Page 1

LCD TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : CL-80

MODEL : 55LP1M-WC

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

Page 2

- 2 -

CONTENTS

CONTENTS .............................................................................................. 2

PRODUCT SAFETY ..................................................................................3

SPECIFICATION........................................................................................6

ADJUSTMENT INSTRUCTION................................................................11

SVC REMOCON ......................................................................................15

TROUBLE SHOOTING............................................................................16

BLOCK DIAGRAM...................................................................................22

WIRING DIAGRAM..................................................................................24

EXPLODED VIEW .................................................................................. 25

REPLACEMENT PARTS LIST ............................................................... 27

SVC. SHEET ...............................................................................................

Page 3

- 3 -

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate high

impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5

1.5KV: 14-19 inch, 26 1.5KV: 19-21 inch,

29.0

1.5KV: 25-29 inch, 30.0 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service and

correction is required to prevent the possibility of premature

component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

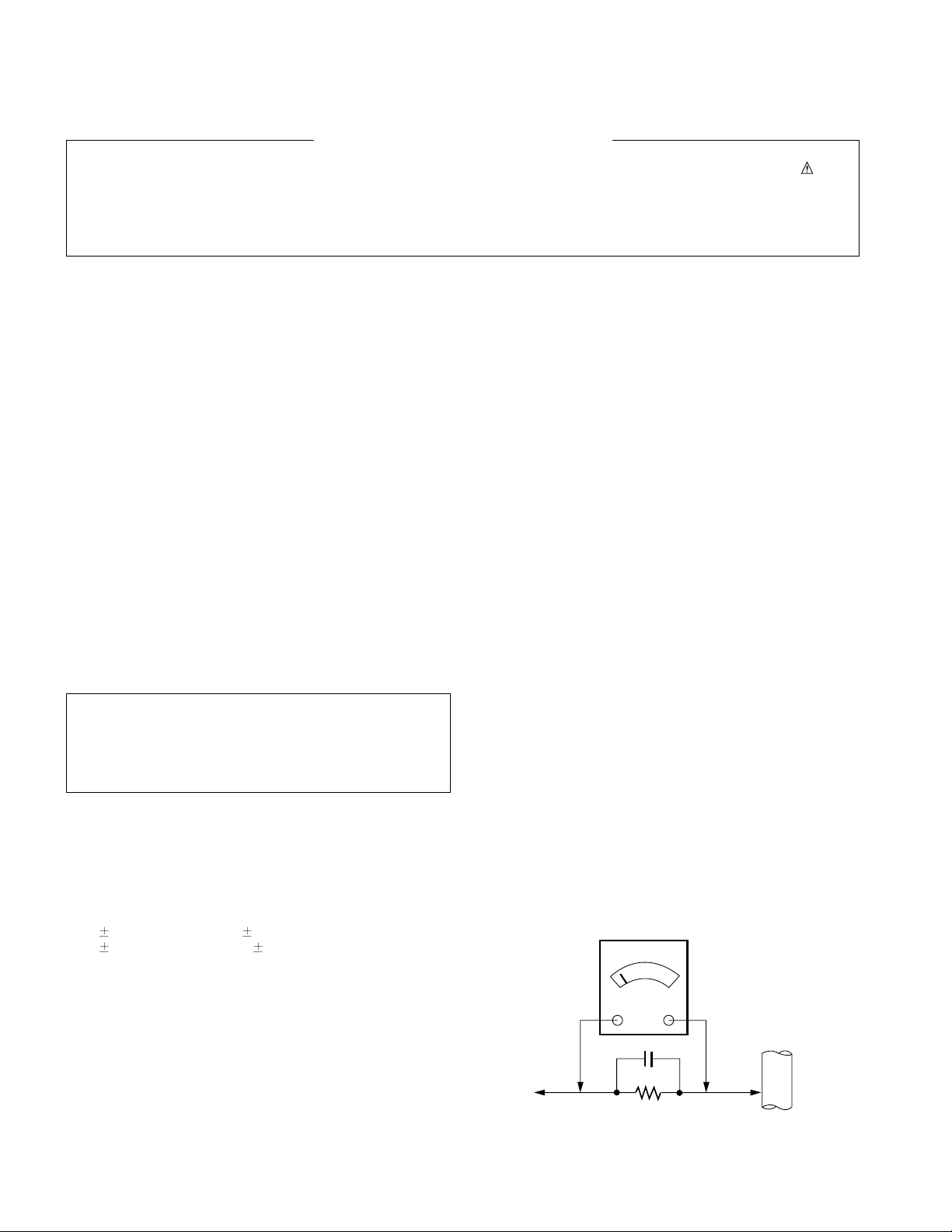

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the High

Voltage Section and the LCD PANEL.

For continued X-RAY RADIATION protection, the replacement

panel must be the same type panel as specified in the

Replacement Parts List.

IMPORTANT SAFETY NOTICE

0.15uF

To Instrument's

exposed

METALLIC PARTS

AC Volt-meter

1.5 Kohm/10W

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

Page 4

- 4 -

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500

o

F to 600oF.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500

o

F to 600oF)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500

o

F to 600oF)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

SERVICING PRECAUTIONS

Page 5

- 5 -

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Page 6

- 6 -

1. Application range

This specification is applied to CL-80 chassis.

2. Requirement for Test

Testing for standard of each part must be followed in below

condition.

(1) Temperature: 25°C ± 2°C

(2) Humidity: 65% ± 10%

(3) Power: Standard input voltage (AC 100-240V, 50/60Hz)

(4) Measurement must be performed after heat-run more than

30min.

(5) Adjusting standard for this chassis is followed a special

standard.

