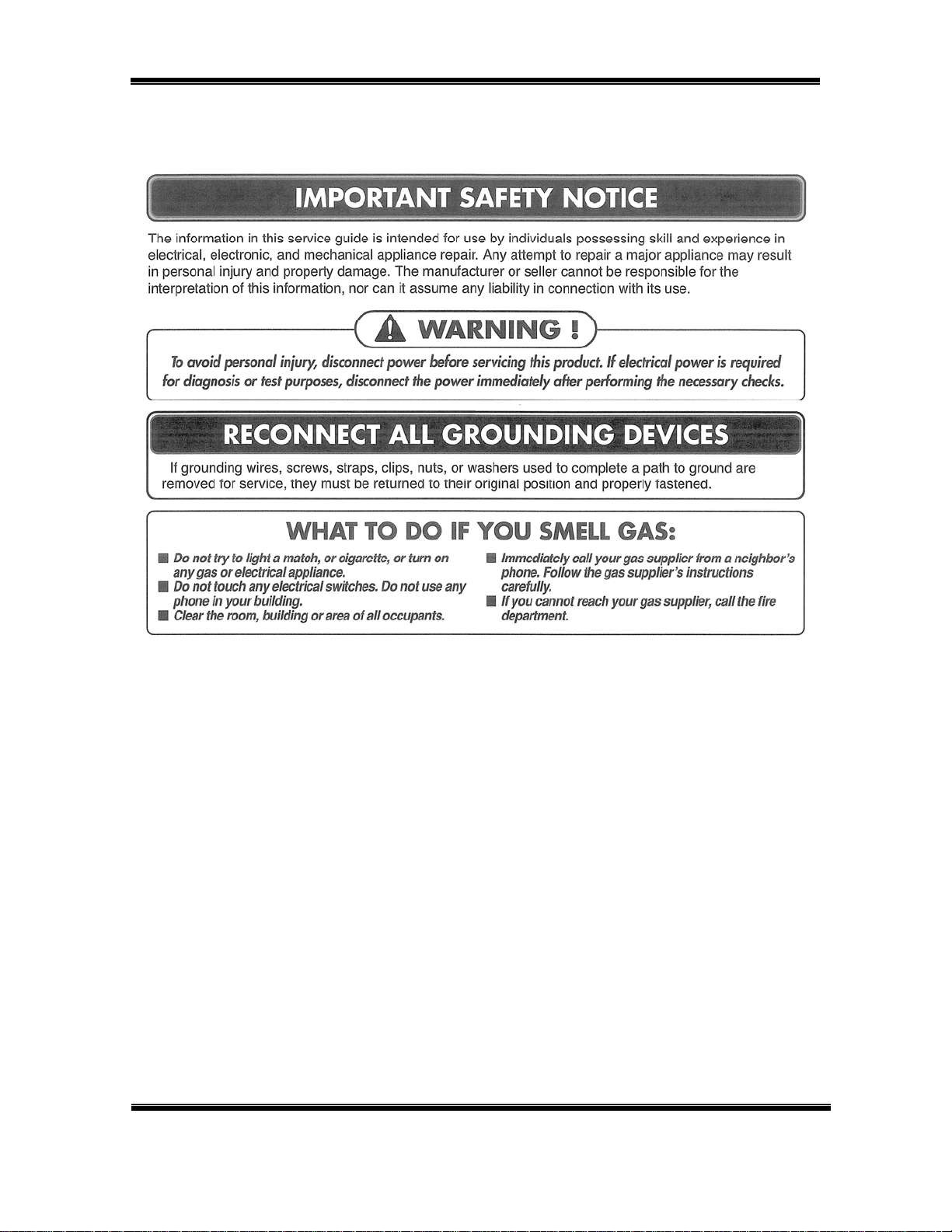

INSTALLATION (Pedestal)

1. Remove the pedestal,

installation hardware, and

instructions from the shipping

container.

2. Level the pedestal on a solid,

flat, level floor. Lock down the

rear adjusters, but leave the

front ones free for now.

Set the dryer on the pedestal

and level it. Level it and lock

down all four adjusters on the

dryer.

Note which holes are for the

REAR FRONT

washer and which are for the

dryer. If you are stacking the

appliances, the washer should

be on the bottom.

For 27” Pedestals

(Washer, Dryer, and Combo)

3. Remove the protective paper

from the adhesive surface of the

bracket.

Be particularly careful, because when

this adhesive makes contact, there is

no adjustment possible.

NOTE: Some kits include two sets of

brackets (curved for the dryer and flat

(shown) for the washer.) Use the

correct bracket for your application.

(See next page.)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 13 of 60 TRAINING MANUAL

Page 14

DRYER

INSTALLATION (Pedestal) continued

4. Holding the adhesive part of the

bracket away from the dryer,

insert the screws and get them

started.

Press the bracket onto the dryer

and tighten the screws.

5. Press the brackets onto the

sides of the dryer and rub the

brackets from side to side to

ensure the total adhesive area is

attached completely.

