Page 1

TRAINING MANUAL

PLASMA DISPLAY PANEL 2006 V2

60PY2DR

50PY2DR

50PX4DR

50PC1DR

50PC1DRA

Digit al Display

Digit al Display

Page 2

IMPORTANT SAFETY NOTICE

The information in this training manual is intended for use by individuals possessing an adequate background in

electrical equipment, electronic devices, and mechanical systems. In any attempt to repair a television or monitor,

personal injury and property damage can result. The manufacturer or seller maintains no responsibility for the interpretation

of this information, nor can it assume any liability in connection with its use. When servicing this product, under no

circumstances should the original design be modified or altered without permission from LG Electronics. Unauthorized

modifications will not only void the warranty, but may lead to property damage or user injury. If wires, screws, straps,

clips, nuts, or washers used to complete a ground path are removed for service, they must be returned to their original

position and properly fastened.

CAUTION

To avoid personal injury, disconnect power before servicing this product. If electrical power is required for diagnosis or

test purposes, disconnect the power immediately after performing the necessary checks. Also be warned that many

household appliances present a weight hazard. At least two people should be involved in the installation or servicing of

such devices. Failure to consider the weight of an appliance could lead to physical injury.

ESD NOTICE

Some of the electronics in appliances are electrostatic discharge (ESD) sensitive. ESD can weaken or damage the electronics

in these appliances in a manner that renders them inoperative or reduces the time until their next failure. Connect a

wrist strap to a green ground connection point or unpainted metal in the appliance. Alternatively, you may touch your

finger repeatedly to a green ground connection point or unpainted metal in the appliance. Before removing a replacement

part from its package, touch the anti-static bag to a green connection point or unpainted metal in the appliance. Avoid

unnecessary contact with electronic parts or terminal contacts. Handle the electronic control assembly by its edges only.

When repackaging a failed electronic control assembly in an anti-static bag, observe the above instructions.

REGULATORY INFORMATION

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of

the FCC Rules. These limits are designed to provide reasonable protection against harmful interference when the equipment

is operated in a residential installation. This equipment generates, uses and can radiate radio frequency energy and, if

not installed and used in accordance with the instruction manual, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a particular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the equipment off and on, the

user is encouraged to try to correct the interference by one or more of the following measures: Reorient or relocate the

receiving antenna; Increase the separation between the equipment and receiver; Connect the equipment into an outlet

on a circuit different from that to which the receiver is connected; Consult the dealer or an experienced radio/TV

technician for help.

The responsible party for this device’s compliance is:

LG Electronics of Alabama, Inc.

201 James Record Road

Huntsville, AL 35824, USA

Digital TV Hotline: 1-800-243-0000

Published 2006 by LG Training

Page 3

TABLE OF CONTENTS

INTRODUCTION .................................. 5

SAFETY INSTRUCTIONS .................... 6

OVERVIEW.................................................... 6

POWER CAUTION ......................................... 6

ELECTRICAL SAFETY NOTICE .................... 7

ELECTRICAL SHOCK WARNING .................. 7

MODEL SPECIFICATIONS .................. 9

MODEL LIST ................................................. 9

MODEL NUMBER FORMATS ...................... 10

SERIAL NUMBER FORMATS ...................... 12

INSTALLATION ................................... 13

GROUNDING ............................................... 13

PLACEMENT ............................................... 13

JACKPACK COVER ..................................... 13

ANTI-TIP BRACKETS ................................. 13

GENERAL MOUNTING ................................ 14

OPERATION ....................................... 15

LANGUAGE ................................................. 15

SETUP MENU ............................................. 15

VIDEO MENU .............................................. 18

AUDIO MENU .............................................. 21

TIME MENU ................................................ 23

OPTION MENU ............................................ 25

MOVIE RATING SYSTEM ............................ 28

TELEVISION RATING SYSTEM .................. 28

CIRCUIT DESCRIPTIONS ................. 29

PCB LAYOUT ............................................. 30

DIGITAL PCB ............................................... 31

DIGITAL BLOCK DIAGRAM.........................32

TUNER PCB ................................................ 34

POWER SUPPLY ......................................... 36

SMPS BLOCK DIAGRAM...........................40

PANEL DRIVE BOARDS ............................. 43

PLASMA PANEL ......................................... 51

50PC1D VOLTAGES...................................30

50PC1D INNERCONNECT...........................53

FIRMWARE UPDATES VIA SERIAL CABLE 82

FIRMWARE UPDATES VIA MDS ................. 84

USING LGIDS AND GPROBE ..................... 86

CONTROL PCB SOFTWARE UPDATE ........ 91

CABLECARD S-CARD....................... 96

DIGITAL CABLE READY (DCR) ................... 96

CEA-NCTA AGREEMENT ............................ 96

TERMS ........................................................ 97

VENDORS ................................................... 97

DCR ARCHITECTURE ................................. 98

HOST-CABLECARD INTERFACE ................ 98

IN-BAND/OOB SPECIFICATION ................ 100

CABLE MENU & MMI ................................ 101

DIGITAL CERTIFICATES DATA .................. 104

EAS(EMERGENCY ALERT SYSTEM) ...... 104

HOST DIAGNOSTICS ............................... 105

ERROR REPORTING ................................ 105

CABLE CARD TROUBLESHOOTING ......... 106

IN-HOME TROUBLESHOOTING ................ 111

CABLECARD TROUBLESHOOTING .......... 114

CABLECARD M-CARD........................117

M-CARD (SA) OPERATION.......................116

M-CARD TERMS......................................129

BUILT-IN DIGITAL VIDEO RECORDER

(DVR) ................................................ 131

TROUBLESHOOTING ................................ 131

TROUBLESHOOTING ........................ 54

SIGNAL CONTROL TROUBLESHOOTING .. 54

Z-SUSTAIN TROUBLESHOOTING ............... 55

TROUBLESHOOTHING THE COF ICS ........ 56

PANEL DRIVE SIGNAL...............................57

MEMORY CARD ERRORS .......................... 64

DISASSEMBLY ................................... 65

PREPARATION ............................................ 65

DISASSEMBLY OF THE DU-42PX12X ........ 65

DISASSEMBLY OF THE 2DR MODELS ...... 72

SOFTWARE UPDATES ...................... 79

UPDATES VIA MEMORY CARD .................. 79

Plasma Training 3 Contents

Page 4

- 4 -

Page 5

SAFETY

SAFETY INSTRUCTIONS

OVERVIEW

1. Read these instructions and the instructions in owners and service manuals.

2. Keep these instructions.

3. Heed all warnings.

4. Follow all instructions.

5. Do not use this apparatus near water.

6. Clean only with dry cloth.

7. Do not block any ventilation openings. Install in accordance with the manufacturer’s instructions.

8. Do not install near any heat sources such as radiators, heat registers, stoves, or other apparatus

(including amplifiers)that produce heat.

9. Do not defeat the safety purpose of the polarized or grounding-type plug. A polarized plug has

two blades with one wider than the other. A grounding type plug has two blades and a third

grounding prong, The wide blade or the third prong are provided for your safety. If the provided

plug does not fit into your outlet, consult an electrician for replacement of the obsolete outlet.

10. Protect the power cord from being walked on or pinched particularly at plugs, convenience

receptacles, and the point where they exit from the apparatus.

11. Only use attachments/accessories specified by the manufacturer.

12. Use only with the cart, stand, tripod, bracket, or table specified by the manufacturer, or sold

with the apparatus. When a cart is used, use caution when moving the cart/apparatus combination

to avoid injury from tip-over.

13. Unplug this apparatus during lightning storms or when unused for long periods of time.

14. Refer all servicing to qualified service personnel. Servicing is required when the apparatus has

been damaged in any way, such as power-supply cord or plug is damaged, liquid has been spilled

or objects have fallen into the apparatus, the apparatus has exposed to rain or moisture, does

not operate normally, or has been dropped.

16. WARNING - To Reduce The Risk Of Fire Or Electric Shock, Do Not Expose This Appliance To Rain Or

Moisture.

17. Wet Location Marking : Apparatus shall not be exposed to dripping or splashing and no objects

filled with liquids, such as vases, shall be placed on the apparatus.

POWER CAUTION

Most appliances recommend they be placed upon a dedicated circuit; that is, a single outlet circuit

which powers only that appliance and has no additional outlets or branch circuits. Check the specification

page of this owner’s manual to be certain. Do not overload wall outlets. Overloaded wall outlets,

loose or damaged wall outlets, extension cords, frayed power cords, or damaged or cracked wire

insulation are dangerous. Any of these conditions could result in electric shock or fire. Periodically

examine the cord of your appliance, and if its appearance indicates damage or deterioration, unplug

it, discontinue use of the appliance, and have the cord replaced with an exact replacement part by an

authorized servicer.

Plasma Training 5 Safety

Page 6

SAFETY

Protect the power cord from physical or mechanical abuse, such as being twisted, kinked, pinched,

closed in a door, or walked upon. Pay particular attention to plugs, wall outlets, and the point where

the cord exits the appliance.

ELECTRICAL SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified

in the Schematic Diagram and Replacement Parts List. It is essential that these special safety parts should be replaced

with the same components as recommended in this manual to prevent , Shock, Fire, or other Hazards. Do not modify the

original design without permission of manufacturer.

ELECTRICAL SHOCK WARNING

An lsolation Transformer should always be used during the servicing of a receiver whose chassis is not isolated from the

AC power line. Use a transformer of adequate power rating as this protects the technician from accidents resulting in

personal injury from electrical shocks. It will also protect the receiver and its components from being damaged by

accidental shorts of the circuit that may be inadvertently introduced during the service operation. If any fuse (or

Fusible Resistor) in this monitor is blown, replace it with the same specified type. When replacing a high wattage

resistor (Oxide Metal Film Resistor, over 1W), keep the resistor 10mm away from PCB. Keep wires away from high voltage

or high temperature parts.

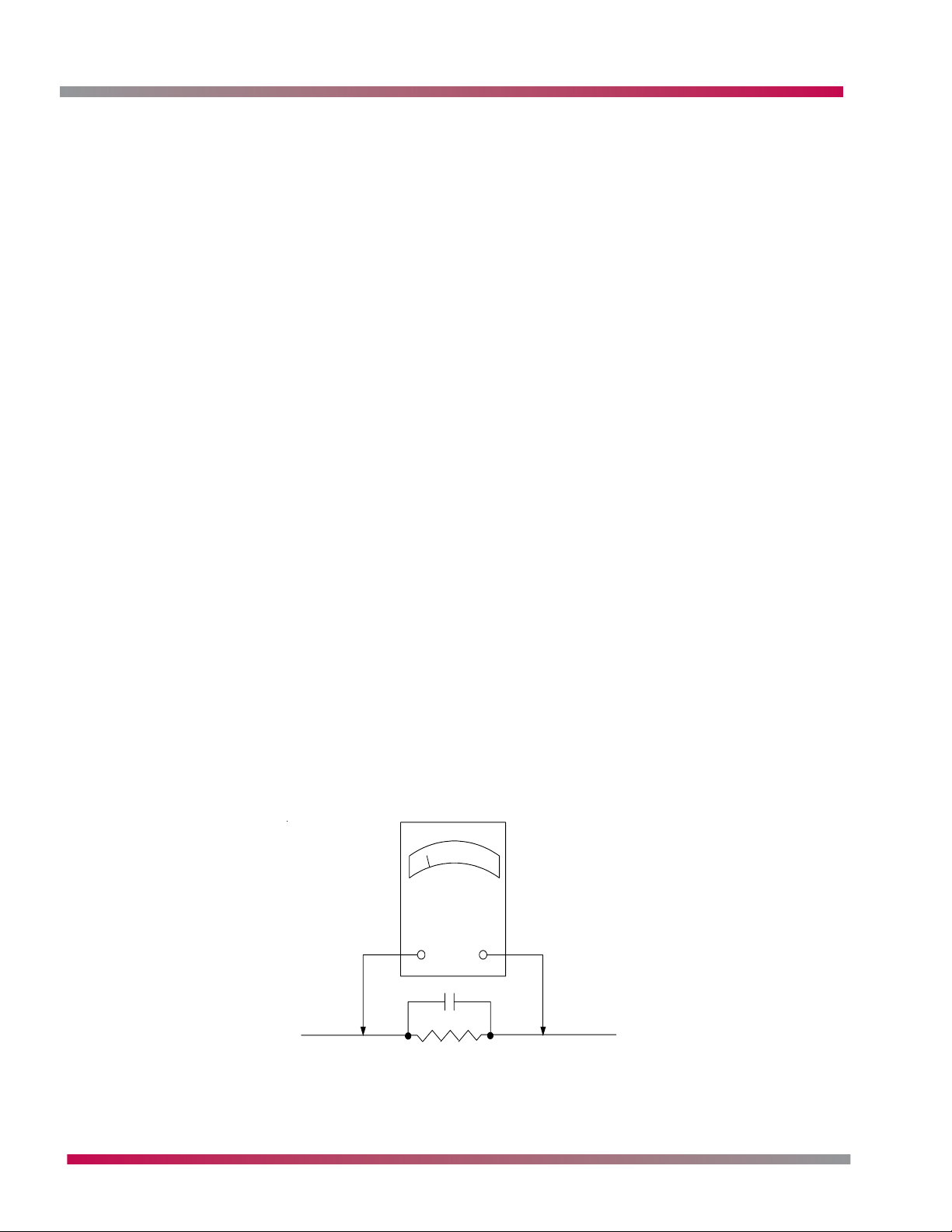

LEAKAGE CURRENT COLD CHECK (ANTENNA COLD CHECK)

With the instrument AC plug removed from AC source, connect an electrical jumper across the two AC plug prongs.

