LG AUDIO LAC-4710RW Schematic

CAR CD/MP3/WMA

RECEIVER

SERVICE MANUAL

MODEL :

LAC4710R

CAUTION

BEFORE SERVICING THE UNIT, READ THE “SAFETY PRECAUTIONS”

IN THIS MANUAL

.

MODEL : LAC4710R

SERVICE MANUAL

P/NO : AFN35097886

OCTOBER, 2007

Website http://biz.lgservice.com

Internal Use Only

CONTENTS

SECTION 1 SUMMARY

SERVICING PRECAUTIONS..........................................................................................................................................1-2

ESD PRECAUTIONS .......................................................................................................................................................1-3

SPECIFICATIONS.............................................................................................................................................................1-4

SECTION 2 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE & WAVEFORMS .............................................................................2-1

1. MAIN, FRONT & TUNER PART................................................................................................................................2-1

2. CD PART.....................................................................................................................................................................2-4

• WAVEFORMS..............................................................................................................................................................2-7

INTERNAL BLOCK DIAGRAM OF ICs......................................................................................................................2-10

1. IC301 (HA13173AH) ................................................................................................................................................2-10

2. IC302 (BA00CCOWFP) ...........................................................................................................................................2-12

3. IC401 (µPD78F1164) ...............................................................................................................................................2-12

4. IC601 (BD3805F) .....................................................................................................................................................2-15

5. IC801 (TB2904HQ) ..................................................................................................................................................2-16

6. IC901 (PT6523) ........................................................................................................................................................2-17

BLOCK DIAGRAM .........................................................................................................................................................2-19

CIRCUIT DIAGRAMS.....................................................................................................................................................2-21

1. MAIN CIRCUIT DIAGRAM ......................................................................................................................................2-21

2. CDP CIRCUIT DIAGRAM........................................................................................................................................2-23

3. FRONT CIRCUIT DIAGRAM ..................................................................................................................................2-25

4. AUX CIRCUIT DIAGRAM........................................................................................................................................2-27

5. LCD LIGHTING CIRCUIT DIAGRAM.....................................................................................................................2-28

PRINTED CIRCUIT DIAGRAMS..................................................................................................................................2-29

1. MAIN P.C.BOARD ....................................................................................................................................................2-29

2. CDP P.C.BOARD .....................................................................................................................................................2-33

3. FRONT P.C.BOARD ................................................................................................................................................2-34

4. AUX P.C.BOARD......................................................................................................................................................2-35

5. LCD LIGHTING P.C.BOARD...................................................................................................................................2-35

SECTION 3 EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION ................................................................................................................3-1

SECTION 4 REPLACEMENT PARTS LIST.............................................................4-1

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1-1

LGE Internal Use Only

SECTION 1 SUMMARY

SERVICING PRECAUTIONS

1. Always disconnect the power source before:

1) Removing or reinstalling any component, circuit board, module or any other instrument assembly.

2) Disconnecting or reconnecting any instrument electrical plug or other electrical connection.

3) Connecting a test substitute in parallel with an electrolytic capacitor in the instrument.

CAUTION: A wrong part substitution or incorrect polarity installation of electrolytic capacitors may result in an

explosion hazard.

2. Do not defeat any plug/socket B+ voltage interlocks with which instruments covered by this service

manual might be equipped.

3. Do not apply power to this instrument and or any of its electrical assemblies unless all solid-state

device heat sinks are correctly installed.

4. Always connect a test instrument’s ground lead to the instrument chassis ground before connecting

the test instrument positive lead. Always remove the test instrument ground lead last.

1) The service precautions are indicated or printed on the cabinet, chassis or components. When servicing,

follow the printed or indicated service precautions and service materials.

2) The Components used in the unit have a specified conflammability and dielectric strength. When replacing

any components, use components which have the same ratings. Components marked in the circuit diagram

are important for safety or for the characteristics of the unit. Always replace with the exact components.

3) An insulation tube or tape is sometimes used and some components are raised above the printed writing

board for safety. The internal wiring is sometimes clamped to prevent contact with heating components.

Install them as they were.

4) After servicing always check that the removed screws, components and wiring have been installed correctly

and that the portion around the service part has not been damaged. Further check the insulation between

the blades of attachment plug and accessible conductive parts.

