Page 1

COLOR TV

SERVICE MANUAL

CAUTION

BEFORE SERVICING THE CHASSIS,

READ THE SAFETY PRECAUTIONS IN THIS MANUAL.

CHASSIS : CW81A

MODEL : 21FU3RL

21FU3RL-T3

website:http://biz.LGservice.com

Internal Use Only

Page 2

- 2 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

CONTENTS

Contents ....................................................................................................2

Safety Precautions....................................................................................3

Specifications............................................................................................4

Adjustment Instructions...........................................................................5

Trouble Shooting ......................................................................................8

Block Diagram.........................................................................................13

Exploded View.........................................................................................14

Exploded View Parts List .......................................................................15

Replacement Parts List ..........................................................................16

SVC. Sheet...................................................................................................

Page 3

- 3 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

SAFETY PRECAUTIONS

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These parts are identified by in the

Schematic Diagram and Replacement Parts List.

It is essential that these special safety parts should be replaced with the same components as recommended in this manual to prevent

X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

General Guidance

An isolation Transformer should always be used during the

servicing of a receiver whose chassis is not isolated from the AC

power line. Use a transformer of adequate power rating as this

protects the technician from accidents resulting in personal injury

from electrical shocks.

It will also protect the receiver and it's components from being

damaged by accidental shorts of the circuitry that may be

inadvertently introduced during the service operation.

If any fuse (or Fusible Resistor) in this TV receiver is blown,

replace it with the specified.

When replacing a high wattage resistor (Oxide Metal Film Resistor,

over 1W), keep the resistor 10mm away from PCB.

Keep wires away from high voltage or high temperature parts.

Due to high vacuum and large surface area of picture tube,

extreme care should be used in handling the Picture Tube. Do

not lift the Picture tube by it's Neck.

X-RAY Radiation

Warning:

To determine the presence of high voltage, use an accurate high

impedance HV meter.

Adjust brightness, color, contrast controls to minimum.

Measure the high voltage.

The meter reading should indicate

23.5 ± 1.5KV: 14-19 inch, 26 ± 1.5KV: 19-21 inch,

29.0 ± 1.5KV: 25-29 inch, 30.0 ± 1.5KV: 32 inch

If the meter indication is out of tolerance, immediate service and

correction is required to prevent the possibility of premature

component failure.

Before returning the receiver to the customer,

always perform an AC leakage current check on the exposed

metallic parts of the cabinet, such as antennas, terminals, etc., to

be sure the set is safe to operate without damage of electrical

shock.

Leakage Current Cold Check(Antenna Cold Check)

With the instrument AC plug removed from AC source, connect an

electrical jumper across the two AC plug prongs. Place the AC

switch in the on position, connect one lead of ohm-meter to the AC

plug prongs tied together and touch other ohm-meter lead in turn to

each exposed metallic parts such as antenna terminals, phone

jacks, etc.

If the exposed metallic part has a return path to the chassis, the

measured resistance should be between 1MΩ and 5.2MΩ.

When the exposed metal has no return path to the chassis the

reading must be infinite.

An other abnormality exists that must be corrected before the

receiver is returned to the customer.

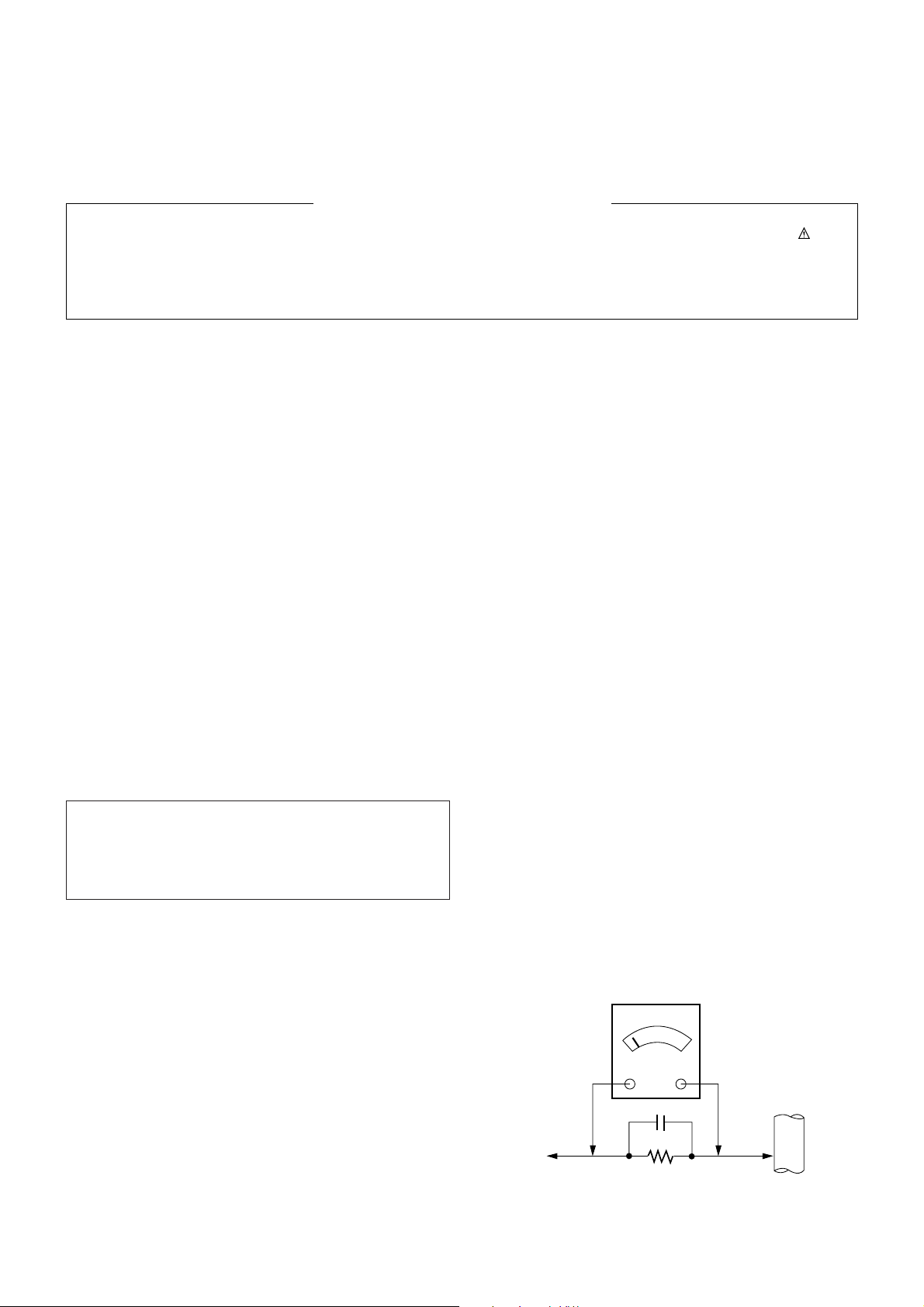

Leakage Current Hot Check (See below Figure)

Plug the AC cord directly into the AC outlet.

Do not use a line Isolation Transformer during this check.

Connect 1.5K/10watt resistor in parallel with a 0.15uF capacitor

between a known good earth ground (Water Pipe, Conduit, etc.)

and the exposed metallic parts.

Measure the AC voltage across the resistor using AC voltmeter

with 1000 ohms/volt or more sensitivity.

Reverse plug the AC cord into the AC outlet and repeat AC voltage

measurements for each exposed metallic part. Any voltage

measured must not exceed 0.75 volt RMS which is corresponds to

0.5mA.

In case any measurement is out of the limits specified, there is

possibility of shock hazard and the set must be checked and

repaired before it is returned to the customer.

Leakage Current Hot Check circuit

The source of X-RAY RADIATION in this TV receiver is the High

Voltage Section and the Picture Tube.

For continued X-RAY RADIATION protection, the replacement

tube must be the same type tube as specified in the

Replacement Parts List.

IMPORTANT SAFETY NOTICE

0.15uF

To Instrument's

exposed

METALLIC PARTS

AC Volt-meter

Good Earth Ground

such as WATER PIPE,

CONDUIT etc.

