Page 1

PLASMA TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : PA64C

MODEL : 42PG60C 42PG60C-UA

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

Page 2

- 2 -

- 2 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An lsolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitary that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this monitor is blown, replace it

with the same specified type.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on positioin, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each esposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits sepcified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Customer Interactive Center

P.O.Box 240007, 201 James Record Road Huntsville,

AL 35824

Digital TV Hotline 1-800-243-0000

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

0.15uF

Page 3

- 3 -

- 3 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SPECIFICATIONS.................................................................4

ADJUSTMENT INSTRUCTIONS ..........................................6

BLOCK DIAGRAM...............................................................15

EXPLODED VIEW...............................................................19

SCHEMATIC DIAGRAM..........................................................

PRINTED CIRCUIT BOARDS.................................................

TABLE OF CONTENTS

Page 4

- 4 -

- 4 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SPECIFICATIONS

NOTE : Specifications and others are subject to change without notice for improvement

.

V Application Range

This spec is applied to the 42” PLASMA TV used PA64C Chassis.

V Specification

Each part is tested as below without special appointment.

1) Temperature : 20±5°C

2) Relative Humidity: 65±10%

3) Power Voltage: Standard Input voltage (100-240V~, 50/60Hz)

* Standard Voltage of each product is marked by models.

4) Specification and performance of each parts are followed each drawing and specification by part number in accordance with SBOM.

5) The receiver must be operated for about 20 minutes prior to the adjustment.

V Test Method

1) Performance : LGE TV test method followed.

2) Demanded other specification

Safety : UL, CSA, IEC specification

EMC : FCC, ICES, IEC specification

Chassis

PA64C 42PG60C-UA

42PG65C-UA

North America LG

Class B

Model Name Market Brand Remark

42PG60C-UA

42PG65C-UA

Safety : UL1492, CSA C22.2.No.1

EMC : FCC Class B, IEC Class B

North America

Model ApplianceMarket Remark

Page 5

- 5 -

- 5 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SPECIFICATIONS

Receiving System

Available Channel

Input Voltage

Market

Screen Size

Aspect Ratio

Tuning System

PDP Module

Operating Environment

Storage Environment

1

2

3

4

5

6

7

8

9

10

No Item Specification Remark

VSB/64 & 256 QAM/NTSC-M

1) VHF: 02~13

2) UHF: 14~69

3) DTV: 02~69

4) CATV: 01~135

5) CADTV: 01~135

AC 100~260V 50/60Hz

North America

42 inch Wide

16:9

FS

PDP42G1A####(1024x768)

1) Temp. : 0 ~ 40deg

2) Humidity : ~ 80%

1) Temp. : -30 ~ 60deg

2) Humidity : 0 ~ 90%

V General Specification

Page 6

- 6 -

- 6 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1. Application Object

These instructions are applied to all of the Plasma TV,

PA64C.

2. Notes

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test equipment.

(2) Adjustments must be done in the correct order.

(3) The adjustments must be performed in the circumstance of

25±5°C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver be must kept 110V, 60Hz

when adjusting.

(5) The receiver must be operational for about 15 minutes

prior to the adjustments.

1) After receiving 100% white pattern, the receiver must be

operated prior to adjustment. (Or 8. White Pattern

condition in EZ - Adjust)

2) Enter into White Pattern

- Press POWER ON Key on the Service Remote

Control (S R/C)

- Enter the Ez - Adjust by pressing ADJ Key on the

Service Remote Control (S R/C).

- Select 7. White Pattern using the CH +/- Key and

press the Enter(Y) Key.

Display the 100% Full White Pattern.

[ Set is activated HEAT-RUN without signal generator in

this mode.

