Page 1

PLASMA TV

MANUAL DE SERVIÇO

ATENÇÃO

Antes de reparar este chassis, leia as PRECAUÇÕES DE SEGURANÇA

contidas neste manual.

CHASSIS : PB82C

MODELO : 50PG60D 50PG60D-SA

website:http://biz.LGservice.com

Internal Use Only

Page 2

- 2 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

CONTEÚDO

CONTEÚDO............................................................................................................... 2

PRECAUÇÕES DE SEGURANÇA ............................................................................3

INSTRUÇÕES DE REGULAÇÃO ..............................................................................4

GUIA DE RESOLUÇÃO DE PROBLEMAS ...............................................................9

DIAGRAMA DE BLOCOS ........................................................................................40

VISTAS EXPLODIDAS............................................................................................. 42

LISTA DAS VISTAS EXPLODIDAS..........................................................................43

DIAGRAMA ELÉTRICO................................................................................................

PAINEL DE CIRCUITO IMPRESSO .............................................................................

Page 3

- 3 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PRECAUÇÕES DE SEGURANÇA

ADVERTÊNCIA : Antes de reparar este chassis., leia as “ PRECAUÇÕES DE RADIAÇÃO POR RAIO X “, “ INSTRUÇÕES

DE SEGURANÇA “ e “ AVISO SOBRE SEGURANÇA DE PRODUTOS “.

Muitas partes elétricas e mecânicas neste chassis, tem características relacionadas com a segurança. Estas características

frequentemente não são verificadas nas inspeções visuais e a proteção que proporcionam contra a RADIAÇÃO DE RAIO “ X “ nem

sempre se obtem utilizando componente com maior potência ou de maior isolação. As peças que têm essas características de

segurança são identificadas por uma marca [ ] impressa sobre o diagrama esquemático e a marca [

★ ] impressa na lista de

partes elétricas. Antes de substituir algum destes componentes, leia cuidadosamente este manual. O uso de peças de reposição que

não tenham as mesmas características de segurança, como especificado na lista de material de reposição, pode gerar Radiação de

Raios “X”.

1. Quando o receptor está em operação, são geradas tensões

potencialmente altas em torno de 25-29 kV. Operar o receptor

fora de seu gabinete ou com a tampa traseira removida pode

causar perigo de choque elétrico.

(1) Ninguém deverá tentar reparar o aparelho sem estar

familiarizado com as precauções que são necessárias

quando se trabalha com um equipamento de alta tensão.

(2) Sempre descarregue o anodo do cinescópio ao terra para

evitar o risco de choque elétrico antes de remover o conector

do anodo (chupeta de alta tensão).

(3) Descarregue completamente o potencial do cinescópio

antes de manuseá-lo. O cinescópio é de alto vácuo, e se

quebrar, os fragmentos de vidro são expelidos violentamente.

2. S e queimar algúm fusível deste receptor de televisão,

substitua-o por outro especificado na lista de peças elétricas.

3. Quando substituir placas de circuito impresso ou módulos, fixe

seus fios nos terminais antes de soldar.

4. Quando substituir uma resistência de potência (resistor de

película de óxido metálico) no painel de circuito impresso,

mantenha os seus terminais com 10mm de distância do

painel.

5. Mantenha os fios e cabos distantes de componentes de alta

potência e de alta temperatura.

6. Este receptor deve operar em redes de 100 a 240 V AC.

7. Antes de devolver este aparelho ao cliente, faça uma

verificação de fuga de corrente sobre as partes metálicas

expostas do gabinete, tais com antenas, terminais, cabeças

de parafusos, tampas de metal, alavancas de controle, etc., e

certifique-se de que o aparelho funciona sem perigo de

choque elétrico. Ligue o cabo de rede do aparelho

diretamente a uma tomada de força de 100-240 V AC. Não

utilize um transformador de isolação durante este teste.

Utilize um voltímetro de no mínimo 1KW por Volt de

sensibilidade, da forma que se segue.

Quando a unidade estiver conectada ao AC, pulse o

comutador primeiramente em “ON” (ligado) e em seguida em

“OFF” (desligado), meça desde um ponto de terra conhecido

(tal como um terminal de terra central da rede elétrica) a

todas as partes metálicas expostas do televisor ( antenas,

teclas metálicas, capas metálicas, alavancas de controle,

etc..) especialmente qualquer parte metálica que possa

oferecer um caminho ao chassis. Nenhuma medição de

corrente elétrica deve exceder 0,5 mA. Repita a prova

mudando a posição do pluque de rede na tomada AC.

Qualquer medição que não esteja dentro dos limites aqui

especificados, representam risco potencial de choque elé

trico que deve ser sanado antes que o aparelho retorne ao

cliente.

INSTRUÇÕES DE SEGURANÇA

AVISO SOBRE SEGURANÇA DE PRODUTO

DEVICE

UNDER

TEST

TEST ALL

EXPOSED MET AL

SURFA CES

2-WIRE CORD

ALSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

EAR TH

GROUND

LEAKAGE

CURRENT

TESTER

(READING SHOULD

NO T BE ABOVE

0.5mA)

+-

Aparelho

a ser

examinado

Probador

de fuga de

corriente

A leitura não deve

exceder 0.5mA

Prove todas as

superficies

metálicas

Também prove com

o plugue de rede

invertendo a

polaridade

Terra

Page 4

- 4 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

INSTRUÇÕES DE REGULAÇÃO

1. Application Object

These instructions are applied to all of the PDP TV, PB82C

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 100~220V,

50/60Hz when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

3. Component 480i/1080p RGB

1080p Manual Adjustment

3-1. Synopsis

Component 480i/1080p RGB 1080p adjustment to set the

black level and the Gain to optimum.

3-2. Test Equipment

(1) Service R/C

(2) 801GF(802B, 802F, 802R) or MSPG925FA Pattern

Generator (480i/1080i The Horizontal 100% Color Bar

Pattern adjust to within 0.7±0.1Vp-p)

[ Because the above pattern can differ by the model and

pattern for each device, you must check the pattern first.

3-3. ADC 480i Component1 Adjustment

(1) Check the connection Component1 to the Test Equipment.

(MSPG-925FA => Model: 209, Pattern: 65)

(2) Select Component1 as the input with 100% Horizontal

Color Bar Pattern(HozTV31Bar) in 480i Mode and select

‘Normal’ in screen.

(3) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and select

the ‘3. ADC 480i Comp1’.

Pressing the Enter Key to adjust automatically.

(4) When the adjustment is over, 'ADC Component1 Success’

is displayed.

(5) If the adjustment has errors, 'ADC Component1 480i Fail’

is displayed. And error massage(‘Component1 Not

Connected’ or ‘Not Valid Format’ or ‘Check Signal Status’)

is displayed for 1 second.

3-4. ADC 1080p or 1080p Component1/

RGB Adjustment

(1) Check the connection Component1, RGB to the Test

Equipment (MSPG-925FA => Model: 225, Pattern: 65)

(2) Select Component1 as the input with 100% Horizontal

Color Bar Pattern(HozTV31Bar) in 1080p Mode and select

‘Normal’ in screen.

(3) After receiving signal for at least 1 second, press the ADJ

Key on the Service R/C to enter the ‘Ez - Adjust’ and select

the ‘4. ADC 1080p Comp1/RGB’.

Pressing the Enter Key to adjust automatically component1.

(4) When the adjustment is over, 'ADC Component1 Success’

is displayed. If the adjustment has errors, 'ADC

Component1 1080p Fail’ is displayed.

(5) After the Component1 adjustment is over, convert the

RGB-DTV Mode and start RGB adjustment.

When the adjustment is over, 'ADC RGB 1080P Success’

is displayed.

(6) Readjust after confirming the case Pattern or adjustment

condition where the adjustment errors.

Error massage is ‘Component1 Not Connected’ or ‘Not

Valid Format’ or ‘Check Signal Status’.

(7) After adjustment is complete, exit the adjustment mode by

pressing the ADJ KEY.

