Page 1

Internal Use Only

US/Canada/Mexico http://aic.lgservice.com

http://eic.lgservice.com

http://biz.lgservice.com

LED TV

SERVICE MANUAL

CHASSIS : 6M62N

MODEL: 32LB520B

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

Printed in Korea

Page 2

CONTENTS

CONTENTS .............................................................................................. 2

SAFETY PRECAUTIONS ........................................................................ 3

SERVICING PRECAUTIONS ................................................................... 4

SPECIFICATION ...................................................................................... 6

ADJUSTMENT INSTRUCTION ............................................................... 8

EXPLODED VIEW .................................................................................. 13

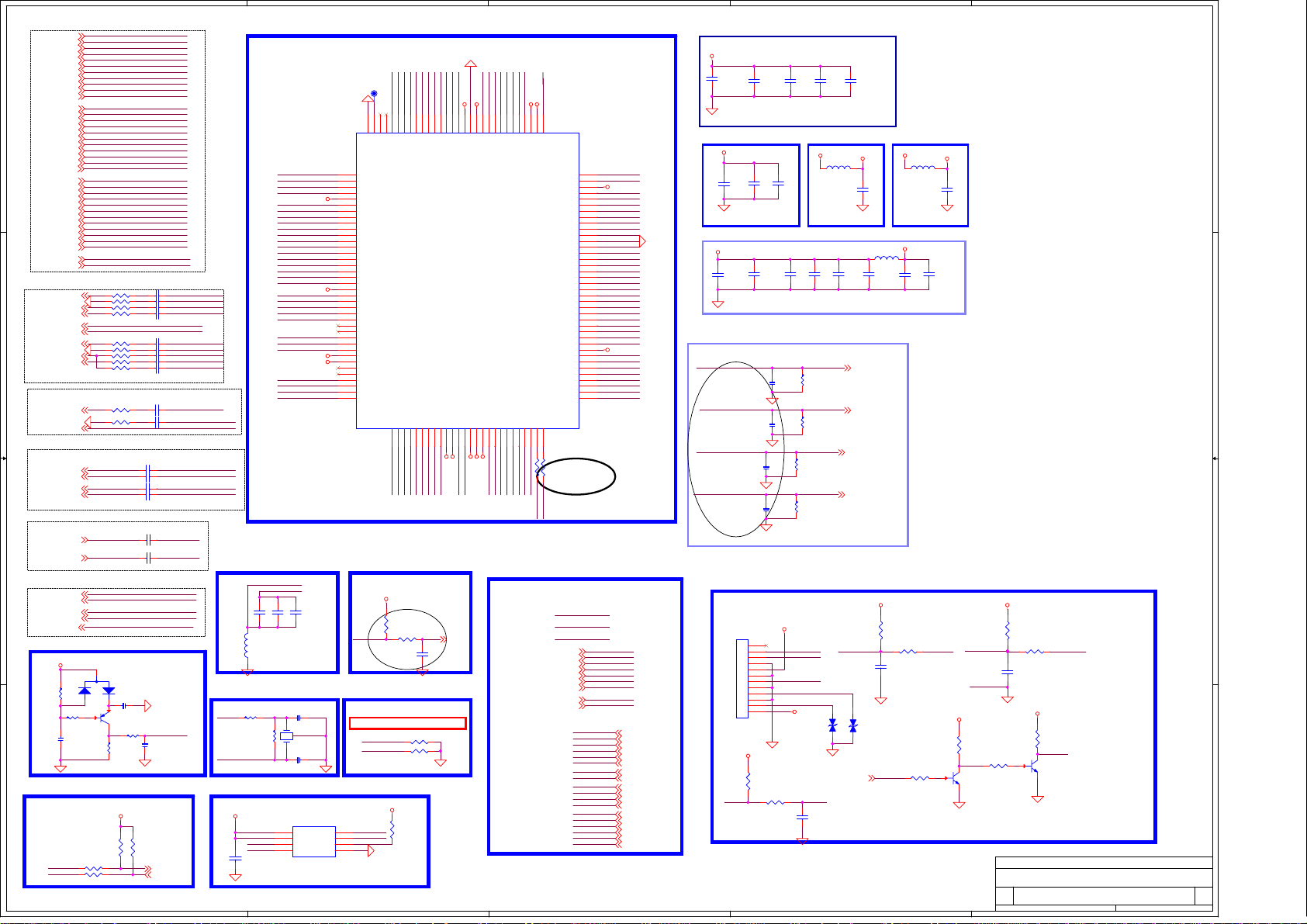

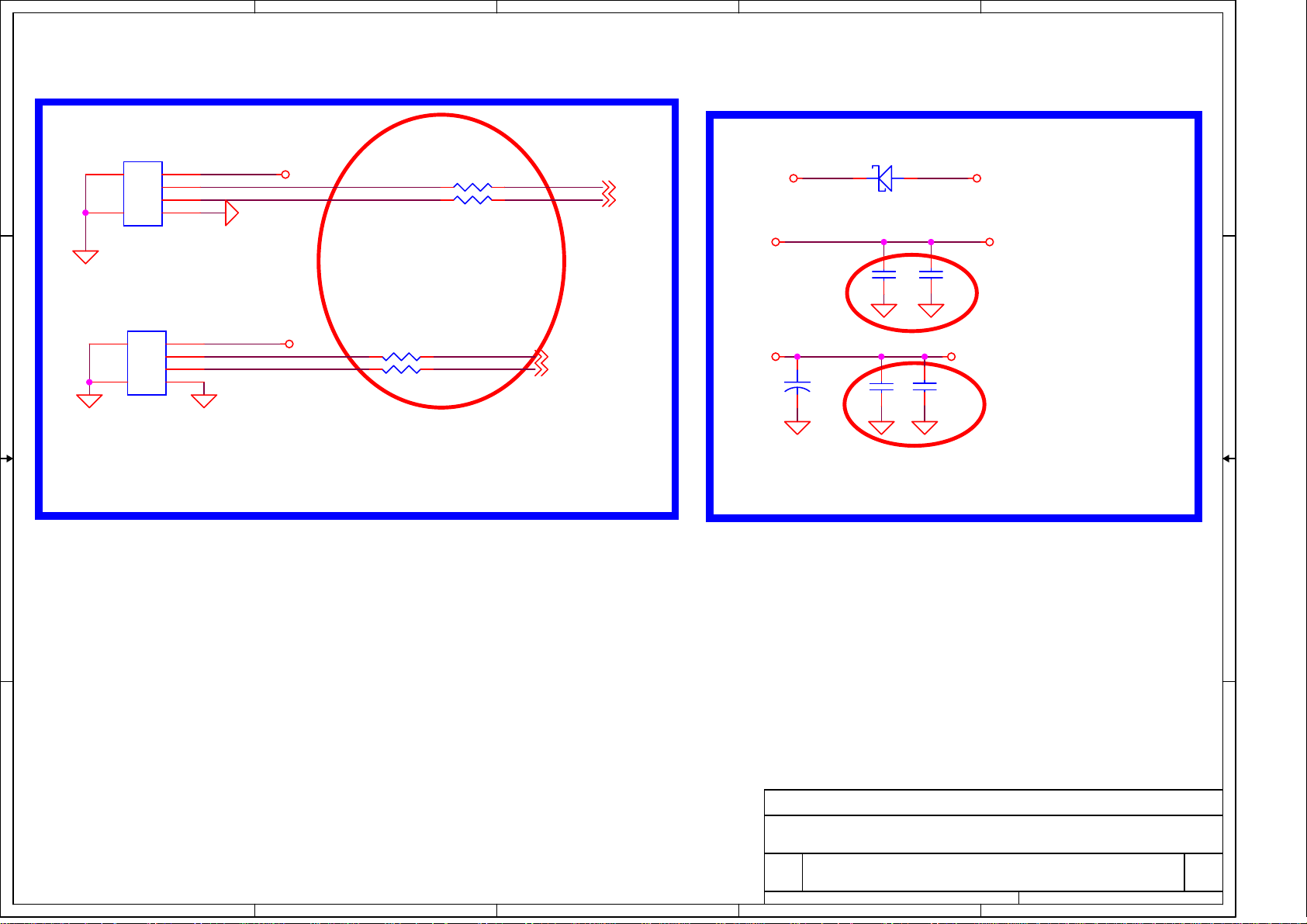

SCHEMATIC CIRCUIT DIAGRAM ..........................................................

14

Only for training and service purposes

- 2 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 3

SAFETY PRECAUTIONS

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circ uitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 10 MΩ and 200 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

the two AC plug prongs. Place the AC

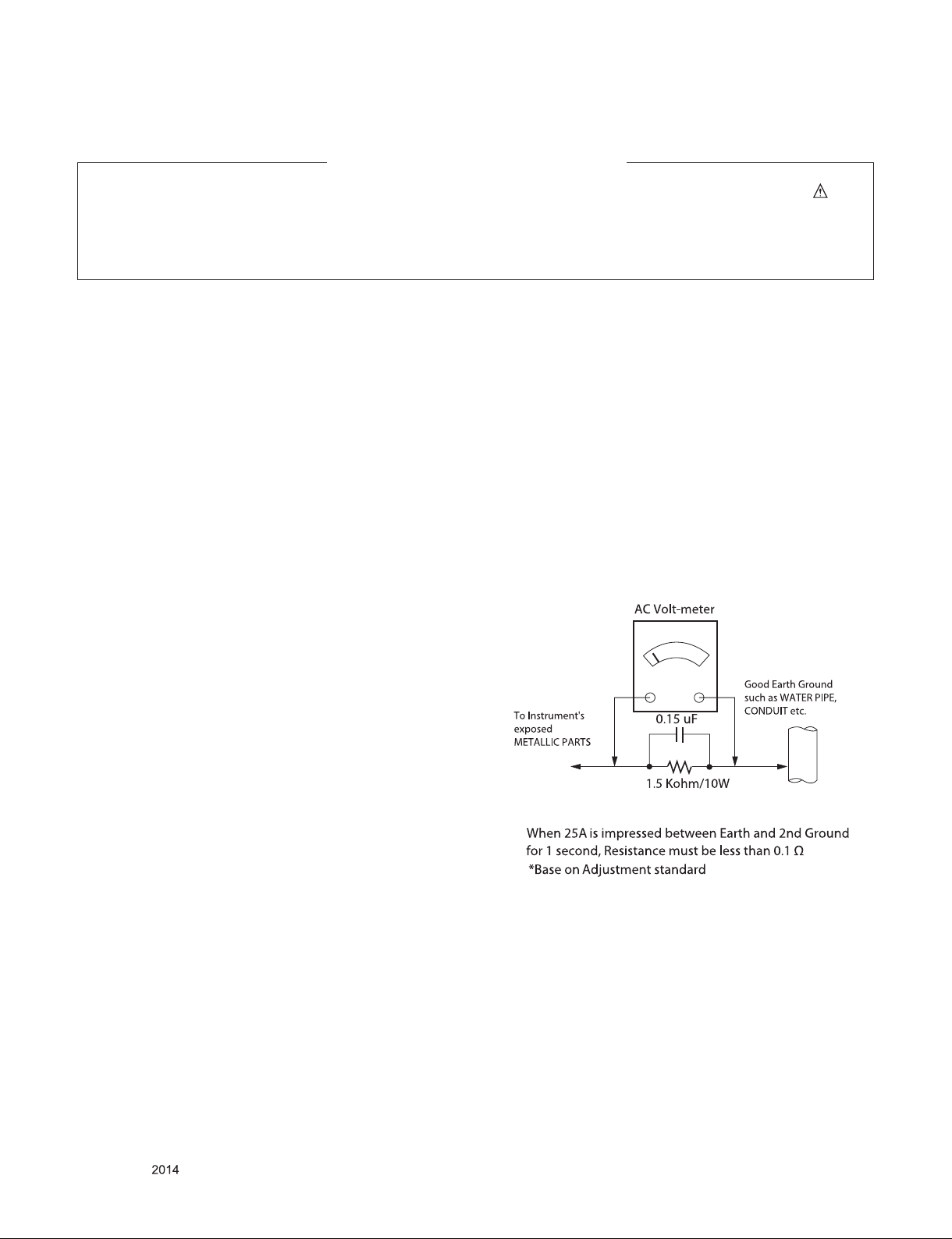

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

out of the limits specified, there is

Leakage Current Hot Check circuit

Only for training and service purposes

- 3 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 4

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conict between the

following servicing precautions and any of the safety precautions

on page 3 of this publication, always follow the safety precautions. Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug

or other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an explosion hazard.

2. Test high voltage only by measuring it with an appropriate

high voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specied otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10 % (by volume) Acetone and 90 %

(by volume) isopropyl alcohol (90 % - 99 % strength)

CAUTION: This is a ammable mixture.

Unless specied otherwise in this service manual, lubrication

of contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks

are correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test xtures specied in this

service manual.

CAUTION: Do not connect the test xture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some eld-effect transistors

and semiconductor “chip” components. The following techniques

should be used to help reduce the incidence of component damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground. Alternatively, obtain and wear a commercially available discharging wrist strap device, which should be removed to prevent

potential shock reasons prior to applying power to the unit

under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4. Use only an anti-static type solder removal device. Some solder removal devices not classied as “anti-static” can generate

electrical charges sufcient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufcient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads electrically shorted together by conductive foam, aluminum foil or

comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material to the chassis or circuit assembly into which the device will

be installed.

