Page 1

SERVICE MANUAL

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL.

Internal Use Only

MODEL: CJ65 (CJ65, CJS65F)

MODEL: CJ65

(CJ65, CJS65F)

Mini Hi-Fi System

P/NO : AFN77612196

MARCH, 2017

Page 2

CONTENTS

SECTION 1 ........ GENERAL

SECTION 2 ........ CABINET & MAIN CHASSIS

SECTION 3 ........ ELECTRICAL

1-1

Page 3

SECTION 1

SUMMARY

CONTENTS

SERVICING PRECAUTIONS ............................................................................................................................ 1-3

ESD PRECAUTIONS ......................................................................................................................................... 1-5

HIDDEN KEY MODE ......................................................................................................................................... 1-6

1. HIDDEN KEY MODE TABLE .................................................................................................................... 1-6

2. HIDDEN KEY MODE DESCRIPTION ....................................................................................................... 1-7

SERVICE INFORMATION FOR EEPROM ........................................................................................................ 1-9

PROGRAM DOWNLOAD GUIDE .................................................................................................................... 1-10

FOTA UPDATE STEP USING BT APP .......................................................................................................... 1-12

SPECIFICATIONS ........................................................................................................................................... 1-14

1-2

Page 4

SERVICING PRECAUTIONS

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

Storage in conductive bag

Drop impact

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

NEVER look directly at the laser beam, and don’t allow

contact with fingers or other exposed skin.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a cotton swab should be used, taking care not to distort lens.

Pressure

Magnet

How to hold the pick-up

Cotton swab

Conductive Sheet

6) Never attempt to disassemble the pick-up.

Spring has excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab.

(Do not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much

of this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

1-3

Pressure

Page 5

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These components

are sensitive to, and easily affected by, static electricity. If such static electricity is high voltage, components

can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must be

taken, therefore, to avoid repair or storage where the temperature or humidity is high, where strong magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1 M)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Armband

Resistor

(1 M)

Resistor

(1 M)

Conductive

Sheet

1-4

Page 6

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive surface

such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can generate

static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL TRIANGLE, IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

“DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A RISK OF

ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN SERVICE

LITERATURE.

1-5

Page 7

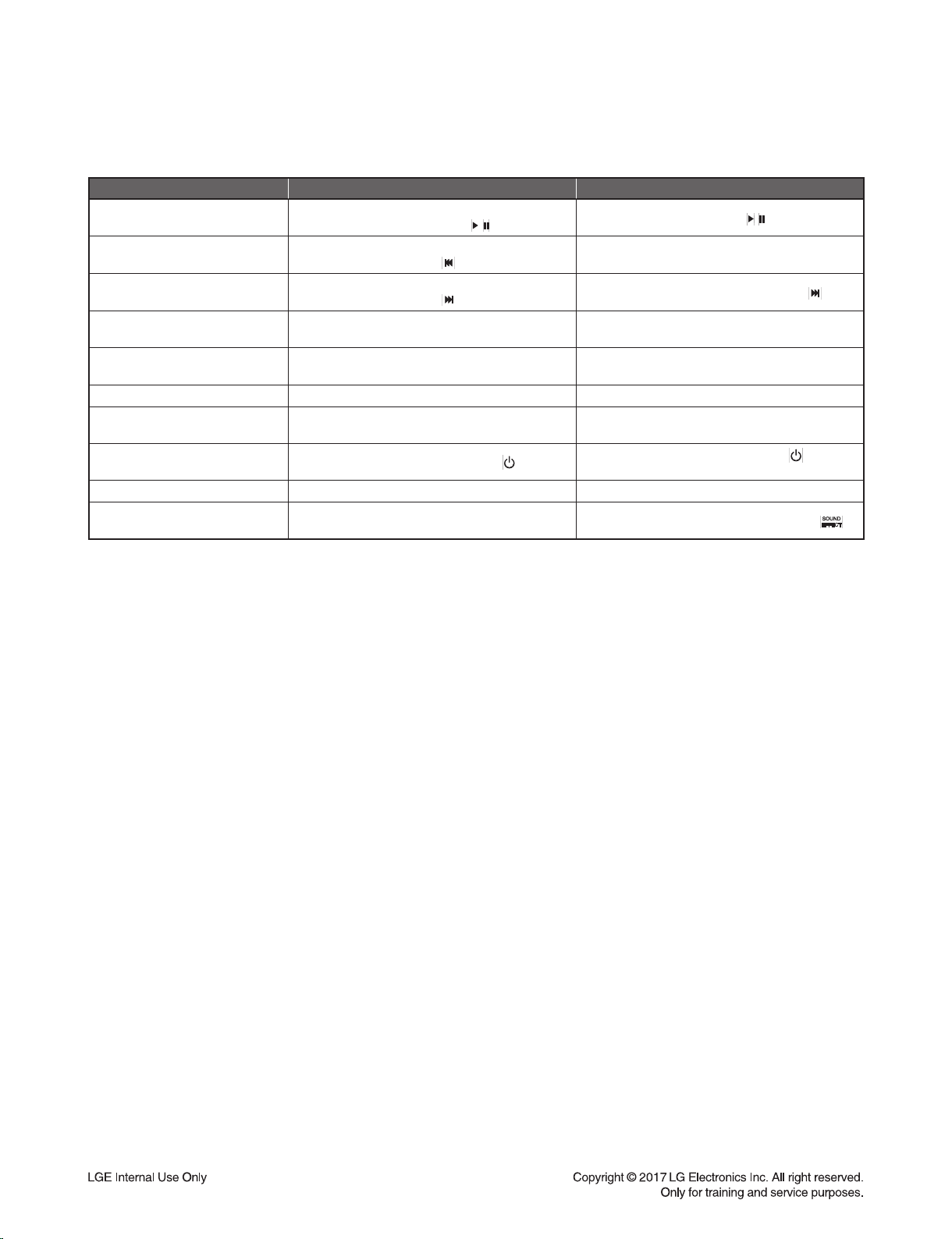

HIDDEN KEY MODE

1. HIDDEN KEY MODE TABLE

HIDDEN MODE ENTRANCE KEY(Audio) EXIT KEY

Version Check

EEPROM INITIAL

Option EDIT

APD Test Display

Disc Lock On/Off

Power Disc Lock On/Off

Demo ALL Key Lock

BT Auto Power On/Off Front/Remote Control Key ‘Power’ for 5s

ChildSafe On/Off Volume 0(Min) + Front ‘OK’ for 3s Volume 0(Min) + Front ‘OK’ for 3s

Measure

Front ‘Stop’

+ Remote Control Key ‘Play’ for 5s

Front ‘Stop’

+ Remote Control Key ‘ ‘ for 5s

Front ‘Stop’

+ Remote Control Key ‘ ‘ for 5s

Front ‘Stop’

+ Remote Control Key ‘3’ for 5s

Front ‘Stop’ +

Remote Control Key ‘Stop’ for 5s

Front ‘Stop’ + Front ‘Open’ for 5s Front ‘Stop’ + Front ‘Open’ for 5s

Front ‘Stop’

+ Remote Control Key ‘9’ for 5s

Front ‘Stop’

+ Remote Control Key ‘1’ for 5s

/

Remote Control Key ‘Play’ for 1.5s

Auto exit

Front ‘Stop’ + Remote Control Key ‘ ‘

Auto exit

Front ‘Stop’

+ Remote Control Key ‘Stop’ for 5s

Front ‘Stop’

+ Remote Control Key ‘9’ for 5s

Front/Remote Control Key ‘Power’

SET Power Off

Remote Control Key ‘SOUND EFFECT’

/

1-6

Page 8

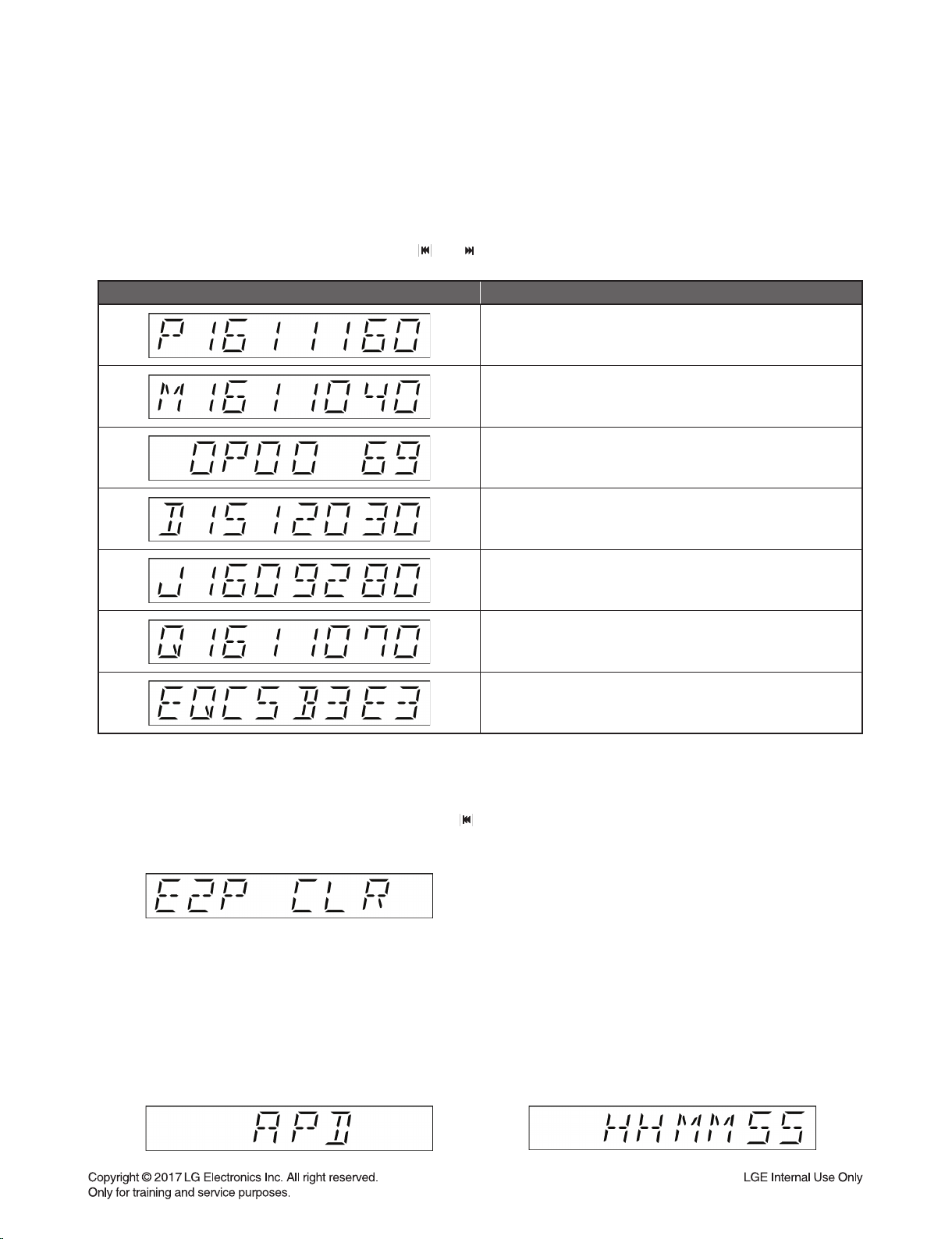

2. HIDDEN KEY MODE DESCRIPTION

2-1. Version Check

- Function : Version Check.