LGE Internal Use Only

1-2

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

ESD PRECAUTIONS

Electrostatically Sensitive Devices (ESD)

Some semiconductor (solid state) devices can be damaged easily by static electricity. Such components

commonly are called electrostatically sensitive devices (ESD). Examples of typical ESD devices are

integrated circuits and some field-effect transistors and semiconductor chip components. The following

techniques should be used to help reduce the incidence of component damage caused by static electricity.

1. Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain

off any electrostatic charge on your body by touching a know earth ground. Alternatively, obtain and

wear a commercially available discharging wrist strap device, which should be removed for potential

shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ESD devices, place the assembly on a conductive

surface such as aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ESD devices.

4. Use only an anti-static solder removal device. Some solder removal devices not classified as "anti-static"

can generate electrical charges sufficient to damage ESD devices.

5. Do not use freon-propelled chemicals These can generate electrical charges sufficient to damage ESD

devices.

6. Do not remove a replacement ESD device from its protective package until immediately before you are

ready to install it. (Most replacement ESD devices are packaged with leads electrically shorted together

by conductive foam, aluminum foil or comparable conductive materials).

7. Immediately before removing the protective material from the leads of a replacement ESD device, touch

the protective material to the chassis or circuit assembly into which the device will by installed.

CAUTION : BE SURE NO POWER IS APPLIED TO THE CHASSIS OR CIRCUIT, AND OBSERVE ALL

OTHER SAFETY PRECAUTIONS.

8. Minimize bodily motions when handing unpackaged replacement ESD devices. (Otherwise harmless

motion such as the brushing together of your clothes fabric or the lifting of your foot from a carpeted floor

can generate static electricity sufficient to damage an ESD device).

CAUTION. GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH ARROWHEAD SYMBOL. WITHIN AN EQUILATERAL

TRIANGLE, IS INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE

OF UNINSULATED "DANGEROUS VOLTAGE" THAT MAY BE OF SUFFICIENT

MAGNITUDE TO CONSTITUTE A RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS INTENED TO

ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF IMPORTANT SAFETY

INFORMATION IN SERVICE LITERATURE.

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1-3

LGE Internal Use Only

SPECIFICATIONS

• GENERAL

Output Power 50W x 4CH (Max.)

Power Source DC 12V

Speaker impedance 4Ω

Ground System Negative

Dimensions (W x H x D) 180 x 51 x 171mm (Without Control Panel)

Net Weight 2.0kg

• CD SECTION

Frequency Response 20Hz ~ 20kHz

S/N Ratio 80dB

Distortion 0.12%

Channel Separation (1kHz) 55dB

• RADIO SECTION

FM

Frequency Range 65 ~ 74, 87.5 ~ 107.9 or 87.5 ~ 108MHz

S/N Ratio 53dB

Distortion 0.7%

Usable Sensitivity 12dBµV

AM (MW)

Frequency Range 520 ~ 1720 or 522 ~ 1620kHz

S/N Ratio 45dB

Distortion 1.0%

Usable Sensitivity 28dBµV

• AUX SECTION

Frequency Response 20Hz ~ 20kHz

S/N Ratio 80dB

Distortion 0.1%

Channel Separation (1kHz) 45dB

Max Input Level (1kHz) 1.1V (35KΩ)