Place the AC switch in the on positioin, connect one lead of ohm-meter to the AC plug prongs tied together and

touch other ohm-meter lead in turn to each exposed metallic parts such as antenna terminals, phone jacks, etc. If

the exposed metallic part has a return path to the chassis, the measured resistance should be between 1M ohm and

5.2M ohm. When the exposed metal has no return path to the chassis the reading must be infinite. An other

abnormality exists that must be corrected before the receiver is returned to the customer.

LEAKAGE CURRENT HOT CHECK

Plug the AC cord directly into the AC outlet. Do not use a line Isolation Transformer during this check. Connect

1.5K/10watt resistor in parallel with a 0.15uF capacitor between a known good earth ground (Water Pipe, Conduit,

etc.) and the exposed metallic parts. Measure the AC voltage across the resistor using AC voltmeter with 1000 ohms/

volt or more sensitivity. Reverse plug the AC cord into the AC outlet and repeat AC voltage measurements for each

exposed metallic part. Any voltage measured must not exceed 0.75 volt RMS which corresponds to 0.5mA. In case

any measurement is out of the limits sepcified, there is possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

LEAKAGE CURRENT HOT CHECK CIRCUIT

Volt Meter

0.15uF

Exposed

Metallic Parts

1.5Kohm/10W

Plasma Training 6 Overview

Good Earth

Ground

Page 7

- 7 -

Page 8

MODEL SPECIFICATIONS

MODEL SPECIFICATIONS

This section covers some of the past and present LG and Zenith Plasma Display Panel (PDP) TVs and

monitors. All models support computer input and RS-232, but not all models support High Definition

(HD) input. Most PDPs feature similar features and specifications. Some of the newer (2005+) models

have built-in ATSC tuners and support CableCARDTM. Note that Commerical models don't have CableCARD

support since it is not needed in a distribution network.

KEY TERMS

SDTV - Standard Definition (480i).

EDTV - Enhanced Definition (480p).

HDTV - High Definition (720p, 1080i).

XD Engine™ - Six distinct processes contribute to picture improvement.

CableCARD - Decoder card for digital cable.

HDMI - High Definition Multimedia Interface. Alternative to DVI. Smaller connector and

supports audio.

HDCP - High-bandwidth Digital Content Protection.

TM

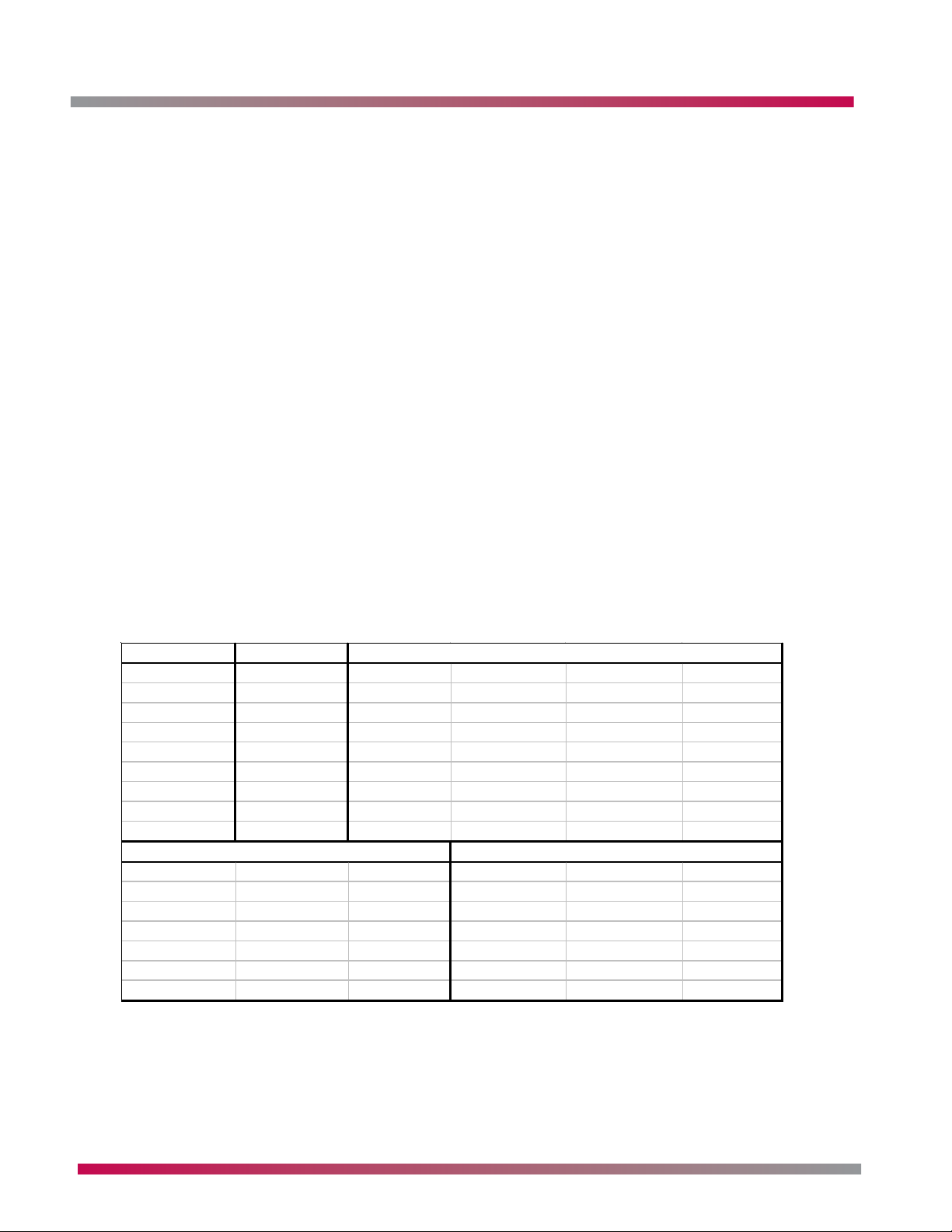

MODEL LIST

Below is a list of all PDP models. This manual focuses on the newer 2005/2006 models, but the

others are listed for reference.

40" EDT V 42" H D T V

DPDP40 42PC1DA D U -42PZ60 MU-42PZ15VB P42W22H RU-42PX10

DPDP40V MU-42PM12X DU-42PZ70 MU-42PZ41 P42W 24B RU-42PX11

MU-40PA10C DU-42PX12XC MU-42PX11 MU-42PZ41VB P42W24BX RU-42PZ90

MU-40PA10 MU-42PZ10 MU-42PZ90 P42W24P MU-42PM11

MU-40PA15 MU-42PZ10B MU-42PZ90C P42W34 42PX3DCV

P40V22 MU-42PZ11 MU-42PZ90H P42W34H 42PC3D

P40V24 MU-42PZ11B MZ-42PZ34 P42W 34P 42PM3MV

MU-42PZ11B MU-42PZ15 P42W22 P42W46X 42PX4D

MU-42PZ15A P42W 22B RU-42PX10C 42PX5D

50" H D T V 60" H D T V

DU-50PZ60 P50W26B 50PX2C D60D VMS MU-60PZ12A P60W 38

DU-50PZ60H 50PB2DR 50PX2D D60DVSA MU-60PZ12B P60W 38H

MU-50PZ41 50PC3D DU-50PX10C DPDP60 MU-60PZ12VB 60PY2DR

MU-50PZ41B 50PC1D R A MU-50PM10 MU-60PZ11 P60W 26 60PB2DR

MU-50PZ41V 50PC1D R 50PY2D R MU-60PZ11B P60W 26A MU -60PZ95V

MU-50PZ41VB 50PY2DR 50PX4DR MU-60PZ12 P60W 26H MU-60PZ10B

P50W 26 50PM1M 50PX1D MU-60PZ15 P60W26P 60PX4DR

42" EDT V

Plasma Training 8 Specifications

Page 9

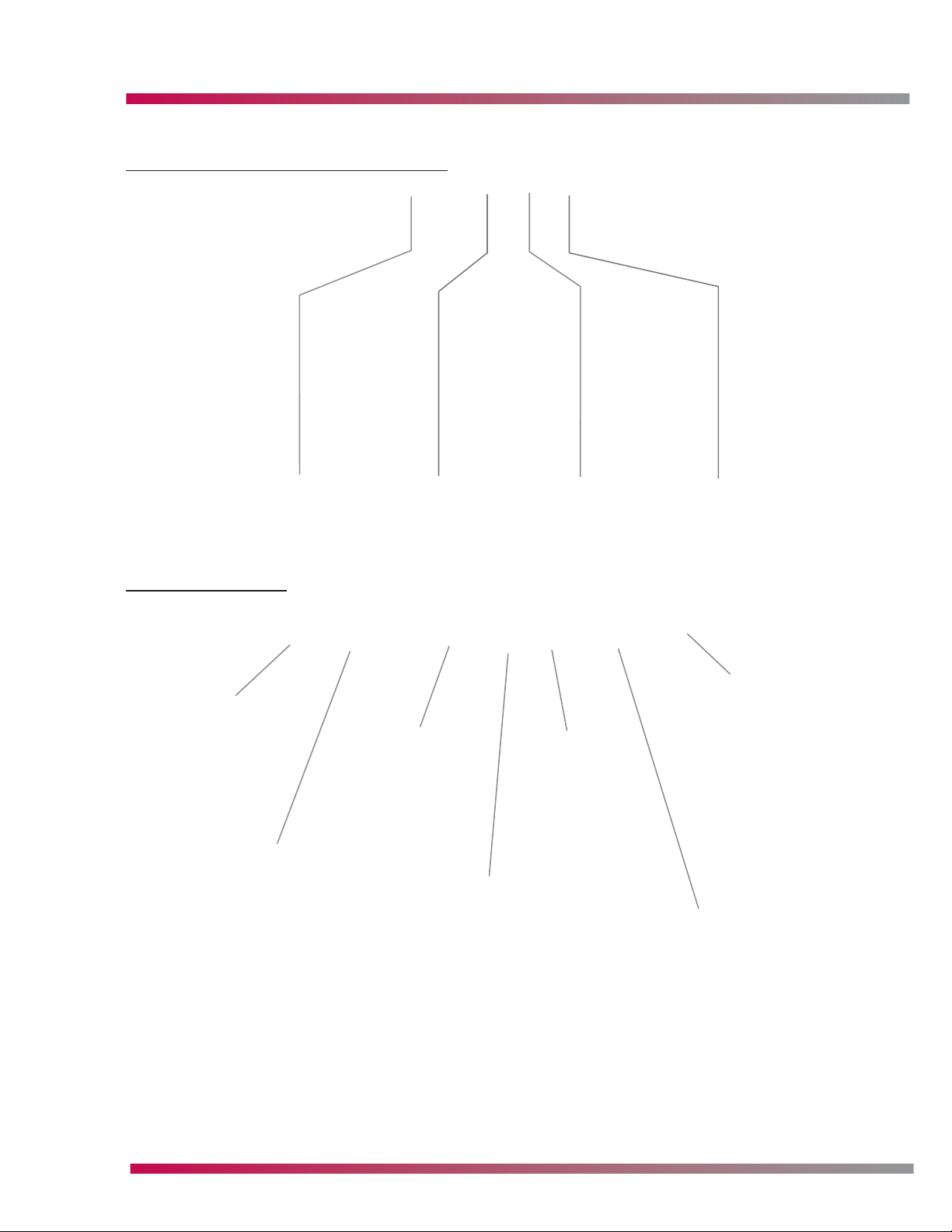

MODEL NUMBER FORMATS

OLDER ZENITH PRODUCTS (20002-2004)

MODEL SPECIFICATIONS

Old Zenith Structure:

Display Type

L = LCD

P = Plasma

R = CRT

Rear Projo

D = Micro

Display

OLDER LG PRODUCTS

Old LG Structure:

L 1 5 V 2 6

Screen Size Aspect Ratio

V= 4:3

W = 16:9

Model Year

2 = 2002

3 = 2003

4 = 2004

M U – 5 0 P Z 9 0 V

Feature Level

2 = Consumer

4 = Commercial

6 = Consumer

Product Type

M= Monitor

D = ATSC Tuner

K = DVD Player

R = NTSC Tuner

T = DVR

Region

U = North America

Z = Europe

T = NA & EU

P = South America

J = Japan

N = Korea

Screen Size

Display Type

F = Flat CRT

L = LCD

P = Plasma

S = Micro Display

Aspect Ratio

A B C = 4:3

X Y Z = 16:9

Options

H = High Altitude

V = Pivot

M = Altitude & Pivot

Q = Home Security

Network

D = DLP

L = LCD

Feature Level

Plasma Training 9 Specifications

Page 10

MODEL SPECIFICATIONS

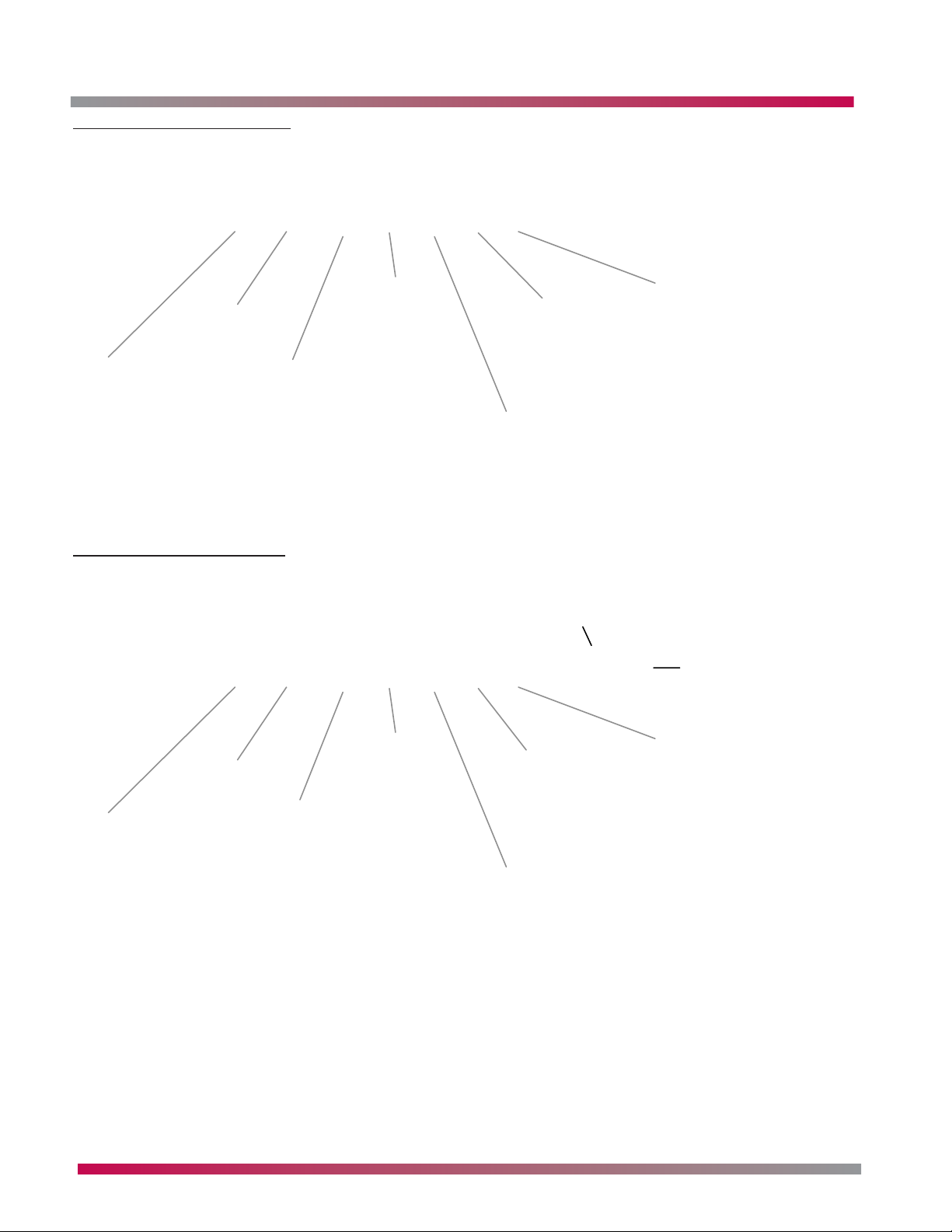

2005 LG/ZENITH PRODUCTS

Current (2005) LG & Zenith Structure:

6 0 P Y 2 D R

Feature

A = 4:3

P = 16:9

X Y Z = 16:9

L = LCOS

S = Slim

W = Wireless

Brand

Z= Zenith

Blank = LG

Screen Size

Display Type

F = Flat CRT

L = LCD

P = Plasma

S = Micro Display

Product Type

R= NTSC Tuner

D = ATSC Tuner

M = No tuner

Series

Options

R = DVR

V = DVD

C = Commercial

NEW LG/ZENITH PRODUCTS

New (2006) LG & Zenith Structure:

5 0 P A 1 D R - U A

Feature Level

C,F,J = Good

B,E,H = Better

A,D,G = Best

Brand

Z= Zenith

Blank = LG

Screen Size

Display Type

P = Plasma

L = LCD

M = LCD RPTV

D = DLP RPTV

S = LCoS RPTV

F = Flat CRT

N = CRT RPTV

J = Projector

C = Directview CRT

Region

U = North America

B = Europe & NA

Tuner

R= NTSC Tuner

D = ATSC Tuner

M = No tuner

Series

Chassis Version

Options

R = DVR

P = DVD

C = Commercial

H = High Altitude

Plasma Training 10 Specifications

Page 11

MODEL SPECIFICATIONS

MODEL NUMBER REVIEW

You should now be able to determine the approximate age of an LCD TV by its model number. Below

is an example using 15” LCD TVs.

New Models (2006): 15LC1R

2005 models: 15LA6R and Z15LA7R

Older models (2003-2004): RU-15LA61 and L15V36

Older models (2002-2003): L15V26

Original Model (1999-2002): ZLD15A1

SERIAL NUMBER FORMATS

1) @ A B C D E F G H I

@=Year

A,B=Month

C,D=Factory Code

E-I=Sequential number (Some MWO models such as “SBM6500B” and “SBM6500W” have 6-digit sequential

number from E-J.)

Product: LG (Goldstar) Brand

2) @ A B C D E F G H I J K

@=Year

A,B=Month

C,D=Factory Code

E,F=2 digit Secret Code

G-K=Sequential number (Some MWO models such as “SMB6500B” and “SMB6500W” have 6-digit sequential

number from G-L.)

Product: LG (Goldstar) Brand (Some Products after January 2004)

3) @ A B C D E F G

@=Year

A=Month (1-9: Jan – Sep., O: Oct, N: Nov, D: Dec)

B-G=Sequential number

Product: Zenith Brand DVD/VCR (Old Serial No)

4) @ A B C D E F G

@=Year

A, B=Month

C-G=Sequential number

Product: Zenith Brand DVD/VCR (Old Serial No)

5) @ A B- C D E F G H I J

@=Year

A=Factory Code (5: Pyungtaik (PT), 8: Shanghai (SH), 9: Indonesia (DI), H: Haeju)

B=Shift (1 or 2)

C=Production Line

D=Day of the week produced (Sunday: 1, Monday: 2, etc.)

E,F=Calendar Week Produced

G-J=Sequential number

Product: Zenith Brand DVD/VCR/ZHS (New Serial No) [DAV Division Products]

Plasma Training 11 Specifications

Page 12

MODEL SPECIFICATIONS

g

)

6) @ A B- C D E F G H I J

@=Year

A=Factory (1: Kumi (DND), 2: Reynosa CTV, 3: Reynosa Wall Projection TV, 4: Five Rivers, 5: Daewoo, 6: Action,

7: Hitachi, 8: Juarez, 9: Springfield, A: Kumi (DID), B: Mexicali (LGEMX))

B=Shift (1 or 2)

C=Production Line

D=Day of the week produced (Sunday: 1, Monday: 2, etc.)

E,F=Calendar Week Produced

G-J=Sequential number

Product: Zenith Brand TV/TVCR/PTV/HDTV/Projector

7) @ A B- C D E F G H I J K

@=Bar-code Start digit must by 0

A,B=Factory Code

C=Line Code (T1: 1, T2: 2)

D=Year

E,F=Month

G-K=Sequential number

Product: Zenith Brand TV/TVCR (Orion, Hatzlachh OEM Product)

8) EXCEPTION

Model: R5000 (Room Air-Con)

NEW LG SERIAL NUMBER STRUCTURE (2004+)

123 45 67 891011121314

\____/ \__/ \__/ \______________/

à Sequential Number (XXXXXXX),

5 to 7 digits (Number or Alphabet)

à Secret Code (VV)

à Production Site (SS), 2 digits (Alphabet)

à Last digit of Year and Month for Production (YMM), 3 digits (Number)

[Example] 403MXXQ05106

1 2 3 4 5 6 7 8 9 10 11 12 13 14 -----14 digit format

4 0 3 MXXQ 0 5 1 0 6 -------12 digit format

\____/ \__/ \__/ \______________/

à 05106: Sequential Number

, 2 digits (Alphabet)

à XQ: 2-Secret Code

à MX: Production Site (produced at LGEMX in Mexico)

à 403: Last di

Plasma Training 12 Specifications

it of Year and Month for Production(manu. In March 2004

Page 13

INSTALLATION

INSTALLATION

GROUNDING

Ensure that you connect the earth ground wire to prevent possible electric shock. If grounding

methods are not possible, have a qualified electrician install a separate circuit breaker. Do not try to

ground the unit by connecting it to telephone wires, lightening rods, or gas pipes.

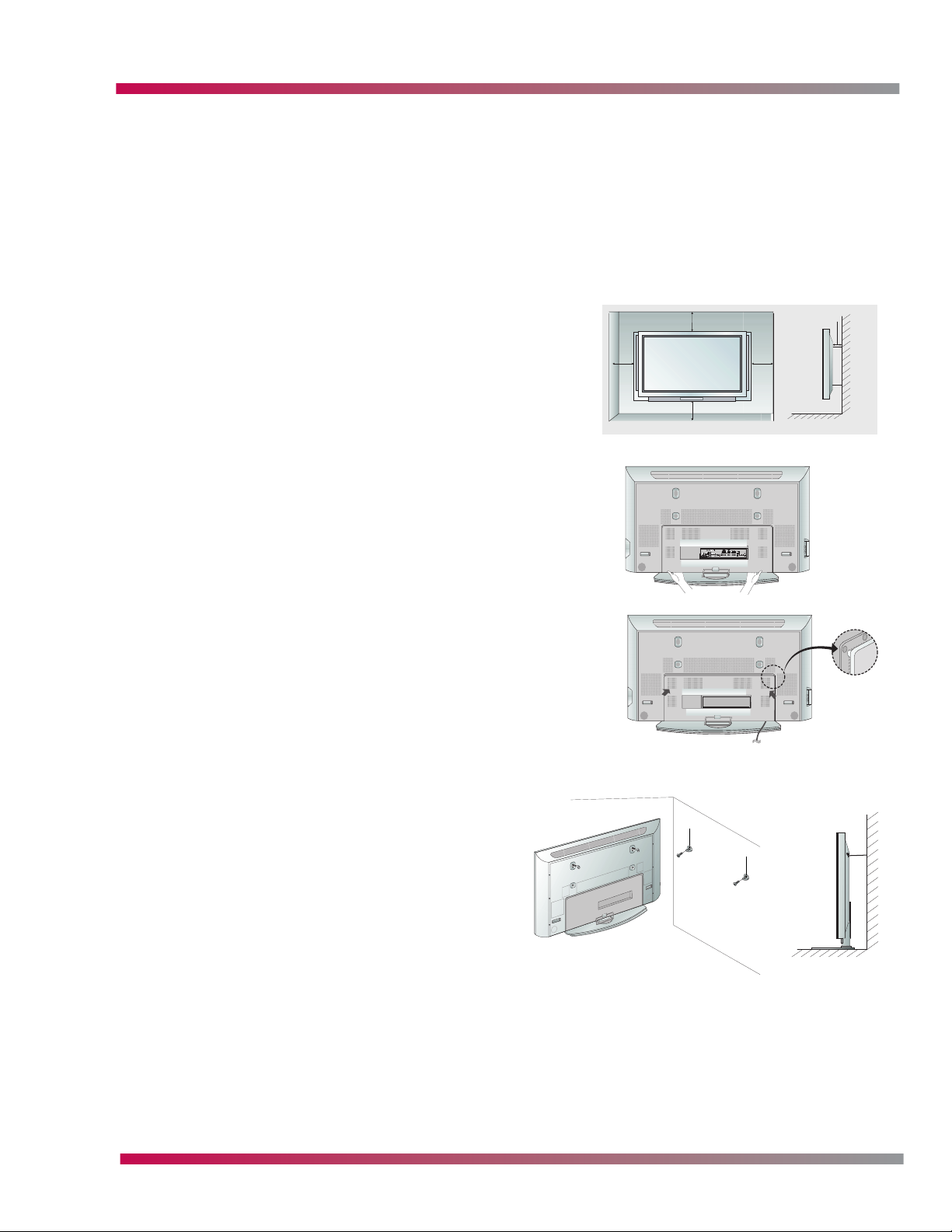

PLACEMENT

The TV can be installed in various ways such as on a wall, or

on a desktop etc. Some models can be mounted verically

(Portrait) or horizontally (Landscape). Do not mount models

that are not denoted as pivot models veritcally. For proper

ventilation, allow a clearance of 4 in. on each side and the

top, 2.36 in. on the bottom, and 4 in. from the wall.

