LG ASNW096FE, ASUW126FUG0, ASNW126F1G0, ASNW126FE, ASNW126F2G0 Service Manual

...

LG

Room Air Conditioner

SERVICE MANUAL

LG

MODELS: ASNW096F1G0

ASNW096FE/V/GG0

ASNW126F1G0

ASNW126FE/V/GG0

ASUW126FUGO

ASNW126F2G0(A12AW2-NF6)

ASUW126FUGO(A12AWU-UF6)

CAUTION

website http://www.lgservice.com

• BEFORE SERVICING THE UNIT, READ THE SAFETY

PRECAUTIONS IN THIS MANUAL.

• ONLY FOR AUTHORIZED SERVICE PERSONNEL.

2 Room Air Conditioner

Air Conditioner Service Manual

TABLE OF CONTENTS

LG Model Name.................................................................................................................................3

Safety Precautions ...........................................................................................................................4

Dimensions .....................................................................................................................................10

Installation.......................................................................................................................................12

Flaring work and connection of piping.........................................................................................15

Checking the drainage and forming the pipings .........................................................................18

Air purging ......................................................................................................................................19

Test running ....................................................................................................................................22

Functions.........................................................................................................................................23

Operation.........................................................................................................................................27

Disassembly....................................................................................................................................40

Troubleshooting Guide ..................................................................................................................42

Schematic Diagram ........................................................................................................................62

Product Specifications ..................................................................................................................68

Exploded View ................................................................................................................................69

Replacement Parts List ..................................................................................................................71

Service Manual 3

LG Model Name

LG Model Name

2006

12 - 345678910

Code Type Code of Model Meaning

1 Producing Center, A~Z L: Chang-won R22 N: India

Refrigerant A: Chang-won R410A Z: Brazil

C: Chang-won R407C D: Indonesia

T: China M: Mexico

K: Turkey R22 V: Vietnam

E: Turkey R410A S: Out Sourcing

H: Thailand

2 Product Type A~Z S: Split Type Air Conditioner

3 Cooling/Heating/Inverter A~Z C: Cooling only

H: Heat pump

X: C/O + E/Heater

Z: H/P + E/Heater

V: AC Inverter C/O

N: AC Inverter H/P

Q: DC Inverter C/O

W: DC Inverter H/P

4, 5 Capacity 0~9 Cooling/Heating Capacity

Ex. "09" → 9,000 Btu/h

6 Electric Range 1~9 1: 115V/60Hz, A: 220V, 50Hz, 3Phase

A~Z 2: 220V/60Hz B: 208~230V, 60Hz, 3Phase

3: 208-230V/60Hz C: 575V, 50Hz, 3Phase

5: 200-220V/50Hz D: 440~460, 60Hz, 3Phase

6: 220-240V/50Hz E: 265V, 60Hz

7: 110V, 50/60Hz F: 200V, 50/60Hz

8: 380-415V/50Hz

9: 380-415V/60Hz

7 Chassis A~Z Name of Chassis of Unit

8 Look A~Z Look,

Color (Artcool Model)

9 Function A~Z

10 Serial No. 0~9 LG Model De

* ARTCOOL COLOR (SF)

velopment Serial No.

Basic A

Basic+4Way B

Plasma Filter C

Plasma Filter+4 Way D

Tele+LCD E

Tele+LCD+Nano plasma+4Way F

Nano Plasma F+(A/changeove)+A/clean+Low A G

Nano Plasma F+(A/changeove)+A/clean+4way+Low A H

Tele+LED+4way I

Internet J

Plasma F+4Way+Oxy generator K

Nano Plasma F+(A/changeove)+A/clean L

Nano Plasma F+(A/changeove)+A/clean+4way M

Nano Plasma F+(A/changeove)+A/clean+PTC N

Nano Plasma F+(A/changeove)+Autoclean+4way+PTC P

Nano Plasma F+(A/changeove)+A/clean+4way+Low A+PTC Q

Negative ION+A/Clean R

(Nano)Plasma+Negative ION+A/Clean S

4way+(Nano)Plasma F+Negative ION+Healthy dehumidification+A/Clean

T

Nano Plasma F+4Way+(A/changeove)+A/clean+ U

1 Kiss

E Red

V Silver

G Gold

Ex.F → SF Chassis

4 Room Air Conditioner

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must

be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is

classified by the following indications.

■ Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

■ Installation

Do not use damaged power

cords, plugs, or a loose socket.

• There is risk of fire or electric

shock.

For electrical work, contact

the dealer, seller, a qualified

electrician, or an Authorized

Service Center.

• There is risk of fire or electric

shock.

Always use the power plug

and socket with the ground

terminal.

• There is risk of electric shock.

Install the panel and the cover

of control box securely.

• There is risk of fire or electric

shock.

Do not modify or extend the

power cord.

• There is risk of fire or electric

shock.

Do not install, remove, or reinstall the unit by yourself

(customer).

• There is risk of fire, electric

shock, explosion, or injury.

Service Manual 5

Safety Precautions

■ Operation

Be cautious when unpacking

and installing the product.

• Sharp edges could cause injury.

Be especially careful of the case

edges and the fins on the condenser and evaporator.

For installation, always contact the dealer or an

Authorized Service Center.

• There is risk of fire, electric

shock, explosion, or injury.

Do not install the product on a

defective installation stand.

• It may cause injury, accident, or

damage to the product.

Be sure the installation area

does not deteriorate with age.

• If the base collapses, the air

conditioner could fall with it,

causing property damage, product failure, and personal injury.

Do not let the air conditioner

run for a long time when the

humidity is very high and a

door or a window is left open.

• Moisture may condense and wet

or damage furnishings.

Take care to ensure that

power cords could not be

pulled out or damaged during

operation.

• There is risk of fire or electrical

shock.

Do not place anything on the

power cord.

• There is risk of fire or electric

shock.

Do not turn the air-conditioner

ON or OFF by plugging or

unplugging the power plug.

• There is risk of fire or electrical

shock.

6 Room Air Conditioner

Safety Precautions

Use a dedicated outlet for this

appliance.

• There is risk of fire or electrical

shock.

Grasp the plug to remove the

cord from the outlet. Do not

touch it with wet hands.

• There is risk of fire or electrical

shock.

Do not place a heater or other

appliances near the power

cable.

• There is risk of fire and electric

shock.

Do not allow water to run into

electric parts.

• It may cause There is risk of

fire, failure of the product, or

electric shock.

Do not store or use flammable

gas or combustibles near the

air conditioner.

• There is risk of fire or failure of

product.

Do not use the product in a

tightly closed space for a long

time.

• Oxygen deficiency could occur.

When flammable gas leaks,

turn off the gas and open a

window for ventilation before

turn the product on. DO NOT

use the telephone or turn

switches on or off.

• There is risk of explosion or fire.

Unplug the unit if strange

sounds, odors, or smoke

comes from it.

• There is risk of electrical shock

or fire

Stop operation and close the

window in storm or hurricane.

If possible, remove the air

conditioner from the window

before the hurricane arrives.

• There is risk of property damage, failure of product, or electric shock.

Thinner

Wax

Service Manual 7

Safety Precautions

■ Installation

Do not open the inlet grill of

the product during operation.

(Do not touch the electrostatic

filter, if the unit is so

equipped.)

• There is risk of physical injury,

electric shock, or product failure.

When the product is soaked

(flooded or submerged), contact an Authorized Service

Center.

• There is risk of fire or eletric

shock.

Ventilate the product from

time to time when operating it

together with a stove, etc.

• There is risk of fire or electrical

shock.

Unplug the appliance before

performing cleaning or maintenance.

• There is risk of electrical shock.

When the product is not be

used for a long time, disconnect

the power supply plug or turn

off the breaker.

• There is risk of product damage

or failure, or unintended operation.

Take care to ensure that

nobody could step on or fall

onto the outdoor unit.

• This could result in personal

injury and product damage.

Always check for gas (refrigerant) leakage after installation

or repair of product.

• Low refrigerant levels may

cause failure of product.

Install the drain hose to

ensure that water is drained

away properly.

• A bad connection may cause

water leakage.

Keep level even when

installing the product.

• To avoid vibration or water leakage.

90˚

8 Room Air Conditioner

Safety Precautions

■ Operation

Do not install the product

where the noise or hot air

from the outdoor unit could

damage the neighborhoods.

• It may cause a problem for your

neighbors.

Use two or more people to lift

and transport the air conditioner.

• Avoid personal injury.

Do not install the product

where it will be exposed to

sea wind (salt spray) directly.

• It may cause corrosion on the

product. Corrosion, particularly

on the condenser and evaporator fins, could cause product

malfunction or inefficient operation.

Do not direct airflow at room

occupants. (Don't sit in the

draft.)

• This could damage your health.

Do not use the product for

special purposes, such as

preserving foods, works of

art, etc. It is a consumer air

conditioner, not a precision

refrigeration system.

• There is risk of damage or loss

of property.

Do not block the inlet or outlet

of air flow.

• It may cause product failure.

Use a soft cloth to clean. Do

not use harsh detergents, solvents, etc.

• There is risk of fire, electric

shock, or damage to the plastic

parts of the product.

Do not touch the metal parts

of the product when removing

the air filter. They are very

sharp!

• There is risk of personal injury.

Do not step on or put anyting

on the product. (outdoor

units)

• There is risk of personal injury

and failure of product.