1.5 Kohm/10W

Page 4

- 4 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

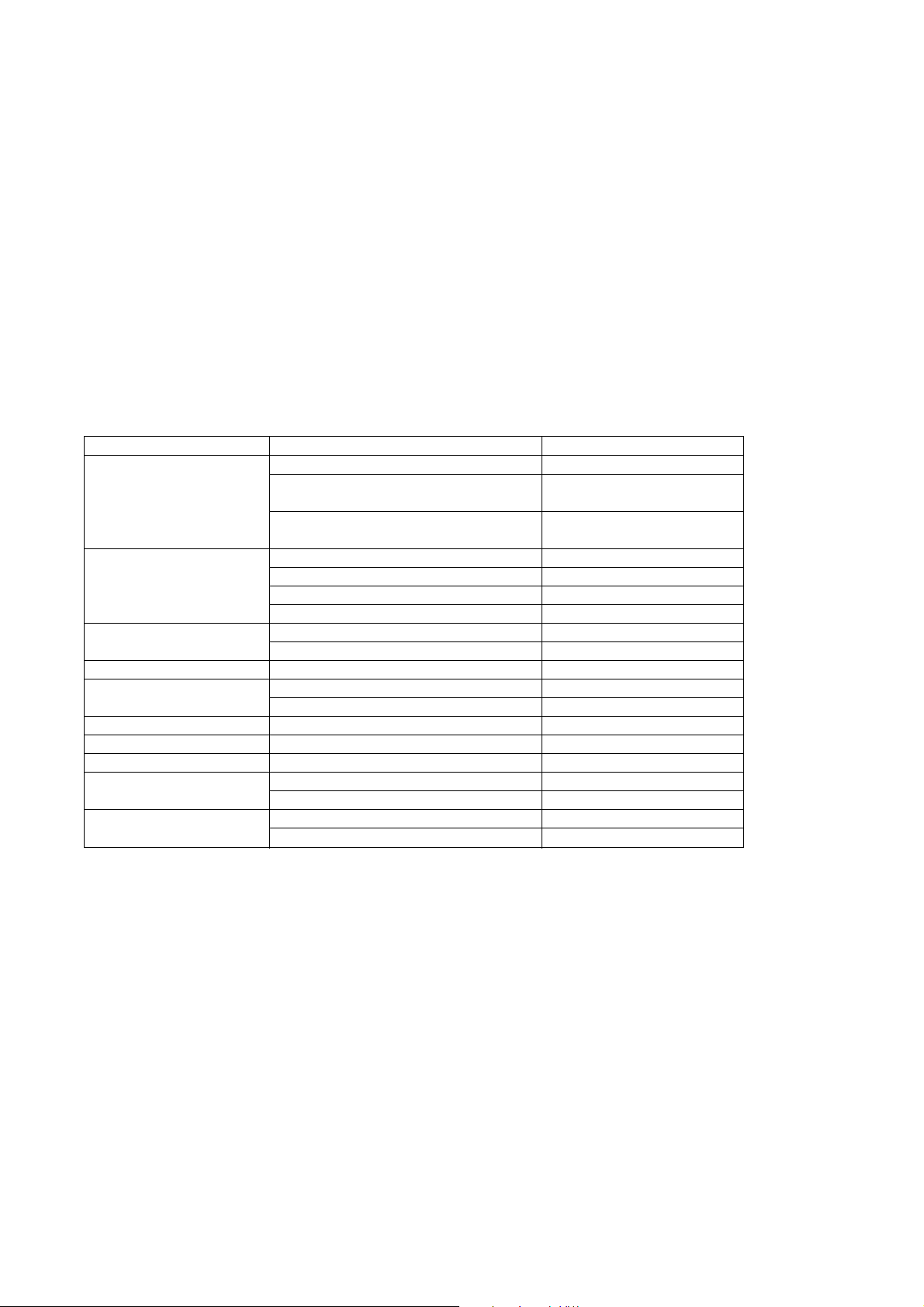

SPECIFICATIONS

Note : Specification and others are subject to change without notice for improvement.

1. Scope

This specification is applied to the CW81A Chassis.

2. Test and Inspection Method

1) performance : LGE TV test method followed.

2) Demanded other specification

- Safety: CB Spec.(EN60065)

- EMC: CE Spec.(EN55020,EN55013)

3. Test Condition

Each part is tested as below without special appiontment

1) Temperature : 20

± 5°C(77 ± 9°F), CST : 40 ± 5°C

2) Relative Humidity : 65

± 10%

3) Power Voltage : Standard input voltage 220V, 50/60Hz

* Standard Voltage of each products is marked by models.

4) Specification and performance of each parts are followed

each drawing and specification by part number in

accordance with B.O.M.

5) The receiver must be operated for about 20 minutes prior to

the adjustment.

Item Specification Remark

Receiving System PAL BG,DK,I / NTSC M(AV3.58/4.43) China/ Indonesia/ Thai/ Vietnam

PAL BG,DK,I / NTSC M(AV3.58/4.43) CIS

SECAM DK

PAL BG,DK,I / NTSC M(AV3.58/4.43) Asia/ Middle East/ Africa

SECAM BG,DK,L

Available Channel VHF : E2 ~ E12

UHF : E21 ~ E69

CATV : S1 ~ S20

HYPER : S21 ~ S41

Input Voltage 220V~, 50/60Hz East Asia

100-240V~, 50/60Hz Others

Market China, Indonesia, Thai, Vietnam, Asia/Africa

Screen Size 14 ~ 21 inch (Flat / Conventional)

21” Super slim/ultra slim

Aspect Ratio 4:3

Display Method CRT

Tuning System FVS

Operating Environment 1) Temp : 0 ~ 40 deg

2) Humidity : ~ 85 %

Storage Environment 3) Temp : -20 ~ 60 deg

4) Humidity : ~ 90 %

4. General Specification

Page 5

- 5 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1. Application Object

These adjustment instructions are applicable to CW81A/B

Chassis.

2. Notes

(1) Because this is a cold chassis, it is not necessary to use

an isolation transformer. However,operating it using a

transformer between the power supply line and chassis

input to prevent electric shock and to protect the test

instrument.

(2)All adjustments must be done in correct sequence.

However, for better productivity, it can be changed in a prepermitted range.

(3) Environment conditions: If not specified, it must be done in

following conditions.

1) Temperature: 25±5°C

2) Humidity : 65±10%

(4) AC Voltage : 100-240V ±10%, 50/60Hz

(5) If not specified, the receiver must be operated for more

than 20 minutes prior to the adjustment.

(6) Signal: Received the standard color signal. (65dB±1dBuV)

PAL/SECAM : LG standard signal means the digital pattern

PAL_EU 05CH

(7) If not specified, APC ON is APC CLEAR(DYNAMIC).

3. AGC Voltage Adjustment

3-1. Necessary Instrument

: Digital Multi meter : 1 set

- Max Input Current : Over 1A/ Max Input Voltage : 500Vdc

- Measurement Range : 10mV-100mVdc/ Accuracy : 0.03%

3-2. Adjustment Preparation

1) Input in the 75Ω cable 65dB(±1dB) LG standard signal.

2) Connect the multi-meter to J105(AGC Check Marking)

3-3. Adjustment

(1) Press the “INSTART” key of factory remote control and

select “VP0 (RF AGC)” adjustment mode.

(2) Press the VOL +/-(

F/G)Key until the multi-meter shows

reading as shown below.

(3) CAUTION : Since the signal strength can be easily

changed by the condition of signal cable , you

need to check the signal strength frequently in

order to prevent misadjustment.

4. Screen Voltage Adjustment

4-1. Adjustment (Use factory remote control)

(1) Input in the 75Ω cable LG standard signal (Digital

Pattern,480NC)

(2) Press the “ADJ” key of factory remote control once to make

the TV set display horizontal line.

(3) Turn the screen volume on the FBT clockwise until the

horizontal line is visible and turn it counterclockwise until

horizontal line faintly visible.

(Exit screen voltage adjustment by press “Enter(

A)” key of

factory remote control.)

5. Purity and Convergence Adjustment

5-1. Purity Adjustment

(1) Adjustment Preparation

1) Receive Red Raster Pattern for purity adjustment.(51ch)

2) Demagnetize the CPT and Cabinet with a degaussing

coil.

(2) Adjustment

1) Pre-adjust the static convergence (STC) with the 4 and

6pole magnet.

2) If the horizontal Line is inline with CPT Mark,2-Pole

magnet should direct 3-9 o’clock direction

3) If not,direct 2-Pole magnet handle toward 6-12 o’clock

direction and adjust the Horizontal Line to fall onto the

mark opening the magnet at an angle.

4) Push the DY(deflection yoke) all the way to the CPT

funnel.

5) Turn the purity magnet(2-pole magnet) so that the

“green” color portion of left side and the “blue” color

portion on the right side have equal amount of

color.

6) Pull the DY slowly backward and fix it when the whole

screen becomes red. (The specified torque for fixing DY

screw should be 10Kg/cm.)

5-2. Convergency Adjustment

(1) Necessary Instrument

1) Degaussing Coil

2) Convergency fixing instrument (special tools)

(2) Adjustment Preparation

1) Operate the unit at the least 15 minutes before

adjustment.

