Page 1

INSTALLATION MANUAL

AIR

CONDITIONER

Please read this installation manual completely before installing the product.

Installation work must be performed in accordance with the national wiring

standards by authorized personnel only.

Please retain this installation manual for future reference after reading it thoroughly.

MULTI

Original instruction

www.lg.com

Copyright © 2017 - 2020 LG Electronics Inc. All Rights Reserved.

MFL68883811

Rev.01_111920

ENGLISH

ESPAÑOL

PORTUGUÊS

Page 2

IMPORTANT SAFETY INSTRUCTIONS

2

ENGLISH

IMPORTANT SAFETY INSTRUCTIONS

READ ALL INSTRUCTIONS BEFORE USING THE APPLIANCE.

Always comply with the following precautions to avoid dangerous situations

and ensure peak performance of your product

WARNING

!

It can result in serious injury or death when the directions are ignored

CAUTION

!

It can result in minor injury or product damage when the directions are

ignored

WARNING

!

• Installation or repairs made by unqualified persons can result in hazards to

you and others.

• Installation work must be performed in accordance with the National

Electric Code by qualified and authorized personnel only.

• The information contained in the manual is intended for use by a qualified

service technician familiar with safety procedures and equipped with the

proper tools and test instruments.

• Failure to carefully read and follow all instructions in this manual can result

in equipment malfunction, property damage, personal injury and/or death.

Installation

• Do not use a defective or underrated circuit breaker. Use the correctly

rated breaker and fuse. There is risk of fire or electric shock.

• For electrical work, contact the dealer, seller, a qualified electrician, or an

Authorized Service Center. Do not disassemble or repair the product by

yourself. There is risk of fire or electric shock.

• Always ground the product as per the wiring diagram. Do not connect the

ground wire to gas or water pipes lightening rod or telephone ground wire.

There is risk of fire or electric shock.

• Install the panel and the cover of control box securely. There is risk of fire

or electric shock due to dust , water etc.

• Use the correctly rated breaker or fuse. There is risk of fire or electric

shock.

• Do not modify or extend the power cable. If the power cable or cord has

scratches or skin peeled off or deteriorated then it must be replaced.

There is risk of fire or electric shock.

Page 3

IMPORTANT SAFETY INSTRUCTIONS

3

ENGLISH

• For installation, removal or reinstall , always contact the dealer or an

Authorized Service Center. There is risk of fire, electric shock, explosion,

or injury.

• Do not install the product on a defective installation stand. Be sure that

the installation area does not deteriorate with age. It may cause product to

fall.

• Never install the outdoor unit on a moving base or a place from where

it can fall down.

The falling outdoor unit can cause damage or injury or even death of a person.

• In outdoor unit the step-up capacitor supplies high voltage electricity to the

electrical components. Be sure to discharge the capacitor completely

before conducting the repair work.

An charged capacitor can cause electrical shock.

• When installing the unit, use the installation kit provided with the product.

Otherwise the unit may fall and cause severe injury.

• Indoor/outdoor wiring connections must be secured tightly and the cable

should be routed properly so that there is no force pulling the cable from

the connection terminals. Improper or loose connections can cause heat

generation or fire.

• Safely dispose off the packing materials. Like screws, nails, batteries, broken things etc after installation or svc and then tear away and throw away

the plastic packaging bags. Children may play with them and cause injury.

• Be sure to check the refrigerant to be used. Please read the label on the

product. Incorrect refrigerant used can prevent the normal operation of the

unit.

• Always install a dedicated circuit and breaker. Improper wiring or installation may cause fire or electric shock.

Operation

• When the product is soaked (flooded or submerged) in water , contact an

Authorized Service Center for repair before using it again. There is risk of

fire or electirc shock.

• Be sure to use only those parts which are listed in the svc parts list.

Never attempt to modify the equipment. The use of inappropriate parts

can cause an electrical shock, excessive heat generation or fire.

• Do not touch , operate, or repair the product with wet hands. Hold the

plug by hand when taking out. There is risk of electric shock or fire.

• Do not place a heater or other heating appliances near the power cable.

There is risk of fire and electric shock.

Page 4

IMPORTANT SAFETY INSTRUCTIONS

4

ENGLISH

• Do not allow water to run into electric parts. Install the unit away from

water sources. There is risk of fire, failure of the product, or electric shock.

• Do not store or use or even allow flammable gas or combustibles near the

product. There is risk of fire.

• Do not use the product in a tightly closed space for a long time. Perform

ventilation regularly. Oxygen deficiency could occur and hence harm your

health.

• Do not open the front grille of the product during operation. (Do not touch

the electrostatic filter, if the unit is so equipped.) There is risk of physical

injury, electric shock, or product failure.

• If strange sound, smell or smoke comes from product.Immediately turn

the breaker off or disconnect the power supply cable. There is risk of electric shock or fire.

• Ventilate the product room from time to time when operating it together

with a stove, or heating element etc. Oxygen deficiency can occur and

hence harm your health.

• When the product is not to be used for a long time, disconnect the power

supply plug or turn off the breaker. There is risk of product damage or failure, or unintended operation.

• Take care to ensure that nobody especially kids could step on or fall onto

the outdoor unit. This could result in personal injury and product damage.

• Take care to ensure that power cable could not be pulled out or damaged

during operation. There is risk of fire or electric shock.

• Do not place ANYTHING on the power cable. There is risk of fire or electric shock.

• When flammable gas leaks, turn off the gas and open a window for ventilation before turning on the product. Do not use the telephone or turn

switches on or off. There is risk of explosion or fire.

CAUTION

!

Installation

• Two or more people must lift and transport the product. Avoid personal

injury.

• Do not install the product where it will be exposed to sea wind (salt spray)

directly. It may cause corrosion on the product.

• Install the drain hose to ensure that the condensed water is drained away

properly. A bad connection may cause water leakage.

• Keep level even when installing the product. To avoid vibration or noise.

Page 5

IMPORTANT SAFETY INSTRUCTIONS

5

ENGLISH

• Do not install the product where the noise or hot air from the outdoor unit

could damage or disturb the neighborhoods. It may cause a problem for

your neighbors and hence dispute.

• Always check for gas (refrigerant) leakage after installation or repair of

product. Low refrigerant levels may cause failure of product.

• Please install safely at a place that can sufficiently endure the weight of

the product.

If the strength is not sufficient, the product may fall and cause injury.

• The user must carry out checks and cleaning of routine to avoid defective

performance. In a special situation, only service personnel can carry out

repair work.

• If the supply cord is damaged, it must be replaced by a special cord or

assembly available from the manufacturer of its service agent.

• Do not install the unit in potentially explosive atmospheres.

Operation

• Do not use the product for special purposes, such as preserving foods,

works of art, etc. It is a consumer air conditioner, not a precision refrigeration system. There is risk of damage or loss of property.

• Do not block the inlet or outlet of air flow. It may cause product failure.

• Use a soft cloth to clean. Do not use harsh detergents, solvents or splashing water etc. There is risk of fire, electric shock, or damage to the plastic

parts of the product.

• Do not touch the metal parts of the product when removing the air filter.

There is risk of personal injury.

• Do not step on or put anything on the product. (outdoor units) There is risk

of personal injury and failure of product.

• Always insert the filter securely after cleaning. Clean the filter every two

weeks or more often if necessary. A dirty filter reduces the efficiency.

• Do not insert hands or other objects through the air inlet or outlet while

the product is operating. There are sharp and moving parts that could

cause personal injury.

• Be cautious when unpacking and installing the product. Sharp edges could

cause injury.

• If the refrigerant gas leaks during the repair, do not touch the leaking

refrigerant gas. The refrigerant gas can cause frostbite (cold burn).

• Do not tilt the unit when removing or uninstalling it. The condensed water

inside can spill.

Page 6

IMPORTANT SAFETY INSTRUCTIONS

6

ENGLISH

• Do not mix air or gas other than the specified refrigerant used in the system. If air enters the refrigerant system, an excessively high pressure

results, causing equipment damage or injury.

• If the refrigerant gas leaks during the installation, ventilate the area immediately. Otherwise it can be harmful for your health.

• Dismantling the unit, treatment of the refrigerant oil and eventual parts

should be done in accordance with local and national standards.