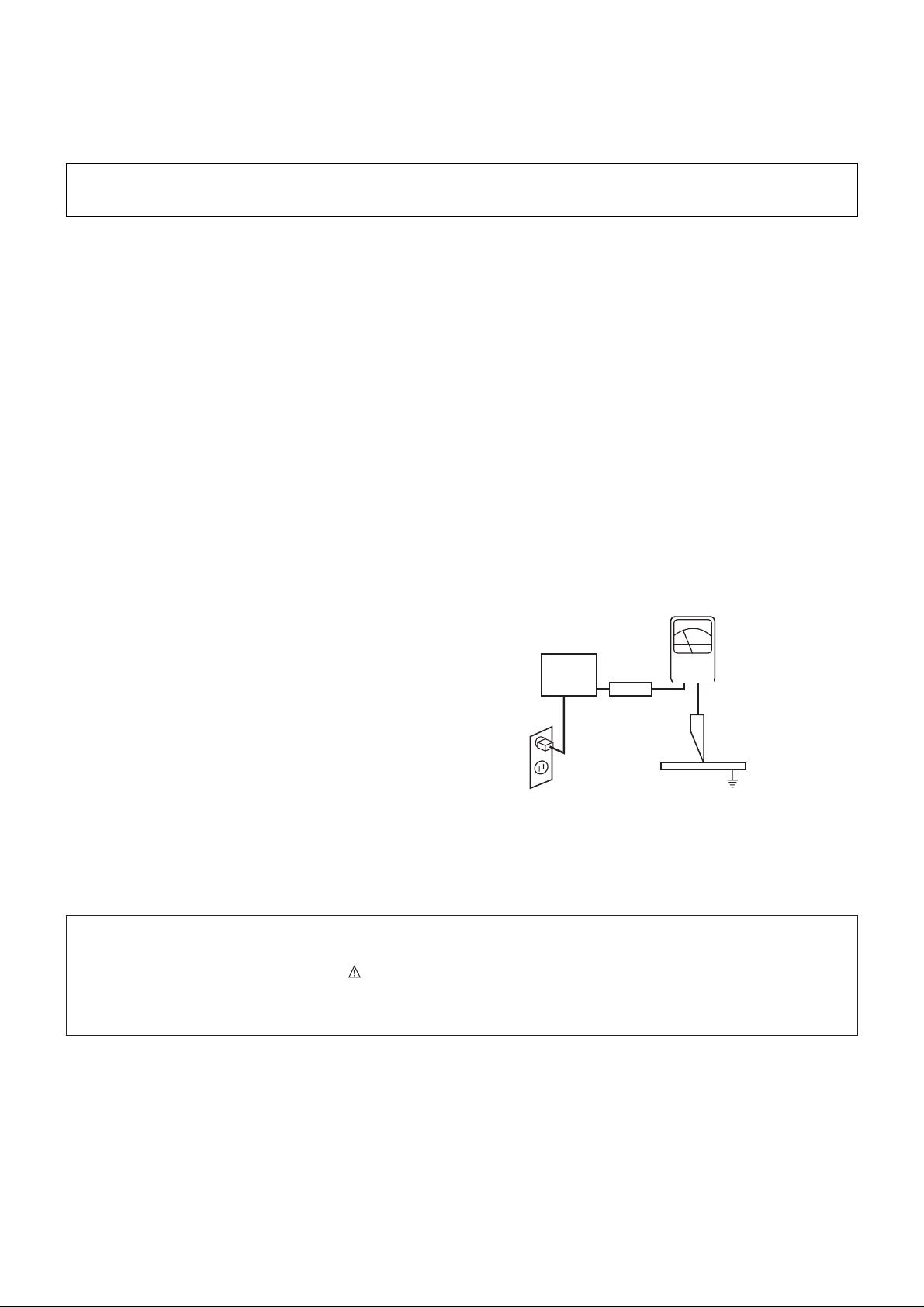

4. EPLD Download

(1) Required Test Equipment: PC, Jig for download

(2) Connect the power of VSC B/D.

(3) Execute download program(iMPACK) of PC.

(4) After execute Programmer, click the Program icon.

(5) After enter, exit.

<Fig. 1> ADC Adjustment Pattern: 480i, 1080p/ 60Hz Pattern

Page 5

- 5 -

<HEAT RUN>

O Preliminary action is applied to the test for afterimage

discharge detection, and 100% FULL WHITE PATTERN

must be operated automatically.

(1) Pressing Power On key on the adjustment R/C

(2) Full Test Pattern(2 min 30sec) --> Full Black

Pattern(30sec) --> Full White Pattern

(Full White Pattern when the main power is turned on

again after being turned off)

(3) Pattern Mode is deselected by pressing CH +/-, Exit Key.

[ Set is activated HEAT-RUN without signal generator in this

mode.

5. Voltage Adjustment(50” Model)

5-1. Test Equipment

(1) D.M.M 1EA

(2) Voltage adjustment bar

5-2. Connection Diagram for Measuring

Refer to Fig 1.

5-3. Adjustment

(1) Va Voltage Adjustment

1) Connect + terminal of D.M.M to Va pin of P811 and

connect – terminal to GND pin of P811.

2) Adjust VR901 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

(2) Vs Voltage Adjustment

1) Connect + terminal of D.M.M to Vs pin of P811 and

connect – terminal to GND pin of P811.

2) Adjust VR951 voltage to match that of the label on the

Top/Right of the panel. (Deviation : ±0.5V)

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Test Pattern 2min 30sec

Test Pattern 30sec

If you turn on a still screen more than 20 minutes (Especially

Digital pattern(13 CH), Cross Hatch Pattern), an afterimage

may occur in the black level part of the screen.

Each PCB Assy must be checked by Check JIG Set before

assembly. (Especially, be careful Power PCB Assy which can

cause Damage to the PDP Module.)

<Fig. 1> Connection Diagram for Measuring (Power Board):

LGIT 50” EAY39190301

Page 6

- 6 -

6. EDID(The Extended Display

Identification Data)/DDC

(Display Data Channel) Download

It is the feature to implement the “Plug and Play” which

automatically reconfigures the user’sl environment to directly

use by exchanging information without any command directly

to the PC or the monitor by the user, which is established by

the VESA

6-1. HDMI EDID Data Input

(1) Required Test Equipment

1) PC, Jig for adjusting DDC. (PC serial to D-sub

Connection equipment)

2) S/W for writing DDC(EDID data write & read)

3) D-Sub cable

4) Jig for HDMI Cable connection

(2) Preparation for Adjustments &

Setting of Device

1) Set devices as below and turn on the PC and JIG.

2) Open S/W for writing DDC (EDID data write & read).

(operated in DOS mode)

6-2. EDID DATA for 50PG60D-SA

:EDID for HDMI-1 (DDC (Display Data Channel) Data)

EDID table =

:EDID for HDMI-2 (DDC (Display Data Channel) Data)

EDID table =

:EDID for HDMI-3 (DDC (Display Data Channel) Data)

EDID table =

:EDID Data for RGB

EDID table =

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

LCD TV SET

(or Digital Board)

