Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS :PA73A

MODEL : 60PY3D 60PY3DF-UA

CANADA : http//biz.lgservice.com

USA : http//www.lgservice.com

: http//biz.lgservice.com

Page 2

- 2 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during

the servicing of a receiver whose chassis is not isolated from

the AC power line. Use a transformer of adequate power rating

as this protects the technician from accidents resulting in

personal injury from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace

it with the same specified type.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source,

connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of

ohm-meter to the AC plug prongs tied together and touch other

ohm-meter lead in turn to each exposed metallic parts such as

antenna terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

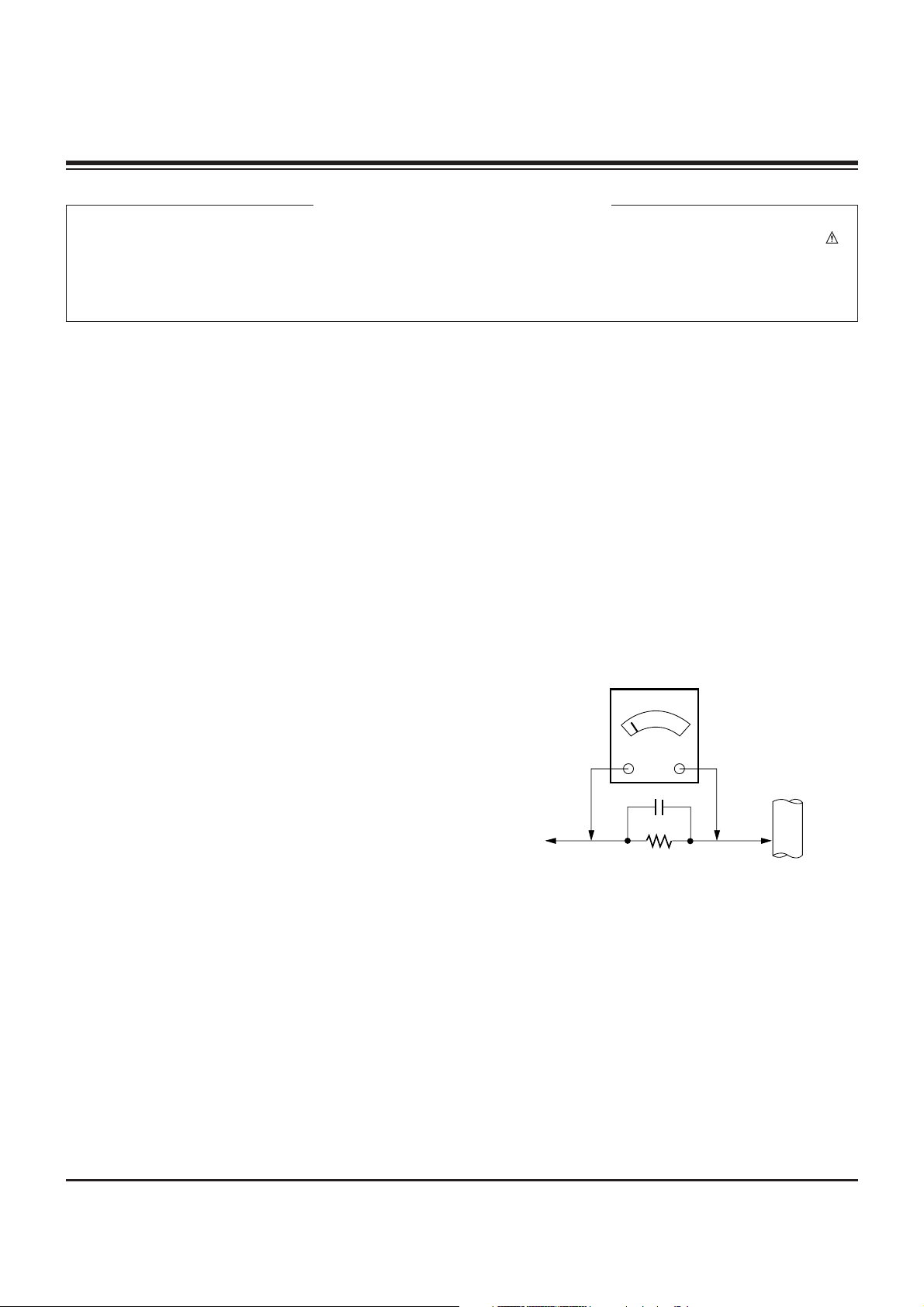

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC

voltmeter with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each esposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 3

- 3 -

SPECIFICATIONS.................................................................4

ADJUSTMENT INSTRUCTIONS ..........................................5

BLOCK DIAGRAM...............................................................11

EXPLODED VIEW...............................................................16

EXPLODED VIEW PARTS LIST .........................................17

REPLACEMENT PARTS LIST............................................18

SCHEMATIC DIAGRAM..........................................................

PRINTED CIRCUIT BOARDS.................................................

TABLE OF CONTENTS

Page 4

- 4 -

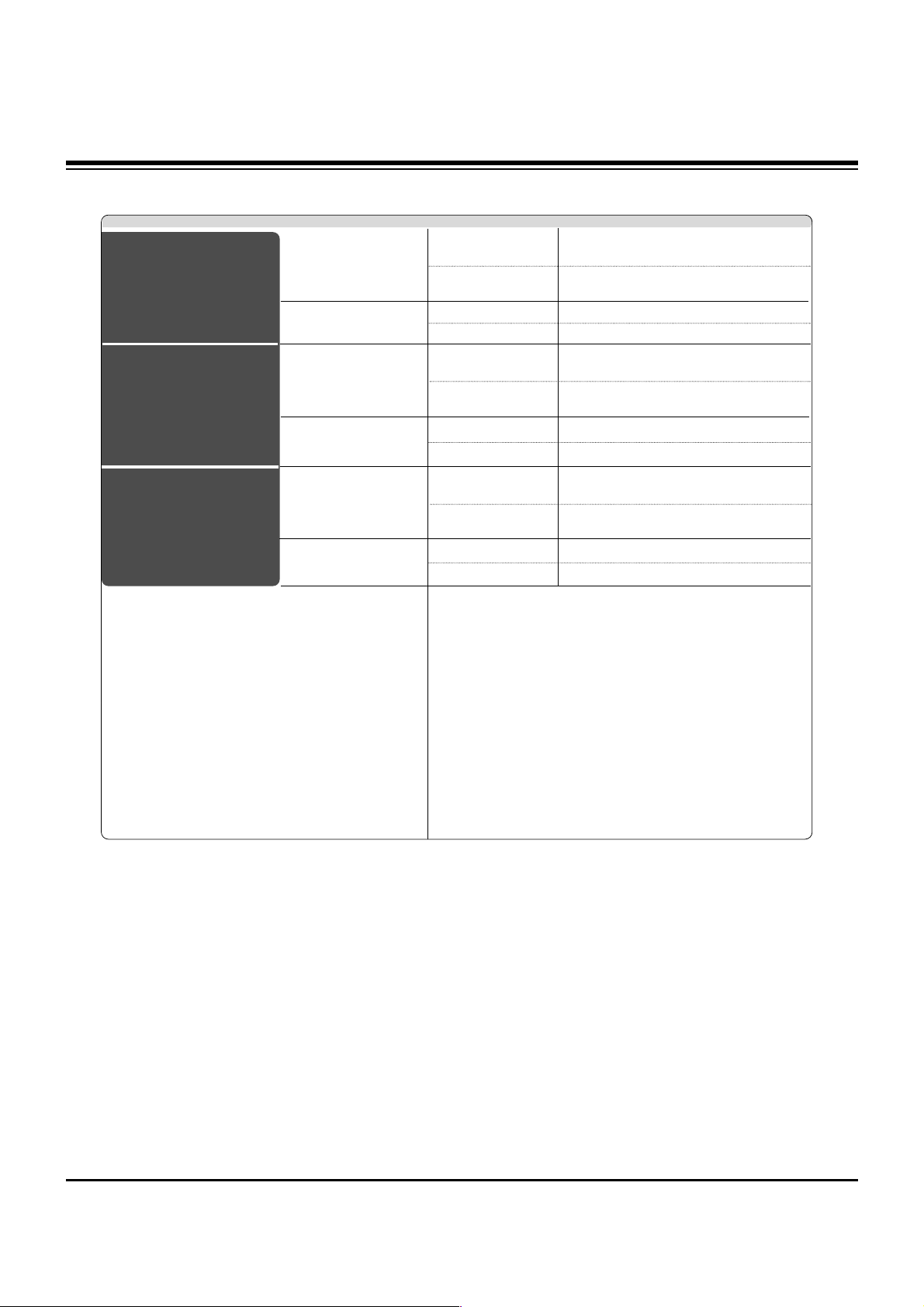

SPECIFICATIONS

The specifications shown above may be changed without prior notice for quality improvement.

Width x Height x Depth With Stand

(inches/mm)

Without Stand

Weight (pounds / kg) With Stand

Without Stand

Width x Height x Depth With Stand

(inches/mm)

Without Stand

Weight (pounds / kg) With Stand

Without Stand

Width x Height x Depth With Stand

(inches/mm)

Without Stand

Weight (pounds / kg) With Stand

Without Stand

32LB9D

( 32LB9D-UA)

47LC7DF

( 47LC7DF-UB)

1920 x 1080 (Dot) (Only 32LB9D model:1366 x 768 (Dot))

AC100-240V~ 50/60Hz

NTSC-M, ATSC, 64 & 256 QAM

VHF 2-13, UHF 14-69, CATV 1-135, DTV 2-69, CADTV 1-135

75 Ω

0 ~ 40°C

Less than 80%

-20 ~ 60°C

Less than 85%

60PY3D

( 60PY3DF-UA)

Resolution

Power requirement

Television System

Program Coverage

External Antenna Impedance

Operating Temperature Range

Operating Humidity Range

Storage Temperature Range

Storage Humidity Range

45.1x32.5x12.0 inches

1144.5x825.6x306.0 mm

45.1x29.7x4.1 inches

1144.5x754.5x103.0 mm

82.4 pounds / 37.5 kg

68.9 pounds / 31.3 kg

63.5x40.8x17.8 inches

1613.6x1036.8x452.0 mm

63.5x38.2x3.9 inches

1613.6x970.0x98.5 mm

180.1pounds / 81.7kg

144.8 pounds / 65.7kg

31.7x24.4x11.2 inches

805.8x619.7x283.9 mm

31.7x21.8x3.1 inches

805.8x554.1x79.0 mm

32.4 pounds / 14.7 kg

27.3 pounds / 12.4 kg

Page 5

1. Application Object

These instructions are applied to all of the PDP TV, PA73A.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 110V, 60Hz

