Page 1

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

COLOR MONITOR

Internal Use Only

SER

CHASSIS NO. : LM14P

MODEL:

CAUTION

BEFORE SERVICING THE UNIT

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

VICE MANUAL

29UM55

,

P/NO : MFL67715298(1406-REV00)

Printed in China

Page 2

CONTENTS

CONTENTS .............................................................................................. 2

PRECAUTION

............................................................................................3

SERVICING PRECAUTIONS.....................................................................4

SPECIFICATIONS......................................................................................6

TIMING CHART .......................................................................................11

ADJUSTMENT .........................................................................................14

BLOCK DIAGRAM...................................................................................18

TROUBLE SHOOTING ............................................................................19

EXPLODED VIEW .................................................................................. 22

SVC. SHEET ...............................................................................................

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 2 -

LGE Internal Use Only

Page 3

PRECAUTION

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD monitor that

are important for safety. These parts are marked on the

schematic diagram and the Exploded View. It is essential

that these critical parts should be replaced with the

manufacturer’s specified parts to prevent electric shock, fire or

other hazard.

•

Do not modify original design without obtaining written

permission from manufacturer or you will void the original parts

and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE WITH

BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged in four

corners.

• Do not press on the panel, edge of the frame strongly or electric

shock as this will result in damage to the screen.

• Do not scratch or press on the panel with any sharp objects,

such as pencil or pen as this may result in damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL) or LIPS

part, must disconnect the AC power because high voltage

appears at inverter circuit about 650Vrms.

• Handle with care wires or connectors of the inverter circuit. If

the wires are pressed cause short and may burn or take fire.

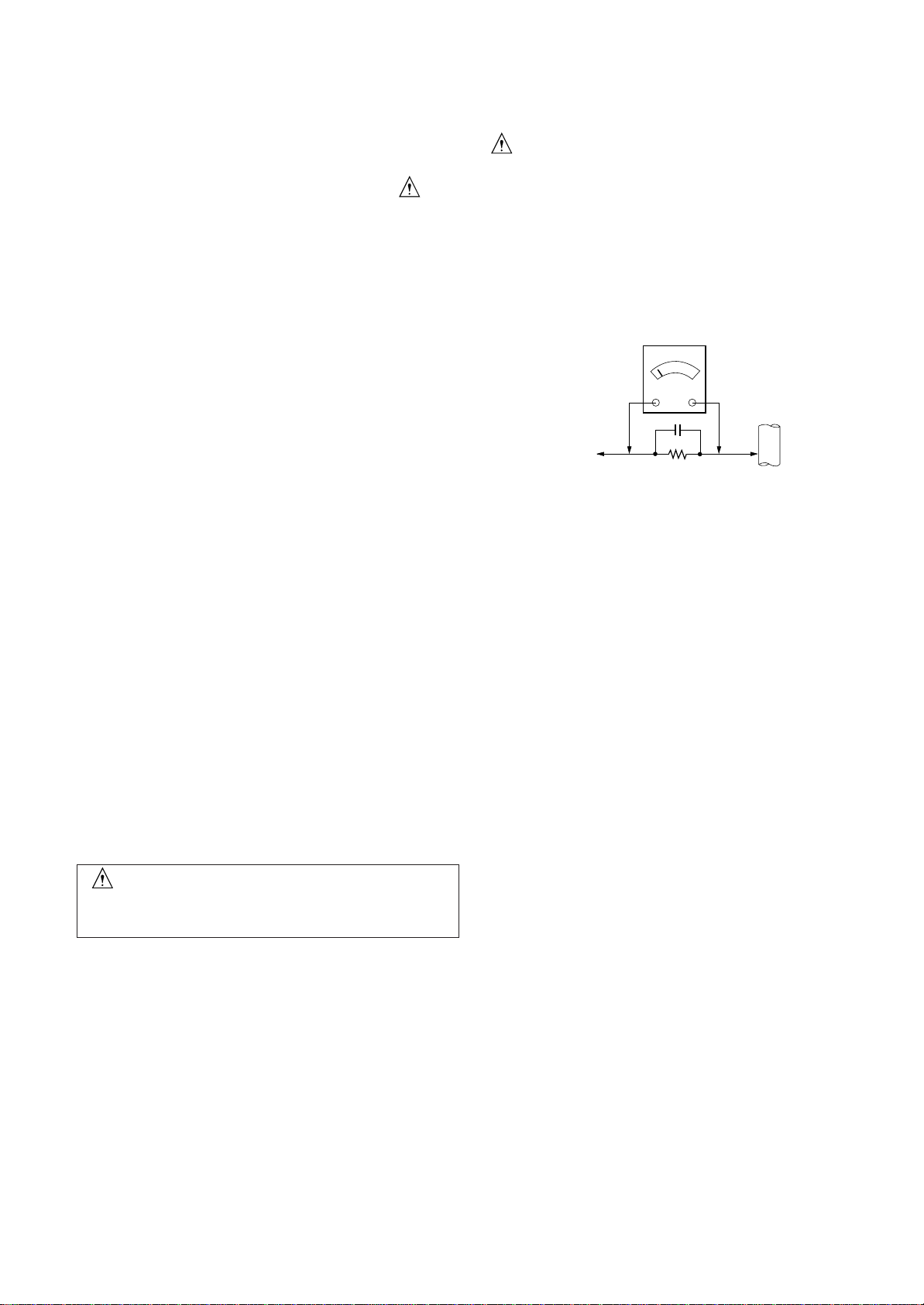

Leakage Current Hot Check Circuit

AC Volt-meter

Good Earth Ground

such as WATER PIPE,

To Instrument's

exposed

METALLIC PARTS

When 25A is impressed between Earth and 2nd Ground

for 1 second, Resistance must be less than 0.1

Adjustment standard

*Base on

0.15uF

1.5 Kohm/10W

CONDUIT etc.

Ω

• Make certain that treatment person’s body are grounded

through wrist band.

• Do not leave the module in high temperature and in areas of

high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within the

module.

• If the surface of panel become dirty, please wipe it off with a

softmaterial. (Cleaning with a dirty or rough cloth may damage

the panel.)

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 3 -

LGE Internal Use Only

Page 4

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

. Removing or reinstalling any component, circuit board

a

module or any other receiver assembly.

b. Disconnecting or re-connecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) is opropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500ºF to 600ºF.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500ºF to 600ºF)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500ºF to 600ºF)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 4 -

LGE Internal Use Only

Page 5

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete TransistorRemoval/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 5 -

