LG 26LH1DC3-UA, 26LH1DC4-UB, 26LH1DC5-UC Schematic

Internal Use Only

website:http://biz.LGservice.com

e-mail:http://www.LGEservice.com/techsup.html

LCD TV

SERVICE MANUAL

MODELS : 26LH1DC3-UA / 26LH1DC4-UB

26LH1DC5-UC

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CONTENTS

CONTENTS............................................................................................... 2

SAFETY PRECAUTIONS ..........................................................................3

SPECIFICATION ........................................................................................6

ADJUSTMENT INSTRUCTION................................................................11

SVC REMOCON ......................................................................................21

TROUBLE SHOOTING GUIDES .............................................................22

TROUBLE SHOOTING ............................................................................24

BLOCK DIAGRAM...................................................................................27

VIDEO AND AUDIO SIGNAL FLOW CHART .........................................34

WIRING DIAGRAM ..................................................................................46

EXPLODED VIEW....................................................................................47

EXPLODED VIEW PARTS LIST..............................................................48

REPLACEMENT PARTS LIST ................................................................49

SVC. SHEET ................................................................................................

Copyright©2007 LG Electronics. Inc. All right reserved. -2- LGE Internal Use Only

Only for training and service purposes

SAFETY PRECAUTIONS

1.5 Kohm/10W

To Instrument's

exposed

METALLIC PARTS

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

AC Volt-meter

IMPORTANT SAFETY NOTICE

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

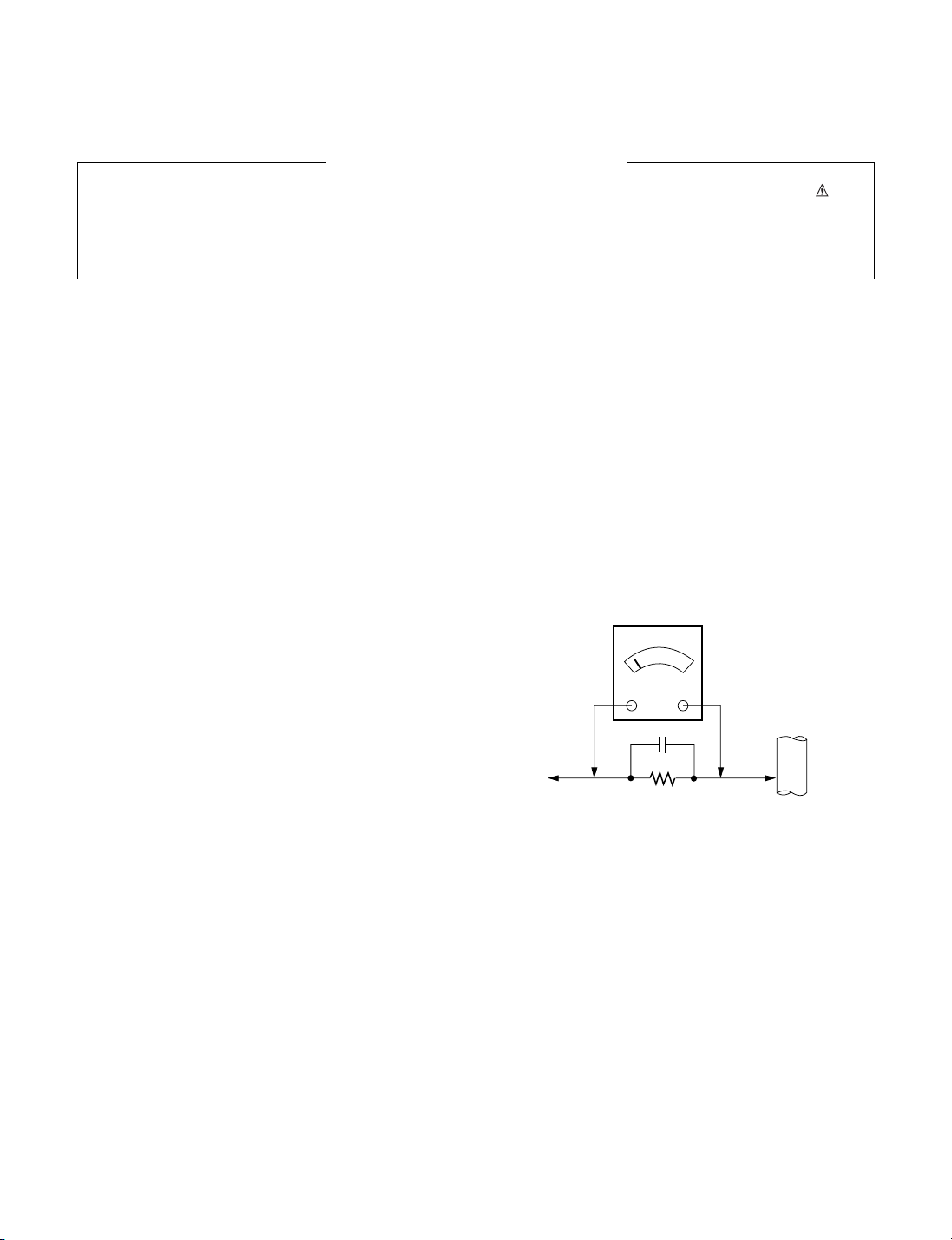

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

0.15uF

Copyright©2007 LG Electronics. Inc. All right reserved. -3- LGE Internal Use Only

Only for training and service purposes

SERVICING PRECAUTIONS

CAUTION : Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE : If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or reconnecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION : A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) isopropyl alcohol (90%-99% strength)

CAUTION : This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION : Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION : Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500。F to 600。F.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500。F to 600。F)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION : Work quickly to avoid overheating the

circuitboard printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500。F to 600。F)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION : Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

Copyright©2007 LG Electronics. Inc. All right reserved. -4- LGE Internal Use Only

Only for training and service purposes

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete Transistor

Removal/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION : Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of the

two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION : Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Copyright©2007 LG Electronics. Inc. All right reserved. -5- LGE Internal Use Only

Only for training and service purposes

SPECIFICATION

NOTE : Specifications and others are subject to change without notice for improvement.

1. Application range

1.1 This spec sheet is applied all of the 26" LCD TV with PPV&RJP.

1.2 Not included spec and each product spec in this spec sheet apply correspondingly to thefollowing each country standard and

requirement of Buyer.

2. Specification

Each part is tested as below without special appointment.

2.1 Temperature : 20

2.2 Relative Humidity : 65

2.3 Power Voltage : input voltage(100~240V@50/60Hz)

* Standard Voltage of each product is marked by models.

2.4 Specification and performance of each parts are followed each drawing and specification by part number in accordance with BOM.

2.5 The receiver must be operated for about 20 minutes prior to the adjustment.

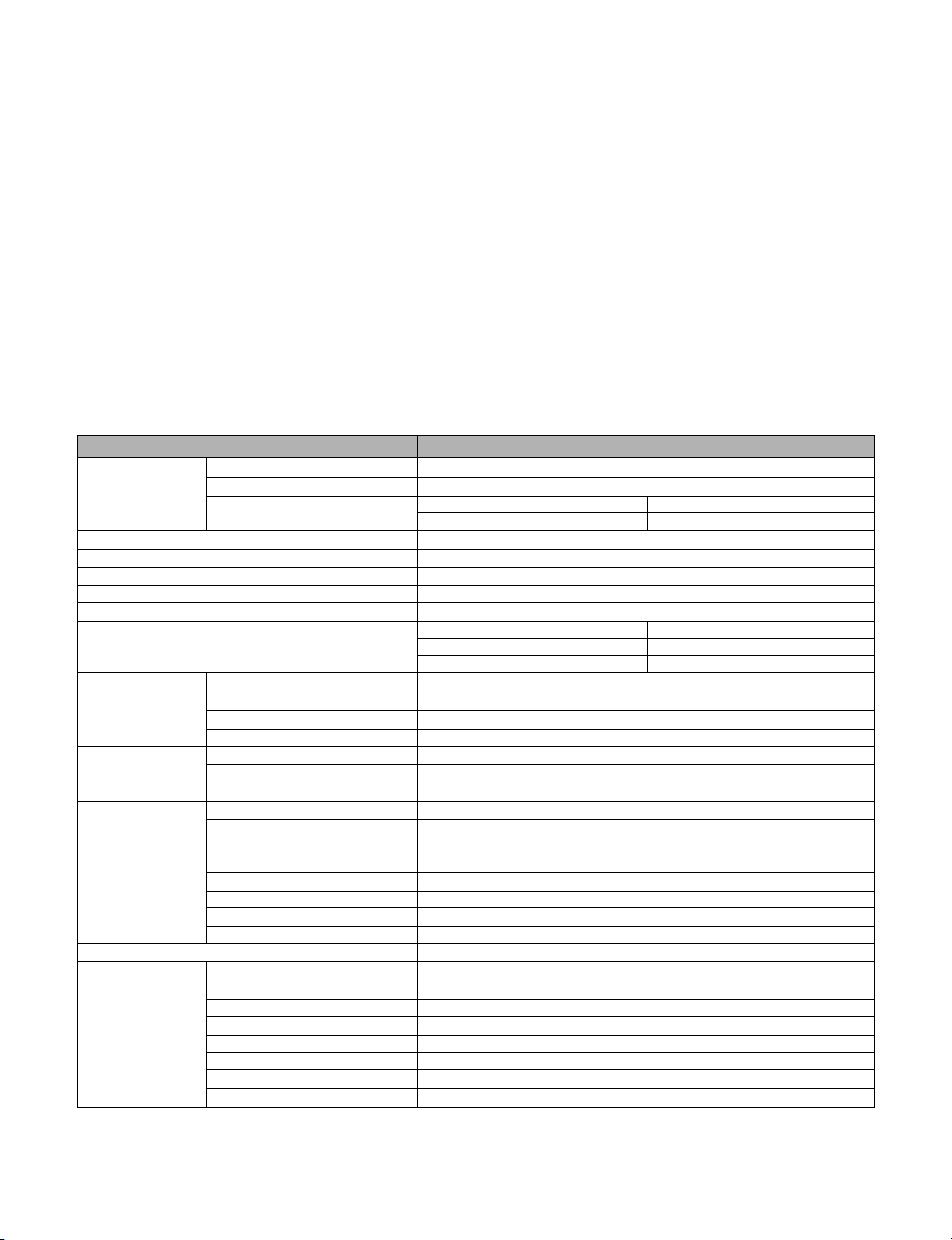

3. General Specification(TV)

Item Specification

Input Signal Receiving System Digital : ATSC/64&256QAM, Analog : NTSC

Input Voltage AC 100~240V(50/60Hz)

Market North America

Screen Size 26 inch Wide

Aspect Ratio 16:9

Tuning System FS

LCD Module LC260WX2-SLB2 LPL

Video Stream Compression MPEG2 MP@HL

Audio Demodulation Dolby Digital(AC3)

Antenna Impedance 75Ω Unbalanced, F-Type Jack, VHF/UHF Tuner

External Input AV Input CVBS : 3, L/R Audio : 3, Auto-Cam port(AV2)

Digital Audio Output SPDIF(Optical)

Function OSD Language English, Spanish, French

±5°C

±10%

Sound Effect Dolby Digital(AC-3)

Available Channel Air CH2~CH69

Cable CH1~CH135

LC260WX2-SLB1 LPL

LC260WX2-SLA1 LPL

Receiving Signal 8VSB, Clear QAM(64, 256), NTSC

Display Interface LVDS 1366X768

Digital Comb-filter Support : 3D Y/C-NTSC Signal

Speaker Power RMS 7.5W+7.5W(8Ω load)

S-Video Input Y/C : 1

Component Input YPbPr(480i~1080i) : 2, L/R Audio : 2

PC Input D-sub15(Max 1366X768 pixel, 60Hz), Phone Jack(Audio)

HDMI Input 480i, 480p, 720p, 1080i

Service Port DSUB 9P Jack(RS-232)

RJP CONTROL Input RJ45 Jack

MPI Input RJ11 Jack

Program Guide MINI-EPG

Digital Noise Reduction Support

Caption EIA608, EIA708

Channel Add/Delete Support

Channel Preview Support

Signal strength Display Support

PPV&PRO : IDIOM Support

Copyright©2007 LG Electronics. Inc. All right reserved. -6- LGE Internal Use Only

