LG 49VM5C-B Product Manual [zh]

Internal Use Only

LG Digital Signage

SERVICE MANUAL

CHASSIS :

MODEL :

CAUTION

BEFORE SERVICING THE CHASSIS, READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

LW56C

49VM5C 49VM5C-BD

P/NO :

MFL67237480 (1607-REV01)

CONTENTS

CONTENTS .............................................................................................. 2

PRECAUTION

SERVICING PRECAUTIONS

SPECIFICATION

ADJUSTMENT INSTRUCTION

BLOCK DIAGRAM

EXPLODED VIEW

........................................................................................... 3

.................................................................... 4

....................................................................................... 6

.............................................................. 12

.................................................................................. 19

.................................................................................. 20

TROUBLE SHOOTING GUIDE ................................................ APPENDIX

Only for training and service purposes

- 2 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

PRECAUTION

To Instrument's

exposed

METALLIC PARTS

AC Volt-meter

*Base on Adjustment standard

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD

monitor that are important for safety. These parts are

marked

on the schematic diagram and the

Exploded View. It is essential that these critical parts

should be replaced with the manufacturer' s specified

parts to prevent electric shock, fire or other hazard.

• Do not modify original design without obtaining written

permission from manufacturer or you will void the

original parts and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE

WITH BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged

in four corners.

• Do not press on the panel, edge of the frame strongly or

electric shock as this will result in damage to the

screen.

• Do not scratch or press on the panel with any sharp

objects, such as pencil or pen as this may result in

damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight or inverter

circuit, must disconnect the AC adapter because high

voltage appears at inverter circuit about 650Vrms.

• Handle with care wires or connectors of the inverter

circuit. If the wires are pressed cause short and may

burn or take fire.

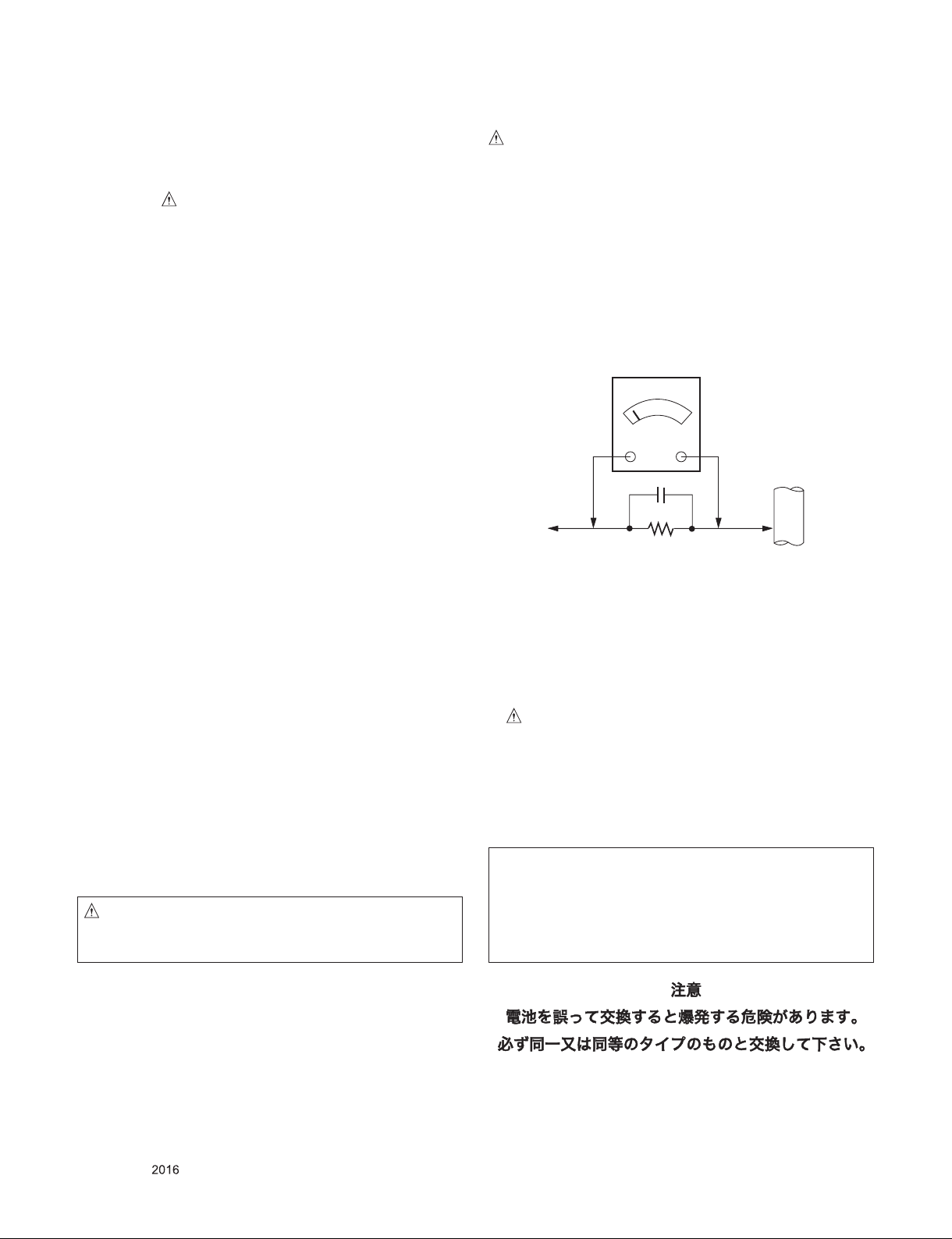

Leakage Current Hot Check Circuit

Good Earth Ground

such as WATER PIPE,

0.15µF

1.5 Kohm/10W

When 25A is impressed between Earth and 2nd Ground

for 1 second, Resistance must be less than 0.1

CONDUIT etc.

• Make certain that treatment person' s body are grounded

• Do not leave the module in high temperature and in

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within

• If the surface of panel become dirty, please wipe it off

through wrist band.

areas of high humidity for a long time.

the module.

with a softmaterial. (Cleaning with a dirty or rough cloth

may damage the panel.)

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

• Replaceable batteries

CAUTION

RISK OF EXPLOSION IF BATTERY IS REPLACED BY

AN INCORRECT TYPE.

DISPOSE OF USED BATTERIES ACCORDING TO

THE INSTRUCTIONS.

REPLACE ONLY WITH THE SAME OR EQUIVALENT

TYPE.

ADVARSEL

Lithiumbatteri - Eksplosionsfare ved fejlagtig

håndtering.

Udskiftning må kun ske med batteri af samme

fabrikat og type.

Levér det brugte batteri tilbage til leverandøren.

Only for training and service purposes

- 3 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500 ˚F to 600 ˚F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500 ˚F to 600 ˚F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500 ˚F to 600 ˚F)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

Only for training and service purposes

- 4 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Only for training and service purposes

- 5 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

SPECIFICATION

1. Application range

This specication is applied to the LW56C chassis.

2. Requirement for Test

Each part is tested as below without special appointment.

1) Temperature: 25 °C ± 5 °C(77 °F ± 9 °F),

CST: 40 °C ± 5 °C

2) Relative Humidity: 65 % ± 10 %

3) Power Voltage

: Standard input voltage (AC 100-240 V~, 50/60 Hz)

* Standard Voltage of each products is marked by models.

4) Specication and performance of each parts are followed

each drawing and specication by part number in accord-

ance with BOM.

5) The receiver must be operated for about 20 minutes prior to

the adjustment.