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

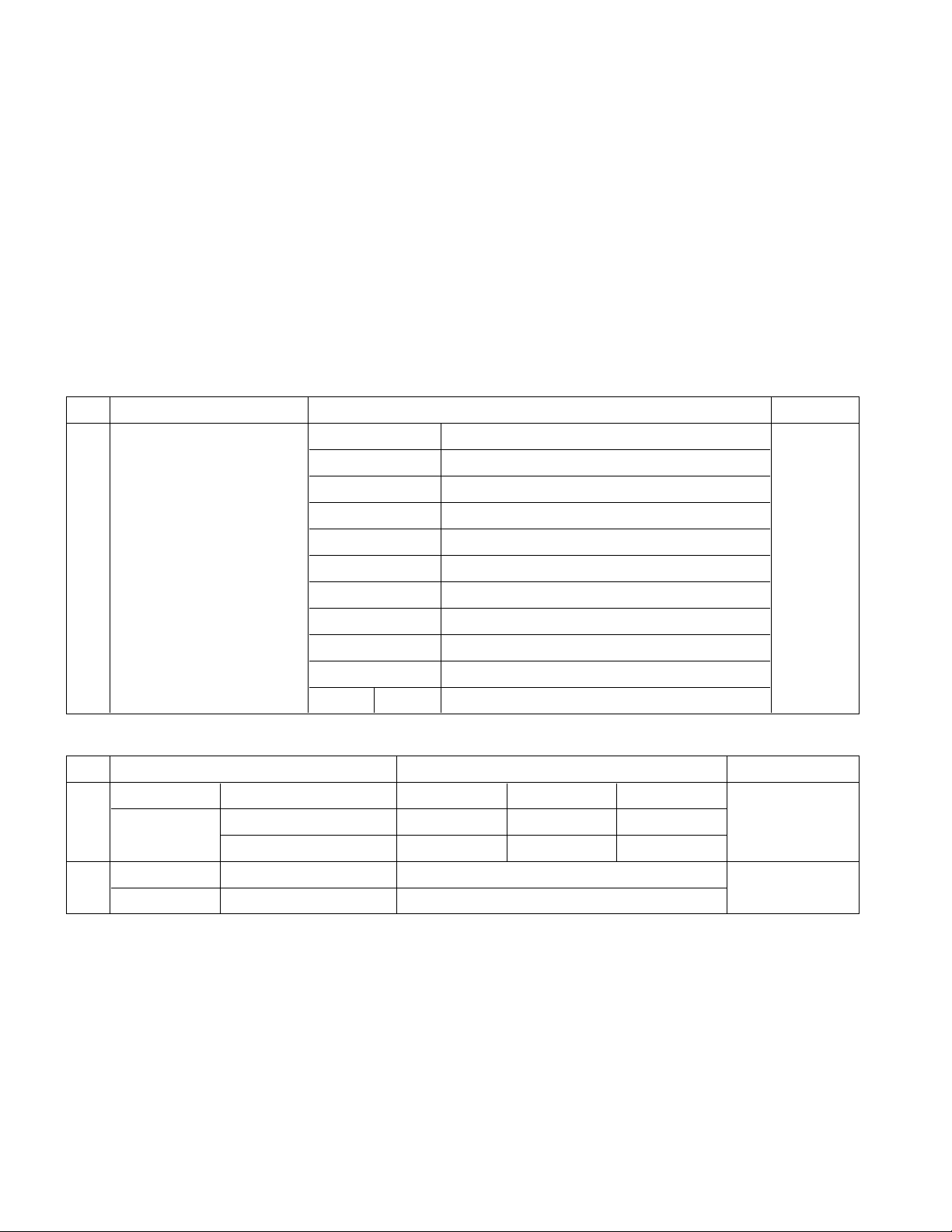

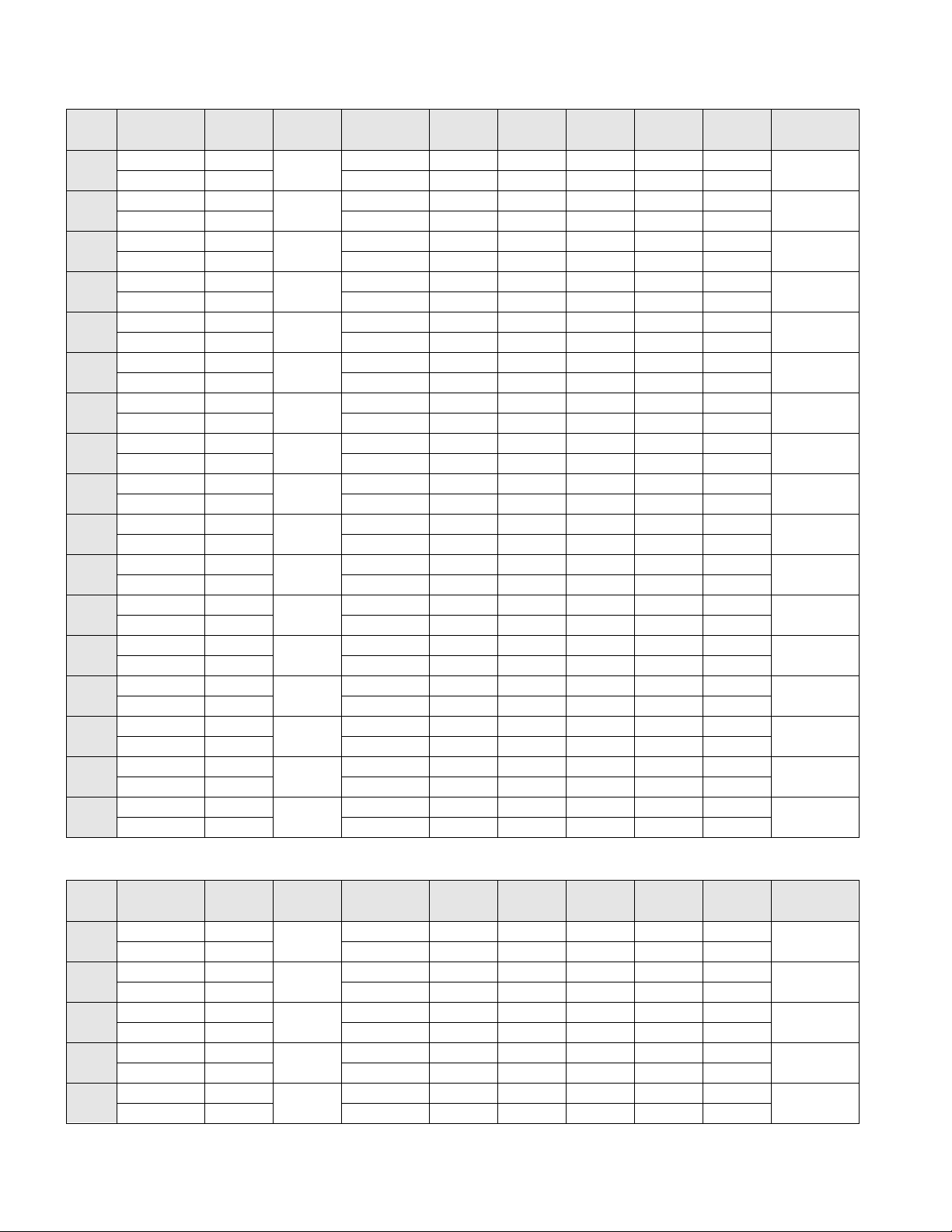

3.General Specification

4. Mechanical specification

No. Item Content Remark

1 LCD Module Feature Maker LPL

Type TFT Color LCD Module

Active Display Area 54.64 inches(1387.86) duaginal

Pixel Pitch [mm] 630mm(H) x 0.630mm(V) x RGB

Electrical Interface LVDS

Color Depth 8bits, 16,777,216 color P/No.

Size[mm] 1264(H) x 738.4(V) x 49.8(D)

6304FLP205A

Surface Treatment Anti-Glare, Hard Coating (3H)

(LC550W01-A5K1)

Operating Mode Normally Black

Black Light Unit 28CCFL(28 lamps)

R/T Typ. 20ms(R.T : 10ms + F.T. : 10ms)

No. Item Content Remark

1 Product Width(W) Length(D) Height(H)

Dimension Before Packing 1612 320 943.2

After Packing 1740 430 1115

2 Product Only Set 75.2kg

Weight With Box 85kg

Page 7

- 7 -

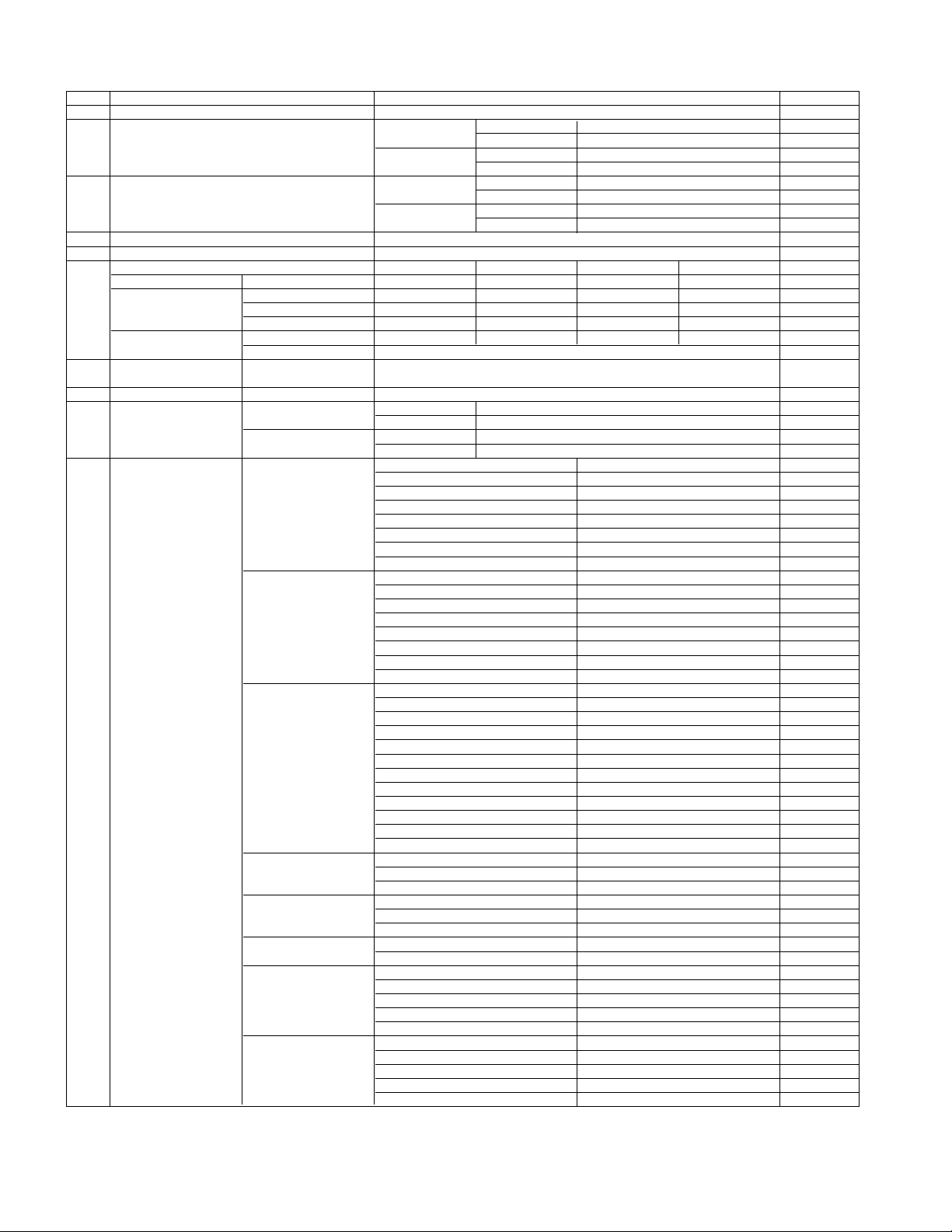

5. Engineering Specification

No. Item Content Remark

1. Supported Sync Type Separate Sync, SOG, Composite Sync, Digital

2 Operating Frequency Analog Horizontal 30 ~83 KHz

Vertical 56 ~85 Hz

Digital Horizontal 30 ~83 KHz

Vertical 56 ~85 Hz

3 Resolution Analog Max 1920 x 1080 @60Hz

Recommend 1920 x 1080 @60Hz

Digital Max 1920 x 1080 @60Hz

Recommend 1920 x 1080 @60Hz

4 Input Voltage Voltage : 100 ~ 240Vac , 50 or 60Hz

5 Inrush Current Cold : 40A , Hot : 40A

6 Operating Condition Sync (H/V) Video LED Wattage

Normal Mode Normal (Typ) On/On Active Green 315W

Without Stand

Sleep Mode Stand by Off/On Off Amber ≤ 4W

(Set = On) Suspend On/Off Off Amber ≤ 4W

(Signal=O) DPMS Off Off/Off Off Amber ≤ 4W

Deep Sleep Mode Power Off Off/Off Off Off ≤ 2W

(Set = Off)

7 MTBF 50,000 HRS with 90% Lamp Life :

Confidence level 50,000 Hours (min)