- Entrance Key : Front ‘Stop’ + Remote Control Key ‘Play’ for 5s.

- Exit Key : Remote Control Key ‘Play’ for 1.5s.

- Operation explanation : Remote Control Key OR .

VFD Display (Example) Result

MCS Version

MICOM Version

OPTION Version

DEMO Version

DJ PRO Version

EQ Version

EQ Check sum Version

2-2. EEPROM Initial

- Function : Initialize data stored in EEPROM and BACKUP RAM data.

- Entrance Key : Front ‘Stop’ + Remote Control Key ‘ ‘ for 5s.

- Exit Key : Auto exit.

- Explanation : ‘E2P CLR’ is displayed on the VPD and turn off the power automatically.

2-3. OPTION EDIT (EEPROM)

- Refer to the page 00.

2-4. APD Test Display

- Function : Auto Power Down timer is displayed on VFD.

- Entrance Key : Front ‘Stop’ + Remote Control Key ‘3’ for 5s.

- Exit Key : Auto Exit.

- Explanation : display APD Timer HH=(hour) MM=(min), SS=(sec).

1-7

Page 9

2-5. Disc Lock On/Off

- Function : Lock Open Key.

- Entrance Key : Front ‘Stop’ + Remote Control Key ‘Stop’ for 5s.

- Exit Key : Front ‘Stop’ + Remote Control Key ‘Stop’ for 5s.

- Operation Explain : Open Key Block ‘LOCKED’.

2-6. Power Disc Lock On/Off

- Function : Lock Power / Open / Front Volume Key.

- Entrance Key : Front ‘Stop’ + Front ‘Open’ for 5s.

- Exit Key : Front ‘Stop’ + Front ‘Open’ for 5s.

2-7. Demo All Key Lock

- Function : All key is blocked on Demo Mode.

- Entrance Key : Front ‘Stop’ + Remote Control Key ‘9’ for 5s.

- Exit Key : Front ‘Stop’ + Remote Control Key ‘9’ for 5s.

- Operation Key : In demo mode, all key blocks.

(only the volume key is effective when All Key Lock is enabled.)

To release Demo Mode, it is available after All Key Lock Off.

2-8. BT Auto Power On/Off

- Function : Ability to disable BT Auto Power On function by network shutdown regulation.

- Entrance Key : Front/Remote Control Key ‘Power’ for 5s.

- Exit Key : SET Power Off with Front / Remote Control Key ‘Power’.

2-9. ChildSafe On/Off

- Function : Power off Fade-in to previous volume.

- Entrance Key : Volume 0(Min) + Front ‘OK’ for 3s.

- Exit Key : Volume 0(Min) + Front ‘OK’ for 3s.

2-10. Measure

- Function : Change to EQ for Measure mode,

Down algorithm operation Disable,

Change to output setting value for measure mode.

- Entrance Key : Front ‘Stop’ + Remote Control Key ‘1’ for 5s

- Exit Key : Remote Control Key ‘SOUND EFFECT’

1-8

Page 10

SERVICE INFORMATION FOR EEPROM

POWER ON

VFD “NO DISC” status

It is possible at any function.

(ex. It is possible at VFD “NO USB” status, too.)

This is an example.

Front ‘Stop’ + Remote control ‘ ’

push same timing during 5 s

FLD “OP00-…..”

Move to appropriate position

And make changes with remote control

“ , , , REPEAT” key.

/

Press ‘Stop’ Key

VFD “WRITE OK”

DETECT NEW EEPROM

(OPTION EDIT SCREEN)

(LGEAP)

NAME

OPT0

OPT1

OPT2

OPT3

OPT4

OPT5

OPT6

OPT7

OPT8

OPT9

OPT10

OPT11

OPT12

OPT13

OPT14

HEX

01

31

2D

26

49

00

00

43

4A

36

35

00

00

00

00

(LGEUS)

HEX

01

31

2D

26

49

00

00

43

4A

36

35

00

00

00

00

Front ‘Stop’ + Remote control ‘ ’

push same timing during 5 s

VFD “E2P CLR”

Completed

1-9

Page 11

PROGRAM DOWNLOAD GUIDE

1. CD PROGRAM

Download program file name must be HG740_CJ65_YYMMDDX.bin

If security program(Water Wall) is activated on PC, you must save the file to the USB storage device

and disable the security software, then download the file to your set.

Downloading file proceeds in the same way at USB1 function and USB2 function.

Caution:

When downloading the file, you should neither unplug the USB device, change to the other function,

nor power off the device. USB device must be unplugged when the downloading process is completed.

ON VFD DISPLAY SCREEN

NO USB

Insert USB device at USB function.

SEARCH

MICOM UP

FINISH

AUTO POWER OFF

1) (Fast) Format USB device.

2) Copy Firmware file to USB device.

1-10

Page 12

2. EQ & DEMO PROGRAM

Download program file name must be EQ_PRG.BIN

If security program(Water Wall) is activated on PC, you must save the file to the USB storage device

and disable the security software, then download the file to your set.

Downloading file proceeds in the same way at USB1 function and USB2 function.

Caution:

When downloading the file, you should neither unplug the USB device, change to the other function,

nor power off the device. USB device must be unplugged when the downloading process is completed.

ON VFD DISPLAY SCREEN

NO USB

Insert USB device at USB function.

SEARCH

EQDEMOUP

FINISH

AUTO POWER OFF

1) (Fast) Format USB device.

2) Copy Firmware file to USB device.