LGE Internal Use Only

Page 6

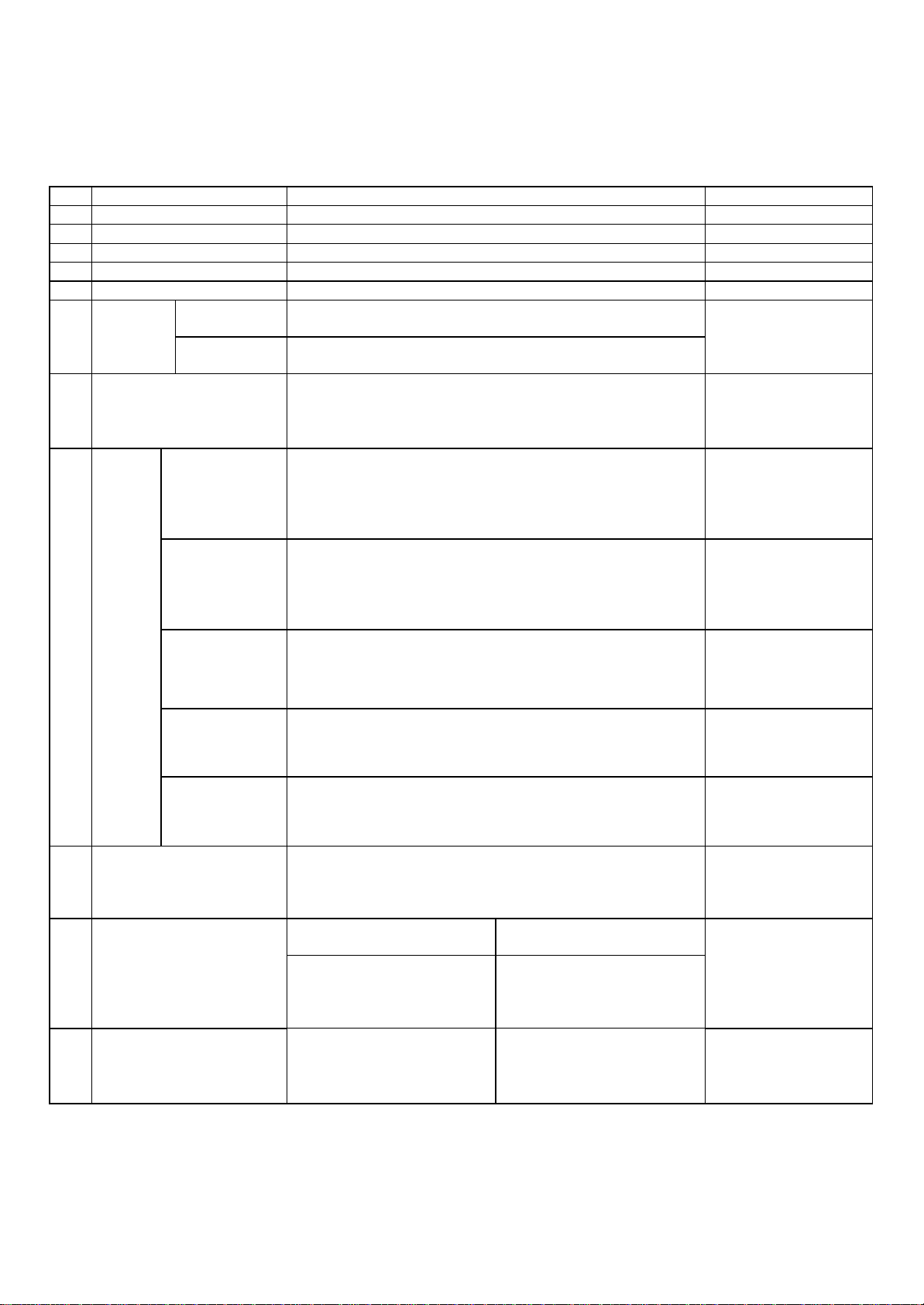

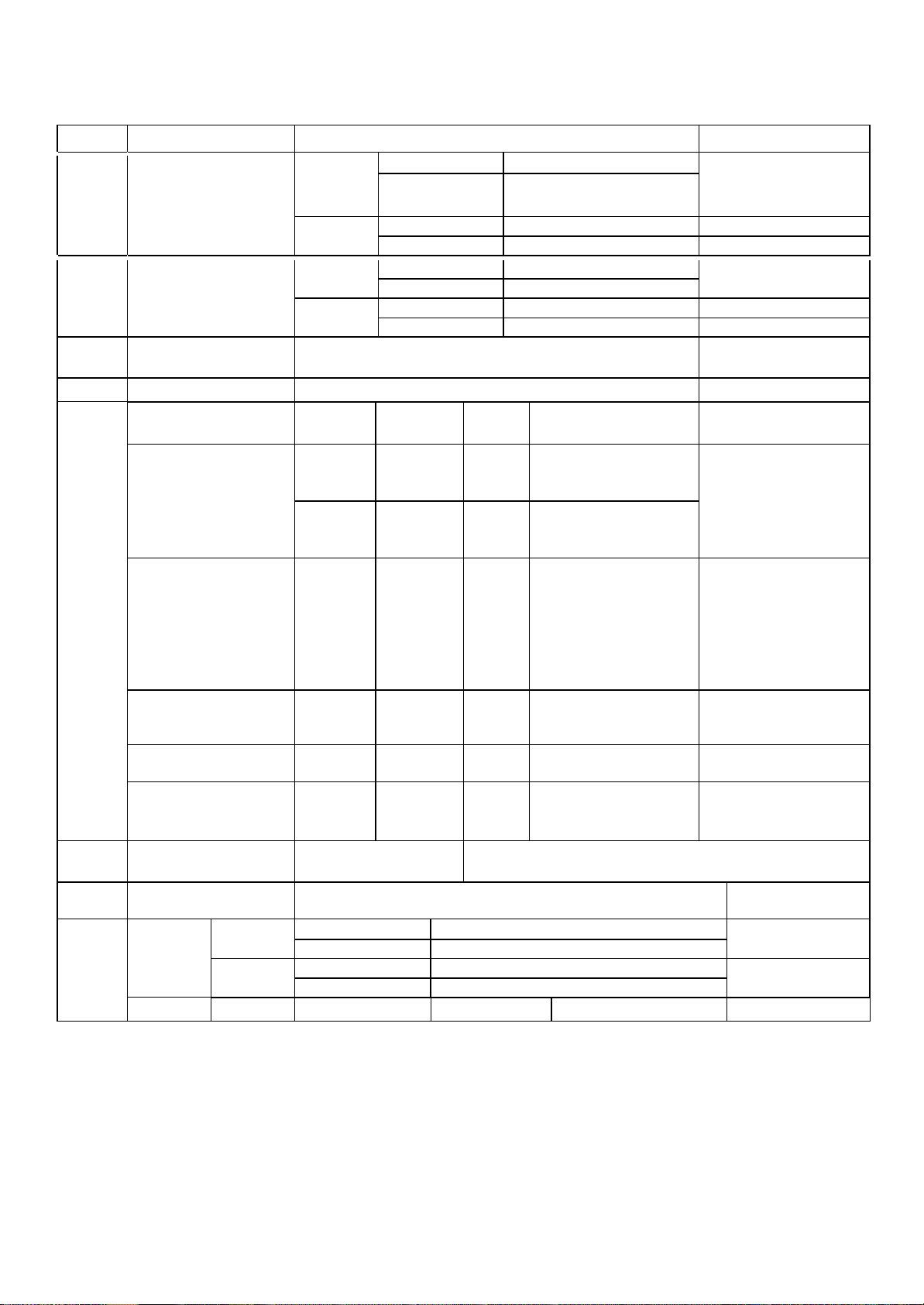

1. General Specification

Co

ntent

SPECIFICATIONS

Item

No

1 C

2 Us

3 Sal

4 Fe

5 Ch

6

7

er Model Name

neral

Ge

Scope

Pow

u

stomer BRAND

29UM55

e region Refer to Suffix standard

ature 29” Wide LCD MONITOR

assis Name LM14P

External SW

&Adj.

nction Picture Mode Ratio, ECO(Super Energy Saving), Six

Fu

er Cord

DVI

MI

HD

LEFT, RIGHT, UP, DOWN, CENTER

Color, Audio Volume(Headphone),

Length : 1.55±0.05 M

Shape : Wall-out

Color : Black

Weight : 130g

Length :

Shape :

Color :

Pin :

Length : 1.8m

Shape : Detachable Type

Color : Black

Weight : 102g

Rem

Refer to Suffix

standard and power

cord table

Do not Support

Support

ark

8 Ca

9 Pow

10

Applying module list

1

Etc (accessory) Manual CD - Support

1

ble

er

Length :

USB

io

Aud

TV

Length : ,Shape : ,Color: ,Pin Do not Support

Shape :

Color :

Length :

Shape :

Color:

Input: AC100~240V 50~60Hz,1.2A Max

Output: DC 19V 2.1A

Adapter

Weight : 190g

P/No Specification

987701 LM290WW2-SSA1

EAJ62

Do not Support

Do not Support

40W

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 6 -

LGE Internal Use Only

Page 7

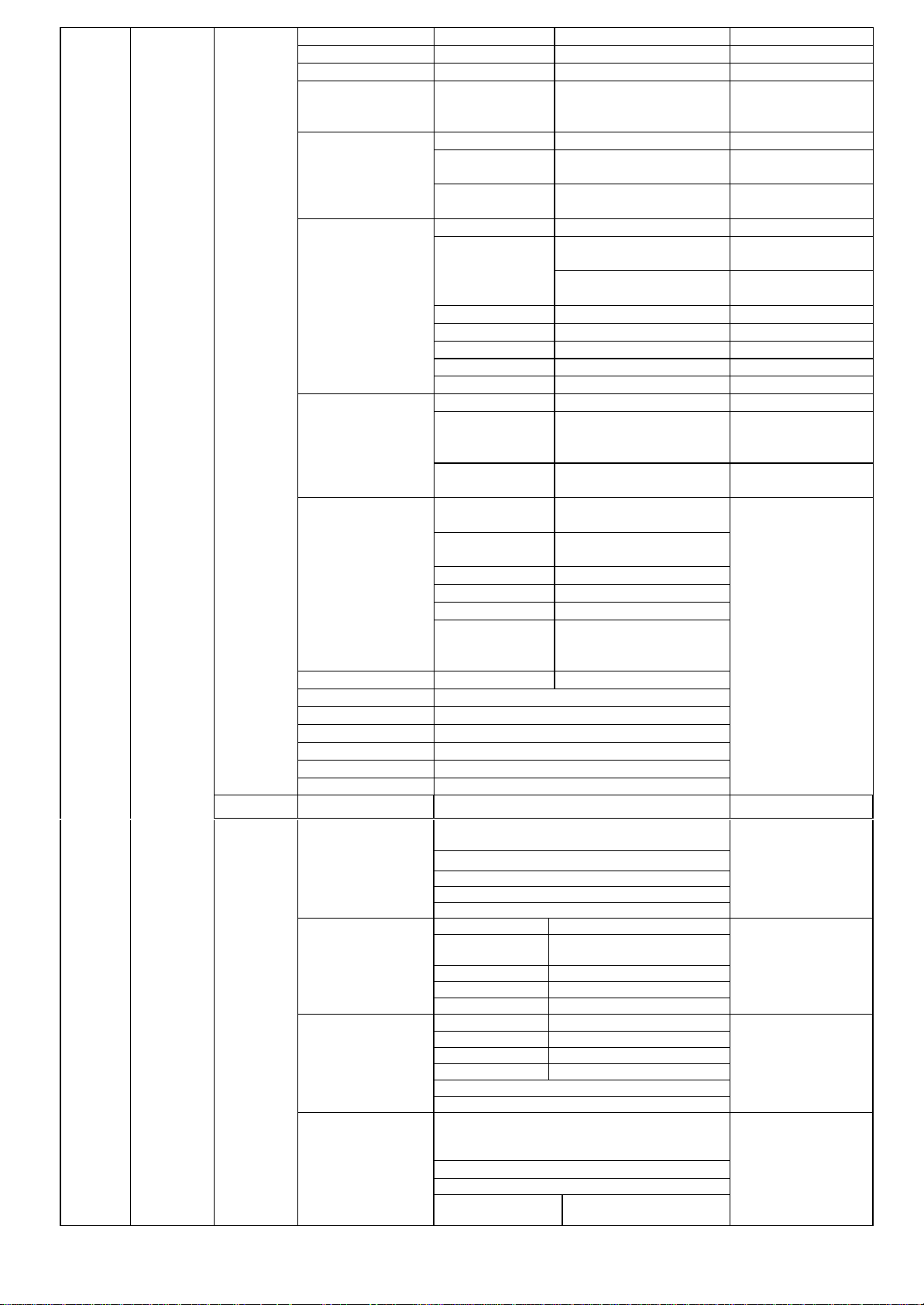

2. Mechanical specification

Rem

ark

No Item Content Remark

Width (W) Length (D) Height (H)

Before Packing 703.0mm 213.2mm 414.2cm With stand

ct

1

2

Produ

Dimension

ct

Produ

Weight

703.0mm 64.0mm 328mm Without stand

After Packing

814mm 405mm 156mm

Only SET 5.2kg Without stand : 4.7kg

With BOX

7.5Kg

3

Con

tainer

Loading

Quantity

4 Sta

nd

Assy

5 Appe

arance General Refer to Standard of LG(56)G2-1011

3. Optical Character

No I

Vie

1

2

3

4 Res

wing Angle

<CR≥10>

L

nance(휘도)

umi

Con

trast Ratio(명암 비)

ponse Time On/off:14ms(TYP, GTG),

Individual

(Vertical Type)

20ft 40ft

Ind

i. Pallet Indi.

525

462 1,080 966

Wood

en

Face_up

40ftH/C

- Indi. : 1,296

- Pallet : 1,152

Type Base detachable

Size

(W x D x H) 124mm x 213.2mm x 42.6mm Only stand ass’y

Til

t Degree

t force F1 /F2 :1.0 ~ 1.5kgf

Til

ding Degree9 None

Fol

tem Criteria

Horizontal(R/L) : +89º/-89º ( (Typ.)

ical(Top/Bottom) : +89º/-89º (Typ.)

Vert

Average Luminance

2

(cd/m

Ave

rage Luminance

2

(cd/m

rage Luminance

Ave

2

(cd/m

r Energy

Supe

Saving On

Lumi

nance

Uniformity

700(MIN), 1000(TYP),

DFC->5,000,000:1(Typ.) / 4,000,000:1(Min)

(It is measured at center point)

-5°(+/-3°)~ +20°(+/-3°)

20

n), 250 (Typ.)