2) Using degaussing coil,remove the stains on CPT &

Cabinet.

3) Received the Cross Hatch Pattern for Convergence

(09ch).

4) Let the Contrast in normal luminance level.

ADJUSTMENT INSTRUCTIONS

G R B

G R B

R

G R B

<Fig. 1>

<Fig. 2>

Page 6

- 6 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

(3) Static Convergence (STC) Adjustment

1) Receive Cross Hatch Pattern (09CH).

2) Before adjusting Static Convergence(STC),adjust the

focus first seeing to it that the WHITE color picture

quality is sharp enough.

3) Converge the RED vertical line and BLUE vertical line in

unity(same line) by changing the angle between the 2

tabs of 4-pole magnet.

4) Converge the RED horizontal and BLUE horizontal line

unity(same line) by turning the 2 tabs of the 4-pole

magnet. At this time,do not change the angle between

the 2 tabs.

5) Converge the R,G,B vertical line in unity(same line) by

changing the angle between the 2 tabs of the 6-pole

magnet.

6) Converge the R,G,B horizontal line in unity(same line) by

turning the 2 tabs of the 6-pole magnet. At this time, do

not change the angle between the 2 tabs.

(4) Dynamic Convergence (DYC) Adjustment

1) Y-Axis Adjustment : Ad j u s t convergence of Y-axis

(vertical) by moving the deflection

yoke(DY) left and right.

2) X-axis Adjustment : Adj u s t convergence of X-axis

(horizontal) by moving the deflection

yoke(DY) up and down.

6. White Balance Adjustment

6-1. Necessary Instrument

(1) Au to White B a l ance Meter (Low/High light Pattern

generator)

(2) CRT Color Analyzer, CA-100 : 1set

(3) Factory Remote Control

6-2. Adjustment Preparation

: Prior to this adjustment, the Screen Voltage adjustment

should be finished.

6-3. Auto Adjustment

(1) Adjust the using Auto White Balance Meter.

(2) Enter CPU OFF mode by press the “IN-START” &”MUTE”

key of factory remote control in turn before adjustment.

Exit CPU OFF mode by press the “MUTE” key of factory

remote control after adjustment finished.

* In case there is excess RED color at screen voltage

adjustment, adjust it using “Volume -(

G)”Key of factory

remote control until the RED color disappear.

6-4. Manual Adjustment

(1) Adjust using white Balance meter and factory remote

controller.

(2) Enter into adjustment mode by pressing the INSTART key

of factory remote control.

(3) Use the CH

D, CHE Key to choose adjustment item.

(4) Use the VOL

F, VOLG Key to change item data.

(5) Adjustment Procedure

1) Make the picture luminance 45Ft-L by change the

“CONTRAST” and “BRIGHTNESS”.

2) Adjust X data of high light with R DRIVE and Y data of

high light with B DRIVE to have color temperature as

shown below.

3) Make the picture luminance 4.5Ft-L by change the

“CONTRAST” and “BRIGHTNESS”.

4) Adjust X data of low light with R BIAS and Y data of low

light with B BIAS to have color temperature as shown

below.

5) Repeat steps a~d until both low and high light have

same reading as shown below.

7. Focus Voltage Adjustment

This adjustment must be done after operating the TV set

receiver sufficiently.

7-1. Adjustment Preparation

Received the LG standard pattern (PAL : Digital Pattern,

480NC, 13CH, NTSC : Crosshatch pattern, Ch.09 ) and set

the picture condition on “APC ON” (CLEAR) mode.

7-2. Adjustment

Turn the focus volume on the FBT upper direction to have the

best focus vertical line (figure 1.(a)) and horizontal line (figure

1.(b)) as shown below.

8. SUB-BRIGHTNESS Adjustment

This adjustment must be done after the White balance

Adjustment.

8-1. Adjustment preparation

(1).NTSC

- Received LG standard Mono scope pattern (CH14).

- Set the picture condition on “APC ON” (CLEAR) mode.

(2). PAL

- Received PAL B/G 5CH pattern.

- Set the picture condition on “PSM ON” (DYNAMIC) mode.

MARKET COLOR TEMPERATURE X-AXIS Y-AXIS REMARK

ALL 13000 268 ± 5 273 ± 5

[ f i gur e 1- PAL]

(a)

(b)

[figure 1- NTSC]

Page 7

- 7 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

8-2 Adjustment

(1) Press the “ADJ” key of the factory remote control twice to

enter to “SUB-BRIGHTNESS” adjustment mode.

(2) PAL MODEL : Change the Sub-Brightness data by

pressing the VOL

F,VOLG KEY so that the 1th, 2th Black

Level in gray scale of PAL B/G 05CH pattern have a little

bit of difference. (See figure 2)

8-3. Sub-Tint Adjustment

This adjustment has to be done only if the picture has bad tint

otherwise, it can be omitted if the picture has good tint.

(1) Received LG standard pattern signal (SMPTE, 2CH).

(2) Set the picture condition on “APC ON” (CLEAR) mode.

(3) Press the “ADJ” key of the factory remote control three

times to enter to “SUB-TINT” adjustment mode.

(4). Change the Sub-Tint data by pressing the VOL¢∏,VOL¢∫

Key until the upper and lower CYAN color becomes same

color.

9. Deflection setting data adjustment

These adjustment will be done by Auto Adjustment

Equipment.

For manual adjustment, it is also possible by the following

procedure.

9-1. Adjustment Preparation

(1) Deflection setting data adjustment can be done only with

remote control.

(2) Press the “INSTART” Key on the factory remote control

continuously to enter to Deflection Adjustment mode.

(3) Press the CH

D, EKey to select adjustment item.

(4) Press the VOL

F, G Key to change the data.

9-2. Adjustment

(1) Horizontal Position Adjustment

Select SVC02 (H-POS) and adjust so that the left and right

vertical line are symmetrical as possible.

(2) Vertical Position Adjustment

Select SVC02 (V-POS) and adjust so that the horizontal

center line coincide with geometric horizontal center of the

CPT.

(3) Vertical Size Adjustment

Select SVC02 (VA) and adjust so that the middle circle of

the Digital Pattern (480NC, 13CH) coincide with the

effective screen of CPT.

9-3. Adjustment (21” Super Slim, Ultra S/S Model)

(1) Vertical Position Adjustment

Select SVC02(V-POS) and adjust so that the horizontal

center line coincide with geometric horizontal center of the

CPT.

(2) Vertical Linearity Adjustment.

Select SVC02(V-LIN) and adjust so that the size of the

upper circle is alike with the one of the lower circle at LG

standard pattern signal (PAL : EU05CH, NTSC : 13CH).

(3) Vertical Size Adjustment.

1) NTSC :Select SVC02(VA) and adjust so that the middle

circle of the Digital Pattern (480NC, 13CH) coincide with

the effective screen of CPT.

2) PAL : Select SVC02(VA) and adjust so that the middle

circle of the Digital Pattern (PAL B/G 5CH) has 6~7mm

gaps from the effective screen of CPT.

(4) Horizontal Position Adjustment

Select SVC02(H-POS) and adjust so that the left and right

vertical line are symmetrical as possible.

(5) Horizontal Size Adjustment

Select SVC02(EW WIDTH) and adjust so that the outer line

of the left, right and the remotest grid will correspond to the

effective boundary surface.(The remotest grid, NTSC:

within 2.5 ~ 3.0 column, PAL: within 0 ~ 25%)

(6) Parabola Adjustment

Select SVC02 (EW PARAB) and adjust so that the vertical

line of the remotest grid at the left or right side of the screen

will be parallel to the vertical line of the center of screen

(7) Trapezoidal Adjustment

Select SVC02(EW TRAPE) and adjust so that the width of

the upper part of screen is alike with the one of the lower

part of screen.

(8) EW UPCOR/ LOCOR Adjustment

Select SVC02(EW UPCOR, EW LOCOR) and adjust so

that the vertical line in the four corners become straight

line.

(9) BOW Adjustment

Select SVC02(HP BOW) and adjust so that the vertical line

in the four corners become straight line.

[Fig.2] PAL B/G 05CH signal

1th VS 2th

BLACK LEVEL have a little bit of difference.