3. General Specication

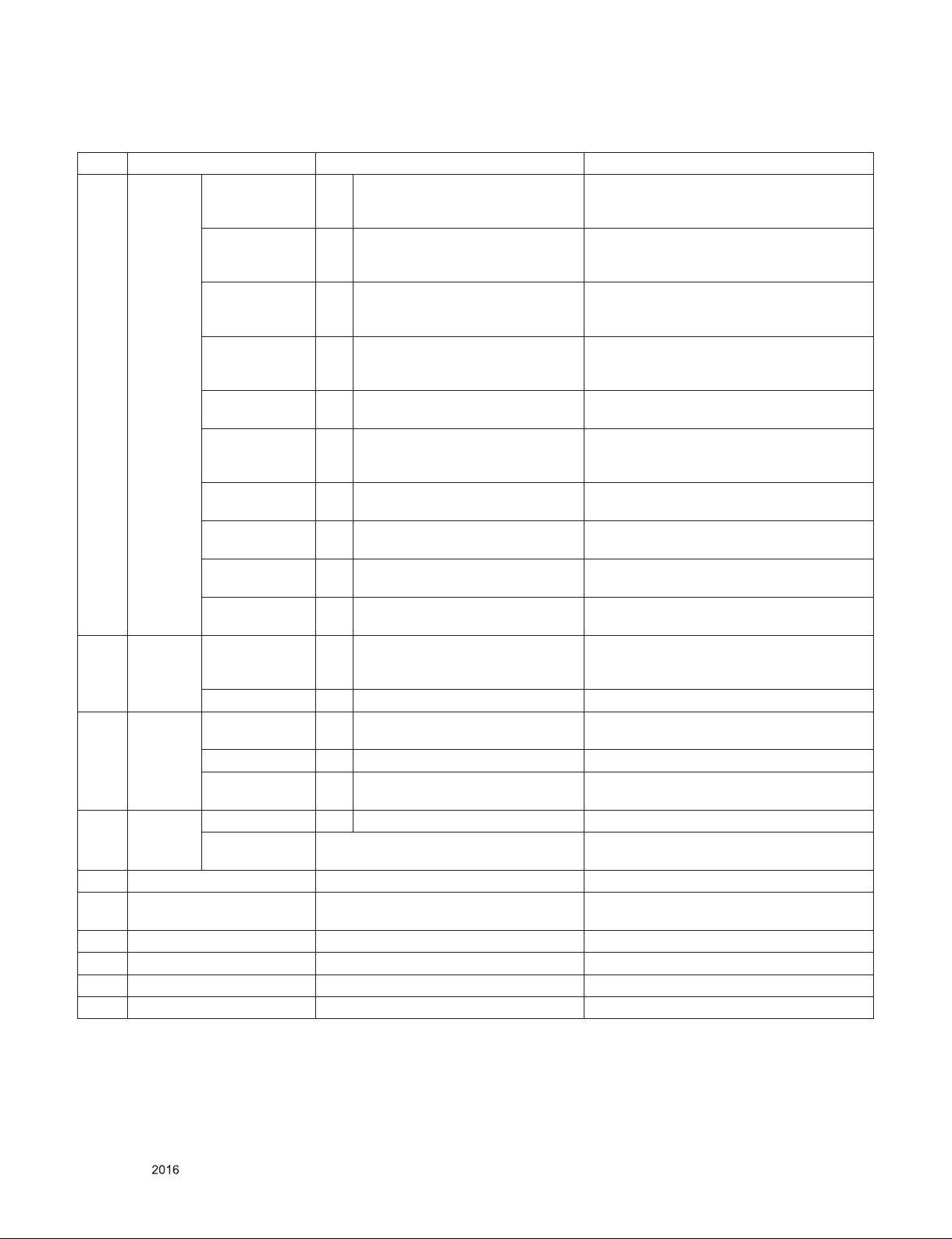

3.1. RGB, DVI-D, HDMI, Display Port (PC) Specication

No. Item Specication Remarks

1 Supported Sync. Type Separate Sync, Digital

Horizontal 30 ~ 83 kHz

Vertical 56 ~ 75 Hz

Horizontal 30 ~ 83 kHz

Vertical 56 ~ 60 Hz

Horizontal 30 ~ 83 kHz

Vertical 56 ~ 60 Hz

Horizontal 30 ~ 83 kHz

Vertical 56 ~ 60 Hz

RGB. 1920×1080 @ 60Hz

DVI/OPS 1920×1080 @ 60Hz

HDMI 3840x2160 @ 30Hz Recommend : 1920*1080@60Hz

Display Port 3840x2160 @ 30Hz Recommend : 1920*1080@60Hz

2 Operating Frequency

3 Resolution

Analog

DVI/OPS

HDMI

Display

Port

Input

Output Display Port 3840x2160 @ 30Hz

Only for training and service purposes

- 6 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

3.2. General Specication

No. Item Content Remark

1 Input HDMI Input

(V2.0)

DP Input(V1.2) 1 4K/30P, DP1.2a HDCP1.3

DVI Input(V1.0) 1 DVI-D HDCP2.2

RGB Input 1 Aanlog Analog (D-SUB 15Pin)

OPS 1 Supporting color format

USB Input(v3.0) 1 EMF, DVIX HD, For SVC(Download),

Wi USB

Input(v2.0)

Component Input 1 Y/Pb/Pr

Composite(AV)

Inputt

Audio In 1 PC/DVI Audio In(L/R), Stereo 3P, 3.5mm Phone Jack

1 4K/30P HDCP2.2

4K/30P Supporting color format

- RGB444 / YCbCr444 / YCbCr422(8/10/12bit)

4K/30P Supporting color format

- RGB444 / YCbCr444 (8bit)

Supporting color format

- RGB444 (10bit)

Supporting color format

- RGB444 (8 Bits)

- RGB444 (10 Bits)

USB3.0, Device: Memory stick, Mouse, Key-

Picture, Music, Movie, SVC

1 For Wi Device

Shared with D-SUB 15Pin

1 PAL, SECAM, NTSC

Shared with D-SUB 15Pin

board, Software Update + Picture + Music +

Movie

2 Output DP Out 1 4K/30P HDCP1.3

4K/30P Supporting color format

- RGB444 / YCbCr444 (8bit)

Audio Out 1 SE, Stereo L/R, 0.5Vrms 3P, 3.5mm Phone Jack

3 External

Control

4 Special

Feature

5 Remote control Wireless Remote Control LG Code

6 Local Key Tact Key(INPUT, MENU, ˄, ˅, <, >, AUTO/

7 Set Installation Wall Mount

8 PIP / PBP Mode X

9 SSC (Split Screen) Mode X

10 Beacon Distance within 20m Dongle(AN-WF500)

RS-232C Input /

Output

IR In 1 IR Receiver 3P, 3.5mm Phone Jack

RJ45 Input/

Output(1EA)

OPS IN 1 OPS

Media Player

Compatibility

1/1 UART Comm. w/ IR Daisy Chain,

Display Control

1/1 RJ45, 100Base-T SuperSign W/C

OPS Ready

External Media player Attachable

8 keys

SET, Φ/l)

