Page 1

LG TRAINING MANUAL

LG TRAINING MANUAL

Fall 2008 PDP Training

42PG20

Page 2

- 4 -

Page 3

Ph o n e Co n t a C t s :

Contact Number Hours of Operation

Customer Service (800) 243-0000 24 hours a day / 7 days a week

Technical Support (800) 847-7597 7am-7pm Mon-Fri / Sat 8-2 CT

Parts Sales (888) 393-6484 7am-7pm Mon-Sat CT

Training Center (256) 774-4051 8am-5pm Mon-Fri CT

We b Co n t a C t s :

Web Site Address Description

LG USA www.lgusa.com Product information

Customer Service us.lgservice.com User manuals, FAQs

GCSC aic.lgservice.com Service manuals, parts, bulletins

Customer Service Academy www.lgcsacademy.com Web training, discussion forum

Live Training lge.webex.com Live training

Published July 2008 by LG Electronics USA Training Center

Copyright © 2008 LG Electronics of Alabama, Inc.

IMPORTANT SAFETY NOTICE

This manual was prepared for use only by properly trained audio-visual service technicians. When servicing this product, under no circumstances

should the original design be modified or altered without permission from LG Electronics. Unauthorized modifications will not only void the

warranty, but may lead to property damage or user injury. All components should be replaced only with types identical to those in the original

circuit and their physical location, wiring, and lead dress must conform to original layout upon completion of repairs. If any fuse (or Fusible

Resistor) in this TV receiver is blown, replace it only with the factory specified fuse type and rating. When replacing a high wattage resistor

(Oxide Metal Film Resistor, over 1W), keep the resistor 10mm away from PCB. Always keep wires away from high voltage or high temperature

parts. Do not attempt to modify this product in any way.

Special components are also used to prevent shock and fire hazard and are required to maintain safe performance. No deviations are allowed

without prior approval by LG Electronics. Service work should be performed only after you are thoroughly familiar with these safety checks and

servicing guidelines. Circuit diagrams may occasionally differ from the actual circuit used. This way, implementation of the latest safety and

performance improvement changes into the set is not delayed until the new service literature is printed.

ElECTROSTATICAllY SENSITIvE DEvICES

Some semiconductor (solid-state) devices can be damaged easily by static electricity. Such components commonly are called Electrostatically

Sensitive (ES) Devices. Examples of typical ES devices are integrated circuits and some field-effect transistors and semiconductor “chip” components.

The following techniques should be used to help reduce the incidence of component damage caused by static electricity.

Immediately before handling any semiconductor component or semiconductor-equipped assembly, drain off any electrostatic charge on the

body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which should

be removed for potential shock reasons prior to applying power to the unit under test. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as an ESD mat, to prevent electrostatic charge buildup or exposure of the assembly.

Use only a grounded-tip soldering iron to solder or unsolder ES devices. Use only an anti-static solder removal device. Some solder removal

devices not classified as “anti-static” can generate electrical charges sufficient to damage ES devices. Do not use refrigerant-propelled chemicals

which can generate electrical charge sufficient to damage ES devices. Do not remove a replacement ES device from its protective package until

immediately before you are ready to install it.

REGUlATORY INFORMATION

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference when the equipment is operated in a residential installation. This

equipment generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction manual, may

cause harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures: Reorient or relocate the receiving antenna;

Increase the separation between the equipment and receiver; Connect the equipment into an outlet on a circuit different from that to which the

receiver is connected; Consult the dealer or an experienced radio/TV technician for help.

The responsible party for this device’s compliance is: LG Electronics of Alabama, Inc. 201 James Record Road. Huntsville, AL 35813, USA. Digital

TV Hotline: 1-800-243-0000

Page 4

Table of ConTenTs

OVERVIEW .................................................. 5

Introduction ....................................................5

Basic Troubleshooting Steps ...........................5

Caution............................................................5

Model Number Structure ...............................6

Serial Number Structure .................................6

Remote Control ..............................................7

New Features .................................................7

Computer Connection ....................................8

Service Menu ...................................................8

Power Consumption .......................................8

Service Remote ...............................................9

Check Firmware Version ............................. 10

Update Firmware ......................................... 10

42PG20 Dimensions .................................... 11

50PG20 Dimensions .................................... 11

DISASSEMBLY ........................................... 12

Introduction ................................................. 12

Back Cover Removal .................................... 12

Switch Mode Power Supply Removal .......... 13

Y-Sus board Removal .................................... 13

Y-Drive board Removal ............................... 13

Z-Sus board Removal ................................... 13

Main board Removal .................................... 13

Control Button Board Removal ................... 13

X-Drive boards Removal .............................. 13

TCP Connector Removal ............................. 15

P232 & P331 Connector Removal ............... 15

Control Button board removal .................... 16

42PG20 Exploded View ............................... 17

Block Diagram .............................................. 18

Signal and Voltage Block Diagram ................ 19

CIRCUIT DESCRIPTIONS ......................... 20

Introduction ................................................. 20

Adjustment Order **Important**................ 20

Power Supply (SMPS) ................................... 21

Y-Sus Board .................................................. 29

Y-Drive Board .............................................. 37

Z-Sus Board ................................................. 42

Control Board .............................................. 44

X-Drive Boards ............................................ 51

Left and Right X-Drive Removal .................. 55

Main (Digital) Board ..................................... 56

Power Switch and Keypad ........................... 61

DISASSEMBLY ........................................... 63

Introduction ................................................. 63

Back Cover Removal .................................... 63

Power Supply Board Removal ...................... 63

Y-Sus Board Removal ................................... 64

Top Y-Drive Board Removal ......................... 64

Bottom Y-Drive Board ................................. 64

Z-Sus Board Removal ................................... 65

Main Board Removal .................................... 65

Control Board Removal ............................... 65

X-Board Removal ......................................... 65

TCP connector removal ............................... 67

P232 & P331 connector removal ................. 67

50PG20 Exploded View ............................... 68

Block Diagram .............................................. 69

Signal and Voltage Block Diagram ................ 70

CIRCUIT DESCRIPTIONS ........................ 71

Introduction ................................................. 71

Adjustment Order **Important**................ 72

Power Supply ............................................... 72

Y-Sustain ....................................................... 82

Y-drive .......................................................... 88

Z-Sus Board ................................................. 93

Control Board .............................................. 97

X-Drive Boards .......................................... 102

Left and Right X-Drive Removal ................ 107

Main (Digital) Board ................................... 108

SCHEMATICS .......................................... 111

42PG20 :: Interconnect .............................. 111

42PG20 :: Waveforms ................................ 112

42PG20 :: Main Board :: Video & BCM ...... 113

42PG20 :: Main Board :: Control ............... 114

42PG20 :: Main Board :: DDR Memory ..... 115

42PG20 :: Main Board :: Tuner ................... 116

42PG20 :: Main Board :: Audio Processor . 117

42PG20 :: Main Board :: Power Regulator . 118

42PG20 :: Main Board :: Inputs .................. 119

42PG20 :: Main Board :: HDMI & USB ...... 120

42PG20 :: Power Supply :: PFC & MCU .... 121

42PG20 :: Power Supply :: Multi & Stby..... 122

42PG20 :: Power Supply :: VA & VA .......... 123

42PG20 :: Main Board :: PCB Layout ......... 124

42PG20 :: Main Board :: Bottom PCB ....... 125

42PG20 :: Sub Boards :: PCB Layout ......... 126

50PG20 :: Main Board :: Interconnect ....... 127

50PG20 :: Main Board :: Control ............... 128

50PG20 :: Main Board :: Video & BCM ...... 129

50PG20 :: Main Board :: Control ............... 130

50PG20 :: Main Board :: DDR Memory ..... 131

50PG20 :: Main Board :: Tuner ................... 132

50PG20 :: Main Board :: Audio Processor . 133

50PG20 :: Main Board :: Power Regulator . 134

50PG20 :: Main Board :: Interface .............. 135

50PG20 :: Main Board :: HDMI & USB ...... 136

50PG20 :: Main Board :: PCB Layout ......... 137

50PG20 :: Main Board :: Bottom PCB ....... 138

50PG20 :: Sub Boards :: PCB Layout ......... 139

PDP Training - Fall 2008 3

Page 5

OVERVIEW

OVERVIEW 2008 PDP

INTRODUCTION

This manual covers two models from the 2008 Plasma Display Panel (PDP) product line.

Each model is an HDTV with integrated HD tuner. All 2008 PDP models include USB Media

Host and SimpLink. USB Media Host consists of a USB port on the back of the TV that

supports USB flash memory drives loaded with media or firmware for the TV. SimpLink

allows for control of other LG SimpLink products via the HDMI connection.

All PDP TV models are covered by a one year parts and labor warranty. Refer to the last

page of the owner’s manual for more warranty information. When making a warranty repair

involving a service bulletin, be sure to refer to the service bulletin number in the warratny

claim.

BASIC TROUBLESHOOTING STEPS

Define - Look at the symptom carefully and determine what circuits could be causing the

failure. Use your senses Sight, Smell, Touch and Hearing. Look for burned parts and

check for possible overheated components. Capacitors will sometimes leak dielectric

material and give off a distinct odor. The frequency of power supplies will change with

the load, or listen for a relay closing, etc. Observation of the front Power LED may

give some clues.

Localize - Carefully check the symptom and determining the circuits to be checked. After

giving a thorough examination using your senses, check the DC Supply Voltages to

those circuits under test. Always confirm the supplies are not only the proper level,

but are noise free. If the supplies are missing check the resistance for possible short

circuits.

Isolate - To further isolate the failure, check for the proper waveforms with an Oscilloscope

to make a final determination of the failure. Look for correct Amplitude Phasing and

Timing of the signals. Also check for the proper Duty Cycle of the signals. Sometimes

“glitches” or “road bumps” will be an indication of an imminent failure.

Correct - The final step is to correct the problem. Be careful of static sensitive components

and make sure to check the DC Supplies for proper levels. Make all necessary

adjustments. Lastly, always perform a Safety AC Leakage Test before returning the

product back to the Customer.

CAUTION

1) A (approximately) 10 minute pre-run time is required before any adjustments are

performed.

PDP Training - Fall 2008 5

Page 6

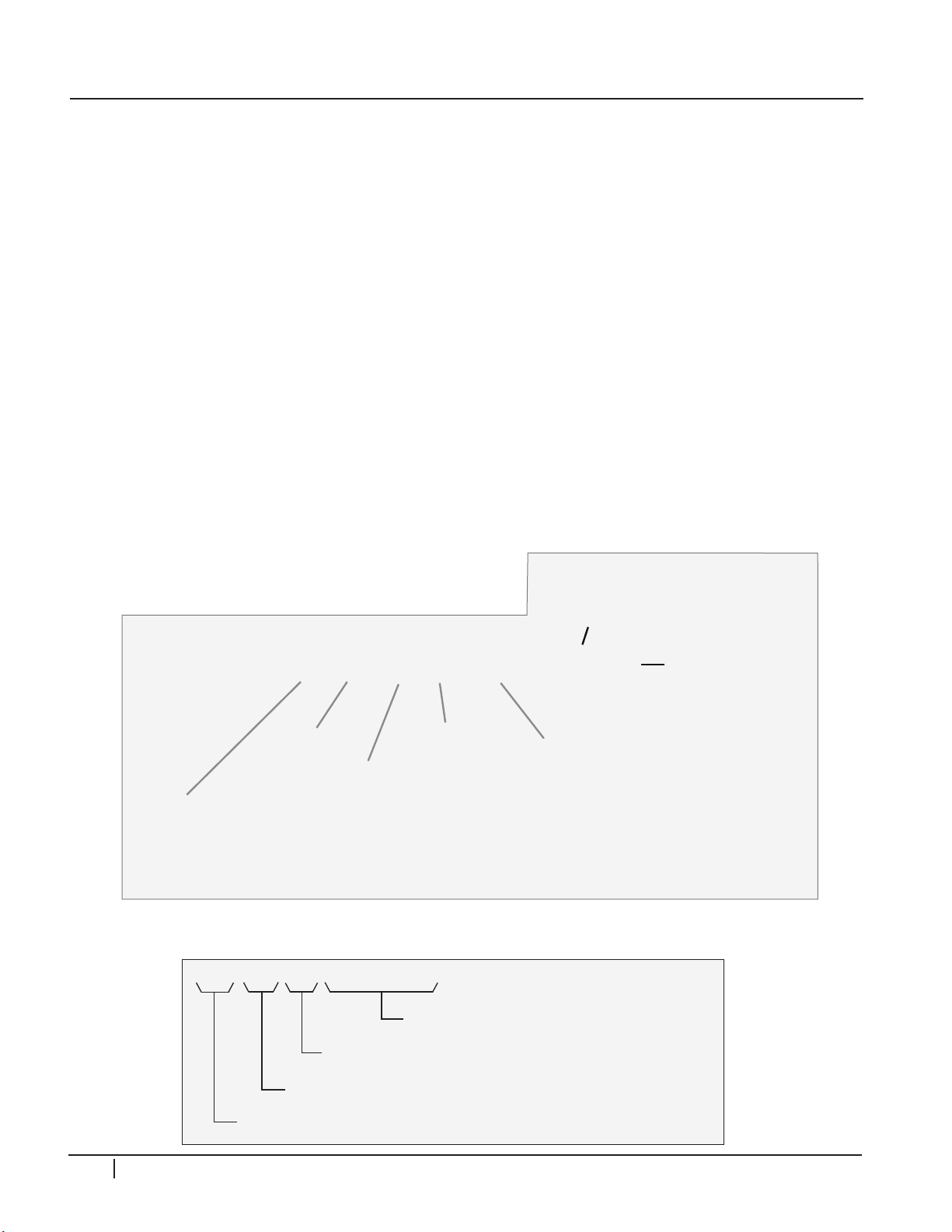

OVERVIEW

403 MX XQ

0 5 1 0 6

Sequential Number (5-7 Numbers)

Production Info (2 Letters)

Production Site (2 Letters)

Production Year and Month (3 Numbers). Ex, March 2004.

2) Refer to the Voltage Sticker inside the panel when making adjustments on the Power

Supply, Y-Sus and Z-Sus boards and adjust to the specified voltage level (±1/2 V).

3) The PDP module uses high voltage, be cautious of electric shock from the PDP

module. Before circuit board removal, check that the Power Supply and drive circuits

are completely discharged because of residual current stored.

4) C-MOS circuits are used extensively for processing the Drive Signals and should be

protected from static electricity.

5) The Plasma television and/or PDP Module must be carried/transported vertical, not

horizontal. (If laying down on its face, foam padding is a must).

6) Exercise care when making voltage and waveform checks to prevent costly short circuits

from damaging the unit.

7) Be cautious of loose screws and other metal objects to prevent a possible short in the

circuitry.

8) New panels and frames are much thinner than previous models. Be Careful with flexing

these panels. Be careful with lifting panels from a horizontal position. Damage to the

Frame mounts or panel can occur.

