CONFIDENTIAL

LED TV

SERVICE MANUAL

CHASSIS : UA83P

MODEL : 43UK6200PUA

MODEL : 43UK6090PUA

CAUTION

BEFORE SERVICING THE CHASSIS, READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

P/NO : MFL70427821 (1807-REV01)

Any reproduction, duplication, distribution (including by way of email, facsimile or other electronic means),

publication, modification, copying or transmission of this Service Manual is STRICTLY PROHIBITED unless you

have obtained the prior written consent of the LG Electronics entity from which you received this Service Manual.

The material covered by this prohibition includes, without limitation, any text, graphics or logos in this Service

Manual.

Copyright © 2018 LG Electronics Inc. All rights reserved. Only training and service purposes.

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ........................................................................ 3

SERVICING PRECAUTIONS ................................................................... 4

SPECIFICATION ....................................................................................... 6

SOFTWARE UPDATE ............................................................................. 9

BLOCK DIAGRAM ................................................................................. 10

EXPLODED VIEW .................................................................................. 22

ASSEMBLY / DISASSEMBLY ................................................................ 23

TROUBLE SHOOTING GUIDE ................................................ APPENDIX

- 2 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

SAFETY PRECAUTIONS

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 MΩ and 5.2 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

- 3 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conict between the

following servicing precautions and any of the safety precautions

on page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board mod-

ule or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specied otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10 % (by volume) Acetone and 90 %

(by volume) isopropyl alcohol (90 % - 99 % strength)

CAUTION: This is a ammable mixture.

Unless specied otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test xtures specied in this

service manual.

CAUTION: Do not connect the test xture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some eld-effect transistors

and semiconductor “chip” components. The following techniques

should be used to help reduce the incidence of component damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging

wrist strap device, which should be removed to prevent potential shock reasons prior to applying power to the unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classied as “anti-static” can generate

electrical charges sufcient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufcient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your

foot from a carpeted oor can generate static electricity sufcient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500 °F to 600 °F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25 cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500 °F to 600 °F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500 °F to 600 °F)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder ows onto and around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

- 4 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent at against the circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing

the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close

as possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the

good copper pattern. Solder the overlapped area and clip off

any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

- 5 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application range

This specification is applied to the LED TV used UA83P

chassis.

2. Test condition

Each part is tested as below without special appointment.

(1) Temperature: 25 °C ± 5 °C, CST: 40 °C ± 2 °C

(2) Relative Humidity: 65 % ± 10 %

(3) Power Voltage

: Standard input voltage (AC 100-240 V~, 50/60 Hz)

* Standard Voltage of each products is marked by models.

(4) Specification and performance of each parts are followed

each drawing and specification by part number in

accordance with BOM.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment.

3. Test method

(1) Performance: LGE TV test method followed

(2) Demanded other specification

- Safety : CE, IEC specification

- EMC : CE, IEC

4. General Specification

No Item Specication Remark

1 Market North America

2 Broadcasting system ATSC / NTSC-M, 64 & 256 QAM

3 Available Channel VHF : 02~13

UHF : 14~69

DTV : 02-69

CATV : 01~135

CADTV : 01~135

4 Receiving system Digital : ATSC, 64 & 256 QAM

Analog : NTSC-M

5 Video Input NTSC-M Rear (1EA)

6 Component Input Y/Cb/Cr, Y/ Pb/Pr Rear (1EA)

7 HDMI Input HDMI 1 PC / DTV format Side, Support 6Gbps

HDMI 2 PC / DTV format Side, Support 6Gbps, Support ARC

HDMI 3 PC / DTV format Rear, Support 6Gbps

HDMI 4 PC / DTV format Rear, Support 6Gbps

8 Audio Input Component / AV Audio / DVI Audio L/R Input ; Rear

Component and AV and DVI use same jack ;

9 SPDIF out(1EA) Optical Audio out Rear (1EA),

10 USB Input(3EA) EMF, DivX HD, For SVC (download) JPEG, MP3, DivX HD

Side(1EA), Rear(1EA)

- 6 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

5. External Input Support Format

5.1. Component (Y, PB, PR)

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) Proposed

1 720*480i 15.73 59.94 13.50 SDTV, DVD 480I(525I)

2 720*480i 15.75 60.00 13.51 SDTV, DVD 480I(525I)

3 720*480p 31.47 59.94 27.00 SDTV 480P

4 720*480p 31.50 60.00 27.02 SDTV 480P

5 1280*720p 44.96 59.94 74.17 HDTV 720P

6 1280*720p 45.00 60.00 74.25 HDTV 720P

7 1920*1080i 33.72 59.94 74.17 HDTV 1080I

8 1920*1080i 33.75 60.00 74.25 HDTV 1080I

9 1920*1080p 67.43 59.94 148.5 HDTV 1080P

10 1920*1080p 67.50 60.00 148.5 HDTV 1080P

5.2. HDMI Input (PC/DTV)

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) Proposed

HDMI-PC

1 640*350 31.46 70.09 25.17 EGA

2 720*400 31.46 70.08 28.32 DOS

3 640*480 31.46 59.94 25.17 VESA(VGA)

4 800*600 37.87 60.31 40 VESA(SVGA)

5 1024*768 48.36 60.00 65 VESA(XGA)

6 1360*768 47.71 60.01 84.75 VESA(WXGA)

7 1152*864 54.34 60.05 80 VESA

8 1280*1024 63.98 60.02 109.00 SXGA Support to HDMI-PC

9 1920*1080 67.5 60 158.40 WUXGA

(Reduced Blanking)

10 1920*1080 135 120 297 UDTV 1080P

11 3840*2160 54 24.00 297.00 UDTV 2160P

12 3840*2160 56.25 25.00 297.00 UDTV 2160P

13 3840*2160 67.5 30.00 297.00 UDTV 2160P

14 4096*2160 53.95 23.97 296.70 UDTV 2160P

15 4096*2160 54 24 297 UDTV 2160P

- 7 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) Proposed

DTV

1 640*480 31.46 59.94 25.12 SDTV 480P

2 640*480 31.5 60.00 25.12 SDTV 480P

3 720*480 15.73 59.94 13.50 SDTV, DVD

480I(525I)

4 720*480 15.75 60.00 13.51 SDTV, DVD

480I(525I)

5 720*576 15.62 50.00 13.50 SDTV, DVD

576I(625I) 50Hz

6 720*480 31.47 59.94 27 SDTV 480P

7 720*480 31.5 60.00 27.02 SDTV 480P

8 720*576 31.25 50.00 27 SDTV 576P

9 1280*720 44.96 59.94 74.17 HDTV 720P

10 1280*720 45 60.00 74.25 HDTV 720P

11 1280*720 37.5 50.00 74.25 HDTV 720P

12 1920*1080i 28.12 50.00 74.25 HDTV 1080I

13 1920*1080i 33.72 59.94 74.17 HDTV 1080I

14 1920*1080i 33.75 60.00 74.25 HDTV 1080I

15 1920*1080p 26.97 23.97 63.29 HDTV 1080P

16 1920*1080p 27.00 24.00 63.36 HDTV 1080P

17 1920*1080p 33.71 29.97 79.120 HDTV 1080P

18 1920*1080p 33.75 30.00 79.20 HDTV 1080P

19 1920*1080p 56.25 50.00 148.5 HDTV 1080P

20 1920*1080p 67.43 59.94 148.35 HDTV 1080P

21 1920*1080p 67.5 60.00 148.50 HDTV 1080P

22 1920*1080p 112.5 100 297.00 UDTV 1080P

23 1920*1080p 134.86 119.88 296.70 UDTV 1080P

24 1920*1080p 135.00 120 297 UDTV 1080P

25 3840*2160p 53.95 23.98 296.70 UDTV 2160P

26 3840*2160p 54 24.00 297.00 UDTV 2160P

27 3840*2160p 56.25 25.00 297.00 UDTV 2160P

28 3840*2160p 61.43 29.97 296.70 UDTV 2160P

29 3840*2160p 67.5 30.00 297.00 UDTV 2160P

30 3840*2160p 112.5 50.00 594 UDTV 2160P

31 3840*2160p 134.86 59.94 593.40 UDTV 2160P

32 3840*2160p 135 60.00 594 UDTV 2160P

33 4096*2160p 53.95 23.98 296.70 UDTV 2160P

34 4096*2160p 54 24.00 297 UDTV 2160P

35 4096*2160 56.25 25.00 297 UDTV 2160P

36 4096*2160 61.43 29.97 296.70 UDTV 2160P

37 4096*2160 67.5 30.00 297 UDTV 2160P

38 4096*2160 112.5 50.00 594 UDTV 2160P

39 4096*2160 134.86 59.94 593.40 UDTV 2160P

40 4096*2160 135 60.00 594 UDTV 2160P

Spec. out but display

- 8 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

SOFTWARE UPDATE

1. USB

(1) Insert the USB memory Stick to the USB port

(2) Automatically detect the SW Version and show the below

message

(3) Click [YES]: initiate the download and install of the update.

2. NSU

(This Function is needed to connect to the internet)

(1) Menu -> All Settings -> General -> About This TV

(2) Click [CHEK FOR UPDATES] : system check newest

version

(4) Click [Check Now]: move to “About This TV” page for

update

(5) TV is updating

(6) After finished the update, below Pop-up appear

(7) Click [Yes] : TV will be DC OFF -> ON

(8) After TV turned on, Check the updated SW Version and

Tool Option

(3) Click [DOWNLOAD AND INSTALL]

(4) TV is updating

(5) After finished the update, below Pop-up appear

(6) Turn OFF the TV and On. Check the updated SW Version

and Tool Option

- 9 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

1. Main IC

Main IC

eMMC (4GB)

CI Slot

USB1 (2.0)

OCP

USB2 (2.0)

HDMI3

HDMI2(ARC)

HDMI1

Air/

Cable

TUNER

(T2/C/A)

TUNER

(S,S2)

DVB-S

LNB

T2/C/S/S2 H-NIM tuner

IF (+/-)

P_TS_OUT

P_TS_IN

Sub MICOM

X_TAL

32.768KHz

I2C 1

IR / KEY

LOGO LIGHT(Ready)

WIFI/BT Combo

USB_WIFI

X_TAL

24MHz

Sub Assy

LAN

ETHERNET

SPDIF

AV/COMP

CVBS/YPbPr

SPDIF OUT

H/P

AMP

RS-232

MAX323

MAIN Audio AMP

I2S Out

I2C 4

Vx1 51P (8 lane)

Vx1 / EPI/ CEDS

FCIC SPI/ I2C 6

EPI

PMIC

Level

shifter

M0

M1

IF_S

IF

GST/MCLK/GCLK/EO/I2C 6

NVRAM (256Kb)

I2C 4

I2C 2

EPI block

IQ (+/-), IP(+/-)

HDMI4

TS

DDR3 2133 X 32

(256MB X 2EA)

DDR3 2133 X 32

(512MB X 2EA)

EPI 60P (65”:8 lane, 55”↓:6lane), CEDS 68P

Area OPT

BLOCK DIAGRAM

- 10 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

2. EPI / CEDS

CEDS 6lane 68Pin / EPI 6Lane 60Pin

BOE Panel

3

840x2160@60p

1

.5Gbps

[ PAD_MOD_TX_P02/N02 ~ P09/ N09 ]

CEDS 6lane 68Pin / EPI 6Lane 60Pin

LGD Panel

3

840x2160@60p

3

Gbps(55” ↓ )

/ 2Gbps(65” )

PMIC

&

L

evel Shif ter

R

T6950( LGD)

S

W50212(BOE)

CLK(x10)

V

GL1

V

ST

G

IP_RST LS_VGL

V

GH_EVEN

V

GH_ODD

H

VDD

EPI 3Lane 60P ( 55” ↓ )

E

PI 4Lane 60P ( 65” )

EPI 3Lane 60P ( 55” ↓ )

E

PI 4Lane 60P ( 65” )

GMA

(

1, 5, 9, 10, 13, 24,18)

[

PAD_MOD_TX_P12(LVA3- )]

PMIC_RESET

LOCKOUT12

GST, E/O, MCLK, GLCK

[ PAD_I2S_IN_WS(TCON1)(GPIO)]

[

PAD_I2S_IN_SD(TCON2)(GPIO)]

[

PAD_SPDIF_IN(TCON3)(GPIO)]

[

PAD_GPIO16(TCON4)(GPIO)]

Sub PMIC

(

RT5093)

VDD

V

COM1

V

COMLFB

V

COMRFB

V

COM2

[ PAD_MOD_TX_P02/ N02 ~ P09/ N09]

GAMMA

(RT6508)

B

OE Only

GMA

(2, 3, 4, 7, 8,

1

1, 12, 15, 16, 17)

[ PAD_GPIO30SCK4]

[

PAD_GPIO31SDA4]

68p in

60p in

68p in

60p in

LDO

(

TJ4320)

VTERM

[ PAD_GPIO17_PM(PM_SPI_CK2]

[

PAD_GPIO18_PM(PM_SPI_DI2)]

[

PAD_GPIO19_PM(PM_SPI_DO2)]

[

PAD_GPIO10_PM(PM_SPI_CZ2)]