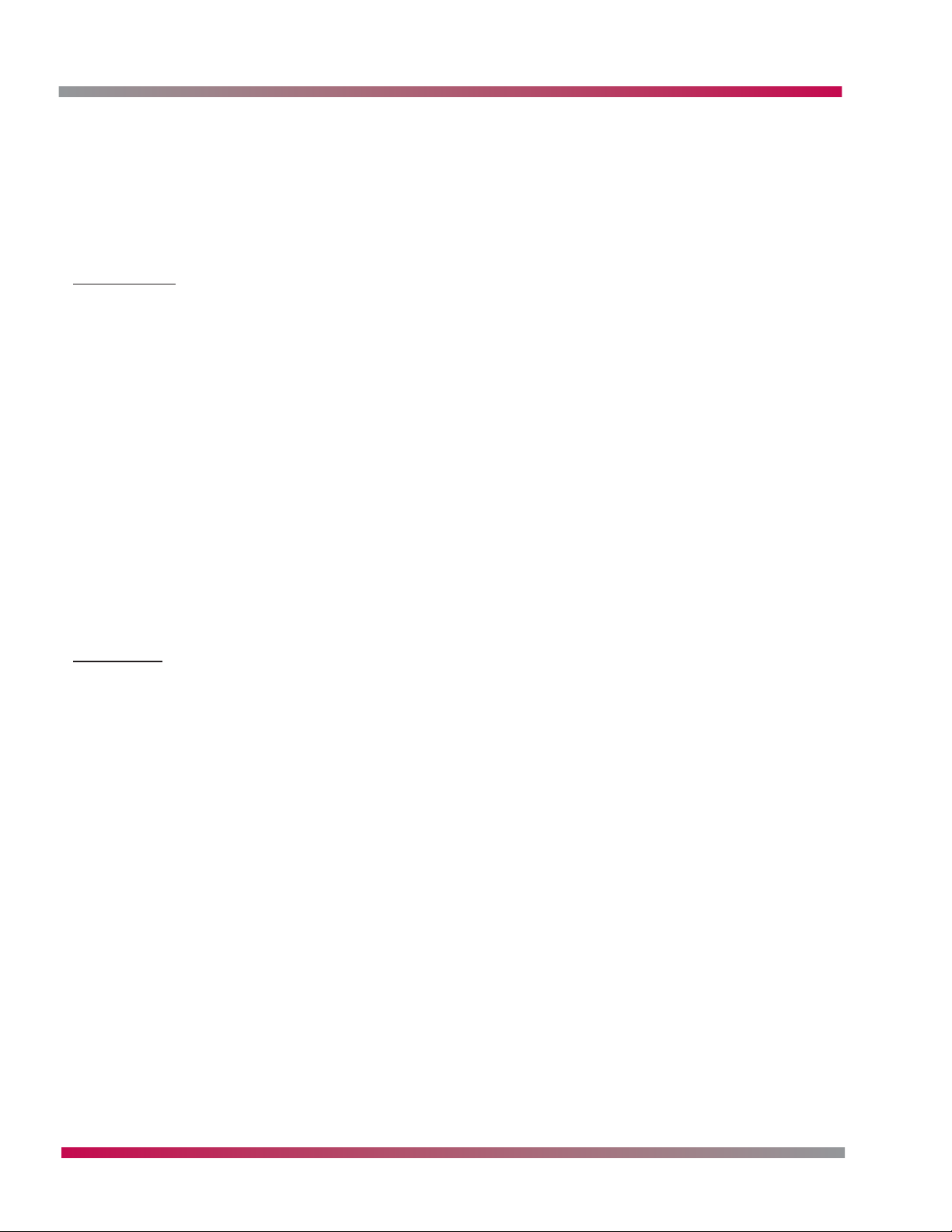

JACKPACK COVER

Some models feature a jackpack cover. Remove the cover by

grasping the lower left and right of the cover and then pulling it

out.

Make the required connections and then replace the cover by

aligning the guide to the bushings and press the cover in place

with your hand.

4 inches

4 inches

2 inches

4 inches4 inches

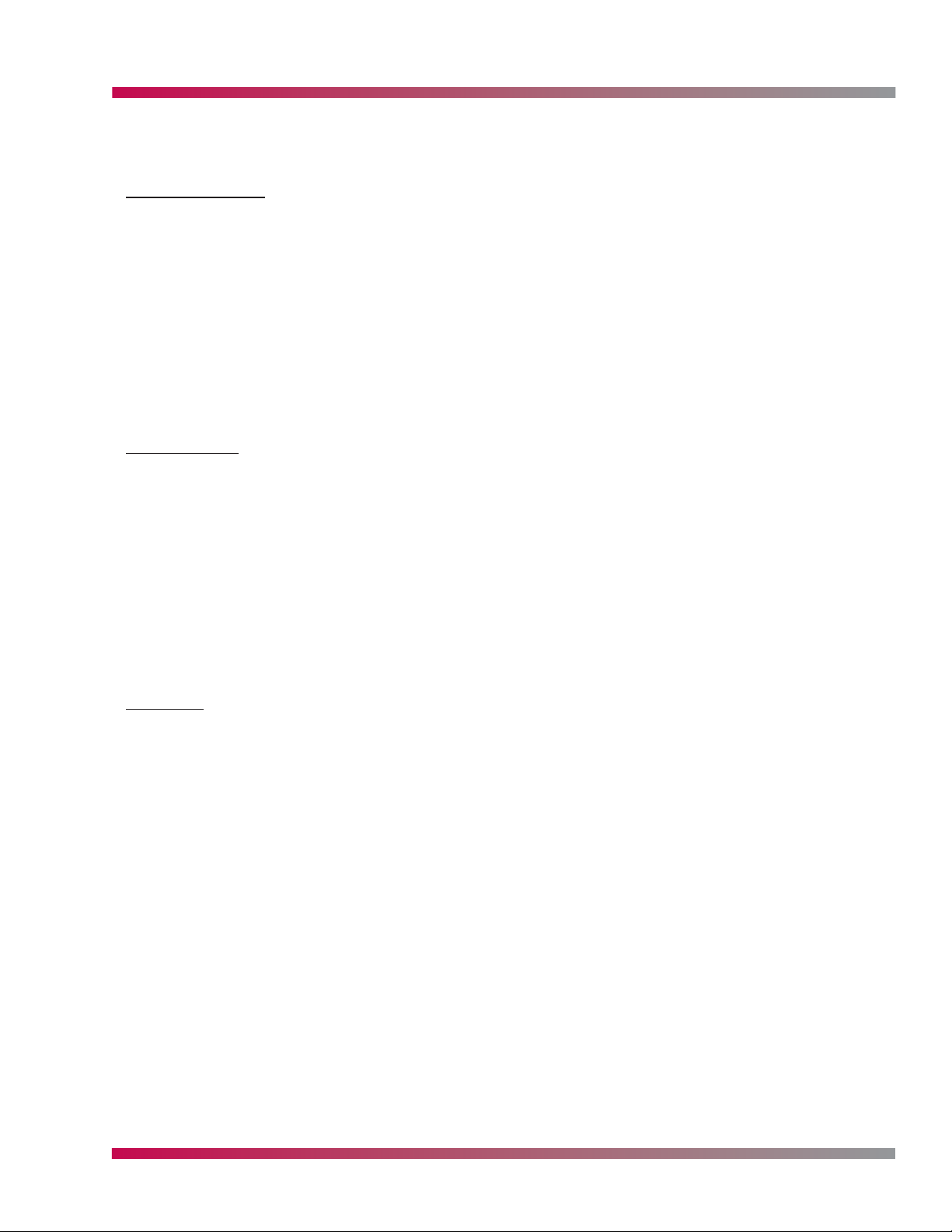

ANTI-TIP BRACKETS

If the set will be mounted on a desk top, secure the

TV assembly by joining it to a wall by using the

included wall brackets. Some models are mounted

differently than others, refer to the owners manual

for the model you are installing.

Plasma Training 13 Installation

Page 14

INSTALLATION

GENERAL MOUNTING

The chart below gives screw sizes needed to mount our plasma units to most wall mounts. The

design of the mount may require longer or shorter screws than the length indicated below. Lengh is

in the far right column. Use 25mm screws for the 42” and 50” plasma models and 15mm for the 60”

models. This is subject to change without notice. Some units require spacers between the mount and

the unit, this also varies by cabinet design.

Nominal

Nominal

Diameter

Diameter

Pitch

Pitch

Root

Root

Radius

Radius

Pitch

Pitch

Diameter

Diameter

Minor

Minor

Diameter

Diameter

Thread

Thread

Height

Height

Drill

Drill

Diameter

Diameter

Length

Length

mmmmh3 H1d3 D1d2=D2rPd = D

mmmmh3 H1d3 D1d2=D2rPd = D

254.20.40.4914.134.0194.480.1150.8M 5.00

254.20.40.4914.134.0194.480.1150.8M 5.00

154.20.40.4914.134.0194.480.1150.8M 5.00

154.20.40.4914.134.0194.480.1150.8M 5.00

Plasma Training 14 Installation

Page 15

OPERATION

OPERATION

This section covers basic TV functions and operation. Refer to the owners manual for additional

information.

NOTE: The DVR (Digital Video Recorder), DCR (Digital Cable Ready) and TV Guide features are

not discussed in this section, they each have their own section near the end of this

manual.

LANGUAGE

For best results, adjust or confirm adjustment of the On-Screen Menu Language first.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Confirm the desired language selection.

U.S. models incorporate the three North American languages

(English, Spanish, French)

5. If the selected language is not desired, change the language by using the

to highlight the desired language setting and press the ENTER button to set the language.

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the OPTION Menu (5

/

buttons to highlight the Language Menu (6

th

Menu) and press

th

Item) and press

/

buttons

TIP: If the language is set to Spanish, the Language Menu will be listed as “Lenguaje”. If the

language is set to French, the Language Menu will be listed as “Langue”. The main menu

list will not change.

SETUP MENU

The Setup Menu houses all of the services and options for TV channels and inputs.

EZ SCAN

The EZ Scan function will automatically scan for all available over-the-air (OTA) broadcast and/or

Cable TV Service channels and adds them to the “Channel Map”. Depending on individual model

features, EZ Scan can scan for OTA-NTSC (analog channels from antenna) labeled TV, OTA-ATSC

(digital channels from antenna) labeled DTV, CATV (analog Cable TV Service channels), and/or CADTV

(digital Cable TV Service channels).

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Press or ENTER to begin the EZ Scan process

5. Once the EZ Scan is complete, press EXIT to completely exit the On-Screen Menu or MENU

to return to the previous menu.

NOTE: If a Cable Box is used to decode CATV channels and output them to the TV via Ch3 or

Ch4, the CATV and CADTV channels will not be scanned by the EZ Scan function.

/

buttons to highlight the SETUP Menu (1st Menu) and press

/

buttons to highlight EZ Scan (1st Item)

NOTE: If a CableCARD™ is used, CATV and CADTV scans are not performed by the EZ Scan

function. CATV and CADTV channels are added to the “Channel Map” via the CableCARD™.

Plasma Training 15 Operation

Page 16

OPERATION

TIP: The EZ Scan function will re-add previously deleted channels to the “Channel Map”. In

order to maintain Channel Map preferences, the manual scan option should be used for

individual channel additions.

MANUAL SCAN

The Manual Scan option allows users to manually add channels to the “Channel Map” without

having to perform a complete scan.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the or ENTER buttons to enter the Manual Scan function

5. Use the

6. Use the button to move to the channel number field

7. Use the

8. Press the ENTER button to save the channel.

9. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the SETUP Menu (1st Menu) and press

/

buttons to highlight Manual Scan (2nd Item)

/

buttons to select the channel type (TV/DTV/CATV/CADTV)

/

buttons to select the channel number

NOTE: Input physical channel numbers instead of virtual channel numbers. (For Example, WXYZ

may broadcast NTSC on Ch 5 and ATSC on Ch 9. Even though the ATSC broadcast appears

as Ch 5-1, 5-2, etc., the physical channel number is Ch 9 while the virtual channel

assignment or “5” is carried in the PSIP data.)

CHANNEL EDIT

The Channel Edit feature allows users to specify channel usage. Users may add or delete channels

from the Channel Map. (The add function primarily operates on channels that have already been

added to the Channel map and previously deleted. Use the Manual Scan function to add a new

channel.) Users may also create a Favorite Channel Map by using the Channel Edit feature and

marking specified channels “FAV”.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use theor ENTER buttons to enter the Channel Edit function

5. Use the

6. To Add / Delete a channel, press the ENTER button

7. To mark or remove a channel from the Favorite Channel Map, press the FAV button

8. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the SETUP Menu (1st Menu) and press

/

buttons to highlight Channel Edit (3rd Item)

/

/

/ buttons to select a channel number

TIP: To switch between channel types, TV, CATV, DTV, CADTV, move to the top of the window

and select the tab that corresponds with the desired channel type.

DTV SIGNAL STRENGTH

The DTV Signal Strength functions displays a bar meter showing the current strength of the incoming

ATSC signal. This feature only applies to digital channel reception and is not available for NTSC

channels. This feature is designed to aid in antenna placement and alignment for ATSC reception.

Plasma Training 16 Operation

Page 17

OPERATION

1. Press MENU on the Remote Control or Front Controls.

2. Use the

3. Use the

4. Use the or ENTER buttons to display the DTV Signal Meter.

5. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

TIP: You may also display the DTV Signal Meter by pressing the SIGNAL button on the Remote

Control.

CHANNEL LABEL

The Channel Label feature allows users the ability to assign a network logo to individual channels.

1. Press MENU on the Remote Control or Front Controls.

2. Use the

3. Use the

4. Use the or ENTER buttons to enter the Channel Label Setup Screen.

5. Use the Channel Up / Down buttons to select the desired channel.

6. Use the

7. Press ENTER to assign the logo to the channel.

8. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the SETUP Menu (1st Menu) and press

/

buttons to highlight DTV Signal (4th Item).

/

buttons to highlight the SETUP Menu (1st Menu) and press .

/

buttons to highlight Channel Label (5th Item).

/

/

/ buttons to select the desired logo.

NOTE: Not all Network Logos are available. Memory limitations restrict the amount of logos

that can be available within the software of the TV.

MAIN INPUT

The Main Input option selects the TV’s input (picture source) to be displayed on the screen.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the or ENTER buttons to enter the Main Input Selection List

5. Use the

6. Press ENTER to confirm input selection

7. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

SUB INPUT

The Sub Input option selects the input (picture source) to be displayed as Picture-In-Picture (PIP).

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the or ENTER buttons to enter the Main Input Selection List

5. Use the

6. Press ENTER to confirm input selection

/

buttons to highlight the SETUP Menu (1st Menu) and press

/

buttons to highlight Main Input (6th Item)

/

buttons to highlight the desired input (Antenna, Cable, Video 1, etc)

/

buttons to highlight the SETUP Menu (1st Menu) and press

/

buttons to highlight Sub Input (7th Item)

/

buttons to highlight the desired input (Antenna, Cable, Video 1, etc.)

Plasma Training 17 Operation

Page 18

OPERATION

7. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

NOTE: Not all inputs are available for Sub Input at all times. When the Main Input being used

is a digital type, the available Sub Inputs are Analog Broadcast, Video, and Front Video.

