MFL69485426

Rev.00_110718

INSTALLATION MANUAL

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

WALL MOUNTED

Original instruction

www.lghvac.com

www.lg.com

Copyright © 2018 LG Electronics Inc. All Rights Reserved.

ENGLISH FRANÇAIS ESPAÑOL

2

ENGLISH

IMPORTANT!

Please read this instruction sheet completely before installing the product.

This air conditioning system meets strict safety and operating standards. As the installer or service person, it

is an important part of your job to install or service the system so it operates safely and efficiently.

WARNING

!

• Installation or repairs made by unqualified persons can result in hazards to you and others. Installation of all field wiring and

components MUST conform with local building codes or, in the absence of local codes, with the National Electrical Code 70 and the

National Building Construction and Safety Code or Canadian Electrical code and National Building Code of Canada.

• The information contained in the manual is intended for use by a qualified service technician familiar with safety procedures and

equipped with the proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result in equipment malfunction, property damage, personal

injury and/or death.

CAUTION

Improper installation, adjustment, alteration, service or maintenance can void the warranty. The weight of the condensing unit

requires caution and proper handling procedures when lifting or moving to avoid personal injury. Use care to avoid contact with

sharp or pointed edges.

Safety Precautions

• Always wear safety eye wear and work gloves when installing equipment.

• Never assume electrical power is disconnected. Check with meter and equipment.

• Keep hands out of fan areas when power is connected to equipment.

• R-410A causes frostbite burns.

• R-410A is toxic when burned.

NOTE TO INSTALLING DEALER

: The Owners Instructions and Warranty are to be given to the owner or prominently displayed near the indoor Furnace/Air Handler

Unit.

WARNING

!

When wiring:

Electrical shock can cause severe personal injury or death. Only a qualified, experienced electrician should attempt to wire this

system.

• Do not supply power to the unit until all wiring and tubing are completed or reconnected and checked.

• Highly dangerous electrical voltages are used in this system. Carefully refer to the wiring diagram and these instructions when

wiring. Improper connections and inadequate grounding can cause accidental injury or death.

• Ground the unit following local electrical codes.

• Connect all wiring tightly. Loose wiring may cause overheating at connection points and a possible fire hazard.

• The choice of materials and installations must comply with the applicable local/national or international standards.

When transporting:

Be careful when picking up and moving the indoor and outdoor units. Get a partner to help, and bend your knees when lifting to

reduce strain on your back. Sharp edges or thin aluminum fins on the air conditioner can cut your finger.

When installing...

... in a wall: Make sure the wall is strong enough to hold the unit's weight. It may be necessary to construct a strong wood or metal

... in a room: Properly insulate any tubing run inside a room to prevent "sweating" that can cause dripping and water damage to wall

... in moist or uneven locatinons: Use a raised concrete pad or concrete blocks provide a solid, level foundation for the outdoor unit.

... in an area with high winds: Securely anchor the outdoor unit down with bolts and a metal frame. Provide a suitable air baffle.

... in a snowy area(for Heat Pump Model): Install the outdoor unit on a raised platform that is higher than drifting snow. Provide

When connecting refrigerant tubing

• Keep all tubing runs as short as possible.

• Use the flare method for connecting tubing.

• Check carefully for leaks before starting the test run.

When servicing

• Turn the power OFF at the main power box(mains) before opening the unit to check or repair electrical parts and wiring.

• Keep your fingers and clothing away from any moving parts.

• Clean up the site after you finish, remembering to check that no metal scraps or bits of wiring have been left inside the unit being

frame to provide added support.

and floors.

This prevents water damage and abnormal vibration.

snow vents.

serviced.

TIPS FOR SAVING ENERGY

TIPS FOR SAVING ENERGY

Here are some tips that will help you minimize the power consumption when you use the air

conditioner. You can use your air conditioner more efficiently by referring to the instructions

below:

• Do not cool excessively indoors. This may be harmful for your health and may consume more

electricity.

• Block sunlight with blinds or curtains while you are operating the air conditioner.

• Keep doors or windows closed tightly while you are operating the air conditioner.

• Adjust the direction of the air flow vertically or horizontally to circulate indoor air.

• Speed up the fan to cool or warm indoor air quickly, in a short period of time.

• Open windows regularly for ventilation as the indoor air quality may deteriorate if the air

conditioner is used for many hours.

• Clean the air filter once every 2 weeks. Dust and impurities collected in the air filter may block the

air flow or weaken the cooling / dehumidifying functions.

3

ENGLISH

For your records

Staple your receipt to this page in case you need it to prove the date of purchase or for warranty

purposes. Write the model number and the serial number here:

Model number :

Serial number :

You can find them on a label on the side of each unit.

Dealer’s name :

Date of purchase :

IMPORTANT SAFETY INSTRUCTIONS

4

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid

dangerous situations and ensure peak performance of your

product

WARNING

!

