LG 26LS3510, 55LS4500, 22LS3500, 22LS3510, 26LS3500-UD Service Manual

...

Printed in KoreaP/NO : MFL67454204 (1203-REV00)

CHASSIS : LA25A

MODEL : 26LS3500 26LS3500-UD

MODEL : 26LS3510 26LS3510-UA

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

LED LCD TV

SERVICE MANUAL

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

Internal Use Only

- 2 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

CONTENTS

CONTENTS .............................................................................................. 2

PRODUCT SAFETY ................................................................................. 3

SPECIFICATION ....................................................................................... 4

ADJUSTMENT INSTRUCTION ................................................................ 6

TROUBLESHOOTING .............................................................................13

BLOCK DIAGRAM ...................................................................................24

EXPLODED VIEW .................................................................................. 25

SCHEMATIC CIRCUIT DIAGRAM ..............................................................

- 3 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Exploded View.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of th e cir cuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1 W), keep the resistor 10 mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1 MΩ and 5.2 MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

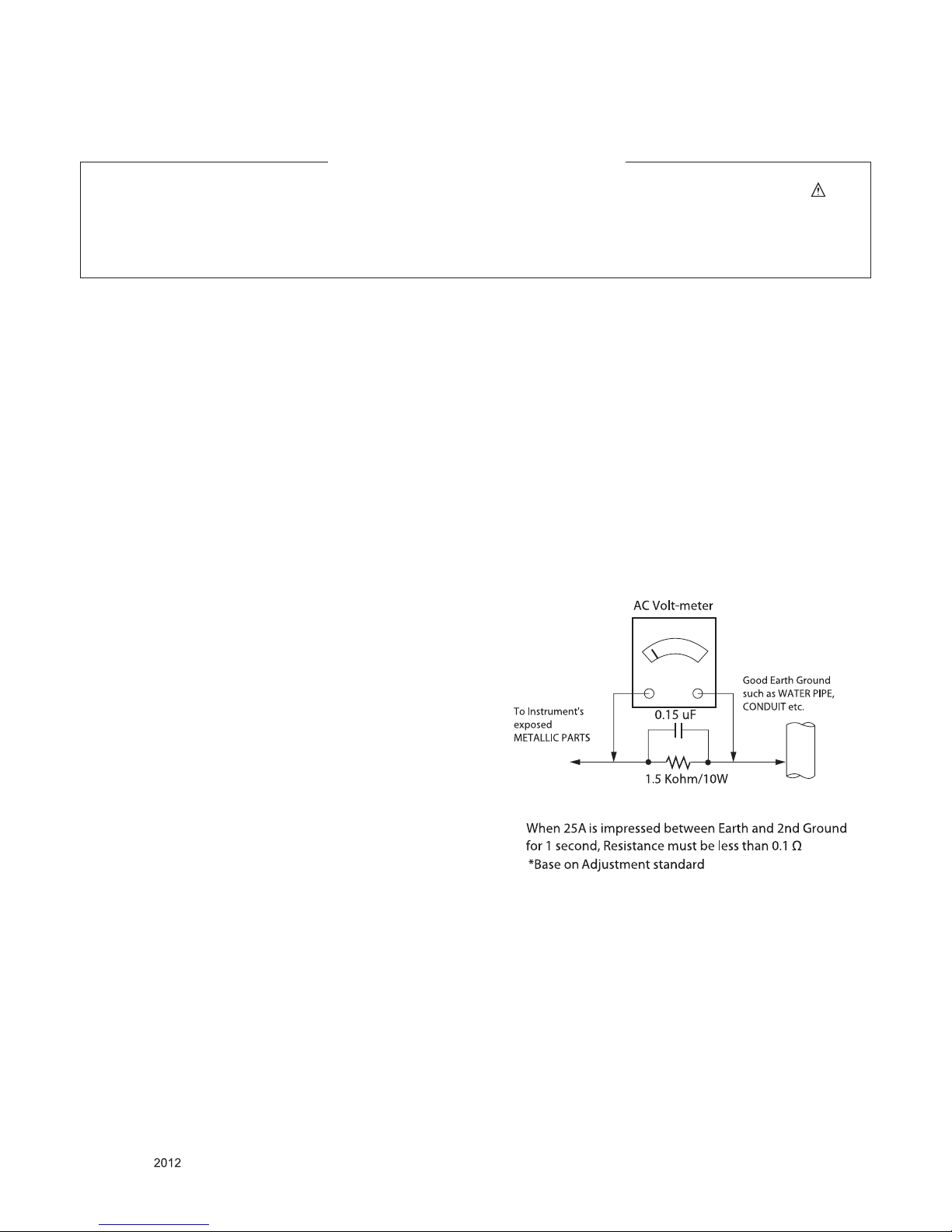

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5 K / 10 watt resistor in parallel with a 0.15 uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exp ose d metallic par t. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5 mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

IMPORTANT SAFETY NOTICE

SAFETY PRECAUTIONS

- 4 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement

.

1. Application range

This spec sheet is applied LCD TV with LA25A/B/C chassis

2. Test condition

Each part is tested as below without special notice.

1) Temperature : 25 ºC ± 5 ºC(77 ± 9 ºF), CST : 40 ± 5 ºC

2) Relative Humidity: 65 % ± 10 %

3) Power Voltage

- AC 110-240 V~, 50/60 Hz

* Standard Voltage of each products is marked by models.

4) Specification and performance of each parts are followed

ea ch drawing and s pe cificatio n b y p art number in

accordance with BOM.

5) The receiver must be operated for about 5 minutes prior to

the adjustment.