when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

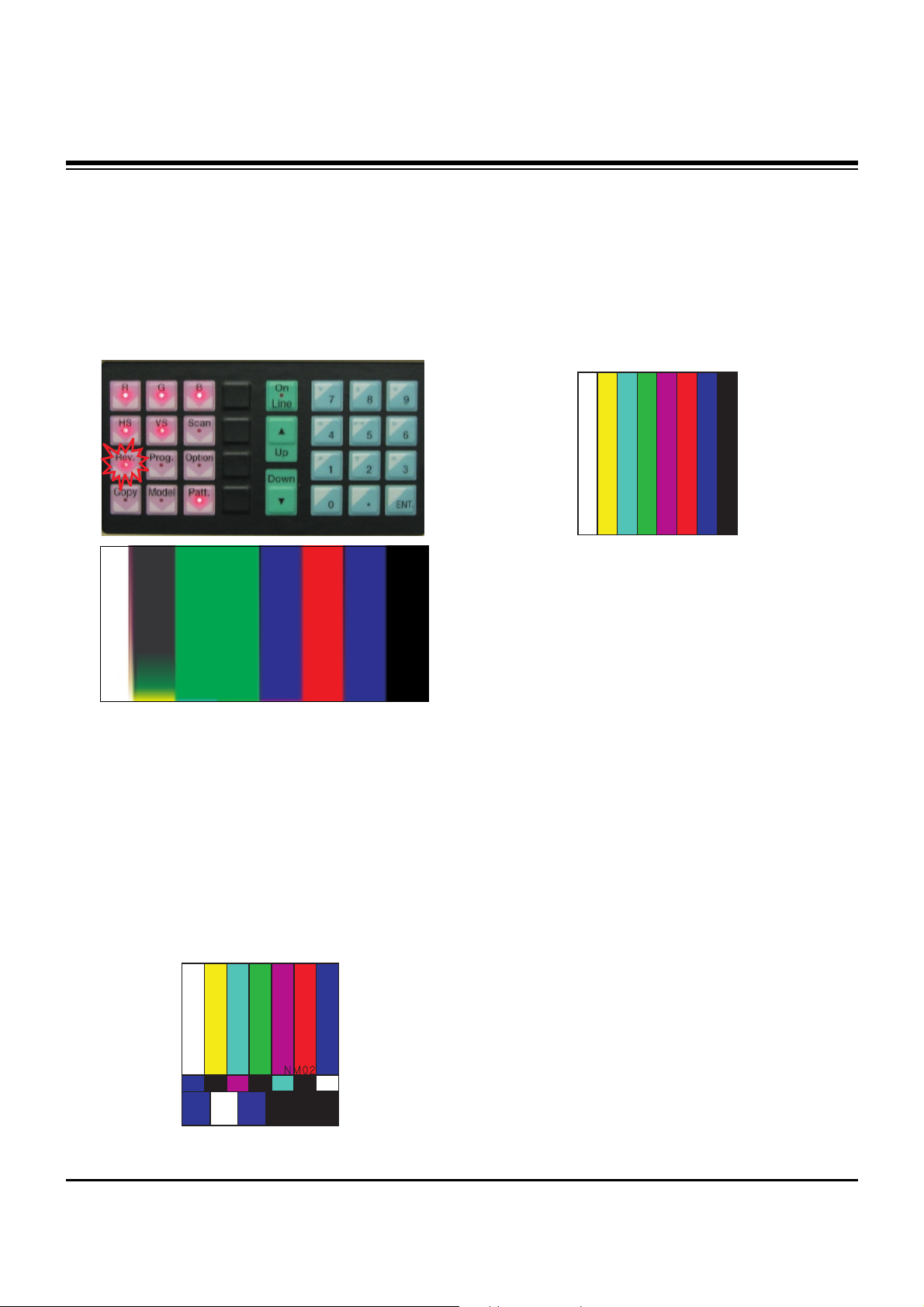

3. Component 480i/1080p RGB

1080p Adjustment

3-1. Synopsis

Component 480i/1080p RGB 1080p adjustment to set the

black level and the Gain to optimum.

3-2. Test Equipment

(1) Service R/C

(2) 801GF(802B, 802F, 802R) or MSPG925FA Pattern

Generator (480i/1080i The Horizontal 100% Color Bar

Pattern adjust to within 0.7±0.1Vp-p)

[ Because the above pattern can differ by the model and

pattern for each device, you must check the pattern first.

3-3. 480i Comp1 Adjustment

(1) Receive the 480i Mode, 100% Horizontal Color Bar

Pattern(HozTV31Bar) to Component 1 port.

(MSPG-925FA: ==> Model : 209, Pattern : 65)

(2) Press the ADJ on the adjustment R/C to enter ‘Ez –

Adjust’. Select ‘1. Adjsut 480i Comp1’ using the

E

and

press the

G

to make the automatic adjustment.

(3) When the adjustment is over, 'ADC Component1 Success’

is displayed. If the adjustment has errors, 'ADC

Component1 408i Fail’ is displayed.

[Fail Message]

- If the component is not connected: Component1 Not

Connected

- If the input format is not 480i: Not Valid Format

- If the input signal is not generated: Check Signal Status

(4) Readjust after confirming the Pattern or adjustment

condition

(5) After adjustment is complete, exit the adjustment mode by

pressing the ADJ.

3-4. 1080p Comp1/RGB Adjustment

(1) Receive the 1080p Mode, 100% Horizontal Color Bar

Pattern(HozTV31Bar) to Component1 and RGB port.

(MSPG-925FA: ==> Model : 225 , Pattern : 65)

(2) After connecting, wait for the image displayed on the

screen

(3) Press the ADJ on the adjustment R/C to enter ‘Ez –

Adjust’. Select ‘2. Adjsut 1080p Comp1/RGB’ using the

E

and press the Gto make the automatic adjustment.

(4) When the adjustment is over, 'ADC Component1 Success’

is displayed. If the adjustment has errors, 'ADC

Component1 1080p Fail’ is displayed.

(5) When the Component1 adjustment is normally completed,

the RGB adjustment automatically starts.

(6) When the adjustment is over, 'ADC RGB 1080p Success’

is displayed.

(7) When the adjustment has errors, 'ADC RGB 1080p Fail’ is

displayed.

[Fail Message]

- If the component is not connected: Component1 Not

Connected

- If the input format is not 480i: Not Valid Format

- If the input signal is not generated: Check Signal Status

(8) Readjust after confirming the Pattern or adjustment

condition

(9) After adjustment is complete, exit the adjustment mode by

pressing the ADJ.

- 5 -

ADJUSTMENT INSTRUCTIONS

<Fig. 1> ADC Adjustment Pattern:

480i/1080i 60Hz HozTV31Bar Pattern

Page 6

- 6 -

4. Auto Adjustment of RF and Video

Adjustment of RF and video signal

4-1. Adjustment

(1) Connect the Video Signal Generator (Master) to AV1 port

and input the signal.

Test Equipment: MSPG925FA Pattern Generator

(Model: 201(NTSC-M), Pattern: 33(100% color Bar))

At this time, press the Rev button certainly.

[ Because the above pattern can differ by the model, pattern

and rev button for each device, you must check the pattern

first.

(2) Apply the RF signal to the antenna. (Make sure that the

signal is received)

(3) Enter the ‘Ez - Adjust’ by pressing the ADJ on the Service

R/C.

After select the ‘3.Adjust RF and Video’, start the

adjustment by pressing the Right Key(

G

).

When it enters the adjustment mode, the screen is

automatically split as TV 2CH SPLIT as shown at the

below figure.

(4) When the adjustment is over, 'RF Configuration Success’ is

displayed. If the adjustment has errors, 'RF Configuration

Error’ is displayed.

(5) When adjusting the RF signal is completed, it is

automatically switched to the Video mode as shown at the

below figure, and the automatic adjustment for the Video

mode starts.

(6) When the adjustment is over, 'AV Configuration Success’ is

displayed. If the adjustment has errors, 'AV Configuration

Error’ is displayed.

ADJUSTMENT INSTRUCTIONS

<Fig. 2>

<Fig. 3>

<Fig. 4>

Page 7

- 7 -

ADJUSTMENT INSTRUCTIONS

<HEAT RUN>

O Preliminary action is applied to the test for afterimage

discharge detection, and 100% FULL WHITE PATTERN

must be operated automatically.

(1) Pressing Power On key on the adjustment R/C

(2) Full Test Pattern(2 min 30sec) --> Full Black

Pattern(30sec) --> Full White Pattern

(Full White Pattern when the main power is turned on

again after being turned off)

(3) Pattern Mode is deselected by pressing CH +/-, Exit Key.

[ Set is activated HEAT-RUN without signal generator in this

mode.

5. Voltage Adjustment(60” Model)

(1) Va Voltage Adjustment

1) Connect + terminal of D.M.M to Va pin of P805 and

connect – terminal to GND pin of P805.

2) Adjust RV501 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

(2) Vs Voltage Adjustment

1) Connect + terminal of D.M.M to Vs pin of P805 and

connect – terminal to GND pin of P805.

2) Adjust RV401 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

6. EDID(The Extended Display

Identification Data)/DDC

(Display Data Channel) Download

It is the feature to implement the “Plug and Play” which

automatically reconfigures the user’sl environment to directly

use by exchanging information without any command directly

to the PC or the monitor by the user, which is established by

the VESA

6-1. Required Test Equipment

(1) PC(S/W: EDID TESTER Ver.2.5)

(2) EDID Download JIG (PC serial to D-sub connection cable)

(3) Connection Cable

Test Pattern 2min 30sec

Test Pattern 30sec

If you turn on a still screen more than 20 minutes (Especially

Digital pattern(13 CH), Cross Hatch Pattern), an afterimage

may occur in the black level part of the screen.

Each PCB Assy must be checked by Check JIG Set before

assembly. (Especially, be careful Power PCB Assy which can

cause Damage to the PDP Module.)

Page 8

- 8 -

ADJUSTMENT INSTRUCTIONS

6-2. Setting of Device

6-3. EDID DATA for 60PY3DF

: EDID for HDMI-1 (DDC (Display Data Channel) Data)

EDID table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

_________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 | 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 | 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0 1 2 3 4 5 6 7 8 9 A B C D E F

_________________________________________________

0 | 02 03 16 F1 47 84 05 03 02 20 22 10 23 15 07 50

10 | 65 03 0C 00 10 00 01 1D 00 72 51 D0 1E 20 6E 28

20 | 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 | 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 | 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 | 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 | 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 10

: EDID for HDMI-2 (DDC (Display Data Channel) Data)

EDID table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

_________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 | 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 | 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0 1 2 3 4 5 6 7 8 9 A B C D E F

________________________________________________

0 | 02 03 16 F1 47 84 05 03 02 20 22 10 23 15 07 50

10 | 65 03 0C 00 20 00 01 1D 00 72 51 D0 1E 20 6E 28

20 | 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 | 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 | 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 | 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 | 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

: EDID for HDMI-3 (DDC (Display Data Channel) Data)

EDID table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

__________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 11 01 03 80 73 41 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 C4 8E 21 00 00 1E 02 3A 80 18 71 38 2D 40

50 | 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 | 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 8A

0 1 2 3 4 5 6 7 8 9 A B C D E F

_________________________________________________

0 | 02 03 16 F1 47 84 05 03 02 20 22 10 23 15 07 50

10 | 65 03 0C 00 30 00 01 1D 00 72 51 D0 1E 20 6E 28

20 | 55 00 C4 8E 21 00 00 1E 01 1D 80 18 71 1C 16 20

30 | 58 2C 25 00 C4 8E 21 00 00 9E 8C 0A D0 8A 20 E0

40 | 2D 10 10 3E 96 00 C4 8E 21 00 00 18 8C 0A D0 8A

50 | 20 E0 2D 10 10 3E 96 00 13 8E 21 00 00 18 26 36

60 | 80 A0 70 38 1F 40 30 20 25 00 C4 8E 21 00 00 1A

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 F0

: EDID DATA for RGB

EDID table =

0 1 2 3 4 5 6 7 8 9 A B C D E F

________________________________________________

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 00 11 01 03 18 73 41 96 0A CF 74 A3 57 4C B0 23

20 | 09 48 4C AF CF 00 31 40 45 40 61 40 81 80 A9 40

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 C4 8E 21 00 00 1A 02 3A 80 18 71 38 2D 40

50 | 58 2C 45 00 C4 8E 21 00 00 1E 00 00 00 FD 00 30

60 | 58 1F 64 11 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 F6

Page 9

- 9 -

ADJUSTMENT INSTRUCTIONS

0 1 2 3 4 5 6 7 8 9 A B C D E F

__________________________________________________

0 | 02 03 04 00 0E 1F 00 80 51 00 1E 30 40 80 37 00

10 | C4 8E 21 00 00 1C F1 27 00 A0 51 00 25 30 50 80

20 | 37 00 C4 8E 21 00 00 1C 26 36 80 A0 70 38 1F 40

30 | 30 20 25 00 C4 8E 21 00 00 0A 00 00 00 00 00 00

40 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

50 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

60 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00

70 | 00 00 00 00 00 00 00 00 00 00 00 00 00 00 00 BC

7. Adjustment of White Balance

7-1. Required Test Equipment

(1) Color Analyzer : CA-210 (CH 9)

=> To adjust color temperature of LCD, CS-1000 is the

Color Analyzer(CA-210) and should be set to use CH 9

in which white, red, green, and blue color are corrected.

Conduct the adjustment according to the coordinates for

White Balance adjustment in the table below.