1-11

Page 13

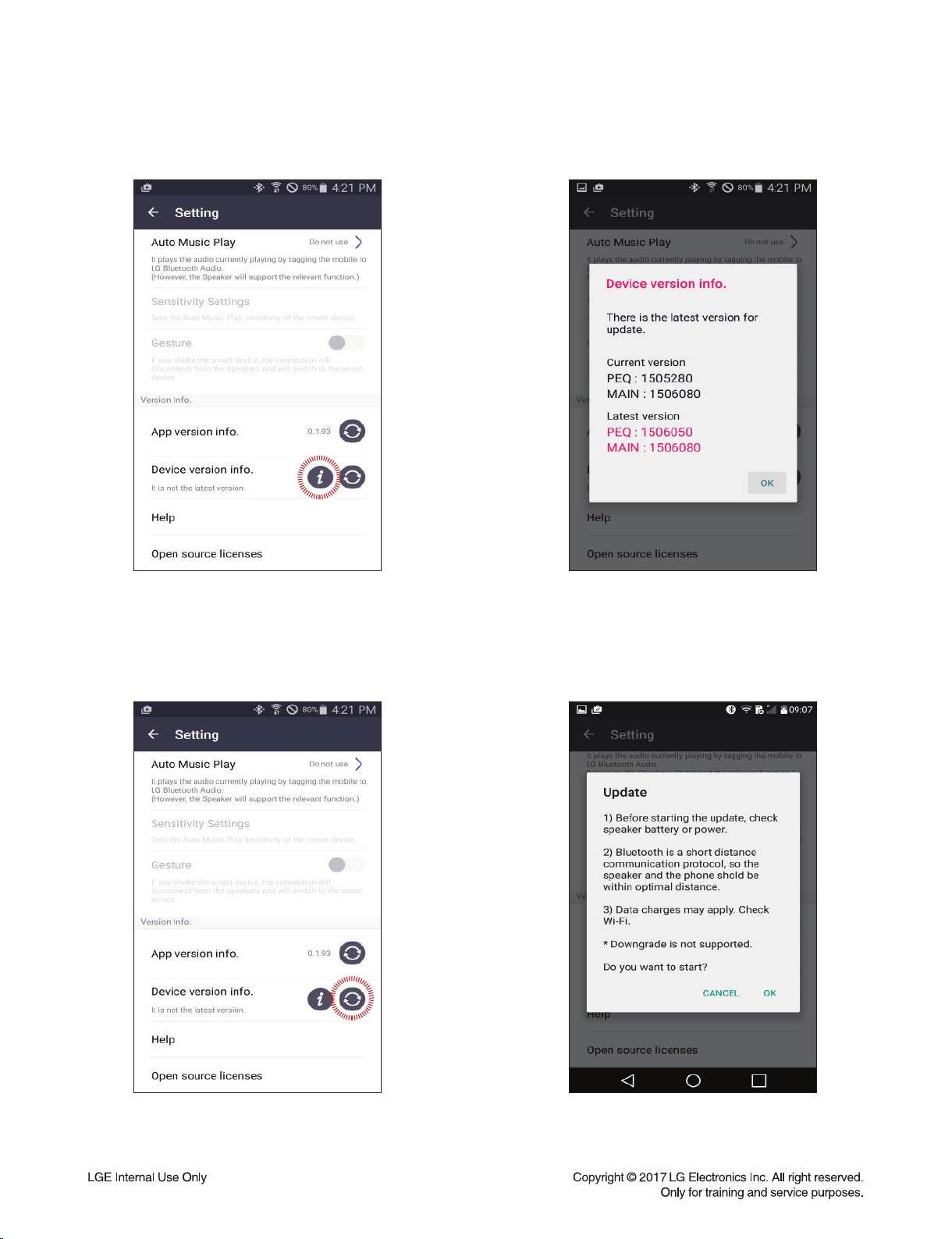

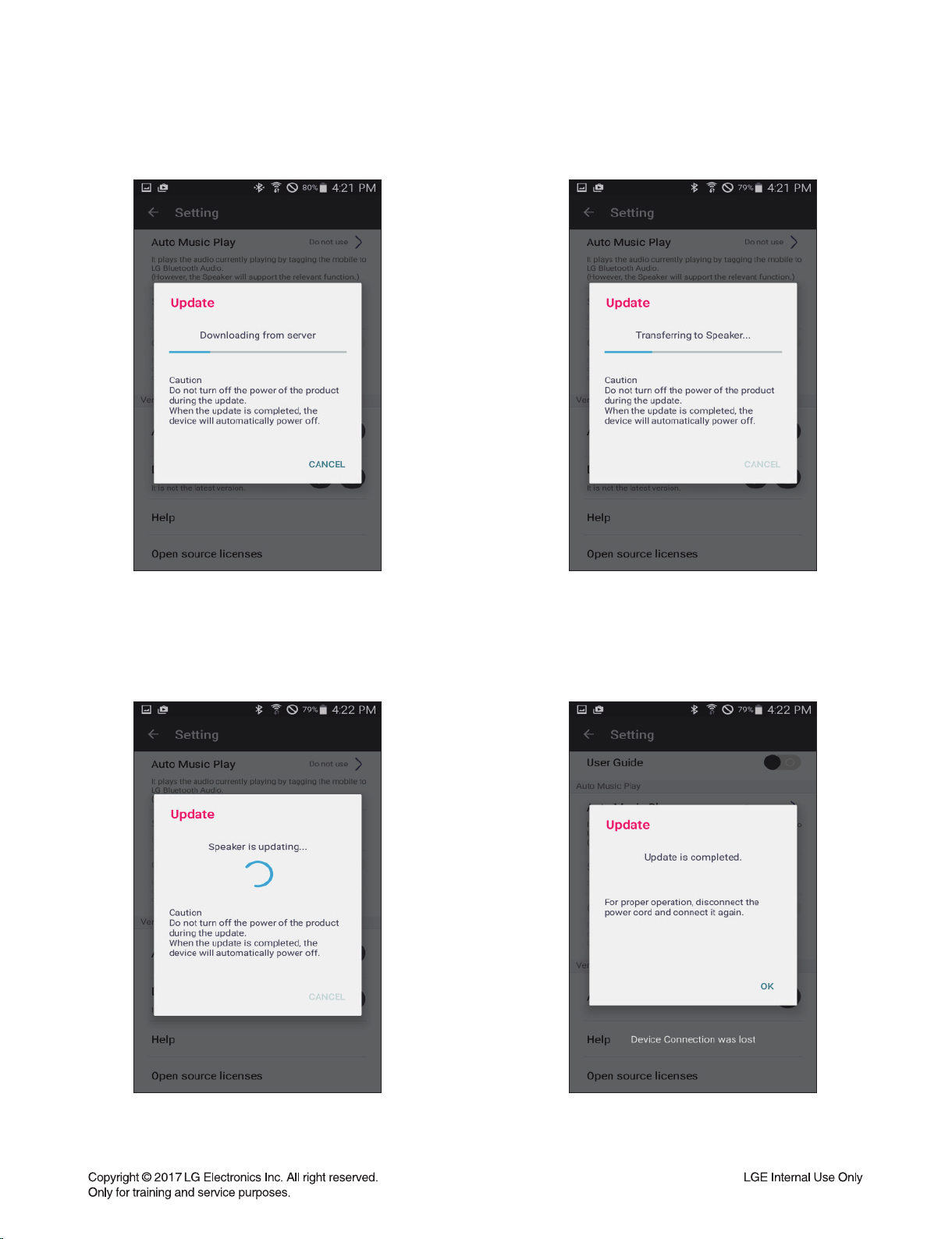

FOTA UPDATE STEP USING BT APP

Step1 : App connecting

(Check FW version)

After connecting the BT App with SET,

the user could fi nd the “Device Version info” on

Setting tab.

Step2 : Device version info

When touch the “Device Version info” button,

user could fi nd the current and latest SET

version on pop-up menu.

Step3 : Select update button

When touch the “Update” button, user could

update the SET fi rmware using FOTA.

Step4 : Confi rm update

Select the OK button on the caution message.

1-12

Page 14

Step5 : Download from CDN server

Step6 : Transfer FW

1st step is download from CDN server to

smart phone. The progress bar is displayed

on BT App.

After completed the download from server,

smart phone start to transfer the fi rmware to the

SET. The progress bar is displayed on BT App.

Step7 : FW Flash Writing Step8 : FOTA complete

After completed the download from the smart

phone, the SET overwrite the fi rmware to fl ash

memory.

When fi nishing the fl ash memory writing, pop-up

message about fi nish is displayed and the SET

auto power off.

1-13

Page 15

SPECIFICATIONS

• GENERAL

Power requirements Refer to the main label on the unit.

Power consumption Refer to the main label on the unit.

Networked standby : 0.5 W

(If all network ports are activated.)

Dimensions (W x H x D) Approx. 350 mm x 163 mm x 251 mm

Operating temperature 5 °C to 35 °C (41 °F to 95 °F)

Operating humidity 60 %

• INPUTS

Analog audio in (AUX IN) 2.0 Vrms (1 kHz, 0 dB), 75 Ω, RCA jack (L, R)

Portable in (PORT.IN) 1.0 Vrms (3.5 mm stereo jack) x 1

Microphone (MIC) Sensitivity 20 mV (1 kHz), 6.3 mm jack x 1

• TUNER

FM Tuning Range 87.5 to 108.0 MHz or 87.50 to 108.00 MHz

AM Tuning Range 522 to 1,620 kHz, 520 to 1,710 kHz or 522 to 1,710 kHz

• SYSTEM

Frequency Response 70 to 20,000 Hz

Signal-to-noise ratio More than 75 dB

Dynamic range More than 75 dB

Bus Power Supply (USB) 5 V 500 mA

• AMPLIFIER (RMS Output power)

Total 900 W RMS

Front 450 W RMS X 2 (3 Ω at 1 kHz, 20 % THD)

• FRONT SPEAKER

Type 2 Way 2 Speaker

Impedance 3 Ω

Rated Input Power 450 W RMS

Max. Input power 900 W RMS

Net Dimensions (W x H x D) Approx. 299 mm x 363 mm x 230 mm

• Design and specifications are subject to change without notice.

1-14

Page 16

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS ......................................................................................................................................... 2-3

1. CABINET AND MAIN FRAME SECTION ................................................................................................. 2-3

2. PACKING ACCESSORY SECTION ......................................................................................................... 2-7

3. SPEAKER SECTION ................................................................................................................................ 2-8

DISASSEMBLY INSTRUCTIONS ................................................................................................................... 2-9

1. Case Top ................................................................................................................................................... 2-9

2. Bracket ...................................................................................................................................................... 2-9

3. Panel Rear .............................................................................................................................................. 2-10

4. MAIN Board & SMPS Board ................................................................................................................... 2-11

5. Main PCB & SMPS PCB ......................................................................................................................... 2-12

6. Panel PCB & Multi Knob ......................................................................................................................... 2-13

7. Bracket SMPS ......................................................................................................................................... 2-14

8. MD ........................................................................................................................................................... 2-14

