Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PT81A

MODEL : 50PG60UD 50PG60UD-DA

website:http://biz.LGservice.com

Internal Use Only

Page 2

- 2 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ..........................................................................3

SPECIFICATION........................................................................................4

ADJUSTMENT INSTRUCTION .................................................................6

TROUBLE SHOOTING ............................................................................11

BLOCK DIAGRAM...................................................................................20

EXPLODED VIEW .................................................................................. 27

SVC. SHEET ...........................................................................................29

Page 3

- 3 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

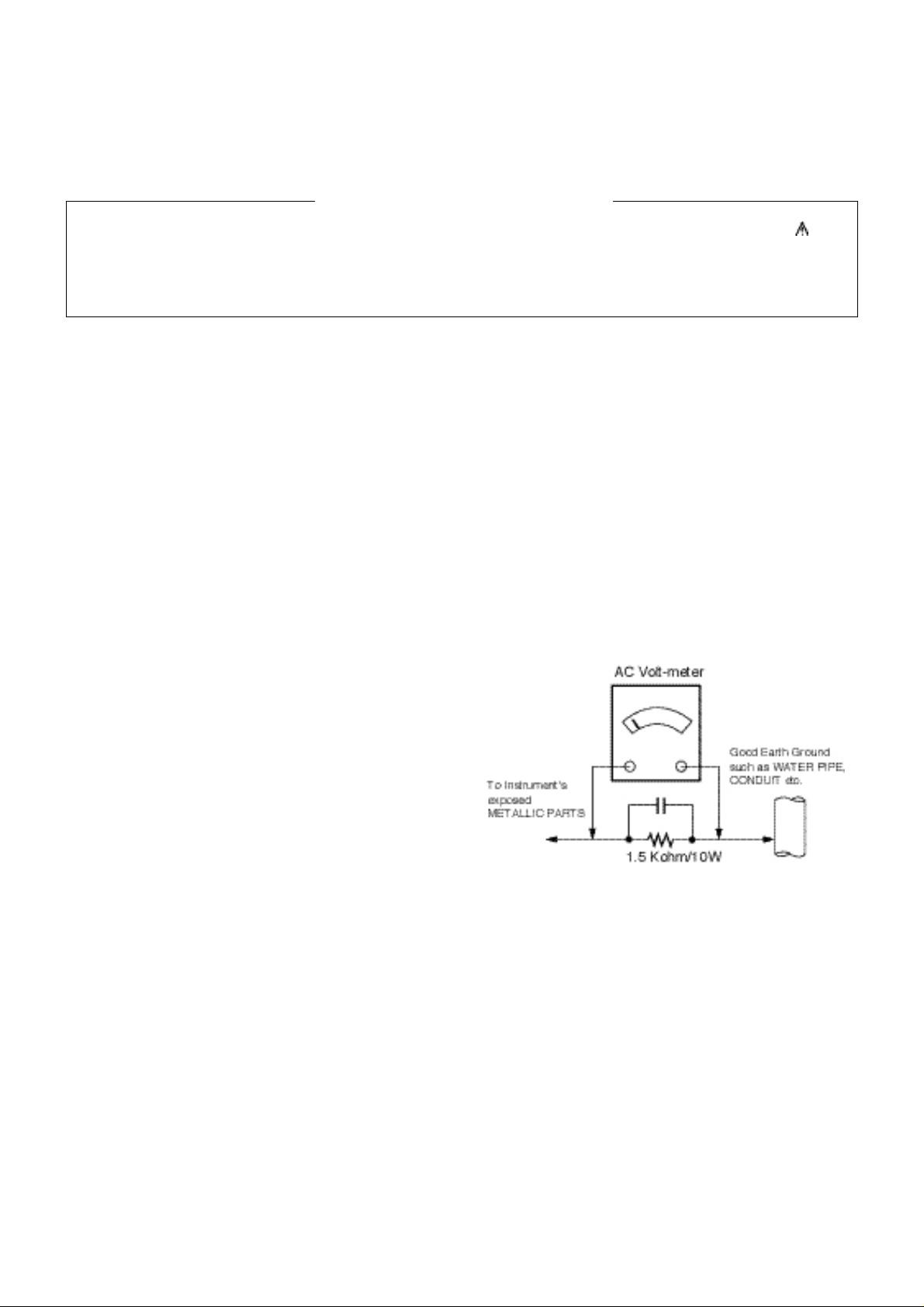

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

IMPORTANT SAFETY NOTICE

0.15uF

Page 4

- 4 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to the 42” PLASMA TV used PT81A Chassis.

V Specification

Each part is tested as below without special appointment.

1) Temperature : 25±5°C (77±9°F), CST : 40±5

2) Relative Humidity: 65±10%

3) Power Voltage: Standard Input voltage (110V@60Hz)

* Standard Voltage of each product is marked by models.

4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with SBOM.

5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

1) Performance : LGE TV test method followed.

2) Demanded other specification

Safety : CE, IEC specification

EMC : CE, IEC

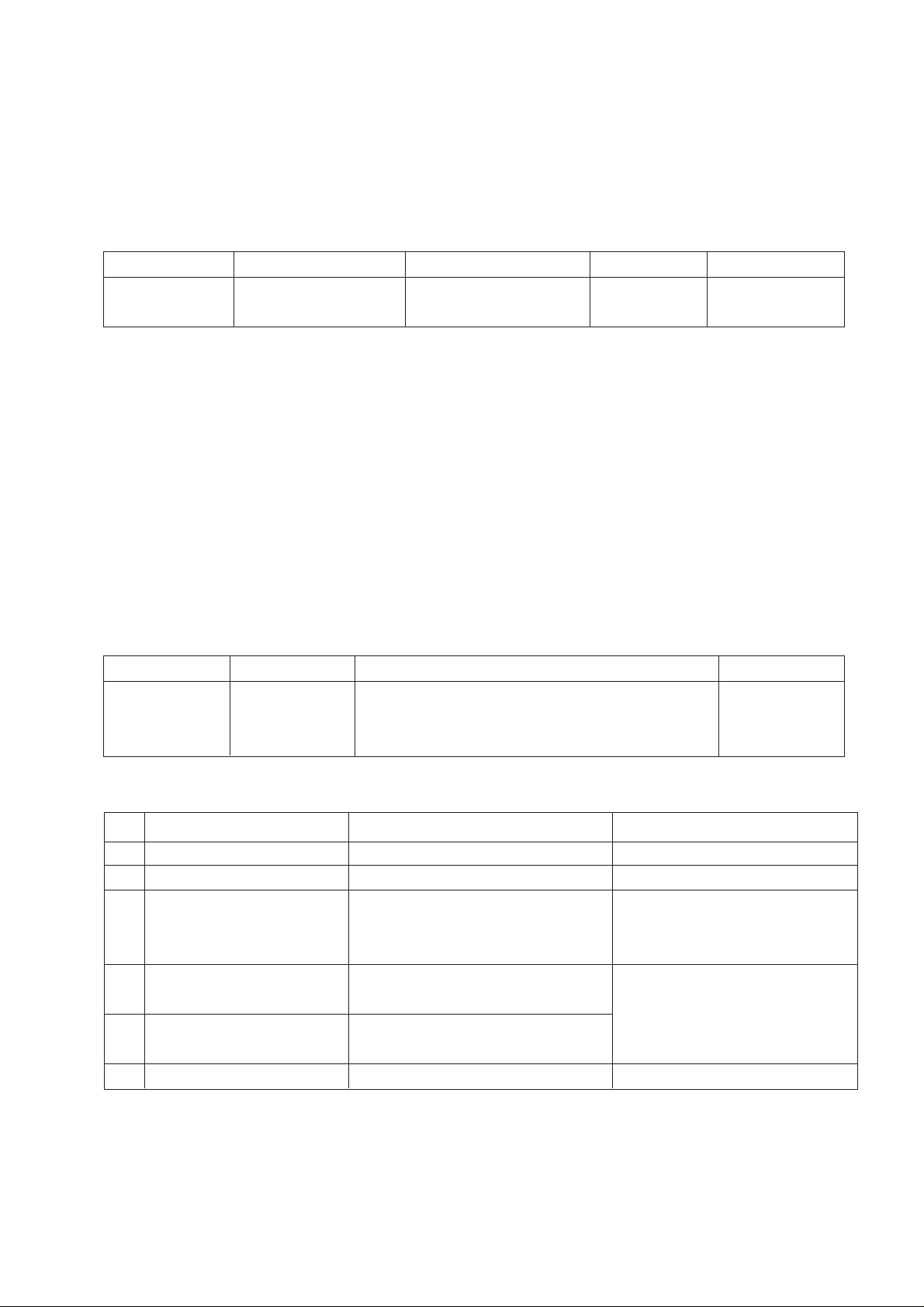

V General Specification ( XGA Module)

Display Screen Device

Aspect Ratio

PDP Module

Operating Environment

Storage Environment

Input Voltage

1

2

3

4

5

6

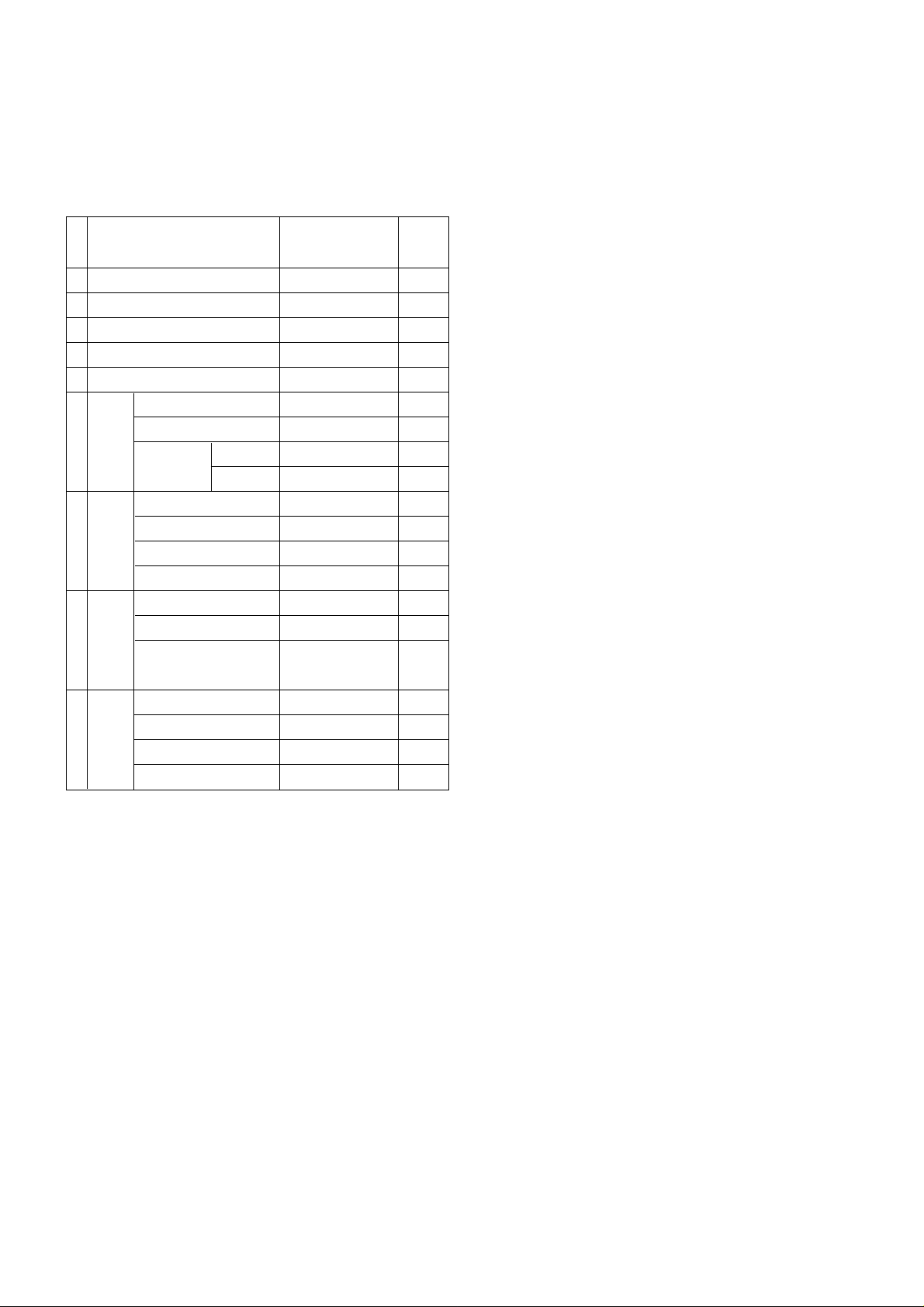

No Item Specification Remark

42” Wide Color Display Module

16:9

PDP42G1,

RGB Closed(Well) Type, Glass Filter(38%)

Pixel Format : 1024horiz. By 768 ver.

1)Temp. : 0~40deg

2)Humidity : 10~80%

3)Temp. : -20~60deg

4)Humidity : 10~90%

100-240V~, 50/60Hz

Plasma Display Panel

LGE SPEC.