Only for training and service purposes

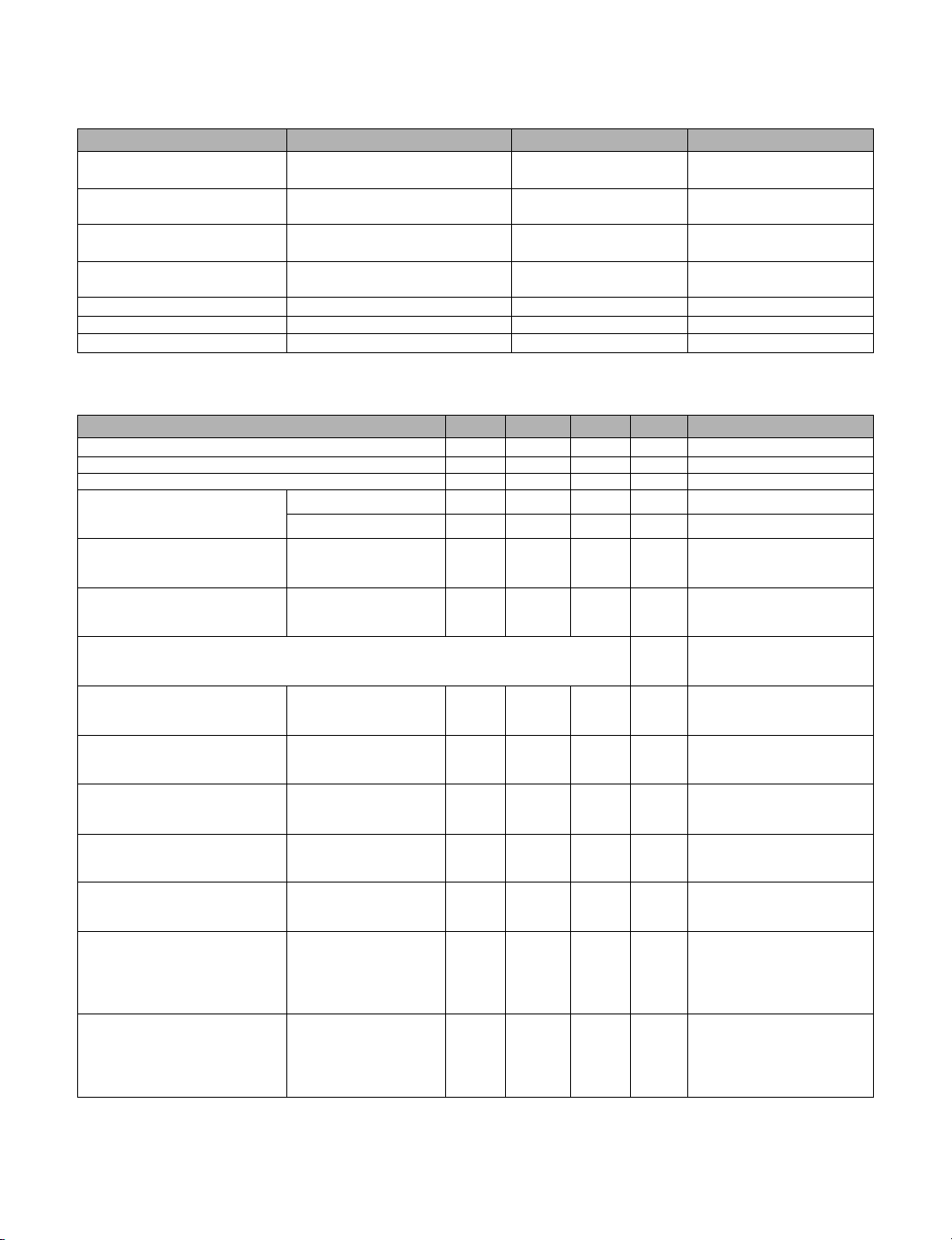

4. DTV Characteristics

4.1 General Specification

Item Specification Unit Remark

VSB Reception Channel 2 ~ 69CH(DTV)

QAM Reception Channel 1 ~ 135CH(CADTV)

Video Resolution ATSC 18 FORMAT

QAM Resolution Sanoff OpenCable FORMAT

VSB / QAM RF Input 75Ω unbalanced input

F-type CONNECTOR input

CH UP/DOWN : Under 3.0 Sec.

Time for stable Sync

RF Dynamic Range 0~-80 dBm

VSB AFC Range Fo +/-250 KHz

QAM AFC Range Fo +/-170 KHz

4.2 Digital Receive Part : 8T VSB Standard

Item Min Typ Max Unit Remark

Dynamic Range -82 -5 dBm 2CH, 3CH, UHF : -80dBm

White Noise(SNR) 15.5 dB

Channel Pull-in Range -250 250 KHz

N/D Co-channel

Ps=7Db , Color Bar

400Hz, 25kHz Dev

N/D Upper Adj-Ch

PS=75Db, Color Bar DTV(-60dBm) 35 42 dB

400Hz, 25kHz Dev

N/D Lower Adj-Ch

PS=75Db , Color Bar DTV(-60dBm) 35 42 dB

400Hz, 25kHz Dev

Ensemble Ghost

(ATTC recommend)

Static Ghost 0° 2

(0.1usec) 90° 2 dB

Static Ghost 0° 2

(0.2usec) 90° 2 dB

Static Ghost 0° 2

(0.3usec) 90° 2 dB

Static Ghost 0° 2

(1.0usec) 90° 2 dB

Static Ghost 0° 2

(5.0usec) 90° 2 dB

Doppler Ghost 0.2Hz 4

(0.1 usec) 0.5Hz 4

Doppler Ghost 0.2Hz 4

(0.2 usec) 0.5Hz 4

DTV(-30dBm) 5 dB

DTV(-60dBm) 5 dB

<TEST EQUIPMENT>

A~G OK ROHDE & SCHWARZ

TV TEST TRANSMETER

180° 2

180° 2

180° 2

180° 2

180° 2

1.0Hz 4 dB

2.0Hz 4

5.0Hz 4

1.0Hz 4 dB

2.0Hz 4

5.0Hz 4

Copyright©2007 LG Electronics. Inc. All right reserved. -7- LGE Internal Use Only

Only for training and service purposes

Item Min Typ Max Unit Remark

Doppler Ghost 0.2Hz 4

(0.3 usec) 0.5Hz 4

(1.0 usec) 1.0Hz 4 dB

(5.0 usec) 2.0Hz 4

4.3 Digital Receive Part : 64/256 QAM

5.0Hz 4

Item Min Typ Max Unit Remark

Dynamic Range 64 QAM -69.0 -32.0 dBm

White Noise(SNR) 64 QAM 27 dB Input RF Level : -50.0 dBm

Channel Pull-in Range (64/256 QAM) -170 170 KHz

N/D Upper Adj-Ch

PS=75Db, Color Bar

400Hz, 25kHz Dev

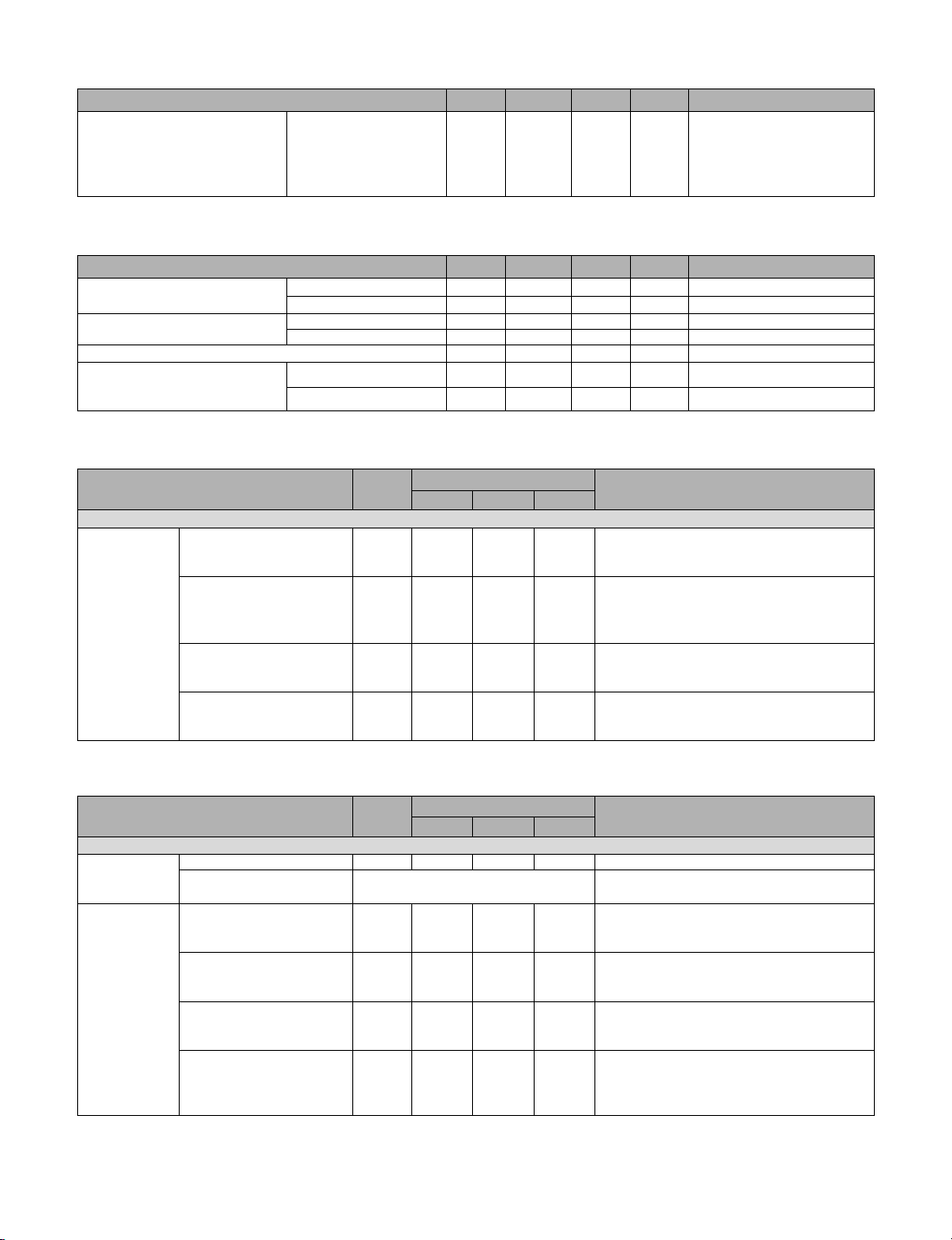

4.4 Video Inputs

256 QAM -63.0 -32.0 dBm

256 QAM 34 dB

64 QAM 21 dB DTV(-40dBm)

256 QAM 16 dB DTV(-40dBm)

Content Unit Spec Remark

Min Typ Max

VIDEO

Input CVBS 1V 480i

-Active Video mV 644 714 786

-Sync 258 286 314

S-Video 1V

-Active Video mV 644 714 786

-Sync 258 286 314

-Color Burst 258 286 314

Component 1V 480i/480p/720p/1080i

-Y/Pb/Pr mV 630 700 770

-Sync 270 300 330

RGB Input DTV : 480i/480p/720p/1080i

-R/G/B mV 630 700 770 PC : *See 5. Signal Timing

-H/V TTL

4.5 Audio

Content Unit Spec Remark

Min Typ Max

AUDIO (Dolby Digital 2CH Out)

OPTICAL UI(EYE PATTERN) % 20 IEC958 COMPOSITE AC-3

OUTPUT CATEGORY 64(HEX)

ANALOG REF. LEVEL @1kHz, -20dBFs

AUDIO -LEFT mVrms 200

OUT -RIGHT 200

CODE

MAX. LEVEL

-LEFT Vrms 2

-RIGHT 2

SEPERATION

-LEFT dB -60

-RIGHT -60

FREQ. @20Hz~20kHz

RESPONSE -19.5 -21 @ 0.5dB ~ -1.0dB

-LEFT

-RIGHT

dB

Copyright©2007 LG Electronics. Inc. All right reserved. -8- LGE Internal Use Only

Only for training and service purposes

THD+N vs FREQ.

-LEFT dBFs -60

-RIGHT -60

THD vs LEVEL @-20dBFs

-LEFT dBFs -60

-RIGHT -60

*DYNAMIC

RANGE -65

-16BIT(L, R) dB -65

-18BIT(L, R) -65

-20BIT(L, R)

*Dynamic Range Control (DRC) is originally the concept of Dolby Digital and used only in Dolby Digital.

But as a similar concept there is the Automatic Volume Correction in the analog TV, and it is used in the same menu

because there is no possibility of conflict between the two.

Therefore, if you turn on the DRC in the menu, the DRC will be active in the digital TV and AVC will be active in the analog TV.

