Page 1

INSTALLATION MANUAL

AIR

CONDITIONER

ENGLISH FRANÇAIS

ESPAÑOL

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

Vertical Air Handling Unit

http://www.lghvac.com

www.lg.com

P/NO : MFL65003102

Copyright © 2010 - 2018 LG Electronics Inc. All Rights Reserved.

Page 2

IMPORTANT!

Please read this instruction sheet completely before installing the product.

This air conditioning system meets strict safety and operating standards. As the installer or service person,

it is an important part of your job to install or service the system so it operates safely and efficiently.

WARNING

• Installation or repairs made by unqualified persons can result in hazards to you and others.

Installation of all field wiring and components MUST conform with local building codes or, in the absence of local

codes, with the National Electrical Code 70 and the National Building Construction and Safety Code or Canadian

Electrical code and National Building Code of Canada.

• The information contained in the manual is intended for use by a qualified service technician familiar with safety

procedures and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction, property

damage, personal injury and/or death.

CAUTION

Safety Precautions

NOTE TO INSTALLING DEALER: The Owners Instructions and Warranty are to be given to the owner

:

Improper installation, adjustment, alteration, service or maintenance can void the warranty.

The weight of the condensing unit requires caution and proper handling procedures when lifting

or moving to avoid personal injury. Use care to avoid contact with sharp or pointed edges.

• Always wear safety eye wear and work gloves when installing equipment.

• Never assume electrical power is disconnected. Check with meter and equipment.

• Keep hands out of fan areas when power is connected to equipment.

• R-410A causes frostbite burns.

• R-410A is toxic when burned.

or prominently displayed near the indoor Furnace/Air Handler Unit.

Special warnings

When wiring:

Electrical shock can cause severe personal injury or death. Only a qualified,

experienced electrician should attempt to wire this system.

• Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

•

•

The choice of materials and installations must comply with the applicable local/national or international standards.

When transporting:

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and

bend your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum fins on

the air conditioner can cut your finger.

When installing...

... in a wall: Make sure the wall is strong enough to hold the unit's weight.

... in a room: Properly insulate any tubing run inside a room to prevent "sweating" that can cause

... in moist or uneven locatinons: Use a raised concrete pad or concrete blocks provide a solid,

... in an area with high winds: Securely anchor the outdoor unit down with bolts and a metal

... in a snowy area(for Heat Pump Model): Install the outdoor unit on a raised platform that is

When connecting refrigerant tubing

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Check carefully for leaks before starting the test run.

When servicing

• Turn the power OFF at the main power box(mains) before opening the unit to check or repair

electrical parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being serviced.

It may be necessary to construct a strong wood or metal frame to provide added support.

dripping and water damage to wall and floors.

level foundation for the outdoor unit. This prevents water damage and abnormal vibration.

frame. Provide a suitable air baffle.

higher than drifting snow. Provide snow vents.

2 Vertical Air Handling Unit

Page 3

Vertical Air Handling Unit Installation Manual

TABLE OF CONTENTS

ENGLISH

Installation Requirements

Features.....................................4

Accessories ..............................4

Duct Connection Dimensions ...5

Safety Precautions ...................6

Installation.................................8

Selection of the best location....8

Upflow Installation ....................9

Duct work................................10

Horizontal-left Installation .......11

Connecting Pipes to the Indoor

Unit .........................................12

Preparation of Piping..............12

Plumbing materials and storage

methods..................................14

Insulation ................................16

Condensate Drain...................17

Wiring Connection ..................19

Electric Heater........................22

Dip Switch Setting of Indoor unit

PCB ........................................23

Group Control Setting.............24

Product Data ...........................28

External Static Pressure & Air

Flow........................................28

Minimum airflow by heater

capacity ..................................29

Electric Heater Static pressure

drop factors.............................29

Air Filter (Field supply) Static

pressure drop factors..............30

Required Parts Required Tools

o Level gauge

o Screw driver

o Electric drill

o Four type "A" screws

o Pipes: Gas side

Liquid side (Refer to

Product Data)

o Insulation materials

o Additional drain pipe

o Hole core drill

o Hexagonal wrench

o Gas-leak detector

o Vacuum pump

o Gauge manifold

o Owner's manual

o Thermometer

o Electric Heater installation

manual

Installation Manual 3

Page 4

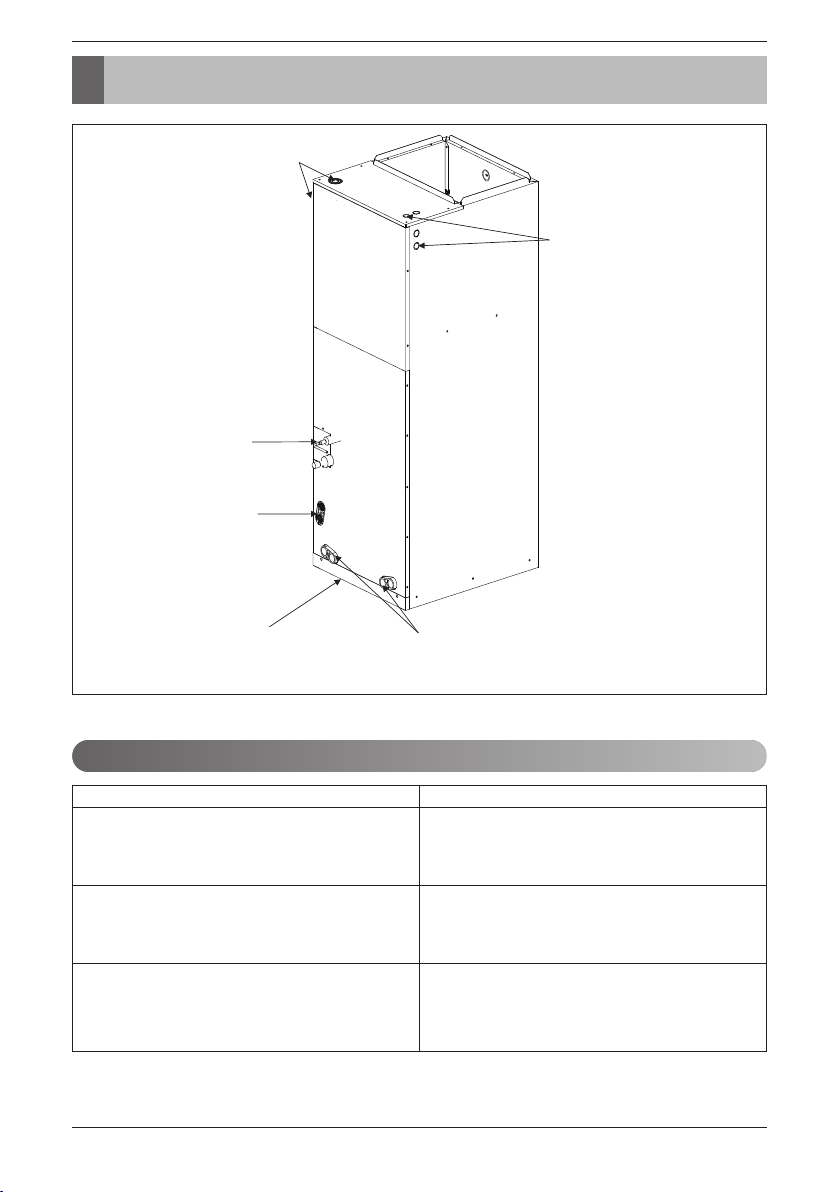

Feature

Features

Wiring knockouts

for conduit

Wiring knockouts

for conduit

Refrigerant

connections

Drain connections

for horizontal

application

Filter access

Accessories

Accessory Model Name

Wired remote controller

Wireless remote controller

Electric heater

4 Vertical Air Handling Unit

Drain connections for

upflow application

PQRCVSL0 (Black Color)

PQRCVSL0QW (White Color)

PQWRCDF0 (Cooling only)

PQWRHDF0 (Heat pump)