Maker : LG

Chassis

PA81A 42PG20D-DA Taiwan LG

Model Name Market Brand Remark

42PG20D-DA BSMITaiwan

Model ApplianceMarket Remark

Page 5

- 5 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

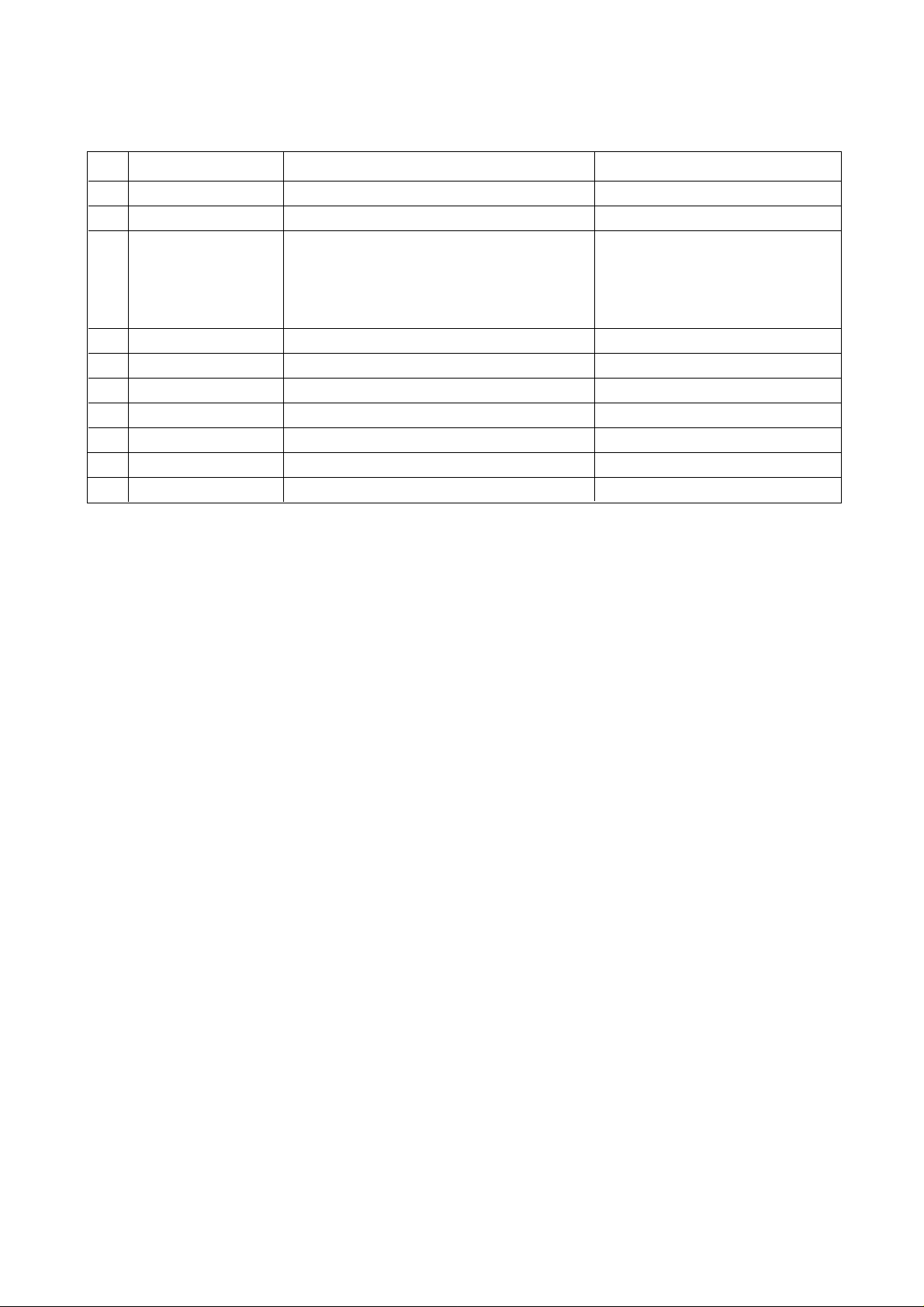

V Module Specification2

Market

Broadcasting system

Receiving system

MNT Out (1EA)

Video Input (2EA)

S-Video Input(1EA)

Component Input(2EA)

RGB Input(1EA)

HDMI Input(2EA)

Audio Input (6EA)

1

2

3

4

5

6

7

8

9

10

No Item Specification Remark

Taiwan

Analog : NTSC-M, DTV : DVB-T

1) VHF : 2~13

2) UHF : 14-69

3) CATV : 1, 14~125

4) DTV : 14~69

NTSC

NTSC

NTSC

Y/Cb/Cr, Y/Pb/Pr

RGB-PC

HDMI-DTV & SOUND

PC Audio, Component, AV

Rear : 1

Rear : 1, Side : 1

Side : 1

60Hz Only

60Hz Only

60Hz Only

L./R Input

Page 6

- 6 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Object

These instructions are applied all of the 42” PLASMA TV,

PT81A Chassis.

2. Note

V The module keeping condition: The normal temperature

condition(more than 15°C)

-> Immediately the line supply.

V The module keeping condition: 0°C

-> The module must be kept for more than 2 hours at the

normal temperature.

V The module keeping condition: -20°C

-> The module must be kept for more than 3 hours at the

normal temperature.

V The case of Gu-mi factory at the winter season.

-> The module must be kept for more than 5 minutes at the

heating zone(40°C~45°C).

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100-240V~,

50/60Hz.

(5) The receiver must be operated for about 15 minutes prior

to the adjustment.

O After RGB Full white HEAT-RUN Mode, the receiver must

be operated prior to adjustment.

O Enter into HEAT-RUN MODE

1) Press the POWER ON KEY on R/C for adjustment.

2) OSD display and screen display PATTERN MODE.

- Select “3. Test Pattern” by using

D/E(CH+/-) and

press ENTER(

V)

- Select “White” by using (

F/GVOL+/-) and press

ENTER(

V)

* Set is activated HEAT-RUN without signal generator in

this mode.

* Single color pattern(RED/BLUE/GREEN) of HEAT-RUN

mode uses to check PANEL.

* Caution : If you turn on a still screen more than 20

minutes(Especially digital attern, cross hatch

pattern), an after image may be occur in the black

level part of the screen.

3.

S/W auto download using the USB

Memory stick

(1) Insert the USB memory sick the PCB ASSEMBLY.

(2) Using ‘power on’ button of the control R/C, power on TV.

(3) S/W download process is executed automatically.

4.

Auto-control adjustment process

(ADC, model-name, EDID)

V

All adjustment process is executed one time through RS-232C.

V Command send -> ADC Calibration -> Model name

download -> EDID download.

V Adjsutment process protocol(RS-232C)

V Defined model name protocol(RS-232C)

5. Manual model name download

(1) Press ADJ KEY on R/C for model name D/L.

(2) Select “0.Model Option” and press ENTER(

V).

(3) Select model name by using

D/E(CH+/-)and press

ENTER(

V).

* The module keeping condition

* Using ‘power on’ button of the control R/C, power on TV.

USB file(EPK) version must be bigger than downloaded

version of main B/D.

* Using ‘power on’ button off the control R/C, power on TV.

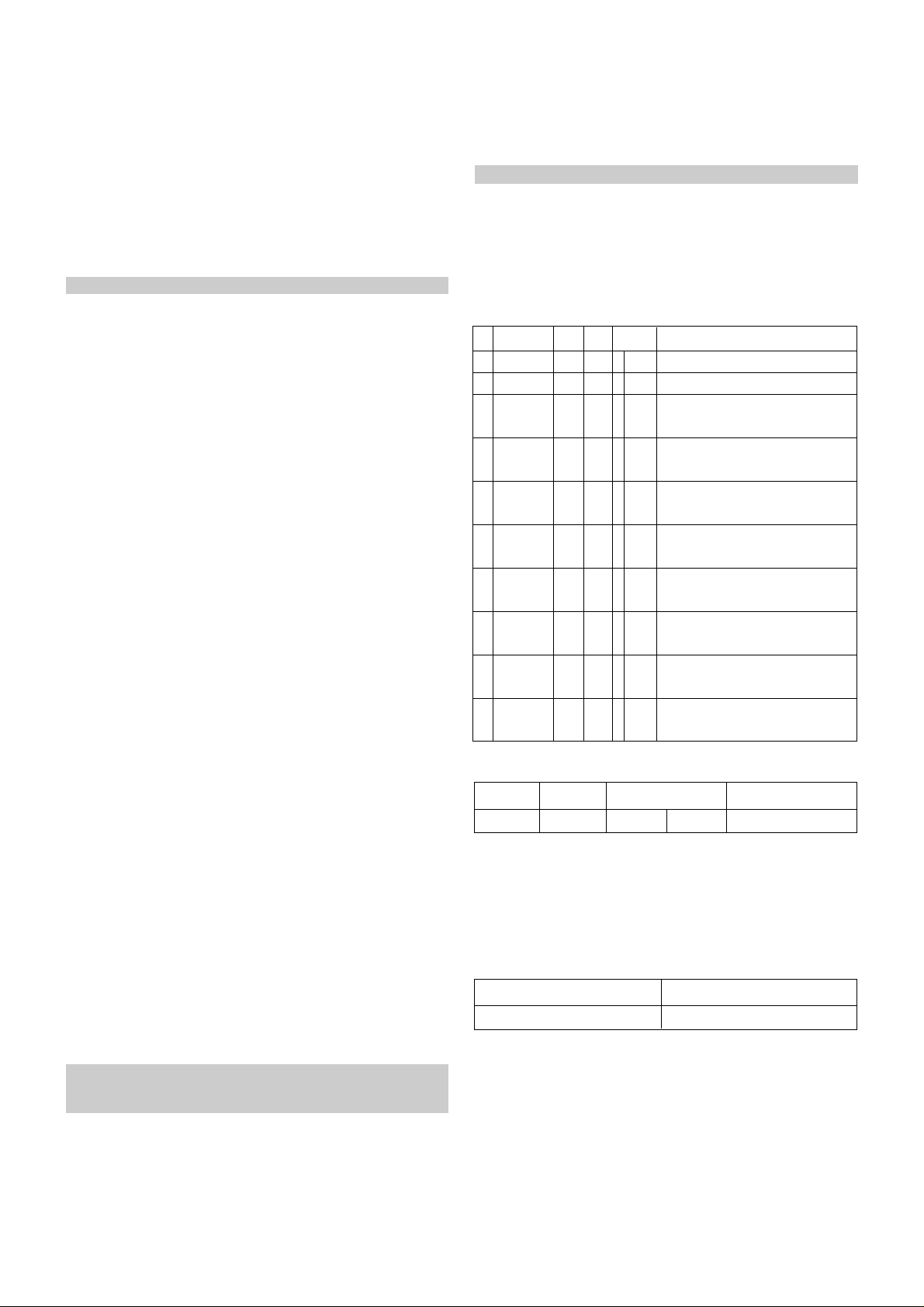

1

2

3

4

5

6

7

8

9

10

Ready

ADC

ADC

Confirmation

ADC

Mode Out

EDID

Download

Check EDID

Status

Download

Mode In

Define model

name

Download

Mode Out

Adjustment

Confirmation

NO

Item

Remark

CMD1 CMD2

Data 0

a

a

a

a

a

a

a

a

a

a

d

d

d

d

e

e

e

e

e

e

0

0

0

9

0~4,9

0~4,9

0

1~9

0

9

0

1

9

9

1

2

0

5

9

9

Ready

ADC start

All=0 ; HDMI1,2,3,4=1,2,3,4 ; RGB=9

All=0 ; HDMI1,2,3,4=1,2,3,4 ; RGB=9

Transmitting adjustment mode In

instruction, operate adjustment command.

Model define index(Data0) are listed at

next table.

EDID data existence check in SET

assembly

ae51

42PG20D-AA

CMD1 CMD2 Data 0 Remark

42PG20D-DA

52013360

Model Name Model Option Value

Page 7

- 7 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

6. Manual

ADC Adjustment

V Adjustment is done using internal ADC, so input signal is

not necessary.

V Do not connect external input cable.

6-1. Required Equipment

(1) Press ADJ KEY on R/C and enter EZ ADJUST.

(2) Select “1.EDID D/L” by using

D/E(CH+/-) and press

ENTER(

V).

(3) Select “Start” by using

F/G(VOL+/-) and press ENTER(V).

(4) ADC Adjustment is executed automatically.

7. EDID Download

7-1. Required Equipment

(1) Press ADJ KEY on R/C and enter EZ ADJUST.

(2) Select “5.EDID D/L” by using

D/E(CH+/-) and press

ENTER(

V).

(3) Select “Start” and press ENTER(

V).

(4) EDID download is executed automatically.

(5) Press EXIT key on R/C.

7-2.

EDID DATA

(1) HDMI1(256bytes)

(2) RGB (128bytes)

-> Detail EDID Options below( , , , , )

. Product ID

. Serial No : Conntrolled on producion line.

. Month, Year : Conntrolled on producion line.

Model Name

Checksum : Changeable by total EDID data.

8. PCMCIA CARD Checking Method

You must adjust DTV 29 Channel and insert PCMCIA CARD

to socket.

(1) If PCMCIA CARD works normally, normal signals display

on screen. But it work abnormally, “No CA module” words

display on screen.

*Do not connect HDMI and RGB cable.

NO SIGNAL or White noise NO SIGNAL

RF Input AV / Component / RGB input

42PG20D 42PG20D 40309(9D75)

40310(9D76)

Analog(RGB)

Digital(HDMI)

MODEL EDID MODEL Product_ID FUNCTION

42PG20D

00 00 00 FC 4C 47 54 56 0A 20 20 20 20 20 20 20

MODEL NAME MODEL NAME(HEX)

* Set up “RF mode” before launching products.

