LG 34UM95-PD/PE Schematic

Internal Use Only

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

IPS LED MONITOR

SERVICE MANUAL

CHASSIS : LM94Q

MODEL : 34UM95 34UM95-PD

MODEL : 34UM95 34UM95-PE

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

P/NO : MFL63731165 (1404-REV01)

Printed in China

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ........................................................................ 3

SPECIFICATION ....................................................................................... 4

ADJUSTMENT INSTRUCTION ................................................................ 5

BLOCK DIAGRAM .................................................................................... 9

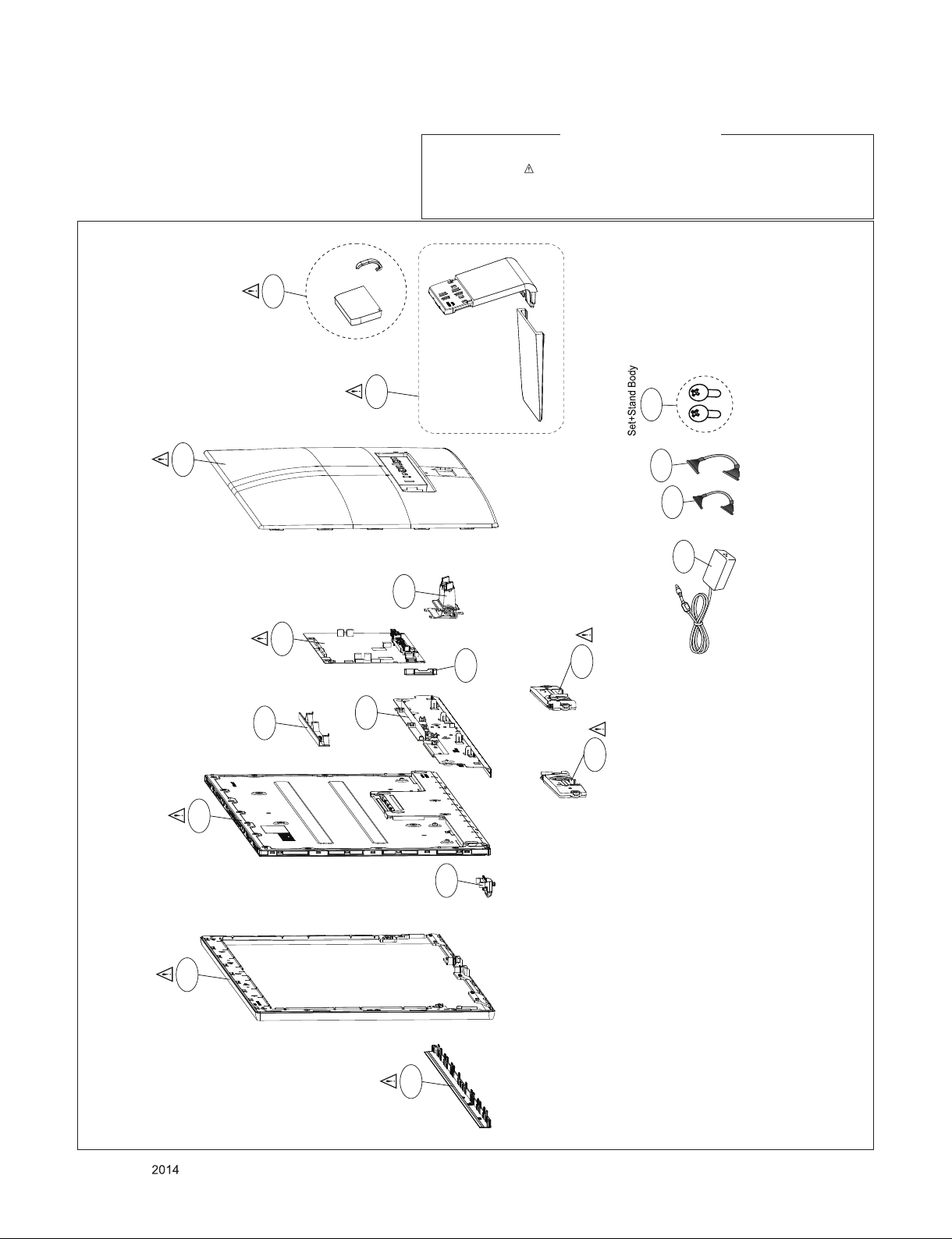

EXPLODED VIEW .................................................................................. 10

SCHEMATIC CIRCUIT DIAGRAM ..............................................................