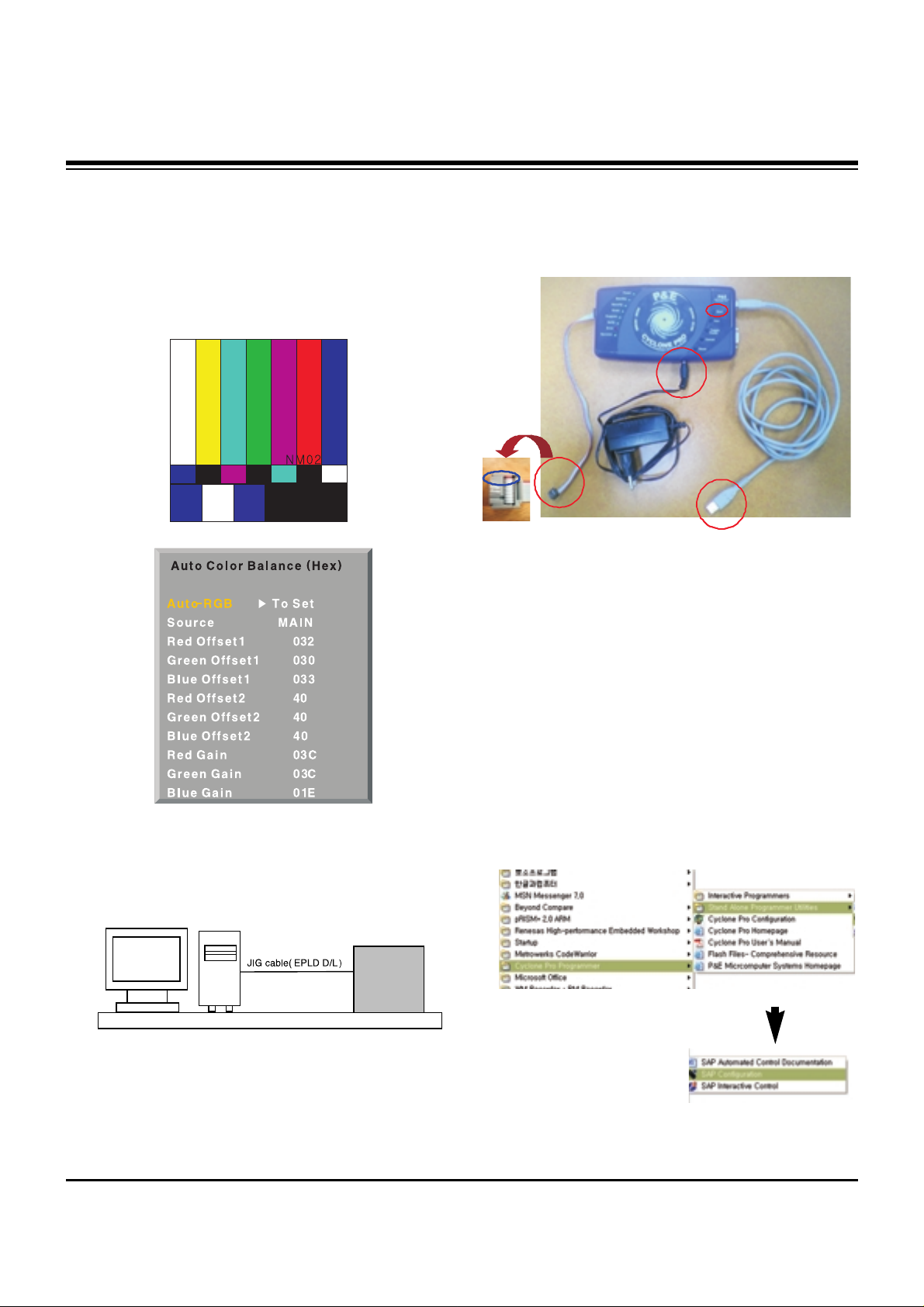

3. Auto AV (CVBS) Color Balance

3-1. Required Equipment

(1) Remote controller for adjustment

(2) AV Pattern Generator: 802F Pattern Generator, Master

(MSPG-925FS), etc

(Which has NTSC-J Composite Video format output with

standard (1.0 Vpp) See Fig. 1)

(3) It is very import to use correct adjustment pattern like

Fig.1.

3-2. Method of Auto AV (CVBS) Color

Balance

(1) Input the NTSC-J Composite Video (Fig.1.) into video

input.