Page 8

- 8 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

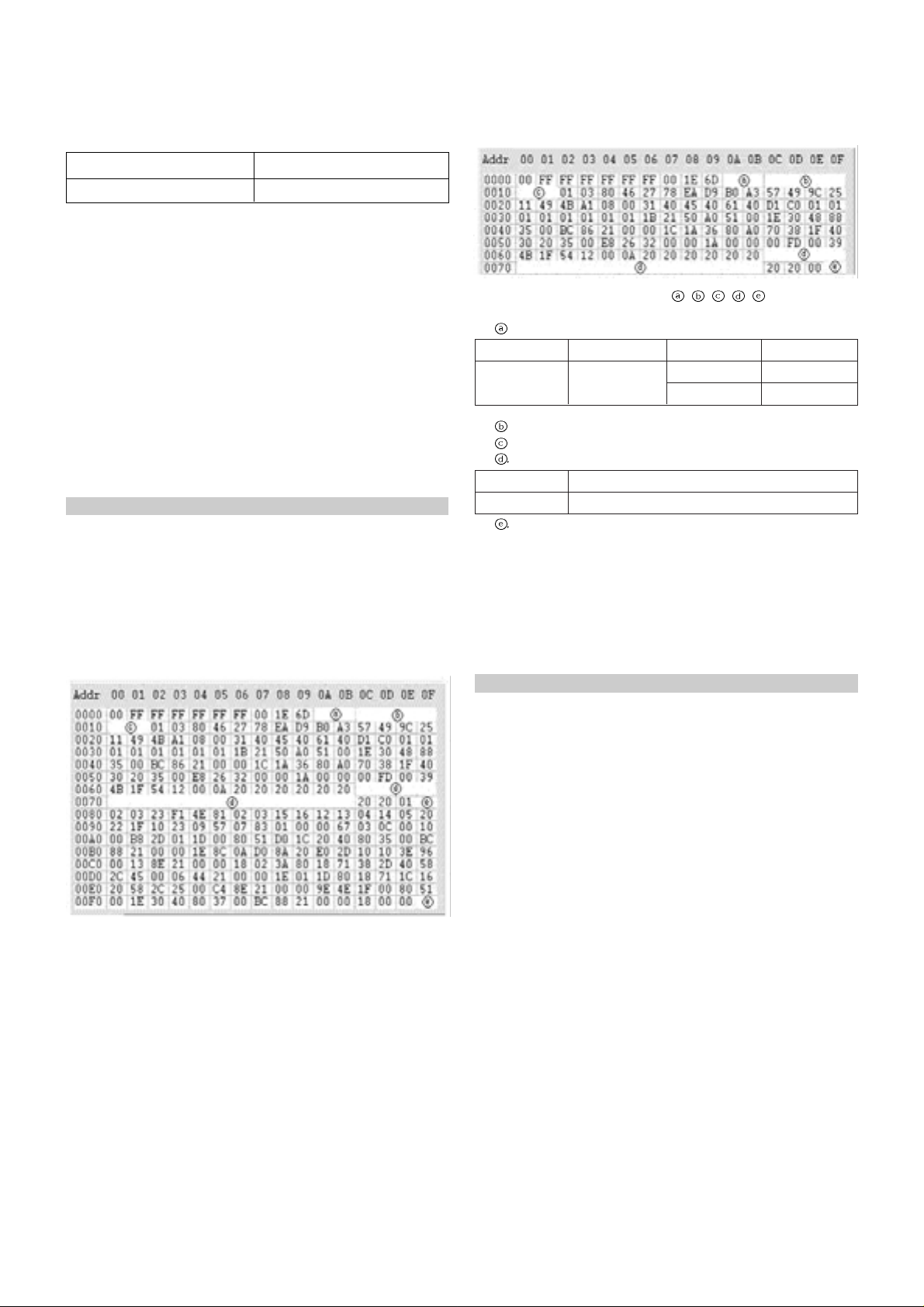

9. POWER PCB Assy Voltage

Adjustments (Va, Vs Voltage adjustments)

9-1. Test Equipment :D.M.M. 1EA

9-2.Connection Diagram for Measuring

: refer to Fig.1

9-3. Adjustment Method

(1) Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P811, connect

- terminal to GND pin of P811.

3) After turning VR901, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

(2) Vs Adjustment

1) Input signal : RF noise signal.

2) Connect + terminal of D.M.M to Vs pin of P811, connect

– terminal to GND pin of P811.

3) After turning VR951, voltage of D.M.M adjustment as

same as Va voltage which on label of panel right/top.

(Deviation; ±0.5V)

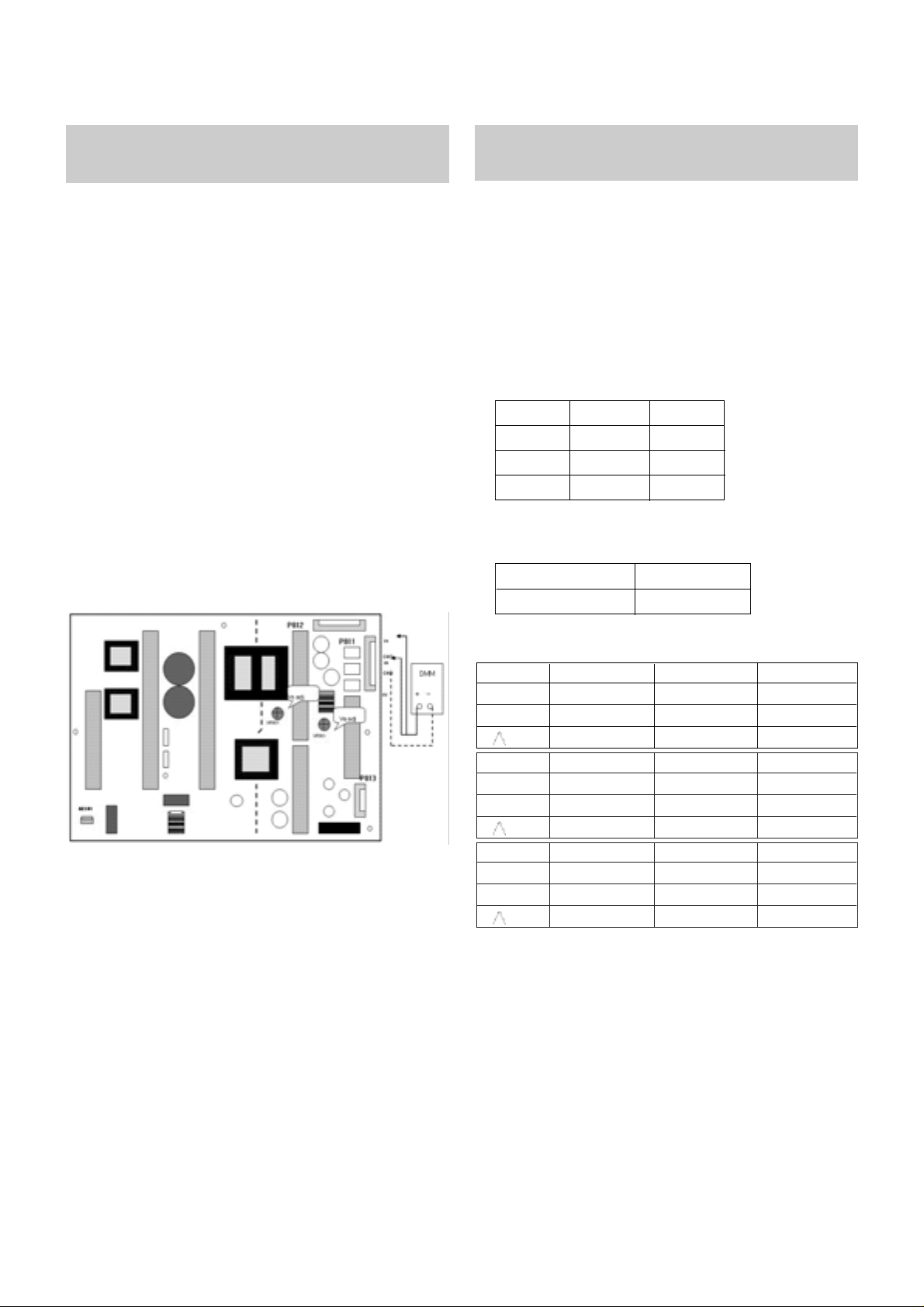

10. Adjustment of White Balance

10-1. Required Equipment

(1) Color Analyzer : CA-1000, CA-100+(CH.10) CA-210(CH.10).

* Please adjust CA-100+/CA-210 by CS-1000 before

measuring.

-> You should use Channel 10 which is Matrix

compensated(White, Red, Green, Blue revised) by CS1000 and adjust in accordance with balance adjustment

coordinate.

W Color temperature standards according to CSM and Module.

W Change target luminance and range of the Auto adjustment

W/B equipment.

W White balance adjustment coordinate and color temperature.

* PC(for communication through RS-232C)

-> UART Baud rate : 115200 bps

Each PCB assembly must be checked by check JIG set.

(Because power PCB Assembly damages to PDP Module,

especially be careful)

(Fig.1) Connection diagram of power adjustment for measuring

* Press the POWER ON KEY on R/C before Model name download.

Befor adjusting White-balance, the AV ADC should be done.

If ADC status were “NG”, Need to ADC adjustment.

PLASMA Remark

11000K

9300K

6500K

Cool

Normal

Warm

CSM

65

20

Range

Target luminance

0.276

0.283

0.000

0.276±0.002

0.283±0.002

0.000

0.276±0.002

0.283±0.002

0.000

X

y

uv

Cool CS-1000 CA-100+(CH.10) CA-210(CH.10)

0.285

0.293

0.000

0.285±0.002

0.293±0.002

0.000

0.285±0.002

0.293±0.002

0.000

X

y

uv

Medium CS-1000 CA-100+(CH.10) CA-210(CH.10)

0.313

0.329

0.003

0.313±0.002

0.329±0.002

0.003

0.313±0.002

0.329±0.002

0.003

X

y

uv

Warm CS-1000 CA-100+(CH.10) CA-210(CH.10)

Page 9

- 9 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

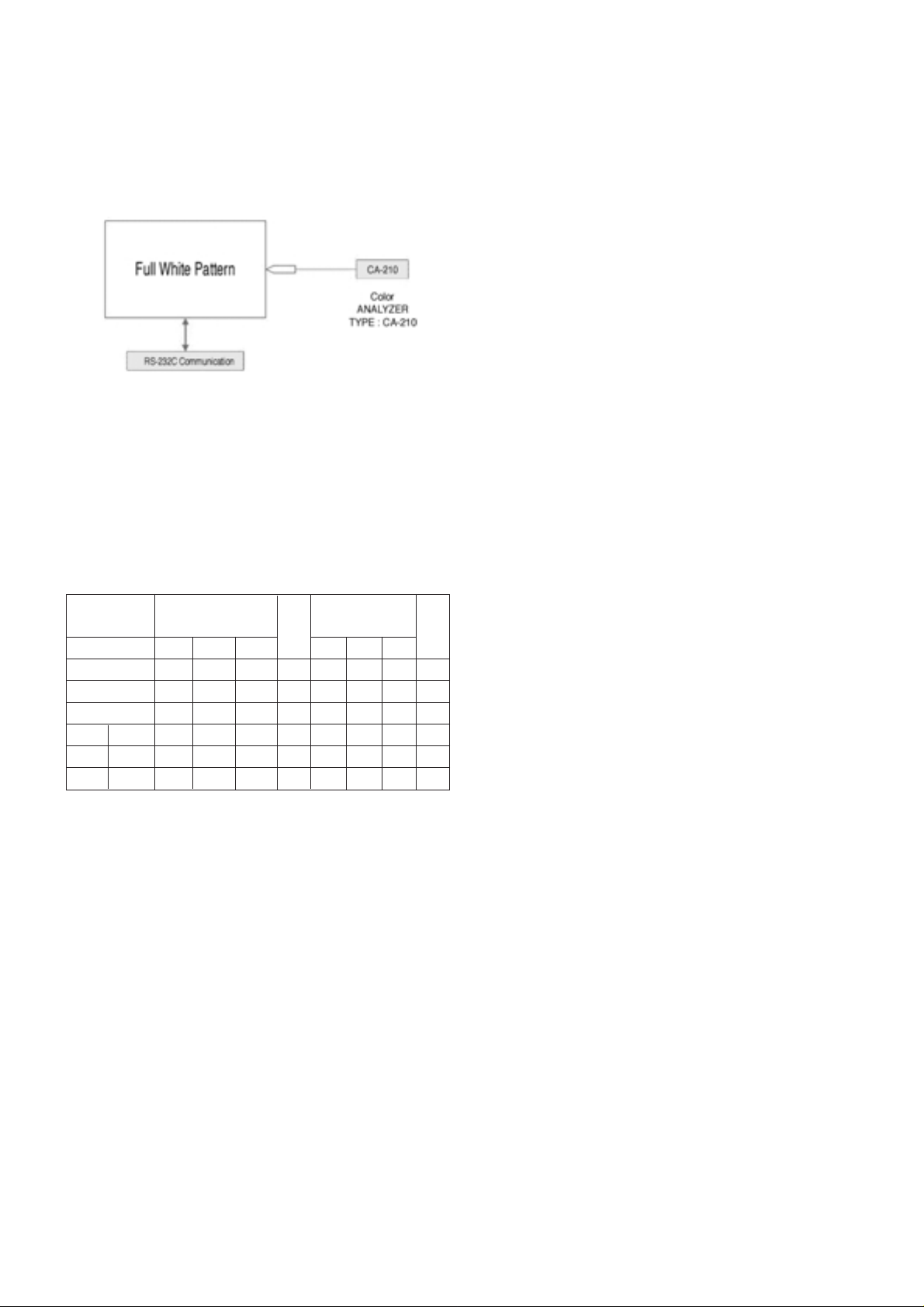

10-2. Connection Picture of the Measuring

Instrument(On Automatic control)

(1) Inside PATTERN is used when W/B is controlled. Connect

to auto controller or push control R/C IN-START -> Enter

the mode of White-Balance, the pattern will come out.

