Page 1

Internal Use Only

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

LED LCD TV

SERVICE MANUAL

CHASSIS : LA2FZ

MODEL : 42LT777H 42LT777H-UA

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Printed in KoreaP/NO : MFL67603807 (1308-REV00)

Page 2

CONTENTS

CONTENTS .............................................................................................. 2

PRODUCT SAFETY ................................................................................. 3

SPECIFICATION ....................................................................................... 4

ADJUSTMENT INSTRUCTION ................................................................ 9

TROUBLESHOOTING ............................................................................. 25

BLOCK DIAGRAM .................................................................................. 26

EXPLODED VIEW .................................................................................. 27

SCHEMATIC CIRCUIT DIAGRAM ..............................................................

Only for training and service purposes

- 2 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 3

SAFETY PRECAUTIONS

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damage d by accidental sho rt s of the circuitr y th at may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 MΩ and 5.2 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

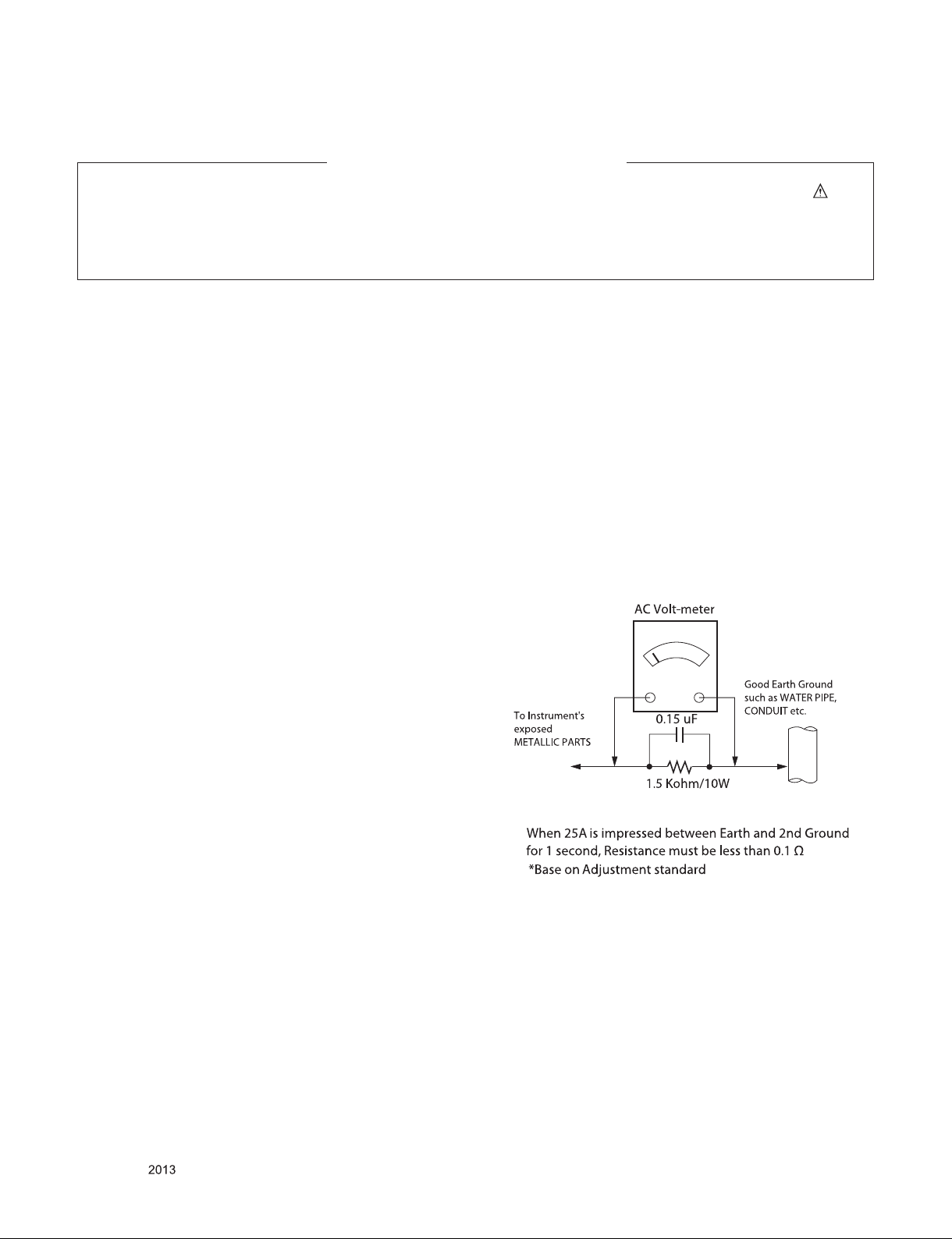

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic par t. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

Only for training and service purposes

- 3 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 4

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application range

This spec sheet is applied Commercial LCD TV with LA2FZ

chassis

3. Test method

1) Performance: LGE TV test method followed

2) Demanded other specification

- Safety : CE, IEC specification

- EMC: CE, IEC specification

2. Test condition

Each part is tested as below without special notice.

1) Temperature : 20 ºC ± 5 ºC

2) Relative Humidity: 65 % ± 10 %

3) Power Voltage

: Standard input voltage (AC 110-240 V~, 50/60 Hz)

* Standard Voltage of each products is marked by models.

4) Specification and performance of each parts are followed

ea ch dr awi ng an d spe cif icat ion by pa rt nu mbe r in

accordance with BOM.

5) The receiver must be operated for about 5 minutes prior to

the adjustment.

