LG ATNH126ELFC, ATNH30GPLED, ATNH186ELFC, ATNH24GPLED, ATNH36GNLED Service Manual

...

Single "A" Air Conditioner

SVC MANUAL(General)

MODEL : Single "A"-Inverter Type

CAUTION

Before Servicing the unit, read the safety precautions in General SVC manual.

Only for authorized service personnel.

Internal Use Only

http://biz.lgservice.com

- 1 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Air Conditioner Service Manual

CONTENTS

Part 1 General Information..........................................................................................................2

1. Safety Precautions........................................................................................................3

2. Model Line up................................................................................................................6

3. Nomenclature ................................................................................................................8

Part 2 Functions & Controls......................................................................................................10

1. List of Functions & Controls......................................................................................11

2. Air flow.........................................................................................................................13

3. Air purifying.................................................................................................................15

4. Installation Functions.................................................................................................16

5. Reliability .....................................................................................................................19

6. Convenience Functions & Controls .........................................................................20

7. Special Function & KIT...............................................................................................31

8. Synchro Operation......................................................................................................48

Part 3 Control logic....................................................................................................................51

1. Compressor.................................................................................................................52

2. Step(frequency) control..............................................................................................54

3. Reversing valve operaton ..........................................................................................57

4. Discharge pipe control ...............................................................................................58

5. Input Current Control..................................................................................................59

6. Outdoor Fan Control...................................................................................................60

7. Defrost Control............................................................................................................63

8. LEV Control .................................................................................................................64

9. Oil restoration operation ............................................................................................70

10. Compressor warm-up control logic ........................................................................70

11. Heat sink control.......................................................................................................71

Part 4 Test Run ..........................................................................................................................72

1. Check before Test Run ...............................................................................................73

2. Test Run Flow chart ....................................................................................................74

Part 5 Trouble Shooting Guide ................................................................................................77

1. Self-diagnosis Function .............................................................................................78

2. Pump Down .................................................................................................................80

3. Evacuation...................................................................................................................81

4. Gas Charging...............................................................................................................82

5. Cycle Part.....................................................................................................................83

6. Electronic Parts...........................................................................................................84

- 2 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. Safety Precautions ............................................................................................................3

2. Model Line up .....................................................................................................................6

3. Nomenclature......................................................................................................................8

Part 1 General Information

Part 1 General Information

- 3 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1. Safety Precautions

1.1 Cautions in Repair

To prevent injury to the user or other people and property damage, the following instructions must be followed.

■ Incorrect operation due to ignoring instruction will cause harm or damage. The seriousness is classified by the following indications.

This symbol indicates the possibility of death or serious injury.

This symbol indicates the possibility of injury or damage to properties only.

■ Meanings of symbols used in this manual are as shown below.

Be sure not to do.

Be sure to follow the instruction.

Dangerous Voltage

Be sure to disconnect the power cable plug from the plug socket before disassembling the equipment for a repair.Internal components and circuit boards are at

main potential when the equipment is connected to the power cables. This voltage is extremely dangerous and may cause death or severe injury if come in contact with it.

Do not touch the discharging refrigerant gas during the repair work.

The discharging refrigerant gas.The refrigerant gas can cause frostbite.

Release the refrigerant gas completely at a well-ventilated place first.

Otherwise, when the pipe is disconnected, refrigerant gas or refrigerating

machine oil discharges and it Can cause injury.

When the refrigerant gas leaks during work, execute ventilation. If the refrigerant

gas touches to a fire, poisonous gas generates. A case of leakage of the refrigerant and the closed room full with gas is dangerous because a shortage of oxygen

occurs. Be sure to execute ventilation.

When removing the front panel or cabinet, execute short-circuit and discharge

between high voltage capacitor terminals. If discharge is not executed, an electric

shock is caused by high voltage resulted in a death or injury.

Do not turn the air-conditioner ON or OFF by plugging or unplugging the power

plug. There is risk of fire or electrical shock.

Part 1 General Information

- 4 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Do not turn on the breaker under condition that front panel and cabinet are

removed.

Be sure to earth the air conditioner with an earthing conductor connected to the

earthing terminal.

Conduct repair works after checking that the refrigerating cycle section has

cooled down sufficiently. Otherwise, working on the unit, the hot refrigerating

cycle section can cause burns.

Do not tilt the unit when removing panels. Otherwise, the water inside the unit

can spill and wet floor.

Do not use the welder in a well-ventilated place. Using the welder in an enclosed

room can cause oxygen deficiency.

Be sure to turn off power switch before connect or disconnect connector, or parts

damage may be occurred.

Do not use a defective or underrated circuit breaker. Use the correctly rated

breaker and fuse. Otherwise there is a risk of fire or electric shock.

Install the panel and the cover of control box securely. Otherwise there is risk of

fire or electric shock due to dust, water etc.

Indoor/outdoor wiring connections must be secured tightly and the cable should

be routed properly so that there is no force pulling the cable from the connection

terminals. Improper or loose connections can cause heat generation or fire.

Do not touch, operate, or repaire the product with wet hands. Hoding the plug by

hand when taking out. Otherwise there is risk of electric shock or fire.

Part 1 General Information

- 5 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

1.2 Inspections after Repair

Check to see if the parts are mounted correctly and wires are connected.

Improper installation and connections can cause an electric shock or an injury.

Check the installation platform or frame has corroded. Corroded installation platform or frame can cause the unit to fall, resulting in injury.

Be sure to check the earth wire is correctly connected.

After the work has finished, be sure to do an insulation tset to check the resistance is 2[Mohm] or more between the charge section and the non-charge metal

section (Earth position). If the resistance value is low, a disaster such as a leak or

electric shock is caused at user’s side.

Check the drainage of the indoor unit after the repair. If drainage is faulty the

water to enter the room and wet floor.

Check to see if the power cable plug is not dirty or loose. If the plug is dust or

loose it can cause an electrical shock or fire.

Do not use a joined power cable or extension cable, or share the same power

outlet with other electrical appliances. otherwise, it can cause an electrical shock,

excessive heat generation or fire.

Do not insert hands or other objects through the air inlet or outlet while the product is operating. There are sharp and moving parts that could cause personal

injury.

Do not block the inlet or outlet of air flow. It may cause product failure

Part 1 General Information

- 6 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

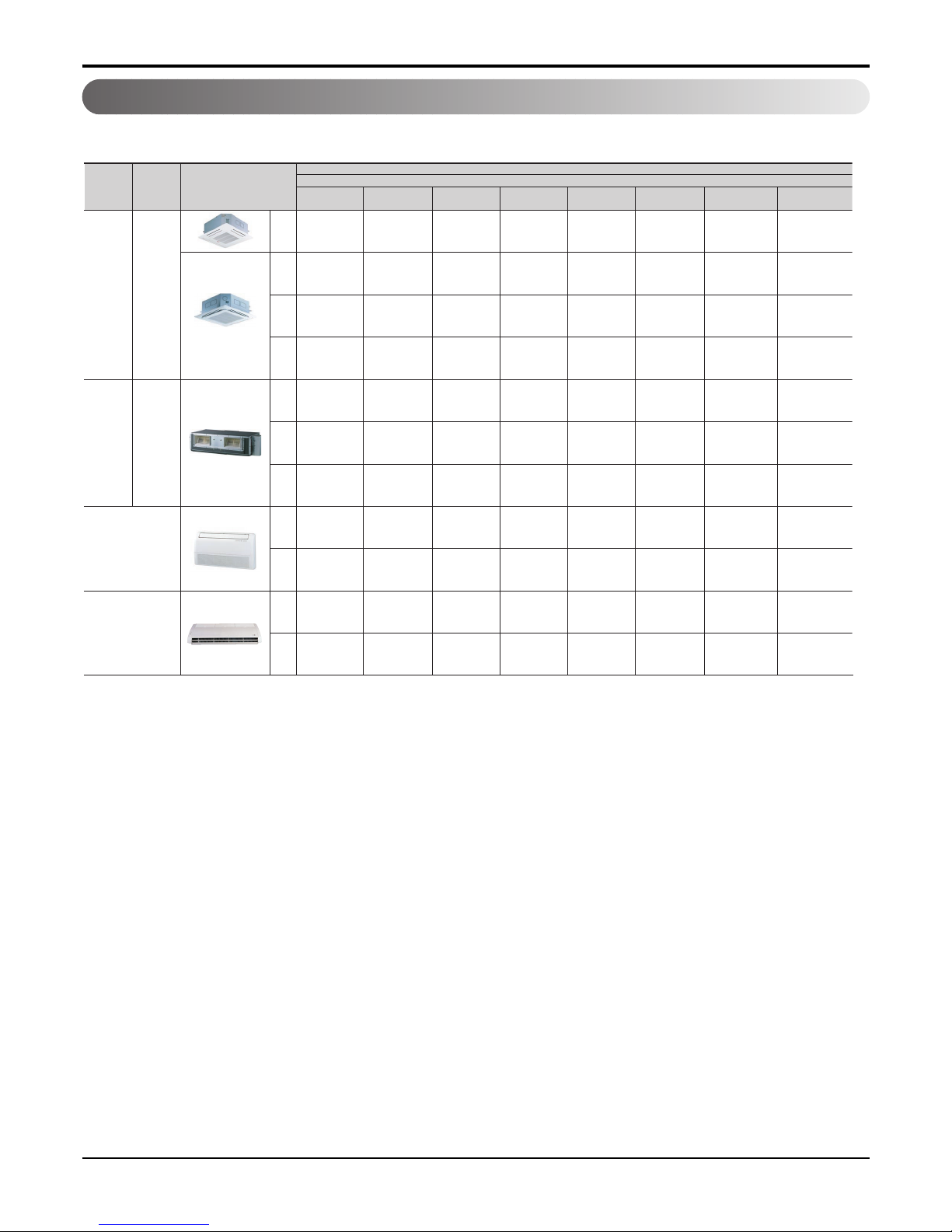

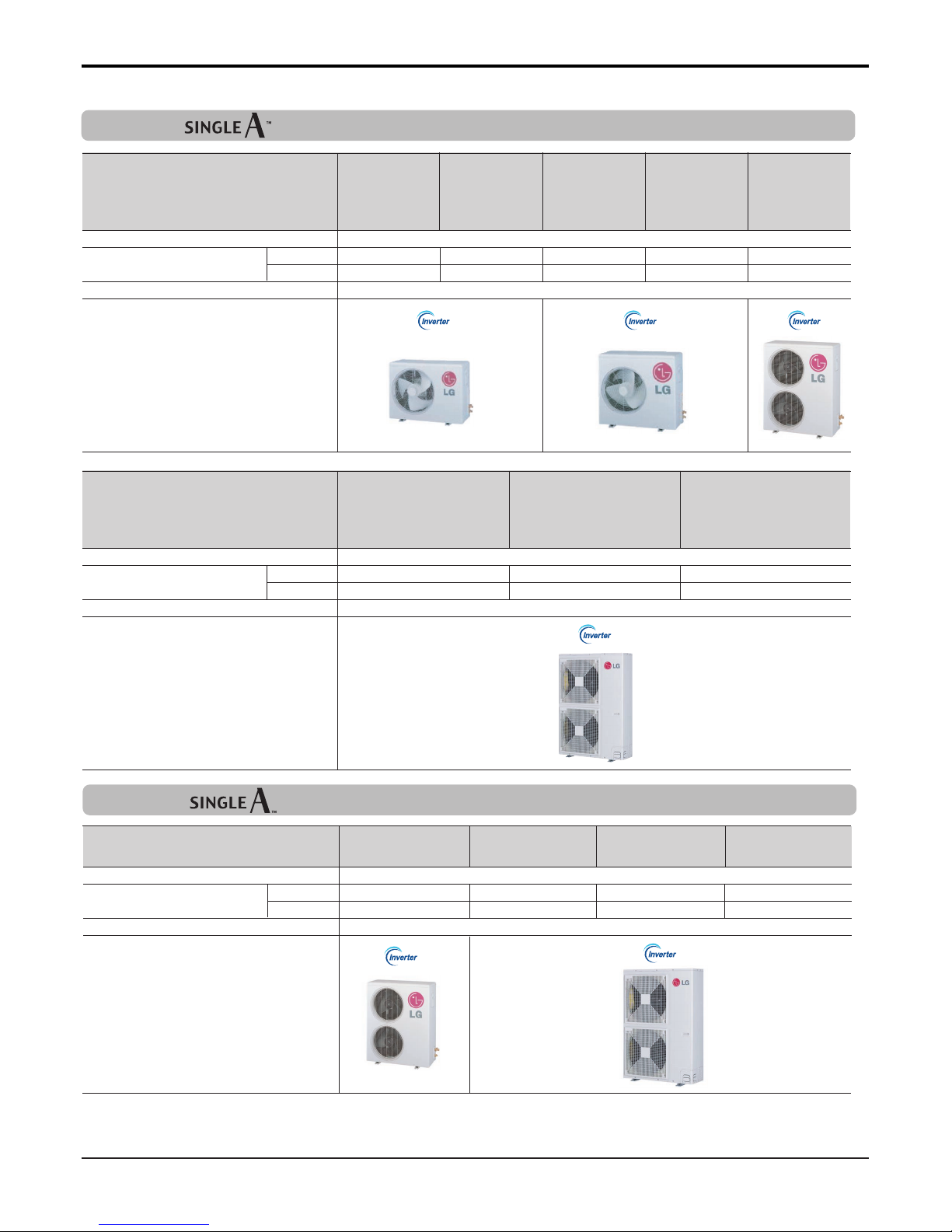

2. Model line up

2.1 Indoor units

3.52

(12)