CAUTION: Be sure no power is applied to the chassis or circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged replacement ES devices. (Otherwise harmless motion such as the

brushing together of your clothes fabric or the lifting of your

foot from a carpeted oor can generate static electricity sufcient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate tip size and shape that will maintain tip temperature within

the range or 500 °F to 600 °F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25 cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500 °F to 600 °F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500 °F to 600 °F)

b. First, hold the soldering iron tip and solder the strand

against the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder ows onto and around both the component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

Only for training and service purposes

- 4 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 5

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

cuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by

gently prying up on the lead with the soldering iron tip as the

solder melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing

the IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close

as possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as possible to diode body.

2. Bend the two remaining leads perpendicularly to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and

if necessary, apply additional solder.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

-

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the

good copper pattern. Solder the overlapped area and clip off

any excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the

lead of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so then

it does not touch components or sharp edges.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

Only for training and service purposes

- 5 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 6

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application range

This specification is applied to the LED TV used

6M62N chassis.

2. Requirement for Test

Each part is tested as below without special appointment.

1) Temperature: 25 °C ± 5 °C(77 °F ± 9 °F), CST: 40 °C ± 5 °C

2) Relative Humidity: 65 % ± 10 %

3) Power Voltage

: Standard input voltage (AC 120V~, 50/60 Hz)

* Standard Voltage of each products is marked by models.

4) Specification and performance of each parts are followed

ea ch drawing and spe ci fication b y p ar t number in

accordance with BOM.

5) ehT receiver must be operated for about 5 minutes prior to

the adjustment.

3. Test method

1) Performance: LGE TV test method followed

2) Demanded other specification

- Safety : UL specification

- EMC : FCC

4. Model General Specification

No. Item Remarks

1. Market US/Canada/Mexico

1) NTSC

2. Broadcasting system

3. Channel Storage 1) VHF : 02~13

2)AIR:ATSC

3)CABLE:64QAM/256QAM

2) UHF : 14~69

3) DTV : 02-69

4) CATV :01~135 (N.America)

5) CADTV : 01~135 (N.America)

4. Receiving system

5. Video(Composite Input) PAL, NTSC 4 System : PAL M, PAL N, NTSC, PAL60

6. Component Input Y/Cb/Cr, Y/Pb/Pr

7. HDMI Input

8. SPDIF out SPDIF out

9. USB Input Music :MP3; Photo: JPEG

10. Headphone

Only for training and service purposes

Analog : Upper Heterodyne

Digital : 8VSB/64&256QAM

HDMI: DTV/DVI

- 6 -

Support HDCP

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 7

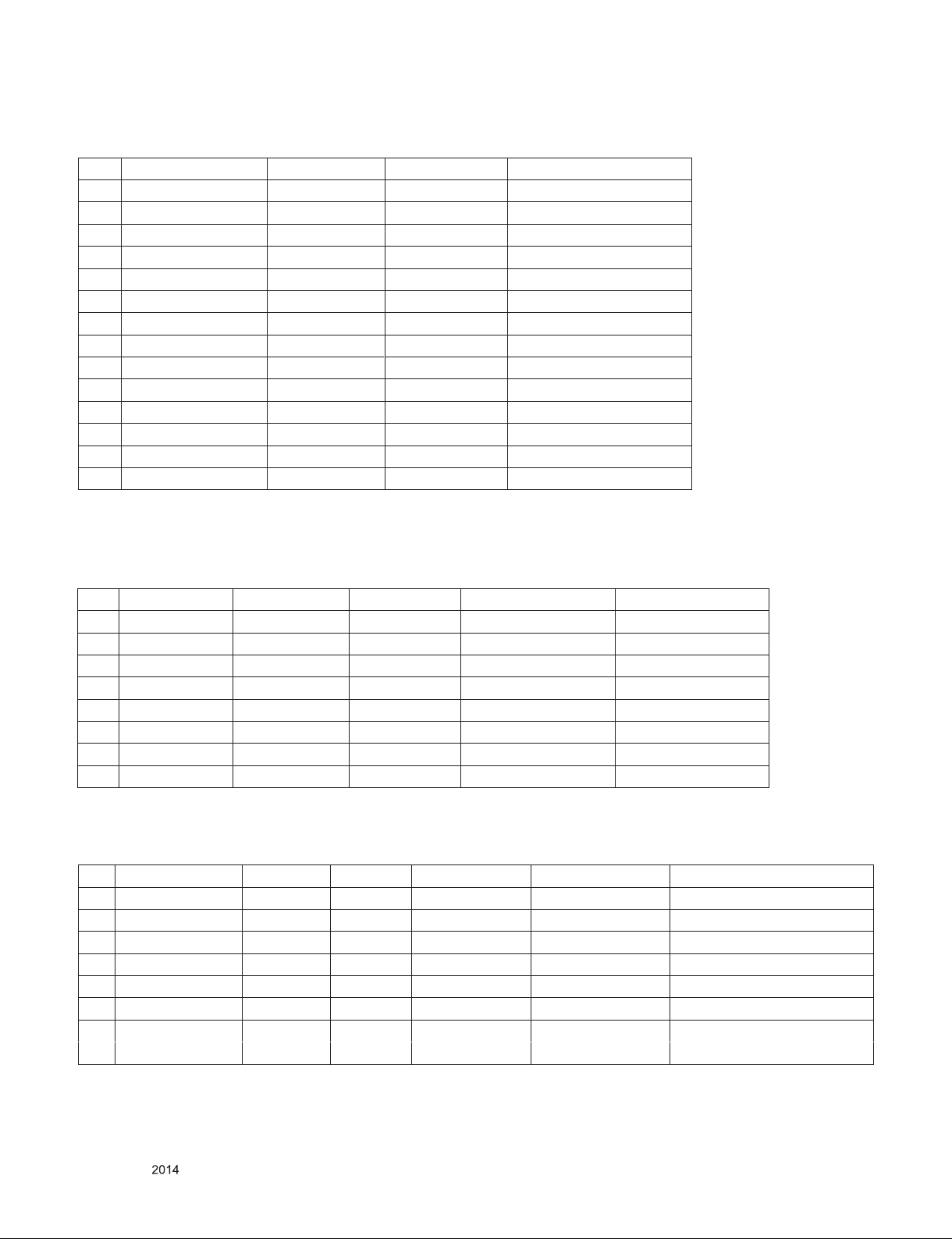

5. Component Video Input (Y, CB /PB , CR /PR )

No. Resolution H-freq(kHz) V-freq(Hz) Porposed

1 720×480 15.73 60.00 SDTV, DVD 480i

2 720×480 15.63 59.94 SDTV, DVD 480i

3 720×480 31.47 59.94 480p

4 720×480 31.50 60.00 480p

1280×720 44.96 59.94 HDTV 720p

5

1280×720 45.00

6

1920×1080

7

1920×1080

8

1920×1080

9

1920×1080

10

11 1920×1080

12 1920×1080

1920×1080

13

14 1920×1080 67.5 60 HDTV 1080p

26.97

27

33.72

33.75

33.75 60.00 HDTV 1080i

33.72

67.432 59.94

60.00 HDTV 720p

23.976

24

29.97

30

59.94 HDTV 1080i

HDTV 1080p

HDTV 1080p

HDTV 1080p

HDTV 1080p

HDTV 1080p

6. HDMI Input : Refer to adjust specification about EDID data.

6.1. DTV mode

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock(MHz) Proposed

1. 640*480 31.469 / 31.5 59.94 / 60 25.175/25.200 SDTV 480P

2.

3.

4. 1280*720 44.96 / 45 59.94 / 60 74.17/74.25 HDTV 720P

5. 1920*1080 33.72 / 33.75 59.94 / 60 74.17/74.25 HDTV 1080I

6.

7.

8.

720*480 31.469 / 31.5 59.94 / 60 27.00/27.03 SDTV 480P

720(1440)*480 15.73 / 15.75 59.94 / 60 27.00/27.028 SDTV 480i

1920*1080 26.97 / 27 23.97 / 24 74.17/74.25 HDTV 1080P

1920*1080 33.716/33.75 29.976/30.00 74.25 HDTV 1080P

1920*1080 67.43 / 67.5 59.94 / 60 148.35/148.50 HDTV 1080P

6.2. PC mode

No. Resolution H-freq(kHz) V-freq.(Hz) Pixel clock(MHz) Proposed Remark

1.

720*400 @70Hz 31.469 70.08 28.321 DOS

2.

640*480 @60Hz 31.469 59.940 25.175 VESA(VGA)

3.

800*600 @60Hz 37.879 60.31 40.000 VESA(SVGA)

4.

1024*768 @60Hz 48.363 60.00 65.000 VESA(XGA)

1280*1024 @60Hz 63.981

5.

1360*768 @60Hz 47.712

6

7.

1920*1080 @60Hz 67.5

Only for training and service purposes

60.020 108 VESA(SXGA)

60.015 85.5 VESA(WXGA)

60.0 148.5

WUXGA

(Reduced blanking)

- 7 -

FHD only(Support to HDMI-PC)

FHD only(Support to HDMI-PC)

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 8

ADJUSTMENT INSTRUCTION

1. Application Range

This specification sheet is applied to all of the LED TV with

MSD3393LU chassis.

2. Designation

(1) Th e ad justm ent is according to the orde r wh ich is

designated and which must be followed, according to the

plan which can be changed only on agreeing.

(2) Power adjustment : Free Voltage.

(3) Magnetic Field Condition: Nil.

(4) Input signal Unit: Product Specification Standard.

(5) Reserve after operation: Above 5 Minutes (Heat Run)

Temperature : at 25 °C ± 5 °C

Relative humidity : 65 ± 10 %

Input voltage : 120V~, 50/60 Hz

(6) Adjustment equipments

: Color Analyzer(CA-210 or CA-310), Service remote control.

(7) Push the “RESTORE" key - For memory initialization.

Case1 : Software version up

1. , BSU yb W/S gnidaolnwod retfA TV set will reboot

automatically.

2. Push “RESTORE” key.

3. Push “Power on” key.

4. Function inspection

5. After function inspection, Push “RESTORE” key.

Case2 : Function check at the assembly line

1. When TV set is entering on the assembly line, Push

“RESTORE” key at first.

2. Push “Power on” key for turning it on.

→ If you push “Power on” key, TV set will recover

channel information by itself.

3. After function inspection, Push “RESTORE” key.

3. Click “Connect”to get communication from the TV set,

and read out the device type.

:

4. Click “HDCP”to enter HDCP management

interface. Change the Value“HDCP Key Index”

to “1”, “HDCP Key Allocation”to "0X390000"for

32LB520B/60LB5200/65LB5200.

3. Main PCB check process

▪ APC - After Manual-Insert, executing APC

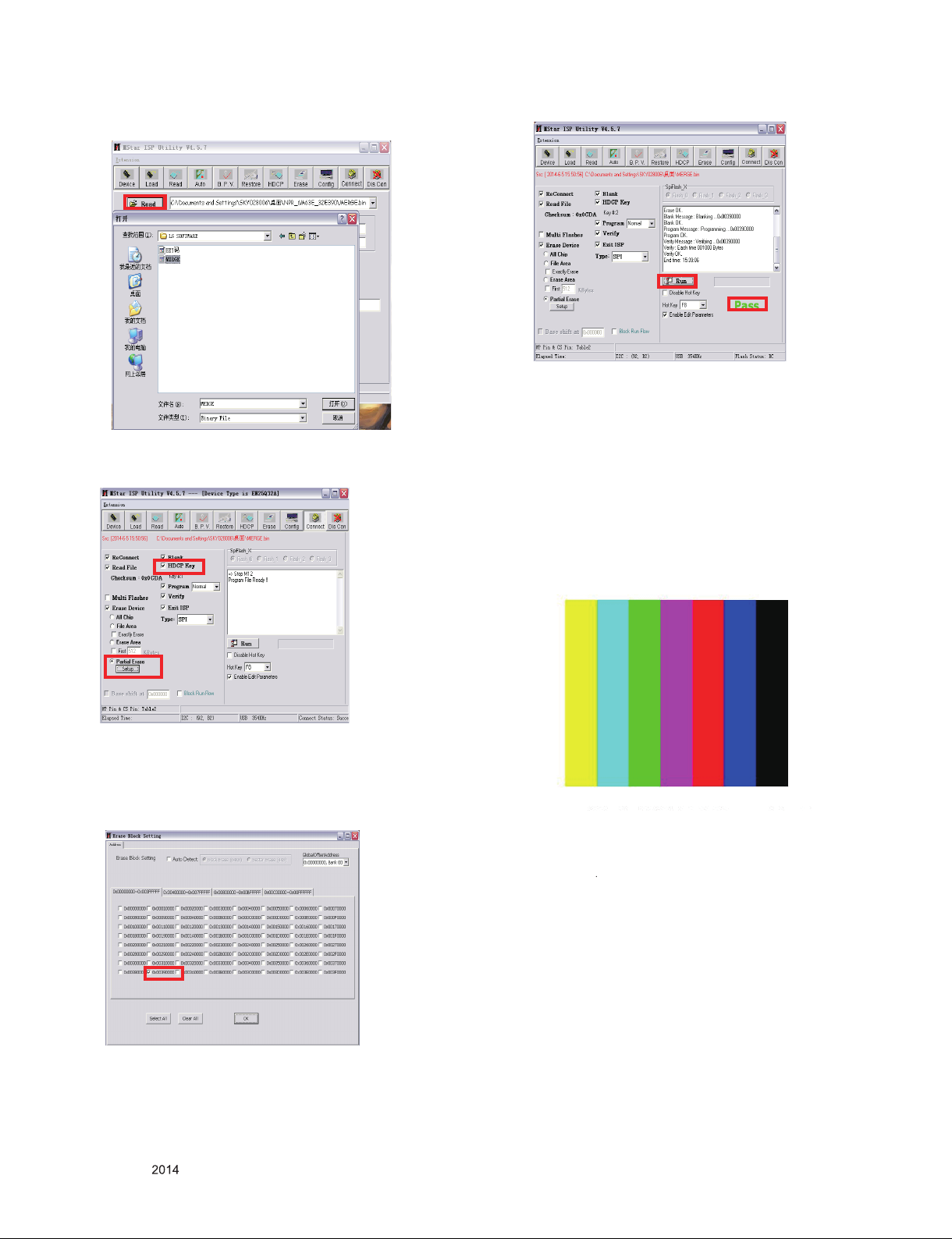

*. Burning HDCP EY

1.