=> MSPG-925FS Model No: 207 / Pattern No: 65 / NTSC-J

(2) Set the EZ Picture to Daylight mode in Video menu.

(3) Press INSTART key on R/C for adjustment.

(4) Press the

G(Vol. +) key operate to set, then it becomes

automatically.

(5) Auto-RGB OK means completed adjustment.

* When adjust main picture, sub picture is included.

ADJUSTMENT INSTRUCTIONS

If you turn on a still screen more than 20 minutes (Especially

Digital pattern(13 CH), Cross Hatch Pattern), an afterimage

may occur in the black level part of the screen.

<Fig. 1> Auto AV (CVBS) Color Balance Test Pattern

Default Value on OSD

Page 7

- 7 -

- 7 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

4. Auto Component Color Balance

4-1. Required Equipment

(1) Remote controller for adjustment

(2) 802F Pattern Generator Which has 720p YPbPr output

with Standard (0.7Vpp) See Fig. 2

(3) It is very important to use correct adjustment pattern like

Fig. 2.

4-2. Method of Auto Component Color

Balance

(1) Input the Component 1280*720p 60Hz signal into

Component.

=> MSPG-925FS Model No: 217 / Pattern No: 65

(2) Set the EZ Pictures to Daylight mode in Video menu.

(3) Press INSTART key on R/C for adjustment.

(4) Press the

G(Vol. +) key operate To set, then it becomes

automatically.

(5) Auto-RGB OK means completed adjustment

5. Auto RGB Color Balance

5-1. Required Equipment

(1) Remote controller for adjustment

(2) 802F Pattern Generator, Master (MSPG-925FS), etc.

(Which has XGA 60Hz PC Format output with standard

(0.7Vpp) See Fig. 3 )

(3) It is very import to use correct adjustment pattern like Fig.

3.

5-2. Method of Auto RGB Color Balance

(1) Input the PC 1024x768 @ 60Hz into RGB.

=> MSPG-925FS Model No: 60 / Pattern No: 65

(2) Set the EZ Pictures to Daylight mode in Video menu.

(3) Press INSTART key on R/C for adjustment.

(4) Press the

G(Vol. +) key operate To set, then it becomes

automatically.

(5) Auto-RGB OK means completed adjustment.

ADJUSTMENT INSTRUCTIONS

<Fig. 2> Auto Component Color Balance Test Pattern

Default Value on OSD

<Fig. 3> Auto RGB Color Balance Test Pattern

Default Value on OSD

Page 8

- 8 -

- 8 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

6. RF Color Balance

(1) Input the RF cable

(2) Set the EZ Pictures to Daylight mode in Video menu.

(3) Press INSTART key on R/C for adjustment.

(4) Press the

G(Vol. +) key operate To set, then it becomes

automatically.

(5) Auto-RGB OK means completed adjustment.

7. EPLD Download

(1) Test Equipment: PC, Jig for download

(2) Connect the power of VSC B/D.

(3) Execute download program(iMPACK) of PC.