Only for training and service purposes

- 7 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

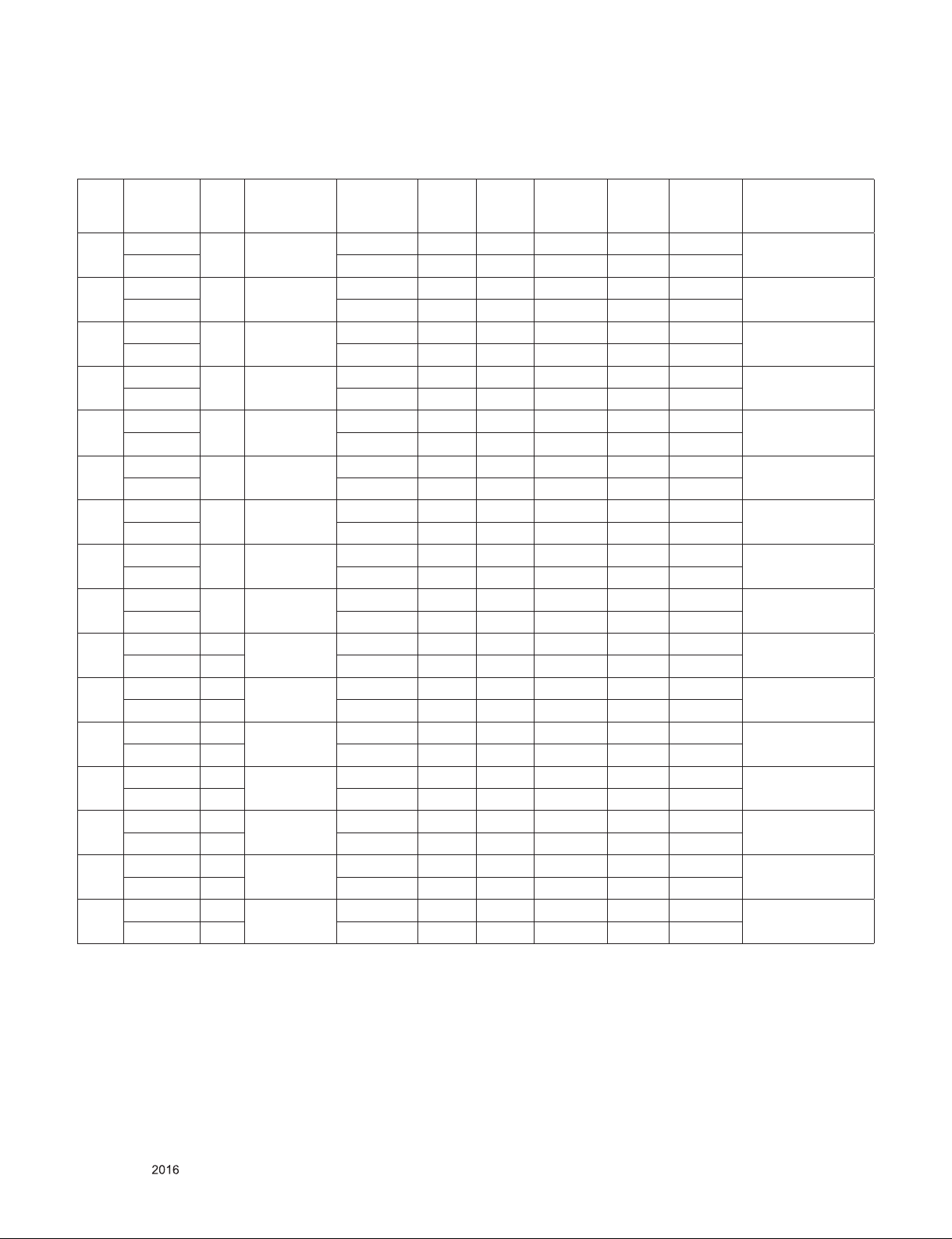

4. Signal Timing (Supporting Resolution)

4.1. RGB (PC Mode)

No. Section Pol. Dot Clock

[MHz]

1 H(Pixels) - 25.175 31.469 800 640 16 96 48 640 x 480

V(Lines) - 59.94 525 480 10 2 33

2 H(Pixels) - 31.5 37.5 840 640 16 64 120 640 x 480

V(Lines) - 75 500 480 1 3 16

3 H(Pixels) - 28.321 31.468 900 720 18 108 54 720 X 400

V(Lines) + 70.8 449 400 12 2 35

4 H(Pixels) + 40 37.879 1056 800 40 128 88 800 x 600

V(Lines) + 60.317 628 600 1 4 23

5 H(Pixels) + 49.5 46.875 1056 800 16 80 160 800 x 600

V(Lines) + 75 625 600 1 3 21

6 H(Pixels) +/- 57.283 49.725 1152 832 32 64 224 832 x 624

V(Lines) +/- 74.55 667 624 1 3 39

7 H(Pixels) - 65 48.363 1344 1024 24 136 160 1024 x 768

V(Lines) - 60 806 768 3 6 29

8 H(Pixels) - 78.75 60.023 1312 1024 16 96 176 1024 x 768

V(Lines) - 75.029 800 768 1 3 28

9 H(Pixels) - 81.75 53.783 1520 1152 64 120 184 1152 x 864

V(Lines) + 59.959 897 864 3 4 26

10 H(Pixels) + 74.25 45 1650 1280 110 40 220 1280 x 720

V(Lines) + 60 750 720 5 5 20

11 H(Pixels) + 108 63.981 1688 1280 48 112 248 1280 x 1024

V(Lines) + 60.02 1066 1024 1 3 38

12 H(Pixels) + 135 79.98 1688 1280 16 144 248 1280 x 1024

V(Lines) + 75.02 1066 1024 1 3 38

13 H(Pixels) + 85.5 47.712 1792 1360 64 11 2 256 1360 x 768

V(Lines) + 60.015 795 768 3 6 18

14 H(Pixels) + 108 60 1800 1600 24 80 96 1600 x 900

V(Lines) + 60 1000 900 1 3 96

15 H(Pixels) - 146.25 65.29 2240 1680 104 176 280 1680 x 1050

V(Lines) + 59.954 1089 1050 3 6 30

16 H(Pixels) + 148.5 67.5 2200 1920 88 44 88 1920 x 1080

+ 60 1125 1080 4 5 46

Frequency

[kHz]/[Hz]

Total

Cycle

(E)

Display

(A)

Front

Porch(B)

Sync.

(D)

Back

Porch(F)