Service Manual 9

Safety Precautions

Always insert the filter securely. Clean the filter every two

weeks or more often if necessary.

• A dirty filter reduces the efficiency of the air conditioner and

could cause product malfunction

or damage.

Do not insert hands or other

objects through the air inlet or

outlet while the air conditioner

is plugged in.

• There are sharp and moving

parts that could cause personal

injury.

Do not drink the water drained

from the unit.

• It is not sanitary and could

cause serious health issues.

Use a firm stool or ladder when cleaning or

maintaining the air conditioner.

• Be careful and avoid personal injury.

Replace the all batteries in the remote control

with new ones of the same type. Do not mix

old and new batteries or different types of batteries.

• There is risk of fire or explosion

Do not recharge or disassemble the batteries.

Do not dispose of batteries in a fire.

• They may burn or explode.

If the liquid from the batteries gets onto your

skin or clothes, wash it well with clean water.

Do not use the remote if the batteries have

leaked.

• The chemicals in batteries could cause burns or

other health hazards.

■ Disuse

10 Room Air Conditioner

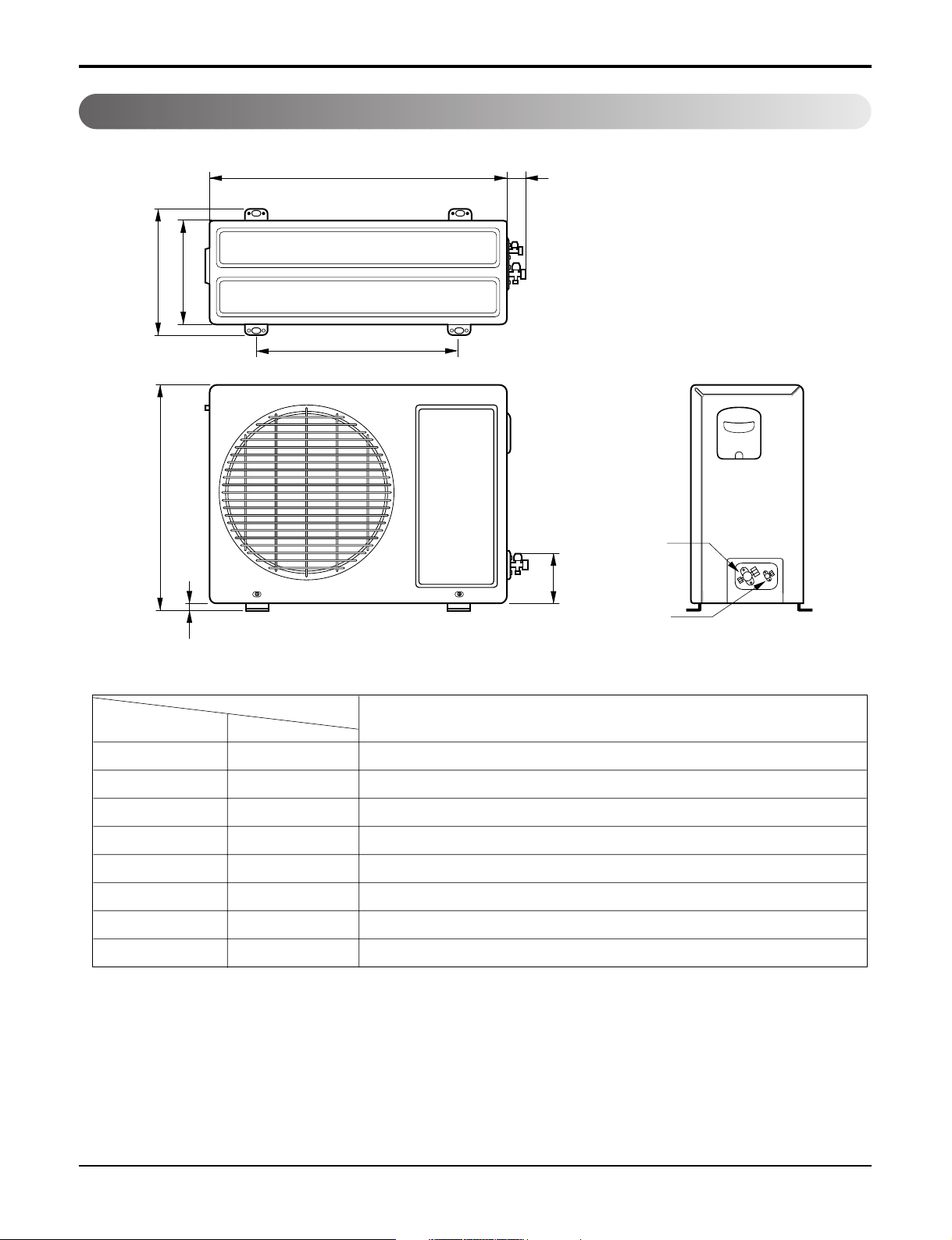

Dimensions

Dimensions

Pipe Hole

Fix Hole

Hanger Hole

H

W

D

W mm 600

H mm 600

D mm 146(143)

Model

Dimension

INDOOR

Indoor Unit

This symbol alerts you to the risk of electric shock.

This symbol alerts you to hazards that could cause harm to the

air conditioner.

This symbol indicates special notes.

NOTICE

Symbols Used in this Manual

Service Manual 11

W

L2

L3

L1

D

H

L4

L5

Gas side

(3-way valve)

Liquid side

(2-way valve)

MODEL

DIM unit

W mm 770

H mm 545

D mm 245

L1 mm 285

L2 mm 64

L3 mm 518

L4 mm 10

L5 mm 100

Dimensions

Outdoor Unit

OUTDOOR

12 Room Air Conditioner

Installation

Installation

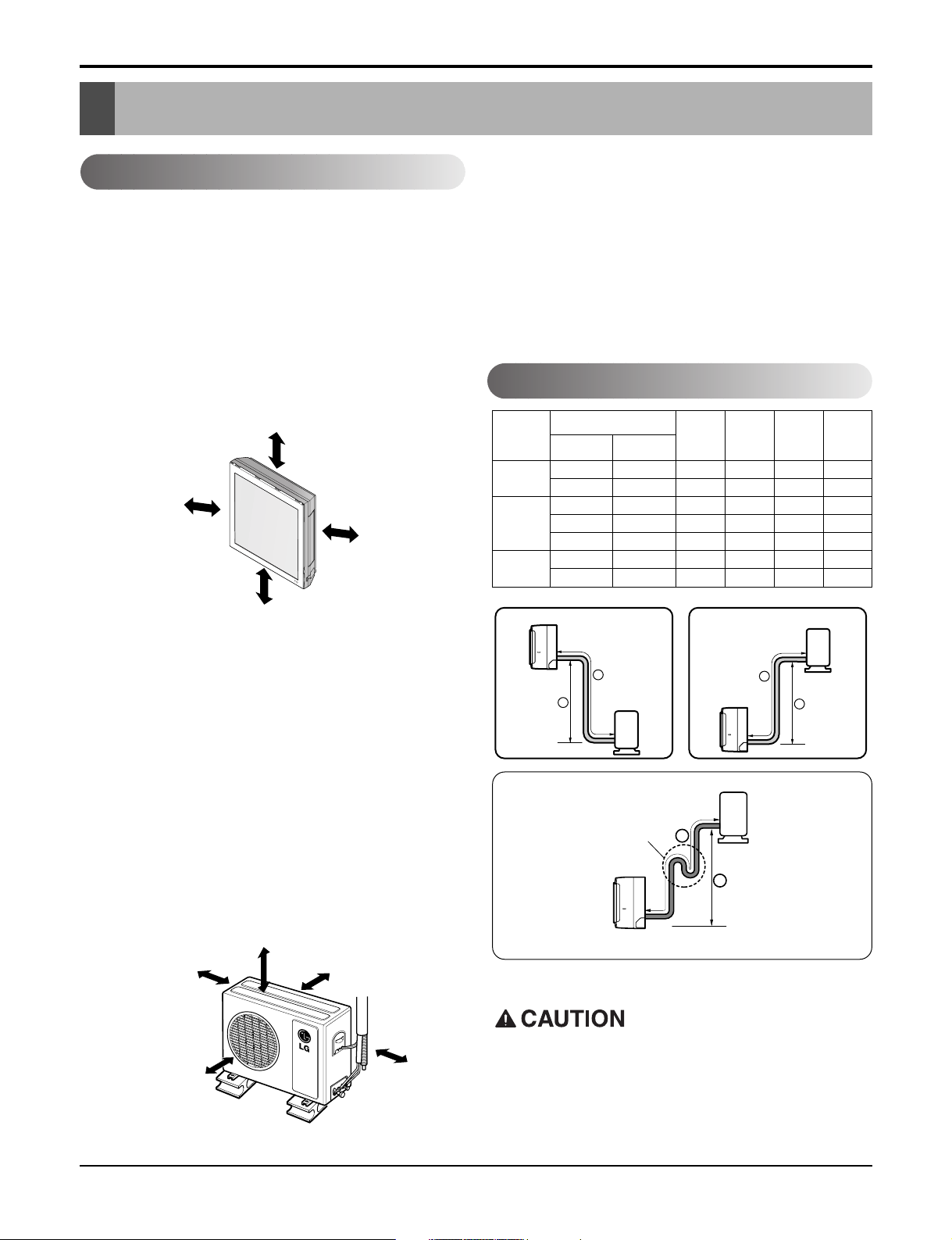

Indoor unit

• Do not have any heat or steam near the unit.