10-3. Auto-control interface and directions

(1) Adjust in the place where the influx of light like floodlight

around is blocked.(illumination is less than 10ux)

(2) Measure and adjust after sticking the Color Analyzer(CA-

100+, CA210) to the side of the module.

(3) Aging time

- After ajing start, keep the power on(no suspension of

power supply) and heat-run over 15minutes.

- keep white pattern using inside pattern.

V Auto adjustment Map(RS-232C)

11. Adjustment of White Balance

(1) Press ADJ KEY on R/C and enter EZ ADJUST.

Select “3. Test Pattern” by using

D/E(CH+/-) and press

ENTER(

V)

Select “White” by using

F/G(VOL+/-) and press ENTER(V)

and heat run over 15minutes.

(2) Zero Calibrate CA-100+/CA-210, and when controlling,

stick the sensor to the center of PDP module.

(3) Press ADJ KEY on R/C and enter EZ ADJUST.

Select “2. White Balance” and press

G(VOL +).

Set test-pattern on and display inside pattern.

(5) Control is carried out on three color temperatures, COOL,

MEDIUM,WARM.

(Control is carried out thress times)

<Temperature : COOL>

- R-Cut / G-Cut / B-Cut is set to 64

- Control R-Gain and G-Gain.

- Each Gain is limited to 192.

<Temperature : MEDIUM>

- R-Cut / G-Cut / B-Cut is set to 64

- Control R-Gain and G-Gain.

- Each Gain is limited to 192.

<Temperature : WARM>

- R-Cut / G-Cut / B-Cut is set to 64

- Control G-Gain and B-Gain.

- Each Gain is limited to 192.

12. Input the Shipping Option Data

1) Push the IN-START key in a Adjust Remocon.

2) Input the Option Number that was specified in the BOM, into

the Shipping area.

3) The work is finished, Push

V Key.

13. Set Information

(Serial No& Model name)

13-1.

Check the serial number & Model Name

(1) Push the menu button in DTV mode.

(2) Select the SETUP -> Diagnostics -> To set.

(3) Check the information.

(Fig.3) Auto AV(CVBS) Color Balance Test Pattern

R Gain

G Gain

B Gain

R Cut

G Cut

B Cut

45G1

Cool Med Warm Cool Med Warm

jg Ja js 00 192 192 192 255

jh Jb je 00 192 192 192 255

ji Jc jf 00 192 192 192 255

65 65 62 128

56 56 53 128

71 70 76 128

RS-232C COMMAND

[CMD ID DATA]

Min

CENTER

(DEFAULT)

MAX

Page 10

- 10 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

14. SET factoring condition

(1) This adjustment is setting factory shipment mode.

(2) Push the IN-STOP key of adjustment remote controller before

the factory shipment.

1

2

3

4

5

6

7

8

9

Antenna

10

Off

16:9

1

Vivid

Medium

Off

Auto

Standard

Off

0

On

On

-Off

On

Off

Normal

Level 0

Item ConditionNo

Remark

Input Mode

Volume Level

Mute

Aspect Ratio

SET ID

Picture PSM

Color Temp.

Advanced Cinema

Black level

Sound SSM

AVL

Balance

TV Speaker

Time Auto Clock

Manual Clock

Off Timer / On Timer

Sleep Timer / Auto Off

Option SIMPLINK

Key Lock

ISM Method

Power Saving

Page 11

- 11 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

TROUBLE SHOOTING GUIDE

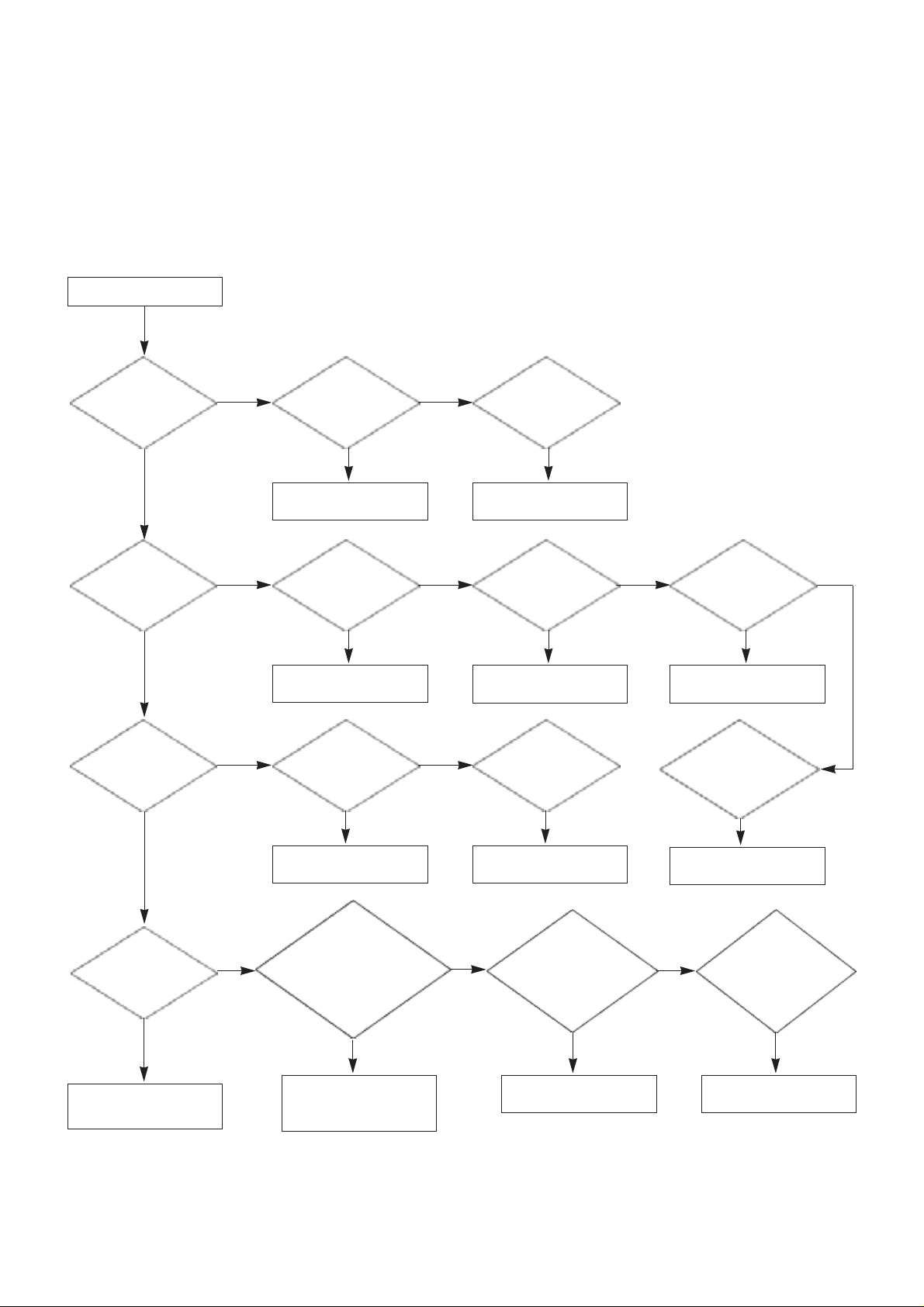

1. Power Board

1-1. The whole flowchart which it follows in voltage output state

Start check

Manufacture enterprise

meaning of a passage

1. Check the Power Off

condition.

Doesn't the

screen whole come

out?

Is it identical

with Power Off

condition?

Yes

Yes

No

No

No

No

No

2. Check the Interface

signal condition.

Is the Interface

signal operated?

Yes

3. Check the St-by 5V

signal circuit.

Doesn't the

low pressure output

come out?

Doesn't the

St-by 5V signal

come out?

Yes

Yes

No

4. Check the 5V Monitor

signal circuit.

Doesn't the

5V Monitor signal

come out?

Yes

7. Check the VSC Vs-ON

signal

Doesn't the

high tension output

come out?

Doesn't the

VSC signal Vs-ON

come out?

Yes

Yes

Does

high tension

output voltage Drop

occur?

When the

Y B/D Module

input connector is

removed, does output

voltage drop

occur?

When the

Y, Z B/D Module

input connector is remove,

does Power Board hightension

output voltage Drop

occur?

Yes No No

9. Check the Power

Board Output high

tension circuit

Yes

10. Check the Z B/D

Module output circuit

Yes

When the

Z B/D Module

input connector is

removed, does output

voltage Drop

occurs?

11. Check the Y B/D

Module output circuit

Yes

No

8. Check the Vs, Va

voltage output circuit.

Doesn't the

Vs, Va voltage output

come out?

Yes

No

No

5. Check the VSC RL-ON

signal.

Doesn't the

VSC signal RL-ON

come out?

Yes

6. Check the VSC low

pressure output

Doesn't the

VSC low pressure

output come out?

Yes

Page 12

- 12 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

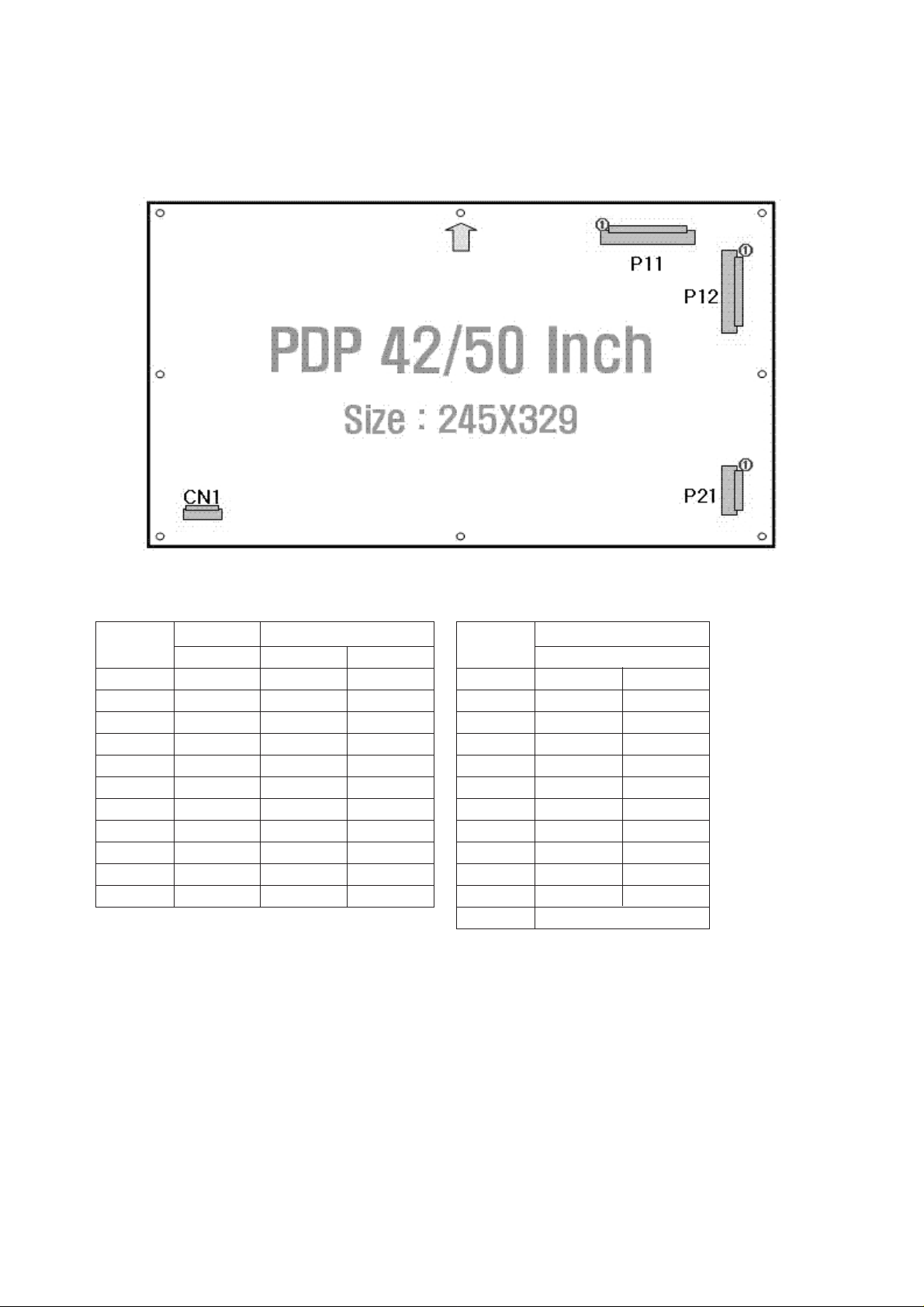

1-2. Power Board Structure

(1) Pin Layout

CN1 P11 P12

AC INLET PDP MODULE

AC

NC

AC

YH396-03P

Vs

Vs

NC

GND

GND

Va

Va

GND

M5V

M5V

YH396-10P

Vs

Vs

NC

GND

GND

Va

Va

GND

M5V

M5V

YH396-10P

1

2

3

4

5

6

7

8

9

10

Wafer P/N

NO

P21

SMW200-22C

VSC BOARD

1/2

3/4

5/6

7/8

9/10

11/12

13/14

15/16

17/18

19/20

21/22

Wafer P/N

16V

GND

12V

GND

5V

5V

GND

GND

5V_MNT

RL_ON

M5V_ON

16V

GND

12V

GND

5V

5V

GND

GND

AC_DET

VaVs_ON

GND

NO

(2) Pin Spec

Page 13

- 13 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2. No Power

(1) Symptom

1) Doesn’t minute discharge at module.