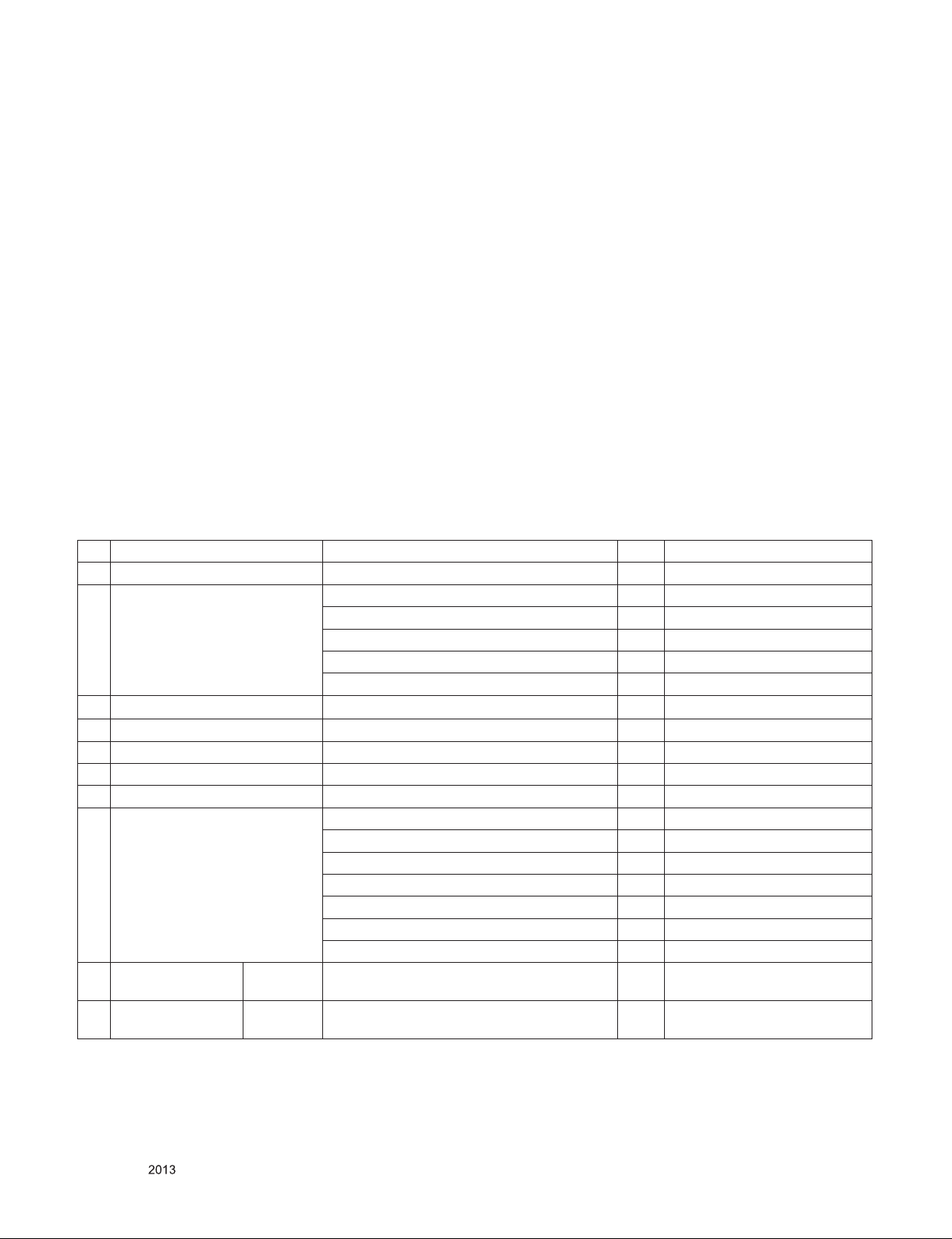

4. General Specification

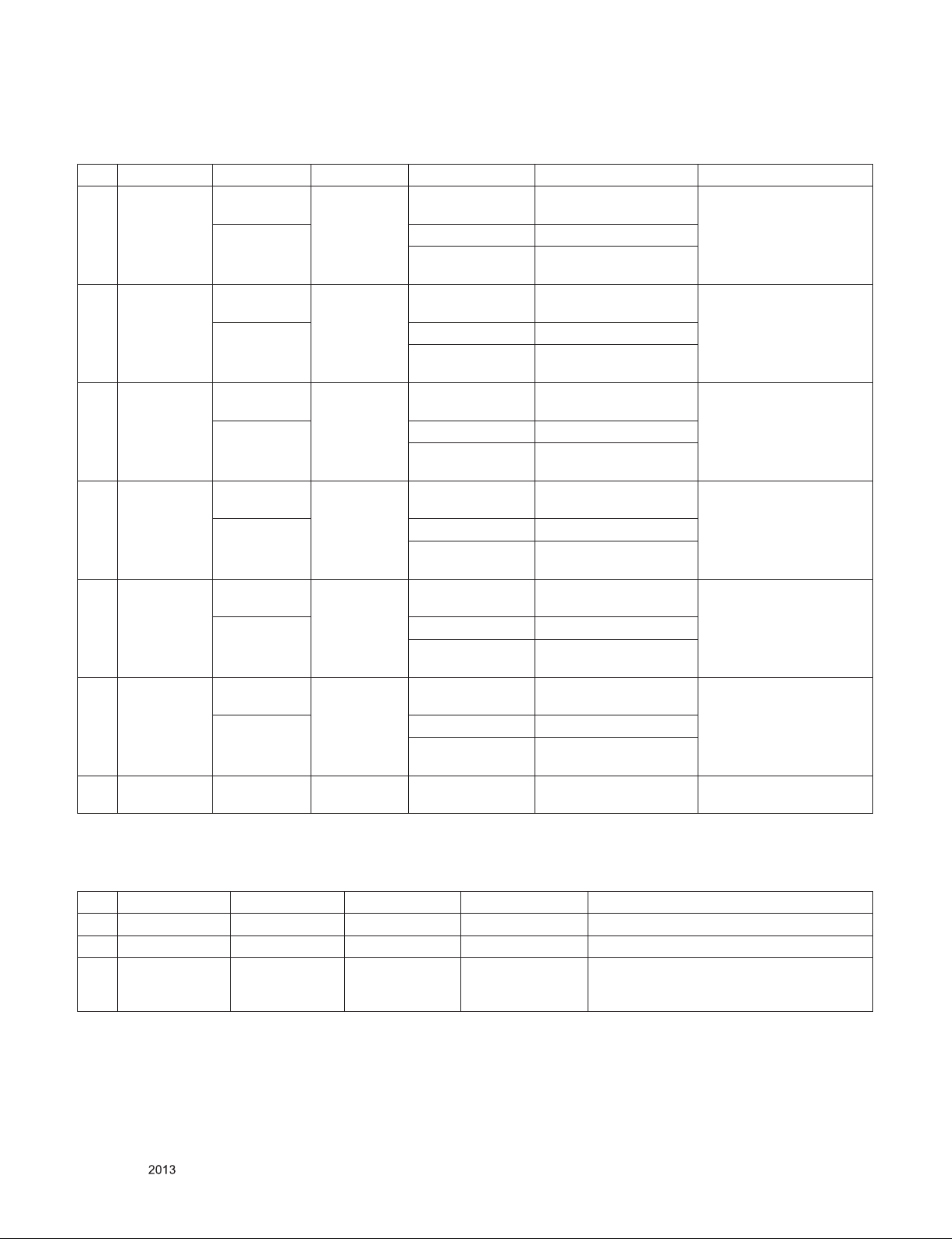

No Item Specication Remark

1 Receiving System 1) ATSC / NTSC-M, 64 & 256 QAM

2 Available Channel 1) VHF : 02~13

2) UHF : 14~69

3) DTV : 02-69

4) CATV : 01~135

5) CADTV : 01~135

3 Input Voltage 1) AC 100 ~ 240V 50/60Hz Mark : 110V, 60Hz (N.America)

4 Market NORTH AMERICA

5 Screen Size 32/37/42/47/55 inches

6 Aspect Ratio 16:9

7 Tuning System FS

8 Module LC320EXN-SEA2 LGD 32LT770H-UA / 32LT777H-UA

LC370EUN-SEM2 LGD 37LT770H-UA / 37 LT777H-UA

LC420EUE-SEM1 LGD 42 LT770H-UA / 42 LT777H-UA

LC470EUE-SEM1 LGD 47 LT770H-UA / 47 LT777H-UA

9 Operating

Environment

10 Storage

Environment

LC420EUG-PFF1 / LC420EUH-PFP1 / LC420EUH-PFM1

LC470EUG-PFF1 / LC470EUH-PFP1 LGD 47 LP870H-UA

LC550EUG-PFF1 / LC550EUH-PFP1 LGD 55 LP870H-UZ

1) Temp : 0 ~ 40 deg

2) Humidity : ~ 80 %

1) Temp : -20 ~ 60 deg

2) Humidity : ~ 85 %

LGD 42 LP870H-UA

Only for training and service purposes

- 4 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 5

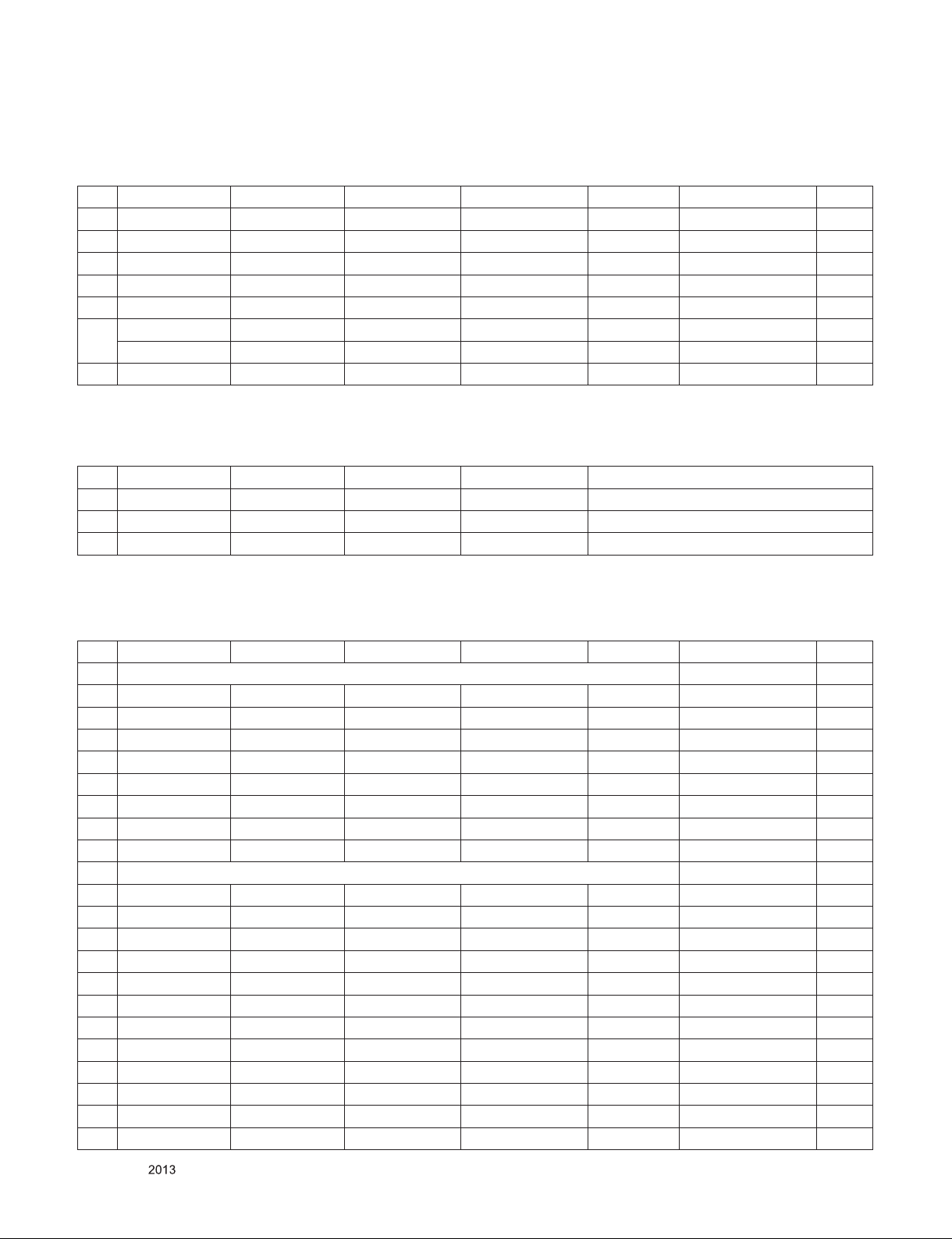

5. Supported video resolutions

5.1. RGB 2D input(PC)

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed DDC

1 640*350 31.468 70.09 25.17 EGA X

2 720*400 31.469 70.08 28.32 DOS O

3 640*480 31.469 59.94 25.17 VESA(VGA) O

4 800*600 37.879 60.31 40.00 VESA(SVGA) O

5 1024*768 48.363 60.00 65.00 VESA(XGA) O

6 1152*864 54.348 60.053 80.002 VESA O

1360*768 47.712 60.015 85.50 FHD only VESA (WXGA) X

7 1920*1080 67.5 60 148.5 FHD only HDTV 1080P O

5.2. RGB 3D input(PC) (OPTION)

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode

1 640*350 31.468 70.09 25.17 Side by Side Top & Bottom

2 720*400 31.469 70.08 28.32 Side by Side Top & Bottom

3 640*480 31.469 59.94 25.17 Side by Side, Top and Bottom

5.3. HDMI 2D Input (PC/DTV)

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed DDC

PC

1 640*350 31.468 70.09 25.17 EGA X

2 720*400 31.469 70.08 28.32 DOS O

3 640*480 31.469 59.94 25.17 VESA(VGA) O

4 800*600 37.879 60.31 40.00 VESA(SVGA) O

5 1024*768 48.363 60.00 65.00 VESA(XGA) O

6 1360*768 47.712 60.015 85.50 VESA (WXGA) X

7 1280*1024 63.981 60.020 108.00 FHD only VESA (SXGA) O

8 1920*1080 67.5 60 148.5 FHD only HDTV 1080P O

DTV

1 720*480 31.50 60 27.027 SDTV 480P

2 720*480 31.469 59.94 27.00 SDTV 480P

3 1280*720 45.00 60.00 74.25 HDTV 720P

4 1280*720 44.96 59.94 74.176 HDTV 720P

5 1920*1080 33.75 60.00 74.25 HDTV 1080I

6 1920*1080 33.72 59.94 74.176 HDTV 1080I

7 1920*1080 67.500 60 148.50 HDTV 1080P

8 1920*1080 67.43 59.94 148.352 HDTV 1080P

9 1920*1080 27.000 24.000 74.25 HDTV 1080P

10 1920*1080 26.97 23.97 74.176 HDTV 1080P

11 1920*1080 33.75 30.000 74.25 HDTV 1080P

12 1920*1080 33.716 29.976 74.176 HDTV 1080P

Only for training and service purposes

- 5 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 6

5.4. HDMI 3D Input(1.4b) (OPTION)

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode Proposed

62.938 / 63

1 640*480

31.469 / 31.5

62.938 / 63

2 720*480

31.469 / 31.5

89.91 / 90

3 1280*720

44.96 / 45

67.432 / 67.5

4 1920*1080

33.72 / 33.75

53.946 / 54

5 1920*1080

26.973 / 27

67.432 / 67.5

6 1920*1080

33.716 / 33.75

7 1920*1080 67.43 / 67.5 59.94 / 60 148.35/148.50

59.94/ 60

59.94 / 60

59.94 / 60

59.94 / 60

23.976 / 24

29.97 / 30.00

50.35/50.4

50.35/50.4 Side-by-side(Full)

25.175/25.2

54.001/54.054

54.001/54.054 Side-by-side(Full)

27.00/27.027

148.351/148.5

148.351/148.5 Side-by-side(Full)

74.17/74.25

148.35/148.5

148.35/148.5 Side-by-side(Full)

74.17/74.25

148.351/148.5

148.351/148.5 Side-by-side(Full)

74.176/74.25

148.35/148.5

148.35/148.5 Side-by-side(Full)

74.175/74.25

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Field alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Frame packing

Line alternative

Top-and-Bottom

Side-by-side(half)

Top-and-Bottom

Side-by-side(half)

(SDTV 480P)

(SDTV 480P)

Secondary(SDTV 480P)

Secondary(SDTV 480P)

(SDTV 480P)

Secondary(SDTV 480P)

Secondary(SDTV 480P)

Primary(HDTV 720P)

(HDTV 720P)

(HDTV 720P)

Primary(HDTV 720P)

Primary(HDTV 720P)

Primary(HDTV 1080I)

(HDTV 1080I)

(HDTV 1080I)

Secondary(HDTV 1080I)

Primary(HDTV 1080I)

Primary(HDTV 1080P)

(HDTV 1080P)

(HDTV 1080P)

Primary(HDTV 1080P)

Primary(HDTV 1080P)

(HDTV 1080P)

(HDTV 1080P)

(HDTV 1080P)

(HDTV 1080P)

Secondary(HDTV 1080P)

Primary(HDTV 1080P)

Secondary(HDTV 1080P)

5.5. HDMI-PC 3D Input (OPTION)

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) 3D input proposed mode

1 1024*768 48.363 60.004 65.000 Side by Side , Top & Bottom

2 1360*768 47.712 60.015 85.500 Side by Side , Top & Bottom

3

1920*1080 67.50 60.00 148.50

- 6 -

Only for training and service purposes

Side by Side , Top & Bottom

Checkerboard, Single Frame Sequential

Row Interleaving, Column Interleaving

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 7

5.6. HDMI 3D Input(1.3) (OPTION)

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed 3D input proposed mode

1

1280*720 45.00 60.00 74.25 HDTV 720P

2 1920*1080 33.75 60.00 74.25 HDTV 1080I Side by Side, Top & Bottom

3

1920*1080 67.50 60.00 148.5 HDTV 1080P

4 1920*1080 27.00 24.00 74.25 HDTV 1080P Side by Side, Top & Bottom, Checkerboard

5 1920*1080 33.75 30.00 74.25 HDTV 1080P Side by Side, Top & Bottom, Checkerboard

Side by Side, Top & Bottom,

Single Frame Sequential

Side by Side, Top & Bottom, Checkerboard

Single Frame Sequential, Row Interleaving,

Column Interleaving

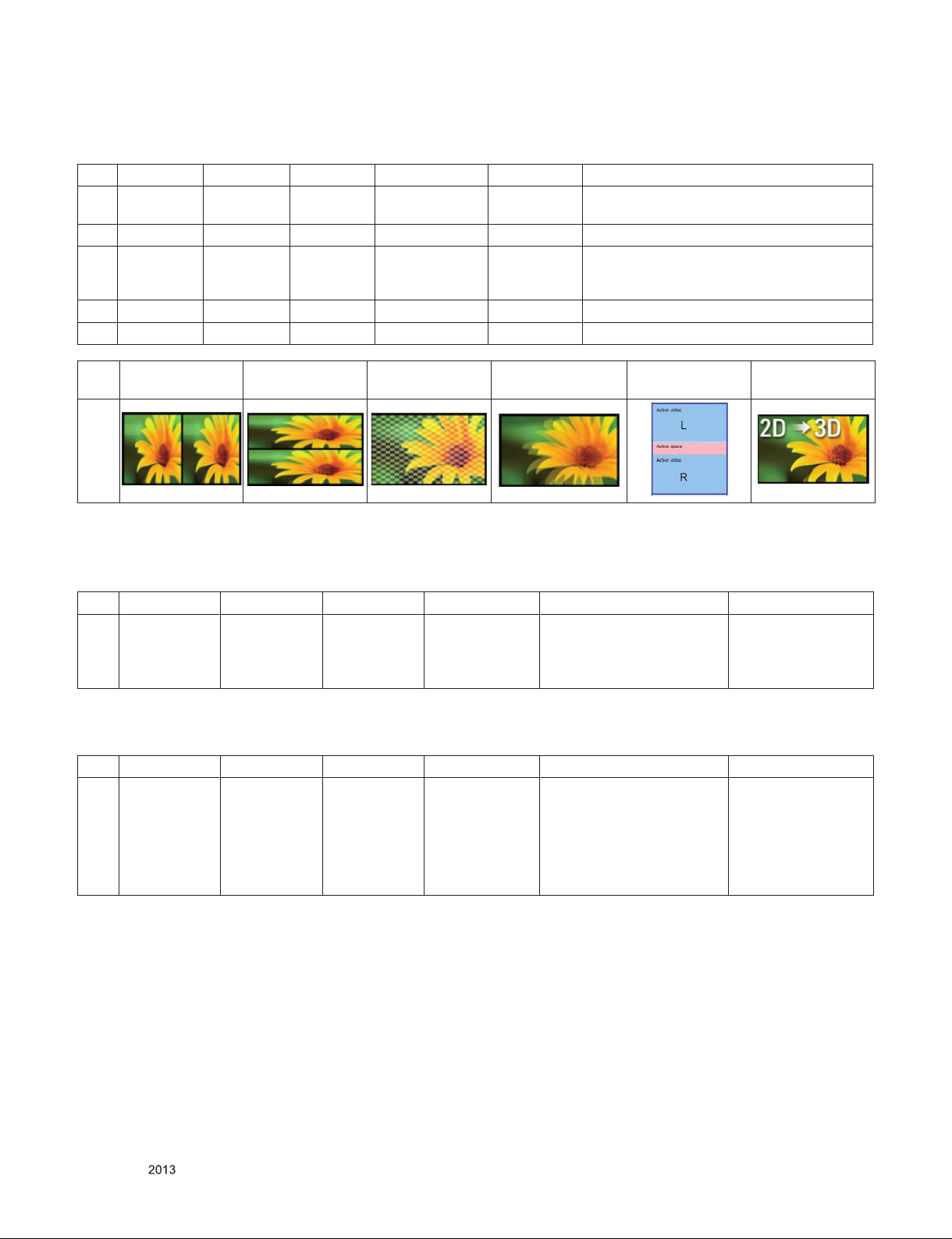

No Side by Side Top & Bottom Checkerboard Single Frame

Sequential

1

Frame Packing 2D to 3D

5.6. USB Input (OPTION)

5.6.1. 3D Auto detection

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) 3D input proposed mode Proposed

1 1920*1080 33.75 30.000 74.25 Side by Side

Top & Bottom

Checkerboard

MPO(Photo)

5.6.1. 3D Auto detection

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) 3D input proposed mode Proposed

1 1920*1080 33.75 30.000 74.25 Side by Side

Top & Bottom

Single Frame Sequential

Row Interleaving

Column Interleaving

[Photo: Side by Side(half)

Top & Bottom]

HDTV 1080P

HDTV 1080P

Only for training and service purposes

- 7 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 8

5.7. RF 3D Input(DTV) (OPTION)

No Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed 3D input proposed mode

1 1280*720 45.000 60 74.25 HDTV 720P Side by Side, Top & Bottom

2 1920*1080 33.75 60 74.25 HDTV 1080I Side by Side, Top & Bottom

5.8. DLNA Input (OPTION)

5.8.1. 3D Auto detection

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) 3D input proposed mode Proposed

1 1920*1080 33.75 30.000 74.25 Side by Side

Top & Bottom

Checkerboard

5.8.2. 3D Manual

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) 3D input proposed mode Proposed

1 1920*1080 33.75 30.000 74.25 Side by Side

Top & Bottom

Checkerboard

Single Frame Sequential

Row Interleaving

Column Interleaving

[Photo: Side by Side(half)

Top & Bottom]

HDTV 1080P

HDTV 1080P

Only for training and service purposes

- 8 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 9

ADJUSTMENT INSTRUCTION

1. Application Range

This spec. sheet applies to LA2FZ Chassis applied LED TV all

models manufactured in TV factory

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25 ±5 °C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100~240V,

50/60Hz.