LGE Internal Use Only

1-4

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

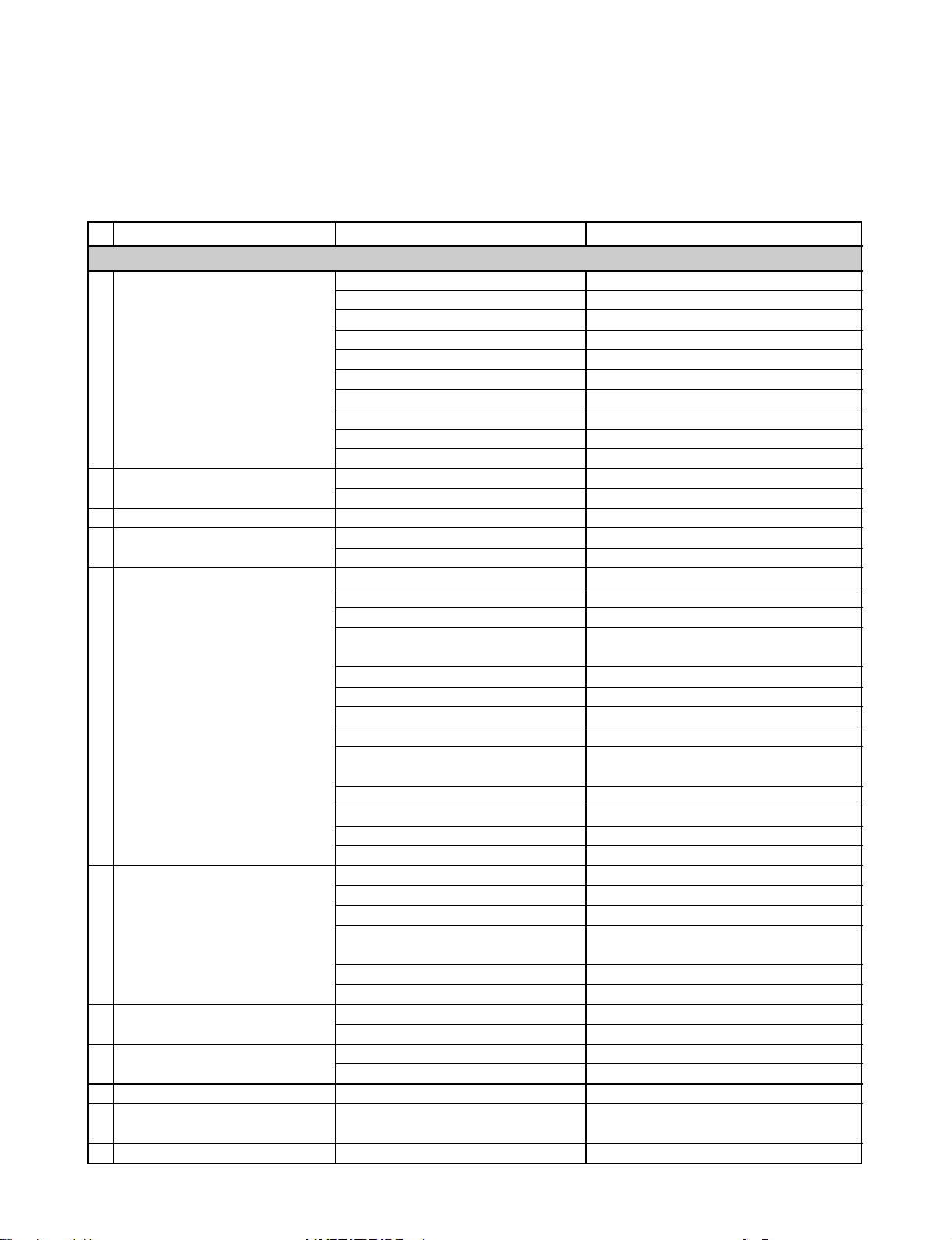

SECTION 2 ELECTRICAL

ELECTRICAL TROUBLESHOOTING GUIDE & WAVEFORMS

1. MAIN, FRONT & TUNER PART

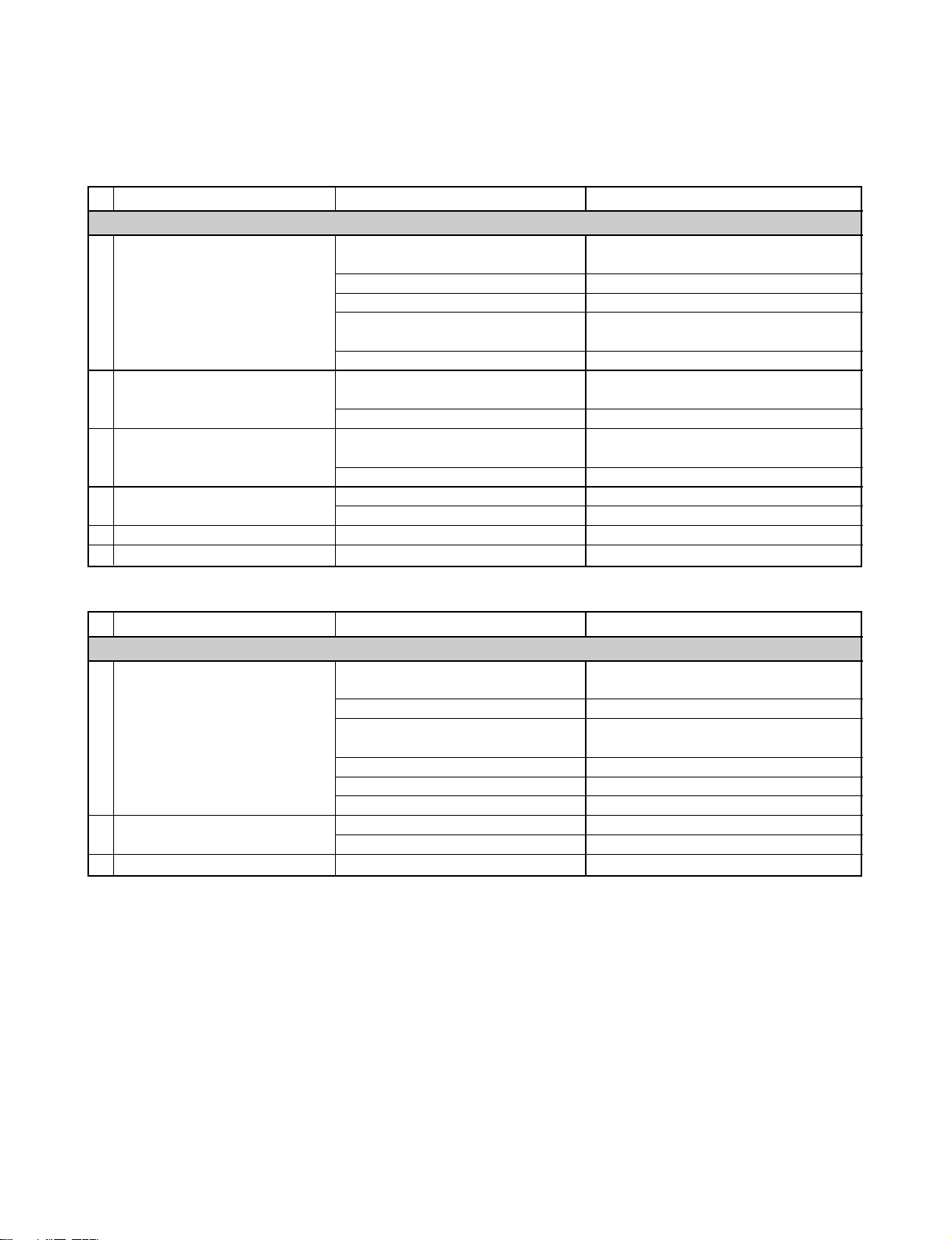

No Symptom Check Point Location No.

SYSTEM CONTROL

1 No Power Checked the Fuse. CN801

Checked the Back up Vdd, Gnd. CN801(16,15)

Checked the Micom Back Up Vdd. IC301(14), D307, IC401(30,47,50,99,100)

Checked the Micom Ground. IC401(20,51,97,98)

Checked the Reset. IC402, IC401(90)

Checked the X-tal. X401, X402

Checked the ACC in. Q301, Q302, IC401(38), CN801(14)

Checked the detachable switch. SW401, IC401(73)

Checked the flipdown Detector. CN901(19), IC401(74)

Checked the Key line. IC401(52,53)

2 Not available Remocon Checked the Remocon Sens Vdd. CN901(14), Q316, Q317, D307

Checked the Remocon Sens line. RM901, IC401(5)

3 Not available to Volume control Checked the Encoder Volume. SW901, IC401(40,41)

4 Not available to Key Control Checked Tact switch. SW902 ~ SW918

