LG LH-C6230P, LH-C6230LGEDG, LH-C6230LGEES, LH-C6230LGEPT, LH-C6230LGEIS Service Manual

...Page 1

SERVICE MANUAL MODELS : LH-C6230P/C6231P/LH-C6230S/LH-C6230W/LH-C6231W/LH-C6230X/LH-C6230Y/C6231Y

DVD/CD/VCR RECEIVER

Home Cinema System

SERVICE MANUAL

P/N : 3829RDT033C JULY, 2003

MODELS: LH-C6230P/C6231P (LGEDG/LGEES/LGEPT/LGEIS)

LH-C6230S (LGEFS/STUH) LH-C6230W (LGESA/LGEGF)

LH-C6231W (LGEAP) LH-C6230X (MOSCOW)

LH-C6230Y/C6231Y (LGEPL/LGEMK)

Page 2

- 1-1 -

SECTION 1. GENERAL

• PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRECAUTIONS

........................

1-2

• SERVICING PRECAUTIONS........................................................................................................ 1-5

• ESD PRECAUTIONS

...................................................................................................................

1-6

• SPECIFICATIONS

.......................................................................................................................

1-7

SECTION 2. AUDIO PART

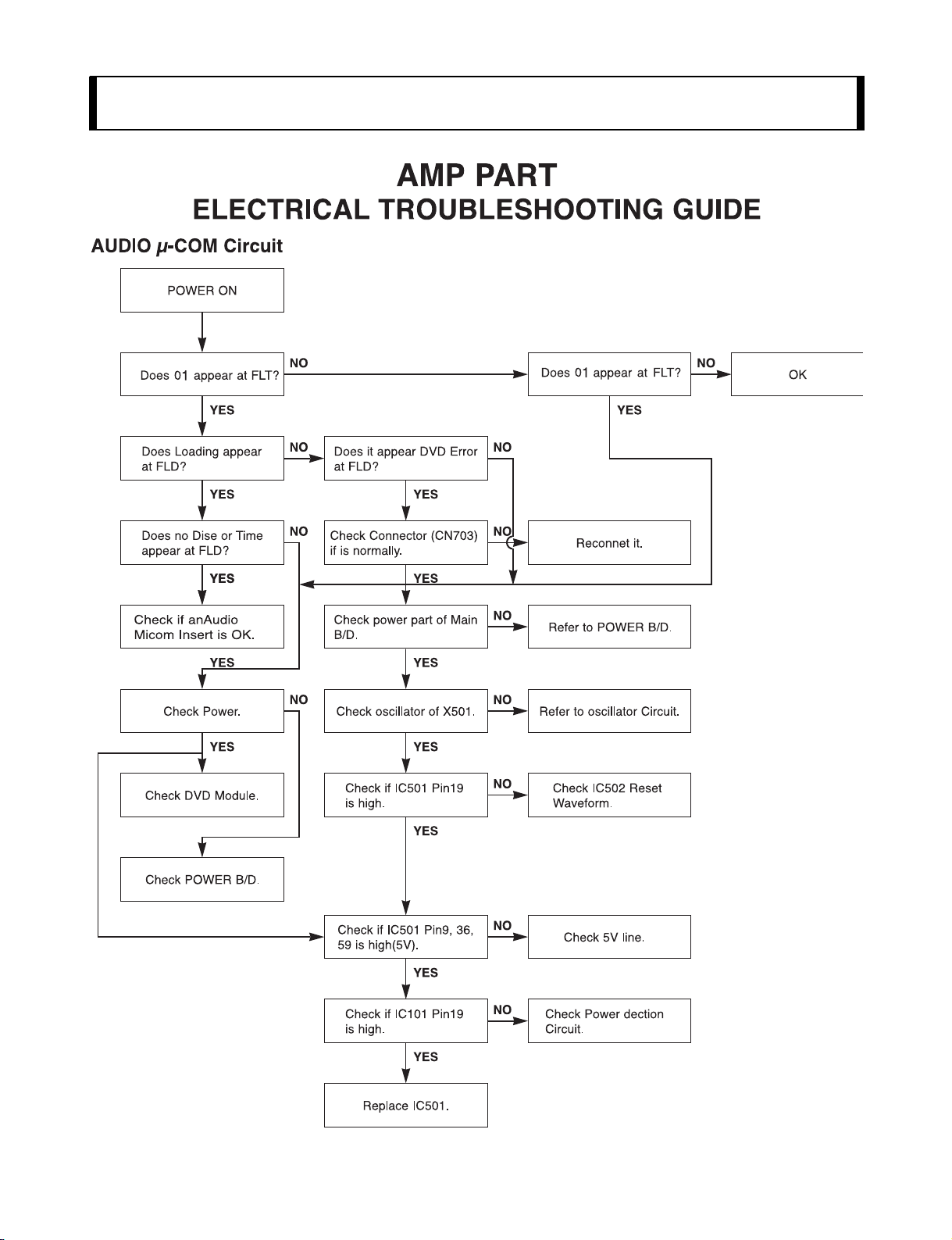

• AMP ELECTRICAL TROUBLESHOOTING GUDIE

.....................................................................

2-1

• BLOCK DIAGRAM......................................................................................................................... 2-2

• AUDIO SCHEMATIC DIAGRAMS

...............................................................................................

2-4

• WIRING DIAGRAM

....................................................................................................................

2-10

• AUDIO VOLTAGE SHEET (IC&TR) ............................................................................................ 2-12

• PRINTED CIRCUIT DIAGRAM ................................................................................................... 2-14

SECTION 3. VCR PART

• ELECTRICAL ADJUSTMENT PROCEDURES

............................................................................

3-1

• VCR ELECTRICAL TROUBLESHOOTING

...................................................................................

3-2

• VCR SHEMATIC DIAGRAMS ..................................................................................................... 3-17

• VCR VOLTAGE SHEET (IC&TR)................................................................................................ 3-29

• PRINTED CIRCUIT DIAGRAMS ................................................................................................. 3-31

SECTION 4. MECHANSIM OF VCR PART

.......................................................................

4-1

SECTION 5. DVD PART

• DVD ELECTRICAL TROUBLESHOOTING................................................................................... 5-1

• DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING ...................................... 5-7

• DVD PART SCHEMATIC DIAGRAMS ........................................................................................ 5-21

• VOLTAGE SHEET (IC&TR) ........................................................................................................ 5-29

• PRINTED CIRCUIT DIAGRAM ................................................................................................... 5-31

SECTION 6. MECHANSIM OF DVD PART

.......................................................................

6-1

SECTION 7. EXPLODED VIEWS PART

...........................................................................

7-1

• Cabinet and Main frame ................................................................................................................ 7-1

• Speaker ........................................................................................................................................ 7-3

SECTION 8. REPLACEMENT PARTS LIST

.....................................................................

8-1

CONTENTS

Page 3

- 1-2 -

SECTION 1. GENERAL PART

CAUTION : DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY,

NEVER PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER S APPROVAL. UNAUTHORIZED MODIFICATIONS WILL NOT ONLY

VOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING LIABLE FOR ANY

RESULTING PROPERTY DAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE

THOROUGHLY FAMILIAR WITH ALL OF THE FOLLOWING SAFETY

CHECKS AND SERVICING GUIDELINES. TO DO OTHERWISE,

INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE

USER.

WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE SHOCK.

SAFETY CHECKS

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRCTED. A

CHECK SHOULD BE MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY

AS TO AVOID POSSIBILITY OF ADJACENT COMPONENT SHORTS.

THIS IS ESPECIALLY IMPORTANT ON THOSE MODULES WHICH ARE

TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES

SUCH AS INSULATORS, BARRIERS, COVERS, SHIELDS, STRAIN

RELIEFS, POWER SUPPLY CORDS, AND OTHER HARDWARE HAVE

BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN

DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD

SOLDER JOINTS, SOLDER SPLASHES OR SHARP SOLDER POINTS.

BE CERTAIN TO REMOVE ALL LOOSE FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION

TO PARTS AND COMPONENTS. FOR FRAYED LEADS, DAMAGED

INSULATION (INCLUDING A.C. CORD). AND REPLACE IF NECESSARY

FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR

A RESISTOR RATED AT 1 WATT OR MORE. LEAD TENSION AROUND

PROTRUNING METAL SURFACES MUST BE AVOIDED.

6. ALL CRITICAL COMPONENTS SUCH AS FUSES, FLAMEPROOF

RESISTORS, CAPACITORS, ETC. MUST BE REPLACED WITH EXACT

FACTORY TYPES, DO NOT USE REPLACEMENT COMPONENTS

OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT MODIFICATIONS.

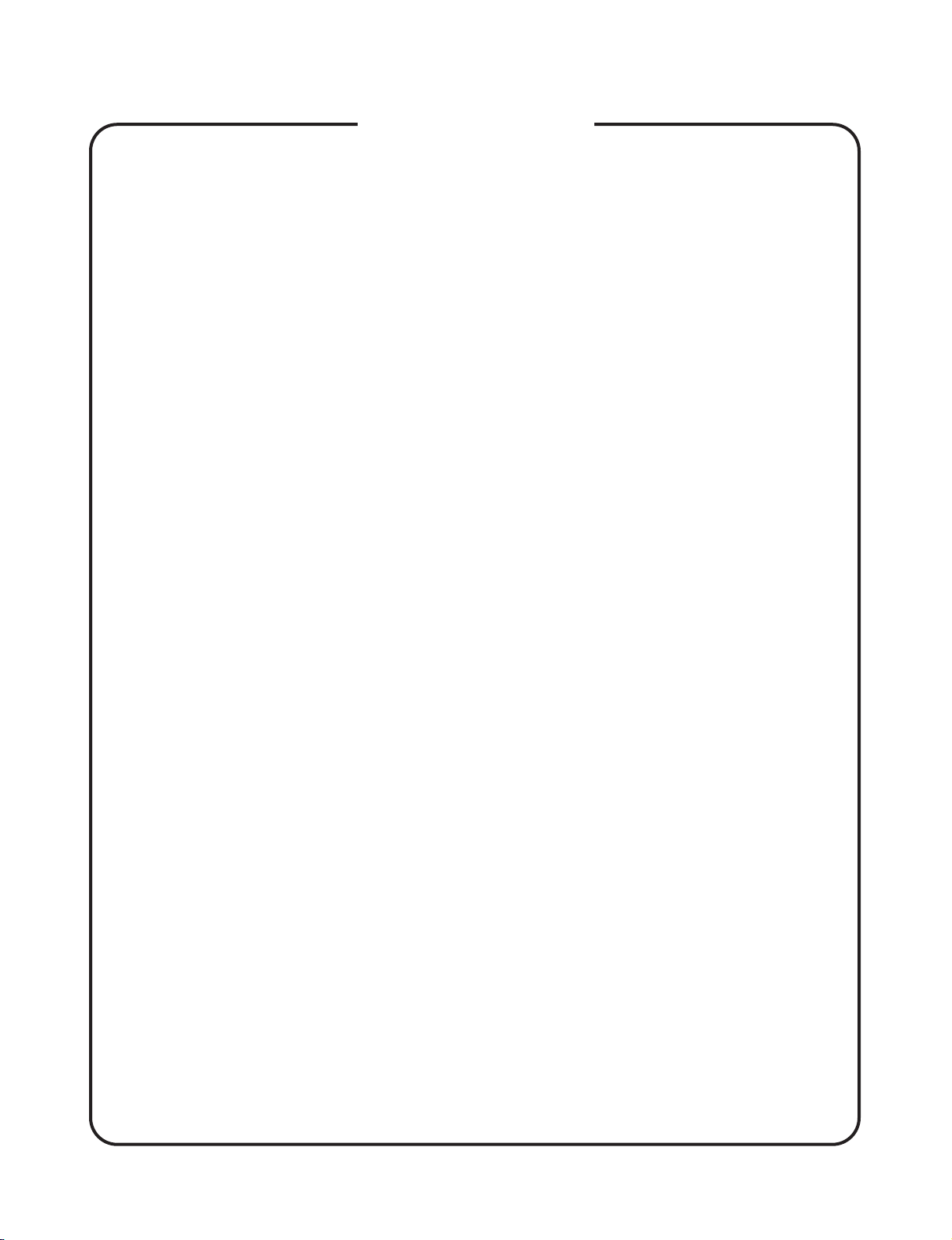

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C.

LEAKAGE TEST ON ALL EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE

WITHOUT DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE

ISOLATION TRANSFORMER DURING THIS TEST USE AN A.C. VOLTMETER, HAVING 5000 OHMS PER VOLT OR MORE SENSITIVITY, IN

THE FOLLOWING MANNER; CONNECT A 1500 OHM 10 WATT RESISTOR, PARALLELED BY A .15 MFD. 150.V A.C TYPE CAPACITOR

BETWEEN A KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, ONE AT A TIME.

MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500

OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C. PLUG

AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED

METALLIC PART. VOLTAGE MEASURED MUST NOT EXCEED 75

VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C ANY

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUST BE CORRECTED IMMEDIATELY.

SUBJECT: GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN

AN EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE

SERVICE PERSONNEL TO THE PRESENCE OF UNINSULATED

DANGEROUS VOLTAGE THAT MAY BE OF SUFFICIENT MAG-

NITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIAN-

GLE IS INTENDED TO ALERT THE SERVICE PERSONNEL TO

THE PRESENCE OF IMPORTANT SAFETY INFORMATION IN

SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V. RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS WHEN

THE HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE

PROPER VALUE IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

2. ONLY FACTORY SPECIFIED C.R.T. ANODE CONNECTORS MUST BE

USED. DEGAUSSING SHIELDS ALSO SERVE AS X-RAY SHIELD IN

COLOR SETS, ALWAYS RE-INSTALL THEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN

ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRA

TION OF THE METER SHOULD BE CHECKED PERIODICALLY

AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE

AT YOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY

THERE IS NO POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY

TIME A COLOR CHASSIS IS SERVICED. THE BRIGHTNESS SHOULD

BE RUN UP AND DOWN WHILE MONITORING THE HIGH VOLTAGE

WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES

NOT EXCEED THE SPECIFIED VALUE AND THAT IT IS REGULATING

CORRECTLY, WE SUGGEST THAT YOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT VOLTAGE REGULATION IS ALWAYS CHECKED AS A STANDARD SERVICING PROCEDURE. AND THAT THE HIGH VOLTAGE READING BE RECORDER ON

EACH CUSTOMER S INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN

A PRODUCT WITH A PROBLEM OF EXCESSIVE HIGH VOLTAGE,

AVOID BEING UNNECESSARILY CLOSE TO THE PICTURE TUBE AND

THE HIGH VOLTAGE SUPPLY. DO NOT OPERATE THE PRODUCT

LONGER THAN IS NECESSARY TO LOCATE THE CAUSE OF EXCES

SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES

DESCRIBED IN THE APPROPRIATE SCHEMATIC AND DIAGRAMS

(WHERE USED).

SUBJECT: IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE

GRAL IMPLOSION PROTECTION SYSTEM, BUT CARE SHOULD BE

TAKEN TO AVOID DAMAGE DURING INSTALLATION, AVOID

SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY FITTING SHELF SPACE. OVER OR CLOSE TO

HEAT DUCT, OR IN THE PATH OF HEATED AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO

INSTALLATIONS WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR

VENTING. THE CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER COVERINGS WHICH MIGHT

OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT. MUST FOLLOW THE FACTORY APPROVED

MOUNTING INSTRUCTIONS A PRODUCT MOUNTED TO A SHELF OR

PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE EQUIVALENT

THICKNESS IN SPACERS) TO PROVIDE ADEQUATE AIR FLOW

ACROSS THE BOTTOM, BOLTS OR SCREWS USED FOR FASTENERS

MUST NOT TOUCH ANY PARTS OR WIRING. PERFORM LEAKAGE

TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON

SLOPING SHELF OR A TILTED POSITION, UNLESS THE PRODUCT IS

PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS

MOUNTING TO THE CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH SMALL CASTERS ACROSS

THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND

WHICH HAS NOT BEEN LISTED BY UNDERWRITERS LABORATORIES,

INC. FOR USE WITH THEIR SPECIFIC MODEL OF TELEVISION

RECEIVER OR GENERICALLY APPROVED FOR USE WITH T.V. S OF

THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS,

EXPLAIN THAT A FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS CONSEQUENCES TO

HOME AND FAMILY.

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

A.C. VOLTMETER

GOOD EARTH GROUND

SUCH AS THE WATER

PIPE. CONDUIT. ETC

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

Page 4

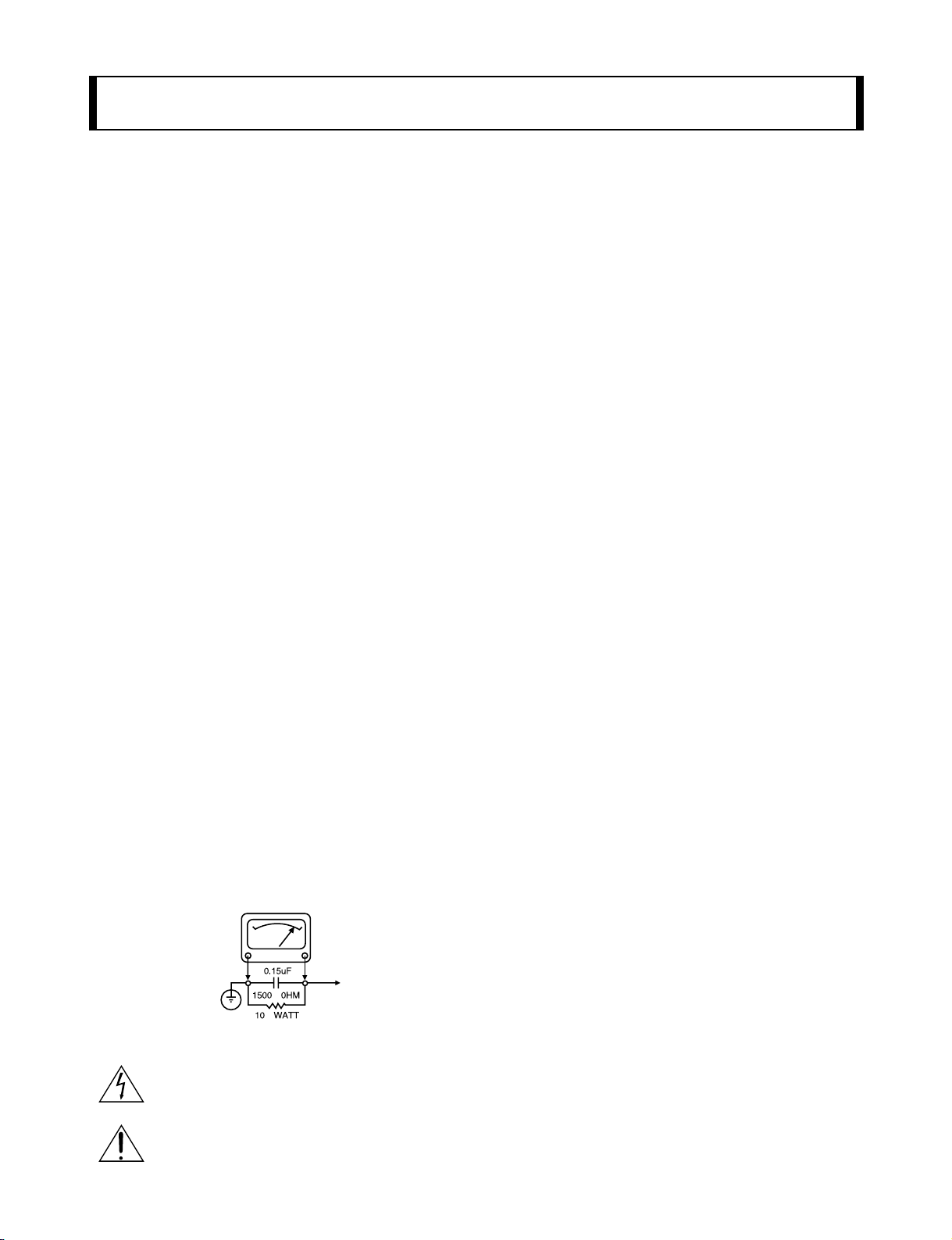

NOTES REGARDING HANDLING OF THE PICK-UP

1. Notes for transport and storage

1) The pick-up should always be left in its conductive bag until immediately prior to use.