(5) The receiver must be operated for about 5 minutes prior to

the adjustment when module is in the circumstance of over

15 °C

In case of keeping module is in the circumstance of 0°C, it

should be placed in the circumstance of above 15°C for 2

hours

In case of keeping module is in the circumstance of below

-20°C, it should be placed in the circumstance of above

15°C for 3 hours.

[Caution]

When still image is displayed for a period of 20 minutes or

longer (especially where W/B scale is strong.

Digital pattern 13ch and/or Cross hatch pattern 09ch), there

can some afterimage in the black level area

4. MAIN PCBA Adjustments

4.1. ADC Calibration

- An ADC calibration is not necessary because MAIN SoC

(LGE35230) is already calibrated from IC Maker

- If it needs to adjust manually, refer to appendix.

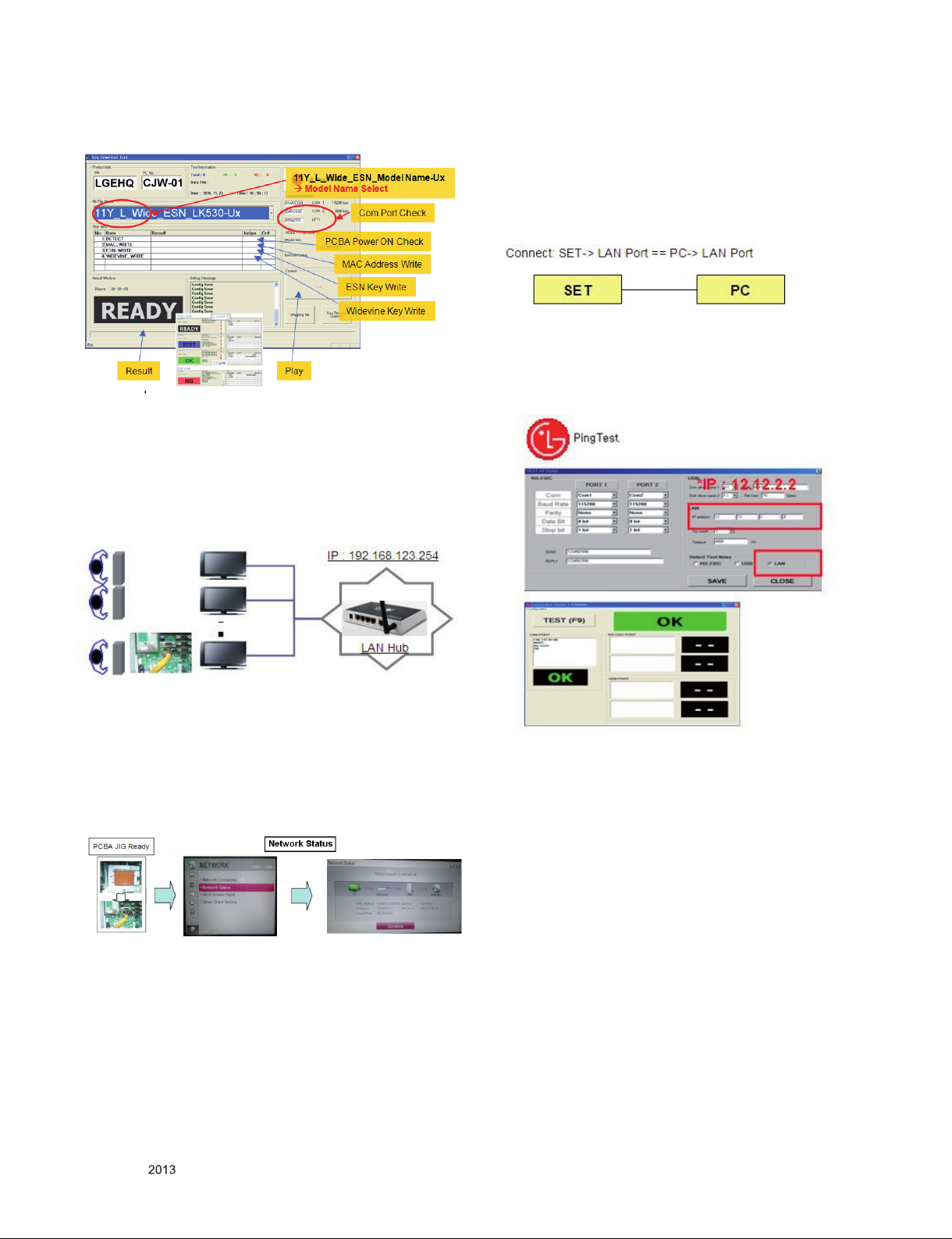

4.2. MAC Address, ESN Key and Widevine

Key download

4.2.1. Equipment & Condition

1) Play file: keydownload.exe

4.2.2. Communication Port connection

1) Key Write: Com 1,2,3,4 and 115200 (Baudrate)

2) Barcode: Com 1,2,3,4 and 9600 (Baudrate)

4.2.3. Download process

1) Select the download items.

2) Mode check: Online Only

3) Check the test process

- US , C anada m o d els: D E T E CT - > M AC_WRI T E ->

WIDEVINE_WRITE

- Korea, Me xic o mo del s: D ETE CT - > MA C_W RIT E ->

WIDEVINE_WRITE

4) Play : START

5) Check of result: Ready, Test, OK or NG

4.2.4. Communication Port connection

1) Connect: PCBA Jig -> RS-232C Port == PC -> RS-232C

Port

3. Adjustment items

3.1. Main PCBA Adjustments

(1) ADC adjustment: Component 480i, 1080p / RGB-PC 1080p

(2) EDID downloads for HDMI and RGB-PC

3.2. Final assembly adjustment

(1) White Balance adjustment

(2) RS-232C functionality check

(3) Factory Option setting per destination

(4) Shipment mode setting (IN-STOP)

(5) GND and HI-POT test

3.3. Appendix

(1) Tool option menu, USB Download (S/W Update, Option and

Service only)

(2) Manual adjustment for ADC calibration and White balance.

(3) Shipment conditions, Channel pre-set

Only for training and service purposes

- 9 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 10

4.2.5. Download

4.2.6. Inspection

- In INSTART menu, check these keys.

4.3. LAN Inspection

4.3.1. Equipment & Condition

▪ Each other connection to LAN Port of IP Hub and Jig

4.4. LAN PORT INSPECTION(PING TEST)

4.4.1. Equipment setting

1) Play the LAN Port Test PROGRAM.

2) Input IP set up for an inspection to Test

Program.

*IP Number : 12.12.2.2.

4.4.2. LAN PORT inspection (PING TEST)

1) Play the LAN Port Test Program.

2) connect each other LAN Port Jack.

3) Play Test (F9) button and confirm OK Message.

4) remove LAN CABLE

4.3.2. LAN inspection solution

▪ LAN Port connection with PCB

▪ Network setting at MENU Mode of TV (Installer Menu -> 119

-> 253 -> Menu)

▪ setting automatic IP

▪ Setting state confirmation

- If automatic setting is finished, you confirm IP and MAC

Address.

Only for training and service purposes

- 10 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 11

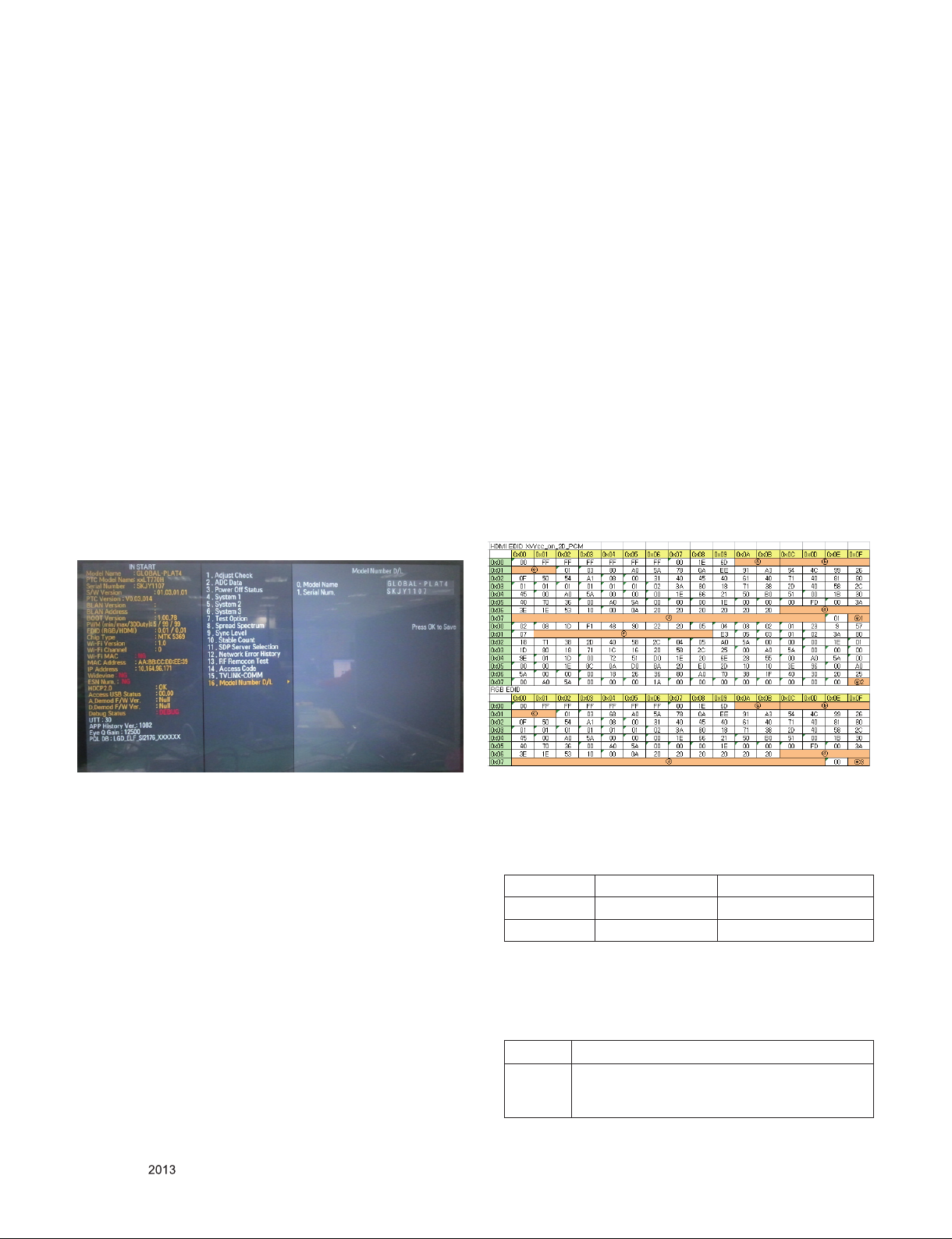

4.5. Model name & Serial number Download

4.5.1. Model name & Serial number D/L

■ Press “Power on” key of service remocon.(Baud rate :

115200 bps)

■ Connect RS232 Signal Cable to RS-232 Jack.

■ Write Serial number by use RS-232.

■ Must check the serial number at Instart menu

4.5.2. Method & notice

A. Serial number D/L is using of scan equipment.

B. Setting of scan equipment operated by Manufacturing

Technology Group.

C. Serial number D/L must be conformed when it is produced

in production line, because serial number D/L is mandatory

by D-book 4.0

※ Manual Download (Model Name and Serial Number)

If th e TV set is do wnl oaded By OTA or Servic e man,

Sometimes model name or serial number is initialized.( Not

always)

There is impossible to download by bar code scan, so It need

Manual download.

a. Press the ‘instart’ key of ADJ remote controller.

b. Go to the menu ‘16.Model Number D/L’ like below photo.

c. Input the Factory model name(ex 47LM960V-ZA) or Serial

number like photo.

4.6. EDID Download

4.6.1. Overview

- It is a VESA regulation. A PC or a MNT will display an optimal

resolution through information sharing without any necessity

of user input. It is a realization of “Plug and Play”.

4.6.2. Equipment

(1) Since EDID data is embedded, EDID download JIG, HDMI

cable and D-sub cable are not need.

(2) Adjust by using remote controller.

4.6.3. Download method

(1) Press Adj. key on the Adj. R/C,

(2) Select EDID D/L menu.

(3) By pressing Enter key, EDID download will begin

(4) If Download is successful, OK is display, but If Download is

failure, NG is displayed.

(5) If Download is failure, Re-try downloads.

※Caution: When EDID Download, must remove RGB/HDMI

Cable.