(In case of VIETNAM MODEL 2th VS 3th)

Page 8

- 8 -

TROUBLE SHOOTING

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

1. TV FUNCTIONAL

2 TU/IF SECTION

J512, J544

Page 9

- 9 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

3. VIDEO PROCESSING

Maneuver defectiveness

Maneuver defectiveness

In case of influx NOISE

- R/C is not operate

Maneuver defectiveness

J624, J625, C603, C604, C609,

C610, R605, R616, R611, R612

, J509

Q241,R247

No color

1, 2, 5

56, 57

52, 54

35, 36, 40

50~54

46~48

4, 9, 20, 24,

49, 62

17~23

LV762xx

4. SMPS PRIMARY

DB801(TS4805G),

DB802(D5SB60)

IC810(STR-W6553A(MONO)), (STR-W6554A(STEREO))

C852, R808, ZD851

Page 10

- 10 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

5. SMPS SECONDARY SECTION

DB801(TS4805G),

DB802(D5SB60)

IC810(STR-W6553A(MONO)), (STR-W6554A(STEREO))

C852, R808, ZD851

6. VERTICAL SECTION

, STV9326

Page 11

- 11 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

7. HORIZONTAL SECTION

L402, L403, L404, C401, C402, C412

8. SOUND PROCESSING SECTION

(LV762xx)

(LC75024/LA72702)

Page 12

- 12 -

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

9. CPT DRIVE SECTION

8

D902

D902

Page 13

- 13 -

BLOCK DIAGRAM

LGE Internal Use OnlyCopyright © 2008 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LA7621 3

LA76213

DVD

(FLAT OPT.)

DVD

(FLAT OPT.)

CPT DRIVECPT DRIVE

FBT

185V

AFC

ABL

HEATER

B+

HDT

Collector

AV1(V/ R/ L)-IN

USOC

H/ P AV-IN

AUDIO B+

B+

(110/ 115V)

(17V/11V)

SMPS

TRANS

SPK.

Front-AV(2)

SCLSDA

EXT

Vid eo-i n

RGB

OUT

TUNER

V_DY

VERTI CAL AMP

STV9 32 6

Rear_AV( 1 )

( PHONE)

Rear_AV( 1 )

( PHONE)

IC02

EEPROM

24C04/16

V-O UT

H-OUT

SPK.

10.5V

Y(G) /C r( R) / Cb( B)

SDA

SCL

LC75024E

A2/ NICAM

MONO

SOUND AMP

LA42101

MONO

SOUND AMP

LA42101

AC

INPUT

(100~240V)

STEREO,

Sou nd Max

SOUND AMP.

LA42102(N)

STEREO,

Sou nd Max

SOUND AMP.

LA42102(N)

R61 0

5V

Option Part

IIC Bus Line

(Mono)

ML-OUT

31

22

17

5 46~48

STEREO

( ~ A43L)

MONO

( ~ A43K )

12

9

3

9

8

10

2

6

24V

1

ST-BY

TRANS

(1W Opt)

57 56 64

9V

From

IC804

IC804

9V REG

IC04

ST-5V REG

9v

From

IC804

IC661

5V

5.1V

IC751LA72730

(STEREO Opt)

IC751 LA72730

(STEREO Opt)

JA01

HIC291

Game Pack(Game Opt)

HIC291

Game Pack(Game Opt)

4,5,6 8 7

From USOC

Video(Game)

Audio( Gam e)

JA02

54

SIF

out

IF

3,611 1 4 7

AV2(V/ R/ L)-I N

2 5 9

LA72702

BTSC

IC701

LIN-TV

RIN-TV

21

1920

R/ L Ou t

L-OUT

R-OUT

SAW

SAW

5

9 10

IF IN

Z102

10 11 13

14

15

12

SIF IN

3261

V-O UT (M ono )

18

17 18

2 7

50

Ext R/ L

IN

49

RGB

9V

SCLSDA

27 26

33V

ST-5V

9v

From

IC804

9v

From

IC804

ST-5v

From

IC04

9v

From

IC804

9v

From

IC804

ST-5v

From

IC04

19

9 24199 24

H-Vc c

5V

VDD

3.3V

Vc c

5V

H-Vc c

5V

VDD

3.3V

Vc c

5V

9v

From

IC804

14

SOUND

5V

SOUND

5V

R62 0

7.5V

R62 0

7.5V

IC803

5V

IC803

5V

Q402

MD1803

IC401

TDA8145

IC301

V-in

FBP in

EW OUT

L401

Vc c

16

EW-OUT

EW IN

5v

From

IC803

62

IF

5V

SDA

SCL

23

24

SCLSDA

51

SPK L/ R

OUT

SCART

SCART

R, G, B

8 33

FB

AV ID

21

TV IN(ST)

M_R/L OUT(ST)

Mon ito r V OUT(ST)

Page 14

- 14 -

LGE Internal Use OnlyCopyright © LG Electronics. Inc. All right reserved.

Only for training and service purposes

EXPLODED VIEW

170

300

112

120

530

531

532

520

101

104

600

400

150

174

320

330

331

370

360

380

390

590

591

Many electrical and mechanical parts in this chassis have special safety-related characteristics. These

parts are identified by in the Schematic Diagram and EXPLODED VIEW.

It is essential that these special safety parts should be replaced with the same components as

recommended in this manual to prevent X-RADIATION, Shock, Fire, or other Hazards.

Do not modify the original design without permission of manufacturer.

IMPORTANT SAFETY NOTICE

Page 15

Copyright © 2007 LG Electronics. Inc. All right reserved.

Only for training and service purposes

LGE Internal Use Only

PUMP-UP

V-IN

VCC

PUMP

GND

V-OUT

STAGE

V-REF

O/

-UP

CEM

INOUT

GNDS

V-DY

H-DY

WARINNG BEFORESERVICING THIS CHASSIS, READ 'X-RA Y

RADIATION PRECAUTION,' `SAFETY PRECAUTION' AND PRODUCT

SAFETY NOTICE IN THIS MANUAL

CAUTION : THE MARKS IN THE SCHEMATIC DIAGRAM AND THE PARTS LIST DESIGNATE

COMPONENTS WHICH HAVE SPECIAL CHARACTERISTICS FOR SAFETY, AND SHOULD

BE REPLACED ONLY WHICH TYPES IDENTICAL TO THOSE IN THE ORIGINAL CIRCUIT OR

SPECIFIED IN THE PARTS LIST. BEFORE REPLACING ANY OF THESE COMPONENTS,READ

CAREFULLY THE PRODUCT SAFETY NOTICE IN THIS MANUAL.

DO NOT DEGRADE THE SAFETY OF THE RECEIVER THROUGH IMPROPER SERVICING.

A0

A1

A2

GND SDA

SCL

TEST

VCC

KS

SAW

I.RE F

GND

OUT

Vcc

EW

SIZE

Y

Cb

Cr

STEREO

PLL

PILOT

PLL

PILOT

PILOT

LEVEL DET

CANCELLER

REGUL

ATOR

MODE

OUT

MATRIX

-6dB

L-R

DEMOD

SAP

DEMOD

SAP BPF

SIF DEMOD

LPF

SAP

DET

ST/SAP

SW

LPF

LPF dbx processor

Offset

Cancell

SYSTEM

CONTROL

I2C

DECODE

Control

ST

SAP

Spectral

RMS DE T

Address

MUTE

L-R/SAP

MUTE

L+R

R-OUT

R-IN

L-OUT

L-IN

B

D/S

GR

FB

V-OUT

V-IN

5

4

2

1

8

6

7

3

10

9

11

12

Ripple

Filter

+OUT2

-OUT2

+OUT1

-OUT1

Input AMP

Out AMP

Out AMP

Vcc Standby

IN1

PREGND

MUTE

IN2

Input AMP

Power

GND

TIMER

0

RESET

ADC

V DET

R

I/O

RESET

G

PORT 1

B

RAM

RST

FS

I

XTSEL

CPU

CPU CLOCK

CORE

VDD3

BASE

TIMER

ROM

OSD

DATA

VDD5

BUS

CLOCK

CVBS

CLOCK

VS

PET_IN

CONTROL

AFT

C_SYNC

HS

POWER_IN

PORT 0

I/ O

TEXT

TELE

PLL

BUS

HS

VS

ABL

ACL

DRIVE/CUT-OFF

OSDSWOSD

CONTRAST

OSD

CONTRAST

BRIGHT

HOR

C/D

1/25 6

HOR

VCO

AFC1

HOR

OUT

PHASE

SHIFTER

FBP

HOR

VCC

AFC2

VER

RAMP

VER

C/D

SEP

VER

SYNC

SEP

E/W

APC1VXO

VCOAPC2 DDS

FSC

(EHT)

1CHIP

VDD

IF

AGC

AGC

RF

SPLL BPF

DET

900K

AMP

VIF

DET

SOUND

DET

VIDEO

AMP

VIDEO

TRAP

VCO

AMP

FM

DET

FM LIM

AMP

BPF

MATRIX

RGB

CLAMP

COLOR

TINT

COLOR

CLAMP

DC ADJ

SW

SEOAM

DECODER

CLMP

PAL SW

DEMODCREST

BS

SGSHARP

DL

BPF

SW

V/Y

ADCYC SW

TRAP

CLMP

SW

VIDEO

DC

VOL

SW

SW

TONE

RGB SW

EXT

CONTRAST

EXT RGB

DRIVE

CUT-O F F

SW

IF

NC

30V

NC

5V

SDA

SCL

CS

NC

AGC

16bit DAC

(MONAURAL)

SRC

(STEREO)

16bit DA C

(A2/DQPSK)

DEMODULATOR

DECODER

NICAM

ADC

PGA(AGC)+10bit

IIC

PLL

OSCILATOR

AMP

98.304MHz

18.432MHz

8

14

13

9

12

11

10

1

2

5

7

REG

BUFF

MODE

SELECT

DET

ALC

ALC

6dB

BUFF

BUFF

BUFF

INOUT

GNDS

LG

DSGD. CHKD.

