LG 42PW340, 42PW340-UB, 42PW350, 42PW350-UA, 42PW350U Service Manual

...

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PU11A

MODEL : 42PW340 42PW340-UB

42PW350 42PW350-UA/UE

42PW350U 42PW350U-UC

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

Printed in Korea

P/NO : MFL66306601(1106-REV01)

- 2 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

CONTENTS

CONTENTS ............................................................................................................................... 2

SAFETY PRECAUTIONS ...........................................................................................................3

SPECIFICATION.........................................................................................................................4

ADJUSTMENT INSTRUCTION ..................................................................................................6

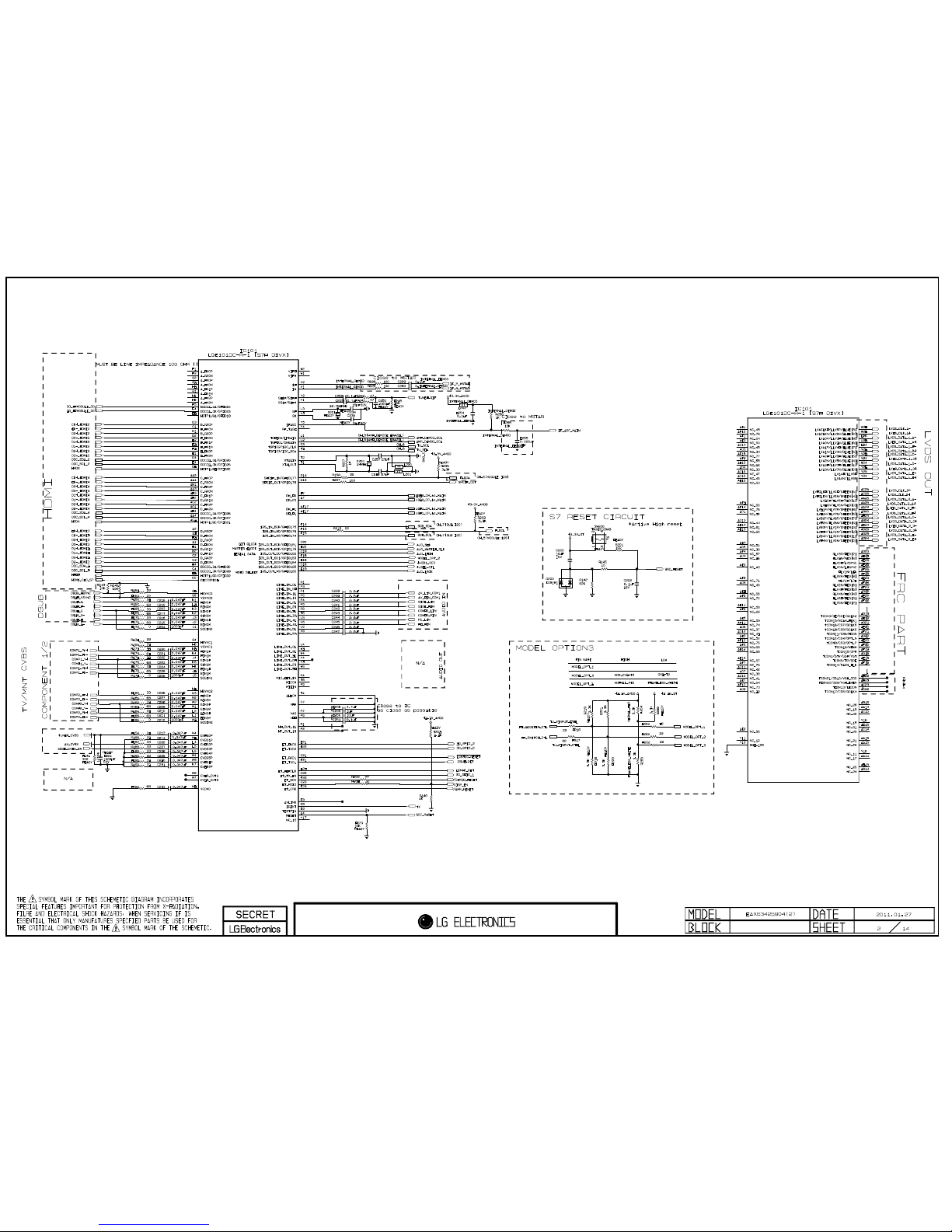

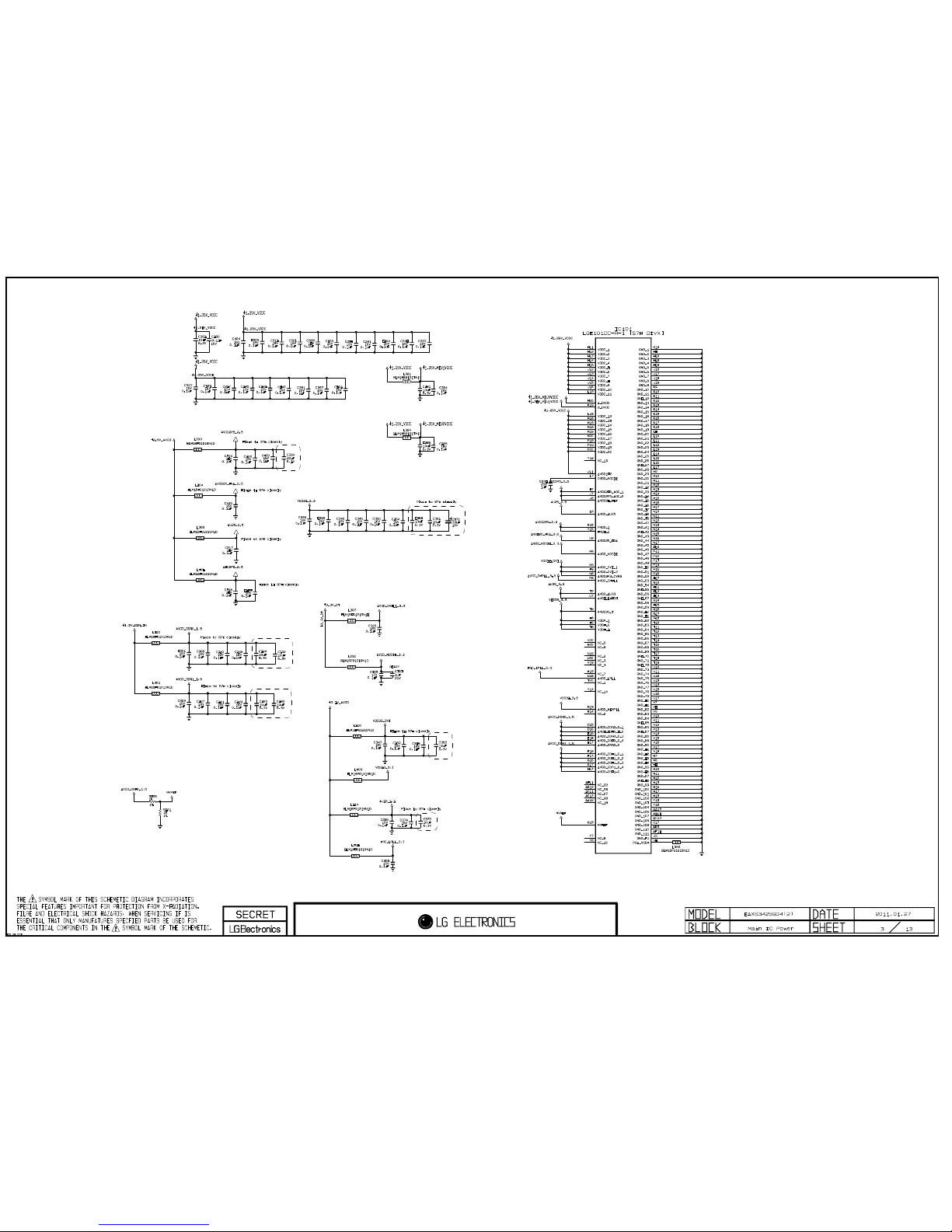

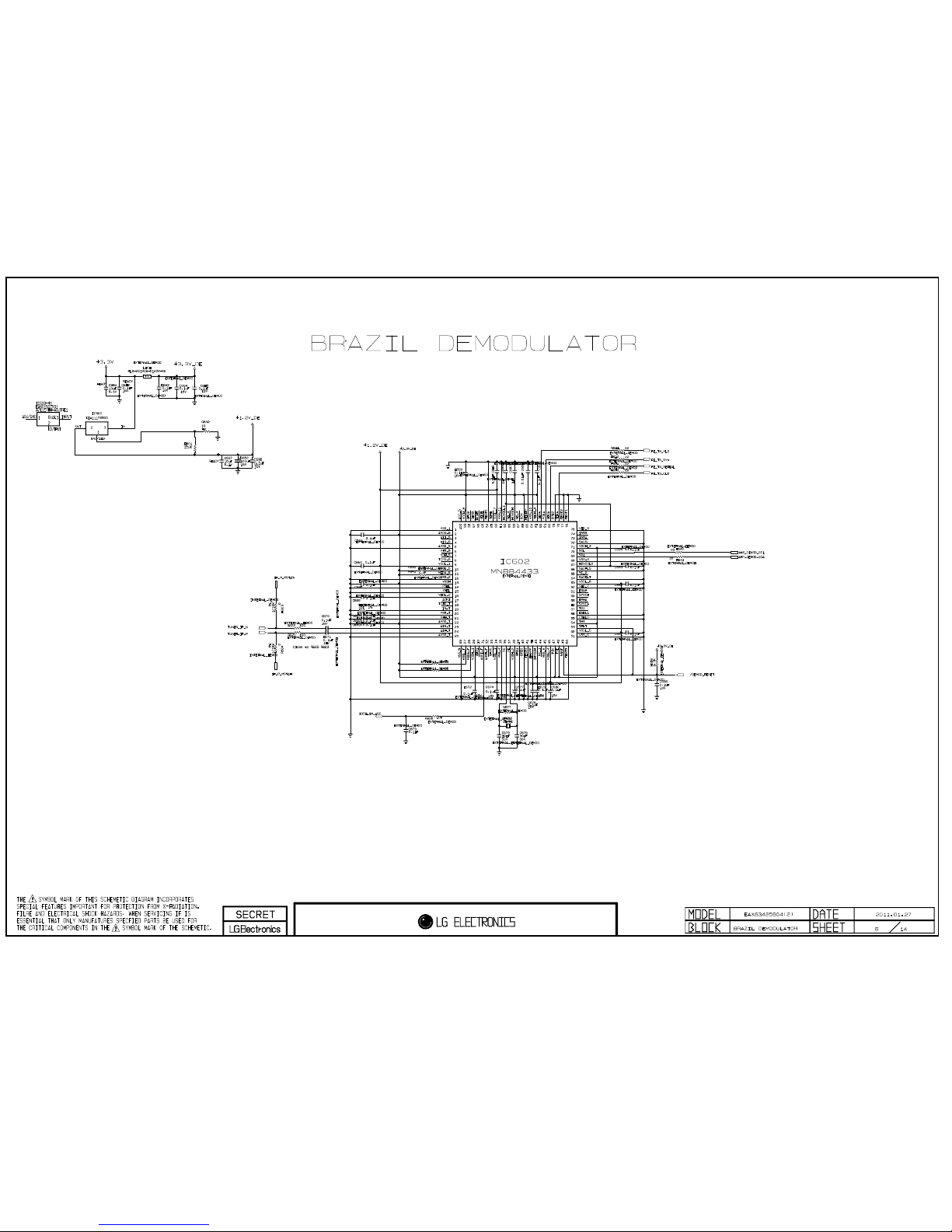

BLOCK DIAGRAM ...................................................................................................................13

EXPLODED VIEW ...................................................................................................................14