• Select a place where there are no obstacles in

front of the unit.

• Make sure that condensation drainage can be

conveniently routed away.

Do not install near a doorway.

• Use a stud finder to locate studs to prevent

unnecessary damage to the wall.

Outdoor unit

• If an awning is built over the unit to prevent direct sunlight or

rain exposure, make sure that heat radiation from the condenser is not restricted.

• Ensure that the space around the back and sides is more

than 30cm. The front of the unit should have more than

70cm of space.

• Do not place animals and plants in the path of the warm air.

• Take the weight of the air conditioner into account and select

a place where noise and vibration are minimum.

• Select a place where the warm air and noise from the air

conditioner do not disturb neighbors.

Rooftop Installations:

• If the outdoor unit is installed on a roof structure,

be sure to level the unit. Ensure the roof structure and anchoring method are adequate for the

unit location.

• Consult local codes regarding rooftop mounting.

More than 20cm

More

than 50cm

More than 1.5m

More

than 50cm

• Capacity is based on standard length and maximum allowance length is on the basis of reliability.

• Oil trap should be installed every 5~7 meters.

Pipe Size

Capacity

(Btu/h)

GAS LIQUID

Max.

Length

A (m)

Additional

Refrigerant

(g/m)

Max.

Elevation

B (m)

Standard

Length

(m)