2) The pick-up should never be subjected to external pressure or impact.

2. Repair notes

1) The pick-up incorporates a strong magnet, and so should never be brought close to magnetic materials.

2) The pick-up should always be handled correctly and carefully, taking care to avoid external pressure and

impact. If it is subjected to strong pressure or impact, the result may be an operational malfunction and/or

damage to the printed-circuit board.

3) Each and every pick-up is already individually adjusted to a high degree of precision, and for that reason

the adjustment point and installation screws should absolutely never be touched.

4) Laser beams may damage the eyes!

Absolutely never permit laser beams to enter the eyes!

Also NEVER switch ON the power to the laser output part (lens, etc.) of the pick-up if it is damaged.

5) Cleaning the lens surface

If there is dust on the lens surface, the dust should be cleaned away by using an air bush (such as used

for camera lens). The lens is held by a delicate spring. When cleaning the lens surface, therefore, a

cotton swab should be used, taking care not to distort this.

6) Never attempt to disassemble the pick-up.

Spring by excess pressure. If the lens is extremely dirty, apply isopropyl alcohol to the cotton swab. (Do

not use any other liquid cleaners, because they will damage the lens.) Take care not to use too much of

this alcohol on the swab, and do not allow the alcohol to get inside the pick-up.

- 1-3 -

Storage in conductive bag

Drop impact

NEVER look directly at the laser beam, and don’t let

contact fingers or other exposed skin.

Magnet

How to hold the pick-up

Pressure

Pressure

Cotton swab

Conductive Sheet

Page 5

- 1-4 -

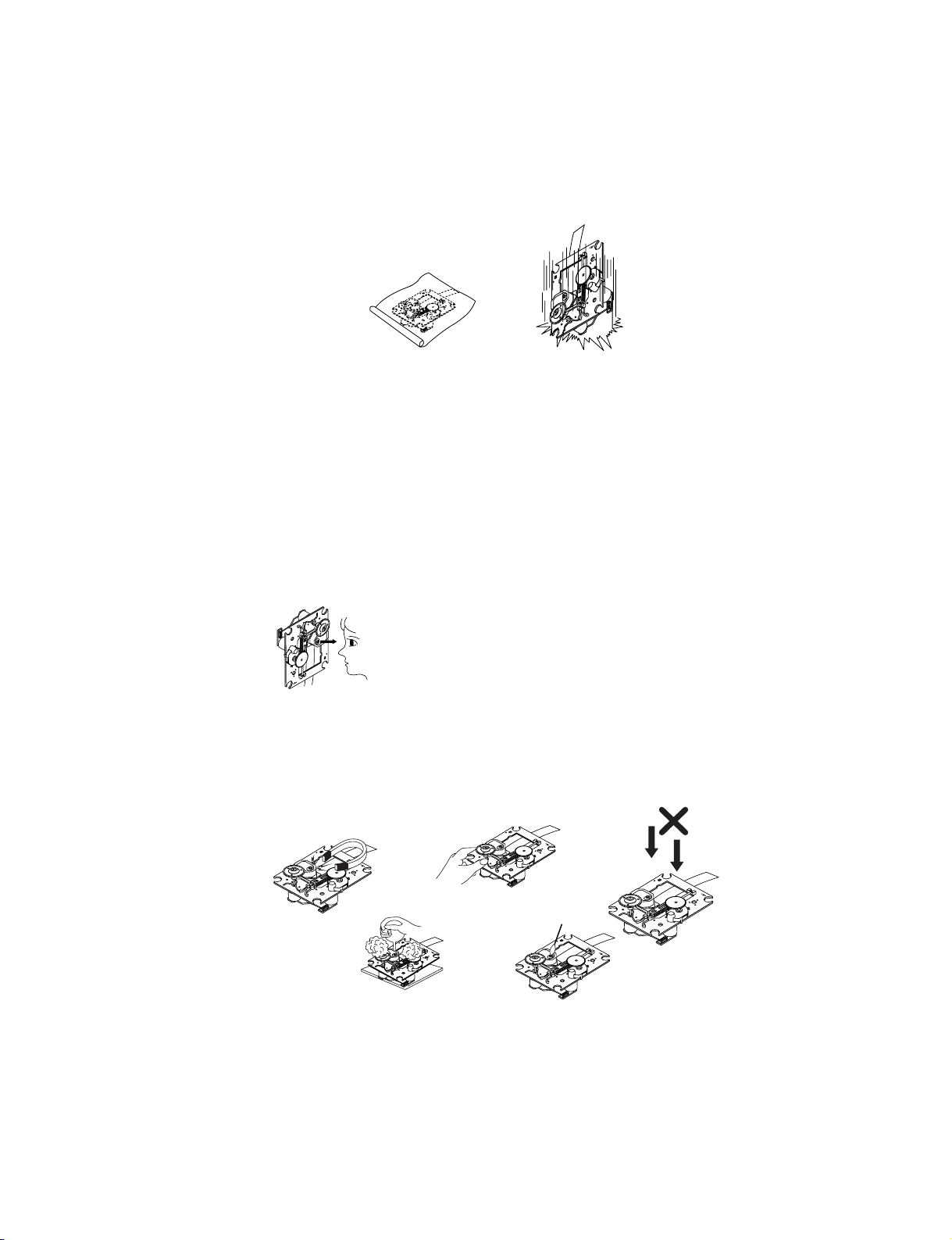

NOTES REGARDING COMPACT DISC PLAYER REPAIRS

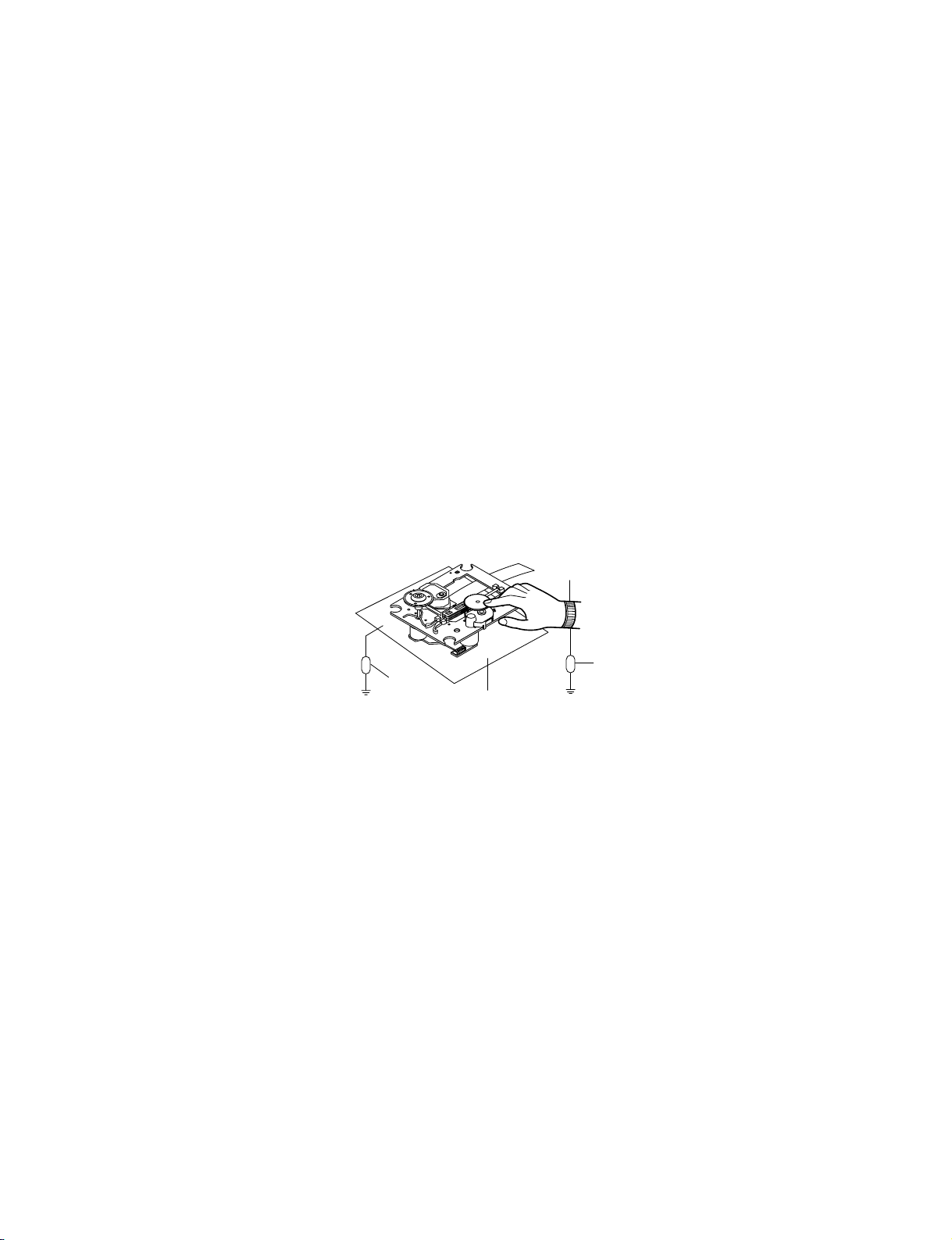

1. Preparations

1) Compact disc players incorporate a great many ICs as well as the pick-up (laser diode). These

components are sensitive to, and easily affected by, static electricity. If such static electricity is high

voltage, components can be damaged, and for that reason components should be handled with care.

2) The pick-up is composed of many optical components and other high-precision components. Care must

be taken, therefore, to avoid repair or storage where the temperature of humidity is high, where strong

magnetism is present, or where there is excessive dust.

2. Notes for repair

1) Before replacing a component part, first disconnect the power supply lead wire from the unit

2) All equipment, measuring instruments and tools must be grounded.

3) The workbench should be covered with a conductive sheet and grounded.

When removing the laser pick-up from its conductive bag, do not place the pick-up on the bag. (This is

because there is the possibility of damage by static electricity.)

4) To prevent AC leakage, the metal part of the soldering iron should be grounded.

5) Workers should be grounded by an armband (1MΩ)

6) Care should be taken not to permit the laser pick-up to come in contact with clothing, in order to prevent

static electricity changes in the clothing to escape from the armband.

7) The laser beam from the pick-up should NEVER be directly facing the eyes or bare skin.

Armband

Conductive

Sheet

Resistor

(1 Mohm)

Resistor

(1 Mohm)

Page 6

- 1-5 -

SERVICING PRECAUTIONS

CAUTION : Before servicing the COMBI HOME THEATER

SYSTEM covered by this service data and its supplements

and addends, read and follow the

SAFETY PRECAUTIONS.

NOTE

: if unforeseen circumstances create conflict between

the following servicing precautions and any of the safety precautions in this publications, always follow the safety precautions.

Remembers Safety First:

General Servicing Precautions

1. Always unplug the COMBI HOME THEATER SYSTEM AC

power cord from the AC power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnection or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an elec-

trolytic capacitor.

Caution : A wrong part substitution or incorrect

polarity installation of electrolytic capacitors may result

in an explosion hazard.

2. Do not spray chemicals on or near this COMBI HOME

THEATER SYSTEM or any of its assemblies.

3. Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner,

cotton-tipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication

of contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

whitch instruments covered by this service manual might

be equipped.

5. Do not apply AC power to this COMBI HOME THEATER

SYSTEM and/or any of its electrical assemblies unless all

solid-state device heat sinks are cerrectly installed.

6. Always connect test instrument ground lead to the

appropriate ground before connection the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter(500V)

to the blades of the attachment plug. The insulation resistance between each blade of the attachment plug and accessible conductive parts (Note 1) should be more than 1Mohm.

Note 1 : Accessible Conductive Parts including Metal panels, Input terminals, Earphone jacks, etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field

effect transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known

earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which

should be removed for potential shock reasons prior to

applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grouned-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static solder removal device. Some

solder removal devices not classified a anti-static can

generate electrical charges sufficient to damage ES

devices.

5. Do not use freon-propelled chemicals. These can

generate electrical charge sufficient to damage ES

devices.

6. Do not remove a replacement ES device from its protec

tive package until immediately before you are ready to

install it. (Most replacement ES devices are packaged with

leads electrically shorted together by conductive foam,

aluminum foil, or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static electricity sufficient to damage an ES device.)

Page 7

- 1-6 -

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called Electrostatically Sensitive Devices (ESD). Examples of typical ESD devices are integrated

circuits and some field-effect transistors and semiconductor chip components. The following techniques should

be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off

any electrostatic charge on your body by touching a known earth ground. Alternatively, obtain and wear a

commercially available discharging wrist strap device, which should be removed for potential shock reasons

prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static" can

generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals. These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are ready

to install it. (Most replacement ESD devices are packaged with leads electrically shorted together by

conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch the

protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL OTHER

SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless motion

such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor can

generate static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN EQUILATERAL

TRIANGLE, IS INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF

UNINSULATED “DANGEROUS VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO

CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENDED TO

ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY

INFORMATION IN SERVICE LITERATURE.

Page 8

- 1-7 -

SPECIFICATIONS

General

Power requirements AC230V ~ , 50 Hz

Power consumption 130 W

Dimensions (approx.) 430 X 90 X 350 mm (w x h x d)

Mass (approx.) 8 kg (17.6 lbs)

Operating temperature 5ßC to 40ßC (41ßF to 104ßF )

Timer 24-hour display type

Operating humidity 5 % to 90 %

DVD Section

Laser Semiconductor laser, wavelength 650 nm

Signal system PAL/NTSC

Frequency response DVD (PCM 96 kHz): 8 Hz to 44 kHz

DVD (PCM 48 kHz): 8 Hz to 20 kHz

CD: 8 Hz to 20 kHz

Signal-to-noise ratio More than 65 dB (ANALOG OUT connectors only)

Harmonic distortion Less than 1.0%

Dynamic range More than 60 dB (DVD)

More than 60 dB (CD)

Outputs

S-VIDEO OUT (Y) 1.0 V (p-p), 75 ohms, negative sync, Mini DIN 4-pin x 1

(C) 0.3 V (p-p) 75 ohms

VCR Section

Head system 4 heads helical scan azimuth system

Maximum recording time SP: 4 h (E-240 tape), LP: 8 h (E-240 tape)

Rewind time About 180 min (E-180 tape)

Input level VIDEO: 1.0 V(p-p), 75 ohms, unbalanced

AUDIO: -6.0 dBm, more than 10 kohms (SCART)

-6.0 dBm, more than 47 kohms (RCA)

Output level VIDEO: 1.0 V(p-p), 75 ohms, unbalanced

Signal-to-noise ratio VIDEO: More than 43 dB

AUDIO: More than 72 dB (Hi-Fi)

More than 42 dB (Mono)

Dynamic range AUDIO: More than 85 dB

Tuner Section

Tuning range FM: 87.5 - 108.0 MHz

AM: 522 - 1611 kHz

Intermediate frequency FM: 10.7 MHz

AM: 450 kHz

Amplifier Section

Stereo mode 20W + 20W (4 ohm at 1 kHz, THD 10%)

Surround mode Front: 20W + 20W (THD 10%)

Centre: 20W

Surround: 20W + 20W (4 ohm at 1 kHz, THD 10%)

Subwoofer: 40W (8 ohm at 30 Hz, THD 10%)

Page 9

- 1-8 -

Speakers

Satellite (LHS-C6230T)

Type 1 Way 1 Speaker

Impedance 4‰

Frequency Response 130 - 20,000 Hz

Sound Pressure Level 83 dB/W (1m)

Rated Input Power 20W

Max Input Power 40W

Net Dimensions (W x H x D) 88 x 100 x 95 mm

Net Weight 0.54 kg

Passive Subwoofer (LHS-C6230W)

Type 1 Way 1 Speaker

Impedance 8‰

Frequency Response 50 - 1,500 Hz

Sound Pressure Level 82 dB/W (1m)

Rated Input Power 40W

Max Input Power 80W

Net Dimensions (W x H x D) 160 x 350 x 325 mm

Net Weight 4.12 kg

Page 10

- 2-1 -

SECTION 2. AUDIO PART

Page 11

- 3-1 -

ELECTRICAL ADJUSTMENT PROCEDURES

1. Servo Adjustment

1) PG Adjustment

Test Equipment

Adjustment And Specification

a) OSCILLOSCOPE

b) NTSC MODEL : NTSC SP TEST TAPE

C) PAL MODEL : PAL SP TEST TAPE

MODE

PLAY

Adjustment Procedure

a) Insert the SP Test Tape and play.

Note - Adjust the distance of X, pressing the Tracking(+) or Tracking(-) when the ATR is blink after the

SP Test Tape is inserted.

b) Connect the CH1 of the oscilloscope to the H/SW(W373, W374) and CH2 to the Video Out for the VCR.

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW(W373, W374), and then check the dis-

tance (time difference), which is from the selected A(B) Head point of the H/SW(W373, W374) signal to

the starting point of the vertical synchronized signal, to 6.5H – 0.5H (416 s, 1H=64 s).

PG Adjustment Method

a-1) Payback the SP standard tape

b-2) Press the 1 key on the Remote controller and the PLAY key on the Front Panel the same time,

then it goes in to Tracking initial mode. (Note : PAL Model 1 key on Remote controller)

c-3) Repeat the above step(No.b-2), then it finishes the PG adjusting automatically.

d-4) Stop the playback, then it goes out to PG adjusting mode after mony the PG data.