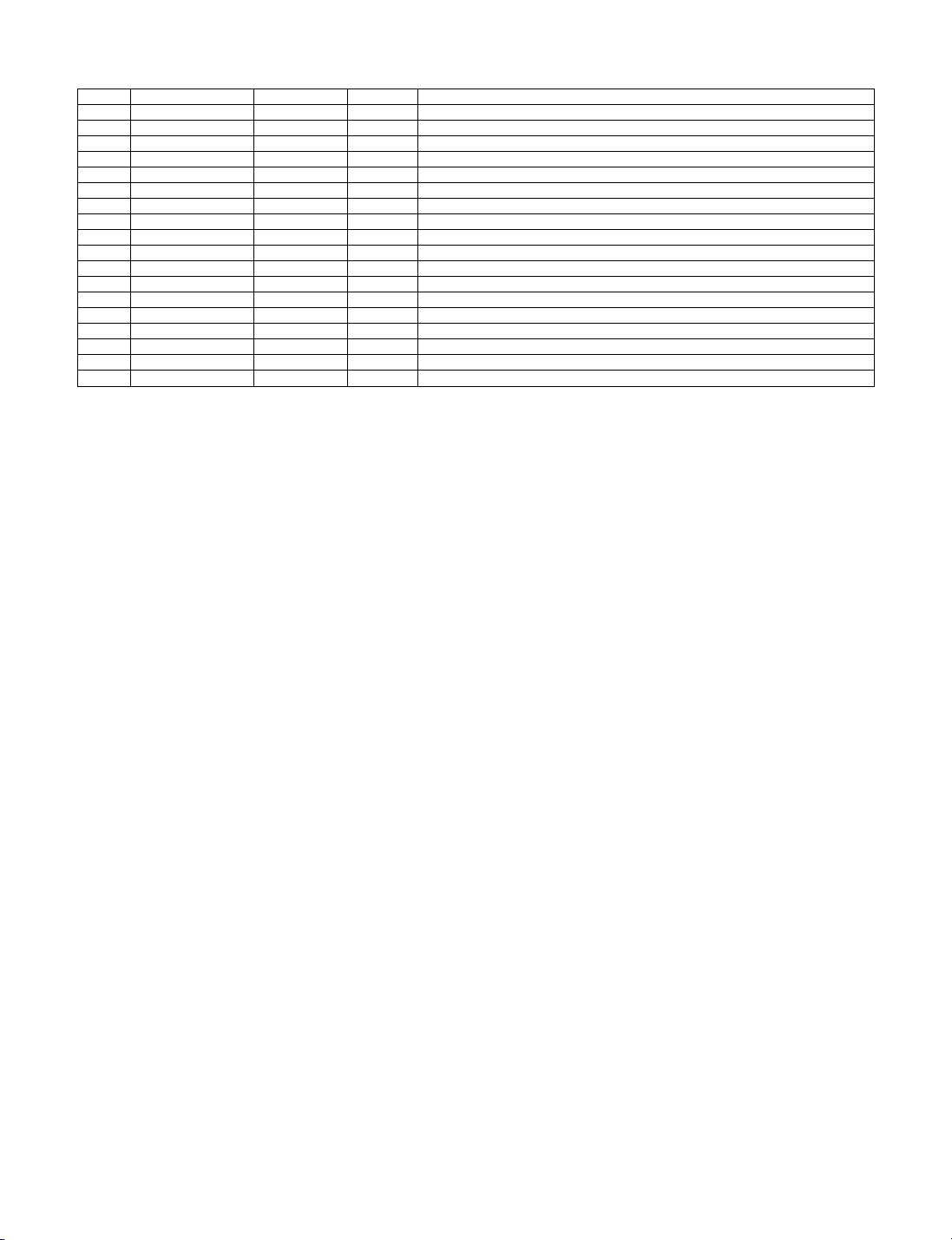

5. Signal Timing (Resolution)

5.1 Component Video Input (Y, CB/PB, CR/PR)

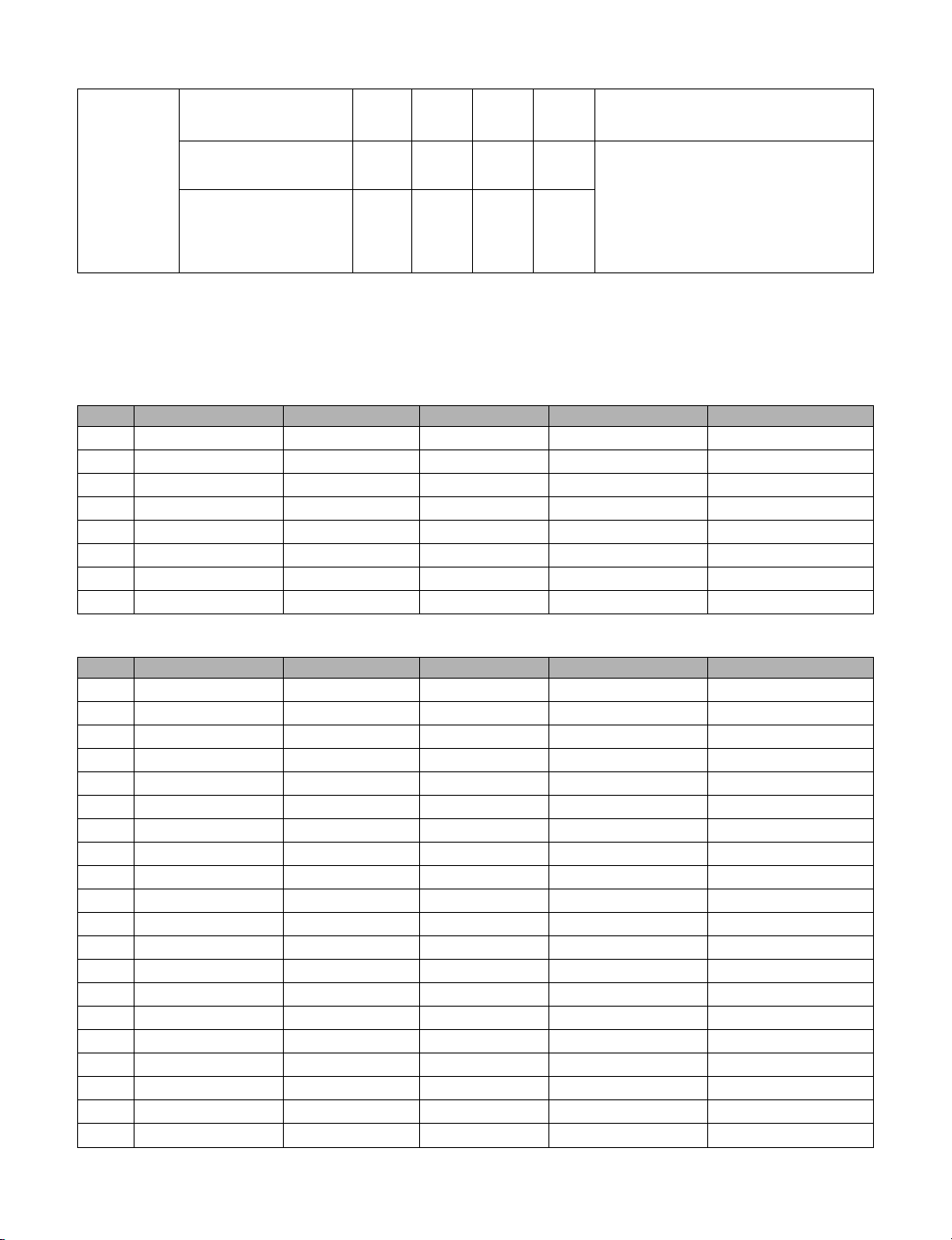

No. Resolution H-freq.(kHz) V-freq.(Hz) Pixel Clock(MHz) Proposed

1720*480 15.75 60 13.51 SDTV, 480i

2720*480 15.734 59.94 13.5 SDTV, 480i

3720*480 31.5 60 27.03 SDTV, 480p

4720*480 31.469 59.94 27 SDTV, 480p

5 1280*720 45 60 74.25 HDTV,720p

6 1280*720 44.96 59.94 74.18 HDTV,720p

7 1920*1080 33.75 60 74.25 HDTV,1080i

8 1920*1080 33.72 59.94 74.18 HDTV,1080i

5.2 PC Mode (RGB)

No. Resolution H-freq.(kHz) V-freq.(Hz) Pixel Clock(MHz) Proposed

1640*350 31.469 70.087 25.17 EGA

2720*400 31.469 70.087 28.32 DOS

3640*480 31.469 59.94 25.175 VGA

4640*480 37.5 75 31.5 VGA

5640*480 43.269 85.008 36 VGA

6800*600 37.879 60.317 40 SVGA

7800*600 46.875 75 49.5 SVGA

8800*600 53.674 85.061 56.25 SVGA

9832*624 49.726 75.552 58.05 MAC

10 1024*768 48.363 60.004 65 XGA

11 1024*768 60.023 75.029 78.75 XGA

12 1024*768 68.677 84.997 94.5 XGA

13 1280*720 44.772 59.855 74.5 VESA

14 1360*768 47.72 59.799 84.75 VESA

15 720*480 31.5 60 31.5 SDTV, 480p

16 720*480 31.469 59.94 59.94 SDTV, 480p

17 1280*720 45 60 74.25 HDTV, 720p

18 1280*720 44.96 59.94 74.18 HDTV, 720p

19 1920*1080 33.75 60 74.25 HDTV, 1080i

20 1920*1080 33.72 59.94 74.18 HDTV, 1080i

Copyright©2007 LG Electronics. Inc. All right reserved. -9- LGE Internal Use Only

Only for training and service purposes

5.3 DVI/HDMI Input : HDMI Ver1.2a

No. Resolution H-freq.(kHz) V-freq.(Hz) Pixel Clock(MHz) Proposed

1 640*480 31.469 59.94 25.17 VGA

2 640*480 37.861 72.8 31.5 VGA

3 640*480 37.5 75 31.5 VGA

4 640*480 43.3 85 36 VGA

5 800*600 35.156 56.25 36 SVGA

6 800*600 37.879 60.31 40 SVGA

7 800*600 48.077 72.18 50 SVGA

8 800*600 46.875 75 49.5 SVGA

9 800*600 53.7 85 56.25 SVGA

10 1024*768 48.363 60 65 XGA

11 1024*768 56.476 70.06 75 XGA

12 1024*768 60.023 75.02 78.75 XGA

13 1024*768 68.7 85 94.5 XGA

14 1280*768 47.78 59.87 79.5

15 1360*768 47.72 59.8 84.75

16 720*400 31.43 70 27.28 DOS

17 720*480 15.75 60 27.03 SDTV, 480i

18 720*480 15.734 59.94 27 SDTV, 480i

19 720*480 31.5 60 31.5 SDTV, 480p

20 720*480 31.469 59.94 59.94 SDTV, 480p

21 1280*720 45 60 74.25 HDTV, 720p

22 1280*720 44.96 59.94 74.18 HDTV, 720p

23 1920*1080 33.75 60 74.25 HDTV, 1080i

24 1920*1080 33.72 59.94 74.18 HDTV, 1080i

Copyright©2007 LG Electronics. Inc. All right reserved. -10- LGE Internal Use Only

Only for training and service purposes

ADJUSTMENT INSTRUCTION

1. Service Menu

To enter the Service Menu, press the MENU button of the TV SET for

5 seconds while keeping the MENU key of the INSTALLER remote

controller pressed.

When using the Service Remote controller, press the “IN-START” or

“ADJ” to enter the Service Menu.

Use the channel UP/DOWN key to move between the items of the

Service Menu.

In the Service Menu, use the left and right key or volume key to adjust the

value in the Sub Item.

In the Service Menu, press ‘ENTER’ to return to the Main Item from the

Sub Item.

Press exit in the main item to end the Service Menu.

Unlike other OSD, the Service Menu does not have any Timeout Exit.

1.1 Service Menu Structure

System Reset – Confirm

Software Version

Chip I2C Test – Memory

Aging Test

White Balance – Offset R

YPbPr : offset/gain – Offset Y

RGB : offset/gain – Offset R

Auto Picture – Auto Brightness

Running Time - Running Time

System All Reset – Confirm

Audio Delay – DTV

AI Control

Last Power Save

Panel Monitoring

Panel ID – Display ID

Reserved

Commercial Flag

Panel Brightness

Epg Mode

SW Upgrade

EXIT

FLASH

EEPROM

TUNER

VIDEO ADC

AUDIO DEC

Uart1 Comm.

Pillow Mode

Uart Mode

Offset G

Offset B

Gain R

Gain G

Gain B

Offset Pb

Offset Pr

Gain Y

Gain Pb

Gain Pr

Reset Mode

Offset G

Offset B

Gain R

Gain G

Gain B

Reset Mode

Auto Contrast

Reset Mode

ATV/CVBS/YC

COMP/PC/HDMI

Reset Mode

Panel Company ID

Model ID

1.2 Service Menu Description

(1) System Reset :

When you press Confirm, the general NVRAM parameters excluding

the parameters of the service scope are initialized and self rebooted.

(This is mainly used after repairing or replacing the board to set to the

initial factory condition.)

(2) Software Version :

This shows you the information of the current Software Version.

The displayed information includes Version, Date, Model name and

Panel information.

(3) Chip I2C Test :

It shows you whether there is any issue in the HW of the major Device

on the Board at its basic level.

(4) Aging Test :

When you press Confirm, the service menu OSD temporarily

disappears and single color Pattern is displayed.

When you press ‘ENTER’ key, it returns to its original condition.

(5) White Balance :

Control the offset/gain of the final end of the Scaler to adjust the white

balance. The adjustment is done by controlling the each offset/gain of

R, G and B.

The Color temperature is adjusted during HDMI 720p Input based on

9800K±500 in 100% White pattern.

(Default : Offset R, G, B=50, 50, 50/Gain R, G, B = 50, 50, 50)

(6) YPbPr : offset/gain : Mst9883C Adjust

Calibrate the Offset/Gain of Mst9883(Video AD).

Because the deviation of Mst9883 is not significant, it does not need

separate calibration.

(Default : Offset Y, Pb, Pr=24, 51, 51/Gain Y, Pb, Pr = 60, 60, 60)

(7) RGB : offset/gain : RTD2023B Adjust

Calibrate the Offset/Gain of the Scaler for PC input process.

After connecting 16-gray or 32-gray pattern to RGB input and selecting

“RGB : offset/gain”, press ‘ENTER’ button on the remote controller.

When the “Reset Mode” is shown, press the right arrow key on the

remote controller to execute auto calibration.

Scaler checks the gray pattern of input and calibrates the offset and

gain automatically to show you the values.