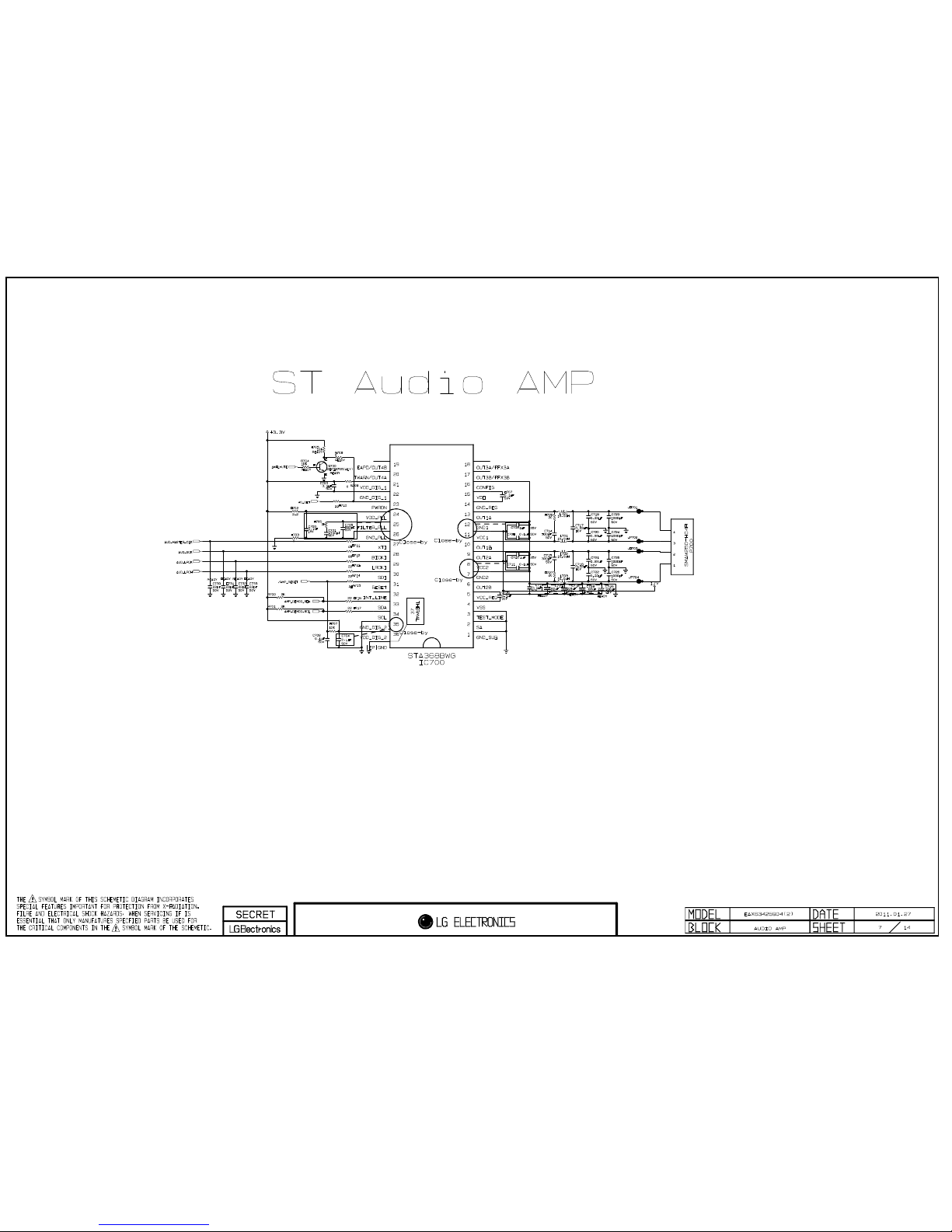

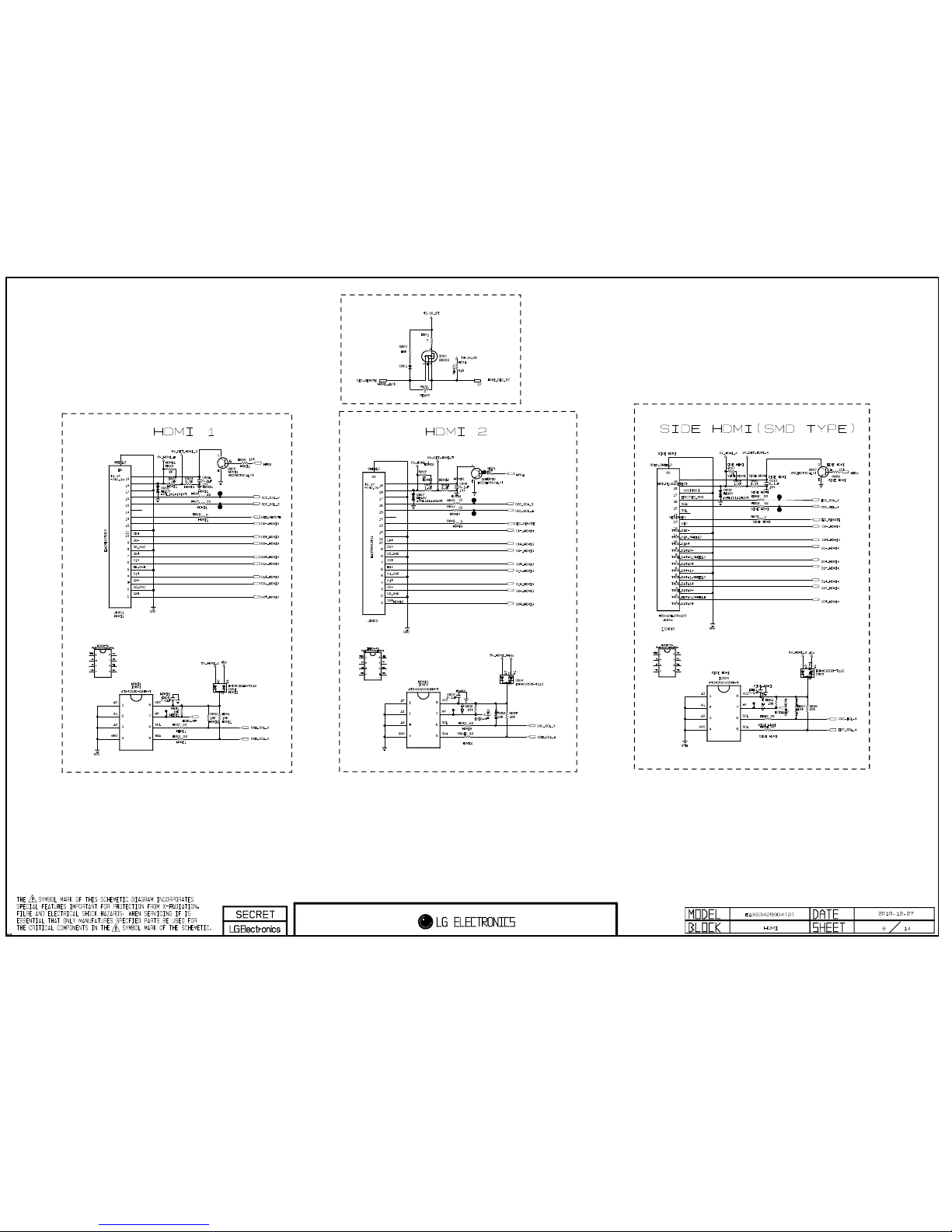

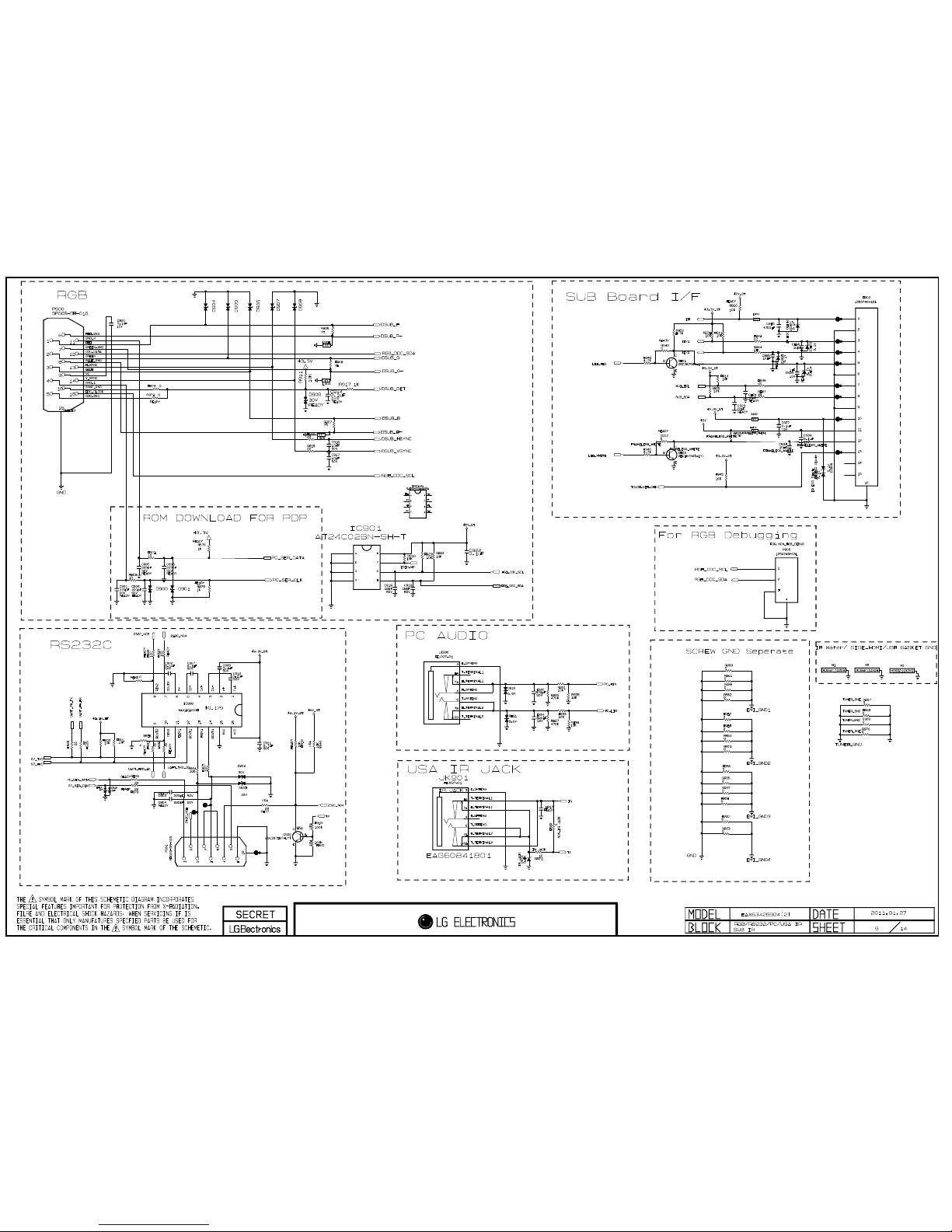

SCHEMATIC CIRCUIT DIAGRAM ..............................................................................................

- 3 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in

the Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to

prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the specified.

When replacing a high wattage resistor (Oxide Metal Film

Resistor, over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube.

Do not lift the Picture tube by it's Neck.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect

an electrical jumper across the two AC plug prongs. Place the

AC switch in the on position, connect one lead of ohm-meter to