MODEL NUMBER STRUCTURE

42 P G 2 0 - U A

Screen Size

Display Type

Brand

Z= Zenith

Blank = LG

SERIAL NUMBER STRUCTURE

P = Plasma

L = LCD

D = DLP RPTV

J = Projector

Year

G = 2008

Region

U = North America

B = Europe & NA

Chassis Version

Series/Feature Level

20/25 = 720p HDTV

30 = Full HD

60 = Full HD & THX

6 PDP Training - Fall 2008

Page 7

INPUT

FAV

MUTE

TV

STB

POWER

Q. MENU MENU

AV MODERETURN

ENTER

VOL

CH

1 2 3

4 5 6

7 8

0

9

FLASHBK

P

A

G

E

DVD

VCR

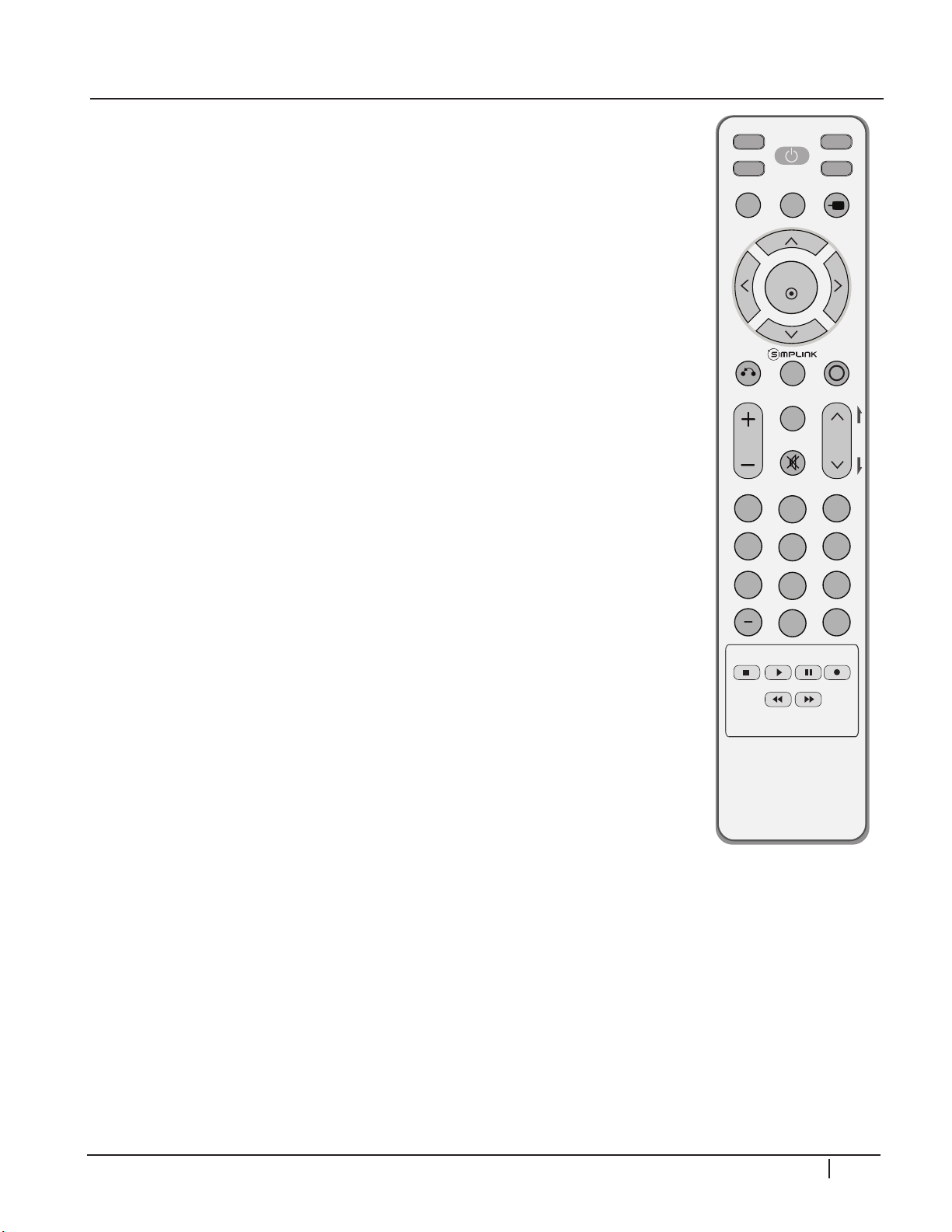

REMOTE CONTROL

2008 models feature a newly designed, easier to use remote. The remote

has fewer buttons than previous designs which was accomplished by

moving many functions to an on-screen Quick Menu. The “Q. MENU”

button on the remote opens the Quick Menu and the user can choose

between options like aspect ratio, closed captions, sleep timer, etc.

The remotes are programmable for other devices. They also support

SimpLink devices. When using SimpLink, the device buttons on the

remote do not need to be pressed to switch modes before controlling

external equipment. So, the External devices are controlled by the TV

instead of the remote.

NEW FEATURES

Below are some of the new features on some 2008 PDP TVs.

FluidMotion (180Hz Effect) - Enjoy smoother, clearer motion with all

types of programming such as sports and action movies. The moving

picture resolution give the impression of performance of up to 3x

the panels actual refresh rate.

OVERVIEW

Full HD 1080p Resolution - Displays HDTV programs in full 1920 x

1080p resolution for a more detailed picture. Standard HD PDPs

are 1365 x 768p.

Expert Menu - Expert Menu features Imaging Science Foundation

Certified Calibration Controls (ISFccc) which allow precise in-home

picture calibrations.

Public Display Mode - This is an additional menu with advanced startup

options like startup volume, start channel, etc. This can be accessed

by holding the Menu key until it vanishes. Then key in 1, 1, 0, 5,

and press enter.

PDP Training - Fall 2008 7

Page 8

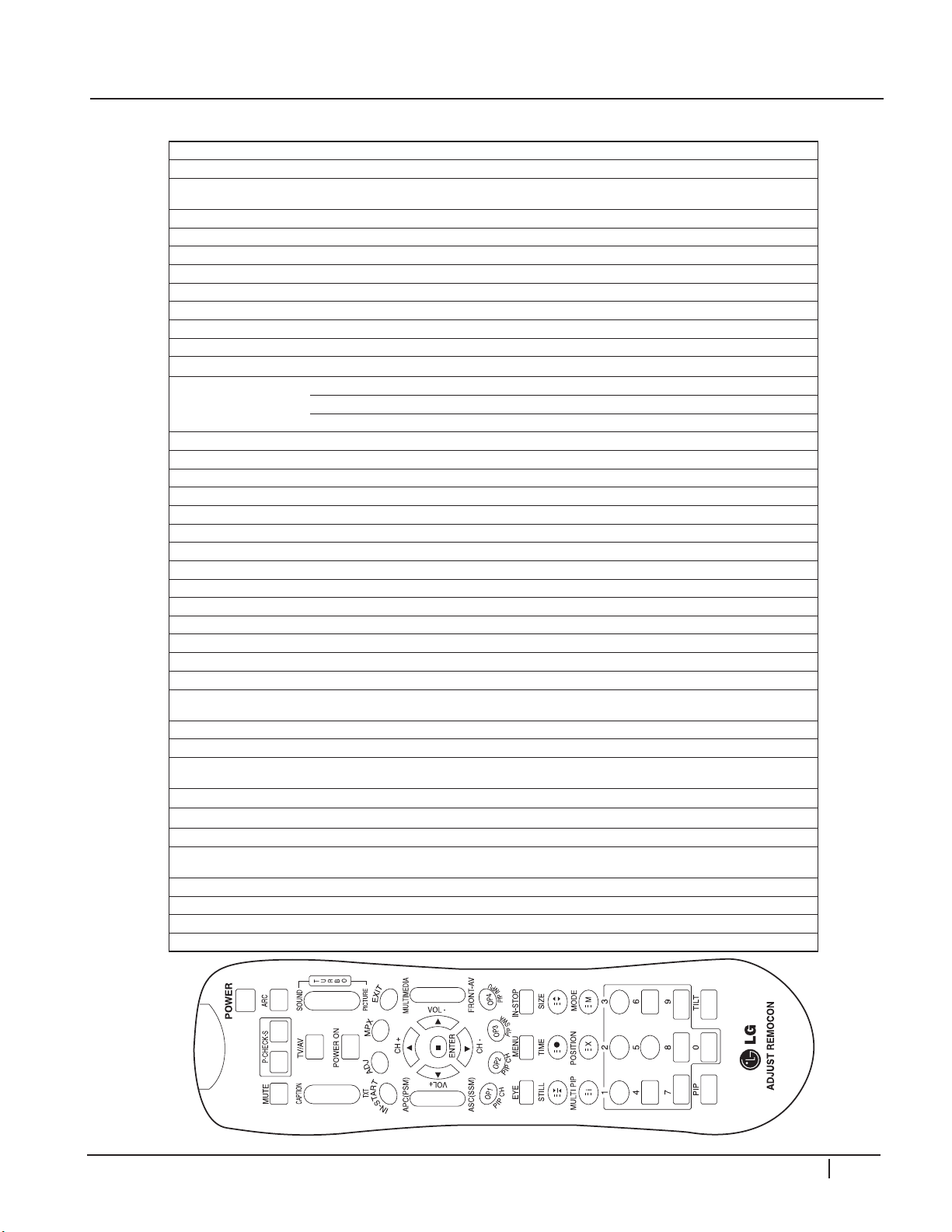

SERVICE REMOTE

NUM KEY FUNCTION

1 POWER To turn the TV on or off

2 POWER ON To turn the TV on automatically if the power is supplied to the TV. Use the POWER key to deactivate; It

3 MUTE To activate the mute function.

4 P-CHECK To check TV screen image easily.

5 S-CHECK To check TV screen sound easily

6 ARC To select size of the main screen (Normal, Spectacle, Wide or Zoom)

7 CAPTION Switch to closed caption broadcasting

8 TXT To toggle on/off the teletext mode

9 TV/AV To select an external input for the TV screen

10 TURBO SOUND To start turbo sound

11 TURBO PICTURE To start turbo picture

12 IN-START To enter adjustment mode when manufacturing the TV sets.

13 ADJ To enter into the adjustment mode. To adjust horizontal line and sub-brightness.

14 MPX To select the multiple sound mode (Mono, Stereo or Foreign language).

15 EXIT To release the adjustment mode.

16 APC(PSM) To easily adjust the screen according to surrounding brightness.

17 ASC(SSM) To easily adjust sound according to the program type.

18 MULTIMIDIA To check component input.

19 FRONT-AV To check the front AV.

20 CH To move channel up/down or to select a function displayed on the screen.

21 VOL To adjust the volume or accurately control a specic function.

22 ENTER To set a specic function or complete setting.

23 PIP CH-(OP1) To move the channel down in the PIP screen. To use as a red key in the teletext mode.

24 PIP CH+(OP2) To move the channel in the PIP screen. To use as a green key in the teletext mode.

25 PIP SWAP(OP3) To switch between the main and sub screens. To use as a yellow key in the teletext mode.

26 PIP INPUT(OP4) To select the input status in the PIP screen. To use as a blue key in the teletext mode.

27 EYE To set a function that will automatically adjust screen status to match. The surrounding brightness so natural

28 MENU To select the functions such as video, voice, function or channel.

29 IN-STOP To set the delivery condition status after manufacturing the TV set.

30 STILL To halt the main screen in the normal mode, or the sub screen at the PIP screen. Used as a hold key in the

31 TIME Displays the teletext time in the normal mode. Enables to select the sub code in the teletext mode.

32 SIZE Used as the size key in the PIP screen in the normal mode. Used as the size key in the teletext mode.

33 MULTI PIP Used as the index key in the teletext mode. Top index will be displayed if it is the top text.

34 POSITION To select the position of the PIP screen in the normal mode. Used as the update key in the teletext mode

35 MODE Used as Mode in the teletext mode.

36 PIP To select the simultaneous screen.

37 TILT To adjust screen tilt.

38 0~9 To manually select the channel.

OVERVIEW

should be deactivated when delivered.

To adjust the screen voltage (automatic): In-start mute Adjust AV (Enter into W/B adjustment mode).

W/B adjustment (automatic): After adjusting the screen W/B adjustment Exit two times

color can be displayed.

teletext mode. Page updating is stopped.

(Text will be displayed if the current page is updated.)

PDP Training - Fall 2008 9

Page 9

OVERVIEW

LP81A LPL L42FHD

Main V1.62 USB V2.14

00 HDCP 0

UTT 97

Tool Option1 39848

Tool Option2 51

Area Option 1

OPTION1 43

OPTION2 46

OPTION3 0

OPTION4 0

System Control

Audio Prescale

Threshold

Power Off History

Panel Control

Davinci / Auto Test

LP81A LPL L42FHD

Main V1.62 USB V2.14

00 HDCP 0

UTT 97

Tool Option1 39848

Tool Option2 51

Area Option 1

OPTION1 43

OPTION2 46

OPTION3 0

OPTION4 0

System Control

Audio Prescale

Threshold

Power Off History

Panel Control

Davinci / Auto Test

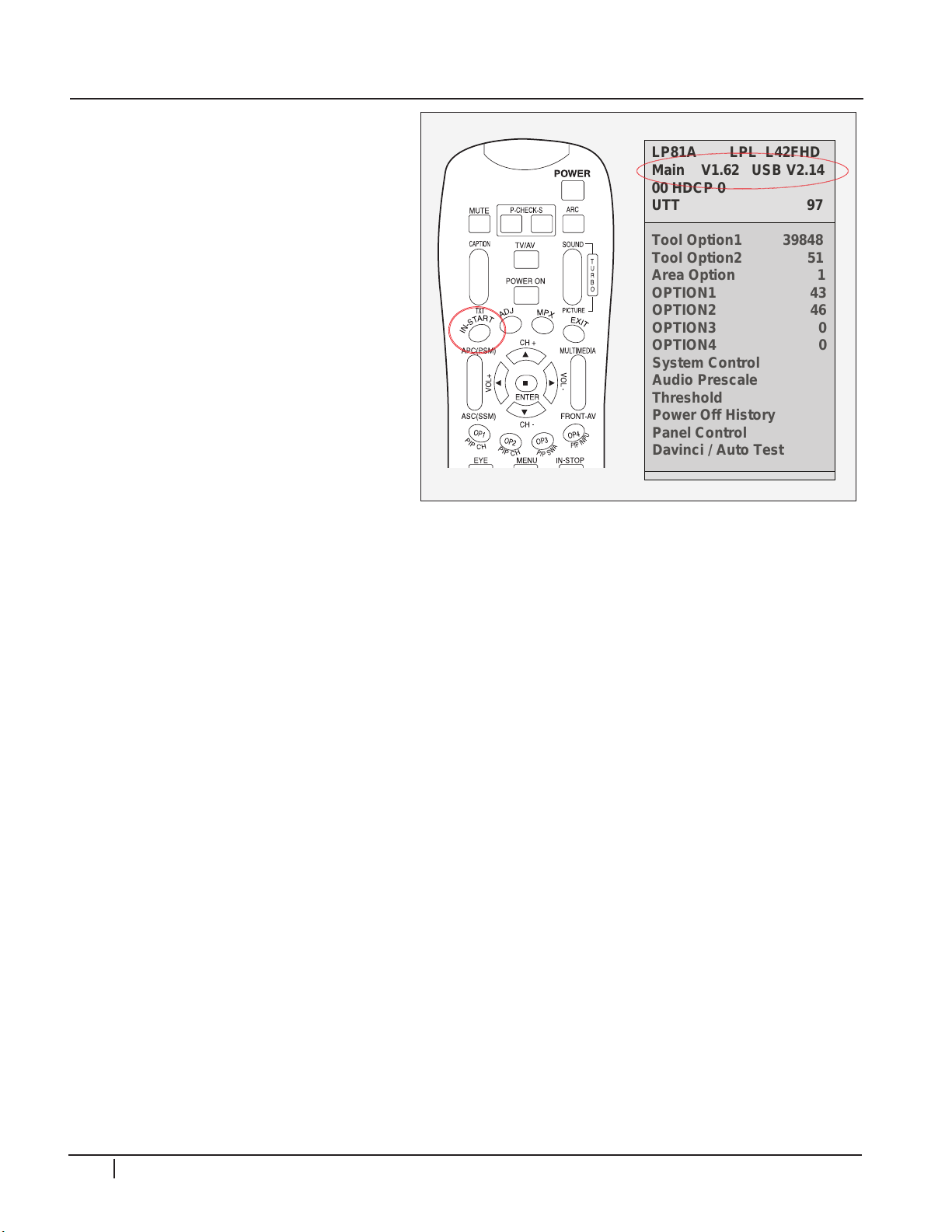

CHECK FIRMWARE VERSION

You can check the firmware version by

opening the service menu. It is located

near the top of the menu.