0(mi

)

)

)

(Full white pattern, 0.7V)

1

(min)

70

(Full white pattern, 0.7V)

150(mi

n)

(Full white pattern, 0.7V)

Max 25% down from S-Energy Saving Off.

75%(min),

Warm

(6500K)

Medium

(8000K)

Cool

(9300K)

Whit

e

e W

Whit

e

Whit

RED

GREEN

E

BLU

5

IE

Color

C

Coordinates

(색 좌표)

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Minimum Nor mal Maximum

W

X

T

.03

WY 0.329

WY 0.3

W

WY

R

X

RY

G

X

GY

B

X

BY

yp-0

Typ-0

X

X

Typ-0

Typ-0

.03 0.295 Typ+0.03 Medium

.03

.03

0.313

05

0.283

.2

98

0

0.660

0.331

0.306

0.609

0.149

0.

062

- 7 -

Typ+0.03

Typ+0.03

Typ+0.03

Warm

(6500K)

(8000K)

Cool

(9300K)

Warm

(6500K)

LGE Internal Use Only

Page 8

4. Engineering Specification

p

ported Sync. Type

1

2 Op

3 Re

4 In

Su

erating Frequency

solution

put Voltage Voltage :100 – 240 Vac, 50 or 60Hz, 1.0A

5 Inrush Current Cold Start : 50 A Hot : 120 A

6

Op

erating Condition

On

Mode

Separate Sync.

Horizontal

MI

HD

DP

HD

MI

DP

Sync

(H/V)

H

Re

Re

Video LED Wattage

On/On Active

/On Active

On

30 ∼ 90kHz

Ve

rtical

orizontal

Ve

rtical 50 ~ 75 Hz

(AV)25~60 Hz,

(PC)50~75 Hz

30 ∼ 90kHz

Max. 2560×1080 @ 60Hz

commend 2560×1080 @ 60Hz

Ma

x. 2560×1080 @ 60Hz

commend 2560×1080 @ 60Hz

ite

Wh

Wh

ite

4

W(Typ)

3

39W

(

Max)

Test condition

1.2560x1080@60Hz

2. burst pattern

3. 100~240V

4. After aging 30min

Adjust brightness

controls until the

luminance of the

Wh

EPA6

.0 On/On Active

Off/On

Sle

ep Mode

On/Off

Off

Off/Off

f Mode

Of

(Power switch off)

ECO

MT

7

BF

Us

8

ing Altitude

- - Off < 0.5W

High,

Low,Off

Low

High

30,000 HRS with 90%

Confidence level

5,000 m (for Reliability) 3,000m(for FOS)

ite

h

ite

W

Blinking

ite

Wh

P

A spec

E

31

.69 W

0.5W

<

iciency

Eff

15±5% (3W/h)

25±5% (5W/h)

Lamp Life : 30,000 Hours(Min)

screen is 200(cd/m2).

-Test Condition

(1)

Env

9

iron

ment

Conditio

n

OSD

0peratin

g

Sto

rage

MENU Brightness 1 - 100

Temperature

midity 10% ~ 80%

Hu

Temperature

H

midity 5% ~ 90% non-condensing

u

10 °C ~ 35 °C

-20 °C ~ 60 °C

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 8 -

LGE Internal Use Only

Page 9

VOL

UME

T

R

EBLE

(Monitor

MENU

block)

set Reset/Cancel

Re

MENU

(AV/TV

block)

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

Contrast 1 – 100

ume 1 – 100, Mute

Vol

put HDMI1 / HDMI2/ DP

In

Wide / Cinema1 /

tio

Ra

Cinema2 / Original /

ECO High, Low, Off

Reader1, Reader2,

Custom, Photo,

Cinema, Game

Fu

nc.

ader mode

Re

c

ture Mode

Pi

PBP On

Main: HDMI1, HDMI2,

DP

b

: HDMI1, HDMI2,

Su

DP

PBP

PBP

n

put

I

io HDMI1, HDMI2, DP

Aud

p On, Off

Swa

Full On, Off

Sub

tio Main

Ra

tio Sub

Ra

Sharpness 0 - 10

Pic

Co

ture

lor

ck Level

sponse

Re

Time

Gamma

Co

lor Temp

Re

d 0 - 100

Gre

en 0 – 100

Blu

e 0 – 100

Six

Color

(BLACK LEVEL enable

at HDMI input)

High, Middle, Low

Gamma0, Gamma1,

Warm, Medium, Cool,

Bla

(Hue,

Saturation)

nguage

La

AV Mode N/A

PC/

n Audio HDMI1/HDMI2,DP

Mai

ton Sound N/A

But

er LED On / Off

Pow

1.2 On / Off

DP

Lock On / Off

OSD

CHANNEL

2~69(AIR) / 1 ~ 125(CABLE)

/DEL CH ADD/DELETE

CHANNEL

AD

JUSTMENT

AU

DIO

UP

SET

ADD

O CHANNEL ON/OFF

AUT

SELEC

FI

CONTRAST 0~100

BRI

S

SHAR

CO

TI

BASS

MUT

SOU

MON

LANGUAGE▶

English/German/French/Esperanto

Italian/Korean…

IMA

OSD

T

CY

T AIR/CABLE

NE TUNE 0 ~ 100

GHTNES

PNESS 0~100

LOR 0~100

NT 0~100

E ON/OFF

ND

O/STEREO

GE SIZE ▶ FULL/1:1

POSITION

R

ANSPAREN

0~100

0~

100

A

N/

/

A

N

0~100

- 9 -

1:1

Reader Off

, Off

Low, High

Gamma2

Custom

0 - 100

de, Original

Wi

de, Original

Wi

16 Language:

English,

Germanic,

French, Spanish,

Italian, Swedish,

Finnish,

Portuguese

Brazilian

Portuguese,

Polish, Russian,

Greek, Chinese,

Japanese,

Korean,

Function Support:

No

Function Support:

No

Function Support:

No

Function Support:

No

LGE Internal Use Only

Page 10

5. Applying module Character

Co

ntent

Item

No

Maker LGD

e IPS

D Module

LC

1

Feature

andard Measurement Condition

St

Typ

ve Display Area 29 inches(73.025cm) diagonal (21:9)

Acti

x

el Pitch [mm]

Pi

e

ctrical Interface 2ch-LVDS(41P), 2ch-LVDS(51P)

El

lor Depth 6-bit + A-FRC, 16.7M colors

Co

(Outline) [mm]

Size

Sur

face Treatment

erating Mode Transmissive mode, normally Black

Op

light Unit White LED

Back

T

R/

.

0876(H)mm x RGB x 0.2628(V)mm

0

602.2(H) x 271.1(V) x16.5(D) (Typ.)

Hard coating (3H) & Anti-Glare treatment

of the front polarizer

Typical 14ms

28ms

Max.

Rem

ark

n Ambient Luminance Level : dark ( < 10 lux)

n Ambient Temperature : Normal Temperature(10 ~ 25 ℃)

n warm-up Time : More than 30min (at Full White Pattern)

n Input Signal : 2560X1080@60Hz

n Contrast : 70

n Brightness : Max. 100

n 6500K : Color Temperature Setting is 6500 K( if it’s not special specification)

n Clock/Clock Phase : The Best Setting

l Another Spec.: Product Specification Standard( LG(55)G1-1034 )

l Cosmetic Spec. : LCD Module IIS Spec.

5.1 Display Area

1) Active Display Area of the LCD Monitor Should be within Cabinet’s Bezel.

2) Distance Difference between Active Area and Bezel

| A-B|<1.0 mm , | C-D|<1.0 mm

A: The Distance from The Left of Active Area to the Bezel

B: The Distance from The Right of Active Area to the Bezel

C: The Distance from The Top of Active Area to the Bezel

D: The Distance from The Bottom of Active Area to the Bezel

Active area

A

A A B

C

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

D

- 10 -

Bezel

LGE Internal Use Only

Page 11

6. EDID

6.1

29

UM55

No Item Content 16진 Data

1 Man

2 Prod

3 Y

4 V

5 Re

6 Seri

7 We

8 Mo

9 Ch

10

Special Item Need to Input Serial Number

**

Protocol : DDC 2AB

Da

ta ( 128 Bytes ) à29UM55

EDID Ver. 1.3 FOR HDMI 1 (256Byte)

ufacturer ID GSM 1E 6D

uct ID

e

ar 2014

e

rsion 1 01

vision

al Number * *

e

k ** **

d

el Name LG ULTRAWIDE --

eck Sum **** ****

(HDMI)

(Display Port)

HDMI : 3

DP : 4

23025(F1 59)

23026(F2 59)

03

04

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 11 -

LGE Internal Use Only

Page 12

D Ver. 1.3 FOR HDMI 2 (256Byte)

EDI

EDID Ver. 1.4 FOR Display Port (256Byte)