6. Tighten all the screws securely.

7. Lower each leg of the dryer one fourth turn with the adjusting

wrench to put a little pressure

between the dryer and pedestal

to prevent any motion and

rattling.

8. Push the dryer into place.

9. Check the level and adjust the

front legs of the pedestal as

necessary. Then lock down the

adjusters.

The pedestal kit includes the mounting

plates (with adhesive covered by

paper) and the screws to attach the

plates. Remember, some pedestal kits

come with two sets of brackets. The flat

tops are for washers; the curved tops

(shown) are for dryers. Use the correct

brackets for your application.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 14 of 60 TRAINING MANUAL

Page 15

DRYER

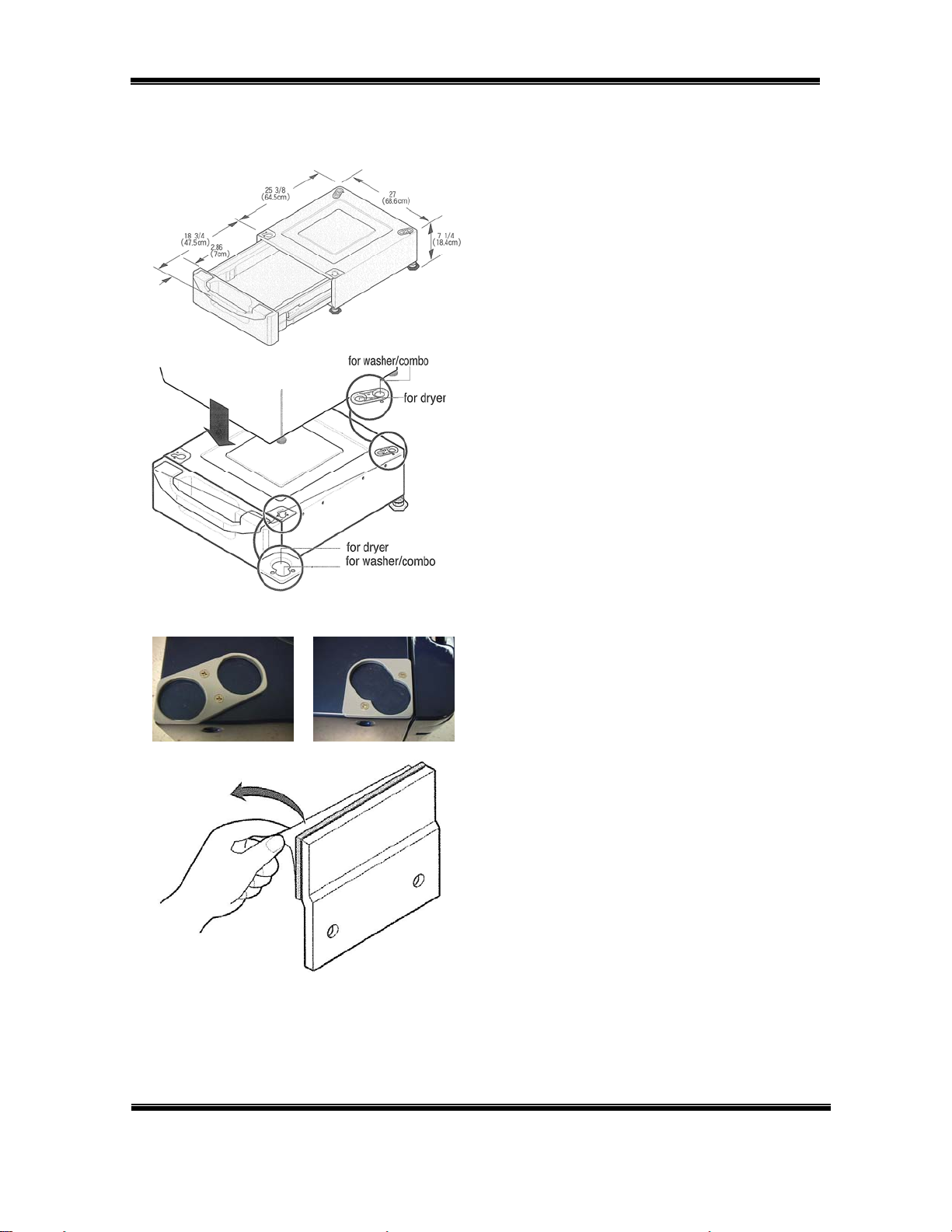

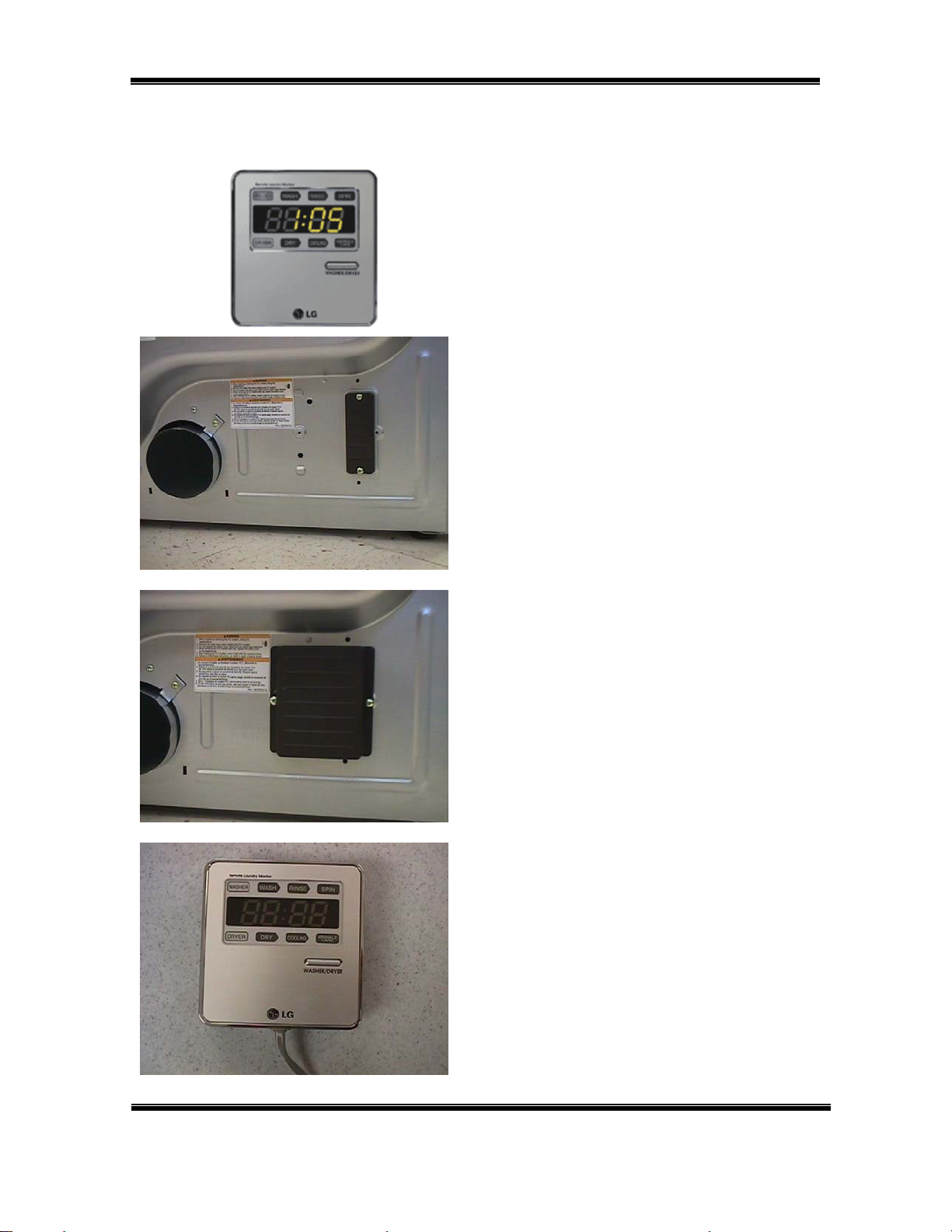

INSTALLATION (Modem and Monitor)

The monitor plugs in to any 110 Volt

outlet in the home. It receives its data

signal via the power lines.

1. Be sure the dryer is unplugged.

Remove the modem cover.

Save the cover for future use; in

the event you must remove the

modem, you can replace the

cover.

REMOTE MONITOR

2. Attach the modem to the socket

with the screws provided.

3. Plug the monitor’s power cord

in an outlet where you can

observe it easily. Use the stand

or the wall mount bracket.

4. Press and hold the button until

the display shows SET.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 15 of 60 TRAINING MANUAL

Page 16

DRYER

ELECTRICAL CONNECTION (Electric Dryer Only)

PIGTAIL INSTALLATION

Install the appropriate power cord for the outlet available. Grounding through the

neutral conductor is prohibited in new branch-circuits, mobile homes, recreational

vehicles, and where prohibited by local code.

4-wire Connection

The 4-wire receptacle looks like this.

Power cord with spade terminals.

Power cord with ring terminals.

Install a strain relief on the power cord.

Then connect the terminals to the

terminal block, matching the wire

colors.

A. Ground screw on chassis

B. Green wire from power cord

C. Strain relief

D. Neutral screw on terminal block

E. Terminal block

F. Neutral wire from power cord

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 16 of 60 TRAINING MANUAL

Page 17

DRYER

ELECTRICAL CONNECTION (Electric Dryer Only) continued

3-wire Connection

The 3-wire receptacle looks like this.

Power cord with spade terminals.

Power cord with ring terminals.

Install a strain relief on the power cord.

Then connect the terminals to the

terminal block, matching the wire

colors. Add a wire to connect the

chassis ground to neutral.