When the Main Input being used is an analog type, the available Sub Inputs are DTV,

Analog, Video, and Front Video.

INPUT LABEL

The Input Label feature allows users to rename the TV’s inputs for easier identification.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the or ENTER buttons to enter the Input Label Selection List

5. Use the

6. Use the

Box, Game, PC, or none)

7. Repeat Steps 5 and 6 to add more input labels

8. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the SETUP Menu (1st Menu) and press

/

buttons to highlight Input Label (8th Item)

/

buttons to select an input source

/

buttons to select the input label (VCR, DVD, Set Top Box, Satellite, Cable

VIDEO MENU

The Video Menu houses all of the services and options for Picture adjustment.

EZ PICTURE

The EZ Picture option is a series of pre-set values for picture appearance for particular program

categories. Typical EZ Picture options include:

Daylight – A bright setting to help compensate for high levels of ambient light normally

experienced during daytime hours.

Night Time – A dim setting to help compensate for reduced levels of ambient light normally

experienced during nighttime hours.

Normal – An average setting to use as a default setting, or as a starting point for adjustments.

Movie – A setting to enhance the appearance of film based movies.

Video Game – A setting to enhance the appearance of video games.

Sports – A setting to enhance the appearance of sporting events.

TIP: There is an additional setting labeled Custom, which has no preset levels. The Custom setting

selects the most recent stored settings from Manual Picture Control.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the VIDEO Menu (2nd Menu) and press

/

buttons to highlight EZ Picture (1st Item) and press

/

buttons to highlight the desired setting

Plasma Training 18 Operation

Page 19

OPERATION

MANUAL PICTURE CONTROL

The Manual Picture Control option allows users to set individual picture controls such as Contrast,

Brightness, Color, Tint, Sharpness, and Color Temperature. The Manual Picture Controls should be

used to properly set the display once it is in a users home. The environment around the display will

affect the perceived quality of the display. For example, the color of the walls and flooring will

affect the color levels seen on the display. Also, the amount of ambient light in the room will affect

the brightness of the display.

To properly set the Manual Picture Control levels:

1. Make sure the display is in its final place in the room. (If the display is moved to another

position, the controls will need to be re-adjusted.)

2. Adjust ambient light. The adjustments should be made for night time movie watching as,

this is when consumers are most critical of picture quality. The room should be darkened

with little to no ambient light in front of the display. For best results, and to reduce the

chance of eye strain, there should be slight ambient light behind the display.

3. Turn off or disable any additional video signal processing such as: XD Engine, Velocity

Scan, etc

4. Set EZ Picture to the Normal setting.

5. Set Color Temperature to the Warm setting.

Contrast – The Contrast control is used to adjust the White Level of the display. The proper setting

for contrast is only high enough to allow the difference between white and light gray to be seen.

When contrast is set too high, light grays will appear washed out or white, and whites can begin to

bloom or over saturate with color (appear slightly blue, pink, or green). When contrast is set too

low, whites will appear gray.

To properly set the Contrast Level, lower the contrast setting so that white becomes gray. Next,

begin stepping up the contrast level until the lightest gray color becomes white (white and gray

sections become one larger section) and then move the control down one step. There should always

be a noticeable difference between white and light gray and also note that for best results on all

display types (and to reduce display wear) the Contrast Level should be no higher than “85”.

Brightness – The Brightness control is used to adjust the Black Level of the display. The proper

setting for brightness is only high enough to allow the difference between black and dark gray to be

seen. When brightness is set too high, blacks will appear washed out or gray. When brightness is set

too low, dark grays will appear black.

To properly set the Brightness Level, begin stepping down the brightness level until the darkest

gray disappears into black (at the same time, black and “blacker-than-black” will mix into one.

Next, step the brightness level up once so that, black and “blacker-than-black” remain together yet

the darkest gray is visible.

NOTE: The Brightness and Contrast controls interact with each other. The current brightness

setting will affect the white level and the current contrast setting will affect the black

level. Therefore, you may need to readjust the contrast setting after adjusting the

brightness setting, and likewise readjust the brightness setting after subsequent contrast

settings. Keep repeating the adjustment until the black and white levels are reached.

Color – The Color control is used to adjust the Color Saturation of the display. The proper setting

for color is to the point where the primary (red, green, & blue) and sub-primary (yellow, cyan, &

magenta) colors appear as their pure, natural colors without “bleeding” into other colors. When

Plasma Training 19 Operation

Page 20

OPERATION

color is set too high, predominant colors, such as red, will bloom and bleed, causing white to

appear pink, and yellow to appear orange. When color is set too low, the entire image will appear

more gray than colored, with the extreme lower limit resulting in a Black & White picture. To

properly set the Color Level, lower the color setting to the point where colors begin to appear gray.

Next, begin stepping up the color level until the primary and sub-primary colors begin to exceed

their normal color representations.

Tint – The Tint control is used adjust the Hue of the display between red or green. The proper

setting for tint is, as with the color setting, to the point where the primary (red, green, & blue)

and sub-primary (yellow, cyan, & magenta) colors appear as their pure, natural colors without

bleeding into other colors. The extreme settings of tint will result in a red/magenta overall hue or

a green/cyan overall hue. To properly set the Tint control, adjust towards red if yellows appear with

a green tint or towards green is yellows appear with a red or orange tint.

NOTE: The Color and Tint controls interact with each other. The current color setting will affect

the hue and the current tint setting will affect the saturation. Therefore, you may need

to readjust the color setting after adjusting the tint setting, and likewise readjust the tint

setting after subsequent color settings. Keep repeating the adjustment until the best

color representation is reached.

TIP: After Color and Tint adjustments are completed, reds may over saturate slightly, causing

yellows to appear orange. You may need to slightly reduce the color level to compensate

for this effect.

Sharpness – The Sharpness control is used to adjust the amount of data added to the display

image. When the sharpness control is set too high, white or jagged edges will appear on black lines

or the edges of objects. When the sharpness control is set too low, the edges of objects or black

lines will appear fuzzy. To properly set the Sharpness control, adjust the setting up or down until

black lines have crisp, clean edges, while maintaining the overall brightness level across the image.

TIP: If a noticeable difference is not seen during the sharpness adjustment, simply place the

control at the 50 mark.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

6. Use the

7. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

Color Temperature – The Color Temperature control is used to adjust the color of gray on the

display between red and blue tint. The Cool setting will provide a slightly blue tint to the picture.

The Warm setting will provide a slightly red tint to the picture. Once the previous adjustments have

been made, the color temperature may be changed for personal preference.

/

buttons to highlight the VIDEO Menu (2nd Menu) and press

/

buttons to highlight the desired control and press

/ buttons to adjust the control

/

buttons to change to another control or

Video Reset

The Video Reset option will revert all video menu options to their factory preset values. The EZ

Picture function will revert to the Daylight setting and the custom settings are the same as Normal.

Plasma Training 20 Operation

Page 21

OPERATION

AUDIO MENU

The Audio Menu provides access to all of the services and options for Sound adjustment.

AUDIO LANGUAGE

The Audio Language setting allows a default language to be specified for any digital broadcasts that

might have alternate audio languages.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

/

buttons to highlight the AUDIO Menu (3

/

buttons to highlight Audio Language (1st Item) and press

/

buttons to select a default audio language

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

EZ SOUNDRITE

The EZ SoundRite option prevents the audio level of television commercials from exceeding the

audio level of preceding television programs.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

/

buttons to highlight the AUDIO Menu (3rd Menu) and press

/

buttons to highlight EZ SoundRite (2nd Item) and press

/

buttons to highlight either Off or On

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

rd

Menu) and press

EZ SOUND

The EZ Sound function is a series of preset audio settings to maximize the sound quality of various

program types.

Normal – Factory presets for treble, bass, and front surround

Stadium – Preset values for sporting events

News – Preset values to dialog with little to no background effects

Music – Preset values for musical events

Theater – Preset values for movies

TIP: There is an additional setting labeled Custom, which has no preset levels. The Custom

setting selects the most recent stored settings from Manual Sound Control.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

/

buttons to highlight the AUDIO Menu (3rd Menu) and press

/

buttons to highlight EZ Sound (3rd Item) and press

/

buttons to highlight the desired setting

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

Plasma Training 21 Operation

Page 22

OPERATION

MANUAL SOUND CONTROL

Balance – The balance control is used to adjust the level of the left and right TV speakers. In

normal conditions, the balance control should be set to the middle (even) position. If the main

viewing position is not centered with the TV, adjust to balance control so that the speaker farther

from the main viewing position is has a higher level.

Treble – The treble control adjusts the level of higher frequencies of the audio

spectrum.

Bass – The bass control adjusts the level of lower frequencies of the audio spectrum.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

6. Use the

7. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the AUDIO Menu (3rd Menu) and press

/

buttons to highlight the desired control and press

/ buttons to adjust the control

/

buttons to change to another control or

FRONT SURROUND

The Front Surround option provides extra processing to mimic surround sound effects using only

the TV’s 2-channel speakers.

3D EchoSound System – SRS Labs process for improving an incoming mono audio signal to

produce a simulated stereo effect. The 3D EchoSound system will also create a three-dimensional

sound by creating a wider and deeper sound stage.

SRS TruSurround XT – SRS Labs process for mimicking multi-channel surround sound effect from

2-channels of audio output. The SRS TruSurround XT process can also provide more clarity and bass

enrichment to stereo signals.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

TV SPEAKER

The TV Speaker selection option is used to either enable or disable the TV’s internal speakers. If the

TV is connected to a home theater system and there is no desire for audio from the TV’s speakers,

the TV’s speakers may be turned off.

/

buttons to highlight the AUDIO Menu (3rd Menu) and press

/

buttons to highlight Front Surround (7th Item) and press

/

buttons to select the desired setting

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

Plasma Training 22 Operation

/

buttons to highlight the AUDIO Menu (3rd Menu) and press 4

/

buttons to highlight TV Speakers (8th Item) and press

/

buttons to select the desired setting

Page 23

OPERATION

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

STEREO / SAP SETUP (NON-MENU OPTION)

This TV can receive both MTS stereo programs and any SAP (Secondary Audio Program) signal that

may be present. Pressing the SAP buttons on the Remote Control will cycle the TV between three

options; Mono, Stereo, and SAP. The Mono and Stereo options will provide audio from the MTS or

mono signal present from the broadcaster. The SAP option will provide audio in either another

language or another topic only if provided from the broadcaster.

NOTE: Even though the TV’s settings may be either Stereo or SAP, when a mono signal is the

only type provided by the broadcaster, mono sound will be heard (unless 3D EchoSound

System is selected).

TIP: If the incoming signal is very weak, selecting Mono will improve the sound output of a

stereo broadcast when the audio is fading in and out.

TIME MENU

The Time Menu provides access to all of the services and options for Clock and Timer adjustments.

AUTO CLOCK

The Auto Clock option allows the TV’s clock to be set automatically via either XDS signals from a

PBS broadcaster or from Gemstar’s TV Guide On Screen (TVGOS) signal. Non-TVGOS models – Auto

Clock will set the clock based on XDS signal from a PBS broadcaster. TVGOS models – Auto

Clock will set the clock based on the incoming TVGOS signal.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. If On is selected, use the

6. Use the

7. Press ENTER to save the selection

8. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

MANUAL CLOCK

The Manual Clock option allows direct setting of the TV’s clock.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Use the

6. Repeat Steps 4 and 5 to set the date and time

7. Press ENTER to save the selection

8. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the TIME Menu (4th Menu) and press

/

buttons to highlight Auto Clock (1st Item) and press

/

buttons to select Off or On and press

/

buttons to select the time zone the TV is located in

/

buttons to select the Daylight Saving option (Auto, Off, On)

/

buttons to highlight the TIME Menu (4th Menu) and press

/

buttons to highlight Manual Clock (2nd Item) and press

/ buttons to select Year

/

buttons to set the current year

Plasma Training 23 Operation

Page 24

OPERATION

NOTE: The Manual Clock option is not available if TVGOS has been setup.

TIMER

The timer functions allow the TV to automatically turn on or off at specified times.

OFF TIMER

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. If set to On, use the

6. If set to On, use the

7. Press ENTER to save the selection

8. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

ON TIMER

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. If set to On, use the

6. If set to On, use the

7. If set to On, use the

8. If set to On, use the V buttons to set the volume for the TV to turn on at

9. Press ENTER to save the selection

10. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the TIME Menu (4th Menu) and press

/

buttons to highlight Off Timer (3rd Item) and press

/

buttons to select Off or On and press

/

buttons to set the hour

/

buttons to set the minute

/

buttons to highlight the TIME Menu (4th Menu) and press

/

buttons to highlight On Timer (4th Item) and press

/

buttons to select Off or On and press

/

buttons to set the hour

/

buttons to set the minute

/

buttons to set the channel for the TV to turn on to

NOTE: The TV must be in Stand-by mode for the On function to operate.

TIP: The time must be set before the timer functions can operate.

NOTE: If there is no interaction from a user (any Remote Control or Front Control button)

within 2 hours of the TV turning On under the On Timer function, the TV will turn back

off. This is a safety measure built into the TV to prevent the TV from accidentally turning

on.

SLEEP TIMER

The Sleep Timer function allows the TV to turn off after specified intervals of time.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

/

buttons to highlight the TIME Menu (4th Menu) and press

/

buttons to highlight Sleep Timer (5th Item) and press

/

buttons to select the desired time interval and press

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

Plasma Training 24 Operation

Page 25

OPERATION

TIP: Pressing the SLEEP button on the Remote Control will also activate the Sleep Timer

function. Once activated, each subsequent press of the SLEEP button will change the

time interval (10, 20, 30, 60, 90, 120, 180, 240 minutes, or off).