CONNECTION

WAVEFORM

V.Out

H/SW(W373, W374)

R/C TRK JIG KEY 6.5 – 0.5H

MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

V.Out

H/SW(W373,W374)

OSCILLOSCOPE

CH1 CH2

V.out

H/SW

R/C KEY

(W373, W374)

H/SW

Composite

VIDEO

SECTION 3. VCR PART

Page 12

- 3-2 -

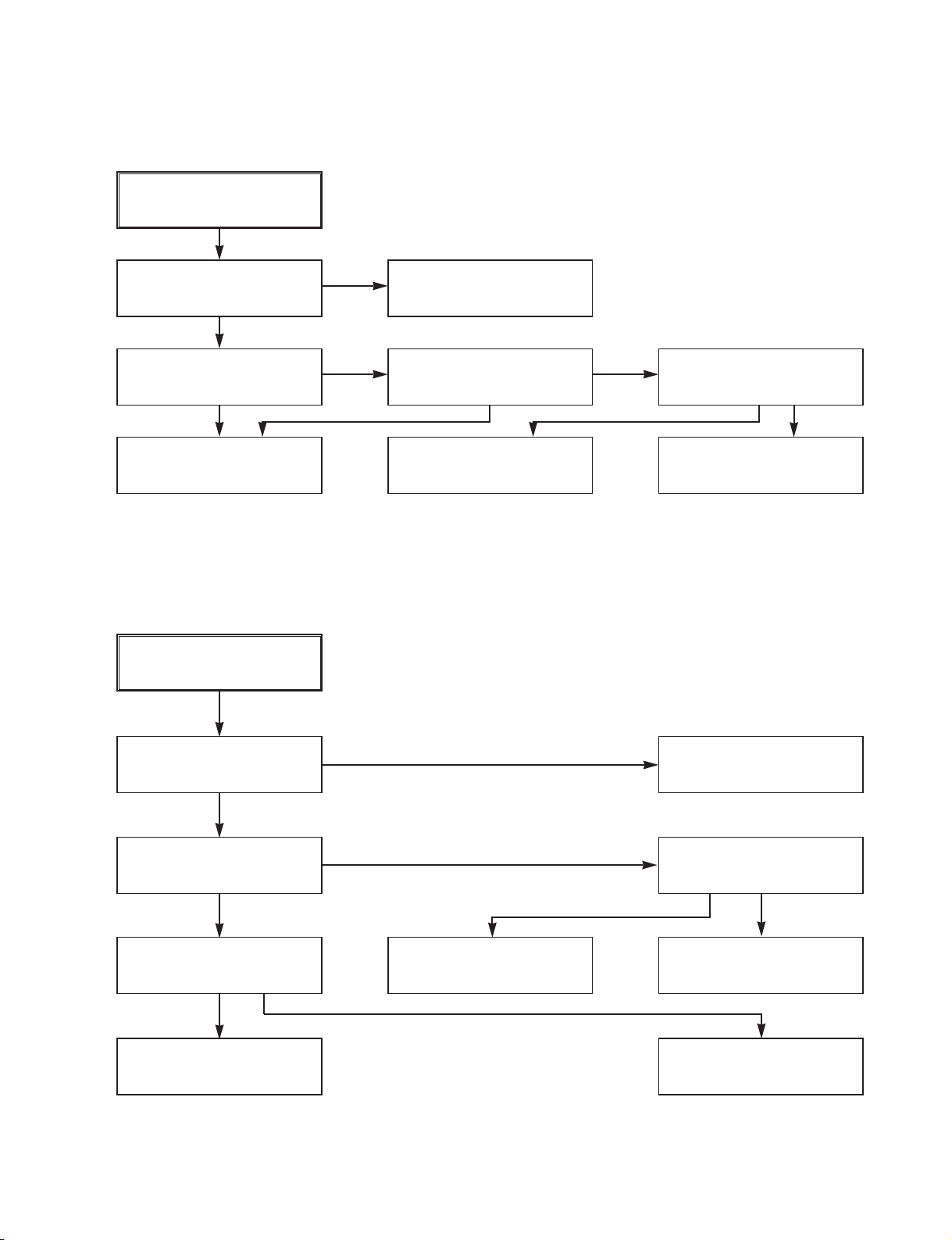

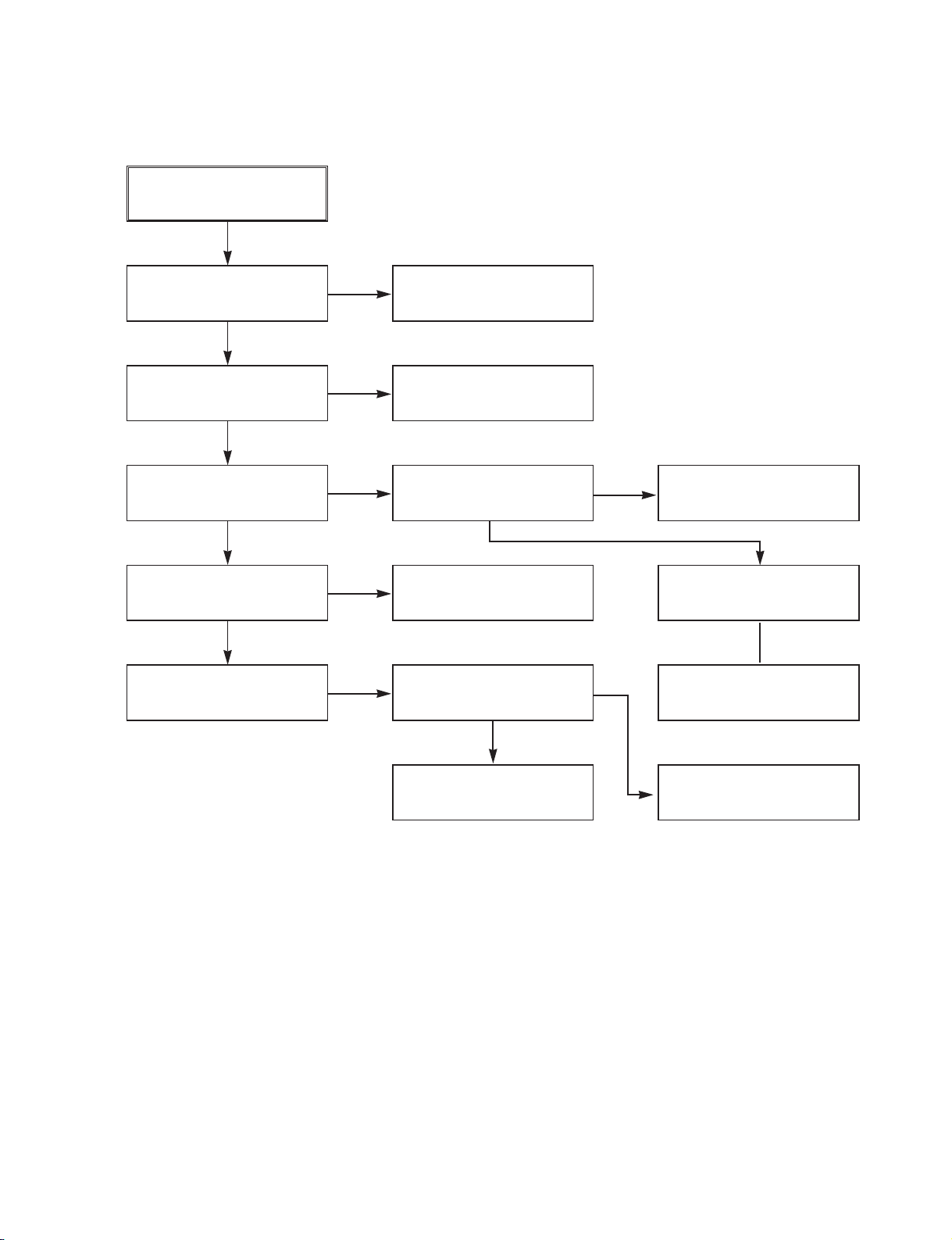

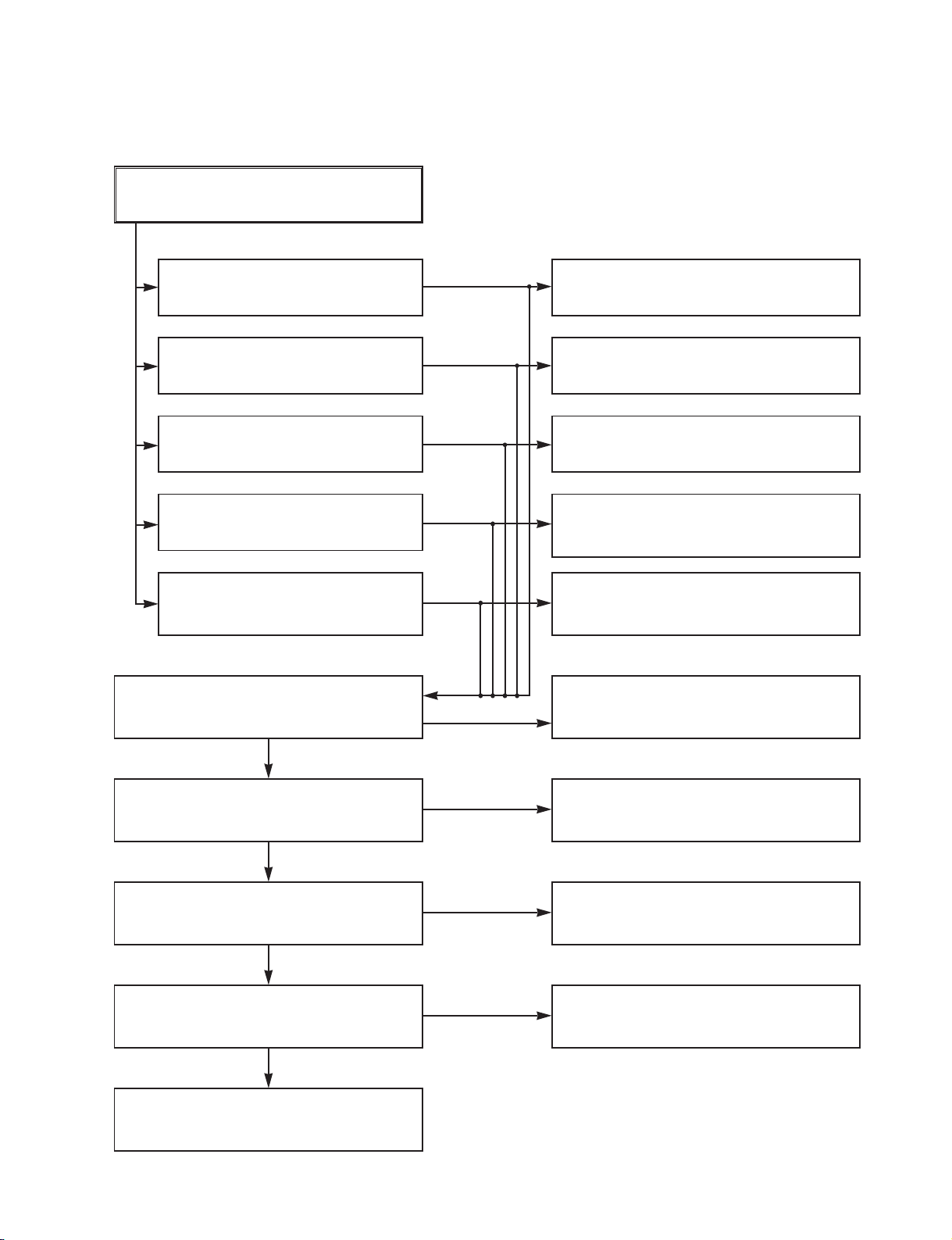

VCR ELECTRICAL TROULBESHOOTING

Page 13

- 3-3 -

Page 14

- 3-4 -

2. SYSTEM/KEY CIRCUIT

(1) AUTO STOP

(2) The unstable loading of a Cassette tape

Auto Stop

Does the SW25 waveform

appear at the IC501

Pin105?

Do the T-UP Reel Pulses

appear at the IC501 Pin49?

Is 12V applied to the

PMC01 Pin8?

Check the Drum Motor

signal.

Does 5.2V appear at the

RS501?

Check the Power Circuit.

Check the Power.

Is 5.3V applied to the

R544 ?

Refer to SMPS 5.3VA

troubleshooting.

Check the IC501

Pins68, 69, 70, 71.

Do T/UP Reel Pulses

appear at the Q514

Base terminal ?

Replace the T/UP Reel

Sensor (RS501).

Check the CST SW and

the peripheral circuitry.

Replace the IC501.

The unstable loading of a

Cassette tape

Does the H signal appear

at the IC501 Pin30 during

inserting the CST ?

Does the L signal appear

at the IC501 Pin72 during

inserting the CST?

Check the Deck

Mechanism.

Caution :

Auto stop can occur because Grease or Oil is dried up

YES

YES

YES

NO

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO NO

YES

YES YES

Page 15

- 3-5 -

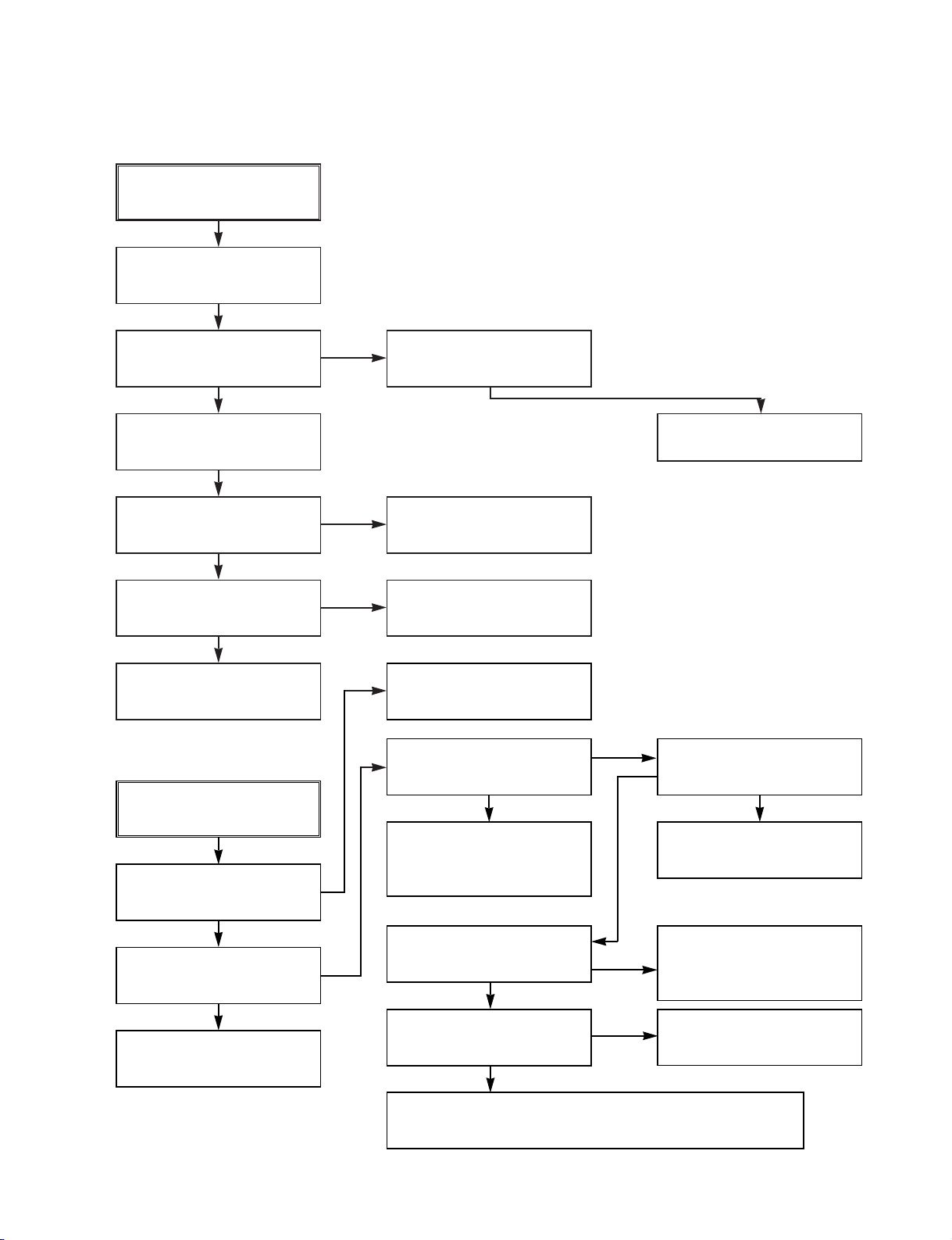

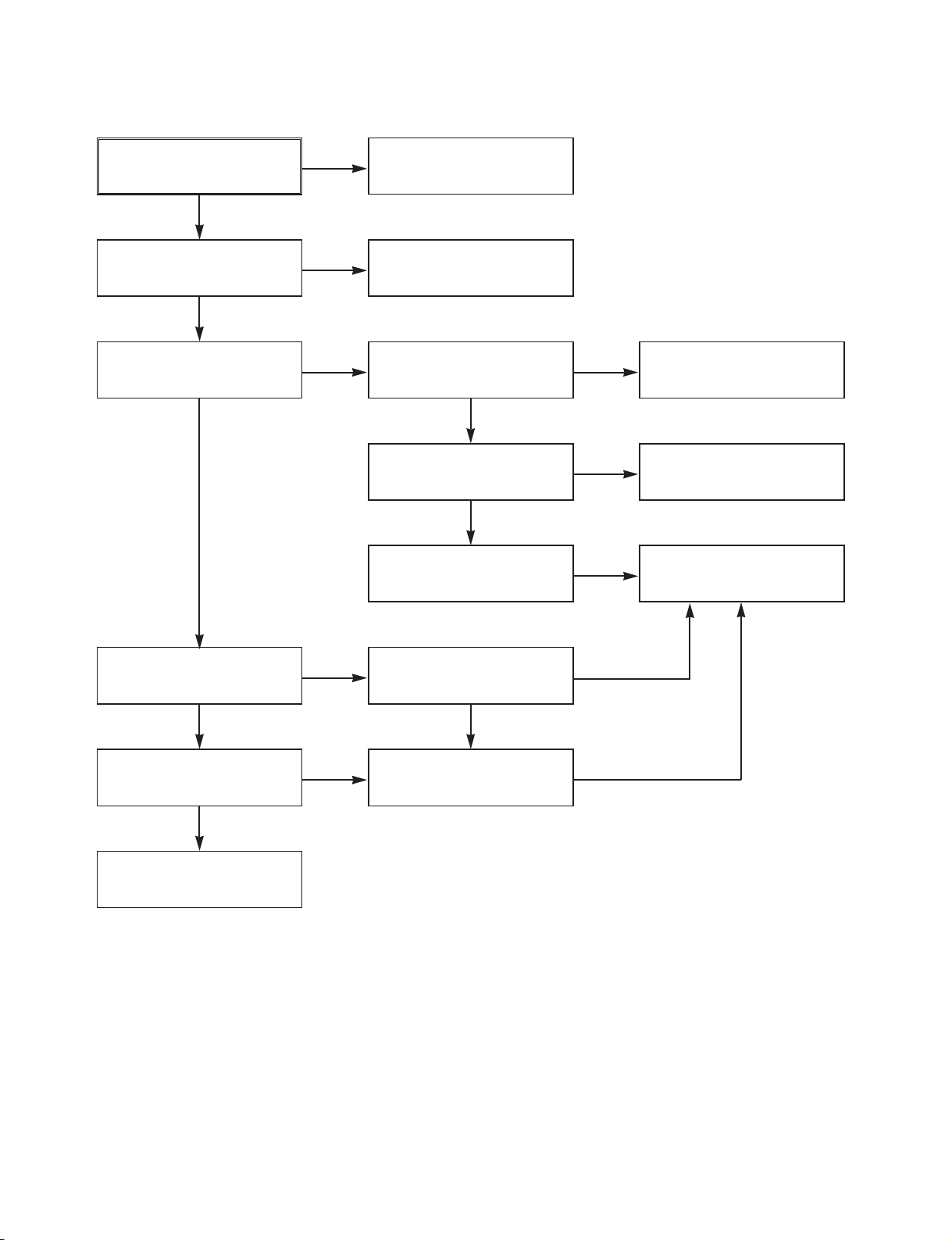

3. SERVO CIRCUIT

(1) Unstable Video in PB MODE

Unstable Video in

PB Mode.