Page 7

- 7 -

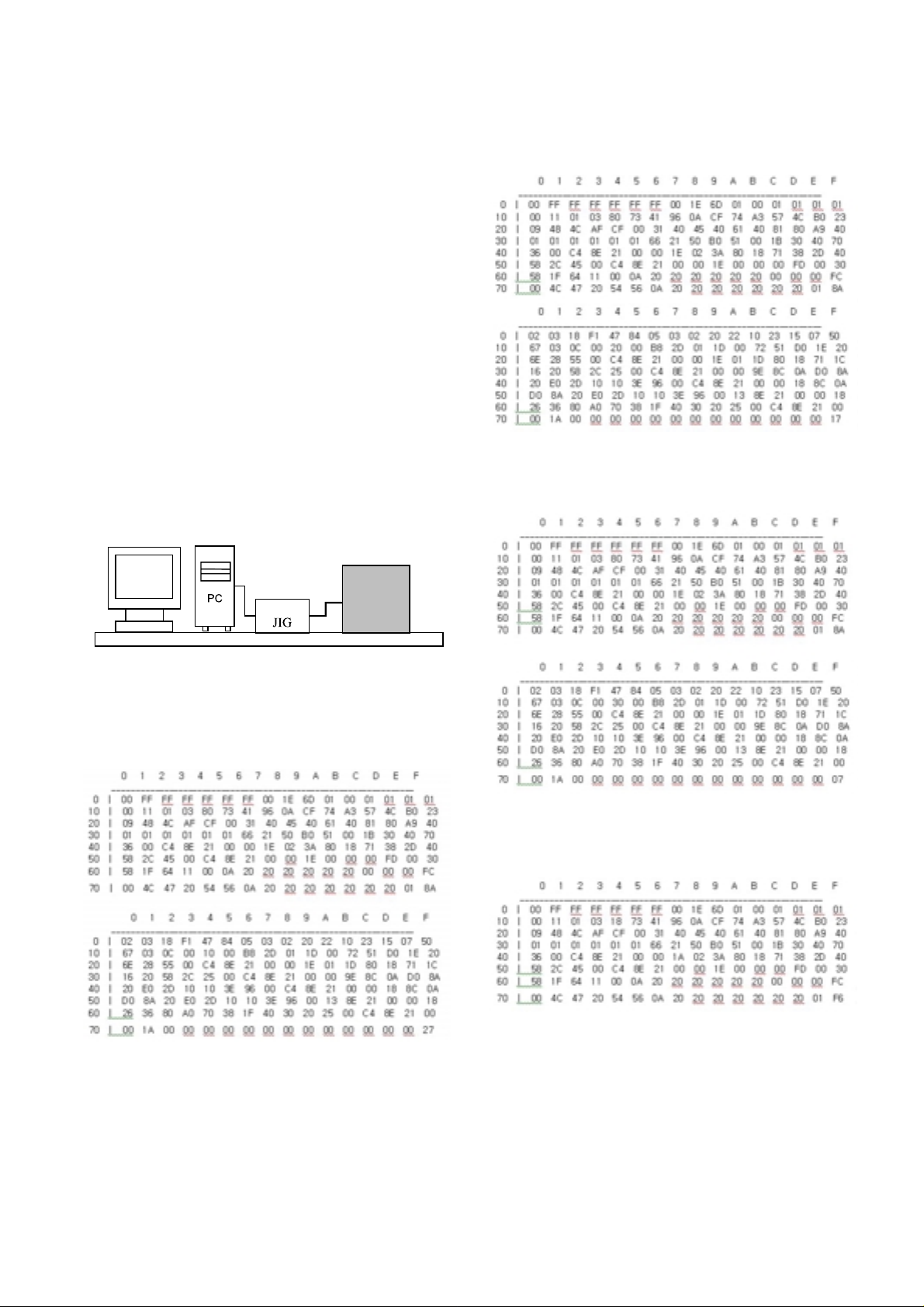

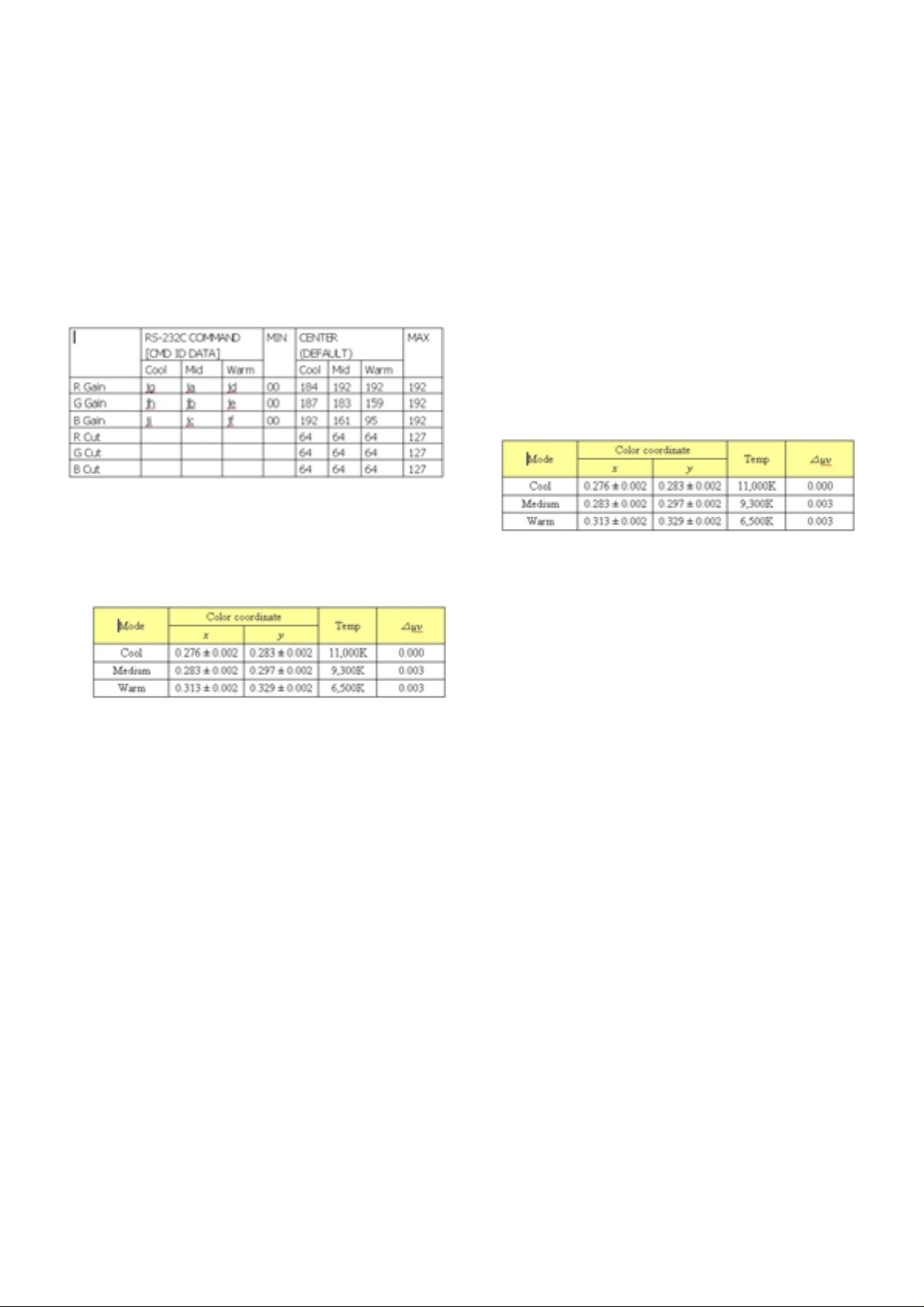

7. Adjustment of White Balance

7-1. Required Test Equipment

(1) Color Analyzer : CA-210 (CH 10), CA-100, CA-100+

=> To adjust color temperature of PDP, CS-1000 is the

Color Analyzer(CA-210) and should be set to use CH 10

in which white, red, green, and blue color are corrected.

Conduct the adjustment according to the coordinates for

White Balance adjustment in the table below.

(2) Computer for adjusting (necessary for the automatic

adjustment, possible to communicate with the RS-232C,

Baud Rate : 115200)

(3) Video Signal Generator MSPG-925F 720p, 216Gray

(Model :217, Pattern 78)

[Full white 216gray]

[

Adjustment Environment and Reference

1) Environment illuminance

Adjust it to 10 LUX or less at the place where the light

source such as lamp should be blocked at maximum.

2) Probe location

- PDP: Locate the Color Analyzer (CA-100, CA-100+,

CA210) close to the module surface to measure and

adjust

- LCD: Maintain the Color Analyzer (CA-210) close to the

module surface by 10cm or less and keep the probe of

the Color Analyzer perpendicular to the module surface

(80°~ 100°).

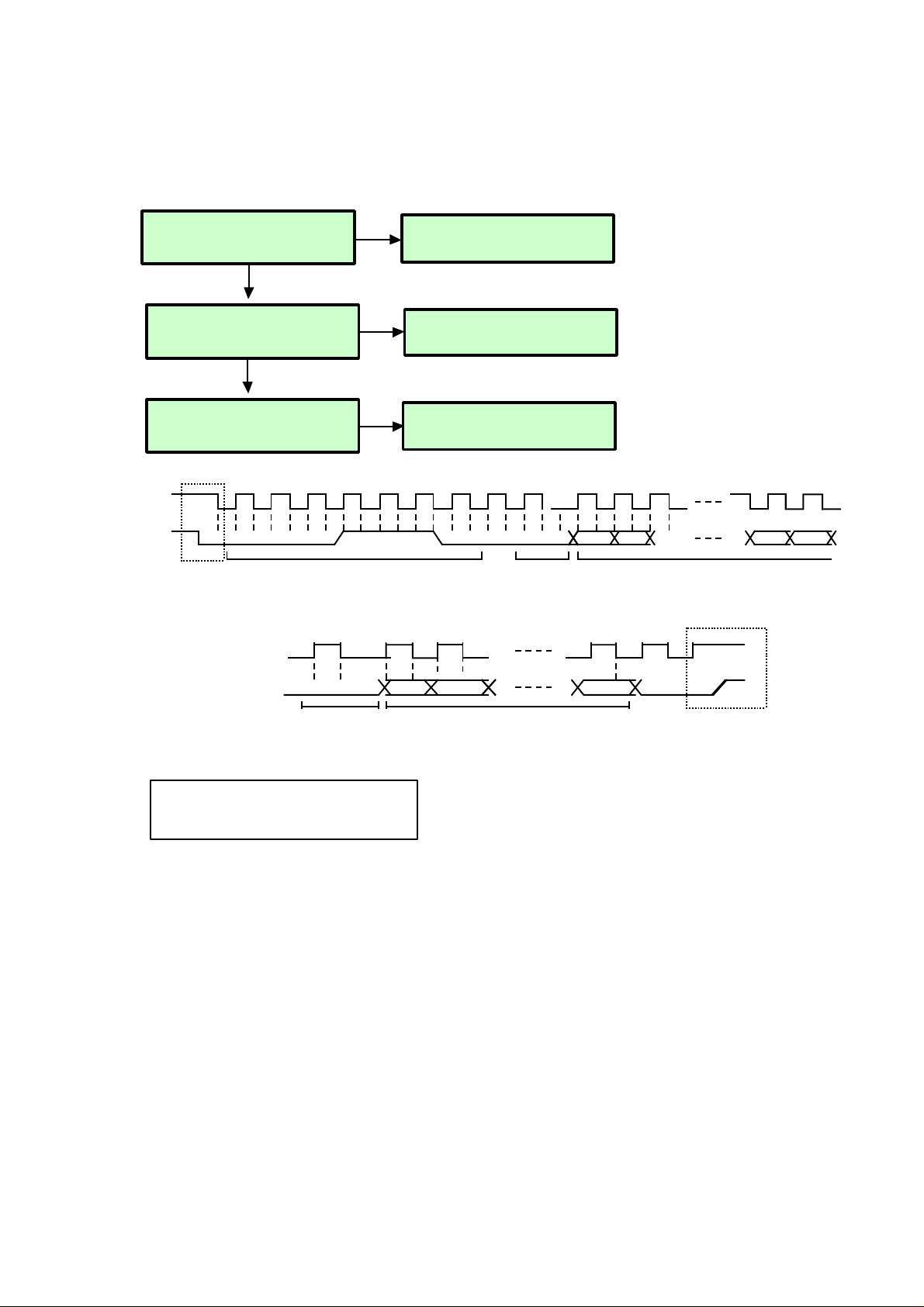

7-2. Connection Diagram of Equipment

for Measuring

(Automatic Adjustment)