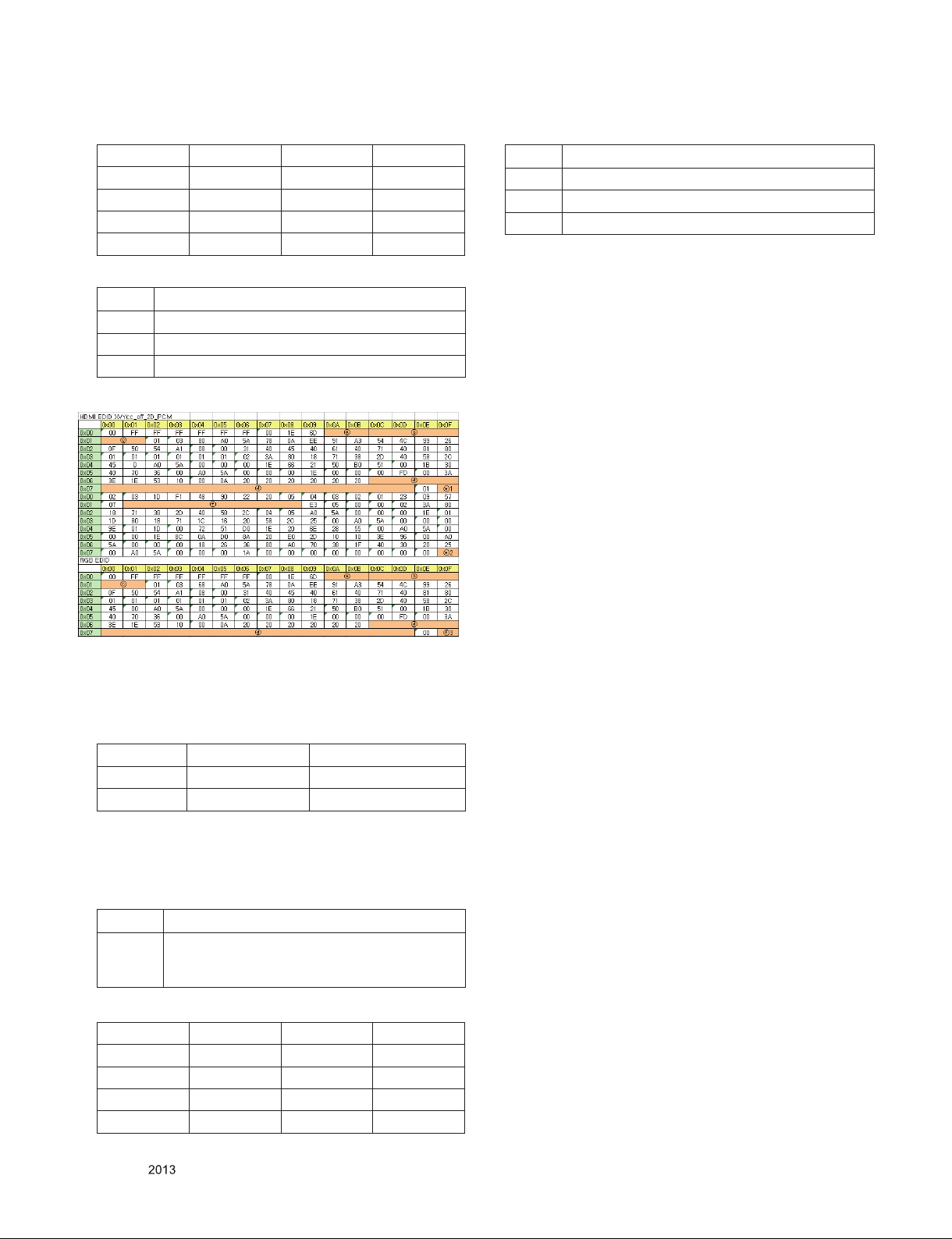

4.6.4. EDID DATA

4.6.4.1. PCM(US) _ XvYcc : 0n

d. Check the model name Instart menu -> Factory name

displayed (ex 47LM960V-ZA)

e. Check the Diagnostics (DTV country only) -> Buyer model

displayed (ex 47LM960V-ZA)

Only for training and service purposes

- 11 -

▪Reference

- HDMI1 ~ HDMI3 / RGB

- In the data of EDID, bellows may be different by S/W or Input

mode.

ⓐ Product ID

HEX EDID Table DDC Function

0001 0100 Analog

0001 0100 Digital

ⓑ Serial No: Controlled on production line.

ⓒ Month, Year: Controlled on production line:

ex) Monthly : ‘01’ -> ‘01’

Year : ‘2012’ -> ‘16’

ⓓ Model Name(Hex): LGTV

Chassis MODEL NAME(HEX)

LA2FF/

LA2FZ/

LA3BF

00 00 00 FC 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 12

ⓔ Checksum(LG TV): Changeable by total EDID data.

ⓔ1 ⓔ2 ⓔ3

HDMI1 43 B5 X

HDMI2 43 A5 X

HDMI3 43 95 X

RGB X X 5C

ⓕ Vendor Specific(HDMI)

INPUT MODEL NAME(HEX)

HDMI1 67 03 0C 00 10 00 80 2D

HDMI2 67 03 0C 00 20 00 80 2D

HDMI3 67 03 0C 00 30 00 80 2D

ⓕ Vendor Specific(HDMI)

INPUT MODEL NAME(HEX)

HDMI1 67 03 0C 00 10 00 80 2D

HDMI2 67 03 0C 00 20 00 80 2D

HDMI3 67 03 0C 00 30 00 80 2D

4.6.4.2. PCM(US) _XvYcc : off

▪Reference

- HDMI1 ~ HDMI3 / RGB

- In the data of EDID, bellows may be different by S/W or Input

mode.

ⓐ Product ID

HEX EDID Table DDC Function

0001 0100 Analog

0001 0100 Digital

ⓑ Serial No: Controlled on production line.

ⓒ Month, Year: Controlled on production line:

ex) Monthly : ‘01’ -> ‘01’

Year : ‘2012’ -> ‘16’

ⓓ Model Name(Hex): LGTV

Chassis MODEL NAME(HEX)

LA2FF/

LA2FZ/

LA3BF

00 00 00 FC 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20

5. Final Assembly Adjustment

5.1. White Balance Adjustment

5.1.1. Overview

5.1.1.1. W/B adj. Objective & How-it-works

(1) Objective: To reduce each Panel’s W/B deviation

(2) How-it-works: When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic Range. In order to

prevent saturation of Full Dynamic range and data, one of

R/G/B is fixed at 192, and the other two is lowered to find

the desired value.

(3) Adj. condition: normal temperature

- Surrounding Temperature: 25±5 °C

- Warm-up time: About 5 Min

- Surrounding Humidity: 20% ~ 80%

- Before White balance adjustment, Keep power on status,

don’t power off

5.1.1.2. Adj. condition and cautionary items

(1) Lighting condition in surrounding area surrounding lighting

should be lower 10 lux. Try to isolate adj. area into dark

surrounding.

(2) Probe location: Color Analyzer (CA-210) probe should be

within 10cm and perpendicular of the module surface

(80°~ 100°)

(3) Aging time

- After Aging Start, Keep the Pow er ON status during 5

Minutes.

- In case of LCD, Back-light on should be checked using no

signal or Full-white pattern.

5.1.2. Equipment

(1) Color Analyzer: CA-210 (NCG: CH 9 / WCG: CH12 / LED:

CH14)

(2) Adj. Computer (During auto adj., RS-232C protocol is

needed)

(3) Adjust Remocon

(4) Vid eo Sign al Gene rator MSP G-925 F 720p/20 4-Gray

(Model: 217, Pattern: 49)

※ Color Analyzer Matrix should be calibrated using CS-1000

ⓔ Checksum(LG TV): Changeable by total EDID data.

ⓔ1 ⓔ2 ⓔ3

HDMI1 43 68 X

HDMI2 43 58 X

HDMI3 43 48 X

RGB X X 5C

Only for training and service purposes

- 12 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 13

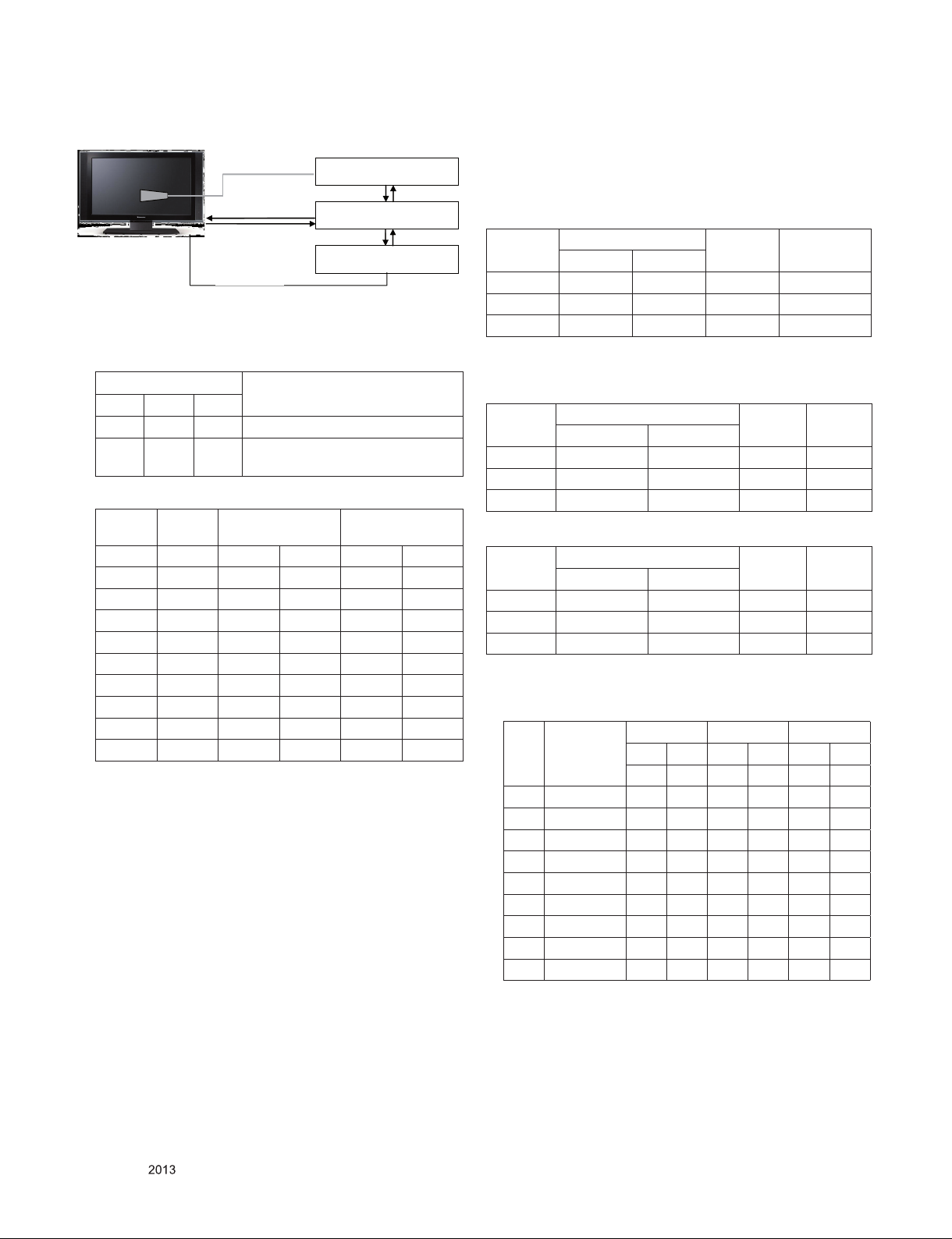

5.1.3. Equipment connection

If TV internal pattern is used, not needed

Color Analyzer

Probe

※

RS-232C

Signal Source

※

Pattern Generator

RS-232C

Computer

RS-232C

5.1.4. Adjustment Command (Protocol)

(1) RS-232C Command used during auto-adj.

RS-232C COMMAND

CMD DATA ID

Explanation

Wb 00 00 Begin White Balance adj.

Wb 00 ff End White Balance adj.

(internal pattern disappears )

(2) Adjustment Map

Adj. item Command

(lower caseASCII)

CMD1 CMD2 MIN MAX

Cool R Gain j g 00 C0

G Gain j h 00 C0

B Gain j i 00 C0

Medium R Gain j a 00 C0

G Gain j b 00 C0

B Gain j c 00 C0

Warm R Gain j d 00 C0

G Gain j e 00 C0

B Gain j f 00 C0

Data Range

(Hex.)

5.1.5. Adjustment method

5.1.5.1 Auto WB calibration

(1) Set TV in ADJ mode using P-ONLY key (or POWER ON

key)

(2) Place optical probe on the center of the display

- It need to check probe condition of zero calibration before

adjustment.

(3) Connect RS-232C Cable

(4) Select mode in ADJ Program and begin a adjustment.

(5) When WB adjustment is completed with OK message,

check adjustment status of pre-set mode (Cool, Medium,

Warm)

(6) Remove probe and RS-232C cable.

▪ W/B Adj. must begin as start command “wb 00 00” , and

finish as end command “wb 00 ff”, and Adj. offset if need

5.1.7. Reference (White Balance Adj. coordinate and

color temperature)

※ LT Series (don’t use G Gain fix(172))

▪ Luminance: 204 Gray

▪ Standard color coordinate and temperature using CS-1000

(over 26 inch)

Mode

Cool 0.269 0.273 13,000K 0.0000

Medium 0.285 0.293 9,300K 0.0000

Warm 0.313 0.329 6,500K 0.0000

▪ St a n d a r d color coord i n a t e a n d t emperatu r e u s i n g

CA-210(CH 14)

(1) LGD

Mode

Cool 0.269±0.002 0.273±0.002 13,000K 0.0000

Medium 0.285±0.002 0.293±0.002 9,300K 0.0000

Warm 0.313±0.002 0.329±0.002 6,500K 0.0000

(2) O/S Module(AUO, CMI, Sharp,IPS…)

Mode

Cool 0.271±0.002 0.276±0.002 13,000K 0.0000

Medium 0.287±0.002 0.296±0.002 9,300K 0.0000

Warm 0.315±0.002 0.332±0.002 6,500K 0.0000

▪ St a n d a r d color coord i n a t e a n d t emperatu r e u s i n g

CA-210(CH-14) – by aging time

(1) Edge LED models (applied only LGD Module) in LGERS

GP4

1 0-2 279 288 295 308 319 338

2 3-5 278 286 294 306 318 336

3 6-9 277 285 293 305 317 335

4 10-19 276 283 292 303 316 333

5 20-35 274 280 290 300 314 330

6 36-49 272 277 288 297 312 327

7 50-79 271 275 287 295 311 325

8 80-149 270 274 286 294 310 324

9 Over 150 269 273 285 293 309 323

Coordinate

X Y

X Y

X Y

Aging time

(Min)

Temp △uv

Coordinate

Coordinate

Cool Medium Warm

X Y X Y X Y

269 273 285 293 313 329

Temp △uv

Temp △uv

5.1.6. Reference (White Balance Adj. coordinate and

color temperature)

(1) Luminance: 204 Gray, 80IRE

(2) Standard color coordinate and temperature using CS-1000

(over 26 inch)

Only for training and service purposes

- 13 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 14

5.2. Tool Option selection

▪ Method: Press Adj. key on the Adj. R/C, then select Tool

option

Model 32LT777H-UA

tool option 1 4100 5 6 7

tool option 2 8389 8389 8389 8389

tool option 3 9229 9229 9229 9229

tool option 4 13006 13006 13004 13004

tool option 5 4315 4187 4187 4187

tool option 6 1305 1305 1305 1305

Tool option 7 128 128 4224 4224

Commercial

Tool Option

Country Group 02 02 02 02

(LGD)