AUTO OFF

The Auto Off function, when activated, will automatically turn the TV off if there is no input signal

for 10 minutes. This feature is useful when watching DVD Movies or using a Cable TV Box.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

OPTION MENU

The Option Menu houses general options and settings for additions control of the TV.

ASPECT RATIO CONTROL (ARC)

The Aspect Ratio Control function adjusts the way that 4:3 programs are displayed.

/

buttons to highlight the TIME Menu (4th Menu) and press

/

buttons to highlight Auto Off (6th Item) and press

/

buttons to select Off or On

Set By Program – Disables ARC processing and allows the original aspect ratio of the incoming

program to be displayed.

4:3 – Displays 4:3 content without any correction, showing bars on both sides of the picture

16:9 – Displays 4:3 content stretched horizontally, consuming the entire screen

Horizon – Displays 4:3 content stretched only at the sides to consume the entire screen. The

center portion of the image is not stretched.

Zoom 1 – Enlarges the overall size of 4:3 content to consume the entire screen without and

distortion. However, the upper and lower portions of the image will be cropped.

Zoom 2 – Enlarges the overall size of 4:3 content to a greater extent than Zoom 1

Cinema Zoom – Adjustable enlargement of the Zoom function. (1-16)

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

CINEMA 3:2 MODE SETUP

The Cinema 3:2 Mode provides additional process for 480i content (particularly movies) to help

reduce the flickering caused during the conversion of 24 fps film to 30fps television signals.

/

buttons to highlight the OPTION Menu (5th Menu) and press

/

buttons to highlight Aspect Ratio (1st Item) and press

/

buttons to select the desired ARC setting

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

Plasma Training 25 Operation

/

buttons to highlight the OPTION Menu (5th Menu) and press

/

buttons to highlight Cinema 3:2 Mode (2nd Item) and press

Page 26

OPERATION

4. Use the

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

NOTE: Cinema 3:2 Mode only operates in 480i mode.

CAPTION

Closed Captions are included in the NTSC and ATSC television signals to provide text of dialog spoken

in the program.

To activate / deactivate Captions:

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to select Off or On

/

buttons to highlight the OPTION Menu (5th Menu) and press

/

buttons to highlight Caption (3rd Item) and press

/

buttons to select Off or On

CAPTION/TEXT

The Caption/Text option is used to select the type (NTSC) or language (ATSC) of captions to be

displayed.

Incoming NTSC broadcast signal:

CC 1 – Closed Captions that are in English and in time with spoken dialog

CC 2 – Closed Captions that are not required to be in time with spoken dialog

CC 3 – Closed Captions that are in an alternate language

CC 4 – Open use, without specifications

Text 1 – Near full screen Closed Captions in time with spoken dialog

Text 2 – Near full screen Closed Captions not required to be in time with dialog

Text 3 – Open use near full screen captions

Text 4 – Open use near full screen captions

NOTE: Most broadcasts will only include CC1 and are not required to use any other format.

Incoming ATSC broadcast signal:

English – English captions

Spanish – Optional Spanish captions

French – Option French captions

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Press ENTER to save the selection

6. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the OPTION Menu (5th Menu) and press

/

buttons to highlight Caption/Text (4th Item) and press

/

buttons to select the desired option

Plasma Training 26 Operation

Page 27

OPERATION

CAPTION OPTION

The Caption Option setting is only available when the incoming signal is a DTV broadcast and if the

settings within the PSIP signal (provided by the broadcaster) allow alteration of the caption

display. When available, the caption text may be altered by size, font, and color.

Size – Set the size of the captions

Font – Set the font of the captions

Text Color – Set the color of the caption text

Text Opacity – Set the opaqueness of the caption text

Background Color – Set the background color of the captions

Background Opacity – Set the opaqueness of the caption’s background

Edge Type – Set a border for the captions

Edge Color – Set a color for the caption border

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

4. Use the

5. Use the

6. Repeat Steps 4 and 5 to set the edit all of the desired items

7. Press ENTER to save the selection

8. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

/

buttons to highlight the OPTION Menu (5th Menu) and press

/

buttons to highlight Caption Option (2nd Item) and press

/

buttons to select the desired item

/ buttons to set the item option

EZ DEMO

The EZ Demo option demonstrates the available menus of the TV.

1. Press MENU on the Remote Control or Front Controls

2. Use the

3. Use the

/

buttons to highlight the OPTION Menu (5th Menu) and press

/

buttons to highlight EZ Demo (7th Item) and press

4. Press EXIT to stop the demonstration

LOCK MENU

The Lock Menu allows change of of the Parental Controls / V-Chip settings for the TV to block

specific channels, ratings and/or inputs. The Parental Control function blocks programs based on

the ratings sent by the broadcaster. The default setting allows all programs to be viewed. To use

this functions, the following must be performed:

1. Set ratings and categories to be blocked

2. Set a Parental Control password

3. Enable the locking system

TO ENTER WHILE LOCKED:

1. Press MENU on the Remote Control or Front Controls

2. Use the

/

buttons to highlight the LOCK Menu (6th Menu) and press

3. Enter the password (0000 is the default password)

Plasma Training 27 Operation

Page 28

OPERATION

4. Use the

5. Use the

6. Press ENTER to save the selection

7. Press EXIT to completely exit the On-Screen Menu or MENU to return to the previous

menu.

TIP: If the password is forgotten, “7777” will reset it.

MOVIE RATING SYSTEM

G – General audience (all ratings below are blocked)

PG – Parental guidance suggested (all ratings below are blocked)

PG-13 – Parents strongly cautioned (all ratings below are blocked)

R – Restricted (all ratings below are blocked)

NC-17 – No one 17 and under admitted (all ratings below are blocked)

X – Adult only

Blocking Off – Permits all programs

TELEVISION RATING SYSTEM

/

buttons to highlight the desired system and press

/

buttons to set the desired blocking

TV-G – General audience

TV-PG – Parental guidance suggested

TV-14 – Parents strongly cautioned

TV-MA – Mature audience only

TV-Y – All children

TV-Y7 – Children 7 years and older

TV RATING CHILDREN (OPTION – SETTING)

Age – TV-Y and TV-Y7

Fantasy Violence – TV-Y7

TV RATING GENERAL (OPTION – SETTING)

Age – TV-G TV-PG TV-14 TV-MA

Dialog (sexual dialog) – TV-PG TV-14

Language (adult language) – TV-PG TV-14 TV-MA

Sex (sexual situations) – TV-PG TV-14 TV-MA

Violence – TV-PG TV-14 TV-MA

INPUT BLOCK (DISABLES EXTERNAL INPUTS)

Video1, Video 2, Front Video

Component 1, Component 2

RGB, HDMI1/DVI, HDMI2

Plasma Training 28 Operation

Page 29

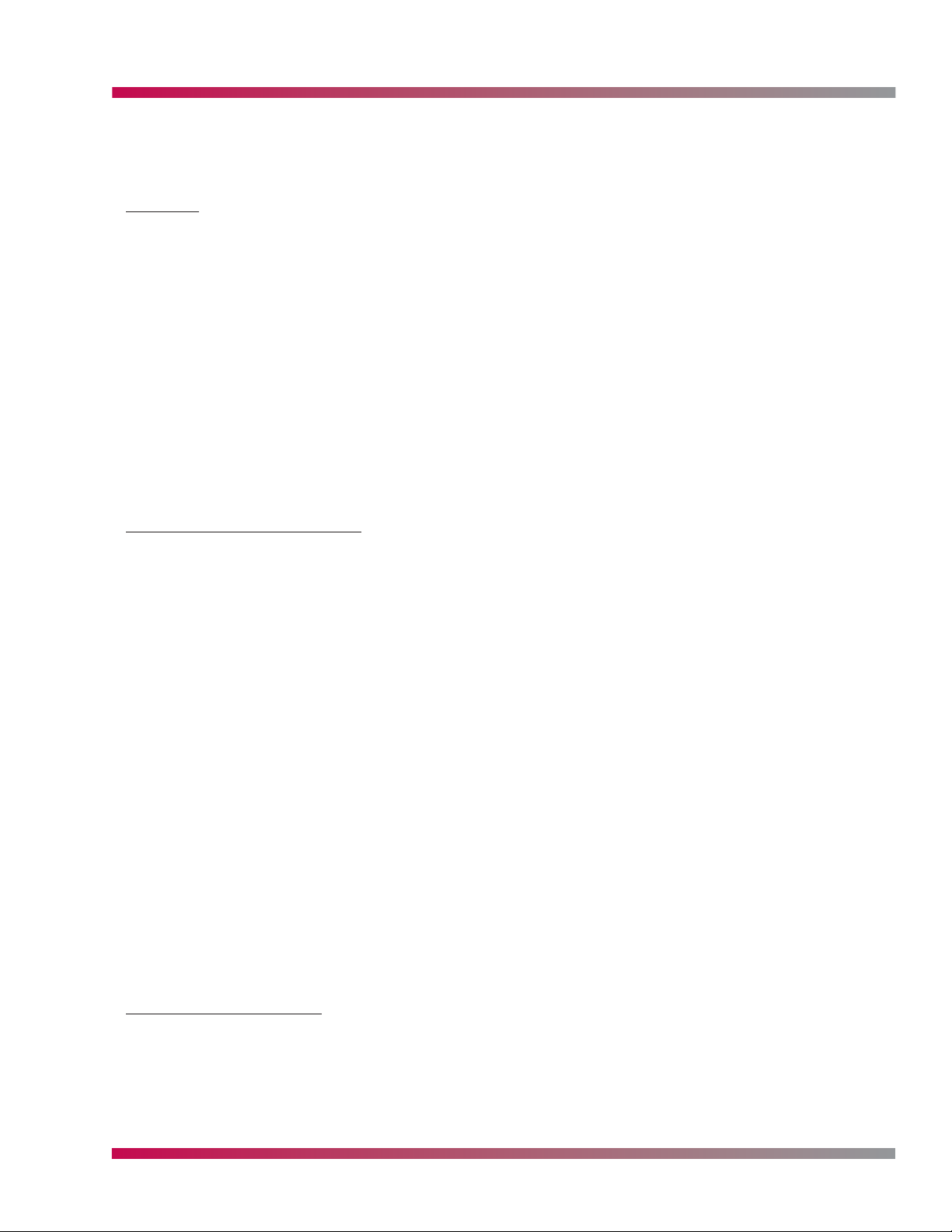

PCB LAYOUT

60PY2DR LAYOUT

CIRCUIT DESCRIPTIONS

Sub Cover

Accessing the Digital PCB or the Tuner PCB is made easier than on past

units by removing the sub back cover. The whole back can be removed

while the unit is on the original stand.