Resolution

Only for training and service purposes

- 8 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

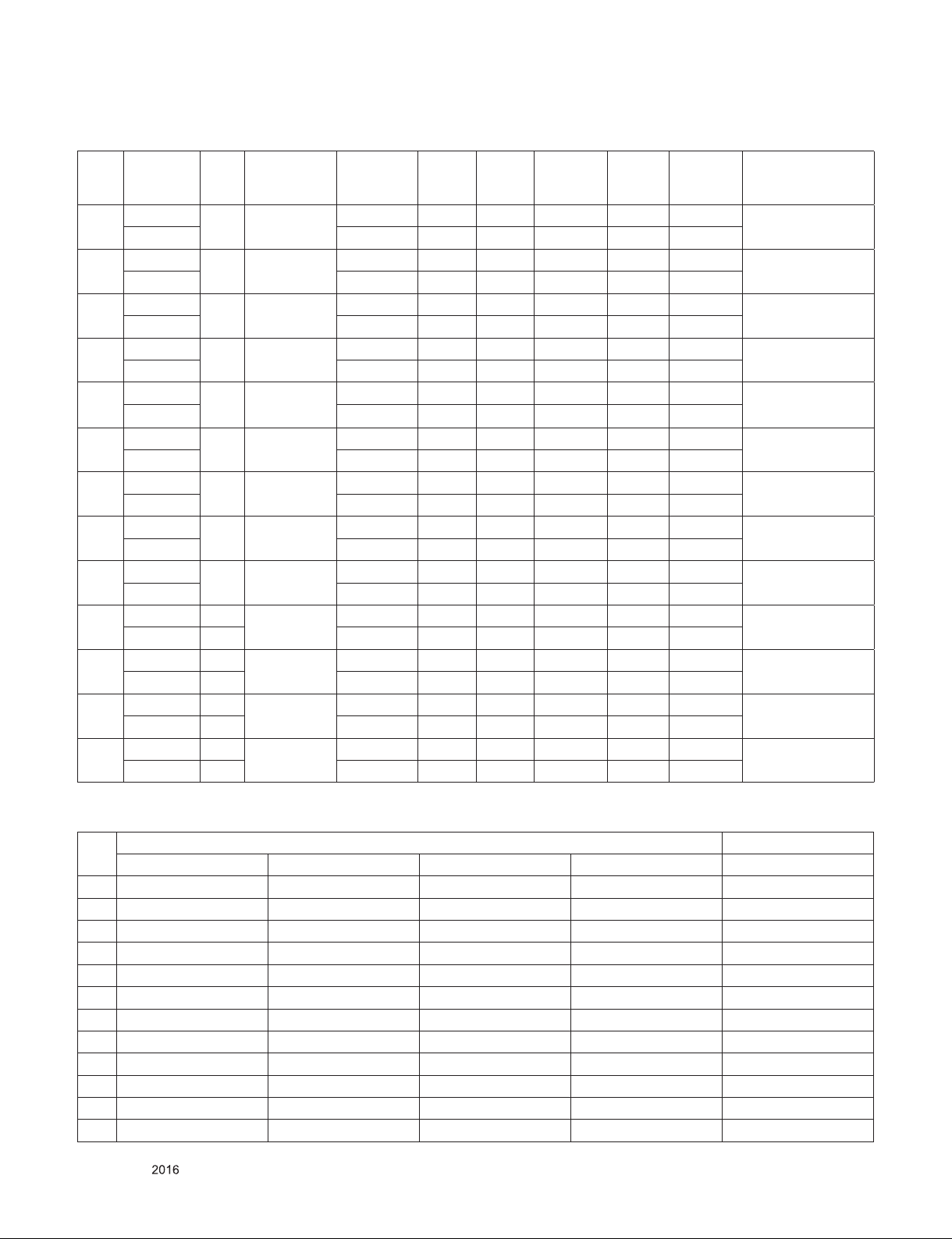

4.2. HDMI, Display Port (PC Mode )

No. Section Pol. Dot Clock

[MHz]

1 H(Pixels) - 25.175 31.469 800 640 16 96 48 640 x 480

V(Lines) - 59.94 525 480 10 2 33

2 H(Pixels) + 40 37.879 1056 800 40 128 88 800 x 600

V(Lines) + 60.317 628 600 1 4 23

3 H(Pixels) - 65 48.363 1344 1024 24 136 160 1024 x 768

V(Lines) - 60 806 768 3 6 29

4 H(Pixels) - 81.75 53.783 1520 1152 64 120 184 1152 x 864

V(Lines) + 59.959 897 864 3 4 26

5 H(Pixels) + 74.25 45 1650 1280 110 40 220 1280 x 720

V(Lines) + 60 750 720 5 5 20

6 H(Pixels) - 83.5 49.702 1680 1280 72 128 200 1280 X 800

V(Lines) + 59.81 831 800 3 6 22

7 H(Pixels) + 85.5 47.712 1792 1366 70 143 213 1366 x 768

V(Lines) + 59.79 798 768 3 3 24

8 H(Pixels) + 108 63.981 1688 1280 48 112 248 1280 x 1024

V(Lines) + 60.02 1066 1024 1 3 38

9 H(Pixels) + 108 60 1800 1600 24 80 96 1600 x 900

V(Lines) + 60 1000 900 1 3 96

10 H(Pixels) - 146.25 65.29 2240 1680 104 176 280 1680 x 1050

V(Lines) + 59.954 1089 1050 3 6 30

11 H(Pixels) + 148.5 67.5 2200 1920 88 44 88 1920 x 1080

V(Lines) + 60 1125 1080 4 5 46

12 H(Pixels) + 154 74.038 2080 1920 48 32 80 1920 x 1200

V(Lines) - 59.95 1235 1200 3 6 26

13 H(Pixels) + 297 67.5 4400 3840 176 88 296 3840 x 2160

H(Pixels) + 30 2250 2160 8 10 72

Frequency

[kHz]/[Hz]

Total

Cycle

(E)

Display

(A)

Front

Porch(B)

Sync.

(D)

Back

Porch(F)

Resolution

4.3. HDMI, Display Port (DTV Mode)

No.