5k~14k

3/8"(Ø9.52) 1/4"(Ø6.35) 4 or 7.5 7 15 20

1/2"(Ø12.7) 1/4"(Ø6.35) 4 or 7.5 7 15 20

1/2"(Ø12.7) 1/4"(Ø6.35) 4 or 7.5 15 30 20

18k~28k 5/8"(Ø15.88) 1/4"(Ø6.35) 4 or 7.5 15 30 20

5/8"(Ø15.88) 3/8"(Ø9.52) 4 or 7.5 15 30 30

30k~38k

5/8"(Ø15.88) 3/8"(Ø9.52) 7.5 15 30 30

3/4"(Ø19.05) 3/8"(Ø9.52) 7.5 15 30 50

If case more than 5m

Outdoor unit

Indoor unit

A

B

Outdoor unit

Indoor unit

A

B

A

Oil trap

Outdoor unit

Indoor unit

B

If piping length is more than 5m

Selection of the Best Location

Piping Length and Elevation

More than 30cm

More than 30cm

More

than 60cm

More than 60cm

More than 70cm

Service Manual 13

Installation

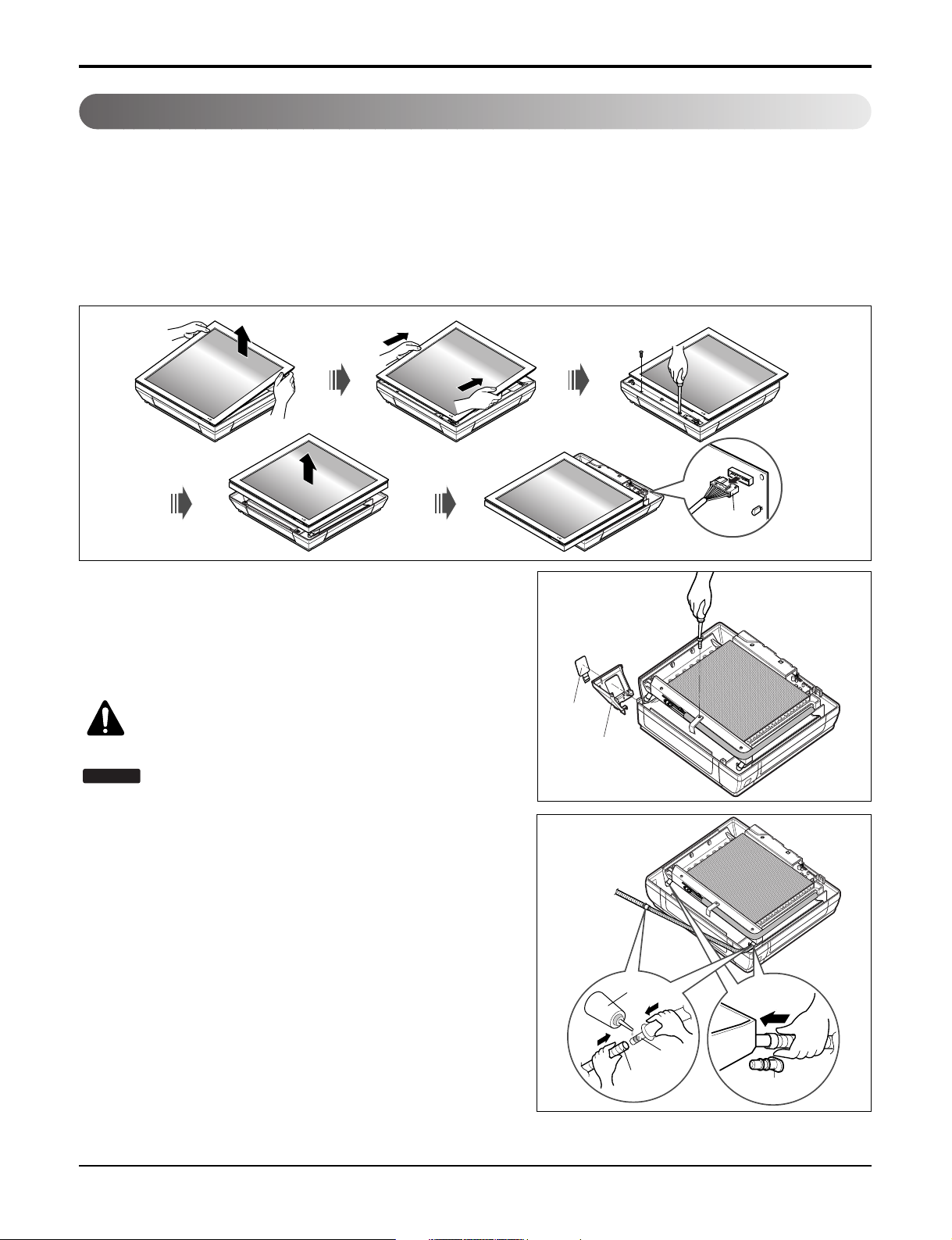

Preparing Work for Installation

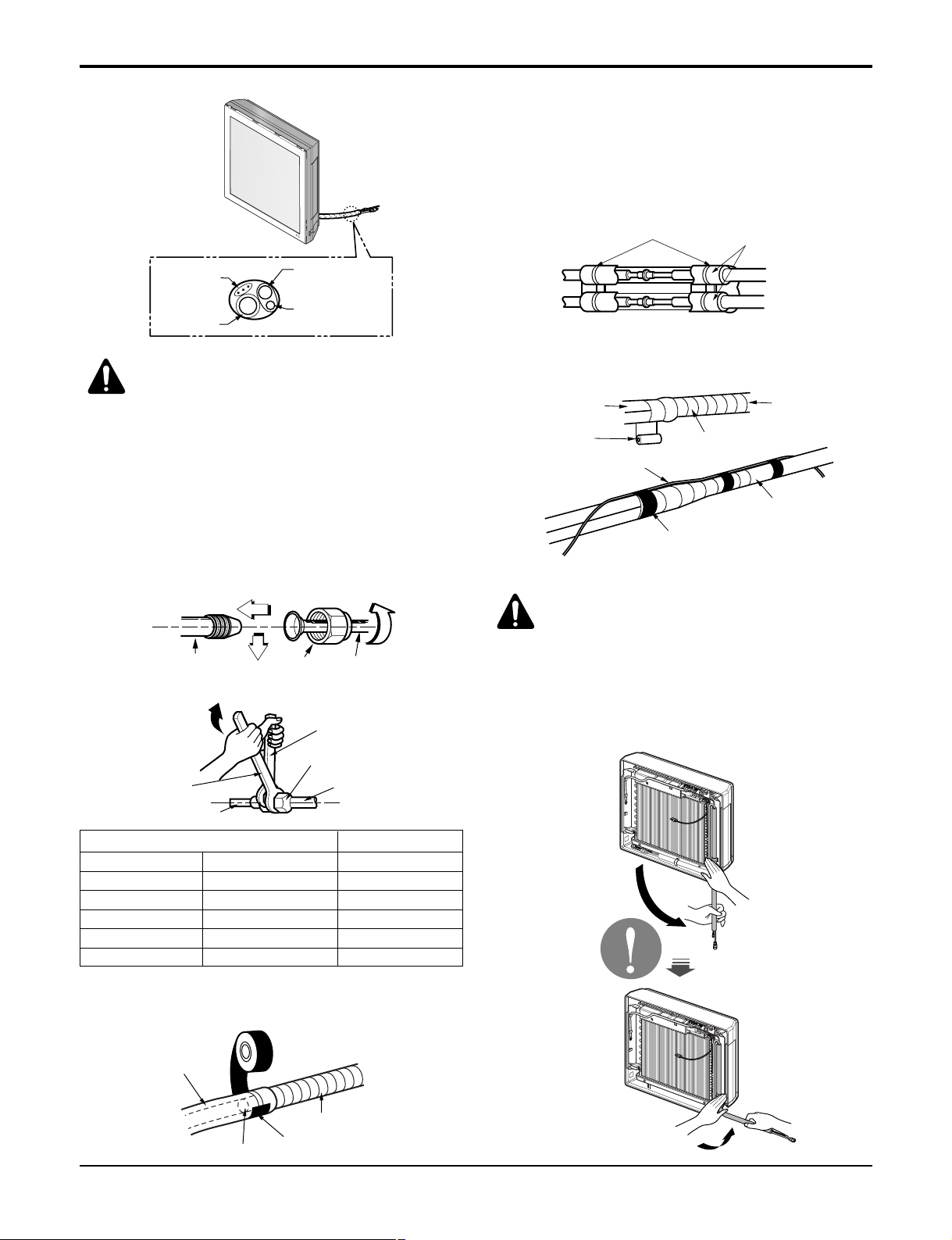

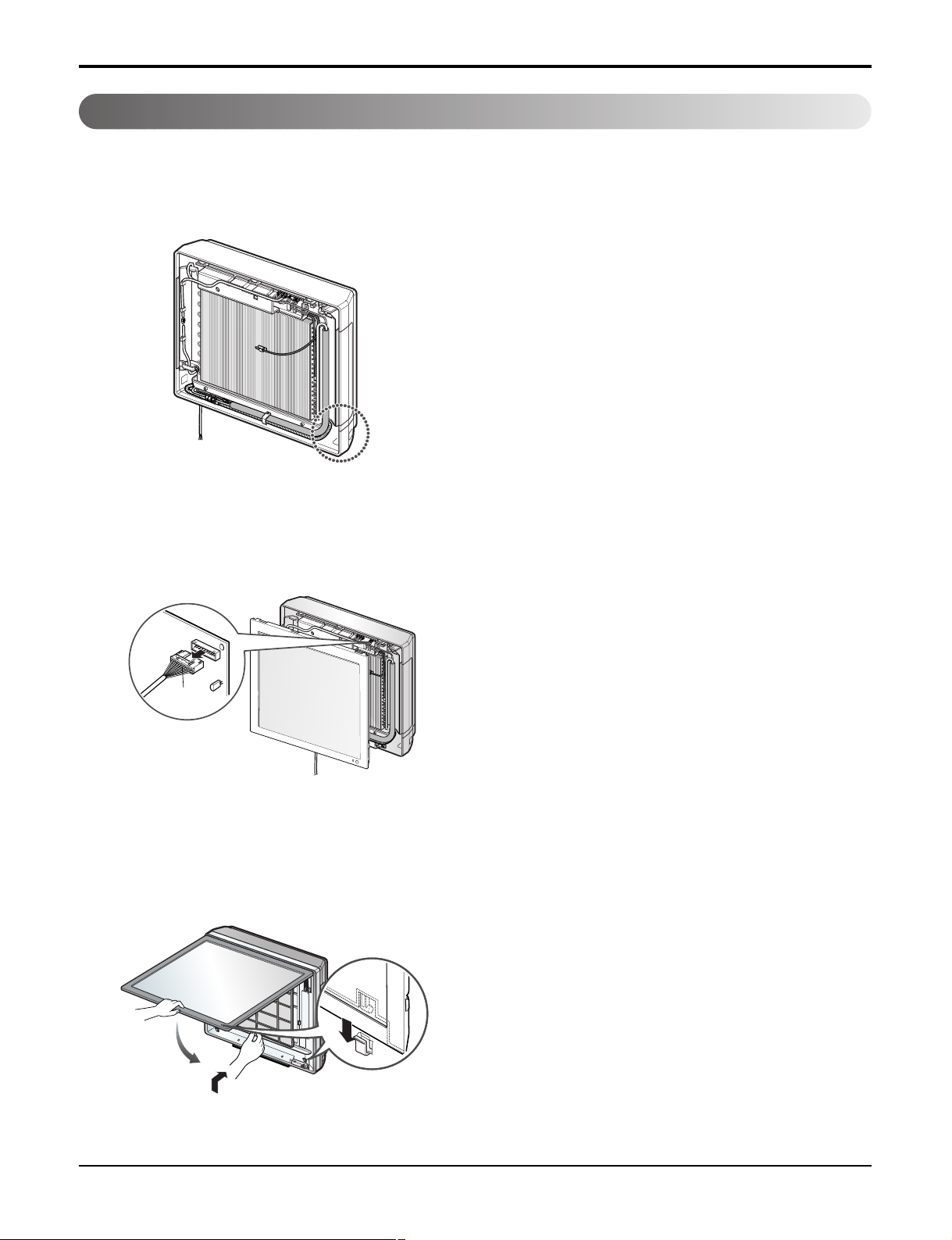

Open panel front

1. Pull the upper part of the front panel.

2. Lift up the panel.

3. To detach the front panel, remove the two screws at the lower part.

4. Detach the front panel from the body.

5. To detach the panel, disconnect the connector at the upper part.

Cover pipe and cover side remove

1. Please remove the screw of the center tuning cover.

2. Pull up the side cover of desired connecting direction, then

cover side is separated.

3. Pick the pipe hole of the side cover.

CAUTION: After removing the pipe hole, cut

the burr for safety.

When making pipe path through rear

wall, you don’t need to pick the pipe hole.

NOTICE

Drain hose junction

1. Remove the rubber stopple in the desired drain direction.

2. Insert drain hose into the handle of drain pan, and

join drain hose and connecting hose according to the

figure by.

Panel Front

Connector

Pipe hole

Side cover

Adhesive

Only the

Only the

desired direction

desired direction

Drain

hose

Connecting

part

rubber cap

14 Room Air Conditioner

Installation

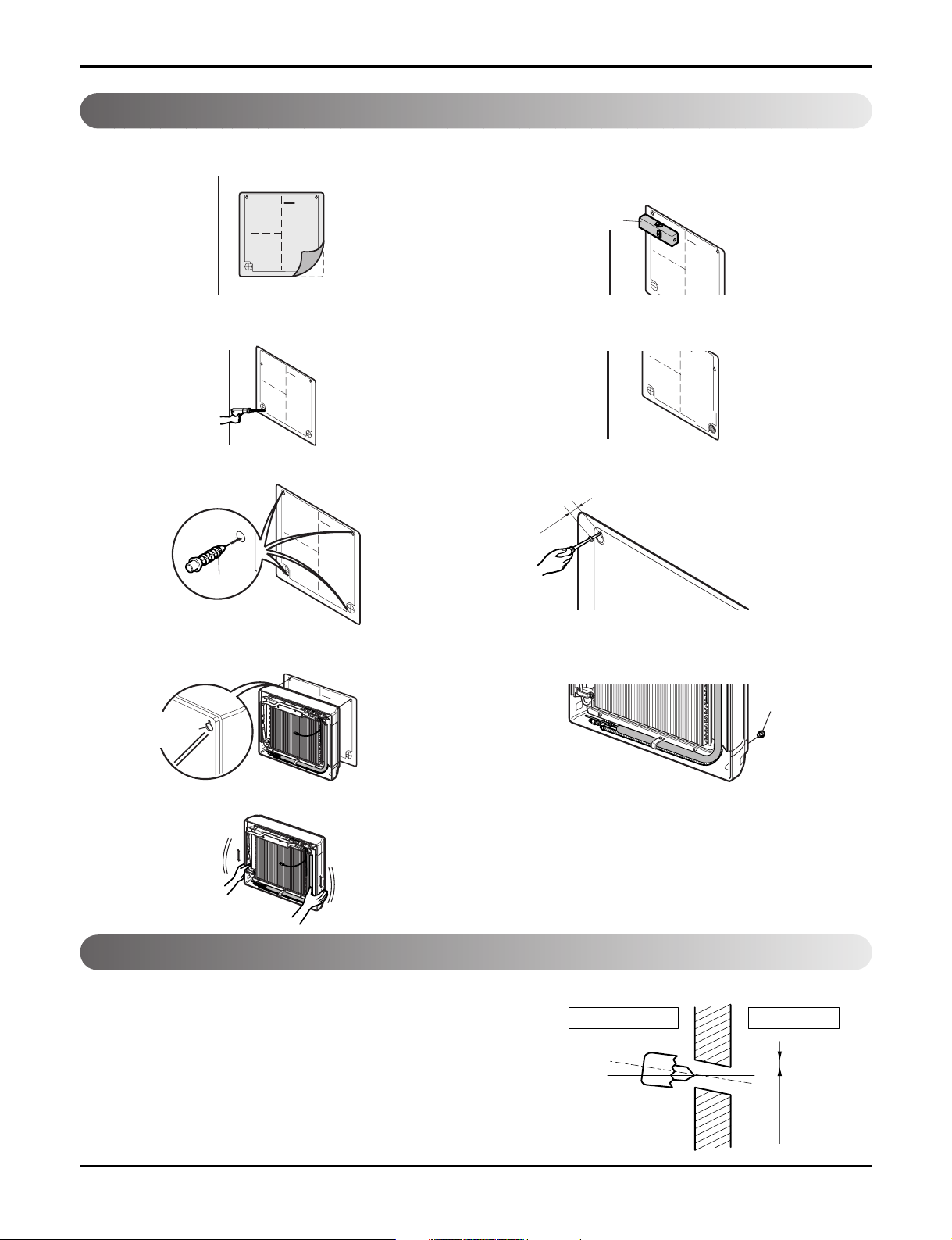

Fixing Indoor Unit

• Drill the piping hole with a ø50mm hole core drill.