Connect your PC to TV set with USB debug cable.

Turn on the TV set, then open the HDCP operating tool

2.

“MStar IS P Utility V4.5.7 Alpha”.

Only for training and service purposes

- 8 -

5. Click “HDCP Key File”to load the HDCP Key file

provided.

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 9

6. Click “Read” to load the main software for this TV set.

7. Click “Auto”to ready for HDCP Key updating. Settings

as below:

9. Click “Run” to update the HDCP Key.

Warm Tips:

The HDCP Key index value will be increased automatically.

That means after you update the first TV set, you only need

to connect another TV set to your PC, click “Connect”, then

“Run” to update.

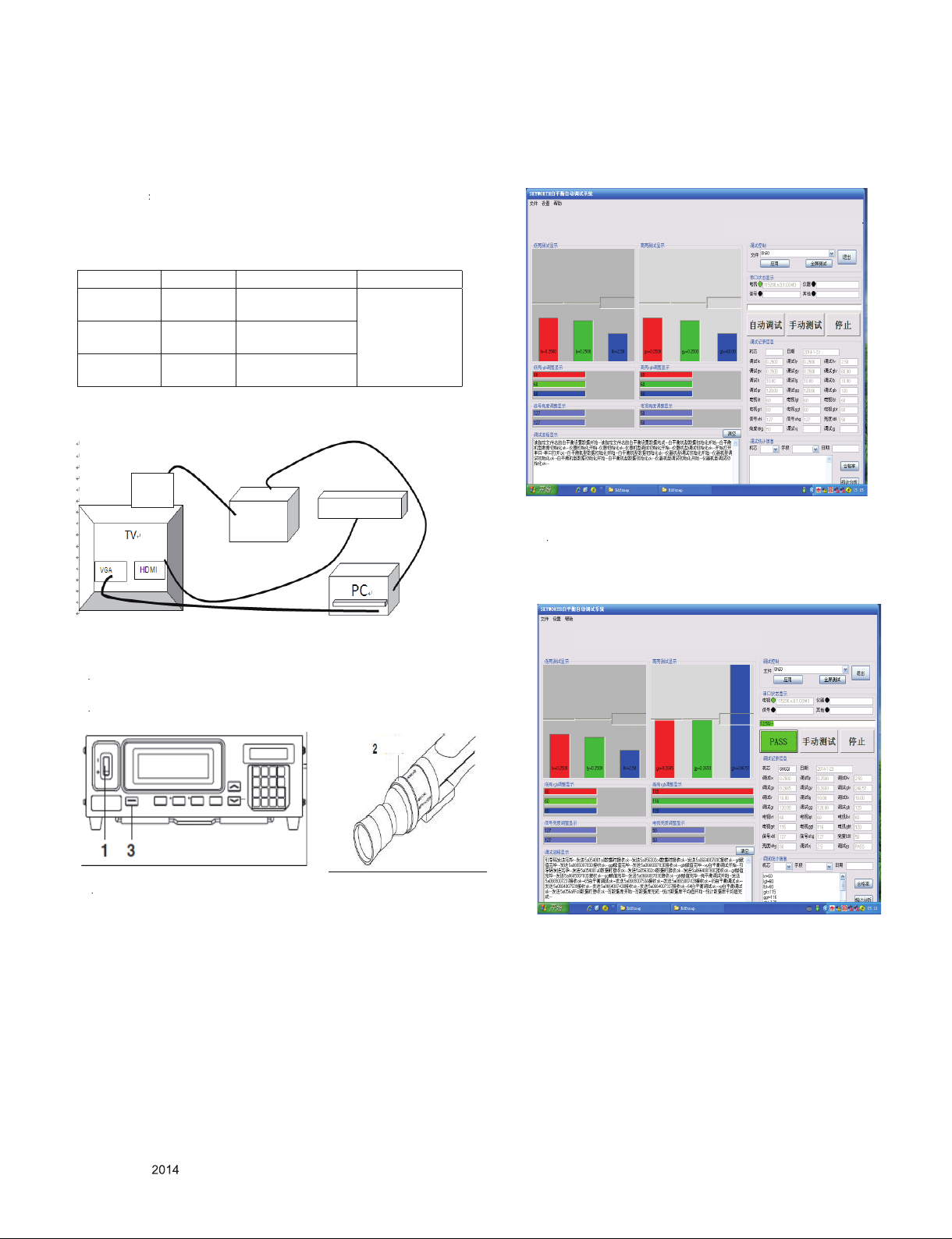

4. ADC Process

4.1. ADC

- Set TV to YUV source by pushing"YUV)key

- Input full color bar signal using HD signal generator

Begin adjust by pushing “ADC ADJ" key

* Required equipment : Factory remote control.

HD signal generator.

EZ ADJUST

0

1. Tool Option2

2. Tool Option3

3. Tool Option4

4. Tool Option5

5. Tool Option Commercial

6. Country Group

7. Area Option

9. White Balance

10. 10 Point WB

11. Test Pattern

12. EDID D/L

13. Sub B/C

14. Ext. Input Adjust

ADC Calibration

ADC Comp 480i

ADC Comp 1080p

ADC Type

Reset

NG

NG

8. Click to select “Partial Erase”, then click Setup. An erase

block setting window will pop up. Choose the bank according

to "0X390000"for 32LB520B/60LB5200/65LB5200. Click

“OK”to confirm.

Only for training and service purposes

- 9 -

100% color bar

Note: 1. The YPBPR Auto White Balance adjust

(AUTO ADC) must be done on the product line.

2

In YPBPR channel ,must adjust the SD

and HD two modes.

4.2. Function Check

4.2.1. Check display and sound

■ Check Input and Signal items.

(1) TV

(2) AV (CVBS)

(3) COMPONENT (1080I/480i)

(4) HDMI

* Display and Sound check is executed by Remote control.

<Caution> Not to push the "RESTORE" key after

completion if the function inspection.

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 10

5. Total Assembly line process

5.1. Adjustment Preparation

▪ W/B Equipment condition

CA310

▪ evobA 5 minutes H/run in the inner pattern. ("power on" key

of Adjustment remote control)

* * The spec of color temperature and coordinate.

Mode Color Temp Color coordinate Remark

Cool (C50) 13,000 K

Medium(0) 9,300 K

Warm(W50) 6,500 K

Auto Adjust -W/B

CH01, Test signal: Inner pattern(80IRE)-LED Module

X=0.271 (±0.002)

Y=0.270 (±0.002)

X=0.286 (±0.002)

Y=0.289 (±0.002)

X=0.313 (±0.002)

Y=0.329 (±0.002)

Probe

Color

analyzer

<Test Signal>

- Inner pattern

for W/B adjust

- External white

pattern

(80IRE, 204gray)

HD signal generator

Click the "application "button and begin to adjust

5

automatically when finished ,it will display PASS.

*STEPS:

1

Connect Debug line.

2. Connect HDMI port and input 80% full white signal.

3

Calibrate the color analyzer (CA310).

Positioning

Ring

4

Open W/B auto adjust system and load saved parameters.

Only for training and service purposes

- 10 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 11

* Manual W/B process using adjust Remote control.

■ Color analyzer(CA310,CA210)should be used in the

calibrated ch.

■ Operate the zero-calibration of the CA310 or CA210,

then stick sensor to the module when adjusting.

■ Enter factory mode by pushing customer remote controller:

input 3195.

■ Select W/B ADJUST item , push "ok" then enter into

adjust page.

■ For manual adjustment, it is also possible by the following

sequence.

(1) Set TV in aging mode by play a picture or music by USB for

more than 30 minutes. (if not executed this step the condition

for w/B will be different).

(2) Push “Exit” key.

(3) Enter factory mode by pushing customer remote controller:

input 3195. Select W/B ADJUST item , push "ok" then en

ter into adjust page.

(4) Zero Calibrate the probe of Color Analyzer, then place it

on the center of LCD module within 10cm of the surface

(5) Select each items (Red/Green/Blue Gain) using

▲/▼(CH +/-) key on Remote control.

(6) Adjust R/ G/ B Gain using ◄/►(VOL +/-) key on R/C.

(7) Adjust three modes all (Cool / Medium / Warm)

- For All model

Fix the one of R/G/B gain and change the others

- For G-FIX model

Cool Mode

1) Fix the one of R/G/B gain to 192 (default data) and

decrease the others. (If G gain is adjusted over 172

and R and B gain less than 192 , Adjust is O.K.)

2) If G gain is less than 172, Increase G gain by up to

172, and then increase R gain and G gain same

amount of increasing G gain.

3) If R gain or B gain is over 255, readjust G gain less

than 172, Conform to R gain is 255 or B gain is 255

Medium / Warm Mode - Fix the one of R/G/B gain

to 192 (default data) and decrease the others.

(8) When adjustment is completed, exit adjustment mode

using EXIT key on Remote control.

* CASE Cool

First adjust the coordinate far away from the target

value(x, y).

1) x, y > target

i) Decrease the R, G.

2) x, y < target

i) First decrease the B gain,

ii) Decrease the one of the others.

3) x > target, y < target

i) First decrease B, so make y a little more than the

target.

ii) Adjust x value by decreasing the R.

4) x < target, y > target

st decrease B, so make x a little more than the

i) Fir

target.

ii) Adjust x value by decreasing the G.

*

After You finish all adjustments and function inspections,

Press “SETTING” button , choose Initial Setting” option,

and choose “Yes”. It will show choose language picture,

then turn off TV and unplug the AC cable.

Only for training and service purposes

- 11 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 12

5.4. Outgoing condition Configuration

■ When pressing RESTORE key by Service remote control,

Red LED are blinked alternatively. And then automatically

turn off. (Must not AC power OFF during blinking)

5.5. GND and HI-POT Test

5.5.1. GND & HI-POT auto-check preparation

(1) Check the POWER CABLE and SIGNAL CABE insertion

condition.

(2) You can’t use Tuner Ground & Tuner signal line at all

models (applied Isolator inner tuner)

5.5.2. GND & HI-POT auto-check

(1) Pallet moves in the station.(POWER CORD / AV CORD is

tightly inserted)

(2) Connect the AV JACK Tester.

(3) Controller on.

(4) GND Test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, execute next process(Hi-pot test).

(Remove A/V CORD from A/V JACK BOX)

(5) HI-POT test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, GOOD Lamp on and move to next

process automatically.

5.5.3. Checkpoint

(1) Test voltage

1) 3 Poles

- GND: 1.5 KV/min at 100 mA

- SIGNAL: 3 KV/min at 100 mA

2) 2 Poles

- SIGNAL: 3 KV/min at 100 mA

(2) TEST time: 1 second

(3) TEST POINT

1) 3 Poles

- GND Test = POWER CORD GND and SIGNAL

CABLE GND.

- Hi-pot Test = POWER CORD GND and LIVE &

NEUTRAL.

2) 2 Poles

- Hi-pot Test = Accessible Metal and LIVE & NEUTRAL.