Only for training and service purposes

- 2 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

SAFETY PRECAUTIONS

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of th e circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 MΩ and 5.2 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exp ose d metallic par t. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

Only for training and service purposes

- 3 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

1. Module General Specification

No Item Content Remark

1 Customer BRAND

2 User Model Name 34UM95

3 Sale region Refer to Sufx standard

4 Feature 34” Wide LCD MONITOR(WQHD)

5 Chassis Name LM94Q

6 General Scope External SW &Adj. 5-way joystick switch

Function PBP, Picture Mode Ratio, Gamma Calibration, SES, Six

Color, 7W speaker x 2, Thunderbolt x 2, Displayport,

HDMI x 2, TCF, Screen split, USB hub(USB3.0 x 1,

USB2.0 x 2), 10-bit color depth(Displayport),

DC switch (34UM95-PE Only)

7 Power Code Length : 1.55±0.05 M

Shape : Wall-out

Color : Black

Weight : 0.16kg

8 Cable TBT(Thunderbolt) Length : ,Shape : ,Color: ,Pin Do not provide

USB Length : ,Shape : ,Color: ,Pin Do not provide

Audio Length : ,Shape : ,Color: ,Pin Do not provide

HDMI Length : 1.8m

Shape : Detachable Type

Color : black

Weight : 0.11kg

9 Power Input: AC100~240V 50~60Hz, 2A Max

Output: DC 19V 7.37A

140W Adapter

Weight : 0.58kg

10 Applying module list P/No Specication

EAJ62509601(ZBD)

EAJ62767601(Dot free)

.

Refer to Sufx standard and power cord

table

EAD00926103

EAY62949006

LM340UW1-SSA1

Only for training and service purposes

- 4 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

ADJUSTMENT INSTRUCTION

1. Application Range

This document is applied to LM94Q chassis 34” LCD Monitor

which is manufactured in Monitor Factory or is produced on

the basis of this data.

2. Designation

(1) Th e ad justm ent is accord ing to the order whic h is

designated and which must be followed, according to the

plan which can be changed only on agreeing.

(2) Power Adjustment: Free Voltage

(3) Magnetic Field Condition: Nil.

(4) Input signal Unit: Product Specification Standard

(5) Reserve after operation: Above 5 Minutes (Heat Run)

Temperature : at 25 °C ± 5 °C

Relative humidity : 65 % ± 10 %

Input voltage : 100 V~ 240 V, 50/60Hz

(6) Adju stment equipments: Color Ana lyzer (CA-210 or

CA-110), DDC Adjustment Jig equipment,

3. Main PCB check process

* APC - After Manual-Insult, executing APC

3.1. ADC Process

(1) 34UM95 doesn’t need ADC process because it has only

digital input like DisplayPort and HDMI.

3.2. EDID Process

3.2.1. EDID Download

F/W includes default EDID for All input ports, aging on Mode If

AC ON, default EDID is automatically loaded to EEPROM.

Update serial number in EDID of HDMI1.

3.2.2. Data ( 128 Bytes )

- EDID Ver. 1.3 FOR HDMI 1 (256Byte)

- EDID Ver. 1.3 FOR HDMI 2 (256Byte)

- EDID Ver. 1.4 FOR Display Port (256Byte)

* Caution : Never connect HDMI Cable when execute NVRAM

Init and AC On at first for downloading HDMI EDID

automatically.

No Item Content 16 Data

1 Manufacturer ID GSM 1E 6D

2 Product ID HDMI 1 : 30423

HDMI 2 : 30423

Display Port : 30424

Thunderbolt : 30427

3 Year 2013 17

4 Version 1 1

5 Revision HDMI : 3

DP : 4

6 Serial Number * *

7 Week ** **

8 Model Name 34UM95 --

9 Check Sum **** ****

10 Special Item Need to Input Serial Number

** Protocol : DDC 2AB

Only for training and service purposes

D7 76

D7 76

D8 76

DB 76

HDMI : 3

DP : 4

- 5 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

- EDID Ver. 1.4 FOR Thunderbolt (256Byte)

3.3. Function Check

3.3.1. Check Screen

■ Check input and signal items. (cf. work instructions)

1. HDMI1/2 (3440 x 1440 @30Hz)

2. DisplayPort1.2 (3440 x 1440 @60Hz) - using PC

3. Thunderbolt (3440 x 1440 @30Hz) - using PC

4. Total Assembly line process

4.1. Write HDCP Key

- Write HDCP Key into EEPROM by using DDC2AB protocol

& HDCP Adjustment Jig equipment.