Main IC

- 11 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

3. Vx1

I2C_ A6

Vx1 8Lane 51P

A

H n

Panel

3840x2160@60p

LOCKAn

A

DATA_FORMAT_0/ 1

[ PAD_GPIO23]

[ PAD_MOD_TX_P00~ 07]

[

PAD_GPIO31SDA4]

[

PAD_GPIO24]

AGP_CTL

A

VX1_MSE

BIT [2:3] DISPLAY TYPE TYPE Data lane RGB/M+ COMMENT

[Level 0 : Level 0] LCD_UHD VBY1 N/A RGB/M+ V16_V17_V18

[Level 0 : Level 1]

[Level 0 : Level 2]

[Level 0 : Level 3]

[Level 1 : Level 0] LCD_UHD LGD_EPI_3G V18 6lane RGB

[Level 1 : Level 1] LCD_UHD LGD_EPI_3G V18 6lane M+

[Level 1 : Level 2] LCD_UHD LGD_EPI_3G V17 6lane M+

[Level 1 : Level 3]

[Level 2 : Level 0] LCD_UHD

BOE_CEDS_1.5

G

V18 12lane RGB

[Level 2 : Level 1] LCD_UHD

BOE_CEDS_1.5

G

17Y_18Y 12lane RGBW

[Level 2 : Level 2]

[Level 2 : Level 3]

[Level 3 : Level 0] LCD_UHD LGD_EPI_3G V18 8lane RGB

V18 8lane :

LGD 65UK75

65UK63

[Level 3 : Level 1] LCD_UHD LGD_EPI_3G V18 8lane M+

[Level 3 : Level 2] LCD_UHD

LGD_EPI_3G

Q- SAC

V18 6lane RGB

Q- SAC :

LGD 49inch

Only

[Level 3 : Level 3] LCD_UHD

LGD_EPI_3G

Q- SAC

V18 6lane M+

[ PAD_MOD_TX_P12(LVA3- )]

[

PAD_MOD_TX_N12 (LVA3+)]

[

PAD_GPIO30SCK4]

[

PAD_GPIO19]

[

PAD_GPIO20]

Main IC

Main IC

IC

Main IC

Main IC

Main IC

Main IC

Main IC

Main IC

Main IC

Main IC

Main IC

- 12 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

4. Tuner

18Y Tuner

Main

[ B1_+3.3V_RF] 3

[ +3.3V_DEMOD_TU] 11

[

B3_+1.2V_DEMOD] 13

[

IF[ P] ] 8

[

IF[ N] ] 7

[

IF_AGC] 5

[

TU_SIF] 6

[

CVBS] 4

[

ERROR] 14

[

MCLK] 15

[

SYNC] 1 6

[

VALID] 17

AC5 [ PAD_TS2_CLK]

A

D4 [ PAD_TS2_SYNC] AC4 [ PAD_TS2_VLD]

E

WBS_TU

F

E_DEMOD1_TS_CLK FE_DEMOD1_TS_SYNC FE_DEMOD1_TS_VAL

D[ 0- 7] 18- 25

F

E_DEMOD1_TS_DATA [ 0- 7]

[

GPIO_27~ 34_TP0_D0~ D7]

[ RESET1_DEMOD] 10

/ TU_RESET1_TU

A

H4 [ PAD_GPIO13]

[

LNB_TX1] 12

[

LNB] 26

I2C_SCL_2

I

2C_SDA_2

+

3.3V_NORMAL

IF_P_TU

I

F_N_TU

T

U_SIF_TU

T

U_CVBS_TU

I

F_AGC_TU

A

L11 [ PAD_IP_T] AM10 [ PAD_IM_T] AM11 [ PAD_IFAGC_T] AL12 / AM12 [ SIF_P/ N]

Y

2 [ PADA_CVBS0]

+ D_Demod_Core

LNB1

I

C7001

LNB1_OUT

1.2 K Ω

5 [ SCL]

6

[ SDA] 8 [ TONECTRL]

2

[ LNB]

33 Ω

33 Ω

AG10 [ PAD_TGPIO2SCK1]

A

H10 [ PAD_TGPIO3SDA1]

AM8 [ PAD_IP_S]

A

L8 [ PAD_IM_S] AK10 [ PAD_QP_S] AL9 [ PAD_QM_S] AK8 [ PAD_IFAGC_S] AH9 [ PAD_GPIO26 (DISEQC_OUT)]

IF_S_IP_MAIN

I

F_S_IN_MAIN IF_S_QP_MAIN IF_S_QN_MAIN

[

I[ P] ] 59

[

I[ N] ] 60

[

Q[ P] ] 62

[

Q[ N] ] 61

[

SAT_AGC] 58

EXT_Demo d

O

ptio n

IF_S_AGC_MIAN

[

SCL_RF] 1

[

SDA_RF] 2

0 Ω

Main Ball No : 27*27 _pac kage

+3. 3V_NORMAL

3

.5V_ST

LNB1_TX

(Phillippine only)

(Phillippine only)

Ready- Not user

Ready- Not user

IC

- 13 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

5. Video / Audio IN/OUT

HDMI_ARC

ST_GPIO_23_H0_ARC[AD8]

[AL12] PAD_SIFP

I2C_SDA_0_AMP1 / I2C_SCL_0_AMP1

AUD_SCK

AMP_RESET_N

AUDA_OUTR

AUDA_OUTL

H/P Jack

SIDE_HP_MUTE

[M3]PAD_EARPHONE_OUTR

[M2]PAD_EARPHONE_OUTL

TU_SIF_TU

H/P AMP

(IC6300)

LPF

[E10]PAD_GPIO7_PM

SPDIF_OUT

HP_LOUT_JACK

HP_ROUT_JACK

LPF

LPF

Main

IC

Tuner

AUD_LRCH

AUD_LRCK

AMP_MUTE

SPK_R+ / R-

SPK_L+ / L-

MAIN AMP

(IC5800)

MICOM

SPK L

SPK R

22

26

[38] CLK_I

[8] WCK

[7] SDATA

[10,11]

[36]

[12]

[30, 33]

[18, 21]

AV/COMP

HDMI2

SPDIF

HP_DET

[AL15]PAD_GPIO21

[

Y3]PADA_CVBS_OUT1

SIF_P

SIF_N

[AM12] PAD_SIFM

DTV/MNT_V_OUT

COMP1_Y/CVBS

[V2]PADA_GIN1P / [Y1] PADA_CVBS1

AV1_CVBS_DET

[

D3]PAD_I2S_OUT_SD2(GPIO

)

COMP1_Pb / COMP1_Pr / COMP1_DET

[W2]PADA_RIN1P / [v3]PADA_BIN1P / [C1] PAD_I2S_OUT_SD1

COMP1/AV1/DVI_L_IN

COMP1/AV1/DVI_R_IN

[

L2]PAD_LINEIN_L0 [L1]PAD_LINEIN_R0

[

E5]PAD_SPDIF_OUT

[E2]PAD_I2S_OUT_WS

[D1]PAD_I2S_OUT_SD

[D2]PAD_I2S_OUT_BCK

[F2]PAD_DDCR_DA / [F3]PAD_DDCR_CK

5

- 14 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Main I

C

HDMI2.0_1_HPD

TMDS1 - D0/D1/D2/CLK

DDC_SCL1 / DDC_SDA1

MICOM

(IC3000)

HDMI2.0_1_5V_DET

HDMI2.0_2_HPD

TMDS2 - D0/D1/D2/CLK

DDC_SCL2 / DDC_SDA2

HDMI2.0_2_5V_DET

HDMI2.0_3_HPD

TMDS3 - D0/D1/D2/CLK

DDC_SCL3 / DDC_SDA3

HDMI2.0_3_5V_DET

HDMI2.0_4_HPD

TMDS4 - D0/D1/D2/CLK

DDC_SCL4 / DDC_SDA4

HDMI2.0_4_5V_DET

HDMI2 with ARC

H

DMI1

H

DMI3

H

DMI4

HDMI_CEC

HDMI_ARC

HDMI_CEC

HDMI_CEC

6. HDMI2.0

- 15 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

RS232C

(IC7200)

WIFI_DM / DP

SOC_RX / TX

USB2.0_2_DM / DP

USB3

DEBUG_RX / TX

Main

USB2

USB2.0_3_DM / DP

MICOM

(IC3000)

Wafer

(P200)

Wafer

(P4000)

DEBUG UART

Wafer

(P201)

5

7 9 10 15 16 19 20

SOC_RX / TX

DCDC OCP

(IC4501)

+5V_USB3

+5V_USB3

WOL/WIFI_POWER_ON

COMBO_RESET

BT_WAKEUP_DEVICE

BT_WAKEUP_HOST

IR

LED_R

KEY2

KEY1

DCDC OCP

(IC4700)

DOUT1

RIN1

PHONE JACK

US Only

IC

7. USB / WIFI / M-REMOTE / UART(Debug)

- 16 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

I2C_SDA6

EPI PMIC

P7100

Vx1 51P

I2C_SCL6

1.8k Ω

I2C_SDA_1

I2C_SCL_1

Main IC

1.8k Ω

+3.3V_NOR

1.8k Ω

1.8k Ω

+3.3V_ST

MICOM

I2C_SDA4

I2C_SCL4

NVRAM

AMP

I2C_SDA2

I2C_SCL2

LNB

Tuner

1.8 k Ω

1.8 k Ω

+3.3V_NOR

1.8k Ω

1.8k Ω

+3.3V_NOR

33 Ω

33 Ω

TCON_I2C_EN

33 Ω

33 Ω

100Ω

33 Ω

EPI / CEDS only

Vx1 only

8. I2C Map

- 17 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

WOL/ETH_POWER_ON

USB_CTL2

Main IC

MICOM

USB1 OCP USB1

INSTANT_BOOT

/USB_ODC2

USB_CTL3

USB2 OCP USB2

/USB_ODC3

SOC_RESET

BIT0~6

HW option

ADC 1~5

PCM_RESET

PCMCIA

OCP

PCM_5V_CTL

DATA_FORMAT_1

Panel

DATA_FORMAT_0

VX1_MSE

AGP_CTRL

HTPDAn/MCKL_A

LOCKAn

PMIC

PWM_DIM2

POWER

PWM_DIM

L/D_CLK

L/D_DO

L/D_VSYNC

TCON_I2C_EN/GCLK_A

VID_CPU

CPU DCDC

VID_CPU2

VID_CORE

CORE DCDC

/TU_RESET1

Tuner

AMP_RESET_N

Audio AMP1

COMP1_DET

Component/AV Jack

HP_DET

H/P Jack

AV1_CVBS_DET

9. GPIO

- 18 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

IC100

RS232C

Debug port

P200

SOC_RX/TX

MICOM DEBUG 4P

P3000

MICOM_DEBUG

AMP

IC5800

AMP_MUTE

MODEL1_OPT_0/1/2/ 3

GND

+13V TO PANEL_VCC

PANEL_CTL

HDMI 1 / 2 / 3 /4

JK3101/JK3102/JK3103/JK3104

HDMI_CEC

RESET IC

IC1300

POWER_DET

POWER WAFER

P1001

INV_CTL

MODE_SELECT_PWM1

RL_ON

I2C_SCL_1_MICOM / I2C_SDA_1_MICOM

WOL/ETH_POWER_ON

SOC_RESET

INSTANT_BOOT

OPT0 NON LOGO LCD/LOGO LCD

NON LOGO OLED/LOGO OLED

OPT1 TV-NON EPI/BOX/TV EPI/BOX

OTP2 RESERVED

OPT3 M16/RTK/H15

MICOM_RESET

MICOM X- TAL

X3001

32.768KHz

51P VX1 Wafer

AM_MODE_DET_OLED

IR / KEY/WIFI/BT

P4000

EDID_WP

3D&L_DIM_EN

3.5V_ST- 1.5V DCDC

IC2303

POWER_ON/OFF2_3

13V- 3.3V NORMAL

IC2300

13V- 1V DCDC

IC2302

POWER_ON/OFF2_4

POWER_ON/OFF1

13V- 5V NORMAL DCDC

IC2500

WIFI_EN

T_CON_SYS_POWER_OFF_OLED

IR

EYE_SCL / EYE_SDA

WOL/WIFI_POWER_ON

BT_WAKEUP_DEVICE

COMBO_RESET

BT_WAKEUP_HOST

KEY1 / KEY2

LED_R

GND

+3.5V WIFI

RETENTION_DISABLE

GND

10k Ω

SYSTEM_DEBUG

Main IC

10. GPIO(MICOM – ABOV)

- 19 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

LDO DCDC

D

13.2V

3.5V ST

4

A

I

C2305

MICOM

IR Ass’y

RS-232

WiFi Module

FET

FET(Q4101)

+AVDD_NODIE

L302

1.5V DDR

3

A

I

C2302

SoC(DDR)

CPU_1V0

3

A

I

C2309

SoC(VDDC_CPU)

FET(Q1101)

Panel_VCC L7601/2 L1100

+AVDD33_AU33

L322

+AVDD_DMPLL

L333

CORE_1V0

1

2A

I

C2310

SoC(VDDC)