UPDATE FIRMWARE

1) Copy the firmware to the top

level on a USB flash drive and to

a folder named LG_DTV. Some

models require the LG_DTV

folder, and some don’t. Put it in

both locations if you are not sure

which is correct. Only copy the

file (or files) for the model you are

currently updating.

2) Turn on the TV and insert the USB

drive to the USB IN port.

3) If the firmware is newer than what is already installed, the upgrade menu should open

automatically. If the update menu doesn’t open, press MENU on the remote and select

OPTION. Now press the 7 key 7 times and the upgrade menu will open.

4) Select START and press ENTER on the remote to start the software upgrade.

5) The TV will copy the update from the drive and then install it. Do not turn the TV off

until it is finished.

6) The TV will automatically turn off and back on after the upgrade is successfully

finished.

7) Check the firmware version to verify the update was succesful.

10 PDP Training - Fall 2008

Page 10

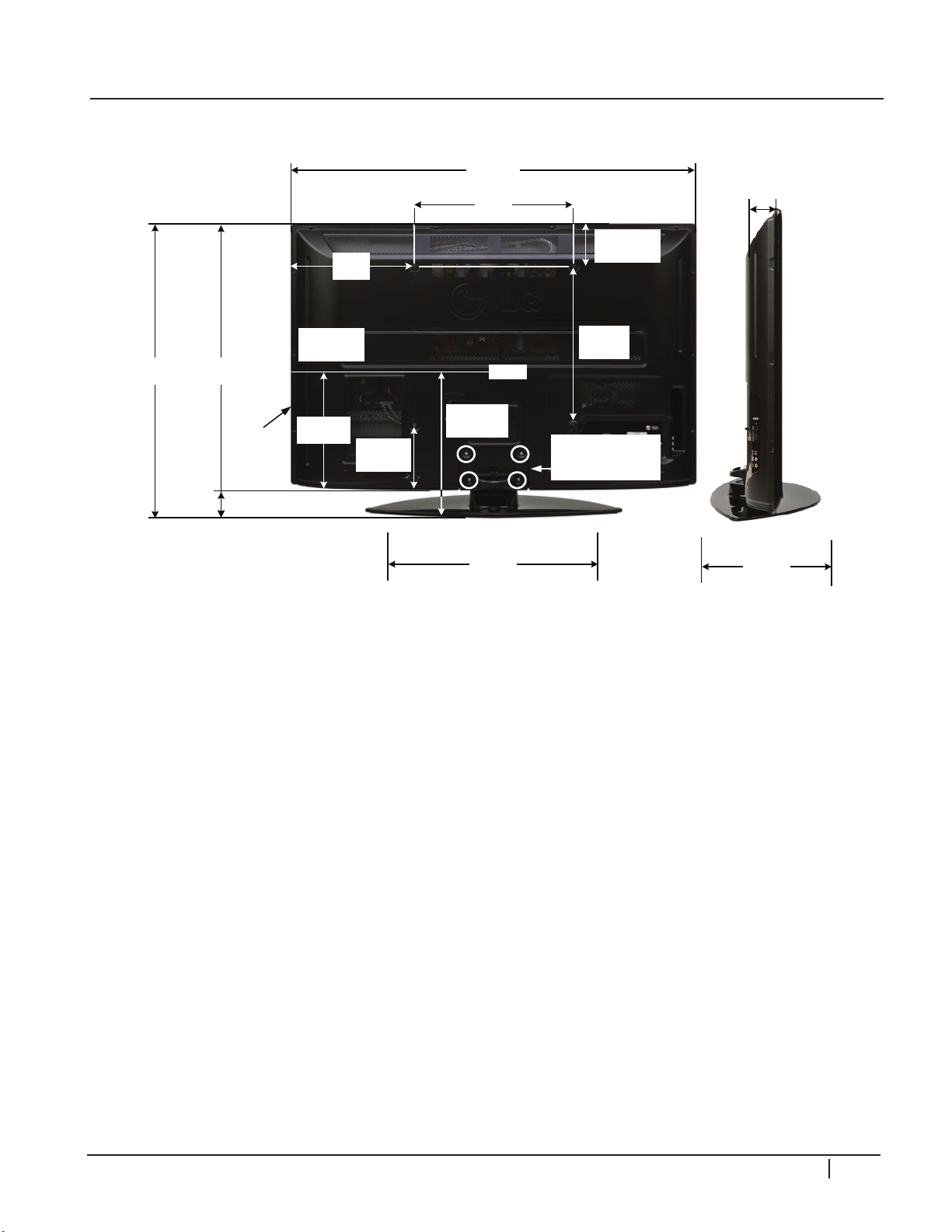

15.8"

400mm

26.7"

678.2mm

6.2"

158mm

40.9"

1038.9mm

28.8"

731.5mm

28.8"

731.5mm

3.4"

86.4mm

12.1"

307.3mm

Center

15.8"

400mm

6.6"

168.78mm

1.93"

49mm

Remove 4 screws to

remove stand for

wall mount

Model No.

Serial No.

Label

15.55"

394.95mm

12.4"

315mm

4.72"

120mm

17.48"

443.95mm

42PG20 DIMENSIONS

DISASSEMBLY

4

2

P

G

2

0

PDP Training - Fall 2008 11

Page 11

OVERVIEW

COMPUTER CONNECTION

A computer can be connected to the RGB (VGA)

or HDMI connection on the TV. The HDMI

connection will require a DVI to HDMI adapter

if the PC has a DVI connector.

Set the monitor output resolution and vertical

frequency on the PC before connecting it to

the TV. Refer to the owner’s manual for a full

list of suported resolutions, some examples are

listed below. The message “OUT OF RANGE”

will appear on the screen if the resoultion is not

supported.

Resolution Vertical

30/40/50/60/70 series

1280x768 60Hz

1360x768 60Hz

1366x768 60Hz

50/60/70 series only

1600x1200 60Hz

1920x1080 60Hz

SERVICE MENU

The service menus can be used to make

adjustments, change color alignment, and get

software versions. There are two service menus.

The Adjust and Instart menu can be accessed

using the service remote (Service remotes are

available from LG parts). They can also be

accesed by holding down the menu button on

the TV and the remote until the user menu

disappears. The menus alternate between Adjust

and Instart every time the menu button is held

down. If the TV asks for a password, enter 0000

(four zeros).

POWER CONSUMPTION

Model

19LS4D-UA 42W 0.85 1W

20LS7D-NB 56W 0.85 1W

20LS7D-UK 56W 0.85 1W

22LC2D-UB 46W 0.85 1W

22LS4D-UA 46W 0.85 1W

23LS7D-NB 78W 0.85 1W

23LS7D-UK 78W 0.85 1W

26LC7DC-UB 110 160W 0.7 1W

26LC7DC-UK 30 160W 0.7 1W

26LC7D-UK 30 160W 0.7 1W

26LG30DC-UA 99 115W 0.36 0.8W

32LC4D-UA 150 190W 0.7 1W

32LC50C-UA 190W 3W

32LC5DC-UA 190W 3W

32LC7DC-UK 170 190W 0.7 1W

32LC7D-UB 150 190W 0.7 1W

32LC7D-UK 170 190W 0.7 1W

32LG30DC-UA 149 171W 0.36 0.8W

32LX50C-UA 190W 3W

32LX5DC-UA 190W 3W

37LC50C-UA 210W 3W

37LC5DC-UA 210W 3W

37LC7DC-UK 190 220W 0.8 1W

37LC7D-UB 180 220W 0.8 1W

37LC7D-UK 190 220W 0.8 1W

37LG30DC-UA 167 191W 0.36 0.8W

42LB50C-UA 240W 3W

42LB5DC-UA 240W 3W

42LC4D-UA 230 240W 0.8 1W

42LC50C-UA 240W 3W

42LC5DC-UA 240W 3W

42LC7DC-UK 220 240W 0.8 1W

42LC7D-UB 230 240W 0.8 1W

42LC7D-UK 220 240W 0.8 1W

42LG30DC-UA 226 244W 0.36 0.8W

TYP MAX UNIT TYP MAX UNIT

8 PDP Training - Fall 2008

Page 12

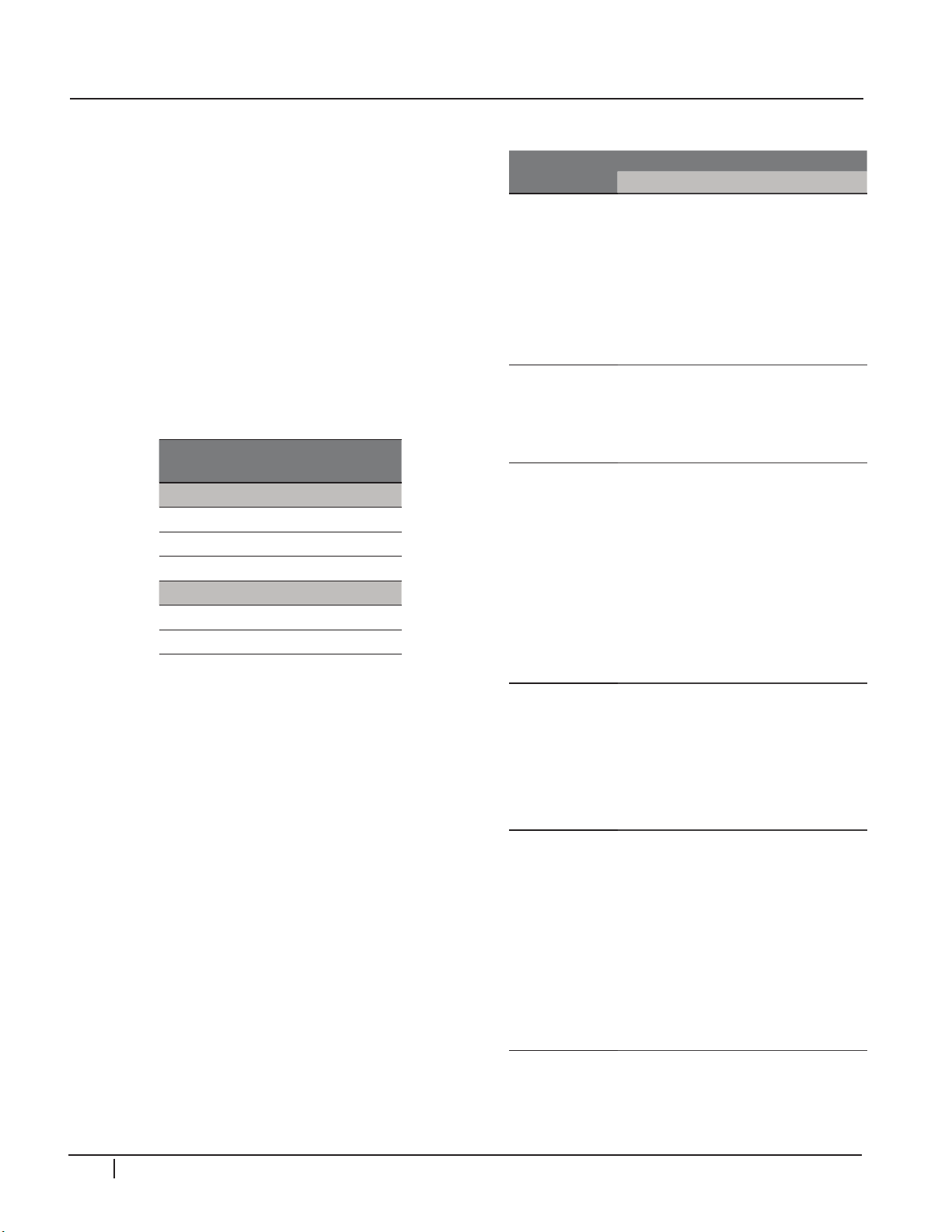

DISASSEMBLY

Y-sus & Z-Sus Drive

Control (Logic)

Y-Drive

Voltage Label

Main (Digital)

Panel ID

Power Supply

Z-Sus

Right X-Board

Left X-Board

Side Input

DISASSEMBLY 42PG20

INTRODUCTION

4

2

P

G

2

0

This section of the manual will discuss disassembly of the 42PG20 PDP Direct View

Television. Upon completion of this section the Technician will have a better understanding

of the disassembly procedures, the layout of the printed circuit boards, and be able to

identify each board. The plugs listed are from left to right Pin 1,2, 3, etc. Remember to

be cautious of ESD as many semiconductors are CMOS and prone to static failure.

BACK COVER REMOVAL

Remove the 22 screws shown. Pay attention to the size and type of screw as there are

different types. Putting in the improper screw when reassembling may cause damage. The

stand does not need to be removed when removing the back.