1555 1555 1555 1555

● Tool option can be reconstructed by Software

37LT777H-UA 42LT777H-UA 47LT777H-UA

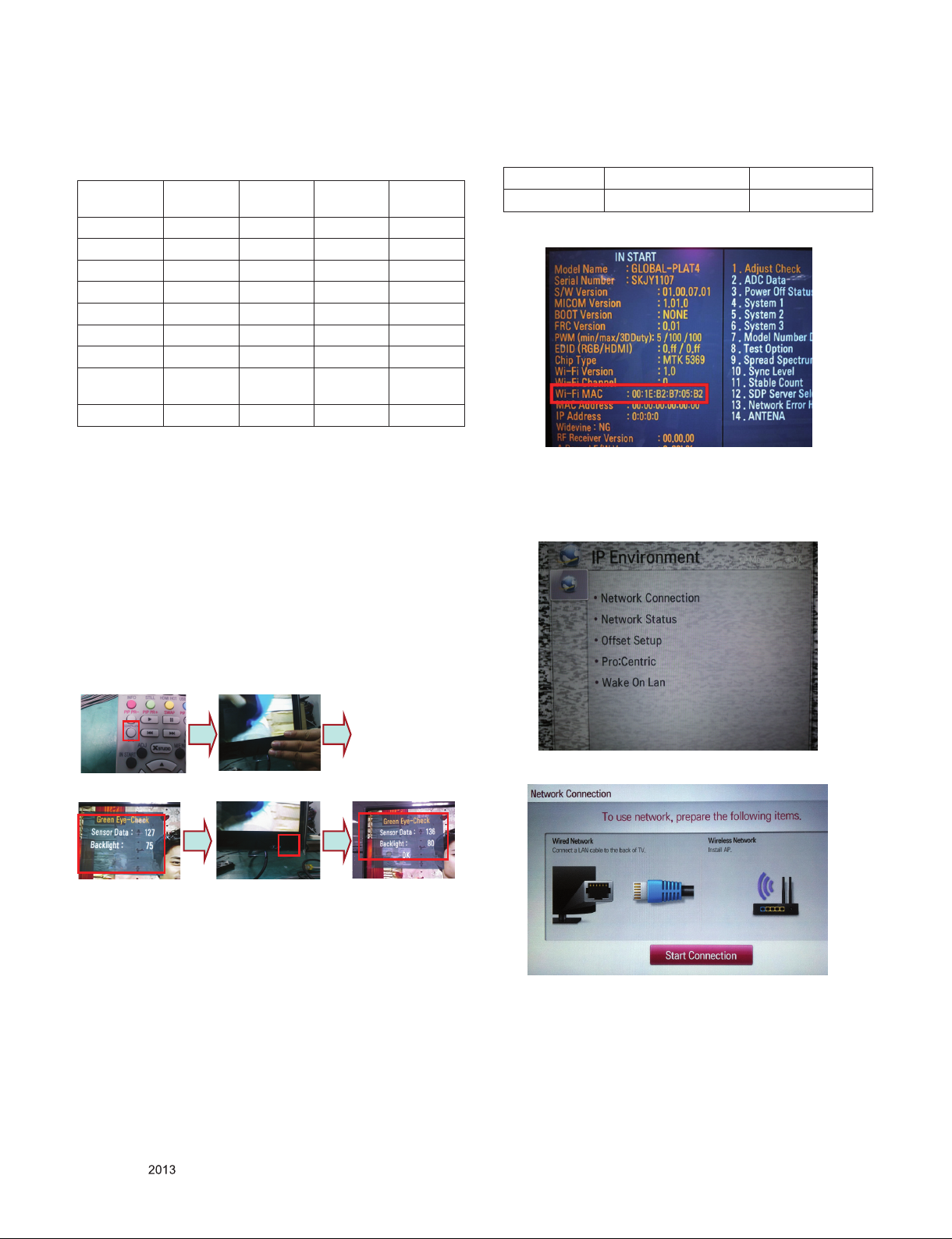

5.4. Wi-Fi MAC Address Check

5.4.1. Using RS232 Command

Command Set ACK

Transmission [A][l][][Set ID][][20][Cr] [O][K][x] or [N][G]

5.4.2. Check the menu on in-start

5.3. EYE-Q Check

Step 1) Turn on the TV..

Step 2) Press 'EY E bu tto n' on the adj ustment rem ote -

controller.

Step 3) Cover 'Eye Q sensor' on the front of set with your

hands, hold it for 6 seconds.

Step 4) Check "the Sensor Data" on the screen, make certain

that Data is below 10. If Data isn’t below 10 in 6

seconds, Eye Q sensor would be bad. You should

change Eye Q sensor.

Step 5) Uncover your hands from Eye Q sensor, hold it for 6

seconds.

Step 6) Check "Back Light(xxx)" on the screen, check data

<Step 2>

<Step 4>

increase . You should change Eye Q sensor.

<Step 3>

<Step 5>

<Step 6>

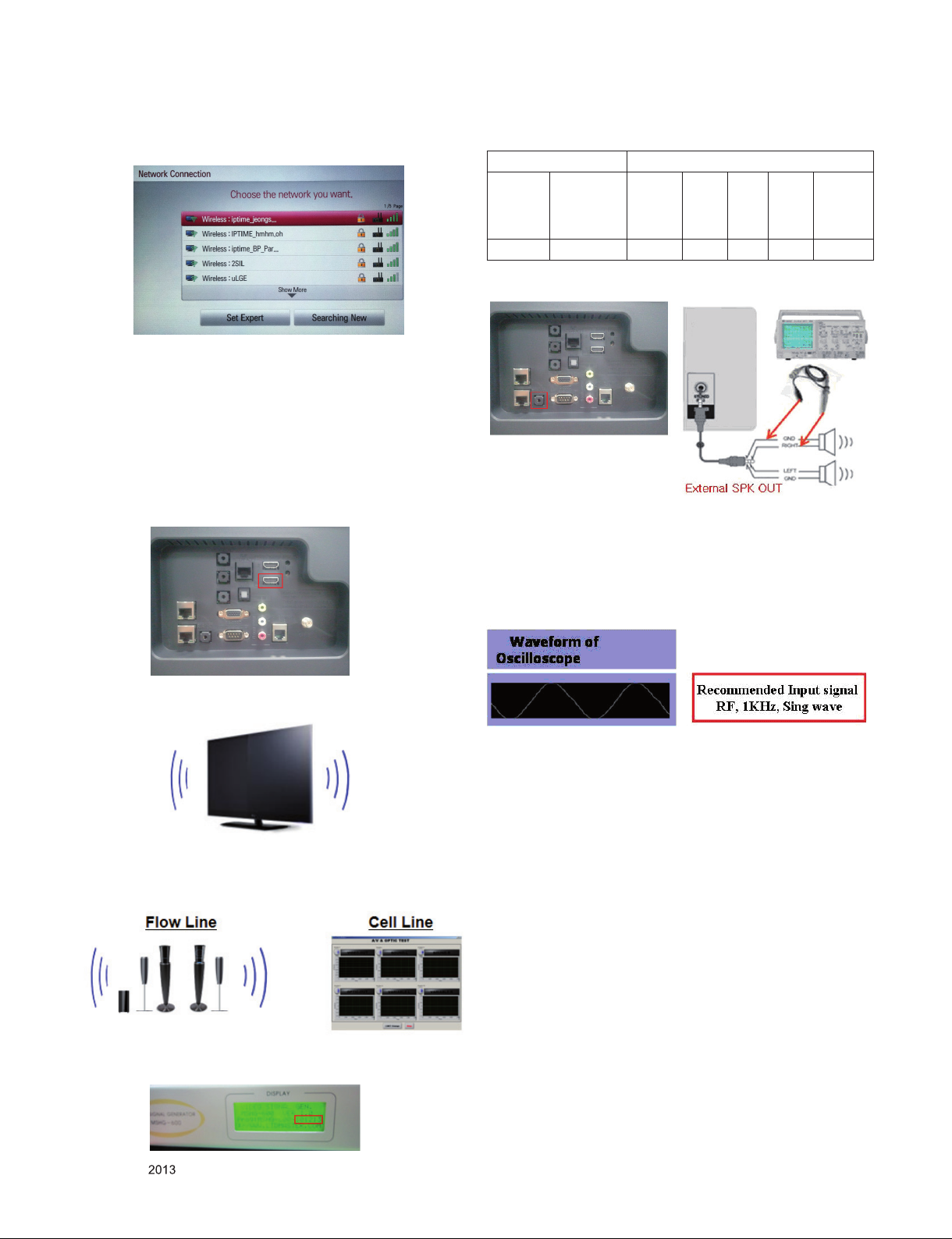

5.5. Wi-Fi Test

Step 1) Turn on TV

Step 2) Select Network Connection option in Network Menu.

Installer menu -> 119 -> 253 -> Menu

Step 3) Select Start Connection Button in Network Connection.

Only for training and service purposes

- 14 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 15

Step 4) If the system finds any AP like blow PIC, it is working

well

5.6. HDMI ARC Function Inspection

5.6.1. Test equipment

- Optic Receiver Speaker

- MSHG-600 (SW: 1220 ↑)

- HDMI Cable (for 1.4 version)

5.6.2. Test method

(1) Insert the HDMI Cable to the HDMI ARC port from the

master equipment (HDMI1)

6. Check Commercial features

Model info. Commercial Feature

Name inch IR Out DC

Power

(12V)

LT770H-UA 32/37/42/47/55 O O O O O

6.1. External SPK Out

6.1.1. Equipment & Condition

▪ Jig (Speaker out JIG) or Oscilloscope

▪ Power only mode

6.1.2. Check the speaker out

1) Connect the External Speaker : check the sound

Connect oscilloscope, you can see this waveform

Out

Ext

SPK

Out

RJP

(RJ-45

interface)

Pro:Idiom

(2) Check the sound from the TV Set

(3) Check the Sound from the Speaker or using AV & Optic

TEST program (It’s connected to MSHG-600)

* Remark: Inspect in Power Only Mode and check SW version

in a master equipment

6.2. IR Out and DC Power Outlet (12V)

6.2.1. Equipment & Condition

▪ Jig (commercial check JIG)

▪ Special 232C Cable for commercial check Jig

▪ Power only mode

▪ PCB Mode (installer menu -> 118 -> 9 )

Only for training and service purposes

- 15 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 16

6.2.2. Check the power out & IR out – commercial

check jig

(1) Connect each other RS232c port on the Commercial Check

JIG

(2) Press RED Color Button on SVC Remote-controller in

power only mode (or PCB Mode)

(3) Check the LED of jig board

- +12V LED (OK condition: Turn On)

- IR LED (OK condition: blinking)

6.2.3. Check the power out & IR out – mini jig

(1) Connect mini jig on RS232c port

(2) Press RED Color Button on SVC Remote-controller in

power only mode (or PCB Mode)

(3) Check the LED of mini jig

6.3. RJP Check

6.3.1. Initial setting

(1) Select Power switch ( up ) as the picture

(2) Set the Switch No.5 to ON (up) as the picture

Others should be set to OFF (down)

6.3.2. Checking Guide

(1) Press the P-ONLY key of R/C

(2) Press the Exit key of R/C

(3) Connect with the TV through RJP cable (wait for the JIG

on)

(4) RJP Pin check is carried out automatically

(5) The result is shown as below

(6) If RJP Pin check finished or you check other function, must

remove the RJP cable from TV

6.2.4. Check the power out & IR out – New jig

(1) Of the DFT process performance tests showing Waite

Massage automatically scan pause

(2) Adjust the remote control Press any Key IR Out Make sure

that only Nomal LED blinks.

(3) ETC Key -> red Pressing the Info Key

i) 5V Out Output 3 seconds

ii) 5V output OFF

iii) 12V Out Output 3 seconds

iv) 12V output OFF(Given the ST output time adjustable)

(4) Nomal LED, 5V LED, 12V LED flicker worker using the

PASS.

(5) After the check is complete automatic test is initiated.

Only for training and service purposes

- 16 -

* RJP Cable : Direct LAN Cable

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 17

6.4. Pro:Idiom Check

(1) Connect the RF Cable

(2) Turn to the Pro:Idiom channel (No. 96-1)

(3) Check the video & sound

** Only displayed at “POWER ONLY” mode

6.5. b-LAN Main board Check

6.5.1. Overview

It is LNET RF modem & FTG card

6.5.2. Equipment

(1) b-LAN Checker: UTC-1000 (with Cable accessory)

(2) Computer(for test result monitoring)

(3) Connection JIG

6.5.3. Equipment connection map & b-LAN Check

6.5.4. Check

6.5.4.1. Setting Procedure

(1) Setting JIG

i) Connect UTC-1000 Equipment to JIG device as a like left

picture

(2) Working procedure

i) Connection

UTC-1000 LAN <- -> PC LAN Port

UTC-1000 TOP1 <- -> Game port(RJ21)

-> TV-LINK CFG (Phone Jack)

UTC-1000 RF1 <- -> b-LAN RF IN

ii) Power on JIG : Switch on front of the JIG

iii) Test Start

UTC-1000 TOP2 <- -> JIG 11pin Connection

iv) Checking b-LAN MAC Address

Check whether it is same their address numbers or not

between b-LAN Label and on the pc address numbers.

※ Checking JIG contents

(1) Check whether displaying all “Pass” or not at the number

3.4.6.7.9 contents of UTC-1000 on the PC

(2) Check “Version 6.27” of the 1. b-LAN Application version

(3) Check whether it is same their address numbers or not

between b-LAN Label and

(4) MAC Address on the pc.

6.6. Ship-out mode check (In-stop)

▪ After final inspection, press In-Stop key of the Adj. R/C and

check that the unit goes to Stand-by mode

Only for training and service purposes

- 17 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 18

7. AUDIO output check

7.1. Audio input condition

(1) RF input: Mono, 1KHz sine wave signal, 100% Modulation

(2) CVBS, Component: 1KHz sine wave signal (0.4Vrms)

(3) RGB PC: 1KHz sine wave signal (0.7Vrms)

7.2. Specification

No Item Min Typ Max Unit Remark

1 Audio

practical

max Output,

L/R

9.0

8.5

10.0

8.9

12.0

9.9WVrms

(1) Measurement

condition

- EQ/AVL/Clear

Voice: Off

(2) Speaker (8Ω

Impedance)

8. GND and HI-POT Test

8.1. GND & HI-POT auto-check preparation

(1) Check the POWER CABLE and SIGNAL CABE insertion

condition

8.2. GND & HI-POT auto-check

(1) Pallet moves in the station. (POWER CORD / AV CORD is

tightly inserted)

(2) Connect the AV JACK Tester.