8 Using Altitude 5,000 m (for Reliability) 3,000 m (for FOS)

9 Environment Operating Temperature 5°C ~ 35°C

Condition Humidity 10% ~ 80%

Storage Temperature -20°C ~ 60°C non condensing

Humidity 5% ~ 95% non-condensing

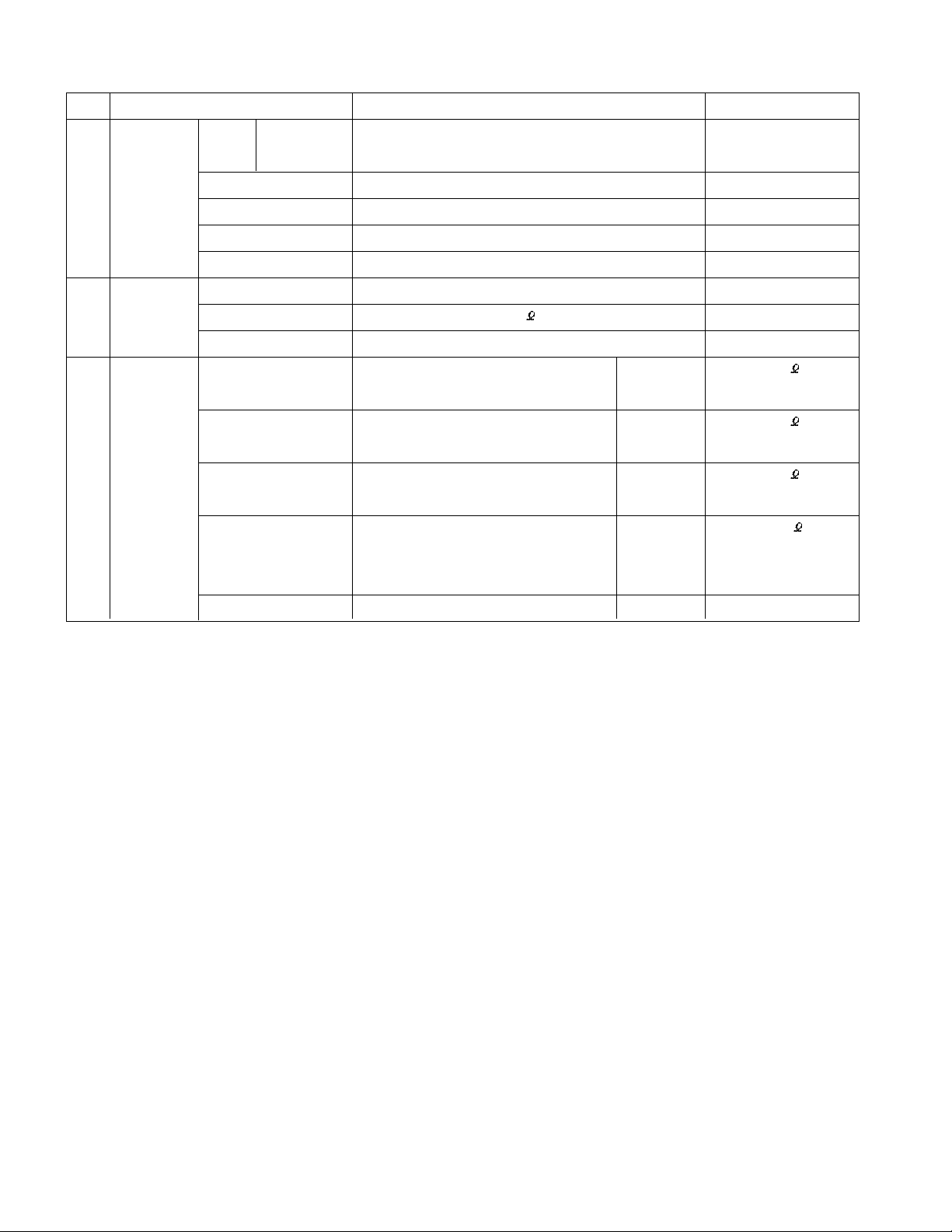

10 Pin D-Sub input 1 : Red Video 9 : E-DDC

2 : Green Video 10 : Sync. GND

3 : Blue Video 11 : Open

4 : Open 12 : SDA

5 : Return 13 : Horizontal Sync.

6 : Red GND 14 : Vertical Sync.

7 : Green GND 15 : SCL

8 : Blue GND Shell : GND

D-Sub Output 1 : Red Video 9 : Open

2 : Green Video 10 : Sync. GND

3 : Blue Video 11 : Open

4 : Open 12 : Open

5 : Open 13 : Horizontal Sync.

6 : Red GND 14 : Vertical Sync.

7 : Green GND 15 : Open

8 : Blue GND Shell : GND

DVI 1 : TMDS Data 2 - 13 : TMDS Data 3 +

2 : TMDS Data 2 + 14 : + 5V Power

3 : TMDS Data 2/4 Shield 15 : Ground (For +5V)

4 : TMDS Data 4 - 16 : Hot Plug Detect

5 : TMDS Data 4 + 17 : TMDS Data 0 -

6 : DDC Clock 18 : TMDS Data 0 +

7 : DDC Data 19 : TMDS Data 0/5 Shield

8 : Analog Vertical Sync 20 : TMDS Data 5 -

9 : TMDS Data 1 - 21 : TMDS Data 5 +

10 : TMDS Data 1 + 22 : TMDS Clock Shield

11 : TMDS Data 1/3 Shield 23 : TMDS Clock +

12 : TMDS Data 3 - 24 : TMDS Clock +

AV In/Out 1: Composite Video

2: Audio L In

3: Audio R In

HDTV(Y,PB,PR) 1: Y

/DVD(Y,CB,CR) 2: Pb (Cb)

3:Pr (Cr)

S-VIDEO 1: GND 3: Y

2: GND 4 : C

RS232C IN 1. NC 2. Rx

3. Tx 4. NC

5. NC 6. GND

7. NC 8. GND

9. NC

RS232C OUT 1. NC 2. Rx

3. Tx 4. NC

5. NC 6. GND

7. NC 8. NC

9. NC

Page 8

- 8 -

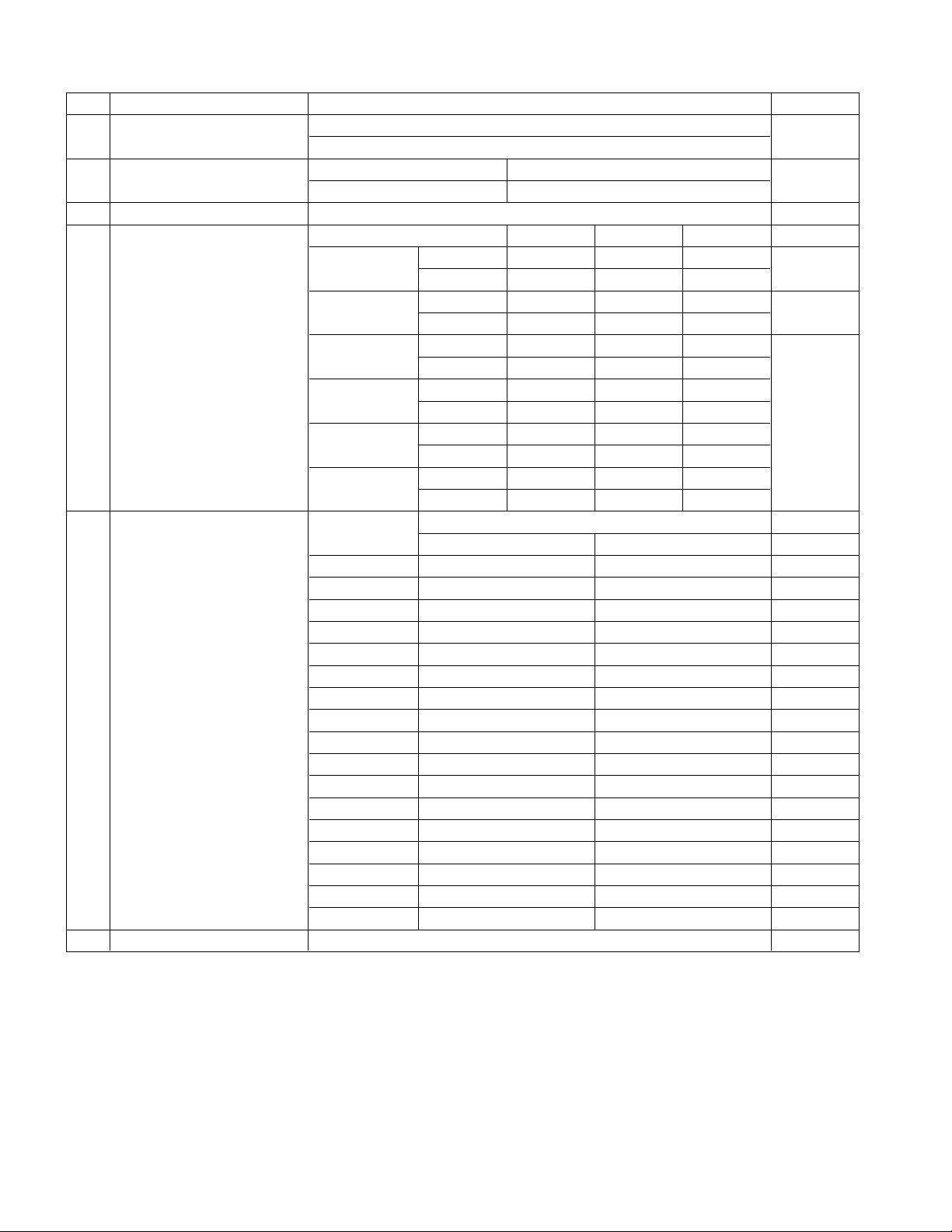

1) PC Mode

MODE

H / V

Sync

Polarity

Frequency

Total

Period

( E )

Video

Active

Time ( A )

Front

Porch

( C )

Sync

Duration

( D )

Back

Porch

( F )