A. Ground screw on chassis

B. Green wire from power cord

C. Strain relief

D. Neutral screw on terminal block

E. Ground-to-neutral connection

F. Neutral wire from power cord

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 17 of 60 TRAINING MANUAL

Page 18

DRYER

ELECTRICAL CONNECTION (Electric Dryer Only) continued

Be sure to tighten all screws firmly, but

do not strip them or distort the contact

area.

Be sure to install a strain relief on the

power cord.

Replace the terminal block cover by

inserting the tabs into the slots and

letting them slide down to engage.

Fold it over to the back of the dryer so

it covers the access to the terminal

block. Be sure no wires are exposed or

could touch any metal surface.

Secure the cover with a screw.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 18 of 60 TRAINING MANUAL

Page 19

DRYER

GAS CONNECTION (Gas Dryer Only)

CAUTION! (This warning applies to both natural gas and propane.)

Gas is both flammable and explosive. Use caution when working with gas.

In most locations, installing and connecting gas is restricted to properly trained

and licensed persons.

Always inspect joints and connections for a leak with a soapy solution. If you see

bubbles, turn the gas off and open a window. If you smell gas, turn off the main

valve and open a window.

The gas dryer requires a 110 Volt, single-outlet, dedicated circuit. The cord is

installed at the factory and no user-intervention is required.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 19 of 60 TRAINING MANUAL

Page 20

DRYER

DRYER CYCLE CHART

* SENSOR DRY The dryness level is set by the customer.

** MANUAL DRY The temperature is set by the customer.

The default settings can be overridden by the customer.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 20 of 60 TRAINING MANUAL

Page 21

DRYER

COMPONENT TESTING PROCEDURES

Testing the various components of the dryer is relatively simple. Most can be

checked without major disassembly.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 21 of 60 TRAINING MANUAL

Page 22

DRYER

COMPONENT TESTING PROCEDURES continued

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 22 of 60 TRAINING MANUAL

Page 23

DRYER

COMPONENT TESTING PROCEDURES continued

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 23 of 60 TRAINING MANUAL

Page 24

DRYER

MOTOR DIAGRAM and SCHEMATIC

To check the motor, turn the power off and allow the capacitor to discharge.

The centrifugal switch serves as a safety device to turn off the fuel (gas or

electricity) to the heater if the motor fails to rotate.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 24 of 60 TRAINING MANUAL

Page 25

DRYER

SAFETY SWITCHES

The centrifugal switch slides back and forth on the motor’s shaft to operate the

contacts as shown in the previous diagram. This switch provides safety in the

event the motor fails. When the motor is running, centrifugal force causes the

weight (black wing in photo) to slide back toward the motor windings. This motion

allows electricity to operate the heater (electric element or gas valve). If the

motor stops, the weight slides forward and turns the power off.

RUN POSITION STOP POSITION

There is an additional safety in the form of a belt switch that shuts off power to

the electric motor if the belt breaks. Belt tension holds the switch closed. If the

belt breaks, the switch opens and power to the motor is cut. When the motor

stops, the centrifugal switch functions as a safety device to turn off the fuel (gas

or electricity).

The centrifugal switch includes a multipin connector (shown).

The belt switch is simple. If the belt

breaks, the spring pulls the lever down

and it presses the switch.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 25 of 60 TRAINING MANUAL

Page 26

DRYER

DISPLAY PWB

The display board is actually two boards connected by a ribbon cable. One board

holds the selector knob and cycle indicator LEDs. The other holds the LCD

display and adjustment buttons to override the pre-set cycle selections.

The DLE7177WM board is shown below. Other models vary slightly.

The gas and electric models have a different display board.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 26 of 60 TRAINING MANUAL

Page 27

DRYER

MAIN PWB

The main board includes the relays that operate electric heaters and gas valves.

The DLE7177WM board is shown below. Other models vary slightly.

The gas and electric models have a different main board.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 27 of 60 TRAINING MANUAL

Page 28

DRYER

Electric Dryer Wiring Diagram

Gas Dryer Wiring Diagram

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 28 of 60 TRAINING MANUAL

Page 29

DRYER

DIAGNOSTIC TEST MODE

The diagnostic test mode is for service testing only. Do not activate the heater

manually with the door open or it will trip the thermostat attached to the heater.

1. Dryer must be in standby mode. (Plugged in, turned off)

2. Press and hold MORE TIME and LESS TIME, then press power.

3. Press START/PAUSE to advance to the next test.

4. Unplug the dryer for one minute after using the diagnostic mode.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 29 of 60 TRAINING MANUAL

Page 30

DRYER

DIAGNOSTIC TEST PROCEDURES

The following pages will assist in troubleshooting and diagnosing issues with the

dryer. Each test will list the appropriate precautionary measures along with

symptoms and the conditions under which the testing should be performed.

TEST 1 – 120 V AC ELECTRICAL SUPPLY

WARNING! Use insulated gloves to avoid electrical shock.

SYMPTOM! No power, display off.

CONDITION! Power on to dryer, controller connected.

continued on next page

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 30 of 60 TRAINING MANUAL

Page 31

DRYER

WARNING! Use insulated gloves to avoid electrical shock.