• Replace the all batteries in the remote control with new ones of the same

type. Do not mix old and new batteries or different types of batteries.

There is risk of fire or product failure.

• Do not recharge or disassemble the batteries. Do not dispose off batteries

in a fire. They may burn or explode.

• If the liquid from the batteries gets onto your skin or clothes, wash it well

with clean water. Do not use the remote if the batteries have leaked. The

chemicals in batteries could cause burns or other health hazards.

• If you eat the liquid from the batteries, brush your teeth and see doctor.

Do not use the remote if the batteries have leaked. The chemicals in batteries could cause burns or other health hazards.

• Do not let the air conditioner run for a long time when the humidity is very

high and a door or a window is left open. Moisture may condense and wet

or damage furniture.

• Do not expose your skin or kids or plants to the cool or hot air draft. This

could harm to your health.

• Do not drink the water drained from the product. It is not sanitary and

could cause serious health issues.

• Use a firm stool or ladder when cleaning, maintaining or repairing the

product at an height. Be careful and avoid personal injury.

• This appliance is not intended for use by persons (including children) with

reduced physical, sensory or mental capabilities or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of the appliance by a person responsible for their safety.

- Children should be supervised to ensure that they do not play with the

appliance.

Page 7

TABLE OF CONTENTS

TABLE OF CONTENTS

7

ENGLISH

2 IMPORTANT SAFETY

INSTRUCTIONS

8 INSTALLATION

9 INSTALLATION OF

INDOOR, OUTDOOR

UNIT

9 Select the best location

10 Foundation for Installation

10 Piping length and elevation

11 Refrigerant charge

11 Drill a hole in the wall

12 FLARING WORK AND

CONNECTION OF PIPING

12 Flaring work

13 Connection of piping - Indoor

15 Connection of piping - Outdoor

16 CONNECTING THE CABLE

BETWEEN INDOOR UNIT

AND OUTDOOR UNIT

16 Connect the cable to the Indoor unit

18 Connect the cable to the Outdoor unit

25 TEST RUNNING

26 FUNCTION

26 DIP S/W Setting

27 Forced Cooling Operation

28 Wiring Error Check

28 Saving Power Consumption

29 Night Quiet Mode

30 Mode Lock

30 SLC (Smart Load Control) Mode ※

18~40(1Ø) kBtu/h

31 PCB Display(14/16/18/21k Model Only)

32 MAX COMBINATION

CAPACITY

33 INSTALLATION GUIDE AT

THE SEASIDE

33 SEASONAL WIND AND

CAUTIONS IN WINTER

34 Airborne Noise Emission

34 Limiting concentration

20 CHECKING THE

DRAINAGE AND FORMING THE PIPINGS

20 Checking the Drainage

21 Forming the Piping

22 AIR PURGING AND EVAC-

UATION

22 Checking method

23 Evacuation

24 INSTALLATION PI485

Page 8

INSTALLATION

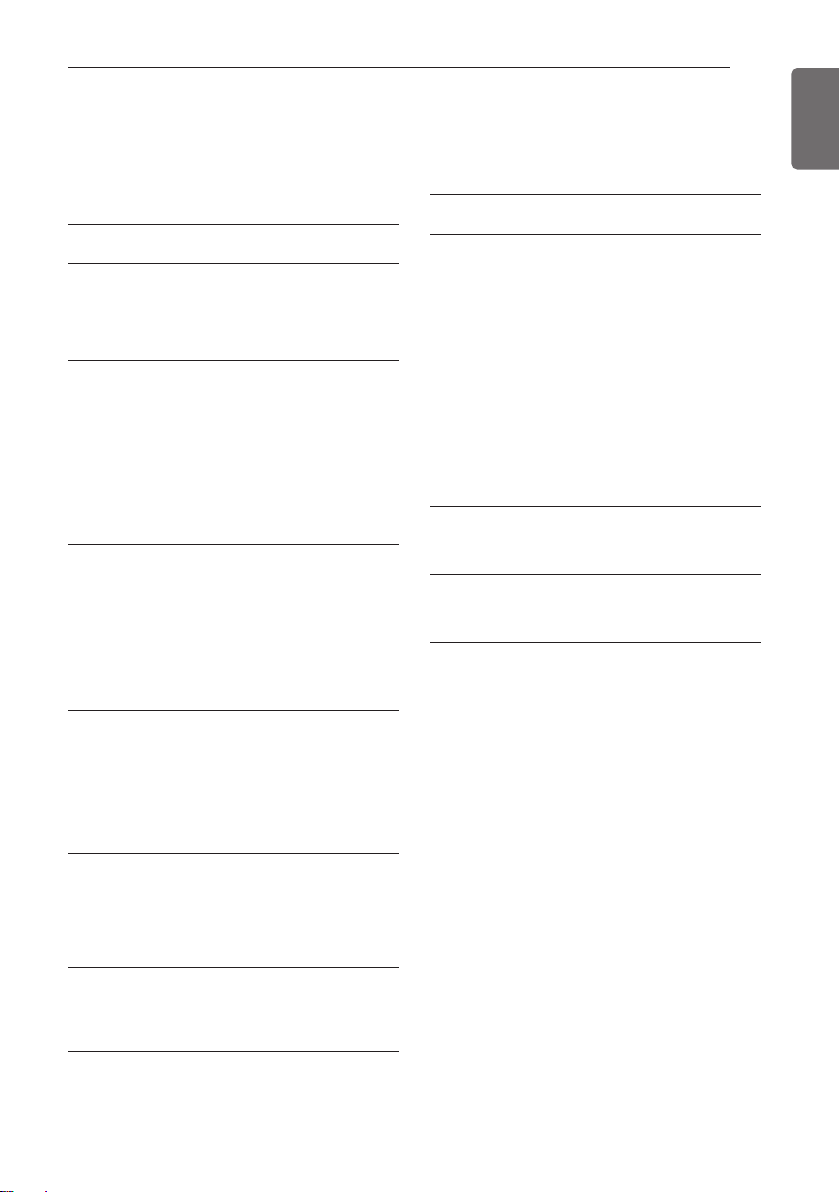

Installation plate

Type "B" screws

Type "A" screw (6 EA) Type "A" screw (8 EA) Type "A" screw (7 EA)

