Page 1

www.lg.com

Ceiling Cassette - 4Way

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it

thoroughly.

INSTALLATION MANUAL

AIR

CONDITIONER

P/NO : MFL42803115

Copyright © 2009 - 2018 LG Electronics Inc. All Rights Reserved.

ENGLISH FRANÇAIS ESPAÑOL

Page 2

2 Indoor Unit

IMPORTANT!

Please read this instruction sheet completely before installing the product.

This air conditioning system meets strict safety and operating standards. As the installer or service person,

it is an important part of your job to install or service the system so it operates safely and efficiently.

• Installation or repairs made by unqualified persons can result in hazards to you and others.

Installation of all field wiring and components MUST conform with local building codes or, in the absence of local

codes, with the National Electrical Code 70 and the National Building Construction and Safety Code or Canadian

Electrical code and National Building Code of Canada.

• The information contained in the manual is intended for use by a qualified service technician familiar with safety

procedures and equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction, property

damage, personal injury and/or death.

CAUTION

Safety Precautions

NOTE TO INSTALLING DEALER: The Owners Instructions and Warranty are to be given to the owner

: Improper installation, adjustment, alteration, service or maintenance can void the warranty.

The weight of the condensing unit requires caution and proper handling procedures when lifting

or moving to avoid personal injury. Use care to avoid contact with sharp or pointed edges.

• Always wear safety eye wear and work gloves when installing equipment.

• Never assume electrical power is disconnected. Check with meter and equipment.

• Keep hands out of fan areas when power is connected to equipment.

• R-410A causes frostbite burns.

• R-410A is toxic when burned.

or prominently displayed near the indoor Furnace/Air Handler Unit.

When wiring:

Electrical shock can cause severe personal injury or death. Only a qualified,

experienced electrician should attempt to wire this system.

• Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these

instructions when wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

•

Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

• The choice of materials and installations must comply with the applicable local/national or international

standards.

When transporting:

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and

bend your knees when lifting to reduce strain on your back. Sharp edges or thin aluminum fins on

the air conditioner can cut your finger.

When installing...

... in a wall: Make sure the wall is strong enough to hold the unit's weight.

... in a room: Properly insulate any tubing run inside a room to prevent "sweating" that can cause

... in moist or uneven locatinons: Use a raised concrete pad or concrete blocks provide a solid,

... in an area with high winds: Securely anchor the outdoor unit down with bolts and a metal

... in a snowy area(for Heat Pump Model): Install the outdoor unit on a raised platform that is

When connecting refrigerant tubing

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Check carefully for leaks before starting the test run.

When servicing

• Turn the power OFF at the main power box(mains) before opening the unit to check or repair

electrical parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have

been left inside the unit being serviced.

It may be necessary to construct a strong wood or metal frame to provide added support.

dripping and water damage to wall and floors.

level foundation for the outdoor unit. This prevents water damage and abnormal vibration.

frame. Provide a suitable air baffle.

higher than drifting snow. Provide snow vents.

Page 3

Installation Manual 3

Ceiling Cassette - 4Way Type Indoor Unit Installation Manual

TABLE OF CONTENTS

o Installation guide map

o Four type "A" screws & plastic

anchors

o Connecting cable

o Pipes: Gas side

Liquid side

(Refer to Product Data)

o Insulation materials

o Additional drain pipe

o Level gauge

o Screw driver

o Electric drill

o Hole core drill

o Horizontal meter

o Flaring tool set

o Specified torque wrenches

(different depending on model No.)