Use the internal pattern to adjust White Balance. The pattern

is automatically given when the automatic adjustment device

is connected or when a user presses ADJ on the remote

controller to start Ez Adjust and then selects 6.White-Balance.

7-3. White Balance Adjustment Method

Basically it uses the internal pattern but when internal pattern

is not possible, you can select HDMI input for adjustment.

Through the option at the most bottom part of the Ez Adjust

Menu 7.White Balance menu, you can select NONE, INNER

and HDMI, and the default is set to INNER. When the

adjustment cannot be done with the internal pattern, you can

select HDMI input for adjustment.

For manual adjustment, press the ADJ KEY of the adjustment

R/C to enter Ez Adjust 7.White-Balance, and the pattern is

automatically displayed. (When you set the Option to INNER,

the default is always set to INNER)

(1) Connect the set according to the internal pattern or HDMI

input in accordance with measuring device connection

diagram.

(2) Set the Baud Rate of RS-232C to 115200. It is set to

115200 as default.

(3) Connect the RS-232C Cable to the set.

(4) Connect the HDMI Cable to the set. (Limited to the set with

HDMI option)

(5) Select and adjust the model applicable to PB82C chassis

from the adjuster.

7-4. Automatic Adjustment

(1) Execute POWER ON(Â) of the adjustment R/C to execute

automatic adjustment or set the Baud Rate to 115200.

(2) Always start adjustment with “wb 00 00” and end

adjustment with “wb 00 ff” (Adjust the offset if necessary)

(3) RS-232C command used for the automatic adjustment

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

(internal pattern)

Connection Diagram for Internal Pattern

Connection Diagram for HDMI Input

wb

wb

wb

wb

wb

wb

00

00

00

00

00

00

00

10

1f

20

2f

ff

White Balance Adjustment Start

Gain Adjustment Start(Internal white pattern)

Gain Adjustment End

Offset Adjustment Start(Internal white pattern)

Offset Adjustment End

White Balance Adjustment End

(Disappear Internal pattern)

RS-232C COMMAND

[CMD ID DATA]

Meaning

Page 8

- 8 -

Ex) Wb 00 00-----white balance Automatic Adjustment Start

Wb 00 10-----Gain Adjustment start (Internal pattern)

Ja 00 ff------Adjustment Data

Jb 00 c0

...

...

Wb 00 1f-----Gain Adjustment End

*(wb 00 20(Start), wb 00 2f(End))----- When adjust Off-set

Wb 00 ff------White Balance Automatic Adjustment End

(Disappear Inside pattern)

(4) Adjustment Map

(5) Execute POWER ON(

Â) of the adjustment R/C to execute

automatic adjustment.

- Set the Baud Rate to 115200.

- Always start adjustment with “wb 00 00” and end

adjustment with “wb 00 ff”

- Adjust the offset if necessary

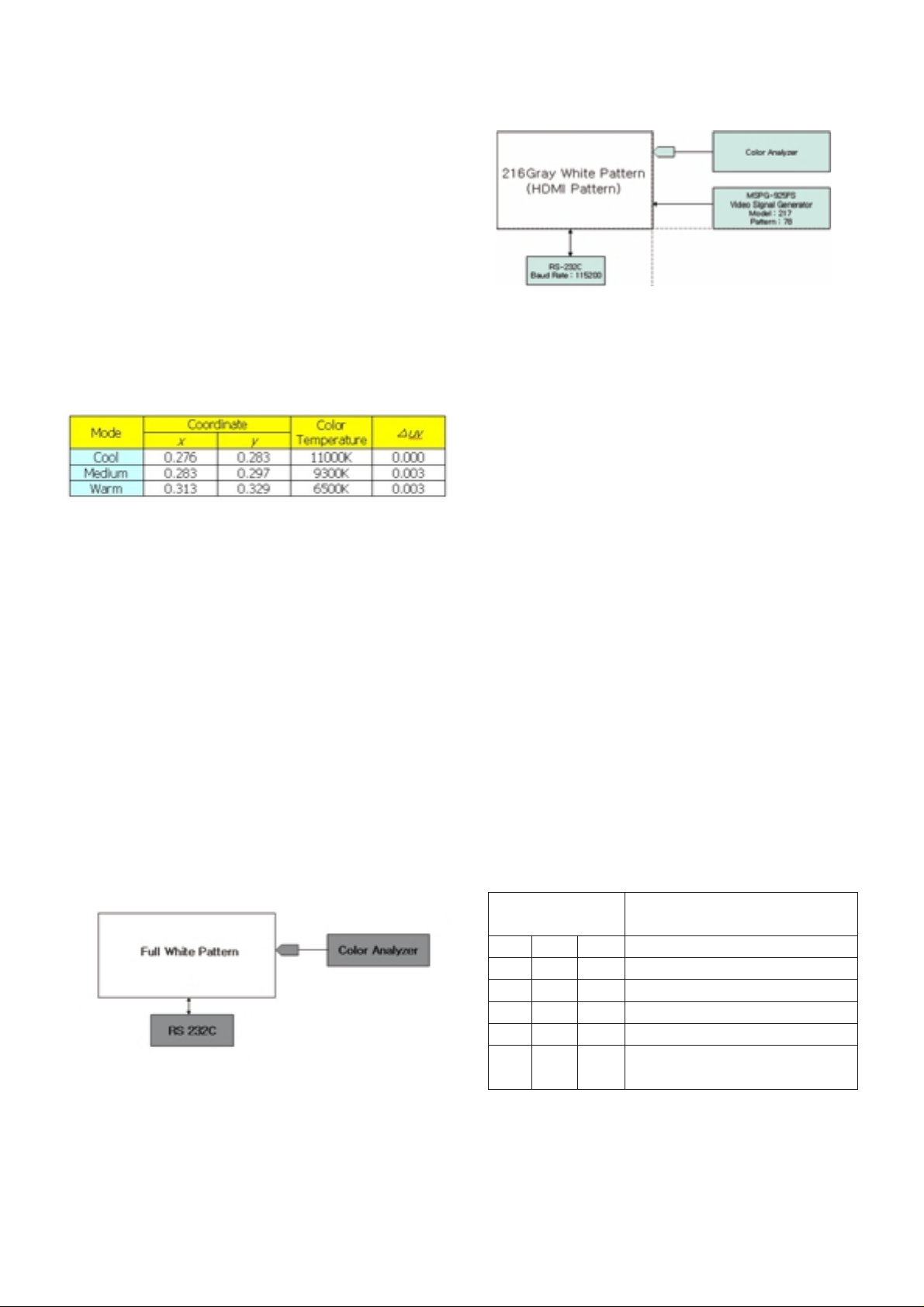

7-5. Manual Adjustment

(1) Required Test Equipment: CA-210 (CH-10), CA-100(CH-

10), CA-100+(CH-10)

=> To adjust color temperature of PDP, CS-1000 is the

Color Analyzer and should be set to use CH 10 in which

white, red, green, and blue color are corrected. Conduct

the adjustment according to the coordinates for White

Balance adjustment in the table below.

(2) Enter the ‘Ez - Adjust’ by pressing the ADJ on the Service

R/C.

(3) Select 10.TEST PATTERN using the CH + / - KEY and

press the Enter KEY to execute a heat run for more than

30 minutes.

(4) Zero Calibrate CA-100+/CA-100 Probe, and stick the

sensor to the center of PDP module surface when you

adjust.

Execute a Zero Calibration for CA-210 Probe and put it at

distance of less than 10Cm from the PDP module surface

center during the adjustment.

(5) Select ‘7. White-Balance’ of ‘Ez - Adjust’ by pressing the

ADJ KEY on the Service R/C. Then enter adjustment mode

by pressing the Right KEY (

G

) .