BOARD LAYOUT

12 PDP Training - Fall 2008

Page 13

DISASSEMBLY

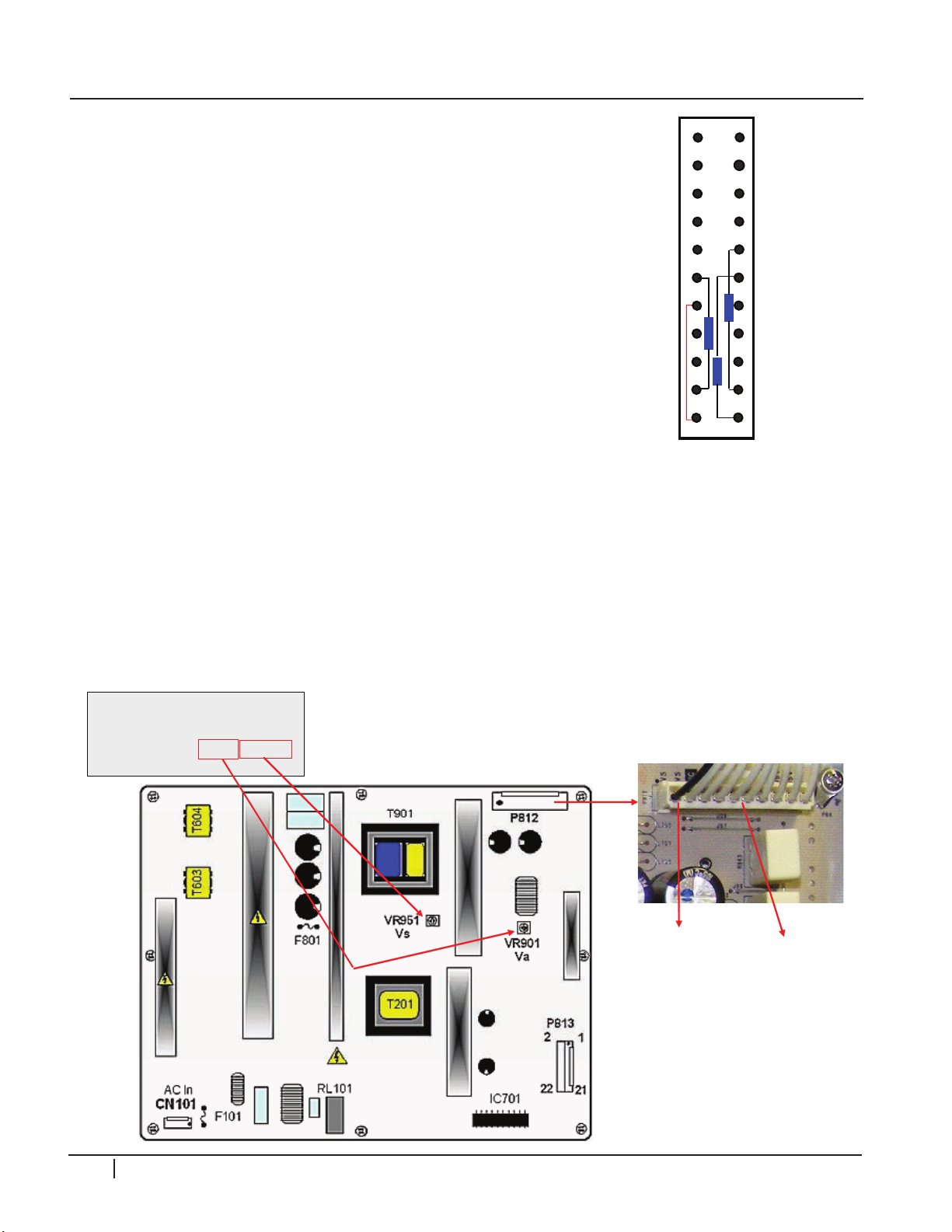

SWITCH MODE POWER SUPPLY REMOVAL

Disconnect the following connectors: P812, P813, CN101. Remove the 8 screws holding the

board in place. Remove the board. When replacing, be sure to readjust the Va/Vs voltages

in accordance with the Panel Label. Confirm VSC, -Vy and Zbias as well.

Y-SUS BOARD REMOVAL

4

Disconnect the following connectors: P201, P801, P101, P202. Remove the 8 screws

holding the board in place. Remove the board. When replacing, be sure to readjust the

Va/Vs voltages in accordance with the Panel Label. Confirm VSC, -Vy and Zbias as well.

Y-DRIVE BOARD REMOVAL

Disconnect the following Flexible Ribbon Connectors: P1, P2, P3, P4, P5, P6, P7 and

P8. Disconnect the following connectors: P201, P801, P101, P202. Remove the 3 screws

holding the board in place. Remove the board by lifting slightly and sliding the board to

the left unseating P204 and P200. from the Y-Sus board.

Z-SUS BOARD REMOVAL

Remove the support frame holding the Main board. Disconnect the following connectors:

P1, P2 and P3. Remove the 3 screws holding the board in place. Remove the board. When

replacing, be sure to readjust the Va/Vs voltages in accordance with the Panel Label.

Confirm VSC, -Vy and Zbias as well.

MAIN BOARD REMOVAL

Disconnect the following connectors: P701, P302, P303 and JK501. Remove the 2 screws

holding on the decorative plastic piece on the right side. Remove the 4 screws holding

the board in place. Remove the board.

2

P

G

2

0

CONTROL BUTTON BOARD REMOVAL

Disconnect the following connectors: P121, P160, P161 and P162. Remove the 2 screws

holding the board in place. Remove the board. (Note: Power board is behind the Control

board. Remove it’s 2 screws and remove.

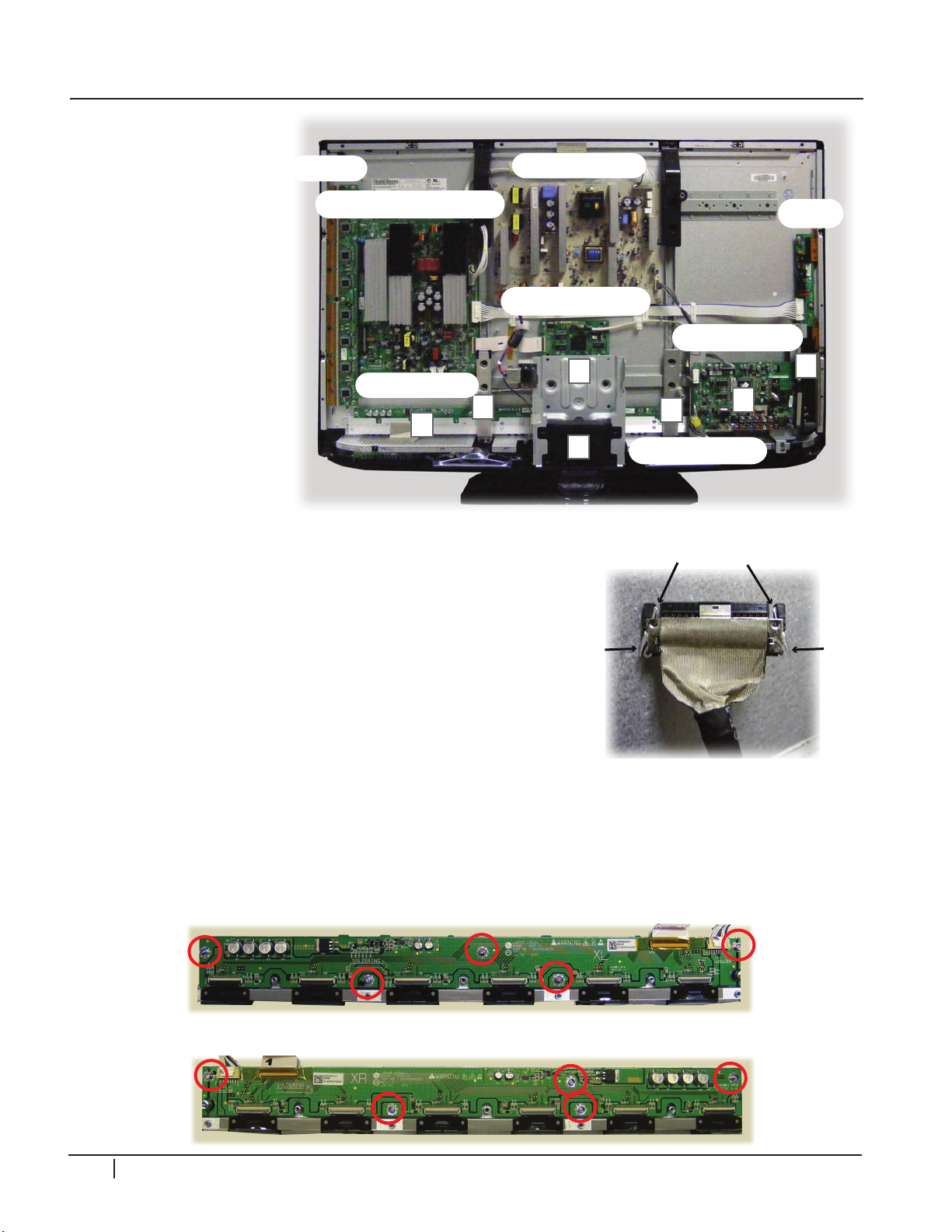

X-DRIVE BOARDS REMOVAL

X-Board Removal will require the most disassembly of all the boards. All the Brackets

and Assemblies marked A-F (Image on next page) will need to be removed including the

Stand. Before an X-Board can be removed. The Heat Sink assembly will also need to be

removed.

Lay the Plasma down carefully on a padded surface. Make sure AC is removed and remove

the back cover and the stand. Carefully remove the LVDS Cable P121 from the Control

board by pressing the Locking Tabs together and pull the connector straight back to

remove the cable. (This prevents damage).

PDP Training - Fall 2008 13

Page 14

DISASSEMBLY

Y-sus & Z-Sus Drive

Control (Logic)

Y-Drive

Main (Digital)

Power Supply

Z-Sus

Right X-Board

Left X-Board

A

F

B

E

E

C

D

A

Locking Tabs

Press In

Press In

Left X-Board

Right X-Board

A) Remove the sStand

mounting support

plastic piece.

4

2

P

G

2

0

B) Remove the stand

m et a l s up p o r t

bracket, unplug AC

ground lug.

C) Remove the 2 screws

from the decorative

black plastic piece

around side input

jacks (Marked B)

and remove.

D) R em ov e t h e 2

screws at the top

of the Main board

Mounting Bracket and peel the tape from the

bottom. Remove connectors P303 and JK501.

Carefully reposition the main board and mounting

bracket up and off to the right side.

E) Remove the metal support brackets marked “E”.

F) Remove the 13 screws holding the heat sink and

carefully lift it straight up and off (remember that

the TCP IC’s are located under the heat sink).

Disconnect all TCP ribbon cables from the defective

X-Drive board and remove the 5 screws holding

the board in place. Reassemble in the reverse order.

Recheck Va/Vs/V-Scan/-VY/Z-Drive.

14 PDP Training - Fall 2008

Page 15

DISASSEMBLY

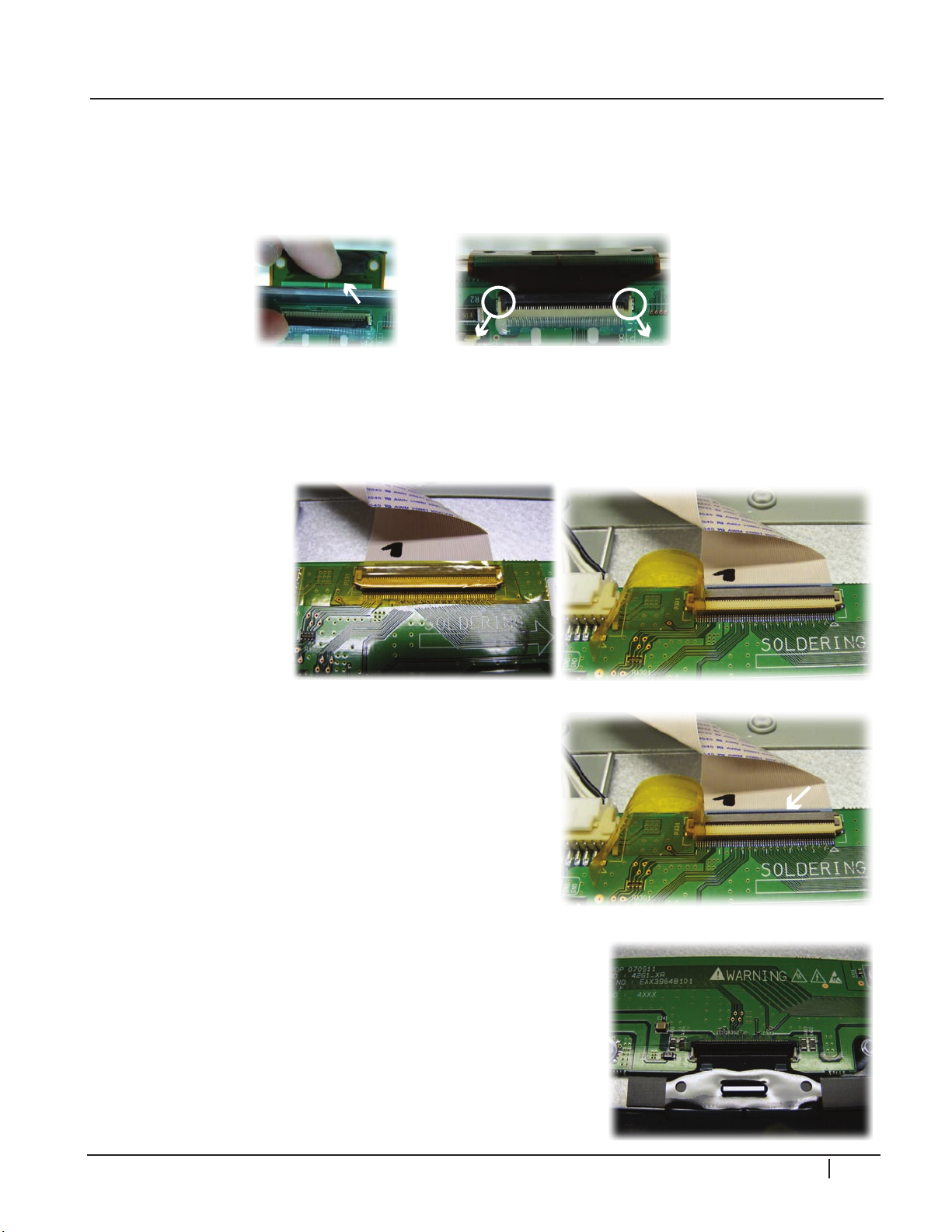

TCP CONNECTOR REMOVAL

Lift up the lock as shown by arrows. (The Lock can be easily broken. It needs to be handled

carefully.) Pull TCP apart as shown by the arrows. The TCP Film can be easily damaged,

handle with care.

P232 & P331 CONNECTOR REMOVAL

The X-Drive boards can be removed after removing the back cover, the main board, and

the heat sink covering the TCPs is removed (15 screws).

Peel the tape off

the connectors and

gently pry the locking

mechanism upward.

4

2

P

G

2

0

Gently pry the locking mechanism upward on all TCP

connectors P201-206 or P301-306.

Carefully lift the TCP ribbon up and off the cushion and

out of the way.