2) Non does not come in into the front LED.

(2) Check following

A Power cord is plugged with TV set? Plug the power cord.

Yes

No

Is the AC-INLET connected with

the power board?

Connect the AC-INLET

Yes

No

Is the Fuse(F101,F801) on

Power Board normal?

Replace the Fuses.

Yes

No

Is the Power Board with

VSC Board though Cable connected?

Connect the Cable.

Yes

No

Measure output voltages(16V,12V,5V) on the power board.

If the measured values is not normal, replace power board.

Page 14

- 14 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3. Protect Mode

(1) Symptom

1) After once shining, it does not discharge minutely

from module.

2) The Rely falls.(The sound is audible “click”)

3) It is converted with the color where the front LED

is red from green.

(2) Check following

Is the Power Board

normal ?

Replace Power

Board.

Is output the normality Low/High

voltage except Stand-by 5V?

Yes

No

No

Is the each connector

normal?

Replace the

connector.

Replace

Y-Board.

After connecting well each connector,

the normality it operates?

Yes

No

Yes

Is the Ctrl Board

normal?

Replace the Ctrl-Board.

Is the output voltage normal after

remove P163 connector of Ctrl-B/D?

Yes

No

Yes

Is the Y-Board

normal?

Is the output voltage

normal after remove

P209 connector of

Y-B/D?

Is the Fuse(FS201) on Y-B/D

normal?(In case of open is replace)

Yes

No

Yes Yes

Replace

Z-Board.

Is the Z-Board

normal?

Is the output voltage

normal after remove

P3 connector of Z-

B/D?

Is the Fuse (FS1) on Z-B/D normal?

(In case of open is replace)

Yes

No

Yes

Is the X- Board

normal?

Is the output voltage normal after

remove P242 connector of

X-B/D?

After remove P211 output voltage normality:

Replace Right X-B/D

After remove P23 output voltage normality:

Replace Left X-B/D

Yes

No

Yes

Is the

VSC Board normal?

Is the output voltage normal after

remove P1001 of VSC Board?

After crisis COF of each board, check the normality operates.

If in case normality operates, correspondence COF Fail is replace the module.

After remove P1001 normal operation:

Replace VSC Board

Yes

No

Is the COF of X, Y, Z

normal ?

No

Yes

Yes

Page 15

- 15 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Does minute discharge

At Module?

Is the LVDC cable

normal?

Is the VAVS on?

Check the PDP Module

Yes

No

YES

Yes

Reconnect the LVDS

cable in P501

No

Is the IC700(FLI106X0H)

Output normal?

Replace the VSC.

No

NO

Replace the Power

board

Is output the normality

Low/High voltage except

stand-by 5V?

NO

4. No Raster

(1) Symptom

1) No OSD and image occur at screen.

2) It maintains the condition where the front LED is green.

(2) Check following

Page 16

- 16 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

5. In case of occurring strange screen into specific mode

5-1. In case the OSD does not displayed

(1) Symptom

1) LED is green.

2) The minute discharged continuously becomes Accomplished from module.

(2) Check following

Is the LVDS cable

normal ?

Is the VSC Board

normal?

Is the LVDS cable

connected?

Connect the LVDS cabel

with the VSC board.

Yes

No

No

Yes

Is the IC100(FLI106X0H)

normal?

Replace the

IC100(FLI106X0H)

No

Is the Ctrl Board of

Module normal?

Replace the Ctrl B/D.

No

No

Yes

Replace the VSC B/D

Replace the LVDS cable.

Yes

Page 17

- 17 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

5-2. In case of does’t display the screen into specific mode

(1) Symptom

1) The screen does not become the display from specific input mode

(RF, AV, Component, RGB, DVI).

(2) Check following

1) Check the all input mode should become normality display

.

(3) In case of becomes unusual display from RF mode

(4) In the case of becomes unusual display from side S-video/AV mod

Is the Tuner normal?

Is the RF cable connected with TV

Set?

Connect the RF cable.

Yes

No

No

Is the IC100(FLI106X0H)

normal?

Replace the Tuner(TU301).

No

Is the Input voltage, IIC Communication

and CVBS output normal?

Yes

Is the IIC communication waveform

between the tuner and IC100 normal?

No

Block A

Replace the

IC100(FLI106X0H).

No

Is the Video input of the AV

(JK105, JK106) normal?

Check the input source

No

Same as Block A

Page 18

- 18 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

(5) In the case of becomes unusual display from Component, RGB mode

(6) In the case of becomes unusual display from HDMI mode

(7) In the case of becomes unusual display from SCART mode

Is the R,G,B input and H,V

Sync of the JK104 normal?

Check the input source

No

Is the HDMI(IC201)

normal?

Yes

Same as Block A

Is the TMDS waveform between the

IC and HDMI jacks normal?

No

Is the Video input of AV

jack normal?

Yes

Same as Block A

Check the input source

No

Replace the IC201.

No

Yes

Same as Block A

Page 19

- 19 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

6. In case of no sound

(1) Symptom

1) LED is Green.

2) Screen display but sound is not output.

(2) Check following

All input(mode) is no

sound?

Only HDMI is No

Sound?

Yes

Download

the EDID data

Yes

No YES

Only RF is no sound?

Check

the Tuner’s IN/OUTPUT

Yes

No

Is the IC629 normal?

Replace the IC629

(MSP4458)

No

Is the IC601 normal?

Replace the IC601

(NTP-3000A)

No

YES

Replace the VSC Board

YES

Is the speakers turned

on?

Set on the speakers on

menu.

No

Is the speaker Cable

connect?

Connect the Speaker

Cable.

No

Yes

Page 20

Only for training and service purposes

- 20 -

BLOCK DIAGRAM

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Page 21

- 21 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 22

Only for training and service purposes

- 22 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Page 23

- 23 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 24

Only for training and service purposes

- 24 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Page 25

- 25 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Page 26

Only for training and service purposes

- 26 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Page 27

- 27 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

EXPLODED VIEW

603

602

601

520

400

590

501

307

120

121

306

560

570

571

310

302

303

305

300

304

200

250

901900

240

209

208

201

204

207

A2

205

206

580

202

203

301

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Page 28

Only for training and service purposes

220

R606

SPDIF_OUTPC_AUDIO_L

PC_AUDIO_R

COMP1_LIN

COMP1_RIN

COMP2_LIN

COMP2_RIN

0.1uF

16V

C602

10uF

16V

C605

0.47uFC611

0.47uFC612

0.47uFC613

0.47uFC614

0.47uFC615

0.47uFC616

1K

R648

6800pF

C644

4.7K

R652

470K

R658

DTV/MNT_LOUT_SC2

DTV/MNT_ROUT_SC2

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

PEJ024-01

JK601

6B

T_TERMINAL2

8

SHIELD_PLATE

7B

B_TERMINAL2

5

T_SPRING

4

R_SPRING

7A

B_TERMINAL1

6A

T_TERMINAL1

3

E_SPRING

CDS3C30GTH

READY

D602

PC_AUDIO_L

PC_AUDIO_R

220K

R624

CDS3C30GTH

READY

D601

220K

R623

SW_ROUT

SW_LOUT

4.7K

R654

470K

R662

1K

R650

6800pF

C648

0.1uF

C660

DTV/MNT_ROUT

2K

R668

2K

R669

DTV/MNT_LOUT

P_+12V

1K

R672

+5V

0.1uF

C657

READY

ZD601

+5V

0.1uF

16V

C604

0.1uF

16V

C606

2SC3052

Q602EB

C

2SC3052

Q608

2SC3052

Q607

2SC3052

Q604EB

C

RT1P141C-T112

Q610

1

2

3

0.1uF

50V

C630

5.6

R635

3.3

R636

1000pF

C632

0.1uF

C634

0.1uF

C635

22000pF

C637

DA-8580

EAP38319001

L605

2S

1S 1F

2F

0.1uF

C638

3.3

R640

0.1uF

C639

0.1uF

C640

4.7K

R641

4.7K

R642

100R643

0.01uF

C678

+3.3V

0.1uF

C641

1uF

C645

5.6

R644

P_+16V

22000pF

C646

0.1uF

50V

C649

0.1uF

C650

0.1uF

C652

3.3K

R646

100

R670

5.6

R671

0.1uF

C653

22000pF

C654

P_+16V

0.01uF

C656

4.7K

R673

0.47uF

C658

3.3

R674

1uF

C662

3.3

R677

22000pFC663

4.7K

R686

DA-8580

EAP38319001

L609

2S

1S 1F

2F

1000pF

C665

0.47uF

C666

3.3

R687

0.01uF

C667

0.1uF

C668

5.6

R688

1uF

C669

0.1uF

C670

0.01uF

C672

0.01uF

C673

100pF

C677

+3.3V

100R645

SPDIF_OUT

DTV/MNT_LOUT

DTV/MNT_ROUT

MUTE_LINE_MNTOUT

SW_RESET

AUDIO_MASTER_CLK

MS_DAT_AMP

MS_WCLK_AMP

MS_BCLK_AMP

SDA2_3.3V

SCL2_3.3V

AUDIO_MUTE

Fiber Optic

JST1223-001

JK602

1

GND

2

VCC

3

VINPUT

4

FIX_POLE

MLB-201209-0120P-N2

L601

MLB-201209-0120P-N2

L608

10uF

16V

C603

MLB-201209-0120P-N2

L607

1uF

C633

47uF

16V

C601

10uF

6.3V

C661

10uF

6.3V

C674

330uF

25V

C679

330uF

25V

C675

10uF

25V

C682

10uF

25V

C683

2.2K

R664

2.2K

R663

33pF

C691

READY

33pF

C688

READY

10uF

C689

MS_WCLK

MS_BCLK

MS_DAT

MS_BCLK_AMP

MS_WCLK_AMP

MS_DAT_AMP

47pF

50V

READY

C619

AUDIO_MASTER_CLK

22

R601

220

R679

220

R678

220

R680

3.3uF

50V

C680

750R610

SIF

0.1uF

C676

SW_RESET

100R614

SIDE_LIN

SIDE_RIN

0

READY

R617

750R602

AV1_LIN

AV1_RIN

100R603

0.01uF

C642

0.01uFC636

100

R604

0.47uFC629

10uF

16V

C628

MS_BCLK

220R609

220R611

0.47uFC627

0.47uFC626

100pFC625

SW_ROUT

100uF

16V

C624

READY

0.01uFC687

220R612

56pF

C622

SCL1_5V

0.47uFC621

SDA1_5V

0.47uFC620

SW_LOUT

MS_DAT

DTV/MNT_LOUT_SC2

+5V

+8V_MSP

56pF

C610

750R616

4.7uF

10V

C609

470pF

C608

100R615

MSP4458G-C4

IC602

1

I2C_CL

2

I2C_DA

3

I2S_CL

4

I2S_WS

5

I2S_DA_OUT

6

I2S_DA_IN1

7

I2S_DA_OUT4

8

I2S_WS4

9

I2S_CL4

10

DVSUP

11

DVSS

12

I2S_DA_IN2/3

13

NC1

14

I2S_CL3

15

I2S_WS3

16

RESETQ

17

DACA_R

18

DACA_L

19

VREF2

20

DACM_R

21

DACM_L

22

NC2

23

NC3

24

NC4

25

SC2_OUT_R

26

SC2_OUT_L

27

VREF1

28

SC1_OUT_R

29

SC1_OUT_L

30

CAPL_A

31

AHVSUP

32

CAPL_M

33

AHVSS34AGNDC35SC4_IN_L36SC4_IN_R37ASG138SC3_IN_L39SC3_IN_R40ASG241SC2_IN_L42SC2_IN_R43ASG344SC1_IN_L45SC1_IN_R46VREFTOP47MONO_IN48AVSS

49

AVSUP

50

ANA_IN1+

51

ANA_IN?