Resolution H-freq(kHz) V-freq(Hz) Proposed

1 31.5 60 EDTV 480p 480/60P

2 31.25 50 EDTV 576p 576/50P

3 37.5 50 HDTV 720p 720/50P

4 45 60 HDTV 720p 720/60P

5 28.1 50 HDTV 1080i 50Hz 1080/50i

6 33.75 60 HDTV 1080i 60Hz 1080/60i

7 56.25 50 HDTV 1080P 50Hz 1080/50P

8 67.432 59.94 HDTV 1080P 60Hz 1080/60P

9 67.5 60 HDTV 1080P 60Hz 1080/60P

10 54 24 UDTV 2160P 24Hz 2160/24P

11 56.25 25 UDTV 2160P 25Hz 2160/25P

12 67.5 30 UDTV 2160P 30Hz 2160/30P

Only for training and service purposes

Specication Remark

- 9 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

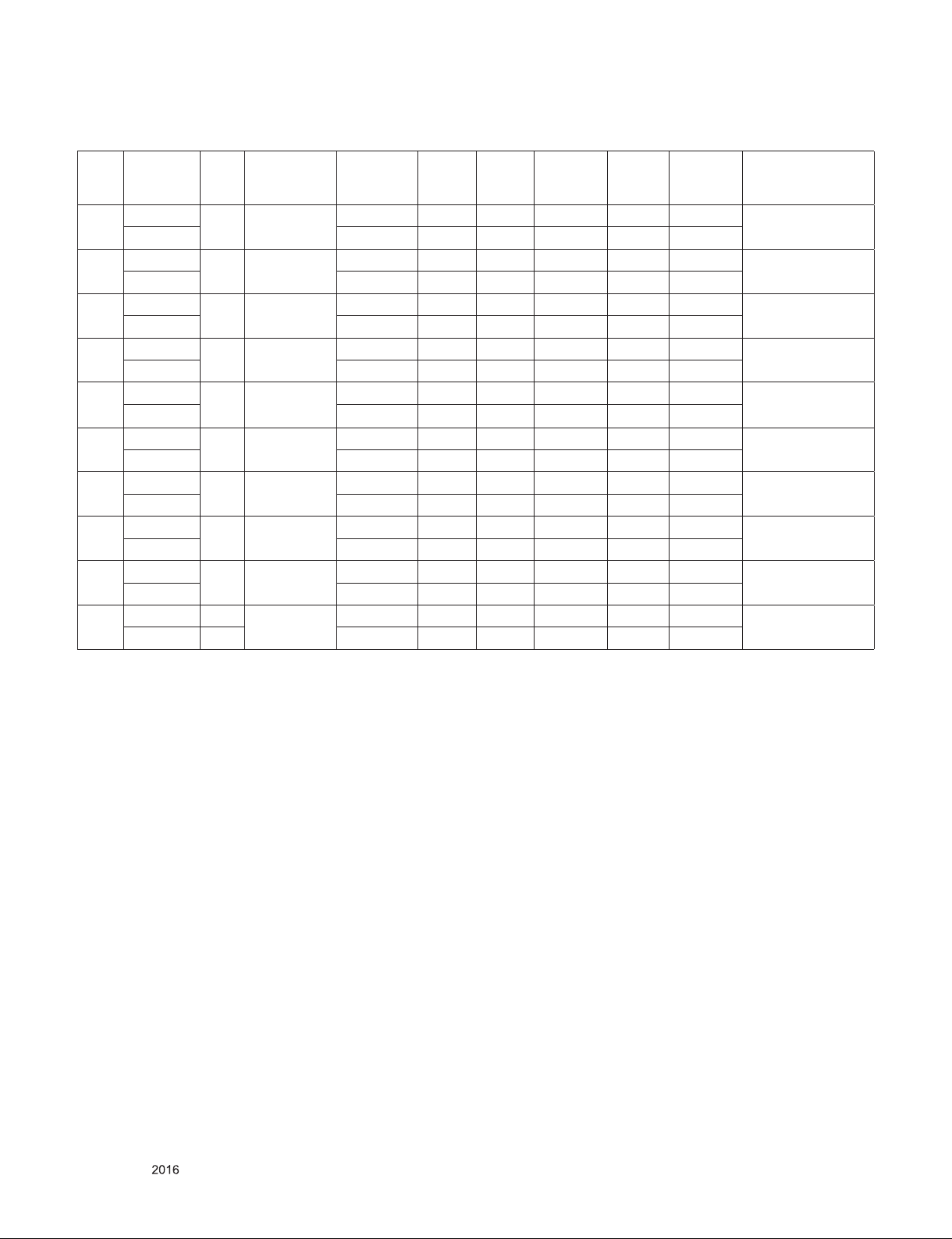

4.4. DVI-D (PC Mode )

No. Section Pol. Dot Clock

[MHz]

1 H(Pixels) - 25.175 31.469 800 640 16 96 48 640 x 480

V(Lines) - 59.94 525 480 10 2 33

2 H(Pixels) + 40 37.879 1056 800 40 128 88 800 x 600

V(Lines) + 60.317 628 600 1 4 23

3 H(Pixels) - 65 48.363 1344 1024 24 136 160 1024 x 768

V(Lines) - 60 806 768 3 6 29

4 H(Pixels) - 81.75 53.783 1520 1152 64 120 184 1152 x 864

V(Lines) + 59.959 897 864 3 4 26

5 H(Pixels) + 74.25 45 1650 1280 110 40 220 1280 x 720

V(Lines) + 60 750 720 5 5 20

6 H(Pixels) + 85.5 47.712 1792 1366 70 143 213 1366 x 768

V(Lines) + 59.79 798 768 3 3 24

7 H(Pixels) + 108 63.981 1688 1280 48 112 248 1280 x 1024

V(Lines) + 60.02 1066 1024 1 3 38

8 H(Pixels) + 108 60 1800 1600 24 80 96 1600 x 900

V(Lines) + 60 1000 900 1 3 96

9 H(Pixels) - 146.25 65.29 2240 1680 104 176 280 1680 x 1050

V(Lines) + 59.954 1089 1050 3 6 30

10 H(Pixels) + 148.5 67.5 2200 1920 88 44 88 1920 x 1080

V(Lines) + 60 1125 1080 4 5 46

Frequency

[kHz]/[Hz]

Total

Cycle

(E)

Display

(A)

Front

Porch(B)

Sync.

(D)

Back

Porch(F)

Resolution

Only for training and service purposes

- 10 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

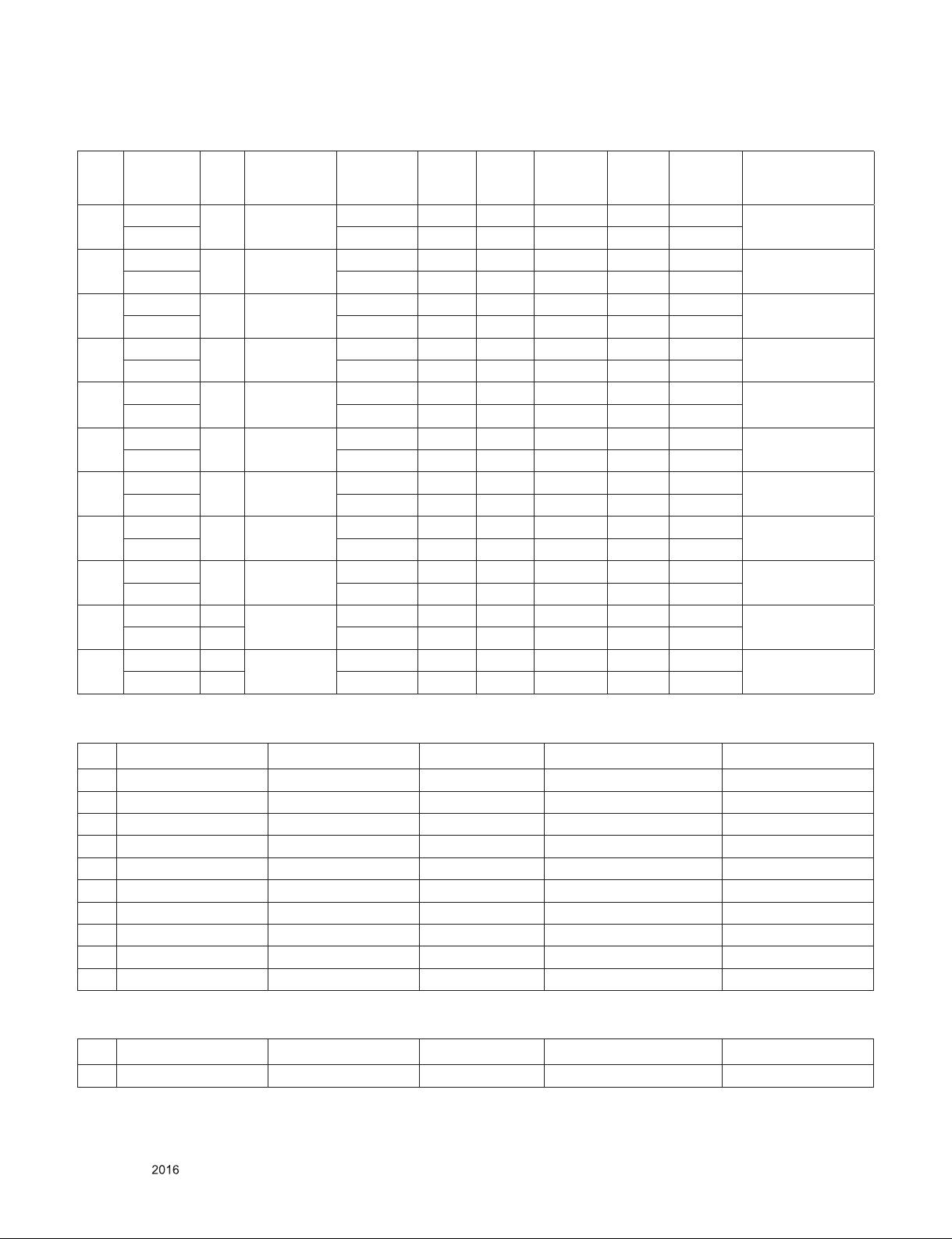

4.5. OPS (PC Mode )

No. Section Pol. Dot Clock

[MHz]

1 H(Pixels) - 25.175 31.469 800 640 16 96 48 640 x 480

V(Lines) - 59.94 525 480 10 2 33

2 H(Pixels) + 40 37.879 1056 800 40 128 88 800 x 600

V(Lines) + 60.317 628 600 1 4 23

3 H(Pixels) - 65 48.363 1344 1024 24 136 160 1024 x 768

V(Lines) - 60 806 768 3 6 29

4 H(Pixels) - 81.75 53.783 1520 1152 64 120 184 1152 x 864

V(Lines) + 59.959 897 864 3 4 26

5 H(Pixels) + 74.25 45 1650 1280 110 40 220 1280 x 720

V(Lines) + 60 750 720 5 5 20

6 H(Pixels) - 83.5 49.702 1680 1280 72 128 200 1280 X 800

V(Lines) + 59.81 831 800 3 6 22

7

H(Pixels) + 85.5 47.712 1792 1366 70 143 213 1366 x 768

V(Lines) + 59.79 798 768 3 3 24

8 H(Pixels) + 108 63.981 1688 1280 48 112 248 1280 x 1024

V(Lines) + 60.02 1066 1024 1 3 38

9 H(Pixels) + 108 60 1800 1600 24 80 96 1600 x 900

V(Lines) + 60 1000 900 1 3 96

10 H(Pixels) - 146.25 65.29 2240 1680 104 176 280 1680 x 1050

V(Lines) + 59.954 1089 1050 3 6 30

11 H(Pixels) + 148.5 67.5 2200 1920 88 44 88 1920 x 1080

V(Lines) + 60 1125 1080 4 5 46

Frequency

[kHz]/[Hz]

Total

Cycle

(E)

Display

(A)

Front

Porch(B)

Sync.