ANEH053B1

ANEH103B2

ANEH153B2

ANEH203B2

Page 5

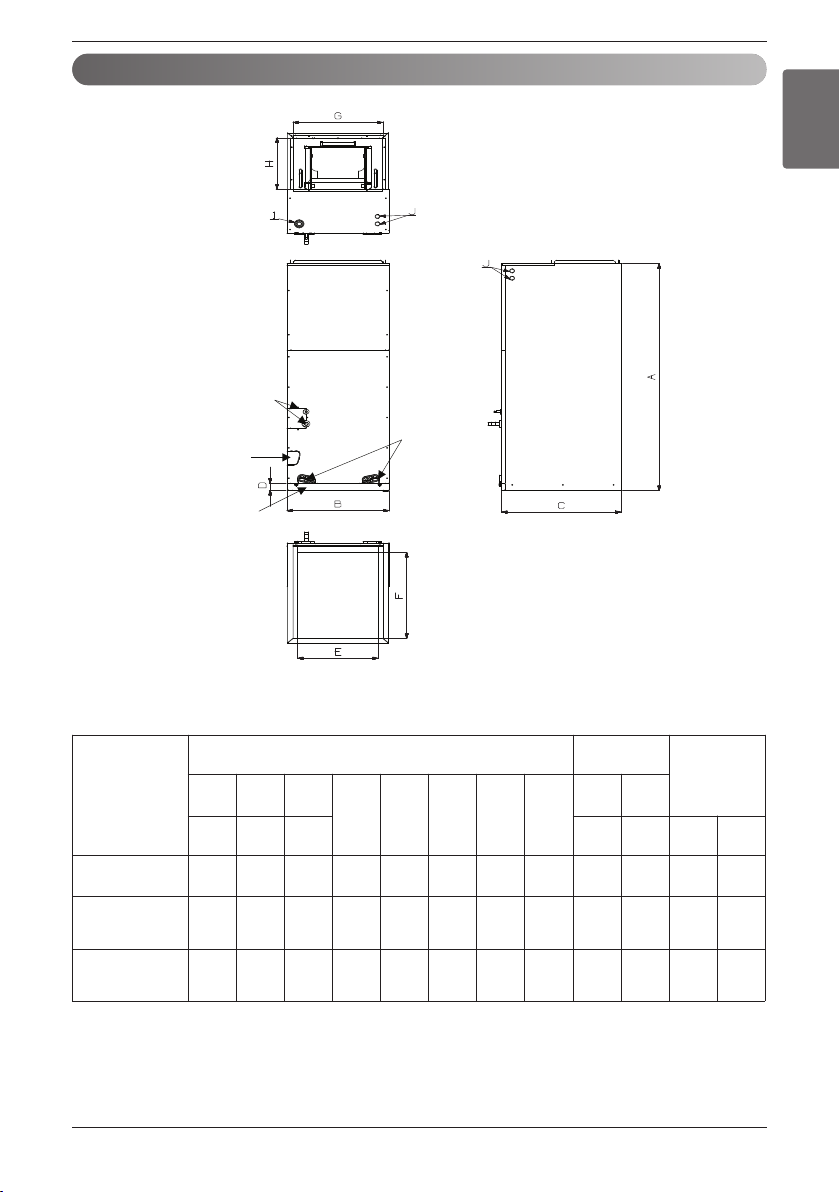

Feature

Duct Connection Dimensions

<Top>

Refrigerant

connections

Drain connections

for horizontal

application

Air filter cover

<Front>

Drain

connections

for upflow

application

ENGLISH

<Side-right>

Capacity

(kBtu/h (RT))

12(1.0)

18(1.5)

24(2.0)

30(2.5)

36(3.0)

42(3.5)

48(4.0)

54(4.5)

<Bottom>

Dimensions

A B C

Knock out

I J

D E F G H

Height Width Depth Power

48-5/8

(1236)18(457)

48-5/8

(1236)18(457)

55-1/8

(1401)25(635)

21-3/8

(540)

21-3/8

(540)

21-3/8

(540)

1-9/16

17-1/2

(40)

(445)20(530)17(432)

1-9/16

17-1/2

(40)

(445)20(530)17(432)

1-9/16

24-1/2

(40)

(623)20(530)24(610)

12-1/8

(308)

12-1/8

(308)

12-1/8

(308)

1-11/16

(43)

1-11/16

(43)

1-11/16

(43)

(Unit: inch(mm))

Wiring

Commu

nication

7/8

(22)

7/8

(22)

7/8

(22)

Refrigerant

Connections

Pipe size

Liquid Gas

1/4

1/2

(6.35)

(12.7)

3/8

5/8

(9.52)

(15.88)

3/8

5/8

(9.52)

(15.88)

Installation Manual 5

Page 6

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be followed.

n Be sure to read before installing the air conditioner.

n Be sure to observe the cautions specified here as they include important items related to safety.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the

following indications.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

n Meanings of symbols used in this manual are as shown below.

Be sure not to do.

Be sure to follow the instruction.

Installation

• Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated circuit.

- There is risk of fire or electric shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized Service

Center.

- Do not disassemble or repair the product. There is risk of fire or electric shock.

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

• Do not let the air conditioner run for a long time when the humidity is very high and a door or a window is left open.

- Moisture may condense and wet or damage furniture.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the case edges and the fins on the con-

denser and evaporator.

• For installation, always contact the dealer or an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the air conditioner could fall with it, causing property damage, product failure,

and personal injury.

6 Vertical Air Handling Unit

Page 7

Safety Precautions

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge. Do not compress

air or Oxygen and do not use Flammable gases. Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

Operation

• Do not store or use flammable gas or combustibles near the product.

- There is risk of fire or failure of product.

Installation

• Always check for gas (refrigerant) leakage after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Install the drain hose to ensure that water is drained away properly.

- A bad connection may cause water leakage.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Do not install the product where the noise or hot air from the outdoor unit could damage the neighborhoods.

- It may cause a problem for your neighbors.

• Use two or more people to lift and transport the product.

- Avoid personal injury.

• Do not install the product where it will be exposed to sea wind (salt spray) directly.

- It may cause corrosion on the product. Corrosion, particularly on the condenser and evaporator

fins, could cause product malfunction or inefficient operation.

• If you eat the liquid from the batteries, brush your teeth and see doctor. Do not use the remote if the

batteries have leaked.

- The chemicals in batteries could cause burns or other health hazards.

• Safely dispose of the packing materials.

- Packing materials, such as nails and other metal or wooden parts, may cause stabs or other

injuries.

- Tear apart and throw away plastic packaging bags so that children may not play with them. If chil-

dren play with a plastic bag which was not torn apart, they face the risk of suffocation.

ENGLISH

Installation Manual 7

Page 8

Installation

Installation

Selection of the best location

• Where optimum air distribution can be ensured.

• Where nothing blocks air passage and install the duct work.

• Where condensate can be properly drained.

• Where the ceiling is strong enough to bear the indoor unit weight.

• Where the false ceiling is not noticeably on an incline.

• Where sufficient clearance for maintenance and service can be ensured.

• Where piping between indoor and outdoor units is possible within the allowable limit. Refer to the

installation manual for the outdoor unit.