It can result in serious injury or death when the directions are

ignored

CAUTION

!

It can result in minor injury or product damage when the

directions are ignored

WARNING

!

• Installation or repairs made by unqualified persons can result

in hazards to you and others.

• Installation MUST conform with local building codes.

• The information contained in the manual is intended for use

by a qualified service technician familiar with safety

procedures and equipped with the proper tools and test

instruments.

• Failure to carefully read and follow all instructions in this

manual can result in equipment malfunction, property

damage, personal injury and/or death.

Installation

• Don’t use a power cord, a plug or a loose socket which is

damaged.

- Otherwise, it may cause a fire or electrical shock.

• For electrical work, contact the dealer, seller, a qualified

electrician, or an Authorized Service Center.

- Do not disassemble or repair the product. There is risk of fire

or electric shock.

IMPORTANT SAFETY INSTRUCTIONS

• Always ground the product.

- There is risk of fire or electric shock.

• Install the panel and the cover of control box securely.

- There is risk of fire or electric shock.

• Always install a dedicated circuit and breaker.

- Improper wiring or installation may cause fire or electric

shock.

• Use the correctly rated breaker or fuse.

- There is risk of fire or electric shock.

• Do not modify or extend the power cable.

- There is risk of fire or electric shock.

• Do not let the air conditioner run for a long time when the

humidity is very high and a door or a window is left open.

- Moisture may condense and wet or damage furniture.

• Be cautious when unpacking and installing the product.

- Sharp edges could cause injury. Be especially careful of the

case edges and the fins on the condenser and evaporator.

• For installation, always contact the dealer or an Authorized

Service Center.

- There is risk of fire, electric shock, explosion, or injury.

5

ENGLISH

• Do not install the product on a defective installation stand.

- It may cause injury, accident, or damage to the product.

• Be sure the installation area does not deteriorate with age.

- If the base collapses, the air conditioner could fall with it,

causing property damage, product failure, and personal

injury.

• There is a risk of fire and explosion.

- Inert gas (nitrogen) should be used when you check

plumbing leaks, cleaning or repairs of pipes etc.

If you are using combustible gases including oxygen,

product may have the risk of fires and explosions.

• Use a vacuum pump or Inert (nitrogen) gas when doing

leakage test or air purge. Do not compress air or Oxygen and

do not use Flammable gases. Otherwise, it may cause fire or

explosion.

- There is the risk of death, injury, fire or explosion.

6

ENGLISH

Operation

IMPORTANT SAFETY INSTRUCTIONS

• Do not turn on the breaker or power under condition that front

panel, cabinet, top cover, control box cover are removed or

opened.

-

Otherwise, it may cause fire, electric shock, explosion or death.

-

For refrigerant leakage, consult your dealer. When the air

conditioner is to be installed in a small room, it is necessary to

take proper measures so that the amount of any leaked

refrigerant does not exceed the limiting concentration even

when it leaks. If the refrigerant leaks exceeding the level of

limiting concentration, an oxygen deficiency accident may

happen.

• Do not store or use flammable gas or combustibles near the

product.

- There is risk of fire or failure of product.

• Never use flammable spray such as hair spray, lacquer, or

paint near the unit.

• Tear apart and throw away plastic packaging bags so that

children will not play with them.

CAUTION

!

Installation

• Always check for gas (refrigerant) leakage after installation or

repair of product.

- Low refrigerant levels may cause failure of product.

• Install the drain hose to ensure that water is drained away

properly.

- A bad connection may cause water leakage.

• Keep level even when installing the product.

- To avoid vibration or water leakage.

• Use two or more people to lift and transport the product.

- Avoid personal injury.

