Page 1

W ASHING MACHINE

SERVICE MANUAL

READ THIS MANUAL CAREFULLY TO DIAGNOSE

PROBLEMS CORRECTLY BEFORE SERVICING THE UNIT.

MODEL: CW2079CWD/CW2079CWN

CAUTION

!

Page 2

JUNE. 2007 PRINTED IN KOREA

P/No.: MFL30599105

Page 3

2

CONTENTS

1. IMPORTANT SAFETY INSTRUCTIONS.......................................................................................3

2. SPECIFICATIONS.........................................................................................................................4

3. FEATURES AND TECHNICAL EXPLANATION........................................................................... 5

4. PARTS IDENTIFICATION ............................................................................................................ 7

5. INSTALLATION INSTRUCTIONS................................................................................................. 8

6. OPERATION..........................................................................................................................14~16

7. WIRING DIAGRAM/PROGRAM CHART.....................................................................................17

8. TROUBLESHOOTING...........................................................................................................18~20

8-1. BEFORE PERFORMING SERVICE...................................................................................18

8-2. QC TEST MODE.................................................................................................................18

8-3. HOW TO CHECK THE WATER LEVEL FREQUENCY......................................................18

8-4. HOW TO CHECK THE RPM...............................................................................................18

8-5. ERROR DISPLAY ...............................................................................................................19

9. DIAGNOSIS AND TROUBLESHOOTING.............................................................................21~28

10. DISASSEMBLY INSTRUCTIONS .......................................................................................29~38

11. EXPLODED VIEW .....................................................................................................................39

11-1. CABINET & CONTROL PANEL ASSEMBLY....................................................................39

11-2. DRUM & TUB ASSEMBLY................................................................................................40

11-3. DISPENSER ASSEMBLY .................................................................................................41

Page 4

3

1. IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USE

WARNING!

For your safety, the information in this manual must be followed to minimize the risk of fire

or explosion, electric shock, or to prevent property damage, personal injury, or loss of life.

IIMMPPOORRTTAANNTT

SSAAFFEETTYY IINNSSTTRRUUCCTTIIOONNSS

• Read all instructions before using the washer.

• Do not wash articles that have been previously

cleaned in, washed in, soaked in, or spotted with

gasoline, dry cleaning solvents, or other

flammable or explosive substances, as they give

off vapors that could ignite or explode.

• Do not add gasoline, dry cleaning solvents, or

other flammable or explosive substances to the

wash water. These substances give off vapors that

could ignite or explode.

• Under certain conditions, hydrogen gas may be

produced in a hot water system that has not been

used for 2 weeks or more. HYDROGEN GAS IS

EXPLOSIVE. If the hot water system has not been

used for such a period, before using the washing

machine, turn on all hot water faucets and let the

water flow from each for several minutes. This will

release any accumulated hydrogen gas. As the gas

is flammable, do not smoke or use an open flame

during this time.

• Do not allow children to play on or in the washer.

Close supervision of children is necessary when

the washer is used near children.

• Before the washer is removed from service or

discarded, remove the door to prevent children

from hiding inside.

• Do not install or store the washer where it will be

exposed to the weather.

• Do not tamper with controls.

• Do not repair or replace any part of the washer or

attempt any servicing unless specifically

recommended in the user-maintenance

instructions or published user-repair instructions

that you understand and have the skills to carry

out.

• See Installation Instructions for grounding

requirements.

• ALWAYS follow the fabric care instructions

supplied by the garment manufacturer.

• Do not place items exposed to cooking oil in your

washer. Items contaminated with cooking oils may

contribute to a chemical reaction that could cause

a load to catch fire.

• Do not use fabric softeners or products to

eliminate static unless recommended by the

manufacturer of the fabric softener or product.

WARNING: To reduce the risk of fire, electric shock, or injury to persons when using the washer, follow basic

precautions, including the following:

SSAAVVEE TTHHEESSEE IINNSSTTRRUUCCTTIIOONNSS

This appliance must be grounded. In the event of malfunction or breakdown, grounding will reduce the risk

of electric shock by providing a path of least resistance for electric current. This appliance is equipped with

a cord having an equipment-grounding conductor and grounding plug. The plug must be plugged into an

appropriate outlet that is properly installed and grounded in accordance with all local codes and ordinances.

• Do not use an adapter or extension cord.

• Do not remove ground prong.

• If you don’t have the proper outlet, consult an electrician.

GROUNDING INSTRUCTIONS

WARNING: Improper connection of the equipment-grounding conductor can result in risk of electric shock.

Check with a qualified electrician or serviceman if you are in doubt as to whether the appliance is

properly grounded. Do not modify the plug provided with the appliance - if it does not fit the outlet,

have a proper outlet installed by a qualified electrician.

!

!

!