o Spanner .......Half union

o Hexagonal wrench

o Gas-leak detector

o Vacuum pump

o Gauge manifold

o Owner's manual

o Thermometer

Installation Parts.......................4

Safety Precautions ...................5

Installation.................................8

Selection of the best location...8

Ceiling dimension and hanging

bolt location .............................9

Wiring Connection .................10

Plumbing materials and storage

methods.................................13

Installation of Decoration

Panel .....................................15

Drain Piping...........................16

Dip Switch Setting .................18

Group Control Setting............19

Installation Requirements

Required Parts Required Tools

ENGLISH

Page 4

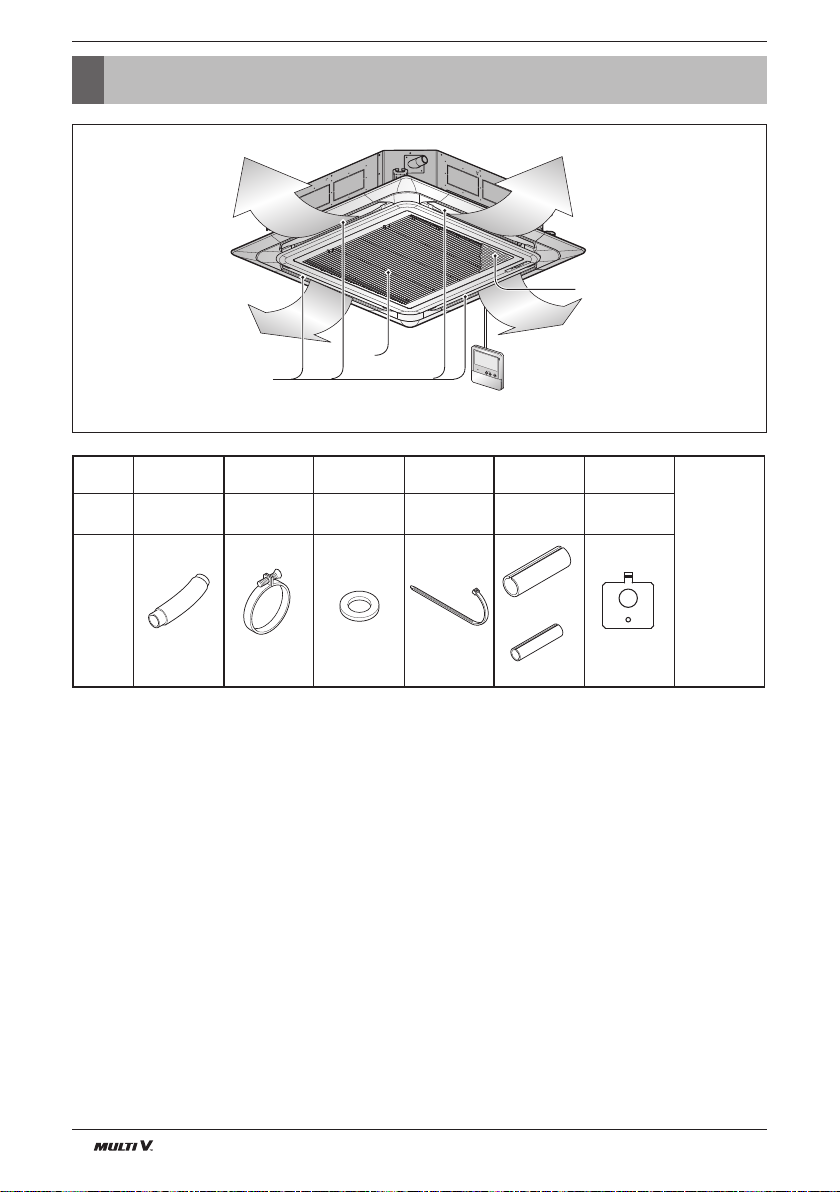

4 Indoor Unit

Installation Parts

Installation Parts

Air Outlet

Air

Intake

TEMP

R

emote C

o

ntr

o

l

l

er

Wired Remote Controller(Optional)

Anti-bacteria filter

Name

Quantity

Shape

Drain hose

1 EA

Clamp metal

2 EA

Washer for

hanging backet

8 EA

Plastic band

4 EA

Insulation for

fitting

1 SET

for gas pipe

for liquid pipe

Conduit

mounting plate

1 EA

(Other)

• Paper

pattern for

installation

• Owner's

manual

• Installation

manual

Page 5

Installation Manual 5

ENGLISH

Safety Precautions

Safety Precautions

To prevent injury to the user or other people and property damage, the following instructions must be followed.

n Be sure to read before installing the air conditioner.

n Be sure to observe the cautions specified here as they include important items related to safety.

n Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the

following indications.

n Meanings of symbols used in this manual are as shown below.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

Be sure not to do.