(Default : Offset R, G, B=128, 128, 128/Gain R, G, B = 128, 128, 128)

(8) Auto Picture :

Adjust the range of brightness and contrast that applies to the

standard of Video Preset.

When you adjust this value, it gives the same effect to dynamic and

mild of Video Preset.

The Standard Brightness can be differently adjusted depending on the

characteristics of the Panel.

That is, for the panel characteristics with luminance value that cannot

be adjusted with Panel Brightness, it means that the Standard

Brightness of Auto Picture can be adjusted.

For more detail, refer the pages 12, item (17) Panel Brightness.

(9) Running Time :

The System shows the accumulated operating time the Power is

turned On.

When Reset, it is reset to 0.

Copyright©2007 LG Electronics. Inc. All right reserved. -11- LGE Internal Use Only

Only for training and service purposes

(10) System All Reset :

It reboots itself after initializing not only the general NVRAM

Parameter but also Service Parameter.

(White Balance, YPbPr offset/gain, RGB offset/Gain etc.)

*** Therefore do not run System All Reset unless it is a special case.

If this item must be initialized, write down the adjusted value after

factory delivery of Panel brightness, Auto Picture, White Balance,

YPbPr offset/gain and RGB offset/Gain on paper then execute the

initialization.

Then after the execution, use the remote controller to re-enter the

written value without separate adjustment, and you can realize

the same TV quality.

(11) Audio Delay

Adjust the Audio Delay. The Group can be classified into 3 types.

- DTV Group

- ATV/CVBS/YC Group

- COMP/PC/HDMI Group

(12) AI Control :

This is the function to set ON/OFF to support the AI automatically in

the panel that supports the DCR(Dynamic Contrast Ratio) function.

*** The Default value is OFF and must be maintained at OFF without

separate notification.

(13) Last Power Save :

This is the item to set whether to save the Last Power.

(14) Panel Monitoring :

This is the item to set whether to use Panel Abnormal Detection

Monitoring.

(15) Panel ID :

This is the item to set the Panel ID.

You can set the Display ID, Panel Company ID and Model ID of the

Panel currently connected.

The Display ID is fixed to LCD and the Panel Company ID toggles

among LG, SAMSUNG and AUO.

When the Panel Company ID is decided, you must set the Model IT

accordingly.

(16) Commercial Flag :

This is the item to set whether to communicate with the Network

Board or operate Stand alone.

This must always be set to ON unless it is a special testing

environment.

(17) Panel Brightness :

This is the item to adjust the brightness of the panel.

The default set value is 70 and can be adjusted to between 1 and 100.

When the value is set to 1, it is the lowest value (20%) and when set to

100, it is the highest brightness (100%).

The PWM signal sent out from MICOM is converted to DC voltage to

adjust the brightness of the panel.

As a reference, the DC voltage value sent out from the board

according to the set value is as follows.

Set Point Output DC Voltage(V)

1 0.210

10 0.345

20 0.520

30 0.715

40 0.945

50 1.215

60 1.530

70 1.850

80 2.200

90 2.630

100 3.170

Under the condition of HDMI 1080i Input, Video mode : Standard,

Color temperature : Normal.

Set the generator signal source to Grays11/1080i30/HDMI (H8C).

Change to the HDMI input mode, observe the TV display screen.

Adjust the PANEL BRIGHT item of the TV SERVICE MENU, to make

the measured Bright Value of the CA-210 should be 25(cd/m2) in the

2nd bars from Left side of the GRAYS11 pattern on the TV display

screen.

If you couldn’t get the suitable Bright Value 25(cd/m2), adjust the

AUTO BRIGHT of the AUTO PICTURE item on the Service menu.

(18) Epg Mode :

This is the item to set the condition of Epg.

It Toggles among Mini, Full and None.

(19) SW Upgrade :

This is the item to Upgrade the Software using the RF Stream.

Send the stream with the Upgrade program to the desired channel

using the generator and setup as follows.

- RF Mode (Air or Cable) selection : For the remote controller,

press left/right to select 0(Air) or 1(Cable).

- RF Freq : Select the channel number with the stream.

- FE Mode(VSB/64QAM/256QAM) : Use the left/right button of the

remote controller to select 0(VSB), 1(64QAM) or 2(256QAM).

But you must not set 64QAM/256QAM for Air.

After completing the all the settings, select upgrade start to start the

upgrade.

When all the upgrade is normally completed, the system will

automatically reboot. Even if it fails, you must turn the power off and

then turn it back on to return to its normal condition.

(20) EXIT

Exit the Service Menu.

Copyright©2007 LG Electronics. Inc. All right reserved. -12- LGE Internal Use Only

Only for training and service purposes

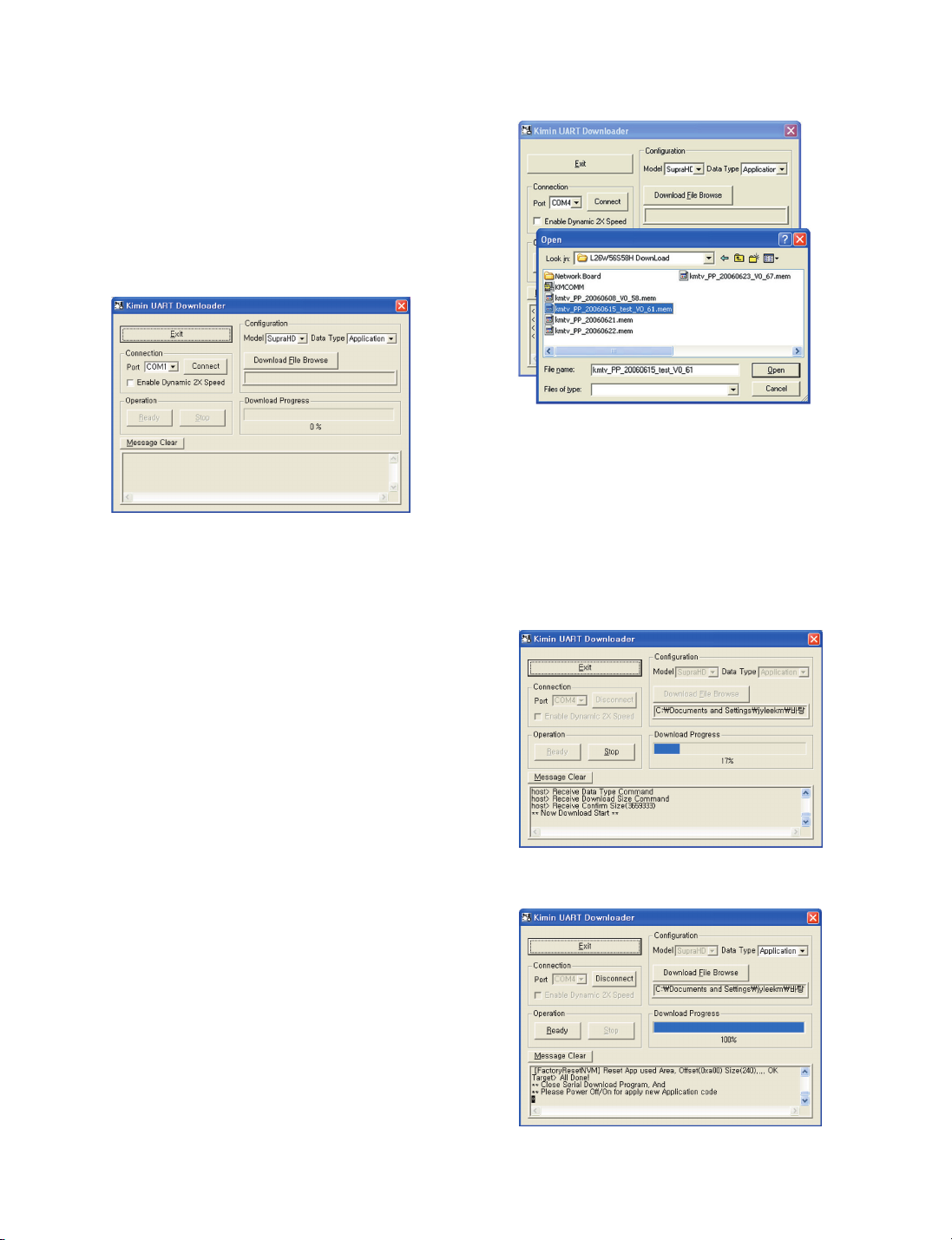

2. Software Upgrade

2.1 Serial Upgrade

(1) DTV B/D Program Download

[Preparations]

•

Required equipment : PC, D-SUB 9pin Female to Female cross type

•

S/W : KMCOMM.exe

[Menu item description]

①

Exit : End the program.

②

Port : Setup the serial port for the Host to use. COM1~COM4

③

Connect : KMCOMM uses the host serial port setup in ②.

④

Model : Main chipset type setup to be used in TV.

(For this model it is SupraHD)

⑤

Data Type : Setup the S/W type of file to Download.

⑥

Speed : Increase the download speed up to twice Dynamically.

⑦

Download File Browse : Select the ‘*.mem’ file to Download.

⑧

Download File Status : This indicates the files setup to currently

download.

⑨

Ready : Standby until the TV can communicate with KMCOMM.

⑩

Stop : Stop the standby for communication with the TV.

⑪

Download Progress : This indicates the progress of download

to the TV.

⑫

As the window to show you the download status in message,

you can see the progress status in detail.

RS-232C cable

7) Click on the Download File Browse button, select “.mem” file,

and click on the Open button.

8) Click on the Connect button of the Connection group, and

check whether the Ready button of the Operation group is

activated.

(At this time, check whether “<Connect COM port success>” is

shown in the Message window.)

9) Click on the Ready button of the Operation group.

10) Press the UPDATE button on the back of the TV and plug the

power cord.

11)

When the Download Progress Bar becomes 100%, check whether

the Message window shows “Close Serial Download Program,

And Please Power Off/On for apply new Application code” and the

Ready button of the Operation group is activated. (Make sure the

power is not disconnected before the Download is complete.)

[Executing order]

1) Unplug the power cord of the TV.

2) Set the RS-232C SELECT switch on the back of the TV in the

direction of NORMAL(DTV).

3) With the RS-232C Cable, connect the RS-232C port of the TV

and the COM port of the PC.

4) Execute the “KMCOMM.exe” program on the PC.

5) After checking the port number connected to the TV from

Control Panel →System →Hardware →Device Manager

→

Ports, set the Port for the Connection group.

6) Check whether the Model of the Configuration group is set to

SupraHD, and the Data type to Application.

12)

If there is no problem, end the “KMCOMM.exe” program and unplug

the power cord, and then plug the power cord to check whether it is

operating normally.

Copyright©2007 LG Electronics. Inc. All right reserved. -13- LGE Internal Use Only

Only for training and service purposes

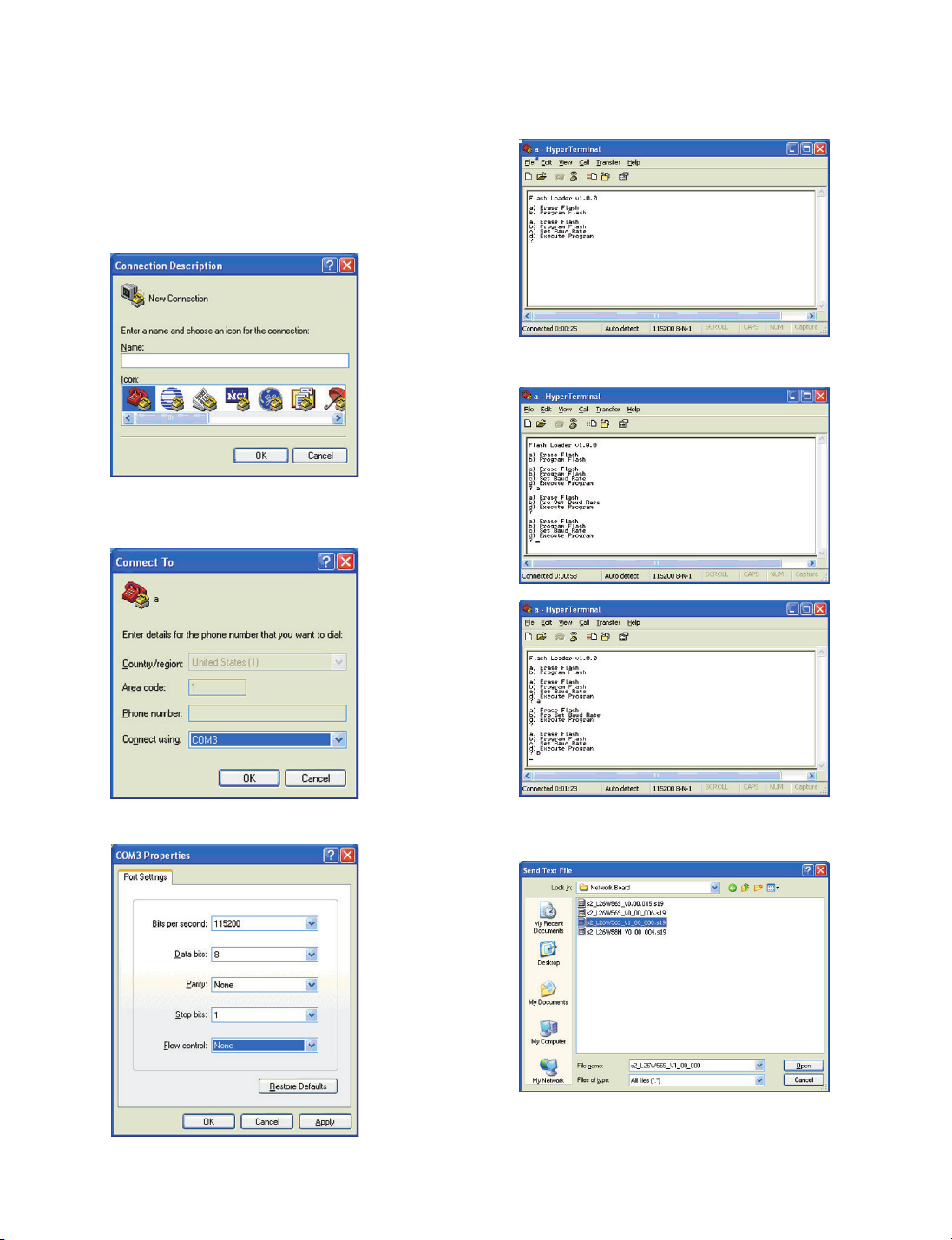

(2) Control B/D Program Download

[Executing order]

1) Check whether the TV is for lodging or Healthcare.