Page 5

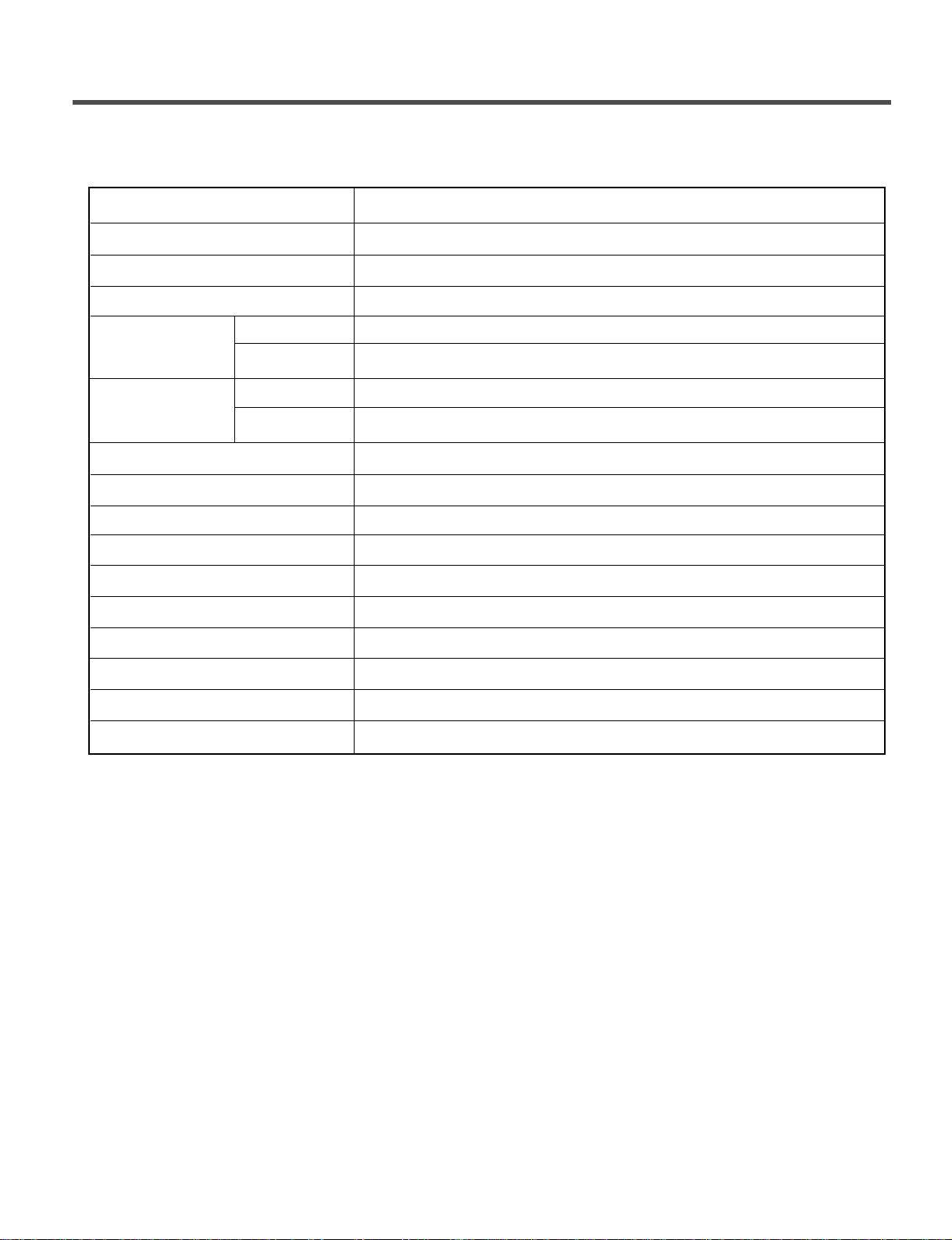

4

2. SPECIFICATIONS

MODEL CW2079CWD/CWN

COLOR BLUE WHITE

POWER SUPPLY 120V~, 60 Hz

PRODUCT WEIGHT 190 lbs. (86 kg)

WASHING 155 W

DRAIN MOTOR 80 W

WASH 45 rpm

SPIN

0-1000 rpm

CYCLES 4

OPTIONS ADD SUPER WASH Cycle

OPERATIONAL WATER PRESSURE 14.5-116 psi (100-800 kPa)

CONTROL TYPE Electronic

WASH CAPACITY [cu. ft.] 3.32 (IEC 3.83)

DIMENSIONS 27” (W) X 293/4” (D) X 3811/16” (H), 5013/16” (D, door open)

DOOR SWITCH TYPE PTC + Solenoid

WATER LEVEL 10 steps (by sensor)

LAUNDRY LOAD SENSING Incorporated

ERROR DIAGNOSIS Incorporated

ELECTRIC POWER

CONSUMTION

REVOLUTION SPEED

Page 6

5

3. FEATURES & TECHNICAL EXPLANA TION

3-1. FEATURES

■ Direct Drive System

The advanced Brushless DC motor directly drives the drum

without belt and pulley.

■

The Tilted Drum and Extra Large Door Opening

Tilted drum and extra large door opening make it possible

to load and unload easily.

■

Ultra Capacity

The larger drum enables not just higher head drop and stronger centrifugal

force, but also less tangling and wrinkling of the laundry. Heavier loads, such

as king size comforters, blankets, and curtains, can be washed.

■

Large Door and Window

The large window lets you see the wash as it progresses.

■

The Stainless Steel drum

Stainless Steel Drum doesn't rust.

■

Automatic Wash Load Detection

Automatically detects the load and optimizes the washing time.

Page 7

6

3-2. WATER LEVEL CONTROL

● This model incorporates a pressure sensor which can sense the water level in the tub.

● The water supply is stopped when the water level reaches the preset level; then the selected cycle begins.

● Spinning does not proceed until the water in the tub drains to a certain level.

3-3. DOOR CONTROL

● The door can be opened by pulling the door handle whenever washer is not in operation.

● When the cycle is completed, the DOOR LOCKED light will turn off.

● If a power failure has occurred while in operation, the door will unlock after 2 minutes.

● Clicking sounds can be heard when the door is locked/unlocked.

3-4. THE DOOR CAN NOT BE OPENED

● While program is operating.

● While Door Lock lights turn on.

● While the drum is rotating.

3-5. DOOR LOCKED LAMP LIGHTS

● When the frequency of water level is lower than 22.9 kHz.

(It can be canceled when the frequency is more than 23.8 kHz.)

● When the temperature inside the tub is higher than 45° C (104° F) and water level is not 25.5 kHz.

(It can be canceled when the water level is 25.5 kHz or the temperature inside the tub is lower than

40° C (113° F). )