3. Test method

1) Performance: LGE TV test method followed

2) Demanded other specification

- Safety : UL, CSA, IEC specification

- EMC: FCC, ICES, IEC specification

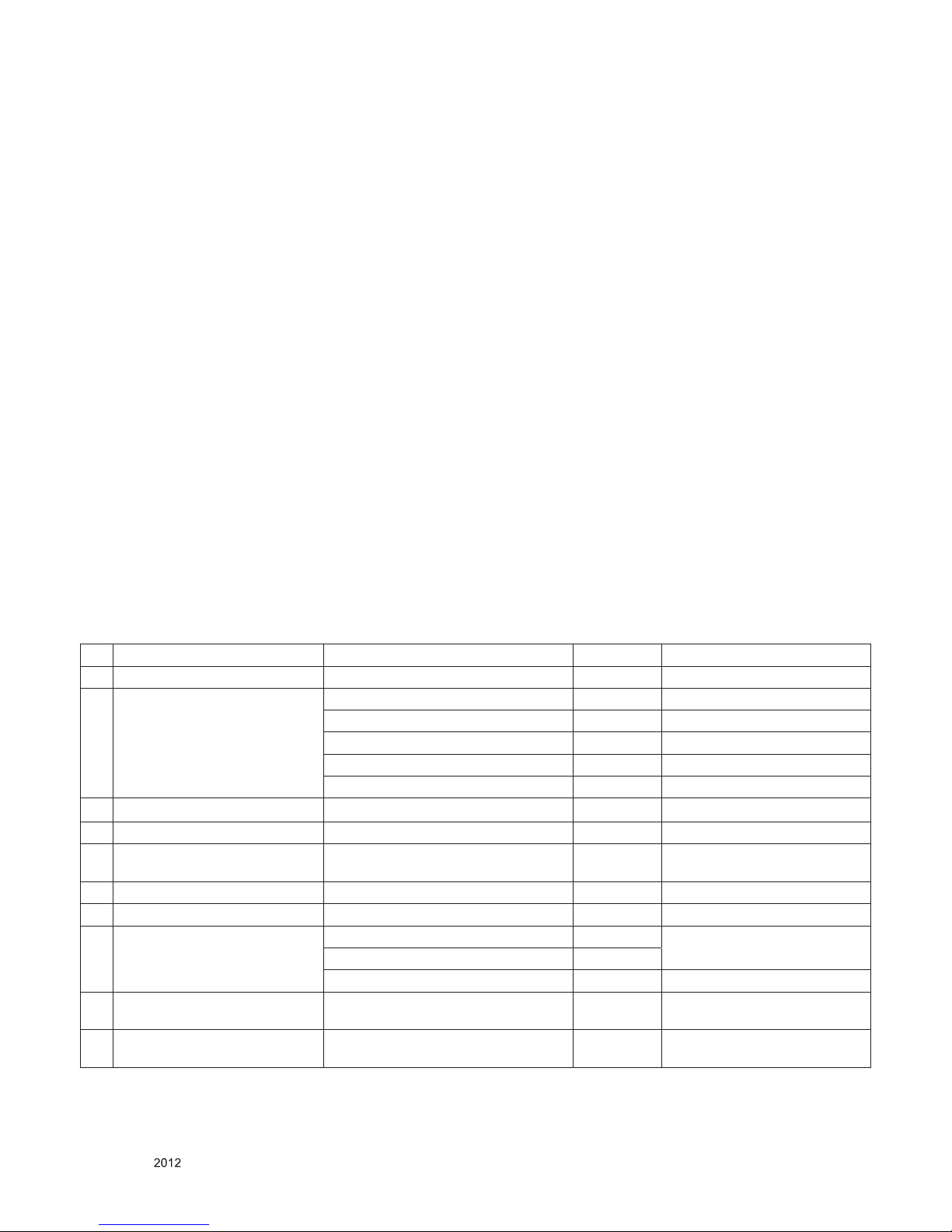

4. General Specification

No Item Specication Remark

1 Receiving System 1) ATSC / NTSC-M

2 Available Channel 1) VHF : 02~13

2) UHF : 14~69

3) DTV : 02-69

4) CATV : 01~135

5) CADTV : 01~135

3 Input Voltage 1) AC 100 ~ 240V 50/60Hz

120V, 50/60Hz on the label (USA)