2-1

Page 17

2-2

Page 18

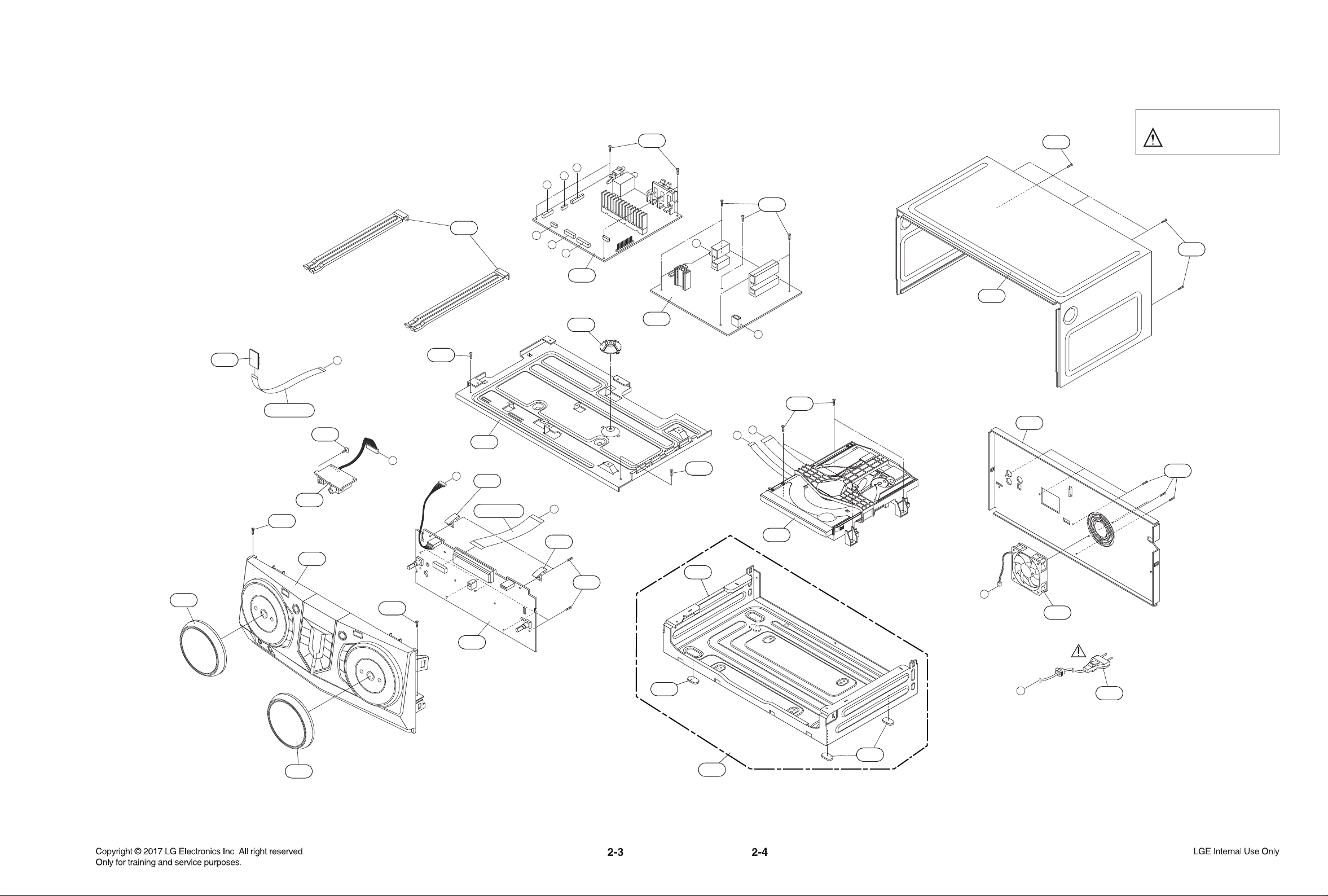

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION (CJ65)

D

A

B

MIC

262

BT

265

265

252

252

A42

H

300

498

A52

C

F

CABLE2

A00

254

254

443

E

FRONT

A43

266

443

G

443

274

443

263

498

443

443

264

443

443

D

E

F

G

C

B

A

A47

273

A46

443

MAIN

SMPS

443

H

CABLE1

A45

272

A44

NOTES) THE EXCLAMATION POINT WITHIN AN

EQUILATERAL TRIANGLE IS INTENDED

TO ALERT THE SERVICE PERSONNEL

TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION IN SERVICE

LITERATURE.

Page 19

Page 20

2. PACKING ACCESSORY SECTION

801 Owner’s manual

825 FM antenna

Packing

803

808 Batteries

900 Remote control

804 Bag

802 Box

2-7

Page 21

3. SPEAKER SECTION

• FRONT SPEAKER (CJS65F)

A60

2-8

Page 22

DISASSEMBLY INSTRUCTIONS

1. Case Top

1-1) Remove the 5 Screws.

1-2) Remove the Case Top.

Figure 1

2. Bracket

2-1) Remove the two Brackets between Front & Back Panel.

You can easily remove the Bracket after the hook detach from Front Panel.

Figure 2

2-9

Page 23

3. Panel Rear

3-1) Remove the 4 Screws from the Panel Rear.

3-2) Remove the Power Cord & FAN Cable from the SMPS Board.

3-3) Remove the Panel Rear.

2

2

1

Figure 3

2-10

Page 24

4. MAIN Board & SMPS Board

4-1) Remove the 9 Screws from the MAIN Board & SMPS Board.

4-2) Remove the 6 Cables from the MAIN Board.

4-3) Remove the Power Cord from the SMPS Board.

4-4) Remove the MAIN Board & SMPS Board.

2

2

3

1

Figure 4

2-11

Page 25

5. Main PCB & SMPS PCB

5-1) Remove the 2 Screws.

5-2) Unhook the 5 Locking Tabs by using Flat-head screwdriver.

5-3) Remove the Panel Front Assembly.

Figure 5

2-12

Page 26

(H1)

(L2)

(L2)

(H1)

6. Panel PCB & Multi Knob

6-1) Multi Knob

6-1-1) Insert a Flat-head screwdriver in the hole (H1).

6-1-2) Remove the Multi Knob.

6-2) Jack PCB

6-2-1) Remove the 2 Screws.

6-2-2) Remove the Jack PCB.

6-3) BT Module

6-3-1) Unhook the Locking tab (L1).

6-3-2) Remove the BT Module.

6-4) Front PCB

6-4-1) Remove the 7 Screws.

6-4-2) Unhook the 2 Locking tabs (L2) from the Panel PCB.

6-4-2) Remove the Front PCB.

(L1)

(H1)

(H1)

(L2)

(L2)

1

2

(H1)

(H1)

2

(L2)

(L2)

Figure 6

2-13

Page 27

7. Bracket SMPS

7-1) Remove the Bracket SMPS.

Figure 7

8. MD

8-1) Remove the 2 Screws from the MD.

8-2) Remove the MD.

Figure 8

2-14

Page 28

SECTION 3

ELECTRICAL

CONTENTS

ONE POINT REPAIR GUIDE ............................................................................................................................3-2

1. NO POWER ............................................................................................................................................3-2

2. NO BOOTING WHEN POWER ON THE SET........................................................................................3-4

3. VFD IS NOT DISPLAYED WHEN POWER ON THE SET .....................................................................3-5

4. NO OPERATION OF MD ........................................................................................................................3-6

5. NO SOUND ...........................................................................................................................................3-11

ELECTRICAL TROUBLESHOOTING GUIDE .................................................................................................3-17

1. POWER (SMPS) ...................................................................................................................................3-17

2. MCS PART CHECK ..............................................................................................................................3-20

3. IC503(GD25Q80) CHECK ....................................................................................................................3-20

4. FLD DISPLAY CHECK .........................................................................................................................3-21

5. PWM MODULATION CHECK ...............................................................................................................3-22

6. POWER AMP PART CHECK ...............................................................................................................3-23

7. TUNER / AUX FUNCTION CHECK ......................................................................................................3-24

8. TUNER FUNCTION CHECK.................................................................................................................3-24

9. CD FUNCTION .....................................................................................................................................3-25

10. DOUBLE USB FUNCTION ...................................................................................................................3-26

WAVEFORMS OF MAJOR CHECK POINT ....................................................................................................3-27

WIRING DIAGRAM ..........................................................................................................................................3-29

BLOCK DIAGRAMS ........................................................................................................................................3-31

1. SYSTEM BLOCK DIAGRAM ................................................................................................................3-31

2. SMPS BLOCK DIAGRAM .....................................................................................................................3-33

3. POWER BLOCK DIAGRAM .................................................................................................................3-35

CIRCUIT VOLTAGE CHART ........................................................................................................................... 3-37

1. INPUT VOLTAGE OF ICs .....................................................................................................................3-37

2. INPUT VOLTAGE OF CONNECTORS .................................................................................................3-37

3. VOLTAGE OF CAPACITORS ...............................................................................................................3-38

PRINTED CIRCUIT BOARD DIAGRAMS .......................................................................................................3-39

1. SMPS P.C.BOARD ...............................................................................................................................3-39

2. MAIN P.C.BOARD ................................................................................................................................3-41

3. FRONT P.C.BOARD .............................................................................................................................3-43

4. MIC P.C.BOARD DIAGRAM .................................................................................................................3-45

3-1

Page 29

ONE POINT REPAIR GUIDE

1. NO POWER

If the unit doesn’t work by no power problem, repair the set according to the following guide.

1-1. FUSE & BRIDGE DIODE

1-1-1. Solution

Please check and replace F901, BD901, TH901 or TH903 on SMPS board.

1-1-2. How to troubleshoot (Countermeasure)

1) Check if the fuse F901 is open or short-circuit.

2) Check if the bridge diode BD901 is short-circuit by over current with a digital multi meter.

3) Check if the NTC thermistor TH901 or TH903 is normal or open.

1-1-3. Service hint (Any picture / Remark)

< F901 >

If F901 is not short-circuit,

replace it with a same specifi ca-

tions one.

< BD901 >

If BD901 is short-circuit,

replace it with a new one.

3-2

< TH901 >

If TH901 is open,

replace it with a new one.

Page 30

ONE POINT REPAIR GUIDE

NO POWER

If the unit doesn’t work by no power problem, repair the set according to the following guide.

1-2. D951

1-2-1. Solution

Please check and replace D951 on SMPS board.

1-2-2. How to troubleshoot (Countermeasure)

1) Check the anode-cathod voltage of D951 with a digital multi-meter, it is normally 0.2 ~ 0.3 V.

If it doesn’t have any voltage, it’s destroyed. Replace it with a new one.

1-2-3. Service hint (Any picture / Remark)

< SMPS schematic diagram >

3-3

Page 31

ONE POINT REPAIR GUIDE

2. NO BOOTING WHEN POWER ON THE SET

The set doesn’t work when press the power button on the front board or the remote control.

2-1. FLASH MEMORY

2-1-1. Solution

Please check and replace IC501 on MAIN board.

2-1-2. How to troubleshoot (Countermeasure)

1) Check 12VA to CN102 in standby mode.

If there is no 12 VA, check the SMPS.

2) Check 12VA and PVDD when power on the set.

-

If the set doesn’t work regardless of what the KEY2 changes high to low while pressing the power button.

X500 and X501 work normally but, if you can not power on the set, replace IC500 with a new one on

the MAIN board.

2-1-3. Service hint (Any picture / Remark)

< Signal check point >

3-4

Page 32

ONE POINT REPAIR GUIDE

3. VFD IS NOT DISPLAYED WHEN POWER ON THE SET

When power on the set, any icons or characters on VFD are not displayed.

3-1. VFD

3-1-1. Solution

Please check and replace VFD300 on FRONT board.

3-1-2. How to troubleshoot (Countermeasure)

1) Check if 12 VA is output from SMPS to VFD via the MAIN board.

2) Check if Check if LED_5 V, DVCC_3 V output from the MAIN board.

3) Check if IC500 outputs VFD_D0, VFD_CLK and VFD_STB to the FRONT board.

4) Check if VFD300 output SW signal to the FRONT board.