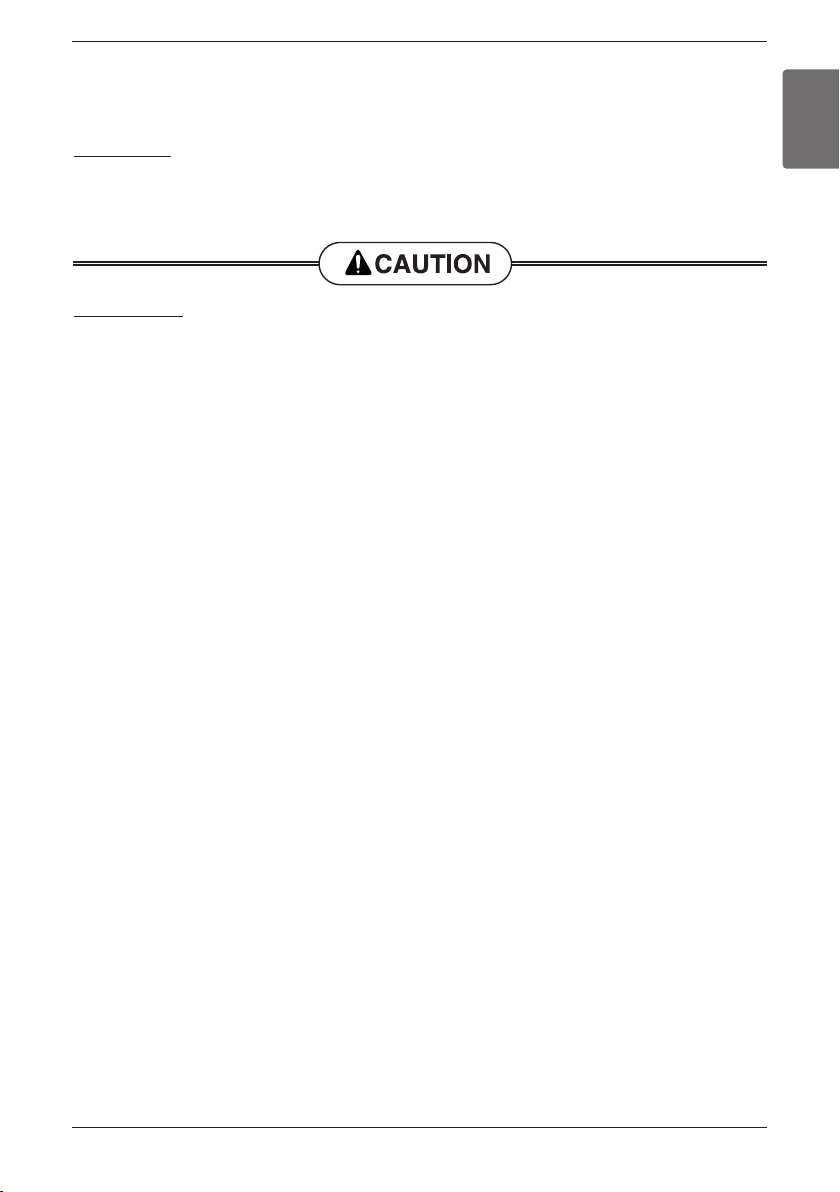

• Vertical Air Handling Unit can be installed for upflow and horizontal-left positions.

More than

350(13-25/32)

More than

600(23-5/8)

clearance from

access panels

for Service

More than

350(11-25/32)

NOTE : The primary and secondary drain line must be trapped to allow proper drainage of condensate

water, If the secondary drain line is not used, it must be capped.

In the case of sea coast installation, salt residue may cause corrosion of cabinet and component

parts. Please take appropriate anti-corrosion measures.

8 Vertical Air Handling Unit

More than

250(9-27/32)

More than

250(9-27/32)

Unit: mm (inch)

Page 9

Installation

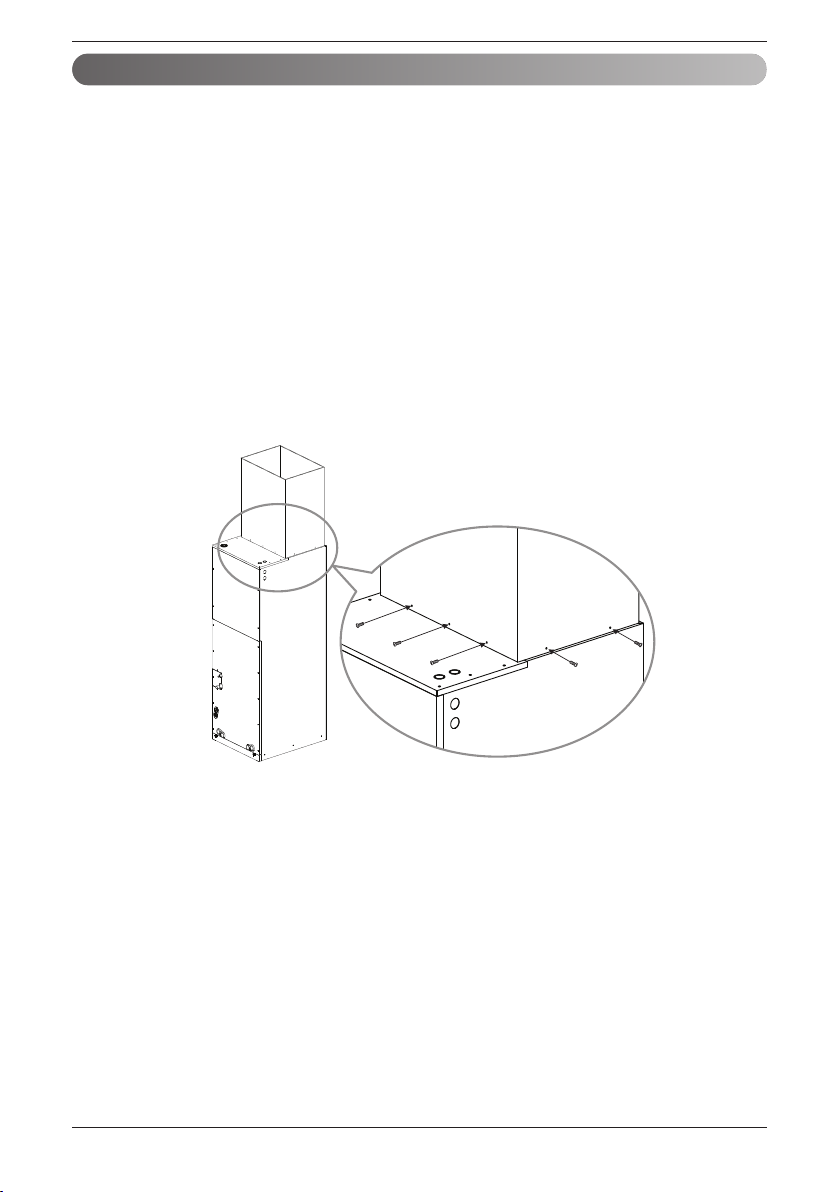

Upflow Installation

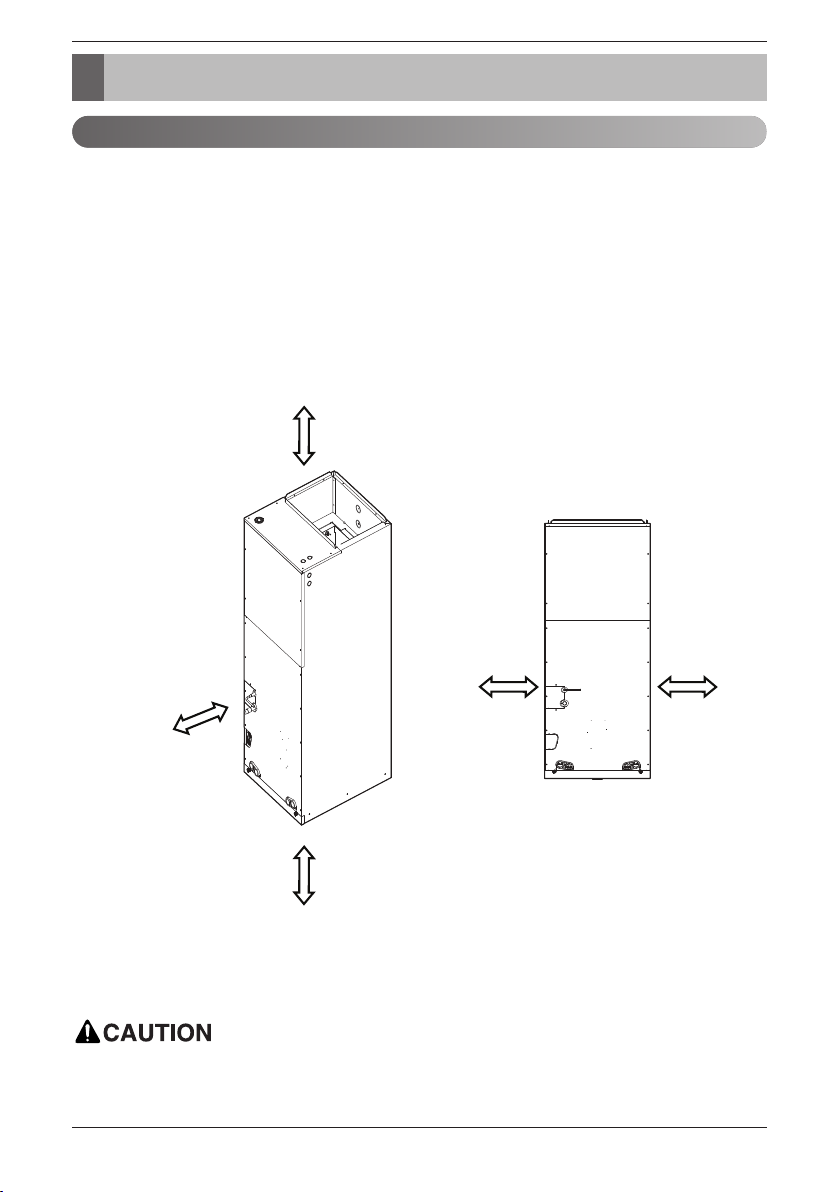

• Position unit for plenum installation.