the AC plug prongs tied together and touch other ohm-meter

lead in turn to each exposed metallic parts such as antenna

terminals, phone jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

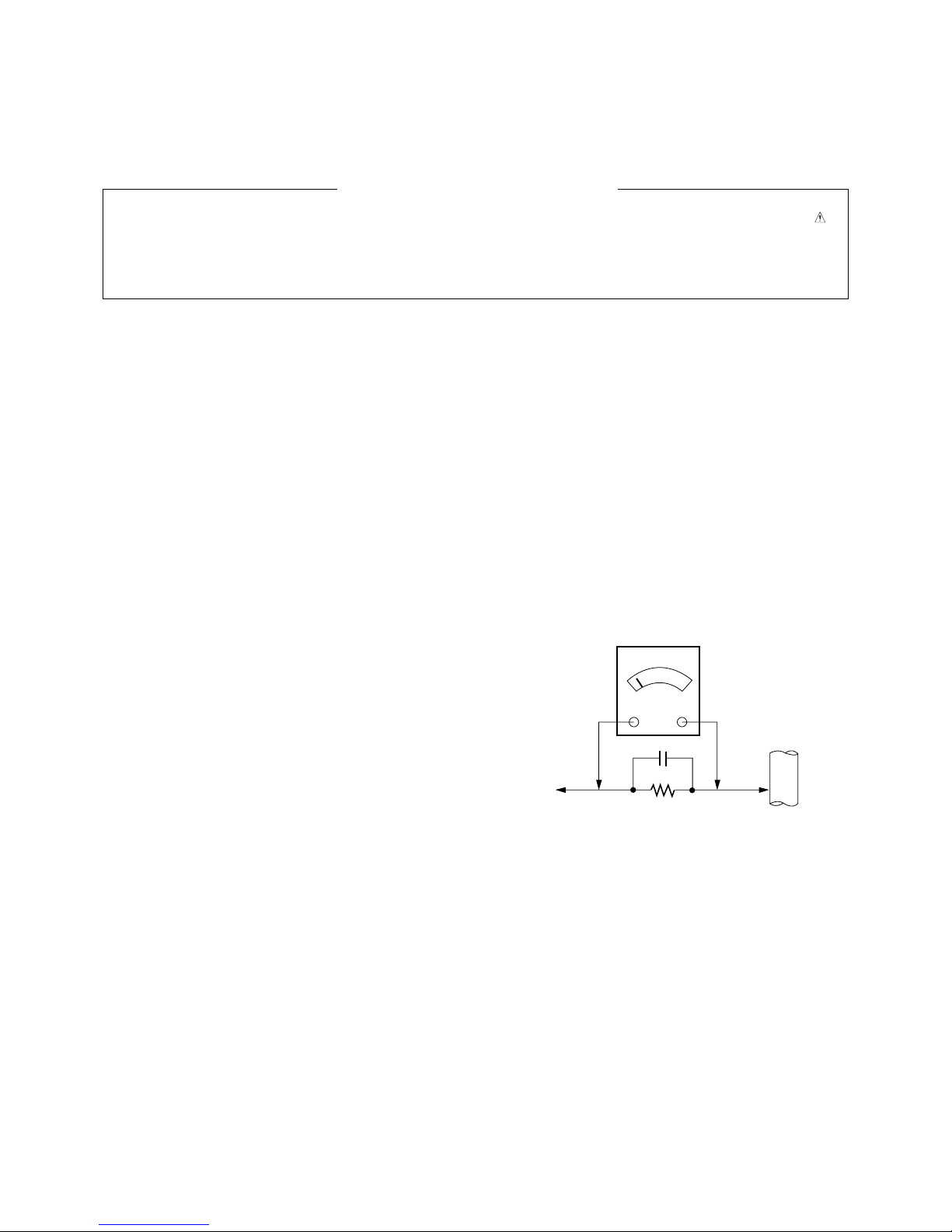

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC

voltage measurements for each exposed metallic part. Any

voltage measured must not exceed 0.75 volt RMS which is

corresponds to 0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

1.5 Kohm/10W

To Instrument’s

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

- 4 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application Range

(1) This spec sheet is applied all of PDP TV with PU11A chassis.

2. Specification

Each part is tested as below without special appointment.