(4) After executing the hot key on the Programmer, click icon

(5) End after confirming

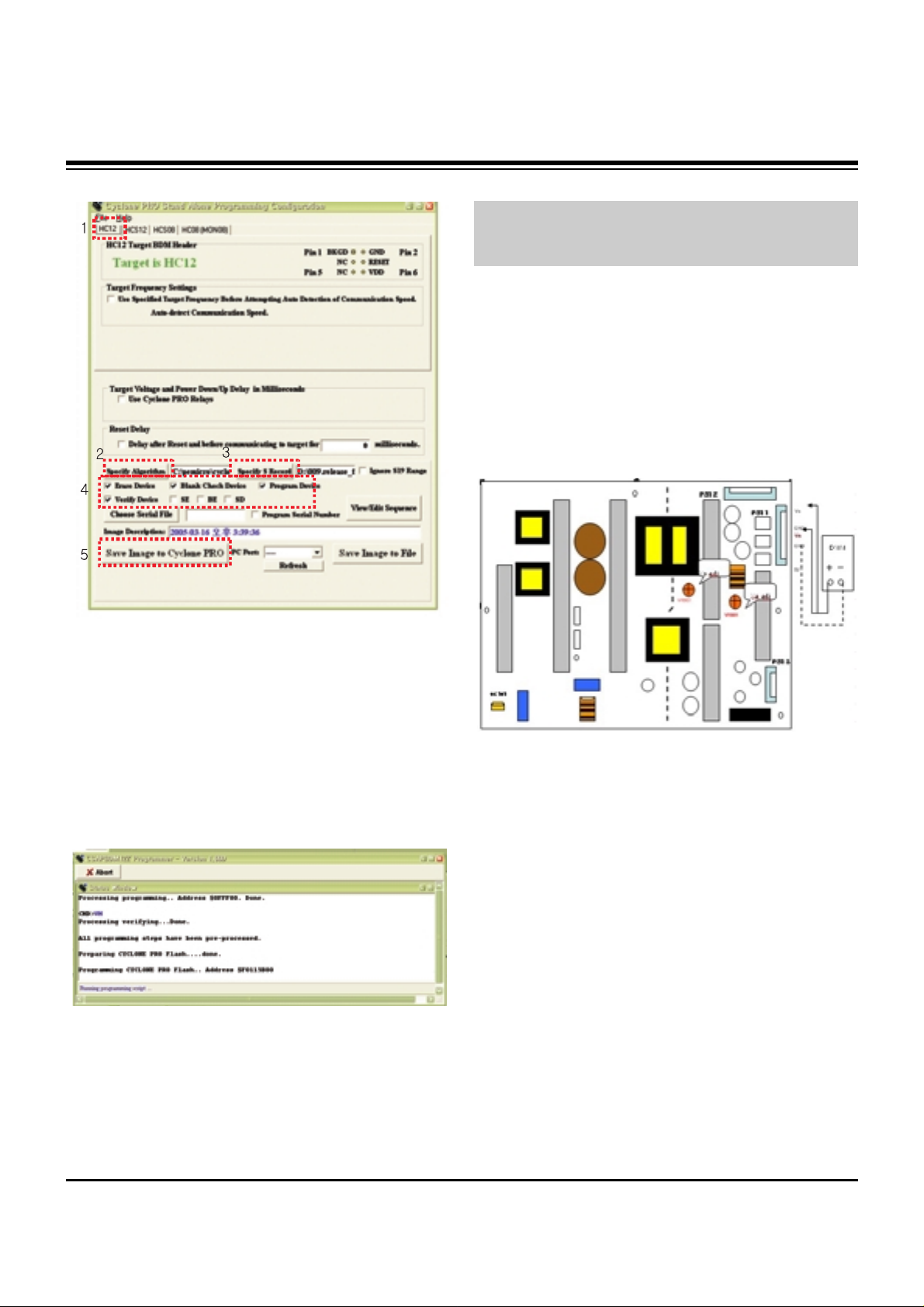

8. PTC MICOM Download

8-1. PTC MICOM JIG

(1) Connect power.

(2) Connect the jack(No. 1) to PTC Micom.

(3) Connect the USB Cable(No. 2) and computer.

(4) Execute download program(SAP Configuration)

[ (Caution) PTC Download JIG can save Download file in

memory by Download Program(SAP Configuration).

Because it has a memory chip inside.

After saving the file, you can download it by just pressing

Start button (number 4.).

8-2. Download program(SAP Configuration)

Execute

ADJUSTMENT INSTRUCTIONS

Default Value on OSD

PC

VSC

B/D

Connection Diagram of EPLD Download

Mic om

Micom

Jig

Jig

3.3.

4.Start

4. Start

Mic om

Micom

Jig

Jig

3.3. Power

2. Connect Computer1. Connect Micom port of TV board

4.Start

4. Start Button

<SAP Configuration Process>

(Connect red line (a part of arrow) to port 1)

Page 9

- 9 -

- 9 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

(1) Select HC12.

(2) Specify Algorithm: Select the 9S12dt128_128k.12P file.

(3) Specify S Record: Select the Download file.

