Page 1

Internal Use Only

North/Latin America http://aic.lgservice.com

Europe/Africa http://eic.lgservice.com

Asia/Oceania http://biz.lgservice.com

COLOR MONITOR

SERVICE MANUAL

CHASSIS NO. : LM14B

MODEL: 24M35H

CAUTION

BEFORE SERVICING THE UNIT,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

P/NO : MFL67715246 (1311-REV00) Printed in China

Page 2

CONTENTS

CONTENTS .............................................................................................. 2

PRECAUTION............................................................................................3

SERVICING PRECAUTIONS.....................................................................4

SPECIFICATIONS......................................................................................6

TIMING CHART .......................................................................................11

ADJUSTMENT .........................................................................................14

BLOCK DIAGRAM...................................................................................18

TROUBLE SHOOTING ............................................................................19

EXPLODED VIEW .................................................................................. 22

SVC. SHEET ...............................................................................................

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 2 -

LGE Internal Use Only

Page 3

PRECAUTION

WARNING FOR THE SAFETY-RELATED COMPONENT.

• There are some special components used in LCD monitor that

are important for safety. These parts are marked on the

schematic diagram and the Exploded View. It is essential

that these critical parts should be replaced with the

manufacturer’s specified parts to prevent electric shock, fire or

other hazard.

• Do not modify original design without obtaining written

permission from manufacturer or you will void the original parts

and labor guarantee.

TAKE CARE DURING HANDLING THE LCD MODULE WITH

BACKLIGHT UNIT.

• Must mount the module using mounting holes arranged in four

corners.

• Do not press on the panel, edge of the frame strongly or electric

shock as this will result in damage to the screen.

• Do not scratch or press on the panel with any sharp objects,

such as pencil or pen as this may result in damage to the panel.

• Protect the module from the ESD as it may damage the

electronic circuit (C-MOS).

WARNING

BE CAREFUL ELECTRIC SHOCK !

• If you want to replace with the new backlight (CCFL) or LIPS

part, must disconnect the AC power because high voltage

appears at inverter circuit about 650Vrms.

• Handle with care wires or connectors of the inverter circuit. If

the wires are pressed cause short and may burn or take fire.

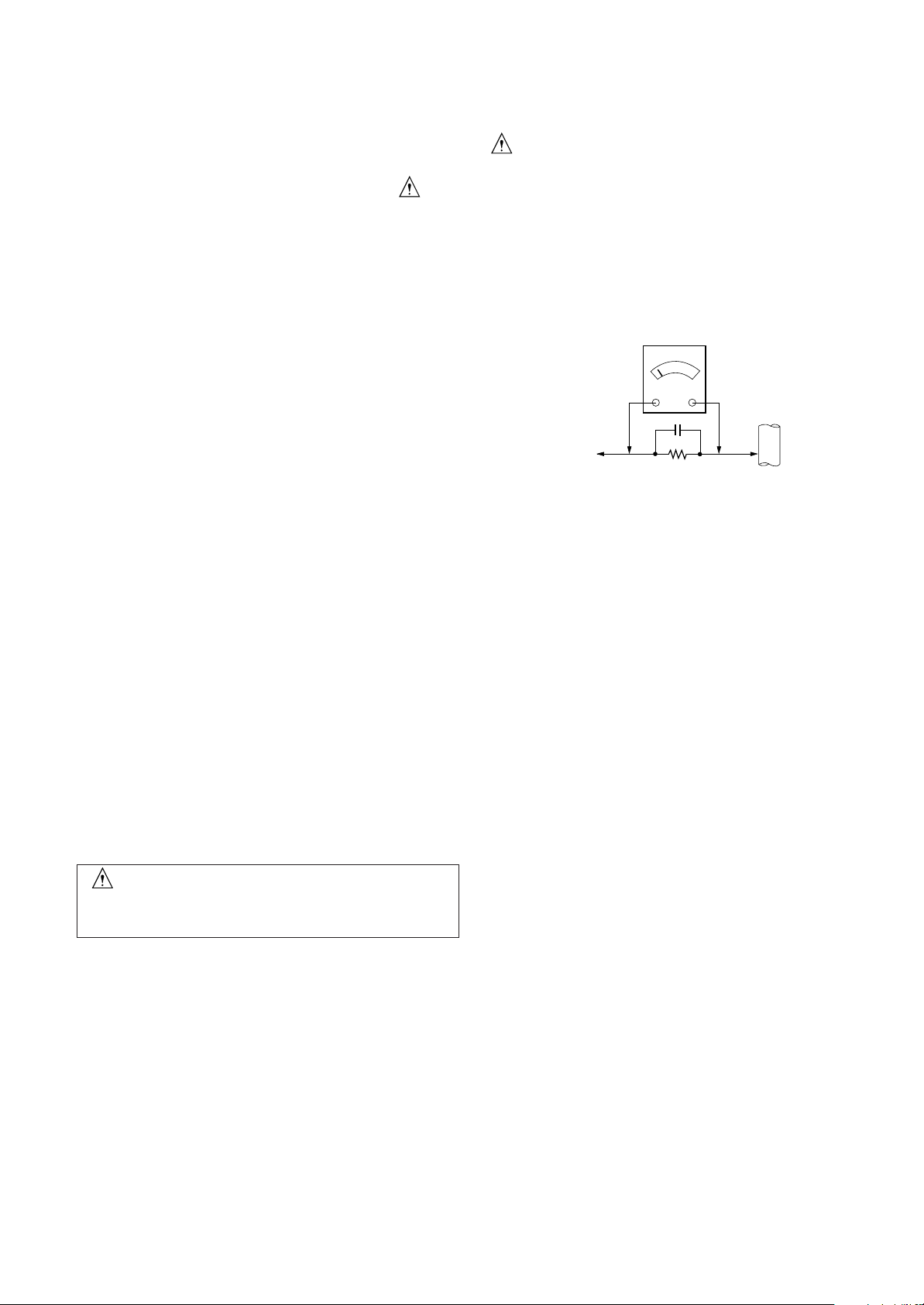

Leakage Current Hot Check Circuit

AC Volt-meter

Good Earth Ground

such as WATER PIPE,

To Instrument's

exposed

METALLIC PARTS

When 25A is impressed between Earth and 2nd Ground

for 1 second, Resistance must be less than 0.1

*Base on Adjustment standard

0.15uF

1.5 Kohm/10W

CONDUIT etc.

Ω

• Make certain that treatment person’s body are grounded

through wrist band.

• Do not leave the module in high temperature and in areas of

high humidity for a long time.

• The module not be exposed to the direct sunlight.

• Avoid contact with water as it may a short circuit within the

module.

• If the surface of panel become dirty, please wipe it off with a

softmaterial. (Cleaning with a dirty or rough cloth may damage

the panel.)

CAUTION

Please use only a plastic screwdriver to protect yourself

from shock hazard during service operation.