(1) Temperature : 25 °C ± 5 °C (77 °F ± 9 °F), CST : 40 °C ± 5 °C

(2) Relative Humidity : 65 % ± 10 %

(3) Power Voltage : Standard input voltage (100 V - 240 V ~ 50 / 60 Hz)

* Standard Voltage of each product is marked by models

(4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with

BOM.

(5) The receiver must be operated for about 5 minutes prior to the adjustment.

3. Test Method

(1) Performance : LGE TV test method followed.

(2) Demanded other specification

Safety : UL, CSA, IEC specification, CE

EMC : FCC, ICES, IEC specification, CE

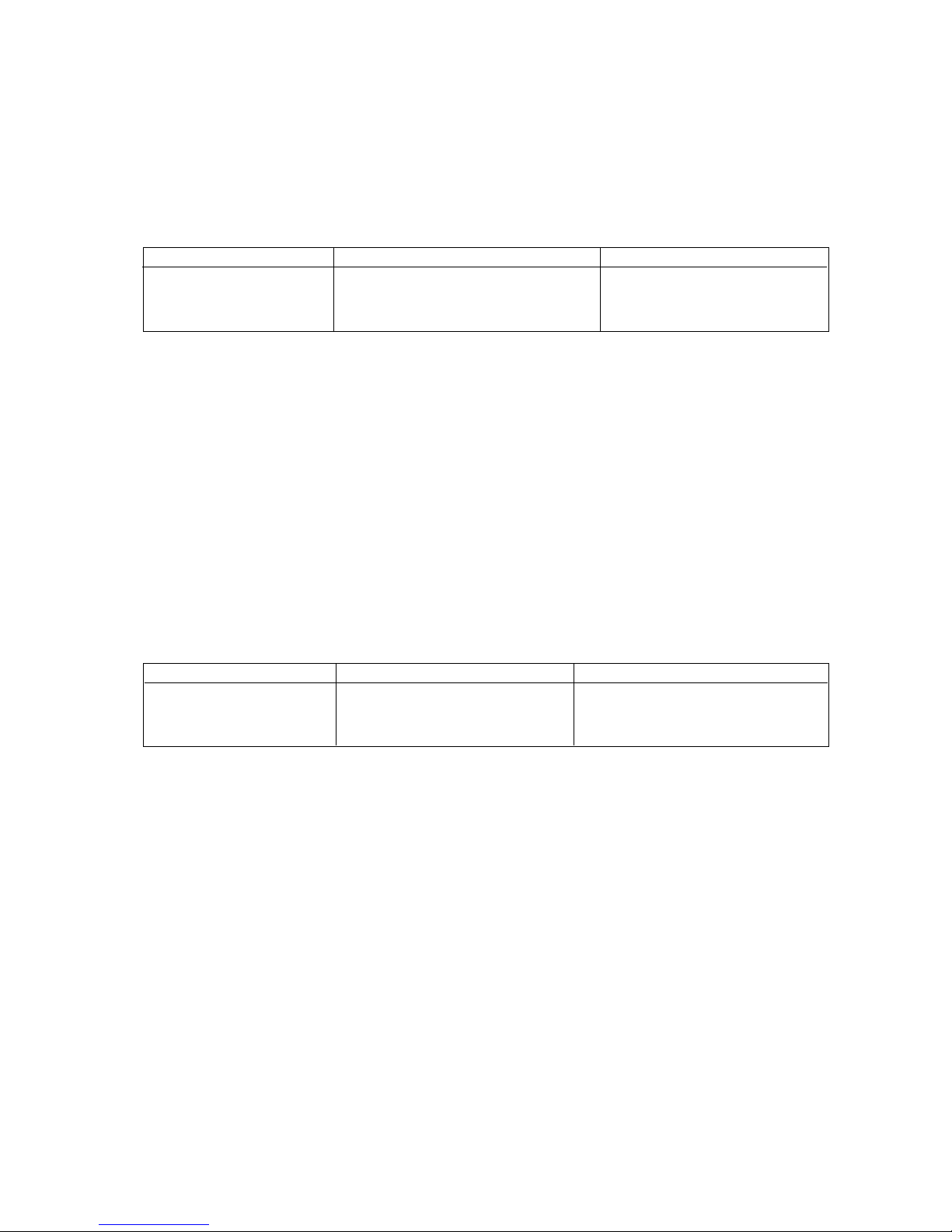

Model Name Market Brand

42PW340-UB

42PW350-UA/UE North America / Canada / Maxico LG

42PW350U-UC

Model Name Market Appliance

42PW340-UB Safety : UL1492, USA C22.2 No. 1

42PW350-UA/UE North America / Canada / Maxico EMC : FCC Class B, IC Class B

42PW350U-UC

- 5 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

4. General Specification

No Item Specification Remark

1. Receiving System 1) ATSC / NTSC-M

2. Available Channel 1) VHF : 02~13

2) UHF : 14~69

3) DTV : 02-69

4) CATV : 01~135

5) CADTV : 01~135

3. Input Voltage 1) AC 100 ~ 240V 50/60Hz N.America Mark : 110V, 60Hz

4. Market NORTH AMERICA ,KOREA

5. Screen Size 42 inch Wide(1024 × 768) 42PW340-UA

50 inch Wide(1024 × 768) 50PW340-UA / 50PW350-UB

50 inch Wide(1920 × 1080) 50PZ250-UA

60 inch Wide(1920 × 1080) 60PZ250-UA

6. Aspect Ratio 16:9

7. Tuning System FS

8. Module PDP42T3#### (1024 × 768) 42PW340-UA

PDP50T3#### (1024 × 768) 50PW340-UA / 50PW350-UB

PDP50R303## (1920 × 1080) 50PZ250-UA

PDP60R103## (1920 × 1080) 60PZ250-UA

9. Operating Environment 1) Temp : 0 ~ 40 deg

2) Humidity : ~ 80 %

10. Storage Environment 1) Temp : -20 ~ 60 deg

2) Humidity : ~ 85 %

- 6 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Range

This spec. sheet applies to PU11A Chassis applied PDP TV

all models manufactured in TV factory.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order. But it is

flexible when its factory local problem occurs.

(3) The adjustment must be performed in the circumstance of

25 cC ± 5 cC of temperature and 65 % ± 10 % of relative

humidity if there is no specific designation.

(4) The input voltage of the receiver must keep 100 V - 240 V,

50 / 60 Hz.

(5) Before adjustment, execute Heat-Run for 5 minutes.

V After Receive 100% Full white pattern (06CH) then

process Heat-run

(or “8. Test pattern” condition of Ez-Adjust status)

V How to make set white pattern

1) Press Power ON button of Service Remocon

2) Press ADJ button of Service remocon. Select “10.

Test pattern” and, after select “White” using

navigation button, and then you can see 100% Full

White pattern.

* In this status you can maintain Heat-Run useless any

pattern generator

* Notice: if you maintain one picture over 20 minutes

(Especially sharp distinction black with white pattern –

13Ch, or Cross hatch pattern – 09Ch) then it can

appear image stick near black level.

3. Adjustment items

3-1. PCB Assembly adjustment

(1) Adjust 480i Comp1

(2) Adjust 1080p Comp1/RGB

- If it is necessary, it can adjustment at Manufacture Line

- You can see set adjustment status at “9. ADJUST

CHECK” of the “In-start menu”

3-2. Set Assembly Adjustment

(1) EDID (The Extended Display Identification Data )

(2) Color Temperature (White Balance) Adjustment

(3) Make sure RS-232C control

(4) Selection Factory output option

4. PCB Assembly Adjustment

4-1. Using RS-232C

- Adjust 3 items at 3-1 PCB assembly adjustments

“ (3) Adjustment sequence” one after the order.

(1) Adjustment protocol

(2) Necessary items before Adjustment items

O Pattern Generator : (MSPG-925FA)

O Adjust 480i Comp1

(MSPG-925FA:model :209, pattern :65) – Comp1 Mode

O Adjust 1080p Comp1

(MSPG-925FA:model :225 , pattern :65) – Comp1 Mode

O Addjust RGB (MSPG-925FA:model :225 , pattern :65)

– RGB-PC Mode

* If you want more information then see the below Adjustment

method (Factory Adjustment)

(3) Adjustment sequence

O aa 00 00: Enter the ADC Adjustment mode.