Does the Noise level of the

screen change

periodically?

Do the CTL pulses appear

at the IC501 Pin8?

Is adjusting the height of

the CTL Head accurate?

Readjust the height of the

CTL Head.

Replace the IC501.

Refer to When the Y signal

doesn t appear on the

screen in PB Mode .

Does the CFG waveform

appear at the IC501

Pin9?

On tracking do the CTL

pulses move?

Does the Video Envelope

waveform appear at the

IC501 Pin24?

Replace the IC501.

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

(2) When the Drum Motor

(2) doesn t run.

Do the DFG Pulses appear

at the PMC01 Pin11?

Replace the Cap M.

Aren t the foil patterns and

the Components between

IC501 Pin104 and PMC01

Pin11 short?

Replace the IC501.

Refer to (2)

No 12VA of Power section

Do the Drum PWM Pulses

appear at the IC501

Pin107?

Aren t the foil patterns and

the Components between

IC501 Pin107 and PMC01

Pin12 short?

Do the DFG Pulses appear

at the IC501 Pin104?

Do the Drum PWM Pulses

appear at the IC501

Pin107?

Aren t the connecting patterns and the Components

between IC501 Pin107 and PMC01 Pin12 short?

When the Drum Motor

doesn t run,

Does 12V appear at the

PMC01 Pin8?

Does 2.8V appear at the

PMC01 Pin12?

Check the connector

(PMC01) and the Drum

Motor Ass y.

NO

YES

YES

YES

NO

NO

NO

NO

NO

YES

YES

YES

Page 16

- 3-6 -

Does the CFG signal appear at the

PMC01 Pin1?

Does the PWM signal appear at the

IC501 Pin108?

Does 2.8V appear at the PMC01?

Check the PMC01 and the Capstan

Motor Ass y.

Does the Capstan PWM signal appear at

the IC501 Pin108?

Aren t the foil patterns and Components

between IC501 Pin108 and PMC01

Pin9 short?

Does the CFG signal come into the

IC501 Pin9?

Aren t the foil patterns and Components

between IC501 Pin108 and PMC01

Pin9 short?

(3) When the Capstan Motor doesn t run,

NO

NO

NO

YES

YES

YES

When the Capstan Motor doesn t run,

Does 12VA appear at the PMC01?

YES

Replace the IC501.

YES

NO

NO

YES

Refer to SMPS(CAPSTAN/12Volt)

Trouble Shooting .

Aren t the foil patterns and component

between IC501 Pin9 and PMC01

Pin1 short?

Check the Capstan Motor Ass y.

NO

Page 17

- 3-7 -

(4) KEY doesn t working

KEY doesn t working.

Is 5V applied to the IC501

Pin36?

Does LED or FLD change

when a function button is

pressed?

Refer to SMPS 5.3VA

Trouble Shooting .

Replace the defective

switches.

YES

NO

NO

Page 18

- 3-8 -

4. Y/C CIRCUIT

(1) No Video in EE Mode,

No Video in EE Mode

Check the 24Pin of Tuner.

Does the Video signal

appear at the IC301 Pin48?

Is 5V applied to the IC301

Pins18, 24, 42, 55, 72, 91?

Does the Video signal

appear at the IC301 Pin65?

Does the Video signal

appear at the IC501 Pin19?

Does the Video signal

appear at the Emitter terminal of the Q307, Q308?

Check the 5.2VT, 5.3VA

Line. (Power Circuit)

Is I2C BUS signal applied to

the IC301 Pins68, 69?

Check C316. (AGC)

Chck the path of the signal

between the IC301 Pin65

and IC501 Pin17.

Replace the IC301.

Does the 12VT, 5.3VA

appear at the Emitter terminal of the Q804, Q308.

Replace the Q804, Q308.

Check the 12VT, 5.3VA

Line. (Power Circuit)

Check the System Circuit.

(Refer to SYSTEM I

2

C BUS

CHECK Trouble Shooting )

YES

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

NO

Page 19

- 3-9 -

(2) When the Y(Luminance) signal doesn t appear on the screen in PB Mode,

Is 5.2VT, 5.3VA applied to the

IC301 Pins24, 42, 55, 72, 91?

Is the I2C Bus siganl applied

to the IC301 Pins68, 69 ?

Does the normal RF signal

appear at the IC301 Pin78?

Check the line of the 5.2VT,

5.3VA Line. (Power Circuit)

Check the System Circuit.

(IC501 Pin105)

Check the V.H.S/W level.

(Check R303, R304)

Replace the IC301.

Refer to SYSTEM I2C BUS

CHECK Trouble Shooting .

Is the V.H.S/W signal

applied to the IC301 Pin70?

Is V.H.S/W H about 3.4V

at the IC301 Pin70?

Clean the Drum.

Check the path of the

Y(Luminance) RF signal.

(Check C327)

Check the path of the

Y(Luminance) RF signal.

(Check the C312)

Does the Y(Luminance) RF

signal appear at the IC301

Pin76?

Is the Y(Luminance) Video

waveform showed up at

theIC301 Pin43?

Replace the IC301.

NO

NO

NO

NO

NO

NO

NO

NO

YES

YES

YES

YES

YES

YES

YES

YES

YES

Page 20

- 3-10 -

(3) When the C(Color) signal doesn t appear on the screen in PB Mode,

Is 5.2VT/5.3VA applied to the

IC301 Pins24, 42, 55, 72, 91.

Is the Color Rotary signal

applied to the IC301

Pin70?

Check the line of the 5.2VT/

5.3VA Line. (Power Circuit)

Replace the X301.

Check the Color Pass.

Check the Color Rotary

Circuit. (IC501 Pin99 )

Check the Color Rotary

level. (Check the R303)

Does the X301(4.43MHZ)

oscillate?

Replace the IC301.

Does the Color signal

appear at the IC301 Pin21?

Is Color Rotary H

about 3.4V?

Replace the IC301.

NO

NO

NO

YES

YES

YES

YES

NO

NO

NO

YES

Does the Color signal

appear at the IC301

Pin25 ?

Page 21

- 3-11 -

(4) When the Video signal doesn t appear on the screen in REC Mode,

Is the EE signal normal?

Is 5.2VT/5.3VA applied to the

IC301 Pins24,42,55,72,91?

Does the RF signal appear

at the IC301 Pin78?

Check EE Mode.

Check the System of REC

H . (the IC501 Pin47

/ the D301)

Replace the IC301.

Check the line of the 5.2VT/

5.3VA Line.(Power Circuit)

Check PB Mode.

Is the REC H signal

(about 4V) applied to the

IC301 Pin80?

Check the circuit of the

IC301 Pins85, 86.

Check REC Luminance

Pass & Color Pass.

Does PB Mdoe operate

normally?

Does the REC RF signal

appear at the IC301

Pins88,89,94,95?

Check the Drum &

Drum Connector

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

YES

YES

YES

Page 22

- 3-12 -

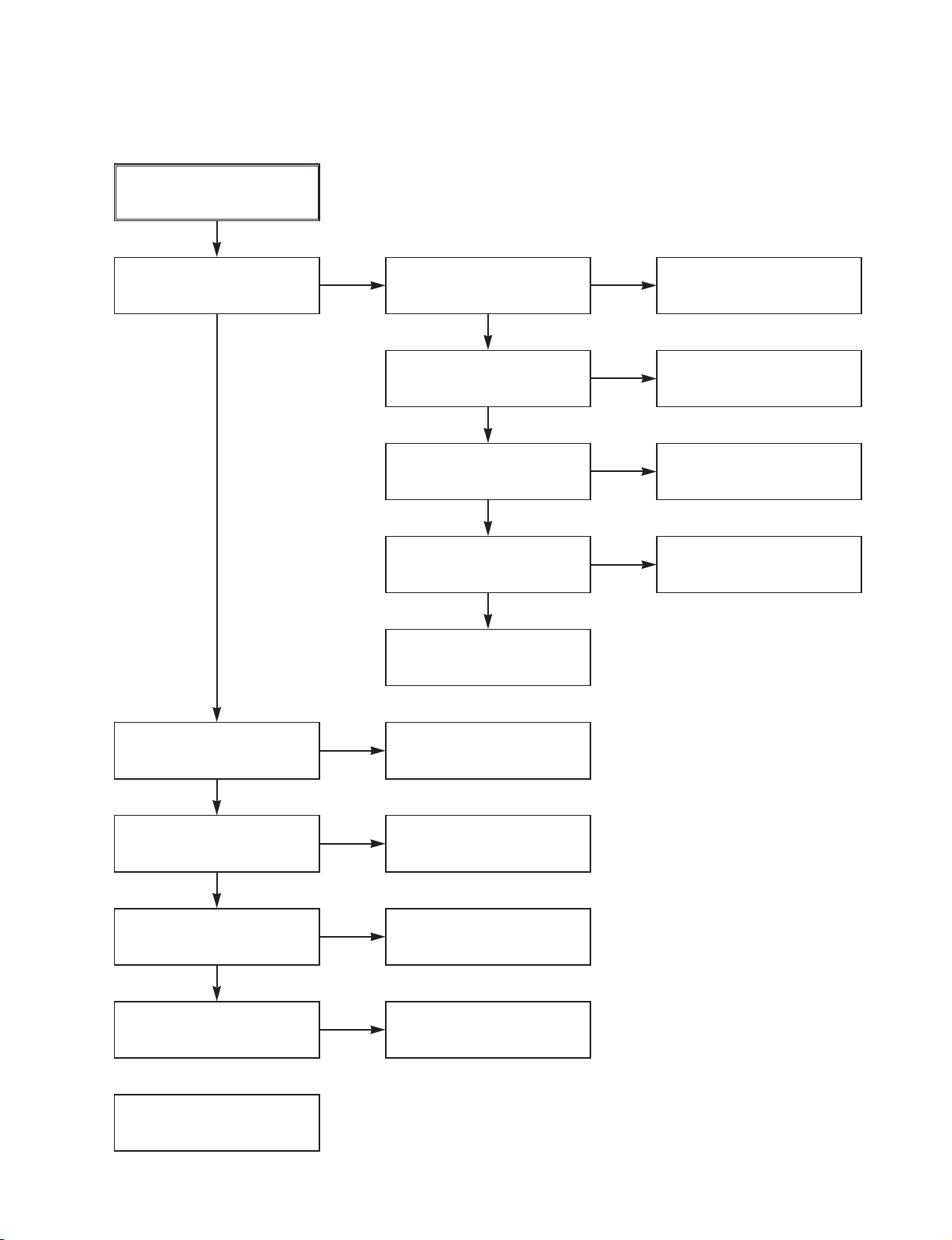

5. Hi-Fi CIRCUIT

(A) No Sound(EE Mode)

YES

No Sound.

Check the TU Audio of IC801

Pins1, 3.

Check the DVD Audio of IC801

Pins4, 5.

Check the AV1 Audio of IC801

Pins6, 7.

Check the AV2 Audio of IC801

Pins8, 9.

Check the AV3 Audio of IC801

Pins10, 11.

Check the Vcc of IC801 Pins34, 40,

IC802 Pin4.

YES

Check the IIC Clock and DATA at

IC801 Pins42, 43, IC802 Pins32, 33.

YES

Check the Audio of IC801 Pins16, 17.

YES

Check the Audio of IC802 Pins22, 26.

YES

Check the JK801.

Check the IC751 Pins30, 31.

NO

Check the DVD MODULE.

(P8D01 Pins3, 5).

NO

Check the Scart1 Jack.

(SC901 Scart1 Audio in Pins2, 6).

NO

Check the front Jack.

(PM602 Pins3, 5).

Check the Scart2 Jack.

(SC901 Scart2 Audio in Pins2, 6).

NO

NO

Check the Power 5.2V, 12VT.

YES

NO

Check the IC501 Pins59, 60.

NO

Replace IC801.

Replace IC802.

NO

NO

Page 23

- 3-13 -

(B) Hi-Fi Playback

YES

YES

YES

YES

PB mode

No Sound.

Check the Vcc of IC801

(Pins34, 40)

Check the Hi-Fi Selection switch.

(IC801 Pin41) and the Tape quality.

Is the RF Envelope at

IC801 Pin44 over 2Vp-p?

YES

Check IC801 Pin42(Data),

Pin43(Clock)

YES

Do Audio Signals appear at

IC801 Pin16(L-CH), 17(R-CH)?

YES

Do Audio Signals appear at

IC802 Pin10(L-CH), 16(R-CH)?

YES

YES YES

Do Audio Signals appear at

IC802 Pins22, 26?

Do Audio Signals appear at

JK801?

Check Power 5.2V, 12VT.

NO

Check IC501 Pin25

(A.H/SW)

NO

NO

Check the parts of -COM

(IC501 Pins59, 60)

NO

Check the Connection at

P3D01 Pins7, 9.

NO

Check the A.IN line of

IC802(C808, C809)

NO

Check the Vcc of IC802

Pin4.

Replace IC802.

Check the Jack(JK801)

NO

NO

Check Power.

NO

Page 24

- 3-14 -

(C)

Hi-Fi REC.

It is impossible to record Hi-Fi Audio

signal.

Check Vcc of IC801.(Pins34, 40)

YES

YES

Check IC801 Pin42(Data), Pin43(CLOCK).

YES

Do Audio signals appear at IC801

Pins16, 17?

YES

Do FM Audio signals appear at IC801

Pin36?

YES

Check the Contact Point of Drum

Connector if good then Replace the Drum.

YES

Check Power 5V, 12VT.

NO

Check ports of -COM.

Check Audio input signal of IC801

Pins2, 3(TU.A.), 4, 5(DVD.A.),

6, 7(AVI.A.), 8, 9(AV2.A.), 10, 11(AV3.A.).

NO

Replace IC801.