(D)

Back

Porch(F)

Resolution

4.6. Component(Y/Pb/Pr)

Resolution H-freq(kHz) V-freq(Hz)

1 720*576 15.625 50.00 SDTV, DVD 576i

2 720*576 31.25 50.00 EDTV 576p

3 1280*720 45.00 60.00 HDTV 720p

4 1280*720 37.5 50 HDTV 720p

5 1280*720 44.96 59.94 HDTV 720p

6 1920*1080 31.25 50.00 HDTV 1080i 50Hz For Australian

7 1920*1080 56.25 50 HDTV 1080P 50Hz

8 1920*1080 33.75 60.00 HDTV 1080i 60Hz (ATSC)

9 1920*1080 33.72 59.94 HDTV 1080i 59.94Hz

10 1920*1080 67.5 60 HDTV 1080P 60Hz

4.7. CVBS(AV, Composite)

Resolution H-freq(kHz) V-freq(Hz)

1 NTSC, PAL - - All of NTSC and PAL

Only for training and service purposes

- 11 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

ADJUSTMENT INSTRUCTION

1. Application Range

This spec. sheet applies to LW56C Chassis applied all of Signage Monitors manufactured in SIGNAGE SET factory.

2. Specication

1) Because this is not a hot chassis, it is not necessary to

use an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

2) Adjustment must be done in the correct order.

3) The adjustment must be performed in the circumstance of

25 °C ± 5 °C of temperature and 65 % ± 10 % of relative

humidity if there is no specic designation.

4) The input voltage of the receiver must keep AC 100-240

V~, 50/60 Hz.

5) At rst Worker must turn on the SET by using Power Only

key.

6) The receiver must be operated for about 5 minutes prior to

the adjustment when module is in the circumstance of over

15.

In case of keeping module is in the circumstance of 0 °C, it

should be placed in the circumstance of above 15 °C for 2

hours.

In case of keeping module is in the circumstance of below -20

°C, it should be placed in the circumstance of above 15 °C for

3 hours.

Caution) When still image is displayed for a period of 20 minutes or longer (especially where W/B scale is strong. Digital

pattern 13ch and/or Cross hatch pattern 09ch), there can

some afterimage in the black level area

3. Adjustment items

3.1. Main PCBA Adjustments MAC Address

Download

▪ Adjust RGB (ADC)

▪ EDID/DDC download

▪ MAC Address Download

- Above adjustment items can be also performed in Final

Assembly if needed. Both Board-level and Final assembly

adjustment items can be check using In-Star Menu 1.ADJUST CHECK.. RGB-PC Adjust will be calculated by 480i

adjust value.

3.2. Final Assembly adjustment

▪ White Balance adjustment

▪ RS-232C functionality check

▪ Factory Option setting per destination

▪ Ship-out mode setting (In-Stop)

4. Automatic Adjustment

4.1. ADC Adjustment

4.1.1. Overview

ADC adjustment is needed to nd the optimum black level

and gain in Analog-to-Digital device and to compensate RGB

deviation.

4.1.2. Equipment & Condition

1) JIG (RS-232C protocol)

2) MSPG-925 Series Pattern Generator(MSPG-925FA, pattern -65)

- Resolution : 1080p (Inner Pattern)

1024*768 RGB (Inner Pattern)

- Pattern : Horizontal 100% Color Bar Pattern

- Pattern level : 0.7±0.1 Vp-p

- Image

4.1.3. Adjustment

4.1.3.1. Adjustment method

▪ Using RS-232C, adjust items listed in 3.1 in the other shown

in “4.1.3.3”

4.1.3.2. Adj. protocol

Protocol Command Set ACK

Enter adj. mode aa 00 00 a 00 OK00x

Source change

Begin adj. ad 00 10

Return adj. result

Read adj. data

Conrm adj. ad 00 99

End adj. aa 00 90 a 00 OK90x

xb 00 60

xb 00 10

(main)

ad 00 20

(sub )

ad 00 21

Ref.) ADC Adj. RS232C Protocol_Ver1.0

4.1.3.3. Adj. order

▪ aa 00 00 [Enter ADC adj. mode]

▪ xb 00 60 [Change input source to RGB(1024*768)]

▪ ad 00 10 [Adjust 1024*768RGB]

▪ aa 00 90 End adj.

Ref) ADC adj. RS232C Protocol_Ver1.0

b 00 OK04x (Adjust 480i, 1080p Comp1 )

b 00 OK06x (Adjust 1920*1080 RGB)

OKx (Case of Success)

NGx (Case of Fail)

(main)

000000000000000000000000007c007b006dx

(Sub)

000000070000000000000000007c00830077x

NG 03 00x (Fail)

NG 03 01x (Fail)

NG 03 02x (Fail)

OK 03 03x (Success)

3.3. Etc.

▪ Ship-out mode

▪ Service Option Default

▪ Tool option menu, USB Download(S/W Update, Option,

Service only)

▪ ISP Download(Option)

Only for training and service purposes

- 12 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

4.2. MAC address & HDCP2.2 D/L

4.2.1. Equipment & Condition

1) Play le: keydownload.exe

4.2.2. Communication Port connection

1) Key Write: Com 1,2,3,4 and 115200 (Baudrate)

2) Barcode: Com 1,2,3,4 and 9600 (Baudrate)

4.2.3. Download process

1) Select the download items.