(4) LEAKAGE CURRENT: At 0.5 mArms

Only for training and service purposes

- 12 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 13

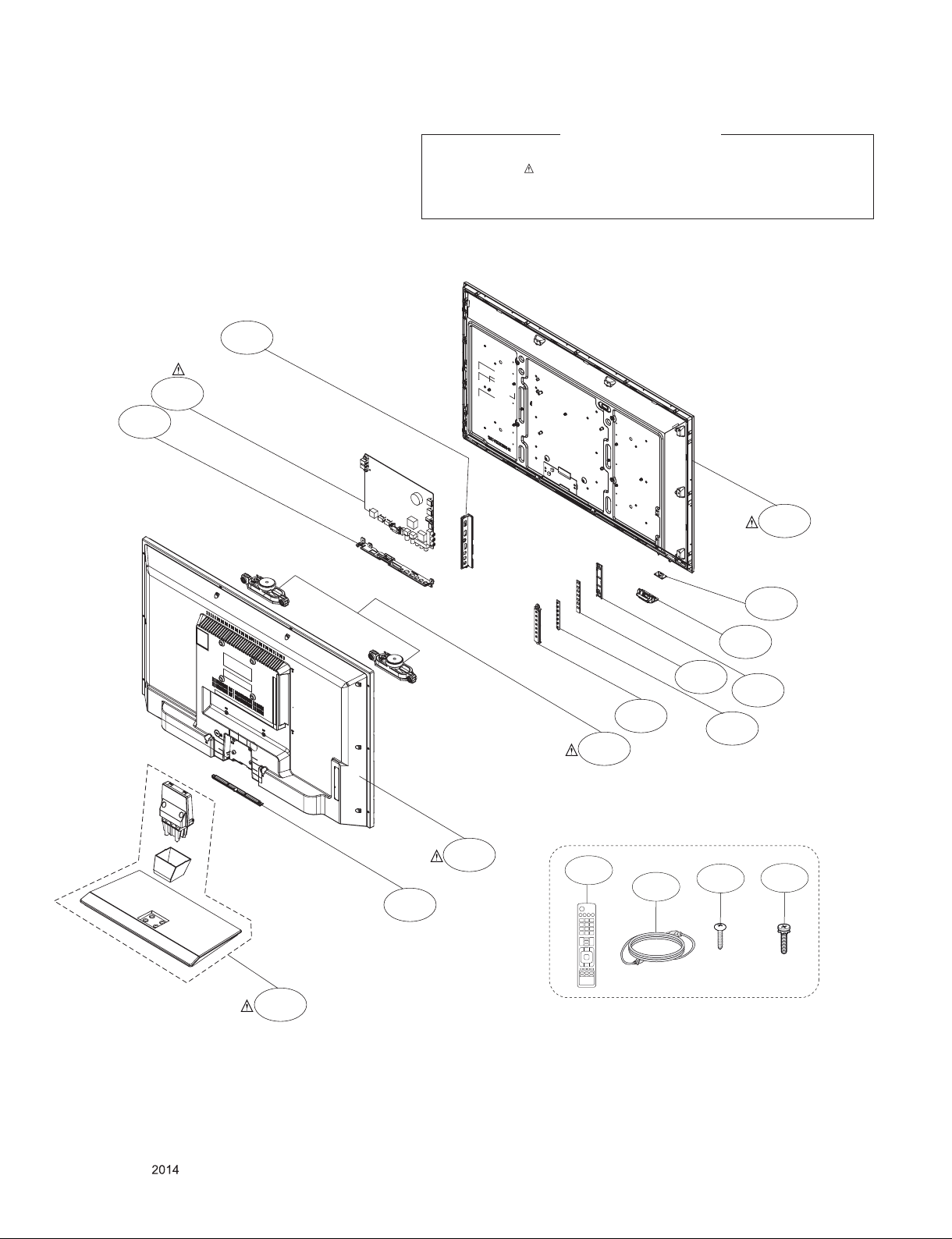

522

540

521

EXPLODED VIEW

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essenti al that these spec ial safety parts s hould be replace d with the same compone nts as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

200

900

610

400

120

A2

511

A3

510

512

A9

500

600

513

A10

Only for training and service purposes

- 13 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Page 14

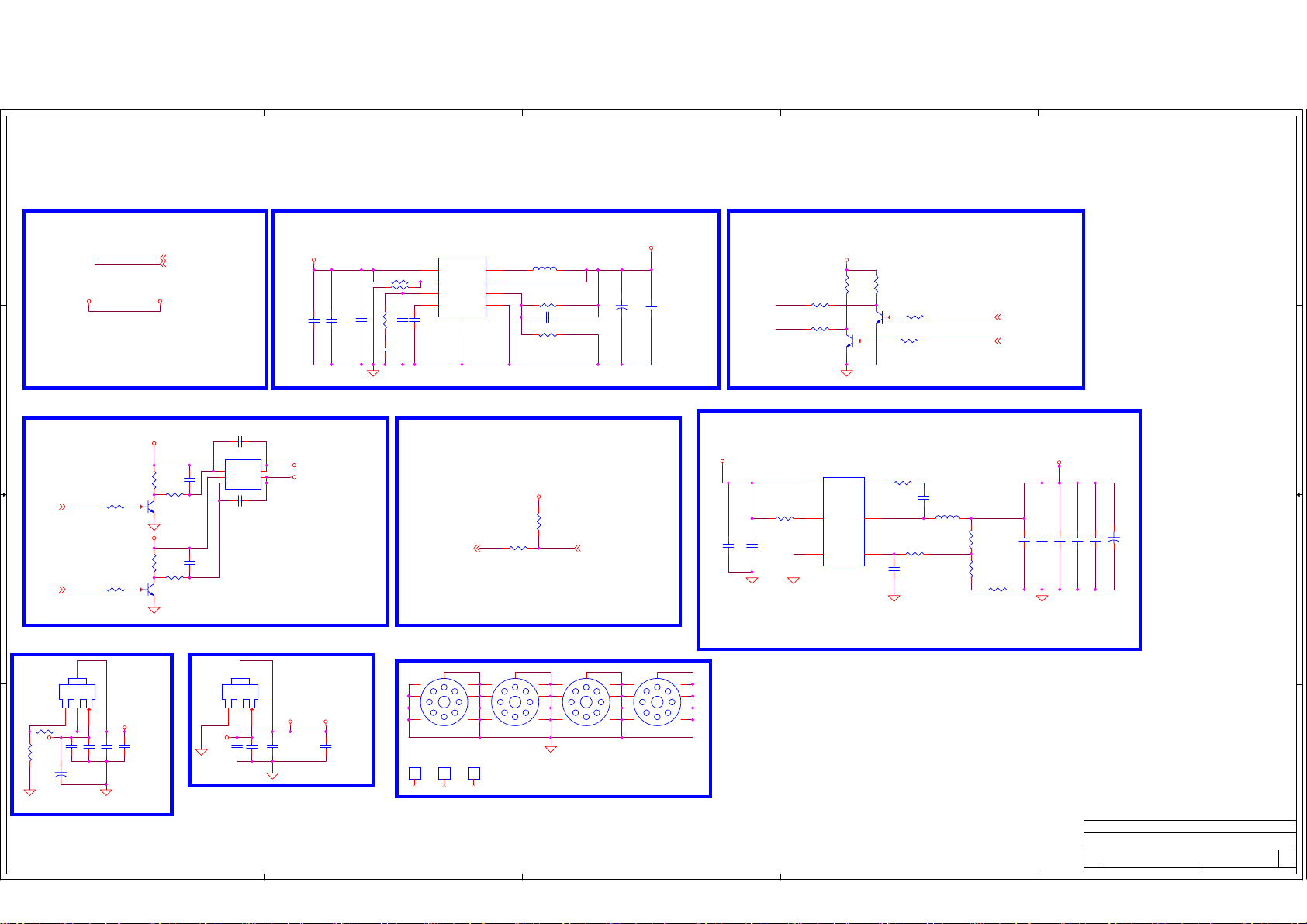

SCHEMATIC CIRCUIT DIAGRAM

5

Connetor

D D

+12V_PWR

BL-ON/OFF

BL-ADJUST

+12V

BL-ON/OFF

BL-ADJUST

5V Standby Power(option) 3A

+12V_PWR

C2

C3

10uF/16V/0805

0.1uF/0402/16V

10uF/16V/0805

C4

20K/0402/5%

2.2nF/0402/16V

4

R1 100K/0402/5%

R3 27K/0402/5%

C5

1nF/0402/16V/NC

R7

0.1uF/0402/16V

C8

C6

U1

AOZ3015PI/SOP8

2

VIN

7

EN

6

COMP

4

VCC

3

2

Inverter controller

+5V_Standby

9

L1 22uH_3A

LX

8

Vo

5

FB

1

PGND

AGND

3

R1

R5 51K/0402/1%

C7

0.1uF/0402/16V/NC

R2

R10 9.1K/0402/1%

+

CA3

470uF/16V/EC3.5

C1

0.1uF/0402/16V

BL-ON/OFF

BL-ADJUST

R6

100R/0402/5%

R9

22K/0402/5%

+5V_Normal

R2

200R/0402/5%/NC

Q2

3904/SOT-23

2 3

R4

4.7K/0402/5%

Q1

3904/SOT-23

2 3

1

1

10K/0402/5%

R11

4.7K/0402/5%

R8

VBL_CTRL

BRI_ADJ

1

Vout=0.8V*(1+R1/R2)

C

Power Switch

STANDBY

STANDBY

B

STANDBY

STANDBY

R15

22K/0402/5%

R24

22K/0402/5%

+5V_Standby

R12

100K/0402/5%

1

Q3

3904/SOT-23

2 3

+12V_PWR

R21

100K/0402/5%

1

Q4

3904/SOT-23

2 3

0.1uF/0402/16V

R13

100K/0402/5%

0.1uF/0402/16V

R23

100K/0402/5%

C9

0.1uF/0402/16V/NC

U2

4953/SOP8

1

2

3

C10

4

C20

S1

G1

S2

G2

C11

0.1uF/0402/16V/NC

8

+5V_Normal

D1

7

D1

6

+12V_NORMAL

D2

5

D2

Standby controller

+3.3V_Normal

STANDBY

STANDBY

R19

200R/0402/5%

H :Power on

L :Power off

R16

4.7K/0402/5%

PWR-ON/OFF

If POWER BOARD IS 5stb ONLY ,PL NOT PATCH THESE GUY.

1.5V/1.8V Power_Normal

4

U4

ADJ

OUT

AMS1117-Adj

IN

C22

2.2uF/0603/16V

0.1uF/0402/16V

CA9

+

200uF/35V/ECS-5M

321

0.1uF/0402/16V

C24

C23

2.2uF/0603/16V

+1.8V_DDR2

C25

R1

220R/0402/5%/470R/0402/5%

R26

+5V_Normal

R2

R27

100R/0402/5%

A A

3.3V Power

4

ADJ

OUT

+5V_Standby

C26

2.2uF/0603/16V

0.1uF/0402/16V

IN

321

C27

U5

AMS1117-3.3

+3.3V_Normal

C28

2.2uF/0603/16V

+3.3V_Normal

C29

0.1uF/0402/16V

Test Point & MARK

H1

1

5

4

3

2

NC

1

1

H5

NC

NC

H2

9

8

7

6

H6

1

5

9

4

8

3

7

2

6

NC

1

H7

NC

H3

1

5

4

3

2

NC

H4

1

5

9

4

8

3

7

2

6

NC

1.15V Core Power

+12V_PWR

C17

10uF/16V/0805

C18

10uF/16V/0805

Vout=0.8V*(1+R1/R2)

NOTICE:

9

8

7

6

R17

10K/0402/5%

3

5

1

U3

MP1470

IN

EN

GND

R14

6

BST

20R/0402/5%

C12

2

SW

4

FB

C21

10pF/0402/16V

If chip is 3393,The R2 Value is 10K 1%

If chip is 6306,The R2 Value is 8.2K 1%

1uF/0402/16V

L2

22uH_3A

R18

4.7K/0402/1%

R1

R20

100K/0402/5%

Resistors close to the DC-DC

R22

10K/0402/1% or 8.2K/0402/1%

R2

C13

10uF/16V/0805

R25

470R/0402/5%

Max :1.0A

VDDC

0.1uF/0402/16V

C19

C14

10uF/16V/0805

10uF/16V/0805

C15

10uF/16V/0805

C16

100uF/35V/ECS-5M

+

CA8

Vout=1.25V*(R1+R2)/R1

C

B

NOTICE:

If chip is 3393,The R1 Value is 220R 5% Vout=1.8V

If chip is 6306,The R1 Value is 470R 5% Vout=1.5V

5

4

Title

Title

Title

Custom

Custom

3

2

Custom

MSD3393

MSD3393

MSD3393

System power

System power

System power

1

veRrebmuN tnemucoDeziS

veRrebmuN tnemucoDeziS

veRrebmuN tnemucoDeziS

1.0

1.0

teehS:etaD

1 9Friday, September 27, 2013

1 9Friday, September 27, 2013

1 9Friday, September 27, 2013

teehS:etaD

teehS:etaD

1.0

of

of

of

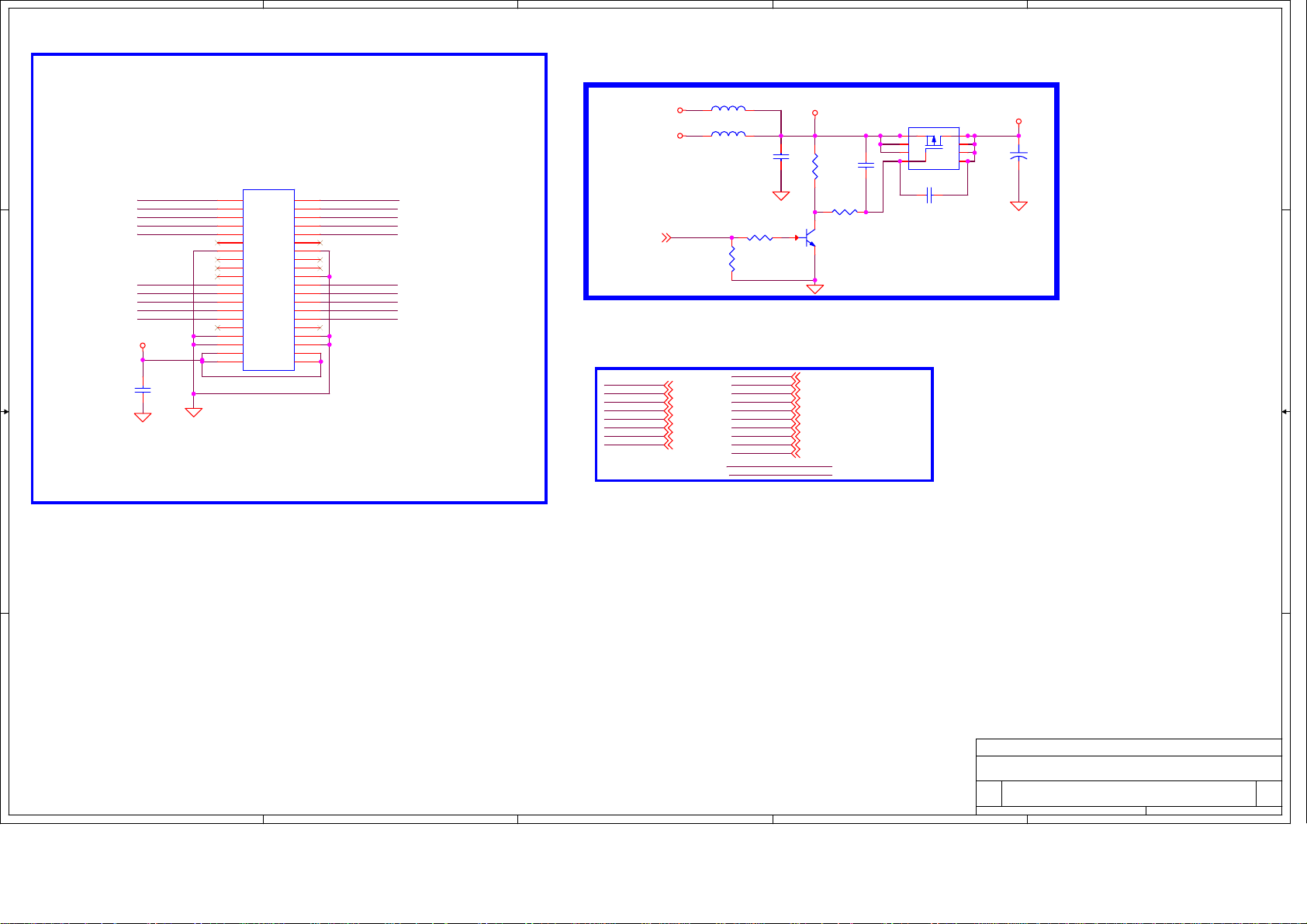

Page 15

5

HDMI Interface

HDMI0-RX0P

HDMI0-RX0N

HDMI0-RX1P

HDMI0-RX1N

HDMI0-RX2P

HDMI0-RX2N

HDMI0-CLKN

HDMI0-CLKP

HDMI0-SCL

HDMI0-SDA

HDMI0-HPDIN

HDMI1-RX0P

HDMI1-RX0N

HDMI1-RX1P

D D

HDMI1-RX1N

HDMI1-RX2P

HDMI1-RX2N

HDMI1-CLKN

HDMI1-CLKP

HDMI1-SCL

HDMI1-SDA

HDMI1-HPDIN

HDMI2-RX0P

HDMI2-RX0N

HDMI2-RX1P

HDMI2-RX1N

HDMI2-RX2P

HDMI2-RX2N

HDMI2-CLKN

HDMI2-CLKP

HDMI2-SCL

HDMI2-SDA

HDMI2-HPDIN

MHL_CABLE-DET

HDMI-ARC

HDMI-CEC

PC & YPBPR Interface

VGA-Rin

VGA-Gin

VGA-Bin

VGA_HSYNC

VGA_VSYNC

C C

YPbPr_PR

YPbPr_Y

YPbPr_PB

CVBS IN & OUT

AV1

CVBS1_OUT

HDMI0-RX0P

HDMI0-RX0N

HDMI0-RX1P

HDMI0-RX1N

HDMI0-RX2P

HDMI0-RX2N

HDMI0-CLKN

HDMI0-CLKP

HDMI0-SCL

HDMI0-SDA

HDMI0-HPDIN

HDMI1-RX0P

HDMI1-RX0N

HDMI1-RX1P

HDMI1-RX1N

HDMI1-RX2P

HDMI1-RX2N

HDMI1-CLKN

HDMI1-CLKP

HDMI1-SCL

HDMI1-SDA

HDMI1-HPDIN

HDMI2-RX0P

HDMI2-RX0N

HDMI2-RX1P

HDMI2-RX1N

HDMI2-RX2P

HDMI2-RX2N

HDMI2-CLKN

HDMI2-CLKP

HDMI2-SCL

HDMI2-SDA

HDMI2-HPDIN

MHL_CABLE-DET

HDMI-ARC

HDMI-CEC

R28 33R/0402/5%

R29 68R/0402/5%

R30 33R/0402/5%

R31 33R/0402/5%

R32 33R/0402/5%

R33 68R/0402/5%

R34 33R/0402/5%

R35 33R/0402/5%

R36 0R/0402/5%

R38 150R/0402/5%

R39 180R/0402/5%

C48 47nF/0402/16V

C49 47nF/0402/16V

C50 47nF/0402/16V

C51 47nF/0402/16V

VGA_HSYNC

VGA_VSYNC

C52 47nF/0402/16V

C53 47nF/0402/16V

C54 47nF/0402/16V

C55 47nF/0402/16V

C56 1nF/0402/16V

C58 47nF/0402/16V

C60 47nF/0402/16V

RGB0_R+

RGB0_GRGB0_G+

RGB0_B+

RGB1_R+

RGB1_GRGB1_G+

RGB1_B+

RGB1_SOG

CVBS0+

CVBS_VCOM

CVBS1_OUT

HDMI2-RX1N

HDMI2-RX1P

HDMI2-RX2N

HDMI2-RX2P

+3.3V_Normal

HDMI1-CLKN

HDMI1-CLKP

HDMI1-RX0N

HDMI1-RX0P

HDMI1-RX1N

HDMI1-RX1P

HDMI1-RX2N

HDMI1-RX2P

VGA_HSYNC

RGB0_B+

RGB0_G+

RGB0_GRGB0_R+

VGA_VSYNC

+3.3V_Normal

RGB1_B+

RGB1_SOG

RGB1_G+

RGB1_GRGB1_R+

CVBS0+

CVBS_VCOM

CVBS1_OUT

LINEIN_R1

LINEIN_L1

AU_VAG

AU_VRM

VDDC

+3.3V_AU

AUDIO IN

VGA-Lin_AU

VGA-Rin_AU

AV1-Lin

AV1-Rin

VGA-Lin_AU

VGA-Rin_AU

AV1-Lin

AV1-Rin

C61 2.2uF/0603/16V

C63 2.2uF/0603/16V

C64 2.2uF/0603/16V

C65 2.2uF/0603/16V

LINEIN_L1

LINEIN_R1

LINEIN_L4

LINEIN_R4

DIF IN

VIFP

IFP

IFN

B B

USB & SPDIF_OUT

USB2_DUSB2_D+

USB1_DUSB1_D+

SPDIF_OUT

C67

0.1uF/0402/16V

VIFM

C68

0.1uF/0402/16V

USB2_DUSB2_D+

USB1_DUSB1_D+

SPDIF_OUT

C69

2.2uF/0603/16V

L6

AU_VRM

AU_VAG

C70

0.1uF/0402/16V

2.2uF/0603/16V

C71

RESET

+5V_Standby

DEBUG

A A

MUST pull high to 5VSTB

ISP AND VGA EDID

R49

100K/0402/5%

R50

10K/0402/5%

C78

2.2uF/0603/16V

UART-TX

R66 100R/0402/5%

UART-RX

R67 100R/0402/5%

3

D1

BAV99

C75

1

2

2.2uF/0603/16V

1

Q5

3906/SOT-23

R52

3 2

R54

100K/0402/5%

+5V_Standby

R64

4.7K/0402/5%

1K/0402/5%

R65

4.7K/0402/5%

5

System-RST

C77

1nF/0402/16V

UART_TX

UART_RX

0R/0603/5%

XTAL

R51

XTALO

0R/0402/5%

XTALI

FLASH

+3.3V_Normal

SPI_SCK

SPI_SDI

C81

0.1uF/0402/16V

R53

1M/0402/5%

Y1

24MHz

3

U7

MX25L3205

8

VDD

7

HOLD#

6

SCK

5

SI

C76

33pF/0402/16V

C79

33pF/0402/16V

WP#

4

TP4

HDMI2-RX0N

HDMI2-RX0P

1

131

127

128

132

129

130

U6

Test

MARK

MARK

E-PAD

RX0P_B

RX0N_B

1

RX1N_B

2

RX1P_B

3

RX2N_B

4

RX2P_B

5

AVDD_MOD

6

RXCN_A

7

RXCP_A

8

RX0N_A

9

RX0P_A

10

RX1N_A

11

RX1P_A

12

RX2N_A

13

RX2P_A

14

HSYNC0

15

BIN0P

16

GIN0P

17

GIN0M

18

RIN0P

19

VSYNC0

20

AVDD3P3_ADC

21

BIN1P

22

SOGIN1

23

GIN1P

24

GIN1M

25

RIN1P

26

VSYNC1

27

CVBS1

28

CVBS0

29

VCOM

30

CVBS_OUT1

31

VDDC

32

AVDD_AU33

33

AUR0

34

AUL0

35

AUR1

36

AUL1

37

VAG

38

VRM

AUR440AUOUTL3

AUL4

MSD3393LU

39

LINEIN_L4

LINEIN_R4

+3.3V_TU

Close to Mstar IC

R43

10K/0402/5%

IFAGC

R46

0R/0402/5%

CHIP_CONFIG

{IPAD_PWM1, PAD_PWM0}

B51_NO_EJ

PWM1

R57 4.7K/0402/5%

PWM0

R58 4.7K/0402/5%

+3.3V_Normal

1

SPI_CSN

CE#

2

SPI_SDO

SO

3

#F_WP

4

VSS

4

VDDC

HDMI2-CLKN

HDMI2-CLKP

HDMI0-RX1P

HDMI0-RX2N

HDMI0-RX2P

125

126

123

124

122

RX2P_D

RX1P_D

RX2N_D

RXCP_B

RXCN_B

AVDD5V_MHL

HDMI2-SCL

HDMI0-RX0P

120

RX1N_D

HDMI2-HPDIN

HDMI0-RX0N

HDMI0-CLKN

HDMI0-CLKP

116

117

118

119

112

115

113

114

RX0P_D

RX0N_D

RXCP_D

RXCN_D

AVDD_5V

HOTPLUG_B

GND_EFUSE

VDDC/AVDDL_DVI

HDMI0-RX1N

121

MSD3393LU

48

+3.3V_ADC

IFAGC-T

VDDC/DVDD_DDR_CMD54VDDIO_CMD

AVDD_MOD

AVDD3P3_DADC

55

53

51

52

+1.8V_DDR2

+3.3V_PLL

+3.3V_Normal

VDDC

XTALO

XTALI

TUNER_SDA

AUOUTL043AUOUTR3

41

42

LINE3OUT_L

LINE3OUT_R

LINE0OUT_L

LINE0OUT_R

C72

22nF/0402/16V

4'h00

R63

10K/0402/5%

VIFP46VIFM47AUOUTR044IFAGC45XIN50AVDD3P3_DMPLL49Xout

VIFM

VIFP

IFAGC

MHL_CABLE-DET

HDMI2-SDA

111

110

DDCDB_CL

DDCDB_DA

GPIO0/GPIO44

GPIO1/GPIO45

57

56

TUNER_SCL

MHL_VBUS-EN

HDMI1-SDA

109

MHL_DET

AMP-MUTE

HDMI1-SCL

HDMI0-SDA

107

108

DDCDA_CL

DDCDA_DA

DDCDC_DA

GPIO3/GPIO4758GPIO4/GPIO4859LVA3P61GPIO2/GPIO46

GPIO5/GPIO49

60

PWR-ON/OFF

SPDIF_OUT

VDDC

+1.8V_DDR2

ARC_DET

HDMI0-SCL

105

103

106

104

DDCDC_CL

VDDIO_DATA

VDDC/DVDD_DDR_DATA

HOTPLUG_C/D

LVA3M62LVACKP

64

63

R70

22R/0402/5%

B3_RXE3-

B2_RXE3+

B4_RXEC+

B5_RXEC-

PWR-ON/OFF

MHL_VBUS-EN

PANEL_ON/OFF

SAR2

SAR1

SAR0

AVDD_MOD

DP_P1

DM_P1

DP_P0

DM_P0

RESET

INT/GPIO64

TEST

DDCA_CK

DDCA_DA

SPI_CK

SPI_CZ

SPI_DI

SPI_DO

PWM0

PWM1

HOTPLUG_A

LDE/LVB0M

LCK/LVB0P

LVB1M

LVB1P

LVB2M

LVB2P

AVDD_MOD

LVB3M

LVB3P

LVA0M

LVA0P

LVA1M

LVA1P

LVA2M

LVA2P

LVACKM

R72

22R/0402/5%

IR-in

KEY0-SAR0

KEY1-SAR1

BRI_ADJ

VBL_CTRL

AMP-MUTE

ARC_DET

TUNER_SCL

TUNER_SDA

IRIN

CEC

ARC

102

101

100

99

98

97

96

95

94

93

92

91

90

89

88

87

86

85

84

83

82

81

80

79

78

77

76

75

74

73

72

71

70

69

68

67

66

65

FOR EMI

R7_RXO0R6_RXO0+

R5_RXO1R4_RXO1+

R3_RXO2R2_RXO2+

G7_RXO3G6_RXO3+

G3_RXE0G2_RXE0+

G1_RXE1G0_RXE1+

B7_RXE2B6_RXE2+

B5_RXECB4_RXEC+

B3_RXE3B2_RXE3+

3

KEY1-SAR1

KEY0-SAR0

+3.3V_Normal

USB2_D+

USB2_DUSB1_D+

USB1_DSystem-RST

PANEL_ON/OFF

IR-in

HDMI-CEC

UART-RX

UART-TX

HDMI-ARC

SPI_SCK

SPI_CSN

SPI_SDI

SPI_SDO

BRI_ADJ

VBL_CTRL

HDMI1-HPDIN

HDMI0-HPDIN

R7_RXO0R6_RXO0+

R5_RXO1R4_RXO1+

R3_RXO2R2_RXO2+

+3.3V_Normal

G7_RXO3G6_RXO3+

G3_RXE0G2_RXE0+

G1_RXE1G0_RXE1+

B7_RXE2B6_RXE2+

PWR-ON/OFF

PWM0

PWM1

MHL_VBUS-EN

AMP-MUTE

PANEL_ON/OFF

ARC_DET

TUNER_SCL

TUNER_SDA

R7_RXO0R6_RXO0+

R5_RXO1R4_RXO1+

R3_RXO2R2_RXO2+

G7_RXO3G6_RXO3+

G3_RXE0G2_RXE0+

G1_RXE1G0_RXE1+

B7_RXE2B6_RXE2+

B5_RXECB4_RXEC+

B3_RXE3B2_RXE3+

3

VDDC 1.15V

VDDC

C30

2.2uF/0603/16V

DDR2 1.8V

+1.8V_DDR2

C35

2.2uF/0603/16V

3.3V

+3.3V_Normal

C40

2.2uF/0603/16V

C31

0.1uF/0402/16V

C36

0.1uF/0402/16V

C41

0.1uF/0402/16V

0.1uF/0402/16V

C32

0.1uF/0402/16V

3.3V audio

+3.3V_Normal

C38

0.1uF/0402/16V

C42

0.1uF/0402/16V

C33

0.1uF/0402/16V

L3

0R/0603/5%

0.1uF/0402/16V

C43

Audio Line Out

LINE0OUT_L

LINE0OUT_R

LINE3OUT_L

LINE3OUT_R

Close to Mstar IC

IR&KEYB

J1

CON20W-J20-12

IR_in

1nF/0402/16V

1nF/0402/16V

1nF/0402/16V

1nF/0402/16V

1

2

3

4

5

6

7

8

9

10

11

12

+5V_Standby

R60

10K/0402/5%

R62

1K/0402/5%

C165

C57

C62

C66

+5V_Standby

KEY0-in

KEY1-in

IR_in

LED_G

LED_R

R37

200K/0402/5%

R40

200K/0402/5%

R41

200K/0402/5%

R42

200K/0402/5%

+3.3V_Normal

IR-in

C80

33pF/0402/16V

D13

ESD

2

C34

0.1uF/0402/16V

1

3.3V MPLL

+3.3V_Normal

+3.3V_AU

C37

0.1uF/0402/16V

L5

0R/0603/5%

C44

C45

0.1uF/0402/16V

AV_AUOUTL1

AV_AUOUTR1

LINEOUT_APML

LINEOUT_APMR

+3.3V_Normal

R44

8.2K/0402/5%

KEY0-in KEY0-SAR0

C74

0.1uF/0402/16V

D12

ESD

STANDBY

L4

0R/0603/5%

+3.3V_ADC

C46

2.2uF/0603/16V

R47

1K/0402/5%

R61

22K/0402/5%

+3.3V_PLL

C39

0.1uF/0402/16V

C47

0.1uF/0402/16V

+3.3V_Normal

Q7

1

3904/SOT-23

2 3

KEY1-in

R55

2K/0402/5%

LED_G

+3.3V_Normal

R45

8.2K/0402/5%

R59

4.7K/0402/5%

R48

1K/0402/5%

C73

0.1uF/0402/16V

+3.3V_Normal

Q6

1

3904/SOT-23

R56

2K/0402/5%

LED_R

2 3

KEY1-SAR1

Standby :L :Power on Green Led

H :Power off Red Led

Title

Title

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet

Date: Sheet

2

Date: Sheet

MSD3393

MSD3393

MSD3393

MAIN CHIP

MAIN CHIP

MAIN CHIP

1

1.0

1.0

29Wednesday, June 11, 2014

29Wednesday, June 11, 2014

29Wednesday, June 11, 2014

1.0

of

of

of

Page 16

5

4

LVDS CONNECTOR ( 1 DIP + 2 SMT OPTIONAL )