SYMPTOM! Check the TAB RELAY connections.

CONDITION! Power on to dryer, controller connected.

POWER CONNECTION

CONNECTION STATUS (Electric)

CONNECTION STATUS (Electric)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 31 of 60 TRAINING MANUAL

Page 32

DRYER

If the power connection is reversed, the dryer will not operate and components

can be damaged.

CONNECTION STATUS REVERSED (Incorrect) (Electric)

CONNECTION STATUS REVERSED (Incorrect) (Gas)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 32 of 60 TRAINING MANUAL

Page 33

DRYER

TEST 2 – Thermistor Test (Power Off)

WARNING! Use insulated gloves to avoid electrical shock.

SYMPTOM! tE1 and tE2 error codes occur during the test.

Heater does not turn off.

Significant difference between actual and sensed

temperature.

CONDITION! Power off.

Table – Thermistor resistance/temperature

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 33 of 60 TRAINING MANUAL

Page 34

DRYER

TEST 3 – Motor Test

WARNING! Discharge (see below) before measuring resistance.

SYMPTOM! Motor, fan, and heater do not function.

CONDITION! Turn power off, unplug dryer, and discharge by shorting line

and neutral to ground at the end of the power cord.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 34 of 60 TRAINING MANUAL

Page 35

DRYER

TEST 4 – Moisture Sensor Test

WARNING! Discharge (see below) before measuring resistance.

SYMPTOM! Dryness of clothing does not match set dry level.

CONDITION! Turn power off, unplug dryer, and discharge by shorting line

and neutral to ground at the end of the power cord.

Measure resistance.

Table – IMC Ratio and Display Value (IMC = Initial Moisture Content)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 35 of 60 TRAINING MANUAL

Page 36

DRYER

TEST 5 – Door Switch Test

WARNING! Discharge before measuring resistance.

SYMPTOM! Door opening not sensed (dryer runs with door open).

CONDITION! Turn dryer off, unplug, discharge, and measure resistance.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 36 of 60 TRAINING MANUAL

Page 37

DRYER

TEST 6 – Heater Switch (Electric Dryer Only)

WARNING! Discharge before measuring resistance.

SYMPTOM! Heater does not operate.

CONDITION! Turn power off, unplug, discharge, and measure resistance.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 37 of 60 TRAINING MANUAL

Page 38

DRYER

TEST 7 – Gas Valve Test (Gas Dryer Only)

WARNING! Use insulated gloves to avoid electrical shock.

SYMPTOM! Heater does not operate.

CONDITION! Power on.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 38 of 60 TRAINING MANUAL

Page 39

DRYER

TEST 8 – Semiconductor (Sensor) Test

WARNING! Discharge before measuring resistance.

SYMPTOM! Resistance is not 300Ω ± 20Ω

CONDITION! Turn power off, unplug, discharge, and measure resistance.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 39 of 60 TRAINING MANUAL

Page 40

DRYER

GAS CONVERSION (Natural to Propane)

WARNING! Improper installation and/or adjustment of orifices and gas valves

can result in fire, explosion, and suffocation. Installation and

adjustment should be performed ONLY by a trained, licensed, and

certified gasfitter.

NOTICE! The dryer is shipped from the factory equipped for natural gas.

1. Close the adjustment screw.

Notice there is a nut on the adjustment

screw. This nut is secured to the thread

with a sealing compound. The nut is

pre-positioned to the place the valve

would be properly adjusted for LP. It’s

purpose is to provide a shoulder for

positioning the adjustment screw if the

dryer is converted from natural gas to

propane.

NOTE: The conversion should be

performed by a licensed and certified

gasfitter.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 40 of 60 TRAINING MANUAL

Page 41

DRYER

GAS CONVERSION (Natural to Propane) continued

2. Replace the orifice. (See photo, previous page.]

You’ll have to remove the top plate and front cover to change the orifice.

Installing the correct orifice is critical! This should be performed ONLY by

trained, licensed, and certified service personnel.

3. The conversion kit includes a propane orifice, complete instructions for

making the conversion, and a label indicating the conversion kit has

been installed. All conversion work, including testing and adjusting, must

be completed by a trained, licensed, and certified gasfitter.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 41 of 60 TRAINING MANUAL

Page 42

DRYER

GAS VALVE OPERATION

The gas valve is a two-stage valve. When the ignition sequence begins, the

igniter is turned on and valve one opens. When the igniter reaches 370° F

(188° C), the igniter is turned off and valve two is opened. If the flame detector

does not detect ignition, valve two is closed and the process is restarted. If

ignition occurs as planned, the drying cycle will operate.

GAS IGNITION SEQUENCE GAS VALVE CONSTRUCTION

IGNITION FLOW CHART

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 42 of 60 TRAINING MANUAL

Page 43

DRYER

DISASSEMBLY and REPAIR INSTRUCTIONS

TOP PLATE

1. Remove three screws along the

back of the top (cover) plate.