Checked Key line. IC410(52,53)

5 No sound Checked the E-VR Vdd. IC301(10), IC601(16)

Checked the E-VR Ground. IC601(1,22)

Checked the E-VR control. IC601(22,23), IC401(1,2)

Checked the E-VR Signal in/out. IC601(3,5,6,7,10,11)

IC601(12,13,14,15)

Checked the E-VR Mute Control IC601(19), IC401(6)

* Power IC Checked the Power IC Vdd. IC801(6,20)

: Refer to next page Checked the Power IC Ground. IC801(1,2,8,13,18,24)

Checked the Power IC Control. IC801(4, 22), IC401(3,10)

Checked the Power IC Signal in/out. IC801(11,12,14,15)

IC801(3,5,7,9,17,19,21,23)

Checked the Power IC Mute. IC801(22)

Checked the Power IC Standby. IC801(4)

Checked the Power IC Ripple. IC801(10)

Checked the Main Connector. CN801(1,2,3,4,8,9,12,13)

6 No Line out signal Checked the E-VR Vdd. IC301(10), IC601(16)

Checked the E-VR Ground. IC601(1,22)

Checked the E-VR control. IC601(20,21), IC401(1,2)

Checked the E-VR Signal in/out. IC601(3,5,6,7,10,11)

IC601(12,13,14,15)

Checked the Line out Mute circuit Q705, IC401(48)