4 Market NORTH AMERICA

5 Screen Size 22/26/32 inch Wide (1366 × 768) HD + 60Hz 22/26/32LS3500-UD,

22/26/32LS3510-UA

6 Aspect Ratio 16:9

7 Tuning System FS

8 Module(Edge LED) LC260EXN-SDA1 LGD 26LS3500-UD/26LS3510-UA

T260XVN01.4 AUO

V216BG1-LE1 CMI 22LS3500-UD/22LS3510-UA

9 Operating Environment 1) Temp : 0 ~ 40 deg

2) Humidity : ~ 80 %

10 Storage Environment 1) Temp : -20 ~ 60 deg

2) Humidity : ~ 85 %

- 5 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

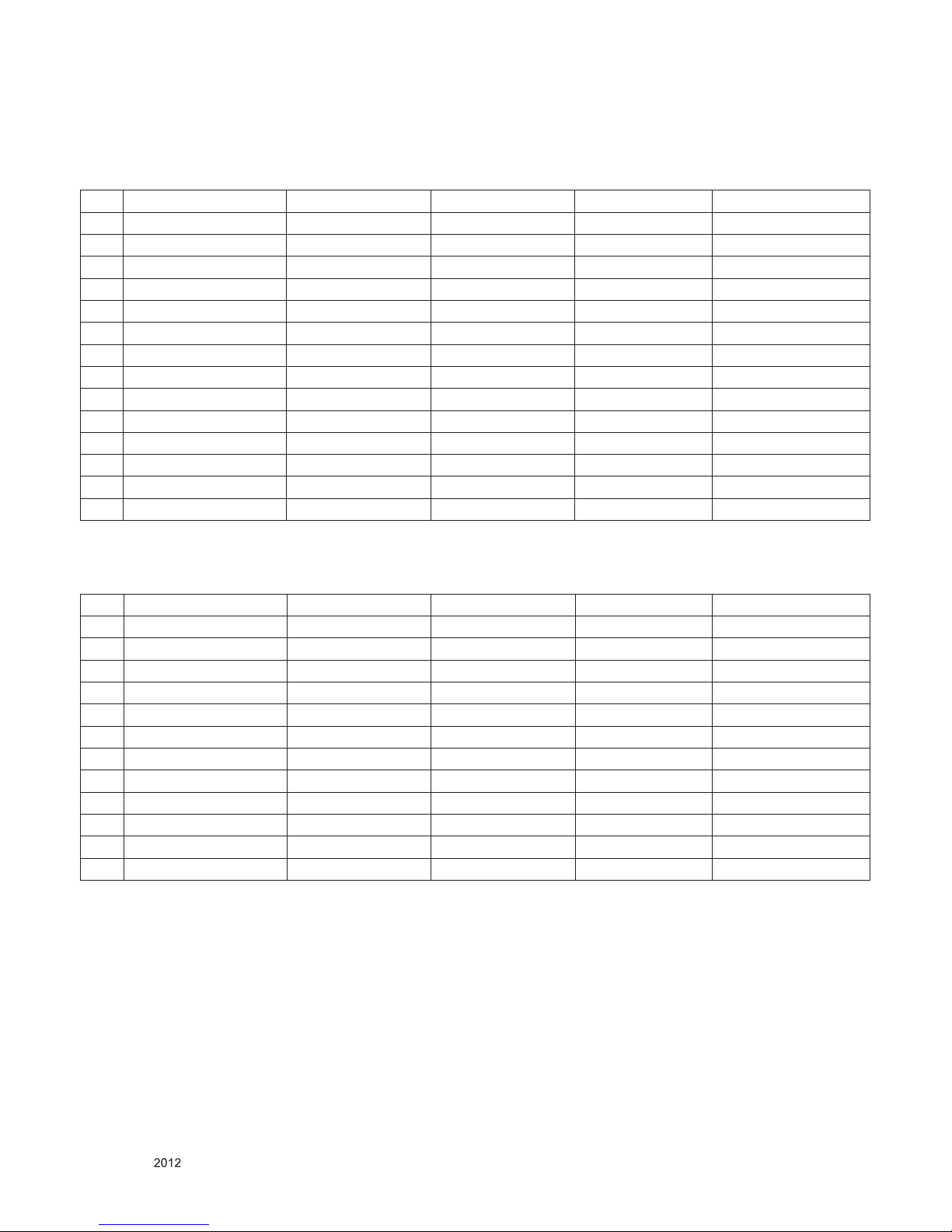

5. Supported video resolutions

5.1. Component input(Y, CB/PB, CR/PR)

5.2. HDMI Input (DTV)

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed

1. 720*480 15.73 60.00 13.5135 SDTV ,DVD 480I

2. 720*480 15.73 59.94 13.50 SDTV ,DVD 480I

3. 720*480 31.50 60.00 27.027 SDTV 480P

4. 720*480 31.47 59.94 27.00 SDTV 480P

5. 1280*720 45.00 60.00 74.25 HDTV 720P

6. 1280*720 44.96 59.94 74.176 HDTV 720P

7. 1920*1080 33.75 60.00 74.25 HDTV 1080I

8. 1920*1080 33.72 59.94 74.176 HDTV 1080I

9. 1920*1080 67.50 60.00 148.50 HDTV 1080P

10. 1920*1080 67.432 59.94 148.352 HDTV 1080P

11. 1920*1080 27.00 24.00 74.25 HDTV 1080P

12. 1920*1080 26.97 23.94 74.176 HDTV 1080P

13. 1920*1080 33.75 30.00 74.25 HDTV 1080P

14. 1920*1080 33.71 29.97 74.176 HDTV 1080P

No. Resolution H-freq(kHz) V-freq.(kHz) Pixel clock Proposed

1. 720*480 31.47 60.00 27.027 SDTV 480P

2. 720*480 31.47 59.94 27.00 SDTV 480P

3. 1280*720 45.00 60.00 74.25 HDTV 720P

4. 1280*720 44.96 59.94 74.176 HDTV 720P

5. 1920*1080 33.75 60.00 74.25 HDTV 1080I

6. 1920*1080 33.72 59.94 74.176 HDTV 1080I

7. 1920*1080 67.50 60.00 148.50 HDTV 1080P

8. 1920*1080 67.432 59.94 148.352 HDTV 1080P

9. 1920*1080 27.00 24.00 74.25 HDTV 1080P

10. 1920*1080 26.97 23.976 74.176 HDTV 1080P

11. 1920*1080 33.75 30.00 74.25 HDTV 1080P

12. 1920*1080 33.71 29.97 74.176 HDTV 1080P

- 6 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Application Range

This spec. sheet applies to LA25A Chassis applied LCD TV all

models manufactured in TV factory.

2. Specification

(1) Because this is not a hot chassis, it is not necessary to use

an isolation transformer. However, the use of isolation

transformer will help protect test instrument.

(2) Adjustment must be done in the correct order.

(3) The adjustment must be performed in the circumstance of

25 ±5 °C of temperature and 65±10% of relative humidity if

there is no specific designation.

(4) The input voltage of the receiver must keep 100~240V,

50/60Hz.

(5) At first Worker must turn on the SET by using Power Only

key.

(6) The receiver must be operated for about 5 minutes prior to

the adjustment when module is in the circumstance of over

15 °C

In case of keeping module is in the circumstance of 0°C, it

should be placed in the circumstance of above 15°C for 2

hours

In case of keeping module is in the circumstance of below

-20°C, it should be placed in the circumstance of above

15°C for 3 hours

[Caution]

When still image is displayed for a period of 20 minutes or

longer (especially where W/B scale is strong.

Digital pattern 13ch and/or Cross hatch pattern 09ch), there

can some afterimage in the black level area

3. Adjustment items

3.1. Main PCBA Adjustments

(1) ADC adjustment: Component 480i, 1080p / RGB-PC 1080p

(2) EDID downloads for HDMI and RGB-PC

3.2. Final assembly adjustment

(1) White Balance adjustment

(2) RS-232C functionality check

(3) Factory Option setting per destination

(4) Shipment mode setting (IN-STOP)

(5) GND and HI-POT test

3.3. Appendix

(1) Shipment conditions

(2) Tool option menu

(3) USB Download (S/W Update, Option and Service only)