5.28

(18)

7.03

(24)

8.79

(30)

10.6

(36)

12.3

(42)

14.1

(48)

17.6

(60)

TE

ATNH126ELFC

[UT12 NEC]

AVNH126ELAC

[UV12 NEC]

AVNH186BLAC

[UV18 NBC]

AVNH246BLAD

[UV24 NBD]

AVNH306BLAD

[UV30 NBD]

ATNH186ELFC

[UT18 NEC]

ABNH186HLAC

[UB18 NHC]

ABNH246HLAD

[UB24 NHD]

ABNH306GLAD

[UB30 NGD]

ABNH366GLAD

[UB36 NGD]

ABNH426RLAD

[UB42 NRD]

ABNH486RLAD

[UB48 NRD]

ABNH606RLAD

[UB60 NRD]

AVNH366KLAD

[UV36 NKD]

AVNH426LLAD

[UV42 NLD]

AVNH486LLAD

[UV48 NLD]

AVNH606LLAD

[UV60 NLD]

ATNH24GPLED

[UT24NPD]

ATNH30GPLED

[UT30NPD]

ATNH36GNLED

[UT36NND]

ATNH42GMLED

[UT42NMD]

ATNH48GMLED

[UT48NMD]

ATNH60GMLED

[UT60NMD]

TN

TM

Category Type

Model Name

Capacity, kW(kBth/h)

Chassis

4way

Ceiling

cassette

TP

BH

BG

BR

VE

VB

VK

VL

Ceiling & floor

Ceiling suspended

Ceiling

oncealed

duct

High

static

pressure

Part 1 General Information

- 7 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

2.2 Outdoor units

DC Inverter

AUUW126C

[UU12W UEC]

AUUW186C

[UU18W UEC]

AUUW246D

[UU24W UED]

AUUW306D

[UU30W UED]

AUUW366D

[UU36W UED]

No. of connectable indoor units Max.1

Total capacity index of connectable kW 3.52 5.28 7.03 8.79 10.6

indoor units kBtu/h 12 18 24 30 36

Power supply 1Ø, 220-240V, 50Hz

Chassis

Inverter (1Ø)

DC Inverter

AUUW426D

[UU42W U3D]

AUUW486D

[UU48W U3D]

AUUW606D

[UU60W U3D]

No. of connectable indoor units Max.1

Total capacity index of connectable kW 12.5 14.0 15.0

indoor units kBtu/h 42 48 51

Power supply 1Ø, 220-240V, 50Hz

❈ Synchro available

Chassis

3Phase Inverter

AUUW368D

[UU37W UED]

AUUW428D

[UU43W U3D]

AUUW488D

[UU49W U3D]

AUUW608D

[UU61W U3D]

No. of connectable indoor units Max.1

Total capacity index of connectable kW 10.6 12.5 14.0 15.0

indoor units kBtu/h 36 42 48

51

Power supply 3Ø, 380-415V, 50Hz

Chassis

Inverter (3Ø)

❈ Synchro available

Part 1 General Information

- 8 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

3. Nomenclature

• Global Model Name

3.1 Indoor unit s

3.2 Decoration panel(For ceiling cassette models)

3.3 Outdoor units

A T NH 1 8 6 E L CA

Serial Number

Functions

A : Basic C : Plasma Air Purifier E: Elevation grille

Look : Basic

Chassis Name

Electrical Ratings

6:1

G: 1Ø 220V~240V, 50/60Hz

Ø,220V-240V,50Hz 8:3 Ø,380V-415V,50Hz

Capacity code

Model Type

C: Cooling Only H: Heat Pump

R410A Universal Indoor Unit

ATN : Universal Ceiling Cassette Type Indoor Unit

ABN : Universal Ceiling Concealed Duct Type Indoor Unit

AVN : Universal Ceiling & Floor Type Indoor Unit

A U UH 1 8 6A

Serial Number

Electric Standard (Phase, Volts, Freq)

6:1 Ø,220V-240V,50Hz 8:3 Ø ,380V-415V,50Hz

Capacity code

Model Type

C : Cooling Only H : Heat Pump W: Inverter Heat Pump

R410A Universal Outdoor Unit

PT- H E A

Functions

A: Basic C:For Indoor Unit with Plasma Air Purifier.

Indoor Unit Chassis

Model Type

C : Cooling Only H : Heat Pump U: Universal

Decoration Panel of Ceiling Cassette Type Indoor Unit

Part 1 General Information

- 9 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

• Europe Model Name

3.4 Indoor units

UT 24

Capacity code

Type

T : Cassette

B : Duct

V : Convertible

Model Type

U : Universal Model

Decoration panel

PT -HEC

Function Key

C: Plasma filter model, A: Basic model

Indoor unit chassis

Type of indoor unit

C: Cooling Only, H: Heat Pump U:Universal

PT: Decoration panel for Cassette model

3.5 Outdoor units

UU 24 W

Type of Air conditioner

W: Inverter

No mark for non-inverter

Capacity code

Type

U : Outdoor Units

Model Type

U : Universal Model

- 10 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

Part 2 Functions & Controls

1. List of Functions & Controls ...........................................................................................9

2. Air flow ............................................................................................................................11

2.1 Auto swing (left & right) ...............................................................................................11

2.2 Auto swing (up & down) ..............................................................................................11

2.3 Chaos swing (up/down)...............................................................................................11

2.4 Air flow step.................................................................................................................12

2.5 Chaos wind (auto wind)...............................................................................................12

2.6 Jet Cool Mode Operation ............................................................................................12

2.7 Swirl wind Swing .........................................................................................................12

3. Air purifying ....................................................................................................................13

3.1 PLASMA Air Purifying System ....................................................................................13

4. Installation Functions ....................................................................................................14

4.1 E.S.P. (External Static Pressure) Setting ....................................................................14

4.2 High Ceiling operation.................................................................................................16

5. Reliability ........................................................................................................................17

5.1 Hot start ......................................................................................................................17

5.2 Self-diagnosis Function...............................................................................................17

5.3 Soft dry operation........................................................................................................17

6. Convenience Functions & Controls .............................................................................20

6.1 Auto changeover operation ........................................................................................21

6.2 Child Lock Function.....................................................................................................24

6.3 Forced operation .........................................................................................................24

6.4 Group Control..............................................................................................................25

6.5 Sleep Timer Operation ................................................................................................27

6.6 Timer(On/Off) ..............................................................................................................27

6.7 Weekly Program..........................................................................................................27

6.8 Two Thermistor Control ...............................................................................................28

6.9 Filter Sign clear ...........................................................................................................29

7. Special Function & KIT ..................................................................................................31

7.1 Wide Wired Remote controller(PQRCUSA0) installation guide ..................................31

Group control ..............................................................................................................31

Installer Setting-How to enter installer setting mode...................................................32

Installer Setting-Test Run mode .................................................................................34

Installer Setting-Setting Address of Central Control....................................................35

Installer Setting-E.S.P..................................................................................................36

Installer Setting-Thermistor .........................................................................................38

Installer Setting-Ceiling Height Selection ....................................................................39

Installer Setting-Static Pressure Setting......................................................................40

Installer Setting-Group Setting ....................................................................................41

Installer Setting-Mode Override Setting ......................................................................42

Installer Setting-Dry Contact Mode Setting .................................................................43

Installer Setting-Zone state setting..............................................................................44

Installer Setting-Option Function Setting.....................................................................45

7.2 Zone Controller ...........................................................................................................46

7.3 Auto Elevation Grille....................................................................................................47

8. Synchro operation..........................................................................................................48

- 11 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

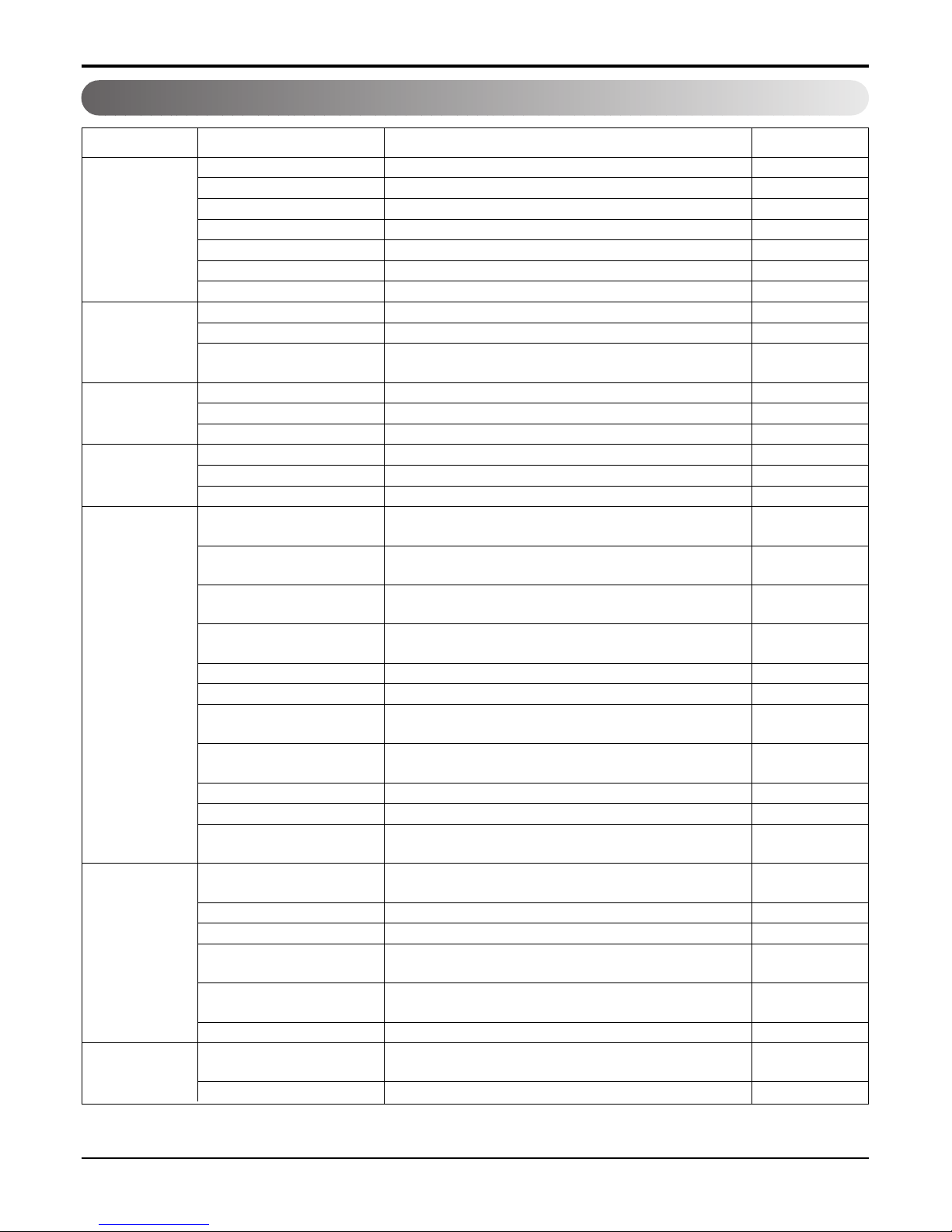

1. List of Functions & Controls

Auto swing (left & right) Optional

Auto swing (up & down) Optional

Chaos swing (up & down) Optional

Airflow steps (fan/cool/heat)

Chaos wind (auto wind) Optional

Jet cool (Power wind)

Swirl wind Swing Optional

Deodorizing filter

Plasma air purifier Optional

Pre-filter

(washable/anti-fungus)

Drain pump Optional

E.S.P. control Optional

High ceiling operation Optional

Hot start

Self diagnosis

Soft dry operation

Auto changeover

Optional

Auto clean

Optional

Auto operation

Optional

(artificial intelligence)

Auto restart operation

Child lock Optional

Forced operation

Group control

Optional

Sleep mode

Timer (on/off)

Timer (weekly)

Two thermistor control

Optional

Standard wired remote

Optional

controller

Deluxe wired remote controller Optional

Simple wired remote controller Optional

Wired remote Controller

Optional

(for hotel use)

Wireless remote controller

Optional

(simple)

Wireless LCD remote control Optional

General central controller

Optional

(Non LGAP)

Dry contact Optional

Category Function Description Remark

Horizontal Airflow Direction control

Vertical Airflow Direction control

Vertical Airflow Direction control

Indoor Fan speed Control

Indoor Fan speed Control by chaos pattern

Powerful cooling mode

Distribute & stir the Air inside.