LNB L7100

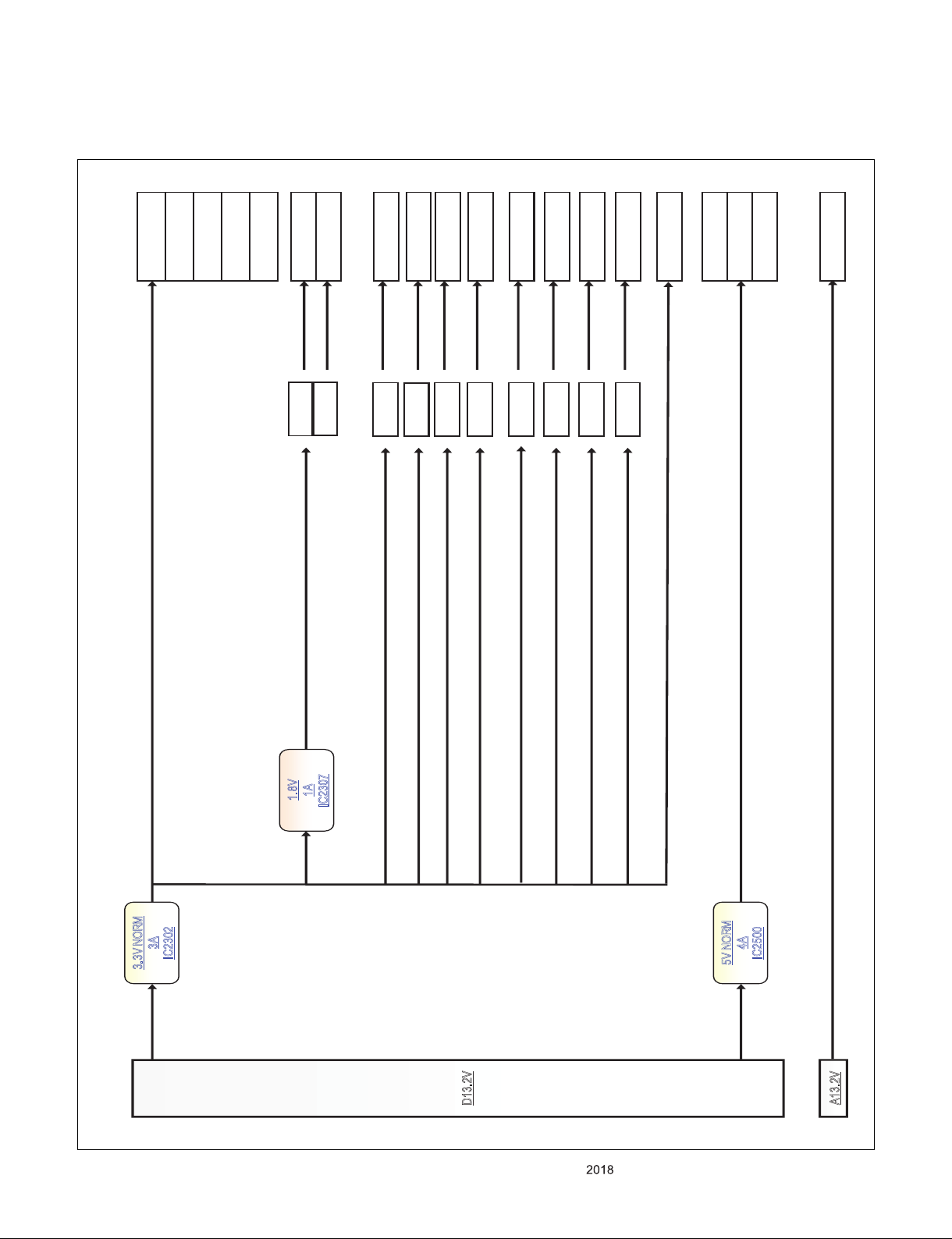

11. Power

- 20 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

D

13.2V

3.3V NORM

3

A

I

C2302

HP Amp

NVRAM

SPDIF OUT

Pull up

GAMMA IC

SoC(

VDDP_3318_C

)

SoC(+VDDP33)

L319

1.8V

1

A

I

C2307

L330

SoC(EMMC1V8)

EMMC VCCQ

EMMC VCC

L2300

Audio Amp

L5801

+3.3V_DEMOD

L6503

+3.3V_TU

L6505

LNB

L7001

5V NORM

4

A

I

C2500

USB1 OCP

USB2 OCP

CI OCP

A13.2V

Audio Amp

EPI_FCIC Flash

L2301

L331

+1.2V_DEMOD

L6900

12. Power 2

- 21 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

400

800

540

521

120

820

LV1

121

500

570

571

LV2

AR1

700

A10

ARC1

530

HP1

HW1

HS1

200

900

EXPLODED VIEW (SET)

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

- 22 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

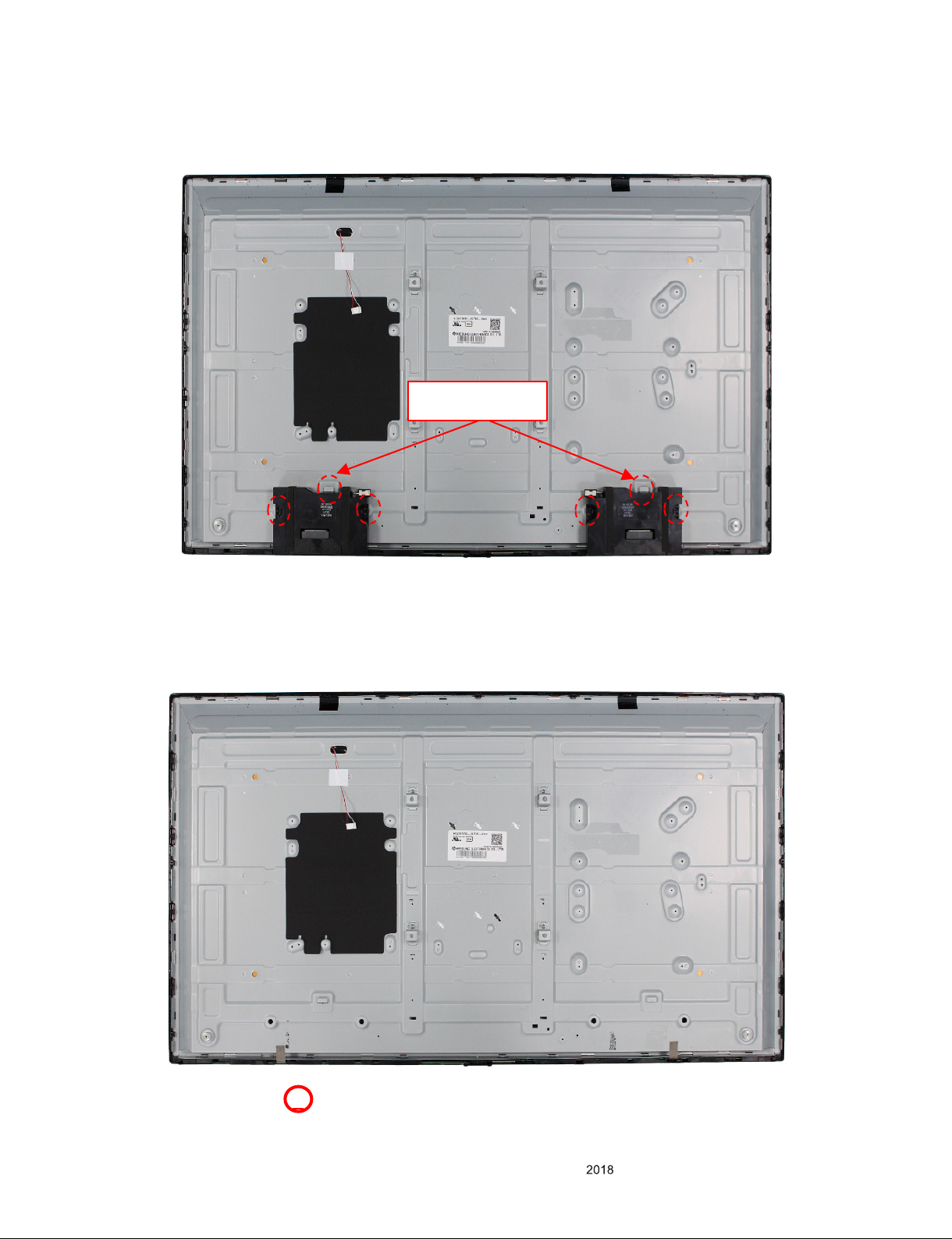

DISASSEMBLY GUIDE (SET)

1

1

1

1

1

3

Latch 8 EA

Screw 5EA(M3*5.5)

1

Hook 11 EA

Screw 2EA(P3*10)

Screw 1EA(P4*10)

Hook Latch

1. After Screw Disassemble, please remove B/C from Module

- 23 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Detach tape

2. Detach Tape

3. Remove all sort of cable

- 24 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

WIFI/BT IR Sub Assy

Disassemble screw(1ea) and

Remove cable from holder

Detach Hook

4. IR assy, Wi-Fi PCB assy disassembly

- 25 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

“A” “B”

1

1

1

1

1

1

1

1

1

Screw 9EA(M3*5.5)

1

5. Screw disassembly

- 26 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

6. Speaker disassembly

Detach hook

Screw 4EA(M3*5.5)

1

7. Screw disassembly

- 27 -

Copyright © LG Electronics Inc. All rights reserved.

Only for training and service purposes.

TROUBLE SHOOTING GUIDE

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Contents of Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

No. Error symptom (High category) Error symptom (Mid category) Page Remarks

1

2 No video/No audio 2

3 Picture broken/ Freezing 3

4 Color error 4

5

6

7

8

9 Wrecked audio/discontinuation/noise 10

10

11

12

A. Video error

B. Power error

C. Audio error

D. Function error

No video/Normal audio 1

Vertical/Horizontal bar, residual image,

light spot, external device color error

No power 6

Off when on, off while viewing, power

auto on/off

No audio/Normal video 9

Remote control & Local switch checking

MR remote operating checking 12

Wifi operating checking 13

7,8

11

5

14 External device recognition error 14

15 E. Noise Circuit noise, mechanical noise 15

16 F. Exterior error Exterior defect 16

First of all, Check whether there is SVC Bulletin in GSCS System for these model.

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

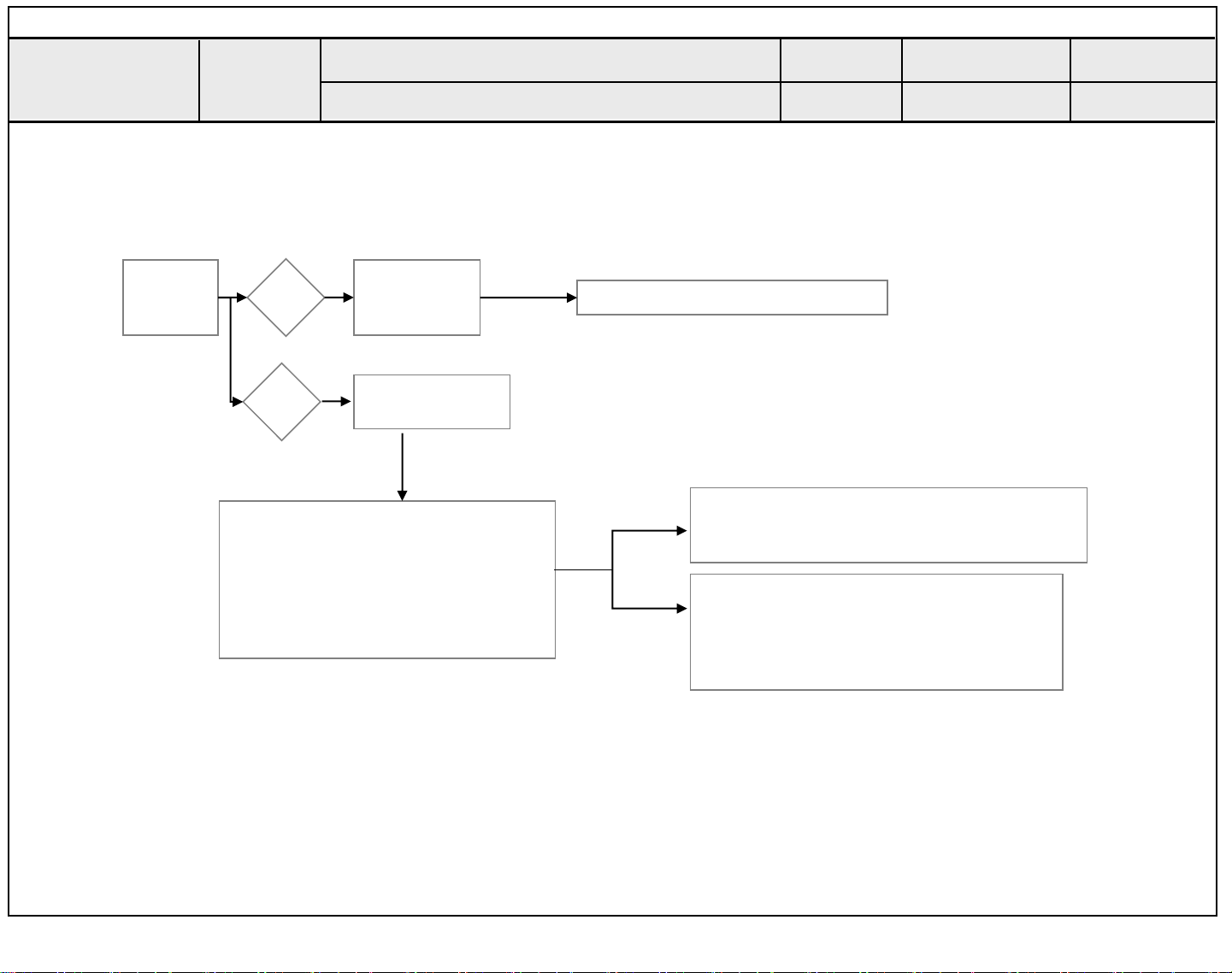

Error

symptom

A. Video error

No video/ Normal audio

Established

date

Revised date

First of all, Check whether all of cables between board is inserted properly or not.