PDP Training - Fall 2008 15

Page 16

4

2

P

G

2

DISASSEMBLY

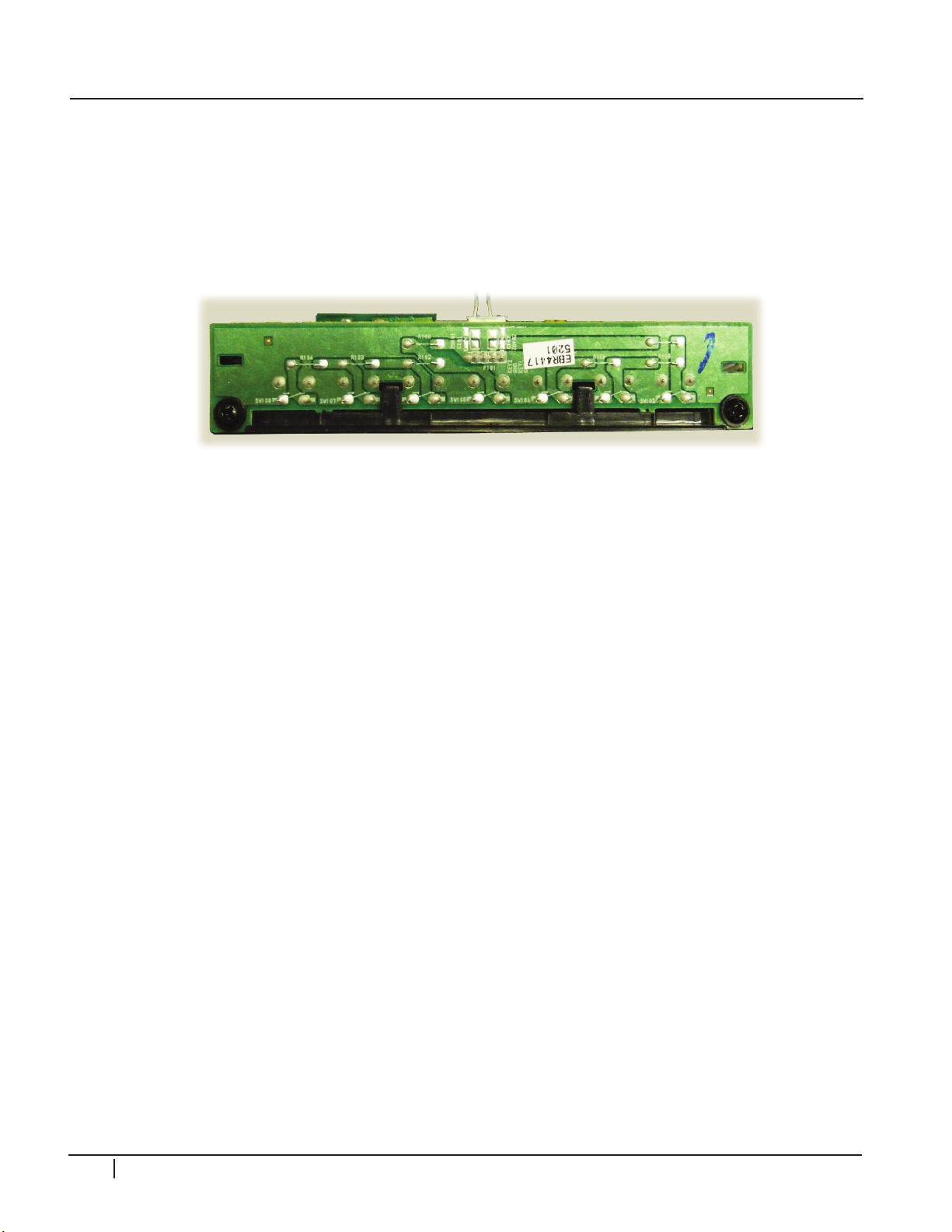

CONTROL BUTTON BOARD REMOVAL

The control button board and power switch board are located in the lower left hand section

(as viewed from the rear).

To remove, unplug the connector P101 and remove the 2 screws. Under each screw there

is a black tab. Release these tabs to lift the board upward. Then remove the connector

from the power switch board and remove it’s two screws.

0

16 PDP Training - Fall 2008

Page 17

300

305

400

203

205

202

240

204

302

200

206

250

201

303

304

306

900

580

560

571

120

561

570

301

260

590

501

270

603

520

602

601

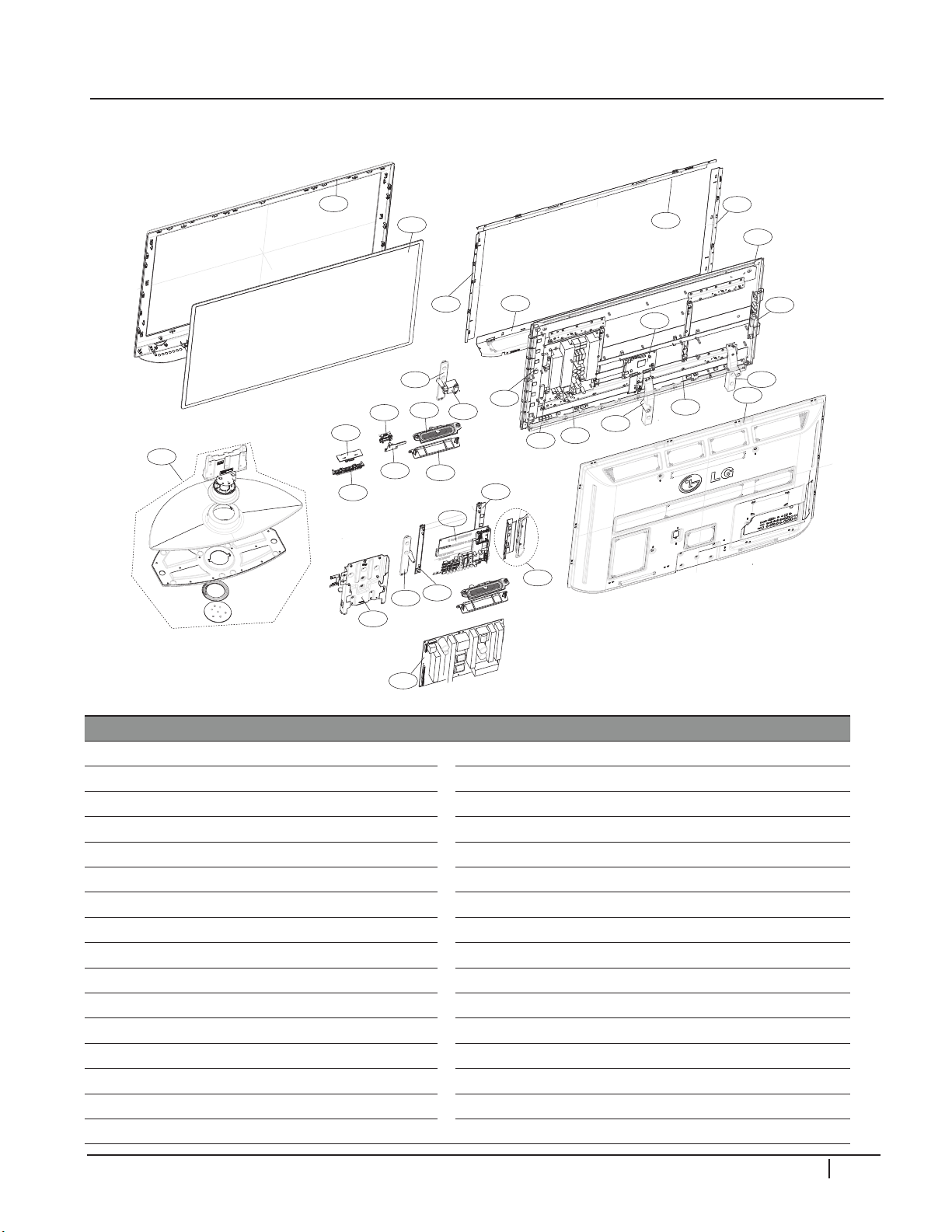

42PG20 EXPLODED VIEW

DISASSEMBLY

4

2

P

G

2

Part numbers subject to change.

Check GCSC (aic.lgservice.com) for

the current part numbers.

Location Part Num Description Location Part Num Description

120 EAB42609901

200 EAJ41970710

201 EBR39594901

202 EBR39712601

203 EBR39595001

204 EBR39595101

205 EBR39706801

206 EBR41668901

240 AJJ35680107

250 AJJ35680108

260 AJJ35680203

270 AJJ35680204

300 ABJ35121812 Front Cabinet 601 ABA35619217

301 ABA36825001 Speaker Bracket Assembly 602 MGJ41163807

302 AJJ35122402

303 AJJ35122502

Full Range Speaker

PDP Panel (PDP Module)

Control board (CTRL)

Y-drive (YDRV)

Left X-Drive (XRLB)

Right X-Drive (XRRB)

Y-Sustain (YSUS)

Z-Sustain (ZSUS)

Top Right Support

Top Left Support

Bottom Right Support

Bottom Left Support

Top Filter Support

Bottom Filter Support

304 AJJ35122602

305 MDJ42350902

306 AJJ35122702 Left Supporter Assembly

400 ACQ35123228 Rear Cover Assembly

501 MGJ41164512 Main Supporter Plate

520 EBR43929102 Hand Insert PCB Assembly,Main

560 EBR43385504

560 EBR48957101

561 MBG41119902

570 EBR44168002

571 ABA36967703 Bracket Assembly

580 EAY43533901

603 MGJ40268206 Side AV Shield

900 AAN35132205

Right Filter Support

Glass Filter

Main/Digital PCB

Sub PCB

Control Buttons

Sub PCB

Power Supply (SMPS)

Side Input Bracket Assembly

Main board Supporter

Stand (Base Assembly)

0

PDP Training - Fall 2008 17

Page 18

4

2

P

G

2

CIRCUIT DESCRIPTIONS

BLOCK DIAGRAM

0

18 PDP Training - Fall 2008

Page 19

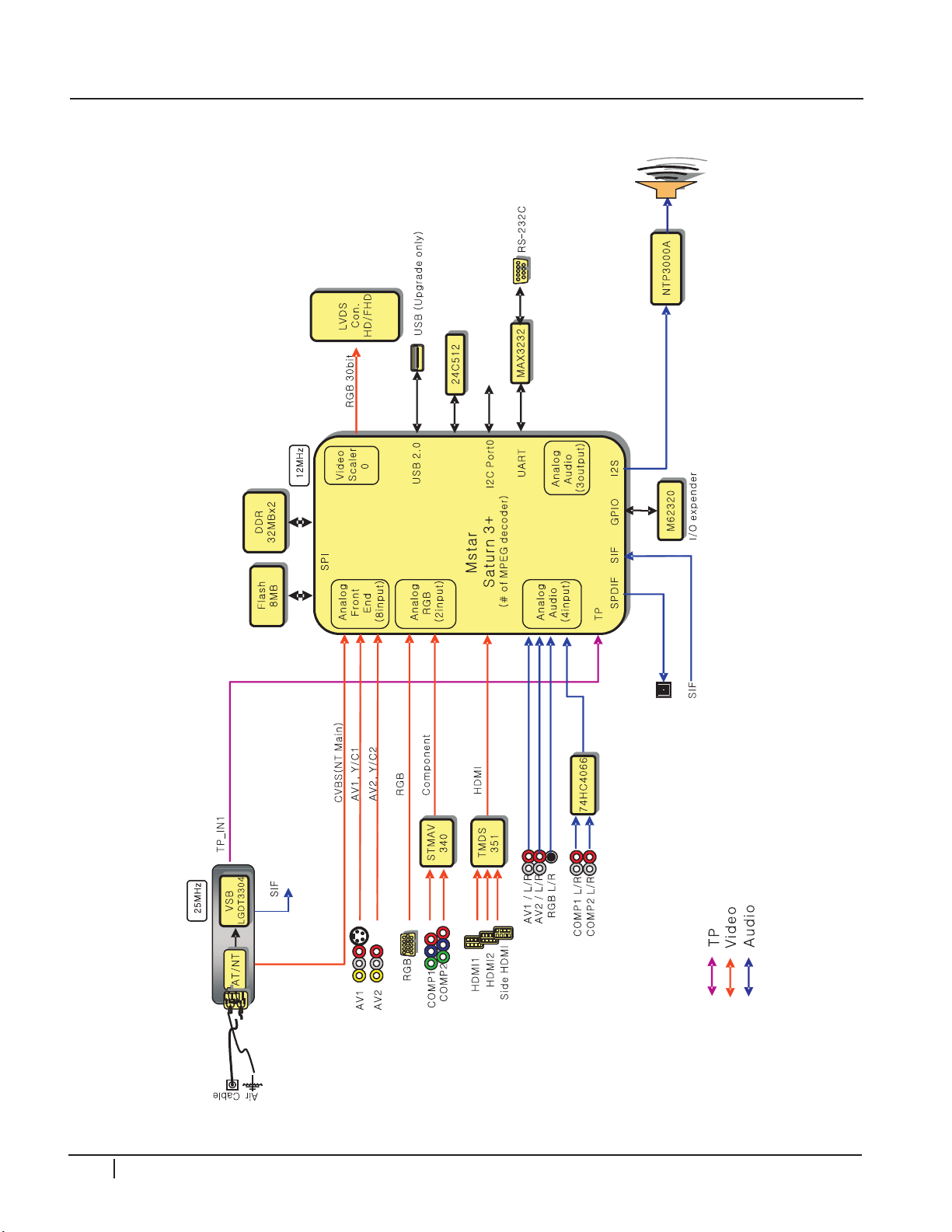

SIGNAL AND VOLTAGE BLOCK DIAGRAM

42PG20 SIGNAL and VOLTAGE DISTRIBUTION DIAGRAM

Display Panel

Horizontal Address

P100

5V

Drive Signal

NEW

Y-SUS

PWB

With Z-Drive

P204

P201

P801

P211

P101

P202

Drive Data

Clock (i2c)

P200

M5V, Va, Vs

P812

P813

CN101

STB +5V, 16V, 5V

SMPS

Turn On

Commands

SMPS

PWB

AC

Input

Filter

NEW

P1

SMPS OUTPUT VOLTAGES

STB +5V, 16V, 5V

Z-SUS

Drive Signals

Logic Signals

P160

AC Voltage

Det

P701

P302

P303

JK501

MAIN

PWB

Speakers

Control

Keys

Power

Keys

X-PWB-Right

X-PWB-Left

P201 P202 P203 P204 P205 P206 P301 P302 P303 P304 P305 P306

RGB Logic Signals

15V, Va

RGB Logic Signals

3.3V

CONTROL

PWB

P162

LVDS

Y Drive PWB

Z SUS PWB

P161

P121

P1 P2 P3 P4 P5 P6 P7 P8

P2P3

Outputs Only

P232

P211 P311 P331

Display Panel Vertical Address

IR

Vs

Display Panel

Horizontal Address

5V

DISASSEMBLY

4

2

P

G

2

0

PDP Training - Fall 2008 19

Page 20

CIRCUIT DESCRIPTIONS

Remember, the Voltage Label MUST be followed,

it is specific to the panel’s needs.

All label references are from a specific panel.

They are not the same for every panel encountered.

-VY

Z_BIAS

Panel

“Rear View”

Manufacturer

Bar Code

Set-

Up

Ve

Vscan

CIRCUIT DESCRIPTIONS 42PG20

INTRODUCTION

4

2

P

G

2

0

It is critical that the DC Voltage adjustments be checked whenever troubleshooting a

problem. Especially when:

1) The SMPS (Switch Mode Power Supply), Y-Sus (Y-Sustain) or Z-Sus (Z-Sustain)

are replaced.

2) The panel is replaced, since the SMPS does not come with new panel.

3) A picture issue is encountered.