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 12 -

LGE Internal Use Only

Page 13

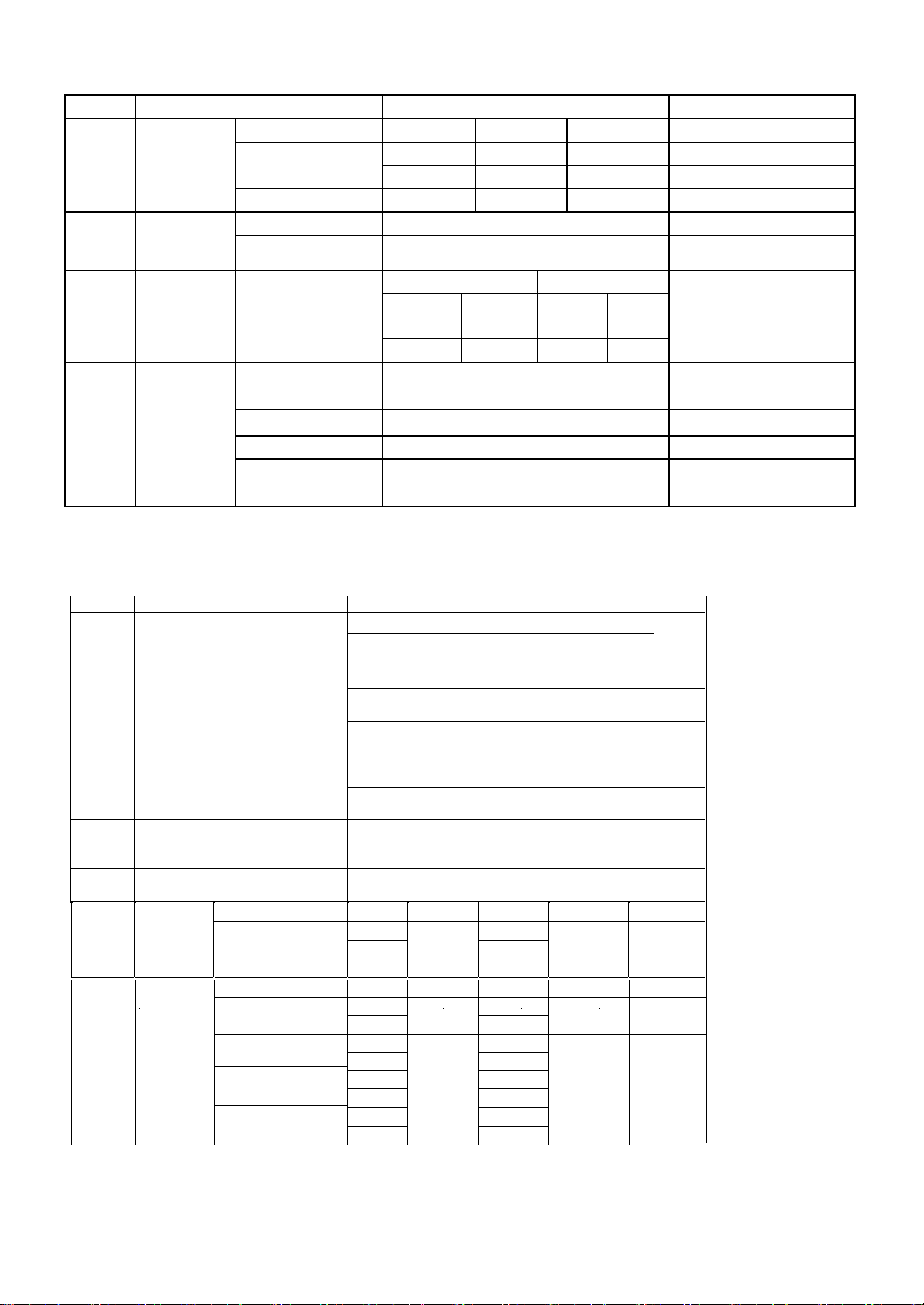

(1) Signal(Video & Sync)

deo

Vi

Sync

TIMING CHART

C

B

(2)

H

V Timing

/

HD

mode section

xels) -

1

2

H(Pi

nes)

V(Li

xels) -

H(Pi

nes)

V(Li

H(Pixels) -

3

V(Li

nes)

H(Pixels) +

4

5

6

nes)

V(Li

H(Pi

xels) +

nes)

V(Li

H(Pi

xels) nes)

V(Li

MI/DP

polar

ity

DE

DOT

CLOCK

[MHz]

28.321

+

25.175

-

-

+

+

-

31.5

40.0

49.5

65.0

F

A

Frequency

[kHz]/[Hz]

Total

Period

(E)

Display

(A)

Front

Porch

(D)

Sync.

(C)

31.468 900 720 18 108 54

70

.08

44

9

40

0

12

2

31.469 800 640 16 96 48

59

.94

52

5

48

0

10

2

37.5 840 640 16 64 120

75

50

0

48

0

1

3

37.879 1056 800 40 128 88

60

.317

62

8

60

0

1

4

46.875 1056 800 16 80 160

75

.0

62

5

60

0

1

3

48.363 1344 1024 24 136 160

60

.0

80

6

76

8

3

6

Back

Porch

(B)

35

33

16

23

21

29

Resolution

720 X 400

640 x 480

640 x 480

800 x 600

800 x 600

1024 x 768

7

8

9

10

11

12

13

14

15

H(Pi

V(Li

H(Pi

V(Li

H(Pi

V(Li

H(Pixels) +

V(Li

H(Pi

V(Li

H(Pixels) +

V(Li

H(Pi

V(Li

H

(Pi

V(Li

H(Pixels) -

V(Lines) +

xels) +

nes)

+

78.75

xels) +

nes)

+

108

xels) +

nes) + 60 750 720 5 5 20

74.25

60.123 1312 1024 16 96 176

75

.029

80

0

76

8

1

3

28

67.5 1600 1152 64 128 256

75

90

0

86

4

1

3

32

45 1650 1280 110 40 220

63.981 1688 1280 48 112 248

nes)

+

xels) +

nes)

+

nes) + 60.00 1000 900 1 3 96

xels) -

nes)

+

xels) +

-

nes)

108

135

108.0

146.25

148.50

60

.02

10

66

10

24

1

3

38

79.976 1688 1280 16 144 248

75

.025

10

66

10

24

1

3

38

60.00 1800 1600 24 80 96

65.29 2240 1680 104 176 280

59

.954

10

89

50

10

3

6

30

67.50 2200 1920 88 44 148

60

11

25

10

4

80

5

36

66.7 2784 2560 64 64 96

185.58

60 1111 1080 3 10 18

1024 x 768

1152 x 864

1600 x 900

1280x720

1280 x

1024

1280 x

1024

1680 x

1050

1920 x

1080

2560 x

1080

l DVI

: DTV Mode is not supported (interlace mode)

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 13 -

LGE Internal Use Only

Page 14

(3)

MI Video

HD

in

put

ctory support

Fa

mode

(Pres

1 48

2 57

3 72

4 72

5 10

6 10

rizontal

et Mode)

Ho

frequency

(KHz)

Vert

frequency

(Hz)

0P 31.5 60

6P 31.25 50

0P 37.5 50

0P 45 60

80P 56.25 50

80P 67.5 60

ical

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 14 -

LGE Internal Use Only

Page 15

ADJUSTMENT

1. Coverage

Apply to 73.025

Gumi Korea) or made in accordance with the standard of Gumi

Factory process.

Wide monitor made in Monitor Factory

cm

2. Appointment

2.1 Adjustment must be done as fixed sequence, and adjustment

sequence can be modified after agreement withthe responsible

R&D engineer considering mass-production condition.

2.2 Power : AC 100 - 240 Voltage (Free)

2.3

Input signal:

2.3.1 RGB Input: As Product Standard (Signal ROM : LB800K

Ver1.6)

2

.3.2 RJ-45 input : As Product Standard (Ethernet connection

through network from Host PC)

* PC spec for MK(Minikey) Loader (TBD): CPU - Dual core 2.0

GHzD, Memory - 2 GByteD

*PC spec for Host PC (TBD): CPU - Dual core 2.0 GHzD,

Memory - 2 GByteD

2.4 Warm-up Time: Over than 30 minutes

.

5 Adjustment

2

Display adjust equipment, VG-813(or VG819), Oscilloscope,

PC (More than 486

program.

equipment : White balance equipment (CA-110),

computer ) & White balance adjust

3. Adjustment

3.1 Overview

Use factory automation equipment and adjust automatic

movement. But, do via passivity adjust in erroroccurrence.

PC audio volume : MAX

* LAN cable

* Router

*

PC: vSpace S/W for N+ ( Ver 4.5.xx.xx ) --- Caution: Ver

4.4.xx.xx for N1742L family

3.2.2 Total Assembly Line

· Ready : Heat-run during5 minutes in the state with signal

Connect input signal to D-sub.

·

· Default value before adjustment : Contrast “70” , Brightness

‘100(Max)”

3.2.3 Adjustment of Horizontal/Verticality screen

position, Clock and Clock Phase at each Mode.

· There is no special factory mode adjustment. Writing initial value

of EEPROM in Board Assembly

and Reset mode. (EEPROM is initialized when AC Power is

ON first.)

· If the change of FOS data is needed after M.P, it is possible by

writing Mode Data with EEPROM write command or modifying

the Mode Data in MICOM itself.

line is adjusting Preset Mode

3.2.4 Color coordinates adjustment and Luminance

adjustment.

3.2.4.1 Color coordinates adjustment

· Monitor Contrast / Brightness

- Contrast : 70

- Brightness : 100(Max)

· CA-110: Set “channel 9”

· Signal Generator : At cut-off and drive --> 16 step pattern for

ADC (Program No.: 31)

- Output Voltage : 700 mVp-p

- Output Mode : Mode 12 (SXGA 60 Hz)mode Setting.

3.2 Adjustment order

(refer to the Adjustment standard and adjustment command table)

3.2.1 Board Assembly Line

3.2.1.1 15pin D-sub (RGB)

· Connect input signal to 15pin D-sub.

· Check the firmware version & model name. And write the

firmware code to the serial Flash ROM by ISP.

· Ready for adjustment : check whether adjustment command

works normally or not and the operating state of each mode.

· Check the display state of gray color when 256 gray scale

patterns is embodied.

· Read by EEPROM Read Command to check whether initial

value is correct or not.

3.2.1.2 MK( Minikey ) Loading

· Open MK Loader Tool on MK Loader PC.

( * MK Loader PC should be connected Internet)

· Connect input signal to RJ-45 input with LAN cable connected

network devices such as routers.

· Turn on the Monitor set.

· Click the box when the °∞empty port °∞box is changed to “write

mini-key” in MK Loader Tool.

3.2.1.2 RJ-45 input

· Connect input signal to RJ-45 input with LAN cable connected

network devices such as routers.

· Check USB 1.1 Port (Keyboard/ Mouse) : @RJ-45 input

· Check USB 2.0 Port (USB Memory Stick 2port) : @RJ-45 input

· Check Audio (Ear-phone out/ Mic in/ Speaker) : @RJ-45 input,

3.2.4.2.Adjustment : Board Assembly Line

· Select RGB mode

16 step pattern for ADC (Program No.31 (Mode 12,Pattern

· Input

11)). (Video level : 700 mVp-p)

· Adjust by commanding AUTO_COLOR_ADJUST

· Confirm “Success” message in Screen or Check the data of

0xFE, 0xFF address of EEPROM(0XA6) is 0xAA after waiting 5

seconds.

· If there is “FAULT” message or the data of 0xFE, 0XFF address

of EEPROM(0xA6) is not 0xAA, do adjust again.

· If all Adjustment is completed, the values of 6500K, User Color

and 9300K are saved automatically.

· Select RGB mode

· Input 16 step pattern for ADC (Program No.31 (Mode 12,Pattern

11)). (Video level : 700mVp-p)

· Adjust by commanding AUTO_COLOR_ADJUST

· Confirm “Success” message in Screen or Check the data of

0xFE,0xFF address of EEPROM(0xA6) is 0xAA after waiting 5

seconds.

3.2.4.3. Confirm at Total Assembly Line: adjustment

· Check the data of 0xFE, 0xFF address of EEPROM(0xA6) is

0xAA.

If the data of 0XFE, FF address of EEPROM(0xA6) is not

·

0xAA, do adjust again by 3.2.4.2.