(Main B/D↔ Power B/D, LVDS or EPI Cable, Speaker Cable, IR B/D Cable,,,)

☞A18 ☞A1

No video

Normal audio

Normal

audio

N

Move to No

video/No audio

Y

Check Back Light

On with naked eye

☞A18

Check Power Board 13.2V output

On

Normal

voltage

N

Repair Power

Board or parts

Y N Check Power

Board

13.2V etc.

Y

Replace Inverter

or module

Normal

voltage

N

Repair Power

Board or parts

End

Replace T-con/Main

Y

Board or module

1/16

※Precaution

Always check & record S/W Version and White

Balance value before replacing the Main Board

☞A4 & A2

Replace Main Board

1

Re-enter White Balance value

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

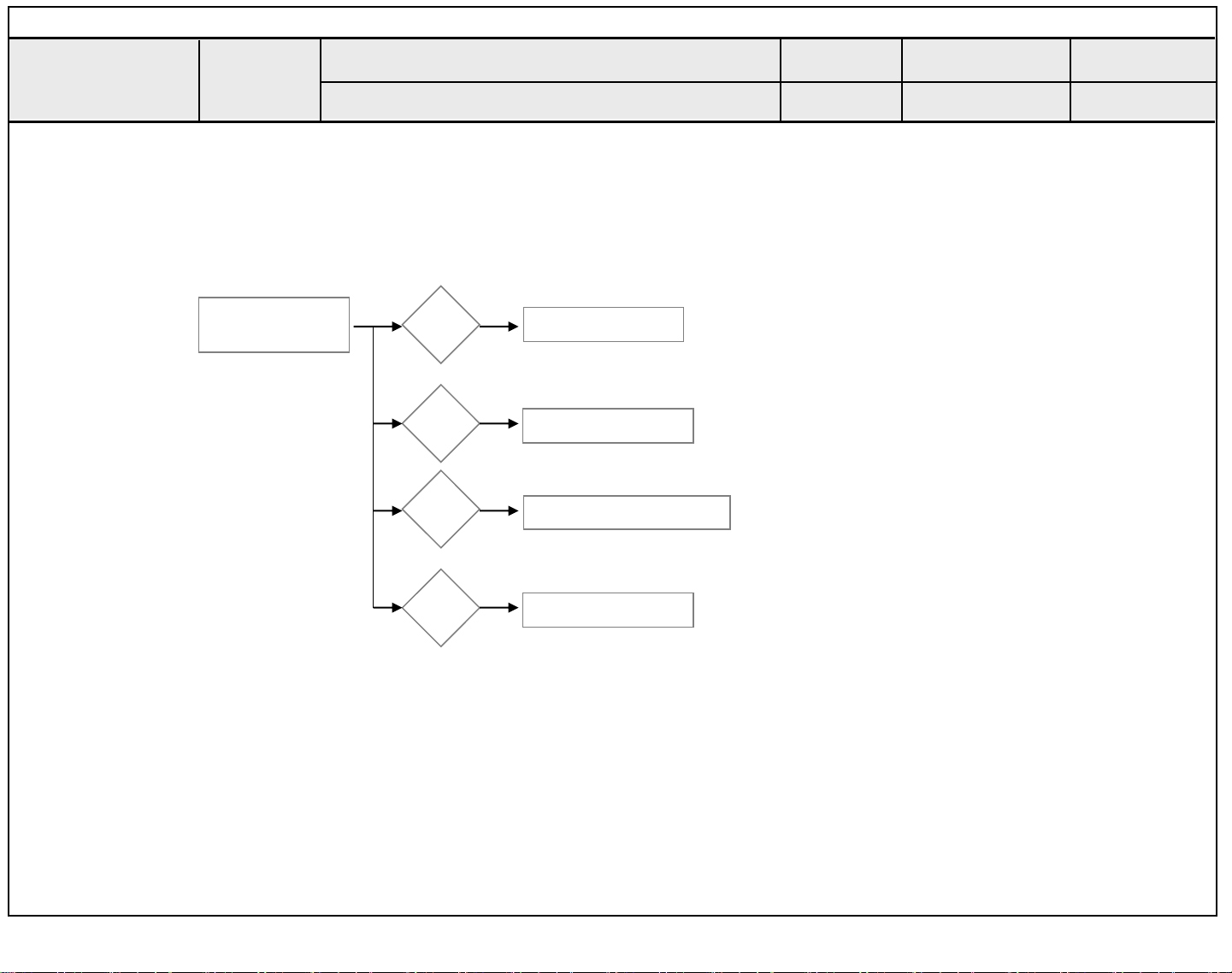

Error

symptom

No Video/

No audio

☞A18

Check various

voltages of Power

Board (13.2V…)

A. Video error

No video/ No audio

Normal

voltage?

Replace Power

Board and repair

parts

Y

N

Check and

replace

MAIN B/D

Established

date

Revised date

End

2/16

2

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

☞ A3

Check RF Signal level

Normal

Signal?

N

Check RF Cable

Connection

1. Reconnection

2. Install Booster

Normal

Picture?

Y

Close

Y

N

Error

symptom

A. Video error

Picture broken/ Freezing

Established

date

Revised date

. By using Digital signal level meter

. By using Diagnostics menu on OSD

( Advanced→ Channels→ Channel Tuning→ Manual Tuning → Check the Signal )

- Signal strength (Normal : over 50%)

- Signal Quality (Normal: over 50%)

Check whether other equipments have problem or not.

(By connecting RF Cable at other equipment)

→ DVD Player ,Set-Top-Box, Different maker TV etc`

☞ A4

Normal

Picture?

Contact with signal distributor

or broadcaster (Cable or Air)

Y

S/W Version

N

Check

SVC

Bulletin?

S/W Upgrade

Normal

Picture?

Y

N

Y

N

Check

Tuner soldering

N

Replace

Main B/D

Y

3/16

Close

Close

3

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

☞A6

Check color by input

-External Input

-AV

-HDMI

☞A8

Check Test pattern

Error

symptom

Color

error?

Check error

color input

mode

☞ A7

※ Check

and replace

Y

Link Cable

(EPI or Vx1

N

Cable) and

contact

condition

External Input/

Component

error

A. Video error

Color error

Color

error?

Check

external

device and

cable

N

Y

Replace Main B/D

Established

date

Revised date

External device

/Cable

normal

N

Color

error?

End

Y

Y

Replace module

N

Replace Main/T-con B/D

4/16

HDMI

error

Check external

device and

cable

4

Request repair

for external

device/cable

N

External device

/Cable

normal

Y

Replace Main/T-con B/D

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Vertical / Horizontal bar, residual image,

A. Video error

light spot, external device color error

Vertical/Horizontal bar, residual image, light spot

☞A6

Check color condition by input

-External Input

-HDMI

☞A8

Check Test pattern

Screen

normal?

N

Replace

module

Y

Check

external

device

connection

condition

Normal?

N

Request repair

for external

device

External device screen error-Color error

☞ A7

Check and

Y

replace Link

Cable

Established

date

Revised date

Screen

normal?

End

N

Y

Replace Main/T-con B/D

For LGD panel

Replace Main B/D

For other panel

5/16

Replace

Module

N

Screen

normal?

Y

End

Check S/W Version

Check

version

S/W Upgrade

Normal

screen?

End

N

Y

N

Y

Check screen

condition by input

-External Input

-Component

-HDMI/DVI

External

Input

error

Component

error

HDMI/

DVI

5

Connect other external

device and cable

(Check normal operation of

External Input, Component,

RGB and HDMI/DVI by

connecting Jig, pattern

Generator ,Set-top Box etc.

Connect other external

device and cable

(Check normal operation of

External Input, Component,

RGB and HDMI/DVI by

connecting Jig, pattern

Generator ,Set-top Box etc.

Screen

normal?

Request repair for

external device

Screen

normal?

N

Y

Y

N

Replace

Main/T-con

B/D

Replace

Main /T-con

B/D

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

symptom

☞A17

Check

LED

. Stand-By: Red or Turn On

. Operating: Turn Off

Power LED

Check Power cord

was inserted properly

Error

On?

N

Normal?

Y

Close

N

Y

B. Power error

Check ST-BY 3.5V

☞A18

No power

DC Power on

by pressing Power Key

On Remote control

Y

Normal

Y

voltage?

N

Established

date

Revised date

☞A18

Y

N

Check Power

On ‘”High”

Replace Main B/D

Normal

operation?

☞A18

Measure voltage of each output of Power B/D

N

Y

Replace Main B/D

Normal

voltage?

Replace Power B/D

OK?

Y

6/16

Replace

Power

B/D

Replace Power

B/D

6

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check outlet

Check A/C cord

Check for all 3- phase

power out

Error

symptom

Error?

Y

Fix A/C cord & Outlet

and check each 3

phase out

B. Power error

Off when on, off while viewing, power auto on/off

N

Abnormal

Abnormal

Established

Revised date

CPU

1

date

Replace Main B/D

7/16

Normal?

Replace Power B/D

Y

N

End

7

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Off when on, off while viewing, power auto on/off

B. Power error

* Please refer to the all cases which can be displayed on power off mode.

Power Off list Explanation Action contents

KEYTIMEOUT

1SEC Power OFF

ACDET

5V MNT

CPUABNORMAL If the CPU attempts to reset in case of abnormal operation and Shut Down in case of failure.

NO POLING

CPUCMD

INV_ERROR

ONRF_FAIL RESULT : Reboot, CONDITION : OLED module compensation is running but fails. Check & Change OLED Module

PNWASHFAIL Power off by panel noise wash function fail case. Check & Change OLED Module

RESET When Micom is reset by AC Off

KEY Power off by Local key

OFFTIMER Power off by Off timer

SLEEPTIMER Power off by sleep timer

NOSIG Power off by No Signal

FANSTOP Power off by FAN operation stopped

INSTOP Power off by Instop Key

AUTO OFF Power off by auto off function

RESREC Power off by reserved recording

RECEND Power off when recording stops

SWDOWN Reboot by SW down load function

UNKNOWN

COMP_END OLED threshold voltage degradation(Compensation) completes.

PNWASHDONE Power off by panel noise wash function complited. (OLED)

Power off when TV is not turned off during a certain time

RESULT : micom force to trigger TV power off.

CONDITION : When pressing power key while power on/off status, CPU does not response within 8 seconds

Almost the same as Power Off by KEYTIMEOUT. If there is no vaild communication

Bet ween CPU and MICOM for more than 5 seconds, the MICOM switcheds off PSU and

Records. Power off by 1SEC Power off. In this case, we don’t have information where the

malfunction exactly occurred. But in in indicates that CPU had stopped and rebooted.

In case of AC Off (It is normal when the power cord is unplugged.) Normal

If there are many ACDETs connected, Power Board is defective

Power off by unstable AC power detect.

RESULT : micom check the stable power.

CONDITION : When AC on or DC on, stabilization check routine (Power Detect High

Check) fail after multi power on.

Power off when receiving no ack.

RESULT : TV power off/on (Reboot)

CONDITION : There is no I2C response from CPU for 15 seconds.

Power off by main SoC command. Check & Change Main B/D

Power off by module error (OLED)

CONDITION : OLED Module send signal to micom

No meaning (same as initial value)

Established

date

Revised date

8/16

Check & Change Main B/D

Check & Change Main B/D

Check & Change Power B/D

Check & Change Power B/D

Check & Change Main B/D

Check & Change Main B/D

Check & Change OLED Module

Normal Case

8

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

No audio

Screen normal

Error

C. Audio error

symptom

No audio/ Normal video

☞A20 ☞A21+A18

Check user

menu >

Speaker off

Off

Y

Cancel OFF

Check audio

N

13.2V of Power

Board

Established

date

Revised date

Normal

voltage

Replace Power Board and repair parts

Y

N

9/16

Check

Speaker

disconnection

Disconnection

Y

Replace Speaker

9

N

Replace MAIN Board

End

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check input

signal

-RF

-External Input

signal

Error

symptom

C. Audio error

Wrecked audio/ discontinuation/noise

Established

date

Revised date

→ abnormal audio/discontinuation/noise is same after “Check input signal” compared to No audio

☞A21+A18

Check audio

B+ Voltage (13.2V)

Normal

voltage?

N

Replace Power B/D

Replace Main B/D

N

Y

Y

Signal

normal?

N

Y

(When RF signal is not

received)

Request repair to external

cable/ANT provider

(In case of

External Input

signal error)

Check and fix

external device

Wrecked audio/

Discontinuation/

Noise for

all audio

Wrecked audio/

Discontinuation/

Noise only

for D-TV

Wrecked audio/

Discontinuation/

Noise only

for Analog

Wrecked audio/

Discontinuation/

Noise only

for External Input

Check and replace

speaker and

connector

Replace Main B/D

Connect and check

other external

device

Normal

audio?