Drill the piping hole at either the right or the left with

the hole slightly slanted to the outdoor side.

Drill a Hole in the Wall

5-7mm

(0.2~0.3")

Indoor

WALL

Outdoor

Plastic anchors

INSTALLATION GUIDE MAP

10mm

INSTALLATION GU

INSTAIIATION GUIDE MAP

Plastic anchors

INSTALLATION GUIDE MAP

INSTALLATION GUIDE MAP

Hanger hole

(Rear side of

the product)

3. Make a hole with a diameter of 6mm and

depth of 30-35mm by piercing a screw

point.

5. Drive the fore plastic anchors into drilled

points.

7. Hang the hole of product at the upper

screws, and remove the map. (Falling

attention)

9. Check the fixed product with light power.

1. Attach an Installation guide map on the

desired surface.

2. Look at suited horizon by horizontal

meter on the horizontal setting line, and

fix lightly the map by adhesive tape.

4.

Drill the pierted part as a diameter of 50mm

for connecting piping. (In case of piercing

rear surface)

6.

First, Drive the two points of the upper

parts by screws. (Leave 10mm for hanging

the product)

8. Drive the lower parts after facing the hole

of product with plastic anchors, and fix

completely the upper screws.

10.

In case of nothing wrong, connect the

pipe and the wire. (Refer to installation

manual)

I

NSTALLATION GUIDE MAP

Horizontality

Service Manual 15

Flaring work and connection of piping

Flaring work and connection of piping

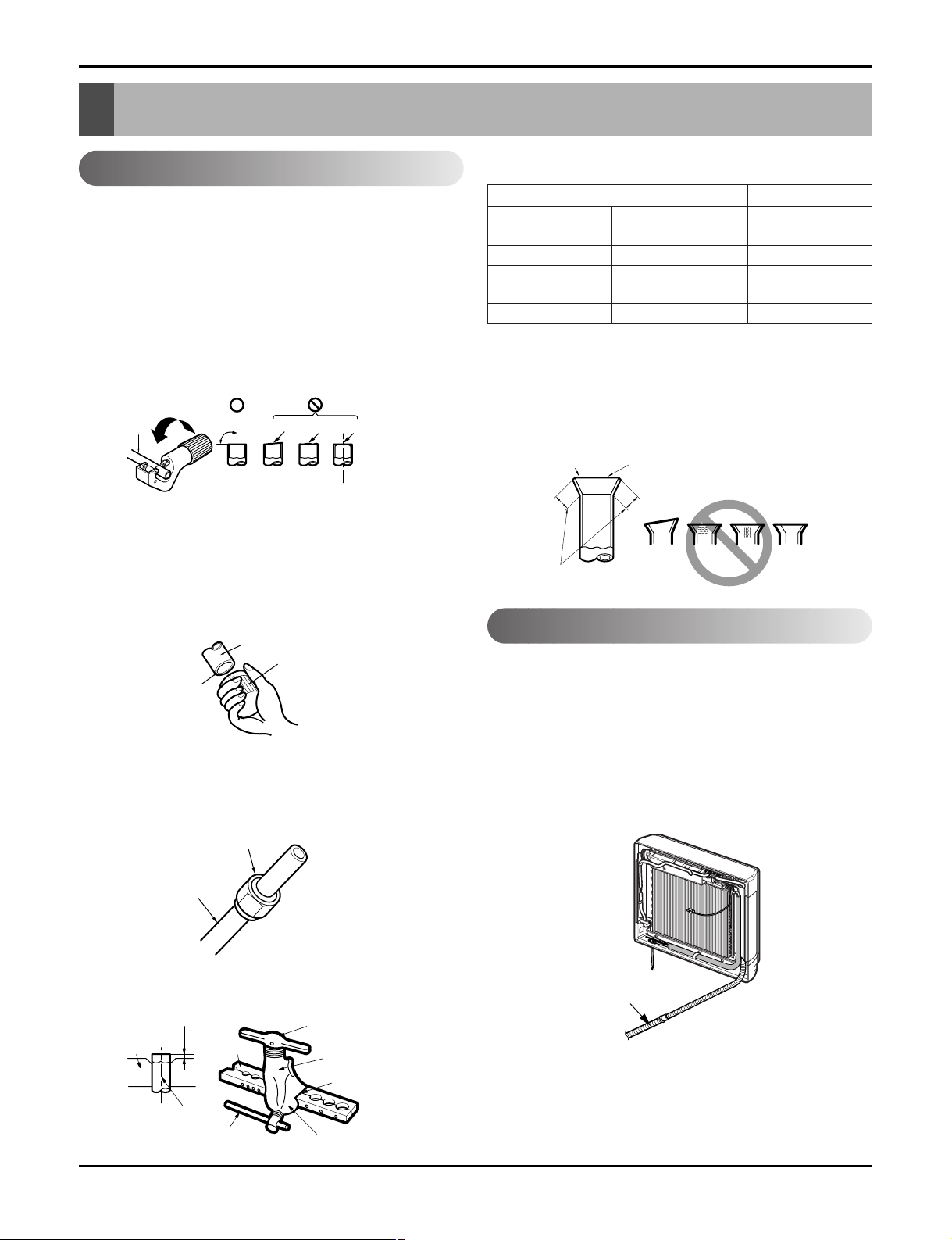

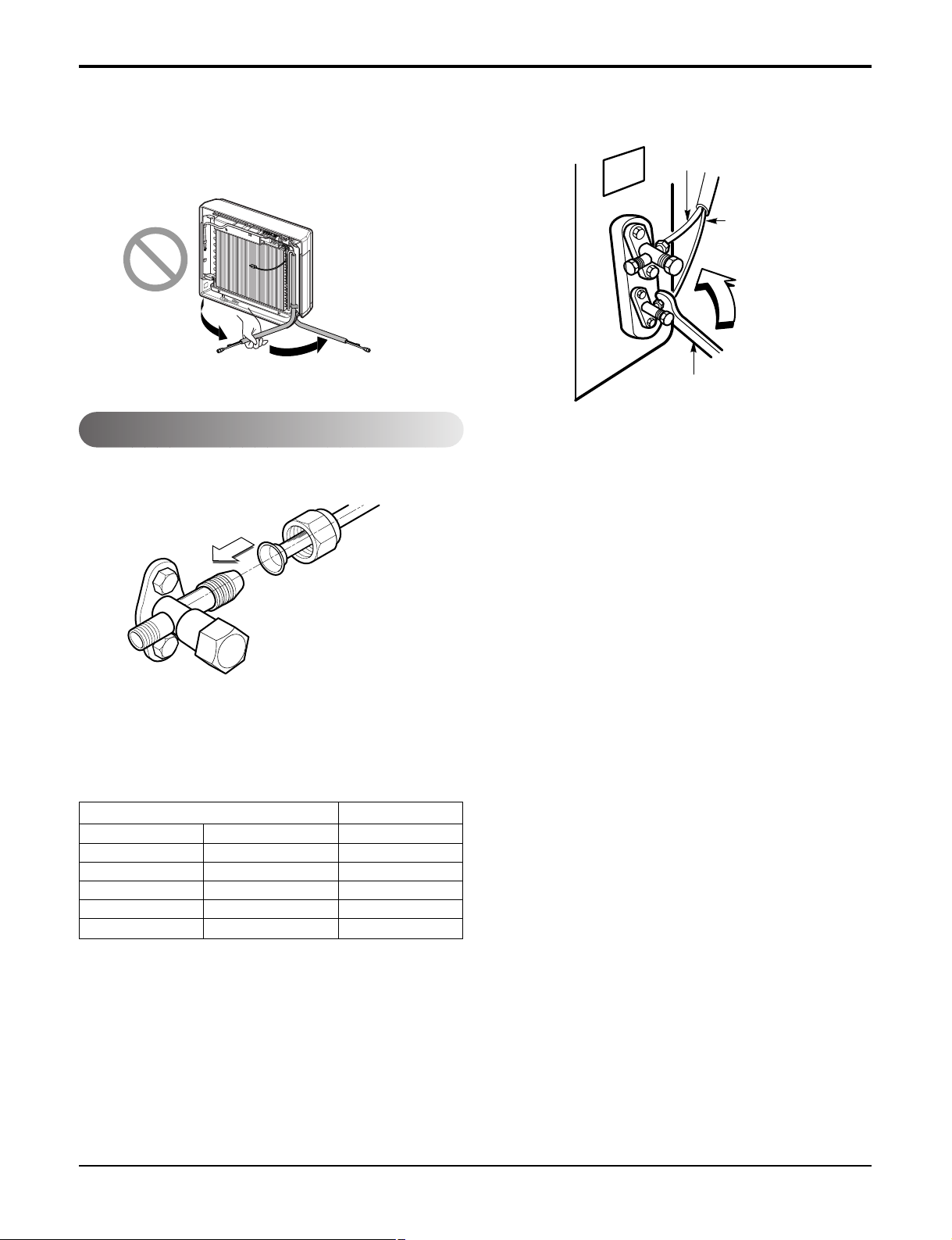

Flaring work

Flaring work

Main cause for refrigerant leakage is due to defect in the

flaring work. Carry out correct flaring work using the following procedure.