Holder Remote Control

Type "A" screw and plastic anchors

500(19-11

/16

) or

le

ss

8

ENGLISH

INSTALLATION

Installation Parts

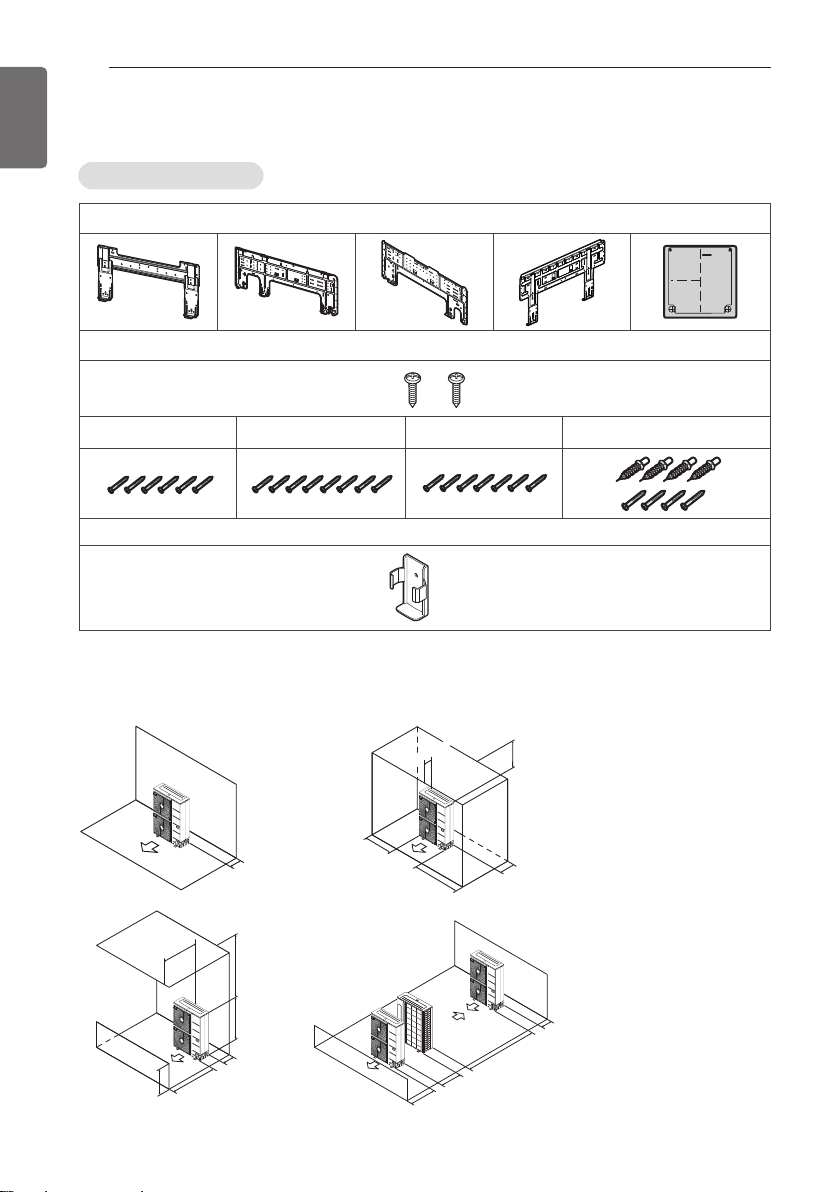

Clearance of side discharge unit [Unit : mm(inch)]

Do not install the product where sufficient ventilation is not secured.

The performance may be decreased or the product may not be operated.

s

les

300(11-13/16)

or

more

500(19-11/16) or

600(23-19/

or

more

32)

600(23-19/32) or more

1000(39-3/8) or more

300(11-13/16)

or more

ss

ss

e

rom

or

more

ro )8/

3-9

3(0001

H

more

300(11-13/16)

or

500(19-11/16) or le

500(19-11/16) or le

D

L

1000(39-3/8)

h In case of series or another installation, please refer to related PDB.

39-3/8) or more

(

0

001

300(11-13/16)

or more

300(11-13/16)

or more

2000(78-3/4) or more

Page 9

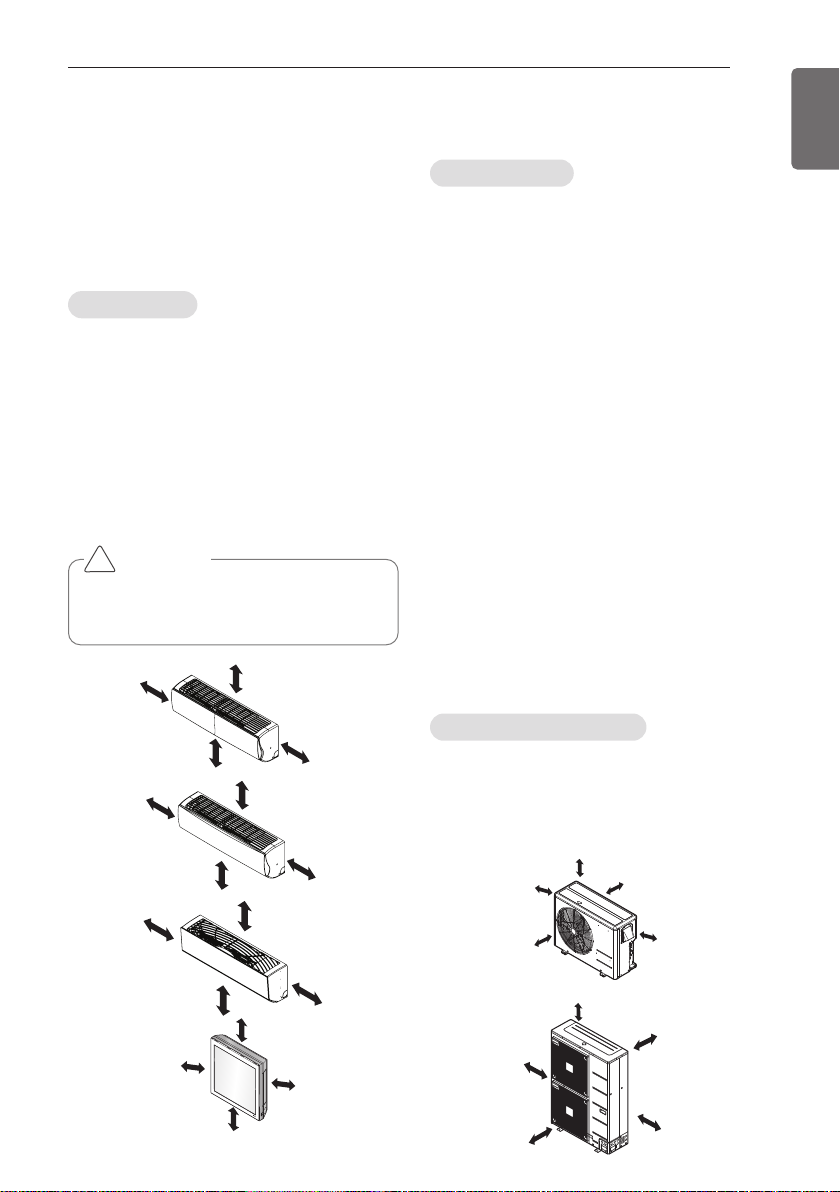

INSTALLATION OF INDOOR, OUTDOOR UNIT

More than 20cm

More than

10cm

More than 2.3m

More than

10cm

More than 20cm

More than

10cm

More than 2.3m

More than

10cm

More than 20cm

More

than 50cm

More than 1.5m

More

than 50cm

More than 20cm

More than

10cm

More than 2.3m

More than

10cm

more than

70cm

more than

30cm

more than

30cm

more than

60cm

more than 60cm

more than

70cm

more than

30cm

more than 60cm

more than

30cm

more than

60cm

INSTALLATION OF INDOOR, OUTDOOR UNIT

9

ENGLISH

Read completely, then follow step by step.

You need to select adequate installation location

considering the following conditions, and make

sure to acquire the consent of the user.

Select the best location

1 Do not have any heat or steam near the unit.

2 Select a place where there are no obstacles

3 Make sure that condensation drainage can be

4 Do not install near a doorway.

5

6 Use a stud finder to locate studs to prevent

Indoor unit

in front of the unit.

conveniently routed away.

Ensure the spaces indicated by arrows from the

wall, ceiling, fence or other obstacles.

unnecessary damage to the wall.

CAUTION

!

Install the indoor unit on the wall where

the height from the floors more than 2.3

meters. (ART COOL Type Only 1.5m)

Outdoor unit

1 If an awning is built over the unit to prevent

direct sunlight or rain exposure, make sure

that heat radiation from the condenser is not

restricted.

2 Ensure that the spaces indicated by arrows

around front, back and side of the unit.

3 Do not place animals and plants in the path of

the warm air.

4 Take the air conditioner weight into account

and select a place where noise and vibration

are minimum.

5 Select a place so that the warm air and noise

from the air conditioner do not disturb neighbors.

6 Place that can sufficiently endure the weight

and vibration of the outdoor unit and where

even installation is possible.

7 Place that has no direct influence of snow or

rain.

8 Place with no danger of snowfall or icicle

drop.

9 Place without weak floor or base such as

decrepit part of the building or with a lot of

snow accumulation.

10 Sufficient ventilation is secured.

Rooftop Installations

If the outdoor unit is installed on a roof structure,

be sure to level the unit. Ensure the roof structure and anchoring method are adequate for the

unit location. Consult local codes regarding

rooftop mounting.

Page 10

INSTALLATION OF INDOOR, OUTDOOR UNIT

10

ENGLISH

Foundation for Installation

• Check the strength and level of the installation ground so that the unit will not cause any oper-

ating vibration or noise after installation.

• Fix the unit securely by means of the foundation bolts. (Prepare 4 sets of M12 foundation bolts,

nuts and washers each which are available on the market.)

• It is best to screw in the foundation bolts until their length are 20 mm from the foundation sur-

face.