3

2

1

HI CONNECTOR

D D

CN2

DIP/20*2

R7_RXO0R5_RXO1R3_RXO2R1_RXOCG7_RXO3-

G3_RXE0G1_RXE1B7_RXE2-

C C

B5_RXECB3_RXE3-

VCC-Panel

C85

0.1uF/0402/16V

40

A0-

38

A1-

36

A2-

34

AC-

32

A3-

30

A4-

28

GND

26

DCR-I

24

MODE

22

SG

20

B0-

18

B1-

16

B2-

14

BC-

12

B3-

10

B4-

8

GND

6

GND

4

VCC

2

VCC

A0+

A1+

A2+

ACA3+

A4+

GND

DCR-O

GND

B0+

B1+

B2+

BC+

B3+

B4+

GND

GND

VCC

VCC

39

37

35

33

31

29

27

25

23

I/O

21

19

17

15

13

11

9

7

5

3

1

R6_RXO0+

R4_RXO1+

R2_RXO2+

R0_RXOC+

G6_RXO3+

G2_RXE0+

G0_RXE1+

B6_RXE2+

B4_RXEC+

B2_RXE3+

Power for panel

+5V_Normal

+12V_NORMAL

PANEL_ON/OFF

Net to other page

R7_RXO0R6_RXO0+

R5_RXO1R4_RXO1+

R3_RXO2R2_RXO2+

G7_RXO3G6_RXO3+

FB3 0R/1206/5%/NC

FB4 0R/1206/5%

PANEL_ON/OFF

R7_RXO0R6_RXO0+

R5_RXO1R4_RXO1+

R3_RXO2R2_RXO2+

G7_RXO3G6_RXO3+

0.1uF/0402/16V/NC

R71

4.7K/0402/5%

R73

10K/0402/5%

G3_RXE0G2_RXE0+

G1_RXE1G0_RXE1+

B7_RXE2B6_RXE2+

B5_RXECB4_RXEC+

B3_RXE3B2_RXE3+

R1_RXOC- B5_RXECR0_RXOC+ B4_RXEC+

VPANEL_IN

C82

100K/0402/5%

1

3904/SOT-23

G3_RXE0G2_RXE0+

G1_RXE1G0_RXE1+

B7_RXE2B6_RXE2+

B5_RXECB4_RXEC+

B3_RXE3B2_RXE3+

R68

100K/0402/5%

Q9

2 3

C83

1uF/0402/16V/NC

R69

U8 9435/SOP8

1

S

2

3

4

AO3401A/SOT-23/NC

D

S

D

S

D

G

D

Q8

C84

0.1uF/0402/16V/NC

5

6

7

8

470uF/16V/EC3.5

VCC-Panel

CA11

+

B B

A A

Title

Title

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

B

B

B

Date: Sheet

Date: Sheet

5

4

3

2

Date: Sheet

MSD3393

MSD3393

MSD3393

LVDS Interface

LVDS Interface

LVDS Interface

1.0

1.0

1.0

of

of

of

39Wednesday, June 11, 2014

39Wednesday, June 11, 2014

39Wednesday, June 11, 2014

1

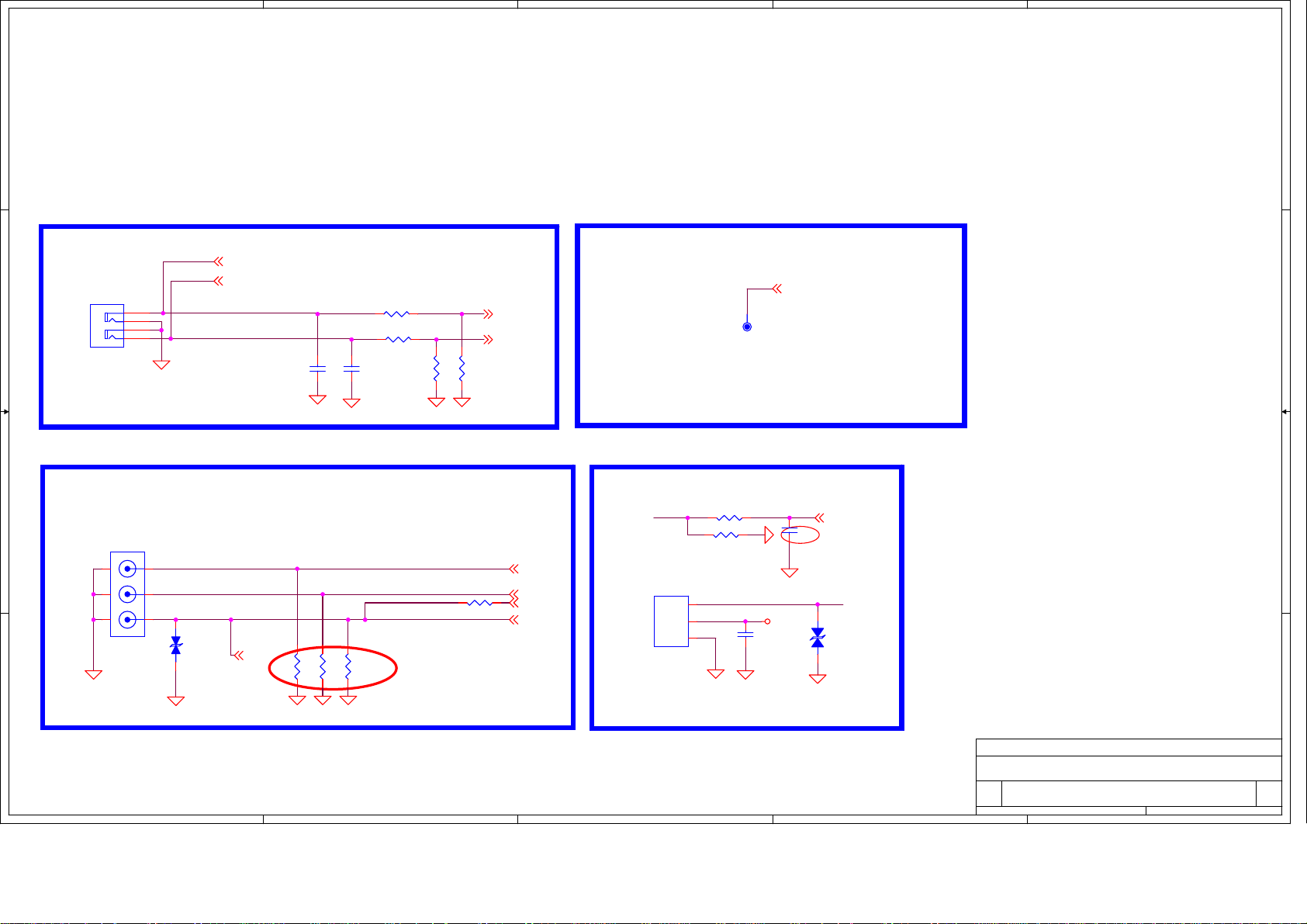

Page 17

5

D D

4

3

2

1

AUDIO IN

P1

WHITE

1

C C

RED

RCA-2P

HD_L

2

3

4

HD_R

HD_L

HD_R

220pF/0402/16V/NC

C87

C86

220pF/0402/16V/NC

R76 10K/0402/5%

R77 10K/0402/5%

R79

12K/0402/5%

AV1-Lin

AV1-Rin

R80

12K/0402/5%

YPBPR & AV IN

B B

P2

YPbPr_PR

YPbPr_PB

AV1

YPbPr_Y

RCA-3P

12

34

56

D14

ESD

AV1-IN

R85

75R/0402/5%

R84

75R/0402/5%

75R/0402/5%

Close to Mstar IC

R83

R199

0R/0402/5%

VIDEO OUT

SPDIF OUT

R81

330R/0402/5%

SPDIF_O

R82

100R/0402/5%

P14

3

INPUT

2

VCC

1

GND

NC/FIBER-OPTIC

1

TP2

Closed to IC

+5V_Normal

NC/C88

0.1uF/0402/16V/NC

CVBS1_OUT

FOR ATV/AV DEBUG

SPDIF_OUT

C102

33pF/0402/16V

SPDIF_O

NC/RV1

ESD

A A

Title

Title

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

B

B

B

Date: Sheet

Date: Sheet

5

4

3

2

Date: Sheet

MSD3393

MSD3393

MSD3393

Video Interface

Video Interface

Video Interface

1.0

1.0

1.0

of

of

of

49Monday, July 14, 2014

49Monday, July 14, 2014

49Monday, July 14, 2014

1

Page 18

5

4

3

2

1

VGA

P4

D D

C C

R92

10K/0402/5%

1617

11

12

13

14

15

VGA/15 PIN

R93

10K/0402/5%

1

6

2

7

3

8

4

9

5

10

DDC_SCL_D

DDC_SDA_D

R90100R/0402/5%

R91100R/0402/5%

VGA-Rin

VGA-Gin

VGA-Bin

UART_RX

UART_TX

VGA_VSYNC

VGA_HSYNC

VGA AUDIO IN

P5

PHONEJACK

1

2

5

3

4

R86 10K/0402/5%

R87 10K/0402/5%

R88

12K/0402/5%

R89

12K/0402/5%

VGA-Lin_AU

VGA-Rin_AU

C89

220p/0402/16V

VGA-Lin_AU

VGA-Rin_AU

C90

220p/0402/16V

B B

VGA-Bin

VGA-Gin

VGA-Rin

R94

75R/0402/5%

R95

R96

75R/0402/5%

75R/0402/5%

VGA-Bin

VGA-Gin

VGA-Rin

Close to Mstar IC

A A

Title

Title

Title

MSD3393

MSD3393

MSD3393

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

A

A

A

Date: Sheet

Date: Sheet

5

4

3

Date: Sheet

VGA Interface

VGA Interface

VGA Interface

2

of

of

of

59Wednesday, May 14, 2014

59Wednesday, May 14, 2014

59Wednesday, May 14, 2014

1

1.0

1.0

1.0

Page 19

5

4

3

2

1

USB INTERFACE

D

C C

5

6

5

6

P6

USB_A

5

6

5

6

1

1

2

3

4

P7USB_A

1

2

3

4

USB1_D1-_in

USB1_D1+_in

USB2_D1-_in

USB2_D1+_in

2

3

4

1

2

3

4

+5V_USB0

+5V_USB0

R97 2.2/0402/5%

R98 2.2/0402/5%

R99 2.2R

R100 2.2R

USB2_D-

USB2_D+

USB1_DUSB1_D+

USB2_D+

USB1_DUSB1_D+

USB2_D-

USB POWER

D2

+5V_USB0

C91

0.1uF/0402/16V

CA10

+

200uF/35V/ECS-5M

C93

0.1uF/0402/16V

+5V_Normal5V_USB

5V_USB

C92

2.2uF/0603/16V

5V_USB+5V_USB0

C94

2.2uF/0603/16V

D

B

A

Title

Title

Title

MSD3393

MSD3393

MSD3393

USB Interface

USB Interface

A

A

A

5

4

3

USB Interface

2

teehS:etaD

teehS:etaD

teehS:etaD

of

of

of

6 9Monday, July 14, 2014

6 9Monday, July 14, 2014

6 9Monday, July 14, 2014

1

veRrebmuN tnemucoDeziS

veRrebmuN tnemucoDeziS

veRrebmuN tnemucoDeziS

1.0

1.0

1.0

B

A

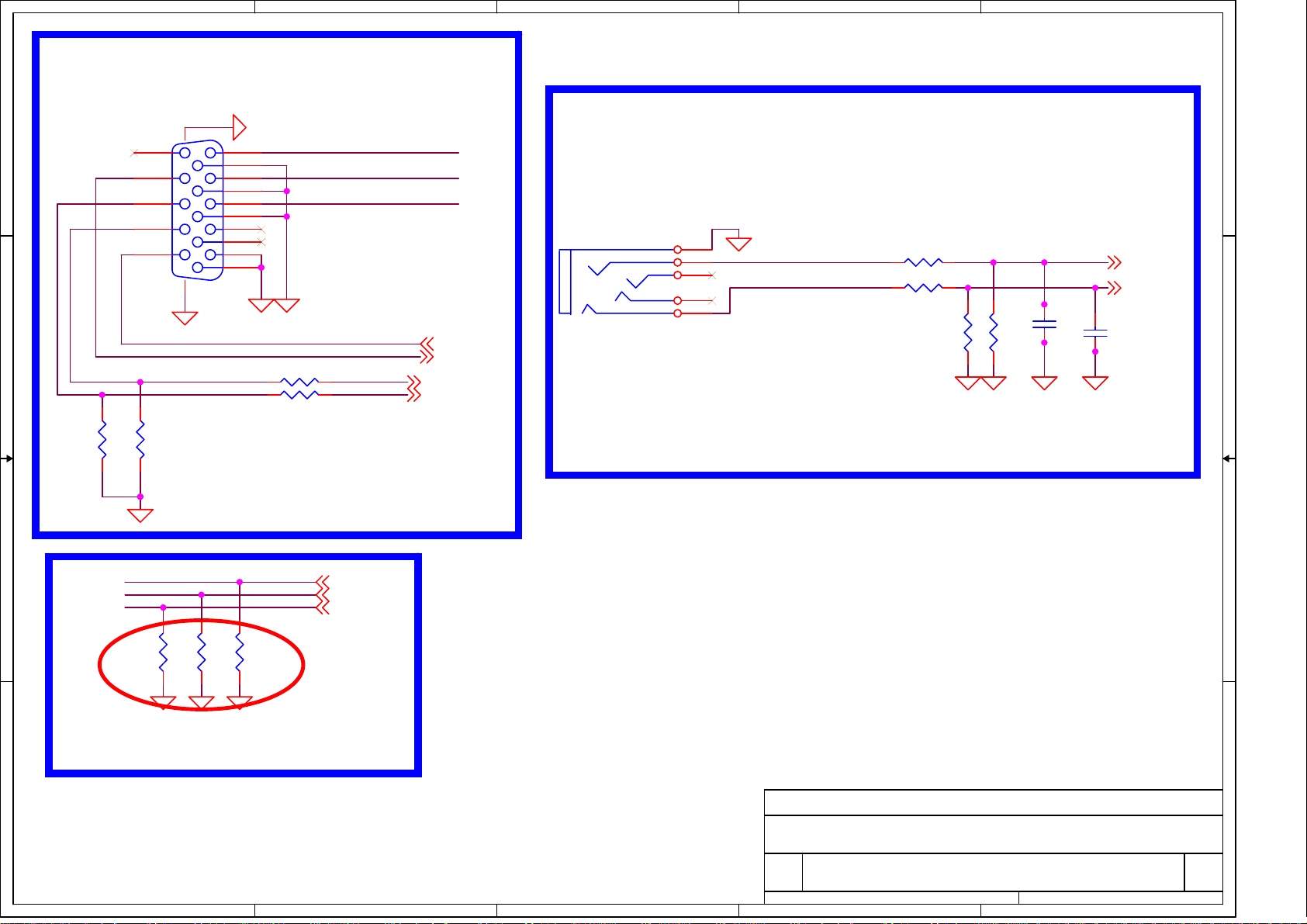

Page 20

5

P8

20

GND

21

GND

22

GND

23

GND

18

+5V

17

CEC/DDC GND

15

DDC SCL

16

DDC SDA

13

CEC

19

HPD

2

Dat2 shield

5

Dat1 shield

8

Dat0 shield

11

clk shield

D D

7

DAT0+

9

DAT0-

4

DAT1+

6

DAT1-

1

DAT2+

3

DAT2-

10

clk+

12

clk-

14

ARC1

HDMI

P9

20

GND

21

GND

22

GND

23

GND

18

+5V

17

CEC/DDC GND

15

DDC SCL

16

DDC SDA

13

CEC

19

HPD

2

Dat2 shield

5

Dat1 shield

8

Dat0 shield

11

clk shield

7

DAT0+

9

DAT0-

4

DAT1+

6

DAT1-

1

DAT2+

3

DAT2-

10

clk+

12

clk-

C C

14

ARC1

HDMI

P10

20

GND

21

GND

22

GND

23

GND

18

+5V

17

CEC/DDC GND

15

DDC SCL

16

DDC SDA

13

CEC

19

HPD

2

Dat2 shield

5

Dat1 shield

8

Dat0 shield

11

clk shield

7

DAT0+

9

DAT0-

4

DAT1+

6

DAT1-

1

DAT2+

3

DAT2-

10

clk+

12

clk-

14

ARC1

B

HDMI

HDMI3_RX0P

HDMI3_RX0N

HDMI3_RX1P

HDMI3_RX1N

HDMI3_RX2P

HDMI3_RX2N

HDMI3_CLKP

HDMI3_CLKN

HDMI3/5V

HDMI_ARC

HDMI3-DDC-SCL

HDMI3-DDC-SDA

CEC

HDMI3-HPD

HDMI1/5V

HDMI1-DDC-SCL

HDMI1-DDC-SDA

CEC

HDMI1-HPD

HDMI1_RX0P

HDMI1_RX0N

HDMI1_RX1P

HDMI1_RX1N

HDMI1_RX2P

HDMI1_RX2N

HDMI1_CLKP

HDMI1_CLKN

HDMI2-DDC-SCL

HDMI2-DDC-SDA

CEC