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 3 -

LGE Internal Use Only

Page 4

SERVICING PRECAUTIONS

CAUTION: Before servicing receivers covered by this service

manual and its supplements and addenda, read and follow the

SAFETY PRECAUTIONS on page 3 of this publication.

NOTE: If unforeseen circumstances create conflict between the

following servicing precautions and any of the safety precautions on

page 3 of this publication, always follow the safety precautions.

Remember: Safety First.

General Servicing Precautions

1. Always unplug the receiver AC power cord from the AC power

source before;

a. Removing or reinstalling any component, circuit board

module or any other receiver assembly.

b. Disconnecting or re-connecting any receiver electrical plug or

other electrical connection.

c. Connecting a test substitute in parallel with an electrolytic

capacitor in the receiver.

CAUTION: A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2. Test high voltage only by measuring it with an appropriate high

voltage meter or other voltage measuring device (DVM,

FETVOM, etc) equipped with a suitable high voltage probe.

Do not test high voltage by "drawing an arc".

3. Do not spray chemicals on or near this receiver or any of its

assemblies.

4. Unless specified otherwise in this service manual, clean

electrical contacts only by applying the following mixture to the

contacts with a pipe cleaner, cotton-tipped stick or comparable

non-abrasive applicator; 10% (by volume) Acetone and 90% (by

volume) is opropyl alcohol (90%-99% strength)

CAUTION: This is a flammable mixture.

Unless specified otherwise in this service manual, lubrication of

contacts in not required.

5. Do not defeat any plug/socket B+ voltage interlocks with which

receivers covered by this service manual might be equipped.

6. Do not apply AC power to this instrument and/or any of its

electrical assemblies unless all solid-state device heat sinks are

correctly installed.

7. Always connect the test receiver ground lead to the receiver

chassis ground before connecting the test receiver positive

lead.

Always remove the test receiver ground lead last.

8. Use with this receiver only the test fixtures specified in this

service manual.

CAUTION: Do not connect the test fixture ground strap to any

heat sink in this receiver.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid-state) devices can be damaged easily

by static electricity. Such components commonly are called

Electrostatically Sensitive (ES) Devices. Examples of typical ES

devices are integrated circuits and some field-effect transistors and

semiconductor "chip" components. The following techniques

should be used to help reduce the incidence of component

damage caused by static by static electricity.

1. Immediately before handling any semiconductor component or

semiconductor-equipped assembly, drain off any electrostatic

charge on your body by touching a known earth ground.

Alternatively, obtain and wear a commercially available

discharging wrist strap device, which should be removed to

prevent potential shock reasons prior to applying power to the

unit under test.

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

2. After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such as

aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3. Use only a grounded-tip soldering iron to solder or unsolder ES

devices.

4. Use only an anti-static type solder removal device. Some solder

removal devices not classified as "anti-static" can generate

electrical charges sufficient to damage ES devices.

5. Do not use freon-propelled chemicals. These can generate

electrical charges sufficient to damage ES devices.

6. Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum foil

or comparable conductive material).

7. Immediately before removing the protective material from the

leads of a replacement ES device, touch the protective material

to the chassis or circuit assembly into which the device will be

installed.

CAUTION: Be sure no power is applied to the chassis or circuit,

and observe all other safety precautions.

8. Minimize bodily motions when handling unpackaged

replacement ES devices. (Otherwise harmless motion such as

the brushing together of your clothes fabric or the lifting of your

foot from a carpeted floor can generate static electricity

sufficient to damage an ES device.)

General Soldering Guidelines

1. Use a grounded-tip, low-wattage soldering iron and appropriate

tip size and shape that will maintain tip temperature within the

range or 500ºF to 600ºF.

2. Use an appropriate gauge of RMA resin-core solder composed

of 60 parts tin/40 parts lead.

3. Keep the soldering iron tip clean and well tinned.

4. Thoroughly clean the surfaces to be soldered. Use a mall wirebristle (0.5 inch, or 1.25cm) brush with a metal handle.

Do not use freon-propelled spray-on cleaners.

5. Use the following unsoldering technique

a. Allow the soldering iron tip to reach normal temperature.

(500ºF to 600ºF)

b. Heat the component lead until the solder melts.

c. Quickly draw the melted solder with an anti-static, suction-

type solder removal device or with solder braid.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

6. Use the following soldering technique.

a. Allow the soldering iron tip to reach a normal temperature

(500ºF to 600ºF)

b. First, hold the soldering iron tip and solder the strand against

the component lead until the solder melts.

c. Quickly move the soldering iron tip to the junction of the

component lead and the printed circuit foil, and hold it there

only until the solder flows onto and around both the

component lead and the foil.

CAUTION: Work quickly to avoid overheating the circuit

board printed foil.

d. Closely inspect the solder area and remove any excess or

splashed solder with a small wire-bristle brush.

- 4 -

LGE Internal Use Only

Page 5

IC Remove/Replacement

Some chassis circuit boards have slotted holes (oblong) through

which the IC leads are inserted and then bent flat against the

circuit foil. When holes are the slotted type, the following technique

should be used to remove and replace the IC. When working with

boards using the familiar round hole, use the standard technique

as outlined in paragraphs 5 and 6 above.

Removal

1. Desolder and straighten each IC lead in one operation by gently

prying up on the lead with the soldering iron tip as the solder

melts.

2. Draw away the melted solder with an anti-static suction-type

solder removal device (or with solder braid) before removing the

IC.

Replacement

1. Carefully insert the replacement IC in the circuit board.

2. Carefully bend each IC lead against the circuit foil pad and

solder it.

3. Clean the soldered areas with a small wire-bristle brush.

(It is not necessary to reapply acrylic coating to the areas).

"Small-Signal" Discrete TransistorRemoval/Replacement

1. Remove the defective transistor by clipping its leads as close as

possible to the component body.

2. Bend into a "U" shape the end of each of three leads remaining

on the circuit board.

3. Bend into a "U" shape the replacement transistor leads.

4. Connect the replacement transistor leads to the corresponding

leads extending from the circuit board and crimp the "U" with

long nose pliers to insure metal to metal contact then solder

each connection.

Power Output, Transistor Device

Removal/Replacement

1. Heat and remove all solder from around the transistor leads.

2. Remove the heat sink mounting screw (if so equipped).

3. Carefully remove the transistor from the heat sink of the circuit

board.

4. Insert new transistor in the circuit board.

5. Solder each transistor lead, and clip off excess lead.

6. Replace heat sink.

Circuit Board Foil Repair

Excessive heat applied to the copper foil of any printed circuit

board will weaken the adhesive that bonds the foil to the circuit

board causing the foil to separate from or "lift-off" the board. The

following guidelines and procedures should be followed whenever

this condition is encountered.

At IC Connections

To repair a defective copper pattern at IC connections use the

following procedure to install a jumper wire on the copper pattern

side of the circuit board. (Use this technique only on IC

connections).

1. Carefully remove the damaged copper pattern with a sharp

knife. (Remove only as much copper as absolutely necessary).