Frame

H-Beam

100

Spring washer

Nut

75

Foundation bolt executing method

200

Anti-vibration

Concrete

base

materials

Four bolt are

required

3 thread ridges

75

200

[Unit:mm]

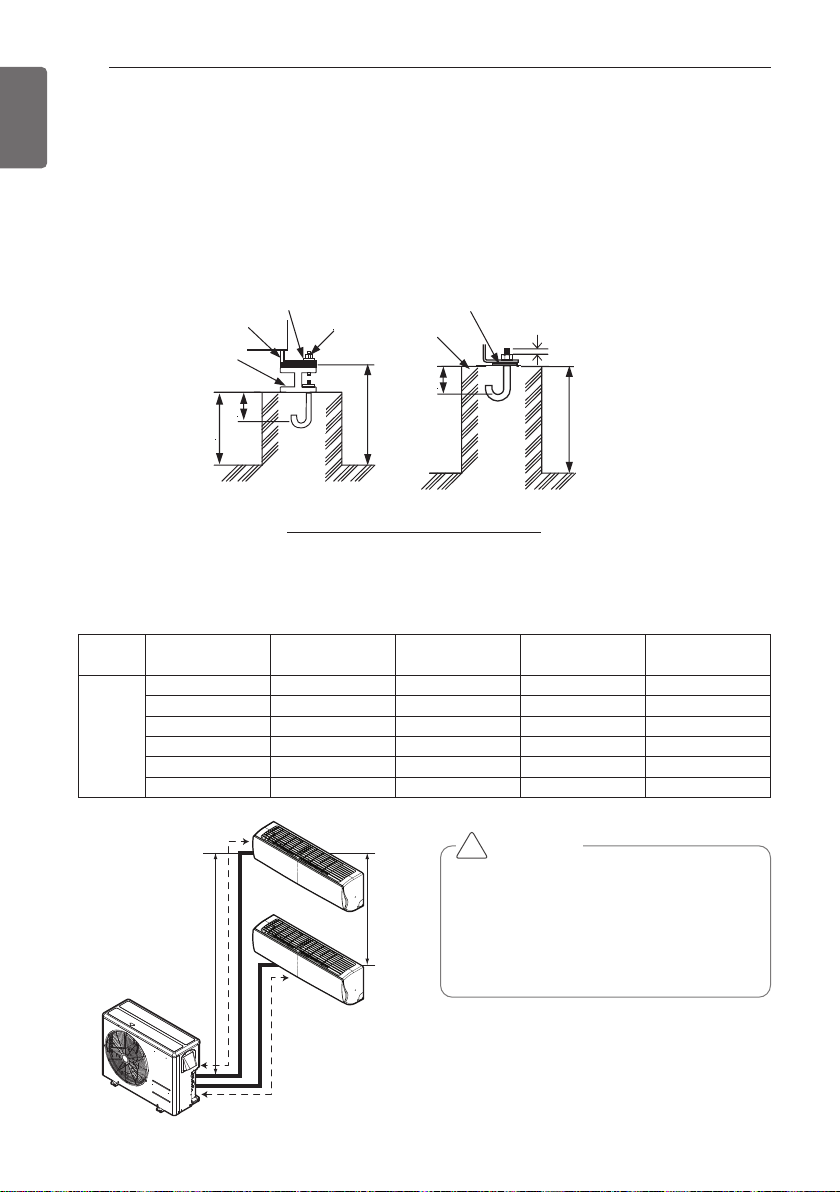

Piping length and elevation

Multiple Piping Models (Unit: m)

Phase Capacity(kBtu/h) Total Length Max Length(A/B)

14/16 30 20 15 7.5

18 50 25 15 7.5

1Ø

21 50 25 15 7.5

24/27 70 25 15 7.5

30 75 25 15 7.5

40 85 25 15 7.5

Max Elevation

(h1)

In - In Elevation

(h2)

A

h1

B

Multiple Piping Type

CAUTION

!

Capacity is based on standard length and

h2

maximum allowance length is on the

basis of reliability. If outdoor unit is at

higher elevation than the indoor units,

after 24m of vertical height, 1 oil trap is

required.

Page 11

INSTALLATION OF INDOOR, OUTDOOR UNIT

Refrigerant charge

The calculation of the additional charge should be taken in account for the length of extra pipe.

Multiple Piping Models (Unit: m)

Capacity

Phase

• Multiple Piping Models

(kBtu/h)

14/16 7.5 20 30 20 20

18 7.5 25 50 22.5 20

1Ø

Additional charge (g) = ((A Room Installation Length – Standard Length ) x 20g/m

h CF = Max. number of connectable indoor unit – Total number of connected indoor unit

21 7.5 25 50 22.5 20

24/27 7.5 25 70 30 20

30 7.5 25 75 37.5 20

40 7.5 25 85 37.5 20

Standard

Length(m)

+ (B Room Installation Length – Standard Length ) x 20g/m +.. )

- CF(Correction Factor) x 150

Max Piping for

one room(m)

Max total Piping

Length

Chargeless

Length

Additional

Charge(g/m)

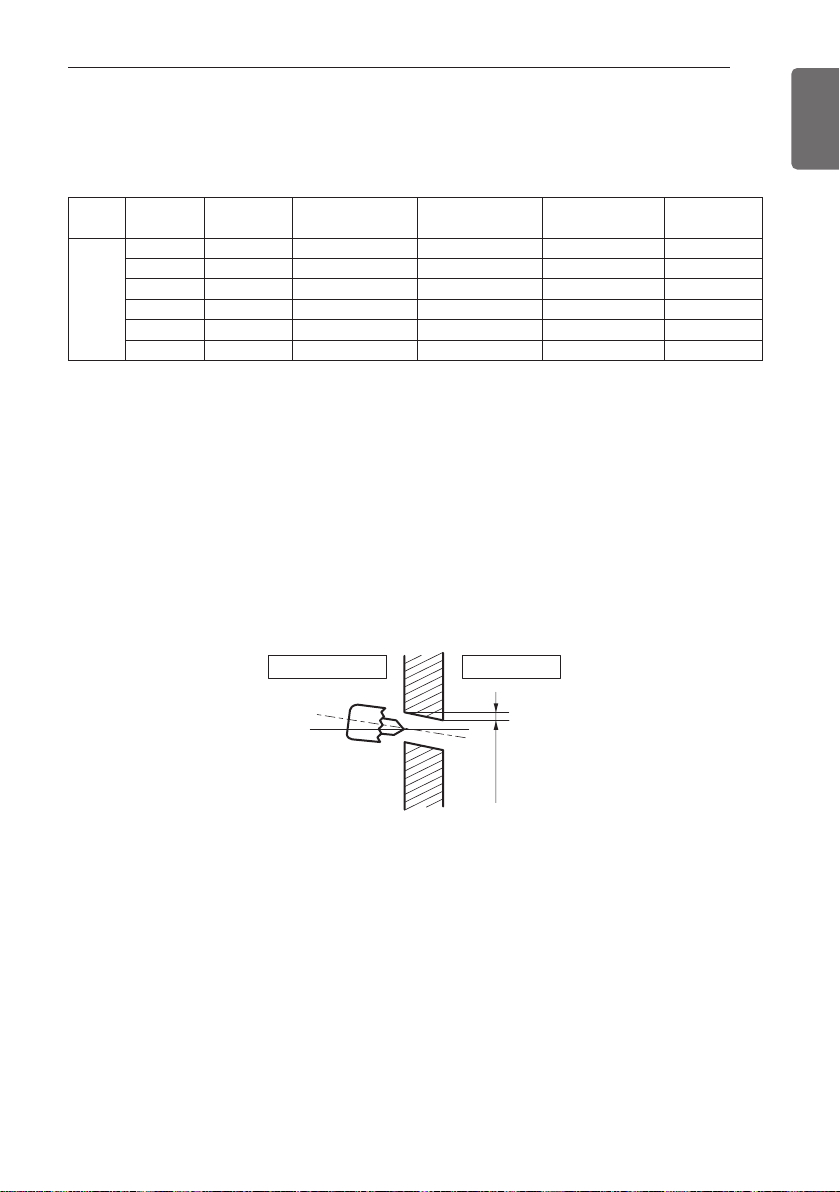

Drill a hole in the wall

Drill the piping hole with a Ø65mm hole core drill. Drill the piping hole at either the right or the

left with the hole slightly slanted to the outdoor side.