2) Mode check: Online Only

3) Check the test process : DETECT -> MAC -> HDCP2.2

4) Play: Press Enter key

5) Check of result: Ready, Test, OK or NG

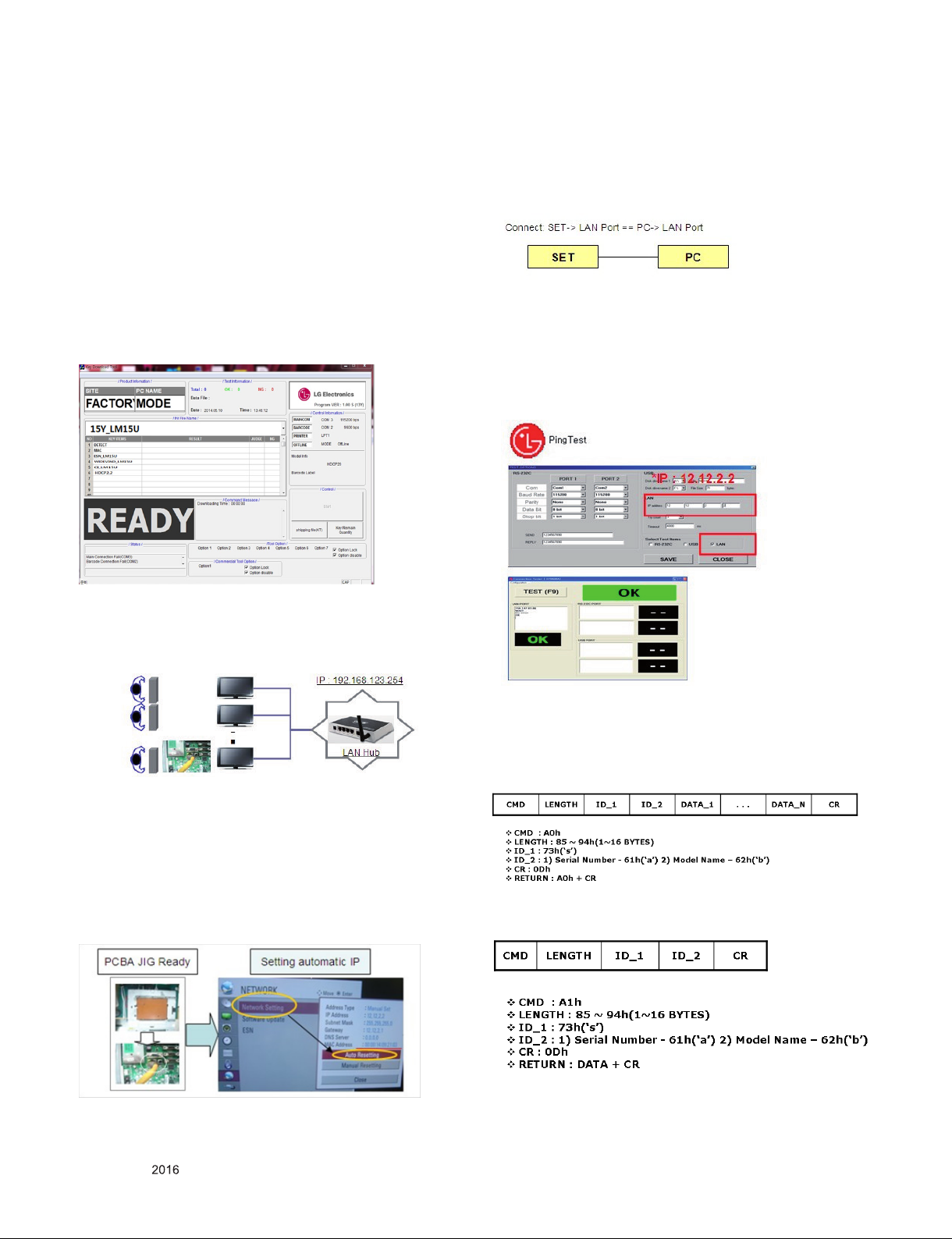

4.4. LAN PORT INSPECTION(PING TEST)

4.4.1. Equipment setting

1) Play the LAN Port Test PROGRAM.

2) Input IP set up for an inspection to Test Program.

*IP Number : 12.12.2.2

4.4.2. LAN PORT inspection(PING TEST)

1) Play the LAN Port Test Program.

2) Connect each other LAN In Port Jack.

3) Play Test (F9) button and conrm OK Message.

4) Remove LAN CABLE

5) Connect each other LAN Out Port Jack.

6) Play Test (F9) button and conrm OK Message.

7) Remove LAN CABLE

4.3. LAN Inspection

4.3.1. Equipment & Condition

▪ Each other connection to LAN Port of IP Hub and Jig

4.3.2. LAN inspection solution

1) LAN Port connection with PCB

2) Network setting at MENU Mode of SET (Installer Menu →

119 → 253 → Menu)

3) Setting automatic IP

4) Setting state conrmation

→ If automatic setting is nished, you conrm IP and MAC

Address.

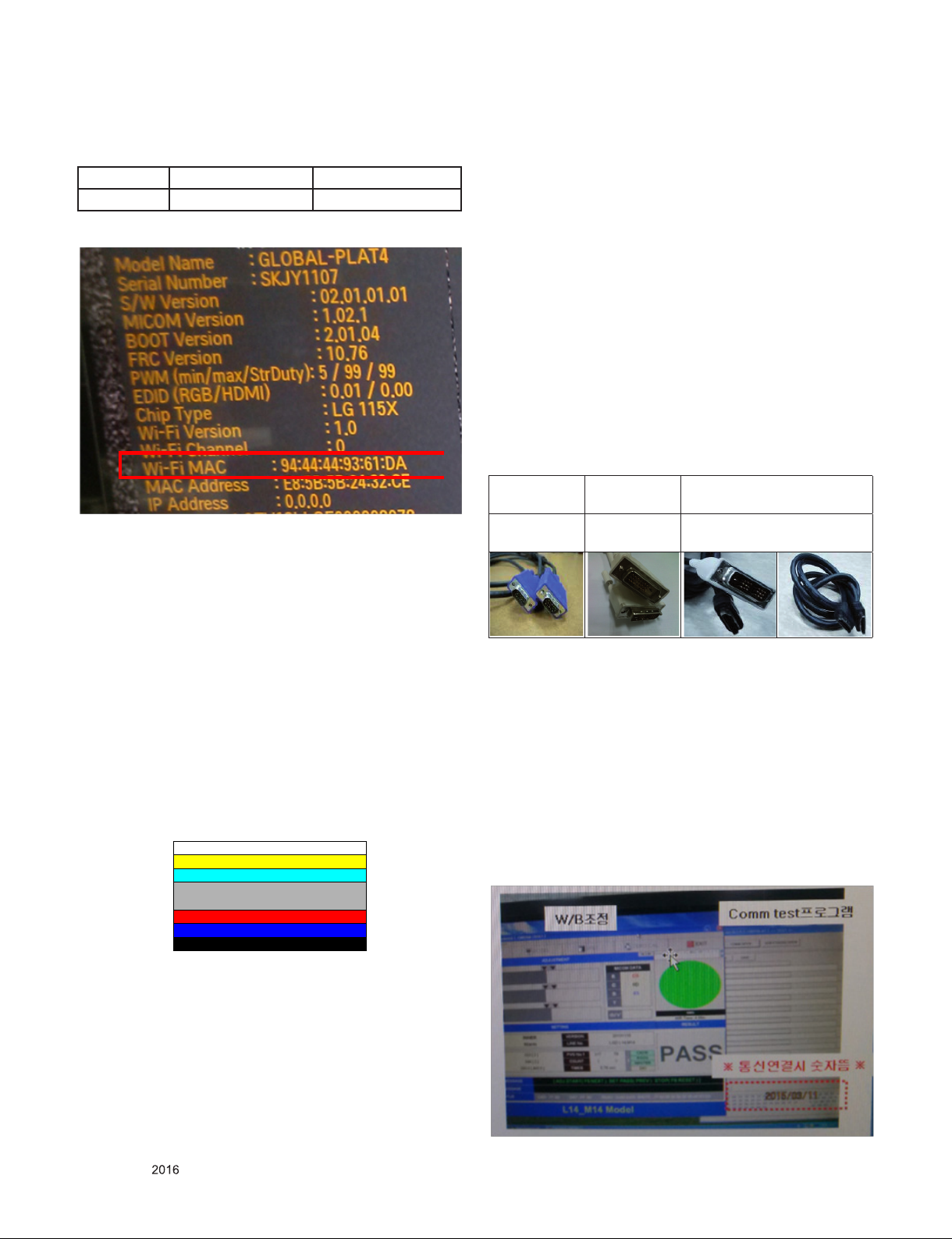

4.5. Serial number download

Connect Bar Code scan equipment and set by RS-232C

cable.

1) E2PROM Data Write

2) E2PROM Data Read

Only for training and service purposes

- 13 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

4.5. WIFI MAC ADDRESS CHECK

4.5.1. Using RS232 Command

Command Set ACK

Transmission [A][l][][Set ID][][20][Cr] [O][K][x] or [N][G]

- check the menu on in-start

5. Manual Adjustment

5.1. ADC adjustment

5.1.1. Overview

▪ ADC adjustment is needed to nd the optimum black level

and gain in Analog-to-Digital device and to compensate RGB

deviation.