(The internal pattern of full white appears by pressing

G

)

(6) The adjustment is conducted in three levels of color

temperature; COOL, MEDIUM, and WARM.

1) When R GAIN is set to 192

- Control G GAIN and B GAIN by lowering from 192.

2) When B GAIN is set to 192

- Control R GAIN and G GAIN by lowering from 192.

3) When G GAIN is set to 192

- Control R GAIN and B GAIN by lowering from 192.

One of R Gain / G Gain / B Gain should be kept on 192,

and adjust other two lower than 192.

(When R/G/B GAIN are all 192, it is the FULL DYNAMIC

Range of Module)

(7) Use the Vol. +, - key for adjustment.

(8) When the adjustment is completed, press the ENTER (

Á

KEY) button to move to the Ez –Adjust screen. Press the

ADJ KEY to exit the adjustment mode.

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 9

- 9 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

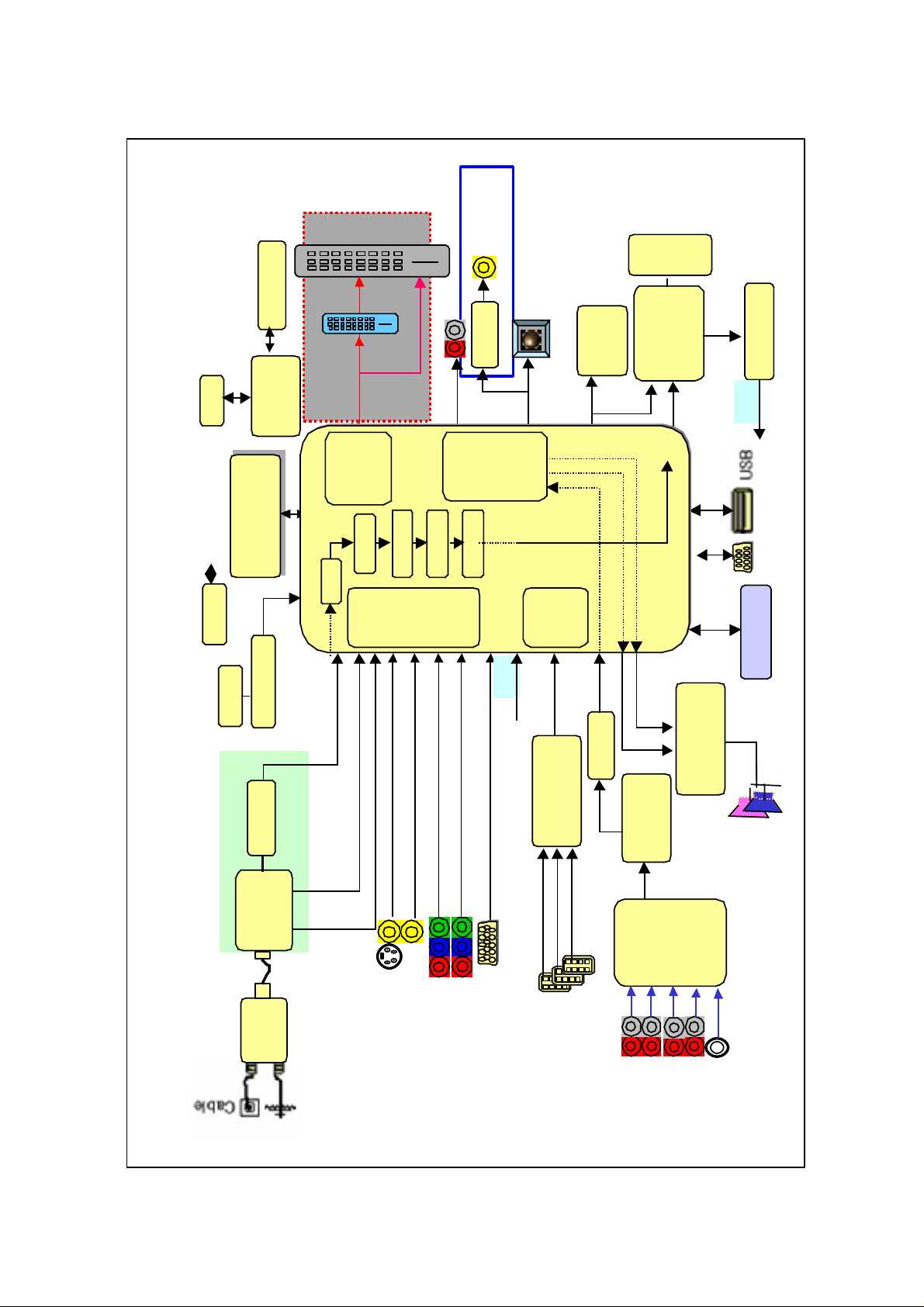

GUIA DE RESOLUÇÃO DE PROBLEMAS

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000A

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

4:2:2 20bit YCbCr

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

74HC04

SPDIF Out

(Coaxial)

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

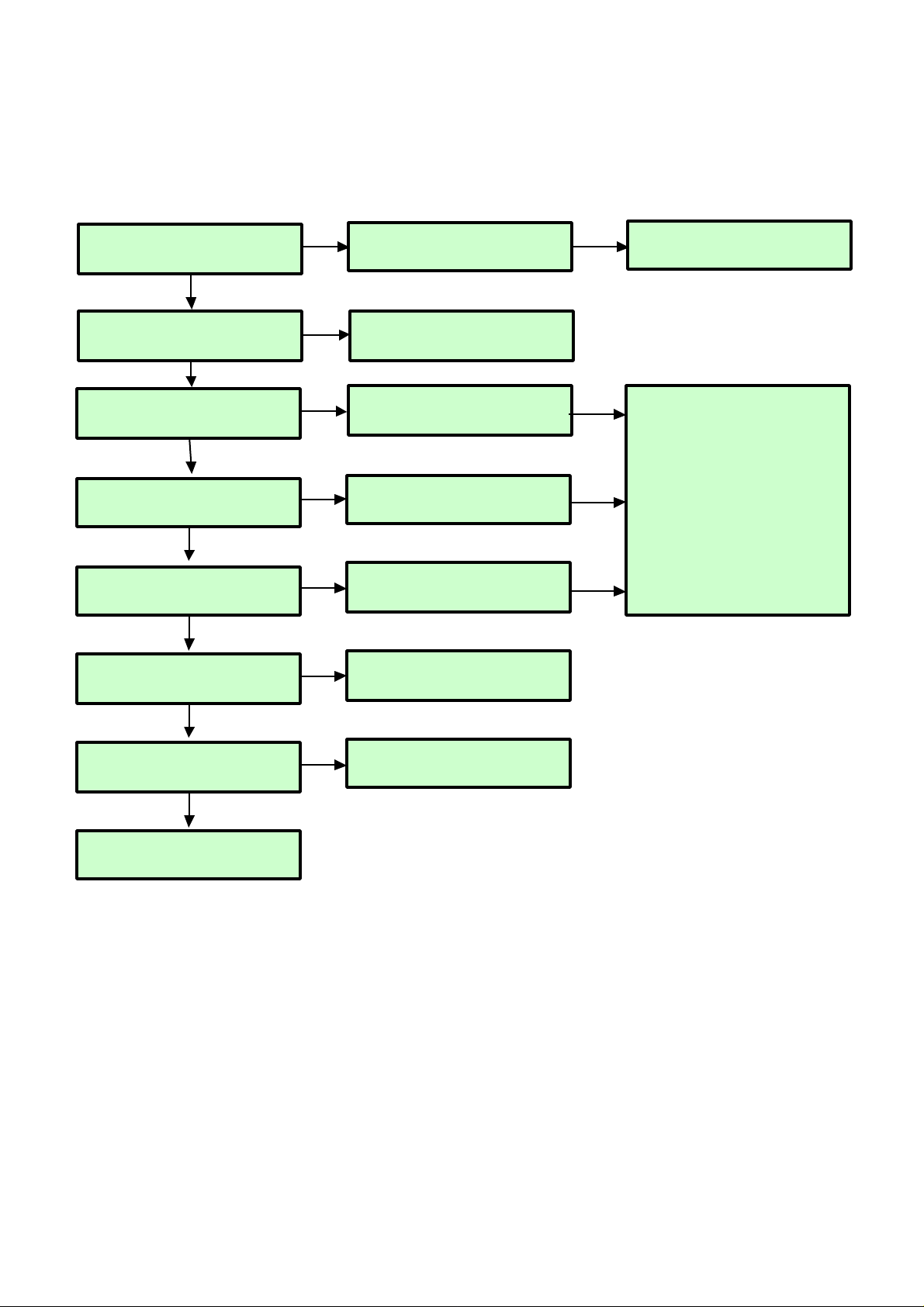

Power-Up Boot Fail Trouble Shooting

LCD Only

Page 10

- 10 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Power-Up Boot Fail Trouble Shooting

Check P801 All

Voltage Level (16V, 12V, 5V)

Check Power connector

OK ?