11

ENGLISH

Indoor

WALL

Outdoor

5-7mm

(3/16"~5/16")

Page 12

FLARING WORK AND CONNECTION OF PIPING

Copper

tube

90°

Slanted Uneven Rough

Pipe

Reamer

Point down

Flare nut

Copper tube

12

ENGLISH

FLARING WORK AND CONNECTION OF PIPING

Flaring work

Main cause for gas leakage is due to defect in flaring work. Carry out correct flaring work in the

following procedure.

Cut the pipes and the cable

- Use the piping kit accessory or the pipes purchased locally.

- Measure the distance between the indoor

and the outdoor unit.

- Cut the pipes a little longer than measured

distance.

- Cut the cable 1.5m longer than the pipe

length.

Burrs removal

- Completely remove all burrs from the cut

cross section of pipe/tube.

- Put the end of the copper tube/pipe in a

downward direction as you remove burrs in

order to avoid dropping burrs into the tubing.

Putting nut on

- Remove flare nuts attached to indoor and

outdoor unit, then put them on pipe/tube

having completed burr removal.

(not possible to put them on after flaring

work)

Flaring work

- Carry out flaring work using flaring tool as

shown below.

Pipe diameter

Inch (mm)

Ø 1/4 (Ø 6.35) 0.04~0.05 (1.1~1.3)

Ø 3/8 (Ø 9.52) 0.06~0.07 (1.5~1.7)

Ø 1/2 (Ø 12.7) 0.06~0.07 (1.6~1.8)

Ø 5/8 (Ø 15.88)

Ø 3/4 (Ø 19.05)

Firmly hold copper pipe in a bar in the

dimension shown in the table below.

0.06~0.07 (1.6~1.8)

0.07~0.08 (1.9~2.1)

A inch (mm)

Wing nut type Clutch type

0~0.02

(0~0.5)

Bar

<Wing nut type>

"A"

Copper pipe

<Clutch type>

Page 13

FLARING WORK AND CONNECTION OF PIPING

Inclined

Inside is shining without scratches.

Smooth all round

Even length

all round

Surface

damaged

Cracked Uneven

thickness

= Improper flaring =

Check

- Compare the flared work with figure below.

- If flare is noted to be defective, cut off the

flared section and do flaring work again.

Connection of piping - Indoor

Preparing the indoor unit's piping and drain hose for installation through the wall.

1 Route the indoor tubing and the drain hose in the direction of rear left or right

Drain hose

Drain hose

Drain hose

13

ENGLISH

2 Tape the tubing, drain hose and the connecting cable. Be sure that the drain hose is located at

If the drain hose is routed inside the room, insulate the hose with an insulation material* so

that dripping from "sweating"(condensation) will not damage furniture or floors.

*Foamed polyethylene or equivalent is recommended.

the lowest side of the bundle. Locating at the upper side can cause drain pan to overflow

inside the unit.

CAUTION

!

Tape

Connecting

pipe

Drain hose

Connecting cable

Tape

Connecting

pipe

Drain hose

Connecting cable

Connecting

cable

Drain hose

Gas side

piping

Liquid side

piping

Loop

Page 14

FLARING WORK AND CONNECTION OF PIPING

Drain hose

Connecting

Indoor unit tubing

Flare nut

Pipings

Torque wrench

Indoor unit tubing

Spanner (fixed)

Connection pipe

Flare nut

Vinyl tape(narrow)

Adhesive

Drain pipe

Indoor unit drain hose

Plastic bands

Insulation material

Vinyl tape(narrow)

Connection

pipe

Connecting cable

Vinyl tape

(wide)

Wrap with vinyl tape

Indoor

unit pipe

Pipe

14

ENGLISH

Indoor unit installation

Hook the indoor unit onto the upper portion of

the installation plate.(Engage the two hooks of

the rear top of the indoor unit with the upper

edge of the installation plate.) Ensure that the

hooks are properly seated on the installation

plate by moving it left and right.

Press the lower left and right sides of the unit

against the installation plate until the hooks

engage into their slots(clicking sound).

Connecting the pipings to the indoor unit and

drain hose to drain pipe

- Align the center of the pipings and sufficiently tighten the flare nut by hand.

- Tighten the flare nut with a wrench.

Outside diameter

mm inch N.m

Ø6.35 1/4 16±2

Ø9.52 3/8 38±4

Ø12.7 1/2 55±6

Ø15.88 5/8 75±7

Ø19.05 3/4 110±10

- When extending the drain hose at the indoor

unit, install the drain pipe.

Torque

Wrap the insulation material around the connecting portion.

- Overlap the connection pipe insulation material and the indoor unit pipe insulation material. Bind them together with vinyl tape so that

there is no gap.

- Wrap the area which accommodates the rear

piping housing section with vinyl tape.

Page 15

FLARING WORK AND CONNECTION OF PIPING

Wrap with vinyl tape

Drain hose

Pipe

Vinyl tape(wide)

Ø12.7(1/2 inch) Connector

Outdoor unit

Main gas

side valve

Main liquid

side valve

Gas side piping

ROOM A

ROOM B

ROOM C

ROOM D

ROOM E

Liquid

side piping

- Bundle the piping and drain hose together by

wrapping them with vinyl tape over the

range within which they fit into the rear piping housing section.

CAUTION

!

Installation Information (For right piping) For right piping, follow the instruction below.

15

ENGLISH

Good case

Press on the upper side of clamp and unfold

the tubing to downward slowly.

Connection of piping - Outdoor

Align the center of the piping and sufficiently

tighten the flare nut by hand.

Connecting pipe order

1) ROOM A~E gas side pipe

2) ROOM A~E liquid side pipe

Finally, tighten the flare nut with torque wrench

until the wrench clicks.

- When tightening the flare nut with torque wrench

Bad case

Following bending type from left to right could

cause problem of pipe damage.

ensure the direction for tightening follows the arrow

on the wrench.

Outside diameter

mm inch N.m

Ø6.35 1/4 16±2

Ø9.52 3/8 38±4

Ø12.7 1/2 55±6

Ø15.88 5/8 75±7

Ø19.05 3/4 110±10

Torque

Page 16

CONNECTING THE CABLE BETWEEN INDOOR UNIT AND OUTDOOR UNIT

16

ENGLISH

CONNECTING THE CABLE BETWEEN INDOOR

UNIT AND OUTDOOR UNIT

Connect the cable to the Indoor unit

Connect the cable to the indoor unit by connecting the wires to the terminals on the control

board individually according to the outdoor unit connection. (Ensure that the color of the wires of

the outdoor unit and the terminal No. are the same as those of the indoor unit.)

The earth wire should be longer than the common wires.

The circuit diagram is not subject to change without notice.

When installing, refer to the circuit diagram behind the panel front of Indoor Unit the wiring diagram on the Control Cover Inside Outdoor Unit.

CAUTION

!

• The circuit diagram is not subject to change without notice.

• Be sure to connect wires according to the wiring diagram.

• Connect the wires firmly, so that not to be pulled out easily.

• Connect the wires according to color codes by referring the wiring diagram.

2 Unit 3 Unit

4 Unit 5 Unit

Page 17

CONNECTING THE CABLE BETWEEN INDOOR UNIT AND OUTDOOR UNIT

GN/YL

20mm

NORMAL

CROSS-SECTIONAL

AREA 0.75mm

2

H07RN-F

ø7.5mm

GN/YL

20mm

5 Unit

CAUTION

!

Provide a circuit breaker between power source

and the unit as shown below.

Main power source

Air

Conditioner

Circuit Breaker

Use a circuit breaker

or time delay fuse.

17

ENGLISH

CAUTION

!

The power cord connected to the outdoor unit should be complied with the following specifications (Cable type approved by HAR or SAA).

NORMAL CROSS SECTIONAL AREA 2.5 2.5 2.5 2.5 2.5 2.5 2.5 3.5

The power connecting cable connected to the indoor and outdoor unit

should be complied with the following specifications (This equipment

shall be provided with a cord set complying with the national regulation).

Pipes and wires should be purchased separately for installation of the

product.

Phase 1Ø

Capacity (kBtu/h) 14 16 18 21 24 27 30 40

Cable Type H07RN-F

Page 18

CONNECTING THE CABLE BETWEEN INDOOR UNIT AND OUTDOOR UNIT

18

ENGLISH

Connect the cable to the Outdoor unit

1 Remove the cover control from the unit by

loosening the screw.