Air filtration using Deodorizing filter

Air filtration using plasma filter

Air filtration using pre-filter

Drain water pump

Changeable External Static Pressure

Function to Control the Air Volume by Ceiling Height

To prevent cold wind blow on heating mode start

Error code displays

Dehumidification

Cooling mode is automatically changed to heating mode and

vice verse

After cooling operation, this function makes the

evaporator dry

Air volume & set temp. are automatically selected for comfort

on Cooling/Heating mode

When power returns after a power failure, unit restarts in the

previous operating mode

Protect the unit operation without approval

Operation without remote controller

Where several products are linked, one specific control

device can control a specific number of products.

Air volume & set temp. are automatically changed for com-

fortable sleep

Operation by Timer setting

Operation by weekly reservation

Option to control temperature by referring thermistor in the

Indoor unit or the LCD wired remote.

Standard wired remote controller

Deluxe wired remote controller

Simple wired remote controller

Wired remote controller (for hotel use)

Wireless remote controller (simple)

Wireless LCD remote control

General central controller

Dry contact

Airflow

Installation

Air purifying

Reliability

Convenience

Individual control

CAC network

function

- 12 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

Network Solution (LGAP) Optional

PDI

(Power Distribution Indicator)

Optional

PI 485 Optional

Zone control

Optional

Low ambient operation

Space Control Optional

Auto Elevation Optional

Outdoor Normal

Comp. control

EEV control

FAN control

Oil Return Control

Oil equalizing

Sump Heating

Protection Control

Inverter protection

Defrost / Deicing

High pressure switch Optional

Low pressure switch Optional

Phase protection Optional

Restart delay

Optional

(3-minutes)

Self diagnosis

Soft start Optional

Test function

Category Function Description Remark

Network Solution (LGAP)

PDI (power distribution indicator)

Network control using PI 485 (Internet)

control the operation of the Air conditioning unit where each

zone

For operation at low temp.

Vanes angle can be controlled by pair.

Grille is automatically down to clean

Outdoor Control

Compressor Control

EEV Control

FAN control

Oil Return Control

Oil equalizing Control

Sump Heating Control

Protection Control

Inverter protection

Condenser frost prevention

Detect high pressure for safety

Detect low pressure for safety

Misconnection prevention for three phase

For overload prevention

Error code displays

Soft start for compressor

Test operation

CAC network

function

Special Function

& KIT

Other

Functions

& Controls

Notes: The Exploded View part has the particular Function table for each model.

- 13 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

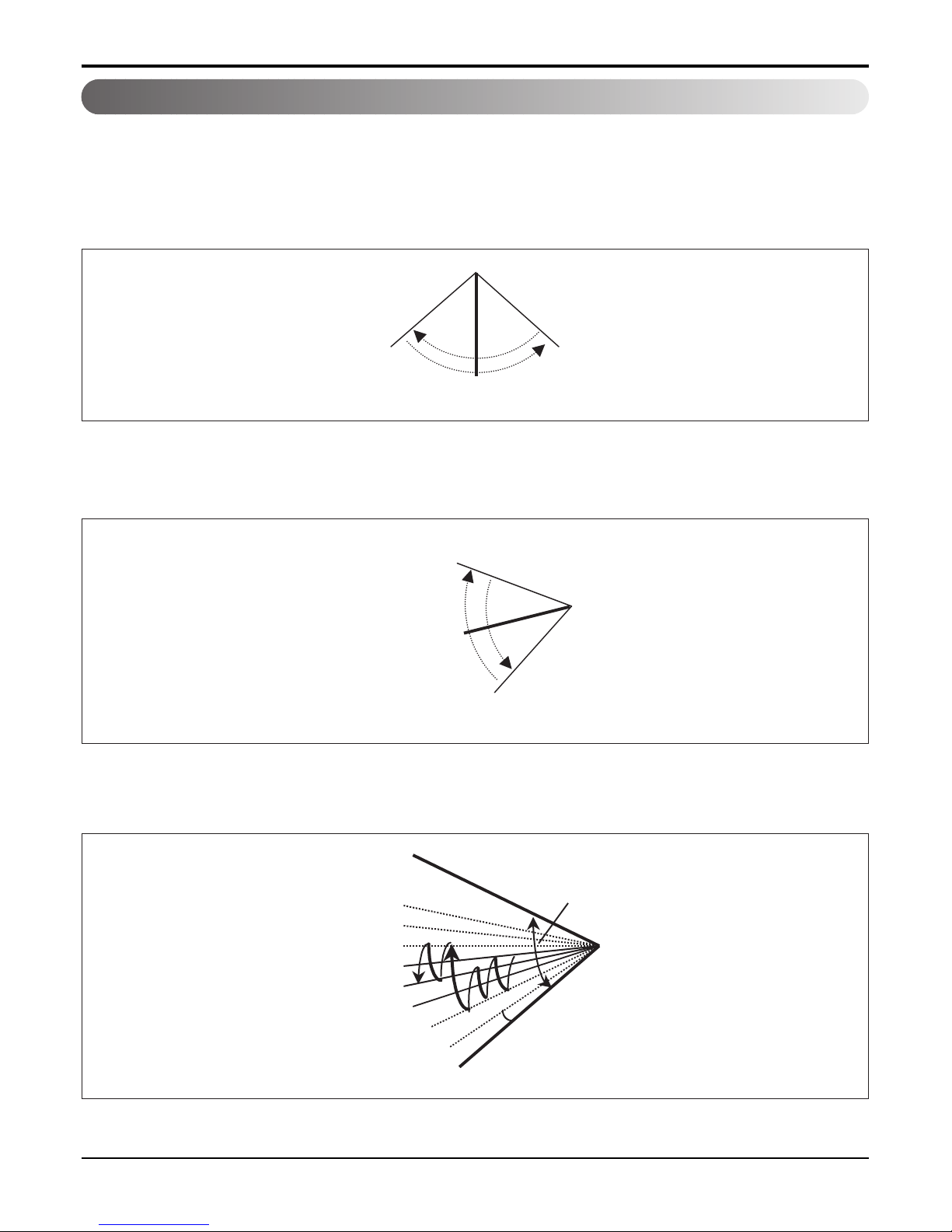

2. Air flow

2.1 Auto swing (left & right)

RightLeft

110° ~ 120°

Open

Close

110° ~ 120°

Mode2

Mode3

Mode4

Mode5

Mode6

Mode7

Mode8

Mode9

OPEN

CLOSED

7~8°

110~120°

• By the horizontal airflow direction control key input, the left/right louver automatically operates with the auto swing or it

is fixed to the desired direction.

2.2 Auto swing (up & down)

• By the auto swing key input, the upper/lower vane automatically operates with the auto swing or it is fixed to the

desired direction.

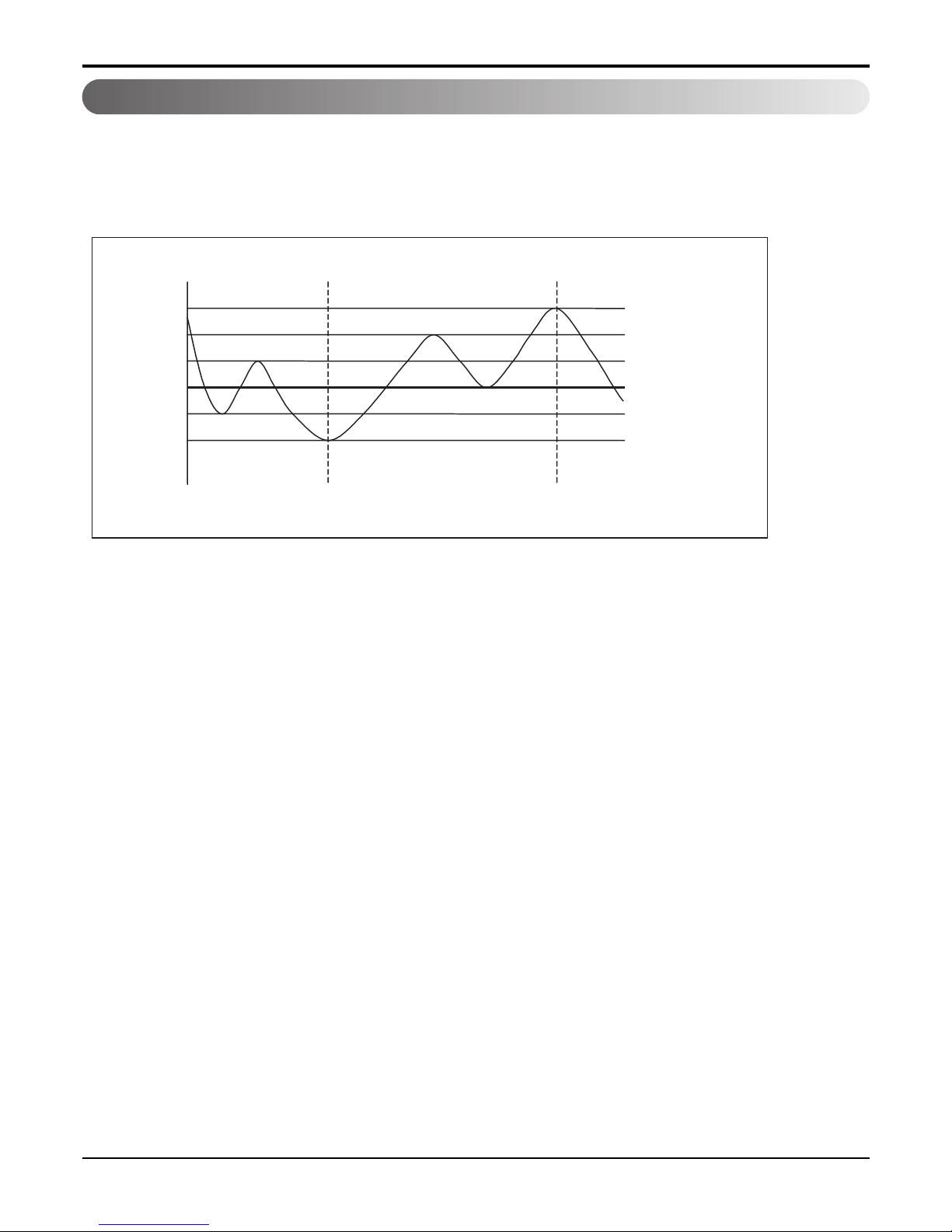

2.3 Chaos swing (up/down)

• By the Chaos swing key input, the upper/lower vane automatically operates with the chaos swing or it is fixed to the

desired direction.

* Some Models are different with swing width and swing pattern.

NOTE: Some Models are different by swing width and swing pattern.

- 14 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

2.4 Air flow step

• Indoor fan motor control have 6 steps.

• Air volume is controlled "SH", "H", "Med", Low" by remote controller.

• "LL" step is selected automatically in Hot start operation.

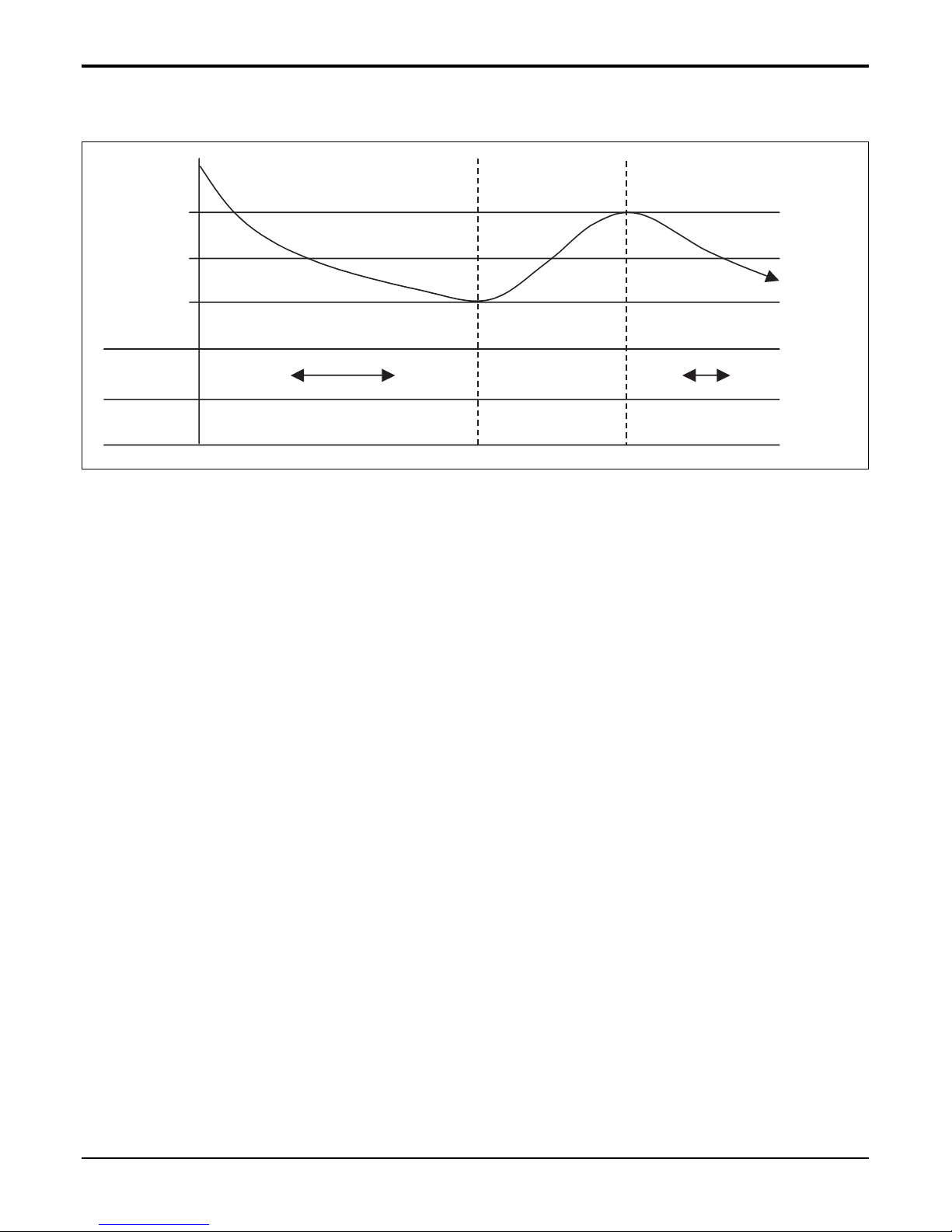

2.5 Chaos wind (auto wind)

• When "Auto" step selected and then operated, the high, medium, or low speed of the airflow mode is operated for

2~15 sec. randomly by the Chaos Simulation

2.6 Jet Cool Mode Operation

• While in heating mode or Fuzzy operation, the Jet Cool key cannot be input.