5.1.2. Equipment & Condition

▪ Adjust Remote control

▪ 801GF(802B, 802F, 802R) or MSPG925FA Pattern Genera-

tor

- Resolution: 480i Comp1 (MSPG-925FA: model-209,

pattern-65)

- Resolution : 1024*768 RGB (Inner Pattern)

- Pattern : Horizontal 100% Color Bar Pattern

- Pattern level: 0.7±0.1 Vp-p

- Image or Inner pattern.

3) If ADC calibration is failure, after rechecking ADC pattern or

condition, retry calibration

5.2. EDID / DDC Download(EDID PCM)

5.2.1. Overview

It is a VESA regulation. A PC or a MNT will display an optimal

resolution through information sharing without any necessity

of user input. It is a realization of “Plug and Play”.

5.2.2. Equipment

▪ Since embedded EDID data is used, EDID download JIG,

HDMI cable and D-sub cable are not need.

▪ Adjust remocon

5.2.3. Download method

1) Press Adj. key on the Adj. R/C,

2) Select EDID D/L (PCM) menu.

3) By pressing Enter key, EDID download will begin

4) If Download is successful, OK is display, but If Download is

failure, NG is displayed.

5) If Download is failure, Re-try downloads.

For Analog

EDID

D-sub to D-

sub

* Caution) When EDID Download, must remove HDMI / D-sub

5.2.4. RS232 IN / OUT INSPECTION

1) Connect RS232 In/Out cable with daisy chain. You can

control several products at one time by connecting them to

a single PC.,

2) Check the RS232 command.

i) RS232S Out Setting to PC

- Set device port “COM” ( check control panel on PC)

- Set Baud Rate “115200”

ii) Run RS232C Command program (ex. W/B adjust Program)

and Comm Test Program for RS232C Out Check.

iii) After Running Rs232C Command (ex. W/B adjust), Check

Data from RS232C out on Comm Test Program Window.

For DVI EDID For HDMI EDID

DVI to DVI DVI-D to HDMI

or HDMI to HDMI

Cable.

▪ Must use standard cable

5.1.3. Adjust method

5.1.3.1. ADC RGB

1) Press the In-start Key on the ADJ remote after at least 1

min of signal reception. Then, select ADC Calibration. And

Press OK Button on the menu “Start”. The adjustment will

start automatically.

2) If ADC RGB is successful, “ADC RGB Success” is displayed and ADC RGB is completed. If ADC calibration is

failure, “ADC RGB Fail” is displayed.

Only for training and service purposes

- 14 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

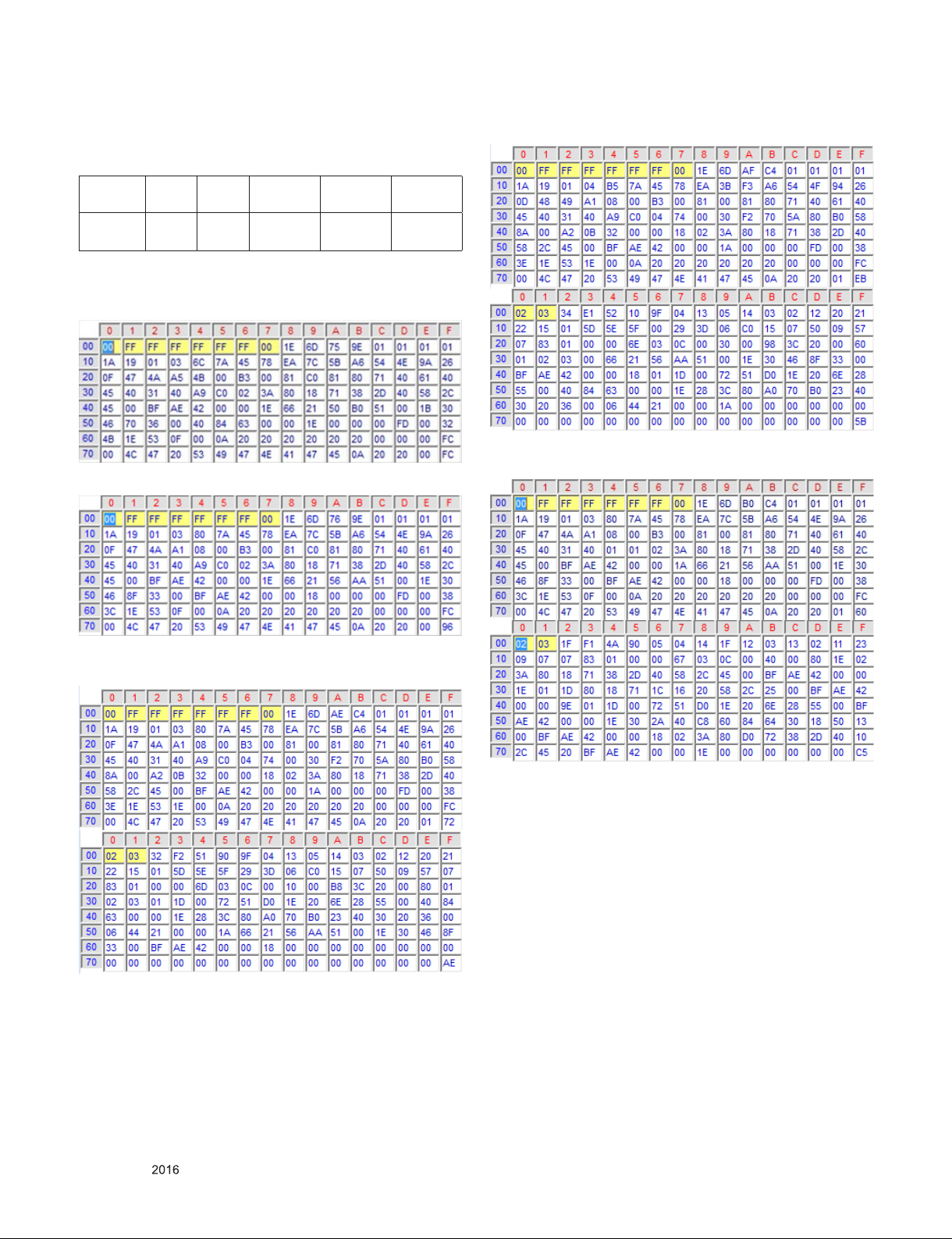

5.2.5. EDID DATA

5.2.5.1. EDID

Input RGB DVI HDMI Display-

Check-

Sum

* Checksum(HDMI/RGB/DVI/Displayport/OPS)

1) RGB (Check Sum : 0xFC)

2) DVI (Check Sum : 0x96)

0xFC 0x96 0x72,

0xAE

Port

0xEB,

0x5B

4) DP (Check Sum : 0xEB, 0x5B)

OPS

0x60,

0XC5

5) OPS (Check Sum : 0X60, 0xC5)

3) HDMI (Check Sum : 0x72, 0xAE)

5.3. White Balance Adjustment

5.3.1. Overview

▪ W/B adj. Objective & How-it-works

- Objective: To reduce each Panel’s W/B deviation

- How-it-works: When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic Range.

In order to prevent saturation of Full Dynamic

range and data, one of R/G/B is xed at

192, and the other two is lowered to nd the

desired value.

- Adj. condition: normal temperature

1) Surrounding Temperature: 25 ± 5 °C

2) Warm-up time: About 5 Min

3) Surrounding Humidity: 20 % ~ 80 %

4) Before White balance adjustment, Keep power on status,

don’t power off

Only for training and service purposes

- 15 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Loading...

Loading...