O xb 00 40: Change the mode to Component1 (No actions)

O ad 00 10: Adjust 480i Comp

O ad 00 10: Adjust 1080p comp

O xb 00 60: Change to RGB-PC mode(No action)

O ad 00 10: Adjust 1080p RGB

O xb 00 90: Endo of Adjustmennt

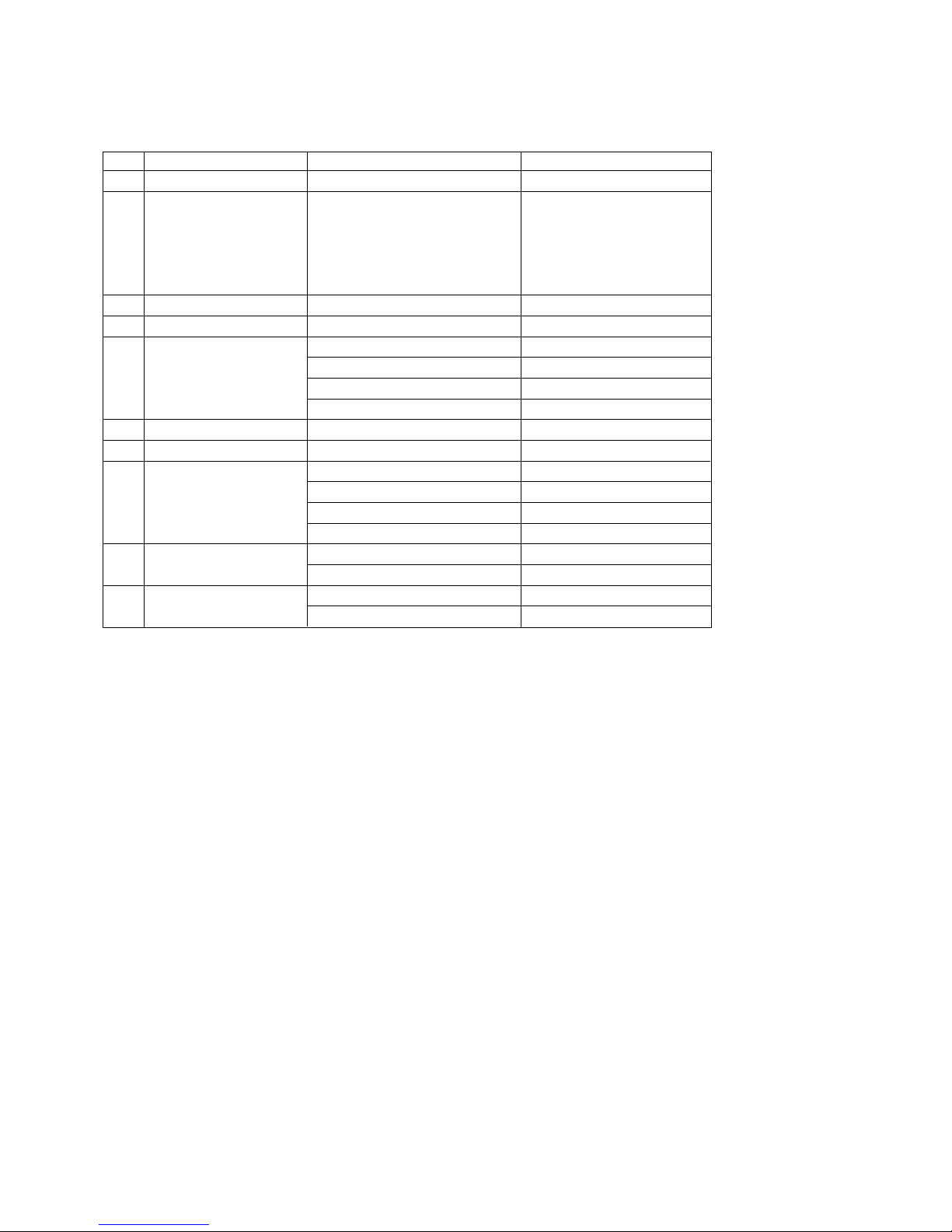

< See ADC Adjustment RS232C Protocol_Ver1.0 >

Order Command Set response

1. Inter the aa 00 00 a 00 OK00x

Adjustment

mode

2. Change the XB 00 40 b 00 OK40x (Adjust 480i Comp1 )

Source XB 00 60 (Adjust 1080p Comp1)

b 00 OK60x (Adjust 1080p RGB)

3. Start ad 00 10

Adjustment

4. Return the OKx ( Success condition )

Response NGx ( Failed condition )

5. Read data ( main ) (main : component1 480i, RGB 1080p)

Adjustment ad 00 20 00000000000000000000000007c007b006dx

data ( main ) (main : component1 480i, RGB 1080p)

ad 00 30 000000070000000000000000007c00830077x

6. Confirm ad 00 99 NG 03 00x (Failed condition)

Adjustment NG 03 01x (Failed condition)

NG 03 02x (Failed condition)

OK 03 03x (Success condition)

7. End of ad 00 90 d 00 OK90x

Adjustment

5. Factory Adjustment

PU11A : USE INTERNAL ADC(S7R) : using internal pattern.

5-1. Auto Adjust Component

480i/1080p RGB 1080p

(1) Summary : Adjustment component 480i/1080i and RGB

1080p is Gain and Black level setting at Analog

to Digital converter, and compensate the RGB

deviation

(2) Using instrument

1) Adjustment remocon, 801GF(802B, 802F, 802R) or

MSPG925FA pattern generator

(It can output 480i/1080i horizontal 100 % color bar

pattern signal, and its output level must setting

0.7 V ± 0.1 V p-p correctly)

* You must make it sure its resolution and pattern cause every

instrument can have different setting

2) Adjustment method 480i Comp1, Adjust 1080p

Comp1/RGB (Factory adjustment)

O ADC 480i Component1 adjustment -

- Check connection of Component1

- MSPG-925FA Ë Model: 209, Pattern 65

O Set Component 480i mode and 100% Horizontal

Color Bar Pattern(HozTV31Bar), then set TV set to

Component1 mode and its screen to “NORMAL”

O ADC 1080p Component1 / RGB adjustment

- Check connection both of Component1 and RGB

- MSPG-925FA Ë Model: 225, Pattern 65

O Set Component 1080p mode and 100% Horizontal

Color Bar Pattern(HozTV31Bar), then set TV set to

Component1 mode and its screen to “NORMAL”

O After get each the signal, wait more a second and

enter the “IN-START” with press IN-START key of

Service remocon. After then select “7. External ADC”

with navigator button and press “Enter”.

O After Then Press key of Service remocon “Right

Arrow(VOL+)”

O You can see “ADC Component1 Success”

O Component1 1080p, RGB 1080p Adjust is same

method.

O Component 1080p Adjustment in Component1 input

mode

O RGB 1080p adjustment in RGB input mode

O If you success RGB 1080p Adjust. You can see “ADC

RGB-DTV Success”

Caution : Set Volume 0 after adjustment

5-2. Use Internal ADC(S7R)

- ADJ(EZ ADJUST) -> 6.ADC Calibration -> ADC

Calibration(START)

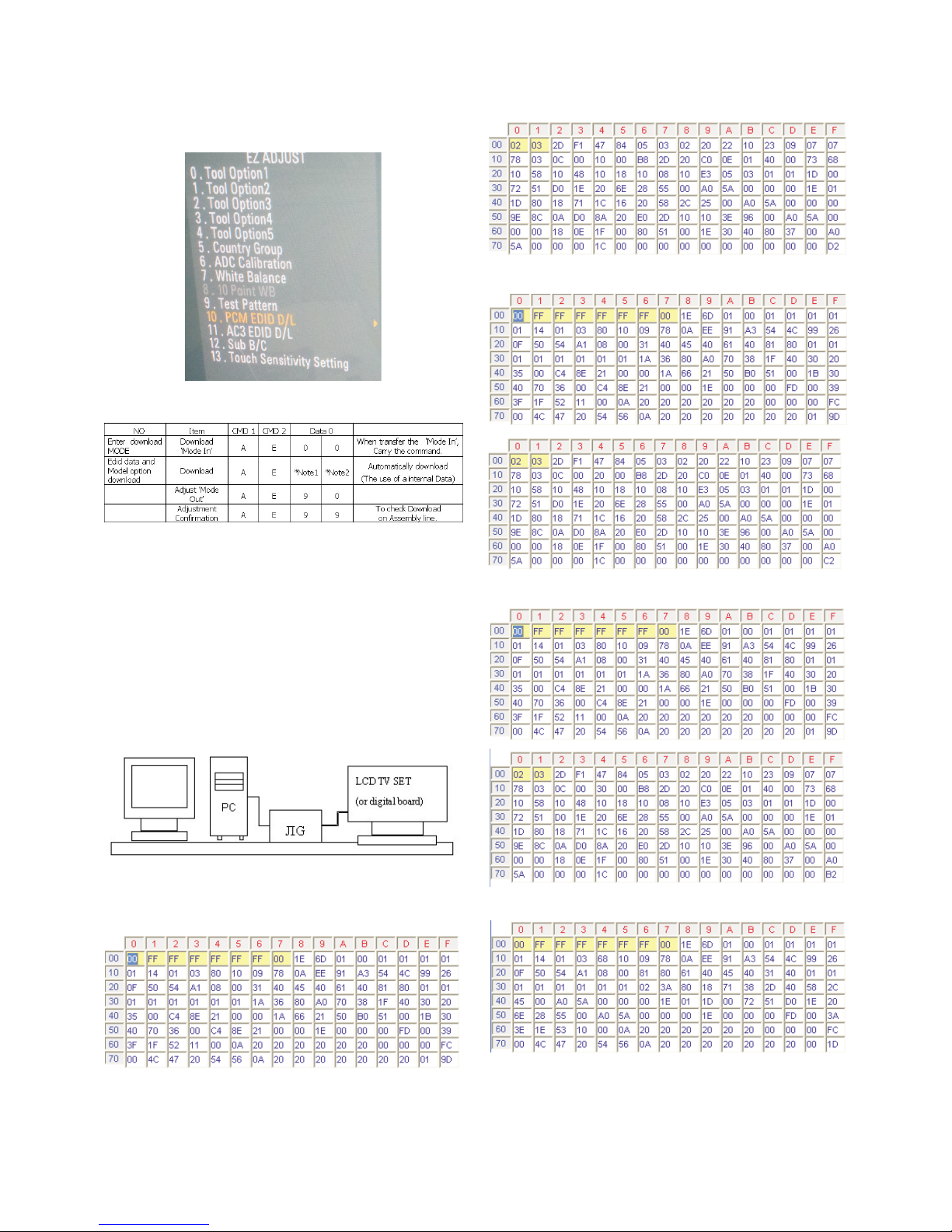

5-3. EDID(The Extended Display

Identification Data) / DDC(Display Data

Channel) download

(1) Summary

1) It is established in VESA, for communication between

PC and Monitor without order from user for building user

condition. It helps to make easily use realize “Plug and

Play” function.