(4) Preset CH Information

4. MAIN PCBA Adjustments

* Download

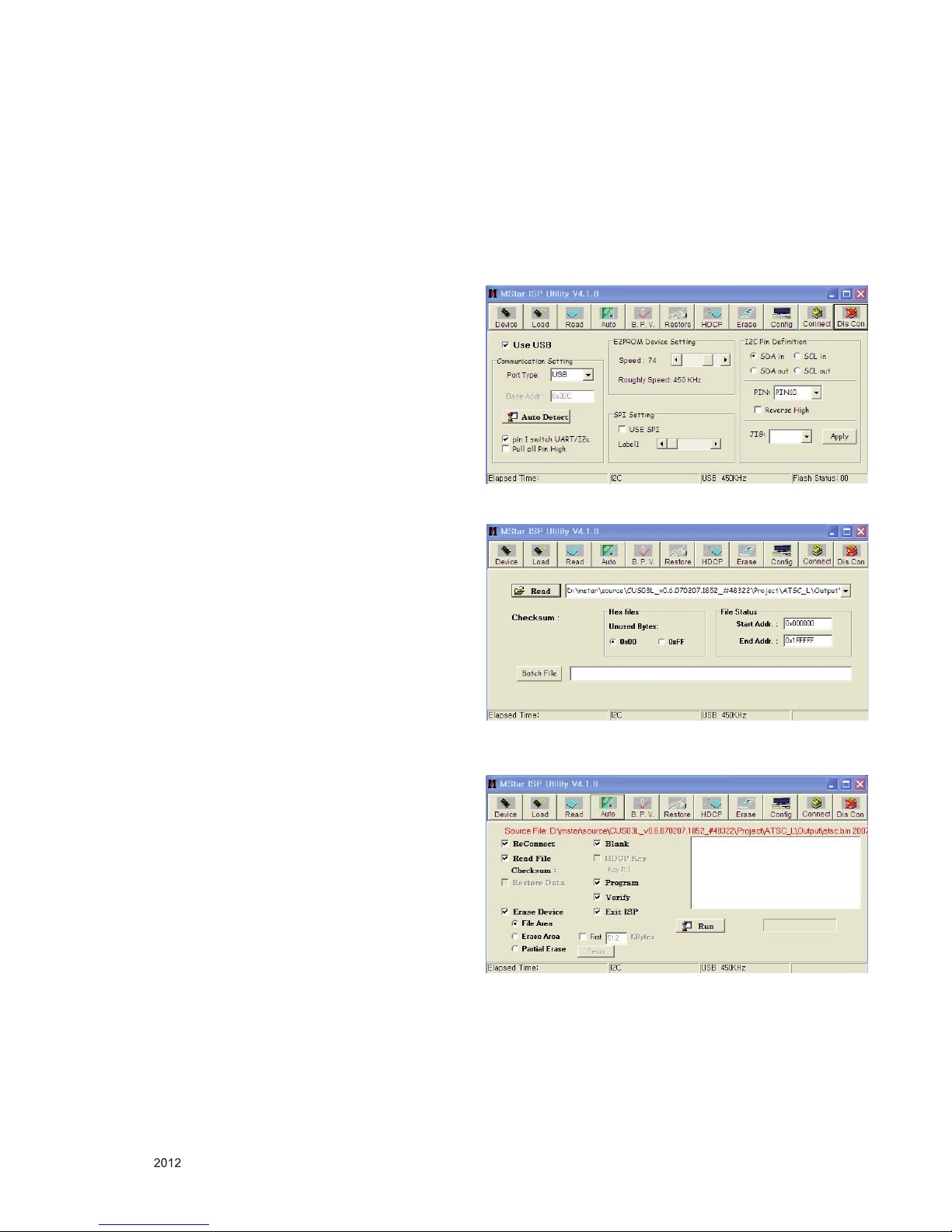

(1) Execu te ISP progr am “Mstar ISP Utility” and then click

“Config” tab.

(2) Set as below, and then click “Auto Detect” and check “OK”

message. If display “Error”, Check connect computer, jig, and

set.

(3) Click “Connect” tab. If display “Can’t ”, Check connect

computer, jig, and set.

(4) Click “Read” tab, and then load download file(XXXX.bin) by

clicking “Read”

(5) Click “Auto” tab and set as below

(6) Click “Run”.

(7) After downloading, check “OK” message.

- 7 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

4.1. ADC Calibration

4.1.1. Overview

▪ ADC adjustment is needed to find the optimum black level

and gain in Analog-to-Digital device and to compensate RGB

deviation

4.1.2. Equipment & Condition

(1) Protocol: RS-232C

(2) Inner Pattern

- Resolution : 1080p(Comp)