Resolution

Dot

Clock

1 H(Pixels) + 25.175 31.469 800 640 16 96 48 640 x 350

V(Lines) - 70.8 449 350 37 2 60

2 H(Pixels) - 28.321 31.468 900 720 18 108 54 720 X 400

V(Lines) + 70.8 449 400 12 2 35

3 H(Pixels) - 25.175 31.469 800 640 16 96 48 640 x 480

V(Lines) - 59.94 525 480 10 2 33

4 H(Pixels) - 31.5 37.5 840 640 16 64 120 640 x 480

V(Lines) - 75 500 480 1 3 16

5 H(Pixels) - 36.0 43.269 832 640 56 56 80 640 x 480

V(Lines) - 85.0 509 480 1 3 25

6 H(Pixels) + 40.0 37.879 1056 800 40 128 88 800 x 600

V(Lines) + 60.317 628 600 1 4 23

7 H(Pixels) + 49.5 46.875 1056 800 16 80 160 800 x 600

V(Lines) + 75.0 625 600 1 3 21

8 H(Pixels) + 56.25 53.674 1048 800 32 64 152 800 x 600

V(Lines) + 85.061 631 600 1 3 27

9 H(Pixels) +/- 57.283 49.725 1152 832 32 64 224 832 x 624

V(Lines) +/- 74.55 667 624 1 3 39

10 H(Pixels) - 65.0 48.363 1344 1024 24 136 160 1024 x 768

V(Lines) - 60.0 806 768 3 6 29

11 H(Pixels) - 78.75 60.123 1312 1024 16 96 176 1024 x 768

V(Lines) - 75.029 800 768 1 3 28

12 H(Pixels) + 94.5 68.68 1376 1024 48 96 208 1024 x 768

V(Lines) + 85.00 808 768 1 3 36

13 H(Pixels) + 74.5 44.772 1664 1280 64 128 192 1280 x 720

V(Lines) + 59.855 748 720 3 5 20

14 H(Pixels) + 84.75 47.72 1776 1360 72 136 208 1360 x 768

V(Lines) + 59.799 798 768 3 5 22

15 H(Pixels) + 108.0 63.981 1688 1280 48 112 248 1280 x 1024

V(Lines) + 60.02 1066 1024 1 3 38

16 H(Pixels) + 135.00 79.98 1688 1280 16 144 248 1280 x 1024

V(Lines) + 75.02 1066 1024 1 3 38

17 H(Pixels) + 138.5 66.587 2080 1920 48 32 80 1980 x 1080

V(Lines) - 60 1111 1080 3 5 23

6. Signal Timing(Resolution)

2) DTV Mode

Component Video Input (Y/Pb/Pr)

MODE

H / V

Sync

Polarity

Frequency

Total

Period

( E )

Video

Active

Time ( A )

Front

Porch

( C )

Sync

Duration

( D )

Back

Porch

( F )

Resolution

Dot

Clock

1 H(Pixels) - 25.175 31.469 800 640 16 96 48 SDTV

V(Lines) - 59.94 525 480 10 2 33 480P

2 H(Pixels) - 27.027 31.5 858 720 16 62 60 HDTV

V(Lines) - 60 525 480 10 2 33 720P (HDCP)

3 H(Pixels) - 74.176 44.955 1650 1280 70 40 260 HDTV

V(Lines) - 59.94 750 720 5 5 60 720P (HDCP)

4 H(Pixels) - 74.250 33.750 2200 1920 44 44 192 HDTV

V(Lines) - 60.053 562 540 2 5 15 1080I (HDCP)

5 H(Pixels) - 74.176 33.716 2200 1920 44 44 192 HTDV

V(Lines) - 59.994 562 540 2 5 15 1080I (HDCP)

Page 9

- 9 -

7. Special Function

No. Contents Description Remark

1 Audio Output Output 10W + 10W Volume :Adjust

AMP Rating (Rated Out put ± 10%)

Freq. Character 100Hz ~ 10KHz Range ( -3 dB )

T.H.D Within 10%

Input Sensitivity 0.700Vrms

S/N Less then 40dB

2 Speaker Type Built-In

Impedance 8

Input Max : 15W, Normal : 10W

3 AV Video Level Input : 0.7±0.15 V p-p 75

Terminal Resistor

Sync Level nput : 0.286±0.075 V p-p 75

Terminal Resistor

Color Burst Input : 0.214±0.072 V p-p 75

Terminal Resistor

Audio Level NTSC Input : 0.40±0.1 V rms 600

PAL Input: 0.5±0.1

PC Input : 0.7±0.1

Video Cross Talk 43 dB

Page 10

- 10 -

8. Optical Character

No Item Criteria Remark

1 Viewing Angle Horizontal(R/L) : +85

°/-85° (min.), 88°/-88° (Typ.)

<CR

≥

10> Vertical(Top/Bottom) : +85

°/-85° (min.), 88°/-88°(Typ.)

2 Luminance Luminance (cd/m2) 400 cd/m2 (min.) 500cd/m2 (Typ) 9300K

Variation 1.33

3 Contrast Ratio Without AI :400(min.),550(Typ.), With AI:800 (min),1200(Typ)

4 CIE Color Coordinates Minimum Typ Maximum

White WX 0.372 0.402 0.432 3600K

WY 0.364 0.394 0.424

White WX 0.283 0.313 0.343 6500K

WY 0.299 0.329 0.359

White Wx 0.254 0.284 0.314 9300K

Wy 0.265 0.295 0.325

Red RX 0.610 0.640 0.670

RY 0.312 0.342 0.372

Green GX 0.255 0.285 0.315

GY 0.577 0.607 0.637

Blue BX 0.117 0.147 0.177

BY 0.035 0.065 0.095

5 Grey Level Gray Level Typ.

Relative Brightness Without AI Without AI

L0 0.17 0.17

L15 0.55 0.55

L31 0.94 0.94

L47 2.20 2.20

L63 4.21 4.21

L79 7.39 7.39

L95 11.58 11.58

L111 16.57 16.57

L127 22.36 22.36

L143 30.14 30.14

L159 39.72 39.72

L175 50.50 50.50

L191 61.48 61.48

L207 73.25 73.25

L223 84.63 84.63

L239 94.01 94.01

L255 100.0 100.0

6 Light Leakage Condition: Do not visible at 300 Lux

Page 11

- 11 -

1. Coverage

Apply to monitor that is made or do standard here upon and

manufacture in monitor factory this standard.

2. Appointment

2.1 Adjustment can must follow, and confer with design part

and change order in order designated.

2.2 Power : Free Voltage

2.3 Input signal : based engineering specification

2.4 pre operating : over 30 min

2.5 Adjust equipment : White balance equipment (CA-110/CA-

210), Display adjust equipment (VG-828 or VG848)

Oscilloscope, PC (Pentium level) , TV/AV Pattern

Generator & 55" LCD TV.

HDCP Adjusting Jig equipment.

3. Adjustment

3.1 Overview

Use factory automation equipment and adjust automatic

movement. But, do through handwork adjust in error

occurrence.

3.2 Adjustment order

3.2.1 Adjustment Line process

ENTER SERVICE ADJUSTMENT MENU.

Connect input signal to 15pin D-sub.

Adjust ready : Adjust command normally action existence

and nonexistence and mode action state.

Checking.

Confirm that normally gray color is embodied inputing 256

gray scale patterns.

3.2.2 Total Assembly Line

Ready : Heat-run during 120 minutes in state with signal.

Connect input signal to 15pin D-sub.

Before adjust default value : Contrast Outgoing

condition, Brightness Outgoing condition

3.2.3 Each mode horizontal/Verticality screen position,

Clock, Clock Phase Adjustment.

There is no special factory mode adjust.

When power ON u-com is default data wright at the

adjustment line.

#Caution) That keep power-on more than 10 seconds

after power-on first time

EEPROM contents read to compare at the adjustment

line.

3.2.4 Color coordinates adjustment and Luminance

adjustment. (input D-sub Analog )

3.2.4.1 Color coordinates adjust ready.

When each color coordinates & Black level adjust.

Contrast : outgoing condition

Brightness : outgoing condition

Signal Generator

Output Voltage : 700 mVp-p

Output Mode : #13 ( WXGA 60 Hz) mode Setting.

Before adjustment command "start preset

adjustment" next start adjustment

3.2.4.2 Black level adjustment (Bias Adjustment.)

Input black pattern none SOG signal.

Input command AUTO_COLOR_ADJUST(0xF1),

0x00 after adjustment.

After wait about 2 second, confirm the massage

"ok",confirm 0xAA the address 0x00 of EEPROM

0xA0 again adjust.(because auto adjustment fail)

3.2.4.3 PRESET 1 (9300 K) Color coordinates adjustment

and confirmation (Gain Adjustment)

Input full white pattern none SOG signal.

Input command AUTO_COLOR_ADJUST(0xF1),

0x01after adjustment.

After wait about 3 second, confirm the massage "ok",

and, confirm 0xAA the address 0x01 of EEPROM

0xA0.

f display the massage "FAIL" or not 0xAA the

address 0x01 of EEPROM 0xA0 again adjust.

(because auto adjustment fail)

3.2.4.4 PRESET 2 (6500 K) Color coordinates adjustment

and confirmation

The input is Full White Pattern

None adjustment process.

It sends an instruction The AUTO_MODE_CHANGE

(0xF2), 0x02

Auto stored 6500K R = 9300K R, 6500K G = 9500K

G - 10, 6500K B = 9300K B- 40.

Confirm x= 0.313±0.030, y=0.329±0.030

ADJUSTMENT INSTRUCTION

Page 12

3.2.5 Color coordinates Adjustment and brightness

Adjustment (AV input)

3.2.5.1 Color coordinates adjustment provisions:

Adjusting Each color coordinate and Black level

EZ Video : Standard

ACC : Normal

Input signal :

Adjust after input signal of PAL MODE l ,because

major sales area is EU.