(4) Check the check box of Erase Device, Blank Check

Device, Porgram Device, Verify Device.

[ (Caution) Don’t check anywhere except one like picture as

shown.

(5) Press “Save Image to Cyclone PRO” button.

And then the file is downloaded to Download JIG from PC.

(6) When Download is finished, you can download the file by

pressing “start” button on Download JIG.

At first, you download the file, you should not download it

again.

9. POWER PCB Assy Voltage

Adjustment

(Va, Vs Voltage Adjustment)

Caution: Set up “RF mode(noise)” before voltage adjustment.

9-1. Test Equipment :D.M.M 1EA

9-2. Connection Diagram for Measuring

Refer to Fig 4.

9-3. Adjustment

(1) 42” Va Adjustment

1) After receiving 100% Full White Pattern, HEAT RUN.

2) Connect + terminal of D.M.M to Va pin of P811 and

connect – terminal to GND pin of P811.

3) After turning VR901, voltage of D.M.M adjustment as

same as Va voltage which on label of panel Top/Right.

(Deviation : ±0.5V)

(2) 42” Vs Adjustment

1) Connect + terminal of D.M.M to Vs pin of P811 and

connect – terminal to GND pin of P811.

2) After turning VR951, voltage of D.M.M adjustment as

same as Vs voltage which on label of panel Top/Right.

(Deviation : ±0.5V)

ADJUSTMENT INSTRUCTIONS

<Execute SAP Configuration>

<Picture is downloaded to Download JIG>

Each PCB Assy must be checked by Check JIG Set before

assembly. (Especially, be careful Power PCB Assy which can

cause Damage to the PDP Module.)