(2) Computer for adjusting (necessary for the automatic

adjustment, possible to communicate with the RS-232C,

Baud Rate : 115200)

(3) Video Signal Generator MSPG-925F 720p, 216Gray

(Model :217, Pattern 78)

7-2. Connection Diagram of Equipment

for Measuring

(Automatic Adjustment)

Use the internal pattern to adjust White Balance. The pattern

is automatically given when the automatic adjustment device

is connected or when a user presses ADJ on the remote

controller to start Ez Adjust and then selects 6.White-Balance.

7-3. White Balance Adjustment Method

Basically it uses the internal pattern but when internal pattern

is not possible, you can select HDMI input for adjustment.

Through the option at the most bottom part of the Ez Adjust

Menu 7.White Balance menu, you can select NONE, INNER

and HDMI, and the default is set to INNER. When the

adjustment cannot be done with the internal pattern, you can

select HDMI input for adjustment.

For manual adjustment, press the ADJ KEY of the adjustment

R/C to enter Ez Adjust 7.White-Balance, and the pattern is

automatically displayed. (When you set the Option to INNER,

the default is always set to INNER)

(1) Connect the set according to the internal pattern or HDMI

input in accordance with measuring device connection

diagram.

(2) Set the Baud Rate of RS-232C to 115200. It is set to

115200 as default.

(3) Connect the RS-232C Cable to the set.

(4) Connect the HDMI Cable to the set. (Limited to the set with

HDMI option)

(5) Select and adjust the model applicable to PA73A chassis

from the adjuster.

7-4. Automatic Adjustment

(1) Execute POWER ON(Â) of the adjustment R/C to execute

automatic adjustment or set the Baud Rate to 115200.

(2) Always start adjustment with “wb 00 00” and end

adjustment with “wb 00 ff” (Adjust the offset if necessary)

(3) RS-232C command used for the automatic adjustment

Ex) Wb 00 00-----white balance Automatic Adjustment Start

Wb 00 10-----Gain Adjustment start (Internal pattern)

Ja 00 ff------Adjustment Data

Jb 00 c0

...

...

Wb 00 1f-----Gain Adjustment End

*(wb 00 20(Start), wb 00 2f(End))----- When adjust Off-set

Wb 00 ff------White Balance Automatic Adjustment End

(Disappear Inside pattern)

(internal pattern)

Connection Diagram for Internal Pattern

Connection Diagram for HDMI Input

wb

wb

wb

wb

wb

wb

00

00

00

00

00

00

00

10

1f

20

2f

ff

White Balance Adjustment Start

Gain Adjustment Start(Internal white pattern)

Gain Adjustment End

Offset Adjustment Start(Internal white pattern)

Offset Adjustment End

White Balance Adjustment End

(Disappear Internal pattern)

RS-232C COMMAND

[CMD ID DATA]

Meaning

Page 10

- 10 -

ADJUSTMENT INSTRUCTIONS

(4) Adjustment Map

7-5. Manual Adjustment

(1) Required Test Equipment: CA-100

(2) Enter the ‘Ez - Adjust’ by pressing the ADJ on the Service

R/C.

(3) Select 9.TEST PATTERN using the CH + / - KEY and

press the Enter KEY to execute a heat run for more than

30 minutes.

(4) Zero Calibrate of the Color Analyzer, then attach sensor to

PDP module surface when you adjust.

(5) Select ‘6. White-Balance’ of ‘Ez - Adjust’ by pressing the

ADJ KEY on the Service R/C. Then enter adjustment mode

by pressing the Right KEY (

G

) .

(The internal pattern of full white appears by pressing

G

)

(6) The adjustment is conducted in three levels of color

temperature; COOL, MEDIUM, and WARM.

1) For all color temperatures, fix R-Cut / G-Cut / B-Cut to

64.

2) Color Temperature: Cool, Medium, Warm

Adjust the High Light by using the G Gain / R Gain.

R, G, B Gain does not go over 192.

Full White 216gray

[Cool]

X; 0.276±0.002 Y; 0.283±0.002

Color temperature: 11000°K

dUV: -3dUV

[Medium]

X; 0.285±0.002 Y; 0.293±0.002

Color temperature: 9300°K

dUV: -3dUV

[Warm]

X; 0.313±0.002 Y; 0.329±0.002

Color temperature: 6500°K

dUV: -3dUV

R Gain

G Gain

B Gain

R Cut

G Cut

B Cut

Jg

Jh

Ji

Cool

Ja

Jb

Jc

Mid

RS-232C COMMAND

[CMD ID DATA]

CENTER

(DEFAULT)(Decimal)

Jd

Je

Jf

00

00

00

255

255

255

127

127

127

Warm

Min

Max

(Deci

mal)

184

189

192

64

64

64

Cool

192

184

161

64

64

64

Mid

192

150

84

64

64

64

Warm

Page 11

- 11 -

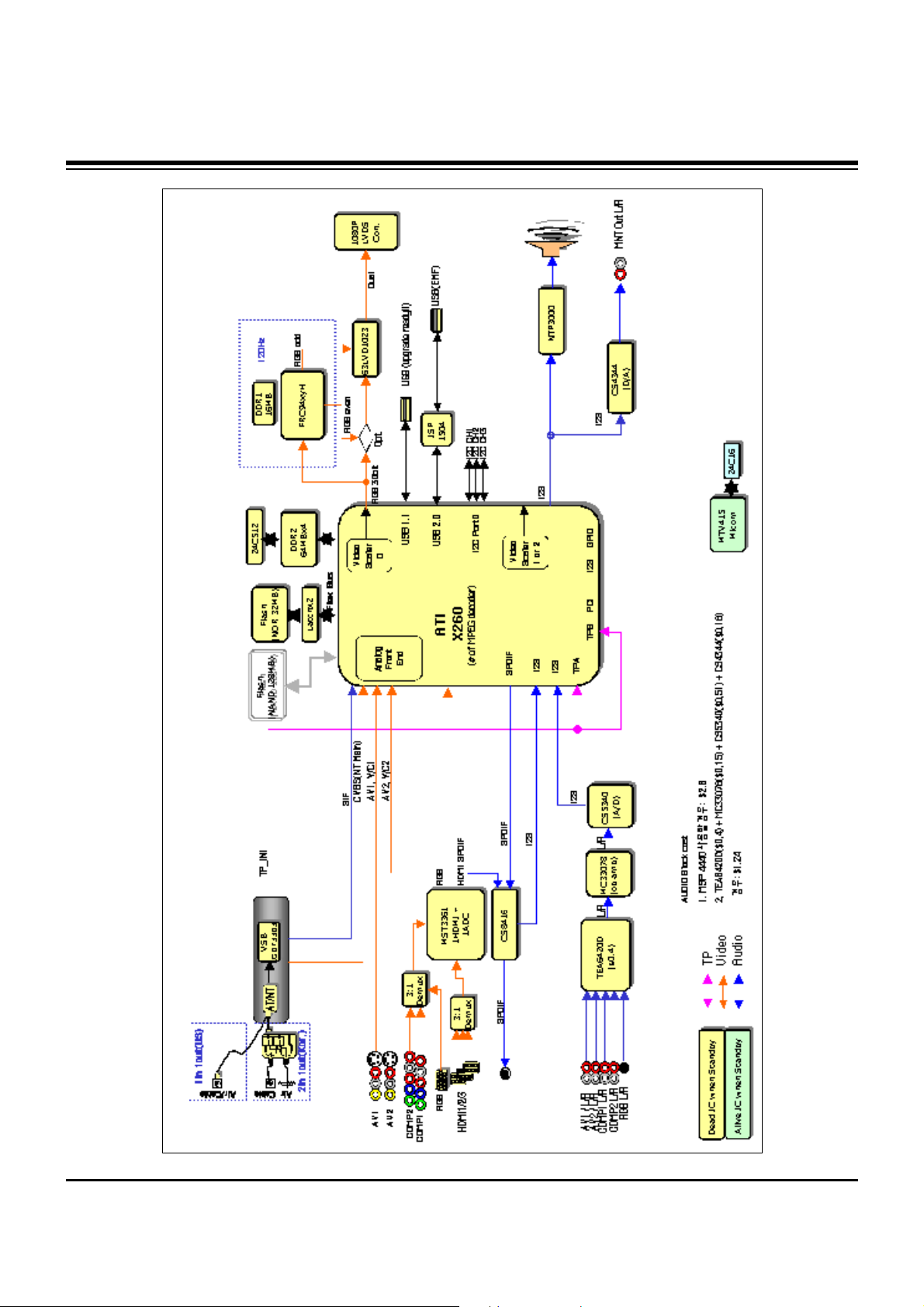

BLOCK DIAGRAM

Page 12

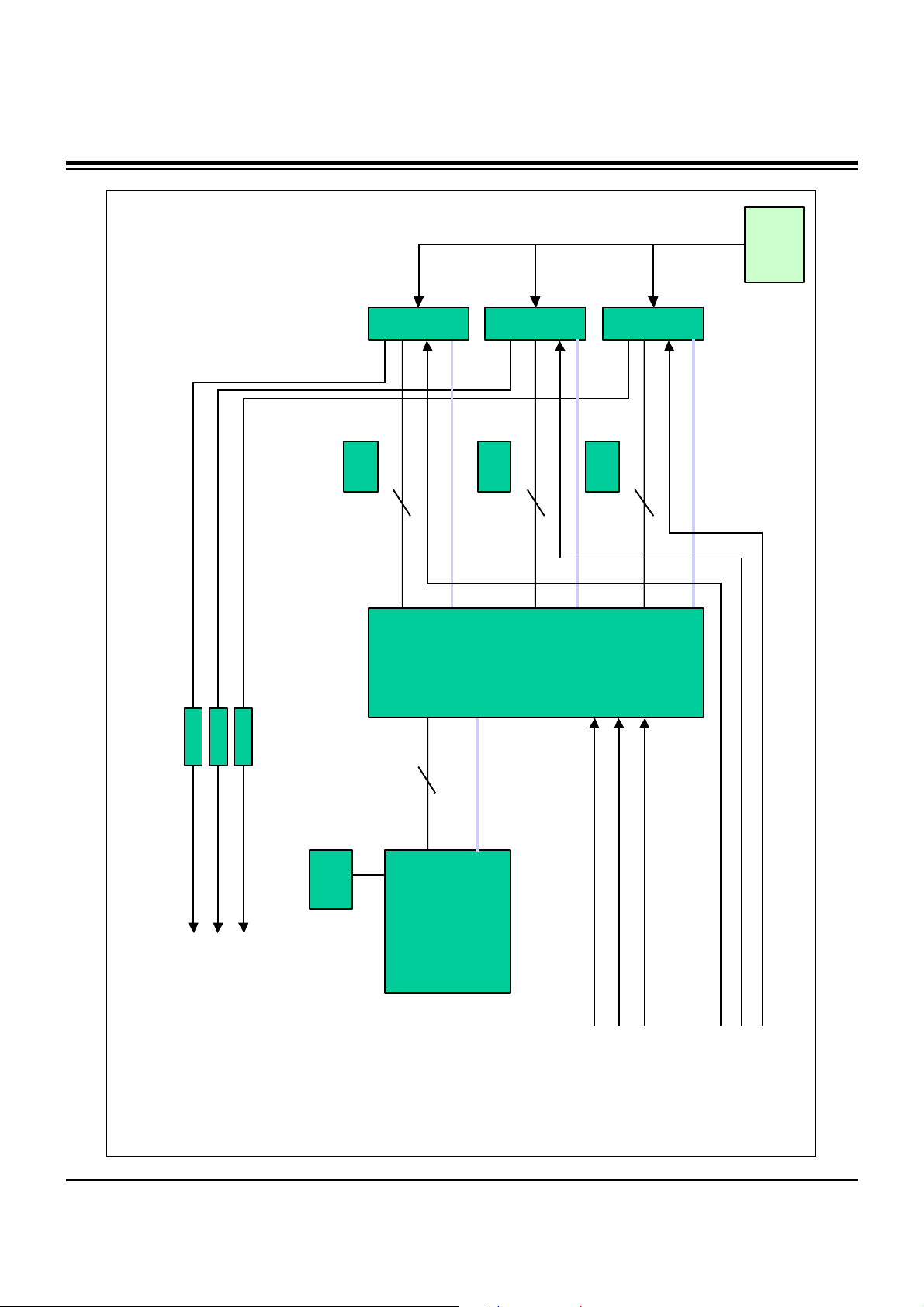

- 12 -

BLOCK DIAGRAM

ddc1

hpd1ddc

ddc2

ddc3

hpd2

hpd3

5v1

5v2

5v3

hdmi1

hdmi2

hdmi3

detect1

detect2

detect3

To cpu

mst3361

sel1

sel2

sel3

From

cpu

MST3361 + TMDS341AFPC , 3 port HDMI (HPD Control)

Hdmi_sig1

Hdmi_sig2

Hdmi_sig3

EDID1

HDCP

rom

EDID2

EDID1

Hdmi_sig

TMDS341

hpd1

hpd2

hpd3

Micom

CEC

CEC

CEC

Page 13

- 13 -

BLOCK DIAGRAM

ATI

(X260)

I2C Master

AT/NT Tuner

0xC2

HDMI

ADC

(MST3361)

0X9C

Temp.