TABLE OF CONTENTS

3 TIPS FOR SAVING ENERGY

4 IMPORTANT SAFETY INSTRUCTIONS

8 INSTALLATION PARTS

8 INSTALLATION TOOLS

9 INSTALLATION MAP

10 INSTALLATION

10 Select the best Location

10 Fixing Installation Plate

11 Drill a Hole in the Wall

11 Flaring Work

12 Connecting the Piping

16 Checking the Drainage

18 Manual the decor, air filter Assembly & Disassembly

19 Wiring Connection

22 DIP Switch Setting

23 Group Control Setting

28 Model Designation

28 Airborne Noise Emission

28 Limiting concentration

TABLE OF CONTENTS

7

ENGLISH

INSTALLATION PARTS

8

ENGLISH

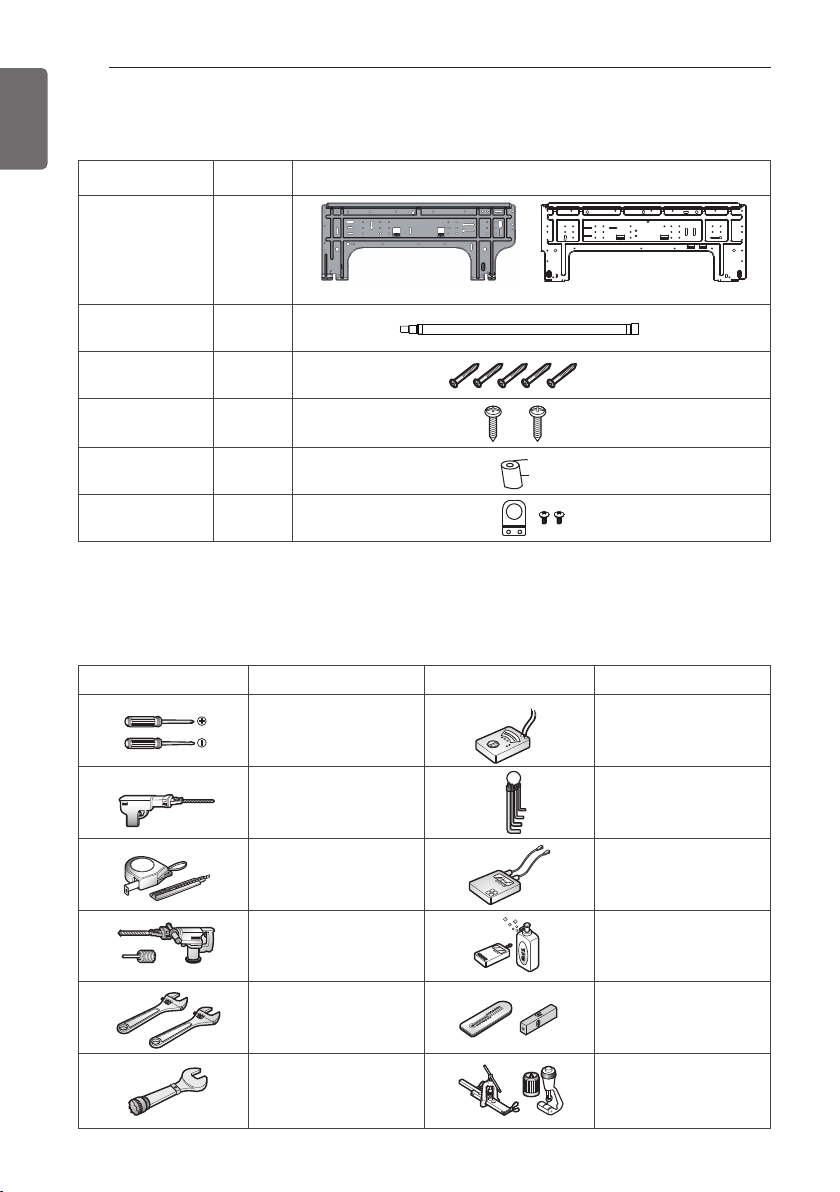

INSTALLATION PARTS

Name

Installation plate

Quantity Shape

1 EA

SJ SK

Drain hose

Type "A" screw

Type "C" screw

Cloth tape

Conduit

mounting plate

Cloth tape is not attached to the product.