<Fig. 4> 42 inch Power PCB Assy Voltage Adjustment

Page 10

- 10 -

- 10 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

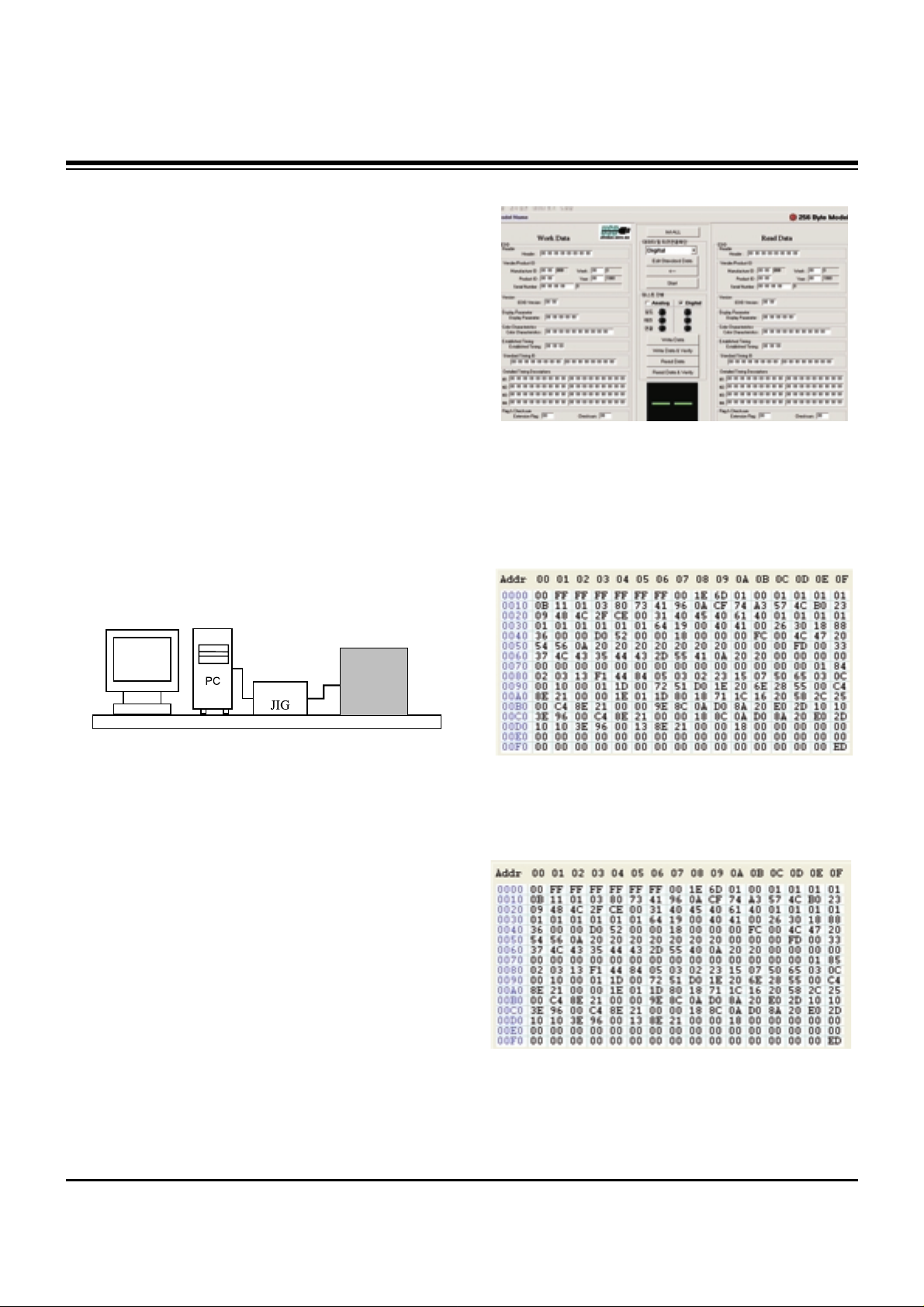

10. EDID(The Extended Display

Identification Data)/DDC

(Display Data Channel) Download

It is the feature to implement the “Plug and Play” which

automatically reconfigures the user’sl environment to directly

use by exchanging information without any command directly

to the PC or the monitor by the user, which is established by

the VESA

10-1. HDMI EDID Data Input

(1) Required Test Equipment

1) PC, Jig for adjusting DDC. (PC serial to D-sub

Connection equipment)

2) S/W for writing DDC(EDID data write & read)

3) D-Sub cable

4) Jig for HDMI Cable connection

(2) Preparation for Adjustments &

Setting of Device

1) Set devices as below and turn on the PC and JIG.

2) Open S/W for writing DDC (EDID data write & read).

(operated in DOS mode)

10-2. Download Method

(1) Set devices as above and turn on the PC and JIG.

(2) Execute DDC Program (EDID data write & read).

(3) Select the EDID data of the said model by selecting Model

-> Open at the menu.

(4) Check the item(s) to download from the <Test processing>

items.

1) HDMI & RGB: Digital & Analog Check

2) (Only)HDMI: Check only the digital

(5) Press ESC (Cancel mode) -> F8 (Auto mode). (Set ‘Auto

Detecting‘)

(6) Connect the said signal cable to the set.

(7) Make sure that the window “Perform the write operation?“

is displayed.

(8) Press the Enter key or the space key to download.

(9) After checking the ’OK’ message after downloading,

disconnect the connected cable.

10-3. EDID DATA for PA64C

:EDID for HDMI 1 (DDC (Display Data Channel) Data)

EDID table =

HDMI1(84ED)

:EDID for HDMI 2 (DDC (Display Data Channel) Data)

EDID table =

HDMI2(85ED)

ADJUSTMENT INSTRUCTIONS

LCD TV SET

(or Digital Board)

<Fig. 5>

Page 11

- 11 -

- 11 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

:EDID for RGB

EDID table(F6) =

11. Adjustment of White Balance

Adjust to equalize the white color caused by the module

deviation

11-1. Required Test Equipment

(1) Color Analyzer: CA-100+(CH 10), CA-100(CH10), CA-

210U(CH 10)

(2) Computer for adjusting (necessary for the automatic

adjustment, possible to communicate with the RS-232C)

(3) Remote controller for adjusting

* Use the instrument with the matrix compensated by the CS-

1000 as the color analyzer.