If the SW signal isn’t output, replace VFD300 with new one.

5) check if Q300 and Q301 to the FRONT board.

If the VH signal isn’t output, replace Q300, Q301 with new one.

If the VH signal is output, replace VFD300 with new one.

3-1-3. Service hint (Any picture / Remark)

< Waveform of GR and SG signal >

3-5

Page 33

ONE POINT REPAIR GUIDE

4. NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD disc if

the servo motors in MD don’t work. This step is for checking the SPINDLE MOTOR among them.

4-1. SPINDLE MOTOR

4-1-1. Solution

Please check and replace IC400, IC401 on MAIN board.

4-1-2. How to troubleshoot (Countermeasure)

1) Check the SPDO signal from pin24 of IC401.

If no signal, check 3.3 V(RF) and X400.

2) Check the SPIN- & SPIN+ from IC400 to CN401 for driving SPINDLE motor. It is about 3.6 Vp-p.

If no signal, check +1.8 V and +5 V for IC401.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the spindle motor is sort-circuit or has any trouble, it can not rotate CD discs.

Please check the function after changing another MD.

4-1-3. Service hint (Any picture / Remark)

About 3.6 Vpp

< Waveform of SP- & SP+

for driving SPINDLE motor >

< Signal check point >

3-6

Page 34

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD disc if

the servo motors in MD don’t work. This step is for checking the SLED MOTOR among them.

4-2. SLED MOTOR

4-2-1. Solution

Please check and replace IC400, IC401 on MAIN board.

4-2-2. How to troubleshoot (Countermeasure)

1) Check the SLDO signal from Pin23 of IC400.

If no signal, check 3.3 V(RF) and X400.

2) Check the SLED+ & SLED- from IC401 to CN401 for driving SPINDLE motor. It is about 2.9 Vp-p.

If no signal, check +1.8 V and +5 V for IC401.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the sled motor is sort-circuit or has any trouble, it can not move the pickup module.

Please check the function after changing another MD.

4-2-3. Service hint (Any picture / Remark)

SL- TO CN401

SL+ TO CN401

< Waveform of SLED- & SLED+

for driving SLED motor >

< Signal check point >

3-7

Page 35

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD disc if

the servo motors in MD don’t work. This step is for checking the TRAY OPEN / CLOSE MOTOR among

them.

4-3. TRAY OPEN / CLOSE MOTOR

4-3-1. Solution

Please check and replace IC400, IC401 on MAIN board.

4-3-2. How to troubleshoot (Countermeasure)

1) Check MOT_OPEN & MOT_CLOSE signals from Pin K4, L4 of IC500 to IC400.

If no signal, check +1.8 V & + 5 V to IC401.

2) Check LOAD± from IC401 to CN401 for driving the tray open / close motor. It is about 3.85 Vp-p.

If no signal, check +5 V to IC401. If it has any trouble, replace it with a new one.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the tray motor is sort-circuit or has any trouble, it can not open or close the tray.

Please check the function after changing another MD.

4-3-3. Service hint (Any picture / Remark)

MOT_OPEN

CLOSE

LO- TO CN401

LO+ TO CN401

< Waveform for driving

TRAY open / close motor >

< Signal check point >

3-8

Page 36

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD disc if

the pickup module in MD doesn’t work. This step is for checking the LASER TRACKING ACTUATOR.

4-4. LASER TRACKING ACTUATOR

4-4-1. Solution

Please check and replace IC400, IC401 on MAIN board.

4-4-2. How to troubleshoot (Countermeasure)

The tracking actuator makes the laser beam be positioned in the center of a track on CD disc.

1) Check the TRD signal from Pin22 of IC400.

If no signal, check 3.3 V(RF) and X400.

2) Check TR- & TR+ from IC408 to CN401 for driving the tracking actuator.

If no signal, check +1.8 V and +5 V for IC408.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the pickup module has any trouble, it can not move the laser beam on the left or right side.

Please check the function after changing another MD.

4-4-3. Service hint (Any picture / Remark)

< Waveform of TR±

for driving TRACKING actuator >

< Signal check point >

3-9

Page 37

ONE POINT REPAIR GUIDE

NO OPERATION OF MD

When no sound output in the CD function, you can not listen to music reading data from a CD disc if

the pickup module in MD doesn’t work. This step is for checking the LASER FOCUSING ACTUATOR.

4-5. LASER FOCUSING ACTUATOR

4-5-1. Solution

Please check and replace IC400, IC401 on MAIN board.

4-5-2. How to troubleshoot (Countermeasure)

The focusing actuator makes the laser beam keep a regular interval with the surface of a CD disc.

1) Check the FOD signal from Pin21 of IC400.

If no signal, check 3.3 V(RF) and X400.

2) Check F- & F+ from IC408 to CN401 for driving the focusing actuator.

If no signal, check +1.8 V and +5 V for IC401.

3) Check if the FFC cable is solidly connected between CN401 and MD.

4) Check the MD.

If the pickup module has any trouble, it can not move the laser beam on the top or bottom side.

Please check the function after changing another MD.

4-5-3. Service hint (Any picture / Remark)

< Waveform of F±

for driving FOCUSING actuator >

< Signal check point >

3-10

Page 38

ONE POINT REPAIR GUIDE

5. NO SOUND

There is no sound output in the CD FUNCTION, repair the set according to the following guide.

5-1. IN THE CD FUNCTION

5-1-1. Solution

Please check and replace IC501, IC601 on MAIN board.

5-1-2. How to troubleshoot (Countermeasure)

1) Check CD_BCLK, CD_LRCK, & CD_DOUTA signals from IC401 to IC500.

If no signal, check if the RF & servo signals from MD is entered to IC401.

Refer to the “No operation of MD” guide on Item 4.

2) Check the following I2S signal flow. < I2S audio signal Interface >

- ADC_BCK : IC500_Pin E1 --> IC700_Pin23

- ADC_LRCK : IC500_Pin D1 --> IC700_Pin22 (44.1 kHz)

- MIX_DATA_0 : IC500_Pin E2 --> IC700_Pin24

- MIX_DATA_1 : IC500_Pin R2 --> IC700_Pin25

- ADC_MCLK : IC500_Pin D2 --> IC700_Pin44

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

3) Check if “Digital audio AMP block” on Item 5-2 is normal.

5-1-3. Service hint (Any picture / Remark)

P/UP

M

IC401

12.288 MHZ

PWM

TAS5548

DSP IC500

176 PIN

USB 2.0 OTG

Main Processor

USB 1.1

ARM

Host/Device

926EJS

400Mhz

SRAM (10K)

SDRAM

Controller

Boot ROM (20KB)

Interrupt

controller

CDROM x8 speed

Decoder

ADC (12bit*5ch)

GDMA 3ch

Timer, Watchdog

GPIO (72 Max)

NAND Controller

within BCH codec

SPI 4ch (Max)

14bits ECC

FR,FL

TAS5624LA

BGA

Audio DSP-0

16KB

DSP

I-Cache

133Mhz

16KB

D-Cache

GDMA 2ch

RTC & Wake up

UART 4ch (Max)

SDHC-SDIO 4ch (Max)

SRAM29KB

I-Cache 8KB

D-Cache 8KB

I2C 2ch

Audio DSP-1

SRAM29KB

DSP

I-Cache 8KB

133Mhz

D-Cache 8KB

I2S (7.1ch)

SPDIF (Rx, Tx)

ADPCM

PLL

Clock Controller

Reset Controller

Test Controller

MCS_MCLK (16.93 MHz)

MCS_BCK(1.4 MHz)

MCS_DATA_OUT

MCS_LRCK(44.1 KHz)

< Waveform of I2S audio interface signals >

< I2S Signal Flow >

3-11

Page 39

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output by DIGITAL AUDIO AMP DAMAGE, repair the set according to the following

guide.

5-2. BY DIGITAL AUDIO AMP DAMAGE (IN ALL FUNCTIONS)

5-2-1. Solution

Please check and replace C744(IC701), C746(IC702) on MAIN board.

5-2-2. How to troubleshoot (Countermeasure)

1) Check PWM_FL±, PWM_FR± & PWM_SW± signals from IC700 to IC701 & 702 each input function.

If no signal, check if I2S audio signals are entered to IC700.

Refer to “I2S audio signal interface” on Item 5-1.

2) Check PVDD.

If PVDD is abnormal, check the SMPS.

3) Check +12 V for driving the gate of AMP IC.

a. All the powers are normal, but if +12 V is low, there is possible for AMP IC to be damaged.

b. Remove C742, C746(IC702), C740, C744(IC701) one by one.

When removed a inductance, if +12 V is recovered, the IC connected to it was damaged.

c. Replace the IC with a new one.

4) Check the impedance between IC701/IC702_OUT_A/OUT_B/OUT_C/OUT_D & GND.

a. If the impedance is 0 Ω, the IC must be damaged.

b. After removing the heat sink, replace it with a new one.

5-2-3. Service hint (Any picture / Remark)

< Signal check point >

3-12

Page 40

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the USB FUNCTION, repair the set according to the following guide.

5-3. IN THE USB FUNCTION

5-3-1. Solution

Please check and replace IC500 on MAIN board & IC104 on USB board.

5-3-2. How to troubleshoot (Countermeasure)

1) Check +5V_USB to USB board.

If the USB LED are turned on, the voltage is okay, if so not, check +5.6 V to pin6 of CN502.

2) Check USB D1± or USB D2± from MAIN board to USB board.

a. Check 2.0_D1±signals(pin U7, U8 ) or 1.1_D1± signals(pin A7, A8 ) to IC500.

b. Check USB± signals to CN502(pin1, 2, 4, 5).

If there is any trouble, check the power for each IC. The power is normal but , if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

3) Check if “Digital audio AMP block” on item 5-2 is normal.