1 EA

5 EA

2 EA

1 EA

1 EA

INSTALLATION TOOLS

Figure FigureName

Screw driver

Name

Multi-meter

Electric drill

Measuring tape, Knife

Hole core drill

Spanner

Torque wrench

Hexagonal wrench

Ammeter

Gas-leak detector

Thermometer,

Level

Flaring tool set

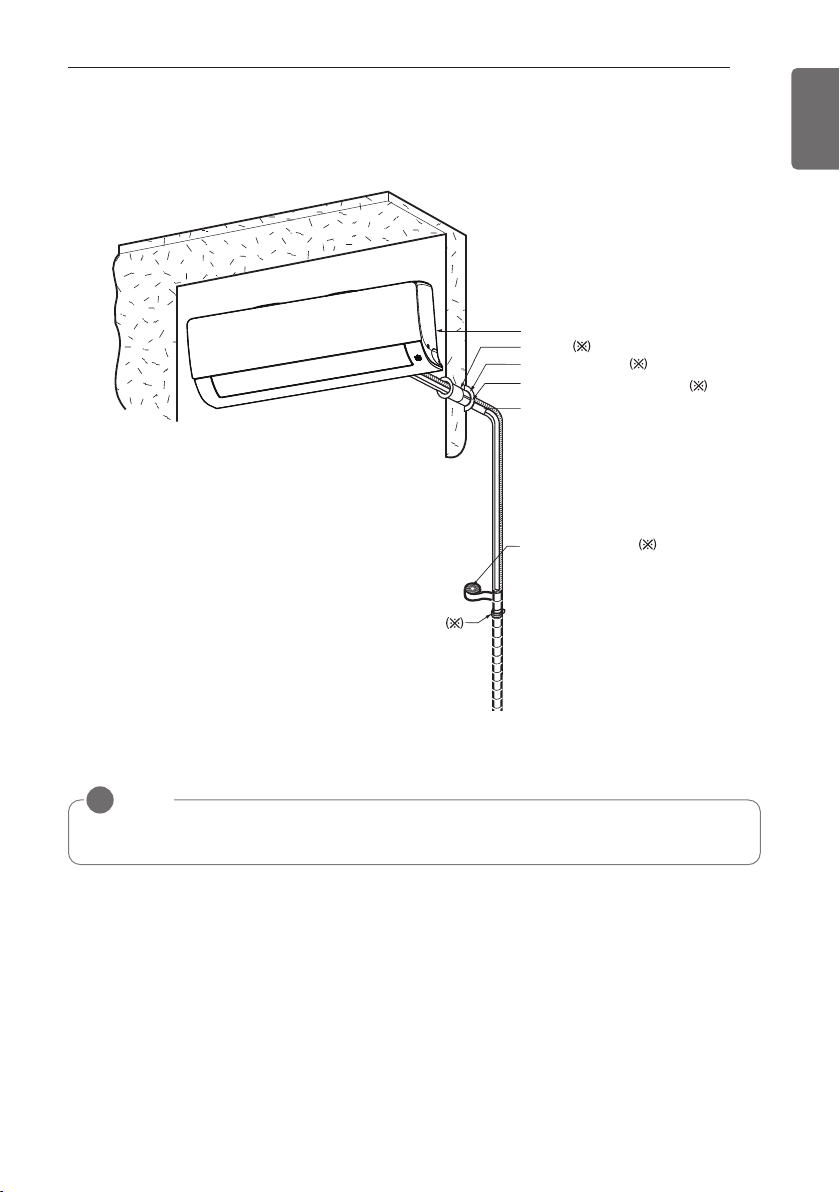

INSTALLATION MAP

Vinyl tape (Wide)

• Apply after carrying out a

drainage test.

• To carry out the drainage

test, remove the air filters

and pour water into the heat

exchanger.

Saddle

Installation plate

Sleeve

Bushing-Sleeve

Putty(Gum Type Sealant)

Bend the pipe as closely

on the wall as possible,

but be careful that it

doesn't break.

INSTALLATION MAP

9

ENGLISH

* The feature can be changed according to type of model.

NOTE

!

• You should purchase the installation parts.

10

83(3-1/4)

Φ6565

(Φ

2-9/16)

Φ6565

(Φ

2-9/16)

83(3-1/4)

ENGLISH

INSTALLATION

INSTALLATION

Select the best Location

- There should not be any heat or steam near

the unit.

- Select a place where there are no obstacles

around of the unit.

- Make sure that condensation drainage can

be conveniently routed away.

- Do not install near a doorway.

- Ensure that the interval between a wall and

the left (or right) of the unit is more than 100

mm. The unit should be installed as high as

possible on the wall, allowing a minimum of

200 mm from ceiling.

- Use a metal detector to locate studs to

prevent unnecessary damage to the wall.

More than

100(4)

More than

2300(90-9/16)

* The feature can be changed according to

type of model.

CAUTION

!

Install the indoor unit on the wall where

the height from the floor is more than

2300 mm.

Fixing Installation Plate

The wall you select should be strong and solid

enough to prevent vibration

1 Mount the installation plate on the wall

with type "A" screws. If mounting the unit

on a concrete wall, use anchor bolts.

- Mount the installation plate horizontally

by aligning the centerline using Horizontal

meter .

More than

200(7-14/16)

Unit : mm(inch)

More than

100(4)

Installation Plate

Type "A" Screws

Chassis

Hook

2 Measure the wall and mark the centerline.

It is also important to use caution

concerning the location of the installation

plate. Routing of the wiring to power

outlets is through the walls typically.

Drilling the hole through the wall for piping

connections must be done safely.

Unit Outline

Φ65

(Φ2-9/16)

Left rear piping

Unit Outline

Φ65

(Φ2-9/16)

Tubatura posteriore sinistra

134(5-1/4)

Place a level on raised tab

418(16-7/16)

Installation Plate

98(3-7/8) 134(5-1/4)

152(6)

Place a level on raised tab

494(19-7/16)

2-9/16)

Measuring

83(3-1/4)

83(3-1/4)

Measuring Tape

Tape

Hanger

418(16-7/16)

Φ65

(Φ2-9/16)

194(7-5/8)

Unit : mm(inch)

504(19-7/8)

Φ65

(Φ2-9/16)

2-9/16)

83(3-1/4)

83(3-1/4)

150(5-7/8)

Unit : mm(inch)

Right rear piping

Right rear piping

Drill a Hole in the Wall

Flare nut

Copper tube

- Drill the piping hole with a Ø 65 mm hole

core drill. Drill the piping hole at either the

right or the left with the hole slightly slanted

to the outdoor side.