• The plenum should be secured in order to support the installation of adapter callers accommodate the

installation of any duct work.

• Seal all duct work according to local codes to prevent air leakage. Ensure that filter access is unobstructed.

• The air handler support platform should be sturdy enough to support the cabinet plus any accessory

components including filter box.

• The minimum height clearance is 14inches(350mm) to maintain proper air flow.

• Vibration isolators (purchased locally) must be placed between the unit and the pedestal.

• An illustration showing an example of where a vibration isolator should be added would clarify what

the installing contractor should do to properly position the isolator.

Field Supplied

Supply Duct

Field

Supplied Return

Plenum

ENGLISH

More than

1inch (25mm)

More than 6 screws (M4*25L)

Do not connect the screws on Front and Rear side, it may cause the filter can not be mounted.

Installation Manual 9

Page 10

Installation

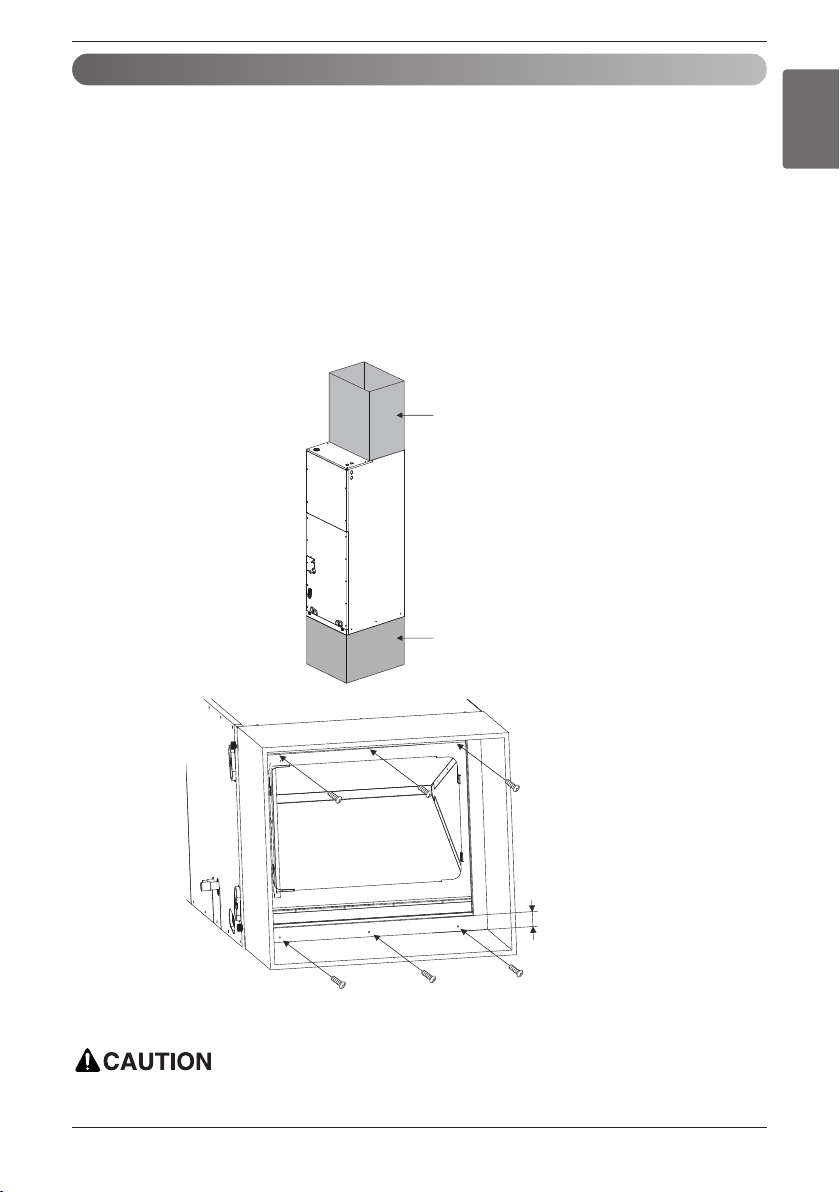

Duct work

• Over 10 screws should be used for joining supply duct with the unit.

• To prevent vibration transmission, exploit flexible connectors between duct and the unit. It is mandatory that the flexible connector between unit and duct at discharge connection should be made off heat

resistive material when electric heater is installed.

• Duct work must be insulated and covered with vapor barrier when routed through unconditioned

space.

• Internal acoustical insulation lining may necessary for the metal duct system if it do not have 90°

elbow and 10ft. of main duct to first branch takeoff.

• It is advised that a fibrous duct work could be used as a substitute if built and installed in accordance

with the most recent edition of SMACNA construction standard on fibrous glass ducts.

• Collectively fibrous duct work and acoustical lining shall obey National Fire Protection Association

standards 90A or B as tested by UL standard 181 for class 1 air ducts.

• Seal around the delivery duct subsequent to when the duct is secured so that to facilitate prevention

of air leakage.

10 Vertical Air Handling Unit

More than 10 screws

(M4*25L)

Page 11

Installation

Horizontal-left Installation

ENGLISH

• It is particular that the units should not be installed in such a manner that the access panels facing up

or down

• It should be confirmed that the installation is in accordance with all relevant building codes that may

necessitate installation of external condensate pan.

-Set up a support for unit by locating it in or above external condensate pan.

• Angle steel support brackets with threaded rods which supporting the units from the underside should

be used as shown in the figure below if the units are suspended.

• If not suspended then also it should be supported as same as mentioned above and also carefully

isolated to avoid sound transmission. The size of the support should comparatively bigger than the

unit and the unit must be place at centre of the support.

• Locally available vibration isolators must be placed between the unit and the support.

• The same installation method of up flow type has to be used in the case of Return Plenum and supply duct.

Field Supplied

Supply Duct

More than 3/8 inch

(9.5mm) threaded rod

Field Supplied

Return Plenum

More than 1-1/2

inch(38 mm) X 1-1/2

inch(38 mm) angle

Recommended

length more than 26

B

C

A

inch(660 mm) with

2 inch(50 mm)

clearance on both

sides of unit

Suspension support locations

Caapcity

(kBtu(RT))

12(1.0)

18(1.5)

24(2.0)

30(2.5)

36(3.0)

42(3.5)

48(4.0)

54(4.5)

ABC

4(100) 23(580)

4(100) 29(730) 48(1220)

(Unit : inch(mm))

Dimension

41-1/2

(1050)

To ensure proper drainage for horizontal installations, unit must be installed so it is within 1/8” level of

the length and width of unit.

Installation Manual 11

Page 12

Installation

Copper

pipe

90°

Slanted Uneven Rough

Pipe

Reamer

Point down

Cut the edge

Liquid pipe

Gas pipe

Upper front panel

Air filter cover

Top screw

Bottom screw

Lower front

panel

Refrigerant

pipe cover

Preparation of Piping

Cut the pipes

1. Use the pipes purchased locally.

2. Measure the distance between the indoor and the outdoor unit.

3. Cut the pipes a little longer than measured distance.

Burrs removal

1. Completely remove all burrs from the cut cross section of pipe/tube.

2. While removing burrs put the end of the copper tube/pipe in a downward direction while removing

burrs location is also changed in order to avoid dropping burrs into the tubing.

1. First detach the upper front panel followed by air

12 Vertical Air Handling Unit

Connecting Pipes to the Indoor Unit

filter cover from the body.

2. Detach the lower front panel and refrigerant pipe

cover from the body.