TITLEUNIT

DWG NO.

SCALE Date

mm

APPD.

SCL

SDA

EW

GAME/FM_DATA

GAME_CLK/FM_CLK

SPK_L

MUTE

EYE

MUTE

EW

POWER/FM_CE

IR

FRONT/SIDE-R

REAR-R

REAR-L

FRONT/SIDE-L

SPK_R

REAR-L

SIDE-R

SIDE-L

SIDE-V

FRONT-V

FRONT-L

REAR-L

VER-OUT

HOR-OUT

FBP

B-OUT

G-OUT

R-OUT

ABL

R-OUT

G-OUT

B-OUT

VIF_IN2

SDA

SCL

SDA

IR

SDA

SCL

TV-R

VIF_IN1

REAR-R

MNT_L-OUT

MNT_R-OUT

FB_IN

AV1-ID

DVD-Y/G_IN

DVD-Cb/B_IN

RESET

HOR-OUT

RF_AGC

MNT_L-OUT

EXT_R-IN

EXT_V-IN

TV-L

TV-R

GAME_ID//FM_CE

GAME_DATA/FM_DATA

EYE

DOWNLOAD

DOWNLOAD_CLK

DOWNLOAD_DATA

GAME_CLK/FM_CLK

DVD-Cr/R_IN

REAR-V

MNT_V-OUT

HS

FBP

HS

VS

FRONT/SIDE-V

DVD-Cb/B_IN

FB_IN

DVD-Cr/R_IN

DVD-Y/G_IN

FB_OUT

DVD-Cr/R

DVD-Y / G

DVD-Cb/B

FRONT/SIDE_L

EHT

NICAM_RESET

VIF_IN2

FRONT-R

REAR-V

RESET

NICAM_RESET

FM_ON_OFF

DEGAUSS

ABNORMAL

SCL

SDA

AV1_ID/DOWNLOAD_DATA

DEGAUSS/FM_ON_OFF/USB_SW/DOWNLOAD

KEY

SPK-L

SPK-R

VIF_IN1

RF_AGC

FRONT/SIDE-V

SCL

SDA

EXT_V-IN

SDA

SCL

MNT_L-OUT

REAR-V

FRONT/SIDE-V

REAR-V

POWER/FM_CE

EHT

POWER/FM _CE

VER-OUT

VS

ABNORMAL

POWER/FM_CE

DVD-Y/G

DVD-Cr/R

DVD-Cb/B

SIF_OUT

PAL/NTSC

SIF_OUT

MNT_R-OUT

MNT_V-OUT

FB_OUT

TV-L

EXT_L-IN

EXT_R-IN

KEY

EXT_L-IN

ABL

IR

SCL

GID/SW/DL

POWER

TV-R

TV-L

TO DG COIL

P802

1

2

STV9326

IC301

1234567

D815

TVR06J

RL801

6920VB1001E

100

R906

1.6/2W (RF )

FR401

30K(RN)

R311

0.1u F

C210

560

R524

3.9K

R510

100uF

10V

C28

1N4148

D405*

2.7K

R307

P6

330uF

10V

C108

18K

R108

0.01uF

C534

1N4148

D902

4.7K

R803

1N4148

D403

1.5K/0.5 W

R919

1N4148

D603

3.3K

R501

1.5/0.5W

R310

100

R562

470p

C229*

75

R100*

47

R401

0.5W

1.0/0.5W

(RF)

R303

100K

R150

0.1uF

50V

C527

P01

123

C607*

10uF

16V

T/W

L212

100

R564

470P/500V

C303

P119

1

2

3

4

5

0.47uF

50V

C524

220

R516

P601

1

2

3

10K

R60

0.01

C548*

1uF

50V

C760

0.01uF

C510

680

R72

1N4148

D604

T/W

R614

1000uF

16V

C850

1K

R565

470p

C225*

1N4005

D302

T4AL250V

F801

470P

C233

100

J554

1000uF

16V

C826

1uF

50V

C757

ABL

0.1u F

50V

C517

0.05/0.5 W

(RP)

FR501

MONO

J636

100uF

10V

C518

C51

82P

123A

FB905*

0.1u F

C506

100

R505

150

R404

180/2W

(RS)

R315

T/W

L904

100

J509

470p

C222*

P201

1

2

3

4

5

6

R66

3.3K

0.01u F

C633

P703

1

2

3

100uF

10V

C833

T/W

L903

C295

10uF

16V

1000P

C107

T802

6200JB8008G

150-06 T

T804

150-F06T

1

2

3

4

BF421

Q403

10K

R618

12K

R522

4.43MHz

X501

0.047uF

MYL

C533

1N4148

D501

(10u)

J/W

L216

390

R922

1/7W

R801

75

R252

CHOKE

82uH

L802

4.7uF

50V

C415

470uF

35V

C309

125-022R

FB801

620/0.5W

R302*

1.5K

R409

1.6K

R18

CH+(PR+)

SW16

220

R69

T/W

L901

470p

C223*

2UH

FB201

1500P

C516

100

R506

1.2K

R17

560P/2KV

C417

2SC6092(SS/ULTRA)

2SC6093(Normal/FLAT)

Q402

47K/2W

(RS)

R804

T/W

L211

SK901

KIA78R09API

IC804

12

3

4

C56*

330P

VOL-

SW13

P602

1

2

3

4

75

R250

P02A

1

2

345

1/2W

150

R236

100K

R109

1000P/1KV

C813

CK

C605

47uF

16V

RU3AMV

D813

10uF

16V

C756

L-HP

18K(RN)

R301

18K/2W

(RS)

R912

C26

330uF

10V

0.1uF

C211

CH-(PR-)

SW15

T/W

L224

HIC291

12345

678

470K

R858

0.5

P401

1

2

3

4

4.7uF

250V

C901

10.5V

10uF

25V

C407

9.1V

ZD502*

0.68uF

50V

C312

680

R531

1.2/0.5W(SS CPT)*

FR932*

SW801(SUB:SW1801)

1N4148

D805

0.01uF

C767*

T/W

L225

P902

1

2

3

4

5

6

7

8

9

C2330-Y

Q901

47uF

16V

C308

75

R249

5.1V

ZD804*

0.01uF

C764

4.7u F

50V

C242

(PHONE)

JA01

23

4567

1

PC17L1

IC802

124

3

(RC)

8.2M/0.5 W

R814

510

R530

RU3AMV

D826

1.5K/0.5W

R920

39/2W

RS

R132

T/W

L221

100K

R408

GAME-VIDEO

0.01uF

C806*

470P

C231

T/W

L902

P03A

123

4

100

R760

270P

C902

GAME-AUDIO

1000uF

35V

C831

0.05/0.5 W

(RP)

FR825

4.7u F

250V

C540

15K

R312

16V

10uF

C201

Q672

2SC5343

(MPP)

153/2.0K V

C414

10K

R410

CPT EARTH

P910

1

10u

L230

C103 M

Q301

103

C538*

(PP)

223/200V

C514

AFC

75K

R705

4.7K

R58

0.1uF

C212

33K/0.5W

(RS)

R110

P101

123

75K

R706

VD801

TVR621D

P1

1K

R154

18K

R617

3900uF

MYL

C301

300

R513

36K(RN)

R518

100

510

R523

100uF

10V

C409

1/2W

150

R235

1N4148

D847

Q10

C3198Y

P801

AC-IN

1

2

100uF

10V

C853

100

J501

100uF

10V

C511

1000P

C805

1kV

P902-1

1

2

3

4

5

Q845

C5343Y

1

2

3

330

R504

9.1V

ZD504*

240K

R420

22K(RN)

R512

0.1uF

C612

100V

9.1V

ZD503*

0.01u

C855 *

100

R921

10K

R607

1K

R615

36K

R552

10uF

16V

C763

C30

0.01

123A

FB805*

1uF

50V

C759

100

R916

4.7K

R831*

470P

C234

2.2M/0.5 W

R902

1.8K

R908

0.05/0.5W

(RP)