WALL

Indoor

Outdoor

5-7mm

(3/16"~5/16")

INSTALLATION

Putting nut on

- Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after finishing

flare work)

11

ENGLISH

Flaring Work

Main cause for gas leakage is due to defect of

flaring work. Carry out correct flaring work in

the following procedure.

Cut the pipes and the cable

1 Use the piping kit accessory or the pipes

purchased locally.

2 Measure the distance between the indoor

and the outdoor unit.

3 Cut the pipes a little longer than measured

distance.

4 Cut the cable 1.5m longer than the pipe

length.

Copper

pipe

Burrs removal

1. Completely remove all burrs from the cut

cross section of pipe/tube.

2. While removing burrs put the end of the

copper tube/pipe in a downward direction

while removing burrs location is also

changed in order to avoid dropping burrs

into the tubing.

Point down

90 °

Slanted Uneven Rough

Pipe

Reamer

Flaring work

1

Firmly hold copper pipe in a bar with the

dimension shown in below table table below.

2 Carry out flaring work with the flaring tool.

<Wing nut type>

Bar

Pipe diameter

Inch (mm)

Ø 1/4 (Ø 6.35) 1.1~1.3

Ø 3/8 (Ø 9.52) 1.5~1.7

Ø 1/2 (Ø 12.7) 1.6~1.8

Ø 5/8 (Ø 15.88) 1.6~1.8

"A"

Copper pipe

<Clutch type>

A inch (mm)

Wing nut type Clutch type

0~0.02

(0~0.5)

12

ENGLISH

INSTALLATION

Check

1 Compare the flared work with the figure

by.

2 If a flared section is defective, cut it off

and do flaring work again.

Smooth all round

Even length

all round

Inside is shiny without scratches

= Improper flaring =

Surface

damaged

Cracked Uneven

Inclined

thickness

Connecting the Piping

1 Pull the cover at the bottom of the indoor

unit. Pull the cover ① → ②.

2 Remove the cover from the indoor unit.

ڹ

ڸ

ڸ

ڸ

ڹ

3 Pull back the tubing holder.

4 Remove pipe port cover and positioning

the tubing

Indoor unit back side view

Right

Downwards

* The feature can be changed according to

type of model.

Tubing holder

Left

Backwards

Assembly of chassis cover

1 Insert 3 hooks of the chassis cover into

gap of the chassis certainly.

2 Push the hooks to assemble chassis

cover. Push the chassis cover ① → ②.

ڹ

ڸ

ڸ

ڸ

ڸ

ڹ

INSTALLATION

13

ENGLISH

Good case

- Press on the tubing cover and unfold the

tubing to downward slowly. And then bend

to the left side slowly.

Bad case

- Following bending case from right to left

directly may cause damage to the tubing.

* The feature can be changed according to

type of model.

* The feature can be changed according to

type of model.

CAUTION

!

Installation Information. For right piping.

Follow the instruction above.

14

ENGLISH

INSTALLATION

Installation of Indoor Unit

1 Hook the indoor unit onto the upper

portion of the installation plate.( engage

the three hooks at the top of the indoor

unit with the upper edge of the installation

plate) Ensure that the hooks are properly

seated on the installation plate by moving

it left and right

Installation plate

2 Unlock the tubing holder from the chassis

and mount between the chassis and

installation plate in order to separate the

bottom side of the indoor unit from the

wall.

Tubing Holder

* The feature can be changed according to

type of model.

Piping

1 Insert the connecting cable through the

bottom side of indoor unit and connect the

cable (You can see detail contents in

'Connecting the cables' section)

<Left side piping>

<Right side piping>

View

Terminal block of indoor unit

L(L1) N(L2) 3(A) 4(B)

Indoor power input

Slide up the metal

plate cover

Outdoor unit

2 Secure the cable onto the control board

with the cable retainer.

3 Tape the tubing pipe, drain hose and the

connection cable. Be sure that the drain

hose is located at the lowest side of the

bundle. Locating at the upper side can

cause overflow from the drain pan through

the inside of the unit.

<Left side piping>

Tape

Connecting

cable

Drain hose

Connecting pipe

<Right side piping>

View

Terminal block of indoor unit

L(L1) N(L2) 3(A) 4(B)

Indoor power input

Outdoor unit

Slide up the metal

plate cover

Tape

Connecting

cable

Drain hose

Connecting pipe

* The feature can be changed according to

type of model.

INSTALLATION

Gas Pipe

Liquid Pipe

Cutting Line

Cutting Line

Good Case Bad Case

* Tubing cutting line have to be upward.

Vinyl tape(narrow)

Connection pipe

Connecting cable

Vinyl tape (wide)

Wrap with vinyl tape

Indoor unit pipe

Pipe

15

ENGLISH

CAUTION

!