Connect the wires to the terminals on the

control board individually as the following.

2 Secure the cable onto the control board

with the holder (clamper).

3 Refix the cover control to the original posi-

tion with the screw.

4 Use a recongnized circuit breaker between

the power source and the unit. A disconnection device to adequately disconnect all

supply lines must be fitted.

1Ø Models

Capacity (kBtu/h) 14 16 18 21 24 27 30 40

Circuit Breaker (A) 15 15 20 20 25 25 25 30

CAUTION

!

After the confirmation of the above conditions, prepare the wiring as follows.

Outdoor unit

Terminal block

Over 15mm

Holder for

ower supply

p

cord

Cover control

Power cord

Connecting cable

Loosen terminal screw

Terminal block

1 Never fail to have an individual power circuit specifically for the air conditioner. As for the

method of wiring, be guided by the circuit diagram posted on the inside of control cover.

2 Firmly tighten the terminal screws to prevent them loosening. After tightening, pull the

wires lightly to confirm that they do not move. (If they are loose the unit, the unit will not

operate normally or it can cause burn-out of the wires.)

3 Specification of power source.

4 Confirm that electrical capacity is sufficient.

5 See to that the starting voltage is maintained at more than 90 percent of the rated volt-

age marked on the name plate.

6 Confirm that the cable thickness is as specified in the power source specification.

(Particularly note the relation between cable length and thickness.

7 Do not install an earth leakage circuit breaker in a wet or moist area.

8 The following would be caused by voltage drop.

- Vibration of a magnetic switch, which will damage the contact point, fuse breaking, disturbance of the normal function of the overload.

9

The means for disconnection from a power supply shall be incorporated in the fixed wiring

and have an air gap contact separation of at least 3mm in each active(phase) conductors.

10 The Power cord connected to the unit should be selected according to the following

specifications.

Page 19

CONNECTING THE CABLE BETWEEN INDOOR UNIT AND OUTDOOR UNIT

Round pressure terminal

Power wire

Connect same thickness

wiring to both sides.

It is forbidden to connect

two to one side.

It is forbidden to

connect wiring of

different thicknesses.

Precautions when laying power wiring

Use round pressure terminals for connections to the power terminal block.

When none are available, follow the instructions below.

- Do not connect wiring of different thicknesses to the power terminal block. (Slack in the power

wiring may cause abnormal heat.)

- When connecting wiring which is the same thickness, do as shown in the figure below.

19

ENGLISH

- For wiring, use the designated power wire and connect firmly, then secure to prevent outside

pressure being exerted on the terminal block.

- Use an appropriate screwdriver for tightening the terinal screws. A screwdriver with a small

head will strip the head and make proper tighterning impossible.

- Over-tightening the terminal screws may break them.

Page 20

Downward slope

Do not raise

Water

leakage

Accumulated

drain water

Air

Waving

Water

leakage

Tip of drain hose

dipped in water

Water

leakage

Ditch

Less than

50mm gap

CHECKING THE DRAINAGE AND FORMING THE PIPINGS

20

ENGLISH

CHECKING THE DRAINAGE AND FORMING

THE PIPINGS

Checking the Drainage

To check the drainage.

1 Pour a glass of water on the evaporator.

2 Ensure the water flows through the drain

hose of the indoor unit without any leakage and goes out the drain exit.

Connecting area

drain hose

Leakage

checking

Drain pan

Drain

hose

Leakage

checking

2 Do not make drain piping.

Drain piping

1 The drain hose should point downward for

easy drain flow.

Page 21

CHECKING THE DRAINAGE AND FORMING THE PIPINGS

• Trap is required to prevent water from entering

into electrical parts.

Plastic

band

Taping

Drain hose

Pipings

Connecting

cable

Power supply

cord

Seal a small opening

around the pipings

with gum type

sealer.

Seal a small opening

around the pipings

with gum type sealant.

Trap

Trap

21

ENGLISH

Forming the Piping

Form the piping by wrapping the connecting

portion of the indoor unit with insulation material and secure it with two kinds of vinyl tape.

- If you want to connect an additional drain

hose, the end of the drain outlet should be

routed above the ground. Secure the drain

hose appropriately.

In cases where the outdoor unit is installed

below the indoor unit perform the following.

1 Tape the piping, drain hose and connecting

cable from down to up.

2 Secure the tapped piping along the exterior

wall using saddle or equivalent.

In cases where the Outdoor unit is installed

above the Indoor unit perform the following.

1 Tape the piping and connecting cable from

down to up.

2 Secure the taped piping along the exterior

wall. Form a trap to prevent water entering

the room.

3 Fix the piping onto the wall by saddle or

equivalent.

Page 22

AIR PURGING AND EVACUATION

22

ENGLISH

AIR PURGING AND EVACUATION

The air and moisture remaining in the refrigerant system have undesirable effects as indicated below.

- Pressure in the system rises.

- Operating current rises.

- Cooling(or heating) efficiency drops.

- Moisture in the refrigerant circuit may freeze

and block capillary tubing.

- Water may lead to corrosion of parts in the

refrigeration system.

Therefore, after evacuating the system, take a

leak test for the piping and tubing between

the indoor and outdoor unit.

Checking method

Preparation

Check that each tube(both liquid and gas side

tubes) between the indoor and outdoor units

have been properly connected and all wiring

for the test run has been completed. Remove

the service valve caps from both the gas and

the liquid side on the outdoor unit. Check that

both the liquid and the gas side service valves

on the outdoor unit are kept closed at this

stage.

CAUTION

!

To avoid nitrogen entering the refrigerant

system in a liquid state, the top of the

cylinder must be higher than its bottom

when you pressurize the system. Usually,

the cylinder is used in a vertical standing

position.

- Do a leakage test of all joints of the

tubing(both indoor and outdoor) and both gas

and liquid side service valves.

Bubbles indicate a leak. Be sure to wipe off

the soap with a clean cloth.

- After the system is found to be free of leaks,

relieve the nitrogen pressure by loosening

the charge hose connector at the nitrogen

cylinder. When the system pressure is

reduced to normal, disconnect the hose from

the cylinder.

Indoor unit

Manifold valve

Outdoor unit

Lo Hi

Pressure

gauge

Charge hose

Leakage test

Connect the manifold valve(with pressure

gauges) and dry nitrogen gas cylinder to this

service port with charge hoses.

CAUTION

!

Be sure to use a manifold valve for leakage

test. If it is not available, use a stop valve for

this purpose. The "Hi" knob of the manifold

valve must always be kept close.

- Pressurize the system to no more than

551 P.S.I.G. with dry nitrogen gas and

close the cylinder valve when the gauge

reading reached 551 P.S.I.G. Next, test

for leaks with liquid soap.

Nitrogen gas

cylinder(in vertical

standing position)

Page 23

AIR PURGING AND EVACUATION

Lo Hi

Manifold valve

Vacuum pump

Open

Open

Pressure

gauge

Indoor unit

Outdoor unit

23

ENGLISH

WARNING

!

Use a vacuum pump or Inert (nitrogen)

gas when doing leakage test or air purge.

Do not compress air or Oxygen and do

not use Flammable gases. Otherwise, it

may cause fire or explosion.

- There is the risk of death, injury, fire or

explosion.

Evacuation

- Connect the charge hose end described in

the preceding steps to the vacuum pump to

evacuate the tubing and indoor unit.

Confirm the "Lo" knob of the manifold valve

is open. Then, run the vacuum pump.

The operation time for evacuation varies with

tubing length and capacity of the pump. The

following table shows the time required for

evacuation.

Required time for evacuation when 30 gal/h

If tubing length is

less than 10m (33 ft)

Less than 0.5 Torr Less than 0.5 Torr

- When the desired vacuum is reached, close

the "Lo" knob of the manifold valve and stop

the vacuum pump.

Finishing the Job

vacuum pump is used

If tubing length is

longer than 10m (33

ft)

- Replace the valve caps at both gas and liquid

side service valves and fasten them tight.

This completes air purging with a vacuum pump.

The air conditioner is now ready to test run.

- With a service valve wrench, turn the valve

stem of liquid side valve counter-clockwise to

fully open the valve.