10/16

End

Check and fix external device

10

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

D. Function error

Remote control & Local switch checking

1. Remote control(R/C) operating error

☞A22

Check R/C itself

Operation

Check R/C Operating

When turn off light

in room

If R/C operate,

Explain the customer

cause is interference

from light in room.

operating?

Normal

Y

N

Check & Replace

Baterry of R/C

Normal

operating?

Replace R/C

Check & Repair

Cable connection

Connector solder

Y

Close

N

Normal

operating?

Y

Close

☞A22

N

Check B+3.5V

On Main B/D

Established

date

Revised date

☞A22

N

Y

Check IR

Output signal

Normal

Voltage?

☞A18

Check 3.5v on Power B/D

Replace Power B/D or

Replace Main B/D

(Power B/D don’t have problem)

11/16

Replace

Main B/D

Normal

Signal?

N

Repair/Replace

IR B/D

Y

11

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

D. Function error

MR remote operating checking

2. MR18(Magic Remocon) operating error

☞A4

Check the

INSTART menu

RF Receiver ver

is “00.00”?

☞A23

Check & Repair

Y

RF assy

connection

☞A4

RF Receiver ver

is “00.00”?

Y

N

Check MR18

itself Operation

N

Close

Normal

operating?

Check & Replace

Battery of MR18

Normal

operating?

N

Replace

MR18

Y

N

Y

Press the

wheel

Close

Established

date

Revised date

Is show ok

message?

Y

Close

Is show ok

message?

Close

Y

Turn off/on the

N

set and press

the wheel

N

12/16

Press the back

key about 5sec

Down load the Firmware

* INSTART MENU14.RF

Remocon Test3. Firmware

download

* If you conduct the loop at 3times, change the MR18.

12

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

3.Wifi operating error

☞A4

Check the

INSTART menu

Wi-Fi Mac value

is “NG”?

☞A24

Check & Repair

Y

Wifi cable

connection

☞A4

Wi-Fi Mac value

is “NG”?

D. Function error

Wifi operating checking

☞A24

N

Check the Wifi wafer

N

Close

1pin

Established

Revised date

Normal

Voltage?

Y

Close

date

N

13/16

Replace

Main B/D

Change the Wifi

Y

assy

13

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check

input

signal

Error

symptom

Y

Signal

input?

N

Check and fix

external device/cable

D. Function error

External device recognition error

Check technical

information

- Fix information

- S/W Version

Technical

information?

Fix in

accordance

with technical

information

Y

External Input and

N

Component

Recognition error

HDMI/

DVI, Optical

Recognition error

Established

date

Revised date

14/16

Replace Main B/D

Replace Main B/D

15

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Identify

nose

type

Error

symptom

Circuit

noise

Mechanical

noise

※ Mechanical noise is a natural

phenomenon, and apply the 1st level

description. When the customer does not

agree, apply the process by stage.

※ Describe the basis of the description

in “Part related to nose” in the Owner’s

Manual.

Check

location of

noise

Check location of

noise

Circuit noise, mechanical noise

E. Noise

Replace PSU

OR

Established

date

Revised date

※ When the nose is severe, replace the module

(For models with fix information, upgrade the

S/W or provide the description)

※ If there is a “Tak Tak” noise from the

cabinet, refer to the KMS fix information and

then proceed as shown in the solution manual

(For models without any fix information,

provide the description)

15/16

16

Standard Repair Process

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Zoom part with

exterior damage

Module

damage

Cabinet

damage

Remote

control

damage

F. Exterior defect

Exterior defect

Replace module

Replace cabinet

Replace remote control

Established

date

Revised date

16/16

Stand

dent

Replace stand

17

Contents of Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

No. Error symptom Content Page Remarks

1

A. Video error_ No video/Normal

audio

2 Check White Balance value A2

3

A. Video error_ video error /Video

lag/stop

4 Version checking method A4

5 Tuner Checking Part A5

A. Video error _Vertical/Horizontal bar,

6

residual image, light spot

7 A. Video error_ Color error

9

10 Exchange Main Board (1) ~ (3)

<Appendix>

Defected Type caused by T-Con/

11 Exchange Module (1) ~ (3)

Inverter/ Module

Check LCD back light with naked eye A1

TUNER input signal strength checking

method

Connection diagram A6

Check Link Cable (Vx1/EPI) reconnection

condition

Check Cable (1) ~ (2)

A3

A7

A-1/11

A-2/11

A-3/11 ~

A-5/11

A-6/11 ~

A-8/11

12 Exchange T-Con (1) ~ (2)

13 Exchange Power Board(PSU) A-11/11

A-9/11 ~

A-10/11

Continue to the next page

Contents of Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Continued from previous page