If the drain hose is routed inside the room

insulate the hose with an insulation material*

so that dripping from sweating condensation)

will not damage furniture or floors.

* Foamed polyethylene or equivalent is

recommended.

Connecting the installation pipe

and drain hose to the indoor unit.

1 Align the center of the pipes and

sufficiently tighten the flare nut by hand

Indoor unit tubing Flare nut Pipes

2 Tighten the flare nut with a wrench

Outside diameter

mm inch kgf.m

Ø6.35 1/4 1.8~2.5

Ø9.52 3/8 3.4~4.2

Ø12.7 1/2 5.5~6.5

Ø15.88 5/8 6.3~8.2

Ø19.05 3/4 9.9~12.1

Torque

Wrap the insulation material

around the connecting portion.

1 Overlap the connection pipe insulation

material and the indoor unit pipe insulation

material. Bind them together with vinyl

tape so that there may be no gap.

Insulation material

2 Set the tubing cutting line upward.

Wrap the area which accommodates the

rear piping housing section with vinyl tape.

Torque wrench

Indoor unit tubing

3 When needed to extend the drain hose of

indoor unit, assembly the drain pipe as

shown on the drawing

Drain pipe

Adhesive

Open-end wrench

(fixed)

Flare nut

Connection pipe

Indoor unit drain hose

Vinyl tape(narrow)

3 For left rear piping, bundle the piping and

drain hose together by wrapping them

cloth tape over the range within which

they fit into the rear piping housing

section.

Wrap with cloth tape

Pipe

Cloth tape

Drain hose

* Wrap the piping of the indoor unit that are

visible from the outside with vinyl tape.

16

Downward slope

ENGLISH

INSTALLATION

Finishing the indoor unit

installation

1 Mount the tubing holder in the original

position.

2 Ensure that the hooks are properly seated

on the installation plate by moving it left

and right.

3 Press the lower left and right sides of the

unit against the installation plate until the

hooks engage into their slots (clicking

sound).

4 Finish the assembly by screwing the unit

to the installation plate by using two

pieces of type "C" screws. And assemble a

chassis cover.

Checking the Drainage

To check the drainage

1 Pour a glass of water on the evaporator.

2 Ensure the water flows through the drain

hose of the indoor unit without any

leakage and goes out the drain exit.

Connecting area

drain hose

Leakage

checking

Drain pan

Drain

hose

Leakage

checking

Drain piping

1 The drain hose should point downward for

easy drain flow.

Type 'C' screw

2 Do not make drain piping like the

Do not raise

Water

leakage

Accumulated

drain water

Air

Waving

Water

leakage

Tip of drain hose

dipped in water

Water

leakage

Ditch

Less than

50mm gap

following.

INSTALLATION

17

ENGLISH

* The feature can be changed according to

type of model.

INSTALLATION

18

ENGLISH

Manual the decor, air filter Assembly & Disassembly

INSTALLATION

Wiring Connection

- Connect the wires to the terminals on the control board individually according to the outdoor

unit connection.

- Ensure that the color of the wires of outdoor unit and the terminal No. are the same as those of

indoor unit respectively.

19

ENGLISH

SJ/SK

Terminal block of indoor unit

L(L1) N(L2) 3(A) 4(B)

Indoor power input

※Resistance measurement position for incorrect wiring.

CAUTION

!

The connecting cable connected to the indoor and outdoor unit

should be complied with the following specifications (This

equipment shall be provided with a cable set complying with the

national regulation).

If the supply cable is damaged, it must be replaced by a special

cable or assembly available from the manufacturer of its service

agent.

WARNING

!

Make sure that the screws of the terminal are free from looseness.

Outdoor unit

ODU ODU

Terminal block of outdoor unit

Indoor unit

IDU IDU

Central controller

INTERNET

DRY1

10±3 mm

NORMAL

CROSS-SECTIONAL

AREA 0.75 mm

DRY2

35±5 mm

GN/YL

GND

2

12V

20 mm

CAUTION

!

The Power cord connected to the unit should be selected according to the following

specifications.

INSTALLATION

Round pressure terminal

Power wire (Ground wire)

20

ENGLISH

Precautions when laying power and ground wiring

Use round pressure terminals for connections to the power terminal block.

When laying ground wiring, you must use round pressure terminals.

When none are available, follow the instructions below.

- Do not connect wiring of different thicknesses to the power terminal block. (Slack in the power

wiring may cause abnormal heat.)

- When connecting wiring which is the same thickness, do as shown in the figure below.

Connection method of the connecting cable(Example)

SJ/SK Chassis

L(L1)

N(L2)

3(A) 4(B)

Power Supply

High Voltage

Conduit

Conduit mounting plate

Lock nut

Transmission

INSTALLATION

CAUTION

!