- Turn the valve stem of gas side valve counterclockwise to fully open the valve.

- Loosen the charge hose connected to the gas

side service port slightly to release the pressure,

then remove the hose.

- Replace the flare nut and its bonnet on the gas

side service port and fasten the flare nut securely with an adjustable wrench. This process is

very important to prevent leakage from the system.

Page 24

INSTALLATION PI485

T

h

i

s

i

s

t

h

e

s

p

a

c

e

for

i

n

s

t

a

l

l

a

ti

o

n

o

f

P

I

4

8

5

G

a

te

w

a

y.

T

h

i

s

i

s

t

h

e

s

p

a

c

e

f

o

r

in

s

t

a

l

l

a

t

i

o

n

o

f

P

I

4

8

5

Ga

t

e

w

a

y.

(

Ac

c

e

s

s

o

r

y

)

(

A

c

c

e

s

s

o

r

y

)

P

l

e

a

s

e

c

o

nn

e

c

t

t

h

e

w

i

r

e

a

fte

r

i

n

s

ta

l

l

i

n

g

P

I

4

8

5

P

l

e

a

s

e

c

o

n

n

ec

t

t

h

e

w

i

r

e

a

f

te

r

i

n

s

t

a

l

l

i

n

g

P

I

4

8

5

G

a

te

w

a

y.

G

a

t

e

w

a

y.

Screw HoleScrew Hole

Screw HoleScrew Hole

M

EZ30

1

7

1

8

0

2

ME

Z30

1

7

18

0

2

24

ENGLISH

INSTALLATION PI485

Fix the PI485 PCB as shown in Fig.

Detailed installation method refer to PI485 Installation Manual.

18kBtu/h, 21kBtu/h

24kBtu/h, 27kBtu/h, 30kBtu/h

1Ø : 40kBtu/h

Page 25

Bolt

Tubing connection

Discharge

temperature

Discharge air

Intake temperature

Discharge

temperature

Discharge air

Intake temperature

Discharge

temperature

Discharge air

Intake temperature

TEST RUNNING

TEST RUNNING

25

ENGLISH

- Check that all tubing and wiring have been

properly connected.

- Check that the gas and liquid side service

valves are fully open.

Prepare remote control

Remove the battery cover by pulling it according to the arrow direction.

Insert new batteries making sure that the (+)

and (–) of battery are installed correctly.

Reattach the cover by pushing it back into

position.

NOTE

!

• Use 2 AAA(1.5volt) batteries. Do not

use rechargeable batteries.

• Remove the batteries from the remote

control if the system is not going to be

used for a long time.

- For reference, the gas side pressure of optimum condition is as below.(Cooling)

Refrigerant

R410A 35°C (95°F)

!

If the actual pressure are higher than

shown, the system is most likely overcharged, and charge should be removed.

If the actual pressure are lower than

shown, the system is most likely undercharged, and charge should be added.

The air conditioner is now ready for use.

Outside ambi-

ent TEMP.

NOTE

The pressure of

the gas side

service valve.

8.5~9.5kg/cm2G

(120~135 P.S.I.G.)

Evaluation of the performance

Operate unit for 15~20 minutes, then check

the system refrigerant charge:

- Measure the pressure of the gas side service

valve.

- Measure the temperature of the intake and

discharge of air.

- Ensure the difference between the intake

temperature and the discharge is more than

8°C.

Page 26

FUNCTION

26

ENGLISH

FUNCTION

DIP S/W Setting

If you set the DIP Switch when power is on, the change in setting is not

applicable. The changing setting is enabled only when Power is reset.

DIP Switch

1234

Normal Operation (No Function)

Forced Cooling Operation

Wiring Error Check

Saving Power Consumption (Step 1)

Saving Power Consumption (Step 2)

Mode Lock (Cooling)

Mode Lock (Heating)

Night Quiet Mode (Step 1)

Night Quiet Mode (Step 2)

Function

Mode Lock (Cooling) + Night Quiet Mode (Step 1)

Mode Lock (Cooling) + Night Quiet Mode (Step 2)

Mode Lock (Cooling) + Saving Power Consumption (Step 1)

Mode Lock (Cooling) + Saving Power Consumption (Step 2)

Mode Lock (Heating) + Saving Power Consumption (Step 1)

Mode Lock (Heating) + Saving Power Consumption (Step 2)

SLC (Smart Load Control) Mode

WARNING

!

When you set the DIP switch, you should turn off the circuit breaker or shut the power

source of the product down.

CAUTION

!

• Unless the applicable DIP switch is set properly, the product may not work.

• If you want to set a specific function, request that the installer sets the DIP switch appropriately during installation.

Page 27

14/16/18/21(1Ø) kBtu/h 40(1Ø) kBtu/h

DIP-SW

SW01N

DIP SW2

Forced Cooling Operation

Adding the refrigerant in winter.

Setting Procedure

1 Set the DIP Switch as follow after shutting

the power source down.

FUNCTION

27

ENGLISH

24/27/30(1Ø) kBtu/h

2 Reset the power.

3 Check that the Red LED of PCB is on dur-

ing work.

(The indoor unit is operated by force.)

4 Add the specific amount of refrigerant.

CAUTION

!

- When the green LED of PCB is on,

compressor is going to be off because

of low pressure.

- You should return the DIP Switch to

operate normally after finishing the

operation.

Page 28

28

1 s1 s

1 s

LED1

(Red)

LED1

(Gree n)

1 s

3

3

2

2

ENGLISH

FUNCTION

Wiring Error Check

You can check whether or not the wiring is correct.

Setting Procedure

1 Set the DIP Switch as follow after shutting

the power source down.

2 Reset the power.

3 Check that the Re and Green LED of PCB

are on during work. (The indoor unit is

operated by force.)

4 If the wiring is correct, the Green LED will

light up.

If the wiring is wrong, display as below

(Display only wrong connection.)

• Red LED : Piping Number

• Green LED : Wiring Number (Room)

Example)

If the Red LED blinks twice and the Green

LED blinks 3 times, 2nd pipe is connected to

3rd room.

CAUTION

!

• If Indoor unit doesn’t communicate to out-

door Unit, function could not be operated

correctly.

• Only the wrong wiring connection is dis-

played. You should change connection correctly to operate the product.

• If Outdoor and Indoor temperature is too

low in winter, the wiring error check function will not be operated.

(Red LED is lighting)

Saving Power Consumption

Saving Power Consumption operation is the

function which enables efficient operation by

lowering the maximum power consumption

value.

Power

consumption

and current

Nomal

Time

5 You should return the DIP Switch to oper-

ate normally after finishing wiring error

check.

Setting Procedure

1 Set the DIP Switch as follow after shutting

the power source down.

Step 1 Step 2

2 Reset the power.

Page 29

FUNCTION

Saving Power Consumption Current level.

Phase 1Ø

Model 14k 16k 18k 21k 24k 27k 30k 40k

Step1(A) 889912131522

Step2(A) 778810111318

Saving Power Consumption with Mode Lock.

Saving Power

Consumption (step 1)

+ Mode Lock (Cooling)

Saving Power

Consumption (step 1)

+ Mode Lock (Heating)

29

ENGLISH

Saving Power

Consumption (step 2)

+ Mode Lock (Cooling)

Saving Power

Consumption (step 2)

+ Mode Lock (Heating)

Night Quiet Mode

Night Quiet Mode operation lowers the noise level of the outdoor unit by changing the comp frequency and fan speed. This function is operated all night long.

Setting Procedure

1 Set the DIP Switch as follow after shutting the power source down.

h Noise level :Step 1 > Step 2

Step 1 Step 2

2 Reset the power.

Night Quiet Mode with Mode Lock.

Mode Lock (Cooling)

+ Night Quiet Mode

(step 1)

CAUTION

!

• If comp frequency and fan speed are down, the cooling capacity may decrease accordingly.

• This function is only available for Cooling Mode.

• If you want to stop the Night Quiet Mode, Change the DIP Switch.

• If operating indoor unit is set by the fan speed “Power”, Night Quiet Mode will be stopped

until fan speed “Power” is changed.