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 15 -

LGE Internal Use Only

Page 16

2.4.4. Confirm PRESET 6500K Color coordinates and Adjust

3.

PRESET 9300K Color coordinates .

· Set as Aging mode ON, by commanding AGING_ON/OFF

command code.

· Select Module that is being used in present production by

commanding MODULE SELECT. ( It is not needed so far.

However, it will be needed to apply other modules)

· Send SYSTEM RESET command to set Module data.

· Input Full White Pattern (Video level : 700 mVp-p)

· Set as 9300K by commanding COLOR_MODE_CHANGE

Command code.

· Check to meet x = 0.283 ± 0.03, y=0.298 ± 0.03, and confirm.

· Only if it does not meet, adjust as below steps.

· Adjust to meet x = 0.283 ± 0.01, y=0.298 ± 0.01 in 5 minutes. and

confirm.

· Save 9300K Color by commanding COLOR SAVE Command

code.

· Set as 6500K by commanding COLOR_MODE_CHANGE

Command code.

· Check to meet x = 0.313 ± 0.03, y=0.329 ± 0.03, and confirm.

· Only if it does not meet, adjust as below steps.

· Adjust to meet x = 0.313 ± 0.01, y =0.329 ± 0.01, and confirm.

· Save 6500K Color by commanding COLOR SAVE Command

code.

· Set as sRGB by commanding COLOR_MODE_CHANGE

Command code.

· Adjust to meet Y = 150 ± 50, and confirm.

· Save sRGB Color by commanding COLOR SAVE Command

code.

3.2.4.5. Confirm User color coordinates .

· Confirm Whether User color is saved same as 6500K.

· After confirming Color coordinates, Must return to 6500K

3.2.5 Confirm Operation state.

3.2.5.1 Operation mode : Confirm whether each appointed mode

operate correctly or not.

3.2.5.2 Confirmation of Adjustment condition and operation :

Confirm whether it meet Auto/Manual equipment Adjustment

standard or not.

· Confirm Analog screen state : Confirm screen state at below

mode.

Appointment mode (RGB input):

640*480 @60Hz (Mode 1),

800*600@75Hz(Mode 5),

1024*768@60Hz(Mode 8),

1280*1024@60Hz(Mode 12),

SMPTE pattern(Check 0%,5%,95%,100%)

–Mode can be added.

3.2.5.3. Confirm Auto adjustment operation.

· Input Analog 1 Dot on/off & Rectangle Pattern at Mode

12(1280x1024@60 Hz)

· Confirm adjustment operation by changing Clock, Phase, H/V

Position.

· Check Clock, Phase by pressing AUTO Key.

· Confirm first set of new lot by periods

3.2.5.4 Other quality

· Confirm that each items satisfy under standard condition that was

written product spec.

· Confirm Applying Module & MICOM Setting --> Confirm with

Service OSD

- Confirm at Service OSD by “Menu + Power key” on .(from

Power off)

- Confirm first set of new lot by periods, and confirm periodically

when there is Process change or Adjustment setting change.

3.2.5.5. OSD & Adjustment device Confirmation : Confirm

operation mentioned as product spec.

· Vary Brightness and Contrast and confirm the variation of

Luminance and display status.

· Operate the f-engine function and confirm variation of Luminance.

· Make sure to do FACTORY RESET after confirmation of OSD

function.

3.2.5.6. Confirm the display state by inputting 8 color Bar Pattern &

256 Gray Scale pattern.

3.2.5.7. DPM operation confirmation : Check if Power LED Color

and Power Consumption operates as standard.

· Measurement Condition : 230 V@ 50 Hz (Analog)

· Confirm DPM operation at the state of screen without Video

Signal.

3.2.5.8. RJ-45 input

· Connect input signal to RJ-45 input with LAN cable connected

network devices such as routers.

· Check USB 1.1 Port (Keyboard/ Mouse) : @RJ-45 input

· Check USB 2.0 Port (USB Memory Stick 2port) : @RJ-45 input

· Check Audio (Ear-phone out/Mic in/Speaker) : @RJ-45 input, PC

audio volume : MAX

* LAN cable

* Router

* PC: vSpace S/W for N+ ( Ver 4.5.xx.xx ) --- Caution: Ver

4.4.xx.xx for N1742L family

3.2.5.9. DDC EDID Write

( Set as Aging mode ON, by commanding AGING_ON/OFF

command code. )

1) SUFFIX: xxxxxPN

· Connect analog Signal Cable to D-sub wafer.

· Write EDID DATA to EEPROM(24C08) by using DDC2AB

protocol.

· Check whether written EDID data is correct or not.

(refer to Product spec).

--> After writing EDID, send Elapsed Time Clear command.

(Elapsed time should not be displayed, after EDID writing)

: Confirm periodically (in the first set of new lot, process change)

whether module name and aging time disappeared on the selfdiagnostics OSD with signal cable disconnected.

--> If Elapsed Time Clear command isn°Øt executed, module

name, aging time and TCO word appear on the self-diagnostics

OSD.(Module name and aging time should not appear after

writing EDID)

--> Make sure to do FACTORY RESET at the final process.

3.2.5.10. Shipping condition

· Contrast : 70

· Power Switch

· Brightness : “100(Max)”

· Color Select : Preset ( 6500K )

· Language Select : Refer to product spec.

· OSD Position : Center

· Power indicator : ON

· Flatron f-engine : Normal

: Off

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 16 -

LGE Internal Use Only

Page 17

4.Standard of Auto/Manual equipment adjustment

No

Category Class(Type) Rule Remark

ety UL UL60950-1 YES

Saf

CSA

1

EMC F

2

X-Ra

3

(CRT only)

Lo

4

Radiation

5 TC

Ergo

6

Etc

(Korea)

y

w

O

nomics ISO9241 (CRT) ISO9241-3, 7, 8 NO

(cUL) CSA C22.2 No.60950-1-03 YES

TU

V-GS(TUV-Type) EN60950-1 TUV-Type

O

SEMK

CE EN

EN60950-1 No

C

C CLASS B FCC 47 CFR Part 15 Class B YES

55022B, EN55024, EN61000-3-2, 3 YES

DHHS DHHS Rule 21 CFR Subchapter J N/A

C HWC Radiation Emitting Device ACT N/A

HW

MPR II MPR 1990:8; MPR 1990::01

TCO6.0 Emission, Ergonomics, Ecology, Energy

saving

ISO

13406-2 (LCD) ISO13406-2,ISO9241-307 NO

KC(SAFETY) Electric Supplies Safety Rule

(K60950)

NO

YES

NO

7

KC(EMC) MIC

CCC GB4943, GB9254, GB17625.1 YES

Etc

8

(China)

Te

st Hi-Pot 1500 V ac or 2121Vdc, 1 sec, under 10mA No

9

h Continuity 25 A, 1 sec, under 0.1 ohm No

Eart

10 EPA 6.0

11

EPEAT Gold

te

No

Energy Star 6.0

#3 - CRT monitor only

#4 – Different from Models

#5 – Different from Models

#6 - ISO9241-3, 7, 8 - CRT monitor only

ICO13406-2 / ISO 9241-307 - LCD monitor only

Ordinance 825

MIC Notice 100,Class B,

NO

Electric Article Technical Standard Ⅲ

Ene

rgy Star Display Version 6.0 YES

Yes

#7 –Safety Certification(안전인증) – Different from Models

* – Update to new standard regulation and Revision 3.0

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 17 -

LGE Internal Use Only

Page 18

5. Pattern for Adjustment

Pattern 0 : FULL BLACK (State of without video signal )

Pattern 1 : FULL WHITE (Don’t display other Character except for White Pattern)

Pattern 3 : FULL WHITE

Pattern 4 :

Pattern 5 : 1 Dot on, 1 Dot off & Rectangle Pattern

Pattern 6 : Vertical Sync only input (Use signal cable of which Pin #5 is GND)

Pattern 7 : Horizontal Sync only input (Use signal cable of which Pin #5 is GND)

Pattern 8 : State of without Vertical/Horizontal Sync and Video Signal. (Use signal cable of which Pin #5 is GND)

Pattern 9 : 8 Color Bar Pattern + 16 Gray Level Pattern

Pattern 10 : SMPTE Pattern

Pattern 11 : 16 Gray Step Pattern (700mV)

Cross hatch pattern (Horizontal 10Line, Vertcial 8Line) & Rectangle Pattern

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 18 -

LGE Internal Use Only

Page 19

BLOCK DIAGRAM (Main)

hFlash

Flas

AM

(1GB)

DDR2

SDR

AM

DDR2

SDR

(1GB)

tick

(Control Key)

Joys

Address[0:12]

DDR2

Address[0:12]

DDR2

DDR2 Data[0:15]

MemoryMemory

(2M)(2M)

SPI_DI

SPI_CSN

SPI_DO

SPI_WP

SPI_CLK

LVDS

41p

DDR2 Data[0:15]

Key1, Key2

A-out_L

A_out_R

phoneHeadphone

Head

TMDS

OM

EEPR

1HDMI 1

HDMI

el (2560x1080)

Pan

version)

TMDS

NT68370

LVDS

51p

WLED PDIM

WLED_ADIM

WLED_ENABLE

(E-

OM

EEPR

DPRXAUXN

DPRX_AUXP

2HDMI 2

HDMI

DPDP

Driver ICLED Driver IC

D

LE

DT1631SDT1631S

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 19 -

LGE Internal Use Only

Page 20

TROUBLESHOOTING GUIDE

1. NO POWER

`

X200

power issue

No

ADAPTER

CHECK

NO

ck JK500

Che

NO

IC100

Is

CRYSTAL X200

CK

CHE

PINN1,PINN2 PULSE

IC510-#3 IC509#3

IC100

CHECK

IC505 or IC506

CHECK IC500 or IC509 or

IC510

NO

S

YE

PIN4(19V)

IC500 PIN2(19V),PIN3(10V)

Is

YES

,IC510 PIN2(19V),PIN3(5V)

,IC509 PIN2(19V),PIN3(3.3V)

NO

IC505, PIN2(1.3V)

Is

CHECK

YES

IC506 PIN2(1.9V)

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 20 -

IC510-#2

LGE Internal Use Only

Page 21

2. NO RASTER (OSD IS NOT DISPLAYED) – MAIN

IC509 PIN3(3.3V)

CHECK

CHECK X200

1.