- Pattern : Horizontal 100% Color Bar Pattern

- Pattern level : 0.7±0.1 Vp-p

4.1.3. Adjustment

4.1.3.1. Adjustment method

- Connect to Jig by using RS-232, adjust Component

4.1.3.2. Adj. protocol

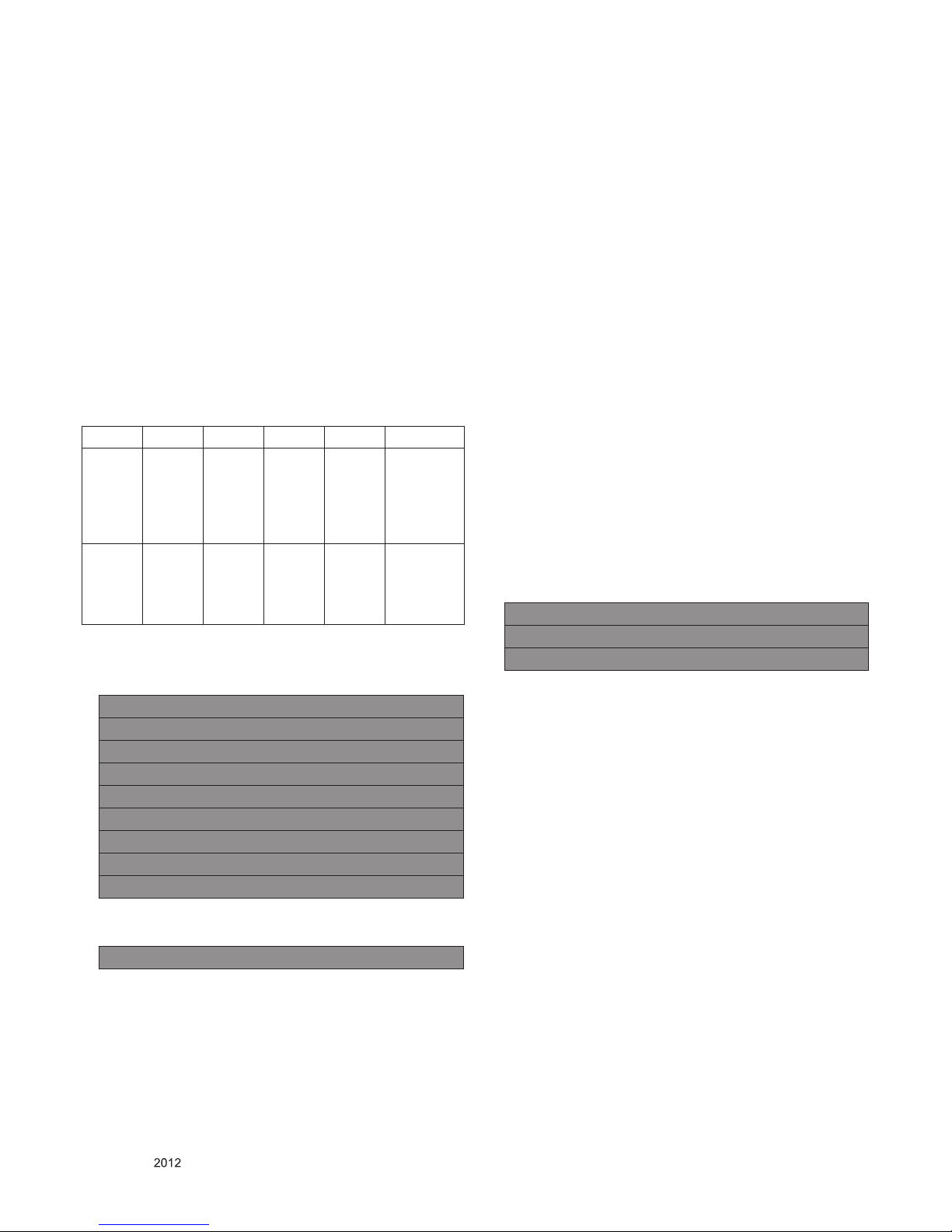

Protocol CMD 1 CMD 2 Data 1 Data 2 Remark

Enter

adj

mode

a a 00 00 When

transfer

the ‘Mode

In’,Carry

the command.

Start

ADC adj

a d 00 10 Automati-

cally adjustment (Use

internal

pattern)

4.1.3.3. Manual ADC process using Service Remocon

After enter Service Mode by pushing “ADJ” key, execute “ADC

Adjust” by pushing “►” key at “ 0. ADC CALIBRATION ”.

0. TOOL OPTION1

1. TOOL OPTION2

2. TOOL OPTION3

3. Country Group

4. ADC CALIBRATION

5. W/B ADJUST

6. EDID D/L (PCM)

7. SUB B/C ADJUST

※ Manual ADC Confirmation using Service Remocon. After

enter Service Mode by pushing “INSTART” key,

ADJUST ADC (COMPONENT) : OK

4.2. EDID Download

4.2.1. Overview

▪ It is a VESA regulation. A PC or a MNT will display an

optimal resolution through information sharing without any

necessity of user input. It is a realization of “Plug and Play”.

4.2.2. Equipment

(1) Since EDID data is embedded, EDID download JIG, HDMI

cable and D-sub cable are not need.

(2) Adjust by using remote controller.

4.2.3. Download method (using DFT)

PC(for communication through RS-232C), UART baud rate:

115200 bps

Command : aa 00 00 (Start Factory mode)

Command : ae 00 10 (Download All EDID)

Command : aa 00 90 (End of Factory mode)

4.2.4. Download method (using Service Remocon)

(1) Press Adj. key on the Adj. R/C,

(2) Select EDID D/L menu.

(3) By pressing Enter key, EDID download will begin

(4) If Download is successful, OK is display, but If Download is

failure, NG is displayed.

(5) If Download is failure, Re-try downloads.

※Caution: When EDID Download, must remove RGB/HDMI

Cable.

(6) EDID Write confirmation

EDID D/L (PCM)

HDMI1 : OK

HDMI2 : OK

- 8 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

4.3. EDID DATA

4.3.1. North America (PCM)

4.3.1.1. HD Model

4.3.1.1.1. 8BIT

■ HDMI 1-HD (C/S : 71CF)

EDID Block 0, Bytes 0-127 [00H-7FH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

---------------------------------------------------------------------------------

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 01 16 01 03 80 A0 5A 78 0A EE 91 A3 54 4C 99 26

20 | 0F 50 54 A1 08 00 31 40 45 40 61 40 71 40 01 01

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 40 84 63 00 00 1E 64 19 00 40 41 00 26 30

50 | 18 88 36 00 40 84 63 00 00 1E 00 00 00 FD 00 3A

60 | 3E 1E 53 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 71

EDID Block 1, Bytes 128-255 [80H-FFH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

---------------------------------------------------------------------------------

0 | 02 03 19 F1 48 10 22 20 05 84 03 02 01 23 09 57

10 | 07 67 03 0C 00 10 00 80 1E 02 3A 80 18 71 38 2D

20 | 40 58 2C 04 05 40 84 63 00 00 1E 01 1D 80 18 71

30 | 1C 16 20 58 2C 25 00 40 84 63 00 00 9E 01 1D 00

40 | 72 51 D0 1E 20 6E 28 55 00 40 84 63 00 00 1E 8C

50 | 0A D0 8A 20 E0 2D 10 10 3E 96 00 40 84 63 00 00

60 | 18 26 36 80 A0 70 38 1F 40 30 20 25 00 40 84 63

70 | 00 00 1A 00 00 00 00 00 00 00 00 00 00 00 00 CF

■ HDMI 2-HD (C/S : 71BF)

EDID Block 0, Bytes 0-127 [00H-7FH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

---------------------------------------------------------------------------------

0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 01 16 01 03 80 A0 5A 78 0A EE 91 A3 54 4C 99 26

20 | 0F 50 54 A1 08 00 31 40 45 40 61 40 71 40 01 01

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 40 84 63 00 00 1E 64 19 00 40 41 00 26 30

50 | 18 88 36 00 40 84 63 00 00 1E 00 00 00 FD 00 3A

60 | 3E 1E 53 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 71

EDID Block 1, Bytes 128-255 [80H-FFH]]

0 1 2 3 4 5 6 7 8 9 A B C D E F

---------------------------------------------------------------------------------