Be sure to follow the instruction.

Installation

• Do not use a defective or underrated circuit breaker. Use this appliance on a dedicated

circuit.

- There is risk of fire or electric shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an Authorized

Service Center.

- Do not disassemble or repair the product. There is risk of fire or electric shock.

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric shock.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

Page 6

6 Indoor Unit

Safety Precautions

• Do not let the air conditioner run for a long time when the humidity is very high and a door

or a window is left open.

- Moisture may condense and wet or damage furniture.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the case edges and the fins on

the condenser and evaporator.

• For installation, always contact the dealer or an Authorized Service Center.

- There is risk of fire, electric shock, explosion, or injury.

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the air conditioner could fall with it, causing property damage,

product failure, and personal injury.

• Use a vacuum pump or Inert (nitrogen) gas when doing leakage test or air purge.

Do not compress air or Oxygen and Do not use Flammable gases.

Otherwise, it may cause fire or explosion.

- There is the risk of death, injury, fire or explosion.

Operation

• Do not store or use flammable gas or combustibles near the product.

- There is risk of fire or failure of product.

Page 7

Installation Manual 7

ENGLISH

Safety Precautions

Installation

• Always check for gas (refrigerant) leakage after installation or repair of product.

- Low refrigerant levels may cause failure of product.

• Install the drain hose to ensure that water is drained away properly.

- A bad connection may cause water leakage.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Do not install the product where the noise or hot air from the outdoor unit could damage the

neighborhoods.

- It may cause a problem for your neighbors.

• Use two or more people to lift and transport the product.

- Avoid personal injury.

• Do not install the product where it will be exposed to sea wind (salt spray) directly.

- It may cause corrosion on the product. Corrosion, particularly on the condenser and

evaporator fins, could cause product malfunction or inefficient operation.

• If you eat the liquid from the batteries, brush your teeth and see doctor. Do not use the

remote if the batteries have leaked.

- The chemicals in batteries could cause burns or other health hazards.

Page 8

8 Indoor Unit

Installation

• There should not be any heat source or steam near the unit.

• There should not be any obstacles to the air circulation.

• A place where air circulation in the room will be good.

• A place where drainage can be easily obtained.

• A place where noise prevention is taken into consideration.

• Do not install the unit near the door way.

• Ensure the spaces indicated by arrows from the wall, ceiling, or other obstacles.

• The indoor unit must have the maintenance space.

Read completely, then follow step by step.

Selection of the best location

CAUTION : In case that the unit is installed near the sea, the installation parts

may be corroded by salt. The installation parts (and the unit) should be taken

appropriate anti-corrosion measures.

CAUTION : Don't install additional ventilation products on the cabinet of cassette type air conditioner.

h Please use an annexed sheet or the corrugated

cardboard on the bottom of packing as installation sheet.

h When using the bottom sheet, please use it

after separating the installation sheet from

packing of the product floor by using a knife etc

as a picture below.

Annexed sheet

Or

Packing corrugated

cardboard on the

bottom

Installation

* Case of the size

[Width : 570(22-

* Case of the size

[Width : 840(33-

7

/16)] x [Depth : 570(22-7/16)]

30(1-3/16)

1

±3(

/8)

1

/16)] x [Depth : 840(33-1/16)]

15(19/32) ±3(1/8)

Ceiling

Ceiling Board

500(19-11/16)

or more

)

8

/

3

or more

1000(39-

)

32

/

13

10(

or more

“A”