Replace Power board

Y

NY

Check IC801 #2 Pin / L805

Voltage Level 3.3V

Replace IC801/ L805 &

Recheck

Y

N

Check IC803 #5 Pin / L807

Voltage Level 2.6V

Replace IC803 or L807 &

Recheck

Y

N

Check C830, C853, C856

Voltage Level 1.2V

Replace IC802 or IC805 &

Recheck

Y

N

Check X200 Clock

54MHz

Replace X200

Y

N

Check R154 Clock

33MHz

Maybe BCM3553 has troubles.

Y

N

Replace IC101 Flash Memory

N

N

N

Check Micom IC407

Redownload or replace

Check Q801 Output

Voltage Level (5V)

C882, C880, C884,C885

Replace Q801

C882, C880, C884,C885 & Recheck

N

Y

Page 11

- 11 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

No OSD Trouble Shooting

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000A

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

74HC04

SPDIF Out

(Coaxial)

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

LCD Only

4:2:2 20bit YCbCr

Page 12

- 12 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

No OSD Trouble Shooting

Check P902

#33(TXAC-) , #32(TXAC+) ,

#17(TXBC-) , #16(TXBC+)

Maybe BCM3553 has problems

Check LVDS Cable

Check PDP Module

Control board

Refer to Module CAS

Y

N

Y

Replace Cable

N

Y

Check PDP Vs,Va Voltage

Module 5V

Replace Power

N

Check P801 Disp_EN ,

VaVs ON, 5V_MNT

Check Micom Path

N

Y

Page 13

- 13 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

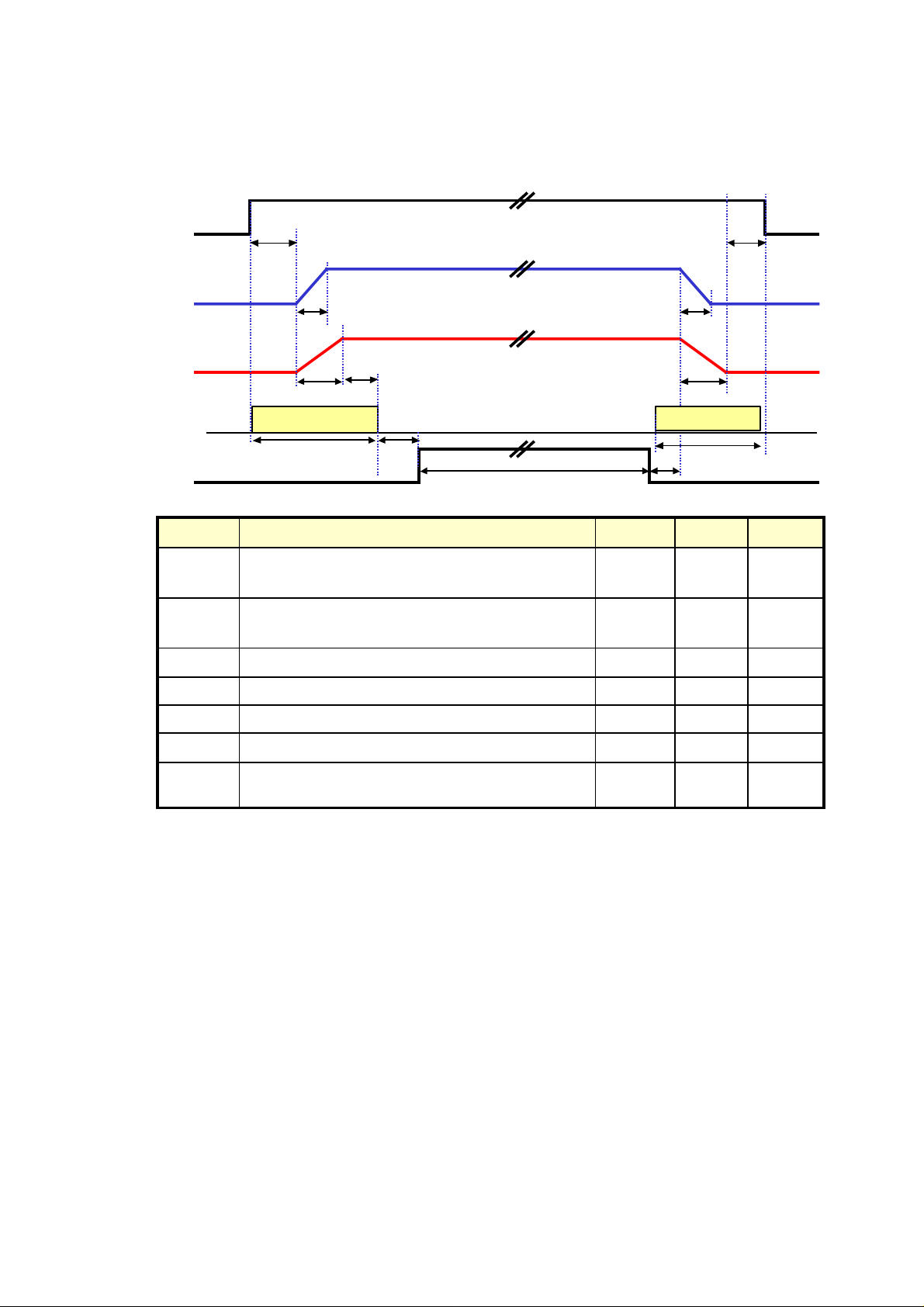

No OSD Trouble Shooting (Module Power Sequence)

Normal Display

Vcc

(5V)

Va

Vs

DISPEN

T

VaR

T

VsR

T

On

T

VaF

T

VsF

T

Off

☞1)

Power_on

3 Sec

Power_off

3 Sec

Min

100ms

Min.

2Frame

(Recommend: 2 sec)

msec50090Falling Time of Vs (90% to 10%)T

VsF

msec2000600

Time interval between 90% of Vcc and 90% of Vs

when Power On

T

on

+

T

VsR

msec800100Rising Time of Vs (10% to 90%)T

VsR

msec30050Falling Time of Va (90% to 10%)T

VaF

msec30010Rising Time of Va (10% to 90%)T

VaR

msec-20

Time interval between 10% of Vs and 90% of Vcc

when Power Off

T

Off

msec-500

Time interval between 90% of Vcc and 10% of Vs

when Power On

T

On

unitMax.Min.DescriptionSymbol

Page 14

- 14 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Module Control Trouble Shooting

Check the PDP Module Control

Board

Replace Module Control Board

N

Y

Check the IIC Tthe IIC Test

- Debug Menu IIC Test

Remove R937, R936

Check each IC sharing

IIC channel 2

N

Check P902 SCL,SDA line SCL,SDA

line R937, R936

Check Signal

N

Y

SCL (continue)

SDA (continue)

ACK

By Slave

9 1

D0

D7

9

ACK

By Slave

Command Data

for Addr

Stop

By Master

D6

SCL

8

SDA

00

111

A7W

Start

By

Master

Chip ID Address Byte

(0x1C)

ACK

By Slave

0

1

9 1

A6 A1 A0

Command Address

Addr=A[7:0]

0

Write

only

Master : Image Board

Slave : PDP Module

Page 15

- 15 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS341A

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

Digital TV Video Trouble Shooting

4:2:2 20bit YCbCr

Page 16

- 16 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Digital TV Video Trouble Shooting

Check RF Cable

Check TP Clock, Data, Sync

R925 (38.1MHz), R804, R803

Maybe Tuner(TU800) has problems

Check BCM3553 Output TP Clock,

Data, Sync

R153, R155, R152

Check BCM7412 Clock, Hsync, Vsync

R1088 (Typ . 74.25MHz), R1087, R1086

Y

Y

N

Check Tuner 5V Power

IC810 #3 Pin

Replace IC810

Y

N

Y

Maybe BCM3553(IC100) has problems

N

Maybe BCM7412(IC1000) has problems

N

Check PLD Clock, Hsync , Vsync

R1102 (Typ. 74.25MHz), R1100, R1101

Y

Redownload PLD file or replace

N

Maybe BCM3553(IC100) has problems

Y

Check D805 color

Bad Tuner. Replace Tuner.