Page 8

7

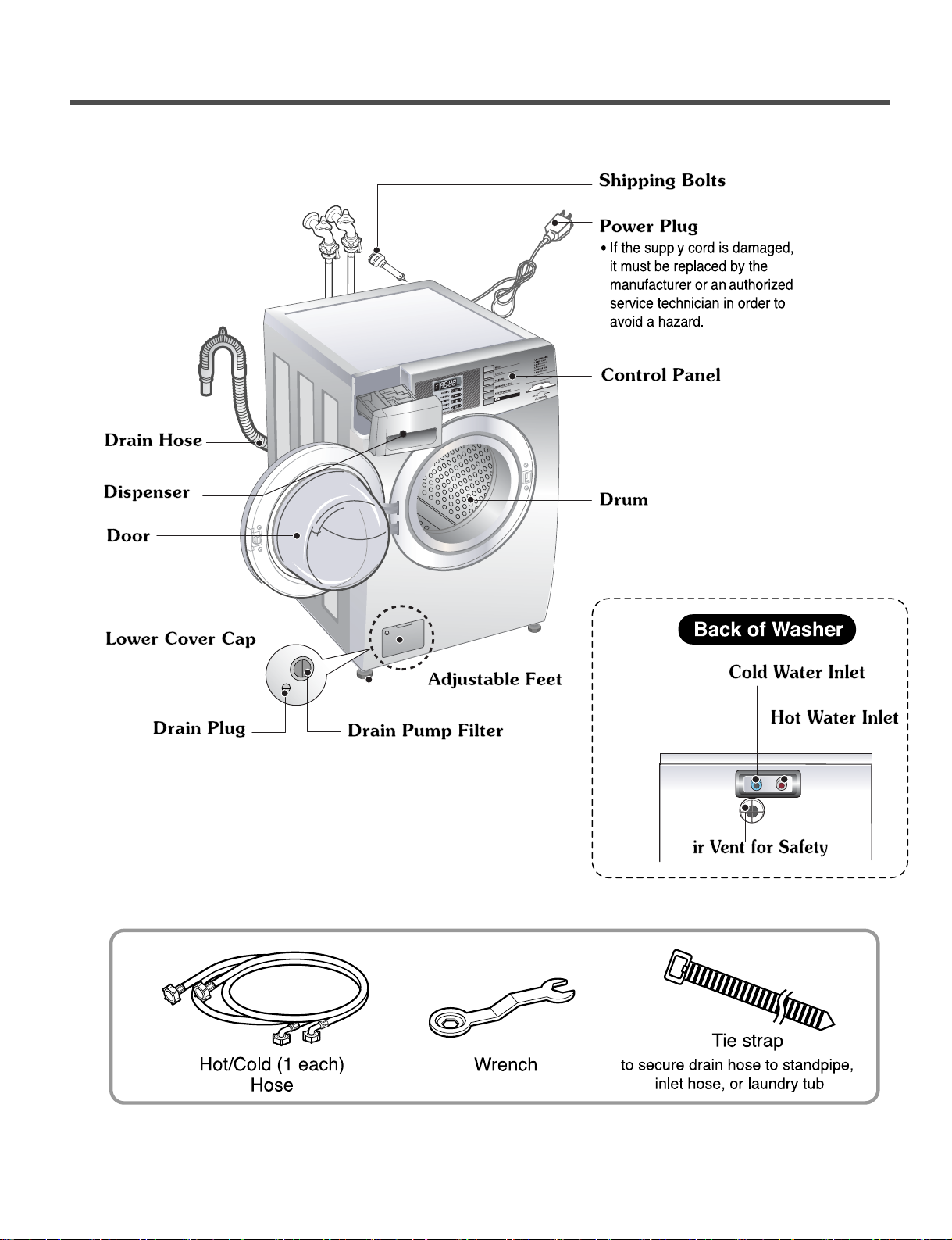

4. PARTS IDENTIFICATION

■ ACCESSORIES

A

Page 9

8

5. INSTALLATION INSTRUCTIONS

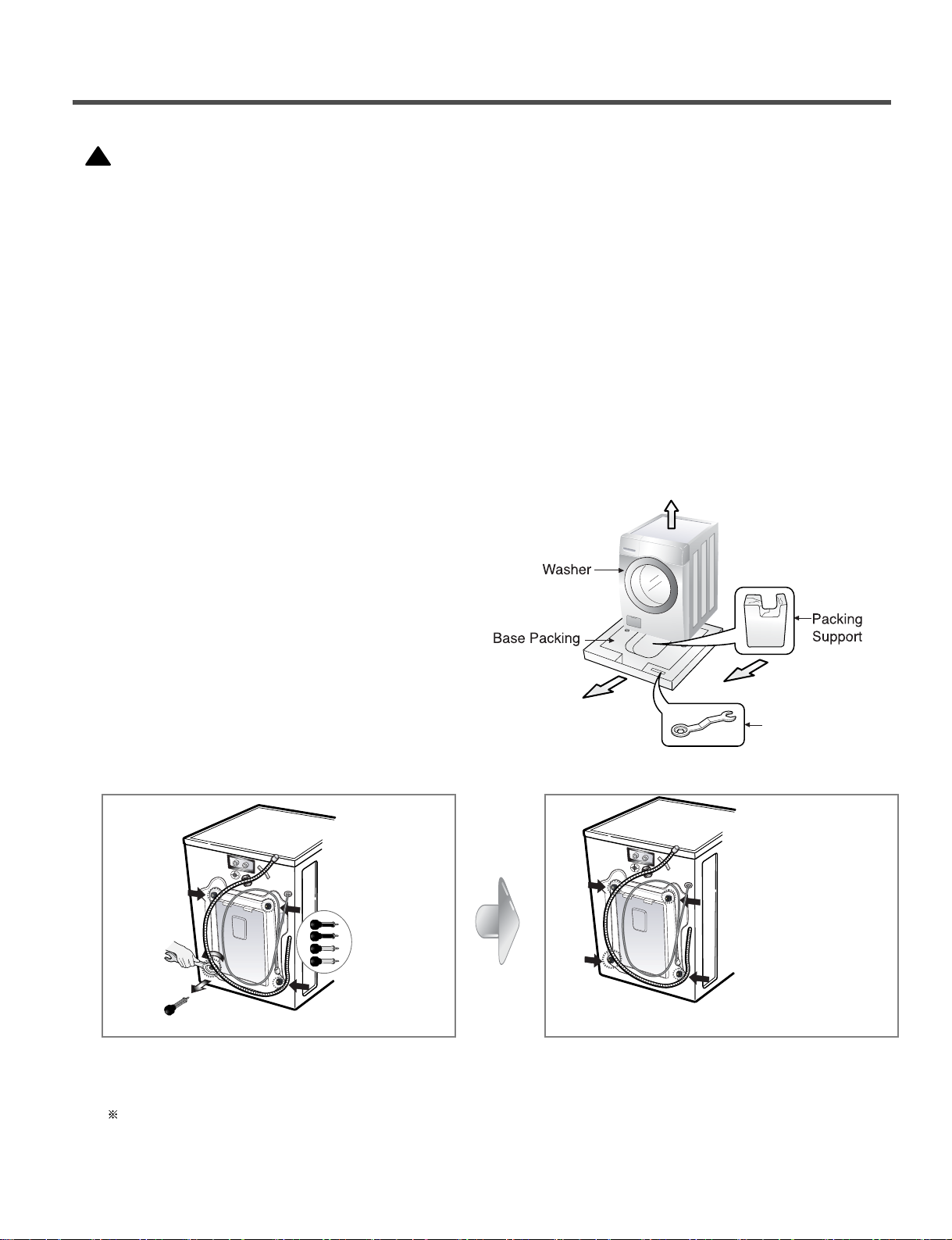

Unscrew the 4 bolts with the wrench supplied

Take out the 4 bolts by twisting the braces slightly

Keep the

4 bolts and the wrench for future use

(Whenever the appliance is transported, the

shipping bolts and braces must be replaced.)

Close the holes with the caps supplied.

The appliance is fitted with shipping bolts to prevent

internal damage during transportation.

Packing and all shipping bolts must be removed

before using the washer.

☞ When unpacking the base, be sure to remove

the additional packing support in the middle of

the base packing.

■ Shipping bolts

• Washer is heavy. Two or more people may be needed to install and move the appliance.

Failure to do so can result in back or other injury.

• Store and install the washer where it will not be exposed to temperatures below freezing or exposed to

outdoor weather conditions. Failure to follow this warning can cause serious injury, fire, electrical shock, or

death.

• This appliance must be properly grounded for personal safety. Properly ground washer to conform with all

governing codes and ordinances. Failure to follow this warning can cause serious injury, fire, electrical shock,

or death.

• Do not install the washer in humid spaces to reduce the risk of electric shock. Failure to follow this

warning can cause serious injury, fire, electrical shock or death.

• The base opening must not be obstructed by carpeting when the washer is installed on a carpeted floor.

• Do not remove ground prong. Do not use an adapter or extension cord. Plug into a grounded 3 prong outlet.

Failure to follow this warning can cause serious injury, fire, electrical shock or death.

■ Removing shipping bolts

CAP

!