When it is input while in the other mode operation (cooling, dehumidification, ventilation), the Jet Cool mode is operated.

• In the Jet Cool mode, the indoor fan is operated at super-high speed for 30 min. at cooling mode operation.

• In the Jet Cool mode operation, the room temperature is controlled to the setting temperature, 18°C.

• When the sleep timer mode is input while in the Jet Cool mode operation, the Jet Cool mode has the priority.

• When the Jet Cool key is input, the upper/lower vanes are reset to those of the initial cooling mode and then operated

in order that the air outflow could reach further.

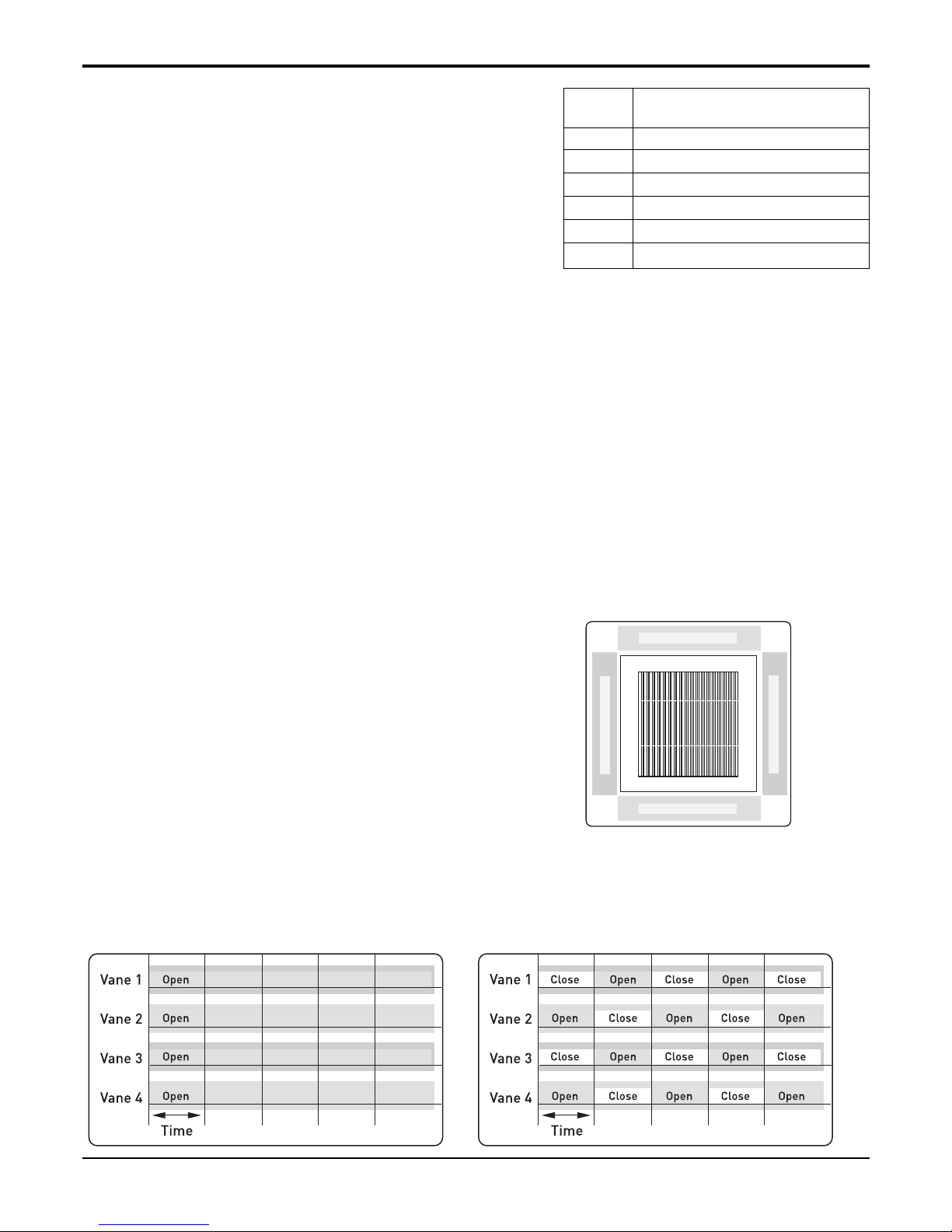

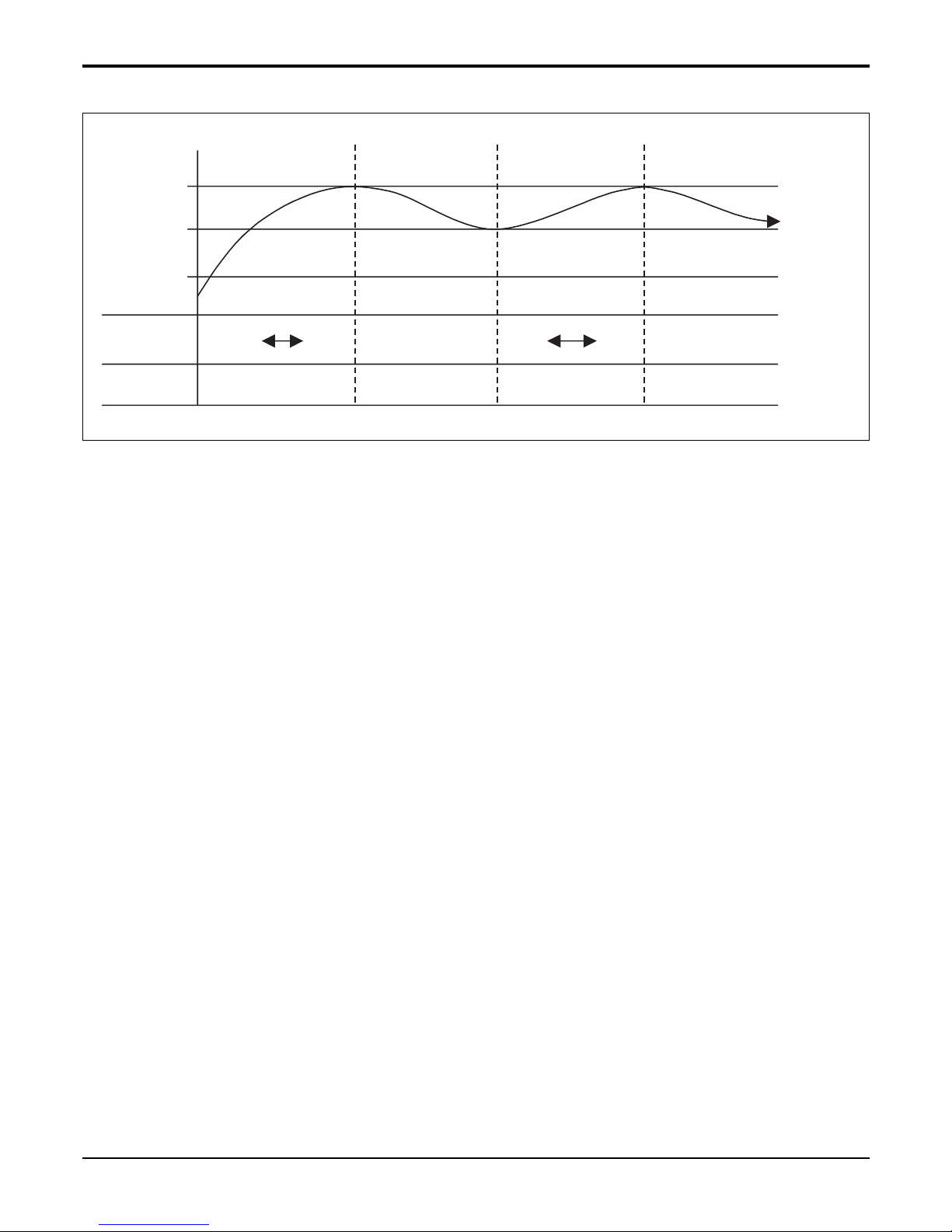

2.7 Swirl wind Swing

• It is the function for comfort cooling/heating operation.

• The diagonal two louvers are opened the more larger

than the other louvers. After one minute, it is opposite.

• Comparison of Air Flow Types

4-Open (conventional) Swirl Swing (New)

LL Very low, In heating mode

L Low

M Med

H High

SH Super high

Auto Chaos wind

Step Discription

Vane 4

Vane 2

Vane 1 Vane 3

Part 2 Functions & Controls

3.1 PLASMA Air Purifying System

The PLASMA Air Purifying System not only removes microscopic contaminants and dust, but also removes house

mites, pollen, and pet fur to help prevent allergic diseases like asthma. This filter that can be used over and over again

by simply washing with water.

3. Air purifying

- 15 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Ionizer

Photo-Catalyst Coated Mesh

Dust particles

Odour

Dust electrode discharge

Odour molecule

Generating plasma

+

+

+

+

Polluted Air

Purified fresh Air

+4.8KV discharge

+

Part 2 Functions & Controls

- 16 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

4.1 E.S.P. (External Static Pressure) Setting

4.1.1 Open the rear cover of the wired remote-controller to set the mode.

4.1.2 Select one of three selectable modes as follows.

■ Without Zone System

1. Position V-H, F-H

• This position sets the maximum E.S.P. as a default set.

2. Position V-L

• This position sets the minimum E.S.P. as a default set.

■ With Zone System

1. Position V-H

• Maximum E.S.P. setting & Fan speed is varied according to the state of dampers by micom.

2. Position F-H

• Maximum E.S.P. setting & Fan speed doesn't vary according to the opening & closing of dampers.

3. Position V-L

• Minimum E.S.P setting & Fan speed is varied according to the state of dampers by micom.

* Maximum : 8mmAq

Minimum : 0mmAq

4.1.3 Move the slide switch to set position.

4.1.4 Close the rear cover and check if it works normally.

4. Installation Functions

TH

R14H

SW TH

REMO

MAIN

2TH

OP7

R18H

R17H

OP6

LO

STAND

SW HIGH

HI

R03S

C070

R04S

R02S

R01S

OP3

OP2 OP1

R19H

R11H

R13H R12H

OP5R16H OP4

R15H

CO1H

V-H

V-L

F-H

Slide switch for ceiling height

Part 2 Functions & Controls

- 17 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

4.1.5 How to Set E.S.P?

Procedure of RPM change:

Ex) External Static pressure is 4mmAq for Model 36K.

• To protect the unit, compressor is designed to be off during E.S.P. setting.