0 | 02 03 19 F1 48 10 22 20 05 84 03 02 01 23 09 57

10 | 07 67 03 0C 00 20 00 80 1E 02 3A 80 18 71 38 2D

20 | 40 58 2C 04 05 40 84 63 00 00 1E 01 1D 80 18 71

30 | 1C 16 20 58 2C 25 00 40 84 63 00 00 9E 01 1D 00

40 | 72 51 D0 1E 20 6E 28 55 00 40 84 63 00 00 1E 8C

50 | 0A D0 8A 20 E0 2D 10 10 3E 96 00 40 84 63 00 00

60 | 18 26 36 80 A0 70 38 1F 40 30 20 25 00 40 84 63

70 | 00 00 1A 00 00 00 00 00 00 00 00 00 00 00 00 BF

4.3.2. AC3 EDID Data

4.3.2.1. HD Model

4.3.2.1.1. 8BIT

■ HDMI 1-HD (C/S : 715D)

EDID Block 0, Bytes 0-127 [00H-7FH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

------------------------------------------------------------------------------0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 01 16 01 03 80 A0 5A 78 0A EE 91 A3 54 4C 99 26

20 | 0F 50 54 A1 08 00 31 40 45 40 61 40 71 40 01 01

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 40 84 63 00 00 1E 64 19 00 40 41 00 26 30

50 | 18 88 36 00 40 84 63 00 00 1E 00 00 00 FD 00 3A

60 | 3E 1E 53 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 71

EDID Block 1, Bytes 128-255 [80H-FFH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

--------------------------------------------------------------------------------

0 | 02 03 1C F1 48 10 22 20 05 84 03 02 01 26 15 07

10 | 50 09 57 07 67 03 0C 00 10 00 80 1E 02 3A 80 18

20 | 71 38 2D 40 58 2C 04 05 40 84 63 00 00 1E 01 1D

30 | 80 18 71 1C 16 20 58 2C 25 00 40 84 63 00 00 9E

40 | 01 1D 00 72 51 D0 1E 20 6E 28 55 00 40 84 63 00

50 | 00 1E 8C 0A D0 8A 20 E0 2D 10 10 3E 96 00 40 84

60 | 63 00 00 18 26 36 80 A0 70 38 1F 40 30 20 25 00

70 | 40 84 63 00 00 1A 00 00 00 00 00 00 00 00 00 5D

■ HDMI 2-HD (C/S : 714D)

EDID Block 0, Bytes 0-127 [00H-7FH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

------------------------------------------------------------------------------0 | 00 FF FF FF FF FF FF 00 1E 6D 01 00 01 01 01 01

10 | 01 16 01 03 80 A0 5A 78 0A EE 91 A3 54 4C 99 26

20 | 0F 50 54 A1 08 00 31 40 45 40 61 40 71 40 01 01

30 | 01 01 01 01 01 01 66 21 50 B0 51 00 1B 30 40 70

40 | 36 00 40 84 63 00 00 1E 64 19 00 40 41 00 26 30

50 | 18 88 36 00 40 84 63 00 00 1E 00 00 00 FD 00 3A

60 | 3E 1E 53 10 00 0A 20 20 20 20 20 20 00 00 00 FC

70 | 00 4C 47 20 54 56 0A 20 20 20 20 20 20 20 01 71

EDID Block 1, Bytes 128-255 [80H-FFH]

0 1 2 3 4 5 6 7 8 9 A B C D E F

--------------------------------------------------------------------------------

0 | 02 03 1C F1 48 10 22 20 05 84 03 02 01 26 15 07

10 | 50 09 57 07 67 03 0C 00 20 00 80 1E 02 3A 80 18

20 | 71 38 2D 40 58 2C 04 05 40 84 63 00 00 1E 01 1D

30 | 80 18 71 1C 16 20 58 2C 25 00 40 84 63 00 00 9E

40 | 01 1D 00 72 51 D0 1E 20 6E 28 55 00 40 84 63 00

50 | 00 1E 8C 0A D0 8A 20 E0 2D 10 10 3E 96 00 40 84

60 | 63 00 00 18 26 36 80 A0 70 38 1F 40 30 20 25 00

70 | 40 84 63 00 00 1A 00 00 00 00 00 00 00 00 00 4D

4.4. Tool Option Input

- Input Model Tool Option according to BOM

- 9 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

5. Final Assembly Adjustment

5.1. White Balance Adjustment

5.1.1. Overview

5.1.1.1. W/B adj. Objective & How-it-works

(1) Objective: To reduce each Panel’s W/B deviation

(2) How-it-works: When R/G/B gain in the OSD is at 192, it

means the panel is at its Full Dynamic Range. In order to

prevent saturation of Full Dynamic range and data, one of

R/G/B is fixed at 192, and the other two is lowered to find

the desired value.

(3) Adj. condition: normal temperature

- Surrounding Temperature: 25±5 °C

- Warm-up time: About 5 Min

- Surrounding Humidity: 20% ~ 80%

- Before White balance adjustment, Keep power on status,

don’t power off

5.1.1.2. Adj. condition and cautionary items

(1) Lighting condition in surrounding area surrounding lighting

should be lower 10 lux. Try to isolate adj. area into dark

surrounding.

(2) Probe location: Color Analyzer (CA-210) probe should be

within 10cm and perpendicular of the module surface

(80°~ 100°)

(3) Aging time

- After Aging Sta rt, Keep the Power ON status during 5

Minutes.

- In case of LCD, Back-light on should be checked using no

signal or Full-white pattern.