2. carefully scratch away the solder resist and acrylic coating (if

used) from the end of the remaining copper pattern.

3. Bend a small "U" in one end of a small gauge jumper wire and

carefully crimp it around the IC pin. Solder the IC connection.

4. Route the jumper wire along the path of the out-away copper

pattern and let it overlap the previously scraped end of the good

copper pattern. Solder the overlapped area and clip off any

excess jumper wire.

At Other Connections

Use the following technique to repair the defective copper pattern

at connections other than IC Pins. This technique involves the

installation of a jumper wire on the component side of the circuit

board.

1. Remove the defective copper pattern with a sharp knife.

Remove at least 1/4 inch of copper, to ensure that a hazardous

condition will not exist if the jumper wire opens.

2. Trace along the copper pattern from both sides of the pattern

break and locate the nearest component that is directly

connected to the affected copper pattern.

3. Connect insulated 20-gauge jumper wire from the lead of the

nearest component on one side of the pattern break to the lead

of the nearest component on the other side.

Carefully crimp and solder the connections.

CAUTION: Be sure the insulated jumper wire is dressed so the

it does not touch components or sharp edges.

Diode Removal/Replacement

1. Remove defective diode by clipping its leads as close as

possible to diode body.

2. Bend the two remaining leads perpendicular y to the circuit

board.

3. Observing diode polarity, wrap each lead of the new diode

around the corresponding lead on the circuit board.

4. Securely crimp each connection and solder it.

5. Inspect (on the circuit board copper side) the solder joints of

the two "original" leads. If they are not shiny, reheat them and if

necessary, apply additional solder.

Fuse and Conventional Resistor

Removal/Replacement

1. Clip each fuse or resistor lead at top of the circuit board hollow

stake.

2. Securely crimp the leads of replacement component around

notch at stake top.

3. Solder the connections.

CAUTION: Maintain original spacing between the replaced

component and adjacent components and the circuit board to

prevent excessive component temperatures.