2. Trouble in IC100

CHECK CONNECTION From HDMI TO

IC100

NO

NO

NO

S

YE

12MHz

ck IC100 PIN

B19(3.3V)

Che

No Raster(OSD is not displayed)

00 PIN N1,N2

IC1

YES

CLK

IC100 PIN C14

Is

e in cable or LCD module

Troubl

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 21 -

LGE Internal Use Only

Page 22

3. TROUBLE IN DPM

Trouble in DPM

NO

ECK PC. PC is going to the DPM

CH

mode

k R133 AND R196

Chec

ECK HDMI CLK

CH

NO

S

YE

YES

IC100 PIN H4

Copyright ©

Only for training and service purposes

2010 LG Electronics. Inc. All right reserved.

- 22 -

Trouble in IC100

LGE Internal Use Only

Page 23

EXPLODED VIEW

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

920

400

610

700

900

910

560

710

520

540

200

300

LV2

LV1

Page 24

1 6

IC100

RX1CBD1RX1CD2RX10BE1RX10E2RX11BF1RX11F2RX12BG1RX12G2RX2CBJ1RX2CJ2RX20BK1RX20K2RX21BL1RX21L2RX22BM1RX22M2RXAUX1NC1RXAUX1C2RXAUX2NH1RXAUX2H2BIN1+P2BIN1-P1SOGINR3GIN1+R2GIN1-R1RIN-T1RIN+T2HSYNCI0U1VSYNCI0U2RX3CB

NT68370(D VER.)

C126 1uF

C125 1uF

C124 1uF

C122 1uF

C121 1uF

C119 1uF

C118 1uF

C127 1uF

DP_AUXN

DP_AUXP

DP_RX0P

DP_RX0N

DP_RX1N

DP_RX1P

DP_RX2N

DP_RX2P

DP_RX3N

DP_RX3P

HDMI1_RX2-

HDMI1_RXC-

HDMI1_RX1-

HDMI1_RX0-

HDMI1_RX2+

HDMI1_RX1+

HDMI1_RX0+

HDMI1_RXC+

DP_RX1NDP_RX1N

D121

OPT

1

TMDS_CH1-

IP4283CZ10-TBA

[TVS DIODE FOR ESD PROTECTION]

DP_RX1P

DP_RX0N

3

2

TMDS_CH1+4TMDS_CH2-

GND_1

DP_RX1P

DP_RX0N

DP_RX0P

NC_17NC_28GND_29NC_310NC_4

6

5

TMDS_CH2+

DP_RX0P

D122

IP4283CZ10-TBA

D119

IP4283CZ10-TBA

D115

IP4283CZ10-TBA

DP_RX3N

OPT

1

DP_RX3N

DP_RX3P

2

TMDS_CH1-

DP_RX3P

HDMI2_RXC-

OPT

1

TMDS_CH1-

HDMI2_RXC-

HDMI2_RX1-

OPT

1

TMDS_CH1-

HDMI2_RX1-

TMDS_CH1+4TMDS_CH2-

HDMI2_RXC+HDMI2_RXC+

2

HDMI2_RX1+

2

HDMI2_RX1+

A15

B15

DP_RX2P

DP_RX2N

NC_17NC_28GND_29NC_310NC_4

6

3

5

TMDS_CH2+

GND_1

DP_RX2P

DP_RX2N

HDMI2_RX0+

6

3

TMDS_CH1+4TMDS_CH2-

5

GND_1

HDMI2_RX0- HDMI2_RX0-

HDMI2_RX0+

HDMI2_RX2-

6

3

TMDS_CH1+4TMDS_CH2-

5

GND_1

HDMI2_RX2+

HDMI2_RX2-

RX3C

RX30B

A14

NC_17NC_28GND_29NC_310NC_4

TMDS_CH2+

HDMI2_RX2+

NC_17NC_28GND_29NC_310NC_4

TMDS_CH2+

RX30

B14

RX31B

A13

B13

RX31

RX32B

RX32

A12

B12

D123

IP4283CZ10-TBA

D120

IP4283CZ10-TBA

.04

D116

IP4283CZ10-TBA

RX4CB

RX4C

A11

B11

HDMI2_RXC+

HDMI2_RXC-

DP_AUXN

OPT

1

TMDS_CH1-

DP_AUXN

HDMI1_RX1-

OPT

1

TMDS_CH1-

HDMI1_RX1-

HDMI1_RXC-

OPT

1

TMDS_CH1-

HDMI1_RXC-

RX40B

A10

B10

HDMI2_RX0-

DP_AUXP

2

DP_AUXP

HDMI1_RX1+

2

HDMI1_RX1+

HDMI1_RXC+

RX40

RX41BA9RX41B9RX42BA8RX42

B8

HDMI2_RX0+

HDMI2_RX2+

HDMI2_RX1-

HDMI2_RX2-

HDMI2_RX1+

DP_DET

3

GND_1

TMDS_CH1+4TMDS_CH2-

DP_DET

HDMI1_RX2-

3

TMDS_CH1+4TMDS_CH2-

GND_1

HDMI1_RX2-

HDMI1_RXC+

HDMI1_RX0-

3

2

TMDS_CH1+4TMDS_CH2-

GND_1

HDMI1_RX0-

DP_HPD

6

NC_17NC_28GND_29NC_310NC_4

5

TMDS_CH2+

DP_HPD

HDMI1_RX2+

NC_17NC_28GND_29NC_310NC_4

6

5

TMDS_CH2+

HDMI1_RX2+

HDMI1_RX0+

NC_17NC_28GND_29NC_310NC_4

6

5

TMDS_CH2+

HDMI1_RX0+

DP_RX0N

DP_RX1N

DP_RX2N

DP_RX3N

34UM65

Signal Input

DP_RX0P

100K

R164

100K

R162

100K

R160

100K

R158

DP_RX1P

DP_RX2P

DP_RX3P

100K

R165

100K

R163

100K

R161

100K

R159

HDMI_5V

+5V

A2CA1

D112

BAT54C

A2CA1

D109

BAT54C

IC101

M24C02-RMN6T

C107

0.1uF

16V

HDMI2_SCL

HDMI2_SDA

EDID_WP

R155

10K

D111

OPT

50V

C110

R128

10K

OPT

R127

10K

R126

10K

VCC

8

HDMI2

EEPROM

1

E0

68pF

D110

OPT

50V

C109

68pF

R125

33

R124

33

SDA6SCL7WC

5

3E22E14

VSS

DP_RX3P

DP_RX3N

ML_LANE_3+

ML_LANE_3-

GND_3

2

1

3

JK100

DP

62L020S-34A1N-7T0201-HF_

DP_RX2N

ML_LANE_2-

GND_2

4

DP_RX1N

DP_RX2P

ML_LANE_1-

ML_LANE_2+

7

6

GND_1

8

+3.3V

+3.3V

+3.3V

DP_RX0N

DP_RX1P

ML_LANE_1+

ML_LANE_0-

9

10

GND_0

11

DP_PLUG

R117 33

R110

1M

R108

10K

R153

10K

DP_RX0P

0

R100

CONFIG1

ML_LANE_0+

13512

0

R101

CONFIG2

14

DP_AUXP

C104 0.1uF 16V

AUX_CH+

15

HDMI2_DET

+3.3V

HDMI2_RXC-

0

R190

TMDS_CLK-

12

+3.3V

HDMI2_RXC-

0

CEC

CLK-11CLK_SHIELD

12

R195

10K

HDMI2_SCL

R1790R1800R182

HDMI2_SCL-1

RESERVED13CEC

SCL

14

15

R112

10K

HDMI2_SCL

0

R149

SCL

14NC13

15

1K

R181

HDMI_5V

HDMI2_SDA

HDMI2_SDA-1

DDC/CEC_GND

SDA

17

16

HDMI2_DET

1K

R168

HDMI_5V

HDMI2_SDA

R1670R169

SDA

DDC/CEC_GND

16

17

R192 1K

0

HOT_PLUG_DETECT

VDD[+5V]

19

18

R107 1K

0

HPD18+5V_POWER

19

C128

C102

0.1uF

20

0.1uF

20

16V

BODY_SHIELD

16V

SHIELD

HDMI2_HPD

33

R178

HDMI2_HPD

33

R140

10K

OPT

R191

D102

10K

OPT

R105

D108

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FIRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFACTURES SPECIFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

+5V

IC103

M24C02-RMN6T

16V

HDMI1_RX2+

HDMI1

EDID_WP

R157

10K

D129

OPT

C117

68pF

33

R144

3E22E14

HDMI1_RX0+

HDMI1_RX1-

DATA 0+6DATA 1-

7

50V

D126

C116

68pF

50V

OPT

33

SDA6SCL7WC

5

VSS

HDMI1_DET

R196 1K

R133

DATA 0_SHI ELD

8

HDMI1_RX0-

CLK+

DATA 0-

9

HDMI1_RXC+

10

+3.3V

HDMI1_RXC-

CEC

CLK-11CLK_SHIELD

12

14NC13

HDMI1_SCL

JP106

SCL

15

10K

HDMI_5V

HDMI1_SDA

JP107

SDA

16

DDC/CEC_GND

17

R129 1K

HPD18+5V_POWER

19

HDMI1_HPD

C111

0.1uF

16V

R132

33

10K

R114

OPT

D117

20

SHIELD

R150

10K

OPT

R147

10K

R146

10K

R143

VCC

8

HDMI1

EEPROM

1

E0

HDMI1_RX2-

HDMI1_RX1+

DATA 1_SHI ELD

DATA 2_SHI ELD

DATA 1+1DATA 2+

DATA 2-

5

2

4

3

Option: "29UM65/34UM65"

Location is left side

HDMI2_RX2-

HDMI2_RX1+

HDMI2_RX1-

HDMI2_RX2+

0

0

0

R184

R1850R187

R183

R186

TMDS_DATA1_SHIELD

TMDS_DATA2_SHIELD

TMDS_DATA1+

TMDS_DATA2+

TMDS_DATA2-

TMDS_DATA1-

5

2

4

1

3

JK104

HDMI2

Angle

51U019S-3441N-6RLGM5-HF

Option: "25UM65/29UB65"

Location is rear

0

R170

JK10 1

HDMI2

25UM65/29UB65

51V0 19S-3 5SN-CR 2-B-L G

6

29UM65/34UM65

HDMI2_RX2+

HDMI2_RX2-

HDMI2_RX1+

R1710R1720R1730R1740R1750R1760R177

DATA 1_SHI ELD

DATA 2_SHI ELD

DATA 1+1DATA 2+

DATA 2-

5

2

4

3

HDMI2_RX0+

0

TMDS_DATA0_SHIELD

TMDS_DATA0+

8

7

HDMI2_RX1-

HDMI2_RX0+

DATA 0_SHI ELD

DATA 0+6DATA 1-

8

7

HDMI2_RXC+

HDMI2_RX0-

0

0

R189

R188

TMDS_CLK+

TMDS_DATA0-

9

10

HDMI2_RXC+

HDMI2_RX0-

CLK+

DATA 0-

9

10

TMDS_CLK_SHIELD

11

HDMI_5V

A2CA1

D127

BAT54C

A2CA1

D125

BAT54C

C115

0.1uF

DP_HPD

DP_DET

DP_AUXN

R118 33

C105 0.1uF 16V

R113

1M

100K

R109

AUX_CH-

17

RETURN

HOT_PLUG

18

R154

+3.3V

DP_PWR[3.3V]