2. Slide the top plate backward.

3. Lift the top plate off and set it

aside.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 43 of 60 TRAINING MANUAL

Page 44

DRYER

CONTROL PANEL

1. Remove two screws, one on

each corner of the control panel.

2. Disconnect all connectors.

NOTE: The connectors are all

different to prevent

misassembly.

3. Pull the control panel upward,

then forward. Be sure to

disengage all the plastic tabs

along the top.

4. Lay the control panel on its face

on a soft, protective cloth.

5. Remove nine screws on the

display PWB.

6. Remove four screws on the

main PWB.

7. Disassemble the control panel.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 44 of 60 TRAINING MANUAL

Page 45

DRYER

FRONT CABINET

1. Remove the top plate.

2. Remove the control panel.

3. Remove the door, if necessary

for the repair.

4. Remove two screws in the

bottom of the door opening.

5. Remove four screws from the

top of the front cabinet.

6. Tilt the front away from the dryer

and disconnect the door switch

wire harness.

DOOR REVERSAL

1. Remove two screws that hold

the door. Remove the door and

set it aside on a soft, protective

cloth. Save the hinge shim.

2. Remove two screws near the

latch.

3. Remove two screws and the

latch piece.

4. Rotate everything 180° and

reinstall so the door opens from

the other side.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 45 of 60 TRAINING MANUAL

Page 46

DRYER

TUB FRONT

1. Remove the top plate.

2. Remove the front cabinet.

3. Disconnect the door lamp (top)

and electrode sensor (bottom).

4. Remove the four screws holding

the front assembly.

5. Lift the tub front up and away.

DRUM, BELT, and PULLEY

1. Remove the drum front.

2. Reach in and remove the belt

from the motor and pulley.

3. Lift the drum out through the

front of the dryer. The belt

will still be around the drum.

4. To replace the drum, put the belt

around it and set into the dryer

to rest on the two rubber wheels

on the tub back. Let the belt

hang.

6. Replace the tub front, holding

the drum up so it can set on the

two rubber wheels on the tub

front.

7. Make sure the belt is around the

circumference of the drum near

the point where it usually rides.

8. Reach in through the front or the

side and loop the belt around

the motor shaft and the pulley.

Rotate the drum by hand a

couple of turns to seat it.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 46 of 60 TRAINING MANUAL

Page 47

DRYER

DRUM LAMP

The drum light can usually be changed without a major disassembly, unless the

bulb is frozen in the socket. If the bulb can’t be changed using this procedure,

you’ll have to remove the front cover and the lampholder to get to the socket.

1. Open the door.

2. Hold the lamp shield in place

and remove the screw.

3. Slide the shield toward the

screw and remove it.

4. Unscrew the bulb and replace it

with a 15-watt, 120 V,

candelabra-base bulb.

5. Replace the shield and screw.

Notice the bulb holder has feet that

hold it in place and tabs to keep it

positioned properly.

The socket can be removed and

replaced by squeezing the tabs and

pulling the bulb and socket into the

housing. Press it back into place after

changing the bulb.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 47 of 60 TRAINING MANUAL

Page 48

DRYER

VENT REPLACEMENT

1. Use the VENT KIT to change

the exhaust direction.

(Part # 383EEL9001B)

On the back of the dryer,

remove the screw securing the

exhaust duct.

2. (A) Remove the knockout on the

left, right*, or bottom, as

necessary.

* Right vent option not available

on gas dryers due to internal

piping interference.

(B) Insert the replacement pipe.

(C) Attach the pipe with a screw.

3. Pre-assemble the elbow and a

replacement duct and secure

the joint with duct tape.

4. Insert the pre-assembled elbow

into the dryer through the vent

hole and connect it to the

internal pipe.

5. Tear off some pieces of duct

tape and secure that joint as

well.

6. Connect the pipe to the exhaust

duct.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 48 of 60 TRAINING MANUAL

Page 49

DRYER

FILTER ASSEMBLY and MOISTURE SENSOR

1. Remove the lint filter.

2. Remove three screws holding

the cover grid.

3. Remove the cover grid.

4. Disconnect the electrode

sensors.

BACK COVER

1. Remove the top plate.

2. Remove the front cover.

3. Remove the tub front.

4. Remove the drum.

5. Remove 7 screws.

6. Remove the back cover.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 49 of 60 TRAINING MANUAL

Page 50

DRYER

AIR DUCT

1. Remove the top plate.

2. Remove the front cover.

3. Remove the filter.

4. Remove 2 screws at the top of

the air duct.

5. Remove the air duct.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 50 of 60 TRAINING MANUAL

Page 51

DRYER

ROLLERS

1. Remove the top plate.

2. Remove the front cover.

3. Remove the tub front.

4. Remove the drum (if replacing

the back rollers.)

5. Use an open-end wrench to

remove and replace the shaft

and roller.

NOTE:

If the shaft is OK and you are replacing

only the roller, you can squeeze the

triangular retainer to remove and

replace the roller without removing the

shaft from the machine.

Be sure to install the small bushings.

These must be between the roller and

the retainer on both sides of the roller.