None

red

Check BCM7412 Input Clock

R107 (27MHz)

Replace it

N

Y

Page 17

- 17 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Clock Operate below 81Mbps

Valid Pin --> high Pull - up

DVI Output (DDR Mode)

Digital TV Video Trouble Shooting

Refer to BCM7412 Input / Output Signal

Page 18

- 18 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(64MB)

CS5340

L/R

Serial TP

20bits

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351A

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

Analog TV Video Trouble Shooting

4:2:2 20bit YCbCr

12bit YC 4:2:2

Page 19

- 19 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Analog TV Video Trouble Shooting

Check RF Cable

Check CVBS signal

TU800 #17 Pin

Maybe Tuner(TU800) has problems

Check CVBS signal

IC808 #8 Pin

Check CVBS signal

C658

Y

Y

N

Check Tuner 5V Power

IC810 #3 Pin

Replace it

Y

N

Y

Replace IC808 or check L800 5V power

N

Replace it

N

Y

Maybe BCM3553(IC100) has problems

Page 20

- 20 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(64MB)

CS5340

L/R

Serial TP

20bits

20bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351A

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

Component Video Trouble Shooting

12bit YC 4:2:2

Page 21

- 21 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

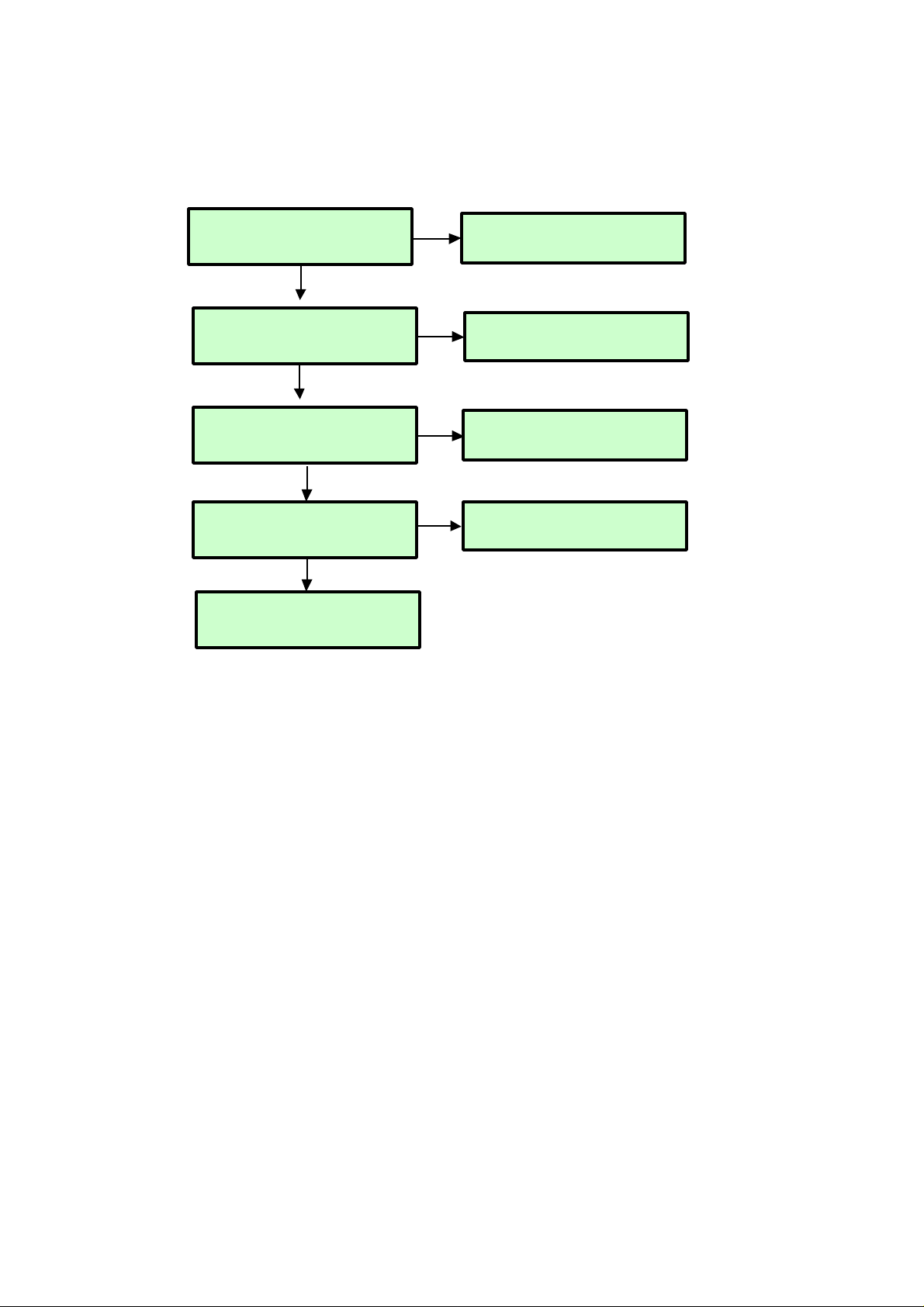

Component Video Trouble Shooting

Check signal format

Is it supported?

Check signal

L700, L701. L702 / L704, L705, L706

Replace it.

Check signal

C638, C639, C640 / C628, C629, C630

Y

Y

N

Check JK700 / JK702

Replace connector

Y

N

Y

Replace it

N

Maybe BCM3553(IC100) has problems

Y

Check Component Cable

Page 22

- 22 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(64MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351A

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

RGB Video Trouble Shooting

20bit YCbCr 4:2:2

Page 23

- 23 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

RGB Video Trouble Shooting

Check signal format

Is it supported?

Check signal, Hsync, Vsync

C742, C743, C744, R839, R843

Replace it.

Check signal

R767, R774, R778

Y

Y

N

Check JK706

Replace connector

Y

N

Y

Check the Transistor Buffer Circuit

N

Maybe BCM3553(IC100) has problems

Check L703 Voltage Level 9V

Y

Replace L708 / Q701 / Q702 / Q703

N

Check Signal

C635, C636, C637

Y

Replace it

N

Check RGB Cable

Y

Page 24

- 24 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(64MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

AV Video Trouble Shooting

20bit YCbCr 4:2:2

Page 25

- 25 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

AV Video Trouble Shooting

Check signal format

Is it supported?

Check signal

R755 (Composite), R814 / R815 (S-Video) (Rear)

R758 (Composite)

Replace it.

Check signal

C651 (Composite), C648 / C649 (S-Video) (Rear)

C652 (Composite) (Side)

Y

N

Check JK701 (Rear)

Check JK705 (Side)

Replace connector

Y

N

Y

Replace it

N

Maybe BCM3553(IC100) has problems

Y

Check AV Cable / S-Video Cable

Y

Page 26

- 26 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(64MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

HDMI Video Trouble Shooting

20bit YCbCr 4:2:2

Page 27

- 27 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

HDMI Video Trouble Shooting

Check signal format

Is it supported?

Y

Check J600 / J601 / J1101

Replace connector

Y

N

Y

Check HDMI Cable

Check EDID NVRAM

(IC1102, 603, 604)

Power & I2C Signal (#5, #6)

Replace it or redownload

Y

N

Check HDCP Key NVRAM (IC102)

Power & I2C Signal (#5, #6)

Replace it

Y

N

Check IC804 Out Voltage Level

3.3V

Replace it

Y

N

Check L823 Voltage Level 3.3V

Replace it

Y

N

Check IC601 Clock Signal

#26, #27

Replace it

Y

N

Maybe BCM3553(IC100) has problems

Page 28

- 28 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000A

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(64MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS341A

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

All Source Audio Trouble Shooting

20bit YCbCr 4:2:2

Page 29

- 29 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

All Source Audio Trouble Shooting

Make sure you can t hear any audio

Check Signal

L504, L505

Replace it.

Check Signal

L508, L509, L510, L511

Y

N

Check IC501 Power 19V, 3.3V, 1.8V

L500, L501, L502, L503

Replace L

Y

N

Y

Replace it

N

Check Connector

P501

Y

Check BCM3553 I2S Output

R627, R628, R629

Y

Replace it.