Cut the pipes and the cable.

• Use the piping kit accessory or pipes purchased locally.

• Measure the distance between the indoor and the outdoor unit.

• Cut the pipes a little longer than the measured distance.

• Cut the cable 1.5m longer than the pipe length.

Check

• Compare the flared work with figure below.

• If flare is noted to be defective, cut off the flared sec-

tion and re-flare it.

• Preparing the indoor unit's piping and drain hose for installation through the wall.

• Route the indoor tubing and the drain hose in the direction

of rear left or right

• Tape the tubing, drain hose and the connecting cable. Be

sure that the drain hose is located at the lowest side of the

bundle. Locating at the upper side can cause drain pan to

overflow inside the unit.

• Carry out flaring work using flaring tool as shown below.

Burr removal

• Completely remove all burrs from the cut cross section of

pipe/tube.

• Put the end of the copper tube/pipe in a downward direction as you remove burrs in order to avoid dropping burrs

into the tubing.

Putting nut on

• Remove flare nuts attached to indoor and outdoor unit,

then put them on pipe/tube having completed burr removal.

(not possible to put them on after flaring work)

Flaring work

• Firmly hold copper pipe in a die in the dimension shown in

the table above.

Bar

Copper pipe

Clamp handle

Red arrow mark

Cone

Yoke

Handle

Bar

"A"

Inclined

Inside is shiny without scratches

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Pipe

Reamer

Point down

Flare nut

Copper tube

Drain hose

mm inch mm

Ø6.35 1/4 0~0.5

Ø9.52 3/8 0~0.5

Ø12.7 1/2 0~0.5

Ø15.88 5/8 0~1.0

Ø19.05 3/4 1.0~1.3

Outside diameter A

Connection of piping -- Indoor

Copper

pipe

Slanted Uneven Rough

90°

16 Room Air Conditioner

Flaring work and connection of piping

Wrench

Indoor unit tubing

Open-end wrench (fixed)

Connection pipe

Flare nut

Indoor unit tubing Flare nut Pipes

Vinyl tape(narrow)

Adhesive

Drain pipe

Indoor unit drain hose

Plastic bands

Insulation material

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Vinyl tape

(wide)

Wrap with vinyl tape

Indoor

unit pipe

Pipe

Connecting the pipings to the indoor unit and

drain hose to drain pipe.

• Align the center of the pipes and sufficiently tighten

the flare nut by hand.

• Tighten the flare nut with a wrench.

• When extending the drain hose at the indoor unit, install the

drain pipe.

Wrap the insulation material around the connecting portion.

•Overlap the connection pipe insulation material and the

indoor unit pipe insulation material. Bind them together with

vinyl tape so that there is no gap.

• Wrap the area which accommodates the rear piping hous-

ing section with vinyl tape.

mm inch kg.m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

Outside diameter Torque

CAUTION: If the drain hose is routed inside

the room, insulate the hose with an insulation

material* so that dripping from

"sweating"(condensation) will not damage furniture or floors.

*Foamed polyethylene or equivalent is recommended.

Connecting

cable

Gas side piping

Liquid side piping

Drain hose

Loop

CAUTION: Installation Information

For right piping. Follow the instruction

below.

Good case

• Press on the upper side of clamp and unfold the tubing to downward slowly.

Service Manual 17

Flaring work and connection of piping

Bad case

• Following bending type from left to right may cause

damage to the turbing.

Align the center of the pipings and sufficiently

tighten the flare nut by hand.

Finally, tighten the flare nut with torque wrench

until the wrench clicks.

• When tightening the flare nut with torque wrench, ensure

the direction for tightening follows the arrow on the wrench.

Connection of the pipes-Outdoor

mm inch kg.m

Ø6.35 1/4 1.8

Ø9.52 3/8 4.2

Ø12.7 1/2 5.5

Ø15.88 5/8 6.6

Ø19.05 3/4 6.6

Outside diameter Torque

Outdoor unit

Gas side piping

(Bigger diameter)

Liquid side

piping

(Smaller

diameter)

Torque wrench

18 Room Air Conditioner

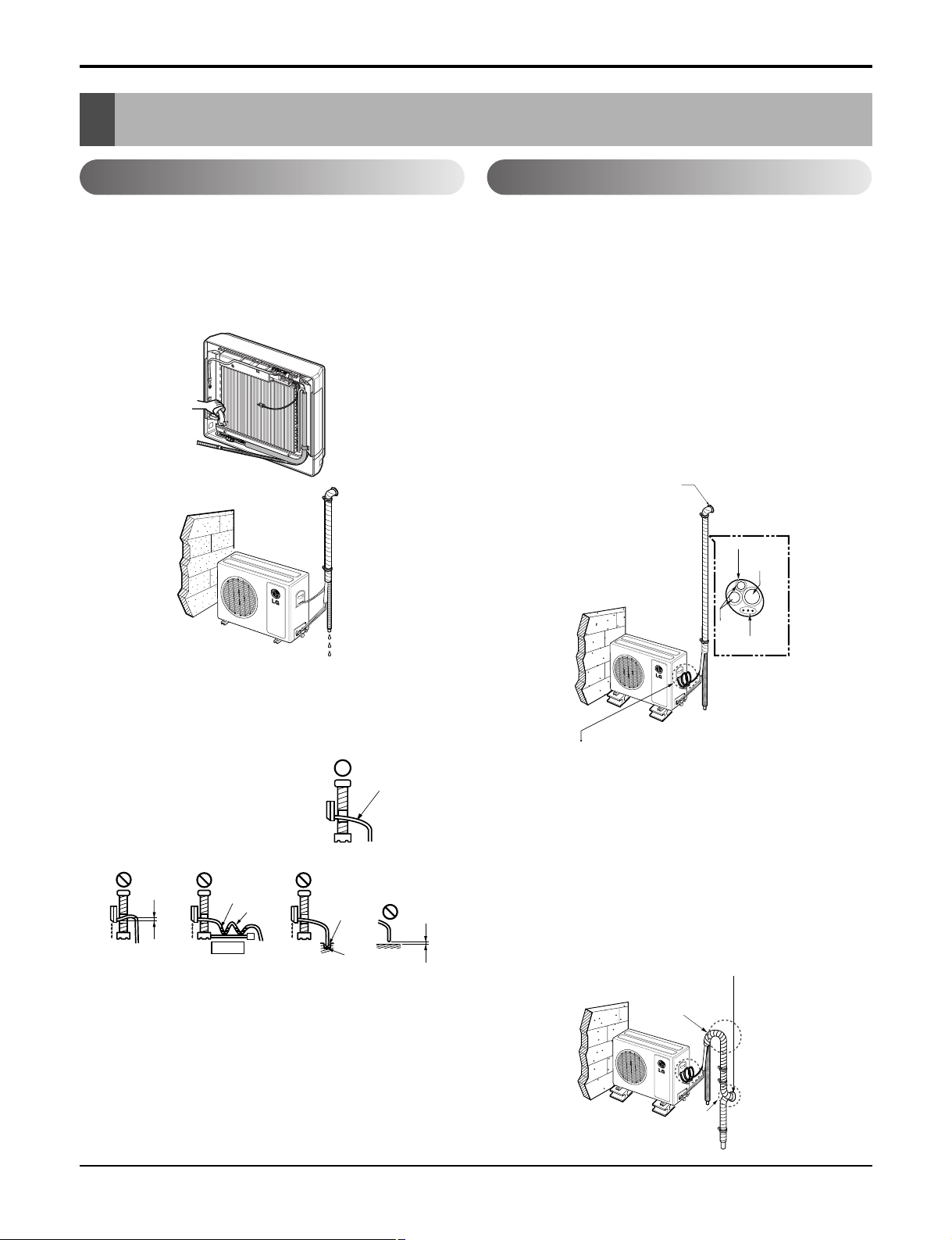

Checking the drainage and forming the pipings

Checking the drainage and forming the pipings

Checking the drainage Form the piping

To check the drainage.

• Pour a glass of water on the evaporator.

• Ensure the water flows through the drain hose of the indoor

unit without any leakage and goes out the drain exit.

Form the piping by wrapping the connecting

portion of the indoor unit with insulation material and secure it with two kinds of vinyl tapes.

• If you want to connect an additional drain hose, the end of

the drain outlet should be routed above the ground. Secure

the drain hose appropriately.

In cases where the outdoor unit is installed

below the indoor unit perform the following.

• Tape the piping, drain hose and connecting cable from

down to up.

• Secure the tapped piping along the exterior wall using saddle or equivalent.

In cases where the Outdoor unit is installed

above the Indoor unit perform the following.

• Tape the piping and connecting cable from down to up.

• Secure the taped piping along the exterior wall. Form a trap

to prevent water entering the room.

• Fix the piping onto the wall by saddle or equivalent.

Drain piping

• The drain hose should point downward for easy drain flow.

• Do not make drain piping.

Downward slope

Do not raise

Accumulated

drain water

Tip of drain hose

dipped in water

Air

Waving

Water

leakage

Water

leakage

Ditch

Less than

50mm gap

Water

leakage

Taping

Drain hose

Pipings

Connecting cable

Trap is required to prevent water

from entering electrical parts.

Seal small openings

around pipings with a

gum type sealer.

Seal a small opening

around the pipings

with gum type sealer.