- If error is occurred, try to write again.

Insert HDMI Jack which is connected with PC for White

Balance or equivalent device.

-> Total Assembl y line shoul d check whether the co lor

coordinate(x,y) data refer to below table were meet or not.

* Note : Manual W/B process

(1) Push the “OK” key for 3 sec.

(2) and push the “LEFT” or “RIGHT” Key.

(3) In Service Menu.

* When doing Adjustment, Please make circumstance as

below.

Color Temperature Luminance(cd/m2)

Cool Medium Warm Cool Medium Warm

9,300k 8,000k 6,500k Min :

170

°K °K °K

X=0.283

(±0.03)

Y=0.298

(±0.03)

*Note : x,y coordinates are drifted about 0.007 after 30 mins

* Note : Manual W/B process

X=0.295

(±0.03)

Y=0.305

(±0.03)

<Test Signal>

Inner pattern

(255gray,100IRE)

heat-run. So checking color coordinate within 5-min at

total assembly line, consider x,y coordinates might be

up to 0.007 than x,y target of each color temperature.

1) Power off => Power on

( ‘<-’ 3 times, ‘->’ 1 time and push ‘◎’)

2) and push the “<-” or “->”.

3) In Service Menu.

X=0.313

(±0.03)

Y=0.329

(±0.03)

Min :

200

<Test Signal>

Inner pattern

(255gray,100IRE)

Min :

260

4.2. White balance adjustment

- Adjust PRES ET Warm(6500K) Color coor dinates and

Gamma calibration .

■ Input Gamma calibration Pattern (R,G,B, Grey 20 )

■ Set as Warm(6500K) by commanding COLOR_MODE_

CHANGE Command code.

■ Gamma calibration and verify

Start - Read Elapsed time - Measure - Verify - Output

Report - End

■ Warm(6500K) Color adjustment.

Adjust to meet x/y color coordinate as below.

2~4 min 4~8min 8~10min 10~25min 25~40min 40min~

x 0.318 0.318 0.317 0.316 0.314 0.313

y 0.339 0.338 0.337 0.334 0.332 0.329

* Save Warm(6500K) Color by commanding COLOR SAVE

Command code.

Only for training and service purposes

* When doing Adjustment, Please make circumstance as

below.

4.3. DPM Operation check

■ Measurement Condition: 100 ~ 240 V @ 50/60Hz

(1) Set Input to DVI-D, DisplayPort, HDMI1, HDMI2

(2) Turn off the source device.

(3) Check DPM operation refer to the below table.

Operating

Condition

Sleep

mode

Off

mode

- 6 -

Sync (H/V)

or Video

Off/Off Off RED

- - Off 0.5(PD)

EUT

(MSPG6100)

LED

(SET)

blinking

Off 0.3(PE)

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Wattage

(W)

1.2

5. Signal composition for adjustment

5.1. I2C (100K BPS)

5.2. COMMUNICATION START

# Until ACK BIT goes LOW, Repeat it.

5.3. Command form.

Command form use DDC2AB standard communication

protocol.

a. LEN : DATA BYTE number to send.

b. CMD : Command language that monitor executes.

c. VAL : FOS DATA

d. CS : Dada’s CHECHSUM that transmit

e. DELAY : 50MS

f. A : Acknowledge

5.4. Screen adjust command (LENGTH = 84)

5.5. EEPROM Data Write

5.5.1 Siganl TABLE

LEN : 84h+Bytes

CMD : E8h

ADH : E2PROM Slave Address(A0,A2,A4,A6,A8,AA,AC,AE),

Not 00h(Reserved by Buffer To EEPROM)

ADL : E2PROM Sub Address(00~FF)

Data : Write data

Delay : 20ms

5.5.2. Command Set

No.

Adjustment

contents

1 EEP R O M

WRITE

2 (84+n) n-byte Write

* Use

■ FOS Default write :

<14mode data> write

SyncFlags,HPeriodH, HPeriodL, VtotalH,VtotalL,

SrcHTotalH, SrcHTotalL

SrcHStartH, SrcHStartL, SrcVStartH,SrcVStartL,

HsyncPhase

■ Temporary Data write: Write to particular address of

EEPROM.