Ceiling Board

11

500(19-

/16)

or more

) or less

16

/

13

300(11-

Below 36 kBtu(10.6 kW) At least 1800(70-

Over 36k Btu(10.6 kW) At least 1800(70-

“A”

23

3600(141-

11

4200(165-

/32) or less

/32) or less

7

/8),

7

/8),

Floor

Unit:mm(inch)

Page 9

Installation Manual 9

ENGLISH

Installation

Ceiling dimension and hanging bolt location

Level gauge

Ceiling

Ceiling board

Unit:mm(inch)

570(22-7/16) Unit size

570(22-7/16) Unit size

450(17-11/16)

(Hanging bolt)

75(3)

75(3)

600(23-5/8) (Ceiling opening)

600(23-5/8) (Ceiling opening)

521(20-1/2)(Hanging bolt)

39.5(1-9/16)

39.5(1-9/16)

TE Chassis TQ/TR Chassis

TM/TN/TP Chassis

Unit:mm(inch)Unit:mm(inch)

875(34-7/16) (Ceiling opening)

787(30-15/16)

(Hanging bolt)

bolt)

684(26-15/16)(Hanging bolt)

671(26-7/16)

875(34-7/16) (Ceiling opening)

840(33-1/16)

Unit size

840(33-1/16)

Unit size

585~660(20-3/8~26)(Ceiling opening)

517(23)

461(18-1/8)

517(23)

585~660(20-3/8~26)

(Ceiling opening)

523(20-9/16)

570(22-7/16)

570(22-7/16)

319(12-9/16)319(12-9/16)

319(12-9/16)

• The dimensions of the paper model for installation are the same as those of the ceiling opening dimensions.

• Avoid the following installation location.

1. Such places as restaurants and kitchen where considerable amount of oil steam and flour is generated.

These may cause heat exchange efficiency reduction, or water drops, drain pump mal-function.

In these cases, take the following actions;

• Make sure that ventilation fan is enough to cover all noxious gases from this place.

• Ensure enough distance from the cooking room to install the air conditioner in such a place where it may

not suck oily steam.

2. Avoid installng air conditioner in such

places where cooking oil or iron powder is

generated.

3. Avoid places where inflammable gas is

generated.

4. Avoid place where noxious gas is

generated.

5. Avoid places near high frequency

generators.

CAUTION :

• This air-conditioner uses a drain

pump.

• Install the unit horizontally using a

level gauge.

• During the installation, care should be

taken not to damage electric wires.

• Select and mark the position for fixing bolts and piping hole.

• Decide the position for fixing bolts slightly tilted to the drain

direction after considering the direction of drain hose.

• Drill the hole for anchor bolt on the wall.

Air conditioner

Take enough

distance

Cooking table

Use the ventilation fan

for smoke-collecting

hood with sufficient

capacity.

Page 10

10 Indoor Unit

Installation

• The following parts are local purchasing.

① Hanging Bolt - W 3/8 or M10

② Nut - W 3/8 or M10

③ Spring Washer - M10

④ Plate Washer - M10

Terminal Block Indoor

1(L1) 2(L2) 3(A) 4(B)

3(A) 4(B)

INDOOR

POWER INPUT

A ----BABAB

GND 12V

DRY2DRY1

INTERNETIDUSODU

Outdoor

Unit

• TR/TQ/TE Chassis

• TM/TN/TP Chassis

COMMUNICATION LINE(IDU-ODU)

Terminal Block Indoor

Terminal Block

Indoor

1(L1) 2(L2)

Terminal Block Indoor

RD YL 5(A) 5(B)BK

POWER

INPUT

TO AIR

FRESH KIT

ABA - - --BAB

GND 12VDRY2DRY1INTERNETIDUSODU

Outdoor

Unit

power cord

Indoor cord

Remote

control cord

1(L1)2(L2)

• Open the control box cover and connect the remote control cord and Indoor power wires.

Wiring Connection

WARNING : Make sure that the screws of the terminal are free from looseness.

CAUTION : Tighten the nut and bolt to

prevent unit from falling off.