52

ANA_IN2+

53

TESTEN

54

XTAL_IN

55

XTAL_OUT

56

TP

57

AUD_CL_OUT

58

NC5

59

NC6

60

D_CTR_I/O_1

61

D_CTR_I/O_0

62

ADR_SEL

63

STANDBYQ

64

NC7

0.1uF

C686

DTV/MNT_ROUT_SC2

MS_WCLK

10uF

16V

C685

0.47uFC690

MLB-201209-0120P-N2

L611

0

R621

0

R620

62K

R628

2SC3875S

Q611

0.01uF

C692

1.5K

R627

470

R626

24K

R625

3.3uF

C694

0.01uF

C693

4.7uF

10V

C618

3.9K

R630

3.9K

R631

6.8K

R698

6.8K

R697

MLB-201209-0120P-N2

L602

390pF

50V

C631

390pF

50V

C671

390pF

50V

C651

390pF

50V

C664

FLI10610H-AA

IC100

AUD_IN_L1

M3

AUD_IN_R1

M4

AUD_IN_L2

M1

AUD_IN_R2

M2

AUD_IN_L3

N5

AUD_IN_R3

M5

AUD_IN_L4

N3

AUD_IN_R4

N4

AUD_IN_L5

N1

AUD_IN_R5

N2

AUD_MCLK0

AC1

AUD_MCLK1

AB5

SIF_RTN

L6

AUDIN_I2S_BCLK

AC2

AUDIN_I2S_WCLK

AB3

AUDIN_I2S_DAT

AA4

AUDIN_SPDIF_IN

AA5

AUD_VREFP

L3

AUD_VCM

L5

AUD_VREFN

L4

AUD_OUT1_L

R1

AUD_OUT1_R

R2

AUD_OUT2_L

T3

AUD_OUT2_R

T4

AUD_OUT_HP_L

T1

AUD_OUT_HP_R

T2

AUDO_SPDIF_OUT

AD1

AUDO_I2SA_BCLK

AB4

AUDO_I2SA_WCLK

AC5

AUDO_I2SA_DAT0

AC4

AUDO_I2SB_DAT1

AD2

AUDO_I2SB_DAT2

AE2

AUDO_I2SB_BCLK

AC3

AUDO_I2SB_WCLK

AD3

AUDO_MUTE

AE1

LS_OUT_L

R3

LS_OUT_R

R4

LS_OUT_SW

R5

18.432MHz

X601

TP2115

TP2116

TP2117

TP2118

TP2122

TP2124

TP2127

TP2128

TP2137TP2138

TP2157

TP2158

TP2159

TP2160

47pF

50V

C696

47pF

50V

C697

NTP3000A

EAN41584001

IC601

1

BST1A

2

VDR1A

3

/RESET

4

AD

5

VSS_IO

6

CLK_I

7

CLK_O

8

VDD_IO

9

DGNDPLL

10

AGNDPLL

11

LFM

12

AVDDPLL

13

DVDDPLL

14

NC_1

15

DVSS

16

DVDD

17

SDATA

18

WCK

19

BCK

20

SDA

21

SCL

22

PWM_3B/PWM_HP2

23

PWM_3A/PWM_HP1

24

PROTECT

25

FAULT

26

VDR2B

27

BST2B

28

PGND2B_1

29

PGND2B_2

30

OUT2B_1

31

OUT2B_2

32

PVDD2B_1

33

PVDD2B_2

34

PVDD2A_1

35

PVDD2A_2

36

OUT2A_1

37

OUT2A_2

38

PGND2A_1

39

PGND2A_2

40

BST2A

41

VDR2A

42

NC_2

43

VDR1B44BST1B45PGND1B_146PGND1B_247OUT1B_148OUT1B_249PVDD1B_150PVDD1B_251PVDD1A_152PVDD1A_253OUT1A_154OUT1A_255PGND1A_156PGND1A_2

+1.8V

+1.8V

+1.8V

TP2195

TP2198

SMAW250-04

JK603

1

2

3

4

100

R689

1uF

10V

C698

2pF

50V

C623

2pF

50V

C617

L603

L604

L606

L610

SPDIF OPTIC JACK

OPTION

MNT/DTV OUT

SCART2

Buffer

PC Sound

Douglas

95

08.03.1

2

AUDIO

PWM AMP

PIN12 : R SPEAKER

PIN34 : L SPEAKER

- 29 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Page 29

Only for training and service purposes

CPL_DDR2_CAS_N

CPL_DDR2_CK_N

CPL_DDR2_DQS1_N

CPL_DDR2_A[0-12]

DDR2_RAS_N

CPL_DDR2_DQS3_P

CPL_DDR2_DQS0_N

DDR2_CKE

CPL_DDR2_DQS2_N

DDR2_WE_N

CPL_DDR2_DQS0_P

330uF

6.3V

C741

DDR2_A[0-12]

DDR2_DQS3_N

DDR2_DQS2_N

DDR2_A[0-12]

DDR2_VREF

DDR2_VREF

CPL_DDR2_DQS3_N

1uF

6.3V

C742

CPL_DDR2_BA1

DDR2_DQS1_N

DDR2_DQS2_P

DDR2_CAS_N

CPL_DDR2_BA0

CPL_DDR2_CK

DDR2_ODT_T

DDR2_DQS0_P

CPL_DDR2_DQS2_P

CPL_DDR2_DQS1_P

CPL_DDR2_CS_N

CPL_DDR2_DM[0-3]

DDR2_DQS1_P

DDR2_CS_N

330uF

6.3V

C720

DDR2_DQS3_P

DDR2_ODT

1uF

6.3V

C721

DDR2_DQS0_N

DDR2_BA1

CPL_DDR2_WE_N

CPL_DDR2_CKE

CPL_DDR2_RAS_N

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

+1.8V_DOUGLAS_DDR

+1.8V_DOUGLAS_DDR

+1.8V_DOUGLAS_DDR

+1.8V_DOUGLAS_DDR

+1.8V_DOUGLAS_DDR

DDR2_VREF

CPL_DDR2_D[0-31]

DDR2_D[0-31]

CPL_DDR2_D[0-31]

DDR2_D[0-31]

CPL_DDR2_DQS1_N

CPL_DDR2_DQS0_N

CPL_DDR2_DQS2_P

CPL_DDR2_DQS3_N

CPL_DDR2_DQS0_P

CPL_DDR2_DQS1_P

CPL_DDR2_DQS3_P

CPL_DDR2_DQS2_N

CPL_DDR2_A[0-12]

DDR2_DQS2_N

DDR2_DQS2_P

CPL_DDR2_DM[0-3]

DDR2_DM[0-3]

DDR2_A[0-12]

CPL_DDR2_CS_N

CPL_DDR2_RAS_N

CPL_DDR2_CAS_N

CPL_DDR2_CK

CPL_DDR2_CK_N

CPL_DDR2_CKE

CPL_DDR2_BA0

CPL_DDR2_WE_N

CPL_DDR2_BA1

DDR2_CK_N

DDR2_CK

DDR2_CAS_N

DDR2_CS_N

DDR2_RAS_N

DDR2_CKE

DDR2_BA0

DDR2_WE_N

DDR2_BA1

DDR2_DQS3_P

DDR2_DQS3_N

DDR2_DQS0_P

DDR2_DQS0_N

DDR2_DQS1_P

DDR2_DQS1_N

DDR2_CK_N

DDR2_BA0

DDR2_CK

DDR2_CAS_N

DDR2_BA0

DDR2_WE_N

DDR2_RAS_N

DDR2_CK_N

DDR2_BA1

DDR2_CK

DDR2_ODT_T

DDR2_CKE

DDR2_CS_N

DDR2_DM[0-3]