PAL:CVBS(576i), 576i (HDTV port), 1080i / 60Hz

(HDTV port ) it Adjusts 3 Modes.

Before Adjustment It shows a "PRESET

ADJUSTMENT START" message. And adjustment

begins.

3.2.5.2 Black level adjustment (Bias adjustment) :

The input is 1080i/60Hz signal in Component input

and 16/255 Gray Level.

Brightness Range 0.9~1.1 cd/m2, In the Sub Bright

(0x86) In order to hold the variable brightness.

*Reference : With CVBS input & COMPONENT INPUT

576i It is not with from Adjustment. It does default setting

for this value.

3.2.5.3 White Level Adjustment (Gain Adjustment)

The Display is 240/255 Gray Level.

For Adjustment the R Gain is fixed at 100, to adjust

G/B gain , the color coordinates

55LP1M-WC (x = 0.283±0.010, y = 0.298±0.010)

(G Gain is variable ,its range is 0 ~ 100)

Only when the G gain goes over 100 it fixes the G

gain 100 and R/B gain is variable

It makes the color coordinate. (Generally only R gain

Or G gain is fixed to 100)

3.2.5.4 Gray Scale Check

The input can be 3 modes PAL : CVBS(576i) , 576i

(HDTV port), 1080i (HDTV port ).

For each mode 16 GREY pattern is displayed

Check 0 level is not displayed and 1/16 Grey is

displayed.

The 15/16 Gray and 16/16 Gray are checked

separately.

3.2.6 Operation condition check

3.2.6.1 Operational mode: Every mode, which is in

specification, is checked that it is accurate and are

operated.

3.2.6.2 Adjustment condition and operation check:

Satisfactory yes or no adjustment of screen

adjustment standards

Analog/Digital screen condition check: From lower

part mode screen condition good yes or no check

Designation mode : 640x350 (70Hz) - 1 mode,

800x600 (75Hz) - 2 mode,

1024x768(60Hz) -12 mode,

1280x768(60 Hz)-13 mode

The input selection time is 8 seconds after key is

pressed and Analog or Digital display comes on the

screen.

3.2.6.3 H/V Position, Clock, Clock Phase and Auto

Calibration operation check

The Mode 13 (1280*768,60Hz) 1line from on/off

pattern H/V Position and the Clock, Clock Phase it is

variable each and it is checked it operates normally

The Clock, Clock phase are adjusted by auto

calibration when they have become variable. They

are checked.

3.2.6.4 Color operation check: 9300K, 6500, 3600K ,USER

COLOR are checked for normal operation.

It is checked that 9300 and USER COLOR setting

are same.

Other quality : Satisfactory yes or no adjustment

against each item from the standard

condition which is written clearly in the

product specification

(1) Each SOURCE image and Sound check

A/V : supports NTSC, PAL

3.2.6.5 Audio Spec

Speaker: 8ohm

INPUT(PC AUDIO) : 0.7Vrms , OUTPUT : 10W

INPUT(A/V) : 0.4Vrms(NTSC), 0.5Vrms(PAL), OUTPUT : 10W

- 12 -

Page 13

3.2.6.6 OSD and terminal check. Check clearly,adjustment

follows the product specification.

3.2.6.7 The input is Color bar pattern and 256 Gray scale

pattern and check if normal color is displayed

properly

3.2.6.8 PM operation confirmation: the power LED glow and

voltage power consumption is checked

(When No image signal condition)

3.2.6.9 E-DDC EDID Write

- Analog Part EDID Data store

Connect Analog Signal Cable to D-SUB Jack

Write DDC data 24C02 and check DDC function

operates normally and DDC data is written correctly

(EDID Data product specification reference)

-Stores Digital Part EDID Data

Connect Digital Signal Cable to DVI-D Jack.

Write DDC data 24C02 and check DDC function

operates normally and DDC data is written correctly

(EDID Data product specification reference)

3.2.6.10 HDCP Write

Connect Digital Signal Cable to DVI-D Jack.

Write HDCP data 24C16 and check HDCP function

operates normally and HDCP data is written correctly

3.2.6.11 RS 232C

Connect serial cable to RS232C

Send the instruction " 0x04, 0xaa, 0xff, 0x53"and

check "OK" Message. is display on screen.check

"OK" Message. is display on screen.

CHECK THE SVC Aging On IF CANNOT OPERATE

3.2.6.12 All Reset

All Tests finish when inside service mode. the

"NVRAM INITIAL" makes it ON with Initial Data.

3.2.6.13 LANGUAGE: The default language is ENGLISH as

in the Product Specification

Another language can be set as per Product

Specification.

3.2.6.14 CNN option

1) Enter the Service menu Adjustment.

2) In the Setup MENU select CNN ON/OFF and set up

as. Default is CNN OFF. (Don't need select this

option that is only for CNN)

3.2.6.15 FAN Operation check (ALL Model)

1) Enter the Srrvice Adjustment Menu

2) Select Menu's "FAN" and make by "On".

3) Confirm FAN's operating

3.2.6.16 Temperature (Ambient) confirm (ALL Model)

1) Enter the Service Adjustment Menu.

2) Confirm temperature value.

(This value is ambient temperature of set . If it is

baggage value, set is badness.)

3.2.6.17 Light Sensor value confirm

1) Enter the Service Adjustment Menu.

2) Confirm Light Value's value.

(Can know if cover sensor on hand. In the present

case, sensor value amounts to 0.)

(According to brightness, confirm change of value of

sensor.)

(If sensor value does not change, it is badness.)

- 13 -

Page 14

- 14 -

4. Shipping Condition

No. Item Shipping Condition Remark.

1 Shipping SOURCE RGB1

Condition DC Power S/W OFF

Monitor part EZ Video (none active)

ACC 6500K

EZ Audio Flat

Balance 0

AVL Off

SRS WOW Off

Input RGB1

Child Lock Off

Language English

Power Indicator On

Transparency 20

Tile mode Off

Reset Set ID 1

Logo Display Lamp On

Light Sensor Off

ARC Full

Auto-configure Clock Phase Position Horizontal -

Vertical -

PIP/POP/PBP Off

AV part EZ Video Dynamic

ACC Normal

EZ Audio Flat

Balance 0

AVL Off

SRS WOW Off

Input AV

Child lock Off

Language English

Power Indicator On

Transparency 20

Tile Mode Off

Reset Set ID 1

Logo Display Lamp On

Light Sensor Off

ARC Full

PIP/POP/PBP Off

Page 15

- 15 -

SVC REMOCON

NO KEY FUNTION

REAMARK

1 POWER

2 POWER ON

3 MUTE

4 P-CHECK

5 S-CHECK

6 ARC

7 CAPTION

8 TXT

9 TV/AV

10 TURBO SOUND

11 TURBO PICTURE

12 IN-START

13 ADJ

14 MPX

15 EXIT

16 APC(PSM)

17 ASC(SSM)

18 MULTIMIDIA

19 FRONT-AV

20 CH

21 VOL

22 ENTER

23 PIP CH-(OP1)

24 PIP CH+(OP2)

25 PIP SWAP(OP3)

26 PIP INPUT(OP4)

27 EYE

28 MENU

29 IN-STOP

30 STILL

31 TIME

32 SIZE

33 MULTI PIP

34 POSITION

35 MODE

36 PIP

37 TILT

38 0~9

To turn the TV on or off

To turn the TV on automatically if the power is supplied to the TV. (Use the

POWER key to deactivate): It should be deactivated when delivered.

To activate the mute function.

To check TV screen image easily.

To check TV screen sound easily

To select size of the main screen (Normal, Spectacle, Wide or Zoom)

Switch to closed caption broadcasting

To toggle on/off the teletext mode

To select an external input for the TV screen

To start turbo sound

To start turbo picture

To enter adjustment mode when manufacturing the TV sets.

To adjust the screen voltage (automatic):

In-start

mute Adjust AV(Enter into W/B adjustment mode)

W/B adjustment (automatic):

After adjusting the screen W/B adjustment Exit two times (Adjustment completed)

To enter into the adjustment mode. To adjust horizontal line and sub-brightness.

To select the multiple sound mode (Mono, Stereo or Foreign language)

To release the adjustment mode

To easily adjust the screen according to surrounding brightness

To easily adjust sound according to the program type

To check component input

To check the front AV

To move channel up/down or to select a function displayed on the screen.

To adjust the volume or accurately control a specific function.

To set a specific function or complete setting.

To move the channel down in the PIP screen.

To use as a red key in the teletext mode

To move the channel in the PIP screen

To use as a green key in the teletext mode

To switch between the main and sub screens

To use as a yellow key in the teletext mode

To select the input status in the PIP screen

To use as a blue key in the teletext mode

To set a function that will automatically adjust screen status to match

the surrounding brightness so natural color can be displayed.

To select the functions such as video, voice, function or channel.

To set the delivery condition status after manufacturing the TV set.

To halt the main screen in the normal mode, or the sub screen at the PIP screen.

Used as a hold key in the teletext mode (Page updating is stopped.)

Displays the teletext time in the normal mode

Enables to select the sub code in the teletext mode

Used as the size key in the PIP screen in the normal mode

Used as the size key in the teletext mode

Used as the index key in the teletext mode (Top index will be

displayed if it is the top text.)

To select the position of the PIP screen in the normal mode

Used as the update key in the teletext mode (Text will be

displayed if the current page is updated.)

Used as Mode in the teletext mode

To select the simultaneous screen

To adjust screen tilt

To manually select the channel.

Shortcut keys

Shortcut keys

Shortcut keys

Use the AV

key to enter

the screen

W/B

adjustment

mode.