Check the Line out Jack CN703

8 Heard Pop Noise Checked the Mute Control. IC601(19), IC801(4,22), IC401(3,6,10)

Checked the AF Mute. TU101(19), IC401(4)

9 Not avaliable to Telephone Mute Checked the telephone Mute Control. CN801(5), Q305, Q306, IC401(62)

Checked the Mute Control. IC601(19), IC801(4,22), IC401(3,6,10)

10 Not avaliable to ANT(Motor Type) Control Checked the ANT Control. IC301(12,13), IC401(87)

11 Not avaliable to Remote Checked the Remote control. CN801(6), IC402(1,2,4), Q308, Q309

(External AMP) IC401(63,64)

12 No output Beep sound. Checked the Beep Control. IC401(80)

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2-1

LGE Internal Use Only

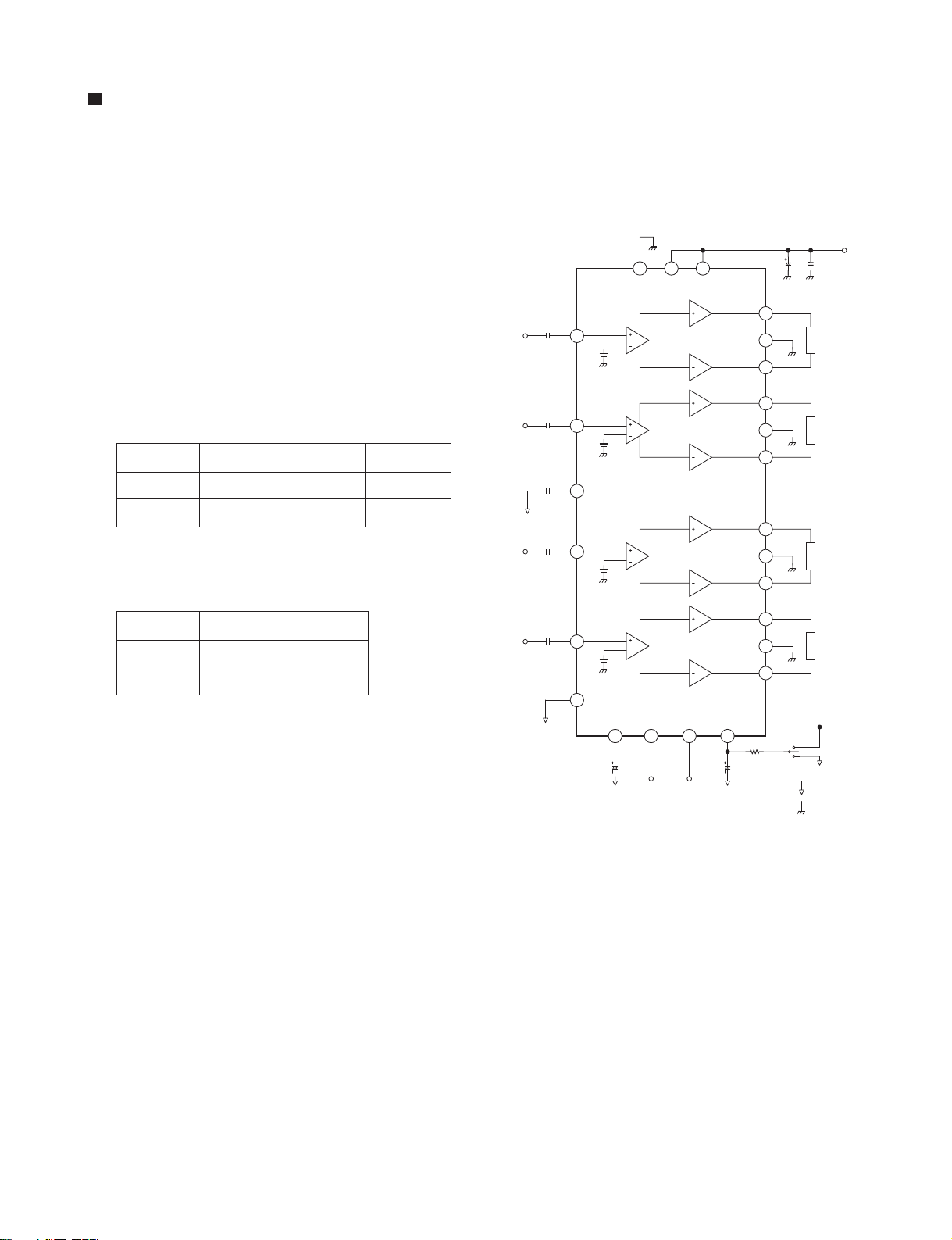

CAUTION - Tip for repair

A

Before exchange power amp IC(TB2904) for no audio problem, you have to check

below list.