1/16W

10

AR707

1/16W

10

AR711

1/16W

10

AR704

1/16W

10

AR708

1/16W

10

AR716

1/16W

10

AR706

1/16W

10

AR717

1/16W

10

AR710

HYB18TC512160BF-3S

IC701

J2

VREF

J8

CK

H2

VSSQ2

B7

UDQS

N8

A4

P8

A8

L1

NC4

L2

BA0

R8

NC3

K7

RAS

F8

VSSQ3

F3

LDM

P3

A9

M3

A1

N3

A5

K8

CK

R3

NC5

L3

BA1

J7

VSSDL

L7

CAS

F2

VSSQ4

B3

UDM

M2

A10/AP

K2

CKE

R7

NC6

M7

A2

N7

A6

M8

A0

J1

VDDL

K3

WE

E8

LDQS

P7

A11

K9

ODT

A2

NC1

N2

A3

P2

A7

H8

VSSQ1

F7

LDQS

A8

UDQS

R2

A12

L8

CS

E2

NC2

E7

VSSQ5

D8

VSSQ6

D2

VSSQ7

A7

VSSQ8

B8

VSSQ9

B2

VSSQ10

P9

VSS1

N1

VSS2

J3

VSS3

E3

VSS4

A3

VSS5

G9

VDDQ1

G7

VDDQ2

G3

VDDQ3

G1

VDDQ4

E9

VDDQ5

C9

VDDQ6

C7

VDDQ7

C3

VDDQ8

C1

VDDQ9

A9

VDDQ10

R1

VDD1

M9

VDD2

J9

VDD3

E1

VDD4

A1

VDD5

B9

DQ15

B1

DQ14

D9

DQ13

D1

DQ12

D3

DQ11

D7

DQ10

C2

DQ9

C8

DQ8

F9

DQ7

F1

DQ6

H9

DQ5

H1

DQ4

H3

DQ3

H7

DQ2

G2

DQ1

G8

DQ0

HYB18TC512160BF-3S

IC703

J2

VREF

J8

CK

H2

VSSQ2

B7

UDQS

N8

A4

P8

A8

L1

NC4

L2

BA0

R8

NC3

K7

RAS

F8

VSSQ3

F3

LDM

P3

A9

M3

A1

N3

A5

K8

CK

R3

NC5

L3

BA1

J7

VSSDL

L7

CAS

F2

VSSQ4

B3

UDM

M2

A10/AP

K2

CKE

R7

NC6

M7

A2

N7

A6

M8

A0

J1

VDDL

K3

WE

E8

LDQS

P7

A11

K9

ODT

A2

NC1

N2

A3

P2

A7

H8

VSSQ1

F7

LDQS

A8

UDQS

R2

A12

L8

CS

E2

NC2

E7

VSSQ5

D8

VSSQ6

D2

VSSQ7

A7

VSSQ8

B8

VSSQ9

B2

VSSQ10

P9

VSS1

N1

VSS2

J3

VSS3

E3

VSS4

A3

VSS5

G9

VDDQ1

G7

VDDQ2

G3

VDDQ3

G1

VDDQ4

E9

VDDQ5

C9

VDDQ6

C7

VDDQ7

C3

VDDQ8

C1

VDDQ9

A9

VDDQ10

R1

VDD1

M9

VDD2

J9

VDD3

E1

VDD4

A1

VDD5

B9

DQ15

B1

DQ14

D9

DQ13

D1

DQ12

D3

DQ11

D7

DQ10

C2

DQ9

C8

DQ8

F9

DQ7

F1

DQ6

H9

DQ5

H1

DQ4

H3

DQ3

H7

DQ2

G2

DQ1

G8

DQ0

10

R778

10

R779

10

R780

10

R781

10

R782

10

R783

10

R784

10

R785

10

R786

10

R787

10

R788

10R789

10R790

10R791

10

R792

10

R793

10

R794

10R795

10

R796

10

R797

10

R798

10

R799

10

R724

10R725

10

R706

10

R703

10

R701

10

R702

10R705

10R704

10R707

10K

R772

10R710

6801%R771

6801%R770

0.1uF

C713

0.1uF

C737

0.1uF

C708

0.1uF

C710

0.1uF

C705

0.1uF

C714

0.1uF

C728

0.1uF

C727

0.1uF

C717

0.1uF

C729

0.1uF

C706

0.1uF

C709

0.1uF

C711

0.1uF

C707

0.1uF

C725

0.1uF

C726

0.1uF

C712

0.1uF

C715

0.1uF

C738

0.1uF

C724

200

R712

200

R711

0.1uF

50V

C754

0.1uF

C704

0.1uF

C703

DDR2_ODTDDR2_ODT_T

10

R777

0.1uF

50V

C755

0.1uF

C702

0.1uF

16V

C750

0.1uF

C722

0.1uF

16V

C753

10uF

6.3V

C751

10uF

6.3V

C752

10R716

10R715

10R714

10R713

0.1uF

C723

0.1uF

C701

0.1uF

C716

0.1uF

C733

0.1uF

C732

0.1uF

C734

0.1uF

C730

0.1uF

C731

0.1uF

C736

0.1uF

C735

294

R709

1%

FLI10610H-AA

IC100

DDR_D0

F24

DDR_D1

M24

DDR_D2

J25

DDR_D3

K26

DDR_D4

M26

DDR_D5

E25

DDR_D6

L25

DDR_D7

F26

DDR_D8

E29

DDR_D9

L29

DDR_D10

H28

DDR_D11

J29

DDR_D12

L27

DDR_D13

E27

DDR_D14

K28

DDR_D15

F28

DDR_D16

Y24

DDR_D17

AF28

DDR_D18

AC25

DDR_D19

AD26

DDR_D20

AF26

DDR_D21

W25

DDR_D22

AE25

DDR_D23

Y26

DDR_D24

W29

DDR_D25

AE29

DDR_D26

AB28

DDR_D27

AC29

DDR_D28

AE27

DDR_D29

W27

DDR_D30

AD28

DDR_D31

Y28

DDR_DQS0

H25

DDR_DQS0_N

H26

DDR_DQS1

G28

DDR_DQS1_N

G29

DDR_DQS2

AB25

DDR_DQS2_N

AB26

DDR_DQS3

AA28

DDR_DQS3_N

AA29

DDR_A0

P27

DDR_A1

U29

DDR_A2

R26

DDR_A3

U26

DDR_A4

P25

DDR_A5

T28

DDR_A6

R27

DDR_A7

V28

DDR_A8

R29

DDR_A9

T29

DDR_A10

V25

DDR_A11

R28

DDR_A12

V26

DDR_DM0

K24

DDR_DM1

J27

DDR_DM2

AD24

DDR_DM3

AC27

DDR_BA0

U28

DDR_BA1

T27

DDR_CAS_N

P24

DDR_RAS_N

N26

DDR_CS_N

N25

DDR_WE_N

T25

DDR_CK

P29

DDR_CK_N

N29

DDR_CKE

U27

DDR_ODT

M27

DDR_CAL

U24

HYB18TC512160B2F-3S

IC701-*1

PG60

J2

VREF

J8

CK

H2

VSSQ2

B7

UDQS

N8

A4

P8

A8

L1

NC4

L2

BA0

R8

NC3

K7

RAS

F8

VSSQ3

F3

LDM

P3

A9

M3

A1

N3

A5

K8

CK

R3

NC5

L3

BA1

J7

VSSDL

L7

CAS

F2

VSSQ4

B3

UDM

M2

A10/AP

K2

CKE

R7

NC6

M7

A2

N7

A6

M8

A0

J1

VDDL

K3

WE

E8

LDQS

P7

A11

K9

ODT

A2

NC1

N2

A3

P2

A7

H8

VSSQ1

F7

LDQS

A8

UDQS

R2

A12

L8

CS

E2

NC2

E7

VSSQ5

D8

VSSQ6

D2

VSSQ7

A7

VSSQ8

B8

VSSQ9

B2

VSSQ10

P9

VSS1

N1

VSS2

J3

VSS3

E3

VSS4

A3

VSS5

G9

VDDQ1

G7

VDDQ2

G3

VDDQ3

G1

VDDQ4

E9

VDDQ5

C9

VDDQ6

C7

VDDQ7

C3

VDDQ8

C1

VDDQ9

A9

VDDQ10

R1

VDD1

M9

VDD2

J9

VDD3

E1

VDD4

A1

VDD5

B9

DQ15

B1

DQ14

D9

DQ13

D1

DQ12

D3

DQ11

D7

DQ10

C2

DQ9

C8

DQ8

F9

DQ7

F1

DQ6

H9

DQ5

H1

DQ4

H3

DQ3

H7

DQ2

G2

DQ1

G8

DQ0

HYB18TC512160B2F-3S

IC703-*1

PG60

J2

VREF

J8

CK

H2

VSSQ2

B7

UDQS

N8

A4

P8

A8

L1

NC4

L2

BA0

R8

NC3

K7

RAS

F8

VSSQ3

F3

LDM

P3

A9

M3

A1

N3

A5

K8

CK

R3

NC5

L3

BA1

J7

VSSDL

L7

CAS

F2

VSSQ4

B3

UDM

M2

A10/AP

K2

CKE

R7

NC6

M7

A2

N7

A6

M8

A0

J1

VDDL

K3

WE

E8

LDQS

P7

A11

K9

ODT

A2

NC1

N2

A3

P2

A7

H8

VSSQ1

F7

LDQS

A8

UDQS

R2

A12

L8

CS

E2

NC2

E7

VSSQ5

D8

VSSQ6

D2

VSSQ7

A7

VSSQ8

B8

VSSQ9

B2

VSSQ10

P9

VSS1

N1

VSS2

J3

VSS3

E3

VSS4

A3

VSS5

G9

VDDQ1

G7

VDDQ2

G3

VDDQ3

G1

VDDQ4

E9

VDDQ5

C9

VDDQ6

C7

VDDQ7

C3

VDDQ8

C1

VDDQ9

A9

VDDQ10

R1

VDD1

M9

VDD2

J9

VDD3

E1

VDD4

A1

VDD5

B9

DQ15

B1

DQ14

D9

DQ13

D1

DQ12

D3

DQ11

D7

DQ10

C2

DQ9

C8

DQ8

F9

DQ7

F1

DQ6

H9

DQ5

H1

DQ4

H3

DQ3

H7

DQ2

G2

DQ1

G8

DQ0

DDR2_A[9]

CPL_DDR2_DM[2]

DDR2_A[10]

DDR2_A[6]

DDR2_A[4]

DDR2_A[10]

DDR2_A[3]

DDR2_A[8]

DDR2_A[2]

DDR2_A[9]

DDR2_A[12] DDR2_A[12]

CPL_DDR2_DM[0]

DDR2_A[5]

DDR2_A[6]

DDR2_A[2]

DDR2_A[0]

DDR2_A[7]

CPL_DDR2_DM[3]

DDR2_A[5]

DDR2_A[1]

DDR2_A[4]

DDR2_A[8]

CPL_DDR2_DM[1]

DDR2_A[3]

DDR2_A[0]

DDR2_A[7]

DDR2_A[1]

DDR2_A[11] DDR2_A[11]

CPL_DDR2_D[30]

CPL_DDR2_D[25]

CPL_DDR2_D[28]

CPL_DDR2_D[29]

CPL_DDR2_D[24]

CPL_DDR2_D[31]

DDR2_D[30]

DDR2_D[25]

DDR2_D[28]

DDR2_D[29]

DDR2_D[24]

DDR2_D[31]

CPL_DDR2_D[13]

CPL_DDR2_D[8]

CPL_DDR2_D[15]

CPL_DDR2_DM[3]

CPL_DDR2_DM[1]

CPL_DDR2_D[14]

CPL_DDR2_D[9]

CPL_DDR2_D[12]

CPL_DDR2_A[10]

CPL_DDR2_A[3]

CPL_DDR2_A[7]

CPL_DDR2_A[12]

CPL_DDR2_A[2]

CPL_DDR2_A[9]

CPL_DDR2_A[5]

CPL_DDR2_A[1]

CPL_DDR2_A[8]

CPL_DDR2_A[11]

CPL_DDR2_A[6]

DDR2_DM[3]

DDR2_DM[1]

DDR2_A[6]

DDR2_A[11]

DDR2_A[8]

DDR2_A[1]

DDR2_A[5]

DDR2_A[9]

DDR2_A[2]

DDR2_A[12]

DDR2_A[7]

DDR2_A[3]

DDR2_A[10]

DDR2_D[14]

DDR2_D[9]

DDR2_D[12]

DDR2_D[15]

DDR2_D[8]

DDR2_D[13]

DDR2_DM[2]

DDR2_DM[3]

CPL_DDR2_D[0]

CPL_DDR2_D[1]

CPL_DDR2_D[2]

CPL_DDR2_D[3]

CPL_DDR2_D[4]

CPL_DDR2_D[5]

CPL_DDR2_D[6]

CPL_DDR2_D[7]

CPL_DDR2_D[8]

CPL_DDR2_D[9]

CPL_DDR2_D[10]

CPL_DDR2_D[11]

CPL_DDR2_D[12]

CPL_DDR2_D[13]

CPL_DDR2_D[14]

CPL_DDR2_D[15]

CPL_DDR2_D[16]

CPL_DDR2_D[17]

CPL_DDR2_D[18]

CPL_DDR2_D[19]

CPL_DDR2_D[20]

CPL_DDR2_D[21]

CPL_DDR2_D[22]

CPL_DDR2_D[23]

CPL_DDR2_D[24]

CPL_DDR2_D[25]

CPL_DDR2_D[26]

CPL_DDR2_D[27]

CPL_DDR2_D[28]

CPL_DDR2_D[29]

CPL_DDR2_D[30]

CPL_DDR2_D[31]

DDR2_D[15]

DDR2_D[14]

DDR2_D[13]

DDR2_D[12]

DDR2_D[11]

DDR2_D[10]

DDR2_D[9]

DDR2_D[8]

DDR2_D[7]

DDR2_D[6]

DDR2_D[5]

DDR2_D[4]

DDR2_D[3]

DDR2_D[2]

DDR2_D[1]

DDR2_D[0]

DDR2_D[16]

DDR2_D[17]

DDR2_D[18]

DDR2_D[19]

DDR2_D[20]

DDR2_D[21]

DDR2_D[22]

DDR2_D[23]

DDR2_D[24]

DDR2_D[25]

DDR2_D[26]

DDR2_D[27]

DDR2_D[28]

DDR2_D[29]

DDR2_D[30]

DDR2_D[31]

DDR2_DM[1]

DDR2_DM[0]

CPL_DDR2_D[18]

CPL_DDR2_D[19]

CPL_DDR2_DM[2]

CPL_DDR2_D[22]

CPL_DDR2_D[17]

CPL_DDR2_D[20]

CPL_DDR2_D[21]

CPL_DDR2_D[16]

CPL_DDR2_D[23]

CPL_DDR2_D[5]

CPL_DDR2_D[0]

CPL_DDR2_D[7]

CPL_DDR2_DM[0]

CPL_DDR2_D[2]

CPL_DDR2_D[3]

CPL_DDR2_D[6]

CPL_DDR2_D[1]

CPL_DDR2_D[4]

CPL_DDR2_A[0]

CPL_DDR2_A[1]

CPL_DDR2_A[2]

CPL_DDR2_A[3]

CPL_DDR2_A[4]

CPL_DDR2_A[5]

CPL_DDR2_A[6]

CPL_DDR2_A[7]

CPL_DDR2_A[8]

CPL_DDR2_A[9]

CPL_DDR2_A[10]

CPL_DDR2_A[11]

CPL_DDR2_A[12]

DDR2_D[18]

DDR2_D[19]

DDR2_DM[2]

DDR2_D[22]

DDR2_D[17]

DDR2_D[20]

DDR2_D[21]

DDR2_D[16]

DDR2_D[23]

DDR2_D[5]

DDR2_D[0]

DDR2_D[7]

DDR2_D[2]

DDR2_DM[0]

DDR2_D[3]

DDR2_D[6]

DDR2_D[1]

DDR2_D[4]

CPL_DDR2_D[26]

CPL_DDR2_D[27] DDR2_D[27]

DDR2_D[26]

DDR2_D[10]

CPL_DDR2_D[10]

CPL_DDR2_D[11]

DDR2_D[11]

CPL_DDR2_A[4] DDR2_A[4]

CPL_DDR2_A[0] DDR2_A[0]