Mode Lock (Cooling)

+ Night Quiet Mode

(step 2)

Page 30

FUNCTION

30

ENGLISH

Mode Lock

Setting Procedure

1 Set the DIP Switch as follow after shutting the power source down.

Only Cooling Mode Only Heating Mode

2 Reset the power.

Mode Lock with Night Quiet Mode

Mode Lock (Cooling)

+ Night Quiet Mode

(step 1)

Saving Power Consumption with Mode Lock.

Mode Lock (Cooling)

+ Saving Power

Consumption (step 1)

Mode Lock (Cooling)

+ Saving Power

Consumption (step 2)

SLC (Smart Load Control) Mode

Through the most efficient operation according to the in/outdoor load, must minimize the

energy consumption.

Power

consumption

Normal

Mode Lock (Cooling)

+ Night Quiet Mode

(step 2)

Mode Lock (Heating)

+ Saving Power

Consumption (step 1)

Mode Lock (Heating)

+ Saving Power

Consumption (step 2)

※ 18~40(1Ø) kBtu/h

Setting Procedure

1 Set the DIP Switch as follow after the

power source down.

SLC

(Smart Load Control)

2 Reset the power.

Time

CAUTION

!

• The cooling/heating capacity may decrease depending on the in/outdoor load.

• If you want to stop the SLC Mode, Change the DIP Switch.

Page 31

PCB Display(14/16/18/21k Model Only)

It is useful to check the cycle data without LGMV.

Operating Method

Whenever you push the Tact Switch, the cycle information will be shown as below.

h After 1page is displayed, subsequently 2page is displayed.

FUNCTION

31

ENGLISH

Tact S/W

14/16k 18/21k Example 1page 2page

- 1 time Low Pressure 890kpa ‘LP’ ’ 89’

- 2 time Hi Pressure 2900kpa ‘HP’ ‘290’

1 time 3 time Discharge Temp. 85°C ‘DS’ ’ 85’

2 time 4 time Cond Out Temp. -10°C ‘CS’ ‘-10’

3 time 5 time Suction Temp. -10°C ‘SS’ ‘-10’

4 time 6 time ODU Air Temp. -10°C ‘AS’ ‘-10’

5 time 7 time Current 15A ‘A’ ‘ 15’

6 time 8 time Voltage 230V ‘V’ ‘230’

7 time 9 time Comp Hz 100Hz ‘F’ ‘100’

8 time 10 time DC Link Voltage 230V ‘dc’ ‘230’

Item

TACT-SW1

Display

WARNING

!

When you push the Tact Switch, use the material non-conducting electricity.

Page 32

MAX COMBINATION CAPACITY

32

ENGLISH

MAX COMBINATION CAPACITY

Multi Piping Type

Capacity

(kBtu/h)

14 2 5,7,9,12 21

16 2 5,7,9,12 24

18 3 5,7,9,12,18 30

21 3 5,7,9,12,18 33

24 4 5,7,9,12,18,24 39

27 4 5,7,9,12,18,24 41

30 5 5,7,9,12,18,24 48

40 5 5,7,9,12,18,24 52

The combination of indoor unit is to be decided that the sum of indoor unit capacity index must

be smaller than the maximum combination capacity of outdoor unit. We recommend to calculate

indoor unit capacity like below.

If you do not follow our recommendation, it will have some problems in low ambient condition

i.e. some indoor unit will not be able to heat very well in heating mode.

CALCULATION METHOD FOR THE CONNECTABLE TOTAL CAPACITY OF INDOOR UNIT

Sum up the capacity of all indoor unit, but high static duct type indoor unit capacity weights 1.3

times

Max Room No.

Combination Indoor Capacity

(kBtu/h)

Max Combination Capacity

(kBtu/h)

1 Outdoor unit : A9UW566FA3(FM56AH)(connectable maximum capacity is 73kBtu)

Ex)

Indoor unit:

AMNH186BHA0[MB18AH],AMNH246BHA0[MB24AH],AMNH246BHA0[MB24AH]

(18 + 24 + 24) x 1.3 = 66 x 1.3 = 85.8kBtu: this combination has a some problem

2 Out door unit: FM56AH

Indoor unit:

AMNH186BHA0[MB18AH],AMNH246BHA0[MB24AH],AMNH18GD5L0[MS18AH]

(18 + 24) x 1.3 + 18 + 72.6: this combination can be ok

Page 33

Sea wind

Sea wind

Sea wind

Windbreak

INSTALLATION GUIDE

AT THE SEASIDE

CAUTION

!

• Air conditioners should not be installed

in areas where corrosive gases, such as

acid or alkaline gas, are produced.

• Do not install the product where it could

be exposed to sea wind (salty wind)

directly. It can result corrosion on the

product. Corrosion, particularly on the

condenser and evaporator fins, could

cause product malfunction or inefficient

performance.

• If outdoor unit is installed close to the

seaside, it should avoid direct exposure

to the sea wind. Otherwise it needs

additional anticorrosion treatment on the

heat exchanger.

Selecting the location(Outdoor Unit)

If the outdoor unit is to be installed close to

the seaside, direct exposure to the sea wind

should be avoided. Install the outdoor unit on

the opposite side of the sea wind direction.

INSTALLATION GUIDE AT THE SEASIDE

- It should be strong enough like concrete to

prevent the sea wind from the sea.

- The height and width should be more than

150% of the outdoor unit.

- It should be keep more than 70 cm of space

between outdoor unit and the windbreak for

easy air flow.

Place with fluent water draining

- Install at a place with fluent water draining to

prevent damage from localized heavy rain

and avoid frequent flooded area.

• Periodic ( more than once/year ) cleaning of the dust or salt particles stuck on

the heat exchanger by using water.

33

ENGLISH

In case, to install the outdoor unit on the

seaside, set up a windbreak not to be

exposed to the sea wind.

SEASONAL WIND AND

CAUTIONS IN WINTER

- Sufficient measures are required in a snow

area or severe cold area in winter so that

product can be operated well.

- Get ready for seasonal wind or snow in winter even in other areas.

- Install a suction and discharge duct not to let

in snow or rain.

- Install the outdoor unit not to come in contact with snow directly. If snow piles up and

freezes on the air suction hole, the system

may malfunction. If it is installed at snowy

area, attach the hood to the system.

- Install the outdoor unit at the higher installation console by 50cm than the average

snowfall (annual average snowfall) if it is

installed at the area with much snowfall.

- Where snow accumulated on the upper part

of the Outdoor Unit by more than 10cm,

always remove snow for operation.

Page 34

SEASONAL WIND AND CAUTIONS IN WINTER

34

ENGLISH

Airborne Noise Emission

The A-weighted sound pressure emitted by

this product is below 70 dB.

** The noise level can vary depending on the

site.

The figures quoted are emission level and are

not necessarily safe working levels. Whilst

there is a correlation between the emission

and exposure levels, this cannot be used reliably to determine whether or not further precautions are required. Factor that influence

the actual level of exposure of the workforce

include the characteristics of the work room

and the other sources of noise, i.e. the number of equipment and other adjacent processes and the length of time for which an operator exposed to the noise. Also, the permissible exposure level can vary from country to

country. This information, however, will

enable the user of the equipment to make a

better evaluation of the hazard and risk.

Limiting concentration

Limiting concentration is the limit of Freon gas

concentration where immediate measures

can be taken without hurting human body

when refrigerant leaks in the air. The limiting

concentration shall be described in the unit of

kg/m3(Freon gas weight per unit air volume)

for facilitating calculation.

Limiting concentration: 0.44kg/m3(R410A)

Calculate refrigerant concentration

Refrigerant

concentration

Model

A5UW30GFA2

A3UW21GFA2

A2UW16GFA2

Frequency / Voltage

• Argentina : 50 Hz 220-240 V~

• Mexico, Brazil : 60 Hz 220 V~

Total amount of replenished refrig-

erant in refrigerant facility (kg)

=

Capacity of smallest room where

indoor unit is installed (m

Current(A)

17.0

11.0

9.0

3

)

Page 35

Model / Modelo (s) :

A5UW30GFA2, A3UW21GFA2, A2UW16GFA2

LG Electronics México, S.A de C.V

Sor Juana lnés de la Cruz No. 555

Col. San Lorenzo Industrial

Tlalnepantla de Baz Estado de México C.P. 54033

Tel. 55 5321 1919

Página web http://www.lg.com.mx

Loading...

Loading...