1. Check VCC (pin 20, 6) & GND

2. Check input pin 11, 12, 14, 15

3. Check Standby, pin 4

: Follow the below list.

4. Check Mute function, pin 22

: Follow the below list.

Stand-by Power Sound Voltage

ON OFF OFF 0 to 1.5

OFF ON ON 3.5 to 6V

5. Check Ripple pin 10.

: Normally it is high (about 10V)

Mute Sound Voltage

ON OFF 0 to 1.5

OFF ON 3.5 to 6V

6. Re-soldering all the pin of IC.

: Prevent crack of solder line.

* Keep changed IC, We request that you send it to HQ.

C1

C1

C6

C1

C1

PRE-GND

1 20 6

TAB V

IN1

11

IN2

12

C-GND

16

IN3

15

IN4

14

13

STBYRIP

10 25 22

2

C

4

CC1VCC2

OFF-SET

DET

OUT1

()

PW-GND1

OUT1 ( )

OUT2 ( )

PW-GND2

OUT2 ( )

OUT3 ( )

PW-GND3

OUT3 ( )

OUT4 ( )

PW-GND4

OUT4 ( )

MUTE

4

C

3

5

C

C

+

9

8

7

+

5

2

3

+

17

18

-

19

+

21

24

-

23

R

1

R

L

R

L

R

L

R

L

5 V

PLAY

MUTE

: PRE-GND

: PW-GND

Picture 1) Power IC desc.

LGE Internal Use Only

2-2

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

No Symptom Check Point Location No.

DISPLAY & LIGHTING

1 No Display or Checked the LCD DRV Vdd. Q322, Q316, Q317

Some Display is broken IC901(58,59)

Checked the LCD DRV Ground. IC901(60)

Checked the LCD DRV OSC. IC901(61)

Checked the LCD DRV control. IC401(75,79,85,86),

IC901(57,62,63,64)

Checked the LCD DRV to LCD Pattern.

2 No LCD Lighting or Checked the LCD Lighting VDD. Q319, Q320, Q322, IC301(4,9)

Color is different IC401(64)

Checked the LED. LD930, LD931

3 Not avaliable to LCD Lighting Checked the LCD Lighting Control. CN801(11), Q303, Q304, Q321,

control IC401(58)

Checked the LED. LD930, LD931

4 No Key Lighting Checked the LED Lighting Vdd. IC301(4,9), IC401(64)

Checked the LED. LD901 ~ LD923

5 Don't moved Level bar Checked the Level Meter control. IC401(54,57)

6 Not avaliable to Dimmer control Chekced the Dimmer control. CN801(11), Q303, Q304, IC301(4,9)

IC901(1 ~ 55)

No Symptom Check Point Location No.

TUNER FUNCTION

1 Not available to Tuner Checked the Tuner Vdd. TU101(4,16), IC301(10), IC401(39)

Q350, Q351

Checked the Tuner Ground. TU101(3, 5,10,17)

Checked the PLL data. TU101(11,12,13,14,15)

IC401(67,68,44,45,46)

Checked the RF signal in. TU101(1, 2)

Checked the S-Meter control. TU101(7)

Checked the SD & ST IND. TU101(6)

2 Tuner no sound Checked the Tuner Signal out. TU101(8,9), IC601(6,7)

Checked the AF mute. TU101(19), IC401(4)