Be sure to test the power line and communication line for incorrect wiring before power is

applied.

1) If the power line and communication line are swapped over, the product will be damaged.

2) Incorrect wiring confirmation test method

: Measure the resistance across the power terminals (L,N) using a multi meter.

- Resistance value of a normal connection: 1MΩ or more

- Incorrect wiring resistance value: 500MΩ or less

CAUTION

!

After the confirmation of the above conditions, prepare the wiring as follows:

1) Never fail to have separate power specially for the air conditioner. As for the method of

wiring, follow the circuit diagram pasted on the inside of control box cover.

2) Provide a circuit breaker switch between power source and the unit.

3) The screw which fasten the wiring in the casing of electrical fittings are liable to come loose

from vibrations to which the unit is subjected during the course of transportation. Check

them and make sure that they are all tightly fastened. (If they are loose, it could give rise to

burn-out of the wires.)

4) Confirm the Specification of power source

5) Confirm that electrical capacity is sufficient.

6) Be sure that the starting voltage is maintained at more than 90 percent of the rated voltage

marked on the name plate.

7) Confirm that the cable thickness is as specified in the power sources specification.

(Particularly note the relation between cable length and thickness.)

8) Do not install the leakage breaker in a place which is wet or moist.

Water or moist may cause short circuit.

9) The following troubles would be caused by voltage drop-down.

- Vibration of a magnetic switch, damage on the contact point there of, fuse breaking,

disturbance to the normal function of a overload protection device.

- Proper starting power is not given to the compressor.

10) Before applying power to the indoor unit, be sure to check for incorrect wiring of the power

and communication lines.

21

ENGLISH

INSTALLATION

22

ENGLISH

DIP Switch Setting

Indoor Unit

Function Description Setting Off Setting On Default

SW1 Communication N/A (Default) - - Off

SW2 Cycle N/A (Default) - - Off

SW3 Group Control

Dry Contact

SW4

Mode

SW5 Installation

SW6 Heater linkage N/A - - Off

Ventilator

linkage

Vane selection

SW7

(Console)

Region selection

SW8 Etc. Spare - - Off

* Whether the DIP Switch function of PCB is applied or not may be different depending on the

model.

Selection of Master

or Slave

Selection of Dry

Contact Mode

Fan continuous

operation

Selection of

Ventilator linkage

Selection of up/down

side Vane

Selection tropical

region

Master Slave Off

Wired/Wireless remote

controller

Selection of Manual or

Auto operation Mode

Continuous operation

Removall

Linkage Removal

Up side + Down side

Vane

General model Tropical model

Working

Up side Vane

Auto

- Off

Only

Off

Off

CAUTION

!

For Multi V Models, DIP switch 1, 2, 6, 8 must be set OFF.

Outdoor Unit

In case that the products meet specific conditions, “Auto addressing” function can start

automatically with the improved speed by turning the DIP switch #3 of the outdoor unit and

resetting the power.

* Specific conditions:

- All names of the indoor units are ARNU****4

- The serial number of Multi V super IV (outdoor units) is after October 2013,

DIP switch 7 segment

Outdoor Unit PCB Outdoor Unit DIP Switch

Group Control Setting

Group Control 1

n Wired remote controller 1 + Standard Indoor Units

or

Master Slave Slave Slave

INSTALLATION

LGAP Network System

23

GND

Signal

12 V

ENGLISH

Display Error Message

Master

Only connect serial signal and

GND lines between indoor units.

n DIP Switch in PCB

① Master Setting

- No. 3 Off

② Slave Setting

- No. 3 On

Indoor Unit DIP Switch

Some products have no DIP switch on PCB. It is possible to set indoor units to Master or Slave

by using the wireless remote controller instead of DIP switch.

For the details of the setting, please refer to the manual of the wireless remote controller.

1. It is possible to 16 indoor units(Max.) by one wired remote controller.

Set only one indoor unit to Master, set the others to Slave.

2. It is possible to connect with every type of indoor units.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

- The Master indoor unit is possible to recognize Dry Contact and Central Controller only.

5. In case that any error occurs at indoor unit, the error code is displayed on the wired remote

controller.

It is possible to control the other indoor units except the error units.

INSTALLATION

GND

Signal

12 V

Slave

Slave

Master

or

Donʼt connect serial 12 V line

LGAP Network System

Master

Master Master

Display Error Message

24

ENGLISH

* It is possible to connect indoor units since Feb. 2009.

* It can be the cause of malfuctions when there is no setting of master and slave.

* In case of Group Control, it is possible to use following functions.

- Selection of operation, stop or mode

- Temperature setting and room temperature check

- Current time change

- Control of flow rate (High/Middle/Low)

- Reservation settings

- It is not possible at some functions.

Group Control 2

n Wired remote controllers + Standard Indoor Units

* It is possible to control 16 indoor units(Max.) with the master wired remote control.