NO

NO

Page 25

- 3-15 -

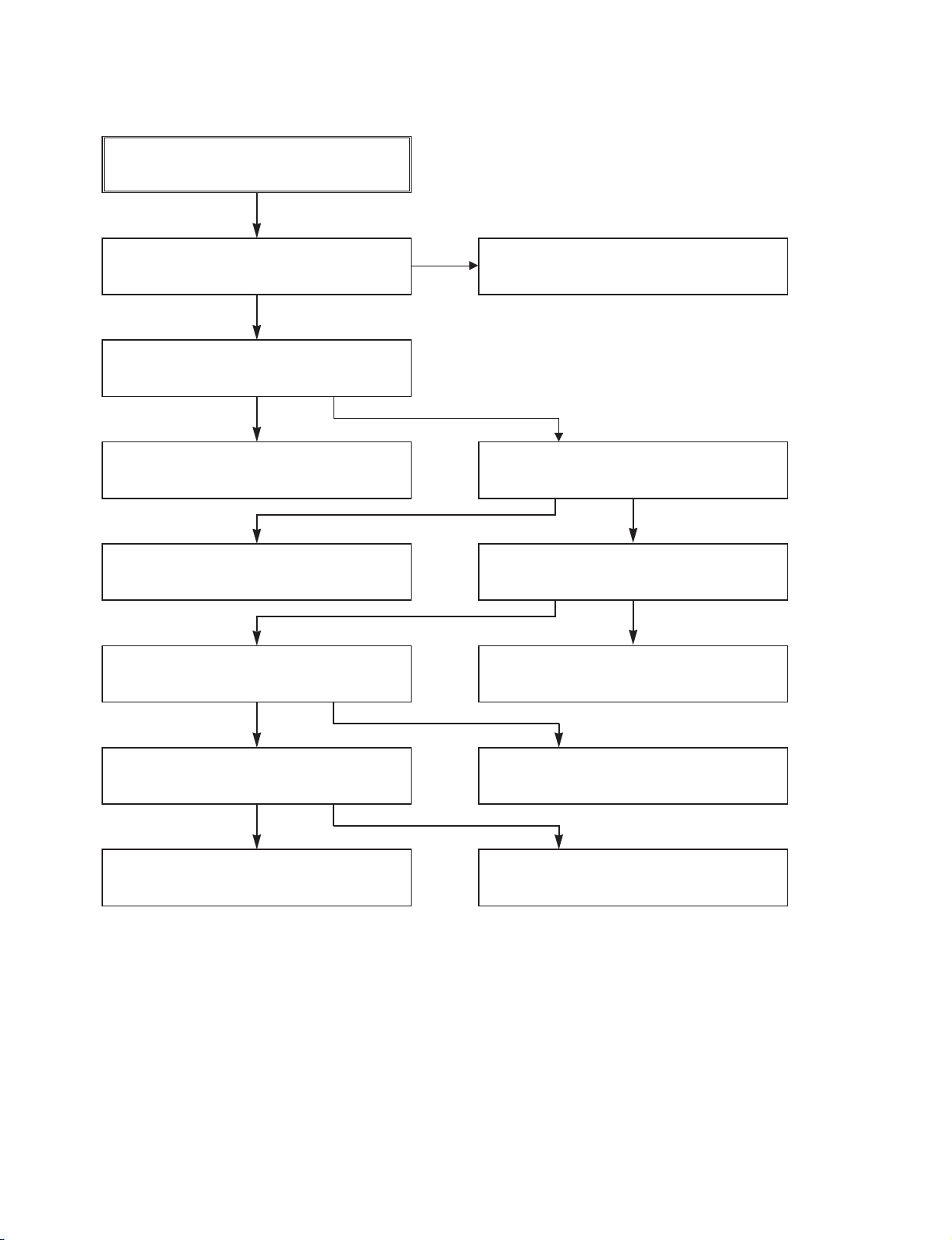

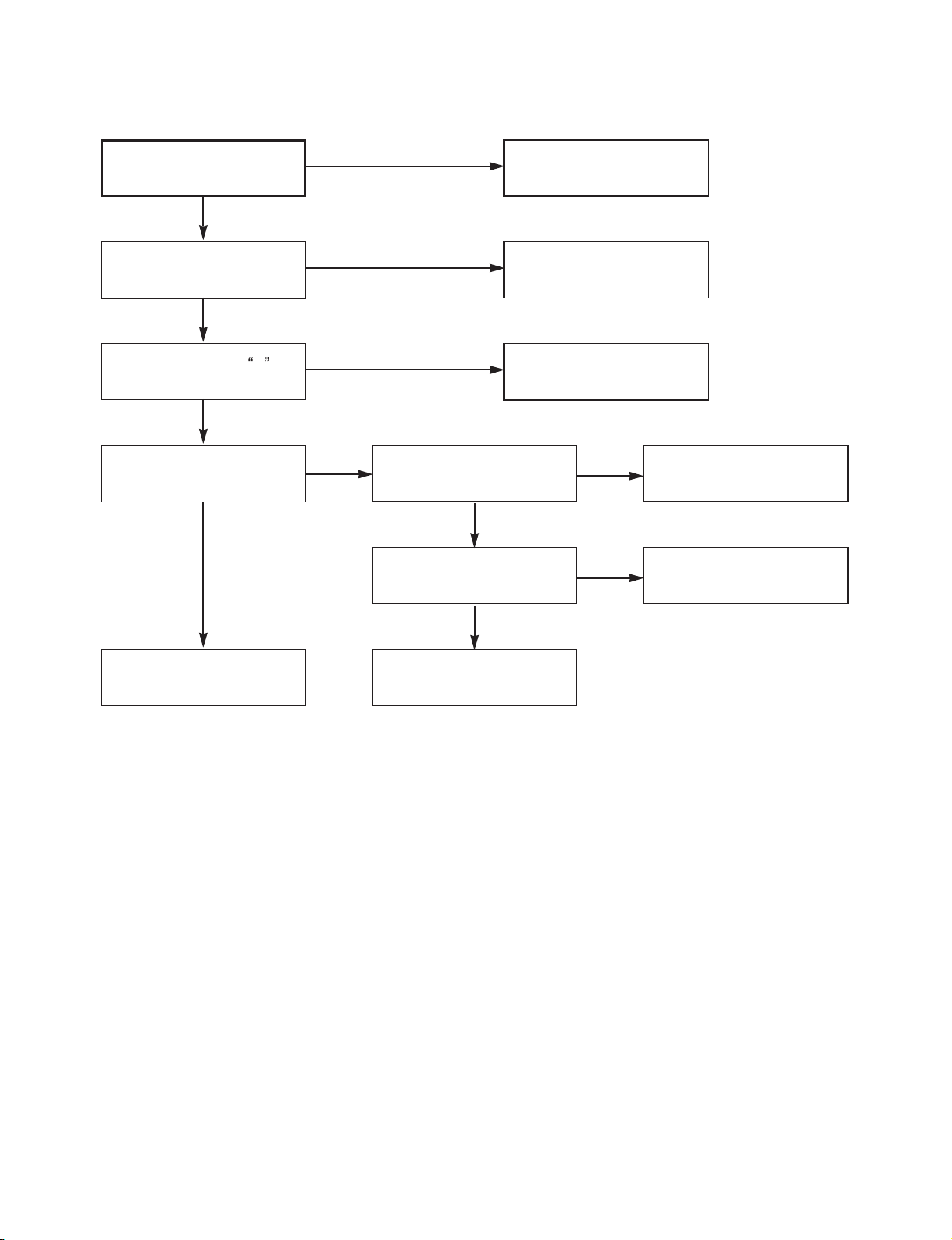

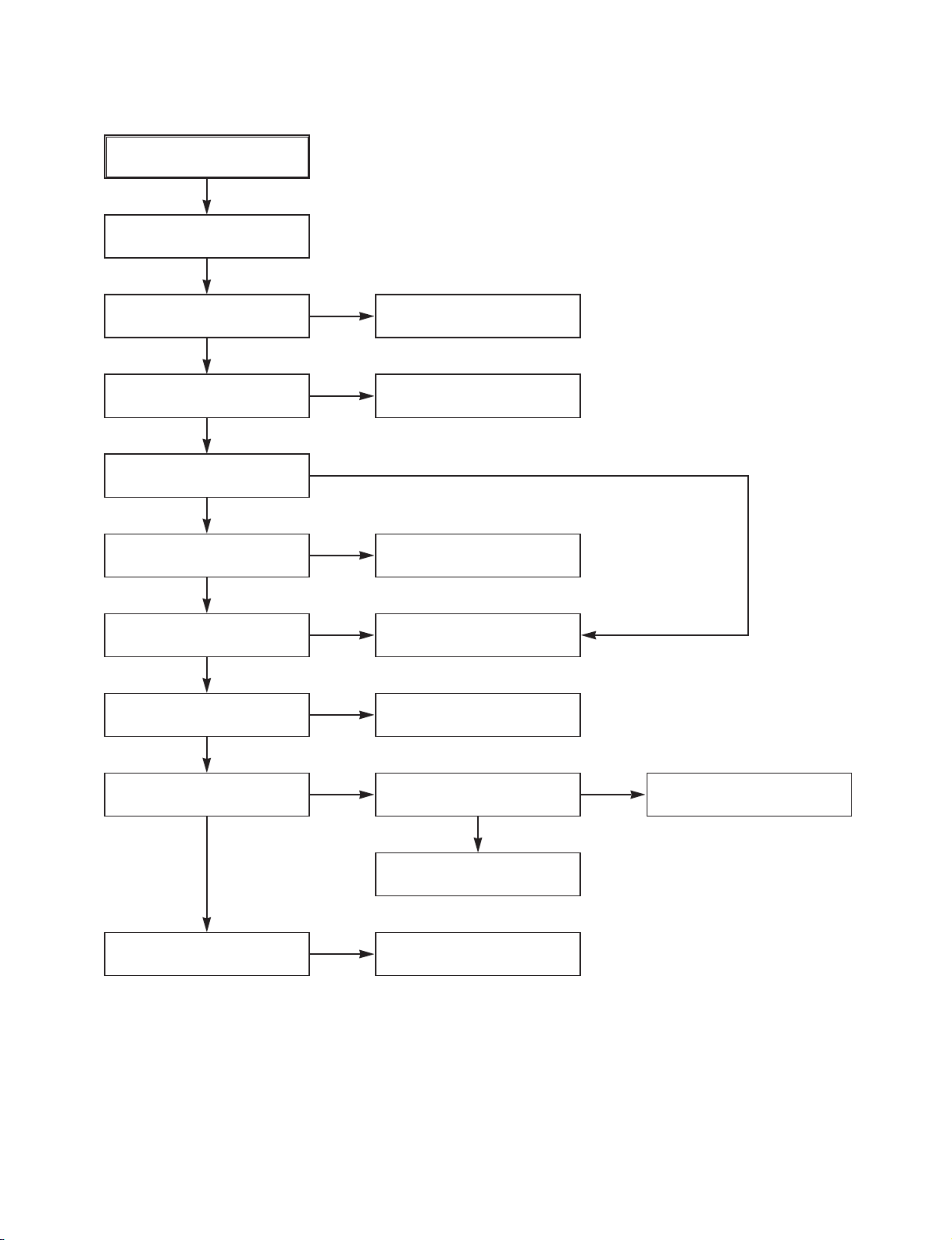

6. Tuner/IF CIRCUIT

(A) No Picture on the TV screen

No picture on the TV

screen

Does the Video signal at

the TU701 Pin24.

YES

YES

YES

Is +33V applied to TU701

Pin16?

YES

Is +5V applied to TU701

Pin13?

NO

Does Sync appear at

IC501 Pin111.

NO

Does the Video signal at

the IC501 Pin19.

YES

NO

Does the Video signal at

the IC301 Pin61.

YES

NO

NO

Does the Video signal at

the IC802 Pin30.

Check the signal flow from IC802

Pin30 to SC901 Pin19.

YES

Check 33V line.

NO

Check 5V line.

NO

YES

Does the Clock signal

appear at TU701 Pin11?

Check the lIC Clock Signal

of -COM Pin59.

NO

YES

Does the data signal

appear at TU701 Pin12?

Replace Tuner.

Check the signal flow from

TU701 Pin24 to IC301 Pin48.

Check the signal from IC301

Pin65 to IC501 Pin17.

Check the signal from IC501

Pin19 to IC301 Pin56.

Check the signal from IC501

Pin61 to IC802 Pin1.

Check the lIC Data Signal

of -COM Pin60.

NO

Page 26

- 3-16 -

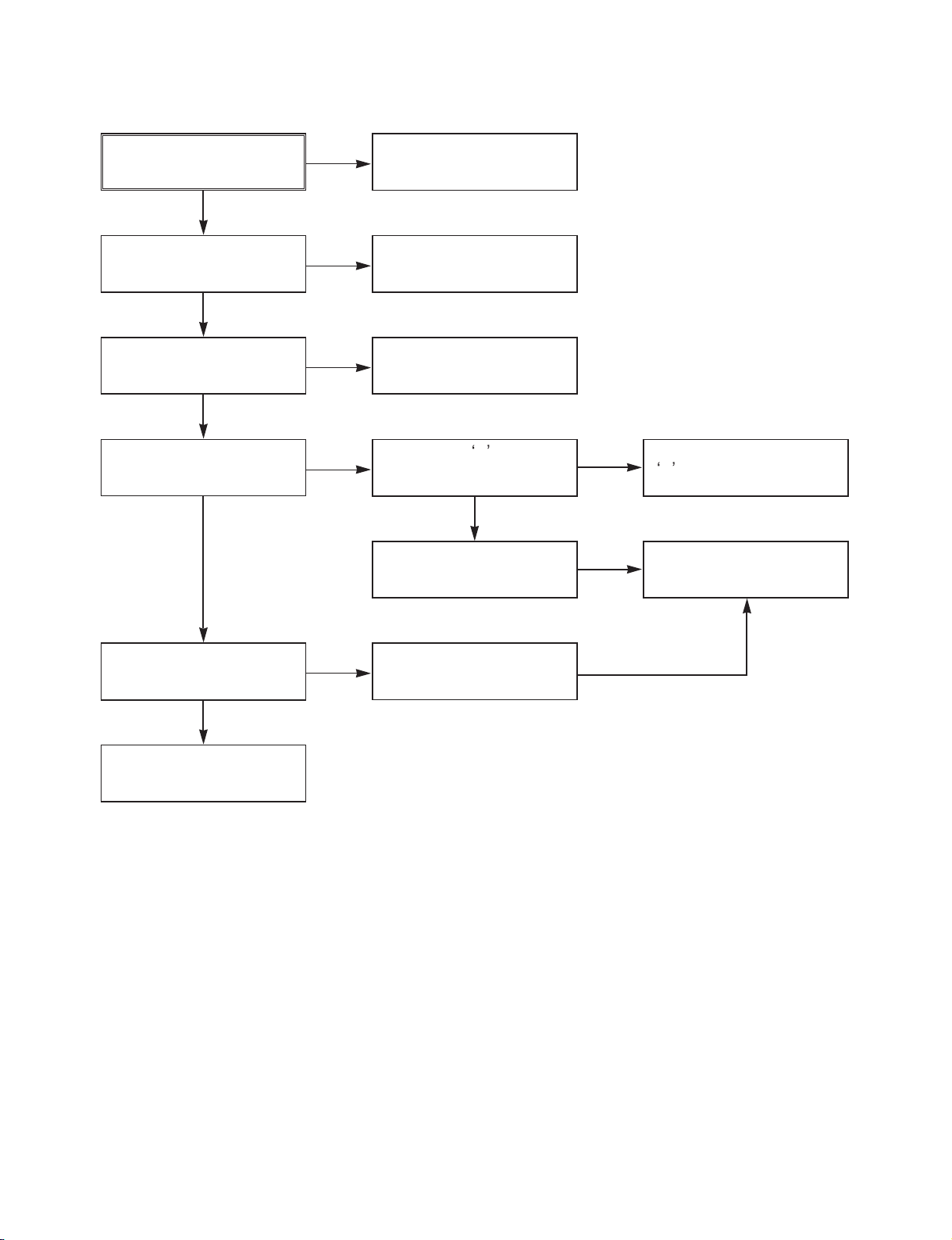

(B) No Sound

No Sound.

Check the Vcc of IC751 Pins1, 11, 19,

22, 33.

YES

Check 5.2V Line.

NO

Check the Tuner SiF signal at IC751

Pin2.

YES

Check the oscillator of IC751 Pins5, 6.

YES

Check the Audio of IC751 Pins30, 31.

YES

Check the Audio of IC801 Pins2, 3.

YES

Check the Audio of IC801 Pins16, 17.

YES

Check the Audio of IC802 Pins22, 26.

YES

Check the Signal flow from IC802

Pins22, 26, SC901 Pins1, 3.

YES

Check the Tuner SIF of TU701 Pin22.

NO

Replace X751

NO

Check the IIC Clock and Data at IC751

Pins12, 13.

NO

Check the signal flow from IC751

Pins30, 31 to IC801 Pins2, 3.

NO

Check the IIC Clock and Data at IC801

Pins42, 43.

NO

Check the signal flow from IC801

Pins16, 17 to IC802 Pins10, 16.