Sensor

(LM75)

0X94

U-Com

(MTV416)

0x50

I2C_CH1 (+3.3V_L & +5V_L)

I2C_CH2 (+3.3V_L & +5V_L)

I2C_CH3 (+3.3V_L)

Port

Expander

(M62320)

0X74

Audio

Switch

(TEA6420)

0X9A

DASP

(NTP3000)

0X54

PDP Module

0x1C

VSB/QAM

(LGDT3703)

Main

0X1C

Live

Dead

CS8416A

0X20(W)

0X21(R)

EEPROM

(24LC512)

0xA6

CH1

CH2

CH3

FRC94XYH

0x94

EEPROM

(24LC16)

5V

5V

5V

2.5V

IIC channel map

Page 14

- 14 -

BLOCK DIAGRAM

+12.0V

+12.0V

+6.0V

+6.0V

CS4344

CS4344

CS5340

CS5340

PQ05DZ1U

PQ05DZ1U

KIA78R09

KIA78R09

FAN1

FAN1

KIA78R09

KIA78R09

FAN2, 3

FAN2, 3

MC33078

MC33078

X260

X260

HYB18T512(4EA)

HYB18T512(4EA)

AZ1117H-1.8

AZ1117H-1.8

LM75

LM75

ICL3232CBNZ

ICL3232CBNZ

+5.0VST

+5.0VST

+3.3V_L

+3.3V_L

AT/NT Tuner

AT/NT Tuner

+5V_L

+5.0V

SI3865

SI3865

PQ05DZ1U

PQ05DZ1U

Live Power

Dead Power

Live-on

AZ1117H-3.3

AZ1117H-3.3

LGDT3703(MAIN)

LGDT3703(MAIN)

SC1565-1.8

SC1565-1.8

ISL6549CB

ISL6549CB

1.2V

1.8V

ISL6549CB

ISL6549CB

1.8V

MK3727D

MK3727D

74LVT16373(2EA)

74LVT16373(2EA)

S29GL256

S29GL256

THC63LVD1023

THC63LVD1023

+3.3V_L

HYB18T512(4EA)

HYB18T512(4EA)

MK3727D

MK3727D

+19.0V

+19.0V

NTP3000

NTP3000

NTP3000

NTP3000

1.8V

BA033FP-3.3

BA033FP-3.3

MTV416

MTV416

AZ1086-1.8

AZ1086-1.8

AZ1117H-3.3

AZ1117H-3.3

SC1565-2.5

SC1565-2.5

MST3369

MST3369

9.0V

TEA6420

TEA6420

9.0V

CS8416

CS8416

KIA78R09

KIA78R09

MK3727D

MK3727D

MIC2505

MIC2505

3.3VST_MICOM

24C08

24C08

FRC94XYH

FRC94XYH

Live-on

24C512

24C512

STMAV335

STMAV335

ISP1504

ISP1504

MIC2505

MIC2505

KIA7805

KIA7805

AZ1085S-3.3

AZ1085S-3.3

AZ1085S-1.8

AZ1085S-1.8

24C16

24C16

FRC

FRC

SC1565-2.6

SC1565-2.6

MIC3910-2.5

MIC3910-2.5

SC1592-1.0

SC1592-1.0

12.0V

HY5DU281622

HY5DU281622

SC2595-1.0

SC2595-1.0

Power Block

Page 15

- 15 -

NOTES

Page 16

- 16 -

EXPLODED VIEW

400

240

102

101

103

602

600

303

304

306

307

121

300

302

301

305

120

603

601

580

581

582

260

250

208

201

202

203

204

204

200

205

206

209

207

205

206

207

560

570

540

542

541

502

520

501

590

A21

A2

901

900

Page 17

- 17 -

EXPLODED VIEW PARTS LIST

101 EAL30846301 Fan Module,G6015S12b2 1.8KRPM DC 12V 840MA 12W 60HZ 200MM3

102 MJH32511701 Supporter,PRESS EGI 0.6 NON EGI FAN_SUPP

103 AJJ31606802 Supporter Assembly,60PY30, SKD, FAN SUPPORTER ASSY

AJJ31606801 Supporter Assembly,60PY30, FAN SUPPORTER ASSY

120 EAB33735401 Speaker Assembly,50PY3 SLIM SPEAKER ASSY RIGHT

121 EAB33735402 Speaker Assembly,50PY3 SLIM SPEAKER LEFT ASSY

200 EAJ32791801 PDP,Module-FullHD PDP60H10000.ADLGB FULLHD 60INCH 1920X1080 16/9 PDP DIVISION

EAJ32791701 PDP,Module-FullHD PDP60H10000.AKLGG FULLHD 60INCH

201 EBR32922301 PCB Assembly,EBR32922301 CTRL ASS’Y 60 H1 Full-HD CTRL PDP DIVISION

202 EBR32015901 PCB Assembly,EBR32015901 YDRV ASS’Y 60 H1 Full-HD YDRV TOP PDP DIVISION

203 EBR32016101 PCB Assembly,EBR32016101 YDRV ASS’Y 60 H1 Full-HD YDRV BOTTOM PDP DIVISION

204 EBR32003901 PCB Assembly,EBR32003901 XRLB ASSY 60 H1 Full-HD XLB & XRT PDP DIVISION

205 EBR32004501 PCB Assembly,EBR32004501 XRCLBT ASSY’ 60 H1 Full-HD XCLB & XCRT PDP DIVISION

206 EBR32004601 PCB Assembly,EBR32004601 XRCRBT ASSY’ 60 H1 Full-HD XCRB & XCLT PDP DIVISION

207 EBR32004701 PCB Assembly,EBR32004701 XRRB ASSY 60 H1 Full-HD XRB & XLT PDP DIVISION

208 EBR32324201 PCB Assembly,EBR32324201 YSUS ASS’Y 60 H1 Full HD PDP DIVISION

209 EBR32324301 PCB Assembly,EBR32324301 ZSUS ASS’Y 60 H1 Full HD PDP DIVISION

240 AJJ30996203 Supporter Assembly,60PY30, SKD, Vertical Supporter Right Assy.

AJJ30996201 Supporter Assembly,60PY30, Vertical Supporter Right Assy

250 AJJ30996204 Supporter Assembly,60PY30, SKD, Vertical Supporter Left Assy.

AJJ30996202 Supporter Assembly,60PY30, Vertical Supporter Left Assy.

260 AJJ31606903 Supporter Assembly,60PY30, MODULE SUPP_SIDE HOR.+ SUPP_SIDE. PANTON ASSY

AJJ31606902 Supporter Assembly,60PY30, MODULE SUPP_SIDE HOR.+ SUPP_SIDE, Press

300 ABJ30995004 Cabinet Assembly,60PY3DR-UA PA71A 60 LG, C/SKD

ABJ30995002 Cabinet Assembly,60PY3DR-UA PA71A 60 LG

301 ADV31660202 Frame Assembly,60py30 mf-056l 60 frame assy, LG

302 MBH32314201 Cabinet,MOLD ABS 60PY30 ABS E3, Cabinet, XCANVAS

303 AJJ30996402 Supporter Assembly,60PY30, Filter Supporter Top, SKD

AJJ30996401 Supporter Assembly,60PY30, Filter Supporter Top

304 AJJ30996502 Supporter Assembly,60PY30, Filter Supporter Bottom Assy C/SKD

AJJ30996501 Supporter Assembly,60PY30, Filter Supporter Bottom Assy

305 5230V00018B Filter,CUTTING ACRYL TOP 60PY2DR ø‹ 60inch PDP MITSUI 60 GLASS FILTER

306 AJJ30996603 Supporter Assembly,60PY30, SKD, Filter Supporter Right Assy

AJJ30996601 Supporter Assembly,60PY30, Filter Supporter Right Assy

307 AJJ30996703 Supporter Assembly,60PY3, SKD, Filter Supporter Left Assy

AJJ30996701 Supporter Assembly,60PY30, Filter Supporter Left Assy

400 ACQ30995608 Cover Assembly,Rear 60PY3DF-ZA PD75A 60 Back Cover Assy, SKD, Without DVR & Without Woofer

ACQ30995604 Cover Assembly,Rear 60PY3D PA71A 60 Back Cover Assy, Without DVR & Without Woofer

501 AGU31681105 Plate Assembly,PLATE TUNER BOT SMALL, 60PY3DF-UA(E3)

502 AGU31680911 Plate Assembly,PLATE TUNER COVER SMALL, 60PY3 E3 /AMERICA

520 EBR36117301 PCB Assembly,Main PA73A 60PY3DF-UA AUSLLHX 60PY3DF-UA MAIN MANUAL ASSY

540 EAJ33837501 VFD,16SL02HS1 237

541 ABA32560202 Bracket Assembly,BRACKET 60PY3DF-ZA PD75A VFD BRACKET ASSY, CSKD

ABA32560201 Bracket Assembly,BRACKET 60PY3DF-ZA PD75A VFD BRACKET ASSY

542 EBT34918701 Chassis Assembly,SUB PA71A 60PY3DR VFD ASSY.

560 EBR36865501 PCB Assembly,Audio BUZZER ASSEMBLY SOUND S.T PDP 50PB3,60PY3 PDP BUZZER B/D YANG WOO CO

570 EBR33918301 PCB Assembly,SUB M.I PA71A 50PB3DR KOREA 50PB3DR PRE AMP

580 EAY32929201 SMPS,AC/DC 1H391W 100VTO240V 800W 50 TO 60HZ UL/CE/TUV 60INCH PDP FULL HD

581 EAY32929401 SMPS,AC/DC 1H391W-PFC 100VTO240V 800W 50 TO 60HZ UL/CE/TUV 60INCH PDP FULL HD

582 EAY32929901 SMPS,AC/DC 1H391W-ACIN 100VTO240V 800W 50 TO 60HZ UL/CE/TUV 60INCH PDP FULL HD

590 EAM35012702 Filter,AC Line IF2-N10CEWL1 1.1mH 250VAC 10A 0.22uF 1000pF

600 EBT36207701 Chassis Assembly,SUB PA73A SUB PA73A 60PY3DF-UB SIDE AV ASSY

601 EBR35103101 PCB Assembly,SUB M.I PA71A SIDE A/V

602 ABA30998703 Bracket Assembly,AV PY30 AB E3_SIDE AV BRACKET ASSY, USA,With USB

603 MGJ32323501 Plate,Shield PRESS AL 1.0 SHIELD AL E3 PY30 SHIELD,SIDE AV

900 AAN30997003 Base Assembly,STAND 60PY3 PA64F Stand Assy, SKD

AAN30997001 Base Assembly,STAND 60PY30 PA64F Stand Assy,

901 MCK32693801 Cover,MOLD ABS 60PY3 ABS COVER CABLE

A2 6710900011Z Remote Controller,COMPLEX LA73A 42LB5DF-UA USA_Full HD_NON DVR

A21 3550V00684B Cover,BATTERY BACK ABS, HF-380 BK

No.

Part No.