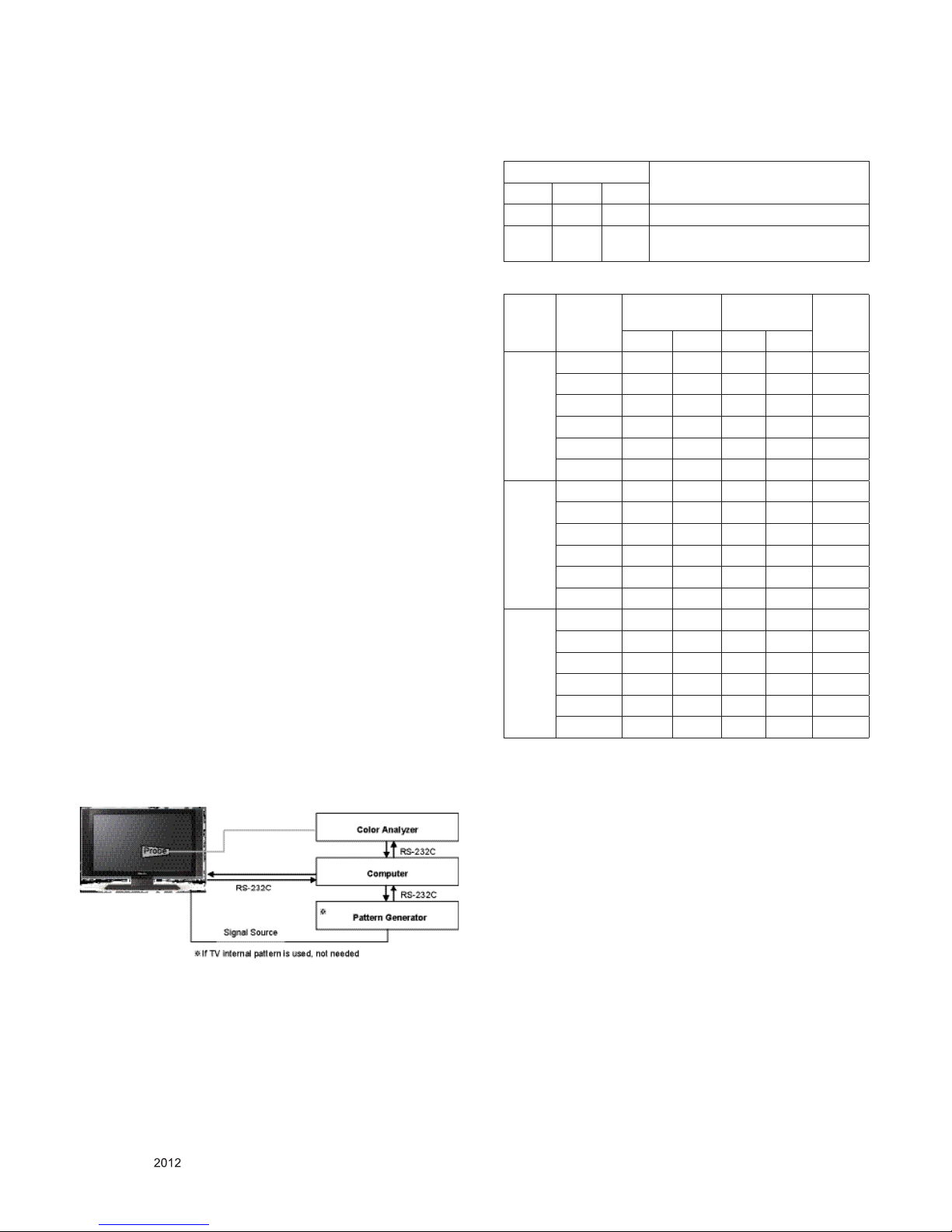

5.1.2. Equipment

(1) Color Analyzer: CA-210 (NCG: CH 9 / WCG: CH12 / LED:

CH14)

(2) Adj. Computer (During auto adj., RS-232C protocol is

needed)

(3) Adjust Remocon

(4) Vi deo Signal Generator MSPG-925F 720p/204- Gray

(Model: 217, Pattern: 49)

※ Color Analyzer Matrix should be calibrated using CS-1000

5.1.3. Equipment connection

5.1.4. Adjustment Command (Protocol)

(1) RS-232C Command used during auto-adj.

RS-232C COMMAND

Explanation

CMD DATA ID

Wb 00 00 Begin White Balance adj.

Wb 00 ff End White Balance adj.

(internal pattern disappears )

(2) Adjustment Map

Adj. item

Command

(lower caseASCII)

Data Range

(Hex.)

Default

(Decimal)

CMD1 CMD2 MIN MAX

Cool R Gain j g 00 C0 172

G Gain j h 00 C0 172

B Gain j i 00 C0 192

R Cut 64

G Cut 64

B Cut 64

Medium R Gain j a 00 C0 192

G Gain j b 00 C0 192

B Gain j c 00 C0 192

R Cut 64

G Cut 64

B Cut 64

Warm R Gain j d 00 C0 192

G Gain j e 00 C0 192

B Gain j f 00 C0 172

R Cut 64

G Cut 64

B Cut 64

- 10 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

5.1.5. Adjustment method

5.1.5.1 Auto WB calibration

(1) Set TV in ADJ mode using P-ONLY key (or POWER ON

key)

(2) Place optical probe on the center of the display

- It need to check probe condition of zero calibration before

adjustment.

(3) Connect RS-232C Cable

(4) Select mode in ADJ Program and begin a adjustment.

(5) When WB adjustment is completed with OK message,

check adjustment status of pre-set mode (Cool, Medium,

Warm)

(6) Remove probe and RS-232C cable.

▪ W/B Adj. must begin as start command “wb 00 00” , and

finish as end command “wb 00 ff”, and Adj. offset if need

5.1.5.2. Manual adj. method

(1) Set TV in Adj. mode using POWER ON

(2) Zero Calibrate the probe of Color Analyzer, then place it on

the center of LCD module within 10cm of the surface..

(3) Press ADJ key -> EZ adjust using adj. R/C -> 6. White-

Balance then press the cursor to the right (KEY►).

(When KEY(►) is pressed 204 Gray(80IRE) internal pattern

will be displayed)

(4) One of R Gain / G Gain / B Gain should be fixed at 192,

and the rest will be lowered to meet the desired value.

(5) Adj. is performed in COOL, MEDIUM, WARM 3 modes of

color temperature

5.1.6 Reference (White Balance Adj. coordinate and

color temperature)

▪ Luminance: 204 Gray

▪ Standard color coordinate and temperature using CS-1000

(over 26 inch)

Mode

Coordinate

Temp △uv

X Y

Cool 0.269 0.273 13,000K 0.0000

Medium 0.285 0.293 9,300K 0.0000

Warm 0.313 0.329 6,500K 0.0000

▪ S ta ndard color coord inate an d t emper at ure us ing

CA-210(CH 14)

Mode

Coordinate

Temp △uv

X Y

Cool 0.269±0.002 0.273±0.002 13,000K 0.0000

Medium 0.285±0.002 0.293±0.002 9,300K 0.0000

Warm 0.313±0.002 0.329±0.002 6,500K 0.0000

5.2. Option selection per country

5.2.1. Overview

(1) Tool option selection is only done for models in Non-USA

North America due to rating

(2) Applied model: LA25C Chassis applied to CANADA and

MEXICO

5.2.2. Country Group selection

(1) Press ADJ key on the Adj. R/C, and then select Country

Group Menu

(2) Depending on destination, select US, then on the lower

Country option, select US, CA, MX.