2) For EDID data write, we use DDC2B protocol.

5-4. Auto Download

(1) After enter Service Mode by pushing “ADJ” key,

(2) Enter EDID D/L mode.

(3) Enter “START” by pushing “OK” key.

Caution

- Never connect HDMI & D-sub Cable when the user

downloading .

- Use the proper cables below for EDID Writing.

- 7 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

< Adjustment pattern : 480i / 1080p 60Hz Pattern >

- 8 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

O It only needs to PCM EDID D/L for North America Product.

(42PW350-UA)

* Edid data and Model option download(RS232)

5-5. Manual Download

(1) Write HDMI EDID data

1) Using instruments

- Jig. (PC Serial to D-Sub connection) for PC, DDC

adjustment.

- S/W for DDC recording (EDID data write and read)

- D-sub jack

- Additional HDMI cable connection Jig.

2) Preparing and setting.

- Set instruments and Jig. Like pic.5), then turn on PC

and Jig.

- Operate DDC write S/W (EDID write & read)

- It will operate in the DOS mode.

EDID DATA (Model name = LG TV)

- HDMI1 EDID table(3D HD) US(PCM)

- HDMI2 EDID table(3D HD) US(PCM)

- HDMI3 EDID table(3D HD) US(PCM)

- RGB EDID table(3D HD) US (PCM)

< For write EDID data, setting Jig and another instruments >

- 9 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

- HDMI1 EDID table(3D HD) US(AC3)

- HDMI2 EDID table(3D HD) US(AC3)

- HDMI3 EDID table(3D HD) US(AC3)

- RGB table(3D HD) US (AC3)

* See Working Guide if you want more information about EDID

communication.

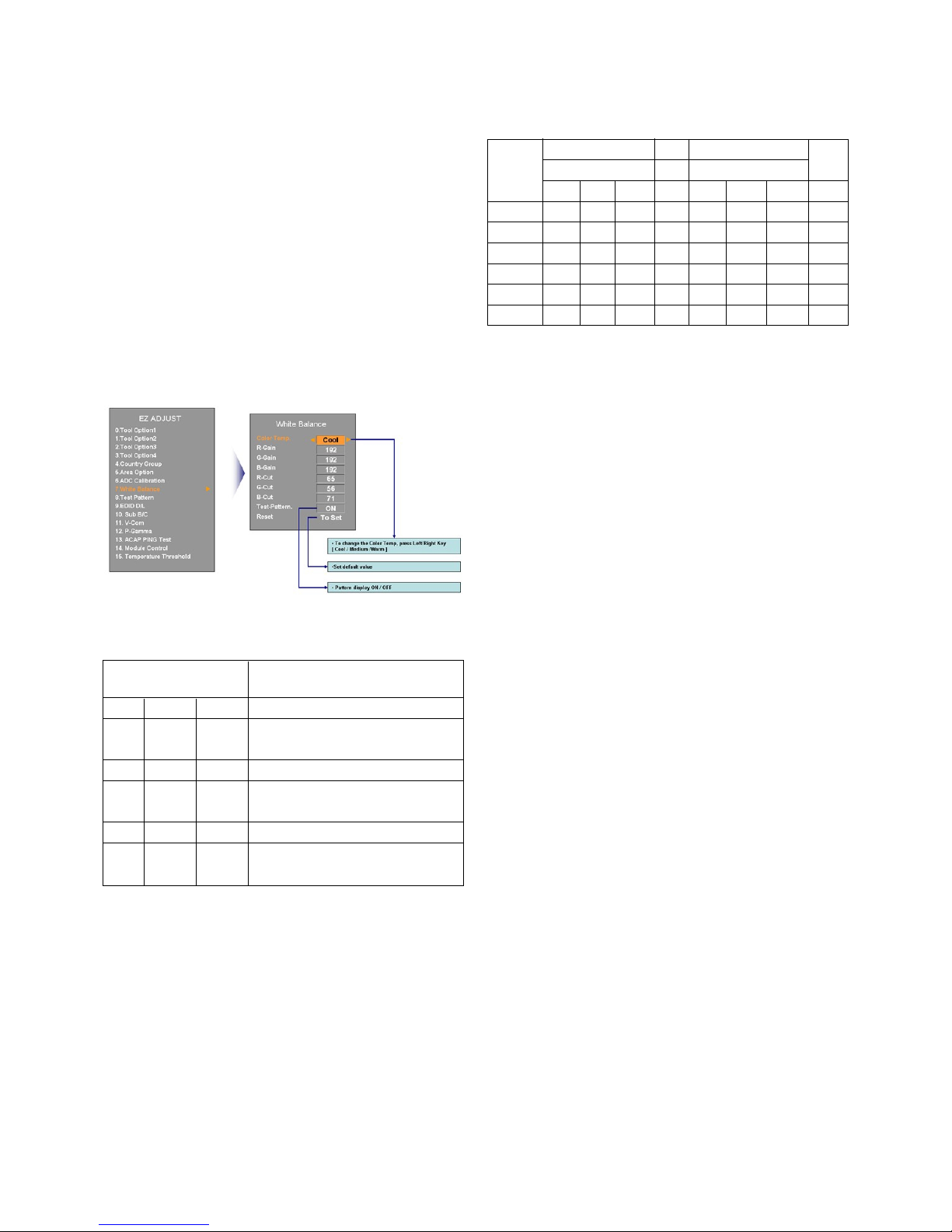

5-6. Adjustment Color Temperature

(White balance)

(1) Using Instruments

1) Color Analyzer: CA-210 (CH 9)

- Using LCD color temperature, Color Analyzer (CA-

210) must use CH 9, which Matrix compensated

(White, Red, Green, Blue compensation) with CS-

2100. See the Coordination bellowed one.

2) Auto-adjustment Equipment (It needs when Autoadjustment – It is availed communicate with RS-232C :

Baud rate: 115200)

3) Video Signal Generator MSPG-925F 720p, 216Gray

(Model: 217, Pattern 78)

(2) Connection Diagram (Auto Adjustment)

1) Using Inner Pattern

2) Using HDMI input

< Connection Diagram for Adjustment White balance >

(3) White Balance Adjustment

- If you can’t adjust with inner pattern, then you can adjust

it using HDMI pattern. You can select option at “Ez-Adjust

Menu – 7. White Balance” there items “NONE, INNER,

HDMI”. It is normally setting at inner basically. If you can’t

adjust using inner pattern you can select HDMI item, and

you can adjust.

- In manual Adjust case, if you press ADJ button of service

remocon, and enter “Ez-Adjust Menu – 7. White Balance”,

then automatically inner pattern operates. (In case of

“Inner” originally “Test-Pattern. On” will be selected in The

“Test-Pattern. On/Off”.

O Connect all cables and equipments like Pic.5)

O Set Baud Rate of RS-232C to 115200. It may set

115200 orignally.

O Connect RS-232C cable to set

O Connect HDMI cable to set

V RS-232C COMMAND(Commonly apply)

O wb 00 00”: Start Auto-adjustment of white balance.

O “wb 00 10”: Start Gain Adjustment (Inner pattern)

O “jb 00 c0” :

O …

O “wb 00 1f”: End of Adjustment

* If it needs, offset adjustment (wb 00 20-start, wb 00 2f-

end)

O “wb 00 ff”: End of white balance adjustment (inner

pattern disappear)

V Adjustment Mapping information

O When Color temperature (White balance) Adjustment

(Automatically)

- Press “Power only key” of service remocon and

operate automatically adjustment.

- Set BaudRate to 115200.

O You must start “wb 00 00” and finish it “wb 00 ff”.

O If it needs, then adjustment “Offset”.

(4) White Balance Adjustment (Manual adjustment)

1) Test Equipment: CA-210

- Using PDP color temperature, Color Analyzer (CA-

210) must use CH 10, which Matrix compensated

(White, Red, Green, Blue compensation) with CS-

2100. See the Coordination bellowed one.

2) Manual adjustment sequence is like bellowed one.

- Turn to “Ez-Adjust” mode with press ADJ button of

service remocon.

- Select “10.Test Pattern” with CH+/- button and press

enter. Then set will go on Heat-run mode. Over 30

minutes set let on Heat-run mode.