Douglas

96

DDR2

- 30 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Page 30

Only for training and service purposes

10K

R1128

3.3uH

L105

3.3uH

L106

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

D113

220K

R1172

220K

R1169

D123 D125D124 D115

CHAPLIN_TX

100

R1188

READY

D116

0.1uF

C143

READY

D119

100

R1186

READY

D118

0.1uF

C141

100

R1187

CHAPLIN_RX

0.1uF

C145

READY

D121

DEBUG_RX

0.1uF

C144

100

R1189

0.1uF

C142

D114

D117

1KR1180

D129

12pF

C132

AT24C02BN-10SU-1.8

IC102

3

2

415

6

7

8

74HC14D

IC103

3

2

4

1

6

5

78

9

10

11

12

13

14

D128

10K

R1215

D130

D126

12pF

C133

SD05

D127

10K

R1214

0

R1155

1K

R1174

+5V

0.1uF

C150

4.7K

R1175

4.7K

R1166

D122

D120

GND

GND

+3.3V_STBY +3.3V_STBY

P_+5V

D134 D131D132D133

220K

R1310

100pF

C160

READY

100pF

C161

READY

100

R1164

100

R1165

100

R1185

100

R1325

READY

100

PC_COMMAND

R1322

UCOM_RX

100

READY

R1324

6.8K

R1327

6.8K

R1328

100

R1181

100

R1177

220K

R1309

0

R1110

4.7K

R1111

D135

75

R1157

75

R1158

75

R1163

75

R1308

75

R1168

75

R1171

75

R1119

75

R1312

75

R1170

1000pF

C110

READY

1000pF

C109

READY

470K

R1136

470K

R1137

DTV/MNT_LOUT

DTV/MNT_VOUT

COMP1_RIN

COMP1_LIN

COMP1_Pr

COMP1_Pb

VGA_R

D_SUB_SDA

VGA_G

VGA_B

DS_HS

DS_VS

D_SUB_SCL

D_SUB_SCL

D_SUB_SDA

DS_VS

V_SYNC_PC

H_SYNC_PC

DS_HS

+3.3V

1000pF

C165

1000pF

C162

220uF

16V

C118

DTV/MNT_ROUT

SIDE_LIN

SIDE_RIN

SIDE_CIN

SIDE_YIN/SIDE_VIN

SIDE_S_SW

82

R1344

2SC3052

Q108EB

C

2SA1504S

Q103EB

C

2SC3052

Q106EB

C

P_+12V

330

R1343

47

R1342

330

R1341

470

R1345

1K

R1340

27K

R1339

27K

R1338

330

R1337

330

R1336

0.1uF

READY

C148

PC_SER_DATA

PC_SER_CLK

RGB_LINK

30V

READY

D137

0.1uF

16V

C112

+3.3V

COMP1_LINK

30V

D138

10K

R1150

0.1uF

16V

C116

+3.3V

SIDE_CVBS_LINK

30V

D139

10K

R1152

0.1uF

16V

C119

+3.3V

1K

R1159

1K

R1160

DEBUG_TX

0

READY

R1347

UART_SEL

NLASB3157DFT2G

IC1013

3

B0

2

GND

4

A

1B16

SELECT

5

VCC

+3.3V_STBY

10K

R1346

0.1uF

16V

C167

UCOM_TX

6.8K

R1304

READY

6.8K

R1303

READY

0

R1156

4.7pF

C108

4.7pF

C106

4.7pF

C107

22

R1334

22

R1333

22

R1335

3.9K

R1179

3.9K

R1178

1K

R1138

10K

R1149

100

R1184

GND

D111

3.9K

R1371

75

R1355

D110

75

R1368

D108

COMP2_LIN

220K

R1369

+3.3V

30V

D109

0.1uF

16V

C123

1K

R1366

D112

3.9K

R1364

10K

R1363

COMP2_Pr

75

R1365

COMP2_LINK

6.8K

R1353

6.8K

R1367

D107

COMP2_Pb

COMP2_RIN

220K

R1357

D101

AV1_LIN

D102

AV1_RIN

100pF

READY

C121

100pF

READY

C120

220K

R1359

220K

R1361

AV1_CVBS

75

R1362

D106

AV1_CVBS_LINK

TP1611

TP1612

TP1614

TP1616

TP1618

6.8K

R1351

READY

6.8K

R1354

READY

0

R1352

0

R1360

0

R1307

0

R1306

10uF

16V

C111

0.1uF

16V

C163

1K

R1143

+3.3V

30V

READY

D140

10K

R1147

MAX3232CDR

IC101

3

C1-

2

V+

4

C2+

1

C1+

6

V-

5

C2-

7

DOUT2

8

RIN29ROUT2

10

DIN2

11

DIN1

12

ROUT1

13

RIN1

14

DOUT1

15

GND

16

VCC

KCN-DS-1-0089

JK104

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

0

R1349

KCN-DS-1-0088

P101

1

2

3

4

5

6

7

8

9

10

PPJ150-09

JK902

3A [RD]O_SPRING1

2A [RD]1P_CAN1

4A [RD]CONTACT1

2B [WH]1P_CAN1

3B [WH]0_SPRING1

2C [YL]1P_CAN1

3C [YL]O_SPRING1

4C [YL]CONTACT1

2D [RD]1P_CAN2

3D [RD]O_SPRING2

4D [RD]CONTACT2

2E [WH]1P_CAN2

3E [WH]0_SPRING2

2F [YL]1P_CAN2

3F [YL]O_SPRING2

4F [YL]CONTACT2

10K

R1113

+3.3V_STBY

TP2058

TP2059

TP2060

TP2061

PPJ218-01

JK105

5C

[RD]CONTACT

2C

[RD]U_CAN

4C

[RD]O_SPRING

2B

[WH]U_CAN

3B

[WH]C_LUG

2A

[YL]U_CAN

5A

[YL]CONTACT

4A

[YL]O_SPRING

TP2082TP2083

TP2102

TP2103

JP75

JP76

JP77

JP78

JP79

JP80

JP81

JP82

JP83JP84

JP85

JP86

JP87

JP88

JP89

JP90

JP91JP92

JP93

PSJ018-01

JK106

1 GND_TER

2 C_LUG_S1

3 C_LUG_L1

6NC1

7 COM1

8 NO1

9NC2

10 COM2

11 NO2

12

SHIELD

4 C_LUG_S2

5 C_LUG_L2

D141

D142

D143

KDS184

D144

A2CA1

RGB_+5V

RGB_+5V

TP2141

TP2142

PPJ209-02

JK101

4A

[GN]CONTACT

2A [GN]1P_CAN

3A [GN]O_SPRING

2B

[BL]1P_CAN

5B [BL]C_LUG_L

2C [RD]1P_CAN1

5C

[RD]C_LUG_L

2D [WH]1P_CAN

5D

[WH]C_LUG_L

2E [RD]1P_CAN2

4E [RD]CONTACT

3E [RD]O_SPRING

PPJ209-02

JK103

4A [GN]CONTACT

2A [GN]1P_CAN

3A

[GN]O_SPRING

2B

[BL]1P_CAN

5B [BL]C_LUG_L

2C [RD]1P_CAN1

5C [RD]C_LUG_L

2D [WH]1P_CAN

5D

[WH]C_LUG_L

2E

[RD]1P_CAN2

4E [RD]CONTACT

3E

[RD]O_SPRING

TP2181

TP2182

0

R1122

COMP2_Y

4.7pF

READY

C102

4.7pF

READY

C103

0

R1123

TP1613

COMP1_Y

JP511

10

R1127

10

R1126

220pF

50V

C124

220pF

50V

C127

270pF

50V

C125

270pF

50V

C126

CAT24C02WI-GT3

IC102-*1

3

A2

2

A1

4

VSS

1

A0

5

SDA

6

SCL

7

WP

8

VCC

RCA-517HA-00A-01

JK101-*1

PG60

4A[GN]CONTACT

2A[GN]1P_CAN

3A[GN]O_SPRING

2B[BL]1P_CAN

5B[BL]C_LUG_L

2C[RD]1P_CAN1

5C[RD]C_LUG_L

2D[WH]1P_CAN

5D[WH]C_LUG_L

2E[RD]1P_CAN2

4E[RD]CONTACT

3E[RD]O_SPRING

RCA-517HA-00A-01

JK103-*1

PG60

4A[GN]CONTACT

2A[GN]1P_CAN

3A[GN]O_SPRING

2B[BL]1P_CAN

5B[BL]C_LUG_L

2C[RD]1P_CAN1

5C[RD]C_LUG_L

2D[WH]1P_CAN

5D[WH]C_LUG_L

2E[RD]1P_CAN2

4E[RD]CONTACT

3E[RD]O_SPRING

RCA-639HA-00A-02

JK902-*1

PG60

3A[RD]O_SPRING1

2A[RD]1P_CAN1

4A[RD]CONTACT1

2B[WH]1P_CAN1

3B[WH]0_SPRING1

2C[YL]1P_CAN1

3C[YL]O_SPRING1

4C[YL]CONTACT1

2D[RD]1P_CAN2

3D[RD]O_SPRING2

4D[RD]CONTACT2

2E[WH]1P_CAN2

3E[WH]0_SPRING2

2F[YL]1P_CAN2

3F[YL]O_SPRING2

4F[YL]CONTACT2

SIDE CVBS & S_VIDEO

Y

R

Pr

Pb

L

COMPONENT 1

1 : Data carrier detect

2 : RX

3 : TX

4 : DTR(Data terminal ready

5 : GND

6 : DSR(Data set ready)

7 : RTS(Request to send)

8 : CTS(Clear to send)

9 : RI(Ring indicator)

RS-232C Input

9.+5V DC

3.BLU

ROM DOWNLOAD FOR PDP

7.G_GNC

4.RESERVED

5.GND

11.RGB Input

12.SDA

13.HSYNC

OPT

2.GRN

1.RED

11.RESERVED

14.VSYNC

15.SCL

8.B_GND

6.R_GND

10.SYNC_GND

19

Douglas

External Jack

Pb

L

Y

COMPONENT 2

R

Pr

AV 1, MORNITOR OUT

HIGH : CONNECTED

HIGH : CONNECTED

HIGH : CONNECTED

HIGH : CONNECTED

LOW : CONNECTED

LOW : Y/C

- 31 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Page 31

Only for training and service purposes

RL_ON/PWR_ONOFF

VAVS_ON

3.3V_ON

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

HDMI3_5V_DET

HDMI2_5V_DET

HDMI1_5V_DET

SW_RESET

19.66080Hz

X801

+3.3V_DOUGLAS

FE_RESET

HP_DET_S/W_2

HP_DET_S/W_4

DTV/MNT_SWITCH

HDMI4_5V_DET

HDMI_SW_EQ

5pF

READY

C809

5pF

READY

C808

LED_G

0.1uF

50V

C807

KEY2

LED_R

KEY1

P_+5V

IR

M5V_ON

MLB-201209-0120P-N2

L801

RGB_LINK

SIDE_S_SW

COMP1_LINK

SIDE_CVBS_LINK

+3.3V_STBY

+3.3V_STBY

22

R8057

+3.3V_STBY

KEY2

22

R8053

+3.3V_STBY

UART_SEL

RESET

AUDIO_MUTE

22

R8030

DISP_EN

P_+5V

KEY1

0.1uF

16V

C814

D_SUB_SDA

100

R8054

15K

R8055

+3.3V_STBY

22

R8044

UCOM_RX

UCOM_TX

0.1uF

16V

C813

IR

SCL2_3.3V

22

R8072

1/16W

47K

R8061

LED_R

0.1uF

16V

C818

100

R8069

47K

R8075

AC_DET

5V_MNT

0.1uF

16V

C819

100

R8031

1.8V_DOUGLAS_EN

6.8K

R8070

1.26V_DOUGLAS_EN

KIA7029AF

IC803

2

G

3O1

I

MUTE_LINE_MNTOUT

100

R8092

+3.3V_STBY

22

R8051

LED_G

22

R8071

CEC_0

3.3K

R8041

4.7K

R8040

D_SUB_SCL

SDA2_3.3V

4.7uF

10V

C803

0

R8087

READY

P_+5V

10K

R8029

10K

R8052

10K

R8063

10K

R8050

10K

R8068

10K

R8073

10K

R8080

READY

10K

R8065

READY

10K

R8082

10uF

6.3V

C825

24pF

C801

24pF

C802

MODULE_SER_CLK

MODULE_SER_DATA

BOOSTER

0.1uF

16V

C804

READY

HDMI_SEL1

HDMI_SEL2

12505WS-12A00

P803

1

IR

2

GND

3

KEY2

4

GND

5

KEY1

6

GND

7

STBY_5V

8

GND

9

LED_R

10

GND

11

LED_G

12

GND

13

SPK_R

6.8K

R8095

3.3K

R8049

FLI10610H-AA

IC100

VXI_CLK

A18

VXI_DE

C18

VXI_VS

B18

VXI_HS

D18

VXI_D0

E19

VXI_D1

A17

VXI_D2

B17

VXI_D3

C17

VXI_D4

D17

VXI_D5

F17

VXI_D6

A16

VXI_D7

B16

VXI_D8

C16

VXI_D9

D16

VXI_D10

D19

VXI_D11

E16

VXI_D12

A15

VXI_D13

B15

VXI_D14

C15

VXI_D15

D15

VXI_D16

E15

VXI_D17

A14

VXI_D18

B14

VXI_D19

C14

VXI_D20

D14

VXI_D21

E14

VXI_D22

E17

VXI_D23

E18

TESTMODE0

C27

TESTMODE1

C26

VXO_CLK

AD19

VXO_DE

AE19

VXO_VS

AG18

VXO_HS

AF18

VXO_D0

AF15

VXO_D1

AH16

VXO_D2

AJ16

VXO_D3

AE15

VXO_D4

AE16

VXO_D5

AF16

VXO_D6

AG16

VXO_D7

AH17

VXO_D8

AJ17

VXO_D9

AE17

VXO_D10

AF17

VXO_D11

AG17

VXO_D12

AH18

VXO_D13

AJ18

VXO_D14

AD15

VXO_D15

AE18

REF_CLK

A22

XTAL_IN

A23

CLKOUT

E12

OBUFC_CLK

F21

NC_1

F7

NC_2

F8

NC_3

F9

NC_4

F10

NC_5

F11

SIF_IN

K6

WT61P8-RN440WT

IC802

1

VDD33V

2

GND

3

OSCO

4

OSCI

5

GPIOB6/SSDA

6

GPIOB5/SSCL

7

GPIOB4/P05

8

GPIOB3/P04

9

GPIOB2/IR

10

GPIOB1/IRQ3/CEC

11

GPIOB0/IRQ2

12

GPIOC7/P17/IRQ1

13

GPIOC6/P16/IRQ0

14

GPIOC5/P15/TXD1

15

GPIOC4/P14/RXD1

16

GPIOC3/AD317GPIOC2/AD218GPIOC1/AD119GPIOC0/AD0

20

DSDA1

21

DSCL1

22

GPIOA5/DSDA2

23

GPIOA4/DSCL2

24

GPIOA3/PWM7/P03

25

GPIOA2/PWM6/P02

26

GPIOA1/PWM5/P01

27

GPIOA0/PWM4/P00

28

GPIOD7/RXD2

29

GPIOD6/TXD2

30

GPIOD5/P13/AD7

31

GPIOD4/P12/AD6

32

GPIOD3/P11/AD5

33

GPIOD2/P10/AD4

34

GPIOD1/HIN2

35

GPIOD0/HIN1

36

GPIOE7/VIN1

37

GPIOE6/VIN2

38

GPIOE5/P07

39

GPIOE4/LPWM/P06

40

GPIOE3/PWM3

41

GPIOE2/PWM2

42

GPIOE1/PWM1

43

NRST44GPIOE0/PWM0

TP2135

TP2136

10K

R8058

+3.3V_STBY

P_+5V

100pF

50V

C833

100pF

50V

C831

470pF

50V

C826

470pF

50V

C832

24MHz

X802

18pF

50V

C812

18pF

50V

C817

10K

READY

R8093

+3.3V_STBY

10K

R8094

BLM18AG121SN1D

L804

BLM18AG121SN1D

L803

BLM18AG121SN1D

L802

BLM18AG121SN1D

L805

BLM18AG121SN1D

L806

+3.3V_DOUGLAS

10K

READY

R8004

10K

READY

R8001

10K

READY

R8003

10K

READY

R8002

0.1uF

C815