No. Error symptom Content Page Remarks

14

B. Power error_ No power

15 Check power input Voltage & ST-BY 3.5V A18

16

17

18

19

20 Motion Remote operation checking method A24

21

22 Check items after Main B/D replacement A28

23 Adjustment Test pattern – ADJ Key A29

B. Power error_Off when on, off

while viewing

C. Audio error_ No audio/Normal

video

D. Function error

E. Etc

Check front display LED A17

POWER OFF MODE checking method A20

Checking method in menu when there is no

audio

Voltage and speaker checking method when

there is no audio

Remote control operation checking method A23

How to use the Service remote control A25-A27

A21

A22

24

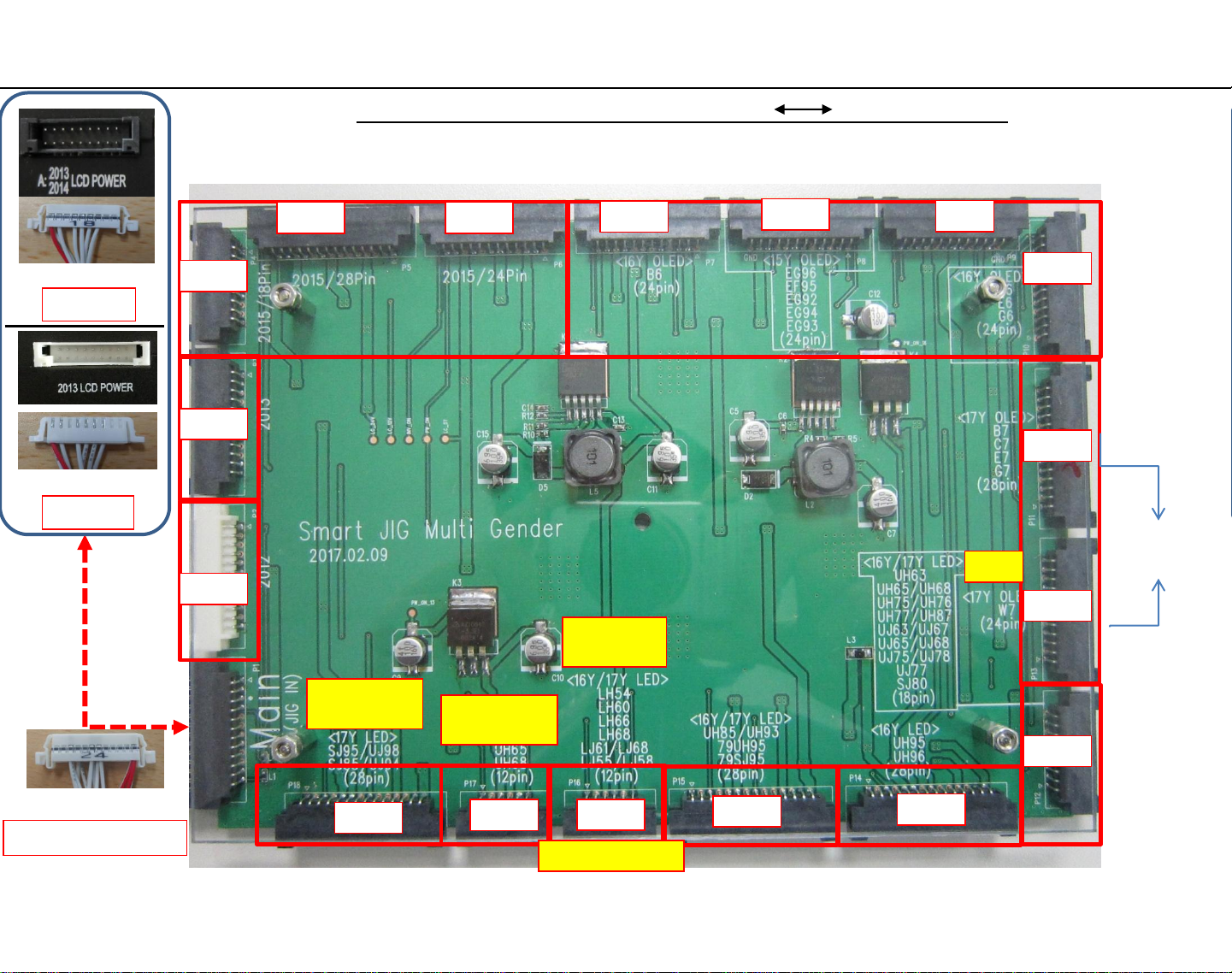

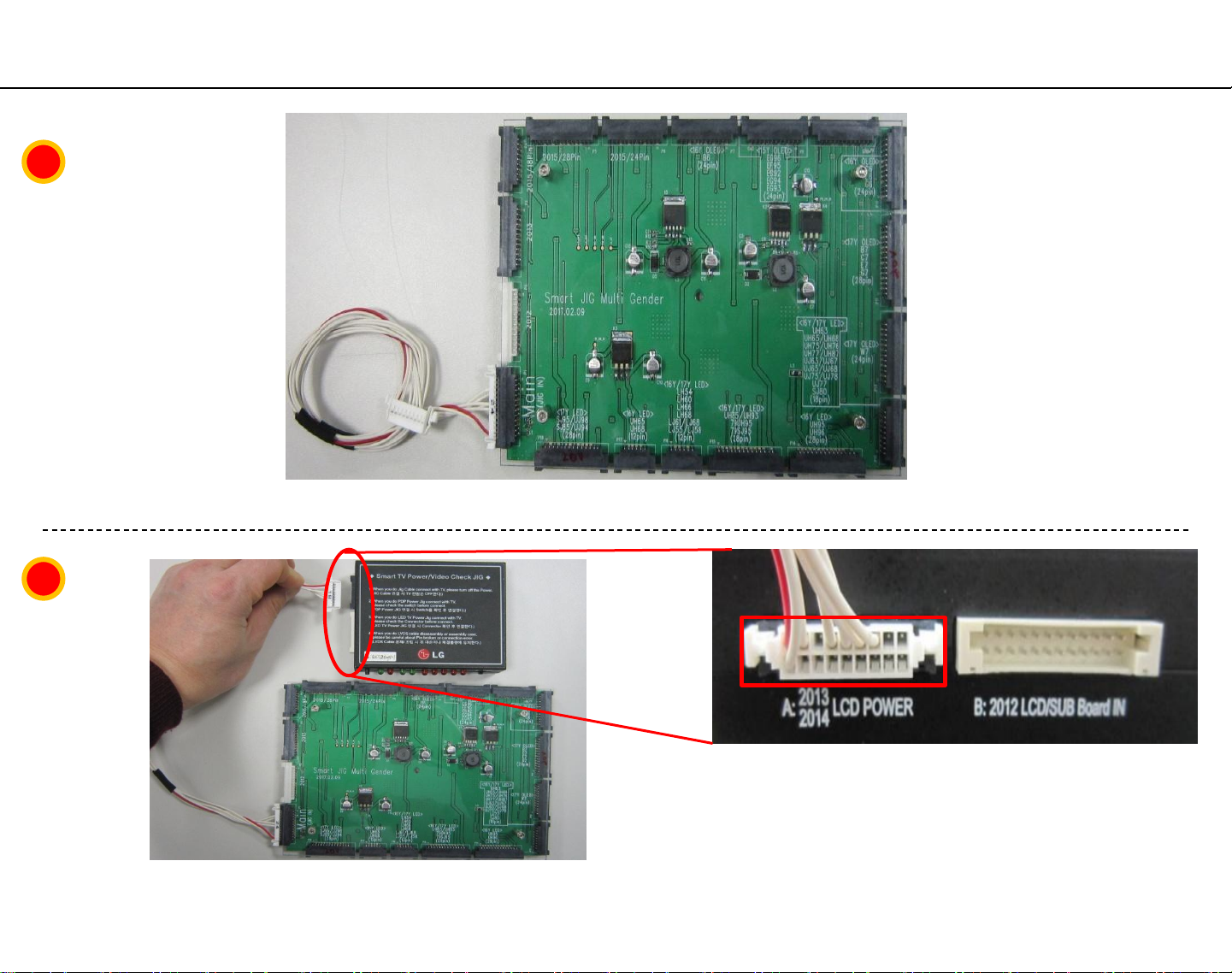

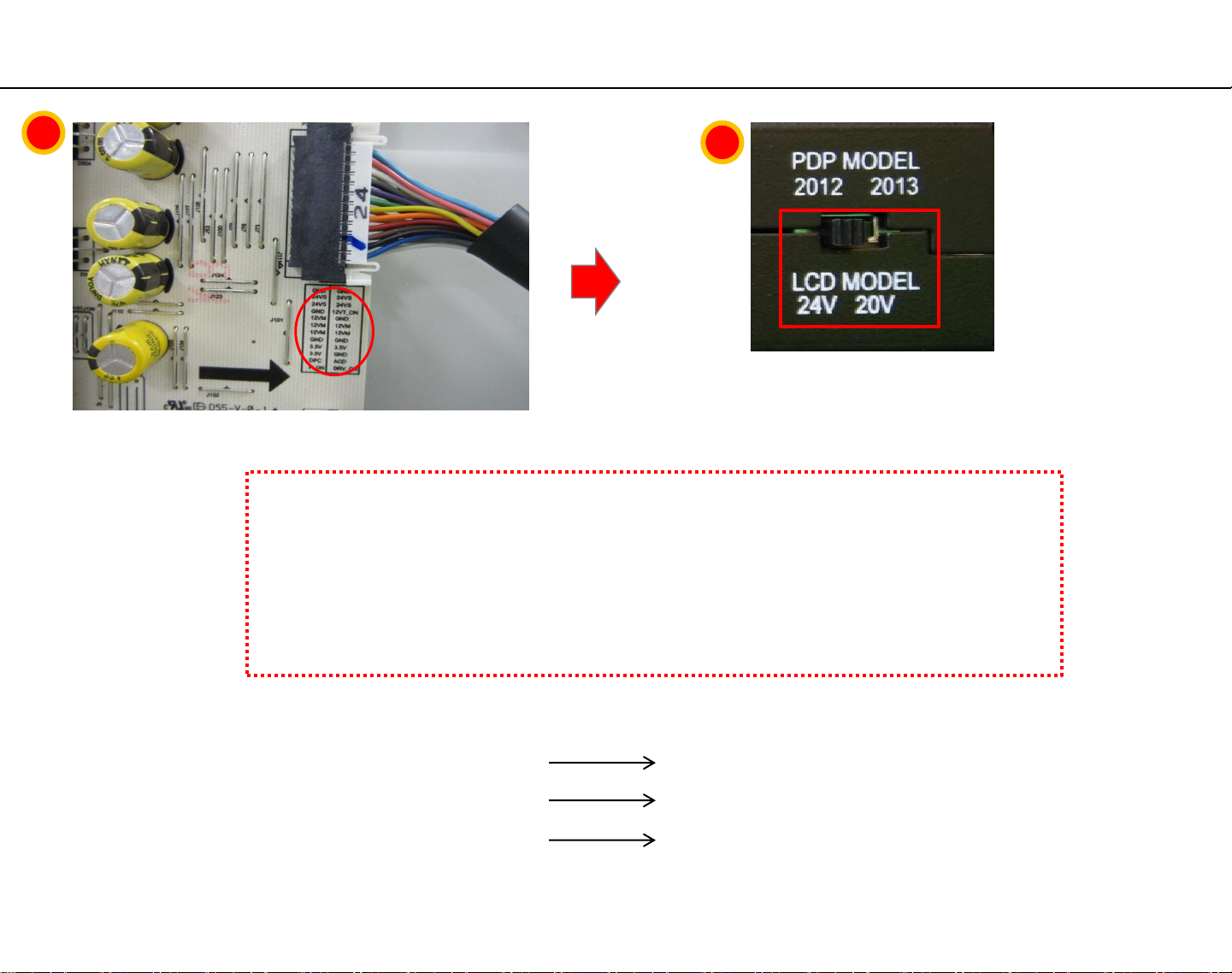

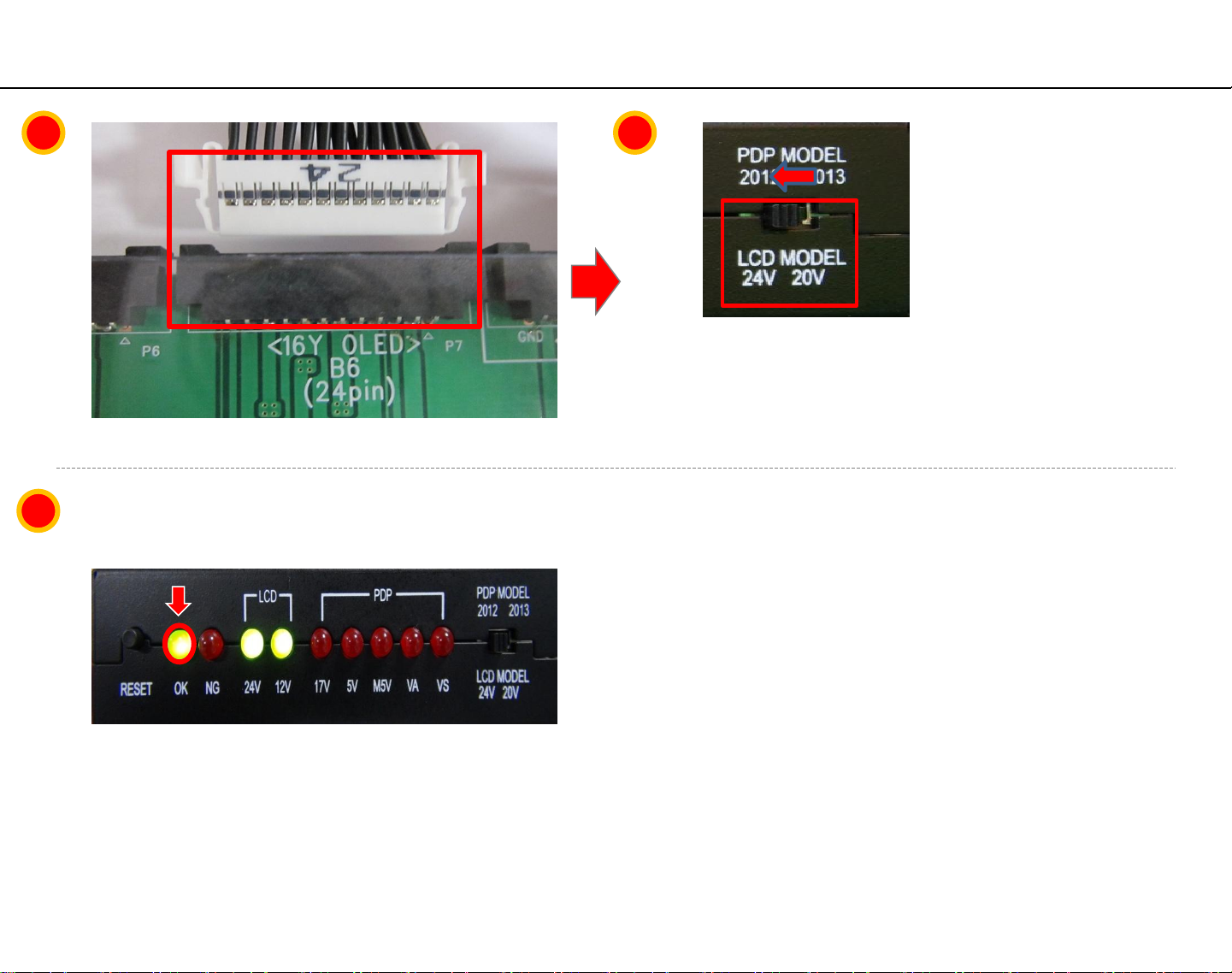

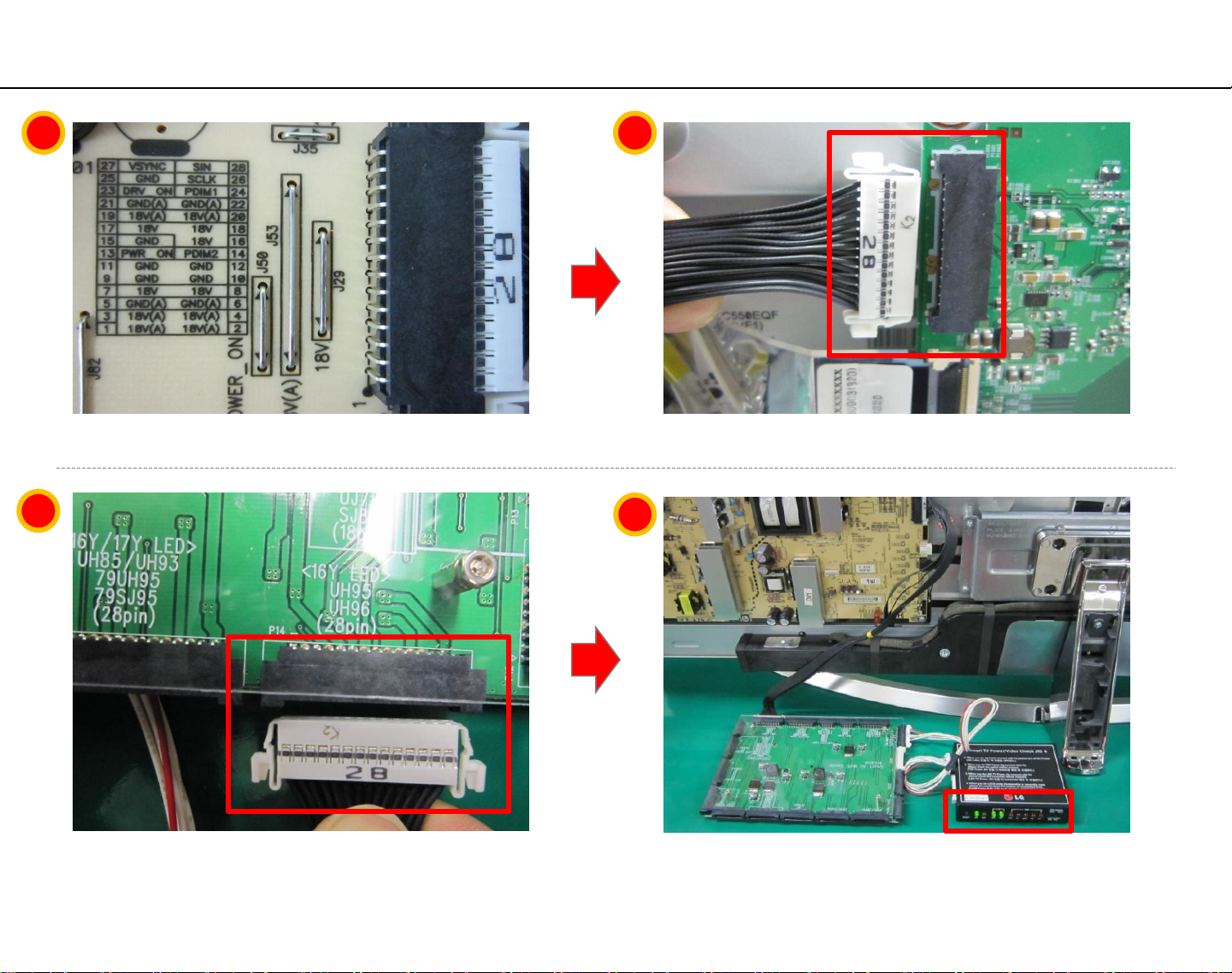

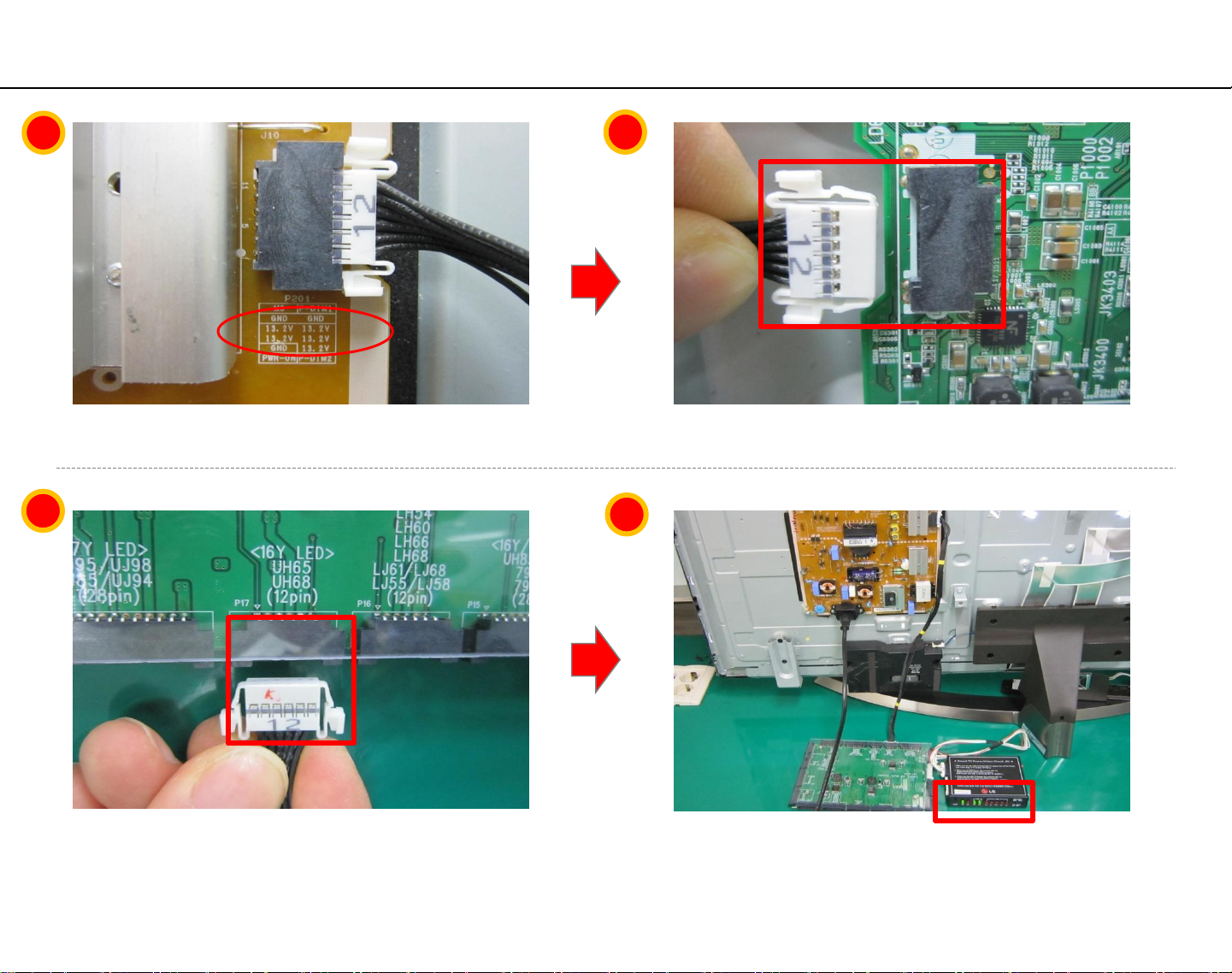

How to use JIG

(Power B/D Diganostic Smart Jig Multi Gender

A30

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

A. Video error_No video/Normal audio

Check LCD back light with naked eye

Established

date

Revised

date

A1

After turning on the power and disassembling the case, check with the naked eye,

whether you can see light from locations.