Note: While detaching the lower front panel,

remember to remove the top and bottom screws.

Page 13

Installation

Cut the edge

Liquid pipe

Gas pipe

Cutting the Pipe for Cutting the Pipe for

3/8inch (9.52mm).3/8inch (9.52mm).

Cutting Position is less Cutting Position is less

than 0.4inch (10mm).than 0.4inch (10mm).

Cutting the Pipe for

3/8inch (9.52mm).

Cutting Position is less

than 0.4inch (10mm).

Cutting the Pipe for

3/8inch (9.52mm).

Cutting Position is less

than 0.4inch (10mm).

Liquid pipe

Liquid pipe

Gas pipeGas pipe

Liquid pipe

Brazing for

Brazing for

1/4inch(6.35mm) 1/4inch(6.35mm)

Brazing for

1/4inch(6.35mm)

Brazing for

1/4inch(6.35mm)

Gas pipe

Cap

CapCap

Brazing

Brazing Brazing

Cut the edge

Liquid pipe

Gas pipe

Cut the edgeCut the edge

Liquid pipeLiquid pipe

Gas pipeGas pipe

Cut the edge

Liquid pipe

Gas pipe

Lower

front

panel

Upper

front

panel

Refrigerant

pipe cover

Cut the edge

Gas pipe

ENGLISH

3. Cut the refrigerant pipe (Liquid Pipe edge)

and make sure the factory charged refrigerant is emerging out. (This confirms there is

no leakage.)

4. Detach Liquid and Gas Pipe

- Gas Pipe: Remove the Cap by Brazing

Liquid Pipe: There are 2 kinds of Liquid Pipe.

-

Liquid Pipe Detach Pipe

1/4 (6.35) Brazing

3/8 (9.52) Cutting

- If you do not use proper cutter size

when cutting liquid pipe, it would make

damage to the gas pipe.

5. Connect the field piping by brazing.

6. Attach the two panels to the body.

- Wrap the gas and liquid pipe with wet towel.

(If not wrapped with a wet towel, there may

be damages drain pan or pipe insulations.)

Note: Overlap the connection pipe insulation material and the indoor unit pipe insulation material. Bind

Completely remove the refrigerant and then do brazing. Otherwise, high pressure is a risk

of injury due to explosions

them together with vinyl tape so that there may be no gap.

Installation Manual 13

Page 14

Installation

Moisture

Dust

Leakage

Always blow nitrogen into pipe which is brazed. Always use a non-oxidizing brazing material for brazing the parts and do not use flux. If not, oxidized film can cause clogging or damage to the compressor unit and flux can harm the copper piping or refrigerant oil.

6

1

2

45

3

1 Refrigerant piping 4 Taping

2 Pipe to be brazed 5 Valve

3 Nitrogen 6 Pressure-reducing valve

Note : The torch tip should be positioned at the opposite angle to shop the

correct way to apply heat on the pipe coupling.

Plumbing materials and storage methods

Pipe must be able to obtain the specified thickness and should be used with low

impurities.

Also when handling storage, pipe must be careful to prevent a fracture, deformity

and wound.

Should not be mixed with contaminations such as dust, moisture.

Refrigerant piping on three principles

Drying Cleanliness Airtight

Should be no moisture

inside

Items

- Significant hydrolysis of refrigerant oil

Cause failure

Countermeas

14 Vertical Air Handling Unit

- Degradation of refrigerant oil

- Poor insulation of the compressor

- Do not cold and warm

- Clogging of EEV, Capillary

- No moisture in the pipe

- Until the connection is completed, the

plumbing pipe entrance should be

strictly controlled.

- Stop plumbing at rainy day.

- Pipe entrance should be taken side or

ure

bottom.

- When removal burr after cutting pipe,

pipe entrance should be taken down.

- Pipe entrance should be fitted cap

when pass through the walls.

- Degradation of refrigerant oil

- Poor insulation of the compressor

- Do not cold and warm

- Clogging of EEV, Capillary

- No dust in the pipe.

- Until the connection is completed, the

plumbing pipe entrance should be

strictly controlled.

- Pipe entrance should be taken side or

bottom.

- When removal burr after cutting pipe,

pipe entrance should be taken down.

- Pipe entrance should be fitted cap

when pass through the walls.

No dust inside.

There is no refrigerant

leakage

- Gas shortages

- Degradation of refrigerant oil

- Poor insulation of the compressor

- Do not cold and warm

- Airtightness test should be.

- Brazing operations to comply with standards.

- Flare to comply with standards.

- Flange connections to comply with

standards.

Page 15

Installation

Nitrogen substitution method

Welding, as when heating without nitrogen substitution a large amount of the oxide film is formed on the internal piping.

The oxide film is a caused by clogging EEV, Capillary, oil hole of accumulator and suction hole of oil pump in compressor.

It prevents normal operation of the compressor.

In order to avoid this problem, Welding should be done after replacing air by nitrogen gas.

When welding plumbing pipe, the work is required.

◆How to work

Regulator

ENGLISH

Welding Point

Oxide scale

Note) should not block the outlet side.

When the internal pressure in pipe is above the

atmospheric pressure, pinhole is occurred and it

is a leakage cause.

1. Always use the nitrogen.(not use oxygen, carbon dioxide, and a Chevron gas):

Please use the following nitrogen pressure 0.02MPa

Oxygen --------- Promotes oxidative degradation of refrigerant oil.

Because it is flammable, it is strictly prohibited to use

Carbon dioxide --- Degrade the drying characteristics of gas

Chevron Gas ---- Toxic gas occurs when exposed to direct flame.

2. Always use a pressure reducing valve.

3. Please do not use commercially available antioxidant.

The residual material seems to be the oxide scale is observed.

In fact, due to the organic acids generated by oxidation of the alcohol contained in the anti-oxidants, ants nest corrosion

occurs. (causes of organic acid → alcohol + copper + water + temperature)

Nitrogen gas

Pressure 0.02MPa less

Taping

(Should not

contain air)

Auxiliary valve

Nitrogen

Installation Manual 15

Page 16

Installation

Union for liquid pipe

Refrigerant pipe

and thermal

insulator

(Local supply)

Union for gas pipe

Thermal insulator for

refrigerant pipe(Local supply)

Hose crip for thermal insulator

(Local supply)

Make sure that there is no clearance here.

Overlap with thermal

insulator for piping.

Thermal insulator for refrigerant pipe

(Field supply)

Thermal insulator for

Piping (Field supply)

Hose crip for thermal insulator (Field supply)

Insulation

Insulate the joint and tubes completely.

Thermal insullaton : All thermal insulation must comply with local requirement.

Recommend

Classification

Liquid Pipe

Gas Pipe

16 Vertical Air Handling Unit

Ø1/4(6.35)

Ø3/8(9.52)

Above Ø1/2

(12.7)

Ø3/8(9.52)

Ø1/2 (12.7)

Ø5/8(15.88)

Ø3/4(19.05)

Ø7/8(22.22)

Ø1(25.4)

Ø1-1/8(28.58)

Ø1-1/4(31.75)

Ø1-3/8(34.9)

Ø1-1/2(38.1)

Ø44.45(1-3/4)

Air conditioned location Non-air conditioned location

Note1)

General

location

Above t 3/8

(9.52)

Above t 1/2

(12.7)

Above t 1/2

(12.7)

Note2)

Special

location

Above t 3/8

(9.52)

Above t 1/2

(12.7)

Above t 3/4

(19.05)

Note3)

General

location

Above t 3/8

(9.52)

Above t 1/2

(12.7)

Above t 3/4

(19.05)

Note4)

condition

Above t 3/8

(9.52)

Above t 1/2

(12.7)

Above t 1 (25)

Above t 3/4

(19.05)

Above t 1 (25) Above t 1 (25)

Negative

Page 17

Installation

* Note 1) General location: When the pipe passes through indoors in which the indoor unit is operated

- Apartment, classroom, office, mall, hospital, office-tel etc.

Note 2) Special location

1. When the location is air conditioned but has severe temperature/humidity difference due to

high ceiling

- Church, auditorium, theater, lobby etc.