Shortcut keys

Shortcut keys

Shortcut keys

Page 16

- 16 -

TROUBLESHOOTING

1. NO POWER

NO POWER

(POWER INDICATOR OFF)

CHECK POWER BOARD

CHECK J601 VOLTAGE

(5V, 12V, 18V)?

NO

CHECK POWER BOARD

CHECK

J603 VOLTAGE

(12V, 24V) ?

NO

1. KEY PART IC CHECK

(U401, U402, U403)

2. CHECK KEY

CONTROL BOARD

YES

YES

YES

YES

CHECK X401

CHECK

X401

(14.318MHz) ?

NO

CHECK MICOM (U402)

SUB POWER PORT

CHECK J601

10PIN

(SUB POWER) ?

NO

Page 17

- 17 -

2. NO RASTER(OSD IS NOT DISPLAYED)

NO RASTER

(OSD IS NOT DISPLAYED)

CHECK THE PERIPHERAL

IC U402

CHECK U402

OUTPUT WAVE?

NO

CHECK WAFER AND

POWER BOARD

CHECK

INVERTER

VOLTAGE

(12V, 24V)?

NO

1. CHECK INVERTER

2. CHECK T-CON BOARD

YES

YES

YES

CHECK MODULE LINK

CABLE

CHECK

MODULE INPUT

WAVE?

NO

Page 18

- 18 -

3. NO RASTER STATE ON VIDEO SIGNAL

REMARK : POWER CHECK

POWER CHECK OF CXA2040 (U201) : U204(9V)

POWER CHECK OF UPD64012 (U801) : U803(3.3V), U804(1.5V)

POWER CHECK OF MST9883C (U303) : U304(3.3V)

POWER CHECK OF MDIN150H (U901) : U907(3.3V), U908(2.5V)

POWER CHECK OF GM1601H (U402)

NO RASTER IS COMPONENT

CHECK CABLE OF VIDEO

CHECK CXA2040(U201) I/O

SIGNAL?

CHECK UPD64012(U801) I/O

SIGNAL?

CHECK THE PERIPHERAL

IC U303 AND COMPONENT1 CABLE

YES

CHECK THE PERIPHERAL

CX2040(U201)

NO IN / OUTPUT SIGNAL

CHECK THE PERIPHERAL

UPD 64012(U801)

NO IN / OUTPUT SIGNAL

CHECK THE PERIPHERAL

MDIN150H(U901, U909)

NO IN / OUTPUT SIGNAL

CHECK THE PERIPHERAL

GM1601H(U402)

AND SDRAM(U401, U406)

NO IN / OUTPUT SIGNAL

NO PROBLEM

NO PROBLEM

NO PROBLEM

NO

NO

CHECK MDIN150H(U901) I/O

SIGNAL?

CHECK GM1601H(U402) I/O

SIGNAL?

NO RASTER STATE ON VIDEO SIGNAL

Page 19

- 19 -

4. NO RASTER STATE ON RGB SIGNAL

NO RASTER STATE ON RGB SIGNAL

INPUT WAFER CHECK (J101)

REMARK : POWER CHECK

POWER CHECK OF BA7657F (U121) : 5VP

POWER CHECK OF SCHMITT TRIGGER (U123, U124) : 5VP

POWER CHECK OF MC14066B (U122) : 5VP

POWER CHECK OF GM1601H (U402)

CHECK THE PERIPHERAL

BA7657F(U121)

NO IN / OUTPUT SIGNAL

CHECK BA7657F(U121) I/O

SIGNAL?

CHECK THE PERIPHERAL

SCHMITT TRIGGER (U123,U124)

NO IN / OUTPUT SIGNAL

NO PROBLEM

CHECK BA7657F(U121) I/O

SYNC?

NO PROBLEM

CHECK GM1601H(U402) I/O

SIGNAL?

CHECK THE PERIPHERAL

GM1601H(U402)

AND SDRAM(U401, U406)

NO IN / OUTPUT SIGNAL

NO PROBLEM

CHECK THE MODULE

CHECK THE INVERTER

Page 20

- 20 -

5. NO RASTER STATE ON DVI SIGNAL

NO RASTER STATE ON DVI SIGNAL

REMARK : POWER CHECK

POWER CHECK OF GM1601H (U402)

INPUT WAFER CHECK (J102)

CHECK GM1601H(U402) I/O

SIGNAL?

CHECK THE PERIPHERAL

GM1601H(U402)

AND SDRAM(U401, U406)

NO IN / OUTPUT SIGNAL

NO PROBLEM

CHECK THE MODULE

CHECK THE INVERTER

Page 21

- 21 -

6. SOUND TROUBLE SHOOTING

REMARK : POWER CHECK

POWER CHECK OF MSP3420G (U501) : U522(8V), L502(8V), L501(5V), L505(5V)

POWER CHECK OF TPA3004 (U502) : 18V

CHECK SOUND OF VCR,DVD,PC,SETOP

BOX...

CHECK GMSP3420G(U501) I/O

SIGNAL?

CHECK SOUND INPUT

= PC (J707)

= DTV / DVD (J702)

= VIDEO (SVBS, S-VIDEO) (J701)

CHECK THE PERIPHERAL

MSP3420G (U501)

NO IN / OUTPUT SIGNAL

NO PROBLEM

CHECK TPA3004(U502) I/O

SIGNAL?

1. CHECK OUTPUT WAFER(J501)

2. CHECK CONNECTOR CABLE

3. CHECK SPEAKER

CHECK THE PERIPHERAL TPA3004

(U502)

NO IN / OUTPUT SIGNAL

NO PROBLEM

Page 22

BLOCK DIAGRAM

- 22 -

DVI

RGB1

RGB2

RGB Out

PC

Sound

Compo nent1 In

Compo nent2 In

Compo nent1 (2)

Sound

CVBS In

CVBS Out

S-VIDEO

LCD Module

Inverter Assy

Power Assy

RS232 In/Out

ADC

TMDS

LVD S

128Mb

DDR

(U401)

8Mb

Flash

Memory

(U403)

Comp1

Comp2

S/W

(U201)

(CXA2040AQ)

Y/C

ADC

(U303)

(MST9883C)

Video Decoder

(U801)

(UPD64012)

SDRAM

(U802)

(K4S161622)

De-interlace

(U901)

(MDIN150H)

(K4S643232)

SDRAM (U902)

4:2:2

(16bit)

4:4:4 (16bit)

(M29W800DT)

Audio

Decoder

(U501)

(MSP3420G)

Amp

(U502)

(TPA 3004)

(gm1601H-CF-LF)

Video Signal Processor

(U402)

(HY5DU281622ETP)

Signal Selector

(U121)

RGB

(SOG)

Low

Distortion

Amp

RGB

(SOG)

TMDS

30P Wafer10P/12P Wafer

Regulator

Power FET Bloc k

1.5V/1.8V/2.5V/3.3V/5V/

12V/18V

LVDS

4:2:2 (16bit)

HD-YPbPr

(480i ~ 1080i)

YCbCr

(480i/576i)

CVBS OUT

Y OUT

C OUT

CVBS IN

CVBS OUT

RGB

(SOG)

Control Assy

15P Wafer

10P Wafer

9P Wafer

24V

12

P Wafer

FAN Assy (42”)

Temp

Sensor

(LM35DT)

(U523)

Speaker

4P Wafer

3P/ 5P Wafe r

Logo LED Assy

Left Right

RightLeft

PC Audi o

Compo nent

Aud io

CVBS

Aud io

DTV Audio (Comp1 )

DVD Audi o (Comp 2)

PC Audio

CVBS Audio

SCL

SDA

H/V

SCL

SDA

H/V

SCL

SDA

H/V

SCL

SDA

H/V

SCL

SDA

SCL2/SDA2

SCL/SDA

SCL/SDA

H/V/CLK

H/V/CLK

4:2:2

(16bit)

SCL2/SDA2

SCL/SDA

SCL2/SDA2

SCL/SDA

5V/8V

18V

1.8V

2.5V

3.3V

2.5V

3.3V

1.5V/3.3V

3.3V

2.5V/3.3V

3.3V

9V

3.3V

8009)

128Mb

DDR

(U406)

SDRAM

(U909)

(K4S643232)

(BA7657F)

(AD

4P Wafer

Light Sensor Assy

Page 23

BLOCK DIAGRAM DESCRIPTION

- 23 -

1. INPUT SELECTION CIRCUIT

1) D-SUB RGB INPUT SELECT : This section is composed of

Signal selector IC(BA7657F_U121) and peripheral devices.

The BA7657F(U121) IC select RGB1 signal or RGB2

signal and the signal is sent to gm1601H(402).

2) VIDEO INPUT SELECT : This section is composed of Video

switching IC(CXA204Q_U201) and peripheral devices.

Video switching IC(CXA2040Q_U201) select CVBS video or

S-video and the signal is sent to Video decoder (UPD64012)

3) DVI signal input is directly fed to SCALER,

DTV(Component1) signal input is given to Scaler IC(U402)

via MST9883C(U303).

DVD(Component2) signal input is given to Scaler IC via

Video Decoder IC(UPD64012_U801).

2. DDC COTROLLER

This section is composed gm1601H(U402) ,EEPROM IC

(U404, U115, U120) and peripheral devices.

gm1601H(U402) is controlling peripheral devices through IIC

Line.

Major functions of this block are :

(1) Controlling of u-COM and Flash memory through DDC-

SCLA, DDC-SDAA of D-sub connector.

(2) Storage of EDID DATA in the EEPROM(U115, U120).

3. ANALOG DIGITAL CONVERTER

This section is composed of MST9883C(U303) and peripheral

devices. gm1601H(U402) is controlling MST9883C through IIC

Line.