CMD(hex) LEN Explanation

E8 94 16-Byte Write

Only for training and service purposes

- 7 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

5.6. E2PROM Data Read

5.6.1. Signal TABLE

5.6.2. COMMAND SET

No. Adjustment

contents

1 EEPROM

READ

2 80 0-Page 80~FF Read

3 A2 0 1-Page 0~7F Read

4 80 1-Page 80~FF Read

5 A4 0 2-Page 0~7F Read

6 80 2-Page 80~FF Read

7 A6 0 3-Page 0~7F Read

8 80 3-Page 80~FF Read

9 A8 0 4-Page 0~7F Read

10 80 4-Page 80~FF Read

11 AA 0 5-Page 0~7F Read

12 80 5-Page 80~FF Read

13 AC 0 6-Page 0~7F Read

14 80 6-Page 80~FF Read

15 AE 0 7-Page 0~7F Read

16 80 7-Page 80~FF Read

CMD

ADH

ADL

(hex)

(hex)

E7 A0 0 0-Page 0~7F Read

Explanation

(hex)

5.6.3. Use

Read E2PROM’s specic area as unit of 128(80h)-byte. (84h)

5.6.4 EDID Write

EEPROM access by using DDC2B protocol

■ 1-Byte write

L : 0x00~0x7F

D : data

■ 8-byte write

L : 0x00,0x10,….0x70

5.6.5. EDID Read

- DDC2B Command.(A0/A1)

- 128 Byte transfer of EDID Buffer of MICOM

Only for training and service purposes

- 8 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

BLOCK DIAGRAM

5YKVEJ

8 8

&&4

)$

&&4

/

(NCU J

/GOQT[

5&4#/

5&4#/

)$

8 8

&&4&CVCA=?

%5A5&1A

92 A 52 +A 5% -A

5&+A

R

.8&5

R

.8&5

#FFTGUUA=?

5NCXG

06

#FFTGUUA=?

(CNEQP

4KFIG

/*\

%.-(TGSWGPE[

)GPGTCVQT

%NQEM)GPGTCVQT

(5V41065OGGI8

2%+G

2QYGT

625

5YKVEJ

2QYGT

625

7RUVTGCO

6JW PF GTDQNV

#5/

75$5YKVEJ+%

#5/

75$*WD+%

#5/#

*WD%QPVTQN NGT

6JWPFGT

$1.6,CEM

6JW PF GT

$1.6,CEM

72

75$

5VTGCO

&QYP

75$

5VTGCO

&QYP

75$

5VTGCO

&QYP

75$

5VTGCO

&%.-/*\

2CPGNZ

9.'&A'0#$.'

9.'&A2&+/

9.'&A#&+/

&7A85

.'&&TKXGT+%

&7A&'

&7 A(#56A/76'

52+A%.-A+1

R

.8&5

R

.8&5

5'A92

5'A5%.

''241/

'#

&65

*+A+06'

5'A5&#

52+A%'A+1

/

''A%5A0

''A&1

''A%.-

''A&+

/

(NCUJ

/GOQT[

&2A6:.KPG

&CKU[%JCKP

52+A5+1

52+A5+1

52+A5+1

52+A5+1

&25KIPCN

75$A5%.

/CUVGT

06

*2A#176A4

*2A#176A.

)$

&&4&CVC=?

#FFTGUU=?

&&4

5&4#/

)$

#FFTGUU=?

%5 5&1 9 2A52+

5%-5&+

/

(NCU J

/GOQT[

*2. 4QWV

&&4&CVC=?

&&4

5&4#/

675$

75$VQ7#46 +%

75$A5&#

75$

''241/

#7&A#

#7& A.4%-

&09

&KIKVCN#/2

52.

524

(NCUJ

/GOQT[

%QPVTQN-G[

,Q[UVKEM-G[

&2

#&%-';-';

+%-';A5%.-';A5&#

#7& A5%-

#7& A/%.-

6/&5

*&/+

#0). '

*&/+

''241/

6/&5

*&/+

--

*&/+

''241/

Only for training and service purposes

- 9 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

910

EXPLODED VIEW

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

400

200

700

520

900

710

600

800

930

LV2

LV1

540

121

120

300

Only for training and service purposes

310

330

- 10 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Loading...

Loading...