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Set no. Time

01 03 05 07 09 11 13 15 17 19 21 23

OPERATION

FAN SPEED

SUB FUNCTION

SET TEMP

HI

AUTO SWING

Time

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Set no. Time

01 03 05 07 09 11 13 15 17 19 21 23

OPERATION

FAN SPEED

SUB FUNCTION

SET TEMP

HI

AUTO SWING

Time

Time

SUB FUNCTION

SET TEMP

OPERATIONAUTO SWING

Preheat

ZONE

Operation unit Program set

Room Temp

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Set no. Time

01 03 05 07 09 11 13 15 17 19 21 23

FAN SPEED

HI

Time

SUB FUNCTION

SET TEMP

OPERATIONAUTO SWING

Preheat

ZONE

Operation unit Program set

Room T

MED

LO

AUTO

JET

Heater

Defrost

Filter

Humidify

Out door

Set no. Time

emp

01 03 05 07 09 11 13 15 17 19 21 23

FAN SPEED

HI

2

Timer

1

2

3

5

4

Timer

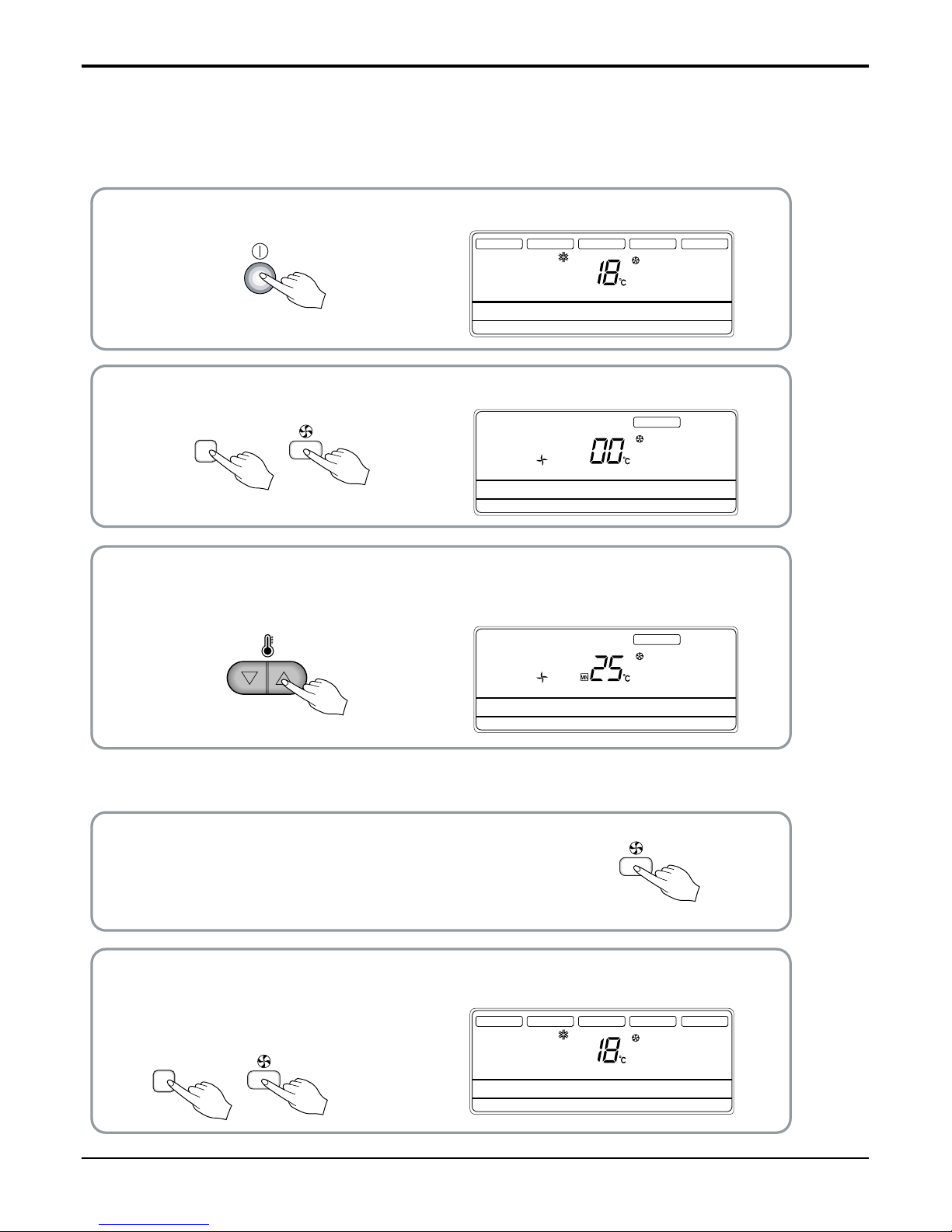

Push the"On/Off"button.

The unit will start.

Push the "Timer" and "Wind" button simultaneously for more then 3 seconds.

Push the "Up" of "Down" button for E.S.P adjustment.

And, adjust the number which you want.(In this example, the number is "225". Refer to the

PDB)

Shift the fan speed mode by pressing the fan speed button.

And then, Adjust numbers of next steps by repeating the stage 3.

(In this example, the numbers are "237" and "243" respectly)

Push the "Timer" and "Wind" button simultaneously for more than 3 seconds.

Then, Wind Data is memorized by the EEPROM of the main PCB.

Note: The range of selection is from 1~254. Since, the display is two Digit only.

If the range selection is above 100 then the third digit will appear in the screen as shown.

Part 2 Functions & Controls

- 18 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

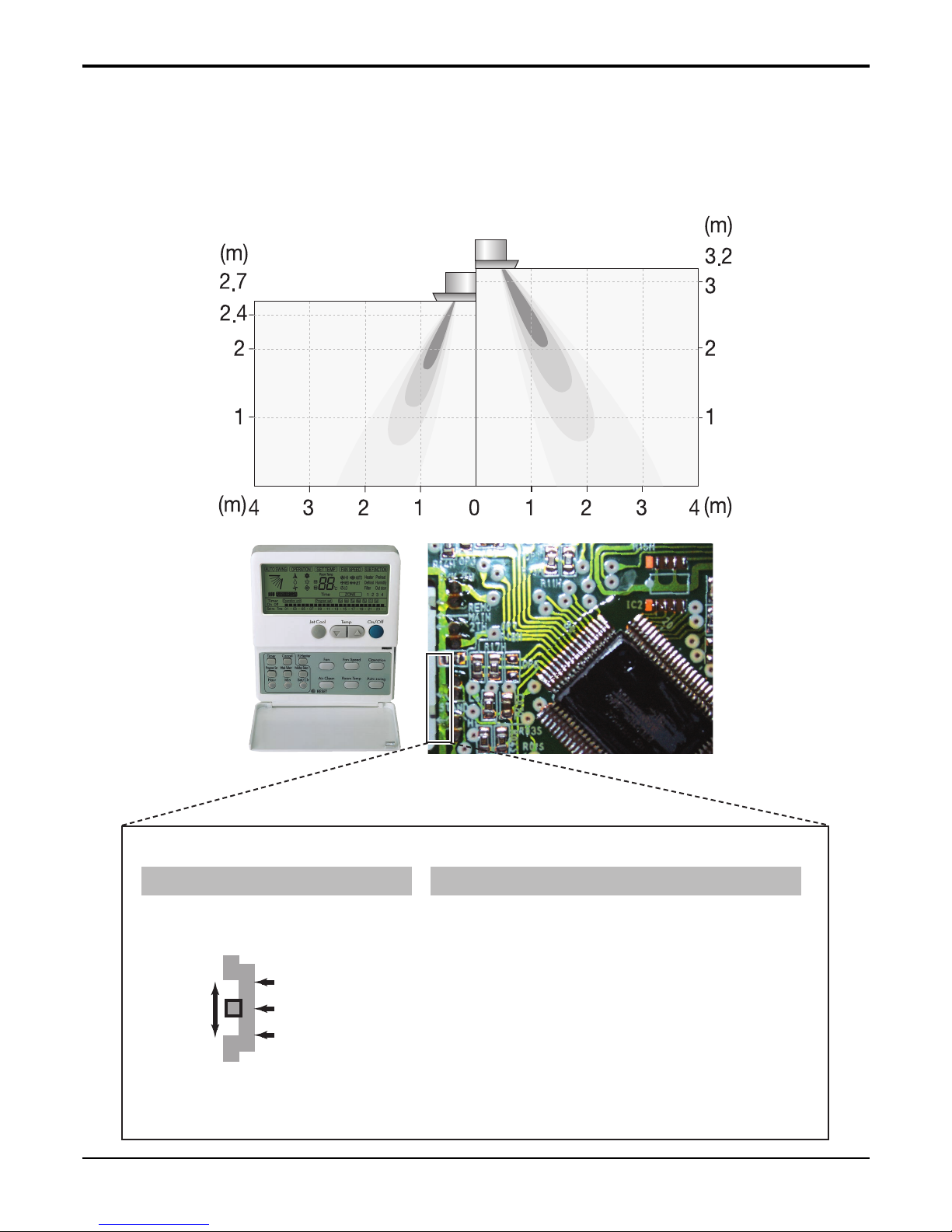

4.2 High Ceiling operation

Function to Control the Air Volume by Ceiling Height Control of the air intensity has been made possible by employing a

height-control algorithm for the interior fan.

According to the height of the installation, it provides variability of indoor fan motor rpm. If the height of installation is low

then you can adjust low rpm of indoor fan motor. On the other hand if the height of the installation is high you can adjust

high rpm of indoor fan motor. Selection of speed can be done by slide switch at the back of the LCD wired remote.

Installation on the

normal-height ceiling

installation on the

higher ceiling

Elevation Choice

Conditions of Release

Low

Standard

Hi

- When the elevation is low: lower than 2.4m in height.

- Operate the device at one level lower than the

standard level.

- When the elevation is standard: about 2.7m in

height.

- Operate the device at the standard air flow level.

- When the elevation is high: higher than 3.0m in

height.

- Operate the device at one level higher than the

standard level.

Part 2 Functions & Controls

- 19 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

5.1 Hot start

• When heating is started, the indoor fan is stopped or very slow to prevent the cold air carry out

• When the temp. of heat exchanger reach 30°C(model by model), indoor fan is started.

5.2 Self-diagnosis Function

• The air conditioner installed can self-diagnosed its error status and then transmits the result to the central control.

Therefore, a rapid countermeasure against failure of the air conditioner allows easy management and increases the

usage life of air conditioner.

• Refer to trouble shooting guide.

5.3 Soft dry operation

• When the dehumidification operation input by the remote control is received, the intake air temperature is detected and

the setting temp is automatically set according to the intake air temperature.

• While compressor off, the indoor fan repeats low airflow speed and stop.

• While the intake air temp is between compressor on temp. and compressor off temp., 10-min dehumidification opera-

tion and 4-min compressor off repeat.

Compressor ON Temp. ➔ Setting Temp+0.5°C

Compressor OFF Temp. ➔ Setting Temp-0.5°C

• The indoor fan speed is automatically set to the low, so the shift of the indoor fan speed is impossible because of

already being set to the best speed for Dry Operation by Micom Control.

5. Reliability

Intake air Temp. Setting Temp.

26°C ≤ intake air temp. 25°C

24°C ≤ intake air temp.< 26°C intake air temp. -1°C

22°C ≤ intake air temp. < 24°C intake air temp. -0.5°C

18°C ≤ intake air temp. < 22°C intake air temp.

intake air temp. < 18°C18°C

Part 2 Functions & Controls

- 20 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

6. Convenience Functions & Controls

6.1 Auto changeover operation

• The air conditioner changes the operation mode automatically to keep indoor temperature.

• When room temperature vary over ±2°C with respect to setting temperature, air conditioner keeps the room tempera-

ture in ±2°C with respect to setting temperature by auto change mode.

SET Temp.