2) Unplug the power cord of the TV.

3) Set the RS-232C select switch on the back of the TV in the

direction of CONTROL.

4) With the RS-232C cable, connect the RS-232C port of the TV

and the COM port of the PC.

5)

Execute “Hyper Terminal” program of PC and assign the Name and Icon.

6) After checking the port number connected to the TV from

Control Panel → System → Hardware → Device Manager

→ Ports, set the Port for the Connect using.

8) Check if the “Hyper Terminal” is connected.

Turn on the TV while pressing the UPDATE SWITCH on the

rear part of TV, and check the following menu screen.

9)

Input “a” to execute the Erase Flash. When it displays the menu screen,

input “b” to execute the Program Flash.

7)

Set 115200 for Bit per second, 8 for Data bits, None for Parity,

1 for Stop bits, None for Flow control, and then click on “OK” button.

10)

Click on the “Transfer” menu on the above and select “Send text file”.

Select the “.s19” file to download and click on “Open” button.

(Check whether the TV is for lodging or Healthcare.)

Copyright©2007 LG Electronics. Inc. All right reserved. -14- LGE Internal Use Only

Only for training and service purposes

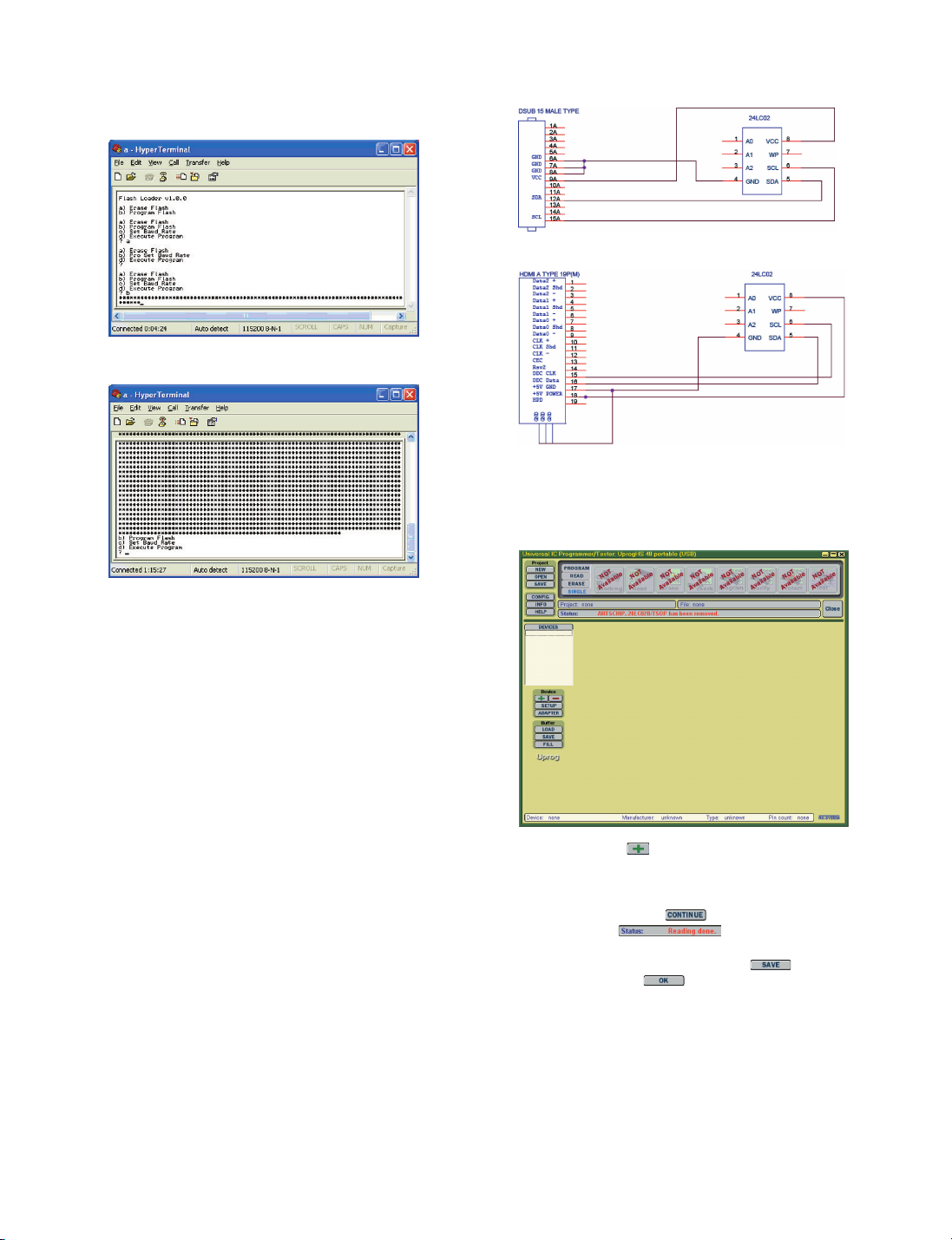

11) Check if the Downloading process is as following and wait

until it completes. (Make sure the power is not disconnected

before the download is complete.)

12) When the downloading process is completed and it shows the

menu screen, turn off TV and then turn it on again.

[Wiring diagram of EEPROM 24LC02 and RGB PC EDID Cable]

[Wiring diagram of EEPROM 24LC02 and HDMI EDID Cable]

[Data read of EEPROM using RGB PC port and HDMI port]

1)

Connect the USB port of the PC and the UprogHS 48 Potable

using the USB Cable, and connect the UprogHS 48 Potable with

the TV using the HDMI and RGB PC EDID Cable.

2)

Execute the UprogHS 48 Potable program.

13) Change the RS-232C SELECT Switch on the rear part of TV

into the NORMAL(DTV) and turn it off.

Turn it on again after 5 seconds.

14) Check the PTC Version from Service Menu of the TV.

(3) RF Upgrade

This is how to upgrade program in the TV set without any

separate equipment.

ATSC Stream generator sends the stream with the upgrade

program, and the “SW Upgrade” is selected from the service

menu of the TV to execute the setting.

- Select RF Mode(Air or Cable) : Press the left/right button on the

remote controller to select 0(Air) or 1(Cable).

- RF Freq : Select the channel number including the upgrade

program Stream.

- FE Mode(VSB/64QAM/256QAM) : Use the left/right button

of the remote controller to select 0(VSB), 1(64QAM) or 2(256QAM).

But you must not set 64QAM/256QAM for Air.

After completing the all the settings, select upgrade start to

start the upgrade.

When all the upgrade is normally completed, the system will

automatically reboot. Even if it fails, you must turn the power

off and then turn it back on to return to its normal condition.

(4) EDID Data Write : RGB PC port, HDMI port EDID down load

(Read/Write)

• Required equipment : PC, EEPROM Programmer(Ex : UprogHS 48

Potable), HDMI EDID Cable, RGB PC EDID

Cable

• S/W : Ex)Uprog.exe

3)

Click on the Device button and select the 24LC02B/TSOP as

the Device.

4)

Click on the Read button of the SINGLE TAB to read the Data of

EEPROM.

5)

Proceed by clicking on the button.

6) After checking the , compare the Data Read

from EEPROM with the Default Data.

7) To save the Data in the BUFFER, click on the button of Buffer

group, and then click on button of the Save File window.

8) Save the file in “.dat” format and end the program.

Copyright©2007 LG Electronics. Inc. All right reserved. -15- LGE Internal Use Only

Only for training and service purposes

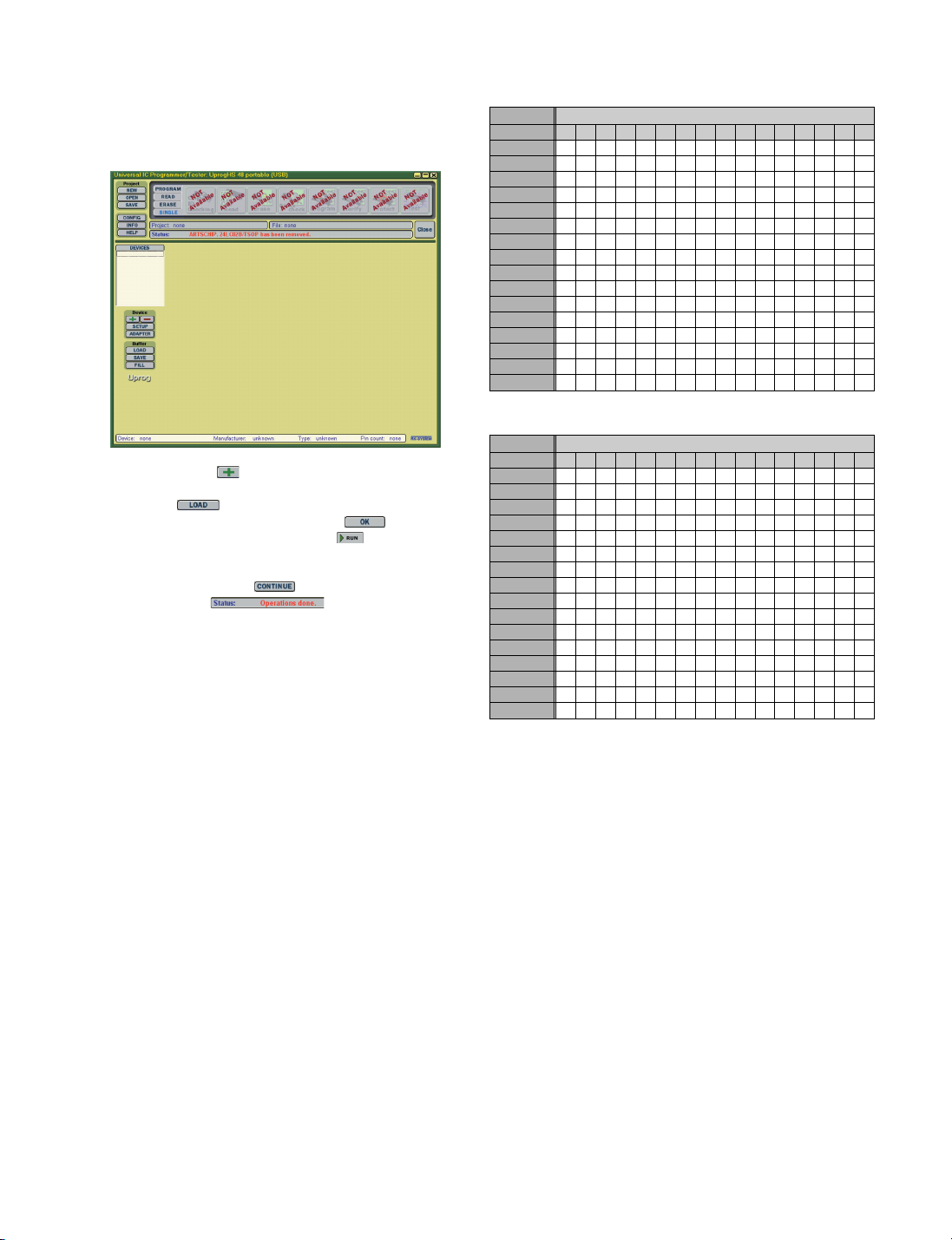

[Data Write of EEPROM using RGB PC port and HDMI port]

1)

Connect the USB port of the PC and the UprogHS 48 Potable

using the USB Cable, and connect the UprogHS 48 Potable with

the TV using the HDMI and RGB PC EDID Cable.

2)

Execute the UprogHS 48 Potable program.

4)

Click on the Device button and select the 24LC02B/TSOP as

the device.

5) Click on the button of Buffer group and open the “.dat” file

to Write on the EEPROM, and then click on .

6) After clicking the PROGRAM Tab, click on button to write on

EEPROM when the Erase, Blank check, Program and Verify

button are activated.

7) Proceed by clicking on the button.

8) After checking the end the program.