See photo.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 51 of 60 TRAINING MANUAL

Page 52

DRYER

BLOWER HOUSING

1. Remove the top plate.

2. Remove the front cover.

3. Remove the tub front.

4. Remove the drum.

5. Remove the two screws and

the cover on the air guide.

6. Remove the nut and washer on

the blower shaft.

7. Remove the fan from the shaft.

8. Press down the hooked end of

the clamps and remove them.

9. Disconnect and remove the

motor.

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 52 of 60 TRAINING MANUAL

Page 53

DRYER

EXPLODED VIEW (Control Panel and Top Plate Assembly)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 53 of 60 TRAINING MANUAL

Page 54

DRYER

EXPLODED VIEW (Cabinet and Door Assembly)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 54 of 60 TRAINING MANUAL

Page 55

DRYER

EXPLODED VIEW (Drum and Motor – Electric Model)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 55 of 60 TRAINING MANUAL

Page 56

DRYER

EXPLODED VIEW (Drum and Motor – Gas Model)

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 56 of 60 TRAINING MANUAL

Page 57

DRYER

PARTS LIST

Loc Description

*001 Owner's Manual 3829EL3009B 3829EL3009B 3829EL3009B 3829EL3009B

*002 Box, Carton 3890EZ3613A 3890EZ3613A 3890EZ3613A 3890EZ3613A

*004 Manual, Service 3828EL3005D 3828EL3005D 3828EL3005D 3828EL3005D

A110 Panel Assembly, Control 3721EL0009C 3721EL0009A 3721EL0009D 3721EL0009B

A120 PCB Assembly, Display 6871EL1011A 6871EL1011A 6871EL1011B 6871EL1011B

A130 PCB Assembly, Main 6871EL1013C 6871EL1013C 6871EL1013D 6871EL1013D

A140 Knob Assembly 4941ER3005A 4941ER3005A 4941ER3005A 4941ER3005A

A210 Plate Assembly, Top 3457ER1006X 3457ER1006D 3457ER1006X 3457ER1006D

A211 Plate, Upper 3300EL2001E 3300EL2001A 3300EL2001E 3300EL2001A

A300 Bracket, Hinge 4810EL3006A 4810EL3006A 4810EL3006A 4810EL3006A

A305 Bracket, Hinge 4810EL3006B 4810EL3006B 4810EL3006B 4810EL3006B

A310 Cabinet Cover Assembly 3551EL0009B 3551EL0009A 3551EL0009B 3551EL0009A

A320 Locker Assembly 4027EL1001A 4027EL1001A 4027EL1001A 4027EL1001A

A330 Switch, Micro 6601EL3001A 6601EL3001A 6601EL3001A 6601EL3001A

A330 Safety Switch Assembly 6601EL3001A 6601EL3001A 6601EL3001A 6601EL3001A

A390 Frame Assembly 3211EL1004A 3211EL1004A 3211EL1004A 3211EL1004A

A400 Door Assembly 3581EL0004A 3581EL0004A 3581EL0004A 3581EL0004A

A410 Locker, Hook 4026EL3007A 4026EL3007A 4026EL3007A 4026EL3007A

A420 Outer Door Frame 3212EL1015A 3212EL1015A 3212EL1015A 3212EL1015A

A430 Hinge 4774EL2001A 4774EL2001A 4774EL2001A 4774EL2001A

A450 Inner Door Frame 3212EL1005B 3212EL1005B 3212EL1005B 3212EL1005B

A460 Gasket 4986EL2004A 4986EL2004A 4986EL2004A 4986EL2004A

A500 Cabinet Assembly 3091EL0003P 3091EL0003M 3091EL0003Q 3091EL0003N

A510 Cap (Knockout cover) 5006EL3001G 5006EL3001D 5006EL3001G 5006EL3001D

A520 Bracket, Base 4810EL3001A 4810EL3001A 4810EL3001A 4810EL3001A

A525 Bracket, Base 4810EL3009A 4810EL3009A 4810EL3009A 4810EL3009A

A530 Bracket, Base 4810EL3009B 4810EL3009B 4810EL3009B 4810EL3009B

A540 Leg 4778EL3001A 4778EL3001A 4778EL3001A 4778EL3001A

A560 Cover, Guide 3550EL3007A 3550EL3007A 6411ER1005B 6411ER1005B

A570 Cover, Safety 3550EL3002A 3550EL3002A

A600 HARNESS, PWB 6877EL1019B 6877EL1019B 6877EL1020B 6877EL1020B

A700 Rack 3750EL1001B 3750EL1001B 3750EL1001B 3750EL1001B

A800 Parts As’by

F110 Heater Assembly (Elec) 5301EL1001G 5301EL1001G

F120 Bracket, Heater 4810EL1007A 4810EL1007A