Hanging bolt

(W3/8 or M10)

Nut

(W3/8 or M10)

Spring washer

(M10)

Keep the length of the bolt

from the bracket to 40 mm(1-1/2 inch)

Flat washer for M10

(accessory)

Flat washer for M10

(accessory)

Nut

(W3/8 or M10)

Ceiling board

Paper model

for installation

Ceiling

105 mm(4-1/8 inch, TM/TN/TP chassis)

Air Conditioner body

Keep the length of 15 mm (19/32 inch, TM/TN/TP

chassis) (TM,TN,TP chassis), 31~34 mm

(1-7/32~1-11/32 inch)(TQ,TR chassis) between

the air conditioner bottom surface and

the ceiling surface

Set screw of

paper model (4 pieces)

Open the ceiling board

along the outer edge of the

paper model

108 mm(4-1/4 inch, TM/TN/TP chassis)

Ceiling board

Page 11

Installation Manual 11

ENGLISH

Installation

CAUTION:

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have an individual power specialized for the air conditioner. As for the method of

wiring, be guided by the circuit diagram posted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screws which fasten the wiring in the casing of electrical fittings are liable to come loose

from vibrations to which the unit is subjected during the course of transportation. Check

them and make sure that they are all tightly fastened. (If they are loose, it could give rise to

burn-out of the wires.)

4) Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage

marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Never fail to equip a leakage breaker where it is wet or moist.

9) The following troubles would be caused by voltage drop-down.

• Vibration of a magnetic switch, damage on the contact point, fuse breaking, disturbance by the nor-

mal function of an overload protection device.

• Proper starting power is not given to the compressor.

HAND OVER

Teach the customer the operation and maintenance procedures, using the operation manual.

(air filter cleaning, temperature control, etc.)

WARNING : Loose wiring may cause the terminal to overheat or result in unit

malfunction.

A fire hazzard may also exist.

Therefore, be sure all wiring is tightly connected.

Connection method of the connecting cable(Example)

Lock nut

Conduit

mounting

plate

Conduit

1(L1)

2(L2)

Power Supply

High Voltage

(208/230V)

1(L1) 2(L2)

Page 12

12 Indoor Unit

Installation

CAUTION :

The connecting cable connected to the indoor and outdoor unit should be complied with the following specifications (This equipment shall be provided with a cord set complying with the

national regulation).

If the supply cord is damaged, it must be replaced by a special cord or assembly available from

the manufacturer of its service agent.

u Precautions when laying power and ground wiring

Use round pressure terminals for connections to the power terminal block.

When laying ground wiring, you must use round pressure terminals.

When none are available, follow the instructions below.

• Do not connect wiring of different thicknesses to the power terminal block. (Slack in the power wiring

may cause abnormal heat.)

• When connecting wiring which is the same thickness, do as shown in the figure below.

• For wiring, use the designated power wire and connect firmly, then secure to prevent outside pressure

being exerted on the terminal block.

• Use an appropriate screwdriver for tightening the terinal screws. A screwdriver with a small head will

strip the head and make proper tighterning impossible.

• Over-tightening the terminal screws may break them.

Round pressure terminal

Power wire(Ground wire)

10±3mm

35±5mm

GN/YL

AWG18

20mm

Page 13

Installation Manual 13

Installation

ENGLISH

Pipe must be able to obtain the specified thickness and should be used with low

impurities.

Also when handling storage, pipe must be careful to prevent a fracture, deformity

and wound.

Should not be mixed with contaminations such as dust, moisture.

Plumbing materials and storage methods

Refrigerant piping on three principles

Drying Cleanliness Airtight

Should be no moisture

inside

No dust inside.