+0.5°C

-0.5°C

-2°C

+4°C

+2°C

Cooling

operation

Heating operation Cooling

operation

Cooling thermo off

Heating thermo off

Switching point

Switching point

Part 2 Functions & Controls

- 21 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

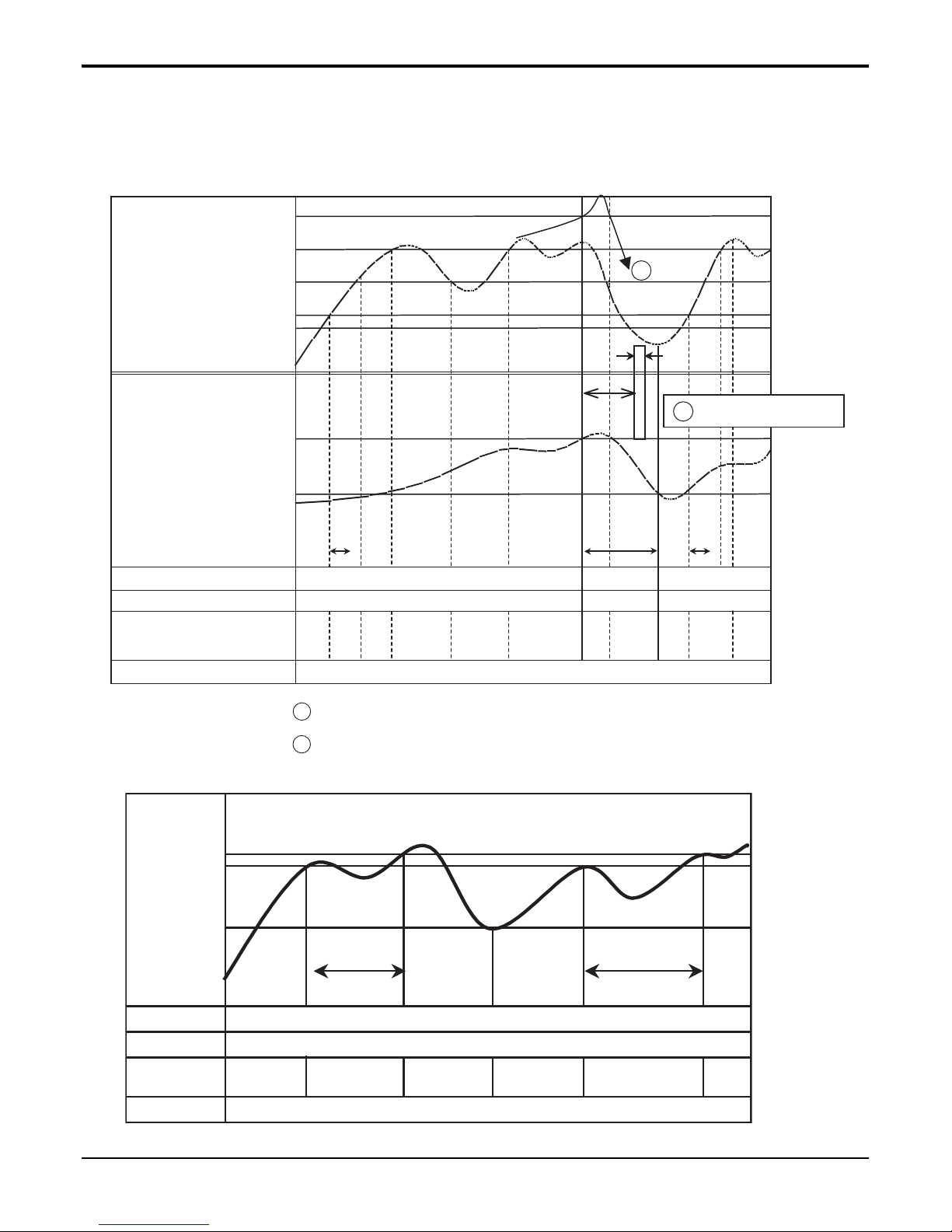

■ Cooling & heating Opeattions

6.1.1 Cooling Mode

Setting

Temp.

-0.5°C.

+0.5°C.

Comp. OFF

Comp. ON Comp. OFF Comp. ON

INV. Comp.

Frequency

Constant

Comp.

Low

High Low

Thermo.

ON

Thermo

OFF

High

• Operating frequency of compressor depends on the load condition, like the difference between the room temp. and the

set temp., frequency restrictions.

• If the compressor operates at some frequency, the operating frequency of compressor cannot be changed within 30

seconds. ( not emergency conditions)

• Compressor turned off when

- intake air temperature is in between ±0.5°C of the setting temp. limit for three minutes continuously.

- intake air temperature reaches below 1.0°C of the temperature of setting temp..

• Compressors 3 minutes time delay.

- After compressor off, the compressor can restart minimum 3 minutes later.

- Compressor operating range is form 40% to 110% of rated condition.

Part 2 Functions & Controls

- 22 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

6.1.2 Heating Mode

+2°C.

+4°C.

Comp. OFF

Comp. ON Comp. OFF Comp. ON Comp. OFF

INV. Comp.

Frequency

Constant

Comp.

Low

High LowHigh Comp. OFF

Thermo

ON

Thermo

OFF

Setting

Temp.

• Operating frequency of compressor depend on the load condition, The difference between the room temp. and set

temp., frequency restrictions.

• If compressor operates at some frequency, the operating frequency of compressor cannot be changed within 30 sec-

onds.

• Condition of compressor turned off

- When intake air temperature reaches +4°C above the setting temperature.

• Condition of compressor turned on

- When intake air temperature reaches +2°C above the setting temperature.

* Condition of indoor fan turned off

- While in compressor on : indoor pipe temp. < 20°C (Option)

- While in compressor off : indoor pipe temp. < 30°C (Option)

• While in defrost control, between the indoor and outdoor fans are turned off.

• Compressor 3 minutes delay

- After compressor off, the compressor can restart minimum 3 minutes later.

NOTE: Some Models are different by temperature of thermo ON/OFF.

Part 2 Functions & Controls

- 23 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

* Some Models are different with temperature of indoor fan ON/OFF

■ Heating Mode Operation Details

The unit will operate according to the setting by the remote controller and the operation diagram is shown as following.

COMP

Outdoor fan

Indoor fan

4way valve

Setting Temperature

+2°C

(Thermo ON)

Setting Temperature

+4°C

(Thermo OFF)

Indoor unit

Heat-Exchanger

temperature

1min

Minimum

3min

1min

3min

Setting

fan

speed

Setting

fan

speed

Setting

fan

speed

ON

ON

ON

ON

Low

LowLowLow

Low

Lo

OffOffOff

ON

OFF

OFF

Low fan during 10sec

A

A

B

B

Intake Air Temperature

• Compressor-off interval : - While the indoor Heat-Exchanger temperature is higher than 27°C, fan operates

at low speed, when it becomes lower than 26°C fan stops.

- For eleminating latent heat-loss, fan operates at low speed for 10 seconds periodically.

(Option)36°C

(Option)34°C

(Option)29°C

(Option)27°C

(Option)16°C

ON

ON

Off Off

Low

Low

1min1min

(Option)

20°C

(Option)

27°C

(Option)

33°C

Indoor unit

Heat-Exchanger

temperature

Setting fan

speed

Setting fan

spped

Compressor

Outdoor fan

Indoor fan

4way Valve

ON

- 24 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

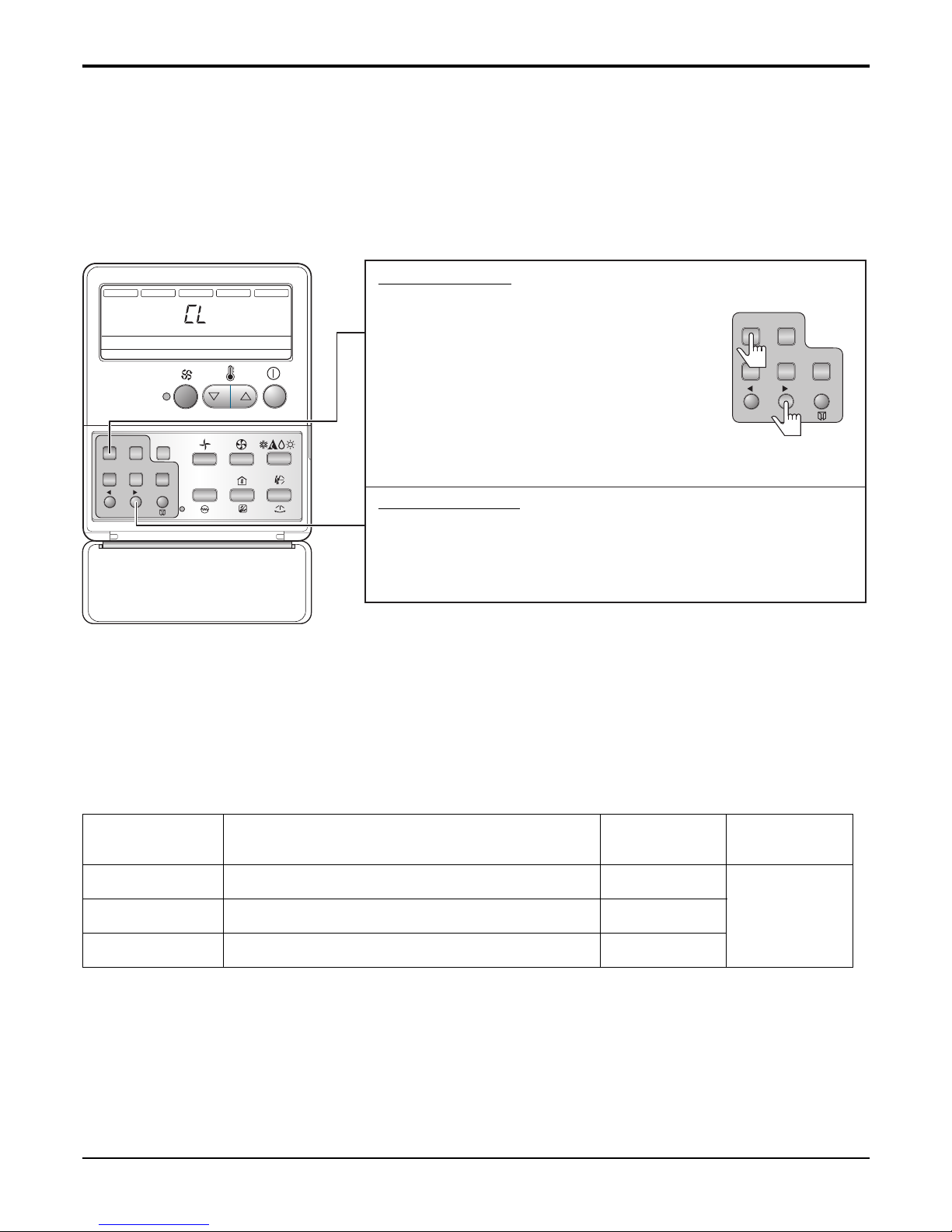

6.2 Child Lock Function

This function prevents children or others from tampering with the control buttons on the unit.

It is then controlled by the remote controller.

• All the buttons on indoor display panel will blocked.

• The unit will be controlled only by remote controller.

The function is used to restrict children to not to use the air conditioner carelessly.(CL is an abbreviated form of Child

Lock.)

Timer

On Off

01 03 05 07 09 11 13 15 17 19 21

23

Operation unit Program set

Room Temp

Time

AUTO

ZONE

1234

JET

Heater

Defrost

Preheat

Humidify

Filter

Out door

HI

MED

LO

Set no. Time

AUTO SWING

OPERATION SET TEMP FAN SPEED

SUB FUNCTION

Timer

Program

Hour

Cancel 2ndF

Week Holiday

Set/Clr

Min

RESET

PLASMA

Timer

Program

Hour

Cancel

Week

Holiday

Set/Clr

Min

1 If you press the preset and minute setup button for

3 seconds at the same time, the operation condition switches to the child lock function and will be

indicated as "CL" on the indication monitor.

At that time, remote control doesn't switch to the

selected mode and "CL" appears on the indication

monitor for 3 seconds if you press another button.

However, it normally performs the actions of the

room temperature indication function and wireless

remote control.

1 Press the preset and minute setup button over 3 seconds at the same

time.

In that case, the child lock function cancels and will be indicated as

the previous condition.

Function setup

Function cancel

6.3 Forced operation

• To operate the appliance by force in case when the remote control is lost, the forced operation selection switch is on

the main unit of the appliance, and operate the appliance in the standard conditions.

• The operating condition is set according to the outdoor temp. and intake air temperature as follows.

• The unit select the last operation mode in 3 hours.

• Operating procedures when the remote control can't be used is as follows :

- The operation will be started if the ON/OFF button is pressed.

- If you want to stop operation, re-press the button.

Indoor temp.

over 24°C

21~24°C

below 21°C

Setting temp.

22°C

22°C

22°C

Setting speed of

indoor fan

High speed

Operating Mode

Cooling

Healthy Dehumidification

Heating

- 25 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

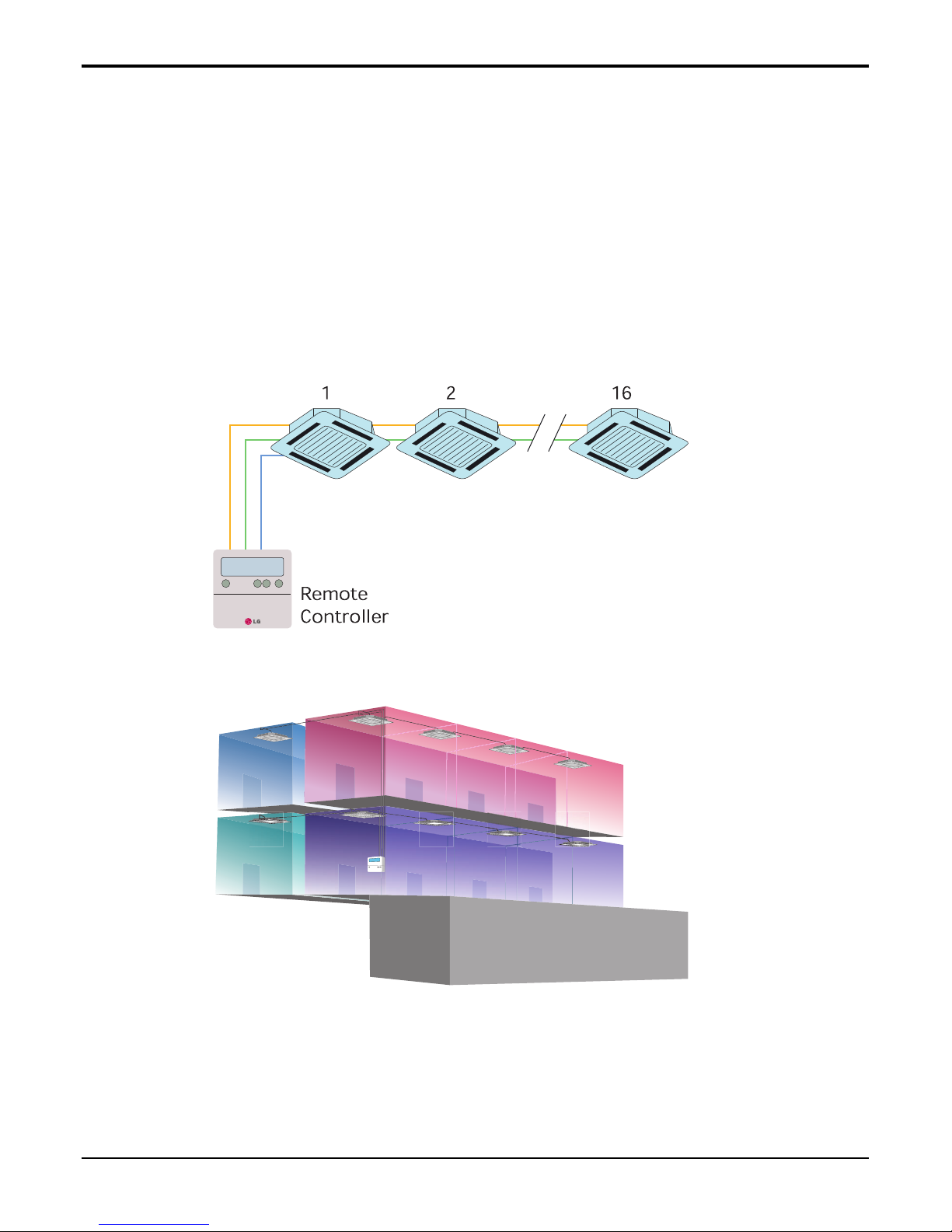

6.4 Group Control

6.4.1 Operation Summary

• Where several products are linked, one specific control device can control a specific number of products.