Trap

Trap

Service Manual 19

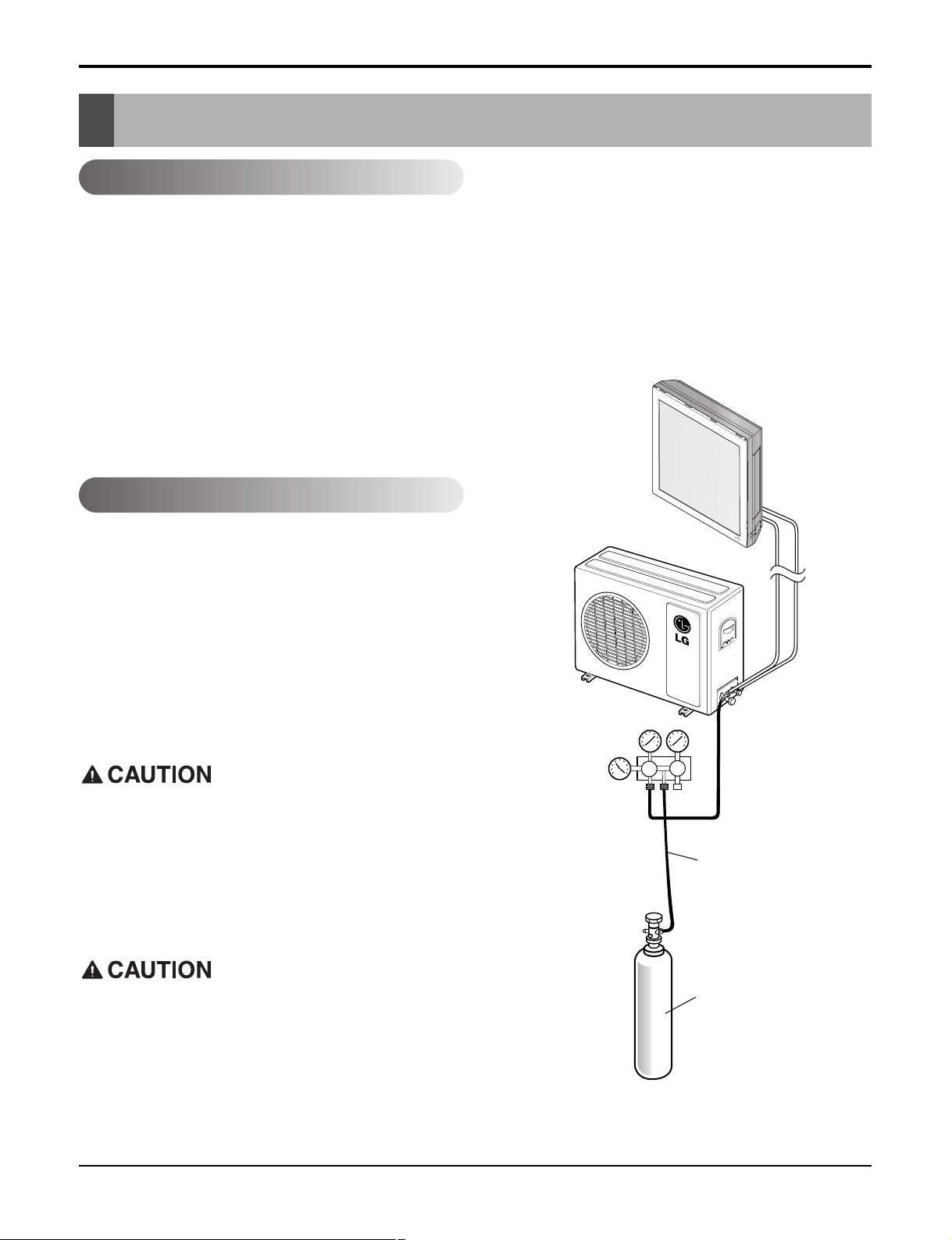

Air purging

Air and moisture remaining in the refrigerant system have

undesirable effects as indicated below.

• Pressure in the system rises.

• Operating current rises.

• Cooling(or heating) efficiency drops.

• Moisture in the refrigerant circuit may freeze and block cap-

illary tubing.

• Water may lead to corrosion of parts in the refrigeration

system.

Therefore, the indoor unit and tubing between the indoor and

outdoor unit must be leak tested and evacuated to remove

any noncondensables and moisture from the system.

• Do a leak test of all joints of the tubing(both indoor and outdoor) and both gas and liquid side service valves.

Bubbles indicate a leak. Be sure to wipe off the soap with a

clean cloth.

• After the system is found to be free of leaks, relieve the

nitrogen pressure by loosening the charge hose connector

at the nitrogen cylinder. When the system pressure is

reduced to normal, disconnect the hose from the cylinder.

Preparation

• Check that each tube(both liquid and gas side tubes)

between the indoor and outdoor units have been properly

connected and all wiring for the test run has been completed. Remove the service valve caps from both the gas and

the liquid side on the outdoor unit. Note that both the liquid

and the gas side service valves on the outdoor unit are

kept closed at this stage.

Leak test

• Connect the manifold valve(with pressure gauges) and dry

nitrogen gas cylinder to this service port with charge hoses.

• Pressurize the system to no more than 150 P.S.I.G. with

dry nitrogen gas and close the cylinder valve when the

gauge reading reached 150 P.S.I.G. Next, test for leaks

with liquid soap.

Air Purging

Air purging

Air purging with vacuum pump

Be sure to use a manifold valve for air purging. If it is not

available, use a stop valve for this purpose. The "Hi" knob

of the manifold valve must always be kept close.

To avoid nitrogen entering the refrigerant system in a liquid

state, the top of the cylinder must be higher than its bottom

when you pressurize the system. Usually, the cylinder is

used in a vertical standing position.

Lo Hi

Indoor unit

Outdoor unit

Manifold valve

Charge hose

Nitrogen gas

cylinder(in vertical

standing position)

Pressure

gauge

20 Room Air Conditioner

Air purging

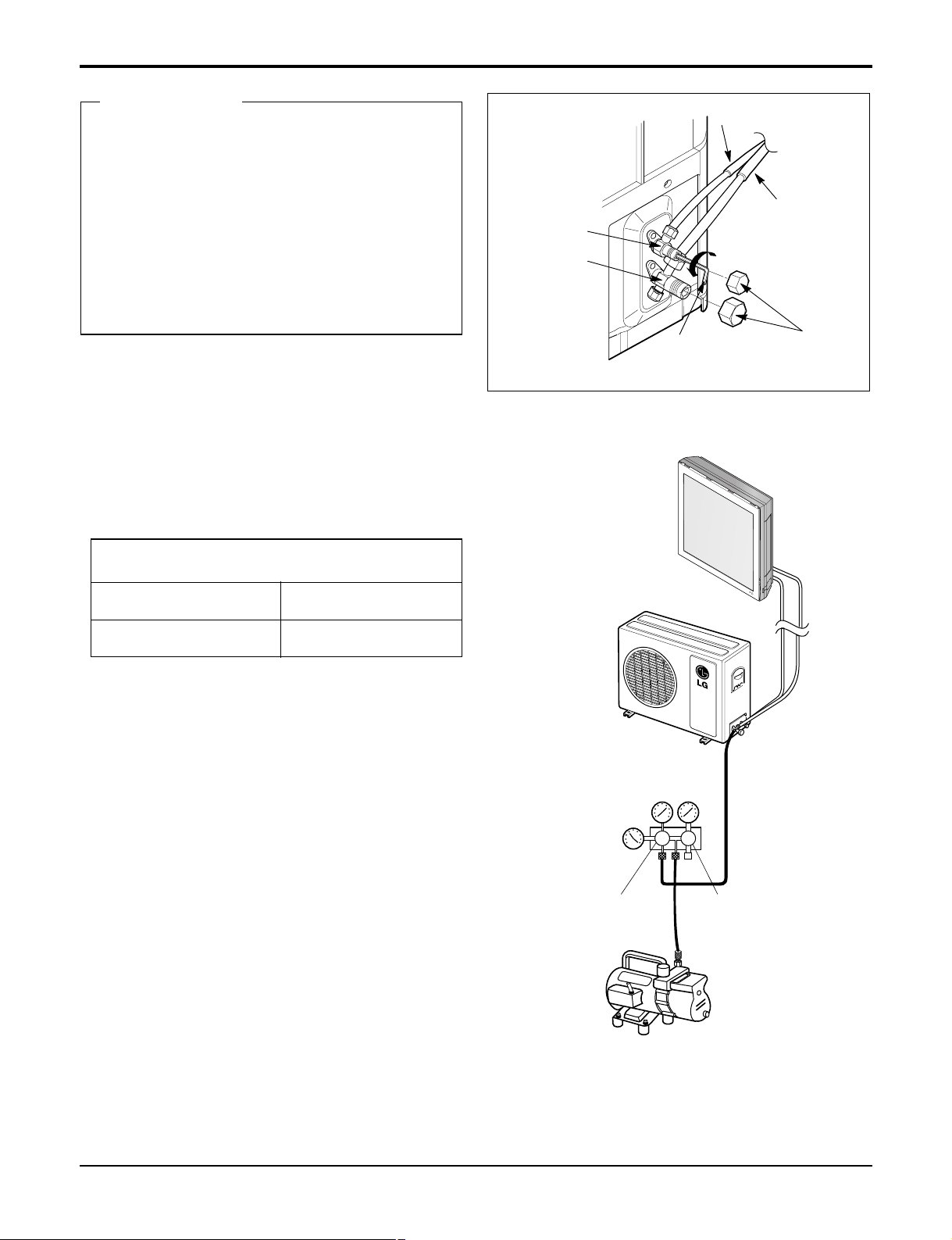

Evacuation

• Connect the charge hose end described in the preceding

steps to the vacuum pump to evacuate the tubing and

indoor unit.