2. When the location is air conditioned but the internal temperature/humidity of the ceiling finishing is high

- Bathroom/swimming pool locker room etc. (Building with roof ceiling of sandwich assembly

type)

Note 3) General location: When the pipe passes indoors where the indoor unit is not operated

- Hall way etc. (Dormitory, school, office-tel)

Note 4) Negative condition: When below conditions 1 and 2 are met.

1. When the pipe passes indoors where the indoor unit is not operated

2. When the humidity is high, regionally, and there is no air flow in the pipe passing area

- When installing the outside unit within the outside pipe tray or at a location where it is ok to

have freezes, apply 13t.

- If you are not sure with the selection of heat insulation material, coordinate with the supervision or HQ.

- The thickness of the above heat insulation material is based on the heat conductivity of

0.088W/m°C.

ENGLISH

Condensate Drain

• The drainage performance has to be optimized by installing both primary and secondary drain lines

along with properly sized condensate traps in order to prevent property damage.

• Care should be taken to avoid the blocking of filter access panel while connecting condensate drain

lines. The primary and secondary condensate traps has to be primed after connecting to the drain

pan.

• A field supplied external condensate pan has to be installed underneath the entire unit if the unit is

above the living space . Other wise damage may result due to condensate over flow. Also a additional

external condensate line should run from unit in to the pan.

• The entire condensate should be drained from the external condensate pan to some noticeable

area. It is advised to install traps in condensate lines as near to the coil as possible. The outlet of

each trap should be below its connection to the condensate pan avert condensate from overflowing

drain pan.

• If located above the living area then all traps should be prime and insulated and also tested for leakage.

• PVC 3/4 inch(19.05mm) male pipe thread fitting is advised to use at condensate pan with gentle tight.

• For easy drain flow the drain hose has to be pointed downward.

• Care should be taken to not use pipe joint connection or PVC/CPVC for units drain line connection.

Use only Teflon tape.

• For preventing winter freeze up on condensate line special means should be provided for drainage.

Installation Manual 17

Page 18

Installation

Drainage hole

U-Trap

B

C

A ≥

2-9/16 inch

(70mm)

B ≥ 2C

C ≥ 2 x SP

SP = External Pressure

(in.wc)

Ex) External Pressure

= 0.4in.wc(10mmAq)

A ≥ 2-9/16 inch(70mm)

B ≥ 1-7/12 inch(40mm)

C ≥ 19/24 inch(20mm)

A

Make sure to be closed.

Unit

Drainage pipe

(Field supply)

Thermal insulator

(Field supply)

Applied U-Trap Dimension

CORRECT

• Install the U-Trap to prevent

a water leakage caused by the blocking

of intake air filter.

Upflow Drain Horizontal-left Drain

INCORRECT

3/4 inch(19.05mm)

connector

Horizontal-left

Drain Knockout

Air filter cover

Main drain along with suitable trap.

( Field supplied trap with sufficient

depth can be used. P-traps of standard

size are not sufficient. Refer the figure

for recommended condensate trap.)

Supplementary drain

with proper trap. (field

supplied kit can be used)

GRADIENT OF UNIT AND DRAIN PIPING

• Alway lay the drain with downward inclination(1/50 to 1/100).

Prevent any upward flow or reverse flow in any part.

• 5/24 inch(5mm) or thicker formed thermal insulator shall always be provided for the drain pipe.

The supplied flexible drain hose should not be strained.

A strained hose may cause leakage of water.

18 Vertical Air Handling Unit

Page 19

Installation

Wiring

knockouts

Control

Box Cover

Upper

Front Panel

Wiring Connection

Connect the wires to the terminals on the control board individually according to the outdoor unit

connection.

Ensure that the color of the wires of outdoor unit and the terminal No. are the same as those of

indoor unit respectively.

208/230V 1Φ 60Hz

Outdoor unit

Terminal Block Indoor

1(L1) 2(L2) 3(A) 4(B)

INDOOR POWER

INPUT

<208/230 1Φ 60Hz>

Min wire size

(AWG)

Power cable 22 1/2 (21.3) 7/8 (22.2)

Communication cable 22 1/2 (21.3) 7/8 (22.2)

* Copper wire should be used.

Indoor unit Central controller

SODU SODU

IDU IDU

DRY1 DRY2 GND INTERNET

Size of conduit

(inch(mm))

Outdoor

unit

12V

Unit : inch(mm)

Knockout diameter

(inch(mm))

ENGLISH

1. Detach the upper panel & control box cover.

And remove two wiring Knockouts.

Installation Manual 19

Page 20

Installation

power cable

communication cable

Lock nut

Conduit

mounting plate

1/2inch(21.3 mm)

Conduit

2. Install conduit to the wiring knockouts.

Connect power/communication cable to terminal block through the wiring knockouts.

NOTE :

1. Separately wire power supply cord and connecting cable.

2. Use heat-proof electrical wiring capable of withstanding temperature up to 75°C(167°F).

3. Use outdoor and waterproof connection cable NRTL(UL, ETL, CSA...) listed and rated more than

300V for the connection between indoor and outdoor unit. and this cable should be enclosed in

conduit.

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have individual power specialized for the air conditioner. As for the method

of wiring, follow by the circuit diagram posted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screws which fasten the wiring in the casing of electrical fittings are liable to come

loose from vibrations to which the unit is subjected during the course of transportation.

Check them and make sure that they are all tightly fastened. (If they are loose, it could

give rise to burn-out of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is within 10% plus or minus of nameplate voltage rating.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip GFCI breaker when installing the air handler near wet or moist locations.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point, fuse breaking, disturbance by the

normal function of an overload protection device.

• Proper starting power is not given to the compressor.

HAND OVER

Teach the customer the operation and maintenance procedures, using the operation manual.

(air filter cleaning, temperature control, etc.)

NOTE : Openings where field wiring enters the cabinet must be completely sealed.

20 Vertical Air Handling Unit

Page 21

Installation

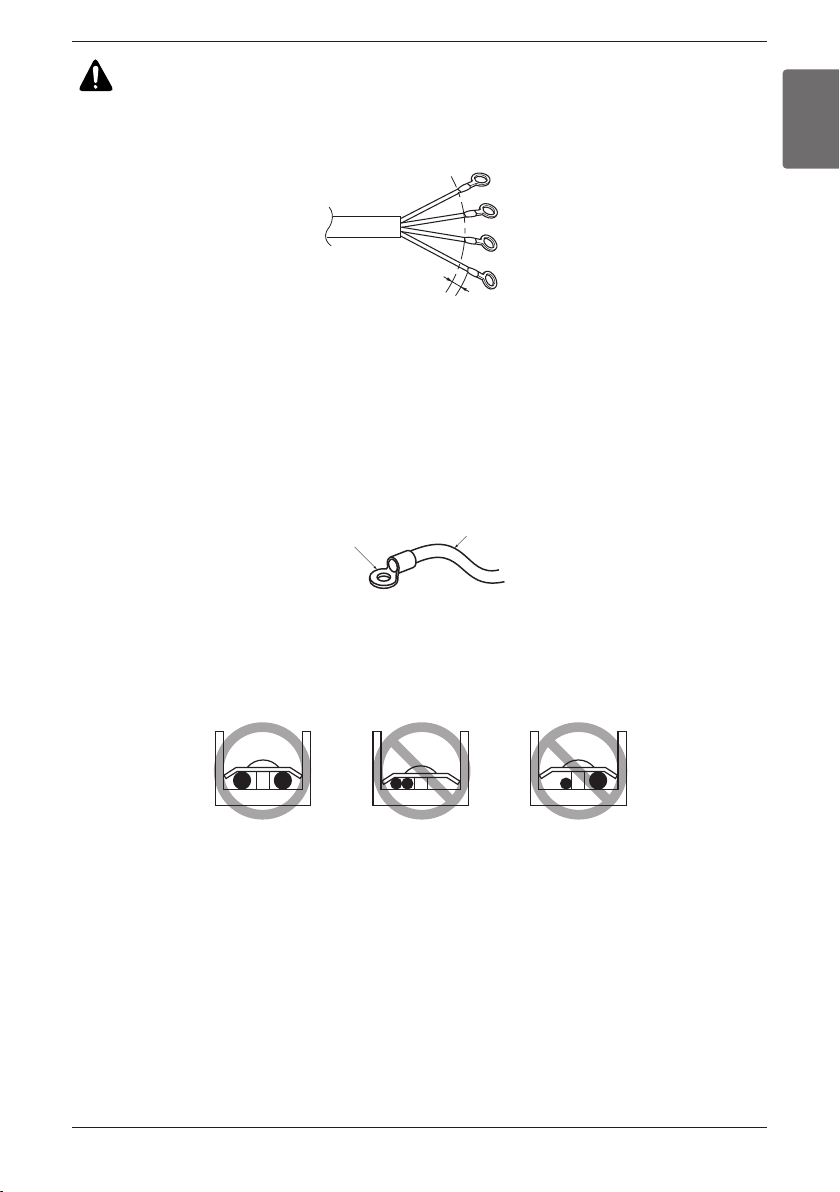

Round pressure terminal

Power wire(Ground wire)

CAUTION :

ENGLISH

The connecting cable connected to the indoor and outdoor unit should be complied with the following specifications (This equipment shall be provided with a cord set complying with the national regulation).