5-3-3. Service hint (Any picture / Remark)

DSP IC500

176 PIN

USB 2.0 OTG

Main Processor

16KB

ARM

DSP

I-Cache

926EJS

133Mhz

16KB

400Mhz

D-Cache

Boot ROM (20KB)

ADC (12bit*5ch)

Timer, Watchdog

GPIO (72 Max)

SPI 4ch (Max)

SDHC-SDIO 4ch (Max)

12.288 MHZ

PWM

Audio DSP-0

GDMA 2ch

RTC & Wake up

UART 4ch (Max)

USB 1.1

Host/Device

SRAM (10K)

SDRAM

Controller

Interrupt

controller

CDROM x8 speed

Decoder

GDMA 3ch

NAND Controller

within BCH codec

14bits ECC

SRAM29KB

I-Cache 8KB

D-Cache 8KB

I2C 2ch

Audio DSP-1

SRAM29KB

DSP

I-Cache 8KB

133Mhz

D-Cache 8KB

I2S (7.1ch)

SPDIF (Rx, Tx)

ADPCM

PLL

Clock Controller

Reset Controller

Test Controller

FR,FL

USB1_D±

USB2_D±

D- to pin 1&4 of CN502

D+ to pin 2&5 of CN502

< Waveform of USB D± signal >

< USB function signal fl ow >

3-13

Page 41

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the AUX FUNCTION, repair the set according to the following guide.

5-4. IN THE AUX FUNCTION

5-4-1. Solution

Please check and replace IC202 on MAIN board.

5-4-2. How to troubleshoot (Countermeasure)

1) Check AUX_L/R signals to IC202 (Pin29, 30).

2) Check if MCS_BCK, MCS_LRCK & MCS_MCLK are entered from IC500 to IC202.

3) Check if ADC_DATA is entered from IC202 to IC500.

If no signal, check +5 V & +3.3 V(ADC) for IC201. If is NG, replace it a new one.

4) Check the following I2S signal flow from IC801 to IC602. (Refer to Item 5-1.)

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 5-2.

If AMP is damaged, replace it with a new one.

5-4-3. Service hint (Any picture / Remark)

AUX

DSP IC500

176 PIN

AUX _L /R

12.288 MHZ

PWM

IC202

FR,FL

USB 2.0 OTG

USB 1.1

Host/Device

SRAM (10K)

SDRAM

Controller

Interrupt

controller

CDROM x8 speed

Decoder

GDMA 3ch

NAND Controller

within BCH codec

14bits ECC

Main Processor

16KB

ARM

I-Cache

926EJS

16KB

400Mhz

D-Cache

Boot ROM (20KB)

ADC (12bit*5ch)

Timer, Watchdog

GPIO (72 Max)

SPI 4ch (Max)

< AUX function signal fl ow >

Audio DSP-0

133Mhz

SRAM29KB

DSP

I-Cache 8KB

133Mhz

D-Cache 8KB

GDMA 2ch

RTC & Wake up

UART 4ch (Max)

I2C 2ch

SDHC-SDIO 4ch (Max)

Audio DSP-1

SRAM29KB

DSP

I-Cache 8KB

D-Cache 8KB

I2S (7.1ch)

SPDIF (Rx, Tx)

ADPCM

PLL

Clock Controller

Reset Controller

Test Controller

< Signal check point >

3-14

Page 42

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the TUNER FUNCTION, repair the set according to the following guide.

5-5. IN THE TUNER FUNCTION

5-5-1. Solution

Please check and replace IC202, TU200 on MAIN board.

5-5-2. How to troubleshoot (Countermeasure)

1) Check if TUNER_LR is entered from Pin1, 3 of TU200 to IC202(Pin27, 28).

If no signals, check +3.3 V for tuner power.

Check if the tuner control signals (CLK, DAT, CE, RST, SLT) are entered from IC500 to TU200.

If it doesn’t work, replace TUNER with a new one.

2) Check if MCS_BCK, MCS_LRCK, & MCS_MCLK are entered from IC500 to IC202.

3) Check if ADC_DATA is entered from IC202 to IC500.

If no signal, check +5 V & +3.3 V(ADC) for IC202. If is NG, replace it with a new one.

4) Check the following I2S audio signal flow from IC500 to IC700. (Refer to Item 5-1.)

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 5-2.

If AMP is damaged, replace it with a new one.

5-5-3. Service hint (Any picture / Remark)

DSP IC500

176 PIN

TUN ER

A

TUNER_ L/R

12.288 MHZ

PWM

IC202

FR,FL

USB 2.0 OTG

USB 1.1

Host/Device

SRAM (10K)

SDRAM

Controller

Interrupt

controller

CDROM x8 speed

Decoder

GDMA 3ch

NAND Controller

within BCH codec

14bits ECC

BGA

Main Processor

16KB

ARM

I-Cache

926EJS

16KB

400Mhz

D-Cache

Boot ROM (20KB)

ADC (12bit*5ch)

Timer, Watchdog

GPIO (72 Max)

SPI 4ch (Max)

Audio DSP-0

SRAM29KB

DSP

I-Cache 8KB

133Mhz

D-Cache 8KB

GDMA 2ch

RTC & Wake up

UART 4ch (Max)

I2C 2ch

SDHC-SDIO 4ch (Max)

Audio DSP-1

SRAM29KB

DSP

I-Cache 8KB

133Mhz

D-Cache 8KB

I2S (7.1ch)

SPDIF (Rx, Tx)

ADPCM

PLL

Clock Controller

Reset Controller

Test Controller

< TUNER IN function signal fl ow >

< Signal check point >

3-15

Page 43

ONE POINT REPAIR GUIDE

NO SOUND

There is no sound output in the PORTABLE FUNCTION, repair the set according to the following

guide.

5-6. IN THE PORTABLE FUNCTION

5-6-1. Solution

Please check and replace IC202 on MAIN board.

5-6-2. How to troubleshoot (Countermeasure)

1) Check PT_L/R signals to IC202 (Pin1, 2).

2) Check if MCS_BCK, MCS_LRCK, & MCS_MCLK are entered from IC500 to IC202.

3) Check if ADC_DATA is entered from IC202 to IC500.

If no signal, check +5 V & +3.3 V(ADC) for IC202. If NG, replace it a new one.

4) Check the following I2S signal flow from IC500 to IC700. (Refer to Item 5-1.)

If there is any trouble, check the power for each IC. The power is normal but, if the signal waveform to

the IC is distorted or no signal, replace it with a new one.

5) Check if the digital audio AMP block is okay. Refer to “Digital Audio AMP” guide on Item 5-2.

If AMP is damaged, replace it with a new one.

5-6-3. Service hint (Any picture / Remark)

DSP IC500

176 PIN

PTB_L/R

Port able

12.288 MHZ

PWM

IC202

FR,FL

USB 2.0 OTG

USB 1.1

Host/Device

SRAM (10K)

SDRAM

Controller

Interrupt

controller

CDROM x8 speed

Decoder

GDMA 3ch

NAND Controller

within BCH codec

14bits ECC

Main Processor

16KB

ARM

I-Cache

926EJS

16KB

400Mhz

D-Cache

Boot ROM (20KB)

ADC (12bit*5ch)

Timer, Watchdog

GPIO (72 Max)

SPI 4ch (Max)

< PORTABLE function signal fl ow >

Audio DSP-0

133Mhz

SRAM29KB

DSP

I-Cache 8KB

133Mhz

D-Cache 8KB

GDMA 2ch

RTC & Wake up

UART 4ch (Max)

I2C 2ch

SDHC-SDIO 4ch (Max)

Audio DSP-1

SRAM29KB

DSP

I-Cache 8KB

D-Cache 8KB

I2S (7.1ch)

SPDIF (Rx, Tx)

ADPCM

PLL

Clock Controller

Reset Controller

Test Controller

< Signal check point >

3-16

Page 44

ELECTRICAL TROUBLESHOOTING GUIDE

1. POWER (SMPS)

No 5.6 VA

YES

F901 normal?

YES

BD901 normal?

YES

TH901(TH903) normal?

YES

Is Vcc

(10 V ~ 18 V) supplied to

IC901 pin7?

YES

D933 normal?

NO

Replace F901 (Use the same fuse).

NO

Replace BD901.

NO

Replace TH901.

NO

D902 normal?

NO

Check or replace D902.

NO

Replace D933.

YES

Is there

about 2.5 V at

IC941 Pin1?

YES

D951 normal?

YES

Is there

about 2.5 V at IC951

pin1?

YES

Power line of main PCB is short.

NO

Replace IC941.

NO

Replace D951.

NO

Replace D951.

3-17

Page 45

ELECTRICAL TROUBLESHOOTING GUIDE

No PVDD

YES

F901 normal?

YES

BD901 normal?

YES

TH901(TH903) normal? Replace TH901.

YES

NO

NO

NO

Replace F901 (Use the same fuse).

Replace BD901.

(10 V ~ 18 V) supplied to

Is Vcc

IC911 pin4?

YES

Q901 normal?

YES

D951 normal?

NO

NO

NO

NO

D903 normal?

YES

Check or replace D903.

NO

Q901 base “H”?

YES

• Check P-CTRL “H” signal from MCS.

• Check PC902.

Check or replace Q911.

Replace Q901.

Replace D951.

YES

Is there about 2.5 V

at IC951 pin1?

YES

Power line of main PCB is short.

NO

Replace IC951.

3-18

Page 46

ELECTRICAL TROUBLESHOOTING GUIDE

No 12 V

YES

Is Vcc (15 V)

supplied to IC931?

YES

IC931 pin4 “H”?

YES

Check or replace IC931.

NO

NO

Check or replace D935.

Check P-CTRL “H” signal from MCU.

No VFD

YES

D931 normal?

YES

ZD931 normal?

YES

Q300 / Q301 normal?

YES

Check or replace VFD.

NO

NO

NO

3-19

Check or replace D931.

Check or replace ZD931.

Check or replace Q300 / Q301.

Page 47

ELECTRICAL TROUBLESHOOTING GUIDE

2. MCS PART CHECK

MCS PART CHECK

YES

Check if voltage of CN102

Pin13, 14 is 12 VA.

YES

Check if IC100

have 3.3 VA output.

YES

Check if IC101

have 1.2 VA output.