Y-Drive

X-Top Drives

Secondary

Power

Board

Primary

Power

Board

AC

Filter/Rectifier

Z-Drive

Tuner BoardDigital BoardControl Board

Plasma Training 29 Adjustments

X-Bottom Drives

Page 30

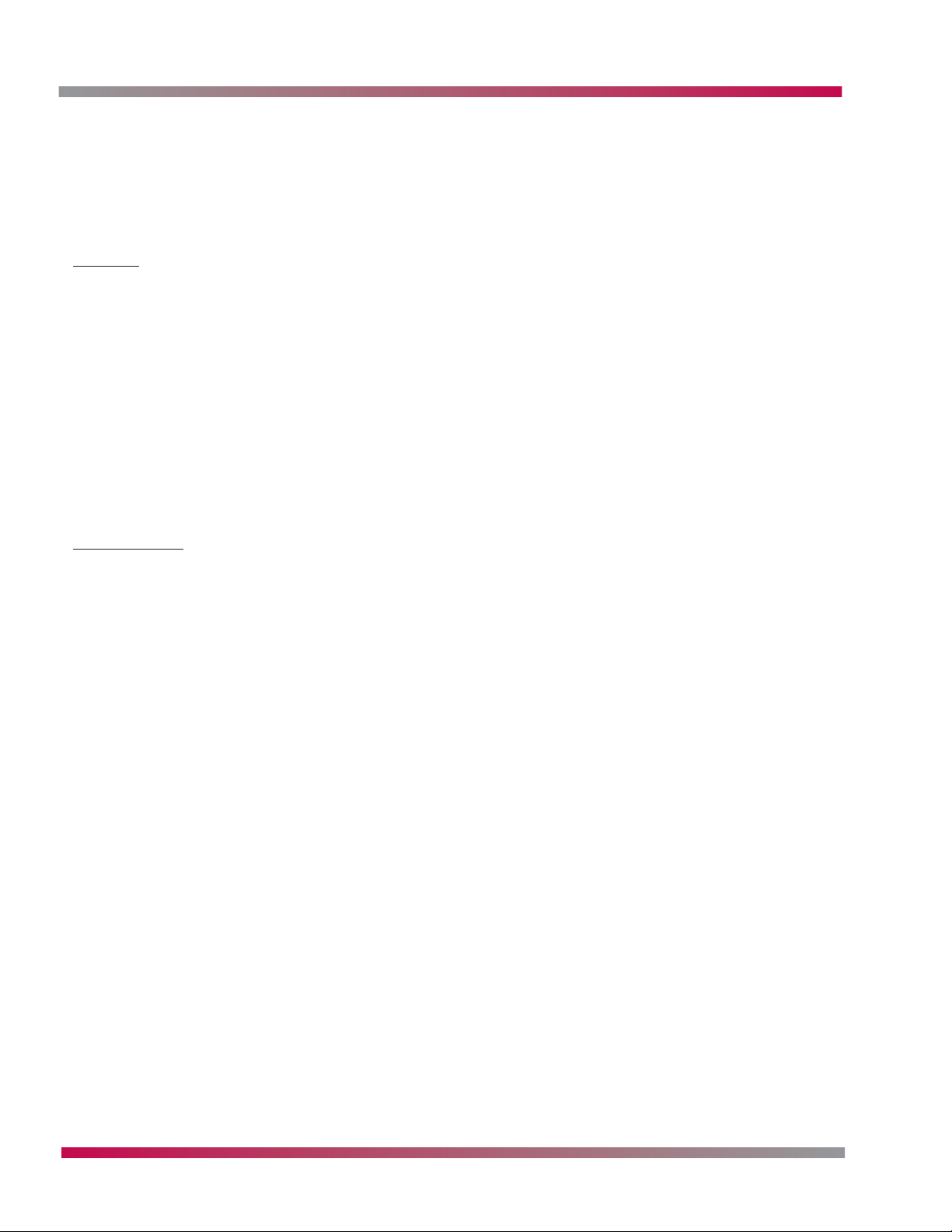

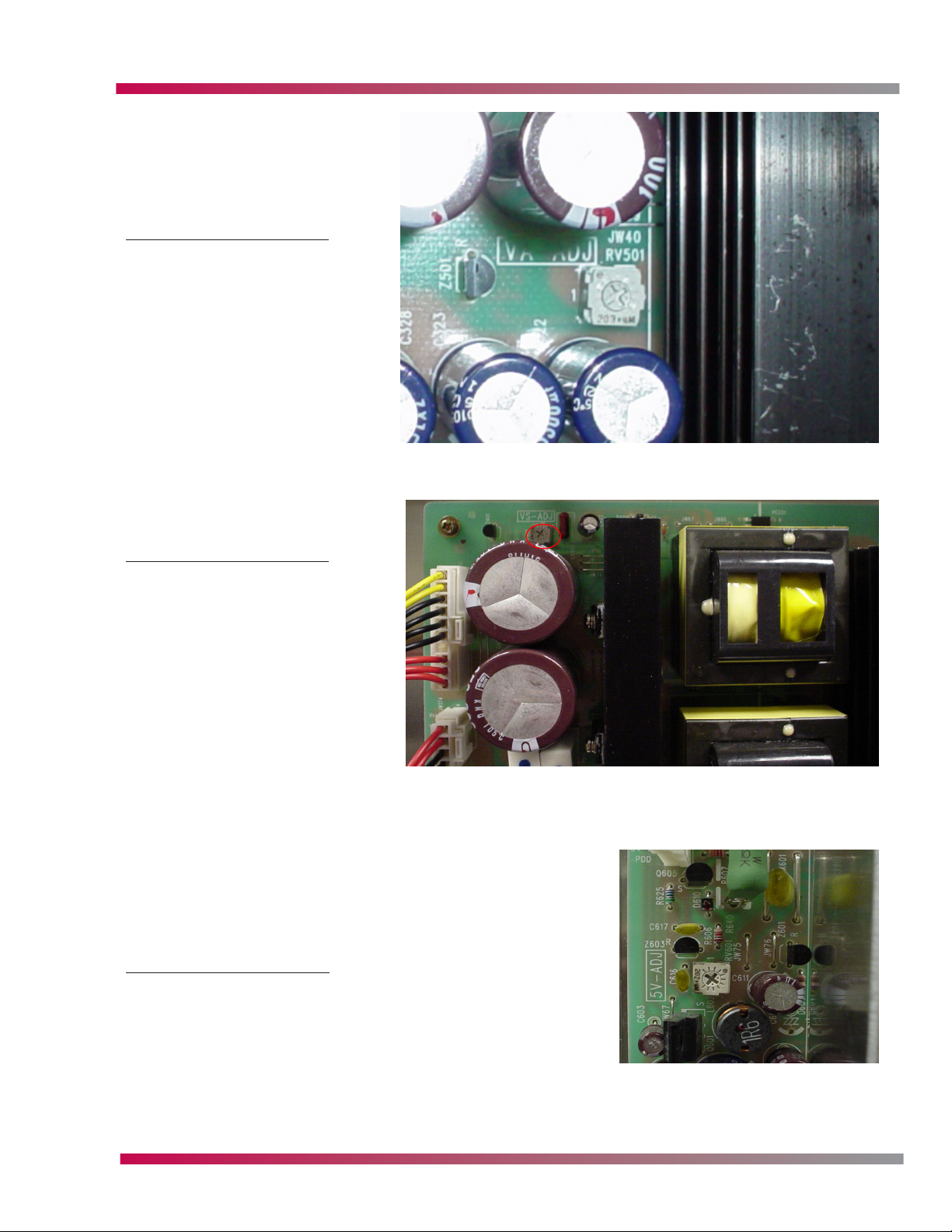

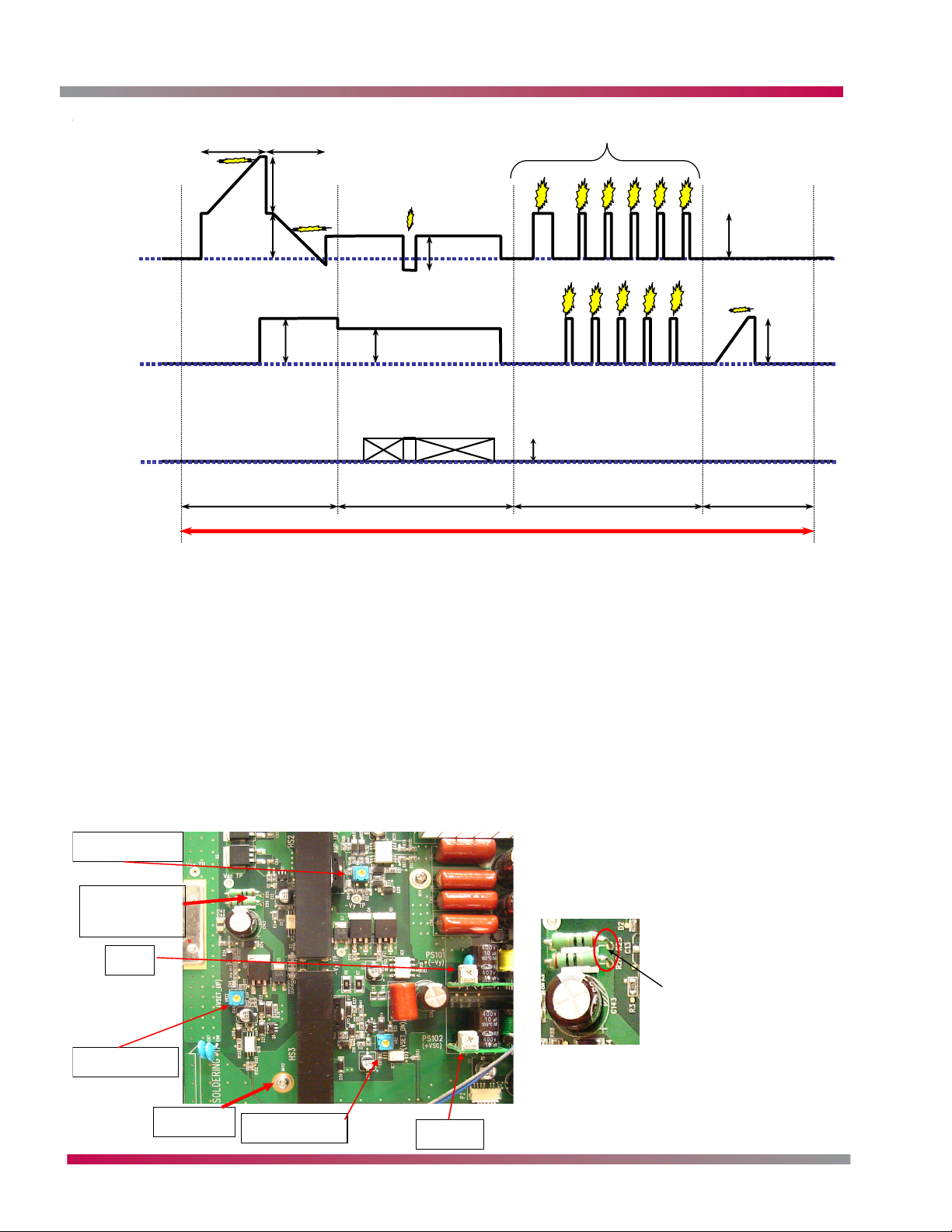

CIRCUIT DESCRIPTIONS

50PX4DR LAYOUT

Control

SMPS

50PC1DR LAYOUT

Squirrel cage fan

SMPS

HDD

Control

Digital

Tuner

SMPS

Tuner

Digital

HDD

Tuner

Digital

NOTE: This fan does not startup when the unit is powered on from a cold start for 2-3 minuets.

Plasma Training 30 Adjustments

Page 31

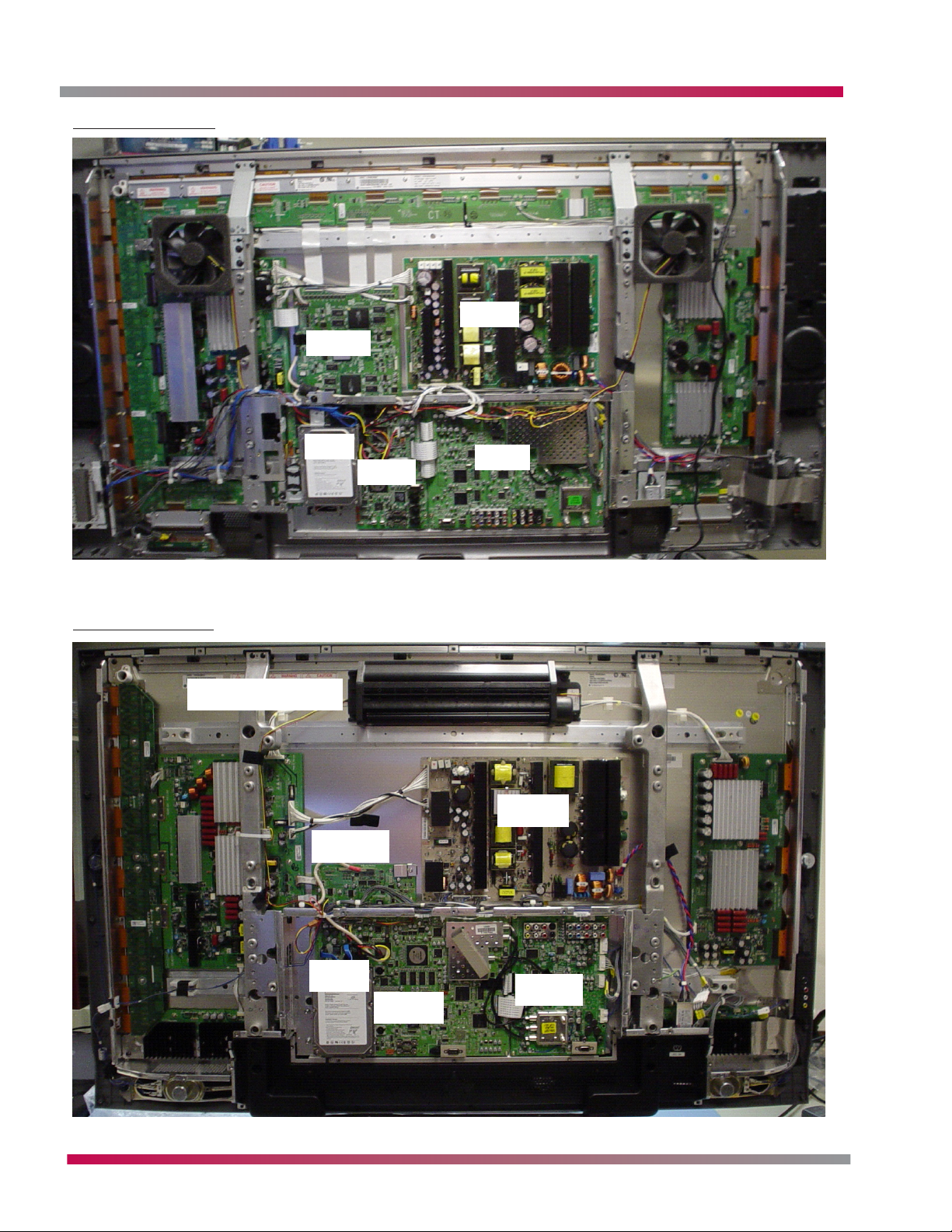

CIRCUIT DESCRIPTIONS

DIGITAL PCB

The digital board below is from the 60PY2DR, other models may differ slightly.

The digital PCB provides Digital Signal Processing (dsp) and controls the state of each FET on each

DRIVER B/D with R, G, B, each with 8bit input. This board contains the Cablecard slot and supporting

buffers which are shared with the Cablecard while it is in operation due to the data flow from the

cable headend to the card. This data flow constantly updates the channel list and the CP (Copy

Protect) data and the channel authorization list and the encription and descramble data. This is done

every ten to twenty seconds. This PCB also is host to the HDD (Hard Disk Drive) control circuit. This

circuit will recognize the HDD if it is programmed and formated correctly. These drives are setup

especially for this function, thus a drive from another vender will not function in this unit. This is

done for CP (Copy Protect) reasons. If the HDD is suspect of errors or video issues, power down the

unit and remove A/C and disconnect the IDE cable and power the unit back on. If the problem still

exists, the problem is not on the HDD. The unit can be used without the HDD connected. In this

situation the unit will function normally except any function related to the HDD or demo mode which

is stored on the HDD. This PCB also contains all of the Digital inputs. The analog to digital conversion

is done on this PCB as well.

Plasma Training 31 Adjustments

Page 32

CIRCUIT DESCRIPTIONS

4

4

TX/RX P2,N2

1394_OUT_TP[0:7]

PX4D PDP BLOCK

PX4D PDP BLOCK

POD_TP[0:7] LK,VALID,SOP

11

1.8V

Reg.