NO

Page 27

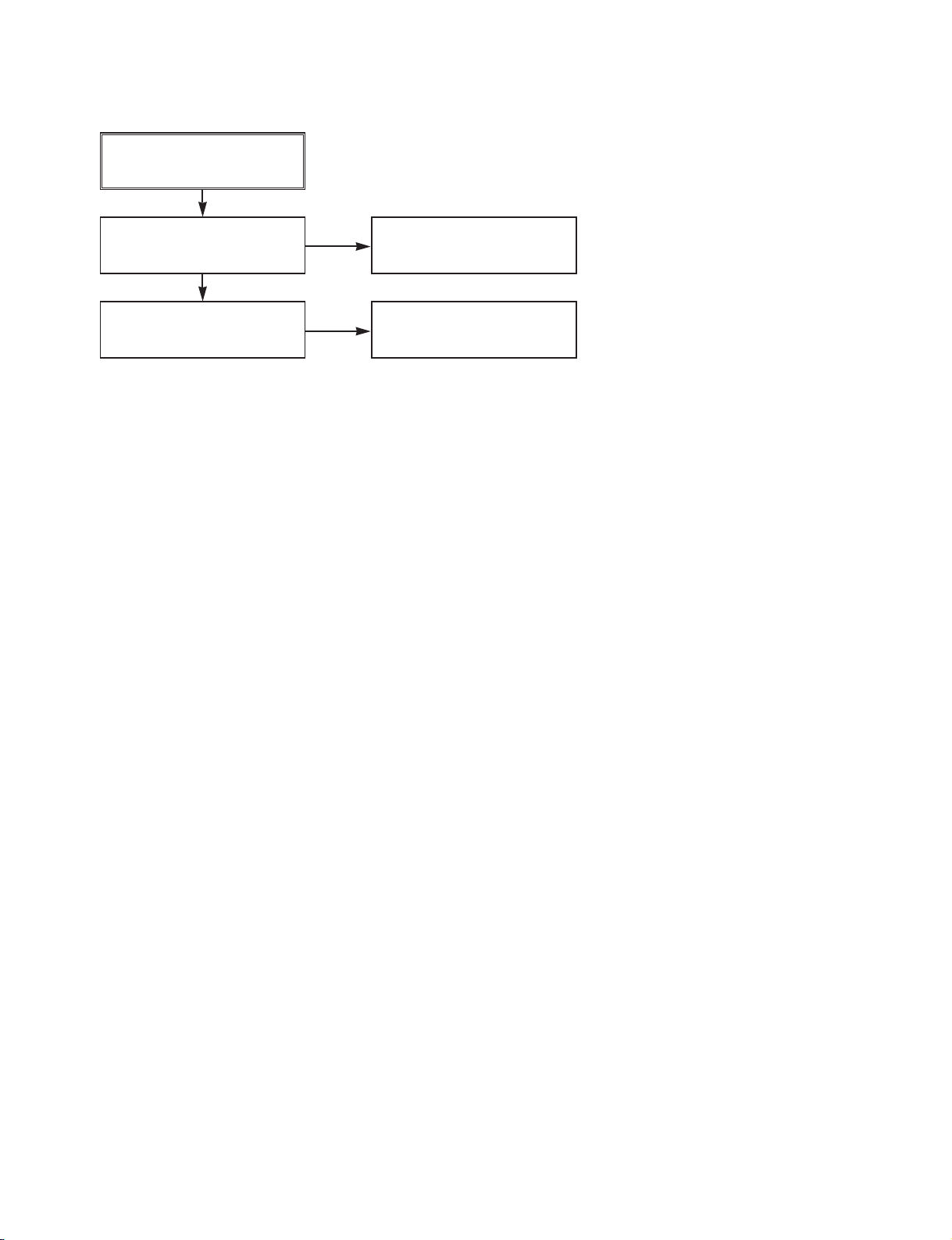

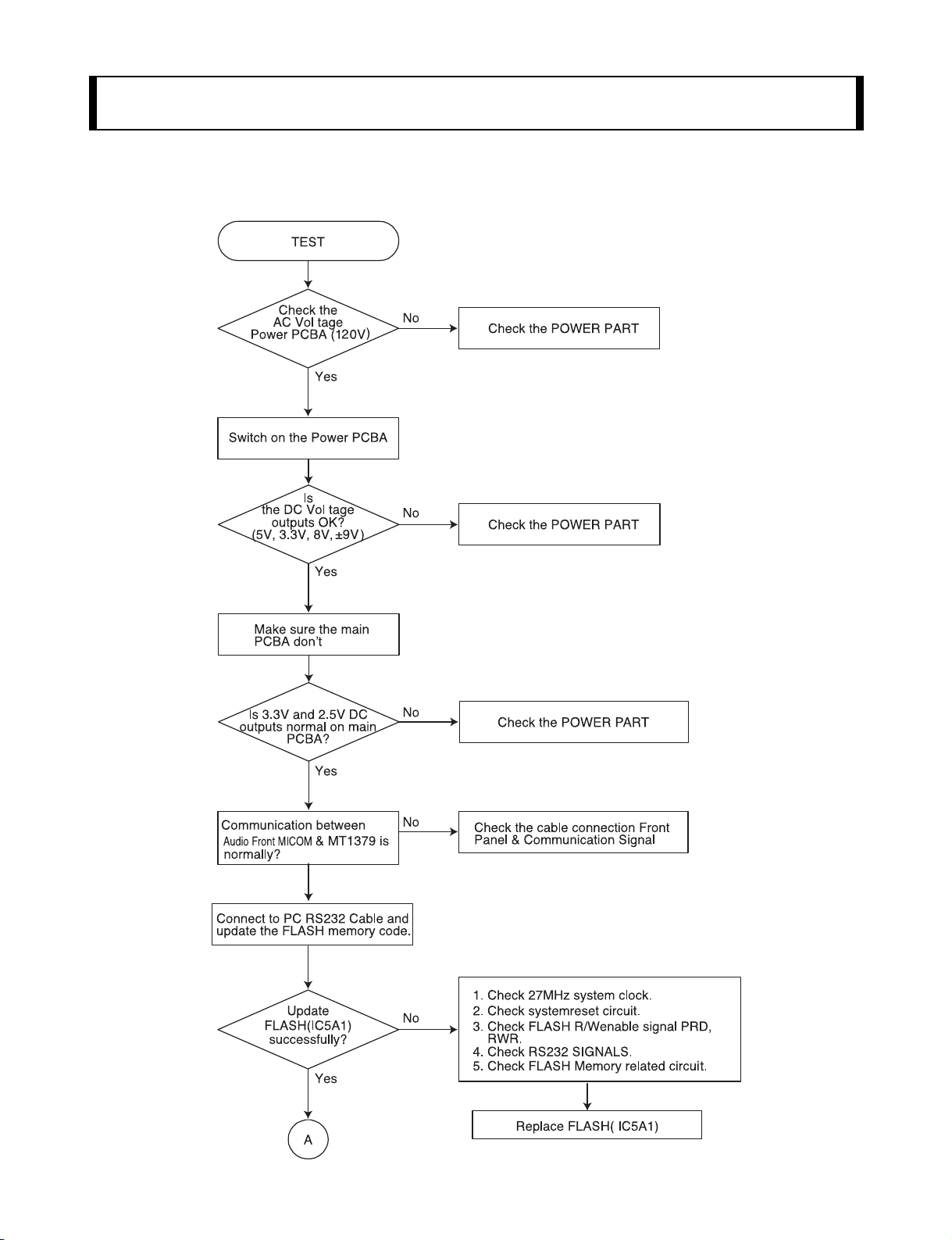

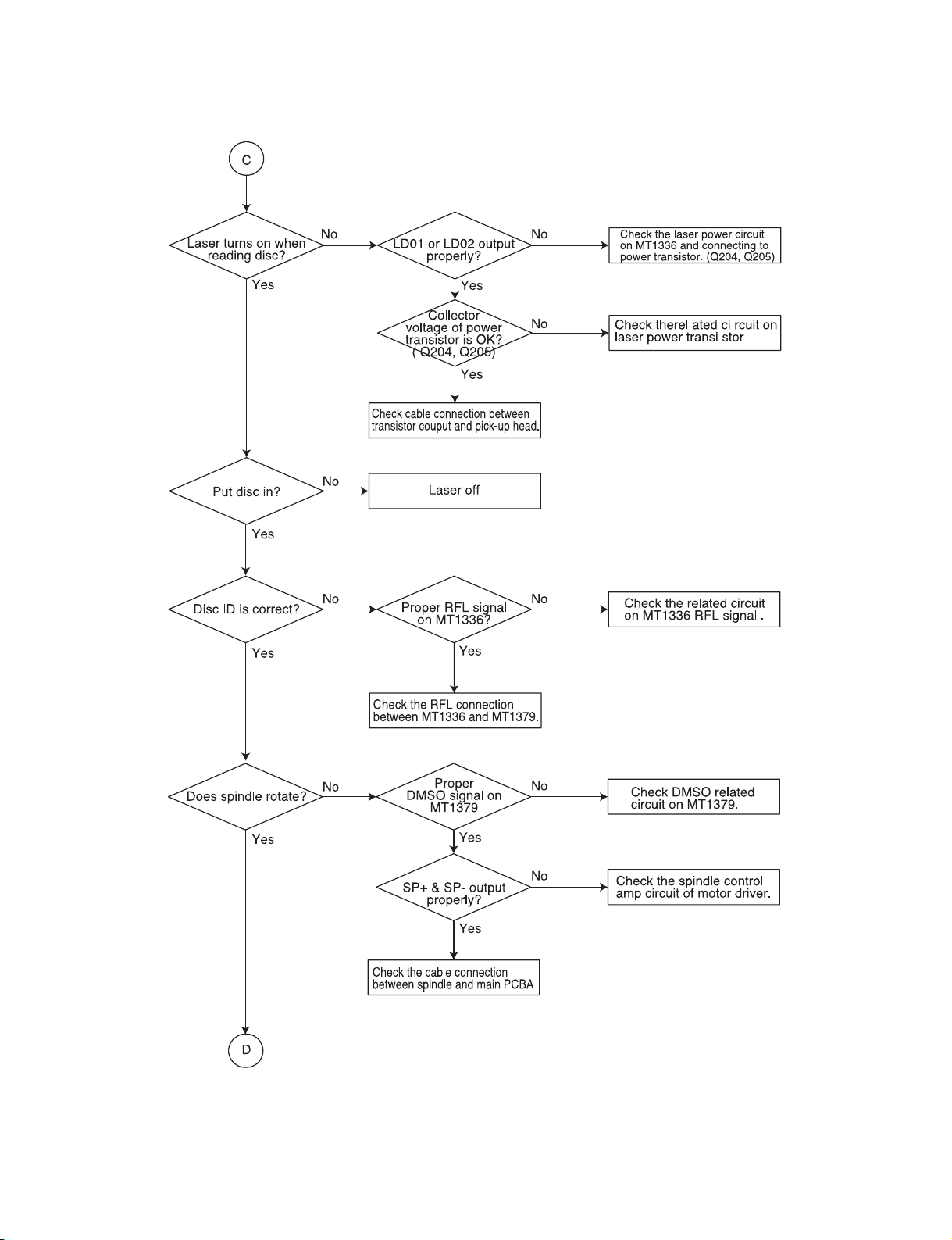

- 5-1 -

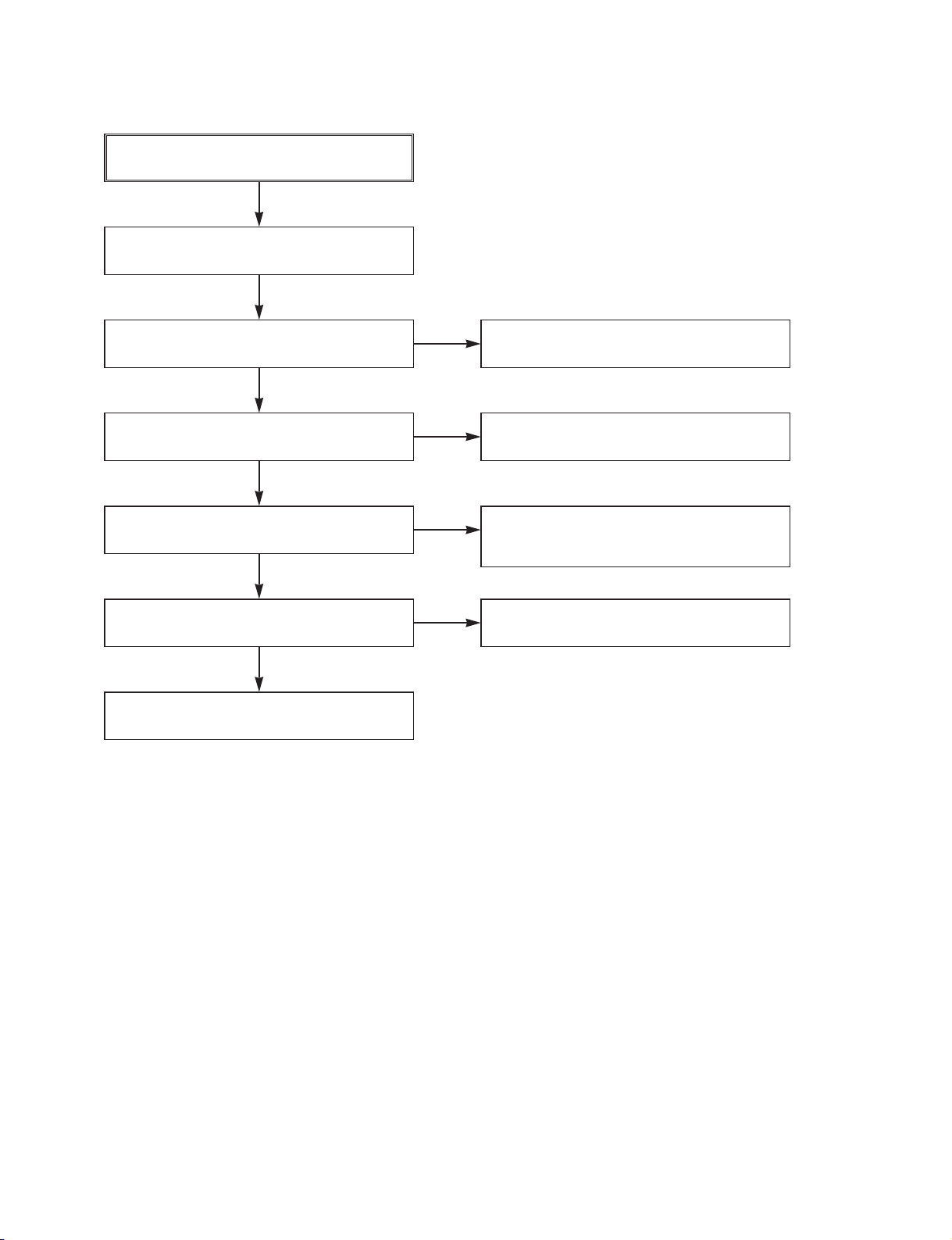

DVD ELECTRICAL TROUBLESHOOTING

1. Test & debug flow

SECTION 5. DVD PART

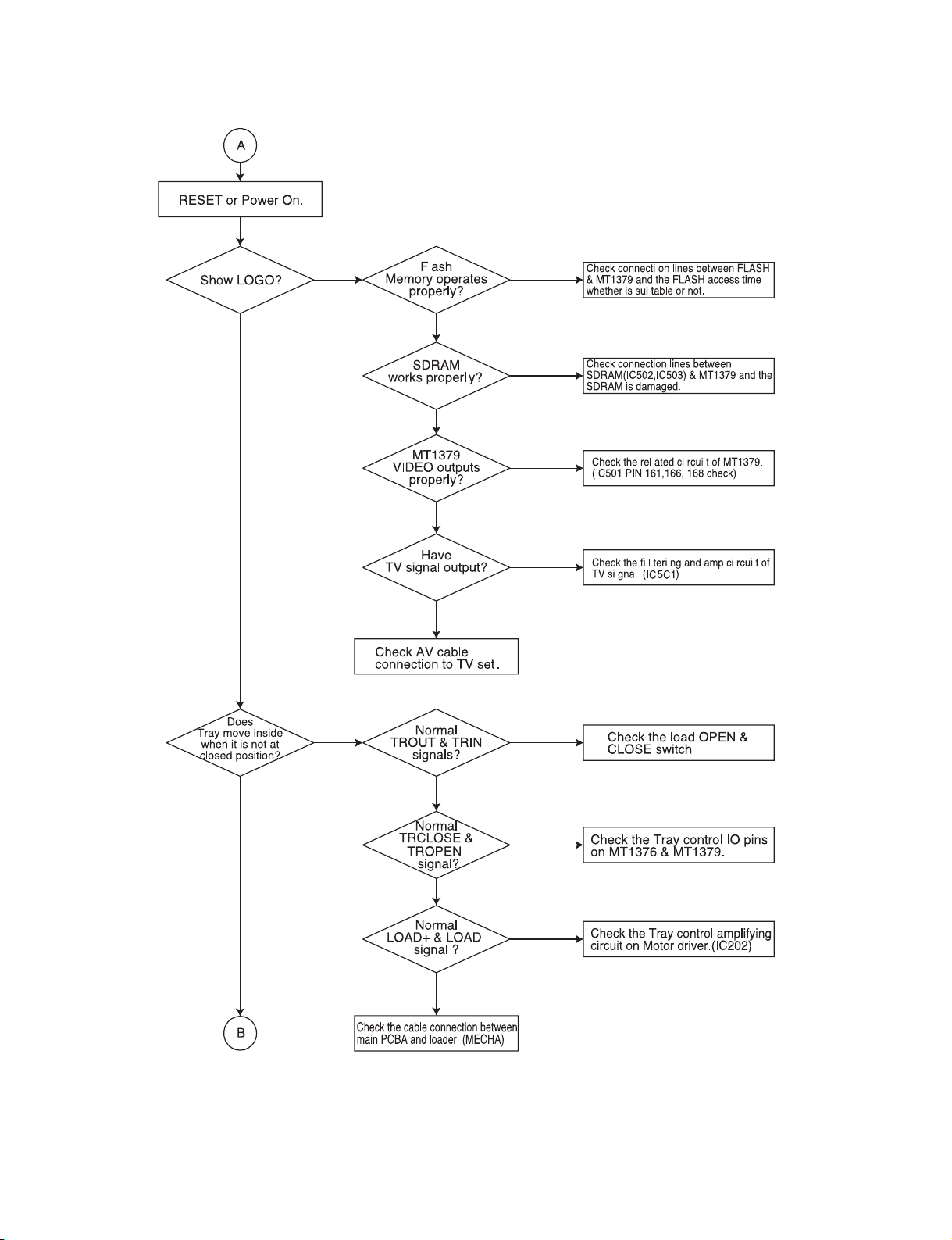

Page 28

- 5-2 -

Page 29

- 5-3 -

Page 30

- 5-4 -

Page 31

- 5-5 -

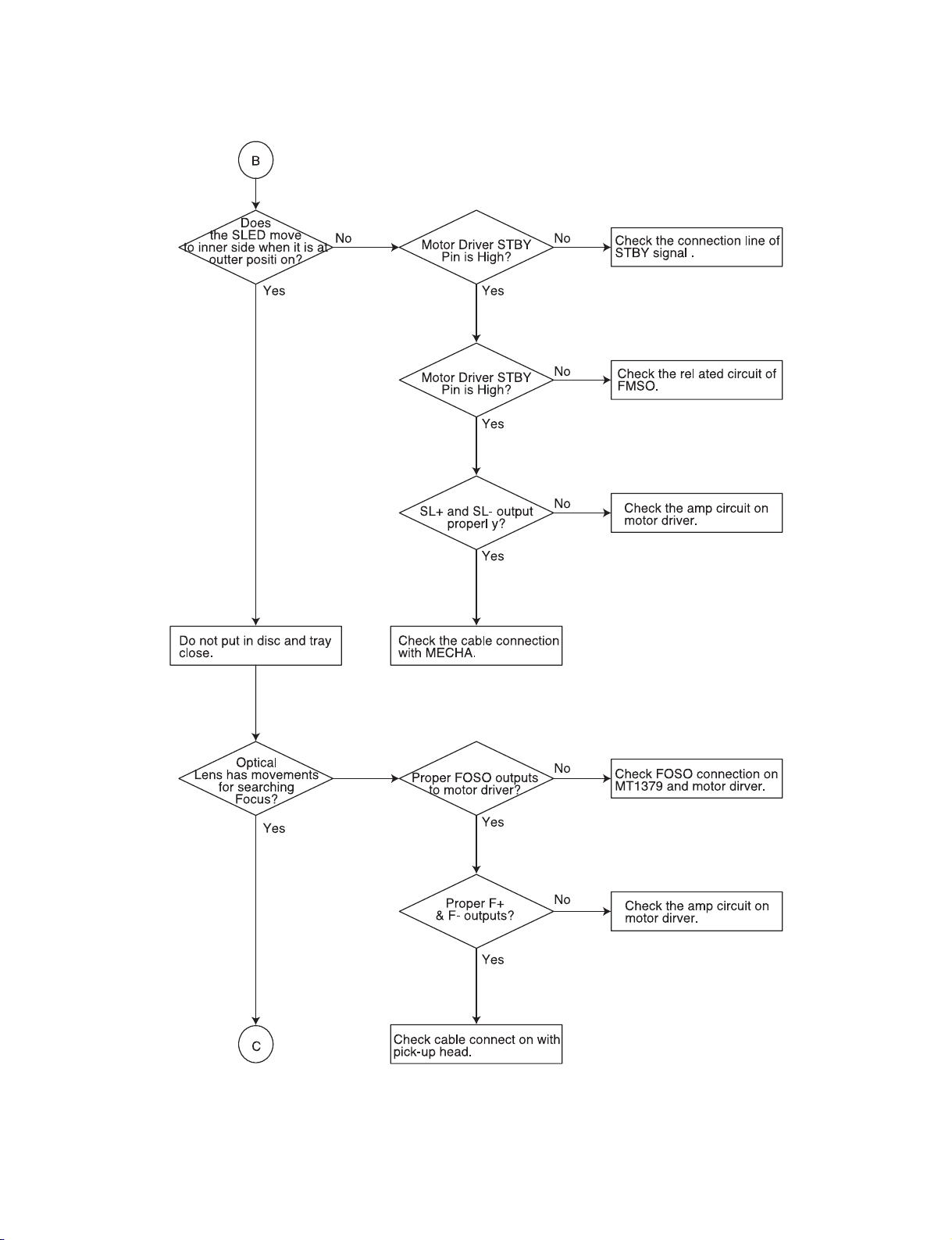

Page 32

- 5-6 -

Page 33

- 5-7 -

DETAILS AND WAVEFORMS ON SYSTEM TEST

AND DEBUGGING

1. SYSTEM 27MHz CLOCK,RESET,FLASH R/W SIGNAL

1) MT1379 main clock is at 27MHz(X501)

2) MT1336 reset is high active

Page 34

- 5-8 -

3) RS232 waveform during procedure(Downloading)

4) Flash R/W enable signal during download(Downloading)

Page 35

- 5-9 -

2. SDRAM CLOCK

1) MT1379 main clock is at 27MHz(X501)

3. TRAY OPEN/CLOSE SIGNAL

1) Tray open/close waveform

Page 36

- 5-10 -

2) Tray close waveform

3) Tray open waveform

Page 37

- 5-11 -

4. SLED CONTROL RELATED SIGNAL (NO DISC CONDITION)

5. LENS CONTROL RELATED SIGNAL(NO DISC CONDITION)

Page 38

- 5-12 -

6. LASER POWER CONTROL RELATED SIGNAL

(NO DISC CONDITION)

7. DISC TYPE JUDGEMENT WAVEFORM

Page 39

- 5-13 -

Page 40

- 5-14 -

8. FOCUS ON WAVEFORM

Page 41

- 5-15 -

9. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION)

Page 42

- 5-16 -

10. TRACKING CONTROL RELATED SIGNAL(System checking)

Page 43

- 5-17 -

11. RF WAVEFORM

12. MT1379 AUDIO OPTICAL AND COAXIAL OUTPUT (ASPDIF)

Page 44

- 5-18 -

13. MT1379 VIDEO OUTPUT WAVEFORM

1) Full colorbar signal(CVBS)

2) Y

Page 45

- 5-19 -

3) C

14. AUDIO OUTPUT FORM AUDIO DAC

1) Audio related Signal

Page 46

- 5-20 -

MEMO

Page 47

- 7-3 -

• SPEAKER

Satellite speaker

• MODEL: LHS-C6230T

853

852

851

850

861

854

862

A800

LOCA.NO PART NO DESCRIPTION SPECIFICATION REMARKS

850 3701RM0042A NET ASSEMBLY SPK LHS-D6230T L.SILVER

851 6400FTTC02A SPEAKER,FULLRANGE F30C-D366 TOPTONE FULL-RANGE(H

853 3110RMP009A CASE REAR LH-6230TE MOLD STANDARD

854 6871RU4116B PWB(PCB) ASSEMBLY,SUBSET(AUDIO FE-3620TE 2P NEW TERMINAL 150M

855 6871RU9271A PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-D6230T FRONT WIRE(5M) R CH

856 6871RU9271B PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-D6230T FRONT WIRE(5M)/ L C

857 6871RU9271C PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-D6230T CENTER WIRE(5M)/ (G

858 6871RU9271D PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-D6230T REAR WIRE(10M) R/CH