YES

X500: 24 MHz, X500: 32.768 kHz

Check the operation.

YES

OK

NO

Refer to SMPS troubleshooting.

NO

Check and change IC100.

NO

Check and change IC101.

3. IC503(GD25Q80) CHECK

CHECK IC500 PIN.

YES

pinA12, pinB12 SF_SCK :

Check

SF_MISO

YES

OKOK

NO

Check MCS

voltage 3.3 VA.

YES

Check MCS.

YES

OKOK

3-20

NO

NO

Refer to MCS troubleshooting.

Replace MCS.

Page 48

ELECTRICAL TROUBLESHOOTING GUIDE

4. FLD DISPLAY CHECK

FLD DISPLAY CHECK

YES

CN102 Pin13,14 input

Check

NO

Refer to SMPS troubleshooting.

voltage.

YES

Check if both end voltage of F+, F- are over 1.85 V

VH : over 27 V.

YES

Check

CN300 connection and

power Pin14, 16,17

(VIN, F+, VDD).

NO

Check CN300 connection.

YES

Check

VFD300 voltage Pin27,

26, 31, 32 VH: over 27

V, SW Signal, F- : over

3 V is OK?

NO

If voltage isn’t over VH : 27 V, F- : 3 V

and, SW signal is not operation?

YES

YES

Check VFD300.

NO

NO

Check each Pin voltage.

YES

OK

Replace VFD300.

Check

IC500->VFD300 data

communication STB/

DATA/ CLK

YES

FLD light on?

YES

OKOK

NO

YES

OK

Check input data

IC500 Pin F2, B3, B1.

YES

Check output data IC500 Pin B3.

YES

Check IC500.

YES

OKOK

3-21

NO

Replace IC500.

Page 49

ELECTRICAL TROUBLESHOOTING GUIDE

5. PWM MODULATION CHECK

PWM MODULATION PART

CHECK

YES

Check

CN102 Pin13, 14

(12 VA)

YES

• Check IC700(TAS5548) VDD 3.3 V - Pin9,14.35,50.

• Check X700 (12.288 MHz).

YES

Check

X700(12.288 MHz)

operation.

YES

Check IC700 Pin21 CLK input.

NO

NO

SMPS troubleshooting.

Refer to

Check X700

(12.288 MHz).

YES

OK

NO

Replace X700(12.288 MHz).

YES

Check

IC700(TAS5548) input

data Pin24, 25

PWM wave.

YES

Check PWM

modulator output

FL: Pin48(-),49(+)

FR: Pin46(-),47(+).

Other output

check.

YES

NO

NO

Check CD

Assy communication

Pin22, 23, 24.

YES

Check

IC700 input

data.

YES

OK

YES

Check IC700.

YES

NO

NO

NO

Refer to CD troubleshooting.

Check each line resistor output.

Replace IC700.

OK

OK

3-22

Page 50

ELECTRICAL TROUBLESHOOTING GUIDE

6. POWER AMP PART CHECK

POWER AMP PART CHECK

YES

CN102 Pin13, 14: +12 VA

Check

Pin5, 6, 7 : 36 V.

YES

Check IC701, IC702

Pin29, 30, 31, 36, 37, 38 input voltage.

YES

Check IC701, IC702

Pin2: +12 V input.

YES

Check PWM Modulator input

IC701 Pin14, 15 / IC702 Pin5, 6. 14, 15.

NO

Refer to SMPS troubleshooting.

NO

Check each line resistor output voltage.

YES

Check IC701, IC702

Pin27, 28, 32, 35, 39, 40.

YES

Check output line coil.

YES

OK

NO

Replace the coil.

3-23

Page 51

ELECTRICAL TROUBLESHOOTING GUIDE

7. TUNER / AUX FUNCTION CHECK

FUNCTION CHECK

YES

Check IC202

(PCM1865) Pin27, 28,

29, 30 input.

YES

Check IC202

(PCM1865) Pin18, 19

output data.

YES YES

Check

IC500(MLC3730)

input data.

YES

YES

OK

NO

NO

NO

Check JK200,TU200.

Check

IC202 Pin8: ADC +3.3 V

Pin13,14,25: DVCC

+3.3 V.

Check IC202

Pin8: ADC +3.3 V,

Pin13, 14, 25: DVCC +3.3 V.

NO

NO

Check CN102 Pin13,14: 12 VA.

Pin18,19:ADC, MIC_DATA SDOUT,

Check IC202

Pin17: BCK, Pin16: LRCK,

Pin15: MCLK.

YES

Replace IC201.IC500(MLC3730) output data.

8. TUNER FUNCTION CHECK

TUNER FUNCTION CHECK

YES

Check tuner module(TU200)

operation.

YES

Check IC500 Pin P7, P8, P10, P11.

YES

Refer to function check.

NO

NO

3-24

Check tuner module voltage

(Pin4: +3.3 V).

Check tuner module data.

Page 52

ELECTRICAL TROUBLESHOOTING GUIDE

9. CD FUNCTION

CD FUNCTION

YES

Can the

disc insert?

YES

Disc reading

is ok?

YES

Is no signal at spk?

NO

NO

Is load +,- ok?

YES

Is Motor ok? (about 12 Ω)

IM driving

(Focus and tracking) is ok?

NO

NO

NO

Is Motor_open/close OK?

(IC400 Pin9,10)

YES

Check IC400.

Check loading motor.

Check IC400

(Motor drive IC).

NO

Focus,

tracking, sled signal

is ok?

YES

Is the MD(CN400 Pin7)

about 190 mV?

YES

Check

the signal of IC401

Pin52,53,54.

YES

Check

the signal (16.9344

MHz) at IC401

Pin51.

YES

Check IC500

input/output and

control line.

YES

Refer to function check.

NO

NO

NO

Check Vcc of IC401.

Check Cristal (X400).

Replace IC500.

3-25

NO

NO

Check IM (pick-up).

Replace Cristal (X400).

Page 53

ELECTRICAL TROUBLESHOOTING GUIDE

10. DOUBLE USB FUNCTION

USB FUNCTION

YES

Plug-in USB device.

YES

Display “NO USB”.

YES

Display “READ”.

YES

Display “NO FILE”.

YES

Check USB audio file in USB device

(MP3, WMA file is playable)

NO

Check USB_5 V.

YES

Check USB_D-/D+

(R383, 384).

YES

Check IC500

(Pin U7, U8/ A7, A8).

NO

NO

NO

Check CON301.

Check USB jack

(JK301/ JK302).

Replace IC500.