Description

Page 18

- 18 -

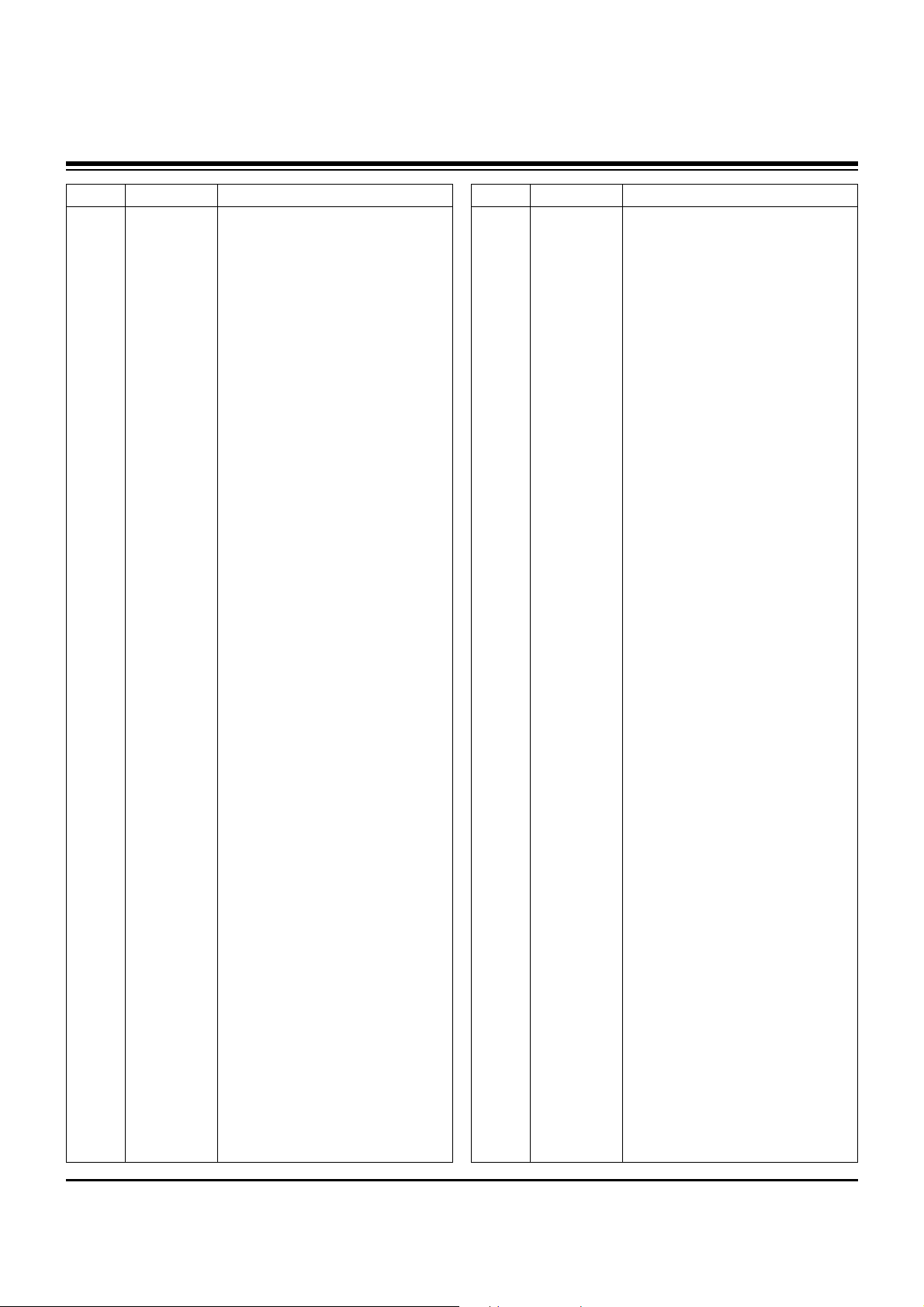

REPLACEMENT PARTS LIST

LOCA. NO PART NO DESCRIPTION

Q300

Q301

Q302

Q303

Q304

Q305

Q306

Q307

Q308

Q309

Q310

Q311

Q312

Q313

Q314

Q315

Q316

Q317

Q318

Q319

Q400

Q401

Q402

Q403

Q404

Q405

Q406

Q407

Q409

Q410

Q411

Q500

Q501

Q503

Q504

Q505

Q506

Q508

Q510

Q511

Q512

Q513

Q514

Q515

Q516

Q601

EBK32756101

EBK32756101

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

0TR387500AA

EBK32756101

0TFDI80001B

0TFDI80001B

0TFDI80001B

0TFDI80001B

0TR387500AA

0TR104009AF

0TR104009AF

0TR387500AA

0TR387500AA

0TR104009AF

0TR104009AF

0TFDI80001B

0TR104009AF

0TR104009AF

0TR387500AA

0TR387500AA

0TR387500AA

0TFDI80001B

0TFDI80001B

0TR387500AA

0TR387500AA

0TR150400BA

0TR150400BA

0TR387500AA

0TR387500AA

0TR102009AM

0TFDI80001B

0TFDI80001B

0TFDI80001B

0TR150400BA

FET,Si4800BDY N-CHANNEL M

FET,Si4800BDY N-CHANNEL M

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

FET,Si4800BDY N-CHANNEL M

FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

2SC3875S(ALY) NPN 5V

KRC104S NPN 40V

KRC104S NPN 40V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

KRC104S NPN 40V

KRC104S NPN 40V

FET,2N7002(F) N-CHANNEL D

KRC104S NPN 40V

KRC104S NPN 40V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

2SA1504S(ASY) PNP -5V

2SA1504S(ASY) PNP -5V

2SC3875S(ALY) NPN 5V

2SC3875S(ALY) NPN 5V

KRA102S PNP -30V 0V FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

2SA1504S(ASY) PNP -5V

LOCA. NO PART NO DESCRIPTION

IC101

IC200

IC201

IC202

IC203

IC206

IC207

IC208

IC300

IC301

IC302

IC303

IC304

IC305

IC306

IC307

IC308

IC310

IC400

IC401

IC402

IC403

IC404

IC405

IC406

IC407

IC408

IC409

IC501

IC505

IC507

IC508

IC600

IC601

IC602

IC603

IC604

IC605

IC605

IC700

IC704

IC705

IC707

IC708

IC711

IC712

EAN32808701

EAN33624401

EAN33931901

EAN33931901

EAN33624401

EAN33624401

0IMCRAL021A

EAN33624401

0IKE702900G

0IMCRSJ001B

0IPMG00049A

0IPMG00049A

EAN33573001

0ISTLPH026A

0IPRP00009A

0IKE702900G

0IPMGA0010A

0IMCRAL006A

0IMCRSJ001B

0IPMGA0010A

0IPRP00696C

EAN32724701

0IMMRCS012B

0IMMRAL014D

0IMMRAL014D

0IMMRAL014D

0IMMRAL014D

EAN35942401

0IPRPCI017A

EAN32404601

0IPMG00049A

0IMCRMN028C

0IPMGKE030A

EAN32174001

0IPMGSH019A

0IPMGA0010A

0ICTMLG019A

0IPMG00049A

0IPMGSH019A

EAN32662801

0IPMGKE030A

0IMI623200B

0IPMGKE032A

0IPMGKE032A

0IPMGKE030A

EAN32013101

XILLEON260 500MVTO2.1V,35

HYB18TC512160BF-3S 512MBI

TC74LCX16373AFT 2V~3.6V 5

TC74LCX16373AFT 2V~3.6V 5

HYB18TC512160BF-3S 512MBI

HYB18TC512160BF-3S 512MBI

AT24C512W-10SU-2.7 512KBI

HYB18TC512160BF-3S 512MBI

KIA7029AF - 3TO15V 2.9V

SC1565IST-2.5TR 2.2TO5V 2

AZ1117H-1.8TR/E1[H13A] 3.

AZ1117H-1.8TR/E1[H13A] 3.

SC2621ASTRT 18V 5V~17.4

74LVC14APW 1.2TO3.6V 01

ICL3232CBNZ 3VTO5.5V - SS

KIA7029AF - 3TO15V 2.9V

AZ1117H-3.3 4.75TO10V 3.3

AT24C16AN-10SU-2.7 16KBIT

SC1565IST-2.5TR 2.2TO5V 2

AZ1117H-3.3 4.75TO10V 3.3

MST3361M-LF-170 3.3V_2.5V

STMAV335 4.0TO5.5V 5NSEC

CAT24WC08W-T(MST3000) 8KB

AT24C02BN-10SU-1.8 2KBIT

AT24C02BN-10SU-1.8 2KBIT

AT24C02BN-10SU-1.8 2KBIT

AT24C02BN-10SU-1.8 2KBIT

TMDS341APFCR 3TO3.6V 10NS

CS8416-CZZR 3.13VTO3.46V,

NTP3000 7TO30V 5.5V 01%

AZ1117H-1.8TR/E1[H13A] 3.

MSP4450K-QA-D6 7.6TO8.7V_

KIA78R05F 6TO12V 5V 8W DP

THC63LVD1023 3.0VTO3.6V 1

PQ018EZ02ZPH(PB-FREE) 2.3

AZ1117H-3.3 4.75TO10V 3.3

LGDT3303 3TO5 25m 16M TQF

AZ1117H-1.8TR/E1[H13A] 3.