(3) Controller (GWS103-4) on.

(4) GND Test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, execute next process (Hi-pot test).

(Remove A/V CORD from A/V JACK BOX)

(5) HI-POT test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, GOOD Lamp on and move to next process

automatically.

9. USB S/W Download

(Optional, Service only)

(1) Put the USB Stick to the USB socket

(2) Automatically detecting update file in USB Stick

- If your downloaded program version in USB Stick is Lower,

it didn’t work. But your downloaded version is Higher, USB

data is automatically detecting

(Download Version Hig h & Powe r on ly mode, Set is

automatically Download)

(3) Show the message “Copying files from memory”

(4) Updating is staring

8.3. Checkpoint

(1) Test voltage

- GND: 1.5KV/min at 100mA

- SIGNAL: 3KV/min at 100mA

(2) TEST time: 1 second

(3) TEST POINT

- GND Test = POWER CORD GND and SIGNAL CABLE GND.

- Hi-pot Test = POWER CORD GND and LIVE & NEUTRAL.

(4) LEAKAGE CURRENT: At 0.5mArms

Only for training and service purposes

- 18 -

(5) Updating Completed, The TV will restart automatically

(6) If your TV is turned on, check your updated version and

Tool option. (explain the Tool option, next stage)

* If downloading version is more high than your TV have, TV

can lost all channel data. In this case, you have to channel

recover. if all channel data is cleared, you didn’t have a

DTV/ATV test on production line.

* After downloading, have to adjust TOOL OPTION again.

(1) Push "IN-START" key in service remote controller.

(2) Select "Tool Option 1" and Push “OK” button.

(3) Punch in the number. (Each model has their number.)

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 19

10. Optional adjustments

10.1. Manual ADC Calibration

10.1.1. Equipment & Condition

(1) Adjustment Remocon

(2) 801GF (80 2B, 802F, 80 2R) or MSPG92 5FA Pat tern

Generator

- Resolution : 48 0 i Comp1 ( MSPG-925FA : m o d e l - 2 0 9 ,

pattern-65)

- Resolution : 10 80p C o mp1 ( MSPG -925 FA : mod e l-2 2 5,

pattern-65)

- Resolution : 1080p R G B ( M S P G - 9 2 5 F A : model-22 5 ,

pattern-65)

- Pattern : Horizontal 100% Color Bar Pattern

- Pattern level : 0.7±0.1 Vp-p

10.1.2. Adjust method

8.1.2.1 ADC 480i/1080p Comp1, RGB

(1) Check connected condition of Comp1/RGB cable to the

equipment

(2) Give a 480i Mode, Horizontal 100% Color Bar Pattern to

Comp1. (MSPG-925FA -> Model: 209, Pattern: 65)

(3) Change input mode as Component1 and picture mode as

“Standard”

(4) Press the In-start Key on the ADJ remote after at least 1

min of signal reception. Then, select 7.External ADC. And

Press OK or Right Button for going to sub menu.

(5) Press OK in Comp 480i menu

(6) Give a 1080p Mode, Horizontal 100% Color Bar Pattern to

Comp1. (MSPG-925FA -> Model: 225, Pattern: 65)

(7) Press OK in Comp 1080p menu

(8) Perform (6) and (7) in RGB-PC

(9) If ADC Comp is successful, “ADC Component Success” is

displayed. If ADC calibration is failure, “ADC Component

Fail” is displayed.

(10) If ADC calibration is failure, after rechecking ADC pattern

or condition, retry calibration

(11) If AD C RG B ca lib rat ion is s ucc ess ful , “A DC R GB

Success” is displayed. If ADC calibration is failure, “ADC

RGB Fail” is displayed.

(12) If ADC calibration is failure, after recheck ADC pattern or

condition, retry calibration

10.2. Manual White balance Adjustment

10.2.1. Adj. condition and cautionary items

(1) Lighting condition in surrounding area surrounding lighting

should be lower 10 lux. Try to isolate adj. area into dark

surrounding.

(2) Probe location: Color Analyzer (CA-210) probe should be

within 10cm and perpendicular of the module surface

(80°~ 100°)

(3) Aging time

▪ After Aging Start, Keep the Power ON status dur ing 5

Minutes.

▪ In case of LCD, Back-light on should be checked using no

signal or Full-white pattern.

10.2.2. Equipment

(1) Color Analyzer: CA-210 (NCG: CH 9 / WCG: CH12 / LED:

CH14)

(2) Adj. Computer (During auto adj., RS-232C protocol is

needed)

(3) Adjust Remocon

(4) Vid eo Si gnal Ge nerat or MSPG -925F 720p/2 16-Gr ay

(Model: 217, Pattern: 78)

10.2.3. Adjustment

(1) Set TV in Adj. mode using POWER ON

(2) Zero Calibrate the probe of Color Analyzer, then place it on

the center of LCD module within 10cm of the surface.

(3) Press ADJ key -> EZ adjust using adj. R/C -> 6. White-

Balance then press the cursor to the right (KEY►).

When KEY(►) is pressed 216 Gray internal pattern will be

displayed.

(4) One of R Gain / G Gain / B Gain should be fixed at 192,

and the rest will be lowered to meet the desired value.

(5) Adj. is performed in COOL, MEDIUM, WARM 3 modes of

color temperature.

▪ If internal pattern is not available, use RF input. In EZ Adj.

menu 6.White Balance, you can select one of 2 Test-pattern:

ON, OFF. Default is inner(ON). By selecting OFF

Only for training and service purposes

- 19 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 20

TROUBLESHOOTING

Power-Up Boot Fail Trouble Shooting guide

Check P2401 All

Voltage Level (3.5V, 12V, 24V)

Y

Check Q2407 output Voltage(12V)

Y

Check LVDS Cable

Y

Check LCD Module

Control board

N

Check power connector and

RL_ON signal OK ?

N

Check Q2407 application circuit

Or replace Q2407

N

Replace Cable

No OSD Trouble Shooting guide

Check P2401 All

Voltage Level (3.5V, 12V, 24V)

N

Check power connector and

RL_ON signal OK ?

N

Replace Power Board

N

Replace Power Board

Y

Check IC8701 RESET and

UPDATE pin

Y

Check X8700 Clock

32.768KHz

Y

Check IC8701 IIC

Comm unication status

Y

Check IR input state of IC8701

57pin

Y

Re-down load PTC Micom

N

Check switch SW8700, SW8701

N

Check X8700 application circuit

or Replace X8700

N

Check IIC lin e or replace IC8701

N

Check IR board

Only for training and service purposes

- 20 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 21

Analog RF Video Trouble Shooting guide

Check RF cable & signal

Y

Check TU8900 Pin5

(Video output)

Y

Check tu ner 5V power R8953

Y

Check tu ner 3.3V power L8904

Y

Check tu ner 1.8V power IC8900

2pin : 1.8V

Y

Check MTK LVDS output

N

N

N

N

N

Replace Tu ner.

Y

Check IC2404

Replace L8904

Replace IC8900

Replace IC105

N

Replace IC2404

Only for training and service purposes

- 21 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 22

Digital RF Trouble Shooting guide

Check RF cable & signal

Y

Check tu ner 5V power R8953

Y

Check IIC Sign al

TU8900 Pin#4,12

Y

Check DIF Signal

TU8900 Pin#6,14

Y

Check X100

and application circuit

Replace IC105

N

N

N

N

Check IC2404

Replace TU8900

Replace TU8900

Replace X100

N

Replace IC2404

Only for training and service purposes

- 22 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 23

Composite Video Trouble Shooting guide

Check inpu t signal format.

Is it supported?

Y

Check AC cable for damage

For damage or open condu ctor

Y

Check JK3800

Can you see the normal waveform?

Y

Check th e input of MTK(IC105).

Measure waveform at C360 becau se it’s more easy to check.

Can you see the normal waveform?

Y

This board has big problem because Main chip (MTK) have some trou bles.

After checking th oroughly all path once again, You should decide to replace MTK or not.

N

Replace JK3800

HDMI Video Trouble Shooting guide

Check inpu t signal format.

Is it supported?

Y

Check AC cable for damage

For damage or open condu ctor

Y

Check JK3301/JK3302/JK3303

Can you see the normal waveform?

Y

Check HDCP key NVRAM(IC100)

Power & I2C signal

Y

Check th e input of MTK(IC105).

Measure waveform at R3314, R3315, R3308, R3309, R3328, R3329 becau se it’s more easy to check.

Can you see the normal waveform?

Y

This board has big problem because Main chip (MTK) have some trou bles.

After checking th oroughly all path once again, You should decide to replace MTK or not.

N

Replace JK3301, JK3302, JK3303

N

Replace IC100

Only for training and service purposes

- 23 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 24

RGB-PC Video Trouble Shooting guide

Check inpu t signal format.

Is it supported?

Y

Check AC cable for damage

For damage or open condu ctor

Y

Check JK3603

Can you see the normal waveform?

Y

Check th e input of MTK(IC105).

Measure waveform at R323, R324 because it’s more easy to check.

Can you see the normal waveform?

Y

This board has big problem because Main chip (MTK) have some trou bles.

After checking th oroughly all path once again, You should decide to replace MTK or not.

N

Replace JK3603

Analog RF Audio Trouble Shooting guide

Check RF cable & signal

Check TU8900 Pin2

(SIF output)

Y

Check Audio AMP ou tput

L5402,L5403,L5404,L5405

Y

Check IC5400

Y

Check C352

(SIF signal to IC105)

Y

Replace IC105

N

N

N

Replace Tu ner

Replace L5402,L5403,L5404,L5405

Replace IC5400

Only for training and service purposes

- 24 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 25

Composite / RGB-PC Audio in Trouble Shooting guide

Check inpu t signal format.

Is it supported?

Y

Check AC cable for damage

For damage or open condu ctor

Y

Check JK3800

Can you see the normal waveform?

Y

Check th e input of MTK(IC105).

Measure waveform at C345, C346, C319, C320 because it’s more easy to check.

Can you see the normal waveform?

Y

Check Audio AMP ou tput

L5402,L5403,L5404,L5405

Y

This board has big problem because Main chip (MTK) have some trou bles.

After checking th oroughly all path once again, You should decide to replace MTK or not.

N

N

Replace L5402,L5403,L5404,L5405

Replace JK3800

HDMI Audio in Trouble Shooting guide

Check inpu t signal format.

Is it supported?

Y

Check AC cable for damage

For damage or open condu ctor

Y

Check JK3301/JK3302/JK3303

Can you see the normal waveform?

Y

Check Audio AMP ou tput

L5402,L5403,L5404,L5405

Y

This board has big problem because Main chip (MTK) have some trou bles.

After checking th oroughly all path once again, You should decide to replace MTK or not.

Only for training and service purposes

N

N

Replace L5402,L5403,L5404,L5405

Replace JK3301, JK3302, JK3303

- 25 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 26

BLOCK DIAGRAM

RJ12

RF

Rear

(256Kb)

SYSTEM EEPROM X 1

SYSTEM

DDR3 X 4

I2C

(2Gb)

b-L AN

SM ART

I2C

IC

Dmod.

A/V

M ain

SIF

CVBS(M)

DIF(+/-)

CVBS

Demod

MPI/SPI

Pro:idiom

I2C

TS_S

TS_S/P

S/W

PTC

(MICOM)

( RX/TX)

DEBUG

RS-232C

IR &Key

RJP

Speaker

S e nsor

Inteligent

( HD)

( FHD)

I2C

MDC/MDIO

37 / 4 2/47

30P

51P

(8bit)

LVDS

L

32

R

AMP

Audio

HDCP

I2C

EEPROM

I2S Out

최대 동작주파수 : 800 MHz

MT5369

NAND

Flash(2GB)

I2C

Side

USB

(DP/D M)

(HUB)

USB1

USB2

HDMI3

Local Dimming

S/W

HDMI

(ARC)

HDMI1

HDMI2

(RX/TX)

Ethernet

PHY

HUB IC

Ethernet

LAN1

LAN2

Chip

MDC/MDIO

CVBS

L/R OUT

Video

Video

Audio

Audio

RGB,H/V

Audio

SPDIF OUT

AMP

Ext SPK

Rear

A/V1

PC-Audio

PC-RGB

OPTIC

Ext SPK

Wi-Fi

Only for training and service purposes

- 26 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 27

521

EXPLODED VIEW

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essenti al that these spe cial safe ty parts should be replace d with the same compon ents as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