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 5 -

LGE Internal Use Only

Page 6

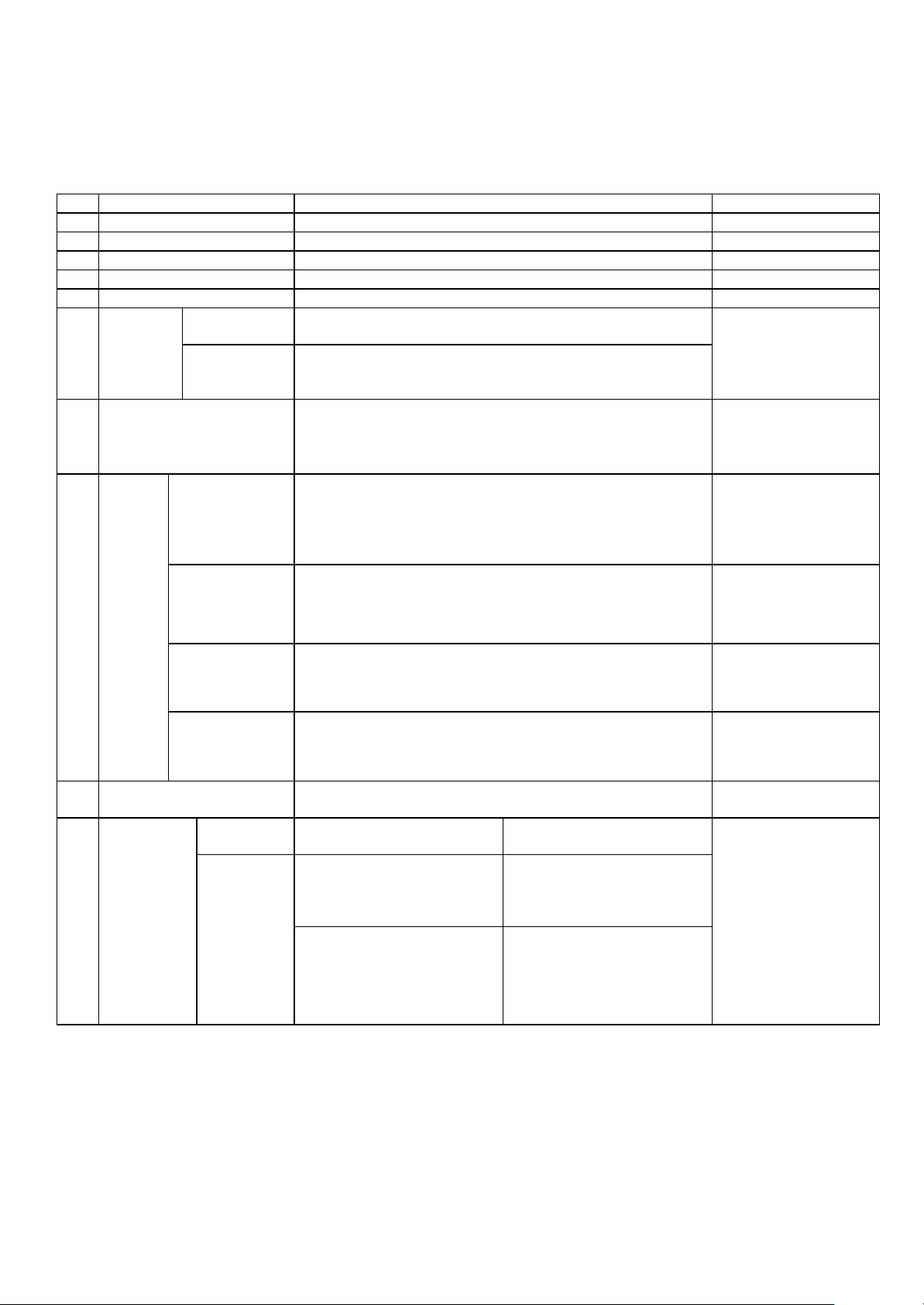

SPECIFICATIONS

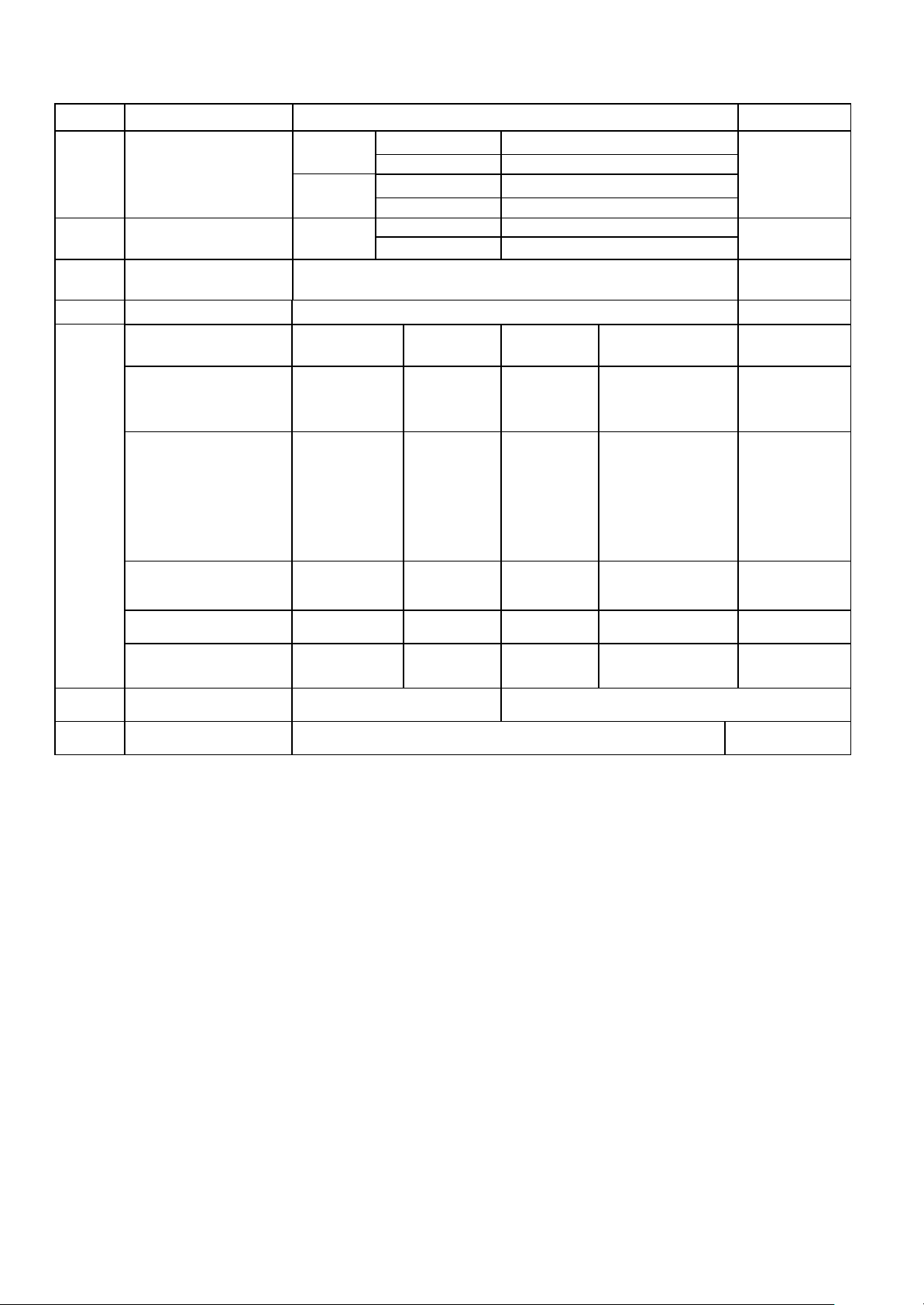

1. General Specification

No Item

1 Customer BRAND

2 User Model Name 24M35

3 Sale region Refer to Suffix standard

4 Feature 23.6” Wide LCD MONITOR

5 Chassis Name LM14B

General External SW

Scope &Adj.

6

7

Power Cord

Signal Cable

(D-SUB)

Function OSD,DDC2B,DDC2AB, HDCP, Control Lock,

MENU,READER,FUNC,AUTO,INPUT/EXIT, POWER

Original Ratio / Wid

e, black level, Super Energy Saving, Picture mode

Length : 1.5±0.05 M

Shape : Wall-out

Color : Black

Length : 1.5m

Shape : Detachable Type

Color : Black

Pin : Triple Row, 15 Pin D-Sub

Content Remark

Refer to Suffix

standard and power

cord table

Refer to BOM

Length : 1.5m

DVI Do not Support

8 Cable

Audio Length : ,Shape : ,Color: ,Pin

TV Length : ,Shape : ,Color: ,Pin

9 Power Refer to BOM

P/No Specification

10

Applying

module list

Panel biz

Shape : Detachable Type

Color : Black

Pin : Triple Row, 18-Position DVI-D

Adapter

- Wall Mount Type

CMI(LGM236AC32)

CMI:EAJ62131901

BLU:EBV60978023

BOE(LGM236AB32)

BOE:EAJ62072001/2

BLU:EBV60978022

M236HGE-P02

LM23030023B

HM236WU3-100

LM23030023A

Do not Support

Do not Support

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 6 -

LGE Internal Use Only

Page 7

2. Mechanical specification

No

1

2

3

Product

Dimension

Product

Weight

Container

Loading

Quantity

4 Stand

Assy

Item Content Remark

Before Packing

Width (W) Length (D) Height (H)

55.6

21.5

43.8

With stand

55.6 9.8 34.1 Without stand

After Packing

Only SET

With BOX

Individual or

Palletizing

62.5

41.4

4.24kg

20ft 40ft

Individual Palletizi

ng

14.5

3.0kg With stand

2.7kg

Individu

al

Palletizin

g

Without stand

816 630 1664 1400

Type Base detachable

Size (W x D x H) 25.0*21.5*3.1

Tilt Degree

-3°(+/-3°)~ +20°(+5°/-0°)

Tilt force 0.8~1.3kgf

Folding Degree None

5 Appearance General Refer to Standard of LG(56)G2-1011

** C/A + B/C GAP: 0.5mm (Design gap)

3. Optical Character

3.1 Normal Mode

No Item Criteria Remark

1

2

Luminance(휘도)

Light Leakage Condition: Do not visible at 300 Lux

Average

Luminance

(cd/m

2

)

Average

Luminance

(cd/m )

2

Average

Luminance

(cd/m )

2

Luminance

Uniformity

120 (min)

(Full

white pattern, 0.7V)

150(min),200 (Typ.)

(Full white pattern, 0.7V)

120(min)

(Full white pattern, 0.7V)

75%(min),

Medium

Warm

Brightness:100

Contrast:100

Cool

3.2 Reader Mode

Pattern Coordinate

Wx 0.365

White

Wy 0.360

Wx 0.353

Wy 0.367

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

Minimum Normal Maximum

Typ-0.030 Typ+0.030

Typ-0.030 Typ+0.030

- 7 -

Reader 1

Reader 2

LGE Internal Use Only

Page 8

4. Engineering Specification

1

2 Operating Frequency

3 Resolution

4 Power Voltage

5 Inrush Current Cold Start : 50 A Hot : 120 A

6

7

8

Supported Sync. Type

Separate Sync.Digital

Analog

HDMI

Analog

HDMI

Horizontal 30 ∼ 83kHz

Vertical 56 ∼ 75 Hz

Horizontal 30 ∼ 83kHz

Vertical 56~61HZ

Max. 1920×1080 @ 60Hz

Recommend 1920×1080 @ 60Hz

Input :100 – 240 Vac, 50 or 60Hz, 1.0A

Output:19V 1.2A

Operating Condition

Sync

(H/V)