859 6871RU9271E PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-D6230T REAR WIRE(10M)/ L/C

861 353M025V SCREW,DRAWING + 2 D3.0 L6.0 MSWR3/FZB

862 353M025W SCREW,DRAWING + 2 D3.0 L14.0 MSWR3/FZB

A800 6401RM0045A SPEAKER ASSEMBLY F30C-D384-2 SHIN POONG LHS-D62

RUN DATE : 05.JUNE.2003

Page 48

Passive(Sub) Woofer

• MODEL: LHS-C6230W

852

854

855

853

851

861

LOCA.NO PART NO DESCRIPTION SPECIFICATION REMARKS

851 3720RMF045A PANEL,FRONT FRONT LH-6230WE STANDARD

852 3701RM0043A NET ASSEMBLY SPK LHS-D6230W SILVER STANDARD

853 3091RMW050A CABINET ASSEMBLY ASSY LH-6230WE ALL PB 9T

854 6400WTTJ03A SPEAKER,WOOFER F65C-D365 TOPTONE WOOFER LHS-6

855 6871RU9271F PWB(PCB) ASSEMBLY,SUBSET(AUDIO LHS-D6230W SUB WOOFER 2.5M, OR

861 353M050C SCREW BH 3.5X16 FBK

RUN DATE : 05.JUNE.2003

- 7-4 -

Page 49

BLOCK DIAGRAM

2-2 2-3

Page 50

AUDIO SHEMATIC DIAGRAMS

• U-COM SCHEMATIC DIAGRAM

2-4 2-5

Page 51

• FUNCTION & POWER SCHEMATIC DIAGRAM

2-6 2-7

Page 52

• MAIN AMP SCHEMATIC DIAGRAM

2-8 2-9

Page 53

WIRING DIAGRAM

2-10 2-11

Page 54

AUDIO VOLTAGE SHEET (IC&TR)

[FRONT] [MAIN]

LOC. PART PIN NUM. STOP DVD PLAY

IC501 LC87F57C 1 4.2 4.2

2 5 5

3 0 0

4 0 0

5 0 0

6 0 0

7 0 0

8 0 0

9 5 5

10 0 0

11 0 0

12 0 0

13 0 0

14 0 0

15 0 0

16 0 0

17 0 0

18 0 0

19 5 5

20 2.5 2.5

21 2.5 2.5

22 2.5 2.5

23 2.5 2.5

24 5 5

25 2.5 2.5

26 4.6 4.6

27 2.5 4.6

28 2.5 2.3

29 2.5 2.5

30 2 2.5

31 5 5

32 0 0

33 5 0

34 0 0

35 0 0

36 5 5

37 0 0

38 0 0

39 0 0

40 0 0

41 0 0

42 0 2.3

43 0 0

44 0 2.3

45 0 2.3

46 5 5

47 0.3 2.3

48 0.3 2.3

49 2.5 2.3

50 0 2.3

51 4.4 4.4

52 0.3 0

53 5 5

54 0.3 0.5

55 0.3 0

56 0 0

LOC. PART PIN NUM. STOP DVD PLAY

57 2.3 2.3

58 2.3 2.3

59 4.9 5

60 0 0

61 0 0

62 0 0

63 0 0

64 4 4

LOC. PART PIN NUM. STOP DVD PLAY

IC707 KIA7805 1 11.9 11.9

200

355

IC703 KIA7812 1 18.4 18.4

200

3 11.9 11.9

IC701 KIA7909 1 0 0

2 -18.6 -18.6

3-9-9

IC702 KA7809 1 18.4 18.4

200

399

IC704 KA78R12 1 18.4 18.4

21212

300

455

IC706 KIA7805 1 11 11

200

355

IC705 KIA7805 1 11 11

200

355

D507 D5402 ANODE -0.2 -0.2

CATHODE 11 11

D511 D5402 ANODE -0.2 -0.2

CATHODE 11 11

BD501 KBU6G 1 -18.6 -18.6

200

300

4 18.4 18.4

IC101 KIA4580 1 4.5 4.5

2 4.5 4.5

3 4.5 4.5

400

5 4.5 4.5

6 4.5 4.5

7 4.5 4.5

899

IC102 CS5331A 1 1.4 1.4

2 1.6 1.6

3 1.6 1.6

4 1.5 1.5

5 2.2 2.2

600

755

8 2.2 2.2

IC103 4052 1 0 0

200

300

400

500

600

7 -4.5 -4.5

800

900

10 0 0

LOC. PART PIN NUM. STOP DVD PLAY

11 0 0

12 0 0

13 0 0

14 0 0

15 0 0

16 4.5 4.5

IC105 M60446AFP 5 5.2 5.2

30 -5.3 -5.3

42 5 5

IC200 TDA7265 1 -18.7 -18.7

200

3 18.6 18.6

400

5 9.3 9.3

6 -18.6 -18.6

700

800

900

10 0 0

11 0 0

IC250 TDA7265 1 -18.7 -18.7

200

3 18.6 18.6

400

5 9.3 9.3

6 -18.6 -18.6

700

800

900

10 0 0

11 0 0

IC300 TDA7265 1 -18.7 -18.7

200

3 18.6 18.6

400

5 9.3 9.3

6 -18.6 -18.6

700

800

900

10 0 0

11 0 0

IC400 TDA7265 1 -18.7 -18.7

200

3 18.6 18.6

400

5 9.3 9.3

6 -18.6 -18.6

700

800

900

10 0 0

11 0 0

2-12 2-13

Page 55

PRINTED CIRCUIT DIAGRAM

• MAINAMP & FRONT P.C. BOARD (SOLDER SIDE)

2-14 2-15

Page 56

• MAINAMP & FRONT P.C. BOARD (COMPONENT SIDE)

2-16 2-17

Page 57

• FUNCTION & POWER P.C. BOARD (SOLDER SIDE)

2-18 2-19

Page 58

• FUNCTION & POWER P.C. BOARD (COMPONENT SIDE)

2-20 2-21

Page 59

VCR SHEMATIC DIAGRAMS

• SYSTEM SCHEMATIC DIAGRAM

3-17 3-18

Page 60

• A(AUDIO)/V(VIDEO) SCHEMATIC DIAGRAM

3-19 3-20

Page 61

• POWER SCHEMATIC DIAGRAM

NOTE: Warning

Parts that are shaded are critical With respect

to risk of fire or electrical shock.

NOTE:

1. Shaded(■) parts are critical for safety.Replace only

with specified part number.

2. Voltages are DC-measured with a digital voltmefer

during Play mode.

3-21 3-22

Page 62

• TU/IF. ACSS SCHEMATIC DIAGRAM

3-23 3-24

Page 63

• HIFI/TUNER SCHEMATIC DIAGRAM

3-25 3-26

Page 64

• A/V JACK, SCART SCHEMATIC DIAGRAM

3-27 3-28

Page 65

VCR VOLTAGE SHEET (IC&TR)

MODE

PIN NO.

1 0.9 0 2.2 2.17 0 0 1.78 2.78

2 4.85 4.85 2.2 2.17 0 2.53 0 0

3 0 0 2.2 2.17 9.12 9.06 2.85 2.84

4 0.1 0.1 2.2 2.17 2.48 2.48 0 0

5 0.1 0.1 2.2 2.19 4.8 4.79 2.8 2.83

6 0 0 2.2 2.2 0 2.08 4.73 4.71

7 0.1 0 2.2 0 1.76 0 2 2.02

8 0.1 0 2.2 2.2 0 2.2 0 0

9 0.3 0.9 2.2 2.2 0 0

10 0.68 0.85 2.2 2.2 0 0

11 0.02 3.19 4.7 4.67 0 2.5

12 0.02 0 0.99 0.98 2.5 2.66

13 0.02 0 0.99 0.96 1.72 2.5

14 3.8 3.8 1.85 1.76 2.5 4.74

15 0 2.3 1.54 0.36 4.76 2.52

16 4.47 0 0 0 2.52 0

17 0.15 0 2 2.44 0 0.39

18 4.77 2.38 2.4 2.47 0.56 2.66

19 4.77 2.38 0 0 2.52 2.66

20 4.06 0 2.4 3.33 2.52 2.66

21 4.05 0.1 1.7 2.55 2.52 2.66

22 0 4.85 2.8 3.09 2.52 0

23 0 4.82 4.7 4.7 0.17 2.07

24 0 0 0 0 2.02 0

25 4.84 0 4.03 0 0 2.07

26 4.77 2.5 2.15 2.2 2.02 2.07

27 0 0 1.46 1.8 2.02 0

28 0 0 2.13 2.1 0 0

29 0 0 1.7 2.24 3.33 2.84

30 0 0 2.13 2.13 0 2.84

31 2.5 2.6 4 4 2.52 3.56

32 4.19 4.17 2.13 2.13 4.72 4.71

33 4.23 4.17 2.35 2.35 2.35 2.33

34 0 0 2.8 3.1 2.35 0

35 1.48 1.5 2.77 2.82 0 0

36 1.48 1.4 2.1 2.1 4.76 4.74

37 4.29 4.7 2.17 2.66 4.76 4.74

38 2 2 0 0 4.76 4.74

39 2.11 2 1.72 1.23 4.76 2.33

40 0 0 0 0 4.6 0

41 0 0.1 0.84 0.83 2.52 2.64

42 0 0 2.15 2.15 2.52 2.61

43 0 0 0 0 2.54 2.65

44 2.1 2.2 4.69 4.67 2.54 2.65

45 2.2 2.2 4.72 4.7 0.57 0.41

46 0 0 2.11 2.94 4.76 4.74

47 1.3 1.2 2.84 3.65 2.5 0

48 0 0 2.8 4.23 1.75 2.62

49 0 0 3.79 3.77 3.78 0

50 0.9 2.3 0 2.29 0 0

51 0 0.2 2.11 2.1 1.79 0

52 1.5 2.3 0 4.7 1.22 0

53 4.7 4.7 4.18 4 3.81 0

54 0 1.9 4.18 4.8 9.12 9.06

55 2.17 2.7 0.68 0.8 6.22 0.22

IC501 IC301 IC801 IC302

STOP PLAY STOP PLAY STOP PLAY STOP PLAY

MODE

PIN NO.

56 0.9 2.2 0 0 2.96 0.23

57 0 0 3.07 2.36 2.16 2.1

58 0 0 4.43 0 4.53 0

59 0 0 0.35 0.29 2.54 2.53

60 2.5 2.3 0.65 0.19 3.81 0

61 4.6 4.5 1.07 2.23 3.13 0.22

62 4.3 4.3 0 0 3.86 0

63 4.4 0.1 3.72 3.7 3.8 0

64 0 0.1 0.97 1.23 2.45 0

65 1.1 0.8 1.66 0.72 3.84 0.29

66 4.7 4.75 1.66 0.72 4.03 0.3

67 4.7 4.75 1.66 0.72 3.85 0.3

68 4.7 3.8 1.66 4.62 3.85 0.3

69 4.7 4.7 4.7 4.68 0 0

70 4.2 4.1 0 0 0 0

71 4.8 4.76 0 0 0 0

72 4.8 4.76 1.65 1.65 3.85 0.3

73 4.4 4.4 1.65 1.65 3.85 0

74 0 0 1.65 1.65 0 2.49

75 4.7 0 0 0 3.85 0.2

76 0 2.4 2.19 0 3.15 0.2

77 0 2.4 4.72 4.7 0 0

78 4.5 4.4 2.19 2.18 4.45 4.33

79 4.6 4.6 0 0 0 0

80 0 3.2 2.19 2.18 4.45 4.32

81 0 0

82 3.3 3.3

83 4.4 0

84 0 0

85 1.3 1.2

86 0 1.2

87 3.5 2.18

88 0 0

89 0 0.19

90 0 1.25

91 2.3 2.35

92 0 2.35

93 0 0

94 2.3 2.32

95 2.3 2.32

96 0 2.34

97 0.6 0

98 4.7 4.69

99 0 4.77

100 0.6 0.8

IC501 IC301 IC801 IC302

STOP PLAY STOP PLAY STOP PLAY STOP PLAY

3-29 3-30

Page 66

PRINTED CIRCUIT DIAGRAMS

• TUNER P.C BOARD

3-31 3-32

Page 67

• VCR P.C BOARD

3-33 3-34

Page 68

• VCR P.C BOARD

3-35 3-36

Page 69

DVD PART SCHEMATIC DIAGRAMS

• MPEG SCHEMATIC DIAGRAM

5-225-21

Page 70

• SERVO SCHEMATIC DIAGRAM

5-23 5-24

Page 71

• AUDIO SCHEMATIC DIAGRAM

5-25 5-26

Page 72

• INTERFACE SCHEMATIC DIAGRAM

5-27 5-28

Page 73

VOLTAGE SHEET (IC&TR)

5-29 5-30

Page 74

PRINTED CIRCUIT DIAGRAM

• DVD P.C. BOARD(SOLDER SIDE)

5-31 5-32

Page 75

• DVD P.C. BOARD (COMPONENT SIDE)

5-33 5-34

Page 76

A48

A26

265

A49

A00

A45

A46

285

A47

250

330

276

A42B

A42

284

277

267

A43

283

300

320

264

260

321

AUDIO TUNER

SECTION 7. EXPLODED VIEWS

• CABINET AND MAIN FRAME

NOTE) Refer to “SECTION 7 REPLACEMENT

PARTS LIST” in order to look for the

part number of each part.

7-1 7-2

Page 77

SECTION 4. MECHANSIM OF VCR PART

Page 78

- 4-1 -

DECK MECHANISM PARTS LOCATIONS

4

6

3

2

7

9

5

11

18

16

19

17

19

12

13

15

10

1

31

14

8

15

33

Top View

Bottom View

20

24

23

20

24

22

21

29

30

29

30

25

32

27

26

28

NOTE : When reassembly perform the

procedure in the reverse order.

1 Drum Assembly 3 Screw A-1 T

2 Plate Top 2 Hook A-2 T

2 3 Holder Assembly CST Chassis Hole A-2 T

2 4 Opener Door Chassis Hole A-2 T

5 Bracket Assembly 3 Hook A-2 T

L/D Motor

2,3,4 6 Gear Assembly Rack F/L 1 Hook, Chassis Hole A-2 T

2,3,4,6 7 Arm Assembly F/L Chassis Hole A-2 T

8 Lever Assembly S/W 1 Hook A-2 T

9 Arm Assembly Cleaner Chassis Embossing A-3 T

10 Head F/E Chassis Embossing A-3 T

11 Base Assembly A/C Head 1 Screw A-3 T

2,3 12 Brake Assembly T 1 Hook A-4 T

2,3 13 Brake Assembly RS 1 Hook A-4 T

2,3 14 Arm Assembly Tension 2 Hook A-4 T

2,3,12,13, 15 Reel S/Reel T A-4 T

14

16 Base Assembly P4 Chassis Embossing A-5 T

17 Opener Lid Chassis Embossing A-5 T

17 18 Arm Assembly Pinch Shaft A-5 T

17 19 Lever T/Up / Arm T/Up 1 Hook A-5 T

17,18 20

Belt Capstan/Motor Capstan

3 Screw A-6 B

21 Lever F/R Locking Tab A-6 B

20, 21 22 Clutch Assembly D35 Washer A-6 B

23 Brake Assembly Capstan Locking Tab A-6 B

24 Gear Drive/Gear Cam Washer/Hook A-7 B

25 Gear Sector 1 Hook A-7 B

20,21,23, 26 Plate Slider Shaft Guide A-7 B

24,25

20,21,23, 27 Lever Tension 1 Hook A-7 B

24,25,26

2,3,14,20, 28 Lever Spring Locking Tab A7 B

21,25,23,

24,26

25 29

Gear Assembly P2/Gear Assembly P3

Boss A-8 B

2,3,14,25, 30

Base Assembly P2/Base Assembly P3

Chassis Slot A-8 B

29

2,3,14,25, 31 Base Loading 1 Screw A-9 T

29

2,3,14 32 Base Tension Chassis Embossing A-9 B

2,3,20,21, 33 Arm Assembly Idler Locking Tab A-9 T

22

Starting

No.

Procedure

Part Fixing Type

Fig-

ure

View

1) When reassembling, confirm Mechanism and Mode

Switch Alignment Position (Refer to Page 4-13)

2) When disassembling, the Parts for Starting No. Should

be removed first.

T:Top, B:Bottom

Page 79

- 4-2 -

DECK MECHANISM DISASSEMBLY

(S3)

(S2)

(S2)

(S3)

(A)

Stator

Carbon Brush

Drum Motor

Rotor

Drum Sub Assembly

Drum FPC

(S1)

(S1)

(S1)

Holder FPC

H1

H2

1. Drum Assembly (Fig. A-1-1)

1) Unplug the Drum FPC Connector.

2) Remove three Screws(S1) on bottom side and separate

the Drum assembly.

3) Unhook (H1), (H2) and separate the Holder FPC and

Cap FPC.

1-1. Drum Motor

1) Remove two Screws(S2) and disassemble the Stator of

the Drum Motor.

2) Remove two Screws(S3) and separate the Rotor of the

Drum Motor from the Drum Sub assembly.

NOTE

When reassembling, confirm (A) portion of the Drum Sub

assembly whether the Carbon Brush is in there or not.

Fig. A-1

(Fig. B-1)

Holder FPC

Drum FPC

Cap FPC

Figure in the opposite direction

(Fig. A-1-1)

Page 80

- 4-3 -

DECK MECHANISM DISASSEMBLY

(B)

(E)

(C1)

(C)

Plate Top

Arm Assembly F/L

Spring Lever S/W

Gear Assembly Rack F/L

Chassis

Opener Door

Bracket Assembly L/D Motor

Holder Assembly CST

(B’)

(C’)

(D)

(E’)

(H6)

(A)

(B)

Lever Assembly S/W

(H8)

Fig. A-2

(Fig. A-2-1)

(Fig. A-2-2)

(Fig. A-2-6)

(Fig. A-2-7)

(Fig. A-2-5)

(Fig. A-2-3)

(Fig. A-2-4)

Page 81

- 4-4 -

DECK MECHANISM DISASSEMBLY

2. Plate Top (Fig. A-2-1)

1) Pull the (B) portion of the Plate Top back in direction of

arrow and separate the right side of it.

2) pull the (B ) portion of the Plate Top back in direction of

arrow and separate the left side of it.

(Used tools : (-) type driver, anything tool with sharp

point or flat point.)

NOTE

(1) When reassembling, push the Plate Top after alignment

the two position(C), (C ) as below Fig.

3. Holder Assembly CST (Fig.A-2-2)

1) Move the Holder Assembly CST in direction of arrow and

separate the left side of it first through the (D) position of

the Chassis.

2) Disassemble the right side of the Holder Assembly CST

from each guided hole of the Chassis.

NOTE

When reassembling, insert the (E) part of the Holder

Assembly CST in the (E ) hole of the Chassis first and

assemble the left side of it.

4. Opener Door (Figure. A-2-3)

1) Turn the Opener Door clockwise and remove it through

the guide hole of the Chassis.

5. Bracket Assembly L/D Motor

(Fig. A-2-4)

1) Unplug the Connector(C1).