3-26

Page 54

WAVEFORMS OF MAJOR CHECK POINT

1

2

3

4

Fig 1. SDRAM

①IC504 pin38, ②IC504 pin53

③IC504 pin35, ④IC504 pin19

6

7

CLK

DATA

ADDRESS

CS

CD_BCK

CD_LRCK

5

9

10

11

CD-16 M

Fig 2. SERVO

⑤IC500 pin M1

MCS_MCLK

MCS_BCK

MCS_LRCK

8

13

14

CD_DATA

Fig 3-1. AUDIO PATH

⑥IC500 pin N4, ⑦ICIC500 pin N1

⑧ICIC500 pin N2

USB_5 V

D+

D-

Fig 4. USB

⑬IC500 pin A8, ⑭IC500 pin A7

12

ADC_DATA

Fig 3-2. AUDIO PATH

⑨IC500 pin D2, ⑩IC500 pin E1

⑪IC500 pin D1, ⑫IC500 pin E2

3-27

Page 55

3-28

Page 56

3-29 3-30

ڜڜڨڐړڔٻ

ڤڞڐڋڋٻ

ڟڮګٻ

ڤڞڏڋڌٻ

ڭڡٻڤڞٻ

ڤڞڒڋڋٻ

ګڲڨٻ

ڤڞڍڋڍٻ

ڜڟڞٻ

ڤڞڐڋڎٻ

ڡڊڮٻڌڑڨٻ

ڤڞڐڋڏٻ

ڮڟڭڜڨٻ

ڤڞڏڋڋٻ

ڨۊۏۊۍٻڟڭٻ

گېۉۀۍٻ

ڨڤڞٻ

ګگڝٻ

ڰڮڝڌٻ

ڰڮڝڍٻ

ٻٻٻٻ ٻ ٻ ٻ ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

ٻ

ڨڜڤکٻ

ڝگٻ

ۈۊڿېۇۀٻ

ڜڰڳٻڤۉٻ

ڮڨګڮٻ

ڣڼۍۉۀێێٻ

ڡڡڞ

ٻٻٻٻ

ڡڧٻ

ڭڧٻ

ڥڜڞڦٻ

ڤڞڍڋڏٻ

ڠڳګڠکڟڠڭٻ

ڤڞڍڋڋٻ

ڎ

ګٻ

ڡڭڪکگٻ

ڌڏګٻڝٻگڪٻڝٻ

ړ

ګ

ٻ

ڌڏګ

ٻ

ڝ

ٻ

گڪٻڝٻ

ړ

ګ

ٻ

ړګٻ

ڰڮڝٻ

ڌڒګٻ

ڌڋګٻ

ړګٻ

ڰڮڝٻ

ڌڒګٻ

ڨڟٻ

ڌڋګ

ٻ

ڍڎګٻ

ڌڋګ

ٻ

ڍڎګٻ

ڮګڦںڭٻ

ڮګڦںڧٻ

jq[[⏈GmhuG㇡㥐G

WIRING DIAGRAM

Page 57

3-31 3-32

BLOCK DIAGRAMS

1. SYSTEM BLOCK DIAGRAM

ڤڤڞڐڋڋٻ

ڨڼۄۉٻڟڮګٻ

ٻ

ٻٻ

ڃچڎډڎڱںڞڟڇٻڱڞڞڌډڍڄٻ

ڟڠڞڦٻٻٻ

ڨڠڞڣڜکڤڮڨٻ

ڨٻ

ګڊڰګٻ

ڃڱڞڞڐڋڄٻ

ٻ

ٻ

گڪګٻ

ڝڧڪڞڦٻ

ڱۊۇېۈۀڊٻ

ڦۀ۔ڊێےۄۏھۃٻ

ڃچڎډڎڱڜڇڐڱڇچڌڍڱڄٻ

ڌڑڨڝٻ

ڮڟڭڜڨٻٻ

ڏڨڝٻ

ڡۇڼێۃٻ

ڤڞڏڋڋٻ

ڨۊۏۊۍٻڟۍۄۑۀٻ

ڰڮڝڌٻ

ڰڮڝڍٻ

ڤڞڏڋڌٻ

ڮڠڭڱڪٻڤڞٻ

ڤڞڍڋڍٻ

ڜڟڞٻ

ڟڭڨںڲڠکڊڞڜڮڊٻ

ڭڜڮڊڮڠڧڊڞڧڦڊڞڦڠٻ

ٻڮۋۀڼۆۀۍٻ

ڧۄۂۃۏۄۉۂٻ

ڜڟڞںڟڜگڜٻ

ڨڞڮںڝڞڦڊڧڭڞڦڊڨڞڧڦٻ

ڡڭڪکگڃڝگڧڄٻ

ڨڋڋںڌڐٻ

ڜڋڋںڌڑٻ

ڮڡںڟڤڊڟڪٻ

ڮڡںڞڮڊڮڞڦٻ

ڱڡڟںڮگڝڊڞڧڦڊڟڪڊڭڮگڇٻ

ڨڜڤکٻڱڪڧںڜڊڝڇٻ

ڦڠڴٻڌڊڍٻ

ڪګںڮڲڇڞڧںڮڲڇڰګںڮڲڇڟکںڮڲڇڟںڮڠکڮڠٻ

ڨڪگںڨڰگڠڇڞڧڪڮڠڇڪګڠکٻ

ڜڇڝڇڞڇڟڇڠڇڡڇګڟٻٻٻ

ڧڟٻ

ڮګڟڪڊڮڧڟڪٻ

ڊڡڪڟڊگڭڟٻ

ڧڪڜڟڇڮڧڠڟڇٻ

ڮګڤکڇگڭڇڡٻ

ڟڍڮچڊڈٻ

ګڲڨںڧڭڞڦڊڝڞڦڊڟڜگڜٻ

ڞڟںڭڲڊڨڞڧڦڊڧڭڞڦڊڝڞڦڇٻ

ڞڟںڟڜگٻ

ڞڟںڭڮگٻ

ڡۊۍٻڜڰڳٻ

ڌډڌٻڍډڋٻ

[CJ65 : Total 2hch 900W]

[CJ44 : Total 2ch 460W]

ڌڨڝٻ

ڮڊڡۇڼێۃٻ

ڮڡںڟڤڊڟڪٻ

ڮڡڍںڞڮڊڮڞڦٻ

ڜڰڳٻڤکٻ

گڰکڠڭٻ

ڃڡڨڊڜڨڄٻ

ګگڝٻ

ڨڤڞٻٻ

ڧګڡٻ

ڤڞڒڋڍٻ

ڜڨګٻ

ڤڞڒڋڋٻ

ګڲڨٻ

ڡڭڪکگڃڝگڧڄٻ

ڟڌچڊڈٻ

ڡڨڊڜڨٻ

ڤڞڍڋڋٻ

ڨڤڞٻڪګٻڜڨګٻ

ڤڭٻٻ

ڭۀھۀۄۑۀۍٻٻ

ࣜࣧࣜࣽࣜࣜࣾࣜ

ࣜ

ࣾࣜ

ڭڨڞٻٻڤکٻ

ڧڠڟٻ

ڧۄۂۃۏۄۉۂٻ

ڱڡڟٻ

ࣽࣽࣜࣜࣾࣜ

ࣜࣾࣜ

ڤڞڒڋڌٻ

ڜڨګٻ

Page 58

3-33 3-34

2. SMPS BLOCK DIAGRAM

Page 59

3-35 3-36

3. POWER BLOCK DIAGRAM

8#

8(&

(#0

(4106.'&

/2

6.8

8#

/#+0&52

/.%

6.8

8#

8#

$6/1&7.'

4/%

(55&4#/

4'5'6+%

625%

75$

75$

5;%

8(&

%5

/+%#/2

&48

670'4

6#5

4(+%$7

':2'0&'4

52-.'&

&8%%A8

2WNNWRࢲଡ

/+%#&%

2%/

25'05'

/161&4+8'

#/

52-.'&

%&2+%-72

8(&(

625%

645YKVEJKPI

#OR8

645YKVEJKPI

8

&8%%A8

28&&

8

6#5

6#5$

6#5

6#5$

zztwzG

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

O#

#

O#

O#

O#

O#

O#

O#

#

O#

Page 60

CIRCUIT VOLTAGE CHART

1. INPUT VOLTAGE OF ICs 3. VOLTAGE OF CAPACITORS 2. INPUT VOLTAGE OF CONNECTORS

3-37 3-38

Location No. Pin No. SPEC [V] Test [V]

IC100

DC-DC Converter

4 VIN : 2.7~5.5 V VIN : 5.16 V

IC101

DC-DC Converter

4 VIN : 2.7~5.5 V VIN : 5.16 V

IC102

DC-DC Converter

1 VIN : 4.2~17 V VIN : 12.11 V

IC103

Analog Switch

5 VIN : 2.5~5.5 V VIN : 3.37 V

IC104

Analog Switch

5 VIN : 4.5~5.5 V VIN : 5.16 V

IC105

Analog Switch

5 VIN : 4.5~5.5 V VIN : 5.16 V

IC200

Line Driver

9 VDD : 3.0~3.6 V VIN : 3.33 V

IC202

A/D Converter

AVDD : 8

DVDD : 13

IOVDD : 14

AVDD : 3.0~3.6 V

DVDD : 3.0~3.6 V

IOVDD : 3.0~3.3 V

AVDD : 3.32 V

DVDD : 3.33 V

IOVDD : 3.33 V

IC400

Motor Driver

8, 19 VCC : 4.3~13.2V VCC : 5.14V

IC401

RF Amplifi er

1, 17, 47, 53, 58

DVDD,AVDD :

2.7~3.6 V

DVDD,AVDD : 3.34 V

IC500

Digital Signal

Processors

VDD12 : A9, E9, J14,

T10, P9, U4, J4

VDD33 : A4, B7,

A10, D14, P14, U9,

U5, U6, P4, D4

VDD12 : 1.08~1.32 V

VDD33 : 3.0~3.6 V

VDD12 : 1.2 V

VDD33 : 3.37 V

IC501

Serial Flash

Memory

8 VCC : 2.7~3.6 V VCC : 3.37 V

IC502

Voltage Detector

2 VCC : 1.1~5.5 V VCC : 3.37 V

IC503

Serial Flash

Memory

8 VCC : 2.7~3.6 V VCC : 3.37 V

IC504

SDRAM

1, 3, 9, 14, 27, 43, 49

VDD,VDDQ :

3.0~3.6 V

VCC : 3.37 V

IC700

Sound/Audio

Processor

9, 14, 50

DVDD : 3.0~3.6 V

AVDD : 3.0~3.6 V

DVDD : 3.34 V

AVDD : 3.34 V

IC701,IC702

Audio Amplifi er

PVDD : 29, 30, 31,

36, 37, 38

GVDD : 1, 22

VDD : 2

PVDD : 12~38 V

GVDD : 10.8~13.2 V

VDD : 10.8~13.2 V

PVDD : 36.20 V

GVDD : 11.82 V

VDD : 11.96 V

Block Location No. Spec. Test

Main

C121 220 uF / 10 V 3.06

C134 100 uF / 16 V 5.16

C169 100 uF / 16 V 11.23

C402 100 uF / 16 V 5.14

C411 47 uF / 16 V 3.34

C418 3.3 uF / 16 V 0.50

C421 47 uF / 16 V 1.66

C447 220 uF / 16 V 5.14

C713 100 uF / 16 V 3.34

C766 330 uF / 50 V 36.20

C770 330 uF / 50 V 36.20

C771 330 uF / 50 V 36.20

Control

C300 47 uF / 16 V 3.12

C310 47 uF / 16 V 3.34

CE300 47 uF / 16 V 12.03

CE301 1 uF / 50V 30.49

CE303 1 uF / 50 V 21.31

CE304 1 uF / 50 V 26.30

CE305 1 uF / 50 V 17.09

CE306 47 uF / 16 V 5.12

CE330 100 uF / 16 V 5.16

CE331 100 uF / 16 V 5.16

Pin Name Spec. Range [%] Test

Pin No MAIN(CN902) <-> SMPS (CN102)

5, 6, 7 PVDD 35.5 ±10 % 35.75

13, 14 12VA 12.1 ±10 % 12.16

Pin No MAIN(CN502) <-> USB(CN301)

1, 2 USB_5V 5.15 ±10 % 5.16

Pin No MAIN(CN5101) <-> BT Module

1 VDD 3.4 ±10 % 3.38

Pin No MAIN(CN101) <-> FRONT(CN300)

1 DVCC_3.3V 3.4 ±10 % 3.38

2 LED_5V 5.1 ±10 % 5.16

4 12VA_VFD 12 ±10 % 12.15

6 3.3VA 3.4 ±10 % 3.34

Pin No MAIN(CN400) <-> MD (Pick-up)

8 VCC 5 ±10 % 5.14

Page 61

3-39 3-40

PRINTED CIRCUIT BOARD DIAGRAMS

1. SMPS P.C.BOARD DIAGRAM

(TOP VIEW) (BOTTOM VIEW)

NOTE) Warning

Parts that are critical with respect to risk

of fire or electrical shock.

Page 62

3-41 3-42

2. MAIN P.C.BOARD DIAGRAM

(TOP VIEW) (BOTTOM VIEW)

Page 63

3-43 3-44

3. FRONT P.C.BOARD DIAGRAM

(TOP VIEW)

(BOTTOM VIEW)

Page 64

3-45 3-46

4. MIC P.C.BOARD DIAGRAM

(TOP VIEW)

(BOTTOM VIEW)

Page 65

3-47 3-48

Loading...

Loading...