Video LED Wattage

On Mode

(ENERGY STAR

On/On Active White 19W(Max)

@standard)

On Mode On/On Active White

Sleep Mode

Off Mode

(Power switch off)

Off/On

On/Off

Off

Off/Off

- - Off < 0.3W

White

Blinking

Super Energys Saving Low/High/Off On White

MTBF 30,000 HRS with 90%

Confidence level

Lamp Life : 30,000 Hours(Min)

25W (typ)

29W(max)

< 0.3W

Efficiency up to:

Low:15%±5%(≥2W)

High:25%±5%(≥4W)

Using Altitude 5,000 m (for Reliability) 3,000m(for FOS)

Test condition

EPA6.0 Metho

d

Refer to P51

Test condition

1. 1920x1080

@60Hz

2. burst patter

3. 100~240V

4. After aging

30min

-Test Condition

(1)

n

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 8 -

LGE Internal Use Only

Page 9

9 Environme 0perating Temperature

nt

Condition

Storage Temperature

Humidity 10% ~ 80%

Humidity 5% ~ 90% non-condensing

BRIGHTNESS 0 ~ 100

COLOR TEMP

ORIGINAL RA

TIO

MENU

(Monitor b

lock)

BLACK LEVE BLACK LEVEL enabl

L e at HDMI input

10 °C ~ 35 °C

-20 °C ~ 60 °C

WARM

PRESET MEDIUM

COOL

RED

USER GREEN

BLUE

WIDE

ORIGINAL

▶ HIGH / LOW

OSD

MENU

MENU

(AV/TV bl

ock)

LANGUAGE ▶ ENGLISH

17 Language:

English, Germanic, F

rench, Spanish, Italia

n, Swedish, Finnish,

Portuguese Brazilian

Portuguese, Polish,

Russian, Greek, Chi

nese, Japanese, Kor

FACTORY RE

SET

▶ NO( /YES )

ean, Ukrainian

Hindi

CHANNEL

2~69(AIR) / 1 ~ 125(CABLE)

ADD/DEL CH ADD/DELETE

CHANNEL No Support:

AUTO CHANNEL ON/OFF

SELECT AIR/C

ABLE

FINE TUNE 0 ~ 100

CONTRAST 0~100

BRIGHTNESS 0~100

ADJUSTMENT SHARPNESS 0~100 No Support:

COLOR 0~100

TINT 0~100

AUDIO No Support:

VOLUME 0~100

BASS 0~100

TREBLE

0~100

SETUP

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

MUTE ON/OFF

SOUND

MONO/STEREO

LANGUAGE▶ English/German/French/Espe

ranto

Italian/Korean…

IMAGE SIZE ▶ FULL/1:1

OSD POSITION

TRANSPARENCY 0~100

- 9 -

No Support:

LGE Internal Use Only

Page 10

5. Applying module Character

Maker BOE

Type TFT

Active Display Area 521.28 (H)x293.22(V)

Pixel Pitch [mm] 0.2715(H)mm x 0.2715(V)mm.

LCD Module

1

Feature

Viewing Angle

2

<CR≥10>

Contrast Ratio(명암 비)

3

Electrical Interface 2ch-LVDS

Color Depth 16.7M colors

Size (Outline) [mm] 545.1 (W) x 320.5(H) x7.1(T) (Typ.)

Surface Treatment

Operating Mode TN mode, normally White

Back light Unit White LED

Haze 25%,3H hard coating

Horizontal(R/L) : +45º/-45º ( (Typ.)

Vertical(Top/Bottom) : +20º/-45º (Typ.)

700(MIN), 1000(TYP), DFC->5,000,000:1(Typ.)

4

5

Response Time On/off:5ms(TYP),

W

White

X

Minimum Normal Maximum

Typ-0.030

WY 0.329

W

WY

W

WY

R

X

RY

G

X

GY

B

X

BY

X

Typ-0.030

X

Typ-0.030

Typ-0.03

CIE Color

Coordinates

(색 좌표)

White

White

Red

Green

Blue

0.313

0.302

0.311

0.283

0.298

0.643

0.342

0.317

0.628

0.148

0.064

Typ+0.030

Typ+0.030

Typ+0.030

Typ-0.03

Warm

(6500K)

Medium

(8000K)

Cool

(9300K)

Warm

(6500K)

5.1 Display Area

1) Active Display Area of the LCD Monitor Should be within Cabinet’s Bezel.

2) Distance Difference between Active Area and Bezel

| A-B|<1.0 mm , | C-D|<1.0 mm

A: The Distance from The Left of Active Area to the Bezel

B: The Distance from The Right of Active Area to the Bezel

C: The Distance from The Top of Active Area to the Bezel

D: The Distance from The Bottom of Active Area to the Bezel

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 10 -

C

Active area

A

A A B

Bezel

D

LGE Internal Use Only

Page 11

6. EDID

6.1 24M35H

No Item Content

1 Manufacturer ID GSM 1E 6D

2 Product ID

3 Year 2013 17

4 Version 1 01

5 Revision Analog : 03 03

6 Serial Number

7 Week

8 Model Name

9 Check Sum

10 Special Item Need to Input Serial Number

* Protocol : DDC 2AB

Data ( 128 Bytes ) --Æ24M35H

EDID Ver. 1.3 FOR ANALOG ( 128Byte)

(Analog) 23118 5A4E

(HDMI) 23120 5A50

* *

** **

24M35

**** ****

16진 Data

--

EDID Ver. 1.3 FOR HDMI ( 256Byte)

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 11 -

LGE Internal Use Only

Page 12

(1) Signal(Video & Sync)