FR301

100

R761

1.0/0.5W

(RF)

R304

100P

C130*

10UH

L502

C102M

Q813

R-HP

L-SPK

330uF

450V

C803

0.01uF

C535

5.1V

ZD102

SFAF504G

D824

0.033u F

MYL

C17

620

R20

100uF

35V

C307

270P

C904

2K

R616

D2SB60 (Normal/FLAT)

DB801

TS4B05G(ULTRA/SSlim)

DB802

2K

R612

12K(RN)

R519

1N4003

D901*

75

R251

0.47u F

50V

C531

CK

470P/1KV

C821

KIA78L05BP

IC04

1

2

3

4.7K

R82

510

R553

103

C106*

10UH

L217

1N4148

D303

82K

R306

100K

R22

100UF

10V

C832*

10uF

16V

C110

T/W

L223

TV/VIDEO(MENU)

SW11

163-051F(3P)

TH801

TH802

163-054D(2P)

1.2/2W

(RF)

FR403

4.7K

R23

75

R211

0.1u F

50V

C702

1000P

C294

43K

R308

T/W

L222

C2330-Y

Q902

390

R905

1N4148

D601

CPT

1uF

50V

C762

0.01u

C601*

VOL+

SW14

220P

C236

1M

R42

MENU(OK)

SW12

10UH

L218

1N4148

D602

470P

C232

1uF

50V

C761

100K

R11

K7260M(PAL)

Z111

M1971M(NTSC)

1

2

3

4

5

15K

R554

P5

BA282

D111

33V

ZD103

12K(RN)

R305

EBJ34806701

T402

1

2

3

4

6

5

7

8

9

10

P902-2

1

2

3

4

10K/0.5W

(RS)

R550

2.0K/0.5 W

R403

220P

C237

470p

C226*

0.1u F

275V

C802

T/W

L3

EU1ZV

D804*

A1266

Q601

08/02/29

17:01:33

CW81A.cir/001.sht

220

R65

100

R41

47K/2W

(RS)

R805

1200P/2KV

C908

0.1u F

50V

C704

2.2u F

50V

C16

2.2

R604

T/W

L213

2200P/4KV

C843

0.1uF

MYL

C314

0.22u F

MYL

C310

100K

R621*

100uF

10V

C40

10K/0.5 W

R407

180V

47K

R826

(CK)

470P/1KV

C812

680

R1

120

R555

390

R915

4.7K

R825

100P

C131*

1uF

50V

C313

18K/2W

(RS)

R923

3.9K

R509

2.2K

R113

5.6/2W

(RS)

R620

4.7K

R21

2200uF

25V

C311

270P

C907

22K(RN)

R313

220uF

160V

C814

220

R514

100uF

16V

C766

TVR06J

D505

220uF

10V

C246

0.33uF

50V

C15

C3228

Q401

56K/0.5 W

R547

CK

470P/500V

C404

75

R226

9.1V

ZD412*

10000pF

C322

0.01uF

C20

1000P

C804

1kV

82K

R423

2.2K

R112

C2330-Y

Q903

10uF

16V

C765

1N4148

D502*

J617

560

R19

39

R515

0.01uF

C507

1uF

50V

C758

4.7uF

50V

C243

3.9K

R508

4.7K

R111

TVR06J

D301

125-022 R

L804

LED

LD11

21

100uF

160V

C835

0.047uF

MYL

C306

470P

C235

39K

R502

220P

C541

1uF

50V

C504

300

R421

4.7K

R832

1.5K/0.5 W

R918

100uF

10V

C526

J637

*

C523

100uF

16V

IC02

24C04/24C16

1

2

3

45

6

7

8

0.01uF

C101

8.2/0.5W

R873

100

R563

10u

L231

10uF

50V

C103

30K

R532

330uF

25V

C602

18K/2W

(RS)

R917

100

R507

T/W

R556

10uF

100V

C408

750

R16

220K

C215*

R-SPK

100P

C19

C50

82P

*

560

R535

KIA7805API

IC803

1

2

3

J116

T/W

4.43MHz TRAP

Z601

0.01uF

C116

PA01

123

151-C02B

H-DRIVE

T403

123

4

FRONT AV

JA02

0.01uF

MYL

C432

1N4148

D411

620

R462

330

R463

1K

R461

3.9K

R460

100K

R459

6mH

L401

26.5u H

L402

334/400 V

C412

273/630 V

C406

RS4FS

D406

RU4AM

D407

20K

R455

6.8K

R309

IC401

TDA8145

1

2

3

45

6

7

8

1K/1W(RS)

R416

120K

R456

5.1K

R414

2.7K/2W

(RS)

R406

2.7K/2W(RS )

R316

C551*

0.068uF

MYL

C305*

22uF

50V

C509

3.0K/2 W

(RS)

R402*

J106

C5343

Q16

J117

T/W

0.02/0.5W

(RP)

FR816

15K

R451

1K

R450

5.6K

R517

39K

R457

0.047u F

MYL

C434

473/630 V

C401

450uH

L404

334/400V

C402

1.6mH

L403

1K

R845

J811

T/W

4.7K(RN)

R844

1K

R841

9.1V

ZD851

39K

R843

0.022uF

MYL

C818

47

R840

Q801

C5343

3.9K

R835

47uF

10V

C828

91K(RN)

R815

91K(RN)

R816

30K(RN)

R842

KA431

Q840

1uF

250V

C847

T/W

R884

0.022u F

C502

330

R537

C512*

1K

R13

2.2u F

50V

C13

JA01

(DVD)

0.1uF

C613

2.2

R601

2K

R611

2.2

R603

4.7uF

50V

C603

ST

J611

C608

2.2uF

50V

2.2

R602

100

R609

2K

R605

C611

47uF

25V

0.1uF

C614

0.018uF

MYL

C609

0.1uF

C606

0.018uF

MYL

C604

4.7uF

50V

C610

100

J517

9V

9V

9V

9V

9V

9V

S-Vcc

S-Vcc

5V_1

5V_1

5V_1

5V_1

5V_2

30V

30V

J13

T/W

ST-5 V

ST-5V

ST-5V

ST-5V

ST-5V

100K

R622*

9V

620

R528

J227

T/W

5V_1

ST-5V

50V

1uF

C648

50V

4.7uF

C676

22uF

50V

C681

LA72702

IC605

123456789

101112 13

1415161718192021222324

1uF

50V

C666

1uF

50V

C638

1uF

50V

C670

2.2uF

50V

C657

47uF

10V

C691

10uF

50V

C675

10uF

50V

C672

4.7uF

50V

C656

4.7uF

50V

C654

22uF

50V

C682

4.7uF

50V

C642

0.1uF

C645

0.1uF

C678

100

R666

100

R665

4.7K

R678

10UH

L604

5V_1

JA01

(FULL SCART)

1

2

3

4

5

6

789

10

11

121314

15

16

17

18

192021

100

R503

75

R203

100

R202

100K

R207

240K

R208

1uF

50V

C22

IC601

100

R542

100

R543

R250

T/W

100

R561

100uF

10V

C521

1uF

50V

C675

1uF

50V

C672

39K

R539*

P551B

@value

10

987654321

P551A

@value

10

987654321

J568

T/W

J222

T/W

J224

T/W

J225

T/W

J226

T/W

R415

T/W

330P

C688

330P

C687

2.2uF

50V

C683

0.1uF

C633

0.1uF

C631

560K

R667

5V_1

0.1uF

C673*

5V_1

0.01uF

C632*

0.01u F

C630*

47uF

10V

C681

0.01uF

C684

0.01uF

C668*

47uF

10V

C685*

0.01uF

C662*

0.01uF

C661

0.01uF

C680

0.01uF

C645*

0.01u F

C631

1.5V

3.3V

1.5V

0.1uF

C635

47uF

10V

C670

0.1uF

C634

0.1u F

C665

0.1u F

C667

47uF

10V

C666

T/W

R631

12pF

CC

C689

12pF

CC

C690

18.432MHz

X661

1M

R630

SIF

SIF

10k

R668

100

R666

100

R665

10K

R661*

10K

R664*

330p

C653

1K

R662

1k

R633

4.7uF

50V

C672

4700p

C687

4.7uF

50V

C675

4700p

C688

1k

R632

Z602

4.5MHz

1

3

2

J721*

T/W

P211A

1

2

3

4

IC810

W6553A(MONO)

W6554A(STEREO)

1

2

3

4

5

6

7

220

1/2W

R838

6.8K

R807

30

R810

J842

T/W

D845

UF4005

22uF

50V

C840

0.1u F

50V

C841

0.01uF

MYL

C852

1000pF

1.6KV

C817

221/2KV

C859*

?