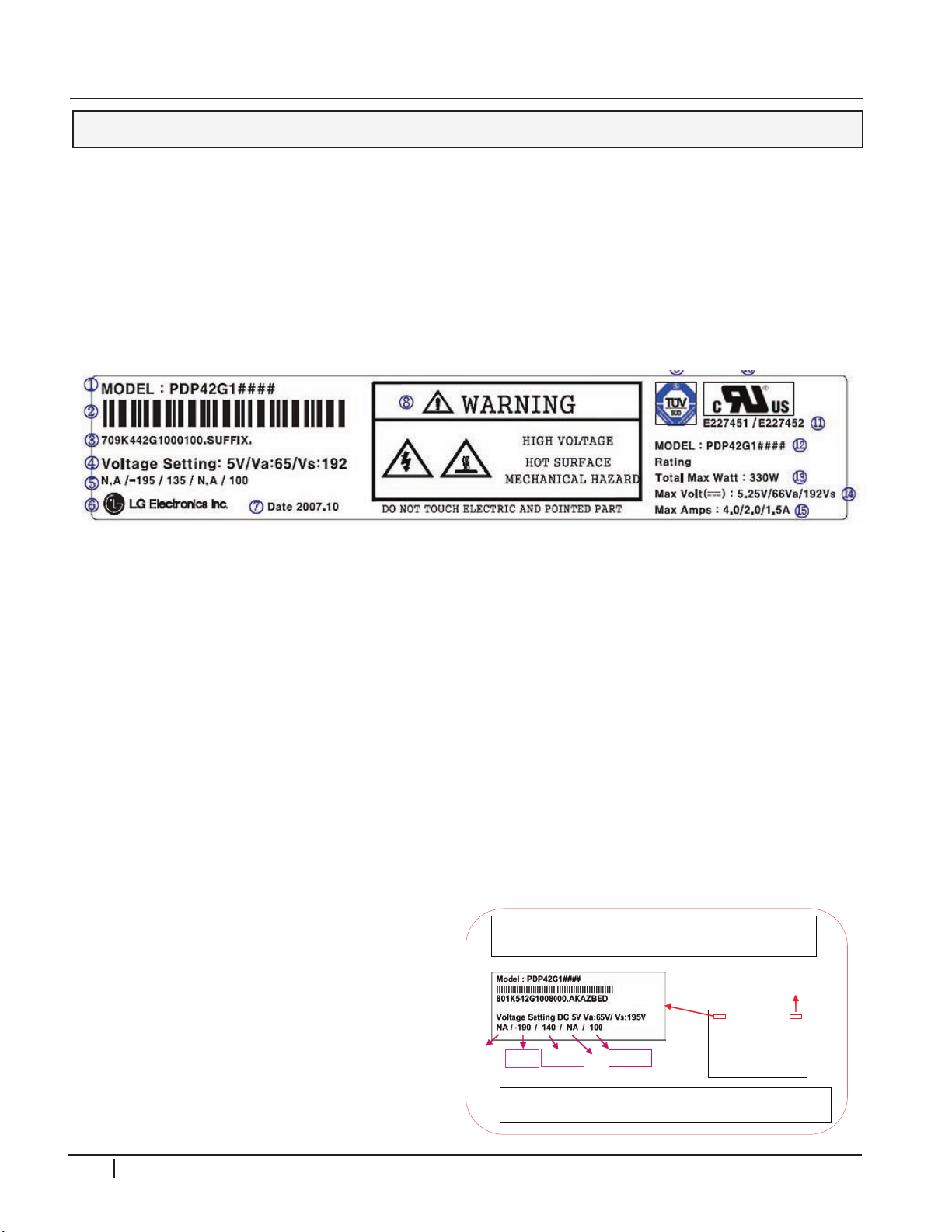

PANEl lAbEl

(1) Model Name

(2) Bar Code

(3) Manufacture No.

(9) TUV Approval Mark

(10) UL Approval Mark

(11) UL Approval No.

(4) Adjusting Voltage DC, Va, Vs

(5) Adjusting Voltage (Set Up/-Vy/Vsc/Ve/Vzb)

(6) Trade name of LG Electronics

(7) Manufactured date (Year/Month)

(8) Warning

ADJUSTMENT ORDER **IMPORTANT**

DC vOlTAGE ADJUSTMENTS

SMPS board: Va Vs (Do SMPS adjustments first)•

Y-Sus board: Adjust Vscan, -Vy•

Y-Sus board: Adjust Zbias •

WAvEFORM ADJUSTMENTS

Y-Sus board: Ramp Up, Ramp Down.

Only necessary when:

1) The Y-Sus board is replaced.

2) “Mal-Discharge” problems.

3) Abnormal picture issues.

20 PDP Training - Fall 2008

(12) Model Name

(13) Max. Watt (Full White)

(14) Max. Volts

(15) Max. Amps

Page 21

POWER SUPPLY (SMPS)

Hot Ground Symbol represents a SHOCK Hazard

F801

340V Fuse

10Amp/230V

F101

340V Fuse

10Amp/230V

P812

To Y/Z-Sus

Standby

Source

PFC

Circuit

CN 101

AC Input

VS Source

VA Source

IC701

Sub Micon

P813

To Main

VA VR901

380V Source

16V, 12V, 5V, 3.2V

Source

VS VR951

CIRCUIT DESCRIPTIONS

4

2

P

G

2

0

= Shock Hazard

PDP Training - Fall 2008 21

Page 22

4

2

CIRCUIT DESCRIPTIONS

SMPS Outputs

Board Voltage Description

VS Drives the display panel Horizontal Grid

Y-Sus

Main

VA Responsible for display panel Vertical Grid

M5V VCC

16V Audio B+ Supply

5V Control Circuits

Used to develop Bias Voltages on the Y-Sus,

X-Drive, and Control boards

Adjustments

Voltage Location

VA RV901

VS RV951

M5V VCC Fixed

P

G

2

0

POWER SUPPlY OPERATION

Refer to the figures on page 25-27. AC Voltage is supplied to the SMPS board at Connector

CN101 from the AC Input Filter. Standby 5V is developed from 340V source supply

(which during standby measures 159V hot ground). This supply is also used to generate

all other voltages on the SMPS.

The 5V (standby) voltage is routed to the Sub Micon circuit (IC701) on the SMPS and

through P813 to the Main board or Micon (IC100). LD703 will glow green to indicate

STBY 5V has arrived.

AC detect Pin 18 of P813 is generated on the SMPS by monitoring the AC input and

rectifying a small sample voltage. This AC Detect Voltage is routed to IC701 on the Sub

Micon on the SMPS and the Micon (IC100) located on the Main board. It is used as a

basic “SMPS OK” signal.

When the Micon (IC100) on the Main board receives an “ON“ command from either the

keyboard or the Remote IR Signal, it outputs a high to RL-ON. This signal first turns on

a DC level shifter Q706 which creates 5V General. LD703 now glows amber indicating

5V General has been generated. This 5V General now provides the pull up voltages that

supply the output circuits to the SMPS. The RL-ON enters the SMPS board at Pin 19 of

P813. The RL-ON Voltage is sensed by the Sub Micon (IC701) circuit which causes the

Relay Drive Circuit to close Relay RL101. this brings the PFC source up to full power by

increasing the 159V standby to 340V. At this time the 16V source becomes active and

sent to the Main board via P813.

The next step is for the Micon (IC105) on the Main board to output a high on M5V_ON

Line to the SMPS at P813 Pin 21 which is sensed by the Sub Micon IC (IC701) on the

SMPS turning on the 5V VCC line. The last step to bring the supply to “Full Power” occurs

when the Micon (IC100) on the Main board brings the VS-ON line high at Pin 20 of

P813 on the SMPS board which when sensed by the Sub Micon IC (IC701) turns on the

VA and VS Supplies (VA is brought high before VS).

Note: If a voltage is missing, check for proper resistance before proceeding.

22 PDP Training - Fall 2008

Page 23

CIRCUIT DESCRIPTIONS

Understanding the Power On Sequence when Troubleshooting a possible Power Supply

Failure will simplify the process of isolating which circuit board failed to operate properly.

In this Section we will investigate the Power on Sequence and examine ways to locate

quickly where the failure occurred.

Check the Power On LED for Operation. A Red LED indicates a presence of 5V STB and

AC-ON/DETECT. Failure of the Power ON LED to light is an indication of loss of 5V STB

or AC ON/ Detect remember the 5V STB and AC-ON/DETECT are developed on the

SMPS and sent to the Main board. Check LD703 for Green glow.

4

2

When Power is pressed, look for LD703 to change to Amber. Listen for a Relay Click. The

click of the Relay is an indication of RL-ON going high. RL-ON is sent from the Main board

to the SMPS and when present, the IC701 controls the relay operation. RL-ON going High

and no relay is a failure of the SMPS. RL-ON staying low is a failure of the Main board.

Relay Operation means that the SMPS if working properly will output the 16V Supply to

the Main board. This voltage will allow the Tuner, Audio and Video Circuits on the Main

board to function, and if connected to an Antenna Input, Audio would be present. If the

Relays closed and these supplies failed suspect a problem with the SMPS.

The next step of operation calls for the M5V_ON line from the Main board to the SMPS

to go high pin 21 of P813. A high on the M5V_ON line activates the 5V VCC line. Loss

of 5V VCC results in no “Raster”, no Display Panel Reset, no Y, Z, Control or X-board

operation. Loss of 5V VCC and M5V_ON going high could be caused by any of these

boards or failure of the SMPS. M5V_ON staying low indicates a problem on the Main

board.

VS-ON is the last step of the Power Sequence and is responsible for bringing the VS

and VA voltages up. The VS-ON signal pin 20 of P813 is sent from the Main board to

the SMPS as a high, VS and VA and full operation of the Display Panel are now enabled.

Loss of VS-ON results in loss of VA and VS and no Raster, no Panel Display Reset but

audio would be present. If VS-ON went high and VS and VA where missing the problem

P

G

2

0

PDP Training - Fall 2008 23

Page 24

CIRCUIT DESCRIPTIONS

Model : PDP42G1####

||||||||||||||||||||||||||||||||||||||||||||||||||||

801K542G1008000 .AKAZBED

Voltage Setting :DC 5V Va :65V/ Vs:195V

NA / -190 / 140 / NA / 100

Vs TP

P812

Pin 1 or 2

Use Full White Raster

Va TP

P812

Pin 5 or 6

2

4

6

8

10

12

14

16

18

22

16V

Gnd

NC

Gnd

5VSTB

5VSTB

Gnd

Gnd

AC Det

VS_ON

Auto Gnd

2

4

6

8

10

12

14

16

18

22

16V

Gnd

NC

Gnd

5VSTB

5VSTB

Gnd

Gnd

AC Det

VS_ON

Auto Gnd

20

3

5

7

9

11

13

15

17

19

21

Gnd

NC

Gnd

5VSTB

5VSTB

Gnd

Gnd

5_V Det

RL_ON

M5V_ON

1

15V

3

5

7

9

11

13

15

17

19

21

Gnd

NC

Gnd

5VSTB

5VSTB

Gnd

Gnd

5_V Det

RL_ON

M5V_ON

1

15V

could be caused by a failure on the SMPS or a circuit

using these voltages. A resistance check should narrow

the possible failures quickly.

4

2

P

G

2

0

POWER SUPPlY STATIC TEST

This test can confirm the proper operation of the SMPS

without the need to exchange the board.This Power

Supply can operate in a No Load State. This means that

by applying AC power to SC101 and all other plugs

disconnected, this power supply will function. Simply

removing P813 (Lower Right Hand Side of the board),

will cause the “AUTO” Pin 22 to go high from its normal

low state allowing the Power Supply to go to full power

on mode when AC Power is Supplied. Be careful after this

test and make sure the VA and VS lines have discharged before reconnecting the supply

cables.

If the Y-Sus and Z-Sus boards are working normal, “Display Panel Reset” will be visible

when the SMPS comes up to full power. Shorting the Auto Pattern Gen. test points at

this time should result in test patterns on the screen.

vS/vA ADJUSTMENTS

This Power Supply will come up and run with “no” load (P812 pulled). Pull P813, apply AC

power, and the Power Supply starts. Y-Sus/Z-Sus runs “Yes” both Y and Z waveforms.

24 PDP Training - Fall 2008

Page 25

42PG20 Power Supply Controls from Micro Side

76

Pulse

R1045

RL-ON

Pull-Down

Va/Vs-On

166

Pull-Down

R137

M5V-On

115

INT

R184

AC-DET

AC-DET

I

O

1

1A

2

1Y

14

3.3V

128

HW-RESET

P701

18

R727

R764

R717

R723

R718

R715

19

R763

RL-ON

R711

R6070

R716

+5V-General

21

0ohm

RL-ON

M5V-On

AC-DET

VS-On

80

Pull-Up

R126

5V-MNT

17

5V-DET

R722

R720

R142

R141

C142

C143

68010K

SW100

Vcc

R135

167

R136

R732

R736

R729

20

0ohm

Q704

R6071

+5V-General

+5V-General

Q702

C713

Q703

C701

IC101

D100

IC104

254

255

X100

12Mhz

Vcc

9

10

11

12

+5V-ST

Level Shifter

LD703

Set Off +5VST Red

Set On 5VGen Amber

22

Gnd

Q706

+5V-General

4

6

5

RL-ON

LD703

1.8V

1.6V

IC100

RedGreen

3

2

MICRO POWER SUPPlY CONTROl

CIRCUIT DESCRIPTIONS

4

2

P

G

2

0

PDP Training - Fall 2008 25

Page 26

4

42PG20 Power Supply Controls from Micro Side 1

st

STEP

115

INT

R184

AC-DET

AC-DET

IO1

1A

2

1Y

14

3.3V

128

HW-RESET

P701

18

R727

AC-DET

R142

R141

C142

C143

68010K

SW100

Vcc

R135

C713

IC101

D100

IC104

254

255

X100

12Mhz

Vcc

9 10 11 12

Gnd

22

IC100

+5V-ST

RL-ON

LD703

1.8V

Green

5V-SBY Arrives

from SMPS

AC-DET Arrives

from SMPS

Micro Receives Vcc

AC-DET creates

Micro Reset

Oscillator

starts

LED703 receives

5VST and glows Green

A

B

B

A

A

D

A

C

SW 100 Manual

Micro. Reset

AC-DET is

Monitored

by uP

2

P

G

2

0

CIRCUIT DESCRIPTIONS

MICRO POWER SUPPlY CONTROl - STEP1

26 PDP Training - Fall 2008

Page 27

P701

118

9

10

11

12

+5V-ST

Q706

+5V-General

Level Shifter

4

6

LD703

1.8V1.6V

Red

5

42PG20 Power Supply Controls from Micro Side 2

nd

STEP

119

KEY

CONTROLS

IC100

114

REMOTE

IR In

R764

VS-On

80

Pull-Up

R126

5V-MNT

17

5V-DET

R722

R720

167

R136

R732

R736

R729

20

0ohm

Q704

R6071

+5V-General

+5V-General

C701

Green

Appears Amber

166

R137

M5V-On

R711

R6070

R716

+5V-General

21

0ohm

M5V-On

Q702

76

Pulse

R1045

RL-ON

R717

R723

R718

R715

+5V-ST

19

R763

RL-ON

RL-ON

Q703

22

RL-ON

To other

circuts

Receives

Power On

Command

From Side Keys or

Remote

Outputs Relay On (RL-ON) command

Turns on Power Supply Relay

Turns on Q706

Creates 5V General

Lights

Amber

Outputs M5V On command

Turns on 16V/12V Power Supplies

5V General allows 5V Detect

To be Generated

Outputs VS-On which turns on Va and

Vs in the Power Supply

A

E

B

D

F

C

B

3

2

MICRO POWER SUPPlY CONTROl - STEP2

CIRCUIT DESCRIPTIONS

4

2

P

G

2

0

PDP Training - Fall 2008 27

Page 28

4

2

P

G

2

CIRCUIT DESCRIPTIONS

PIN vOlTAGES

P701 “Main” to P813 “SMPS”

Pin Label STBY Run No Load Diode Pin Label STBY Run No Load Diode

1 15V 0V 16.5V

3 Gnd Gnd Gnd

5 NC NC NC

7 Gnd Gnd Gnd

9 5V 5V 5V

11 5V 5V 5V

13 Gnd Gnd Gnd

15 Gnd Gnd Gnd

17 5_V Det .15V 5V

19 RL_On 0V 3.73V

21 M5V_ON 3.27V 3.24V

16.5V

Gnd

NC

Gnd

5V

5V

Gnd

Gnd

5V

0V

0V

3.8V 2 15V 0V 16.5V

Gnd 4 Gnd Gnd Gnd

Open 6 NC NC NC

Gnd 8 Gnd Gnd Gnd

0.75V 10 5V 5V 5V

0.75V 12 5V 5V 5V

Gnd 14 Gnd Gnd Gnd

Gnd 16 Gnd Gnd Gnd

3.25V 18 AC Det 5V 5V

Open 20 Vs_On 0V 3.2V

1.22V 22 AUTO Gnd Gnd

16.5V

Gnd

NC

Gnd

5V

5V

Gnd

Gnd

5V

0V

5V

2.82V

Gnd

Open

Gnd

0.75V

0.75V

Gnd

Gnd

Open

1.22V

Gnd

0

P812 “Power Supply” to P201 “Y-Sus”