Video

Sync

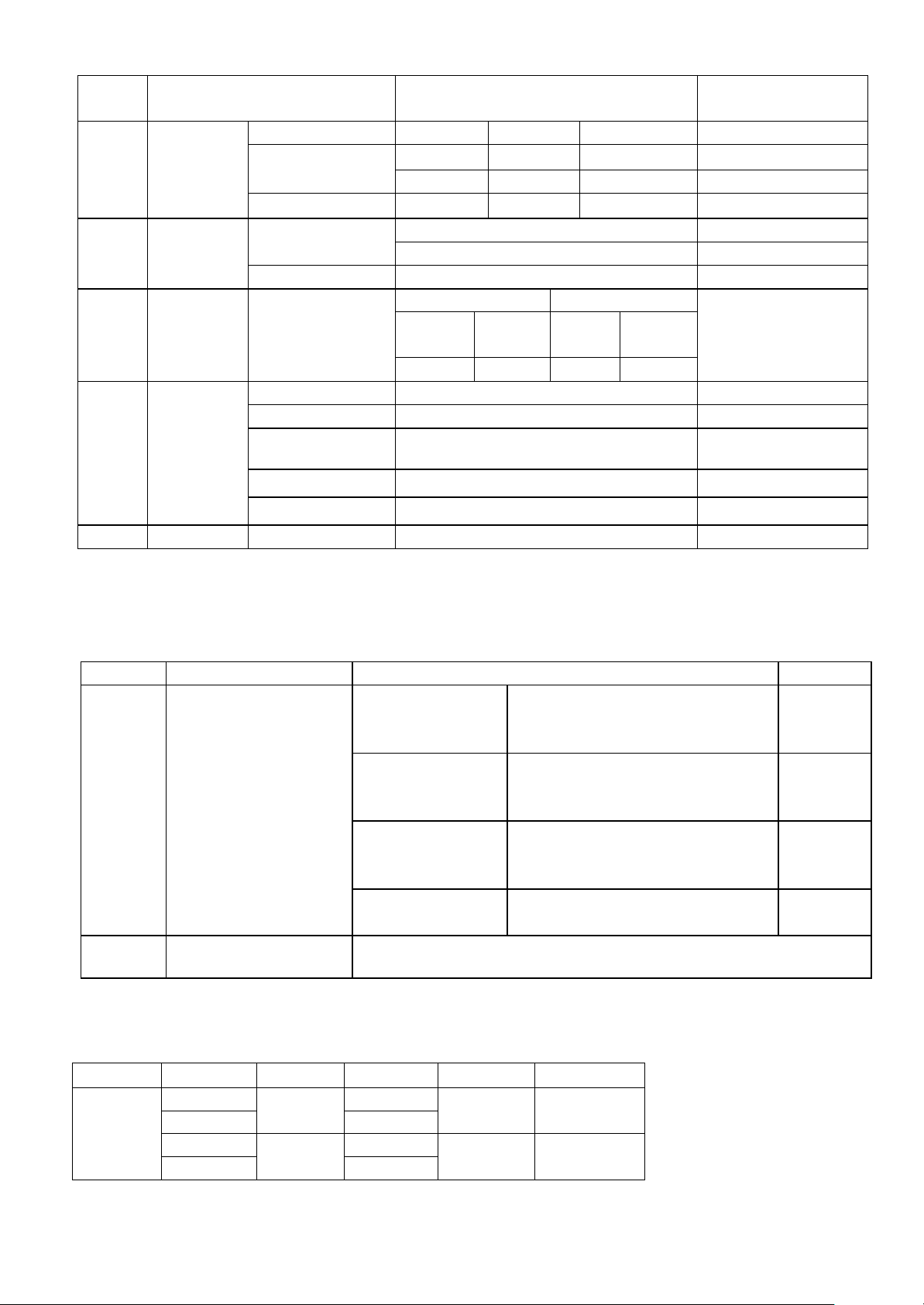

TIMING CHART

C

B

(2) H/V Timing

CLASSIF

MODE

ICATION

H(Pixels) -

1

V(Lines) + 70.08 449 400 12 2 35

H(Pixels) -

2

V(Lines) - 59.94 525 480 10 2 33

H(Pixels) -

3

V(Lines) - 75 500 480 1 3 16

H(Pixels) +

4

V(Lines) + 60.317 628 600 1 4 23

H(Pixels) +

5

V(Lines) + 75.0 625 600 1 3 21

H(Pixels) -

6

V(Lines) - 60.0 806 768 3 6 29

H(Pixels) +

7

V(Lines) + 75.029 800 768 1 3 28

H(Pixels) + 108.0 67.500 1600 1152 64 128 256

8

V(Lines) + 75.000 900 864 1 3 32

H(Pixels) +

9

V(Lines) + 60.02 1066 1024 1 3 38

H(Pixels) +

10

V(Lines) + 75.035 1066 1024 1 3 38

Polar

ity

DE

DOT

CLOCK

[MHz]

28.321

25.175

31.5

40.0

49.5

65.0

78.75

108.0

135.0

Frequency

[kHz]/

[Hz]

31.468 900 720 18 108 54

31.469 800 640 16 96 48

37.5 840 640 16 64 120

37.879 1056 800 40 128 88

46.875 1056 800 16 80 160

48.363 1344 1024 24 136 160

60.023 1312 1024 16 96 176

63.981 1688 1280 48 112 248

79.976 1688 1280 16 144 248

F

A

To ta l

Display

Period

(A)

(E)

Front

Porch

(D)

Sync.

(C)

Back

Resolut

Porch

ion

(B)

720 X

400

640 x

480

640 x

480

800 x

600

800 x

600

1024 x

768

1024 x

768

1152 x

864

1280 x

1024

1280 x

1024

11

12

H(Pixels) -

146.25

V(Lines) + 59.954 1089 1050 3 6 30

H(Pixels) +

148.50

V(Lines) + 60 1125 1080 4 5 36

65.290 2240 1680 104 176 280

67.50 2200 1920 88 44 148

z D-SUB/DVI DTV Mode is not supported (interlace mode)

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 12 -

1680 x

1050

1920 x

1080

LGE Internal Use Only

Page 13

Factory support

(Preset Mode)

mode

Horizontal

frequency

(KHz)

Vertical

frequency

(Hz)

HDMI

1 480P 31.5 60 O

2 576P 31.25 50 O

3 720P 37.5 50 O

4 720P 45 60 O

5 1080i 28.12 50 O

6 1080i 33.75 60 O

7 1080P 56.25 50 O

8 1080P 67.5 60

(Recommend Mode)

O

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 13 -

LGE Internal Use Only

Page 14

ADJUSTMENT

1. Coverage

Apply to 58.4

Gumi Korea) or made in accordance with the standard of Gumi

Factory process.

cm (23 inch)

Wide monitor made in Monitor Factory

2. Appointment

2.1 Adjustment must be done as fixed sequence, and adjustment

sequence can be modified after agreement withthe responsible

R&D engineer considering mass-production condition.

2.2 Power : AC 100 - 240 Voltage (Free)

2.3

Input signal:

2.3.1 RGB Input: As Product Standard (Signal ROM : LB800K

Ver1.6)

2.3.2 RJ-45 input : As Product Standard (Ethernet connection

through network from Host PC)

* PC spec for MK(Minikey) Loader (TBD): CPU - Dual core 2.0

GHzD, Memory - 2 GByteD

*PC spec for Host PC (TBD): CPU - Dual core 2.0 GHzD,

Memory - 2 GByteD

2.4 Warm-up Time: Over than 30 minutes

2.5 Adjustment

Display adjust equipment, VG-813(or VG819), Oscilloscope,

PC (More than 486

program.

equipment : White balance equipment (CA-110),

computer ) & White balance adjust

3. Adjustment

3.1 Overview

Use factory automation equipment and adjust automatic

movement. But, do via passivity adjust in erroroccurrence.

PC audio volume : MAX

* LAN cable

* Router

* PC: vSpace S/W for N+ ( Ver 4.5.xx.xx ) --- Caution: Ver

4.4.xx.xx for N1742L family

3.2.2 Total Assembly Line

· Ready : Heat-run during5 minutes in the state with signal

· Connect input signal to D-sub.