HDMI2-HPD

MHL_CD_SENSE

HDMI2_RX0P

HDMI2_RX0N

HDMI2_RX1P

HDMI2_RX1N

HDMI2_RX2P

HDMI2_RX2N

HDMI2_CLKP

HDMI2_CLKN

HDMI2/5V

HDMI3_RX2P

HDMI3_RX2N

HDMI3_RX1P

HDMI3_RX1N

HDMI3_RX0P

HDMI3_RX0N

HDMI3_CLKP

HDMI3_CLKN

HDMI1_RX2P

HDMI1_RX2N

HDMI1_RX1P

HDMI1_RX1N

HDMI1_RX0P

HDMI1_RX0N

HDMI1_CLKP

HDMI1_CLKN

R101 5.1R/0402/5%

HDMI3-RX2P

HDMI3-RX2N

R103 5.1R/0402/5%

HDMI3-RX1P

R107 5.1R/0402/5%

R108 5.1R/0402/5%

HDMI3-RX1N

HDMI3-RX0P

R109 5.1R/0402/5%

HDMI3-RX0N

R111 5.1R/0402/5%

HDMI3-CLKP

R113 5.1R/0402/5%

HDMI3-CLKN

R115 5.1R/0402/5%

R116 5.1R/0402/5%

R117 5.1R/0402/5%

R119 5.1R/0402/5%

R121 5.1R/0402/5%

R123 5.1R/0402/5%

R125 5.1R/0402/5%

R126 5.1R/0402/5%

R130 5.1R/0402/5%

HDMI2_RX2P

HDMI2_RX2N

HDMI2_RX1P

HDMI2_RX1N

HDMI2_RX0P

HDMI2_RX0N

HDMI2_CLKP

HDMI2_CLKN

HDMI1-RX2P

HDMI1-RX2N

HDMI1-RX1P

HDMI1-RX1N

HDMI1-RX0P

HDMI1-RX0N

HDMI1-CLKP

HDMI1-CLKN

R131 5.1R/0402/5%

HDMI2-RX2P

HDMI2-RX2N

R132 5.1R/0402/5%

HDMI2-RX1P

R133 5.1R/0402/5%

HDMI2-RX1N

R134 5.1R/0402/5%

HDMI2-RX0P

R137 5.1R/0402/5%

HDMI2-RX0N

R139 5.1R/0402/5%

R141 5.1R/0402/5%

HDMI2-CLKP

HDMI2-CLKN

R143 5.1R/0402/5%

HDMI0-RX2P

HDMI0-RX2N

HDMI0-RX1P

HDMI0-RX1N

HDMI0-RX0P

HDMI0-RX0N

HDMI0-CLKP

HDMI0-CLKN

HDMI1-RX2P

HDMI1-RX2N

HDMI1-RX1P

HDMI1-RX1N

HDMI1-RX0P

HDMI1-RX0N

HDMI1-CLKP

HDMI1-CLKN

HDMI3-DDC-SCL

HDMI3-DDC-SDA

HDMI2-RX2P

HDMI2-RX2N

HDMI2-RX1P

HDMI2-RX1N

HDMI2-RX0P

HDMI2-RX0N

HDMI2-CLKP

HDMI2-CLKN

10K/0402/5%

HDMI1-DDC-SCL

HDMI1-DDC-SDA

HDMI3/5V

R104

10K/0402/5%

10K/0402/5%

HDMI2-DDC-SCL

HDMI2-DDC-SDA

R105

R110 33R/0402/5%

R112 33R/0402/5%

HDMI1/5V

R124

R122

10K/0402/5%

AVDD5V_CD

47K/0402/5%

4

HDMI0-SCL

HDMI0-SDA

R127INS163289633R/0402/5%

R129 33R/0402/5%

R136

R135

10K/0402/5%

R140 33R/0402/5%

R142 33R/0402/5%

HDMI1-SCL

HDMI1-SDA

HDMI3-HPD

HDMI2-SCL

HDMI2-SDA

HDMI3/5V

HDMI1-HPD

R102

1K/0402/5%

Q10

1

R114 4.7K/0402/5%

3904/SOT-23

2 3

HDMI1/5V

R118

1K/0402/5%

3904/SOT-23

2 3

Q11

1

R128 4.7K/0402/5%

HDMI2-HPD

R106

10K/0402/5%

HDMI0-HPDIN

R120

10K/0402/5%

HDMI0-HPDIN

HDMI1-HPDIN

R138 33R/0402/5%

HDMI1-HPDIN

HDMI2-HPDIN

HDMI2-HPDIN

3

2

1

HDMI3

HDMI1

CEC & ARC MHL

HDMI_ARC HDMI-ARC

CEC

HDMI3/5V

C95

2.2uF/0603/16V

R144 200R/0402/5%

R148 4.7K/0402/5%

HDMI-CEC

R150

10K/0402/5%

HDMI-ARC

HDMI-CEC

ARC_DET

HDMI2/5V

+5V_Standby

R145 0R/0402/5%

D3

2

1

AVDD5V_CD

3

BAT54C/SOT23/NC

HDMI2/5V

R152 10R/0402/5%

AVDD5V_MHL

MHL_CD_SENSE

C96

47nF/0402/16V

R146 100R/0402/5%

R149

300K/0402/5%

MHL_CABLE-DET

MHL_CABLE-DET

MHL_VBUS-EN

R155

NC/1K/0402/5%

R154

100/0402/5%

+5V_Standby

R151

10K/0402/5%

R147 10K/0402/5%/NC

QA1

5

4

/EN

GND

AP2181DWG-7

HDMI2/5V

/OC3VIN

1

VOUT

2

B

HDMI2 With MHL

A A

Title

Title

Title

D

D

5

4

3

2

D

1

MSD3393

MSD3393

MSD3393

HDMI Interface

HDMI Interface

HDMI Interface

teehS:etaD

teehS:etaD

teehS:etaD

7 9Wednesday, June 11, 2014

7 9Wednesday, June 11, 2014

7 9Wednesday, June 11, 2014

of

of

of

veRrebmuN tnemucoDeziS

veRrebmuN tnemucoDeziS

veRrebmuN tnemucoDeziS

1.0

1.0

1.0

Page 21

Silicon TUNER

5

P12

1

234

CON3

234

3

4

5

6

7

16

17

18

19

5

P13

1

5

RCA1_6

D D

C C

120pF/0402/50V/NC

1

2

47nF/0402/16V/NC

C100

D11

ESD

+3.3V_TU

C98

1

2

3

C101

120pF/0402/50V

+3.3V_TU

C166

1nF/0402/16V

12

11

C1

VDD

GND

RF1

GND

GND

RFC

5

4

C167

1nF/0402/16V

10

C2

9

GND

8

RF2

7

GND

GND

6

PE42750DS/NC

U9

C168

1nF/0402/16V

R157

0R/0402/5%

C169

1nF/0402/16V

C99

0.1uF/0402/16V/NC

R158

0R/0402/5%

+1.8V_TU

C170

1nF/0402/16V

R153

100R/0402/5%/NC

C171

C1

1nF/0402/16V

4

47pF/0402/16V

C172

270nH/0603/ 5%

C173 91pF/0402/16V

L23

L22

180nH/0603/ 5%

C183

180pF/0402/16V

IF_AGC IFAGC-T

C133

0.1uF/0402/16V

C174

1nF/0402/16V

L25

R165

100R/0402/5%

Close Tuner

3

+3.3V_TU

L27

600R/0402/500mA

2158 FOR LOW SINGER WATER WAVE

2157 CAN CANCLE

C178

C177

68pF/0402/16V

68pF/0402/16V

22

L28

270nH/0603/ 5%

L26 270nH/0603/ 5%

270nH/0603/ 5%

C175 180pF/0402/16V R203 100R/0402/5%

C176 180pF/0402/16V

L29

270nH/0603/ 5%

IFAGC-T

23

24

25

26

27

28

29

RF_REF

RF_IP

RF_IN

RF_SHIELD

ADDR

RSTB

AGC1

GND_EPAD

22pF/0402/16V

close 20pin

21

+3.3V

GPIO1

1

0R/0402/5%

C1

C179

0.1uF/0402/16V

20

+3.3V

Si2158

GPIO22AGC2

R206

24 MHz /ESR< 120 , CL=8pF

22pF/0402/16V

3

Y2

C180

19

GND

U10

3

R202

0R/0402/5%

IF_AGC

24MHz

18

XTAL_O

SCL

4

0R/0402/5%

SCL-T

17

XTAL_I/RCLK

SDA

5

R201

SDA-T

C181

16

XOUT

+3.3V

6

+3.3V_TU

15

7

+1.8V

LDO_ADJ

ALIF_P

ALIF_N

DLIF_P

+3.3V

DLIF_N

+1.8V

GND

1

+3.3V_TU

R205

3.3R/0402/1%

Q16

3906

3 2

C182

2.2uF/0402/16V

14

13

12

R204 100R/0402/5%

11

10

9

8

+1.8V_TU

+1.8V_TU

+3.3V_TU

+1.8V_TU

2

1

IF-IN+

IF-IN-

DIF IN&OUT

B B

C120

C122

56pF/0402/16V

5

100pF/0402/16V

L10 0R/0603/5%

C132

100pF/0402/16V

C123

33pF/0402/16V/NC

C121

0.1uF/0402/16V

R164

510R/0402/5%/NC

C126

0.1uF/0402/16V

VIFPIF-IN+

IF-IN- VIFM

L9 0R/0603/5%

BPF_IN

L11 0R/0603/5% L12 0R/0603/5%

A A

AGC RC Filter &I2C

IFN

IFP

4

SDA-T

SCL-T

20pF/0402/16V/NC

C124

R16010K/0402/5%

R16110K/0402/5%

+3.3V_Normal

C125

20pF/0402/16V/NC

Close MSD IC

R162 100R/0402/5%

R163 100R/0402/5%

TUNER_SDA

TUNER_SCL

TUNER POWER

U11

ASM1117-3.3_1A

ADJ1OUT2OUT

IN

C127

10uF/0805/16V

3

3

C1280.1uF/0402/16V

+5V_Normal

C131

10uF/0805/16V

10uF/0805/16V

+3.3V_TU

Title

Title

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

C

C

C

Date: Sheet

Date: Sheet

2

Date: Sheet

MSD3393

MSD3393

MSD3393

Tuner

Tuner

Tuner

1

1.0

1.0

89Wednesday, May 14, 2014

89Wednesday, May 14, 2014

89Wednesday, May 14, 2014