This IC is converting DTV(YPbPR) signal in to 16 bit Interlace

signal and the signal is sent to De-interlace

IC(MDIN150H_U901)

This output signal have CONTRAST, BRIHTNESS,

SHARPNESS, COLOR, TINT information.

4. VIDEO DECODER

This section is composed of UPD64012(U801) and peripheral

devices.

gm1601H(U402) is controlling UPD64012 through IIC Line.

This IC is controlling CVBS input signal ,S-VIDEO(Y/C) input

signal and DVD(YCbCr) input signal and converting input

signals in to 16 bit interlace signal and the signal is sent to Deinterlace IC(U901).

This output signal have CONTRAST, BRIHTNESS,

SHARPNESS, COLOR, TINT information.

5. DE-INTERLACER

This section is composed of MDIN150H(U901) and peripheral

devices.

gm1601H(U402) is controlling MDIN150H through IIC Line.

This IC is converting 16bit interlace input signal in to 16bit Deinterlace signal and the signal is sent to Video Signal

Processor IC(gm1601H_U402).

6. AUDIO DECODER

This section is composed of MSP3420G(U501) and peripheral

devices.

gm1601H(U402) is controlling MSP3420G through IIC Line.

This IC is processing audio signal output of A/V Jack, PC Audio

Jack.

This IC's output signal is sent to Audio Amplifier IC

(TPA3004_U502).

7. AUDIO AMPLIFIER

This section is composed of TPA3004(U502) OR TPA3001

(U507) and peripheral devices.

Audio Amplifier's function is amplification of sound signal

received from Audio Decoder.

Input Audio signal is amplified according to the DC Volume

control curve.

8. VIDEO SIGNAL PROCESSOR (FORMAT CONVERTER)

This section is composed of gm1601H(U402) and peripheral

devices.

gm1601H(SCALER_U402) have in built u-COM in IC.

(1) This IC include A/D Converter, Pre-Amp, PLL Circuit.

(2) This IC include TMDS Receiver and LVDS Transmitter.

TMDS Receiver is decoding input DVI Signal and LVDS

Transmitter is encoding the output Signal .

Also, gm1501H have Format Converter (Scaling) function.

This IC convert Various sized Digital signal to LCD

Module's resolution (Full HD Format).

9. DC/DC COVERTER

DC/DC Converters change Power output voltage (DC 5V, 12V,

24V) to 1.5V, 2.5V, 3.3V, 5V, 8V, 9V.

(To be used by different IC on the main board.)

10. TEMPERATURE SENSING AND FAN CONTROL

This section is composed of LM35DT(U523), KIA358F(U524)

and peripheral devices.

The temperature at surface of LM35DT(U523) is sensed and

converted to HEX code by KIA358(U524).

gm1601H(U402) receives sensing HEX values from

KIA358F(U524)and control FAN.

11. LIGHT SENSING AND BRIGHTNESS CONTROL

This section is composed of Sensor Board Assy's

TLS2550(U702) and peripheral devices.

TLS2550(U702) IC senses amount of ambient light and

converts to HEX CODE.

gm1601H(U402) receives sensing HEX values and controls

System's Brightness.

12. POWER SUPPLY BLOCK

Power supply receives AC voltage (100-240 V, 50/60Hz,) and

converts to System voltage that are 5V, 12V, 18V and 24V DC

voltage.

These voltages supports main board, inverter board and

module's T-con board.

This Circuit contains PFC(Power Factor Correction) circuit. The

Minimum Power efficiency is about 75%.

Page 24

- 24 -

2

WIRING DIAGRAM

2

8

9

6631T25026G-4P

6631T20032N-12P

2

1

6631T11023G-30P

2

6631T20032N-12P

6

6631T12005C-3P

3

6631T20020U-9P

6631T12006Z-4P

6631T20013V-3P

7

5

4

6631T20020V-10P

6631T20013D-7P

6631T20032N-12P

Page 25

- 25 -

EXPLODED VIEW

260

270

030

240

090

080

120

130

250

230

040

220

210

110

100

200

190

180

010

050

020

170

070

160

060

050

150

140

Page 26

- 26 -

EXPLODED VIEW PARTS LIST

No.

PART NO.

DESCRIPTION

3091TKE020K CABINET ASSEMBLY, 55LP1M BRAND 3090TKE017A NON

6304FLP296A

LCD(LIQUID CRYSTAL DISPLAY), LC550W01-A5K2 LG PHILPS TFT COLOR A5K1+STATUS PIN

or 6304FLP205A LCD(LIQUID CRYSTAL DISPLAY), LC550W01-A5K1 LG PHILPS TFT COLOR AI/ODC

3809TKE023C BACK COVER ASSEMBLY, M5500C . COMMERICAL

3043TKK215C TILT SWIVEL ASSEMBLY, M5500C . SWIVEL.

4950TKK967A METAL, SUPPORT SIDE MODULE RZ-55LP10

4951TKK217A METAL ASSEMBLY, FRAME LEFT DN-55LP10

4951TKK216A METAL ASSEMBLY, FRAME DN-55LP10 RIGHT

4950TKS318C METAL, FRAME, MAIN M5500C

4951TKS238E METAL ASSEMBLY, FIX FAN ASSY NOT ASSEMBLE PARTS PPB ONLY M46/5500

6871TPT320C

PWB(PCB) ASSEMBLY,POWER, M5500C COMMERCIAL POWER TOTAL BRAND WITHOUT RS-232

3313TL4010C MAIN TOTAL ASSEMBLY, 55LP1M-WC BRAND CL-80

4950TKK968A METAL, SUPPORT SIDE BOARD RZ-55LP10

4950TKA367A METAL, SHIELD, M5500C COMMERICAL

6871TST6621

PWB(PCB) ASSEMBLY,SUB, M5500C ETC TOTAL BRAND IR BOARD (ADD CONNECTOR)

6871TSTB54A PWB(PCB) ASSEMBLY,SUB, M5500C CONTROL TOTAL BRAND COMMERCIAL

4950TKK971A METAL, SUPPORT C/A BOTTOM RZ-55LP10

6871TST791B

PWB(PCB) ASSEMBLY,SUB, M5500C LED & P/SW TOTAL BRAND COMMERCIAL (ADD CONNECTOR)

6871TST775B

PWB(PCB) ASSEMBLY,SUB, M5500C LED & P/SW TOTAL BRAND LOGO LIGHT BOARD (WITH CONNECTOR)

6871TSTA02A

PWB(PCB) ASSEMBLY,SUB, M4600C (PB FREE) SUB TOTAL BRAND (LIGHT SENSOR)

6871TKT302A

PWB(PCB) ASSEMBLY,INTERFACE, M5500C INTERFACE TOTAL BRAND (COMMERCIAL RS232 BOARD)

4950TKA286B METAL, REAR POWER BRACKET M5500C

3550TKK630C COVER, M5500 REAR FOR COMMERICAL

6401TZZ056B SPEAKER ASSEMBLY, M5500C LEFT FRONT BK

6401TZZ055B SPEAKER ASSEMBLY, M5500C RIGHT FRONT BK

4950TKK978A METAL, PLATE AL DECO SPK REAR RZ-55LP10

3551TKK556C COVER ASSEMBLY, M5500C TOTAL . COMMERICAL

6410TCW007A

POWER CORD, LSG-31+LS-70 LONGWELL CCC 1870MM WALL CD/PB FREE BLACK-For china

6410TUW008A

POWER CORD, LP31+LS13 LONGWELL UL/CSA 1870MM WALL CD/PB FREE BLACK-For U.S.A

010

020

030

040

050

060

070

080

090

100

110

120

130

140

150

160

170

180

190

200

210

220

230

240

250

260

270

Page 27

- 27 -

DATE: 2005. 11. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C102 0CE477EF638 470UF KMG 16V M FM5 TP 5

C105 0CE477EF638 470UF KMG 16V M FM5 TP 5

C110 0CE477EF638 470UF KMG 16V M FM5 TP 5

C151 0CE477EF638 470UF KMG 16V M FM5 TP 5

C612 0CE477EF638 470UF KMG 16V M FM5 TP 5

C619 0CE477EF638 470UF KMG 16V M FM5 TP 5

C623 0CE477EF638 470UF KMG 16V M FM5 TP 5

C680 0CE477EF638 470UF KMG 16V M FM5 TP 5

C681 0CE477EF638 470UF KMG 16V M FM5 TP 5

C225 0CH8336H611 33UF 25V M 85STD(CYL) R/TP

C118 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C149 0CH5471K416 470PF 50V 5% NP0 2012 R/TP

C206 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C226 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C234 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C289 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C292 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C306 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C320 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C369 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C370 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C373 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C377 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C379 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C401 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C402 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C408 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C4101 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C414 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C415 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C416 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C417 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C418 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C420 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C433 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C434 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C435 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C436 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C438 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C441 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C442 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C443 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C459 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C460 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C461 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C462 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C468 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C469 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C470 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C471 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C472 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C473 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C474 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C475 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C476 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

DATE: 2005. 11. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C477 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C478 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C479 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C480 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C481 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C482 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C483 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C484 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C487 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C488 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C489 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C490 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C491 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C492 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C493 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C494 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C495 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C496 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C497 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C498 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C499 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C523 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C530 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C531 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C532 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C537 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C546 0CH5560K416 56PF 50V 5% NP0 2012 R/TP

C548 0CH5560K416 56PF 50V 5% NP0 2012 R/TP

C578 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C583 0CH3105H946 "1UF 2012 25V 80%,-20% F(Y5V"

C584 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C602 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C614 0CH3103K516 10000PF 50V 10% B(Y5P) 2012