WARNING

Wrench

Page 10

9

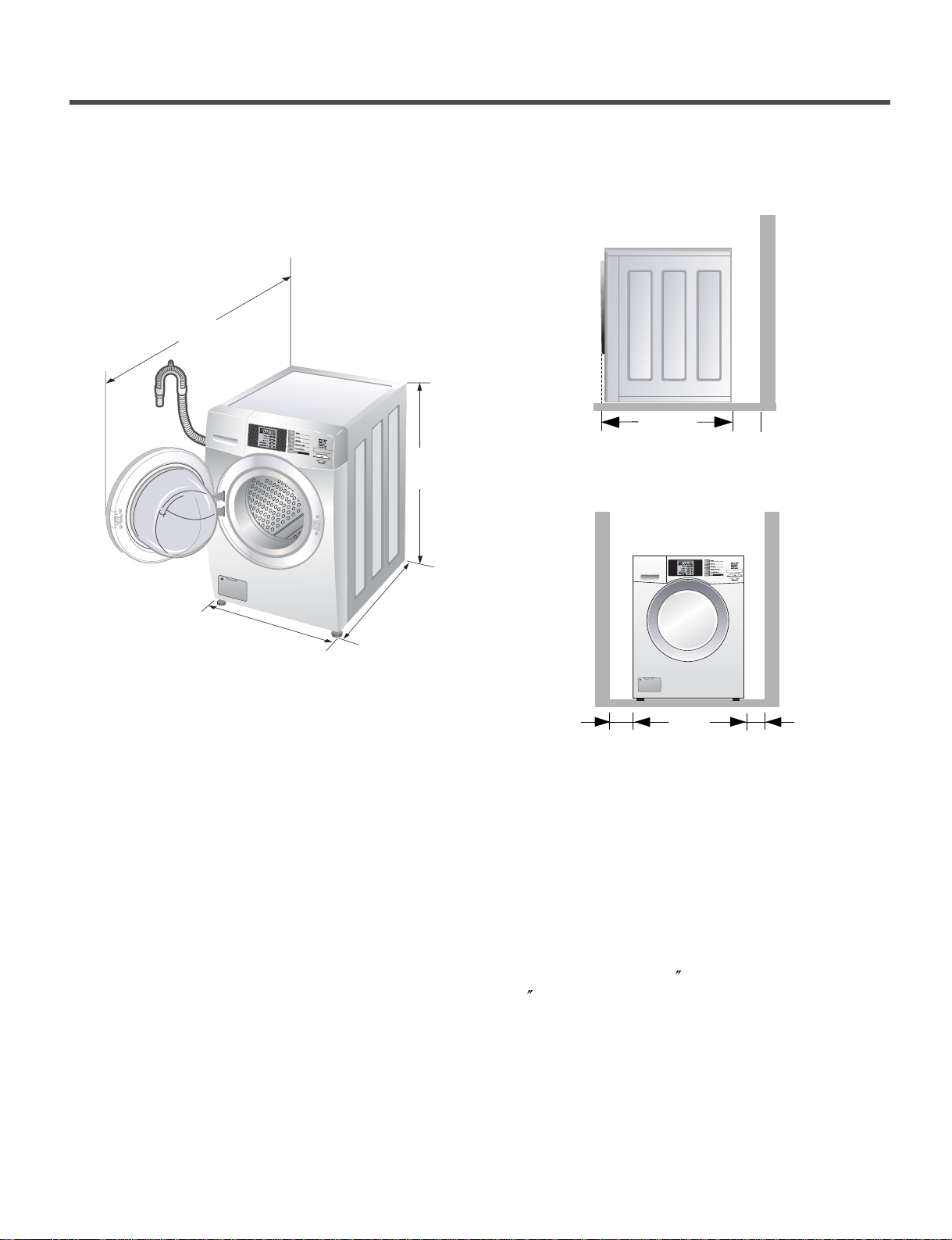

■ Installation clearances

The location must be large enough to open

the washer door completely.

■ Washer dimensions

The following dimensions shown are for the minimum

spacing allowed.

Additional spacing should be considered for

installation and servicing.

• Additional clearances might be required for wall,

door, and floor moldings.

• Additional spacing of 4 (10 cm) on back,

1 (2.5 cm) on all sides of the washer is

recommended to reduce noise transfer.

Companion appliance spacing should also be

considered.

■ Minimum installation spacing for

recessed area installation.

Front view

Side view

27"

(68.6 cm)

29

3

/

4

"

(75.6 cm)

38

11

/

16

"

(98.3 cm)

50

13

/

16

"

(129.1 cm)

29 3/4"

(75.6 cm)

4"

(10 cm)

27"

(68.6 cm)

1"

(2.5 cm)

1"

(2.5 cm)

Page 11

10

• Must be within 60 (1.5 m) of either side of the

washer. Do not overload the outlet with more

than one appliance.

• Time-delay fuse or circuit breaker is recommended.

NOTE: It is the personal responsibility and obligation

of the customer to have a proper outlet

installed by a qualified electrician.

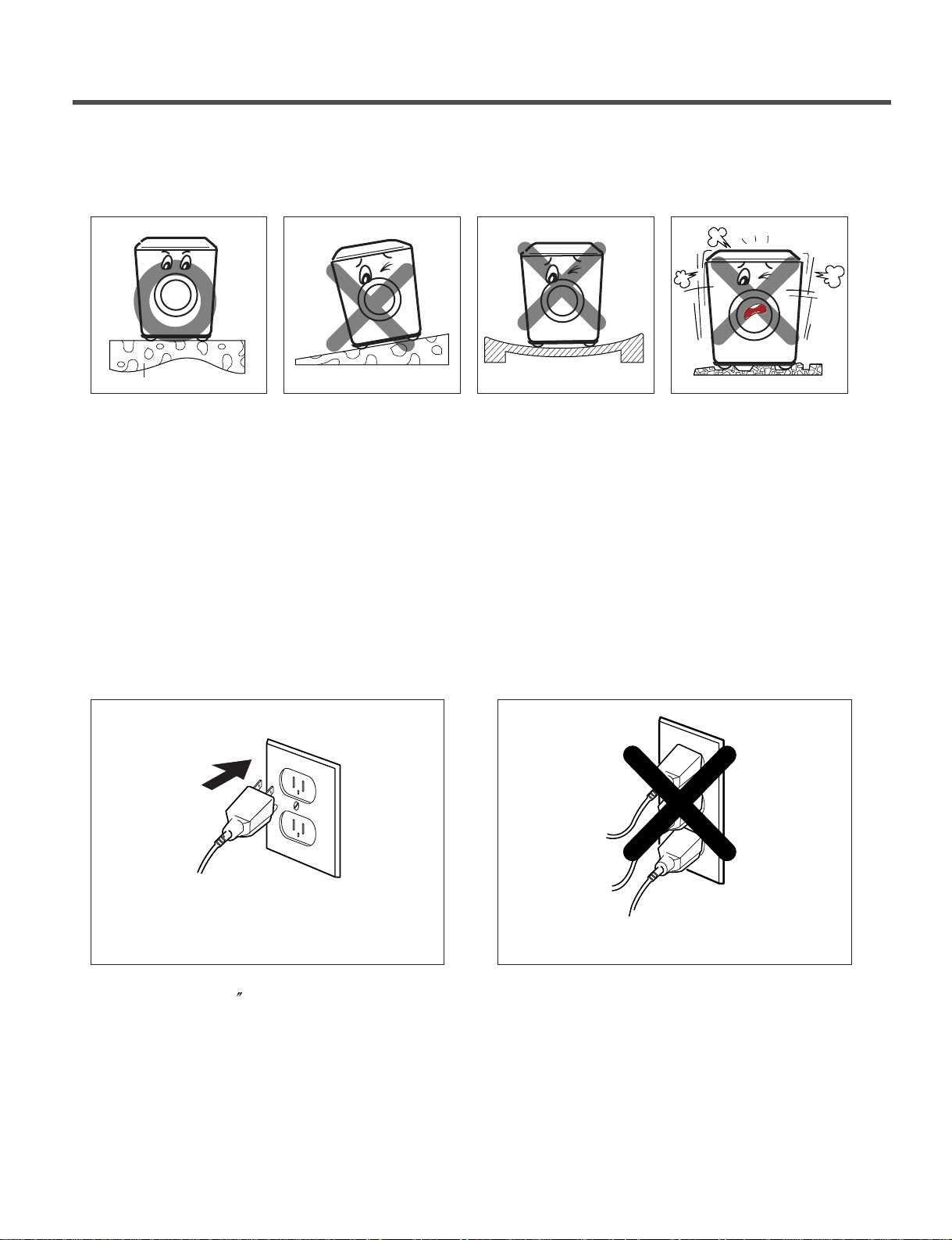

■ Level floor

• Allowable slope under entire washer is 1°.

• To minimize noise and vibration, the washer

MUST be installed on a solidly constructed

floor.

• Carpeting and soft tile surfaces are not

recommended.

• Never install the washer on a platform or

weakly supported structure.

NOTE: A firm, solid floor is even more critical to a

front-loading washer than to a top-loader.

If your floor is wood and/or frame

construction, you may need to reinforce it.