[RGB PC EEPROM Default Data]

ADDRESS BUFFER (HEX)

0123456789ABCDEF

00000000 00 FF FF FF FF FF FF 00 4E 64 01 00 01 00 00 00

00000010 00 10 01 03 08 50 2D 78 0E EE 91 A3 54 4C 99 26

00000020 0F 50 54 AF EE 00 31 59 45 59 61 59 01 01 01 01

00000030 01 01 01 01 01 01 1B 21 50 A0 51 00 1E 30 48 88

00000040 35 00 C4 8E 21 00 00 18 0E 1F 00 80 51 00 1E 30

00000050 40 80 37 00 C4 8E 21 00 00 1E 00 00 00 FD 00 38

00000060 5A 20 50 0B 00 0A 20 20 20 20 20 20 00 00 00 FC

00000070 00 48 44 54 56 20 20 20 20 20 20 20 20 0A 00 37

00000080 FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

00000090 FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

000000A0 FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

000000B0 FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

000000C0 FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

000000D0 FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

000000E0 FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

000000F0 FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF FF

[HDMI EEPROM Default Data]

ADDRESS BUFFER (HEX)

0123456789ABCDEF

00000000 00 FF FF FF FF FF FF 00 4E 64 01 00 01 00 00 00

00000010 00 10 01 03 81 50 2D 78 0A EE 91 A3 54 4C 99 26

00000020 0F 50 54 AF EE 00 31 59 45 59 61 59 01 01 01 01

00000030 01 01 01 01 01 01 64 19 00 40 41 00 26 30 18 88

00000040 36 00 C4 8E 21 00 00 18 1B 21 50 A0 51 00 1E 30

00000050 48 88 35 00 C4 8E 21 00 00 18 00 00 00 FD 00 38

00000060 55 20 50 0B 00 0A 20 20 20 20 20 20 00 00 00 FC

00000070 00 48 44 54 56 20 20 20 20 20 20 20 20 0A 01 E5

00000080 02 03 1B F2 44 85 84 03 07 26 09 07 07 15 07 50

00000090 83 01 00 00 66 03 0C 00 10 00 80 01 1D 80 18 71

000000A0 1C 16 20 58 2C 25 00 C4 8E 21 00 00 9E 01 1D 00

000000B0 72 51 D0 1E 20 6E 28 55 00 C4 8E 21 00 00 1E 8C

000000C0 0A D0 8A 20 E0 2D 10 10 3E 96 00 C4 8E 21 00 00

000000D0 18 8C 0A A0 14 51 F0 16 00 26 7C 43 00 C4 8E 21

000000E0 00 00 98 0E 1F 00 80 51 00 1E 30 40 80 37 00 C4

000000F0 8E 21 00 00 1E 00 00 00 00 00 00 00 00 00 00 C6

Copyright©2007 LG Electronics. Inc. All right reserved. -16- LGE Internal Use Only

Only for training and service purposes

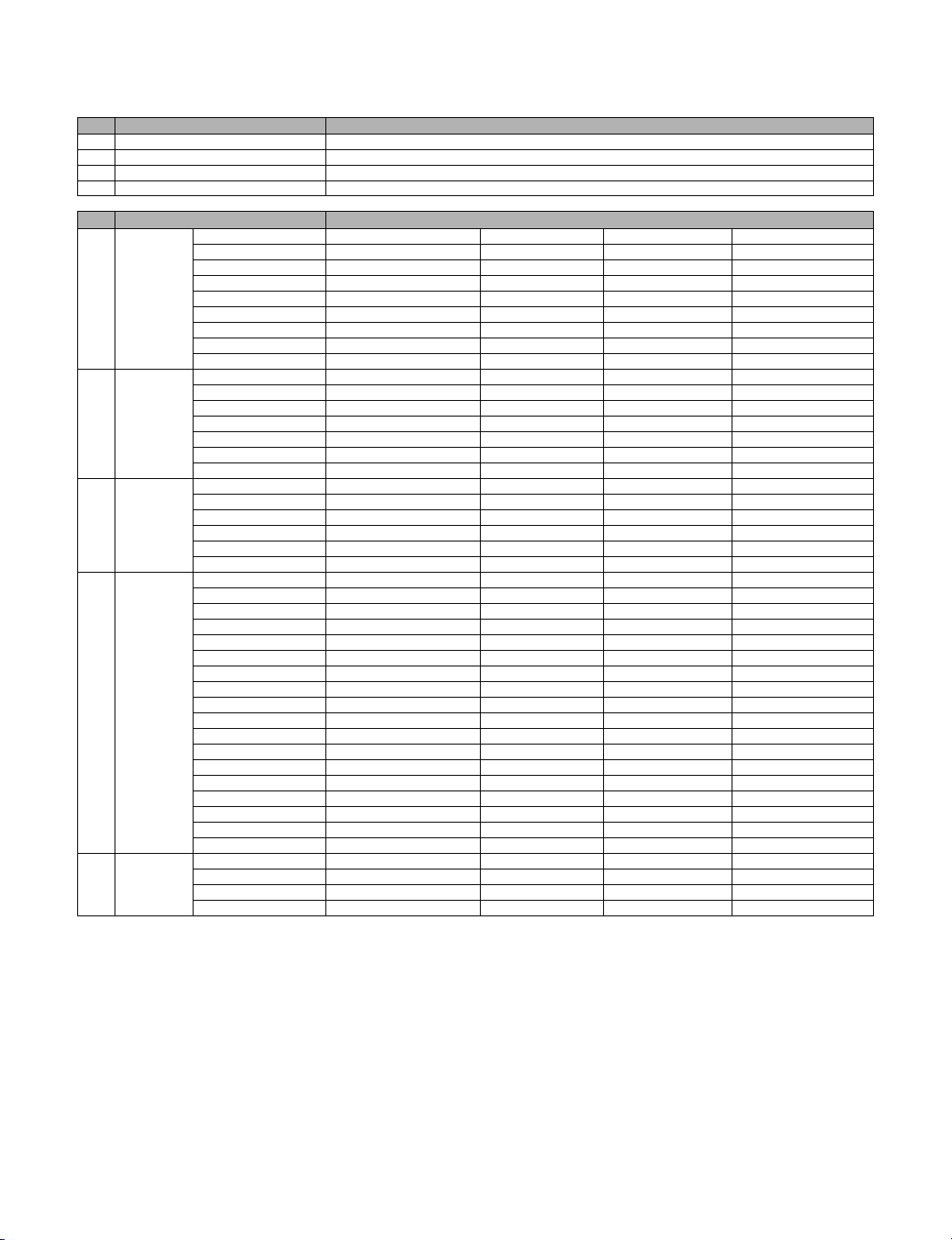

3. Commercial Interface Installer’s Menu Setting

3.1 Accessing the Installer’s Menu

Make sure TV is on. Installer’s menu items can be accessed by using an installer’s remote control.

Just press MENU repeatedly(at least 10 times) until the TV seems to stop responding, then press 9, 8, 7, 6, then ENTER.

To exit the Installer’s Menu, press ENTER again. Any changes you make will be stored in nonvolatile memory.(The menu also disappears automatically.)

The Installer’s menu opens with item 000 INSTALLER SEQ 000. Use the Up/Down arrow keys to sequence through the available menu items.

Or, access an item directly by keying in the line number, then pressing MENU. For example, to access the Sleep Timer option which is item 015,

press 0-1-5, then MENU. To change a setting, use the Left/Right arrow keys. Or, enter a value directly. Press ENTER to remove Installer menu display.

Typical Installer Menu

26LH1DCX-UX INSTALLER MENU

000 INSTALLER SEQ 000

UPN : 000-000-000-000 FPGA 09F1

PTC V1.00.003 CPU V1.24.00

3.2 Using the Installer’s Menu

Items 000 ~ 117 are immediately accessible only upon entering the Installer’s Menu.

Their numbers, descriptions, ranges, factory default settings, and a place for listing any changes made on-site are given below and on the following pages.