3 Not available to RDS Checked the RDS data. TU101(20,21), IC401(65,83)

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2-3

LGE Internal Use Only

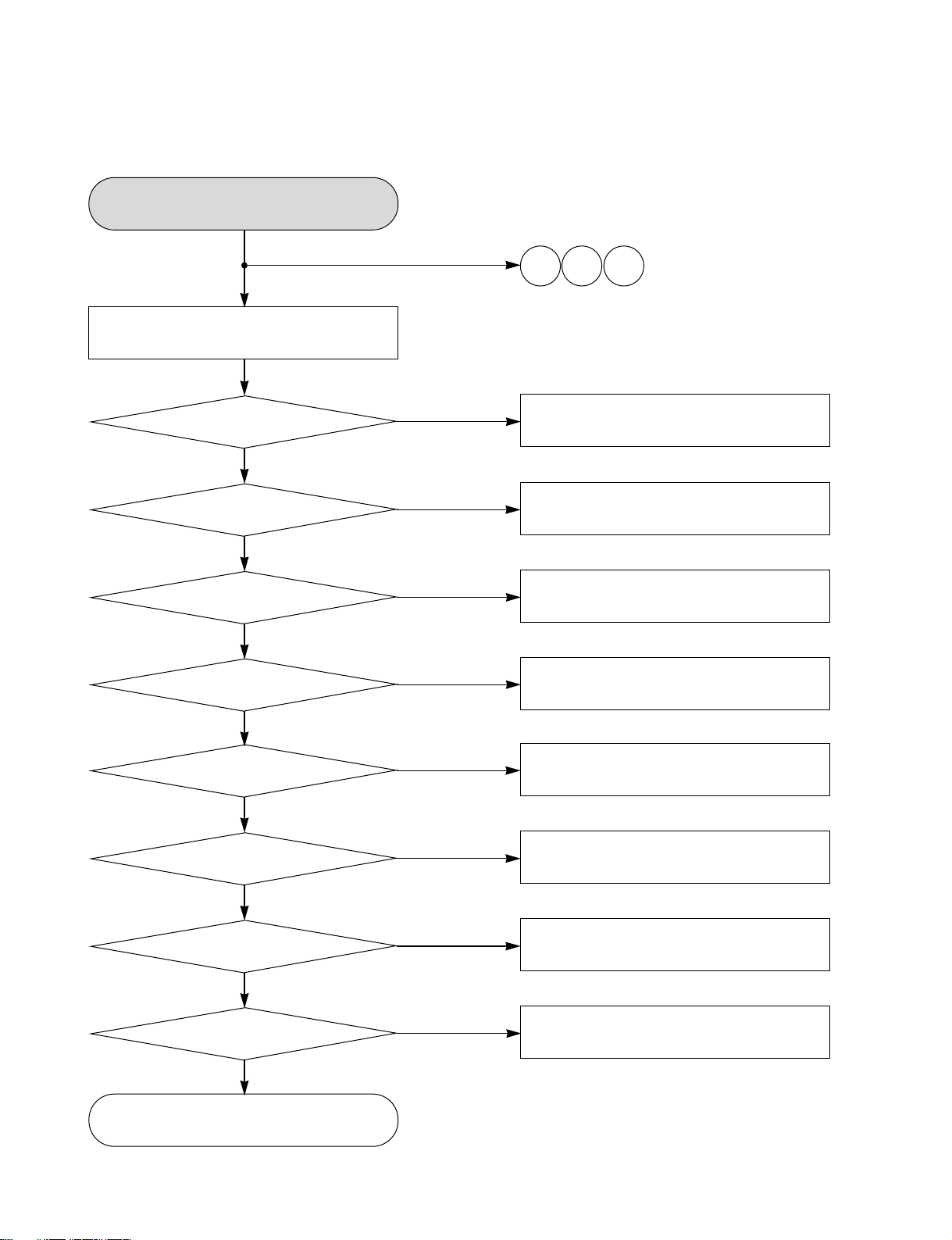

2. CD PART

Something wrong with the CD player?

No loading?

YES

A B C

Checked the CD Vdd?

YES

Checked the CD DSP ground?

YES

Checked the motor DRV

VDD?

YES

Checked the CD DSP reset?

YES

Checked the CD DSP X-tal?

YES

Checked the disc in

load switch?

NO

NO

NO

NO

NO

NO

Fig 1, 2

CN510(13, 6)

IC506(26, 32, 47, 78, 18)

IC504(7, 8, 20)

IC506(72)

X503

CN509(15)

Checked the loading

Checked the 8/12cm

LGE Internal Use Only

YES

motor control?

YES

sens switch?

YES

OK

NO

Fig 3, 4

NO

Fig 1, 2

2-4

CN509(12, 17)

IC513(12, 14, 15)

CN509(10)