There is no refrigerant

leakage

Items

Moisture

Dust

Leakage

Cause fail-

ure

- Significant hydrolysis of refrigerant

oil

- Degradation of refrigerant oil

- Poor insulation of the compressor

- Do not cold and warm

- Clogging of EEV, Capillary

- Degradation of refrigerant oil

- Poor insulation of the compressor

- Do not cold and warm

- Clogging of EEV, Capillary

- Gas shortages

- Degradation of refrigerant oil

- Poor insulation of the compressor

- Do not cold and warm

Countermea

sure

- No moisture in the pipe

- Until the connection is completed,

the plumbing pipe entrance should

be strictly controlled.

- Stop plumbing at rainy day.

- Pipe entrance should be taken

side or bottom.

- When removal burr after cutting

pipe, pipe entrance should be

taken down.

- Pipe entrance should be fitted cap

when pass through the walls.

- No dust in the pipe.

- Until the connection is completed,

the plumbing pipe entrance should

be strictly controlled.

- Pipe entrance should be taken

side or bottom.

- When removal burr after cutting

pipe, pipe entrance should be

taken down.

- Pipe entrance should be fitted cap

when pass through the walls.

- Airtightness test should be.

- Brazing operations to comply with

standards.

- Flare to comply with standards.

- Flange connections to comply with

standards.

Page 14

14 Indoor Unit

Installation

Nitrogen substitution method

Welding, as when heating without nitrogen substitution a large amount of the oxide film is formed on the internal piping.

The oxide film is a caused by clogging EEV, Capillary, oil hole of accumulator and suction hole of oil pump in compressor.

It prevents normal operation of the compressor.

In order to avoid this problem, Welding should be done after replacing air by nitrogen gas.

When welding plumbing pipe, the work is required.

◆How to work

CAUTION :

1. Always use the nitrogen.(not use oxygen, carbon dioxide, and a Chevron gas):

Please use the following nitrogen pressure 0.02 MPa

Oxygen --------- Promotes oxidative degradation of refrigerant oil.

Because it is flammable, it is strictly prohibited to use

Carbon dioxide --- Degrade the drying characteristics of gas

Chevron Gas ---- Toxic gas occurs when exposed to direct flame.

2. Always use a pressure reducing valve.

3. Please do not use commercially available antioxidant.

The residual material seems to be the oxide scale is observed.

In fact, due to the organic acids generated by oxidation of the alcohol contained in the anti-oxidants, ants nest corrosion

occurs. (causes of organic acid → alcohol + copper + water + temperature)

Regulator

Welding Point

Oxide scale

Note) should not block the outlet side.

When the internal pressure in pipe is above the

atmospheric pressure, pinhole is occurred and it

is a leakage cause.

Nitrogen gas

Pressure 0.02 MPa less

Taping

(Should not

contain air)

Auxiliary valve

Nitrogen

Page 15

Installation Manual 15

ENGLISH

Installation

1. Temporarily fix two decoration panel fixing screws (hexagon M5 screw) on the unit body. (Tighten by

amount 10 mm(3/8 inch) in length.

The fixing screws (hexagon M5 screw) are included the indoor unit box.

2. Remove the air inlet grille from the decoration panel. (Remove the hook for the air inlet grille cord.)

3. Hook the decoration panel key hole ( ) on the screws fixed in step above, and slide the panel so

that the screws reach the key hole edge.

4. Retighten completely two temporarily fixed screws and other two screws. (Total 4 screws)

5. Connect the louver motor connector and display connector.

6. After tightening these screws, install the air inlet grille (including the air filter).

Inlet Grille

The decoration panel has its installation

direction.

Before installing the decoration panel,

always remove the paper template.

Air conditioner

unit

Ceiling

board

Decoration panel

Decoration

panel

Fit the insulator (this part) and

be careful for cool air leakage

Good example

Air

Cool air leakage

(no good)

Bad example

Ceiling

board

Air conditioner unit

Installation of Decoration Panel

CAUTION : Install

certainly the decoration panel.

Cool air leakage

causes sweating.

Water drops fall.