C807*

?

C808*

125-022K

FB810

125-022K

FB844

J843

T/W

75K

R839

39K(RN)

R806

3300pF

MYL

C842

15V

ZD846

5.6K

R808

IC501

LV762xx

EXT-R_IN1EXT-L_IN

2

INT-V_IN

3

VCC[5V]4Video/Chroma/Vertical

EXT-V_IN5NC/MONI-R

6

YC-Y7YC-C[FB_IN]

8

1CHIP_VDD[3.3V]

9

DVD-Y[G_IN]

10

CR_IN[R_IN]

11

4.43MHz

12

CB_IN[B_IN]

13

APC-FILTER14Chroma

FSC[EHT]

15EW16

VEROUT

17

V-RAMP

18

VCO_IREF

19

HOR_VCC[5V]

20

AFC-FILTER21Horizontal

HOR_OUT

22

FBP23CPU_VDD[ST-5V]24FILT25CPU_VDD226P0027P0128P0229P1330P1431P15

32

FM_OUT[MONI-L]

64

FM-FILTER

63

IF_VCC[5V]

62

VIDEO_OUT/SVO

61

VIF_AGC

60

APC-FILTER

59

RF_AGC

58

VIF_IN157VIF_IN2

56

IF_GND55

SIF_OUT

54

APC-FILTER

53

SIF

SIF_IN

52

SPK-R_OUT51SPK-L_OUT

50

RGB_VCC[9.0V]

49

R_OUT

48

G_OUT47B_OUT

46

ABL

45

1CHIP_GND

44

CPU_GND43FILTSLC

42

RESET

41

P0740P0639P0538P0437P0336P1735P1634P11

33

4.7uF

50V

C280

??

C845*

TU101

6700MF0018A(CIS)

6700MF0018B(PAL)

6700NFNS11E(KOREA)

6700NFNS11F(NTSC FR TYPE)

6700NFNS11G(NTSC PHONE TYPE)

6700NFNS11H(NTSC DIN TYPE)

100uF

10V

C636

100uF

10V

C615

1.5V REG.

IC606

1

2

3

3.3V

1.5V

10K

R541

2200P/500 V

CK

C421

330/0.5W

R441

J403

T/W

0.1u F

50V

C677

5V_2

5V_1

5V_1

5V_1

T/W

R853

J413

T/W

0.022uF

50V

C574

0.01u F

?

1000p

C549*

330K

R538*

100

R511

1.2UH

L528

5.1M

R684

2.2M

R654

0.1uF

C664

C114*

0.1uF

J830

T/W

J402

T/W

J303

T/W

J306

T/W

J301

T/W

J401

T/W

60uH

L405*

?

L406*

J404*

T/W

J814

T/W

0.1uF

275V

C816

123A

FB817*

?

C839

J810

T/W

6322A00030A

TH803*

J906T/ W

J903

T/W

J905

T/W

1N4003

D903

J907

T/W

J620

T/W

?

C627*

J607

T/W

30P

C552*

IC651

LC75024E

AVDD331AOUTR

2

AVSS3LRVREF4AVDD335NC6AOUTL7AVDD338VRT9VCOM

10

VRB

11

SIF2

12

AVSS

13

AVDD33

14

AVDD33

15

AVSS

16

AVDD15

17

AVSS

18

XVSS

19

XIN

20

XOUT

21

AVDD3342MRVREF

41

AVSS

40NC39

AVDD3338TESTB137TESTB0

36

TEST

35NC34NC33NC32NC31

IOVSS

30

IOVDD33

29

RSTB

28

SDA27SCL

26SA25

DVDD15

24

DVSS

23

XVDD33

22

5V_1

J720

T/W

J705

T/W

J281

T/W

J704

T/W

T/W

J673

T/W

J703

T/W

J641

T/W

J652

T/W

J642

1K

R6331KR632

T/W

J651

T/W

J643T/W

J653

T/W

J672

J527

T/W

T/W

R40

T/W

J562

J519

T/W

T/W

J508

J112

T/W

T/W

J111

10UH

L663

J633*

T/W

10UH

L662

T/W

R654

T/W

J645

T/W

J641

T/W

J648

T/W

J642

T/W

J647

47uF

10V

C650

J22

T/W

J23

T/W

T/W

J525

J555

T/W

J541

T/W

T/W

J109

4.7uH

L503

T/W

J101

T/W

J558

T/W

J552

T/W

J201

T/W

J557

T/W

J507

0.01uF

C562*

0.01uF

C563*

0.01uF

C564*

0.01 8

MYL

C542*

0.1

(PP)

C545

?

R521*

T/W

J524

T/W

J560

9.1V

ZD407*

T/W

J513

T/W

J528

T/W

J532

T/W

J504

4.7K

R566

T/W

J706

T/W

J707

T/W

R701

T/W

J521

T/W

R704

T/W

J503

T/W

J506

T/W

J24

T/W

J522

T/W

J559

0.01uF

C29

T/W

J542

T/W

J702

T/W

J625

T/W

J624

T/W

J515

T/W

J512

T/W

J544

T/W

J546

J535

T/W

0.01u F

C528*

T/W

J537

T/W

J543

T/W

J520

T/W

J510

T/W

J567

J286

T/W

J564

T/W

J520

T/W

J563

T/W

T/W

C283

J285

T/W

T/W

J282

T/W

J292

T/W

J287

T/W

J288

T/W

J549

J637

T/W

T/W

J289

T/W

J290

J553

T/WT/ W

R536

T/W

J283

T/W

J284

J291

T/W

J286

T/W

100

J534

T/W

R567

T/W

J281

T/W

R711

J534

T/W

J638

T/W

J646

T/W

100uF

10V

C857*

3.3V REG.

IC603

1

2

3

J551

T/W

J804

T/W

J709

T/W

510

R247

A1266

Q241

T/W

J280

T/W

J687

T/W

J672

T/W

J550

T/W

R780

T/W

J565* T/W

J818

0.1uF

C283

10uH

L501

100

J511

T/W

J540

J556

T/W

J526

T/W

47K

R318

5V_1

J819

T/W

J634

T/W

J523

T/W

J664*

T/W

33/2W

(RS)

R610*

100uF

10V

C699*

J665

T/W

5.1V

ZD601*

0.33uF

C630

100pF

C639

T/W

J646

10UH

L665

T/W

J650

J647

T/W

3.3V

47uF

10V

C691*

47uF

10V

C692*

10UH

L664

125-022R

FB601

T/W

J110

J3

T/W

2.7K/2W

(RS)