400

510

500

IMPORTANT SAFETY NOTICE

LV1

200

800

540

530

501

550

810

120

910

A10

A7

900

* Set + Stand

* Stand Base + Body

300

Only for training and service purposes

- 27 -

A21

A2

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 28

M_RFModule_ISP

Copyright ⓒ 2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

EAX6430790* : LD22* / LC22*

EAX6443420* : LT22* / LJ22* / LA22* / LB22*

+3.3V_NORMAL

R103

R104

4.7K

OPT

4.7K

R105

NVRAM

IC104

AT24C256C-SSHL-T

OPT

4.7K

A0

1

A1

2

A2

3

GND

4

8

7

6

5

NVRAM_ATMEL

HDCP EEPROM

HDCP_EEPROM_ST

IC100

M24C16-R

VCC

8

1

WC

2

7

SCL

3

6

SDA

4

5

I2C

R128

1.2K

R110 33

R111 33

R112 33

R113 33

R114 33

R115 33

R116 33

R117 33

R118 33

R121 33

R122 33

R123 33

R108

R106

4.7K

MTK_FHD

MTK_Int_FRC/URSA5

R107

4.7K

R109

MTK_HD

MTK_NO_FRC/FRC3

STB_SCL

STB_SDA

OPCTRL_11_SCL

OPCTRL_10_SDA

OSCL1

OSDA1

OSCL2

OSDA2

OSCL0

OSDA0

OPCTRL_1_SCL

OPCTRL_0_SDA

+3.3V_NORMAL

R179

22

NC_1

NC_2

NC_3

VSS

R101

4.7K

MTK_FRC3/URSA5

R102

4.7K

MTK_NO_FRC/Int_FRC

IC104-*1

M24256-BRMN6TP

E0

1

E1

2

E2

3

+3.3V_NORMAL

VCC

WP

SCL

SDA

VSS

4

NVRAM_ST

Write Protection

- Low : Normal Operation

- High : Write Protection

R136 33

R137 33

+3.3V_NORMAL

C101

0.1uF

16V

R181 4.7K

R191 22

R192 22

R131

1.2K

R134

2.7K

R139

2.7K

R142

2.7K

Model Option

R130

4.7K

R132

R125

4.7K

4.7K

MTK_OPTIC_Tx_IC

R127

4.7K

4.7K

MTK_NON_OPTIC_Tx_IC

4.7K

MTK_3D_DEPTH_IC

MTK_DDR_768MB

R133

4.7K

R129

4.7K

MTK_DDR_DEFAULT

MTK_NON_3D_DEPTH_IC

VCC

8

WC

7

SCL

6

SDA

5

I2C_SCL1

I2C_SDA1

R173

2.7K

R135

4.7K

MTK_CP_BOX

R138

4.7K

MTK_NON_CP_BOX

IC104-*2

R1EX24256BSAS0A

A0

8

1

A1

7

2

A2

6

3

VSS

5

4

NVRAM_RENESAS

I2C_SCL5

I2C_SDA5

HDCP_EEPROM_MICRO

IC100-*1

24LC16B

A0

A1

A2

VSS

VCC

8

1

WP

7

2

SCL

6

3

SDA

4

5

+3.3V_NORMAL

R188

R185

2.7K

2.7K

R140

4.7K

R175

4.7K

R186

MTK_DVB_S_TUNER

MTK_DVB_T2_TUNER

R141

MTK_NON_DVB_T2_TUNER

4.7K

R184

4.7K

MTK_NON_DVB_S_TUNER

MTK_DVB_C2_TUNER

R187

MTK_NON_DVB_C2_TUNER

VCC

WP

SCL

SDA

I2C_1 : AMP, L/DIMMING

I2C_2 : T-CON

I2C_3 : MICOM

I2C_4 : S/Demod,T2/Demod, LNB

I2C_5 : NVRAM, HDCP KEY

I2C_6 : TUNER_MOPLL(T/C,ATV)

R160

R156

2.7K

4.7K

2.7K

R189

4.7K

MTK_EPI

R164

2.7K

R177

2.7K

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_2

MODEL_OPT_3

/S2_RESET

MODEL_OPT_4

MODEL_OPT_5

MODEL_OPT_6

MODEL_OPT_7

MODEL_OPT_8

MODEL_OPT_9

MODEL_OPT_10

4.7K

R190

4.7K

MTK_NON_EPI

JTAG

JTRST#

JTDI

JTMS

JTCLK

JTDO

+3.3V_NORMAL

R147

1K

OPT

R148

1K

R143 33

JTAG

I2C_SCL1

I2C_SDA1

I2C_SCL2

I2C_SDA2

I2C_SCL3

I2C_SDA3

I2C_SCL4

I2C_SDA4

I2C_SCL5

I2C_SDA5

I2C_SCL6

I2C_SDA6

R150

1K

R151

1K

OPT

+3.3V_NORMAL

AR100

10K

JTAG

+3.3V_NORMAL

R144

10K

JTAG

R145

10K

JTAG

R153

1K

OPT

LED_PWM0

LED_PWM1

OPCTRL3

R154

1K

NO_FRC

MODEL_OPT_0

MODEL_OPT_1

MODEL_OPT_2

MODEL_OPT_3

MODEL_OPT_4

MODEL_OPT_5

MODEL_OPT_6

MODEL_OPT_7

MODEL_OPT_8

MODEL_OPT_9

3D DEPTH

CP BOX

T2 Tuner

S Tuner

Reserved

MODEL_OPT_10

MODEL OPTION 8 is just for CP Box

It should not be appiled at MP

R146

10K

JTAG

R149

10K

JTAG

0

0

DDR

EPI

+3.3V_NORMAL

R152

1K

JTAG

JTAG

P100

12507WS-12L

1

2

3

4

5

6

7

8

9

10

11

12

13

Close to eMMC Flash

(IC8100)

EMMC_CLK

R174

10K

STRAPPING LED_PWM0 LED_PWM1 OPCTRL3

ICE mode + 27M + Serial boot 0 0 0

ICE mode + 27M + ROM to Nand boot 0 0 1

ICE mode + 27M + Rom to eMMC boot 0 1 0

from eMMC pins (share pins w/s NAND)

ICE mode + 27M + ROM to eMMC boot 0 1 1

from SDIO pins

SoC

LG FRC2

internal

FRC

0

1

HIGH

FHD

OPTIC

3D_Depth_IC

DDR_768MB

Enable

Support

Support

Support

Reserved

1

0

LOW

HD

NON_OPTIC

NON_3D_Depth_IC

DDR_Default

Disable

Not Support

Not Support

Default

Not Support

1

1

M22

M21

M20

MDS62110213

MTK_H/S_3.5T

MTK_H/S_3.5T

MDS62110213

MDS62110213

MTK_H/S_3.5T

To HDMI

M23

MDS62110213

MTK_H/S_3.5T

HDMI_CEC_MTK

/USB_OCD1

M24

MDS62110214

MTK_H/S_9.5T

USB_CTL1

R1014 0

C102

0.1uF

OPT

OPT

C106

0.1uF

OPT

/TU_RESET_1

R193

R176

R162

R163

MODEL_OPT_4

JTCLK

JTDI

JTDO

JTMS

JTRST#

OSDA0

OSCL0

OSDA1

OSCL1

AVDD_33SB

C116

0.1uF

AVDD_33SB

C117

0.1uF

VDD3V3

C118

0.1uF

LAN1_DET

LAN2_DET

EXT_PWR_DET

OPC_EN

RESET_BY_CPU

PTC_WOL

/UPDATE_BY_CPU

/USB2SER_RESET

/PROIDIOM_RESET_SOC

R1013

ERROR_OUT

M_RFModule_ISP

10K

10K

10K

10K

M_RFModule_RESET

/LGDT3305_RESET

/TU_RESET

/S2_RESET

Crystal Matching Test result

: 27pF -> 20pF -> 24pF

X-TAL

X100

27MHz

C113

24pF

IC105

LGE2112

AP14

JTCK

AM14

JTDI

AR14

JTDO

AR15

JTMS

AN14

JTRST

AP12

OSDA0

AN12

OSCL0

AP15

OSDA1

AN15

OSCL1

MT5369_XTAL_IN

MT5369_XTAL_OUT

C107

2.2uF

10V

EXT_PWR_DET

R1015

R1016

R1004

R1010

R1012

MODEL_OPT_0

0

MODEL_OPT_1 LED_PWM0

OPT

MODEL_OPT_3

MODEL_OPT_7

MODEL_OPT_5

MODEL_OPT_6

AT34

XTALI

AU34

XTALO

AK27

AVDD33_XTAL_STB

AH26

AVSS33_XTAL_STB

AK18

AVDD33_VGA_STB

AK17

AVSS33_VGA_STB

AK23

AVDD33_PLLGP

AM27

AVSS33_PLLGP

AJ20

AVDD10_LDO

C108

2.2uF

10V

H32

GPIO0

F37

GPIO1

F36

GPIO2

G37

GPIO3

G36

GPIO4

G35

GPIO5

G34

GPIO6

H34

GPIO7

L34

GPIO8

L32

GPIO9

K33

GPIO10

K32

GPIO11

H33

GPIO12

L35

GPIO13

K36

GPIO14

J32

GPIO15

J34

GPIO16

K34

GPIO17

K35

GPIO18

K37

GPIO19

J36

GPIO20

J37

GPIO21

J35

GPIO22

J33

GPIO23

G33

GPIO24

H35

GPIO25

H31

GPIO26

F34

GPIO27

E36

100

OPT

100

OPT

100

OPT

GPIO28

N33

GPIO29

P32

GPIO30

M35

GPIO31

M37

GPIO32

M33

GPIO33

F35

GPIO34

E35

GPIO35

E37

GPIO36

N32

GPIO37

M34

GPIO38

M36

GPIO39

M32

GPIO40

L33

GPIO41

E33

GPIO42

E32

GPIO43

F32

GPIO44

100

A29

GPIO45

D31

GPIO46

C31

GPIO47

E30

0

GPIO48

E31

GPIO49

F31

GPIO50

E29

GPIO51

AP9

GPIO52

AT9

GPIO53

AR9

GPIO54

AU9

GPIO55

AN23

ADIN0_SRV

AN24

ADIN1_SRV

AP23

ADIN2_SRV

AR23

ADIN3_SRV

AU23

ADIN4_SRV

AT23

ADIN5_SRV

AM24

ADIN6_SRV

AM23

ADIN7_SRV

C115

24pF

U0TX

U0RX

U1RX

U1TX

POWE

POOE

POCE1

POCE0

PDD7

PDD6

PDD5

PDD4

PDD3

PDD2

PDD1

PDD0

PARB

PACLE

PAALE

EMMC_CLK

OPWRSB

ORESET

OIRI

FSRC_WR

STB_SCL

STB_SDA

DEMOD_RST

DEMOD_TSCLK

DEMOD_TSDATA0

DEMOD_TSDATA1

DEMOD_TSDATA2

DEMOD_TSDATA3

DEMOD_TSDATA4

DEMOD_TSDATA5

DEMOD_TSDATA6

DEMOD_TSDATA7

DEMOD_TSSYNC

DEMOD_TSVAL

CI_INT

CI_TSCLK

CI_TSDATA0

CI_TSSYNC

CI_TSVAL

PVR_TSCLK

PVR_TSVAL

PVR_TSSYNC

PVR_TSDATA0

PVR_TSDATA1

SPI_CLK1

SPI_CLK

SPI_DATA

SPI_CLE

OPWM2

OPWM1

OPWM0

SD_D0

SD_D1

SD_D2

SD_D3

SD_CMD

SD_CLK

LDM_CS

LDM_CLK

LDM_VSYNC

LDM_DO

LDM_DI

LED_PWM1

LED_PWM0

OPCTRL11

OPCTRL10

OPCTRL9

OPCTRL8

OPCTRL7

OPCTRL6

OPCTRL5

OPCTRL4

OPCTRL3

OPCTRL2

OPCTRL1

OPCTRL0

R119

MT5369_XTAL_OUTMT5369_XTAL_IN

0

AR18

AP18

AU16

AT16

A35

C33

B34

D33

D29

C30

D30

B31

A31

B32

A32

C32

D32

A34

C34

C29

SOC_TX

SOC_RX

AM20

AM22

R158

AU21

D27

AT21

AR21

T34

T32

T36

U36

T33

T30

V33

V32

V31

V30

T35

T31

N36

T37

R35

R37

R36

R34

R32

R33

P33

P34

N37

P35

N34

N35

AU12

AT12

AR12

A37

C35

A36

B35

B36

B37

AT11

AU11

AR10

AM9

AP10

AN22

AP21

AU20

AT20

AN18

AP20

AM18

AN19

AP19

AR19

AN21

AM19

AN20

AR20

OPT

R159

SOC <- Ext. Demod.

R1005

R1006

R1007

R1008

R1011

R1009

0

EMMC_CMD

EMMC_DATA[7]

EMMC_DATA[6]

EMMC_DATA[5]

EMMC_DATA[4]

EMMC_DATA[3]

EMMC_DATA[2]

EMMC_DATA[1]

EMMC_DATA[0]

EMMC_CLK

33

IR

4.7K

STB_SCL

STB_SDA

TS_S_IN_1_CLK

TS_S_IN_1_VAL

TS_S_IN_1_SYNC

TS_S_IN_1_DATA

SOC -> P:I

22

22

22

22

+3.3V_NORMAL

R166

2.7K

OPT

R169 10K

L/DIM0_SCLK

L/DIM0_VS

L/DIM0_MOSI

LED_PWM1

5V Tolerance

OPCTRL_11_SCL

OPCTRL_10_SDA

100

OPT

DSUB_DET

AV1_CVBS_DET

AMP_RESET_SOC

OPCTRL3

EXT_SPK_DET

OPCTRL_1_SCL

OPCTRL_0_SDA

12pF crystal & load cap.

12pF crystal

PTC Interface

PTC_TX_MTK

PTC_RX_MTK_3.3V

+3.3V_NORMAL

R1001 100

C

E

R172 22

TS_S_OUT_CLK

TS_S_OUT_VAL

TS_S_OUT_SYNC

TS_S_OUT_DATA

R168

4.7K

OPT

OPT

R197

1K

PWM1_PULL_DOWN_1K

0.1uF

X100-*1

27.0MHZ

12pF Crystal

C113-*1

8pF

50V

12pF crystal

EMMC_DATA[2-7]

+3.3V_NORMAL

R155

10K

Q1001

MMBT3904(NXP)

B

R1002

10K

OPT

TS_S_IN_0_CLK

TS_S_IN_0_DATA

SOC <- P:I

TS_S_IN_0_SYNC

TS_S_IN_0_VAL

R161

4.7K

OPT

R171

R170

R198

1K

PWM2_PULL_DOWN_1K

C122

C121

0.1uF

OPT

OPT

C115-*1

8pF

50V

R157

4.7K

OPT

R178

4.7K

OPT

SOC_RESET

C114

0.1uF

16V

OPT

22

PWM_DIM2

PWM_DIM1

22

A_DIM

C120

2.2uF

10V

OPT

/USB_OCD2

USB_CTL2

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FILRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFATURES SPECFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

xxLT760H-UA

MID_MAIN_1

2011.09.29

8

Page 29

PLACE AT JACK SIDE

Copyright ⓒ 2013 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

Port was changed !!!!