Front-loaders use substantially faster spin

speeds than top-loaders, causing greater

vibration. If the floor is not solid, your washer

will vibrate. You will hear and feel the

vibration throughout your house.

· Connect the power plug to the wall outlet. · Avoid connecting several electric devices, as

doing so may cause a fire.

■

CONNECT POWER PLUG

■

INST ALL THE APPLIANCE

ON A FLA T AND FIRM SURFACE

solid floor

Page 12

11

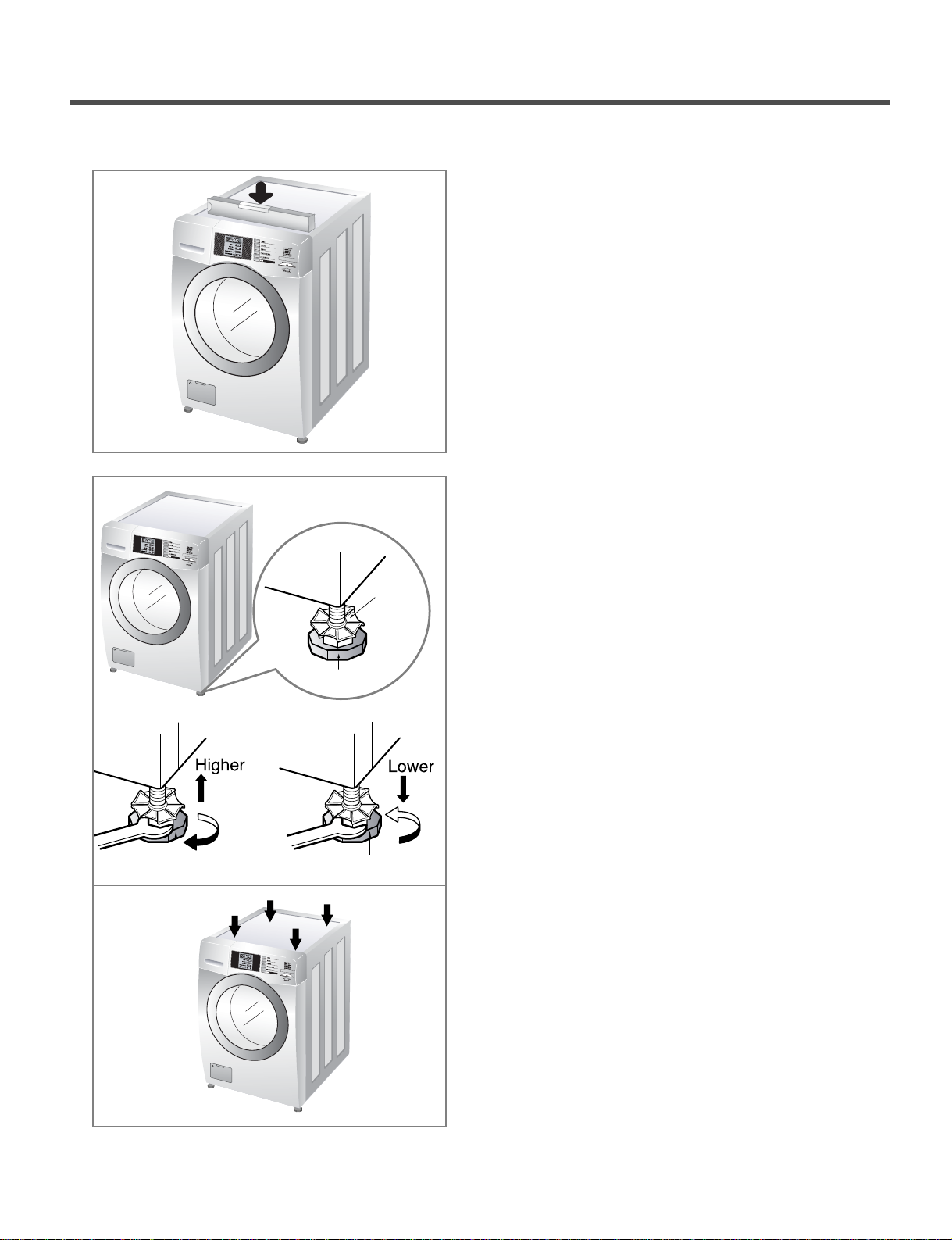

■ Level adjustment

• Leveling the washing machine properly prevents

excessive noise and vibration.

Install the appliance on a solid and level floor surface,

preferably in a corner of the room.

• If the floor is uneven, adjust the adjustable feet as

required. (Do not insert pieces of wood, etc. under

the feet.)

NOTE: Extend the feet no more than necessary to level

the washer. The more the feet are extended, the

more the washer will vibrate.

• Make sure that all four feet are stable and resting on

the floor and then check that the appliance is

perfectly level (Use a level).

• After the washer is level, tighten the lock nuts up

against of the base of the washer. All lock nuts must

be tightened.

• It is critical to adjust the feet perfectly. This must be

done while the washer is spinning with a load. Use

the wrench (supplied) to adjust the feet until there is

no vibration. Then tighten the lock nuts to prevent

further adjustment.

NOTE: If there is vibration and noise during the spin

cycle, re-check the leveling of the washer, adjust

the feet as required, and tighten the lock nuts

securely to prevent changes in adjustment.

Run the washer with a test load to make certain

your washer is properly leveled. Put an

unbalance weight part in the machine.

You can check noise and/or vibration on high

speed spin rpm through the QC test mode

(refer to page 18).

When the machine spins at high speed, verify

that it is stable. If not, adjust the feet

accordingly.

✽ Diagonal Check

When pushing down the edges of the washing machine

top plate diagonally, the machine should not move up

and down at all. (Please, check both directions.)

Lock nut

Adjustable feet

Adjustable feet Adjustable feet

Page 13

12

• Water supply pressure must be between

14.5 and 116 psi (100~800 kPa).

• Do not crossthread when connecting the inlet hose

to the valve.

• If the water supply pressure is more than 116 PSI,

a pressure reducing device should be installed.

• Two sealing washers are supplied with the water

inlet hoses to prevent water leaks.

• Check for leakage of washing machine connections

by turning the tap completely on.

• Periodically check the condition of the hose and

replace the hose if necessary.

• Make sure that there is no kink in the hose and that

it is not crushed.

• Be sure that the two water input ports are connected

to the correct water faucets. The connector for hot

water is colored red; the cold is blue.

■ Connecting the water supply hoses

NOTE: Use new hoses when installing a washing machine. Replace them periodically.

Old hoses should not be used.

■ Electrical connection

• Do not use an extension cord or double adapter.

• If the supply cord is damaged, it must be replaced by a qualified person in order to avoid a hazard.

• If the machine will not be used for an extended time, unplug it and shut off the water supply.

• Connect the machine to a grounded outlet in accordance with current wiring regulations.

• The appliance must be positioned so that the plug is easily accessible.

Do not install your washing machine in a room where temperatures below freezing may occur.

Frozen hoses may burst under pressure. The reliability of the electronic control unit may be impaired

at temperatures below the freezing point.

If the appliance is delivered in the winter months and temperatures are below freezing,

store the washing machine at room temperature for a few hours before putting it into operation.

!

WARNING! Concerning the power cord

Most appliances recommend they be placed upon a dedicated circuit; that is, a single outlet circuit which powers only that

appliance and has no additional outlets or branch circuits. Check the specification page of this owner's manual to be

certain.