Piping side

Air conditioner unit

Decoration panel fixing screws

(hexagon M5 screws)

Temporally fitting at 2 places

(Tightening about 10 mm)

Decoration panel

Control box cover

Louver motor

Display

Lead wire for

louver motor and

display

Decoration panel fixing screws

(Hexagon M5 screw)

Inlet Grille

Inlet Grille

Page 16

16 Indoor Unit

• Drain piping must have down-slope (1/50 to 1/100): be sure not to

provide up-and-down slope to prevent reversal flow.

• During drain piping connection, be careful not to exert extra force

on the drain port on the indoor unit.

• The outside diameter of the drain connection on the indoor unit is

32 mm(1-1/4 inch).

•

Be sure to install heat insulation on the drain piping.

Piping material: Polyvinyl chloride pipe inner diometes

Ø 25 mm(1 inch) and pipe fittings

The air conditioner uses a drain pump to drain water.

Use the following procedure to test the drain pump operation:

• Connect the main drain pipe to the exterior

and leave it provisionally until the test comes

to an end.

• Feed water to the flexible drain hose and

check the piping for leakage.

• Be sure to check the drain pump for normal

operating and noise when electrical wiring is

complete.

• When the test is complete, connect the flexible drain hose to the drain port on the indoor

unit.

Heat insulation material: Polyethylene foam with thickness more than 8 mm(5/16 inch).

Drain test

Maintenance

drain port

Upward

routing

not allowed

Pipe clamp

Indoor unit

1/50~1/100

• TE : 700 mm

(27-9/16 inch)

• TM/TN/TP : 800 mm

(31-12 inch)

MAX

Feed water

Drain Pump

Drain pan

Flexible drain hose

(accessory)

Main

drain pipe

Glue the joint

Drain

port

Drain hose connection

Use the clip (accessory)

1/50~1/100

Flexible drain hoseFlexible drain hoseFlexible drain hose

• TE : 700 mm

(27-9/16 inch)

• TM/TN/TP : 800 mm

(31-12 inch)

MAX

Drain Piping

CAUTION : The supplied flexible drain

hose should not be curved, neither

screwed. The curved or screwed hose

may cause a leakage of water.

Installation

Page 17

Installation Manual 17

ENGLISH

Installation

Attention

1. Possible drain-head height is up to 700 mm (279/16 inch). So, it must be installed below 700 mm

(27-9/16 inch).

2. Keep the drain hose downward up to 1/50~1/100

inclination.

Prevent any upward flow or reverse flow in any

part.

3. 5mm or thicker formed thermal insulator is provided for the drain pipe.

4. Upward routing is not allowed.

5. Be sure to check the drain pump for normal operation and abnormal noise when electrical wiring is

complete.

1/50~1/100

MAX 700 mm

(27-9/16 inch)

Elbow

Drain pump

Unit

Drain pipe

(Local supply)

Thermal insulator

(Local supply)

Wall

Drain hose

Page 18

Dip Switch Setting

For Multi V Models, Dip switch 1, 2, 6, 8 must be set OFF.

Function Description Setting Off Setting On Default

SW1

SW2

SW3

SW4

SW5

SW6

SW7

SW8

Communication

Cycle

Group Control

Dry Contact Mode

Installation

Heater linkage

Ventilator linkage

Vane selection

(Console)

Region selection

Etc.

N/A (Default)

N/A (Default)

Selection of Master or Slave

Selection of Dry Contact

Mode

Fan continuous operation

N/A

Selection of Ventilator linkage

Selection of up/down side

Vane

Selection tropical region

Spare

-

-

Master

Wired/Wireless remote

controller

Selection of Manual or Auto

operation Mode

Continuous operation Removall

-

Linkage Removal

Up side + Down side Vane

General model

-

-

-

Slave

Auto

-

-

Working

Up side Vane

Only

Tropical model

-

Off

Off

Off

Off

Off

Off

Off

Off

18 Indoor Unit

Installation

Page 19

Installation Manual 19

Installation

ENGLISH

Group Control Setting

Wired remote controller 1 + Standard Indoor Units

Dip Switch in PCB (Cassette and Duct Type indoor units)

1. It is possible to 16 indoor units(Max) by one wired remote controller.

Set only one indoor unit to Master, set the others to Slave.