F130 Thermostat 6931EL3003D 6931EL3003D

F140 Thermostat Assembly 6931EL3001E 6931EL3001E

F200 Duct Assembly 5209EL1001C 5209EL1001C 5209EL1001D 5209EL1001D

K100 Tub Assembly, Drum 3045EL1002E 3045EL1002E 3045EL1002E 3045EL1002E

K120 Lifter 4432EL1002B 4432EL1002B 4432EL1002B 4432EL1002B

K130 Belt, Poly V 4400EL2001A 4400EL2001A 4400EL2001A 4400EL2001A

(Side Vent Kit) 383EEL9001B 383EEL9001B 383EEL9001B 383EEL9001B

DLE8377NM DLE8377WM DLG8388NM DLG8388WM

Part No Part No Part No Part No

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 57 of 60 TRAINING MANUAL

Page 58

DRYER

Loc Description

K140 Gasket 4036EL3001A 4036EL3001A 4036EL3001A 4036EL3001A

K210 Tub, Drum (Front) 3044EL1001A 3044EL1001A 3044EL1001B 3044EL1001B

K221 Lamp, Incand., Assembly 6913EL3002C 6913EL3002C 6913EL3002C 6913EL3002C

K222 Lamp, Incandescent, Bulb 6913EL3001A 6913EL3001A 6913EL3001A 6913EL3001A

K230 Cover, Lamp 3550EL2001A 3550EL2001A 3550EL2001A 3550EL2001A

K240 Duct Assembly 5209EL1002A 5209EL1002A 5209EL1002A 5209EL1002A

K250 Roller Assembly 4581EL2002A 4581EL2002A 4581EL2002A 4581EL2002A

K251 Roller Assembly 4581EL3001A 4581EL3001A 4581EL3001A 4581EL3001A

K310 Filter Assembly, Lint 5231EL1003B 5231EL1003B 5231EL1003B 5231EL1003B

K320 Cover, Guide 3550EL1006B 3550EL1006B 3550EL1006B 3550EL1006B

K330 Guide, Filter 4974EL1003B 4974EL1003B 4974EL1003B 4974EL1003B

K340 Sensor 6500EL3001A 6500EL3001A 6500EL3001A 6500EL3001A

K350 Cable & Wire 6631EL3003B 6631EL3003B 6631EL3003B 6631EL3003B

K360 Holder 4930EL2004B 4930EL2004B 4930EL2004B 4930EL2004B

K400 Tub, Drum (Rear) 3044EL0002B 3044EL0002B 3044EL0002B 3044EL0002B

K510 Casing Assembly 5835EL1002A 5835EL1002A 5835EL1002A 5835EL1002A

K520 Housing As’by, Blower 3661EL1001E 3661EL1001E 3661EL1001E 3661EL1001E

K530 Duct Assembly 5209EL1006A 5209EL1006A 5209EL1006A 5209EL1006A

K540 Guide Assembly 4975EL3001A 4975EL3001A 4975EL3001A 4975EL3001A

K550 Thermistor, NTC 6323EL2001B 6323EL2001B 6323EL2001B 6323EL2001B

K560 Thermostat 6931EL3002A 6931EL3002A 6931EL3002A 6931EL3002A

K600 Bracket, Motor 4810EL1002A 4810EL1002A 4810EL1002A 4810EL1002A

K610 Motor, Unclassified 4681EL1002A 4681EL1002A 4681EL1002A 4681EL1002A

K620 Clamp 4860EL3001A 4860EL3001A 4860EL3001A 4860EL3001A

K640 Switch, Micro 3W40025Q 3W40025Q 3W40025Q 3W40025Q

K650 Pulley Assembly, Motor 4561EL3002A 4561EL3002A 4561EL3002A 4561EL3002A

K651 Pulley, Idle 4560EL3001A 4560EL3001A 4560EL3001A 4560EL3001A

M110 Valve Assembly, Gas

M140 Guide, Burner

M141 Bracket, Base

M150 Pipe Assembly

M160 Igniter

M170 Orifice, Natural Gas

M171 Orifice, Propane

M180 Connector, Mech, Pipe

M181 Seal

M190 Pipe Assembly

M210 Funnel

M220 Thermostat Assembly

M230 Thermostat Assembly

M240 Sensor Assembly

M250 Supporter, Holder

DLE8377NM DLE8377WM DLG8388NM DLG8388WM

Part No Part No Part No Part No

5221EL2002A 5221EL2002A

4974EL1001A 4974EL1001A

4810EL3002A 4810EL3002A

5201EL3001A 5201EL3001A

5318EL3001A 5318EL3001A

4948EL4001B 4948EL4001B

4948EL4002B 4948EL4002B

4932EL4001A 4932EL4001A

4036EL3002A 4036EL3002A

5201EL2001A 5201EL2001A

3016EL1001A 3016EL1001A

6931EL3004B 6931EL3004B

6931EL3003C 6931EL3003C

6501EL3001A 6501EL3001A

4980EL3001A 4980EL3001A

DLE8377xM/DLG8388xM

DLE7177WM/DLE7188WM Page 58 of 60 TRAINING MANUAL

Page 59

(this page intentionally blank)

Page 60

© 2006 LG Electronics, Inc.

Printed in the USA

Loading...

Loading...