PQ018EZ02ZPH(PB-FREE) 2.3

KA7809ERTM 35V to 40V 9V

KIA78R05F 6TO12V 5V 8W DP

M62320FP(SOP) 4.5TO5.5V 0

KIA78R09F 10TO25V 9V 8W D

KIA78R09F 10TO25V 9V 8W D

KIA78R05F 6TO12V 5V 8W DP

MIC2505-2YM 2.7V TO 7.5V

IC

RUN DATE : 2007.5.3

TRANSISTOR

Page 19

- 19 -

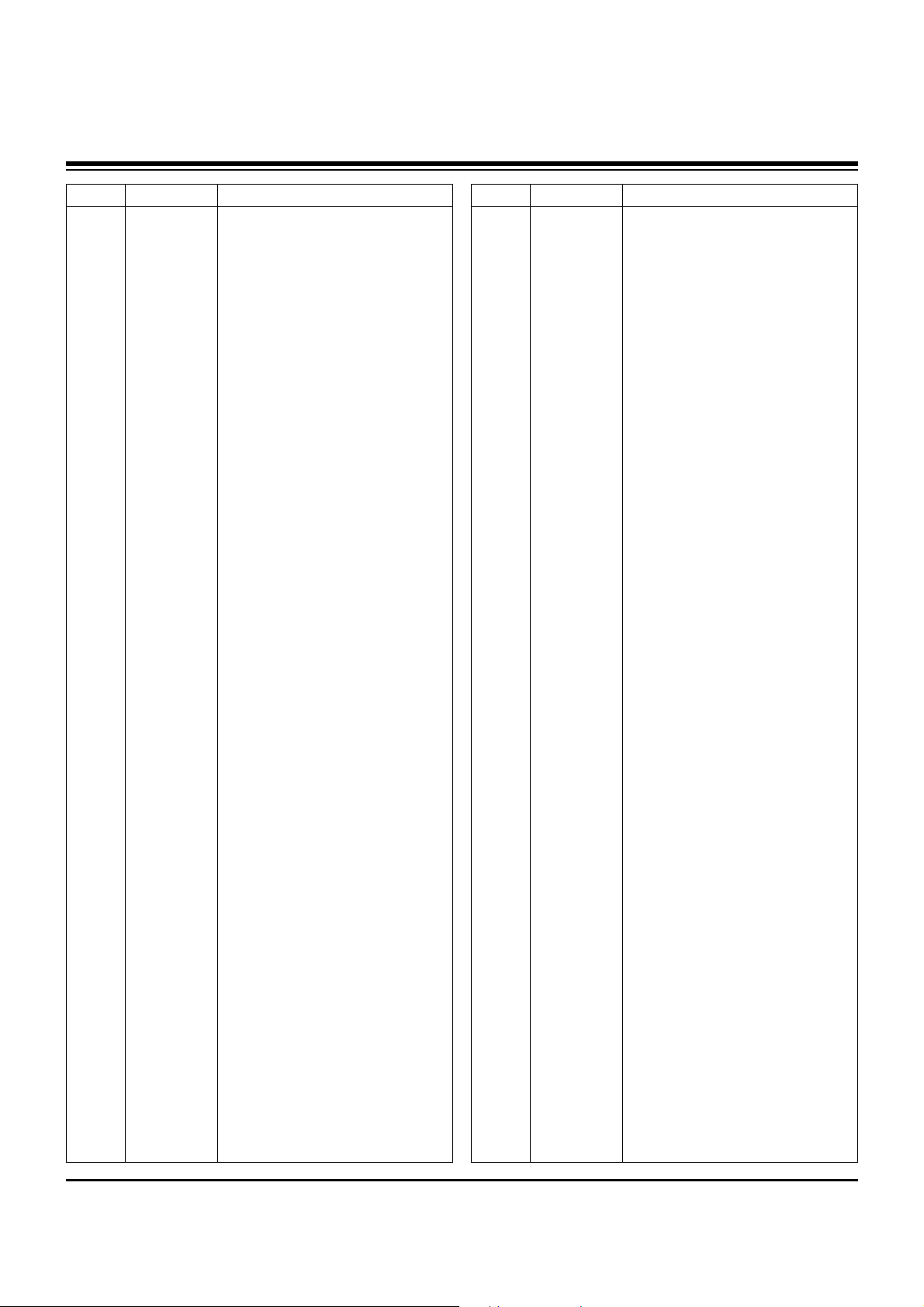

LOCA. NO PART NO DESCRIPTION

Q602

Q602

Q603

Q603

Q611

Q702

D300

D301

D302

D303

D304

D402

D404

D408

ZD405

ZD406

ZD407

ZD408

ZD409

ZD415

ZD416

ZD417

ZD418

ZD419

ZD420

ZD421

ZD501

ZD502

ZD700

ZD705

ZD710

ZD711

ZD712

C1

C1

C2

C200

C201

C202

C203

C204

C205

C206

C207

C208

C209

C210

0TFDI80001B

0TFDI80001B

0TFDI80001B

0TFDI80001B

0TR387500AA

0TFVI80067A

0DSGD00038A

0DRSE00038A

0DRSE00038A

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DD184009AA

0DZ360009EB

0DZ360009EB

0DZ560009DA

0DZ560009DA

0DZ560009DA

0DZ360009EB

0DZ560009DA

0DZ560009DA

0DZ560009DA

0DZ560009DA

EAH33945901

EAH33945901

0DZ560009DA

0DZRM00248A

0DZ360009EB

0DZ360009EB

0DZ560009DA

0DZ360009EB

0DZ360009EB

0CE477DD618

0CE4763F618

0CH3104K566

0CK104BF56A

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE33970001

0CK104BF56A

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

FET,2N7002(F) N-CHANNEL D

2SC3875S(ALY) NPN 5V

FET,SI3865BDV(E3) N-CHANN

1N4148W 1.25V 100V 150MA 2A

SDC15 1.3V 14.3VTO16.4V 21.

SDC15 1.3V 14.3VTO16.4V 21.

KDS184 KDS184 TP KEC - 85V

KDS184 KDS184 TP KEC - 85V

KDS184 KDS184 TP KEC - 85V

KDS184 KDS184 TP KEC - 85V

KDS184 KDS184 TP KEC - 85V

Zener,UDZS3.6B 3.6V 3.6TO3.845V 1

Zener,UDZS3.6B 3.6V 3.6TO3.845V 1

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

Zener,UDZS3.6B 3.6V 3.6TO3.845V 1

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

CDS3C30GTH 3V 120V 1.9

CDS3C30GTH 3V 120V 1.9

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

Zener,RLZ8.2B 8.2V 7.78TO8.19V 8O

Zener,UDZS3.6B 3.6V 3.6TO3.845V 1

Zener,UDZS3.6B 3.6V 3.6TO3.845V 1

Zener,UDZS5.6B 5.6V 5.49TO5.73V 6

Zener,UDZS3.6B 3.6V 3.6TO3.845V 1

Zener,UDZS3.6B 3.6V 3.6TO3.845V 1

EGR477M010T6G1G11G 470uF 20%

ESF476M016T1A5E05G 47uF 20% 1

0805B104K500CT 100nF 10% 50V

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

LOCA. NO PART NO DESCRIPTION

C211

C2114

C2115

C2116

C2117

C2119

C212

C2120

C2122

C2124

C2126

C2127

C2127

C2128

C213

C2130

C2131

C2132

C2133

C2134

C2136

C2137

C2138

C2139

C214

C2140

C2141

C2142

C2143

C2144

C2145

C2146

C2147

C2148

C2149

C215

C2150

C2151

C2152

C2153

C2154

C2155

C2156

C2157

C2158

C2159

C216

C2160

C2161

C2162

C2163

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK106EF56A

0CC150BK4AA

0CC150BK4AA

0CZZB00035A

0CK102BK56A

0CK104BF56A

0CK104BF56A

0CK106EF56A

0CK104BF56A

0CK106EF56A

0CK104BF56A

0CK106EF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE107WF6DC

0CK105CD56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE226WF6DC

EAE30840301

EAE33970001

EAE33970001

EAE33970001

EAE33970001

EAE33970001

EAE33970001

0CK104BF56A

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C3216X7R1C106KT 10uF 10% 16V

C1005C0G1H150JT 15pF 5% 50V C

C1005C0G1H150JT 15pF 5% 50V C

GRM1555C1H330J 33pF 5% 50V C0

0402B102K500CT 1nF 10% 50V X7

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C3216X7R1C106KT 10uF 10% 16V

C1005X7R104KET 100nF 10% 16V

C3216X7R1C106KT 10uF 10% 16V

C1005X7R104KET 100nF 10% 16V

C3216X7R1C106KT 10uF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC100M 100uF 20% 16

C1608X7R1A105KT 1uF 10% 10V X

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

10SVPC68M 68uF 20% 10V 1.97A

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

REPLACEMENT PARTS LIST

DIODE

CAPACITOR

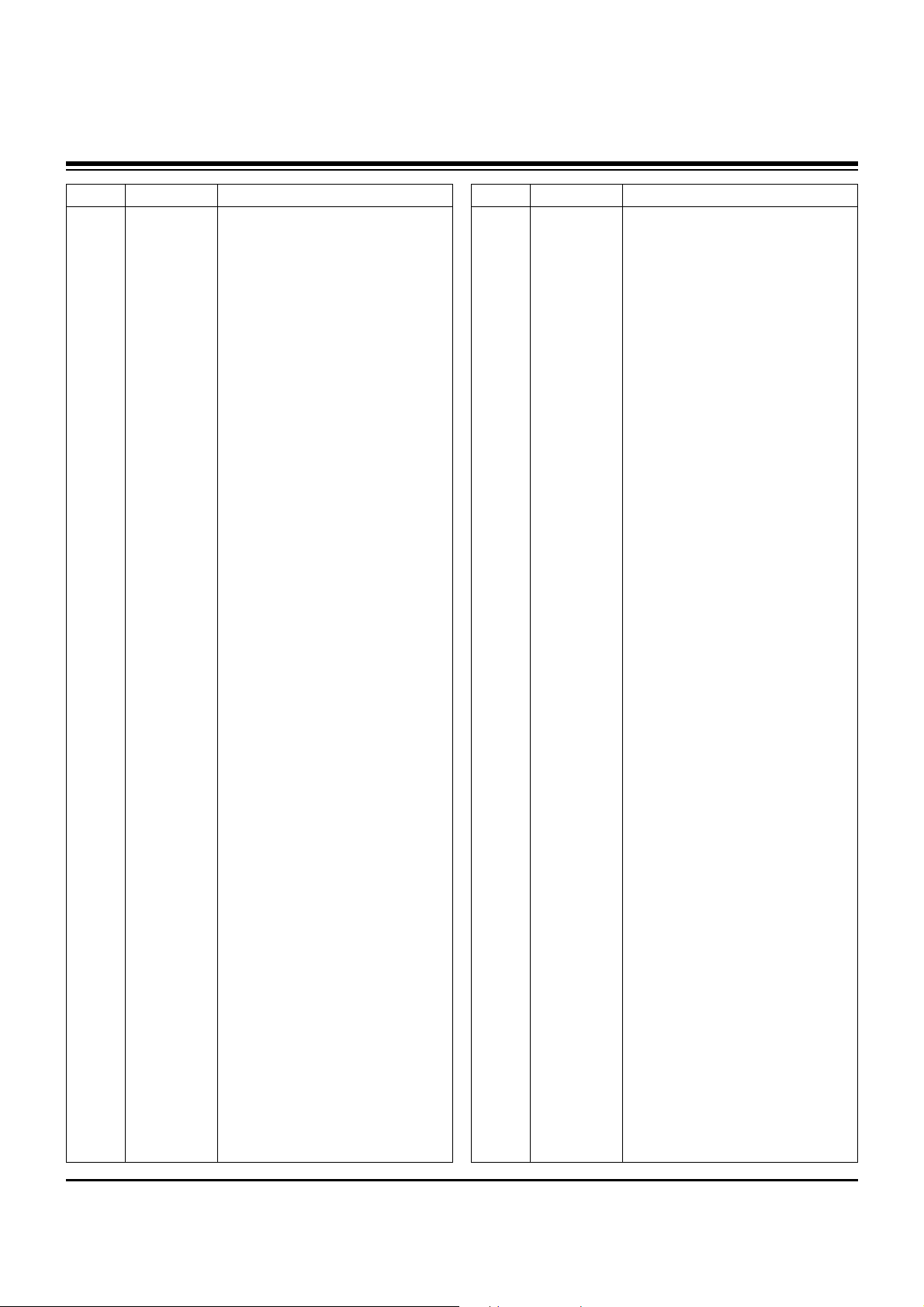

Page 20

- 20 -

LOCA. NO PART NO DESCRIPTION

C2164

C2165

C2166

C2167

C2168

C2169

C217

C2170

C2171

C2172

C2173

C2174

C2175

C2176

C2177

C2178

C2179

C218

C2180

C2181

C2182

C2183

C2184

C2185

C2186

C2187

C2188

C2189

C2189

C219

C2190

C2191

C2192

C2193

C2194

C2195

C2196

C2197

C2198

C2199

C220

C2200

C2201

C2202

C2203

C2204

C2205

C2206

C2207

C2208

C2209

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE226WF6DC

EAE30840301

EAE33970001

EAE33970001

EAE33970001

EAE33970001

EAE33970001

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE226WF6DC

0CE107WF6DC

0CE107WF6DC

EAE30840301

0CK105CD56A

0CK105CD56A

0CK105CD56A

0CK105CD56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK105CD56A

EAE33970001

0CK105CD56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

10SVPC68M 68uF 20% 10V 1.97A

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

MVK6.3TP16VC100M 100uF 20% 16

MVK6.3TP16VC100M 100uF 20% 16

10SVPC68M 68uF 20% 10V 1.97A

C1608X7R1A105KT 1uF 10% 10V X

C1608X7R1A105KT 1uF 10% 10V X

C1608X7R1A105KT 1uF 10% 10V X

C1608X7R1A105KT 1uF 10% 10V X

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1608X7R1A105KT 1uF 10% 10V X

CS1005X5R105K6R3NR 1uF 10% 6.