6.4.2 Specific Operation

• Connecting line is linked to each of the indoor equipments for communication.

A specific control device is connected to each of them and this control device can control the same function.

• Group control function is enabled by cutting an optional jump wire in the wired remote control. At this time, the main

system will not respond in order to prevent data collision.

• While executing group control command, use the random data(0-3minutes) in the main body of indoor equipment for

limiting starting current.

• Control device can control up to 16 indoor equipments.

- 26 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

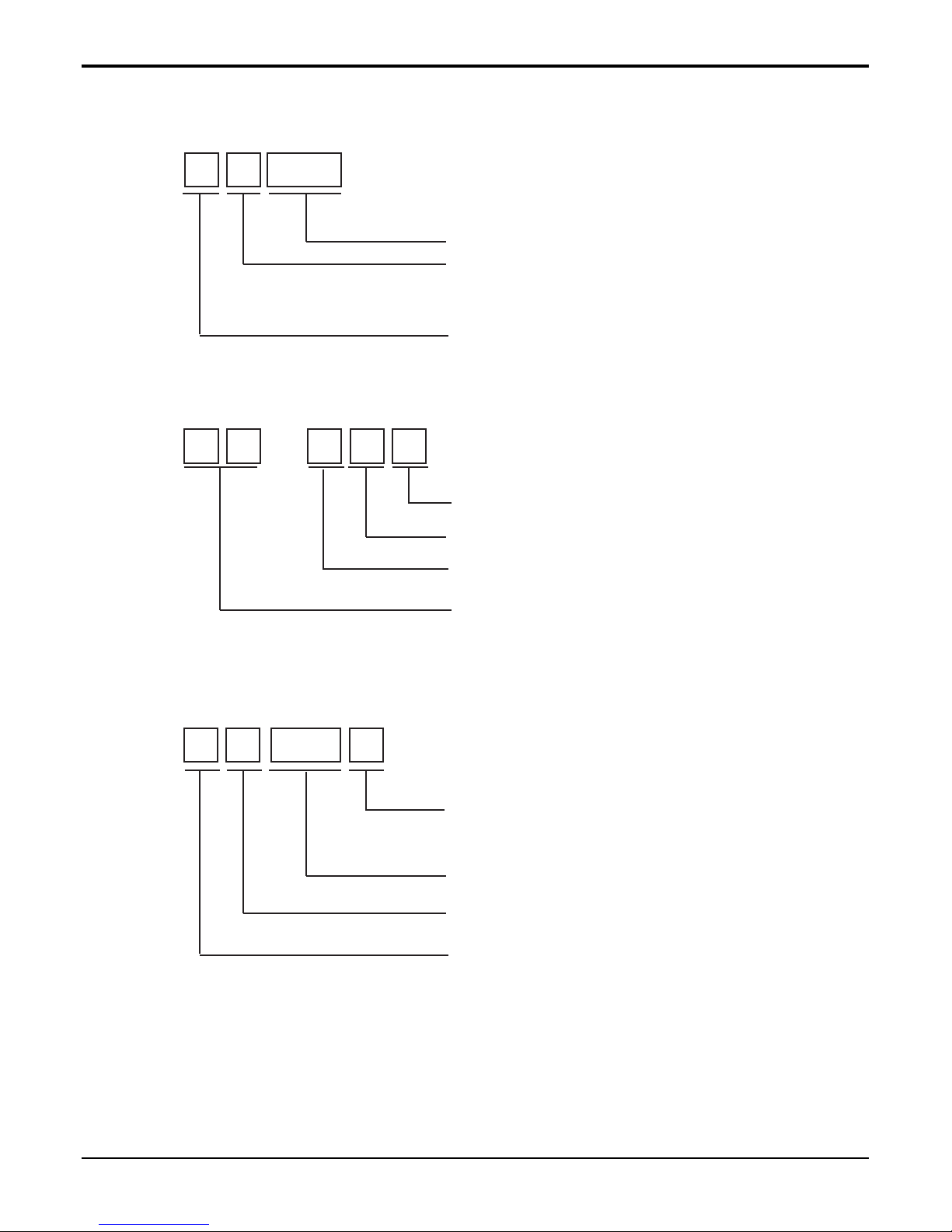

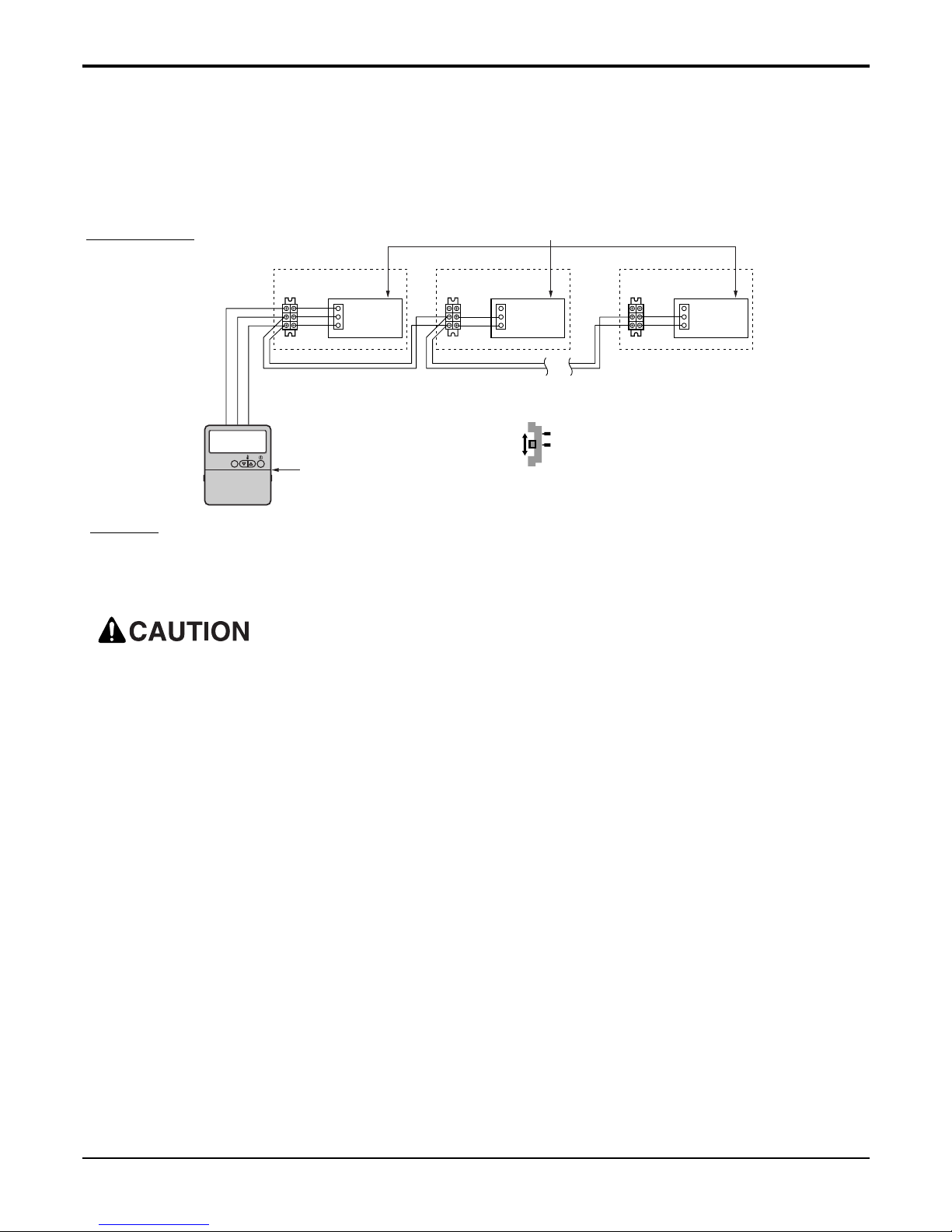

6.4.3 Group Control(Optional Wiring)

• You can use a group control operation after connecting the brown and yellow wire of each air-conditioner.

• It operates maximum 16 Units by only one Wired Remote Controller,

and each Unit starts sequentially to prevent overcurrent.

Wiring design

Features

• Use Only One Wired Remote Controller with several air conditioners(max. 16 Units)

• Random starting to prevent overcurrent.

Operation unit

ZONE

1234

Humidify

JET

AUTO

AUTO SWING OPERATION

FAN SPEED

Program set

SUB FUNCTION

SET TEMP

Room Temp

HI

MED

LO

Heater

Defrost

Filter

Preheat

Out door

Time

Timer

On

Set no. Time

Off

01 03 05 07 09 11 13 15 17 19 21 23

Indoor Unit 1

Terminal(Local Supply)

Block

Terminal(Local Supply)

Block

Terminal(Local Supply)

Block

Main PCB

#1

Main PCB

#2

Main PCB

#16

Wired Remote Controller

Indoor Unit 2

Main PCB

Indoor Unit 16

Connector

RED(12V)

YL(SIGNAL)

BR(GND)

RED(12V)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

YL(SIGNAL)

BR(GND)

Connecting Cable(Local Supply)

Connector Connector

....

....

Single

Group

• Be careful not to exchange the color of wires.

• The maximum length of connecting wire should be below 200m(25Ω) on connect-

ing each units.

• Use a wire more than 0.5mm2

- 27 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

6.5 Sleep Timer Operation

• When the sleep time is reached after <1,2,3,4,5,6,7,0(cancel) hr> is input by the remote control while in appliance

operation, the operation of the appliance stops.

• While the appliance is on pause, the sleep timer mode cannot be input.

• While in cooling mode operation, 30 min later since the start of the sleep timer, the setting temperature increases by

1°C. After another 30 min elapse, it increases by 1°C again.

• When the sleep timer mode is input while in cooling cycle mode, the airflow speed of the indoor fan is set to the low.

• When the sleep timer mode is input while in heating cycle mode, the airflow speed of the indoor fan is set to the medi-

um.

6.6 Timer(On/Off)

6.6.1 On-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance starts to operate.

• The timer LED is on when the on-timer is input. It is off when the time set by the timer is reached.

• If the appliance is operating at the time set by the timer, the operation continues.

While in Fuzzy operation, the airflow speed of the indoor fan is automatically selected according to the temperature.

6.6.2 Off-Timer Operation

• When the set time is reached after the time is input by the remote control, the appliance stops operating.

• The timer LED is on when the off-timer is input. It is off when the time set by the timer is reached.

• If the appliance is on pause at the time set by the timer, the pause continues.

6.7 Weekly Program

• If necessary, an operator can make an On/Off reservation of the product for a period of one week.

- On/Off schedule of operation for a period of One week.

• No need to turn the unit On/Offmanually during working days.

On/Off time is scheduled in micom of the wired remote control.

Part 2 Functions & Controls

Operation Time Table (Example)

Mon Tue Wed Thu Fri Sat Sun

Off

Setting

Temp.