- Let CA-210 to zero calibration and must has gap more

10cm from center of PDP module when adjustment.

- Press “ADJ” button of service remocon and select

“7.White-Balance” in “Ez-Adjust” then press “

G” button

of navigation key. (When press “

G” button then set will

go to full white mode)

- Adjust at three mode (Cool, Medium, Warm)

- If “cool” mode

Let B-Gain to 192 and R, G, B-Cut to 64 and then

control R, G gain adjustment High Light adjustment.

- If “Medium” and “Warm” mode Let R-Gain to 192 and

R, G, B-Cut to 64 and then control G, B gain

adjustment High Light adjustment.

- All of the three mode

Let R-Gain to 192 and R, G, B-Cut to 64 and then

control G, B gain adjustment High Light adjustment.

- With volume button (+/-) you can adjust.

- After all adjustment finished, with Enter (_ key) turn to

Ez-Adjust mode. Then with ADJ button, exit from

adjustment mode

- 10 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

RS-232C COMMAND

[CMD ID DATA] Meaning

wb 00 00 White Balance adjustment start.

wb 00 10 Start of adjust gain

(Inner white pattern)

wb 00 1f End of gain adjust

wb 00 20 Start of offset adjust

(Inner white pattern)

wb 00 2f End of offset adjust

wb 00 ff End of White Balance adjust

(Inner pattern disappeared)

RS-232C COMMAND

CENTER

[CMD ID DATA] MIN (DEFAULT) MAX

Cool Mid Warm Cool Mid Warm

R Gain jg Ja jd 00 184 192 192 192

G Gain jh Jb je 00 187 183 159 192

B Gain ji Jc jf 00 192 161 95 192

R Cut 64 64 64 127

G Cut 64 64 64 127

B Cut 64 64 64 127

* Attachment: White Balance adjustment coordination and color

temperature.

O Using CS-1000 Equipment.

- COOL : T=11000K, _uv=0.000, x=0.276 y=0.283

- MEDIUM : T=9300K, _uv=0.000, x=0.285 y=0.293

- WARM : T=6500K, _uv=0.000, x=0.313 y=0.329

O Using CA-210 Equipment. (10 CH)

- Contras value : 216 Gray

- Brighness spec.

6. Test of RS-232C control.

- Press In-Start button of Service Remocon then set the “4.Baud

Rate” to 115200. Then check RS-232C control and

7. Selection of Country option.

- Selection of country option is allowed only North American

model (Not allowed Korean model). It is selection of Country

about Rating and Time Zone.

(1) Models: All models which PB82C Chassis (See the first

page.)

(2) Press “In-Start” button of Service Remocon, then enter the

“Option” Menu with “PIP CH-“ Button

(3) Select one of these three (USA, CANADA, MEXICO)

defends on its market using “Vol. +/-“button.

Caution : Don’t push The INSTOP KEY after completing the

function inspection

Caution : Inspection only PAL M / NTSC

8. GND and ESD Testing

8-1. Prepare GND and ESD Testing.

- Check the connection between set and power cord

8-2. Operate GND and ESD auto-test.

(1) Fully connected (Between set and power cord) set enter

the Auto-test sequence.

(2) Connect D-Jack AV jack test equipment.

(3) Turn on Auto-controller(GWS103-4)

(4) Start Auto GND test.

(5) If its result is NG, then notice with buzzer.

(6) If its result is OK, then automatically it turns to ESD Test.

(7) Operate ESD test

(8) If its result is NG, then notice with buzzer.

(9) If its result is OK, then process next steps. Notice it with

Good lamp and STOPER Down.

8-3. Check Items.

(1) Test Voltage

GND: 1.5KV/min at 100mA

Signal: 3KV/min at 100mA

(2) Test time: just 1 second.

(3) Test point

- GND test: Test between Power cord GND and Signal

cable metal GND.

- ESD test: Test between Power cord GND and Live and

neutral.

(4) Leakage current: Set to 0.5mA(rms)

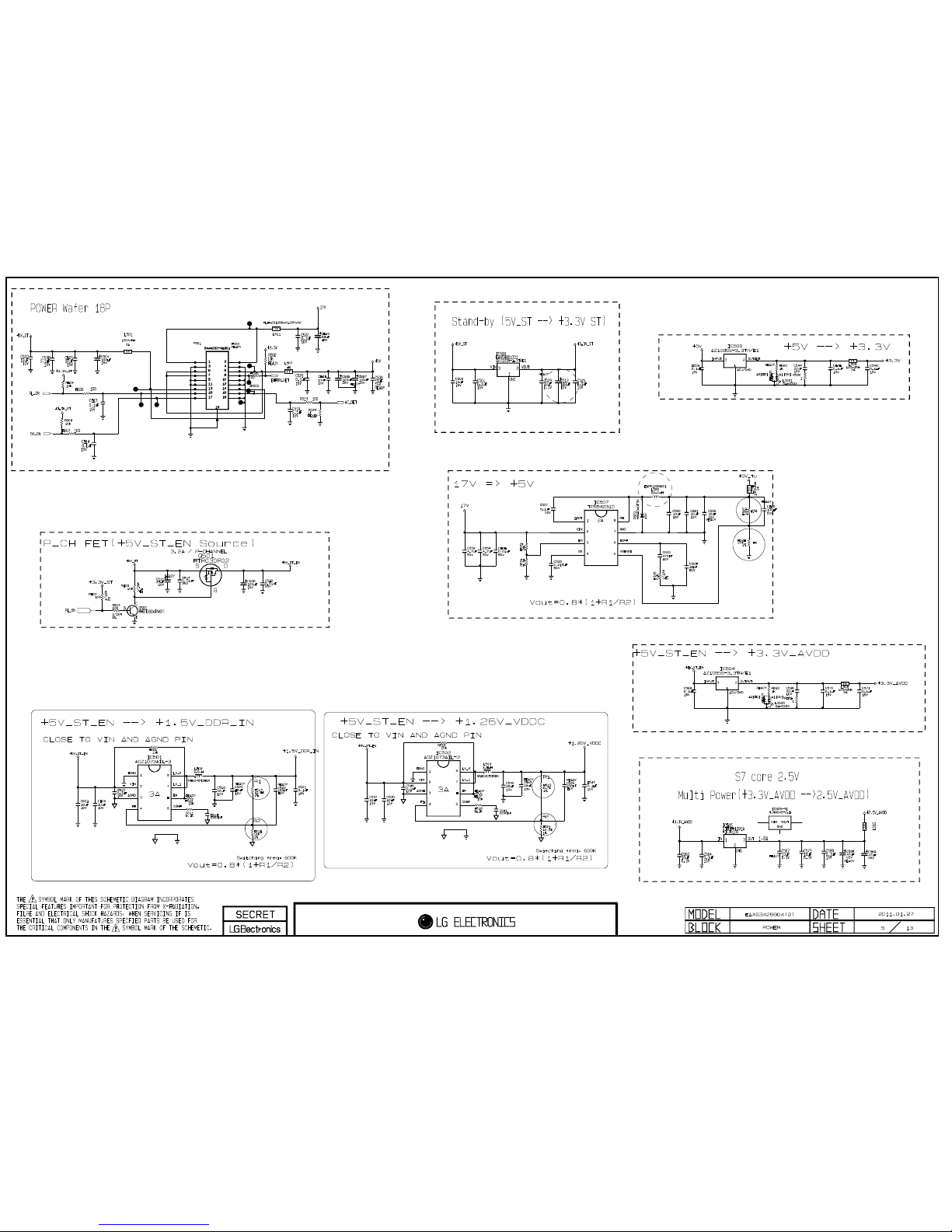

9. POWER PCB Ass’y Voltage

Adjustment

(Va/Vs Voltage Adjustment)

(1)Test equipment : D.M.M 1EA

(2) Connection Diagram for Measuring : refer to fig.1

- 11 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

Color Test Color Coordination

temperature Equipment x y

COOL CA-210 0.276±0.002 0.283±0.002

MEDIUM CA-210 0.285±0.002 0.293±0.002

WARM CA-210 0.313±0.002 0.329±0.002

Item Min Typ Max Unit Remark

White 49 60 - cd/m - 100%Window White

average Pattern

brightness - 100IRE(255Gray)

- Picture: Vivid(Medium )

Brightness -20 +20 % - 85IRE(216Gray) 100%

uniformity Window White Pattern

- Picture: Vivid(Medium)

< fig.1 : 42 inch Power PCB Assy Voltage adjustment >

9-1. Adjustment method

(1) Vs adjustment (refer fig.1)

1) Connect + terminal of D.M.M. to Vs pin of P811, connect

-terminal to GND pin of P811

2) After turning VR901, voltage of D.M.M adjustment as

same as Vs voltage which on label of panel left/top (

deviation ; ±0.5V)

(2) Va adjustment (refer fig.1)

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M. to Va pin of P811, connect

-terminal to GND pin of P811.

3) After turning VR502,voltage of D.M.M adjustment as

same as Va voltage which on label of panel left/top

(deviation; ±0.5V)

10. Default Service option.

10-1. ADC-Set.