Pin Label Standby Run Diode Mode

1 Vs 0V *194V Open

2 Vs 0V *194V Open

3 NC NC NC NC

4 Gnd 0V 0V Gnd

5 Gnd 0V 0V Gnd

6 Va 0V *65V Open

7 Va 0V *65V Open

8 Gnd 0V 0V Gnd

9 M5V 0V 5V .83V

10 M5V 0V 5V .83V

CN101 “Power Supply” from AC In

Pin Standby Run Resistance

1 120VAC 120VAC 480K

2 N/C - -

3 120 VAC 120VAC 480K

28 PDP Training - Fall 2008

Page 29

Y-SUS BOARD

VR602

V-Set Up

P204

To Y-Drive

VR601

V-Set Down

C221

Drive TP

VSC ADJ VR501

P200

To Y-Drive

R210

-VY TP

R211

VSC TP

-VY ADJ VR502

FS201

5A

Z-Bias ADJ VR905

P101

Logic Signals

From Control

Z-Bias TP R496

P801

Z-Drive to

Z output

P201

Vs & Va

From SMPS

FS701 (Va)

10A

P202

FS202 (Vs)

4A 250V

CIRCUIT DESCRIPTIONS

4

2

P

G

2

Board Voltage

SMPS

Developed on

Y/Z-Sus

VS Supplies the Horizontal Grid

VA Supplies the Vertical Grid

VCC 5V 5V Supplies Bias to Y/Z-Sus, Control, and X-Boards

-VY -VY Sets the Negative excursion of the Y SUS Drive Waveform

V-Set Up

VR602

V-Set Down

VR601

16V To the X-Drives and TCP ICs

VSC VSC Set the amplitude of the complex waveform

Ramp UP sets Pitch of the Top Ramp of the Drive Waveform

V Set Down sets the Pitch of the Bottom Ramp of the Drive Waveform

SMPS Outputs

0

PDP Training - Fall 2008 29

Page 30

4

30F122

Forward 0.5V ~ 0.7V

Reverse: OL

30F122

Forward 0.4V ~ 0.5V

Reverse: OL

RF2001

Forward 0.3V ~ 0.5V

Reverse: OL

RF2001

Forward 0.3V ~ 0.5V

Reverse: OL

45F123

Forward 0.3V ~ 0.5V

Reverse: OL

45F123

Forward 0.9V ~ 1.0V

Reverse: OL

VR502

Model : PDP42G1####

||||||||||||||||||||||||||||||||||||||||||||||||||||

801K542G1008000.AKAZBED

Voltage Setting:DC 5V Va:65V/ Vs:195V

NA / -190 / 140 / NA / 100

VSC

-VY

Model : PDP42G1####

||||||||||||||||||||||||||||||||||||||||||||||||||||

801K542G1008000.AKAZBED

Voltage Setting:DC 5V Va:65V/ Vs:195V

NA / -190 / 140 / NA / 100

VSC

-VY

Lower Left

Side of Y-Sus

VSC TP

-Vy TP

VR501

Lower Left

Side of Y-Sus

Middle Left

Side of Y-Sus

R210

R211

+

-

+

-

2

P

G

2

CIRCUIT DESCRIPTIONS

vSC AND -vY ADJUSTMENTS

Set should run for 15 minutes, this is the “Heat Run” mode. Set screen to White Wash

mode or 100IRE White input. Adjust –Vy to 190V (+/- 1V). Adjust VSC to 140 (+/1V).

0

Y-SUS OUTPUT FETS

-

+

+-

30 PDP Training - Fall 2008

+-

+ -

Page 31

CIRCUIT DESCRIPTIONS

0V

A) Observe the

Ramp Up portion

A

Y Setup Ramp VR602

150V p/p

+/- 5V

Y Drive PWB

Waveform Test Point

B

B) Observe the

Ramp Down

“Time” portion

Y Setup Ramp

VR601

110 us

+/- 5us

2

nd

Pulse

100us

2.00ms

100V per division

1.00ms

100V per division

V-Set Down

VR601

V-Set Up

VR602

Upper left side of the Y-Sus board

v-SET UP AND v-SET DOWN ADJUSTMENTS

VSC and –VY Must have already been completed. Observe the Picture while making these

adjustments. Normally, they do not have to be done.

4

2

P

G

2

0

PDP Training - Fall 2008 31

Page 32

4

FIG1

FIG2

FIG3

Area to

be adjusted

Area to

be adjusted

Zoomed out

Area to

be adjusted

Outlined

Area

FIG4

FIG5

FIG6

Area to

be adjusted

Area to

be adjusted

Area to

be adjusted

Zoomed out

Outlined

Area

2

P

CIRCUIT DESCRIPTIONS

v-SET UP AND v-SET DOWN ADJUSTMENTS

Fig1 top shows the Y-Drive Waveform signal

locked in at 4ms per/div. The signal for Vsetup

is outlined within the Waveform.

At 400uSec per/division, the Fig1 lower

waveform shows Vsetup isolated.

Fig2 top is 2ms per/division. The signal for

Vsetup is now easier to recognize and is

outlined within the Waveform.

G

2

0

At 100uSec per/division, the Fig2 lower

waveform shows Vsetup isolated.

At 1ms per/division, the signal for Vsetup is

now clearly visible. It is outlined within the Fig

3 top waveform.

At 40uSec per/division in Fig3 lower, the

adjustment for Vsetup can be made.

Fig4 top shows the signal locked in at 4ms

per/div and the outlined signal for Vsetdn.

At 400uSec per/division, Fig4 lower waveform

shows Vsetdn isolated.

At 2ms per/divison as in Fig5 top, the outlined

signal for Vsetdn is now easier to recognize.

At 100uSec per/division, Fig5 lower waveform

shows Vsetdn isolated.

At 1ms per/division the outlined signal for

Vsetdn is now clearly visible in Fig6 top.

At 40uSec per/division as in Fig6 lower, the

adjustment for Vsetdn can be made.

32 PDP Training - Fall 2008

Page 33

v-SET UP TOO hIGh OR lOW

V-Set Up Too High

CIRCUIT DESCRIPTIONS

The center begins to wash out and arc due to Vset UP

peeking too late and alters the start of the Vset DN

phase.

4

2

P

G

2

V-Set Up Too Low

v-SET DOWN TOO hIGh OR lOW

V-Set Down Too High

0

Very little alteration to the picture, the wave form

indicates a distorted Vset UP. The peek widens due to

the Vset UP peeking too quickly.

All of the center washes out due to increased Vset_DN

time.

V-Set Down Too Low

The center begins to wash out and arc due to decreased

Vset DN time.

PDP Training - Fall 2008 33

Page 34

4

Y-Sus P101

Generates Vsc, -Vy and V Set Up

from Vs by DC/DC Converters

Control Board

Circuits generate

Y Sustain Waveform

Distributes 5V VS

Distributes 5V

Logic signals

needed to

generate drive

waveform

Distributes 16V VA

Receive 5V VCC, Va, Vs

from SMPS

Transfer Waveform

to Y Drive Board

Z SUS Section on the

Same PWB

Left/Right X Board

Display Panel

Power Supply Board - SMPS

FETs amplify Sustain

Waveform

2

P

G

2

CIRCUIT DESCRIPTIONS

Y-SUS blOCk DIAGRAM

0

Y-SUS P101 TO CONTROl P160

These connector pins are too close to read

without possible damage to the board. It’s a

60 Pin connector but only has labels 1-19

on the Control board. Looking closely, these

test points are “every other pin”. The bottom

TP represents the “19” label on the Control

board. Pin 1 on the Y-Sus board is actually pin

60 on the Control board side. Take resistance

readings with the board disconnected using the

Diode mode on a digital volt meter. However,

this connector has many more pins than shown

on the Control board Labeling. Roughly 39 pins

34 PDP Training - Fall 2008

Page 35

CIRCUIT DESCRIPTIONS

4

2

P

G

2

P101 “Y-Sus” to P160 “Control”

0

2 CLK 0V 3.2V 2.87V 22 Set_DN2 0V 0.2V 2.87V 42 5V OV 4.75V 0.76V / (1.7K)

1 Gnd Gnd Gnd Gnd 21 Gnd Gnd Gnd Gnd 41 5V OV 4.75V 0.76V / (1.7K)

Pin Label STBY Run Diode Mode Pin Label STBY Run Diode Mode Pin Label STBY Run Diode Mode

5 Gnd Gnd Gnd Gnd 25 Gnd Gnd Gnd Gnd 45 n/c n/c n/c n/c

4 STB 0V 0.76V 2.87V 24 PASS_TOP 0V 0.2V 2.87V 44 5V OV 4.75V 0.76V / (1.7K)

3 Gnd Gnd Gnd Gnd 23 Gnd Gnd Gnd Gnd 43 5V OV 4.75V 0.76V / (1.7K)

6 OSC1 0V 0V 2.87V 26 DELTA_Vy 0V 0.16V 2.87V 46 n/c n/c n/c n/c

7 Gnd Gnd Gnd Gnd 27 Gnd Gnd Gnd Gnd 47 Z-ENABLE 0V 0V 1.25V

8 OSC2 0V 3V 2.87V 28 DET_LEVEL 0V 0V 2.87V 48 Gnd Gnd Gnd Gnd

9 Gnd Gnd Gnd Gnd 29 Gnd Gnd Gnd Gnd 49 Z-BIAS 0V 1.71V 1.1V

10 D ATA 0V 0.6V 2.87V 30 SLOPE_RETE 0V 0V 2.87V 50 Gnd Gnd Gnd Gnd

11 Gnd Gnd Gnd Gnd 31 Gnd Gnd Gnd Gnd 51 VZB-SEL 0V 0V 1.1V

12 SUS_DN 0V 0V 2.87V 32 SET_UP 0V 1.9V 2.87V 52 Gnd Gnd Gnd Gnd

13 Gnd Gnd Gnd Gnd 33 Gnd Gnd Gnd Gnd 53 Z-ER_UP 0V 1.25V 1.1V

14 SUS_UP 0V 2V 2.87V 34 Set_DN_2 0V 1.4V 2.87V 54 Gnd Gnd Gnd Gnd

15 Gnd Gnd Gnd Gnd 35 Gnd Gnd Gnd Gnd 55 Z-ER_DN 0V 1.35V 1.1V

20 SET_UP 0V 0.26V 2.87V 40 5V OV 4.75V 0.76V / (1.7K) 60 Gnd Gnd Gnd Gnd

19 Gnd Gnd Gnd Gnd 39 n/c n/c n/c n/c 59 Z-Sus_DN 0V 1.15V 1.1V

18 ER_UP 0V 2V 2.87V 38 Y-Enable 0V 0.6V 2.87V 58 Gnd Gnd Gnd Gnd

17 Gnd Gnd Gnd Gnd 37 Gnd Gnd Gnd Gnd 57 Z-Sus_UP 0V 0.35V 1.1V

16 ER_DN 0V 1.2V 2.87V 36 X_ER 0V 2.9V 2.87V 56 Gnd Gnd Gnd Gnd

PDP Training - Fall 2008 35

Page 36

4

P204

To Y-Drive

P101

Logic Signals

From Control

P801

Z-Drive to

Z output

P201

Vs & Va

From SMPS

P202

P200

To Y-Drive

2

P

G

2

CIRCUIT DESCRIPTIONS

Y-SUS CONNECTIONS

“Y-Sus” P801 to “Z-Drive” P1

Pin Label Standby Run Diode Mode

1 +Vs 0V *194V Open

2 Gnd Gnd Gnd Gnd

3 ZSUS 0V 70.46V Open

4 Gnd Gnd Gnd Gnd

5 ZSUS 0V 70.46V Open

6 Gnd Gnd Gnd Gnd

7 ZSUS 0V 70.46V Open

8 Gnd Gnd Gnd Gnd

9 ZSUS 0V 70.46V Open

10 Gnd Gnd Gnd Gnd

11 ZSUS 0V 70.46V Open

Note: Voltages will vary in accordance with Panel

Label

0

P202 “Y-Sus” to “X-Drive Left” P242

Pin Label Standby Run Diode Mode

1 Gnd Gnd Gnd Gnd

2 Gnd Gnd Gnd Gnd

3 15V 0V 15.8V 1V

4 ER2 0V 61.5V Open

5 ER2 0V 61.5V Open

6 Va 0V 64.9V Open

7 Gnd Gnd Gnd Gnd

8 Gnd Gnd Gnd Gnd

9 15V 0V 15.8V 1V

10 ER1 0V 61.5V Open

11 ER1 0V 61.5V Open

12 Va 0V *64.9V Open

Note: Voltages will vary in accordance with Panel

Label

P201 “Y-Sus” to “Power Supply” P812

Pin Label Standby Run Diode Mode

1 Vs 0V *194V Open

2 Vs 0V *194V Open

3 NC NC NC NC

4 Gnd 0V 0V Gnd

5 Gnd 0V 0V Gnd

6 Va 0V *65V Open

7 Va 0V *65V Open

8 Gnd 0V 0V Gnd

9 M5V 0V 5V .83V

10 M5V 0V 5V .83V

Note: Voltages will vary in accordance with

Panel Label

36 PDP Training - Fall 2008

Page 37

CIRCUIT DESCRIPTIONS

Top

Logic Signals

from the Y-Sus Board

P200

P100

Clock and Data

from the Y-Sus Board

Bottom

IC101

IC102

IC103

IC104

IC105

IC106

IC107

IC108

Y-DRIVE BOARD

Y-Drive board works as a path supplying the Sustain and Reset waveforms which are made

in the Y-Sustain board and sent to the panel through scan driver IC’s. The Y-Drive boards

supply a waveform which selects the horizontal electrodes sequentially. The 42PG20 uses

8 driver ICs on 1 Y-Drive board.

4

2

P

G

2

5 Volts and Logic Signals from Y-Sus board are supplied to the Drive board on connector

P200. Logic Signals are from P100. The 5V supply is underneath the board.

0

PDP Training - Fall 2008 37

Page 38

4

Gently Pry Up Here

Locking Tab in Upright Position

Before removing, lift

up slightly to be sure

ribbon cable is released.

2

P

G

CIRCUIT DESCRIPTIONS

REMOvING RIbbON CAblES

To remove the Ribbon Cable from the connector, first carefully lift the Locking Tab from

the back and tilt it forward (lift from under the tab as shown in Fig 1). The locking tab

must be standing straight up as shown in Fig 2. Lift up the entire Ribbon Cable gently to

release the Tabs on each end. (See Fig 2) Gently slide the Ribbon Cable free from the

connector. To reinstall the Ribbon Cable, carefully slide it back into the slot see ( Fig 3),

be sure the Tab is seated securely and press the Locking Tab back to the locked position

see (Fig 2 then Fig 1).