C1608X7R1A105KT 1uF 10% 10V X

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

LOCA. NO PART NO DESCRIPTION

C221

C2210

C2211

C2212

C2213

C2214

C2215

C2216

C2217

C2218

C2219

C222

C2220

C2221

C2222

C2223

C2224

C2225

C2226

C2227

C2228

C2229

C223

C2230

C2231

C2232

C2233

C2234

C2239

C224

C2240

C2241

C2242

C2243

C2244

C225

C226

C227

C228

C229

C230

C231

C232

C233

C234

C235

C236

C238

C239

C240

C241

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK106EF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE30840301

0CK104BF56A

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE33970001

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE33970001

EAE33970001

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE30840301

0CK104BF56A

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C3216X7R1C106KT 10uF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

10SVPC68M 68uF 20% 10V 1.97A

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

10SVPC68M 68uF 20% 10V 1.97A

C1005X7R104KET 100nF 10% 16V

REPLACEMENT PARTS LIST

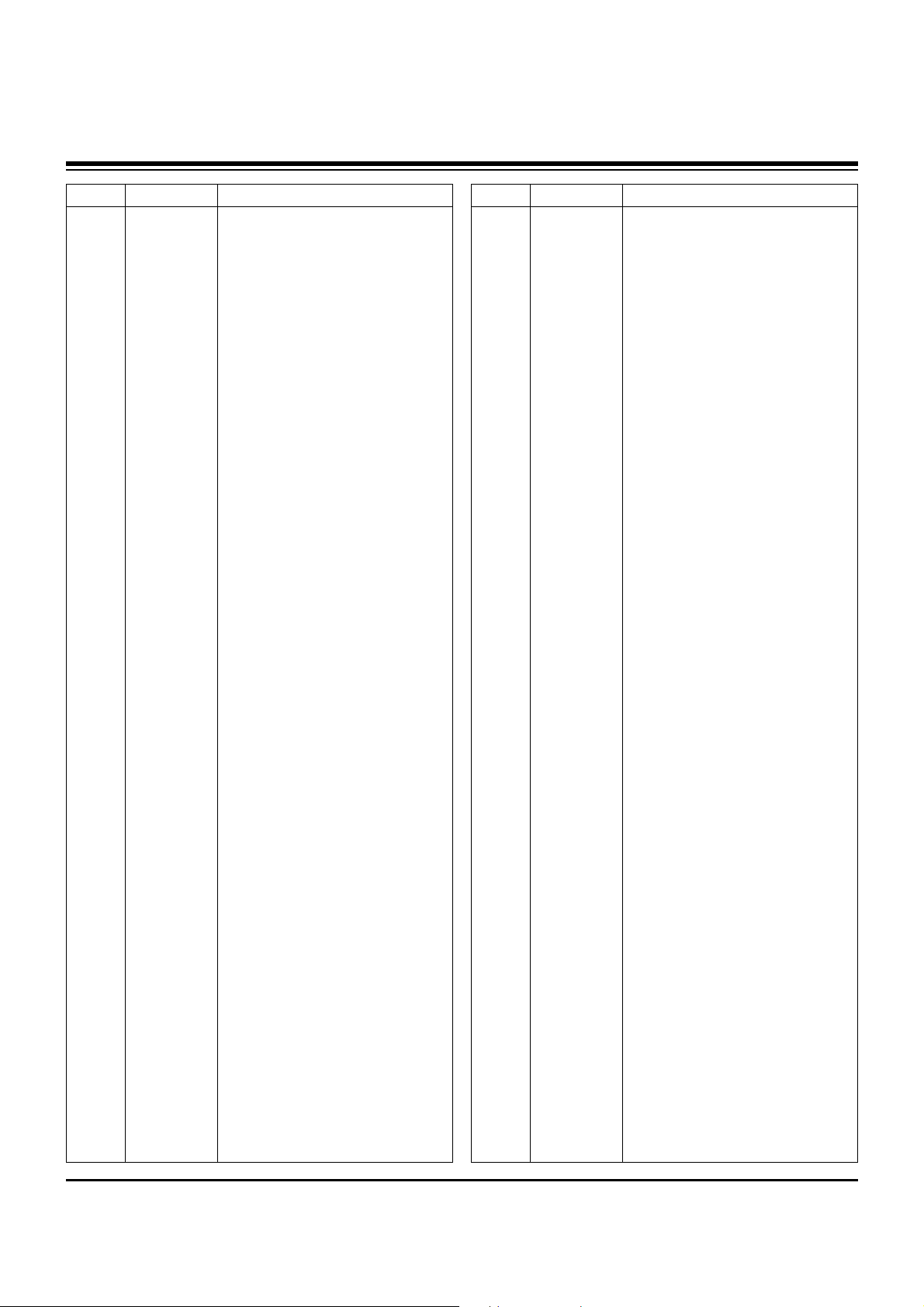

Page 21

- 21 -

LOCA. NO PART NO DESCRIPTION

C242

C243

C244

C246

C250

C252

C256

C257

C260

C264

C265

C266

C276

C285

C3

C3

C300

C301

C302

C303

C304

C305

C306

C307

C309

C310

C311

C312

C313

C314

C315

C316

C317

C318

C319

C320

C321

C322

C323

C324

C325

C326

C327

C328

C329

C330

C331

C332

C333

C334

C335

0CE106WFKDC

EAE33970001

EAE33970001

EAE33970001

EAE33970001

EAE33970001

EAE33970001

EAE33970001

EAE30840301

EAE33970001

EAE30840301

EAE33970001

EAE33970001

0CK104BF56A

0CH5101K416

0CH3104K566

0CE226WF6DC

0CK104BF56A

0CE336WD6D8

0CE476WF6DC

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CE476WF6DC

0CK104BF56A

0CE226WF6DC

0CK104BF56A

0CK222BKG6A

0CC221BKFAA

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE476WF6DC

0CE476WF6DC

0CE476WF6DC

0CK106DC67A

0CK106DC67A

0CK106DC67A

0CK106DC67A

0CK106DC67A

0CK106DC67A

0CK106DC67A

0CK106DC67A

0CK105EJ56A

0CK104BF56A

EAE33970001

EAE33970001

EAE33970001

EAE33970001

0CK105EJ56A

MVK4.0TP16VC10M 10uF 20% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

10SVPC68M 68uF 20% 10V 1.97A

CS1005X5R105K6R3NR 1uF 10% 6.

10SVPC68M 68uF 20% 10V 1.97A

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

C1005X7R104KET 100nF 10% 16V

C2012C0G1H101JT 100pF 5% 50V

0805B104K500CT 100nF 10% 50V

MVK5.0TP16VC22M 22uF 20% 16V

C1005X7R104KET 100nF 10% 16V

RC1A336M05005VR 33uF 20% 10V

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

C1005X7R104KET 100nF 10% 16V

0402B222K500CT 2.2nF 10% 50V

C1005C0G1H221JT 220pF 5% 50V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

JMK212JB106MG-T 10uF 20% 6.3V

JMK212JB106MG-T 10uF 20% 6.3V

JMK212JB106MG-T 10uF 20% 6.3V

JMK212JB106MG-T 10uF 20% 6.3V

JMK212JB106MG-T 10uF 20% 6.3V

JMK212JB106MG-T 10uF 20% 6.3V

JMK212JB106MG-T 10uF 20% 6.3V

JMK212JB106MG-T 10uF 20% 6.3V

GMK316BJ105KL-T 1uF 10% 35V X

C1005X7R104KET 100nF 10% 16V

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

CS1005X5R105K6R3NR 1uF 10% 6.

GMK316BJ105KL-T 1uF 10% 35V X

LOCA. NO PART NO DESCRIPTION

C336

C337

C338

C339

C340

C341

C342

C343

C344

C345

C346

C347

C348

C349

C350

C351

C352

C353

C354

C355

C356

C357

C360

C361

C362

C365

C366

C367

C368

C369

C370

C372

C373

C374

C4

C400

C4000

C4001

C4002

C4003

C4004

C4005

C4006

C4007

C4008

C4009

C401

C4010

C4011

C4012

C4013

0CE476WF6DC

0CK332CK56A

0CK104BF56A

0CK471BK56A

0CH2334F566

0CH2334F566

EAE32166101

0CH2334F566

0CH2334F566

0CE106WFKDC

0CE107WF6DC

0CK103CK56A

0CK104BF56A

0CC221BKFAA

0CC221BKFAA

0CH5470K618

0CH5470K618

0CK104BF56A

0CE476WF6DC

0CK104BF56A

0CE226WF6DC

0CE476WF6DC

0CK104BF56A

0CH5220K618

0CH5220K618

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE107WF6DC

0CK104BF56A

0CE106WFKDC

0CK104BF56A

0CK104BF56A

0CH5101K416

0CE476WF6DC

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK103CK56A

0CK104BF56A

0CK103CK56A

0CK103CK56A

0CK104BF56A

0CK104BF56A

MVK6.3TP16VC47M 47uF 20% 16V

C1608X7R1H332KT 3.3nF 10% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R1H471KT 470pF 10% 50V

0805B334K160CT 330nF 10% 16V

0805B334K160CT 330nF 10% 16V

CS1005XR473K250CR 047uF 10%

0805B334K160CT 330nF 10% 16V

0805B334K160CT 330nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK6.3TP16VC100M 100uF 20% 16

0603B103K500CT 10nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1005C0G1H221JT 220pF 5% 50V

C1005C0G1H221JT 220pF 5% 50V

0402N470M500LT 47pF 5% 50V C0

0402N470M500LT 47pF 5% 50V C0

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

0402N220M500LT 22pF 5% 50V C0

0402N220M500LT 22pF 5% 50V C0

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC100M 100uF 20% 16

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C2012C0G1H101JT 100pF 5% 50V

MVK6.3TP16VC47M 47uF 20% 16V

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

REPLACEMENT PARTS LIST

Page 22

- 22 -

LOCA. NO PART NO DESCRIPTION

C4014

C4015

C402

C404

C405

C406

C407

C408

C409

C410

C412

C413

C414

C415

C416

C417

C419

C420

C421

C423

C424

C425

C426

C427

C428

C429

C430

C431

C432

C436

C439

C440

C441

C442

C449

C450

C451

C452

C453

C454

C457

C459

C460

C465

C466

C467

C468

C469

C470

C471

C476

0CH5220K618

0CH5220K618

0CK104CK56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE476WF6DC

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK473CH56A

EAE32166101

0CK102BK56A

0CK473CH56A

0CK104BF56A

EAE32166101

0CK473CH56A

0CK104BF56A

EAE32166101

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE106WFKDC

0CK104BF56A

0CK102BK56A

0CK104BF56A

0CC180BKFAA

0CK104BF56A

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK101BK4EA

0CK471BK56A

0CC180BKFAA

0CK101BK4EA

0402N220M500LT 22pF 5% 50V C0

0402N220M500LT 22pF 5% 50V C0

0603B104K500CT 100nF 10% 50V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1608X7R1E473KT 47nF 10% 25V

CS1005XR473K250CR 047uF 10%

0402B102K500CT 1nF 10% 50V X7

C1608X7R1E473KT 47nF 10% 25V

C1005X7R104KET 100nF 10% 16V

CS1005XR473K250CR 047uF 10%

C1608X7R1E473KT 47nF 10% 25V

C1005X7R104KET 100nF 10% 16V

CS1005XR473K250CR 047uF 10%

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

0402B102K500CT 1nF 10% 50V X7

C1005X7R104KET 100nF 10% 16V

C1005C0G1H180JT 18pF 5% 50V C

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005C0G1H101JT 100pF 5% 50V

C1005X7R1H471KT 470pF 10% 50V

C1005C0G1H180JT 18pF 5% 50V C

C1005C0G1H101JT 100pF 5% 50V

LOCA. NO PART NO DESCRIPTION

C477

C478

C481

C482

C484

C487

C488

C491

C492

C495

C496

C5000

C5001

C5002

C5003

C5004

C5005

C5006

C5007

C5008

C5009

C5010

C5012

C5013

C5014

C5015

C5016

C5016

C5017

C5018

C5019

C5020

C5021

C5022

C5023

C5024

C5025

C5026

C5027

C5028

C5029

C5030

C5031

C5032

C5033

C5034

C5035

C5036

C5037

C5038

C5039

0CH5220K618

0CH5220K618

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE106WFKDC

0CE106WFKDC

0CK104BF56A

0CK104BF56A

0CE106WFKDC

0CK104BF56A

0CE105WK6DC

0CE105WK6DC

0CE106WFKDC

0CK104BF56A

0CK102BK56A

0CK103CK56A

0CK103CK56A

0CK223CK56A

0CK103CK56A

0CK104BF56A

0CK104BF56A

0CE226WF6DC

0CC020CK01A

0CC020CK01A

0CK104CK56A

0CC560CK41A

0CC560CK41A

0CC560CK41A

0CE335WK6D8

0CC560CK41A

0CK103CK56A

0CK474CH94A

0CK222CK56A

0CK474CH94A

0CK222CK56A

0CE226WF6DC

0CK474CH94A

0CK222CK56A

0CK474CH94A

0CK222CK56A

0CK104CK56A

0CK474CH94A

0CK222CK56A

0CK474CH94A

0CK103CK56A

0CK222CK56A

0CK474CH94A

0CK222CK56A

0CK474CH94A

0CC101CK41A

0402N220M500LT 22pF 5% 50V C0

0402N220M500LT 22pF 5% 50V C0

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP50VC1M 1uF 20% 50V 5.

MVK4.0TP50VC1M 1uF 20% 50V 5.