C625 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C633 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C645 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C648 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C655 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C664 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C669 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C802 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C805 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C807 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C809 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C811 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C813 0CK106EF56A 10UF 3216 16V 10% X7R R/TP

C818 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C819 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C823 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C824 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C825 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C826 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C827 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C828 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

REPLACEMENT PARTS LIST

CAPACITOR

For Capacitor & Resistors, the

charactors at 2nd and 3rd digit in the

P/No. means as follows;

CC, CX, CK, CN, CH : Ceramic

CQ : Polyestor

CE : Electrolytic

CF : Fixed Film

RD : Carbon Film

RS : Metal Oxide Film

RN : Metal Film

RH : CHIP, Metal Glazed(Chip)

RR : Drawing

Page 28

- 28 -

DATE: 2005. 11. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C829 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C830 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C831 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C832 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C833 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C834 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C835 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C836 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C837 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C838 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C839 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C840 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C841 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C842 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C843 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C844 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C907 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C908 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C910 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C911 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C912 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C913 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C917 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C919 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C920 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C921 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C922 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C923 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C924 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C927 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C928 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C929 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C930 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C932 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C933 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C937 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C938 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C939 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C940 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C941 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C942 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C943 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C944 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C945 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C946 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C956 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C957 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C971 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C972 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C973 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C985 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C986 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C987 0CH3104K566 0.1UF 50V 10% X7R 2012 R/TP

C103 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C1049 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C1059 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C106 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C113 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C114 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C116 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C122 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C124 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

DATE: 2005. 11. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C126 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C128 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C129 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C130 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C131 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C132 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C134 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C135 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C136 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C137 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C138 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C141 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C142 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C144 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C146 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C148 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C150 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C152 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C153 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C229 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C243 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C244 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C316 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C317 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C318 0CK473CK56A 47000PF 1608 50V 10% R/TP X

C319 0CK473CK56A 47000PF 1608 50V 10% R/TP X

C341 0CK473CK56A 47000PF 1608 50V 10% R/TP X

C342 0CK473CK56A 47000PF 1608 50V 10% R/TP X

C346 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C347 0CK473CK56A 47000PF 1608 50V 10% R/TP X

C348 0CK473CK56A 47000PF 1608 50V 10% R/TP X

C358 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C360 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C365 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C368 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C376 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C381 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C382 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C403 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C404 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C405 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C406 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C409 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C411 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C412 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C413 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C421 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C422 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C423 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C424 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C427 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C428 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C501 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C5012 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C5013 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C5014 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C502 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C5020 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C5021 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C5022 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C506 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C507 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

Page 29

DATE: 2005. 11. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C508 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C509 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C510 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C511 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C512 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C513 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C514 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C515 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C519 0CK224CF56A 0.22UF 1608 16V 10% R/TP X7

C529 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C533 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C535 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C542 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C543 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C545 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C547 0CH3105H946 "1UF 2012 25V 80%,-20% F(Y5V"

C549 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C550 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C551 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C553 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C554 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C555 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C556 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C557 0CK152CK51A 1500PF 1608 50V 10% R/TP B(

C558 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C559 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C560 0CK152CK51A 1500PF 1608 50V 10% R/TP B(

C563 0CH3105H946 "1UF 2012 25V 80%,-20% F(Y5V"

C565 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C566 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C567 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C568 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C570 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C571 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C572 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C574 0CK332CK51A 3300PF 1608 50V 10% R/TP B(

C575 0CK332CK51A 3300PF 1608 50V 10% R/TP B(

C576 0CK474CH94A "0.47UF 1608 25V 80%,-20% R/"

C579 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C580 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C582 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C586 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C604 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C606 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C607 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C609 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C610 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C611 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C615 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C617 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C620 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C621 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C622 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C629 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C634 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C639 0CK105CF94A "1UF 1608 16V 80%,-20% R/TP"

C654 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C656 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C660 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C661 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C679 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C682 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

DATE: 2005. 11. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C683 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C684 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C801 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C803 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C804 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C806 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C808 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C810 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C812 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C814 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C815 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C816 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C817 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C820 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C821 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C822 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C852 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C853 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C854 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C860 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C861 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C862 0CK103CK51A 0.01UF 1608 50V 10% R/TP B(

C9010 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C9011 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C905 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C906 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C909 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C918 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C926 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C934 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C935 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C954 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C955 0CK104CK56A 0.1UF 1608 50V 10% R/TP X7R

C112 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C117 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C119 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C120 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C121 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C123 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C140 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C143 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C231 0CC680CK41A 68PF 1608 50V 5% R/TP NP0

C340 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C425 0CC270CK41A 27PF 1608 50V 5% R/TP NP0

C426 0CC270CK41A 27PF 1608 50V 5% R/TP NP0

C429 0CC150CK41A 15PF 1608 50V 5% R/TP NP0

C430 0CC270CK41A 27PF 1608 50V 5% R/TP NP0

C463 0CC220CK41A 22PF 1608 50V 5% R/TP NP0

C464 0CC220CK41A 22PF 1608 50V 5% R/TP NP0

C503 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C504 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C539 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C540 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C541 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C544 0CC560CK41A 56PF 1608 50V 5% R/TP NP0

C552 0CC3R3CK01A 3.3PF 1608 50V 0.25 PF R/TP

C561 0CC271CK41A 270PF 1608 50V 5% R/TP NP0

C562 0CC3R3CK01A 3.3PF 1608 50V 0.25 PF R/TP

C569 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C573 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C605 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C618 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

- 29 -

Page 30

DATE: 2005. 11. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C636 0CC102CK41A 1000PF 1608 50V 5% R/TP NP0

C702 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C704 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C706 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C708 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C713 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C714 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C720 0CC331CK41A 330PF 1608 50V 5% R/TP NP0

C725 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C726 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C727 0CC101CK41A 100PF 1608 50V 5% R/TP NP0

C728 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C730 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C732 0CC471CK41A 470PF 1608 50V 5% R/TP NP0

C848 0CC220CK41A 22PF 1608 50V 5% R/TP NP0

C849 0CC220CK41A 22PF 1608 50V 5% R/TP NP0

C901 0CC3R3CK01A 3.3PF 1608 50V 0.25 PF R/TP

C9012 0CC821CK41A 820PF 1608 50V 5% R/TP NP0

C902 0CC3R3CK01A 3.3PF 1608 50V 0.25 PF R/TP

C948 0CC821CK41A 820PF 1608 50V 5% R/TP NP0

C1002 0CE107WH6DC 100UF MVK 25V 20% R/TP(SMD)

C1061 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD)

C125 0CE476VC6DC 47UF MV 6.3V 20% R/TP(SMD)

C127 0CE476VC6DC 47UF MV 6.3V 20% R/TP(SMD)

C133 0CE476VC6DC 47UF MV 6.3V 20% R/TP(SMD)

C139 0CE476VC6DC 47UF MV 6.3V 20% R/TP(SMD)

C145 0CE476VC6DC 47UF MV 6.3V 20% R/TP(SMD)

C147 0CE476VC6DC 47UF MV 6.3V 20% R/TP(SMD)

C205 0CH8226F691 22UF 16V 20% 105STD (CYL) R

C212 0CE225VK6DC 2.2UF MV 50V 20% R/TP(SMD)

C222 0CE335VK6DC 3.3UF MV 50V 20% R/TP(SMD)

C227 0CE225VK6DC 2.2UF MV 50V 20% R/TP(SMD)

C228 0CE225VK6DC 2.2UF MV 50V 20% R/TP(SMD)

C233 0CE227VF6DC 220UF MV 16V 20% R/TP(SMD)

C238 0CE227VF6DC 220UF MV 16V 20% R/TP(SMD)

C288 0CH8226F691 22UF 16V 20% 105STD (CYL) R

C291 0CH8226F691 22UF 16V 20% 105STD (CYL) R

C304 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C305 0CE227VF6DC 220UF MV 16V 20% R/TP(SMD)

C349 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C366 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C407 0CH8226F691 22UF 16V 20% 105STD (CYL) R

C410 0CE335VK6DC 3.3UF MV 50V 20% R/TP(SMD)

C437 0CH8226F691 22UF 16V 20% 105STD (CYL) R

C5015 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C5019 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C505 0CE227VF6DC 220UF MV 16V 20% R/TP(SMD)

C516 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD)

C517 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD)

C524 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C525 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C526 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C527 0CE476WF6DC 47UF MVK 16V 20% R/TP(SMD)

C528 0CE475VK6DC 4.7UF MV 50V 20% R/TP(SMD)

C534 0CH8476H691 47UF 25V 20% 105STD (CYL) R

C536 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD)

C538 0CH8476H691 47UF 25V 20% 105STD (CYL) R

C564 0CH8476H691 47UF 25V 20% 105STD (CYL) R

C577 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD)

C581 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD)

C585 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD)

C587 0CH8106F691 10UF 16V 20% 105STD (CYL) R

DATE: 2005. 11. 01.

*S *AL LOC. NO. PART NO. DESCRIPTION / SPECIFICATION

C588 0CH8106F691 10UF 16V 20% 105STD (CYL) R

C601 0CH8476K611 47UF 50V 20% 85STD (CYL) R/

C603 0CE227VF6DC 220UF MV 16V 20% R/TP(SMD)

C608 0CH8476K611 47UF 50V 20% 85STD (CYL) R/

C616 0CE227VF6DC 220UF MV 16V 20% R/TP(SMD)

C624 0CH8226F691 22UF 16V 20% 105STD (CYL) R

C626 0CE107WF6DC 100UF MVK 16V 20% R/TP(SMD)

C627 0CH8476K611 47UF 50V 20% 85STD (CYL) R/