· Default value before adjustment : Contrast “70” , Brightness

‘100(Max)”

3.2.3 Adjustment of Horizontal/Verticality screen

position, Clock and Clock Phase at each Mode.

· There is no special factory mode adjustment. Writing initial value

of EEPROM in Board Assembly line is adjusting Preset Mode

and Reset mode. (EEPROM is initialized when AC Power is

ON first.)

· If the change of FOS data is needed after M.P, it is possible by

writing Mode Data with EEPROM write command or modifying

the Mode Data in MICOM itself.

3.2.4 Color coordinates adjustment and Luminance

adjustment.

3.2.4.1 Color coordinates adjustment

· Monitor Contrast / Brightness

- Contrast : 70

- Brightness : 100(Max)

· CA-110: Set “channel 9”

· Signal Generator : At cut-off and drive --> 16 step pattern for

ADC (Program No.: 31)

- Output Voltage : 700 mVp-p

- Output Mode : Mode 12 (SXGA 60 Hz)mode Setting.

3.2 Adjustment order

(refer to the Adjustment standard and adjustment command table)

3.2.1 Board Assembly Line

3.2.1.1 15pin D-sub (RGB)

· Connect input signal to 15pin D-sub.

· Check the firmware version & model name. And write the

firmware code to the serial Flash ROM by ISP.

· Ready for adjustment : check whether adjustment command

works normally or not and the operating state of each mode.

· Check the display state of gray color when 256 gray scale

patterns is embodied.

· Read by EEPROM Read Command to check whether initial

value is correct or not.

3.2.1.2 MK( Minikey ) Loading

· Open MK Loader Tool on MK Loader PC.

( * MK Loader PC should be connected Internet)

· Connect input signal to RJ-45 input with LAN cable connected

network devices such as routers.

· Turn on the Monitor set.

· Click the box when the °∞empty port °∞box is changed to “write

mini-key” in MK Loader Tool.

3.2.1.2 RJ-45 input

· Connect input signal to RJ-45 input with LAN cable connected

network devices such as routers.

· Check USB 1.1 Port (Keyboard/ Mouse) : @RJ-45 input

· Check USB 2.0 Port (USB Memory Stick 2port) : @RJ-45 input

· Check Audio (Ear-phone out/ Mic in/ Speaker) : @RJ-45 input,

3.2.4.2.Adjustment : Board Assembly Line

· Select RGB mode

16 step pattern for ADC (Program No.31 (Mode 12,Pattern

· Input

11)). (Video level : 700 mVp-p)

· Adjust by commanding AUTO_COLOR_ADJUST

· Confirm “Success” message in Screen or Check the data of

0xFE, 0xFF address of EEPROM(0XA6) is 0xAA after waiting 5

seconds.

· If there is “FAULT” message or the data of 0xFE, 0XFF address

of EEPROM(0xA6) is not 0xAA, do adjust again.

· If all Adjustment is completed, the values of 6500K, User Color

and 9300K are saved automatically.

· Select RGB mode

· Input 16 step pattern for ADC (Program No.31 (Mode 12,Pattern

11)). (Video level : 700mVp-p)

· Adjust by commanding AUTO_COLOR_ADJUST

· Confirm “Success” message in Screen or Check the data of

0xFE,0xFF address of EEPROM(0xA6) is 0xAA after waiting 5

seconds.

3.2.4.3. Confirm at Total Assembly Line: adjustment

· Check the data of 0xFE, 0xFF address of EEPROM(0xA6) is

0xAA.

· If the data of 0XFE, FF address of EEPROM(0xA6) is not

0xAA, do adjust again by 3.2.4.2.

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 14 -

LGE Internal Use Only

Page 15

3.2.4.4. Confirm PRESET 6500K Color coordinates and Adjust

PRESET 9300K Color coordinates .

· Set as Aging mode ON, by commanding AGING_ON/OFF

command code.

· Select Module that is being used in present production by

commanding MODULE SELECT. ( It is not needed so far.

However, it will be needed to apply other modules)

· Send SYSTEM RESET command to set Module data.

· Input Full White Pattern (Video level : 700 mVp-p)

· Set as 9300K by commanding COLOR_MODE_CHANGE

Command code.

· Check to meet x = 0.283 ± 0.03, y=0.298 ± 0.03, and confirm.

· Only if it does not meet, adjust as below steps.

· Adjust to meet x = 0.283 ± 0.01, y=0.298 ± 0.01 in 5 minutes. and

confirm.

· Save 9300K Color by commanding COLOR SAVE Command

code.

· Set as 6500K by commanding COLOR_MODE_CHANGE

Command code.

· Check to meet x = 0.313 ± 0.03, y=0.329 ± 0.03, and confirm.

· Only if it does not meet, adjust as below steps.

· Adjust to meet x = 0.313 ± 0.01, y =0.329 ± 0.01, and confirm.

· Save 6500K Color by commanding COLOR SAVE Command

code.

· Set as sRGB by commanding COLOR_MODE_CHANGE

Command code.

· Adjust to meet Y = 150 ± 50, and confirm.

· Save sRGB Color by commanding COLOR SAVE Command

code.

3.2.4.5. Confirm User color coordinates .

· Confirm Whether User color is saved same as 6500K.

· After confirming Color coordinates, Must return to 6500K

3.2.5 Confirm Operation state.

3.2.5.1 Operation mode : Confirm whether each appointed mode

operate correctly or not.

3.2.5.2 Confirmation of Adjustment condition and operation :

Confirm whether it meet Auto/Manual equipment Adjustment

standard or not.

· Confirm Analog screen state : Confirm screen state at below

mode.

Appointment mode (RGB input):

640*480 @60Hz (Mode 1),

800*600@75Hz(Mode 5),

1024*768@60Hz(Mode 8),

1280*1024@60Hz(Mode 12),

SMPTE pattern(Check 0%,5%,95%,100%)

–Mode can be added.

3.2.5.3. Confirm Auto adjustment operation.

· Input Analog 1 Dot on/off & Rectangle Pattern at Mode

12(1280x1024@60 Hz)

· Confirm adjustment operation by changing Clock, Phase, H/V

Position.

· Check Clock, Phase by pressing AUTO Key.

· Confirm first set of new lot by periods

3.2.5.4 Other quality

· Confirm that each items satisfy under standard condition that was

written product spec.

· Confirm Applying Module & MICOM Setting --> Confirm with

Service OSD

- Confirm at Service OSD by “Menu + Power key” on .(from

Power off)

- Confirm first set of new lot by periods, and confirm periodically

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

when there is Process change or Adjustment setting change.

3.2.5.5. OSD & Adjustment device Confirmation : Confirm

operation mentioned as product spec.

· Vary Brightness and Contrast and confirm the variation of

Luminance and display status.

· Operate the f-engine function and confirm variation of Luminance.

· Make sure to do FACTORY RESET after confirmation of OSD

function.