Do not overload wall outlets. Overloaded wall outlets, loose or damaged wall outlets, extension cords, frayed power cords,

or damaged or cracked wire insulation are dangerous. Any of these conditions could result in electric shock or fire.

Periodically examine the cord of your appliance, and if its appearance indicates damage or deterioration, unplug it,

discontinue use of the appliance, and have the cord replaced with an exact replacement part by an authorized servicer.

Protect the power cord from physical or mechanical abuse, such as being twisted, kinked, pinched, closed in a door, or

walked upon. Pay particular attention to plugs, wall outlets, and the point where the cord exits the appliance.

Page 14

13

■ Installation of drain hose

• The drain hose should not be placed higher than

96 in. from the bottom of the washer.

• Properly securing the drain hose will protect the

floor from damage due to water leakage.

• Place the end of the drain hose in the hole of the

floor drain system.

• When installing the drain hose at a sink, secure it

so it cannot break away and cause flooding and

damage.

• Properly securing the drain hose will protect the

floor from damage due to water leakage.

· Make sure that the hose is not twisted.

· Avoid submerging the end of the hose.

Page 15

14

6. OPERATION

1 2

5 4 3

1 2

5 4 3

■ COIN TYPE (CW2079CWN )

■ CARD TYPE (CW2079CWD)

1. DISPLAY LED

2. CYCLE BUTTON

3. START BUTTON

4. STATUS LED

5. CYCLE LED

Page 16

15

The START LED flashes when the full vend price

has been satisfied and the cycle has been chosen.

33

START BUTTON

• LED flashes whenever the washing

cycle is in operation.

• LED flashes whenever the Rinsing

cycle is in operation.

• LED flashes whenever the Spining

cycle is in operation.

• LED flashes whenever the door lock

is activated.

44

STATUS LED

WHITES, COLORS, DELICATES, PERMANENT

PRESS or ADD SUPER WASH LED is lit for the

cycle is in operation.

55

CYCLE LED

The display shows the vend price and remaining time

and programming options. Error codes are also

displayed here.

11

Display LED

Press the CYCLE button to select the desired cycle

based on laundry types and conditions.

Use for hot washing for heavy fabrics, such as white

clothes, table linens, and heavily soiled clothes.

22

CYCLE BUTTON

WHITES

Use for warm washing for heavy fabrics, such as

jeans, corduroys, or work clothes.

COLORS

Use for cold washing for synthetic fabrics, such as

washable knit fabric and no-iron finishes.

DELICATES

Use for warm washing for sturdy fabrics, such as

work casual work.

PERMANENT PRESS

1 2

5 4 3

CYCLE LED STATUS LED START BUTTON

DISPLAY LED CYCLE BUTTON

Page 17

16

■ Select cycles designed for different types of fabric and soil levels.

CYCLE

Whites

Add super wash

- Adds an additional 5 minutes of washing time and an extra rinse

Cotton, Linen, Towels, Shirts,

Sheets

Hot/Cold High O

Colors

Mixed Loads, Work Clothes,

Jeans, Shirts

Warm/Cold High O

Delicates

Dress Shirts/Blouses,

Nylons, Sheer or Lacy Garment

Cold/Cold Low O

Perm Press

Dress Shirts/Pants, Wrinkle

Free Clothing, Poly/Cotton

Blend Clothing, Tablecloths.

Warm/Cold Medium O

Fabric type

Wash/Rinse

Temp.

Spin

Speed

Add Super

Wash

Page 18

17

7. WIRING DIAGRAM/PROGRAM CHART

Water Supply :W-S

Intermittent Spin :1 -S

Disentangle : D -T

Basic Cycle

Optional Cycle

SPIN

10min

WASH

10min

RINSE

16min

60 * 60

1806018060180

60 60 60

180

60 * 60

60

~

Approx.

Working

Time

(min)

1 2 3 4 5 6 7 8

9

10 11 12 13 14 15 16 17

W

-

S

W A S H

D R A I N

1

/

S

W

/

S

R I N S E

D R A I N

W

/

S

R I N S E

D R A I N

W

/

S

R I N S E

D R A IN

S P I N

D

/

T

E N D

INITIAL STAGE

1

NORMAL

SUPER

CYCLE

2 3

WHITE

COLOR

PERM PRESS

DELICATES

37

37

35

35

C Y C L E

S T E P

C

O

U

R

S

E

Time

(sec)

10

10

6

8

1

/

S

1809180

8

1

/

S

360

-

660

360

-

660

360

-

660

360

-

660

■ Card T ype (CW2079CWD) ■ Coin Type (CW2079CWN)

■ Pogram Chart

Page 19

18

8. TROUBLESHOOTING

8-1. BEFORE PERFORMING SERVICE

■ Be careful of electric shock when disconnecting parts while troubleshooting.

■ The voltage of each terminal is 120V~ when the unit is plugged in.

8-2. QC TEST MODE.

The washer must be empty.

■ Card Type

1. Insert Service Card

2. Display

3. Press the Start button repeatedly to cycle through the test modes.

■ Coin Type

1. Open the Service Door

2. Display

3. Press the Start button repeatedly to cycle through the test modes.

Number of times the

START button is pressed

Check Point

None

1time

2 times

3 times

4 times

5 times

6 times

7 times

8 times

9 times

10 times

11 times

12 times

13 times

14 times

15 times

Turns on all lamps and locks the door

Tumble Clockwise.

Low Speed Spin

High Speed Spin

Inlet valve for main water turns on.

Inlet valve for hot wash turns on.

Inlet valve for softener turns on.

Inlet valve for bleach turns on.

Tumble counter clockwise.

Drain Pump turns on

Turns on all lamps.

Button Checks.

High Speed Spin

Displayed 1F81 and ES XX alternately. - XX

(Version)

rpm (40~50)

rpm (600)

rpm (1000)

Water level frequency (261~)

Water level frequency (261~)

Water level frequency (261~)

Water level frequency (261~)

rpm (40~50)

Water level frequency (261~)

Displayed 1F81 and ES XX alternately.

Displayed 1F81 and ES XX alternately.

rpm (1000)

Display

8-3. HOW TO CHECK THE WATER LEVEL FREQUENCY

■ Press and hold the ADD SUPER WASH and PERMANENT PRESS buttons simultaneously.

When you check the water level, the first digit is a 0 which means 2.

A display indicating 041 is a water level frequency of 241 multiplied by 0.1 KHz , for an

actual frequency of 24.1 KHz.

8-4. HOW TO CHECK THE RPM

■ Press the ADD SUPER WASH AND WHITES button simultaneously.

Under 200 rpm: The display indicates the rpm. (Under 200 rpm)

Over 200 rpm: The display indicates the rpm. (x 10 rpm)

So, for example a display indicating 050 : rpm of 050 x 10 rpm = 500rpm

Page 20

19

8-5. ERROR DISPLAY

• If you press the ST AR T button when an error is displayed, any error except will disappear and the

machine will go into the pause status.

ERROR SYMPTOM CAUSE

WATER INLET

ERROR

• Correct water level (246) is not reached within 3 minutes

after water is supplied or it does not reach the preset water

level within 12 minutes.

• The load is too small.

• The appliance is tilted.

• Laundry is gathered to one side.

• Non distributable things are put into the drum.

1

2

IMBALANCE

ERROR

• Not fully drained within 3 minutes.

3

DRAIN

ERROR

• Water is overflowing (water level frequency is over 213).

※ If is displayed, the drain pump will operate to

drain the water automatically.