N

Replace connector

N

Check speaker

Y

Replace speaker

N

Maybe NTP3000 has problems. Replace it

Y

Page 30

- 30 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom )

NTP3000A

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351A

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

Digital TV Audio Trouble Shooting

20bit YCbCr 4:2:2

Page 31

- 31 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Digital TV Audio Trouble Shooting

Check video output

Follow procedure All source audio trouble

shooting

Y

Follow procedure digital TV video

trouble shooting

N

N

Maybe BCM3553 internal audio DSP has

problems. Replace it

Page 32

- 32 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom)

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS341A

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

Analog TV Audio Trouble Shooting

20bit YCbCr 4:2:2

Page 33

- 33 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Analog TV Audio Trouble Shooting

Check video output

Follow procedure All source audio trouble

shooting

Y

Follow procedure analog TV video

trouble shooting

N

N

Maybe BCM3553 audio block has

problems. Replace it

Check L801 voltage level 5V Replace it

N

Y

Check SIF signal

C801 / C806 / Q800

Replace it

N

Y

Check SIF signal

R726 / C665

Replace it

N

Y

Page 34

- 34 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom)

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:4:4

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS341A

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

74HC04

SPDIF Out

(Coaxial)

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

Component / RGB / AV Audio Trouble Shooting

20bit YCbCr 4:2:2

Page 35

- 35 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Component / RGB / AV Audio Trouble Shooting

Check video output

Y

Follow procedure external

input video trouble shooting

N

Check Connector

J700 / J702 (Component)

J703 (RGB)

J701 / P700 & cable (AV Rear, AV Side)

Replace connector

N

Y

Check signal

C734 / R746 / C735 / R752 (Component1)

C736 / R829 / C737 / R833 (Component2)

C733 / R837 / C732 / R838 (RGB)

C701 / R816 / C700 / R817 (AV Rear)

C729 / R858 / C728 / R859 (AV Side)

Replace it

N

Y

Check IC500 power L512 voltage level 9V Replace it

N

Y

Check signal

R532 / R533 / C555 / R568 / C563 / R582

Replace it or IC500

N

Y

Check IC503 power L513 voltage level 9V Replace it

N

Y

Check signal

C554 / R569 / R581 / C562

Replace it or IC503

N

Y

Check IC502 power L514 voltage level

3.3V & L515 voltage level 5V

Replace it

N

Y

Check IC502 power L514 voltage level

3.3V & L515 voltage level 5V

Replace it

N

Y

Check I2S signal

R548 / R549 / R550

Replace it or IC502

N

Y

Check Audio clock

R134

Replace it

N

Y

Maybe BCM3553 has problems

Page 36

- 36 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

HDMI Audio Trouble Shooting

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom)

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

20bit YCbCr 4:2:2

Page 37

- 37 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

HDMI Audio Trouble Shooting

Check video output

Follow procedure All source audio trouble

shooting

Y

Follow procedure HDMI video trouble

shooting

N

N Maybe BCM3553 audio block has

problems. Replace it

Check EDID NVRAM (IC1101, 603, 604)

Power & I2C Signal (#5, #6)

Replace it or redownload

Y

N

Page 38

- 38 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Flash

(32MB)

DDR1(128MB)

(16Mx16x4)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom)

NTP3000

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS/Y/C

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

20bits

12bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

USB Trouble Shooting

20bit YCbCr 4:2:2

Page 39

- 39 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

USB Trouble Shooting

Check USB 2.0 Cable

Check L205 voltage level 5V

Y

N

Replace it or IC202

Check JK201

Replace it

Y

N

Check USB Device

If device is 2.5 inch HDD, check power adaptor

Y

Maybe BCM3553 has problems

Y

¥ Exception

- USB power could be disabled by inrushing current

- In this case, remove the device and try to reboot the TV (AC power off/on)

Page 40

- 40 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

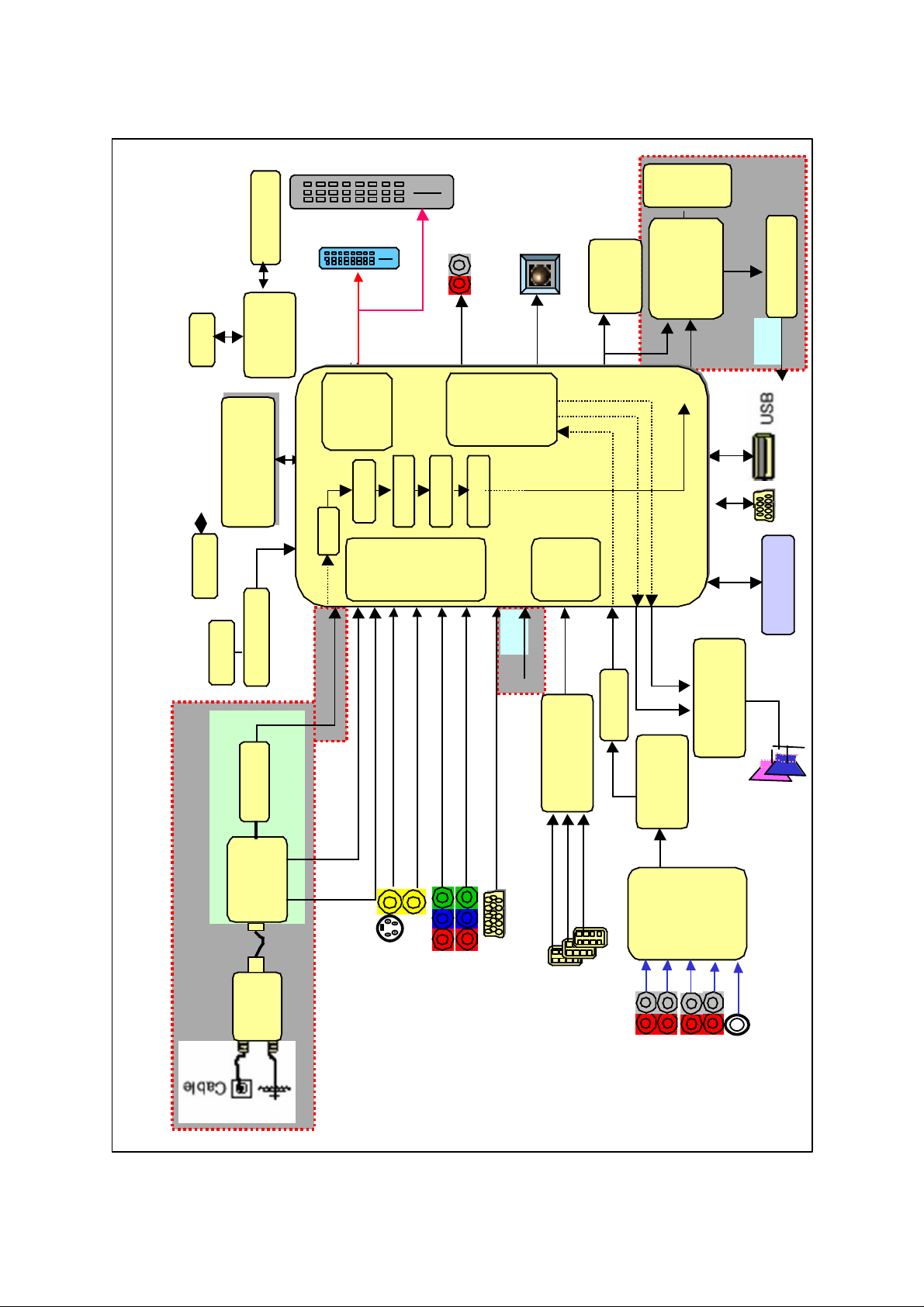

DIAGRAMA DE BLOCOS

Flash

(32MB)

DDR1(128MB)

DDR1(128MB)

(16Mx16x4)

TEA6420

Audio

SW

MTV416

(Micom)

NTP3000A

(Digital AMP)

64Bit I/F

RGB-PC

HDMI

1/2/3

COMP 1

COMP 2

AV1

AV2

RGB-PC

I2S

MCLK

Digital out

COMP1

COMP2

AV1

AV2

BCM7412

(MPEG4

Decoder)

Analog

/Digital

Tuner

TC90512

DVI

I2S

SIF

SPDIF Out

CVBS

CVBS

Y/Cb/Cr

R/G/B

DDR1

(32MB)

CS5340

L/R

Serial TP

30bits

20bit YCbCr 4:2:2

NIM TUNER

TMDS_RX+-

EPM240F

MNT out (Audio Only)

TMDS351

(3x1,S/W)

CVBS/Y/C

MC33078

(AMP)

L/R

RS232

RX/TX

DVI

4:4:4 30bit YCbCr

Full HD(1080P)

WXGA(768P)

RF

Switch

DM1/DP1

Serial

TP

74HC04

SPDIF Out

(Coaxial)

Video

Front

End

Dual

HDMI

Rx

HD/SD

Video

Encoder

Audio

DSP

USB2.0

PKT

HSX

PCI/

EBI

HD-DVI

IB0

Parse2

RSBUF

XCBUF

RMX0

BCM3553

Local KEY

24C16

74LVC14APW

X-tal(54M)

Reset

KIA7029

NVRAM

I2C

LCD Only

Page 41

- 41 -

MEMO

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 42

- 42 -

Copyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

VISTAS EXPLODIDAS

603

602

601

520

400

590

501

307

120

121

306

560

570

571

310

302

303

305

300

304

200

250

901900

240

209

208

201

204

207

A2

A21

205

206

580

202

203

301

401

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Page 43

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 44

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 45

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 46

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

MAIN(TOP) MAIN(BOTTOM)

PRE-AMP(TOP)

CONTROL(TOP)

CONTROL(BOTTOM)

PRE-AMP(BOTTOM)

Page 47

Depto de Assistência Técnica

Av. D. Pedro I, W7777 - Distrito Industrial

Piracangagua II - Taubaté - SP - Brasil

Cx. Postal 324 - CEP 12.010-970

Tel. : (012) 221-8555 Fax. : (012)221-8550

Jan., 2008

Printed in KoreaP/NO : MFL42027405

LG Electronics Inc.

Loading...

Loading...