19

20

OPT

D103

C101

0.1uF

16V

0

OPT

21

JK10 2

51V0 19S-3 5SN-CR 2-B-L G

R111 1K

GND_4

16

HDMI1_SCL

HDMI1_SDA

Page 25

H12

H13

GND_1

H14

GND_2

H15

GND_3

H16

GND_4

H17

GND_5

H18

GND_6

J12

GND_7

J13

GND_8

J14

GND_9

J15

GND_10

J16

GND_11

GND_12

J17

GND_13

J18

GND_14

K12

GND_15

K13

GND_16

K14

GND_17

K15

K16

GND_18

GND_19

K17

GND_20

K18

L12

GND_21

GND_22

L13

GND_23

L14

GND_24

L15

L16

GND_25

GND_26

L17

L18

GND_27

GND_28

M12

GND_29

M13

M14

GND_30

GND_31

M15

M16

GND_32

GND_33

M17

GND_34

M18

GND_35

N12

N13

GND_36

GND_37

N14

N15

GND_38

GND_39

N16

GND_40

N17

GND_41

N18

P12

GND_42

GND_43

P13

P14

GND_44

GND_45

P15

GND_46

P16

GND_47

P17

P18

GND_48

GND_49

R12

GND_50

R13

R14

GND_51

GND_52

R15

GND_53

R16

GND_54

R17

R18

GND_55

GND_56

T12

GND_57

T13

T14

GND_58

GND_59

T15

GND_60

T16

GND_61

T17

T18

GND_62

GND_63

U12

U13

GND_64

GND_65

U14

GND_66

U15

GND_67

U16

GND_68

U17

GND_69

U18

GND_70

GND_71Y3GND_72

AA3

AB3

AC3

AD3

AD4

AD5

AD6

AD7

AD8

AD9

AD10

AD11

AD12

AD13

AD14

AD15

AD16

N10

P10

GND_73

GND_74

GND_75

GND_76

GND_77

GND_78

GND_79

GND_80

GND_81

GND_82

GND_83

GND_84

GND_85

GND_86

GND_87

GND_88

ADC_GND

OSC_GND

IC100

NT68370(D VER.)

CVDD_1

CVDD_2

CVDD_3

G17

G18

G19

+1.3V_MULTI

C272

0.1uF

C265

0.1uF

C257

0.1uF

C231

0.1uF

C269

10uF

C248

10uF

C243

10uF

C220

+1.3V_MULTI

P202

10uF

1

CVDD_4

H19

16V

16V

16V

16V

10V

10V

10V

10V

J19

3

CVDD_5

CVDD_6

CVDD_7

K19

L19

M19

LVDS JACK2

5

CVDD_8

CVDD_9

N19

CVDD_10

P19

R19

CVDD_11

CVDD_12

CVDD_13

CVDD_14

CVDD_15

T19

U19

V17

V18

+3.3V_SCALER

CVDD_16

VDD12RX_1

V19

G11

+1.3V_SCALER

C253

0.1uF

C264

0.1uF

C268

0.1uF

C235

0.1uF

C267

0.1uF

C226

10uF

C262

10uF

C261

10uF

VDD12RX_2

VDD33RX_1G9VDD33RX_2H9VMM_ADC12_1

M9

H10

+1.3V_MULTI

+3.3V_SCALER

16V

16V

16V

16V

16V

10V

10V

10V

VMM_ADC12_2N9VCCA/VCCD_1

VCCA/VCCD_2

VCC_CLK

V9

V10

V12

+1.3V_MULTI

+1.3V_SCALER

+3.3V_MULTI

19

VX1_EXT12_1

VX1_EXT12_2

W18

W19

+1.3V_SCALER

21

APR1_V12_1J9APR1_V12_2

APR1_V12_3K9APR1_V12_4

J10

K10

C271

0.1uF

16V

C266

10uF

10V

C252

0.1uF

16V

C245

10uF

10V

C225

10uF

10V

DP_AVDD_PLL_1

J21

K21

+1.3V_MULTI

+1.9V

DP_AVDD_PLL_2

DP_AVDD_1

DP_AVDD_2

J20

K20

+3.3V_SCALER

TVCC33_1

TVCC33_2

TVCC33_3

VCC_LDO33M7VCC_ADC33M8MPLL33N8OSC_VCC33N7VDD_DLLP7VCCA_LVDS_1

E11

E12

E13

C260

0.1uF

16V

C249

0.1uF

16V

C242

0.1uF

16V

C237

10uF

10V

C228

10uF

10V

VCCA_LVDS_2

R21

T21

+3.3V_MULTI

+3.3V_SCALER

DP_AVDD_33_1

DP_AVDD_33_2

G20

H20

F20

+3.3V_MULTI

42

VCC33_SSCK

OSC_MVCC3IO

D21

+3.3V_SCALER

DVDD_1

E15

DVDD_2

E16

DVDD_3

E17

+3.3V_SCALER

VDD_VBYONE_33V_1

VDD_VBYONE_33V_2

V12T_1

V12T_2

V20

W20

F10

F11

G10

+1.3V_MULTI

V12T_3

VDD_CORE/VDD_MMU_1

VDD_CORE/VDD_MMU_2

VDD_CORE/VDD_MMU_3

U7

U8

V7

V8

+1.9V

VDD_CORE/VDD_MMU_4

VDD_CORE/VDD_MMU_5

VDD_CORE/VDD_MMU_6

VDD_CORE/VDD_MMU_7

VDD_CORE/VDD_MMU_8

VDD_CORE/VDD_MMU_9

VDD_CORE/VDD_MMU_10

W7

W8

W9

W10

W11

W12

VDD_CORE/VDD_MMU_11

VDD_CORE/VDD_MMU_12

VDD_CORE/VDD_MMU_13

VDD_CORE/VDD_MMU_14

VDD_CORE/VDD_MMU_15

VDD_CORE/VDD_MMU_16

Y7

W13

Y8

W14

W15

W16

W17

+1.9V

VDD_CORE/VDD_MMU_17

VDD_CORE/VDD_MMU_18

VDD_CORE/VDD_MMU_19

VDD_CORE/VDD_MMU_20

VDD_CLK

Y9

Y6

Y10

Y11

Y12

10K1%

R205

MVREF

C202

R206

0.1uF

10K1%

2 6

GPIO/Scaler Power/LVDS

34UM65

GND2GND

FI-RE41S-HF-J-R1500

P201

1

FI-RE51S-HF-J-R1500

+PANEL_PWR2+PANEL_PWR3+PANEL_PWR4+PANEL_PWR

+10V_PANEL

IC100

TXD4P4TXD4N

TXD3P6TXD3N7GND8TXDCLP9TXDCLN10GND11TXD2P12TXD2N13TXD1P14TXD1N15TXD0P16TXD0N17GND18GND

TXD4P

TXD4N

TXD3P

TXD3N

TXDCLP

TXDCLN

TXD2P

TXD2N

TXD1P

LVDS JACK1

R221

C216

10K

10uF

TXA0N

N24

TXA0N

25V

N23

5NC6

TXA0P

N26

TXA0P

TXA1N

N25

TXA1N

GND7GND8GND9GND

TXA1P

P24

TXA1P

TXA2N

P23

TXA2N

TXA2P

P26

TXA2P

TXACLP

TXACLN

P25

TXACKN

TXACKP

R24

10

11

13

GND

TXB3P14TXB3N15GND16TXBCLP17TXBCLN18GND19TXB2P20TXB2N21TXB1P22TXB1N23TXB0P24TXB0N

TXB4P12TXB4N

TXB4N

TXB4P

TXB3P

TXB0N

TXA4N

TXA3N

TXA3P

TXA4P

R23

R26

R25

T24

T23

TXA3N

TXA3P

TXA4N

TXA4P

TXB0N

TXD1N

TXB3N

TXB0P

T26

TXB0P

TXB1N

T25

TXB1N

TXD0P

TXB1P

U24

TXB1P

TXD0N

TXBCLP

TXB2N

U23

TXB2N

TXB2P

U26

TXB2P

TXC4P20TXC4N

TXC3P22TXC3N23GND24TXCCLP25TXCCLN26GND27TXC2P28TXC2N29TXC1P30TXC1N31TXC0P32TXC0N33GND34NC35NC36NC37NC38NC39NC40NC41NC

TXC4P

TXBCLN

TXBCLN

TXBCLP

U25

TXBCKN

TXBCKP

V24

TXB3N

V23

TXB3N

TXB2P

TXB3P

V26

TXB3P

TXC4N

TXB2N

TXB4N

V25

TXB4N

TXB4P

TXB4P

TXC3P

TXB1P

TXC3N

TXB1N

TXC0N

W24

W23

TXC0N

TXB0P

TXC0P

W26

TXC0P

TXC1N

TXC1N

TXCCLP

TXCCLN

25

HIGH-10bit

NC-8bit

Bit Select

TXB0N

TXC2P

TXC2N

TXC1P

W25

Y24

Y23

TXC1P

TXC2N

TXC2P

26NC27

TXA4P28TXA4N

TXCCLN

Y26

TXCCKN

TXC2P

TXA4P

TXCCLP

Y25

TXCCKP

AA24

TXC0P

TXC1N

TXC2N

TXA4N

TXC3N

AA23

TXC3N

TXC3P

TXC3P

TXC0N

TXC1P

29

TXA3P30TXA3N31GND32TXACLP33TXACLN34GND35TXA2P36TXA2N37TXA1P38TXA1N39TXA0P40TXA0N41GND

TXA3P

TXA3N

TXACLP

TXD0N

TXD1N

TXC4P

TXD0P

TXC4N

AA26

AA25

AB24

AB23

AB26

TXC4N

TXC4P

TXD0N

TXD0P

TXD1N

TXACLN

TXD1P

AB25

AC24

TXD1P

TXD2N

AC23

TXD2N

TXA2P

TXD2P

AC26

TXD2P

TXA2N

TXDCLP

TXDCLN

AC25

TXDCKN

TXDCKP

AD24

TXA1P

TXD3N

AD23

TXD3N

TXD3P

AD26

TXD3P

TXA1N

TXD4N

TXD4N

AD25

TXA0P

TXD4P

TXD4P

+3.3V

TXA0N

R960

P_LED

OPT

4.7K

R215

R216

1K

1K

R209

KEY1

R21933R220

33

KEY2

R208

4.7K

B

SIGN2

C

Q200

MMBT3904-(F)

OPT

4.7K

R203

SIGN1

E

C203

68pF

D203

D202

D201

C214

1uF

D200

+3.3V

52

42NC43

44NC45

46

LVDS Format

ODC Select47NC48NC49NC50NC51GND

PWM_OUT

R961

0

10K

OPT

R962

0

ITLC

High : Interlace mode

Low : Normal mode

GND

+5V

L201

L200

RED LED OPT

WHITE LED OPT

BLM18PG121SN1D

BLM18PG121SN1D

DP_TX0N

NT68370(D VER.)