* Other than those, it is same with the Group Control 1.

Group Control 3

n Mixture connection with indoor units and Fresh Air Intake Unit

INSTALLATION

25

ENGLISH

LGAP Network System

Slave

Display Error Message

M

FAU

Master

Master

FAU

Slave

Display Error Message

or

Master

N

Master

* In case of connecting with standard indoor unit and Fresh Air Intake Unit, separate Fresh Air

Intake Unit with standard units. (N, M ≤ 16) (Because setting temperature are different.)

* Other than those, it is same with Group Control 1.

FAU

Standard Standard

FAU FAU

FAU

Standard Standard

GND

Signal

12 V

* FAU : Fresh Air Intake Unit

Standard: Standard Indoor Unit

INSTALLATION

26

ENGLISH

2 Remote Control

n Wired remote controller 2 + Indoor unit 1

LGAP Network System

Slave

GND

Signal

12 V

Master

Master

Display Error Message

Slave

Slave

or

Slave

1. It is possible to connect two wired remote controllers (Max.) with one indoor unit.

Set only one indoor unit to Master, set the others to Slave.

Set only one wired remote controller to Master, set the others to Slave.

2. Every types of indoor unit is possible to connect two remote controller.

3. It is possible to use wireless remote controller at the same time.

4. It is possible to connect with Dry Contact and Central controller at the same time.

5. In case that any error occurs at indoor unit, the error code is displayed on the wired remote

controller.

6. There isn't limits of indoor unit function.

INSTALLATION

Accessories for group control setting

It is possible to set group control by using below accessories.

Indoor unit 2 EA +Wired remote controller Indoor unit 1 EA +Wired remote controller 2EA

* PZCWRCG3 cable used for connection * PZCWRC2 cable used for connection

27

ENGLISH

PZCWRCG3

Master

Slave

PZCWRC2

Master Slave

Master

CAUTION

!

Apply totally enclosed noncombustible conduit in case of local building code Requiring plenum

cable usage.

INSTALLATION

28

ENGLISH

Model Designation

ARN U G15 ASJ 4

Serial Number

Combinations of functions

A:Basic function L: Neo Plasma(Wall Mounted)

C: Plasma(Ceiling Cassette) N : Ionizer

G: Low Static K: High Sensible Heat

U: Floor Standing without Case

SE/S8/SJ/SK - R: Mirror V: Silver B:Blue(ART COOL Type Panel Color)

SF - E: Red V: Silver G:Gold 1: Kiss (Photo changeable)

Q: Console Z: Fresh Air Intake Unit

Chassis Name

Electrical Ratings

1 : 1 Ø, 115 V, 60 Hz

6 : 1 Ø, 220 - 240 V, 50 Hz

3 : 1 Ø, 208/230 V, 60 Hz

Total Cooling Capacity in Btu/h

EX) 5,000 Btu/h ➝ '05' 18,000 Btu/h ➝ '18'

Combination of Inverter Type and Cooling Only or Heat Pump

N: AC Inverter and H/P V: AC Inverter and C/O

U: DC Inverter and H/P and C/O

System with Indoor Unit using R410A

❈ LGETA:U Ex) URN

2 : 1 Ø, 220 V, 60 Hz

7 : 1 Ø, 100 V, 50/60 Hz

G :

1 Ø, 220 - 240 V, 50 Hz/1 Ø, 220 V, 60 Hz

Airborne Noise Emission

The A-weighted sound pressure emitted by this product is below 70 dB.

** The noise level can vary depending on the site.

The figures quoted are emission level and are not necessarily safe working levels. Whilst there is

a correlation between the emission and exposure levels, this cannot be used reliably to

determine whether or not further precautions are required. Factor that influence the actual level

of exposure of the workforce include the characteristics of the work room and the other sources

of noise, i.e. the number of equipment and other adjacent processes and the length of time for

which an operator exposed to the noise. Also, the permissible exposure level can vary from

country to country. This information, however, will enable the user of the equipment to make a

better evaluation of the hazard and risk.

Limiting concentration

Limiting concentration is the limit of Freon gas concentration where immediate measures can be

taken without hurting human body when refrigerant leaks in the air. The limiting concentration

shall be described in the unit of kg/m

calculation

Limiting concentration: 0.44 kg/m3 (0.027 lbs/ft3)

n Calculate refrigerant concentration

Refrigerant concentration =

3

(Freon gas weight per unit air volume) for facilitating

Total amount of replenished refrigerant in refrigerant facility [kg(lbs)]

Capacity of smallest room where indoor unit is installed [m

3

(ft3)]

US

CANADA

Please call the installing contractor of your product, as warranty service will be

provided by them.

Service call Number # : (888) LG Canada, (888) 542-2623

Numéro pour les appels de service : LG Canada, 1-888-542-2623

Loading...

Loading...