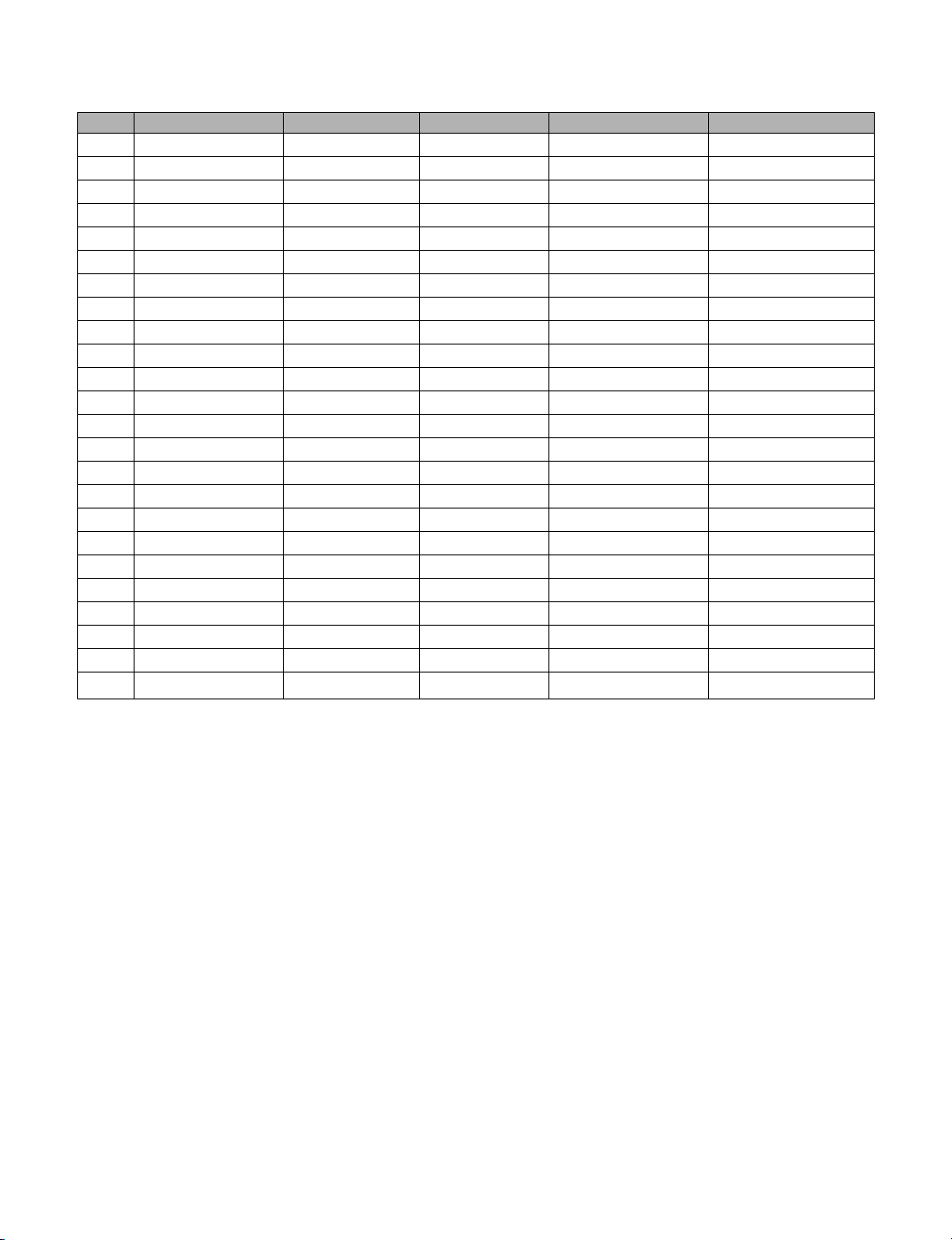

Installer Menu Items 000 through 117

Menu

Item Range Value

000 INSTALLER SEQ 000~3 000 Leave default set 0.

001 POWER MANAGE 000~7 000 Sets number of hours of no activity before auto shut off.

002 AC ON 000~1 000 Set to 1 to enable auto turn on at power up.

003 BAND/AFC 000~3 001 Selects Tuning band.

004 STRT CHANNEL 000~127, 255 255 Channel at turn-on (Set 255 to return to last channel before power off).

005 CHAN LOCK 000~1 000 If set to 1, cannot tune from current channel.

007 STRT VOLUME 000~63, 255 255 Sets Volume level at TV turn-on(Set 255 to retain last volume level).

008 MIN VOLUME 000~63 000 Sets minimum allowable volume setting.

009 MAX VOLUME 000~63 63 Sets maximum allowable volume setting.

010 MUTE DISABLE 000~1 000 Set to 1 to disable mute function.

011 KEY DEFEAT 000~1 000 Disables menu navigation keys on display panel.

015 SLEEP TIMER 000~1 001 Set to 1 to enable Sleep Timer.

016 EN TIMER 000~1 000 Set to 1 to enable On/Off Timers.

017 ALARM 000~1 001 Set to 1 to enable Alarm.

021 V-CHIP 000~1 001 Set to 1 to enable V-Chip functions.

022 MAX BLK HRS 000~99 012 Sets number of V-Chip(Parental Control) blocking hours.

023 CAPTION LOCK 000~1 000 Set to 1 to retain caption setting at power off.

028 CH. OVERIDE 000~1 001 If set to 0, limits direct access to favorite channels.

029 OLD OCV 000~1 001 Set to 1 to change M.P.I. operation to OCV.

030 ACK MASK 000~1 000 If set to 1, changes M.P.I. for some OCV boxes.

031 POLL RATE 020~169 094 Selects poll rate for M.P.I.

032 TIMING PULSE 186~227 207 Sets baud rate for M.P.I.

034 CAMPORT EN 000~1 001 Set to 1 to enable Video 2 input.

035 CAMPPORT EN 000~1 001 Enables plasma panel DVI input port, set to 1 for DTV or 2 for PC. Set 0 to disable.

038 YPrPb EN 000~1 001 Set to 1 to enable display panel Component 1 input jacks.

039 REAR AUX EN 000~1 001 Set to 1 to enable display panel Video 1 input jack.

040 AUTO CAMPORT 000~1 001 For CRT-type TVs. Default set to 1 to automatically switch to Camport.

046 STRT AUX SRCE 001~7, 255 255 Sets the starting AUX source.

047 AUX STATUS 000~1 000 Set to 1 for M.P.I. AUX source reported as channel number instead of Channel 0.

053 DIS. CH-TIME M. 000~1 000 Set to 1 to disable Channel-Time display.

069 EN. CH-T COL. 000~1 001 Set to 1 to enable custom color for the Channel-Time display.

070 FOR. CH-TIME 000~7 002 Chooses custom foreground color for the Channel-Time display.

071 BCK. CH-TIME 000~7 002 Chooses custom background color for the Channel-Time display.

073 CH NOT AVBLE 000~1 000

075 REVERT CH 000~1 000 If set to 1 and loss of M.P.I. communication occurs, TV tunes to Start Channel.

078 UPN MSB 000~255 000 User programmable number, most significant byte.

079 UPN MSB-1 000~255 000 User programmable number, most significant byte - 1.

080 UPN MSB-2 000~255 000 User programmable number, most significant byte - 2.

081 UPN LSB 000~255 000 User programmable number, least significant byte.

Function

Value Default

Brief Description of Function and Comments

If set to 1 and channel override is 0, "NOT AVAILABLE" message is Displayed when

directly accessing a channel not in the favorite channel list.

Copyright©2007 LG Electronics. Inc. All right reserved. -17- LGE Internal Use Only

Only for training and service purposes

082 CHKSUM ERROR 000~1 001 Enforces rigid M.P.I. checksum.

083 HANDSHK TIME 000~5 005 Relaxes M.P.I. timing to be compatible with PC based Windows controlled systems.

084 PERMANENT BLK 000~1 000 Removes block hours setting for Parental Control and make blocks permanent.

087 REAR RGB EN. 000~2 002 Enables RGB1 input, set to 1 for DTV, or 2 for PC. Set to 0 to disable.

088 EN NOISE MUTE 000~1 001 If set to 1, mutes audio if no signal is present.

090 KEY LOCK 000~1 000 If set to 1, keyboard is locked out, IR is still functional.

091 YPrPb2 EN 000~1 001 Set to 1 to enable plasma Component 2 input jacks.

092 RGB2 ENABLE 000~2 002 Enables RGB2 input, Set to 1 for DTV, or 2 for PC. Set to 0 to disable.

093 RJP AVAILABLE 000~1 000 Set to 1 to enable.

094 SAP MENU EN 000~1 001 Set to 0 to disable feature on Function menu. Set 1 to enable feature on Function menu.

096 DEF. ASP. RATIO 000~134 002 Sets default aspect ratio at power up. See detailed descriptions and item 106.

101 IR BLASTER N/A N/A Not applicable.

102 ATSC BAND 000~4 004 Selects ATSC band.

103 ATSC TUNE MODE 000~1 001 Sets ATSC tuning mode. Set to 0 for virtual channel, set to 1 for physical channel.

104 START MINOR CH 000~255 000 Selects Minor start channel. Set 0 for NTSC. Not 0, sets Minor channel number.

106 ASP RATIO LOCK 000~1 000 Retains set aspect ratio on power cycle. Set to 0 for default ratio on power cycle.

107 BANNER N/A N/A Not applicable.

116 VIDEO MUTE EN 000~1 000 Set to 0 for normal, set to 1 for Blank.

117 FACT DEFAULT 000~1 000 0=Normal. 1=Loads presets of all above settings.

Copyright©2007 LG Electronics. Inc. All right reserved. -18- LGE Internal Use Only

Only for training and service purposes

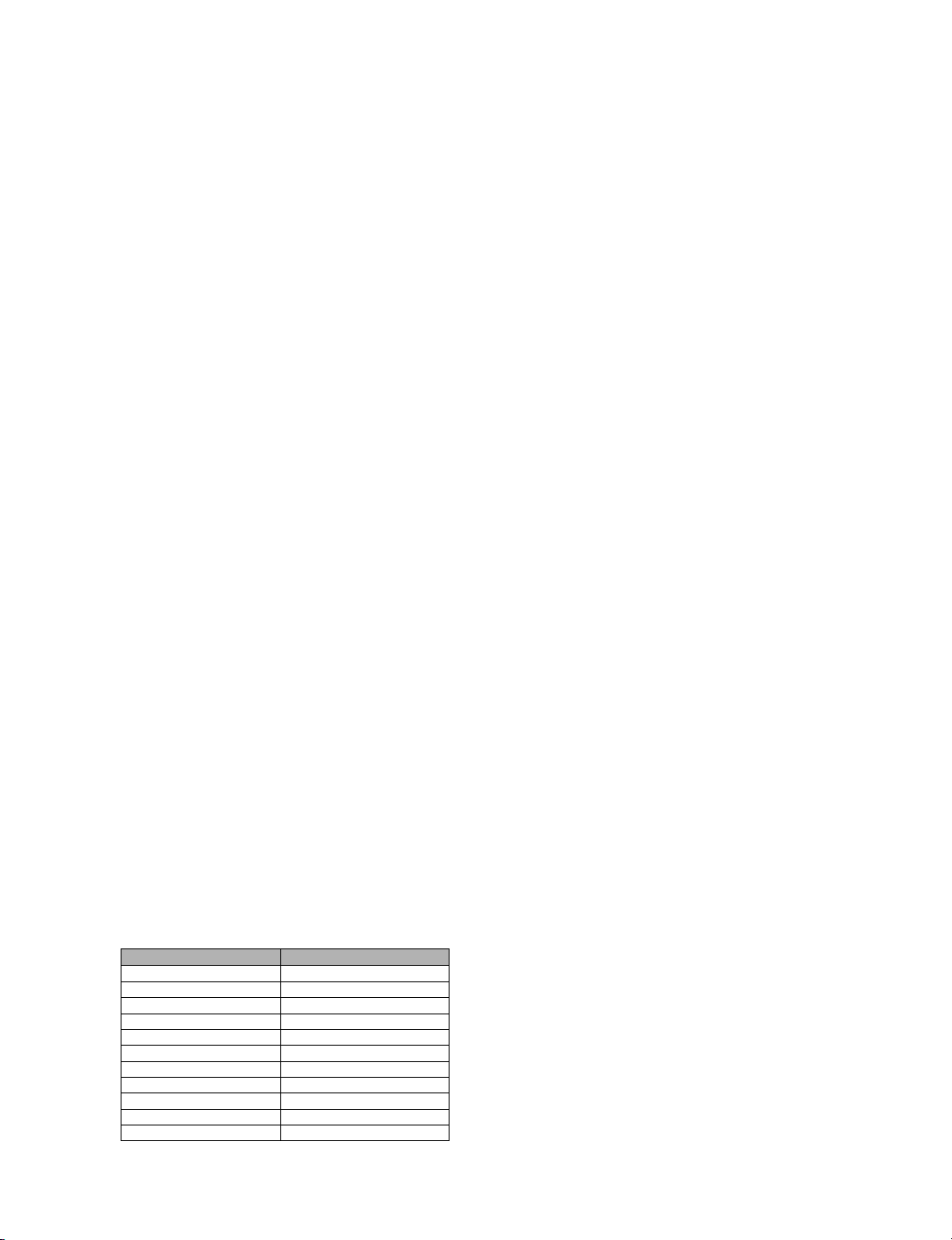

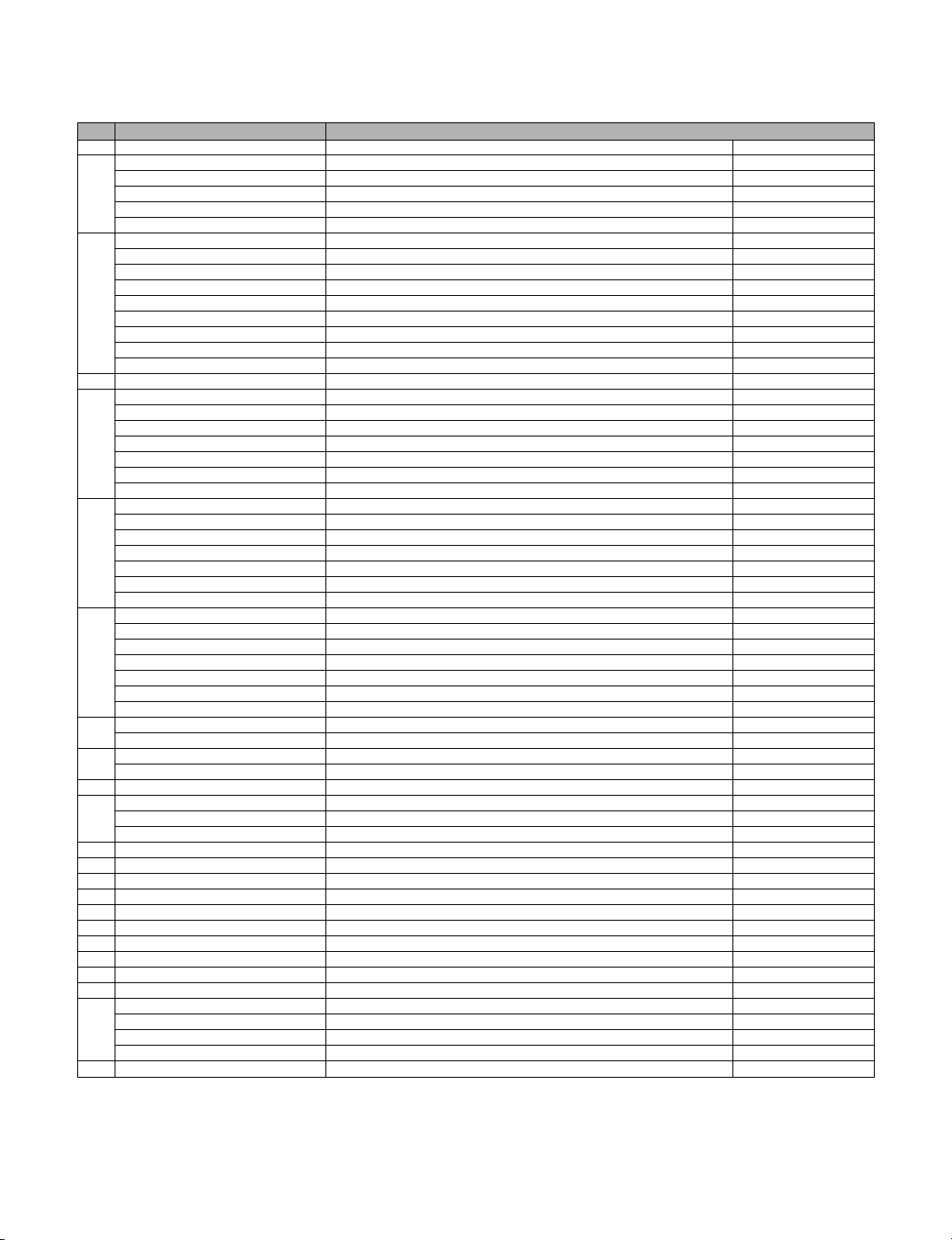

4. Shipment Condition : Product & Customer Menu – Setup

No. General Item Default Condition

1 RS232C Select Leave default set 0.

2 Input mode TV02CH

3 Volume Level 20

4 Mute Off

No. User OSD Menu Item Default Condition

1 Picture Mode Standard Contrast 91

Brightness 80

Sharpness 54

Color 68

Tint 0(Center)

Color Temperature Cool

Screen Format 16:9

Noise Reduction Off

Film Mode Off

2 Sound Mode Standard Treble 0(Center)

Bass 0(Center)

Balance 0

(Digital Output)

Auto Volume Off

Multi-Track Stereo

Internal Speaker On

3 Channel (Antenna) (Only Item display)

Auto Memorizing Yes

Channel Label Default

Channel List Empty

Fine Tune Auto

Signal Strength (DTV Only)

4 Setup Time Clock Manual

(Manual Clock)

Daylight Saving Yes

Time Zone Eastern

(On Timer) (Only Item display)

(Off Timer) (Only Item display)

Auto Off Off

V-Chip Please Enter your PIN. 0000(Default) Changing PIN New PIN

On/Off Off

TVPG Rating (Only Item display)

MPAA Rating (Only Item display)

Can. English Rating (Only Item display)

Can. French Rating (Only Item display)

(PC) (Only RGB PC Input)

Menu Language English

Menu Transparency Semi Opaque

Set ID 1

5 Caption On/Off Off

(Analog Mode)

(Digital Mode)

(Digital Font Option)