On

Off

25°C25°C25°C25°C25°C

09:00

12:00

08:00

17:00

09:00

12:00

08:00

12:00

09:00

12:00

- 28 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Part 2 Functions & Controls

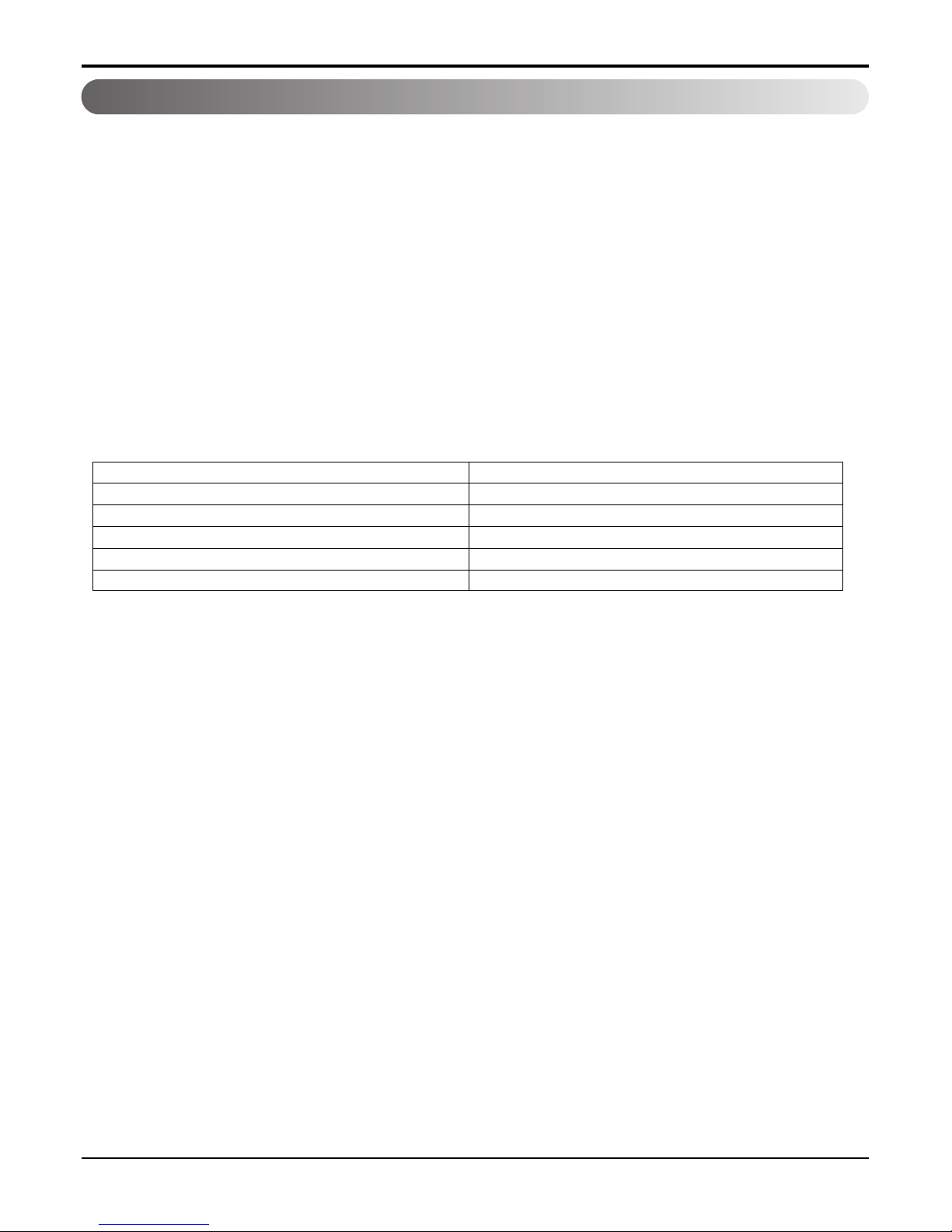

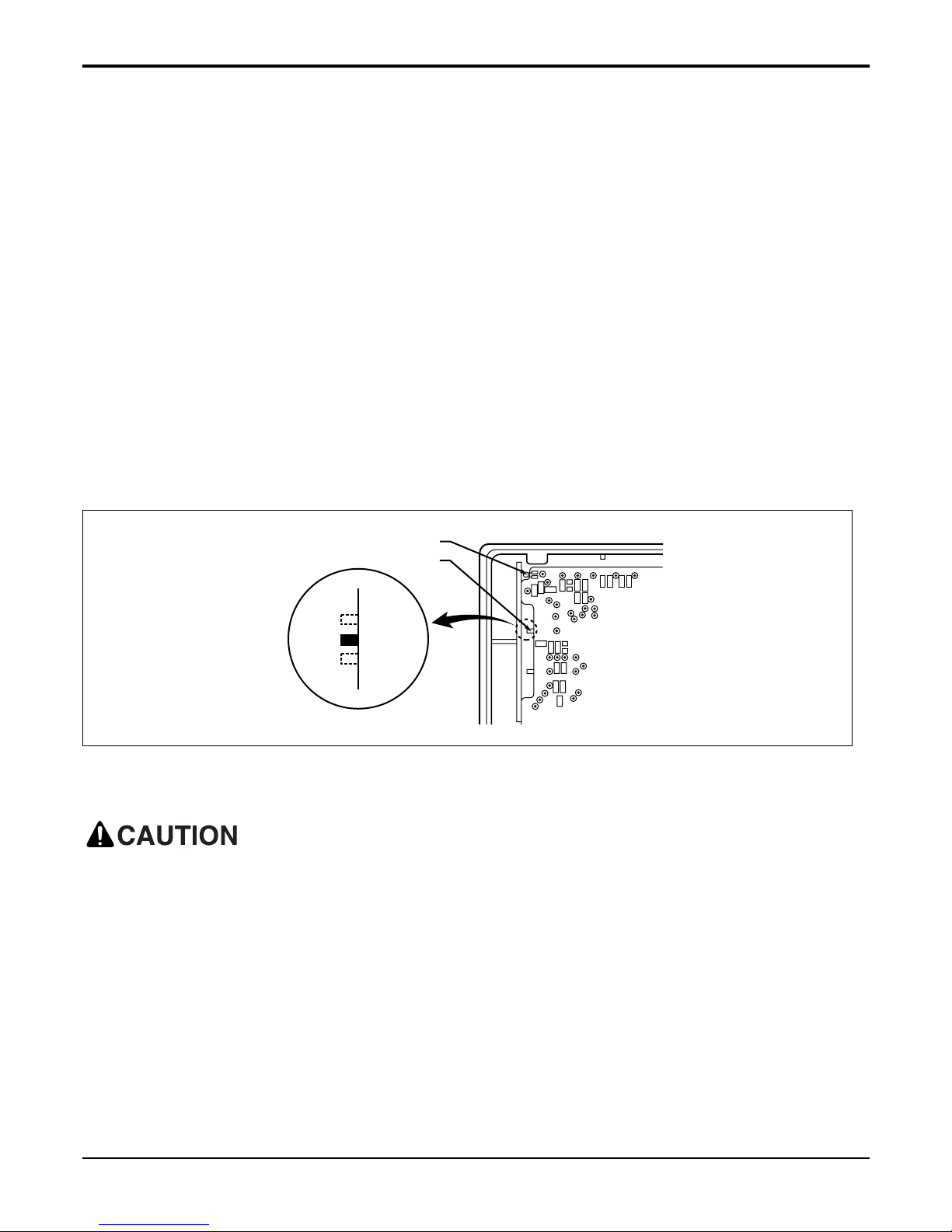

6.8 Two Thermistor Control

There may be a significant difference between temperature taken at the installed product indoor temperature. Two thermistor control provides option to control temperature by referring any of the two temperatures.

With help of the slide switch at the back of the wired remote controller, selection of the thermistor for controlling the unit

can be One thermistor is in the Indoor unit & the one is in the LCD wired remote.

■ Two Thermistor System

6.8.1 Open the rear cover of the wired remote-controller to set the mode.

6.8.2 Select one of three selectable modes as follows.

• Position 1:

The room temperature is controlled by the thermistor of the main body.

• Position 2:

The room themperature is controlled by the thermistor of the wired remote-controller, control the

temperature according to the position of wired remote-controller.

• Position 3:

The room temperature is controlled by lower temperature between the temperature of main body and of

remote-controller sensor.

6.8.3 Move the slide switch to set position.

6.8.4 Close the rear cover and check if it works normally.

• Select the position after counselling with a customer.

• In case of cooling mode, room temperature is controlled by the main body sensor.

• To control the room temperature by a wired remote controller, install controller(room temp. sensor) to sense the

temperature more accurately.

• Maunfactured in the position 3.

TH

R14H

SW TH

REMO

MAIN

2TH

OP7

R18H

R17H

OP6

LO

STAND

SW HIGH

HI

R03S

C070

R04S

R02S

R01S

OP3

OP2 OP1

R19H

R11H

R13H R12H

OP5R16H OP4

R15H

CO1H

REMO

Room Temp. sensor

2TH

MAIN

Position 2

Position 1

Position 3

Slide switch for 2 Thermistor

Part 2 Functions & Controls

- 29 -

Copyright ©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

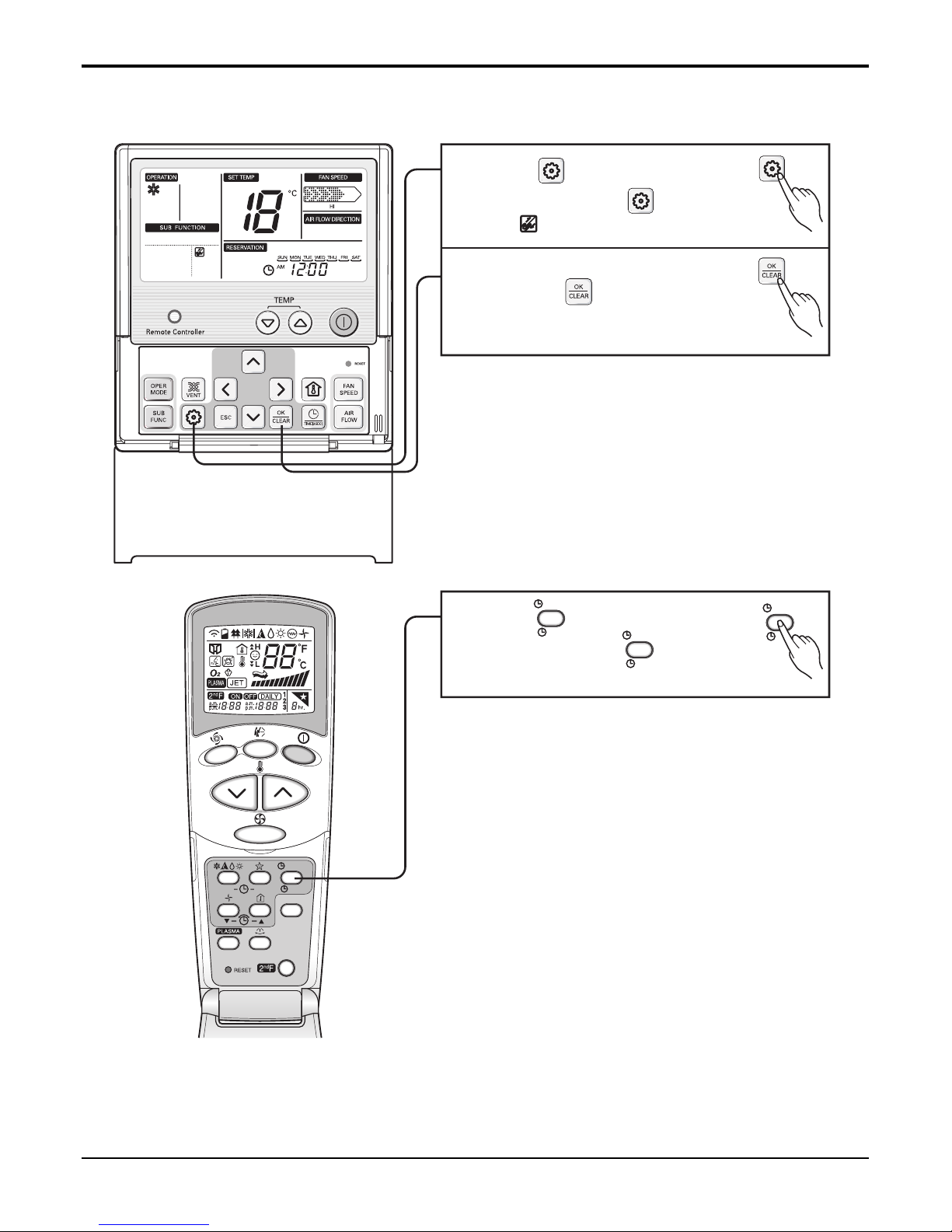

6.9 Filter Sign clear

This function is to clear the indicator of indoor filter cleaning

Press button.

Repeat pressing button until

the icon flash.

1

When the flashing, press the

button to clear this display.

2

ON

OFF

CANCEL

AUTO CLEAN

SET

Press button.

Repeat pressing button

3 times.

1

CANCEL

SET

CANCEL

SET

CANCEL

SET

Loading...

Loading...