Reset

PVSB/OOB

X-tal (M)

IF±(6M)

nd

2

IIC A

0¡¿C2

ATSC/NTSC

U-

Com

CableANT.

(TPA±,TPB±)*2

1394

Controller

1394_IN_TP[0:7]

MUX

CPLD

11

VPP_SW

POD/OOB

Controller

LGDT3502

VSB_DATA

(LGDT3701)

IF_AGC

Tuner

(TDVS-H701P)

RF

TX/RX P1,N1

I/F

X-tal

(25M)

SATA

(TSB43DA42)

PC`I Bus

CableCARD circuit

(XC95144XL)

2

Flag

8

D

PI

14

8

PO

8

CRX

2

IIC D

0¡¿1C

OOB IF+/-

MSP

4440

SIF

OOB Tuner

(TAEU-H015P)

SW

IIC A

0¡¿C6

(SiI3512)

HD2_NT2CLK

TPN_SYS_CLK

EPLD_CLK

SDRAM

Voltage

LTC1470

Controller

POD

DRX

IIC D

0¡¿50

uCom

(M37151)

MSP

4440

SIF

NTSC Tuner

(TAFM-H103P)

IIC A

0¡¿C0

LGDPLL

CY2305SC

32MByte (8MB x4)

VPP1

DPLL_R[1:3]

(LGDT1901A)

FR_60

HD2_SYS_CLK

VCXO

27Mhz

64-Bit I/F

1.8V

Reg.

TP/D1

9

HD2_TP[0:7]

OR3

656 Data[0:7]

9

IIC C

0¡¿8A

Video Decoder

+3D Comb

X-tal

(24.576M)

V

IN5

V

OUT2

TV

IN1

IN1

YC

V, L R

2

3

Rear AV_1

Rear S_1

Video In/Out

Video In/Out

HD2_VDPClk (74.25M)

HD2_MAIN_PWM

CLK

(uPD64011A)

Sub

IN3

EPF_L/R

XDR_DATA_R/G/B[0:9]

IEP LGDT4410

IIC C

0¡¿1E

HD-II (Ver2.2)

-TP De-Mux

- MPEG Decoding : MP@HL

H,V,CLK

YCbCr24

3

OR1

OR4

H,V,CLK

YCbCr

3

16

IIC C

0¡¿B8

)

Video Decoder

+3D Comb

X-tal

(24.576M

OUT1

A/V SW

(CXA2069)

IN4

IN6

IN4

YC

V,LR

3

2

Side AV_4

Side S_4

MNT_V_Out

HD2_CVBS_OUT

HD-II

IIC C

12

LVDS Tx.

(THC63LVD103)

RGB

DOutClk

3

HV,Hact

30

-Format Converter

-Host I/F, Memory I/F

-Digital I/F

-Video DAC, NTSC Encoder

FID

OR2

Gemstar VBI Slicer & IR CKT

FID

(uPD64011A)

2MB

SDRAM

Main

IIC D

0¡¿90

OUT3

OUT1

2

Ext_ Audio LR

4440

M_MSP

0¡¿1C

SPDIF Out

MUX

(74LCX157)

SPDIF_BYPASS_SEL

HD2_ICE958_OUT

HD2_DAC_SCK/LRCK

AH_SPDIFCLK

-AC-3 Decoder/SPDIF In/out

OR1

OR4

YCbCr

H,V, CLK

24

ADC

(AD9883A)

(6/38MHz)

Active LPF

YCbCr

3

)

IIC D

0¡¿84

Video SW

(CXA2181

IN4

IN3

YCbCr

YCbCr

3

3

Comp_1

Comp_2

Control GPIO

SPDIF_IN_BYPASS

System

3

IN1

IN2

RGBHV

5

RGB-PC

Peripheral Bus

CPLD1

(XC95288XL)

)

(PIC18F1220

Slicer U-COM

H,V

SYNC

(MM1108XF)

SEPARATOR

CXA2069

IIC C

0¡¿98

FID

H,V,CLAMP

3

(XC95288XL)

System CPLD1

H,V

5

EPF_RGB-PC RGBHV

SPDIF In1(DVI)

SPDIF Receiver.

Slicer Data

(LM311M)

Voltage Comp.

ANALOG DE/

MULTIPLEXER

Sub_CVBS

OR2

HV_pol

HV_PC

AT/NT Tuner

SPDIF In2(DVD)

Sil9021

RX_HDMI_SPDIF

IIC B

0¡¿20

(CS8415A)

EEPROM

IIC B

0¡¿58

IR U-COM

(PIC18F242)

(74HCT4053)

PWM AMP

(TAS5122)

PWM_L/R

IIC D

0¡¿CC

PWM

MODULATOR

2

LPF

LPF

I2S

I2S_MCLK

NT Tuner

SIF

2

LR

LR

CXA2069

MNT_Out

RS-232C

(ST3232)

PCI Bus

(AT24LC512)

IIC C

0¡¿AE

GLink

GEM_IR_OUT

HD-II

I2S In

3

(NSP2100A)

AUDIO ADC

BUFFER

ANALOG_L/R

IIC D

0¡¿80

Sound Proc

LR

LR

2

2

Comp_2

Comp_1

SDRAM

64MB(32MBx2)

32Bit Bus I/F

Reset

CPU [PPC 405GPr]

EN[0:3(GPIO)]

G_LINK_CONN

IIC A

HD-II

I2S

Out

3

Buffer

(CS5331)

(74LCX244)

I2S Out

(MC33078)

3

(MSP4440)

LR

2

2

RGB(Phone)

KIA7029

74LCX244

- SDRAM Controller

- Peripheral Controller

- Local BUS I/F

IIC B

OR1

RGB

24

RXD[0:2]¡¾, RXCLK¡¾

8

HDMI 1

Flash Memory

16MB(8MBx2)

Peripheral Bus

- Serial(2), GPIO, I2Cr

I2C Hub

(PCA9516)

IIC D

IIC C

OR4

H,V,

CLK

3

SiL 9021

HDMI Rx

BSS83

BSS83

RXD[0:2]¡¾, RXCLK¡¾

DDC(I2C)

M

EEPRO

M

EEPRO

2

HDMI 2

CS8415A

RX_HDMI

SPDIF

IIC C

0¡¿60,68

BSS83

BSS83

DDC(I2C)

8

2

Plasma Training 32 Adjustments

Page 33

1394_OUT_TP[0:7]

POD_TP[0:7]

CLK,VALID,SOP

(PY2DR - PX4DR) PDP DVR BLOCK

(PY2DR - PX4DR) PDP DVR BLOCK

OOB/POD Controller

LGDT350

VSB DATA

/RESET

+3.3V

1.8V

Reg.

IF±(6M)

nd

2

IIC A

0¡¿C2

ATSC/NTSC

U-

Com

CableANT.

4

(TPA±,TPB±)*2

1394

Controller

1394_IN_TP[0:7]

TP_ENC[0:7]

MUX

CPLD

(XC95144XL)

11

VPP_SW

VPP_SW

2

POD/OOB

Controller

2

11

DRX / CRX

IIC D

X-tal

LGDT3701

IF_AGC

SIF

Tuner

(TDVS-H701F)

RF

SW

4

TX/RX P2,N2

TX/RX P1,N1

X-tal

(25M)

(SiI3512)

SATA I/F

(TSB43DA42)

HD2_NT2CLK

PCI Bus

KFIR-II

TP_V1[0:7]

PDR_PES[0:7]

TPN-II

TPN_TP[0:7]

2

Voltage

Flag

8

D

Add.

[0:13]

14

PI

8

8

PO

IIC D

0¡¿1C

uCom

(25M)

M_MSP

4440

M_MSP

SIF

OOB IF+/-

OOB Tuner

(TAEU-H015P)

6

0¡¿C

IIC A

IIC A

A)

LGDPLL

(LGDT1901

C

CY2305S

TPN_SYS_CLK

EPLD_CLK

SDRAM

32MByte (8MB x4)

SDRAM

(4Mx16Bit)

(LGDT1303)

KFIR-II

LTC1470

Controller

VPP1

POD

IIC C

0¡¿50

(M37151)

V

V

4440

NTSC Tuner

(TAUM-H501P)

0

Video In/Out

Video In/Out

0¡¿C

HD2_VDPClk

FR_60

HD2_SYS_CLK

VCXO

27Mhz

HD2_MAIN_PWM

64-Bit I/F

Reg.

1.8V

TP/D1

9

TP_ENC[0:7]

HD2_TP[0:7]

OR3

244

Buf.

9

656 Data[0:7]

CLK

SDRAM

(1Mx 16Bit)

)

X-tal

0¡¿BA

(24.576M

2

Filter

(FMS6410)

2

IN5

(Sub)

OUT2

TV

IN1

IN1

YC

V, L R

3

2

Rear AV_1

Rear S_1

CXA2069

XDR_DATA_R/G/B[0:9]

DPLL_R[1:3]

HD2_REC_CVBS

IEP

LGDP441

(74.25M)

IIC C

0¡¿1e

HD-II (Ver2.2)

-TP De-Mux

TPN-II /

MUX CPLD

TP_ENC[0:7]

KFIR-II

(BCM7040)

244

Buf.

PDR

CLK

Sub MSP4440

(UPD64011)

Video Decoder

Filter

(FMS6410)

2

OUT1

A/V SW

(CXA2069)

IN3

IN6

IN4

V,LR

3

EPF_L/R

Side AV_2

HD2_CVBS_OUT

HD-II

TX[0:4]¡¾

0

- MPEG Decoding : MP@HL

-Format Converter

PCI Bus

SDRAM

(2Mx 32Bit)

SDRAM

X-tal

IIC C

0¡¿B8

2

IIC A

(Main)

IN4

YC

2

Side S_2

MNT_V_Out

12

TXC¡¾

LVDS Tx.

RGB

3

HV,Hact

-Host I/F, Memory I/F

-Digital I/F

YCbCr

24

OR1

YCbCr

16

(1Mx 16Bit)

(24.576M)

IIC B

IIC C

IIC B

OUT3

Ext_ Audio LR

M_MSP

(THC63LVD103)

LGDP4411

DOutClk

30

HD2_ICE958_OUT

-Video DAC, NTSC Encoder

-AC-3 Decoder/SPDIF In/out

FID

H,V,CLK

3

OR2

OR4

FID

H,V,CLK

3

(UPD64011)

Video Decoder

IIC D

0¡¿90

OUT1

2

4440

SPDIF Out

MUX

(74LCX15

OR1

YCbCr

ADC

Active LPF

YCbCr

IIC B

0¡¿84

IN4

YCbCr

YCbCr

3

Comp_1

Comp_2

SPDIF_IN_BYPASS

7)

SPDIF_BYPASS_SEL

VBI Slicer & IR (USA Only)

OR4

H,V,

CLK

24

3

(AD9883A)

(FMS6407)

3

Video SW

(CXA2181

IN3

RGBHV

3

RGB-PC

CIRCUIT DESCRIPTIONS

RS-232C

(ST3232)

Sil9021

RX_HDMI_SPDIF

PCI Bus

0¡¿20

EEPROM

(AT24LC512)

IIC C

CPU

UART1_RX/TX

GEM_IR_OUT

PIC18F242

PWM AMP

(TAS5122)

PWM AMP

(TAS5122)

I2S In

PWM

(NSP6241B)

AUDIO ADC

MODULATOR

BUFFER

ANALOG_L/R

I2S

I2S_MCLK

0

0¡¿8

IIC D

SIF

2

LR

LR

2

2

Comp_1

Comp_2

MNT_Out

0¡¿A6

G_LINK_CONN

HD-II

3

(CS5331)

)

(MC33078

Main

(MSP4440)

Sound Proc

LR

2

RGB(Phone) LR

SDRAM

64MB(32MBx2)

32Bit Bus I/F

Reset

CPU [PPC 405GPr]

EN[0:3(GPIO)]

A

IIC

HD-II

I2S Out

3

Buffer

(74LCX244)

I2S Out

3

2

KIA7029

74LCX24

- SDRAM Controller

- Peripheral Controller

- Local BUS I/F

IICBIIC

OR1

RGB

H,V,

24

SiI 9021

HDMI Rx

BSS83

BSS83

EEPROM

8

2

DDC(I2C)

RXD[0:2]¡¾, RXCLK¡¾

- Serial(2), GPIO, I2Cr

I2C Hub

OR4

EEPROM

)

IN1

IN2

5

Control GPIO

Peripheral Bus

CPLD1

System

(XC95288XL)

AH_SPD

H,V

SYNC

SEPARATOR

CXA2069

IIC C

0¡¿98

H,V,CLAMP

3

System CPLD1

H,V

5

EPF_RGB-PC RGBHV

SPDIF In1(DVI)

HD2_DAC

SCK/LRCK

IFCLK

ANALOG DE/

MULTIPLEXER

(MM1108XF)

Voltage

MAIN_CVBS

OR2

FID

HV_pol

(XC95288XL)

HV_PC

KFIR-II

I2S

IIC D

0¡¿88

0

Sub

MSP444

Side L/R

Rear L/R

NT Tuner

SPDIF In2(DVD)

IIC B

(CS8415A)

SPDIF Receiver.

U-COM

(PIC18F1220)

(74HCT4053)

Comp.

(LM311M)

PWM_L/R

IIC D

0¡¿2C

2

LPF

LPF

NT Tuner

AT/NT Tuner

LR

CXA2069

EPF_L/R

Flash Memory

16MB(8MBx2)

Peripheral Bus

4

6)

(PCA951

D

C

IIC

CS8415A

RX_HDMI_SPDIF