11-2. Adjustment of White Balance

O

Operate the Zero-calibration of the CA-100, then attach

sensor to PDP module surface when you adjust.

O

Manual adjustment is also possible by the following sequence.

(1) Enter ‘Ez - Adjust’ by pressing ADJ KEY on the Service

Remote Control.

(2) Select "8. WHITE PATTERN" using CH +/- Key and HEAT

RUN at least 30 minutes by pressing the ENTER Key.

(3) Receive the Window pattern signal from Digital Pattern

Generator. (AV Input: connect the ‘HDMI’)

(4) After attaching sensor to center of screen, select ‘5. White-

Balance’ of ‘Ez - Adjust’ by pressing the ADJ KEY on the

Service R/C. Then enter adjustment mode by pressing the

Right KEY (

G

) .

(5) Adjust the Hight Light using R Gain/G Gain/B Gain.(Cool).

Adjust the Hight Light using R Gain/G Gain/B Gain.

(Medium).

Adjust the Hight Light using R Gain/G Gain/B Gain.(Warm).

(6) Adjust using Volume +/- KEY.

(7) After adjustment is complete, exit the adjustment mode by

pressing the ADJ KEY.

High Level: 216gray

[Cool]

X; 0.276±0.002 Y; 0.283±0.002

Color temperature: 11000°K±1000°K

[Medium]

X; 0.285±0.002 Y; 0.293±0.002

Color temperature: 9300°K±1000°K

[Warm]

X; 0.313±0.002 Y; 0.329±0.002

Color temperature: 6500°K±1000°K

ADJUSTMENT INSTRUCTIONS

R Gain

G Gain

B Gain

R offset

G offset

B offset

Jg

Jh

Ji

Cool

Ja

Jb

Jc

Med

RS-232C

COMMAND

CENTER

(DEFAULT)

Jd

Je

Jf

00

00

00

ff

ff

ff

7f

7f

7f

Warm

Min Max

80

75

68

80

74

85

Cool

80

73

6E

80

74

82

Med

80

75

68

80

74

85

Warm

Page 12

- 12 -

- 12 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

12. Commercial Model Test Item

12-1. IR In/Out Check

ADJUSTMENT INSTRUCTIONS

Page 13

- 13 -

- 13 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

12-2. Lodgenet Card & Auto Camport Check

12-3. RJP(Remote Jack Pack) Check

ADJUSTMENT INSTRUCTIONS

Page 14

- 14 -

- 14 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

12-4. MPI Card Check

ADJUSTMENT INSTRUCTIONS

Page 15

- 15 -

- 15 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

BLOCK DIAGRAM

Page 16

- 16 -

- 16 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

BLOCK DIAGRAM

Page 17

- 17 -

- 17 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

BLOCK DIAGRAM

Page 18

- 18 -

- 18 -

LGE Internal Use OnlyCopyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

BLOCK DIAGRAM

Page 19

- 19 -

- 19 -

LGE Internal Use Only

EXPLODED VIEW

307

120

121

306

560

570

LV1

310

571

302

202

205

590

240

501

250

540

530

580

204

203

303

305

300

304

301

200

206

201

603

602

601

520

270

260

400

A2

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Page 20

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 21

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 22

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 23

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 24

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 25

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 26

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 27

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 28

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 29

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 30

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 31

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 32

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Page 33

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

MAIN(TOP)

Page 34

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

MAIN(BOTTOM)

Page 35

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

CONTROL(TOP) CONTROL(BOTTOM)

PRE AMP(TOP)

PRE AMP(BOTTOM)

VERTICAL(TOP) VERTICAL(BOTTOM)

Page 36

Copyright©2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

MPI(TOP)

MPI(BOTTOM)

Page 37

Sep., 2008

Printed in KoreaP/NO : MFL54063801

CANADA: LG Electronics Canada, Inc. 550 Matheson

Boulevard East Mississauga, Ontario L4Z 4G3

USA : LG Electronics Alabama, Inc.

P.O.Box 240007, 201 James Record Road Bldg 3

Huntsville, AL 35824

Loading...

Loading...