To HDMI

+1.2V_MTK_AVDD

VDD3V3

USB2 w/o HUB

HDMI_CEC_MTK

DDC_SCL_2_JACK

DDC_SCL_3_JACK

DDC_SCL_4_JACK

DDC_SDA_2_JACK

DDC_SDA_3_JACK

DDC_SDA_4_JACK

5V_HDMI_2_JACK

5V_HDMI_3_JACK

5V_HDMI_4_JACK

HDMI_HPD_3_JACK

HDMI_HPD_4_JACK

C303

0.1uF

C304

0.1uF

USB1 w/ HUB

VDD3V3

C308

0.1uF

C302

0.1uF

MTK_HPD

0.1uF

VDD3V3

C306

C307

0.1uF

USB2SER_DP

USB2SER_DM

R304

R305

R307 1K

USB_DP1

USB_DM1

USB_DP2

USB_DM2

WIFI_DP

WIFI_DM

+1.2V_MTK_AVDD

C316

0.1uF

C314

100pF

50V

OPT

C315

100pF

50V

OPT

R308

1.2K

OPT

R309

100K

Panel Power On/Off

PANEL_CTL

C336

1uF

10V

C337 1uF

10V

C319

10uF

16V

C320

10uF

16V

+1.2V_MTK_AVDD

C350

0.1uF

C312

33pF

Close to MT5369

C310

33pF

R332 10K

C341

0.047uF

For PCB Pattern

PC_L_IN_SOC

PC_R_IN_SOC

HDMI_ARC

Panel Inverter On/Off

PC_R_IN_SOC

PC_L_IN_SOC

AV1_R_IN_SOC

AV1_L_IN_SOC

TUNER_SIF

R334 51

R335 51

Close to Tuner

MODEL_OPT_8

MODEL_OPT_9

MODEL_OPT_10

AMP_MUTE

EXT_SPK_MUTE

INV_CTL

MODEL_OPT_2

EMMC_RST

C354

0.1uF

AV1_CVBS_IN_SOC

VDD3V3

C347

0.1uF

For PCB Pattern

R311 30K

TU_CVBS

R318 22

R319

R347 0

R348 0

R310 30K

R339

2.2K

OPT

+1.2V_MTK_AVDD

DSUB_VSYNC

DSUB_HSYNC

OPT

22

OPT

R338 0

C305

1uF

25V

C352 0.01uF

C351

0.1uF

Close to MT5369

R341 100

R340 100

C358

0.01uF

50V

VDD3V3

R342 10K

0.047uF

C355

OSCL2

OSDA2

R343

24K

1%

R337 0

VDD3V3

C362

0.1uF

C363

1uF

25V

TP300

C360 0.047uF

C359 0.047uF

C361 1uF

VDD3V3

C329

C330

C364

0.1uF

R333

AV1_CVBS_IN

AV1_L_IN

2K

2K

AVDD33_DAC

AVDD33_DAC1

AVSS33_DAC

AVSS33_DAC1

VDACX_OUT

VDACY_OUT

AVDD33_VDAC

AVDD12_RGB

AVSS12_RGB

AVSS33_VDAC

AOCLKN

AOCLKP

AECLKN

AECLKP

BOCLKN

BOCLKP

BECLKN

BECLKP

AR0_ADAC

AL0_ADAC

AR1_ADAC

AL1_ADAC

AR2_ADAC

AL2_ADAC

AR3_ADAC

AL3_ADAC

ASPDIF0

ASPDIF1

AOBCK

AOLRCK

AOMCLK

AOSDATA4

AOSDATA3

AOSDATA2

AOSDATA1

AOSDATA0

HSYNC

VSYNC

VGA_SDA

VGA_SCL

AO3N

AO3P

AO4N

AO4P

AO2N

AO2P

AO1N

AO1P

AO0N

AO0P

AE4N

AE4P

AE3N

AE3P

AE2N

AE2P

AE1N

AE1P

AE0N

AE0P

BO4N

BO4P

BO3N

BO3P

BO2N

BO2P

BO1N

BO1P

BO0N

BO0P

BE4N

BE4P

BE3N

BE3P

BE2N

BE2P

BE1N

BE1P

BE0N

BE0P

ALIN

COM

SOG

COM1

PB1P

PR1P

Y1P

SOY1

COM0

PB0P

PR0P

Y0P

SOY0

RP

GP

BP

DSUB_VSYNC_SOC

DSUB_HSYNC_SOC

CHANGE SYMBOL

AG3

AG4

AG1

AG2

AF3

AF4

AE3

AE4

AE1

AE2

AD1

AD2

AL3

AL4

AL1

AL2

AK3

AK4

AJ3

AJ4

AJ1

AJ2

AH3

AH4

AT2

AU2

AT1

AU1

AR1

AR2

AP1

AP2

AN1

AN2

AM3

AM4

AT6

AU6

AP6

AR6

AP5

AR5

AT4

AU4

AP4

AR4

AP3

AR3

AN35

AN34

AM32

AM34

AM37

AM33

AM36

AM35

AG30

AF30

AK30

AE30

Y33

AR16

Y32

AR11

AP11

AM12

AM10

AM11

AN11

AN10

AN9

AN25

AM25

AR25

AR24

AU24

AP24

AT24

AR22

AP22

AT26

AR26

AP26

AU26

AP25

AU28

AT28

AR28

AP27

AR27

AU30

AP29

AD20

AD21

AD19

AJ22

AJ21

AL24

TXA4N

TXA4P

TXB4N

TXB4P

R3761.2K

R3771.2K

Don’t use as GPIO

C3660.01uF

C3670.01uF

C3680.01uF

C3690.01uF

C3701500pF

OPT

R3490

R3500

TXA4N

TXA4P

TXA3N

TXA3P

TXACLKN

TXACLKP

TXA2N

TXA2P

TXA1N

TXA1P

TXA0N

TXA0P

TXB4N

TXB4P

TXB3N

TXB3P

TXBCLKN

TXBCLKP

TXB2N

TXB2P

TXB1N

TXB1P

TXB0N

TXB0P

C365

0.01uF

VDD3V3

C397

1200pF

TP301

TP302

TP303

TP304

CH3

CH2

CH1

CH6

CH5

CH4

C398

1200pF

C380

0.1uF

R366 100

R367 100

R368 100

R371 100

R356100

R357100

R358100

R359100

RGB_DDC_SDA

RGB_DDC_SCL

DTV/MNT_V_OUT_SOC

+1.2V_MTK_AVDD

C382

0.1uF

AV1_R_IN

R3781.2K

R3791.2K

DAC_3V3

C387

22pF

OPT

DSUB_HSYNC_SOC

DSUB_VSYNC_SOC

C399

1200pF

C389

22pF

OPT

OPT

R324

22

R323

F27

E27

F30

F29

B27

A27

B28

A28

C28

D28

E28

F28

B29

AG6

AJ6

AF6

AE6

AH7

AJ5

AG5

AF5

AE5

AH5

AG7

U35

U34

V35

V34

22

LGE2112

TCON0

TCON1

TCON2

TCON3

TCON4

TCON5

TCON6

TCON7

TCON8

TCON9

TCON10

TCON11

TCON12

AVDD12_LVDS_1

AVDD12_LVDS_2

AVDD12_VPLL

AVDD33_LVDSB

AVDD33_LVDSA

AVSS12_LVDS_2

AVSS12_LVDS_1

AVSS12_VPLL

AVSS33_LVDSB

AVSS33_LVDSA

REXT_VPLL

AIN0_R_AADC

AIN0_L_AADC

AIN1_R_AADC

AIN1_L_AADC

AIN2_R_AADC

AIN2_L_AADC

AIN3_R_AADC

AIN3_L_AADC

AIN4_R_AADC

AIN4_L_AADC

AIN5_R_AADC

AIN5_L_AADC

AIN6_R_AADC

AIN6_L_AADC

AVDD33_AADC

AVSS33_AADC

VMID_AADC

MPXP

ADCINP_DEMOD

ADCINN_DEMOD

AVDD33_DEMOD

AVDD12_DEMOD

AVSS33_DEMOD

AVSS12_DEMOD

IF_AGC

RF_AGC

LOUTN

LOUTP

OSCL2

OSDA2

SC0

SY0

CVBS3P

CVBS2P

CVBS1P

CVBS0P

CVBS_COM

AVDD33_CVBS_1

AVDD33_CVBS_2

AVSS33_CVBS_1

AVSS33_CVBS_2

R325

OPT

R326

IC105

AVDD33_VDAC_BG

AVSS33_VDAC_BG

5pF

50V

OPT

5pF

50V

OPT

AU37

AU35

AT35

AT37

AU36

AP34

AT36

AR37

AR33

AP32

AR36

AP37

AR35

AP36

AL31

AJ28

AJ27

AN28

AU32

AT32

AD22

AL27

AM28

AJ26

AP31

AN30

AP28

AR29

AT30

AR30

AR31

AN29

AP30

AK24

AK25

AL25

AM26

ZD300

5.48VTO5.76V

ZD301

5.48VTO5.76V

R328

470K

OPT

R329

470K

OPT

C393

22pF

OPT

C3001

1200pF

SPDIF_OUT

ARC

C396

33pF

OPT

BLM18PG121SN1D

C344

27pF

50V

OPT

1608 sizs For EMI

C338

560pF

50V

OPT

1608 sizs For EMI

R345 30K

C339

560pF

50V

OPT

AUD_SCK

AUD_LRCK

AUD_MASTER_CLK

AUD_LRCH

R344 30K

C348

R330

C342

100pF

50V

C343

100pF

50V

C340

75

47pF

1%

50V

C345

10uF

16V

C346

10uF

16V

For PCB Pattern

EXT_SPK_ROUT_MAIN

EXT_SPK_LOUT_MAIN

100pF

50V

PLACE AT JACK SIDE

C333 / C334 / C335 MTK Recommend : 10 pF

AV1_CVBS_IN_SOC

AV1_L_IN_SOC

AV1_R_IN_SOC

C333

47pF

50V

C335

47pF

50V

C334

47pF

50V

L300

L301

BLM15BD121SN1

L304

BLM15BD121SN1

DSUB_R+

DSUB_G+

DSUB_B+

DTV/MNT_V_OUT_SOC

TP373

BLM15BD121SN1

R322

D301

75

ADLC 5S 02 015

5.5V

R321

D300

75

ADLC 5S 02 015

5.5V

R320

D302

75

ADLC 5S 02 015

5.5V

1608 sizs For EMI

180

C300

560pF

50V

OPT

1608 sizs For EMI

C301

560pF

50V

OPT

C311 1uF

R303

82

C309

OPT

R314

0

R336

0

10V

MAIN_IF_AGC

+5V_NORMAL

PC_L_IN

PC_R_IN

IC105

LGE2112

AA32

HDMI_CEC

AG33

HDMI_0_SCL

AE33

HDMI_1_SCL

AC33

HDMI_2_SCL

AH32

HDMI_3_SCL

AF33

HDMI_0_SDA

AD33

HDMI_1_SDA

AB33

HDMI_2_SDA

AH33

HDMI_3_SDA

AG31

1K

HDMI_0_PWR5V

AE31

1K

HDMI_1_PWR5V

AC31

HDMI_2_PWR5V

AH31

HDMI_3_PWR5V

AG32

HDMI_0_HPD

AE32

HDMI_1_HPD

AC32

HDMI_2_HPD

AJ32

HDMI_3_HPD

AA24

AVDD12_HDMI_0_RX

Y24

AVDD12_HDMI_1_RX

W24

AVDD12_HDMI_2_RX

AB24

AVDD12_HDMI_3_RX

AB29

AVDD33_HDMI_0_RX

AA29

AVDD33_HDMI_1_RX

Y29

AVDD33_HDMI_2_RX

AC29

AVDD33_HDMI_3_RX

AB30

AVSS33_HDMI_RX_1

AD30

AVSS33_HDMI_RX_2

AF31

AVSS33_HDMI_RX_3

AF32

AVSS33_HDMI_RX_4

C36

USB_DP_P0

C37

USB_DM_P0

D36

USB_DP_P1

D37

USB_DM_P1

AT13

USB_DP_P2

AU13

USB_DM_P2

AT14

USB_DP_P3

AU14

USB_DM_P3

D35

AVDD33_USB_P0P1

AP13

AVDD33_USB_P2P3

D34

AVSS33_USB_P1

AR13

AVSS33_USB_P2

W35

PCIE11_TXP

W34

PCIE11_TXN

Y34

PCIE11_RXN

Y35

PCIE11_RXP

U24

AVDD12_PCIE11

V24

AVDD33_PCIE11

W30

AVSS12_PCIE11

W36

PCIE11_REFCKN

W37

PCIE11_REFCKP

HDMI_0_RX_0

HDMI_0_RX_0B

HDMI_0_RX_1

HDMI_0_RX_1B

HDMI_0_RX_2

HDMI_0_RX_2B

HDMI_0_RX_C

HDMI_0_RX_CB

HDMI_1_RX_0

HDMI_1_RX_0B

HDMI_1_RX_1

HDMI_1_RX_1B

HDMI_1_RX_2

HDMI_1_RX_2B

HDMI_1_RX_C

HDMI_1_RX_CB

HDMI_2_RX_0

HDMI_2_RX_0B

HDMI_2_RX_1

HDMI_2_RX_1B

HDMI_2_RX_2

HDMI_2_RX_2B

HDMI_2_RX_C

HDMI_2_RX_CB

HDMI_3_RX_0

HDMI_3_RX_0B

HDMI_3_RX_1

HDMI_3_RX_1B

HDMI_3_RX_2

HDMI_3_RX_2B

HDMI_3_RX_C

HDMI_3_RX_CB

TXVP_0

TXVN_0

RXVN_1

RXVP_1

PHYLED1

PHYLED0

AVDD12_REC

AVDD33_COM

AVDD33_LD

AVSS33_LD

AVSS33_COM

AVSS12_REC

AG35

AG34

AG37

AG36

AF35

AF34

AH35

AH34

AE37

AE36

AD35

AD34

AC35

AC34

AE35

AE34

AB35

AB34

AA35

AA34

AA37

AA36

AC37

AC36

AK35

AK34

AJ35

AJ34

AJ37

AJ36

AJ33

AK33

AT18

AU18

AU17

AT17

AN16

AM16

AD15

REXT

+1.2V_MTK_AVDD

AD14

AD16

AD17

AL16

AL15

AL14

C323

0.1uF

D0+_HDMI2_JACK

D0-_HDMI2_JACK

D1+_HDMI2_JACK

D1-_HDMI2_JACK

D2+_HDMI2_JACK

D2-_HDMI2_JACK

CK+_HDMI2_JACK

CK-_HDMI2_JACK

D0+_HDMI3_JACK

D0-_HDMI3_JACK

D1+_HDMI3_JACK

D1-_HDMI3_JACK

D2+_HDMI3_JACK

D2-_HDMI3_JACK

CK+_HDMI3_JACK

CK-_HDMI3_JACK

D0+_HDMI4_JACK

D0-_HDMI4_JACK

D1+_HDMI4_JACK

D1-_HDMI4_JACK

D2+_HDMI4_JACK

D2-_HDMI4_JACK

CK+_HDMI4_JACK

CK-_HDMI4_JACK

R31524K

VDD3V3

C328

0.1uF

EPHY_TDP

EPHY_TDN

EPHY_RDN

EPHY_RDP

EPHY_ACTIVITY

EPHY_LINK

MAIN_PDIF

MAIN_NDIF

R300