C25

C12

D13

PE7/CBUS4

PD6/DIN_VS

IC100

NT68370(D VER.)

PC3/CECB2PC0/CEC/SCK_O

B3

P_LED

DP_TX0P

DP_TX1N

DP_TX1P

DP_TX2N

DP_TX2P

DP_TX3N

DP_TX3P

DP_AUXN

DP_AUXP

C26

D25

D26

E25

E26

F25

F26

G25

G26

5V_DET_INT

/FAULT

HDMI2_SCL

HDMI2_SDA

C13

D14

C14

PF2/CD_SENSE3/DIN_HS_CS

PA4/DDC_SCL2/RXD2/DIN_0

PA5/DDC_SDA2/TXD2/DIN_HREF_DE

PF7/VBUS4/WD_I

PA6/DDC_SCL3/RXD3

PA7/DDC_SDA3/TXD3

D12

C11

D11

HP_DET

DVI_SDA

DVI_SCL

+3.3V_SCALER

+3.3V_SCALER

HDMI2_DET

C15

D15

C16

B16

A16

PE6/CBUS3

PF6/VBUS3/SD_I

PB1/ADC1/INTE1/DIN_3

PB0/ADC0/INTE0/DIN_4

PF3/CD_SENSE4

PD5/IR_PORT1/MCLK_O

PE4/CBUS1/HPD1

PF4/VBUS1B4PB4/DDC_SCL0/RXD0

A3

A4

C3

C4

DP_PLUG

DVI_DET

HDMI1_HPD

R204

1K

R202

1K

PANEL_ON

+5V

R211 10K

D17

PE1/ADDR1/DIN_1

PE0/LPD_IN0/ADDR0

PB5/DDC_SDA0/TXD0

D3

DP_TXHDP

DPTX_OSCI

G24

H24

J24

WLED_PDIM

WLED_ENABLE

C17

B17

PC1/LPD_OUT/PWMA

PC2/DBC/PWMB/SD_O

PF0/CD_SENSE1

PD4/IR_PORT3E3PE5/CBUS2/HPD2

PF5/VBUS2F4PB6/DDC_SCL1/RXD1

D4

F3

G3

DP_DET

DP_HPD

DPTX_OSCIO

EDP_TX0P

H26

PB7/DDC_SDA1/TXD1

PF1/CD_SENSE2

PC7/IR_PORT2/SCK_I

PA0/ADC4/PWMA

G4

H3

H4

T3

EDID_WP

HDMI1_SDA

HDMI1_DET

HDMI1_SCL

EDP_TX0N

EDP_TX1P

EDP_TX1N

EDP_TX2P

EDP_TX2N

EDP_TX3P

EDP_TX3N

EDP_AUXN

EDP_AUXP

EDP_TXHDP

H25

J26

J25

K26

K25

L26

L25

M25

M26

K24

HDMI2_HPD

DVI_HPD

A20

B20

C20

D20

A19

OUT_P

OUT_N

PG3/DIN_6/DUI_INTE

PG1/DIN_2/DUI_SPI_CE

PG2/DIN_5/DUI_SPI_SIO

PA1/ADC5/PWMB

PC4/DDC_SCL4/RXD4

PC5/DDC_SDA4/TXD4

PD7R4RSTNV3OSCIN1OSCON2OPT1V1OPT0V2PE2/DBC/PWMC/M2_SPI_CE3

T4

P3

P4

OSCI

PD_CTRL

R200

10K

OSCO

R207

10K

OPT

+3.3V_SCALER

R236

10K

OPT

+3.3V_SCALER

C207

0.1uF

16V

R238

R237

ITLC

+3.3V_SCALER

EXT_SWING

3P_OPEN

3N_OPEN

AE25

AF21

AE21

3.3V_AMP_POWER_ON

B19

C19

D19

A18

B18

D18

C18

DU_VS/PA4

DU_DE/PA5

PG7/DIN_7/DUO_INTE

PG0/DIN_CK/DUI_SPI_CK

PG6/DIN_8/DUO_SPI_SIO

PG5/DIN_23/DUO_SPI_CE

PG4/DIN_22/DUO_SPI_CK

PE3/PWMD/M2_SPI_CE4

PA2/ADC6/PWMC/DIN_19

PA3/ADC7/PWMD/DIN_18

PB2/ADC2/INTE2/DIN_21

PB3/ADC3/INTE3/DIN_20

P34/RXD5/DIN_16

AC16

AD17

AC17

AE17

AF17

AE18

AD18

KEY2

KEY1

WLED_ADIM

BUZZER_PWM

10K

10K

2P_OPEN

2N_OPEN

1P_OPEN

1N_OPEN

0P_OPEN

0N_OPEN

LOCKN_OPEN

HTPDN_OPEN

AF22

AE22

AF23

AE23

AF24

AE24

AD22

AC22

A17

J3

J4

K3

K4

L3

L4

M3

M4

N3

HI_M_S_SEL

HI_INTE/PA2

SPI_CE3/P34

SPI_CE2/P31

SPI_CE1/P30

SPI_SIO4/PB3

HI_SPI_CK/P35

DU_FAST_MUTE/PD0

P35/TXD6/DIN_15

PC6/AMUTE/M2_SPI_CE2/AO_IN/DIN_17

P30/RXD/AO_OUT/DIN_14

P31/TXD/AO_OUTB/DIN_13

PD2/M2_SPI_SO/SD_I/DIN_12

AD19

AC18

AF18

AC19

AE19

AE20

SPI_SIO3/PB2

PD3/M2_SPI_CE1/WD_I/DIN_11

PD0/M2_SPI_CLK/SCK_I/DIN_10

PD1/M2_SPI_SI/DIN_9

SPI_CE

SPI_SO

SPI_CLK

AF19

AF20

AD20

AC20

AC21

AD21

SDOCSSCK

WP_SPI

N4

SPI_SIO2/PB1

SPI_SIO1/PB0

SPI_SI

SDI

P200

C213

0.1uF

+3.3V

VCC

8

IC201

W25Q80BVSSIG

1

Flash shall be chagned 16Mbit

CS

when scaler being revised

CS

12507WR-08L

R231

10K

HOLD[IO3]

7

FLAH

8MBIT

2

DO[IO1]

SDO

1+3.3V

SCKWP_SPI

CLK

6

3

%WP[IO2]

2KEY1

SDI

DI[IO0]

5

4

GND

3KEY2

C208

C212

C211

68pF

4SCL

5SDA

Control key

OPT

68pF

OPT

68pF

OPT

6GND

7

8

9

OSCI

R2011M1%

X200

12MHz

C201

22pF

C200

22pF

If h/sink applied,

X200 shall move away h/sink area

OSCO

THE SYMBOL MARK OF THIS SCHEMETIC DIAGRAM INCORPORATES

SPECIAL FEATURES IMPORTANT FOR PROTECTION FROM X-RADIATION.

FIRE AND ELECTRICAL SHOCK HAZARDS, WHEN SERVICING IF IS

ESSENTIAL THAT ONLY MANUFACTURES SPECIFIED PARTS BE USED FOR

THE CRITICAL COMPONENTS IN THE SYMBOL MARK OF THE SCHEMETIC.

Page 26

MBA[0-1]

MBA[1]

AB10

MBA1

MBA[0]

AB9

MBA0

MA[0-12]

MA[11]

MA[12]

AB5

AC14

MA12

MA[10]

AC5

MA11

MA[9]

AC4

MA10

MA[8]

AB14

MA9

MA[7]

AB6

MA8

MA[6]

MA7

AC13

MA[5]

MA6

4 6

MA[0]

MA[1]

MA[2]

MA[3]

MA[4]

AB8

AB13

AB7

MA5

MA4

MA3

AC12

MCSN

MCKE

MCASN

MRASN

AC6

AB12

AC11

AC7

AC10

AC9

AC8

MA2

MA1

MA0

MCSN

MCKE

MRASN

MCASN

MWEN

MWEN

MCLK1N

AC15

MCLK1-

MCLK1P

AB15

MCLK1+

AF16

MCLK0N

MCLK0P

AE16

MCLK0-

MCLK0+

AB11

ODT

R47322

OPT

AB4

ODT

PHY_TM

DDR

+1.9V

C417

C416

C415

C414

C413

C412

C411

C410

C409

C408

C407

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

0.1uF

10uF

10V

0.1uF

0.1uF

0.1uF

0.1uF

Close to DDR Power Pin

+1.9V

R471

IC100

MDQ31

MDQ30

MDQ29

MDQ28

MDQ27

MDQ26

MDQ25

MDQ24

MDQ23

MDQ22Y1MDQ21

MDQ20W1MDQ19W2MDQ18

MDQ17Y2MDQ16

MDQ15

MDQ14

MDQ13

MDQ12

MDQ11

MDQ10

MDQ9

MDQ8

MDQ7

MDQ6

MDQ5

MDQ4

MDQ3

MDQ0

MDQ1

MDQ2

MDQS3B

MDQS3

MDQS2B

MDQS2

MDQS1B

MDQS1

MDQS0B

MDQS2P

NC5

L1

R3

AF11

R44022

NC6

R7

AE11

R44122

MDQS1N

MDQS1P

AF10

R44222

MDQS0

AE10

R44322

MDQS0N

MDQS0P

NC1

NC2

A2

+1.9V

R475 0R474 0

NC3

R8

E2

VSSDL

J7

VDDL

J1

NT68370(D VER.)

AE2

AB2

AE3

AA2

AA1

AF3

AB1

AF2

AF4

AF5

AE5

AE4

AF9

AF8

AE8

AE9

AE7

AE6

AF6

AF7

AD2

AD1

AC2

AE12

AE13

AF13

AF12

AF14

AF15

AE15

R40622

R40522

R40922

R40822