2. It is possible to connect with every type of indoor units.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

GND

Signal

12 V

Master

Slave

Slave

Slave

Master

Display Error Message

Only connect serial signal and GND lines

between slave indoor unit

LGAP Network System

- No. 3 Off - No. 3 On

- The Master indoor unit is possible to recognize Dry Contact and Central Controller only.

- In case of Central controller and Group controller at the same time, it is possible to connect

standard 2series indoor units or later since Feb. 2009.

- In case of Central controller setting, the Central controller can control indoor units after

setting only the address of master indoor unit.

- Slave indoor unit will be operated like master indoor unit.

- Slave indoor unit can not be individually controlled by Central controller.

- Some remote controller can’t perform with Dry Contact and Central controller at the same

time. So contact us further information about it.

1. Group Control 1

Page 20

20 Indoor Unit

Installation

2. Group Control 2

5. In case of any error occurs at indoor unit, display on the wired remote controller.

Exception of the error indoor unit, an individual indoor unit control possibility.

6. In case of Group Control, it is possible to use following functions.

- Selection of operation options (operation/stop/mode/set temperature)

- Control of flow rate (High/Middle/Low)

- It is not possible at some functions.

Master/Slave setting of indoor units be set possible using a PCB Dip Switch.

It is possible to connect indoor units since Feb. 2009.

In the other cases, please contact LGE.

It can be the cause of malfuctions when there is no setting of master and slave.

2. Group Control 2

Wired remote controllers + Standard Indoor Units

LGAP Network System

Master

Master

Slave

Donʼt connect serial 12V line

Display Error Message

Slave

Slave

Slave

GND

Signal

12 V

It is possible to control N indoor units by wired remote controller M units. (M+N≤17 Units)

Set only one indoor unit to Master, set the others to Slave.

Set only one wired remote controller to Master, set the others to Slave.

Other than those, it is same with the Group Control 1.

Page 21

Installation Manual 21

Installation

ENGLISH

Mixture connection with indoor units and Fresh Air Intake Unit

In case of connecting with standard indoor unit and Fresh Intake Unit, separate Fresh Air Intake

Unit with standard units.

(Because setting temperature are different.)

Other than those, it is same with Group Control 1.

GND

Signal

12 V

LGAP Network System

Display Error Message

FAU

Master

FAU

Slave

Master

Master

Master

Slave

FAU

Standard Standard

FAU FAU

Standard Standard

FAU

* FAU : Fresh Air Intake Unit

Standard: Standard Indoor Unit

3. Group Control 3

Page 22

22 Indoor Unit

Installation

Wired remote controller 2 + Indoor unit 1

1. It is possible to connect two wired remote controllers with one indoor unit.

2. Every types of indoor unit is possible to connect two remote controller.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

5. In case of any error occurs at indoor unit, display on the wired remote controller.

6. There isnʼt limits of indoor unit function.

LGAP Network System

Display Error Message

Master

Master

Slave

❈ Maximum 2wired remote controllers can be connected with 1 indoor unit.

4. 2 Remote Control

Slave

Mas te r

Mas ter

PZCWRCG3

Mas ter S lave

PZCWRC2

Indoor unit 2 EA +Wired remote controller

❈ PZCWRCG3 cable used for connection ❈ PZCWRC2 cable used for connection

Indoor unit 1 EA +Wired remote controller 2EA

It is possible to set group control by using below accessories.

5. Accessories for group control setting

• Apply totally enclosed noncombustible conduit in case of local building code Requiring plenum

cable usage.

Page 23

US

Please call the installing contractor of your product, as warranty service will be

provided by them.

CANADA

Service call Number # : (888) LG Canada, (888) 542-2623

Numéro pour les appels de service : LG Canada, 1-888-542-2623

Loading...

Loading...