2) Unhook three Hooks(H3, H4, H5) on bottom side of the

Chassis, lift up the Bracket Assembly L/M and disassemble the Bracket Assembly L/D Motor.

6. Gear Assembly Rack F/L (Fig. A-2-5)

1) Move the Gear Assembly Rack F/L in direction of

arrow(A) and unhook the Hook(H6) pulling back in front.

2) Separate the Gear Rack F/L in direction of arrow(B).

NOTE

When reassembling, align the gear part of the Gear

Assembly Rack F/L with the Gear Drive as below Fig.

7. Arm Assembly F/L (Fig. A-2-6)

1) Move the Arm Assembly F/L in direction of arrow and

separate the left side of it first.

2) Disassemble the Arm Assembly F/L from each guided

hole of the Chassis.

8. Lever Assembly S/W(Fig. A-2-7)

1) Unhook the Hook(H8) in the left side of the Chassis and

remove the Lever Assembly S/W.

(B’)

(C’)

(C)

(B)

(D)

Holder assembly CST

Chassis

Gear Rack F/L

Gear Drive

(H8)

Chassis

(H3)

(H4)

(H5)

Bracket assembly L/M

Page 82

- 4-5 -

DECK MECHANISM DISASSEMBLY

9. Arm Assembly Cleaner (Fig. A-3-1)

1) Breakaway the (A) portion as Fig. A-3-1 from the

embossing of the Chassis, turn the Arm assembly

Cleaner to clockwise direction and lift it up.

10. Head F/E (Fig. A-3-2)

1) Breakaway the (A) portion of the Head F/E from the

embossing of the Chassis, turn it to counterclockwise

direction and lift it up.

11. Base Assembly A/C Head (Fig. A-3-3)

1) Remove the Screw(S4) and lift the Base Assembly A/C

Head up.

(A)

Arm Assembly

Cleaner

Base Assembly A/C Head

(S4)

Head F/E

(A)

Chassis

Fig. A-3

(Fig. A-3-1)

(Fig. A-3-3)

(Fig. A-3-2)

Page 83

- 4-6 -

DECK MECHANISM DISASSEMBLY

Brake Assembly T

Spring TB

(H9)

Reel T

Brake Assembly RS

Spring RS

Arm Assembly Tension

Spring Tension

Reel S

Base Tension

(H11)

(H12)

Chassis

(H10)

Fig. A-4

12. Brake Assembly T (Fig. A-4-1)

1) Unhook the Spring TB from the Hook(H9) of the Chassis.

2) Lift the Brake Assembly T up.

13. Brake Assembly RS (Fig. A-4-2)

1) Unhook the Spring RS from the Hook(H10) of the

Chassis.

2) Lift the Brake Assembly T up.

14. Arm Assembly Tension (Fig. A-4-3)

1) Unhook the Spring Tension from the Hook(H11) of the

Arm Assembly Tension.

2) Unhook the Hook(H12) of the Base Tension and lift the

Arm Assembly Tension up.

NOTE

Difference for Springs

15. Reel S / Reel T (Fig. A-4-4)

1) Difference for Reel S / Reel T

Spring TB

Spring RS

Color (Black)

Spring Tension

Reel S Reel T

(Fig. A-4-1)

(Fig. A-4-3)

(Fig. A-4-4)

(Fig. A-4-4)

(Fig. A-4-2)

Page 84

- 4-7 -

DECK MECHANISM DISASSEMBLY

Fig. A-5

16. Base Assembly P4 (Fig. A-5-1)

1) Breakaway the (A) portion of the Base Assembly P4 from

the embossing of the Chassis.

2) Turn the Base Assembly P4 to counterclockwise direction

and lift it up.

17. Opener Lid (Fig. A-5-2)

1) Breakaway the (B) portion of the Opener Lid from the

embossing of the Chassis.

2) Turn the Opener Lid to clockwise direction and lift it up.

18. Arm Assembly Pinch (Fig. A-5-3)

1) Lift the Arm Assembly Pinch up.

NOTE

When reassembling, confirm the (C) portion of the Arm

Assembly Pinch is inserted to the Chassis hole correctly as

Fig.

19. Lever T/up (Fig. A-5-4)/

Arm T/up (Fig. A-5-5)

1) Unhook the Hook(H13) of the bottom Chassis and lift the

Lever T/up up.

2) Lift the Arm T/up up.

(Fig. A-5-2)

(Fig. A-5-1)

(Fig. A-5-3)

(Fig. A-5-5)

(Fig. A-5-4)

(B)

Base Assembly P4

(B)

Opener Lid

Arm

Assembly

Pinch

(C)

(C)

Lever T/up

(H13)

(A)

Arm T/up

(H13)

Chassis

Page 85

- 4-8 -

DECK MECHANISM DISASSEMBLY

Chassis

(S5)

Belt Capstan

Motor Capstan

Washer(W1)

Lever F/R

Clutch Assembly D35

Brake Assembly Capstan

(L1)

(L2)

(L1)

Fig. A-6

20. Belt Capstan (Fig. A-6-1)/

Motor Capstan (Fig. A-6-2)

1) Remove the Belt Capstan.

2) Remove the three Screws(S5) on bottom Chassis and lift

the Motor Capstan up.

21. Lever F/R (Fig. A-6-3)

1) Unlock the Locking Tab(L1) as Fig. A-6-3 and lift the

Lever F/R up.

22. Clutch Assembly D35 (Fig. A-6-4)

1) Remove the Washer(W1) and lift the Clutch Assembly

D35 up.

23. Brake Assembly Capstan

(Fig. A-6-5)

1) Pull the Locking Tab(L2) back in direction of arrow and lift

it up.

(Fig. A-6-1)

(Fig. A-6-2)

(Fig. A-6-3)

(Fig. A-6-5)

(Fig. A-6-4)

Page 86

- 4-9 -

DECK MECHANISM DISASSEMBLY

Gear Drive

Washer (W2)

Gear Cam

Plate Slider

Lever Tension

Lever spring

Base Loading

Gear Sector

(L3)

(H15)

(H16)

(H14)

(A)

Chassis

Gear Drive Hole(C)

Gear Cam Hole(B)

Gear Drive Hole(A)

Fig. A-7

24. Gear Drive (Fig. A-7-1)/

Gear Cam (Fig. A-7-2)

1) Remove the Washer(W2) and lift the Gear Drive up.

2) Unhook the Hook(H14) of the Gear Cam and lift the Gear

Cam up.

NOTE

When reassembling, align the Gear Drive Hole(A) and the

Gear Cam Hole(B) in a straight line after the Gear Drive

Hole(C) is aligned with the Chassis Hole as Fig.

25. Gear Sector (Fig. A-7-3)

1) Unhook the Hook(H15) of the Base Loading on bottom

Chassis and lift the Gear Sector up.

26. Plate Slider (Fig. A-7-4)

1) Just lift the Plate Slider up.

27. Lever Tension (Fig. A-7-5)

1) Unhook the (A) portion of the Lever Tension from the

Hook(H16) of the Chassis.

2) Turn the Lever Tension to counterclockwise direction and

lift it up.

28. Lever Spring (Fig. A-7-6)

1) Unlock the Locking Tab(L3) of the bottom Chassis and lift

the Lever Spring up.

(Fig. A-7-4)

(Fig. A-7-5)

(Fig. A-7-6)

(Fig. A-7-1)

(Fig. A-7-2)

(Fig. A-7-3)

Page 87

- 4-10 -

DECK MECHANISM DISASSEMBLY

Gear Assembly P3

Gear Assembly P2

Base Assembly P2

Base Assembly P3

(A)

(B)

Chassis

Gear Assembly P2 Hole

Gear Sector Hole(A)

Plate Slider Hole(B)

Lever Spring Boss

Gear Assembly P3 Hole

Fig. A-8

29. Gear Assembly P2 (Fig. A-8-1)/

Gear Assembly P3 (Fig. A-8-2)

1) Just lift the Gear Assembly P2 up.

2) Just lift the Gear Assembly P3 up.

NOTE

When reassembling, align the two holes of the Gear

Assembly P2 and P3 in a straight line after confirmation

whether the Gear Sector Hole(A) and the Plate Slider

Hole(B) are aligned or not as Fig.

30. Base Assembly P2 (Fig. A-8-3)/

Base Assembly P3 (Fig. A-8-4)

1) Move the Base Assembly P2 in direction of arrow(A)

along the guide hole of the Chassis and disassemble it

on bottom side.

2) Move the Base Assembly P3 in direction of arrow(B)

along the guide hole of the Chassis and disassemble it

on bottom side.

(Fig. A-8-1)

(Fig. A-8-2)

(Fig. A-8-3)

(Fig. A-8-4)

Page 88

- 4-11 -

DECK MECHANISM DISASSEMBLY

Fig. A-9

31. Base Loading (Fig. A-9-1)

1) Remove the Screw(S7).

2) Lift the Base Loading up.

32. Base Tension (Fig. A-9-2)

1) Breakaway the (A) portion of the Base Tension from the

embossing of the Chassis.

2) Turn the Base Tension to counterclockwise direction and

lift it up.

33. Arm Assembly Idler (Fig. A-9-3)

1) Make narrower the two parts, (B) and (C), as Fig. A-9-3.

2) Lift the Arm assembly Idler up.

NOTE

When disassembling, be careful not to be caught the (D) part

by the Chassis as Fig.

(Fig. A-9-1)

(Fig. A-9-2)

(Fig. A-9-3)

Base Tension

(A)

(S7)

Base Loading

Arm Assembly Idler

(B) (C)

(D)

Chassis

Page 89

- 4-12 -

Page 90

- 4-13 -

DECK MECHANISM ADJUSTMENT

Purpose:To determine if the Mechanism is in the correct position, when a Tape is ejected.

1. Mechanism Alignment Position Check

1) Turn the Power S/W on and eject the Cassette by pressing the Eject Button.

2) Remove the Top Cover and Plate Assembly Top, visually check if the Gear Cam Hole is aligned with the

Chassis Hole as below Fig. C-2.

3) IF not, rotate the Shaft of the Loading Motor to either

clockwise or counterclockwise until the alignment is as

below Fig. C-2.

4) Remove the Screw which fixes the Deck Mechanism and

Main Frame and confirm if the Gear Cam is aligned with

the Gear Drive as below Fig. C-1(A).

5) Confirm if the Mode S/W on the Main P.C.Board is

aligned as below Fig. C-1(B).

6) Remount the Deck Mechanism on the Main P.C.Board

and check each operation.

Gear Cam

Gear Drive

(A)

Mode S/W

(B)

L/D Motor Assembly

Gear Cam

Chassis Hole

Gear Cam Hole

(A)

(B)

(A’)

(B’)

Gear Drive Hole

Test Equipment/ Fixture

Blank tape

Test Conditions (Mechanism

Condition)

Eject Mode (with Cassette ejected)

Check Point

Mechanism and Mode Switch Position

Fig. C-1

Fig. C-2

CHECK DIAGRAM

BOTTOM VIEW

TOP VIEW

Gear Cam (o) and Gear Drive (o) groove alignment

Page 91

- 4-14 -

DECK MECHANISM ADJUSTMENT

Purpose: To insure smooth transport of the tape during each mode of operation.

If the tape transport is abnormal, then check the torque as indicated by the chart below.

2. Preparation for Adjustment (To set the

Deck Mechanism of the loading state

without inserting a cassette tape).

1) Unplug the power cord from the AC outlet.

2) Disassemble the Top Cover and Plate Assembly Top.

3) Plug the power cord into the AC outlet.

4) Turn the power S/W on and push the Lever Stopper of

the Holder Assembly CST to the back for loading the

cassette without tape.

Cover the holes of the End Sensors at the both sides of

the Chassis to prevent a light leak.

Then the Deck Mechanism drives to the Stop Mode.

In this case, the Deck Mechanism can accept inputs of

each mode, however the Rewind and Review operation

can not be performed for more than a few seconds

because the Take-up Reel Table is in the Stop State

and can not be detected the Reel Pulses.

3. Checking Torque

NOTE:

The values are measured by using a Torque Gauge and

Torque Gauge Adaptor with the Torque Gauge affixed.

NOTE:

The torque reading to measure occurs when the tape

abruptly changes direction from Fast Forward to Rewind

Mode, when quick braking is applied to both Reels.

S

R

K

VIDEO

CASSETTE

TORQUE

METER

VHT-303

S

R

K

-

V

H

T

-

S

S

R

K

-

V

H

T

T

300

250

200

150

50

0

300

250

200

150

50

0

100

Test Equipment/ Fixture

¥ Torque Gauge(600g/cm ATG)

¥ Torque Gauge Adaptor

¥ Cassette Torque Meter

SRK-VHT-303

Checking Method

¥ Perform each Deck Mechanism mode without

inserting a cassette tape(Refer to above No.2

Preparation for Adjustment).

¥ Read the measurement of the Take-up or Supply

Reels on the Cassette Torque Meter(Fig. C-3-2).

¥ Attach the Torque Gauge Adaptor to the Torque

Gauge and then read the value of it(Fig. C-3-1).

Fig. C-3-2

Fig. C-3-1

Torque Gauge

Torque Gauge

Adaptor

Reel Table

Item

Fast Forward Torque

Rewind Torque

Play Take-Up Torque

Review Torque

Mode

Fast Forward

Rewind

Play

Review

Test Equipment

Cassette Torque Gauge

Cassette Torque Gauge

Cassette Torque Meter

Cassette Torque Meter

Measurement Reel

Take-Up Reel

Supply Reel

Take-Up Reel

Supply Reel

Measurement Values

More than 400g/cm

More than 400g/cm

40~100g/cm

120~210g/cm

Test Conditions

(Mechanism Condition)

¥ Play (FF) or Review (REW) Mode

¥ Cassette Torque Meter (SRK-VHT-303)¥ Torque Gauge (600g.cm ATG)

Page 92

- 4-15 -

DECK MECHANISM ADJUSTMENT

4.Guide Roller Height Adjustment

Adjustment Procedure

1) Confirm if the tape runs along the tape guide line of the

Lower Drum.

2) If the tape runs the bottom of the guide line, turn the

Guide Roller Height Adjustment Screw to clockwise

direction.

3) If it runs the top, turn to counterclockwise direction.

4) Adjust the height of the Guide Roller to be guided to the

guide line of the Lower Drum from the starting and ending point of the Drum.

Purpose: To regulate the height of the tape so that the bottom of the tape runs along the

tape guide line on the Lower Drum.

Test Equipment/ Fixture

Post Height Adjusting Driver

Test Conditions (Mechanism Condition)

Play or Review Mode

Adjustment Point

Guide Roller Height Adjustment

screws on the Supply and Take-Up

Guide Rollers.

Fig. C-4-1

Upper Flange

Guide Roller

Retaining Screw

Guide Roller Height

Adjustment screw

ADJUSTMENT DIAGRAM

Test Equipment/Fixture

Oscilloscope

Alignment Tape

Post Height Adjusting

Driver

Test Equipment Connection Points

CH-1:PB RF Envelope

CH-2:NTSC: SW 30Hz

PAL: SW 25Hz

Head Switching Output

Point

RF Envelope Output

Point

Test Conditions VCR(VCP) State

Play an Alignment Tape

Adjustment Point

Guide Roller Height

Adjustment Screws

Fig. C-4-2

Fig. C-4-3

P3 POST

ADJUSTMENT

P2 POST

ADJUSTMENT

Turn the Roller Guide Height

Adjustment Screw slightly

to flatten the waveform.

Tracking Control at center

RF ENVELOPE OUTPUT TEST POINT

OSCILLOSCOPE

HEAD SWITCHING OUTPUT TEST

POINT

Turn(Move) the Tracking

Control to both directions

4-1. Preliminary Adjustment

4-2. Precise Adjustment

Adjustment Procedure

1) Play an Alignment Tape after connecting the probe of the

Oscilloscope to the RF Envelope Output Test Point and

Head Switching Output Test Point.

2) Tracking Control(in PB Mode) : Center Position(When

this adjustment is performed after the Drum Assembly

has been replaced, set the Tracking Control so that the

RF Output is Maximum).

3) Height Adjustment Screw : Flatten the RF waveform.

(Fig. C-4-2)

4) Turn(Move) the Tracking Control(in PB Mode) clockwise

and counterclockwise.(Fig. C-4-3)

5) Check that any drop of RF Output is uniform at the start

and end of the waveform.

NOTE

If the adjustment is excessive or insufficient the tape will

jam or fold.

Waveform Diagrams

Connection Diagram

Page 93

- 4-16 -

DECK MECHANISM ADJUSTMENT

5. Audio/Control (A/C) Head Adjustment

10.9

Purpose: To insure that the tape passes accurately over the Audio and Control Tracks in

exact alignment of the both Record and Playback Modes.

Test Equipment/ Fixture

Blank Tape

Screw Driver(+) Type 5mm

Play the blank tape

Test Conditions (Mechanism Condition)

Adjustment Point

Tilt Adjustment Screw(C)

Height Adjustment Screw(B)

Azimuth Adjustment Screw(A)

Fig. C-5-1

A/C Head Base

Fig. C-5-2

Height Adjustment

Screw(B)

Tilt Adjustment

Screw(C)

Azimuth Adjustment

Screw(A)

X-Value Adjustment

Hole

Fixed Screw

Fig. C-5-3

A/C Head

Tape

Tape

0.2~0.25mm

P4

5-1. Preliminary Adjustment (Height and Tilt Adjustment)

Perform the Preliminary Adjustment, when there is no Audio Output Signal with the Alignment Tape.

1) Initially adjust the Base Assembly A/C Head as shown

Fig. C-5-1 by using the Height Adjustment Screw(B).

2) Play a blank tape and observe if the tape passes accurately over the A/C Head without tape curling or folding.

3) If folding or curling is occured then adjust the Tilt

Adjustment Screw(C) while the tape is running to resemble Fig. C-5-3.

4) Reconfirm the tape path after Playback about 4~5 seconds.

NOTE

Ideal A/C head height occurs when the tape runs between

0.2~0.25mm above the bottom edge of the A/C Head core.

Adjustment Procedure/Diagrams

A/C Head Assembly

Page 94

- 4-17 -

DECK MECHANISM ADJUSTMENT

Purpose: To obtain compatibility with the other VCR(VCP) Models.

5-2. Confirm that the tape passes smoothly

between the Take-up Guide and Pinch

Roller(using a mirror or the naked eye).

1) After completing Step 5-1.(Preliminary Adjustment), check

that the tape passes around the Take-up Guide and Pinch

Roller without folding or curling at the top or bottom.

(1) If folding or curling is observed at the bottom of the

Take-up Guide then slowly turn the Tilt Adjustment

Screw(C) in the clockwise direction.

(2) If folding or curling is observed at the top of it then

slowly turn the Tilt Adjustment Screw(C) in the

counterclockwise direction.

NOTE:

Check the RF envelope after adjusting the A/C Head, if the

RF waveform differs from Fig. C-5-4, performs Precise

Adjustment to flat the RF waveform.

Test Equipment/ Fixture

Oscilloscope

Alignment Tape(SP)

Screw Driver(+) Type 5mm

Connection Point

Audio output jack

Test Conditions