GN/

YL

20mm

(25/32 inch)

If the supply cord is damaged, it must be replaced by a special cord or assembly available from

the manufacturer of its service agent.

u Precautions when laying power and ground wiring

Use round pressure terminals for connections to the power terminal block.

When laying ground wiring, you must use round pressure terminals.

When none are available, follow the instructions below.

• Do not connect wiring of different thicknesses to the power terminal block. (Slack in the power wiring

may cause abnormal heat.)

• When connecting wiring which is the same thickness, do as shown in the figure below.

• For wiring, use the designated power wire and connect firmly, then secure to prevent outside pressure

being exerted on the terminal block.

• Use an appropriate screwdriver for tightening the terinal screws. A screwdriver with a small head will

strip the head and make proper tighterning impossible.

• Over-tightening the terminal screws may break them.

Installation Manual 21

Page 22

Installation

Electric Heater

Feature (Example: 5kW)

Bi metal

Bracket

Terminal Block

Relay

Heater Cable

Heater Coil

* Note: Image shown above may vary depends on model capacity.

Available heater in model

Capacity

(kBtu/h (RT))

12(1.0)

18(1.5)

24(2.0)

30(2.5)

36(3.0)

42(3.5)

48(4.0)

54(4.5)

5 101520

○

○

○○

○○

○○

○○○○

○○○○

○○○○

※ If you want to know more optional operation, please refer to the Electric Heater Manual.

※ Heater Model

5kW: ANEH053B1

10kW: ANEH103B2

15kW: ANEH153B2

20kW: ANEH203B2

Heater Capacity (kW)

Not available Not available Not available

Not available Not available Not available

Not available Not available

Not available Not available

Not available Not available

22 Vertical Air Handling Unit

Page 23

Installation

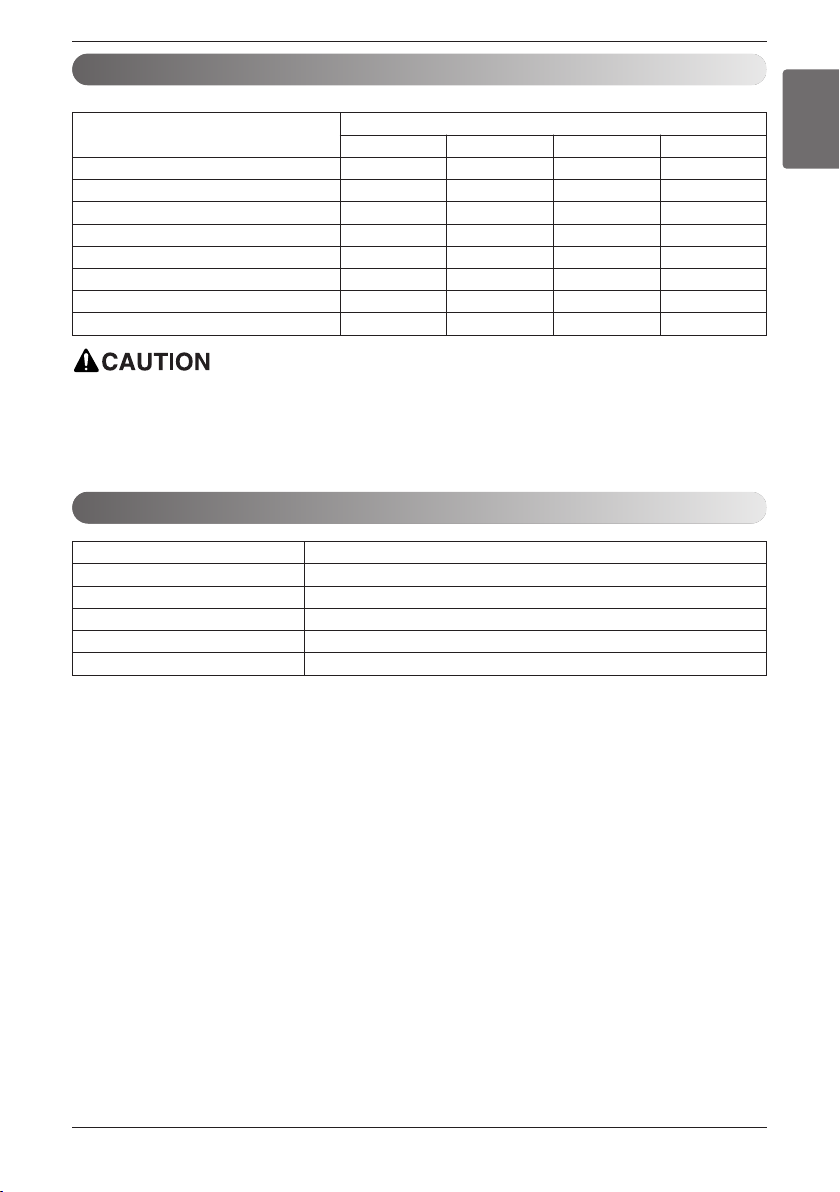

Dip Switch Setting of Indoor unit PCB

Function Description Setting Off Setting On Default

Communication

SW1

Cycle

SW2

Group Control

SW3

Dry Contact Mode

SW4

Installation

SW5

Heater linkage

SW6

Ventilator linkage

SW7

Vane selection

(Console)

Region selection

Etc.

SW8

1. In Multi V Models without Electric Heater

- Dip switch 1, 2, 6, 8 must be set OFF.

2. In the case of Multi V Models with Electric Heater, Dip switch 5,6 must be set ON.

- SW 5 ON: Fan operates continuously. (During defrosting or oil return operation, uninterrupted heating can be attained, as a result of continuous heater and fan operation.)

- SW5 OFF: Fan discontinuous operation (There would be reduction in heating capacity

while defrosting or oil return operation.)

- SW6 ON: Automatic Heater operation (Heater operates automatically according to the

heater logic without owner’s intervene.)

- SW6 OFF: Heater manual operation (Owner’s involvement is required for on/off operation.

But the heater operation would be as per the heater logic.)

N/A (Default)

N/A (Default)

Selection of Master or Slave

Selection of Dry Contact

Mode

Fan continuous operation

Selection of Heating Working

Selection of Ventilator linkage

Selection of up/down side

Vane

Selection tropical region

Spare

-

-

Master

Wired/Wireless remote

controller

Selection of Manual or Auto

operation Mode

Continuous operation Removall

-

Linkage Removal

Up side + Down side Vane

General model

-

Up side Vane

Tropical model

-

-

Slave

Auto

-

-

Working

Only

-

ENGLISH

Off

Off

Off

Off

Off

Off

Off

Off

Installation Manual 23

Page 24

Installation

Wired remote controller 1

Dip Switch in PCB (Cassette and Duct Type indoor units)

1. It is possible to 16 indoor units(Max) by one wired remote controller.

Set only one indoor unit to Master, set the others to Slave.

2. It is possible to connect with every type of indoor units.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

GND

Signal

12 V

Master

Slave

Slave

Slave

Display Error Message

Only connect serial signal and GND lines

between slave indoor unit

LGAP Network System

- No. 3 Off - No. 3 On

- The Master indoor unit is possible to recognize Dry Contact and Central Controller only.