Confirm PIN

Copyright©2007 LG Electronics. Inc. All right reserved. -19- LGE Internal Use Only

Only for training and service purposes

5. Shipment Condition : Service Menu – Setup

No. Service Menu Item Default Condition

1 System Reset Confirm

2 Software Version DM-327KA Aug 02 2006 V1.24 SUB V3.2

3 Chip I2C Test Memory : OK

4 Aging Test (Enter)

5 White Balance Offset R 50

6 YPbPr : offset/gain Offset Y 24

7 RGB : offset/gain Offset R 128

8 Auto Picture Auto Brightness ADJ Value(50)

9 Running Time Running Time * HOURS

10 System All Reset Confirm

11 Audio Delay DTV 0

12 AI Control OFF

13 Last Power Save ON

14 Panel Monitoring OFF

15 Panel ID - Display ID Display ID : 0(LCD)

16 Panel Company ID Panel Company ID : 0(LG)

17 Model ID Model ID : 22(LG_LC260WX2_SL02)

18 Reserved

19 Commercial Flag ON

20 Panel Brightness ADJ Value(70)

21 Epg Mode Mini

22 SW Upgrade RF Mode 0(Air)

23 EXIT (Enter)

Display ID : 0(LCD)

Panel Company ID : 0(LG)

Model ID : 22(LG_LC260WX2_SL02)

HW ID : 0

FLASH : OK

EEPROM : OK

TUNER : OK

VIDEO ADC : OK

AUDIO DEC : OK

Uart1 Comm. : NOT OK

Pillow Mode : 0

Uart Mode : 0

Offset G 50

Offset B 50

Gain R ADJ Value(50)

Gain G ADJ Value(50)

Gain B ADJ Value(50)

Reset Mode

Offset Pb 51

Offset Pr 51

Gain Y 60

Gain Pb 60

Gain Pr 60

Reset Mode

Offset G 128

Offset B 128

Gain R ADJ Value(128)

Gain G ADJ Value(128)

Gain B ADJ Value(128)

Reset Mode

Auto Contrast 91

Reset Mode

ATV/CVBS/YC 0

COMP/PC/HDMI 0

RF Freq 20

FE Mode 0(Vsb)

Upgrade Start

6. Shipment Condition : Installer Menu – Setup

(See 3. Commercial Interface Installer’s Menu Setting page.)

Copyright©2007 LG Electronics. Inc. All right reserved. -20- LGE Internal Use Only

Only for training and service purposes

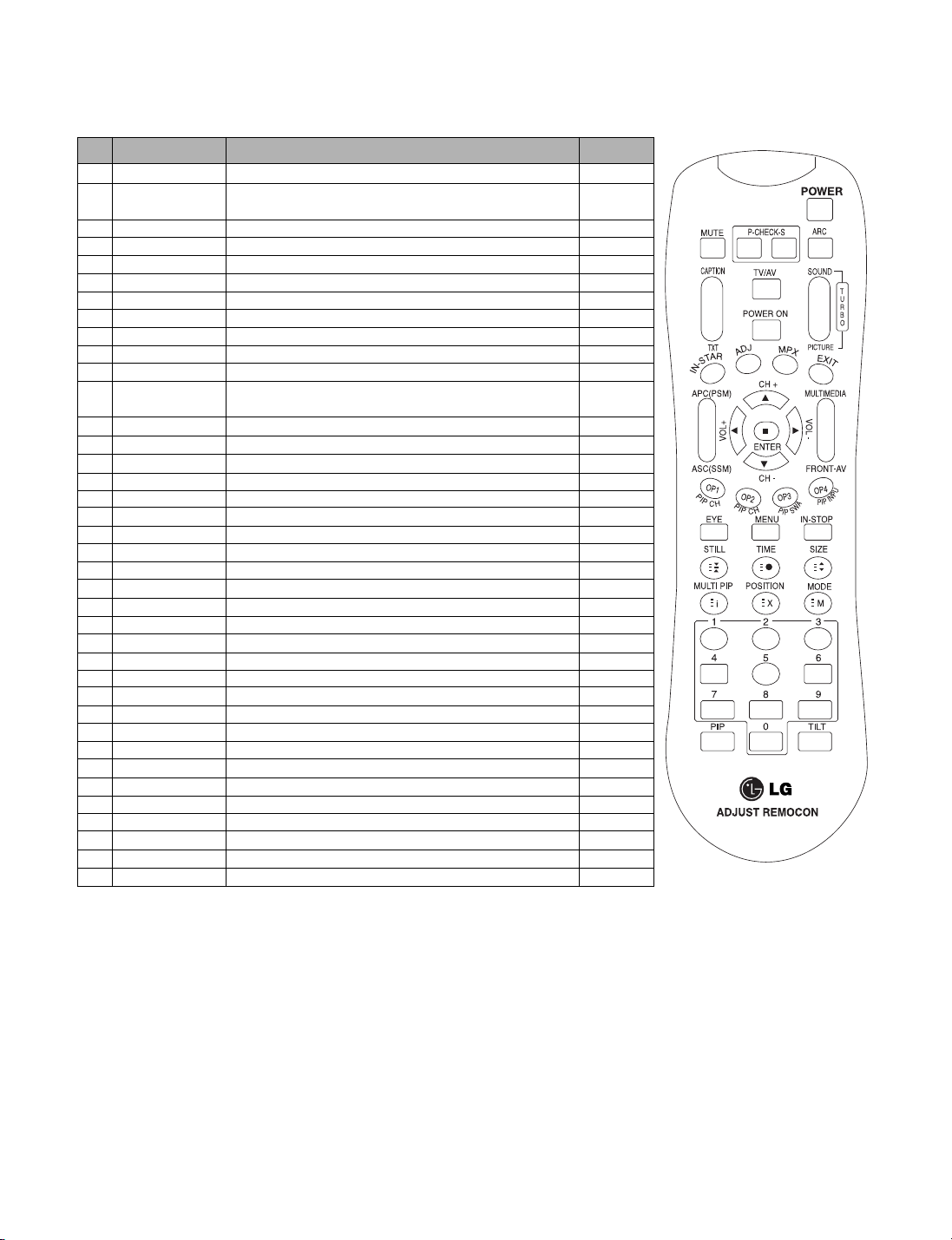

SVC REMOCON

NO KEY FUNTION

POWER

1

POWER ON

2

MUTE

3

P-CHECK

4

S-CHECK

5

ARC

6

CAPTION

7

TXT

8

TV/AV

9

TURBO SOUND

10

TURBO PICTURE

11

IN-START

12

ADJ

13

MPX

14

EXIT

15

APC(PSM)

16

ASC(SSM)

17

MULTIMIDIA

18

FRONT-AV

19

±

CH

20

VOL±

21

ENTER

22

PIP CH-(OP1)

23

PIP CH+(OP2)

24

PIP SWAP(OP3)

25

PIP INPUT(OP4)

26

EYE

27

MENU

28

IN-STOP

29

STILL

30

TIME

31

SIZE

32

MULTI PIP

33

POSITION

34

MODE

35

PIP

36

TILT

37

0~9

38

To turn the TV on or off.

To turn the TV on automatically if the power is supplied to the TV. (Use the

POWER key to deactivate) : It should be deactivated when delivered.

To activate the mute function.

N/A

N/A

To select size of the main screen. (Normal, Spectacle, Wide or Zoom)

Switch to closed caption broadcasting.

N/A

To select an external input for the TV screen.

N/A

N/A

To enter adjustment mode when manufacturing the TV sets.

W/B adjustment. (automatic)

To enter into the adjustment mode.

To select the multiple sound mode. (Mono, Stereo or Foreign language)

To release the adjustment mode.

To easily adjust the screen according to surrounding brightness.

To easily adjust sound according to the program type.

To check component input.

To check the front AV.

To move channel up/down or to select a function displayed on the screen.

To adjust the volume or accurately control a specific function.

To set a specific function or complete setting.

N/A

N/A

N/A

N/A

N/A

To select the functions such as picture, sound, channel, setup, caption.

To set the delivery condition status after manufacturing the TV set.

To halt the main screen in the nomal mode.

N/A

N/A

N/A

N/A

N/A

N/A

N/A

To manually select the channel.

REAMARK

Shortcut keys

Shortcut keys

Shortcut keys

Shortcut keys

Shortcut keys

Shortcut keys

Copyright©2007 LG Electronics. Inc. All right reserved. -21- LGE Internal Use Only

Only for training and service purposes

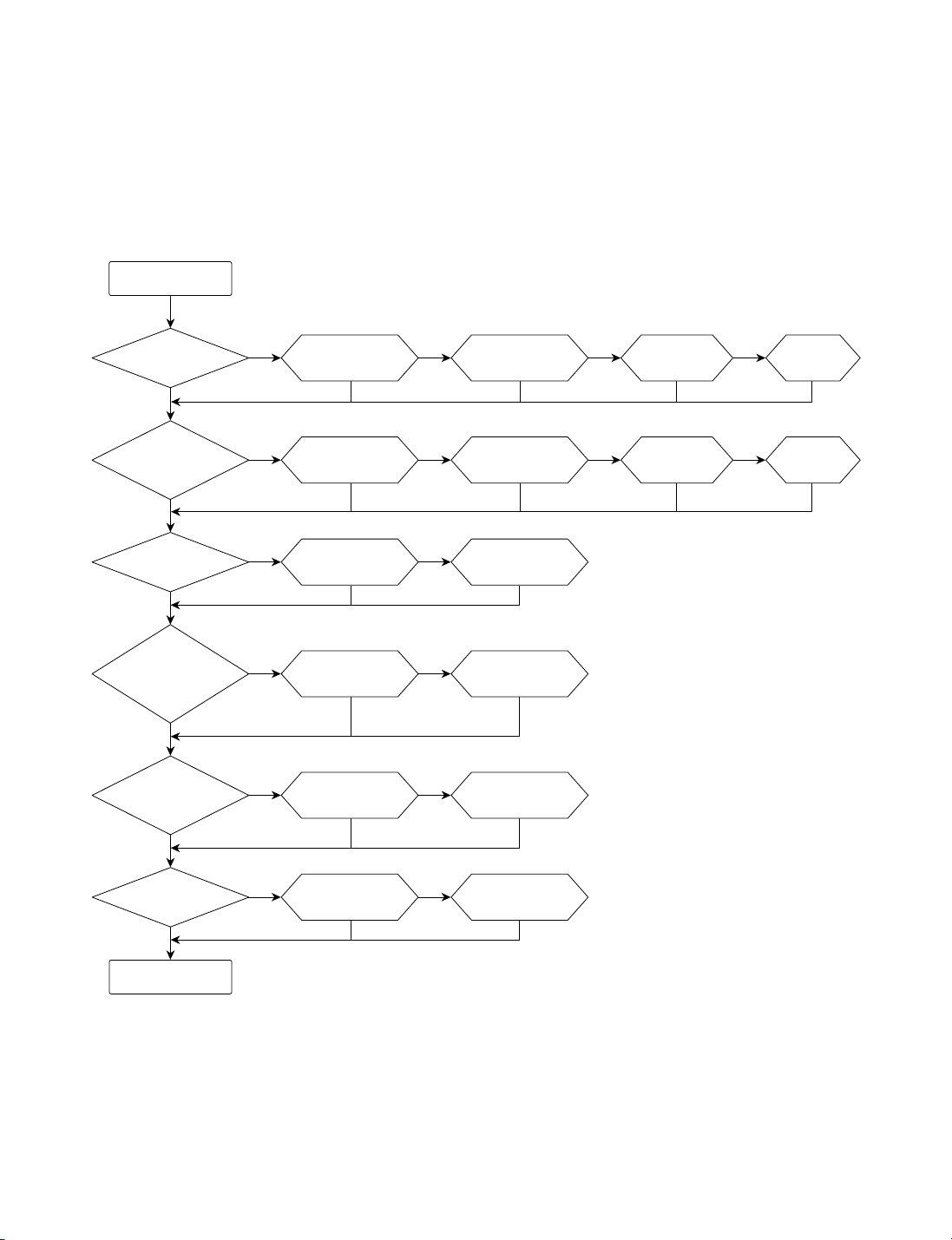

Check for problems

in Main Board

Normal operation

Main Board

LED ON?

Power Cable(13 PIN)

Check / Replace

Front Cable(7 PIN)

Check / Replace

SMPS

Check / Replace

Main Board

Replace

PC Serial port

Check the setting

Serial Cable

Check / Replace

LVDS Cable

Check / Replace

Main Board

Replace

External equipment/

Cable Check / Replace

Main Board

Replace

External equipment/

Cable Check / Replace

Main Board

Replace

Speaker Cable

Check / Replace

Check for problems

in audio

MICOM

Check the operation

Main Board

Replace

Is it communicating

with the Service Port?

Is the screen

color normal?

Is the color normal

when PC/HDMI

is selected?

Is the color normal

when External Input/

S-Video/Component

is selected?

Is the left/right audio

output normal?

YES

YES

YES YES YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

YES YES

YES

YES

YES

YES

YES

NO NO NO NO

NO NO

NO NO

NO NO

NO NO

NO NO

NO NO

TROUBLE SHOOTING GUIDES

Copyright©2007 LG Electronics. Inc. All right reserved. -22- LGE Internal Use Only

Only for training and service purposes

Loading...

Loading...