A1

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

<ALL MODELS>

A. Video error_No video/Normal audio

Check White Balance value

Established

date

Revised

date

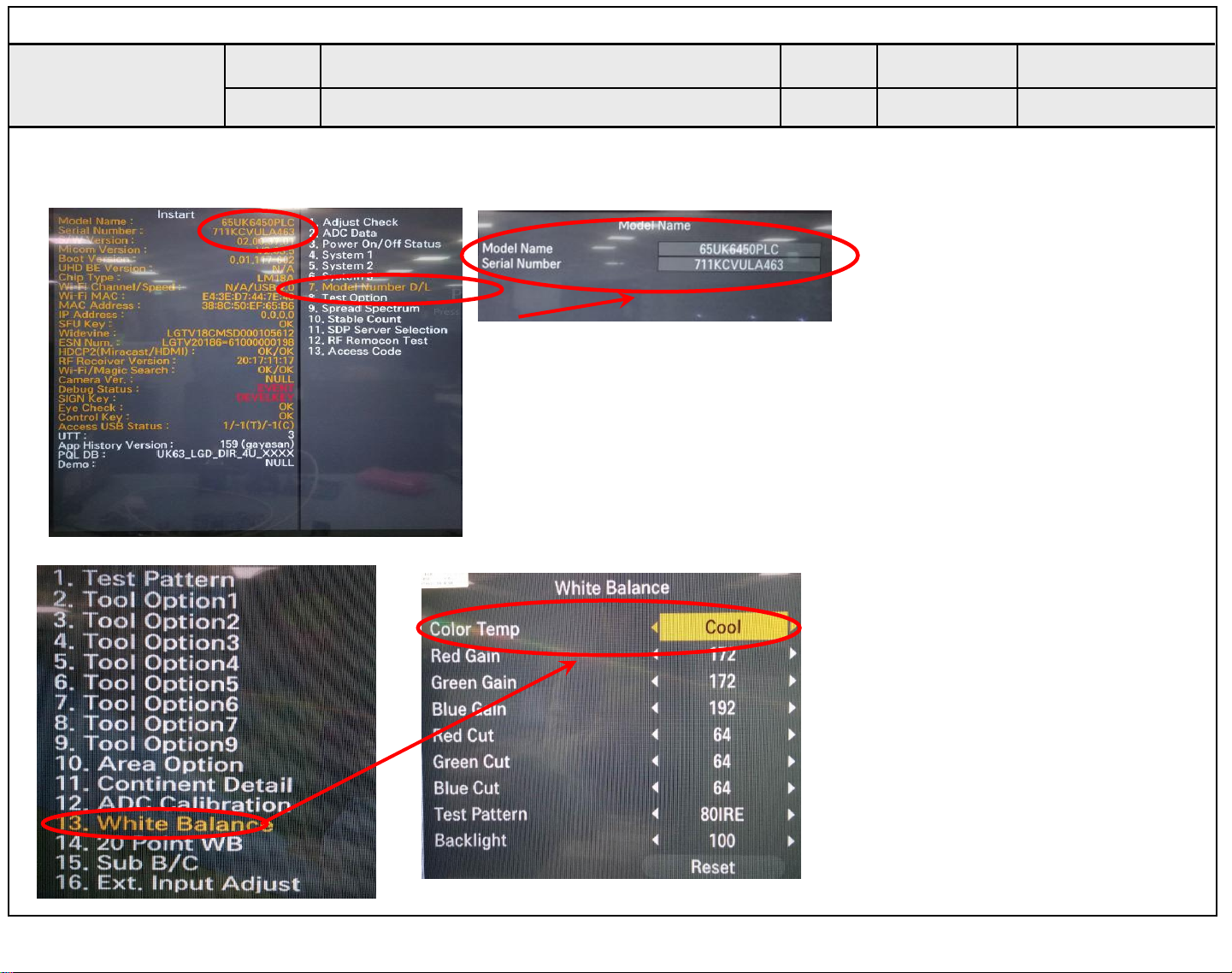

A2

Entry method

1. Press the ADJ button on the remote control for adjustment.

2. Enter into White Balance.

3. After recording the R, G, B (GAIN, Cut) value of Color Temp

(Cool/Medium/Warm), re-enter the value after replacing the MAIN BOARD.

A2

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

<ALL MODELS>

A. Video error_Video error, video lag/stop

TUNER input signal strength checking method

Established

date

Revised

date

Advanced Channels Channel Tuning

Manual Tuning

A3

When the signal is strong,

use the attenuator (-10dB, -

15dB, -20dB etc.)

A3

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

A. Video error_Video error, video lag/stop

Version checking method

Established

date

Revised

date

A4

<ALL MODELS>

1. Checking method for remote control for adjustment

Version

Press the IN-START with the remote

control for adjustment

A4

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

A. Video error_Video error, video lag/stop

TUNER checking part

Established

date

Revised

date

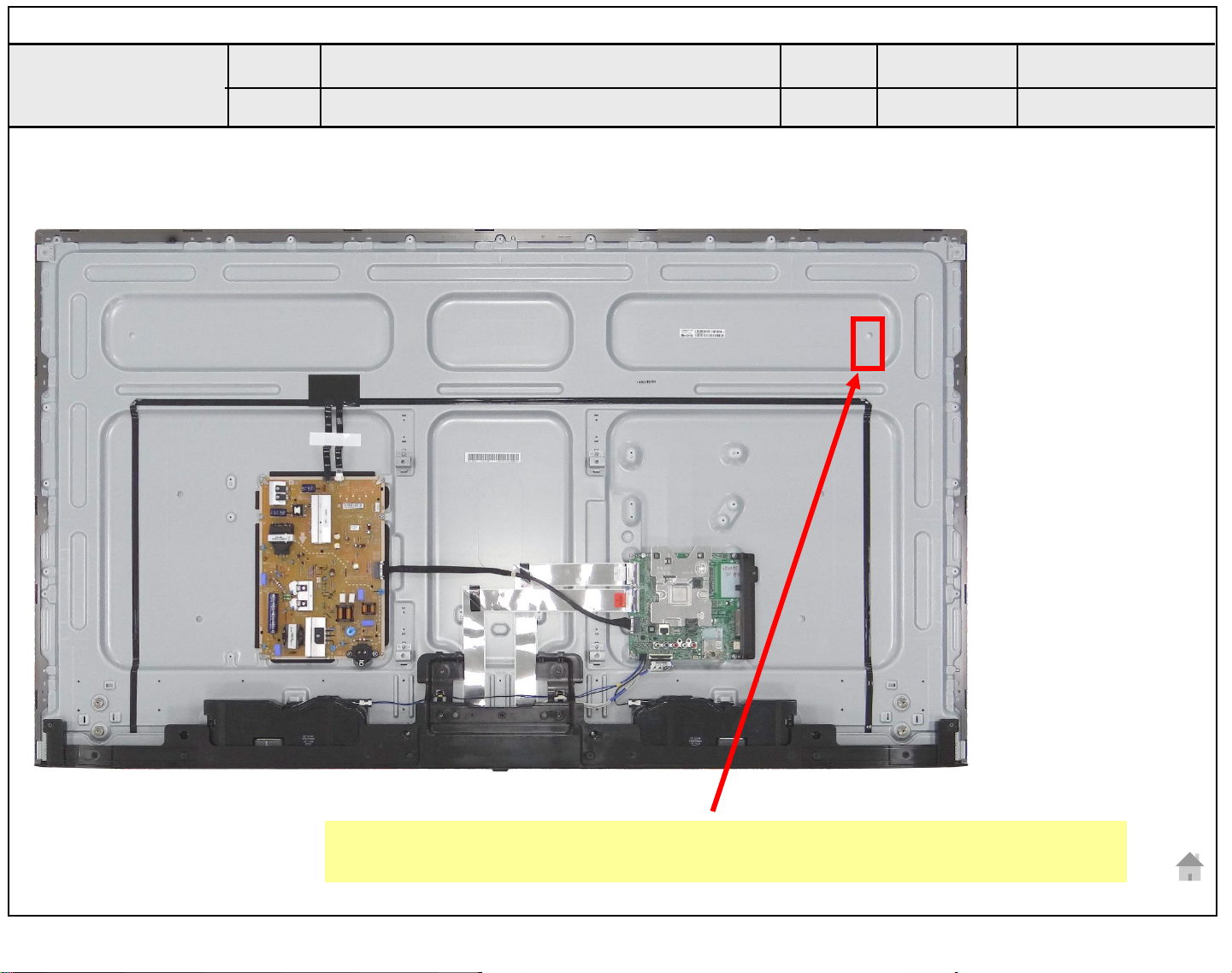

A5

Checking method:

1. Check the signal strength or check whether the screen is normal when the external device is connected.

2. After measuring each voltage from power supply, finally replace the MAIN BOARD.

A5

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

<ALL MODELS>

A. Video error _Vertical/Horizontal bar,

residual image, light spot

connection diagram (1)

Established

date

Revised

date

A6

As the part connecting to the external input, check

the screen condition by signal

A6

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

Check Link Cable(EPI) reconnection condition

A. Video error_Color error

Established

date

Revised

date

A7

Check the contact condition of the Link Cable, especially dust or mis insertion.

A7

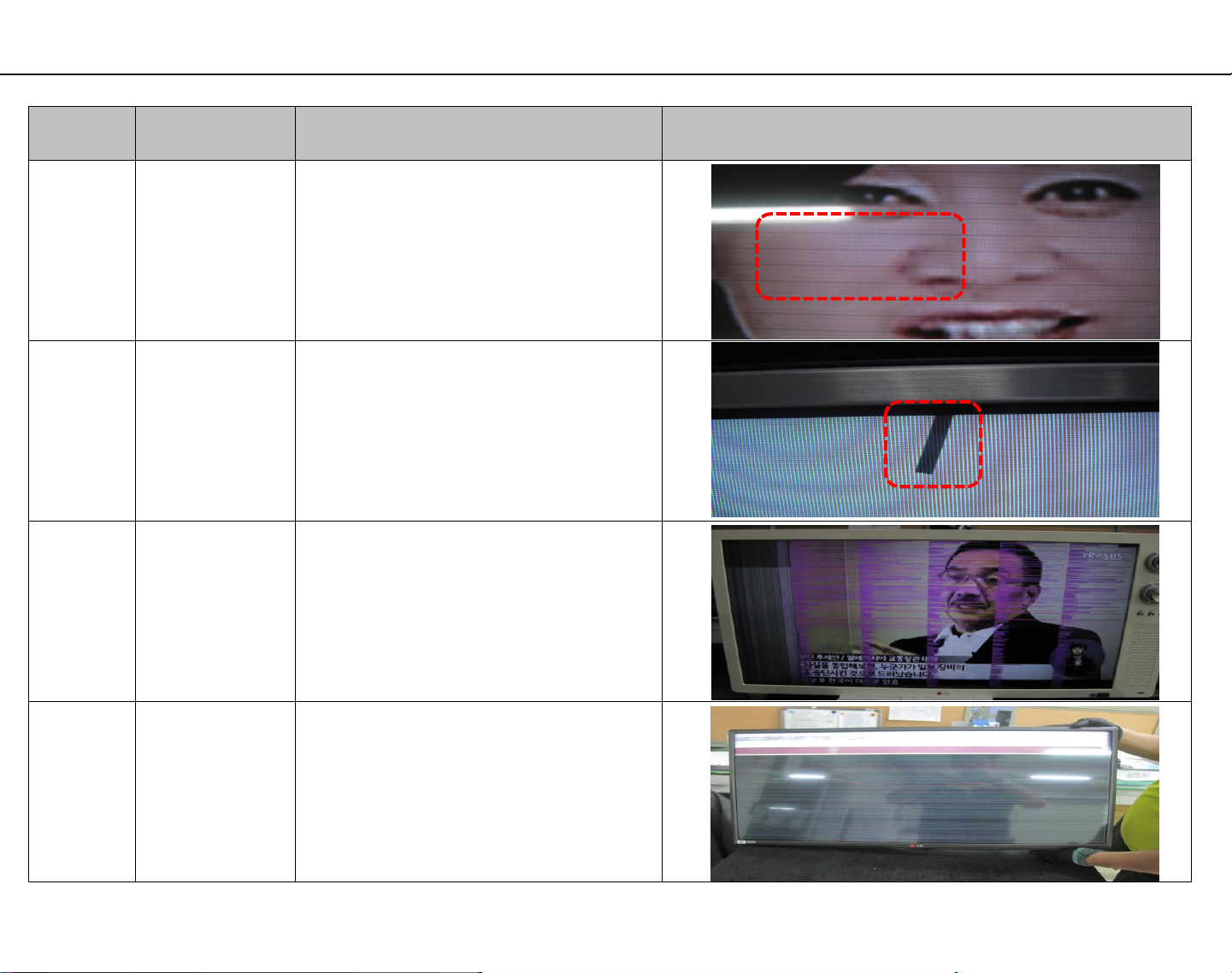

Appendix. Examples of Symptoms(Image error)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check for poor cable contact

Item

CABLE Color smear

CABLE R Color Excessive

CABLE Screen darkness

Symptom

Name

Cause Symptom Image

Pin 단선

Poor broken pin of FFC cable

Color is Excessive due to FFC Cable

Contact.

screen is dark due to poor contact due

to disconnection of the FFC cable pin.