4

OVER FLOW

ERROR

• The SENSOR SWITCH ASSEMBLY is out of order.

5

PRESSURE

SENSOR

ERROR

• Door not all the way closed.

• Loose electrical connections at door switch and

PWB Assembly.

• The DOOR SWITCH ASSEMBLY is out of order.

6

DOOR OPEN

ERROR

Page 21

20

ERROR SYMPTOM CAUSE

• The connector (3-pin, male, white) in the MOTOR

HARNESS is not connected to the connector

(3-pin, female, white) of STATOR ASSEMBLY.

• The electric contact between the connectors

(3-pin, male, white) in the MOTOR HARNESS

and 4-pin, female, white connector in the MAIN PWB

ASSEMBLY is bad or unstable.

• The MOTOR HARNESS between the STATOR

ASSEMBLY and MAIN PWB ASSEMBLY is cut (open

circuit).

• The hall sensor is out of order/defective.

7

LOCKED

MOTOR

ERROR

• Loose Ball Sensor Connector.

• Ball Sensor is out of order.

※ Displayed only when the START button is first pressed

in the QC Test Mode.

8

BALL SENSOR

ERROR

•

Disconnection of Card Reader Wire.

10

CARD

READER

ERRER

• EEPROM is out of order.

※ Displayed only when the START button is first pressed

in the QC Test Mode.

9

EEPROM

ERROR

Page 22

21

9. DIAGNOSIS AND TROUBLESHOOTING

1. Be careful of electric shock if disconnecting parts while troubleshooting.

2. First, check the connection of each electrical terminal with the wiring diagram.

3. If you replace the MAIN PWB ASSEMBLY, reinsert the connectors correctly.

NO

YES

YES

YES

YES

NO

NO

NO

NO

YES

PWB ASSEMBLE, DISPLAY

5 5

5

5

1

3

4

Is the supplied voltage 120 V AC?

Is the voltage between the FILTER ASSEMBLY

connectors

and 120 V AC?

Is the LED lamp on?

Are the connectors

on the PWB loose?

Is wire of the DISPLAY PWB ASSEMBLY

broken?

Replace DISPLAY PWB ASSEMBLY

or repair wire.

Check the fuse or reset

the circuit breaker.

Replace the FILTER

ASSEMBLY (CIRC).

Replace MAIN PWB

ASSEMBLY.

Reconnect.

Replace the CABLE

(HARNESS)

NO POWER

WARNING

!

Page 23

22

NO

YES

YES

NO

YES

NO

YES

NO

NO

YES

NO

Main washer

Safterner

Is the tap opened?

Is the tap frozen?

Is the water supply shut-off?

Is filter in the inlet valve clogged with

foreign material?

Open the tap.

After separating the hose

from the washing machine

soak in hot water for 10

minutes.

Is resistance between each terminal of the INLET

V ALVE ASSEMBLY 0.8-1.2

kΩ

?

Verify the voltage of the inlet valve connector is

120 V AC.

Refer to page 18, QC TEST MODE.

Replace the INLET

V ALVE ASSEMBLY.

※Make sure the tap is closed before

replacing.

Check electrical connection.

Replace the MAIN PWB

ASSEMBL Y.

IE ERROR (NO WATER SUPPLY)

Clean the filter of

INLET V ALVE ASSEMBLY

Page 24

23

NO

YES

YES

NO

NO

NO

NO

YES

YES

NO

12

34

(Yellow 4pin)

Repair the DRAIN HOSE

ASSEMBL Y.

Reconnect or repair the

connector

Replace the DRAIN

PUMP ASSEMBL Y.

Replace the MAIN PWB

ASSEMBL Y.

Is the drain hose twisted or frozen?

Is the connector disconnected or disassembled?

Is the coil of the drain pump too high or low?

(resistance of the coil is 10-20 Ω)

When checking voltage between connectors

(

and ) during drain, is the voltage 120 V AC

as in the figure?

OE ERROR (DRAIN TROUBLE)

Page 25

24

YES

YES

YES

NO

NO

YES

NO

Main washer

softener

Hose

PRESSURE S/W ASSEMBLY

YES

Hose

PRESSURE S/W ASSEMBLY

YES

NO

Replace the INLET

V ALVE ASSEMBLY.

※Make sure the tap is closed

before replacing.

Replace the

PRESSURE S/W

ASSEMBL Y.

Replace the

PRESSURE S/W

ASSEMBL Y.

Is resistance between each terminal of INLET

V ALVE ASSEMBLY 0.8~1.2kΩ?

Is water continuously supplied?

Is PRESSURE S/W ASSEMBL Y broken?

Check electrical connection.

Replace the MAIN PWB ASSEMBL Y.

Is PRESSURE S/W ASSEMBL Y broken?

Check electrical connection.

Replace the MAIN PWB ASSEMBL Y.

FE ERROR

PE ERROR (

PRESSURE S/W TROUBLE)

Page 26

25

YES

NO

NO

YES

DOOR S/W

ASSEMBLY

dE ERROR (DOOR ERROR)

Was the load too large?

Is DOOR SWITCH ASSEMBLY broken?

Does the spring of Latch Hook actuate?

Check the DOOR SWITCH

ASSEMBLY Connector and

MAIN PWB ASSEMBLY

(Blue 4 pin , Yellow 4 pin

and white 3 pin connector .

Replace the DOOR

SWITCH ASSEMBLY.

Replace Door Assembly.

1

3

2

Page 27

26

YES

YES

YES

NO

NO

Base Packing

Level

Have all the transit bolts and base packing

been removed?

Remove the transit bolts

and Base packing.

Move the washer or

reinforce the floor.

Is the washer installed on a solidly constructed

floor?

Check if the washer is perfectly level as follows:

Check the leveling of the washer with a level

and check that the washer is stable.

Put an unbalance part (rubber) inside of drum

and start QC test mode and run in high spin

(Refer to page 17)

When the machine is spinning in high speed,

verify that it is stable.

VIBRATION & NOISE IN SPIN

If it is not stable, adjust feet accordingly. After

the washer is level, tighten the lock nuts up

against of the base of the washer. All lock nuts

must be tightened.

If you do not have the unbalance part, put 4.5 to

6.5 lbs (2 to 3 kg) of clothing.

When the machine is spinning at high speed,

verify that it is stable.

Page 28

27

YES

YES

YES

NO

NO

NO

YES

DRAWER

DRAWER

CAP

Is water supplied?

Are the plugs correctly connected to the terminals

of the INLET V ALVE ASSEMBLY?

Is detergent/softener/bleach put in the correct

compartment of the DRAWER?

Is the detergent/softener/bleach CAP clogged?

Refer to page 22

IE ERROR

Check the wiring.

Put it in the correct

compartment

Clean the CAP and

DRAWER

DETERGENT/SOFTENER/BLEACH DOES NOT FLOW IN

ABNORMAL SOUND

Secure the bolt.

Replace the ST ATOR

ASSEMBL Y or ROTOR

ASSEMBL Y.

Is the motor bolt loose?

Is there friction noise coming from the motor?

Page 29

28

YES

YES

SUDS OVERFLOW FROM THE APPLIANCE

Is HE(High Efficiency) detergent used?

Is the proper amount of detergent used

as recommended?

Recommend to reduce the amount

of detergent.

This appliance has an automatic suds sensing function which

prevents overflow.