Selection is done using +, - KEY

(3) Using DFT(Auto)

※ PC (for communication through RS-232C) -> UART Baud

rate : 115200 bps

Command : ah 00 00 DATA(Area Number(hexadecimal)

ITEM DATA(Area Number) AREA

AREA OPTION1 0 USA

1 CANADA

2 MEXICO

3 COMMERCIAL

5.2.3. Tool Option Inspection

▪ Press Adj. key on the Adj. R/C, then select Tool option

Model Tool 1 Tool 2 Tool 3 Tool 4

42CS530-UB LGD 01028 04354 45120

42CS560-UE LGD 01028 08450 45120

42CS560-UE AUO 09216 08450 45120

37CS560-UE LGD 00772 08450 45120

32CS560-UE LGD 00516 08450 45120

32CS560-UE AUO 08704 08450 45120

32CS460-UC

32CS461-UA

LGD 00512 00258 45120

32CS460-UC

32CS461-UA

AUO 08704 00258 45120

26CS460-UA LGD 00257 00258 45120

32LS3400-UA LGD 545 12546 45128

42LS3400-UA LGD 1057 12546 45128

22LS3500-UD CMI 4113 12546 45128

26LS3500-UD LGD 273 12546 45128

AUO 8464 12546 45128

32LS3500-UD AUO 8722 12546 45128

32LS3500-UD LGD

● Tool option can be reconstructed by Software

5.3. Ship-out mode check (In-stop)

- After final inspection, press In-Stop key of the Adj. R/C and

check that the unit goes to Stand-by mode

- 11 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

6. GND and HI-POT Test

6.1. GND & HI-POT auto-check preparation

(1) Check the POWER CABLE and SIGNAL CABE insertion

condition

6.2. GND & HI-POT auto-check

(1) Pallet moves in the station. (POWER CORD / AV CORD is

tightly inserted)

(2) Connect the AV JACK Tester.

(3) Controller (GWS103-4) on.

(4) GND Test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, execute next process (Hi-pot test).

(Remove A/V CORD from A/V JACK BOX)

(5) HI-POT test (Auto)

- If Test is failed, Buzzer operates.

- If Test is passed, GOOD Lamp on and move to next process

automatically.

6.3. Checkpoint

(1) Test voltage

- GND: 1.5KV/min at 100mA

- SIGNAL: 3KV/min at 100mA

(2) TEST time: 1 second

(3) TEST POINT

- GND Test = POWER CORD GND and SIGNAL CABLE GND.

- Hi-pot Test = POWER CORD GND and LIVE & NEUTRAL.

(4) LEAKAGE CURRENT: At 0.5mArms

7. AUDIO output check

7.1. Audio input condition

(1) RF input: Mono, 1KHz sine wave signal, 100% Modulation

(2) CVBS, Component: 1KHz sine wave signal (0.4Vrms)

(3) RGB PC: 1KHz sine wave signal (0.7Vrms)

7.2. Specification

No Item Min Typ Max Unit Remark

1 Audio

practical

max Output,

L/R

9.0

8.5

10.0

8.9

12.0

9.9WVrms

(1) Measurement

condition

- EQ/AVL/Clear

Voice: Off

(2) Speaker (8Ω

Impedance)

8. EYE-Q TEST

Step 1) Turn on the TV..

Step 2) Press ' EY E button' o n t he adjustm en t remote -

controller.

Step 3) Cover 'Eye Q sensor' on the front of set with your

hands, hold it for 6 seconds.

Step 4) Check "the Sensor Data" on the screen, make certain

that Data is below 10. If Data isn’t below 10 in 6

seconds, Eye Q sensor would be bad. You should

change Eye Q sensor.

Step 5) Uncover your hands from Eye Q sensor, hold it for 6

seconds.

Step 6) Check "Back Light(xxx)" on the screen, check data

increase . You should change Eye Q sensor.

<Step 2>

<Step 5>

<Step 6>

<Step 3>

<Step 4>

- 12 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

9. USB S/W Download

(optional, Service only)

(1) Put the USB Stick to the USB socket

(2) Automatically detecting update file in USB Stick

- If your downloaded program version in USB Stick is lower

than that of TV set, it didn’t work. Otherwise USB data is

automatically detected.

(3) Show the message “Copying files from memory”

(4) Updating is staring.

(5) Updating Completed, The TV will restart automatically

(6) If your TV is turned on, check your updated version and

Tool option.

* If downloading version is more high than your TV have, TV

can lost all channel data. In this case, you have to channel

recover. If all channel data is cleared, you didn’t have a DTV/

ATV test on production line.

* After downloading, TOOL OPTION setting is needed again.

(1) Push "IN-START" key in service remote controller.

(2) Select "Tool Option 1" and Push “OK” button.

(3) Punch in the number. (Each model has their number.)

- 13 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All rights reserved.

Only for training and service purposes

TROUBLESHOOTING

1. Power-up boot check

Check stand-by Voltage.

P403 9~12pin : +3.5V_ST

Check Power connector

Check X201 clock

24 MHz

Replace X201

Check P403 PWR_ON.

1pin : 3.3V

Replace Mstar(IC101) or Main board

Check Multi Voltage

P403 2pin:24V ,17pin:12V

Replace Power Board

Check Inverter Control & Error Out

P403 18 pin : High

P403 24 pin : low

Check Power Board or Module

Check IC402/3/7 Output Voltage

IC402 : 2.5V

IC403 : 1.1V

IC407 : 1.5V

Q403 : 3.3V

Replace IC402/3/7, Q403

Re-download software.

Check Micom Voltage

L404 : +3.5V

Replace L404

Check LVDS Power Voltage

Q409 : 12V

Replace Q409

Check Mstar LVDS Output

Replace Mstar(IC101) or Main Board

Change Module

ok

ok

ok

ok

ok

ok

ok

ok

ok

No

No

ok

Replace Power board.

ok

Main B/D 3.5V Line

Short Check

No

No

No

No

No

No

No

No

Loading...

Loading...