CABLE G Color Excessive

G color transient due to poor FFC cable

connection

A - 1/11

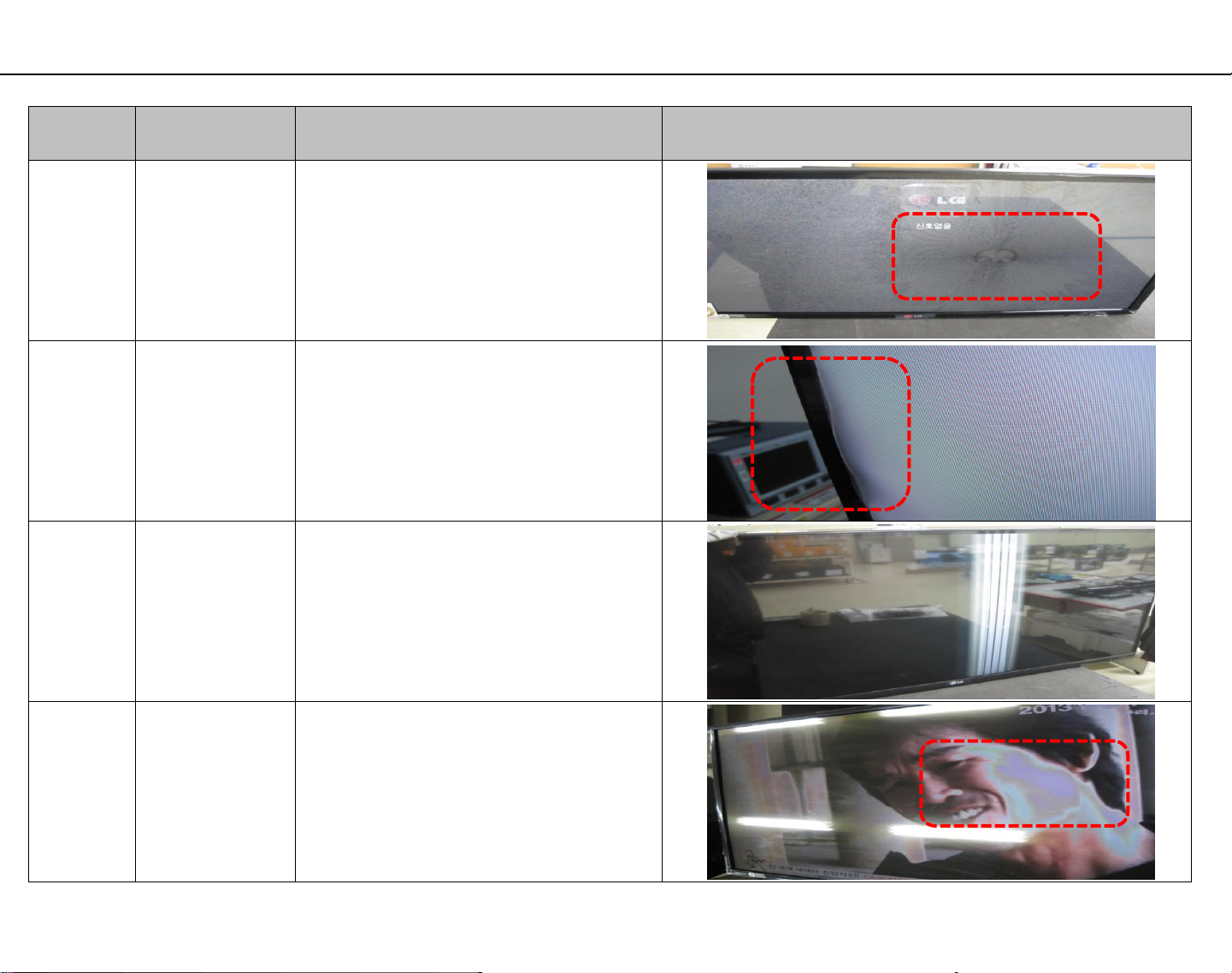

Appendix. Examples of Symptoms(Image error)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check for poor cable contact

Item

CABLE Color spread LVDS cable connection problem

CABLE Color spread LVDS cable connection problem

CABLE Color spread LVDS cable connection problem

Symptom

Name

Cause Symptom Image

CABLE Screen stop

Due to foreign substance withi nLVDS

cable PIN

A - 2/11

Appendix. Examples of Symptoms(Main)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check parts by symptom

Item

Main Screen noise Bit noise from horizontal screen

Main Screen noise

Main Dark picture Dark left-side screen

Symptom

Name

Cause Symptom Image

Broken screen due to

Main IC problem

Main Broken picture

Picture problem due to tuner

Top/bottom screen part

Inner side quality problem

A - 3/11

Appendix. Examples of Symptoms(Main)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check parts by symptom

Item

Main Broken screen Broken screen in a horizontal manner

Main Screen spread Screen corner appears blurry

Main Color Spread Color spread on the screen

Symptom

Name

Cause Symptom Image

Main Blurry Screen Blurry picture on the screen

A - 4/11

Appendix. Examples of Symptoms(Main)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check parts by symptom

Item

Main Broken picture

Main

Main

Symptom

Name

Right-side

Screen

problem

LG logo

Screen problem

Cause Symptom Image

No problem at the initial stage,

G-color spread after 10 minutes

Right-side screen problem

Screen picture spread problem

Main

Right-side

picture problem

No problem at the initial stage.

During Heat run, right-side picture

problem

A - 5/11

Appendix. Examples of Symptoms(Module)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check parts by symptom

Item

MODULE

MODULE Internal matter

MODULE Image broken

Symptom

Name

Isometric

Horizontal Bar

Cause Symptom Image

Isometric horizontal bars occur

throughout the screen

BLU internal foreign matter inflow

6 block image broken

MODULE Image broken Screen sync signal broken

A - 6/11

Appendix. Examples of Symptoms(Module)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check parts by symptom

Item

MODULE Image broken

MODULE

MODULE Vertical smear

Symptom

Name

Bend on the

screen

Cause Symptom Image

Internal damage and image breakage

due to external impact

Bending due to lateral external impact

and internal bending of BLU

Vertical spreading on cube screen in no

signal

MODULE Over color Screen contour part brightly Over color

A - 7/11

Appendix. Examples of Symptoms(Module)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check parts by symptom

Item

MODULE Vertical bar Center Vertical Bar

MODULE Screen darkness

MODULE Vertical bar Center Vertical Bar

Symptom

Name

Cause Symptom Image

Center of the screen 1 block dark

Darkness at the

MODULE

bottom of the

screen

MODULE internal BLU breakage

A - 8/11

Appendix. Examples of Symptoms(T-Con)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check parts by symptom

Item

T-CON

T-CON

T-CON

Symptom

Name

screen lower

image broken

screen lower

image broken

screen lower

image broken

Cause Symptom Image

T-Con is defective and the picture below

the screen is broken

T-Con is defective and the picture below

the screen is broken

T-Con is defective and the picture below

the screen is broken

T-CON

screen lower

image broken

T-Con is defective and the picture below

the screen is broken

A - 9/11

Appendix. Examples of Symptoms(T-Con)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Check parts by symptom

Item

T-CON Image Broken

T-CON

T-CON Image Broken

Symptom

Name

Darkness at the

top of the screen

Cause Symptom Image

T-CON Wafer Locking The strength is

weak and cable contact failure occurs

Initial normal operation,

upper darkness during heat run

The entire screen is dark and bit noise

occurs

T-CON Image Broken

The entire screen is dark and bit noise

occurs

A - 10/11

Appendix : Exchange Power Board (PSU)

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

No Light

No picture/Sound Ok

A - 11/11

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

ST-BY condition: On or Off

Power ON condition: Turn Off

B. Power error _No power

Check front Power Indicator

Established

date

Revised

date

A17

A17

Standard Repair Process Detail Technical Manual

SET Model

Power P/N, Name

43UK63

EAY64529501, LGP43DJ-17U1

MS Level

Range [V]

LED On/Off

MS (0V)

0 ~ 0.25

Off

MS (2V)

1.75 ~ 2.25

On (Home mode)

MS (3V)

2.75 ~ 3.25

On (Store Mode)

Picture Condition : VIVID (Back light 100)

Min

Max

61.2V

74.8V

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

Power Check Sequence

1. AC input Check : SK100 (100~240Vac)

2. PWR-ON Check :

- SET On : above 3V

- SET St-by : 0V

3. 13.2V DC Check :

- SET On : 13.2V

- SET St-by : 7.8V

4. MS Level Check : MS

5. LED voltage Check : P801, Pin 1-7

※ Home mode : General Customer

Store mode : use Store

B. Power error _No power

Check power input voltage and ST-BY 7.8V

P801

Established

date

Revised

date

A18

P201

all condition meets, Power Board OK.

SK100 (AC input)

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

<ALL MODELS>

B. Power error _Off when on, off whiling viewing

POWER OFF MODE checking method

Established

date

Revised

date

A20

Entry method

1. Press the IN-START button of the remote

control for adjustment

2. Check the entry into adjustment item 3

A20

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

<ALL MODELS>

C. Audio error_No audio/Normal video

Checking method in menu when there is no audio

Established

date

Revised

date

A21

Checking method

1. Press the Setting button on the remote control

2. Select the Sound function of the Menu

3. Select the Sound Out

4. Select TV Speaker

A21

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

C. Audio error_No audio/Normal video

Voltage and speaker checking method

when there is no audio

②

Established

Revised

date

①

date

A22

Checking order when there is no audio

1.Check the contact condition of or 13.2V connector of Main Board

2. Measure the 13.2V input voltage supplied from Power Board

(If there is no input voltage, remove and check the connector)

3.Connect the tester RX1 to the speaker terminal and if you hear the Chik Chik sound when you touch the

GND and output terminal, the speaker is normal.

A22

③

1 SPK_R-FT

2 SPK_R+FT

3 SPK_L-FT

4 SPK_L+FT

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

Remote control operation checking method

D. Function error

Established

date

Revised

date

A23

①

IR & EYE Sensor

IR & LOGO light Rear

IR

LED

Checking order to check remote control

Checking order

1.Check IR cable condition between IR & Main board.( Check picture number① and ②)

2.Check the standby 3.5V on the terminal 16 pin (③)

3.AS checking the Pre-Amp(IR LED light) , the power is in ON condition, an Analog Tester

needle should move slowly, otherwise, it’s defective.

Eye

②

③

Pin

1

2

3

4

5

6

7

8

9

BT_WAKEUP_DEVICE

10

11

12

13

14

15

16

17

18

19

20

21

22 VCC

23 KEY2

24 KEY1

25 GND

Pin name

VCC

USB_DM

USB_DP

GND

WOL/WIFI_ON

VCC

COMBO_RESET

GND

BT_WAKEUP_HOST

GND

GND

EYE_SDA

EYE_SCL

GND

IR

LED_R

GND

A23

Standard Repair Process Detail Technical Manual

Copyright © 2018 LG Electronics Inc. All rights reserved.

Only for training and service purposes.

Error

symptom

Content

Remote control operation checking method

D. Function error

Established

date

Revised

date

A24

① Wifi & BT Front

Wifi & BT Rear

②

Checking order to check motion remote/wifi

Checking order

1.Check BT/Wifi cable condition between BT/Wifi assy & Main board.

2.Check the 3.5V on the terminal 22

③

Pin

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15