When excessive suds are sensed, the suds removing

implementations such as drain, water input, and pause will

operate, without rotating the drum

Page 30

29

10. DISASSEMBLY INSTRUCTIONS

DISPLAY PWB ASSEMBLY

CONTROLPANELASSEMBLY

DISPLAYPWBASSEMBLY

✽ Be sure to unplug the machine before disassembling and repairing the parts.

1. Pull out the DRAWER.

Do not pull out the DRAWER too forcefully as it

can be broken.

2. Unscrew 3 screws

3. Disassemble the CONTROL P ANEL ASSEMBLY

- Pull out the CONTROL P ANEL .

Do not pull out the CONTROL P ANEL too

forcefully as it can be broken.

4. Disconnect the DISPLA Y PWB ASSEMBLY

connector from CABLE (HARNESS).

1. Disassemble the CONTROL P ANEL ASSEMBLY

(refer to page 28)

2. Unscrew the 4 screws from the CONTROL PANEL

ASSEMBL Y.

3. Disassemble the DISPLA Y PWB ASSEMBLY.

⇩

DRAWER

CONTROL PANEL

ASSEMBLY

CONTROL PANEL

ASSEMBLY

Page 31

30

TOP PLATE ASSEMBLY

1. Disassemble the CONTROL P ANEL ASSEMBLY

(refer to page 29)

2.

Remove 2 screws on the

CONTROL P ANEL

frame.

3.

Push the TOP PLATE backward forcefully.

4.

Lift the TOP PLATE.

Page 32

31

1. Disassemble the CONTROL P ANEL ASSEMBLY

(refer to page 29).

2. Disassemble the

TOP PLATE

ASSEMBL Y

(refer to page 30).

3. Unscrew a screw on PRESSURE SWITCH

ASSEMBL Y

4. Remove all wire from hooks.

5. Remove the Protective Cover.

6. Disconnect the connectors.

7. Unscrew 1 screw on the back.

8. Disassemble the MAIN PWB ASSEMBL Y.

CONNECTOR

PROTECT COVER

MAINPWBASSEMBLY

Page 33

32

1. Disassemble the CONTROL P ANEL ASSEMBLY

(refer to page 29).

2. Disassemble the

TOP PLATE

ASSEMBL Y

(refer to page 30).

3. Disassemble the clamps and hoses.

4.

Disassemble the bellows at the lower side of DISPENSER

1. Disassemble the CONTROL P ANEL ASSEMBLY

(refer to page 29).

2. Disassemble the

TOP PLATE

ASSEMBL Y

(refer to page 30).

3.

Disassemble the 4 connectors from the VALVES.

4. Disassemble the clamps and hoses.

5. Unscrew the 2 screws in the back.

Connector Color

①①

Blue Housing (OR-BK)

②②

White Housing (WH-BK)

③③

Blue Housing (GY -BK)

④④

Red Housing (BL-BK)

DISPENSER ASSEMBL Y

Clamp

DISPENSERASSEMBLY

INLETVALVEASSEMBLY

Page 34

33

1. Disassemble the CONTROL P ANEL ASSEMBLY

(refer to page 29).

2. Open the DOOR.

3. Disassemble the CLAMP ASSEMBL Y.

4. Unscrew the 4 screws from the upper part of the

CABINET COVER.

5. Unscrew the screw from CAP COVER.

6. Unscrew the screw from inside CAP COVER.

7. Put a flat (

-

) screwdriver or putty knife into both sides

of the CAP COVER, and pull it out.

3

CAP COVER

CABINETCOVER

Page 35

34

9. Tilt the CABINET COVER.

10. Disconnect the DOOR S/W connector.

※※

NOTE: When assembling the CABINET

COVER, connect the connector.

1 1. Lift and separate the CABINET COVER.

8. Unscrew the screw from the lower side of the CABINET

COVER.

1. Disassemble the CABINET COVER

(refer to page 32).

2. Disassemble the CLAMP ASSEMBL Y.

3. Disassemble the GASKET.

TUB GASKET

CLAMP

GASKET

Page 36

35

1. Open the DOOR.

2. Unscrew the 7 screws from the HINGE COVER.

3. Put a flat ( - ) screwdriver into the openng of the hinge, and

pull out the HINGE COVER.

4. Unscrew a screw from the lower side of DOOR.

5. Lift door and remove.

DOORASSEMBLY

1. Open the DOOR and disassemble the CLAMP

ASSEMBL Y.

2. Unscrew the 2 screws.

3. Remove connector from DOOR S/W ASSEMBLY.

DOOR SWITCH

ASSEMBLY

CLAMP

ASSEMBLY

DOORLOCKSWITCHASSEMBLY

※※

Be careful! The door is heavy .

※※

NOTE

• Reconnect the connector after replacing the

DOOR SWITCH ASSEMBL Y.

HINGE COVER

Page 37

36

PUMP ASSEMBLY

THERMISTOR

1. Disassemble the CABINET COVER

(refer to page 33).

2.

Separate the PUMP HOSE and the BELLOWS

from the PUMP ASSEMBLY.

3. Unscrew 2 screws.

4.

Remove the PUMP ASSEMBLY in arrow

direction.

1. Disassemble the CABINET COVER

(refer to page 33).

2.

Unplug the white connector from the THERMISTOR.

3.

Pull it out by holding the bracket of the THERMISTOR.

1. Disassemble the CONTROL P ANEL ASSEMBLY

(refer to page 29).

2. Disassemble the

TOP PLATE

ASSEMBL Y

(refer to page 30).

3. Disassemble two (or three) connectors from

the NOISE FILTER.

4. Unscrew a screw from the TOP BRACKET.

NOISE FILTER

NOISEFILTER

Page 38

37

BACK COVER

SENSOR ASSEMBLY(BALL SENSOR)

1.

Unscrew the 4 screws from the BACK COVER.

2.

Unscrew a screw from the lower-right side of the

CABINET.

3.

Disconnect the connector from PWB HARNESS.

Page 39

38

ROTOR

MOTOR ASSEMBLY

DAMPER

1.

Disassemble the BACK COVER.

2.

Remove the bolt.

3.

Pull out the ROTOR.

4.

Unscrew the 2 screws from the tub bracket.

5.

Remove the 6 bolts on the stator.

6.

Unplug the 2 connectors from the STATOR.

1.

Disassemble the CABINET COVER or BACK COVER.

2.

Disassemble the damper hinges from the tub

and base.

3.

Separate the dampers.

※※

NOTE

• Do not re-use an old damper pin. Always

replace it with a new one.

STATOR

Page 40

39

11. EXPLODED VIEW

11-1. CABINET & CONTROL P ANEL ASSEMBLY

A105

A201

A155

A440

A430

A100

A101

A104

A102

F110

F210

A485

A455

A450

A110

A150

A154

A131

A390

A153

A151

A130

A140

A133

A310

A300

A303

A200

A141

A410

A152

A103

A490

A220

A495

Page 41

40

11-2.

DRUM & TUB ASSEMBLY

K344K346

K123

K143

K360K351

F140

K411

K410

K110

K140

K310

K510

K111

K350

K115

K340

K342

K131

K311

F315

F465

K125

F466

F467

K550

F463

K130

K530

F464

K121

K122

K610

K611

K141

F145

K520

F461

K540

F468

K105

K135

Page 42

41

11-3.

DISPENSER ASSEMBLY

˚

HOT (RED)

COLD (BLUE)

F324

F462

F300

F226

F220

F440

F436

F431

F430

F160

F170

F441

F435

F120

F130

F432

A275

A276

F321

F326

F323

Loading...

Loading...