1.0

of

of

of

4

C1290.1uF/0402/16V

C130

Page 22

5

4

+12V_NORMAL

3

2

1

PVCCL

PVCCL

BSPL

OUTPL

PGND

OUTNL

BSNL

BSNR

OUTNR

PGND

OUTPR

BSPR

PVCCR

PVCCR

R194

10K/0402/5%

C135

28

27

26

25

24

23

22

21

20

19

18

17

16

15

VCC-AMP

0.1uF/0402/16V

C161

0.1uF/0402/16V

+5V_Standby

R196

4.7K/0402/5%

D D

LINEOUT_APML

LINEOUT_APMR

C C

B B

AU. AMP

R166 150R/0402/5%

2.2nF/0402/50V/NC

R189 150R/0402/5%

2.2nF/0402/50V/NC

C164

47nF/0603/16V

R171

C138

47K/0402/5%

C136

47nF/0603/16V

C156

R185

47K/0402/5%

L1

C154

R186

R183

R1

R179

22K/0402/5%

VCC-AMP

R184

22K/0402/5%

22K/0402/5%/NC

22K/0402/5%/NC

R190

1uF/0603/16V

10R/0402/5%

1uF/0603/16V

R172 1K/0402/5%

MUTE_AMP

R175 150R/0402/5%

R187 4.7K/0402/5%

R191

C157

3K/0402/5%

1uF/0603/16V

C163

L1

C144

1uF/0603/16V

R192

150R/0402/5%

C155

+12V_NORMAL

R169

100K/0402/5%

220nF/0402/10V

C159

220nF/0402/16V

R1

1N4148

R195

100K/0402/5%

TPA3110

R167

100K/0402/5%

U12

1

1

PVCCL

SD

2

FAULT

3

LINP

4

LINN

5

GAIN0

6

GAIN1

7

AVCC

8

AGND

9

GVDD

10

PLMIT

11

RINN

12

RINP

13

NC

14

PBTL

IC-TPA3121D2_0

+12V_NORMAL

D4

Q14

3906/SOT-23

CA2

+

100uF/16V/ECS-5M

GVDD

29

AMP-MUTE

H: MUTE, L: UN-MUTE

C143

220nF/0603/50V

C146

220nF/0603/50V

C153

220nF/0603/50V

C158

220nF/0603/50V

CA1

+

100uF/35V/ECS-5M

D6

1N4148

D10

1N4148

L13

E-MUTE

VCC-AMP

D5

1N4148

0R/1206/5%

R198

L14

22uH/2.7A

L16

22uH/2.7A

L18

22uH/2.7A

L20

22uH/2.7A

MUTE

47K/0402/5%

21

21

21

C152

220nF/0805/50V

21

C160

R208

100K/0402/5%

C137

220nF/0805/50V

C145

220nF/0805/50V

220nF/0805/50V

1

MUTE_AMP

Q15

3904/SOT-23

2 3

CON2

1

2

3

4

CON/4P/2.5MM

AUDIO OP

C147

AV_AUOUTR1

2.2uF/0603/16V

AV_AUOUTL1

C148

2.2uF/0603/16V

EARPHONE MUTE

D8

R350

10K/0402/5%

1N4148/SMD223

R355

100K/0402/5%

R178

4.7K/0402/5%

R177 4.7K/0402/5%

1nF/0402/16V

+12V_NORMAL

R380

0R/0402/5%

D7

1N4148/SMD223

CA4

+

100uF/16V/ECS-5M

C149

1nF/0402/16V

C150

R356

470K/0402/5%

R341

10K/0402/5%

INR

OP_VCC

INL

P11

PHONEJACK

3906/SOT-23

OP_VCC1

EP_AMP_MUTE

Q13

INR

R225 100K/0402/5%

R332 4.7K/0402/5%

EP_AMP_MUTE

R382

4

3

MUTE

5

2

1

R336 1K/0402/5%

R378

22K/0402/5%

C97

2.2uF/0402/16V

R383

0

1

NC/24K

Q17

3904/SOT-23

2 3

1

2

3

4

OP_VCC

R193

1K

U13

BH3544F/SOIC8

RO

MUTE

RIN

GND

R200

24K

22R/0402/5%

R207

1K

R377 1K/0402/5%

VCC

LO

BIAS

LIN

D9 1N4148/SMD223

8

7

EARPHONE_JACK_L

6

5

100uF/16V/ECS-5M

R236

100uF/16V/ECS-5M

R23522R/0402/5%

EP_AMP_MUTEE-MUTE

INL

CA5

100uF/16V/ECS-5M

+5V_Normal

OP_VCC1EARPHONE_JACK_R

+

CA7

CA6

EARPHONE_JACK_R

EARPHONE_JACK_L

A A

Title

Title

Title

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

Custom

Custom

Custom

Date: Sheet

Date: Sheet

5

4

3

2

Date: Sheet

MSD3393

MSD3393

MSD3393

Amplifier

Amplifier

Amplifier

1

1.0

1.0

1.0

of

of

of

99Wednesday, May 14, 2014

99Wednesday, May 14, 2014

99Wednesday, May 14, 2014

Page 23

5

D D

C C

A1

CY101

471/400VAC

CX101

CY106

101/400VAC

DP1

RL256

DP3

RL256

2 3

1 4

CX102

474/275VAC

TNR101

RL256

RL256

474/275VAC

LF101

10MH

DP2

DP4

CY102

471/400VAC

CY105

101/400VAC

TH101

A2

RP1

1M/1/4W

IN4007

1M/1/4W

DP6

RP5

RP2

1M/1/4W

+

CP1

68U 450V

10M/1W

IN4007

1M/1/4W

RP12

RP11

220K/1/4W

DP5

RP6

1M/1/4W

RP3

+

68U 450V

RP13

10M/1W

CP2

RP7

1M/1/4W

RP8

1M/1/4W

RP4

1M/1/4W

ZD206

3.3V

RP14

10M/1W

ZD204

30V

RP17

100K

RP15

10M/1W

CP4 471

CP5

104

RP18

10K

CP7

102

100K/1/4W

RP20

SPECIFICATION

INPUT: 90-264V AC

OUTPUT:

B B

N

123

CN101

FUSE T3.15A 250VAC

L

FP1

L

RP16

470K/1/6W

5

6

7

8

CP6

10M/1/8W

154

+25V/1.7A

+12V/2A

4

FUSE T2A 250VAC

ICP1

TEA1733

5

6

7

8

RP19

3

RP29

100/0.25W

FP2

CP3

RP24

1K/1/6W

CP9

102

RP21

33R/1/8W

ZD201

RP25

22K/1/6W

CP10

27V

RP28

100K 2W

224

DP7

LL4148

RP22

10R/1/6W

DPA8

5397

1 2

1N4007

+

CP11

4.7U 50V

1

10K/1/6W

ZD202

5V1/1W

DP9

QP1

RP23

DP8

5397

23

ZD205

18V

RP26

0.15/2W

4R7/1/4W

RP27

CY104

471/400VAC

TP7

7

8(NC)

9

10(NC)

12

11

TRANSFORMER S

CY103

NC

ICP2

PC817C

4

HSP1

1

2

3

4

1

23

392/630V

4

4

3

3

2

2

1

1

CP8

104

RPA29

100/0.25W

DP11

SB10200

3

4

1

2

CP13

102/1KV

DP10

SB10100

RP30

47/0.25W

CP12

471/1KV

RPA30

47/0.25W

+

CP17

1000UF25V

5

6

RP31

220/1/6W

RP32

1K/1/6W

CP23

224

ICP3

TL431

+

1000U 35V

+

CP18

1000uF/25V

RP33

10K/1/6W

CP15

0U7H

2

+

1000U 35V

LP2

RP36

39K/1/6W

RP34

10K/1/6W

CP19

RP35

NC

+

CP20

1000uF/25V

CP14

RP42

1.5K/2W

104

32

QP6

8050

CP16

104

32

1

QP5

8050

1

1K/1/6W

CP22

104

RP41

RP40

4.7K/1/6W

RP37

10K/1/6W

ZD301

30V

RP38

1K/1/6W

ZD302

33V

DP13

LL4148

1

+24V

1

CNV24

NC / SIP2_2.5mm

RP43

4.7K/1/6W

DP14

LL4148

2

Aging socket

ZD303

15V

+24V_Normal

+12V

Aging socket

1

2

CNV12

NC / SIP2_2.0mm

A A

Title

Title

Title

3.5Frame

3.5Frame

3.5Frame

Size Document Number Rev

Size Document Number Rev

Size Document Number Rev

<Doc> <RevCode>

C

<Doc> <RevCode>

C

<Doc> <RevCode>

C

Date: Sheet of

Date: Sheet of

5

4

3

2

Date: Sheet

1

of

11Sunday, November 17, 2013

11Sunday, November 17, 2013

11Sunday, November 17, 2013

Page 24

5

+24V_Normal

RP50

100K

+12V

UP4

1

UVLO

2

EN

3

PWM1

4

PWM2

5

PWM3

6

PWM4

7

PWM5

8

PWM6

9

FBP

10

ISET

11

IFBV

12

IFB1

13

IFB2

14

IFB3

42434445464748

TPS61196

VIN

FAULT

FSW

VDD

GDRV

ISNS

PGND

REF

COMP

OVP

AGND

IFB6

IFB5

IFB4

29303132333435363738394041

28

27

26

25

24

23

22

21

20

19

18

17

16

15

49

D D

RP60

200K

BL-ON/OFF

RP58

RP52

10K

180K

CP32

RP62