V R-Gain adjustment Value (default 128)

V G-Gain adjustment Value (default 128)

V B-Gain adjustment Value (default 128)

V R-Offset adjustment Value (default 128)

V G-Offset adjustment Value (default 128)

V B-Offset adjustment Value (default 128)

10-2. White balance. Value.

10-3. Temperature Threshold

V Threshold Down Low 20

V Threshold Up Low 23

V Threshold Down High 70

V Threshold Up High 75

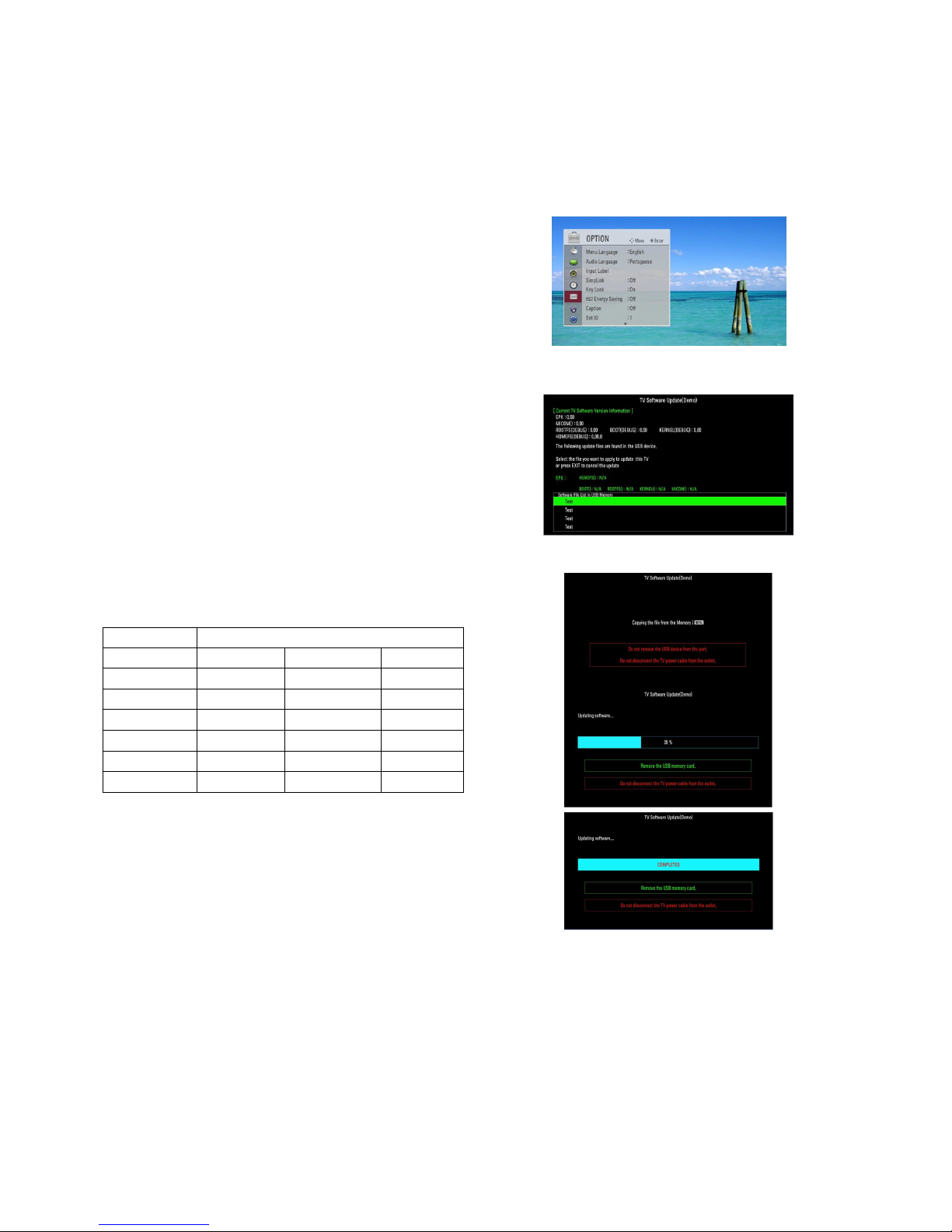

11. USB DOWNLOAD

(*.epk file download)

V Put the USB Stick to the USB socket

V Press Menu key, and move OPTION

V Press “FAV” Press 7 times.

V Select download file (epk file)

V After download is finished, remove the USB stick.

V Press “IN-START” key of ADJ remote control, check the

S/W version.

CAUTION

- DO NOT REMOVE USB MEMORY CARD FROM USB PORT

WHEN YOU FIND BELOW DESCRIPTION

- " Do not remove the memory card from the port! "

- 12 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

CENTER (DEFAULT)

Cool Mid Warm

R Gain 192 192 192

G Gain 192 192 192

B Gain 192 192 192

R Cut 64 64 64

G Cut 64 64 64

B Cut 64 64 64

- 13 -

LGE Internal Use OnlyCopyright ©2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

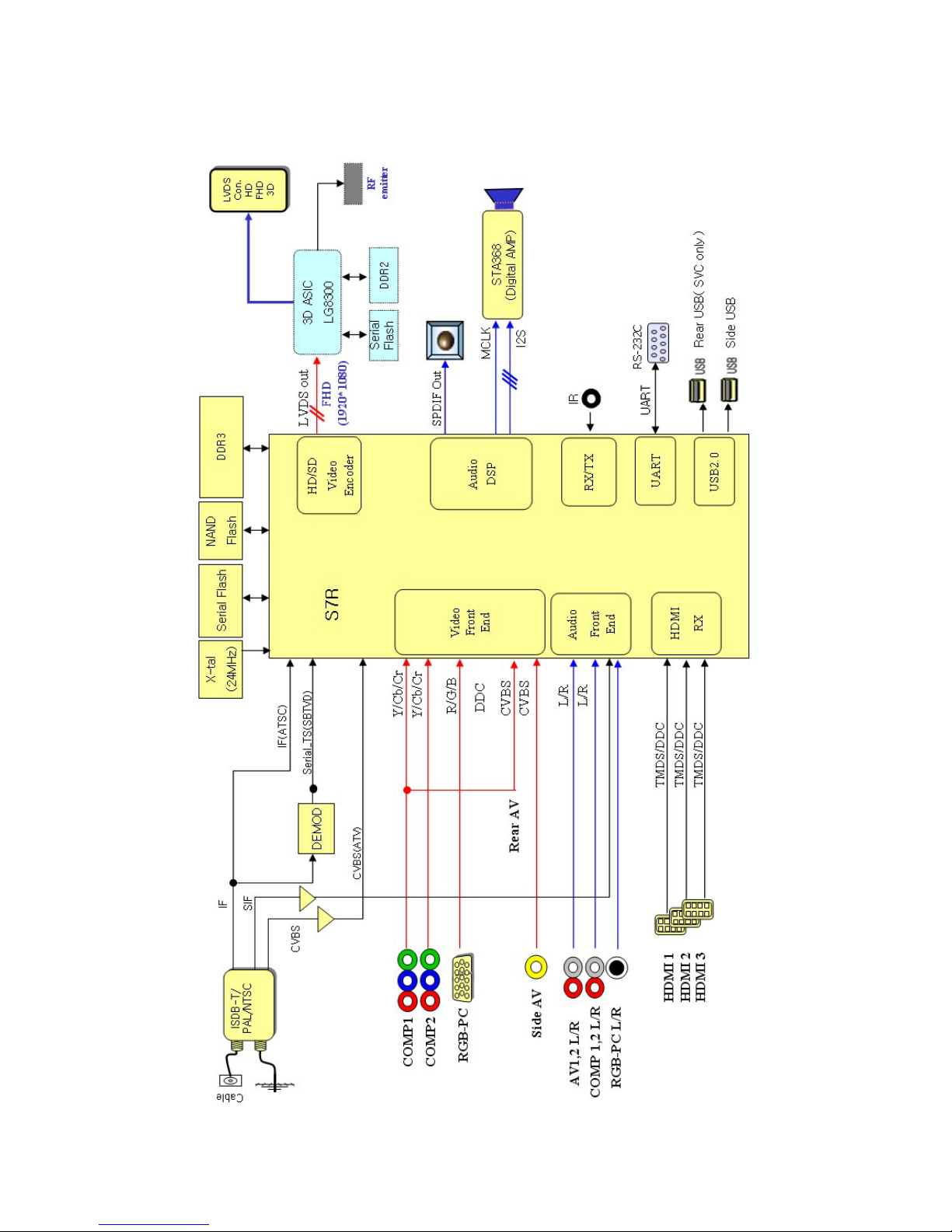

BLOCK DIAGRAM

- 14 -

LGE Internal Use Only

EXPLODED VIEW

900

910

203

590

204

601

207

520

400

200

240

580

301

305

120

300

206

202

205

302

303

304

501

602

201

570

560

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

A10

A9

LV1

A12

A21

A2

A4

Copyright © 2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

Copyright © 2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

Copyright © 2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

Copyright © 2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

Copyright © 2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

Copyright © 2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

Copyright © 2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

Copyright © 2011 LG Electronics Inc. All rights reserved.

Only for training and service purposes

LGE Internal Use Only

Loading...

Loading...