2

0

Fig 1

INCORRECT INSTAll

In the image to the right, the ribbon cable is improperly

seated into the connector. You can tell by observing

the linearity. The Locking Tab will offer a greater

resistance to closing in this case. Note that the cable

is crooked. In this case the tab on the ribbon cable was

improperly seated at the bottom. This can cause bars,

lines, intermittent lines abnormalities in the picture.

Remove the ribbon cable and re-seat it correctly.

Fig 2

Fig 3

38 PDP Training - Fall 2008

Page 39

CIRCUIT DESCRIPTIONS

Anywhere

BACK SIDE OF Y-DRIVE

RED LEAD ON

A

RED LEAD ON “B”

READING 0.73 V

BLACK LEAD ON

A

BLACK LEAD ON “B”

READING “OPEN”

A

B

FORWARD

REVERSE

RED LEAD ON

BUFFER IC

BLACK LEAD ON “ANY”

OUTPUT LUG.

READING 0.73 V

OUTPUT LUGS

BLACK LEAD ON

BUFFER IC

RED LEAD ON “ANY”

OUTPUT LUG.

READING “OPEN”

Indicated by Red outline

BACK SIDE OF Y-DRIVE PWB

Indicated by Red outline

Y-DRIvE bUFFER TROUblEShOOTING

Using the “Diode Test” on the DVM, check the pins for shorts or abnormal loads. You

can check all 8 buffer ICs using this procedure. Using the “Diode Test” on a digital volt

meter, check the pins for shorts or abnormal loads. Any of the output lugs can be tested.

Look for shorts indicating a defective Buffer IC.

4

2

+

-

+

G

2

P

0

+

-

-

-

+

PDP Training - Fall 2008 39

Page 40

4

OS2

P200

TOP (Front View)

OS2

LE

CLK

DATA

52.3V

0V

-87.9V

-87.9V

0V

0V

-83V

-88V

-87.9V

-83V

-90.8V

-87.9V

-85.2V

2

P

G

2

0

CIRCUIT DESCRIPTIONS

P200 ON ThE Y-DRIvE

Voltages taken with unit running and snow as a picture.

40 PDP Training - Fall 2008

Page 41

CIRCUIT DESCRIPTIONS

FS201

5V

Z-Bias ADJ VR905

P101

Logic Signals

From Control

Z-Bias TP R496

P801

Z-Drive to

Z output

P201

Vs & Va

From SMPS

FS701 (Va)

10A

P202

5V/Va to Left X

FS202 (Vs)

4A 250V

Y-Sus

Output

ICs

Y-Sus

Section

Z-Sus

Section

+

-

Z-bIAS ADJUSTMENT

The Z-Sus Drive section is now located on the Y-Sus board. Set should run for 15 minutes

in “Heat Run” mode prior to any adjustments. Set screen to white wash mode or 100IRE

White input. Adjust VZ (Z-Bias) to 100V (+/- 1V).

Read the Label on the back of the

upper left hand side of the panel.

Adjust R946 to that voltage.

4

2

P

G

2

Board Voltage Description

Y-Sus

Z-Sus Z-Bias

VS

VA

M5V VCC

Z-Sus Input Voltages

VS is input at P3 pins 1 and 2 and supplied to the

driver IC circuit.

VA inputs at P3 pins 6 and 7 and supplied to the

driver IC circuit.

5V in input P3 pins 9 and 10. It is used to Bias

the circuits on the Z_ SUS board.

Z Bias Voltage is used to Bias the output circuits

driving the Sustain and Erase

Pulses, removing previous images from the

PDP. Z-bias is measured from the

Vzb TP on the Z -SUS board and adjusted by

VZB Adj.

0

PDP Training - Fall 2008 41

Page 42

4

Z-Drive Wavefrorm

2 ms/Div

100 us/Div

(Vzb) Z-Bias VR905

Vzb Voltage

100V ±1V

Probe Test Point

2

P

G

2

CIRCUIT DESCRIPTIONS

Z-SUS BOARD

Provides the SUSTAIN PULSE and ERASE PULSE for generating SUSTAIN discharge in

the panel by receiving Drive signals from the Y/Z-Sus board. This waveform is supplied

to the panel through FPC (Flexible Printed Circuit (Z). Z-Bias is a “DC” adjustment. The

effects of this adjustment can be observed on the scope looking at the Z-Sus output.

This Waveform is just for reference to observe the effects of Zbz adjustment. Note: The

Vzb Adjustment is a DC level adjustment.

0

“Y-Sus” P801 to “Z-Drive” P1

Pin Label Standby Run Diode Mode

1 +Vs 0V *194V Open

2 Gnd Gnd Gnd Gnd

3 ZSUS 0V 70.46V Open

4 Gnd Gnd Gnd Gnd

5 ZSUS 0V 70.46V Open

6 Gnd Gnd Gnd Gnd

7 ZSUS 0V 70.46V Open

8 Gnd Gnd Gnd Gnd

9 ZSUS 0V 70.46V Open

10 Gnd Gnd Gnd Gnd

11 ZSUS 0V 70.46V Open

42 PDP Training - Fall 2008

Page 43

Z-SUS blOCk DIAGRAM

Circuits generate erase,

sustain waveforms

Generates Z Bias 100V

Distributes Logic Signals

Distributes 5V VCC, VA, VS

FET Makes Drive waveform

Display Panel

Via FPC

(flexible printed circuit )

Control Board

Z-SUS Section of the Y-

SUS PWB Receives

VS M5V

Y-SUS Board

Z-SUS FETs

Via P801 to P1

NO IPMs

Z-SUS PWB

CIRCUIT DESCRIPTIONS

4

2

P

G

2

0

PDP Training - Fall 2008 43

Page 44

4

IC211

P160

To Y/Z-Sus

P162

To X-Drive Right

Temperature

LEDs

P121

P131

Download

Connection

P164

n/c

IC121

Auto Gen

Test Pattern

IC201

MCM

IC212

IC213

IC122

IC133

IC171

Pin1 = 3.29V

Pin2 = 1.20V

Pin3 = 0V

IC171

IC101

VS_DA

3V ~3.3V

P161

To X-Drive Left

Crystal

2

P

G

CIRCUIT DESCRIPTIONS

CONTROL BOARD

2

0

Control board Inputs

Board Input

Main LVDS

Y-Sus 5V VCC

Developed

CONTROl bOARD TEST

For a quick board test. (All board connectors Disconnected). Jump 5V from Power Supply

to IC121 Pin 1. If the Temp LED lights, Pretty much guaranteed, board is OK. When the

Television has a problem related to; Shutdown caused by Main board No Picture. This

can be checked by disconnecting the Main board from all connectors. Apply AC power.

Since P813 is not connected, the set will come on. Short the two pins on the Auto Test

Pattern lands.

1.8V

3.3V

44 PDP Training - Fall 2008

Page 45

CIRCUIT DESCRIPTIONS

P121

Auto Gen

P161

P162

P164 P131

TEMP LEDS

IC121

X101

Download

Connector

IC212

IC213

IC201

IC211

IC101 IC133

D15 D16 D17

Crystal TP

50Mhz

VS_DA

Control PWB Check

3V ~ 3.3V

RGB Logic

Signals to

Center X PWB

RGB Logic

Signals to

Center R PWB

Auto Test Pattern Generator

Short Lands together

IC171

Pin 1 – 3.29V

Pin 2 – 1.20V

Pin 3 – 0V

IC122

IC122

Pin 1 – 4.75V

Pin 2 – 3.3V

Pin 3 – 0V

P160

Logic Signals to

Y-SUS PWB

Control Board

IC121

Pin 1 – 4.75V

Pin 2 – 3.3V

Pin 3 – 0V

IC171

LVDS

If there is a picture of cycling colors, the Y-Sus, Y-Drive, Z-Sus, Power Supply, Control

boards and Panel are all OK. Same test to tell if No Video is caused by the Main board.

Quick observation Of Temperature LEDs will tell if the Control board is running. With the

unit on. If none of D15, 16, 17 are illuminated. Check supplies to the board. If they are

present replace the Control board.

4

2

P

G

2

0

PDP Training - Fall 2008 45

Page 46

4

50 Mhz

Example of Normal Signals measured at 200mv/cm at 5µs/cm.

Menu OnMenu O

1

3

5

7

9

11

13

15

17

19

21

2

4

6

8

10

12

14

16

18

20

22

-

indicates signal pins.

P302 on Main Board

Locking Tabs

Press In

Press In

2

P

CIRCUIT DESCRIPTIONS

CRYSTAl ClOCk

Ch eck t he ou tpu t o f

the Oscillator package.

The freq uency of the

sine wave is 50 MHZ.

Missing this clock signal

can halt operation of the

unit.

G

2

0

lvDS CAblE

Video Signals from the Main board to the Control board

are referred to as Low Voltage Differential Signals or LVDS.

Their presence can be confirmed with the Oscilloscope by

monitoring the LVDS signals with no input signal selected

while pressing the

Menu Button on and off with the remote control

or keypad. Loss of these signals would confirm the

failure is on the Main board.

P121 on the Control board shown. Press the two

outside tabs inward to release.

46 PDP Training - Fall 2008

Page 47

CONTROl bOARD SIGNAl blOCk

DRAM

MCM

DRAM

DRAM

EEPROM

MCM

16 line

Resistor Array

192 Lines output Total

IC201

2 Buffer

Outputs

per TCP

CONTROL PWB

X-DRIVE PWB

PANEL

96 Lines per Buffer

The Control board supplies Video Signals to

the TCP (Tape Carrier Package) ICs. If there is a

bar defect on the screen, it could be a Control

board problem. This Picture shows Signal Flow

Distribution to help determine the failure

depending on where the it shows on the screen.

CIRCUIT DESCRIPTIONS

4

2

P

G

2

P121 “Control” to P302 “Main”

Pin Stby Run Diode Check Pin Stby Run Diode Check

1 Gnd Gnd Gnd 2 0V 0V 1V

3 0V 0V 1V 4 0V 1.26V 1V

5 0V 1.19V 1V 6 0V 0V Gnd

7 0V 1.26V 1V 8 0V 1.19V 1V

9 0V 0V 1V 10 0V 0V 1V

11 0V 1.15V 1V 12 0V 1.26V 1V

13 Gnd Gnd Gnd 14 0V 0V Gnd

15 0V 0V 1V 16 0V 0V 1V

17 0V 0V 1V 18 0V 0V 1V

19 Gnd Gnd Gnd 20 0V 0.21V 1V

21 0V 0V 1V 22 0.89V 0.56V 2.5V

23 0V 5.29V 2.4V 24 0V 1.26V 1V

25 0V 1.2V 1V 26 Gnd Gnd Gnd

27 0V 3.29V 1.3V 28 0.89V 3.29V Open

29 0.89V 3.29V Open 30 0V 0V Open

31 Gnd Gnd Gnd

0

PDP Training - Fall 2008 47

Page 48

4

14 Pins Related

to Z-Sus

39 Pins related

to Y-Sus

This labeling does not refer to

P160 pin ID. This too has

ground between each pin.

These are responsible for Z

Drive signals.

Pins 17, 18, 19, 20 and 21

Deliver +5V to the Control

board from the Y-Sus. Easy to

check using 20th hash mark.

P160

20th Hash Mark

2

P

G

2

CIRCUIT DESCRIPTIONS

CONTROl TO Y-SUS

P160 is show below. These pins are very close together, so use caution when taking voltage

measurements. This connector is a little confusing in its labeling. It is actually a 60 pin

connector. This shows the Pin Labeling that is shown on the silk screening. Remember,

this connector has many more pins than the labels indicate. Actual Pin 1 (ground) 2

(Z-Sus-DN) 3 (ground) 4 (Z-Sus-UP) 5 (ground), etc. In other words, there is a ground

between each pin except the +5V area.

0

48 PDP Training - Fall 2008

Page 49

CIRCUIT DESCRIPTIONS

4

2

P

G

2

P101 “Y-Sus” to P160 “Control”

0

2 CLK 0V 3.2V 2.87V 22 Set_DN2 0V 0.2V 2.87V 42 5V OV 4.75V 0.76V / (1.7K)

1 Gnd Gnd Gnd Gnd 21 Gnd Gnd Gnd Gnd 41 5V OV 4.75V 0.76V / (1.7K)

Pin Label STBY Run Diode Mode Pin Label STBY Run Diode Mode Pin Label STBY Run Diode Mode

5 Gnd Gnd Gnd Gnd 25 Gnd Gnd Gnd Gnd 45 n/c n/c n/c n/c

4 STB 0V 0.76V 2.87V 24 PASS_TOP 0V 0.2V 2.87V 44 5V OV 4.75V 0.76V / (1.7K)

3 Gnd Gnd Gnd Gnd 23 Gnd Gnd Gnd Gnd 43 5V OV 4.75V 0.76V / (1.7K)

6 OSC1 0V 0V 2.87V 26 DELTA_Vy 0V 0.16V 2.87V 46 n/c n/c n/c n/c

7 Gnd Gnd Gnd Gnd 27 Gnd Gnd Gnd Gnd 47 Z-ENABLE 0V 0V 1.25V

8 OSC2 0V 3V 2.87V 28 DET_LEVEL 0V 0V 2.87V 48 Gnd Gnd Gnd Gnd

9 Gnd Gnd Gnd Gnd 29 Gnd Gnd Gnd Gnd 49 Z-BIAS 0V 1.71V 1.1V

10 D ATA 0V 0.6V 2.87V 30 SLOPE_RETE 0V 0V 2.87V 50 Gnd Gnd Gnd Gnd

11 Gnd Gnd Gnd Gnd 31 Gnd Gnd Gnd Gnd 51 VZB-SEL 0V 0V 1.1V

12 SUS_DN 0V 0V 2.87V 32 SET_UP 0V 1.9V 2.87V 52 Gnd Gnd Gnd Gnd

13 Gnd Gnd Gnd Gnd 33 Gnd Gnd Gnd Gnd 53 Z-ER_UP 0V 1.25V 1.1V

14 SUS_UP 0V 2V 2.87V 34 Set_DN_2 0V 1.4V 2.87V 54 Gnd Gnd Gnd Gnd

15 Gnd Gnd Gnd Gnd 35 Gnd Gnd Gnd Gnd 55 Z-ER_DN 0V 1.35V 1.1V

20 SET_UP 0V 0.26V 2.87V 40 5V OV 4.75V 0.76V / (1.7K) 60 Gnd Gnd Gnd Gnd

19 Gnd Gnd Gnd Gnd 39 n/c n/c n/c n/c 59 Z-Sus_DN 0V 1.15V 1.1V

18 ER_UP 0V 2V 2.87V 38 Y-Enable 0V 0.6V 2.87V 58 Gnd Gnd Gnd Gnd

17 Gnd Gnd Gnd Gnd 37 Gnd Gnd Gnd Gnd 57 Z-Sus_UP 0V 0.35V 1.1V

16 ER_DN 0V 1.2V 2.87V 36 X_ER 0V 2.9V 2.87V 56 Gnd Gnd Gnd Gnd

PDP Training - Fall 2008 49

Page 50

4

Signal Cable

Power Cables

(Va, 15V)

2

P

G

CIRCUIT DESCRIPTIONS

CONTROl TO X-DRIvE

Connector P161 on the Control board connects to P232 on the left X-Drive. Connector

P162 on the Control board connects to P331 on the right X-Drive. These pins are covered

in silicon, so no measurement can be made.

2

0

CONTROl TO X-bOARD

50 PDP Training - Fall 2008

Page 51

CIRCUIT DESCRIPTIONS

Left X-Board

P311

Right X-Board

P232