R405

33pF/

10pF

C520

33pF

C503

33pF

C546

75K

R222

75K

R221

T/W

R223

J826

T/W

J626

T/W

J635

T/W

J601

T/W

J102*

T/W

0.01uF

C105

390

R105

0.01uF

C104

22

R104

1.2K

R103

100

R101

0.82

L102

0.01uF

C115

C3197

Q101

3.6K

R102

47uF

16V

C111

9V

J405

T/W

TVR06J

D304

470uF

10V

C525

C102M

Q502

C102M

Q111

CP12

0.01uF

16V

CP13

0.01uF

16V

LP05

10uH

LP03

10uH

CP07

0.01u F

50V

RP10

1K

1/10 W

5%

CP20

47uF

10V

RP09

1K

1/10W

5%

ICP03

S1117-18PIC

1

GND

2

OUTPUT3INPUT

P551B

35238-1010

123456789

10

CP30

47uF

10V

LP04

10uH

CP04

47pF

50V

CP34

0.1u F

50V

RP14101/10W

5%

RP13101/10W

5%

CP19

0.01uF

50V

CP25

47uF

10V

RP28

10

1/10W

5%

QP02

2SC3875S

E

B

C

ICP04

KA75270Z

2

G

3O1

I

QP01

2SC3875S

E

B

C

CP33

0.1uF

50V

CP08

47uF

10V

CP31

0.01uF

50V

CP18

47pF

50V

LP06

10uH

CP35

0.1u F

50V

RP11

100

1/10W

5%

CP10

330uF

10V

CP05

47pF

50V

35238-1010

P552B

123456789

10

CP29

0.01uF

50V

CP27

0.01uF

50V

RP30

1K

1/10W

5%

CP01

22pF

50V

RP03

100

5%

1/6W

CP23

0.01uF

50V

RP31

22K

1/10W

5%

CP28

47uF

10V

ICP02

S1117-33PIC

1

GND

2

OUTPUT3INPUT

RP01

220

1/6W

5%

CP11

0.01uF

16V

RP17

10

1/10W

5%

RP12101/10W

5%

CP06

47pF

50V

XP01

20.25MHz

RP15

10K

1/10W

5%

ICP01

PVP9390A-QG-A1

1

XOUT

2

XIN

3

VSS18_14VDD18_1

5

GPO0

6

SEL

7

OUT38OUT29OUT1

10

VSS33DAC11VDD33DAC

12

FSW

13

IN3

14

IN2

15

IN1

16

VDD18ADC

17

VSS18ADC

18

CVBS1

19

TEST

20

CVBS2

21

TM

22

CVBS3

23

CVBS424VSS33ADC25VDD33ADC26YIN27UIN28VIN29RESET30VDD18_231VSS18_232POR33GPO2

34

I2C1

35

I2C2

36

SDA

37

SCL

38

INTR

39

VDD33PAD

40

VSS33PAD

41

VSP

42

HSP

43

GPO1

44

CLKOUT

CP32

47uF

10V

CP16

47pF

50V

RP08

100

1/10W

5%

CP02

22pF

50V

LP02

10uH

CP17

47pF

50V

CP21

47uF

10V

RP02

220

1/6W

5%

RP05

1K

1/10W

5% CP03

47pF

50V

RP04

100

1/6W

5%

LP01

10uH

RP06

100

1/6W

5%

CP36

0.1uF

50V

RP34

1K

1/10W

5%

RP33

1K

1/10W

5%

RP07

22K

1/10W

5%

0.1

MYL

C515*

100p

C245*

0.1uF

C529

R904

R913

C2330-Y

Q904

R706

T/W

R711

T/W

R317*

J864

T/W

J841

T/W

J825

T/W

J822

T/W

J820

T/W

J812

T/W

T803

61709MC016D

J813

T/W

J801

T/W

J802

T/W

J803

T/W

J808

T/W

J806

T/W

J807

T/W

J809

T/W

T/W

J712

J708

T/W

T/W

J690

T/W

J698

T/W

J667

J656

T/W

J602

T/W

J621

T/W

J622

T/W

J623

ST

J605

T/W

J108

T/W

J606

J604

T/W

T/W

J609

100

J516

T/W

J518

J409

T/W

J220

T/W

J221

T/W

J223

T/W

J151

J6

LA72730

IC751

LIN-11LIN-22LIN-33RIN-14RIN-25RIN-36VIN-1

7

VCC

8

VIN-2

9

GND

10

VIN- 3

11

R_MONITOR

12

L_MONITOR16SCL13SDA14NC15ALC_FILT17VIDEO_OUT18AUDIO_R_OUT19AUDIO_L_OUT20VIN-TV21BIAS_FILTER22RIN-TV23LIN-T V

24

A1275Y

Q103

30K

R114

C102M

Q104

T/W

J203

J502

T/W

KIA78R05API

IC806

12

3

4

J829

T/W

J828

T/W

T/W

R811

2200uF

25V

C838

TVR06J

D806

125-022 R

FB808

470P/500 V

C836

CK

180/2W

(RS)

R314

T/W

J539

100pF

C532

1K

R606

T/W

J293

9V

TH402*

300ohm

TH401*

300ohm

SCREEN

5V

510(14")

FOCUS

*

180V

*

26V

GAME/FM DATA

V2

D

GAME ID/FM CE

L2

G

G

G

R2

Option

MONO:330/0.5W

NC

GND

W/O HP

SDA

11

SCL

12

CPT BOARD

MONO

<L-IN>

10

<R-IN>

<V-OUT>

Headphone

<L-OUT>

14

<B+ : 115V>

STEREO:510/0.5 W

13

<MONO 4PIN OPT.>

OCP

GND

180V

HEATER

MONO OPTION

9V

B

EBY41778501

G

* : OPTION

R

2.2/0.5W(LG CPT)

H-GND

<SCHEMATIC DIAGRAM OF CW-81A>

'07.05.08

CIRCUIT DIAGRAM

CW-81A CHASSIS

IN

(CK)

FOCUS

180V

SCREEN

COLD

AFC

HOT

C

ABL

C3229(21" )

26V

D833*

<R-OUT>

HEATER

<V-IN>

COL

12V

C3229(21")

BK

OUT

GK

<EYE OPT.>

HEATER

RK

GND

B

H-GND

DEG OPTION

RU2AMV

HEATER

C3229(21" )

HOT

V-NECK

9V

270P(14" )

B

VIDEO/NC

390P(14")

G

GND

390P(14")

R

AUDIO/FM ON_OFF

510(14")

ANODE(HV)

GAME/FM CLK/IR

510(14")

KEY

A

VERSION 1.11 2008.02.26

POWER

HEADPHONE R V

(MONO)

L

PAL

NTSC

HV

INNER

112V

??

3.00V

CH-/PR-

VOLTAGE

0.81 V

0V

2.48 V

<KEY MATRIX>

CH+/PR+

1.88VMENU/OK

VOL+/VOL+

T-SOUND

NT/PAL

T-PICTURE

TV_VIDEO/MENU 1.34V

??

VOL-/VOL-

<DVD_R-IN>

<DVD_L-IN>

LA42101 (10W MONO MAX)

LA42102N(15W+15W MAX)

<PAL>

ABNNORMAL

<NICAM/A2 OPT.>

<DOWNLOAD OPT.>

BTSC

<AV STEREO OPT.>

<NTSC>

W/TEXT W/O TEXT

NTSC

PAL

NICAM/A2

<SIDE A/V OPT>.

<MONO>

<STEREO>

<MONO OPT.>

<MONO OPT.>

<MONO 4P,W/SCART OPT.>

<W/O SCART,PIP>

<W/SCART,PIP>

<GAME, FM TX OPT.>

<STEREO,W/O SCART OPT.>

<W/O PIP>

FB-IN

Cb-IN

Y-IN

Cr-IN

GND

5V

R-OUT

G-OUT

B-OUT

FB-OUT

SDA

SCL

VS

HS

GND

GND

GND

TV_VIDEO

AV1

AV2

<PIP OPT.>

<W/PIP OPT.>

<W/PIP OPT.>

<IC VERSION>

BPF

Slave Address=0x38

<W/O BPF OPT.>

<W/FM TX OPT.>

MNT_R

MNT_L

GND

GND

D

NC

S/GND

VIN

SS/ADJ

FB

BD

MONO :IC810(W6553A), R806(RN ???)

STEREO:IC810(W6554A), R806(RN 39K)

MODE INPUT

VIN1 REAR

VIN2 FRONT/SIDE

VIN3 GAME

VIN-T V RF

MONO

LV76210

LV76220

LV76230

PAL/NT

SOUNDIC

SYSTEM

PAL/NT/SECAM

COMB

EW

TXT

Surround

A2+NICAMBTSC

LV76211

LV76221

LV76231

LV76233

LV76212

LV76222

LV76213

LV76232

LV76223

LC75024

LA72702N

AV-ST

RF-ST

IC

*ASSEMBLE SUSOC(AV/ST)IC WITH RF/ST IC FOR RF-ST MODEL

PAL/NT/SECAM

PAL/NT/SECAM

PAL/NT

PAL/NT/SECAM

PAL/NT/SECAM

PAL/NT

PAL/NT/SECAM

PAL/NT

PAL/NT/SECAM

PAL/NT/SECAM

A2/NICAM

BTSC

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

X

LA42102L(10W+10W MAX)

<STEREO OPT.>

<SS/ULTRA OPT.>

<FLAT,Normal OPT. >

<SS/ULTRA OPT.>

<FLAT,Normal OPT.><SS OPT. ><ULTRA OPT.>

B+

<MONO/AV ST OPT.>

GND

GND

IR

KEY

POWER

ST-5V

GND

EYE

GND

9V

NC

<MONO/AV ST OPT.>

<W/O RELAY>

<W/O NICAM>

<NICAM>

W/O ST-BY 1W

W/ NICAM

W/O ST-BY 1W

B+

S-Vcc

10.5 V

???V

GND

S-GND

GND

COLD

GND

<RF ST>

<MONO/

AV ST OPT.>

<MONO/AV ST>

<PRE AMP OPT.>

<MUTE OPT.>

Slave Address=0x80

VCD Slave Address=0xBA

EEPROM Slave Address=0xA0

TUNER Slave Address=0xC0

Slave Address=0x92

AV1

GND

AV2

GND

GNDRFSCL

SDLVSHS

FB0RI5VROBO

GOBIGND

FBI

GI

CPT BOARD

PIP BOARD

NARROW RANGE OPT.

<W/O ST-BY 1W OPT>

<W/ST-BY 1W OPT>

W/ST-BY 1W

=>Initial model: 21"ULTRA S/S(21FU1R) .

Page 16

May, 2008

Printed in KoreaP/NO : MFL41322905

Loading...

Loading...