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

0402B102K500CT 1nF 10% 50V X7

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

UMK107JB223KA-T 22nF 10% 50V

0603B103K500CT 10nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

C1608C0G1H020CT 2pF 25PF 50

C1608C0G1H020CT 2pF 25PF 50

0603B104K500CT 100nF 10% 50V

C1608C0G1H560JT 56pF 5% 50V C

C1608C0G1H560JT 56pF 5% 50V C

C1608C0G1H560JT 56pF 5% 50V C

MVK4.0TP50VC3.3M 3.3uF 20% 50

C1608C0G1H560JT 56pF 5% 50V C

0603B103K500CT 10nF 10% 50V X

0603F474Z250CT 470nF -20TO+80

0603B222K500CT 2.2nF 10% 50V

0603F474Z250CT 470nF -20TO+80

0603B222K500CT 2.2nF 10% 50V

MVK5.0TP16VC22M 22uF 20% 16V

0603F474Z250CT 470nF -20TO+80

0603B222K500CT 2.2nF 10% 50V

0603F474Z250CT 470nF -20TO+80

0603B222K500CT 2.2nF 10% 50V

0603B104K500CT 100nF 10% 50V

0603F474Z250CT 470nF -20TO+80

0603B222K500CT 2.2nF 10% 50V

0603F474Z250CT 470nF -20TO+80

0603B103K500CT 10nF 10% 50V X

0603B222K500CT 2.2nF 10% 50V

0603F474Z250CT 470nF -20TO+80

0603B222K500CT 2.2nF 10% 50V

0603F474Z250CT 470nF -20TO+80

C1608C0G1H101JT 100pF 5% 50V

REPLACEMENT PARTS LIST

Page 23

- 23 -

LOCA. NO PART NO DESCRIPTION

C5040

C5041

C5042

C5043

C5044

C5045

C5046

C5047

C5048

C5049

C505

C5050

C5051

C5052

C5053

C506

C507

C509

C511

C512

C513

C515

C523

C524

C525

C527

C528

C529

C530

C531

C532

C533

C534

C535

C536

C539

C540

C541

C542

C546

C547

C548

C549

C550

C551

C552

C556

C557

C558

C559

C560

0CK222CK56A

0CK222CK56A

0CK222CK56A

0CK103CK56A

0CC471CK41A

0CE335WK6D8

0CK104CK56A

0CE107WF6DC

0CE106WFKDC

0CE106WFKDC

0CK101BK4EA

0CE475WK6DC

0CE475WK6DC

0CK104CK56A

0CK104CK56A

0CK104BF56A

0CE226WF6DC

0CK103CK56A

0CK104BF56A

0CK101BK4EA

0CK101BK4EA

0CK104BF56A

0CK103CK56A

0CE226WF6DC

0CE226WF6DC

0CE335WK6D8

0CK103CK56A

0CK104BF56A

0CK104CK56A

0CK101BK4EA

0CE106WFKDC

0CK102BK56A

0CK104CK56A

0CK104BF56A

0CE106WFKDC

0CE335WK6D8

0CE335WK6D8

0CK104BF56A

0CK104CK56A

0CK105CD56A

0CZZB00035A

0CZZB00035A

0CE226WF6DC

0CE226WF6DC

0CK223CK56A

0CK103CK56A

0CE337WJ6D8

0CK104CK56A

0CK104CK56A

0CK223CK56A

0CK104BF56A

0603B222K500CT 2.2nF 10% 50V

0603B222K500CT 2.2nF 10% 50V

0603B222K500CT 2.2nF 10% 50V

0603B103K500CT 10nF 10% 50V X

C1608C0G1H471JT 470pF 5% 50V

MVK4.0TP50VC3.3M 3.3uF 20% 50

0603B104K500CT 100nF 10% 50V

MVK6.3TP16VC100M 100uF 20% 16

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP16VC10M 10uF 20% 16V

C1005C0G1H101JT 100pF 5% 50V

MVK5.0TP50VC4.7M 4.7uF 20% 50

MVK5.0TP50VC4.7M 4.7uF 20% 50

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

0603B103K500CT 10nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

C1005C0G1H101JT 100pF 5% 50V

C1005C0G1H101JT 100pF 5% 50V

C1005X7R104KET 100nF 10% 16V

0603B103K500CT 10nF 10% 50V X

MVK5.0TP16VC22M 22uF 20% 16V

MVK5.0TP16VC22M 22uF 20% 16V

MVK4.0TP50VC3.3M 3.3uF 20% 50

0603B103K500CT 10nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

0603B104K500CT 100nF 10% 50V

C1005C0G1H101JT 100pF 5% 50V

MVK4.0TP16VC10M 10uF 20% 16V

0402B102K500CT 1nF 10% 50V X7

0603B104K500CT 100nF 10% 50V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

MVK4.0TP50VC3.3M 3.3uF 20% 50

MVK4.0TP50VC3.3M 3.3uF 20% 50

C1005X7R104KET 100nF 10% 16V

0603B104K500CT 100nF 10% 50V

C1608X7R1A105KT 1uF 10% 10V X

GRM1555C1H330J 33pF 5% 50V C0

GRM1555C1H330J 33pF 5% 50V C0

MVK5.0TP16VC22M 22uF 20% 16V

MVK5.0TP16VC22M 22uF 20% 16V

UMK107JB223KA-T 22nF 10% 50V

0603B103K500CT 10nF 10% 50V X

MVK12.5TP35VC330M 330uF 20% 3

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

UMK107JB223KA-T 22nF 10% 50V

C1005X7R104KET 100nF 10% 16V

LOCA. NO PART NO DESCRIPTION

C561

C562

C563

C564

C565

C566

C567

C568

C569

C570

C571

C572

C573

C574

C575

C575

C576

C581

C582

C583

C584

C585

C586

C587

C588

C589

C590

C592

C593

C594

C595

C596

C597

C598

C599

C600

C600

C6008

C6009

C601

C6010

C6015

C6015

C6017

C6018

C6019

C6021

C6022

C6023

C6024

C6025

0CK104CK56A

0CE106WFKDC

0CK103CK56A

0CK105CD56A

0CK105CD56A

0CK223CK56A

0CK223CK56A

0CK105CD56A

0CK104CK56A

0CE337WJ6D8

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CK103CK56A

0CK104CK56A

0CK474CH94A

0CK474CH94A

0CK102CK56A

0CK102CK56A

0CK102CK56A

0CK102CK56A

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CK104CK56A

0CK474DK56A

0CK474DK56A

0CK103CK56A

0CE105WK6DC

0CK103CK56A

0CK104CK56A

0CK104CK56A

0CK103CK56A

0CK103CK56A

0CK104BF56A

0CE476WF6DC

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE30840301

0CK226FF67A

0CK226FF67A

0CK102BK56A

0CK102BK56A

0CK102BK56A

0CK102BK56A

0CC180BKFAA

0CC180BKFAA

0CK103BH56A

0603B104K500CT 100nF 10% 50V

MVK4.0TP16VC10M 10uF 20% 16V

0603B103K500CT 10nF 10% 50V X

C1608X7R1A105KT 1uF 10% 10V X

C1608X7R1A105KT 1uF 10% 10V X

UMK107JB223KA-T 22nF 10% 50V

UMK107JB223KA-T 22nF 10% 50V

C1608X7R1A105KT 1uF 10% 10V X

0603B104K500CT 100nF 10% 50V

MVK12.5TP35VC330M 330uF 20% 3

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

0603B103K500CT 10nF 10% 50V X

0603B104K500CT 100nF 10% 50V

0603F474Z250CT 470nF -20TO+80

0603F474Z250CT 470nF -20TO+80

0603B102K500CT 1nF 10% 50V X7

0603B102K500CT 1nF 10% 50V X7

0603B102K500CT 1nF 10% 50V X7

0603B102K500CT 1nF 10% 50V X7

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

UMK212BJ474KG-T 470nF 10% 50V

UMK212BJ474KG-T 470nF 10% 50V

0603B103K500CT 10nF 10% 50V X

MVK4.0TP50VC1M 1uF 20% 50V 5.

0603B103K500CT 10nF 10% 50V X

0603B104K500CT 100nF 10% 50V

0603B104K500CT 100nF 10% 50V

0603B103K500CT 10nF 10% 50V X

0603B103K500CT 10nF 10% 50V X

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

10SVPC68M 68uF 20% 10V 1.97A

EMK325BJ226MM-T 22uF 20% 16V

EMK325BJ226MM-T 22uF 20% 16V

0402B102K500CT 1nF 10% 50V X7

0402B102K500CT 1nF 10% 50V X7

0402B102K500CT 1nF 10% 50V X7

0402B102K500CT 1nF 10% 50V X7

C1005C0G1H180JT 18pF 5% 50V C

C1005C0G1H180JT 18pF 5% 50V C

C1005X7R1E103KT- 10nF 10% 25V

REPLACEMENT PARTS LIST

Page 24

- 24 -

LOCA. NO PART NO DESCRIPTION

C6026

C603

C604

C605

C605

C609

C610

C611

C612

C613

C614

C616

C617

C618

C619

C620

C621

C622

C623

C624

C625

C626

C627

C628

C629

C630

C631

C632

C633

C634

C635

C635

C636

C637

C637

C638

C639

C640

C641

C642

C644

C645

C647

C648

C649

C656

C660

C661

C663

C666

C667

0CK103BH56A

0CE106WFKDC

0CK104BF56A

0CK103BH56A

EAE32166601

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CE107WF6DC

0CK104BF56A

0CK102BK56A

0CE476WF6DC

0CK104BF56A

0CE226WF6DC

0CK104BF56A

0CE106WFKDC

EAE30840301

0CK104BF56A

0CE476WF6DC

0CE476WF6DC

0CK104BF56A

0CE226WF6DC

0CK104BF56A

0CE476WF6DC

0CK104BF56A

0CK103BH56A

0CK103BH56A

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK102BK56A

0CH2334F566

0CK104BF56A

C1005X7R1E103KT- 10nF 10% 25V

MVK4.0TP16VC10M 10uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25V

CH1005CG391J500NR 390pF 5% 50

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC100M 100uF 20% 16

C1005X7R104KET 100nF 10% 16V

0402B102K500CT 1nF 10% 50V X7

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP16VC10M 10uF 20% 16V

10SVPC68M 68uF 20% 10V 1.97A

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK5.0TP16VC22M 22uF 20% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R1E103KT- 10nF 10% 25V

C1005X7R1E103KT- 10nF 10% 25V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

0402B102K500CT 1nF 10% 50V X7

0805B334K160CT 330nF 10% 16V

C1005X7R104KET 100nF 10% 16V

LOCA. NO PART NO DESCRIPTION

C668

C670

C671

C672

C673

C674

C675

C676

C677

C678

C679

C680

C681

C682

C683

C685

C686

C687

C696

C697

C700

C7000

C7001

C7002

C7003

C7005

C7006

C7007

C7008

C701

C7010

C7011

C7012

C7013

C7014

C7015

C7028

C704

C705

C706

C707

C709

C710

C711

C712

C713

C714

C715

C716

C717

C718

0CK104BF56A

0CE105WK6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE30281301

EAE30281301

0CK104BF56A

0CK104BF56A

0CE105WK6DC

0CE106WFKDC

0CE476WF6DC

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

0CK104BF56A

EAE30840301

0CE476WF6DC

0CE476WF6DC

0CK104BF56A

0CK103CK56A

0CE107WF6DC

0CK104BF56A

0CK103CK56A

0CK471BK56A

0CK471BK56A

0CK471BK56A

0CK471BK56A

0CK104BF56A

0CK104CK56A

0CE225WK6DC

0CK104CK56A

0CE225WK6DC

0CE225WK6DC

0CK104BF56A

0CK104BF56A

0CK101BK4EA

0CK101BK4EA

C1005X7R104KET 100nF 10% 16V

MVK4.0TP50VC1M 1uF 20% 50V 5.

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

CS1005C0G200J400NR 20pF 5% 50

CS1005C0G200J400NR 20pF 5% 50

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

MVK4.0TP50VC1M 1uF 20% 50V 5.

MVK4.0TP16VC10M 10uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

C1005X7R104KET 100nF 10% 16V

10SVPC68M 68uF 20% 10V 1.97A

MVK6.3TP16VC47M 47uF 20% 16V

MVK6.3TP16VC47M 47uF 20% 16V

C1005X7R104KET 100nF 10% 16V