Confirm the "Lo" knob of the manifold valve is open. Then,

run the vacuum pump.

The operation time for evacuation varies with tubing length

and capacity of the pump. The following table shows the

time required for evacuation.

• When the desired vacuum is reached, close the "Lo" knob

of the manifold valve and stop the vacuum pump.

Finishing the job

• With a service valve wrench, turn the valve stem of liquid

side valve counter-clockwise to fully open the valve.

• Turn the valve stem of gas side valve counter-clockwise to

fully open the valve.

• Loosen the charge hose connected to the gas side service

port slightly to release the pressure, then remove the hose.

• Replace the flare nut and its bonnet on the gas side service

port and fasten the flare nut securely with an adjustable

wrench. This process is very important to prevent leakage

from the system.

• Replace the valve caps at both gas and liquid side service

valves and fasten them tight.

This completes air purging with a vacuum pump.

The air conditioner is now ready to test run.

(1) Remove the caps from the 2-way and 3-way valves.

(2) Remove the service-port cap from the 3-way valve.

(3) To open the 2-way valve turn the valve stem counter-

clockwise approximately 90°, wait for about 2~3 sec, and

close it.

(4) Apply a soap water or a liquid neutral detergent on the

indoor unit connection or outdoor unit connections by a

soft brush to check for leakage of the connecting points

of the piping.

(5) If bubbles come out, the pipes have leakage.

Soap water method

Gas side

Liquid side

Cap

Hexagonal wrench

2-way valve

(Open)

3-way valve

(Close)

Required time for evacuation when 30 gal/h vacuum

pump is used

10 min. or more 15 min. or more

If tubing length is less than 10m (33 ft)

if tubing length is longer than 10m (33 ft)

Indoor unit

Outdoor unit

Lo Hi

Manifold valve

Vacuum pump

Pressure

gauge

Open

Close

Service Manual 21

Air purging

1. First, Check the side cover assembly exactly, and fix

the power cord in the bottom groove of cover side

left.

2. Assemble connecting lead wire with controller, fix the

upper part of panel front, and match the lower part of

panel front.

3. Screw up panel front, and suspend the hook of panel

front in the groove.

Panel Front

Connector

Panel Front Assembly

22 Room Air Conditioner

Test running

Test Running

1. Check that all tubing and wiring have been properly

connected.

2. Check that the gas and liquid side service valves are

fully open.

Prepare remote controller

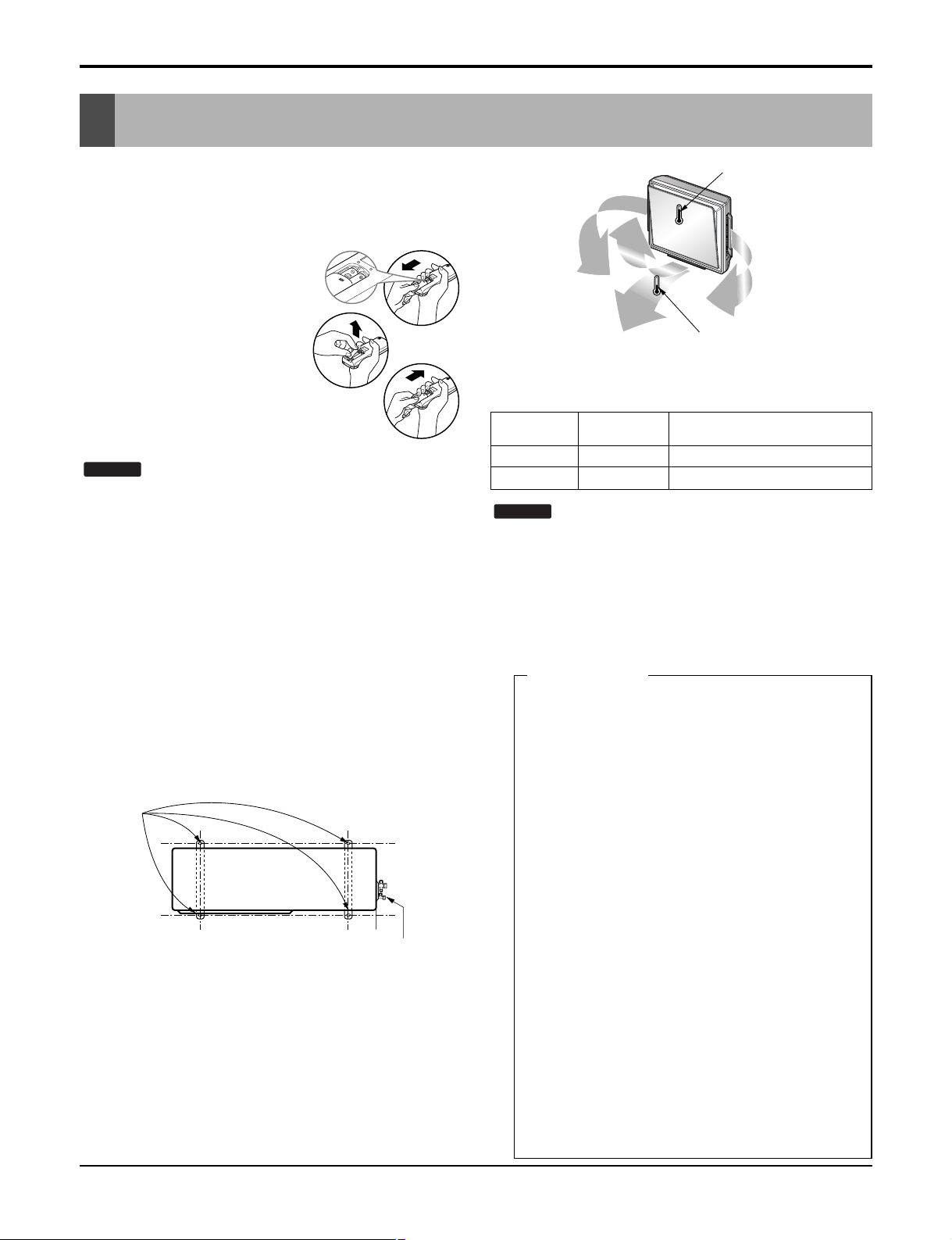

1. Remove the battery cover

by pulling it according to the

arrow direction.

2. Insert new batteries making

sure that the (+) and (–) of

battery are installed correctly.

3. Reattach the cover by

pushing it back into position.

• Use 2 AAA(1.5volt) batteries. Do not use

rechargeable batteries.

• Remove the batteries from the remote

control if the system is not going to be

used for a long time.

Settlement of outdoor unit

• Anchor the outdoor unit with a bolt and

nut(ø10mm) tightly and horizontally on a concrete

or rigid mount.

• When installing on the wall, roof or rooftop, anchor

the mounting base securely with a nail or wire

assuming the influence of wind and earthquake.

• In the case when the vibration of the unit is conveyed to the hose, secure the unit with an antivibration bushing.

Evaluation of the performance

Operate unit for 15~20 minutes, then check the system

refrigerant charge:

1. Measure the pressure of the gas side service valve.

2. Measure the temperature of the intake and discharge

of air.

3. Ensure the difference between the intake temperature and the discharge is more than 8°C(46°F)

(Cooling) or (Heating).

4. For reference; the gas side pressure of optimum

condition is as below.(Cooling)

If the actual pressure is higher than shown,

the system is most likely over-charged, and

charge should be removed. If the actual pressure are lower than shown, the system is

most likely undercharged, and charge should

be added.

The air conditioner is now ready for use.

NOTICE

NOTICE

Bolt

Tubing connection

Discharge

temperature

Discharge air

Intake temperature

R-22 35°C (95°F) 4~5kg/cm2G(56.8~71.0 P.S.I.G.)

R-410A 35°C (95°F) 8.5~9.5kg/cm

2

G(120~135 P.S.I.G.)

Outside ambient

TEMP.

Refrigerant

The pressure of the gas side

service valve.

This is performed when the unit is to be relocated

or the refrigerant circuit is serviced.

Pump Down means collecting all refrigerant in the

outdoor unit without loss in refrigerant gas.

CAUTION:

Be sure to perform Pump Down procedure with the

unit cooling mode.

Pump Down Procedure

1. Connect a low-pressure gauge manifold hose to

the charge port on the gas side service valve.

2. Open the gas side service valve halfway and purge

the air from the manifold hose using the refrigerant

gas.

3. Close the liquid side service valve(all the way in).

4. Turn on the unit's operating switch and start the

cooling operation.

5. When the low-pressure gauge reading becomes 1

to 0.5kg/cm2 G(14.2 to 7.1 P.S.I.G.), fully close the

gas side valve stem and then quickly turn off the

unit. At that time, Pump Down has been completed

and all refrigerant gas will have been collected in

the outdoor unit.

PUMP DOWN

Loading...

Loading...