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

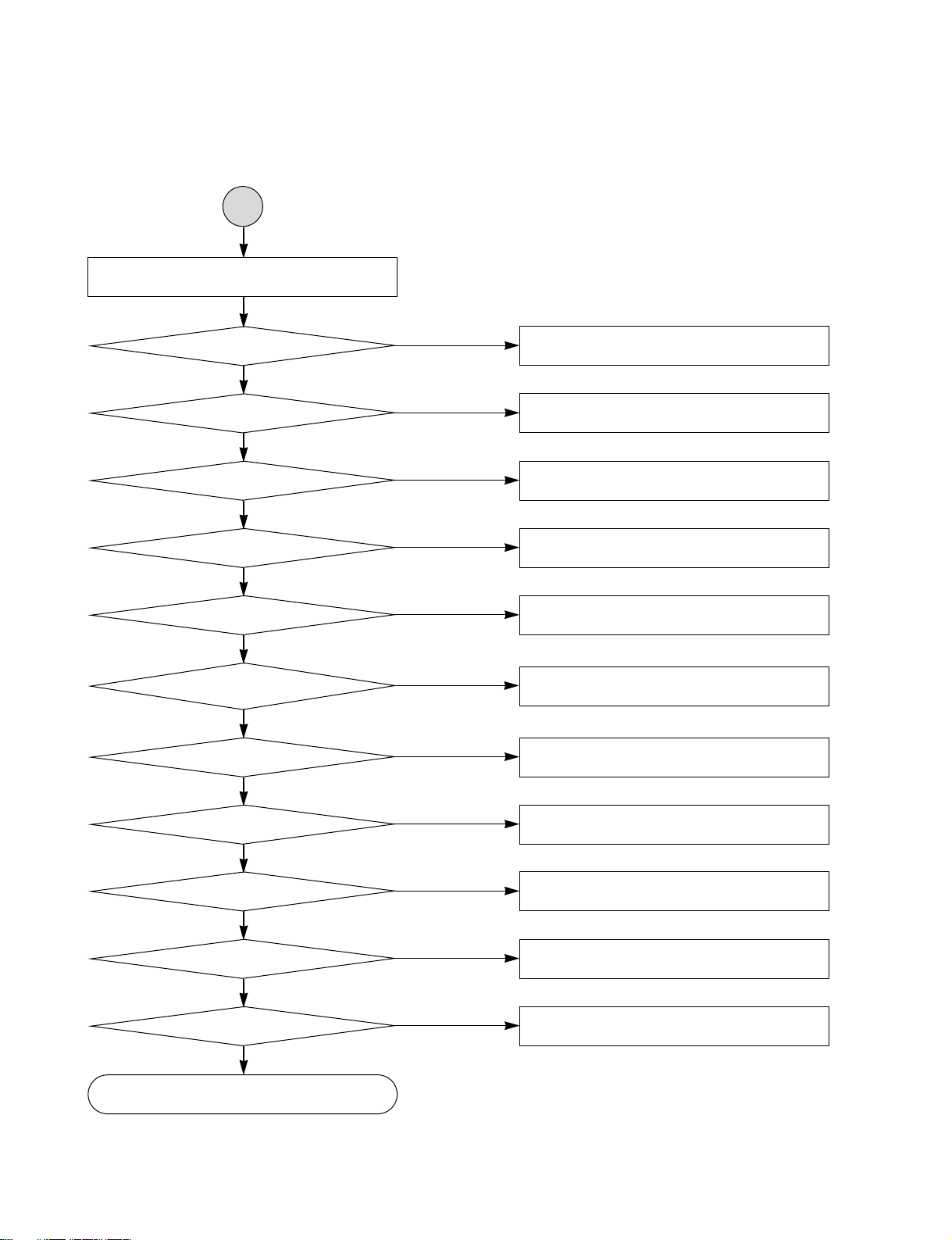

A

No reading & "FILE CHECK"

DISPLAY?

YES

Checked the limit switch?

YES

Checked the motor DRV

mute control?

YES

Checked the motor

LD control?

YES

Checked the CD DSP control?

YES

Checked the focus control?

YES

NO

Fig 1, 2

NO

NO

Fig 3, 4

NO

Fig 10, 11

NO

Fig 5

CN509(8)

CN509(16)

D5, D6

IC506(67, 68, 69, 70, 71)

IC506(25)

IC513(17, 18)

Checked the focus error

level out.(FE mon)?

YES

Checked the PLL locking.

(FSEQ)?

YES

Checked the RF signal

out check?

YES

Checked the spindle

motor control?

YES

Checked the TRVP control?

YES

Checked the tracking control?

YES

OK

NO

Fig 5

NO

Fig 9

NO

Fig 8

NO

Fig 7

NO

Fig 13

NO

Fig 6

IC506(25)

R517

IC506(54)

IC506(41, 16)

IC506(21)

IC513(8, 5)

PN504(5, 6)

IC506(24)

IC513(19, 20)

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2-5

LGE Internal Use Only

Loading...

Loading...