- In case of Central controller and Group controller at the same time, it is possible to connect

standard 2series indoor units or later since Feb. 2009.

- In case of Central controller setting, the Central controller can control indoor units after

setting only the address of master indoor unit.

- Slave indoor unit will be operated like master indoor unit.

- Slave indoor unit can not be individually controlled by Central controller.

- Some remote controller can’t perform with Dry Contact and Central controller at the same

time. So contact us further information about it.

Master

Group Control Setting

1. Group Control 1

24 Vertical Air Handling Unit

Page 25

It is possible to control N indoor units by wired remote controller M units. (M+N≤17 Units)

Set only one indoor unit to Master, set the others to Slave.

Set only one wired remote controller to Master, set the others to Slave.

Other than those, it is same with the Group Control 1.

Slave

Display Error Message

Donʼt connect serial 12V line

Master

(2) Group Control 2

Wired remote controllers

GND

Signal

12 V

Slave

Slave

Slave

Master

LGAP Network System

6. In case of Group Control, it is possible to use following functions.

- Selection of operation options (operation/stop/mode/set temperature)

- Control of flow rate (High/Middle/Low)

- It is not possible at some functions.

Master/Slave setting of indoor units be set possible using a PCB Dip Switch.

It is possible to connect indoor units since Feb. 2009.

In the other cases, please contact LGE.

It can be the cause of malfuctions when there is no setting of master and slave.

5. In case of any error occurs at indoor unit, display on the wired remote controller.

Exception of the error indoor unit, an individual indoor unit control possibility.

2. Group Control 2

Installation

ENGLISH

Installation Manual 25

Page 26

Installation

Display Error Message

Master

Slave

1. It is possible to connect two wired remote controllers with one indoor unit.

2. Every types of indoor unit is possible to connect two remote controller.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

5. In case of any error occurs at indoor unit, display on the wired remote controller.

6. There isnʼt limits of indoor unit function.

❈ Maximum 2wired remote controllers can be connected with 1 indoor unit.

Wired remote controller 2 + Indoor unit 1

GND

Signal

12 V

Slave

Slave

Slave

Master

LGAP Network System

3. 2 Remote Control

26 Vertical Air Handling Unit

Page 27

Installation

Slave

Mas te r

Mas ter

PZCWRCG3

Mas ter Slav e

PZCWRC2

Indoor unit 2 EA +Wired remote controller

❈ PZCWRCG3 cable used for connection ❈ PZCWRC2 cable used for connection

Indoor unit 1 EA +Wired remote controller 2EA

It is possible to set group control by using below accessories.

4. Accessories for group control setting

Apply totally enclosed noncombustible conduit in case of local building code Requiring plenum

cable usage.

ENGLISH

Installation Manual 27

Page 28

Product Data

Product Data

External Static Pressure & Air Flow

Capacity

(kBtu/h(RT))

54(4.5)

48(4.0)

42(3.5)

36(3.0)

30(2.5)

24(2.0)

18(1.5)

12(1.0)

Flow rate

(CFM)

High(1475) 77 82 87 93 98

Middle(1400) 74 79 84 91 96

Low(1260) 67 75 80 87 90

High(1400) 74 79 84 91 96

Middle(1260) 67 75 80 87 90

Low(1000) 56 65 72 77 84

High(1250) 67 75 80 87 90

Middle(1100) 61 67 75 80 87

Low(1000) 56 65 72 77 84

High(990) 80 85 90 95 100

Middle(880) 65 72 80 85 92

Low(800) 65 69 77 82 90

High(880) 65 72 80 85 92

Middle(800) 62 69 77 82 90

Low(630) 53 65 70 75 85

High(710) 56 67 74 78 87

Middle(640) 53 65 70 75 85

Low(480) 53 55 64 70 79

High(580) 53 60 68 74 84

Middle(530) 53 58 66 72 82

Low(480) 53 55 64 70 79

High(530) 53 58 66 72 82 84 92 92 92 92

Middle(480) 53 56 64

Low(380) 53 54 62 69 77 83 92 92 92 92

0.1 0.2 0.3 0.4 0.5

Setting Value @ ESP(in.wc)

0.6 0.7 0.8 0.9 1.0

102 110 115 115 11 5

102 110 115 115 11 5

98 102 11 0 11 5 11 5

102 110 115 115 11 5

98 102 11 0 11 5 11 5

90 98 105 108 115

98 102 11 0 11 5 11 5

92 100 108 110 115

90 98 105 108 115

103 103 103 103 103

98 103 103 103 103

96 101 101 101 101

98 103 103 103 103

96 101 101 101 101

91 96 96 96 96

94 98 98 98 98

91 96 96 96 96

84 92 92 92 92

85 95 95 95 95

84 92 92 92 92

83 92 92 92 92

70

79 83 92 92 92 92

Air handler units are UL Listed up to 0.5 in.wc external static pressure, including air filter, set coil, and largest

kW size heater, unless otherwise noted.

• Flow rate(CFM) is decreased by 3% per 0.1in.wc from 0.8 in.wc to 1.0 in.wc

• If flow rate(CFM) is increased by 400CFM/ton from 1.5RT to 2.5RT of capacity, the ESP value should be

increased by 4.

• If flow rate(CFM) is increased by 400CFM/ton from 3.0RT to 4.5RT of capacity, the ESP value should be

increased by 5.

• in.wc = inch Water Column, inAq

• Factory Default: High Static Pressure,

High static pressure is 0.5 in.wc,

Low static pressure is 0.3 in.wc

If you set ESP incorrectly, the air conditioner may cause cooling & heating capacity down or malfunction.

28 Vertical Air Handling Unit

Page 29

Product Data

Minimum airflow by heater capacity

Capacity

(kBtu/h (RT))

12(1.0) 380 Not available Not available Not available

18(1.5) 380 Not available Not available Not available

24(2.0) 480 480 Not available Not available

30(2.5)

36(3.0) 780 780 Not available Not available

42(3.5) 1000 1000 1000 1000

48(4.0) 1000 1000 1000 1000

54(4.5) 1300 1300 1300 1300

5 101520

630

Do not use less than minimum airflow.

There is risk of fire or damage to the product.

Heater Capacity (kW)

630 Not available Not available

Electric Heater Static pressure drop factors

Heater Capacity(kW) Static pressure drop (in.wc)

0 0

5 – 0.01

10 – 0.02

15 – 0.04

20 – 0.06

ENGLISH

(Unit : CFM)

If the electric heater has been installed, then the ESP value has to be set.

For every increase in static pressure by 0.01 inWC, the ESP value should be increased by 1.

If the setting ESP value is inappropriate, the provided safety device will turn off the heater according to

the airflow.

* in.wc = inch Water Column, inAq

Installation Manual 29

Page 30

Product Data

Air Filter (Field supply) Static pressure drop factors

Capacity(kBtu/h(RT)) Flow Rate(CFM) Static pressure drop (in.WC)

High(530) -0.02

12 (1.0)

18 (1.5)

24 (2.0)

30 (2.5)

36 (3.0)

42 (3.5)

48 (4.0)

54 (4.5)

Middle(480) -0.02

Low (380) -0.01

High(580) -0.03

Middle(530) -0.02

Low(480) -0.02

High(710) -0.04

Middle(640) -0.03

Low(480) -0.02

High(880) -0.05

Middle(800) -0.05

Low(630) -0.03

High(990) -0.07

Middle(880) -0.05

Low(800) -0.05

High(1250) -0.11

Middle(1100) -0.09

Low(1000) -0.07

High(1400) -0.14

Middle(1260) -0.11

Low(1000) -0.07

High(1475) -0.18

Middle(1400) -0.16

Low(1260) -0.12

If the air filter has been installed, then the ESP value has to be set.

For every increase in static pressure by 0.01 inWC, the ESP value should be increased by 1.

Note : Filters should be used a rating of MERV 4 or less.

If you use filters that has a rating MERV 5 or above, it can cause cooling & heating capacity

down.

30 Vertical Air Handling Unit

Page 31

US

CANADA

Please call the installing contractor of your product, as warranty service will be

provided by them.

Service call Number # : (888) LG Canada, (888) 542-2623

Numéro pour les appels de service : LG Canada, 1-888-542-2623

Loading...

Loading...