3.2.5.6. Confirm the display state by inputting 8 color Bar Pattern &

256 Gray Scale pattern.

3.2.5.7. DPM operation confirmation : Check if Power LED Color

and Power Consumption operates as standard.

· Measurement Condition : 230 V@ 50 Hz (Analog)

· Confirm DPM operation at the state of screen without Video

Signal.

3.2.5.8. RJ-45 input

· Connect input signal to RJ-45 input with LAN cable connected

network devices such as routers.

· Check USB 1.1 Port (Keyboard/ Mouse) : @RJ-45 input

· Check USB 2.0 Port (USB Memory Stick 2port) : @RJ-45 input

· Check Audio (Ear-phone out/Mic in/Speaker) : @RJ-45 input, PC

audio volume : MAX

* LAN cable

* Router

* PC: vSpace S/W for N+ ( Ver 4.5.xx.xx ) --- Caution: Ver

4.4.xx.xx for N1742L family

3.2.5.9. DDC EDID Write

( Set as Aging mode ON, by commanding AGING_ON/OFF

command code. )

1) SUFFIX: xxxxxPN

· Connect analog Signal Cable to D-sub wafer.

· Write EDID DATA to EEPROM(24C08) by using DDC2AB

protocol.

· Check whether written EDID data is correct or not.

(refer to Product spec).

--> After writing EDID, send Elapsed Time Clear command.

(Elapsed time should not be displayed, after EDID writing)

: Confirm periodically (in the first set of new lot, process change)

whether module name and aging time disappeared on the selfdiagnostics OSD with signal cable disconnected.

--> If Elapsed Time Clear command isn°Øt executed, module

name, aging time and TCO word appear on the self-diagnostics

OSD.(Module name and aging time should not appear after

writing EDID)

--> Make sure to do FACTORY RESET at the final process.

3.2.5.10. Shipping condition

· Contrast : 70

· Power Switch : Off

· Brightness : “100(Max)”

· Color Select : Preset ( 6500K )

· Language Select : Refer to product spec.

· OSD Position : Center

· Power indicator : ON

· Flatron f-engine : Normal

- 15 -

LGE Internal Use Only

Page 16

4.Standard of Auto/Manual equipment adjustment

No. Item Adjustment & measurement

standard

1 Voltage(V) 12V± 0.6 V

5V± 0.3V / 3.3V± 0.25V

2 Color

coordinates

(9300/6500K)

Color

3

coordinates

(6500K)

Color

coordinates

(9300K)

Luminance 6500K More than

Position

5 Screen

Compensation

6 DPM

Confirmation

(RGB/LAN)

7

8 Withstanding Voltage

9

10 Cutoff /ADC Adjustment Pattern

11 Network Test with PC

Gray scale Confirmation Linear gray Scale MODE 12 Pattern 9 Full screen

confirmation

Ground Confirmation

Black

Level

DRIVE1

DRIVE2

H 4 Screen

V

CLOCK

PHASE

AUTO FULL SIZE MODE

Normal Mode 40W(Typ) Pattern 4 Blue

Stand By Mode 1W/ - Pattern 6

Suspend Mode 1W/ - Pattern 7 Flicker

DPMS Off 1W/15W Pattern 8 Flicker

Power Switch

Off

2.5V± 0.2V

Auto Adjustment MODE 12 Pattern 0

u uí= 0. 198 ± 0. 00 5

v ví=0.468± 0.005

X

Y

220 cd/m2

FULL SIZE MODE

When 1500Vac or 2121Vdc is

impressed between the first of

power (Live/Neutral) and

ground (Earth) for 1 second,

check whether something

wrong happens or not.

When 25A is impressed

between Earth and 2nd Ground

for 1 second, Resistance must

be less than 0.1

1280*1024@60Hz (700mVp-p)

CPU : Dual core 2.0 GHz

Memory : 2 GByte

Teradiciís PCoIP Host Card

LAN cable

0.283± 0.004

0.298± 0.004

FULL SIZE

1W

16 step pattern for ADC

,

Operation

mode

MODE 13 Pattern4

MODE 12 Pattern1

MODE 12

(700 mVp-p)

MODE

1 - 13

12-13

12-13

MODE 12

MODE 12 Pattern11

,

1280 * 1024

Operation

Pattern

Pattern1

Pattern4 Full Screen

Pattern 4

Pattern 4

Measurement

Position

Each power

of Screen

of Screen

of Screen

Full screen

Full screen

TP of

Center

Center

Center

Flicker

off

*Check items No. 2, 3, 4, 5 and 7 at RGB input.

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 16 -

LGE Internal Use Only

Page 17

5. Pattern for Adjustment

Pattern 0 : FULL BLACK (State of without video signal )

Pattern 1 : FULL WHITE (Don’t display other Character except for White Pattern)

Pattern 3 : FULL WHITE

Pattern 4 : Cross hatch pattern (Horizontal 10Line, Vertcial 8Line) & Rectangle Pattern

Pattern 5 : 1 Dot on, 1 Dot off & Rectangle Pattern

Pattern 6 : Vertical Sync only input (Use signal cable of which Pin #5 is GND)

Pattern 7 : Horizontal Sync only input (Use signal cable of which Pin #5 is GND)

Pattern 8 : State of without Vertical/Horizontal Sync and Video Signal. (Use signal cable of which Pin #5 is GND)

Pattern 9 : 8 Color Bar Pattern + 16 Gray Level Pattern

Pattern 10 : SMPTE Pattern

Pattern 11 : 16 Gray Step Pattern (700mV)

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 14 -

LGE Internal Use Only

Page 18

BLOCK DIAGRAM (Main)

PANEL

S

FUNCTION/AUTO/INPUT(Exit)

(IPS ,FHD)

V_LED

21.5” 23.8”

LVDS

HDMI IIC

24C02

Embedded

LED Driver

NT6877x

(Novatek)

RGB IIC

HDMI_TMDS

HDMI 1

R/G/B/H/V

RGB

H/P

LED

SPI

(White)

CLK

Data/

Key 0/1

4M

SERIAL

6 Keys : Power/MENU/MY KEY/

Flash

LED B/L

19V

From Adapter

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

T-Con 5V

19-to-5V DC/DC

- 15 -

2Ch LDO

System 3.3V

System 1.2V

LGE Internal Use Only

Page 19

TROUBLESHOOTING GUIDE

1. NO POWER

JK100

IC 102

IC 102

IC 102

IC 201

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 16 -

LGE Internal Use Only

Page 20

2. NO RASTER (OSD IS NOT DISPLAYED) – MAIN

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 17 -

LGE Internal Use Only

Page 21

3. TROUBLE IN DPM

Copyright © 2010 LG Electronics. Inc. All right reserved.

Only for training and service purposes

- 18 -

LGE Internal Use Only

Page 22

500

420

400

910

900

540

or

200

330

300

2010

Page 23

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 24

PDF created with pdfFactory Pro trial version www.pdffactory.com

Page 25

Loading...

Loading...